Toshiba 15dl72 Service Manual

SERVICE MANUAL

DOCUMENT CREATED IN JAPAN, Oct., 2002

FILE NO. 050-200224

LCD TV

15DL72

SAFETY PRECAUTION

WARNING: Service should not be attempted by anyone unfamiliar with the necessary precautions on this TV.

The following are the necessary precautions to be observed before servicing this chassis.

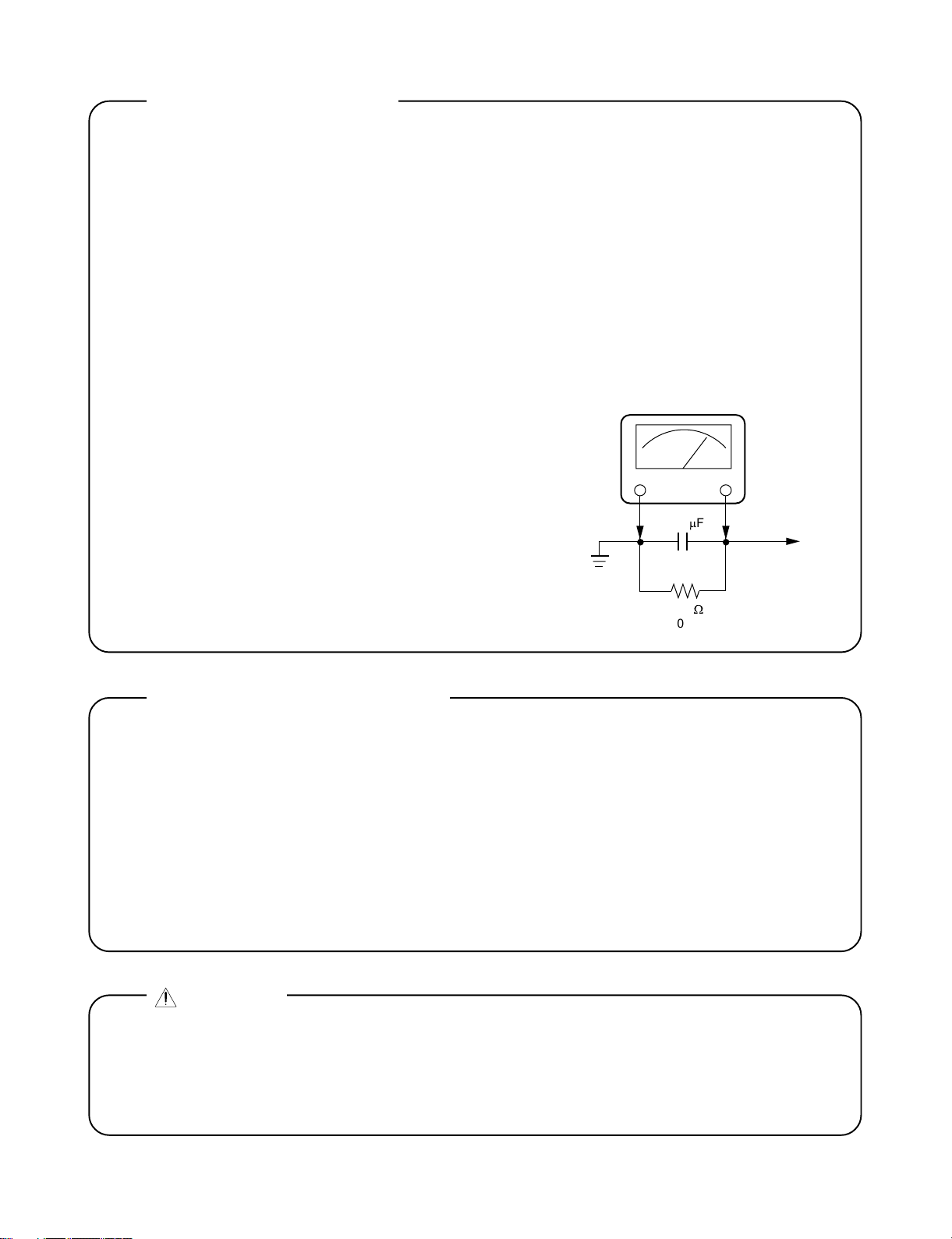

1. An isolation Transformer should be connected in the power line between the TV and the AC line before any

service is performed on the TV.

2. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in

place, such as; non-metallic control knobs, insulating covers, shields, isolation resistor-capacitor network

etc.

3. Before returning the set to the customer, always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as terminals, screwheads, metal overlays, control shafts etc. to be sure

the set is safe to operate without danger of electrical shock. Plug the AC line cord directly into a AC outlet

(do not use a line isolation transformer during this check). Use an AC voltmeter having 5000W per volt or

more sensitivity in the following manner: Connect a 1500W

10W resistor, paralleled by a 0.15 mF, AC type capacitor,

between a known good earth ground (water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500W

resistor and 0.15 mF capacitor. Reverse the AC plug at

the AC outlet and repeat AC voltage measurements for

each exposed metallic part. Voltage measured must not

exceed 5.25V(rms). This corresponds to 3.5 mA(AC). Any

value exceeding this limit constitutes a potential shock

hazard and must be corrected immediately.

Good earth ground

such as a water

pipe, conduit, etc.

AC VOLTMETER

0.15 mF

1500

W

10W

Place this probe on

each exposed

metallic part.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts

which have these special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the schematic diagram

and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts which do not have the same safety characteristics as specified in the parts list may create

shock, fire or other hazards.

DANGER

The components such as the power supply and FL inverter carry high voltages. When you partially disassemble the computer and turn on the components, use extreme care not to touch the connectors and components to avoid the risk of electrical shock. Do not disassemble individual components during first-level maintenance.

3-1

SAFETY NOTICE

Handling the LCD Module

Safety Precaution

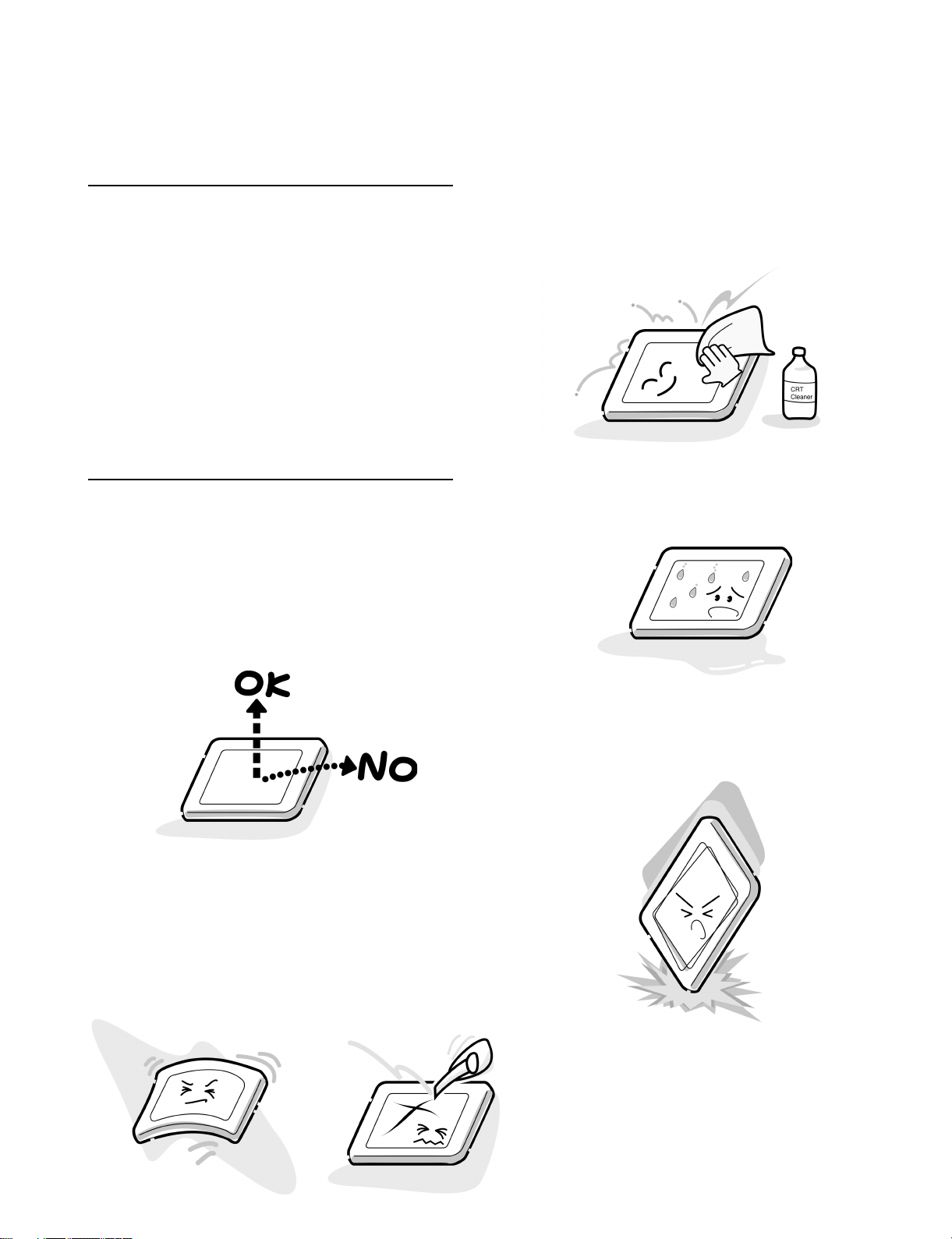

In case the screen is damaged

and the internal liquid leaks, do

not suck or drink the internal

fluid. Nor do you touch it either,

otherwise you might be poisoned

or get a rash with your skin. If

the internal fluid enters your

mouth, rinse with water. If it

adheres to your skin or clothes,

wipe it away with alcohol and

then wash with water. If it enters

your eyes, wash with running

water immediately.

Precautions for handling the LCD module

The LCD module can be easily damaged during assembly

or disassembly. Observe the following precautions when

handling the LCD module:

1. When installing the LCD module in the LCD cover, be

sure to seat it so that it is properly aligned and

maximum visibility of the display is maintained.

3. If the panel’s surface gets dirty, wipe it with cotton or

a soft cloth. If it is still dirty, try breathing on the

surface to create a light condensate and wipe it again.

If the surface is very dirty, we recommend a CRT

cleaning agent. Apply the agent to a cloth and then

wipe the panel’s surface. Do not apply cleanser

directly to the panel. Also, never scratch the surface.

4. If water or other liquid is left on the panel’s surface for

a long period, it can change the screen’s tint or stain it.

Be sure to quickly wipe off any liquid.

2. Be careful to align the four holes at the right side and

left side of the LCD module with the corresponding

holes in the LCD cover before securing the module

with four screws. Do not force the module into place,

because stress can affect its performance. Also, the

panel’s polarized surface is easily scarred, so be

careful when handling it.

5. Glass is used in the panel, so be careful not to drop it

or let it strike a hard object, which could cause

breakage or cracks.

6. CMOS-LSI circuits are used in the module, so guard

against damage from electrostatic discharge. Be sure

to wear a wrist or ankle ground when handling the

module.

9. Do not disassemble the LCD module. Disassembly can

cause malfunctions.

7. Do not expose the module to direct sunlight or strong

ultraviolet rays for long periods.

8. Do not store the module at temperatures below

specifications. Cold can cause the liquid crystals to

freeze, lose their elasticity or otherwise suffer damage.

10. If you transport the module, do not use packing

material that contains epoxy resin (amine) or silicon

glue (alcohol or oxime). These materials can release

gas that can damage the panel’s polarization.

CONTENTS

ADJUSTMENT PROCEDURES AND PART REPLACEMENT

1. REMOVAL .................................................................................. 1-1

1-1. Front Panel .......................................................................... 1-1

1-2. LCD Panel ............................................................................ 1-1

1-3. Inverter PC Board ............................................................... 1-2

1-4. Sensor PC Board ................................................................. 1-3

1-5. Handle .................................................................................. 1-3

1-6. LCD Rear Cover ................................................................. 1-3

1-7. Wall Hanging Plate ............................................................. 1-4

1-8. Bottom Cover ....................................................................... 1-4

1-9. Side Cover ............................................................................ 1-4

1-10.Rear Terminal Panel, Main PC Board .............................. 1-4

1-11.Front Net, Speaker .............................................................. 1-5

1-12.Switch PC Board ................................................................. 1-5

1-13.Hinge, Top Cover ................................................................ 1-5

SERVICING DIAGRAMS

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION ..................................... 2-1

1-1. Solid Resistor Indication ..................................................... 2-1

1-2. Inductor Indication ............................................................. 2-1

1-3. Capacitance Indication ....................................................... 2-1

1-4. Waveform and Voltage Measurement .............................. 2-1

1-5. Precautions for Part Replacement ..................................... 2-1

2. BLOCK DIAGRAMS .................................................................. 2-2

2-1. Power Block Diagram ......................................................... 2-2

2-2. Inverter Block Diagram ...................................................... 2-3

2-2-1.

Pin Assignments (microprocessor) IC701: KS88C6348 ...

2-3. Main Block Diagram ........................................................... 2-5

3. CIRCUIT DIAGRAMS ............................................................... 2-7

3-1. Power Supply Circuit Diagram .......................................... 2-7

3-2. Microprocessor Circuit Diagram ....................................... 2-9

2-4

SECTION 1

2. GND LEAD WIRE CONNECTION DIAGRAM .................... 1-6

3. LOCATION OF MAIN PARTS ................................................. 1-7

4. TROUBLESHOOTING .............................................................. 1-8

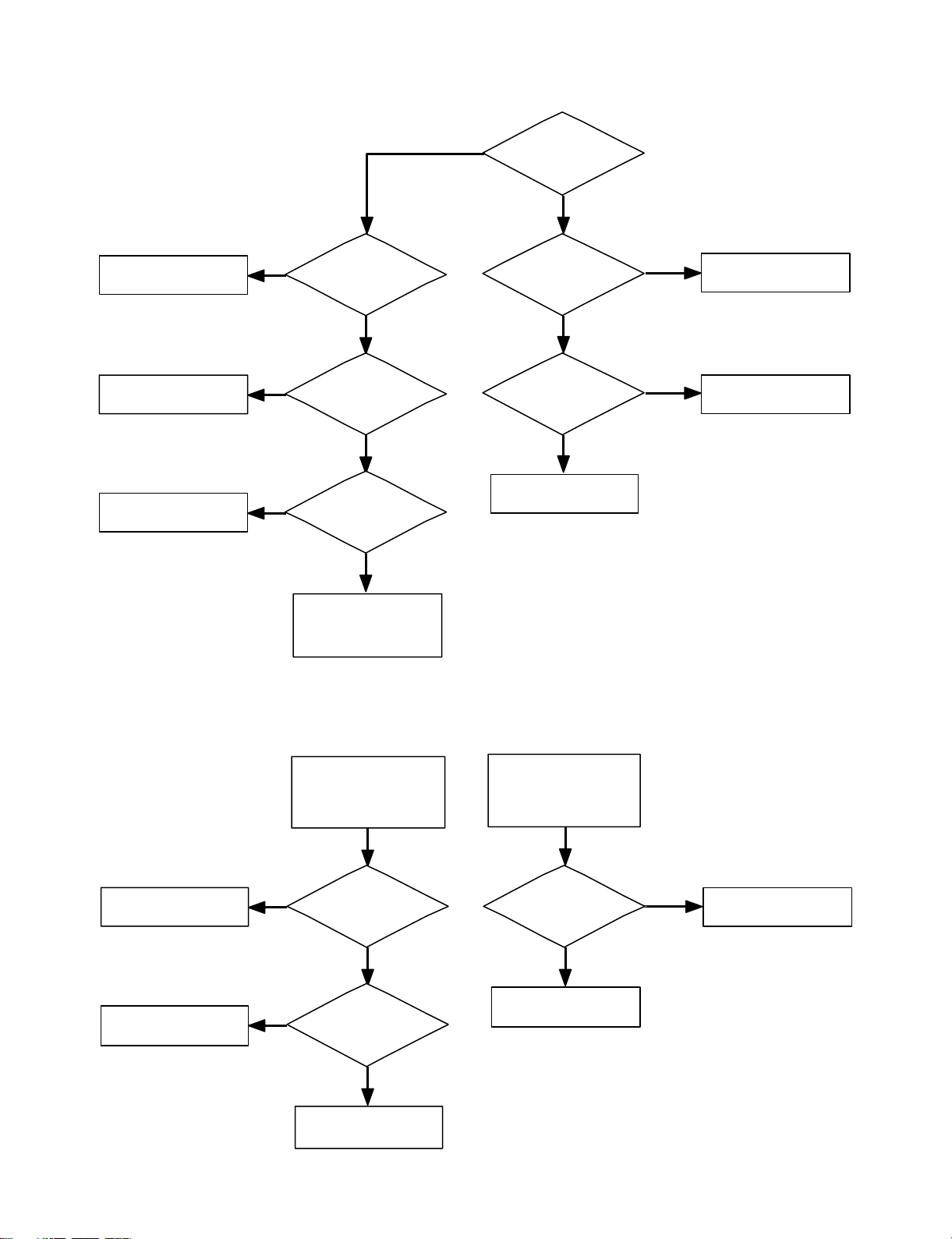

4-1. No Power (No Video & No Sound) .................................... 1-8

4-2. No Video ............................................................................... 1-9

4-2-1. No Video (Sound O.K) .................................................... 1-9

4-2-2. No Video (Sound O.K) .................................................... 1-9

4-3. No Sound (Video O.K) ...................................................... 1-10

SECTION 2

3-3. Input Jack Circuit Diagram ............................................. 2-11

3-4. VPC3230 Circuit Diagram ............................................... 2-13

3-5. TTX&Caption Circuit Diagram ...................................... 2-15

3-6. MXIC Circuit Diagram .................................................... 2-17

3-7. Frame Buffer Circuit Diagram ........................................ 2-19

3-8. Panel Interface Circuit Diagram ..................................... 2-21

3-9. Sound Circuit Diagram ..................................................... 2-23

3-10.Wow Control Circuit Diagram ........................................ 2-25

3-11.Sound Amplifier Circuit Diagram ................................... 2-27

3-12.Pin Voltage ......................................................................... 2-29

3-13.Waveforms ......................................................................... 2-36

4. PC BOARDS .............................................................................. 2-41

4-1. Main PC Board .................................................................. 2-41

4-2. Switch PC Board ............................................................... 2-45

4-3. Sensor PC Board ............................................................... 2-45

SAFETY PRECAUTION ................................................................. 3-1

NOTICE ............................................................................................. 3-1

ABBREVIATIONS ........................................................................... 3-1

1. Integrated Circuit (IC) ............................................................ 3-1

2. Capacitor (Cap) ....................................................................... 3-1

3. Resistor (Res) ........................................................................... 3-1

SECTION 3

PARTS LIST

4. EXPLODED VIEWS ................................................................... 3-2

4-1. Packing Assembly ................................................................ 3-2

4-2. Chassis Assembly ................................................................ 3-3

5. PARTS LIST ................................................................................ 3-4

This page is not printed.

SECTION 1

LCD panel (2)

Screw (1)

Screw (1)

Screws (1)

GND lead wire

GND lead wire

ADJUSTMENT PROCEDURES AND PART

REPLACEMENT

1. REMOVAL

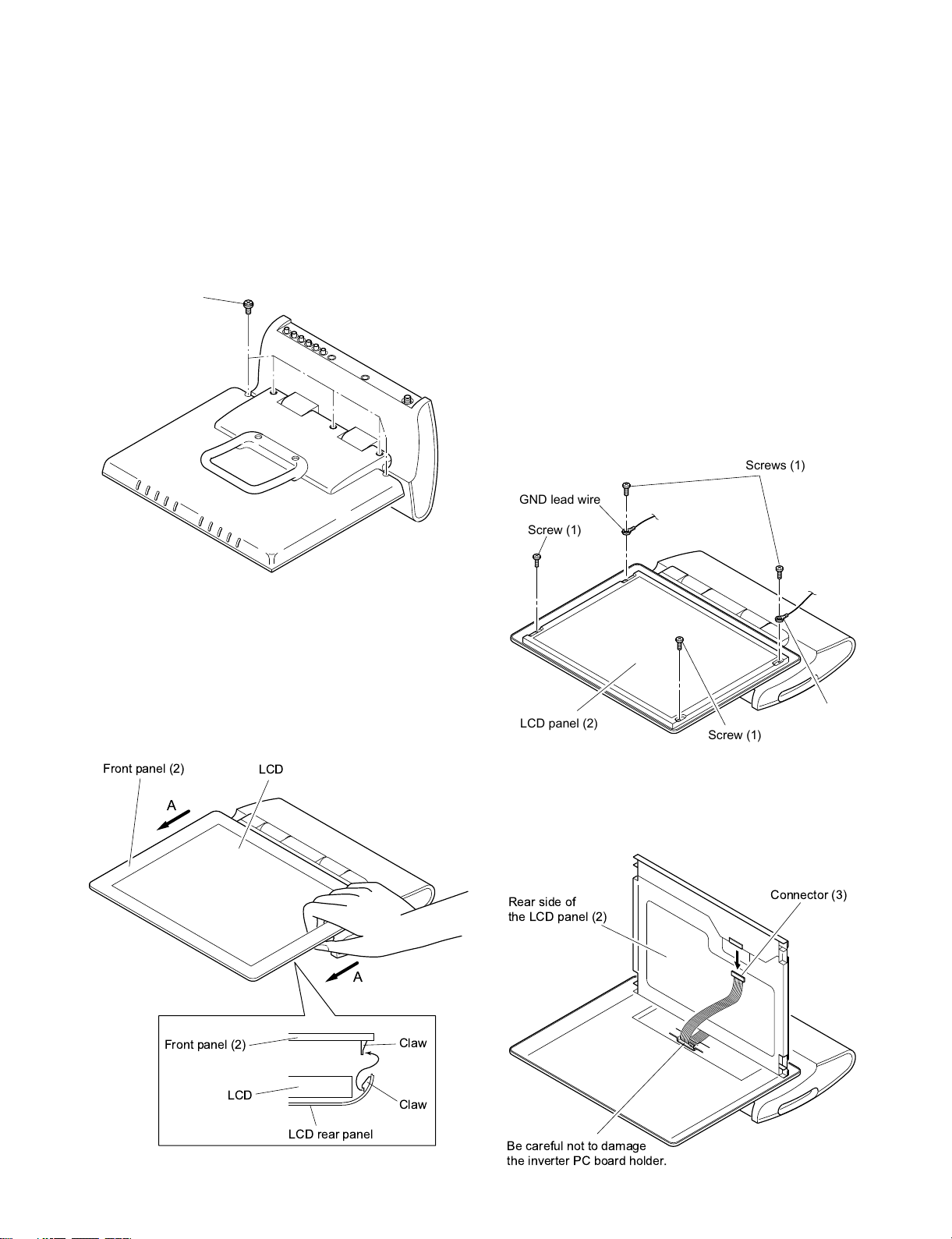

1-1. Front Panel

1. Remove five screws (1).

Screws (1)

Fig. 1-1-1

Note:

• A "snapping" sound will be heard when the claw is

released.

• Take care not to scratch the LCD.

• Caution should be taken to avoid injury from edges on

metal areas when removing the LCD panel.

• Return the wiring to their original positions during

assembly and take care not to get wires caught in the

front panel.

1-2. LCD Panel

1. Remove four screws (1).

2. Place the main unit horizontally (similar to use when

hanging on wall), insert finger from the inner side (2)

and release the front panel (2) claws in order from the

bottom (arrow A) (there are eleven peripheral claws).

Front panel (2)

A

Front panel (2)

LCD

LCD

A

Claw

Claw

Fig. 1-1-3

2. Lift the LCD panel (2) up and remove the connector

(3) from back.

Rear side of

the LCD panel (2)

Connector (3)

Fig. 1-1-2

LCD rear panel

Be careful not to damage

the inverter PC board holder.

1-1

Fig. 1-1-4

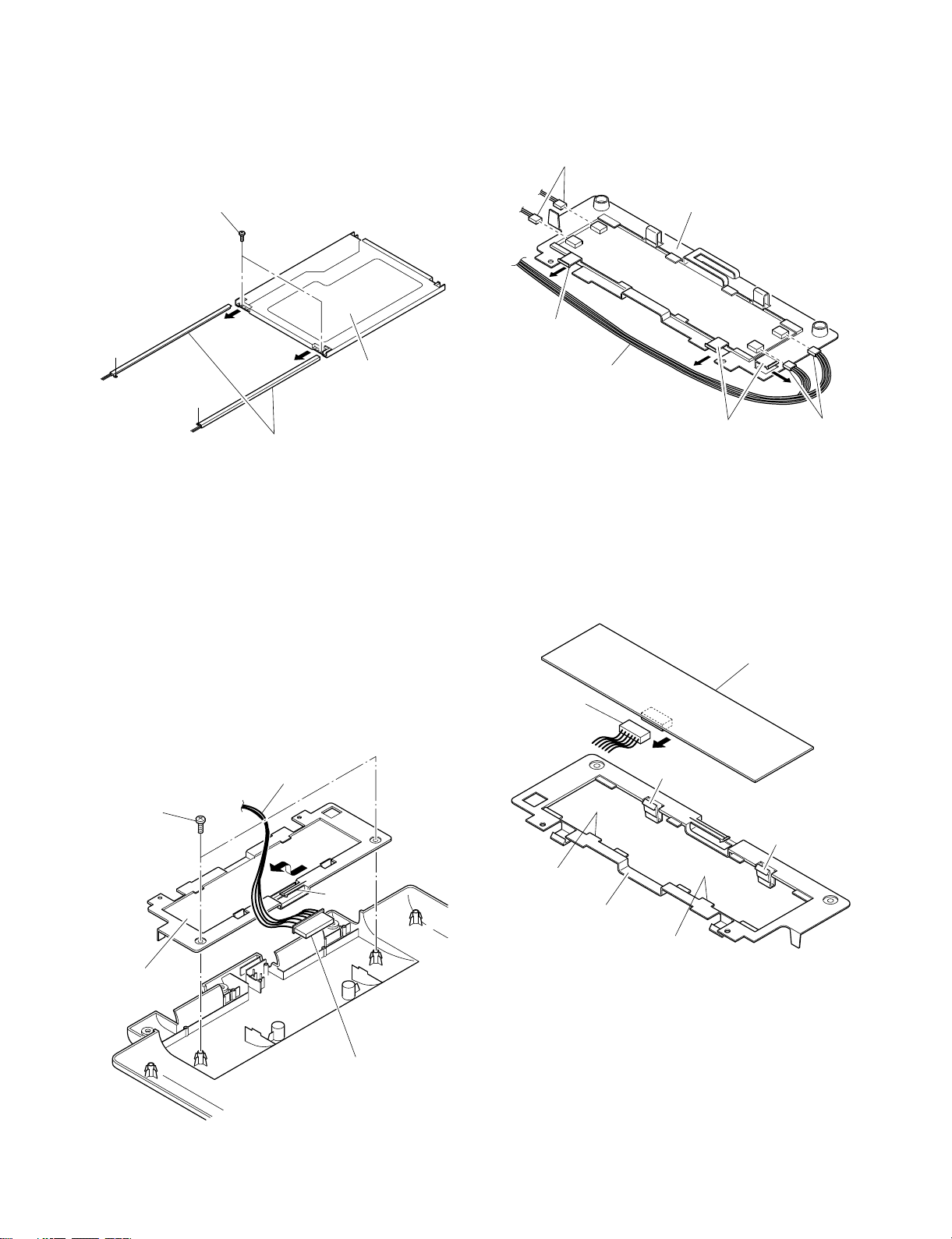

3. Turn the LCD (2) on its back and remove two screws

(4).

4. Slide the back lights (5) on the top and bottom out to

the left side and remove the LCD (2).

Screws (4)

3. Remove the connectors (4) from the four locations and

remove the wire from the three locations of claw B.

Connector (4)

Inverter PC board

holder (2)

Claw B

Rear side of the

LCD panel (2)

Back light (5)

Fig. 1-1-5

Note:

• Return the wiring to their original position when

assembling.

1-3. Inverter PC Board

1. Remove the wire of connector (1) from the inverter PC

board holder (2) claw A.

2. Remove two screws (3).

Wire

Screws (3)

Wire

Claw B

Connector (4)

Fig. 1-1-7

4. Release four claws C, then remove the inverter PC

board holder (2) from the inverter PC board (5).

5. Remove the connector (6) from the one location, then

remove the inverter PC board (5).

Inverter PC board (5)

Connector (6)

Claw C

Claw C

Inverter PC board

holder (2)

Fig. 1-1-6

Claw A

Connector (1)

Claw C

Inverter PC board

holder (2)

Claw C

Fig. 1-1-8

Note:

• Return the wiring to their original position when

assembling.

• The inverter PC board contains high voltage circuitry

and therefore the power supply plug should always be

unplugged during disassembly and assembly.

Additionally, care should be taken when servicing

1-2

while the power is on.

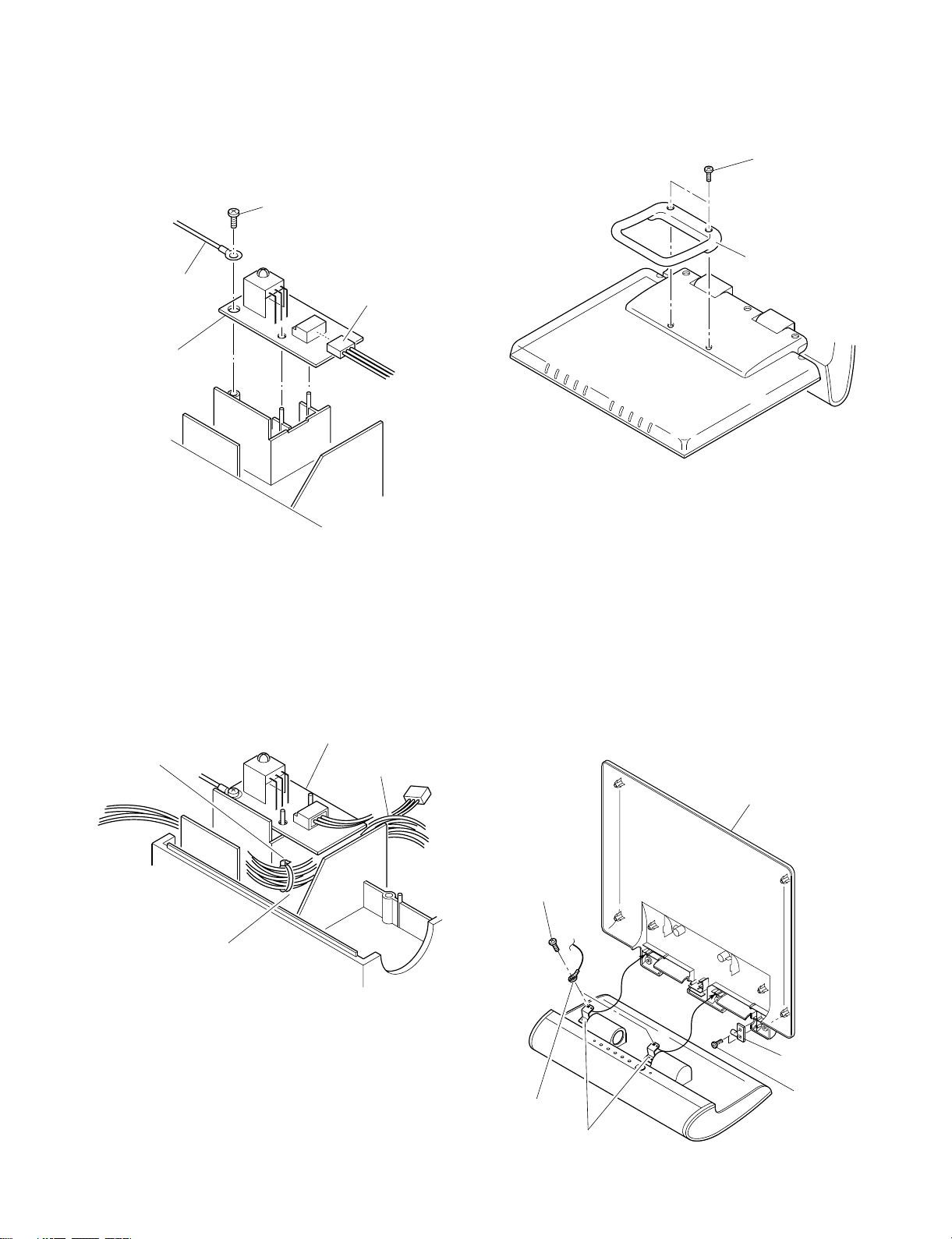

1-4. Sensor PC Board

1. Remove one screw (1) and remove the connector (2)

from the one location, then remove the sensor PC

board (3).

Screws (1)

GND lead wire

Connector (2)

Sensor

PC board (3)

Fig. 1-1-9

Note:

• When attaching the sensor PC board (3), bundle the

wires with the band (4) and insert into groove then

attach the sensor PC board (3) from the top.

Sensor PC board (3)

Bundled wires (4)

GND lead wire

1-5. Handle

1. Remove two screws (1), then remove the handle (2).

Screws (1)

Handle (2)

Fig. 1-1-11

1-6. LCD Rear Cover

1. Remove the front panel, the LCD panel and the

inverter PC board. (Refer to item 1-1, 1-2 and 1-3.)

2. Remove two screws (1), then remove the support (2).

3. Remove two screws (3) and remove the LCD rear

cover (4) in a vertical position.

Note:

• If not removed when in a vertical position, the hinges

may become deformed.

Place the bundled wires (4)

into this groove and attach the

sensor board (3) on the top.

Fig. 1-1-10

LCD rear cover (4)

Screws (3)

Support (2)

Screws (1)

GND lead wire

Guide

Fig. 1-1-12

1-3

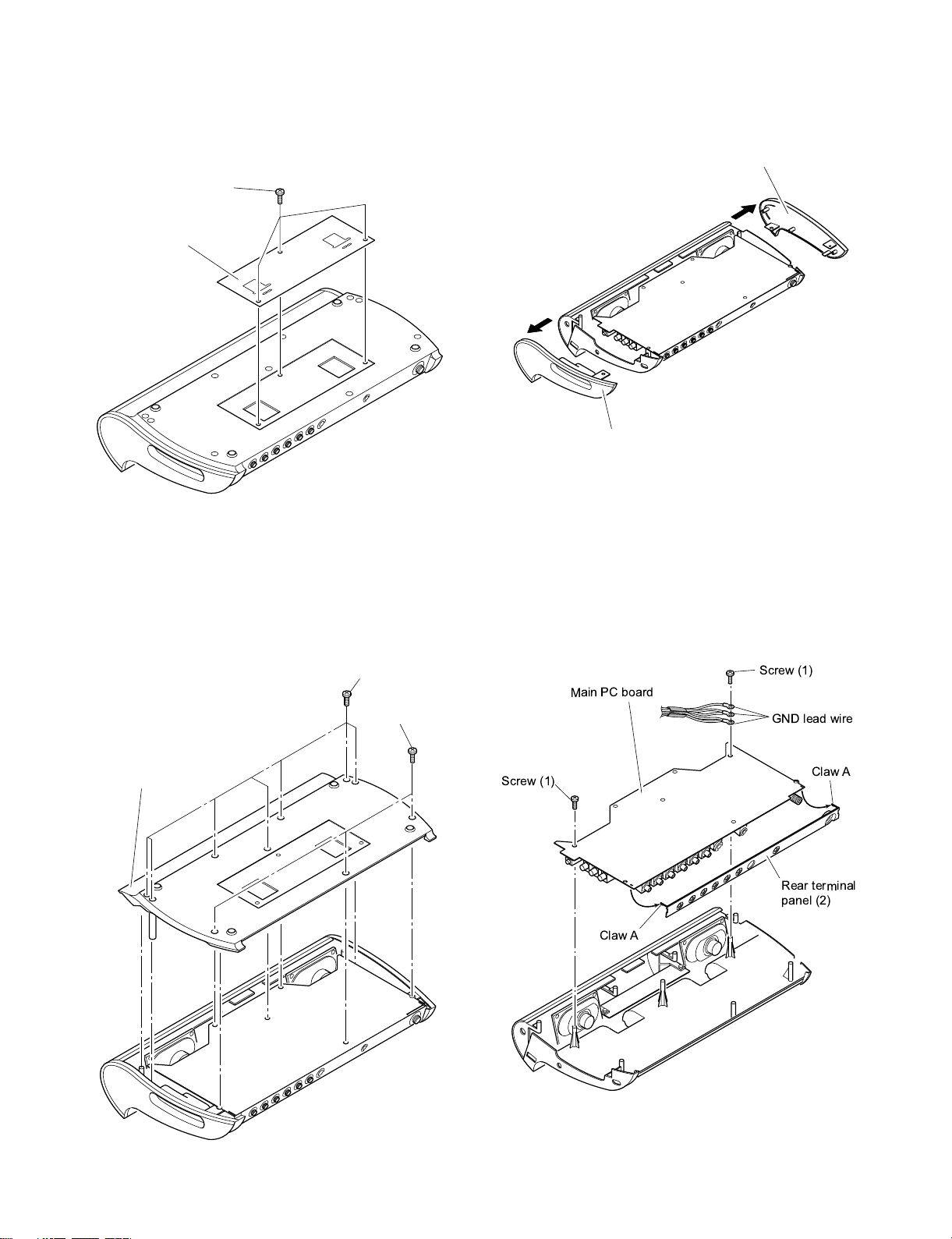

1-7. Wall Hanging Plate

1. Remove three screws (1), then remove the wall

hanging plate (2).

Screws (1)

Wall Hanging Plate (2)

1-9. Side Cover

1. Remove the left and right side covers.

Side cover (right)

Side cover (left)

Fig. 1-1-15

Fig. 1-1-13

1-8. Bottom Cover

1. Remove seven screws (1) and three screws (2), then

remove the bottom cover (3).

Screws (1)

Screws (2)

Bottom cover (3)

1-10. Rear Terminal Panel, Main PC

Board

1. Remove two screws (1).

2. Remove two claws A, then remove the rear terminal

panel (2).

Screw (1)

Main PC board

GND lead wire

Screw (1)

Claw A

Claw A

Rear terminal

panel (2)

Fig. 1-1-14

Fig. 1-1-16

1-4

3. Remove the connectors (4) from the five locations,

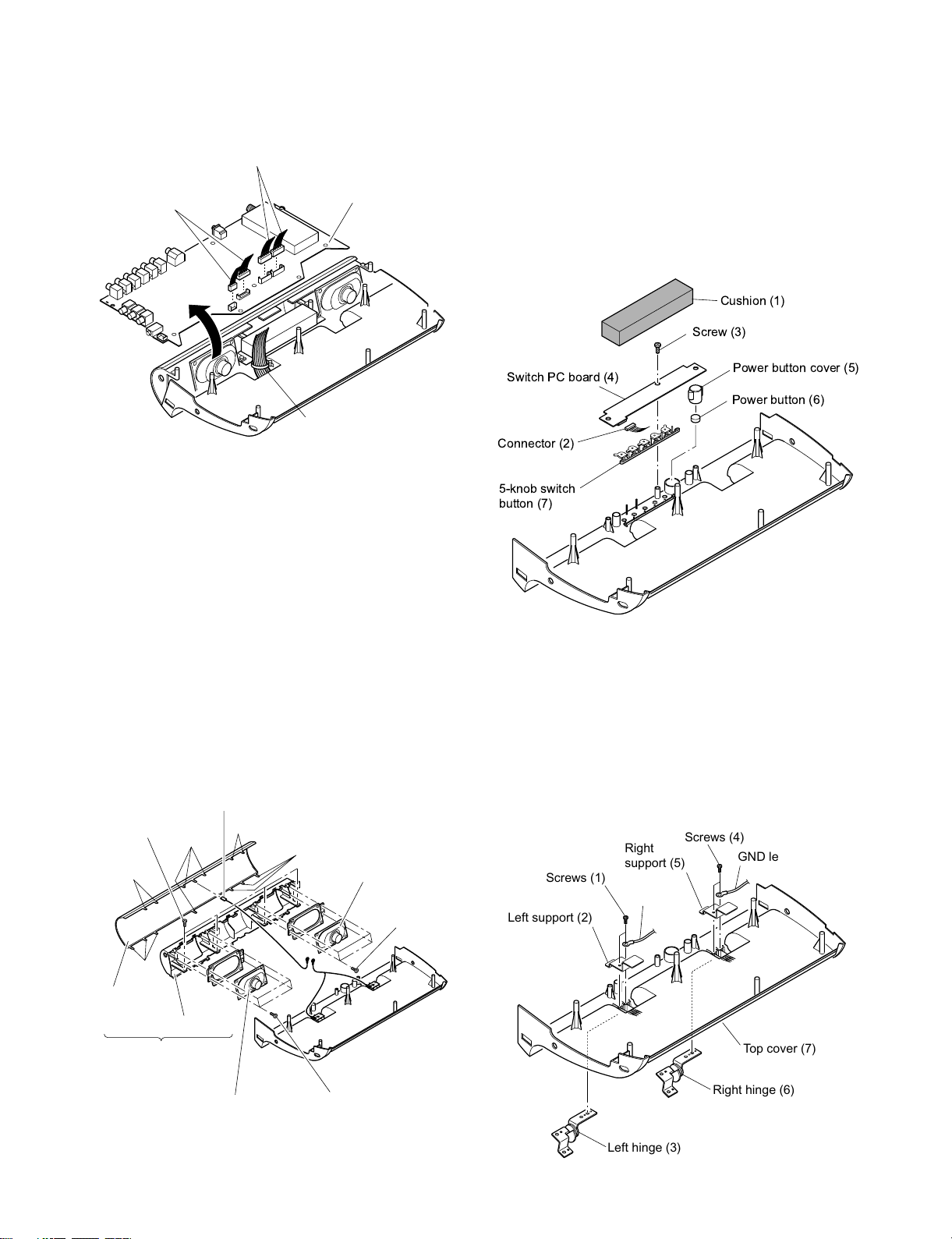

Cushion (1)

Connector (2)

Screw (3)

Switch PC board (4)

Power button cover (5)

Power button (6)

5-knob switch

button (7)

then remove the main PC board (5).

Connector (4)

Connector (4)

Main PC board (5)

Bundled wires

Fig. 1-1-17

Note:

• Return the wiring to their original positions during

assembly.

1-12.Switch PC Board

1. Remove the cushion (1).

2. Remove the connector (2).

3. Remove one screw (3), then remove the switch PC

board (4).

4. Remove the power button (5), the power button cover

(6) and the 5-knob switch button (7).

1-11.Front Net, Speaker

1. Remove four screws (1).

2. Remove the GND lead wire (2), then remove the front

net assembly (3).

3. Remove four screws (4), then remove the right speaker

(5), four screws (6) and the left speaker (7).

4. The front net assembly (3) will come apart to the front

net (8) and the chassis (9) when claws A are released.

GND lead wire (2)

Screws (1)

Claw A

Claw A

Front net (8)

Front net assembly (3)

Claw A

Chassis (9)

Claw A

Left speaker (7)

Fig. 1-1-18

Claw A

Right speaker (5)

Screws (4)

Screws (6)

Fig. 1-1-19

1-13.Hinge, Top Cover

1. Remove two screws (1), remove the left support (2)

and the left hinge (3).

2. Remove two screws (4), the right support (5) and the

right hinge (6), then remove the top cover (7).

Screws (4)

GND lead wire

Top cover (7)

Right hinge (6)

Screws (1)

Left support (2)

Right

support (5)

GND

lead wire

Left hinge (3)

1-5

Fig. 1-1-20

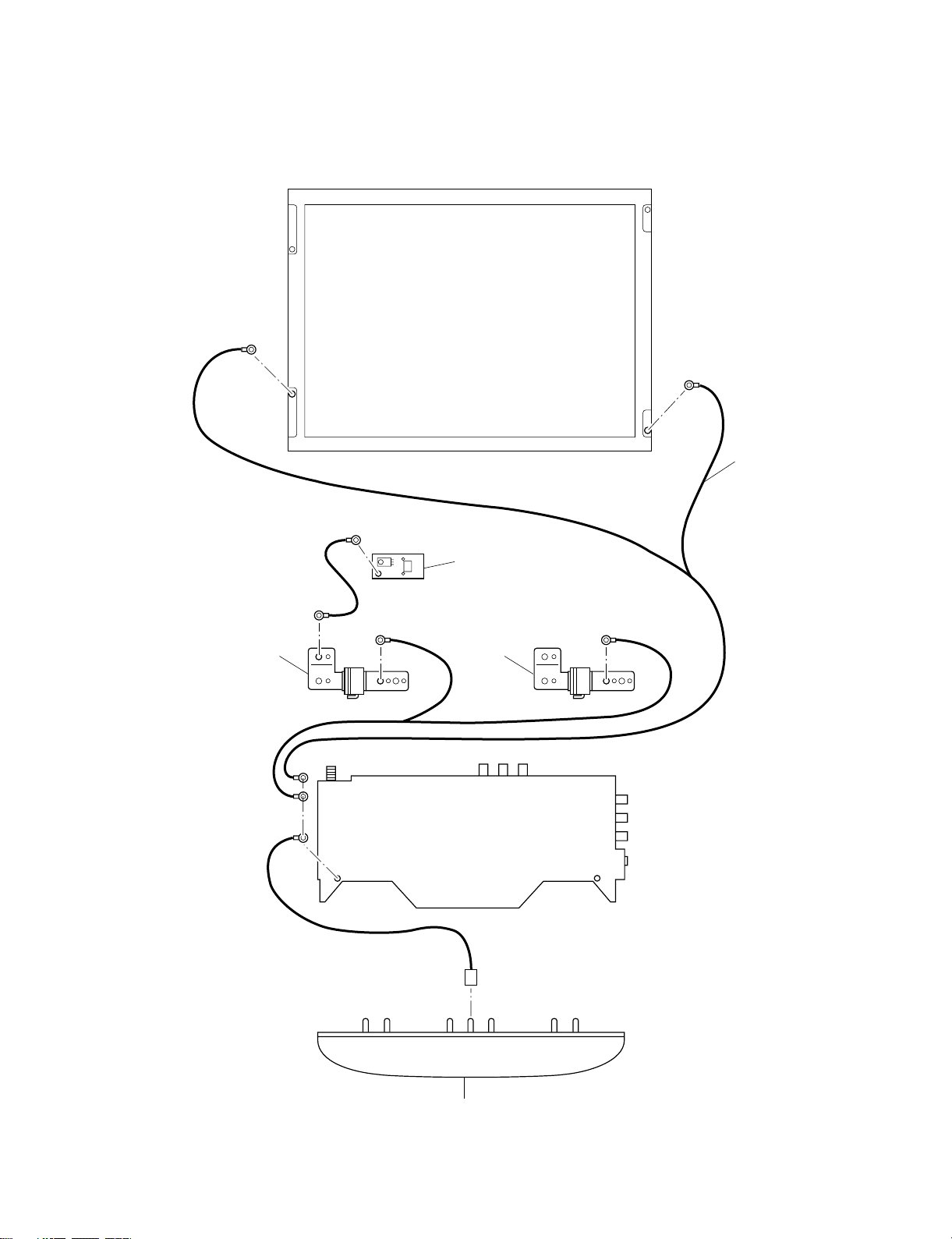

2. GND LEAD WIRE CONNECTION DIAGRAM

When assembling, refer to the diagram below for the GND lead wire connection.

LCD

GND lead wire

Sensor PC board

Hinge Hinge

Main PC board

Front net

Fig. 1-2-1

1-6

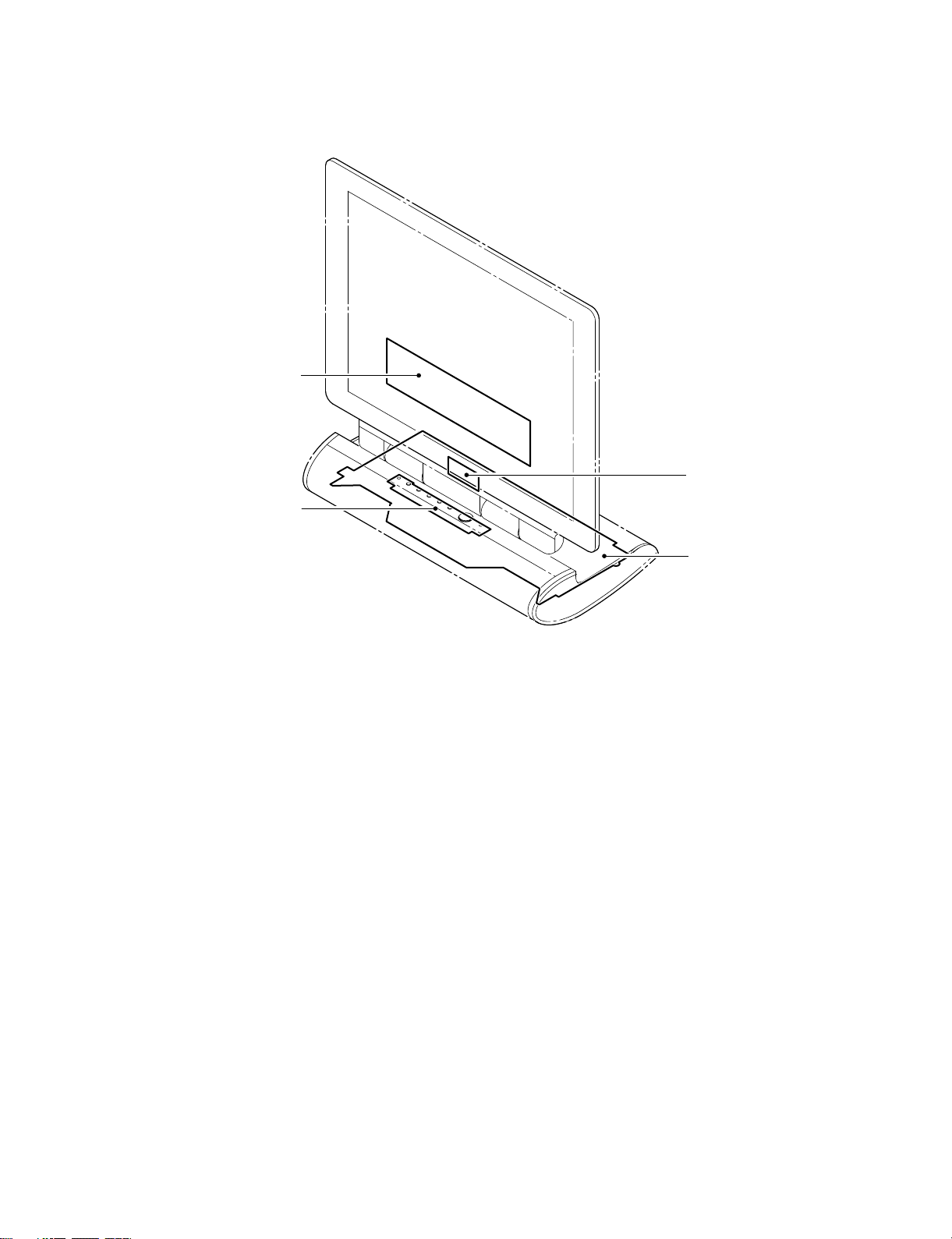

3. LOCATION OF MAIN PARTS

U004 Inverter PC board

U002 Switch PC board

U003 Sensor PC board

U001 Main PC board

Fig. 1-3-1

1-7

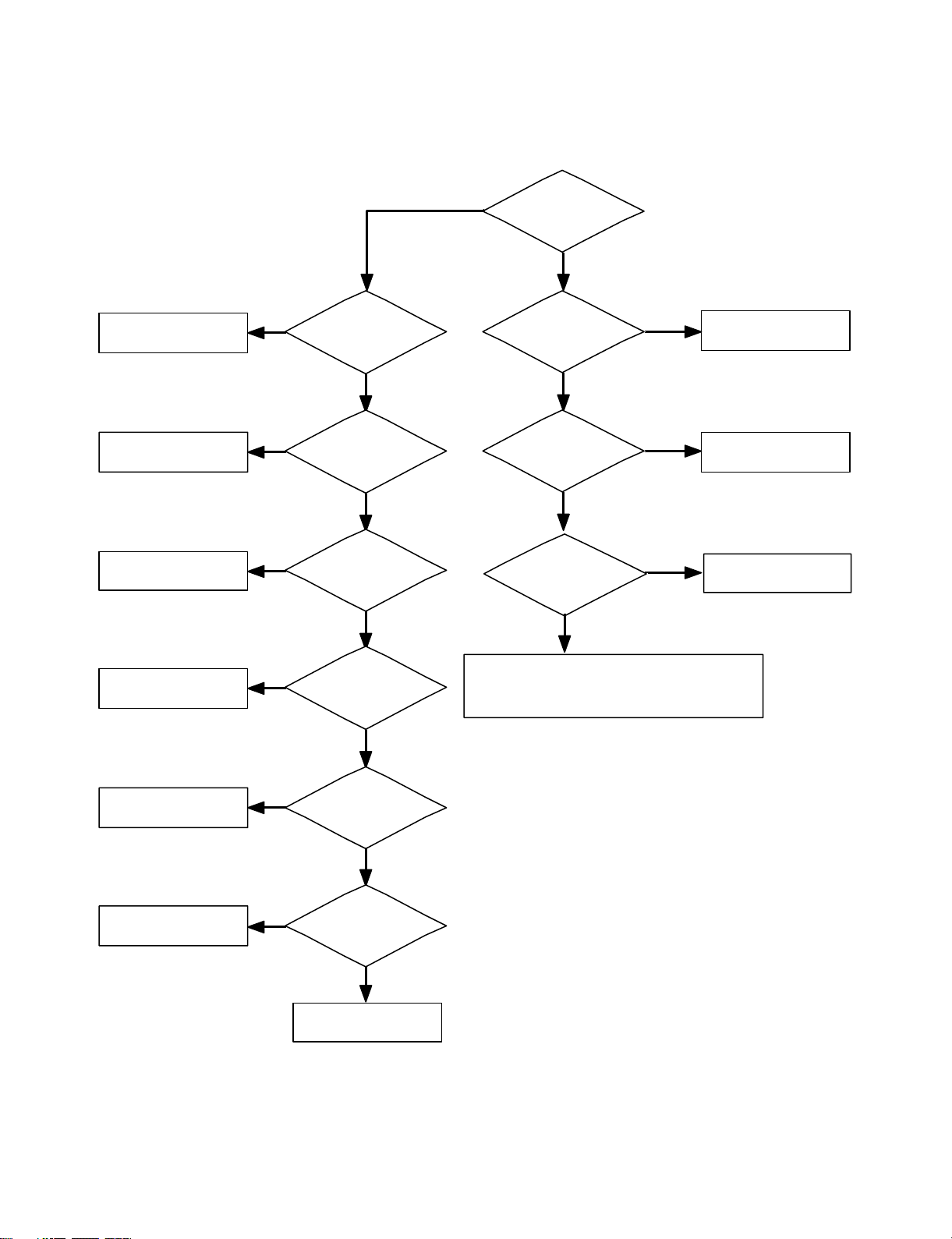

4. TROUBLESHOOTING

4-1. No Power (No Video & No Sound)

12Vcc = 12V ?

(IC801 Pin 5)

CHECK/REPLACE

F801, L801, ADAPTER

CHECK/REPLACE

IC801

CHECK/REPLACE

Q801

CHECK/REPLACE

IC702

N

N

IC801

Pin 1 = 12V ?

5Vcc = 5V ?

Y

Y

IC801

Pin 4 = LOW ?

3.3Vcc = 3.3V ?

N

Y

IC701

Pin 19 = HIGH ?

IC201 Pin 34, 35

OSC O.K ?

N

N

IC701

Pin 11 = 5V ?

IC201 (MXCS, MXSDA, MXSCL, MX_RESET),

Y

Y

Y

Y

CHECK/REPLACE

IC400

N

N

N

CHECK/REPLACE

IC803, L804, D802

CHECK/REPLACE

IC804

CHECK/REPLACE

X201, IC201

CHECK/REPLACE

IC704

CHECK/REPLACE

X701, IC701

N

Pin 18 = HIGH ?

N

IC701 Pin 13, 14

OSC O.K ?

CHECK/REPLACE

SCL, SDA LINE

Y

IC701

Y

Y

Fig. 1-4-1

1-8

4-2. No Video

4-2-1. No Video (Sound O.K)

OSD DISPLAY

O.K ?

CHECK/REPLACE

IC701, INVERTER

CHECK/REPLACE

IC201, IC301

CHECK/REPLACE

IC302, Q301, IC701

N

LCD PANEL

LAMP ON ?

N

OUTPUT O.K ?

N

Pin = 3.3V ?

CHECK/REPALCE

LCD PANEL,

INTERFACE CABLE

Y

IC301

Y

IC301

Y

N

IC201 PDA [0..23]

SIGNAL O.K ?

Y

Y

CHECK/REPLACE

IC201

N

IC101

Pin 62, 63 OSC O.K ?

N

CHECK/REPLACE

X101, IC101

Y

CHECK/REPLACE

IC101

4-2-2. No Video (Sound O.K)

CHECK/REPLACE

IC101, D104, L105

CHECK/REPLACE

IC501, IC601

Y

Y

RF MODE O.K

A/V MODE NG ?

IC501 Pin 7

SIGNAL O.K ?

N

IC501 Pin 1, 3

INPUT SIGNAL O.K ?

N

CHECK

INPUT CABLE

Fig. 1-4-2

RF MODE N.G

A/V MODE O.K ?

IC502 Pin 3

SIGNAL O.K ?

N

CHECK/REPLACE

TU1, Q502

Y

CHECK/REPLACE

IC502, Q501, IC601

Fig. 1-4-3

1-9

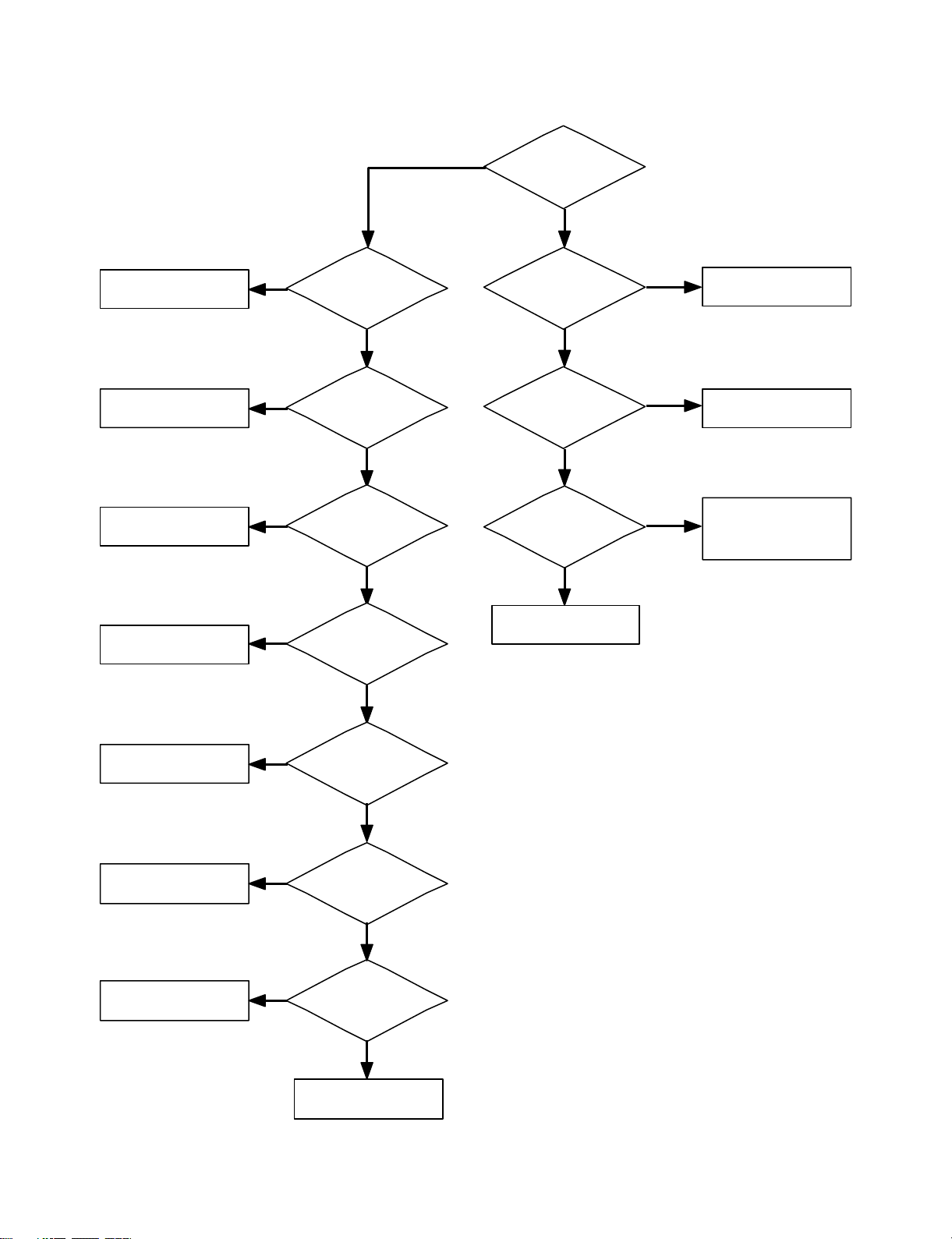

4-3. No Sound (Video O.K)

IC601 Pin 27, 28

OUTPUT O.K ?

CHECK/REPLACE

IC601, L601, L602

CHECK/REPLACE

IC802

CHECK/REPLACE

IC601, X601

CHECK/REPLACE

IC701, IC601

N

IC601 Pin 66, 65

11, 12, 13 = 5V ?

Y

N

IC601

Pin 39 = 8V ?

Y

N

IC601

Pin 71, 72 OSC O.K ?

Y

N

IC601 Pin 21

(A_RESET) = HIGH ?

N

IC681 Pin 4, 6

OUTPUT O.K ?

Y

Y

CHECK/REPLACE

SPEAKER, WIRE

N

IC681

Pin 7 = 12V ?

N

CHECK/REPLACE

IC681, R681

Y

IC681

Pin 8 = HIGH ?

N

CHECK/REPLACE

IC681, Q681

Q682, Q683

Y

CHECK/REPLACE

IC681

CHECK/REPLACE

IC601

CHECK/REPLACE

IC651

CHECK/REPLACE

IC601

Y

Y

IC601 Pin 47, 48

INPUT O.K ?

N

Y

IC601 Pin 33, 34

OUTPUT O.K ?

N

Y

IC601

INPUT O.K ?

N

CHECK

AUDIO INPUT JACK

Fig. 1-4-4

1-10

SECTION 2

SERVICING DIAGRAMS

1. CIRCUIT SYMBOLS AND SUPPLEMENTARY EXPLANATION

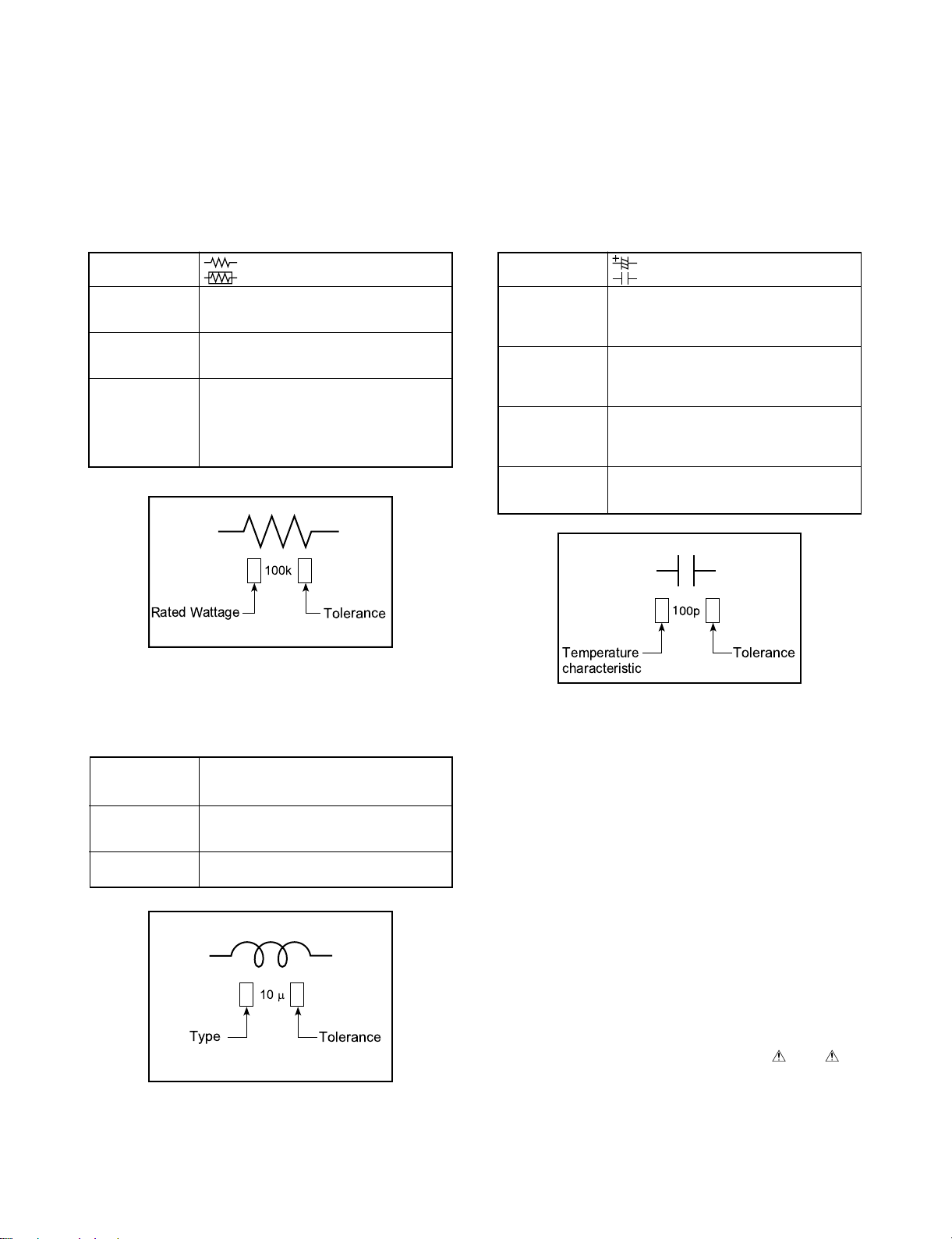

1-1. Solid Resistor Indication

Table 2-1-1

Symbol ..... Carbon film

Unit None ..... W

Tolerance None ..... ±5%

Rated Wattage (1) Chip Parts

Rated Wattage

..... Oxide metal film

k ..... kW

M ..... MW

F .....±1%

K ..... ±10%

None .. 1/16W

(2) Other Parts

None .. 1/6W

Other than above, described in the Circuit

Diagram.

100k

Tolerance

Fig. 2-1-1

1-3. Capacitance Indication

Table 2-1-3

Symbol .....

Unit None ..... F

Rated voltage None ..... 50V

Tolerance (1) Ceramic, plastic, and film capacitors

Temperature None ..... SL

characteristic For others, temperature characteristics are

(Ceramic capacitor)

Temperature

characteristic

m .....mF

n ..... nF

p ..... pF

For other than 50V and electrolytic

capacitors, described in the Circuit

Diagram.

(2) Electrolytic, Trimmer

described.

Electrolytic, Special electrolytic

..... Ceramic, Film

None .. ±5% or more

Tolerance is not described.

100p

Tolerance

1-2. Inductor Indication

Table 2-1-2

Unit None ..... H

Tolerance None ..... ±5%

Type PL ..... Peaking

m .....mH

m .....mH

K ..... ±10%

M ..... ±20%

Others display model

10

m

Type

Fig. 2-1-2

Tolerance

Fig. 2-1-3

1-4. Waveform and Voltage Measurement

• The various wave forms of the color circuit and

voltage measurement values are for when the service

color bar signal is received with ample reception and a

proper image is received.

• Other various wave forms of circuits and voltage

measurement values are for when general broadcasts

are normally received and will differ slightly depend-

ing on the broadcast contents. Use it as a standard

during servicing.

• All voltage values except the waveforms are expressed

in DC and measured by a digital voltmeter.

1-5. Precautions for Part Replacement

• In the schematic diagram, parts marked (ex.

F800) are critical part to meet the safety regulations,

so always use the parts bearing specified part codes

(SN) when replacing them.

• Using the parts other than those specified shall violate

the regulations, and may cause troubles such as

2-1

operation failures, fire etc.

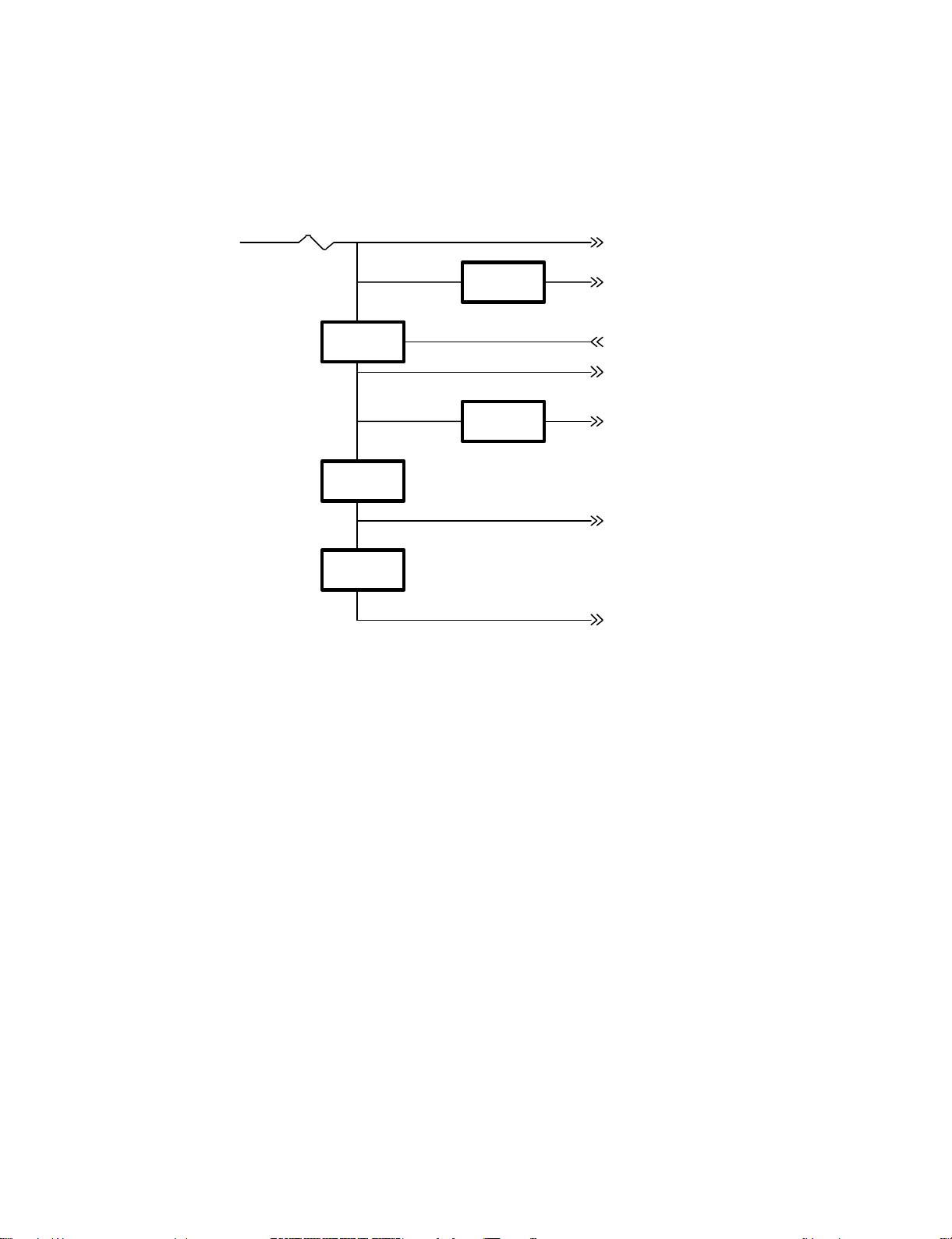

2. BLOCK DIAGRAMS

2-1. Power Block Diagram

DC12V

F801

IC801

FET_SW

IC803

5V REG.

IC804

3.3V REG.

IC702

5V REG.

IC702

8V REG.

VIN

INVERTOR,SOUND AMP

5VM

POWER

12VCC

8VCC

5VCC

3.3VCC

Fig. 2-2-1

2-2

Loading...

Loading...