Toshiba 60th, 1550 Series Manual

TOSHIBA THE 60TH SERIES ANALOG COPIERS – THE DISPUTABLE TOSHIBA 1550 COPIER

Following the Toshiba 1360/70 copier, reviewed in the

previous article, comes the Toshiba 1550 copier. As mentioned

in the title, this is a much disputed model – some technicians

love it, others hate it. But nevertheless this is one of the most

common copiers in East Europe (in Bulgaria for sure). This

model is situated in the upper segment of the lower class copiers

and so is designated for small to middle offices and not for copy

and print centers. So the problem with this model arises whet

users try to overwork it. In my practice as a service technician I

have had both good and bad experience with this model.

There are users that never had any issues with the

copier, other than the usual maintenance and periodical

replacements of parts. These users’ monthly copy-volume never

exceeds 5000 to 10 000 copies. The only other issue with such

machines is the dusty environment they often operate in, which

causes periodical cleaning to be performed twice as often as the

normal interval of 60 000 copies. So the conclusion is that is

users don’t overwork their machines and provide them with

regular maintenance, they will serve them longer, causing less

trouble to the service technician that maintains them. Even more

– given the proper maintenance the consumable replacement

parts such as drums, heat rollers etc. can “live” up to twice the

copy count given by the manufacturer. This is the case with the

happy technicians mentioned above.

However there are cases when everything that can go

wrong with this model does. This is the case with machines

often overworked and poorly maintained. Such machines often

operate in poor conditions (dust, humidity etc.) and are used in

copy centers. They age very quickly and the mechanical parts

wear very quickly too. Given the fact that many of the parts in

the machine are made of plastic (a negative tendency fully

developed in later e-Studio models), all this issues are a “recipe

for disaster”.

The good news is that if one knows the weak points of

the machine and the most common places to search for wear and

clean during periodical maintenance, the copier will work

reliably and you will come to like this controversial model. The

most common weak spots and failures of the model will be

discussed in the articles to come. But first let me once more

emphasize the importance of periodical maintenance and the

preventive inspection check – this is the main goal of this article.

PERIODICAL MAINTENANCE – USEFUL PRACTICES

The manufacturer recommends the periodical

maintenance to be performed at 60 000 copies, which is also the

recommended service-live of most of the consumable parts in

the copier:

Inspection every 60,000 copies

(1) Preparation

1) Ask the key operator about the present machine

conditions and note them down.

2) Before starting the maintenance work, make and retain a

few sample copies for later comparison.

3) Turn off the power switch and disconnect the power cord

plug.

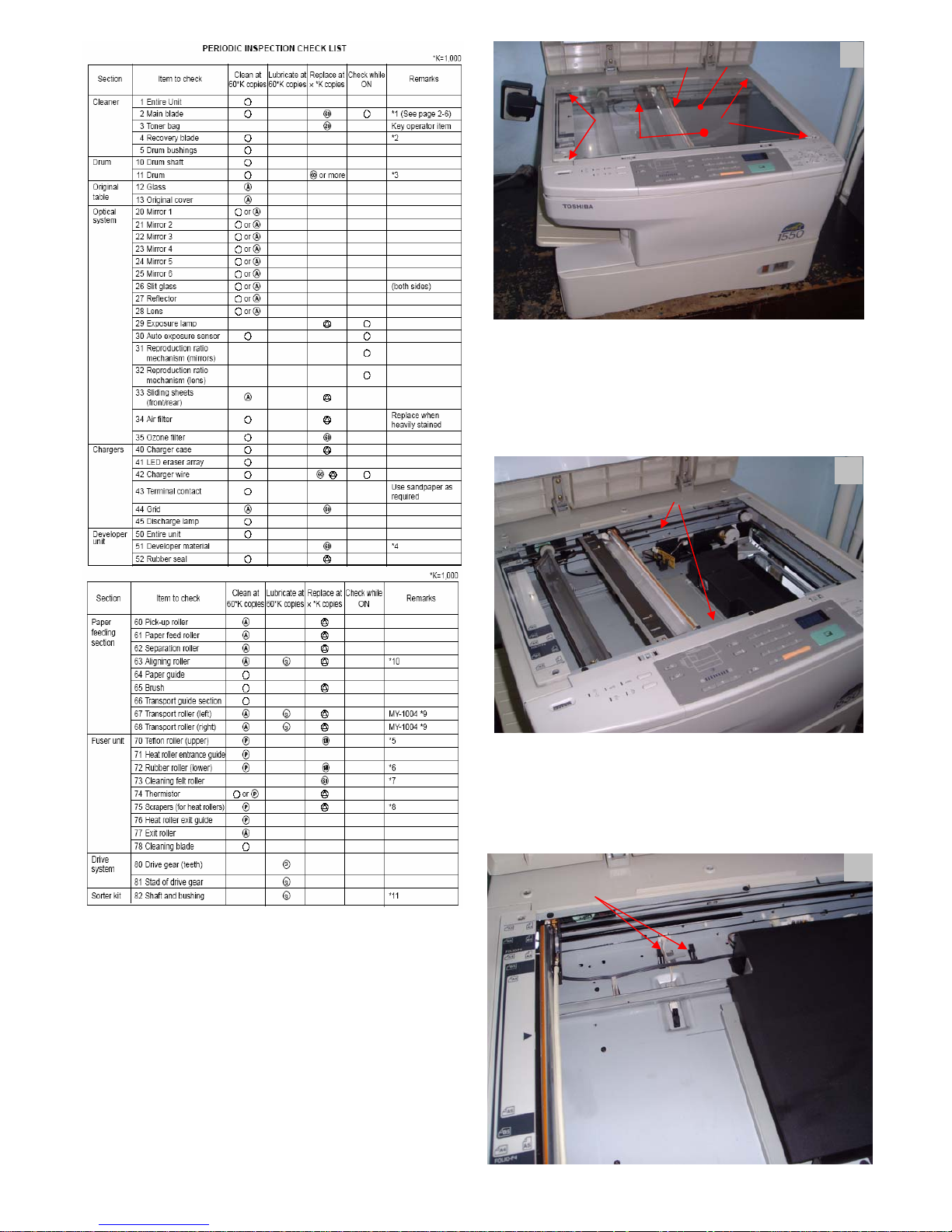

(2) The period inspection should be conducted in accordance

with the PERIODIC INSPECTION CHECK LIST shown

below. Perform the inspection by referring to the figures, as

well as to the explanations in the Service Manual of the

machine when necessary.

(3) After the inspection has been completed, plug in the

machine and turn the power switch on, and

confirm the general operation of the machine by making a

few copies and comparing them to those

made previously.

Inspection and over-haul every 180,000 copies

(1) Replace all the cosumables.

(2) Check to see if there is any damage to parts of the drive

section (gear, pulley, timing belt, etc.). Replace parts on

principle if damaged.

(3) Check to see if there is any damage or peeling of adhered

parts (tape, Mylar, etc.). Replace any affected parts.

(4) Check to see if all the switches and sensors operate properly.

Replace them if they are not operating properly.

(5) Clean the inside of the machine thoroughly.

Symbols used in the Periodic Inspection Check List:

1. Optical section cleaning

1.1 Remove screws A and the original glass retaining plate.

Remove the original glass and clean it both sides with

window cleaner. Note – do not remove screws B. They are

used for correction of image skew and registration of the

copy image.

1.2 Remove screw C and the L-shaped plate with it. Remove the

lens cover D, carefully in the direction E, careful not to

break the drive tooth belt of the lens assembly and the

carriage drive wire. See figure 1.

1

1.3 Clean with dry lint free cloth mirrors 1, 2, 3, 4 and 5 as well

as the expo-lamp reflector.

1.4 Clean with isopropyl alcohol the sliders A of the carriage 1

and 2. Note – be careful not to bend carriage 3, because it is

mounted only to the rear side of the copier. Bending will

result in copy image skew. See figure 2.

1.5 Inspect the ends A of the process unit holder that protrude

from the optical unit bottom. If they are broken the process

unit will move from side to side causing image distortion

and excessive wear of the main drive gear assembly. See

figure 3.

A

B

C

D

E

2

A

3

A

Loading...

Loading...