Page 1

TM

ClimaDry

ClimaDry Whole House

noitpO noitacfiidimuheD

Tranquility 27

Tranquility 20

Applications Guide

97B0051N01

Revision: 18 April, 2008B

Table of Contents

Model Nomenclature Example 2

ClimaDry Overview 3

ClimaDry Benefits 3

ClimaDry Features 3

ClimaDry Applications 3

ClimaDry Sequence of Operation 5

ClimaDry Component Functions 6

ClimaDry Application Considerations 6

ClimaDry Schematic 7

TT Blower Data 8

TS ECM Blower Data 9

TS PSC Blower Data 10

Reheat Coil Pressure Drop Table 11

TS Air Coil Face Area Table 11

Wiring Diagram 12

Flushing/Purging Units 13

Revision History 14

Page 2

A0 7 2 DG 0 1 D L K

4 5 6 7

8

9 10 12 13 14

026, 038, 049, 064, 072

Unit Size

Return Air Flow Configuration

Voltage

C = CXM

Controls

D = DXM

+

A = Current Revision

Revision Level

Heat Exchanger Options

Cabinet

Supply Air Flow &

Motor Configuration

TT

1 2

TT = Tranquility Two-Stage Scroll

Series

V

3

V = Vertical Up

Configuration

L = Left Return

R = Right Return

0 = None

Water Circuit Options

S

15

S = Standard

Standard

H = Horizontal

D = Vertical Down

0 = Residential

1 = HWG w/Internal Pump

Supply Configuration Motor

K TTV

N TTD

P TTH

W TTH

Top

Down

Back

Straight

ECM

ECM

ECM

ECM

Standard

Coated Air Coil

Copper Cupro-Nickel

A J

Rev.: 18 April, 2008B

ClimaDry

*

D N/A

G = 208-230/60/1

11

Notes

+

= Only Available With ClimaDry Option

*

= Not Available On DownFlow Units

� CAUTION! �

Water Source Heat Pump systems (including Water Loop Heat Pump systems) must have antifreeze protection to 20°F [-6.7°C] for ClimaDry applications. The ClimaDry option MUST NOT be used on open water loop

systems, or any system without antifreeze protection.

Notes:

1. ClimaDry reheat option must be ordered with original equipment (cannot be eld added). Unit must have DXM

control. Not available for units with internal water valve, or ow regulator options. Check unit product catalog for

limitations and specic requirements.

2. ClimaDry cannot be used on open loop systems, only closed loop systems.

3. ClimaDry systems must use appropriate antifreeze solutions.

4. ClimaDry is not recommended for applications with poor water quality (see water quality guidelines in unit IOM).

The copper heat exchanger with cast iron pump (standard ClimaDry option) are designed for closed loop systems.

5. Max working water pressure for the ClimaDry option is 145psig.

6. Available with TT, TS models. Check unit product catalog data nomenclature for models with ClimaDry reheat

option.

7. Thermostat must be either:

1. Thermostat with dehumidication mode (similar to ATA32U02)

2. Thermostat and separate humidistat or dehumidistat controller (see Table 3 for DXM DIP settings).

8. ClimaDry units must have minimum entering air temperature of 70°F DB / 61°F WB

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

2

Page 3

Overview

ClimaDry™ Whole House Dehumidication Overview

Indoor Air Quality (IAQ) and Relative Humidity (RH)

are increasingly becoming design issues that must be

addressed by selecting heating and cooling equipment

with advanced capabilities. The ClimateMaster

ClimaDry™ reheat option (patent pending) offers unique

features unlike anything currently available today.

ClimateMaster’s ClimaDry reheat option is an innovative

means of providing modulating reheat without the

complication of refrigeration controls. ClimaDry is Hot

Gas Generated Reheat, which utilizes one of the biggest

advantages of a water source heat pump (WSHP), the

transfer of energy through the loop piping system.

ClimaDry simply diverts condenser water through a

water-to-air coil that is placed after the evaporator coil.

If condenser water is not warm enough, the internal

“run-around” loop increases the water temperature with

each pass through the condenser coil.

Features Include:

• Modulating reheat for precise control of supply

air temperatures

• 100% reheat (operates as a whole house

dehumidier)

• “Neutral” supply air temperature even at part load

(non-design) conditions

• Supply air temperature adjustment, +/- 3°F

[+/-1.7°C] from 72°F [22°C] factory setpoint with

optional potentiometer

• Integrated factory supplied reheat controls – simply

attach a humidistat or dehumidistat

• Microprocessor (DXM) controls standard

• Ultra simple refrigeration circuit

• All water system eliminates refrigeration circuit

modications (same refrigeration circuit as units

without ClimaDry)

• Stable refrigeration pressures, even at low EWTs

• All components located inside the cabinet

•

Moves heat of rejection from ground loop to supply

air stream

ClimaDry Benets

ClimaDry is like no other reheat option on the market.

Proportional reheat is controlled to the desired leaving

air temperature set point (factory set point of 72°F,

[22°C}), no matter what the loop temperature is. Since

dehumidication operation will occur under less than full

load cooling conditions a good percentage of the time,

it is important to have a reheat function that provides

100% reheat in the spring and fall when the loop is cool.

Supply air temperature is eld adjustable to +/- 3°F

[+/- 1.7°C] for even greater exibility with an optional

potentiometer.

Competitors without ClimaDry typically use an on/off

(non-modulating) refrigeration based reheat circuit,

typically referred to as “Hot gas reheat” (HGR). HGR

needs higher condensing temperatures to work well,

typically 85°F [29°C] entering water temperature (EWT).

With HGR, cooler water temperatures produce cooler

supply air temperatures, which could overcool the

space, requiring additional space heating from another

source or a special auto-change-over relay to allow

the unit to switch back and forth between reheat and

heating. Rarely does HGR provide 100% reheat, like

ClimaDry.

A key benet to ClimaDry is a simple and easy to

troubleshoot refrigerant circuit. No switching valves or

hard to diagnose leaky check valves are utilized. No

unusual refrigerant pressures occur during the reheat

mode. The ClimaDry refrigerant circuit is like every other

ClimateMaster unit (without reheat), so everything the

technician already knows applies to troubleshooting

the ClimaDry refrigeration circuit. Plus, the water loop

portion of the ClimaDry option is easy to understand

and diagnose.

Availability

ClimaDry is currently available on ClimateMaster

residential Tranquility 27™ (TT) and Tranquility 20™ (TS)

series units (vertical and horizontal units only).

ClimaDry Applications

With the ClimaDry option, return air from the space is

conditioned by the air-to-refrigerant (evaporator) coil, then

reheated by the water-to-air (reheat) coil to dehumidify

the air, but maintain the same space temperature (thus

operating as a whole house dehumidier). The moisture

removal capability of the heat pump is determined by

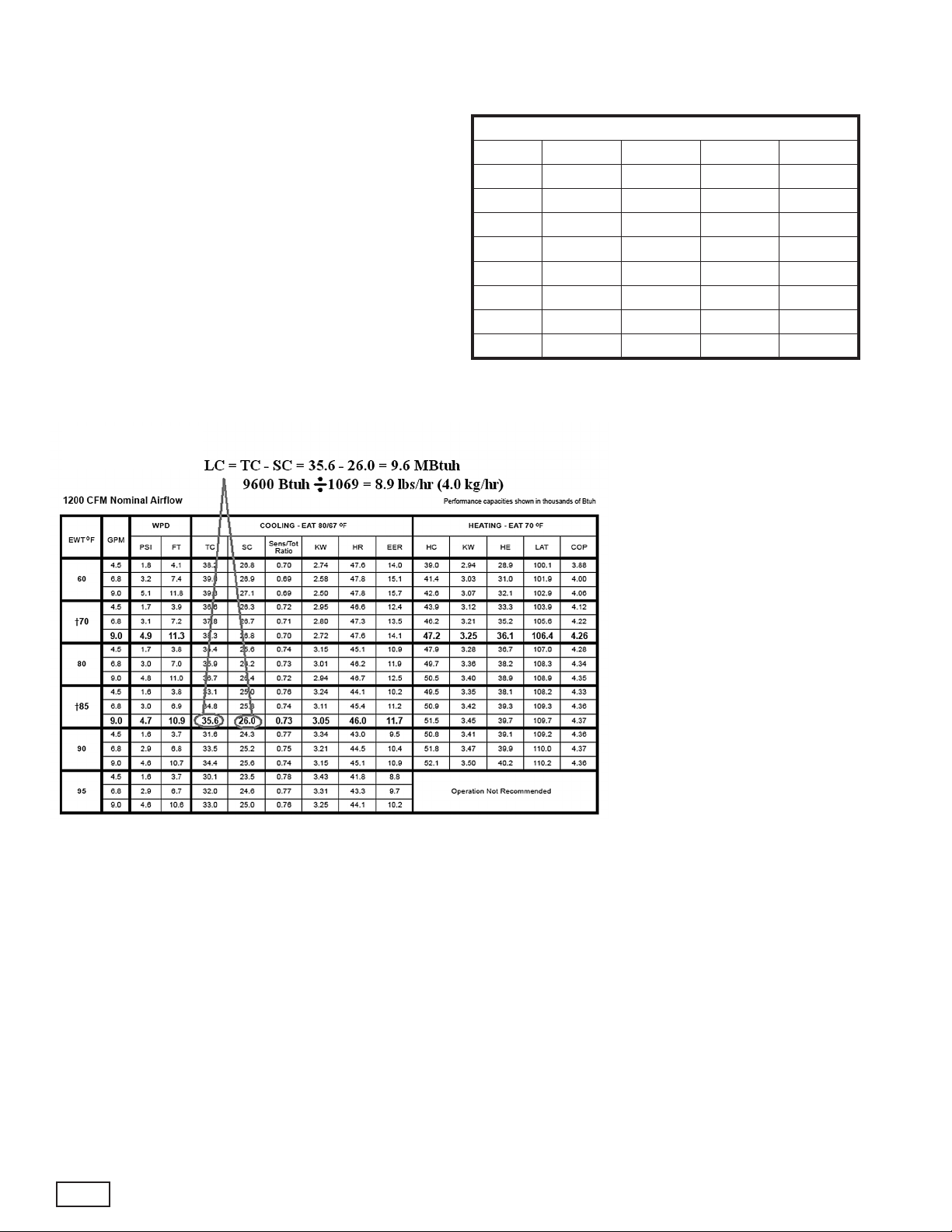

the unit’s latent capacity rating. Latent Capacity (LC)

equals Total Capacity (TC) minus Sensible Capacity (SC).

For example, at 85°F [29°C] EWT, the moisture removal

capability (latent capacity) of a ClimateMaster size 036

heat pump is 9.6 MBtuh [2.8kW] as shown in gure 1.

Dividing the latent capacity by 1,069 BTU/LB of water

vapor at 80°F DB and 67°F WB [26.7°C DB and 19.4°C

WB] moist air enthalpy, converts the amount of moisture

removal to pounds per hour (multiply pounds per hour

by 0.4536 to obtain kg/hr). Calculations are shown

in gure 1. Most ClimateMaster heat pumps have a

sensible-to-total (S/T) ratio of 0.72 to 0.76. Therefore,

approximately, 25% of the cooling capacity is dedicated

to latent cooling capacity (moisture removal). When

selecting a unit with ClimaDry, the space sensible

and latent loads should be calculated. If the unit will

be used for space cooling, a unit with at least enough

capacity to satisfy the building sensible load should be

selected. If the latent cooling load is not satised by

the selection, a larger unit with enough latent capacity

will be required. The ClimaDry Option can be used for

the additional moisture load. If the unit will be used for

dehumidication purposes only, the latent capacity is

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

3

Page 4

the only consideration necessary. In this case, sensible

load is immaterial. Example latent capacities for a

typical ClimateMaster heat pump are shown in table 1.

ClimaDry is especially useful in Northern Climates,

where the heat pump may be oversized in the cooling

mode to provide enough heating capacity. Units with

ClimaDry will compensate for these applications

by operating as a whole house dehumidier when

necessary to maintain space Relative Humidity (RH).

Since the ClimaDry option is internal to the unit,

installation is much easier than a separate whole house

dehumidier. Plus, an additional compressor and

controls can be eliminated, simplifying the system and

lowering operating and installation costs.

Figure 1: Example Size 036 Performance

Performance Data

Model 036

Table 1: Typical Unit Latent capacity

Latent Capacity at 85°F [29.4°C] EWT

Size MBtuh lbs/hr kW kg/hr

18 4.7 4.4 1.4 2.0

24 6.1 5.7 1.8 2.6

30 6.8 6.4 2.0 2.9

36 9.6 9.0 2.8 4.1

42 11.0 10.3 3.2 4.7

48 12.7 11.9 3.7 5.4

60 15.2 14.2 4.5 6.4

70 16.9 15.8 5.0 7.2

Dividing the latent capacity by

1,069 BTU/LB of water vapor at

80°F DB and 67°F WB [26.7°C

DB and 19.4°C WB] moist air

enthalpy, converts the amount

of moisture removal to pounds

per hour (multiply pounds per

hour by 0.4536 to obtain kg/hr).

Calculations are shown in gure 1.

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

4

Page 5

ClimaDry Sequence Of Operation

A heat pump equipped with ClimaDry can operate

in three modes; cooling, cooling with reheat, and

heating. The cooling/heating modes are like any other

ClimateMaster WSHP. The reversing valve (“O” signal)

is energized in cooling, along with the compressor

contactor(s) and blower relay. In the heating mode the

reversing valve is de-energized. Almost any thermostat

will activate the heat pump in heating or cooling modes.

The DXM microprocessor board, which is standard with

the ClimaDry option, will accept either heat pump (Y,O)

thermostats or non-heat pump (Y,W) thermostats (see

CXM/DXM AOM for detailed DXM information).

The reheat mode requires either a separate humidistat/

dehumidistat or a thermostat that has an integrated

dehumidication function for activation. The DXM

board is congured to work with either a humidistat or

dehumidistat input to terminal “H” (DIP switch settings

for the DXM board are shown below in table 2). Upon

receiving an “H” input, the DXM board will activate the

cooling mode and engage reheat. Table 3 shows the

relationship between thermostat input signals to the DXM

board and unit operation.

There are ve operational inputs for single stage units

and seven operational inputs for two stage units:

-Fan Only

-1st Stage Cooling

-2nd Stage Cooling

-1st Stage Heating

-2nd Stage Heating

-3rd Stage Heating (If applicable)

-Reheat Mode

• Fan Only: A (G) call from the thermostat to the (G)

terminal of the DXM control board will bring the unit

on in fan only mode.

•

1st Stage Cooling: A simultaneous call from (G),

(Y1), and (O) to the (G), (Y1), (O/W2) terminals of the

DXM control board will bring the unit on in 1st Stage

Cooling.

Table 2: Humidistat/Dehumidistat Logic and DXM 2.1, 2.2., 2.3 DIP settings

Sensor 2.1 2.2 2.3 Logic Reheat (ON) - H Reheat (OFF) - H

Humidistat OFF OFF OFF Reverse 0 VAC 24 VAC

Dehumidistat OFF ON OFF Standard 24 VAC 0 VAC

Table 3: ClimaDry Operating Modes

Input Output

Mode

No Demand ON/OFF5OFF OFF OFF OFF OFF ON/OFF5OFF OFF OFF OFF OFF

Fan Only ON/OFF5ON OFF OFF OFF OFF ON/OFF5ON OFF OFF OFF OFF

Cooling 1st Stage ON ON ON OFF OFF OFF ON ON ON OFF OFF OFF

Cooling 2nd Stage ON ON ON ON OFF OFF ON ON ON ON OFF OFF

Cooling & Dehumidistat

Dehumidistat Only ON/OFF5OFF OFF OFF OFF ON ON ON ON ON OFF ON

Heating 1st Stage OFF ON ON OFF OFF OFF OFF ON ON OFF OFF OFF

Heating 2nd Stage OFF ON ON ON ON/OFF5OFF OFF ON ON ON ON/OFF5OFF

Heating 3rd Stage

Heating & Dehumidistat

1

Cooling input takes priority over dehumidify input.

2

DXM is programmed to ignore the H demand when the unit is in heating mode.

3

N/A for single stage units; Full load operation for dual capacity units.

4

Single stage unit: W = 2nd Stage backup elec. heat; Two-Stage units: W = 3rd stage backup elec. heat.

5

ON/OFF = Either ON or OFF.

4

O G Y1 Y2

1

ON ON ON ON/OFF5OFF ON ON ON ON ON/OFF5OFF OFF

OFF ON ON ON ON

2

OFF ON ON ON/OFF5ON/OFF5ON OFF ON ON ON/OFF5ON/OFF5OFF

3

W H O G Y1 Y2

4

OFF OFF ON ON ON ON

3

Backup

Elec Heat

Reheat

4

OFF

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

5

Page 6

• 2nd Stage Cooling: A simultaneous call from (G),

(Y1), (Y2), and (O) to the (G), (Y1), (Y2), and (O/W2)

terminals of the DXM control board will bring the unit

on in 2nd Stage Cooling. When the call is satised

at the thermostat the unit will continue to run in 1st

Stage Cooling until the 1st Stage Cooling call is

removed or satised, shutting down the unit.

NOTE: Not all units have two-stage cooling

functionality.

• 1st Stage Heating: A simultaneous call from (G) and

(Y1) to the (G) and (Y1) terminals of the DXM control

board will bring the unit on in 1st Stage Heating.

• 2nd Stage Heating: A simultaneous call from (G), (Y1),

and (Y2) to the (G), (Y1), and (Y2) terminals of the

DXM control board will bring the unit on in 2nd Stage

Heating. When the call is satised at the thermostat

the unit will continue to run in 1st Stage Heating until

the call is removed or satised, shutting down the

unit.

NOTE: Not all units have two-stage heating

functionality. 2nd stage heating for units with

PSC fan and single stage compressor is auxiliary

electric heat (Y, W1, G).

• 3rd Stage Heating (ECM fan models only): A

simultaneous call from (G), (Y1), (Y2), and (W)

terminals to the (G), (Y1), (Y2), and (W1) terminals

of the DXM board will bring the unit on in 3rd Stage

Heating (compressor plus auxiliary electric heat).

• Reheat Mode: A call from the Humidistat/

Dehumidistat to the (H) terminal of the DXM control

board will bring the unit on in Reheat Mode if

there is no call for cooling. When the Humidistat/

Dehumidication call is removed or satised the unit

will shut down.

NOTE: Cooling always overrides Reheat

Mode. In the Cooling mode, the unit cools and

dehumidies. If the cooling thermostat is satised

but there is still a call for dehumidication, the

unit will continue to operate in Reheat Mode.

ClimaDry Component Functions

The ClimaDry option consists of the

following components:

• Proportional Controller

• Supply Air Sensor

• Motorized Valve

• Internal Loop Pump

• Hydronic Reheat Coil

reheat coil during the reheat mode of operation. The

proportional controller sends a signal to the motorized

valve based on the supply air temperature.

The internal loop pump circulates condenser water

through the hydronic reheat coil during the reheat mode

of operation. In this application, the internal loop pump

is only energized during the reheat mode. The Hydronic

Coil is utilized to reheat the air to the setpoint of the

proportional controller. Condenser water is diverted by

the motorized valve and pumped through the hydronic

reheat coil by the internal loop pump in proportion to the

control setpoint. The amount of reheating is dependent

on the setpoint and how far from setpoint the supply

air temperature is. The factory setpoint is 72°F [22°C],

generally considered “neutral” air.

ClimaDry Application Considerations

The reheat coil adds a small amount of resistance to the

air stream. Consult the correction tables on page 8 of

this manual for details.

Unlike most hot gas reheat options, the ClimaDry option

will operate over a wide range of EWTs. Special ow

regulation (water regulating valve) is not required for

low EWT conditions. Temporary, slight overcooling of

the space may result on rare occasions with ground

loop (geothermal) systems during extremely low EWT

conditions. Since dehumidication is generally only

required in cooling, most ground loop systems will not

experience these conditions.

Water-Source Heat Pumps with ClimaDry should not be

used as make-up air units. These applications require

equipment specically designed for make-up air.

� CAUTION! �

Water Source Heat Pump systems (including Water Loop Heat Pump systems) must have antifreeze

protection to 20°F [-6.7°C] for ClimaDry applications.

The ClimaDry option MUST NOT be used on open

water loop systems, or any system without antifreeze

protection.

The Proportional Controller operates on a 24 VAC

power supply and automatically adjusts the water valve

based upon the Supply Air Sensor. The Supply Air

Sensor senses supply air temperature at the blower inlet

providing the input signal necessary for the proportional

control to drive the motorized valve during the reheat

mode of operation. The Motorized Valve is a proportional

actuator/three-way valve combination used to divert

the condenser water from the coax to the hydronic

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

6

Page 7

Figure 2: ClimaDry Schematic

Water Out

(To Water Loop)

Water In

(From Water Loop)

Mixing Valve

COAX

Evaporator Coil

Reheat

Coil

Refrigerant Out

(Cooling)

Refrigerant In

(Cooling)

Entering Air

Leaving

Air

Note:

All components shown

are internal to the heat

pump unit.

Internal Pump

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

7

Page 8

Table 4: Tranquility 27™ Blower Performance Data

Airow in CFM with wet coil and clean air lter

Max

Model

ESP

(in. wg)

0.50 1/2 4 810 950 475 630 740 475 920 1060 475 4 1060

026

038

049

064

Factory shipped on Tap Setting 2

During Auxiliary operation (residential units only) the CFM will run at the higher of the heating or AUX settings

Airow is controlled within +/- 5% up to Max ESP shown with wet coil and standard lter

0.50 1/2 3 725 850 425 560 660 425 825 950 425 3 950

0.50 1/2 2 620 730 370 490 570 370 710 820 370 2 820

0.50 1/2 1 520 610 300 600 690 300 1 690

0.50 1/2 4 1120 1400 700 870 1090 700 1120 1400 700 4 1400

0.50 1/2 3 1000 1250 630 780 980 630 1000 1250 630 3 1350

0.50 1/2 2 860 1080 540 670 840 540 860 1080 540 2 1350

0.50 1/2 1 730 900 450 730 900 450 1 1350

0.75 1 4 1460 1730 870 1140 1350 870 1560 1850 870 4 1850

0.75 1 3 1300 1550 780 1020 1210 780 1400 1650 780 3 1660

0.75 1 2 1120 1330 670 870 1040 670 1200 1430 670 2 1430

0.75 1 1 940 1120 560 1010 1200 560 1 1350

0.75 1 4 1670 2050 1020 1300 1600 1020 1860 2280 1020 4 2280

0.75 1 3 1500 1825 920 1160 1430 920 1650 2050 920 3 2040

0.75 1 2 1280 1580 790 1000 1230 790 1430 1750 790 2 1750

0.75 1 1 1080 1320 660 1200 1470 660 1 1470

Fan

Motor

(hp)

Tap

Setting

Cooling Mode Dehumid Mode Heating Mode

Stg 1 Stg 2 Fan Stg 1 Stg 2 Fan Stg 1 Stg 2 Fan

Residential

Units Only

AUX

CFM

Aux/

Emerg

Mode

Tranquility 27™ (TT) Series with ClimaDry Reheat Option

All Tranquility 27™ (TT) units have an ECM fan motor as a standard feature. The small

additional pressure drop of the reheat coil causes the ECM motor to slightly increase RPM to

overcome the added pressure drop, and maintain selected CFM up to the maximum ESP.

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

8

Page 9

Table 5: Tranquility 20™ ECM Blower Performance Data

Airow in CFM with wet coil and clean air lter

Max

Model

ESP

(in. wg)

018 0.50 1/2

024 0.50 1/2

030 0.50 1/2

036 0.50 1/2

042 0.50 1/2

048 0.75 1

060 0.75 1

070 0.75 1

Fan

Motor

(hp)

Tap

Setting

4 620 750 380 480 590 380 620 750 380 4 750

3 570 700 350 450 550 350 570 700 350 3 700

2 510 620 310 400 480 310 510 620 310 2 650

1 430 530 270 430 530 270 1 650

4 780 950 470 610 740 470 870 1060 470 4 1060

3 700 850 420 540 660 420 780 950 420 3 950

2 630 770 360 490 600 360 670 820 390 2 820

1 550 670 300 570 690 340 1 690

4 920 1130 560 720 880 560 1000 1230 560 4 1230

3 820 1000 500 640 780 500 900 1100 500 3 1100

2 740 900 450 580 700 450 800 980 450 2 980

1 660 800 400 700 850 400 1 850

4 1150 1400 700 900 1090 700 1150 1400 700 4 1400

3 1020 1250 630 800 980 630 1020 1250 630 3 1350

2 890 1080 540 690 840 540 890 1080 540 2 1350

1 740 900 450 750 920 450 1 1350

4 1290 1580 790 1010 1230 790 1290 1580 790 4 1580

3 1150 1400 700 900 1090 700 1150 1400 700 3 1400

2 1050 1280 640 820 1000 640 1020 1240 640 2 1350

1 920 1120 560 900 1080 560 1 1350

4 1420 1730 870 1110 1350 870 1520 1850 865 4 1850

3 1270 1550 780 990 1210 780 1350 1650 775 3 1650

2 1180 1440 720 920 1120 720 1190 1450 720 2 1450

1 1050 1280 640 1020 1250 640 1 1350

4 1680 2050 1030 1310 1600 1030 1870 2280 1030 4 2280

3 1500 1830 910 1170 1420 910 1680 2050 910 3 2050

2 1400 1700 850 1090 1330 850 1480 1800 850 2 1800

1 1300 1580 790 1270 1550 790 1 1550

4 1830 2230 1100 1420 1740 1100 1830 2230 1100 4 2230

3 1600 1950 980 1250 1520 980 1720 2100 980 3 2100

2 1440 1750 880 1120 1360 880 1670 1950 880 2 1950

1 1200 1580 790 1460 1780 790 1 1780

Cooling Mode Dehumid Mode Heating Mode

Stg 1 Stg 2 Fan Stg 1 Stg 2 Fan Stg 1 Stg 2 Fan

Residential

Units Only

AUX

CFM

Aux/

Emerg

Mode

See ECM control section for details on setting taps.

Tranquility 20™ (TS) Series with ClimaDry Reheat Option (ECM Motor)

All Tranquility 20™ (TS) units with optional ECM fan motor automatically adjust for the reheat coil. The

small additional pressure drop of the reheat coil causes the ECM motor to slightly increase RPM to

overcome the added pressure drop, and maintain selected CFM up to the maximum ESP.

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

9

Page 10

Table 6: Tranquility 20™ (TS) Series PSC Blower Performance Data

(Without ClimaDry)

Model

018

024

030

036

042

048

060

070

Black areas denote ESP where operation is not recommended.

Units factory shipped on medium speed. Other speeds require eld selection.

All airow is rated and shown above at the lower voltage if unit is dual voltage rated, e.g. 208V for 208-230V units.

Fan

Speed

MED 600 450 602 601 599 590 581 583 585 579 573 560 547 492

LOW 600 450 531 529 527 522 517 512 506 501 495 479 462

MED 850 600 841 833 825 817 809 800 790 777 763 747 731 686 623

LOW 850 600 723 715 707 703 698 689 680 668 656 642 627

MED 950 750 1048 1037 1025 1016 1007 994 981 962 943 915 886 822

LOW 950 750 890 887 884 879 874 865 855 842 829 809 789

MED 1250 900 1171 1164 1156 1145 1133 1113 1092 1064 1035 997 958

LOW 1250 900 983 967 950 943 936 936

MED 1400 1050 1332 1323 1314 1298 1282 1263 1243 1206 1169 1115 1060

LOW 1400 1050 1130 1109 1088 1086 1084 1066 1048 1052 1055

MED 1600 1200 1384 1382 1379 1375 1371 1356 1341 1318 1294 1261 1227

LOW 1600 1200

MED 1950 1500 2058 2049 2039 2028 2016 2000 1983 1966 1949 1935 1920 1874 1807 1750 1670 1582

LOW 1950 1500 1868 1863 1858 1858 1858 1848 1838 1822 1806 1799 1792 1749 1699 1636 1570

MED 2100 1800 2171 2167 2162 2162 2162 2158 2153 2135 2117 2101 2085 2024 1971 1891 1823

LOW 2100 1800 2010 2008 2006 2006 2006 2006 2006 1992 1977 1962 1947 1892 1851

Rated

Airow

HI 600 450 704 708 711 702 693 692 690 683 675 658 640 598 515

HI 850 600 965 960 954 943 931 923 914 898 882 862 842 794 725 635

HI 950 750 1271 1250 1229 1207 1185 1164 1143 1118 1093 1061 1029 953 875 753

HI 1250 900 1411 1407 1402 1390 1378 1370 1361 1326 1290 1248 1205 1083 942

HI 1400 1050 1634 1626 1618 1606 1594 1583 1571 1539 1507 1464 1420 1265 1078

HI 1600 1200 1798 1781 1764 1738 1711 1688 1665 1630 1595 1555 1514 1420 1239

HI 1950 1500 2311 2306 2300 2290 2279 2268 2257 2233 2209 2175 2140 2088 1990 1901 1856 1752

HI 2100 1800 2510 2498 2486 2471 2455 2440 2424 2401 2377 2348 2318 2247 2161 2078 1986 1855

Min

CFM

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

Airow (cfm) at External Static Pressure (in. wg)

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

10

Page 11

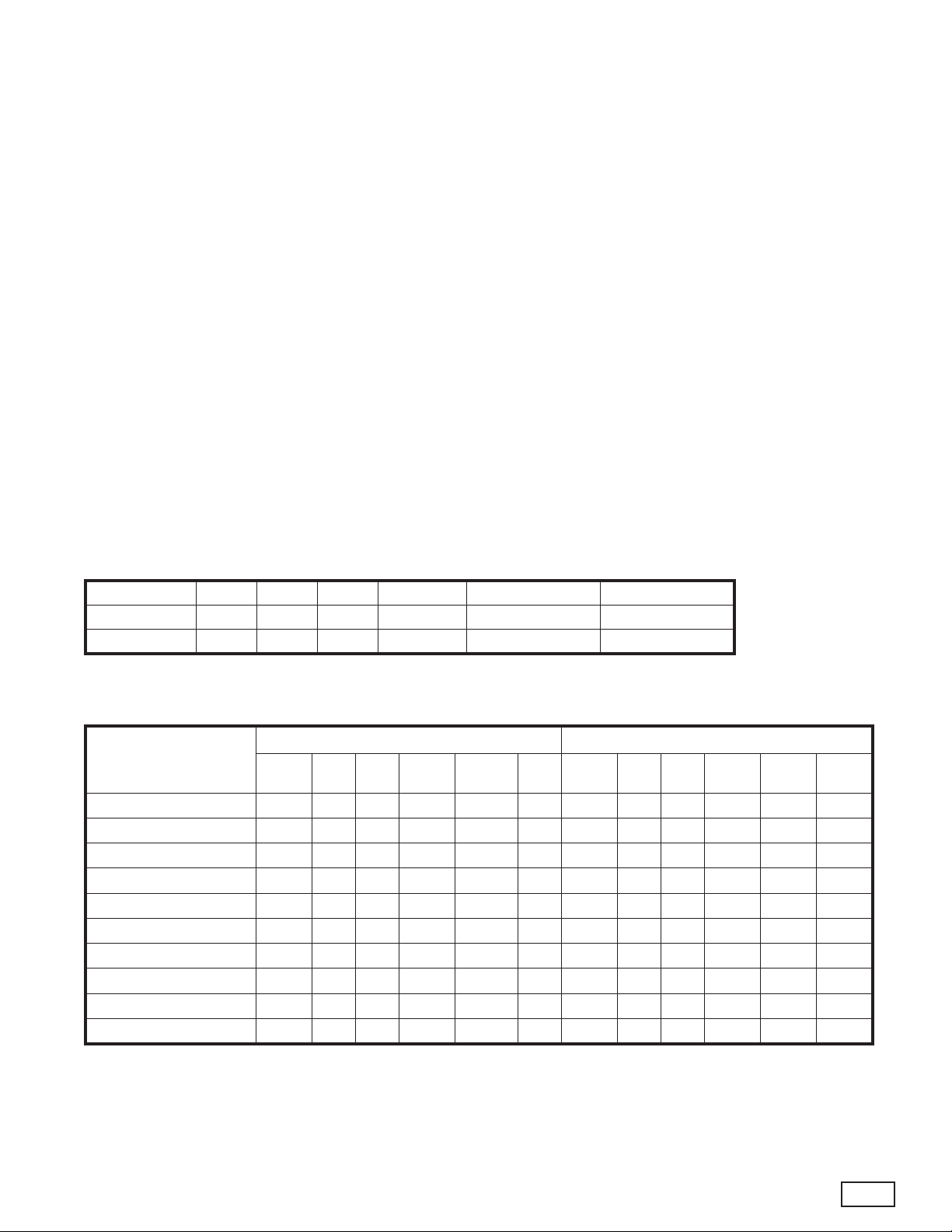

Table 7: ClimaDry Reheat Coil Pressure Drop - TS Units (PSC Motor)

Coil Face

Velocity

FPM

200 0.037 0.033 0.031 0.028 0.026

250 0.052 0.046 0.042 0.038 0.034

300 0.077 0.066 0.059 0.051 0.044

350 0.113 0.096 0.085 0.073 0.061

400 0.181 0.160 0.145 0.131 0.117

450 0.242 0.226 0.215 0.205 0.194

500 0.360 0.345 0.335 0.326 0.316

For TS units with ClimaDry Reheat coil applications, calculate face velocity of the entering air. From the table above, nd ESP for Reheat application.

The loss includes wet coil loss.

TSH/V/D

018

In. of Water

TSH/V/D with Reheat ESP Loss

TSH/V/D

024, 030

In. of Water

TSH/V/D

In. of Water

036

TSH/V/D

042, 048

In. of Water

TSH/V/D

060, 070

In. of Water

Example:

Reheat coil pressure drop can be determined from the above table. Coil velocity (FPM) = Airow (CFM) / Face Area (sq. ft.).

1) TSH036 has a face area of 4.86 sq. ft. (see physical data table in I.O.M.).

2) At 1,100 cfm, coil velocity (FPM) = 1,100 / 4.86 = 226 FPM.

3) From above table, it will be necessary to subtract 0.037 from the blower performance ESP.

4) On medium speed, the TSH036 (without reheat - see blower table) can deliver 1,100 CFM at 0.28 in. wg. with the

standard PSC motor; with the reheat coil, it now delivers 1,085 CFM at 0.28 in. wg. or 1,100 CFM at 0.24 in. wg.

5) If the decrease in airow is acceptable, no changes are necessary. Otherwise, high speed fan should be used

to overcome the pressure drop of the reheat coil.

Table 8: TS Air Coil Face Area

Model

Coil Face

Area, sq. ft.

(sq. m)

018 024 030 036 042 048 060 070

Horiz. Vert. Horiz. Vert. Horiz. Vert. Horiz. Vert. Horiz. Vert. Horiz. Vert. Horiz. Vert. Horiz. Vert.

3.38

(0.3135)

3.33

(0.3097)

3.88

(0.3600)

3.89

(0.3613)

3.88

(0.3600)

3.89

(0.3613)

4.86

(0.4516)

4.86

(0.4516)

5.56

(0.5161)

5.56

(0.5161)

5.56

(0.5161)

5.56

(0.5161)

6.25

(0.5806)

6.25

(0.5806)

6.25

(0.5806)

6.25

(0.5806)

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

11

Page 12

Tranquility 27™ with ClimaDry™ Electrical Wiring Diagram - 96B0037N74

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

12

Page 13

Flushing/Purging Units with ClimaDry

Units equipped with ClimaDry must be ushed/purged

with a ush cart. Detailed general ushing /purging

instruction can be found in the Flow Controller III IOM.

The unit must be powered (but not operating) during

ushing/purging. Unit power is required to operate

the three-way modulating valve during ushing.

When ushing/purging units equipped with ClimaDry

the earth loop should be fully ushed/purged before

attempting to ush/purge the heat pump. Once the

earth loop is ushed, position the ushing valves to

ush the heat pump. Then with ushing ow re-directed

through the unit, energize the modulating three-way

dehumidication valve to allow ow through the

dehumidication hydronic circuit.

Energize the modulating three-way dehumidication

valve by removing the red wire from the ACC1 ‘N.O.’

terminal on the DXM board. Connect this wire to the

ACC1 ‘NC’ terminal of the DXM controller, as shown

in gure 1, to energize the modulating three-way

dehumidication valve. Once energized, the valve will

take 45 – 75 seconds to fully shift. Continue ushing

during this time. After the valve has completed its shift,

use the air bleed from the top of the reheat coil to purge

air from the coil.

Note, if the ClimaDry sensor, located in the supply

air stream is above 70°F it must be disabled to allow

the modulating valve to shift. Disable this sensor by

removing the white wire from the Low Voltage Terminal

Block (LVTB) shown in gure 1.

Under extreme circumstances this procedure may be

required multiple times to purge all air from the circuit.

After completing the ushing/purging procedure, restore

the red wire to the ACC1 ‘N.O.’ terminal on the DXM for

normal operation. Return the white sensor wire to the

LVTB, if it was removed, as shown in gure 2.

White Thermistor Wire Red Three-Way Valve Wire

Figure 2. Normal Unit Wiring

Extra care must be taken when using non-pressurized

ow centers to ensure all air is removed from the unit

and no additional air is allowed into the system. If air is

allowed to collect in the ClimaDry piping, nuisance trips

may occur. Additional ush/purge cycles may be used

when required.

Figure 1. Flushing/Purging Wiring

White Thermistor Wire Red Three-Way Valve Wire

De-energize the valve by removing the red wire from the

ACC1 ‘NC’ terminal on the DXM board. The valve will

spring return to its normal position in just a few seconds.

After the valve has fully returned, repeat the process of

running the valve through its cycle and purging air from

the reheat coil.

ClimaDry Whole House Dehumidication - ClimateMaster Geothermal Heat Pumps - Rev.: 18 April, 2008B

13

Page 14

Revision Log:

ISO 9001:2000

Certified

Quality: First & Always

AIR CONDITIONING &

REFRIGERATION

INSTITUTE

Date Page # Description

18 April, 2008 All First Published

ClimateMaster works continually to improve its products. As a result, the design and specifications of each product at the time for order may be

changed without notice and may not be as described herein. Please contact ClimateMaster’s Customer Service Department at 1-405-745-6000 for

specific information on the current design and specifications. Statements and other information contained herein are not express warranties and do

not form the basis of any bargain between the parties, but are merely ClimateMaster’s opinion or commendation of its products.

The management system governing the manufacture of ClimateMaster’s products is ISO 9001:2000 certified.

© ClimateMaster, Inc. 2008

*97B0051N01*

97B0051N01

TM

35 Earl Martin Dr.

Elmira, ON N3B 3L4

Phone: 800-367-9810

Fax: 877-684-3112

www.nextenergy.ca

Loading...

Loading...