Page 1

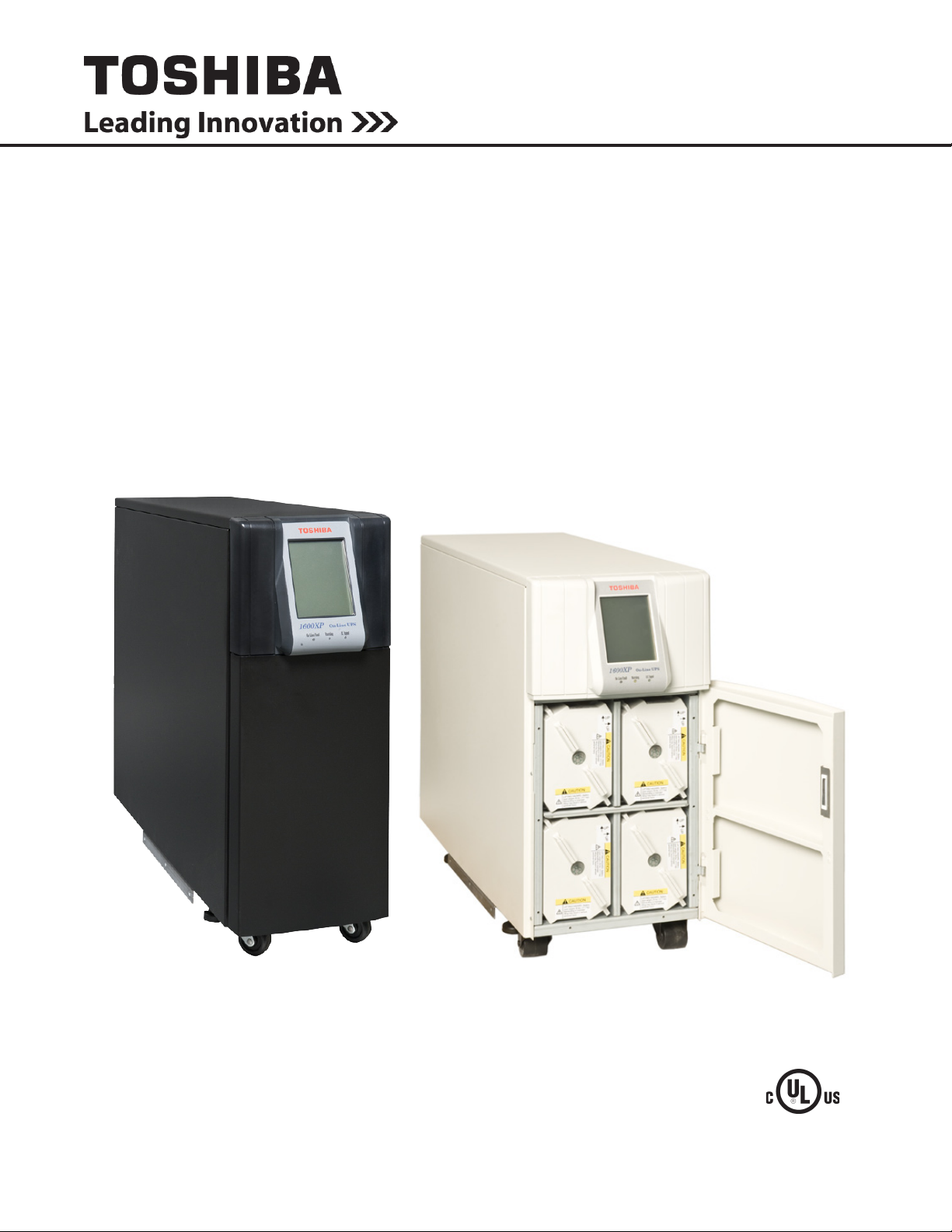

UNINTERRUPTIBLE POWER SYSTEM (UPS)

1600XP/1600XPi SERIES

INSTALLATION AND OPERATION MANUAL

SINGLE PHASE - 3.6/6/8/10/14/18/22 KVA

1600XPi 1600XP

Part # 60616-00112

July 2015

Manufactured in the USA

© Copyright 2014 TOSHIBA International Corporation

All rights reserved.

Page 2

b

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 3

Product Use and Warranty Restrictions

The Toshiba products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, ofce equipment, measuring equipment, industrial robotics, domestic

appliances, etc.). These Toshiba products are neither intended nor warranted for usage in equipment that

requires extraordinarily high quality and/or reliability or where a malfunction or failure may cause loss

of human life or bodily injury (Unintended Usage). Unintended Usage includes atomic energy control

instruments, airplane or spaceship instruments, transportation instruments, trafc signal instruments,

combustion control instruments, life-support equipment, all types of safety devices, etc. Unintended Usage

of Toshiba products listed in this document shall be made at the customer’s own risk.

NOTICE

PLEASE INFORM A TOSHIBA INTERNATIONAL CORPORATION REPRESENTATIVE IN

CASE OF INCONSISTENCIES, OMISSIONS, OR QUESTIONS.

The instructions contained in this manual are not intended to cover all of the details or variations in

equipment, or to provide for every possible contingency concerning installation, operation, or maintenance.

Should further information be required or if problems arise which are not covered sufciently, contact your

Toshiba sales ofce.

The contents of this instruction manual shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation UPS Division. The warranty contained in the contract between the parties is the sole warranty

of Toshiba International Corporation UPS Division and any statements contained herein DO NOT create

new warranties or modify the existing warranty.

Any electrical or mechanical modications to this equipment without prior written consent of Toshiba

International Corporation will void all warranties and may void the UL/CUL listing. Unauthorized modications

can also result in personal injury, loss of life, or destruction of the equipment.

QUALIFIED PERSONNEL ONLY

Qualied Personnel are those who have the skills and knowledge relating to the construction,

installation, operation, and maintenance of the electrical equipment and have received safety

training on the hazards involved (Refer to the latest edition of NFPA 70E for additional safety

requirements).

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 4

UNINTERRUPTIBLE POWER SYSTEM (UPS)

Please complete the following information and retain for your records.

Unless otherwise specied, the warranty period for the UPS or UPS part is 36 months from the shipment

date (see Toshiba International Corporation bill of lading).

Unless otherwise specied, the warranty period for a UPS battery is 24 months from the shipment date (see

Toshiba International Corporation bill of lading).

JOB NUMBER

MODEL NUMBER

SERIAL NUMBER

APPLICATION

SHIPMENT DATE

INSTALLATION DATE

INSPECTED BY

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 5

Purpose

This manual provides information on how to safely install your Toshiba International Corporation power

electronics product. This manual includes a section of general safety instructions that describes the warning

labels and symbols that are used throughout the manual. Read the manual completely before installing,

operating, or performing maintenance on this equipment.

This manual and the accompanying drawings should be considered a permanent part of the equipment and

should be readily available for reference and review. Dimensions shown in the manual are in metric and/or

the English customary equivalent.

Toshiba International Corporation reserves the right, without prior notice, to update information, make

product changes, or discontinue any product or service identied in this publication.

Toshiba is a registered trademark of the Toshiba Corporation. All other product or trade references appearing

in this manual are registered trademarks of their respective owners.

Toshiba International Corporation shall not be liable for direct, indirect, special, or consequential damages

resulting from the use of the information contained within this manual.

This manual is copyrighted. No part of this manual may be photocopied or reproduced in any form without

the prior written consent of Toshiba International Corporation.

© Copyright 2015 Toshiba International Corporation

All rights reserved.

Printed in the U.S.A.

Toshiba Customer Support Center

Contact the Toshiba Customer Support Center for assistance with application information or for any

problems that you may experience with your Uninterruptible Power System (UPS).

Toshiba Customer Support Center

8 a.m. to 5 p.m. (CST) – Monday through Friday

USA Toll Free (877) 867-8773 – Field Service Tech Support

USA Toll Free (855) 803-7087 – Pre-sales Application Support

toshibaups1@tic.toshiba.com

Fax (713) 896-5212

You may also contact Toshiba by writing to:

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: 1600XP/1600XPi Product Manager

For further information on Toshiba products and services, please visit our website at:

https://www.toshiba.com/tic/industrial/uninterruptible-power-systems

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 6

f

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 7

Table of Contents

1. General Safety Instructions ........................................................................1

1.1 Symbols ............................................................................................1

1.2 Signal Words ....................................................................................2

1.3 Regulatory Compliance Statement ...................................................2

2. Equipment Warning Labels ........................................................................3

3. Important Safety Instructions .....................................................................5

3.1 Qualied Personnel Only ..................................................................6

4. Inspection/Storage/Disposal ......................................................................7

4.1 Inspection .........................................................................................7

4.2 Unpacking .........................................................................................7

4.3 Storage .............................................................................................7

4.4 Disposal ............................................................................................7

5. Installation Precautions ..............................................................................8

6. Conductor Routing and Grounding ...........................................................10

7. Operating Precautions ................................................................................10

8. UPS Connections ........................................................................................11

8.1 Terminal Block - 208/240 VIN, 120/280/240 V

8.2 Terminal Block - 240 VIN, 100/200 V

............................................13

OUT

8.3 EPO and Remote Shutdown.............................................................14

8.4 Cable Size and Tightening Torque .................................................... 14

8.5 Battery Cabinet Connections ............................................................14

OUT ......................................................11

9. Product Description ....................................................................................15

9.1 Application and Use ..........................................................................15

9.2 Output Rating....................................................................................15

9.3 Power Backup...................................................................................15

9.4 Power Conditioning...........................................................................15

10. Operating Modes .......................................................................................16

10.1 Static-Bypass (Stop operation) .......................................................16

10.2 On-Line (Run operation) ...............................................................16

10.3 Battery Backup (On batteries) ........................................................17

10.4 EPO (Emergency Power Off) Function ...........................................17

10.5 Battery Backup Time and Discharge Process ..............................18

10.6 Battery Low Voltage Tolerances .....................................................18

10.7 Battery Recharging .........................................................................19

10.8 Battery Test ..................................................................................... 20

11. Operating the UPS .....................................................................................20

11.1 Initial Startup (First Power-Up) ......................................................21

11.2 Battery Parameter Settings ............................................................21

1600XP/XPi Series Installation and Operation Manual – 60616-012

i

Page 8

11.3 Starting the UPS (Normal) ..............................................................23

11.4 Stopping the UPS ...........................................................................23

12. Display and Keys ......................................................................................24

12.1 Front Panel Layout .........................................................................24

12.2 Display Manual Controls .................................................................24

13. LCD Touchscreen Layout .........................................................................25

13.1 Startup Display ..............................................................................25

13.2 Operating Keys ..............................................................................26

13.3 Status Indicators .............................................................................27

13.4 Light Emitting Diodes (LED) ...........................................................27

14. Touchscreen Menu Tree ............................................................................28

14.1 Front Panel Layout .........................................................................28

14.2 Keypad Controls .............................................................................29

14.3 Screen: Security Passwords & Keypad ..........................................30

14.4 Forget/Reset Password .................................................................31

15. Screen Tab: Main .......................................................................................32

16. Screen Tab: Monitor ..................................................................................33

16.1 Records .........................................................................................35

16.2 Audible Alarm Functions .................................................................36

17. Screen Tab: Settings .................................................................................37

17.1 Changing UPS Parameter Settings ................................................39

17.2 Settings Parameters .......................................................................40

17.3 Recalibrate the Touchscreen ..........................................................41

18. Communication Interfaces .......................................................................42

18.1 Remote Contacts ............................................................................42

18.2 UPS LAN Shutdown Signal Operation ...........................................43

18.3 RS-232C .........................................................................................43

18.4 RemotEye Network Card ................................................................44

18.5 (Optional) EMD ...............................................................................45

19. Optional MB (Maintenance Bypass) Units ..............................................46

19.1 Internal Maintenance Bypass .........................................................46

19.2 (Optional) External Maintenance Bypass .......................................47

20. Optional TVSS (Transient Voltage Surge Suppressor) ..........................48

21. External Battery Cabinet Connections ....................................................49

22. Optional Receptacle Panel Installation Instructions ..............................50

23. UPS Protection System.............................................................................51

23.1 UPS Protection Devices .................................................................51

23.2 UPS Protection Devices Fault Response ......................................51

23.3 System Fault Messages .................................................................53

23.4 System Warning Messages ............................................................54

ii

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 9

23.5 System Mode Messages ................................................................56

23.6 System Status Messages ...............................................................56

24. Preventive Maintenance/Parts Replacement ..........................................57

24.1 Preventive Maintenance .................................................................57

24.2 Cleaning the Touchscreen ..............................................................58

24.3 Battery Pack Replacement ..............................................................58

24.4 Part Replacement ...........................................................................60

25. External Layouts/Dimensions/Shipping Weights ...................................61

25.1 Electrical Conduit Knock-out Data ..................................................61

25.2 Unit and Shipping Weights .............................................................61

25.3 Dimensional Data ..........................................................................61

25.4 External Layout ...............................................................................62

Appendix A: 1600XP/1600XPi Specications ...............................................A1

Standard Model: 3.6 – 10 kVA .................................................................A1

Standard Models: 14 – 22 kVA ................................................................A4

Appendix B: 1600XP/1600XPi Command Parameter Table .........................B-1

Appendix C: 1600XP/1600XPi Dimensions and Weights .............................C1

3.6 – 6 kVA Dimensions ...........................................................................C1

3.6 – 6 kVA Dimensions (w/ Optional MBS) .............................................C2

8 – 10 kVA Dimensions ............................................................................C3

14 – 22 kVA Dimensions (w/ Optional MBS) ...........................................C4

Appendix D: Battery Backup Tables (Internal & External Battery Cabinets) D1

3.6kVA – UH3G2L036C61T / H3BG2L036C61T .....................................D1

6kVA – UH3G2L060C61T / H3BG2L060C61T ........................................D3

8kVA – UH3G2L080C61T / H3BG2L080C61T .........................................D5

10kVA – UH3G2L100C61T / H3BG2L100C61T .......................................D7

14kVA – UH3G2L140C61T / H3BG2L140C61T .......................................D9

18kVA – UH3G2L180C61T / H3BG2L180C61T .......................................D11

22kVA – UH3G2L220C61T / H3BG2L220C61T .......................................D13

Appendix E: External Battery Cabinets (Matching) - Outlines ....................E1

Appendix F: External Battery Cabinets (Non-Matching) ..............................F1

F.1 Estimated Runtime............................................................................F1

F.2 Battery Cabinet Outlines ................................................................... F2

Index ..................................................................................................................I-1

1600XP/XPi Series Installation and Operation Manual – 60616-012

iii

Page 10

iv

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 11

1. General Safety Instructions

DO NOT attempt to transport, install, operate, maintain or dispose of this equipment until you have read and

understood all of the product safety information provided in this manual.

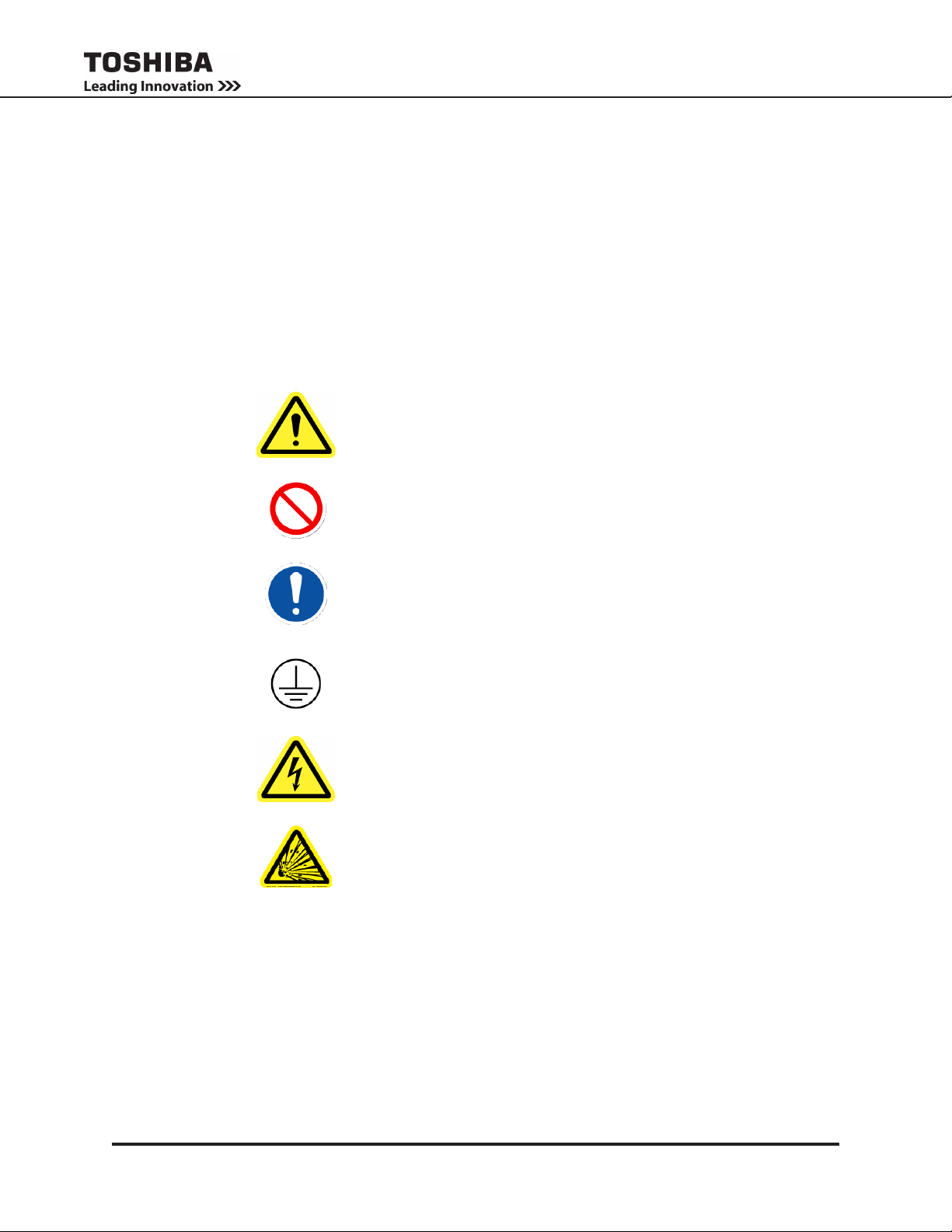

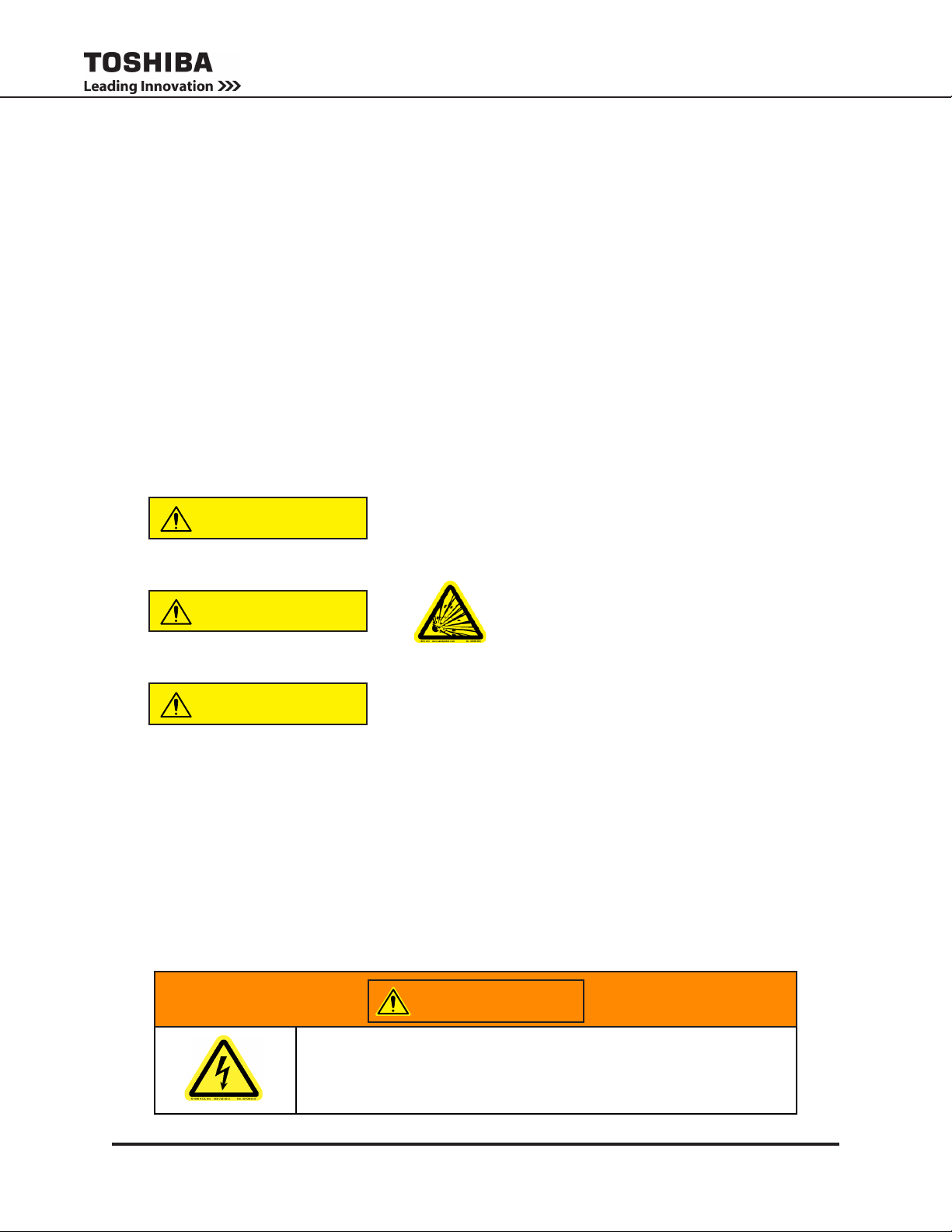

1.1 Symbols

The symbols listed below are used throughout this manual. When symbols are used in this manual they will

include important safety information that must be carefully followed.

Safety Alert Symbol indicates that a potential

personal injury hazard exists.

Prohibited Symbol indicates DO NOT take action.

Mandatory Symbol indicates that the following

instruction is required.

Ground Symbol indicates the location of the

equipment grounding conductor.

Electrical – Voltage & Shock Hazard Symbol

indicates parts inside may cause electric shock.

Explosion Hazard Symbol indicates parts may

explode.

1600XP/XPi Series Installation and Operation Manual – 60616-012

1

Page 12

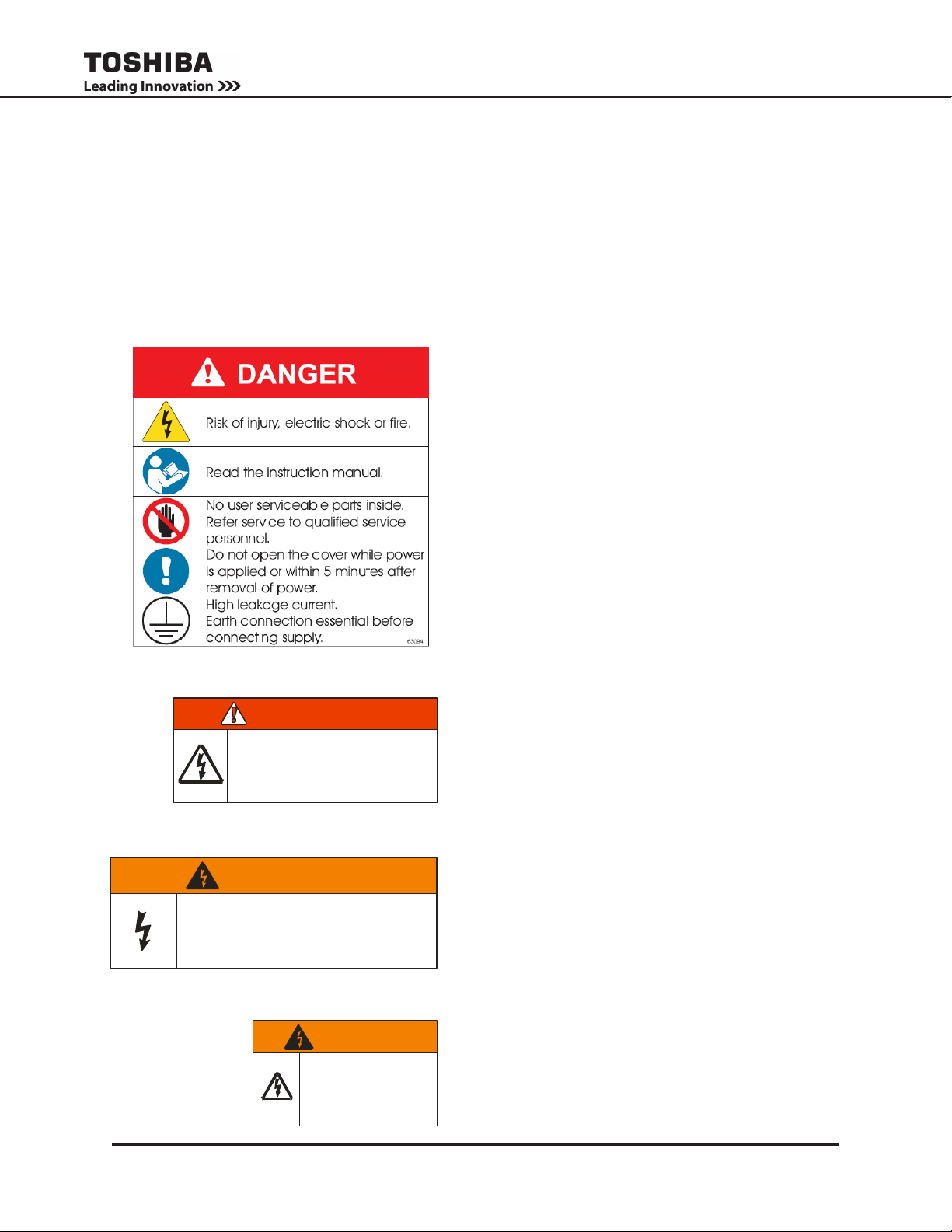

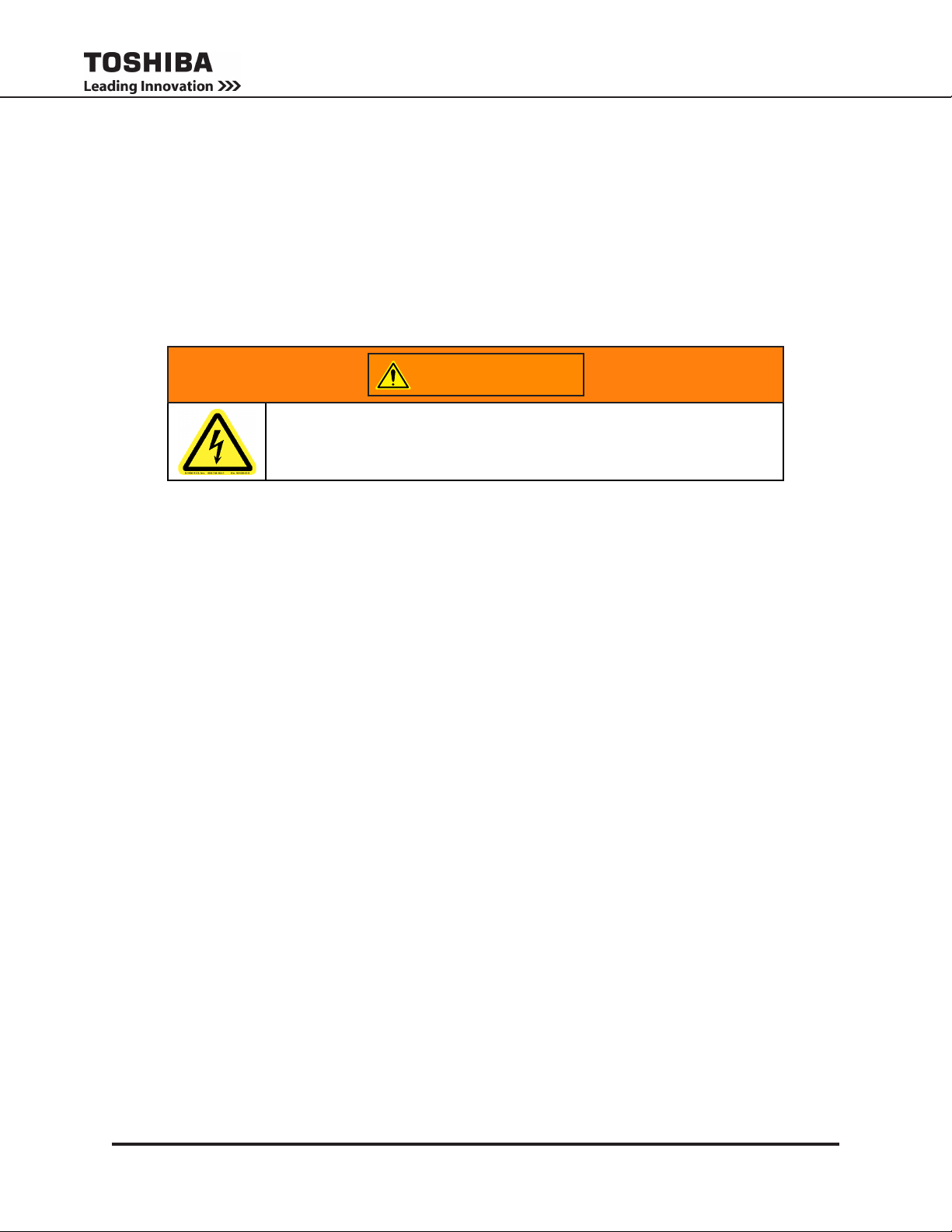

1.2 Signal Words

The signal words listed below are used throughout this manual. When the words DANGER, WARNING,

CAUTION and NOTICE are used in this manual they will include important safety information that must be

carefully followed.

The word DANGER in capital letters preceded by

DANGER

WARNING

CAUTION

the safety alert symbol indicates that an imminently

hazardous situation exists, and if not avoided

will result in loss of life or serious injury to

personnel.

The word WARNING in capital letters preceded by

the safety alert symbol indicates that a potentially

hazardous situation exists, and if not avoided

may result in loss of life or serious injury to

personnel.

The word CAUTION in capital letters preceded by

the safety alert symbol indicates that a potentially

hazardous situation exists, and if not avoided may

result in minor or moderate injury.

The word NOTICE in capital letters without the safety

NOTICE

alert symbol indicates a potentially hazardous

situation exists, and if not avoided may result in

equipment and property damage.

1.3 Regulatory Compliance Statement

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy, and if it is not installed and used in accordance with the

instruction manual, it may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the user will be required

to correct the interference at his own expense.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired

operation.

Notice: The FCC regulations provide that changes or modications made to this device that are not

approved by Toshiba International Corporation may void the authority granted to the user by the FCC to

operate this equipment.

EMC Directive Class A Note

This UPS is commercial in design and not intended for use at anytime in a Residential Environment.

2

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 13

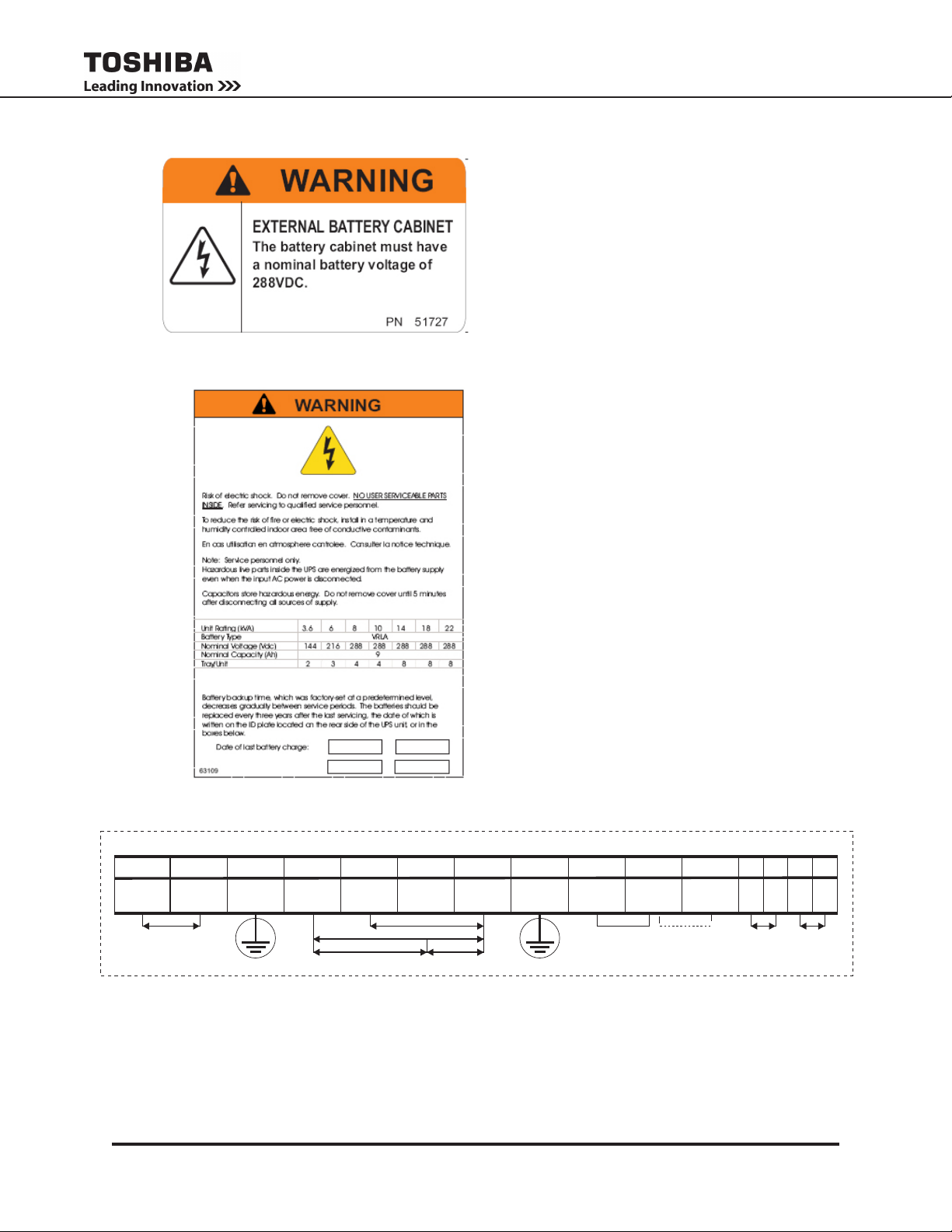

2. Equipment Warning Labels

PN 51727

EXTERNAL BATTERY CABINET

The battery cabinet must have

a nominal battery voltage of

288VDC.

WARNING

DANGER/ATTENTION

Risk of electrical s hock. Do not touch u nin sulated

battery ter minals. Batter ies shoul d be serviced b y

qua lified s ervice r epresentative only. Miswiring of

battery c ould result in electrcal shoc k a nd/or fire.

Risque de choc elec trique. Le c ircuit des batteries

nest pa s eso lede sec teur. Les cosses des ba tteries

peu ven t presenter une tension dange reuse part

rappor t a la terre. Verifier avan t de touch er.

DANGER

Batte ry fuse is al ways

l ive . R isk of ele ctr ica l

shock. Check fuse

voltage an d disconnec t

external batte ries

befo re changing fus e.

48518 SHEET

TYPEFORM

OUTPUT

UNINTERRUPTIBLE POWER SUPPLY

INPUT

LIST ED

POWER

SUPPLY

C US

EPO

14

15

16

17

EPO 1

EPO 2

RE M O TE

REMOTE

1

L1

L2 G

X1 X2

208V

120V

120V

20 8/2 40V

O UTPUT

I N PUT

N

X3

G

208V

USE COPPER 90 C ONDUCTORS ON LY. REFER TO INSTRUCTION MANUAL REGARDING TIG HTENING TORQUE OF TERMINAL BLO CKS. FACTO RY WIRED FOR 208V INPUT.

C OM

2

3

4

5

6 7

8

11

12

13

240V

240V

RE M O TE

JUMPER SEL ECTION

50802

WARNING

Th is un it con tains se aled lead a cid batt erie s.

La ck of preventative m ainte nan ce c ould r esult

in b atteries e xpl od ing a nd emittin g gass es an d/or

flam e. Annu al prev entative main tena nce must be

pe rform ed by a n autho riz ed, trai ne d te chni cian.

WARNING

CRI TICAL F USE SIZ ING

Incorrect fu se replacem ent size

may res ult in fire or inadeq uate

equipm ent protection.

Repla ce onl y with s ame type

and rating of fuse.

49455 SHEET

PN 51727

EXTERNAL BATTERY CABINET

The battery cabinet must have

a nominal battery voltage of

288VDC.

WARNING

DANGER/ATTENTION

Risk of el ectrical shock. Do not touch u ninsu lated

battery ter minals. Batteri es sh ould be serviced b y

qualified s ervice repre sentative only. Miswiring of

battery c ould result in electrcal shoc k and/or fire.

Risque de choc elec trique. Le c ircuit des ba tteries

nest pa s eso lede s ecteur. Les cosses des batteries

peuven t presenter une te nsion dange reuse part

rappor t a la terre. Verifier avan t de touch er.

DANGER

Batte ry fuse is always

liv e. R i sk of e lect ri cal

shock. Check fuse

voltage an d disconnec t

external batteries

before cha nging fuse.

48518 SHEET

TYPEFORM

OUTPUT

MFD. IN U.S.A. FROM FOREIGN AND DOMESTIC COMPONENTS

HOUSTON, TEXAS

UNINTERRUPTIBLE POWER SUPPLY

INPUT

SERIAL NO.

PN 6038 1

LISTED

POWER

SUPPLY

27E5

C US

EPO

14

15

16

17

EPO 1

EPO 2

RE M O TE

REMOTE

1

L1

L2 G

X1 X2

208V

120V

120V

208/ 240 V

O UTP UT

I NPUT

N

X3

G

208V

USE COPPER 90 CO NDUCTORS O NLY. REFER TO INSTRUCTION MANUAL REGARDING TIGHTENING TO RQUE OF TERMINAL BLOCKS. FA CTO RY WIRED FOR 208V INPUT.

C OM

2

3

4

5

6 7

8

11

12

13

240V

240V

RE M O TE

JUMPER SELECTION

50802

WARNING

CR ITICAL FUSE SIZ ING

Incor rect fuse replacem ent size

may r esult in fire or inadequate

equ ipm ent protec tion.

Repla ce onl y with same t ype

and rating of fus e.

48518 SHEET

TYPEFORM

OUTPUT

MFD. IN U.S.A. FROM F OREIGN AND DOMESTIC COMPONENTS

HOUSTON, TEXAS

UNINTERRUPTIBLE POWER SUPPLY

INPUT

SERIAL NO.

PN 60381

LIST ED

POWER

SUPPLY

27E5

C US

EPO

14

15

16

17

EPO 1

EPO 2

RE M O TE

REMOTE

1

L1

L2 G

X1 X2

208V

120V

120V

20 8/2 40V

O UTPUT

I N PUT

N

X3

G

208V

USE COPPER 90 C ONDUCTORS ON LY. REFER TO INSTRUCTION MANUAL REGARDING TIG HTENING TORQUE OF TERMINAL BLO CKS. FACTO RY WIRED FOR 208V INPUT.

C OM

2

3

4

5

6 7

8

11

12

13

240V

240V

RE M O TE

JUMPER SEL ECTION

50802

The following pages show examples of warning labels that may be attached to either the interior or exterior of the UPS. Do not remove or cover any of the labels. If the labels are damaged or if additional

labels are required, contact your equipment representative for additional labels.

These labels are placed to provide useful information or to indicate an imminently hazardous situation

that may result in severe equipment/property damage, serious injury, or loss of life if instructions are

not followed.

P/N 63094 – External warning sign.

• Unit contains potentially dangerous voltages.

• Read the instruction manual before operating.

• There are no user serviceable parts inside.

Refer service to qualied personnel.

• Do not open the cover while power is applied,

or within ve minutes after removal of power.

• Potentially hazardous leakage current may

exist. Ensure the grounding is connected

before connecting the utility power.

1600XP/XPi Series Installation and Operation Manual – 60616-012

P/N 48518 – Battery terminals can deliver

dangerous electrical shock. Service by

qualied service representatives only.

P/N 49455 – UPS Batteries require an-

nual preventative maintenance. Failure to

perform regular maintenance could result in

batteries exploding, or emitting gasses or

ame.

P/N 49455 – Replace Fuse only

with one of same type and range.

Incorrect fuse size may result in

equipment damage.

3

Page 14

Battery Cabinet Warning Label.

* For reference only, DC voltage varies by

kVA size of the UPS.

P/N 63109 – There are no user-serviceable parts

behind cover. Wait ve minutes after disconnect-

ing the UPS to allow the internal capacitors to

discharge completely.

Date of last recorded battery change.

o

3

G

4

X1

5

X2

120V

240V

OUTPUT

6

N

(0V*)

208V

120V

7

X3

15

8

G

11

208V

12

COM

INPUTVOLTAGE

JUMPERSELECTION

14

13

240V

(*)FORSINGLEHOTWIRE

16

EPO1

EPO2

REMOTE17REMOTE

EPO REMOTE

1

L1

(L*)

USECOPPER90 CONDUCTORSONLY.REFERTOINSTRUCTIONMANUALREGARDINGTORQUEOFTERMINALBLOCKS.FACTORYWIREDFOR208VINPUT.

2

L2

(N*)

208/240V

INPUT

P/N63093 - Power Terminal Label

4

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 15

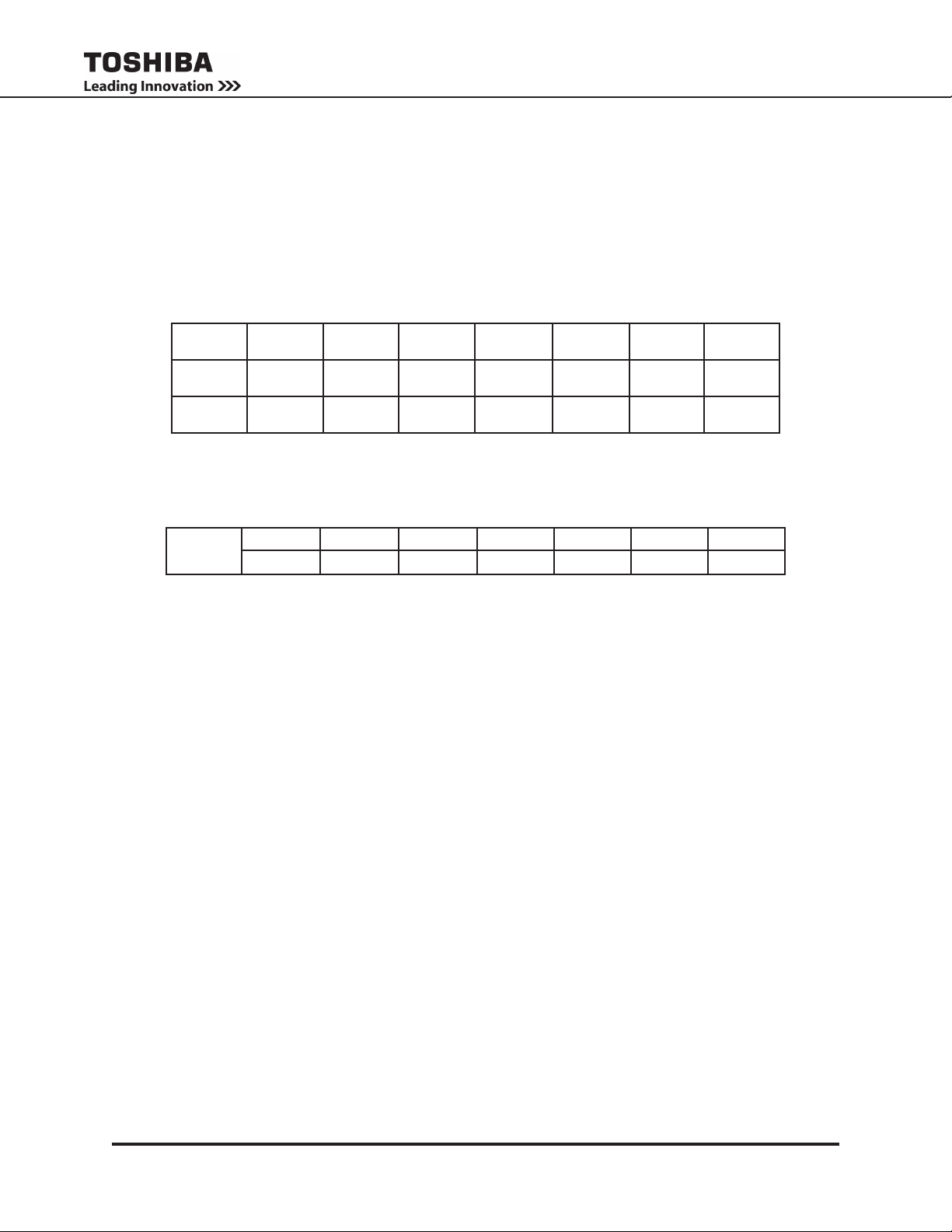

3. Important Safety Instructions

This manual contains important instructions that should be followed during the installation and maintenance

of the UPS and its batteries.

Hardwired UPS units are not equipped with an over-current protection device nor an output disconnect for

the AC output. Circuit breakers should be provided by the user between the UPS Input and utility power,

and the UPS output and the load input. These devices should be rated as follows:

240VAC

RATING

Input

Breaker

Output

Breaker

* Ratings are for an 80% rated device.

The nominal battery voltages for these models are as follows:

BATTERY

VOLTAGE

Servicing of the batteries should only be performed by a qualied factory authorized representative who

is knowledgeable about batteries and the required precautions. Keep unauthorized personnel away from

batteries. To arrange for battery replacement, contact Toshiba Customer Support Center.

1. Turn off, lockout, and tagout all equipment before connecting the power wiring to the equipment or

when performing maintenance.

2. The maximum ambient operating temperature is 104 °F (40 °C).

3. Access panels should only be removed by authorized Toshiba eld Service personnel.

4. UPS servicing should be performed by qualied Toshiba representatives only.

5. Battery servicing should be performed by qualied Toshiba representatives only.

6. Contact your Toshiba authorized service center for battery replacement.

3.6 kVA 6 kVA 8 kVA 10 kVA 14 kVA 18 kVA 22 kVA

30 A 50 A 60 A 70 A 100 A 100 A 125 A

20 A 35 A 45 A 60 A 80 A 100 A 125 A

3.6 kVA 6 kVA 8 kVA 10 kVA 14 kVA 18 kVA 22 kVA

144 Vdc 216 Vdc 288 Vdc 288 Vdc 288 Vdc 288 Vdc 288 Vdc

1600XP/XPi Series Installation and Operation Manual – 60616-012

5

Page 16

3.1 Qualied Personnel Only

Qualied personnel are those who have the skills and knowledge relating to the construction,

installation, operation, and maintenance of the electrical equipment and have received safety

training on the hazards involved (Refer to the latest edition of NFPA 70E for additional safety

requirements).

Qualied personnel shall:

1. Have read the entire operation manual.

2. Be trained and authorized to safely energize, de-energize, ground, lockout and tag circuits

and equipment, and clear faults in accordance with established safety practices.

3. Be trained in the proper care and use of protective equipment such as safety shoes, rubber

gloves, hard hats, safety glasses, face shields, ash clothing, etc., in accordance with

established safety practices.

4. Be trained in rendering rst aid.

5. Be knowledgeable about batteries and their required handling and maintenance precautions.

For further information about workplace safety visit www.osha.gov.

Misuse of this equipment may result in human injury

CAUTION

and equipment damage. In no event will Toshiba

Corporation be responsible or liable for either

indirect or consequential damage or injury that may

result from the misuse of this equipment.

CAUTION

CAUTION

To be performed by Qualied Personnel Only:

DO NOT open or mutilate the batteries. Released

electrolyte is harmful to the eyes and skin and could

also be toxic.

DO NOT dispose of the battery module in

a re. The batteries inside may explode.

1. Verify that the UPS is off and that the power is disconnected from the power source.

2. Remove watches, rings or other metal objects.

3. Use tools with insulated handles to prevent inadvertent shorts.

4. Wear rubber safety gloves and boots.

5. DO NOT place tools or any metal parts on top of batteries.

6. Determine if the battery is inadvertently grounded. If inadvertently grounded, remove source of

ground.

WARNING

Contact with any part of a grounded battery can result in

electrical shock.

The likelihood of shock will be reduced if such grounds are removed

prior to installation or maintenance.

6

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 17

4. Inspection/Storage/Disposal

4.1 Inspection

Inspect for shipping damage upon receipt of the UPS. Use caution when removing the unit from the pallet.

Refer to labels or documentation attached to packing material.

4.2 Unpacking

Check the unit for loose, broken, bent or otherwise damaged parts. If damage has occurred during shipping,

keep all original crating and packing materials for return to the shipping agent. The warranty does not apply

to damage incurred during shipping. Ensure that the rated capacity and the model number specied on the

nameplate conform to the order specications.

4.3 Storage

During periods of non-use, the following guidelines are recommended for storage.

Storage Preparation

1. Power up the UPS and allow it to operate with no load for 24 hours to fully charge the

batteries.

2. Stop the unit (see Stop Operation on page 16).

3. Place the MCCB switch (see Appendix C for location) in the Off position.

Storing Conditions

• For best results, store the UPS in the original shipping container and place on a wood

or metal pallet.

• Storage temperature: -4 – 104 °F (-20 – 40 °C).

• The optimum storage temperature is 70 °F (21 °C). A higher ambient temperature will

require recharging more frequently during storage.

Avoid storage locations that:

• Are subject to extreme temperature changes or high humidity.

• Are subject to high levels of dust or metal particles.

• Are subject to excessive vibration.

• Have inclined oor surfaces.

Storage Maintenance

• If stored at an ambient temperature less than 68 °F (20 °C), recharge the batteries every

9 months.

• If stored at an ambient temperature of 68 – 86 °F (20 – 30 °C), recharge the batteries

every 6 months.

• If stored at an ambient temperature of 86 – 104 °F (30 – 40 °C), recharge the batteries

every 3 months.

4.4 Disposal

Contact your local or state environmental agency for details on disposal of electrical components and

packaging in your particular area.

It is illegal to dump lead-acid batteries in landlls or dispose of improperly.

NOTE: Battery Pack cases are ABS Plastic No. 7.

Please help our Earth by contacting the environmental protection agencies in your area, the battery

manufacturer, or call Toshiba toll-free at (877) 867-8773 for more information about recycling.

1600XP/XPi Series Installation and Operation Manual – 60616-012

7

Page 18

5. Installation Precautions

fig 1

fig 2

1

2

3

Unpacking Instructions

P/N 48537

TYPEFORM

OUTPUT

MFD. IN U.S.A. FROM FOREIGN AND DOMESTIC COMPONENTS

HOUSTON , TEXAS

UNINTERRUPTIBLE POWER SUPPLY

INPUT

SERIAL NO.

PN 6038 1

LISTED

POWER

SUPPLY

27E5

C US

EPO

14

15

16

17

EPO 1

EPO 2

RE M O TE

REMOTE

1

L1

L2 G

X1 X2

208V

120V

120V

208/ 240 V

O UTPUT

I NPUT

N

X3

G

208V

USE COPPER 90 C ONDUCTORS ON LY. REFER TO INSTRUCTION MANUAL REGARDING TIGHTENING TORQUE O F TERMINAL BLOCKS. FACTORY WIRED FOR 208V INPUT.

C OM

2

3

4

5

6 7

8

11

12

13

240V

240V

RE M O TE

JUMPER SELECTION

50802

NOTICE

1. Observe the following environmental restrictions:

• Install the unit in a well-ventilated location; allow at least 4 inches (10 cm) on all sides for air

ventilation and for maintenance.

• Install the unit where the ambient temperature is within the range specied in Appendix A -

“Specications”.

• DO NOT install the UPS in areas that are subject to high humidity.

• DO NOT install the UPS in areas that allow exposure to direct sunlight.

• DO NOT install the UPS in areas that allow exposure to high levels of airborne dust, metal

particles, or ammable gases.

• DO NOT install the UPS in areas near sources of electrical noise. Ensuring a proper earth ground

will reduce the effects of electrical noise and will reduce the potential for electrical shock.

• DO NOT install the UPS in areas that would allow uids or any foreign object to get inside the

UPS.

2. UPS is intended for permanent installation only. Install the unit in a stable, level and upright position

that is free of excessive vibration.

3. Follow the instructions on the unpacking label afxed to the exterior of the UPS.

4. Retain the shipping rails for use as permanent mounting of the UPS.

8

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 19

5. Once the installation is complete, use a 3/4 inch wrench to screw down the UPS leveling feet located

next to the four casters, until the unit is no longer resting on the casters.

6. The UPS generates and can radiate radio-frequency energy during operation. Although RFI noise

lters are installed inside of the unit, there is no guarantee that the UPS will not inuence some

sensitive devices that are operating near by. If such interference is experienced, the UPS should be

installed farther away from the affected equipment and/or powered from a different source than that

of the affected equipment.

7. It is the responsibility of the installer of this equipment to provide a suitable disconnect for the Control

Panel supplying power to this equipment.

This disconnect must:

Be suitable for the Voltage and Full Load Ampere Rating of all downstream equipment supplied by

the Panel;

The supply disconnecting device shall be one of the following types:

• Switch-disconnector, with or without fuses, in accordance with IEC 60947-3, utilization

category AC-23B or DC-23B

• As above, except one that has an auxiliary contact that in all cases causes switching devices

to break the load circuit before the opening of the main contacts of the disconnector.

• A circuit breaker suitable as an isolation device per IEC 60947-2

• Any other switching device in accordance with an IEC product standard that also meets the

isolation requirements of IEC 60947-1 and is appropriate for on-load switching of motors or

other inductive loads;

Be approved for use as a disconnect for the country in which this equipment is installed.

Be provided with a Lock Out Tag Out capability in the Off (Down) position.

8. Allow 5 minutes after power is removed for internal capacitors to fully discharge before attempting

to service the unit.

9. The user should provide output over-current protection for hardwired UPS systems. See Appendix

A - “Specications” for the device rating.

10. After ensuring that all power sources are turned off and isolated in accordance with established

lockout/tagout procedures, connect the power source wiring of the correct voltage to the input

terminals of the UPS.

11. The end user must supply suitable strain relief for the power cord and the cord must extend a

distance of 1/2 diameter beyond the clamp.

12. Connect the output terminals of the UPS to the load in line with local wiring regulations. Size the

branch circuit conductors in accordance with NEC Table 310.16.

1600XP/XPi Series Installation and Operation Manual – 60616-012

9

Page 20

6. Conductor Routing and Grounding

1. Use separate metal conduits for routing the input power, output power, and control circuits.

2. Follow the wire size and tightening torque specications listed in “” on page 14.

3. Always ground the unit to reduce the potential for electrical shock and to help reduce electrical

noise.

4. A separate ground cable should be run inside the conduit with the input power, output power, and

control circuits.

WARNING

THE METAL OF CONDUIT IS NOT AN ACCEPTABLE GROUND.

7. Operating Precautions

1. The UPS should not be powered up until the entire operation manual has been read.

2. The voltage of the input power source must be within the range of +10% to -30% of the rated

input voltage. The input frequency must be within the rated input frequency range. Voltages and

frequencies outside of the permissible range may activate the internal protection devices.

3. The UPS should not be used with a load that has a rated input that is greater than the rated output

of the UPS.

4. DO NOT use the UPS to provide power to motors that require high starting current or with motors

that require a long starting time, such as vacuum cleaners and machine tools (oversizing the UPS

for lock rotor current would be required).

5. DO NOT insert metal objects or combustible materials in the ventilation slots of the UPS.

6. DO NOT place, hang, or paste any objects on the exterior surfaces of the UPS.

7. The capacitors of the UPS maintain a residual charge for a while after turning the UPS off.

8. DO NOT attempt to disassemble, modify, or repair the UPS. Repairs and servicing should only be

performed by Toshiba Field Service personnel.

9. DO NOT remove any covers of the UPS when the power is on.

10. Turn the power on only after installing ALL of the covers.

11. If the UPS should emit smoke, produce an unusual odor, or make sound, turn the power off

immediately.

12. Changing/replacing the UPS Batteries should only be performed by Toshiba eld service personnel.

13. Warning signs should be placed on or near the load as a notication that the load is being powered

by the UPS.

14. Additional warnings and notications shall be posted at the equipment installation location as

deemed required by Qualied Personnel.

10

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 21

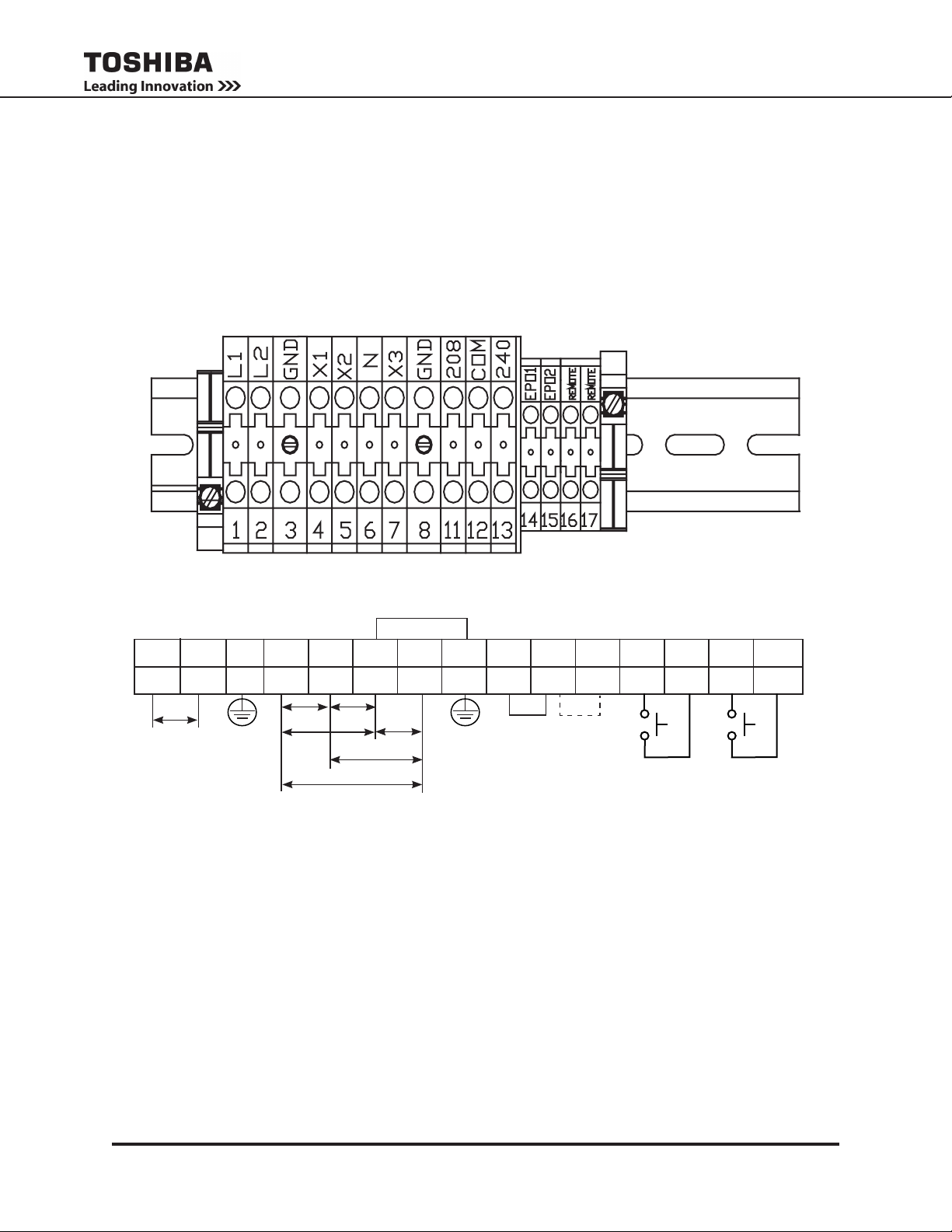

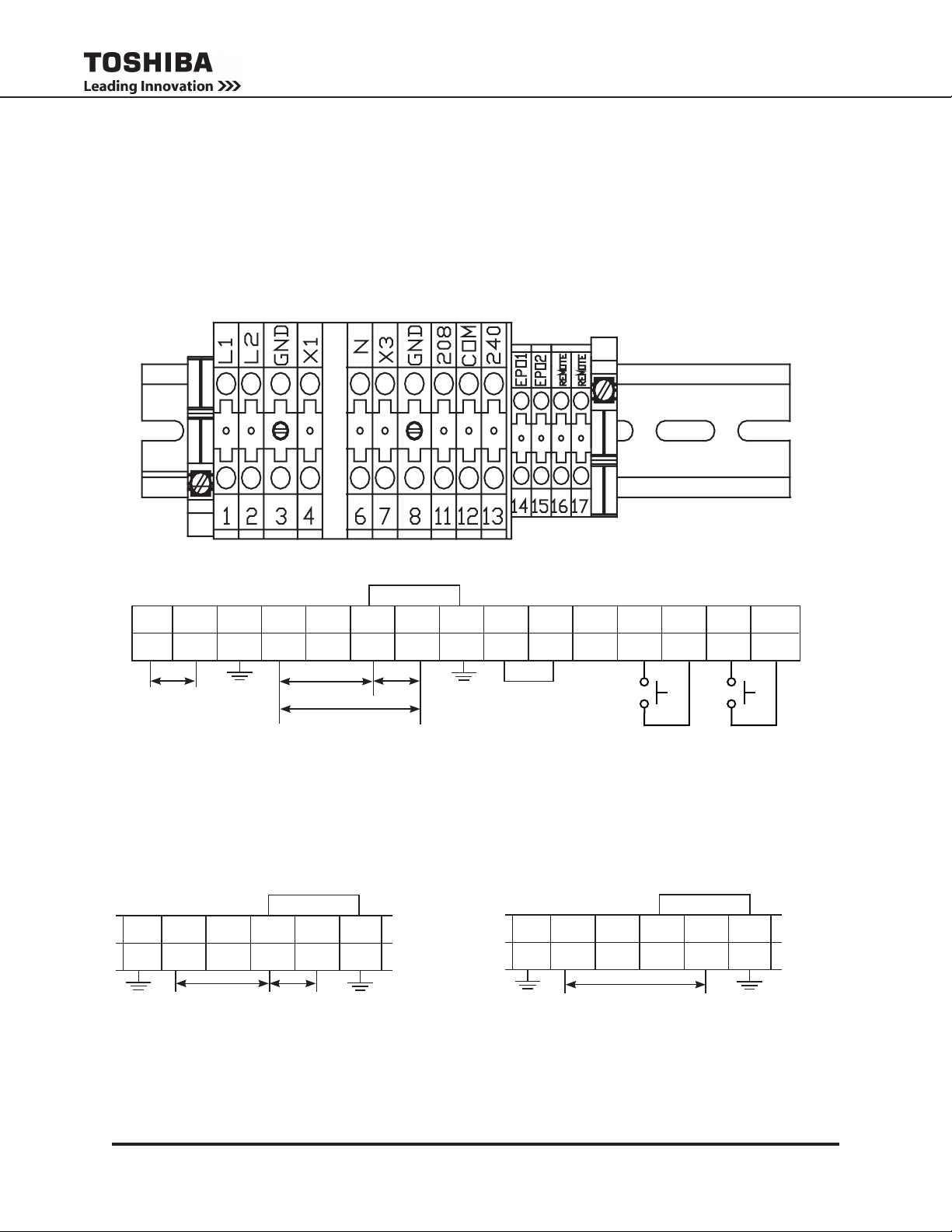

8. UPS Connections

8.1 Terminal Block - 208/240 VIN, 120/280/240 V

OUT

The following illustration is a detail view of the terminal block and wiring connections used for 208/240

volt units (see “Appendix C: 1600XP/1600XPi Dimensions and Weights” on page C1).

1,2

208

12 1413 15

COM

240GX3

16 17

REMOTE1

EPO2EPO1

REMOTE2

1

L1 (L*)

2

L2 (N*)

3

G X1 X2

Factory Installed N - G Jumper

8765 114

N (0V)

32 V 88 V

208/240 Vin

INPUT

* – If only one input line is hot, connect hot line to terminal 1 (L), and connect the Neutral line to terminal 2 (N).

NOTE 1 – If AC input power is 208 Vac rated, short terminals 11 and 12 with a jumper wire. DO NOT jumper terminal 13 to 12 or

11. Factory Setting is 208 Vac. Use the jumper wire provided by Toshiba. DO NOT add any additional jumpers.

NOTE 2 – If AC input power is 240 Vac rated, short terminals 12 and 13 with a jumper wire. DO NOT jumper terminal 11 to 12 or

13. Use the jumper wire provided by Toshiba. DO NOT add any additional jumpers.

NOTE 3 – EPO and Rmt Contacts function – See Section 8.2

120 V

240 V

OUTPUT

208 V

120 V

Jumper selection

See notes 1&2

240V208V

EPO

NONO

3

Rmt Contacts

3

1600XP/XPi Series Installation and Operation Manual – 60616-012

11

Page 22

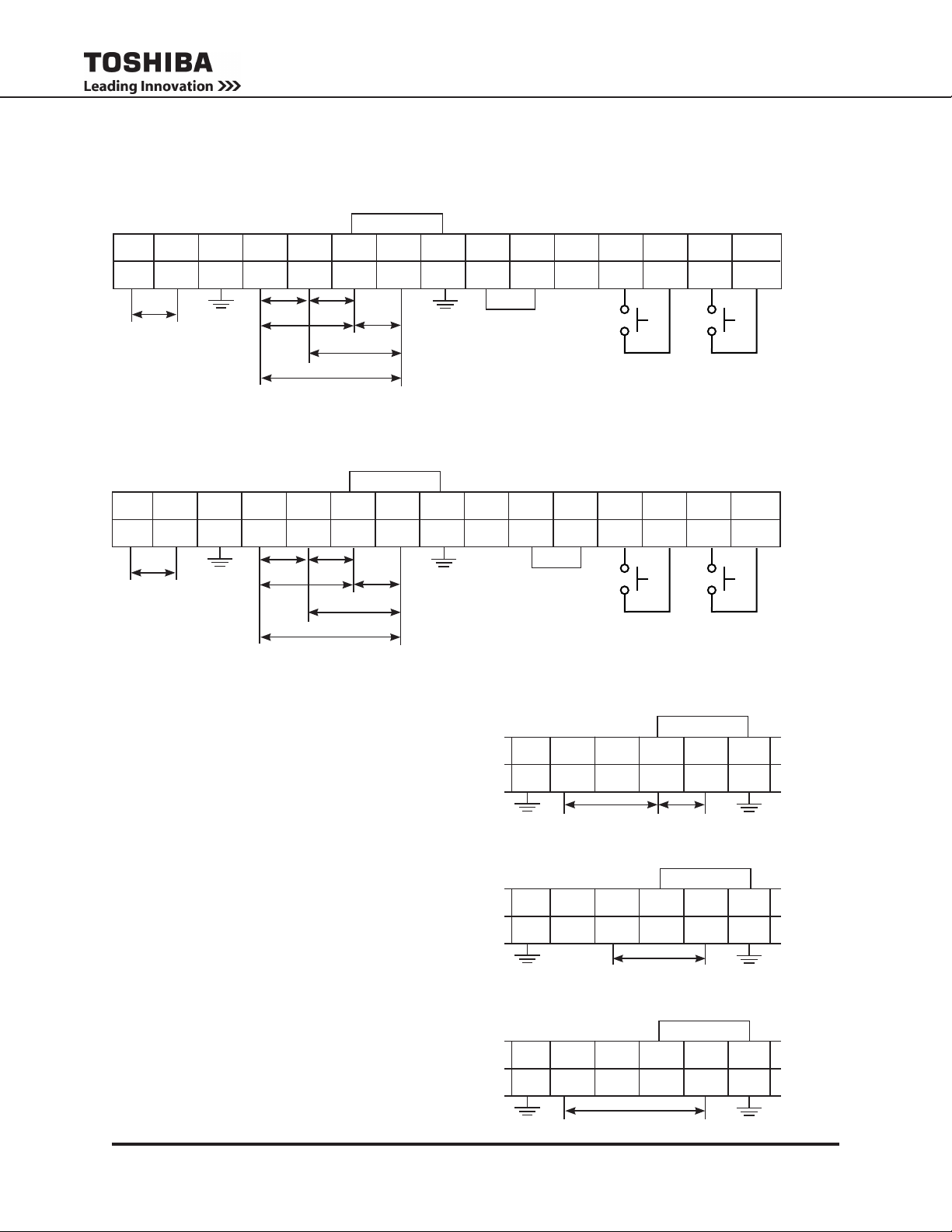

Input and Jumper wire/bus strip connection for:

208 Vin – Using provided jumper, connect terminals 11 – 12.

Factory Installed N - G Jumper

1

2 3

L2 G X1 X2 N

L1

208 Vin

32 V 88 V

120 V

240 V

120 V

208 V

8765 114

208

Jumper

240 Vin – Using provided jumper, connect terminals 13 – 12.

Factory Installed N - G Jumper

1

2 3

L2 G X1 X2 N

L1

240 Vin

32 V 88 V

120 V

240 V

120 V

208 V

8765 114

208

Output Cabling for:

12 1413 15

COM

240GX3

EPO2EPO1

EPO

12 1413 15

COM

Jumper

240GX3

EPO2EPO1

EPO

Factory Installed N - G Jumper

16 17

REMOTE1

NONO

Rmt Contacts

REMOTE2

16 17

REMOTE1

REMOTE2

NONO

Rmt Contacts

120 Vout

Connect load across Terminals 4 – 6 or 6 – 7.

208 Vout

Connect load across terminals 5 – 7.

240 Vout

Connect load across terminals 4 – 7.

12

3 87654

GX3G X1 X2 N

120 V

120 V

Factory Installed N - G Jumper

3 87654

X2

N

208 Vout

Factory Installed N - G Jumper

GX3G X1

3 87654

GX3G X1 X2 N

240 Vout

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 23

8.2 Terminal Block - 240 VIN, 100/200 V

OUT

The following page shows the terminal connections for the 1600XP typeform UH3G2L060C61TM.

Terminal Block

The following illustration shows a detailed view of the terminal block and wiring connections used for

208 Vin, 100/200 V

units.

out

DO NOT USE

Factory Installed N - G Jumper

1

2 3

L2 G X1

L1

208 Vin

DO NOT

USE

100 V

200 V

N

100 V

8765 114

208

12 1413 15

COM

240GX3

Jumper

EPO2EPO1

EPO

16 17

REMOTE1

NONO

Rmt Contacts

Output Cabling for:

100 Vout: 200 Vout:

Connect load across Terminals 4 – 6 or 6 – 7. Connect load across terminals 4 – 7.

Factory Installed N - G Jumper

GX3G X1 X2 N

200 Vout

3 87654

Factory Installed N - G Jumper

100 V

100 V

3 87654

GX3G X1 X2 N

REMOTE2

1600XP/XPi Series Installation and Operation Manual – 60616-012

13

Page 24

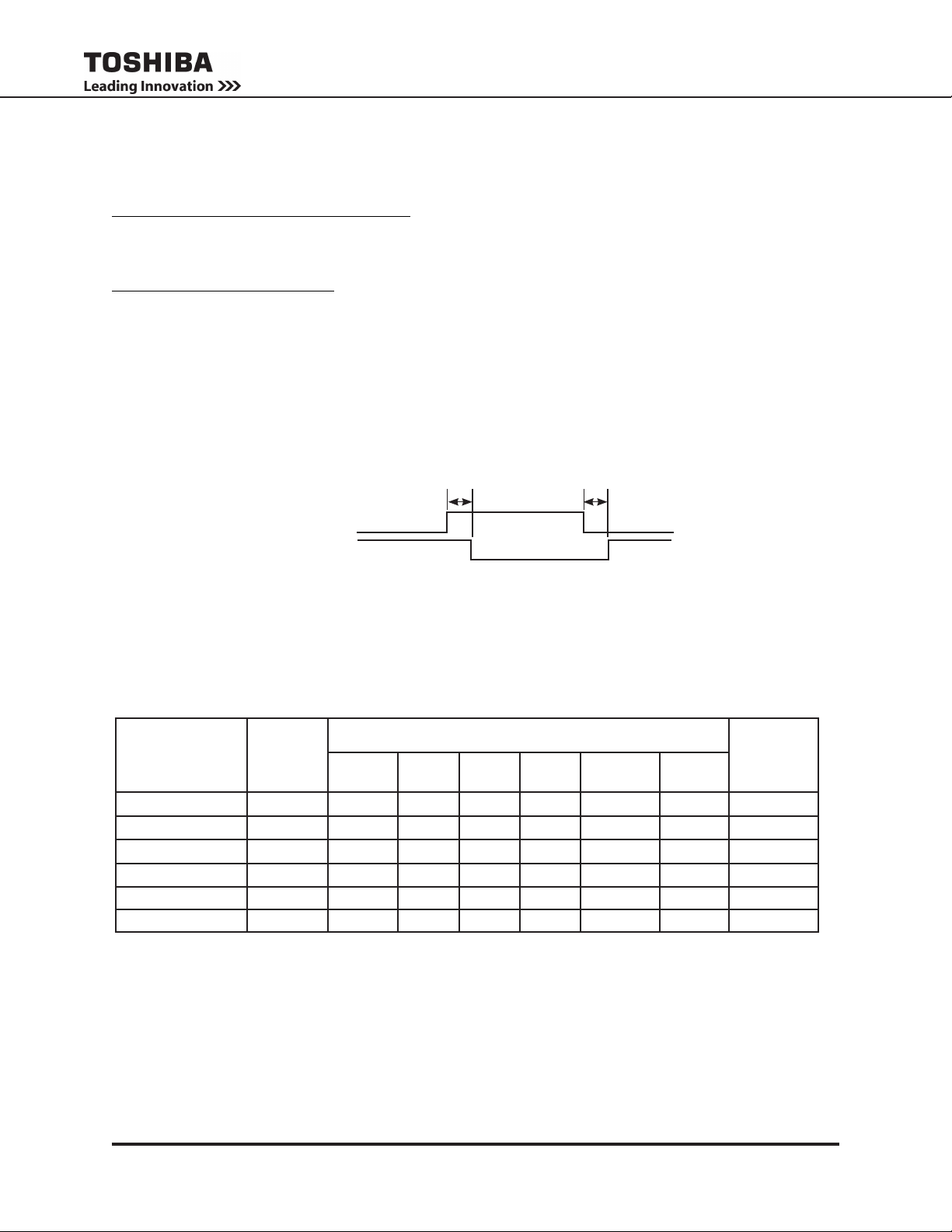

8.3 EPO and Remote Shutdown

EPO (Emergency Power Off): TB1-14, -15

The EPO is a NO (Normally Open) dry contact switch. When the EPO is closed, the Input circuit break-

er to the UPS opens and all power to the unit is removed, including backup power from the batteries.

Remote Shutdown: TB1-16, -17

The Remote Shutdown is a NO (Normally Open) dry contact switch. When the Remote Shutdown

switch is closed, the UPS transfers from Normal/Backup to Bypass after a 1 – 2 sec. detection delay.

(See the diagram below)

When the closed Remote Shutdown switch is opened, the UPS transfers from Bypass back to it’s initial

state (Normal/Backup) after a 1 – 2 sec. detection delay.

If the UPS is in bypass when the Remote Shutdown is closed, no action is taken.

Detection Delay

Remote Status

Switch

UPS Mode

FIGURE 8.2-1 REMOTE STATUS SHUTDOWN TIMING

1-2 Sec.

Open

Normal / Backup Mode

Closed

Bypass Mode

Detection Delay

1-2 Sec.

8.4 Cable Size and Tightening Torque

Use the following table to select the recommended wire size and terminal lug tightening torque for I/O

wire connections. Use 90 °C copper conductors for all Input, Output, and Ground wiring.

Item

Terminal

Number

3.6 kVA 6 kVA 8 kVA 10 kVA

AC Input Lines 1 and 2 10 (8) 8 (8)

AC Output Lines 4, 5, and 7 12 (8) 10 (8)

AC Output Neutral 6 12 (8) 10 (8)

Ground 3 and 8 12 (8) 10 (8)

Cable Size – AWG

14 – 18

kVA

8 (1/0) 6 (1/0)

8 (1/0) 6 (1/0)

4 (1/0) 1 (1/0) 14.2 (1.56)

4 (1/0) 1 (1/0) 14.2 (1.56)

8 (1/0) 6 (1/0) 4 (1/0))

8 (1/0) 6 (1/0) 4 (1/0))

22 kVA

1 (1/0) 14.2 (1.56)

1 (1/0) 14.2 (1.56)

EPO Switch 14 and 15 16 16 16 16 16 16 9.0 (0.99)

Remote Switch 16 and 17 16 16 16 16 16 16 9.0 (0.99)

Note: Wire size is presented as the recommended size followed by a bold number in () indicating the maximum wire

size the terminal block can accommodate. See Appendix C for knock-out hole sizes on the back of each model.

Tightening

Torque

lb.-in. (N•m)

8.5 Battery Cabinet Connections

Optional external battery cabinets can be used to extend the backup time of the UPS beyond that

available with the internal batteries. The external battery cabinets connect to the UPS via Anderson-

style connectors. See Section 20.

14

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 25

9. Product Description

An uninterruptible power system (UPS) is a system that is installed between the commercial power and the

load equipment. The UPS provides steady AC output power during commercial power short-term blackouts

or brownouts. This power is provided for a sufcient amount of time so that the load can be shut down in an

orderly fashion. This prevents loss of data and possible damage to both hardware and software.

During normal operation, the UPS uses commercial AC power. It absorbs all of the high voltage spikes and

transients caused by switching and faults, and all of the common-mode and normal mode noise which is

associated with commercial AC power. The UPS converts it all to clean DC power. From this power, the

UPS charges its batteries and generates its own extremely high quality AC waveform output. The result of

this process is maximum power conditioning and regulation.

If the AC power supplied to the UPS drops below a specied voltage level, the unit’s batteries automatically

begin supplying power instead of receiving it. This insures that the loads connected to the UPS continue

to receive power with no interruption. When AC input power becomes available again, operation returns to

normal. The unit’s batteries begin to recharge so they will be ready for the next power interruption.

9.1 Application and Use

Toshiba 1600XP/1600XPi Series of On-Line UPS provides continuous computer-grade AC power in a

compact, high performance, and energy efcient unit. The UPS unit ensures safe and reliable operation of

critical ofce equipment. All units feature an audible alarm which sounds if the battery voltage drops below

a specied minimum during use. This is an additional aid to help protect valuable ofce data banks. All units

allow for computer interfacing.

9.2 Output Rating

Toshiba 1600XP and 1600XPi Series (208/240V) offers UPS models with the following capacities:

MODEL Output Capacity @ 240 V Output kW @ .85PF 240 V

UH3G2L036C61T, H3BG2L036C61T 3.6 kVA 3.1 kW

UH3G2L060C61T, H3BG2L060C61T 6 kVA 5.1 kW

UH3G2L080C61T, H3BG2L080C61T 8 kVA 6.8 kW

UH3G2L100C61T, H3BG2L100C61T 10 kVA 8.5 kW

UH3G2L140C61T, H3BG2L140C61T 14 kVA 11.9 kW

UH3G2L180C61T, H3BG2L180C61T 18 kVA 15.3 kW

UH3G2L220C61T*, H3BG2L220C61T* 22 kVA* 18.7 kW*

All models are RoHS compliant with the batteries being exempt from the directive.

*NOTE: Derate to 18.7 kVA (15.9 kW) for 50 Hz operation.

9.3 Power Backup

When an electrical power failure occurs, the UPS’s internal batteries automatically supply back-up power

to the load without interruption. For example, when used to support a computer, the UPS back-up assures

enough additional time to complete the activity and store the data. This allows an orderly shutdown after a

power failure has occurred.

9.4 Power Conditioning

When commercial power is present, the UPS supplies conditioned power to the load while maintaining its

batteries in a charged condition. The UPS protects against the normal, everyday pr oble ms ass ocia ted

with unreliable commercial power, including power sags, surges, signal interference, and spikes. This

protection keeps power-line problems from reaching your load, where they can cause equipment to operate

erratically, or damage software and hardware.

1600XP/XPi Series Installation and Operation Manual – 60616-012

15

Page 26

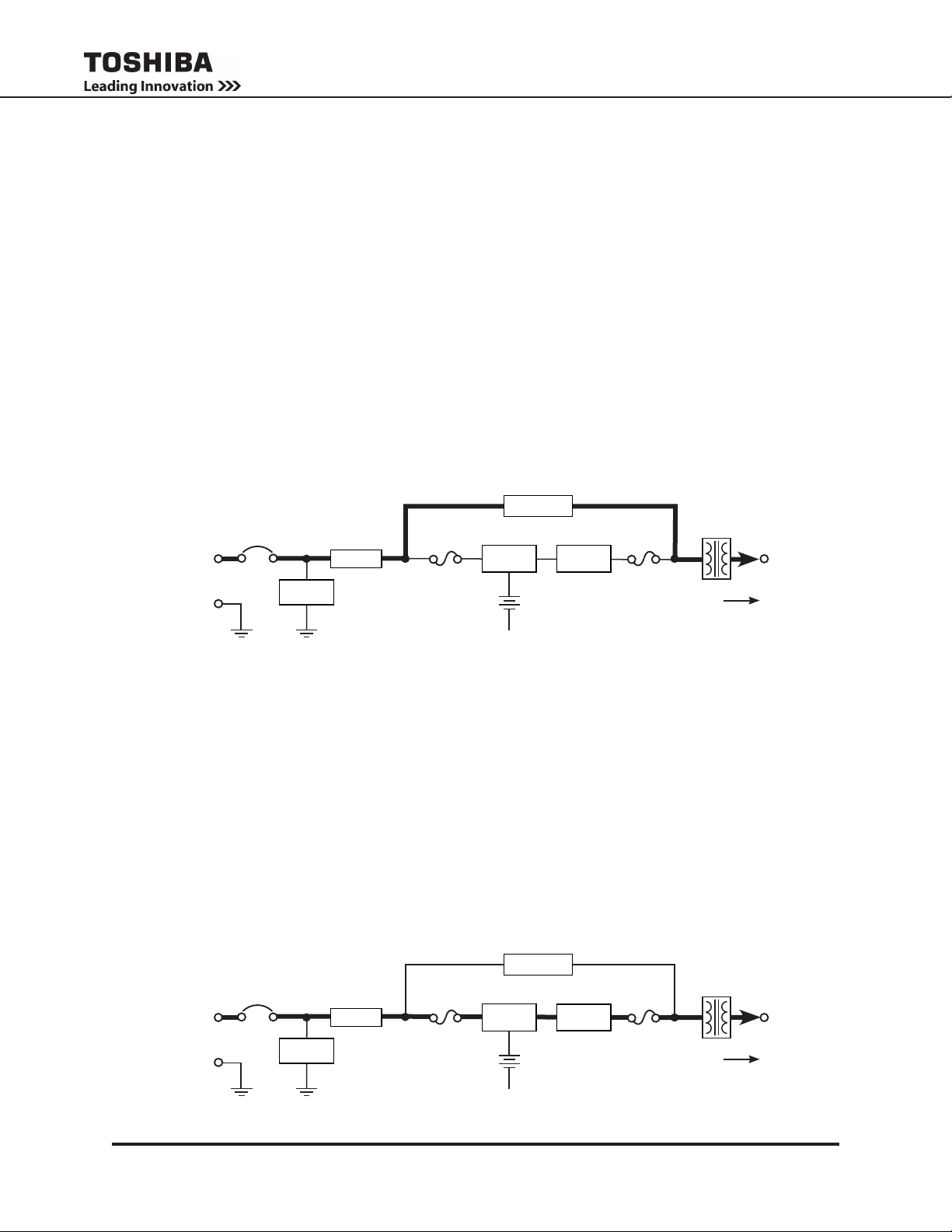

10. Operating Modes

10.1 Static-Bypass (Stop operation)

If the UPS unit is severely overloaded or develops an internal fault, power ow is automatically switched

from the unit’s main circuit to the bypass circuit. Power ow through the bypass is shown in the following

illustration. This change-over occurs automatically in phase in less than one-quarter cycle of the input

waveform. The switching period is not long enough to cause interruptions to occur in most loads.

• If the power ow is transferred to the bypass circuit due to an internal fault the UPS will continue to

supply power to the load through the bypass and indicate a system fault message (see “24.3 System

Fault Messages” on page 53).

• If the power ow is transferred to the bypass circuit due to an overload condition (see “24.4 System

Warning Messages” on page 54), then the power ow will automatically transfer from the UPS’s

bypass circuit back to the inverter circuit after removing the overload if set to do so (AutoXfer

parameter (Cmd ID 660)).

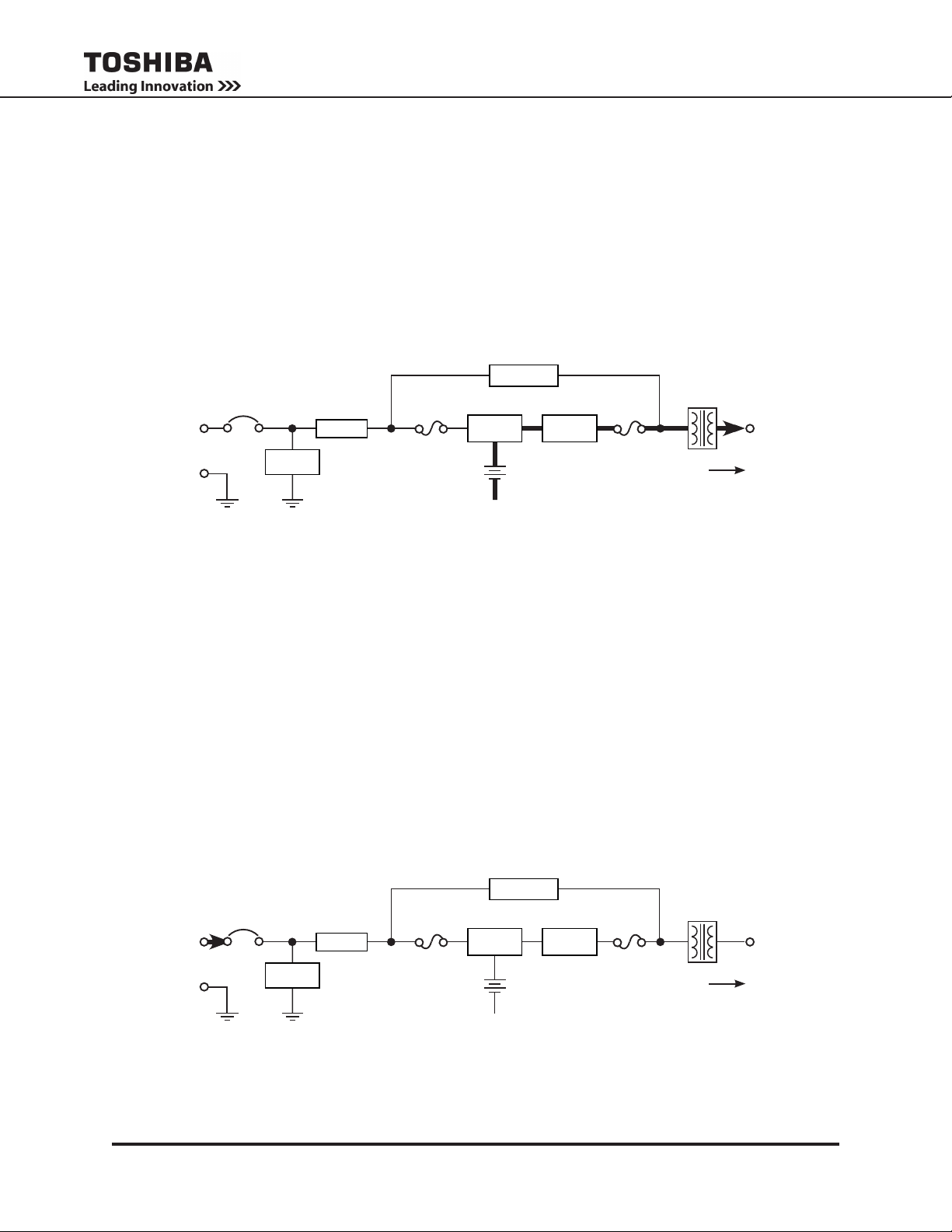

Input

Power

MCCB

Surge

Absorber

Bypass

Input

Line Filter Inverter

Fuse

Batteries

*Static Switch

Rectier/

Chopper

+

–

Negative Bus

* Switches are

solid state

devices.

Output

Fuse

Isolation

Transformer

Power Flow

Output

Power

POWER FLOW IN BYPASS FOR ALL MODELS

10.2 On-Line (Run operation)

The following illustration shows circuit power ow when the UPS is operating normally in the On-Line

mode. The UPS rectier, including a boost chopper circuit, converts AC input power to DC power. The

boost chopper circuit maintains a constant voltage, with current limiting, for charging the batteries. The

inverter section generates a high quality sinu soidal output voltage. The unit’s batteries are always

maintained in a constantly charged state when the UPS is in the run operation mode.

16

Input

Power

MCCB

Surge

Absorber

Bypass

Input

Line Filter Inverter

Fuse

Batteries

*Static Switch

Rectier/

Chopper

+

–

Negative Bus

* Switches are

solid state

devices.

POWER FLOW IN ON-LINE MODE FOR ALL MODELS

1600XP/XPi Series Installation and Operation Manual – 60616-012

Output

Fuse

Isolation

Transformer

Power Flow

Output

Power

Page 27

10.3 Battery Backup (On batteries)

The following illustration shows power ow during the battery backup mode. When commercial AC power

failures occur, the UPS’s batteries instantly begin supplying DC voltage to the UPS’s main inverter circuit.

This circuit changes (inverts) the DC power into AC power. The AC power is available at the output of the

unit.

This back-up process will continue until the UPS’s battery voltage drops below a specic minimum level.

When this occurs, the batteries will stop supplying power to the load. This minimum level is the rated

minimum voltage (Vmin). The rated battery voltage chart on page 19 shows (Vmin). The battery backup

time and discharge process is explained on page 19.

Input

Power

MCCB

Surge

Absorber

Line Filter

Input

Fuse

Bypass

Batteries

*Static Switch

Rectier/

Chopper

+

–

Negative Bus

Inverter

* Switches are

solid state

devices.

Output

Fuse

Isolation

Transformer

Power Flow

Output

Power

POWER FLOW IN BATTERY BACKUP FOR ALL MODELS

10.4 EPO (Emergency Power Off) Function

These units are equipped with terminals for receiving an emergency power-off (EPO) command via a

closed-contact switch at a remote location (see Terminal Block Details on page 11, and terminal block

location in Appendix C). This safety feature enables quick shut-down of the UPS’s AC input breaker,

output and battery circuits.

Usually the emergency power off switch is installed in a central location that is easily accessible to

personnel concerned with the operation of the UPS unit and the load equipment connected to it. The EPO

function is initiated by pressing the switch to the closed (shutdown) position.

The effect of using the EPO switch is the same whether the UPS unit is in AC input mode, battery backup

mode, or the circuit bypass mode. The following gure shows the UPS condition after application of the

EPO switch.

Input

Power

MCCB

Surge

Absorber

Bypass

Input

Line Filter Inverter

Fuse

Batteries

*Static Switch

Rectier/

Chopper

+

–

Negative Bus

POWER FLOW AFTER AN EPO COMMAND FOR ALL MODELS

1600XP/XPi Series Installation and Operation Manual – 60616-012

* Switches are

solid state

devices.

Output

Fuse

Isolation

Transformer

Power Flow

Output

Power

17

Page 28

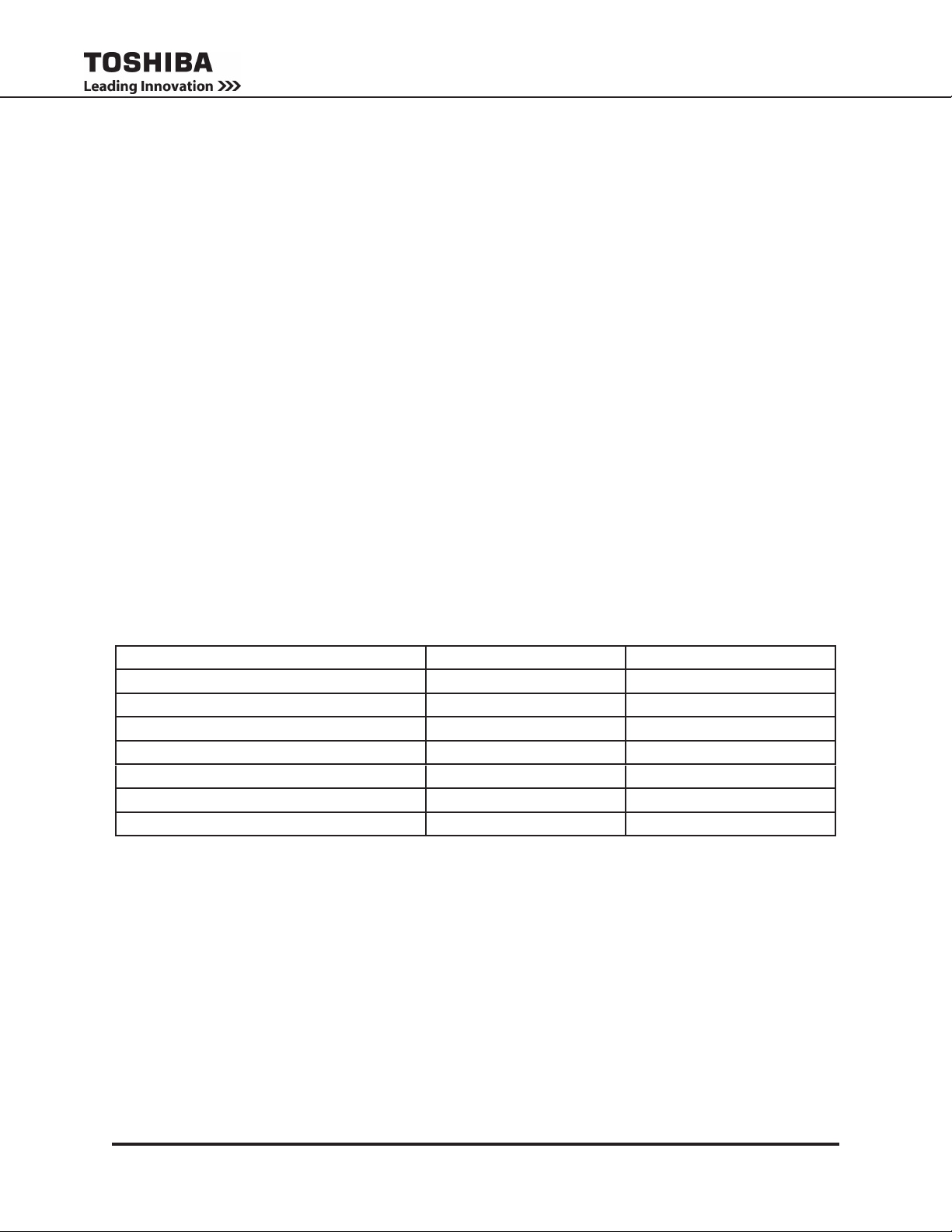

10.5 Battery Backup Time and Discharge Process

The UPS internal batteries provide approximately 5-7 minutes of back-up time depending on the 1600XP/

1600XPi unit kVA rating. These times are valid when the unit is operating under full load and at the

rated power factor. The exact length of these times will depend on the UPS model used, condition of

the batteries, amount and type of load, temperature and other variables. See battery backup time in

“Appendix A: 1600XP/1600XPi Specications” on page A1.

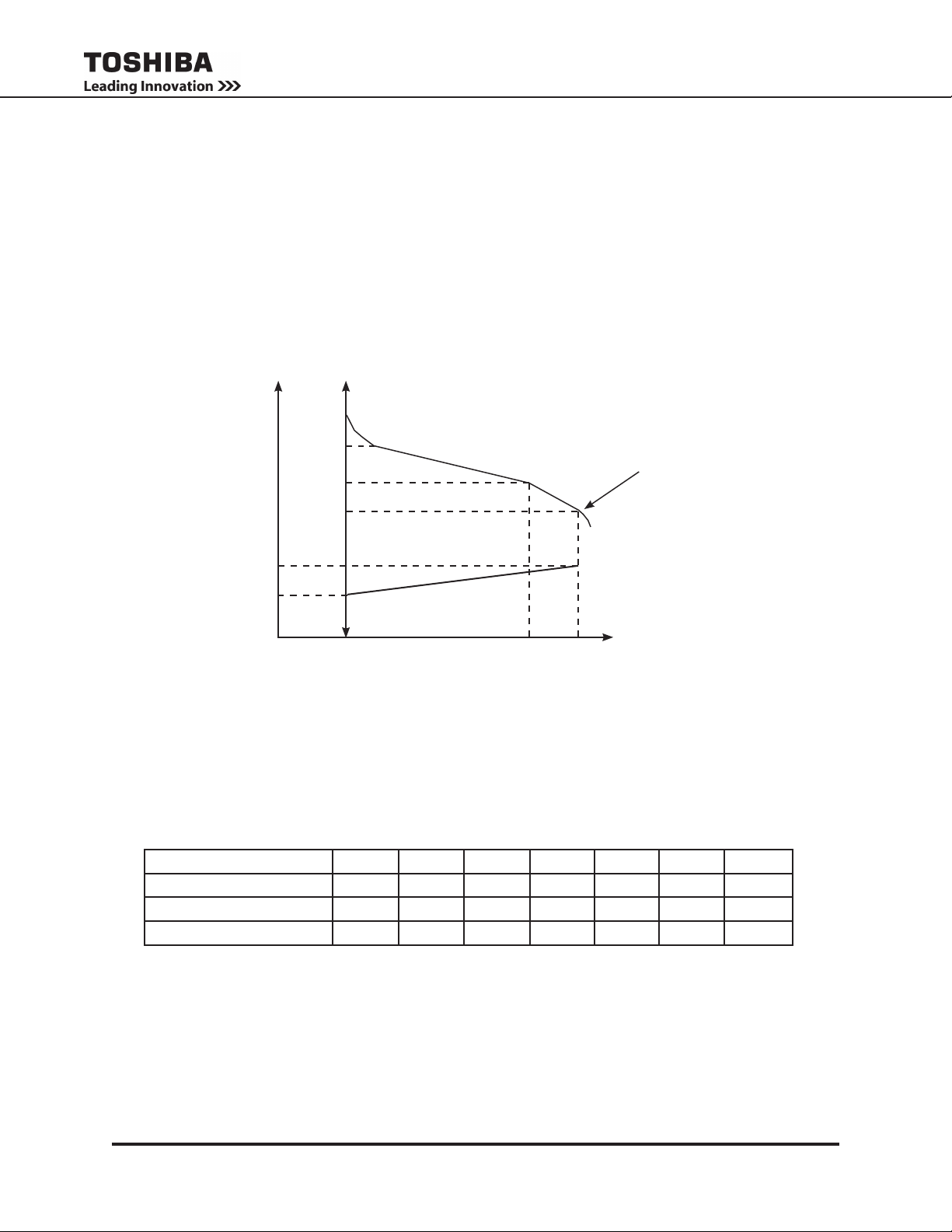

The following illustration graphically shows the battery discharge process at full load conditions.

CURRENT VOLTAGE

V

NOM

SHUTDOWN

I

MAX

I

MIN

V

LOW

V

MIN

100% 20% 0%

BATTERY CAPACITY

10.6 Battery Low Voltage Tolerances

Excessive discharge will cause the UPS battery voltage to drop. The chart shown below lists the voltage

level at which each UPS low-voltage alarm will sound and at what level the low-voltage condition will

cause the unit to automatically shut down.

UPS Capacity

Nominal voltage (Vnom)

Alarm voltage (Vlow)

Shutdown voltage (Vmin)

3.6 kVA 6 kVA 8 kVA 10 kVA 14 kVA 18 kVA 22 kVA

144 Vdc 216 Vdc 288 Vdc 288 Vdc 288 Vdc 288 Vdc 288 Vdc

130 Vdc 192 Vdc 246 Vdc 246 Vdc 246 Vdc 246 Vdc 246 Vdc

114 Vdc 170 Vdc 227 Vdc 227 Vdc 227 Vdc 227 Vdc 227 Vdc

18

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 29

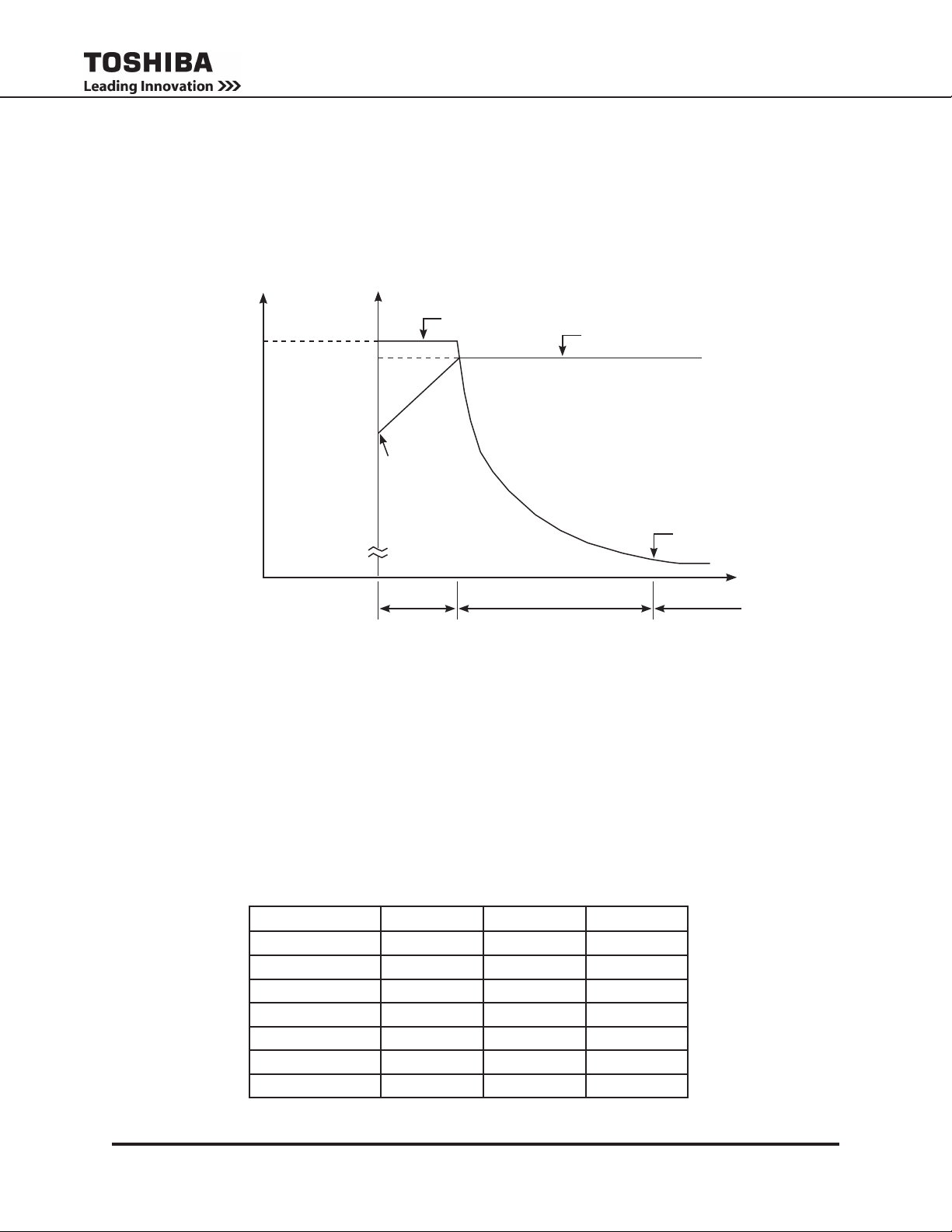

10.7 Battery Recharging

The illustration below shows a graphical representation of the UPS battery recharge process after a full

discharge.

CURRENT VOLTAGE

I

CHARGE

V

MAX

V

MIN

0 0

DISCHARGE

SHUT-OFF

POINT

PERIOD 1

CHARGING

CURRENT

PERIOD 2

BATTERY

CHARGE

VOLTAGE

FULLY

CHARGED

TIME

PERIOD 3

The recharge process usually consists of three periods. During the rst period, the current is maintained

at approximately 1 ampere. This current limit is the maximum value that can be used to charge the

batteries (for minimal recharge time) while assuring safety and long battery life. In the second period,

constant-voltage control starts and current gradually decreases as the batteries charge to their normal

fully charged state. In the third period, a slight trickle current continues to ow into the batteries to keep

them fully charged and oating at the normal Vdc level. A full recharge usually requires 24 hours (90%

recharge in 12 hours) after a complete discharge.

The following chart shows the rated maximum and minimum battery voltages and the charge current for

each of the sizes.

RATED BATTERY VOLTAGES

Model Vmax Vmin Icharge

3.6 kVA 163 V 114 V 1.0 A

6 kVA 245.7 V 170 V 1.0 A

8 kVA 327 V 227 V 1.0 A

10 kVA 327 V 227 V 1.0 A

14 kVA 327 V 227 V 1.0 A

18 kVA 327 V 227 V 1.0 A

22 kVA 327 V 227 V 1.0 A

1600XP/XPi Series Installation and Operation Manual – 60616-012

19

Page 30

10.8 Battery Test

The 1600XP/1600XPi allows the user to conduct automatic or manual battery tests as desired. The

following steps detail the battery test procedures.

Automatic Battery Test:

1. The Automatic Battery Test Procedure is performed only if it is enabled during startup.

2. Once the battery test is completed, Cmd 654 - Battery Test Condition Status is set to “Battery

Test Prohibited”. It will be re-enabled once timer Cmd 655 - Battery Test Frequency is reached.

Manual Battery Test:

The UPS must be in Online mode.

1. Change the security setting to “ADMIN”.

2. On the display, press the Monitor tab.

3. On the display, press the C&C key.

4. Use the Page (<< and >>) and Record (< and>) navigation keys to verify the following:

a. Cmd 652 - Battery Test Startup must be set to “Disable”

b. Cmd 653 - Enable Battery Test set to “Enable” to allow the battery test to be performed.

c. Cmd 655 - Battery Test Frequency should be set to “0” (Daily Test)

d. Cmd 654 - Battery Test Condition Status should read “Enable - Battery Test OK

to perform”

NOTE: If Cmd 654 is “Disable”, the user will have to power down and restart the unit to

perform the battery test.

e. Navigate to Cmd 609 - Requested State and press the “BattTest” button on the display.

• If the test passes, the display returns to the Monitor screen.

• If the test fails, the display returns to the Monitor screen and displays BTSTFL in the warning

section at the bottom left of the display, and the “Warning” LED blinks until the fault is cleared.

11. Operating the UPS

The 1600XP/1600XPi should be installed by a certied electrician. Once installed, the 1600XP/1600XPi

is designed to be operated by any user. Anyone not familiar with this UPS should read the manual

before attempting to operate it.

20

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 31

11.1 Initial Startup (First Power-Up)

The rst time the UPS is activated after being shipped from the factory, the following parameters need

to be set by the customer for site-specic ratings. Input Rated Voltage, Output Rated Voltage, UPS

Date, and UPS Time. Review Sections 13 and 14 before initializing the UPS.

1. Login to the UPS as ADMIN. See Section 14.3 detailed login directions.

2. The input frequency defaults to 60 Hz in, 60 Hz out. Change frequency values only if required.

3. The rst screen displayed during the initial startup sequence requires the operator to select the

nominal Input Voltage.

4. Select from 208V, 230V, or 240V, and press the Write key.

5. If the command has been accepted, the word “Successful” will appear at the bottom left side of the

display.

6. Repeat the process in step 3 in selecting the Rated Output Voltage.

7. Use the keypad to type in the current date in the format: Day mm/dd/yyyy. (e.g. Mon 10/05/2009)

and press Write.

8. Use the keypad to type in the current time in 12 hour format: hh:mm AM (e.g. 12:15 PM) and press

Write.

9. The Main screen is now displayed. Verify the UPS is in BYPASS mode. The mode (lower right side

of the display) should display Bypass. If it does not display Bypass, press and momentarily hold

the STOP button on the Main display.

NOTE: The internal batteries recharge in both Bypass and On-Line modes. As soon as the input

breaker is closed, the internal batteries will begin recharging.

10. With the UPS in bypass mode, cycle power to the UPS as follows:

• At the rear of the UPS switch the main circuit breaker MCCB to OFF.

• Leave the UPS off until the DC bus is safely discharged (approximately 5 – 10 minutes).

• Restart the UPS by switching the main circuit breaker ON.

The table below summarizes the initialization parameters:

ID Command Options

111 Rated Vin Select from 208V, 230V, or 240V, and press Write. (This parameter sets

the multiplier for the Over-/Under voltage detectors.)

215 Rated Vout Select from 208V, 230V, or 240V, and press Write. (This parameter sets

the multiplier for the Over-/Under voltage detectors.)

634 UPS Date Input the date in this format: Mon 10/05/2009 and press Write.

635 UPS Time Input the current time in 12 hour format: 12:15 PM and press Write.

11. After setup is completed, log back in as USER. See section 14.3 for guidance.

11.2 Battery Parameter Settings

Table 11-1 for setting the battery parameters during initial setup for these congurations: Stand-alone

UPS; UPS + 1 Battery Cabinet; UPS + 2 Battery Cabinets.

1600XP/XPi Series Installation and Operation Manual – 60616-012

21

Page 32

Table 11-1 Initial Battery Parameter Settings - Matching Battery Cabinets

Parameter Description UPS

Size

UPS

Only

UPS +

1 BC

1

511 Internal Battery Capacity in A-hr All 9 9 9

512 # Internal Batteries in Series String 3.6 kVA 12 12 12

6 kVA 18 18 18

8 - 22 kVA 24 24 24

513 # Internal Battery Strings in Parallel 3.6 - 10 kVA 1 1 1

14 - 20 kVA 2 2 2

522 Enable Ext. Battery Cabinet BC1

2

3.6 - 6 kVA Disable Disable Disable

8 - 22 kVA Disable Enable Enable

523 Enable Ext. Battery Cabinet BC2

2

3.6 - 6 kVA Disable Disable Disable

8 - 22 kVA Disable Disable Enable

524 E00xternal Batt. Cabinet Status All 0 1 1

525 # External Batt. Packs in Series String

3.6 kVA 0 12 12

(UH31-BC-0370, H3B-BC-0370)

(UH31-BC-0650, H3B-BC-0650) 6 kVA 0 18 18

(UH31-BC-1825, H3B-BC-1825) 8-22 kVA 0 24 24

526 # External Batt. Strings in Parallel

3.6 kVA 0 3 6

(UH31-BC-0370, H3B-BC-0370)

(UH31-BC-0650, H3B-BC-0650) 6 kVA 0 2 4

(UH31-BC-1825, H3B-BC-1825) 8-22 kVA 0 3 6

527 External Battery Capacity in A-hr All 0 9 9

1 These settings apply to 1600XP/1600XPi matching battery cabinets.

2 For use with BC-1825 only. Otherwise, always “Disable”.

UPS +

2 BC

1

Table 11-2 Initial Battery Parameter Settings - Non-Matching Battery Cabinets

Parameter Description UPS

Size

UPS

Only

UPS +

1 BC

1

511 Internal Battery Capacity in A-hr All 0 0 0

512 # Internal Batt. Packs in Series String 3.6 kVA 0 0 0

6 kVA 0 0 0

8-22 kVA 0 0 0

513 # Internal Batt. Strings in Parallel 3.6 - 10 kVA 0 0 0

14 - 20 kVA 0 0 0

522 Enable Ext. Battery Cabinet BC1 All Disable Disable Disable

523 Enable Ext. Battery Cabinet BC2 All Disable Disable Disable

524 External Batt. Cabinet Status All 0 1 1

525 # External Batteries in Series String 3.6 kVA 0 12 12

6 kVA 0 18 18

8-22 kVA 0 24 24

22

1600XP/XPi Series Installation and Operation Manual – 60616-012

UPS +

1

2 BC

Page 33

Parameter Description UPS

Size

526 # External Batt. Strings in Parallel 3.6 kVA 0 1 1

6 kVA 0 1 1

8-22 kVA 0 1 1

527 External Battery Capacity in A-hr All 0 9 9

1 These settings apply to 1600XP/1600XPi Non-matching battery cabinets.

2 Battery runtimes on the UPS display will not be accurate when using a non-Toshiba external battery

cabinet.

UPS

Only

UPS +

1 BC

1

UPS +

1

2 BC

11.3 Starting the UPS (Normal)

Turn the main circuit breaker (MCCB) on the back of the UPS (see Appendix A) to the ON position. The

breaker should remain in the ON position.

Verify that the On-Line LED on the front panel (see “12.1 Front Panel Layout” on page 24) lights green.

The UPS will now be supplying power in the On-Line mode. If the On-Line LED is not illuminated push and

hold the RUN key for approximately 3 seconds.

NOTICE

When running the UPS for the rst time charge the batteries for at least 24

hours (input breaker on) before operating the connected load. Failure to do so

will result in reduced battery backup time.

11.4 Stopping the UPS

To stop the UPS press and hold the STOP key approximately 3 seconds until the On-Line LED changes

from green to off (audible beep). The UPS is now in the bypass mode.

NOTICE

If the input breaker is turned off while UPS is in the bypass mode, the output

power stops. Any load devices will lose power.

Ensure that all sensitive loads have been previously shut down.

To completely stop the UPS, turn the input breaker at the back of the UPS to the OFF position.

1600XP/XPi Series Installation and Operation Manual – 60616-012

23

Page 34

12. Display and Keys

12.1 Front Panel Layout

The front panel consists of several elements for monitoring and operation of the UPS. Panel components

are shown in the illustration below:

HARDWARE RUN/STOP SWITCH

LCD TOUCH SCREEN

DISPLAY CONTRAST ADJUSTMENT

(MIDDLE LEFT SIDE OF PANEL)

96% 100%

HOME

Main Monitor Settings Records

USR

12:35 PMINV

1600XP

On-Line UPS

UPS Controls

UPS Serial Number

20080112345

UPS Typeform

UXPB2B100C6

DVCOH

ASYN

ASYNDVCOH

1600XP On-Line UPS

RUN

STOP

On-Line

Shutdown

On-Line/Fault Warning A/C Input

DISPLAY RESET SWITCH

STATUS LEDS (PAGE 25)

(LOWER RIGHT SIDE OF PANEL)

12.2 Display Manual Controls

Hardware Run/Stop Switch – Pressing the contact switch momentarily will toggle the UPS state between

RUN and Bypass. For Instance, while the UPS is in RUN mode, pressing the switch will change the

mode to Bypass. Pressing the switch again will switch the UPS back to RUN mode.

Display Reset Switch – When necessary, the touchscreen display can be reset by using a thin probe,

such as a paper clip, to press the display reset switch.

Display Contrast Adjustment – The display is shipped with the display adjusted for optimum visibility. If

necessary use a trimmer adjustment tool to ne tune the display contrast for improved visibility.

24

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 35

13. LCD Touchscreen Layout

The touchscreen serves as input and display. Touch the active portion of the display to execute a command.

13.1 Startup Display

The default opening screen for the UPS is the Main screen. The operator can begin operating the UPS

immediately by pressing the RUN key.

Only the Main and Settings tab screens allow operator input. The Monitor and Records display screens

are read-only. No data can be entered in these screens

From the Main screen, the UPS can be placed On-Line by pressing RUN, or placed in Bypass Mode by

pressing STOP. A key status indicator at the upper right-hand corner of each key indicates which key is

active: a dot indicates that key is active; no dot indicates that key is not active. See the illustration below.

The Settings screen allows modication of the UPS operating parameters.

At the top of the display are four status indicators: % Load, Battery Information, UPS System Status, and

System Time.

Security Level: USR – User

ADM – Administrator

% FullLoad

Home Page

Battery Information

96%

HOME

100%

USR

Speaker

On/Off

INV

Touchscreen lock

UPS System Status

12:35 PM

12-Hour

Clock

Function Tabs

LCD TOUCHSCREEN

DISPLAY LAYOUT

Fault Code

Main Monitor Settings Records

1600XP

On-Line UPS

UPS Controls

UPS Serial Number

20080112345

UPS Typeform

UXPB2B100C6

DVCOH

Warning Code

ASYN

RUN

STOP

On-Line

Key Status Indicator

(UPS is in On-Line mode)

RUN key

Key Status Indicator

(UPS is NOT in Bypass

mode)

STOP key

UPS

System

Mode

At the top left of the display are a bank of four touch-sensitive keys:

Home – Pressing HOME key returns the display to the top menu of the currently selected tab.

Security Level – Pressing the Security Level key activates the log-in security screen.

(Speaker) – Pressing the Speaker key will disable/enable the audible alarm.

Touchscreen Lock – Locks touchscreen except for this key.

1600XP/XPi Series Installation and Operation Manual – 60616-012

25

Page 36

The second row of keys are the function tabs.

At the bottom of the display three event codes display the latest operational information: Faults, Warnings,

and the current UPS System Mode. (See page 53 to page 56.)

13.2 Operating Keys

The icons listed in the table below identify the touch-sensitive keys on the main touchscreen. The keys are

different types of controls that can be activated by pressing that area of the touchscreen.

Key Functional Description

Run Key - Press and hold the key 1-2 seconds (until the UPS ‘beeps’) to put the UPS in

RUN RUN

STOP STOP

On-Line mode. The active status indicator (upper right dot) will appear on the RUN key

and disappear from the STOP key.

Stop Key - Press and hold the key 1-2 seconds (until the UPS ‘beeps’) to put the UPS in

Bypass mode. The active status indicator (upper right dot) will appear on the STOP key

and disappear from the RUN key.

HOME

USR

Main

Monitor

Settings

Records

Home Key - Press to return to top menu of respective tab.

Security Level Key. Press to open security login screen.

Event Alarm Mute Key- Press to silence current event alarm.

Alarm Muted Key- Alarm remains silenced until next event.

Touchscreen Enabled Key- Press to disable (lockout) all touchscreen keys except this

key.

Touchscreen Disabled Key - Press to enable (un-lock) touchscreen.

Four function tab keys: Main, Monitor, Settings, Records

Main - Start and Stop keys, UPS Serial number and typeform.

Monitor - Shows Mimic display for accessing Input/Output/Bypass/Battery data.

Settings - Provides access to adjustable performance parameters.

Records - Access fault, warning and other records.

As displayed on:

Monitor and Settings screens:

Records screens:

BAT 2 / 3

2 / 3

Go To First Page/Record Key.

26

BAT

2 / 3

Go to Previous Page/Record Key.

Menu selection under Monitor and Settings tabs.

Shows the current page or record number, and total number of pages or records.

Go to Next Page/Record Key.

Go To Last Page/Record Key.

1600XP/XPi Series Installation and Operation Manual – 60616-012

Page 37

13.3 Status Indicators

The four top and three bottom UPS status Indicators on the main screen and their meanings are listed in

the table below.

Indicator Functional Description

96% Shows the current load percentage.

Battery Information: In On-Line and Battery Back-up mode the display alternates between

battery charge percentage and estimated remaining battery runtime in:

Format

100% / 11’

100% / 9’ 35”

xx M – Minutes for Runtimes > 10 min.

xx M.xx S – Minutes and Seconds for Runtimes < 10 min.

100% / N/A

INV

In other modes, the display alternates between battery charge percentage and “N/A.”

Shows current UPS Status. Indicator will change as the UPS status changes. For a

detailed listing see page 56.

12:35 PM System Time

DVCOH Fault Description Code – For a detailed listing see page 53.

ASYN Warning Description Code – For a detailed listing see page 54.

On-Line Current Operating Mode of the UPS – For a detailed listing see page 56.

13.4 Light Emitting Diodes (LED)

The following table describes the front panel LED behaviors and the associated meaning.

LED Behavior Signicance/Meaning

Green - ON UPS is in On-Line, Backup, or Battery Test mode.

Green - OFF UPS in Bypass mode.

On-Line/

Fault