Page 1

FILE NO. 050-200513

DOCUMENT CREATED IN JAPAN, Sept., 2005

SERVICE MANUAL

LCD Color Television

15DL15

15DL75

20DL75

TOSHIBA CORPORATION 2005

-

1

-

Published in Japan, Sep. 2005 (YC)

Page 2

TABLE OF CONTENTS

SERVICE SAFETY PRECAUTIONS ........................................................................................................................................ 3

HANDLEING THE LCD MODULE ........................................................................................................................................... 5

1. SERVICE MODE .................................................................................................................................................................. 7

1-1. STARTING SERVICE MODE ......................................................................................................................................... 7

2. ADJUSTMENT ..................................................................................................................................................................... 8

2-1. ADJUSTMENT TOOLS AND CONDITIONS ................................................................................................................. 8

2-2. AUTO GAIN/OFFSET ADJUSTMENT ........................................................................................................................... 8

2-3. DDC EDID DATA READ & WRITE ................................................................................................................................. 9

3. VCTI FIRMWARE INSTALLATIONS/UPGRADING ............................................................................................................ 19

3-1. VCTI FIRMWARE INSTALLATIONS ............................................................................................................................ 20

3-2. SCALER FIRMWARE INSTALLATIONS...................................................................................................................... 26

4. TROUBLESHOOTING........................................................................................................................................................ 33

5. EXPLODED VIEW .............................................................................................................................................................. 39

6. CHASSIS AND CABINET REPLACEMENT PARTS LIST ................................................................................................. 40

7. PC BOARDS TOP & BOTTOM VIEW................................................................................................................................. 50

8. SCHEMATIC DIAGRAM ..................................................................................................................................................... 54

8-1. WIRING DIAGRAM ...................................................................................................................................................... 55

8-2. BLOCK DIAGRAM (20DL75) ....................................................................................................................................... 56

8-3. BLOCK DIAGRAM (15DL15,15DL75) ......................................................................................................................... 57

-

2

-

Page 3

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

SERVICE SAFETY PRECAUTIONS

• The caution items shown here describe major safety issues and should always be observed.

• The meanings of the various indications are as follows.

WARNING

CAUTION

* Physical damage means major damage to a home, furnishings and other possessions.

Examples of marks

SHOCK HAZARD

PROHIBIT DISASSEM-

BLING

UNPULUG

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users due to a product defect after the service operation is completed, could possibly be in

danger of injury or even death in the event of operational error.

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users after the service operation is completed, could possibly be in danger of injury, or

where there could be physical damage in the event of operational error.

The" indicates caution (including danger and warning).

"

The actual meaning of this caution is indicated inside the

The example shown to the left indicates the danger of "electrical shock".

The

indicates a forbidden action.

The actual meaning of this caution is indicated inside the

The example shown to the left indicates that disassembly is forbidden.

The

-

indicates a forced action (an action that must be performed).

The actual meaning of this forced action is indicated by

The example shown to the left indicates that the power plug must be disconnected.

or nearby illustrations or text.

or nearby illustrations or text.

-

or nearby illustrations or text.

-

3

-

Page 4

KEEP CHILDREN

AWAY

UNPULUG

SHOCK HAZARD

USE SPECIFIED

PARTS

CAUTION FOR

WIRING

CAUTION FOR

ASSEMBLING /

WIRING

WARNING

• Always advise users to keep children away.

There is danger of injury to children from tools, disassembled products, etc.

• Always disconnect the power plug before starting work whenever power is not required.

Failure to disconnect the power plug before starting work can result in electrical shock.

• Depending on the model, use an insulation transformer or wear gloves when servicing with the

power on, and disconnect the power plug to avoid electrical shock when replacing parts.

In some cases, alternating current is also impressed in the chassis, so electrical shock is possible if the chassis is contacted with the power on.

• Always use the replacement parts specified for the particular model when making repairs.

The parts used in products have the necessary safety characteristics such as inflammability,

voltage resistance, etc.; therefore, use only replacement parts that have these same characteristics.

Use only the specified parts when the

• Parts mounting and routing of the wiring should be the same as that used originally.

For safety purposes, insulating materials such as tubing or tape is sometimes used and printed

circuit boards are sometimes mounted floating.

Also make sure that wiring is routed and clamped to avoid parts that generate heat and which

use high voltage. Always follow the original scheme.

• After a repair has been completed, reassemble all disassembled parts, and route and reconnect the wiring, in accordance with the original scheme.

Do not allow internal wiring to be pinched by cabinets, panels, etc.

Any error in reassembly or wiring can result in electrical leakage, flame, etc., and may be

hazardous.

mark is included in a circuit diagram or parts list.

CHECK INSULATION

RESISTANCE

PROHIBIT

REMODELING

• After completing the work, disconnect the power plug from the outlet, remove the antenna, turn

on the power switch. Then, use a 500V insulation resistance meter to check the insulation

resistance of the antenna terminal, other metallic parts and between the prongs of the power

plug to make sure that the insulation resistance is 1M 1 or more.

The set will require inspection and repair if the insulation resistance is below this value.

• Never remodel the product in any way.

Remodeling can result in improper operation, malfunction, or electrical leakage and flame,

which may be hazardous

-

4

-

Page 5

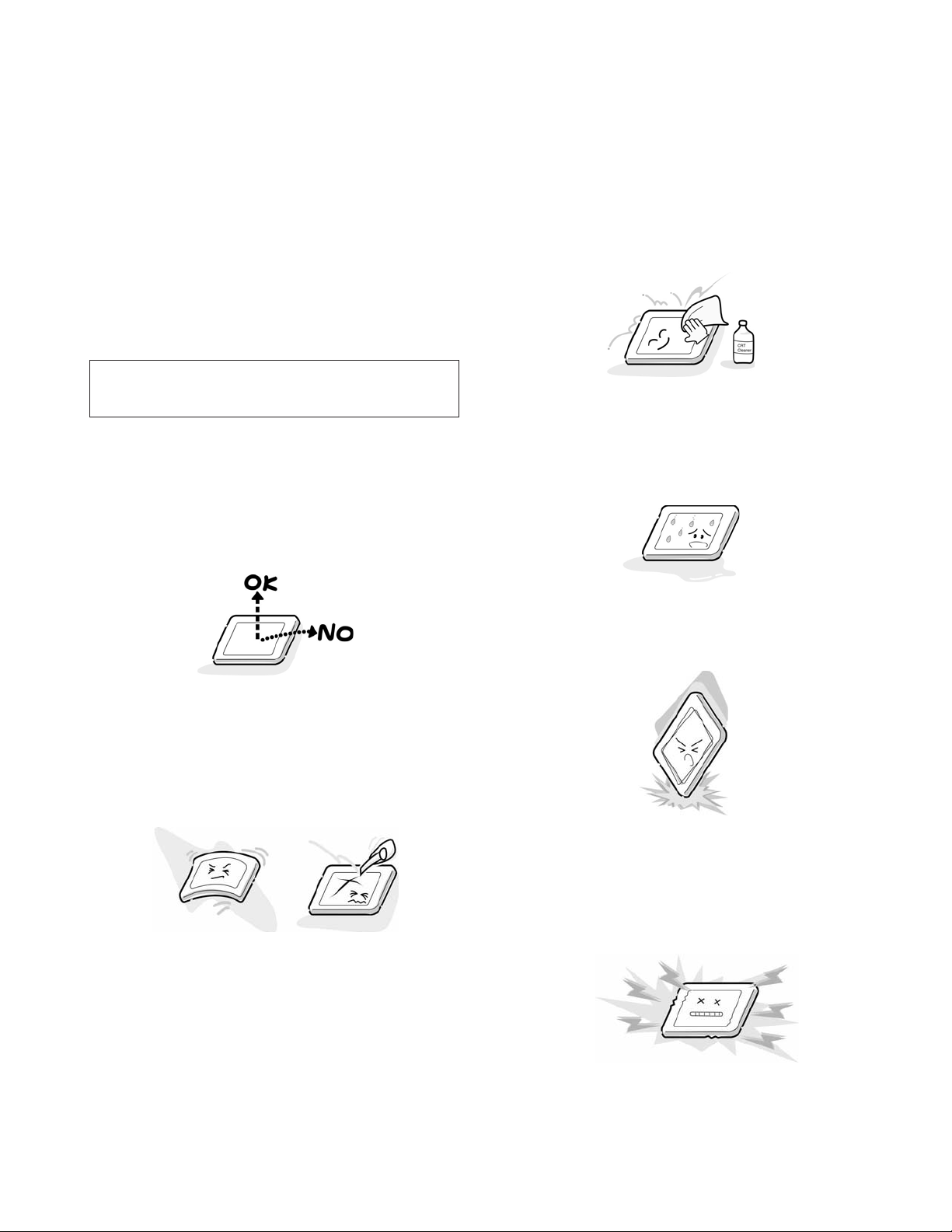

HANDLING THE LCD MODULE

a

n

r

r

y

n

r

e

h

d

-

Safety Precautions

In the event that the screen is damaged or the liquid crystal

(fluid) leaks, do not breathe in or drink this fluid. Also, never

touch this fluid.

Such actions could cause toxicity or skin irritation. If this fluid

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the skin or clothing, wipe off

with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly

with running water.

Precautions for Handling the LCD Module

CAUTION

The LCD module can easily be damaged during disassembly

or reassembly; therefore, always observe the following precautions when handling the module.

1. When attaching the LCD module to the LCD cover, position it appropriately and fasten at the position where the

display can be viewed most conveniently.

The metal edges of the LCD module

are sharp, handle it with care.

3. If the panel surface becomes soiled, wipe with cotton or

soft cloth. If this does not remove the soiling, breathe o

the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleane

as a cleaner. Wipe off the panel surface by drop the cleane

on the cloth. Do not drop the cleaner on the panel. Pa

attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for a

extended period of time can result in discoloration o

stripes. Immediately remove any type of fluid from th

screen.

2. Carefully align the holes at all four corners of the LCD

module with the corresponding holes in the LCD cover

and fasten with screws. Do not strongly push on the module because any impact can adversely affect the performance. Also use caution when handling the polarized screen

because it can easily be damaged.

5. Glass is used in the panel, so do not drop or strike wit

hard objects. Such actions can damage the panel.

6. CMOS-LSI circuitry is used in the LCD module, so avoi

damage due to static electricity. When handling the mod

ule, use a wrist ground or anchor ground.

-

5

-

Page 6

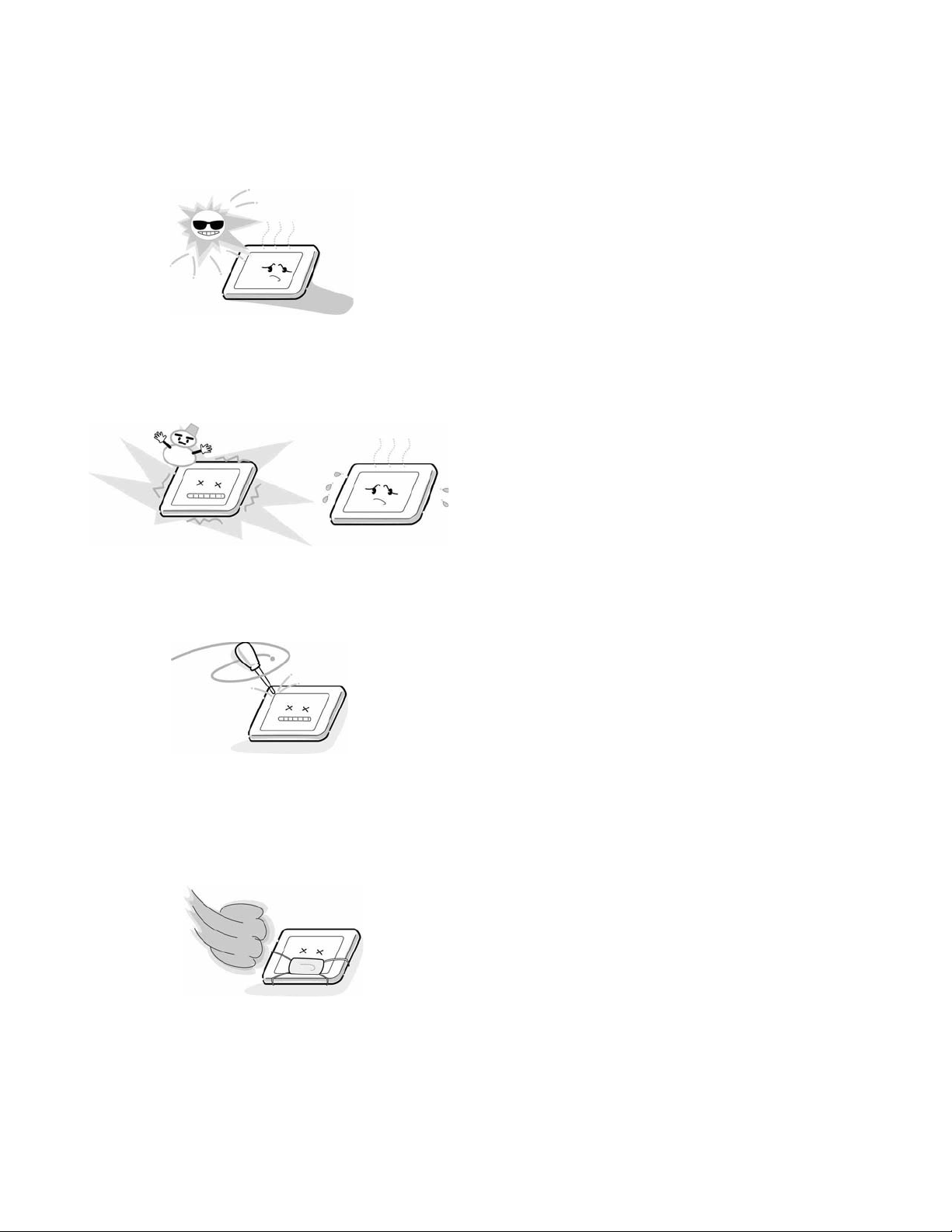

7. Do not expose the LCD module to direct sunlight or strong

ultraviolet rays for an extended period of time.

8. Do not store the LCD module below the temperature conditions described in the specifications. Failure to do so

could result in freezing of the liquid crystal due to cold air

or loss of resilience or other damage.

9. Do not disassemble the LCD module. Such actions could

result in improper operation.

10. When transporting the LCD module, do not use packing

containing epoxy resin (amine) or silicon resin (alcohol or

oxim). The gas generated by these materials can cause

loss of polarity.

-

6

-

Page 7

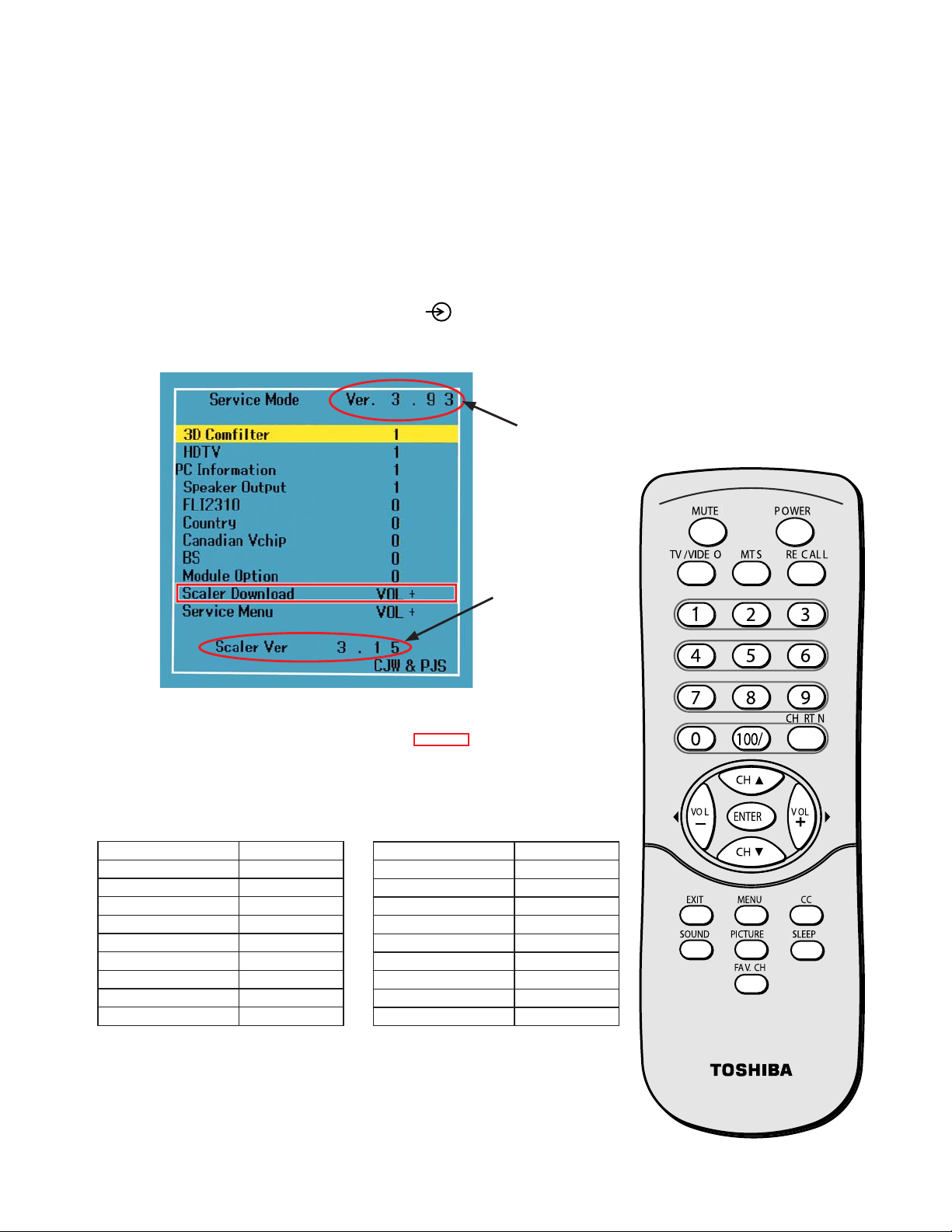

1.Service Mode

1-1.Starting Service Mode

*Set LCD TV to the normal TV signal receive mode.

Note: In this "Service Mode" section, [ ] shows a button.

1-1-1. Press [MUTE] on the remote control once.

1-1-2. Presss [MUTE] again, and press [

Service mode displayed on TV screen

Items other than those enclosed by are default

settings.

] on LCD TV.

VCTi version

Scaler version

15-inch TV

Item Default setting

3D Comb Filter 0

HDTV 1

PC Information 1

Speaker Outout 0

FLI2310 0

Country 2

Canadian Vchip 0

BS 0

Module Option 4

20-inch TV

Item Default setting

3D Comb Filter 1

HDTV 1

PC Information 1

Speaker Outout 1

FLI2310 0

Country 2

Canadian Vchip 0

BS 0

Module Option 0

- 7 -

Page 8

2. Adjustment

Note: In this "Adjustment" section, [ ] shows a button.

2-1.Adjustment Tools and Conditions

Tools: Pattern Generator (801GF, MSPG925F)

DDC Adjustment Tool

PC

Remote Control

Conditions: Heat Run 30 minutes or more

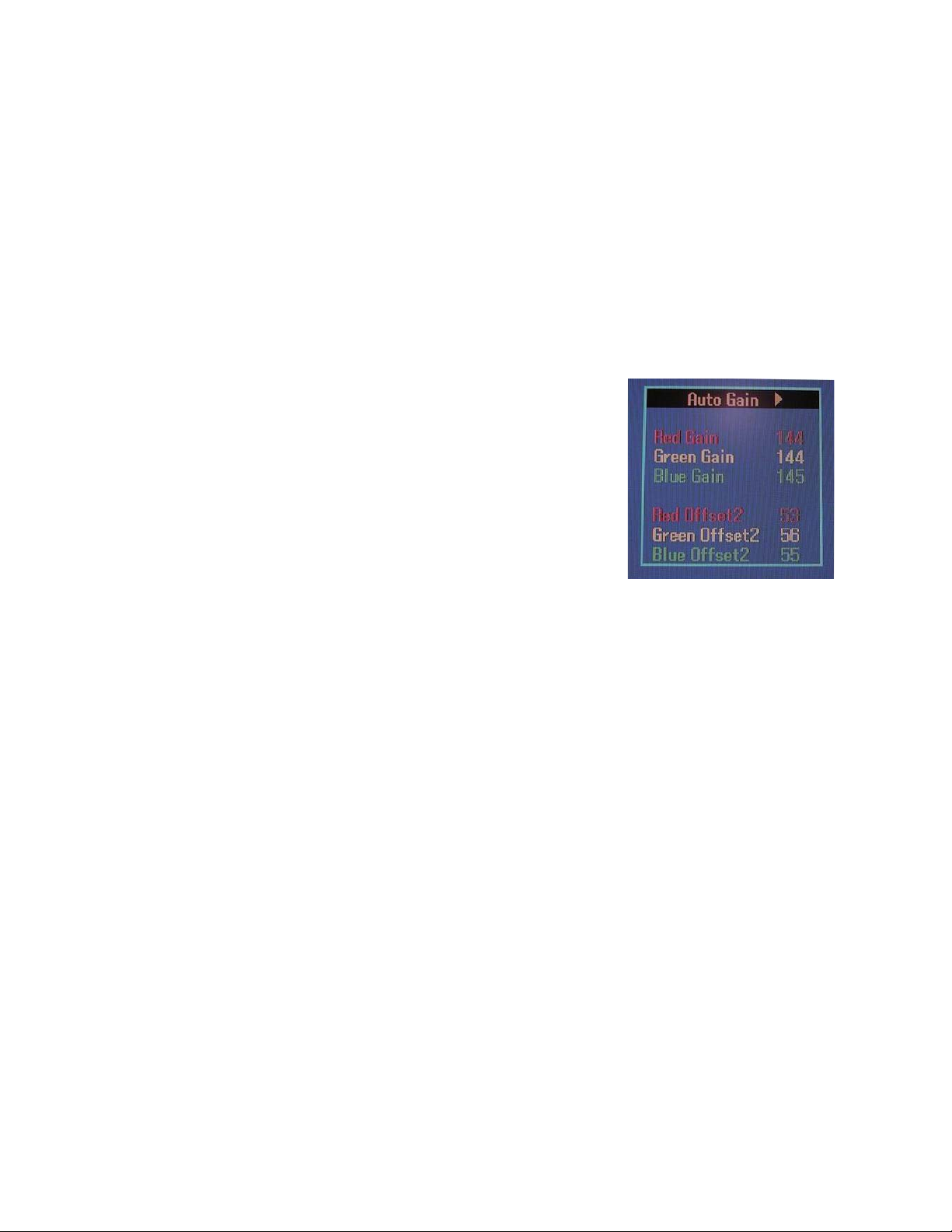

2-2. Auto Gain/Offset Adjustment

2-2-1. RF Mode Adjustment (normal TV receive mode)

No reguired

2-2-2. Component Mode Adjustment

Preparation

Carry out Heat Run for 30 minutes or more before adjustment

(with no RF signal).

1) Connect Y, Pb, and Pr output signals of Pattern Generator

to the component jack (Y, Pb, Pr) of LCD TV.

2) Connect Y, Pb, and Pr output signals of Pattern Generator

to the component jack (D Jack) of LCD TV.

3) Change the TV input mode to component mode.

4) Select 480p Mode (Y:100% Pb/Pr:75%) in Pattern Generator. Select Pattern 33 (Color Bar Pattern

signal) in Pattern Generator (MSPG925F).

5) Go into service mode, and Auto Gain menu appears, and then press VOL [+].

6) Press [OK] to store the adjustment data.

(Adjustment in component mode or PC mode)

2-2-3. PC Mode Adjustment

Preparation

Carry out Heat Run for 30 minutes or more before adjustment (with no RF signal).

Connect Pattern Generator to the 15-pin D-Sub Jack of LCD TV.

1) Change the TV input mode to PC mode.

2) Set Pattern Generator to the following:

15DL15,15DL75: XGA (1024x768) 16-step or 11-step grayscale

20DL75 : VGA (640x480) 16-step grayscale

3) Go into service mode, and Auto Gain menu appears, and then press VOL [+].

4) Press [OK] to store the adjustment data.

- 8 -

Page 9

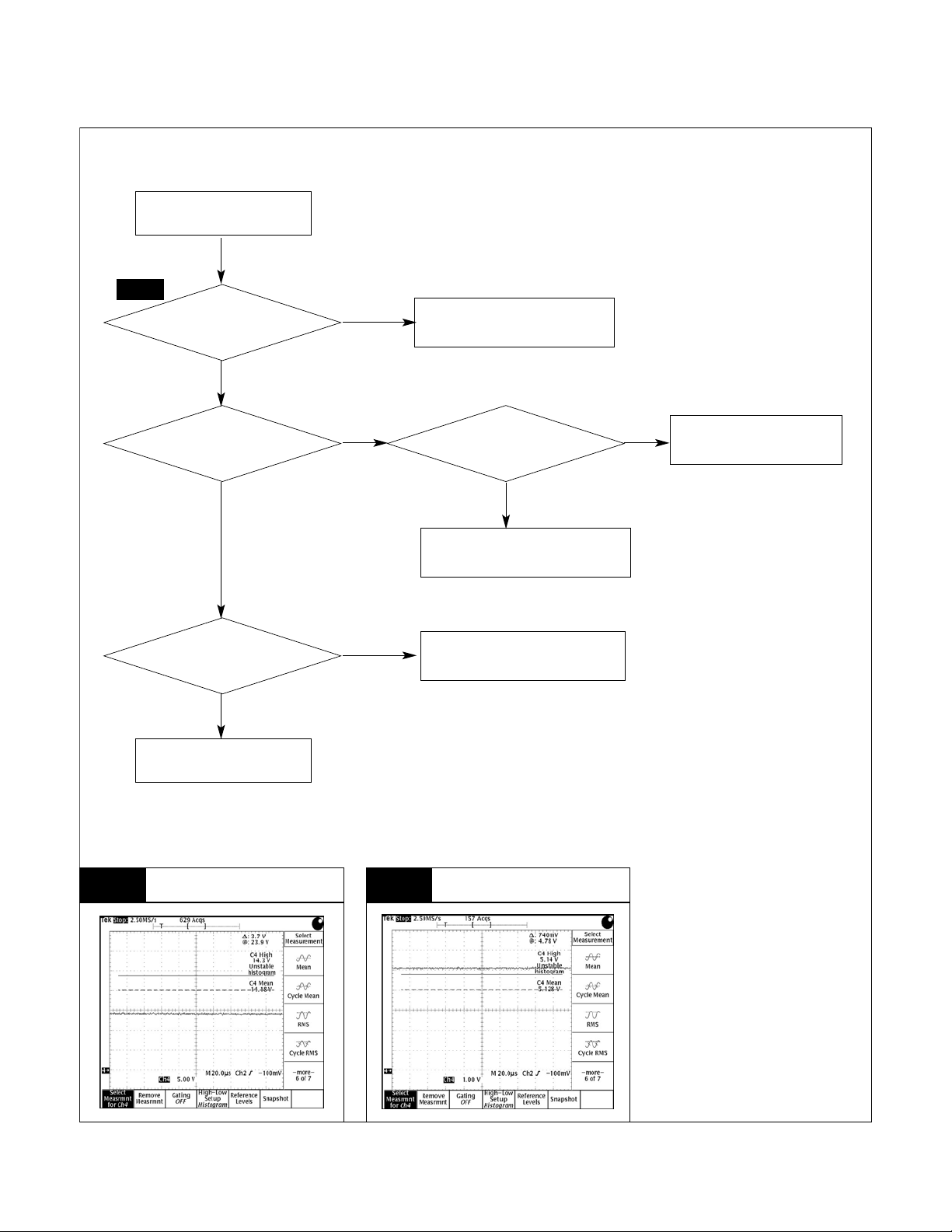

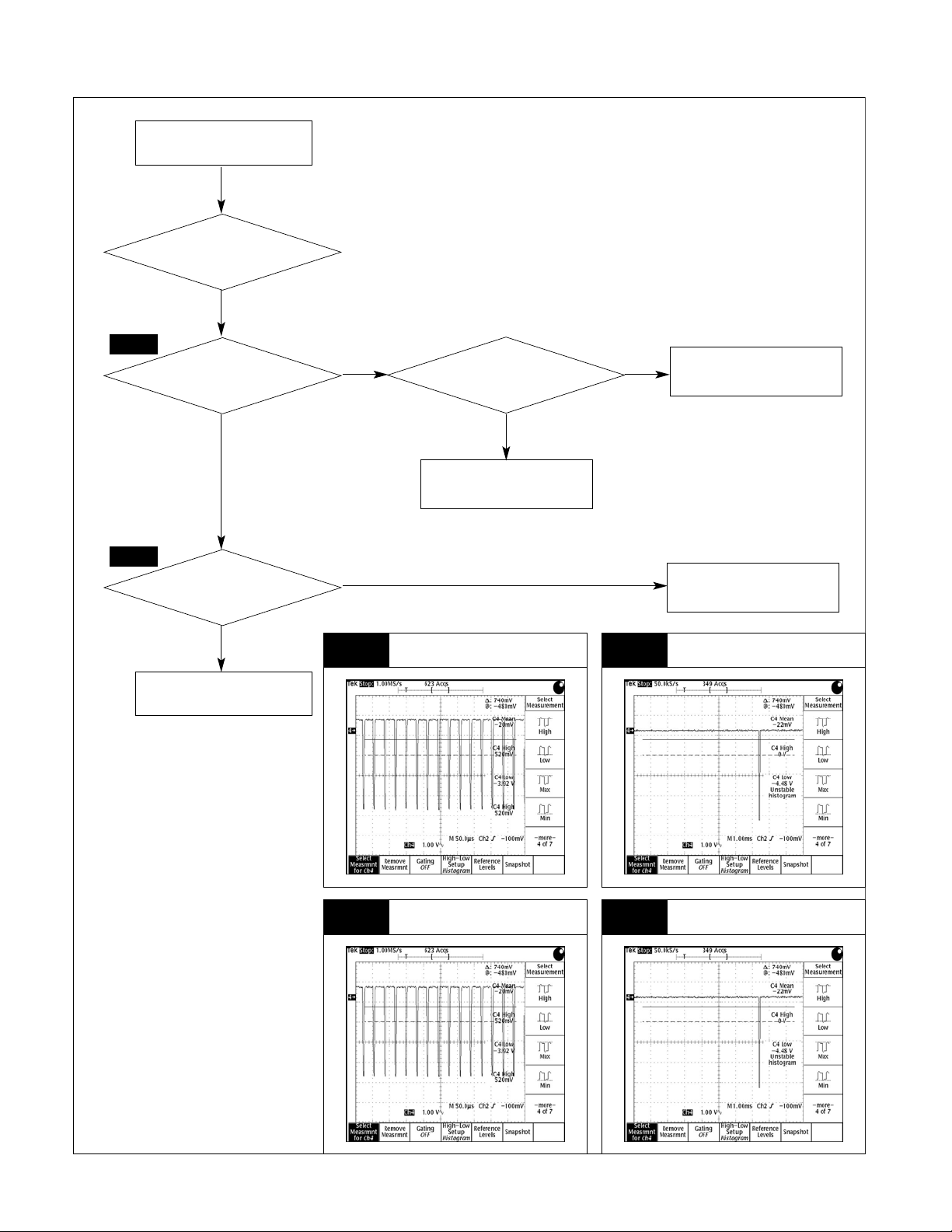

4. TROUBLESHOOTING

Process A

No power

Ref.1/1-1

Check 15V or ST_ 5V

of Power B/D

Pass

Fail

Check short circuits of Main B/D

or Change Power B/D

Check Output of

IC1004, IC1005(Main B/D)

Pass

Check IR Assy

Pass

Check P101 Connector

Check IC 1004, IC1005

Fail Fail

Fail

PIN 7 LEVEL(High 3.3V)

Pass

Change IC1004 , IC1005

or check short circuits of Main B/D

Change IR Assy

Change IC200

Of Main B/D

15V : P1100, #1, 2Ref.1 ST_5V : P1100, #6, 7Ref.1-1

- 33 -

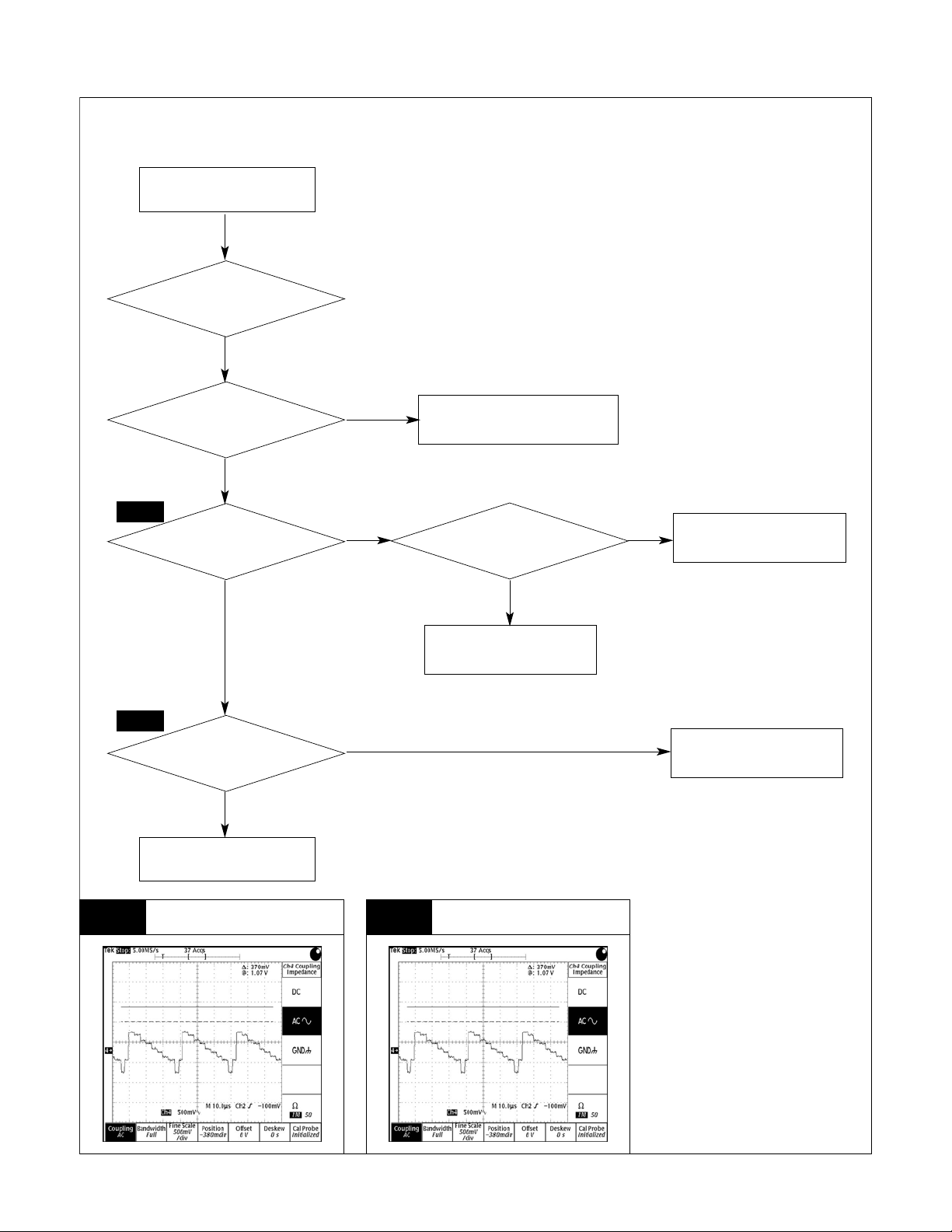

Page 10

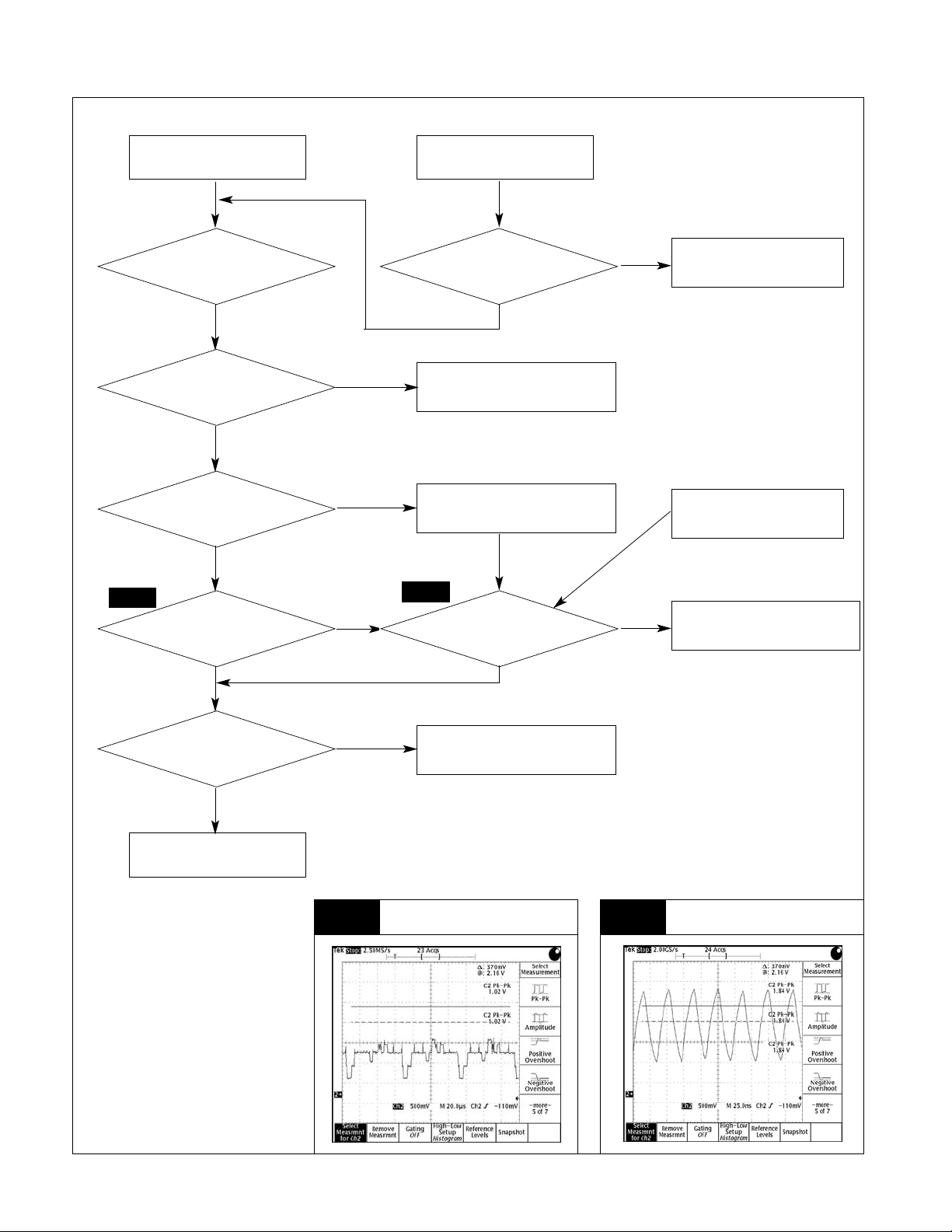

Process B

No Raster on Component

,D2 Signal

Repeat Process A

Pass

Check

R217 of Main B/D

1.Component Jack (high)

2.D-JACK (LOW)

Pass

Ref.2

Check the Input/

Output of IC701 of Main B/D

Fail

Fail

Check short circuits of Main B/D

& JACK B/D

Check R715 of Main

Level(high 3.3V)

Check short circuits of

Main B/D

Fail

Ref.2

Pass

Ref.3

Check the input / output

IC500 of Main B/D

Pass

Check input source cable

and jack

Component Y signal Input :

IC701(Swiching IC), #3

Ref.3

Pass

Re-soldering or

Change IC701

Fail

Component Y signal Input :

IC500(Scaler IC), #147

Re-soldering or

Change IC500

- 34 -

Page 11

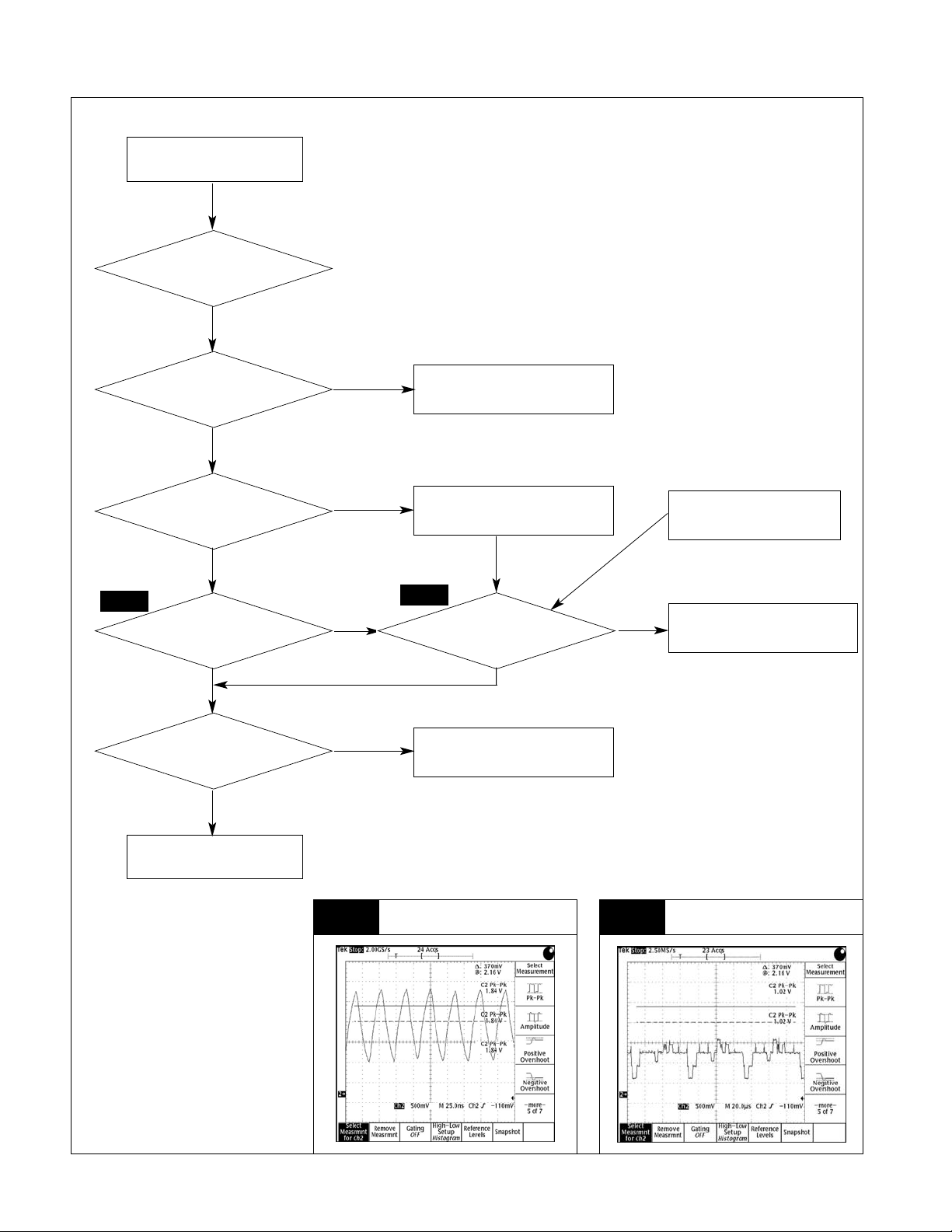

No Raster on PC Signal

Repeat Process A

Pass

Ref.4/4-1

Check the input/

output of IC701 of Main B/D

Fail

Check R715 of Main B/D

Level(LOW 0V)

Pass

Check short circuits of

main B/D

Fail

Pass

Ref.5/5-1

Check the Input / Output

IC500 of Main B/D

Pass

Check input source cable

and Jack

Ref.4

Ref.5

Re-soldering or

Change IC701 of Main B/D

Fail

H Sync Input :

IC701 (Swiching IC), #23

H Sync Input :

IC500 (Scaler IC), #181

Ref.4-1

Ref.5-1

Re-soldering or

Change IC500

V Sync Input :

IC701 (Swiching IC), #13

V Sync Input :

IC500 (Scaler IC), #182

- 35 -

Page 12

No Raster on video Signall

(Video1)

Repeat Process A

Pass

Pass

No Raster on TV(RF)

Signal

Check the output of

TU100

Fail

Check 5V, 33V of TU100

Re-soldering or Change

the defect part

Check the input

source

Pass

Check R217 Level

(Video1,RF : HIGH 3.3v)

Pass

Ref.7

Check the Input/Output

of IC200

Pass

Check the Input/Output

of IC500

Pass

Fail

Fail

Fail

Pass

Fail

Check short circuits of Main B/D

& JACK B/D

Check short circuits of Main B/D

& JACK B/D

Ref.6

Check the Input/Output

of IC300

Check short circuits of Main B/D

or Change IC500

Option

Fail

Only for 20DL75

Check short circuits of main

B/D or Change the defect part

Check cable

and Jack

Ref.6

Y separated Output :

IC300 (Comb Filter), #96

- 36 -

Ref.7

ITU656 Clock Out :

IC200(VCTI), #83

Page 13

No Raster on video Signall

(Video2 , S-video)

Repeat Process A

Pass

Check the input

source

Pass

Check R212 of Main B/D

1.Video2 : HIGH

2.s-video : LOW

Pass

Ref.8

Check the Input/Output

of IC200

Pass

Check the input/output

of IC500

Pass

Check short circuits of Main B/D

Fail

Fail

Fail Fail

Pass

Fail

& side B/D

Check short circuits of Main B/D

& JACK B/D

Ref.9

Check the Input/Output

of IC300

Check short circuits of Main B/D

or Change IC500

Only for 20DL75

Check short circuits of Main

B/D or Change the defect part

Check cable

and Jack

Ref.8

ITU656 Clock Out :

IC200(VCTI), #83

- 37 -

Ref.9

Y separated Output :

IC300 (Comb Filter), #96

Page 14

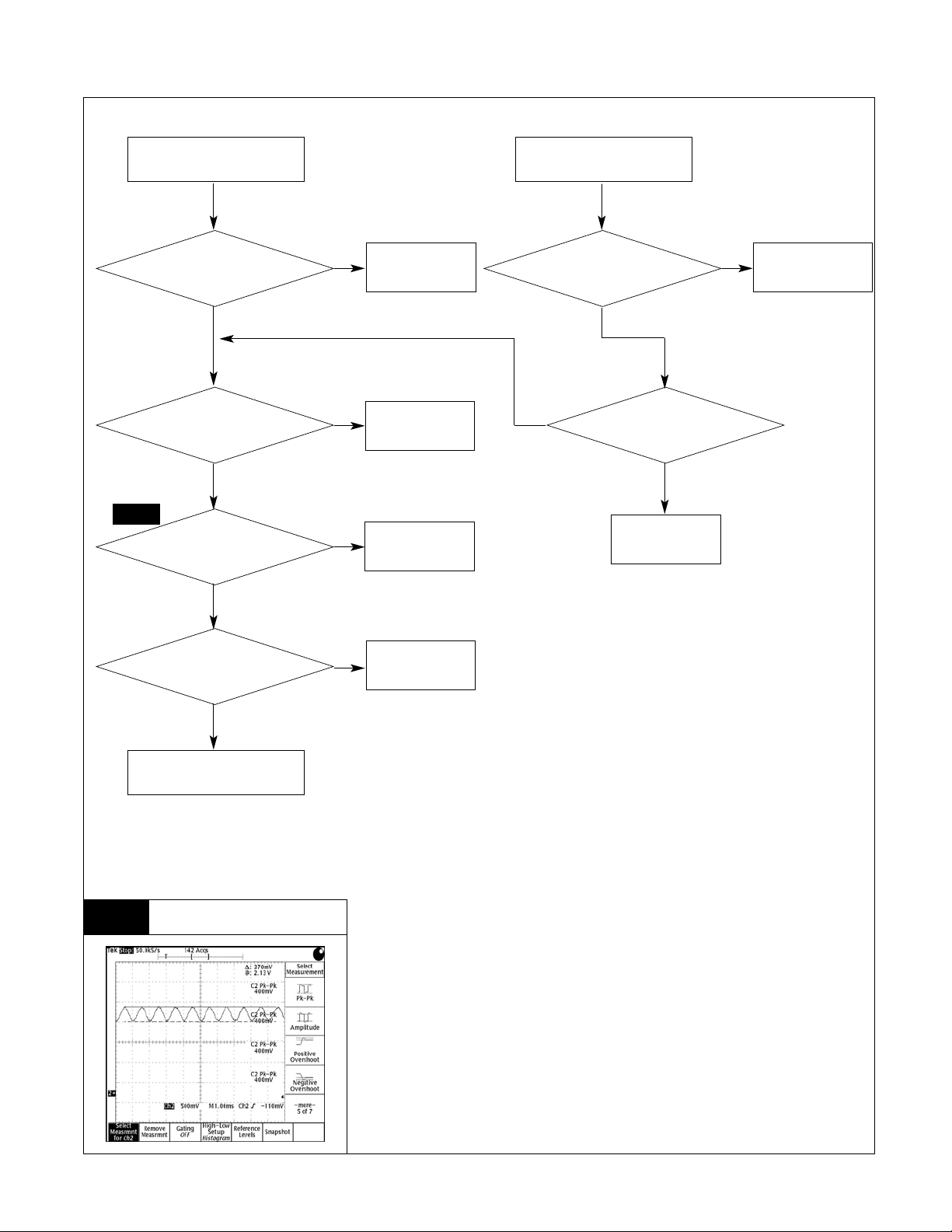

No Sound

(ALL MODE)

No Sound

(Only VIDEO 1 or PC mode)

Check the input

source

Pass

Check the input/output

of IC200 of Main B/D

Pass

Ref.10

Check the input/output

of IC600 of Main B/D

Pass

Check the speaker

Fail

Fail

Fail

Fail

Change source

Input

Pass

Re-soldering or

Change IC200

Re-soldering or

Change IC600

Change

speaker

Check the R750 Level

Video1 : High

PC : Low

Pass

Check Input / Ouput

& 12V Of IC 702

Chang IC 702

Fail

Check short

circuits of Main B/D

Fail

Check the speaker wire

Ref.10

Sound Input :

IC600 (Audio AMP), #3, 5

Pass

- 38 -

Page 15

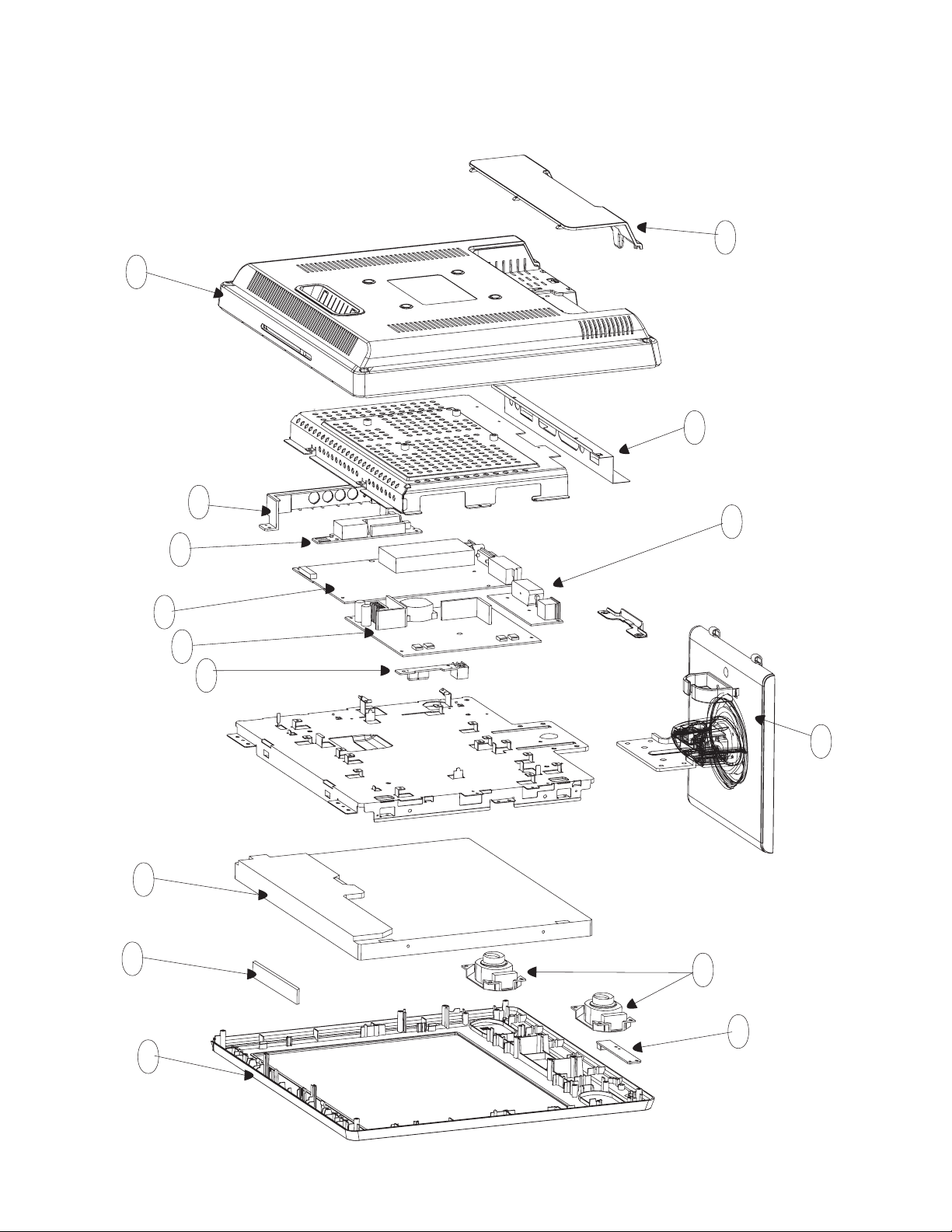

5. EXPLODED VIEWS

15DL15,15DL75,20DL75

030

110

100

050

160

170

020

130

090

080

070

040

150

140

010

- 39 -

Page 16

6. CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “SERVICE SAFETY PRECAUTIONS” ON PAGE 3 OF

THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in

the original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SERVICE SAFETY PRECAUTIONS. Do not degrade

the safety of the receiver through improper servicing.

NOTICE:

•

The part number must be used when ordering parts, in order to assist in processing, be sure to include the

Model number and Description.

•

The PC board assembly with ∗ mark is no longer available after the end of the production.

Model : 15DL15/15DL75/20DL75

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are ±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

Location

No.

Parts No. Reference Description

#1:[15DL15]

#2:[15DL75]

#3:[20DL75]

CAPACITORS

C1 72795154 0CH6101K416 CERAMIC, 100PF 50V 5% NP0 201

C2 72795154 0CH6101K416 CERAMIC, 100PF 50V 5% NP0 201

C3 72795154 0CH6101K416 CERAMIC, 100PF 50V 5% NP0 201

C4 #1,#2 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C6 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C7 72795170 0CC471CK41A CERAMIC, 470PF 1608 50V 5% R/

C8 72795157 0CH6471K416 CERAMIC CHIP, 470F 50V J NP0 2012

C9 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C10 72795161 0CH6331K416 CERAMIC CHIP, 330PF 50V J NP0 2012

C11 72795194 0CE226WJ6DC ELECTROLYTIC, 22UF MVK 35V 20% R/T

C12 72795194 0CE226WJ6DC ELECTROLYTIC, 22UF MVK 35V 20% R/T

C20 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C24 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C53 72795163 0CC101CK41A CERAMIC, 100PF 1608 50V 5% R/

C66 72795163 0CC101CK41A CERAMIC, 100PF 1608 50V 5% R/

C100 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C101 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C102 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C103 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C104 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C105 72795185 0CK273DK51A CERAMIC, 27000PF 2012 50V 10%

C106 72795169 0CC390DK41A CERAMIC, 39PF 2012 50V 5% NP0

C108 72795146 0CE108EF618 ELECTROLYTIC, 1000UF KMG 16V 20% F

C109 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C110 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C111 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C112 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C113 72795151 0CH3332K516 CERAMIC CHIP, 3300PF 50V K B 2012

C114 72795183 0CK225DH94A

C115 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C116 72795166 0CC271CK41A CERAMIC, 270PF 1608 50V 5% R/

C117 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C118 72795193 0CE225WK6DC ELECTROLYTIC, 2.2UF MVK, RC 50V 20%

C119 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C120 72795193 0CE225WK6DC ELECTROLYTIC, 2.2UF MVK, RC 50V 20%

C121 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C150 72795148 0CH8106F691 ELECTROLYTIC, 10UF 16V 20% 105STD

C151 72795148 0CH8106F691 ELECTROLYTIC, 10UF 16V 20% 105STD

C152 72795148 0CH8106F691 ELECTROLYTIC, 10UF 16V 20% 105STD

CERAMIC, 2.2UF 2012 25V 80%, -

-

40

-

Page 17

Location

No.

C200 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C201 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C202 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C205 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C207 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C208 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C209 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C212 72795196 0CE475WJ6DC ELECTROLYTIC, 4.7UF MVK 35V 20% R/

C214 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C216 72795169 0CC390DK41A CERAMIC, 39PF 2012 50V 5% NP0

C218 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C222 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C223 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C224 72795173 0CH3822K516 CERAMIC, 8200PF 2012 50V 10%

C226 72795186 0CK334CF94A CERAMIC, 0.33UF 1608 16V 80%,

C228 72795152 0CH3334K946 CERAMIC, 0.33UF 50V 80%, -20%

C229 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C230 72795175 0CK102CK56A CERAMIC, 1000PF 1608 50V 0.1

C231 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C232 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C233 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C234 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C235 72795175 0CK102CK56A CERAMIC, 1000PF 1608 50V 0.1

C236 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C239 72795177

C240 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C242 72795152 0CH3334K946 CERAMIC, 0.33UF 50V 80%, -20%

C243 72795186 0CK334CF94A CERAMIC, 0.33UF 1608 16V 80%,

C245 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C246 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C248 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C250 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C251 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C252 72795175 0CK102CK56A CERAMIC, 1000PF 1608 50V 0.1

C253 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C254 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C255 #3 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C256 72795175 0CK102CK56A CERAMIC, 1000PF 1608 50V 0.1

C257 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C258 72795175 0CK102CK56A CERAMIC, 1000PF 1608 50V 0.1

C259 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C260 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C261 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C262 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C263 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C264 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C265 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C266 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C268 72795160 0CH6220K416 CERAMIC, 22PF 2012 50V 5% NP0

C270 72795180 0CK106EF56A

C271 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C272 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C273 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C275 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C276 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C300 #3 72795148 0CH8106F691 ELECTROLYTIC, 10UF 16V 20% 105STD

C302 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C303 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C305 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C306 #3 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C307 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C308 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C309 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C311 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C312 #3 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C313 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C315 #3 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C316 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C317 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C318 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C319 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C320 #3 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

Parts No. Reference Description

0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

CERAMIC, 10UF 3216 16V 10% X7

-

41

-

Page 18

Location

No.

C321 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C322 #3 72795156 0CH6152K406 CERAMIC CHIP, 1500PF 50V J SL 2012

C323 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C324 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C325 #3 72795165 0CC270DK41A CERAMIC, 27PF 2012 50V 5% NP0

C326 #3 72795158 0CH6820K416 CERAMIC, 82PF 2012 50V 5% C0G

C328 #3 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C329 #3 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C332 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C333 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C334 #3 72795187 0CK474CH94A CERAMIC, 0.47UF 1608 25V 80%,

C335 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C336 #3 72795167 0CC330CK41A CERAMIC, 33PF 1608 50V 5% R/T

C337 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C338 #3 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C340 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C341 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C342 #3 72795187 0CK474CH94A CERAMIC, 0.47UF 1608 25V 80%,

C343 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C344 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C346 #3 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C347 #3 72795176 0CK103CK51A CERAMIC, 0.01UF 1608 50V 10%

C348 #3 72795149 0CH8226F691 ELECTROLYTIC, 22UF 16V 20% 105STD

C349 #3 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C350 #3

C351 #3 72795149 0CH8226F691 ELECTROLYTIC, 22UF 16V 20% 105STD

C352 #3 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C353 #3 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C354 #3 72795168 0CC331CK41A CERAMIC, 330PF 1608 50V 5% R/

C355 #3 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C504 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C505 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C506 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C507 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C508 72795176 0CK103CK51A CERAMIC, 0.01UF 1608 50V 10%

C509 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C510 72795176 0CK103CK51A CERAMIC, 0.01UF 1608 50V 10%

C511 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C512 72795176 0CK103CK51A CERAMIC, 0.01UF 1608 50V 10%

C514 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C515 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C530 72795153 0CH6080K116 CERAMIC, 8PF 2012 50V 0.5 PF

C532 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C544 72795162 0CC080CK11A CERAMIC, 8PF 1608 50V 0.5 PF

C545 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C553 72795192 0CE107WH6DC ELECTROLYTIC, 100UF MVK 25V 20% R/

C554 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C555 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C712 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C713 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C714 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C715 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C716 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C717 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C718 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C719 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C720 #1,#2 72795150 0CH8476F691 ELECTROLYTIC, 47UF 16V 20% 105STD

C721 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C722 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C723 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C725 72795157 0CH6471K416 CERAMIC CHIP, 470F 50V J NP0 2012

C727 72795178 0CK105CF94A CERAMIC, 1UF 1608 16V 80%, -20

C729 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C731 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C733 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C750 72795196 0CE475WJ6DC ELECTROLYTIC, 4.7UF MVK 35V 20% R/

C758 72795199 0CH8106J691 ELECTROLYTIC, 10UF 35V 20% 105STD

C759 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C900 72795179 0CK105DK94A CERAMIC, 1UF 2012 50V 80%, -20

C905 72795182 0CK224CF56A CERAMIC, 0.22UF 1608 16V 10%

C906 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, -

Parts No. Reference Description

72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

#3 72795197 0CE476WF6DC ELECTROLYTIC, 47UF MVK 16V 20% R/T

-

42

-

Page 19

Location

No.

C907 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C908 72795182 0CK224CF56A CERAMIC, 0.22UF 1608 16V 10%

C909 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C910 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C911 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C912 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C914 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C915 72795182 0CK224CF56A CERAMIC, 0.22UF 1608 16V 10%

C916 72795192 0CE107WH6DC ELECTROLYTIC, 100UF MVK 25V 20% R/

C917 72795171 0CH3103K516 CERAMIC, 10000PF 50V 10% B(Y5

C918 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C919 72795179 0CK105DK94A CERAMIC, 1UF 2012 50V 80%, -20

C920 72795182 0CK224CF56A CERAMIC, 0.22UF 1608 16V 10%

C921 72795179 0CK105DK94A CERAMIC, 1UF 2012 50V 80%, -20

C922 72795164 0CC221CK41A CERAMIC, 220PF 1608 50V 5% R/

C923 72795179 0CK105DK94A CERAMIC, 1UF 2012 50V 80%, -20

C924 #1,#2 72795189 0CH3474H946 CERAMIC, 0.47UF 25V 80%, -20%

C925 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C927 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C929 #3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C930 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C931 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C933 72795197 0CE476WF6DC ELECTROLYTIC, 47UF MVK 16V 20% R/T

C934

C1001 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1002 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C1003 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1004 72795192 0CE107WH6DC ELECTROLYTIC, 100UF MVK 25V 20% R/

C1006 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C1008 72795197 0CE476WF6DC ELECTROLYTIC, 47UF MVK 16V 20% R/T

C1009 72795198 0CE477EJ618 ELECTROLYTIC, 470UF KMG 35V 20% FL

C1010 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C1011 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1013 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C1014 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C1015 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1016 72795192 0CE107WH6DC ELECTROLYTIC, 100UF MVK 25V 20% R/

C1017 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C1018 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C1019 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1021 72795189 0CH3474H946 CERAMIC, 0.47UF 25V 80%, -20%

C1022 72795176 0CK103CK51A CERAMIC, 0.01UF 1608 50V 10%

C1024 72795189 0CH3474H946 CERAMIC, 0.47UF 25V 80%, -20%

C1025 72795176 0CK103CK51A CERAMIC, 0.01UF 1608 50V 10%

C1027 72795181 0CK222CK51A CERAMIC, 2200PF 1608 50V 10%

C1030 72795184 0CK226FF67A CERAMIC, 22UF 3225 16V 20% X5

C1032 72795151 0CH3332K516 CERAMIC CHIP, 3300PF 50V K B 2012

C1034 72795184 0CK226FF67A CERAMIC, 22UF 3225 16V 20% X5

C1035 72795198 0CE477EJ618 ELECTROLYTIC, 470UF KMG 35V 20% FL

C1037 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C1038 72795146 0CE108EF618 ELECTROLYTIC, 1000UF KMG 16V 20% F

C1039 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C1040 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C1042 72795146 0CE108EF618 ELECTROLYTIC, 1000UF KMG 16V 20% F

C1043 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1044 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C1045 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C1046 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1050 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1051 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C1052 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1053 #3 72795192 0CE107WH6DC ELECTROLYTIC, 100UF MVK 25V 20% R/

C1054 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C1056 #3 72781846 0CE107BH618 ELECTROLYTIC, 100UF KME TYPE 25V 20% FL TP 5

C1057 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C1059 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

C1101 72795198 0CE477EJ618 ELECTROLYTIC, 470UF KMG 35V 20% FL

C1110 #3 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C1112 #3 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, C1118 #3 72795191 0CE107WF6DC ELECTROLYTIC, 100UF MVK 16V 20% R/

C1120 #3 72795183 0CK225DH94A CERAMIC, 2.2UF 2012 25V 80%, -

Parts No. Reference Description

#3 72795172 0CH3104K566 CERAMIC, 0.1UF 50V 10% X7R 20

72795192 0CE107WH6DC ELECTROLYTIC, 100UF MVK 25V 20% R/

-

43

-

Page 20

Location

No.

C1300 72795188 0CK475DD57A CERAMIC, 4.7UF 2012 10V 10% X

C1301 72795174 0CH6470K416 CERAMIC, 47PF 50V 5% NP0 2012

C1502 72795157 0CH6471K416 CERAMIC CHIP, 470F 50V J NP0 2012

C1505 72795161 0CH6331K416 CERAMIC CHIP, 330PF 50V J NP0 2012

C1515 72795145 0CE106BF618 ELECTROLYTIC, 10UF KME TYPE 16V 20% FL TP 5

C1700 72795180 0CK106EF56A CERAMIC, 10UF 3216 16V 10% X7

C2000 72795177 0CK104CK56A CERAMIC, 0.1UF 1608 50V 10% R

C2002 72795147 0CE226BH638 ELECTROLYTIC, 22U KME 25V M FM5 T

C2003 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C2004 72795147 0CE226BH638 ELECTROLYTIC, 22U KME 25V M FM5 T

C2005 72795155 0CH6102K406 CERAMIC CHIP, 1000PF 50V J SL 2012

C2009 72795200 0CE476BH638 ELECTROLYTIC, 47UF KME 25V M FM5 T

C2010 72795200 0CE476BH638 ELECTROLYTIC, 47UF KME 25V M FM5 T

C2011 72795159 0CH6151K416 CERAMIC, 150PF 2012 50V 5% NP

C3012 72795190 0CE107BF618 ELECTROLYTIC, 100UF KME TYPE 16V 2

Parts No. Reference Description

RESISTORS

R1 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R2 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R4 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R5 72795377 0RJ0682D677 METAL GLAZE, 68 OHM 1/10 W 5% 160

R6 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R7 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R8 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R10 72795372 0RH5602D622 METAL GLAZE, 56K OHM 1 / 10 W 201

R11 72795375 0RJ0222D677 METAL GLAZE, 22 OHM 1/10 W 5% 160

R12 72795378 0RJ0752D677 METAL GLAZE, 75 OHM 1/10 W 5% 160

R13 72795395 0RJ4703D677 METAL GLAZE, 470K OHM 1/10 W 5% 1

R14 72795347 0RH4703D622 METAL GLAZE, 470K OHM 1 / 10 W 20

R15 72795371 0RH2402D622 METAL GLAZE, 24K OHM 1 / 10 W 201

R20 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R21 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R22 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R23 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R24 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R26 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R27 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R28 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R33 72795347 0RH4703D622 METAL GLAZE, 470K OHM 1 / 10 W 20

R34 #3 72795347 0RH4703D622 METAL GLAZE, 470K OHM 1 / 10 W 20

R35 72795370 0RH1802D622 METAL GLAZE, 18K OHM 1 / 10 W 201

R37 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R38 72795341 0RH3301D622 METAL GLAZE, 3.3K OHM 1 / 10 W 20

R39 72795337 0RH2001D622 CHIP, 2.0K 1/10W 5 D.R/TP

R42 72795396 0RJ5101D677 METAL GLAZE, 5.1K OHM 1/10 W 5% 1

R43 72795348 0RH5101D622 METAL GLAZE, 5.1K OHM 1 / 10 W 20

R54 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R58 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R60 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R64 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R67 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R70 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R71 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R72 72795359

R73 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R74 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R75 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R76 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R77 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R78 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R100 72795401 0RH0562D622 CHIP, 56 1/10W 5 D.R/TP

R101 72795354 0RH8200D622 METAL GLAZE, 820 OHM 1 / 10 W 201

R102 72795368 0RH1501D622 METAL GLAZE, 1.5K OHM 1 / 10 W 20

R103 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R104 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R105 72795340 0RH3000D622 METAL GLAZE, 300 OHM 1 / 10 W 201

R106 72795335 0RH0682D622 METAL GLAZE, 68 OHM 1 / 10 W 2012

R109 72795352 0RH7501D622 METAL GLAZE, 7.5K OHM 1 / 10 W 20

R110 72795353 0RH7502D622 METAL GLAZE, 75K OHM 1 / 10 W 201

R111 72795395 0RJ4703D677 METAL GLAZE, 470K OHM 1/10 W 5% 1

R112 72795399 0RJ7501D677 METAL GLAZE, 7.5K OHM 1/10 W 5% 1

R113 72795392 0RJ3301D677 METAL GLAZE, 3.3K OHM 1/10 W 5% 1

0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

-

44

-

Page 21

Location

No.

R114 72795396 0RJ5101D677 METAL GLAZE, 5.1K OHM 1/10 W 5% 1

R115 72795374 0RJ0102D677 METAL GLAZE, 10 OHM 1/10 W 5% 160

R116 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R117 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R150 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R151 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R152 72795384 0RJ1002D677 METAL GLAZE, 10K OHM 1/10 W 5% 16

R153 #3 72795384 0RJ1002D677 METAL GLAZE, 10K OHM 1/10 W 5% 16

R154 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R156 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R159 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R163 72795382 0RJ1001D677 METAL GLAZE, 1K OHM 1/10 W 5% 160

R165 72795375 0RJ0222D677 METAL GLAZE, 22 OHM 1/10 W 5% 160

R167 72795368 0RH1501D622 METAL GLAZE, 1.5K OHM 1 / 10 W 20

R200 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R202 72795341 0RH3301D622 METAL GLAZE, 3.3K OHM 1 / 10 W 20

R203 72795341 0RH3301D622 METAL GLAZE, 3.3K OHM 1 / 10 W 20

R204 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R205 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R207 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R209 72795392 0RJ3301D677 METAL GLAZE, 3.3K OHM 1/10 W 5% 1

R210 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R211 72795403 0RH1201D622 METAL GLAZE, 1.2K OHM 1 / 10 W 20

R212 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R214 72795382 0RJ1001D677 METAL GLAZE, 1K OHM 1/10 W 5% 160

R215 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R217 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R218

R220 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R222 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R225 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R227 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R229 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R230 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R233 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R234 72795344 0RH4700D622 METAL GLAZE, 470 OHM 1 / 10 W 201

R235 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R236 72795336 0RH1500D622 METAL GLAZE, 150 OHM 1 / 10 W 201

R237 72795390 0RJ2202D677 METAL GLAZE, 22K OHM 1/10 W 5% 16

R238 72795386 0RJ1500D677 METAL GLAZE, 150 OHM 1/10 W 5% 16

R239 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R240 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R241 72795344 0RH4700D622 METAL GLAZE, 470 OHM 1 / 10 W 201

R242 72795336 0RH1500D622 METAL GLAZE, 150 OHM 1 / 10 W 201

R244 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R257 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R260 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R266 72795375 0RJ0222D677 METAL GLAZE, 22 OHM 1/10 W 5% 160

R270 72795375 0RJ0222D677 METAL GLAZE, 22 OHM 1/10 W 5% 160

R301 #3 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R302 #3 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R305 #3 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R307 #3 72795344 0RH4700D622 METAL GLAZE, 470 OHM 1 / 10 W 201

R309 #3 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R311 #3 72795344 0RH4700D622 METAL GLAZE, 470 OHM 1 / 10 W 201

R312 #3 72795352 0RH7501D622 METAL GLAZE, 7.5K OHM 1 / 10 W 20

R313 #3 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R314 #3 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R315 #3 72795399 0RJ7501D677 METAL GLAZE, 7.5K OHM 1/10 W 5% 1

R316 #3 72795384 0RJ1002D677 METAL GLAZE, 10K OHM 1/10 W 5% 16

R317 #3 72795352 0RH7501D622 METAL GLAZE, 7.5K OHM 1 / 10 W 20

R318 #3 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R319 #3 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R320 #3 72795379 0RJ0822D677 METAL GLAZE, 82 OHM 1/10 W 5% 160

R322 #3 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R323 #3 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R324 #3 72795343 0RH3602D622 METAL GLAZE, 36K OHM 1 / 10 W 201

R325 #3 72795393 0RJ3900D677 METAL GLAZE, 390 OHM 1/10 W 5% 16

R326 #3 72795366 0RH1004D622 METAL GLAZE, 1M OHM 1 / 10 W 2012

R327 #3 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R328 #3 72795365 0RH1003D622 METAL GLAZE, 100K OHM 1 / 10 W 20

R329 #3 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

Parts No. Reference Description

72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

-

45

-

Page 22

Location

No.

R330 #3 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R331 #3 72795352 0RH7501D622 METAL GLAZE, 7.5K OHM 1 / 10 W 20

R332 #3 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R333 #3 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R334 #3 72795382 0RJ1001D677 METAL GLAZE, 1K OHM 1/10 W 5% 160

R335 #3 72795379 0RJ0822D677 METAL GLAZE, 82 OHM 1/10 W 5% 160

R336 #3 72795170 0CC471CK41A CERAMIC, 470PF 1608 50V 5% R/

R337 #3 72795378 0RJ0752D677 METAL GLAZE, 75 OHM 1/10 W 5% 160

R500 72795349 0RH5600D622 METAL GLAZE, 560 OHM 1 / 10 W 201

R502 72795402 0RH0822D622 METAL GLAZE, 82 OHM 1 / 10 W 2012

R503 72795376 0RJ0472D677 METAL GLAZE, 47 OHM 1/10 W 5% 160

R504 72795402 0RH0822D622 METAL GLAZE, 82 OHM 1 / 10 W 2012

R505 72795376 0RJ0472D677 METAL GLAZE, 47 OHM 1/10 W 5% 160

R506 72795402 0RH0822D622 METAL GLAZE, 82 OHM 1 / 10 W 2012

R507 72795376 0RJ0472D677 METAL GLAZE, 47 OHM 1/10 W 5% 160

R508 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R509 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R514 72795342 0RH3600D622 METAL GLAZE, CHIP 360-J 1/10 W

R515 72795354 0RH8200D622 METAL GLAZE, 820 OHM 1 / 10 W 201

R516 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R519 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R520 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R521 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R523 72795341 0RH3301D622 METAL GLAZE, 3.3K OHM 1 / 10 W 20

R525 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R529 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R531 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R532 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R533 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R534 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R535 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R536 #3 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R537 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R539 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R540 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R544 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R546 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R548 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R557 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R559 72795375 0RJ0222D677 METAL GLAZE, 22 OHM 1/10 W 5% 160

R595 72795384 0RJ1002D677 METAL GLAZE, 10K OHM 1/10 W 5% 16

R704 72795347 0RH4703D622 METAL GLAZE, 470K OHM 1 / 10 W 20

R705 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R713 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R715 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R721 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R723 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R725 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R728 72795350 0RH6202D622 METAL GLAZE, 62K OHM 1 / 10 W 201

R730 72795388 0RJ2001D677 METAL GLAZE, 2K OHM 1/10 W 5% 160

R732 72795396 0RJ5101D677 METAL GLAZE, 5.1K OHM 1/10 W 5% 1

R750 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R751 72795346 0RH4702D622 METAL GLAZE, 47K OHM 1 / 10 W 201

R752 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R758 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R762 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R764 72795387 0RJ1501D677 METAL GLAZE, 1.5K OHM 1/10 W 5% 1

R903 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R904 72795469 0RJ1203D677 METAL GLAZE, 120K OHM 1/10 W 5% 1

R905 #1,#2 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R906 #1,#2 72795469 0RJ1203D677 METAL GLAZE, 120K OHM 1/10 W 5% 1

R907 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R908 72795469 0RJ1203D677 METAL GLAZE, 120K OHM 1/10 W 5% 1

R910 72795365 0RH1003D622 METAL GLAZE, 100K OHM 1 / 10 W 20

R912 72795394 0RJ4701D677 METAL GLAZE, 4.7K OHM 1/10 W 5% 1

R913 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R914 72795386 0RJ1500D677 METAL GLAZE, 150 OHM 1/10 W 5% 16

R915 72795394 0RJ4701D677 METAL GLAZE, 4.7K OHM 1/10 W 5% 1

R916 72795373 0RJ0000D677 METAL GLAZE, 0 OHM 1/10 W 5% 1608

R917 72795394 0RJ4701D677 METAL GLAZE, 4.7K OHM 1/10 W 5% 1

R919 72795346 0RH4702D622 METAL GLAZE, 47K OHM 1 / 10 W 201

R920 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

Parts No. Reference Description

-

46

-

Page 23

Location

No.

R922 72795365 0RH1003D622 METAL GLAZE, 100K OHM 1 / 10 W 20

R1000 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R1001 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R1002 #3 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R1003 72795384 0RJ1002D677 METAL GLAZE, 10K OHM 1/10 W 5% 16

R1004 72795382 0RJ1001D677 METAL GLAZE, 1K OHM 1/10 W 5% 160

R1005 #1,#2 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R1006 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R1007 72795365 0RH1003D622 METAL GLAZE, 100K OHM 1 / 10 W 20

R1009 72795398 0RJ6801D477 METAL GLAZE, 6.8K OHM 1/10 W 1% 1

R1010 72795399 0RJ7501D677 METAL GLAZE, 7.5K OHM 1/10 W 5% 1

R1011 72795389 0RJ2202D477 METAL GLAZE, 22K OHM 1/10 W 1% 16

R1012 72795397 0RJ5601D477 METAL GLAZE, 5.6K OHM 1/10 W 1% 1

R1013 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R1014 72795400 0RJ9311D477 METAL GLAZE, 9.31K OHM 1/10 W 1%

R1017 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R1018 72795385 0RJ1211D477 METAL GLAZE, 1.21K OHM 1/10 W 1%

R1019 72795369 0RH1502D622 METAL GLAZE, 15K OHM 1 / 10 W 201

R1020 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R1021 72795365 0RH1003D622 METAL GLAZE, 100K OHM 1 / 10 W 20

R1022 72795383 0RJ1002D477 METAL GLAZE, 10K OHM 1/10 W 1% 16

R1024 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R1201 72795358 0RD6200Q609 CARBON FILM, 620 1/4W(3 5% TA52

R1202 72795356 0RD2401Q609 CARBON FILM, 2.40K 1/4W(3 5% TA52

R1204 72795355 0RD1801Q609 CARBON FILM, 1.80K 1/4W(3 5% TA52

R1205 72795357 0RD3301Q509 CARBON FILM, 3.3K OHM 1/4 W (3.4)

R1207

R1208 72795356 0RD2401Q609 CARBON FILM, 2.40K 1/4W(3 5% TA52

R1209 72795358 0RD6200Q609 CARBON FILM, 620 1/4W(3 5% TA52

R1300 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R1303 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R1304 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R1305 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R1306 72795345 0RH4701D622 METAL GLAZE, 4.7K OHM 1 / 10 W 20

R1309 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R1502 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R1505 72795347 0RH4703D622 METAL GLAZE, 470K OHM 1 / 10 W 20

R1507 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R1508 72795370 0RH1802D622 METAL GLAZE, 18K OHM 1 / 10 W 201

R1510 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R1523 #3 72795359 0RH0000D622 METAL GLAZE, 0 OHM 1 / 10 W 2012

R1700 72795381 0RJ1000H680 METAL GLAZE, 100 OHM 1/2 W 5% 502

R2000 72795380 0RJ1000D677 METAL GLAZE, 100 OHM 1/10 W 5% 16

R2002 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R2004 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R2005 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R2006 72795384 0RJ1002D677 METAL GLAZE, 10K OHM 1/10 W 5% 16

R2007 72795360 0RH0222D622 METAL GLAZE, 22 OHM 1 / 10 W 2012

R2008 72795361 0RH0752D622 METAL GLAZE, 75 OHM 1 / 10 W 2012

R2009 72795362 0RH1000D622 METAL GLAZE, 100 OHM 1 / 10 W 201

R2010 72795337 0RH2001D622 CHIP, 2.0K 1/10W 5 D.R/TP

R2011 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R2012

R2013 72795363 0RH1001D622 METAL GLAZE, 1K OHM 1 / 10 W 2012

R2014 72795339 0RH2700D622 METAL GLAZE, 270 OHM 1 / 10 W 201

R2016 72795334 0RH0472D622 METAL GLAZE, 47 OHM 1 / 10 W 2012

R2017 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R2020 72795402 0RH0822D622 METAL GLAZE, 82 OHM 1 / 10 W 2012

R2021 72795364 0RH1002D622 METAL GLAZE, 10K OHM 1 / 10 W 201

R2022 72795339 0RH2700D622 METAL GLAZE, 270 OHM 1 / 10 W 201

R2023 72795402 0RH0822D622 METAL GLAZE, 82 OHM 1 / 10 W 2012

R2024 72795338 0RH2200D622 METAL GLAZE, 220 OHM 1 / 10 W 201

Parts No. Reference Description

72795355 0RD1801Q609 CARBON FILM, 1.80K 1/4W(3 5% TA52

72795351 0RH6801D622 METAL GLAZE, 6.8K OHM 1 / 10 W 20

COIL & TRANSFORMERS

L1 72795273 0LC0233002A INDUCTOR, CHIP, 3.3UH CERATECH R/TP

L3 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L4 #3 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L51 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L54 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L59 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L61 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L62 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

-

47

-

Page 24

Location

No.

L100 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L101 72795272 0LA1000K139 INDUCTOR, AXIAL, LEAD, 100UH 10% A 4.0 X 10.5 TA52 L102 72795274 0LC1020101A INDUCTOR, CHIP, 1UH 10% 2012 R/TC FI

L103 72795279 0LCTO00018A INDUCTOR, CHIP, 888FU-101M TOKO R/TP

L104 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L200 72795275 0LC1032101A INDUCTOR, CHIP, 10UH 10% 3216 R/TC F

L201 72795275 0LC1032101A INDUCTOR, CHIP, 10UH 10% 3216 R/TC F

L213 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L300 #3 72795275 0LC1032101A INDUCTOR, CHIP, 10UH 10% 3216 R/TC F

L307 #3 72795273 0LC0233002A INDUCTOR, CHIP, 3.3UH CERATECH R/TP

L308 #3 72795275 0LC1032101A INDUCTOR, CHIP, 10UH 10% 3216 R/TC F

L500 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L701 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L902 72795201 6140VR0005B COIL, ENERGY RECOVERY, SLF7045T-330MR82 TDK

L1008 72795202 6140VR0008B COIL, ENERGY RECOVERY, SLF12575T-150M3R2 1

L1010 #3 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L1012 #1,#2 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L1102 #3 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L1103 #3 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L1109 #3 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L1111 #1,#2 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L1503 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L1505 72795276 0LC2000005D INDUCTOR, CHIP, F1-B2012-332KJT, 3.3

L1701 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L2000 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L2001 72795246 6210TCE001A FERRITECORE, BEAD, HB-1S2012-080JT CERA

L2002 72795215 6210TCE001G FILTER, EMI, HH-1M3216-501 CERATE

L2003 72795277 0LC2000005F INDUCTOR, CHIP, F1-C2012-562KJT, 5.6U

Parts No. Reference Description

SEMICONDUCTORS

Q50 #1,#2 72795446 0TR387500AA TRANSISTOR, CHIP 2SC3875S(ALY) B

Q100 72795447 0TR388109AA TRANSISTOR, KTC3881 CHIP TP KEC

Q201 72795445 0TR150400BA TRANSISTOR, CHIP 2SA1504S(ASY) B

Q202 72795446 0TR387500AA TRANSISTOR, CHIP 2SC3875S(ALY) B

Q203 72795445 0TR150400BA TRANSISTOR, CHIP 2SA1504S(ASY) B

Q300 #3 72795446 0TR387500AA TRANSISTOR, CHIP 2SC3875S(ALY) B

Q902 72795445 0TR150400BA TRANSISTOR, CHIP 2SA1504S(ASY) B

Q903 72795446 0TR387500AA TRANSISTOR, CHIP 2SC3875S(ALY) B

Q905 72795448 0TFIR80017B TRANSISTOR, FET, IRLML5203TRPBF, LF IN

Q1000 72795446 0TR387500AA TRANSISTOR, CHIP 2SC3875S(ALY) B

Q2001 72795445 0TR150400BA TRANSISTOR, CHIP 2SA1504S(ASY) B

Q2002 72795446 0TR387500AA TRANSISTOR, CHIP 2SC3875S(ALY) B

D101 72795241 0DSRM00148A DIODE, 1SS355 ROHM R/TP SOD

D301 #3 72795242 0DVTB00048A DIODE, VARICAP1SV324E, LF TOSHIBA R

D1000 72795238 0DR340009AA DIODE, MBRS340 TP FAIRCHILD

D1200 72795240 0DSGF00019A DIODE, 1N4148 GULF TP DO35

LED1301 72795283 0DLBE0138AA DIODE, LED, BRIGHT DIODE, LED, ELECTRONI

ZD1 72795243 0DZ510009EE DIODE, ZENER, UDZ S 5.1B TP ROHM-K

ZD21 72795243 0DZ510009EE DIODE, ZENER, UDZ S 5.1B TP ROHM-K

ZD2004 72795244 0DZ620009HB DIODE, ZENER, UDZ S 6.2B TP ROHM S

IC20 72795256 0IMMRSG036A IC, M24C02-WMN6T(P), LF S

IC100 72795271 0ITK118100B IC, TK11840L 8P SOT23L R

IC200 #1 72795250 0IZZTSA079B IC, ML-05TA TOSHIBA VCTI

IC201 72795255 0IMCRAL006A IC, AT24C16AN-10SU-2.7, L

IC202 72795253 0IKE702700D IC, KIA7027AF 3, SOT-89

IC203 72795260 0IMI623200B IC, M62320FP, I/O EXPANDE

IC300 #3 72795264 0IPRPTO022A IC, TC90A65FG, LF TOSHIBA

IC500 72795262 0IPRPGN015C IC, GM2221-BC-LF, PB FREE

IC501 72795255 0IMCRAL006A IC, AT24C16AN-10SU-2.7, L

IC550 72795252 0IZZTSA080B

IC600 72795261 0IPRP00522A IC, TPA3008D2PHPRG4, LF T

IC701 72795269 0IRH765700B IC, BA7657F 24P, SOP TP I

IC702 72795254 0ISA722200A IC, LA7222 (1280 AUDIO) - - - IC1000 72795259 0IMCRNS007E IC, LMS1587CS-3.3 NATION

IC1001 72795265 0IMCRKE010A IC, KIA7812AF KEC 2P DPA

IC1002 72795266 0IPMGKE044A IC, KIA7808AF KEC 2P DPA

IC1003 72795268 0IPMGSG018D IC, LD1086DT18TR-LF SGSIC1004 72795257 0IMCRMZ001A IC, MP1583DN-Z, LF MONOLI

IC1006 72795245 0TF492509AA TRANSISTOR, FET, SI4925DY TP TEMIC 30

IC1007 72795268 0IPMGSG018D IC, LD1086DT18TR-LF SGSIC1012 #3 72795258 0IMCRNS007B IC, LM2941S NATIONAL SEM

#2,#3 72796164 0IPRPMN003H IC, VCT49X3F-F2-100, LF M

IC, ML-05TA TOSHIBA SCAL

-

48

-

Page 25

Location

No.

IC1102 #3 72795267 0IPMGNS001D IC, LM1117MPX-2.5, NOPB N

IC2000 72795270 0ISTL00026A IC, MC14066BDR2G, LF ON S

Parts No. Reference Description

MISCELLANEOUS

P1100 72795205 6631T20028G CONNECTOR ASSEMBLY, 11P-12P H-B 100MM UL

P1200 72795206 6631T20028Z CONNECTOR ASSEMBLY, 4P-5P H-B 220MM UL10

P2000 72781918 6620K00007E SOCKET, POWER, I-SHENG AC UL/CSA 2P

PA1300 72795333 6726TV0001A REMOCON RECEIVER, TSOP4838SO1 VISHAY 3

SW1200 72795435 140-313B SWITCH, TACT, TACT 2LEAD 160G(TA) LG C&D NON 5V 0.001A HORIZON

X200 72795406 6202VDT002E CRYSTAL, SX-1SMD SUNNY RADIAL

X300 #3 72795404 156-A01B CRYSTAL, HC49U SUNNY RADIAL 3

X500 72795405 6202VDT002B CRYSTAL, SX-1 SUNNY SC14.3MHZ

Y151 72796185 6410TUW009A POWER CORD, LP-11W LS-7CWA LONGW

Z100 72795248 6200QL3002F SAW FILTER, X6966M EPCOS ST SIP5

PC BOARD ASSEMBLIES

070 #1,#2 72795330 6871TSTB53B PC BOARD ASSY, SUB, TOSHIBA 15 INCH(NT-C

*

*

080 #1,#2 72795313 6871TPT281G PC BOARD ASSY, POWER, 15DL75(TSB) POWER TO

*

*

090 #1,#2 72781877 3313TN1039B MAIN TOTAL ASSEMBLY, TOSHIBA 15 USA (NT-C

*

*

100 #1,#2 72795327 6871TSTB52C PC BOARD ASSY, SUB, TOSHIBA 15(NT-CKD)SI

*

*

130 72795324 6871TSTB50A PC BOARD ASSY, SUB, TOSHIBA 20-15 (NT-CK

*

140 #1,#2 72781902 6871TSTB51J PC BOARD ASSY, SUB, TOSHIBA 15 USA (NT-C

*

*

170 72781907 6871TSTB49D PC BOARD ASSY, SUB, TOSHIBA 20-I5 USA C

*

#3 72795329 6871TSTB53A PC BOARD ASSY, SUB, TOSHIBA 20 INCH(NT-C

#3 72795312 6871TPT280Q PC BOARD ASSY, POWER, 20LS30(TOSHIBA) POWE

#3 72795287 3313TN2045A MAIN TOTAL ASSEMBLY, T20LS30 (NT-CKD) MAI

#3 72781906 6871TSTB52E PC BOARD ASSY, SUB, TOSHIBA 20 (NT-CKD)S

#3 72781905 6871TSTB51C PC BOARD ASSY, SUB, TOSHIBA 20-15 USA (N

TUNER

TU100 72795449 6700VS0003D TUNER, TAEW-G052P LGIT MULT

ACCESSORIES

A701 #1 72796117 3890TKD002R CORTON BOX, 17LZ50 BRAND SKD PCB

A702 #1 72781894 3920TKP022C PACKING, RZ-17LZ20 PULP SKD P

K902 72781910 6710T00018A REM OCON HAND UNIT, 15/20DL75 USA TOSHIB

Y101 #1 72782033 3828TUO242D OWNERS MANUAL, T15DL15-MA T15DL15 U

#2 72781832 3890TSEA33C CORTON BOX, T15DL75-MA TOSHIBA S

#3 72781833 3890TSEA18B CORTON BOX, T20DL75-MA TOSHIBA 2

#2 72795303 3920TKE369A PACKING, TOSHIBA 15V EPS TOP/

#3 72795304 3920TKE370A PACKING, TOSHIBA 20V EPS TOP/

#2,#3 72781880 3828TUO242B MANUALT15/20DL75-MA 15/20D

CABINET PARTS

010 #1,#2 72781837 3091TKB053E CABINET ASSEMBLY, 15V TOSHIBA 3090TKB0

020 #1,#2 72795282 6304FLP234A LCD, LC150X02-TL01 LG PHI

030 #1,#2 72781823 3809TKB034E BACK COVER ASSEMBLY, TOSHIBA 15V 3808TKB0

040 #1 72795441 3043TKK247C TILT SWIVEL ASSEMBLY, TOSHIBA 15V (RM, RT, R

050 #1,#2 72795220 3550TKK863B COVER, TOSHIBA 15V REAR COV

110 #1,#2 72781859 3551TAK001E COVER ASSEMBLY, TOSHIBA REAR 3550TKK

150 #1 72795434 6401TZZ064B SPEAKER ASSEMBLYML-05TA TOSHIBA 15 L

160 #1,#2 72795222 3550TKK864A COVER, TOSHIBA 15V SIDE AV

#3 72781839 3091TKL164J CABINET ASSEMBLY, T20DL75 TOSHIBA 3090

#3 72795280 6304FLP188A LCD, LC201V02-A3KA LG PHI

#3 72781825 3809TKL114F BACK COVER ASSEMBLY, TOSHIBA 3808TKL118A

#3 72781923 3043TKK244J TILT SWIVEL ASSEMBLY, TOSHIBA 20V , (C/SKD

#3 72795216 3550TKK856B COVER, TOSHIBA REAR DOOR(C/

#3 72781864 3551TKK588J COVER ASSEMBLY, TOSHIBA 20V REAR 355

#2 72781919 6400GTTS01A SPEAKER, N1527C-6603-1 TOPTON

#3 72796232 6400GKTX01B SPEAKER, F1527C-6428-2 K-TONE

#3 72795224 3550TKK924B COVER, TOSHIBA 20 PIECE EAR

-

49

-

Page 26

* The information contained in this section subjects to model.

MAIN BOARD BOTTOM (FOIL) SIDE

-

50

-

7. PC BOARDS TOP & BOTTOM VIEW

Page 27

MAIN BOARD

TOP (COMPONENT) SIDE

-

51

-

Page 28

JACK

TOP (COMPONENT) SIDE

CONTROL BOARD

TOP (COMPONENT) SIDE

TOP (COMPONENT) SIDE

SIDE BOARD (20DL75)

-

52

-

BOTTOM (FOIL) SIDE

CONTROL BOARD

JACK

BOTTOM (FOIL) SIDE

BOTTOM (FOIL) SIDE

SIDE BOARD (20DL75)

Page 29

TOP (COMPONENT) SIDE

SIDE BOARD (15DL75)

IR BOARD

TOP (COMPONENT) SIDE

BOTTOM (FOIL) SIDE

TOP (COMPONENT) SIDE

HEADPHONE BOARD (15DL75)

TOP (COMPONENT) SIDE

HEADPHONE BOARD (20DL75)

HEADPHONE BOARD (15DL75)

-

53

-

BOTTOM (FOIL) SIDE

SIDE BOARD (15DL75)

IR BOARD

BOTTOM (FOIL) SIDE

BOTTOM (FOIL) SIDE

HEADPHONE BOARD (20DL75)

Page 30

8. SCHEMATIC DIAGRAM

MODEL : 15DL15 / 15DL75 / 20DL75

WARNING : BEFORE SERVICING THIS CHASSIS, READ THE "SERVICE SAFETY PRECAUTIONS" ON PAGE 3 OF

THIS MANUAL.

CAUTION : The international hazard symbols " " in the schematic diagram and the parts list designate components which

have special characteristics important for safety and should be replaced only with types identical to those in the original

circuit or specified in the parts list. The mounting position of replacements is to be identical with originals. Before replacing

any of these components, read carefully the SERVICE SAFETY PRECAUTIONS on the MANUAL for this model. Do not

degrade the safety of the receiver through improper servicing.

NOTE:

1. RESISTOR Resistance is shown in ohm [K = 1.000, M = 1.000.000]. All resistors are 1/6W and 5%

tolerance carbon resistor, unless otherwise noted as the following marks.

1/2R = Metal or Metal oxide of 1/2 watt 1/2S = Carbon compsistion of 1/2 watt

1RF = Fuse resistor of 1 watt 10W = Cement of 10 watt

K = ±10% G = ±2% F = ± 1%

2. CAPACITOR Unless otherwise noted in schematic, all capacitor values less than 1 are expressed in

?F, and the values more than 1 in pF.

All capacitors are ceramic 50V, unless otherwise noted as the following marks.

Electolytic capacitor Mylar capacitor

3. The parts indicated with " * " have special characteristics, and should be replaced with identical parts only.

4. Voltages read with DIGITAL MULTI-METER from point indicated to chassing ground, using a color bar signal with all

controls at normal, line voltage 220 volts.

5. Waveforms are taken receiving color bar signal with enough sensitivity.

6. Voltage reading shown are nominal values and may vary ±20% except H.V.

* The information contained in this section subjects to model.

SCHEMATIC DIAGRAM STRUCTURE:

SCALER .............................................................................................................................................................. 1/17

3D COMB ............................................................................................................................................................ 2/17

POWER............................................................................................................................................................... 3/17

AMP .................................................................................................................................................................... 4/17

INPUT ................................................................................................................................................................. 5/17

S/W & ROM......................................................................................................................................................... 6/17

INTERFACE ........................................................................................................................................................ 7/17

TUNER ................................................................................................................................................................ 8/17

VCTI .................................................................................................................................................................... 9/17

D-JACK ............................................................................................................................................................. 10/17

COMPONENT JACK ......................................................................................................................................... 11/17

EARPHONE ...................................................................................................................................................... 12/17

KEY ................................................................................................................................................................... 13/17

SCART JACK .................................................................................................................................................... 14/17

LED & IR ........................................................................................................................................................... 15/17

SIDE AV (20DL75) ............................................................................................................................................ 16/17

SIDE AV (15DL15/15DL75) .............................................................................................................................. 17/17

-

54

-

Page 31

8-1. WIRING DIAGRAM

5

4

CONTROL BOARD

2

MAIN BOARD

1

6

3

7

10

10

9

AC POWER BOARD

INVERTER BOARD

8

-

55

-

Page 32

8-2. BLOCK DIAGRAM (20DL75)

V

A

_

E

D

I

S

Y / C

V

e

P

E

S

A

Ear

L

R

From AMP

phon

PC AUDIO

KER

PC

J2 1

PC AUDIO

VIDEO 2 L,R

TTL OUT

IC550

IC550

(FLASH)

AT49F002F

AT49F 002 F

IC600

IC600

TPA3008D2

(Audio Amp)

TPA3008 D 2

(Audio Amp)

(FLASH)

IC500

IC500

GM2221

(SCALER)

GM2221

(SCALER)

PC RGB

To Ear Phone

BA7657F

IC701

Component(Y,Pb, Pr)

POWER

VIDEO2_V, Y/C

656 F ORMAT

VCT49xy F

VCT49xy F

CVBS

IC200

IC200

TC90A65 F

TC90A65 F

IF DECO DER

IF DECO DER

IC300

IC300

(3D CO MB FILTER)

Y / C

`

`

VIDEO DEC ODER

VIDEO DEC ODER

SOUND PROCESSOR

(USA Only)

(U SA Only)

(3D CO MB FILTER)

MICO M

MICO M

SOUND PROCESSOR

,-

IF+

S

A

S

W

A

W

IC702

LA722 2

IC201

IC201

AT24C16

AT24C16

(EEPROM)

(EEPROM)

Tuner

TU100

Tuner

TU10014066

Z100

14066

PC RGB

PC AUDIO

VIDEO 1 _L,R

IC2000

IC2000

VIDEO 1 _V

r

P

J2 0

J2 0

D-S U B

D-S U B

FOR SEVIC E(ISP)

VIDEO 1 _V

1. 15V

2. 15V

3. GND

4. GND

5. 5V

6. 5V

7. GND

8. 33V

9. CTL

10. EXT

11. B R

b

Compone nt(Y,Pb,Pr)

AUDIO_OUT

POWER B/ D

-

56

-

YP

AC IN

COMPONENT

AUDIO_OUT

Page 33

8-3. BLOCK DIAGRAM (15DL15,15DL75)

V

A

_

E

D

I

S

Y / C

L

V

R

LVDS

IC500

IC500

GM2221

(SCALER)

GM2221

(SCALER)

IC550

IC550

AT49F 002 N

TPA3008D 2

TPA3008 D 2

AT49F002 N

IC600

IC600

(FLASH)

(FLASH)

(Audio Amp)

(Audio Amp)

To Ear Phone

IC701

BA7657F

PC RGB

Component(Y,Pb, Pr)

POWER

VIDEO 2 L,R

VIDEO2_V, Y/C

656 F ORMAT

VCT49xyF

VCT49xy F

CVBS

IC200

IC200

IF DECO DER

IF DECO DER

TC90A65 F

TC90A65F

`

`

VIDEO DEC ODER

From AMP

MB FILTER)

IC300

IC300

(3D CO MB FILTER)

(3D CO

Y / C

VIDEO DEC ODER

SOUND PROCESSOR

SOUND PROCESSOR

MICO M

MICO M

Ear

e

phon

S

AT24C16

AT24C16

,-

IF+

A

S

A

IC702

LA7222

IC201

IC201

(EEPROM)

W

(EEPROM)

W

PC AUDIO

Tuner

TU100

Tuner

TU10014066

Z100

14066

PC RGB

PC AUDIO

VIDEO 1 _L,R

P

S

IC2000

IC2000

E

A

KER

PC

J2 1

PC AUDIO

J2 0

J2 0

D-S U B

D-S U B

FOR SEVIC E(IS P)

VIDEO 1 _V

VIDEO 1 _V

1. 15V

2. 15V

3. GND

4. GND

5. 5V

6. 5V

7. GND

8. 33V

9. CTL

10. EXT

11. B R

r

P

b

Compone nt(Y,Pb,Pr)

AUDIO_OUT

POWER B/ D

-

57

-

YP

AC IN

COMPONENT

AUDIO_OUT

Page 34

1. Video Controller Unit & Display Data Conversion Unit

The video controller unit receives the video signals inputted through the tuner, AV port (VIDEO1, VIDEO2), and

converts them into an ITU656 signal through the microcomputer (VCTI) combined with the video decoder that

integrates various functions in one chip.

Either component YPbPr signal or PC RGB signal is selected by the switching IC and inputted to a scaler

(GM2221), which is sent to the LCD module after being modified to an LVDS signal through the integrated LVDS

IC.( only 15 inch Module)

Or, it is sent to the LCD module as a TTL output. (only 20 inch Module)

VCTi is the main microprocessor that handles video signal processing and sound signal processing. It also

manages the RF signals received from the tuner.

The scaler can control timing to fit into the LCD panel, and can also control the size and position of the input

signal.

2. Power Supply Unit

The power supply unit provides 15V and 5V DC power to the mainboard.

The PWM Step- Up DC/ DC Converter circuit is used to generate the 33V used for the tuner.

15V power is directly used by the sound amplifier IC and is also used to generate 5V and 3.3V power through the

Step- Down DC/ DC Converter. 5V power is converted to 3.3V and 1.8V power through the regulator, which in

turn supplies electrical power for ICs such as VCTI and scaler.

* The information contained in this section subjects to model.

-

58

-

Page 35

* The information contained in this section subjects to model.

(1/17)

15DL15,15DL75,20DL75

SCALER

-

59

-

Page 36

(2/17)

15DL15,15DL75,20DL75

3D COMB

-

60

-

Page 37

(3/17)

15DL15,15DL75,20DL75

POWER

-

61

-

Page 38

(4/17)

15DL15,15DL75,20DL75

AMP

-

62

-

Page 39

(5/17)

15DL15,15DL75,20DL75

INPUT

-

63

-

Page 40

(6/17)

15DL15,15DL75,20DL75

S/W & ROM

-

64

-

Page 41

(7/17)

15DL15,15DL75,20DL75

INTERFACE

-

65

-

Page 42

(8/17)

15DL15,15DL75,20DL75

TUNER

-

66

-

Page 43

(9/17)

15DL15,15DL75,20DL75

VCTI

-

67

-

Page 44

(10/17)

15DL15,15DL75,20DL75

D-JACK

-

68

-

Page 45

(11/17)

15DL15,15DL75,20DL75

COMPONENT JACK

-

69

-

Page 46

(12/17)

15DL15,15DL75,20DL75

HEADPHONE

-

70

-

Page 47

(13/17)

15DL15,15DL75,20DL75

CONTROL

-

71

-

Page 48

(14/17)

15DL15,15DL75,20DL75

SCART_JACK

-

72

-

Page 49

(15/17)

15DL15,15DL75,20DL75

LED & IR

-

73

-

Page 50

20DL75

SIDE AV

(16/17)

-

74

-

Page 51

(17/17)

15DL15,15DL75

SIDE AV

-

75

-

Page 52

Loading...

Loading...