Page 1

TOSHIBA

FILE NO.050-200217

SERVICE MANUAL

COLOR TELEVISION

20AR22

20AR32

AUTO VOLT AGE

MTS STE REO

AUTO VOLT AGE

DOCUMENT CREATED IN JAPAN, Aug., 2002

Page 2

20AR22

S49F614LK20A/

20AR32

COLOR TELEVISION

Chassis No. MSA

AUTO VOLT AGE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

» ELECTRICAL SPECIFICATIONS .........................................................................................................1

» IMPORTANT SERVICE SAFETY PRECAUTION .................................................................................2

» LOCATION OF USER'S CONTROL .....................................................................................................4

» INSTALLATION AND SERVICE INSTRUCTIONS ................................................................................5

» CHASSIS LAYOUT .............................................................................................................................13

» BLOCK DIAGRAM ..............................................................................................................................15

» SCHEMATIC DIAGRAMS ...................................................................................................................20

» PRINTED WIRING BOARD ASSEMBLIES ........................................................................................28

» REPLACEMENT PARTS LIST ............................................................................................................32

» PACKING OF THE SET ......................................................................................................................39

MTS ST EREO

AUTO VOLT AGE

MODELS

CONTENTS

20AR32

Page

20AR22

ELECTRICAL SPECIFICATIONS

POWER INPUT........................................ 110-220 V AC 50/60 Hz

POWER RATING

20AR21 ................................................................................72 W

20AR31 ................................................................................79 W

PICTURE SIZE .......................................... 1,192 cm2 (185sq inch)

CONVERGENCE ............................................................. Magnetic

SWEEP DEFLECTION .................................................... Magnetic

FOCUS ............................................................... QPF Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ..................................... 45.75 MHz

Sound IF Carrier Frequency...................................... 41.25 MHz

Color Sub-Carrier Frequency .................................... 42.17 MHz

(Nominal)

AUDIO POWER

OUTPUT RATING

20AR21 ................................... 1.5 + 1.5 W (at 10% distortion)

20AR31 ................................... 3.0 + 3.0 W (at 10% distortion)

SPEAKER

SIZE ................................................................ 9 × 5 cm (Round)

VOICE COIL IMPEDANCE

20AR21 ....................................................... 32 ohm at 400 Hz

20AR31 ......................................................... 4 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF.....................................................75 ohm Unbalanced

TUNING RANGES

VHF-Channels...............................................................2 thru 13

UHF-Channels ............................................................14 thru 69

CATV Channels ...........................................................1 thru 125

Specifications are subject to change without

prior notice.

1

1

Page 3

20AR22

20AR32

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only b y qualified service technicians who are thoroughly

familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The nonisolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC v oltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the picture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integr al implosion

protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTA GE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation. The

only potential source of X-ray in current solid state

TV receivers is the picture tube. Howe ver , the picture

tube does not emit measurable X-Ray radiation, if

the high voltage is as specified in the "High Voltage

Check" instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that ser vicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated v alue

−no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, the brightness should

be tested while monitoring the high voltage with a

meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified or

make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test measurements

on a receiver with excessiv e high voltage, av oid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

2

Page 4

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

20AR22

20AR32

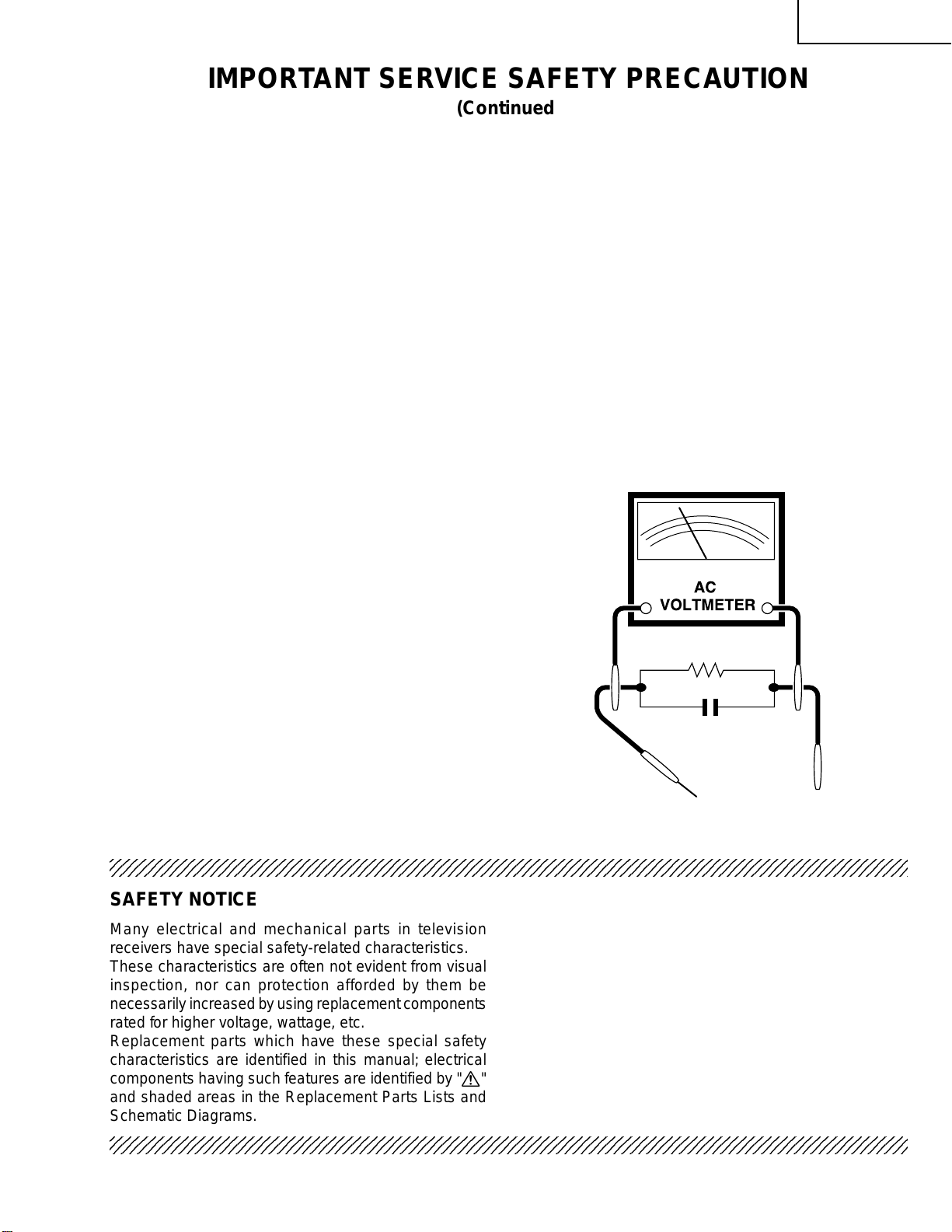

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators and etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~220 volt AC

outlet, (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to earth ground.

• Use an AC voltmeter ha ving with 5000 ohm per v olt,

or higher, sensitivity to measure the A C voltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon and etc.) and measure the AC voltage

drop across the resistor.

AII checks must be repeated with the AC ine cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp .

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by " å"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

For continued protection, replacement parts must be

identical to those used in the original circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

3

Page 5

20AR22

20AR32

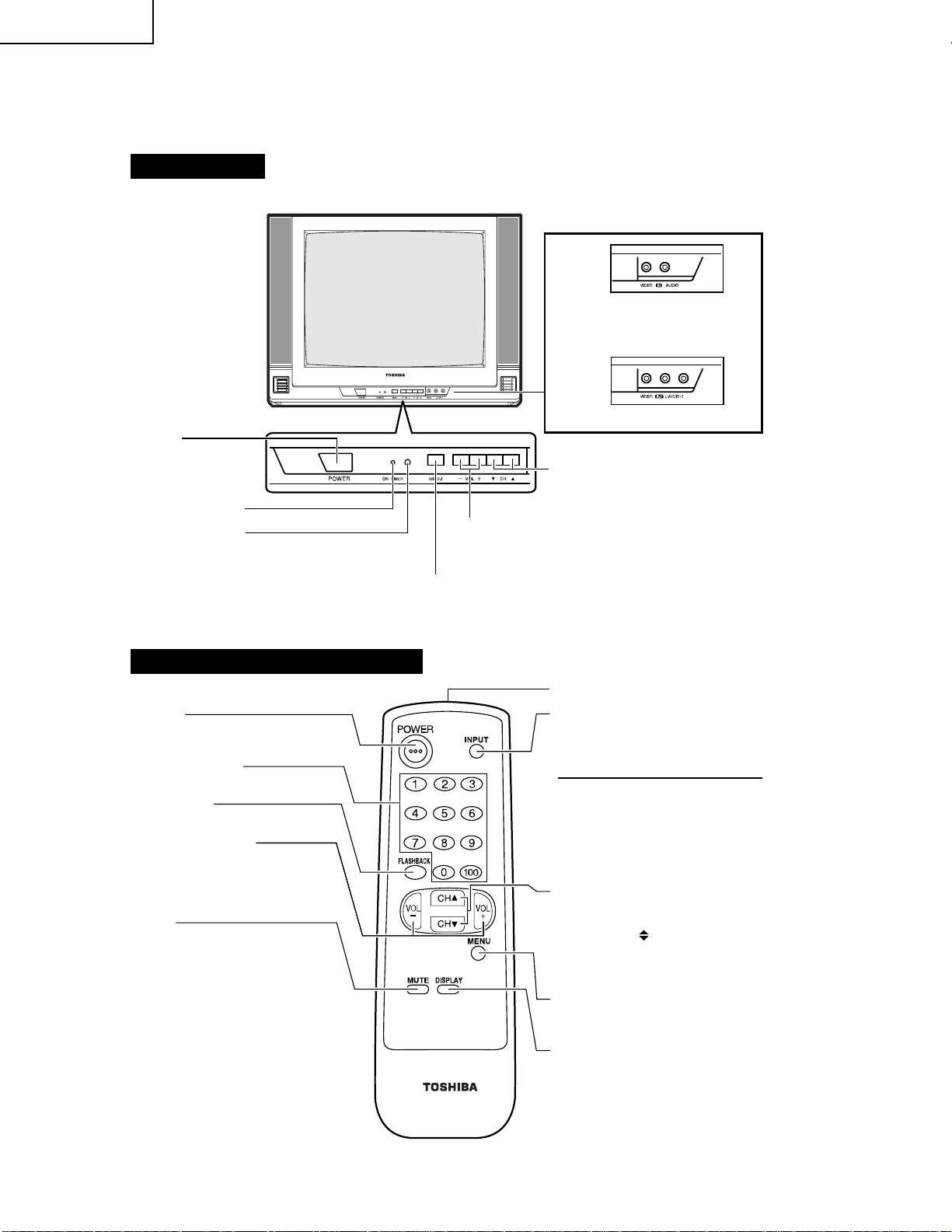

LOCATION OF USER'S CONTROL

Front Panel

POWER

Press → On.

Press again → Off.

ON TIMER indicator.

SENSOR AREA FOR

REMOTE CONTROL

MTS STEREO

AUTO VOLTAGE

VOLUME UP/DOWN

(+) Increases sound.

(–) Decreases sound.

(20AR22)

VIDEO/AUDIO TERMINALS

(VIDEO/A

provided on the rear

(20AR32)

VIDEO/AUDIO TERMINALS

CHANNEL UP/DOWN

(') Selects next higher channel.

(") Selects next lower channel.

UDIO terminals are also

.)

Basic Remote Control Functions

POWER

Press → On.

Press again → Off.

REMOTE KEYPAD

Accesses any channel from keypad.

FLASHBACK

Returns to previous channel.

VOLUME UP/DOWN

(+) Increases sound.

(–) Decreases sound.

• In menu mode, changes or selects

the TV adjustments.

MUTE

Press → Mutes sound.

Press again → Restores sound.

• CLOSED CAPTION appears when

sound is muted.

MENU

Press;Accesses MAIN MENU.

Press again ;Exits MAIN MENU.

Infrared Transmitter Window

INPUT

Press→ Switch to external video input

mode.

Press agai n → Switch to TV mo de.

(20AR22)

Press → Switch to external video

INPUT 1 mode.

Press 2 time s → Switch to exte rnal

video INPUT 2 mode.

Press 3 times → Switch back to the

original TV mode. (20AR32)

CHANNEL UP/DOWN

(') Selects next higher channel.

(" ) Selects next lower channel.

• Moves the “

screen.

MENU

Press → Accesses MAIN MENU.

Press again → Exits

DISPL

Press→ Displays receiving cha nnel for

4 seconds.

CT-818

Press again→ Removes display.

• Te

channel when in Closed Caption

mode.

” mark of the MENU

MAIN MENU.

AY

mporarily displays receiving

4

Page 6

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1)When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2)Before performing adjustments, the TV set must be on at least 15 minutes.

20AR22

20AR32

CIRCUIT PROTECTION

The receiver is protected by a 3.15A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

+B DC REGULATOR CONFIRMATION

The + B DC output voltage adjustment is not included

in this circuit.However, should confirmation be

reguired proceed as follows.

1. Actuate receiver with 220V AC input voltage.

2. Receive a local channel.

3. Connect positive lead of digital voltmeter to C754

positive side on PWB-A ; negative lead to chassis

ground.

4. Confirm this voltage reading is as below.

CAUTION: The reading should be within +130.0 ± 2.0V

DC to ensure normal function and circuitry

reliability.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high v oltage system, B+ system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

HIGH VOLT A GE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 110~220V

AC line voltage, with a strong air signal or a properly

tuned in test signal.

3. Receve a good local channel.

4. The voltage should be approximately, 25.5kV (at

pictuer MAX Bright center condition).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components.

1. Apply 220V AC using a variac transf ormer for accurate

input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to TP653 and make sure

that the voltmeter reads 21.4 ± 1.5 V.

5. Apply external 27.9V DC at TP653 by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the AC cord and make

a short circuit between TP651 and TP652. No w make

sure that normal picture appears on the screen.

7. If the operation of the hor izontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

5

Page 7

20AR22

20AR32

For adjustments of this model, the bus data is conver ted to various analog signals by the D/A converter

circuit.

Note: There are still a few analog adjustments in this series such as focus and master screen voltage.

Follow the steps below whenever the service adjustment is required. See "Table-B" to determine, if service adjustments are required.

1. Service mode

Before putting unit into the service mode, check that

customer adjustments are in the normal mode. Use

the reset function in the video adjustment menu to

ensure customer controls are in their proper (reset)

position.

2. Service item selection

Once in the service mode, press the Ch-up or Chdown button on the remote controller or at the set.

The service adjustment item will vary in increments

of one. Select the item you wish to adjust.

3. Data number selection

Press the Vol-up or down button to adjust the data

number.

To enter the ser vice mode and exit service mode.

Short JA137&JA138 for 1 Second and release to switch

to the service mode position, and the microprocessor is

in input mode.(Adjustment through the I2C bus control.)

To exit the service mode, turn the television off by

pressing the power button.

SERVICE ADJUSTMENT ITEM

Figure A.

DATA NUMBER

25AGC:

6

Page 8

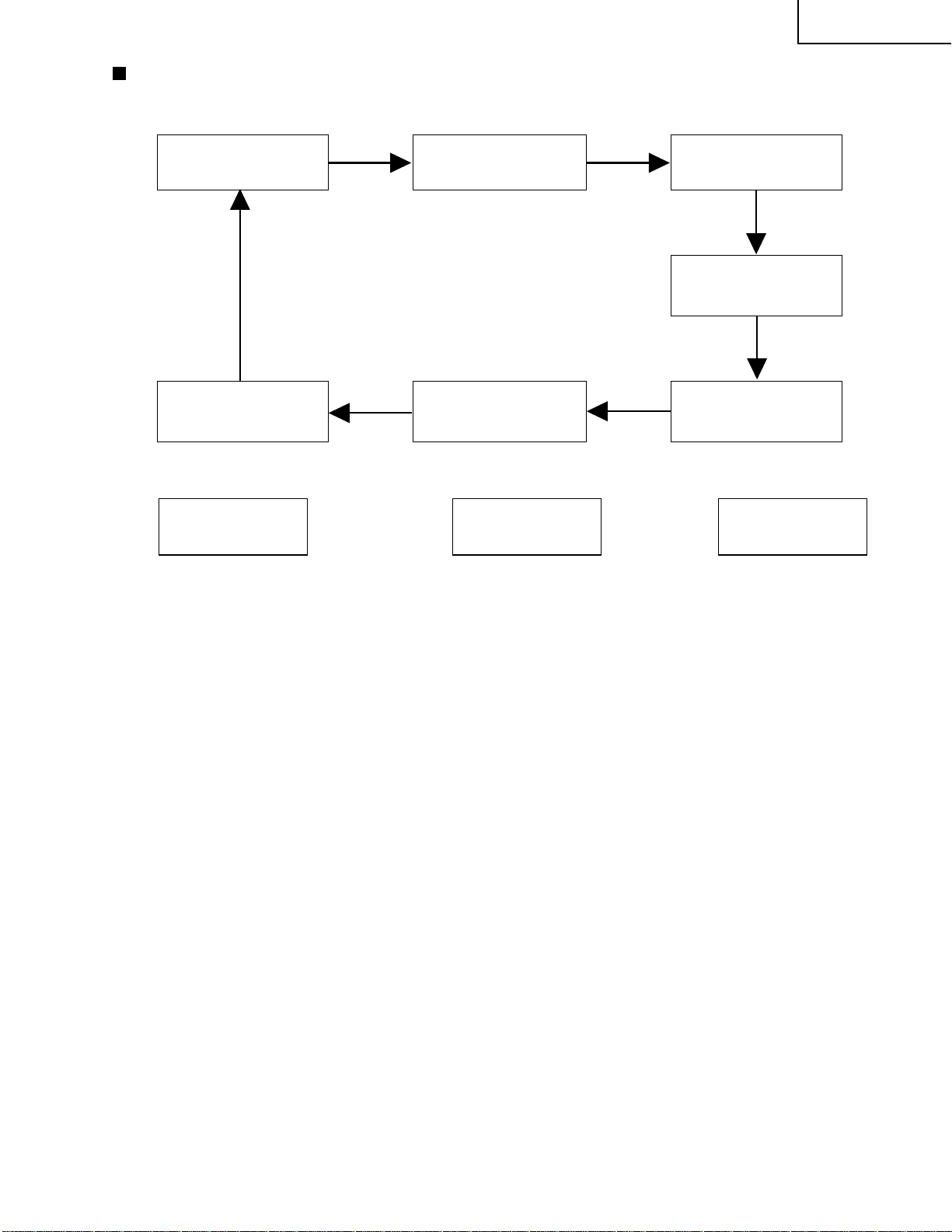

SERVICE MODE

(1) In the Service Mode, Key is used to select the mode in the following oreder.

AGC & WHITE POINT SUB

GEOMETRIC ADJ. ADJ.

MODE MODE MODE

FEATURE IC MTS

OPTION OPTION ADJ.

MODE MODE MODE

20AR22

20AR32

OFFSET

ADJ.

MODE

AGC &

GEOMETRIC

MODE

AGC TAKE OVER POINT (AGC)

VERTICAL SLOPE (V-LIN)

VERTICAL AMP (V-AMP)

VERTICAL SHIFT (V-CENT)

VERTICAL ZOOM (V-ZOOM)

HORIZONTAL SHIFT (H-CENT)

EAST-WEST WIDTH (H-SIZE)

HORIZONTAL PARALLELOGRAM (EW//)

EAST-WEST PARABOLA / WIDTH (PARA)

EAST-WEST UPPER CORNER

PARABOLA (COR(U))

EAST-WEST LOWER CORNER

PARABOLA (COR(L))

EAST-WEST TRAPEZIUM (TRAPE)

HORIZONTAL BOW (HB)

S-CORRECTION (S-COR)

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

WHITE POINT

ADJ.

MODE

W.P. RED OFFSET HIGH /

OFFSET BLUE TONE (DRI-R-HI)

W.P. GREEN OFFSET HIGH /

OFFSET BLUE TONE (DRI-G-HI)

W.P.BLUE OFFSET HIGH /

OFFSET BLUE TONE (DRI-B-HI)

W.P. RED MH / STD (DRI-R-MH)

W.P. GREEN MH / STD (DRI-G-MH)

W.P. BLUE MH / STD (DRI-B-MH)

W.P. RED OFFSET ML /

OFFSET RED TONE (DRI-R-ML)

W.P. GREEN OFFSET ML /

OFFSET RED TONE (DRI-G-ML)

W.P. BLUE OFFSET ML /

OFFSET RED TONE (DRI-B-ML)

W.P. RED OFFSET LOW (DRI-R-LO)

W.P. GREEN OFFSET LOW (DRI-G-LO)

W.P. BLUE OFFSET LOW (DRI-B-LO)

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

SUB

ADJ.

MODE

MAX VOLUME (SUB-VOL)

SUB CONTRAST (SUB-CON)

SUB TINT (SUB-TINT)

SUB COLOUR (SUB-COL)

SUB BRIGHTNESS (SUB-BRI)

SUB SHARPNESS (SUB-SHP)

MAX HOTEL VOLUME (HTL-VOL)

HOTEL PROGRAM NO(HTL-PRG)

BLUE BACK CONTRAST (BB-CON)

OSD GRB REFERENCE (RGB)

BLACK LEVEL OFFSET R(CUT-R)

BLACK LEVEL OFFSET G(CUT-G)

CATHODE DRIVE LEVEL(CDL)

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

7

Page 9

20AR22

20AR32

OFFSET

ADJ.

MODE

Y-D TIME (TV) [ YD ] (DL-TV)

Y-D TIME (AV) [ YD ] (DL-AV)

INITIAL/DEFAULT LANGUAGE (INIT)

FA O-MAX V OLUME (FA O-V OL)

ENERGY SAVE OFFSET (ESV_OFFS)

CLOSE CAPTION POSITION (CCPOS)

↓

↓

↓

↓

↓

↓

IC

OPTION

MODE

VERTICAL SCAN DISABLE (VSD)

BLACK STRETCH (BKS)

AUTOMATIC VOLUME LEVELLING (AVL)

FAST FILTER IF-PLL ( FFI )

ENABLE VERTICAL GUARD ( EVG )

EHT TRACKING MODE ( EHT )

OVERSCAN SWITCH OFF (OSO)

AUTO COLOUR LIMIT (ACL)

FORCED COLOUR-ON (FCO)

VIDEO MUTE AT IDENT LOSS (VMI)

VIDEO MUTE AT PROGRAM/SOURCE CHANGE (VMC)

HOTEL MODE (HTL)

GAIN FM DEMODULATOR (BTSC)

CHARGE PUMP (CP)

FM WINDOW SELECTION (FMWS)

SOUND MUTE BIT 0 (SM0)

SOUND MUTE BIT 1 (SM1)

IF AGC SPEED BIT 0 (AGC0)

IF AGC SPEED BIT 1 (AGC1)

PHI 1 TIME CONSTANT FOR FE (FOA-FE)

PHI 1 TIME CONSTANT FOR FE (FOB-FE)

PHI 1 TIME CONSTANT FOR AV (FOA-AV)

PHI 1 TIME CONSTANT FOR AV (FOB-AV)

FORCED SLICING LEVEL FOR VERTICAL SYNC.(FSL)

SYNCHRONISATION OF OSD/TEXT DISPLAY (HP2)

RGB BLANK (RGBL)

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

MTS

ADJ.

MODE

ATTENUATE INPUT SIGNAL LEVEL (ATT)

VCO FREE RUNNING FREQUENCY ADJ. (VCO)

STEREO, SAP, DBX FILTER ADJ. (FILTER)

STEREO SEPARATION ADJUSTMENT (300HZ) (WIDEBAND)

STEREO SEPARATION ADJUSTMENT (3kHZ) (SPECTRAL)

BASS LEVEL (BASS)

TREBLE LEVEL (TREBLE)

↓

↓

↓

↓

↓

↓

↓

FEATURE

OPTION

MODE

↓

V-CHIP (V-CHIP)

MTS DECODING ENABLED (MTS)

DEMO MODE (DEMO)

REAL TIME CLOCK / ON TIMER (CLOCK)

ENERGY SAVE (E-SAVE)

PERSONAL PREFERENCE PROGRAM (P_PREF)

UNIVERSAL PLUS (UNIV+)

SPEAKER ON/OFF (SPEAKER)

FIXED AUDIO OUT (FAO)

VIEW TIMER (VIEW-TM)

FRENCH LANGUAGE (FRENCH)

EZ SETUP / AUTOPRESET (EZ-SETUP)

WHITE TEMP OR FAVORITE COLOR (W-TEMP)

AV ENABLED OR DISABLED (AV)

AV2 ENABLED OR DISABLED (AV2)

DYNAMIC SKIN CONTROL (DSK)

RATIO PRE- AND OVERSHOOT BIT 0 (RPO0)

RATIO PRE- AND OVERSHOOT BIT 1 (RPO1)

GAIN FM DEMODULATOR (AGN)

AUTO SWITCH OFF ENABLED (AUTO-OFF)

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

FORWARD : CH DOWN KEY

REVERSE : CH UP KEY

( ) means OSD display.

Figure B: ADJUSTMENT CATEGORIES

1Press the CH DOWN/UP key on the remote controller to get ready to select the mode one by one.

2Press the CH DOWN/UP key on the remote controller to select the modes reversibly one by one.

3Using the VOLUME UP/DOWN key on the remote controller, the data can be modified.

(OSD disturbance can be erased by R/C display key)

8

Page 10

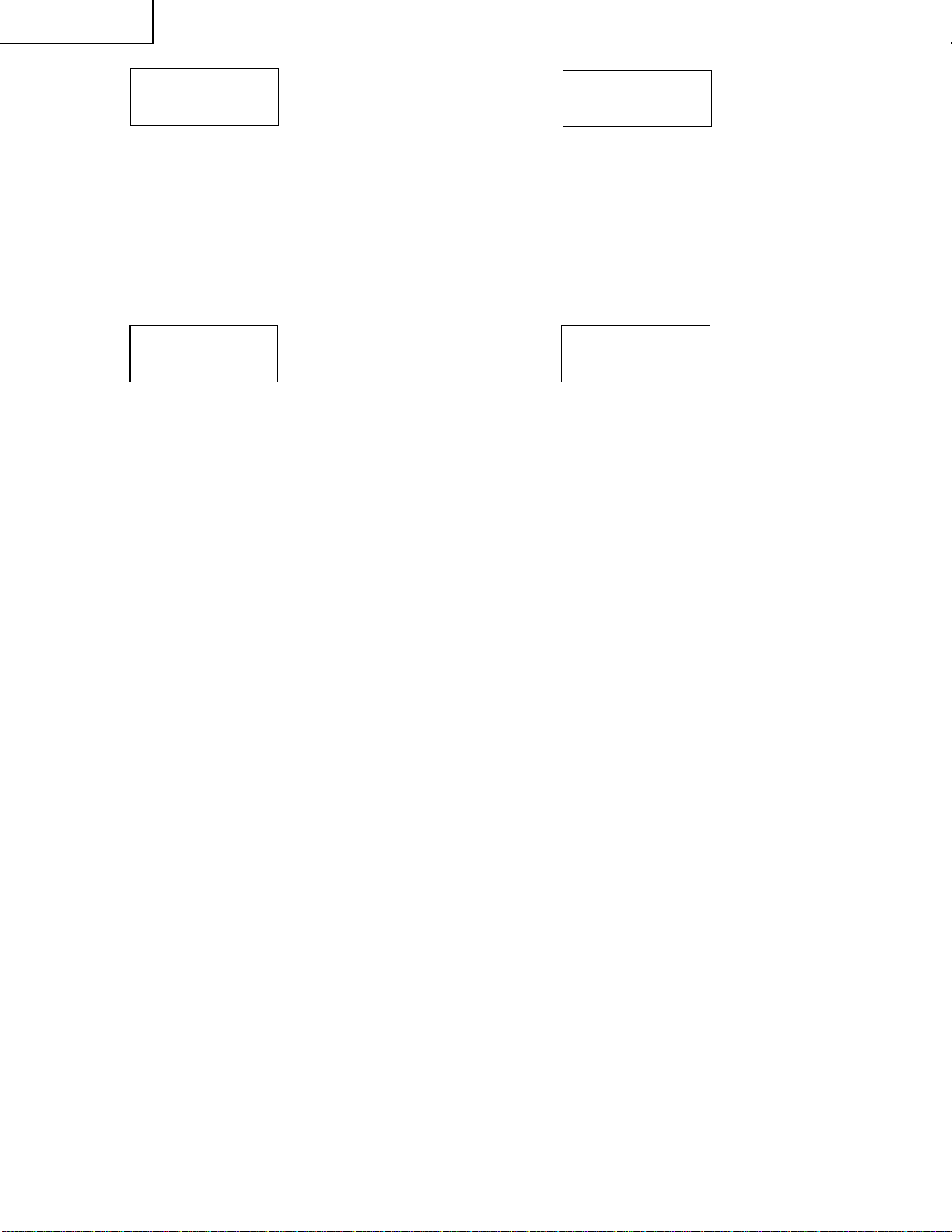

SER VICE MODE

20AR22

20AR32

SERVICE

POSITION

AGC AGC TAKE OVER POINT 0~63 14 ADJ

V-LIN VERTICAL SLOPE 0~63 32 ADJ

V-AMP VERTICAL AMP 0~63 32 ADJ

V-CENT VERTICAL SHIFT 0~63 32 ADJ

V-ZOOM VERTICAL ZOOM 0~63 32 FIX

H-CENT HORIZONTAL SHIFT 0~63 32 ADJ

H-SIZE EAST-WEST WIDTH 0~63 32 FIX

EW// HORIZONTAL PARALLELOGRAM 0~63 32 FIX

PARA EAST-WEST PARABOLA / WIDTH 0~63 32 FIX

COR(U) EAST-WEST UPPER CORNER PARABOLA 0~63 32 FIX

COR(L) EAST-WEST LOWER CORNER PARABOLA 0~63 32 FIX

TRAPE EAST-WEST TRAPEZIUM 0~63 32 FIX

HB HORIZONTAL BOW 0~63 32 FIX

S-COR S-CORRECTION 0~63 0 FIX must be "17"

DRI-R-HI “W,P RED OFFSET HIGH / OFFSET BLUE TONE” 0~63 32 FIX must be "32"

DRI-G-HI W.P. GREEN OFFSET HIGH / OFFSET BLUE TONE 0~63 32 FIX must be "33"

DRI-B-HI W.P.BLUE OFFSET HIGH / OFFSET BLUE TONE 0~63 32 FIX must be "37"

DRI-R-MH W.P. RED MH / STD 0~63 25 FIX must be "32"

DRI-G-MH W.P. GREEN MH / STD 0~63 32 ADJ

DRI-B-MH W.P. BLUE MH / STD 0~63 32 ADJ

DRI-R-ML W.P. RED OFFSET ML / OFFSET RED TONE 0~63 32 FIX must be "32"

DRI-G-ML W.P. GREEN OFFSET ML / OFFSET RED TONE 0~63 32 FIX must be "32"

DRI-B-ML W.P. BLUE OFFSET ML / OFFSET RED TONE 0~63 32 FIX must be "25"

DRI-R-LO W.P. RED OFFSET LOW 0~63 32 FIX must be "32"

DRI-G-LO W.P. GREEN OFFSET LOW 0~63 32 FIX must be "22"

DRI-B-LO W.P. BLUE OFFSET LOW 0~63 32 FIX must be "19"

SUB-VOL MAX VOLUME 0~63 63 FIX must be "63"

SUB-CON SUB CONTRAST 0~63 63 FIX must be "54"

SUB-COL SUB COLOUR 0~63 32 ADJ

SUB-BRI SUB BRIGHTNESS 0~63 32 ADJ

SUB-TINT SUB TINT 0~63 32 ADJ

SUB-SHP SUB SHARPNESS 0~63 32 FIX must be "27"

HTL-VOL MAX HOTEL VOLUME 0~63 32 FIX

HTL-PRG HOTEL PROGRAM NO 0~125 or >125 for none 255 FIX

BB-CON BLUE BACK CONTRAST 0~15 10 FIX must be "5"

RGB OSD GRB REFERENCE 0~15 15 FIX must be "5"

CUT-R BLACK LEVEL OFFSET R 0~63 32 ADJ

CUT-G BLACK LEVEL OFFSET G 0~63 32 ADJ

CDL CATHODE DRIVE LEVEL 0~15 0 FIX must be "6"

DL-TV Y-D TIME (TV) [ YD ] 0~15 12 FIX must be "2"

DL-AV Y-D TIME (AV) [ YD ] 0~15 12 FIX must be "8"

INIT INITIAL/DEFAULT LANGUAGE 0(English), 1(Spanish), 0 FIX must be "1"

FAO-VOL FAO-MAX VOLUME 0~63 63 FIX must be "63"

ESV_OFFS ENERGY SAVE OFFSET 0~63 10 FIX must be "20"

CCPOS CLOSE CAPTION POSITION 0~255 32 ADJ

ATT ATTENUATE INPUT SIGNAL LEVEL 0~15 10 FIX*

VCO VCO FREE RUNNING FREQUENCY ADJ. 0~63 32 FIX*

FILTER “STEREO, SAP, DBX FILTER ADJ. “ 0~63 28 FIX* 20AR22=FIX

WIDEBAND STEREO SEPARATION ADJUSTMENT (300HZ) 0~63 32 FIX* 20AR32=ADJ

SPECTRAL STEREO SEPARATION ADJUSTMENT (3kHZ) 0~63 27 FIX*

BASS BASS LEVEL 0Å‘15 8 FIX

TREBLE TREBLE LEVEL 0Å‘15 8 FIX

VSD VERTICAL SCAN DISABLE 0 or 1 when item selected 0 FIX

BKS BLACK STRETCH 0(disable) or1(enable) 1 FIX

AVL AUT OMATIC VOLUME LEVELLING 0(disable) or1(enable) 1 FIX

FFI FAST FILTER IF-PLL 0(disable) or1(enable) 0 FIX

EVG ENABLE VERTICAL GUARD 0(disable) or1(enable) 1 FIX

EHT EHT TRACKING MODE 0(disable) or1(enable) 1 FIX

OSO OVERSCAN SWITCH OFF 0(disable) or1(enable) 0 FIX

ACL AUTO COLOUR LIMIT 0(disable) or1(enable) 0 FIX

FCO FORCED COLOUR-ON 0(disable) or1(enable) 0 FIX

VMI VIDEO MUTE AT IDENT LOSS 0(disable) or1(enable) 1 FIX

VMC VIDEO MUTE AT PROGRAM/SOURCE CHANGE 0(disable) or1(enable) 1 FIX

HTL HOTEL MODE 0(disable) or1(enable) 0 FIX

BTSC GAIN FM DEMODULATOR 0(disable) or1(enable) 0 FIX

CP CHARGE PUMP 0(fast tuning) or 1 0 FIX

ADJUST ITEM

RANGE

2(French)

(moderate speed tuning)

DATA

INITIAL VALUE

FIX/ADJ

REMARK

Table - A

9

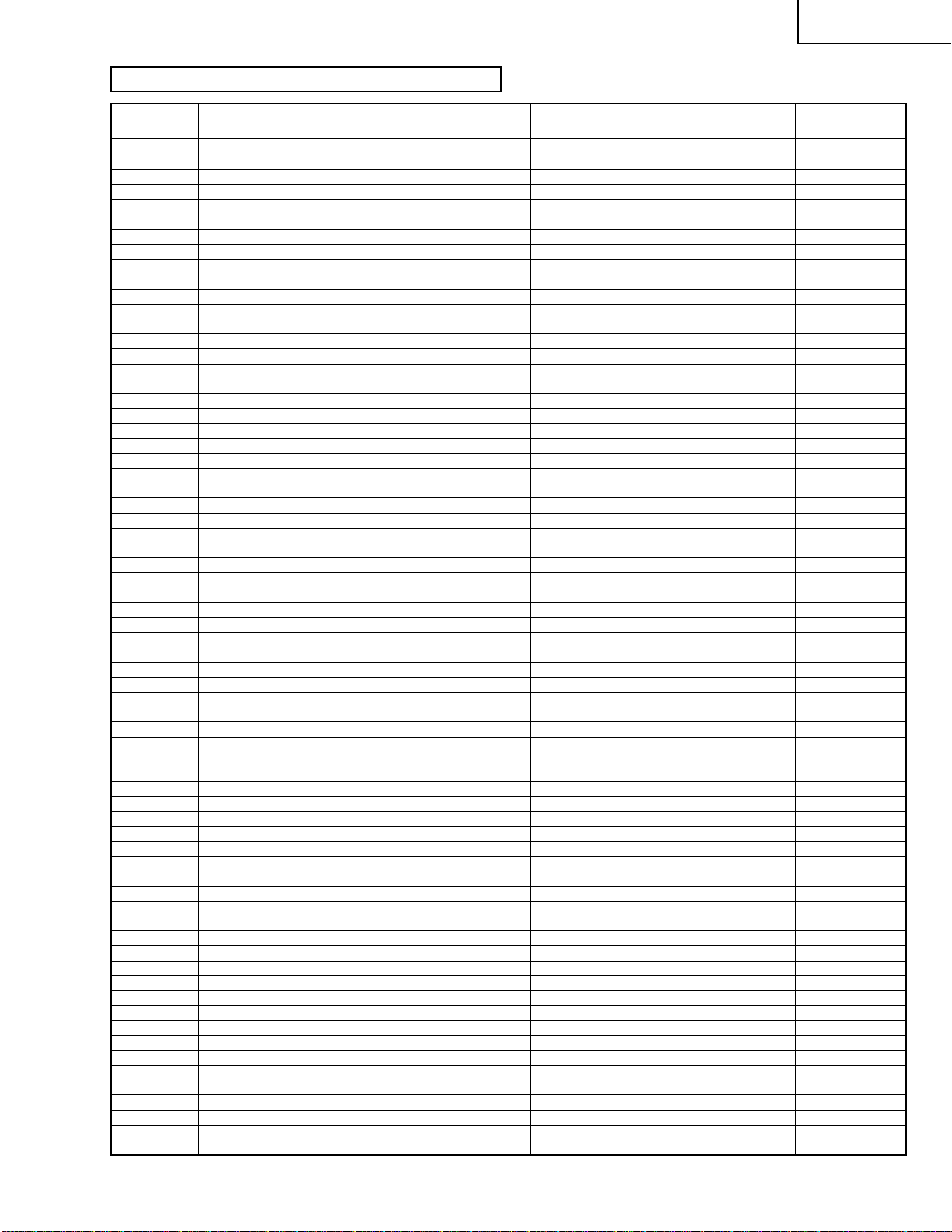

Page 11

20AR22

20AR32

SERVICE

POSITION

FMWS FM WINDOW SELECTION 0(disable) or1(enable) 0 FIX

SM0 SOUND MUTE BIT 0 (SM0) 0(disable) or1(enable) 1 FIX

SM1 SOUND MUTE BIT 1 0(disable) or1(enable) 0 FIX

AGC0 IF AGC SPEED BIT 0 0(disable) or1(enable) 1 FIX

AGC1 IF AGC SPEED BIT 1 0(disable) or1(enable) 0 FIX

FOA-FE PHI 1 TIME CONSTANT FOR FE 0(disable) or1(enable) 0 FIX

FOB-FE PHI 1 TIME CONSTANT FOR FE 0(disable) or1(enable) 0 FIX

FOA-AV PHI 1 TIME CONSTANT FOR AV 0(disable) or1(enable) 1 FIX

FOB-AV PHI 1 TIME CONSTANT FOR AV 0(disable) or1(enable) 1 FIX

FSL FORCED SLICING LEVEL FOR VERTICAL SYNC. 0(disable) or1(enable) 0 FIX

HP2 SYNCHRONISATION OF OSD/TEXT DISPLAY 0(disable) or1(enable) 0 FIX

RGBL RGB BLANK 0(disable) or1(enable) 0 FIX

V-CHIP V-CHIP 0(disable) or1(enable) 0 FIX

MTS MTS DECODING ENABLED 0(disable) or1(enable) 0 FIX*

DEMO DEMO MODE 0(disable) or1(enable) 1 FIX

CLOCK REAL TIME CLOCK / ON TIMER 0(disable) or1(enable) 1 FIX must be "1"

E-SAVE ENERGY SAVE 0(disable) or1(enable) 1 FIX

P_PREF PERSONAL PREFERENCE PROGRAM 0(disable) or1(enable) 0 FIX

UNIV+ UNIVERSAL PLUS 0(disable) or1(enable) 0 FIX

SPEAKER SPEAKER ON/OFF 0(disable) or1(enable) 0 FIX

FAO FIXED AUDIO OUT 0(disable) or1(enable) 0 FIX

VIEW-TM VIEW TIMER 0(disable) or1(enable) 1 FIX must be "1"

FRENCH FRENCH LANGUAGE 0(disable) or1(enable) 0 FIX

EZ-SETUP EZ SETUP / AUTOPRESET 0(AUTOPRESET) or 1 FIX

W-TEMP WHITE TEMP OR FAVORITE COLOR 0(FC) or 1(WT) 0 FIX

AV AV ENABLED OR DISABLED 0(without ext. source) or 0 FIX

AV2 AV2 ENABLED OR DISABLED 0(1 input) or 1(2 input) 0 FIX*

DSK DYNAMIC SKIN CONTROL 0(disable) or1(enable) 0 FIX

RPO0 RATIO PRE- AND OVERSHOOT BIT 0 0(disable) or1(enable) 0 FIX

RPO1 RATIO PRE- AND OVERSHOOT BIT 1 0(disable) or1(enable) 0 FIX

AGN GAIN FM DEMODULATOR 0(normal) or1(+6dB) 0 FIX

AUTO-OFF AUTO SWITCH OFF ENABLED 0(disable) or1(enable) 1 FIX

PON-CH 0(disable) or1(enable) 0 FIX

ADJUST ITEM

RANGE

1(EZ SETUP)

1(with external source)

DATA

INITIAL VALUE

FIX/ADJ

REMARK

20AR22→0/20AR32→1

20AR22→0/20AR32→1

Table - A

Holding down to short JA137 & JA138 and turn on the main power SW will automatically write the initial values into

IC1003.

This is only can done when a new EEPROM is used. (Judge with the first 4 bytes.)

PART REPLACED

IC801

IC1003

CRT

NECESSARY

ADJUSTMENT

X

X

UNNECESSARY

X

NOTES

Data is stored in IC1003.

Holding down to short JA137 & JA138 and turn on the main

power SW will automatically write the initial values into IC1003.

This is only can done when a new EEPROM is used. (Judge

with the first 4 bytes.)

Adjust items related to picture tube only.

Table - B

10

Page 12

Ë

WA VEFORM 1

YCYGMGR BW

SAME LEVEL

SERVICE ADJUSTMENT

RF AGC Adjustment

1. Receive a good local channel.

2. Enter the ser vice mode signal category and select

the service adjustment "AGC".

3. Set the data value to point where no noise or beat

appears.

4. Select another channel to confir m that no noise or

beat appears.

CHROMA ADJUSTMENT

No. Adjusting point Adjusting procedure/conditions Waveform and others

1

SUB-TINT (I

BUS CONTROL)

2

C

1. Receive the "Colour Bar" signal through AV in.

2. Connect the oscilloscope to TP853 (Pin (5) of

P882) BLUE-OUT.

» Range : 100mV/div . (AC)(Use Probe 10:1)

» Sweep time : 10 µsec/div.

3. Call the "SUB-TINT" mode in ser vice mode. Adjust the "SUB-TINT" bus data to obtain the wav eform shown as Fig 1.

4. "SUB-TINT" bus data decrease 4 steps to get final waveform. (Fig 2.)

5. Clear the SERVICE mode.

Fig 1

FINAL WA VEFORM

Fig 2

20AR22

20AR32

HORIZONTAL AND VERTICAL DEFLECTION LOOP ADJUSTMENT

No. Adjusting point Adjusting procedure/conditions Waveform and others

V-SLOPE(I2C

1

BUS CONTROL)

V-CENTER (I2C

2

BUS CONTROL)

3

V - AMP (I2C

BUS CONTROL)

4

S-CORRECTION (I2C BUS

CONTROL)

H - CENTER

5

Focus

6

adjustment

1. Receive Monoscope Pattern Signal.

2. Call the "V-LIN" mode.

3. Increase or decrease "V-LIN" by Volume key till

the horizontal line in the center of monoscope is

just at the position where the blanking starts.

1. Call the "V-CENT" mode.

2. Increase or decrease "V-CENT" by Volume key till

the picture is centered.

1. Call the "V-AMP" mode.

2. Increase or decrease "V - AMP" by V olume ke y to

set overscan of 10.0% typical.

Adjustment Spec 10.0% range ±1%.

FIXED DATA, NO NEED TO ADJUST.

1. Call the "H-CENT" mode.

2. Increase or decrease "H-CENT" by Volume key

to center the picture horizontal.

1. Receive the "Monoscope Pattern" signal.

2. Press R/C to set Picture NORMAL condition.

3. Adjust the focus control to get the best focus.

11

Page 13

20AR22

1 2 3 4 5

20AR32

CRT CUT-OFF, BACKGROUND AND SUB-CONTRAST ADJUSTMENT

No. Adjusting point Adjusting procedure/conditions Waveform and others

CRT CUTOFF

1

ADJUSTMENT

(I2C BUS

CONTROL)

SUB-BRIGHT-

2

NESS

ADJUSMENT

(I2C BUS

CONTROL)

WHITE BAL-

3 # 11,600° K X : 0.273

ANCE SERVICE MODE

ADJ. (I2C BUS

CONTROL)

1. Switch TV to VIDEO mode ,BLUE BACK OFF, with

NO VIDEO signal.

2. Press R/C to set Picture Normal condition.

3. Connect the oscilloscope to Red OUT from

IC801.(TP47R)

Range : 1 V/Div (DC)

Sweep : 5 msec/Div

4. Adjust SCREEN VR ,so that the tip of signal reach

3.5 Vdc + 0.1 Vdc.

1. Call " SUB-BRI" in service mode. (Receive Crosshatch pattern with 5 black level windows)

2. Adjust the " SUB BRIGHT " bus data in order that

the line 1, 2 and 3 have the same darkness

wherelse line 4 is slightly brighter than line 1, 2

and 3 and finally line 5 will be the brighter than

line 4.

1. Receive the "Monoscope Pattern" signal.

2. Press R/C to set Picture NORMAL condition.

3. Connect the DC miliammeter betw een the TP 602

( - ) TP 603 ( + ).

4. Check Beam current should be around (990µA)

5. Set it to service mode and adjust the DRI-G-MH,

& DRI-B-MH data to have a colour temperature

of 11,600°K ( white ).

6. Receive "WHITE" pattern, WITH BURST signal,

and set BRIGHTNESS Y by generator, to ** 10

cd/m2 (MINOL T A CA-100) b y reducing LUMINA TE

Y signal.

7. Adjust "CUT-R" & "CUT-G" to get 11,600°K. Then

go back NORMAL mode (HIGH BRIGHT**) to

check colour temperature. If out of range, back

to (1).

3.5Vdc

1 V

0

1, 2, 3 are in same black level.

Y : 0.280

( MINOLT A COLOUR ANALYZER

CA-100)

*NOTE: Above DATA can be UP/

DOWN by volume key.

LOW HIGH

20" 1.8cd/m2115cd/m

* 11,600° K

DRI-GW="DRI-GS"DATA-5

DRI-BW="DRI-BS" DATA-5

2

4

Maximum

beam check

Note: This adjustment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 500µA.

DRI-R-MH=32 (FIXED)

DRI-G-MH=33 (FIXED)

DRI-B-MH=37 (FIXED)

DRI-R-MH=32 (FIXED)

1. Receive the "Monoscope Pattern" signal.

2. Press R/C to set Picture NORMAL condition.

3. Connect the DC miliammeter between TP603 (+)

and TP602 (–).

(Full Scale: 3 mA Range)

4. Beam current must be within 990 ± 50 µA.

12

Page 14

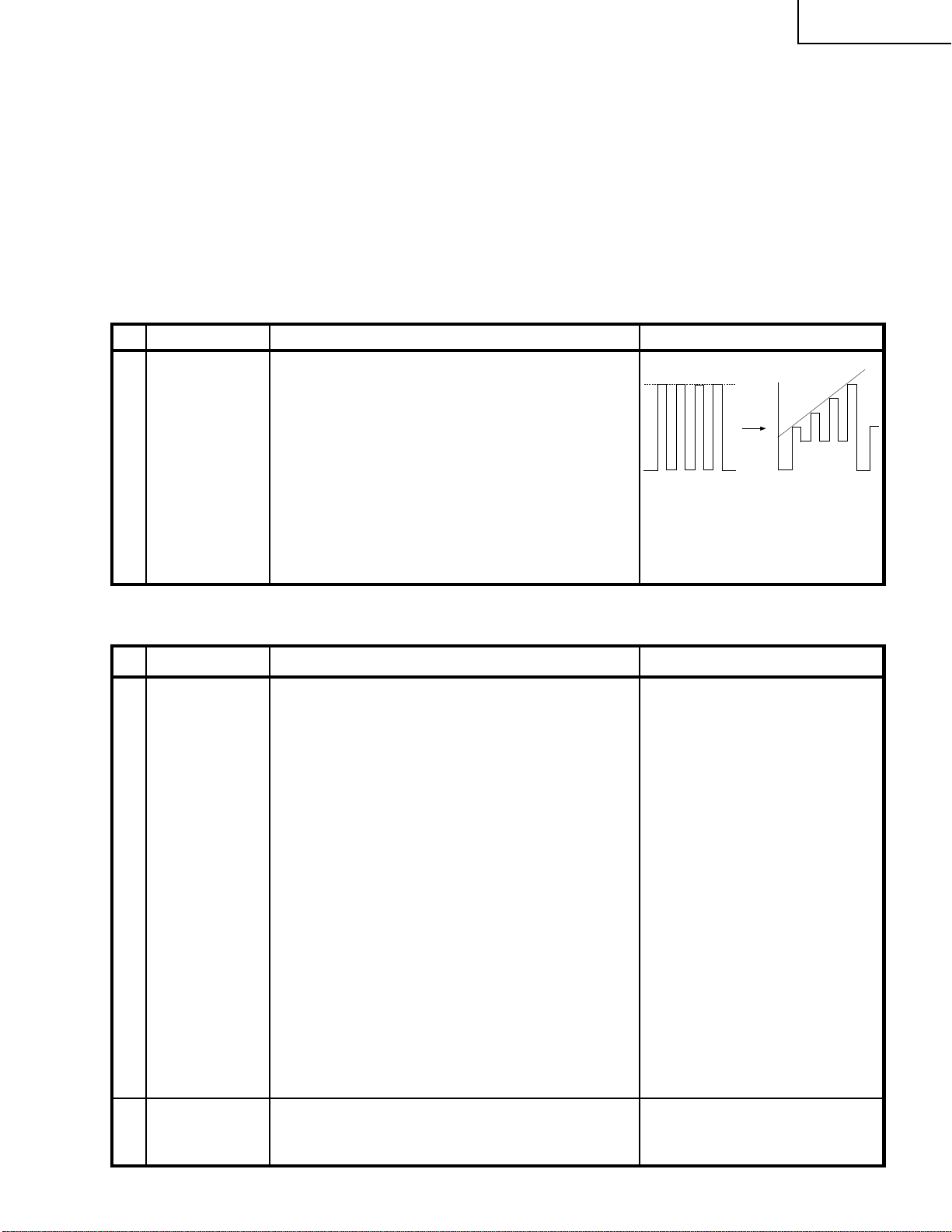

MODEL 20AR22 CHASSIS LAYOUT

H

G

F

20AR22

20AR32

E

D

C

B

A

654321

13

Page 15

20AR22

20AR32

MODEL 20AR32 CHASSIS LAYOUT

H

G

F

E

D

C

B

A

654321

14

Page 16

BLOCK DIAGRAM-1

H

G

F

20AR22

20AR32

E

D

C

B

A

654321

15

Page 17

20AR22

20AR32

MODEL 20AR22 BLOCK DIAGRAM-2

H

G

F

E

D

C

B

A

121110987654321

16

17

Page 18

MODEL 20AR22 BLOCK DIAGRAM-2

H

G

F

E

D

C

B

A

16

Page 19

20AR22

20AR32

17

121110987654321

Page 20

20AR22

20AR32

MODEL 20AR32 BLOCK DIAGRAM-2

H

G

F

E

D

C

B

A

121110987654321

18

19

Page 21

MODEL 20AR32 BLOCK DIAGRAM-2

H

G

F

E

D

C

B

A

18

Page 22

20AR22

20AR32

19

121110987654321

Page 23

20AR22

20AR32

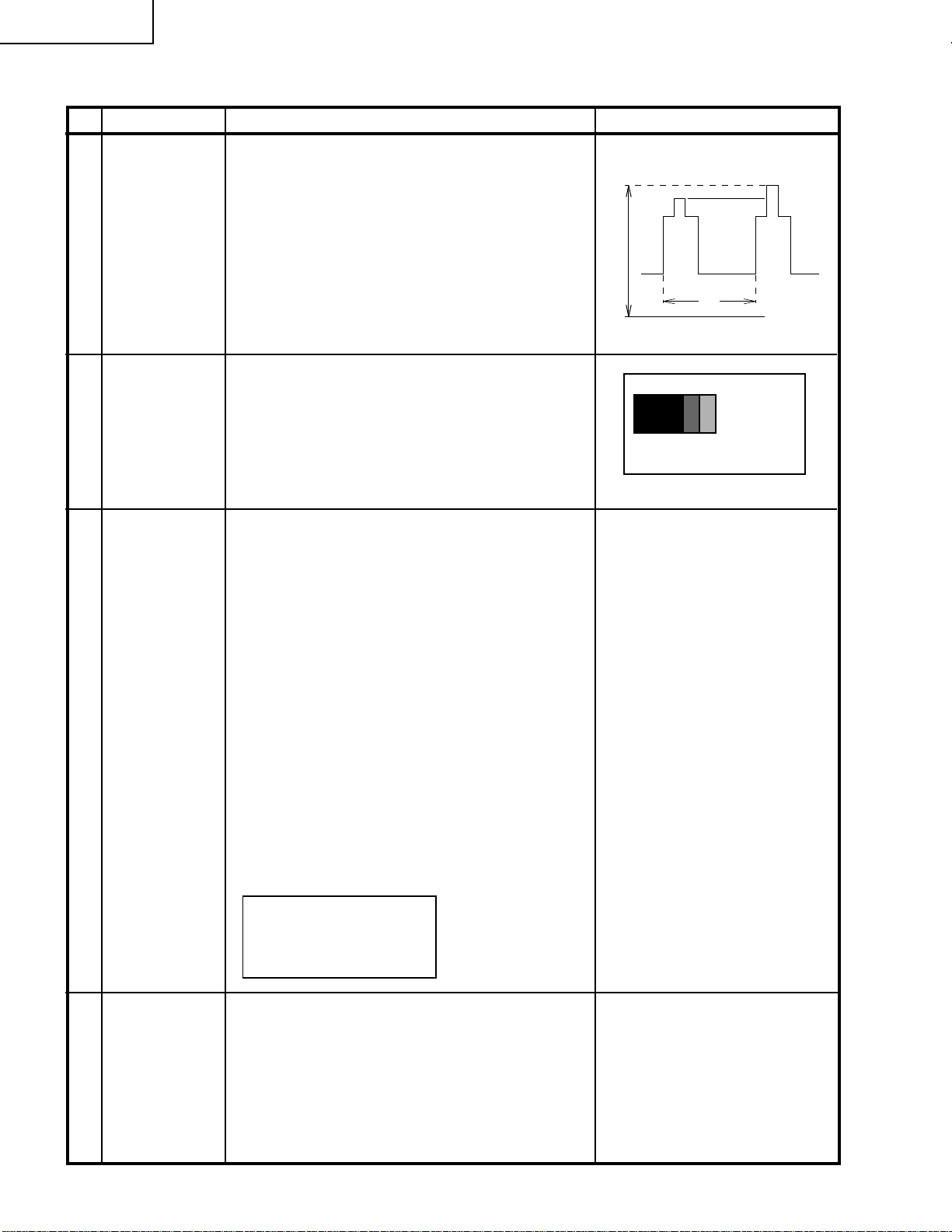

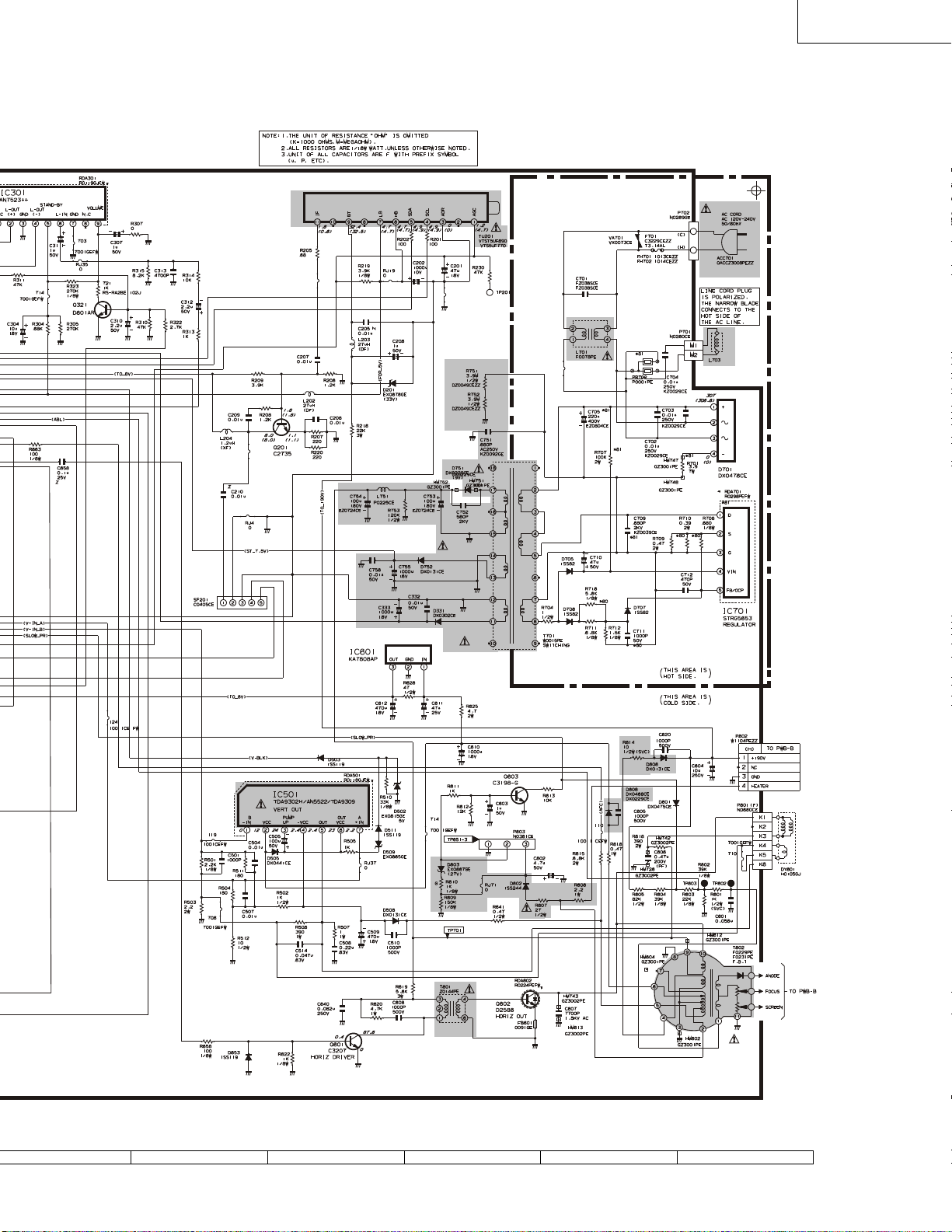

DESCRIPTION OF SCHEMATIC DIAGRAM

NOTES:

1. The unit of resistance "ohm" is omitted.

(K=kΩ=1000Ω, M=MΩ)

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are µ F, unless otherwise noted.

(P=pF=µµF)

4. (G) indicates ±2% tolerance may be used.

5. indicates line isolated ground.

6. indicates hot ground.

VOLTAGE MEASUREMENT CONDITIONS:

1. All DC voltages are measured with DVM connected

between points indicated and chassis ground, line

voltage set at 120V AC and all controls set f or normal

picture unless otherwise indicated.

2. All voltages measured with 1000µ V B & W or Color

signal.

WAVEFORMS

1 1.0 Vp-p

2 2.8 Vp-p

3 2.6 Vp-p

WAVEFORM MEASUREMENT CONDITIONS:

1. Photographs taken on a standard gated color bar

signal, the tint setting adjusted for proper color. The

wave shapes at the red, g reen and blue cathodes of

the picture tube depend on the tint, color level and

picture control.

2.

indicates waveform check points (See chart,

wavefor ms are measured from point indicated to

chassis ground.)

å

AND SHADED ( ) COMPONENTS

= SAFETY RELATED PARTS.

'

MARK= X-RAY RELATED PARTS.

This circuit diagram is a standard one, printed circuits

may be subject to change for product improvement

without prior notice.

4 2.7 Vp-p

5 65.0 Vp-p

Horiz. Rate Horiz. Rate Horiz. Rate Horiz. Rate Horiz. Rate

6 67.0 Vp-p

Horiz. Rate Horiz. Rate Vert. Rate Horiz. Rate Horiz. Rate

q 8.4 Vp-p

Horiz. Rate Vert. Rate Horiz. Rate Horiz. Rate Power Supply Rate

7 80.0 Vp-p

w 40.8 Vp-p

8 3.0 Vp-p 9 2.3 Vp-p

e 98.0 Vp-p

r 1,160 Vp-p

0 116.0 Vp-p

t 415.0 Vp-p

20

Page 24

20AR20

MODEL 20AR22 SCHEMATIC DIAGRAM: Main Unit

20AR32

H

G

F

E

D

C

B

A

21

21

1211109876543

22

Page 25

H

MODEL 20AR22 SCHEMATIC DIAGRAM: Main Unit

G

F

E

D

C

B

A

21

21

Page 26

20AR20

20AR32

22

1211109876543

Page 27

20AR22

MODEL 20AR32 SCHEMATIC DIAGRAM: Main Unit

20AR32

H

G

F

E

D

C

B

A

21

23

1211109876543

24

Page 28

H

MODEL 20AR32 SCHEMATIC DIAGRAM: Main Unit

G

F

E

D

C

B

A

21

23

Page 29

20AR22

20AR32

24

1211109876543

Page 30

SCHEMATIC DIAGRAM: CRT Unit

H

G

F

20AR22

20AR32

E

D

C

B

A

654321

25

Page 31

20AR22

20AR32

MODEL 20AR32 SCHEMATIC DIAGRAM: MTS MODULE Unit

H

G

F

E

D

C

B

A

121110987654321

26

27

Page 32

MODEL 20AR32 SCHEMATIC DIAGRAM: MTS MODULE Unit

H

G

F

E

D

C

B

A

26

Page 33

20AR22

20AR32

27

121110987654321

Page 34

20AR22

20AR32

H

G

F

E

D

C

B

A

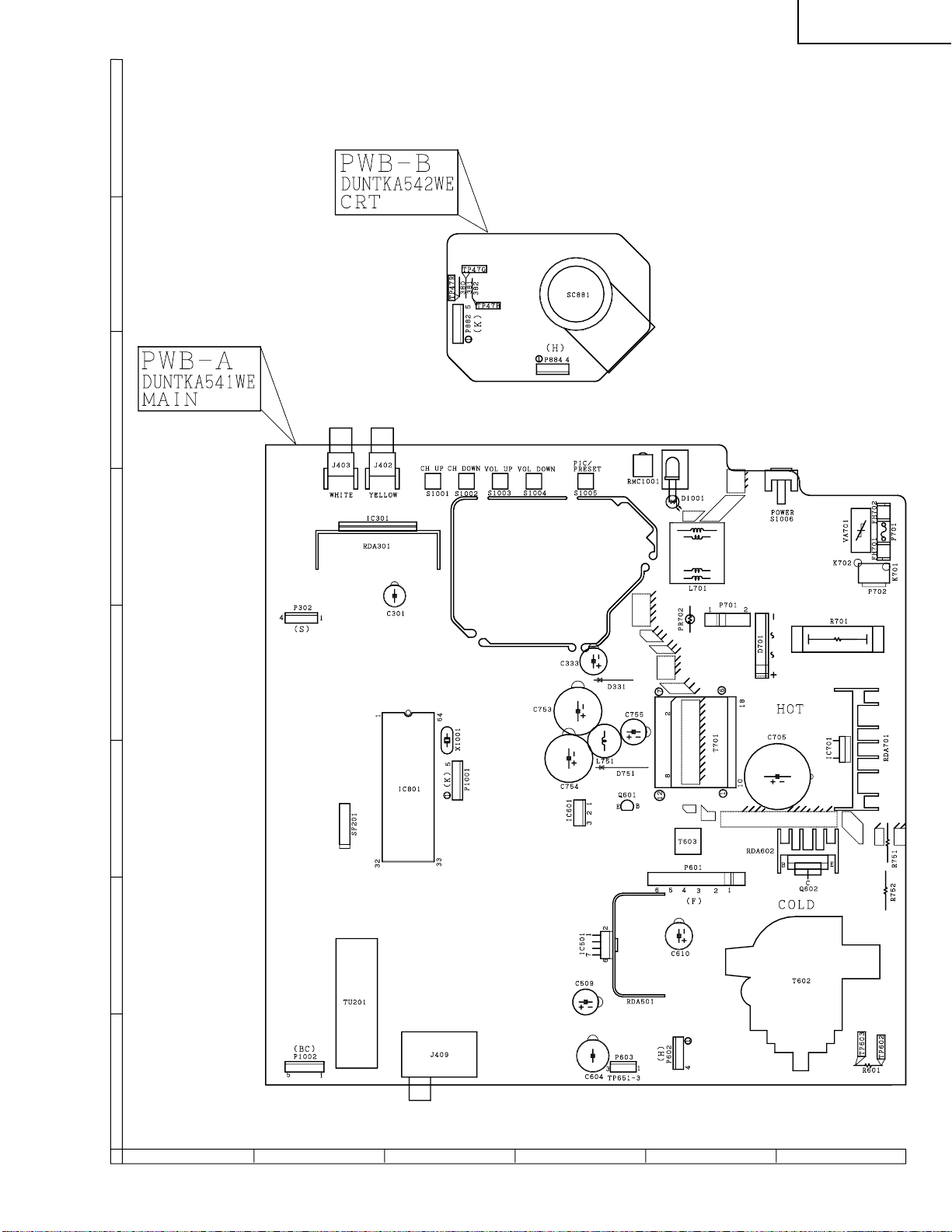

PWB-A: MAIN Unit (Wiring Side)

654321

28

Page 35

20AR22

20AR32

H

G

F

E

D

C

B

PWB-A: MAIN Unit (Chip Parts Side)

A

654321

29

Page 36

20AR22

20AR32

H

G

F

E

D

C

B

PWB-B: CRT Unit (Wiring Side)

A

PWB-B: CRT Unit (Chip Parts Side)

654321

30

Page 37

20AR22

20AR32

H

G

F

E

D

C

B

PWB-E: MTS MODULE Unit (Wiring Side)

A

PWB-E: MTS MODULE Unit (Chip Parts Side)

654321

31

Page 38

20AR22

PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics

identified in this manual; electrical components having such f eatures

are identified by å and shaded areas in the Replacement Parts Lists

and Schematic Diagrams. The use of a substitute replacement part

which does no have the same safety characteristic as the factory

recommended replacement parts shown in this service manual may

create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

★MARK: SPARE PARTS-DELIVERY SECTION

' MARK : X- RAY RELATED PARTS

Toshiba Part No. Part No. Ref.No. Description

PICTURE TUBE

å AD100444 VB48JLL40X/*S V1 Picture Tube

å AD100396 RCiLG0074PEZZ L703 Degaussing Coil

å

AD100397 RCiLH0105GJZZ DY601 Deflection Yoke

AD100333 LHLDW0102GJKZ Wire Holder, x5

AD100350 PMAGF3045CEZZ Purity Magne

AD100363 QEARC2016PEZZ Grounding Strap

AD100356 PSPAG0012MEZZ Wedge, x3

Toshiba Part No. Part No. Ref.No. Description

PWB-A: DUNTK541WEA7 (20AR22)

PWB-A: DUNTK541WEA8 (20AR32)

MAIN UNIT

TUNER

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

å AD100718 VTUVTST5UF690 Tuner

INTEGRATED CIRCUITS

AD100660 VHiAN7523++-1 IC301 AN7523++ (20AR22)

AD100661 VHiLA4600++-1 IC301 LA4600(20AR32)

å AD100662 VHiTDA9302H-1 IC501 TDA9302H

or

AD100637 VHIAN5522++-1

or

AD100663 VHiTDA9308

AD100640 VHiKA7808AP-1 IC601 KA7808API

å AD100641 VHiSTRG5653-1 IC701 STRG5653

AD100722 RH-iX3564CEN3 IC801 IX3564CE

AD100639 VHiBR24C02F1E IC1003 BR24C02F-W

TRANSISTORS

AD100655 VS2SC2735//1E Q201 2SC2735

AD100310 VS2SD601AR/-1 Q253 2SD601A

AD100310 VS2SD601AR/-1 Q254 2SD601A

AD100598 VS2SD601A//-1 Q304 2SD601A (20AR22)

AD100598 VS2SD601A//-1 Q320 2SD601A (20AR32)

AD100310 VS2SD601AR/-1 Q321 2SD601A (20AR22)

AD100598 VS2SD601A//-1 Q401 2SD601A (20AR32)

AD100596 VS2SC3207//-1 Q601 2SC3207

AD100597 VS2SD2586//1E Q602 2SD2586

AD100595 VS2SC3198-G-1 Q603 2SC3198-G

AD100595 VS2SC3198-G-1 Q751 2SC3198-G

AD100595 VS2SC3198-G-1 Q752 2SC3198-G

AD100594 VS2SB709A//-1 Q801 2SB709A

AD100594 VS2SB709A//-1 Q802 2SB709A

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

PWB-A DUNTKA541WEA7 – MAIN Unit (20AR22) —

PWB-A DUNTKA541WEA8 – MAIN Unit (20AR32) —

PWB-B DUNTKA542WEA1 – CRT Unit —

PWB-E DUNTKA545WEA0 – MTS MODULE Unit —

(20AR32)

AD100423 RH-EX0676GEZZ D201 Zener Diode, 33V

DIODES

å AD100409 RH-DX0302CEZZ D331 Diode (20AR22)

å AD100508 RH-DX0247CEZZ D331 Diode (20AR32)

AD100417 RH-EX0615GEZZ D502 Zener Diode, 5V

AD100504 VHD1SS119//-1 D503 Diode

AD100410 RH-DX0441CEZZ D505 Diode

AD100406 RH-DX0131CEZZ D508 Diode

AD100421 RH-EX0665GEZZ D509 Zener Diode

AD100504 VHD1SS119//-1 D511 Diode

AD100419 RH-EX0627GEZZ D531 Zener Diode, 8.2V

AD100419 RH-EX0627GEZZ D532 Zener Diode, 8.2V

AD100412 RH-DX0475CEZZ D601 Diode

å AD100505 VHD1SS244//-1 D602 Diode

å AD 100422 RH-EX0667GEZZ D603 Zener Diode, 27V

å AD100406 RH-DX0131CEZZ D606 Diode

å AD100411 RH-DX0468CEZZ D608 Diode

or

AD100407 RH-DX0229CEZZ

AD100419 RH-EX0627GEZZ D651 Zener Diode, 8.2V

AD100504 VHD1SS119//-1 D653 Diode

AD100413 RH-DX0476CEZZ D701 Diode

AD100506 VHD1SS82///1A D705 Diode

AD100506 VHD1SS82///1A D706 Diode

AD100506 VHD1SS82///1A D707 Diode

å AD100720 RH-DXA006WJZZ D751 Diode

å AD100406 RH-DX0131CEZZ D752 Diode

AD100418 RH-EX0616GEZZ D754 Zener Diode, 5.6V

AD100415 RH-EX0603GEZZ D755 Zener Diode, 3.9V

AD100504 VHD1SS119//-1 D801 Diode

AD100504 VHD1SS119//-1 D802 Diode

AD100504 VHD1SS119//-1 D803 Diode

AD100504 VHD1SS119//-1 D804 Diode

AD100504 VHD1SS119//-1 D805 Diode

AD100504 VHD1SS119//-1 D806 Diode

32

Page 39

20AR22

20AR32

Toshiba Part No. Part No. Ref.No. Description Toshiba Part No. Part No. Ref.No. Description

PWB-A: DUNTK541WEA7 (20AR22)

PWB-A: DUNTK541WEA8 (20AR32)

MAIN UNIT (Continued)

AD100424 RH-PX0013PEZZ AD1001 LED, POWER

AD100504 VHD1SS119//-1 D1004 Diode

AD100414 RH-EX0263TAZZ D1007 Zener Diode

AD100416 RH-EX0611GEZZ D1012 Zener Diode

AD100414 RH-EX0263TAZZ D1018 Zener Diode

AD100414 RH-EX0263TAZZ D1019 Zener Diode

å AD100427 RH-VX0073CEZZ VA701 Varistor

PACKAGED CIRCUITS

AD100428 RMPTP0001PEZZ PR702 Packaged Circuit

AD100403 RCRSB0300CEZZ X1001 Crystal

FILTERS AND COILS

AD100721 RFiLC0013CEZZ CF253 Ceramic Filter

AD100510 VP-DF270K0000 L202 Peaking 27µH

AD100510 VP-DF270K0000 L203 Peaking 27µH

AD100512 VP-XF1R2K0000 L204 Peaking 1.2µH

AD100511 VP-XF120K0000 L253 Peaking 12µH

å AD100726 RCiLF0078PEZZ L701 Coil

å AD100398 RCiLP0225CEZZ L751 Coil

AD100509 VP-DF100K0000 L802 Peaking 10µH

AD100509 VP-DF100K0000 L803 Peaking 10µH

AD100509 VP-DF100K0000 L1030 Peaking 10µH

AD100509 VP-DF100K0000 L1050 Peaking 10µH

AD100509 VP-DF100K0000 L1051 Peaking 10µH

AD100404 RFiLC0405CEZZ SF201 S.A.W Filter

TRANSFORMERS

å AD100435 RTRNZ0144PEZZ T601 Transformer

å AD100432 RTRNF0229PEZZ T602 H-Volt Transformer

or

AD100665 RTRNF0231PEZZ

å AD100434 RTRNW0015PEZZ T701 Transformer

CAPACITORS

[EL. …Electrolytic, M-Poly. …Metalized Polypro Film]

AD100456 VCEA0A1CW476M C201 47 16V EL.

AD100719 VCEA0A1AW108M C202 1000 10V EL.

AD100491 VCKYCY1HF103Z C205 0.01 50V Ceramic

AD100460 VCEA0A1HW105M C206 1.0 50V EL.

AD100482 VCKYCY1HB103K C207 0.01 50V Ceramic

AD100482 VCKYCY1HB103K C208 0.01 50V Cerami

AD100482 VCKYCY1HB103K C209 0.01 50V Ceramic

AD100491 VCKYCY1HF103Z C210 0.01 50V Ceramic

AD100491 VCKYCY1HF103Z C211 0.01 50V Ceramic

AD100492 VCKYCY1HF223Z C231 0.022 50V Ceramic

AD100490 VCKYCY1HB821K C232 820p 50V Ceramic

AD100488 VCKYCY1HB472K C233 4700p 50V Ceramic

AD100480 VCKYCY1EF104Z C234 0.1 25V Ceramic

AD100492 VCKYCY1HF223Z C251 0.022 50V Ceramic

AD100453 VCEA0A1CW107M C252 100 16V EL.

AD100458 VCEA0A1CW477M C301 470 16V EL. (20AR22)

AD100393 RC-EZA009WJZZ C301 220 16V EL. (20AR32)

AD100458 VCEA0A1CW477M C302 470 16V EL. (20AR32)

AD100458 VCEA0A1CW477M C303 470 16V EL. (20AR32)

AD100452 VCEA0A1CW106M C304 10 16V EL.

AD100465 VCEA0A1HW475M C305 4.7 50V EL. (20AR32)

AD100460 VCEA0A1HW105M C306 1.0 50V EL. (20AR32)

AD100460 VCEA0A1HW105M C307 1.0 50V EL. (20AR22)

AD400463 VCEA0A1HW224M C307 0.22 50V EL. (20AR32)

AD100478 VCKYCY1CB473K C308 0.047 16V Ceramic

(20AR32)

AD100464 VCEA0A1HW225M C310 2.2 50V EL. (20AR22)

AD100460 VCEA0A1HW105M C311 1.0 50V EL. (20AR22)

AD100392 RC-EZA008WJZZ C311 100 16V EL. (20AR32)

AD100464 VCEA0A1HW225M C312 2.2 50V EL. (20AR22)

AD100463 VCEA0A1HW224M C312 0.22 50V EL. (20AR32)

AD100478 VCKYCY1CB473K C313 0.047 16V Ceramic

(20AR32)

AD100488 VCKYCY1HB472K C313 4700p 50V Ceramic

(20AR22)

AD100471 VCEAKA1HW224M C314 0.22 50V EL. (20AR32)

å AD100498 VCQYTA1HM103J C332 0.01 50V Mylar

å AD100454 VCEA0A1CW108M C333 1000 16V EL. (20AR22)

å AD100391 RC-EZ1086CEZZ C333 1000 16V EL. (20AR32)

AD100488 VCKYCY1HB472K C356 4700p 50V Ceramic

(20AR22)

AD100452 VCEA0A1CW106M C359 10 16V EL.

AD100464 VCEA0A1HW225M C360 2.2 50V EL. (20AR22)

AD100480 VCKYCY1EF104Z C409 0.1 25V Ceramic

AD100480 VCKYCY1EF104Z C410 0.1 25V Ceramic

AD100481 VCKYCY1HB102K C411 1000p 50V Ceramic

AD100494 VCKYPA1HB102K C501 1000p 50V Ceramic

AD100482 VCKYCY1HB103K C504 0.01 50V Ceramic

AD100462 VCEA0A1HW107M C505 100 50V EL.

AD100482 VCKYCY1HB103K C507 0.01 50V Ceramic

AD100475 VCFYSA1JB224J C508 0.22 63V Mylar

AD100458 VCEA0A1CW477M C509 470 16V EL.

AD100496 VCKYPA2HB102K C510 1000p 500V Ceramic

AD100476 VCFYSA1JB473J C514 0.047 63V Mylar

AD100481 VCKYCY1HB102K C531 1000p 50V Ceramic

AD100481 VCKYCY1HB102K C532 1000p 50V Ceramic

AD100499 VCQYTA1HM104J C533 0.1 50V Mylar

AD100503 VCQYTA1HM563J C601 0.056 50V Mylar

AD100465 VCEA0A1HW475M C602 4.7 50V EL.

AD100460 VCEA0A1HW105M C603 1.0 50V EL.

AD100467 VCEA0A2EW106M C604 10 250V EL.

AD100496 VCKYPA2HB102K C605 1000p 500V Ceramic

AD100472 VCFPVC2DB474J C606 0.47 200V M-Poly.

AD100473 VCFPVC3ZA772H C607 7700p 1.8kV M-Poly.

AD100496 VCKYPA2HB102K C608 1000p 500V Ceramic

AD100454 VCEA0A1CW108M C610 1000 16V EL.

AD100459 VCEA0A1EW476M C611 47 25V EL.

AD100458 VCEA0A1CW477M C612 470 16V EL.

AD100496 VCKYPA2HB102K C620 1000p 500V Ceramic

AD100477 VCFYSB2EB823J C640 0.082 250V

AD100501 VCQYTA1HM222J C651 2200p 50V Mylar

AD100502 VCQYTA1HM472J C652 4700p 50V Mylar

AD100460 VCEA0A1HW105M C653 1.0 50V EL.

AD100492 VCKYCY1HF223Z C654 0.022 50V Ceramic

AD100461 VCEA0A1HW106M C655 10 50V EL.

AD100463 VCEA0A1HW224M C656 0.22 50V EL.

AD100480 VCKYCY1EF104Z C657 0.1 25V Ceramic

AD100480 VCKYCY1EF104Z C658 0.1 25V Ceramic

å AD100394 RC-FZ036SCEZZ C701 0.1 275V Plastic

AD100399 RC-KZ0029CEZZ C702 0.01 250V Ceramic

AD100399 RC-KZ0029CEZZ C703 0.01 250V Ceramic

AD100399 RC-KZ0029CEZZ C704 0.01 250V Ceramic

AD100390 RC-EZ0804CEZZ C705 220 400V EL.

AD100400 RC-KZ0039CEZZ C709 680 2kV Ceramic

AD100466 VCEA0A1HW476M C710 47 50V EL.

AD100494 VCKYPA1HB102K C711 1000p 50V Ceramic

AD100495 VCKYPA1HB471K C712 470p 50V Ceramic

å AD100401 RC-KZ0092GEZZ C751 3300p

å AD100497 VCKYPH3DB561K C752 560p 2000V Ceramic

å AD100389 RC-EZ0724CEZZ C753 100 16V EL.

å AD100389 RC-EZ0724CEZZ C754 33 160V EL.

å AD10 0454 VCEA0A1CW108M C755 1000 16V EL.

å AD100498 VCQYTA1HM103J C756 0.01 50V Mylar

AC250V

Ceramic

AD100450 VCEA0A0JW477M C759 470 6.3V EL.

AD100449 VCEA0A0JW228M C760 2200 6.3V EL.

AD100460 VCEA0A1HW105M C801 1.0 50V EL.

AD100456 VCEA0A1CW337M C802 330 16V EL.

AD100453 VCEA0A1CW107M C803 100 16V EL.

AD100484 VCKYCY1HB222K C804 2200p 50V Ceramic

AD100493 VCKYD41HB102K C805 1000p 50V Ceramic

AD100493 VCKYD41HB102K C806 1000p 50V Ceramic

AD100493 VCKYD41HB102K C807 1000p 50V Ceramic

AD100453 VCEA0A1CW107M C808 100 16V EL.

AD100479 VCKYCY1CF474Z C809 0.47 16V Ceramic

AD100479 VCKYCY1CF474Z C810 0.47 16V Ceramic

AD100453 VCEA0A1CW107M C811 100 16V EL.

AD100474 VCFYFA1HA224J C812 0.22 50V Mylar

AD100474 VCFYFA1HA224J C813 0.22 50V Mylar

AD100487 VCKYCY1HB471K C814 470p 50V Ceramic

AD100487 VCKYCY1HB471K C816 470p 50V Ceramic

33

Page 40

20AR22

20AR32

Toshiba Part No. Part No. Ref.No. Description Toshiba Part No. Part No. Ref.No. Description

PWB-A: DUNTK541WEA7 (20AR22)

PWB-A: DUNTK541WEA8 (20AR32)

MAIN UNIT (Continued)

AD100448 VCEA0A0JW107M C1001 100 6.3V EL.

AD100448 VCEA0A0JW107M C1002 100 6.3V EL.

AD100452 VCEA0A1CW106M C1003 10 16V EL.

AD100479 VCKYCY1CF474Z C1004 0.47 16V Ceramic

AD100479 VCKYCY1CF474Z C1005 0.47 16V Ceramic

AD100452 VCEA0A1CW106M C1006 10 16V EL.

AD100445 VCCCCY1HH330J C1008 33p 50V Ceramic

AD100445 VCCCCY1HH330J C1009 33p 50V Ceramic

AD100448 VCEA0A0JW107M C1010 100 6.3V EL.

AD100479 VCKYCY1CF474Z C1011 0.47 16V Ceramic

AD100479 VCKYCY1CF474Z C1012 0.47 16V Ceramic

AD100448 VCEA0A0JW107M C1013 100 6.3V EL.

AD100499 VCQYTA1HM104J C1016 0.1 50V Mylar

AD100483 VCKYCY1HB221K C1018 220p 50V Ceramic

AD100499 VCQYTA1HM104J C1024 0.1 50V Mylar

AD100448 VCEA0A0JW107M C1026 100 6.3V EL.

RESISTORS

[M-Ox. …Metal Oxide, M-Film …Metal Film]

AD100552 VRS-CY1JF000J RJ1 00 1/16W M-Ox.

(20AR32)

AD100552 VRS-CY1JF000J RJ2 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ4 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ5 00 1/16W M-Ox.

(20AR32)

AD100552 VRS-CY1JF000J RJ8 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ9 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ10 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ13 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ14 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ15 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ16 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ17 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ19 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ21 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ23 00 1/16W M-Ox.

(20AR32)

AD100552 VRS-CY1JF000J RJ24 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ26 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ28 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ32 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ33 00 1/16W M-Ox.

(20AR22)

AD100552 VRS-CY1JF000J RJ34 00 1/16W M-Ox.

(20AR32)

AD100552 VRS-CY1JF000J RJ35 00 1/16W M-Ox.

(20AR22)

AD100552 VRS-CY1JF000J RJ37 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ38 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ41 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ42 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ43 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ46 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ49 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ50 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ51 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ52 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ53 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ55 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ70 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ71 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ73 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ75 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ76 00 1/16W M-Ox.

AD100552 VRS-CY1JF000J RJ77 00 1/16W M-Ox.

AD100552 VRS-CY1JF101J R201 100 1/16W M-Ox.

AD100552 VRS-CY1JF101J R202 100 1/16W M-Ox.

AD100580 VRS-CY1JF680J R205 68 1/16W M-Ox.

AD100558 VRS-CY1JF122J R206 1.2k 1/16W M-Ox.

AD100563 VRS-CY1JF221J R207 220 1/16W M-Ox.

AD100558 VRS-CY1JF122J R208 1.2k 1/16W M-Ox.

AD100572 VRS-CY1JF392J R209 3.9k 1/16W M-Ox.

AD100589 VRS-RG3LB223J R216 22k 3W M-Ox.

AD100526 VRD-RA2BE392J R219 3.9k 1/8W Carbon

AD100563 VRS-CY1JF221J R220 220 1/16W M-Ox.

AD100575 VRS-CY1JF473J R230 47k 1/16W M-Ox.

AD100532 VRD-RA2BE681J R231 680 1/8W Carbon

AD100566 VRS-CY1JF272J R232 2.7k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R233 100 1/16W M-Ox.

AD100571 VRS-CY1JF391J R234 390 1/16W M-Ox.

AD100561 VRS-CY1JF181J R257 180 1/16W M-Ox.

AD100561 VRS-CY1JF181J R258 180 1/16W M-Ox.

AD100573 VRS-CY1JF471J R259 470 1/16W M-Ox.

AD100572 VRS-CY1JF392J R260 3.9k 1/16W M-Ox.

AD100564 VRS-CY1JF223J R261 22k 1/16W M-Ox.

AD100576 VRS-CY1JF560J R262 56 1/16W M-Ox.

AD100576 VRS-CY1JF560J R263 56 1/16W M-Ox.

AD100553 VRS-CY1JF101J R301 100 1/16W M-Ox.

(20AR22)

AD100563 VRS-CY1JF221J R304 220 1/16W M-Ox.

(20AR32)

AD100579 VRS-CY1JF683J R304 68k 1/16W M-Ox.

(20AR22)

AD100568 VRS-CY1JF274J R305 270k 1/16W M-Ox.

AD100525 VRD-RA2BE391J R306 390 1/8W Carbon

(20AR32)

AD100552 VRS-CY1JF000J R307 00 1/16W M-Ox.

(20AR22)

AD100558 VRS-CY1JF122J R307 1.2k 1/16W M-Ox.

(20AR32)

AD100516 VRD-RA2BE103J R308 10k 1/8W Carbon

(20AR32)

AD100529 VRD-RA2BE473J R309 47k 1/8W Carbon

(20AR32)

AD100575 VRS-CY1JF473J R310 47k 1/16W M-Ox.

(20AR22)

AD100575 VRS-CY1JF473J R311 47k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R313 1.0k 1/16W M-Ox.

(20AR22)

AD100555 VRS-CY1JF103J R314 10k 1/16W M-Ox.

AD100558 VRS-CY1JF122J R315 1.2k 1/16W M-Ox.

(20AR32)

AD100583 VRS-CY1JF822J R315 8.2k 1/16W M-Ox.

(20AR22)

AD100556 VRS-CY1JF104J R316 100k 1/16W M-Ox.

(20AR32)

AD100566 VRS-CY1JF272J R322 2.7k 1/16W M-Ox.

(20AR22)

AD100728 VRD-RA2BE274J R323 270k 1/8W Carbon

(20AR22)

AD100553 VRS-CY1JF101J R333 100 1/16W M-Ox.

(20AR22)

AD100570 VRS-CY1JF332J R334 3.3k 1/16W M-Ox.

AD100578 VRS-CY1JF564J R335 560k 1/16W M-Ox.

AD100523 VRD-RA2BE332J R336 3.3k 1/8W Carbon

(20AR32)

AD100578 VRS-CY1JF564J R337 560k 1/16W M-Ox.

(20AR32)

AD100553 VRS-CY1JF101J R340 100 1/16W M-Ox.

(20AR32)

AD100583 VRS-CY1JF822J R341 8.2k 1/16W M-Ox.

(20AR32)

AD100570 VRS-CY1JF332J R362 3.3k 1/16W M-Ox.

(20AR32)

AD100578 VRS-CY1JF564J R363 560k 1/16W M-Ox.

(20AR32)

AD100552 VRS-CY1JF000J R364 100 1/16W M-Ox.

(20AR22)

AD100570 VRS-CY1JF332J R364 3.3k 1/16W M-Ox.

(20AR32)

AD100578 VRS-CY1JF564J R365 560k 1/16W M-Ox.

(20AR32)

AD100553 VRS-CY1JF101J R401 100 1/16W M-Ox.

(20AR22)

AD100553 VRS-CY1JF101J R430 100 1/16W M-Ox.

(20AR32)

34

Page 41

Toshiba Part No. Part No. Ref.No. Description Toshiba Part No. Part No. Ref.No. Description

20AR22

20AR32

PWB-A: DUNTK541WEA7 (20AR22)

PWB-A: DUNTK541WEA8 (20AR32)

MAIN UNIT (Continued)

AD100553 VRS-CY1JF101J R431 100 1/16W M-Ox.

(20AR22)

AD100582 VRS-CY1JF750J R432 75 1/16W M-Ox.

AD100555 VRS-CY1JF103J R433 10k 1/16W M-Ox.

(20AR32)

AD100582 VRS-CY1JF750J R464 75 1/16W M-Ox.

(20AR32)

AD100520 VRD-RA2BE222J R501 2.2k 1/8W Carbon

AD100535 VRD-RM2HD102J R502 1.0k 1/2W Carbon

AD100547 VRN-RL3DB2R2J R503 2.2 2W M-Film

AD100561 VRS-CY1JF181J R504 180 1/16W M-Ox.

AD100554 VRS-CY1JF102J R505 1.0k 1/16W M-Ox.

AD100585 VRS-RG3AB391J R506 390 1W M-Ox.

AD100544 VRN-RL3AB1R0J R507 1.0 1W M-Film

AD100524 VRD-RA2BE333J R510 33k 1/8W Carbon

AD100561 VRS-CY1JF181J R511 180 1/16W M-Ox.

AD100534 VRD-RM2HD100J R512 10 1/2W Carbon

AD100553 VRS-CY1JF101J R531 100 1/16W M-Ox.

AD100553 VRS-CY1JF101J R532 100 1/16W M-Ox.

AD100527 VRD-RA2BE393J R533 39k 1/8W Carbon

AD100584 VRS-RG2HC102J R601 1.0k 1/2W M-Ox.

AD100527 VRD-RA2BE393J R602 39k 1/8W Carbon

AD100521 VRD-RA2BE223J R603 22k 1/8W Carbon

AD100527 VRD-RA2BE393J R604 39k 1/8W Carbon

AD100542 VRD-RM2HD823J R605 82k 1/2W Carbon

å AD100545 VRN-RL3AB2R2 J R606 2.2 1W M-Film

å AD100538 VRD-RM2HD270J R607 27 1/2W Carbon

å AD100518 VRD-RA2BE154J R609 150k 1/8W Carbon

å AD100514 VRD-RA2BE102G R610 1.0k 1/8W Carbon

AD100554 VRS-CY1JF102J R611 1.0k 1/16W M-Ox.

AD100559 VRS-CY1JF123J R612 12k 1/16W M-Ox.

AD100555 VRS-CY1JF103J R613 10k 1/16W M-Ox.

å AD100727 VRD-RG2HC100J R614 10 1/2W Carbon

AD100588 VRS-RG3DB682J R615 6.8k 2W M-Ox.

AD100546 VRN-RL3ABR47J R616 0.47 1W M-Film

AD100587 VRS-RG3DB391J R618 390 2W M-Ox.

AD100590 VRS-RG3LB562J R619 5.6k 3W M-Ox.

AD100586 VRS-RG3AB472J R620 4.7k 1W M-Ox.

AD100514 VRD-RA2BE102J R622 1.0k 1/8W Carbon

AD100551 VRN-VV3DB4R7J R625 4.7 2W M-Film

AD100540 VRD-RM2HD470J R626 47 1/2W Carbon

AD100543 VRN-RL2HCR47J R641 0.47 1/2W M-Film

AD100564 VRS-CY1JF223J R651 22k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R652 1.0k 1/16W M-Ox.

AD100583 VRS-CY1JF822J R653 8.2k 1/16W M-Ox.

AD100567 VRS-CY1JF273J R654 27k 1/16W M-Ox.

AD100571 VRS-CY1JF391J R655 390 1/16W M-Ox.

AD100562 VRS-CY1JF100J R656 10 1/16W M-Ox.

AD100513 VRD-RA2BE101J R658 100 1/8W Carbon

AD100513 VRD-RA2BE101J R663 100 1/8W Carbon

AD100593 VRW-KQ3NC3R9K R701 3.9 7W Cement

AD100550 VRN-SV2HC1R0J R704 1.0 1/2W M-Film

AD100591 VRS-VV3DB104J R707 100k 2W M-Ox.

AD100532 VRD-RA2BE681J R708 680 1/8W Carbon

AD100549 VRN-RL3DBR47J R709 0.47 2W M-Film

AD100548 VRN-RL3DBR39J R710 0.39 2W M-Film

AD100533 VRD-RA2BE682J R711 6.8k 1/8W Carbon

AD100517 VRD-RA2BE152J 1.5k 1/8W Carbon

AD100531 VRD-RA2BE562J R716 5.6k 1/8W Carbon

å AD100429 RR-DZ0049CEZZ R751 3.9M 1/2W Solid

å AD100429 RR-DZ0049CEZZ R752 3.9M 1/2W Solid

å AD100536 VRD-RM2HD124J R753 120k 1/2W Carbon

AD100537 VRD-RM2HD150J R754 15 1/2W Carbon

AD100519 VRD-RA2BE221J R755 220 1/8W Carbon

AD100538 VRD-RM2HD270J R756 27 1/2W Carbon

AD100560 VRS-CY1JF151J R757 150 1/16W M-Ox.

AD100563 VRS-CY1JF221J R801 220 1/16W M-Ox.

AD100563 VRS-CY1JF221J R802 220 1/16W M-Ox.

AD100563 VRS-CY1JF221J R803 220 1/16W M-Ox.

AD100563 VRS-CY1JF221J R804 220 1/16W M-Ox.

AD100583 VRS-CY1JF822J R805 8.2k 1/16W M-Ox.

AD100559 VRS-CY1JF123J R806 12k 1/16W M-Ox.

AD100555 VRS-CY1JF103J R807 10k 1/16W M-Ox.

AD100563 VRS-CY1JF221J R808 220 1/16W M-Ox.

AD100522 VRD-RA2BE224J R809 220k 1/8W Carbon

AD100553 VRS-CY1JF101J R812 100 1/16W M-Ox.

AD100563 VRS-CY1JF221J R813 220 1/16W M-Ox.

AD100583 VRS-CY1JF822J R1002 8.2k 1/16W M-Ox.

AD100577 VRS-CY1JF562J R1003 5.6k 1/16W M-Ox.

AD100577 VRS-CY1JF562J R1006 5.6k 1/16W M-Ox.

AD100577 VRS-CY1JF562J R1007 5.6k 1/16W M-Ox.

AD100583 VRS-CY1JF822J R1008 8.2k 1/16W M-Ox.

AD100577 VRS-CY1JF562J R1009 5.6k 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1011 3.3k 1/16W M-Ox.

AD100525 VRD-RA2BE391J R1012 390 1/8W Carbon

AD100513 VRD-RA2BE101J R1013 100 1/8W Carbon

AD100553 VRS-CY1JF101J R1014 100 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1015 3.3k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1016 100 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1017 3.3k 1/16W M-Ox.

AD100552 VRS-CY1JF000J R1019 00 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1020 100 1/16W M-Ox.

AD100562 VRS-CY1JF183J R1021 18k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1022 100 1/16W M-Ox.

AD100563 VRS-CY1JF221J R1023 220 1/16W M-Ox.

AD100562 VRS-CY1JF183J R1024 18k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1025 100 1/16W M-Ox.

AD100565 VRS-CY1JF224J R1026 220k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1028 100 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1032 3.3k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1034 100 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1035 3.3k 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1036 3.3k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1037 100 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1038 100 1/16W M-Ox.

AD100564 VRS-CY1JF223J R1039 22k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1040 100 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1041 100 1/16W M-Ox.

AD100528 VRD-RA2BE471J R1042 470 1/8W Carbon

AD100553 VRS-CY1JF101J R1046 100 1/16W M-Ox.

AD100570 VRS-CY1JF332J R1047 3.3k 1/16W M-Ox.

AD100572 VRS-CY1JF392J R1050 3.9k 1/16W M-Ox.

AD100581 VRS-CY1JF683J R1051 68k 1/16W M-Ox.

AD100567 VRS-CY1JF273J R1066 27k 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1072 100 1/16W M-Ox.

AD100553 VRS-CY1JF101J R1073 100 1/16W M-Ox.

AD100520 VRD-RA2BE222J JA223 2.2k 1/8W Carbon

(20AR32)

AD100515 VRD-RA2BE102J JA721 1.0k 1/8W Carbon

(20AR22)

SWITCHES

AD100385 QSW-K0003AJZZ S1001 Switch, CH UP

AD100385 QSW-K0003AJZZ S1002 Switch, CH DOWN

AD100385 QSW-K0003AJZZ S1003 Switch, VOL UP

AD100385 QSW-K0003AJZZ S1004 Switch, VOL DOWN

AD100385 QSW-K0003AJZZ S1005 Switch, PICTURE/PRESET

AD100386 QSW-K0114CEZZ S1006 Switch, POWER

MISCELLANEOUS PARTS

å AD100364 QFS-C3229CEZZ F701 Fuse, T3.14AL

AD100387 RBLN-0091GEZZ FB601 Ferrite Bead

AD100365 QFSHD1013CEZZ FH701 Fuse Holder

AD100366 QFSHD1014CEZZ FH702 Fuse Holder

AD100368 QJAKE0210CE04 J402 Jack, Video (AV)

(20AR22)

AD100370 QJAKE0211CE04 J402 Jack, Video (AV)

(20AR32)

AD100369 QJAKE0210CE09 J403 Jack, Audio (L)(AV)

(20AR22)

AD100371 QJAKE0211CE09 J403 Jack, Audio (L)(AV)

(20AR32)

AD100367 QJAKE0210CE02 J404 Jack, Audio (R)(AV)

(20AR32)

AD100372 QJAKF0074CEZZ J409 Jack, Rear AV (20AR22)

AD100373 QJAKG0093CEZZ J409 Jack, Rear AV (20AR32)

35

Page 42

20AR22

20AR32

Toshiba Part No. Part No. Ref.No. Description Toshiba Part No. Part No. Ref.No. Description

PWB-A: DUNTK541WEA7 (20AR22)

PWB-A: DUNTK541WEA8 (20AR32)

MAIN UNIT (Continued)

AD100379 QPLGN0461CEZZ P302 Plug, 4-pin (S)

AD100381 QPLGN0660CEZZ P601 Plug, 6-pin (K)

AD100378 QPLGN0361CEZZ P603 Plug, 3-pin (TP651-3)

AD100376 QPLGN0260CEZZ P701 Plug, 2-pin (M)

AD100377 QPLGN0269GEZZ P702 Plug, 2-pin

AD100380 QPLGN0561CEZZ P1002 Plug, 5-pin (BC)

AD100431 RRMCU0222CEZZ

AD100352 PRDAR0119GJFW

AD100353 PRDAR0120GJFW

AD100351 PRDAR0118GJFW RDA501 Heat Sink, for IC501

AD100354 PRDAR0224PEFW

AD100355 PRDAR0298PEFW

AD100374 QLUGP0102PEZZ TP201 Lug, Test Point

AD100332 LHLDP1066PE00 Holder

AD100339 LHLDW1104PEZZ Holder

AD100340 LHLDW1105PEZZ Holder

AD100344 LX-BZ0086TAFD Screw

AD100345 LX-BZ3049GEFD Screw

AD100347 LX-TZ3004CEFD Screw

AD100361 QCNW-2619PEZZ Connecting Cord

AD100362 QCNW-2620PEZZ Connecting Cord

RMC1001

R/C Receiver

RDA301

Heat Sink, for IC301

RDA301

RDA602

RDA701

(20AR22)

Heat Sink, for IC301

(20AR32)

Heat Sink, for Q602

Heat Sink, for IC701

PWB-B: DUNTK542WEA3

CRT UNIT

TRANSISTORS

AD100425 RH-TX0110BMZZ Q870 TX0110BM

AD100425 RH-TX0110BMZZ Q871 TX0110BM

AD100425 RH-TX0110BMZZ Q872 TX0110BM

AD100426 RH-TX0124BMZZ Q883 TX0110BM

AD100426 RH-TX0124BMZZ Q885 TX0124BM

AD100426 RH-TX0124BMZZ Q887 TX0124BM

DIODES

AD100504 VHD1SS119//-1 D881 Diode

AD100504 VHD1SS119//-1 D882 Diode

AD100504 VHD1SS119//-1 D883 Diode

AD100504 VHD1SS119//-1 D884 Diode

AD100504 VHD1SS119//-1 D885 Diode

CAPACITORS

[EL. …Electrolytic]

AD100446 VCCSCY1HL471J C871 470p 50V Ceramic

AD100446 VCCSCY1HL471J C872 470p 50V Ceramic

AD100446 VCCSCY1HL471J C873 470p 50V Ceramic

AD100496 VCKYPA2HB102K C875 1000p 500V Ceramic

AD100402 RC-KZ0150CEZZ C876 1000p 3kV Ceramic

AD100467 VCEA0A2EW106M C878 10 250V EL.

AD100446 VCCSCY1HL471J C880 470p 50V Ceramic

AD100495 VCKYPA1HB471K C881 470p 50V Ceramic

AD100495 VCKYPA1HB471K C882 470p 50V Ceramic

AD100496 VCKYPA2HB102K C886 1000p 500V Ceramic

RESISTORS

[M-Ox. …Metal Oxide]

AD100573 VRS-CY1JF471J R879 470 1/16W M-Ox.

AD100573 VRS-CY1JF471J R880 470 1/16W M-Ox.

AD100573 VRS-CY1JF471J R881 470 1/16W M-Ox.

AD100592 VRS-VV3DB153J R882 15k 2W M-Ox.

AD100539 VRD-RM2HD272J R883 2.7k 1/2W Carbon

AD100592 VRS-VV3DB153J R884 15k 2W M-Ox.

AD100539 VRD-RM2HD272J R885 2.7k 1/2W Carbon

AD100592 VRS-VV3DB153J R886 15k 2W M-Ox.

AD100539 VRD-RM2HD272J R887 2.7k 1/2W Carbon

AD100573 VRS-CY1JF471J R888 470 1/16W M-Ox.

AD100554 VRS-CY1JF102J R892 1.0k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R893 1.0k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R894 1.0k 1/16W M-Ox.

AD100573 VRS-CY1JF471J R898 470 1/16W M-Ox.

AD100573 VRS-CY1JF471J R899 470 1/16W M-Ox.

å AD100383 QSOCV0840CEZZ SC881 CRT Socket

AD100384 QSOCV0841CEZZ

or

36

MISCELLANEOUS PARTS

Page 43

Toshiba Part No. Part No. Ref.No. Description

PWB-E: DUNTK545WEA0 (20AR32)

MTS MODULE UNIT

20AR22

20AR32

AD100507 VHiCXA2074Q-1 IC3001 CXA2074Q

AD100508 VHiMM1501XN-1 IC3002 MM1501XNRE

TRANSISTORS

INTEGRATED CIRCUITS

AD100595 VS2SC3198-G-1 Q3003 C3198-G

DIODE

AD100420 RH-EX0632GEZZ D3001 Zener Diode

CAPACITORS

AD100447 VCE9GA1HW475M C3001 4.7 50V EL. (N.P)

AD100489 VCKYCY1HB562K C3002 5600p 50V Ceramic

AD100500 VCQYTA1HM123K C3003 0.012 50V Mylar

AD100460 VCEA0A1HW105M C3004 1.0 50V EL.

AD100468 VCEA9A1HW475M C3005 4.7 50V EL.

AD100452 VCEA0A1CW106M C3006 10 16V EL.

AD100465 VCEA0A1HW475M C3007 4.7 50V EL.

AD100491 VCKYCY1HF103Z C3008 0.01 50V Ceramic

AD100455 VCEA0A1CW227M C3009 220 16V EL.

AD100447 VCE9GA1HW475M C3010 4.7 50V EL. (N.P)

AD100465 VCEA0A1HW475M C3011 4.7 50V EL.

AD100447 VCE9GA1HW475M C3012 4.7 50V EL. (N.P)

AD100485 VCKYCY1HB272K C3013 2700p 50V Ceramic

AD100470 VCEACA1HC335K C3015 3.3 50V EL.

AD100447 VCE9GA1HW475M C3016 4.7 50V EL. (N.P)

AD100469 VCEACA1CC106K C3017 10 16V EL.

AD100460 VCEA0A1HW105M C3018 1.0 50V EL.

AD100452 VCEA0A1CW106M C3019 10 16V EL.

AD100452 VCEA0A1CW106M C3020 10 16V EL.

AD100452 VCEA0A1CW106M C3021 10 16V EL.

AD100452 VCEA0A1CW106M C3022 10 16V EL.

AD100452 VCEA0A1CW106M C3031 10 16V EL.

AD100452 VCEA0A1CW106M C3032 10 16V EL.

AD100491 VCKYCY1HF103Z C3033 0.01 50V Ceramic

AD100463 VCEA0A1HW224M C3034 0.22 50V EL.

AD100455 VCEA0A1CW227M C3039 220 16V EL.

[EL. …Electrolytic]

RESISTORS

AD100519 VRD-RA2BE221J R3001 220 1/8W Carbon

AD100519 VRD-RA2BE221J R3002 220 1/8W Carbon

AD100557 VRS-CY1JF105J R3003 1.0M 1/16W M-Ox.

AD100556 VRS-CY1JF104J R3004 100k 1/16W M-Ox.

AD100579 VRS-CY1JF623J R3005 62k 1/16W M-Ox.

AD100570 VRS-CY1JF332J R3007 3.3k 1/16W M-Ox.

AD100569 VRS-CY1JF302J R3008 3.0k 1/16W M-Ox.

AD100572 VRS-CY1JF392J R3010 3.9k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R3011 1.0k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R3012 1.0k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R3013 1.0k 1/16W M-Ox.

AD100554 VRS-CY1JF102J R3014 1.0k 1/16W M-Ox.

AD100513 VRD-RA2BE101J R3015 100 1/8W Carbon

AD100530 VRD-RA2BE560J R3022 56 1/8W Carbon

AD100541 VRD-RM2HD5R6J R3023 5.6 1/2W Carbon

AD100574 VRS-CY1JF472J R3025 4.7k 1/16W M-Ox.

[M-Ox. …Metal Oxide]

MISCELLANEOUS PARTS

AD100382 QPLGZ0810CEZZ P3001 Plug, 8-pin (M)

AD100382 QPLGZ0810CEZZ P3002 Plug, 8-pin (SW)

AD100382 QPLGZ0810CEZZ P3003 Plug, 8-pin (N)

37

Page 44

20AR22

AD100324 GCOVA0110GJSA 1-4 Cover for LED,R/C

Not Available 1-1 Front Cabinet

20AR32

Toshiba Part No. Part No. Ref.No. Description Toshiba Part No. Part No. Ref.No. Description

MISCELLANEOUS PARTS

å

AD100359 QACCZ3008PEZZ ACC701 AC Cord

AD100600 VSP9050PB40YA SP301 Speaker (R)(20AR22)

AD100600 VSP9050PB40YA SP302 Speaker (L)(20AR22)

AD100599 VSP9050PB394A SP301 Speaker (R)(20AR32)

AD100599 VSP9050PB394A SP302 Speaker (L)(20AR32)

AD100331 LHLDK0012PEZZ AC Cord Holder

AD100334 LHLDW1003PEZZ Holder

AD100335 LHLDW1009PEZZ Holder

AD100336 LHLDW1033PEZZ Holder

AD100337 LHLDW1060CEZZ Holder

AD100339 LHLDW1104PEZZ Holder

AD100340 LHLDW1105PEZZ Holder

AD100341 LHLDZ0063PEZZ Holder

AD100346 LX-TZ0104GJFD CRT Screw, x4

AD100348 LX-WZ0102GJFD CRT Washer, x4

AD100338 LHLDW1070PEKZ Holder

AD100342 LHLDZ1002GJZZ Holder

AD100343 LHLDZ1003GJZZ Holder

AD100347 LX-TZ3004CEFD Screw

AD100357 PSPAH0117GJ00 Spacer

AD100358 PSPAH0118GJ00 Spacer

AD100360 QCNW-2562PEZZ Connecting Cord

AD100717 TLABZA134WJZZ Label

AD100441 TCAUS3000GJZZ Caution Card (20AR22)

AD100443 TLABM0109GJZZ Model Label

AD100601 XTASD40P20000 Screw

PACKING PARTS

(NOT REPLACEMANT ITEM)

AD100713 SPAKCA199WJZZ – Packing Case (20AR22) —

AD100715 SPAKCA200WJZZ – Packing Case (20AR32) —

AD100437 SPAKP0102GJZZ – Wrapping Paper —

AD100438 SPAKX0124GJZZ – Buffer Material —

AD100439 SSAKA0101GJZZ – Polyethylene Bag —

CABINET PARTS

20AR22

AD100680 CCABAA106WWH0 1 Front Cabinet Ass’y

AD100324 GCOVA0110GJSA 1-4 Cover for LED, R/C

AD100325 HBDGB0102GJSA 1-2 Badge, "TOSHIBA"

AD100328 JBTN-0113GJSB 1-3 Button, Menu, CH-up/down,

Vol-up/down

AD100330 JBTN-0114GJSB 1-5 Button, Power

AD100349 MSPRC0005PEFW 1-6 Spring for Power Button

AD100322 GCABB0128GJKA 2 Rear Cabinet

SUPPLIED ACCESORRIES

AD100375 QPLGA0017CEZZ AC Plug Adapter

AD100430 RRMCG1589CESA Infrared R/C Unit

AD100684 TiNS-A258WJZZ Operation Manual

AD100696 CCABAA107WEH0 1 Front Cabinet Ass’y

20AR32

Not Available 1-1 Front Cabinet

AD100326 HBDGB1001GJSA 1-2 Badge, "TOSHIBA"

AD100327 JBTN-0113GJSA 1-3 Button, Menu, CH-up/down,

Vol-up/down

AD100329 JBTN-0114GJSA 1-5 Button, Power

AD100349 MSPRC0005PEFW 1-6 Spring for Power Button

AD100323 GCABB0129GJKA 2 Rear Cabinet

1 1-1

2

1-2

1-51-6 1-4 1-3

38

Page 45

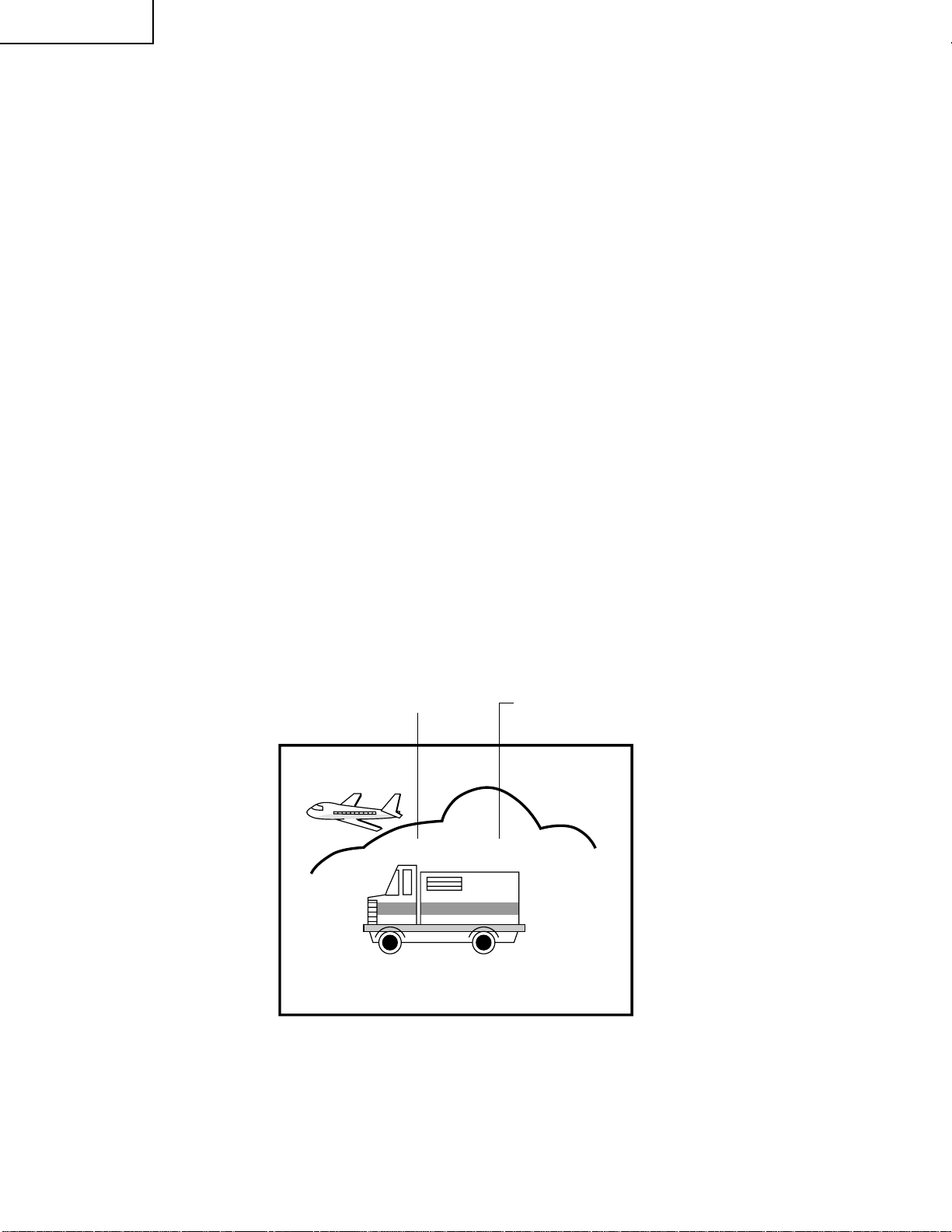

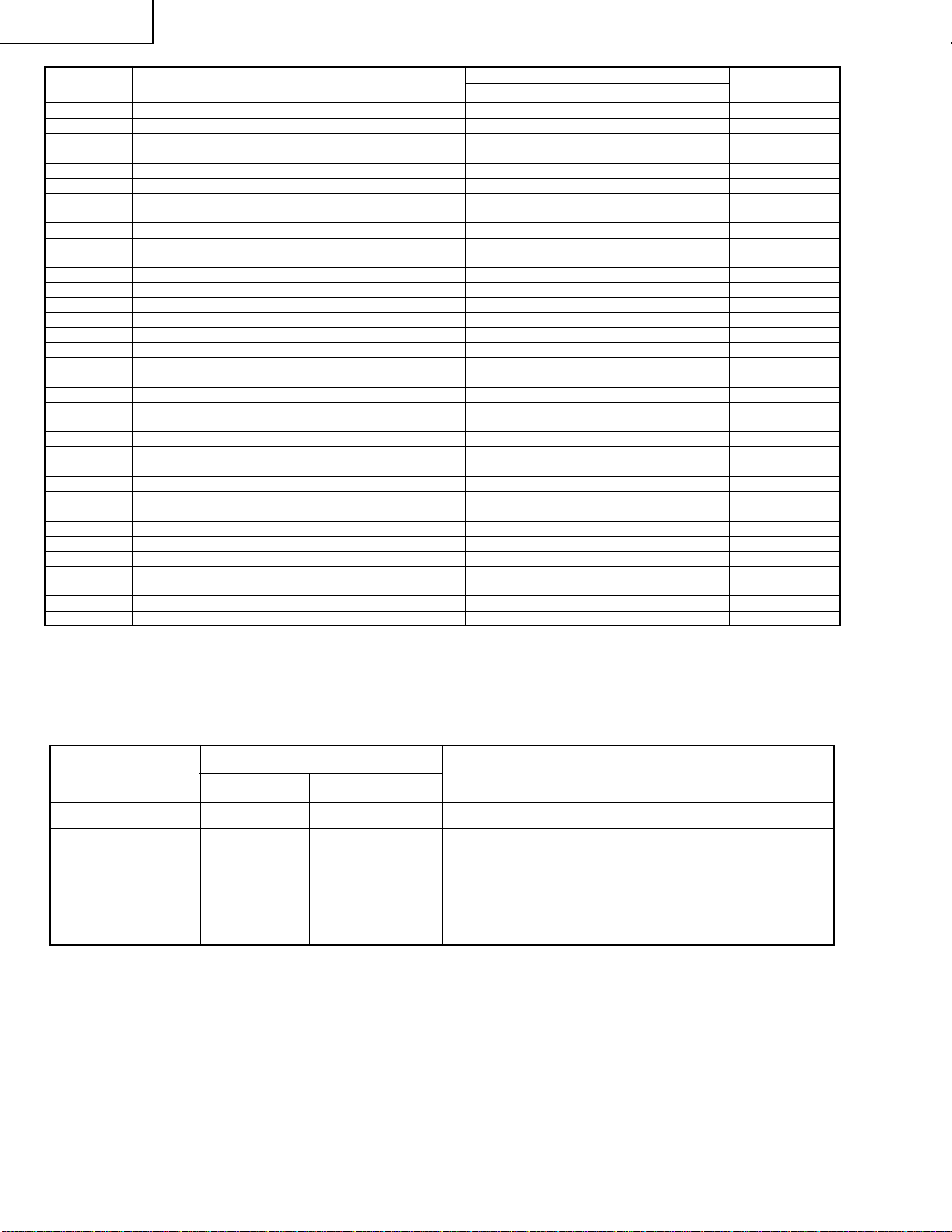

★ Wrapping Paper

20AR22

20AR32

PACKING OF THE SET

★ Polyethylene Bag

Operation Manual

Infrared R/C Unit

★ Batteries

FRONT

★ Buffer Material

★ Packing Case

Use tape to fix

top side of pack

case.

★ MARK : Not Replacement Items.

REAR

Use 12 staples fix

the packing case.

39

Page 46

TOSHIBA CORPORATION

1-1, SHIBAURA 1-CHOME, MINATO-KU, TOKYO 105-8001, JAPAN

Loading...

Loading...