Page 1

SERVICE HANDBOOK

PLAIN PAPER COPIER

PAPER FEEDING UNIT

Click the Page Only button to close the overview area of the window.

Click the Bookmarks and Page button to open the Contents and

display bookmarks created for the document. Click a bookmark’s name

to go to the Page marked by that bookmark.

1550

MY-1004

Click the Thumbnails and Page button to open the overview area and

display thumbnail images of each document page. Click a thumbnail to

go to the page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

Page 2

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND THE SERVICE OF THE 1550/MY-1004

1. Transportation/Installation

• When transporting/installing the copier, using two persons, be sure to use the positions as indicated below.

The copier is fairly heavy and weighs approximately 35 kg (76.8 lb), therefore pay full attention

when handling it.

4 portions

2. Installation

• Be sure to use a dedicated outlet with AC 115V/15A (220V, 240V/10A) or more for its power

source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• To insure adequate working space for the copying operation, keep a minim um clearance of 80 cm

(31.5”) on the left, 80 cm (31.5”) on the right and 10 cm (3.9”) in the rear.

3. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltages sections such as the chargers and the high-voltage transformer.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, etc.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

such as the lamp terminal etc.

• Use suitable measuring instruments and tools.

Page 3

4. Main Service Parts for Safety

• The thermofuse, thermistor, fuse, breaker and door s witch, etc. are particularly important for safety.

Be sure to handle/install them properly.

5. Notice Labels

• Be sure to check the rating plate and the notice labels such as “Unplug the power cord during

service”, “Hot area”, etc. to see if there is any dirt on their surface or if they are properly stuck to the

copier during servicing.

6. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, consumable parts and packing materials, it is

recommended to follow the relevant local regulations or rules.

7. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, toothed washers in the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

Page 4

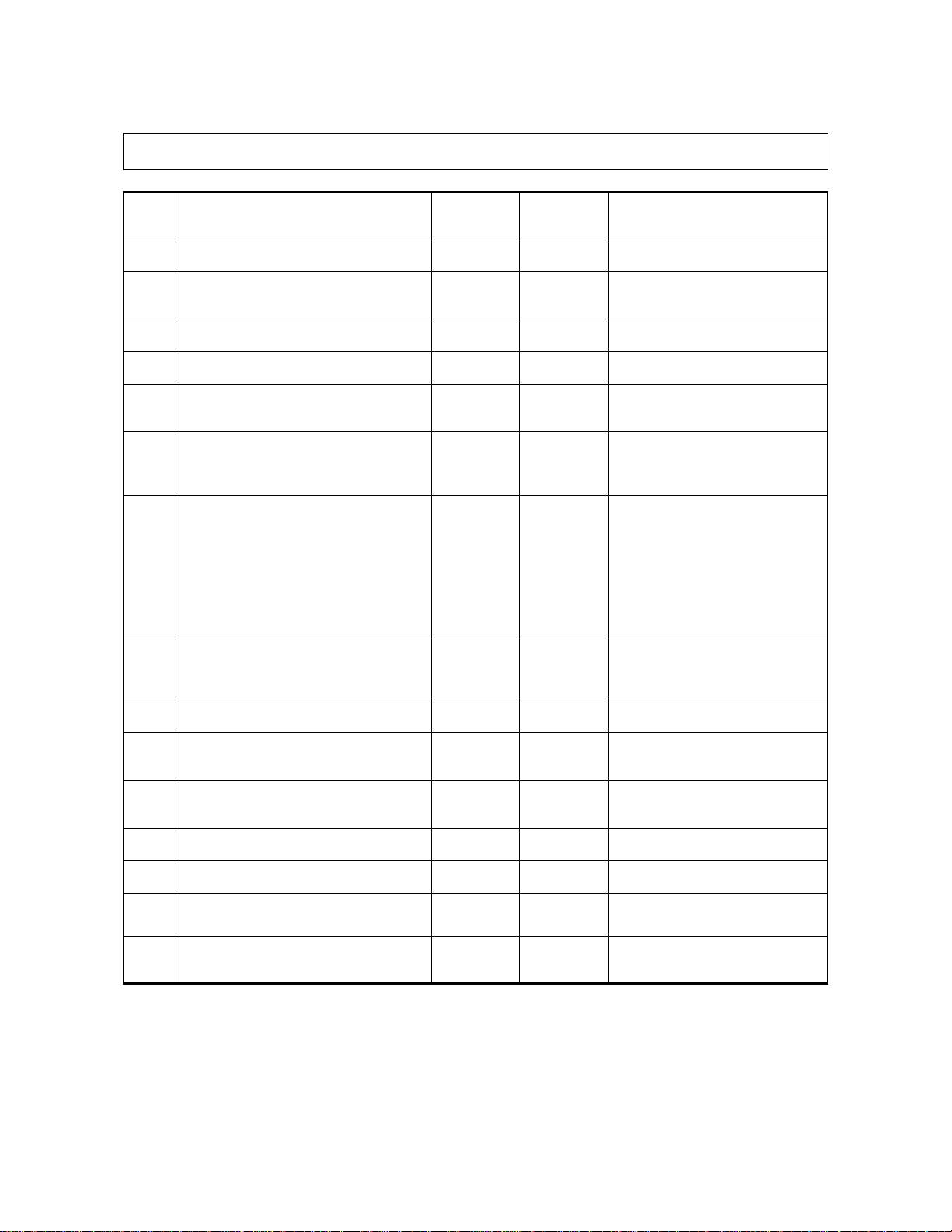

1. ADJUSTMENT ITEMS

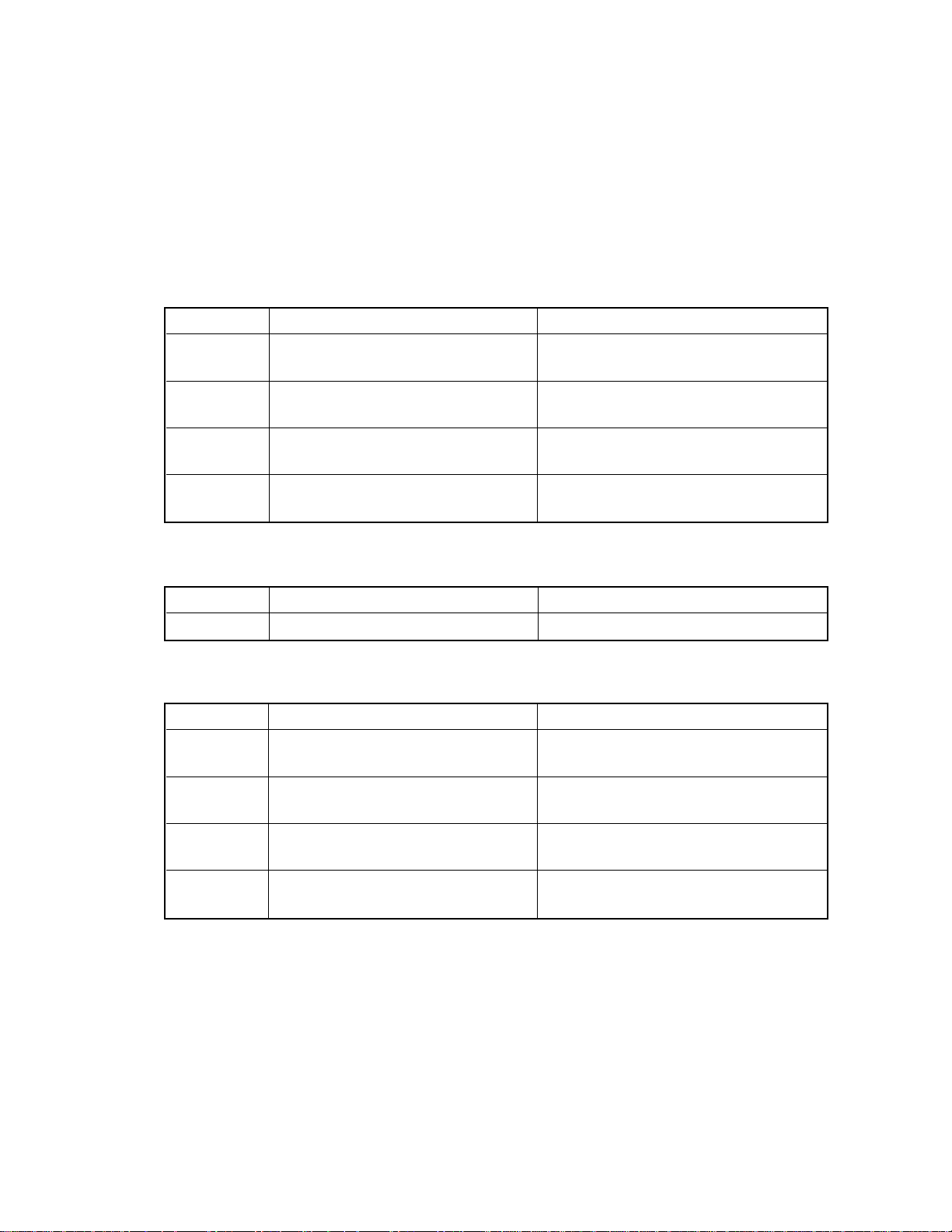

1.1 Error Code Table

When the “CLEAR PAPER” or “CALL SERVICE” symbol is flashing, pressing the “CLEAR/STOP” key

and the “8” key simultaneously causes one of the following error codes to be displayed while the keys are

pressed.

(1) Paper misfeeding in the copier paper path

Error code Content Remarks

E01 Paper misfeeding inside the copier Bypass misfeeding is also included.

(Bypass feeding LED comes ON.)

E02 Paper misfeeding in the neighborhood

of the fuser

E03 Paper misfeeding inside the copier when

the power is turned on.

E05 Non-arrival-at-aligning-switch misfeed- After the paper fed from PFU has passed

ing the transport roller or fed from PPC?

(2) Paper misfeeding in the paper feeding section

Error code Content Remarks

E14 Lower cassette paper misfeeding (PFU) Paper does not arrive at the transport roller.

(3) Paper misfeeding in the ADF transport path

Error code Content Remarks

E71 Misfeeding in the ADF original feeding

section

E72 Midfeeding in the ADF original transport

section

E73 Misfeeding in the ADF original exiting

section

E75 2 in 1 (2nd-original misfeeding in the

feeding section)

1 - 1Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 5

(4) Paper misfeeding in the sorter transport path

Error code Content Remarks

E81 Paper delaying jam in the sorter Paper does not arrive at the entrance

transport path sensor.

E82 Paper staying jam in the sorter Paper stays at the entrance sensor.

transport path.

(5) Service call for the copier’s drive system

Error code Content Remarks

C01 Abnormal operation of the main motor

(6) Service call for the optical system

Error code Content Remarks

C21 Optical system initialization error Scanning, lens or mirror abnormal operation.

C22 Optical system initialization error When the lens is moved in the paper exit

direction at the time of the start of

initialization,and only if it is not detected by

the switch.

C26 Blown exposure lamp detection

(7) Service call for the process system

Error code Content Remarks

C32 Easy setup (UA mode) error

(8) Fuser unit related

Error code Content Remarks

C41 Abnormal thermistor or broken heater

when the power is turned on.

C43 Abnormal thermistor during warming up.

C44 Heater breakage after the copier

becomes ready.

(9) Communication related service call

Error code Content Remarks

C54 Abnormal communication between the

C55 Abnormal communication between ADF

1550 ADJUSTMENT

sorter and the main CPU

and the main CPU

1 - 2

July 1996

®

Oct. 1995 © TOSHIBA CORP.

Page 6

(10) ADF related

Error code Content Remarks

C71 Locked ADF main motor ADF jam LED is flashed.

C72 Maladjusted aligning sensor detection ADF jam LED is flashed.

C73 Faulty EEROM initialization ADF jam LED is flashed .

(11) Sorter related service call

Error code Content Remarks

C81 Abnormal paper transport motor

C82 Abnormal bin-moving motor

C83 Upper limit error

C84 Lower limit error

C85 Home sensor error

C88 Copy-removal sensor error

(12) Service call for other abnormalities

Error code Content Remarks

C94 Faulty optical system initialization in The content is similar to C21 error.

special modes (CH, AJ).

1 - 3Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 7

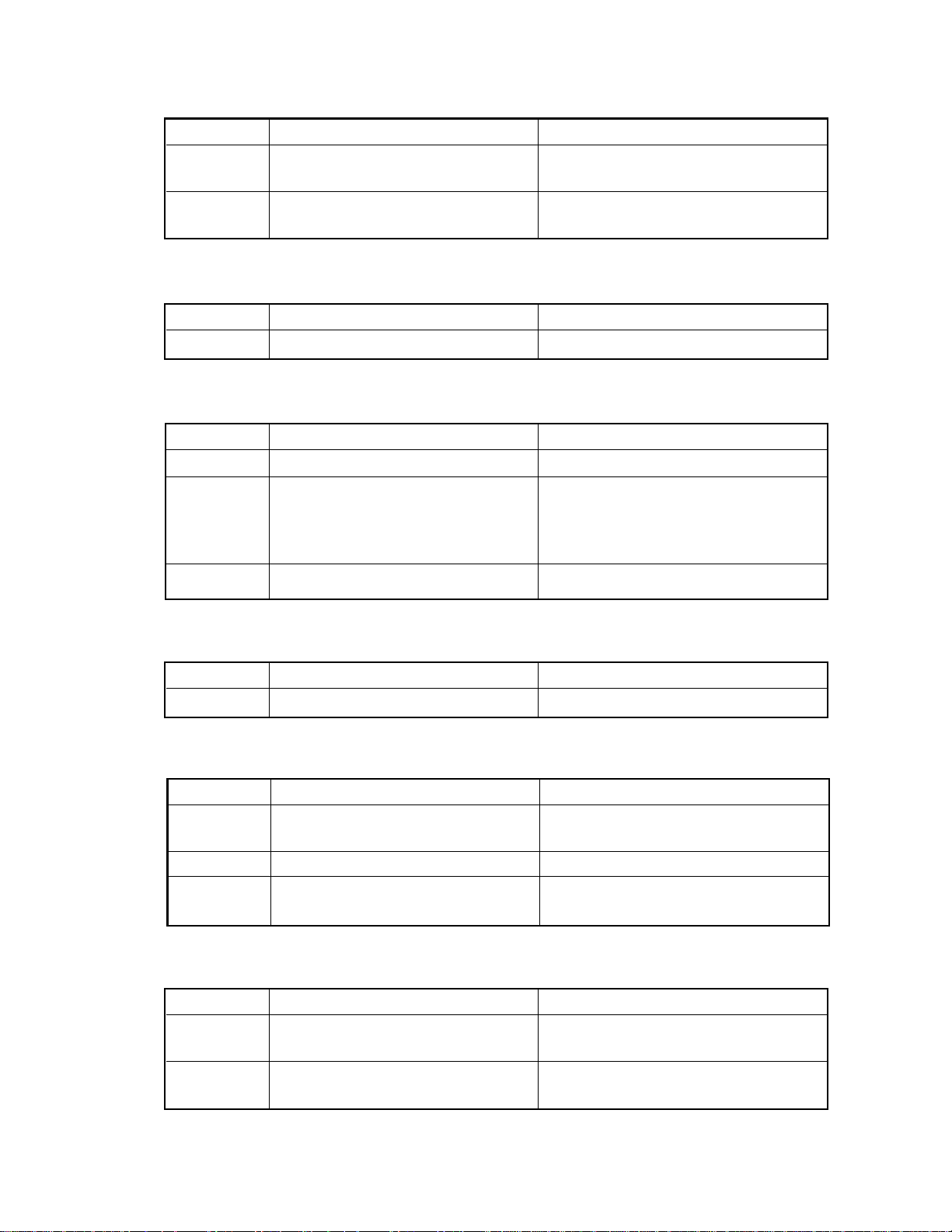

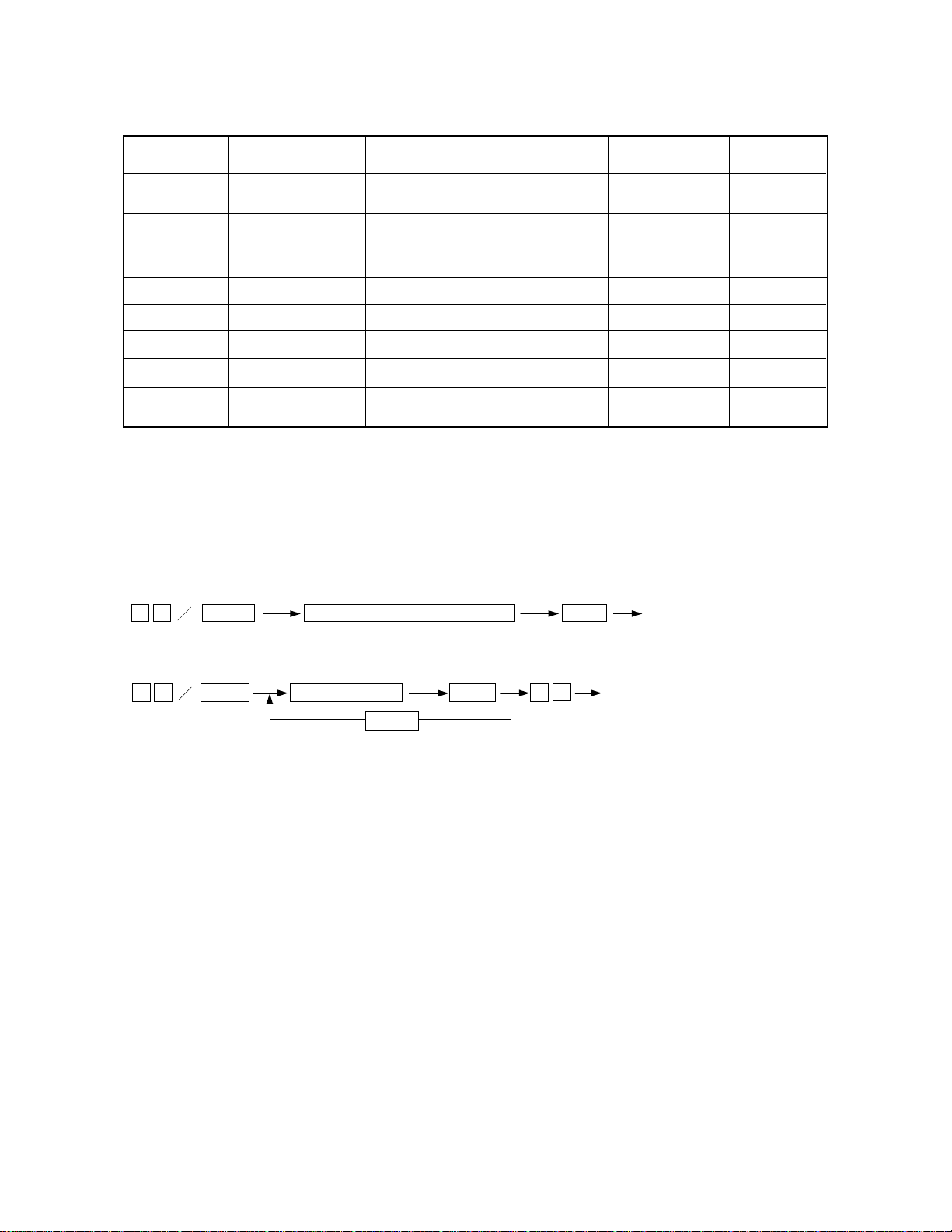

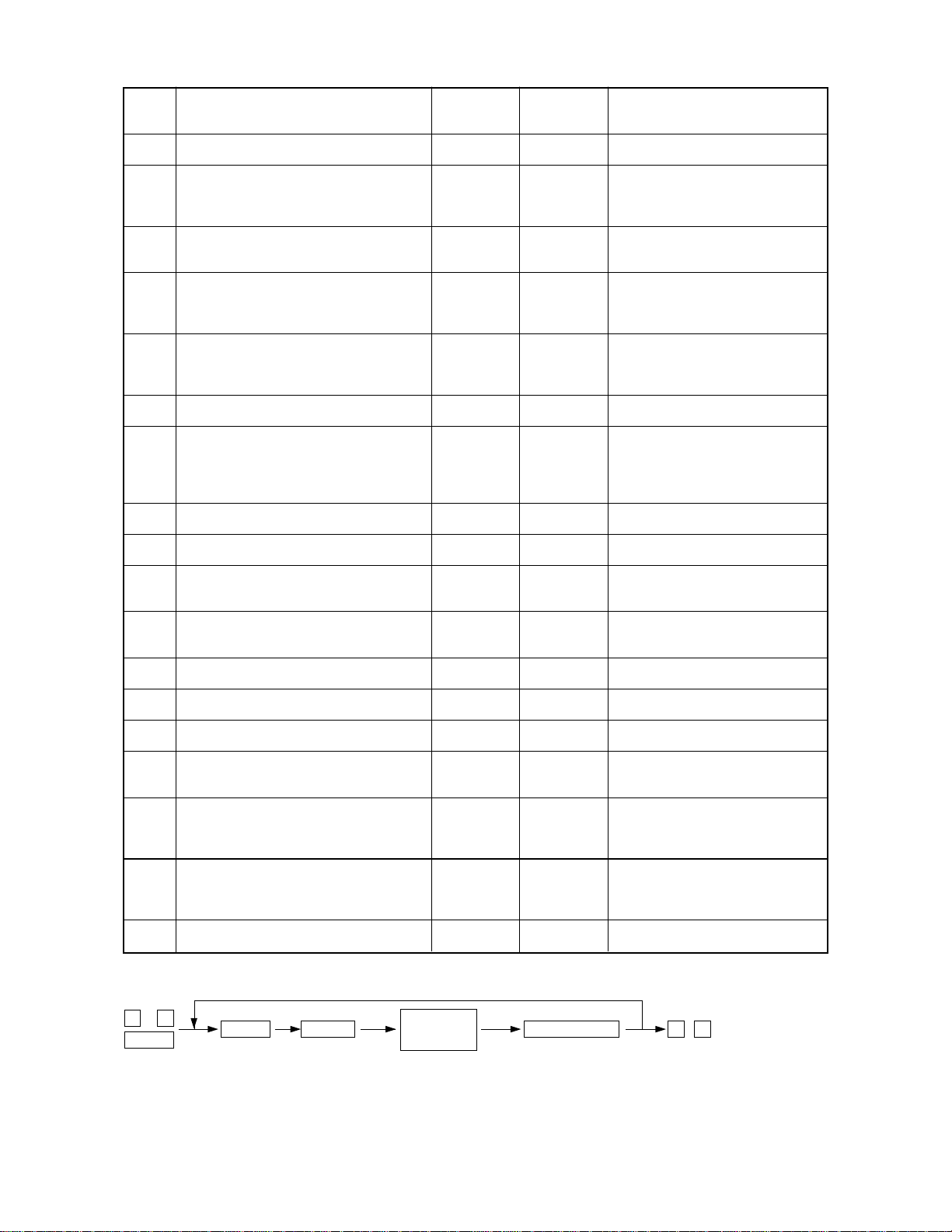

1.2 Self-Diagnostic Mode

Keys pressed

simultaneously

0+1

0+2 Aging mode Aging “09”

0+3 Test mode “09”

0+5 Adjustment mode Various adjustments “09”

0+6 Forced ready mode Forces the copier to become ready. —

0+7 Aging mode Aging (with ADF) “09”

0+8 Setting mode “09”

All control-panel LEDs

ON mode

Mode Description Clearing

All LEDs on the control panel come on.

Motor test and input/output check

(including initialization)

Motor test and input/output checkTest mode0+4 “09”

System changing and setting defaults and

PM counter

“Clear/Stop” key

Note: How to access each mode:

While pressing the two keys for the mode to access (ex. “0” and “5” for the adjustment mode), turn on the

main (power) switch.

<Procedure>

• All control-panel LEDs ON mode (01) :

Indication

—

AG

CH

CH

AJ

—

AG

AD

01

Power

All control-panel LEDs come on C/S Clear

• Aging mode (02) :

02

Power

Aging operation

PRINT

C/S 0 9 Clear

• Test mode (03 or 04) :

For this mode, refer to the “Input/Output Check” on page 1-6.

• Adjustment mode (05) :

For this mode, refer to the “Adjustment Mode” on page 1-9.

1550 ADJUSTMENT

1 - 4

Oct. 1995 © TOSHIBA CORP.

Page 8

•Forced ready mode (06) :

Power

06

Forced ready status

Note: This mode should be used only when checking paper feeding operation.

•Setting mode (08) :

For this mode, refer to “Setting Mode” on page 1-12.

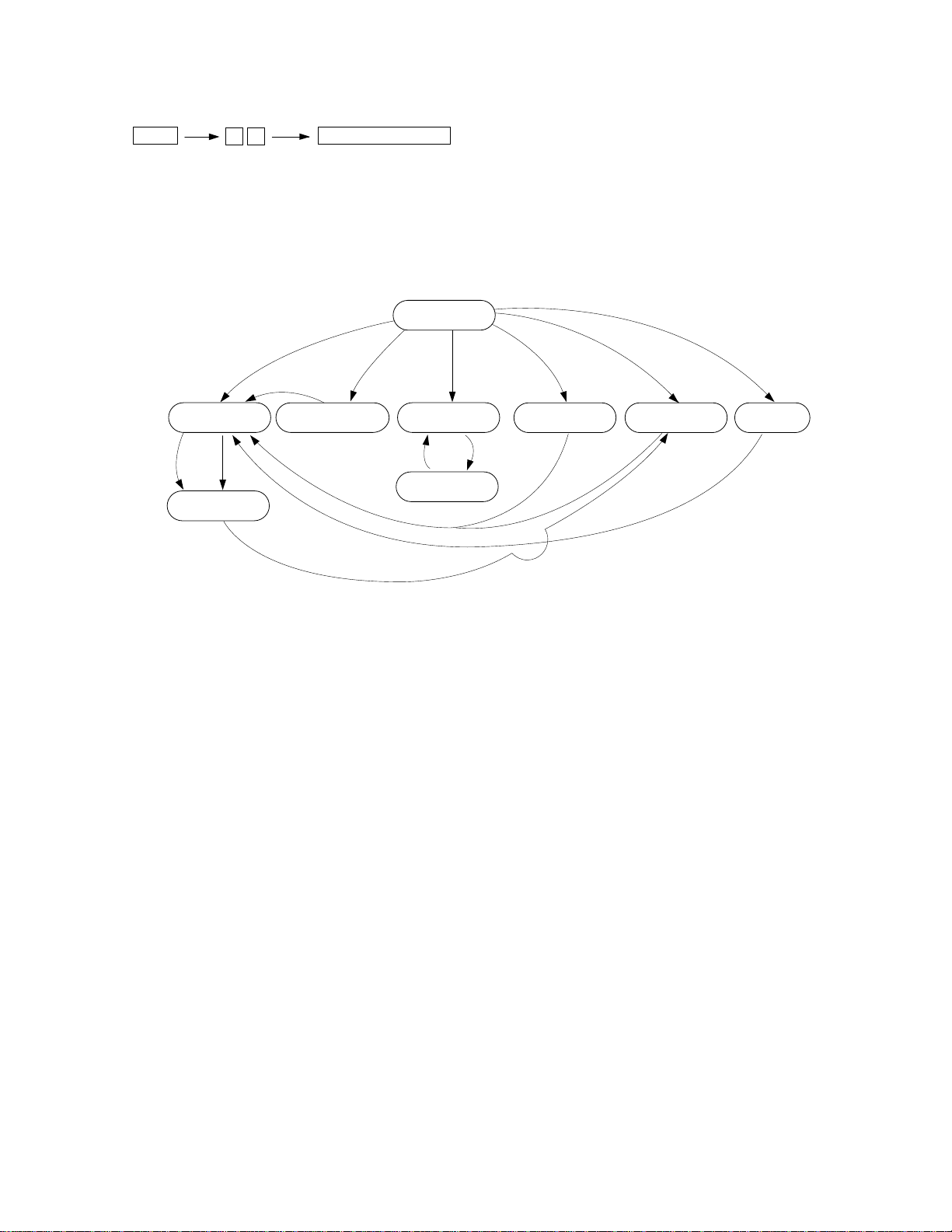

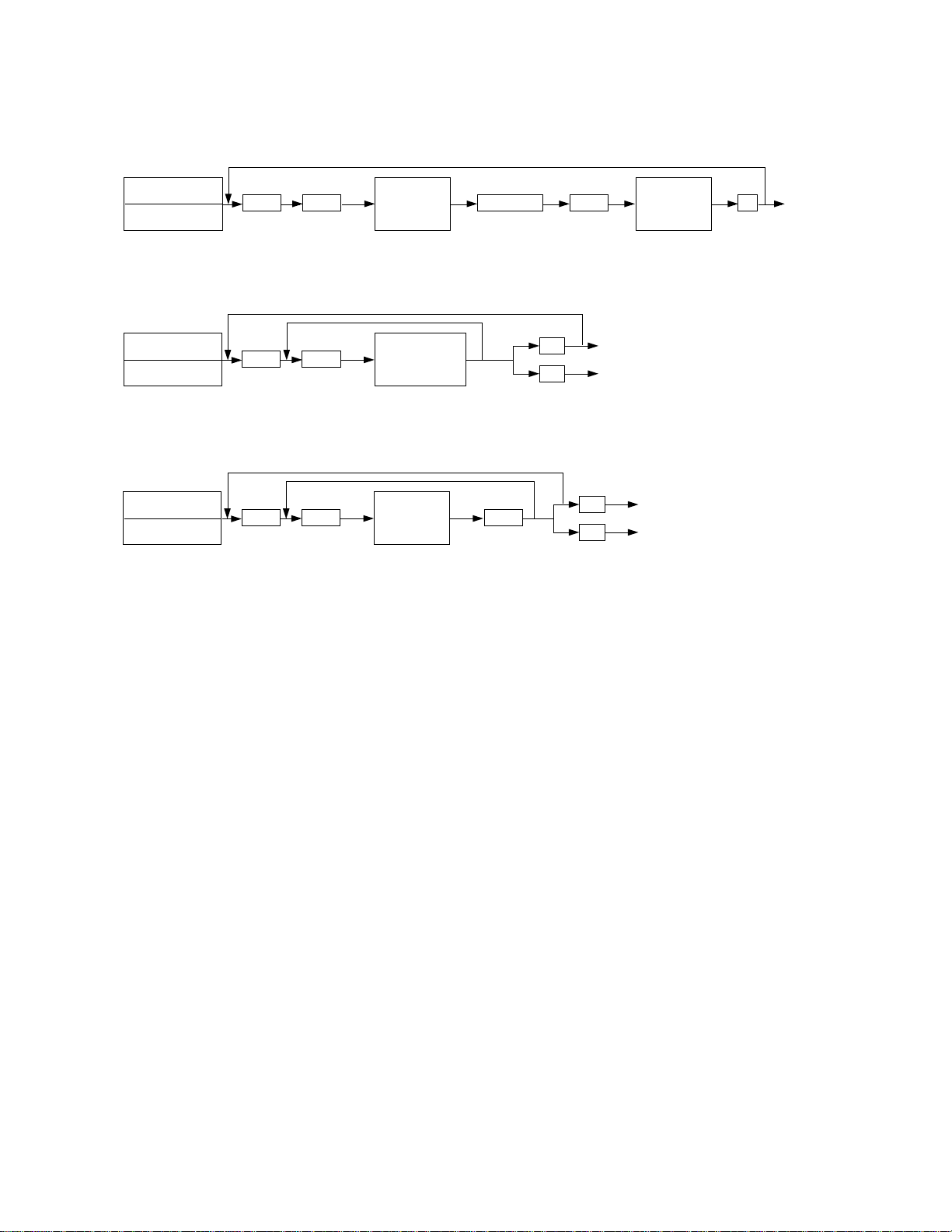

Self-diagnostic mode progress diagram :

Power ON

“06”

Warming up

Stand-by

“C”

All control-panel

LEDs ON

“01”

“05”

“02”

“07”

Aging

“P”

Temporary stop

“C”

“03/04”

Test mode

“09”

“05”

Adjustment mode Setting mode

“08”

“09” “09”

“P” : Press PRINT.

“C” : Press CLEAR/STOP.

1 - 5Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 9

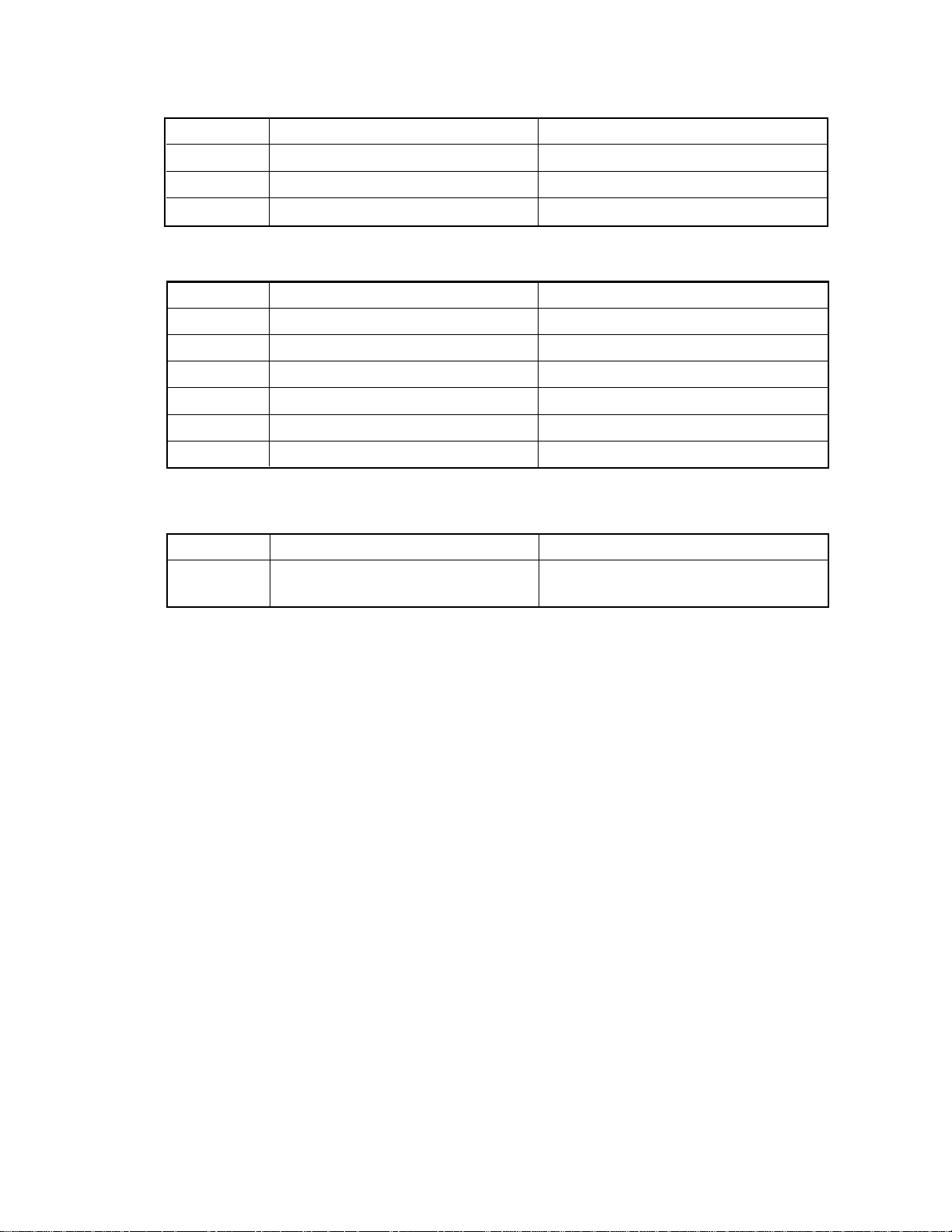

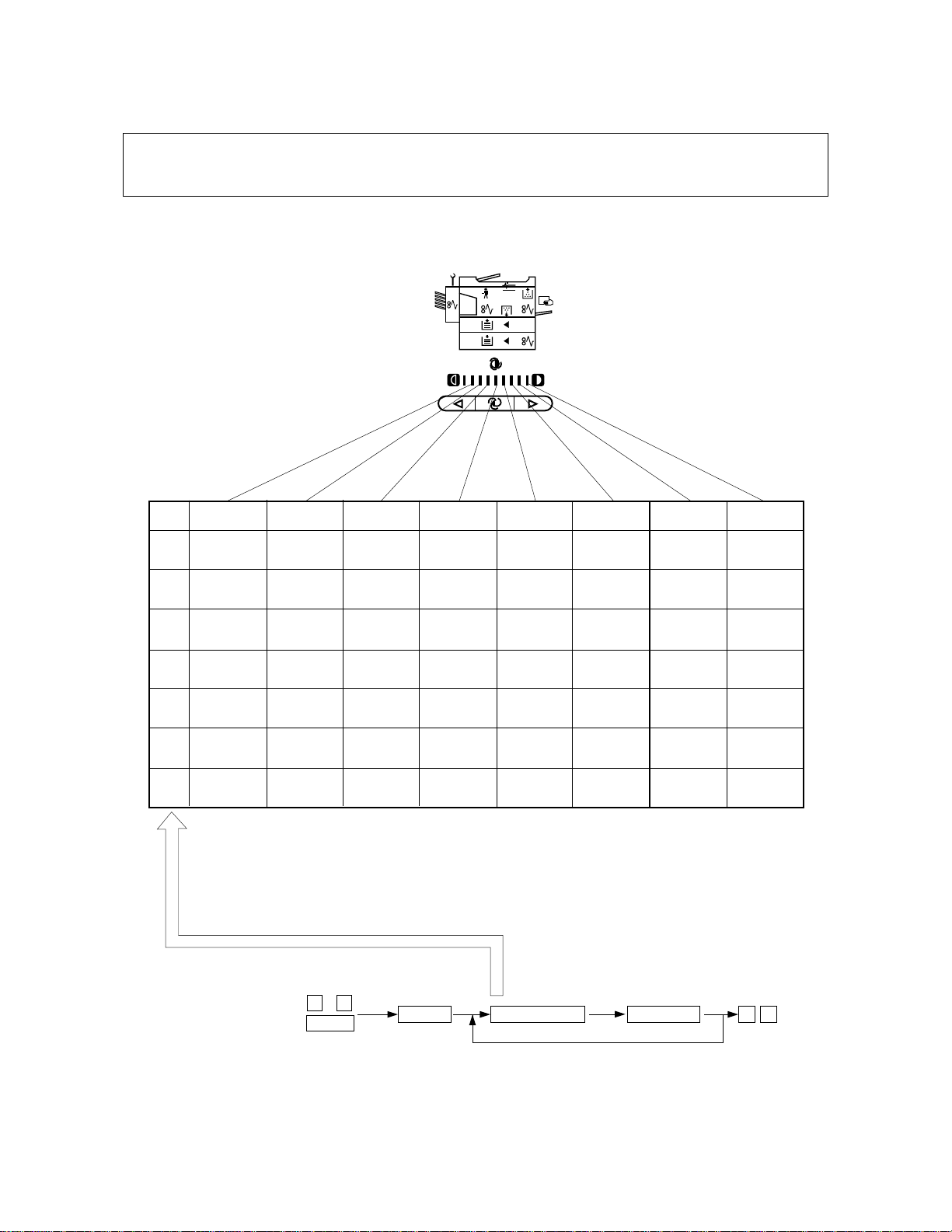

1.2.1 Input check (Test mode 03/04)

In the 03 or 04 test mode, you can check the status of each of the following input signals by pressing

the corresponding keys.

DARKLIGHT AUTO

Input

value

1

2 ————

3

4

5

6

7

EXP1

————

—

EMP-SW

(No paper)

RGT-SW

(Paper

present)

—

( ) means that LEDs come on.

*

EXP2

CTR-CNT

(No CTR)

EXIT-SW

(Paper

present)

CST2

(No cassette)

—

——

EXP3

HTR-RDY

(Not ready)

TNR-FUL

(Normal)

EMP-SW2

(No paper)

Paper width

sensor 2

(ON)

Removal

sensor

(ON)

Paper width

EXP4 EXP5 EXP6

DF-CNT

(No DF)

————

FED-SW

(Paper

present)

sensor 1

(ON)

Limit

sensor

(ON)

PFU cover

switch

(open)

S-CNT

(No sorter)

SIZ03

(OFF)

SIZ13

(OFF)

Empty sensor

(ON)

Bin-home

sensor

(ON)

Developer

unit switch

(none)

MRR-HOM

(Home

position)

SIZ02

(OFF)

SIZ12

(OFF)

Open sensor

One-rotation

sensor

(ON)

(ON)

EXP7 EXP8

Main motor

PLL

(NG)

LNS-HOM

(Home

position)

SIZ01

(OFF)

SIZ11

(OFF)

Exit sensor

(ON)

Paper-on-tray

sensor

(ON)

—

—

CRG-HOM

(Home

position)

SIZ00

(OFF)

SIZ10

(OFF)

Aligning

sensor

(ON)

Entrance

sensor

(ON)

1550 ADJUSTMENT

<Procedure>

03

Power

PRINT

1 - 6

Nemeric keys

LED ON

09

Oct. 1995 © TOSHIBA CORP.

Page 10

1.2.2 Output check mode (Test mode 03/04)

In the 03 or 04 test mode, you can check the status of each of the output signals by entering the

following corresponding code.

Code

1 Main motor

2 Feed roller clutch (copier)

3 Aligning roller clutch (copier)

6 Toner motor

7 Optics fan

8 Exit fan

9 Pick-up roller clutch (copier)

10 Total counter Increases at each “P” key press.

*1

20 Scanning motor At 1st “P” key press, scans forward and backward at 2nd press.

21 Lens motor At 1st “P” key press, moves to 50% position and to 200%

22 Mirror motor At 1st “P” key press, moves to 50% position and to 200%

30 HVT-M

31 HVT-TR

32 HVT-AC

33 Exposure lamp If forced on for 5 sec., it goes off.

61 PFU motor (PFU)

62 Pick-up roller clutch (PFU)

63 Feed roller clutch (PFU)

64 Aligning roller clutch (PFU)

80 DF independent aging At 1st “P” key press, starts and stops at 2nd press.

82 DF pick-up roller rotation

Function Code Function Group

64444474444448

ON

position at 2nd press.

position at 2nd press.

64748 64474448

At 1st “P” key press, comes on and goes off at 2nd press.

ON

11 Main motor

12 Feed roller clutch (copier)

13 Aligning roller clutch (copier)

16 Toner motor

17 Optics fan

18 Exit fan

19 Pick-up roller clutch (copier)

71 PFU motor (PFU)

72 Pick-up roller clutch (PFU)

73 Feed roller clutch (PFU)

74 Aligning roller clutch (PFU)

644444444474444444448

64444474444448

OFF

64474448

OFF

1

2

3

1

83 DF aligning roller

84 DF transport belt rotation

85 DF pick-up roller rotation/Weight solenoid

86 DF weight solenoid

87 DF clutch

90 Sorter transport motor

91 Sorter bin motor

92 Sorter aging without paper At 1st “P” key press, starts and goes off at 2nd press.

*1: Scanning motor rotates at the preset reproduction ratio.

At 1st “P” key press, comes on and stops at

2nd press.

1 - 7Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

3

Page 11

<Operation procedure>

Group 1

03/04

Power supply

Group 2

03/04

Power supply

Group 3

03/04

Power supply

Code Print

Code Print

Code Print

Operation

ON

Operation

(one direction)

Operation

(ON)

Stop code

Print

Print 09 Warm up

C/S

09

C/S

09

Oparation

OFF

Test mode standby state

Warm up

Test mode standby state

Warm up

1550 ADJUSTMENT

1 - 8

Oct. 1995 © TOSHIBA CORP.

Page 12

1.2.3 Adjustment mode (AJ: 05)

In this adjustment mode, the following items can be adjusted or modified. (Refer to the adjustment

code list.) The adjustment mode can be accessed b y turning on the power while pressing the “0” and

“5” keys simultaneously.

Code Description

*2

0 Automatic auto-toner adjustment — — Set to 24.

1 Manual exposure 100% 0~255 128 The larger, the lighter.

2 Manual exposure 154% 0~255 128 The larger, the lighter.

3 Manual exposure 50% 0~255 128 The larger, the lighter.

4 Manual exposure 200% 0~255 128 The larger, the lighter.

5 Auto-exposure 100% 0~255 128 The larger, the lighter.

6 Auto-exposure 154% 0~255 128 The larger, the lighter.

7 Auto-exposure 50% 0~255 128 The larger, the lighter.

8 Auto-exposure 200% 0~255 128 The larger, the lighter.

9 Exposure (light) Inclination 0~255 255

10 Exposure (dark) Inclination 0~255 0

14 Photo exposure 100% 0~255 128 The larger, the lighter.

Allowable Initial

input value value *1

Content

The larger, the lighter at the

light side.

The larger, the lighter at the

dark side.

15 Photo exposure 154% 0~255 128 The larger, the lighter.

16 Photo exposure 50% 0~255 128 The larger, the lighter.

17 Photo exposure 200% 0~255 128 The larger, the lighter.

Lengthwise reproduction

21

ratio adjustment

25 Eraser LED timing adjustment 100%

26 Eraser LED timing adjustment 200% 0~15 8

27 Eraser LED timing adjustment 50%

0~15 8

1 - 9Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Each increase by “1” causes the

lenthwise reproduction ratio to

increase by 0.1%

Each increase by “1” causes the

erased position by LED to shift

approx. 1mm toward the trailing

edge of the paper. But the

image position relative to the

paper does not change. (with

original surface as reference)

Page 13

Code Description

Eraser LED leading edge margin

30

adjustment

Eraser LED trailing edge margin

31

adjustment

35 Margin on the leading edge

36 Margin on the trailing edge

Allowable Initial

input value value *1

0~15 8

0~15 0

Content

Each increase by “1” causes the

erased position by LED to shift

1mm toward the trailing edge.

(with paper surface as reference)

0:No margin

1–15:Margin present (approx.

1mm/step)

38 Grid bias adjustment 0~255 128 The larger, the larger output.

39 Transfer transformer adjustment 0~255 128 The larger, the larger output.

40 Separation transformer adjustment 0~255 128 The larger, the larger output.

42 Grid bias adjustment (photo) 0~255 121 The value should be 121.

*3

49 Automatic auto-exposure adjustment — —

53 Leading edge (copier; 100%)

54 Leading edge (copier; 200%)

55 Leading edge (copier; 50%) 0~15 8

56 Leading edge (bypass feeding)

Each increase by “1” causes the

image to shift 0.80mm toward

the paper leading edge.

57 Leading edge position (PFU)

60 Lens position adjustment (100%)

61 Mirror position adjustment (100%)

Each increase by “1” moves

toward the exit side.

62 Enlargement correction (200%)

63 Enlargement error ratio (200%)

0~40 20

64 Reduction correction ( 50%)

65 Reduction error ratio ( 50%)

80 Aligning value (PFU) 0~31 8

Each increase by “1” causes the

paper to bend more.

81 Aligning value (short size) 0~31 16

82 Aligning value (copier) 0~31 8

83 Aligning value (B5) 0~31 16

Short size: A4/A5-R,LT/ST-R

B5: for B5 only

The adjustment sequence must

be 82

→89→81→83→80.

Each decrease by “1” causes

84 ADF aligning amount 0~15 8

the original stop position to shift

about 1mm toward the original

scale.

ADF original-to-original gap

87

(2 in 1 mode)

0~15 8

Each increase by “1” causes the

gap between the originals to

increase about 1mm.

Each increase by “1” causes

89 Aligning value (middle size) 0~31 16

the paper to bend more

Middle size: A4-R/B5-R/FOLIO,

LG,LT-R

90 Auto-toner adjustment 0~255 128

*4

97 ADF EEPROM initialization — —

*4

ADF aligning sensor

98

automatic adjustment

——

Shows the adjustment value of

the auto toner sensor.

*1: The initial value signifies the value set by the NV-RAM initialization program and not the value set at the time

of shipping from the factory.

1550 ADJUSTMENT

1 - 10

®

July 1996

Oct. 1995 © TOSHIBA CORP.

Page 14

<Procedure>

0

5

Power

*2

05

Power

0

Code

PRINT

PRINT

Adjustment

Automatic auto-toner adjustment

INTERRUPT

Memorize

ENERGY SAVER

Test copy

INTERRUPT

Memorize

09

Clear

0

Clear

9

*3

*4

5

0

Power

05

Power

49

97

98

PRINT

PRINT

Automatic auto-exposure adjustment

ADF EEROM initialization

ADF Aligning roller

automatic adjustment

Ends 2

sec.

later.

09

Clear

(Possible only after the

automatic adjustment

is completed.)

09

Clear

1 - 11Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 15

1.2.4 Setting mode (08)

In this mode, it is possible to set or modify the various modes shown in the following setting code list.

Code Description

2 Size indication by the carriage 0, 1 1 0: None; 1: Available

4 Automatic sort mode 0~3 0

7 Access control mode 0, 1 0 0: None; 1: Available

8 Version 0~2 Each version 0: EUR; 1: UC; 2: JPN

9 ACT selection (reproduction ratio

in the direction of copy movement) 1: UC

10 Timer mode (auto reset) 0~10 3 (45 sec.) 2: 30sec.; 3: 45 sec.

11 Auto power saving 0~15 0

12 Maximum number of copies 0~3 0 1: Max. 99; 2: Max. 9

Allowable Initial

input value value

0, 1

0: EUR

Content

0: None;

1, 2: Sort; 3: Group

0: 100%; 1: 101%

0: None; 1: 15 sec.

4: 60 sec.; N:

0: None; 1: 30 sec.

2: 60 sec.; 3: 90 sec.

4: 120 sec.; 5: 150 sec.

6: 3 min.; 7: 4 min.

8: 5 min.; 9: 7 min.

10: 10 min.; 11: 15 min.

12: 20 min.; 13: 30 min.

14: 45 min.; 15: 60 min.

0: Max. 999 copies

3: Max. 500

N x15 sec.

13 Paper feeding retry 0,1 0 0: Retry; 1: No retry

14 Cassette priority selection 0~4 0

15 Exposure priority selection 0~2 0

16 A3-size double counting 0,1 0 0: Single count; 1: Double count

17 Bypass auto start 0,1 0 0: Manual start; 1: Auto start

19 Sorter priority selection 0~3 0

20 Pre-run ON/OFF 0~15 0

1550 ADJUSTMENT

1 - 12

0: A4/LT

3: Copier; 4: PFU

0: Auto; 1: Manual

3: Photo mode

0: Non-sort;

1, 2: Sort; 3: Group

0: OFF

N x10 sec.

1~15:

Oct. 1995 © TOSHIBA CORP.

Page 16

Code Description

21 Auto cassette change 0,1 1 0: None; 1: Available

Allowable Initial

input value value

Content

22 ADF mode 0~5 0 2: AMS; 3: 2 in 1+AMS

23 Thick paper selection at bypass

pre-running

27 ADF’s APS mode 0~2

Pressing PRINT after suspension of

28

APS/AMS

37 Default sorter key selection 0,1 0 0: Normal; 1: Sort default

38 Heater temperature during power saving 0~7 0 4: 150°C; 5: 160°C

44 All clearing after copying 0,1 0 0: None; 1: Available

51 Easy set-up method (UA mode) 0,1 0 0: No; 1: Yes

52 Quick copy mode 0,1

53 Broken exposure lamp detection 0~2 0

0,1 0 0: None; 1: Available

0: UC

1: EUR

0~2 0 1: 2nd Copying possible

0: EUR

1: UC

0: Manual; 1: APS

4: 2 in 1+APS 5: 2 in

0: Detection for each original;

1: Detection for 1st original only;

2: Prevents copying blank originals

0: 1st copying possible

2: Copying not possible

0: Heater off; 1: 120°C

2: 130°C; 3: 140°C

6: 170°C; 7: 180°C

0: None; 1: Available

0: All exposure modes

1: Auto only; 2: None

54 Coin-vender mode 0,1 0 0: None; 1: Available

58 Reproduction-ratio display time 0~15 0 2+0.2xN sec.

59 LG size 0,1 0 0: 14 inch; 1: 13 inch

62 AMS copy stop switching 0,1 0

63 DF key selection order switching 0,1 → 2in1 + APS → 2in1

69 PM counter setting 0~999,999 0 Other than 0: When set value

79 Current PM counter value 0~999,999 0

0: EUR

1: UC

0: No stop;

1: Temporary stop

0: APS → AMS → 2in1 + AMS

0: APS → AMS → 2in1 + AMS

0:No PM counter;

< code 79, PM call occurs.

<Procedure>

0

Power

8

Code

PRINT

Setting or

modifying

the value

INTERRUPT

Memorize

0

Clear

9

1 - 13Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 17

Code Description

89 Heater abnormal counter 0~7 0

Error code Code 89 Timing of the error Cause of the error

C41 1

C43 4 During warming up

Allowable Initial

input value value

Value

When the power is

turned on

2

Content

Abnormal thermistor

(disconnection) or broken

heater

Abnormal thermistor

(disconnection)

5

C44 6

Absent (normal) 0 --- ---

• When the power is the turned on, if an abnormality occurs, the C41 “CALL

SERVICE” symbol will flash, and the value of the setting mode code 89 will

be counted up.

• When the Code 89 value is 0~1, rewarming up is performed by turning on the

machine again.

If the value is 2 or more, “CALL SERVICE” symbol will flash immediately.

• If an abnormality occurs during warming up or the standby mode, C43 or

C44 “CALL SERVICE” symbol will flash immediately, and the value of the

setting mode code 89 depends on the conditions present at the time of the

occurrence.

After the finish of

warming up

7

Broken heater

Abnormal thermistor

(disconnection)

Broken heater

1550 ADJUSTMENT

1 - 14

® July 1996

Oct. 1995 © TOSHIBA CORP.

Page 18

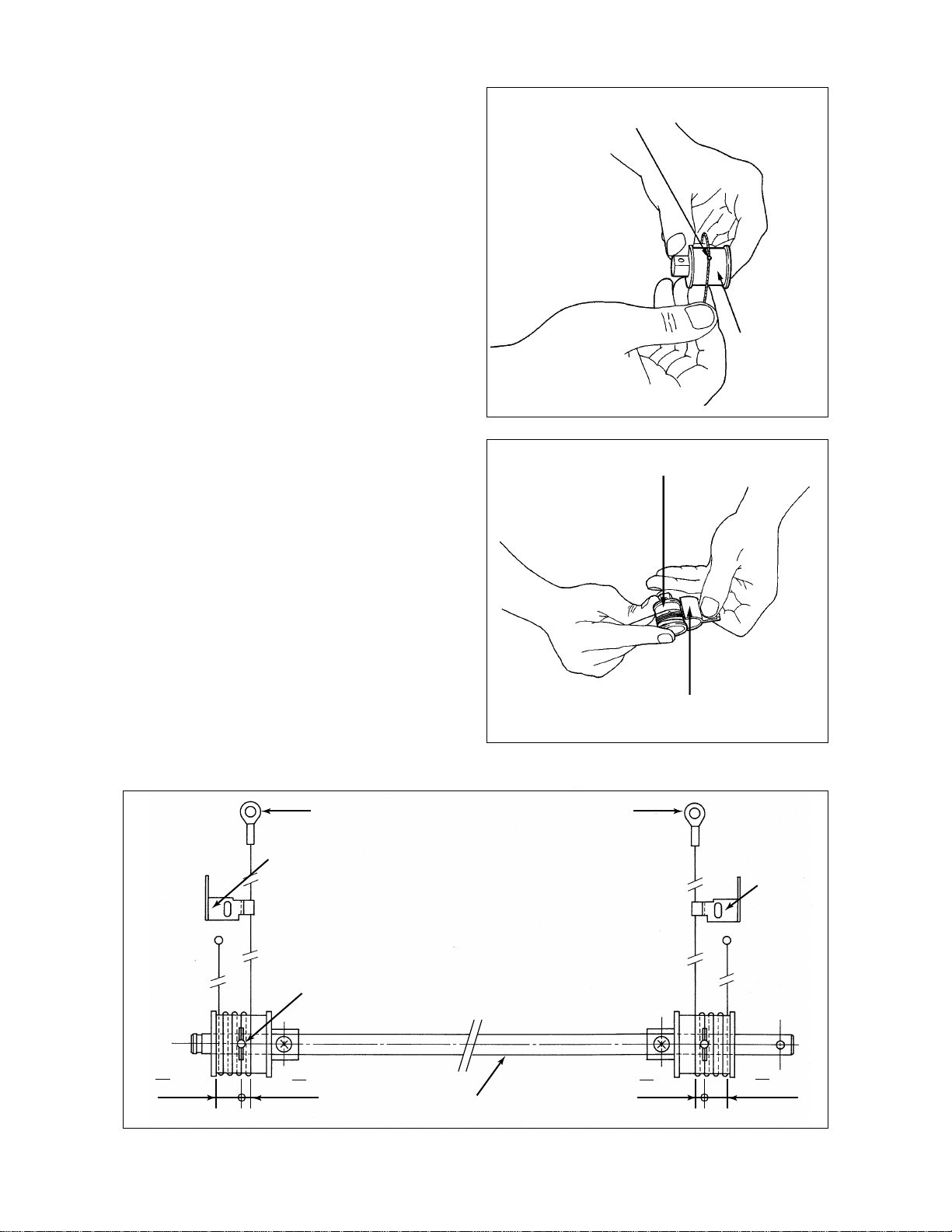

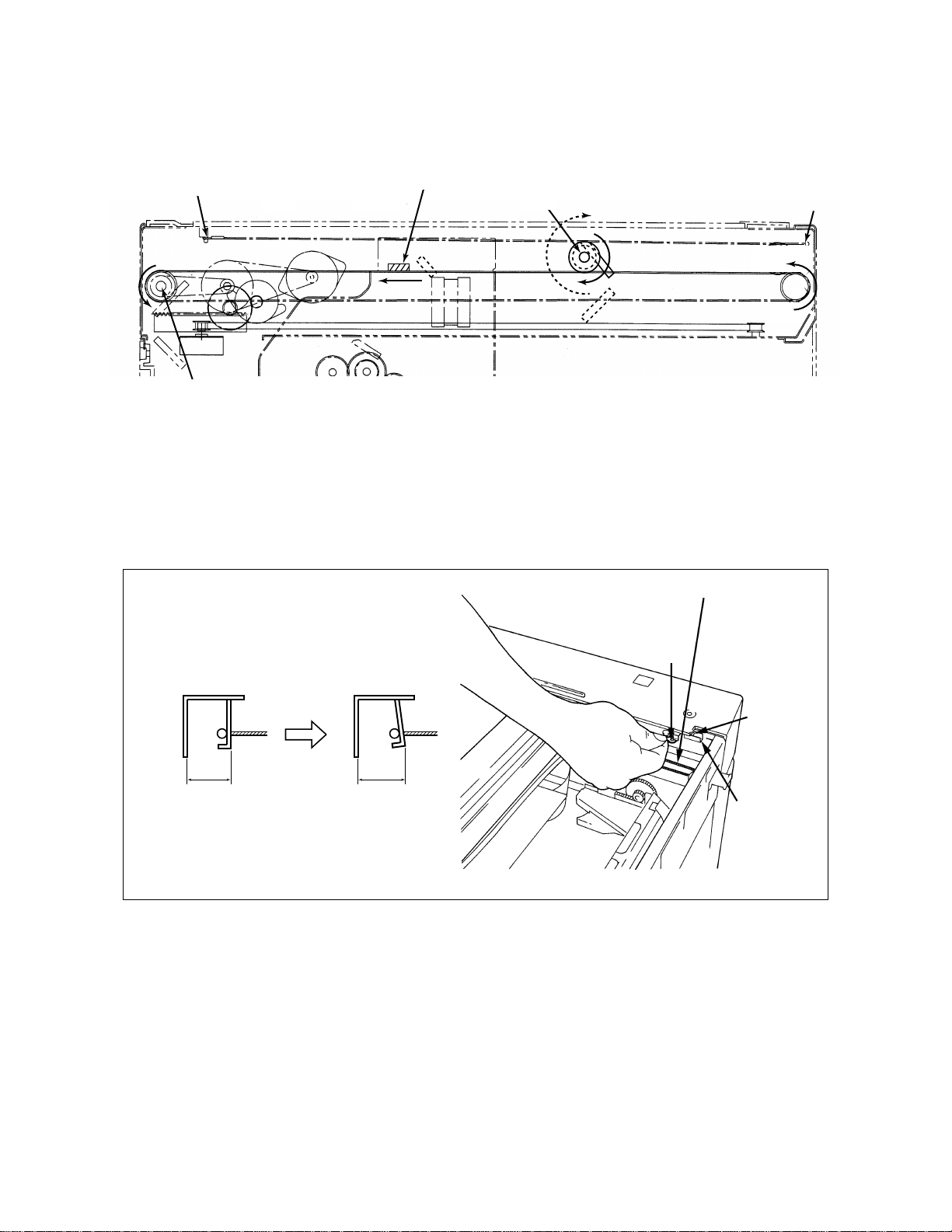

1.3.A Installing the Carriage Drive Wire

(1) Set the wire so that its spherical terminal is

placed in the hole of the wire take-up pulley.

Spherical terminal

Wire takeup pulley

(2) Using the wire holder jig, wrap the wire on the

take-up pulley, 3-1/4 turns of the fixture-side

Wire take-up pulley

end and 5-1/4 turns of the other end.

Wire holder jig

(3) Wrap the wires on the front and rear sides, as shown and fasten them with screws.

[Front side]

Hook (feed side)

Front side wire fixture

(Marking “F”)

Hook (feed side)

[Rear side]

Rear side

wire

fixture

(Marking

“R”)

1

5 turns

4

closely fit

Spherical terminal

1

3 turns

4

closely fit closely fit

Shaft

1 - 15Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

1

3 turns

4

1

5 turns

4

closely fit

Page 19

(4) Install carriage 2.

(5) As shown on figure , attach the wires.

[Feed side]

Wire fixing 1

8.5 turns

4

1

Shaft

Fixed to CRG 1

CRG 2

2

3

6

View as seen from the rear

[Exit side]

Wire fixing 7

5

1.3.B Adjusting the Carriage Wire Tension

After having removed the wire, adjust the tension of the wire with the adjustment screw so that the exit

side leaf spring will be deflected as shown in the drawing below.

Also, always adjust the positions of the carriage 1 and 2 after finishing the tension adjustment.

Carriage drive wire

(12.8)

(Before) (After)

(Deflect it by

2 mm)

(14.8)

Hook

Adjustment

screw

Wire tension

bracket

1550 ADJUSTMENT

1 - 16

Oct. 1995 © TOSHIBA CORP.

Page 20

1.4 Position Adjustment of Carriage 1 and 2

(1) While pushing carriage 2 to exit side, tighten

the screw on the front.

(2) Fasten carriage 1 to the wire: Each screw on

the front and rear should be tightened temporarily.

(3) While pushing carriage 1 to the exit side (car-

riage 2), tighten the screws

[Exit side]

Carriage 2

[Exit side]

..... on the front and rear.

Note: Move carriages 1 and 2 to the exit side by

rotating the shaft and check to make sure

that the claws of both carriages (two for each)

touch the inside surface of the frame at the

same time.

Carriage 1

1 - 17Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 21

1.5 Light Distribution Adjustment

(1) Remove the glass holder (2 screws) and then

the original glass.

(2) Move light-distribution adjustment plate 1 -

3 in the direction of the arrow (@), depend-

ing on the amount of uneven light distribution.

Light-distribution adjustment plate 1

1

Adjustment should be made so that the image becomes darker evenly.

(3) Move light-distribution adjustment plates 1

and 2 in the direction of the arrow.

(When the rear side is darker)

(4) Move light-distribution adjustment plates 2

and 3 in the direction of the arrow.

(When the front side is darker)

Light-distribution

adjustment

plate 2

Light-distribution

adjustment

plate 3

2

3

Direction of movement

Direction of movement

As a result of the above adjustment, there is a possibility that under-exposure or over-exposure may

occur; make exposure adjustment if necessary.

1550 ADJUSTMENT

1 - 18

Oct. 1995 © TOSHIBA CORP.

Page 22

1.6 Image Slanting and Image Distortion Adjustment

(1) Image slanting adjustment

Direction of movement Direction of movement

Image

Paper

A

B

After making a copy with the original aligned correctly with the original scale, if the copy image is

slanting, adjustment should be made by moving the

front side of the original scale.

Slanting as in A:

Adjust the original scale in the direction of the ar-

A

row (

).

Slanting as in B:

Adjust the original scale in the direction of the ar-

A

row (

).

Original scale

1 - 19Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 23

(2) Image distortion adjustment

Step 1

AB

Direction of movement

Step 2

CD

<Adjustment procedure>

After removing the original glass, make adjustment

using the following procedure:

Step 1: If the image is distorted as in

A or B, make adjustment in

the direction of copy movement

using the mirror 2's adjustment

screw to make the image as in

C or D:

Direction of movement

Mirror 2

A

B

In the case of A: Rotate the adjustment screw in

the direction of tightening

(clockwise).

In the case of B: Rotate the adjustment screw in

the direction of loosening

(counter-clockwise).

1550 ADJUSTMENT

1 - 20

Oct. 1995 © TOSHIBA CORP.

Page 24

Step 2: If the image is distorted as in

C or D, using the mirror unit's

adjustment screw , make adjustment in the direction perpendicular to that of copy movement to make the image normal:

In the case of C: Rotate the adjustment screw in

the direction of tightening

(clockwise).

In the case of D: Rotate the adjustment screw in

the direction of loosening

(counter-clockwise.)

D

C

July 1996

1 - 21Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

®

Page 25

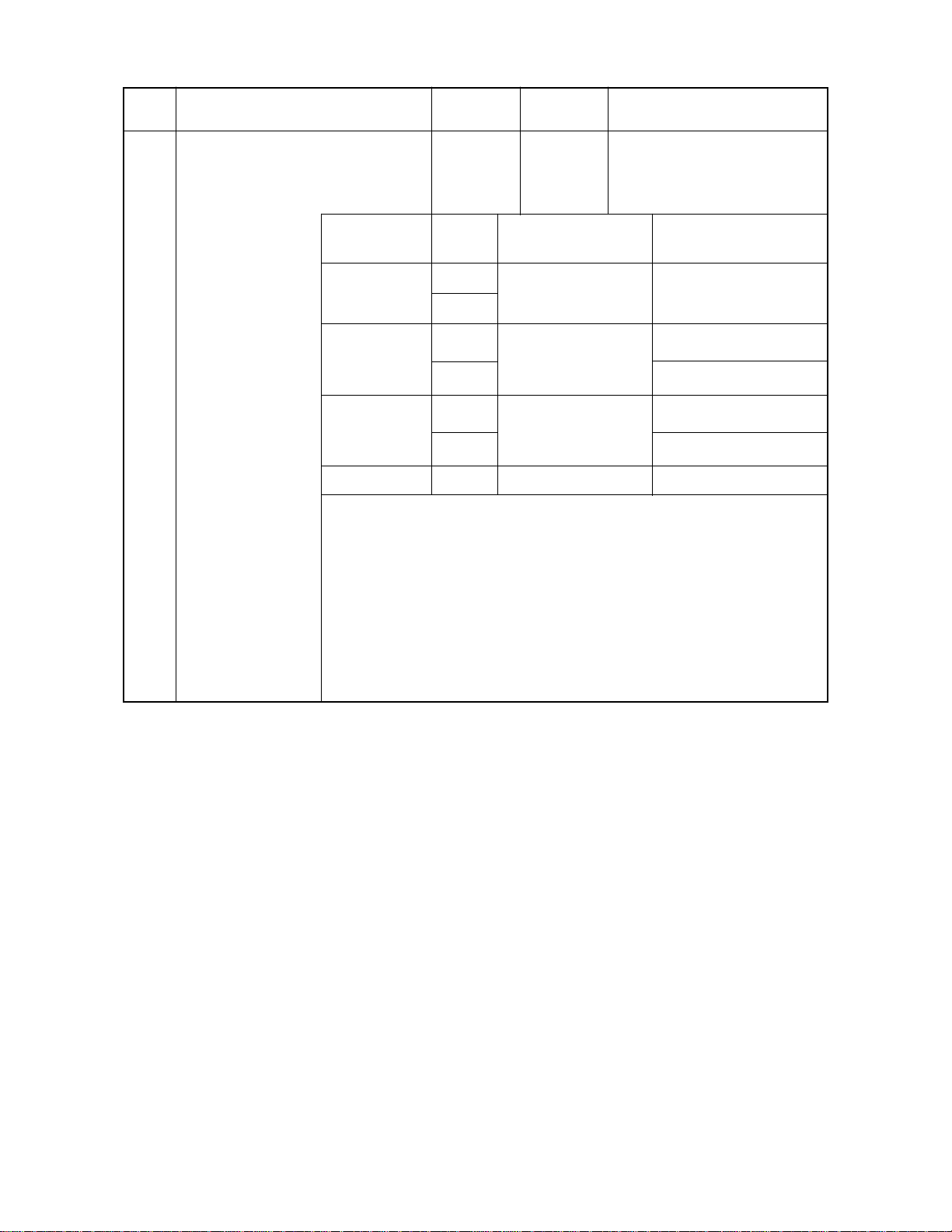

1.7 Mirror and Lens Adjustment

Checking and adjustment regarding the mirrors and the lens should be made by using the following

procedure:

Focus/lateral reproduction-ratio adjustment

(60) ~ (65) Carriages 1/2 Mirrors 1/2

Slanted image

adjustment

Original scale (60) ~ (65)

Note: Do adjustment steps in the dotted-line boxes, as required.

Carriages 1/2

adjustment

Focus/lateral reproduction-ratio adjustment

Inclined focus

adjustment

Lens unit

Mirror unit

Lateral deviation

adjustment

Lens unit

Image distortion

Focus/lateral reproduction-ratio adjustment AJ: Codes 60 - 65

When the lens is replaced or when the focus or the lateral reproduction ratio is not correct, the following

adjustment data need to be re-entered:

Allowable input value Center value

Lens position data (100%) (AJ"05" mode, code 60) 0~40 20

Mirror position data (100%) (AJ"05" mode, code 61) 0~40 20

Lens position data (200%) (AJ"05" mode, code 62) 0~40 20

Mirror position data (200%) (AJ"05" mode, code 63) 0~40 20

Lens position data (50%) (AJ"05" mode, code 64) 0~40 20

Mirror position data (50%) (AJ"05" mode, code 65) 0~40 20

Adjustment should be done as follows:

Lens/mirror position values Mirror position value

100 %

(60)

Mirror position value

50 %

(65)

Normally, adjustment steps in the dotted-line boxes are unnecessary.

100 %

(61)

Lens position value

50 %

(64)

200 %

(63)

Lens position value

200 %

(62)

[A] 100% focus and lateral reproduction-ratio adjustment

(1) Make an actual-sized copy and check for the correct focus and lateral reproduction ratio; if adjust-

ment is necessary, re-enter adjustment data as described below:

a If the focus is inadequate and lateral reproduction ratio is smaller:

Enter a smaller mirror-position value (code 61).

1550 ADJUSTMENT

1 - 22

Oct. 1995 © TOSHIBA CORP.

Page 26

b If the focus is inadequate and the lateral reproduction ratio is enlarged:

Enter a larger mirror-position value (code 61).

c If the focus is adequate but the lateral reproduction ratio is reduced:

Enter a larger lens-position value (code 60).

d If the focus is adequate but the lateral reproduction ratio is increased:

Enter a smaller lens-position value (code 60).

Notes: 1. Moving either the lens or the mirror changes both the focus and the lateral reproduction ratio.

Howev er , the lens-position v alue mainly changes the lateral reproduction r atio and the mirror

position value mainly changes the focus.

2. First adjust the focus, then the lateral reproduction ratio and check the focus again.

3. If the lateral reproduction ratio is not precisely adjusted (within ±0.5%), the focus cannot be

correctly adjusted either.

4. The focus in the center of the image has more margin than that of any of the four corners of

the image due to the characteristics of the lens.

5. For 200% and 50% reproduction ratios, adjustment of the normal focus (mirror position)

makes the lateral reproduction ratio optimal, making it unnecessary to be adjusted.

[B] 200% focus and lateral reproduction-ratio adjustment

(1) Make a 200% copy and check for the correct focus and lateral reproduction ratio.

(2) When the focus and the lateral reproduction ratio are inadequate, re-enter the values of codes 62

and 63 in the AJ "05" mode in the same way as for 100%.

[C] 50% focus and lateral reproduction ratio adjustment

(1) Make a 50% copy and check for the correct focus and lateral reproduction ratio.

(2) When the focus and the lateral reproduction ratio are inadequate, re-enter the values of codes 64

and 65 in the AJ "05" mode in the same way as for 100 %.

1.8 Adjustment of Lateral Misplacement of the Lens Unit

The lens unit has adjustable mechanism.

However, as the adjustment is performed at the time of shipping from the factory, no further adjustment

is needed.

July 1996

1 - 23Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

®

Page 27

1.9 Exposure Adjustment

(1) While pressing keys "0" and '5" sim ultaneously, turn the power supply ON. The display shows "AJ"

and indicates that the machine is in adjustment mode.

(2) Press the automatic exposure key to set the machine to manual exposure, and then select the

center step.

(3) Adjust the exposure in accordance with the procedure shown in the chart below.

Adjustment

sequence ratio

1 Manual exposure 100% 1

2 Automatic adjustment of automatic exposure 50 ~ 200% 49

*3 Light (max.) 9

*4 Dark (min.) 10

5 Manual photo exposure 100% 14

* Make adjustment only when requested by the user.

Exposure mode

Reproduction

100% or

appropriate

reproduction

ratio

Adjustment code

When individual adjustment is required for manual, automatic and manual photo exposure in response to

a request from the user, follow procedure (4).

1 Adjustment of 100% manual exposure

Sequence Operation Display after operation (typical)

1-1 Input code "1" using the digital keys , and press the "Print" key. 120

1-2 [When density is high] (Note 1)

Increase the numerical value, using the "Zoom" key. (Note 2) 129 Zone A

[When density is low]

Reduce the numerical value, using the "Zoom" key. (Note 2) 180

1-3 Press the "Interrupt" key and enter the numerical value in the

memory.

1-4 Press the “Energy saver” key and make a test copy (one) AJ

1-5 If the image of the test copy is not satisfactory, repeat

operations 1-1 through 1-4.

Note 1. Zone A: When the "Zoom" key is pressed, it increases (or decreases) in increments of one.

2. The numerical value in Zone A can be changed by using the digital keys as well as the "Zoom" key.

3. As adjustment of 154%, 50% and 200% manual exposure has already been performed, readjustment is

not required. How e v er , if individual adjustment is requested b y the user, conduct the relevant adjustment

in accordance with procedure (4), described later.

1550 ADJUSTMENT

1 - 24

6447448

Oct. 1995 © TOSHIBA CORP.

Page 28

2 Automatic adjustment of automatic exposure

Sequence Operation Display after operation (typical)

2-0

2-1

2-2

Note 1. As automatic adjustment of automatic exposure is performed on the basis of manual exposure, be sure to

When changing the variable width of the ke y for manual e xposure in accordance with the user’ s request, carry out 3

and 4, described below.

Be sure to adjust manual exposure (100%) beforehand. (Note1)

Place the adjustment chart on the original glass. (Note 2)

Enter code 49 using the digital keys and then press the Print ke y.

* During automatic adjustment, the carriage will shift and the lens

and mirror will move in accordance with the reproduction ratio.

The exposure lamp will flash four times.

* End of automatic adjustment is indicated by return of the display

to test mode.

conduct manual exposure beforehand.

2. Use white Ledger or A3 copy paper as the test chart.

3. When adjustment must be performed in accordance with the user’s request, perf orm by referring to (4), to

be described later.

4. Avoid opening the original cover, pressing keys on the control panel or turning the power OFF, during

automatic adjustment.

Refer to 1

AJ

169

199

AJ

3 Changing the amount of variation in the light image density

Sequence Operation

3-1 Input code “9” using the digital keys and press the “Print” key.

3-2 Use the “Zoom” key to increase the value to lighten the image (and vice versa).

3-3 Press the “Interrupt” key to store the value.

3-4 Press the “Energy saver” key and make a test copy.

3-5 If the image density of the test copy is not satisfactory, repeat operations 3-1 through 3-4.

4 Changing the amount of variation in the dark image density.

Sequence Operation

4-1 Input code “10” using the digital keys and press the “Print” key.

4-2 Use the “Zoom” key to increase the value to lighten the image (and vice versa).

4-3 Press the “Interrupt” key to store the value.

4-4 Press the “Energy saver” key and make a test copy.

4-5 If the image density of the test copy is not satisfactory, repeat operations 4-1 through 4-4.

1 - 25Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 29

5 100% manual photo exposure adjustment

Sequence Operation Display after operation (typical)

5-1

5-2

5-3

5-4

5-5

Input code “14” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 5-1 through 5-4.

1442443

128

138

118

AJ

(4) Adjust exposure in accordance with the procedures shown in the charts below, if requested by the

user for separate adjustment of manual/auto-exposure.

Adjustment

sequence ratio

1 100% 1

2

3 50% 3

Manual exposure center

Exposure mode

Reproduction

154% 2

Adjustment code

4 200% 4

5 100% 5

6

7 50% 7

8 100% 8

9 Light (max.) 9

10 Dark (min.) 10

11 100% 14

12

13 50% 16

14 200% 17

Automatic exposure

Manual photo exposure

154% 6

100 % or

appropriate ratio

154% 15

1550 ADJUSTMENT

1 - 26

Oct. 1995 © TOSHIBA CORP.

Page 30

1 Perform the 100% manual exposure adjustment (3)- 1.

2 154% manual exposure adjustment

Sequence Operation Display after operation (typical)

2-1

2-2

Input code “2” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

130

149

[When density is low]

2-3

2-4

2-5

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 2-1 through 2-4.

443

144424

126

AJ

3 50% manual exposure adjustment

Sequence Operation Display after operation (typical)

3-1

3-2

Input code “3” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

103

109

096

3-3

3-4

3-5

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 3-1 through 3-4.

443

AJ

144424

4 200% manual exposure adjustment

Sequence Operation Display after operation (typical)

4-1

4-2

4-3

4-4

4-5

Input code “4” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 4-1 through 4-4.

443

144424

175

186

166

AJ

1 - 27Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 31

5 100% automatic exposure adjustment

Sequence Operation Display after operation (typical)

5-1

5-2

Input code “5” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

115

127

[When density is low]

5-3

5-4

5-5

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 5-1 through 5-4.

44314

144424

107

AJ

6 154% automatic exposure adjustment

Sequence Operation Display after operation (typical)

6-1

6-2

Input code “6” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

127

139

113

6-3

6-4

6-5

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

44314

AJ

4424

operations 6-1 through 6-4.

7 50% automatic exposure adjustment

Sequence Operation Display after operation (typical)

7-1

7-2

7-3

7-4

7-5

Input code “7” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 7-1 through 7-4.

443

4424

094

087

103

AJ

1550 ADJUSTMENT

1 - 28

Oct. 1995 © TOSHIBA CORP.

Page 32

8 200% automatic exposure adjustment

Sequence Operation Display after operation (typical)

8-1

8-2

Input code “8” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

141

149

[When density is low]

8-3

8-4

8-5

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 8-1 through 8-4.

443

144424

133

AJ

9 When changing the variable width of the key for manual exposure at the user’s request, change the

amount of variation in the light/dark image density in (3)- 3 and 4.

!º Perform the 100% manual photo exposure adjustment in (3)- 5.

!¡ 154% manual photo exposure adjustment

Sequence Operation Display after operation (typical)

11-1

11-2

Input code “15” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

128

138

[When density is low]

11-3

11-4

11-5

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 11-1 through 11-4.

443

144424

118

AJ

!™ 50% manual photo exposure adjustment

Sequence Operation Display after operation (typical)

12-1

12-2

12-3

12-4

12-5

Input code “16” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 12-1 through 12-4.

443

144424

128

138

118

AJ

1 - 29Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 33

!£ 200% manual photo exposure adjustment

Sequence Operation Display after operation (typical)

13-1

13-2

13-3

13-4

13-5

Input code “17” using the digital keys, and press the “Print” key.

[When density is high]

Increase the numerical value, using the “Zoom” key.

[When density is low]

Decrease the numerical value, using the “Zoom” key.

Press the “Interrupt” key and store the numerical value in the

memory.

Press the “Energy saver” key and make a test copy.

If the image density of the test copy is not satisfactory, repeat

operations 13-1 through 13-4.

128

138

118

443

AJ

144424

1550 ADJUSTMENT

1 - 30

Oct. 1995 © TOSHIBA CORP.

Page 34

1.10 Checking and Adjustment of Grid Bias/Transfer/Separation Output

Checking and adjustment of grid bias/transfer/separation output is necessary when the high-voltage transformer is replaced.

At adjustment mode "05" "38" grid bias (Black)

"39" transfer charger

"40" separation charger

64448

Notes: 1. A digital tester with an input resistance of 10 MΩ or more should be used.

<Adjustment procedure>

1. Take out the process unit, and then remove

the developer unit, main charger unit and

drum.

2. Remove the main blade.

3. Using the drum shaft, install the adjustment

jig in the cleaner unit and then set the main

charger unit.

4. Set the process unit into the copier and fasten the earth wire of the jig to the machine

frame with a screw. Then connect the black

(WH) side of the jig’s 3P-connector to the (–)

terminal and the red (WH) side to the (+) terminal of the digital tester, respectively.

5. Push down the upper unit. (Be careful not to

allow the jig’s cord to be pinched).

Jig

Earth wire

3P connector

For measuring the transfer/separation values

1 - 31Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 35

6. Turn on the door switch forecefully.

Note: When measuring the grid bias*, route the (+) terminal of the digital tester through the charger

cleaning shaft gap on the front side of the process unit and contact the charger plate spring with

the (+) terminal.

Frame earth

For measuring the grid bias

7. Setting of digital tester

• In the case of grid bias: Set at 1000 VDC range

• In the case of transfer: Set at 2 VDC range

• In the case of separation: Set at 2 VAC range

05

8.

Power

Code Print

9.

(38,39,40 or 42)

AJ

128

10. Check voltage value using digital tester

*

• Grid bias: –692 ±5 V (Black)

• Transfer: –586 ±20mV

• Separation: AC514 ±21mV (effective value displayed)

1550 ADJUSTMENT

AC464 ±18mV (average value displayed)

1 - 32

Oct. 1995 © TOSHIBA CORP.

Page 36

11. When adjustment is required

Zoom Interruption

(Adjust voltage value) (Memory)

AJ

Note: When voiding occurs on a halftone copy, reduce the separation output.

When deficiency in separation from the drum occurs, or the user uses thin paper frequently, increase the separation output. Be careful to avoid over-increasing or over-decreasing separation

output.

1 - 33Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 37

1.11 Checking and Adjustment of Developer Bias Output

<Adjustment procedure>

(Use code 40 in test mode 05.)

1. Remove the process unit.

2. How to connect digital tester to the machine

• Connect (+) terminal of digital tester to bias

connector (OUT 5)

• Connect (–) common terminal of digital

tester to machine frame.

• Set digital tester to 1000 VDC range.

3.

4.

05

Power

40

Print

AJ

128

Frame earth

5. Check voltage value using digital tester.

–DC200 V ±5 V

OUT 5

VR81

6. If adjustment is required, perform adjustment through VR81 (Bias). (Do not touch the zoom keys

and the digital keys.)

7.

C/S

(Output stop)

AJ

Note: If an overall misty effect is observed, even though exposure is sufficient, increase bias output

through VR81 (Bias). However, when bias output is over-increased, the image contrast declines,

causing a generation of bias leakage, and the carrier tends to stick to the drum easily.

1550 ADJUSTMENT

1 - 34

Oct. 1995 © TOSHIBA CORP.

Page 38

1.12 Drum-to-Sleeve Gap Adjustment

No adjustment is necessary since the guide contacting method is adopted for this machine.

Guide roller

Guide roller

1.13 Development Pole Adjustment

(1) Take out the developer unit from the process

unit.

(2) Adjustment should be made using the adjuster

plate on the rear side:

After loosening the fixing screw of the adjuster

plate, move and adjust it, using the adjustment mark as a guide. Note, however, that

since the pole position was adjusted using a

special jig at the factory , it should be adjusted

only when necessary. When its fixing screw

needs to be loosened for reasons of disassembly, etc., the initial position of the adjuster

plate should be remembered or marked for

later reassembly.

However, whenever the magnetic roller is replaced, the adjustment of the pole-position

height (H) shall be made first.

Marking

Adjuster

H=23.8mm

1 - 35Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 39

1.14 Doctor-to-Sleeve Gap

Jig to be used: Doctor sleeve jig

Procedure:

(1) Remove the developer unit from the process unit.

(2) Remove the top cover and then the developer material.

(3) Remove the charge unit and the drum.

(4) Reinstall the developer unit from which the developer material is removed.

(5) Pull down the developer unit pressure lever to make a pressurized condition.

Adjustment method:

(1) Make sure jig step “0.45” can be inserted

between the sleeve and the leveler and moves

smoothly between the front and rear , and also

jig step “0.55” cannnot be inserted.

(2) Adjust the gap between the sleeve and the

leveler with jig step “0.50” by tightening the

two leveler adjustment screws twice if

necessary. After the adjustment, make sure

using the same method specified above that

jig step “0.45” can be inserted smoothly and

jig step “0.55” cannot be inserted.

Notes: 1. When checking or adjusting the gap,

make the process unit level.

2. When checking or adjusting the gap,

align the marking position of the sleeve

to the position of the leveler.

3. When installing the developer-unit top

Doctor sleeve jig, Step "0.45"

cover, after having inserted the leaf

spring hook, fasten it firmly.

4. After reinstalling the top cover, check

that the rubber seal is placed over the

side seals correctly.

1550 ADJUSTMENT

1 - 36

July 1996

®

Oct. 1995 © TOSHIBA CORP.

Page 40

1.15 Auto-Toner Sensor Adjustment

After the developer material is replaced, the auto-toner sensor needs to be adjusted.

<Procedure> (Code “0” in the 05 adjustment mode)

05

1.

Power

AJ

0

2.

Approx. 3 minutes later

3.

Print

(Example)

19

(Example)

24

If the value is not 24, make adjustment with zoom keys.

INTERRUPT

4.

5.

Install the toner cartridge.

0AJ9

1 - 37Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 41

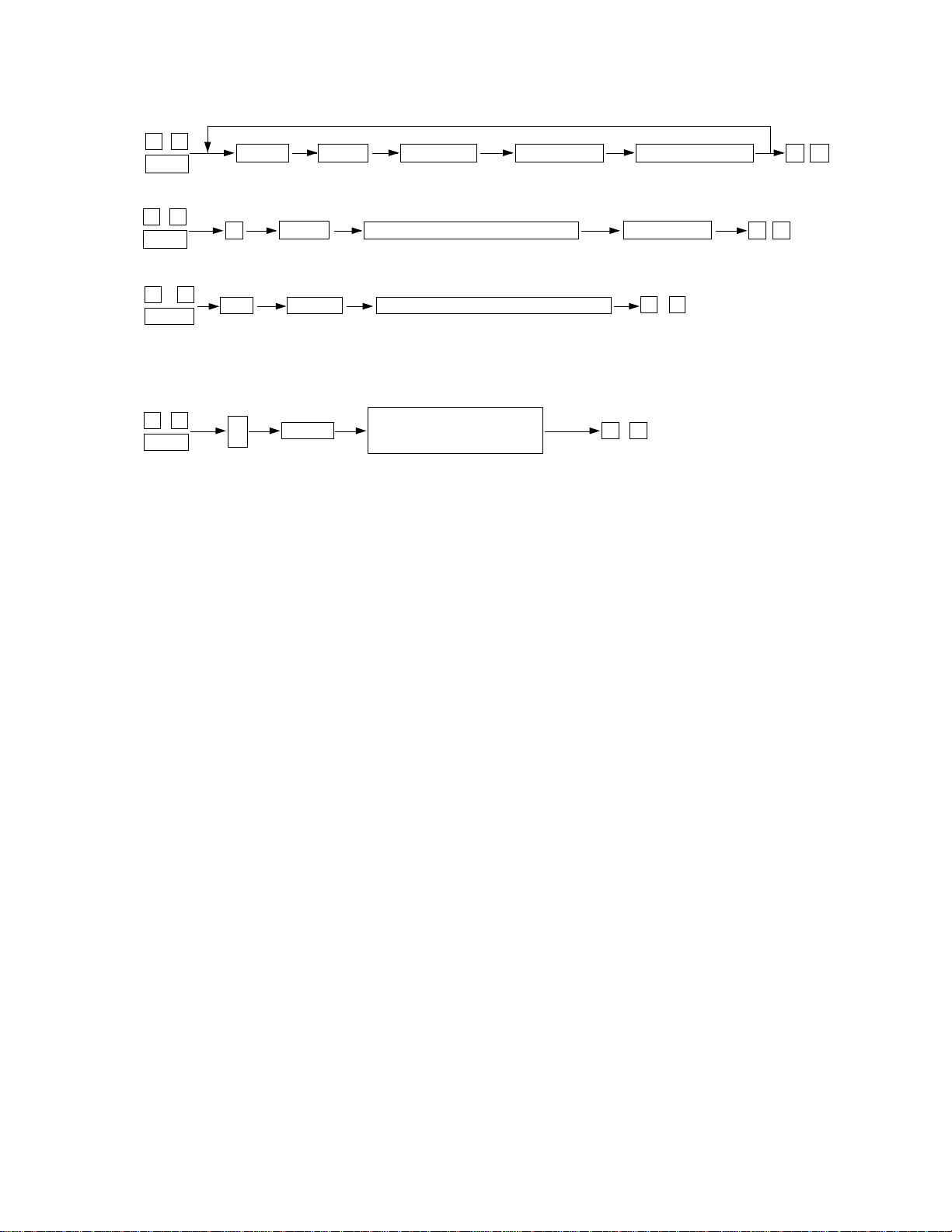

1.16 Adjustment for Scanning Motor Speed, Aligning Amount and Lead Edge Position

Adjustment precedure:

Scanning motor speed

(21)

Note: Normally, Adjustments in the dotted-line boxes are unnecessary.

First of all adjust code 82 because the adjustment amount is based on it.

Aligning amount

Cassette

*(82)→(89)→(81)→(83)→

(PFU cassette (80) optional)

1.16.1 Scanning motor adjustment

(Check and adjustment of the reproduction ratio in

the direction of copy movement)

1. Place a ruler on the glass and make a 100% A4-size copy.

2. Two or three minutes later, compare the copied ruler and the

actual one.

3. If necessary, make adjustment as follows:

Lead edge position

Lead edge position

Cassette~bypass feeding PFU

(53) ~ (56) (57)

Direction of copy paper movement

05

Power

*

Adjust with numeric or zoom keys INTERRUPT

* Larger values make the copy to be enlarged.

21

PRINT

ENERGY SAVER

1.16.2 Aligning amount adjustment

If necessary, you can extend the feed roller life by increasing the aligning amount.

<Procedure> (Use codes 82/89/81/83/80 in the test mode “05”)

1.

Code #

05

Power

ENERGY SAVER

82

Cassette

89

81

83

PFU

80

82 INTERRUPT

(Cassette)

Copy size

A3(LD)

A4-R(LT-R)

A4(LT)

B5

A4

PRINT

Test copy

08

(Current value)

09

15

(New set value)

Test copy

1550 ADJUSTMENT

1 - 38

July 1996

®

Oct. 1995 © TOSHIBA CORP.

Page 42

Notes

• There is no need to do this for machines which do not use B5-sized paper.

• There is no need to do this for machines which are equipped with a PFU.

2. Check the copy for any image void and if there is

any, reduce the new value likes “15” → “14” → “13” ...

until no image void occurs. Check for no paper

misfeeding with the new value.

Voiding

50‘ 100 mm

1.16.3 Lead edge adjustment

Since incorrect lead-edge position can also occur due to paper quality, feed roller surface condition,

etc, first check these itmes before starting adjustment.

Note: The lead edge position of each paper source can be adjusted independently. However, if adjustment for

bypass feeding is necessary, make adjustment in order of the cassette → bypass.

Cassette

100% 200% 50%

(53) (54) (55)

Bypass

100%

(56)

PFU cassette

100%

(57)

<Procedure> (Use the appropriate codes in the “05” test mode.)

Example: Adjustment for the cassette (100%)

05

1.

2.

Power

53

PRINT

AJ

ENERGY SAVER

(Example)

11

Test copy for checking

the lead edge position

July 1996

1 - 39Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

®

Page 43

A = 8 B = 12

Direction of copy paper movement

Document

3. Calculate the new set value:

New value= Current value +

0.8 0.8

66

4.

5.

INTERRUPT

A–B =

AJ

11 +

8–12

= 11–5 = 6

6. Repeat step 2 onward for manual feeding and PFU cassette.

7. Press keys 0 and 9 simultaneously to clear the test mode.

1.17 Registering/Changing ID Codes (Access control mode)

Copy

When ID codes are registered, copies are classified according to each ID code. To make copies, a

registered ID code must be entered using numeric keys.

<Preparation for using the access control mode>

0

8

Power

1550 ADJUSTMENT

7

PRINT

1

INTERRUPT Power OFF

1 - 40

®

July 1996

Oct. 1995 © TOSHIBA CORP.

Page 44

<Registration of the ID code>

• Up to 10 ID codes can be registered. Input a number with three figures.

• Normally, the copier will not start unless one of the ID codes registered is keyed in.

8

PRINT

Power

Input an

ID code

100% Power OFFENERGY SAVER

<Confirmation of the counter value at every code>

• Copy quantity can be recorded at every codes.

• The counter value is 000000 ~ 999999.

8

Power

PRINT

Input an

ID code

PRINT

ZOOM UP

Upper 3 figures

displayed

PRINT

Lower 3 figures

displayed

<ID code list display>

• It is possible to display codes registered in order.

PRINT

8

PRINT

Power

PRINT

Code flashes

<Deletion of the registered ID code>

• Registered codes can be deleted one by one.

8

PRINT

Power

Digital key

Code input

PRINT

ZOOM DOWN

<Change of the counter value>

• The counter value can be changed.

• For example the counter value of 012345 is changed to 123456.

8

PRINT

Power

Input an

ID code

PRINT

ZOOM UP key

Upper 3 figures

displayed

ENERGY SAVER

("---" displayed)

key

Input new

counter

Input new

counter

Completed

value

value

ENERGY SAVER

ENERGY SAVER key

Lower 3 figures

displayed

July 1996

1 - 41Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

®

Page 45

1.18 User Exposure-Adjustment Mode

This mode allows the user to perform some of the exposure adjustment modes if he desires to do so.

The user can adjust the following three modes:

•Manual exposure 100% (05 mode, code 1)

•Auto exposure 100% (05 mode, code 5)

•Photo exposure 100% (05 mode, code 14)

A. Auto exposure adjustment (AJ5)

(1) Press the auto-exposure key to make the auto-exposure LED to

come on.

(2) While pressing the auto-exposure key, press the ZOOM UP (or

ZOOM DOWN) ke y , and the light MAX (or dark MAX) LED flashes.

(3) Each time the light MAX (or dark MAX) LED flashes, the AJ value

ON

ON

is increased (or decreased) by 2.

(4) When you release one of the keys you pressed simultaneously,

the display goes back to step (1), completing the adjustment.

B. Manual exposure adjustment 100% (AJ1)

(1) Press the auto-exposure key to make the center LED of the manual

exposure to come on.

(2) Steps (2)–(4) are same as for the auto exposure adjustment.

Flashing

ON

ON

ON

Flashing

ON

1550 ADJUSTMENT

1 - 42

Oct. 1995 © TOSHIBA CORP.

Page 46

C. Photo exposure adjustment 100% (AJ14)

(1) Press the PHOTO key to make the photo LED and

the manual exposure center LED to come on.

ON

PHOTO

(2) While pressing the PHOT O ke y, press the ZOOM UP

(or ZOOM DOWN) key, and the light MAX (or dar k

MAX) LED flashes.

(3) Steps (3)–(4) are the same as for the auto exposure

adjustment.

ON

Flashing

ON

1 - 43Oct. 1995 © TOSHIBA CORP. 1550 ADJUSTMENT

Page 47

2. PERIODICAL MAINTENANCE

Inspection every 60,000 copies

(1) Preparation

1) Ask the key operator about the present machine conditions and note them down.

2) Before starting the maintenance work, make and retain a few sample copies for later comparison.

3) Turn off the power switch and disconnect the power cord plug.

(2) The period inspection should be conducted in accordance with the PERIODIC INSPECTION CHECK

LIST shown below . Perform the inspection by ref erring to the figures, as well as to the explanations

in the Service Manual when necessary.

(3) After the inspection has been completed, plug in the machine and turn the power switch on, and

confirm the general operation of the machine by making a few copies and comparing them to those

made previously.

Inspection and over-haul every 180,000 copies

(1) Replace all the cosumables.

(2) Check to see if there is any damage to parts of the drive section (gear, pulley, timing belt, etc.).

Replace parts on principle if damaged.

(3) Check to see if there is any damage or peeling of adhered parts (tape, Mylar, etc.). Replace any

affected parts.

(4) Check to see if all the switches and sensors operate properly. Replace them if the y are not operat-

ing properly.

(5) Clean the inside of the machine thoroughly.

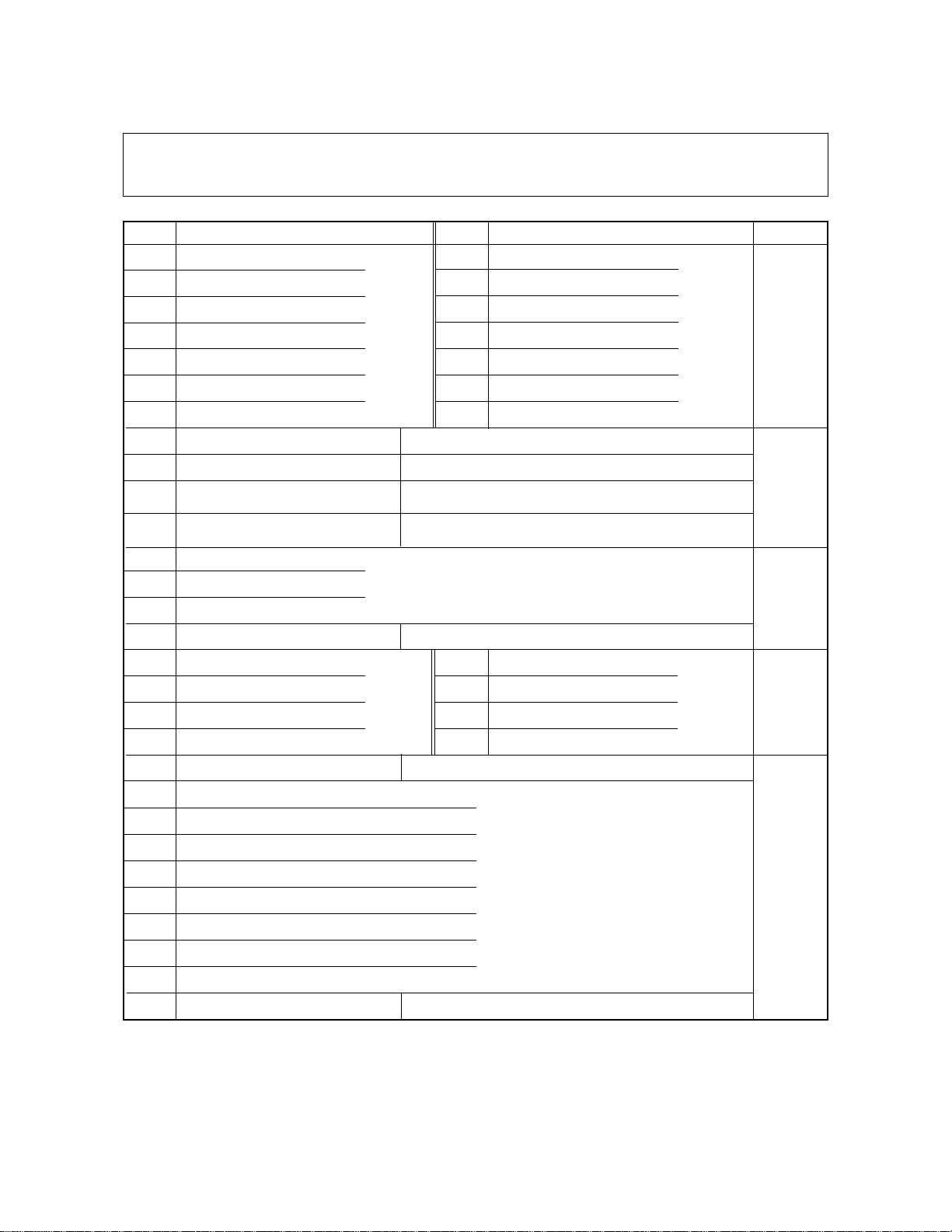

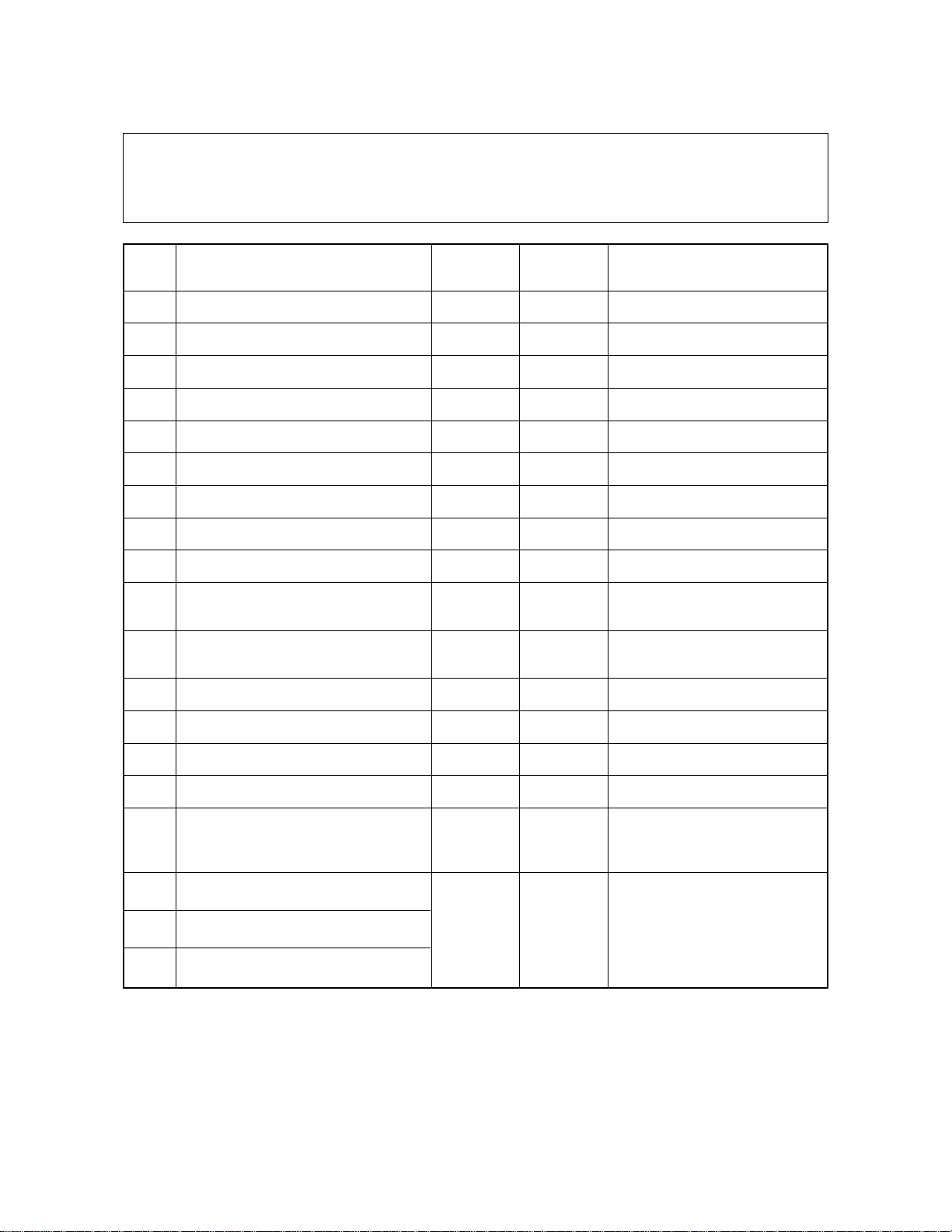

2.1 Periodic Inspection Check List

Symbols used in the Periodic Inspection Check List

Cleaning Lubrication Replacement Date

(A) Cleaning with alcohol (V) Vacuoline (20) Every 20,000 copies Customer’s

(D) Cleaning with a (H) Heavy-medium oil (40) Every 40,000 copies Name

slightly damp cloth (L) Laune 40 (60) Every 60,000 copies Machine

(P) Cleaning with Pit Same thereafter No.

Clean (RC60) Inspector

Cleaning with soft (SI) Silicone oil ( ) Replace in event of

pad, cloth, or cleaner (M) Molytherm deformation or Remarks

(vacuum cleaner) (W) White grease (Molycoat) other damage

Application

2 - 1Oct. 1995 © TOSHIBA CORP. 1550 PERIODICAL MAINTENANCE

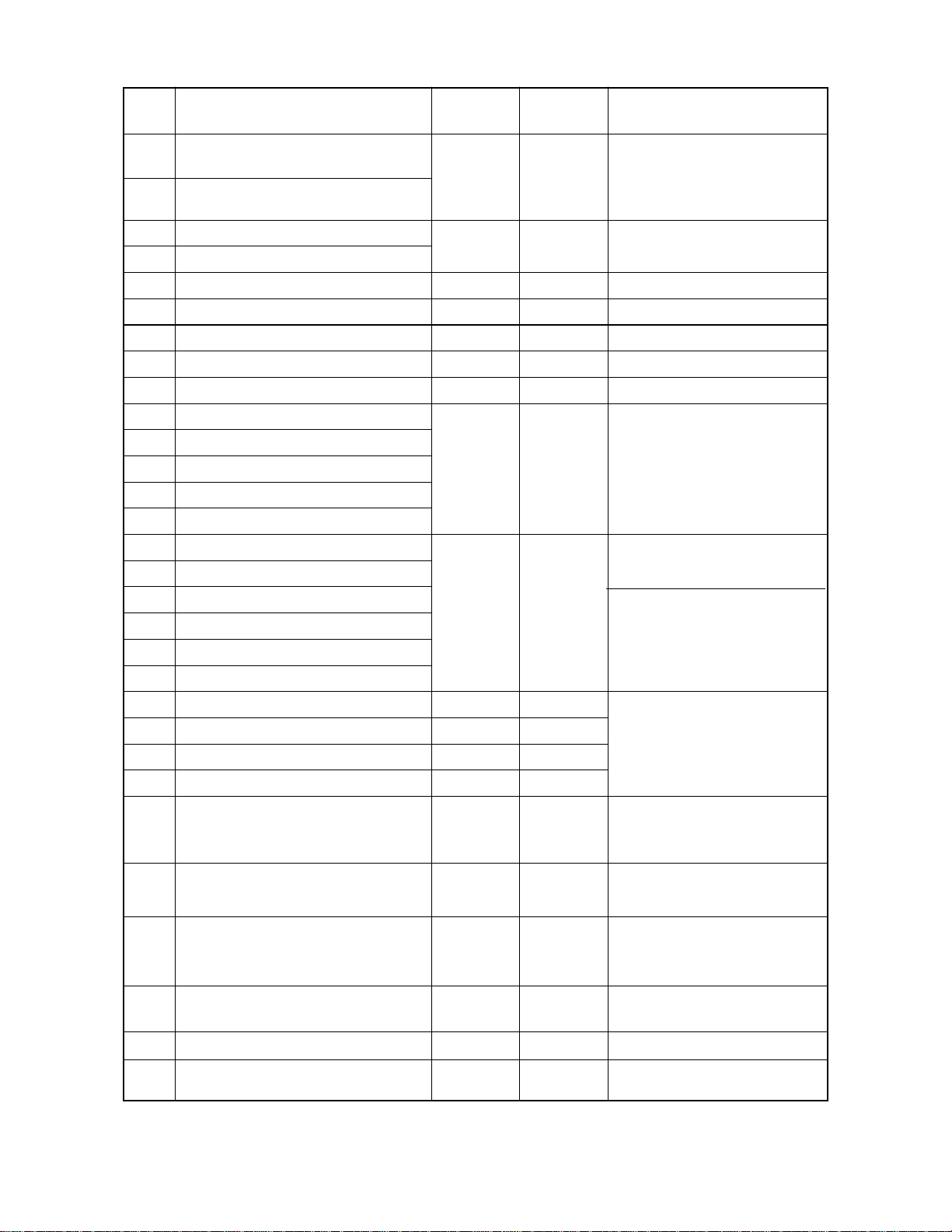

Page 48

PERIODIC INSPECTION CHECK LIST

*K=1,000

Section Item to check

Cleaner 1 Entire Unit

2 Main blade ^º *1 (See page 2-6)

3 Toner bag @º Key operator item

4 Recovery blade *2

5 Drum bushings

Drum 10 Drum shaft

11 Drum ^º or more *3

Original 12 Glass A

table

Optical 20 Mirror 1 or A

system

Chargers 40 Charger case

Developer 50 Entire unit

unit

13 Original cover A

21 Mirror 2

22 Mirror 3 or A

23 Mirror 4 or A

24 Mirror 5 or A

25 Mirror 6 or A

26 Slit glass or A (both sides)

27 Reflector or A

28 Lens or A

29 Exposure lamp

30 Auto exposure sensor

31 Reproduction ratio

mechanism (mirrors)

32 Reproduction ratio

mechanism (lens)

33 Sliding sheets

(front/rear)

34 Air filter

35 Ozone filter ^º

41 LED eraser array

42 Charger wire ^º

43 Terminal contact

44 Grid A^º

45 Discharge lamp

51 Developer material ^º *4

52 Rubber seal

Clean at Lubricate at Replace at

60*K copies 60*K copies x *K copies

or A

A

Check while

ON

Remarks

Replace when

heavily stained

Use sandpaper as

required

2 - 2 Oct. 1995 © TOSHIBA CORP.1550 PERIODICAL MAINTENANCE

®

July 1996

Page 49

*K=1,000

Section Item to check

Clean at Lubricate at Replace at

60*K copies 60*K copies x *K copies

Check while

ON

Paper 60 Pick-up roller A

feeding

section

61 Paper feed roller A

62 Separation roller A

63 Aligning roller A`SI *10

64 Paper guide

65 Brush

66 Transport guide section

67 Transport roller (left) A`SI MY-1004 *9

68 Transport roller (right) A`SI MY-1004 *9

Fuser unit 70 Teflon roller (upper) P `⁄¤‚ *5

71

Heat roller entrance guide

P

72 Rubber roller (lower) P `⁄°‚ *6

73 Cleaning felt roller ^º *7

74 Thermistor or P

75

Scrapers (for heat rollers)

P *8

76 Heat roller exit guide P

77 Exit roller A

78 Cleaning blade

Drive

system

80 Drive gear (teeth) `

SI

81 Stad of drive gear `SI

Sorter kit 82 Shaft and bushing `SI *11

Remarks

2 - 3Oct. 1995 © TOSHIBA CORP. 1550 PERIODICAL MAINTENANCE

®July 1996

Page 50

@£

#¡

@¢

@§

%º%¡%™

$¢

!¡

^¢

^¡

^¶

^•

^™

^¡

^™

$º

#º

#£

!£

!™

#¢

@ª

@¶

@∞

$¡

$™$£

12

#™@•

$∞

^º

^£

^∞

5!º

4

3

^§

&¡

&™

&§ &∞

&¶

$™$£

@¡

@º

@™

#∞

&£

&•

&º

2 - 4 Oct. 1995 © TOSHIBA CORP.1550 PERIODICAL MAINTENANCE

&¢

&¶

Page 51

*º

*º*º *º

#™#¡

*º *º

*º*¡

July 1996

2 - 5Oct. 1995 © TOSHIBA CORP. 1550 PERIODICAL MAINTENANCE

®

Page 52

Remarks in the PERIODIC INSPECTION CHECK LIST:

*1.Main blade

If poor cleaning occurs even before the replacement number of copies are made due to the adhesion

of paper dust, etc., since the blade edge may have been damaged, replace the main blade as required. Cleaning the edge with a dry cotton can damage it, so wipe the edge lightly using a soft cloth

soaked with alcohol; be sure to check for no adhesion of cloth fibers.

*2.Recovery blade

If the edge of the recovery blade is damaged, replace the blade.

*3 Drum

Refer to paragraph 3.2.

*4 Developer material

When the developer material is replaced, be sure to check the auto-toner sensor.

*5 Teflon roller

Refer to paragraph 3.5.

*6.Rubber roller

14243

*7.Cleaning felt roller

Refer to paragraph 3.3.

*8.Scraper

Scraper whose tip is damaged should be replaced. If you try to scrape off the toner firmly caked on the

tip forcefully, it may easily be damaged. So replace scrapers if their tip is heavily stained.

*9.Transport roller

When oiling the transport roller, after having disassembled and cleaned the roller, apply a drop of

silicone oil, and then while turning the bushing to spread the oil, insert it.

*10.Aligning roller

After disassembling the upper or lower aligning roller for cleaning, apply one drop of silicone oil to the

inside of the bushing (sliding portion of the aligning roller).

When reassembly has been accomplished, rotate the roller to facilitate the spreading of the oil.

2 - 6 Oct. 1995 © TOSHIBA CORP.1550 PERIODICAL MAINTENANCE

® July 1996

Page 53

*11.Shaft and bushing

After having disassembled and cleaned the sorter kit roller, apply a drop of silicone oil to the shaft and

the shaft interior, reassemble the roller, and then rotate it to spread the oil. This oiling is perf ormed as

a countermeasure to abnormal noise.

Oiling to the shaft

(Silicone oil)

Oiling to the internal surface of

the bushing (Silicone oil)

July 1996

2 - 7Oct. 1995 © TOSHIBA CORP. 1550 PERIODICAL MAINTENANCE

®

Page 54

2.2 Oiling Cycle Table

No.* Item to be oiled Type of oil Number of copies

63 Aligning roller Silicone oil 60

67 Transport roller (left) Silicone oil 60

68 Transport roller (right) Silicone oil 60

80 Drive gears (teeth) Silicone oil 60

81 Stad of drive gear Silicone oil 60

82 Shaft and bushing Silicone oil 60

* Numbers correspond with those in the PERIODIC INSPECTION CHECK LIST.

Note: Do not give any oil to rollers, belts and belt pulleys.

2.3 Supplies/Parts Replacement Schedule

Oiling cycle

x 1000

Replacement cycle

No.* Parts name Code name (Number of copies

2 Main blade PS-BL1550D 60 P17, I34

3 Toner bag PS-TB1550 20 P6, I38

PS-TB1550E

(for Europe)

11 Drum PS-OD1550 60 or more P14, I1

35 Ozone filter — 60 P3, I7

42 Charger wire — 60 P15, I8/P16, I9

44 Grid — 60 P15, I13

51 Developer material PS-ZD1550 60 —

70 Teflon roller (upper) PS-HR1550U 120 P19, I2

72 Rubber roller (lower) PS-HR2510L 180 P20, I5

73 Cleaning felt roller PS-SR1550H 60 P19, I12

* Numbers correspond with those in the PERIODIC INSPECTION CHECK LIST.

** Refer to SERVICE PARTS LIST ED-1550.

2.4 Jig List

Door switch jig **P100, I1

** Refer to SERVICE PARTS LIST ED-1550.

Drum jig **P100, I2

x 1000)

**Parts List

Page/item No.

Wire holder jig **P100, I3

Doctor sleeve jig **P100, I4

2 - 8 Oct. 1995 © TOSHIBA CORP.1550 PERIODICAL MAINTENANCE

®

July 1996

Page 55

3. PRECAUTIONS FOR STORING AND HANDLING SUPPLIES

3.1 Precautions for Storing Toshiba Supplies

A. Toner and Developer

T oner and de veloper should be stored in a place where the ambient temper ature is below 35°C (95°F)

and should also be protected against direct sunlight during transportation.

B. OPC Drum

Similarly to the toner and developer , OPC drums should be stored in a dark place where the ambient

temperature is below 35°C. Be sure to avoid those places where drums may be subjected to high

humidity, chemicals and/or their fumes.

C. Cleaning Blade and Cleaning Felt

These items should be stored in a flat place where the ambient temperature is below 35°C and should

also be protected against high humidity, chemicals and/or their fumes.

D. Heat Roller and Pressure Roller

Avoid those places where heat rollers may be subjected to high humidity, chemicals and/or their

fumes.

E. Copy Paper

Avoid storing copy paper in a place where the humidity is high.

After a package is opened, be sure to place and store it in a storage bag.

3.2 Inspecting and Cleaning OPC Drum

A. Precautions for Handling

(1) Use of gloves

If fingerprints or oils adhere to the drum surface (which degrades the characteristics of the photoconductor), this affects the quality of the copy image; therefore, do not touch the drum surface with

your bare hands.

(2) Removing and reinstalling drums

Since the OPC drum surface is very sensitive, be sure to handle the drum carefully when installing

and removing it so as not damage its surface.

Be sure to apply patting powder (lubricant) to the entire surface of the drum before installing the

drum into the machine.

Notes:

1. Application of the patting powder is to reduce the friction between the drum and cleaning

blade. If the application of patting powder is neglected, the drum and cleaning blade may be

damaged.

2. When paper fibers adhere to the cleaning blade edge, they may reduce the cleaning efficiency and, in addition, may damage the blade and the drum. So, if any fibers are found

adhering to the blade, be sure to remove them carefully using a soft pad.

3 - 1Oct. 1995 © TOSHIBA CORP. 1550 SUPPLIES

Page 56

3. Installation of Machine and Storage of Drum

Avoid installing the machine in such places where it may be subjected to high temperature,

high humidity, chemicals and their fumes.

Do not leave drums in a bright place for a long time, otherwise the drum will fatigue and will

not produce sufficient image density immediately after being installed in the machine.

However, this effect may decrease as time elapses.

4. Cleaning the Drum

At periodic maintenance calls, wipe clean the entire surface of the drum using the designated

cleaning cotton or soft pad. Use sufficiently thick cleaning cotton so as not to scratch the

drum surface inadvertently with your fingertips or nails. Also, remove your ring and wristwatch before starting cleaning work to prevent accidental damage to the drum.

Be sure not to use other organic solvents or silicone oil as they will ha ve an undesirab le effect

on the drum.

5. Repairing Scratches on OPC Surface

If a scratch exists on the OPC surface through which the aluminium substrate can be seen,

no copy image will be produced on this area and, in addition, the cleaning blade will be

damaged so replacement with a new drum will be necessary.

6. Collecting Used OPC Drums

For disposition of used OPC drums, it is recommended to proceed according to the corresponding regional environmental regulations.

3.3 Checking and Replacing Cleaning Felt Roller

(1) Precautions for Handling

Never allow solvents such as thinner, etc. to adhere to the cleaning felt roller.

(2) Poor Heat-Roller Cleaning and Countermeasures

Poor heat-roller cleaning should be judged b y the deposited toner on the roller. When the f elt roller

has heavy toner deposits, the heat-roller surface may be stained with toner. If this happens, replace the cleaning felt roller.

The cleaning felt roller will be gradually degraded due to subjection to the heat from the heat roller

over a long period of time; therefore, replace it preferably after about 60,000 copies have been

made.

3 - 2 Oct. 1995 © TOSHIBA CORP.1550 SUPPLIES

Page 57

3.4 Checking Drum Cleaning Blade

(1) Precautions for Handling

Pay attention to the following points as the cleaning blade life is determined by its edge condition:

1. Do not allow a hard object to hit on or rub against the blade edge. Do not rub the edge with a

cloth.

2. Do not leave oil (or fingerprints, etc.) on the edge.

3. Do not put solvents such as thinner, etc. on the edge.

4. Do not deposit dirt such as paper fibers, etc. on the blade.

5. Do not place the blade near a heat source.

3.5 Checking and Cleaning Upper and Lower Heat Rollers

(1) Precautions for Handling

• Upper Heat Roller

1. Do not leave oil (fingerprints, etc.) on the heat roller.

2. Be extremely careful not to allow a hard object to hit on or rub against the roller because the thin

Teflon layer coated on the alminum substrate is easily damaged and, if damaged, will result in

poor drum cleaning.

• Lower Pressure Roller

1. Do not leave oil (fingerprints, etc.) on the roller surface.

(2) Checking

1. Check for staining and damage to the heat roller and clean or replace if necessary.

2. Clean the separation claws and check for chipped claws.

3. Check cleaning condition of cleaning felt.

4. Check the thermistor for proper contact with the heat roller.

5. Check the fused condition of the toner image.

6. Check the heat rollers for proper rotation.

(3) Cleaning Procedure for Heat Rollers

When the heat roller becomes dirty, it will cause paper jamming. In that case, wipe the roller surface clean with cotton soaked in alcohol or heat-roller cleaner “RC60” which contains silicone oil.

For a better cleaning effect, clean the roller while it is still warm.

Note: Be careful not to rub against the Teflon-coated surface with your fingernails or hard objects

because it is easily damaged. Do not use silicone oil on the upper heat roller.

3 - 3Oct. 1995 © TOSHIBA CORP. 1550 SUPPLIES

Page 58

4. TROUBLESHOOTING

(1)

Optical system initialization errors

C21

1 Turn the power supply ON/OFF, then visually check that the following units are initialized.

C21