Page 1

SERVICE MANUAL

LCD Color Television

40L7363D(G), (N)

REVISED:01

40L7365D(G), (N)

40M8365D(G)

Page 2

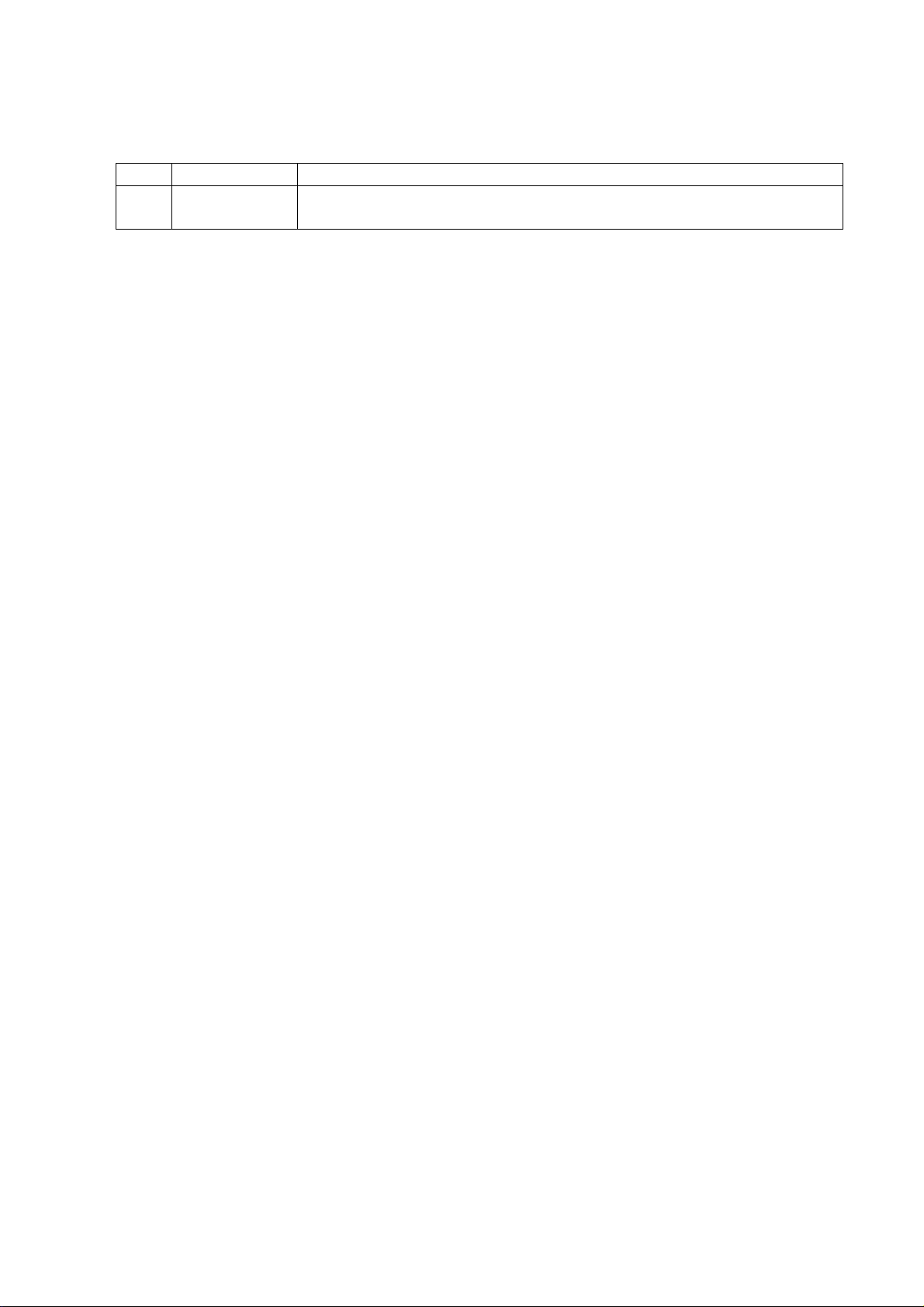

REVISION HISTORY

REV Date Reason for Change

1 Aug/20/2013 - Correction of the “No.” (directions number) of E200 and E250

in Parts List (Exploded View)

Page 3

CONTENTS

1. IMPORTANT NOTICE

2. GREEN PRODUCT PROCUREMENT

3. LEAD-FREE SOLDER

4. SAFETY INSTRUCTION

5. SERVICE MODE

6. LED INDICATIONS FOR SERVICE

7. HOTEL MODE

8. HOTEL CLONE

9. INTERCONNECT

10. EXPLODED VIEW

11. PANEL IDENTIFICATION

12. MAIN BOARD EXCHANGE

13. ABOUT THE MAIN BOARD

1

Page 4

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data provided

herein without prior written consent by Toshiba. Toshiba shall not be liable to

anybody for any damages, losses, expenses or costs, if any, incurred in connection

with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of use of any information or data provided

herein.

Page 5

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase

and use products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts

used in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 30ºC to

40ºC (54ºF to 72ºF). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product especially when soldering large components, through-hole pins, and on PCBs

as the level of heat required to melt lead-free solder is high.

Page 6

(1/4)

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY PRECAUTION"

AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR WITH

THE NECESSARY PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE THE

NECESSARY PRECAUTIONS TO BE OBSERVED BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These items

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

mark is indicated

Page 7

(2/4)

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation,

malfunction, or electrical leakage and flame, which may be hazardous.

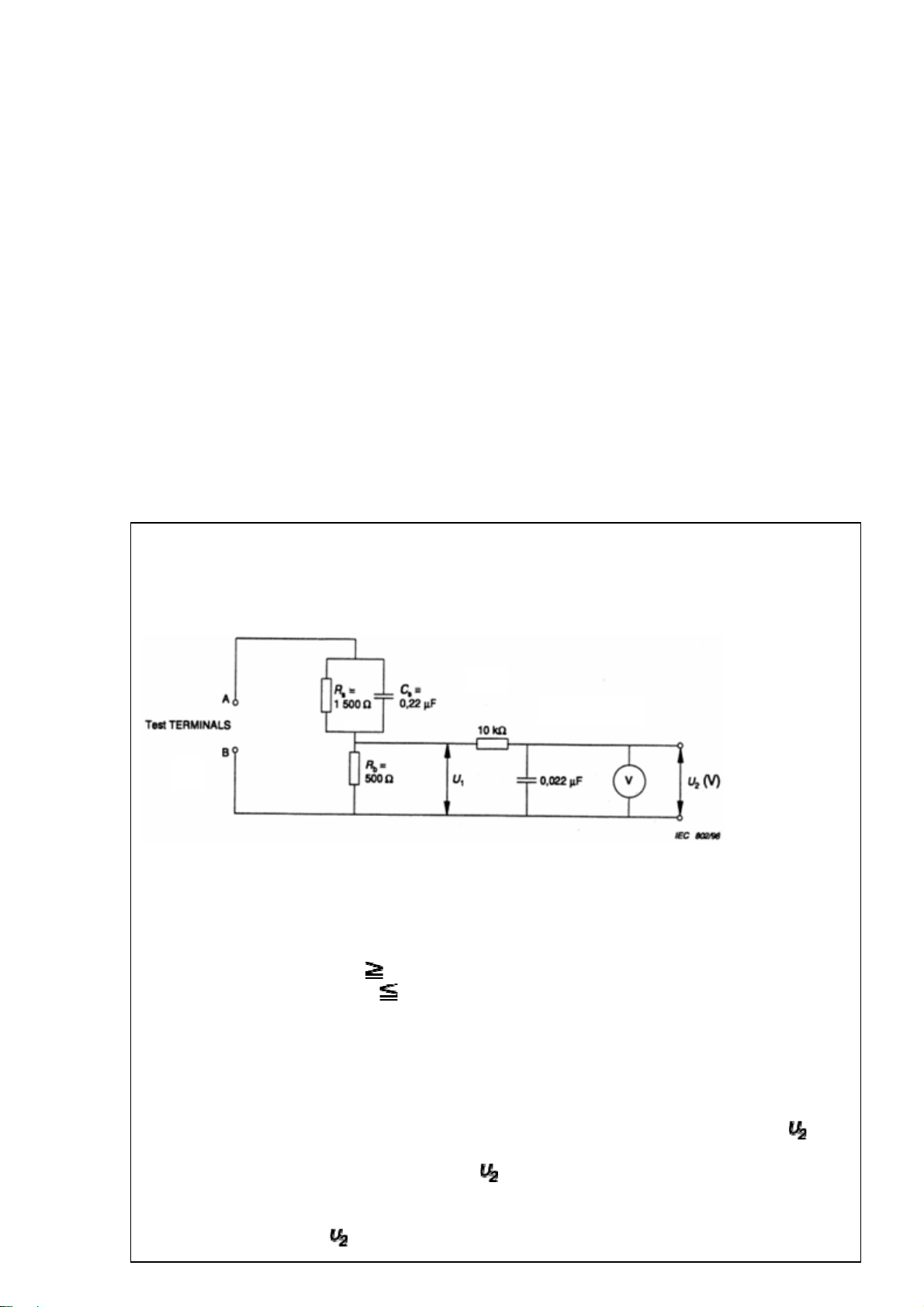

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer for

this check.

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Input resistance :

1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with

the solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of

from the ideal curve as a function of

frequency.

TOUCH CURRENT =

/ 500 (peak value).

Page 8

(3/4)

The potential at any point (TOUCH CURRENT) expressed as voltage and does

not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is

not met.

b)

The measurement of the TOUCH CURRENT shall be carried out in accordance

with IEC 60990, with the measuring network described in Annex D of this

standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c.

correspond to the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

Page 9

(4/4)

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which have these special safety

characteristics are identified in this manual and its supplements; electrical components having

such features are identified by the international hazard symbols on the schematic diagram and

the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use

of substitute replacement parts which do not have the same safety characteristics as specified

in the parts list may create electrical shock, fire, or other hazards.

Page 10

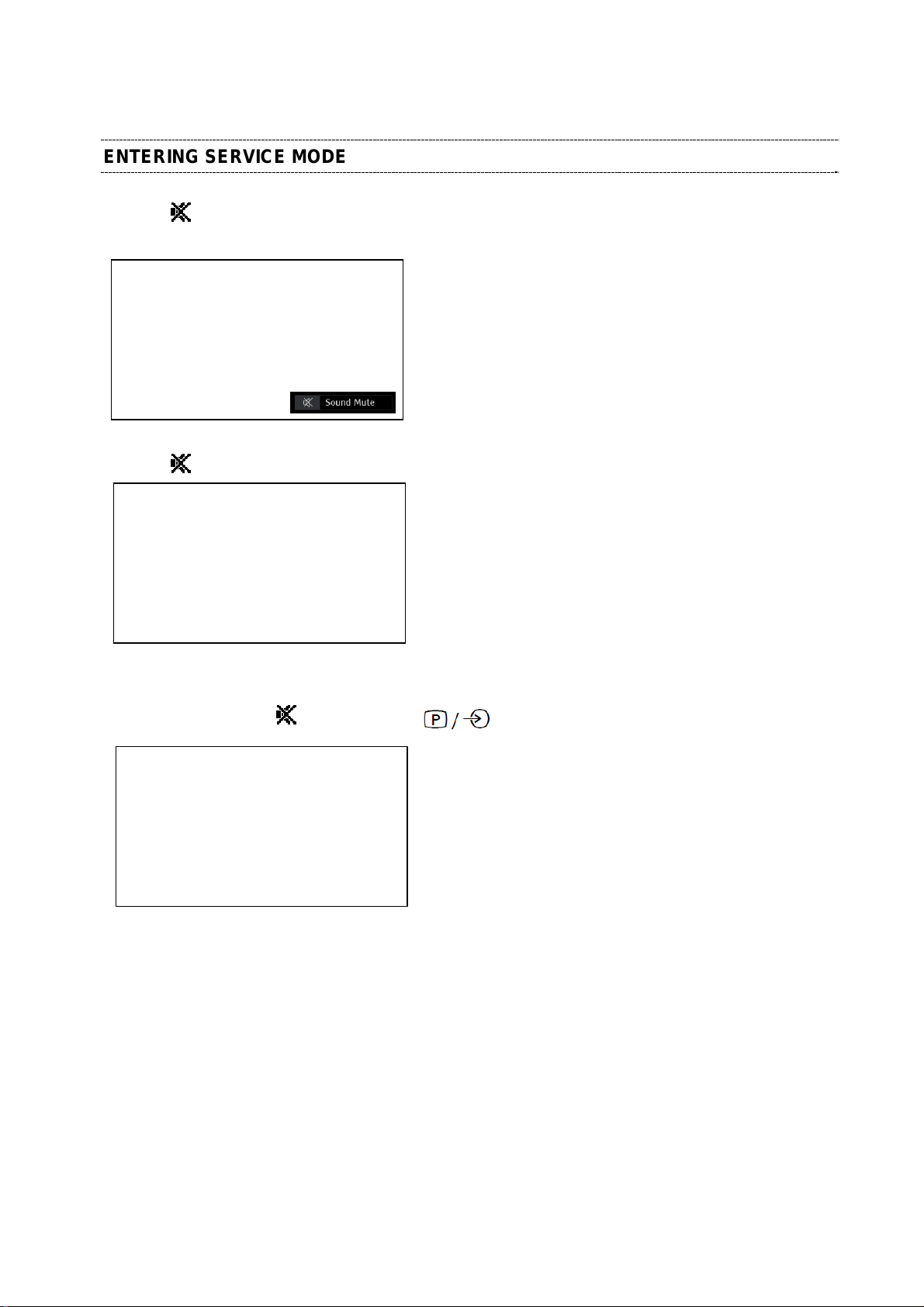

SERVICE MODE

ENTERING SERVICE MODE

1. Press button once on Remote Control.

TV mode changes as follows. Un-Mute => Mute

(1/3)

2. Press

button again and keep pressing.

(Sound Mute is canceled)

3. While pressing the button, press button on TV control panel.

S

(Enter Service Mode)

Page 11

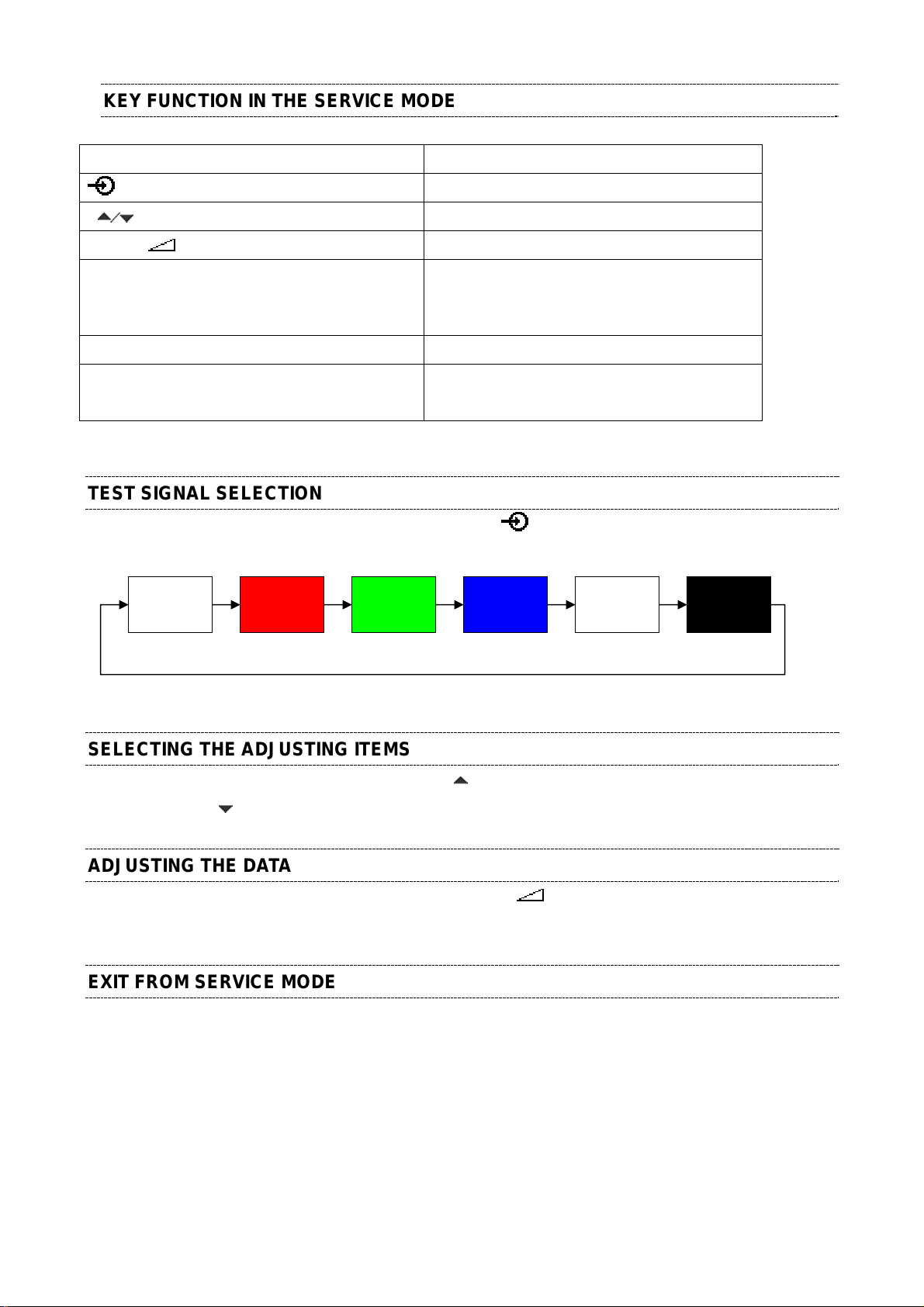

KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Button Function

(2/3)

button (on Remote)

P (on Remote) Selection of the adjustment items

Volume +/– (on Remote) Change of the data value

[7] button Automatic A/D Adjustment

[9] button Self Check display ON

[Exit] button Exit from Service mode

CAUTION: Never try to perform initialization unless you have changed the memory IC.

Test signal selection

(PC, Component, Composite(PAL, NTSC))

Self Check display Off

TEST SIGNAL SELECTION

1) While displaying the adjustment menu, every pressing of button on the Remote Control changes the

built-in test patterns on screen as described below.

Normal

Picture

Blue screen Green screenRed screen

When a pattern is chan

ged at the time of an ATV display, it can display only for a moment.

SELECTING THE ADJUSTING ITEMS

1) While displaying the adjustment menu, press the P button to cycle through the adjustment items in the

order of table. (P

button for reverse order)

ADJUSTING THE DATA

1) While displaying the adjustment menu, press the VOLUME +/– button to change the value of data in

the range from 00H to FFH. The variable range depends on the adjusting item.

EXIT FROM SERVICE MODE

1) Press the [Exit] button on Remote.

Page 12

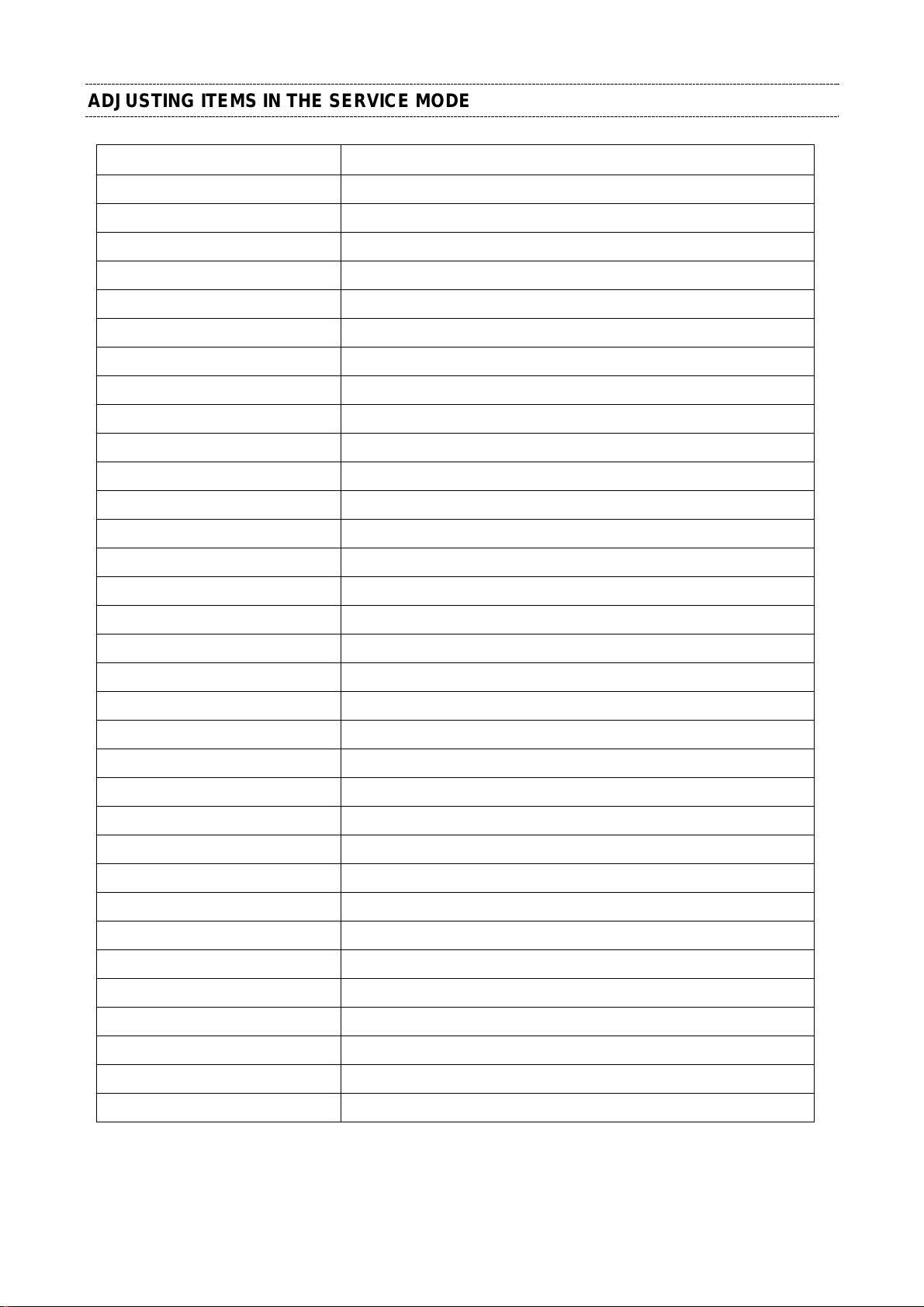

ADJUSTING ITEMS IN THE SERVICE MODE

Item Description

RCUT RED CUTOFF

GCUT GREEN CUTOFF

BCUT BLUE CUTOFF

RDRV RED DRIVE

GDRV GREEN DRIVE

BDRV BLUE DRIVE

OSRC COOL R-CUTOFF-OFFSET for COOL

OSRC NATURAL R-CUTOFF-OFFSET for NATURAL

OSRC WARM R-CUTOFF-OFFSET for WARM

OSGC COOL G-CUTOFF- OFFSET for COOL

OSGC NATURAL G-CUTOFF -OFFSET for NATURAL

OSGC WARM G-CUTOFF-OFFSET for WARM

(3/3)

OSBC COOL B-CUTOFF-OFFSET for COOL

OSBC NATURAL B-CUTOFF-OFFSET for NATURAL

OSBC WARM B-CUTOFF-OFFSET for WARM

OSRD COOL R-DRIVE-OFFSET for COOL

OSRD NATURAL R-DRIVE-OFFSET for NATURAL

OSRD WARM R-DRIVE-OFFSET for WARM

OSGD COOL G-DRIVE-OFFSET for COOL

OSGD NATURAL G-DRIVE-OFFSET for NATURAL

OSGD WARM G-DRIVE-OFFSET for WARM

OSBD COOL B-DRIVE-OFFSET for COOL

OSBD NATURAL B-DRIVE-OFFSET for NATURAL

OSBD WARM B-DRIVE-OFFSET for WARM

OSRD 3D COOL R-DRIVE-OFFSET for COOL (3D)

OSRD 3D NATURAL R-DRIVE-OFFSET for NATURAL (3D)

OSRD 3D WARM R-DRIVE-OFFSET for WARM (3D)

OSGD 3D COOL G-DRIVE-OFFSET for COOL (3 D)

OSGD 3D NATURAL G-DRIVE-OFFSET for NATURAL (3D)

OSGD 3D WARM G-DRIVE-OF FSET for WARM (3D)

OSBD 3D COOL B-DRIVE-OFFSET for COOL (3D)

OSBD 3D NATURAL B-DRIVE-OFFSET for NATURAL (3D)

OSBD 3D WARM B-DRIVE-OFFSET for WARM (3D)

Page 13

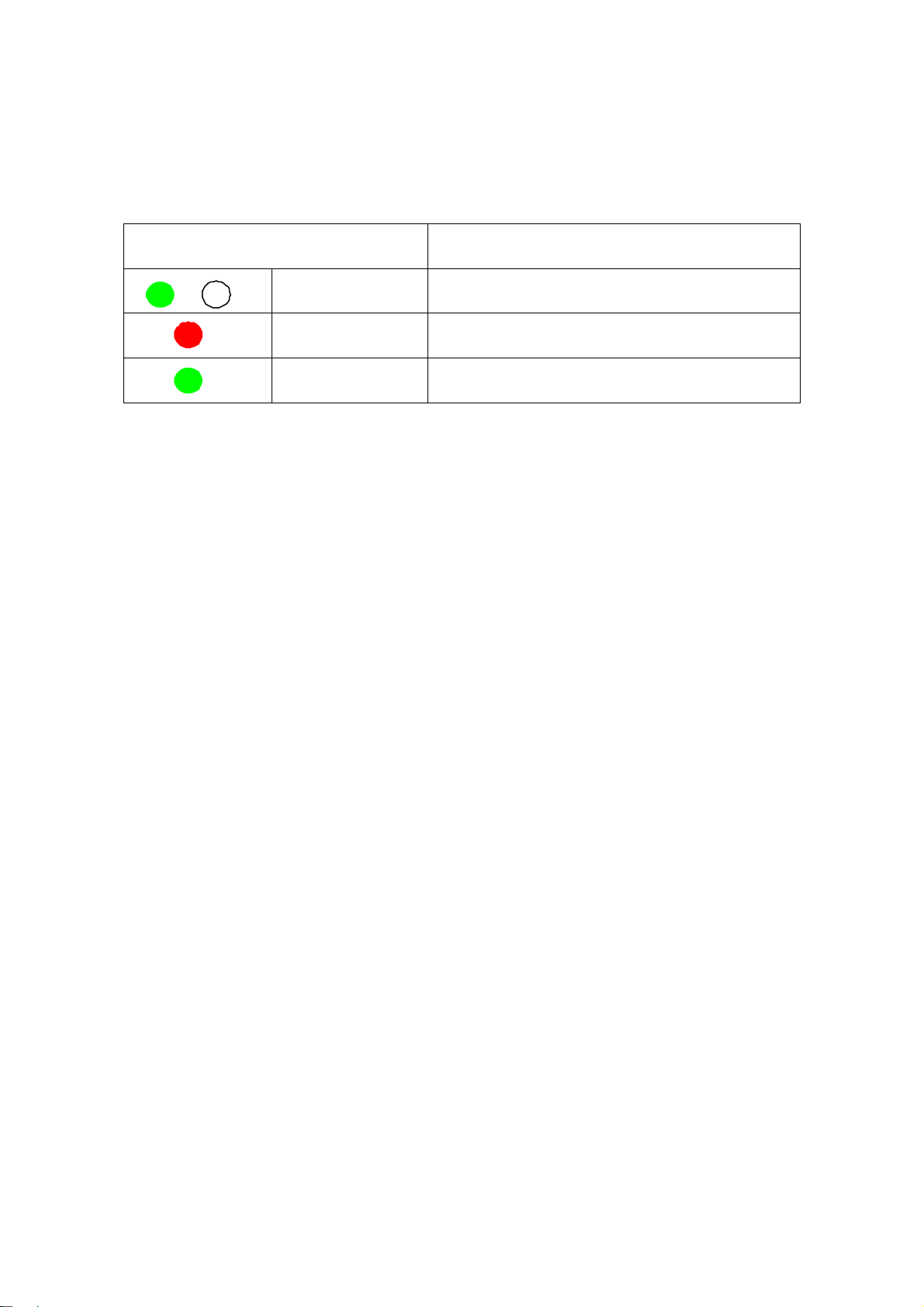

LED INDICATIONS FOR SERVICE

SW Upgrade and Error conditions indicated by the Power LED is described below.

Power LED

/

Green blink SW Upgrade in Progress

Red SW Upgrade Failed

Green SW Upgrade Successful

Page 14

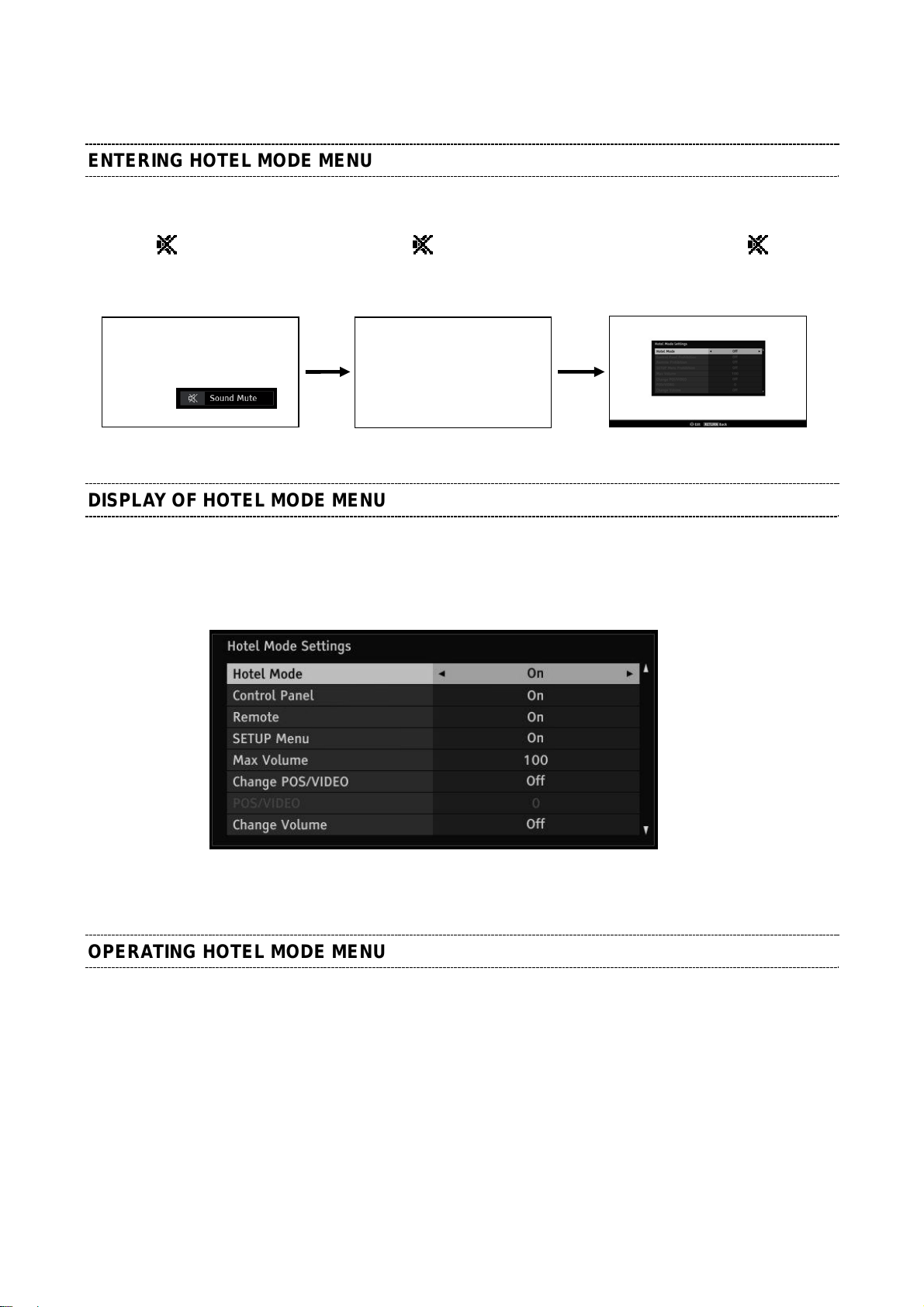

HOTEL MODE

ENTERING HOTEL MODE MENU

Hotel Mode Menu should be shown by the following operation.

1) Press any button on TV to activate Touch Sensor. White LED will light up.

(1/6)

2) Press

Remote Control. keep pressing. press “+” button on TV.

button once on the 3) Press button again and 4) While pre ssing the button,

(Hotel Mode Settings Menu)

DISPLAY OF HOTEL MODE MENU

- The Graphic Design and color of Hotel Mode Menu is the same as the User menu.

(Small differences which do not affect to operation will be acceptable)

- The language will follow the “Menu Language” setting in the menu

(Example of Menu Image)

OPERATING HOTEL MODE MENU

- To enable Hotel Mode, use the or arrow keys while “Hotel Mode” item is highlighted to select “On”.

Once Hotel Mode is on, the Hotel Mode settings will be enabled for adjusting.

- Use ▲ and ▼ buttons to access the hotel mode settings.

Use and buttons to change the settings.

See the table below for explanation of each setting.

- Press Exit when finished adjusting the settings.

Page 15

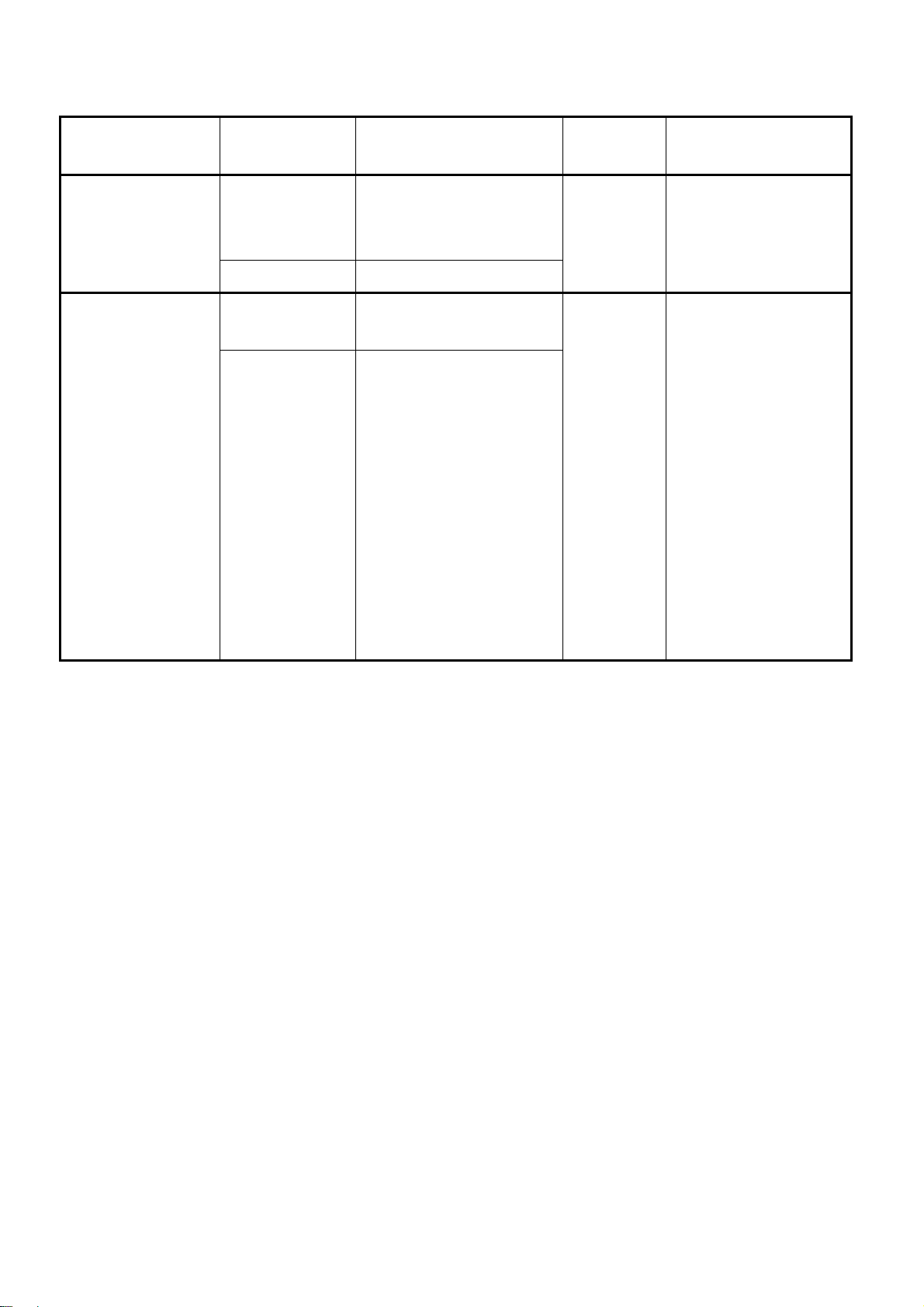

(2/6)

Item Options Description

Hotel Mode

Control Panel

Off Disable Hotel Mode.

All the settings of Hotel Mode

are disabled.

On Enable Hotel Mode

On Allow use of all Control panel

buttons

Off Prohibit use of all control panel

buttons.

But, Power Off -> On by control

panel POWER button is not

prohibited.

(Power On -> Off is prohibited.)

* Entering Service mode/Hotel

mode Menu/Hotel Clone is not

Off -

On - Grayed out when "Hotel

Factory

Gray Out Conditions

settings

Mode" = [Off]

prohibited.

* Control panel buttons are

available during Service mode.

Page 16

(3/6)

Setup Menu

On Remote Enabled Remote Control

Off Remote Disabled

* The following remote codes are

not disabled.

- SOUND MUTE (40BF10)

- Super User mode (40BFFE)

- S mode (40EEC3)

* Remote Enabled during Service

mode/Hotel mode Menu/Hotel

Clone.

* When Remote Control is set to

“Off”, the [Panel Lock] setting in

the main menu will be grayed out

and forced to “Off”.

On Allow access to SETUP menu

Off Prohibit access to the setup

On - Grayed out when "Hotel

Mode" = [Off]

On - Grayed out when "Hotel

Mode" = [Off]

menu.

SETUP menu icon is grayed out

and it is prohibited to select

(skip).

(If gray-out of SETUP menu icon

is difficult,

skipping without gray-out is

acceptable )

Off (Except

Language)

Max Volume 0-100 Set maximum volume level.

Prohibit access to all items in the

setup menu except for the

Language setting.

The prohibited items are not

shown on the menu. (Gray-out

instead of erasing is acceptable)

It limits the volume level which

100 - Grayed out when "Hotel

Mode" = [Off]

can be set by Volume button.

If you set it to 70, Volume bar can

not go to 71 or higher.

Page 17

(4/6)

Change POS/VIDEO

POS/VIDEO

(only available when

“Change POS/VIDEO”

is On)

Off TV Tunes to the last channel or

input viewed when powered on

On TV tunes to preset

“POS/VIDEO” (channel or input)

when TV is powered on.

On (AC) TV tunes to preset

“POS/VIDEO” (channel or input)

only when AC power is applied.

When TV is powered on by

power button, tune to the last

channel or input.

0-99 0-99 (ATV Channel Position)

DTV DT V (DTV channel number can

not be set. The last selected

channel is shown.)

Off - Grayed out when "Hotel

Mode" = [Off]

0

- Grayed out when Hotel

Mode = [Off]

- Grayed out when

"Change POS/VIDEO" =

Change Volume

Volume

(only available when

VIDEO1 VIDEO1

VIDEO2 VIDEO2

VIDEO3 VIDEO3

HDMI1 HDMI1

HDMI2 HDMI2

HDMI3 HDMI3

HDMI4 HDMI4

PC PC

Off TV volume level does not

change when TV powers on

On TV volume level is forced to

“Volume” level when TV is

powered on

0-100 Volume level when TV is

powered on

* The input which

does not exist on

the model should

not be shown.

(eg. “DTV” is not

shown on ATV

models.)

[Off]

Off - Grayed out when "Hotel

Mode" = [Off]

30

- Grayed out when "Hotel

Mode" = [Off]

“Change Volume” is

On)

- Grayed out when

"Change Volume" = [Off]

Page 18

(5/6)

Change Picture Mode

Picture Mode

(only available when

“Change Picture Mode”

is On)

Off Picture setting mode does

not change when TV is

powered on

On Picture setting mode is

forced to “Picture Mode”

mode when TV is powered

on

AutoView AutoView

Dynamic Dynamic

Standard Standard

Movie 1

(EU: Hollywood

Day)

Movie 2

(EU: Hollywood

Night)

Movie 1

(EU: Hollywood Day)

Movie 2

(EU: Hollywood Night)

Off - Grayed out when "Hotel

Mode" = [Off]

AutoView - Grayed out when "Hotel

Mode" = [Off]

- Grayed out when

"Change Selectable

Picture" = [Off]

TV Power

Position Change on

HDMI Input

Disabled TV returns to previous

Standby/On State when

AC power is applied

Force On Power TV on when AC

power is applied

Force Standby Put TV in Standby when

AC power is applied

On

Off When viewing HDMI input,

RF tuning via P

RETURN, and number

buttons is allowed.

(Normal operation)

RF tuning via P▲, P▼,

RETURN, and number

buttons is disabled

▲, P▼,

Disabled - Grayed out when "Hotel

Mode" = [Off]

On - Grayed out when "Hotel

Mode" = [Off]

Page 19

(6/6)

A/D Channel List

On TV shall combine both

Analogue & Digital

channels in one channel

list, and select the

ATV/DTV channel without

boarder.

Off DTV Channel List and

ATV DTV Channel List are

separated.

Off - Grayed out when "Hotel

Mode" = [Off]

Page 20

HOTEL CLONE

The following settings can be copied between sets using the Hotel clone menu:

● Hotel mode menu settings

● DTV Channel Setup (DTV models only)

● ATV Channel Setup

▪ Programme (position)

▪ System

▪ Colour System

▪ Programme Skip

▪ Channel

▪ Manual Fine Tuning

▪ Label

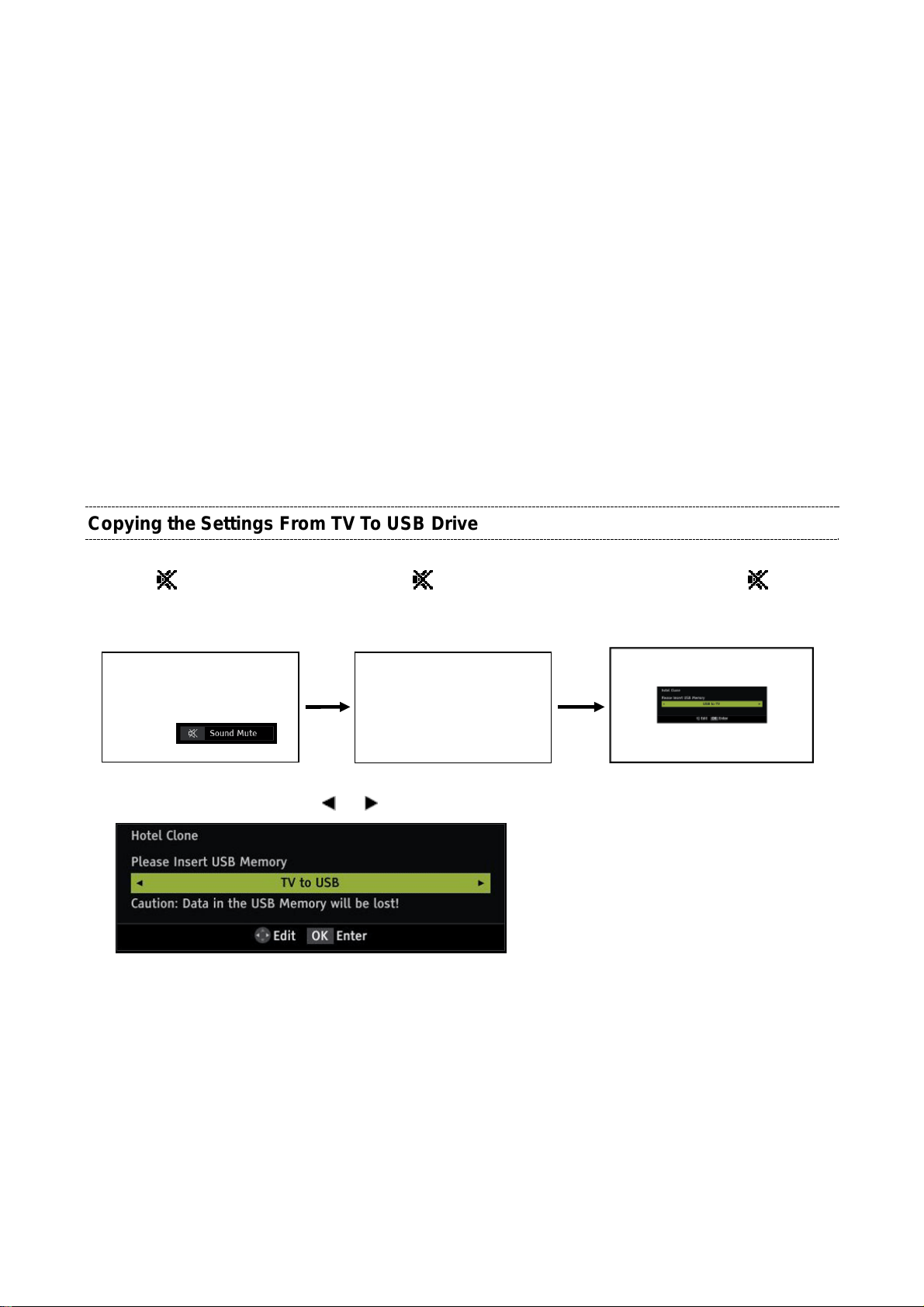

Copying the Settings From TV To USB Drive

(1/2)

1) Press

Remote Control. keep pressing. press “-” button on TV.

4) Select "TV to USB" using the

5) Insert USB Drive and press OK to copy settings to the USB drive.

6) Wait for window that indicates the copying process is complete before removing the USB drive.

button once on the 2) Press button again and 3) While pre ssing the button,

(Hotel Clone menu display)

or arrow keys.

Page 21

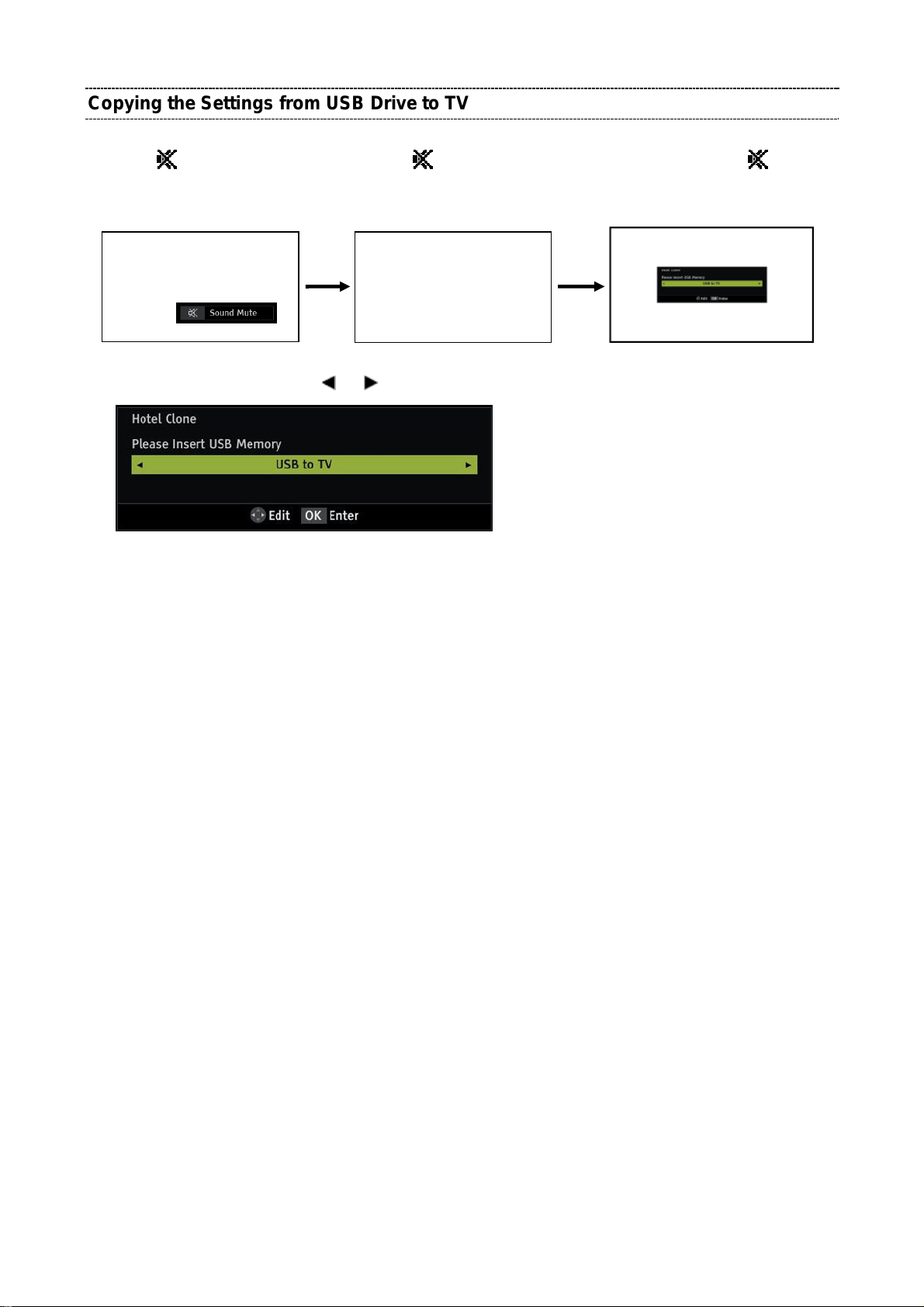

Copying the Settings from USB Drive to TV

(2/2)

1) Press

button once on the 2) Press button again and 3) While pre ssing the button,

Remote Control. keep pressing. press “-” button on TV.

4) Select "USB to TV" using the or arrow keys.

5) Insert USB Drive that settings have previously been saved to and press OK to copy settings to the TV.

6) Wait for settings to be copied.

When the copying has finished successfully, the message "The TV will reboot when this window is

(Hotel Clone menu display)

closed." will be displayed. If the copying is not successful, an error message will be displayed.

7) Exit the menu and the TV will reboot.

8) Remove the USB drive.

Page 22

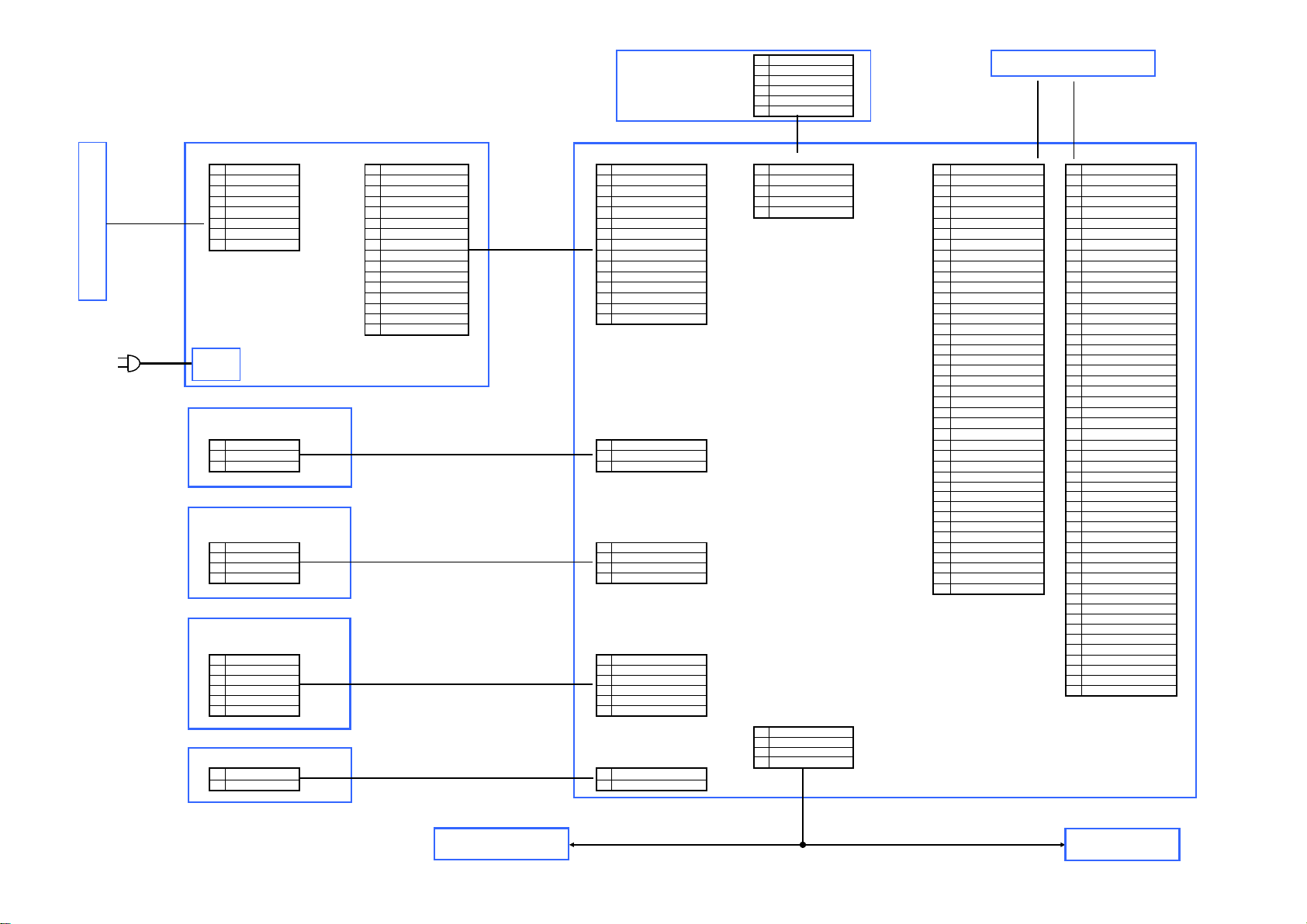

5V2D-

D+

GND5WoWLAN

GND (for cable

Anode

1

12V

1

12V

1

GND

41 NC

51

NC

NC

2

12V

2

12V

2

GND

40 NC

50

NC

Cathode 1

3

12V

3

12V

3

M_USB1DP

39 NC

49

NC

Cathode 2

4

GND_12V

4

GND

4

M_USB1DM

38 NC

48

NC

5

Cathode 3

5

GND_12V

5

GND

5

5V_WLAN

37 NC

47

NC

Cathode 4

6

GND_12V

6

VCC_AUDIO 36 NC

46

NC

Cathode 5

7

NA

7

GND 35 NC

45

LVDS_SEL

8

Cathode 6

8

5V

8

NC 34 NC

44

NC

5V

9

GND 33 GND_T1

43

NC

5V

10

5V1 32 LVC0N

42

NC

NA

11

AC_DETECT 31 LVC0P

41

GND

ACD

12

POWER_TV 30 LVC1N

40

LVA0N

Power_TV

13

BL On/Off 29 LVC1P

39

LVA0P

14

BL ON OFF

14

PWM2 28 LVC2N

38

LVA1N

15

PWM2

15 PWM1

27 LVC2P

37

LVA1P

16

PWM1

26 GND_T1

36

LVA2N

25 LVCCK-

35

LVA2P

24 LVCCK+

34

GND_T1

23 GND_T1

33

LVACKN

CN743

16 LVD0N

26

3D_EN

3

Power Key

3

Power Key 13 LVD1P

23

LVB0P

12 LVD2N

22

LVB1N

11 LVD2P

21

LVB1P

10 GND_T1

20

LVB2N

9 LVDCK-

19

LVB2P

8 LVDCK+

18

GND_T1

7 GND_T1

17

LVBCKN

CN742

6 LVD3N

16

LVBCKP

1

5V1

1

B1 5 LVD3P

15

GND_T1

2

GND

2

B0 4 LVD4N

14

LVB3N

3

GREEN

3

GND 3 LVD4P

13

LVB3P

4

RED

4

5V1 2 GND_T1

12

LVB4N

1 GND

11

LVB4P

10

GND9GND8GND7GND6GND

CN741 5

NC

1

3.3VD_IR

1

3.3VD

4

VCC_LVD

2

GND

2

GND

3

VCC_LVD

3

SENSOR

3

Be Sensor

2

VCC_LVD

4

GND

4

GND

1

VCC_LVD

6

RMT

6

RMT_IN

2

3DIR

2

GND

E270

IR BORAD

MAIN BOARD

LED BORAD

E340

E280

KEYPAD BORAD

E290

E350

E272

3DIR

E320

WLAN MODULE

1

3

4

6

PANEL T-CON

E310A

75034761 (RA)

75034762 (RB)

CN2 CN3 CN90 CN162 CN651 CN650

1

2

3

4

6

PANEL

7

E250

POWER BOARD

9

10

11

12

13

E344

Darfon B191-203

(AC cable)

1

GND

2

ADC_IN

E348

1

2

E260

E346

E343

5 3.3V_STNBY_IR 5 3.3V_STNBY

1

GND

E342

1

E200

22 LVC3N

21 LVC3P

20 LVC4N

19 LVC4P

18 GND_T1

17 GND_T1

GND 15 LVD0P

Function Key 14 LVD1N

CN300

1 R-_AMP

2 R+_AMP

CN652 4 L+_AMP

3DIR1

3 L-_AMP

32

LVACKP

31

GND_T1

30

LVA3N

29

LVA3P

28

LVA4N

27

LVA4P

25

LR_SW

24

LVB0N

Speaker

Speaker

Page 23

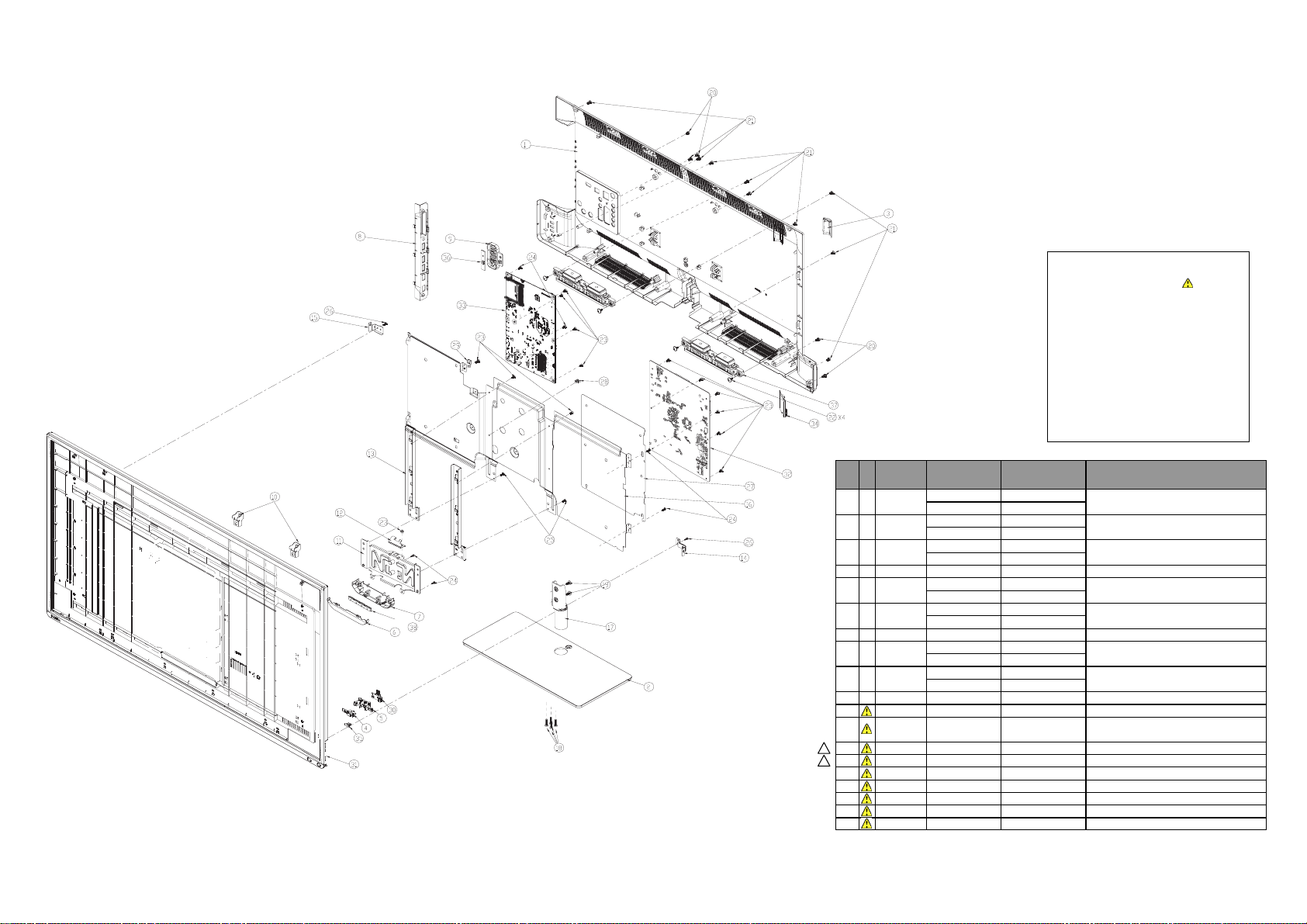

EXPLODED VIEW

)

)

y

40L7363D/40L7365D/40M8365D

SAFETY PRECAUTION

The parts identified by mark

are critical for safety. Replace only

with part number specified. The

mounting position of replacement

is to be identical with originals.

The substitute replacement parts

which do not have the same safet

characteristics as specified in the

parts list may create shock, fire or

other hazards.

40L7363D(G)/(N),40L7365D(G)/(N),40M8365D(G

No. Location

1 E110

E120

2

3 E150 NECK COVER

4 E102 75034688 13EB-4DQ0901 LENS LED RMT

E107 SUPPORT FOR SMALL BOARD

5

E106

6

7 E108 75034755 13EB-4DQ0701 SUPPORT FOR SMALL BOARD

E142

8

9

17 E160 75035441 13EB-4DB0721 NECK ASSY

30 E270 75034704 9C-EB40S02N0 IR BOARD ASSY

31 E300A 75035852

33 E200 75034758 9C-EB40M01V0 MAIN BOARD ASSY

1

32 E250 75034759 0433-0086000 POWER OPEN FRAME BOARD

1

34 E290 75034226 0C05-00JK0TB WLAN MODULE

35 E260 75034223 9C-EB40S02E0 LED BOARD ASSY

36 E280 75034225 9C-EB40S02C0 KEYPAD BOARD ASSY

37 E330 75034707 04A4-01E10TB SPEAKER (LEFT AND RIGHT)

38 E272 75034760 9C-EB40S02P0 IR BOARD 3D ASSY

Toshiba

Service Part

75036200 13EB-4DB0831

75035455 13EB-4DB0641

75035307 13EB-4DB0C11

75036197 13EB-4DB0B01

75035309 13EB-4DQ0411

75035440 13EB-4DQ0H11

75034691 13EB-4DQ0811

75034692 13EB-4DQ0F01

75034753 13EB-4DQ0511

75034754 13EB-4DQ0J01

75034699 13EB-4DQ0111

75034700 13EB-4DQ0D01

75034697 13EB-4DQ0A01

75034698 13EB-4DQ0E01

ODM Partner

Part

Description

UNIT COVER ASSY

STAND ASSY

SUPPORT FOR SMALL BOARD

SIDE BEZEL ASSY

KEY BEZELE140

S-Fit LCD Panel, (Open Cell, SAM,

LSC400HF03-T

Page 24

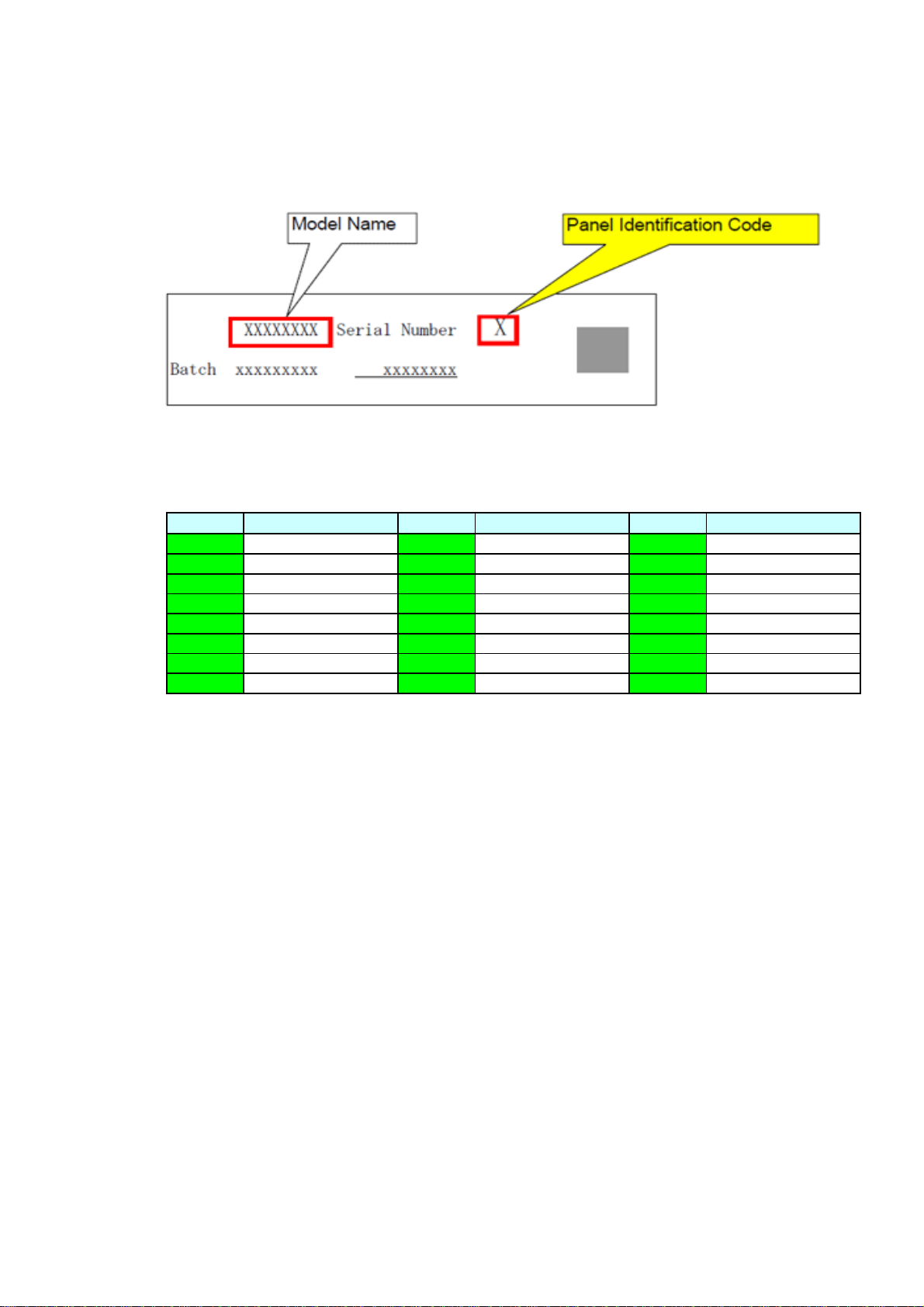

PANEL IDENTIFICATION

A

Serial No. part printed on Rating Label

Panel Identification Code

Marking Marking Marking

BKT

CLU

DMV

ENW

FPX

GQY

HRZ

Panel Vendor

AUO

BriView

CMO

CHILIN

IPS

JS

Panel Vendor

SAMSUNG

LPL/LGD

CPT

Panel Vendor

SHARP

Page 25

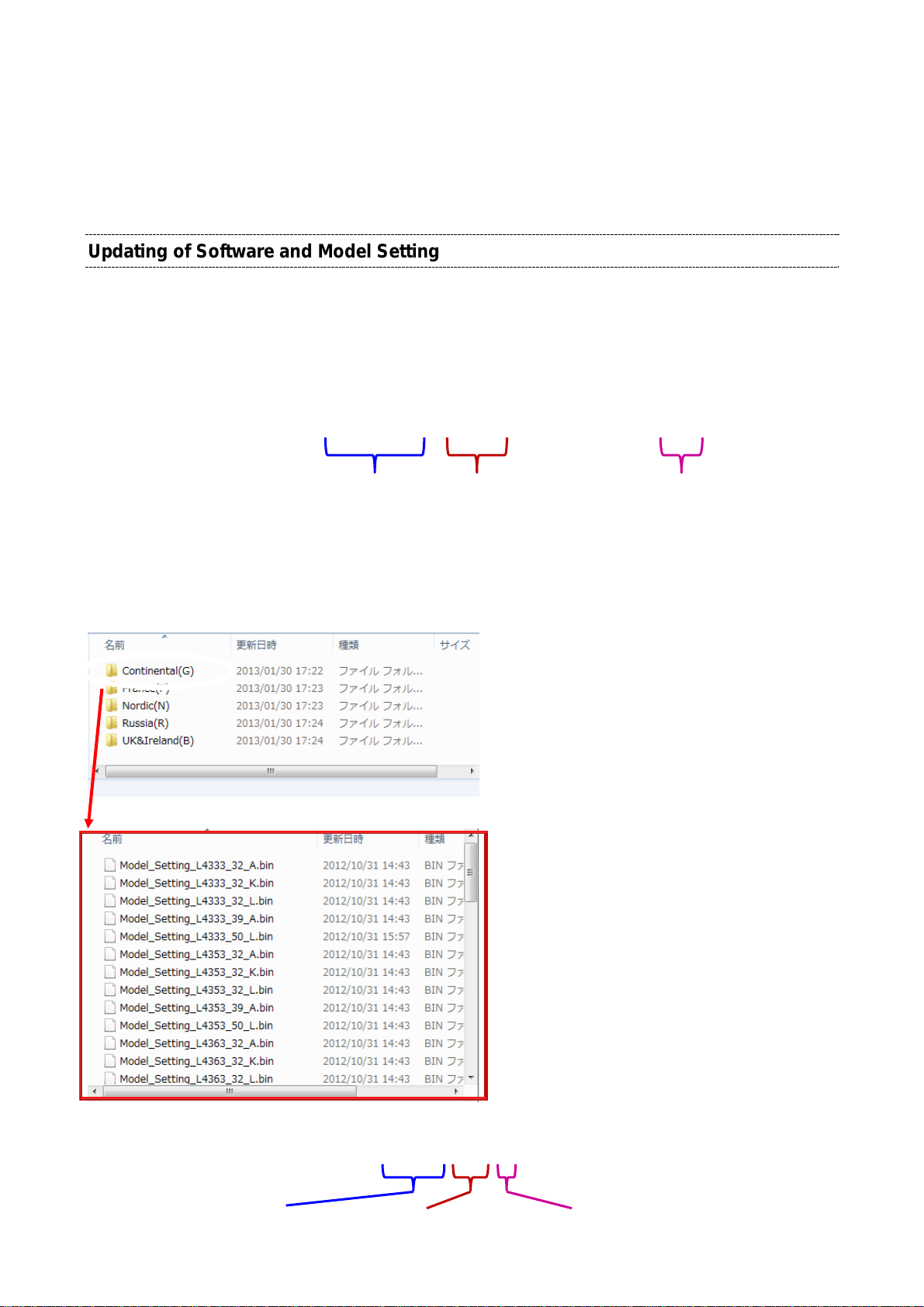

(1/3)

MAIN BOARD EXCHANGE

When Main board is exchanged, the Application SW (Firrmware) and Model Setting need to

be updated.

Please update in the following procedures.

Updating of Software and Model Setting

1. Copy the Application SW (Firmware) file and the Model Setting file to the root of the USB

mass storage device.

Application SW:

[Example] UPDATE_50L7363C_12800_INIT_CLEAR#.enc

This Application SW is for not

only 50L7363C but also the other

models, i.e. all of L73/L63/L43

models.

Model Setting File:

This number is

an example.

“enc” means encrypted.

This SW is encrypted for

security.

Model setting files are categorized by shipout.

Each Shipout folder contains model setting files.

[Example] Model_Setting_L4333_32_A.bin

TV series

Panel size Panel Vendor

Page 26

2. Unplug TV, and then Insert the USB mass storage device to the USB slot of the TV.

3. Plug TV.

Software updating starts.

If Software updating does not start and the front LED lights red, then press [Power] key on

Remote Control to start Software updating.

4. After updating complete, unplug TV and remove the USB mass storage device.

(2/3)

5. Plug TV, then check the updating by using self check screen.

Refer to “Confirmation of Software updating” section on next page.

6.

Update to the newest SW.

This model can be updated from aerial or network to the newest Software.

Refer to the user manual of this model for the updating method.

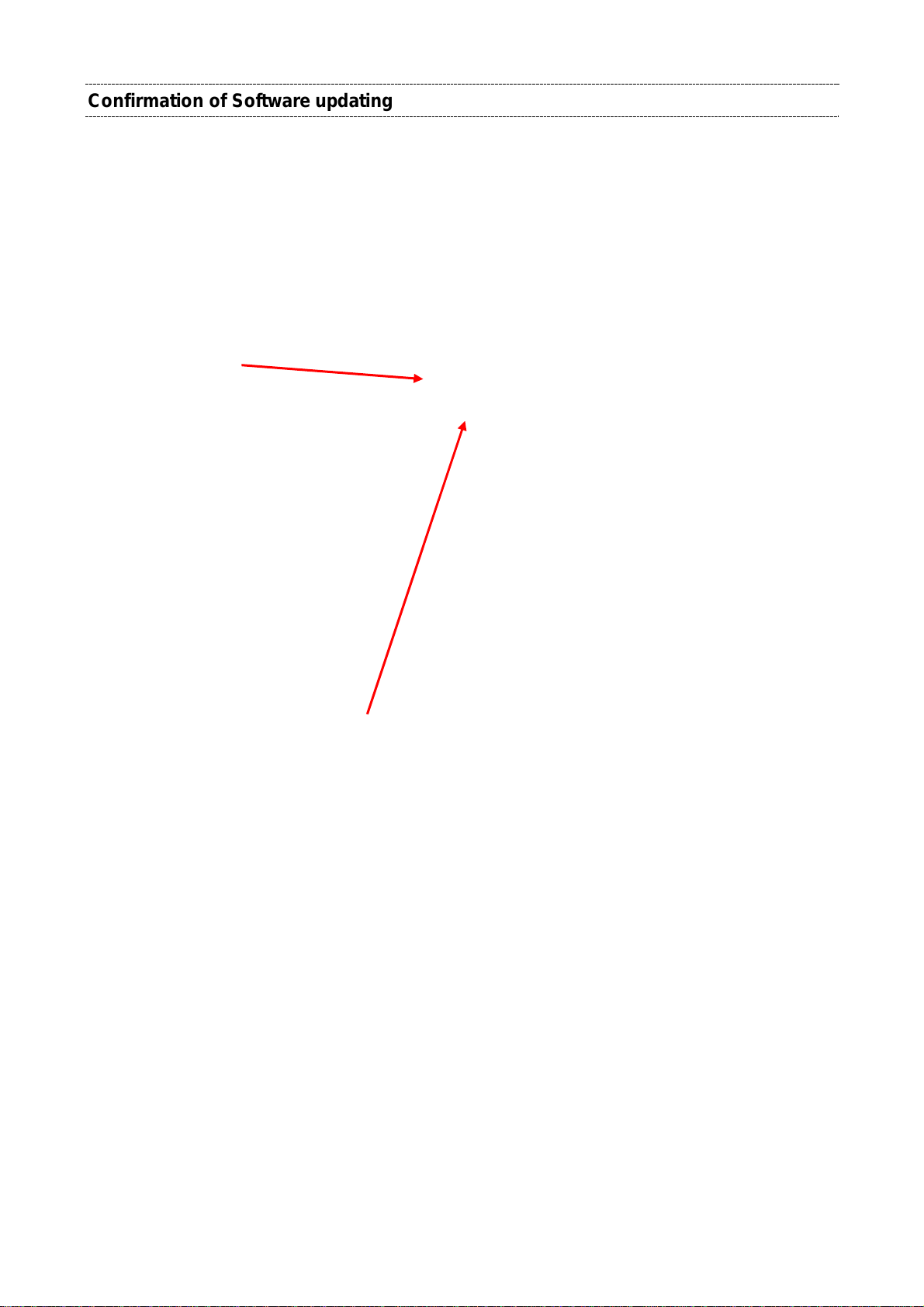

Page 27

Confirmation of Software updating

Check the TV Model and Model Info by using self check screen.

1. Press SETUP on Remote Control.

2. Select “Get Help” >> “System Information”

3. Press “3” “5” “7” “4”

Self check screen is displayed.

TV model and

Panel vendor

(3/3)

th

[The 4

number and Shipout]

10 UK&Ireland (B)

11 France (F)

12 Continental(G)

13 Russia (R)

14 Nordic (N)

Page 28

ABOUT THE MAIN BOARD

The Main PCB is changed to enable easier removal of Tuner.

For Service Parts, only new type is used.

The new type have larger land pattern for soldering the Tuner.

And around the land, attached white silk marking.

New type Main board (Bottom)

Page 29

REV. 01

Aug. /20/2013

Page 30

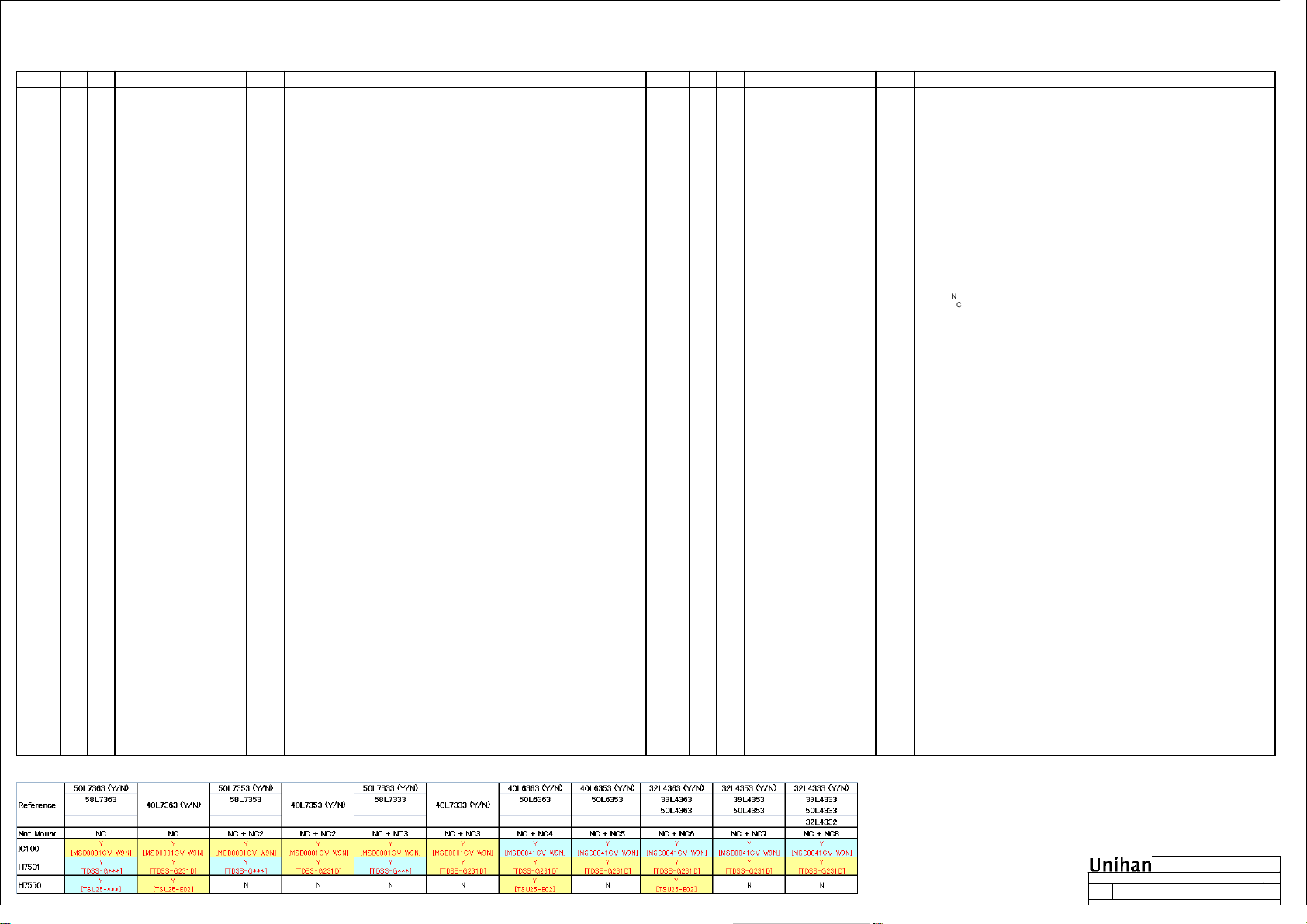

TOSHIBA 2013 L7363 Series Models

VerDate

Stage

SR

2012/10/04 1.01 R_SPI_CLK / R_SPI_CS swap R_SPI_CLK / R_SPI_CS net swap in IC760 side:

ER

2012/10/29

ER

Design Notes

1.002012/09/20 SR Stage Release

1.012012/10/04 1. Change IC790 pin19’s net name to S_CI_BUFFER_ENZ

Add S_CI_BUFFER_ENZ to

ctrl CI Data buffer

ER

2012/10/23 1.01 Test Point change Chage CN741,CN742,CN743,CN652,CN162,CN100 test point size for DFM review

ER

2012/10/26 1.01 Add schumitt buffer on 796 and GPIO

ER

ER

ER

2012/10/26 1.01 GPIO change from IC100 to CI BUS3

ER

ctrl

1.012012/10/26

PC EDID & debug by VGA

IC790

IC790

2012/10/29 1.01 PJ601 change 603 PJ601 was changed to 1242-00KB000ER

2012/10/29 Remove Resistances list below:

2012/10/29 1. Change: R6580 100 KOhm → 4.7KOhm

ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

ER2012/10/29 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/30 R6584 optional change from NC to NC4NC5NC6NC7NC8658Circuit Change Notes 2012/10/26:

2012/10/30 950 12V & 12V_3 swap in the both side of FL957ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/30 ER 1.01 791 1. Change IC789 from TPS2553DBV-1 to R5524N001B-TR-FE

2012/10/30 ER 1.01 Circuit_Notes_TUNER_Demod_2:

2012/10/31 ER 1.01 Test Point requested by production test 660 Add DP716 in net H_PWR4

2012/10/31 ER 1.01 R1218 NC 135 R1218: Mount -> Not Mount

2012/11/01 ER 1.01 Add DP721 for DFM 658 Add DP721 for DFM

ER 1.01 Add Bead for EMI 658

2012/11/01

ER 1.01 D7410 & D7411 NC 9512012/11/07 Keypad D7410 & D7411 NC

2012/11/14 ER 1.01 Change R6580 => 12k Ohm 658 Change R6580 => 12k Ohm

Circuit Change Notes_2012/10/26:

1.01ER

Remove below 0 ohm resistors for

current measure and connect directly

FET Unmount and Relevant Changes

in 3D GLASSES I/F

Insert FL909 & FL957

Place R1218 near IC100.

R6712 and R6713 are deleted

T-CON POWER SW change

Tuner component fine tune

1.01ER

correction

correction

Circuit Change Notes_2012/10/30:

Circuit_Change_Notes_CI3

SHT755 S TUNER

Description

Page

760

R_SPI_CS => IC760.33 / R_SPI_CLK => IC760.28

Res R7613 & RM761C SWAP for easy layout ( 2012/10/29 add)

113, 794

2. Connect S_CI_BUFFER_ENZ to IC100.C7 (GPIO81)

3. reserve a pull-up resistor R1002 on S_CI_BUFFER_ENZ

Tuner H7550 => 04A9-00DF0TB & H7501 => 04A9-00DB0TB2012/10/04 1.01 Tuner change

755,

750

121, 658,

700

104, 796 1. Add R_TSCLK_CI ( from R1130 to IC794.2 ) & R_TSCLK ( from R1131 to R7740 & R7742 )

2. Add Scheumitt buffer ( IC794, R7950, C7963 )

1. Delete DP100 and DP102

113, 609GPIO & related circuit change for DSUB

2. Connect IC100's GPIO5 -> VGA_EEP_WP ( -> Q6110.G, Q6025.G & Q6026.G )

GPIO16 -> M_VDBG_EN ( -> IC620.7 )

GPIO110 -> M_DSUB_I2CCLK ( -> Q6026.S )

GPIO108 -> M_DSUB_I2CDATA ( -> Q6025.S )

113, 6692012/10/26 1.01 GPIO change from IC100 to CI BUS3

1. Delete DP103.

2. Connect IC100's GPIO81 and R6637 by M_WP_HDCP

113, 794 1. Delete DP109.

2. Connect IC100's GPIO8 and R7900 by C_CI_BUS_ENZ

117, 129,

R1103, R1232, R1237, R1601, R1604, R1606, R1608, R6520, R6650, R6651,

160, 653,

R6710, R6711, R6728, R7803, R7804, R7805, R7806, R7807, R7808, R7809,

665, 674,

R7810, R7811, R7812, R7919, R7920, R9000, R9001, R9090,R9091

780, 791,

901, 906

658

2. Mount → Unmount:

Q6582, R6585, R6586, R6587, R6589, C6581

3. Add: C6582 0.1UF/16V, R6590 0 Ohm, R6591 220 Ohm

1. Change Net Name of Power of IC905, Insert FL909 (220ohm/100MHz), and connected FL909 to 12V_3

905, 950

2. Change Net Name of 12V, Insert FL957 (220 ohm/100MHz), and add net 12V_3

135 Place R1218 near IC100.

677 R6712 and R6713 are deleted and it connects directly

653 T-CON POWER SW change

750, 751 1. Change C7506, R7514, R7557, R7714

2. Add C7524, R7610, C7617, C7563, C7731

3. Delete R7513,R7515

2. Remove R7911

755 C7563 connect to R7557 & H7550

CN652: Add FL652, FL653

700

CN741: Add FL737, FL738, FL739, FL740, FL741

CN742: Add FL743, FL744, FL745, FL746

CN743: Add FL747, FL748, FL749

653Add L6541 for T-CON circuit1.01ER2012/11/01 Add L6541 for T-CON circuit

VerDate Design Notes DescriptionStage Page

2012/11/14 PR 1.02 Part change to reduce DDR 800MHz

2012/11/28 PR 1.02 Part change to improve T-COM PWR

2012/12/05 PR 1.02 CN100 NC 121 CN100 NC

2012/12/12 PR 1.02 FL664, FL665 => 0 ohm 660 FL664, FL665 were changed to 0 ohm array for MHL

2012/12/17 PR 1.02 Change part reference 674 FL619 was renamed as FL162

2012/12/18 PR 1.02 Add test point 906 DP901 was add for IC911 pin1

2012/12/24 PR 1.02 PJ601 local use footprint for DFM 603 PJ601 change local use footprint for DFM, floating issue in 1.2mm PCB

2012/12/26 PR 1.02 ON/OFF function of the WLAN power 160 R1608 : 0 Ω -> NC

Emisson

sequence

EMI solution 600 Page 600: Add C6015, C6016, C6017, FL616~FL618

MHL VBUS / IC673 circuit change Remove R6740 & Add R6735, Q6710 near IC673674

The dischage res for T-CON PWR 653 Add R6546

1.02PR2013/01/02 700LED luminosity is adjustted R7032 : 100 -> 680Ω

improve X-tal accuracy for DVB-T2

1.022013/01/08 PR 760

& DVB-S2/S

658, 700 FL652, FL653: P/N: 0901-0019000 GBK160808T-300Y-N

FL737-FL741: P/N: 0901-0027000 GBK160808T-121Y-S<G>

FL743-FL746: P/N: 0901-0027000 GBK160808T-121Y-S<G>

FL747-FL749: P/N: 0901-0027000 GBK160808T-121Y-S<G>

653 C6543 was changed from 0.22uF to 1UF/25V (0603)

Page 602: Add C6032~C6039, FL610~FL612

Page 603: Add C6090~C6093, FL613~FL615

160 FL619 was added for wifi

Remove IC620 and C6085 & Add Q6027 & Q6028To improve the leak current from I2C 609

Add R1608, R1609, R1610USB connector for WLAN 160

R1609 : NC -> 0 Ω

R1610 : NC -> 4.7K Ω

C7614,C7615 27p -> 10p

R7606 0 ohm -> 1.8Kohm

770

C7714,C7715 6p -> 10p

R7710 0 ohm -> 1.5Kohm

improve IFAGC voltage of SoC 751 R7522 : 10Kohm -> 0ohm

Optional Information

000. History & Description

000. History & Description

000. History & Description

Title :

Title :

Title :

Engineer:

Engineer:

Engineer:

CVP DM HW

CVP DM HW

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Projec t Name

Size Projec t Name

Size Projec t Name

A2

EU Lv.2

A2

EU Lv.2

A2

EU Lv.2

Date: Sheet of

Date: Sheet of

Date: Sheet of

CVP DM HW

001 76Tuesday, January 08, 2013

001 76Tuesday, January 08, 2013

001 76Tuesday, January 08, 2013

Rev

Rev

Rev

1.00

1.00

1.00

Page 31

101. MSD8881CV(Video)

M_ADCIMM_ADCIM

751

M_ADCIPM_ADCIP

751

M_HSYNC0M_HSYNC0

608

M_VSYNC0M_VSYNC0

608

M_BIN0MM_BIN0M

606

M_BIN0PM_BIN0P

608

VGAE1(SCART/Comp)E2(Comp)

606

608

608

606

608

600

600

606

608

606

608

606

606

608

606

606

606

606

606

606

606

M_GIN0MM_GIN0M

M_GIN0PM_GIN0P

M_SOGIN0M_SOGIN0

M_RIN0MM_RIN0M

M_RIN0PM_RIN0P

M_HSYNC1M_HSYNC1

M_VSYNC1M_VSYNC1

M_BIN1MM_BIN1M

M_BIN1PM_BIN1P

M_GIN1MM_GIN1M

M_GIN1PM_GIN1P

M_SOGIN1M_SOGIN1

M_RIN1MM_RIN1M

M_RIN1PM_RIN1P

M_BIN2MM_BIN2M

M_BIN2PM_BIN2P

M_GIN2MM_GIN2M

M_GIN2PM_GIN2P

M_SOGIN2M_SOGIN2

M_RIN2MM_RIN2M

M_RIN2PM_RIN2P

IC100B

IC100B

[V-U8881CVF]

[V-U8881CVF]

2/16

2/16

IC100A

IC100A

[V-U8881CVF]

[V-U8881CVF]

1/16

1/16

[ANALOG VIDEO INTERFACE]

[ANALOG VIDEO INTERFACE]

SIG15368

AH8

IM

AG8

AB5

AB4

W3

W2

AA3

AC6

AA2

AA1

AC3

AB2

AB3

AC1

AC2

T2

T3

U1

U2

U3

V1

V3

Y4

Y6

V2

Y2

Y3

Y1

IM

IP

IP

HSYNC0

HSYNC0

VSYNC0

VSYNC0

BIN0M

BIN0M

BIN0P

BIN0P

GIN0M

GIN0M

GIN0P

GIN0P

SOGIN0

SOGIN0

RIN0M

RIN0M

RIN0P

RIN0P

HSYNC1

HSYNC1

VSYNC1

VSYNC1

BIN1M

BIN1M

BIN1P

BIN1P

GIN1M

GIN1M

GIN1P

GIN1P

SOGIN1

SOGIN1

RIN1M

RIN1M

RIN1P

RIN1P

HSYNC2

HSYNC2

BIN2M

BIN2M

BIN2P

BIN2P

GIN2M

GIN2M

GIN2P

GIN2P

SOGIN2

SOGIN2

RIN2M

RIN2M

RIN2P

RIN2P

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

MOUNTING HOLES

SIG15367

SIG14412

SIG14411

SIG14413

SIG14410

SIG14403

SIG14407

SIG14408

SIG14414

SIG14409

SIG14406

SIG14405

SIG14415

SIG14404

H1

H1

1

GND9

2

GND1

3

GND2

4

GND3

C394D138

C394D138

H5

H5

1

GND9

2

GND1

3

GND2

4

GND3

C394D138

C394D138

E1(SCART/Comp)

E2(Comp)

SIG17944

H8

H8

2

112

BRACKET_2P

BRACKET_2P

GND

GND8

GND7

GND6

GND5

GND4

GND8

GND7

GND6

GND5

GND4

9

8

7

6

5

9

8

7

6

5

606

606

607

607

606

M_CVBS3M_CVBS3

M_CVBS2M_CVBS2

M_CVBS1M_CVBS1

M_CVBS0M_CVBS0

M_VCOMM_VCOM

H2

H2

1

GND9

2

GND1

3

GND2

4

GND3

C394D138

C394D138

GND8

GND7

GND6

GND5

GND4

GND_PGA

9

8

7

6

5

W6

CVBS3

SIG17950

SIG17952

SIG17946

CVBS3

W4

CVBS2

CVBS2

U5

CVBS1

CVBS1

V6

CVBS0

CVBS0

V5

VCOM

VCOM

AH6

VIFM

VIFM

AG6

VIFP

VIFP

AB11

AVSS_PGA

AVSS_PGA

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

1

2

3

4

GND GNDGND

H6

H6

1

GND9

2

GND1

3

GND2

4

GND3

C394DO181X157

C394DO181X157

Hole in Left down coner Hole in Right down coner

GND GNDGND

GND8

GND7

GND6

GND5

GND4

9

8

7

6

5

1

2

3

4

H3

H3

C394D138

C394D138

H7

H7

C394D157

C394D157

[ANALOG VIDEO INTERFACE]

[ANALOG VIDEO INTERFACE]

GND9

GND8

GND1

GND7

GND2

GND6

GND3

GND5

GND4

GND9

GND8

GND1

GND7

GND2

GND6

GND3

GND5

GND4

[VIF INTERFACE]

[VIF INTERFACE]

9

8

7

6

5

9

8

7

6

5

RFAGC

RFAGC

IFAGC

IFAGC

GND8

GND7

GND6

GND5

GND4

U4

W5

AG5

AF5

M_CVBSOUT1M_CVBSOUT1

R_IFAGC_SoCR_IFAGC_SoC

9

8

7

6

5

CVBSOUT2

CVBSOUT2

CVBSOUT1

CVBSOUT1

H4

H4

1

GND9

2

GND1

3

GND2

4

GND3

C394D138

C394D138

GND

101. MSD8881CV(Video)

101. MSD8881CV(Video)

Title :

Title :

Title :

Engineer:

Engineer:

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Project Name

Size Project Name

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

EU Lv.2

EU Lv.2

EU Lv.2

Engineer:

101. MSD8881CV(Video)

CVP DM HW

CVP DM HW

CVP DM HW

101 76Tuesday, January 29, 2013

101 76Tuesday, January 29, 2013

101 76Tuesday, January 29, 2013

SCART

605

751

Rev

Rev

Rev

1.00

1.00

1.00

Page 32

103. MSD8881CV (Audio, SIF)

103. MSD8881CV (Audio, SIF)

103. MSD8881CV (Audio, SIF)

103. MSD8881CV (Audio, SIF)

B13

C12

C13

IC100C

IC100C

I2S_IN_WS

I2S_IN_WS

(PU/5V)

I2S_IN_SD

I2S_IN_SD

(PU/5V)

I2S_IN_BCK

I2S_IN_BCK

(PU/5V)

[V-U8881CVF]

[V-U8881CVF]

3/16

3/16

[I2S IN/OUT]

[I2S IN/OUT]

I2S_OUT_WS

I2S_OUT_WS

(PU/5V)

I2S_OUT_SD

I2S_OUT_SD

(PU/5V)

A11

B11

M_I2S_LRCKM_I2S_LRCK

M_I2S_DAOM_I2S_DAO

370

370

E1(Scart)

E2(Comp)

PC & HDMI

(No use Euro)

E3(CVBS)

(only Asia)

SIF

606

606

606

606

607

607

607

607

M_AUL0M_AUL0

M_AUR0M_AUR0

M_AUL2M_AUL2

M_AUR2M_AUR2

M_AUL3M_AUL3

M_AUR3M_AUR3

M_AUL4M_AUL4

M_AUR4M_AUR4

SIG21090

SIG21091

SIG20294

SIG20295

SIG18288 SIG18289

1 2

R1030 47 OHMR1030 47 OHM

SIG21092

1 2

R1031 47 OHMR1031 47 OHM

C1038 1 UF/6.3VC1038 1 UF/6.3V

C1035 0 .1UF/10VC1035 0.1UF/10V

SIG15022

C1036 0 .1UF/10VC1036 0.1UF/10V

12

SIG14912SIG14913SIG14914

12

12

I2S_OUT_MCK

I2S_OUT_MCK

(PU/5V)

I2S_OUT_BCK

I2S_OUT_BCK

(PU/5V)

[S/PD IN/OUT]

E7 D6

SPDIF_IN SPDIF_OUT

SPDIF_IN SPDIF_OUT

AD5

LINEIN_L0

LINEIN_L0

AE5

LINEIN_R0

LINEIN_R0

AD3

LINEIN_L2

LINEIN_L2

AD1

LINEIN_R2

LINEIN_R2

AD2

LINEIN_L3

LINEIN_L3

AE3

LINEIN_R3

LINEIN_R3

AD4

LINEIN_L4

LINEIN_L4

AE4

LINEIN_R4

LINEIN_R4

AC4

LINEIN_L5

LINEIN_L5

AC5

LINEIN_R5

LINEIN_R5

D9

DVDD_NODIE

DVDD_NODIE

AG7

SIFM

SIG14911

SIFM

AF7

SIFP

SIFP

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

[S/PD IN/OUT]

[ANALOG AUDIO INTERFACE]

[ANALOG AUDIO INTERFACE]

[SIF INTERFACE]

[SIF INTERFACE]

(PD/5V)(PU/5V)

LINEOUT_L0

LINEOUT_L0

LINEOUT_R0

LINEOUT_R0

LINEOUT_L2

LINEOUT_L2

LINEOUT_R2

LINEOUT_R2

LINEOUT_L3

LINEOUT_L3

LINEOUT_R3

LINEOUT_R3

EAR_OUTL

EAR_OUTL

EAR_OUTR

EAR_OUTR

AUVRM

AUVRM

AUVRP

AUVRP

AUVAG

AUVAG

C10

C11

AF4

AG4

AG3

AF1

AG1

AG2

AD6

AE6

AE2

AF3

AF2

SIG7806

SIG7807

M_I2S_MCLKM_I2S_MCLK

M_I2S_BCKM_I2S_BCK

M_SPDIFOM_SPDIFO

M_AOUTL0M_AOUTL0

M_AOUTR0M_AOUTR0

M_AOUTL2M_AOUTL2

M_AOUTR2M_AOUTR2

12

C1031 0 .1UF/10VC1031 0.1UF/10V

12

C1032 1 0UF/10V

C1032 1 0UF/10V

mx_c0805

mx_c0805

12

C1033 4 .7UF/6.3V

C1033 4 .7UF/6.3V

mx_c0603

mx_c0603

12

C1034 1 UF/6.3VC1034 1 UF/6.3V

120 370

120 370

604

320

Headphone

320

310

Scart out

310

SIG16698

HEATSINK1

HEATSINK1

2

HEATSINK

HEATSINK

1

KG/1022-0105F

KG/1022-0105F

HEATSINK 65*46*5

HEATSINK 65*46*5

Title :

Title :

Title :

Engineer:

Engineer:

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Project Name

Size Project Name

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

EU Lv.2

EU Lv.2

EU Lv.2

Engineer:

CVP DM HW

CVP DM HW

CVP DM HW

103 76Tuesday, January 29, 2013

103 76Tuesday, January 29, 2013

103 76Tuesday, January 29, 2013

Rev

Rev

Rev

1.00

1.00

1.00

Page 33

104. MSD8881CV (CI/TS)

M_PCM_D7M_PCM_D7

792

M_PCM_D6M_PCM_D6

792

M_PCM_D5M_PCM_D5

792

M_PCM_D4M_PCM_D4

792

M_PCM_D3M_PCM_D3

792

M_PCM_D2M_PCM_D2

792

M_PCM_D1M_PCM_D1

792

M_PCM_D0M_PCM_D0

792

M_PCM_IRQA_NM_PCM_IRQA_N

795

M_PCM_WAIT_NM_PCM_WAIT_N

795

M_PCM_CD_NM_PCM_CD_N

795

AE17

AC17

AE16

AD16

AC16

AC15

AD15

AD14

AC22

AD24

Y25

IC100D

IC100D

PCM_D7

PCM_D7

(PU/5V)

PCM_D6

PCM_D6

(PU/5V)

PCM_D5

PCM_D5

(PU/5V)

PCM_D4

PCM_D4

(PU/5V)

PCM_D3

PCM_D3

(PU/5V)

PCM_D2

PCM_D2

(PU/5V)

PCM_D1

PCM_D1

(PU/5V)

PCM_D0

PCM_D0

(PU/5V)

PCM_IRQA_N

PCM_IRQA_N

(PU/5V)

PCM_WAIT_N

PCM_WAIT_N

(PU/5V)

PCM_CD_N

PCM_CD_N

(PU/5V)

MSD8881CV

MSD8881CV

[V-U8881CVF]

[V-U8881CVF]

4/16

4/16

[COMMON INTERFACE]

[COMMON INTERFACE]

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

(PU/5V)

AD21

AD20

AD22

AD19

AD18

AC20

AE20

AE22

AC23

AD23

AE24

AD25

AB24

AC25

AC24

AC18

AE19

AC19

AC21

AE25

AD17

AE23

PCM_A14

PCM_A14

PCM_A13

PCM_A13

PCM_A12

PCM_A12

PCM_A11

PCM_A11

PCM_A10

PCM_A10

PCM_A9

PCM_A9

PCM_A8

PCM_A8

PCM_A7

PCM_A7

PCM_A6

PCM_A6

PCM_A5

PCM_A5

PCM_A4

PCM_A4

PCM_A3

PCM_A3

PCM_A2

PCM_A2

PCM_A1

PCM_A1

PCM_A0

PCM_A0

PCM_IORD_N

PCM_IORD_N

PCM_IOWR_N

PCM_IOWR_N

PCM_OE_N

PCM_OE_N

PCM_WE_N

PCM_WE_N

PCM_REG_N

PCM_REG_N

PCM_CE_N

PCM_CE_N

PCM_RST

PCM_RST

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

M_PCM_A14M_PCM_A14

M_PCM_A13M_PCM_A13

M_PCM_A12M_PCM_A12

M_PCM_A11M_PCM_A11

M_PCM_A10M_PCM_A10

M_PCM_A9M_PCM_A9

M_PCM_A8M_PCM_A8

M_PCM_A7M_PCM_A7

M_PCM_A6M_PCM_A6

M_PCM_A5M_PCM_A5

M_PCM_A4M_PCM_A4

M_PCM_A3M_PCM_A3

M_PCM_A2M_PCM_A2

M_PCM_A1M_PCM_A1

M_PCM_A0M_PCM_A0

M_PCM_IORD_NM_PCM_IORD_N

M_PCM_IOWR_NM_PCM_IOWR_N

M_PCM_OE_NM_PCM_OE_N

M_PCM_WE_NM_PCM_WE_N

M_PCM_REG_NM_PCM_REG_N

M_PCM_CE_NM_PCM_CE_N

M_PCM_RSTM_PCM_RST

IC100E

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

792

796

796

796

796

796

796

796

796

796

796

796

M_TSI0DATA7M_TSI0DATA7

M_TSI0DATA6M_TSI0DATA6

M_TSI0DATA5M_TSI0DATA5

M_TSI0DATA4M_TSI0DATA4

M_TSI0DATA3M_TSI0DATA3

M_TSI0DATA2M_TSI0DATA2

M_TSI0DATA1M_TSI0DATA1

M_TSI0DATA0M_TSI0DATA0

M_TSI0CLKIM_TSI0CLKI

M_TSI0VALIDM_TSI0VALID

M_TSI0SYNCM_TSI0SYNC

SIG17927

SIG17933

SIG17939

SIG17929

SIG17922

SIG17932

SIG17934

SIG17931

SIG17923

SIG17943

IC100E

[V-U8881CVF]

[V-U8881CVF]

5/16

5/16

[TS INPUT/TS OUTPUT]

[TS INPUT/TS OUTPUT]

AC9

TS0_D7

TS0_D7

(PU/5V)

AC13

TS0_D6

TS0_D6

(PU/5V)

AD13

TS0_D5

TS0_D5

(PU/5V)

AC14

TS0_D4

TS0_D4

(PU/5V)

AE14

TS0_D3

TS0_D3

(PU/5V)

AE8

TS0_D2

TS0_D2

(PU/5V)

AD8

TS0_D1

TS0_D1

(PU/5V)

AC8 AG18

TS0_D0

TS0_D0

(PU/5V)

AC10

TS0_CLK

TS0_CLK

(PU/5V)

AD9

TS0_VLD

TS0_VLD

(PU/5V)

AE9

TS0_SYNC

TS0_SYNC

(PU/5V)

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

TS1_D7

TS1_D7

(PU/5V)

TS1_D6

TS1_D6

(PU/5V)

TS1_D5

TS1_D5

(PU/5V)

TS1_D4

TS1_D4

(PU/5V)

TS1_D3

TS1_D3

(PU/5V)

TS1_D2

TS1_D2

(PU/5V)

TS1_D1

TS1_D1

(PU/5V)

TS1_D0

TS1_D0

(PU/5V)

TS1_CLK

TS1_CLK

(PU/5V)

TS1_VLD

TS1_VLD

(PU/5V)

TS1_SYNC

TS1_SYNC

(PU/5V)

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Project Name

Size Project Name

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

AH15

AG15

AG16

AG17

AH17

AF18

AH18

AF16

AF17

AF19

SIG17940

SIG17937

SIG17936

SIG17938

SIG17935

SIG17941SIG17942

SIG17924

SIG17925

R1130 0 OhmR1130 0 Ohm

R1131 0 OhmR1131 0 Ohm

SIG17930

SIG17926

EU Lv.2

EU Lv.2

EU Lv.2

1 2

1 2

R_TSCLK_CIR_TSCLK_CI

Title :

Title :

Title :

Engineer:

Engineer:

Engineer:

R_DATA7R_DATA7

R_DATA6R_DATA6

R_DATA5R_DATA5

R_DATA4R_DATA4

R_DATA3R_DATA3

R_DATA2R_DATA2

R_DATA1R_DATA1

R_DATA0R_DATA0

R_TSCLKR_TSCLK

R_TSVALR_TSVAL

R_TSSYCR_TSSYC

796 771

796 771

796 771

796 771

796 771

796 771

796 771

796 771

796

771

796 771

796 771

104. MSD8881CV (CI/TS)

104. MSD8881CV (CI/TS)

104. MSD8881CV (CI/TS)

CVP DM HW

CVP DM HW

CVP DM HW

104 76Tuesday, January 29, 2013

104 76Tuesday, January 29, 2013

104 76Tuesday, January 29, 2013

Rev

Rev

Rev

1.00

1.00

1.00

Page 34

106. MSD8881CV (HDMI)

H_HOTPLUGAH_HOTPLUGA

662

H_HOTPLUGBH_HOTPLUGB

662

660

660

660

660

660

660

660

660

660

660

660

660

660

660

660

660

H_DDCDA_DAH_DDCDA_DA

H_DDCDA_CKH_DDCDA_CK

H_DDCDB_DAH_DDCDB_DA

H_DDCDB_CKH_DDCDB_CK

H_RXACKNH_RXACKN

H_RXACKPH_RXACKP

H_RXA0NH_RXA0N

H_RXA0PH_RXA0P

H_RXA1NH_RXA1N

H_RXA1PH_RXA1P

H_RXA2NH_RXA2N

H_RXA2PH_RXA2P

H_RXBCKNH_RXBCKN

H_RXBCKPH_RXBCKP

H_RXB0NH_RXB0N

H_RXB0PH_RXB0P

H_RXB1NH_RXB1N

H_RXB1PH_RXB1P

H_RXB2NH_RXB2N

H_RXB2PH_RXB2P

660 664

660 664

660 664

660 664

IC100F

IC100F

AA5

HOTPLUGA

HOTPLUGA

(PU/5V)

AA6

HOTPLUGB

HOTPLUGB

SIG15805

SIG15806

SIG15797

SIG15813

SIG19020

SIG19021

SIG19022

SIG19023

SIG19024

SIG19025

SIG19026

SIG19027

SIG19028

SIG19029

SIG19030

SIG19031

SIG19032

SIG19033

SIG19034

SIG19035

(PU/5V)

N4

DDCDA_DA

DDCDA_DA

(-/5V)

P6

DDCDA_CK

DDCDA_CK

(-/5V)

P4

DDCDB_DA

DDCDB_DA

(-/5V)

P5

DDCDB_CK

DDCDB_CK

(-/5V)

K3

RXACKN

RXACKN

K2

RXACKP

RXACKP

L3

RXA0N

RXA0N

L2

RXA0P

RXA0P

L1

RXA1N

RXA1N

M3

RXA1P

RXA1P

M1

RXA2N

RXA2N

M2

RXA2P

RXA2P

G3

RXBCKN

RXBCKN

G2

RXBCKP

RXBCKP

H3

RXB0N

RXB0N

H2

RXB0P

RXB0P

H1

RXB1N

RXB1N

J3

RXB1P

RXB1P

J1

RXB2N

RXB2N

J2

RXB2P

RXB2P

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

[V-U8881CVF]

[V-U8881CVF]

6/16

6/16

[HDMI INTERFACE 1/2]

[HDMI INTERFACE 1/2]

ARC

ARC

CEC

CEC

(27k PU/5V)

IC100G

IC100G

[V-U8881CVF]

[V-U8881CVF]

7/16

7/16

[HDMI INTERFACE 2/2]

[HDMI INTERFACE 2/2]

663

670

670

670

670

670

670

670

670

660

660

660

660

660

660

660

660

H_HOTPLUGCH_HOTPLUGC

H_HOTPLUGDH_HOTPLUGD

H_DDCDC_DAH_DDCDC_DA

H_DDCDC_CKH_DDCDC_CK

H_DDCDD_DAH_DDCDD_DA

H_DDCDD_CKH_DDCDD_CK

H_RXCCKNH_RXCCKN

H_RXCCKPH_RXCCKP

H_RXC0NH_RXC0N

H_RXC0PH_RXC0P

H_RXC1NH_RXC1N

H_RXC1PH_RXC1P

H_RXC2NH_RXC2N

H_RXC2PH_RXC2P

H_RXDCKNH_RXDCKN

H_RXDCKPH_RXDCKP

H_RXD0NH_RXD0N

H_RXD0PH_RXD0P

H_RXD1NH_RXD1N

H_RXD1PH_RXD1P

H_RXD2NH_RXD2N

H_RXD2PH_RXD2P

T5

SIG19972

T6

H_ARC1H_ARC1

H_CECH_CEC

660

660

663 670

670 677

670 677

660 664

660 664

SIG17986

Y5

HOTPLUGC

HOTPLUGC

SIG17987

SIG17990

SIG17956

SIG17954

SIG17955

SIG19036

SIG19037

SIG19038

SIG19039

SIG19040

SIG19041

SIG19042

SIG19043

SIG19044

SIG19045

SIG19046

SIG19047

SIG19048

SIG19049

SIG19050

SIG19051

(PU/5V)

AB6

HOTPLUGD

HOTPLUGD

(PU/5V)

N6

DDCDC_DA

DDCDC_DA

(-/5V)

N5

DDCDC_CK

DDCDC_CK

(-/5V)

R5

DDCDD_DA

DDCDD_DA

(-/5V)

R6

DDCDD_CK

DDCDD_CK

(-/5V)

N3

RXCCKN

RXCCKN

N2

RXCCKP

RXCCKP

P3

RXC0N

RXC0N

P2

RXC0P

RXC0P

P1

RXC1N

RXC1N

R3

RXC1P

RXC1P

R1

RXC2N

RXC2N

R2

RXC2P

RXC2P

D3

RXDCKN

RXDCKN

D2

RXDCKP

RXDCKP

E3

RXD0N

RXD0N

E2

RXD0P

RXD0P

E1

RXD1N

RXD1N

F3

RXD1P

RXD1P

F1

RXD2N

RXD2N

F2

RXD2P

RXD2P

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

106. MSD8881CV (HDMI)

106. MSD8881CV (HDMI)

Title :

Title :

Title :

Engineer:

Engineer:

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Project Name

Size Project Name

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

EU Lv.2

EU Lv.2

EU Lv.2

Engineer:

106. MSD8881CV (HDMI)

CVP DM HW

CVP DM HW

CVP DM HW

106 76Tuesday, January 29, 2013

106 76Tuesday, January 29, 2013

106 76Tuesday, January 29, 2013

Rev

Rev

Rev

1.00

1.00

1.00

Page 35

108. MSD8881CV (LVDS)

IC100H

IC100H

[V-U8881CVF]

[V-U8881CVF]

8/16

8/16

[LVDS INTERFACE 1/2]

[LVDS INTERFACE 1/2]

LVA0N

LVA0N

LVA0P

LVA0P

LVA1N

LVA1N

LVA1P

LVA1P

LVA2N

LVA2N

LVA2P

LVA2P

LVACKN

LVACKN

LVACKP

LVACKP

LVA3N

LVA3N

LVA3P

LVA3P

LVA4N

LVA4N

LVA4P

LVA4P

U26

U27

V28

V27

W28

V26

W26

W27

Y26

Y27

AA28

AA27

M_LVA0+1M_LVA0+1

M_LVA0-1M_LVA0-1

M_LVA1+1M_LVA1+1

M_LVA1-1M_LVA1-1

M_LVA2+1M_LVA2+1

M_LVA2-1M_LVA2-1

M_LVACLK+1M_LVACLK+1

M_LVACLK-1M_LVACLK-1

M_LVA3+1M_LVA3+1

M_LVA3-1M_LVA3-1

M_LVA4+1M_LVA4+1

M_LVA4-1M_LVA4-1

IC100I

IC100I

[V-U8881CVF]

[V-U8881CVF]

9/16

9/16

[LVDS INTERFACE 2/2]

650

650

650

650

650

650

650

650

650

650

650

650

[LVDS INTERFACE 2/2]

LVC0N

LVC0N

LVC0P

LVC0P

LVC1N

LVC1N

LVC1P

LVC1P

LVC2N

LVC2N

LVC2P

LVC2P

LVCCKN

LVCCKN

LVCCKP

LVCCKP

LVC3N

LVC3N

LVC3P

LVC3P

LVC4N

LVC4N

LVC4P

LVC4P

AF26

AF27

AH27

AG28

AH26

AG27

AG25

AG26

AG24

AF25

AF24

AH24

M_LVC0+1M_LVC0+1

M_LVC0-1M_LVC0-1

M_LVC1+1M_LVC1+1

M_LVC1-1M_LVC1-1

M_LVC2+1M_LVC2+1

M_LVC2-1M_LVC2-1

M_LVCCLK+1M_LVCCLK+1

M_LVCCLK-1M_LVCCLK-1

M_LVC3+1M_LVC3+1

M_LVC3-1M_LVC3-1

M_LVC4+1M_LVC4+1

M_LVC4-1M_LVC4-1

651

651

651

651

651

651

651

651

651

651

651

651

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

LVB0N

LVB0N

LVB0P

LVB0P

LVB1N

LVB1N

LVB1P

LVB1P

LVB2N

LVB2N

LVB2P

LVB2P

LVBCKN

LVBCKN

LVBCKP

LVBCKP

LVB3N

LVB3N

LVB3P

LVB3P

LVB4N

LVB4N

LVB4P

LVB4P

AB28

AA26

AB26

AB27

AC26

AC27

AD28

AD27

AE28

AD26

AE26

AE27

M_LVB0+1M_LVB0+1

M_LVB0-1M_LVB0-1

M_LVB1+1M_LVB1+1

M_LVB1-1M_LVB1-1

M_LVB2+1M_LVB2+1

M_LVB2-1M_LVB2-1

M_LVBCLK+1M_LVBCLK+1

M_LVBCLK-1M_LVBCLK-1

M_LVB3+1M_LVB3+1

M_LVB3-1M_LVB3-1

M_LVB4+1M_LVB4+1

M_LVB4-1M_LVB4-1

Title :

Title :

Title :

M_LVD0+1M_LVD0+1

651

M_LVD0-1M_LVD0-1

651

M_LVD1+1M_LVD1+1

651

M_LVD1-1M_LVD1-1

651

M_LVD2+1M_LVD2+1

651

M_LVD2-1M_LVD2-1

M_LVDCLK+1M_LVDCLK+1

M_LVDCLK-1M_LVDCLK-1

651

651

651

M_LVD3+1M_LVD3+1

651

M_LVD3-1M_LVD3-1

651

M_LVD4+1M_LVD4+1

651

M_LVD4-1M_LVD4-1

651

108. MSD8881CV (LVDS)

108. MSD8881CV (LVDS)

108. MSD8881CV (LVDS)

CVP DM HW

CVP DM HW

CVP DM HW

108 76Tuesday, January 29, 2013

108 76Tuesday, January 29, 2013

108 76Tuesday, January 29, 2013

Rev

Rev

Rev

1.00

1.00

1.00

650

650

650

650

650

650

650

650

650

650

650

650

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

LVD0N

LVD0N

LVD0P

LVD0P

LVD1N

LVD1N

LVD1P

LVD1P

LVD2N

LVD2N

LVD2P

LVD2P

LVDCKN

LVDCKN

LVDCKP

LVDCKP

LVD3N

LVD3N

LVD3P

LVD3P

LVD4N

LVD4N

LVD4P

LVD4P

AG23

AH23

AG22

AF23

AG21

AF22

AF21

AH21

AG20

AH20

AG19

AF20

Engineer:

Engineer:

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Proj ect Name

Size Proj ect Name

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

EU Lv.2

EU Lv.2

EU Lv.2

Engineer:

Page 36

110. MSD8881CV (DDR3)

M_A_DDR3_DQ31M_A_DDR3_DQ31

125

M_A_DDR3_DQ30M_A_DDR3_DQ30

125

M_A_DDR3_DQ29M_A_DDR3_DQ29

125

M_A_DDR3_DQ28M_A_DDR3_DQ28

125

M_A_DDR3_DQ27M_A_DDR3_DQ27

125

M_A_DDR3_DQ26M_A_DDR3_DQ26

125

M_A_DDR3_DQ25M_A_DDR3_DQ25

125

M_A_DDR3_DQ24M_A_DDR3_DQ24

125

M_A_DDR3_DQ23M_A_DDR3_DQ23

125

M_A_DDR3_DQ22M_A_DDR3_DQ22

125

M_A_DDR3_DQ21M_A_DDR3_DQ21

125

M_A_DDR3_DQ20M_A_DDR3_DQ20

125

M_A_DDR3_DQ19M_A_DDR3_DQ19

125

M_A_DDR3_DQ18M_A_DDR3_DQ18

125

M_A_DDR3_DQ17M_A_DDR3_DQ17

125

M_A_DDR3_DQ16M_A_DDR3_DQ16

125

M_A_DDR3_DQ15M_A_DDR3_DQ15

125

M_A_DDR3_DQ14M_A_DDR3_DQ14

125

M_A_DDR3_DQ13M_A_DDR3_DQ13

125

M_A_DDR3_DQ12M_A_DDR3_DQ12

125

M_A_DDR3_DQ11M_A_DDR3_DQ11

125

M_A_DDR3_DQ10M_A_DDR3_DQ10

125

M_A_DDR3_DQ9M_A_DDR3_DQ9

125

M_A_DDR3_DQ8M_A_DDR3_DQ8

125

M_A_DDR3_DQ7M_A_DDR3_DQ7

125

M_A_DDR3_DQ6M_A_DDR3_DQ6

125

M_A_DDR3_DQ5M_A_DDR3_DQ5

125

M_A_DDR3_DQ4M_A_DDR3_DQ4

125

M_A_DDR3_DQ3M_A_DDR3_DQ3

125

M_A_DDR3_DQ2M_A_DDR3_DQ2

125

M_A_DDR3_DQ1M_A_DDR3_DQ1

125

M_A_DDR3_DQ0M_A_DDR3_DQ0

125

M_A_DDR3_DQS3M_A_DDR3_DQS3

125

M_A_DDR3_DQS2M_A_DDR3_DQS2

125

M_A_DDR3_DQS1M_A_DDR3_DQS1

125

M_A_DDR3_DQS0M_A_DDR3_DQS0

125

M_A_DDR3_DQSB3M_A_DDR3_DQSB3

125

M_A_DDR3_DQSB2M_A_DDR3_DQSB2

125

M_A_DDR3_DQSB1M_A_DDR3_DQSB1

125

M_A_DDR3_DQSB0M_A_DDR3_DQSB0

125

M_A_DDR3_ODTM_A_DDR3_ODT

125

125 129

M_A_DDR3_RESETM_A_DDR3_RESET

IC100J

IC100J

E26

A_DDR3_DQ31

SIG17451

SIG17452

SIG17453

SIG17454

SIG17455

SIG17457

SIG17456

SIG17458

SIG17459

SIG17460

SIG17461

SIG17462

SIG17463

SIG17464

SIG17465

SIG17466

SIG17467

SIG17468

SIG17469

SIG17470

SIG17471

SIG17472

SIG17473

SIG17474

SIG17475

SIG17476

SIG17477

SIG17478

SIG17479

SIG17480

SIG17450

A_DDR3_DQ31

E22

A_DDR3_DQ30

A_DDR3_DQ30

E27

A_DDR3_DQ29

A_DDR3_DQ29

E23

A_DDR3_DQ28

A_DDR3_DQ28

D27

A_DDR3_DQ27

A_DDR3_DQ27

E21

A_DDR3_DQ26

A_DDR3_DQ26

D26

A_DDR3_DQ25

A_DDR3_DQ25

D23

A_DDR3_DQ24

A_DDR3_DQ24

A26

A_DDR3_DQ23

A_DDR3_DQ23

C27

A_DDR3_DQ22

A_DDR3_DQ22

C24

A_DDR3_DQ21

A_DDR3_DQ21

C28

A_DDR3_DQ20

A_DDR3_DQ20

C25

A_DDR3_DQ19

A_DDR3_DQ19

B28

A_DDR3_DQ18

A_DDR3_DQ18

B26

A_DDR3_DQ17

A_DDR3_DQ17

B27

A_DDR3_DQ16

A_DDR3_DQ16

F20

A_DDR3_DQ15

A_DDR3_DQ15

D18

A_DDR3_DQ14

A_DDR3_DQ14

D21

A_DDR3_DQ13

A_DDR3_DQ13

F18

A_DDR3_DQ12

A_DDR3_DQ12

E20

A_DDR3_DQ11

A_DDR3_DQ11

F17

A_DDR3_DQ10

A_DDR3_DQ10

D19

A_DDR3_DQ9

A_DDR3_DQ9

E18

A_DDR3_DQ8

A_DDR3_DQ8

C21

A_DDR3_DQ7

A_DDR3_DQ7

C23

A_DDR3_DQ6

A_DDR3_DQ6

B20

A_DDR3_DQ5

A_DDR3_DQ5

A24

A_DDR3_DQ4

A_DDR3_DQ4

C20

A_DDR3_DQ3

A_DDR3_DQ3

A23

A_DDR3_DQ2

A_DDR3_DQ2

B21

A_DDR3_DQ1

A_DDR3_DQ1

B23

A_DDR3_DQ0

A_DDR3_DQ0

E24

A_DDR3_DQS3

A_DDR3_DQS3

A27

A_DDR3_DQS2

A_DDR3_DQS2

F19

A_DDR3_DQS1

A_DDR3_DQS1

C22

A_DDR3_DQS0

A_DDR3_DQS0

D24

A_DDR3_DQSB3

A_DDR3_DQSB3

C26

A_DDR3_DQSB2

A_DDR3_DQSB2

G19

A_DDR3_DQSB1

A_DDR3_DQSB1

B22

A_DDR3_DQSB0

A_DDR3_DQSB0

E17

A_DDR3_ODT

A_DDR3_ODT

D12

A_DDR3_RESET

A_DDR3_RESET

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

[V-U8881CVF]

[V-U8881CVF]

10/16

10/16

[DDR-3 INTERFACE 1/2]

[DDR-3 INTERFACE 1/2]

A_DDR3_A14

A_DDR3_A14

A_DDR3_A13

A_DDR3_A13

A_DDR3_A12

A_DDR3_A12

A_DDR3_A11

A_DDR3_A11

A_DDR3_A10

A_DDR3_A10

A_DDR3_A9

A_DDR3_A9

A_DDR3_A8

A_DDR3_A8

A_DDR3_A7

A_DDR3_A7

A_DDR3_A6

A_DDR3_A6

A_DDR3_A5

A_DDR3_A5

A_DDR3_A4

A_DDR3_A4

A_DDR3_A3

A_DDR3_A3

A_DDR3_A2

A_DDR3_A2

A_DDR3_A1

A_DDR3_A1

A_DDR3_A0

A_DDR3_A0

A_DDR3_DQM3

A_DDR3_DQM3

A_DDR3_DQM2

A_DDR3_DQM2

A_DDR3_DQM1

A_DDR3_DQM1

A_DDR3_DQM0

A_DDR3_DQM0

A_DDR3_MCLKZ

A_DDR3_MCLKZ

A_DDR3_MCLK

A_DDR3_MCLK

A_DDR3_CKE

A_DDR3_CKE

A_DDR3_BA2

A_DDR3_BA2

A_DDR3_BA1

A_DDR3_BA1

A_DDR3_BA0

A_DDR3_BA0

A_DDR3_WEZ

A_DDR3_WEZ

A_DDR3_RASZ

A_DDR3_RASZ

A_DDR3_CASZ

A_DDR3_CASZ

B15

E11

F15

B16

B18

E12

C15

F12

C16

F14

A17

D14

F13

B17

E13

E25

B25

E19

A20

B19

C19

C18

E15

C17

D15

G15

E16

F16

SIG17481

SIG17482

SIG17483

SIG17484

SIG17485

SIG17486

SIG17487

SIG17488

SIG17489

SIG17490

SIG17491

SIG17492

SIG17493

SIG17494

M_A_DDR3_A14M_A_DDR3_A14

M_A_DDR3_A13M_A_DDR3_A13

M_A_DDR3_A12M_A_DDR3_A12

M_A_DDR3_A11M_A_DDR3_A11

M_A_DDR3_A10M_A_DDR3_A10

M_A_DDR3_A9M_A_DDR3_A9

M_A_DDR3_A8M_A_DDR3_A8

M_A_DDR3_A7M_A_DDR3_A7

M_A_DDR3_A6M_A_DDR3_A6

M_A_DDR3_A5M_A_DDR3_A5

M_A_DDR3_A4M_A_DDR3_A4

M_A_DDR3_A3M_A_DDR3_A3

M_A_DDR3_A2M_A_DDR3_A2

M_A_DDR3_A1M_A_DDR3_A1

M_A_DDR3_A0M_A_DDR3_A0

M_A_DDR3_DQM3M_A_DDR3_DQM3

M_A_DDR3_DQM2M_A_DDR3_DQM2

M_A_DDR3_DQM1M_A_DDR3_DQM1

M_A_DDR3_DQM0M_A_DDR3_DQM0

M_A_DDR3_MCLKZM_A_DDR3_MCLKZ

M_A_DDR3_MCLKM_A_DDR3_MCLK

M_A_DDR3_CKEM_A_DDR3_CKE

M_A_DDR3_BA2M_A_DDR3_BA2

M_A_DDR3_BA1M_A_DDR3_BA1

M_A_DDR3_BA0M_A_DDR3_BA0

M_A_DDR3_WEZM_A_DDR3_WEZ

M_A_DDR3_RASZM_A_DDR3_RASZ

M_A_DDR3_CASZM_A_DDR3_CASZ

IC100K

IC100K

[V-U8881CVF]

[V-U8881CVF]

11/16

11/16

[DDR-3 INTERFACE 2/2]

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

125

M_B_DDR3_DQ15M_B_DDR3_DQ15

127

M_B_DDR3_DQ14M_B_DDR3_DQ14

127

M_B_DDR3_DQ13M_B_DDR3_DQ13

127

M_B_DDR3_DQ12M_B_DDR3_DQ12

127

M_B_DDR3_DQ11M_B_DDR3_DQ11

127

M_B_DDR3_DQ10M_B_DDR3_DQ10

127

M_B_DDR3_DQ9M_B_DDR3_DQ9

127

M_B_DDR3_DQ8M_B_DDR3_DQ8

127

M_B_DDR3_DQ7M_B_DDR3_DQ7

127

M_B_DDR3_DQ6M_B_DDR3_DQ6

127

M_B_DDR3_DQ5M_B_DDR3_DQ5

127

M_B_DDR3_DQ4M_B_DDR3_DQ4

127

M_B_DDR3_DQ3M_B_DDR3_DQ3

127

M_B_DDR3_DQ2M_B_DDR3_DQ2

127

M_B_DDR3_DQ1M_B_DDR3_DQ1

127

M_B_DDR3_DQ0M_B_DDR3_DQ0

127

M_B_DDR3_DQS1M_B_DDR3_DQS1

127

M_B_DDR3_DQS0M_B_DDR3_DQS0

127

M_B_DDR3_DQSB1M_B_DDR3_DQSB1

127

M_B_DDR3_DQSB0M_B_DDR3_DQSB0

127

M_B_DDR3_ODTM_B_DDR3_ODT

127

M_B_DDR3_RESETM_B_DDR3_RESET

127

R24

B_DDR3_DQ15

B_DDR3_DQ15

T22

B_DDR3_DQ14

B_DDR3_DQ14

N25

B_DDR3_DQ13

B_DDR3_DQ13

T23

B_DDR3_DQ12

B_DDR3_DQ12

R23

B_DDR3_DQ11

B_DDR3_DQ11

U23

B_DDR3_DQ10

B_DDR3_DQ10

T24

B_DDR3_DQ9

B_DDR3_DQ9

U24

B_DDR3_DQ8

B_DDR3_DQ8

M27

B_DDR3_DQ7

B_DDR3_DQ7

P27

B_DDR3_DQ6

B_DDR3_DQ6

K27

B_DDR3_DQ5

B_DDR3_DQ5

P26

B_DDR3_DQ4

B_DDR3_DQ4

L27

B_DDR3_DQ3

B_DDR3_DQ3

N26

B_DDR3_DQ2

B_DDR3_DQ2

L26

B_DDR3_DQ1

B_DDR3_DQ1

N27

B_DDR3_DQ0

B_DDR3_DQ0

T25

B_DDR3_DQS1

B_DDR3_DQS1

M26

B_DDR3_DQS0

B_DDR3_DQS0

R25

B_DDR3_DQSB1

B_DDR3_DQSB1

M28

B_DDR3_DQSB0

B_DDR3_DQSB0

P24

B_DDR3_ODT

B_DDR3_ODT

G25

B_DDR3_RESET

B_DDR3_RESET

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

[DDR-3 INTERFACE 2/2]

B_DDR3_A14

B_DDR3_A14

B_DDR3_A13

B_DDR3_A13

B_DDR3_A12

B_DDR3_A12

B_DDR3_A11

B_DDR3_A11

B_DDR3_A10

B_DDR3_A10

B_DDR3_A9

B_DDR3_A9

B_DDR3_A8

B_DDR3_A8

B_DDR3_A7

B_DDR3_A7

B_DDR3_A6

B_DDR3_A6

B_DDR3_A5

B_DDR3_A5

B_DDR3_A4

B_DDR3_A4

B_DDR3_A3

B_DDR3_A3

B_DDR3_A2

B_DDR3_A2

B_DDR3_A1

B_DDR3_A1

B_DDR3_A0

B_DDR3_A0

B_DDR3_DQM1

B_DDR3_DQM1

B_DDR3_DQM0

B_DDR3_DQM0

B_DDR3_MCLKZ

B_DDR3_MCLKZ

B_DDR3_MCLK

B_DDR3_MCLK

B_DDR3_CKE

B_DDR3_CKE

B_DDR3_BA2

B_DDR3_BA2

B_DDR3_BA1

B_DDR3_BA1

B_DDR3_BA0

B_DDR3_BA0

B_DDR3_WEZ

B_DDR3_WEZ

B_DDR3_RASZ

B_DDR3_RASZ

B_DDR3_CASZ

B_DDR3_CASZ

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Project Name

Size Project Name

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet of

E28

H25

M23

F28

H26

G24

F27

J23

F26

J24

G26

K25

K23

G27

J25

P23

K26

J28

J26

J27

L24

H27

L23

N23

M25

M24

EU Lv.2

EU Lv.2

EU Lv.2

M_B_DDR3_A14M_B_DDR3_A14

M_B_DDR3_A13M_B_DDR3_A13

M_B_DDR3_A12M_B_DDR3_A12

M_B_DDR3_A11M_B_DDR3_A11

M_B_DDR3_A10M_B_DDR3_A10

M_B_DDR3_DQM1M_B_DDR3_DQM1

M_B_DDR3_DQM0M_B_DDR3_DQM0

M_B_DDR3_MCLKZM_B_DDR3_MCLKZ

M_B_DDR3_MCLKM_B_DDR3_MCLK

M_B_DDR3_CKEM_B_DDR3_CKE

M_B_DDR3_BA2M_B_DDR3_BA2

M_B_DDR3_BA1M_B_DDR3_BA1

M_B_DDR3_BA0M_B_DDR3_BA0

M_B_DDR3_WEZM_B_DDR3_WEZ

M_B_DDR3_RASZM_B_DDR3_RASZ

M_B_DDR3_CASZM_B_DDR3_CASZ

Title :

Title :

Title :

Engineer:

Engineer:

Engineer:

127

127

127

127

M_B_DDR3_A9M_B_DDR3_A9

M_B_DDR3_A8M_B_DDR3_A8

M_B_DDR3_A7M_B_DDR3_A7

M_B_DDR3_A6M_B_DDR3_A6

M_B_DDR3_A5M_B_DDR3_A5

M_B_DDR3_A4M_B_DDR3_A4

M_B_DDR3_A3M_B_DDR3_A3

M_B_DDR3_A2M_B_DDR3_A2

M_B_DDR3_A1M_B_DDR3_A1

M_B_DDR3_A0M_B_DDR3_A0

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

127

110. MSD8881CV (DDR3)

110. MSD8881CV (DDR3)

110. MSD8881CV (DDR3)

CVP DM HW

CVP DM HW

CVP DM HW

110 76Tuesday, January 29, 2013

110 76Tuesday, January 29, 2013

110 76Tuesday, January 29, 2013

127 129

127 129

Rev

Rev

Rev

1.00

1.00

1.00

Page 37

112. MSD8881CV (MICS)

DP106DP106

S

1

I

G

2

0

9

7

2

IC100L

IC100L

[V-U8881CVF]

[V-U8881CVF]

12/16

12/16

[NAND FLASH INTERFACE]

[NAND FLASH INTERFACE]

132

160

160

160

160

M_SPI_DOM_SPI_DO

M_USB0DPM_USB0DP

M_USB0DMM_USB0DM

M_USB1DPM_USB1DP

M_USB1DMM_USB1DM

AF15

AH14

NF_RBZ

NF_RBZ

[SERIAL FLASH INTERFACE]

[SERIAL FLASH INTERFACE]

SPI_DO

SPI_DO

[USB INTERFACE]

[USB INTERFACE]

C4

DP_P0

DP_P0

B4

DM_P0

DM_P0

DP_P1

DP_P1

DM_P1

DM_P1

NF_WEZ

NF_WEZ

NF_CLE

NF_CLE

NF_WPZ

NF_WPZ

NF_CEZ

NF_CEZ

NF_CEZ1

NF_CEZ1

NF_ALE

NF_ALE

NF_REZ

NF_REZ

SPI_CK

SPI_CK

SPI_DI

SPI_DI

SPI_CZ

SPI_CZ

EMMC_CMD

EMMC_CMD

EMMC_CLK

EMMC_CLK

EMMC_CDZ

EMMC_CDZ

DP_P2

DP_P2

DM_P2

DM_P2

AA25AB25

AA23

Y24

Y23

AB23

AA24

AB22

B1C2

C1

A2

AD11

AC11

W24

A3

B3

SIG17148SIG17196

SIG17144

SIG19762

SIG19764

SIG19763

M_SPI_CLKM_SPI_CLK

M_SPI_DIM_SPI_DI

M_EMMC_CMDM_EMMC_CMD

M_EMMC_CLKM_EMMC_CLK

M_EMMC_CDZM_EMMC_CDZ

M_USB2DPM_USB2DP

M_USB2DMM_USB2DM

132

132

135

135

135

160

160

121 609

121 609

151

151

120

120

700

M_ETRNM_ETRN

M_ETRPM_ETRP

M_XINM_XIN

C_HOSTRSTC_HOSTRST

M_RMT_INM_RMT_IN

M_DDCA_DAM_DDCA_DA

M_DDCA_CKM_DDCA_CK

[ETHER PHY INTERFACE]

[ETHER PHY INTERFACE]

AG11

AH11

SIG17140

SIG17143

SIG18303

RN

RN

RP

RP

[MISC. INTERFACE]

[MISC. INTERFACE]

L5 AB19

RESET

RESET

M5

IRIN

IRIN

(PU/5V)

U6

DDCA_DA

DDCA_DA

(PU/5V)

T4

DDCA_CK

DDCA_CK

(PU/5V)

MSD8881CV

MSD8881CV

MSTAR/MSD8881CV-W9N

MSTAR/MSD8881CV-W9N

TN

TN

TP

TP

LED0

LED0

LED1

LED1

XOUTXIN

XOUTXIN

VSENSE_MIPS

VSENSE_MIPS

DDCR_DA

DDCR_DA

(PU/5V)

DDCR_CK

DDCR_CK