Toshiba 23HLV84 Service Manual

FILE NO. 050-200420

7

8

DOCUMENT CREATED IN JAPAN, Oct., 2004

SERVICE MANUAL

LCD COLOR TELEVISION/

DVD VIDEO PLAYER

23HLV84

CAUTION

THIS

LCD COLOR TELEVISION

TO ENSURE PROPER USE OF THIS PRODUCT, PLEASE READ THIS SER VICE MANUAL CAREFULLY AND RETAIN FOR FUTURE REFERENCE. SHOULD THE UNIT REQUIRE MAINTENANCE,

CONTACT AN AUTHORIZED SERVICE LOCA TION-SEE SERVICE PROCEDURE.

USE OF CONTROLS, ADJUSTMENTS OR THE PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MA Y RESULT IN HAZARDOUS RADIATION EXPOSURE.

TO PREVENT DIRECT EXPOSURE TO LASER BEAM, DO NOT TRY T O OPEN THE ENCLOSURE.

VISIBLE LASER RADIA TION MAY BE PRESENT WHEN THE ENCLOSURE IS OPENED. DO NOT

ST ARE INTO BEAM.

Location of the required Marking

The rating sheet and the safety caution are on the rear of the unit.

EMPLOYS A LASER SYSTEM.

CERTIFICATION: COMPLIES WITH FDA

RADIA TION PERFORMANCE STANDARDS,

21 CFR SUBCHAPTER J.

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is received at the

time of repair, a life of product may become short.

Please perform the following measure against static electricity, be careful of destruction of a laser diode

enough at the time of repair, and work.

• It works on the desk which performed measures against static electricity, such as conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

A1-1 23HLV84

IMPORTANT SERVICE SAFETY INFORMATION

Safety precautions to be followed during servicing:

1.

Parts marked with an are critical parts for safety. Replace only with the one described in the parts

list.

2.

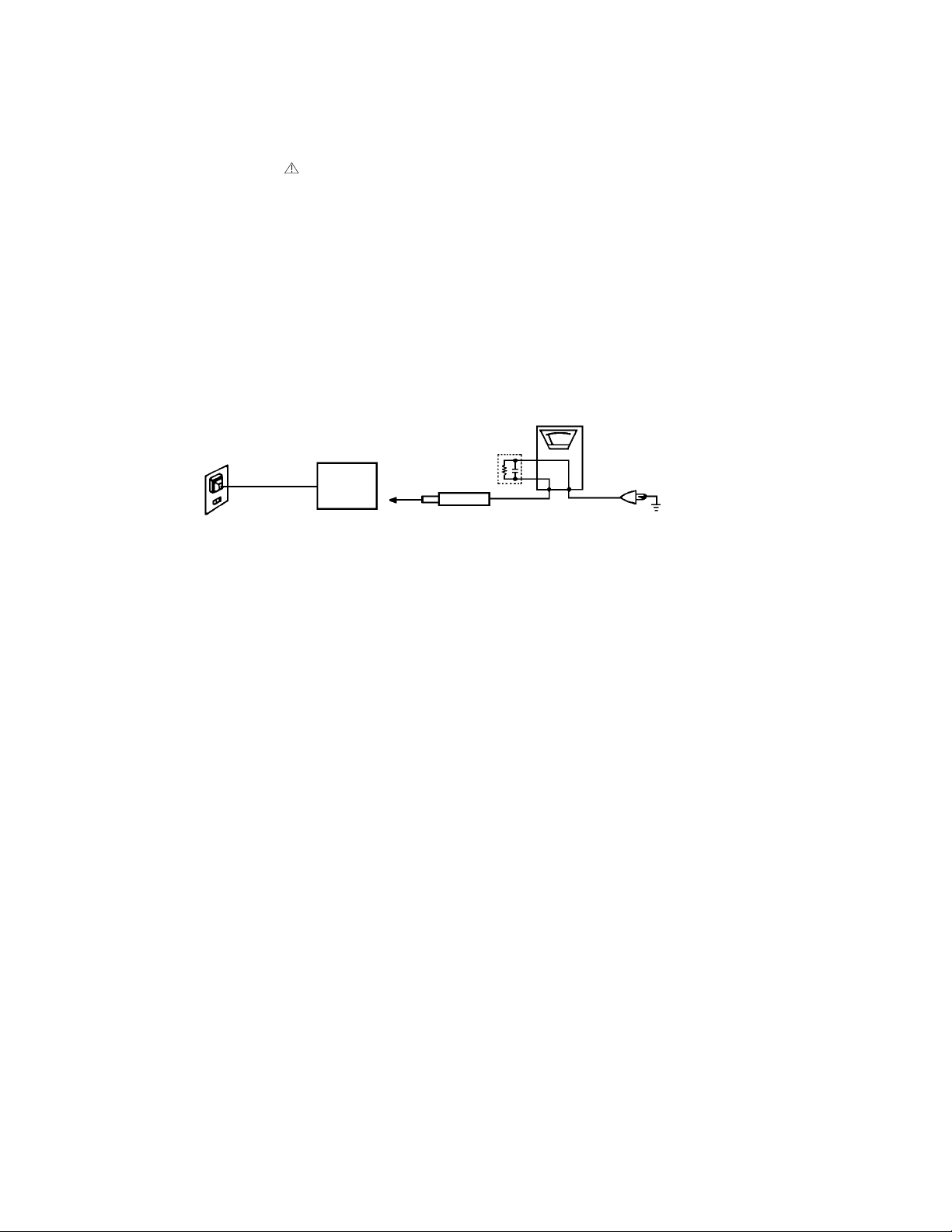

Before returning the DVD product to the customer, make the appropriate leakage current check or

resistance measurements to ensure that exposed parts are properly insulated from the supply circuit.

A leakage current check is recommended for this unit. Plug the AC line cord directly into a 120V 60Hz AC

outlet (do not use an isolation transformer for this check). Use a leakage current tester (Fig. 1) or a

metering system which complies with Underwriters Laboratories (UL 1409). Measure for current from all

exposed metal parts of the cabinet to a known earth ground: particularly, any exposed metal part having a

return path to the chassis. Any current measured must not exceed 0.5mA. Any measurement not within

the limits outlined above are indicative of a potential shock hazard and corrective action must be taken

before returning the unit to the customer.

(Reading should not be above 0.5mA)

Leakage Current Tester

PRODUCT UNDER TEST

1.5K ohm

0.15 µF

2-Blade polarized

type cord set

Test all exposed

metal surfaces

TEST PROBE

Fig. 1 AC Leakage Test

KNOWN EARTH

GROUND

A1-2 23HLV84

IMPORTANT SAFEGUARDS

1.

READ INSTRUCTIONS

All the safety and operating instructions should be read before the unit is operated.

2.

RET AIN INSTRUCTIONS

The safety and operating instructions should be retained for future reference.

3.

HEED WARNINGS

All warnings on the unit and in the operating instructions should be adhered to.

4.

FOLLOW INSTRUCTIONS

All operating and use instructions should be followed.

5.

CLEANING

Unplug this unit from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp

cloth for cleaning.

6.

A TTACHMENTS

Do not use attachments not recommended by the unit’s manufacturer as they may cause hazards.

7.

WATER AND MOISTURE

Do not use this unit near water. For example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool.

8.

ACCESSORIES

Do not place this unit on an unstable cart, stand, tripod, bracket, or table. The

unit may fall, causing serious injury, and serious damage to the unit. Use only

with a cart, stand, tripod, bracket, or table recommended by the manufacturer.

8A.

An appliance and cart combination should be moved with care. Quick stops,

excessive force, and uneven surfaces may cause the appliance and cart

combination to overturn.

9.

VENTILATION

Slots and openings in the cabinet and in the back or bottom are provided for ventilation, to ensure reliable

operation of the unit, and to protect it from overheating. These openings must not be blocked or covered. The

openings should never be blocked by placing the unit on a bed, sofa, rug, or other similar surface. This unit

should never be placed near or over a radiator or heat source. This unit should not be placed in a built-in

installation such as a bookcase or rack unless proper ventilation is provided or the manufacturer’s instructions

have been adhered to.

10.

POWER SOURCES

This unit should be operated only from the type of power source indicated on the rating plate. If you are not sure

of the type of power supply to your home, consult your appliance dealer or local power company. For units

intended to operate from battery power, or other sources, refer to the operating instructions.

11.

GROUNDING OR POLARIZA TION

This unit is equipped with a polarized alternating-current line plug (a plug having one blade wider than the other).

This plug will fit into the power outlet only one way. This is a safety feature. If you are unable to insert the plug

fully into the outlet, try reversing the plug. If the plug should still fail to fit, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the polarized plug. If your unit is equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin, this plug will only fit into a grounding-type power

outlet. This too, is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to

replace your obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

12.

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon

or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they

exit from the appliance.

13.

LIGHTNING

To protect your unit from a lightning storm, or when it is left unattended and unused for long periods of time,

unplug it from the wall outlet and disconnect the antenna or cable system. This will prevent damage to the unit

due to lightning and power line surges.

14.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead power lines or other electric light or

power circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system,

extreme care should be taken to keep from touching such power lines or circuits, as contact with them might be

fatal.

15.

OVERLOADING

Do not overload wall outlets and extension cords, as this can result in a risk of fire or electric shock.

16.

OBJECT AND LIQUID ENTRY

Do not push objects through any openings in this unit, as they may touch dangerous voltage points or short out

parts that could result in fire or electric shock. Never spill or spray any type of liquid into the unit.

PORT ABLE CAR T WARNING

(symbol provided by RETAC)

S3126A

A1-3 23HLV84

IMPORTANT SAFEGUARDS (CONTINUED)

OUTDOOR ANTENNA GROUNDING

17.

If an outside antenna or cable system is connected to the unit, be sure the antenna or cable system is grounded

so as to provide some protection against voltage surges and built-up static charges. Section 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with respect to proper grounding of the mast and supporting

structure, grounding of the lead-in wire to an antenna discharge unit, size of grounding conductors, location of

antenna discharge unit, connection to grounding electrodes, and requirements for the grounding electrode.

SERVICING

18.

Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltage

or other hazards. Refer all servicing to qualified service personnel.

DAMAGE REQUIRING SERVICE

19.

Unplug this unit from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

a.

When the power-supply cord or plug is damaged.

b.

If liquid has been spilled, or objects have fallen into the unit.

c.

If the unit has been exposed to rain or water.

d.

If the unit does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions, as an improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to restore the unit to its normal

operation.

e.

If the unit has been dropped or the cabinet has been damaged.

f.

When the unit exhibits a distinct change in performance, this indicates a need for service.

REPLACEMENT PARTS

20.

When replacement parts are required, be sure the service technician uses replacement parts specified by the

manufacturer or those that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric shock or other hazards.

SAFETY CHECK

21.

Upon completion of any service or repairs to this unit, ask the service technician to perform safety checks to

determine that the unit is in proper operating condition.

WALL OR CEILING MOUNTING

22.

The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

HEAT

23.

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other

products (including amplifiers) that produce heat.

CONNECTING

24.

When you connect the product to other equipment, turn off the power and unplug all of the equipment from the

wall outlet. Failure to do so may cause an electric shock and serious personal injury. Read the owner's manual of

the other equipment carefully and follow the instructions when making any connections.

SOUND VOLUME

25.

Reduce the volume to the minimum level before you turn on the product. Otherwise, sudden high volume sound

may cause hearing or speaker damage.

SOUND DISTORTION

26.

Do not allow the product output distorted sound for a longtime. It may cause speaker overheating and fire.

HEADPHONES

27.

When you use the headphones, keep the volume at a moderate level. If you use the headphones continuously

with high volume sound, it may cause hearing damage.

LASER BEAM

28.

Do not look into the opening of the disc tray or ventilation opening of the product to see the source of the laser

beam. It may cause sight damage.

DISC

29.

Do not use a cracked, deformed, or repaired disc. These discs are easily broken and may cause serious

personal injury and product malfunction.

NOTE TO CATV SYSTEM INSTALLER

30.

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the NEC that provides

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the

grounding system of the building, as close to the point of cable entry as practical.

A1-4 23HLV84

EXAMPLE OF ANTENNA GROUNDING AS PER THE NATIONAL ELECTRICAL CODE

ANTENNA LEAD

IN WIRE

GROUND

CLAMP

ANTENNA

DISCHARGE UNIT

(NEC SECTION 810-20)

ELECTRIC SERVICE

EQUIPMENT

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

NEC-NATIONAL ELECTRICAL CODE

S2898A

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250, PART H)

A1-5 23HLV84

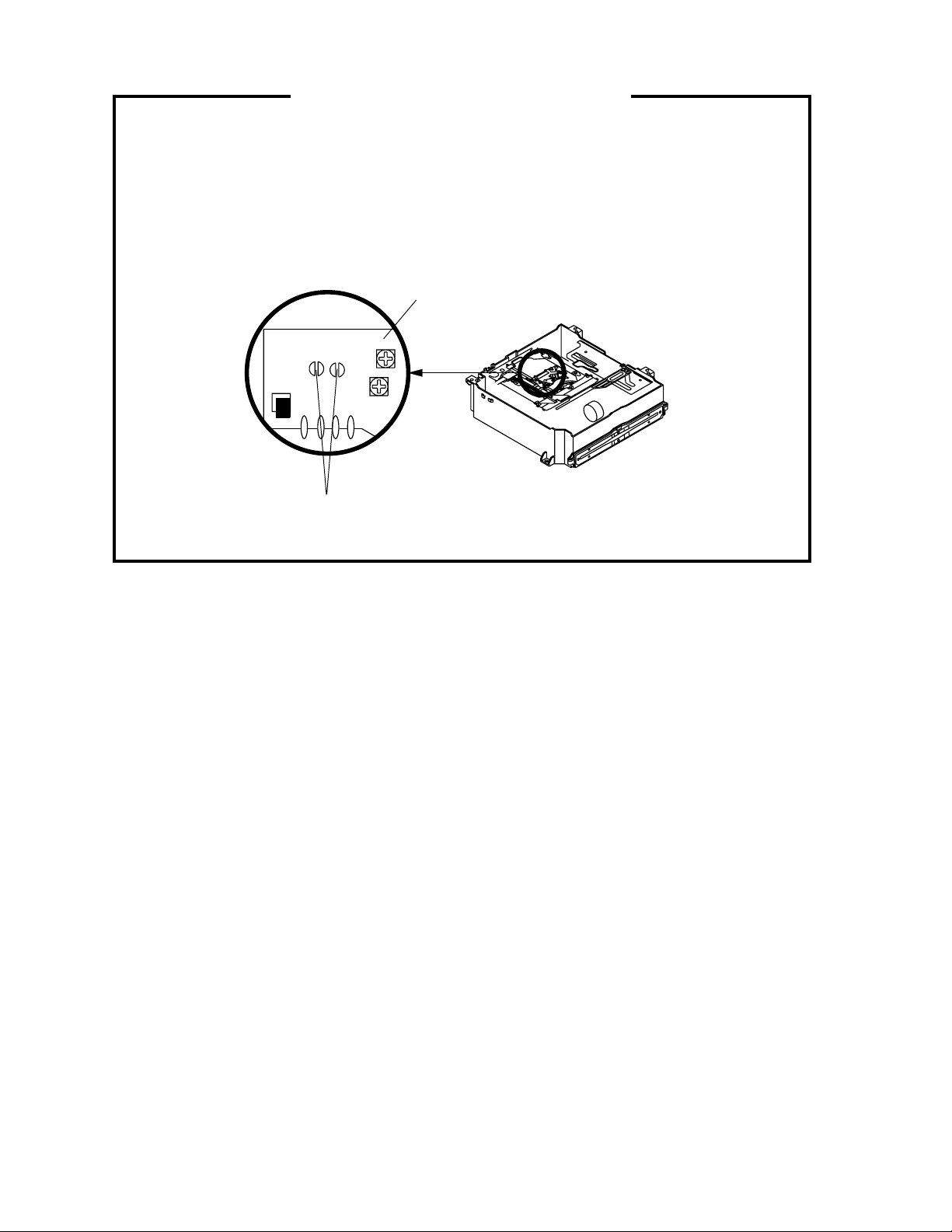

WHEN REPLACING DVD DECK

[ When the removal of the DVD Deck ]

Before removing Pick Up PCB and DVD PCB connector, make the short circuit on the position as

shown Fig. 1 using a soldering. If you remove the DVD Deck with no soldering, the Laser may be

damaged.

[ When the installation of the DVD Deck ]

Remove all the soldering on the short circuit position after the connection of Pick Up PCB and DVD

PCB connector.

Pick Up PCB

Make the short circuit

using a soldering.

Fig. 1

A1-6

23HLV84

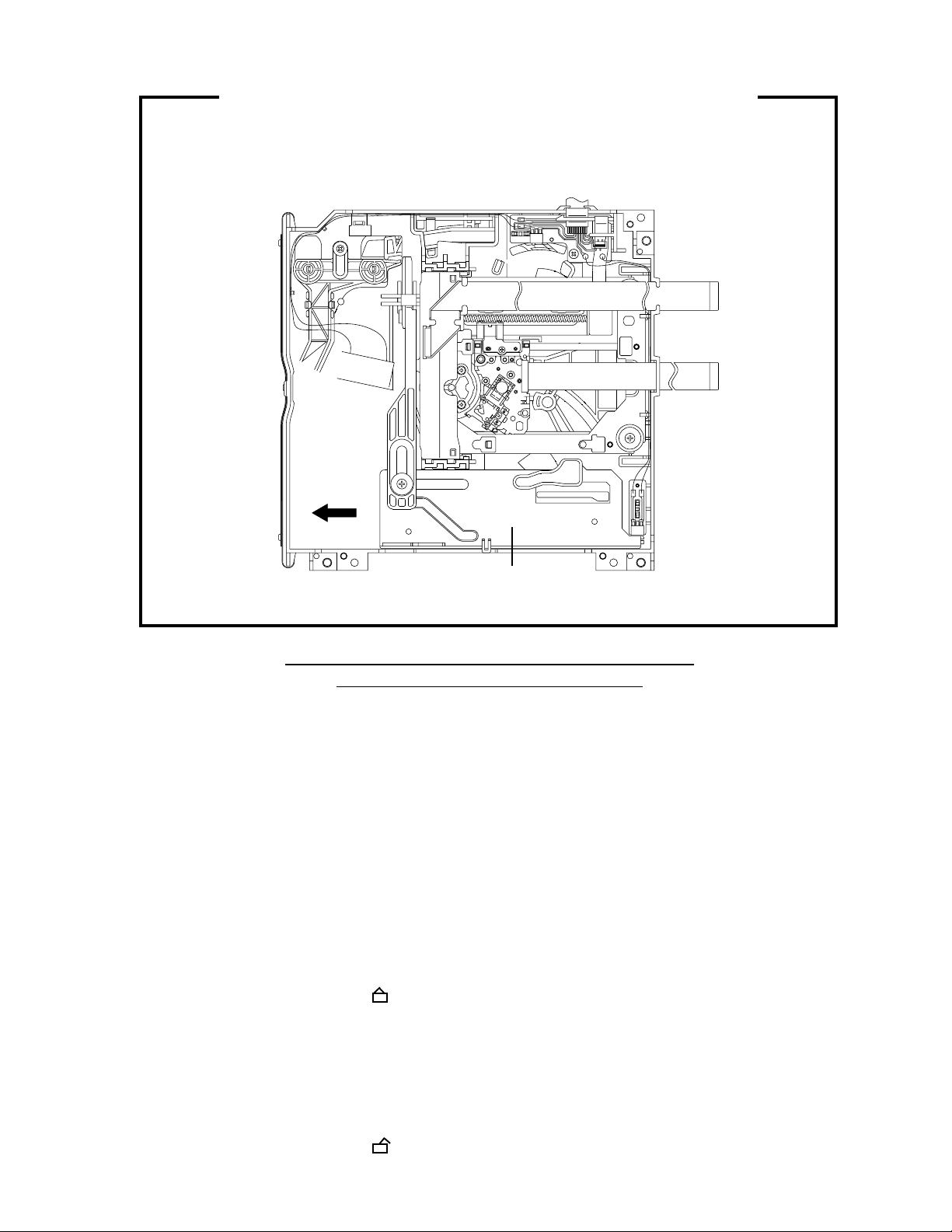

DISC REMOVAL METHOD AT NO POWER SUPPLY

1.

Remove the Back Cabinet. (Refer to item 1 of the DISASSEMBLY INSTRUCTIONS.)

2.

Slide the Rack Loading toward the arrow direction by hand to release the lock. (Refer to Fig. 1)

3.

Take out the Disc from the DVD Deck. Be careful not to scratch on the Disc.

DVD Deck

Rack Loading

Fig. 1

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps below.

Turn Unit ON.

1.

Simultaneously press and hold the 'STOP' key on the front panel.

2.

Press and hold the '7' key on the remote control unit.

3.

Hold both keys for more than 2 seconds.

4.

The On Screen Display message 'PASSWORD CLEAR' will appear.

5.

The 4 digit password has now been cleared

6.

TRAY LOCK

Tray cannot be opened by setting the Tray Lock, please follow the steps below.

Turn Unit ON.

1.

Set the DVD to the Stop Mode.

2.

Press and hold the 'STOP' key on the front panel.

3.

Simultaneously press and hold the '9' key on the remote control unit.

4.

Hold both keys for more than 2 seconds.

5.

The On Screen Display message ' ' will appear.

6.

The Tray Lock has now been set up.

7.

To unlock the Tray Lock, please follow the steps below.

Turn Unit ON.

1.

Set the DVD to the Stop Mode.

2.

Press and hold the 'STOP' key on the front panel.

3.

Simultaneously press and hold the '9' key on the remote control unit.

4.

Hold both keys for more than 2 seconds.

5.

The On Screen Display message ' ' will appear.

6.

The Tray Lock has now been cleared.

7.

A1-7

23HLV84

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

Pb free solder has a higher melting point than standard solder;

•

Typically the melting point is 50°F~70°F(30°C~40°C) higher.

Please use a soldering iron with temperature control and adjust it to 650°F ± 20°F (350°C ± 10°C).

In case of using high temperature soldering iron, please be carefull not to heat too long.

Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

•

All products with the printed circuit board with PbF printing must be serviced with lead free solder.

•

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

A1-8 23HLV84

CONTENTS

CAUTION .................................................................................................................................

PREPARATION OF SERVICING ............................................................................................

IMPORTANT SERVICE SAFETY INFORMATION .................................................................

IMPORTANT SAFEGUARDS..................................................................................................

WHEN REPLACING DVD DECK ............................................................................................

DISC REMOVAL METHOD AT NO POWER SUPPLY ..........................................................

PARENTAL CONTROL - RATING LEVEL .............................................................................

TRAY LOCK.............................................................................................................................

ABOUT LEAD FREE SOLDER (PbF).....................................................................................

CONTENTS ..............................................................................................................................

GENERAL SPECIFICATIONS ................................................................................................

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS AND P. C. BOARDS.........................................

2. REMOVAL OF DVD DECK PARTS ................................................................................

3. REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ............................................

SERVICE MODE LIST .............................................................................................................

CONFIRMATION OF HOURS USED ......................................................................................

WHEN REPLACING EEPROM (MEMORY) IC ......................................................................

ELECTRICAL ADJUSTMENTS...............................................................................................

BLOCK DIAGRAMS

DVD.......................................................................................................................................

TV .........................................................................................................................................

STEREO/SOUND AMP ........................................................................................................

MICON/SUB MICON ............................................................................................................

IN/OUT/HD/VD .....................................................................................................................

INTERFACE..........................................................................................................................

MICON2 ................................................................................................................................

SCALER1/SCALER2/LVDS/ADC/MEMORY/BUS...............................................................

PRINTED CIRCUIT BOARDS

LCD .......................................................................................................................................

DVD/OPERATION2 ..............................................................................................................

AV/REMOCON/OPERATION...............................................................................................

HD-MI/START/SW/END SW ................................................................................................

SCHEMATIC DIAGRAMS

TUNER/STEREO..................................................................................................................

SUB MICON..........................................................................................................................

SOUND AMP ........................................................................................................................

IN/OUT..................................................................................................................................

TV POWER...........................................................................................................................

OPERATION1/REMOCON...................................................................................................

DECODER ............................................................................................................................

SCALER1(1/2) ......................................................................................................................

SCALER1(2/2) ......................................................................................................................

LVDS.....................................................................................................................................

ADC.......................................................................................................................................

IN/OUT2................................................................................................................................

SCALER2..............................................................................................................................

REG/HD/VD ..........................................................................................................................

MEMORY ..............................................................................................................................

BUS TRANSCEIVER............................................................................................................

MPEG/MICON/DSP .............................................................................................................

MEMORY2............................................................................................................................

RF AMP ................................................................................................................................

AUDIO/VIDEO ......................................................................................................................

MOTOR DRIVE ....................................................................................................................

REGULATOR2......................................................................................................................

OPERATION2.......................................................................................................................

INTERFACE..........................................................................................................................

MICON2 ................................................................................................................................

START SW/END SW............................................................................................................

INTERCONNECTION DIAGRAM ............................................................................................

WAVEFORMS ..........................................................................................................................

MECHANICAL EXPLODED VIEWS........................................................................................

DVD DECK EXPLODED VIEWS .............................................................................................

MECHANICAL REPLACEMENT PARTS LIST ......................................................................

DVD DECK REPLACEMENT PARTS LIST............................................................................

ELECTRICAL REPLACEMENT PARTS LIST........................................................................

A1-1

A1-1

A1-2

A1-3~A1-5

A1-6

A1-7

A1-7

A1-7

A1-8

A2-1

A3-1~A3-8

B1-1~B1-3

B2-1~B2-3

B3-1, B3-2

C-1

C-1

C-2, C-3SD

D-1~D-3

E-1, E-2

E-3, E-4

E-5, E-6

E-7, E-8

E-9, E-10

E-11, E-12

E-13, E-14

E-15, E-16

F-1, F-2

F-3, F-4

F-5~F-8

F-9, F-10

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

G-23, G-24

G-25, G-26

G-27, G-28

G-29, G-30

G-31, G-32

G-33, G-34

G-35, G-36

G-37, G-38

G-39, G-40

G-41, G-42

G-43, G-44

G-45, G-46

G-47, G-48

G-49, G-50

G-51, G-52

G-53, G-54

H-1~H-4

I1-1~I1-3

I2-1, I2-2

J1-1~J1-4

J2-1, J2-2

J3-1~J3-16

A2-1 23HLV84

GENERAL SPECIFICATIONS

G-1 TV LCD LCD Size / Visual Size 22.95 inch / 583.0mmV

System LCD Type Color TFT LCD

Color System NTSC

Speaker 2 Speaker

Sound Output Max 5.0W + 5.0W

G-2 DVD System Color System NTSC

Disc DVD, CD-DA, CD-R/RW, Video CD

Disc Diameter 120 mm , 80 mm(with Disc Adapter)

Deck Disc Loading System Slot in Type

Pick up 1-Lens 2-Beams System

Playback time(Max) DVD 1-Layer 135min (4.7GB)

Search speed Fwd 4 step

Slow speed Fwd 1/7 -1/2 times

G-3 Tuning Broadcasting System US System M

System Tuner and System 1Tuner

Receive CH Destination US (W/CABLE)

Intermediate Picture(FP) 45.75MHz

Frequency Sound(FS) 41.25MHz

Preset CH No

Stereo/Dual TV Sound US-Stereo

Tuner Sound Muting Yes

G-4 Signal Video Signal Input Level 1 V p-p/75 ohm

RGB Signal Output Level -Audio Signal Input Level -8.0dBm/50k ohm

G-5 Power Power Source AC 120V, 60Hz

Power Consumption at AC 110W at 120V 60Hz

Protector Power Fuse Yes

Number of Pixels 1366(H) x 768(V)

View Range Left/Right 88/88 degree

Up/Down 88/88 degree

Position Front

Size 1.8 x 3.9 inch

Impedance 16 ohm

10%(Typical) ---

DVD-R/RW (Video Format Only)

Motor 3 Motors

DVD 2-Layer 245min (8.5GB)

CD 74min

Video CD 74min

Actual 2-45 times (DVD, VIDEO CD)

4-40 times (CD)

Rev 4 step

Actual 2-45 times (DVD, VIDEO CD)

4-40 times (CD)

Actual --

Rev 1/7 -1/2 times

Actual --

Tuning System F-Synth

Input Impedance VHF/UHF 75 Ohm

CH Coverage 2~69, 4A, A-5~A-1, A~I, J~W, W+1~W+84

FP-FS 4.50MHz

Output Level -S/N Ratio (Weighted) -Horizontal Resolution at DVD Mode --

--

Output Level at DVD -12.0dBm/1k ohm (-20dBFs 0dBFs=2.0Vrms)

at TV -8 dBm/1k ohm (0dBm=0.775Vrms)

0-600mV /1k ohm (Variable out mode)

Digital Output Level 0.5 V p-p/75 ohm

S/N Ratio at DVD (Weighted) 90dB

Harmonic Distortion 0.02% (1KHz)

Frequency Response : at DVD 4Hz - 22kHz

at Video CD 4Hz - 20kHz

at SVCD 4Hz - 20kHz

at CD 4Hz - 20kHz

DC --

at DC -Stand by (at AC) 1W at 120V 60Hz

Per Year -- kWh/Year

Safety Circuit Yes

IC Protector(Micro Fuse) No

A3-1 23HLV84

GENERAL SPECIFICATIONS

G-6 Regulation Safety UL / CSA

G-7 Temperature Operation +5oC ~ +40oC

G-8 Operating Humidity Less than 80% RH

G-9 On Screen Menu (TV) Yes

Display Menu Type Icon

Picture Yes

Audio Yes

Setup Yes

Option

Locks

PC Monitor Menu Yes

Brightness Yes

Contrast Yes

Hor Position Yes

Ver Position Yes

Phase Yes

Clock Yes

Auto Adjust Yes

Reset Yes

Color Temperature Menu Yes

Radiation FCC / IC

Laser DHHS

Storage -20oC ~ +60oC

Mode(Picture preference) Yes

Brightness Yes

Contrast Yes

Color Yes

Tint Yes

Sharpness Yes

Color Temperature Yes

Cable Clear No

Reset Yes

MTS Yes

Bass Yes

Treble Yes

Balance Yes

Stable Sound Yes

Speakers On/Off Yes

Dolby Virtual Yes

WOW SRS 3D Yes

WOW Focus Yes

WOW Tru Bass Yes

HDMI Yes

Reset Yes

Language Yes

Clock Set Yes

TV/CABLE Yes

CH Program Yes

Add/ Erase Yes

Closed Caption Yes

Picture Size Yes

Picture Scroll Yes

Cinema Mode Yes

Aspect Yes

Back Lighting Yes

Yes

On Timer Yes

Favorite CH No

CH Label Yes

VIDEO Label Yes

Yes

V-Chip Yes

Lock Yes

New Password Yes

Panel Lock Yes

Red Yes

Green Yes

Blue Yes

Reset Yes

A3-2 23HLV84

GENERAL SPECIFICATIONS

Control Level Yes

Stereo, SAP, Mono Yes

CH / AV(Line) / DVD / PC Yes

Color Stream HD (Component) Yes

HDMI Yes

Channel (TV/Cable) Yes

CH Label Yes

Video Label Yes

Clock Yes

Game Timer Yes

Front Panel Lock Yes

On Timer Yes

Sleep Timer Yes

Reset Yes

Sound Mute Yes

V-chip Rating Yes

NOT AVAILABLE Yes

Picture Size Yes

Volume Yes

Brightness Yes

Contrast Yes

Color Yes

Tint Yes

Sharpness Yes

Bass Yes

Treble Yes

Balance Yes

Picture Scroll Yes

Back Lighting Yes

H Position Yes

V Position Yes

Red Yes

Green Yes

Blue Yes

A3-3 23HLV84

GENERAL SPECIFICATIONS

G-10 On Screen Menu (DVD) Yes

Display Menu Type Character

G-11 OSD Language (TV) English, French, Spanish

(DVD) English, French, Spanish

G-12 Clock and Sleep Timer Max Time 120 Min

Timer Step

On Timer Program Yes

Wake Up Timer No

Timer Back-up (at Power Off Mode) more than -- Min Sec

Language Yes

Menu Yes

Subtitle Yes

Audio Yes

Picture Yes

TV Screen Size(4:3, 16:9) Yes

OSD Display On/Off Yes

JPEG Interval Yes

Select Files Yes

Sound Yes

DRC (Dynamic Range Control) Yes

dts Decode No

Output(5.1ch/ 2ch) No

Surround On/Off No

Center On/Off No

Sub Woofer On/Off No

Parental Yes

Password Lock/ Un Lock Yes

Rating Level Yes

Other Yes

OSD Language(Set up Language) Yes

Output(RGB/Composite) No

Eject Yes

No disc Yes

Reading Yes

Play Yes

Still/Pause Yes

Stop Yes

Prohibit Mark Yes

Step Yes

Skip(>>|) Yes

Skip(|<<) Yes

Random Yes (CD, VIDEO CD, MP3, WMA, JPEG )

Repeat Yes

Slow+ Yes

Slow- Yes

Search+ Yes

Search- Yes

Jump Yes

Resume Yes

Title No. Yes

Chapter No. Yes

Track No. Yes

Time Yes

Subtitle No. Yes

Angle No. Yes

Vocal On/Off Yes

Audio No. Yes

Audio Stereo L/R Yes (Video CD)

Zoom Yes

Marker No. No

Program Play Back Yes (CD, VIDEO CD, MP3, WMA, JPEG )

Surround On/Off No

Screen Saver No

MP3/WMA/JPEG Folder Name Yes

File Name Yes

File No Yes

Time Yes (MP3, WMA Only)

Track No Yes

10 Min

A3-4 23HLV84

GENERAL SPECIFICATIONS

G-13 Remote Unit RC-JX

Control Glow in Dark Remocon Yes

Format TOSHIBA / NEC

Custom Code 40-BF / 71-8E h

Power Source Voltage(D.C) 3V

Total Keys 50 Keys

Keys

UM size x pcs UM-4 x 2 pcs

Power

TV(DVD)

VCR

CABLE

1

2

3

TV/DVD

4

5

6

100

7

8

9

0

UP / CH +

LEFT / VOLENTER

RIGHT / VOL+

DOWN / CH EXIT / CANCEL

INPUT

PIC SIZE

MUTE

DISPLAY / RECALL

SLEEP

TV MENU/SETUP

CODE

SUBTITLE

AUDIO SELECT

DVD MENU

TOP MENU

PLAY MODE

RETURN

REPEAT A-B

ANGLE

JUMP

ZOOM/QUICK VIEW

<SKIP

SKIP>

<<REW / SEARCH

PLAY

FF / SEARCH>>

TV/VCR

STOP

PAUSE/STEP

REC

< SLOW

SLOW >

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

A3-5 23HLV84

GENERAL SPECIFICATIONS

G-14 Features Auto Shut Off Yes

(TV) Auto Search No

Comb Filter Yes

3 -D

Energy Star Yes

Game Position No

Power On Memory Yes

Variable Audio Out Yes

Mode (Picture Preference) Yes

Color Temparature Control Yes

Cable Clear No

SAP Yes

Stable Sound Yes

Virtual Dolby Yes

SRS WOW(SRS 3D/Focus/Tru Bass) Yes

CABLE Yes

CH Program (Auto CH Memory) Yes

Closed Caption Yes

Picture Size Yes

Picture Scroll Yes

Cinema Mode Yes

Aspect Yes

On Timer Yes

Sleep Timer Yes

Favorite CH No

CH Label Yes

VIDEO Label Yes

V-Chip Yes

Type USA Type

CH Lock Yes

Video Lock Yes

Game Timer(Max Time:120Min) Yes

Panel Lock Yes

Direct Input Selection Yes

PC Monitor Input Yes

Available Scan Rates (Component/HDMI) 480i/480p/720p/1080i

Auto Setup(Language/CH Program) Yes

Freeze frame No

Features Parental Lock (DVD Only) Yes

(DVD) Tray Lock Yes

Video CD Playback Yes

SVCD Playback

Overlay Graphics And Text No

Command List No

Entry Point Jump No

MP3 Playback Yes

JPEG Yes

WMA Yes

Digital Out (Dolby Digital) Yes

(MPEG) Yes

(PCM) Yes

(DTS) Yes

Down Mix Out (Dolby Digital) Yes

(DTS) No

Screen Saver No

Audio DAC 192kHz / 24bit

No

A3-6 23HLV84

GENERAL SPECIFICATIONS

G-15 Accessories Owner's Manual Language English / French

Remote Control Unit Yes

Rod Antenna

Loop Antenna

U/V Mixer

DC Car Cord (Center+)

Guarantee Card

Warning Sheet

Circuit Diagram

Antenna Change Plug

Service Facility List

Important Safeguard

Dew/AHC Caution Sheet

Quick Set-up Sheet

Battery Yes

AC Adapter

AC Cord (for AC Adapter)

AV Cord (2Pin-1Pin)

Registration Card (NDL Card)

300,75ohm to 75ohm Antenna Adapter Yes

Sheet Information (Return) No

Sheet Information (HDMI) Yes

G-16 Interface Switch Top Power (Tact) Yes

Rear Main Power SW No

Indicator Power Yes (Red)

Terminals Rear Video Input 1 RCA x 1

Side Video Input 2 RCA x 1

G-17 Set Size Approx. W x D x H (mm) 610 x 276 x 484

G-18 Weight Net (Approx.) 11.5kg (25.4 lbs)

w/Guarantee Card Yes

Poles -Terminal --

Terminal --

UM size x pcs UM-4 x 2 pcs

OEM Brand No

Channel Up/Menu Up Yes

Channel Down/Menu Down Yes

Volume Up/Menu > Yes

Volume Down/Menu < Yes

Menu Yes

Play Yes

Eject Yes

Skip+, Search+ Yes

Skip-, Search- Yes

Still/Pause No

Stop Yes

Main Power SW No

Input Select Yes

Stand-by No

On Timer No

Audio Input 1 RCA x 2(Stereo)

S - Input 1

Video Output No

Audio Output

Component Input(w/ Analog Audio L/R)

HDMI Input(w/ Analog Audio L/R)

PC Monitor Input(w/ Analog Audio L/R)

Digital Audio Output Coaxial (DVD Only)

DC Jack (Center +) No

VHF/UHF Antenna Input

AC Outlet No

Audio Input 2 RCA x 2(Stereo)

Other Terminal Headphone

w/o Handle, Stand Approx. W x D x H (mm)

Net w/o Handle, Stand (Approx.) 10.5kg (23.2 lbs)

Gross (Approx.) 14.5kg (32.0 lbs)

Yes

RCA x 2 (Variable)

RCA x 5

HDMI x 1(RCA x 2)

Dsub15pin x 1(RCA x 2)

F Type

610 x 115.5 x 438.5

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

A3-7 23HLV84

GENERAL SPECIFICATIONS

G-19 Carton Master Carton No

Gift Box Yes

Drop Test 1 Corner / 3 Edges / 6 Surfaces

Container Stuffing (40' container) 394

G-20 Material Cabinet Front PS 94V0 DECABROM

PCB Non-Halogen Demand No

G-21 Environment Pb Free Lead-free Solder Yes

Cd Free No

Content --- Sets

Material --- / --Dimensions W x D x H(mm) --Description of Origin ---

Material Double/Brown

W/Color Photo Label No

W/Handle No

Dimensions W x D x H(mm) 720 x 383 x 590

Design As Per Buyer 's

Description of Origin Yes

Height (cm) 62

Sets

Rear PS 94V0 DECABROM

Jack Panel --

Eyelet Demand Yes

Other No

A3-8 23HLV84

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

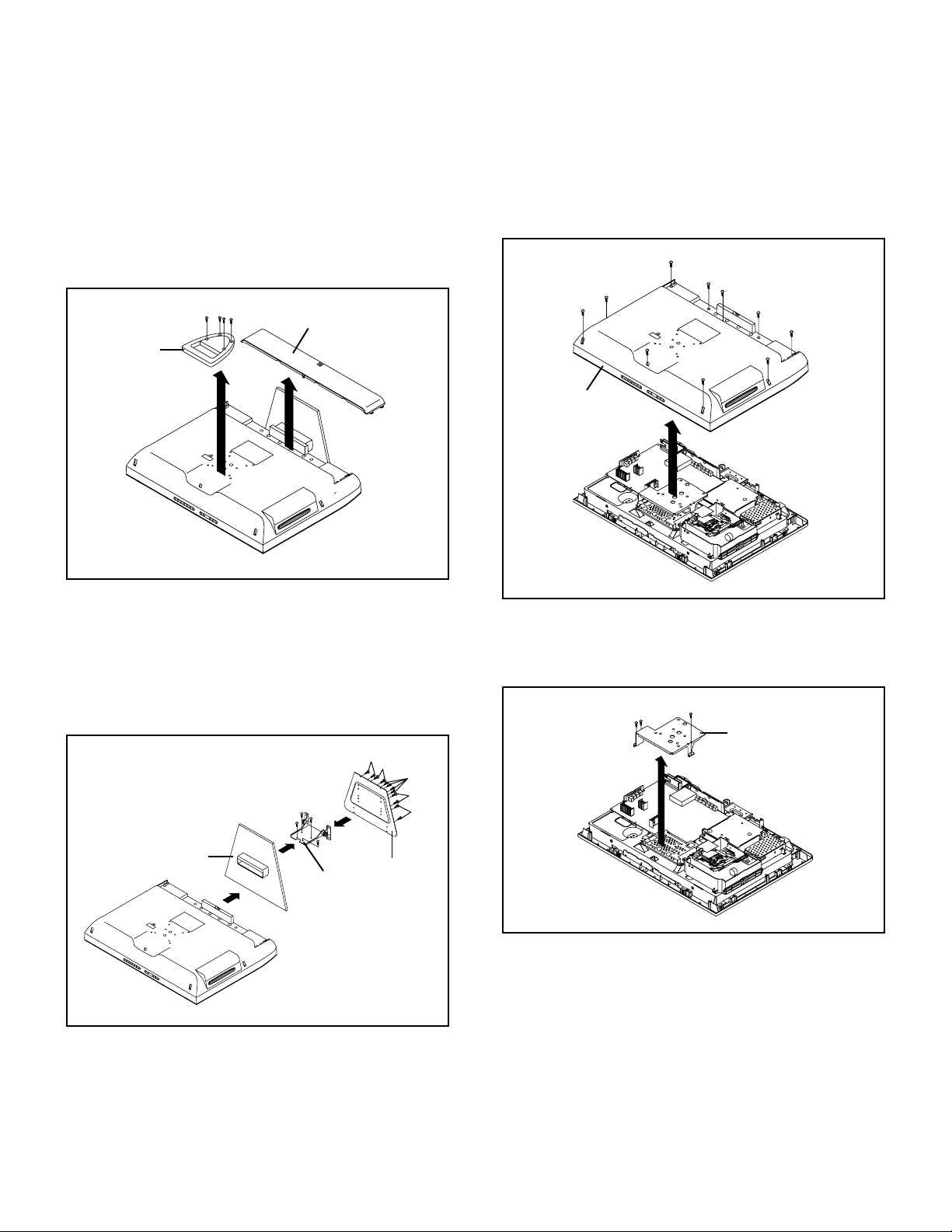

1-1: HANDLE/BACK COVER ASS'Y (Refer to Fig. 1-1)

1.

Remove the 4 screws 1.

2.

Remove the Handle in the direction of arrow (A).

3.

Unlock the 6 supports 2.

4.

Remove the Back Cover Ass'y in the direction of arrow (B).

1

1

1

1

2

Handle

2

(A)

1-2: HINGE ASS'Y (Refer to Fig. 1-2)

1.

Remove the 4 screws 1.

2.

Remove the Stand in the direction of arrow (A).

3.

Remove the 8 screws 2.

4.

Remove the Stand Angle in the direction of arrow (B).

5.

Remove the 4 screws 3.

6.

Remove the Hinge Ass'y in the direction of arrow (C).

Stand

Back Cover Ass'y

2

2

(B)

1

1

1

1

(B)

Hinge Ass'y

(C)

2

2

Fig. 1-1

2

3

Stand Angle

1-3: BACK CABINET (Refer to Fig. 1-3)

1.

Remove the 8 screws 1.

2.

Remove the screw 2.

3.

Remove the screw 3.

4.

Remove the Back Cabinet in the direction of arrow.

1

1

1

1

2

Back Cabinet

3

1

1

1

1

Fig. 1-3

1-4: HANDLE ANGLE (Refer to Fig. 1-4)

1.2.Remove the 3 screws 1.

Remove the Handle Angle in the direction of arrow.

1

1

2

3

2

1

Handle Angle

(A)

Fig. 1-4

Fig. 1-2

B1-1 23HLV84

DISASSEMBLY INSTRUCTIONS

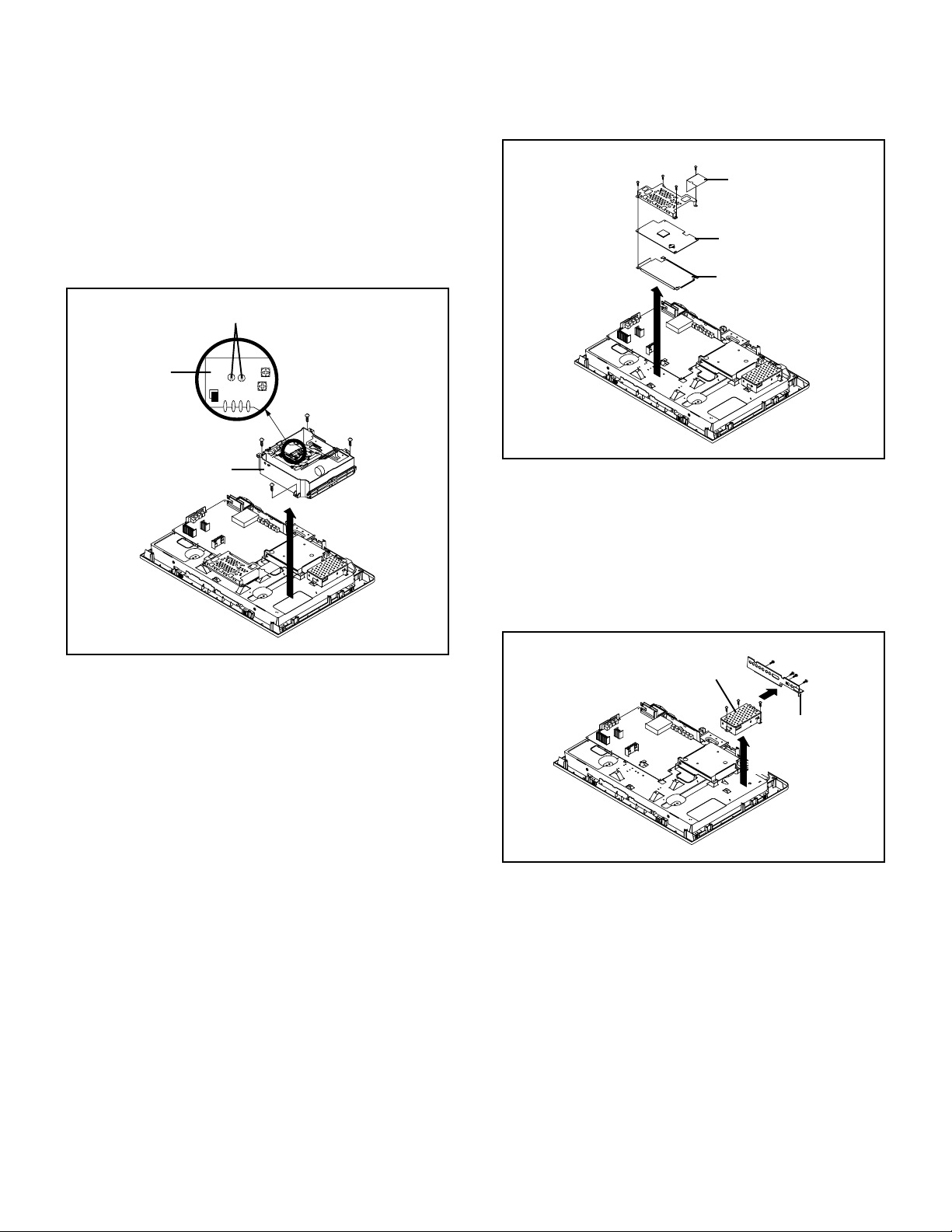

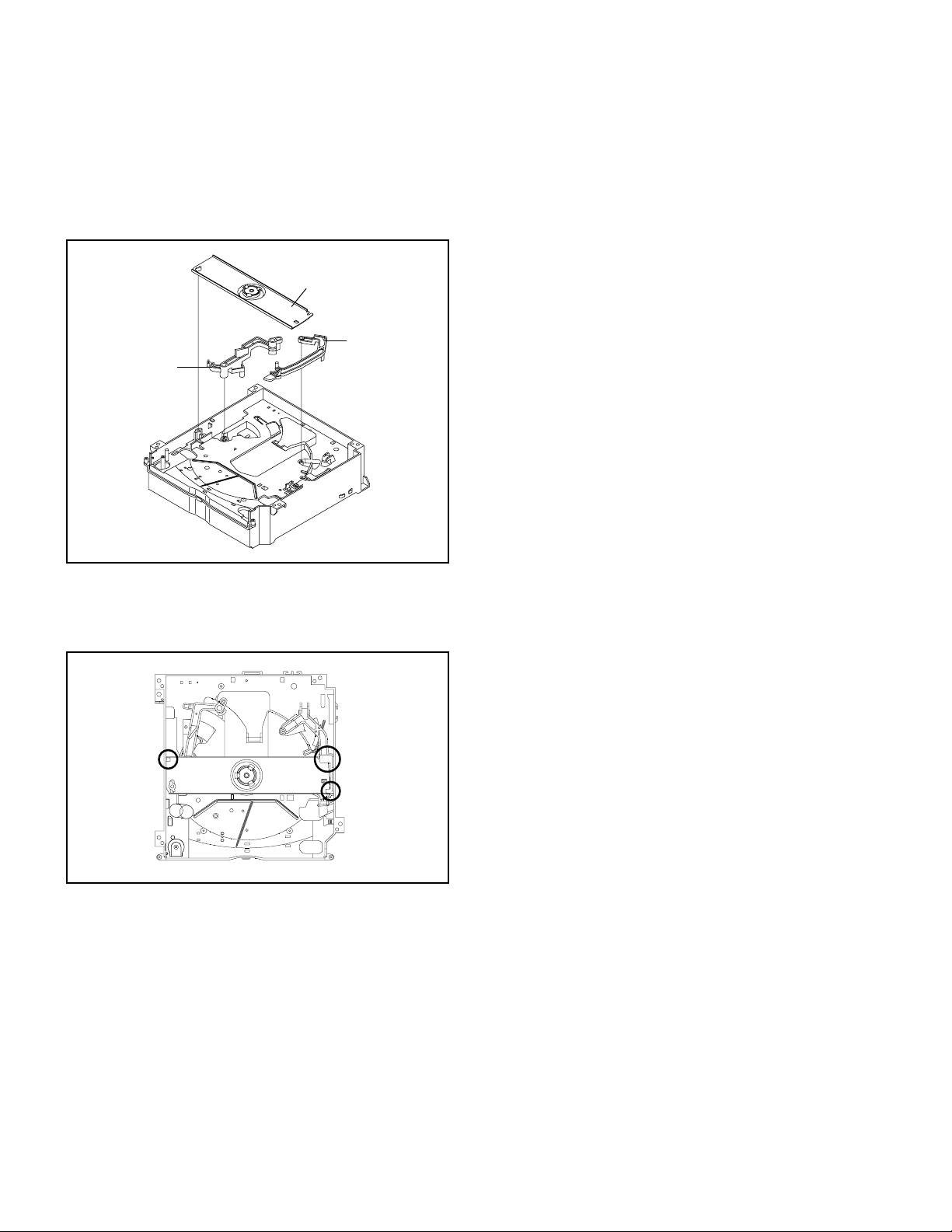

1-5: DVD DECK (Refer to Fig. 1-5)

1.

Make the short circuit on the position as shown Fig. 1-5

using a soldering. If you remove the DVD Deck with no

soldering, the Laser may be damaged.

2.

Disconnect the following connectors:

(CP2301, CP2302 and CP2601).

3.

Remove the 4 screws 1.

4.

Remove the DVD Deck in the direction of arrow.

Make the short circuit

using a soldering.

Pick Up PCB

1

1

DVD Deck

1

1

1

2

2

2

Shield FFC

DVD PCB

Shield DVD

1-7: HD-MI PCB (Refer to Fig. 1-7)

1.

Disconnect the following connector:

(CP803).

2.

Remove the screw 1.

3.

Remove the 3 screws 2.

4.

Remove the Jack Plate 2 in the direction of arrow (A).

5.

Remove the 3 screws 3.

6.

Remove the HD-MI PCB in the direction of arrow (B).

Fig. 1-6

Fig. 1-5

NOTE

Use the Pb Free solder and the exclusive soldering iron.

1.

Manual soldering conditions

2.

• Soldering temperature: 320 ± 20˚C

• Soldering time: Within 3 seconds

• Soldering combination: 45/55 Sn/Pb

When Soldering/Removing of solder, use the drawing

3.

equipment over the Pick Up Unit to prevent the Flux

smoke from it.

When the installation of the DVD Deck, remove all the

4.

soldering on the short circuit position after the connection

of Pick Up PCB and DVD PCB connector.

1-6: DVD PCB (Refer to Fig. 1-6)

1.

Disconnect the following connectors:

(CP501 and CP752).

2.

Remove the screw 1.

3.

Remove the Shield FFC.

4.

Remove the 3 screws 2.

5.

Remove the DVD PCB and Shield DVD in the direction of

arrow.

2

2

HD-MI PCB

3

3

(A)

(B)

3

Jack Plate 2

2

1

Fig. 1-7

1-8: LCD PCB (Refer to Fig. 1-8)

1.

Disconnect the following connectors:

(CP107, CP3200, CP4201 and CP4202).

2.

Remove the 5 screws 1.

3.

Remove the Shield LCD and LCD PCB in the direction of

arrow.

B1-2 23HLV84

DISASSEMBLY INSTRUCTIONS

1

1

1

1

1

Shield LCD

LCD PCB

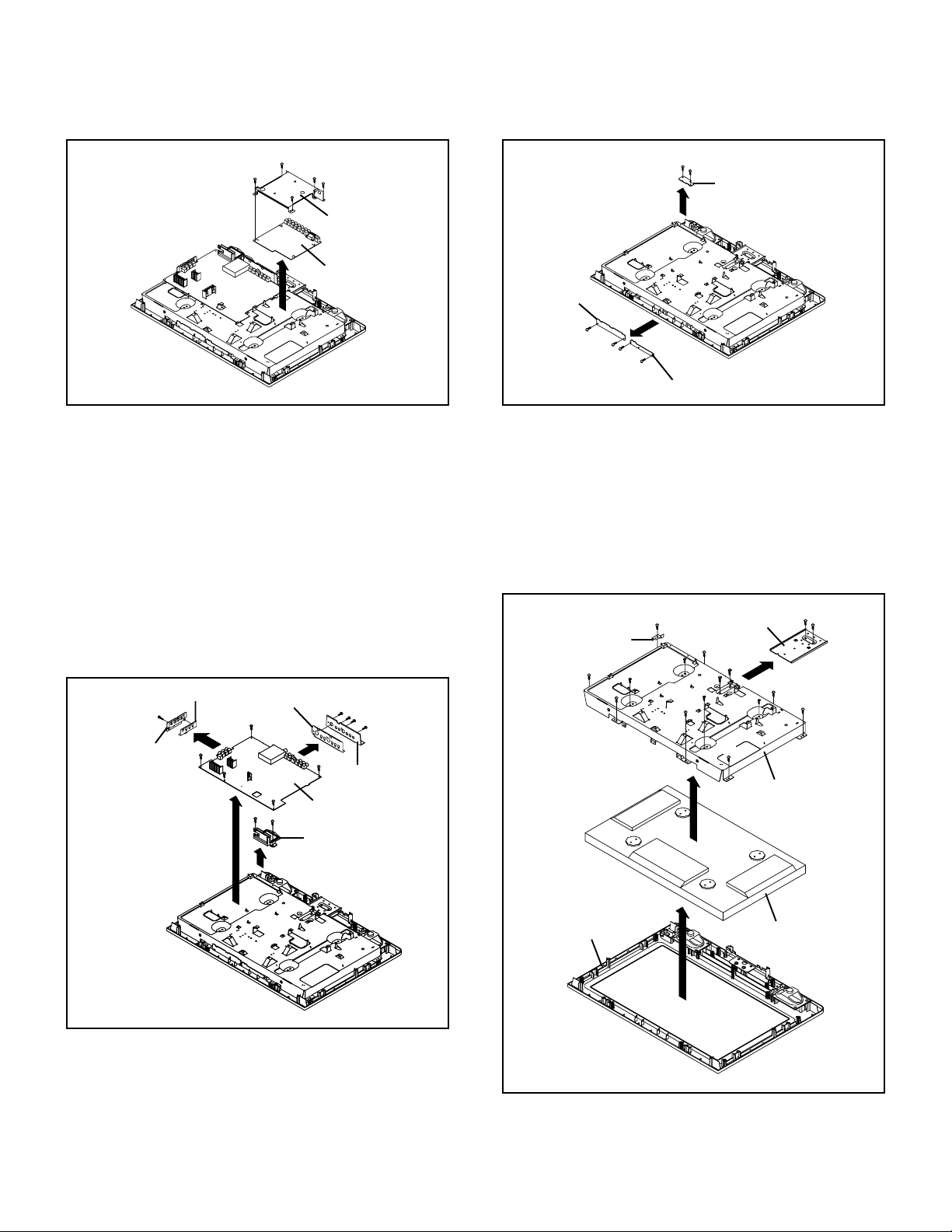

1-9: AV PCB (Refer to Fig. 1-9)

1.

Disconnect the following connectors:

(CP101, CP104 CP301, CP3801 and CP3802).

2.

Remove the 2 screws 1.

3.

Remove the AC Cord Holder in the direction of arrow (A).

4.

Remove the screw 2.

5.

Remove the 3 screws 3.

6.

Remove the Jack Plate 1 and Jack Shield 1 in the

direction of arrow (B).

7.

Remove the screw 4.

8.

Remove the Side Jack Plate and Side Jack Shield in the

direction of arrow (C).

9.

Remove the 5 screws 5.

10.

Remove the AV PCB in the direction of arrow (D).

4

Side Jack Plate

Side Jack Shield

5

(C)

(D)

5

Jack Shield 1

5

5

1

1

(A)

(B)

5

AV PCB

AC Cord Holder

2

3

3

Jack Plate 1

3

Fig. 1-8

2

2

Remocon PCB

(B)

Operation PCB

(A)

1

1

1

1

Operation 2 PCB

Fig. 1-10

1-11: LCD COVER/LCD PANEL (Refer to Fig. 1-11)

1.

Remove the 2 screws 1.

2.

Remove the 2 screws 2.

3.

Remove the Angle Hinge in the direction of arrow (A).

4.

Remove the 4 screws 3.

5.

Remove the 8 screws 4.

6.

Remove the Shield Remocon and LCD Cover in the

direction of arrow (B).

7.

Remove the LCD Panel in the direction of arrow (C).

1

4

4

LCD Cover

1

Shield Remocon

4

4

4

3

3

4

Angle Hinge

4

2

(A)

2

3

3

4

(B)

1-10:

OPERATION PCB/OPERATION 2 PCB/REMOCON

PCB (Refer to Fig. 1-10)

1.

Remove the 4 screws 1.

2.

Remove the Operation PCB and Operation 2 PCB in the

direction of arrow (A).

3.

Remove the 2 screws 2.

4.

Remove the Remocon PCB in the direction of arrow (B).

Fig. 1-9

Front Cabinet

(C)

LCD Panel

Fig. 1-11

B1-3 23HLV84

DISASSEMBLY INSTRUCTIONS

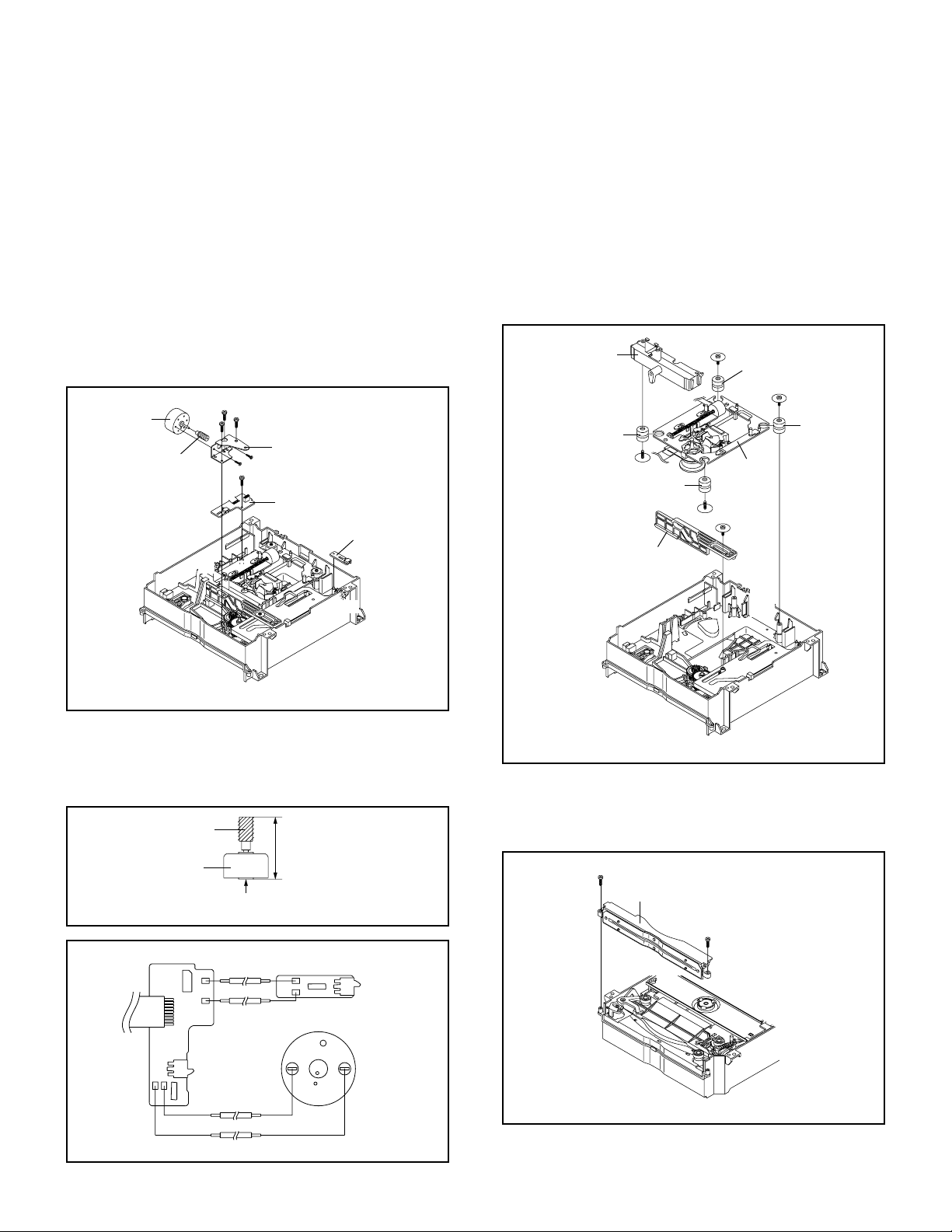

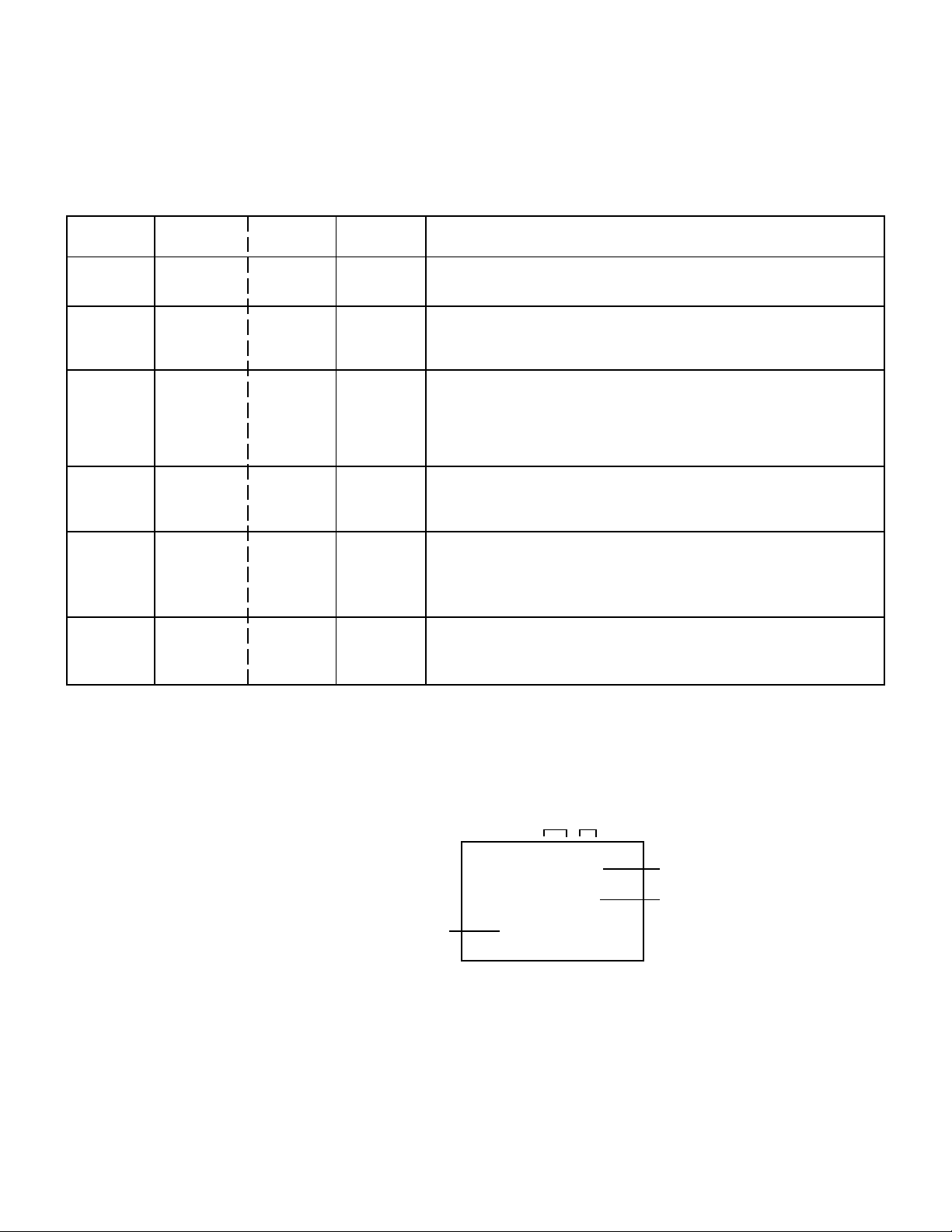

2. REMOVAL OF DVD DECK PARTS

2-1:

LOADING MOTOR ASS'Y/START SW PCB ASS'Y/

END SW PCB ASS'Y (Refer to Fig. 2-1-A)

Remove the 3 screws 1.

1.

Remove the Loading Motor Ass'y.

2.

Remove the 2 screws 2.

3.

Remove the Motor and Loading Worm.

4.

Disconnect the following connector: (CP2).

5.

Remove the screw 3.

6.

Unlock the 2 supports 4 and remove the Start SW PCB

7.

Ass'y.

Unlock the 2 supports 5 and remove the End SW PCB

8.

Ass'y.

1

1

Motor

Loading Worm

1

Loading Motor Bracket

2

2

3

Start SW PCB Ass'y

End SW PCB Ass'y

4

4

2-2:

TRAVERSE UNIT ROD/TRAVERSE UNIT HOLDER/

CD DECK/INSULATOR (Refer to Fig. 2-2)

Remove the screw 1.

1.

Remove the Traverse Unit Rod.

2.

Remove the 2 screws 3.

3.

Unlock the 2 supports 4 and remove the CD Deck Block.

4.

Remove the 2 screws 5.

5.

Unlock the 2 supports 6 and remove the Traverse Unit

6.

Holder.

Remove the 4 Insulators.

7.

Traverse Unit Holder

5

Insulator

4

Insulator

Traverse Unit Rod

2

Insulator

5

4

2

Insulator

CD Deck

1

5

5

• Screw Torque: 1 ± 0.2kgf•cm

Fig. 2-1-A

NOTE

In case of the Loading Worm installation, check if the

1.

value of the Fig. 2-1-B is correct.

When installing the wire, install it correctly as Fig. 2-1-B.

2.

Loading Worm

29.7 ± 0.1mm

Motor

Safety surface for pressing

of the insert.

Start SW PCB Ass'y

Red

Black

End SW PCB Ass'y

Motor

Fig. 2-1-B

• Screw Torque: 3 ± 0.5kgf•cm

2-3: MOUTH ASS'Y (Refer to Fig. 2-3)

Remove the 2 screws 1.

1.

Remove the Mouth Ass'y.

2.

1

Mouth Ass'y

1

3

3

Fig. 2-2

Black

Red

Fig. 2-1-C

• Screw Torque: 0.8 ± 0.2kgf•cm

Fig. 2-3

B2-1 23HLV84

DISASSEMBLY INSTRUCTIONS

DISC L LEVER/DISC STOPPER/LOCKER STOPPER/

ROLLER GEAR (Refer to Fig. 2-4-A)

Remove the screw 1.

1.

Remove the Disc L Lever and Disc L Lever Spring.

2.

Remove the Stopper Spring.

3.

Unlock the support 2 and remove the Locker Stopper.

4.

Unlock the support 3 and remove the Disc Stopper.

5.

Remove the Upper Roller, Roller Rubber and Roller Gear.

6.

1

Disc L Lever

Disc L Lever Spring

Upper Roller

Roller Rubber

Roller Gear

• Screw Torque: 1.1 ± 0.2kgf•cm

Disc Stopper

Stopper Spring

Locker Stopper

2

3

Fig. 2-4-A

NOTE

1.In case of the Upper Roller installation, install correctly as

Fig. 2-4-B.

[OK] [NG]

Upper Roller

Roller Gear Roller Gear

Upper Roller

Fig. 2-4-B

2-6:2-4:

LINK R ASS'Y/LINK L/LINK MID/LINK SPRING

(Refer to Fig. 2-6)

Remove the screw 1.

1.

Remove the Link Spring.

2.

Unlock the support 2 and remove the Link L.

3.

Unlock the support 3 and remove the Link Mid.

4.

Remove the screw 4.

5.

Unlock the 4 supports 5 and remove the Link R Ass'y.

6.

Link Spring

4

Link R Ass'y

5

5

5

• Screw Torque: 0.7 ± 0.1kgf•cm (Screw 1)

• Screw Torque: 1.5 ± 0.2kgf•cm (Screw 4)

1

2

5

3

Link L

Link Mid

Fig. 2-6

2-7: ARM ROLLER ASS'Y/MID ROLLER 1/2 GEAR/

TERMINAL GEAR (Refer to Fig. 2-7)

Remove the screw 1.

1.

Remove the Arm Roller Ass'y.

2.

Remove the Terminal Gear and Mid Roller Gear 1.

3.

Unlock the support 2 and remove the Mid Roller Gear 2.

4.

1

Arm Roller Ass'y

Terminal Gear

Mid Roller Gear 1

Mid Roller Gear 2

RACK LOADING/RACK GEAR/GUIDE ARM

2-5:

SPRING/MID RACK GEAR (Refer to Fig. 2-5)

Remove the Guide Arm Spring.

1.

Unlock the 3 supports 1 and remove the Rack Loading.

2.

Remove the Rack Gear and Mid Rack Gear.

3.

Rack Loading

1

Guide Arm Spring

1

1

Rack Gear

Mid Rack Gear

Fig. 2-5

2

• Screw Torque: 1.5 ± 0.2kgf•cm

Fig. 2-7

B2-2 23HLV84

DISASSEMBLY INSTRUCTIONS

2-8: CLAMPER ASS'Y/DISC GUIDE ARM/DISC R

LEVER (Refer to Fig. 2-8-A)

Unlock the support 1 and remove the Clamper Ass'y.

1.

Unlock the support 2 and remove the Disc Guide Arm.

2.

Unlock the support 3 and remove the Disc R Lever.

3.

Clamper Ass'y

Disc R Lever

Disc Guide Arm

2

3

1

Fig. 2-8-A

NOTE

1. When installing the Clamper Ass'y, check if the Clamper

Ass'y is locked correctly as Fig. 2-8-B.

Fig. 2-8-B

B2-3 23HLV84

DISASSEMBLY INSTRUCTIONS

3. REMOVAL AND INSTALLATION OF FLAT

PACKAGE IC

REMOVAL

1. Put the Masking Tape (cotton tape) around the Flat

Package IC to protect other parts from any damage.

(Refer to Fig. 3-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

Masking Tape

(Cotton Tape)

2. Heat the IC leads using a blower type IC desoldering

machine. (Refer to Fig. 3-2.)

NOTE

Do not add the rotating and the back and forth directions force on the IC, until IC can move back and forth

easily after desoldering the IC leads completely.

IC

Fig. 3-1

Blower type IC

desoldering machine

3. When IC starts moving back and forth easily after

desoldering completely, pickup the corner of the IC using

a tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 3-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering machine

Tweezers

IC

4.5.Peel off the Masking Tape.

Absorb the solder left on the pattern using the Braided

Shield Wire. (Refer to Fig. 3-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 3-3

Braided Shield Wire

Soldering Iron

IC

Fig. 3-2

IC pattern

Fig. 3-4

B3-1 23HLV84

DISASSEMBLY INSTRUCTIONS

INSTALLATION

1. Take care of the polarity of new IC and then install the

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 3-5.)

Soldering Iron

Solder temporarily

Solder temporarily

Fig. 3-5

2. Supply the solder from the upper position of IC leads

sliding to the lower position of the IC leads.

(Refer to Fig. 3-6.)

4. When bridge-soldering between terminals and/or the

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 3-8.)

IC

Thin-tip Soldering Iron

Fig. 3-8

5. Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, be always sure to replace the IC in this

case.

Solder

IC

Supply soldering

from upper position

to lower position

Soldering Iron

Fig. 3-6

3. Absorb the solder left on the lead using the Braided

Shield Wire. (Refer to Fig. 3-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 3-7

B3-2 23HLV84

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit and on the remote control

for more than a standard time (second).

Set

Condition

TV mode

TV mode

TV mode

ALL mode

DVD mode

(No disc)

DVD mode

(Stop)

Set Key Operations

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

STOP 7 2 sec.

STOP 9 2 sec.

Remocon

Key

0 2 sec.

1 2 sec.

6 2 sec.

9 2 sec.

Standard

Time

Releasing of V-CHIP PASSWORD.

Initialization of the factory on.

NOTE:

POWER ON total hours are displayed on the screen.

Refer to the "CONFIRMATION OF HOURS USED"

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display

Adjustment).

Releasing of PARENTAL LOCK.

Refer to the “PARENTAL CONTROL - RATING LEVEL”.

NOTE:

Tray cannot be opened.

Refer to the “TRAY LOCK”.

NOTE: No indications on the screen when the Tray Lock is setting.

If you set a factory initialization, the memories are reset such

as the channel setting, and the POWER ON total hours.

The function will only work without the setting of DVD disc at

DVD mode.

CONFIRMATION OF HOURS USED

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

NOTE: If you set a factory initialization, the total hours is reset to "0".

1.

Turn on the POWER, and set to the TV mode.

2.

Set the VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel

button (6) on the remote control for more than 2 seconds.

4.

After the confirmation of using hours, turn off the power.

MICON Version

C-1 23HLV84

ADDRESS DATA

INIT 000 C5

LCD ON 0010

OEC7114B_001

FIG. 1

Initial setting content of MEMORY IC.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

WHEN REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1 and 2.

Main Micon side EEPROM (IC199) initial setting

ADDRESS DATA

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9

+A

+B +C +D +E +FINI

*1

INI

000

INIT 000 C5

LCD ON 0010

OEC7114B_001

FIG. 1

USA CANADA

C5 45

*1 A2 01 80 A3 10 86 6C C2 C1

05

01 1F 24 40 45 5D 62 45 4A

010

020 00 5A 98 33 04 76

8F 00 00 00 00 00 00 00 00 19

030 01 07 04 40 40 40

77 0F 07 23 1F 07 00 22 46 81

040 C0 00 50 70 72 99 59

00 40 00 12 2A 2A 00 13 00

68 59 00 73 14 1C 2C 24 16

050

060 73 01 45 80 23 00

070

080 00 00 00 00 00 00

090 00 23 27 2A 2D 30

0A0 36 51 53 55 57 58 59

0B0

0C0

0D0 79 42 00 00 00 EF

0E0 18 24 3F 49 00 3F

0F0 --- --- --- --- --- --- ---

99

E6 E6 EB F2 15 F5 08 0D 07 07

00

F1 40 20 5E 70 40 80 11 22

FE 02 12 22 23 00 0D 00 00 00

00 00 00 00 00 00 00 00 00 00

33 39 3C 3F 42 45 48 4B 4E

5A 5C 5D 5E 5F 61 63 65 67

5B

70

6F 71 71 72 72 73 73 74 74

76 76 77 77 77 77 78 78 78 78

06 04 FB F1 F4 F5 F7 3C 4F 02

54 --- --- --- --- --- --- --- ---

B3 03 38 36 03 35000

18 20 05 0A 00 00

00 00 00 00 00 EC

DD 00 00 00 00 19

69 6A 6B 6C 6D 6E

75 75 75 75 76 76

DC 3C 22 22 DA 71 69 33 00

100

110 01 8C 04 03 05 81

120

130 39 0E 14 44 80 80

140 25 FC 00 35 90 08

150

160 80 80 80 6B 3F 68

170

180 06 0A 00 FC 00 ---

F1

69 33 33 44 33 77 59 99 59 01

02 02 81 02 00 0B 01 01 8C

81

81 02 81 02 00 0B 05 35 90 08

80 6B 3F 68 36 62 B5 20 06 00

D0 06 20 80 80 80 6B 3F 68

23

25 FC 00 67 10 A0 C0 03 25 36

62

36 B5 20 06 0A 00 FC 00 89

80 80 80 6B 3F 68 36 62 B5 20

Table 1

0E 38 22 22 DA 71

04 03 05 D0 81 02

36 62 B5 20 01 00

70 98 B5 03 05 94

C-2 23HLV84

WHEN REPLACING EEPROM (MEMORY) IC

1.

Turn on the POWER, and set to the TV mode.

2.

Enter DATA SET mode by setting VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

ADDRESS and DATA should appear as FIG 1.

4.

ADDRESS is now selected and should "blink". Using the UP/DOWN button on the remote, step through the ADDRESS until

required ADDRESS to be changed is reached.

5.

Press RIGHT/LEFT button to select DATA. When DATA is selected, it will "blink".

6.

Again, step through the DATA using UP/DOWN button until required DATA value has been selected.

7.

Pressing RIGHT/LEFT button will take you back to ADDRESS for further selection if necessary.

8.

Repeat steps 4 to 7 until all data has been checked.

9.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

After the data input, set to the initializing of shipping.

10.

Turn on the POWER, and set to the TV mode.

11.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 2 seconds.

12.

After the finishing of the initializing of shipping, the unit will turn off automatically.

The unit will now have the correct DATA for the new MEMORY IC.

Sub Micon side EEPROM (IC104) initial setting

ADDRESS DATA

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9

+A

+B +C +D +E +FINI

INIT 00 18

SUM 1221

ROM 0000

OEC6081B 0100

FIG. 2

1.

Turn on the POWER, and set to the TV mode.

2.

Enter DATA SET mode by setting VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

ADDRESS and DATA should appear as FIG 1.

4.

Again, Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

ADDRESS and DATA should appear as FIG 2.

5.

ADDRESS is now selected and should "blink". Using the UP/DOWN button on the remote, step through the ADDRESS until

required ADDRESS to be changed is reached.

6.

Press RIGHT/LEFT button to select DATA. When DATA is selected, it will "blink".

7.

Again, step through the DATA using UP/DOWN button until required DATA value has been selected.

8.

Pressing RIGHT/LEFT button will take you back to ADDRESS for further selection if necessary.

9.

Repeat steps 5 to 8 until all data has been checked.

10.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

After the data input, set to the initializing of shipping.

11.

Turn on the POWER, and set to the TV mode.

12.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 2 seconds.

13.

After the finishing of the initializing of shipping, the unit will turn off automatically.

The unit will now have the correct DATA for the new MEMORY IC.

18 11 0A 10 0A 00 11 00 00 04

00 00 00 F9 00 00 F9 00 00

10

20 CC CA 80 00 00 00

30 8C 8F 00 00 00 09

40 8F 00 00 00 00 00 00

F9

FF 00 F0 0F EE 00 F7 FF 0E AA

00 00 00 07 8C 8F 00 00 00 07

8C 00 00 00 00 00 00 00 00

Table 2

FA 00 00 FA 00 0000

F9 00 00 00 C0 0F

C-3 23HLV84

ELECTRICAL ADJUSTMENTS

1.

BEFORE MAKING ELECTRICAL

ADJUSTMENTS

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any service

on this chassis.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

•

When you exchange IC and Transistor for a heat sink,

apply the silicon grease on the contact section of the heat

sink. Before applying new silicon grease, remove all the old

silicon grease. (Old grease may cause damage to the IC

and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Oscilloscope

2. AC Voltmeter

3. Pattern Generator

4. Multi-Sound Signal Generator

On-Screen Display Adjustment

Set the VOLUME to minimum.

1.

Press the VOL. DOWN button on the set and the Channel

2.

button (9) on the remote control for more than 2 second

to appear the adjustment mode on the screen as shown

in Fig. 1-1.

NO.

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

FUNCTION

RCUT M

GCUT M

BCUT M

DRI1 M

DRI2 M

MD6 M

DTHON M

DRREF M

RCUT2 M

GCUT2 M

BCUT2 M

GAINR M

GAING M

GAINB M

RCUT C

GCUT C

BCUT C

DRI1 C

DRI2 C

MD6 C

DTHON C

DRREF C

RCUT2 C

GCUT2 C

BCUT2 C

GAINR C

GAING C

GAINB C

RCUT W

NO.

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

FUNCTION

GCUT W

BCUT W

DRI1 W

DRI2 W

MD6 W

DTHON W

DRREF W

RCUT2 W

GCUT2 W

BCUT2 W

GAINR W

GAING W

GAINB W

BRI CEN

BRI MAX

BRI MIN

CON CEN

CON MAX

CON MIN

COL CEN

COL MAX

COL MIN

TIN CEN

TIN MAX

TIN MIN

SHA CEN

SHA MAX

SHA MIN

Fig. 1-2

Function

Step No.

07 RCUT M

15

TV

480i

TH-3

3.

Use the Channel UP/DOWN button or Channel button

(1-0) on the remote control to select the options shown

in Fig. 1-2.

4.

And, press the VOL. DOWN button on the set and the

Channel button (9) on the remote control for more than 2

second to appear the adjustment mode on the screen as

shown in Fig. 1-3.

5.

Use the Channel UP/DOWN button or Channel button

(1-0) on the remote control to select the options shown

in Fig. 1-4.

6.

Press the MENU button on the remote control to end the

adjustments.

7.

To display the adjustment screen for AV, CS and HD-MI

mode, press the INPUT button on the remote control.

And, to display the adjustment screen for DVD mode,

press the TV/DVD button on the remote control.

Press the VOL.DOWN button on the set and the channel

(9) on the remote control for more than 2 second.

Fig. 1-1

NO.

FUNCTION

01

OSD

05

G OFFSET

15

BACK LIGHT CENT

16

BACK LIGHT MAX

17

BACK LIGHT MIN

58

TEST STEREO

59

TEST AUDIO

01 OSD H 9

Fig. 1-3

Fig. 1-4

D-1

23HLV84

Loading...

Loading...