Page 1

SERVICE MANUAL

LCD Color Television

40L3443DG

(Model Information)

Page 2

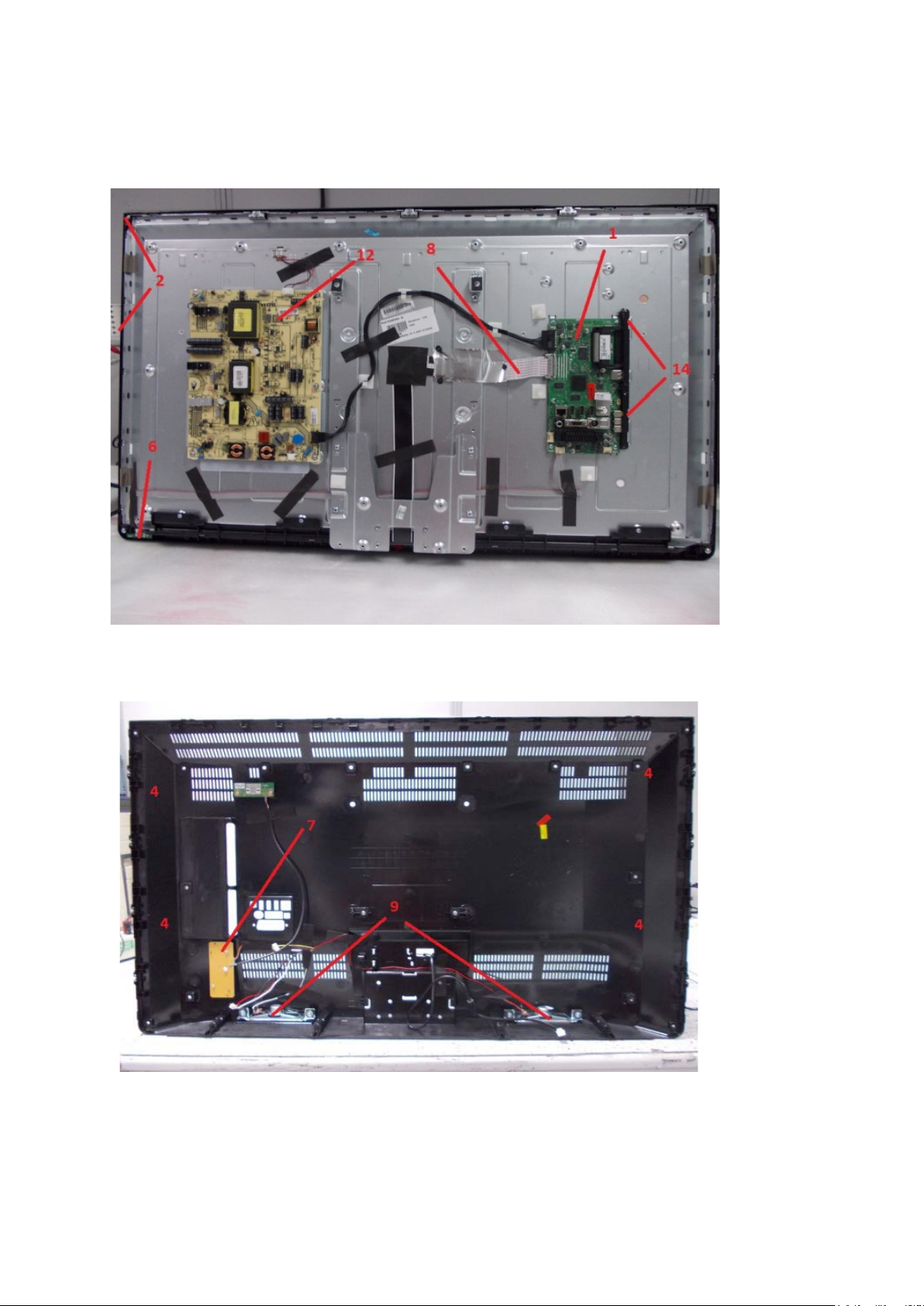

Exploded View of 40L3443DG

1/3

Page 3

2/3

Page 4

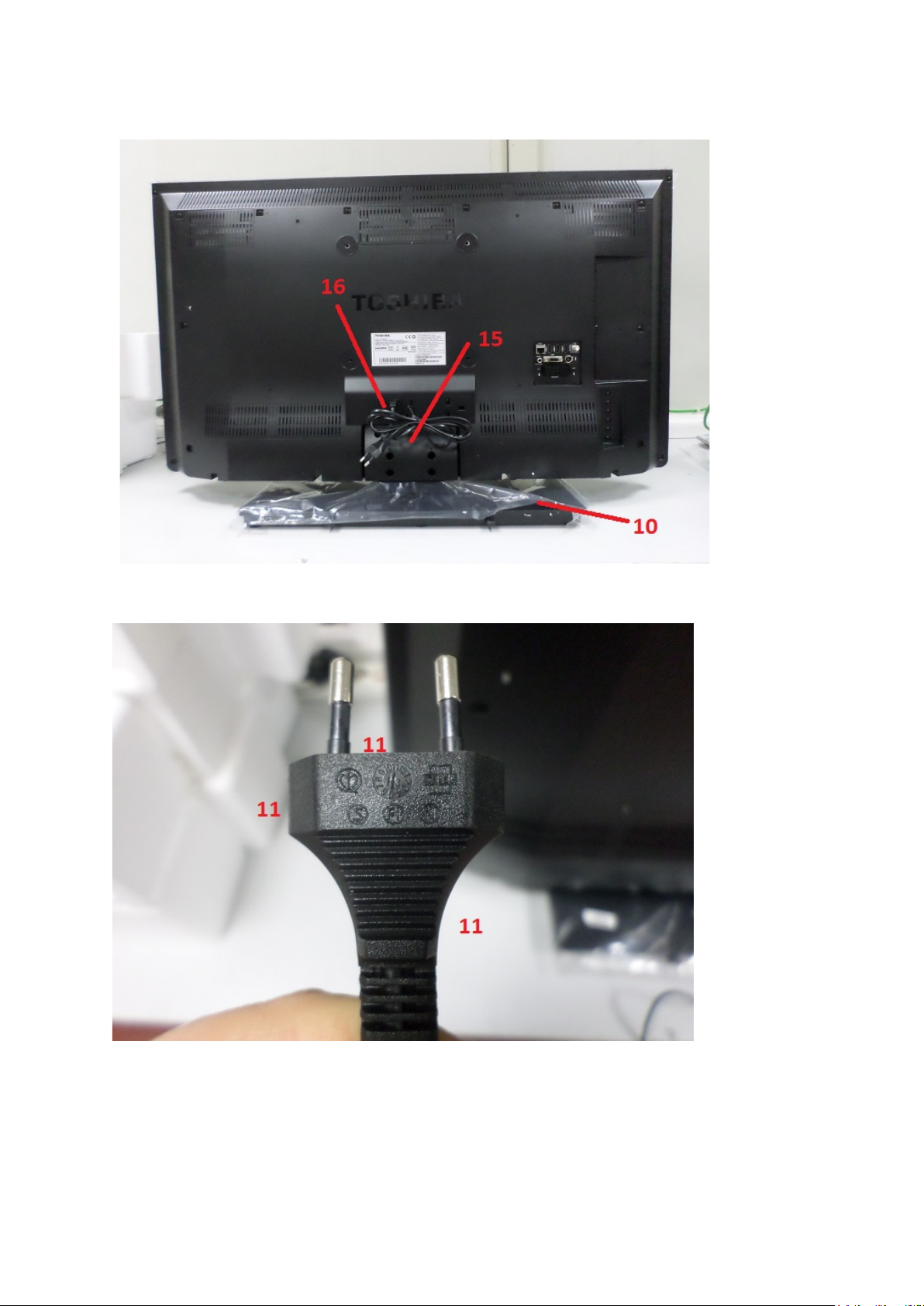

Parts List: 40L3443DG

Vestel

Part #

Description

Service

Code

23161143 LCD PANEL, 40L3433DG, 23161143 (include F-bezel) 75038545

1 M/B 23167494 PC BOARD ASSY, MAIN, 40L3443DG, 23167494 75038638

2 F-bezel 23144821 FRONT BEZEL ASSY, 23144821 75036609

cosmatic Lens 40057270 LENS, LED, 40L1333DG, 40057270 75037278

4 B-cover 23180599 BACK COVER ASSY, 40L3433DG, 23180599 75038547

Lens 40055433 LENS, IR, 32W1333DB, 40055433 75036095

6 IR/B 23123271 PC BOARD ASSY, IR, 23123271 75036603

7 Button Board 23078192 PC BOARD ASSY, KEY, 40L1333B, 23078192 75033184

8 LVDS 23152437 LVDS CABLE, 40L3433DG, 23152437 75038544

9 SPK 23153301 SPEAKER, 40L1333DG, 23153301 75037280

10 Stand Assy 45012055 STAND ASSY, 40L1433DG, 45012055 75038541

11 P cord 30078717 POWER CORD, 32W1333DG, 30078717 75036101

12 P/B 23158490 POWER MODULE, 40L3453R, 23158490 75037530

Carton 50268058 CARTON BOX, 40L3443DG, 50268058 75038639

14 Side IO bezel 40056742 IO BRACKET, 32W3455DB, 40056742 75037337

15 Foot Screw 45011725 SCREW FOR STAND, 45011725 75036610

16 Cover Gromet 40046136

back CVR.Screw 35027715 SCREW, 22B2LF1G, 35027715 75028539

Panel

23162545 LCD PANEL, 40L1433DG, 23162545 (include F-bezel) 75038536

RELEASE PROTECTIVE COVER, AC CABLE, 26DL833B, 40046136

75025759

3/3

Page 5

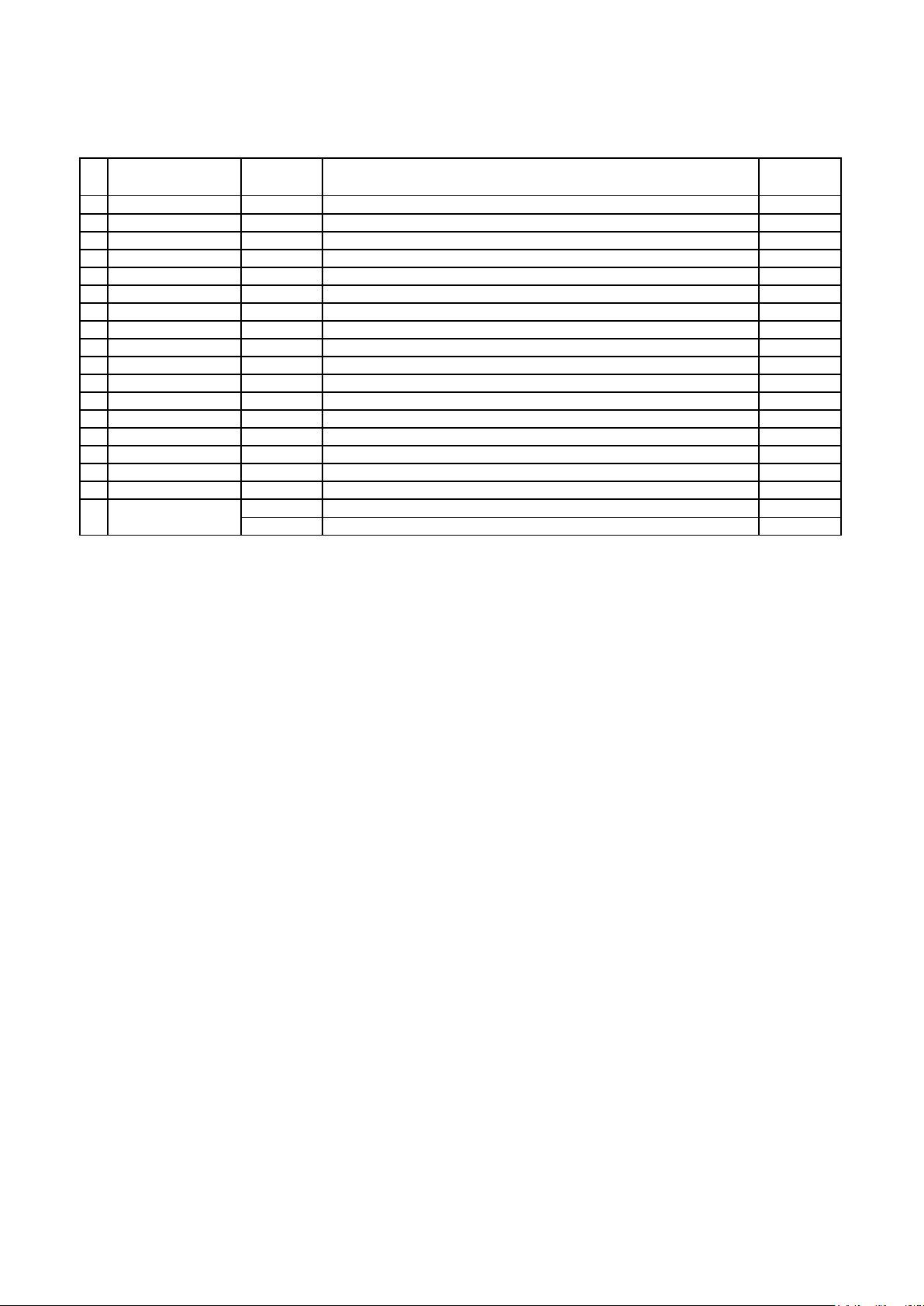

MODEL ID and PANEL ID

Total digits YWK Model ID (SET ID) SERIAL Panel ID

6 digits

2 digits

………

…

Vestel

Code

LPL/LGD

CPT

Panel ID in Global Serial No.

13th digit:

Panel Vendor

AUO

BriView

CMO

CHILIN

Panel Vendor

SHARP

Panel Vendor

SAMSUNG

BONDEDCELL

LSC400HM06-MB7

When the panel version is updated within the same panel vendor, the last digit will be incremented

by 1.

IPS

14th digit:

Max 14 YWK *** ****** **

3 digits 3 digits

(A00001-Z99999)

YWK

Y: Year 8 2008 WK: Week 01 WK01

9 2009 02 WK02

A 2010 03 WK03

B 2011 04 WK04

C 2012

53 WK53

Panel vendor Information (Panel ID)

Marking Marking Marking

A J S

B K T

C L U

D M V

E N W

F P X

G Q Y

H R Z

1-9

Model/Panel I n fo r mation

Model

40L3443DG 8J5 K1 75038638 10088605

Model ID

(SET ID)

Panel ID Main PCB

DVD Module

-

Panel

40FHD50 SAM

Product

Page 6

REV. 00

May/26/2014

Page 7

SERVICE MANUAL

LCD Color Television

40L3443DG

FILE NO. 050-2014046

REVISED:02

(System Information)

Page 8

REVISION HISTORY

REV

Date

Reason for Change

1

Jun/13/2014

- Replacement for Main Schematic with correct ones

2

May/15/2015

- Correction of Step 3 in "FIRMWARE UPDATING"

Page 9

CONTENTS

1. IMPORTANT NOTICE

2. GREEN PRODUCT PROCUREMENT

3. LEAD-FREE SOLDER

4. SAFETY INSTRUCTION

5. FIRMWARE UPDATING

6. INTERCONNECT

7. EXPLODED VIEW

8. HOTEL MODE / HOTEL CLONE

9. SCHEMATIC DIAGRAM

1

Page 10

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data provided

herein without prior written consent by Toshiba. Toshiba shall not be liable to

anybody for any damages, losses, expenses or costs, if any, incurred in connection

with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of use of any information or data provided

herein.

Page 11

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase

and use products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts

used in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 30ºC to

40ºC (54ºF to 72ºF). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product especially when soldering large components, through-hole pins, and on PCBs

as the level of heat required to melt lead-free solder is high.

Page 12

(1 / 3)

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY PRECAUTION" AND "PRODUCT

SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR WITH THE

NECESSARY PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE THE NECESSARY

PRECAUTIONS TO BE OBSERVED BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These

items may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the mark is indicated

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also

make sure that wirings is routed and clamped to avoid parts that generate heat and

which use high voltage. Always follow the manufactured wiring routes / dressings.

Page 13

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation,

malfunction, or electrical leakage and flame, which may be hazardous.

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer for

this check.

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

(2 / 3)

Measuring network for TOUCH CURRENTS

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Annex D

(normative)

Input resistance : 1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

Page 14

(3 / 3)

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with

the solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of from the ideal curve as a function of

frequency.

TOUCH CURRENT = / 500 (peak value).

The potential at any point (TOUCH CURRENT) expressed as voltage and does

not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is

not met.

b) The measurement of the TOUCH CURRENT shall be carried out in accordance

with IEC 60990, with the measuring network described in Annex D of this standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c. correspond

to the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

Page 15

FIRMWARE UPDATING PROCEDURE

Analog - Digital SW update via USB

1. Please copy the files to USB device (root).

Mb9x_en.bin

mboot.bin

usb_auto_update.txt

2. Turn power to OFF by mechanical switch or removing AC plug and plug the USB to TV

2

Press the OK button consecutively for ~5s and at the same time power on the TV set by AC plug.

3.

After ~5s you can release the OK button and shortly after front LED will start blinking and indicate that

the update has started.

4. When the blinks of led is stopped, TV opens autamatically.

5. Power OFF / ON TV set, then TV will be ready

When TV is ON

1. Software can be upgraded on Software Upgrade Mode.

2. To access Software Upgrade Mode, you will need to enter “1505 with your remote controller,

3. When main menu is on. On this mode, a simple yes/no screen appears which asks to upgrade the

software.

In the USB Mass storage devices, there should be the binary whose name likes ‘upgrade_mb9x.bin’.

4.

5. You will see a simple progress menu which shows the status of the upgrade,

6. This will be completed by restarting of the system

Page 16

Wiring Diagram

51 Panel VCC

PANEL

Speaker

1 GND

2 LED 2

3 LED 1

4 IR_IN

5 5V_STBY

LED-IR BOARD

CN11 CN2 CN4 CN501

1 NC 1 GND 1 PIN1 1 V_Led

2 NC 2 GND 2 GND 2 LED1_S

3 NC 3 3V3_VCC 3 STBY 3 LED2_S

4 NC 4 3V3_VCC 4 GND 4 NC

5 OP_PIN5 , 5 24V_VCC_AU 5 BACKLIGHT_ON/OFF 5 LED2_S

6 OP_PIN6 6 3V3_STBY 6 GND 6 LED3_S

7 OP_PIN7 7 12V_STBY 7 PWM DIMMING 7 LED4_S

8 OP_PIN8 8 12V_STBY 8 GND

9 OP_PIN9 9 5V_VCC 9 5V_STBY

CN27 11 OP_PIN11 11 5V_VCC 11 12V_VCC or PIN3

1 GND 12 TX_1_0_N 12 12V_STBY 12 PIN4 or 12V_VCC

2 LED2 13 TX_1_0_P 13 DIMMING

3 LED1 14 TX_1_1_N 14 GND

4 IR_IN 15 TX_1_1_P 15 BACKLIGHT_ON/OFF

5 5V_STBY 16 TX_1_2_N 16 GND

10 OP_PIN10 10 5V_VCC 10 12V_STBY

17 TX_1_2_P 17 POWER PIN13

18 GND

19 TX_1_CLK_N 19 POWER PIN1

20 TX_1_CLK_P 20 GND

21 GND

22 TX_1_3_N

23 TX_1_3_P

24 TX_1_4_N

25 TX_1_4_P

26

27 OP_PIN27

28 TX_2_0_N CN15

29 TX_2_0_P 1 R_AUDIO_P

30 TX_2_1_N 2 R_AUDIO_N

31 TX_2_1_P 3 L_AUDIO_P

32 TX_2_2_N 4 L_AUDIO_N

33 TX_2_2_P

34 GND

35 TX_2_CLK_N

36 TX_2_CLK_P

37 GND

38 TX_2_3_N

39 TX_2_3_P

40 TX_2_4_N

41 TX_2_4_P

42 OP_PIN42

43 OP_PIN43

44 GND

45 GND

46 GND

47

48 Panel VCC

49 Panel VCC

50 Panel VCC

MainBoard MB95 and MB95S

18 GND

CN100

Speaker

Page 17

Exploded View

1/3

Page 18

2/3

Page 19

Parts List

1 M/B

Panel

2 F-bezel

cosmatic Lens

4 B-cover

Lens

6 IR/B

7 Button Board

8 LVDS

9 SPK

10 Stand Assy

11 P cord

12 P/B

Carton

14 Side IO bezel

15 Foot Screw

16 Cover Gromet

back CVR.Screw

3/3

Page 20

HOTEL MODE/HOTEL CLONE

HOTEL TV MENU:

To enter hotel menu, please open main menu by pressing MENU(M) button. When you code following

password "7935", hidden hotel TV menu appears as below:

Figure: Hotel TV Menu

Hotel Mode

Setting "Hotel Mode" item 'On' activates hotel mode. In other words user can do only what he/she is

allowed to do. Restriction level can be determined by using other items on menu namely Volume Limit,

Panel Button, OSD Disable. In hotel mode, users can not reach channel table and install menu so they

could not change any program information.

Last Status

Setting "Last Status" item to 'On' enable TV open with the closing status. Otherwise, if "Last Status" item

is set 'Off' TV opens with standby status.

Volume Limit

Sets the maximum value the volume can have. "Volume Limit" can take values between 0-63.

Fixed Volume Enable

Page 21

Enables (Fixed Volume Enable = On) or prohibits (Fixed Volume Enable = Off) the use of fixed volume

value which is set by menu item "Fixed Volume Value". If Fixed Volume Enable is ON, volume cannot

be set to a value other than the Fixed Volume Value.

Fixed Volume Value

Sets the fixed value the volume can have. If Fixed Volume Limit is ON, volume is set with the value

here.

Headphone Direct Volume

Enables to could set via headphone volume dialog the headphone volume level.

If it is changed to enabled then V+/- keys will change HP volume and left/right option will change

speaker volume unless there is any open osd. If it is disabled it will behave as normal.

Volume control and HP volume control are displayed by volume slider menu.

Figure: Hotel TV headphone slider bar

Panel Lock

Enables (Panel Lock = On) or prohibits (Panel Lock = Off) the use of front panel buttons.

OSD Disable

Disables either only INSTALL menu or all menus, both in analog and digital (IDTV) mode.

All Menus : All menus (MAIN, SOUND, PICTURE, SETTINGS, INSTALLATION) are invisible.

OSD Disable = Disable Setup Menus : Only SETUP menus are invisible.

Invisabel Setup Menus are:

Page 22

Main menu: Installation, Channel list

Settings menu: Language, parental, Sources, Other settings

-

Startup Position

Specifies the starting channel when TV is switched ON. May take one of following values:

AUTO (Last channel when TV is turned off)

TV (TV channel number 1)

Other enabled external sources via service menu or config tool (EXT1, HDMI2, PC, FAV, SVHS

etc.)

Teletext

Enables (Teletext = On) or prohibits (Teletext = Off) the use of teletext (or MHEG if available)

Copy To USB

Copy NVRAM data (service list, preferences, etc.) to USB device. On MB61 and MB60 all nvram data

is stored in 8x32KB Flash files named as Flash0.bin, Flash1.bin ... Flash7.bin. When Copy to USB is

called, those files are copied from TV to USB. Then they can be used for various purposes testing on

another TV or testing/debugging on observatory etc.

Note that USB should be plugged before this operation.

Copy From USB

Copy from USB device data to NVRAM. Just the reverse operation done by copy to USB call.

Previously copied nvram files (Flashx.bin) are copied into TV. If there is no flash file or some of them

are available on USB, the available ones are copied. If no USB is connected, nothing happens.

Page 23

A

B

C

D

E

F

CN6

21

20

1

2

3

4

5

6

7

8

9

HDMI1

10

11

12

13

14

15

16

17

18

19

CN4

21

20

1

2

3

4

5

6

7

8

9

HDMI2

10

11

12

13

14

15

16

17

18

19

PANEL_VCC

R119

4k7

BC848B

BACKLIGHT_ON/OFF

1 2 3 4 5 6 7 8

Q10

47k

R19

1 2

47k

R23

1 2

3V3_VCC

4k7

R121

1 2

R69

1 2

10R

R70

1 2

10R

R66

1 2

10R

R71

1 2

10R

R64

1 2

10R

10R

1 2

R72

R25

47k

1 2

R54

1 2

10R

R53

1 2

10R

R57

1 2

10R

R52

1 2

10R

R59

1 2

10R

10R

1 2

R51

47k

R24

1 2

USB_ENABLE1

USB_ENABLE2

DVD_IR_ON/OFF

PCM_CD1

LNB_POK

EXT_RESET

LINEDROP

R697

1k

R715

2k7

HDMI2_5V

HDMI1_5V

HDMI0_5V

TUNER_RST

PANEL_VCC_ON/OFF

S27

NC

12

4k7

R120

D19

C5V6

R62

1

10R

10R

1

R67

10R

2

R68

10R

1

R65

10R

1

R63

R14

R61

1

10R

10R

1

R56

10R

2

R55

10R

1

R58

10R

1

R60

R22

3V3_STBY

AMP_MUTE

S2_RESET

HP_DETECT

3D_ENABLE

CI_PWR_CTRL

3V3_VCC

4k7

R140

1 2

3V3_VCC

USB_OCD1

HDMI0_5V

M1

N3

N1

N2

P3

P2

M3

M2

V5

V4

AD1

N4

J1

K3

K1

K2

L3

L2

J3

J2

U5

U6

T5

RXA0N

RXA0P

RXA1N

RXA1P

RXA2N

RXA2P

RXACKN

RXACKP

DDCDA_CK

DDCDA_DA

HOTPLUGA

ARC0

RXB0N

RXB0P

RXB1N

RXB1P

RXB2N

RXB2P

RXBCKN

RXBCKP

DDCDB_CK

DDCDB_DA

HOTPLUGB

R10

1k2

HDMI0_RX0N

HDMI0_RX0P

HDMI0_RX1N

HDMI0_RX1P

HDMI0_RX2N

HDMI0_RX2P

HDMI0_CLKN

HDMI0_CLKP

HDMI0_SCL

HDMI0_SDA

HDMI1_RX0N

HDMI1_RX0P

HDMI1_RX1N

HDMI1_RX1P

HDMI1_RX2N

HDMI1_RX2P

HDMI1_CLKN

HDMI1_CLKP

HDMI1_SCL

HDMI1_SDA

R82

3

1

HDMI0_ARC

R85

1 2

1k

R84

1 2

1k

2

1 2

1k

R83

1 2

1k

R8

C14

1uF

6V3

HDMI1_5V

1k2

2

HDMI0_RX2P

HDMI0_RX2N

2

HDMI0_RX1P

HDMI0_RX1N

1

HDMI0_RX0P

HDMI0_RX0N

2

HDMI0_CLKP

HDMI0_CLKN

CEC

2

47k

1 2

HDMI0_SCL

HDMI0_SDA

HDMI0_5V

HDMI0_HPDIN

HDMI0_HPDIN

HDMI1_HPDIN

BC848B

Q2

BC848B

3

2

Q5

1

HDMI1_RX2P

HDMI1_RX2N

HDMI1_RX1P

HDMI1_RX1N

HDMI1_RX0P

HDMI1_RX0N

HDMI1_CLKP

HDMI1_CLKN

CEC

33R

R662

18k

4k7

1 2

R4

HDMI1_SCL

HDMI1_SDA

HDMI1_5V

HDMI1_HPDIN

4k7

1 2

R126

4k7

1 2

R1

33k

33k

R614

R613

R214

R3

4k7

1 2

33k

4k7

R111

1 2

3V3_VCC

AA18

U22

AB22

T22

W21

4k7

R260

1 2

3V3_VCC

C7

GPIO36

E3

GPIO37

F5

GPIO38

B6

GPIO39

E2

GPIO40

D5

GPIO41

B7

GPIO42

D4

GPIO43/UART2_TX

E4

GPIO44/UART2_RX

D7

GPIO45

D6

GPIO46

B8

GPIO47/UART4_TX

A8

GPIO48/UART4_RX

F7

GPIO49

A9

GPIO51

F4

GPIO52

C3

GPIO58

A3

GPIO61

B3

GPIO62

GPIO131

GPIO132

GPIO133

GPIO134

GPIO135

3V3_STBY

4k7

R13

1 2

U28

MAX809LTR

MSD8WB9BX

AE25

R107

15k

R258

220R

3

VCC

GNDRST

2 1

AUX_RESET

GPIO7/PM_UART1_TX

GPIO11/PM_UART1_RX

9

U4

GPIO

NC_3

NC_4

NC_5

NC_6

NC_7

AE1

U23

T25

T24

10k

R108

GPIO12/CSZ1

NC_1

NC_2

A1

T23

A25

NC_0

12V_VCC

5V_VCC

C626

1uF

16V

GPIO6

GPIO8

GPIO10

GPIO13

GPIO14

GPIO15

GPIO16

GPIO17

GPIO18

PWM0

PWM1

PWM2

PWM3

PWM_PM

SAR0

SAR1

SAR2

SAR3

C562

100nF

16V

K5

M5

K6

L5

J4

M4

M7

M6

K4

D3

L6

N6

N24

N25

P23

N23

F6

G5

H5

H6

J6

3V3_STBY

4k7

R129

1 2

R128

1 2

12

R109

3V3_STBY

3V3_STBY

3V3_STBY

4k7

R142

R123

1 2

1 2

4k7

4k7

R110

1 2

R114

100R

R261

100R

R127

1 2

4k7

4k7

3V3_STBY

3V3_STBY3V3_VCC

3V3_STBY

R5

4k7

330k

12

4k7

R12

R144

1 2

12

4k7

R143

3V3_STBY

4k7

SPI_CS

FLASH_WP

3V3_STBY

2

47k

1 2

R273

100R

R347

100R PC_DET

R168

18k

R663

18k

R738

R737

33R

USB_OCD2

HDMI / USB

MSD8WB9BX

DP_P0

DM_P0

D1

D2

USB2_DN

USB2_DP

PROTECT

LED1

LED2

STBY_ON/OFF_NOT

4k7

1 2

R11

TOUCHPAD_SCL

AUX_RESET

TOUCHPAD_SDA

HP_MUTE

PWM0

PWM1

BACKLIGHT_DIM

PWM_OUT_LED3

KEYBOARD

SC_PIN8

DVD_SENSE

DP_P1

DM_P1

AD12

AC13

USB1_DP

USB1_DN

3

U4

GPIO55/LED[0]

TN

B5B4C5C4C6

DVD_WAKEUP

RN

RP

GPIO56/LED[1]

TP

A6

RXC0N

RXC0P

RXC1N

RXC1P

RXC2N

RXC2P

RXCCKN

RXCCKP

DDCDC_CK

DDCDC_DA

HOTPLUGC

RXD0N

RXD0P

RXD1N

RXD1P

RXD2N

RXD2P

RXDCKN

RXDCKP

DDCDD_CK

DDCDD_DA

HOTPLUGD

ETH_RXN

ETH_RXP

ETH_TXP

ETH_TXN

CEC

R1

T3

T1

T2

U3

U2

R3

R2

V6

W6

AD4

F1

G3

G1

G2

H3

H2

F3

F2

R6

T4

R5

T6

R130

R116

5k1

5k1

R125

R122

5k1

5k1

HDMI2_SDA

R86

100R

3V3_VCC

ETH_YEL

ETH_GRN

HDMI2_RX0N

HDMI2_RX0P

HDMI2_RX1N

HDMI2_RX1P

HDMI2_RX2N

HDMI2_RX2P

HDMI2_CLKN

HDMI2_CLKP

HDMI2_SCL

CEC

C52

100nF

10V

HDMI2_5V

R39

1k2

R33

R40

1k

12

1k

2

12

3

1

Q4

BC848B

HDMI2_HPDIN

3V3_STBY

R192

12

10k

PROTECT

TP7

2

1

BC848B

1 2

Q8

R190

10k

R189

1 2

BC858B

10k

Q35

R191

1 2

10k

1V2 - 1V25 -1V5 - 2V5 - 3V3 FROM ICs POWER GOOD PINS

SHORT CCT PROTECTION

SCH NAME :

DRAWN BY :

CN5

21

20

1

2

3

4

5

6

7

8

9

HDMI3

10

11

12

13

14

15

16

17

18

19

R31

1 2

D26

BAW56

D24

BAW56

BC848B

Q7

10k

1 2

R712

1 2

R195

1 2

R194

R343

100R

1 2

1 2

10k

10k

01_HDMI_GPIO_PROT

<YOUR NAME HERE>

47k

R30

47k

1 2

1 2

R611

12

33k

10k

R188

10k

R185

10k

R186

3V3_VCC_TUNER

5V_VCC

R141

1 2

10R

R158

1 2

10R

R106

1 2

10R

R160

1 2

10R

R99

1 2

10R

10R

1 2

R166

24V_VCC_AU

12V_VCC

3V3_VCC

10k

R183

1 2

BC848B

17mb95-3

1

1

2

1

1

Q36

R97

10R

10R

R112

10R

R124

10R

R100

10R

R98

2

R32

47k

1 2

R342

100R

12-03-2013_13:17

87654321

HDMI2_RX2P

HDMI2_RX2N

HDMI2_RX1P

HDMI2_RX1N

HDMI2_RX0P

HDMI2_RX0N

HDMI2_CLKP

HDMI2_CLKN

CEC

HDMI0_ARC

HDMI2_SCL

HDMI2_SDA

HDMI2_5V

HDMI2_HPDIN

1V8_VCC_TUNER

A3

T. SHT:

A

B

C

D

E

F

10

AX M

Page 24

1 2 3 4 5 6 7 8

1V5_VCC 1V5_VCC

100nF

C213

10uF

10V

100nF

C214

10uF

10V

C257

16V

C278

16V

100nF

16V

C248

100nF

16V

C279

100nF

16V

C269

100nF

16V

100nF

100nF

100nF

100nF

16V

16V

C323

C325

DDR0_VREFCA

50V

1nF

DDR0_VREFDQ

1nF

50V

1k

R410

A

1V5_VCC

1k

R414

R411

R415

1k

C247

100nF

1k

C267

100nF

1V5_VCC

1k

R408

1k

R413

R409

R412

1k

C246

100nF

1k

C263

100nF

16V

16V

C322

C324

DDR1_VREFDQ

50V

1nF

DDR1_VREFCA

50V

1nF

1V5_VCC

1V5_VCC

F12

60R

F13

60R

C258

C260

C259

100nF

16V

16V

C250

C249

100nF

16V

16V

C281

C280

100nF

16V

16V

C270 C271

100nF

16V

16V

C261

100nF

16V

C251

100nF

16V

C282

100nF

16V

C272

100nF

16V

C262

100nF

16V

C252

100nF

16V

C283

100nF

16V

C273

100nF

16V

C264

100nF

16V

C253

100nF

16V

C284

100nF

16V

C274

100nF

16V

C265

100nF

16V

C254

100nF

16V

C285

100nF

16V

C275

100nF

16V

C266

100nF

16V

C255

100nF

16V

C286

100nF

16V

C276

100nF

16V

C268

100nF

16V

C256

100nF

16V

C287

100nF

16V

C277

100nF

16V

1V5_DDR0

A

1V5_DDR1

PL1

B

1V5_DDR0

U4

1V5_DDR1

PL4

PL3

PL2

GROUND TERMINALS

B

MSD8WB9BX

DDR0_A00

DDR0_A01

DDR0_A00

C

DDR0_A01

DDR0_A02

DDR0_A03

DDR0_A04

DDR0_A05

DDR0_A06

DDR0_A07

DDR0_A08

DDR0_A09

DDR0_A10

DDR0_A11

DDR0_A12

DDR0_A13

D

DDR0_CK

DDR0_CKB

R321

E

56R

C342

R322

DDR0_BA0

DDR0_BA1

DDR0_BA2

DDR0_CKE

56R

DDR0_RASB

DDR0_CASB

DDR0_WEB

16V

10nF

DDR0_RESETB

R418

240R

N3

P7

P3

N2

P8

P2

R8

R2

T8

R3

L7

R7

N7

T3

J1

L1

M7

L9

T7

J9

M2

N8

M3

J7

K7

K9

L2

J3

K3

L3

T2

L8

B2D9G7K2K8N1N9R1R9A1A8C1C9D2E9F1H2

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

A11

A12/BC

A13

NC1

NC2

NC3

NC4

NC5

NC6

BA0

BA1

BA2

CK_0

CK_1

CKE

CS

RAS

CAS

WE

RESET

ZQ

VDD_4

VDD_3

VDD_2

VDD_1

H5TQ2G63BFR-PB

VSS_3

VSS_2

VSS_1

A9B3E1G8J2J8M1M9P1P9T1T9B1B9D1D8E2E8F9G1G9

VDD_6

VDD_5

VSS_5

VSS_4

VDD_8

VDD_7

VSS_7

VSS_6

VDD_9

U7

VSS_9

VSS_8

VDDQ_2

VDDQ_1

VSS_11

VSS_10

VDDQ_4

VDDQ_3

VSS_12

VDDQ_6

VDDQ_5

VSSQ_2

VSSQ_1

H9

VDDQ_8

VDDQ_7

VSSQ_4

VSSQ_3

VDDQ_9

VREF_DQ

VREF_CA

DQSL_0

DQSL_1

DQSU_1

DQSU_0

VSSQ_6

VSSQ_5

DQL0

DQL1

DQL2

DQL3

DQL4

DQL5

DQL6

DQL7

DQU0

DQU1

DQU2

DQU3

DQU4

DQU5

DQU6

DQU7

DML

DMU

ODT

VSSQ_8

VSSQ_7

H1

M8

E3

F7

F2

F8

H3

H8

G2

H7

D7

C3

C8

C2

A7

A2

B8

A3

F3

G3

B7

C7

E7

D3

K1

VSSQ_9

DDR0_VREFDQ

DDR0_VREFCA

DDR0_DQL0

DDR0_DQL1

DDR0_DQL2

DDR0_DQL3

DDR0_DQL4

DDR0_DQL5

DDR0_DQL6

DDR0_DQL7

DDR0_DQU0

DDR0_DQU1

DDR0_DQU2

DDR0_DQU3

DDR0_DQU4

DDR0_DQU5

DDR0_DQU6

DDR0_DQU7

DDR0_DQSL

DDR0_DQSLB

DDR0_DQSUB

DDR0_DQSU

DDR0_DML

DDR0_DMU

DDR0_ODT

DDR0_A13

DDR0_A02

DDR0_A03

DDR0_A04

DDR0_A05

DDR0_A06

DDR0_A07

DDR0_A08

DDR0_A09

DDR0_A10

DDR0_A11

DDR0_A12

DDR0_DQL0

DDR0_DQL1

DDR0_DQL2

DDR0_DQL3

DDR0_DQL4

DDR0_DQL5

DDR0_DQL6

DDR0_DQL7

DDR0_DQU0

DDR0_DQU1

DDR0_DQU2

DDR0_DQU3

DDR0_DQU4

DDR0_DQU5

DDR0_DQU6

DDR0_DQU7

DDR0_CASB

DDR0_RASB

DDR0_WEB

DDR0_DML

DDR0_DMU

DDR0_ODT

DDR0_BA0

DDR0_BA1

DDR0_BA2

DDR0_RESETB

DDR0_CKE

DDR0_CK

DDR0_CKB

DDR0_DQSL

DDR0_DQSLB

DDR0_DQSU

DDR0_DQSUB

A11

C14

B11

F12

C15

E12

A14

D11

B14

D12

C16

C13

A15

E11

B13

D17

G15

B21

F15

B22

F14

A22

D15

G16

B20

F16

C21

E16

A20

D16

C20

A12

B12

C12

E15

A21

E14

F13

B15

E13

F11

B16

C17

A17

B19

C18

B18

A18

A_DDR3_A0

A_DDR3_A1

A_DDR3_A2

A_DDR3_A3

A_DDR3_A4

A_DDR3_A5

A_DDR3_A6

A_DDR3_A7

A_DDR3_A8

A_DDR3_A9

A_DDR3_A10

A_DDR3_A11

A_DDR3_A12

A_DDR3_A13

A_DDR3_A14

A_DDR3_DQL0

A_DDR3_DQL1

A_DDR3_DQL2

A_DDR3_DQL3

A_DDR3_DQL4

A_DDR3_DQL5

A_DDR3_DQL6

A_DDR3_DQL7

A_DDR3_DQU0

A_DDR3_DQU1

A_DDR3_DQU2

A_DDR3_DQU3

A_DDR3_DQU4

A_DDR3_DQU5

A_DDR3_DQU6

A_DDR3_DQU7

A_DDR3_CASZ

A_DDR3_RASZ

A_DDR3_WEZ

A_DDR3_DML

A_DDR3_DMU

A_DDR3_ODT

A_DDR3_BA0

A_DDR3_BA1

A_DDR3_BA2

A_DDR3_RESET

A_DDR3_CKE

A_DDR3_MCLK

A_DDR3_MCLKZ

A_DDR3_DQSL

A_DDR3_DQSLB

A_DDR3_DQSU

A_DDR3_DQSUB

1

DDR3

B_DDR3_A0

B_DDR3_A1

B_DDR3_A2

B_DDR3_A3

B_DDR3_A4

B_DDR3_A5

B_DDR3_A6

B_DDR3_A7

B_DDR3_A8

B_DDR3_A9

B_DDR3_A10

B_DDR3_A11

B_DDR3_A12

B_DDR3_A13

B_DDR3_A14

B_DDR3_DQL0

B_DDR3_DQL1

B_DDR3_DQL2

B_DDR3_DQL3

B_DDR3_DQL4

B_DDR3_DQL5

B_DDR3_DQL6

B_DDR3_DQL7

B_DDR3_DQU0

B_DDR3_DQU1

B_DDR3_DQU2

B_DDR3_DQU3

B_DDR3_DQU4

B_DDR3_DQU5

B_DDR3_DQU6

B_DDR3_DQU7

B_DDR3_CASZ

B_DDR3_RASZ

B_DDR3_WEZ

B_DDR3_DML

B_DDR3_DMU

B_DDR3_ODT

B_DDR3_BA0

B_DDR3_BA1

B_DDR3_BA2

B_DDR3_RESET

B_DDR3_CKE

B_DDR3_MCLK

B_DDR3_MCLKZ

B_DDR3_DQSL

B_DDR3_DQSLB

B_DDR3_DQSU

B_DDR3_DQSUB

B23

D25

F22

G22

E24

F21

E23

D22

D24

D21

C24

C25

F23

E21

D23

L23

J24

L24

J23

M24

H23

M23

K23

G21

L22

H22

K20

H20

L21

H21

K21

B24

B25

A24

H24

L20

D20

G20

F24

F20

E20

F25

G25

G23

K24

K25

J21

J20

DDR1_A00

DDR1_A01

DDR1_A02

DDR1_A03

DDR1_A04

DDR1_A05

DDR1_A06

DDR1_A07

DDR1_A08

DDR1_A09

DDR1_A10

DDR1_A11

DDR1_A12

DDR1_A13

DDR1_DQL0

DDR1_DQL1

DDR1_DQL2

DDR1_DQL3

DDR1_DQL4

DDR1_DQL5

DDR1_DQL6

DDR1_DQL7

DDR1_DQU0

DDR1_DQU1

DDR1_DQU2

DDR1_DQU3

DDR1_DQU4

DDR1_DQU5

DDR1_DQU6

DDR1_DQU7

DDR1_CASB

DDR1_RASB

DDR1_WEB

DDR1_DML

DDR1_DMU

DDR1_ODT

DDR1_BA0

DDR1_BA1

DDR1_BA2

DDR1_RESETB

DDR1_CKE

DDR1_CK

DDR1_CKB

DDR1_DQSL

DDR1_DQSLB

DDR1_DQSU

DDR1_DQSUB

DDR1_CKBR323

C343

DDR1_CK

56R

R324

DDR1_A00

DDR1_A01

DDR1_A02

DDR1_A03

DDR1_A04

DDR1_A05

DDR1_A06

DDR1_A07

DDR1_A08

DDR1_A09

DDR1_A10

DDR1_A11

DDR1_A12

DDR1_A13

DDR1_BA0

DDR1_BA1

DDR1_BA2

DDR1_CKE

56R

DDR1_RASB

DDR1_CASB

DDR1_WEB

16V

10nF

DDR1_RESETB

R421

240R

N3

P7

P3

N2

P8

P2

R8

R2

T8

R3

L7

R7

N7

T3

J1

L1

M7

L9

T7

J9

M2

N8

M3

J7

K7

K9

L2

J3

K3

L3

T2

L8

B2D9G7K2K8N1N9R1R9A1A8C1C9D2E9F1H2

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10/AP

A11

A12/BC

A13

NC1

NC2

NC3

NC4

NC5

NC6

BA0

BA1

BA2

CK_0

CK_1

CKE

CS

RAS

CAS

WE

RESET

ZQ

VDD_4

VDD_3

VDD_2

VDD_1

H5TQ2G63BFR-PB

VSS_3

VSS_2

VSS_1

A9B3E1G8J2J8M1M9P1P9T1T9B1B9D1D8E2E8F9G1G9

VDD_6

VDD_5

VSS_5

VSS_4

VDD_8

VDD_7

VSS_7

VSS_6

VDD_9

U8

VSS_9

VSS_8

VDDQ_2

VDDQ_1

VSS_11

VSS_10

VDDQ_4

VDDQ_3

VSS_12

VDDQ_6

VDDQ_5

VSSQ_2

VSSQ_1

H9

VDDQ_8

VDDQ_7

VSSQ_4

VSSQ_3

VDDQ_9

VREF_DQ

VREF_CA

DQSL_0

DQSL_1

DQSU_1

DQSU_0

VSSQ_6

VSSQ_5

DQL0

DQL1

DQL2

DQL3

DQL4

DQL5

DQL6

DQL7

DQU0

DQU1

DQU2

DQU3

DQU4

DQU5

DQU6

DQU7

DML

DMU

ODT

VSSQ_8

VSSQ_7

H1

M8

E3

F7

F2

F8

H3

H8

G2

H7

D7

C3

C8

C2

A7

A2

B8

A3

F3

G3

B7

C7

E7

D3

K1

VSSQ_9

DDR1_VREFDQ

DDR1_VREFCA

DDR1_DQL0

DDR1_DQL1

DDR1_DQL2

DDR1_DQL3

DDR1_DQL4

DDR1_DQL5

DDR1_DQL6

DDR1_DQL7

DDR1_DQU0

DDR1_DQU1

DDR1_DQU2

DDR1_DQU3

DDR1_DQU4

DDR1_DQU5

DDR1_DQU6

DDR1_DQU7

DDR1_DQSL

DDR1_DQSLB

DDR1_DQSUB

DDR1_DQSU

DDR1_DML

DDR1_DMU

DDR1_ODT

C

D

E

F

17mb95

SCH NAME :

DRAWN BY :

02_MSTAR_DDR3

87654321

T. SHT:

06-04-2012_10:54

F

A3

10

AX M

Page 25

1 2 3 4 5 6 7 8

Place these resistors

close to MSTAR

47R

R170

R169

ETH_TXP

ETH_TXN

ETH_RXP

ETH_RXN

47R

47R

R172

F52

60R

33R

33R

R171

C22

100nF

16V

TP32

1uF

C127

16V

TS0_CLK

TS1_CLK

1

TS1_D5

2

3

1

2

3

TS0_VLD

TS1_D7

TS1_D6

TS0_SYNC

TS0_D0

TS0_D1 TS1_D4

TS0_D2

RESET

XIN

XOUT

IRIN

8

Place these resistors

close to MSTAR

Ethernet lines must be 100ohm differential pairs

50V

10pFC451

R586

R504

C44810pF

50V

R585

33R

8

R1

7

R2

6

R3

5 4

R4

R587

33R

8

R1

7

R2

6

R3

5 4

R4

TP211

12

N5

AE3

AE2

G4

U4

MSD8WB9BX

P5

DDCA_CK/UART0_RX

R4

DDCA_DA/UART0_TX

R23

UART3_RX/GPIO64

P24

UART3_TX/GPIO65

R24

DDCR_CK

R25

12

4k7

12

4k7

R156

SCH NAME :

DDCR_DA

03_CI_ETH_NAND

3V3_STBY

6V3

SPI_DI

R243

TS0_D3

TS0_D4

TS0_D5

TS0_D6

TS0_D7

TS1_SYNC

TS1_D0

TS1_D1

TS1_D2

TS1_D3

TS1_D4

TS1_D5

TS1_D6

TS1_D7

PCM_RST

PCM_REG

TS0_VLD

TS0_SYNC

TS0_D0

TS0_D1

TS0_D2

R244

V20

AD22

AB21

AE17

AC18

AE18

AA19

AD18

AA21

Y22

R20

W19

T20

AA22

V21

AB16

W22

AE20

AD19

AB17

AB20

AC20

AE21

Y19

AD20

AC19

AB18

AD21

AB19

T21

AA20

Y18

U21

SPI_CLK

10k

10k

CN9

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

PCMNANDD0

PCMNANDD1

PCMNANDD2

PCMNANDD3

PCMNANDD4

PCMNANDD5

PCMNANDD6

PCMNANDD7

PCMA0

PCMA1

PCMA2

PCMA3

PCMA4

PCMA5

PCMA6

PCMA7

PCMA8

PCMA9

PCMA10

PCMA11

PCMA12

PCMA13

PCMA14

PCMIRQA

PCMOE

PCMIORD

PCMCE

PCMWE

PCMCD2

PCMRST

PCMREG

PCMIOWR

PCMWAIT

CI_PWR_CTRL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

5V_VCC

12V_VCC

PCM_NAND_D3

PCM_NAND_D4

PCM_NAND_D5

PCM_NAND_D6

PCM_NAND_D7

PCM_CE

PCM_A10

PCM_OE

PCM_A11

PCM_A9

PCM_A8

PCM_A13

PCM_A14

PCM_WE

CI_PWRCI_PWR

TS1_VLD

PCM_A12

PCM_A7

PCM_A6

PCM_A5

PCM_A4

PCM_A3

PCM_A2

PCM_A1

PCM_A0

PCM_NAND_D0

PCM_NAND_D1

PCM_NAND_D2

4k7

R320

1 2

R242

1 2

10k

4k7

R154

C392

CI_PWR

R316

47k

50V

12pF

nc

Q30

2

2

CI_PWR

PCM_IRQA

TS1_CLK

BSH103

3

1

C1197

1 2

3

Q31

BC847B

1

3V3_STBY

F15

60R

10V

100nF

C101

1

2

10V

10uF

R317

47k

RESET

1N4148

6V3

R331

1k

220uF

C103

D3

R245

C149

21

10k

C3

10uF

10V

10V

100nF

C394

22uF

16V

C102

2

100nF

1

10V

Place these capacitors

close to transformer

speed nets, except for the

chassis ground.

Also keep traces short and

route as matched length

differential pairs. Do not place

any parts or traces under the

transformer.

TP64

1

C390

C39133pF

C99

2

100nF

1

10V

33pF

50V

R395

50V

2

1

RESET

1M

CI_PWR

C100

100nF

10V

24MHz

3

X10

IR_IN

3V3_STBY

3V3_STBY

UART-RX-SC

UART-TX-SC

RESET

2

14

S65

100R

R362

R150

4k7

4k7

R151

TP209

TP210

SYS_SCL

SYS_SDA

3V3_VCC

TS1D5

TS0VLD

TS1D7

TS1D6

TS0SYNC

TS0D0

TS0D1

TS0D2

12

1 2

2V5_VCC

TS0CLK

TS1CLK

100R

R361

D36

C5V6

R157

R21

NF_ALE

W20

NF_WPZ

Y20

NF_CEZ

AC21

NF_CLE

P21

NF_REZ

P22

NF_WEZ

Y21

NF_RBZ

P20

NF_CEZ1

CI/NAND

PCM_D[0]/NF_AD[0]

PCM_D[1]/NF_AD[1]

PCM_D[2]/NF_AD[2]

PCM_D[3]/NF_AD[3]

PCM_D[4]/NF_AD[4]

PCM_D[5]/NF_AD[5]

PCM_D[6]/NF_AD[6]

PCM_D[7]/NF_AD[7]

4

U4

MSD8WB9BX

A2

SPI_CK

B2

SPI_DI

B1

SPI_DO

C2

TEST1

C1

SPI_CZ

R240

MSTAR SPI FLASH

3V3_STBY

TP114

4k7

R153

1

2

3

4 5

PCM_CD2

PCM_A6

PCM_A7

PCM_IRQA

PCM_A12

PCM_WE

PCM_A14

PCM_A13

PCM_A8

PCM_A9

PCM_IOWR

PCM_A11

PCM_OE

PCM_IORD

PCM_A10

PCM_CE

PCM_NAND_D7

U10

MX25L512

CS#

HOLD#

SO

WP#

TP117

3V3_VCC

PCM_IORD

PCM_IOWR

3V3_VCC

3V3_VCC

VCC

SCLK

SIGND

TP113

8

7

6

PCM_CD1

TS0_CLK

PCM_WAIT

CI_PWR

4k7

R716

4k7

R735

1N5819

D5

C98

100nF

10V

R808

4k7

1

R508

33R

1

TP109

3V3_VCC

4k7

R76

4k7

R184

10pFC378

50V

R155

PCM_CD2

3V3_VCC

PCM_A[0]

PCM_A[1]

PCM_A[2]

PCM_A[3]

PCM_A[4]

PCM_A[5]

PCM_A[6]

PCM_A[7]

PCM_A[8]

PCM_A[9]

PCM_A[10]

PCM_A[11]

PCM_A[12]

PCM_A[13]

PCM_A[14]

PCM_IRQA_N

PCM_OE_N

PCM_IORD_N

PCM_CE_N

PCM_WE_N

PCM_CD_N

PCM_RST

PCM_REG_N

PCM_IOWR_N

PCM_WAIT_N

C4

22uF

R509

33R

TP110

R503

33R

4k7

R510

33R

R584

33R

1

R1

2

R2

3

R3

4 5

R4

R583

33R

1

R1

2

R2

3

R3

4 5

R4

R582

33R

1

R1

2

R2

3

R3

4 5

R4

R581

33R

1

R1

2

R2

3

R3

4 5

R4

NAND_ALE

NAND_WPZ

NAND_CEZ

NAND_CLE

NAND_REZ

NAND_WEZ

NAND_RBZ

SPI_CLK

SPI_DI

SPI_DO

R507

33R

R506

33R

TP115

TP116

R505

33R

R152

4k7

1 2

S221

8

7

6

8

7

6

8

7

6

8

7

6

10k

3V3_STBY

1

NC1

2

NC2

3

3V3_NAND

A

3k9

R574

NAND_RBZ

NAND_REZ

NAND_CEZ

3V3_NAND

B

NAND_CLE

NAND_ALE

NAND_WEZ

NAND_WPZ

C

3V3_VCC

F51

60R

NC3

4

NC4

5

NC5

6

NC6

7

RB

8

R

9

E

10

NC7

11

NC8

12

VDD1

NAND128-A

13

VSS1

14

NC9

15

NC10

16

CL

17

AL

18

W

19

WP

20

NC11

21

NC12

22

NC13

23

NC14

NC15 NC16

22uF

C210

6V3

U13

100nF

16V

D

R577

33R

1

8

PCMNANDD2

PCMNANDD1

PCMNANDD0

PCMA0

PCMNANDD6

PCMNANDD5

PCMNANDD4

E

PCMNANDD3

PCMA1

PCMA2

PCMA3

PCMREG

PCMWAIT

PCMA4

F

PCMA5

PCMRST

R1

2

R2

3

R3

4 5

R4

R578

33R

1

R1

2

R2

3

R3

4 5

R4

R579

33R

1

R1

2

R2

3

R3

4 5

R4

R580

33R

1

R1

2

R2

3

R3

4 5

R4

7

6

8

7

6

8

7

6

8

7

6

PCM_NAND_D2

PCM_NAND_D1

PCM_NAND_D0

PCM_A0

PCM_NAND_D6

PCM_NAND_D5

PCM_NAND_D4

PCM_NAND_D3

PCM_A1

PCM_A2

PCM_A3

PCM_REG

PCM_WAIT

PCM_A4

PCM_A5

PCM_RST

NC29

NC28

NC27

NC26

I/O7

I/O6

I/O5

I/O4

NC25

NC24

NC23

VDD2

VSS2

NC22

NC21

NC20

I/O3

I/O2

I/O1

I/O0

NC19

NC18

NC17

C291

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

2524

100nF

16V

C292

R883

75R

R882

75R

R881

75R

R880

75R

R879

75R

R878

75R

R877

75R

R876

75R

3V3_NAND

PCM_NAND_D7

PCM_NAND_D6

PCM_NAND_D5

PCM_NAND_D4

3V3_NAND

PCM_NAND_D3

PCM_NAND_D2

PCM_NAND_D1

PCM_NAND_D0

SPI_CS

SPI_DO

FLASH_WP

3V3_STBY

PCMCD2

PCMA6

PCMA7

PCMIRQA

PCMA12

PCMWE

PCMA14

PCMA13

PCMA8

PCMA9

PCMIOWR

PCMA11

PCMOE

PCMIORD

PCMA10

PCMCE

PCMNANDD7

DRAWN BY :

47R

ETH_GRN

ETH_YEL

C20

100nF

16V

TS1SYNC

TS0D3

TS0D4

TS0D5

TS0D6

TS0D7

TS1D0

TS1D1

TS1D2

TS1D3

TS1D4

TS1VLD

TS1_D[0]

TS1_D[1]

TS1_D[2]

TS1_D[3]

TS1_D[4]

TS1_D[5]

TS1_D[6]

TS1_D[7]

TS1_SYNC

TS0_D[0]

TS0_D[1]

TS0_D[2]

TS0_D[3]

TS0_D[4]

TS0_D[5]

TS0_D[6]

TS0_D[7]

TS0_SYNC

C21

100nF

16V

TS1_CLK

TS1_VLD

TS0_CLK

TS0_VLD

510R

R134

510R

R137

R590

33R

8

1

R1

7

2

R2 TS0_D4

6

3

R3

5 4

R4

R589

33R

8

1

R1

7

2

R2

6

3

R3

5 4

R4

R588

33R

8

1

R1

7

2

R2 TS1_D3

6

3

R3

5 4

R4

AC14

AD14

AE14

AD15

AC15

AD16

AD17

AC17

AC16

AE15

AD13

Y16

AA17

AA16

Y13

AA13

AA14

AB14

AA15

AB15

Y15

Y14

17mb95

CN10

1

TD+

2

TD-

3

TCT

4

RD+

5

RD-

6

RCT

7

NC1

8

NC2

9

GR+

10

GR-

11

YL+

12

YL-

13

SHLD1

14

SHLD2

TS0_D3

TS0_D5

TS0_D6

TS0_D7

TS1_SYNC

TS1_D0

TS1_D1

TS1_D2

TS1_VLD

TS1D0

TS1D1

TS1D2

TS1D3

TS1D4

TS1D5

TS1D6

TS1D7

TS1CLK

TS1VLD

TS1SYNC

TS0D0

TS0D1

TS0D2

TS0D3

TS0D4

TS0D5

TS0D6

TS0D7

TS0CLK

TS0VLD

TS0SYNC

T. SHT:

12-03-2013_13:59

87654321

A

B

C

D

E

F

A3

10

AX M

Page 26

A

B

C

D

1 2 3 4 5 6 7 8

220nH

L5

23

S87

180R

S84

L6

220nH

JK11

C566

47pF

4 3

D8

ESD0P8RFL

21

50V

L1

390nH

C113

120pF

50V

L4

270nH

30067048

50V

C112

120pF

F67

1

4

24 MHz CRYSTAL

RF_IN_N

RF_IN_P

3V3_VCC_SI

3V3_VCC_SI

24

23

22

21

20

19

25

GND1

26

GND2

27

GND3

U14

LM1117

IN OUT

ADJ

1234

10uF

28

GPIO

29

INTB

30

RSTB

31

GND4

32

VDD_IO

3V3_VCC_SI

VOUT

TP111

1

R603

1 2

50V

12pF

TUNER_RST

TUNER_SCL

TUNER_SDA

3V3_VCC 1V8_VCC_TUNER

R187

33R

C1

R196

10k

S83

S89

F164

1 2

60R

3V3_VCC_SI

C6

12pF

C10

12pF

6V3

C449

RF_IP

RF_SHLD1

SCL

VDD_S

2

1

100R

R606

1 2

47R

RF_IN

VDD_H2

RF_SHLD

TUNER

U18

SI2156

GND

VDD_D

SDA

3

4

5

1V8_VCC_SI

C15

100nF

6V3

C435

16V

100uF

S75

1 2

VDD_H1

ADDR

6

RF_IN_P

RF_IN_N

27MHz

3

2

1 4

X1

18

17

XOUT

XTAL_O

XTAL_I

ALIF_AGC

7

NC:1100000(R:1,W:0)

S69

S82

BCLK

VDD_L

DLIF_P

DLIF_N

ALIF_P

VDD_H

ALIF_N

DLIF_AGC

8

S92

3V3_VCC_SI

16

15

14

1V8_VCC_SI

13

12

11

10

3V3_VCC_SI

9

1V8_VCC_TUNER

3V3_VCC_TUNER

R308

470R

R73

470R

D_IF_AGC

S100

C158

F86

60R

C156

1n2F

50V

C163

4n7F

50V

S73

S72

16V

22nF

DIGITAL_IF_P

10V

100nF

DIGITAL_IF_N

pin14

DIGITAL_IF_P

DIGITAL_IF_N

3V3_VCC

IF_AGC

Close To Concept ICClose To SI2156

S99

S98

750R

R312

820R

F65

1 2

60R

F68

1 2

60R

pin20

C157

1n2F

50V

C110

NC

C164

100nF

100nF

C162

C155

1n2F

50V

pin10pin19

C109

C108

10V

100nF

SH1

1

pin4

10V100nF

10V

1k

R333

R307

100R

2

100nF

C144

1n2F

50V

C165

16V

10V

IF_P_T2

IF_N_T2

100nF

C153

1n2F

50V

R797

C159

pin1pin32

IF_AGC_T2

9k1

D_IF_AGC

1V8_VCC_SI

3V3_VCC_SI

C154

1n2F

50V

IF_AGC

I2C Address**pin49

3V3_VCC

IF_AGC_T2

TUNER_SCL

TUNER_SDA

3V3_VCC

OPTIONAL RESISTORS

High : D2

Low : F2

3V3_VDDP

1V2_VDD

3V3_VDDP

10k

R251

R379

47R

R380

47R

10k

R252

S80

S213

TS1_SYNC

TS1_VLD

S77

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

GPIO[0]

VDDP_4

VDDC_3

GND_10

VDDP_5

I2CM_SCL

I2CM_SDA

RF_AGC

IF_AGC

GND_11

VDDC_4

VDDP_6

GND_12

I2CS_SCL

I2CS_SDA

GPIO[3]

33R

R526

33R

R527

48

47

GND_9

TS_SYNC

1

2

50V

C431

27pF

24MHz

AVDD_APLL

46

GND_8

AVDD_33_3

TS_DATA[0]

TS_VLD

3

8

R1R3R2

33R

R591

1

TS1_D0

C43227pF

14

2

X11

3

45

44

XIN

XOUT

TS_DATA[2]

TS_DATA[1]

4

5

6

7

2

3

TS1_D1

TS1_D2

50V

IF_P_T2

IF_N_T2

AVDD25_ADC

AVDD_MPLL_T2

1k

1k

F210

F211

43

42

41

40

39

IM

IP

GND_7

AVDD_25

AVDD_33_2

U17

MSB1231

T2 DEMOD

TS_DATA[4]

VDDC_0

GND_1

VDDP_0

TS_DATA[3]

6

7

8

9

10

R4

4 5

TS1_D3

3V3_VDDP

R4R1R3

5 4

1V2_VDD

TS1_D4

38

37

QM

QP

TS_DATA[6]

TS_DATA[5]

11

12

3

2

R2

7

6

TS1_D5

TS1_D6

AVDD33_ADC

36

35

GND_6

AVDD_33_1

TS_CLK

TS_DATA[7]

13

14

1

33R

R592

8

TS1_D7

AVDD_SAR

34

33

SAR_RSSI

AVDD_33_0

GND_2

TS_ERR

15

16

TP65

33R

R525

GPIO[11]

VDDP_3

VDDC_2

GND_5

VDDP_2

GPIO_2

SPI_CZ

SPI_DO

SPI_DI

SPI_CLK

GPIO_1

GND_4

VDDC_1

GND_3

VDDP_1

RESETZ

C393

TS1_CLK

50V

12pF

A

FLASH_WP_T2

S74

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

S76

3V3_VDDP3V3_VDDP

1V2_VDD1V2_VDD

3V3_VDDP

SPI_CS_T2

SPI_DO_T2

SPI_DI_T2

SPI_CLK_T2

1V2_VDD

3V3_VDDP

16V

100nF

B

EXT_RESET

C

C2

nc

D

F165

5V_VCC

1 2

60R

E

T2 DEMOD SPI FLASH

3V3_VCC

SPI_CS_T2

F

FLASH_WP_T2

3V3_VCC

SPI_DO_T2

33R

R524

10k

R247

C175

R159

4k7

C624

1uF6V3

LM1117

IN OUT

ADJ

1234

10uF 10V

TP121

1

2

3

4 5

TP122

TP123

U6

VOUT

U11

MX25L512

CS#

HOLD#

SO

SCLK

WP#

VCC

TP112

SIGND

8

7

6

100R

R604

1 2

TP120

1

100R

R407

1N5819

R332

4k7

D14

C440

TP118

TP119

C29

100nF

6V3

16V

100uF

R609

68R

12

3V3_VCC

C368

6V3

22uF

C105

10V100nF

SPI_CLK_T2

SPI_DI_T2

3V3_VCC_TUNER

AVDD_APLL

16V

16V

F23

60R

C295

100nF

16V

C305

100nF

16V

C222

10uF

10V

3V3_VCC

3V3_VCC

C294

100nF

C306

100nF

16V

16V

C302

100nF

16V

C293

100nF

16V

C307

100nF

16V

AVDD25_ADC

F22

60R

F21

60R

100nF

2V5_VCC

3V3_VCC

3V3_VCC

1V2_VCC 1V2_VDD

F20

60R

F19

60R

F18

60R

C219

10uF

10V

F24

60R

100nF

C218

10uF

10V

C217

10uF

10V

C223

10uF

10V

C299

16V

C298

100nF

16V

C297

100nF

16V

C303

100nF

16V

AVDD_MPLL_T2

C296

100nF

C304

100nF

C221

10uF

10V

C220

10uF

10V

C308

16V

C301

100nF

16V

C300

100nF

16V

100nF

C309

16V

AVDD_SAR

AVDD33_ADC

3V3_VDDP3V3_VCC

VGA_R

VGA_G

VGA_B

SC_R

SC_G

SC_B

PR_IN

Y_IN

PB_IN

75R

75R

R556

1 2

1 2

SC_CVBS_IN

75R

R558

R557

1 2

VGA_G

VGA_HSNC

VGA_VSNC

SC_FB

Y_IN

68R

R595

68R

R594

68R

R593

68R

R597

68R

R598

68R

R599

68R

R600

68R

R601

68R

R602

S66

S68

S67

33R

R519

33R

R512

33R

R511

33R

R514

33R

R515

33R

R516

33R

R521

33R

R522

33R

R523

47nF

C186

16V

C196

C185

C184

C183

C182

C326

1nF

50V

47nF

C190

16V

C189

C191

C192

C193

C194

C329

1nF

47nF

C200

16V

C199

C201

C202

C203 47nF

C204

1nF

C327

47nF

16V

47nF

16V

47nF

16V

47nF

16V

47nF

16V

47nF

16V

47nF

16V

47nF

16V

16V

Y3

W2

W1

W3

V2

V3

V1

AC1

AC2

AB2

AB1

AB3

AA1

AA3

Y2

AA2

AC3

AC4

AA8

Y7

AA7

Y6

AB6

AA6

AA5

AB8

RIN0M

RIN0P

GIN0M

GIN0P

BIN0M

BIN0P

SOGIN0

HSYNC0

VSYNC0

RIN1M

RIN1P

GIN1M

GIN1P

BIN1M

BIN1P

SOGIN1

HSYNC1

VSYNC1

RIN2M

RIN2P

GIN2M

GIN2P

BIN2M

BIN2P

SOGIN2

HSYNC2

CVBSOUT1

CVBSOUT2

5

U4

MSD8WB9BX

VIDEO

TGPIO0/GPIO73

TGPIO1/GPIO74

TGPIO2/GPIO75

TGPIO3/GPIO76

SCH NAME :

DRAWN BY :

16V

VCOM

CVBS0

CVBS1

CVBS2

CVBS3

VIFP

VIFM

SIFP

SIFM

IFAGC

RFAGC

IP

IM

3V3_VCC

Y5

Y4

W5

W4

AB5

AA4

AB4

AE6

AD6

AD7

AC7

AC8

AD8

AC5

AD5

AD3

AD2

AC6

AE5

47nF

16V

47nF

47nF

C188

C187

C197

16V

47nF

4k7124k7

R161

100nF

100nF

R364

100R

C106

C107

04_TUNER_T2_DEMOD

C195

C198

10V

12

R596

R513

R520

10V

nc

R162

68R

33R

33R

R517

33R

R518

33R

CVBS0_OUT

S70

S71

IF_AGC

TUNER_SCL

TUNER_SDA

17mb95

75R

R560

1 2

OPTIONAL

SC_CVBS_IN

SAV_CVBS

SC_R

DVD_CVBS

DIGITAL_IF_P

DIGITAL_IF_N

T. SHT:

27-03-2012_16:58

87654321

E

F

A3

10

AX M

Page 27

1 2 3 4 5 6 7 8

BTB

1920

3V3_VCC

3V3_STBY

A

12V_STBY 12V_STBY

5V_VCC

12V_STBY

B

3V3_VCC

3V3_STBY

5V_VCC

12V_STBY

C

PROTECT

D

1V5_VCC

3V3_VCC

5V_VCC

1 2

1 2

5V_VCC

60R

F66

F17360R

E

W_ADAPTER

5

4

JK2

3

2

1

F

1718

1516

1314

1112

910

78

56

34

12

CN3

CN2

12

34

56

78

910

1112

1314

1516

1718

1920

S79

R165

4k7

10uF

C225

S88

ADAPTER SOCKET

TP33

TP48

TP35

TP34

3V3_VCC

24V_VCC_AU

5V_VCC

5V_STBY

DIMMING

BACKLIGHT_ON/OFF

power_pin3

power_pin1

S25

S8

S33

nc

S32

24V_VCC_AU

power cable

3V3_VCC

24V_VCC_AU

12V_STBY12V_STBY

5V_VCC

5V_STBY

DIMMING

BACKLIGHT_ON/OFF

power_pin3

power_pin1

LDO3

W/SAT

1

12

2

3

10V

4 5

12

C224

10uF

10V

POK

U15

EN

APL5910

VIN

Q43

Q44

GND

FB

VOUT

NCVCNTL

6

FDC642P

1

6

FDC642P

1

8

C117

7

6

5

3 4

2

5

3 4

2

5V_STBY

C1213

STBY_ON/OFF

STBY_ON/OFF_NOT

1V25_VCC

R2

R811

47k

R250

R1

C1198

33k

6V3

22uF

22k

R37

1k2

R34

30049469 1.13k

100nF

10V

30069495 AP2111 ???

22uF

6V3

U21

LM1117

IN OUT

ADJ

VOUT

1234

TP72

22uF

6V3

INVERTER SOCKET

CN8

TP107

R36

R35

R812

10k

1V26_VCC

22k

2k2

1

2

3

4

5

6

R44

1 2

10k

BC848B

TP37

3V3_VCC

R41

1 2

1k

Q6

TP50

TP38

TP51

DIMMING

BACKLIGHT_ON/OFF

PROTECT

5V_VCC

1 2

5V_VCC

C5

10V220nF

LDO1

1

C119

2

100nF

1

10V

C1214

S5

FS4

7A/32VDC

LDO2

S81

R45

10k

60R

22uF

C24

F63

S6

Q19

BC848B

12

3 4

3 4

3V3_STBY

3V3_STBY

VOUT1

1V2_VCC

1V5_VCC

VOUT2

!

12V_VCC

DC/DC2

12V_INV

!

2V5_VCC

1

POK

12

2

EN

APL5910

3

VIN

6V3

4 5

C151

10uF

10V

5

6

1

2

5

6

1

2

FDC642P

FDC642P

U5

Q27

Q28

GND

VOUT

FB

NCVCNTL

5V_STBY

TP36

8

C152

7

6

!

7A/32VDC

12V_STBY

VDDC

1V5_DDR0

100nF

10V

10k

R163

2k2

R77

FS1

C25

12

6V3

22uF

TP105

TP106

6V3

R290

22k

R289

47k

6V3

22uF

3V3_VCC

R139

1 2

TPS_ENABLE

12V_STBY

12V_INV

FB1

S85

C1209

22uF

S86

FB2

R2

R1

TP108

10k

BC848B

10k

R884

Q46

BC848B

12V_VCC

12V_STBY

50V

C1210

C1211

50V

R288

100R

Q47

12

R822

560R

4n7F

22uF

4n7F

R101

560R

2V5_VCC

C1228

C478

6V3

C479

22uF

C128

1uF

16V

6V3

R49

10k

10k

R48

VFB

18k

R821

10k

R255

12V_VCC

10uH

4u7H

10k

R256

7k5

R651

TPS_ENABLE

12V_VCC

12V_STBY

12

12

C129

DC/DC1

VIN1

1 2

L39

L40

C1188

10uF

16V

1 2

1 2

60R

1

EN

U9

2

VFB

VBST

TPS54528

3

VREG5

4

VSS

50V

8n2F

TPS54528

C1187

10uF

16V

F53

60R

C461

10uF

16V

VIN2

STBY_ON/OFF_NOT

12V_STBY

F4

60R

0R

F3

C131

22uF

16V

8

VIN

7

6

SSW

5

GND

50V

4n7F

C1207

C460

16V

10uF

47nF

16V

C205

C206

C1206

47nF

16V

4n7F

50V

F59

60R

1 2

12V_VCC

STBY_ON/OFF

3V3_STBY

D20

R164

1 2

10k

DC/DC4

C130

C55

100nF

22uF

16V

16V

16V

L3 10uH

C132

C92

100nF

EN1

11

BST

12

VIN1

13

LX1_0

14

LX1_1

15

LX2_0

16

LX2_1

17

VIN2

18

BST2

19

EN2

20

S91

S90

1 2

R198

1 2

10k

C5V6

R176

1 2

10k

R284

3k9

R282

1 2

10k

6V322uF

22uF 6V3

50V

4n7F

C475

R394

100k

R645

120k

C480

4n7F

50V

NC

R197

10k

Q11

BC848B

R96

120k

C133

1 2

1 2

50V

4n7F

C477

20k

R647

8

9

10

SS1

CMP1

RLIM1

TPS65251

RLIM2

SS2

COMP2

23

22

21

FB2

20k

R648

50V

C481

4n7F

MOSFET_CONTROLSTBY_ON/OFF_NOT

STBY_ON/OFF

STBY_ON/OFF

STBY_ON/OFF_NOT

50V22pFC139

R15

4k7

F14

1 2

60R

F62

1 2

60R

F7

60R

F10

60R

FB1

R658

390k

7

FB1

ROSC

U19

FB2

LOW_P

24

VFB

R38

22k

5V_VCC

5V_STBY

C473

FB3

4

5

6

FB3

SYNC

GND_0

PGOOD

27

26

25

S216

PROTECT

MOSFET_CONTROL

MOSFET_CONTROL

R646

C488

10uF

20k

3

CMP3

V7V

28

16V

50V

4n7F

2

SS3

V3V

29

C30

4u7F

10V

12V_STBY

50V

4n7F

C472

R644

120k

1

EN3

RLIM3

BST3

VIN3

LX3_1

LX3_0

GND_2

VIN_2

VIN_1

VIN_0

GND_1

AGND

30

5V_STBY

R47

10k

21

C134

220nF

R46

12

10k

SCH NAME :

DRAWN BY :

40

47nF

39

C207

38

37

36

C463

35

10uF

34

33

32

31

C1189

16V 10uF

21

25V

C135

220nF

12

12

25V

33k

R216

12

33k

R215

Q21

BC848B

05_POWER

50V

4n7F

C1208

16V

60R

F58

R217

R42

R173

1 2

47R

60R

F60

C1190

10uF

16V

12

33k

1k

Q22

BC848B

12

C1191

10uF

16V16V

12V_VCC

12

R174

1 2

47R

S15

3 4

DC/DC3

VIN3

12V_VCC

6V3

L38

4u7H

5

6

1

3 4

2

FS2S10

5

2

7A/32VDC

6

Q29

FDC642P

12V_VCC

1

SW1

17mb95

22uF

C1212

60RF1

1 2

TP90

5k6

R167

VOUT3

10k

R257

C483

4n7F

4k7

R335

1 2

R652

220R

TP52

C137

220uF

6V3

Q32

FDC642P

5V_VCC

SW2

TP89

4A

06-07-2012_14:53

87654321

3V3_VCC

50V

FB3

5V_VCC

C138

220uF

6V3

nc

12V_VCC

A3

T. SHT:

A

B

C

D

E

F

10

AX M

Page 28

1 2 3 4 5 6 7 8

OPTIONS TABLE

FHD 50Hz 3D FFC

3D_EN

PANEL_VCC OP_PIN5

A

OP_PIN42

OP_PIN43

OP_PIN27

OP_PIN10

OP_PIN11

OP_PIN9

OP_PIN6

OP_PIN8

OP_PIN7

OP_PIN5

PANEL_VCC

TX_2_CLK_P

TX_2_CLK_N

TX_2_2_P

TX_2_2_N

TX_2_1_N

TX_2_1_P

TX_2_0_P

PANEL_VCC

LVDS

TX_2_4_N

TX_2_4_P

TX_2_3_N

TX_2_3_P

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

TX_2_0_N

29

30

31

32

TX_1_4_N

TX_1_4_P

TX_1_3_P

TX_1_CLK_P

TX_1_3_N

TX_1_2_P

TX_1_CLK_N

TX_1_1_N

TX_1_1_P

TX_1_2_N

TX_1_0_N

TX_1_0_P

PANEL_VCC

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

123456789

LG BASED 30070519

CN11

MEGA_DCR_IN

PANEL_VCC

OP_PIN42

OP_PIN45

OP_PIN44

OP_PIN41

OP_PIN40

OP_PIN43

B

LVDS

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

10

11

12

13

14

PANEL_VCC

123456789

SAM BASED 30070519

CN12

MEGA_DCR_OUT

PANEL_VCC

PANEL_VCC

19" TO 22" DOUBLE LVDS FFC OPTIONS

PANEL_VCC

PANEL_VCC

OP_PIN9

TX_2_3_P

TX_2_3_N

TX_2_CLK_N

TX_2_CLK_P

TX_2_2_N

TX_2_2_P

TX_2_1_P

TX_2_1_N

TX_2_0_P

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

CN13

18

WXGA FFC

OP_PIN9

OP_PIN8

OP_PIN27

OP_PIN11

SAM

D

CN14

1

2

PANEL_VCC

3

4

5

6

LG

7

CN16

8

1

OP_PIN7

9

10

2

3

TX_1_2_N

TX_1_2_P

TX_1_CLK_N

TX_1_CLK_P

TX_1_3_N

TX_1_3_P

11

12

13

14

15

16

17

18

19

20

21

4

5

6

7

8

9

10

11

12

13

14

TX_1_3_P

TX_2_0_N

19

20

TX_1_1_N

TX_1_1_P

22

23

15

16

TX_1_3_N

TX_1_CLK_P

21

22

TX_1_0_P

24

25

17

18

TX_1_CLK_N

23

24

TX_1_0_N

26

27

19

20

TX_1_2_P

TX_1_2_N

25

26

OP_PIN10

OP_PIN6

28

29

21

22

TX_1_1_P

TX_1_1_N

27

28

OP_PIN5

FFC

30

23

24

TX_1_0_P

TX_1_0_N

29

30

25

26

FFC

PANEL_VCC

12V_VCC

12V_VCC

3D_EN

15.6"

PANEL_VCC

12V_VCC

PANEL_VCC OP_PIN43

PANEL_VCC

BACKLIGHT_ON/OFF

DIMMING

PANEL_VCC

27

28

FFC

29

30

S40

R239

33k

R89

1 2

10k

R236

33k

R88

1 2

10k

R235

33k

R81

1 2

10k

S39

1 2

R221

33k

R80

1 2

10k

S56

R220

33k

R79

1 2

10k

R241

33k

R87

1 2

10k

R248

33k

R91

1 2

10k

R238

33k

R90

1 2

10k

S54

1 2

S53

1 2

S35

R219

33k

R78

1 2

10k

S42

1 2

R218

33k

R50

1 2

10k

S41

1 2

S55

1 2

R246

33k

R92

1 2

10k

12

OP_PIN6

OP_PIN7

OP_PIN8

12

OP_PIN9

OP_PIN9

OP_PIN10

OP_PIN11

OP_PIN27

OP_PIN40

OP_PIN41

12

OP_PIN42

OP_PIN44

OP_PIN45

PANEL SUPPLY SWITCH