Page 1

SERVICE MANUAL

LCD Colour TV

32WL46B

FILE NO. 070-200405

F4LW Chassis

32WL46G

May. 2004 (YC/X)

Page 2

TABLE OF CONTENTS

SERVICE SAFETY PRECAUTIONS ................................................................................................................................... 3

HANDLING

SERVICE MODE

LOCATION OF CONTROLS............................................................................................................................................... 11

LAYOUT OF MAJOR BOARDS........................................................................................................................................... 15

MECHANICAL DISASSEMBLY.......................................................................................................................................... 16

WIRING CONNECTIONS .................................................................................................................................................. 29

EXPLODED VIEW ............................................................................................................................................................. 35

PACKING DISASSEMBLY ................................................................................................................................................. 39

CHASSIS AND CABINET REPLACEMENT PARTS LIST ................................................................................................. 41

PC BOARDS TOP & BOTTOM VIEWS ............................................................................................................................ 53

PC BOARDS BOTTOM VIEW............................................................................................................................................ 67

CIRCUIT BLOCK DIAGRAM

SPECIFICATIONS.......................................................................................................................................................... END

APPENDIX:

THE LCD MODULE .........................................................................................................................................

.................................................................................................................................................................57

SCHEMATIC DIAGRAM

– 2 –

Page 3

SERVICE SAFETY PRECAUTIONS

• The caution items shown here describe major safety issues and should always be observed.

• The meanings of the various indications are as follows.

WARNING

CAUTION

* Physical damage means major damage to a home, furnishings and other possessions.

Examples of marks

SHOCK HAZARD

PROHIBIT DISASSEM-

BLING

UNPLUG

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users due to a product defect after the service operation is completed, could possibly be in

danger of injury or even death in the event of operational error.

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users after the service operation is completed, could possibly be in danger of injury, or

where there could be physical damage in the event of operational error.

The" indicates caution (including danger and warning).

"

The actual meaning of this caution is indicated inside the

The example shown to the left indicates the danger of "electrical shock".

indicates a forbidden action.

The

The actual meaning of this caution is indicated inside the

The example shown to the left indicates that disassembly is forbidden.

-

indicates a forced action (an action that must be performed).

The

The actual meaning of this forced action is indicated by

The example shown to the left indicates that the power plug must be disconnected.

or nearby illustrations or text.

or nearby illustrations or text.

-

or nearby illustrations or text.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 3 –

Page 4

KEEP CHILDREN

AWAY

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

UNPULUG

SHOCK HAZARD

USE SPECIFIED

PARTS

CAUTION FOR

WIRING

CAUTION FOR

ASSEMBLING /

WIRING

WARNING

• Always advise users to keep children away.

There is danger of injury to children from tools, disassembled products, etc.

• Always disconnect the power plug before starting work whenever power is not required.

Failure to disconnect the power plug before starting work can result in electrical shock.

• Depending on the model, use an insulation transformer or wear gloves when servicing with the

power on, and disconnect the power plug to avoid electrical shock when replacing parts.

In some cases, alternating current is also impressed in the chassis, so electrical shock is possible if the chassis is contacted with the power on.

• Always use the replacement parts specified for the particular model when making repairs.

The parts used in products have the necessary safety characteristics such as inflammability,

voltage resistance, etc.; therefore, use only replacement parts that have these same characteristics.

Use only the specified parts when the

• Parts mounting and routing of the wiring should be the same as that used originally.

For safety purposes, insulating materials such as tubing or tape is sometimes used and printed

circuit boards are sometimes mounted floating.

Also make sure that wiring is routed and clamped to avoid parts that generate heat and which

use high voltage. Always follow the original scheme.

• After a repair has been completed, reassemble all disassembled parts, and route and reconnect the wiring, in accordance with the original scheme.

Do not allow internal wiring to be pinched by cabinets, panels, etc.

Any error in reassembly or wiring can result in electrical leakage, flame, etc., and may be

hazardous.

mark is included in a circuit diagram or parts list.

CHECK INSULATION

RESISTANCE

PROHIBIT

REMODELING

• After completing the work, disconnect the power plug from the outlet, remove the antenna, turn

on the power switch. Then, use a 500V insulation resistance meter to check the insulation

resistance of the antenna terminal, other metallic parts and between the prongs of the power

plug to make sure that the insulation resistance is 1M 1 or more.

The set will require inspection and repair if the insulation resistance is below this value.

• Never remodel the product in any way.

Remodeling can result in improper operation, malfunction, or electrical leakage and flame,

which may be hazardous

– 4 –

Page 5

HANDLING THE LCD MODULE

Safety Precautions

In the event that the screen is damaged or the liquid crystal

(fluid) leaks, do not breathe in or drink this fluid. Also, never

touch this fluid.

Such actions could cause toxicity or skin irritation. If this fluid

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the skin or clothing, wipe off

with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the ey es thoroughly

with running water.

Precautions for Handling the LCD Module

The LCD module can easily be damaged during disassembly

or reassembly; therefore, always observe the following precautions when handling the module.

1. When attaching the LCD module to the LCD cover, position it appropriately and fasten at the position where the

display can be viewed most conveniently.

3. If the panel surface becomes soiled, wipe with cotton or a

soft cloth. If this does not remove the soiling, breathe on

the surface and then wipe again.

If the panel surface is extremely solied, use a CR T cleaner

as a cleaner. Wipe off the panel surface b y drop the cleaner

on the cloth. Do not drop the cleaner on the panel. Pay

attention not to scratch the panel surface.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

4. Leaving water or other fluids on the panel screen for an

extended period of time can result in discoloration or

stripes. Immediately remove any type of fluid from the

screen.

2. Carefully align the holes at all four corners of the LCD

module with the corresponding holes in the LCD cover

and fasten with screws. Do not strongly push on the module because any impact can adversely affect the performance. Also use caution when handling the polariz ed screen

because it can easily be damaged.

The metal edges of the LCD module

CAUTION

are sharp, so use caution to avoid injury.

5. Glass is used in the panel, so do not drop or strike with

hard objects. Such actions can damage the panel.

6. CMOS-LSI circuitry is used in the LCD module, so avoid

damage due to static electricity. When handling the module, use a wrist ground or anchor ground.

– 5 –

Page 6

7. Do not expose the LCD module to direct sunlight or strong

9. Do not disassemble the LCD module. Such actions could

result in improper operation.

10.When transporting the LCD module, do not use packing

containing epoxy resin (amine) or silicon resin (alcohol or

oxim). The gas generated by these materials can cause

loss of polarity.

ultraviolet rays for an extended period of time.

GENERAL ADJUSTMENTS

8. Do not store the LCD module below the temperature conditions described in the specifications. Failure to do so

could result in freezing of the liquid crystal due to cold air

or loss of resilience or other damage.

IC INFORMATIONS

Cleaning

Remove the power plug before cleaning.

Do not use solvents such as benzine or thinner to clean the TV.

– These solvents may distort the cabinet or damage its finish.

– If rubber or vinyl products remain in contact with the TV for a long time, a stain may result.

When the cabinet becomes dirty, clean it with a soft, dry cloth.

When the cabinet is very dirty.

– Use a damp cloth to wipe the cabinet clean.

– Finish with a dry cloth.

When cleaning the surface of the LCD display:

– Wipe the panel surface gently with a soft, dry cloth.

When dust has collected on the power plug connectors, remove the plug from the outlet and clean off the

dust.

This dust may cause a fire due to reduced insulation on the plug.

– 6 –

Page 7

SERVICE MODE

1 . ENTERING TO SERVICE MODE

(1) Procedures

1) Press MUTE key of remote hand unit to indicate MUTE

on screen.

2) Press again MUTE key of remote hand unit to keep

pressing until the next procedure.

(OSD display disappears.)

3) In the status of above (2), press MENU key on TV set.

(2) During service mode, indication S is displayed at upper right

corner on screen.

(3) Service mode is not memorized as the last-memory.

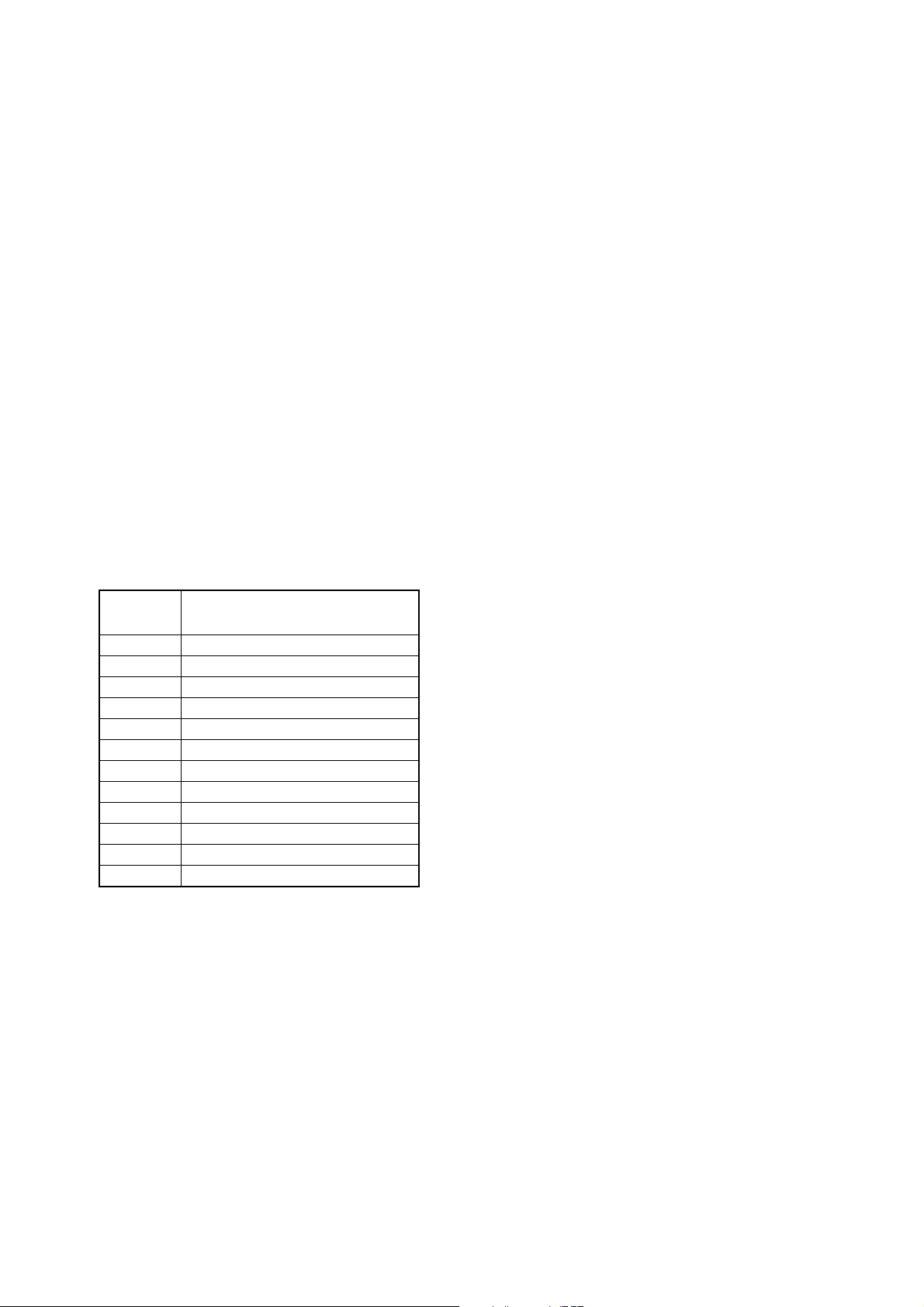

2.TEST SIGNAL SELECTION

The function of VIDEO test signal selection is cyclicall y

changed with VIDEO key (remote unit) in Service mode.

Table 1

Test signal

No.

0

1

2

3

4

5

6

7

8

9

10

0

Signal OFF

NTSC All Red signal

NTSC All Green signal

NTSC All Blue signal

NTSC Cross hatch

NTSC All white signal

PAL All Red signal

P AL All Green signal

PAL All Blue signal

PAL Cross hatch

P AL All white signal

Signal OFF

Name of pattern

3.SERVICE ADJUSTMENT

(1) ADJUSTMENT MENU INDICATION ON/OFF :

MENU key(on TV set)

(2) During display of adjustment menu,the followings are

effective.

1) Selection of adjustment item :

POS UP/DN key (on TV/Remote unit)

2) Adjustment of each item :

VOL UP/DN key (on TV/Remote unit)

3) Direct selection of adjustment item

R CUTOFF : 1 POS (Remote unit)

G CUTOFF : 2 POS (Remote unit)

B CUTOFF : 3 POS (Remote unit)

4) Data setting for PC unit adjustment

SUB CONTRAST : 4 POS (Remote unit)

SUB COLOR : 5 POS (Remote unit)

SUB TINT : 6 POS (Remote unit)

5) Screen adjustment mode ON/OFF: Previous

6) Test signal selection: VIDEO (Remote unit)

* In service mode, serviceable items are limited.

(3) Self check display : 9 POS (Remote unit)

* Cyclic display

2

(4) Initialization of memory (QA02 E

CALL (Remote unit)+POS UP(TV)

Causion : All data of memory IC (including factory setting

value) is initialized by this operation.

(Replacement of memory IC is required.)

(5) Initialization of self check data :

CALL (Remote unit)+POS DN(TV)

PROM) :

– 7 –

(6) BUS OFF :

CALL (Remote unit)+VOL UP(TV)

Page 8

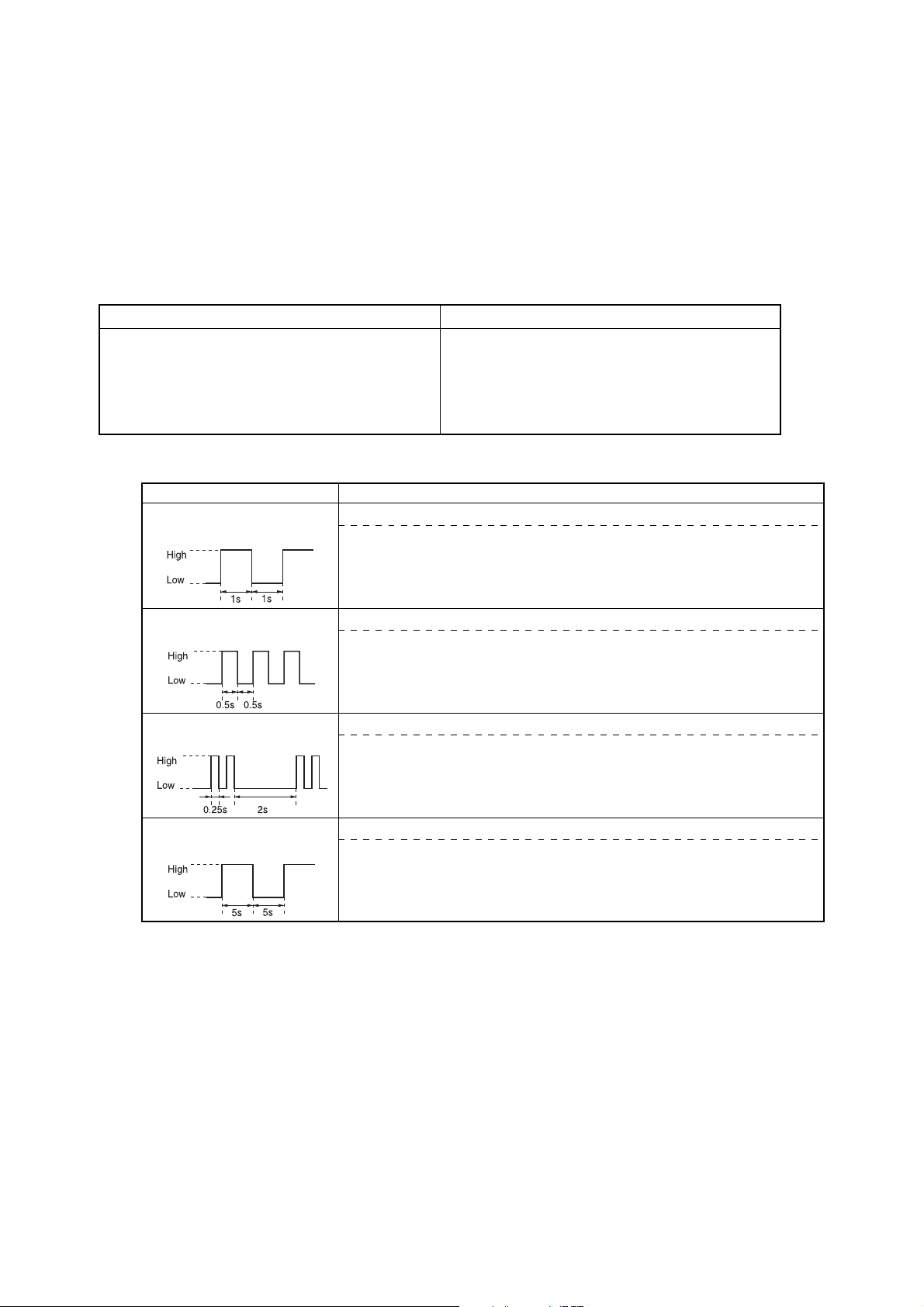

4.FAILURE DIAGNOSIS PROCEDURE

This model is equipped with self diagnosis function inside for trouble shooting.

4-1.Contents to be Confirmed by Customer

Table 2

Contents of self diagnosis

Set Power does not turn on by power-key, or it turns off

automatically.

1.When power protection circuit operates;

2.When FAN STOP was detected:

3.When failure of Audio circuit was detected:

DIAGNOSIS FUNCTION FOR LED INDICATION

LED is lit in 1 second at intervals of 1 second.

TROUBLESHOOTING DIAGNOSIS FUNCTION

LED

Short-circuit detection of BUS line

BUS line may possib ly be short-circuit (SDA to SCL), or BUS line (SDA, SCL)

is grounded.

Power indicator lamp blinks and picture does not come.

1.Power indicator red lamp blinks. (0.5 seconds interval)

2.Power indicator red lamp blinks. (3 seconds interval)

3.Power indicator red lamp blinks. (5 seconds interval)

If these indications appear, repairing work is required.

Display items and actual operation

CAUSE

LED is lit in 0.5 at intervals

of 0.5 second.

LED is lit in 0.25 second at

intervals of 2 second.

LED is lit in 5 seconds at intervals of 5 seconds.

High : Lighting Low : No Lighting

Overcurrent limiter detection

POWER terminal on TV microprocessor becomes LOW at 2 seconds or more .

Interruption of FAN motor function detection

No. 53 terminal on TV microprocessor becomes HIGH for 30 seconds.

Abnormal sound detection

P4 terminal of QS10 becomes LOW for 15 seconds during Speaker is activated.

– 8 –

Page 9

4-2. Contents to be Confirmed in Service Work (Check in Self Diagnosis Mode)

Tab le 3

Contents of self diagnosis

Contents of self diagnosis

B. Indication of part code of microprocessor.(QA01)

C. Total Time of Power on (hour)

D. Number of operation of power protection circuit

E. Check of communication status in BUS line

F. Check of signal line by sync signal detection

Display items and actual operation

* Please see item.4-4

Display items and actual operation

4-3. Executing Self Diagnosis Function

Procedures

(1) Set to service mode.

(2) Pressing “9” key on remote unit displays self diagnosis result on screen.

Every pressing changes mode as below.

SERVICE mode

(3) To exit from service mode, turn power off.

<SELF DIAGNOSIS mode>

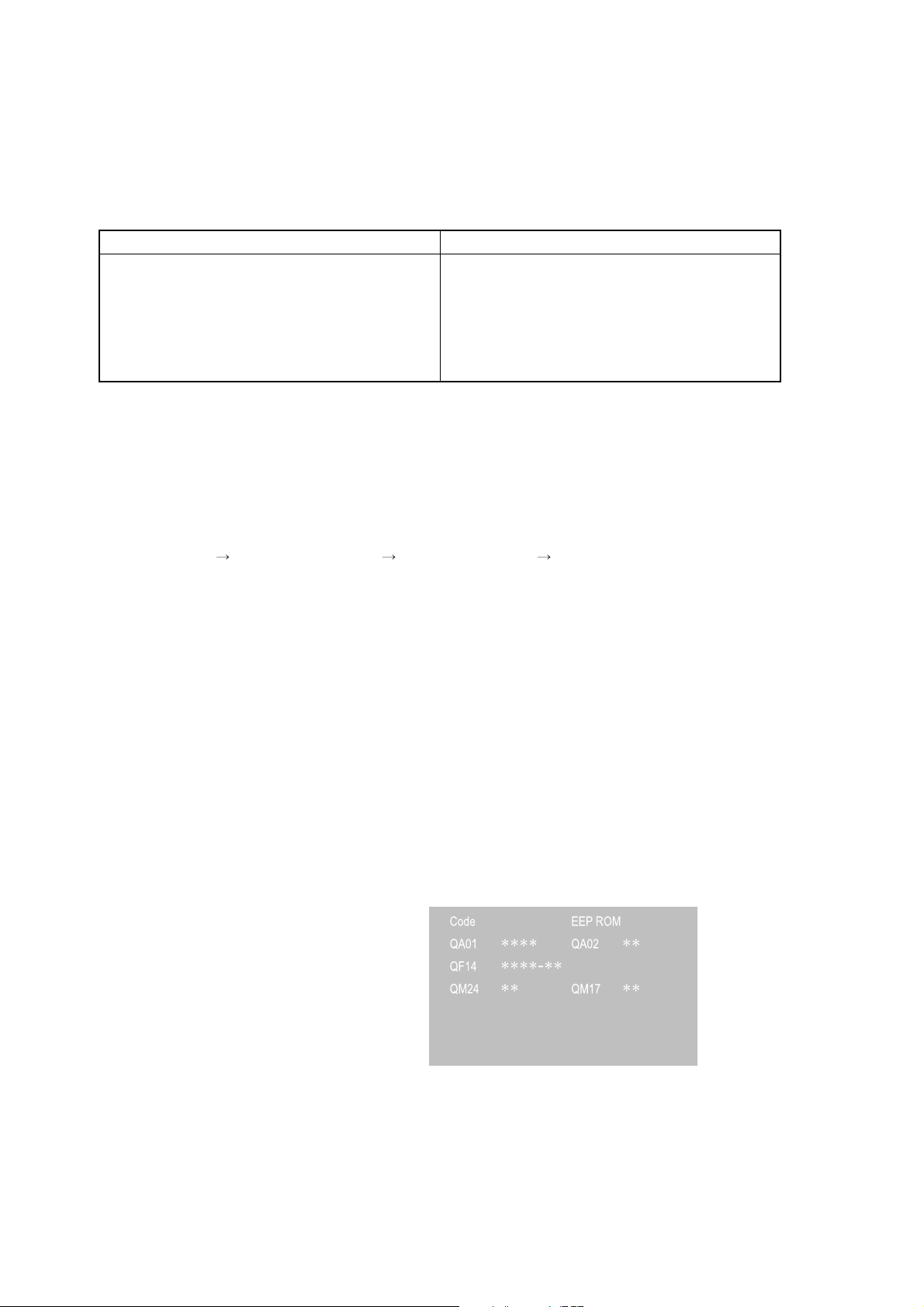

SELF DIAGNOSIS mode M2 System version info V ersion check(QA01,QM24 etc)

<OSD/TEXT M2 Sub System Information> <Version Check>

Description for Version Check Screen

-

QA01

QA02

QF14

QM24

QM17

– 9 –

****

**

****-**

**

**

Version information for MainMicom(QA01)

-

V ersion information for E2PROM(QA02)

-

Version information for M2 Sub-Micom(QF14)

-

Version information for BEP Sub-Micom(QM24)

-

Version information for BEP E2PROM(QM17)

Page 10

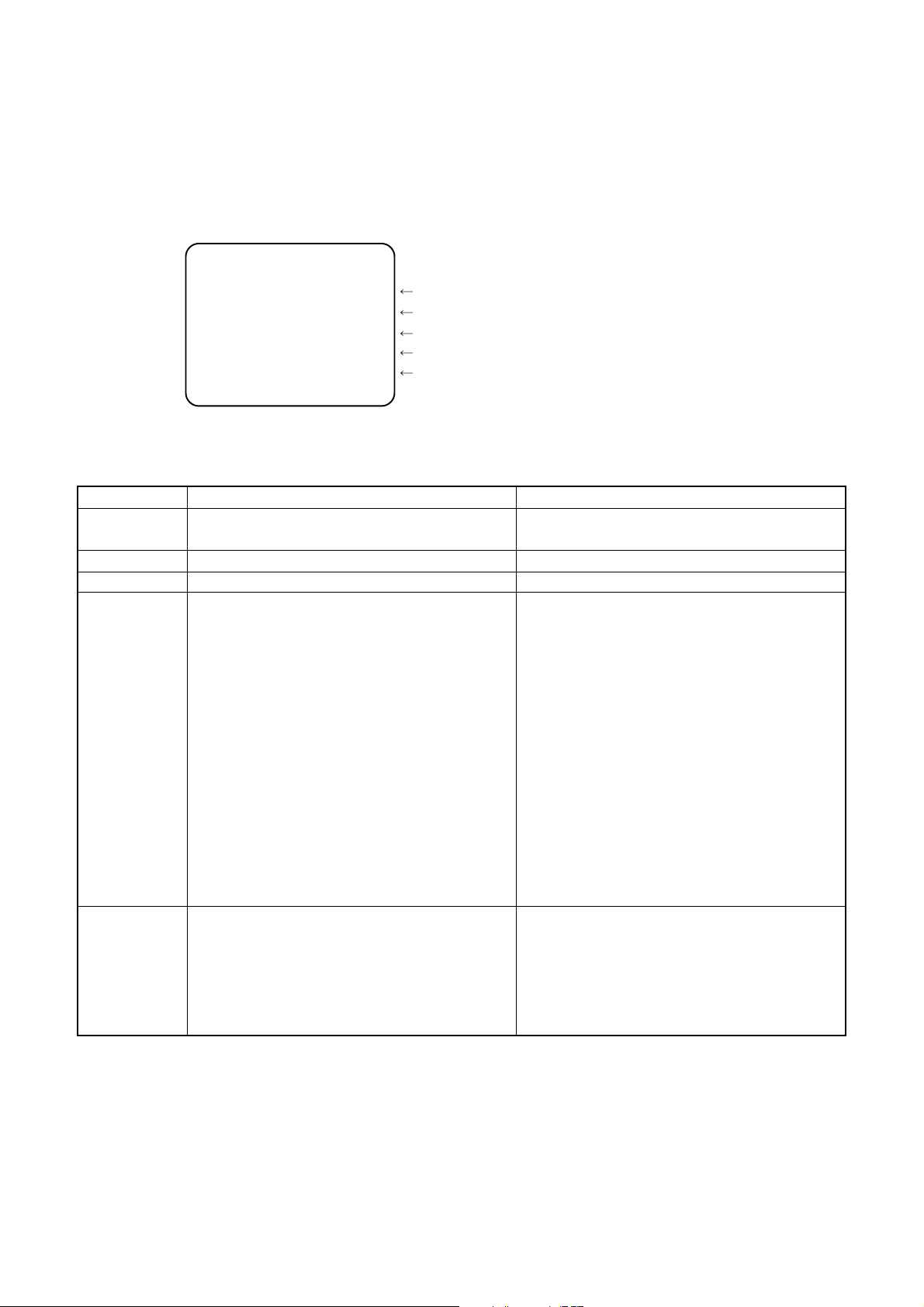

4-4. Self Diagnosis Function Indication & Contents

<Example of screen display>

SELF CHECK

23000XXX B

TIME C

POWER : 000 D

BusCont : OK E

Block : UV V1 V2 V3 V4 F

PC

Fig. 1

Table 4

Item

B) Part code

C) TIME

D) POWER

E) BUS CONT

Indication of part code of microprocessor.

(QA01)

Total Time of Power on (hour)

Number of operation of power protection circuit

Communication state of bus line

Contents

Instruction of results

Indication of“OK”for normal result

Indication of failure place in abnormality

(Failure place to be indicated)

QA02 NG, H001 NG, Q501 NG,

QV01 NG, Q4420 NG

H002 NG

QA02 : E

2

PROM, H001 : MAIN TUNER,

Q501 : MCD QV01: AVSW,

Q4420 : SCAN PROCESSOR

H002 : ITT,DSP,APRO

F) BLOCK

The sync signal part in each video signal supplied

from each block is detected.

Then by checking the existence or non of sync part, the

result of self diagnosis is displayed on screen.

Besides, when “9” key on remote unit is pressed,

diagnosis operation is first executed once.

– 10 –

Note 1. The indication of failure place is only one

place though failure places are plural. When

repair of a failure place finishes, the next

failure place is indicated.

*Indication by color

Select Source

: Sync exists = Green

: No Sync = Red

Other Source

: Black

Page 11

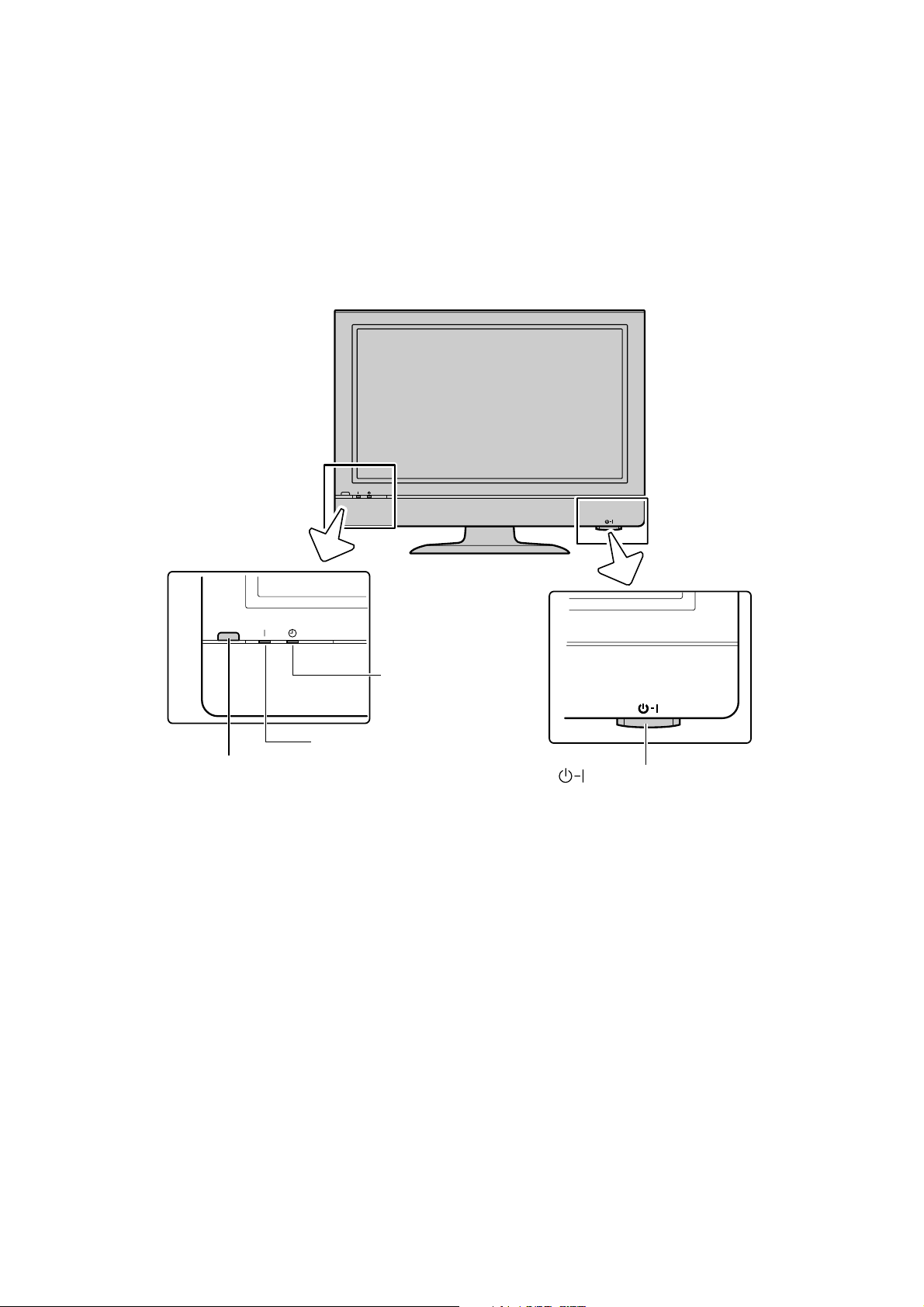

Front

LOCATION OF CONTROLS

TV front view

Remote sensor

On-timer

indicator

(green)

Power indicator

(red)

Power switch

– 11 –

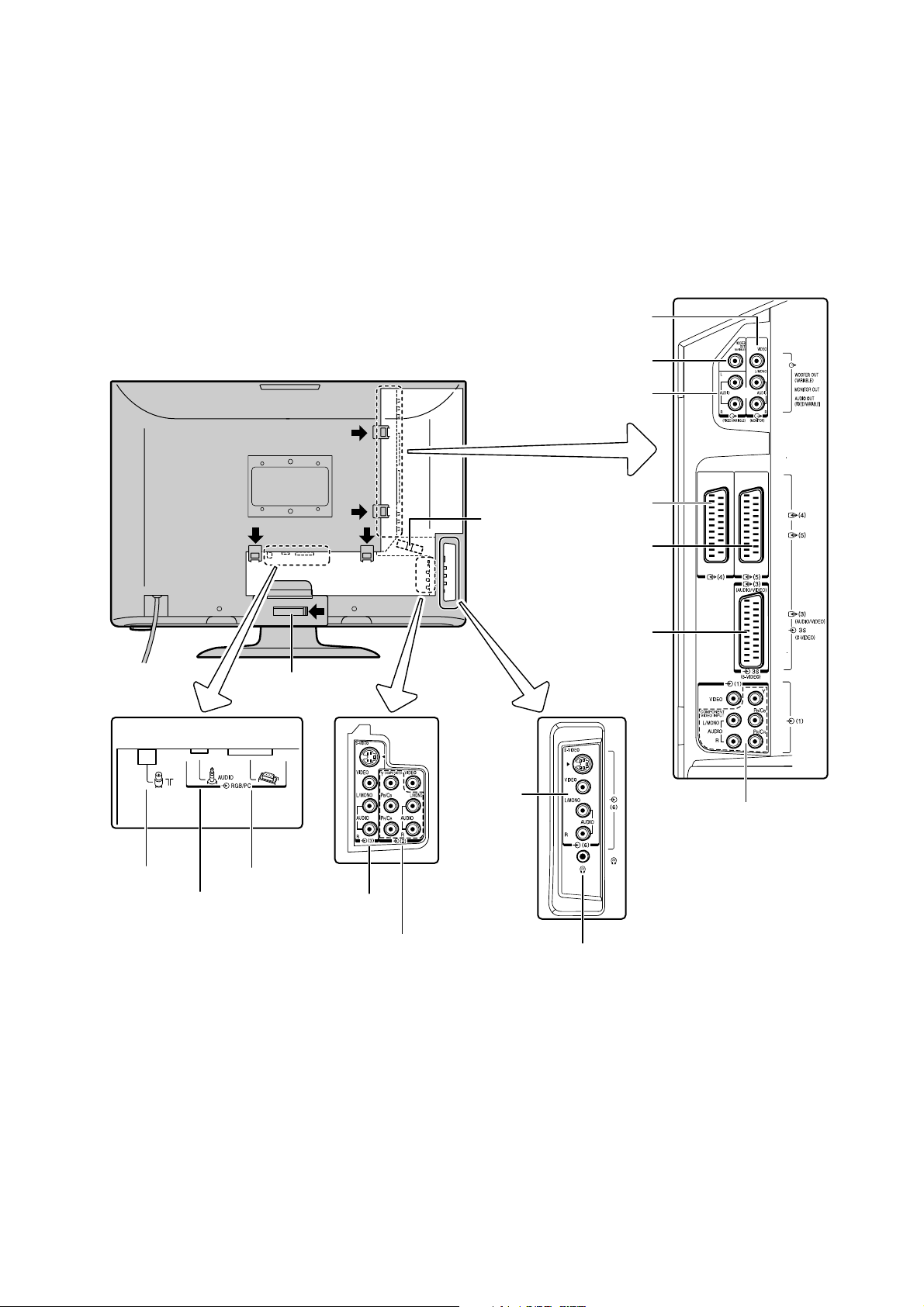

Page 12

Back

Back view

MONITOR OUT [40]

(Audio/Video output)

TV back view

Cable

holder

Cable holder

Back view Side view

Aerial input

Audio input

RGB/PC IN

EXT3 IN

(S-video/Video/

Audio input)

video/Composite

Back view

EXT6 IN

(S-video/

Video/Audio

input)

EXT2 IN

(Component

video/Audio

input)

WOOFER OUT

AUDIO OUT

(Fixed/Variable)

EXT4 IN/OUT

(Scart 4)

EXT5 IN/OUT

(Scart 5)

EXT3 IN/OUT

(Scart 3)

Headphones jack

(3.5 mm, stereo)

EXT1 IN

(Component video/

Composite video/Audio

input)

– 12 –

Page 13

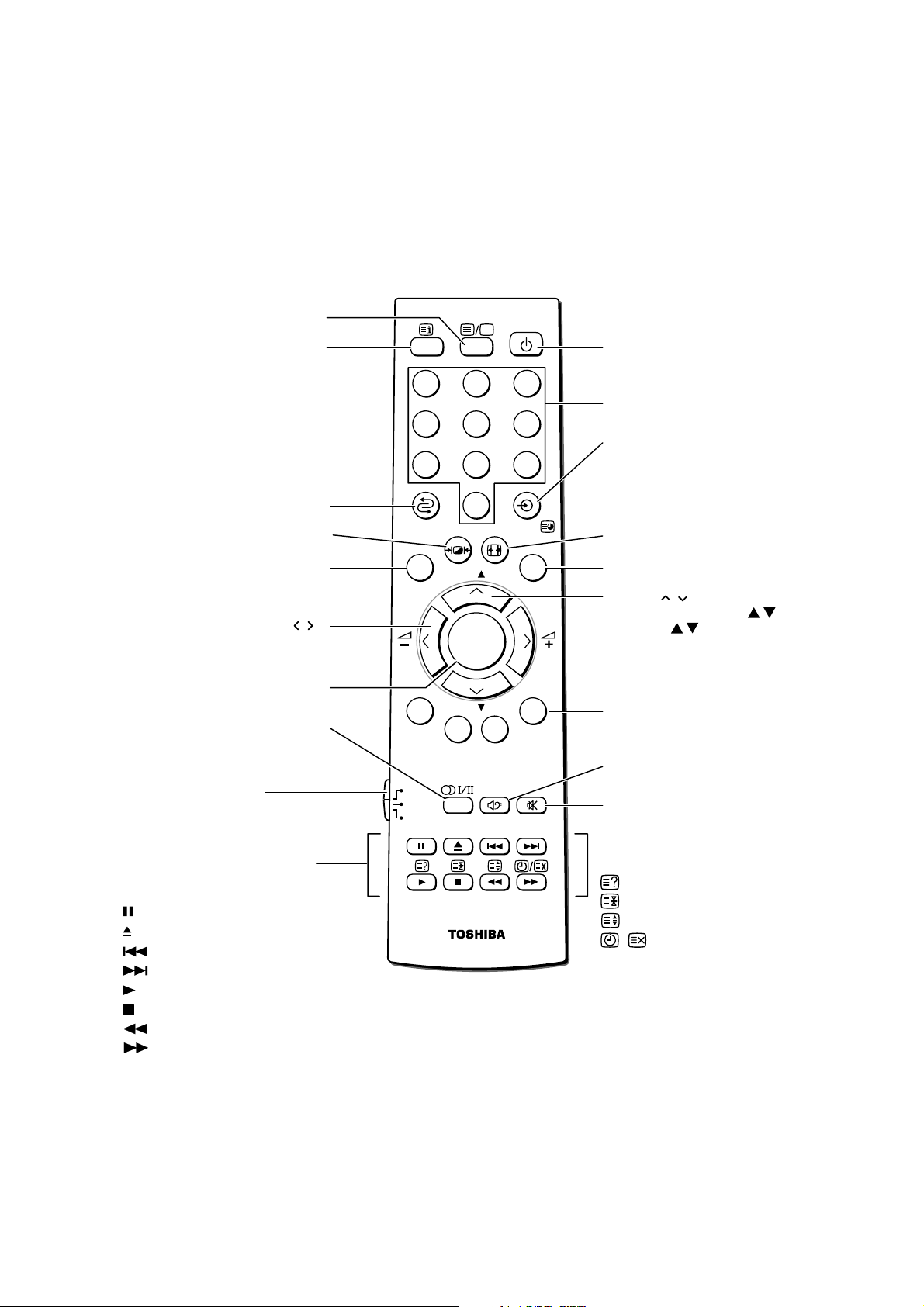

Remote Control

Teletext on/off

Initial/index function for Teletext

CALL

To return to the previous programme

Picture mode selection

MENU

DVD MENU

• Menu

• Volume – +

OK

Stereo/bilingual selection

Mode switch

TV : To control TV

VCR : To control VCR

DVD : To control DVD

When in VCR or DVD mode:

(Only for Toshiba VCR/DVD

players)

to PAUSE

to EJECT

to SKIP-REWIND

to SKIP-FORWARD

to PLAY

to STOP

to REWIND

to FAST FORWARD

CALL

1

4

7

2

5

8

0

MENU EXIT

DVD

MENU

TV

VCR

DVD

P

OK

P

Power on/Standby

(For Toshiba TV/VCR/DVD)

3

Number buttons (0-9)

6

• Input source selection

9

(EXT1 - EXT6, RGB/PC)

• To access sub-pages when in

Teletext

Picture size selection

EXIT

• Menu

• Programme position

• Teletext

Teletext control buttons

(Four coloured buttons : Red,

Green, Yellow, Blue)

Bass boost on/off

External woofer on/off

Sound mute

When in TV (Teletext) mode:

viewing a normal picture

To reveal concealed text

To hold a wanted page

To enlarge teletext display size

/

To select a page whilst

– 13 –

Page 14

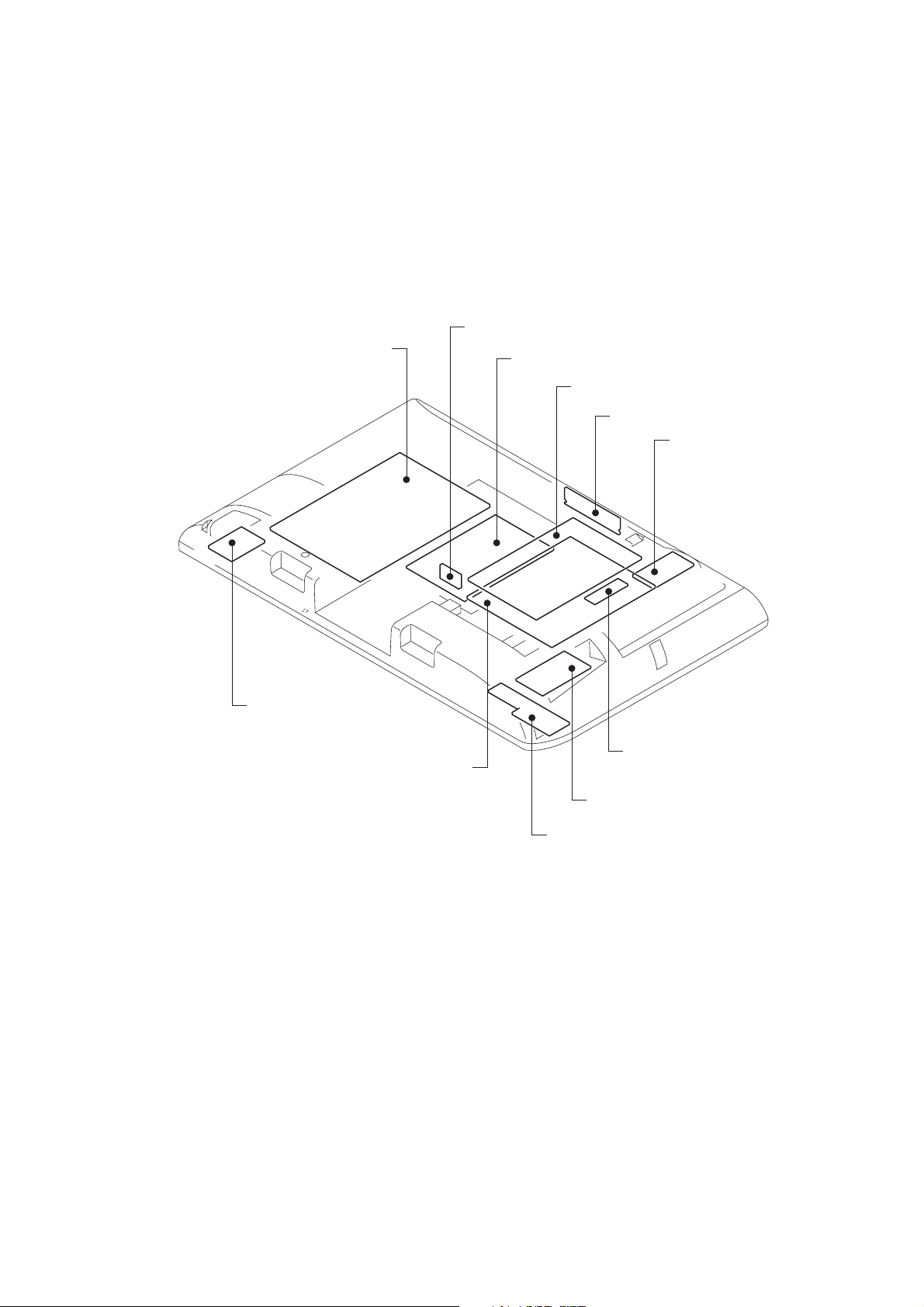

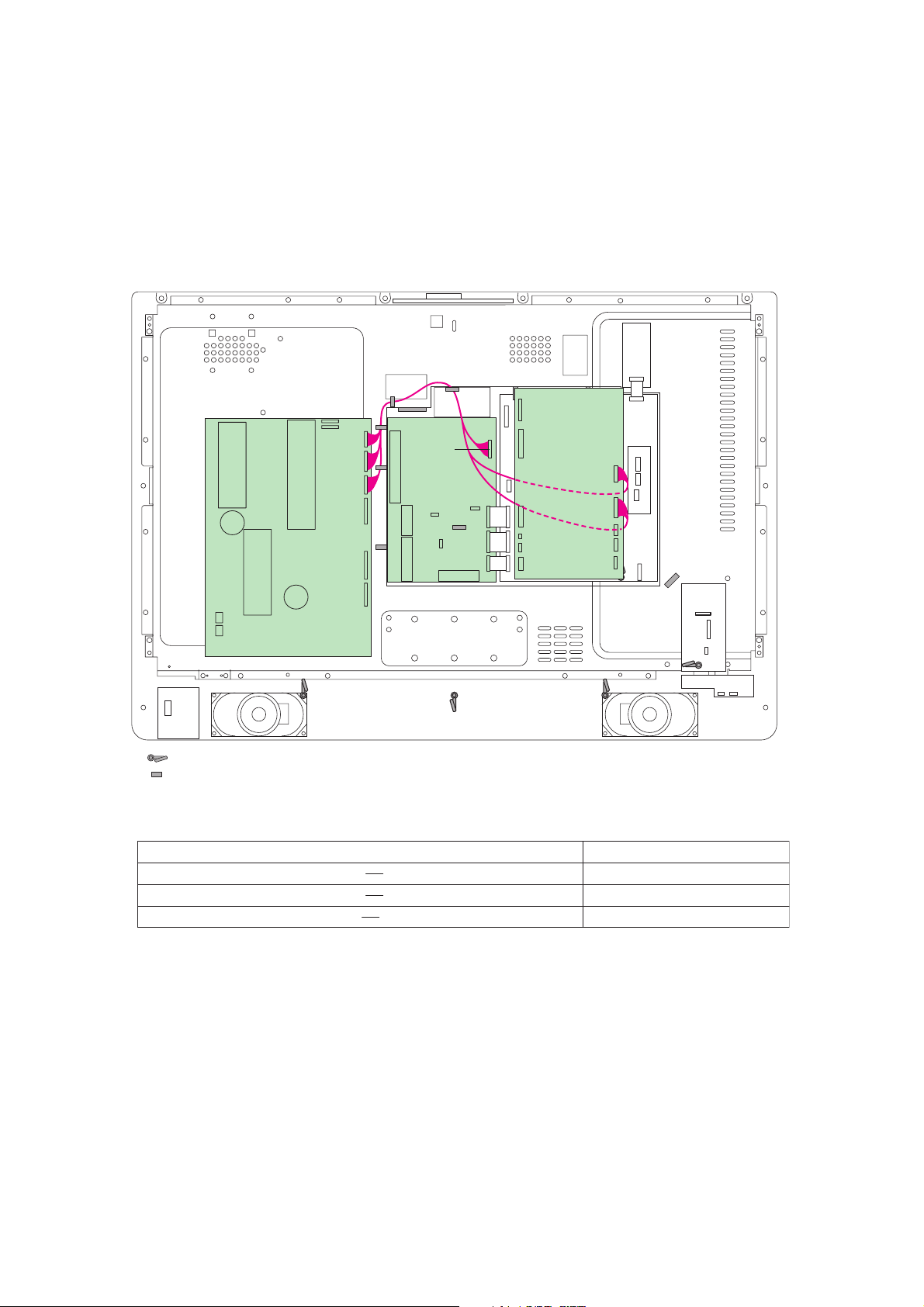

LAYOUT OF MAJOR BOARDS

U800 POWER MODULE UNIT

U002B PC INPUT Board

U002A TN/AOUT Board

U003 SCALER Board

U001E KEY SW Board

U001C AV2 Board

U001D POWER SW Board

U001A SIGNAL Board

U001G D-REWRITE Board

U001B FRONT/AV Board

U001F LED/RMT Board

– 15 –

Page 15

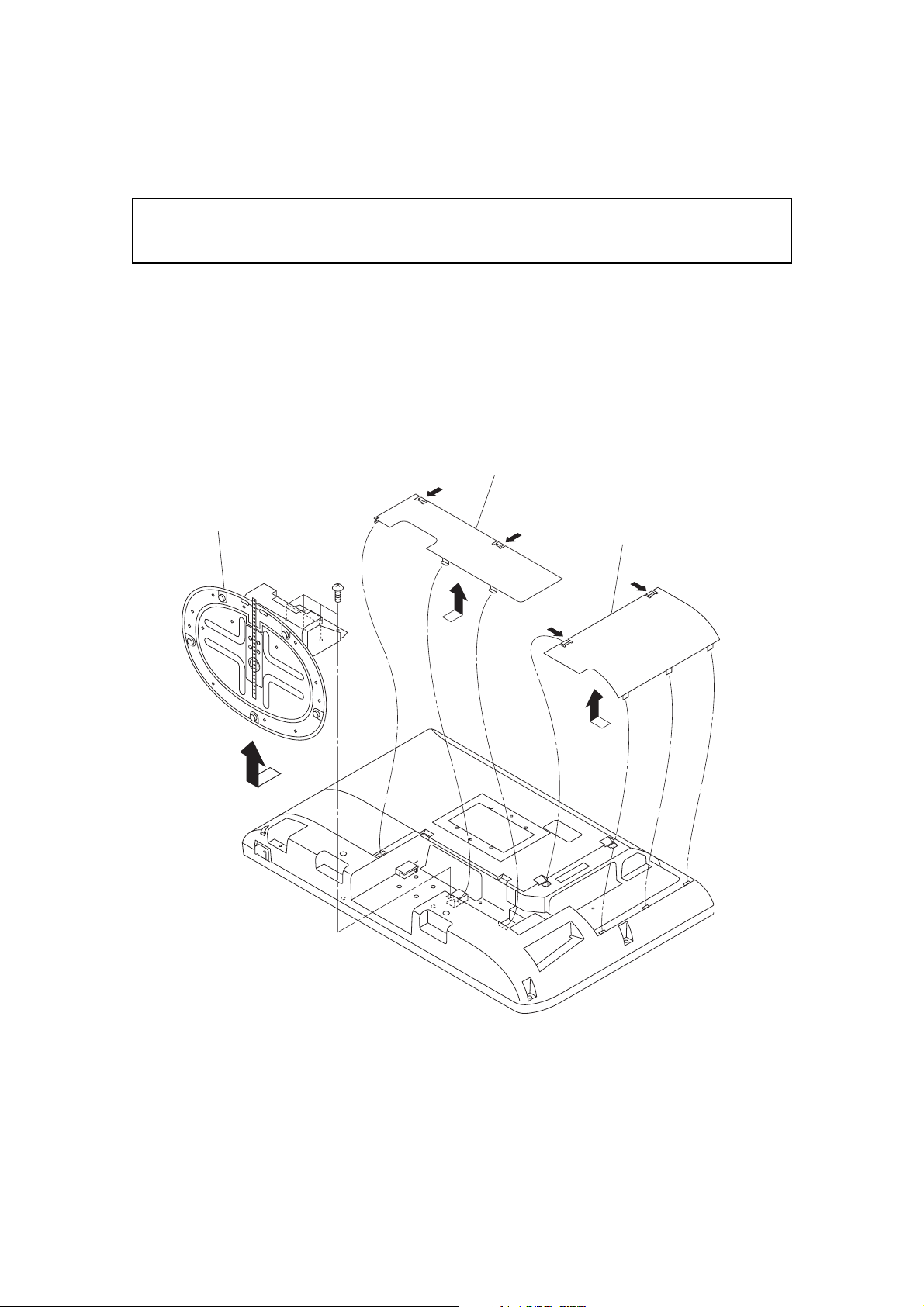

MECHANICAL DISASSEMBLY

• Note: Be sure to lay down the main body (by placing its screen

downward) f or disassembly.

1. Removing the back cover

1) Remove the BC stand cover.

2) Remove the BC terminal cover.

3) Remove 6 screws, then remove the stand.

BC Stand cover

Stand

BC T erminal cover

PP 5x12

– 16 –

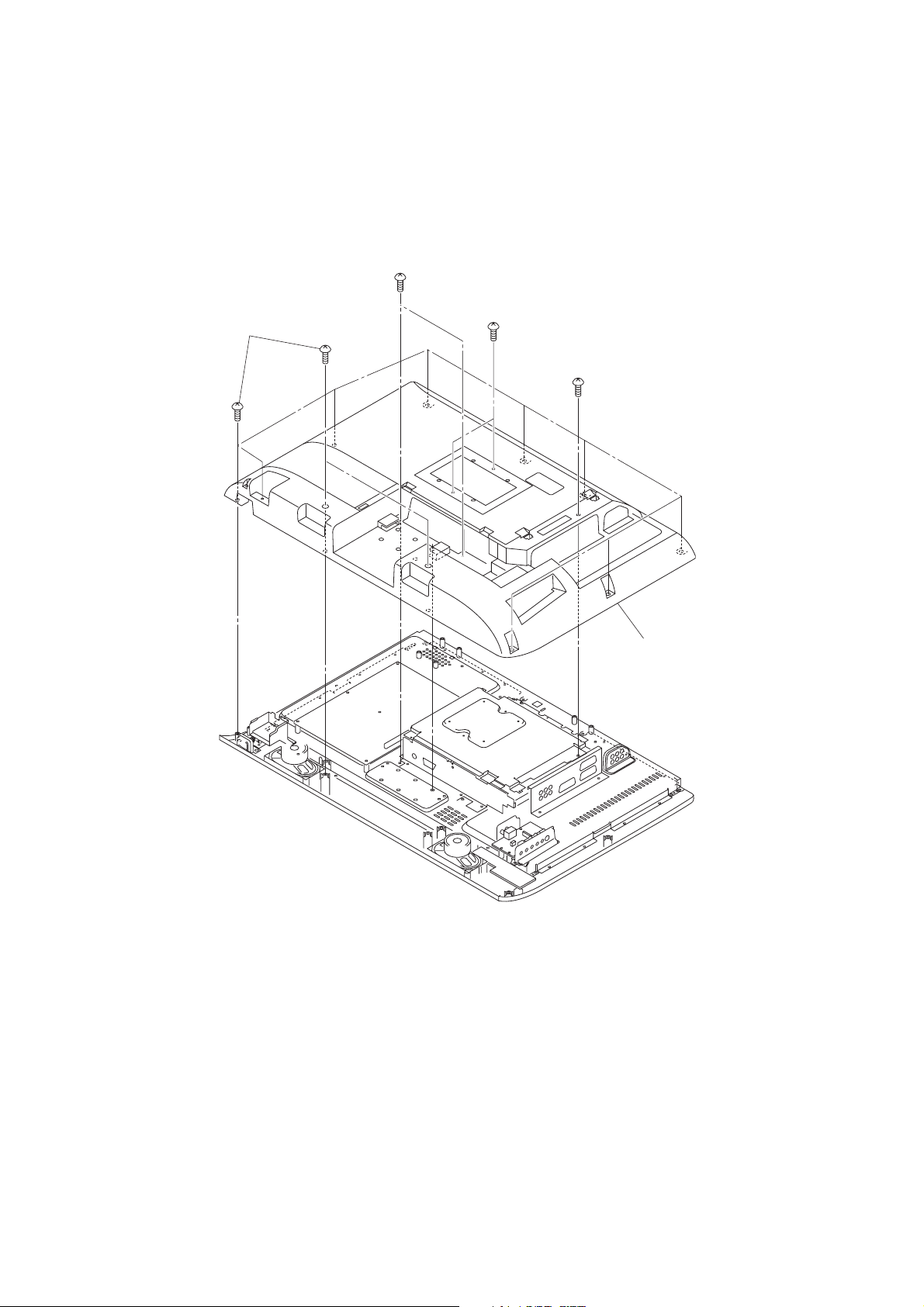

Page 16

4) Remove 11 screws (PBI 4x12).

5) Remove 5 screws (PP 3x6).

6) Remove the back cover.

PP 3x6

PBI 4x12

PP 3x6

PP 3x6

Back cover

– 17 –

Page 17

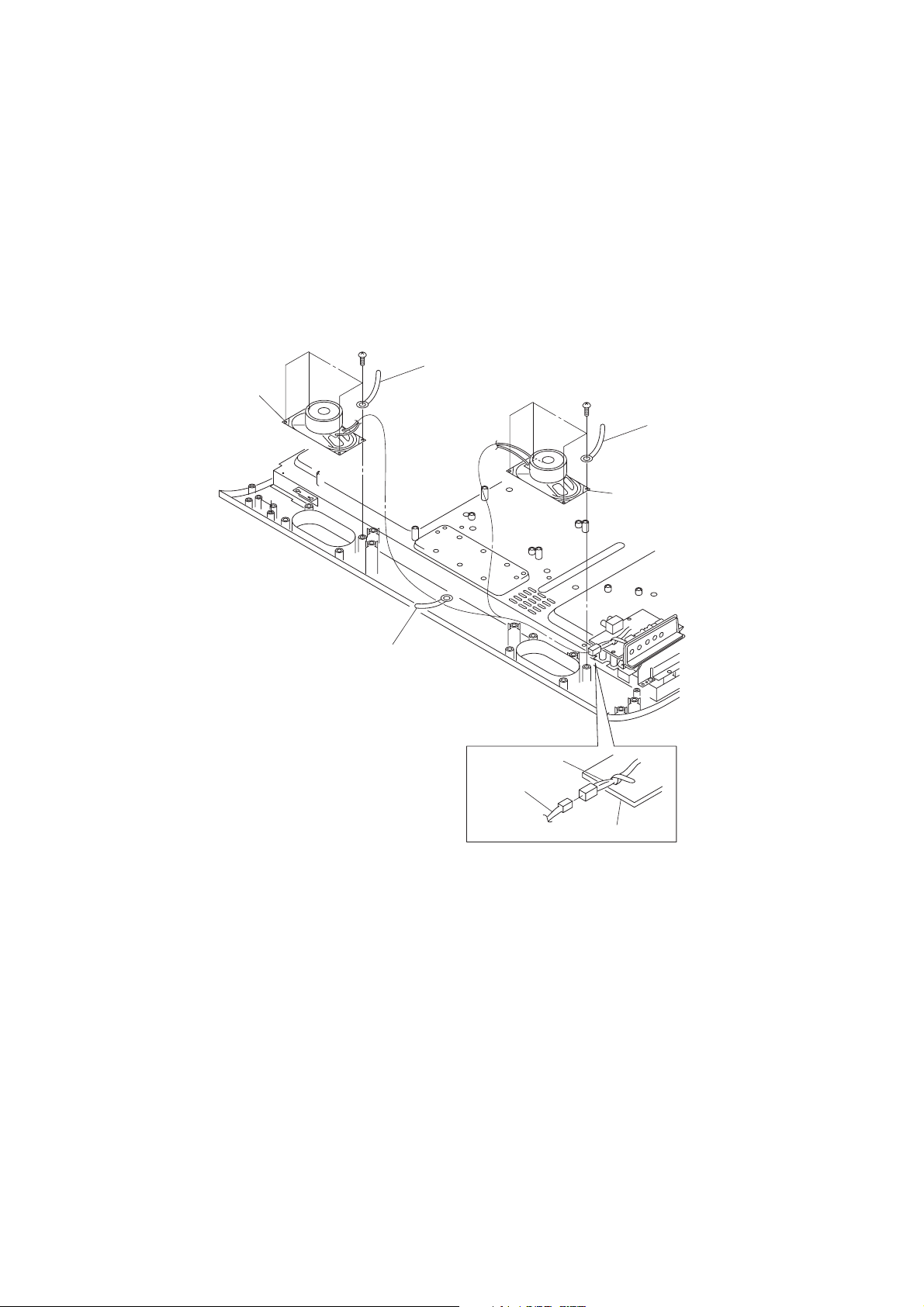

2. Removing the speakers

r

1) Remove the back cover. (Refer to Item 1.)

2) Disconnect the speaker wire harness on the Front/AV board.

3) Remove the wire harness of the 3 wire holders.

4) Remove 4 screws, then remove the left speaker and wire holder.

5) Remove 4 screws, then remove the right speaker and wire holder.

PBI 4x12

Wire holder

Speaker (R)

PBI 4x12

Wire holde

Speaker (L)

Wire holder

Wire harness

Speaker

wire harness

FRONT/AV Board

– 18 –

Page 18

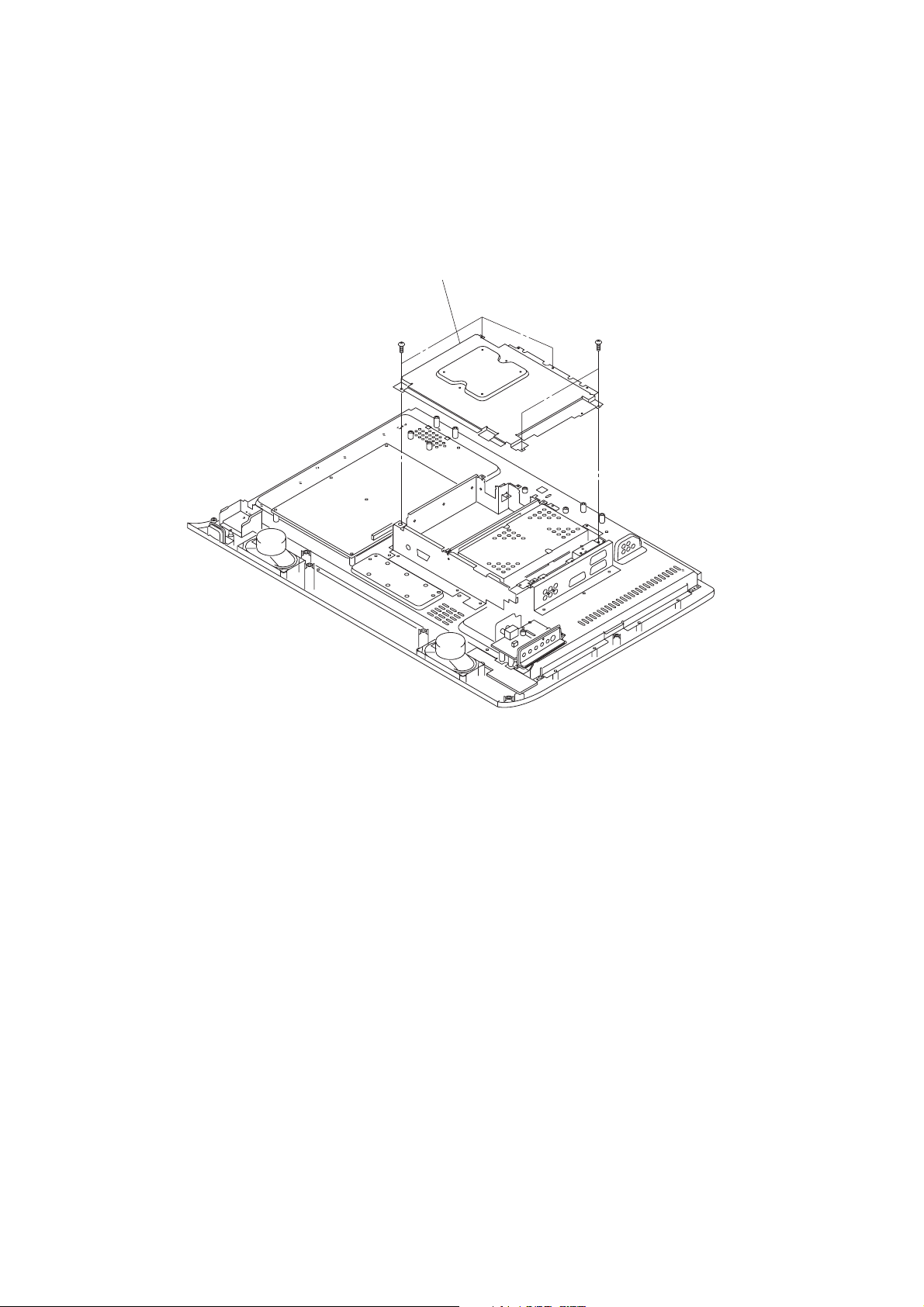

3. Removing the top shield bracket

1) Remove the back cover. (Refer to Item 1.)

2) Remove 5 screws, then remove the top shield bracket.

Top shield bracket

STP 3x8

STP 3x8

– 19 –

Page 19

4. Removing the Power Module unit

1) Remove the back cover. (Refer to Item 1.)

2) Disconnect the power cord from the connector.

3) Remove the 3 wire harnesses from the 3 wire clampers on the plate back R.

4) Disconnect the 8 wire harnesses from the 8 connectors on the Power Module unit.

5) Remove 7 screws, then remove the Power Module unit.

Power cord

STP 3x8

Wire harnesses

POWER MODULE UNIT

Wire harnesses

Plate back R

– 20 –

Wire clampers

Page 20

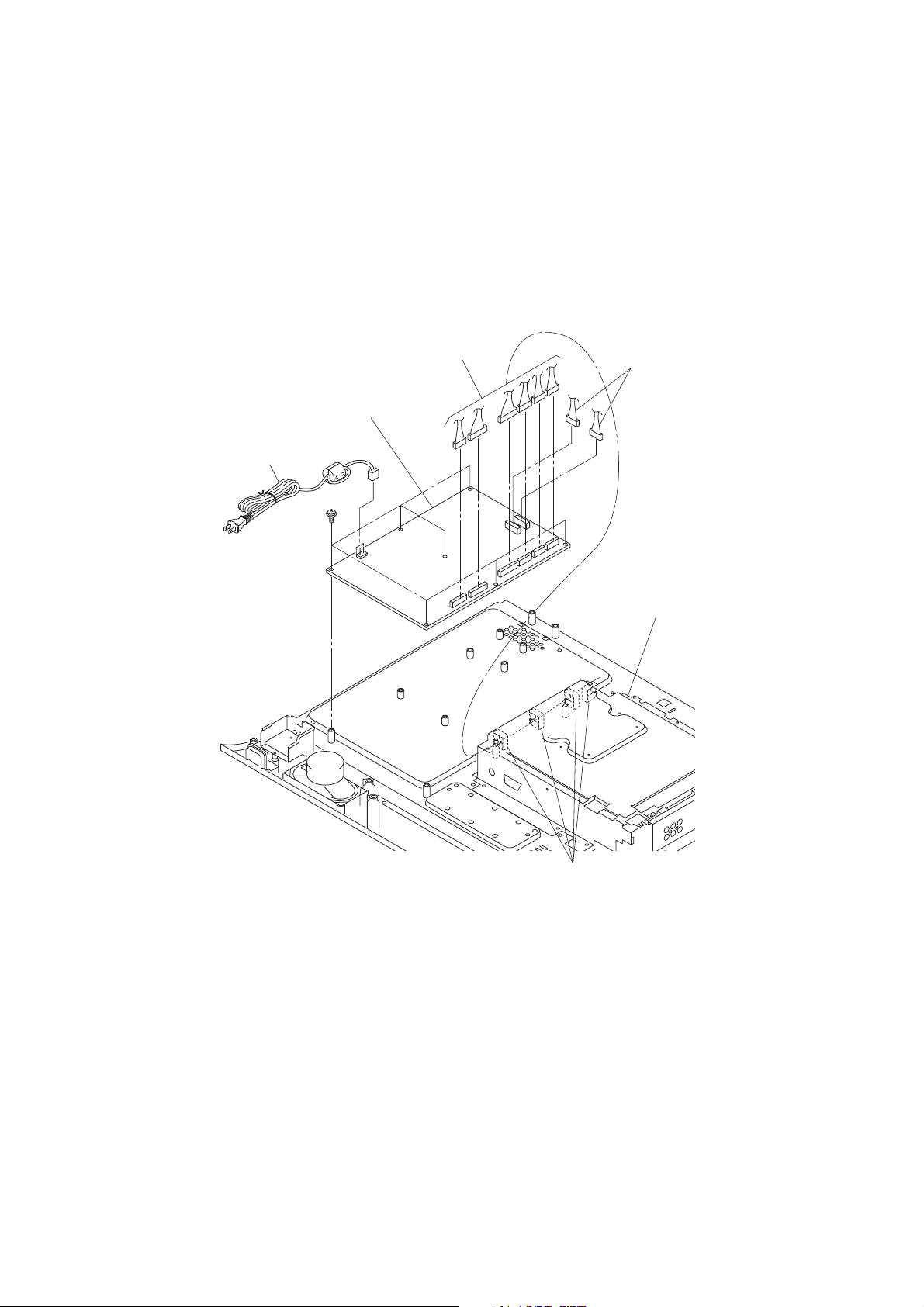

5. Removing the Scaler board

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove 4 screws (STP3x6) and 2 screws (STP3x5), then remove the top shield RM.

4) Disconnect the 8 wire harnesses and 2 FFC from the Scaler board.

5) Remove 4 screws (STP3x5), then remove the Scaler board and bottom shield RM.

STP 3x6

Top shield RM

SCALER board

STP 3x5

STP 3x6

STP 3x5

Wire harnesses

SCALER

board

FFC

Wire harnesses

Bottom

shield RM

– 21 –

Page 21

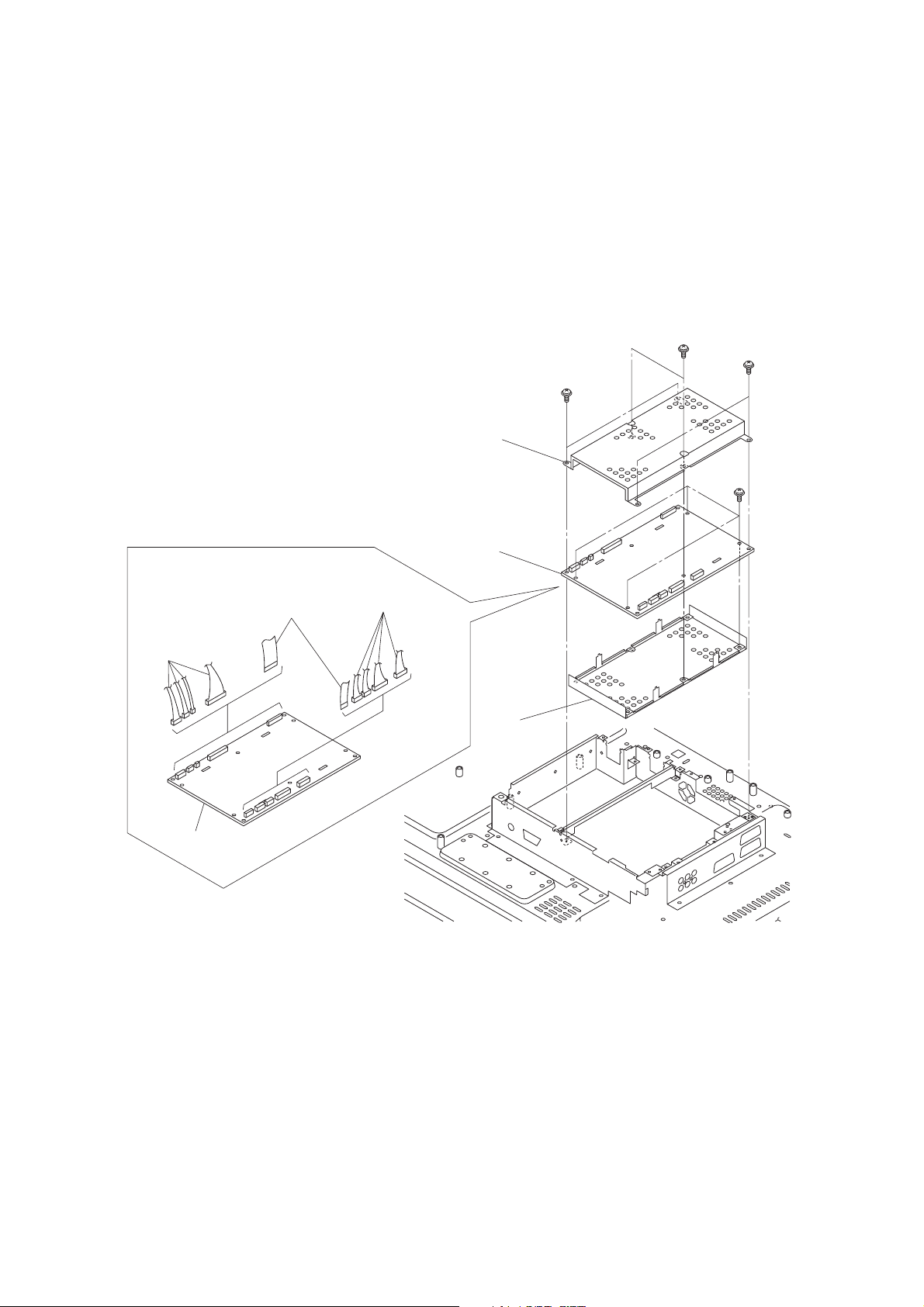

6. Removing the D-Rewrite board

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove the Scaler board. (Refer to Item 5.)

4) Remove 2 screws, then remov e the D-Rewrite board.

5) Disconnect the 2 wire harnesses and 1 FFC on the D-Rewrite board.

6) Remove 2 screws, then remove the digital unit bracket.

7) Remove 2 screws, then remove the scaler unit bracket.

Scaler unit bracket

FFC

D-REWRITE board

STP 3x8

Wire harnesses

Digital unit bracket

STP 3x8

STP 3x8

PP 3x6

– 22 –

Page 22

7. Removing the back terminal plate, back bottom plate and back R plate

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove the Scaler board. (Refer to Item 5.)

4) Remove the D-Rewrite board. (Refer to Item 6.)

5) Remove 5 screws (BIDT 2 3x10BZ) and 2 screws, then remove the back terminal plate.

6) Remove 2 screws (STP 3x8), 2 hexagon nuts and 1 toothed washer, then remove the back bottom plate.

7) Remove 5 screws (STP 3x8), then remove the back R plate .

STP 3x8

Back plate R

STP 3x8

Toothed washer

Back bottom plate

Hexagon nuts

Back terminal plate

STP 3x8

STP 3x8

BIDT2 3x10 BZ

– 23 –

Page 23

8. Removing the TN/AOUT, A V2 and Signal boards

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove the Scaler board. (Refer to Item 5.)

4) Remove the D-Rewrite board. (Refer to Item 6.)

5) Remove the back plates. (Refer to Item 7.)

6) Remove the connector [A] and 3 harnesses from the TN/AOUT board.

7) Remove 5 screws (STP 3x8), then remove the TN/AOUT board.

8) Remove the connector [B] from the Signal board.

9) Remove 3 screws (STP 3x8), then remove the AV2 board.

10) Remove 1 screw (BIDT2 3x10BZ), then remove the AV2 panel.

11) Remove the 6 wire harnesses and 2 FFC from the Signal board.

12) Remove 5 screws (STP 3x8), then remove the Signal board.

STP 3x8

TN/AOUT

board

Connector [A]

Wire harnesses

SIGNAL board

Wire harnesses

Wire

harnesses

FFC

Connector [B]

STP 3x8

Wire harness

STP 3x8

AV2

board

SIGNAL

board

BIDT2 3x10 BZ

AV2 panel

– 24 –

Page 24

9. Removing the Front /AV board

1) Remove the back cover. (Refer to Item 1.)

2) Remove 1 screw (BIDT2 3x10 BZ).

3) Remove 2 screws (PP 3x6), then remove the front AV panel.

4) Remove 1 screw (BIDT2 3x10 BZ) and 1 screw (PP 3x6), then remove the rear AV panel.

5) Disconnect the 2 wire harnesses and 1 FFC from the Front/AV board.

6) Remove 2 screws (PP 3x6), then remove the wire holder and Front/AV board.

Wire harnesses

PP 3x6

Wire holder

FFC

BIDT2

3x10 BZ

PP 3x6

Rear AV panel

FRONT/AV board

PP 3x6

Front AV panel

BIDT2 3x10 BZ

– 25 –

Page 25

10. Removing the Power SW and LED/RMT boards

1) Remove the back cover. (Refer to Item 1.)

2) Remove 3 screws (STP 3x8), then remove the LED/RMT board.

3) Disconnect the 2 wire harnesses from the connector on the LED/RMT board.

4) Remove 2 screws (PP 3x6), then remove the cord holder.

5) Remove 2 screws (STP 3x8), then remove the switch cover and cap.

6) Disconnect the wire harness from the connector on the Power SW board.

7) Remove 3 screws (STP 3x8), then remove the Power SW board.

PP 3x6

Cord holder

Wire harness

STP 3x8

STP 3x8

POWER SW

board

Switch cover

Cap

STP 3x8

LED/RMT board

Wire harnesses

– 26 –

Page 26

11. Removing the chassis frame

1) Remove the back cover. (Refer to Item 1.)

2) Remove the speakers. (Refer to Item 2.)

3) Remove the top shield bracket. (Refer to Item 3.)

4) Remove Power Module unit. (Refer to Item 4.)

5) Remove the Scaler board. (Refer to Item 5.)

6) Remove the D-Rewrite board and bracket. (Refer to Item 6.)

7) Remove the back plate. (Refer to Item 7.)

8) Remove the TU/AOUT, AV2 and Signal boards. (Refer to Item 8.)

9) Remove the Front/AV board. (Refer to Item 9.)

10) Remove the Power SW and LED/RMT boards. (Refer to Item 10.)

11) Remove 10 screws (PBI 4x12) and 8screws (PP 4x10), then remove the chassis frame.

PP 4x10

PP 4x10

PBI 4x12

PP 4x10

Chassis frame

PP 4x10

– 27 –

Page 27

12. Removing the LCD and front bezel cover assembly

1) Remove the back cover. (Refer to Item 1.)

2) Remove the speakers. (Refer to Item 2.)

3) Remove the top shield bracket. (Refer to Item 3.)

4) Remove Power Module unit. (Refer to Item 4.)

5) Remove the Scaler board. (Refer to Item 5.)

6) Remove the D-Rewrite board and bracket. (Refer to Item 6.)

7) Remove the back plate. (Refer to Item 7.)

8) Remove the TU/AOUT,AV2 and Signal boards. (Refer to Item 8.)

9) Remove the Front/AV board. (Refer to Item 9.)

10) Remove the Power SW and LED/RMT boards. (Refer to Item 10.)

11) Remove the chassis frame. (Refer to Item 11.)

12) Remove 2 screws (STP 3x8), then remove the key SW panel.

13) Remove 2 screws (STP 3x8), then remove the Key SW board.

14) Disconnect the wire harness from the connector on the Key SW board.

15) Lift up the LCD slowly from the front bezel cover assembly toward to the arrow direction.

16) Remove 2 screws (PP 4x10), then remove the two bracket panels top.

17) Remove 2 screws (PP 4x10), then remove the two bracket panels bottom.

LCD

PP 4x10

Bracket panel bottom

Front bezel cover assembly

Bracket panel top

PP 4x10

KEY SW panel

Wire harness

STP 3x8

KEY SW board

BTP 4x12

– 28 –

Page 28

WIRING CONNECTION

1.Power Block Module - TN/AOUT - SCALER

P805A

P816A

P809

P809A

U002A

TN/AOUT

BOARD

U003

SCALER

BOARD

PJ10

PJ11

: WIRE HOLDER

: WIRE CLAMPER

P805A (

U800 POWER BLOCK MODULE

P816A (

U800 POWER BLOCK MODULE

P809 (

U800 POWER BLOCK MODULE

U800

POWER BLOCK

MODULE

CONNECTOR (Board name) Description

) PJ10 (U003 SCALER BOARD) WIRE HARNESS, POW-SCALER

) PJ11 (U003 SCALER BOARD) WIRE HARNESS, POW-SCALER

) P809A (U002A TN/AOUT BOARD) WIRE HARNESS, POW-TN/AOUT

– 29 –

Page 29

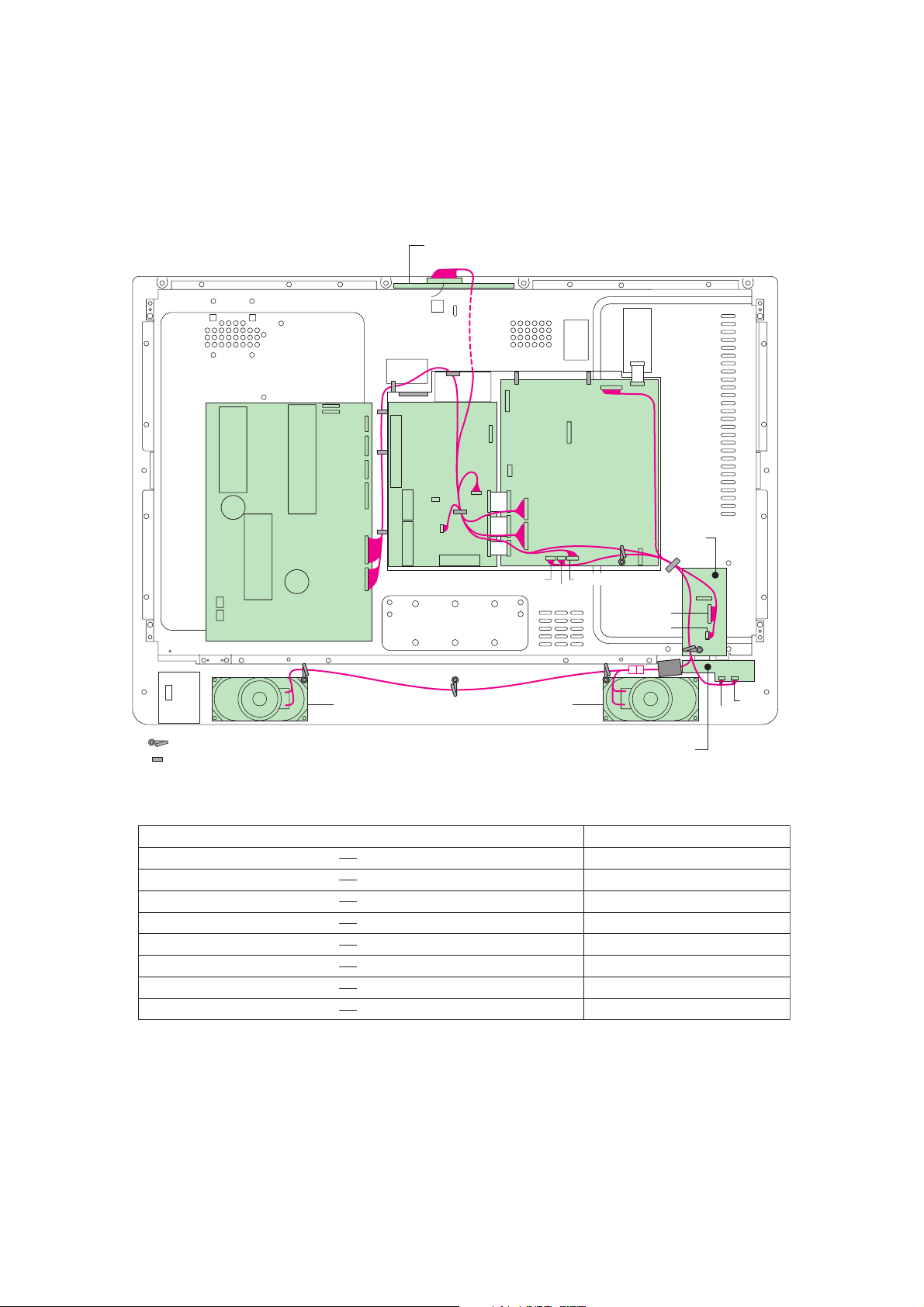

2.Power Block Module - TN/AOUT - SIGNAL - FRONT/AV - KEY SW

LED/RMT - SPEAKER

U001E KEY SW BOARD

PB13B

PV25A

U002A

TN/AOUT

BOARD

U001A

SIGNAL BOARD

P601

P614A

P810B

P811A

P810A

U001B

FRONT/AV

BOARD

-

: WIRE HOLDER

: WIRE CLAMPER

P811B

U800

POWER BLOCK

MODULE

PB11A

SPEAKER (L)SPEAKER (R)

PB12A

PB13A

U001F

LED/RMT BOARD

PV25B

P614B

PB12B

PB11B

CONNECTOR (Board name) Description

PV25A (U001A SIGNAL BOARD) PV25B (U001B FRONT/AV BOARD) WIRE HARNESS, SIG-FAV

PB11A (U001A SIGNAL BOARD) PB11B (U001F LED/RMT BOARD) WIRE HARNESS, SIG-LED-RMT

PB12A (U001A SIGNAL BOARD) PB12B (U001F LED/RMT BOARD) WIRE HARNESS, SIG-LED-RMT

PB13A (U001A SIGNAL BOARD) PB13B (U001E KEY SW BOARD) WIRE HARNESS, SIG-KEY SW

P601 (U002A TN/AOUT BOARD) SPEAKER (L)/(R) WIRE HARNESS, SPK-RELAYED

P614A (U002A TN/AOUT BOARD) P614B (U001B FRONT/AV BOARD) WIRE HARNESS, TN/AOUT-FAV

P811A (U001A SIGNAL BOARD) P811B (

P810A (U001A SIGNAL BOARD) P810B (

U800 POWER BLOCK MODULE

U800 POWER BLOCK MODULE

) WIRE HARNESS, SIGNAL-POW

) WIRE HARNESS, SIGNAL-POW

– 30 –

Page 30

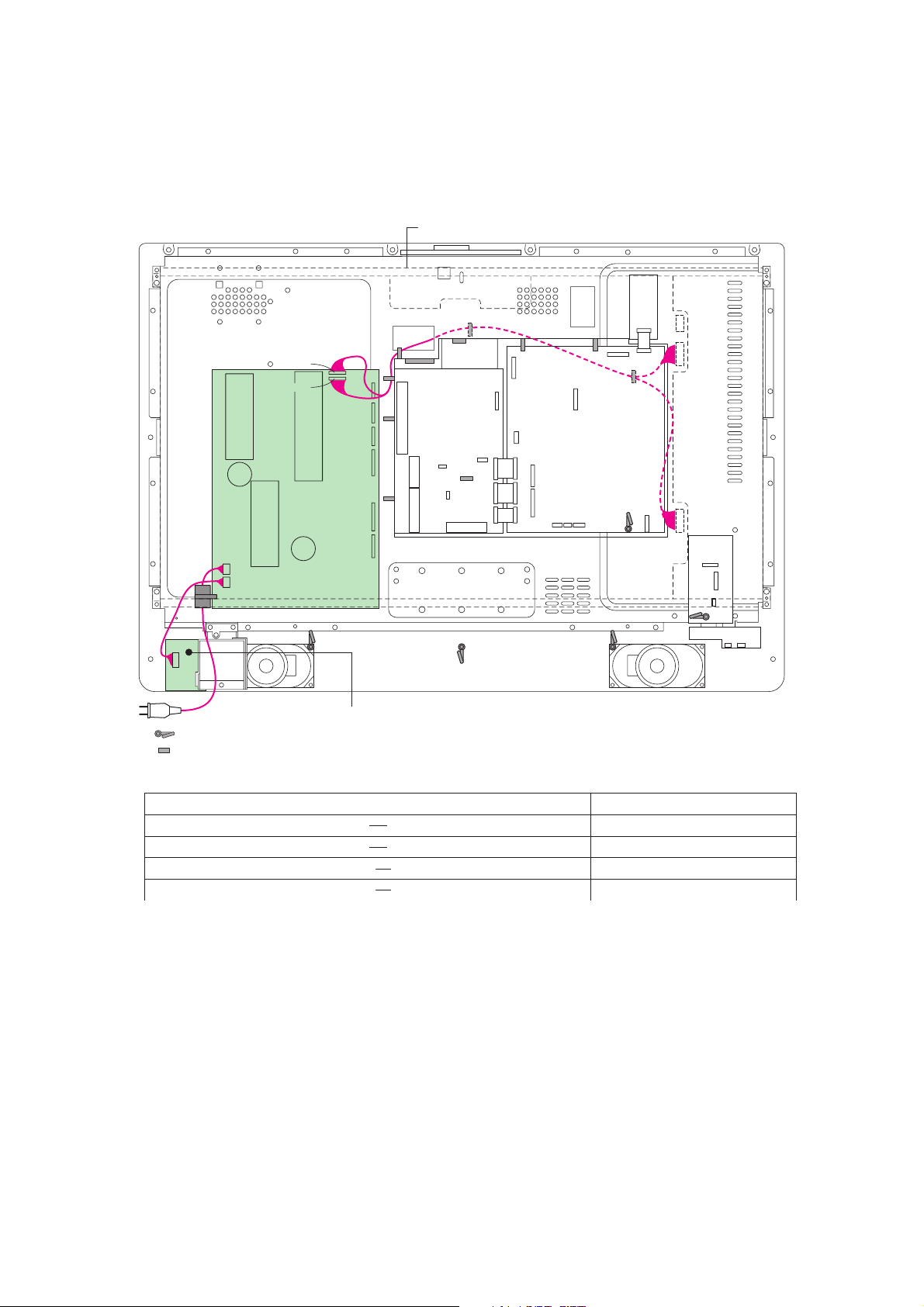

3.Po wer Block Module - LCD Panel

LCD PANEL

P801

P802

P802A

: WIRE HOLDER

: WIRE CLAMPER

CN804

CN805

U800

POWER BLOCK

MODULE

U001D POWER SW BOARD

CN4

CN5

P802 (

U800 POWER BLOCK MODULE

U800 POWER BLOCK MODULE

P801 (

CN804 (

CN805 (

U800 POWER BLOCK MODULE

U800 POWER BLOCK MODULE

CONNECTOR (Board name) Description

) P802A

(U001D POWER SW BOARD)

WIRE HARNESS, POW-POW SW

) POWER CORD POWER CORD

) CN4 (PANEL) WIRE HARNESS, PANEL-POW

) CN5 (PANEL) WIRE HARNESS, PANEL-POW

– 31 –

Page 31

4.TN/AOUT - SIGNAL - AV2 - FRONT/AV

U002A

TN/AOUT

BOARD

P102A

P101B

P214B

U001A

SIGNAL BOARD

P102B

P101A

P214A

PV21A

PV21B

P23A

U001C

AV2 BOARD

U001B

FRONT/AV

BOARD

P23B

: WIRE HOLDER

: WIRE CLAMPER

CONNECTOR (Board name)

Description

P102A (U002A TN/AOUT BOARD) P102B (U001A SIGNAL BOARD) B-B CONNECTOR

P101B (U002A TN/AOUT BOARD) P101A (U001A SIGNAL BOARD) B-B CONNECTOR

P214B (U002A TN/AOUT BOARD) P214A (U001A SIGNAL BOARD) B-B CONNECTOR

PV21A (U001C AV2 BOARD) PV21B (U001A SIGNAL BOARD) B-B CONNECTOR

PV23B (U002A FRONT/AV BOARD) PV23A (U001A SIGNAL BOARD) FFC CABLE, P1.0-19P

– 32 –

Page 32

5.LCD Panel - TN/AOUT - SCALER - SIGNAL - D-REWRITE

LCD PANEL

U002A

TN/AOUT

BOARD

PT01

CN2

PJ15A

PJ15

PJ18

PJ16

PJ12

PJ17

U003

SCALER

BOARD

U001G

D-REWRITE BOARD

CN3

PJ64A

PJ60A

PJ61A

PJ64

PJ60

PJ61

: WIRE HOLDER

: WIRE CLAMPER

U001A

SIGNAL BOARD

CONNECTOR (Board name) Description

PJ16 (U003 SCALER BOARD) PT01 (U002A TN/AOUT BOARD) WIRE HARNESS, TN/AOUT-SCA

PJ12 (U003 SCALER BOARD) CN2 (PANEL) WIRE HARNESS, PANEL-SCA

PJ17 (U003 SCALER BOARD) CN3 (PANEL) WIRE HARNESS, PANEL-SCA

PJ15 (U003 SCALER BOARD) PJ15A (U001A SIGNAL BOARD) FFC CABLE, P1.0-25P

PJ18 (U003 SCALER BOARD) LVDS CABLE CABLE, LVDS 300MM LVDS

PJ61 (U003 SCALER BOARD) PJ61A (U001G D-REWRITE BOARD) FFC CABLE, P1.0-11P

PJ60 (U003 SCALER BOARD) PJ60A (U001G D-REWRITE BOARD) WIRE HARNESS, SCA-DREWRIT

PJ64 (U003 SCALER BOARD) PJ64A (U001G D-REWRITE BOARD) WIRE HARNESS, SIG-DREWRIT

– 33 –

Page 33

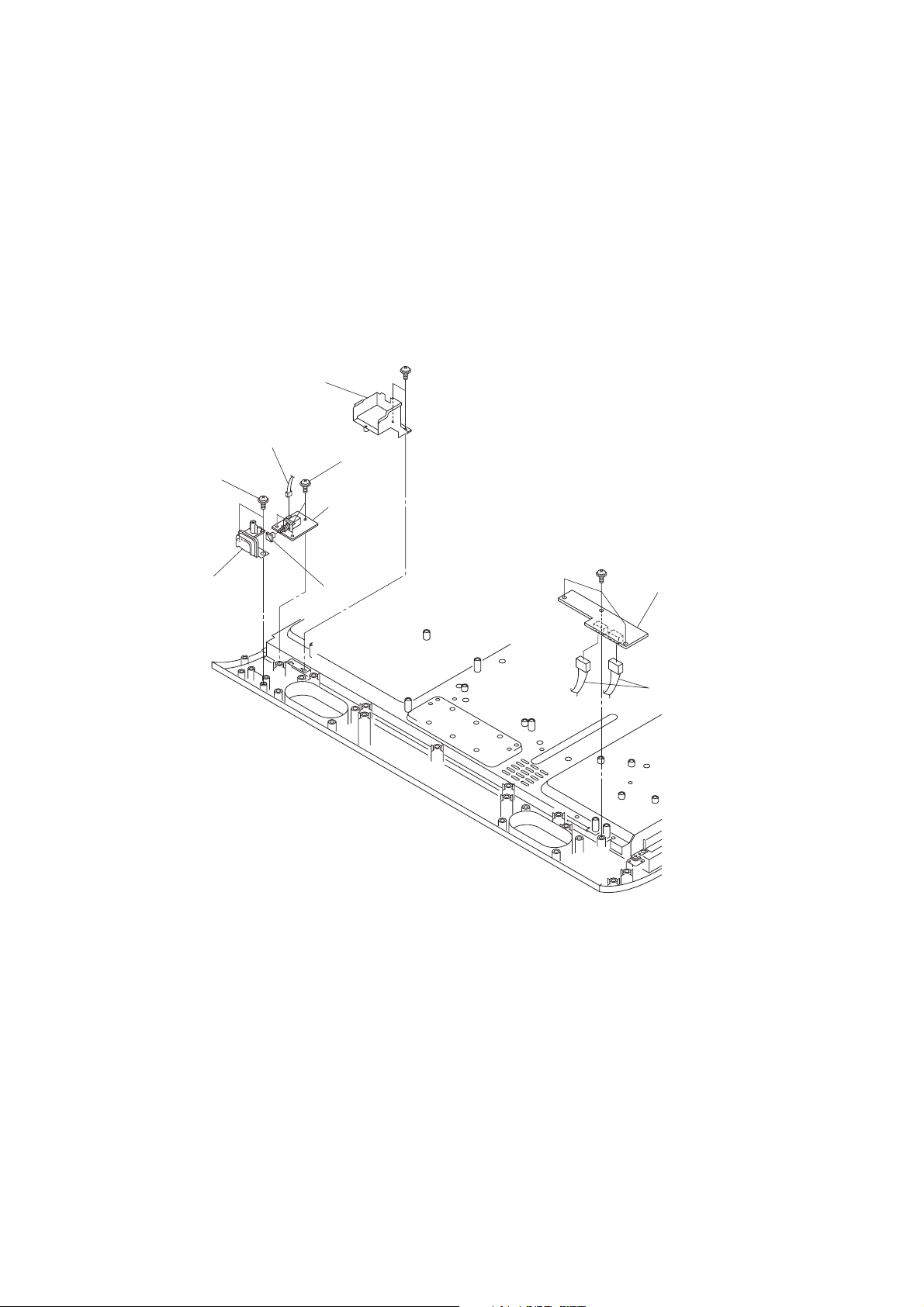

1.Cover Block

A227

EXPLODED VIEWS

A402

PP 5x12

A406

PP 3x6

PBI 4x12

PBI 4x12

PP 3x6

PP 3x6

A401

LOCATION No. Parts No. Description

A401 23532722 COVER, BACK COVER

A402 23532678 COVER, BC STAND COVER

A406 23532679 COVER, BC TERMINAL COVER

A227 23429048 CABINET, STAND

A501 23717176 SCREW, PP5X12+SW+W SZ

A502 23717175 SCREW, PP3X6+SW+W SZ

A505 23035004 SCREW, PBI4X12,SBN

– 35 –

Page 34

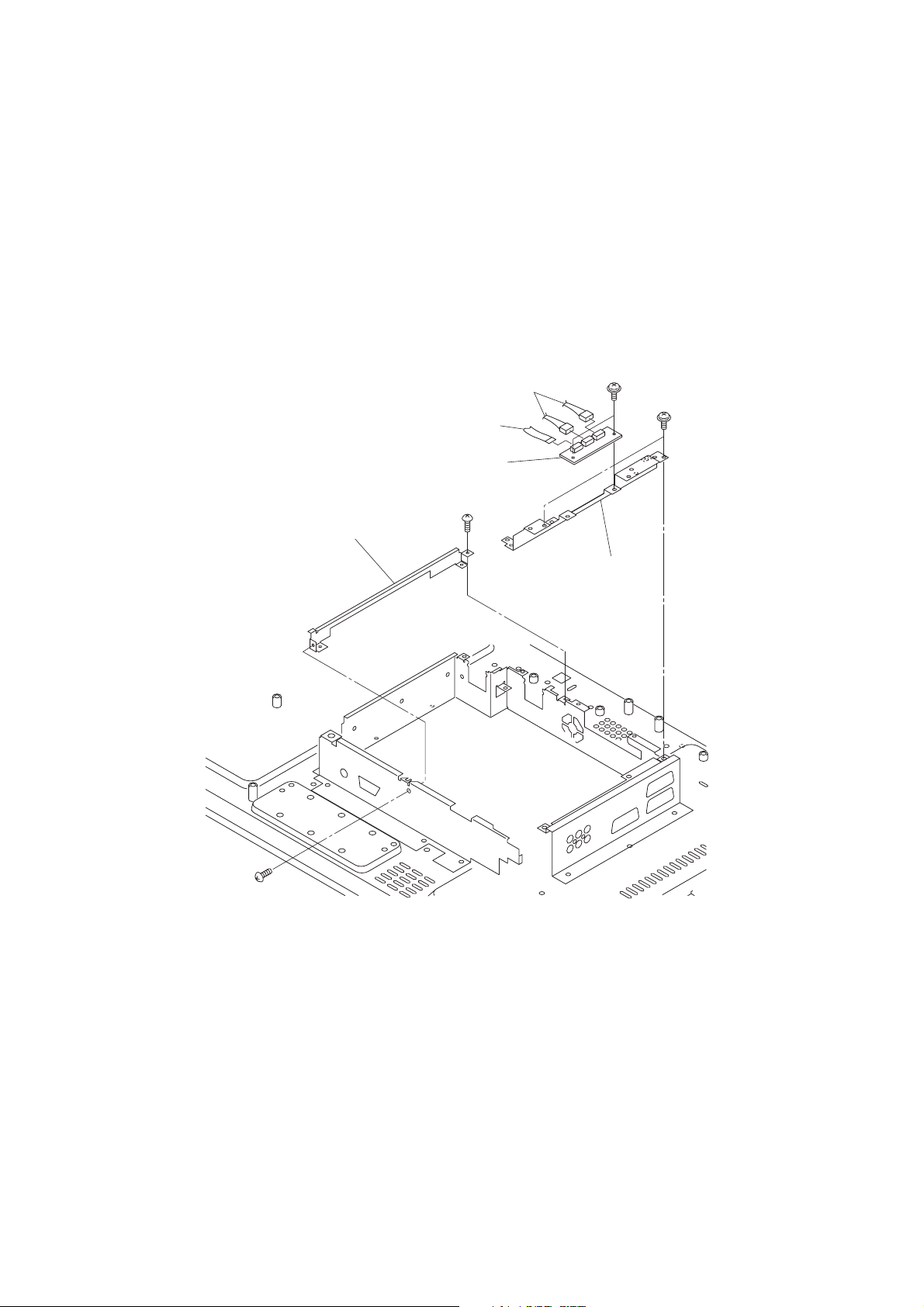

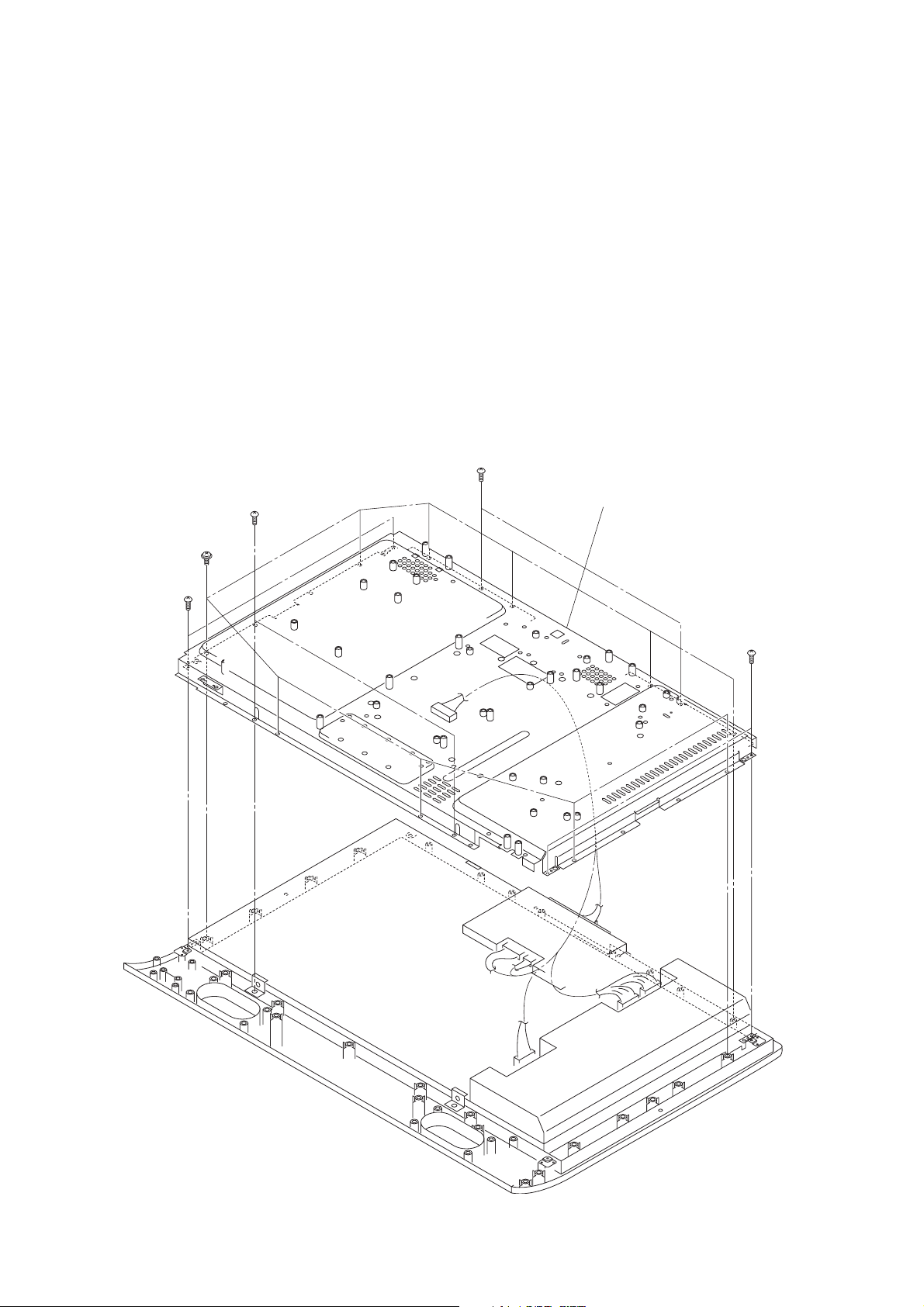

2.Chassis Block 1

ZA02

ZA02

MZ01

ZA01

P801

STP 3x8

STP 3x8

STP 3x5

STP 3x6

STP 3x6

MJ61

STP 3x5

STP 3x8

BIDT2 3x10 BZ

PP 3x6

U800

U003

PP 3x6

A221

U001B

LOCATION No. Parts No. Description

U001B 75000793 PCB PB UNIT FRONT/AV

*

U003 75000791 PCB SCALER

*

P801 23372208 POWER CORD, UK-HK-PSB 10A 250V

23372011 POWER CORD, CEE, VOLEX

A221 23940066 PIECE, REAR AV ASSY

A222 23940063 PIECE, FRONT AV ASSY

(FOR 32WL46B)

(FOR 32WL46G)

BIDT2 3x10 BZ

A222

LOCATION No. Parts No. Description

U800 23122467 UNIT, POWER BLOCK MODULE

*

MJ61 23389212 FFC CABLE P1.0-11P,

ZA01 23103778 FERRITE CORE, TFE1008

ZA02 23103914

A502 23717175 SCREW, PP3X6+SW+W SZ

A503 72471064 SCREW, BIDT2 3*10BZ

– 36 –

CORE, FERRITE CORE 15X22X7 TFE1015AD

Page 35

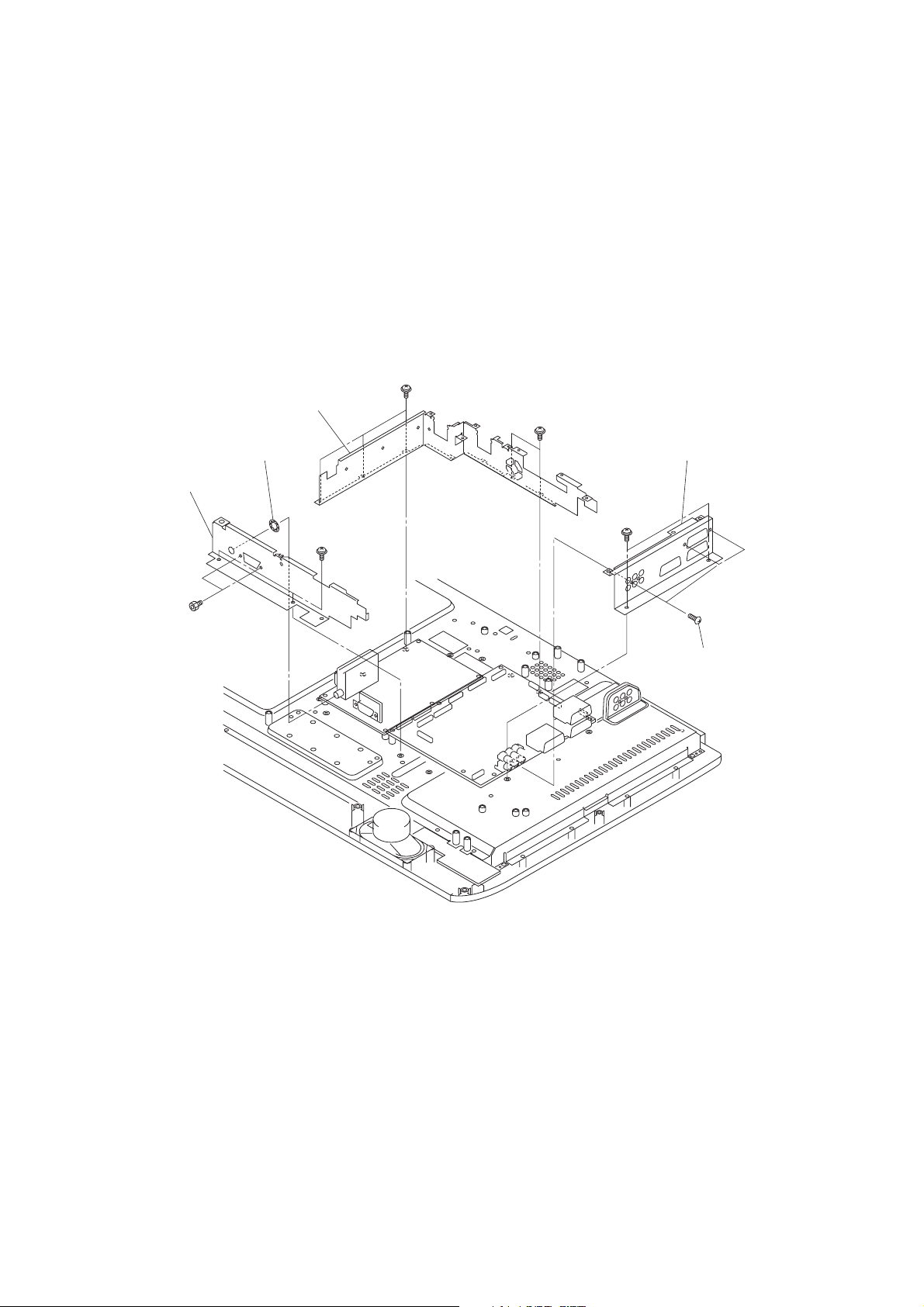

3.Chassis Block 2

STP 3x8

A

STP 3x8

STP 3x8

B

STP 3x8

Hexagon

nut

PP 3x6

Toothed

washer

STP 3x8

STP 3x8

U001G

U002B

MV23

A

U002A

MJ15

U001C

U002B

B

STP

3x8

STP

3x8

STP 3x8

BIDT2

3x10 BZ

BIDT2 3x10 BZ

A224

LOCATION No. Parts No. Description

U001A 75000792 PCB SIGNAL

*

U001C 75000794 PCB PB UNIT AV2

*

U001G 75000798 PCB PB UNIT D-REWRITE

*

U002A 75000799 PCB PB UNIT TN/AOUT

*

U002B 75000800 PCB PB UNIT PC INPUT

*

MJ15 23389211 FFC CABLE, P1.0-25P

MV23 23389213 FFC CABLE, P1.0-19P

A224 23940068 PIECE, TOP AV ASSY

A502 23717175 SCREW, PP3X6+SW+W SZ

A503 72471064 SCREW, BIDT2 3*10BZ

A505 23035004 SCREW, PBI4X12,SBN

– 37 –

Page 36

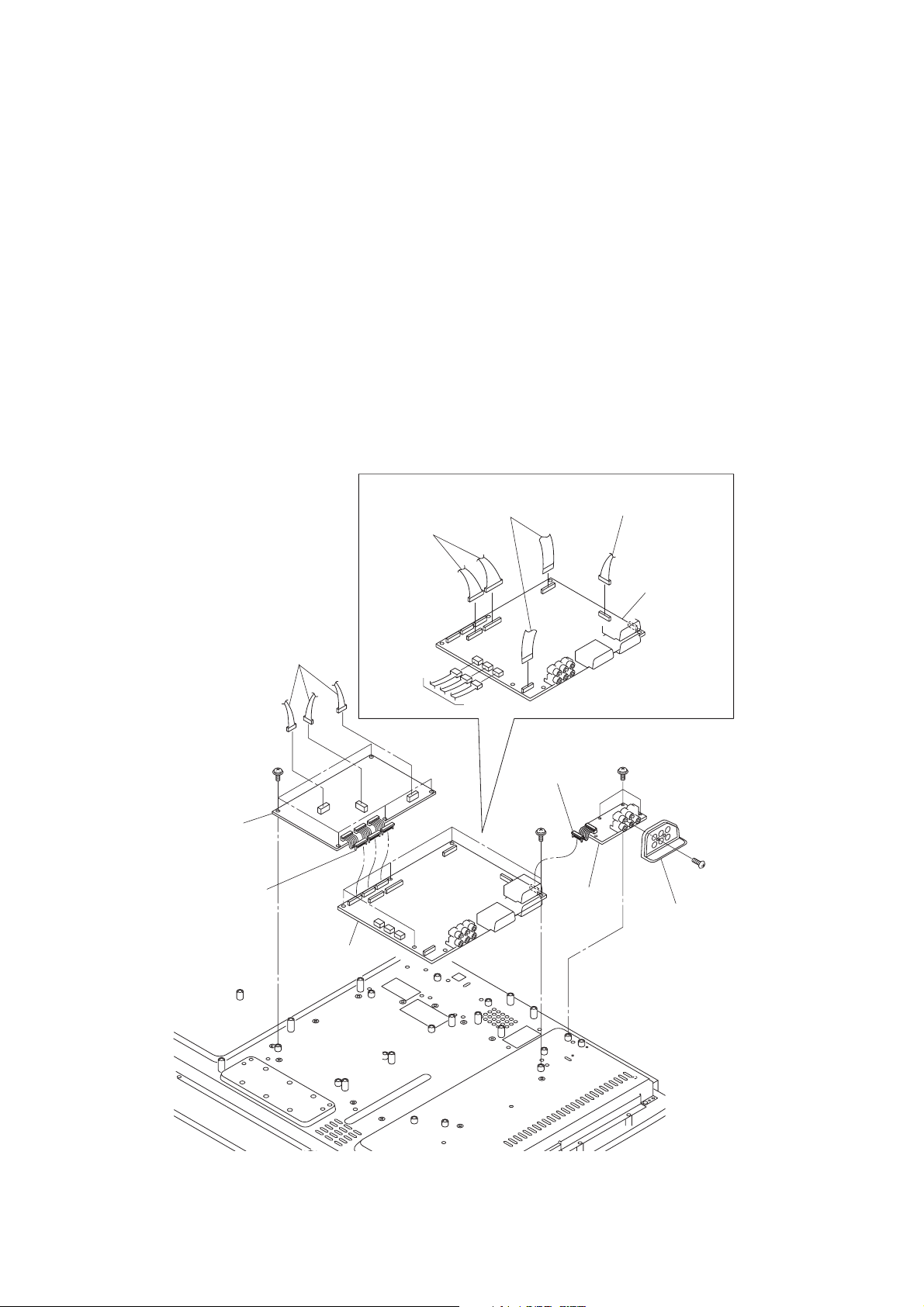

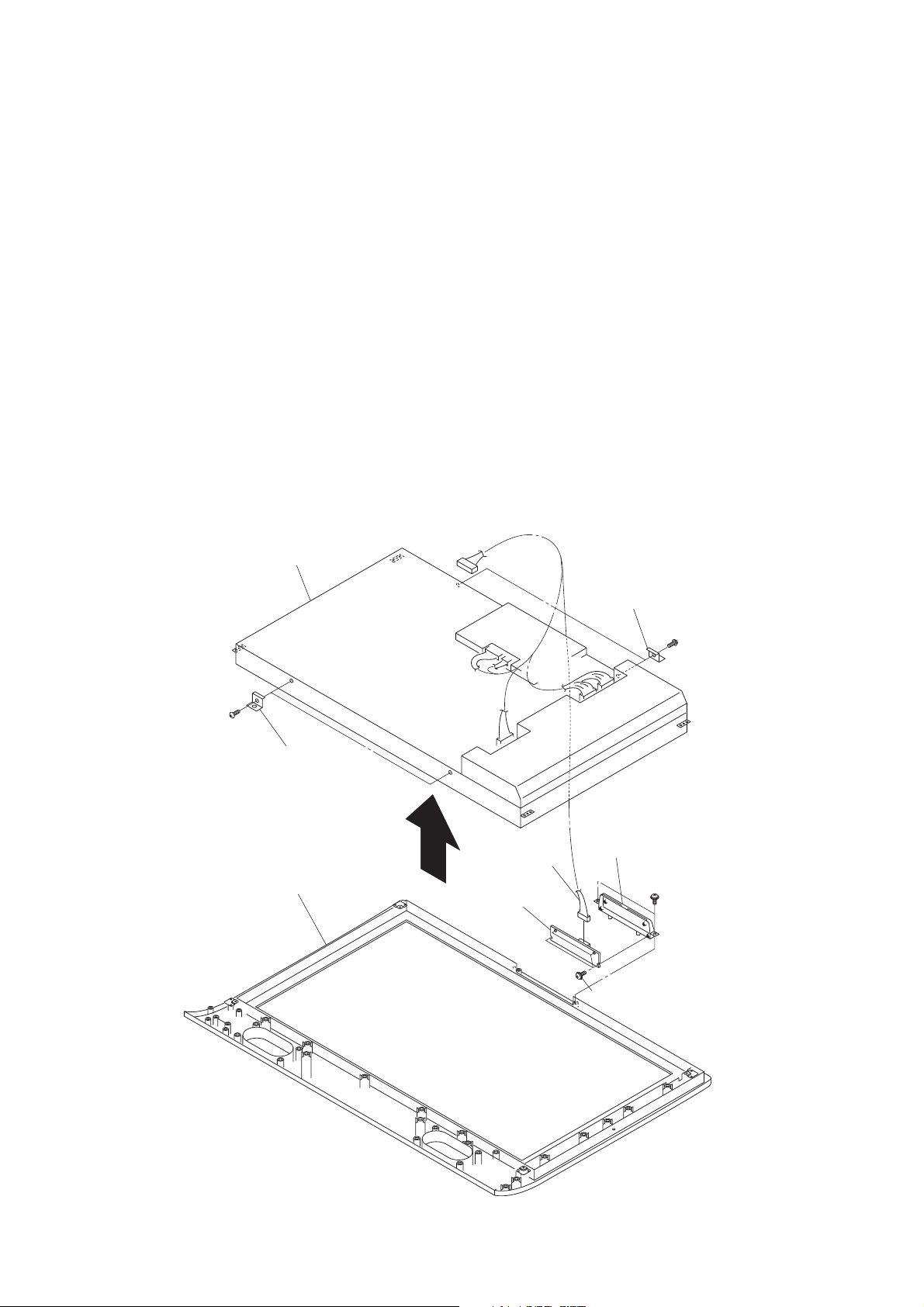

4.LCD and Front Bezel Block

PBI 4x12

PP 4x10

PP

4x10

PP 3x6

A219

PP 4x10

B001

PP 4x10

PP

4x10

PBI 4x12

BIDT2

3x10

U001D

A215

A203

LOCATION No. Parts No. Description

U001D 75000795 PCB PB UNIT POW SW

*

U001E 75000796 PCB PB UNIT KEY SW

*

U001F 75000797 PCB PB UNIT LED/RMT

*

A201 23532720 COVER, FRONT BEZEL ASSY

A202 23940073 PIECE, PIECE KEY ASSY

A219 23528375 HOLDER, HOLDER P CORD PAL

B001 23301560 LCD PANEL, 03SHARP32 32L400V

W661

A201

BIDT2

3x10

U001E

BTB

4x12

BIDT2

3x10

W661

PBI

4x12

LOCATION No. Parts No. Description

W661 23351156 SPEAKER, SPK1410AM, 60X120 8-OHM 10W

A203 23940025 PIECE, PIECE POWER ASSY

A215 23940043 PIECE, CAP P SWITCH

A502 23717175 SCREW, PP3X6+SW+W SZ

A503 72471064 SCREW, BIDT2 3*10BZ

A505 23035004 SCREW, PBI4X12,SBN

U001F

BIDT2

3x10

A202

BIDT2

3x10

BIDT2

3x10

– 38 –

Page 37

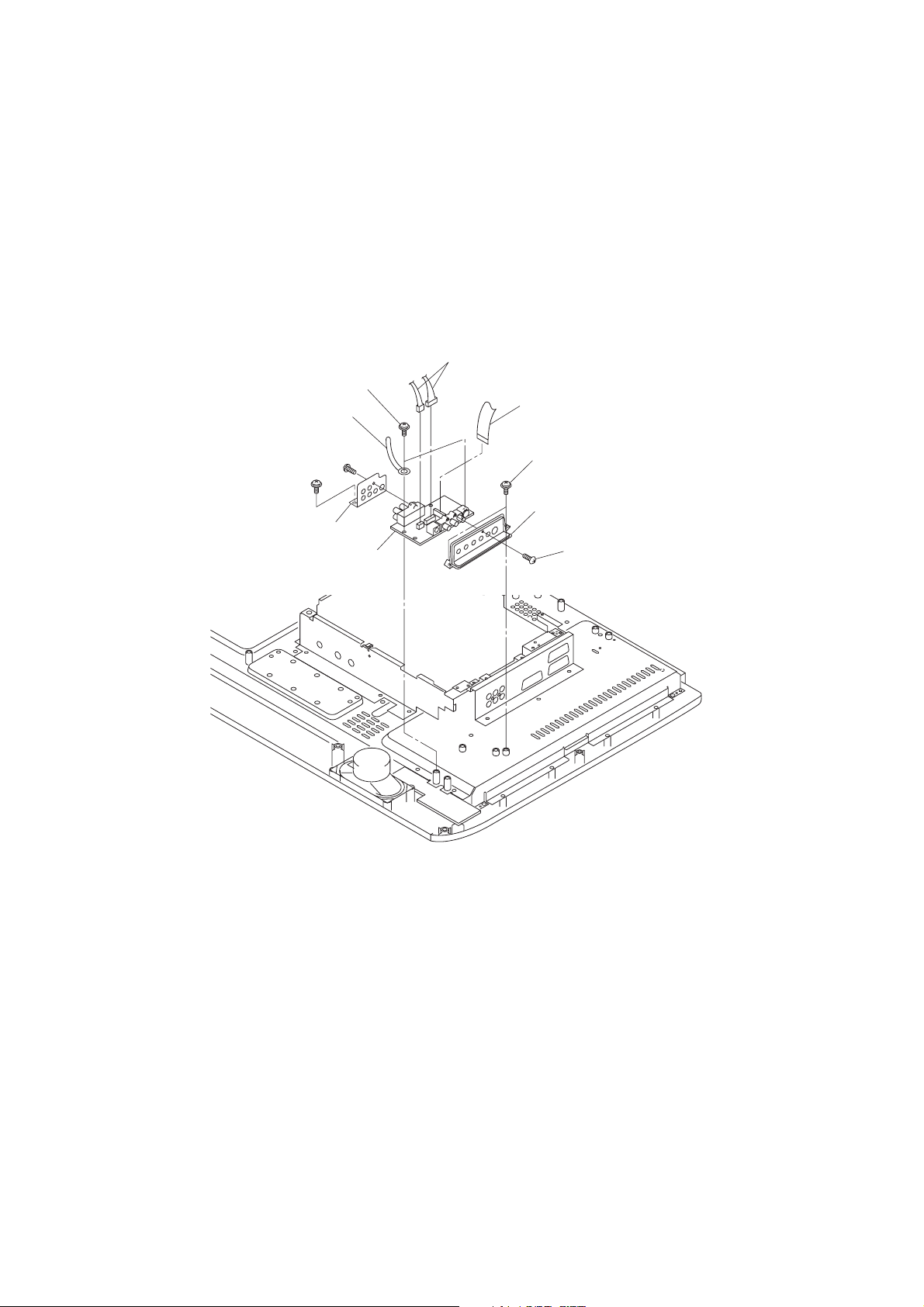

PACKING DISASSEMBLY

A702A

A702B

A705

A703

A701A

A702A

Y170

K902

Y101A

Y101B

Y101C

Y101D

Y101E

Y101F

Y101G

Y109

A701B

LOCATION No. Parts No. Description

A701A 23067683 CARTON, TOP CASE

(FOR 32WL46B)

23067684 CARTON, TO P CASE

(FOR 32WL46G)

A701B 23067688 CARTON, BOTTOM CASE

A702A 23946764 P A CKING, T OP PACKING

A702B 23946765 PACKING, BOTTOM PACKING

A703 23945143 BAG, PROTECTIVE

A705 23518043 PACKING, JOINT

K902 23306469 REMOCON HAND UNIT, CT-90126

Y101A 23566309 OWNERS MANUAL, E LCD

Y101B 23566310 OWNERS MANUAL, F LCD

(FOR 32WL46G)

A702B

A705

LOCATION No. Parts No. Description

Y101C 23566311 OWNERS MANUAL, DEUT G LCD

(FOR 32WL46G)

Y101D 23566312 OWNERS MANUAL, S LCD

(FOR 32WL46G)

Y101E 23566313 OWNERS MANUAL, I LCD

(FOR 32WL46G)

Y101F 23566314 OWNERS MANUAL, NEDR O LCD

(FOR 32WL46G)

Y101G 23566315 OWNERS MANUAL, P LCD

(FOR 32WL46G)

Y109 23945015 BAG, POLYETHYLENE COVER 250X400

Y170 23845800 WIRE HOLDER, NYLON66 D6.8

– 39 –

Page 38

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY RADIATION PRECAUTION", "SAFETY PRE-

CAUTION" AND "PRODUCT SAFETY NOTICE" ON PAGE 3 OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in the

original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the PR ODUCT SAFETY NOTICE. Do not degrade the safety

of the receiver through improper servicing.

NOTICE:

··

·

The part number must be used when ordering parts, in order to assist in processing, be sure to include the

··

Model number and Description.

··

·

The PC board assembly with * mark is no longer availab le after the end of the production.

··

Model : 32WL46B/32WL46G

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are

±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

Location Parts No. Description

No.

#1 : [32WL46B]

#2 : [32WL46G]

CAPACITORS

C101 24109102 CERAMIC CHIP, 50V B 1000PF K

C102 24793221 ELECTROLYTIC, 10V 220UF M

C103 24109102 CERAMIC CHIP, 50V B 1000PF K

C104 24797479 ELECTROLYTIC, 50V 4.7UF M

C105 24617009 ELECTROLYTIC, 10V 330UF M

C106 24109102 CERAMIC CHIP, 50V B 1000PF K

C107 24109103 CERAMIC CHIP, 50V B 0.01UF K

C120 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C121 24763101 ELECTROLYTIC, 16V 100UF M

C150 24109103 CERAMIC CHIP, 50V B 0.01UF K

C151 24109103 CERAMIC CHIP, 50V B 0.01UF K

C152 24109103 CERAMIC CHIP, 50V B 0.01UF K

C160 24590224 PLASTIC FILM, 50V 0.22UF J

C271 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

C280 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

C281 24092616 CERAMIC CHIP, 16V B 0.33UF K

C282 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C283 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

C501 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C502 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C503 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

C504 24109103 CERAMIC CHIP, 50V B 0.01UF K

C505 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

C506 24109103 CERAMIC CHIP, 50V B 0.01UF K

C507 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C508 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C509 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C511 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C512 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C514 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

C516 24105110 CERAMIC CHIP, 50V CH 11PF J

C517 24206478 ELECTROLYTIC, 50V 0.47UF M 7L 3A

C519 24206479 ELECTROLYTIC, 50V 4.7UF M 7L 3A

C521 24092733 CERAMIC CHIP, 50V B 0.022UF K

C522 24109103 CERAMIC CHIP, 50V B 0.01UF K

C523 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C524 24109103 CERAMIC CHIP, 50V B 0.01UF K

C525 24503041 PLASTIC FILM , 63V 0.1UF J

C526 24109103 CERAMIC CHIP, 50V B 0.01UF K

C527 24206229 ELECTROLYTIC, 50V 2.2UF M 7L 3A

C601 24092730 CERAMIC CHIP, 16V B 0.1UF K

C603 24092730 CERAMIC CHIP, 16V B 0.1UF K

Location Parts No. Description

No.

C604 24092611 CERAMIC CHIP, 6.3V B 2.2UF K

C605 24109102 CERAMIC CHIP, 50V B 1000PF K

C606 24109102 CERAMIC CHIP, 50V B 1000PF K

C608 24092730 CERAMIC CHIP, 16V B 0.1UF K

C610 24092731 CERAMIC CHIP, 16V B 1UF K

C611 24092730 CERAMIC CHIP, 16V B 0.1UF K

C612 24761102 ELECTROLYTIC CE04G, 6.3V 1000UF M

C613 24092731 CERAMIC CHIP, 16V B 1UF K

C614 24092730 CERAMIC CHIP, 16V B 0.1UF K

C615 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

C620 24092463 CERAMIC CHIP, 16V B 0.22UF K

C621 24092730 CERAMIC CHIP, 16V B 0.1UF K

C622 24092463 CERAMIC CHIP, 16V B 0.22UF K

C623 24092463 CERAMIC CHIP, 16V B 0.22UF K

C624 24092730 CERAMIC CHIP, 16V B 0.1UF K

C625 24092463 CERAMIC CHIP, 16V B 0.22UF K

C627 24092730 CERAMIC CHIP, 16V B 0.1UF K

C629 24206010 ELECTROLYTIC, 50V 1.0UF M 7L 3A

C630 24092730 CERAMIC CHIP, 16V B 0.1UF K

C631 24092463 CERAMIC CHIP, 16V B 0.22UF K

C632 24092463 CERAMIC CHIP, 16V B 0.22UF K

C635 24763221 ELECTROLYTIC, 16V 220UF M

C636 24763221 ELECTROLYTIC, 16V 220UF M

C640 24762102 ELECTROLYTIC, 04G 10V 1000UF M

C641 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

C642 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

C645 24815103 CERAMIC CHIP, 50V B 10000PF K

C646 24092738 CERAMIC CHIP, 25V B 0.47UF K

C647 24092738 CERAMIC CHIP, 25V B 0.47UF K

C648 24285104 CERAMIC CHIP, 50V B 0.1UF K

C649 24285104 CERAMIC CHIP, 50V B 0.1UF K

C653 24092538 CERAMIC CHIP, 10V F 1UF Z

C661 24109102 CERAMIC CHIP, 50V B 1000PF K

C662 24109102 CERAMIC CHIP, 50V B 1000PF K

C663 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

C664 24203220 ELECTROLYTIC, 16V 22UF M 7L 3A

C665 24206010 ELECTROLYTIC, 50V 1.0UF M 7L 3A

C666 24206010 ELECTROLYTIC, 50V 1.0UF M 7L 3A

C667 24092515 CERAMIC CHIP, 16V F 4.7UF Z

C668 24092515 CERAMIC CHIP, 16V F 4.7UF Z

C669 24105221 CERAMIC CHIP, 50V CH 220PF J

C672 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

C673 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

C677 24109681 CERAMIC CHIP, 50V B 680PF K

C678 24109681 CERAMIC CHIP, 50V B 680PF K

C679 24105221 CERAMIC CHIP, 50V CH 220PF J

– 41 –

Page 39

Location Parts No. Description

No.

C4222 24092538 CERAMIC CHIP, 10V F 1UF Z

C4311 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C4312 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C4313 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C4406 24109103 CERAMIC CHIP, 50V B 0.01UF K

C4407 24109103 CERAMIC CHIP, 50V B 0.01UF K

C4408 24092538 CERAMIC CHIP, 10V F 1UF Z

C4409 24794331 ELECTROLYTIC, 16V 330UF M

C4410 24109103 CERAMIC CHIP, 50V B 0.01UF K

CA03 24105180 CERAMIC CHIP, 50V CH 18PF J

CA04 24105180 CERAMIC CHIP, 50V CH 18PF J

CA13 24105101 CERAMIC CHIP, 50V CH 100PF J

CA14 24105101 CERAMIC CHIP, 50V CH 100PF J

CA15 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

CA34 24109102 CERAMIC CHIP, 50V B 1000PF K

CA42 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CA43 24109103 CERAMIC CHIP, 50V B 0.01UF K

CA44 24109103 CERAMIC CHIP, 50V B 0.01UF K

CA45 24109103 CERAMIC CHIP, 50V B 0.01UF K

CA68 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CA69 24100103 CERAMIC CHIP, 50V F 0.01UF Z

CB01 24794470 ELECTROLYTIC, 16V 47UF M

CB04 24092538 CERAMIC CHIP, 10V F 1UF Z

CB05 24109222 CERAMIC CHIP, 50V B 2200PF K

CB06 24105561 CERAMIC CHIP, 50V CH 560PF J

CB07 24109332 CERAMIC CHIP, 50V B 3300PF K

CB40 24092538 CERAMIC CHIP, 10V F 1UF Z

CB41 24109222 CERAMIC CHIP, 50V B 2200PF K

CB42 24105561 CERAMIC CHIP, 50V CH 560PF J

CB43 24109332 CERAMIC CHIP, 50V B 3300PF K

CB90 24100103 CERAMIC CHIP, 50V F 0.01UF Z

CC01 24109103 CERAMIC CHIP, 50V B 0.01UF K

CC02 24105220 CERAMIC CHIP, 50V CH 22PF J

CC04 24105220 CERAMIC CHIP, 50V CH 22PF J

CC08 24109103 CERAMIC CHIP, 50V B 0.01UF K

CC11 24109102 CERAMIC CHIP, 50V B 1000PF K

CC12 24109102 CERAMIC CHIP, 50V B 1000PF K

CC20 24105220 CERAMIC CHIP, 50V CH 22PF J

CC21 24109102 CERAMIC CHIP, 50V B 1000PF K

CC24 24109103 CERAMIC CHIP, 50V B 0.01UF K

CC25 24109103 CERAMIC CHIP, 50V B 0.01UF K

CC31 24109102 CERAMIC CHIP, 50V B 1000PF K

CC40 24109102 CERAMIC CHIP, 50V B 1000PF K

CC41 24109102 CERAMIC CHIP, 50V B 1000PF K

CC59 24109102 CERAMIC CHIP, 50V B 1000PF K

CC60 24109223 CERAMIC CHIP, 25V B 0.022UF K

CC61 24109223 CERAMIC CHIP, 25V B 0.022UF K

CC62 24109102 CERAMIC CHIP, 50V B 1000PF K

CC63 24109102 CERAMIC CHIP, 50V B 1000PF K

CC64 24109102 CERAMIC CHIP, 50V B 1000PF K

CC65 24109102 CERAMIC CHIP, 50V B 1000PF K

CC66 24109102 CERAMIC CHIP, 50V B 1000PF K

CC67 24109102 CERAMIC CHIP, 50V B 1000PF K

CC68 24109102 CERAMIC CHIP, 50V B 1000PF K

CC69 24109102 CERAMIC CHIP, 50V B 1000PF K

CC70 24109102 CERAMIC CHIP, 50V B 1000PF K

CC71 24109102 CERAMIC CHIP, 50V B 1000PF K

CC72 24109102 CERAMIC CHIP, 50V B 1000PF K

CC73 24109102 CERAMIC CHIP, 50V B 1000PF K

CC74 24109102 CERAMIC CHIP, 50V B 1000PF K

CC75 24109102 CERAMIC CHIP, 50V B 1000PF K

CC76 24109102 CERAMIC CHIP, 50V B 1000PF K

CC77 24109102 CERAMIC CHIP, 50V B 1000PF K

CC78 24109102 CERAMIC CHIP, 50V B 1000PF K

CC79 24109102 CERAMIC CHIP, 50V B 1000PF K

CC80 24109102 CERAMIC CHIP, 50V B 1000PF K

CC81 24109102 CERAMIC CHIP, 50V B 1000PF K

CC82 24109102 CERAMIC CHIP, 50V B 1000PF K

CD01 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CD03 24109332 CERAMIC CHIP, 50V B 3300PF K

CD05 24109333 CERAMIC CHIP CK73B 25V 33000PFK

CD10 24092542 CERAMIC CHIP CK733 B 16V 1.0UF K

CD12 24092542 CERAMIC CHIP CK733 B 16V 1.0UF K

CD13 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CD14 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CD15 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

Location Parts No. Description

No.

CD16 24109333 CERAMIC CHIP CK73B 25V 33000PFK

CD18 24109332 CERAMIC CHIP, 50V B 3300PF K

CD20 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CF34 24092538 CERAMIC CHIP, 10V F 1UF Z

CF38 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CF39 24109103 CERAMIC CHIP, 50V B 0.01UF K

CS01 24092538 CERAMIC CHIP, 10V F 1UF Z

CS02 24092538 CERAMIC CHIP, 10V F 1UF Z

CS03 24092538 CERAMIC CHIP, 10V F 1UF Z

CS04 24092538 CERAMIC CHIP, 10V F 1UF Z

CS05 24092538 CERAMIC CHIP, 10V F 1UF Z

CS06 24092538 CERAMIC CHIP, 10V F 1UF Z

CS07 24092538 CERAMIC CHIP, 10V F 1UF Z

CS08 24092538 CERAMIC CHIP, 10V F 1UF Z

CS09 24092538 CERAMIC CHIP, 10V F 1UF Z

CS10 24092538 CERAMIC CHIP, 10V F 1UF Z

CS11 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CS12 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CS13 24092731 CERAMIC CHIP, 16V B 1UF K

CS14 24092731 CERAMIC CHIP, 16V B 1UF K

CS15 24092538 CERAMIC CHIP, 10V F 1UF Z

CS16 24092538 CERAMIC CHIP, 10V F 1UF Z

CS18 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CS19 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CS20 24092573 CERAMIC CHIP, 16V B 0.47UF K

CS24 24092538 CERAMIC CHIP, 10V F 1UF Z

CS25 24092538 CERAMIC CHIP, 10V F 1UF Z

CS26 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CS27 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS28 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS29 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS30 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS33 24763221 ELECTROLYTIC, 16V 220UF M

CS37 24092538 CERAMIC CHIP, 10V F 1UF Z

CS38 24092538 CERAMIC CHIP, 10V F 1UF Z

CS39 24092573 CERAMIC CHIP, 16V B 0.47UF K

CS40 24202101 ELECTROLYTIC, 04W 10V 100UF M 7L 3A

CS43 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS44 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS45 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS46 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS51 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS63 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS64 24092538 CERAMIC CHIP, 10V F 1UF Z

CS65 24092538 CERAMIC CHIP, 10V F 1UF Z

CS501 24092731 CERAMIC CHIP, 16V B 1UF K

CS502 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS503 24092731 CERAMIC CHIP, 16V B 1UF K

CS504 24105101 CERAMIC CHIP, 50V CH 100PF J

CS505 24105101 CERAMIC CHIP, 50V CH 100PF J

CS506 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS507 24206339 ELECTROLYTIC, 50V 3.3UF M 7L 3A

CS508 24206479 ELECTROLYTIC, 50V 4.7UF M 7L 3A

CS509 24092542 CERAMIC CHIP CK733 B 16V 1.0UF K

CS510 24092542 CERAMIC CHIP CK733 B 16V 1.0UF K

CS511 24105101 CERAMIC CHIP, 50V CH 100PF J

CS512 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV07 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV08 24794471 ELECTROLYTIC, 16V 470UF M

CV10 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV11 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV12 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV13 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV14 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV23 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV24 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV25 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

CV27 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV28 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV35 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV36 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV39 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV40 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV41 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV50 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV51 24085970 ELECTROLYTIC, NONPOLAR, 16V 10UF M 7L

– 42 –

Page 40

Location Parts No. Description

No.

CV52 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV53 24092538 CERAMIC CHIP, 10V F 1UF Z

CV54 24092538 CERAMIC CHIP, 10V F 1UF Z

CV55 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV64 24794471 ELECTROLYTIC, 16V 470UF M

CV65 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV66 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV67 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV68 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV69 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV70 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV71 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV72 24092538 CERAMIC CHIP, 10V F 1UF Z

CV73 24092538 CERAMIC CHIP, 10V F 1UF Z

CV74 24092538 CERAMIC CHIP, 10V F 1UF Z

CV75 24092538 CERAMIC CHIP, 10V F 1UF Z

CV76 24092538 CERAMIC CHIP, 10V F 1UF Z

CV77 24092538 CERAMIC CHIP, 10V F 1UF Z

CV78 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV81 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV82 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV93 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV121 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV128 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV238 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV244 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV245 24092538 CERAMIC CHIP, 10V F 1UF Z

CV246 24092538 CERAMIC CHIP, 10V F 1UF Z

CV247 24092538 CERAMIC CHIP, 10V F 1UF Z

CV252 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV253 24092538 CERAMIC CHIP, 10V F 1UF Z

CV254 24092538 CERAMIC CHIP, 10V F 1UF Z

CV255 24092538 CERAMIC CHIP, 10V F 1UF Z

CV256 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV257 24794471 ELECTROLYTIC, 16V 470UF M

CV258 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV259 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV261 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV263 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV265 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV276 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV280 24092538 CERAMIC CHIP, 10V F 1UF Z

CV281 24092538 CERAMIC CHIP, 10V F 1UF Z

CV282 24092538 CERAMIC CHIP, 10V F 1UF Z

CV283 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV286 24092538 CERAMIC CHIP, 10V F 1UF Z

CV287 24092538 CERAMIC CHIP, 10V F 1UF Z

CV288 24092538 CERAMIC CHIP, 10V F 1UF Z

CV293 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CY650 24591102 PLASTIC FILM, 50V 1000PF J

CZ01 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ02 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ03 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ04 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ05 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ06 24105102 CERAMIC CHIP, 25V CH 1000PF J

CZ07 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ09 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CZ10 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ13 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ14 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ21 24203220 ELECTROLYTIC, 16V 22UF M 7L 3A

CZ22 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CZ23 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CZ24 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CZ25 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CZ26 24100103 CERAMIC CHIP, 50V F 0.01UF Z

CZ27 24100103 CERAMIC CHIP, 50V F 0.01UF Z

CZ28 24105101 CERAMIC CHIP, 50V CH 100PF J

CZ29 24105101 CERAMIC CHIP, 50V CH 100PF J

CZ30 24105151 CERAMIC CHIP, 50V CH 150PF J

CZ31 24092731 CERAMIC CHIP, 16V B 1UF K

CZ32 24109102 CERAMIC CHIP, 50V B 1000PF K

CZ34 24105330 CERAMIC CHIP, 50V CH 33PF J

CZ35 24105181 CERAMIC CHIP, 50V CH 180PF J

CZ36 24100104 CERAMIC CHIP, 25V F 0.1UF Z

Location Parts No. Description

No.

CZ37 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ38 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ39 24105181 CERAMIC CHIP, 50V CH 180PF J

CZ40 24105560 CERAMIC CHIP, 50V CH 56PF J

CZ41 24105270 CERAMIC CHIP, 50V CH 27PF J

CZ42 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ43 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ44 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ45 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ46 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ47 24109103 CERAMIC CHIP, 50V B 0.01UF K

CZ48 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ49 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ51 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ52 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ53 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ54 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ55 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ56 24105330 CERAMIC CHIP, 50V CH 33PF J

CZ57 24105330 CERAMIC CHIP, 50V CH 33PF J

CZ58 24105120 CERAMIC CHIP, 50V CH 12PF J

CZ59 24105120 CERAMIC CHIP, 50V CH 12PF J

CZ60 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ61 24105620 CERAMIC CHIP, 50V CH 62PF J

CZ62 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ63 24105821 CERAMIC CHIP, 25V CH 820PF J

CZ64 24105561 CERAMIC CHIP, 50V CH 560PF J

CZ65 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CZ66 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ67 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ69 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CZ70 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ73 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ74 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ75 24105101 CERAMIC CHIP, 50V CH 100PF J

CZ76 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ77 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ78 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ79 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ80 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ81 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ82 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ83 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ84 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ85 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ86 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ87 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ88 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ89 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CZ93 24088133 OSCON 6.3V 47UF 6SVP47M

RF27 24105121 CERAMIC CHIP, 50V CH 120PF J

RESISTORS

R110 24000445 CHIP JUMPER, 1608TYPE

R229 24000824 CHIP JUMPER, 2125TYPE

R271 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R272 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R273 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R274 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R275 24011683 CHIP, METAL FILM, 1/20W 68K OHM J

R276 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R501 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

R502 24011272 CHIP, 1/20W 2.7K OHM J

R504 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R505 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R506 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

R507 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

R508 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

R509 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

R511 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R512 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R514 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R515 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R516 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R517 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R519 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

– 43 –

Page 41

Location Parts No. Description

No.

R520 24366681 CARBON FILM, 1/6W 680 OHM J

R523 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R524 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R525 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

R543 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

R544 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

R545 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

R601 24554470 OXIDE METAL FILM, 2W 47 OHM J

R604 24000606 CHIP, 1/16W 8.2K OHM F

R605 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R606 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

R607 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R609 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

R610 24011124 CHIP, 1/20W 120K OHM J

R611 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R612 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

R613 24011124 CHIP, 1/20W 120K OHM J

R614 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R615 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R616 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

R617 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R618 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R619 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R620 24871100 CHIP, 1/8W 10 OHM J

R623 24871100 CHIP, 1/8W 10 OHM J

R640 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R641 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R642 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R645 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R646 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R650 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R652 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R655 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

R660 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

R661 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R664 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R665 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R667 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R670 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R671 24011182 CHIP, METAL FILM, 1/20W 1.8K OHM J

R672 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R673 24011182 CHIP, METAL FILM, 1/20W 1.8K OHM J

R674 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

R676 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R677 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R678 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R684 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

R685 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

R686 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R687 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R688 24871101 CHIP, 1/8W 100 OHM J

R690 24871101 CHIP, 1/8W 100 OHM J

R4316 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R4317 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R4328 24011471 CHIP, METAL FILM, 1/20W 470 OHM J

R4329 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R4408 24011361 CHIP, 1/20W 360 OHM J

R4430 24011622 CHIP, METAL FILM, 1/20W 6.2K OHM J

R4465 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

R4467 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R4468 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R4471 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R4472 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R4473 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R4474 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R4476 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

R4477 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

R4504 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R4526 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

R4527 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RA01 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA02 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA03 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA05 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA06 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA07 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

Location Parts No. Description

No.

RA08 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RA09 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA10 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA11 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA12 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA13 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RA14 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RA15 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RA16 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RA20 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA21 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA22 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA24 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA25 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA27 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA28 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA29 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RA30 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RA31 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA34 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA35 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA36 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA37 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA41 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA43 24011333 CHIP, METAL FILM, 1/20W 33K OHM J

RA44 24011333 CHIP, METAL FILM, 1/20W 33K OHM J

RA45 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA53 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA55 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA60 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA63 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA65 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA66 24011224 CHIP, METAL FILM, 1/20W 220K OHM J

RA67 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RA68 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA71 24366683 CARBON FILM, 1/6W 68K OHM J

RA72 24366223 CARBON FILM, 1/6W 22K OHM J

RA73 24366103 CARBON FILM, 1/6W 10K OHM J

RA75 24366103 CARBON FILM, 1/6W 10K OHM J

RA76 24011333 CHIP, METAL FILM, 1/20W 33K OHM J

RA77 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA78 24011224 CHIP, METAL FILM, 1/20W 220K OHM J

RA79 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

RA80 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

RA83 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA84 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA85 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA86 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA88 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RA89 24011272 CHIP, 1/20W 2.7K OHM J

RA91 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA92 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA93 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA94 24011470 CHIP, METAL FILM, 1/20W 47 OHM J

RA95 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RA96 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RA97 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RA98 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RA99 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RA551 24011330 CHIP, 1/20W 33 OHM J

RA552 24011330 CHIP, 1/20W 33 OHM J

RA553 24011330 CHIP, 1/20W 33 OHM J

RA554 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB01 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

RB02 24011471 CHIP, METAL FILM, 1/20W 470 OHM J

RB04 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RB05 24011105 CHIP, METAL FILM, 1/20W 1M OHM J

RB06 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB07 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

RB08 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

RB09 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB10 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RB11 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB12 24011471 CHIP, METAL FILM, 1/20W 470 OHM J

RB13 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RB14 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

– 44 –

Page 42

Location Parts No. Description

No.

RB15 24011470 CHIP, METAL FILM, 1/20W 47 OHM J

RB32 24011105 CHIP, METAL FILM, 1/20W 1M OHM J

RB33 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB34 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

RB35 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

RB46 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB49 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RB81 24011122 CHIP, METAL FILM, 1/20W 1.2K OHM J

RB82 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB83 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB90 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

RB91 24872393 CHIP, 1/16W 39K OHM J

RB92 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

RB93 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

RB94 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RB95 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RB96 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

RB97 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

RB98 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RC01 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC02 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC03 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC04 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC05 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC06 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC07 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC08 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC09 24000445 CHIP JUMPER, 1608TYPE

RC10 24000445 CHIP JUMPER, 1608TYPE

RC11 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC12 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC13 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC14 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC15 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC16 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC40 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC41 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RD01 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

RD02 24011203 CHIP, METAL FILM, 1/20W 20K OHM J

RD04 24011203 CHIP, METAL FILM, 1/20W 20K OHM J

RD07 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD08 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RD10 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD14 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD17 24011203 CHIP, METAL FILM, 1/20W 20K OHM J

RD19 24011203 CHIP, METAL FILM, 1/20W 20K OHM J

RD20 24011273 CHIP, METAL FILM, 1/20W 27K OHM J

RD21 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RF18 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RF19 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RF20 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RF21 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RF22 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RF23 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RF24 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RF25 24000445 CHIP JUMPER, 1608TYPE

RF26 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RF45 24000445 CHIP JUMPER, 1608TYPE

RR01 24871750 CHIP, 1/8W 75 OHM J

RR02 24871750 CHIP, 1/8W 75 OHM J

RR03 24871750 CHIP, 1/8W 75 OHM J

RR524 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS01 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS02 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS03 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS04 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS05 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS06 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS07 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS08 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS09 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS10 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RS11 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS12 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS13 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

RS14 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

Location Parts No. Description

No.

RS15 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS16 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS17 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS18 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS19 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS20 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS21 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS22 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS23 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS24 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS25 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS26 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS27 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS28 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS29 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RS30 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RS31 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS32 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS33 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS34 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS35 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS36 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS37 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS38 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS39 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS40 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS41 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS42 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS43 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS44 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS45 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS46 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS47 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS48 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS49 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

RS50 24011271 CHIP, METAL FILM, 1/20W 270 OHM J

RS51 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS52 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS53 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS54 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS55 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS56 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS57 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS58 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS59 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS60 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RS61 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS62 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RS63 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS64 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS65 24011391 CHIP, METAL FILM, 1/20W 390 OHM J

RS66 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS67 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS68 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS69 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS70 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS75 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS76 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS77 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS78 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS79 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS80 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS81 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS82 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS83 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS84 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

RS85 24000665 FUSIBLE, 1/4W 15 OHM J

RS86 24011391 CHIP, METAL FILM, 1/20W 390 OHM J

RS87 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS90 24011182 CHIP, METAL FILM, 1/20W 1.8K OHM J

RS91 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS92 24011393 CHIP, METAL FILM, 1/20W 39K OHM J

RS93 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

RS94 24011393 CHIP, METAL FILM, 1/20W 39K OHM J

RS95 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

RS96 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

– 45 –

Page 43

Location Parts No. Description

No.

RS97 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS99 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS103 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS112 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS116 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS500 24011393 CHIP, METAL FILM, 1/20W 39K OHM J

RS501 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

RS502 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS503 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS504 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

RS505 24011393 CHIP, METAL FILM, 1/20W 39K OHM J

RS506 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS507 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS508 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS509 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS511 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS512 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS513 24011393 CHIP, METAL FILM, 1/20W 39K OHM J

RS514 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS515 24011392 CHIP, METAL FILM, 1/20W 3.9K OHM J

RS516 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS517 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS520 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS521 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS522 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS523 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS524 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RS525 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RS526 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS527 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS528 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS529 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RS530 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RT01 24019527

RV04 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV05 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV07 24367103 CARBON FILM, 1/6W 10K OHM G

RV08 24367103 CARBON FILM, 1/6W 10K OHM G

RV09 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV10 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV11 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV13 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV14 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV15 24011101 CHIP, METAL FILM, 1/20W 100 OHM J