Page 1

FILE NO. 060-200508

SERVICE MANUAL

LCD Color Television

32WL55A

32WL55E

32WL55R

32WL55T

TOSHIBA CORPORATION, 2005

Published in Japan, Jun. 2005 (YC)

Page 2

TABLE OF CONTENTS

SERVICE SAFETY PRECAUTIONS .................................................................................................................................... 3

HANDLING THE LCD MODULE .......................................................................................................................................... 5

SERVICE MODE .................................................................................................................................................................. 7

LOCATION OF CONTROLS ............................................................................................................................................... 12

LAYOUT OF MAJOR BOARDS .......................................................................................................................................... 15

MECHANICAL DISASSEMBLY .......................................................................................................................................... 16

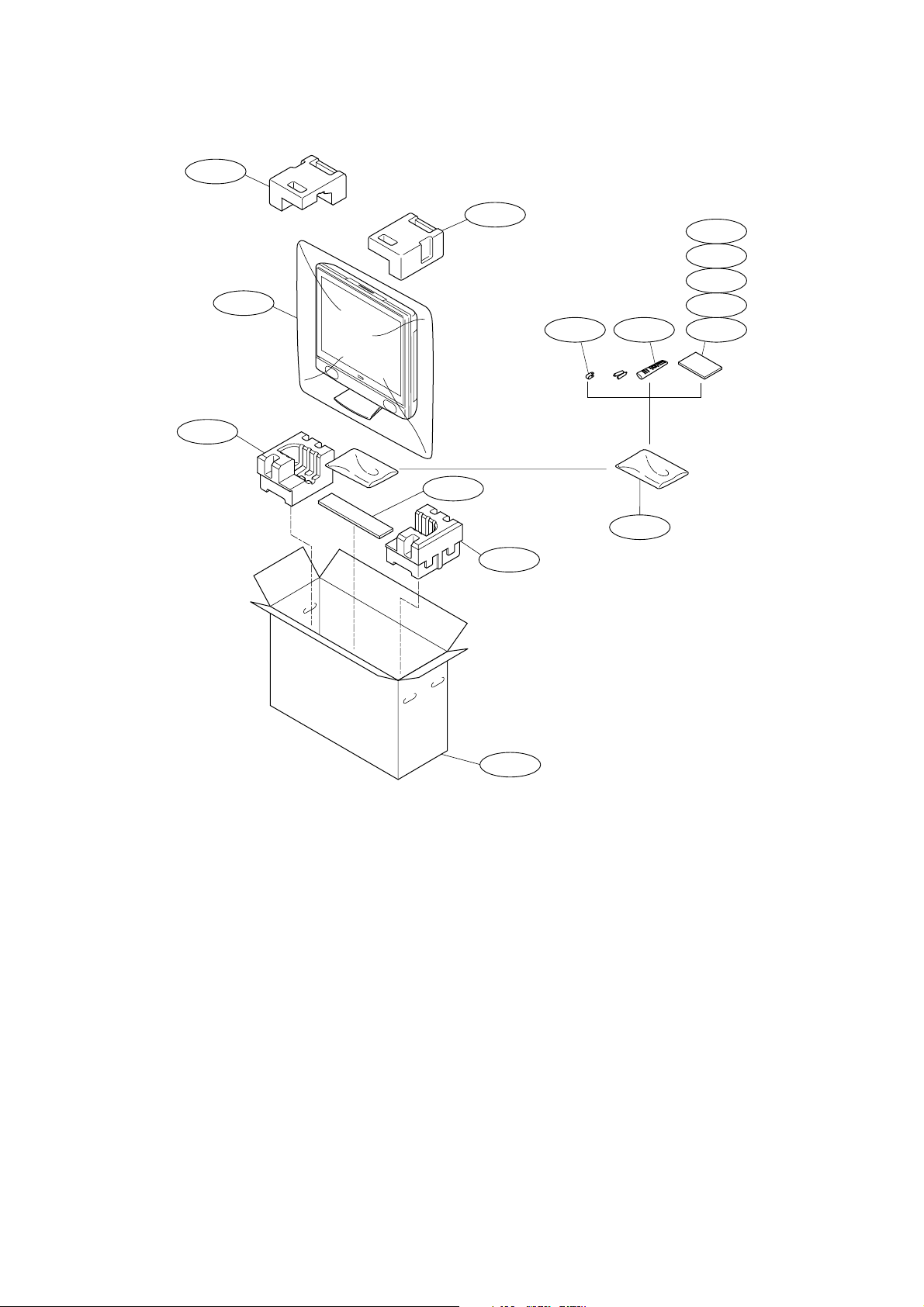

EXPLODED VIEW .............................................................................................................................................................. 18

PACKING DISASSEMBLY ................................................................................................................................................. 20

CHASSIS AND CABINET REPLACEMENT PARTS LIST ................................................................................................. 21

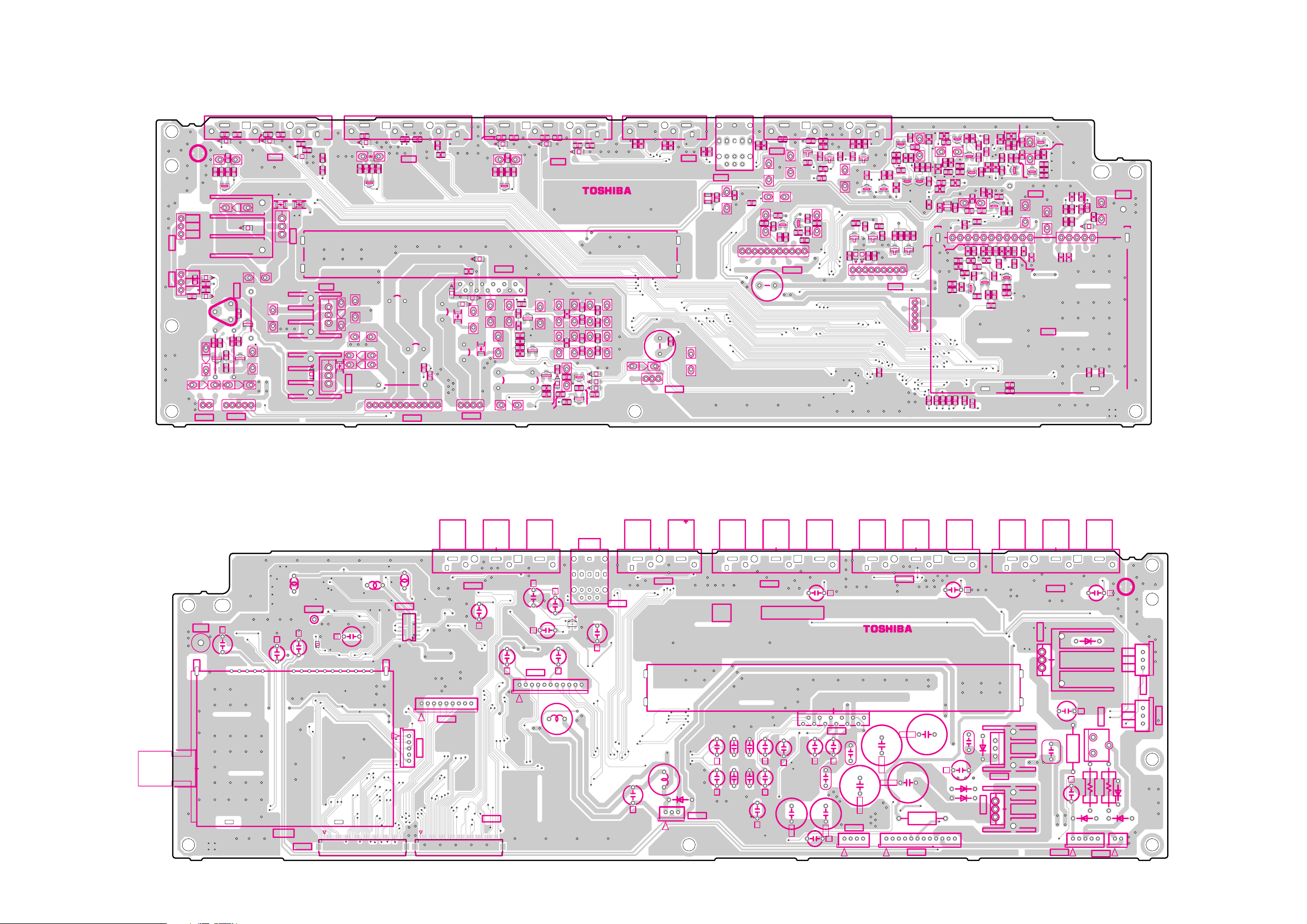

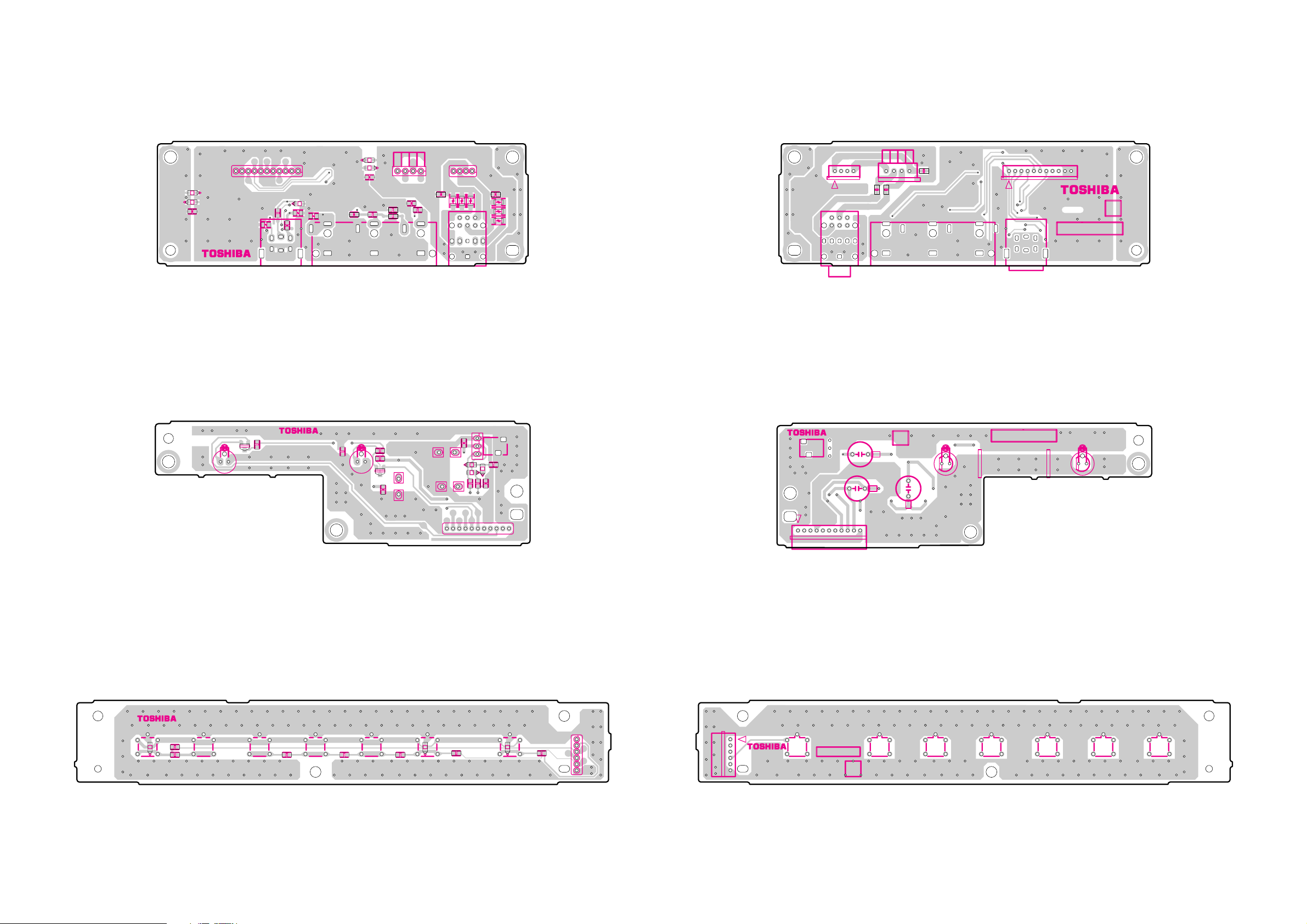

PC BOARDS TOP & BOTTOM VIEW ................................................................................................................................ 27

CIRCUIT BLOCK DIAGRAM .............................................................................................................................................. 40

SPECIFICATIONS ............................................................................................................................................................. 41

APPENDIX:

SCHEMATIC DIAGRAM

-

2

-

Page 3

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

SERVICE SAFETY PRECAUTIONS

• The caution items shown here describe major safety issues and should always be observed.

• The meanings of the various indications are as follows.

WARNING

CAUTION

* Physical damage means major damage to a home, furnishings and other possessions.

Examples of marks

SHOCK HAZARD

PROHIBIT DISASSEM-

BLING

UNPULUG

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users due to a product defect after the service operation is completed, could possibly be in

danger of injury or even death in the event of operational error.

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users after the service operation is completed, could possibly be in danger of injury, or

where there could be physical damage in the event of operational error.

The" indicates caution (including danger and warning).

The actual meaning of this caution is indicated inside the

The example shown to the left indicates the danger of "electrical shock".

indicates a forbidden action.

The

The actual meaning of this caution is indicated inside the

The example shown to the left indicates that disassembly is forbidden.

The

-

indicates a forced action (an action that must be performed).

The actual meaning of this forced action is indicated by

The example shown to the left indicates that the power plug must be disconnected.

"

or nearby illustrations or text.

or nearby illustrations or text.

-

or nearby illustrations or text.

-

3

-

Page 4

KEEP CHILDREN

AWAY

UNPULUG

SHOCK HAZARD

USE SPECIFIED

PARTS

CAUTION FOR

WIRING

CAUTION FOR

ASSEMBLING /

WIRING

WARNING

• Always advise users to keep children away.

There is danger of injury to children from tools, disassembled products, etc.

• Always disconnect the power plug before starting work whenever power is not required.

Failure to disconnect the power plug before starting work can result in electrical shock.

• Depending on the model, use an insulation transformer or wear gloves when servicing with the

power on, and disconnect the power plug to avoid electrical shock when replacing parts.

In some cases, alternating current is also impressed in the chassis, so electrical shock is possible if the chassis is contacted with the power on.

• Always use the replacement parts specified for the particular model when making repairs.

The parts used in products have the necessary safety characteristics such as inflammability,

voltage resistance, etc.; therefore, use only replacement parts that have these same characteristics.

Use only the specified parts when the

• Parts mounting and routing of the wiring should be the same as that used originally.

For safety purposes, insulating materials such as tubing or tape is sometimes used and printed

circuit boards are sometimes mounted floating.

Also make sure that wiring is routed and clamped to avoid parts that generate heat and which

use high voltage. Always follow the original scheme.

• After a repair has been completed, reassemble all disassembled parts, and route and reconnect the wiring, in accordance with the original scheme.

Do not allow internal wiring to be pinched by cabinets, panels, etc.

Any error in reassembly or wiring can result in electrical leakage, flame, etc., and may be

hazardous.

mark is included in a circuit diagram or parts list.

CHECK INSULATION

RESISTANCE

PROHIBIT

REMODELING

• After completing the work, disconnect the power plug from the outlet, remove the antenna, turn

on the power switch. Then, use a 500V insulation resistance meter to check the insulation

resistance of the antenna terminal, other metallic parts and between the prongs of the power

plug to make sure that the insulation resistance is 1M 1 or more.

The set will require inspection and repair if the insulation resistance is below this value.

• Never remodel the product in any way.

Remodeling can result in improper operation, malfunction, or electrical leakage and flame,

which may be hazardous

-

4

-

Page 5

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

HANDLING THE LCD MODULE

Safety Precautions

In the event that the screen is damaged or the liquid crystal

(fluid) leaks, do not breathe in or drink this fluid. Also, never

touch this fluid.

Such actions could cause toxicity or skin irritation. If this fluid

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the skin or clothing, wipe off

with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly

with running water.

Precautions for Handling the LCD Module

The LCD module can easily be damaged during disassembly

or reassembly; therefore, always observe the following precautions when handling the module.

1. When attaching the LCD module to the LCD cover, position it appropriately and fasten at the position where the

display can be viewed most conveniently.

3. If the panel surface becomes soiled, wipe with cotton or a

soft cloth. If this does not remove the soiling, breathe on

the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleaner

as a cleaner. Wipe off the panel surface by drop the cleaner

on the cloth. Do not drop the cleaner on the panel. Pay

attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for an

extended period of time can result in discoloration or

stripes. Immediately remove any type of fluid from the

screen.

2. Carefully align the holes at all four corners of the LCD

module with the corresponding holes in the LCD cover

and fasten with screws. Do not strongly push on the module because any impact can adversely affect the performance. Also use caution when handling the polarized screen

because it can easily be damaged.

The metal edges of the LCD module

CAUTION

are sharp, so use caution to avoid injury.

5. Glass is used in the panel, so do not drop or strike with

hard objects. Such actions can damage the panel.

6. CMOS-LSI circuitry is used in the LCD module, so avoid

damage due to static electricity. When handling the module, use a wrist ground or anchor ground.

-

5

-

Page 6

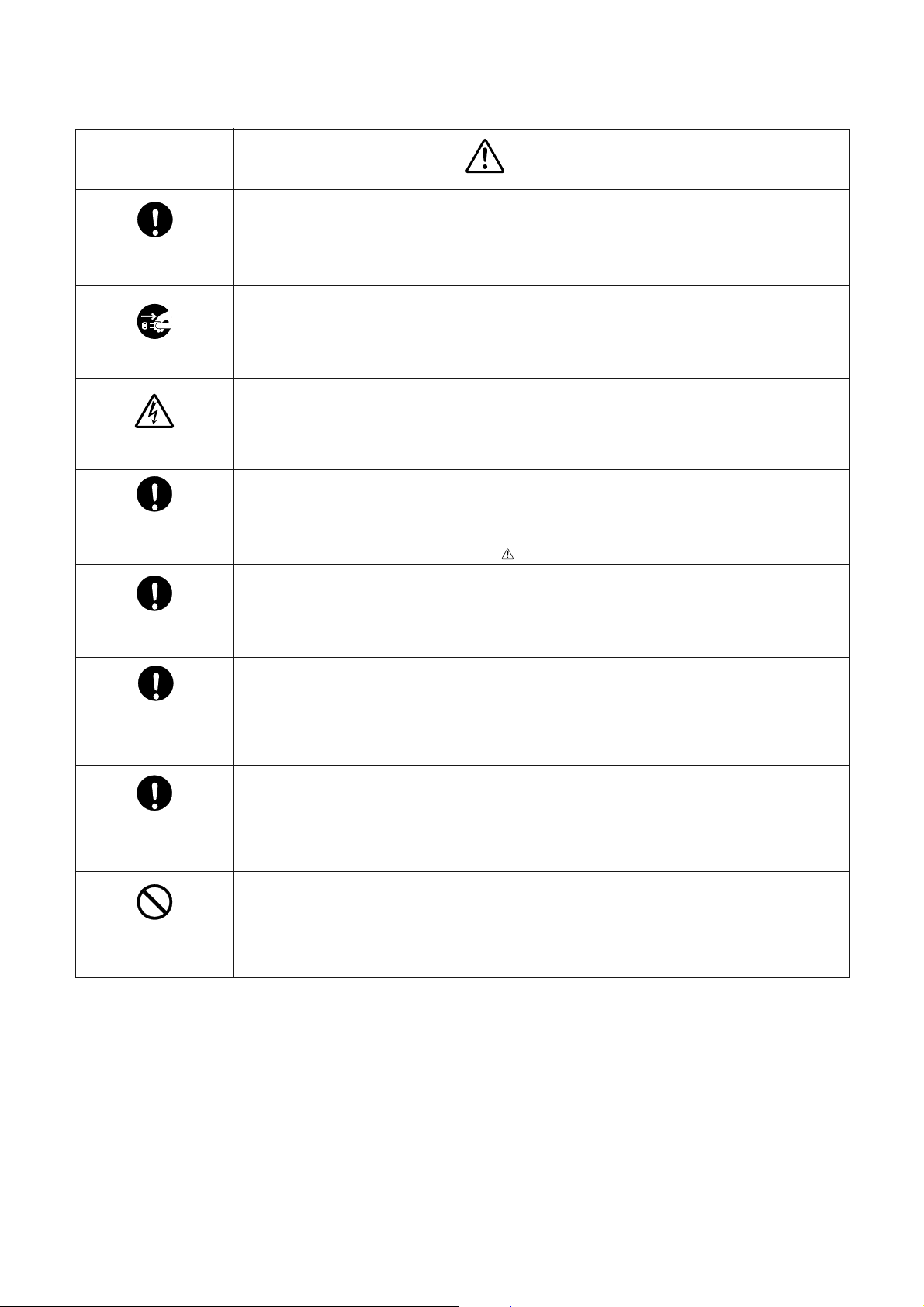

7. Do not expose the LCD module to direct sunlight or strong

ultraviolet rays for an extended period of time.

8. Do not store the LCD module below the temperature conditions described in the specifications. Failure to do so

could result in freezing of the liquid crystal due to cold air

or loss of resilience or other damage.

9. Do not disassemble the LCD module. Such actions could

result in improper operation.

10. When transporting the LCD module, do not use packing

containing epoxy resin (amine) or silicon resin (alcohol or

oxim). The gas generated by these materials can cause

loss of polarity.

-

6

-

Page 7

SERVICE MODE

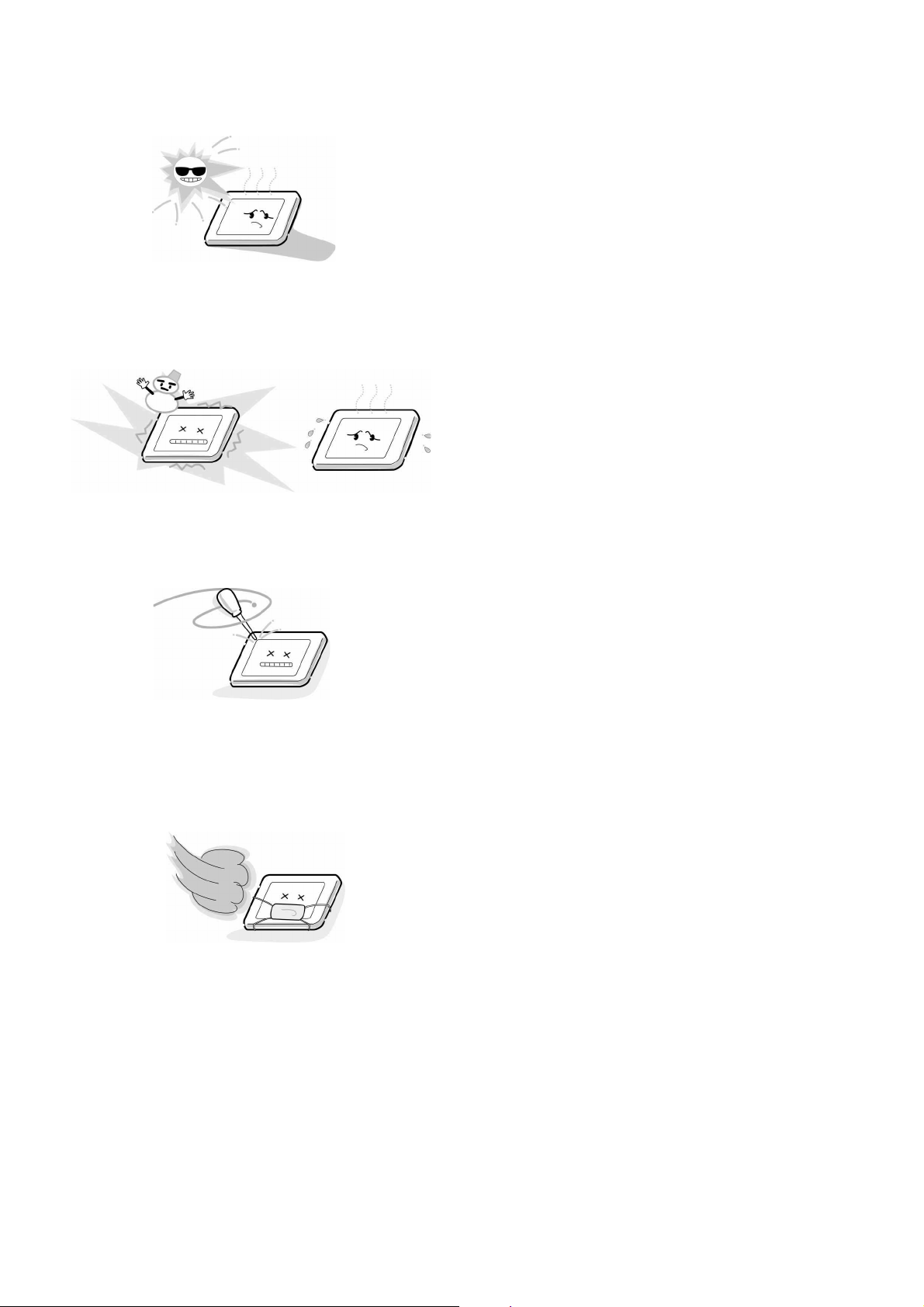

1. ENTERING SERVICE MODE

1) Press

Remote Control. keep pressing. press MENU button on TV set.

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

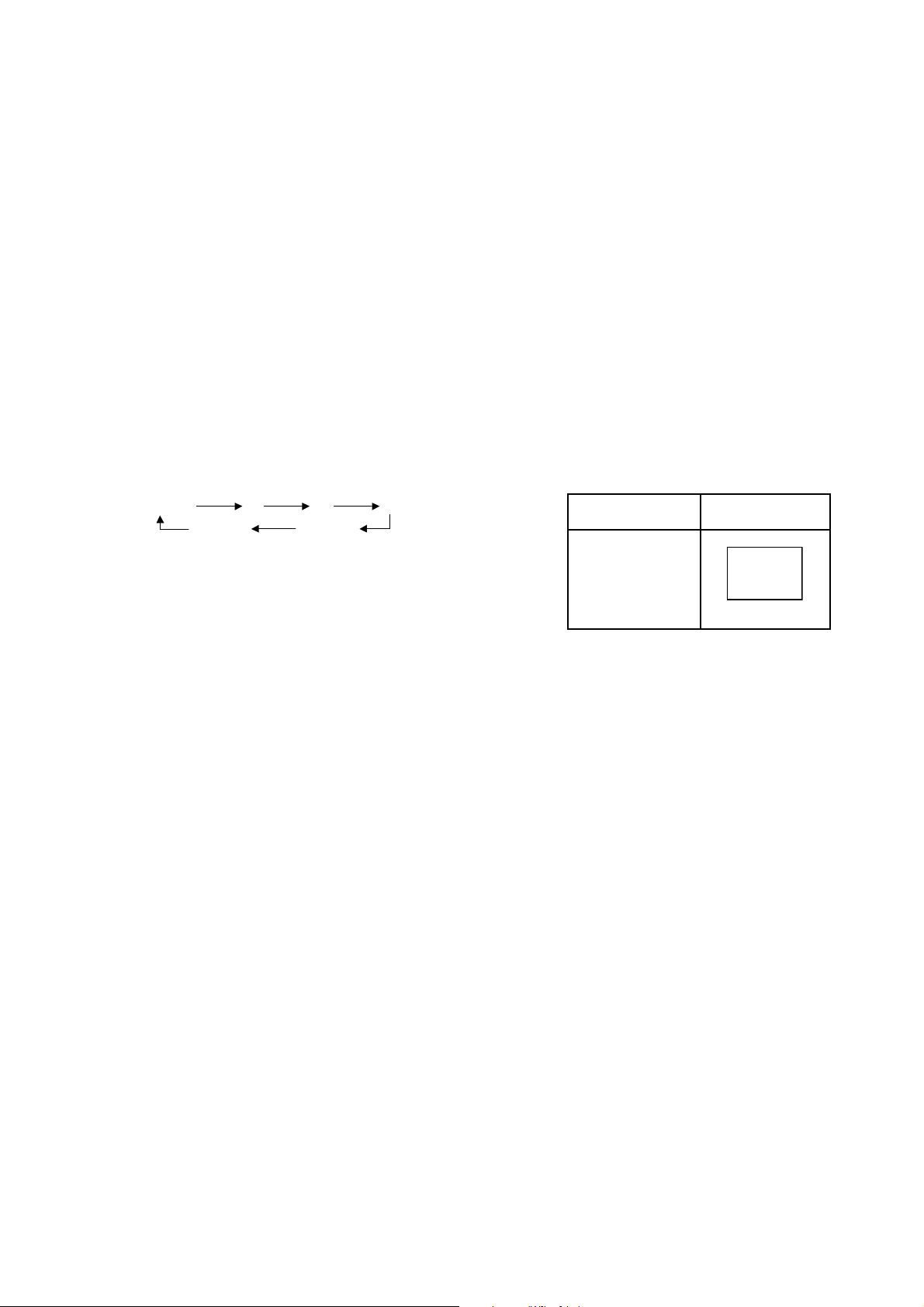

button once on 2) Press button again and 3) While pressing the button,

or Sound Mute

Service mode Adjustment mode

Press

Press

(Service mode display)

Test signal selection : a button (on Remote)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume ; +/– (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory : CALL + Channel button on TV (s)

Reset the count of operating protect

circuit to “00”: CALL + Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“SCNT” selection : 4 button

“COLP” selection : 5 button

“TNTC” selection : 6 button

Automatic A/D Adjustment(PC, Component)

Self diagnostic display ON/OFF : 9 button

CAUTION : Never try to perform initialization unless you have changed the memory IC.

: 7 button

Color thickness correction

note: Displayed differently as shown below, de-

pending on the setting of the receiving color

system.

COLP (PAL)

COLC (NTSC)

COLS (SECAM)

-

7

-

Page 8

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

5. ADJUSTING THE DATA

1) Pressing of VOLUME ; +/– button will change the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA

After replacing EEPROM IC, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the CALL button on the Remote, then press the CHANNEL s button on the TV.The initialization of EEPROM IC

has been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Auto tune” on the owner’s manual.

CAUTION: Never attempt to initialize the data unless EEPROM IC has been replaced.

7. TEST SIGNAL SELECTION

1) Every pressing of a button on the Remote Control changes the built-in test patterns on screen as described below

in SERVICE MODE.

R

All BlackAll White

BSignal off G

Signals Picture

• Red raster

• Green raster

• Blue raster

• All Black

• All White

-

8

-

Page 9

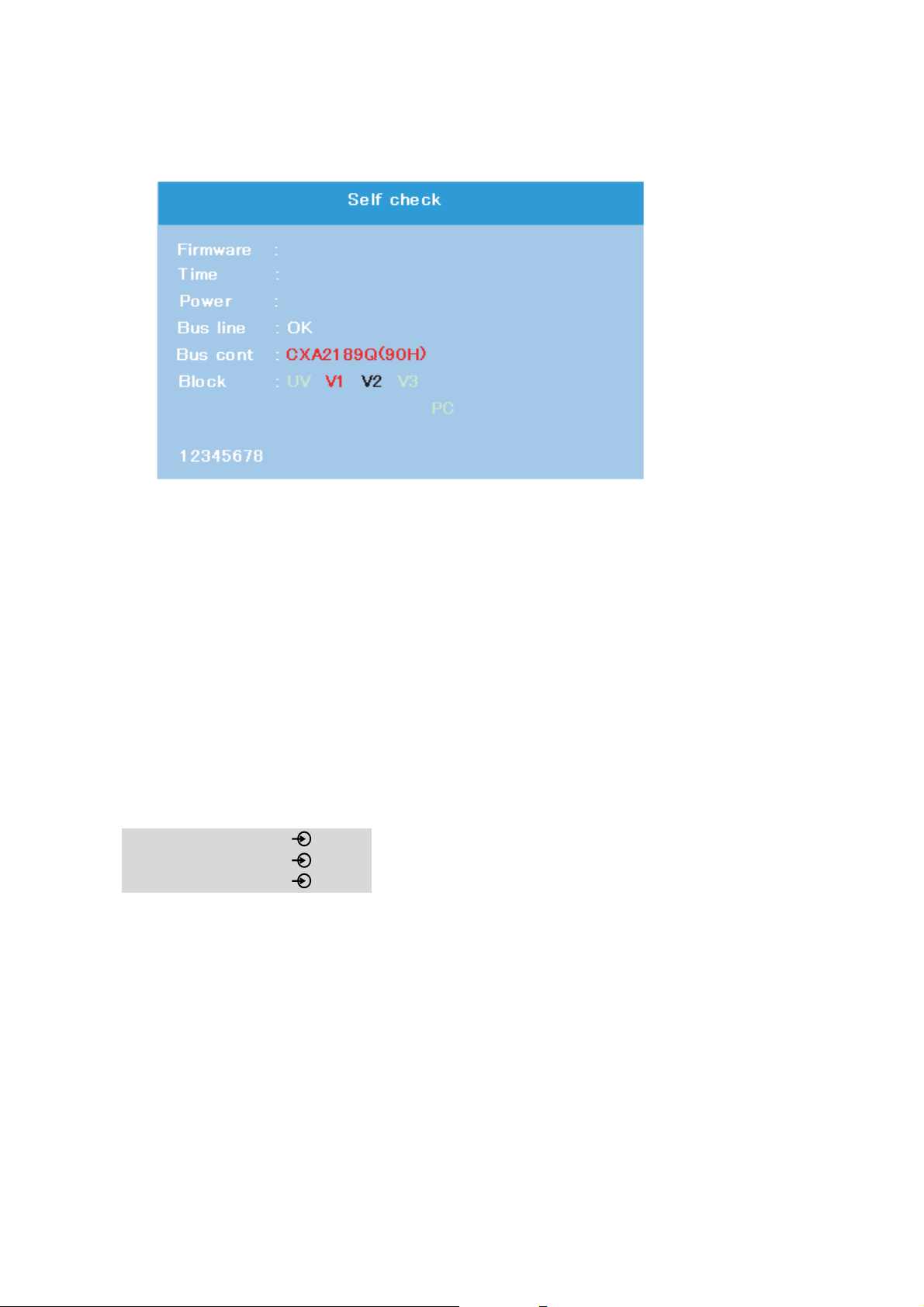

8. SELF DIAGNOSTIC FUNCTION

32WL55A

WL55_ASIA_0100

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s is executed properly.

2) During diagnosis, the following displays are shown.

1

2

3

WL55_ASIA_0100

000000

000

4

5

6

32WL55A

78

1 Firmware :

Version information of microprocessor

In case of file name : WL55_ASIA and Version : 0100 indicates[WL55_ASIA_0100].

2 Time : Total hour of turn the TV on. (Unit : H)

3 Power :Operation number of protecting circuit ----"000" is normal.

When indication is other than "000", overcurrent apt to flow, and circuit parts may possibly be damaged.

4 Bus line : --"OK" is normal

"SCL-GND"(Red indication) : SCL-GND short circuit

"SDA-GND"(Red indication) : SDA-GND short circuit

"SCL-SDA"(Red indication) : SCL-SDA short circuit

5 Bus cont : --- "OK" is normal.

NG is abnormal(Red indication).

When type name of semiconductor indicates.

6 Block

UV : TV reception mode

V1 : VIDEO 1 input mode ( 1)

V2 : VIDEO 2 input mode ( 2)

V3 : VIDEO 3 input mode ( 3)

7 8 digit : CD number

8 Model name (7 digit)

-

9

-

Page 10

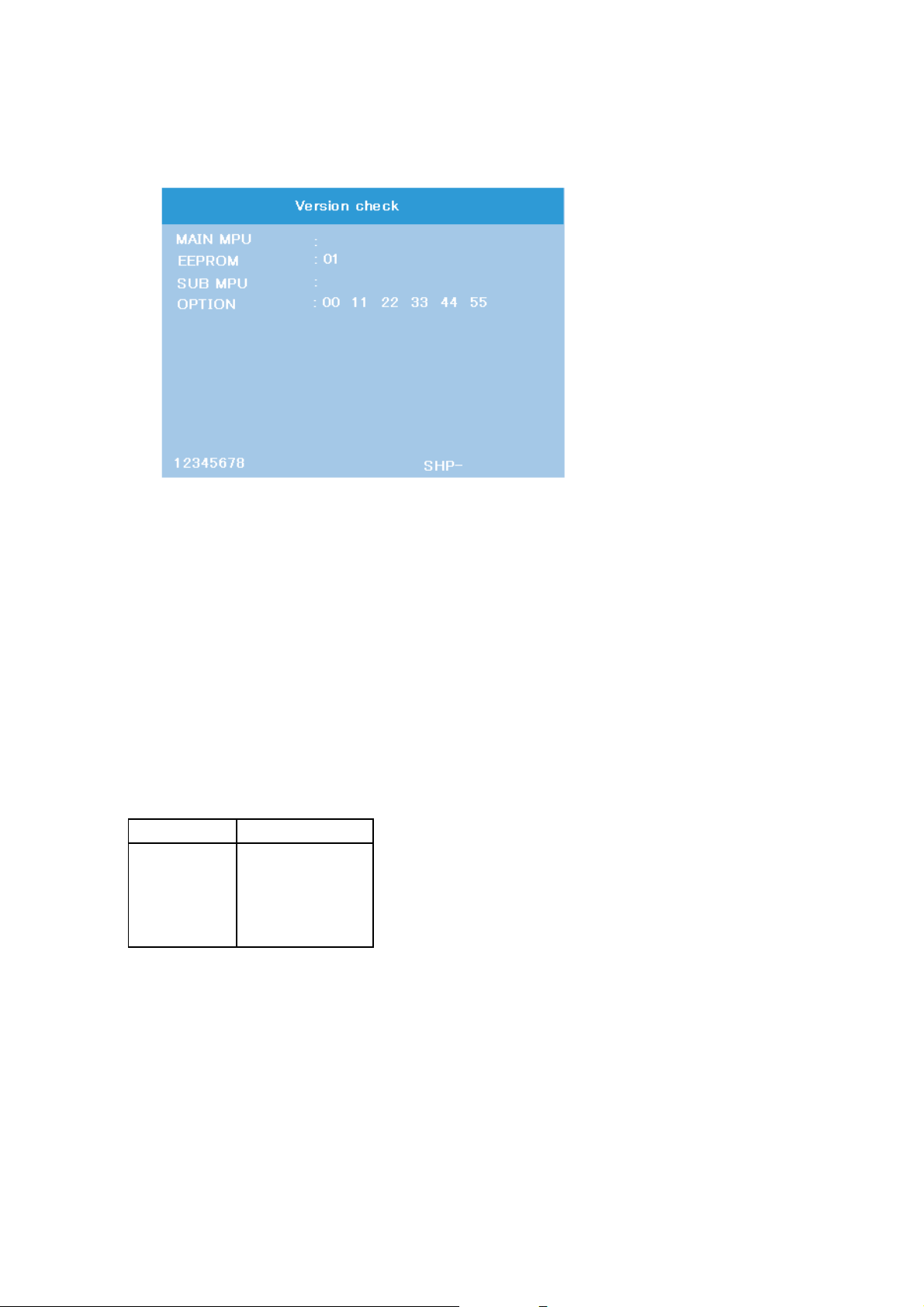

9. VERSION CHECK MODE

1) Press “9” button twice on Remote Control during display of adjustment menu in the service mode. The version of main

MPU will begin to check.

2) During Version Check, the following displays are shown.

1

WL55_ASIA_0100 (A16)

2

3

2E

4

5

32WL55A

32

67

1 MAIN MPU :

Version information of microprocessor

In case of file name : WL55_ASIA, Version 0100 for Code Program Version

and (A16) for OSD Version indicates [WL55_ASIA_0100(A16)]

2 EEPROM :

Version information of EEPROM : Display 1 byte data.

3 SUB MPU :

Version information of SUB MPU : Display 1 byte data.

4 OPTION :

Option information : Display six numbers of 1 byte data.

5 CD number : Display 8 digit number

6 Model name : Display 7 digit number

7 LCD Panel Vender information display

The following Panel Vender and screen size are displayed.

Panel Vender Screen Size(Inch)

LPL -23

SHP -26

CMO -32

-37

-47

Example : SHP-32 indicates that Vender is SHP and Screen Size is 32 inch.

-

10

-

Page 11

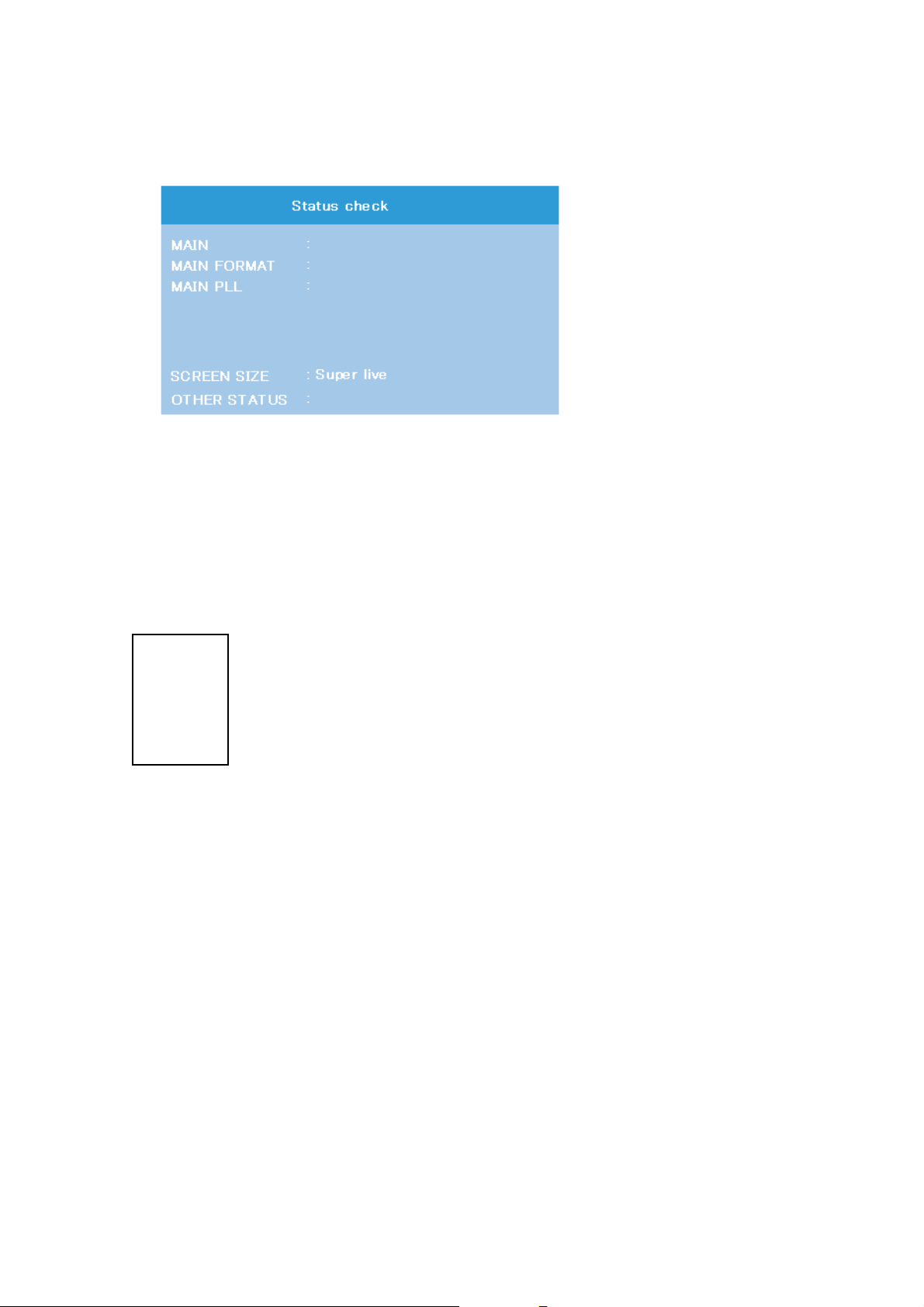

10. STATUS CHECK MODE

1) Press “9” button thrice on Remote Control during display of adjustment menu in the service mode. The status of this model

will begin to check.

2) During Status Check, the following displays are shown.

1

2

3

EXT1

1080i-50

C6 38 54 CE 08

4

5

0000 0000 0000

1 MAIN :

Main source information :

Display RF position number (0 - 99) on the main screen, or Input Source (EXT1/2/3/HDMI etc.)

2 MAIN FORMAT :

Display Video and PC format information

3 MAIN PLL :

Main PLL information : Display 1 byte data at five.

4 SCREEN SIZE :

Display the screen size as follows.

Super live

Cinema

Subtitle

14:9

Wide

4:3

5 OTHER STATUS :

Other status information : Display three numbers of 2 byte data.

-

11

-

Page 12

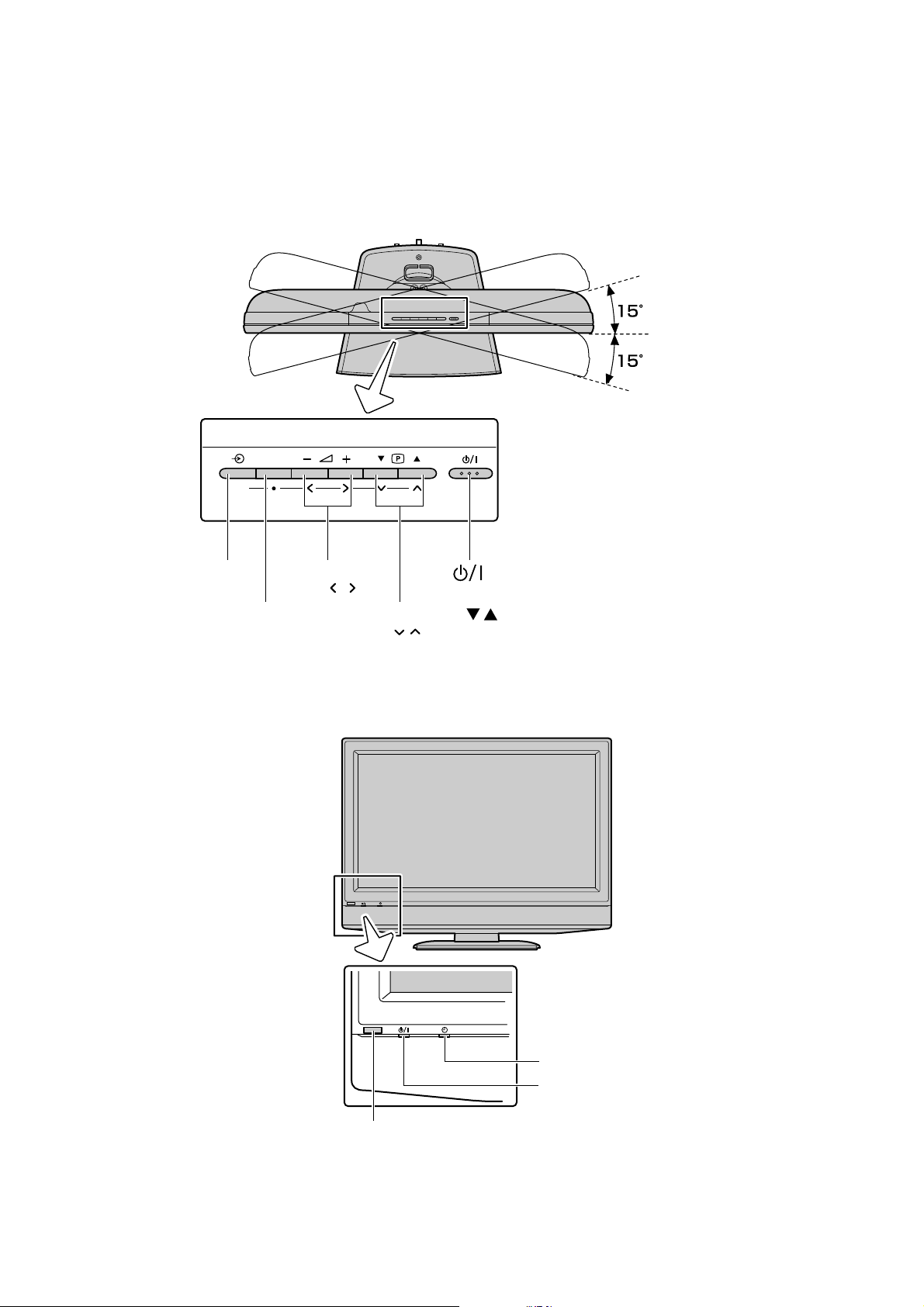

TV top

OK

Top view

MENU

LOCATION OF CONTROLS

TV top view

You can swivel the TV screen.

Swivel angle: 15 degrees to

left and right.

TV front

Input source

selection

MENU

Volume – +

Menu

Power

Program position

Menu

TV front view

Remote sensor

-

12

On-timer indicator (green)

Power indicator (red)

-

Page 13

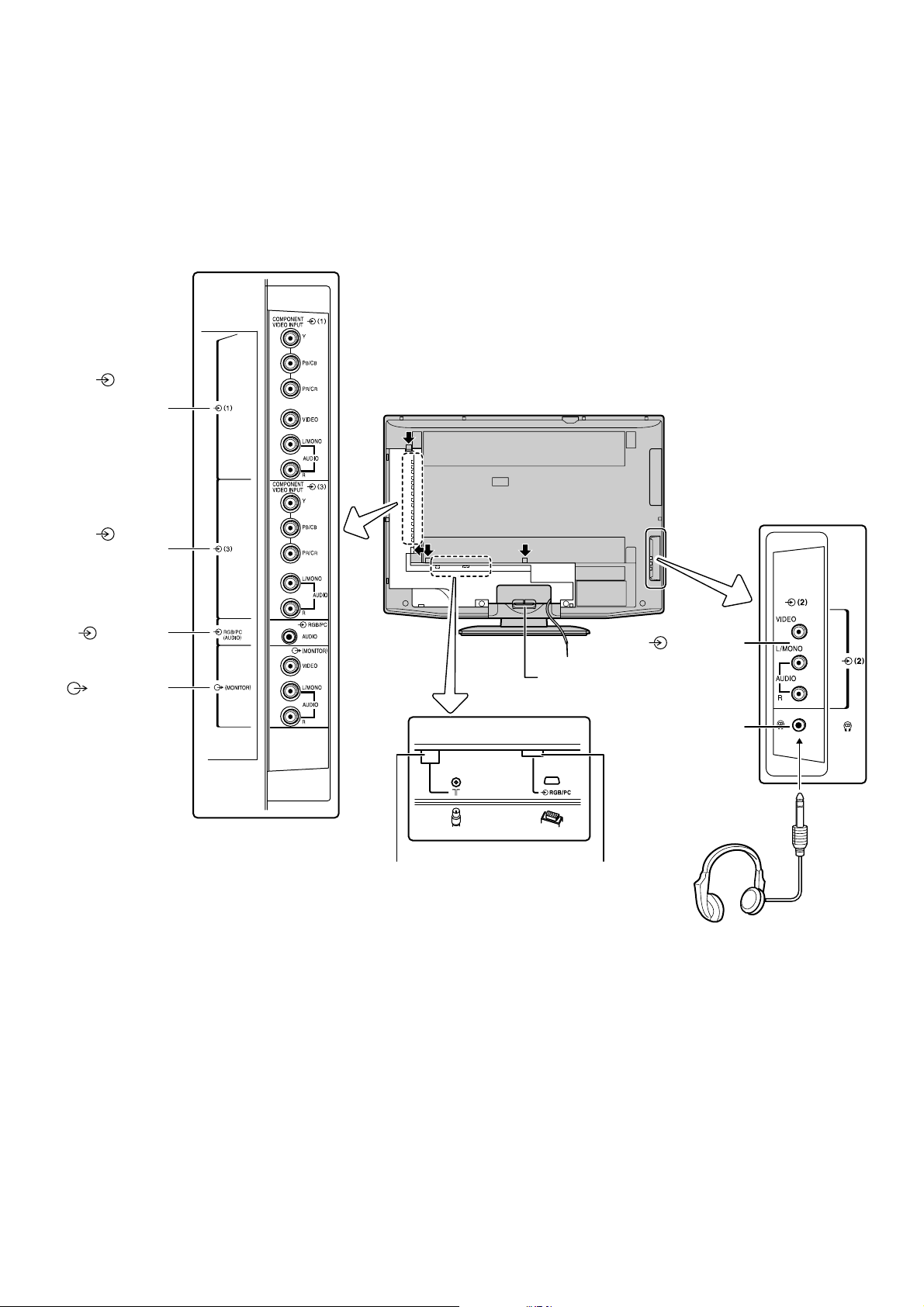

TV back

(1)

Video input/

COMPONENT

VIDEO INPUT

terminals

(3)

COMPONENT

VIDEO INPUT

terminals

Right side view

TV back view

Left side view

RGB/PC

Audio input

MONITOR

output terminals

Power cord

Cable holder

Back view

Antenna input RGB/PC input

(2) Video 2

input terminals

Headphone jack

(3.5 mm, stereo)

Headphones

(Not supplied)

-

13

-

Page 14

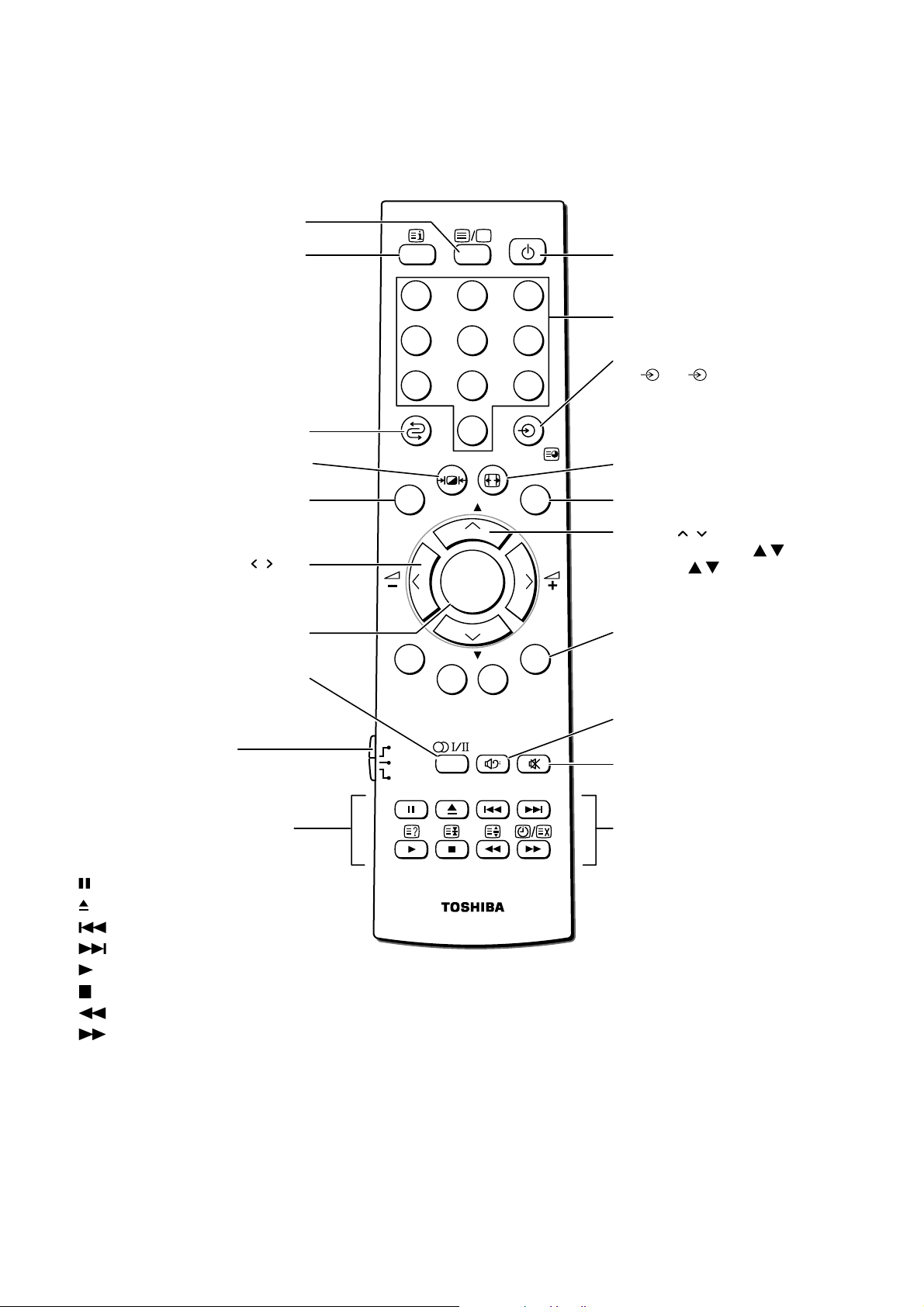

Remote control

Teletext on/off

CALL

Initial/index function for Teletext

To return to the previous program

Picture mode selection

MENU

DVD MENU

• Menu

• Volume – +

OK

Stereo/bilingual selection

CALL

21 3

54 6

87 9

0

MENU EXIT

DVD

MENU

P

OK

P

Power on/Standby

(For Toshiba TV/VCR/DVD)

Number buttons (0-9)

• Input source selection

(

1 –

3, PC)

• To access sub-pages when in

teletext

Picture size selection

EXIT

• Menu

• Program position

• Teletext

Teletext control buttons

(Four colored buttons: Red, Green,

Yellow, Blue)

Mode switch

TV : To control TV

VCR : To control VCR

DVD : To control DVD

When in VCR or DVD mode:

(Only for Toshiba VCR/DVD

players)

to PAUSE

to EJECT

to SKIP-REWIND

to SKIP-FORWARD

to PLAY

to STOP

to REWIND

to FAST FORWARD

TV

VCR

DVD

Bass boost on/off

Sound mute

When in TV (Teletext) mode:

?

To reveal concealed text

v

To hold a wanted page

^

To enlarge teletext display size

y/X

• To select a page while viewing a

normal picture.

• To select the time display.

-

14

-

Page 15

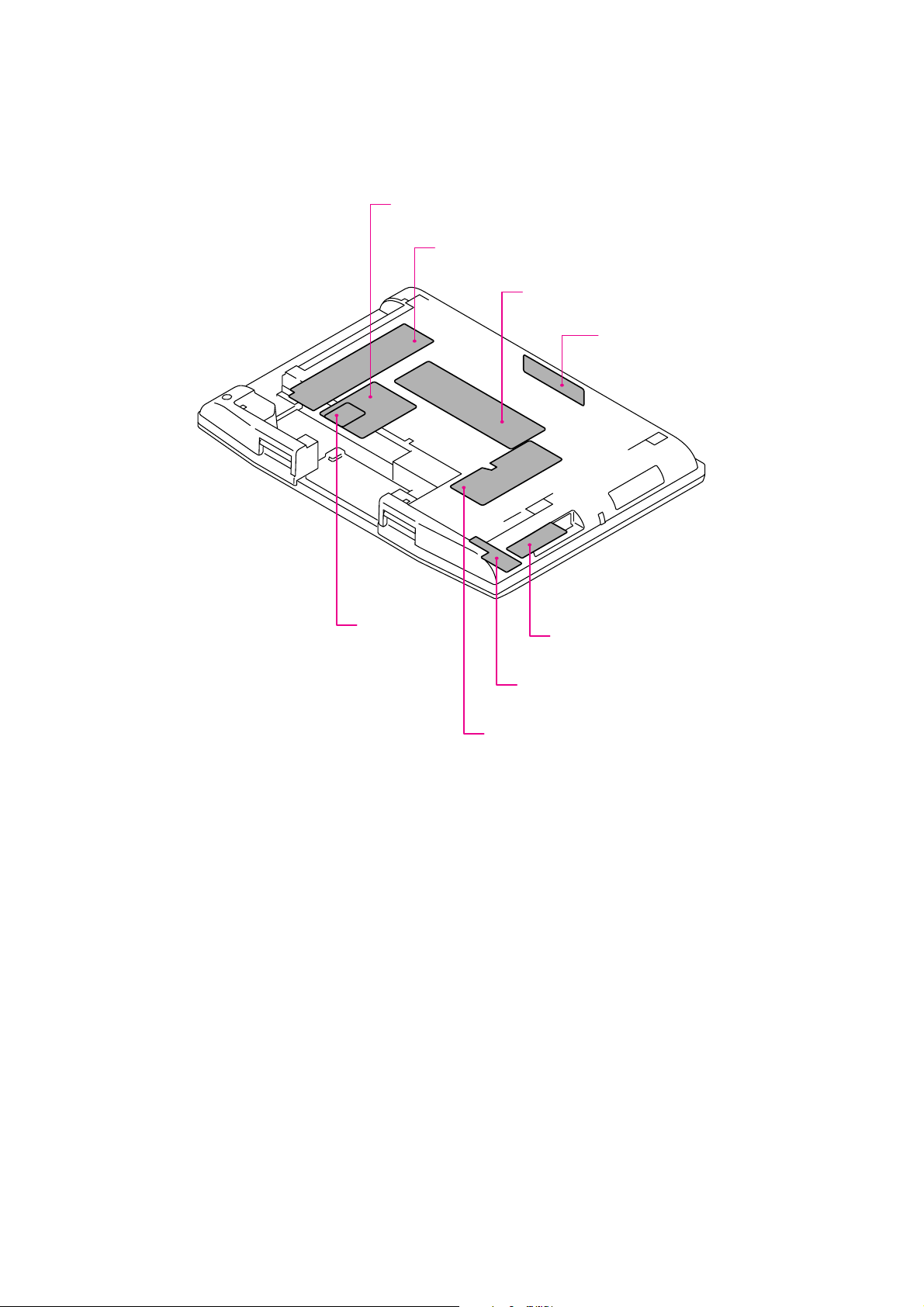

LAYOUT OF MAJOR BOARDS

U113A

SIGNAL BOARD

U111A

AV OTHER BOARD

U112A

POWER BOARD

U111D

KEY BOARD

U111E

PC-IN BOARD

U111B

FRONT AV BOARD

U111C

LED/RMT BOARD

U112B

AC-IN BOARD

-

15

-

Page 16

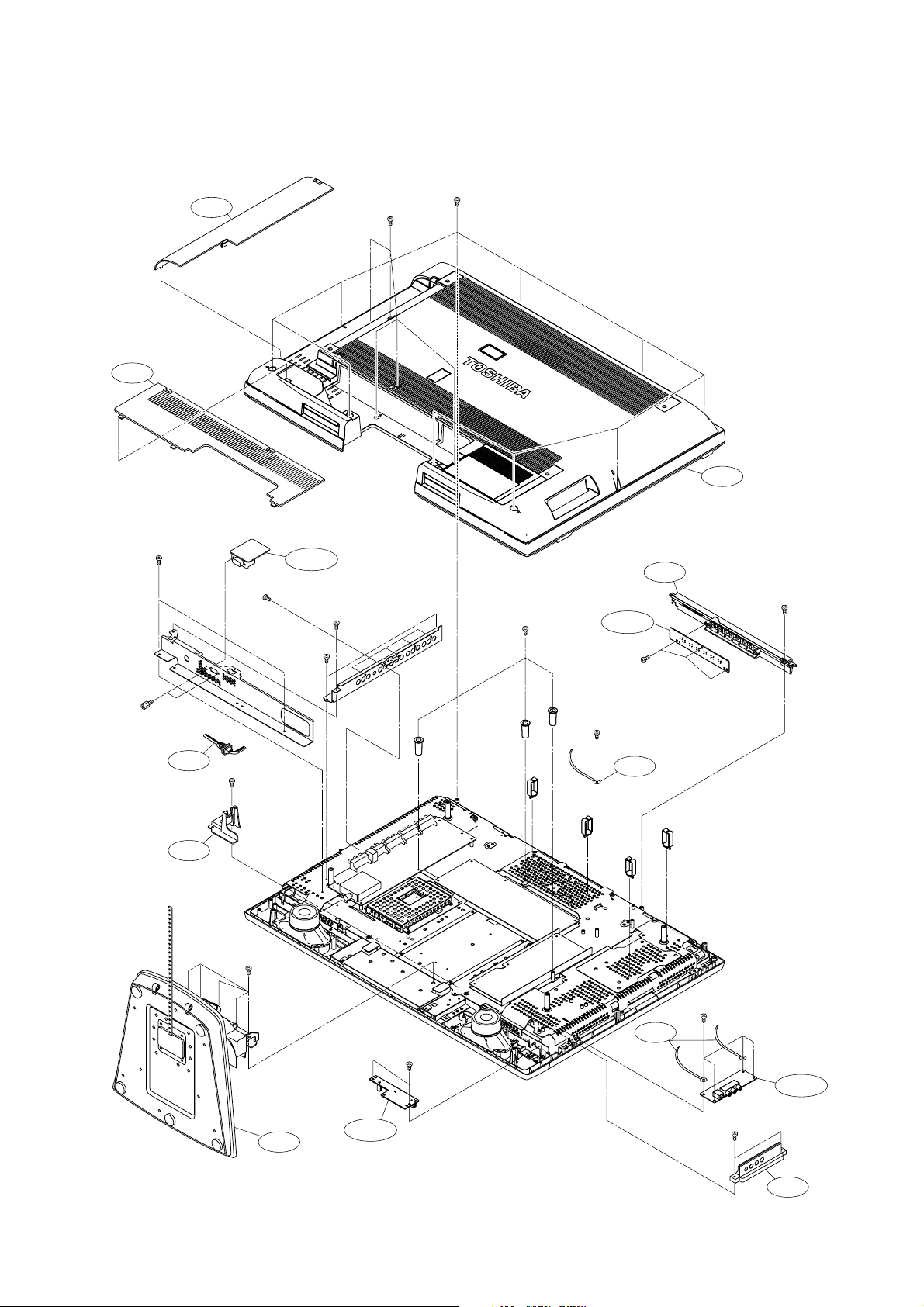

MECHANICAL DISASSEMBLY

1. Remove the stand (foot) and back cover.

A420

A445

A450

PP5×16

SW+W SBN

×

5

PP3×8

+SW+

×

5

W SBN

BITTB4×16 SBN

×

10

A401

2. Remove the boards (FRONT AV, LED/RMT, KEY, PC-IN) and piece key ass'y.

PP3×8+SW+W ECO

×

3

U111D

BITTB3×8 SBN

×

3

PP3×8+SW+W ECO

A340

PP12

PP08

PP3×8

+SW+

PP3×8+SW+W ECO

×

4

U111E

PP3×8

+SW+

W SBN

×

3

+SW+

4-40UNC

JFS-4S L=13

PP3×8+SW+W ECO

P801

A315

PP3×8

+SW+

W SBN

BITTB

3×12 SBN

×

5

PP3×8

W SBN

×

2

BITTB3×12 SBN

×

2

W SBN

U111B

U111C

-

16

PP3×8+SW+W ECO

×

-

2

A320

Page 17

3. Remove the boards (POWER, AC-IN, SIGNAL, AV OTHER) and speaker.

PP3×8+SW+W ECO

×

4

BITTB4×16 SBN

×

4

W661

BITTB4×16 SBN

PP08

×4

W661

PP3×8+SW+W ECO

×

4

PP08

U111A

H001

U113A

PP3×8+SW+W ECO

×

5

U112A

PP3×8+SW+W ECO

×

PP12

5

U112B

4. Remove the display.

PP3×8+SW+W ECO

PP3×8+SW+W ECO

×

2

A317

PB4×5 SNI

×

2

PP4×5 SNI

×

×

2

2

BITTB4×16 SBN

×

14

PB4×5 SNI

×

2

B001

-

17

A201

-

Page 18

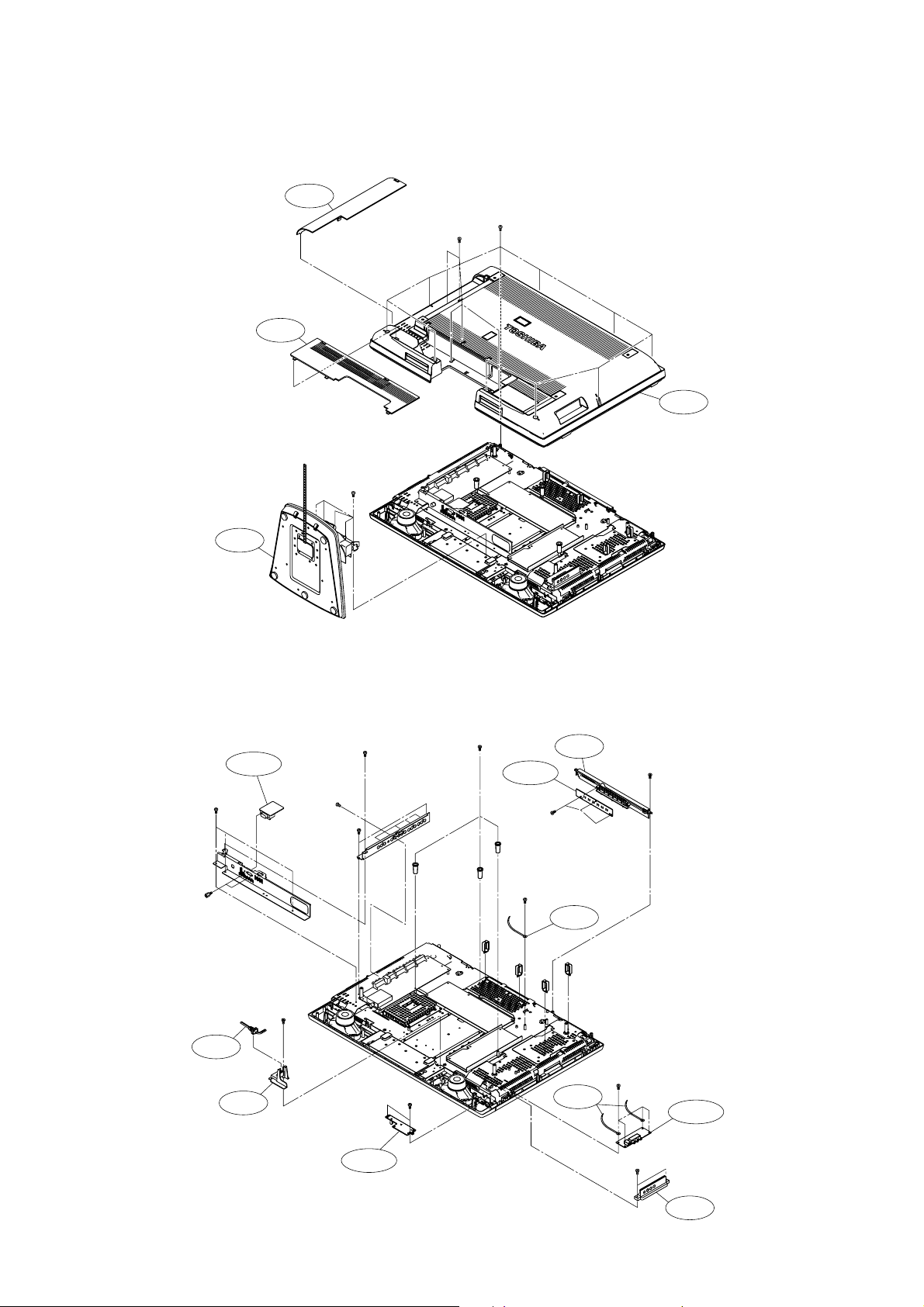

1. Chassis Block

EXPLODED VIEWS

A450

A445

PP3×8+SW+W SBN

×

3

BITTB3×12 SBN ×5

PP3×8

+SW+

×

PP3×8+SW+W SBN

×

5

U111E

PP3×8+SW+W SBN

W SBN

2

BITTB4×16 SBN ×10

PP3×8+SW+W ECO

×

3

A401

A340

PP3×8+SW+W ECO

U111D

BITTB3×8 SBN ×3

4-40UNC

JFS-4S L=13

P801

A315

PP3×8

+SW+

PP5×16

SW+W SBN

×

5

A420

W ECO

BITTB3×12 SBN

U111C

PP3×8+SW+W ECO

PP12

PP3×8+SW+W ECO

×

4

PP08

×

2

U111B

PP3×8+SW+W ECO

×

2

-

18

A320

-

Page 19

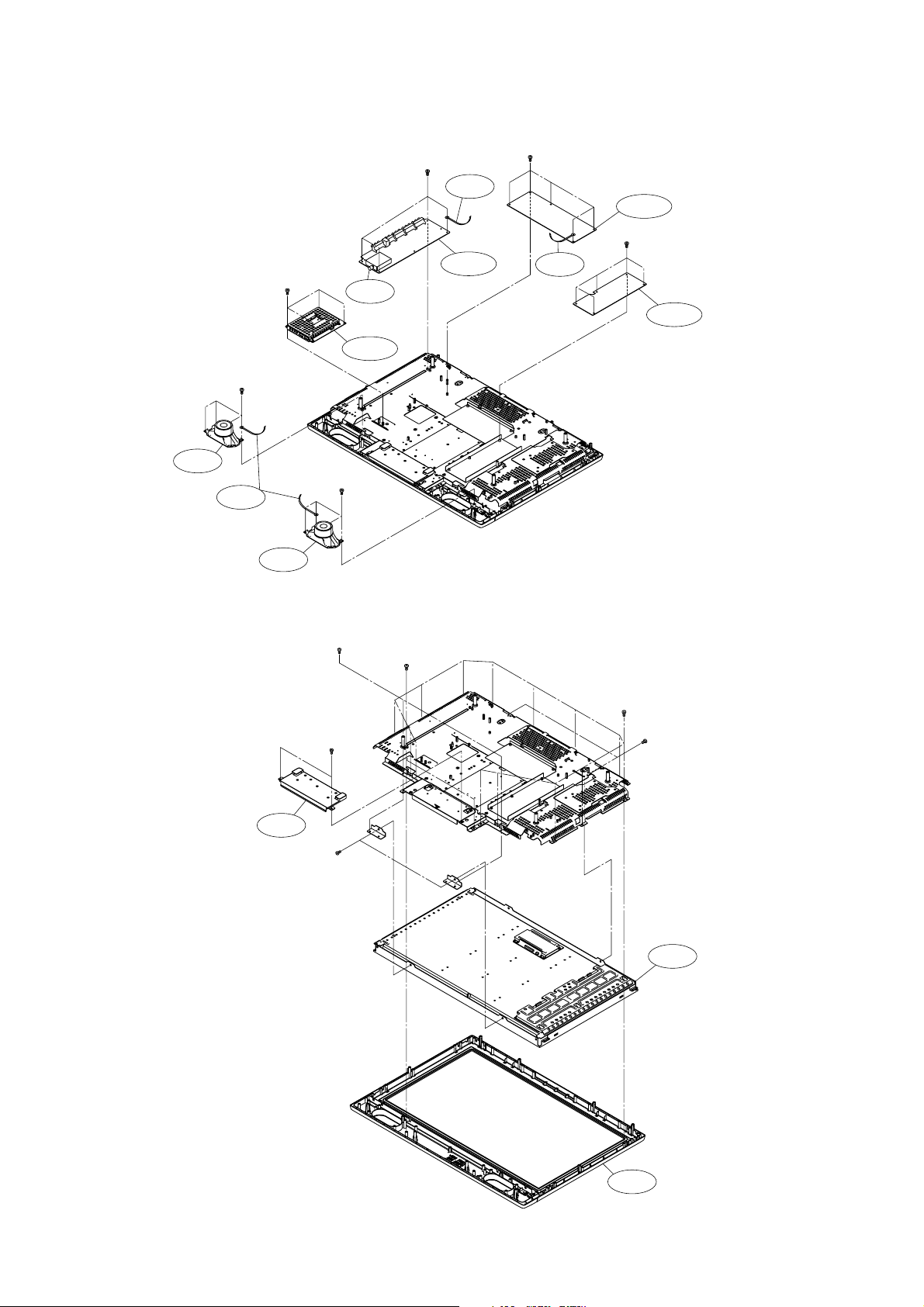

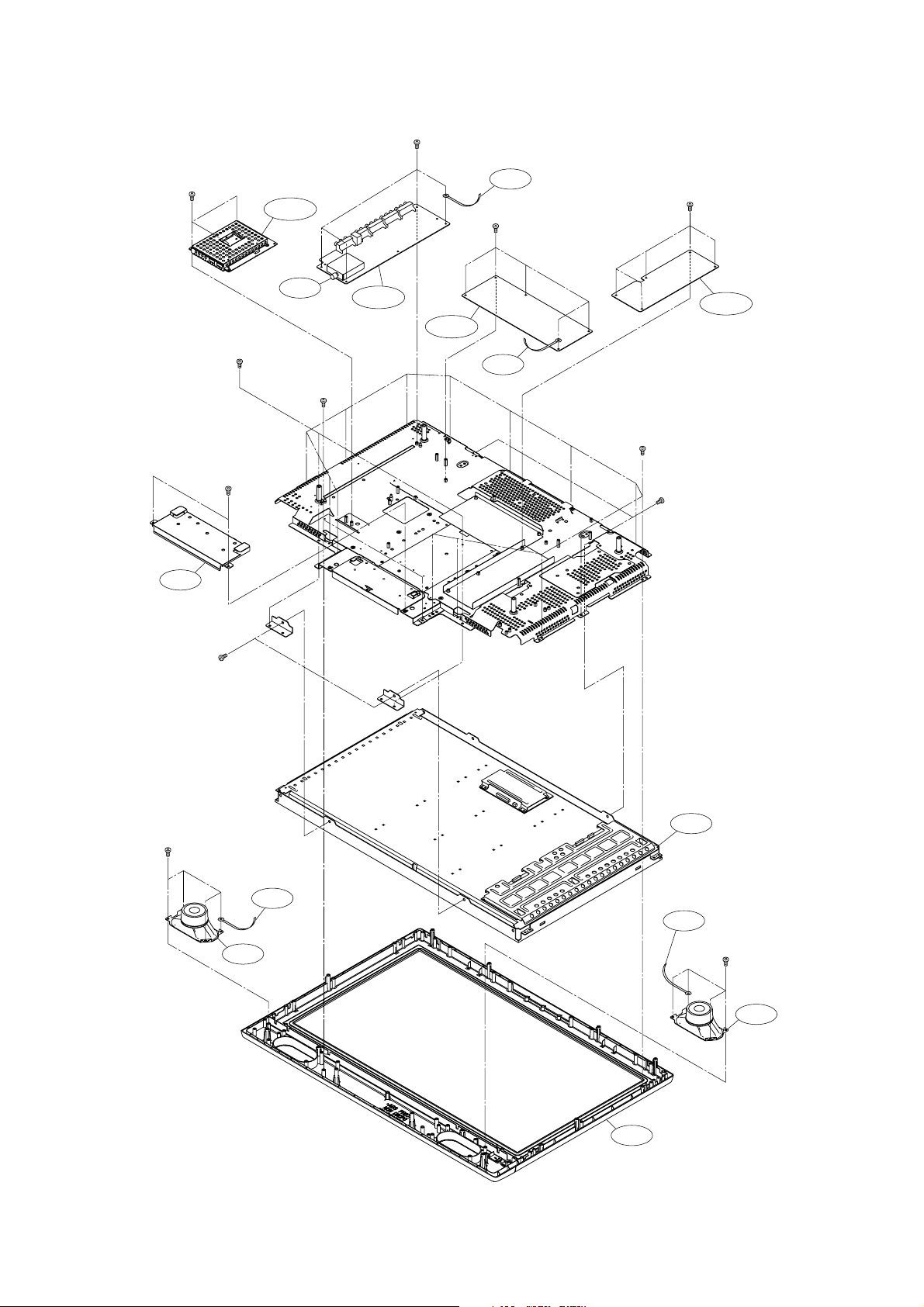

2. Main Block

PP3×8+SW+W ECO

×

4

U113A

PP3×8+SW+W ECO

×

4

PP08

PP3×8+SW+W ECO

×

5

PP3×8+SW+W ECO

×

5

PP3×8+SW+W ECO

PP3×8+SW+W ECO

A317

×

2

PB4×5 SNI

×

2

×

PB4×5 SNI

×

2

2

H001

U111A

U112A

PP12

BITTB4×16 SBN

×

14

PB4×5 SNI

×

2

U112B

BITTB4×16 SBN

×

W661

B001

4

PP08

PP08

-

19

BITTB4×16 SBN

A201

-

×

W661

4

Page 20

A702A

A702B

A703

PACKING DISASSEMBLY

A702A

Y101

Y101A

Y101H

Y101J

Y130Y170 Y101K

A709

Y109

A702B

A701

-

20

-

Page 21

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “SERVICE SAFETY PRECAUTIONS” ON PAGE 3 OF

THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in

the original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SERVICE SAFETY PRECAUTIONS. Do not degrade

the safety of the receiver through improper servicing.

NOTICE:

•

The part number must be used when ordering parts, in order to assist in processing, be sure to include the

Model number and Description.

•

The PC board assembly with ∗ mark is no longer available after the end of the production.

Model : 32WL55A/32WL55E/32WL55R/32WL55T

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are ±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

Location

No.

Parts No. Description

#1:[32WL55A]

#2:[32WL55E]

#3:[32WL55R]

#4:[32WL55T]

CAPACITORS

C101 76109103 CERAMIC CHIP, 50V B 0.01UF K

C102 76073041 ELECTROLYTIC, 16V 470UF M 3A

C103 76109102 CERAMIC CHIP, 50V B 1000PF K

C104 76073084 ELECTROLYTIC, 50V 4.7UF M 3A

C105 76073041 ELECTROLYTIC, 16V 470UF M 3A

C110 76109102 CERAMIC CHIP, 50V B 1000PF K

C111 76109102 CERAMIC CHIP, 50V B 1000PF K

C117 76109103 CERAMIC CHIP, 50V B 0.01UF K

C118 76109103 CERAMIC CHIP, 50V B 0.01UF K

C162 76105101 CERAMIC CHIP, 50V CH 100PF J

C164 76100103 CERAMIC CHIP, 50V F 0.01UF Z

C190 76092730 CERAMIC CHIP, 16V B 0.1UF K

C501 76092730 CERAMIC CHIP, 16V B 0.1UF K

C502 76092730 CERAMIC CHIP, 16V B 0.1UF K

C503 76794470 ELECTROLYTIC, 16V 47UF M

C504 76109103 CERAMIC CHIP, 50V B 0.01UF K

C505 76794470 ELECTROLYTIC, 16V 47UF M

C506 76109103 CERAMIC CHIP, 50V B 0.01UF K

C514 76763221 ELECTROLYTIC, 16V 220UF M

C516 76105110 CERAMIC CHIP, 50V CH 11PF J

C517 76206478 ELECTROLYTIC, 50V 0.47UF M 7L 3A

C519 76797479 ELECTROLYTIC, 50V 4.7UF M

C521 76092733 CERAMIC CHIP, 50V B 0.022UF K

C524 76109103 CERAMIC CHIP, 50V B 0.01UF K

C526 76109103 CERAMIC CHIP, 50V B 0.01UF K

C527 76797229 ELECTROLYTIC, 50V 2.2UF M

C605 76109102 CERAMIC CHIP, 50V B 1000PF K

C606 76109102 CERAMIC CHIP, 50V B 1000PF K

C660 76669479 ELECTROLYTIC, 50V 4.7UF M

C661 76669479 ELECTROLYTIC, 50V 4.7UF M

C662 76109681 CERAMIC CHIP, 50V B 680PF K

C663 76109681 CERAMIC CHIP, 50V B 680PF K

C668 76797100 ELECTROLYTIC, 50V 10UF M

C670 76669100 ELECTROLYTIC, 50V 10UF M

C671 76669100 ELECTROLYTIC, 50V 10UF M

C673 76667470 ELECTROLYTIC, 25V 47UF M 3A

C674 76669010 ELECTROLYTIC, 50V 1UF M 3A

Location

No.

C675 #1 76669220 ELECTROLYTIC, 50V 22UF M 3A

C676 76797101 ELECTROLYTIC, 50V 100UF M

C678 76503041 PLASTIC FILM , 63V 0.1UF J

C679 76503041 PLASTIC FILM , 63V 0.1UF J

C680 76073072 ELECTROLYTIC, 35V 1000UF M 3A

C681 76073072 ELECTROLYTIC, 35V 1000UF M 3A

C682 76073072 ELECTROLYTIC, 35V 1000UF M 3A

C684 76109103 CERAMIC CHIP, 50V B 0.01UF K

C685 76109103 CERAMIC CHIP, 50V B 0.01UF K

C699 76206478 ELECTROLYTIC, 50V 0.47UF M 7L 3A

C699A 23965241 TAPE, CC #12 10MM L30M

C801 76503507 PLASTIC FILM, AC275V 0.22UF K

C802 76503507 PLASTIC FILM, AC275V 0.22UF K

C803 76503437 PLASTIC FILM CQ923D2J154J-A7

C804 76214103 CERAMIC DISC, 500V B 0.01UF K

C805 76092281 CERAMIC DISC, AC250V E 4700PF

C810 76125008 ELECTROLYTIC CE692R 450V 220UF M

C811 #1 76092569 CERAMIC DISC, AC250V E 2200PF M

C812 #1 76092569 CERAMIC DISC, AC250V E 2200PF M

C813 76503047 PLASTIC FILM, 63V 0.33UF J

C815 76503049 PLASTIC FILM, 63V 0.47UF J

C816 76073090 ELECTROLYTIC, 50V 100UF M 3A

C817 76567224 PLASTIC FILM, 50V 0.22UF J

C819 76214101 CERAMIC DISC, 500V B 100PF K

C820 76567224 PLASTIC FILM, 50V 0.22UF J

C821 76092343 CERAMIC DISC, 2KV 680PF K

C822 76092344 CERAMIC DISC, 2KV 820PF K

C823 76092341 CERAMIC DISC, 2KV R 470PF K

C824 76591102 PLASTIC FILM, 50V 1000PF J

C825 76503053 PLASTIC FILM, 63V 1UF J

C826 76092341 CERAMIC DISC, 2KV R 470PF K

C827 76678229 ELECTROLYTIC, 200V 2.2UF M 3A

C851 76092538 CERAMIC CHIP, 10V F 1UF Z

C852 76109102 CERAMIC CHIP, 50V B 1000PF K

C883 76073193 ELECTROLYTIC, 35V 2200UF M 3A

Parts No. Description

#2 76669220 ELECTROLYTIC, 50V 22UF M 3A

#3 76669339 ELECTROLYTIC, 50V 3.3UF M

#4 76669220 ELECTROLYTIC, 50V 22UF M 3A

#2 76092569 CERAMIC DISC, AC250V E 2200PF M

#3 76092567 CERAMIC DISC, AC250V E 1000PF M

#4 76092569 CERAMIC DISC, AC250V E 2200PF M

#2 76092569 CERAMIC DISC, AC250V E 2200PF M

#3 76092567 CERAMIC DISC, AC250V E 1000PF M

#4 76092569 CERAMIC DISC, AC250V E 2200PF M

-

21

-

Page 22

Location

No.

Parts No. Description

Location

No.

Parts No. Description

C884 76073193 ELECTROLYTIC, 35V 2200UF M 3A

C889 76073094 ELECTROLYTIC, 50V 1000UF M 3A

C890 76503047 PLASTIC FILM, 63V 0.33UF J

C6990 76206478 ELECTROLYTIC, 50V 0.47UF M 7L 3A

C8001 76073072 ELECTROLYTIC, 35V 1000UF M 3A

C8100 #1 76125008 ELECTROLYTIC CE692R 450V 220UF M

C8110 76125008 ELECTROLYTIC CE692R 450V 220UF M

CB01 76202221 ELECTROLYTIC, 10V 220UF M 7L 3A

CB02 76202221 ELECTROLYTIC, 10V 220UF M 7L 3A

CB03 76100104 CERAMIC CHIP, 25V F 0.1UF Z

CB04 76100104 CERAMIC CHIP, 25V F 0.1UF Z

CB05 76202221 ELECTROLYTIC, 10V 220UF M 7L 3A

CB38 76100104 CERAMIC CHIP, 25V F 0.1UF Z

CC01 76109102 CERAMIC CHIP, 50V B 1000PF K

CC02 76109102 CERAMIC CHIP, 50V B 1000PF K

CC03 76109102 CERAMIC CHIP, 50V B 1000PF K

CC05 76109102 CERAMIC CHIP, 50V B 1000PF K

CC06 76109102 CERAMIC CHIP, 50V B 1000PF K

CC07 76109102 CERAMIC CHIP, 50V B 1000PF K

CC11 76109102 CERAMIC CHIP, 50V B 1000PF K

CC12 76109102 CERAMIC CHIP, 50V B 1000PF K

CC31 76109102 CERAMIC CHIP, 50V B 1000PF K

CC40 76109102 CERAMIC CHIP, 50V B 1000PF K

CC41 76109102 CERAMIC CHIP, 50V B 1000PF K

CE04 76092281 CERAMIC DISC, AC250V E 4700PF

CE07 76503049 PLASTIC FILM, 63V 0.47UF J

CE09 76668339 ELECTROLYTIC, 35V 3.3UF M 3A

CE10 76125002 ELECTROLYTIC CE692R 450V 120UF M

CE12 76503041 PLASTIC FILM , 63V 0.1UF J

CE13 #3 76092565 CERAMIC DISC, AC250V B 470PF K

CE14 #3 76092565 CERAMIC DISC, AC250V B 470PF K

CE16 76073181 ELECTROLYTIC CE04P35V 56UF M 3A

CE17 76092339 CERAMIC DISC, 2KV 330PF K

CE18 76503253 PLASTIC FILM, 1250VH 0.01UF H

CE23 76214471 CERAMIC DISC, 500V B 470PF K

CE24 76285104 CERAMIC CHIP, 50V B 0.1UF K

CE29 76436561 CERAMIC DISC, 50V SL 560PF J

CE40 76073183 ELECTROLYTIC CE04P35V 220UF M 3A

CE42 76539104 PLASTIC FILM, 50V 0.1UF J

CE43 76503041 PLASTIC FILM , 63V 0.1UF J

CE51 76617023 ELECTROLYTIC, 16V 330UF M

CE52 76092179 CERAMIC CHIP, 25V B 0.22UF K

CE53 76092179 CERAMIC CHIP, 25V B 0.22UF K

CE55 76073181 ELECTROLYTIC CE04P35V 56UF M 3A

CE76 76073181 ELECTROLYTIC CE04P35V 56UF M 3A

CE82 76676470 ELECTROLYTIC, 100V 47UF M 3A

CE85 76073175 ELECTROLYTIC CE04P25V 1800UF M 3A

CE86 76073175 ELECTROLYTIC CE04P25V 1800UF M 3A

CE87 76669100 ELECTROLYTIC, 50V 10UF M

CE90 76503047 PLASTIC FILM, 63V 0.33UF J

CE91 76503041 PLASTIC FILM , 63V 0.1UF J

CE92 76794101 ELECTROLYTIC, 16V 100UF M

CT01 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT04 76105820 CERAMIC CHIP, 50V CH 82PF J

CT05 76092731 CERAMIC CHIP, 16V B 1UF K

CT06 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT07 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT10 76105151 CERAMIC CHIP, 50V CH 150PF J

CT11 76092731 CERAMIC CHIP, 16V B 1UF K

CT12 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT13 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT16 76105151 CERAMIC CHIP, 50V CH 150PF J

CT17 76092731 CERAMIC CHIP, 16V B 1UF K

CT18 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT19 76092790 CERAMIC CHIP CK732B 6.3V 10UF K

CT20 76092789 CERAMIC CHIP, 6.3V B 1UF K

CV13 76100104 CERAMIC CHIP, 25V F 0.1UF Z

CV17 76085988 ELECTROLYTIC, NP, 50V 1UF M 7L

CV18 76794101 ELECTROLYTIC, 16V 100UF M

CV19 76794101 ELECTROLYTIC, 16V 100UF M

CV20 76794220 ELECTROLYTIC, 16V 22UF M

CV51 76794100 ELECTROLYTIC, 16V 10UF M

CV52 76794100 ELECTROLYTIC, 16V 10UF M

CV53 76794100 ELECTROLYTIC, 16V 10UF M

CV54 76794100 ELECTROLYTIC, 16V 10UF M

CV122 76105101 CERAMIC CHIP, 50V CH 100PF J

RESISTORS

R101 76011101 CHIP, 1/20W 100 OHM J

R102 76011101 CHIP, 1/20W 100 OHM J

R103 76011101 CHIP, 1/20W 100 OHM J

R104 76011103 CHIP, 1/20W 10K OHM J

R105 76011273 CHIP, 1/20W 27K OHM J

R107 76000445 CHIP JUMPER, 1608TYPE

R108 76000445 CHIP JUMPER, 1608TYPE

R114 76000445 CHIP JUMPER, 1608TYPE

R167 76011101 CHIP, 1/20W 100 OHM J

R169 76000445 CHIP JUMPER, 1608TYPE

R170 76011682 CHIP, 1/20W 6.8K OHM J

R501 76011682 CHIP, 1/20W 6.8K OHM J

R502 76011272 CHIP, 1/20W 2.7K OHM J

R504 76011101 CHIP, 1/20W 100 OHM J

R505 76011101 CHIP, 1/20W 100 OHM J

R506 76011273 CHIP, 1/20W 27K OHM J

R507 76011392 CHIP, 1/20W 3.9K OHM J

R508 76011682 CHIP, 1/20W 6.8K OHM J

R509 76011153 CHIP, 1/2OW 15K OHM J

R512 76011101 CHIP, 1/20W 100 OHM J

R514 76011102 CHIP, 1/20W 1K OHM J

R515 76011473 CHIP, 1/20W 47K OHM J

R516 76011473 CHIP, 1/20W 47K OHM J

R660 76011473 CHIP, 1/20W 47K OHM J

R662 76011103 CHIP, 1/20W 10K OHM J

R663 76011473 CHIP, 1/20W 47K OHM J

R670 76011472 CHIP, 1/20W 4.7K OHM J

R671 76011472 CHIP, 1/20W 4.7K OHM J

R672 76011182 CHIP, 1/20W 1.8K OHM J

R673 76011182 CHIP, 1/20W 1.8K OHM J

R678 76871229 CHIP, 1/8W 2.2 OHM J

R679 76871229 CHIP, 1/8W 2.2 OHM J

R680 76011103 CHIP, 1/20W 10K OHM J

R681 76011103 CHIP, 1/20W 10K OHM J

R682 76011104 CHIP, 1/20W 100K OHM J

R683 76011223 CHIP, 1/20W 22K OHM J

R684 76011104 CHIP, 1/20W 100K OHM J

R685 76011183 CHIP, 1/20W 18K OHM J

R686 76011102 CHIP, 1/20W 1K OHM J

R687 76871102 CHIP, 1/8W 1K OHM J

R688 76871102 CHIP, 1/8W 1K OHM J

R689 76871102 CHIP, 1/8W 1K OHM J

R695 76871102 CHIP, 1/8W 1K OHM J

R696 76871102 CHIP, 1/8W 1K OHM J

R697 76871102 CHIP, 1/8W 1K OHM J

R801 76004716 METAL GLAZE, 1/2W 2.2M OHM J

R803 76366562 CARBON FILM, 1/6W 5.6K OHM J

R805 76366102 CARBON FILM, 1/6W 1K OHM J

R806 76552470 OXIDE METAL FILM, 1/2W 47 OHM J

R807 76366393 CARBON FILM, 1/6W 39K OHM J

R808 76552101 OXIDE METAL FILM, 1/2W 100 OHM J

R809 76321689 OXIDE METAL FILM, 1/2W 6.8 OHM J

R812 76552681 OXIDE METAL FILM, 1/2W 680 OHM J

R813 76366270 CARBON FILM, 1/6W 27 OHM J

R814 76552390 OXIDE METAL FILM, 1/2W 39 OHM J

R815 76552100 OXIDE METAL FILM, 1/2W 10 OHM J

R816 76011331 CHIP, 1/20W 330 OHM J

R817 76377224 CARBON FILM, 1W 220K OHM J

R821 76322689 OXIDE METAL FILM, 1W 6.8 OHM J

R827 76383103 OXIDE METAL FILM, 2W 10K OHM J

-

22

-

Page 23

Location

No.

Parts No. Description

Location

No.

Parts No. Description

R828 76383103 OXIDE METAL FILM, 2W 10K OHM J

R850 76011101 CHIP, 1/20W 100 OHM J

R851 76011102 CHIP, 1/20W 1K OHM J

R852 76011471 CHIP, 1/20W 470 OHM J

R853 76011103 CHIP, 1/20W 10K OHM J

R854 76011102 CHIP, 1/20W 1K OHM J

R855 76011471 CHIP, 1/20W 470 OHM J

R856 76011102 CHIP, 1/20W 1K OHM J

R857 76011471 CHIP, 1/20W 470 OHM J

R858 76011471 CHIP, 1/20W 470 OHM J

R859 76011102 CHIP, 1/20W 1K OHM J

R861 #1 76120002 CERAMIC COVEREDG 5W 68 J

#2 76120002 CERAMIC COVEREDG 5W 68 J

#3 76007416 CERAMIC COVERED, 5W 82 OHM J

#4 76120002 CERAMIC COVEREDG 5W 68 J

R862 #1 76120002 CERAMIC COVEREDG 5W 68 J

#2 76120002 CERAMIC COVEREDG 5W 68 J

#3 76007416 CERAMIC COVERED, 5W 82 OHM J

#4 76120002 CERAMIC COVEREDG 5W 68 J

R873 76366152 CARBON FILM, 1/6W 1.5K OHM J

R890 76011102 CHIP, 1/20W 1K OHM J

R899 76004718 METAL GLAZE, 1/2W 8.2M OHM J

R4100 76011102 CHIP, 1/20W 1K OHM J

R4101 76011681 CHIP, 1/20W 680 OHM J

R4102 76011471 CHIP, 1/20W 470 OHM J

R4103 76011681 CHIP, 1/20W 680 OHM J

R4104 76011102 CHIP, 1/20W 1K OHM J

R4105 76011102 CHIP, 1/20W 1K OHM J

R4106 76011681 CHIP, 1/20W 680 OHM J

R4107 76011471 CHIP, 1/20W 470 OHM J

R4108 76011681 CHIP, 1/20W 680 OHM J

R4109 76011102 CHIP, 1/20W 1K OHM J

R6601 76011223 CHIP, 1/20W 22K OHM J

R6602 76011103 CHIP, 1/20W 10K OHM J

R6603 76011104 CHIP, 1/20W 100K OHM J

R6604 76011102 CHIP, 1/20W 1K OHM J

R6614 76011102 CHIP, 1/20W 1K OHM J

R6615 76011102 CHIP, 1/20W 1K OHM J

R6616 76011104 CHIP, 1/20W 100K OHM J

R6617 76011104 CHIP, 1/20W 100K OHM J

RA71 76011683 CHIP, 1/20W 68K OHM J

RA72 76011223 CHIP, 1/20W 22K OHM J

RA73 76011103 CHIP, 1/20W 10K OHM J

RA74 76000445 CHIP JUMPER, 1608TYPE

RA77 76011103 CHIP, 1/20W 10K OHM J

RA78 76000445 CHIP JUMPER, 1608TYPE

RA79 76000445 CHIP JUMPER, 1608TYPE

RB08 76011470 CHIP, 1/20W 47 OHM J

RB09 76011470 CHIP, 1/20W 47 OHM J

RB10 76011331 CHIP, 1/20W 330 OHM J

RB15 76011471 CHIP, 1/20W 470 OHM J

RB24 76000445 CHIP JUMPER, 1608TYPE

RC01 76011102 CHIP, 1/20W 1K OHM J

RC02 76011102 CHIP, 1/20W 1K OHM J

RC03 76011102 CHIP, 1/20W 1K OHM J

RC04 76011102 CHIP, 1/20W 1K OHM J

RC05 76011102 CHIP, 1/20W 1K OHM J

RC06 76011102 CHIP, 1/20W 1K OHM J

RC11 76011821 CHIP, 1/20W 820 OHM J

RC12 76011821 CHIP, 1/20W 820 OHM J

RC40 76011821 CHIP, 1/20W 820 OHM J

RC41 76011821 CHIP, 1/20W 820 OHM J

RE03 76553683 OXIDE METAL FILM, 1W 68K OHM J

RE04 76553683 OXIDE METAL FILM, 1W 68K OHM J

RE05 76554683 OXIDE RES 2W 68K J

RE12 76552221 OXIDE METAL FILM, 1/2W 220 OHM J

RE13 76366473 CARBON FILM, 1/6W 47K OHM J

RE15 76366102 CARBON FILM, 1/6W 1K OHM J

RE16 76366102 CARBON FILM, 1/6W 1K OHM J

RE17 76366363 CARBON FILM, 1/6W 36K OHM J

RE18 76019463 METAL PLATE, 2W 0.22 OHM J

RE19 76310829 OXIDE METAL FILM, 1/2W 8.2 OHM J

RE23 76552152 OXIDE METAL FILM, 1/2W 1.5K OHM J

RE41 76011152 CHIP, 1/20W 1.5K OHM J

RE42 76871222 CHIP, 1/8W 2.2K OHM J

RE43 76011753 CHIP, 1/20W 75K OHM J

RE44 76000593 METAL FILM CHIP1/16W 10K F

RE46 76000448 CHIP, 1/16W 1.8K OHM F

RE48 76011222 CHIP, 1/20W 2.2K OHM J

RE51 76011393 CHIP, 1/20W 39K OHM J

RE52 76011152 CHIP, 1/20W 1.5K OHM J

RE53 76871222 CHIP, 1/8W 2.2K OHM J

RE54 76871222 CHIP, 1/8W 2.2K OHM J

RE56 76190012 METAL FILM CHIP1/16W 1.5K F

RE57 76190012 METAL FILM CHIP1/16W 1.5K F

RE58 76190013 CHIP RES 1/16W 22K F

RE59 76011334 CHIP, 1/20W 330K OHM J

RE60 76011473 CHIP, 1/20W 47K OHM J

RE61 76190014 METAL FILM CHIP1/16W 18K F

RE82 76011473 CHIP, 1/20W 47K OHM J

RE83 76011473 CHIP, 1/20W 47K OHM J

RE84 76011152 CHIP, 1/20W 1.5K OHM J

RE87 76011473 CHIP, 1/20W 47K OHM J

RE88 76011103 CHIP, 1/20W 10K OHM J

RE91 76011103 CHIP, 1/20W 10K OHM J

RE93 76011223 CHIP, 1/20W 22K OHM J

RE94 76871271 CHIP, 1/8W 270 OHM J

RE95 76553122 OXIDE METAL FILM, 1W 1.2K OHM J

RE96 76011473 CHIP, 1/20W 47K OHM J

RE97 76553681 OXIDE RES 1W 68 J

RE98 76011104 CHIP, 1/20W 100K OHM J

RR01 76871750 CHIP, 1/8W 75 OHM J

RR02 76871750 CHIP, 1/8W 75 OHM J

RR03 76871750 CHIP, 1/8W 75 OHM J

RR04 76011330 CHIP, 1/20W 33 OHM J

RR05 76011330 CHIP, 1/20W 33 OHM J

RR06 76011330 CHIP, 1/20W 33 OHM J

RT01 76011222 CHIP, 1/20W 2.2K OHM J

RT02 76011223 CHIP, 1/20W 22K OHM J

RT03 76011683 CHIP, 1/20W 68K OHM J

RT04 76011102 CHIP, 1/20W 1K OHM J

RT05 76011101 CHIP, 1/20W 100 OHM J

RT06 76011221 CHIP, 1/20W 220 OHM J

RT07 76011561 CHIP, 1/20W 560 OHM J

RT08 76011221 CHIP, 1/20W 220 OHM J

RT09 76011471 CHIP, 1/20W 470 OHM J

RT10 76011222 CHIP, 1/20W 2.2K OHM J

RT11 76011223 CHIP, 1/20W 22K OHM J

RT12 76011683 CHIP, 1/20W 68K OHM J

RT13 76011102 CHIP, 1/20W 1K OHM J

RT14 76011101 CHIP, 1/20W 100 OHM J

RT15 76011151 CHIP, 1/20W 150 OHM J

RT16 76011391 CHIP, 1/20W 390 OHM J

RT17 76011181 CHIP, 1/20W 180 OHM J

RT18 76011471 CHIP, 1/20W 470 OHM J

RT19 76011222 CHIP, 1/20W 2.2K OHM J

RT20 76011223 CHIP, 1/20W 22K OHM J

RT21 76011683 CHIP, 1/20W 68K OHM J

RT22 76011102 CHIP, 1/20W 1K OHM J

RT23 76011101 CHIP, 1/20W 100 OHM J

RT24 76011151 CHIP, 1/20W 150 OHM J

RT25 76011391 CHIP, 1/20W 390 OHM J

RT26 76011221 CHIP, 1/20W 220 OHM J

RT27 76011471 CHIP, 1/20W 470 OHM J

RT28 76011103 CHIP, 1/20W 10K OHM J

RT29 76011103 CHIP, 1/20W 10K OHM J

RV11 76011223 CHIP, 1/20W 22K OHM J

RV12 76011473 CHIP, 1/20W 47K OHM J

-

23

-

Page 24

Location

No.

Parts No. Description

Location

No.

Parts No. Description

RV21 76011750 CHIP, 1/20W 75 OHM J

RV25 76011750 CHIP, 1/20W 75 OHM J

RV26 76011750 CHIP, 1/20W 75 OHM J

RV27 76011750 CHIP, 1/20W 75 OHM J

RV28 76011750 CHIP, 1/20W 75 OHM J

RV29 76011750 CHIP, 1/20W 75 OHM J

RV30 76011750 CHIP, 1/20W 75 OHM J

RV32 76000445 CHIP JUMPER, 1608TYPE

RV33 76000445 CHIP JUMPER, 1608TYPE

RV34 76000445 CHIP JUMPER, 1608TYPE

RV35 76000445 CHIP JUMPER, 1608TYPE

RV36 76000445 CHIP JUMPER, 1608TYPE

RV37 76000445 CHIP JUMPER, 1608TYPE

RV43 76011101 CHIP, 1/20W 100 OHM J

RV44 76011222 CHIP, 1/20W 2.2K OHM J

RV51 76011101 CHIP, 1/20W 100 OHM J

RV52 76011391 CHIP, 1/20W 390 OHM J

RV54 76011473 CHIP, 1/20W 47K OHM J

RV55 76011473 CHIP, 1/20W 47K OHM J

RV56 76011473 CHIP, 1/20W 47K OHM J

RV57 76011101 CHIP, 1/20W 100 OHM J

RV58 76011391 CHIP, 1/20W 390 OHM J

RV59 76011473 CHIP, 1/20W 47K OHM J

RV60 76011102 CHIP, 1/20W 1K OHM J

RV61 76000445 CHIP JUMPER, 1608TYPE

RV71 76011473 CHIP, 1/20W 47K OHM J

RV72 76011391 CHIP, 1/20W 390 OHM J

RV73 76011101 CHIP, 1/20W 100 OHM J

RV74 76011473 CHIP, 1/20W 47K OHM J

RV76 76011473 CHIP, 1/20W 47K OHM J

RV78 76011101 CHIP, 1/20W 100 OHM J

RV79 76011391 CHIP, 1/20W 390 OHM J

RV80 76011473 CHIP, 1/20W 47K OHM J

RV92 76011103 CHIP, 1/20W 10K OHM J

RV120 76011680 CHIP, 1/20W 68 OHM J

RV123 76872750 CHIP, 1/16W 75 OHM J

COIL & TRANSFORMERS

L101 23248398 COIL, CHOKE, TLN3278D

L102 23103828 INDUCTOR, BEAD, TEM2121M

L103 23103828 INDUCTOR, BEAD, TEM2121M

L191 23103828 INDUCTOR, BEAD, TEM2121M

L504 23289978 COIL, PEAKING, TRF4100AJ

L505 23289022 COIL, PEAKING, TRF4100AT

L801 #1 23217791

#2 23217791

#3 23217787

#4 23217791

L802 #1 23217792

#2 23217792

#3 23217788

#4 23217792

L805 23103304 FERRITE CHOKE, TEM2011AA

L806 23248386 COIL, CHOKE 9X11H 2.0MMH 4.0ATLN3481AA

L807 23248386 COIL, CHOKE 9X11H 2.0MMH 4.0ATLN3481AA

L874 23103304 FERRITE CHOKE, TEM2011AA

L875 23103304 FERRITE CHOKE, TEM2011AA

L876 23103304 FERRITE CHOKE, TEM2011AA

L878 23103304 FERRITE CHOKE, TEM2011AA

L883 23248466 COIL, CHOKE COIL 4.7MMH 8.0ATLN3551AH

L888 23248432 COIL, CHOKE, TLN3499AH

L921 75001248 CHIP BEADS INDUCTOR

L922 75001248 CHIP BEADS INDUCTOR

L923 75001248 CHIP BEADS INDUCTOR

L925 75001248 CHIP BEADS INDUCTOR

L926 75001248 CHIP BEADS INDUCTOR

L930 75001248 CHIP BEADS INDUCTOR

L931 75001248 CHIP BEADS INDUCTOR

L932 75001248 CHIP BEADS INDUCTOR

TRANSFORMER, CHOKE 4.8MH 4.1ATPW2071AS

TRANSFORMER, CHOKE 4.8MH 4.1ATPW2071AS

TRANSFORMER, CHOKE 39MH1.45A TPW2069AS

TRANSFORMER, CHOKE 4.8MH 4.1ATPW2071AS

TRANSFORMER, CHOKE 1.8MH 4.1ATPW2072AS

TRANSFORMER, CHOKE 1.8MH 4.1ATPW2072AS

TRANSFORMER, CHOKE 13MH1.45A TPW2070AS

TRANSFORMER, CHOKE 1.8MH 4.1ATPW2072AS

L933 75001248 CHIP BEADS INDUCTOR

L934 75001248 CHIP BEADS INDUCTOR

L935 75001248 CHIP BEADS INDUCTOR

L936 75001248 CHIP BEADS INDUCTOR

L943 75001248 CHIP BEADS INDUCTOR

LC31 23103238 INDUCTOR, BEAD, TEM2142AD

LC32 23103238 INDUCTOR, BEAD, TEM2142AD

LC33 23103238 INDUCTOR, BEAD, TEM2142AD

LE06 23248386 COIL, CHOKE 9X11H 2.0MMH 4.0ATLN3481AA

LE07 23248386 COIL, CHOKE 9X11H 2.0MMH 4.0ATLN3481AA

LE11 23103304 FERRITE CHOKE, TEM2011AA

LE52 23289025 COIL, PEAKING, TRF4330AT

LE53 23248453 COIL, CHOKE, TLN3283AI

LE73 23248386 COIL, CHOKE 9X11H 2.0MMH 4.0ATLN3481AA

LE74 23248417 COIL, CHOKE, TLN3481AH

LT01 23289027 COIL, PEAKING, TRF4680AT

LT02 23289072 COIL, PEAKING, TRF4151AT

LT03 23289072 COIL, PEAKING, TRF4151AT

LV16 23246662 COIL, CHIP, TRF4100CN

T801 #1 23211881 COIL, LINE FILTER 34X25.5H 13MH TRF3252AD

#2 23211881 COIL, LINE FILTER 34X25.5H 13MH TRF3252AD

#3 23211886 COIL, L/F ET28H 16MH TRF3253AH

#4 23211881 COIL, LINE FILTER 34X25.5H 13MH TRF3252AD

T802 #1 23211881 COIL, LINE FILTER 34X25.5H 13MH TRF3252AD

#2 23211881 COIL, LINE FILTER 34X25.5H 13MH TRF3252AD

#3 23211886 COIL, L/F ET28H 16MH TRF3253AH

#4 23211881 COIL, LINE FILTER 34X25.5H 13MH TRF3252AD

T862 23217784 TRANSFORMER, CONVERTER TPW3572AS

TE62 23217701 TRANSFORMER, CONVERTER TPW3563AS

SEMICONDUCTORS

Q101 23205506 TRANSISTOR, 2SC4081 Q

Q501 23085049 IC, TB1274BFG(DRY)

Q504 23205507 TRANSISTOR, 2SA1576A Q

Q654 23205302 TRANSISTOR, 2SC3326-B(F)

Q655 23205302 TRANSISTOR, 2SC3326-B(F)

Q656 23205325 TRANSISTOR, RN2404(F)

Q662 23205325 TRANSISTOR, RN2404(F)

Q663 23205506 TRANSISTOR, 2SC4081 Q

Q670 23085039 IC, TA8246AHQ

Q671 23205302 TRANSISTOR, 2SC3326-B(F)

Q672 23205302 TRANSISTOR, 2SC3326-B(F)

Q673 23205443 TRANSISTOR, 2SA1162-Y(F)

Q801 23135088 IC, STRZ4369

Q826 23000823 IC, PHOTO COUPLER, TLP421F(GR)

Q851 23205446 TRANSISTOR, 2SC2412K, Q T146

Q852 23205446 TRANSISTOR, 2SC2412K, Q T146

Q853 23205443 TRANSISTOR, 2SA1162-Y(F)

Q854 23205446 TRANSISTOR, 2SC2412K, Q T146

Q855 23205446 TRANSISTOR, 2SC2412K, Q T146

Q883 23135091 IC, SE024N

Q4100 23085635 TRANSISTOR, 2SC3437-Y(TE85L,F)

Q4101 23085635 TRANSISTOR, 2SC3437-Y(TE85L,F)

Q4102 23085635 TRANSISTOR, 2SC3437-Y(TE85L,F)

Q4103 23085635 TRANSISTOR, 2SC3437-Y(TE85L,F)

QB04 23205463 TRANSISTOR, 2SC2712-Y(TE85L,F)

QB07 23205463 TRANSISTOR, 2SC2712-Y(TE85L,F)

QE01 23135072 IC, STRW6765

QE26 23000823 IC, PHOTO COUPLER, TLP421F(GR)

QE40 23085463 IC, SI-8050E

QE52 23205567

QE53 23205330 TRANSISTOR, RN1403(F)

QE64 23085415 IC, BD4746G

QE71 23135085 IC, CE-1050

QE74 23205330 TRANSISTOR, RN1403(F)

QE75 23205446 TRANSISTOR, 2SC2412K, Q T146

QE83 23085389 IC, NJM431L

QE90 23085423 IC, KIA7809API-U/P

QE94 23205292 TRANSISTOR, 2SD2396

TRANSISTOR, CHIP R1=R2=22K SMT RN2403(TE85L,F)

-

24

-

Page 25

Location

No.

Parts No. Description

Location

No.

Parts No. Description

QE95 23205446 TRANSISTOR, 2SC2412K, Q T146

QE96 23205301 TRANSISTOR, 2SA1887(FA,F)

QE97 23205569

QE98 23205568

QT01 23205507 TRANSISTOR, 2SA1576A Q

QT02 23205506 TRANSISTOR, 2SC4081 Q

QT03 23205507 TRANSISTOR, 2SA1576A Q

QT04 23205507 TRANSISTOR, 2SA1576A Q

QT05 23205506 TRANSISTOR, 2SC4081 Q

QT06 23205507 TRANSISTOR, 2SA1576A Q

QT07 23205507 TRANSISTOR, 2SA1576A Q

QT08 23205506 TRANSISTOR, 2SC4081 Q

QT09 23205507 TRANSISTOR, 2SA1576A Q

QT10 23085758 IC, VIDEO SW 5IN-1OUTBA7649AF

QT11 23205402 TRANSISTOR, DTC144EUA

QT12 23205402 TRANSISTOR, DTC144EUA

QV06 23205507 TRANSISTOR, 2SA1576A Q

QV14 23085791 IC, M1510XNRE

QV51 23205506 TRANSISTOR, 2SC4081 Q

QV52 23205506 TRANSISTOR, 2SC4081 Q

QV53 23205506 TRANSISTOR, 2SC4081 Q

QV54 23205506 TRANSISTOR, 2SC4081 Q

D670 23362140 DIODE, KDS160-RTK

D671 23362140 DIODE, KDS160-RTK

D674 23362140 DIODE, KDS160-RTK

D675 23362140 DIODE, KDS160-RTK

D676 23362140 DIODE, KDS160-RTK

D677 23362140 DIODE, KDS160-RTK

D678 23362140 DIODE, KDS160-RTK

D679 23362140 DIODE, KDS160-RTK

D801 23362200 DIODE, VRM=600V IO=6A SIPD5SB60, 7009F07

D805 23357627 DIODE, ZENER, RD9.1ESA B1

D806 23357666 DIODE, ZENER, RD27ESA B3

D809 23357654 DIODE, ZENER, RD36ESA B3

D810 23357666 DIODE, ZENER, RD27ESA B3

D811 23357511 DIODE, AG01A

D812 23357625 DIODE, ZENER, RD9.1ESA B3

D813 23357512 DIODE, AL01Z

D852 23357697 DIODE, 1SS133

D883 23362196 DIODE, SCHOTTKY VRM90V 20A RB215T-90

D884 23362196 DIODE, SCHOTTKY VRM90V 20A RB215T-90

D885 23357408 DIODE, FMX-12S(023-108)

D899 76000656 VARISTOR, TNR15G471K

DA01 23362042 DIODE, ZENER, UDZS6.8B

DA06 23362042 DIODE, ZENER, UDZS6.8B

DA07 23362042 DIODE, ZENER, UDZS6.8B

DB01 23358606 DIODE, LED RED, SLR-56VC3FPQ

DB04 23358605 DIODE, LED GREEN, SLR-56MC3FPQR

DB20 23357406 DIODE, ZENER, UDZS5.6B

DB22 23357703 DIODE, 1SS355

DB23 23357703 DIODE, 1SS355

DE01 23362204 DIODE, DIODE,D3SB60 ,7109F08

DE02 23357511 DIODE, AG01A

DE03 23357511 DIODE, AG01A

DE05 23357104 DIODE, 1SS244

DE06 23357366 DIODE, FR105-B5

DE07 23362103 DIODE, ZENER, DZ33 BS B

DE09 23362074 DIODE, ZENER, DZ6.8 BS B

DE11 23357709 DIODE, RU1P

DE12 23357512 DIODE, AL01Z

DE13 23357512 DIODE, AL01Z

DE14 23357512 DIODE, AL01Z

DE15 23362099 DIODE, ZENER, DZ27 BS B

DE16 23357880 DIODE, ZENER, MTZJ20B

DE17 23357512 DIODE, AL01Z

DE19 23357854 DIODE, ZENER, MTZJ10B

DE50 23357706 DIODE, AK04

DE51 23357842 DIODE, ZENER, MTZJ6.8B

DE52 23357703 DIODE, 1SS355

TRANSISTOR, CHIP VCEO=120V 2SC2713-GR(TE85L,F)

TRANSISTOR, CHIP VCEO=-120V 2SA1163-GR(TE85L,F)

DE54 23357703 DIODE, 1SS355

DE55 23357748 DIODE, ZENER, MA8062-M

DE56 23357800 DIODE, ZENER, MA8300-H

DE72 23357366 DIODE, FR105-B5

DE75 23357408 DIODE, FMX-12S(023-108)

DE90 23357866 DIODE, ZENER, MTZJ12C

DE92 23357862 DIODE, ZENER, MTZJ11B

DE93 23357862 DIODE, ZENER, MTZJ11B

DE94 23357862 DIODE, ZENER, MTZJ11B

DE96 23357840 DIODE, ZENER, MTZJ6.2B

DE97 23357869 DIODE, ZENER, MTZJ13C

DE98 23357869 DIODE, ZENER, MTZJ13C

DE99 23357703 DIODE, 1SS355

IC414 23085936 IC, RESET ICBU4245G-TR

MISCELLANEOUS

B001 23301643 DISPLAY, 05SHP32LQ315T3LZ21

B310 23717219 SCREW, PP3X8+SW+W SBN

B315 23717214 SCREW, BITTB3X12SBN

D801B 23717240 SCREW

D883B 23717240 SCREW

D884B 23717240 SCREW

DE75B 23717240 SCREW

F801 23144304 FUSE, CARTRIDGE 5X20250V 6.3A

F801A 23165433 FUSE HOLDER, 5.2

F801B 23165433 FUSE HOLDER, 5.2

F802 23144380

FE01 23144380

GC20 76000445 CHIP JUMPER, 1608TYPE

GE50 23103304 FERRITE CHOKE, TEM2011AA

GE51 76000445 CHIP JUMPER, 1608TYPE

GJ13 76000445 CHIP JUMPER, 1608TYPE

GJ16 76000445 CHIP JUMPER, 1608TYPE

GR01 76000445 CHIP JUMPER, 1608TYPE

GR02 76000445 CHIP JUMPER, 1608TYPE

GR03 76000445 CHIP JUMPER, 1608TYPE

GR05 76000445 CHIP JUMPER, 1608TYPE

GR06 76000445 CHIP JUMPER, 1608TYPE

GR25 76000445 CHIP JUMPER, 1608TYPE

GR26 76000445 CHIP JUMPER, 1608TYPE

GR27 76000445 CHIP JUMPER, 1608TYPE

GR28 76000445 CHIP JUMPER, 1608TYPE

GR30 76000445 CHIP JUMPER, 1608TYPE

GR31 76000445 CHIP JUMPER, 1608TYPE

GR34 76000445 CHIP JUMPER, 1608TYPE

GR35 76000445 CHIP JUMPER, 1608TYPE

GR601 76011223 CHIP, 1/20W 22K OHM J

GR605 76000445 CHIP JUMPER, 1608TYPE

GT01 76000445 CHIP JUMPER, 1608TYPE

GT02 76000445 CHIP JUMPER, 1608TYPE

GT03 76000445 CHIP JUMPER, 1608TYPE

GV01 76000445 CHIP JUMPER, 1608TYPE

KB01 23009710 REMOCON RECEIVER, GP1UE281RK

MJ22 23389310 CABLE, FFC 0.5 50P L70 23LC100_MJ22

MJ60 23389310 CABLE, FFC 0.5 50P L70 23LC100_MJ22

MZ01 23368908 CABLE, LVDS30P170MM SHP T2 E30-X30

P601 23713755 PLUG, 4P 2.5MM G, B4B-EH-F1-TV4

P602 23713937 CONNECTOR, PLUG 4P B4B-PH-K-S(LF)

P602A 23713937 CONNECTOR, PLUG 4P B4B-PH-K-S(LF)

P661 23023302 EARPHONE JACK

P800 23713702 PLUG, 2P 11.88MM W VT

P801 #1 23372294 POWER CORD, SAA 2.3M 7.5A---2

#2 23372293 POWER CORD, UK-HK-PSB 10A----2

#3 23372297 POWER CORD, CEE

#4 23372297 POWER CORD, CEE

P803A 23713944 CONNECTOR, CONNECT B12B-PH-K-S(LF)

P803B 23713944 CONNECTOR, CONNECT B12B-PH-K-S(LF)

P804 23713942 CONNECTOR, CONNECT B10B-PH-K-S(LF)

P805 23713942 CONNECTOR, CONNECT B10B-PH-K-S(LF)

FUSE, RADIAL LEAD SUB-MINIATUR 250V 3.15A

FUSE, RADIAL LEAD SUB-MINIATUR 250V 3.15A

-

25

-

Page 26

Location

No.

Parts No. Description

Location

No.

Parts No. Description

P811A 23713909 CONNECTOR, CONNECTORB4P-VH(LF)

P811B 23713909 CONNECTOR, CONNECTORB4P-VH(LF)

P812A 23713910 CONNECTOR, CONNECTORB5P-VH(LF)

P812B 23713910 CONNECTOR, CONNECTORB5P-VH(LF)

P813A 23713937 CONNECTOR, PLUG 4P B4B-PH-K-S(LF)

P813B 23713937 CONNECTOR, PLUG 4P B4B-PH-K-S(LF)

P900 23713941 CONNECTOR, CONNECT B9B-PH-K-S(LF)

P900A 23713941 CONNECTOR, CONNECT B9B-PH-K-S(LF)

P902 23713938 CONNECTOR, CONNECT B5B-PH-K-S(LF)

P902A 23713938 CONNECTOR, CONNECT B5B-PH-K-S(LF)

PJ21A 23713934 CONNECTOR, 2MM 3P S WHT B3B-PH-K-S(LF)

PJ22 75000442 CONNECTOR, FPC

PJ22A 23713960 CONNECTOR, 50P FFC 9637S-50Y901

PJ41 23713943 CONNECTOR, CONNECT B11B-PH-K-S(LF)

PJ41A 23713953 CONNECTOR, CONNECT S11B-PH-K-S(LF)

PJ42 23713939 CONNECTOR, CONNECT B6B-PH-K-S(LF)

PJ42A 23713948 CONNECTOR, CONNECT S6B-PH-K-S(LF)

PJ60 75000442 CONNECTOR, FPC

PJ60A 23713960 CONNECTOR, 50P FFC 9637S-50Y901

PJ610 23713819 SOCKET, TWG-P23X-A1

PJ930 23713574

PP08 23974994 BAND, KESSOKU

PP12 23974994 BAND, KESSOKU

PP22 23748085 WASHER, WASHER 10X4.2XT=0.3

PV01 23023418 JACK, PIN RA 3/3P SMKT-3/3P

PV03 23023423 JACK, PIN RA 3P SMK T-4P

PV04 23023419 JACK, PIN RA RESERVERESERVE T-2P

PV11 23023423 JACK, PIN RA 3P SMK T-4P

PV17 23023302 EARPHONE JACK

PV22 23023418 JACK, PIN RA 3/3P SMKT-3/3P

PV25A 23713943 CONNECTOR, CONNECT B11B-PH-K-S(LF)

PV25B 23713943 CONNECTOR, CONNECT B11B-PH-K-S(LF)

PV60 23365833 JACK, PIN 3P, YKC21

PV90 23713710 SOCKET, D-SUB 15P, KRD-8622

Q670B 23717240 SCREW

QE01B 23717240 SCREW

QE90B 23717240 SCREW

QE94B 23717240 SCREW

SA01 23344505 SWITCH, PUSH 1C1P

SA02 23344505 SWITCH, PUSH 1C1P

SA03 23344505 SWITCH, PUSH 1C1P

SA04 23344505 SWITCH, PUSH 1C1P

SA05 23344505 SWITCH, PUSH 1C1P

SA06 23344505 SWITCH, PUSH 1C1P

SA07 23344505 SWITCH, PUSH 1C1P

SR81 23146588 RELAY, DLS5D1-O(M) 0.15W

W661 23351292 SPEAKER, SPK1410AM, 60X120 8-OHM 10W

X501 23153612 CRYSTAL, 16.200 25PPM 25OHM

Z889 23144195 PROTECTOR, 20PSERIES 125V 5A

ZE72 23144185 PROTECTOR, 20PSERIES125V 1A

ZE75 23144195 PROTECTOR, 20PSERIES 125V 5A

ZE94 23144189 PROTECTOR, 20PSERIES125V 2A

CONNECTOR, 7P TOPTYPEBM07B-SRSS-TBT(LF)

PC BOARD ASSEMBLIES

U111A #1 75001393 PC BOARD ASSY, PD2095C1 OTHER

*

*

*

*

*

*

*

*

*

*

*

*

#2 75001393 PC BOARD ASSY, PD2095C1 OTHER

#3 75001348 PC BOARD ASSY, PD2095B1 OTHER

#4 75001393 PC BOARD ASSY, PD2095C1 OTHER

U111B #1 75001394 PC BOARD ASSY, PD2095C2 FRONT-AV

#2 75001394 PC BOARD ASSY, PD2095C2 FRONT-AV

#3 75001349 PC BOARD ASSY, PD2095B2 FRONT-AV

#4 75001394 PC BOARD ASSY, PD2095C2 FRONT-AV

U111C #1 75001395 PC BOARD ASSY, PD2095C3 LED/RMT

#2 75001395 PC BOARD ASSY, PD2095C3 LED/RMT

#3 75001350 PC BOARD ASSY, PD2095B3 LED/RMT

#4 75001395 PC BOARD ASSY, PD2095C3 LED/RMT

U111D #1 75001396 PC BOARD ASSY, PD2095C4 KEY

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

#2 75001396 PC BOARD ASSY, PD2095C4 KEY

#3 75001351 PC BOARD ASSY, PD2095B4 KEY

#4 75001396 PC BOARD ASSY, PD2095C4 KEY

U111E #1 75001397 PC BOARD ASSY, PD2095C5 PC-IN

#2 75001397 PC BOARD ASSY, PD2095C5 PC-IN

#3 75001352 PC BOARD ASSY, PD2095B5 PC-IN

#4 75001397 PC BOARD ASSY, PD2095C5 PC-IN

U112A #1 75001467 PC BOARD ASSY, PD2105C1 POWER

#2 75001467 PC BOARD ASSY, PD2105C1 POWER

#3 75001469 PC BOARD ASSY, PD2105D1 POWER

#4 75001467 PC BOARD ASSY, PD2105C1 POWER

U112B #1 75001468 PC BOARD ASSY, PD2105C2 AC-IN

#2 75001468 PC BOARD ASSY, PD2105C2 AC-IN

#3 75001470 PC BOARD ASSY, PD2105D2 AC-IN

#4 75001468 PC BOARD ASSY, PD2105C2 AC-IN

U113A 75001257 PC BOARD ASSY, PD2131K1 SIGNAL

TUNER

H001 23321499

TUNER, ENG39A07GF, TIF CHI HOR61 IEC PAL+M

ACCESSORIES

A701 #1 23015078 CARTON, CASE 32WL55E

#2 23015078 CARTON, CASE 32WL55E

#3 23015077 CARTON, CASE 32WL55R

#4 23015078 CARTON, CASE 32WL55E

A702A 23946993 PACKING, TOP PACKING 32WE55E

A702B 23946994 PACKING, BOTTOM PACKING 32WL55E

A703 23945224 BAG, PROTECTIVE

A709 23946938 PACKING, CENTER PACKING

Y101 #3 23566646

Y101A #1 23566647 OWNERS MANUAL, ENGL LCD O/M 32WL55A

#2 23566647 OWNERS MANUAL, ENGL LCD O/M 32WL55E

#4 23566647 OWNERS MANUAL, ENGL LCD O/M 32WL55T

Y101H #2 23566648 OWNERS MANUAL, CT LCDO/M 32WL55E

Y101J #2 23566649 OWNERS MANUAL, ARABIC LCDO/M 32WL55E

Y101K #4 23566651 OWNERS MANUAL, THAI LCD O/M 32WL55T

Y109 23945015 BAG, POLYETHYLENE COVER 250X400

Y130 23306590 REMOCON HAND UNIT, CT-90126

Y170 23845800 HOLDER, WIRE, NYLON66 D6.8

OWNERS MANUAL, ENGL/RUSIA LCD O/M 32WL55R

CABINET PARTS

A201 23533412 COVER, FRONT BEZEL ASSY 32WL55A

A231 23717226 SCREW, PB 4X5 SNI

A240 23717267 SCREW, BITTB4X16 SBN

A315 23528409 HOLDER, AC HLD BASE

A317 23533055 COVER, BRACKET SUPPORT

A320 23940353 PIECE, FRONT AV ASSY

A340 23940394 PIECE, PIECE KEY ASSY

A360 23717226 SCREW, PB 4X5 SNI

A365 23717219 SCREW, PP3X8+SW+W SBN

A370 23717267 SCREW, BITTB4X16 SBN

A375 23717214 SCREW, BITTB3X12SBN

A401 23533245 COVER, BACK COVER

A410 23717219 SCREW, PP3X8+SW+W SBN

A411 23717267 SCREW, BITTB4X16 SBN

A420 23436865 FOOT, STAND ASSY

A440 23738074 SCREW, PP 5X16 SW+W SBN

A445 23532988 COVER, BC STAND

A450 23532989 COVER, BACK TERMINAL BOARD

-

26

-

Page 27

AV OTHER BOARD (32WL55A/32WL55E/32WL55T:PD2095C1 32WL55R:PD2095B1) (U111A)

BOTTOM (FOIL) SIDE

P819

P818

DE93

1

2

R896

RV25

DV25

DE91

1

2

3

R894

D897

R894

3

D896

RE87

DE92

2

PJ87A

RV32

RV25

DV25

RV32

RV59

RV59

RV56

RV58

RV70

RV57

RV56

RV58

QV52

RV57

QV52

RV70

DE95

QE91A

D897

R897

R897

R895

R895

QE96

D896 R896

3

2

1

RE88

QE98

RE98

RE84

RE91

RE84

RE97

RE98

RE87

RE93

RE91

QE95

RE93

QE97

RE96

RE96

QE95

RE95

DE94

1

5

PJ63A

RV33

RV26

RV33

DV26

DV26

RV26

PV11

CV52

B

C

DE95

E

CE93

+

ZE90

RE88

CE90

QE98

QE97

CE87

1

RE90

RE90

QE90A

QE94A

DV27

QE91

DE99

DV27

RE85

RV27

RV27

RV34

RV34

RV12

RV11RV12

RV11

RE85

QE90

RE94

B

DE99

C

E

RV21

RV21

DV21

DV21

RV54

RV54

CV51

RV52

RV51

RV53

RV52

QV51

RV53

QV51

DE90

CE91

+

CE92

RE94

DE98

QE94

12

RC02

CC02

CC02

P803B

C8001

GR660

RC01

RC01

CC01

+

C682

GR660

GR601

GR601

1

RC02

+

PV01

RV55

RV55

RV51

C680

+

+

DE97

ZE94

10

RV28

CC01

D675

CV53

D670

D670

C684

C684

12

10

D675

D671

D674

D671

D674

R679

C679

R679

+

R678

C681

1

45

P602A

RV35

RV35 RV28RV29

DV28

DV28

RV71

RV71

RV74

RV72

RV73

RV75

RV72

RV75

QV53

RV73

QV53

Q670

1

5

+

+

R680

C674

R680

C673

C692

C692

R682

C693

C693

C678

R681

R681

R678

C690

+

C6990

C691

+

RV36

RV36

RV30

RV30

RV37

RV37

DV30

DV30

DV29

DV29

RV29

PV03

+

RV74

23547783

Q670A

R6604

R6604

C675

Q671

R682

Q671

Q672

C691

Q672

Q673

Q673

C676

C685

R683

R683

C685

+

D678

R685

C665

C671

++

+

C670

C677

R686

R686

D678

R685

R6603

C667

R673

R671

R673

C663

R671

R677

C663

C662

C662

C664

R684

R6603

R675

R675

R677

R672

R670

R672

R670

R674

R676

R674

R676

C666

R684

D679

D679

Q663

D676

Q663

D676

D677

R6602

D677

R6601

Q662

R6601

R6602

Q662

C661

C660

CC07

RC04

RC03

RC04

CC07

DS-7209

L110

3

RC03

DE96

1

CC03

PJ21A

GR01

GR01

CC03

PV04

C105

CC40

RC40

CC40

RC40

PV17

+

CV13

LV16

RV91

LV16

RV91

+

CV13

RV61

+

CV18

RV76

11

+

RV120

RV120

CC41

RC41

PV22

RC41

CC41

CV20

CV19

+

CV17

+

RV61

RV80

RV80

QV54

RV76

RV78

RV77

CV54

RV78

RV79

RV77

L101

PV25A

QV54

RV79

QV55

QV55

RV85

RC06

Q655

R6614

CC06

RC05

CC06

RC06

Q655

R663

R663

R6614

R661

R661

R662

R662

RV83

+

RV84

RV83

RV82

RV84

RV85

RV81

RV81

1

R6616

RV82

CV55

CC05

R6616

R660

Q656

R660

R6615 RC05

+

R6615

Q656

C668

QT11

R4101

R4101

Q4100

Q4100

R4100

DV44

R4100

9

DV44

QT02

CC05

R6617

R6617

QT02

CT02

Q654

RT28

RT28

QT11

R4102

R4102

Q4101

R4105

DV45

DV45

R4105

CT04

CT02

Q654

RT08

RT08

RT09

RT06

RT09

RT29

RT06

RT29

CT06

QT12

QT12

CT06

R4103

R4103

R4106

R4107

R4107

Q4101

R4106

R4104

R4104

Q4102

GR31

Q4102

Q4103

P900

GR31

P902

CT12

RT04

LT01

RT18

CT05

RT04

CT05

RT05

RT05

CT04

RT16

RT03

CT03

CT11

GT01

RT03

CT11

RT07

CT03

RT07

GT01

RT02

RT01

QT03

QT01

RT02

CT19

QT03

QT01

CT20

CB41

CT20

CB41

R4109

R4108

R4109

R4108

Q4103

R167

C116

C103

R166

C164

1

R162

R161

1

5

GR25

GV14

GV14

GR25

CT08

CT10

QT06

CT12

RT18

RT16

RT13

RT01

CT19

LV42

17

L191

GV15

GV15

RT17

CT10

CT08

QT06

RT17

QT05

QT05

RT15

LT02

RT15

CT09

RT14

CT09

RT14

RT11

GT02

QT04

GT02

QT04

CT01

RT13

RT11

RV44

CT01

CV42

RV44

CV39

GV01

CV42

GV01

LV42

RV60

+

GV02

RV60

GT04

R114

R114

C116

C103

R167

C161

C161

R166

R169

C164

R165

R165

R163

R163

R162

Q161

C163

R161

R168

Q161

R168

C163

GR26

GR30

GR27

GR28

GR28

GR30

GR27

GR26

RT22

RT21

CT18

CT17

RT12

RT12

CT17

RT19

RT10

RT10

RT20

CT07

CT13

CT07

CT13

CC04

CC04

QV06

GV02

QV06

GT04

L102

L191

L102

R107

C190

C190

R169

R103

Q162

R103

Q162

C162

R164

R170

R164

C162

R170

LT03

RT27

CT18

RT22

RT21

GT03

RT19

QT07

QT07

RT20

RV43

RV43

GR03

GR02

+

GR03

C114

C115

R108

R107

Q101

R104

R105

R105

GR112

GR112

GR612

RT23

L103

Q101

R104

GR02

GR612

RT27

RT25

CT15

CT15

QT08

QT08

RT23

GT03

PK05

C104

7

+

C113

C113

C112

C112

C115

R108

QT09

QT09

RT25

CT16

CT16

RT26

RT26

CT14

CT14

RT24

RT24

C117

C117

GR07

GR05

GR07

GR05

C107

R101

R102

R101

63

C110

C111

L103

C114

C111

C110

H001

C118

C118

GR08

P516A

GR06

GR06

GR08

C102

C101

C101

R102

+

D101

D101

2

GR613

GR113

GR613

GR113

P516A

AV OTHER BOARD (32WL55A/32WL55E/32WL55T:PD2095C1 32WL55R:PD2095B1) (U111A)

TOP (COMPONENT) SIDE

LT02

LT03

PK05

C104

+

C102

+

2

C107

3

6

H001

L105

+

7

+

PJ22A

CV39

L105

10

PJ22A PJ60A

LT01

QT10

7

8

+

17

QT10

1

14

1

P902

51

403020

P900

PV22

+

CV19

C668

+

CV17

CV55

PV25A

1

9

PJ60A

4030201050

50

CV20

QV14

+

QV14

+

+

CV54

11

L101

PV17

+

CV18

C105

PV04

PD2095 -1

C661

C667

+

+

+

L110

DE96

1

3

PJ21A

C660

+

C666

C665

C664

PV03

23590196B

Q670A

C671

+

C670

+

C677

C676

CV53

+

++

+

1

5

12

C675

C673

++

+

C678

+

C6990

10

Q670

+

C679

+

C674

C690

P602A

4

C681

PV01

+

C682

5

P803B

ZE94

+

CV51

+

CE91

C680

CE92

+

DE97

C8001

P

10

DE98

DE90

+

QE94

QE90A

QE90

QE94A

PV11

QE91

CE93

CE90

+

PJ63A

CE87

QE91A

ZE90

CV52

+

DE91

1

2

3

P819

1

2

QE96

P818

3

P

+

RE95

RE97

DE92

DE94

5

1

PJ87A

DE93

2

1

-

27

--

28

-

Page 28

-2

23590196B

PD2095

1110987654321

1234

4321

L_GND

L_SPK

R_SPK

R_GND

L_GND

L_AMP

R_AMP

R_GND

P602 P601

LC32

PV60

LC33

PV25B

P661

LC31

PV61

LC32

LC33

LC31

FRONT-AV BOARD

VOL-DN VIDEO HOUSOU

23590196B

-4PD2095

6

1 CH-DN VOL-UP

PUSH-SW

CH-UP

SA06

SA05SA04SA03

PJ42A

SA07

SA01 SA02

FRONT-AV BOARD

(32WL55A/32WL55E/32WL55T:PD2095C2 32WL55R:PD2095B2) (U111B)

BOTTOM (FOIL) SIDE

DV122

DV121

CV122

DV122

CV122

DV121

DS-7209

11 10 9

TUNER GND

TUNER GND

RV122

86 3

754

L_E3

R_E3

GND

GND

V_E3

RV129

RV129

RV122

PV61

SC_E3

S-SW_E3

CV121

21

SY_E3

DV120

DV120

CV121

GND

RV121

PV25B

RV123

RV121

23547783

RV123

E3-V

CC12

D652

D653

13

D653

24

D652

CY650

CY650

RC12

RC12

CC12

E3-L

GR605

PV60

GR604

L_GND

GR604

GR605

CC11

L_SPK

CC11

R_SPK

RC11

E3-R

R_GND

RC11

P601

C606

L_GND

4

321

C606

R689

R689

R688

L_AMP

R688

P661

R_AMP

R_GND

P602

C605

C605

R687

R695

R695

R687

R696

R696

R697

R697

LED/RMT BOARD

(32WL55A/32WL55E/32WL55T:PD2095C3 32WL55R:PD2095B3) (U111C)

BOTTOM (FOIL) SIDE

(32WL55A/32WL55E/32WL55T:PD2095C2 32WL55R:PD2095B2) (U111B)

TOP (COMPONENT) SIDE

LED/RMT BOARD

(32WL55A/32WL55E/32WL55T:PD2095C3 32WL55R:PD2095B3) (U111C)

TOP (COMPONENT) SIDE

DB04A

TIMER

DB04

QB04

RB10

RB10

DS-7209

23547783

QB04

RB22

POWER

DB01

DB01A

QB07

RB18

CB04

RB18

RB15

RB15

QB07

+

CB04

RB22

CB05

CB02

+

DB22

DB23

CB01

11

GND

3.3V

RB08

KB01

CB03

CB03

RB24

DB22

+

RMT

GND

RB24

DB23

DB20

DB20

RB09

CB38

RB08

CB38

RB09

PJ41A

2345678910

1

NC

NC

NC

5V1

LED

RMT

GND

KEY BOARD

(32WL55A/32WL55E/32WL55T:PD2095C4 32WL55R:PD2095B4) (U111D)

BOTTOM (FOIL) SIDE

23547783

SA06

RA78

RA78

RA77

SA05

RA77

DA06

DA06

SA04

RA71

SA03

RA71

RA72

RA72

SA02

RA73

RA73

SA01

RA74

DA01

DA01

RA74

SA07

RA79

DA07

DA07

RA79

DS-7209

PJ42A

1

2

3

4

5

6

TIMER

DB04

DB04A

1

KB01

PJ41A

23456

PD2095

+

+

7

CB01

POWER

-3

DB01

CB02

+

111098

DB01A

CB05

23590196B

KEY BOARD

(32WL55A/32WL55E/32WL55T:PD2095C4 32WL55R:PD2095B4) (U111D)

TOP (COMPONENT) SIDE

-

29

--

30

-

Page 29

PC-IN BOARD

(32WL55A/32WL55E/32WL55T:PD2095C5 32WL55R:PD2095B5) (U111E)

BOTTOM (FOIL) SIDE

PV90

C526

R516

R514

RR04

C514

Q504

RR01

R506

Q504

C516

C517

C527

CC20

GJ13

GJ13

R506

CC20

C526

R511

R512

R512

R511

23547783

DS-7209

DR04

DR04

19

P900A

+

C519

15

R504

R504

GR34

GR35

GR34

DR05

GR35

RR06

RR03

DR03

DR05

DR03

C524

C524

CC31

CC31

R508

R502

C506

C506

R508

R502

+

+

C505

R505

C503

R505

GJ10

P902A

C504

C504

GJ10

DR02

RR03

C502

C502

RR05RR06

DR02

GC20

R501

RR02

RR02

RR01

RR05

RR04

DR01

DR01

+

X501

GC20

C516

C507

C507

+

R515

R516

R515

C521

C521

R507

R507

R509

+

R509

R514

C501

R501

C501

GJ16

L504

L505

GJ16

L510

PC-IN BOARD

(32WL55A/32WL55E/32WL55T:PD2095C5 32WL55R:PD2095B5) (U111E)

TOP (COMPONENT) SIDE

PD2095

C514

X501

-5

C517

C527

L510

PV90

+

39

+

48

+

1

L505

L504

P902A

25

38

Q501

Q501

14

+++

C503

51

23590196B

P900A

24

15

91

C505

C519

-

31

-

Page 30

RE14

DE12

DE17

DE08

CE29

DE19

POWER BOARD (32WL55A/32WL55E/32WL55T:PD2105C1 32WL55R:PD2105D1) (U112A)

BOTTOM (FOIL) SIDE

C

822

C826

C827

DE13

RE16

C824

+

R814

R812

12

C819

C820

CE22

CE23

QE01

CE09

D805

R813

R805

R803

D809

Q801A

C817

R806

D810

DE14

DE07

7

DE15

+

C825

R817

D806

R807

1

R815

C815

808

R

QE01A

1

RE29

CE17

RE15

L803

Q801

P812B

1

RE18

C821

L804

15

14

D811

D812

R809

RE17

DE16

RE13

CE07

CE12

DE09

R

E

12

CE10

250V F3.15AL

F802

C810

24

C804

1

+

CE16

LE11

+

FE01

250V F3.15AL

CAUTION

+

CE18

3

RE19

P811B

CE15

LIVE AREA

D813

+

C816

CE21

DE06

DE05

RE23

LE12

DE11

RE05

C803

C823

P890

R821

L805

C813

CE11

TE62

QE26

T862

Q826

C899

R873

R874

DE77A

CE82

DE77

DE72

+

+

ZE74

ZE73

ZE75

ZE72

5432

CE85

DE75A

L876

L878

D884A

L875

Z889

L874

C890

DE75

+

CE84

D885

G

C

B

DE73A

+

+

CE86

CE83

D884

QE93

C884

+

LE71

+

QE73

RE74

QE93A

B

E

C

P813B

4321

+

C889

Q883

ZE76

DE73

CE43

QE83

CE74

DE71

DS-7209

23547777

D883A

D883

CE41

CE73

CE75

L884

C883

+

L890

QE40

GE50

5

1

CE42

CE40

+

+

LE72

LE52

+

+

LE74

CE76

2

115

12345

PJ62A

DE50

R862

R861

P804

L883

L889

L888

LE53

LE73

DE51

CE50

CE51

CE55

PJ80A

16

10

10

P805

1

1

1

P803A

++

12

POWER BOARD (32WL55A/32WL55E/32WL55T:PD2105C1 32WL55R:PD2105D1) (U112A)

TOP (COMPONENT) SIDE

GJ99

R862

10

10

P805

R861

P804

1

1

P803A

1

L888

DE56

DE56

LE73

DE54

DE54

DE52

DE52

+

DE55

DE55

DE51

12

QE75

QE75

RE82

RE82

RE83

RE83

QE74

QE74

QE71

CE51

5

QE71

6

PJ80A

RE51

RE52

RE51

16

RE52

GJ84

C889

Q883

P

DE73A

D885

RE46

L876

L878

L875

Z889

P

G

C

B

R890

DE73

+

L874

R890

C890

DE75A

+

DE75