Page 1

FILE NO. 030-200001

SERVICE MANUAL

COLOUR TELEVISION

C9PJ Chassis

40PW03G,40PW03B

PRINTED IN U.K Feb., 2000 UK

Page 2

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS........................................................................................................................................3

CRT ASSEMBLY REPLACEMENT AND MOUNTING..............................................................................................4

PICTURE TUBE COMPONENTS ADJUSTMENT....................................................................................................6

SERVICE POSITION................................................................................................................................................ 9

SERVICE MODE .................................................................................................................................................... 10

DESIGN MODE ......................................................................................................................................................13

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

ELECTRICAL ADJUSTMENT................................................................................................................................. 14

CONVERGENCE ADJUSTMENT .......................................................................................................................... 23

SCREEN AND MIRROR ALIGNMENTS ................................................................................................................32

CIRCUIT CHECKS .................................................................................................................................................33

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA ..............................................................................................................................34

LOCATION OF CONTROLS ................................................................................................................................... 35

CIRCUIT BLOCK DIAGRAM ..................................................................................................................................37

TABLE OF CONTENTS

MECHANICAL DISASSEMBLY .............................................................................................................................. 38

CHASSIS AND CABINET REPLACEMENT PARTS LIST......................................................................................39

PC BOARDS BOTTOM VIEW.................................................................................................................................59

TERMINAL VIEW OF TRANSISTORS ................................................................................................................... 73

SPECIFICA TIONS .................................................................................................................................................. 75

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

Page 3

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards, the high

voltage must not be abov e the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a (C) V AC po wer

source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B) & AC voltage (C).

(See SETTING & ADJUSTING DATA on page 34)

Each time a receiver requires servicing, the high voltage

should be checked follo wing the HIGH VOLT AGE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by any one unfamiliar with the necessary precautions on this receiver . The following

are the necessary precautions to be observed before servicing this chassis.

1. An isolation transformer should be connected in the power line between the receiver and the AC line before any service is

performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube. The picture tube

is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter proof goggles and keep picture tube

away from the unprotected body while handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place, such as; nonmetallic control knobs, insulating covers, shields, isolation resistor-capacitor network etc.

2. The only source of X-RAY RADIATION in this TV receiver

is the picture tube. F or contin ued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

3. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NO TICE below.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded b y them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this manual and its supplements; electrical components having such features are identified by

the international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray

radiation or other hazards.

– 3 –

Page 4

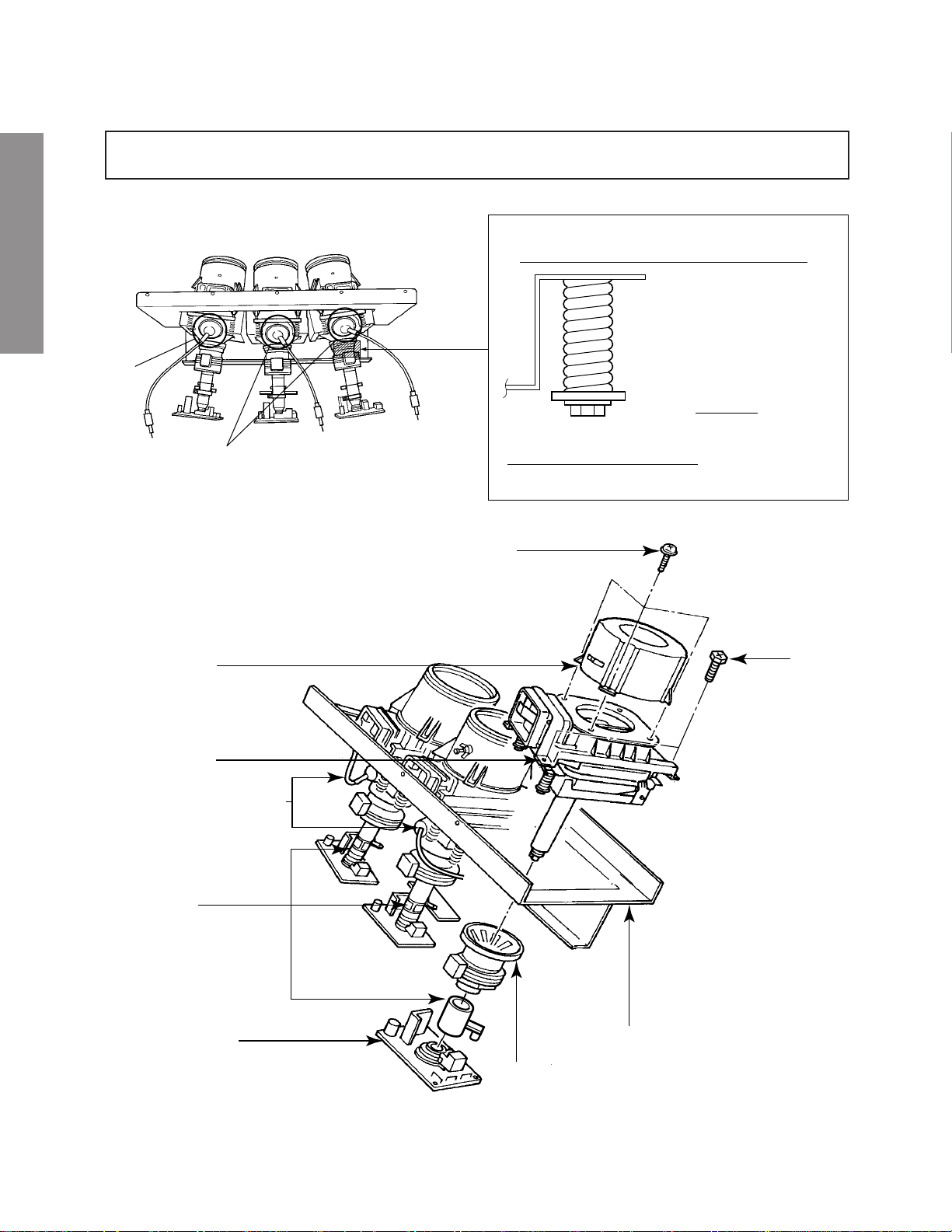

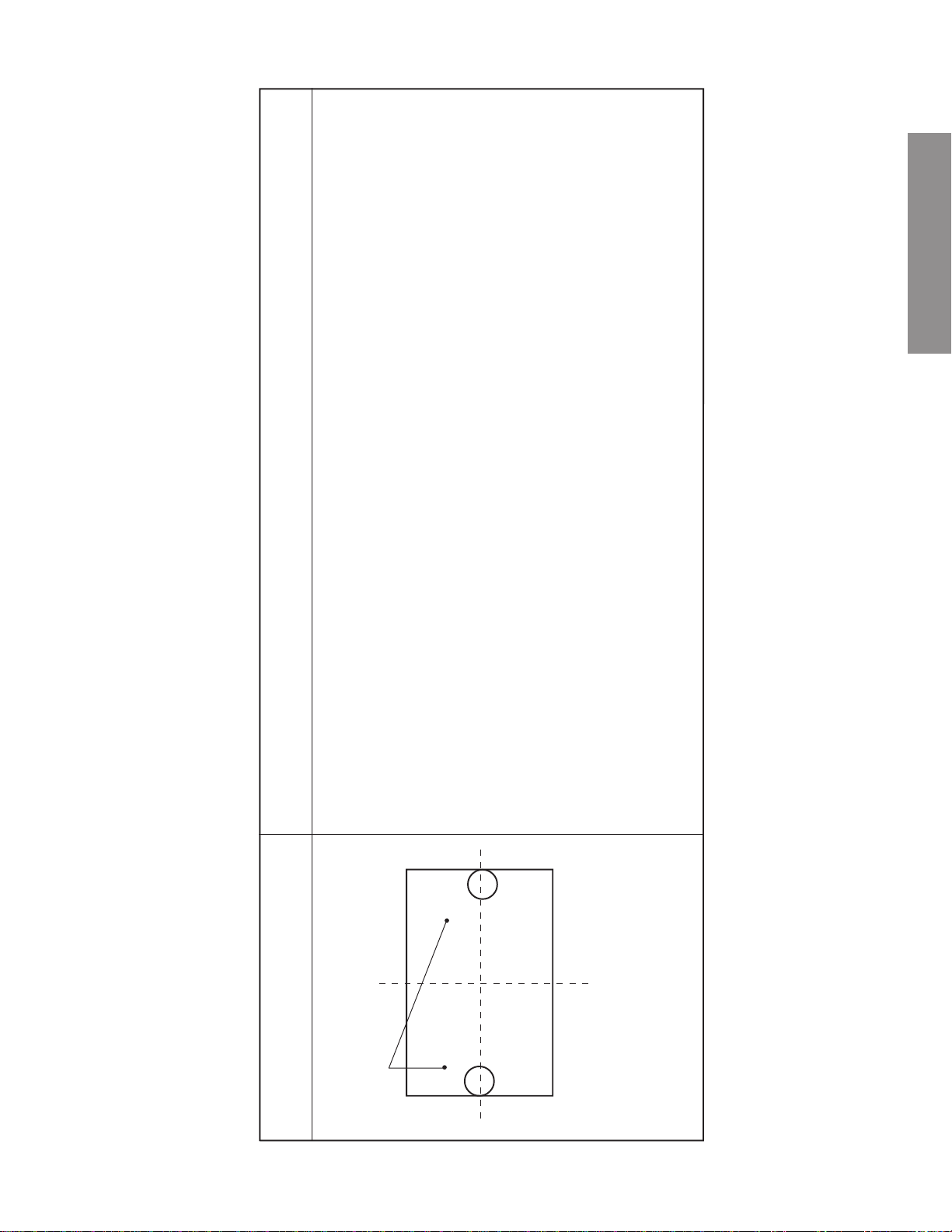

CRT ASSEMBLY REPLACEMENT AND MOUNTING

CAUTION : DO NOT LOOSEN THE HEX HEAD BOLTS WITH SPRINGS (12 PCS), BECAUSE THOSE ARE FOR

SEALING OF CRT COOLANT.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

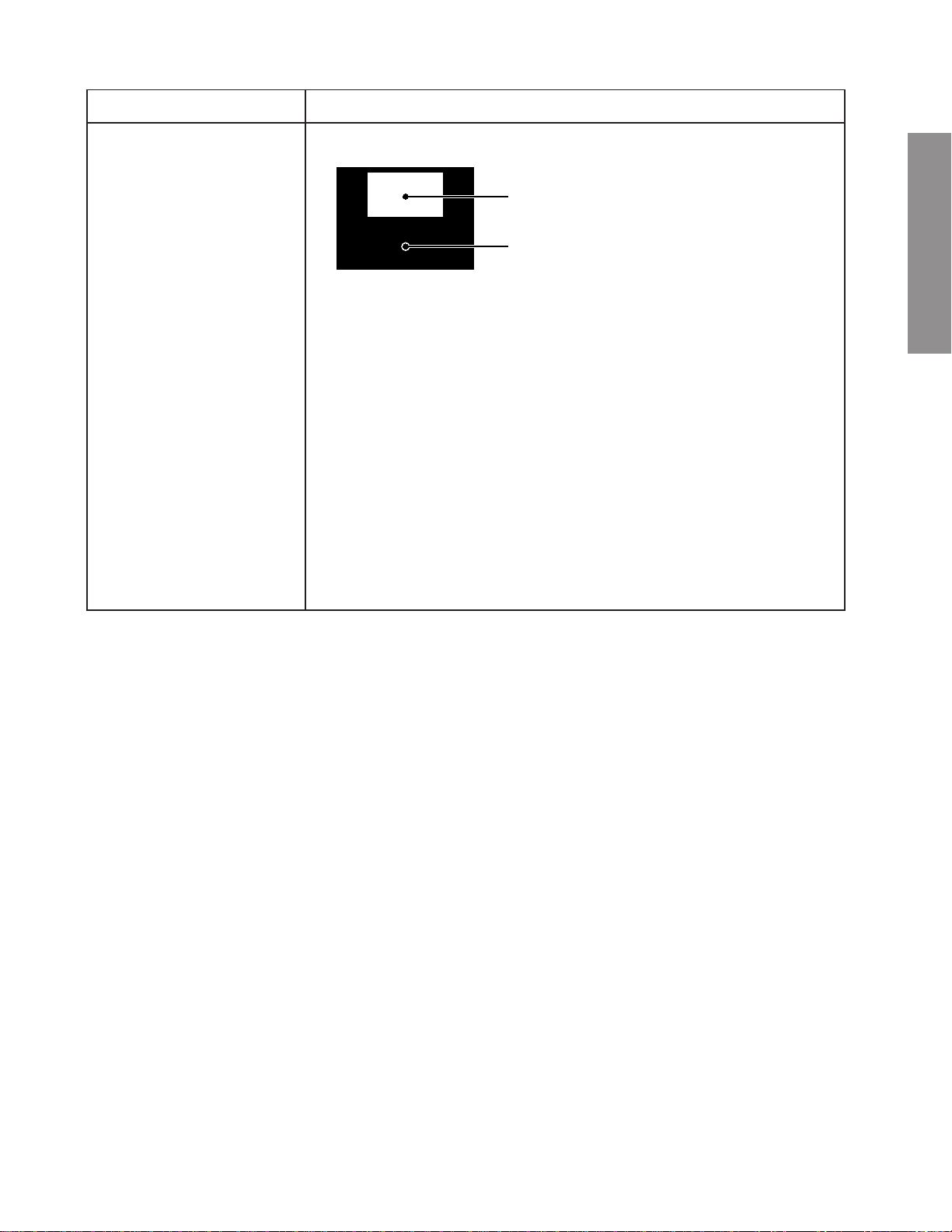

8 o’clock

4 o’clock

Lens Assembly

R

GB

Attention Serviceman

The Hex Head

Bolts with

Springs. (see

sketch) used on

CRT assembly,

are “NOT”

Adjustment Screws

DO NOT LOOSEN-FLUID

LEAKAGE WILL OCCUR.

4 Screws

4 Screws

CRT Assembly

CRT Anode Cap Assembly

S.V.M. Coil

CRT DRIVE Board

CRT Mounting

Deflection Yoke and Conver Yoke

Lens and Neck Components View

– 4 –

Page 5

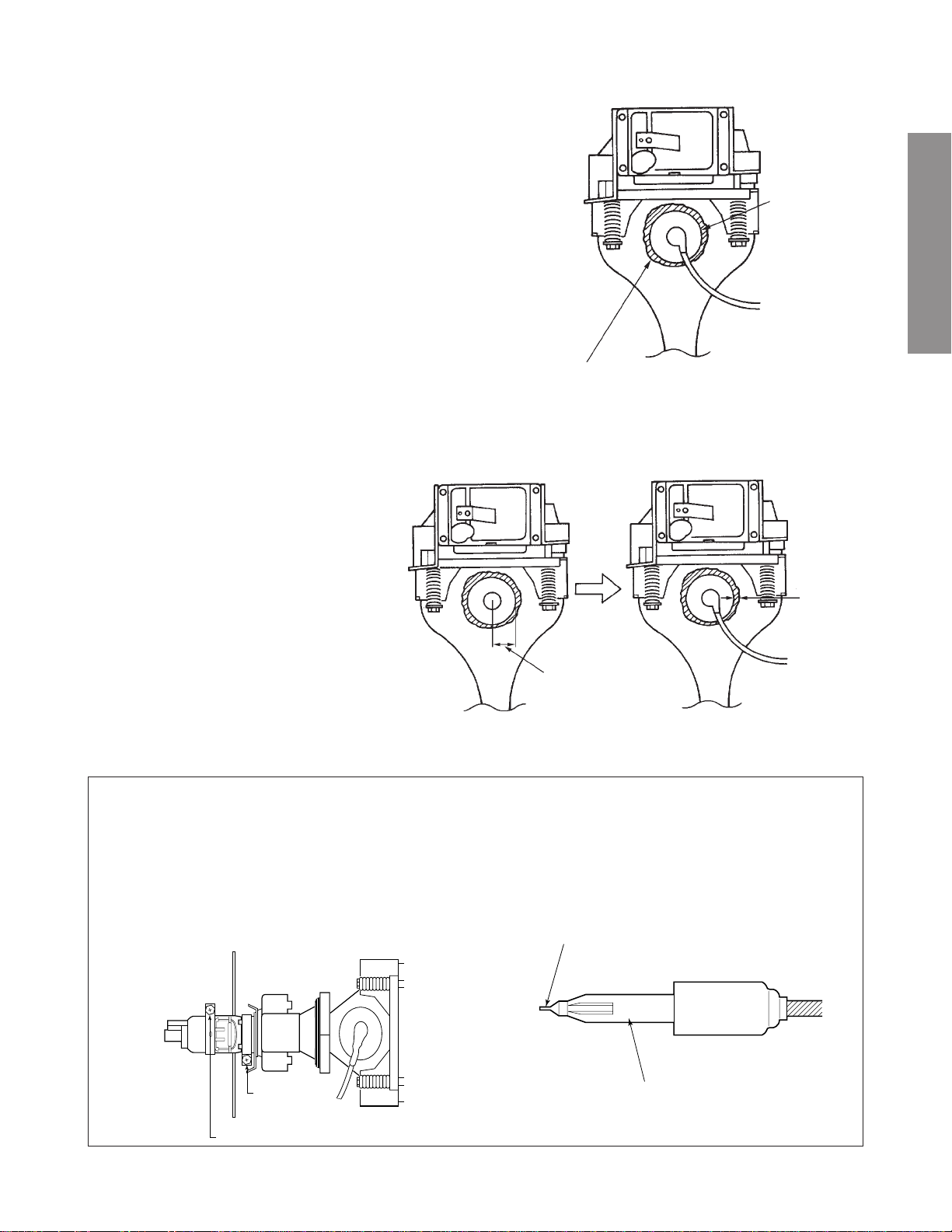

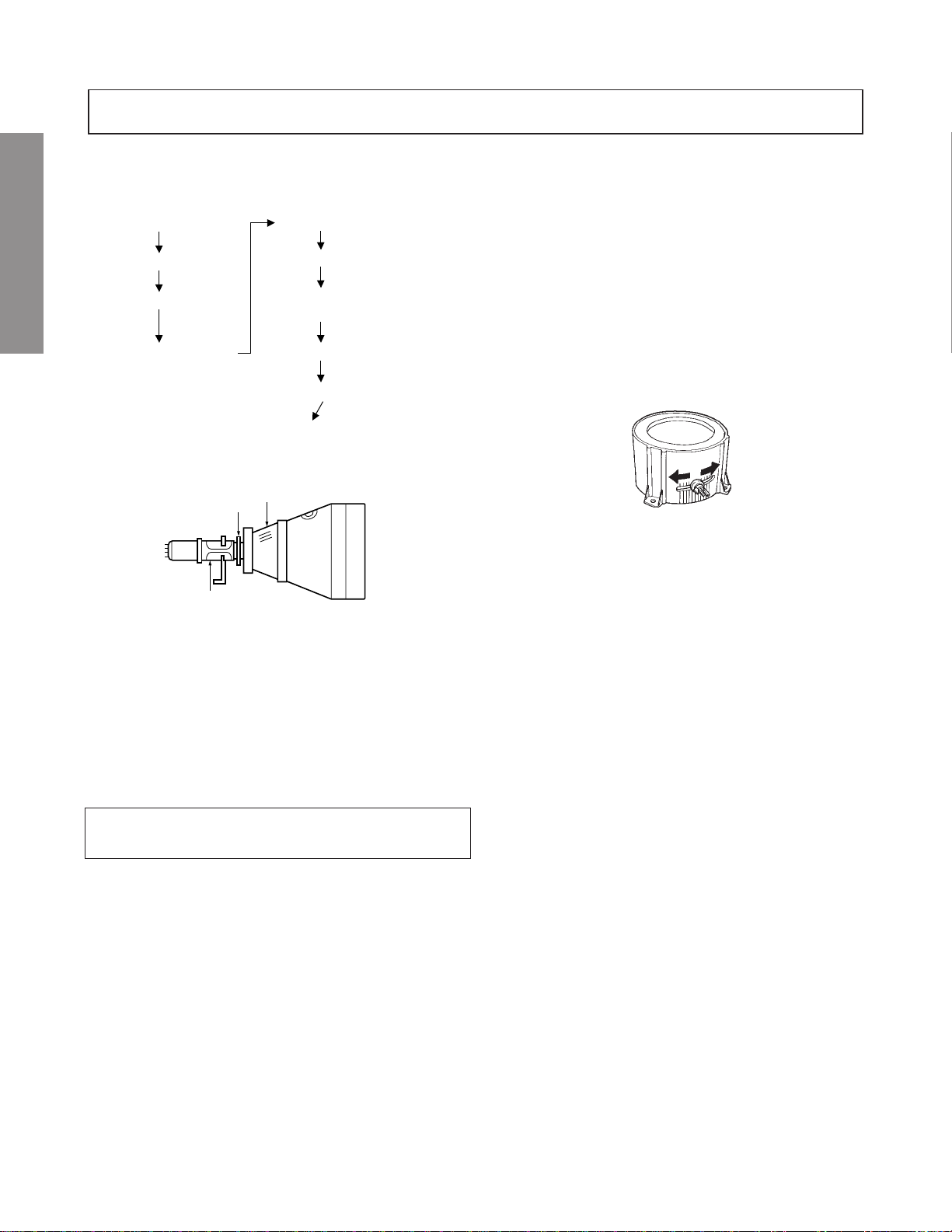

TO REMOVE CRT (Same procedure for R, G, B)

1. Remove CRT DRIVE Board, S. V. M. COIL and

DEF. YOKE from CRT.

2. Remove Lens Assembly.

3. Detach CRT Anode Cap from CRT.

4. Remove CRT Assembly from CRT Mounting.

CRT REPLACEMENT (Same procedure for R, G, B)

Reverse the removal procedures except the followings.

1. Anode Cable should be replaced with new one.

See "SERVICING PRECAUTIONS" shown below.

2. Install silicon (T461B) to the CRT, replace the Anode

cable and put enough silicon again on around the Anode Cap as illustrated.

CAUTION: Align the Anode cable as illustrated on page

4.

ADJUSTING PROCEDURE IN REPLACING CRT

1. R.G.B. CUTOFF (SCREEN VR) ADJUSTMENT (page 6.)

2. R.G.B. FOCUS ADJUSTMENT (page 6.)

3. PICTURE TILT ADJUSTMENT (page 7.)

4. USER CONVERGENCE CENTER CHECK

(Refer to owner's manual.)

5. CENTERING ADJUSTMENT (page 7.)

6. CONVERGENCE ADJUSTMENT (page 23.)

7. WHITE BALANCE ADJUSTMENT (page 15.)

Adjustments are complete.

Anode Cap

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Silicon

(On shaded area)

TSE3843W #23960136

SERVICING PRECAUTIONS

■ Do not use a magnetized screw driver for screws

of Deflection Yoke and Velocity Modulation Coil to

avoid magnetization of electron gun.

Magnetization of electron gun will degrade basic

function and result in unbalance of right and left

shift of user static convergence, and result in no

variable quantity.

2 ~ 5 mm

15 ~ 25 mm

■ When replacing the anode cap assembly (CRT) or

anode lead assembly (F.B.T.), remove the anode

lead holder from old one and attach the holder

again to new anode lead.

■ Check the point of anode lead in a straight

line, if it is winding, please revise it.

Screw

for D.Y

Screw for SVM coil

Anode lead holder

– 5 –

Page 6

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY RADIATION PRECAUTION", "SAFETY PRE-

CAUTION" AND "PRODUCT SAFETY NOTICE" ON PAGE 3 OF THIS MANUAL.

PICTURE TUBE COMPONENTS ADJUSTMENT

ADJUSTING PROCEDURE IN REPLACING CRT

Cutoff

Lens focus

Electrical focus

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Yoke horizontal

DESCRIPTION OF NECK COMPONENTS

S.V.M. COIL

1 Deflection yoke and convergence yoke.

The position on the neck is required most front (CRT funnel side) and the screw is fastened after rotating yoke

adjusting picture tilt.

2 Centering magnet

After adjusting picture tilt, picture position is finally fixed

by this magnet.

In order to get maximum margin of user convergence control for center of screen, this magnet have to be used for

center convergence adjustment.

2

User convergence center check

Centering (PAL)

Convergence adjustment

(PAL/NTSC)

White balance

Sub bright adjustment

End

1

RGB FOCUS ADJUSTMENT

1. Call-up the adjustment mode (see page 10)

2. Press a b utton on the remote controller in order to display

the internally-generated cross-hatch (See TEST SIGNAL

SELECTION on page 11.)

3. Expose only RED by cover ing the GREEN and BLUE

lenses with caps.

4. Loosen the RED lens fixing screws (refer to Fig. a), and

adjust the RED lens focus to obtain the sharpest point

while observing the middle and peripheral sections of the

screen.

Fig. a

5. Use the focus VR of “R” of the focus pack in order to adjust

the electric focus in the middle and peripheral sections of

the screen to its sharpest level.

6. Check the RED focus of the whole screen and if necessary

repeat steps 4 and 5.

7. Fix the RED lens by tightening its fixing screws.

8. Expose only GREEN by covering the RED and BLUE

lenses with caps.

9. Display the internally-generated cross-hatch signal.

10. Adjust the GREEN lens focus on the left border of the

screen to its sharpest level, then check the focus on the

right border, and if it is at its sharpest level, fix it in that

position by tightening the lens screws.

PREPARATION

Operate the receiver for at least 5 minutes.

R, G, B CUTOFF (SCREEN VR) ADJUSTMENT

1. Adjust before replace the screen assembly.

2. Set user control to reset position.

CONTRAST → Max

(

BRIGHTNESS, COLOR, TINT → Center.

3. Call up the adjustment mode display, then select the

item RCUT.

4. Adjust the data of items RCUT, GCUT, and BCUT to

"40H".

5. Press the -/-- button on Remote. (Y-MUTE : ON)

6. Gradually rotate R, G and B screen volume of FOCUS

PAC clockwise or counterclockwise until the raster

appears slightly on the CRT through the each lens, and

leave them.

(Lookin to the lens in order to check the raster.)

7. Press the -/-- button on Remote. (Return to Normal

Picture)

(1) If the horizontal line toward the right border is red-

flared, turn the lens screw slightly right in order to

balance it with the left border. (After adjustment, the

left border tends to be slightly green-flared, and the

right border tends to be slightly red-flared.)

(2) If the horizontal line toward the right border is green-

)

Note: The aim of the above-described adjustment procedure

– 6 –

flared, turn the lens screw slightly left in order to

balance it with the left border. (After adjustment, the

left border tends to be slightly red-flared, and the

right border tends to be slightly green-flared.)

for the Green lens focus is to obtain the best lens focus

after 2 - 3 hours of warming up taking into account the

focus drift; it applies if the war ming up time before the

adjustment is less than 30 minutes. (The horizontal line

in the screen middle section tends to be slightly redflared.)

Page 7

In case of warming up of more than 2 hours under a condition

that the large anode current is running through the projection

tube so that for example the all-white pattern appears, adjust

to obtain the sharpest focus while observing the whole screen

like in the RED case.

11. Press a button on the remote controller in order to displa y

the internally-generated black cross-hatch. (See TEST

SIGNAL SELECTION on page 11.)

12. Use the focus VR of “G” of the focus pack in order to adjust the electric focus in the middle section of the screen

to its sharpest level.

Note: Keep in mind that only the BLUE electric focus is ad-

justed with the black cross-hatch.

20. Check the BLUE focus of the whole screen and if necessary repeat steps 17 and 19.

21. Fix the BLUE lens by tightening its fixing screws.

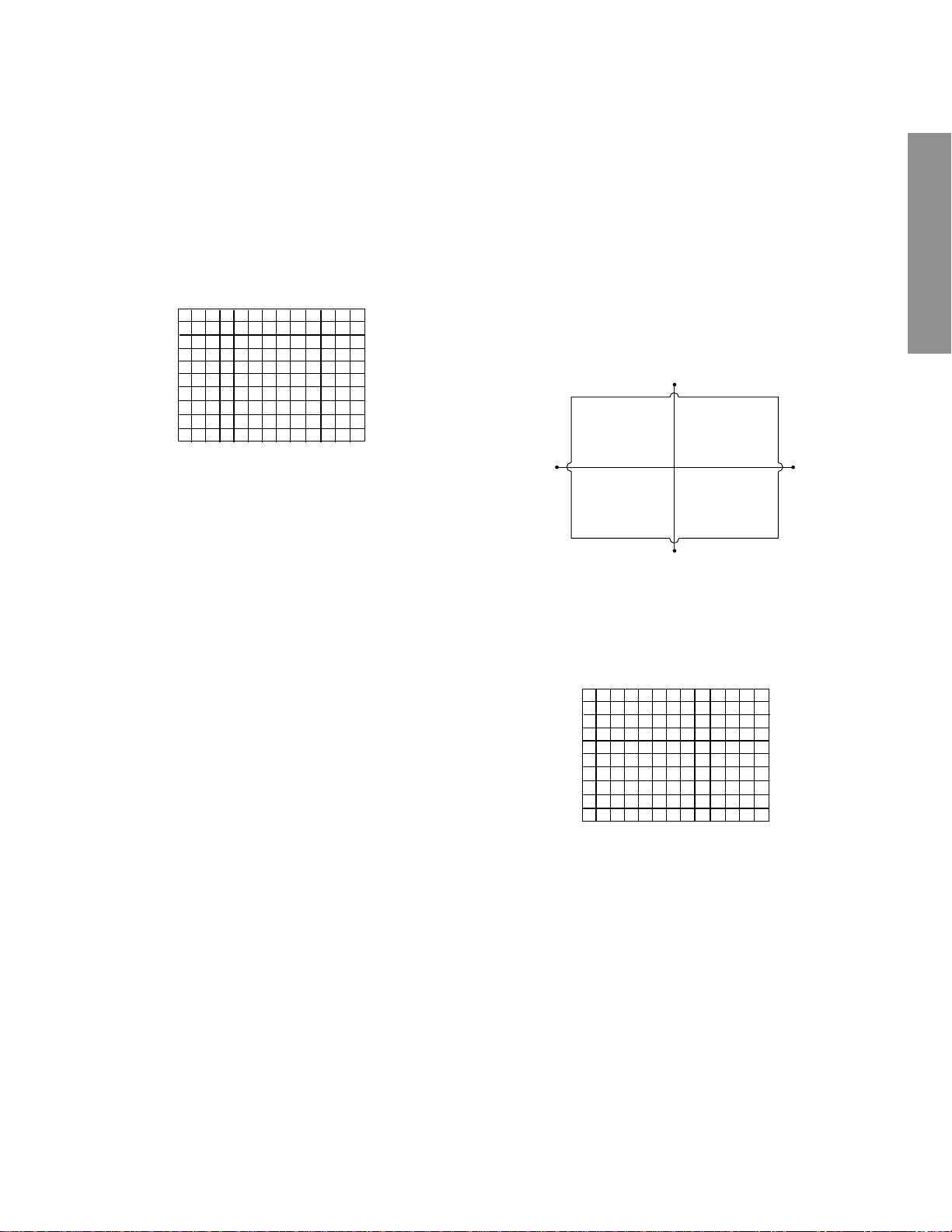

TILT ADJUSTMENT

Rotate R, G, B deflection yoke so that picture becomes horizon, then fasten screw.

CENTERING ADJUSTMENT

1. Stretch a thread between two center slots of screen edge

(top and bottom, left and right).

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Note: Nor mally the most clearly visible point of the scanning

line is the sharpest point of the Green focus, howev er as

the characteristics vary depending on the projection tube,

the sharpest focus points of the vertical and horizontal

lines may not match each other, thus when you turn the

focus VR, if the picture tends to be tremendously unstable

(rolls horizontally or vertically), adjust the balance of the

vertical and horizontal lines to its best position.

13. Check the GREEN focus of the whole screen and if

necessary repeat steps 10 and 11.

14. Fix the GREEN lens by tightening up its fixing screws.

15. Expose only BLUE by covering the RED and GREEN

lenses with caps.

16. Press a button on the remote controller in order to displa y

the internally-generated cross-hatch (See TEST SIGNAL

SELECTION on page 11.)

17. Loosen the BLUE lens fixing screws (refer to Fig. a), and

adjust the BLUE lens focus while observing the middle

and peripheral screen sections.

18. Press a button on the remote controller in order to displa y

the internally-generated black cross-hatch (See TEST SIGNAL SELECTION on page 11.)

19. Use the focus VR of “B” of the f ocus pack in order to adjust

the focus in the middle section of the screen to its sharpest

level.

(The point of the Blue focus becomes sharpest when the

brightness level of BLUE is lowest, the cross-hatch is

clearly visible.)

2. Select the adjustment mode. (See page 10.)

3. Press TV/VIDEO button on the Remote Control to display

the black cross-hatch.

4. Adjust G centering magnet so that the cross-hatch pat-

tern center comes to screen center.

5. Perform HEIGHT adjustment . (See page 14.)

6. Perform WIDTH adjustment. (See page 14.)

7. Check whole quality of green line.

8. Adjust R, B centering magnet so that the cross-hatch pat-

tern center comes to screen center.

– 7 –

Page 8

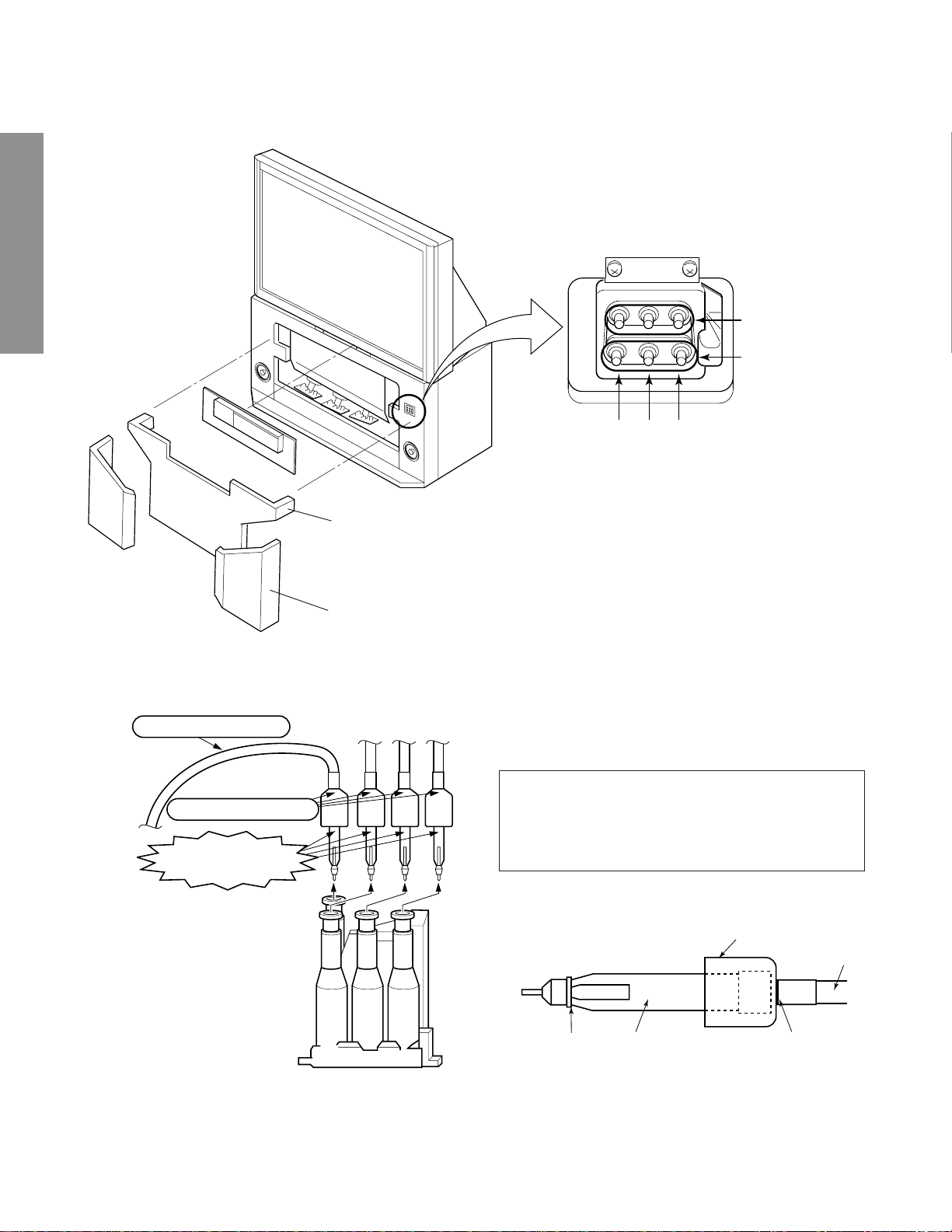

LOCATION OF SCREEN AND FOCUS VR'S

To remove the Speaker grille and Front panel.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SCREEN VR

FOCUS VR

Front panel

Speaker grille

REPLACEMENT OF HIGH VOLTAGE CABLE

ANODE LEAD

RUBBER BOOT

LEAD HOLDER

B

1. When replacing Anode Lead or Anode Cap with new

one, remove Lead Holder from old lead as shown in

figure below , and put it on new lead. Do not throw awa y

Lead Holder.

NOTE : THE LEAD HOLDER IS ATTACHED TO

TP A5007 (Z450), BUT IS NO T A TTACHED TO

ANODE LEAD AND ANODE CAP. RUBBER

BOOT IS ATTA CHED TO ANODE LEAD AND

ANODE CAP.

RG

Fig. a

Z450 TPA5007

– 8 –

2. Detaching Lead Holder

LOCK

LEAD HOLDER

RUBBER BOOT

Fig. b

OLD

ANODE LEAD

or

ANODE CAP

Cut here rubber boot

and lead together to

detach Lead Holder.

Page 9

WARNING: BEFORE SER VICING THIS CHASSIS , READ THE "X-RAY RADIA TION PRECA UTION", "SAFETY PRECAU-

TION" AND "PRODUCT SAFETY NOTICE" ON PAGE 3 OF THIS MANUAL.

SERVICE POSITION

In order to assure the performance, processed wires shall be replaced after the repair work.

Work procedures are as follows:

1. Remove the back board.

2. Remove lead wires.

3. Draw out the chassis.

4. Rest the chassis against the back cabinet, chassis as shown bellow.

After repair work finished, replace it in the opposite procedure.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 9 –

Page 10

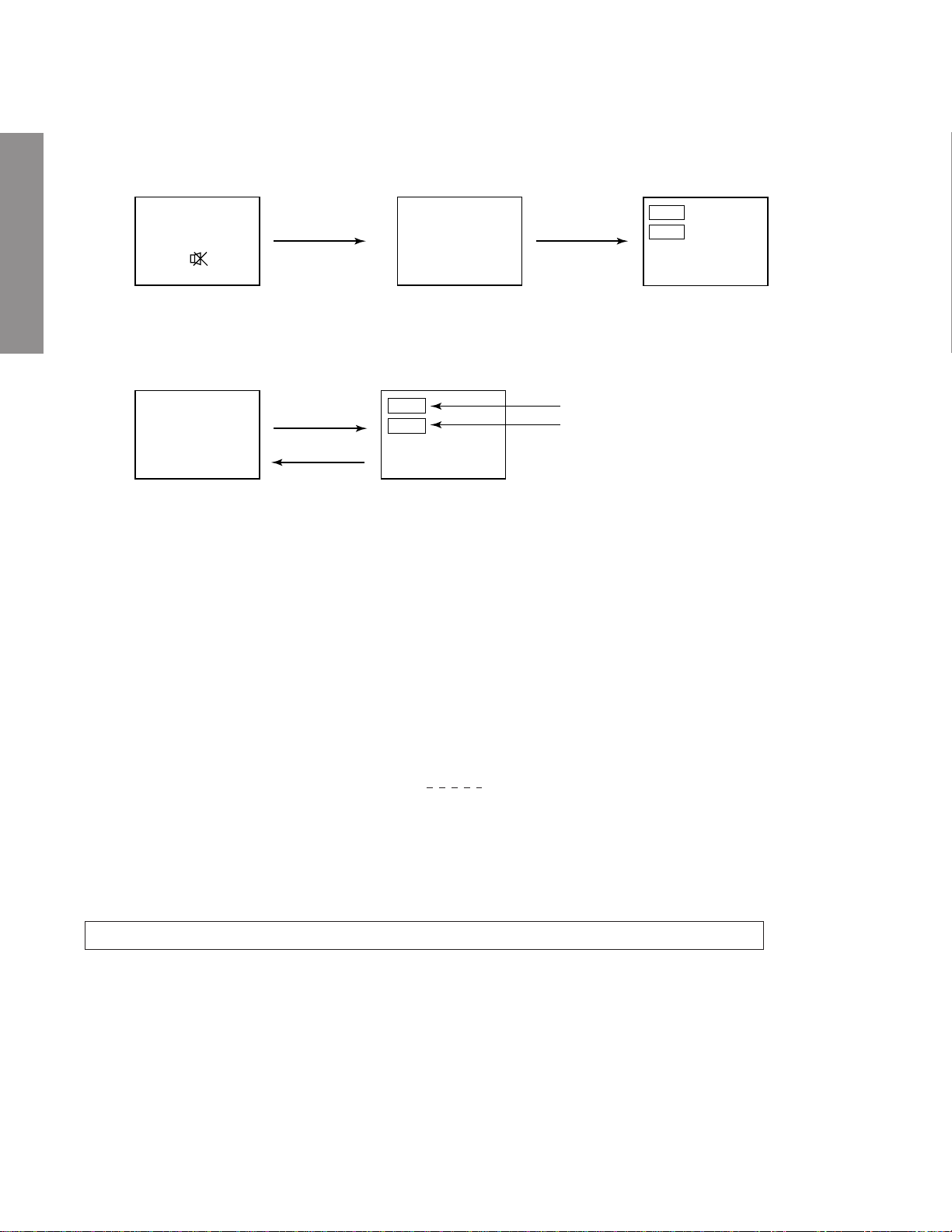

1. ENTERING TO SERVICE MODE

1) Press o button once on

Remote Control.

SERVICE MODE

2) Press o button again to

keep pressing.

3) While pressing the o button,

press MENU button on TV set.

or Sound Mute

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Screen adjustment mode ON/OFF: -/-- button (on Remote)

Test signal selection : a button (on Remote)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume ; +/– (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : CALL + Channel button on TV (s)

Reset the count of operating protect

circuit to “00”: CALL + Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“SCNT” (or “CNTX”) selection : 4 button

“COLC” (or “SCOL”) selection : 5 button

“TNTC” selection : 6 button

Convergence adj : YELLOW button

Self diagnostic display ON/OFF : 9 button

Item

Data

(Service mode display)

Adjustment mode

S

Press

Press

Item

Data

S

Color thickness correction

note: Displayed differently as shown below, de-

pending on the setting of the receiving color

system.

COLP (PAL)

COLC (NTSC)

COLS (SECAM)

CAUTION : Never try to perform initialization unless you have changed the memory IC.

– 10 –

Page 11

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 34)

5. ADJUSTING THE DATA

1) Pressing of VOLUME ; +/– button will change the value of data in the range from 00H to FFH. The variable

range depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the CALL button on the Remote, then press the CHANNEL s button on the TV. The initialization of QA02 has

been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perfor m “Auto search Memory” on the owner’s manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

7. TEST SIGNAL SELECTION

1) Every pressing of a button on the Remote Control changes the built-in test patterns on screen as described below

in SERVICE MODE.

Signal off

NTSC signals (5 patterns)

PAL signals (5 patterns)

Signals Picture

• Red raster

• Green raster

• Blue raster

• All White

• Black cross-hatch

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

The signals marked with are not usable to display in the Test signal for some model.

*

– 11 –

Page 12

8. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

<SELF CHECK>

1

2300****

2

POWER : 00

3

BUS CONT : OK

4

BLOCK : UV V1 V2 V3

QV01

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Indicated color of mode now selected : Green and Red

Indicated color of other modes : White

Green :Normal

Red : The microcomputer operates to provide judgement

of no video signal. The red color is still indicated

though the signal is input, failure may e xist in input

signal line including QV01.

QV01 : In case of indication green ---Normal

In case of indication red with input signal---Failure may exist in output line including QV01.

1 Part number of microcomputer (QA01)

2 Operation number of protecting circuit ----“00” is nor-

mal.

When indication is other than “00”, overcurrent apts to

flow, and circuit parts may possibly be damaged.

3 BUS CONT ----“OK” is normal.

When indication shows “Q uuu (Green: OK, Red:

NG)”, the device with the number ma y possibly be damaged.

NOTE: Component which controls character display on

screen is QT01 (TELETEXT IC.). If this display

function fails to operate due to damage in QT01,

self diagnosis procedure is as follows.

(1) In case that on timer indicator is blinking with

interval of 0.5 seconds; it means protecting circuit (Current limiter) is operating, and circuit

components may possibly be damaged. Check

related components.

4 BLOCK

UV : TV reception mode

V1 : VIDEO 1 input mode (a1)

V2 : VIDEO 2 input mode (a2)

V3 : VIDEO 3 input mode (a3)

The items marked with are not usable to display in the SELF DIAGNOSTIC FUCTION for some model.

*

– 12 –

Page 13

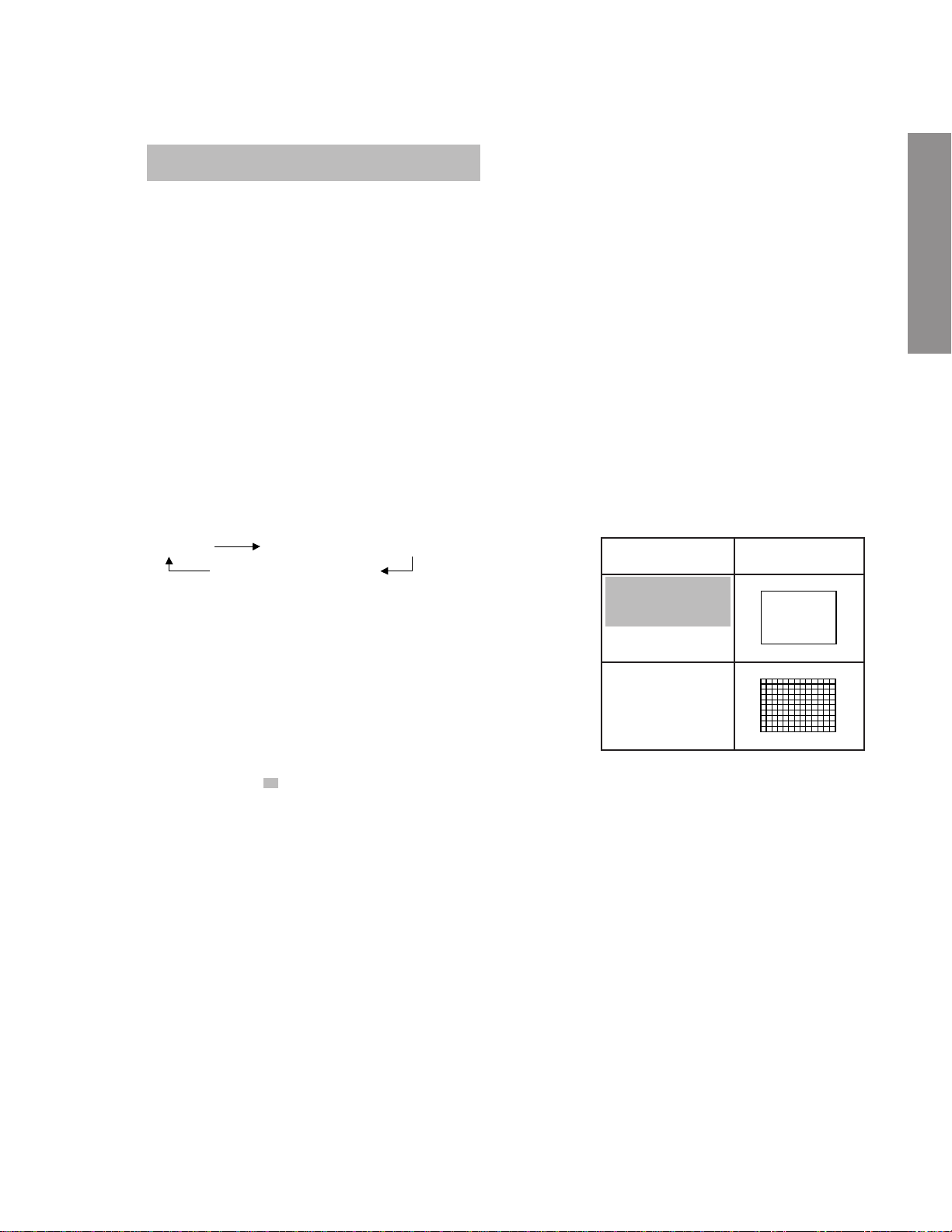

1. ENTERING TO DESIGN MODE

1) Select the Service mode.

DESIGN MODE

2) While pressing CALL button on Remote

and press MENU button on TV.

3) Press MENU button on TV.

S D

(Design mode) (Adjustment mode)

When QA02 is initialized, items “OPT0” and “OPT1” of DESIGN MODE are set to the data of the representative model of this

chassis family.

Therefore, because ON-SCREEN specification remains in the state of the representative of model. This model is required to

reset the data of items “OPT0” and “OPT1”.

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL t button in the design mode changes the adjustment items in the order of table-3.

(s button for reverse order)

Refer to table-3 for data of design mode.

(See SETTING & ADJUSTING DATA on page 34)

3. ADJUSTING THE DATA

Pressing of VOLUME s or t button will change the value of data.

Press

Press

ITEM

DATA

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 13 –

Page 14

PAL

ELECTRICAL ADJUSTMENT

ITEM ADJUSTMENT PROCEDURE

WIDTH

(WID)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

HEIGHT

(HIT)

1. Select picture size WIDE mode.

2. Call up the adjustment mode display, and press the TV/VIDEO

button on the remote untill the white cross dot pattern appears on

the screen.

3. Press the CHANNEL s or t button to select the item WID and

press the VOLUME s or t button to get the pictuer so the left and

right edges of rester begin to lack.

4. Press the VOLUME s or t to advance the data 22 steps.

* CAUTION

"WID" data don't adjust other picture size, only WIDE mode.

1. Call up the adjustment mode display, then select the item HIT.

2. Press the VOLUME s or t button to get the picture so the top of

raster begins to lack.

3. Press the VOLUME s button to advance the data by following steps.

WIDE: 7 steps

Super Live: 11 steps

CINEMA: 10 steps

* CAUTION

First adjust WIDE mode next other.

Note : Check the vertical picture position is correct.

NTSC

WIDTH

(NWID)

HEIGHT

(NHIT)

1. Select picuter size wide mode.

2. Call up the adjustment mode display, and press the TV/VIDEO

button on the remote untill the white cross dot pattern appears on

the screen.

3. Press the CHANNEL s or t button to select the item WID and

press the VOLUME s or t button to get the pictuer so the left and

right edges of rester begin to lack.

4. Press the VOLUME s or t to advance the data 16 steps.

5. Change picture size Super Live and CINEMA adjust "NWID" data

same value for WIDE mode.

1. Call up the adjustment mode display, then select the item HIT.

2. Press the VOLUME s or t button to get the picture so the top of

raster begins to lack.

3. Press the VOLUME s button to advance the data by following steps.

WIDE: 7 steps

Super Live: 13 steps

CINEMA: 10 steps

Note : Check the vertical picture position is correct.

– 14 –

Page 15

ITEM ADJUSTMENT PROCEDURE

WHITE BALANCE

(RCUT)

(GCUT)

(BCUT)

(RDRV)

(BDRV)

Black and White pattern

High light area

Adjust "RDRV" or "BDRV" to be white.

Low light area

Fine adjust "RCUT", "GCUT" or "BCUT" to be black.

1. Set user control to reset position.

CONTRAST → Min.

(

BRIGHTNESS, COLOR, TINT → Center.

2. Call up the adjustment mode display, then select the item RCUT.

3. Adjust the data of items RCUT, GCUT, and BCUT to "40H".

4. Press the a button on PJTV. (Y-MUTE : ON)

5. Gradually rotate R, G and B screen volume of FOCUS PAC clockwise or

counterclockwise until the raster appears slightly on the CRT through the

each lens, and leave them.

(Lookin to the lens in order to check the raster.)

6. Press the a button on PJTV. (Return to Normal Picture)

7. Press the a button on Remote, and select the Black and White pattern.

8. Adjust the data of items RCUT, GCUT and BCUT for proper white-balanced

picture in low light area.

9. Adjust the data of items RDRV and BDRV for proper white-balanced picture in

high light area.

10. Check the white balance in both low and high light areas.

If necessary, perform again steps from 8 to 9.

)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 15 –

Page 16

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2.4 ± 0.1 Vpp

y Adjust the amplitude from the pedestal

4 ± 1.5 linee

level to the white peak.

lines of the sub-bright signal.

y Adjust the number of collapsed black

1.30 ± 0.1 Vpp

W/B and SCNT.

x Carry out adjustment after adjusting the

y Adjust the amplitude of the color bar.

100 ± 10 %

the waveforms can become flat.

x Adjust the P-P value of the upper half.

y Use a synchroscope and adjust so that

x Adjust at the white part.

1.95 ± 0.1Vop

(Apply SCREEN mute during adjust-

ment)

y Adjust the amplitude of the color bar.

0 ± 10 mV

chrome signal part can meet the level of

x Adjust the P-P value of the upper half.

y Adjust so that the level of the mono-

0 ± 10 mV

the H.BLK.

BELL.

chrome signal part can meet the level of

the H.BLK.

BELL.

x Carry out adjustment after adjusting the

y Adjust so that the level of the mono-

x Carry out adjustment after adjusting the

TP46B SIGNAL unit

Sub-bright signal

Dynamic mode

Sub-contrast

Screen adjustment

(PAL-I signal)

Sub-bright signal

Audio system: I

Dynamic mode

Sub-bright

center

TP46B

SIGNAL unit

TPM01

SIGNAL unit

Sub-bright signal

(PAL)

SECAM color bar

Dynamic mode

Sub-color

center

PAL

BELL filter

TP46B

SIGNAL unit

SECAM color bar

Dynamic mode

Sub-color

center

TP02

SECAM color bar

Dynamic mode

SECAM

SECAM

SIGNAL unit

R-Y black level

TP01

SIGNAL unit

SECAM color bar

Dynamic mode

SECAN

B-Y black level

Item Name Setting Input signal Measuring point Adjusting method Adjustment standard

(Reference factory adjustment)

[SCNT]

[BRTC]

[COLP]

[BELL]

– 16 –

[COLS]

[SRY]

[SBY]

Page 17

Point where it

begins to emit light.

For details, refer to

the focus adjust-

ment method

introduced in the

next page.

8750k–0.002uv

8750k–0.002uv

30.7 ± 0.2kV

possible.

x Enter factory-screen-adjustment mode.

y Make the surrounding as dark as

CRT screen

(Y mute, DRV.CUT. = 40 H)

adjust the screen VR to the point where

it begins to emit light.

perform above-mentioned adjustments.

c Directly observe the CRT screen, and

v Use R, G, and B tubes respectively to

possible position by repeating electrical

y Make adjustments to achieve the best

Crosshatch signal

Screen adjustment

Retoma signal

(PAL-I)

axis under adjustment, from any light.

and optical focusing.

x Use jigs to protect the CRTs, except the

c Use R, G, ad B tubes respectively to

).

2

perform above-mentioned adjustments.

bright part (103cd/m

y Adjust the color temperature of the

y Adjust the color temperature of the dark

Screen adjustment

Screen adjustment

).

2

part (17cd/m

y Connect a voltmeter between T461 and

Between T461 and

Phillips pattern

Z450 and adjust the high voltage with

R450.

(User adjustment standard)

Z450

(PAL-I)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Factory- screen-

adjustment mode

Screen

Item Name Setting Input signal Measuring point Adjusting method Adjustment standard

Screen

adjustment

Dynamic mode

Cinema mode

Focus

Focus

adjustment

– 17 –

Bright part W/B

RDRV

BDRV

Dark part W/B

RCUT

BCUT

Dynamic mode

High voltage

High voltage

adjustment

Page 18

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Focus adjustment method (1/2)

(2) GREEN: Internal crosshatch signal (white crosshatch on black background)

(3) User adjustment: Dynamic mode, cinema mode

Conditions: (1) RED, BLUE: Internal Retoma signals (PAL)

(4) Carry out electrical focus and lens focus after rough adjustment.

(5) Use the jig to protect everything, except the color subjected to adjustment, from exposure to light.

each R and B projection tube to the position where the center of the screen gets optimally focused.

G so that the vertical scanning lines on the screen center can appear most clearly.

best possible focus.

(1)Receive the internal Retoma signals, use the focus VR of the focus pack (Z410), and adjust the electrical focus of

(2)Receive the internal crosshatch signals, use the focus VR of the focus pack (Z410), and adjust the electrical focus of

(1)R, B: Receive the internal Retoma signals, watch the screen center and its periphery, and make adjustment to the

(2)G: Adjust this by the method introduced in the next page.

set on the screen.

until immediately before the cutoff adjustment in order to stabilize the G’s coupling liquid temperature.

y Carry out anticipated adjustment on the G lens, considering the time until the lens focus stabilizes.

x The level of anticipated adjustment on the G lens results in a required level of correction, if an adjustment point is

c During a heat run, be sure to keep lower the G’s screen VR of the focus pack from turning on the power of the set

Model Adjustment points Adjustment methods

40PW03G

40PW03B

Electrical focus

– 18 –

Lens focus

(Precautions)

Page 19

GREEN lens focus adjustment

Focus adjustment method (2/2)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

the very best, and check that the left-and-right focus balance is appropriate.

(Check left-and right balance of G lens focus)

(2)Watch the horizon of both the left and right ends on the horizontal axis of the screen, adjust the lens focus of G to

Screen

Model Metodo di regolazione

Adjusting points

[1] 40PW03 series (1)Receive internal crosshatch signals, use the lens cap, and concentrate on the single color of G.

y Use the left (or right) end crosshatch and make the best adjustment on the G’s lens focus.

x Check the right (or left) end focus.

(3)If the left and right lens focus is not properly balanced (tendency for flare), divide and adjust it to the middle grade.

(4)Check on the periphery, and make certain that the focus grade lies within a tolerable level (including flare).

Right end

Left end

– 19 –

ø 100 mm ø 100 mm

(Point of observation)

Inside the circle of 100mm that is in contact with

left and right bezels.

Page 20

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Less than ø7mm

Adjustment standard

screen positions and centering magnet

so that the central + mark of the dummy

screen and the + mark of the Phillips

pattern can overlap in conformity.

(1)Adjust the vertical and horizontal

Upper and lower

flags are to be in

contact

Carry this out individually on 3 tubes of

R, G, and B

(Note) Do not move HPOS, VPOS data

amplitude using HIT data until the upper

and low flags emerge on the screen.

the HIT data until either upper or lower

flag end conforms to the screen end

(Adjust the vertical center of the pattern

to the central mark of the screen.)

(1)Turn the screen size to WIDE.

(2)In the first place, shorten the vertical

(3)Then, extend the vertical amplitude with

The inner circle is

to contact the

screen edge

bottom of the inner circle of Phillips

pattern will contact the screen edge.

(Note) VLIN adjustment is not performed.

(1)Turn the screen size to Super-live.

(2)Adjust with the HIT so that the top and

bottom of the Phillips pattern as shown

in the next page.

(1)Turn the screen size to CINEMA.

(2)Adjust the registers on the top and

(Note) Do not touch the centering magnet

Screen adjustment

Screen adjustment

Completion of adjustment

Phillips pattern

(PAL-I)

Dynamic mode

Phillips pattern

(PAL-I)

Dynamic mode

WIDE mode

Vertical ampli-

tude adjustment

(PAL WIDE)

Screen adjustment

Phillips pattern

(PAL-I)

Dynamic mode

Super-live mode

Vertical ampli-

tude adjustment

(PAL Super-live)

Screen adjustment

Phillips pattern

Dynamic mode

Vertical ampli-

(PAL-I)

CINEMA mode

tude adjustment

(PAL cinema)

Item Name Setting Input signal Measuring point Adjusting method

Screen

position

adjustment

HIT

VLIN

– 20 –

HIT

VLIN

HIT

VLIN

Page 21

Adjustment standard

bottom of the Phillips pattern as shown

in the next page.

(1)Turn the screen size to SUB-TITLE.

(2)Adjust the registers on the top and

(Note) Do not touch the centering magnet

pattern are to contact the screen edge.

be 0.

(1)Turn the screen size to WIDE.

(2)The left and right flags of the Phillips

(3)The user center position adjustment is to

(1)Turn the screen size to WIDE mode.

(2)The 1st line on the screen is to be

hidden by the mask.

mode.

(1)Turn the screen size to SUPER-LIVE

(2)Adjust so that the upper side 3rd line on

the screen will contact the screen edge.

(3)Do not adjust the NVLI.

upper, lower, and left-and-right ends will

contact the screen edge.

(1)Turn the screen size to CINEMA mode.

(2)Adjust so that the character 30 on the

mode.

the register on the screen will contact the

screen.

(1)Turn the screen size to SUB-TITLE

(2)Adjust so that the upper side 5th line of

(3)The NVLI is not to be adjusted.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Screen adjustment

Screen adjustment

Completion of adjustment

Phillips pattern

(PAL-I)

Dynamic mode SUB-

TITLE mode

Vertical ampli-

tude adjustment

(PAL SUB-

TITLE)

Phillips pattern

(PAL-I)

Dynamic mode

WIDE mode

Vertical ampli-

tude adjustment

PAL WIDE

Screen adjustment

Monosco signals

Dynamic mode

Vertical ampli-

Screen adjustment

NTSC

LEADERE-435B

Monosco signals

NTSC

LEADER-435B

WIDE mode

Dynamic mode

SUPER-LIVE mode

tude adjustment

NTSC WIDE

Vertical ampli-

tude adjustment

SUPER-LIVE

Screen adjustment

Monosco signals

NTSC

Dynamic mode

CINEMA mode

NTSC

Vertical ampli-

tude adjustment

Screen adjustment

LEADER-435B

Monosco signals

NTSC

LEADER-435B

Dynamic mode

SUB-TITLE mode

CINEMA

NTSC

Vertical ampli-

tude adjustment

SUB-TITLE

NTSC

Item Name Setting Input signal Measuring point Adjusting method

HIT

VLIN

WID

NHIT

NLIN

– 21 –

NHIT

NHIT

NLIN

NHIT

NLIN

Page 22

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Adjustment standard

edge of the screen.

the WIDE screen also input the identical

(2)Adjust the 2nd left register to the left

(3)When you change the NWID value on

Adjustment standard

data to SUPER-LIVE and CINEMA.

32 ± 0.1 MHz

+9V to #13 terminal

–9V to #14 terminal.

L719.

(2)Adjust emitter’s frequency to Q709 with

Screen adjustment (1)Turn the screen size to WIDE.

Completion of adjustment

Monosco signals

NTSC

LEADER-435B

Dynamic mode

WIDE mode

amplitude

adjustment

WIDE NTSC

Q709 Emitter (1)Apply +5V to #15, #16 terminals

Unit adjustment DIGITAL-CONVER

Item Name Setting Input signal Measuring point Adjusting method

NWIDE Horizontal

– 22 –

Item Name Setting Input signal Measuring point Adjusting method

PLL

Frequency

adjustment

Page 23

CONVERGENCE ADJUSTMENT

1. Screen Adjustment

The four PAL screens Wide/4:3, Super Live, Cinema and Subtitle, and the four NTSC screens Wide/4:3, Super Live,

Cinema and Subtitle are adjusted. When adjusting, input an external signal for matching the sync.

CAUTION: The con vergence circuit eliminates screen distortion but cannot make large corrections such as changing

the overall screen size. Use caution because the protection circuit will be activated if corrections are excessively

large. Before starting to adjust the various screens, alw ays adjust the v ertical size (HIT) and horizontal size (WID) b y

changing the main deflection data.

Execute the adjustment screens in the sequence Wide/4:3 → Super Live → Cinema → Subtitle for both PAL and

NTSC.

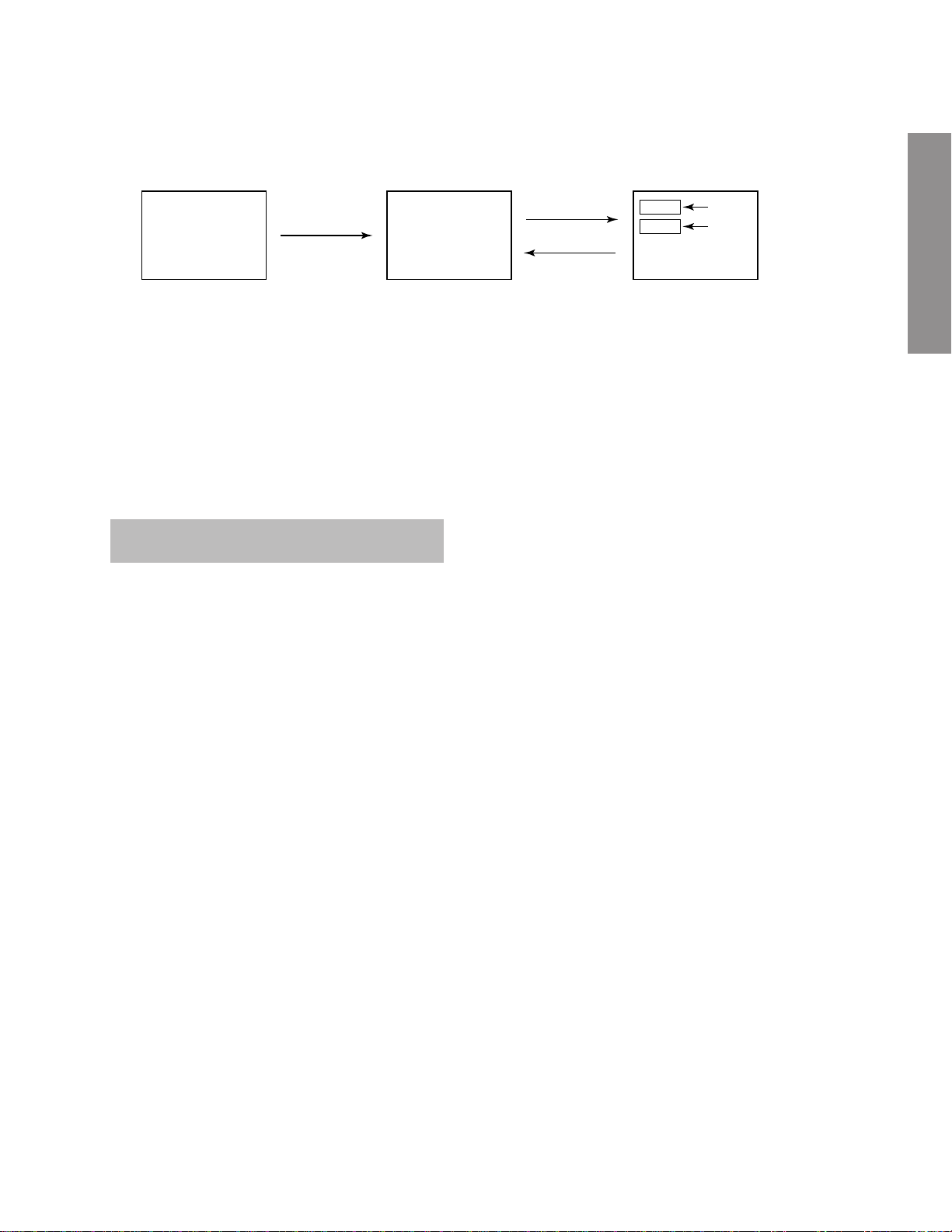

1-1. Entering Adjustmet Menu

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

+ + MENU key

F+Yellow key

Menu screen

CONVER ADJUST MENU

1

Adjust PAL Wide

2

PAL Wide to Others

3

Adjust PAL S.Live

4

Adjust PAL Cinema

5

Adjust PAL S.title

6

PAL to NTSC (Wide)

7

PAL to NTSC (ALL)

8

Adjust NTSC Wide

9

NTSC Wide to Others

10

Adjust NTSC S.Live

11

Adjust NTSC Cinema

12

Adjust S.title

S

Service data indication

+

or

MENU SELECTION

+ key

SCREEN

ADJUSTMENT

CALL: to exit

Adjusting screen

+ key

– 23 –

Page 24

1-2. Remote Control Key

b

h

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

i

g

j

F

1

2

f

Çi

CALL

3

TEXT

4 5 6

7 8

-/--

v

SIZE

MENU EXIT

0

?

ENTER

SELECT

9

a

^

CH

yX

V

l

p

k

c

a o key............... Push this key twice and the set con-

sole menu key to enter the service

mode.

b F key................. Push this key and yellow key to enter

the convergence menu.

c Yellow or 7 key.. Convergence menu key.

g 5 key................. Cursor shift / data change mode

change-over.

h 2 key................. Cursor up / adjusting point up.

i 4 key................. Cursor left / adjusting point left

j 8 key................. Cursor down / adjusting point down

k 6 key................. Cursor right / adjusting point right

l 3 key................. Cursor colour change (Adjusting

colour selection).

m + key................. Execution key on conv ergence menu.

n s key ................ Up key on convergence menu.

o t key ................ Down key on convergence menu.

p CALL key .......... Termination key on convergence

menu.

n

o

REC

a

m

P

VTR/DVD

Fig. 2

– 24 –

Page 25

1-3. Adjusting Screen

1) Adjusting menu

NO Description

1 Adjust PAL Wide Used for manual adjustment of the Wide/4:3 screen in the PAL mode.

2 P AL Wide to others Automatically sa ves approximate supplementary data f or the other P AL screens based

3 Adjust PAL S.Live Used for manual adjustment of the PAL Super Live screen.

4 Adjust PAL Cinema Used for manual adjustment of the PAL Cinema screen.

5 Adjust PAL S.title Used for manual adjustment of the PAL S.title screen.

Item

Returns to the original screen data screen before data conversion, explained below.

on the PAL Wide/4:3 screen data.

First, the PAL Wide/4:3 screen data are converted to Super Live and the values are

saved. Next, the data are converted to Cinema and the values are saved. Finally, the

data are converted to Subtitle and the values are sav ed, and then the operation ends .

Manually check the other screen modes as described below and make corrections if

distortion, etc., is present.

Please be aware that all PAL screens are re-adjusted when this menu is selected and

executed.

Select this mode for Super Live screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

Select this mode for Cinema screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

Select this mode for S.title screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

6 PAL to NTSC (Wide) PAL Wide/4:3 screen data is calculated, converted to NTSC Wide/4:3 approximate

data and saved.

To assure accurate adjustments, select the manual mode explained below and chec k,

then apply color matching and distortion adjustments.

7 PAL to NTSC (All) Data for all PAL screens is converted to approximate data for the NTSC screens and

saved.

To assure accurate adjustments, select the manual mode explained below and chec k,

then apply color matching and distortion adjustments.

8 Adjust NTSC Wide Used for manual adjustment of the NTSC Wide/4:3 screen.

Select this mode for Wide/4:3 screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

9 NTSC Wide to others Approximate supplementary data for the other NTSC screens is automatically saved

based on the NTSC Wide/4:3 screen data.

First, the NTSC Wide/4:3 screen data are converted to Super Live and the values are

saved. Next, the data are converted to Cinema and the values are saved. Finally, the

data are converted to Subtitle and the values are sav ed, and then the operation ends .

Manually check the other screen modes as described below and make corrections if

distortion, etc., is present.

Please be aware that all NTSC screens are re-adjusted when this menu is selected

and executed.

– 25 –

Page 26

NO Description

10 Adjust NTSC S.Live Used for manual adjustment of the NTSC Super Live screen.

11 Adjust NTSC Cinema Used for manual adjustment of the NTSC Cinema screen.

12 Adjust NTSC S.title Used for manual adjustment of the NTSC Subtitle screen.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2) Adjustment Screen

Item

Select this mode for Super Live screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

Select this mode for Cinema screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

Select this mode for Subtitle screen color matching and distortion adjustment.

Use the specified dimensions when adjusting.

X : 1

Y : 1

C : R

S : 08

Wide

Displayed when the cursor blinks and cleared

when the cursor lights steady.

X Cursor horizontal position display

Displayed when the cursor blinks and

cleared when the cursor lights steady.

Displays the current screen mode.

Y Cursor vertical position display

C Cursor color select display

S Menu select display

3) Adjustment Sequence

When the initial screen opens, X = 1, Y = 1, C = R and S = [Select Menu] are displayed as the defaults. The cursor can

now be moved up, down, left and right using the (2), (8), (4) and (6) keys of the remote control. Select the desired

adjustment and press the (5) key; the cursor will light steady and the screen display will be cleared. Again press the (2),

(8), (4) and (6) keys of the remote control to adjust the shape of the screen. When adjustment has been completed, press

the (+) key to return to the Adjustment Menu. When all of the screen adjustments have been completed, turn off the main

power supply of the set to reset the menu.

– 26 –

Page 27

2. Case Study

In many cases, color matching problems can be solved by retur ning the HIT and WID data for main deflection to the

initial adjustment values. Convergence cannot be re-adjusted in the following cases.

2-1 When the CRT has been replaced

Main deflection re-adjustment and color matching are necessary when the CRT has been replaced. Use the following

procedure.

1. Replace the blue and red CRTs.

2. Perform the blue and red yoke horizontal adjustments in relation to the green CRT. Press the yokes and speed

modulation coils + alignments onto the CRTs and fasten after making sure that there are no gaps.

3. Adjust the blue and red alignments (refer to the detailed alignment adjustment item).

4. Use centering magnets to center the blue and red CRTs in relation to the green CRT.

5. Adjust the main deflection HIT and WID data, using the most accurate location in relation to the green as data.

6. Use convergence to match the colors for each screen. Green will not work at this time.

7. When the convergence adjustments have been completed for all screens, then replace the green CRT.

Repeat the procedures in steps 2 - 5 for the green CR T but this time use con vergence to match the colors using red and

blue as reference.

2-2 When replacing the convergence unit

Generally , all of the screens m ust be re-adjusted when the conv ergence unit is replaced, b ut the process can be greatly

shortened by using the following method.

1. Replace the memory (Q711, Q712, Q713) of the new unit with the memory (Q711, Q712, Q713) of the defective unit.

This makes it possible to quickly reproduce the previous screen status when installed in the set.

2. Install the new unit with the old memory in the set and turn on the power . The entire screen will mov e linearly in either

the vertical or horizontal direction.

3. Use centering magnets to re-adjust the green, red and blue centers.

4. There is possibility of color mismatching or differences in screen siz e when the v arious screens are checked. In such

case, adjust the main deflection and apply a slight amount of convergence color matching.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2-3 When none of the above cases apply (rare case)

An unexpected situation or major operational error , etc., could be considered b ut it is recommended that all screens be

matched starting from the beginning. If the initial positions of the centering magnets are unknown, disconnect the

connectors for the convergence sub-yoke outputs one at a time, adjust the CRT centering and then start the following

adjustments.

1. Make sure that there is plenty of room for the static cross convergence to be moved left, right, up and down. If

sufficient space is not available, move to an appropriate location and then re-adjust the centering.

2. Enter the convergence adjustment mode and call out the menu. (Leave the PAL signal connected.)

3. Select 1. Adjust PAL Wide and adjust the PAL mode Wide/4:3 screen manually in accordance with the dimension

diagram.

4. When the Wide/4:3 screen adjustment has been completed, return to the Main Menu and select 2. PAL Wide to

others.

The screen will change automatically and the Wide, Cinema and Subtitle screens will be created automatically.

5. Next, select 3. Adjust PAL S.Live and mainly adjust in the horizontal direction in accordance with the dimension

diagram.

6. Next, select 4. Adjust PAL Cinema and fine adjust to remove any Cinema screen distortion.

7. Next, select 5. Adjust PAL Subtitle and fine adjust to remove any Subtitle screen distortion.

8. Next, select 7. PAL to NTSC (ALL), then calculate and copy the data for all PAL screens in the NTSC mode. At this

time, the calculations and screen shape changes will be performed automatically and the NTSC screen data

corresponding to the PAL screens will be transferred.

9. Select in sequence 8. Adjust NTSC Wide, 10. Adjust NTSC S.Live, 11. Adjust NTSC Cinema and 12. Adjust NTSC

Subtitle, check the respective NTSC screen modes and, if necessary, adjust for any distortion.

All of the screens can be adjusted with the above process but make every effort not to change the factory data unless

absolutely necessary. Try not to change the convergence data any more than necessary.

– 27 –

Page 28

3 Screen adjustment dimensions

3-1 WIDE/4:3 (PAL mode)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

235

207.5

124.5

41.5

0

(screen center)

41.5

124.5

207.5

235

441

367.5

3-2 Super Wide (PAL mode)

220.5

73.5

0

73.5

220.5

367.5

441

249.0

220.0

130.5

40

0

(pattern center)

-5

49.5

136.5

441

367.5

220.5

0

73.5

Caution: Do not perform the VLIN adjustment.

– 28 –

73.5

220.5

367.5

221.0

249.0

441

Page 29

3-3 Cinema (PAL mode)

Note: The cursor will move outside the screen limits in the Cinema mode; theref ore, be careful to consider the position

of the cursor displayed on the screen when making adjustments.

262.5

227.5

157.5

52.5

0

52.5

157.5

227.5

262.5

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

441

367.5

220.5

73.5

0

73.5

220.5

367.5

441

3-4 Subtitle (PAL mode)

Note: The cursor will move outside the screen limits in the Subtitle mode; theref ore, be careful to consider the position

of the cursor displayed on the screen when making adjustments.

Note: Please be aware that the Subtitle screen convergence pattern center is located at the center of the screen but the

image center is located approximately 13mm above that.

272

240

144

48

0

48

144

Screen limit changed

441

367.5

220.5

73.5

0

– 29 –

73.5

220.5

367.5

240

272

441

Page 30

3-5 WIDE/4:3 (NTSC mode)

231

198

99

(screen center)

0

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

3-6 Super Live (NTSC mode)

441

367.5

220.5

73.5

99

198

231

0

73.5

220.5

367.5

441

249

213

105

0

(pattern center)

-5

441

367.5

220.5

0

73.5

Caution: Do not perform the VLIN adjustment.

– 30 –

73.5

220.5

367.5

112

216

249

441

Page 31

3-7 Cinema (NTSC mode)

Note: The cursor will move outside the screen limits in the Cinema mode; therefore , be careful to consider the position

of the cursor displayed on the screen when making adjustments.

Note: Please be aware that the Cinema screen convergence pattern center is located at the center of the screen but

the image center is located approximately 13mm above that.

287

246

123

0

123

246

287

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

441

367.5

220.5

73.5

0

73.5

220.5

367.5

441

3-8 Subtitle (NTSC mode)

Note: The cursor will move outside the screen limits in the Subtitle mode; therefore , be careful to consider the position

of the cursor displayed on the screen when making adjustments.

Note: Please be aware that the Subtitle screen convergence pattern center is located at the center of the screen but

the image center is located approximately 32mm above that.

266

228

114

0

114

228

266

441

367.5

220.5

73.5

0

73.5

220.5

367.5

441

– 31 –

Page 32

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

CAUTION : Do not hold the optical system parts (lens and

mirror) with bare hand to avoid finger-prints on

the surface of those parts.

SCREEN AND MIRROR ALIGNMENTS

ASSEMBLING AND MOUNTING OF

FRONT SCREEN

* Please refer to MECHANICAL DISASSEMBLY page.38.

CLEANING OF LENS AND MIRROR

HOW TO CLEAN LENS AND MIRROR

1. Be sure to remove sand dust with an air brush, etc.

2. When it is stained slightly, breathe upon it and wipe away

with the specified cleaning cloth.

For other stains than the above, wipe the stains away with

the specified cloth into which a cleaning liquid has been

soaked.

Cleaning liquid ................... LENS LUSTER (Manufactured

by Edmund Scientific Co.), etc.

HOW TO CLEAN SCREEN

When cleaning the screen, use a soft cloth so as not to damage the screen.

1. Wipe the stain away with a diluted neutral detergent soaked

cloth.

2. Wipe the detergent away with a water soaked cloth.

3. Wipe the screen with a dry cloth to remove moisture on the

screen.

Note : Absolutely do not use alcohol, benzine, thinner, etc.

for cleaning in order not to wipe away the black print

on the surface.

– 32 –

Page 33

CIRCUIT CHECKS

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on this chassis. Checking should be done following the steps below.

1. Connect an accurate high voltage meter to the anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 34)

4. Vary the BRIGHTNESS to both extremes to be sure the high voltage does not exceed the limit under any conditions.

CAUTION:

When the following parts fail, check the High Voltage after replacing.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Location

No.

T461

D489

Q480

Q483

R435

R489

R490

R450

C440

C443

C444

ANODE VOLTAGE MEASURING METHOD

CAUTION: Take extra precaution when measuring this high voltage. High voltages are also present in surrounding circuit

boards (CRT DRIVE assembly, DEFLECTION assembly, and POWER SUPPLY assembly).

1. Disconnect the FBT anode cable as outlined below. Measure high voltage at the point where the cable enters the FBT.

2. Holding the rubber cover firmly, turn it counterclockwise and check that the lock has been disengaged. (See Fig. b on page

8.)

3. Determine the extent of the rubber cover before disconnecting the cable.

4. Pull straight up the anode cable to disconnect.

5. When reconnecting the cable, proceed in the reverse order.

After reconnecting, tug on the cable to check that it is secure.

Name

Flyback Trans.

Zener Diode

Transistor

IC

Resistor

Resistor

Resistor

VR

Capacitor

Capacitor

Capacitor

Name

TFB3078BD

MTZJ3.6B

2SC2023

TA7508P(J)

33k ohm, ±5%

3.3k ohm, ±5%

3.3k ohm, ±5%

1k ohm

1000pF, ±3%

6800pF, ±3%

5100pF, ±3%

– 33 –

Page 34

CHAPTER 2 SPECIFIC INFORMATIONS

SAFETY INSTRUCTIONS

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SERVICE MODE

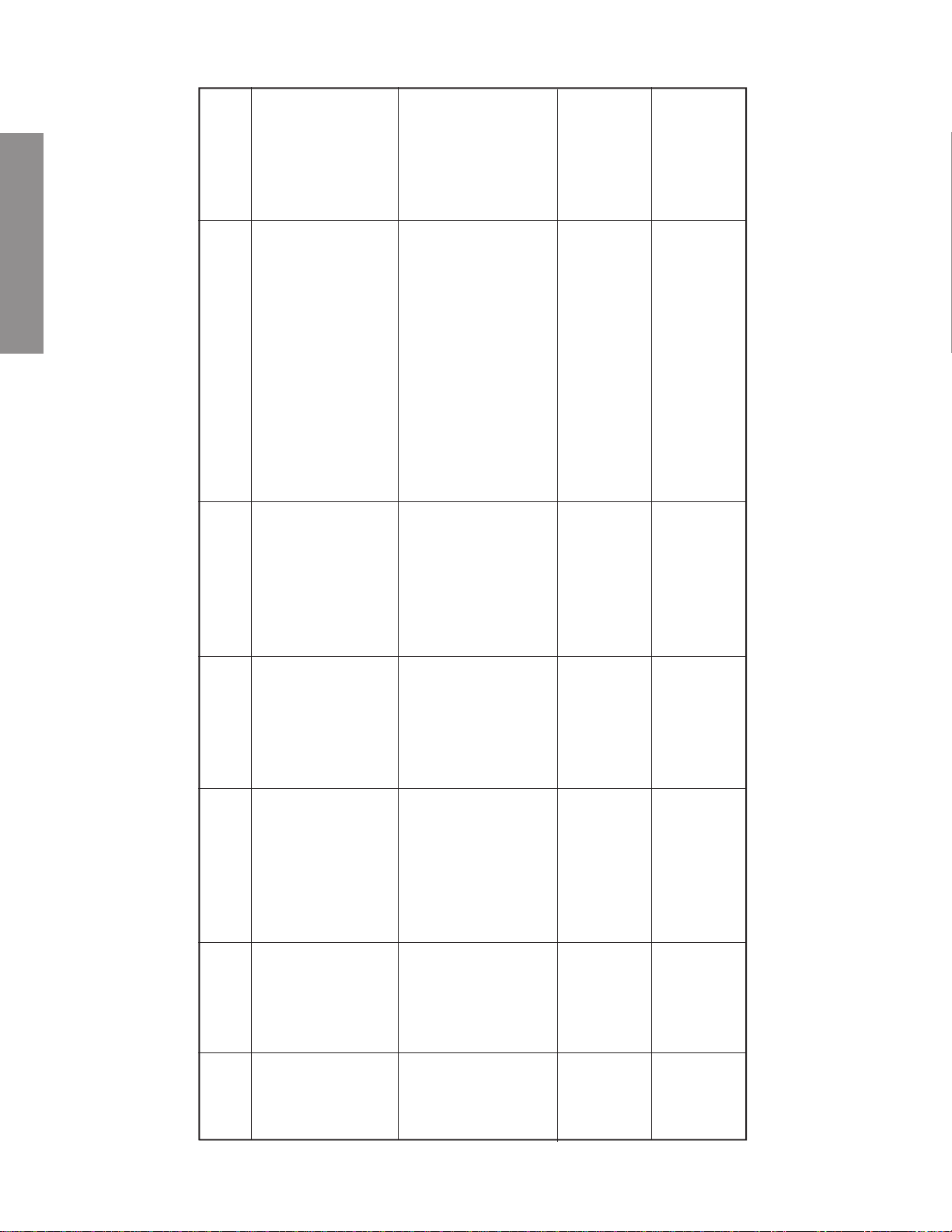

ADJUSTING ITEMS AND DATAS IN THE SERVICE MODE:

SETTING & ADJUSTING DATA

40"

HIGH VOLTAGE AT ZERO BEAM: (A) 31.9 kV

MAX HIGH VOLTAGE:

AV VOLTAGE

Table-1

(B) 32.5 kV

(C) 230 V

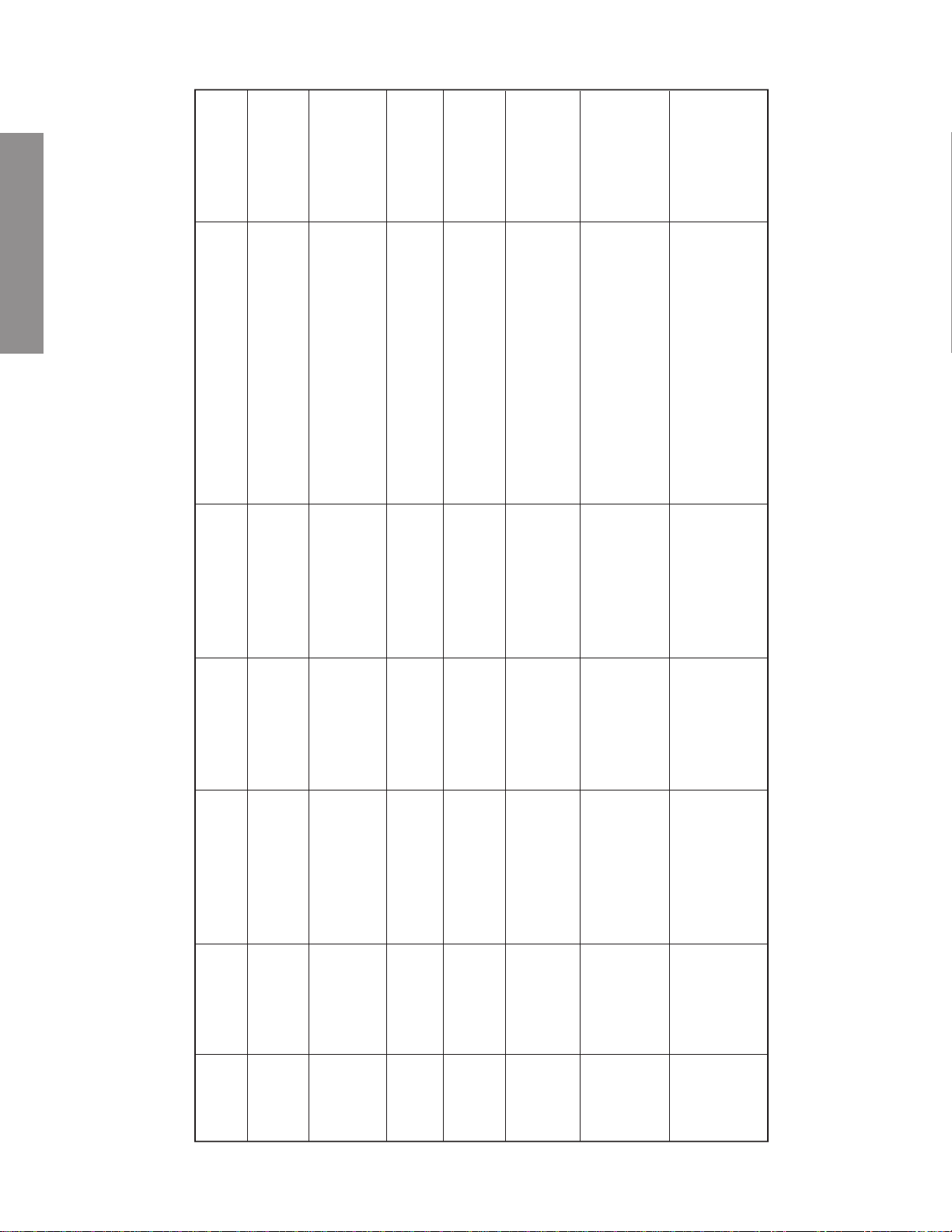

Item

RCUT

GCUT

BCUT

RDRV

BDRV

CNTX

BRTC

COLC

TNTC

COLP

COLS

SCNT

BELL

SRY

SBY

R CUTOFF (B/W)

G CUTOFF (B/W)

B CUTOFF (B/W)

R DRIVE

B DRIVE

SUB CONTRAST MAX

SUB BRIGHT CEN

SUB COLOR CEN NTSC

SUB TINT CEN

SUB COLOR CEN PAL

SUB COLOR CEN SECAM

SUB CONTRAST

SECAM BELL FILTER

SECAM R-Y

SECAM B-Y

DESIGN MODE

ADJUSTING ITEMS AND DATAS IN THE DESIGN MODE:

Item Name of adjustment Preset Data 40PW03G 40PW03B Remarks

Adjustment

Reference data

40H

40H

40H

40H

40H

7FH

80H

FDH

45H

50H

38H

07H

80H

08H

08H

HPOS

VPOS

HIT

GMPS

VLIN

VSC

VPS

VCP

WID

PARA

CNR

TRAP

HCP

VFC

Table-2

Item

50Hz H-POSITION

V-POSITION

HEIGHT

V-POSITION (RASTER)

V-LINEARITY

V-S CORRECTION

V-SHIFT

V-COMPENSATION

PICTURE WIDTH

E-W PARABOLA

E-W CORNER

TRAPEZIUM

H-COMPENSATION

V-F CORRECTION

Adjustment

Reference data

0CH

01H

26H

00H

15H

26H

12H

05H

1EH

02H

10H

40H

04H

0FH

RCUT

OPT1

OPT0

OSD

○○○○○

RCUT

OPTION 1

OPTION 0

4CH

80H

Table-3

– 34 –

4CH 4CH

80H 81H

Page 35

Front

LOCATION OF CONTROLS

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Back

HEAD PHONE

(VIDEO-3) S-VIDEO TERMINAL

VIDEO-3

MENU

VOLUME DOWN

VOLUME UP

POSITION DOWN

MAIN SWITCH

POWER (RED)

ON TIMER (GREEN)

BILINGUAL (ORANGE)

STEREO (GREEN)

EXIT

POSITION UP

WOOFER SWITCH

WOOFER OUT

VIDEO-1 (21PINS FULL)

VIDEO-2 (21PINS S-VIDEO/AV)

AERIAL TERMINAL

AUDIO OUT (FIXED)

VIDEO-3 (S-VIDEO/AUDIO)

VIDEO-3 (21PINS S-VIDEO/AUDIO)

– 35 –

Page 36

Remote Controller

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Keypad Number Buttons

1 or 2 Digit Channel Selection

Menu Control Buttons

Teletext

SIZE

MENU Buttons

3

9

a

^

f

Çi

CALL

TEXT

CH

yX

V

Power ON/ OFF

CALL

Teletext

•Programme Position up/down

VIDEO (+F)

F

F

1

2

4 5 6

7 8

-/--

0

?

v

SIZE

Picture Controls

ENTER

SELECT

Menu Control Buttons

ENTER

MENU EXIT

EXIT

•Stereo/Bilingual

REC

•Sound Mute

Video Recoder Buttons

to operate your Toshiba

Video Recorder

VTR/DVD

– 36 –

P

Volume

Page 37

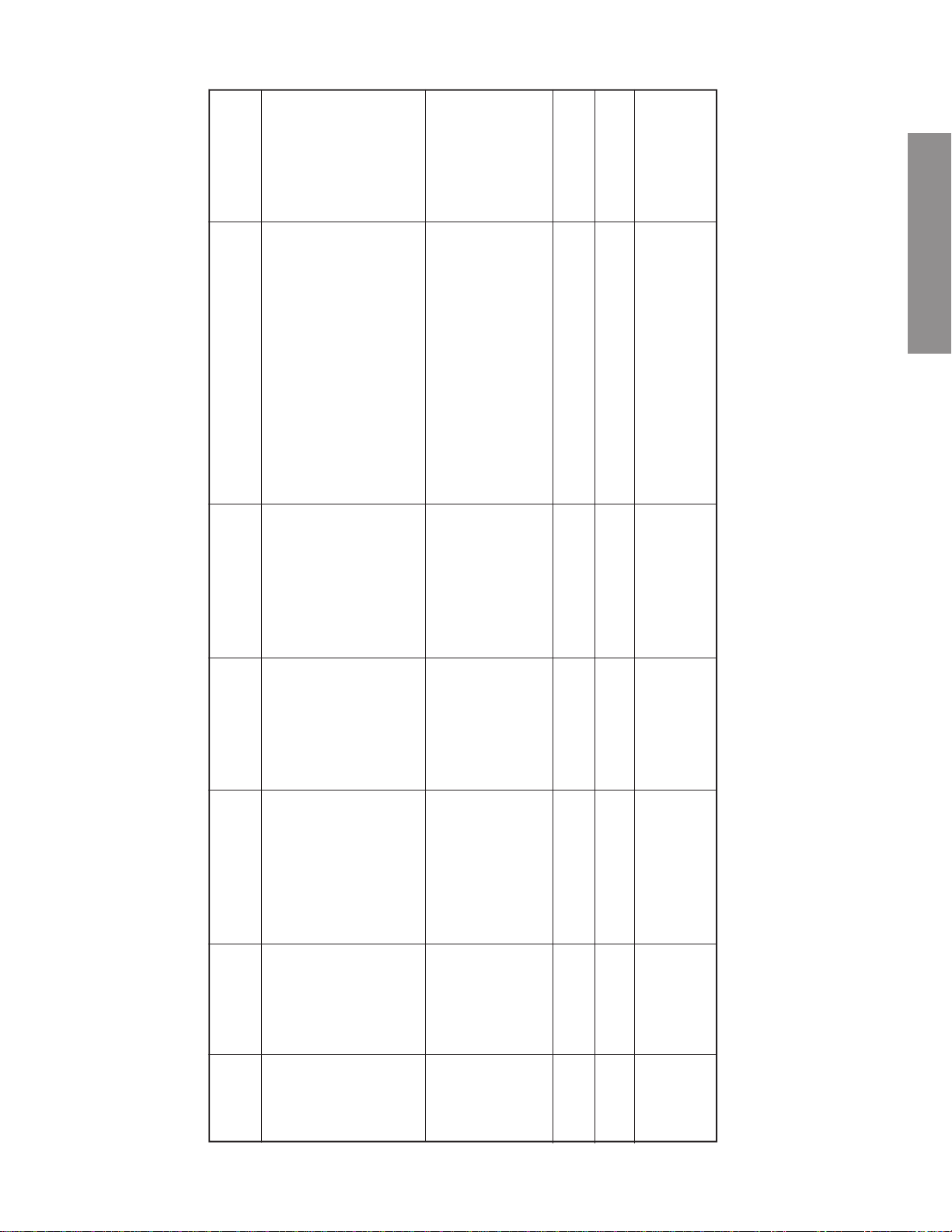

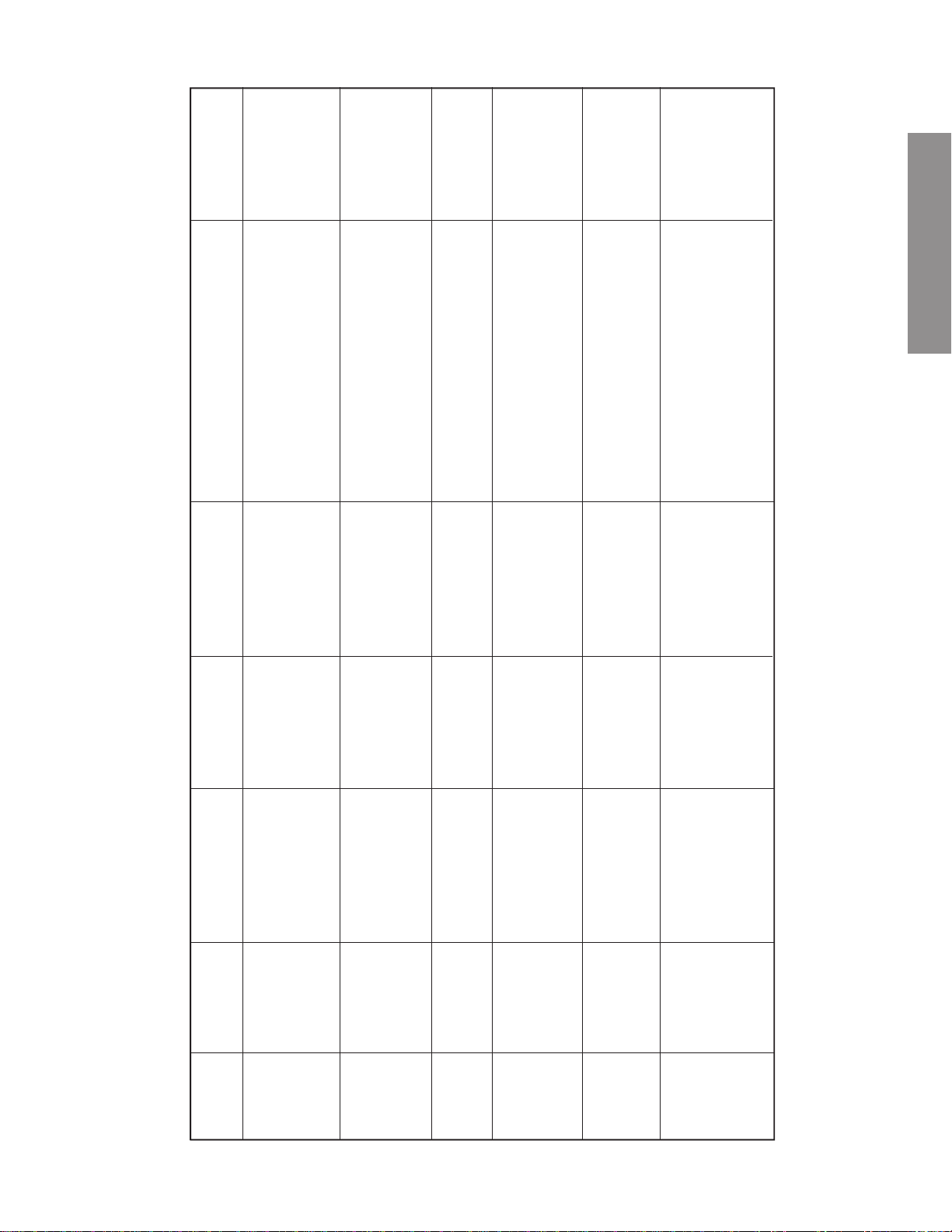

MICRO

COMPUTER

MEMORY

QA01

Q801

I

2

CBUS

QA02

QV01

AV SW

R,G,B

TEXT

QZ01

Q501

R

G

B

QQ01 QQ02

Q601

CRT.R

CRT.G

CRT.B

MAIN/CENTER

Q901

Q911

Q921

Q301

Q404

Q751,Q752

QW51,QW52

DIGITAL

COM.

MAIN

AUDIO OUT

VIDEO OUT

VIDEO OUT

VIDEO OUT

SVM.OUT

V.OUT

H.OUT

CONVER

OUT

DIGITAL

CONVER

DPC.OUT

PROTECTOR

: I

2

C BLOCK

SW.REG.

E/W

CORRECTION

SECAM

1H

DELAY

COLOR/VIDEO/DEF

T862

Z801

+B

E1

21 PIN

(FULL)E221 PIN

(S+AV)

E3

21 PIN

(S+AV)

E3

S VIDEO

E3

FRONT

S+AV

AUDIO FIX

OUT

Y/V

L,R

OSD

QR01

QF01

R,G,B

V

L,R

L,R

QR01

RGB,

SW

L,R

V

V

Y

TIF

H001

MA

H002

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

CIRCUIT BLOCK DIAGRAM

– 37 –

Page 38

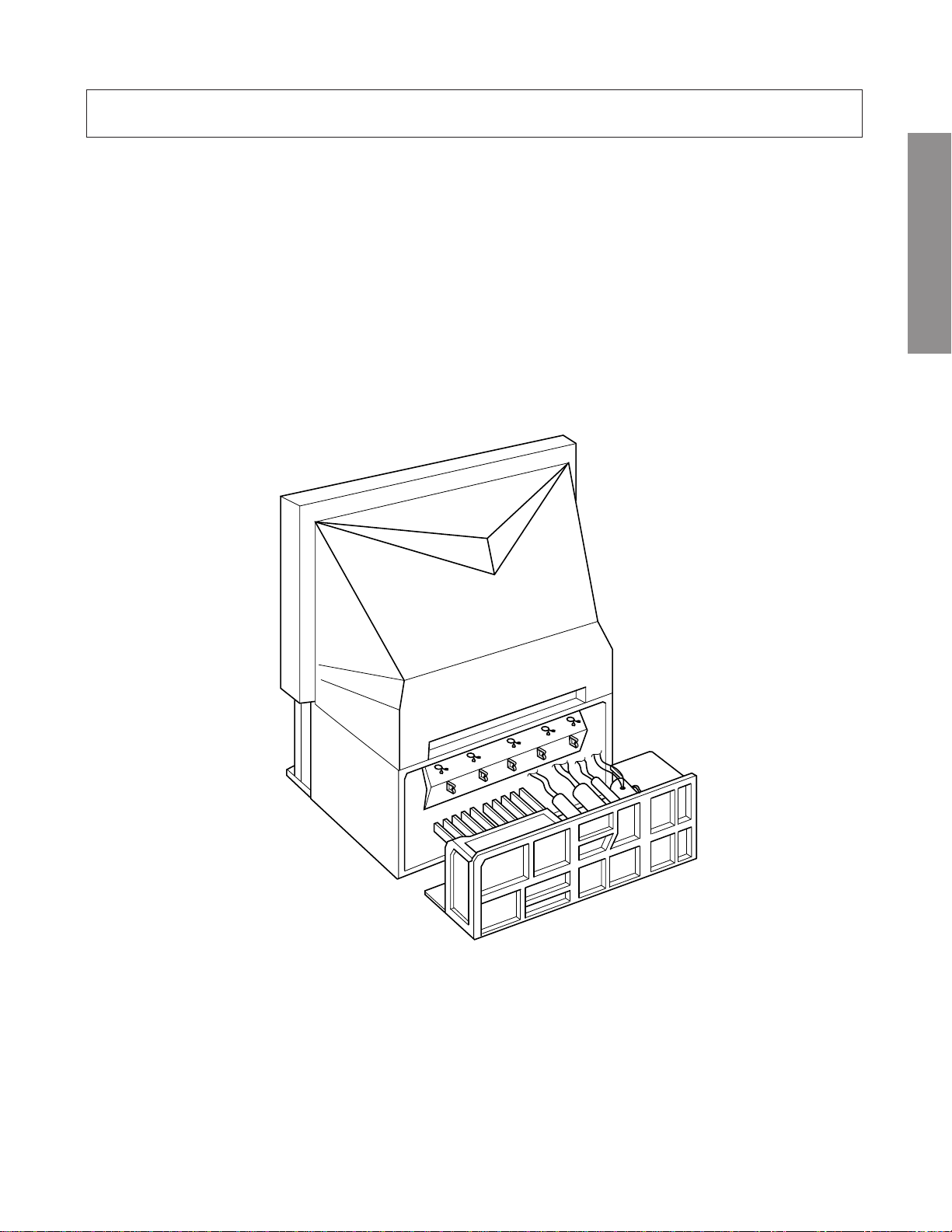

K502

MECHANICAL DISASSEMBLY

K501

K503

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

LABELS

16 SCREWS

8 SCREWS

A201

A264

10 SCREWS

8 SCREWS

A262

K601

A262

SCREWS

A420

A424

A103

A213 (A214)

(A223)

A212

A268

A102

6 SCREWS

K101

K102

K103

– 38 –

Page 39

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY

PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

CAUTION: The international hazard symbols “ ” in the schematic diagram and the parts list designate com-

ponents which have special characteristics important for safety and should be replaced only with types identical to

those in the original circuit or specified in the parts list. The mounting position of replacements is to be identical

with originals. Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE . Do not

degrade the safety of the receiver through improper servicing.

NOTICE:

•

The part number must be used when ordering parts, in order to assist in processing, be sure to include the Model

number and Description.

•

The PC board assembly with * mark is no longer available after the end of the production.

ABBREVIATIONS:

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are ±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

Models : 40PW03G, 40PW03B

Location

No.

Part No. Description

Location

No.

Part No. Description

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

CAPACITORSCAPACITORS

CAPACITORS

CAPACITORSCAPACITORS

C101 24793220 EL, 22?F, ±20%, 10V

C102 24762221 EL, 220?F, ±20%, 10V

C105 24212102 CD, 1000pF, ±10%

C106 24797100 EL, 10?F, ±20%, 50V

C115 24232103 CD, 0.01?F, +80%, -20%

C116 24762221 EL, 220?F, ±20%, 10V

C150 24763102 EL, 1000?F, ±20%, 16V

C183 24766479 EL, 4.7?F, ±20%, 50V

C194 24232103 CD, 0.01?F, +80%, -20%

C201 24538104 PF, 0.1?F

C202 24814103 Chip, 0.01?F, +80%, -20%

C203 24538104 PF, 0.1?F

C204 24669010 EL, 1?F, ±20%, 50V

C205 24669229 EL, 2.2?F, ±20%, 50V

C206 24206220 EL, 22?F, ±20%, 50V

C212 24794100 EL, 10?F, ±20%, 16V

C214 24591334 PF, 0.33?F

C219 24781100 Chip, 10pF, ±0.5pF%, SL

C220 24781100 Chip, 10pF, ±0.5pF%, SL

C221 24781100 Chip, 10pF, ±0.5pF%, SL

C228 24814103 Chip, 0.01?F, +80%, -20%

C229 24669010 EL, 1?F, ±20%, 50V

C230 24763221 EL, 220?F, ±20%, 16V

C231 24814103 Chip, 0.01?F, +80%, -20%

C232 24669010 EL, 1?F, ±20%, 50V

C260 24085967 EL, 47?F, ±20%, 16V,

C261 24669101 EL, 100?F, ±20%, 50V

C262 24814103 Chip, 0.01?F, +80%, -20%

C264 24781150 Chip, 15pF, SL

C273 24206229 EL, 2.2?F, ±20%, 50V

C281 24763101 EL, 100?F, ±20%, 16V

C282 24232103 CD, 0.01?F, +80%, -20%

C283 24794100 EL, 10?F, ±20%, 16V

C284 24794100 EL, 10?F, ±20%, 16V

C295 24232103 CD, 0.01?F, +80%, -20%

C303 24214471 CD, 470pF, ±10%, 500V

C305 24617912 EL, 2.2?F, ±10%, 50V

C306 24617858 EL, 3300?F, ±20%, 35V

C307 24082270 PF, 0.033?F, 100V

Non-Polar

C308 24669221 EL, 220?F, ±20%, 50V

C309 24212101 CD, 100pF, ±10%

C310 24669222 EL, 2200?F, ±20%, 50V

C311 24214561 CD, 560pF, ±10%, 500V

C313 24082057 PF, 0.22?F, 100V

C314 24591103 PF, 0.01?F

C315 24797229 EL, 2.2?F, ±20%, 50V

C316 24232103 CD, 0.01?F, +80%, -20%

C318 24666222 EL, 2200?F, ±20%, 16V

C319 24591102 PF, 1000pF

C320 24669101 EL, 100?F, ±20%, 50V

C321 24591183 PF, 0.018?F

C322 24617915 EL, 1?F, ±10%, 50V

C323 24567474 PF, 0.47?F

C324 24567684 PF, 0.68?F

C330 24591104 PF, 0.1?F

C331 24669229 EL, 2.2?F, ±20%, 50V

C344 24591103 PF, 0.01?F

C351 24667222 EL, 2200?F, ±20%, 25V

C355 24669010 EL, 1?F, ±20%, 50V

C357 24669100 EL, 10?F, ±20%, 50V

C360 24667100 EL, 10?F, ±20%, 25V

C361 24669100 EL, 10?F, ±20%, 50V

C362 24591104 PF, 0.1?F

C363 24085942 EL, 10?F, ±20%, 16V,

Non-Polar

C364 24666100 EL, 10?F, ±20%, 16V

C370 24669101 EL, 100?F, ±20%, 50V

C371 24669100 EL, 10?F, ±20%, 50V

C372 24591104 PF, 0.1?F

C388 24591334 PF, 0.33?F

C403 24591223 PF, 0.022?F

C403 24828124 PF, 0.12?F, 200V

C404 24797229 EL, 2.2?F, ±20%, 50V

C413 24214821 CD, 820pF, ±10%, 500V

C415 24815392 Chip, 3900pF, ±10%

C416 24678100 EL, 10?F, ±20%, 200V

C417 24214391 CD, 390pF, ±10%, 500V

C418 24095883 PF, 0.015?F, ±3%, 630V

C419 24095803 PF, 0.062?F, 400V

C420 24666101 EL, 100?F, ±20%, 16V

– 39 –

Page 40

Location

No.

Part No. Description

Location

No.

Part No. Description

C423 24095779 PF, 0.062?F, 400V

C430 24814103 Chip, 0.01?F, +80%, -20%

C431 24763102 EL, 1000?F, ±20%, 16V

C440 24082326 PF, 1300pF, ±3%, 1500V

C443 24082348 PF, 6800pF, ±3%, 1500V

C444 24082287 PF, 5100pF, ±3%, 1800V

C445 24828473 PF, 0.047?F, 200V

C446 24679330 EL, 33?F, ±20%, 250V

C447 24667102 EL, 1000?F, ±20%, 25V

C448 24640908 EL, 33?F, ±20%, 160V

C460 24669331 EL, 330?F, ±20%, 50V

C463 24212152 CD, 1500pF, ±10%

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

C464 24640872 EL, 10?F, ±20%, 100V

C465 24591332 PF, 3300pF

C466 24567394 PF, 0.39?F

C467 24820153 PF, 0.015?F, 630V

C468 24567474 PF, 0.47?F

C471 24206479 EL, 4.7?F, ±20%, 50V

C475 24820103 PF, 0.01?F, 630V

C477 24092347 CD, 1500pF, ±10%, 2kV

C481 24567104 PF, 0.1?F

C482 24591152 PF, 1500pF

C483 24567224 PF, 0.22?F

C484 24567104 PF, 0.1?F

C485 24669101 EL, 100?F, ±20%, 50V

C493 24591124 PF, 0.12?F

C501 24781101 Chip, 100pF, SL

C502 24814103 Chip, 0.01?F, +80%, -20%

C503 24763221 EL, 220?F, ±20%, 16V

C504 24591222 PF, 2200pF

C505 24774120 Chip, 12pF, CH

C507 24774120 Chip, 12pF, CH

C508 24669010 EL, 1?F, ±20%, 50V

C509 24763101 EL, 100?F, ±20%, 16V

C510 24763101 EL, 100?F, ±20%, 16V

C511 24814103 Chip, 0.01?F, +80%, -20%

C512 24206228 EL, 0.22?F, ±20%, 50V

C513 24814103 Chip, 0.01?F, +80%, -20%

C514 24538104 PF, 0.1?F

C515 24538104 PF, 0.1?F

C516 24781102 Chip, 1000pF, SL

C517 24774010 Chip, 1pF, ±0.25pF, CH

C519 24774010 Chip, 1pF, ±0.25pF, CH

C520 24781102 Chip, 1000pF, SL

C521 24781102 Chip, 1000pF, SL

C524 24781122 Chip, 1200pF, SL

C525 24774181 Chip, 180pF, CH

C554 24814103 Chip, 0.01?F, +80%, -20%

C555 24669010 EL, 1?F, ±20%, 50V

C556 24669010 EL, 1?F, ±20%, 50V

C601 24590102 PF, 1000pF

C602 24590102 PF, 1000pF

C603 24669100 EL, 10?F, ±20%, 50V

C604 24669100 EL, 10?F, ±20%, 50V

C605 24667101 EL, 100?F, ±20%, 25V

C606 24667101 EL, 100?F, ±20%, 25V

C607 24538104 PF, 0.1?F(40PW03G)

C607 24567104 PF, 0.1?F(40PW03B)

C608 24538104 PF, 0.1?F(40PW03G)

C608 24567104 PF, 0.1?F(40PW03B)

C609 24669102 EL, 1000?F, ±20%, 50V

C610 24669102 EL, 1000?F, ±20%, 50V

C611 24667221 EL, 220?F, ±20%, 25V

C613 24666471 EL, 470?F, ±20%, 16V

C636 24666100 EL, 10?F, ±20%, 16V

C661 24436101 CD, 100pF

C665 24669229 EL, 2.2?F, ±20%, 50V

C666 24669229 EL, 2.2?F, ±20%, 50V

C671 24669100 EL, 10?F, ±20%, 50V

C672 24232103 CD, 0.01?F, +80%, -20%

C673 24781102 Chip, 1000pF, SL

C674 24669100 EL, 10?F, ±20%, 50V

C674 24781102 Chip, 1000pF, SL

C675 24669100 EL, 10?F, ±20%, 50V

C675 24781102 Chip, 1000pF, SL

C676 24669100 EL, 10?F, ±20%, 50V

C676 24781102 Chip, 1000pF, SL

C677 24668221 EL, 220?F, ±20%, 35V

C678 24781102 Chip, 1000pF, SL

C679 24781102 Chip, 1000pF, SL

C680 24669222 EL, 2200?F, ±20%, 50V

C681 24781102 Chip, 1000pF, SL

C682 24669010 EL, 1?F, ±20%, 50V

C682 24781102 Chip, 1000pF, SL

C696 24762102 EL, 1000?F, ±20%, 10V

C701 24781330 Chip, 33pF, SL

C702 24781330 Chip, 33pF, SL

C711 24206100 EL, 10?F, ±20%, 50V

C714 24092293 Chip, 0.1?F, +80%, -20%, 25V

C715 24092441 Chip, 1?F, +80%, -20%, 16V

C716 24815822 Chip, 0.0082?F, ±10%

C717 24774470 Chip, 47pF, CH

C718 24774470 Chip, 47pF, CH

C719 24794101 EL, 100?F, ±20%, 16V

C720 24092293 Chip, 0.1?F, +80%, -20%, 25V

C721 24567104 PF, 0.1?F

C722 24092293 Chip, 0.1?F, +80%, -20%, 25V

C724 24092293 Chip, 0.1?F, +80%, -20%, 25V

C725 24092293 Chip, 0.1?F, +80%, -20%, 25V

C726 24092293 Chip, 0.1?F, +80%, -20%, 25V

C727 24092293 Chip, 0.1?F, +80%, -20%, 25V

C728 24763221 EL, 220?F, ±20%, 16V

C729 24092293 Chip, 0.1?F, +80%, -20%, 25V

C730 24567104 PF, 0.1?F

C731 24766010 EL, 1?F, ±20%, 50V

C732 24590822 PF, 0.0082?F

C735 24092293 Chip, 0.1?F, +80%, -20%, 25V

C736 24794470 EL, 47?F, ±20%, 16V

C739 24092293 Chip, 0.1?F, +80%, -20%, 25V

C740 24092293 Chip, 0.1?F, +80%, -20%, 25V

C741 24794470 EL, 47?F, ±20%, 16V

C742 24794470 EL, 47?F, ±20%, 16V

C743 24092293 Chip, 0.1?F, +80%, -20%, 25V

C744 24092293 Chip, 0.1?F, +80%, -20%, 25V

C745 24794470 EL, 47?F, ±20%, 16V

C746 24794470 EL, 47?F, ±20%, 16V

C747 24092293 Chip, 0.1?F, +80%, -20%, 25V

C748 24092293 Chip, 0.1?F, +80%, -20%, 25V

C749 24794470 EL, 47?F, ±20%, 16V

C750 24794470 EL, 47?F, ±20%, 16V

C756 24781391 Chip, 390pF, SL

C761 24590182 PF, 1800pF

C762 24590562 PF, 5600pF

C763 24774391 Chip, 390pF, CH

C765 24590182 PF, 1800pF

C766 24590562 PF, 5600pF

C767 24774391 Chip, 390pF, CH

C769 24590182 PF, 1800pF

– 40 –

Page 41

Location

No.

Part No. Description

Location

No.

Part No. Description

C770 24590562 PF, 5600pF

C771 24774391 Chip, 390pF, CH

C773 24590182 PF, 1800pF

C774 24590562 PF, 5600pF

C775 24774391 Chip, 390pF, CH

C777 24590182 PF, 1800pF

C778 24590562 PF, 5600pF

C779 24774391 Chip, 390pF, CH

C781 24590182 PF, 1800pF

C782 24590562 PF, 5600pF

C783 24774391 Chip, 390pF, CH

C795 24761221 EL, 220?F, ±20%, 6.3V

C798 24763101 EL, 100?F, ±20%, 16V

C799 24763101 EL, 100?F, ±20%, 16V

* C801 24082374 PF, 0.22?F, ±20%, AC250V

* C802 24092557 CD, 220pF, ±20%, AC250V

* C803 24092557 CD, 220pF, ±20%, AC250V

* C804 24092570 CD, 3300pF, ±20%, AC250V

* C805 24082374 PF, 0.22?F, ±20%, AC250V

C807 24073058 EL, 2200?F, ±20%, 25V

C808 24617787 EL, 470?F, ±20%, 16V

C809 24567105 PF, 1?F

C810 24086935 EL, 560?F, ±20%, 400V

C811 24676478 EL, 0.47?F, ±20%, 100V

C812 24092281 CD, 4700pF, ±20%, AC250V

C813 24092281 CD, 4700pF, ±20%, AC250V

C814 24678229 EL, 2.2?F, ±20%, 200V

C815 24567474 PF, 0.47?F

C816 24617817 EL, 22?F, ±20%, 50V

C817 24567224 PF, 0.22?F

C819 24214102 CD, 1000pF, ±10%, 500V

C820 24567224 PF, 0.22?F

C821 24092480 CD, 680pF, ±10%, 2kV

C822 24092481 CD, 820pF, ±10%, 2kV

C823 24092478 CD, 470pF, ±10%, 2kV

C824 24214103 CD, 0.01?F, ±10%, 500V

C825 24591472 PF, 4700pF

C826 24092474 CD, 220pF, ±10%, 2kV

C828 24820683 PF, 0.068?F, 630V

C829 24617820 EL, 100?F, ±20%, 50V

C830 24567105 PF, 1?F

C831 24669220 EL, 22?F, ±20%, 50V

C853 24668102 EL, 1000?F, ±20%, 35V

C855 24214471 CD, 470pF, ±10%, 500V

C856 24214471 CD, 470pF, ±10%, 500V

C857 24214471 CD, 470pF, ±10%, 500V

C858 24214471 CD, 470pF, ±10%, 500V

C859 24214471 CD, 470pF, ±10%, 500V

C860 24669471 EL, 470?F, ±20%, 50V

C861 24668332 EL, 3300?F, ±20%, 35V

C862 24668471 EL, 470?F, ±20%, 35V

C863 24668332 EL, 3300?F, ±20%, 35V

C864 24668471 EL, 470?F, ±20%, 35V

C865 24214471 CD, 470pF, ±10%, 500V

C866 24214471 CD, 470pF, ±10%, 500V

C867 24214471 CD, 470pF, ±10%, 500V

C868 24214471 CD, 470pF, ±10%, 500V

C869 24669222 EL, 2200?F, ±20%, 50V

C870 24214471 CD, 470pF, ±10%, 500V

C871 24214471 CD, 470pF, ±10%, 500V

C872 24214471 CD, 470pF, ±10%, 500V

C873 24214471 CD, 470pF, ±10%, 500V

C874 24212102 CD, 1000pF, ±10%

C875 24667472 EL, 4700?F, ±20%, 25V

C876 24086916 EL, 330?F, ±20%, 160V

C877 24092475 CD, 220pF, ±10%, 2kV

C878 24092475 CD, 220pF, ±10%, 2kV

C879 24092475 CD, 220pF, ±10%, 2kV

C880 24092475 CD, 220pF, ±10%, 2kV

C881 24567474 PF, 0.47?F

C882 24617817 EL, 22?F, ±20%, 50V

C883 24082229 PF, 0.1?F, ±10%, 250V

C884 24617816 EL, 10?F, ±20%, 50V

C885 24617813 EL, 2.2?F, ±20%, 50V