TOSHIBA 1550 Service Manual

SERVICE MANUAL

SORTER

Click the Page Only button to close the overview area of the window.

Click the Bookmarks and Page button to open the Contents and

display bookmarks created for the document. Click a bookmark’s name

to go to the Page marked by that bookmark.

MG-1003

Click the Thumbnails and Page button to open the overview area and

display thumbnail images of each document page. Click a thumbnail to

go to the page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

General Precautions for Installation/Servicing/Maintenance

1. When installing the Sorter MG-1003 to the Plain Paper Copier, be sure to follow the instructions

described in the “Unpacking/Set-Up Procedure for the MG-1003” booklet which comes with each

unit of the MG-1003.

2. The MG-1003 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to unplug the copier first.

4. The MG-1003 is supplied with power from the copier.

5. Use suitable measuring instruments and tools.

6. When servicing or maintaining the MG-1003, be careful about the rotating or operating sections

such as gears, pulleys, sprockets, cams belts, etc.

7. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related materials. Be careful not to assemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Delicate parts for preventing safety hazard problems (such as thermofuses, door switches, sensors,

etc. if any) should be handled/installed /adjusted correctly.

10. During servicing or maintenance work, be sure to check the serial No. plate and other cautionary

labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

11. For the recovery and disposal of used MG-1003s, consumable parts and packing materials, it is

recommended that the relevant regulations/rules should be followed.

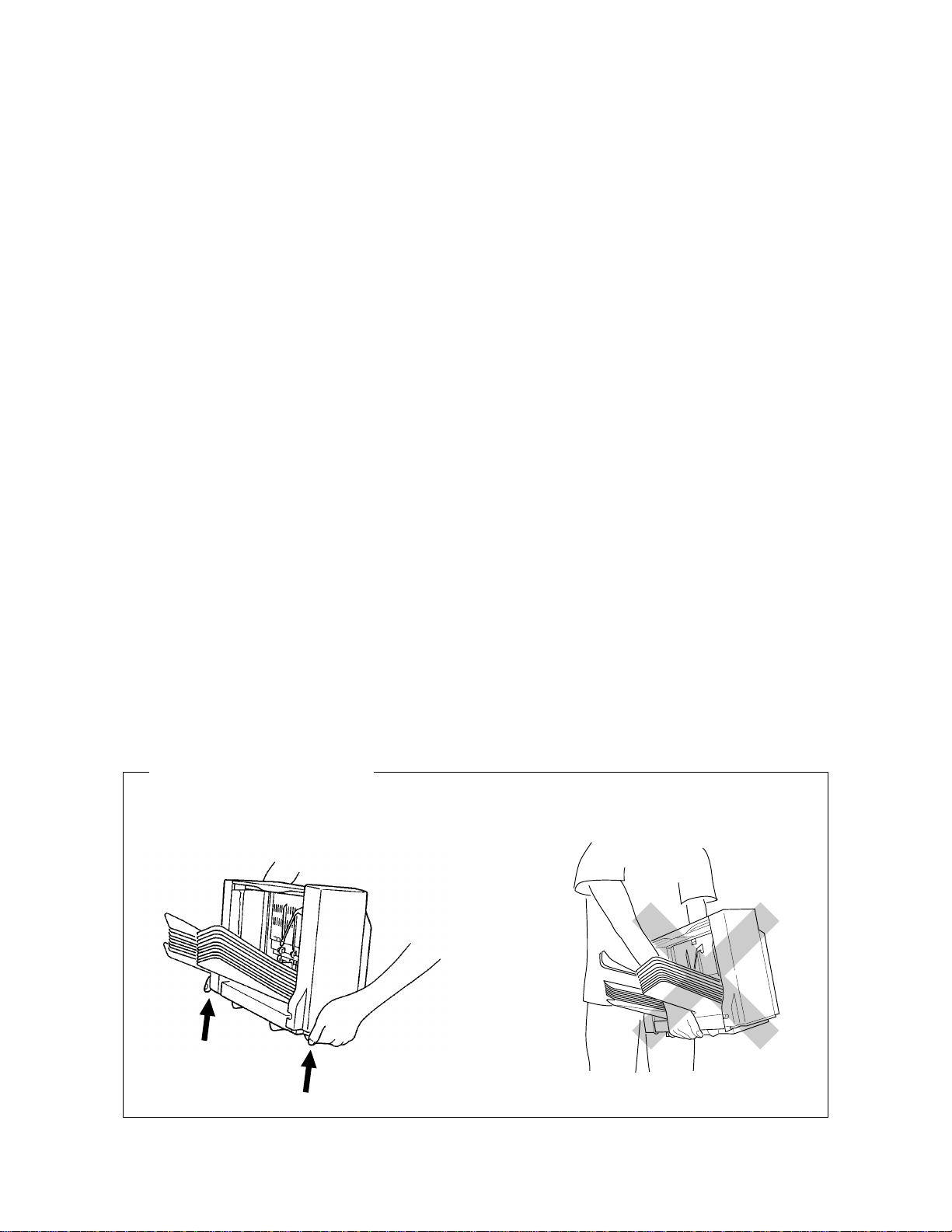

How to lift the Sorter MG-1003

Be sure to hold the sorter in the positions as indicated in Fig. A.

Do NOT hold as in Fig. B.

Fig. A.

Fig. B.

c Copyright 1995 TOSHIBA CORPRATION

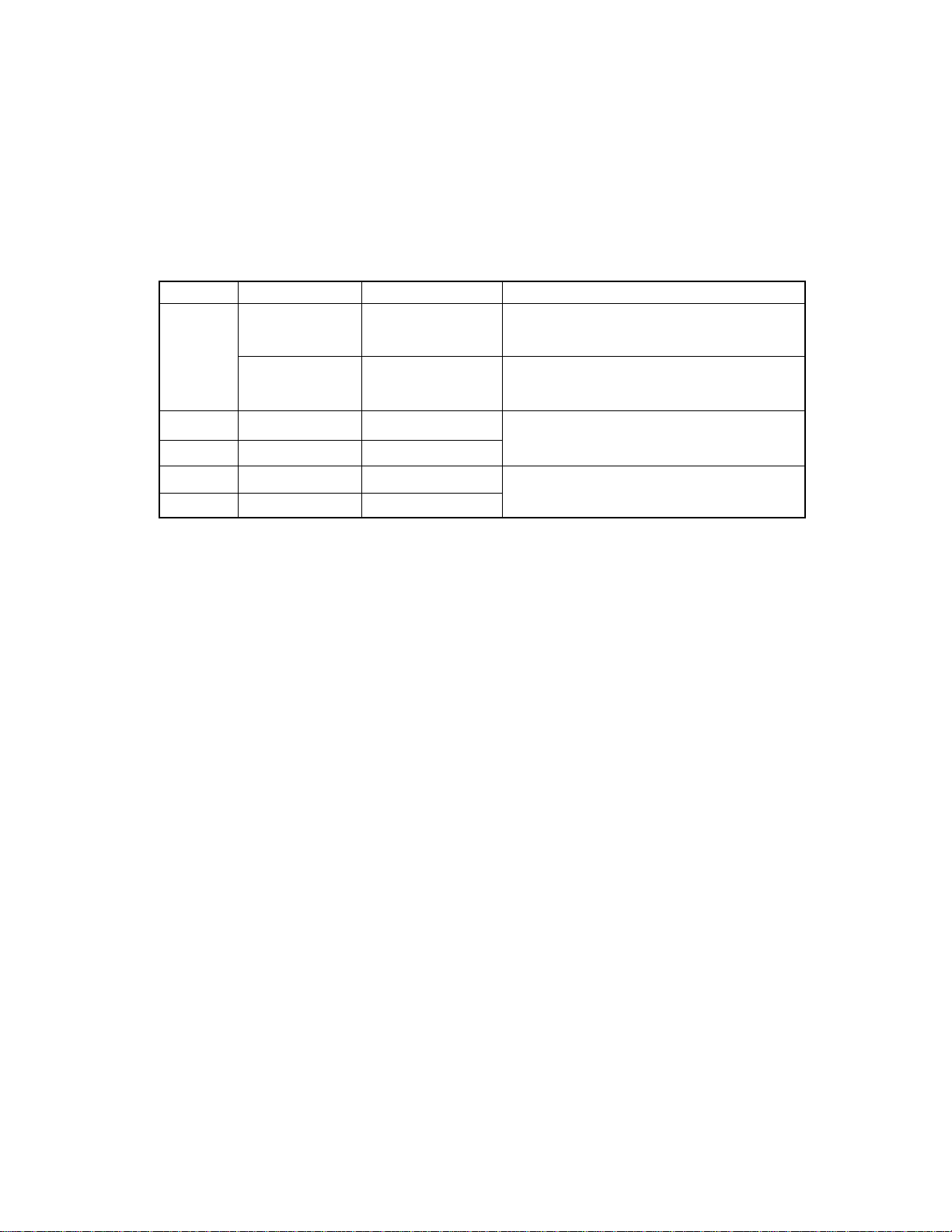

1. PRODUCT SPECIFICATIONS

Model name .................................... MG-1003

Type ................................................ Suspended type

Paper transport method................... Roller transporting

Paper sorting method ...................... Bin moving method

Acceptable paper

Mode

Non-Sort

Sort

Group

Sort

Group

Number of sets

1

1

10

10

10

10

Number of Sheets

60

100

15/bin

15/bin

30/bin

20/bin

A3, LD, B4, LG, FOLIO, COMP

50~127g/m

A4, LG, ST-R, A5-R, LT, B5, A4-R, LT-R,

B5-R 50~127g/m

A3, B4, LD, LG 50~127g/m

A4, A4R, B5, B5R, A5R, LT, LTR, FLO,

STR 50~127g/m

Acceptable size of paper

2

2

2

2

Note: Special paper such as OHP, drawing paper, labels, etc. can be used only in the non-sort

mode.

Number of bins........................... 1~10 (bin 1 doubles the non-sort bin)

Power source used .................... DC24V±10% (supplied from the copier)

Power consumption.................... 30W or less (average, in-rush current not included)

Use environment

Temperature........................... 10~30°C

Humidity ................................. 20~85%RH

Weight ........................................ 6.8 kg aprox.

Dimension .................................. 335(W) x 483(D) x 315(H) mm

SEP. 1995 C TOSHIBA CORP. 1 - 1 MG-1003 PRODUCT SPECIFICATIONS

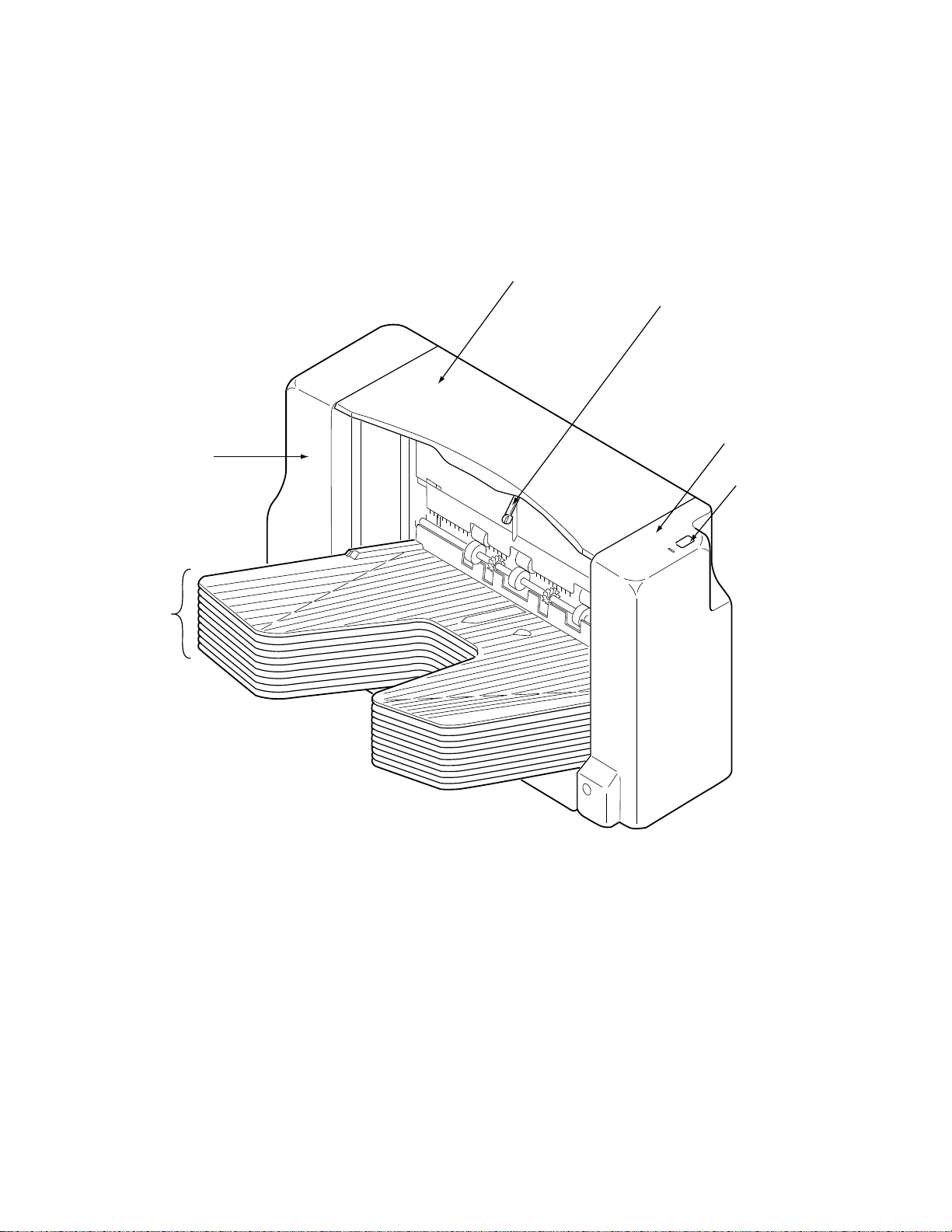

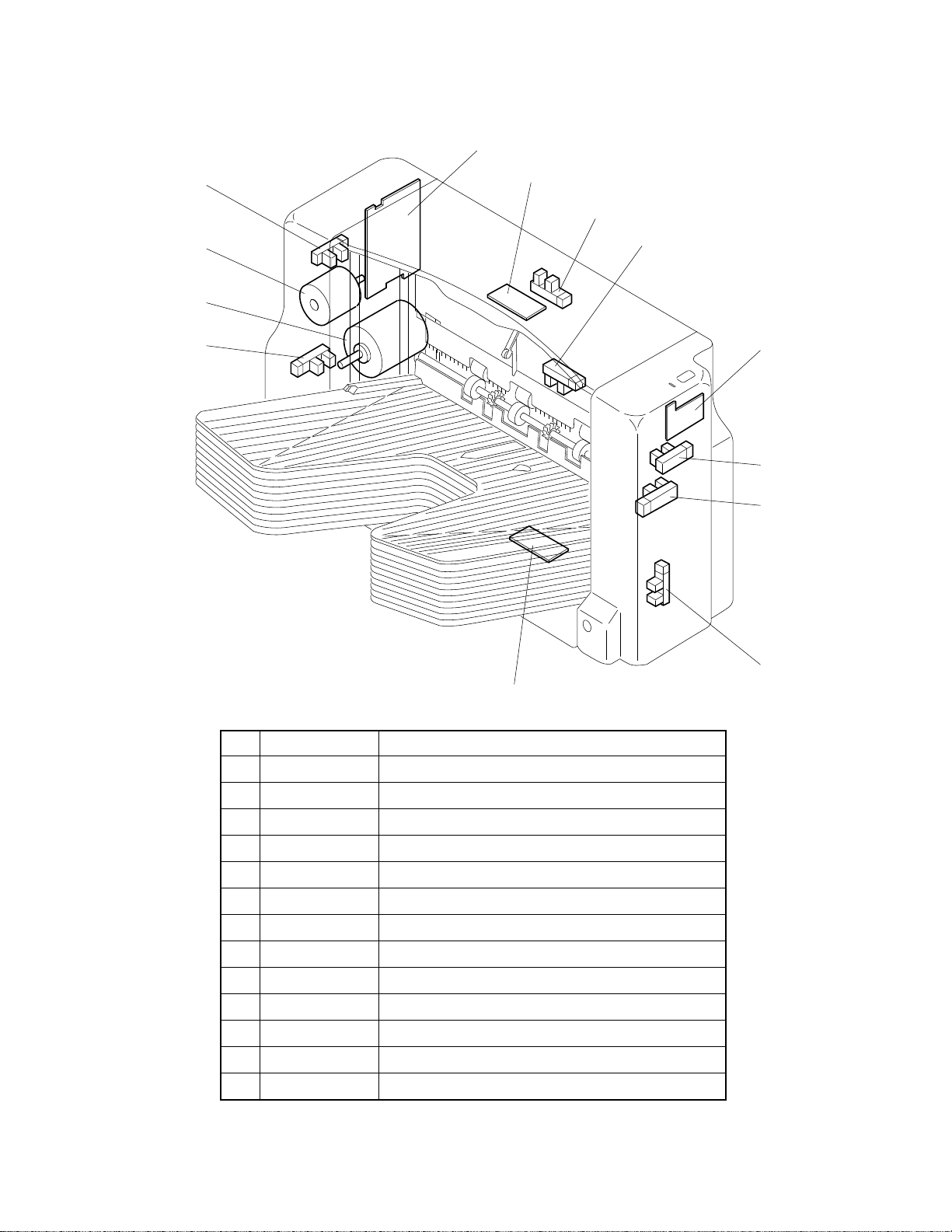

2. NAMES OF MAIN COMPONENTS

2.1 Front Side View

Top cover

Copy-removal

position sensor

Rear cover

Bins

1~10

Front cover

Copy removal

key

SEP. 1995 C TOSHIBA CORP. 2 - 1 MG-1003 NAMES OF MAIN COMPONENTS

2.2 Front Side View (with Covers Removed)

Display PC board

Bin home position

sensor lever

Bin home position

sensor bracket

Main frame

Upper/lower limit sensor

One-rotation detection sensor

2.3 Rear Side View (with Covers Removed)

Copy-removal

position sensor

Paper path

sensor

Main harness

Paper transport

motor

Main frame

Bin home position sensor

Base cover

Control PC board

Harness sub-bracket

Harness bracket

Interface cable

Bin moving motor

sensor

Paper transport roller

assembly

Base cover

Paper transport

motor sensor

Bin moving

motor

Harness assembly

Worm reinforcement plate

Drive belt

Worm gear assembly

SEP. 1995 C TOSHIBA CORP.MG-1003 NAMES OF MAIN COMPONENTS 2 - 2

3. EXPLANATION OF OPERATION

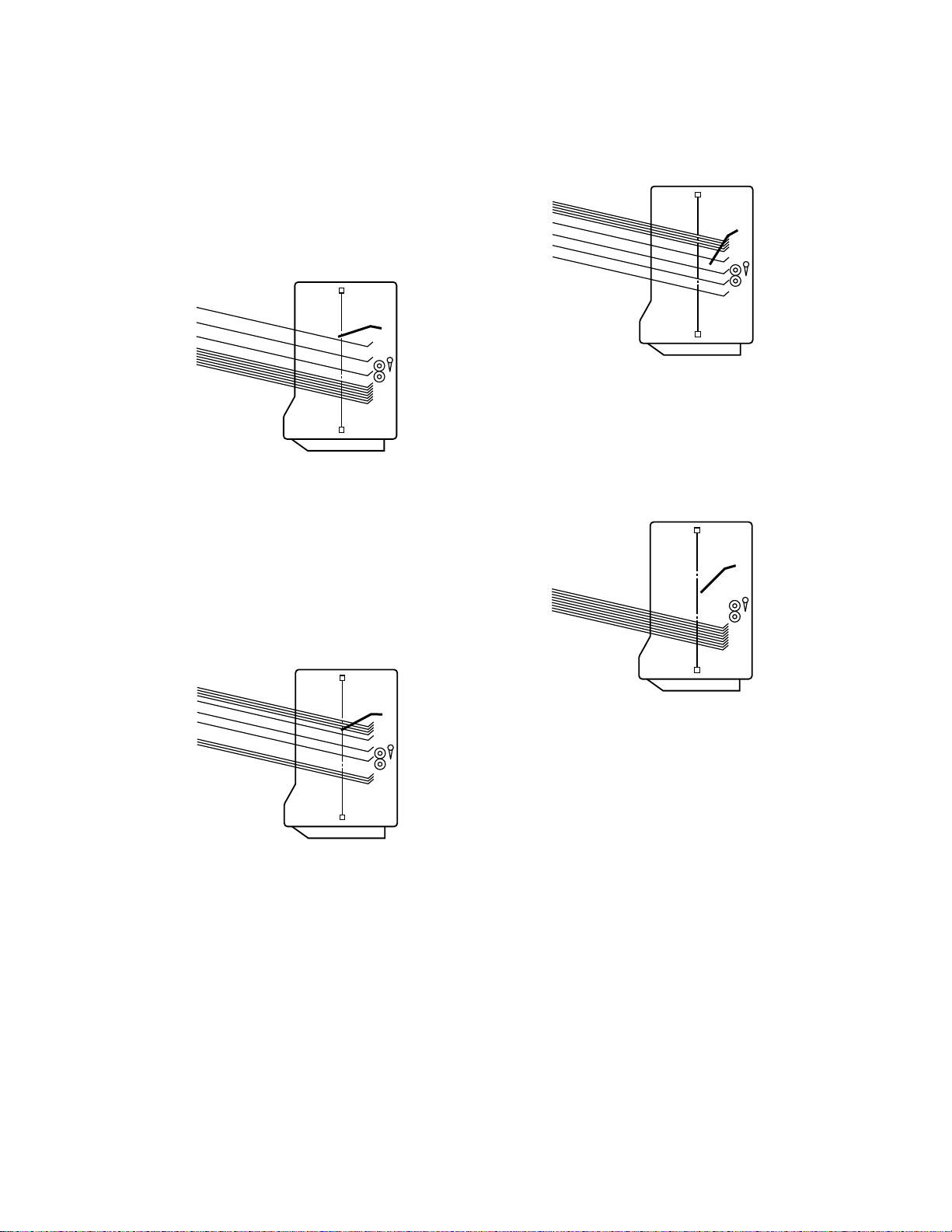

3.1 Non-sort Mode (Cascade Mode)

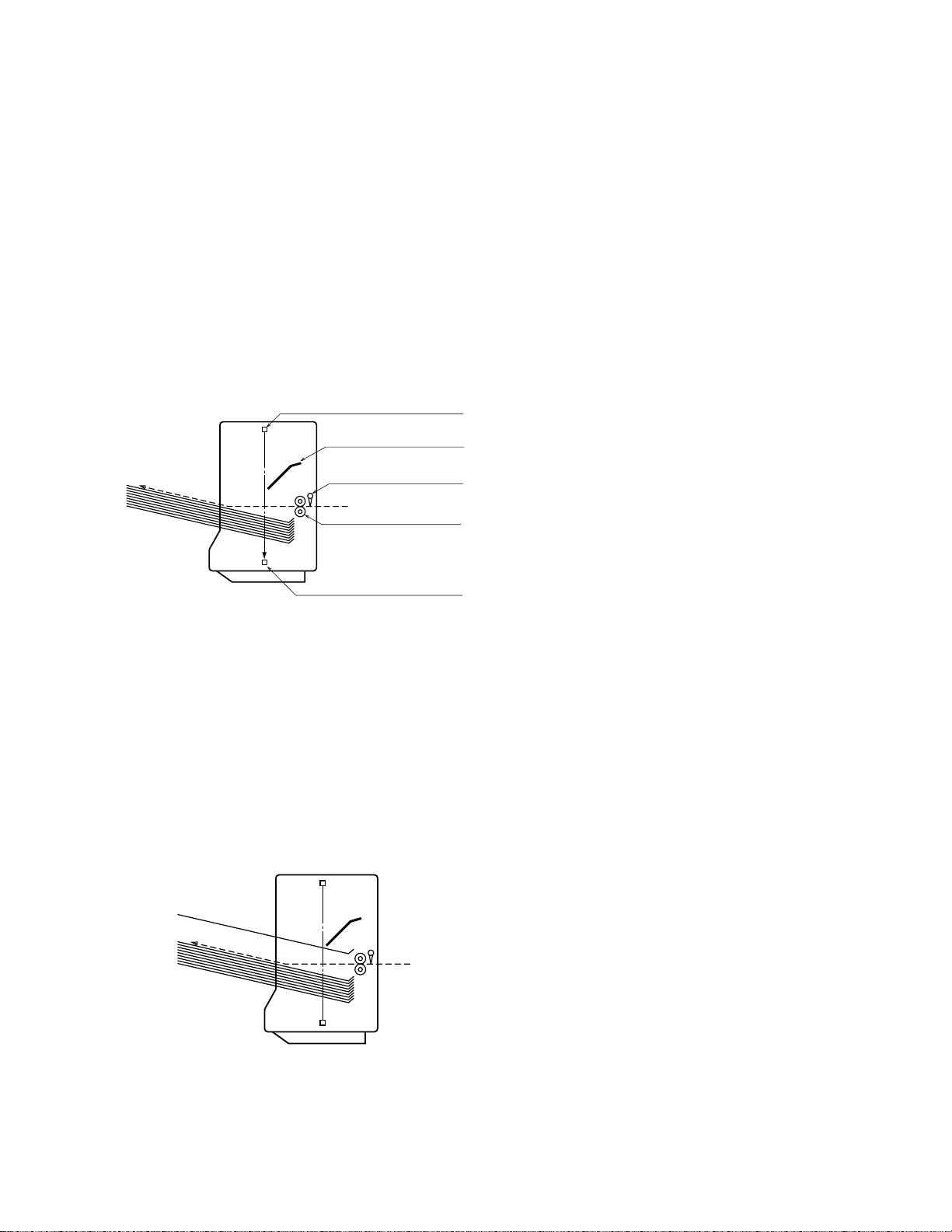

(1) When the sorter receives a paper exit signal

(EXIT) from the copier, the paper transport

motor starts rotating.

The copy exited from the copier is transported

and exited by the paper transport roller into the

top bin. (Fig. 1-1)

Paper sensor-U

(Light emitting side)

Copy removal

position sensor

Paper path sensor

Paper transport roller

Paper sensor-L

(Light receiving side)

Fig. 1-1

(3) When the limit number of sheets exit into each

bin, the bin moves up. This operation continues

until the last bin.

(4) The exiting of sheets into the last bin continues

until a signal indicating the last sheet is received

from the copier.

(5) When a signal to reset the copy run signal (C-

RUN) is received from the copier, the paper

transport motor stops rotating.

(2) When the preset number of copies exiting from

the copier exceeds the limit number of the top

bin, the sorter goes into the cascade mode; a

fixed time after the last sheet of the limit number

passes the paper path sensor, the top bin (bin

1) moves up. (Fig. 1-2)

Fig. 1-2

SEP. 1995 C TOSHIBA CORP. 3 - 1 MG-1003 EXPLANATION OF OPERATION

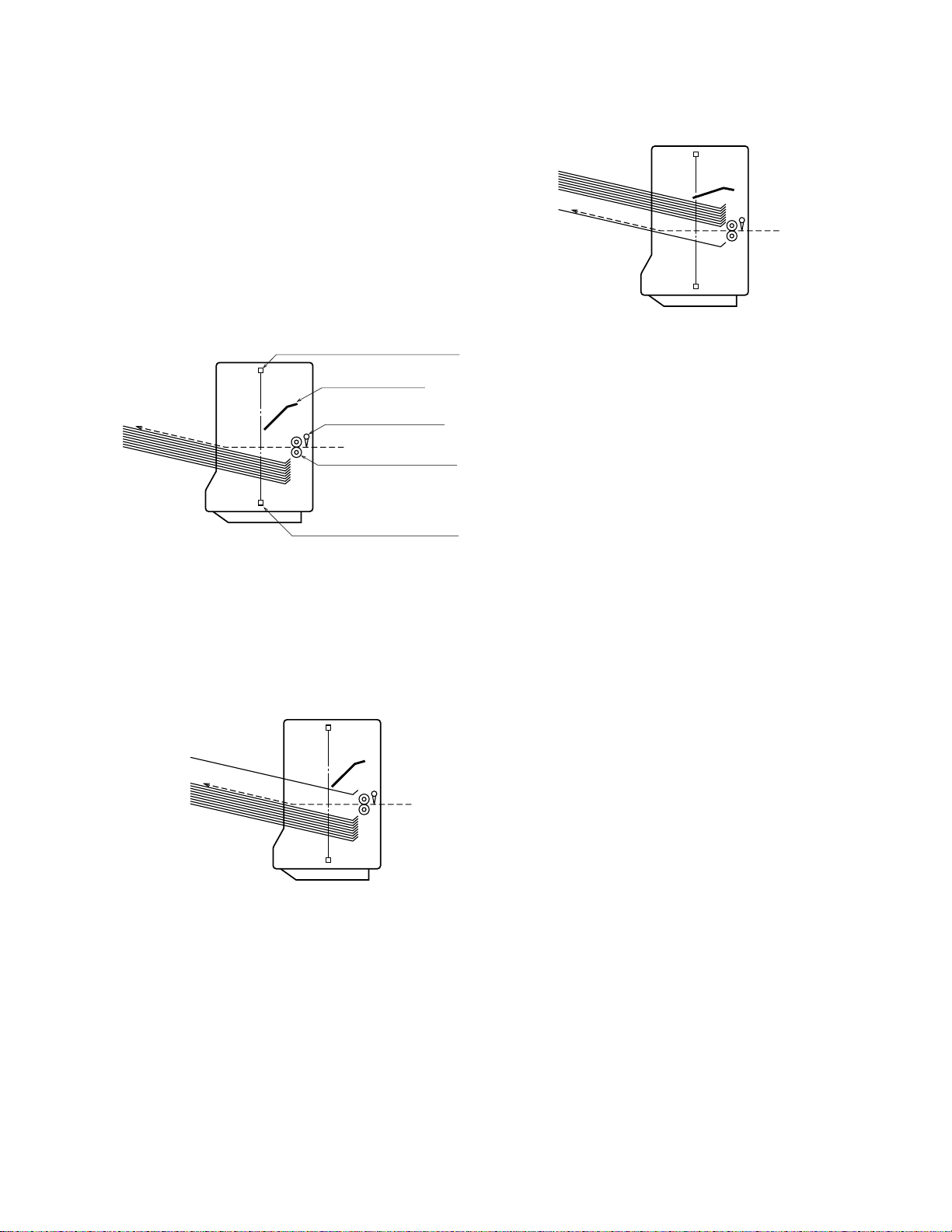

3.2 Sort Mode

(1) When the sorter receives a paper exit signal

(EXIT) from the copier, the paper transport

motor starts rotating.

The copy exited from the copier is transported

and exited by the paper transport roller into the

top bin. (Fig. 2-1)

Paper sensor-U

(Light emitting side)

Copy removal

position sensor

Paper path sensor

Paper transport roller

Paper sensor-L

(Light receiving side)

Fig. 2-1

(2) A fixed timer after the sheet passes the paper

path sensor, the bin moves up (or down). (Fig.

2-2 and Fig. 2-3)

Fig. 2-3

(3) After that, operation in step (2) is repeated until

a signal indicating the last sheet (C-END) is

received from the copier.

(4) For the sheet for which the sorter has received

the last sheet signal (C-END), the sorter does

not move the bin when its passage over the

paper path sensor is detected; a fixed time after

passage of the next sheet is detected, the sorter

changes its moving direction to continue

sorting.

(5) After that, operation in steps (2), (3) and (4) is

repeated.

Fig. 2-2

(6) When the sorter receives a signal to reset the

copy run signal (C-RUN), the paper transport

motor stops rotating.

SEP. 1995 C TOSHIBA CORP.3 - 2MG-1003 EXPLANATION OF OPERATION

3.3 Group Mode

(1) When the sorter receives a paper exit signal

(EXIT) from the copier, the paper transport

motor starts rotating. The sheet exited from

the copier is transported and exited by the paper

transport roller into the top bin. (Fig. 3-1)

Paper sensor-U

(Light emitting side)

Copy removal position

paper sensor

Paper path sensor

Paper transport roller

Paper sensor-L

(Light receiving side)

Fig. 3-1

(2) Sheets continue exiting into the same bin until

(3) After that, the procedure in step (2) is continued

until a reset signal for the copy run signal (CRUN) is received from the copier.

(4) When a signal to reset the copy run signal (C-

RUN) is received from the copier, the paper

transport motor stops rotating.

the sorter receives a last-sheet signal(C-END)

from the copier.

A fixed time after the sheet for which the lastsheet signal was received passes the paper

path sensor, the bin is moved up. (Fig. 3-2)

Fig. 3-2

SEP. 1995 C TOSHIBA CORP. 3 - 3 MG-1003 EXPLANATION OF OPERATION

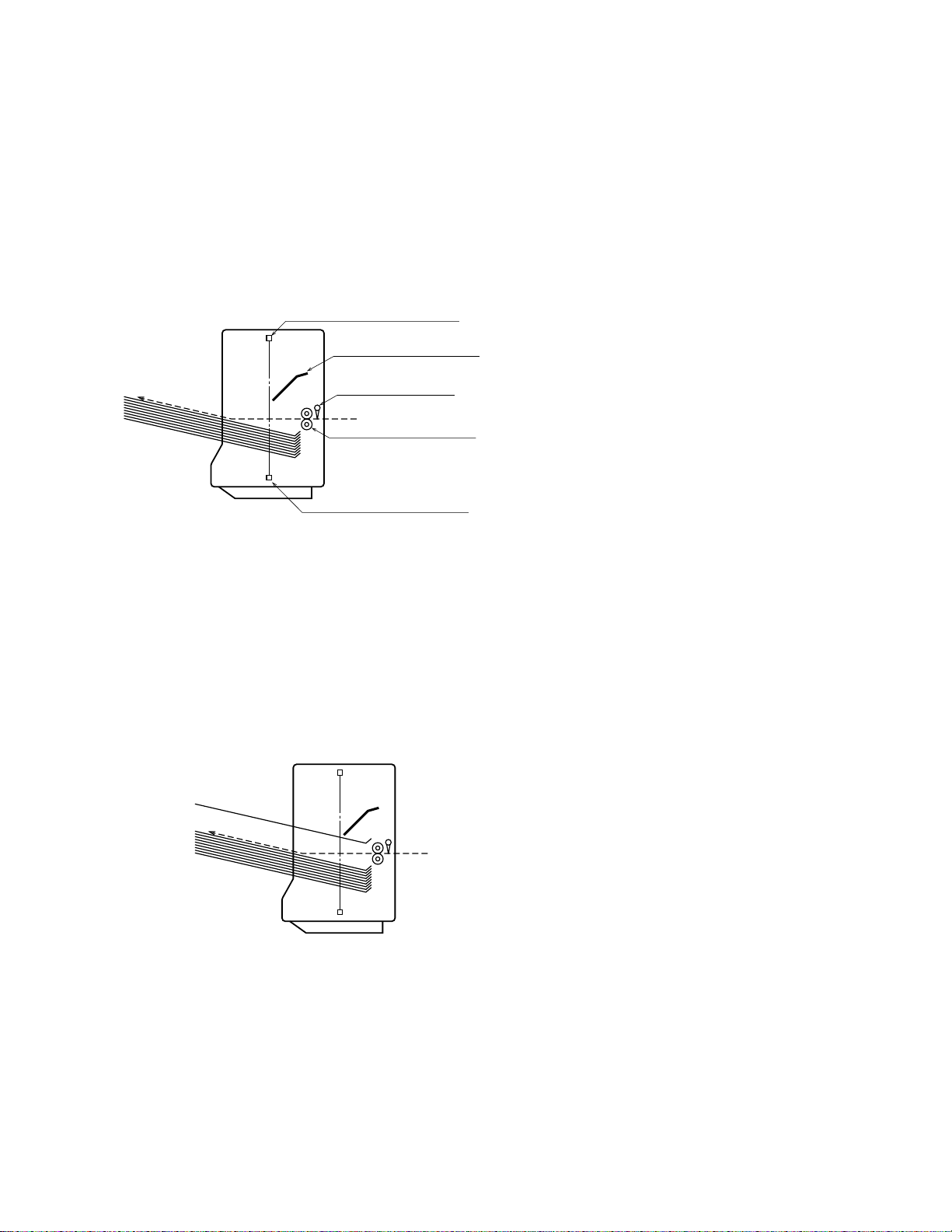

3.4 Copy Removal Mode

(1) When a copy removal signal (AUT-REM) is

received from the copier or when the copy

removal key is pressed, the bins move to the

copy removal position. (Fig. 4-1)

Fig. 4-3

(3) When all sheets on the bins are removed, the

Fig. 4-1

(2) When copies are removed from the bins, the

sorter moves up other bins until the copy

removal position sensor detects the presence

of paper.

(Fig. 4-2 and Fig. 4-3)

Fig. 4-2

bins are initialized. (Fig. 4-4)

Fig. 4-4

* When ADF is used, the copy removal signal

is automatically sent from the copier.

SEP. 1995 C TOSHIBA CORP.3 - 4MG-1003 EXPLANATION OF OPERATION

4. MECHANICAL EXPLANATION

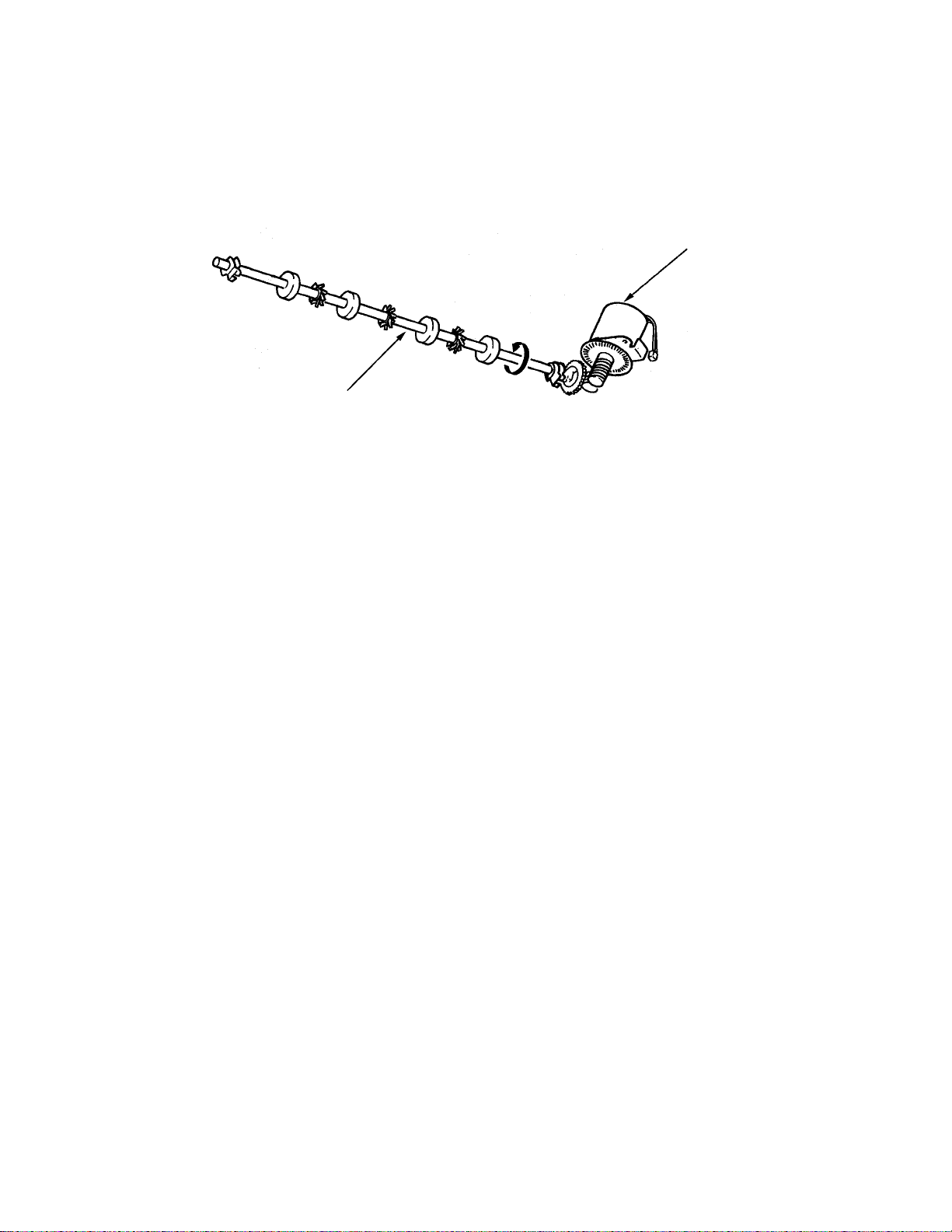

4.1 Paper Transport Mechanism

The drive force of the paper transport motor is transmitted to the paper transport roller through

gears.

Paper transport

motor

Paper transport roller

SEP. 1995 C TOSHIBA CORP. 4 - 1 MG-1003 MECHANICAL EXPLANATION

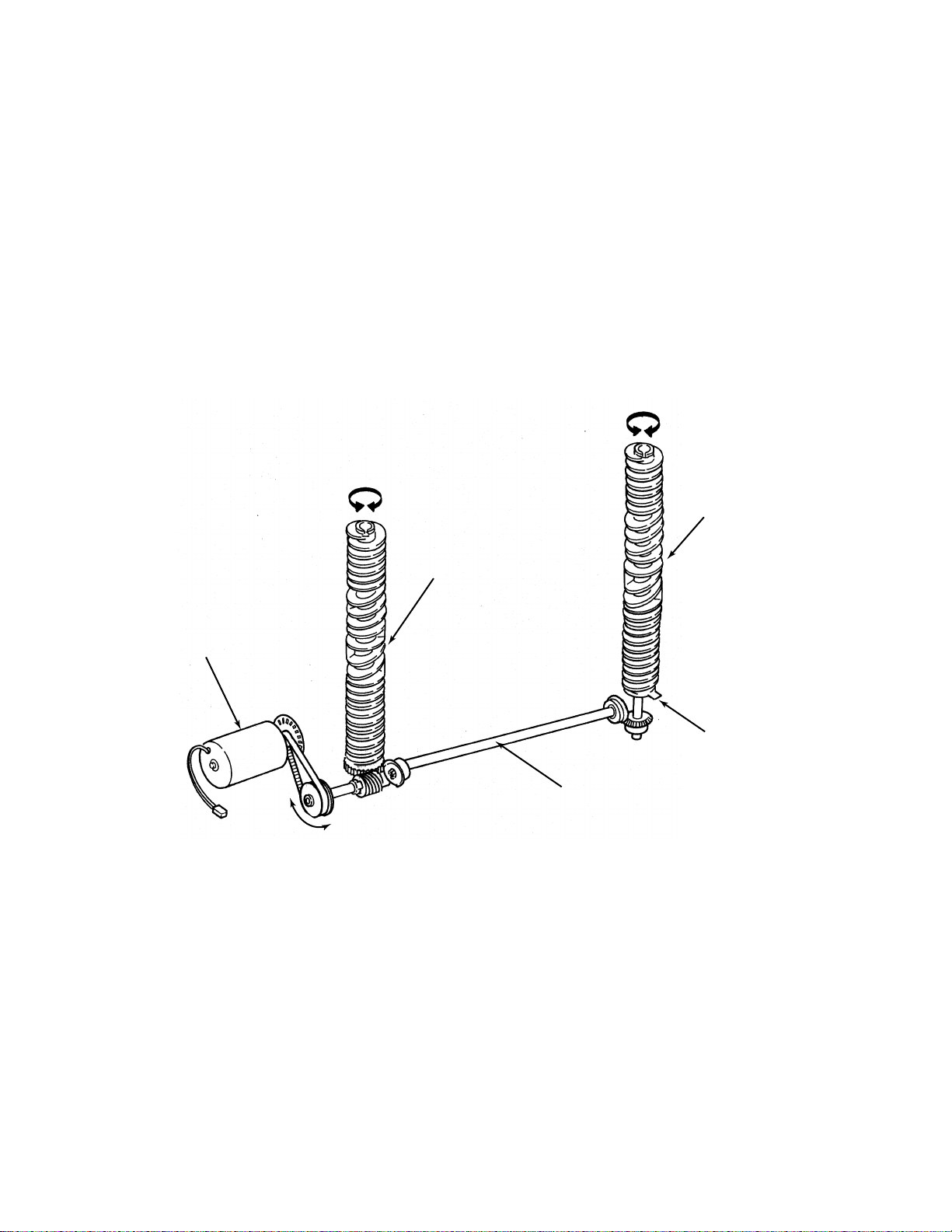

4.2 Bin Up/Down Moving Mechanism

Since this sorter is of a bin moving type, a bin designated moves to the paper transport position

and copy sheets exit into the designated bin.

The drive force of the bin moving motor is transmitted through a timing belt and gears to the spiral

cam 1. At the same time, it is also transmitted through a drive shaft to the spiral cam 2.

The bins are moved up or down by changing the rotation direction of the motor.

The bins are stopped at the preset position by one-rotation detection sensor tab attached to the

spiral cam 2.

Spiral cam 2

Bin moving motor

Spiral cam 1

One-rotation

detection sensor tab

Drive shaft

Down

Up

SEP. 1995 C TOSHIBA CORP.4 - 2MG-1003 MECHANICAL EXPLANATION

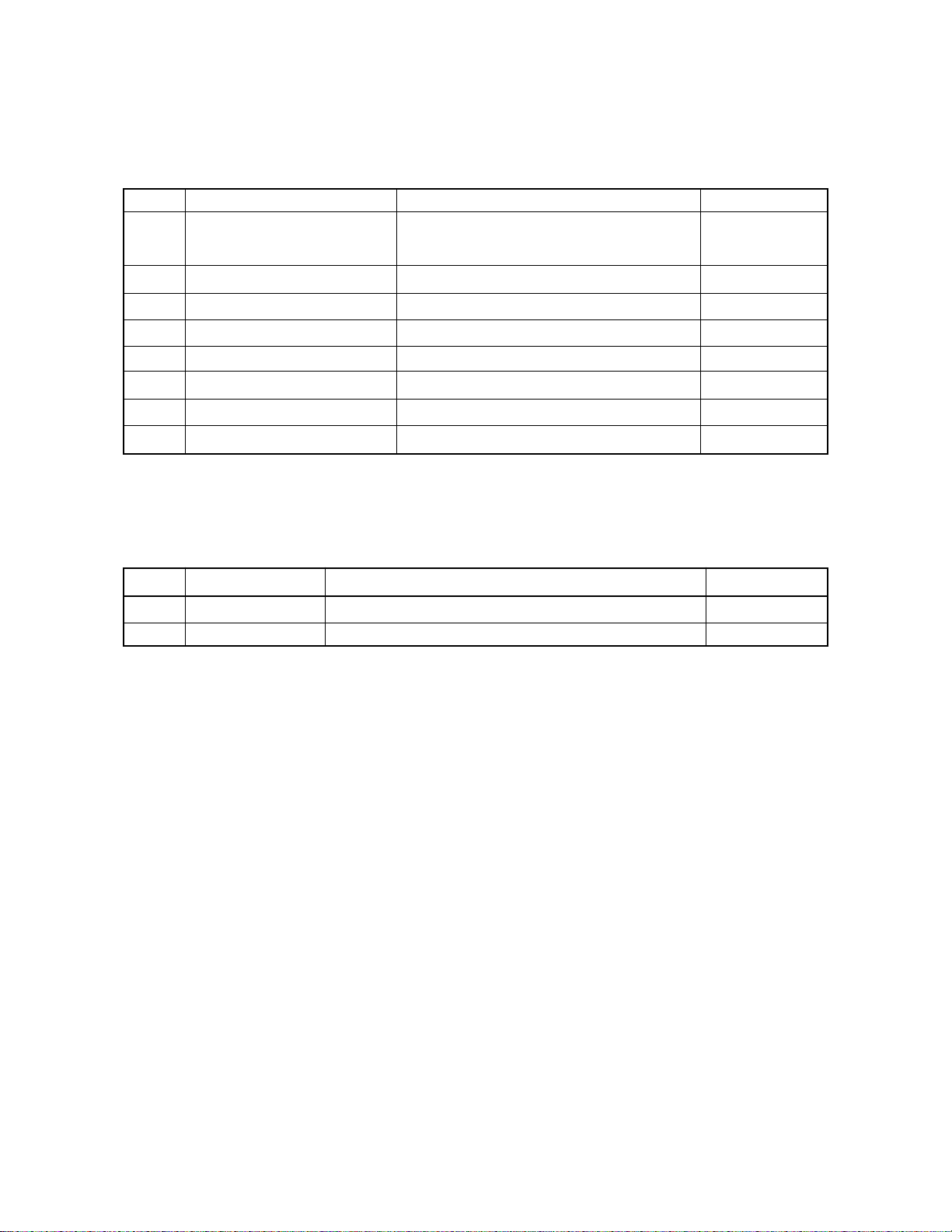

5. NAMES AND FUNCTIONS OF MAIN ELECTRICAL PARTS

5.1 Sensors and Switches

Symbol

SEN1

SEN2

SEN3

SEN4

SEN5

SEN6

SEN7

SEN8

Paper path sensor

Bin home position sensor

One-rotation detection sensor

Copy removal position sensor

Paper sensor-L and -U

Bin moving motor sensor

Paper transport motor sensor

Upper/lower limit sensor

5.2 Motors

Symbol

M1

M2

Paper transport motor

Bin moving motor

Name

Name

Function

Detects paper when its lead edge is sent to the

paper transport roller.

Detects the bin home position.

Detects the bin stop position.

Detects the paper removal position.

Detects the paper presence on the tray.

Detects bin moving motor rotation.

Detects paper transport motor rotation.

Detects the bin limit positions.

Operation and function

Drives the paper transport roller.

Drives the spiral cams that move up and down the bins.

Remarks

Photo-interrupter

Photo-interrupter

Photo-interrupter

Photo-interrupter

Transmission type

Photo-interrupter

Photo-interrupter

Photo-interrupter

Remarks

DC brush motor

DC brush motor

SEP. 1995 C TOSHIBA CORP. 5 - 1 MG-1003 MAIN ELECTRICAL PARTS

5.3 Electrical Parts Location

!™

8

0

!£

7

6

4

1

!¡

2

9

NO

SEN1

1

SEN2

2

SEN3

3

SEN4

4

SEN5

5

SEN5LD

6

SEN6

7

SEN7

8

SEN8

9

M1

!º

PBA-OPPANEL-T

!¡

PBA-CONTROL-T

!™

M2

!£

Symbol

3

5

Description

Paper path sensor

Home position sensor

One-rotation detection sensor

Copy-removal position sensor

Paper sensor-L (Print wiring board assembly)

Paper sensor-U (LED)

Bin moving motor sensor

Paper transport motor sensor

Upper/Lower limit sensor

Paper transport motor

Print wiring board assembly for display

Print wiring board assembly for control

Bin moving motor

SEP. 1995 C TOSHIBA CORP.5 - 2MG-1003 MAIN ELECTRICAL PARTS

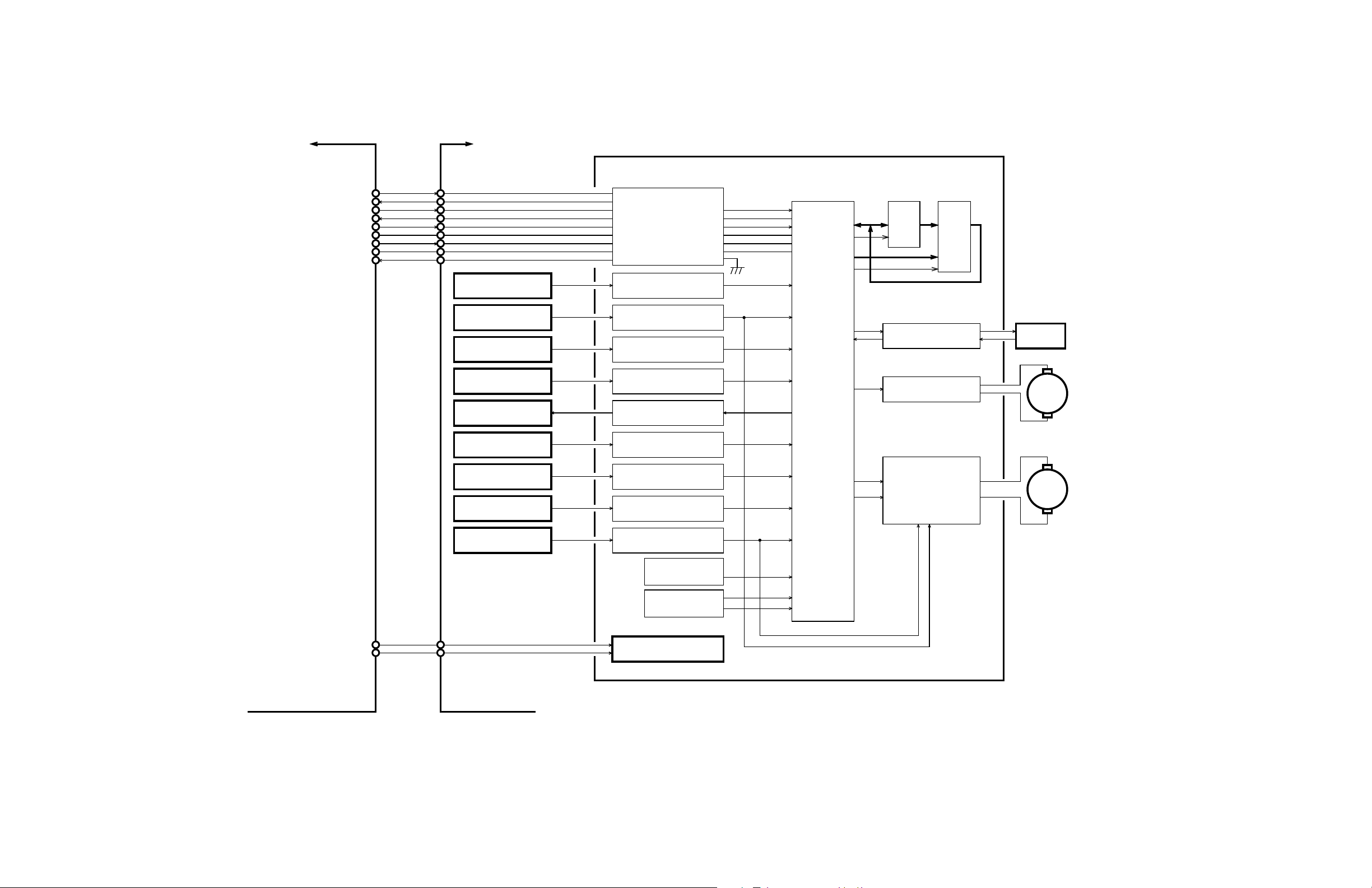

6. BLOCK DIAGRAM FOR TRANSMISSION/RECEPTION OF SIGNALS

Copier side

REQ-S

S-ACK

ACKB-S

S-REQ

TXD

SGND

RXD

SGND

CNT

Sorter side

Paper path sensor

Bin home position

sensor

One-rotation detection

sensor

Copy removal position

sensor

Paper presence LED

Paper presence

sensor

Bin moving motor

rotation detection

Paper transport motor

rotation detection

Upper/Lower limit

sensor

SEN1

SEN2

SEN3

SEN4

SEN5CLK

SEN5

SEN6

SEN7

SEN8

Control PC board

Serial interface

Paper path sensor input

section

Bin home position sensor

input section

One-rotation detection

sensor input section

Copy removal position

sensor input section

Paper presence LED

CLK output section

Paper presence sensor

input section

Bin moving motor rotation

detection CLK input

section

Paper transport motor

rotation detection CLK

input section

Upper/Lower limit sensor

input section

SEN1

SEN2

SEN3

SEN4

SEN5CLK

SEN5

SEN6

SEN7

SEN8

CPU

LATCH

ROM

256K

Display section logic

Paper transport motor

(M1) control section

Bin moving motor (M2)

control section

Display

PC board

M1

Paper transport motor

(M1)

M2

Bin moving motor (M2)

System

reset section

System

clock section

DC24V

Power input section

SEP. 1995 © TOSHIBA CORP. MG-1003 TRANSMISSION/RECEPTION OF SIGNALS6 - 1

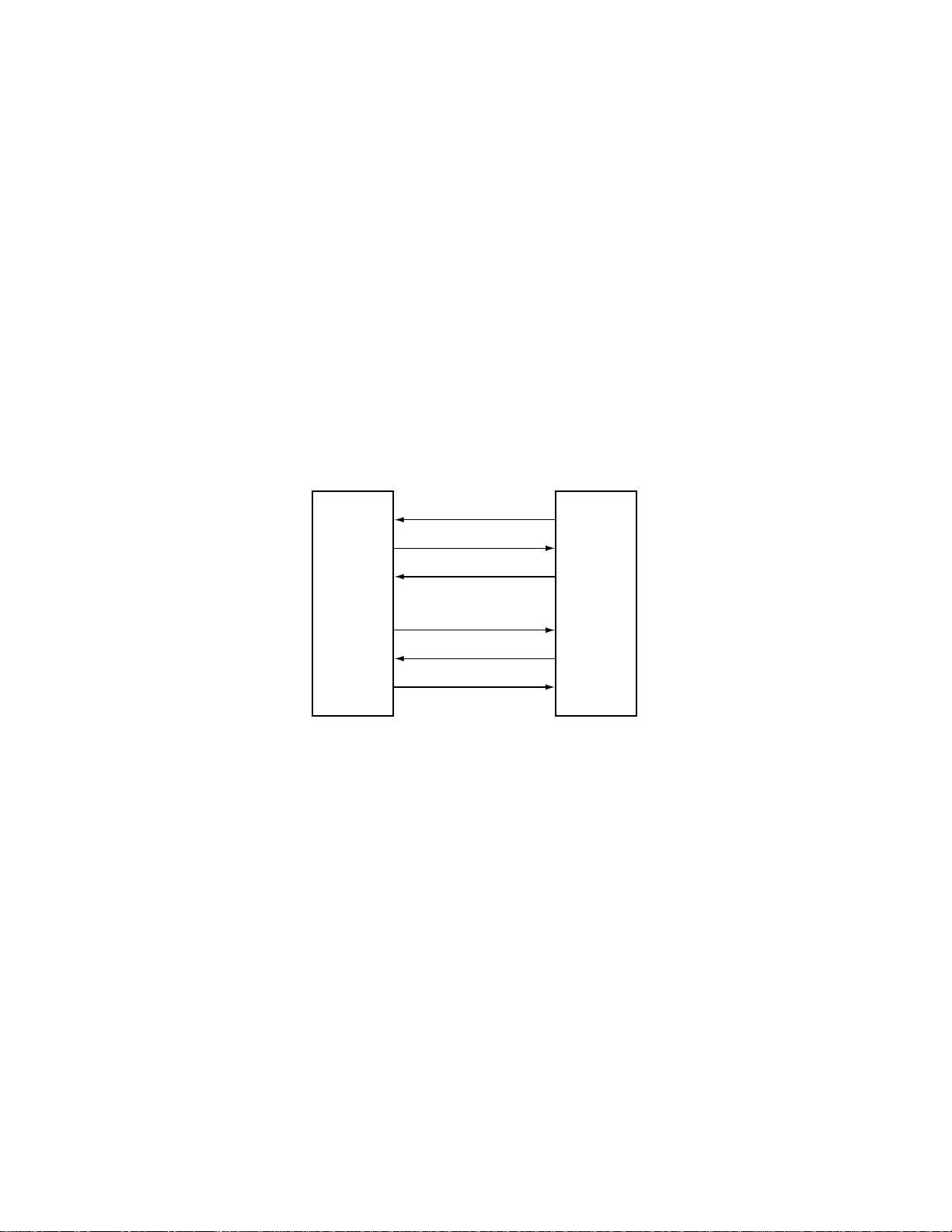

7. INTERFACE SIGNALS

The sending and receiving of signals between the copier and the sorter is conducted by using the

six lines as show below:

REQ1 ..................... Communication request signal (form the copier to the sorter)

REQ2 ..................... Communication request signal (from the sorter to the copier)

ACK1...................... Communication request response signal (from the sorter to the copier)

ACK2...................... Communication request response signal (from the copier to the sorter)

S-TXD .................... Data sent from the copier to the sorter

S-RXD .................... Data sent from the sorter to the copier

Since data transmission between the copier and the sorter (S-TXD and S-RXD) is conducted by

means of serial transmission, it is not possible to check for the correct data transmission in the field.

CopierSorter

REQ1

ACK1

S-TXD

REQ2

ACK2

S-RXD

7 - 1SEP. 1995 C TOSHIBA CORP. MG-1003 INTERFACE SIGNALS

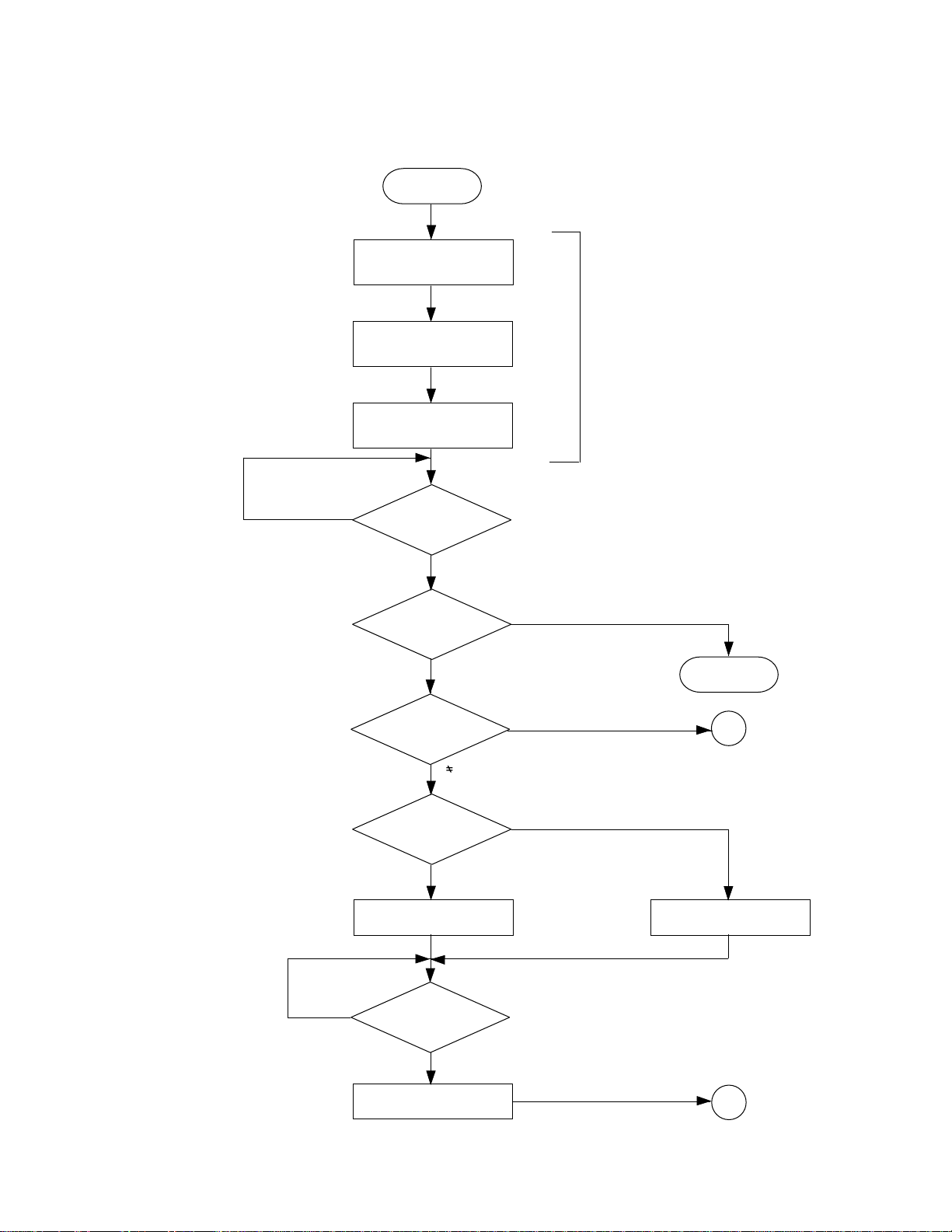

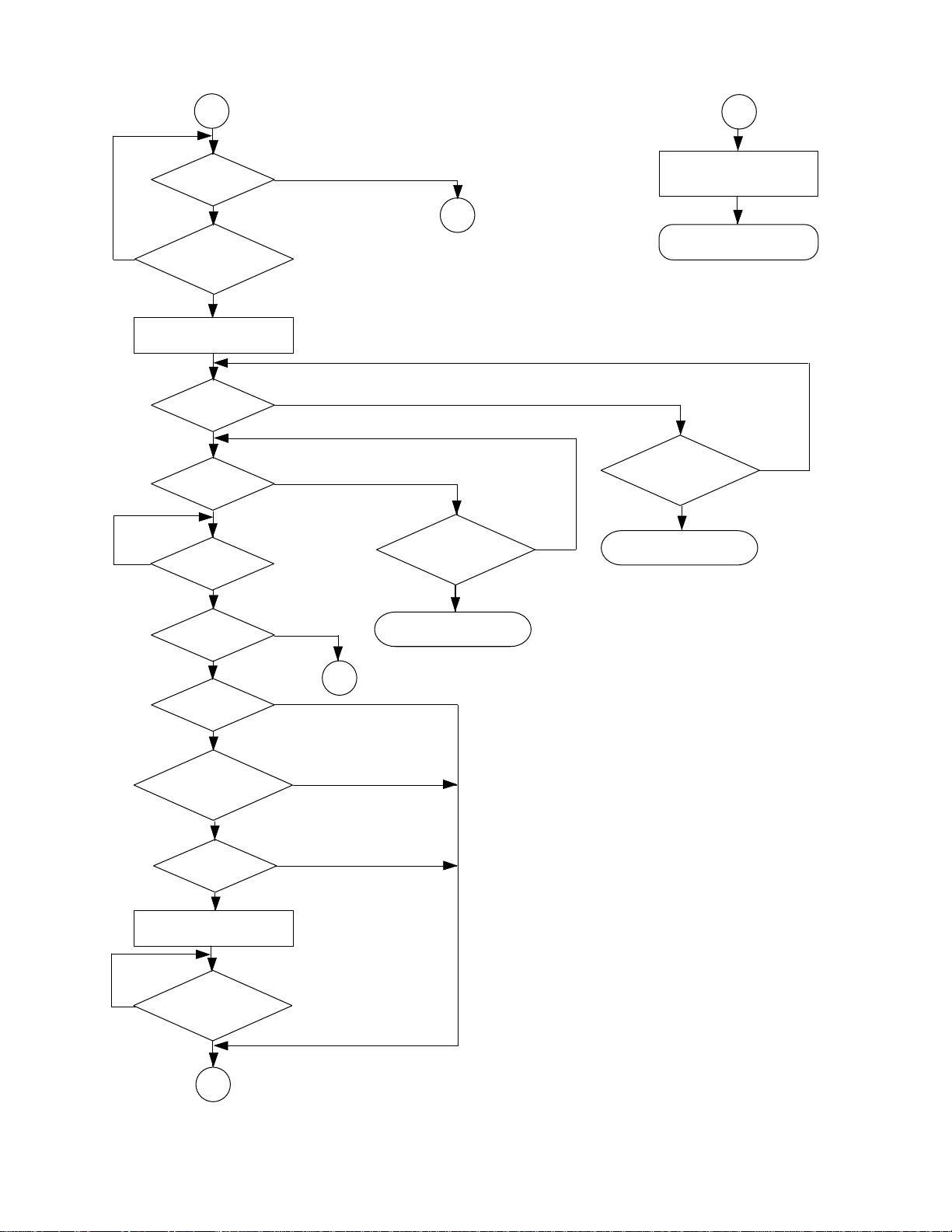

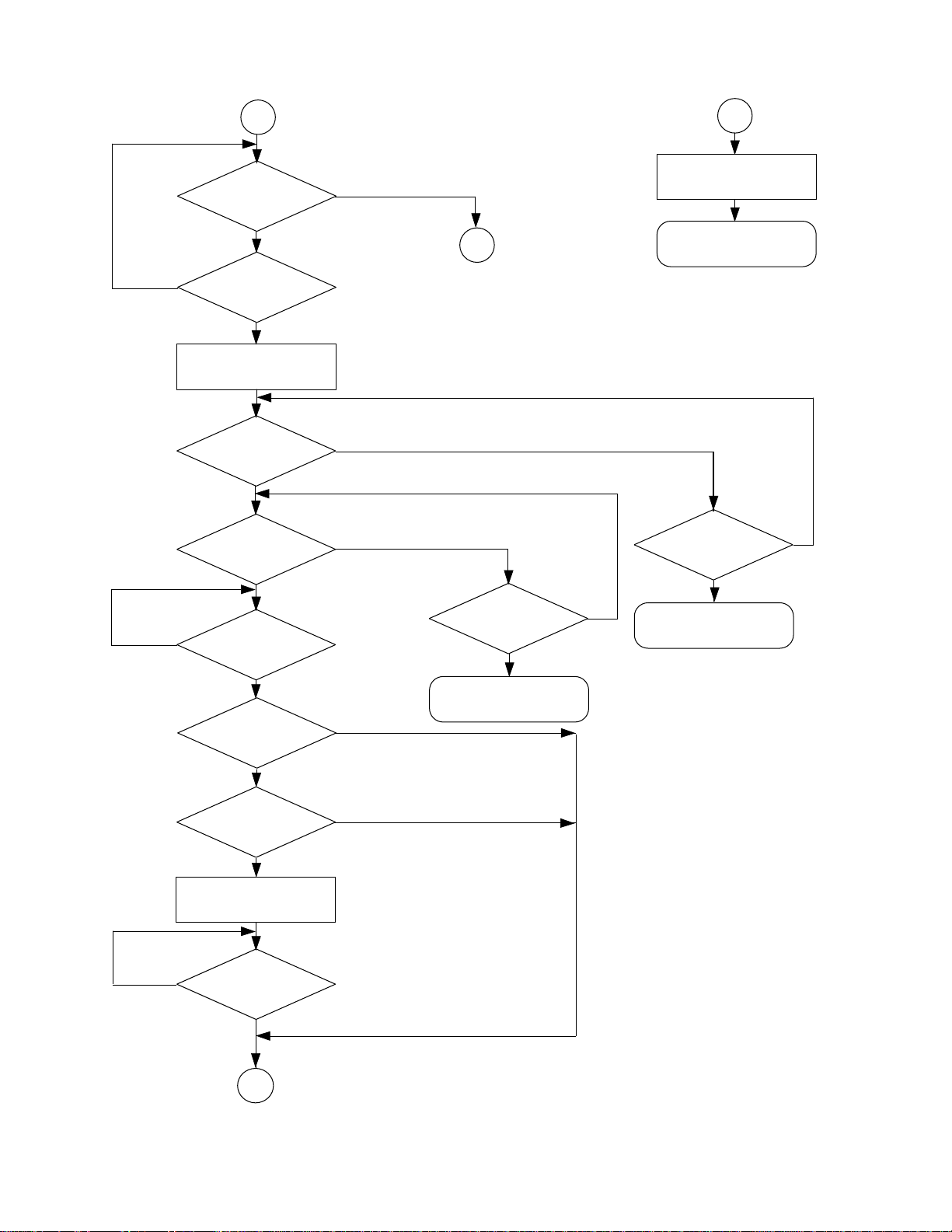

8. OPERATION FLOW CHART

8.1 Non-Sort/Cascade Mode

Stand by

Confirms that the non-sort

mode is selected.

Copy quantity is set at the

copier.

PRINT key is pressed.

NO

Operation

start signal

received?

Paper path

sensor ON?

Target bin?

YES

NO

Present position

User's operation

YES

Sorter jam

=Present position

1

Target bin?

< Present bin

> Present bin

Bin starts moving up.

NO

SEP. 1995 C TOSHIBA CORP. 8 - 1 MG-1003 OPERATION FLOW CHART

Target bin has

arrived?

YES

Bin stops moving.

Bin starts moving down.

1

1

2

NO

NO

Copying?

YES

Paper exit

command

received?

YES

Paper transport

motor starts.

Paper path

sensor ON?

YES

Paper path

sensor OFF?

YES

50msec

has elapsed?

YES

NO

NO

NO

2

Jam timer

has timed out?

YES

NO

Paper transport motor

stops moving.

Jam timer

has timed out?

YES

Sorter jam

Complete

NO

Cascade mode?

Received number

Present position?

Bin starts moving up.

NO

finished moving?

YES

Last sheet?

NO

YES

of copies?

> Max. No. of copies

< Bin 10

Bin has

YES

1

NO

< Max. No. of copies

> Bin 10

Sorter jam

1

MG-1003 OPERATION FLOW CHART

8 - 2

SEP. 1995 C TOSHIBA CORP.

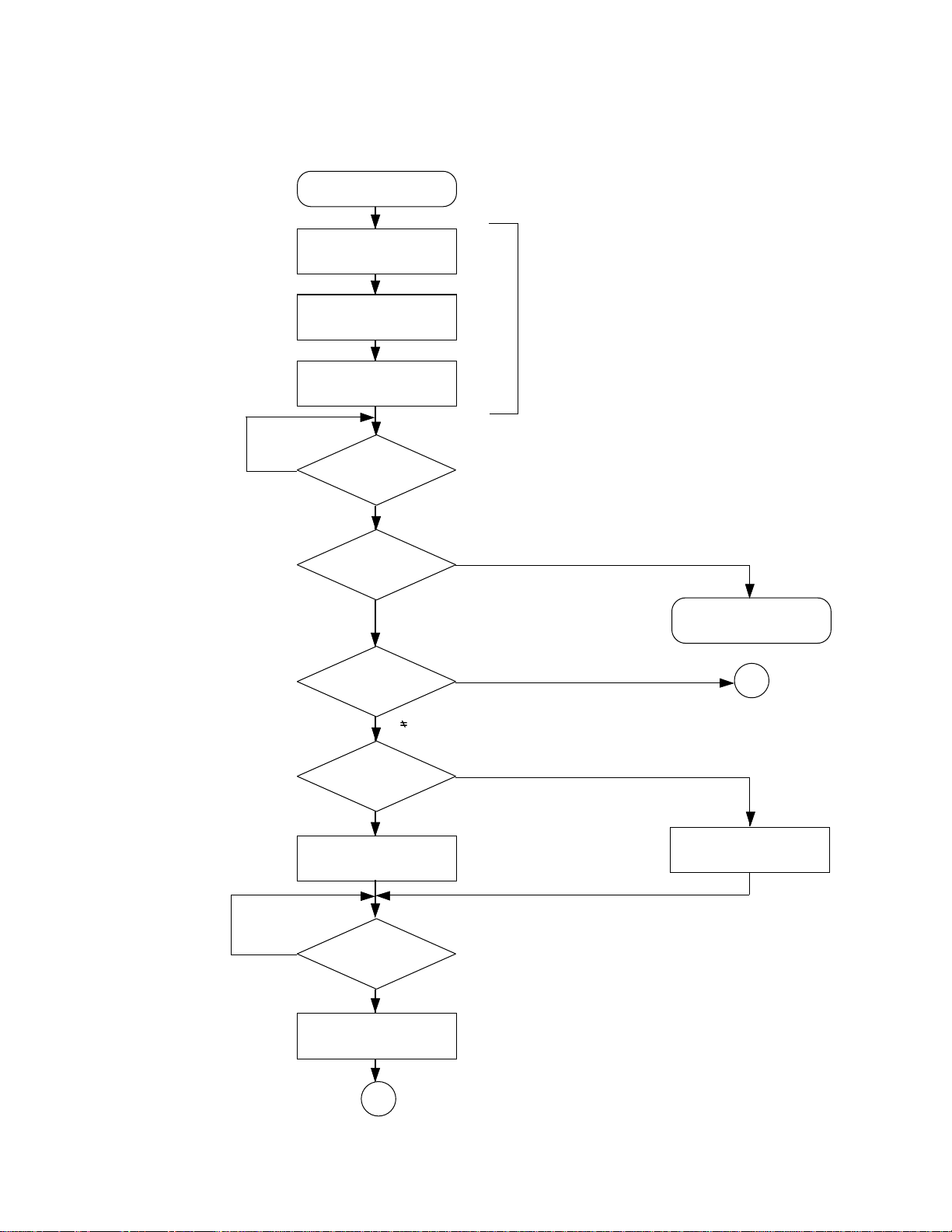

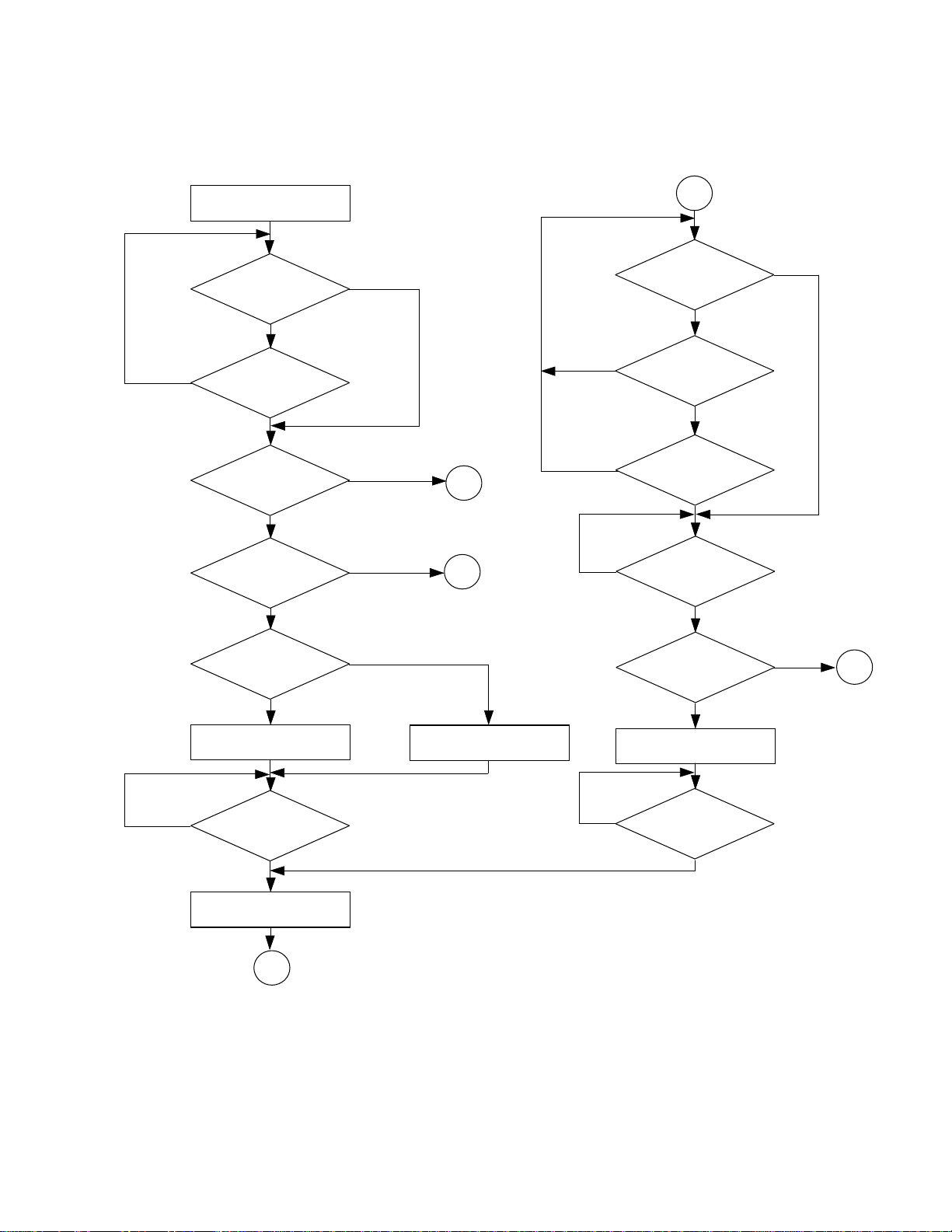

8.2 Sort Mode

Stand by

Confirms that the sort

mode is selected.

Copy quantity set at the

PRINT key is pressed.

NO

Operation

start signal received?

Paper path

sensor ON?

Target bin?

copier.

YES

NO

User's operation

YES

Sorter jam

= Present position

1

Present position

< Present bin

Bin starts moving down.

NO

Target bin?

> Present bin

Bin starts moving up.

Target bin

has arrived?

YES

Bin stops moving

1

SEP. 1995 C TOSHIBA CORP. 8 - 3 MG-1003 OPERATION FLOW CHART

1 2

Paper transport motor

Copying?

NO

stops moving.

NO

NO

YES

Paper exit command

received?

YES

Paper transport motor

starts.

Paper path

sensor ON?

YES

Paper path

sensor OFF?

YES

50msec has elapsed?

NO

NO

2

Jam timer has

timed out?

YES

NO

Complete

Jam timer has

timed out?

YES

Sorter jam

NO

YES

Last sheet?

YES

Present moving

direction?

Up

Bin changes to

downward direction.

1

MG-1003 OPERATION FLOW CHART

NO

Down

Sorter jam

Bin changes to upward

direction.

8 - 4

NO

Bin starts moving.

Bin has

finished moving?

YES

SEP. 1995 C TOSHIBA CORP.

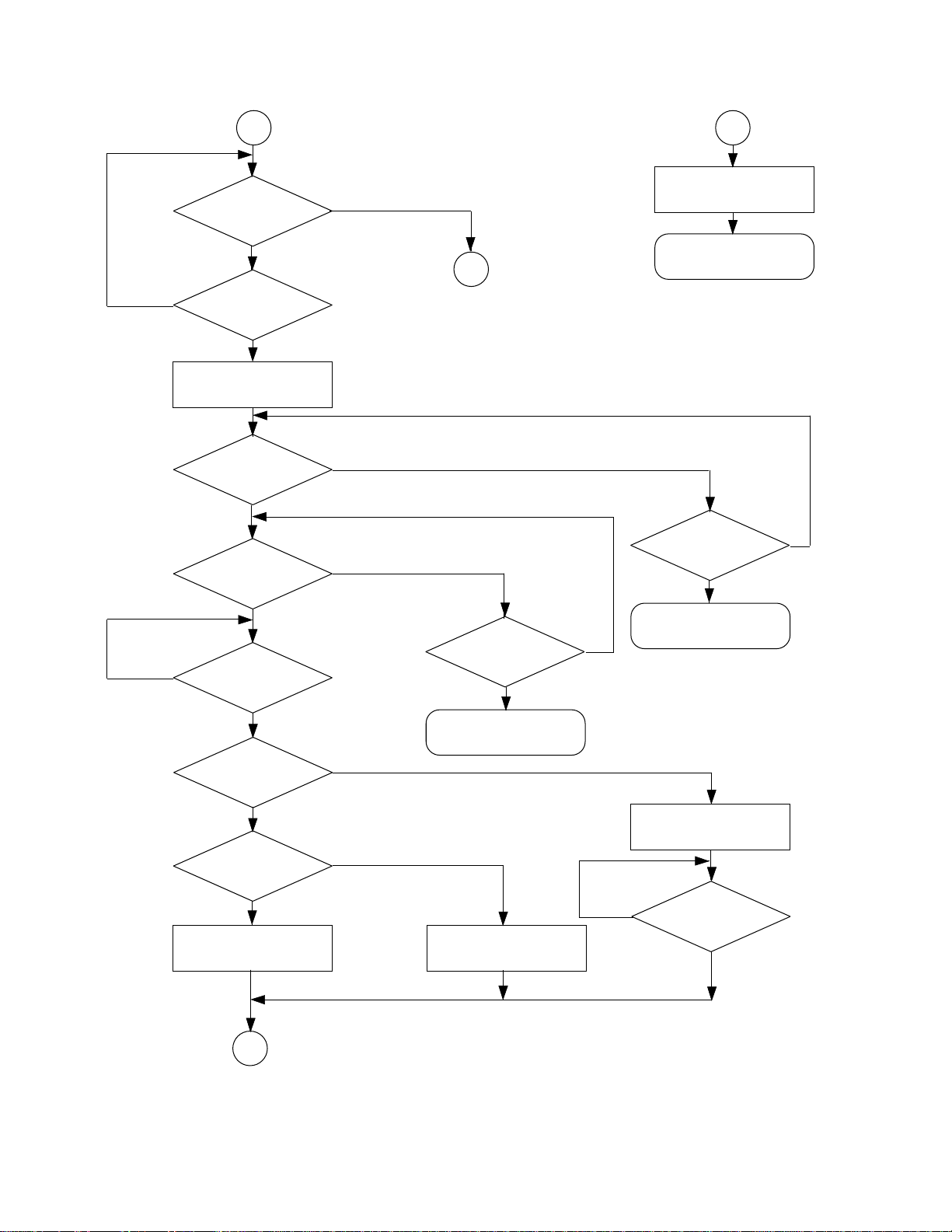

8.3 Group Mode

Stand by

Confirms that the group

mode is selected.

NO

Copy quantity is set at

the copier.

PRINT key is pressed.

Operation start

signal received?

YES

Paper path

sensor ON?

NO

Target bin?

≠ Present position

User's operation

YES

Sorter jam

= Present position

1

< Present bin

Bin starts moving down.

NO

Target bin?

> Present bin

Bin starts moving up.

Target bin

has arrived?

YES

Bin stops moving.

1

SEP. 1995 C TOSHIBA CORP. 8 - 5 MG-1003 OPERATION FLOW CHART

1

Copying

NO

2

Paper transport motor

stops moving.

NO

NO

YES

Paper exit command

received?

YES

Paper transport motor

starts.

Paper path

sensor ON?

YES

Paper path

sensor OFF?

YES

50msec has elapsed?

NO

NO

2

Jam timer has

timed out?

YES

NO

Complete

Jam timer has

timed out?

YES

Sorter jam

NO

NO

YES

Last sheet?

YES

Present position?

< Bin 10

Bin Starts moving up.

Bin has

finished moving?

YES

1

Sorter jam

NO

> Bin 10

MG-1003 OPERATION FLOW CHART

8 - 6

SEP. 1995 C TOSHIBA CORP.

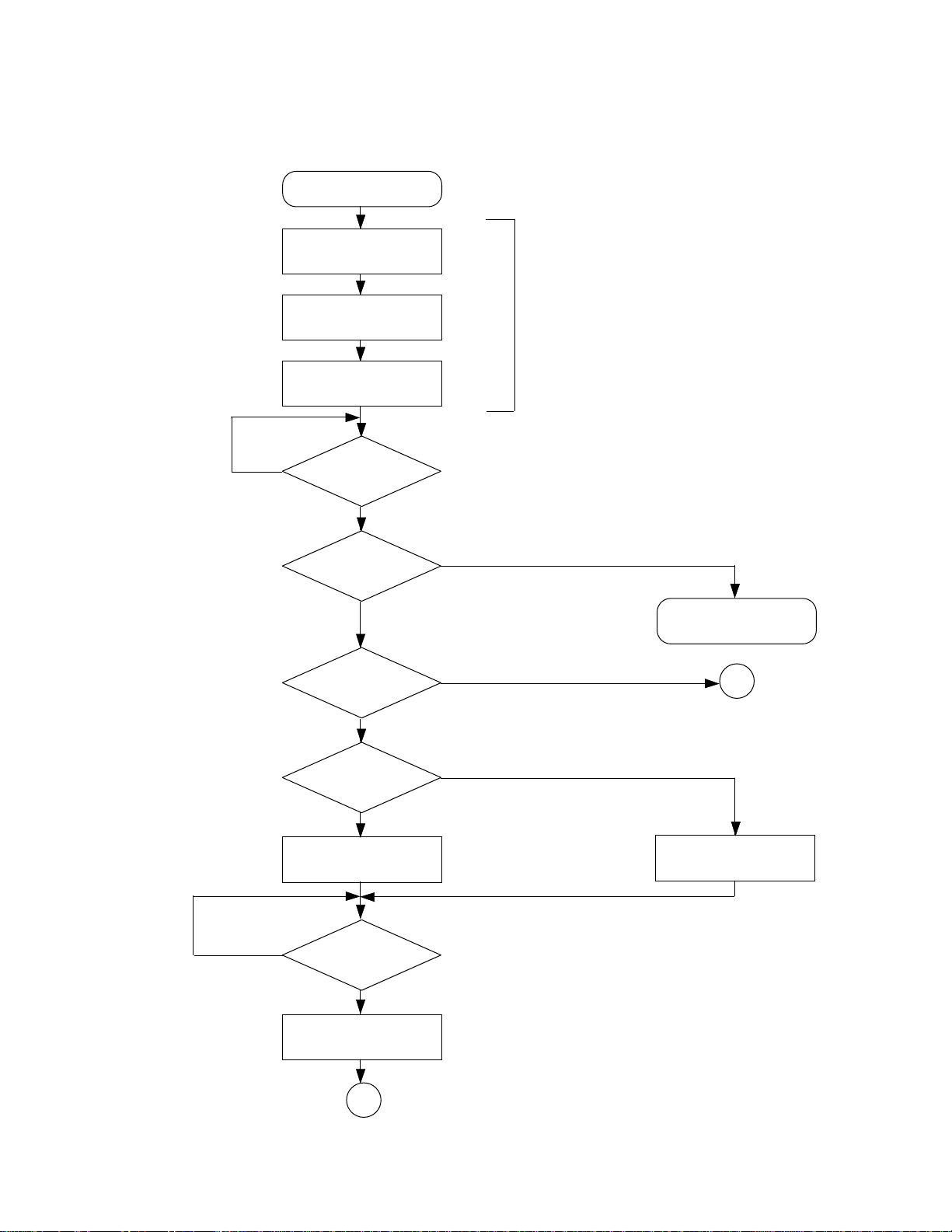

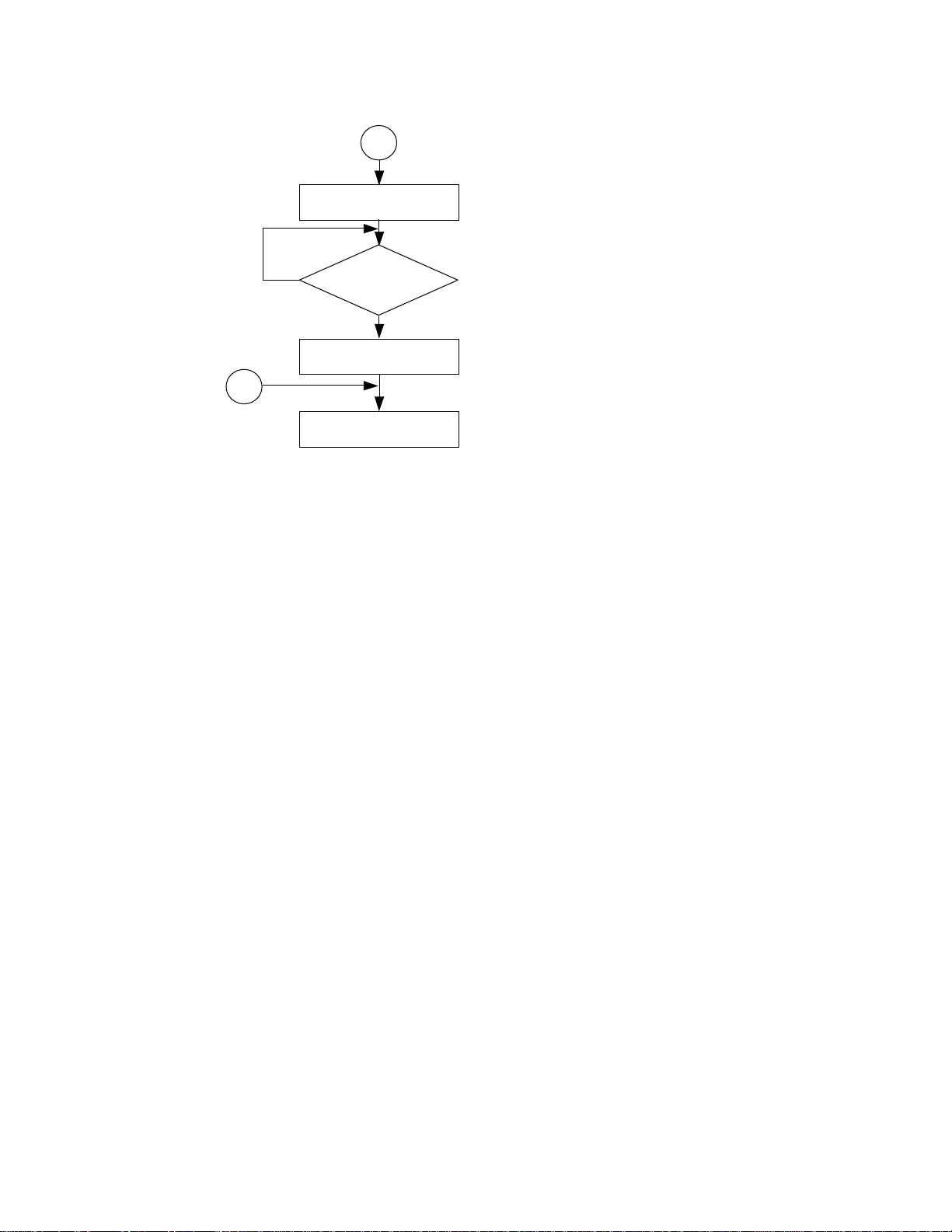

8.4 Copy Removal Mode

NO

Stand by

Copy removal

command received?

NO

Copy removal

key OFF?

YES

Possible to move

to the copy removal

position?

YES

Paper on bin?

YES

YES

NO

NO

3

2

YES

> Bin 10

NO

1

Paper on bin?

YES

Copy removal

position sensor ON?

NO

Present bin position?

< Bin 10

1.5 sec has elapsed?

YES

NO

NO

Present bin position?

< Bin 4

Bin starts moving up.

Copy removal position?

YES

Bin stops moving

1

> Bin 4

Bin starts moving down.

NO

Paper on bin?

YES

Bin starts moving up.

Copy removal

position sensor ON?

YES

NO

3

SEP. 1995 C TOSHIBA CORP. 8 - 7 MG-1003 OPERATION FLOW CHART

3

Bin starts moving down.

2

NO

Bin home position

sensor ON?

YES

Bin stops moving.

Complete.

MG-1003 OPERATION FLOW CHART

8 - 8

SEP. 1995 C TOSHIBA CORP.

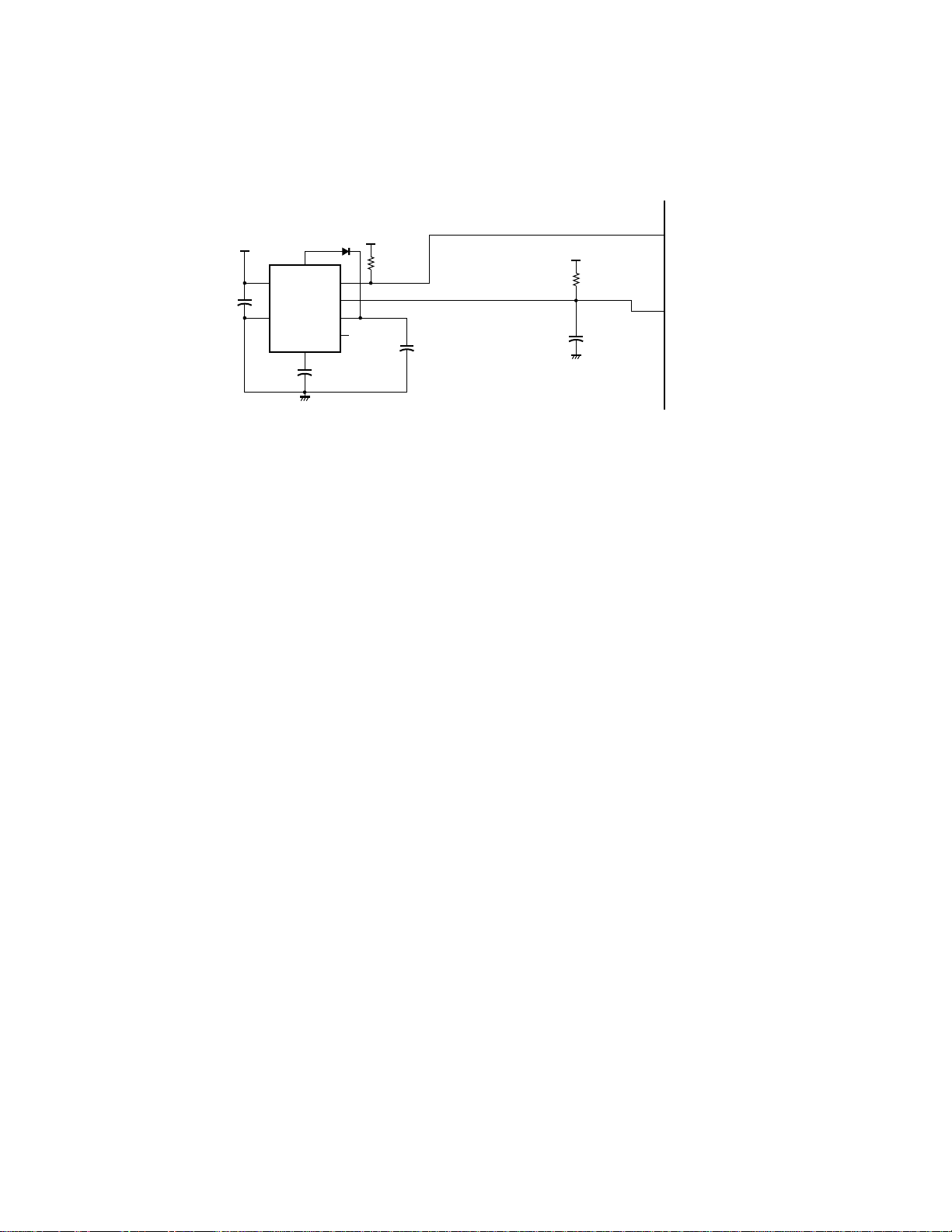

9. EXPLANATION OF CIRCUIT OPERATION

9.1 Reset Circuit

This is a reset circuit.

6

CPU

IC11

7

C17

+5V

+5V

D5

2

1

1

A

*RESIC5

VREF

C22

K

R72

2

3

CK

8

1

CT

6

C18

1

2

2

RES

5

VCC

1

42

GND

VS

7

1

2

SGND

C11

R33

+5V

SGND

1

2

1

2

It is a circuit for generating reset signals for CPU and consists for IC5 and its peripheral circuits.

IC5 has all reset functions concentrated on it and performs such functions as power-on resetting at

the time of power on, resetting when +5V drops abnormally as well as watch-dog timer function.

After the power is turned on, when the power line (+5V line) becomes approx. 0.8V, IC5 starts

functioning, making its pin 8 L level to reset CPU. This reset state is maintained until a fixed time after the

power line has reached approx. 4.3V. The reset hold time is determined by the capacitance of C18,

approx. 100msec in this circuit. After the reset hold time expires, pin 8 of IC5 becomes H level, clearing

the reset state. This causes CPU to start its operation.

Furthermore, when the power line voltage drops to approx. 4.2V, pin 8 of IC5 also becomes L level

and maintains the reset state as long as the power supply voltage is below 4.3V. The reset state is

cleared approx. 100 msec after the power supply voltage has recovered to 4.3V.

Pin 3 of IC5 provides a clock signal input terminal for a watch dog timer and uses the signal output

from pin 6 of CPU. While CPU is functioning normally, this clock signal is a regular pulse signal of a 5msec period with a duty of 50%. But when an abnormal condition such as a CPU runaway occurs, the

clock signal ceases to be output. IC5 always monitors this clock signal and when it stops being generated,

a fixed time later IC5 makes pin 8 L level to produce a reset signal. The clock monitoring time is also

determined by the capacitance of C18 and the same length of 100 msec as the hold time for power-on

resetting.

SEP. 1995 C TOSHIBA CORP. 9 - 1 MG-1003 CIRCUIT OPERATION

Loading...

Loading...