Page 1

SENTINEL FIELD CONTROLLER

User Guide

Page 2

TABLE OF CONTENTS

CHAPTER 1: SENTINEL CONTROL MODULE................................... 4

I. CONTROL MODULE OVERVIEW ......................................................................... 4

II. USER INTERFACE OVERVIEW (KEYPAD & DISPLAY) ................................. 5

Sentinel Control Module Keypad ......................................................................................................... 5

Sentinel Control Module Display ......................................................................................................... 6

III. PROGRAMMING OVERVIEW & NAVIGATION............................................... 8

CHAPTER 2: BASIC CONTROLLER PROGRAMMING.................. 10

I. CONTROLLER SETUP........................................................................................... 10

UTILITY → Time & Day → Edit Mode............................................................................................ 10

UTILITY → Day Change Hour → Edit Mode ................................................................................... 12

UTILITY → Unit Code → Edit Mode ............................................................................................... 12

UTILITY → Station Count → Edit Mode.......................................................................................... 13

UTILITY → N/O Master → Edit Mode............................................................................................. 13

II. SCHEDULE SETUP.............................................................................................. 14

SCHEDULE DATA → Run Days → Edit Mode............................................................................... 14

III. PROGRAM SETUP .............................................................................................. 15

PROGRAM DATA → Start Times → Edit Mode ............................................................................. 15

PROGRAM DATA → Slot-Stn-Time → Edit Mode ......................................................................... 16

PROGRAM DATA → Percent Scale → Edit Mode .......................................................................... 18

PROGRAM DATA → Repeats → Edit Mode ................................................................................... 18

PROGRAM DATA → Repeat Dly Time → Edit Mode..................................................................... 18

PROGRAM DATA → Continuous Run → Edit Mode...................................................................... 19

PROGRAM DATA → Water Window → Edit Mode........................................................................ 19

PROGRAM DATA → Selected Schedule → Edit Mode................................................................... 19

CHAPTER 3: ADVANCED PROGRAMMING..................................... 22

I. OPERATIONS MENU............................................................................................. 22

Manual (Manual Station) .................................................................................................................... 22

Auto Slot/Stn (Manual Program Start)................................................................................................ 22

Rain Off Days ..................................................................................................................................... 23

All Manuals Off (Manual Stations Off).............................................................................................. 23

All Autos Off (Manual / Auto Programs Off)..................................................................................... 23

Stn Days Off ....................................................................................................................................... 23

II. UTILITY MENU..................................................................................................... 23

Program Clear ..................................................................................................................................... 23

Wireless Group ................................................................................................................................... 24

Map Unit Precode ............................................................................................................................... 24

Two-Wire / Irritrol Mode.................................................................................................................... 24

III. FLOW MENU ....................................................................................................... 24

K Factor .............................................................................................................................................. 24

Offset Factor ....................................................................................................................................... 24

Current Flow ....................................................................................................................................... 25

Expected Flows................................................................................................................................... 25

Maximum Flows ................................................................................................................................. 25

Flow Processing.................................................................................................................................. 25

Read Flow Totals ................................................................................................................................25

2

Page 3

IV. ALARMS MENU................................................................................................... 26

Master Minimum ................................................................................................................................26

Unexpected Flow ................................................................................................................................26

Over Flows.......................................................................................................................................... 26

Over Currents...................................................................................................................................... 27

Clear Flow Alarms.............................................................................................................................. 27

Clear Fuse Alarms............................................................................................................................... 27

Clear Map Alarms............................................................................................................................... 27

Clear Power Fail ................................................................................................................................. 27

V. ZONE / ET DATA MENU...................................................................................... 28

Plant Factor:........................................................................................................................................ 28

Application Rate: ................................................................................................................................28

Default ET........................................................................................................................................... 28

Maximum ET...................................................................................................................................... 28

Program ET Toggle............................................................................................................................. 29

Station Type........................................................................................................................................ 29

Map Stations ....................................................................................................................................... 29

3

Page 4

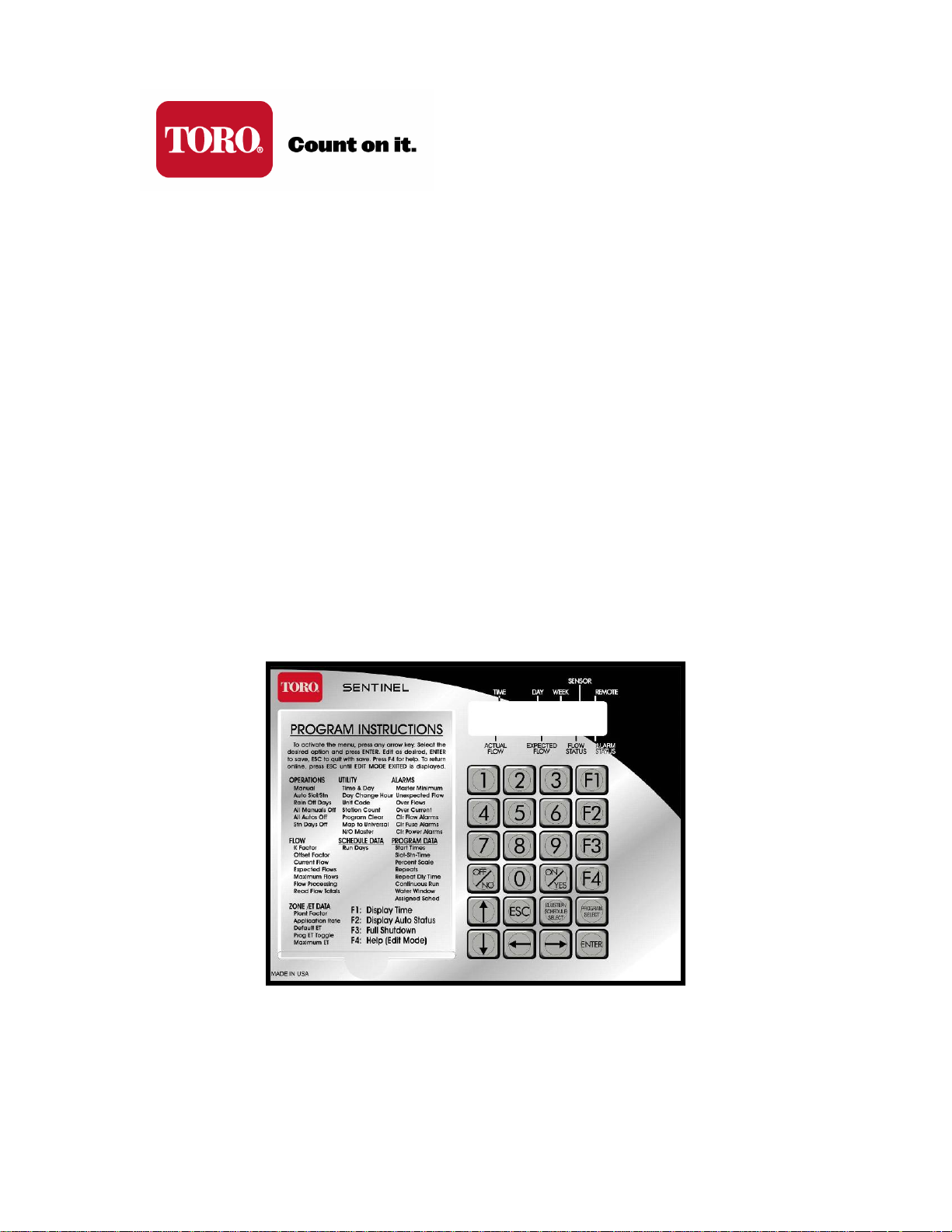

CHAPTER 1: SENTINEL CONTROL MODULE

I. CONTROL MODULE OVERVIEW

Your Sentinel Controller Interface has three main elements to use throughout the

programming process. These are:

Program Instructions

Card

The display, keypad and program instructions card are located on the front panel of the

satellite control module. Programming as covered in this User’s Guide will be through

the keypad and display (not through the central software). The Program Instructions card

is provided as a quick-reference of Main Menu and Submenu elements for controller

programming.

Display Keypad

4

Page 5

Other visible elements of the satellite control module include the radio antenna

connector, the station output ports (up to four 15-pin connectors), and the red “power on”

light, all located on the bottom front side of the control module.

The back side panel of the control module is where the serial port (9-pin connector), data

retrieval port (9-pin connector) and two fuse sockets are located. A red LED light is

provided next to the fuse socket to indicate a blown fuse.

Sentinel satellite controllers are available in various station output configurations in 12station increments, including 12-, 24-, 36-, and 48-stations.

II. USER INTERFACE OVERVIEW (KEYPAD & DISPLAY)

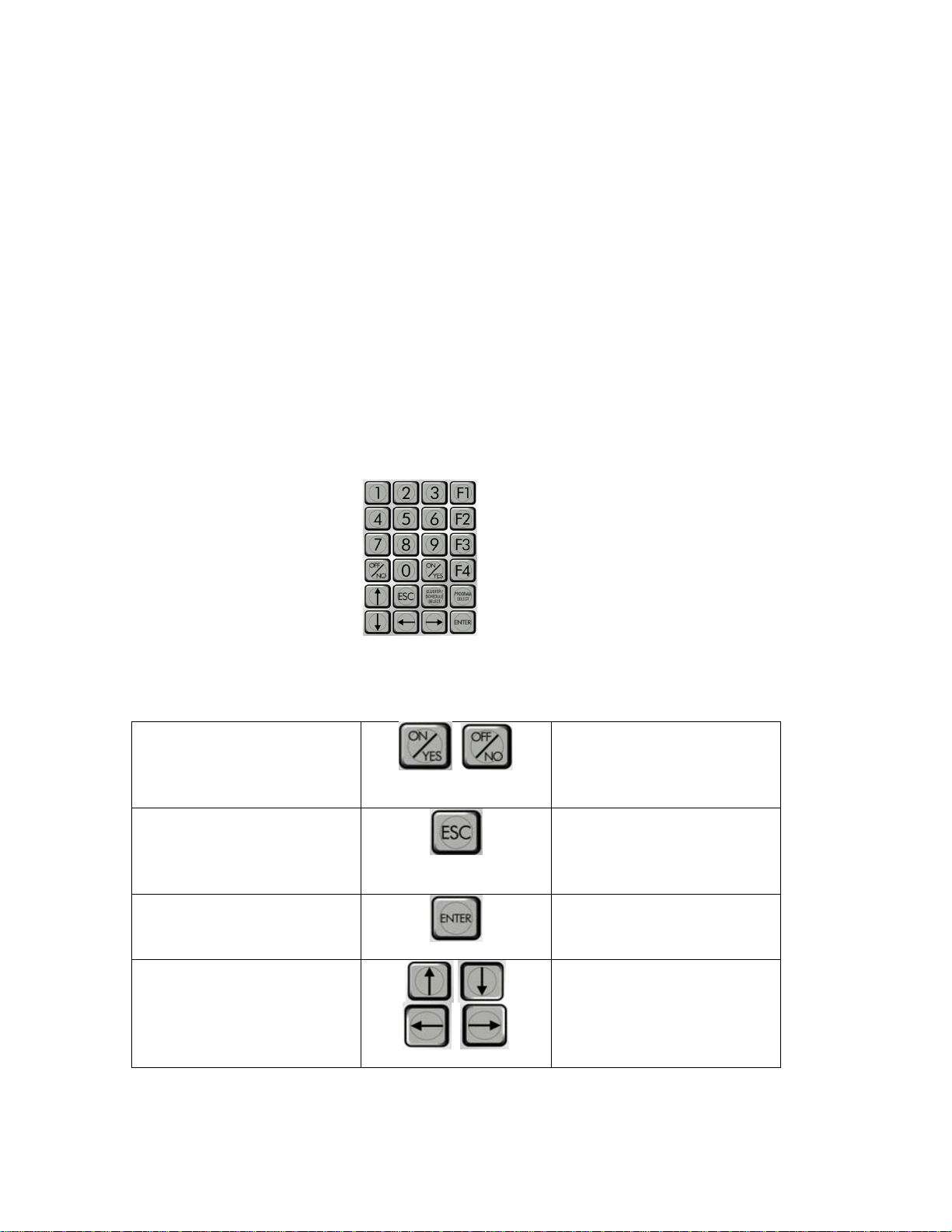

Sentinel Control Module Keypad

The Sentinel Control Module has a 24-button keypad for use as the programming

interface:

This keypad includes numeric buttons 1 – 9 and 0 used for numeric data entry. Also used

in programming and operations are:

ON/YES & OFF/NO Keys

ESC (Escape) Key

ENTER Key

Arrow (Navigation) Keys

Used for manual operations

as well as entering ON /

OFF or YES / NO in

programming.

Used for exiting menus or

Edit Mode and returning to

normal operations (default

screen)

Used for functions like

entering a selected submenu

or saving information.

Used for navigating in

Menus, Submenus, and Edit

Modes, as well an

incrementing values in

programming.

5

Page 6

CLUSTER / SCHEDULE

SELECT Key

PROGRAM SELECT Key

Also included are four F-keys provided on the control module keypad to conveniently

perform the following functions:

F1 Key - Displays the time.

F2 Key - Displays the status of the automatic programs.

F3 Key - Shuts down anything that is running (panic button).

IMPORTANT: The F3 key is not functional while in the Edit mode.

F4 Key - Displays context sensitive help while in the Edit mode.

This button will be

described in more detail in

later parts of this guide.

Used for selecting Clusters

(groups of 4 programs) or

schedules (run days) when

programming.

This button will be

described in more detail in

later pars of this guide.

Used for selecting the

Program (1-4) associated

with a Clusters when

programming.

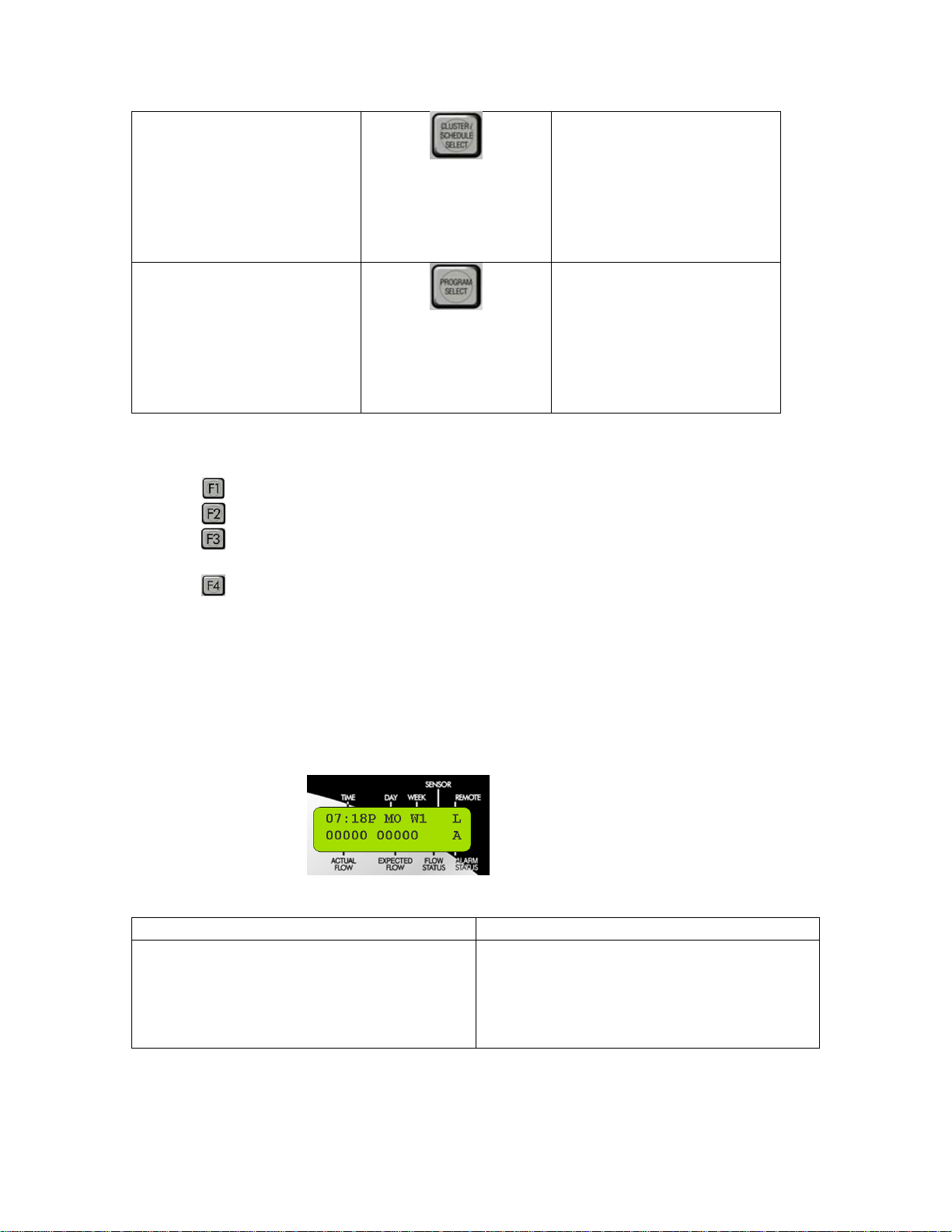

Sentinel Control Module Display

The Sentinel Controller has a two-line LCD for display of information. When you first

walk up to your Sentinel controller, the display should be in its standard mode showing

current time, day, week (of schedule), actual flow (if anything running) and expected

flow. This display should look something like the following:

This display (as shown) indicates:

Upper Line Lower Line

Time – 07:18 P (7:18 PM)

Day – MO (Monday)

Week (of schedule) – W1 (Week 1)

Sensor – No current sensor indication

Remote – L (Locked)

Actual Flow – 00000 (0 GPM)

Expected Flow – 00000 (0 GPM)

Flow Status – No current flow indicator

Alarm Status – A (Alarm Exists)

6

Page 7

The standard indicators in the display are as follows:

TIME HH:MM

A

P

DAY SU

MO

TU

WE

TH

FR

SA

WEEK W1

W2

W3

W4

W5

W6

SENSOR 1

O

C

REMOTE L

A

S

ACTUAL

FLOW

EXPECTED

FLOW

FLOW

STATUS

- :)

A

ALARM

STATUS

00000

00000

+

A

Hours : Minutes (12-hour format)

AM

PM

Sunday

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Week 1 (one) of Schedule

Week 2 (two) of Schedule

Week 3 (three) of Schedule

Week 4 (four) of Schedule

Week 5 (five) of Schedule

Week 6 (six) of Schedule

Sensor Activated - Switch sensor is in

alternate of its Normal condition. E.g. If

Normally Open, then 1 = Sensor

Closed.

Dry contact (switch) sensor is Open

Dry contact (switch) sensor is Closed

Field Unit is in remote “Locked” mode.

Hand held radio will not activate

watering functions within this unit.

Field Unit is programmed for “All

Call” handheld radio operation.

Controller will respond to any and all

handheld commands transmitted.

Field Unit is programmed for “Secure”

handheld radio operation. Controller

will respond only to handheld

commands addressed to its unit code.

5-digit numeric indicator of current

flow through connected flow sensor

5-digit numeric indicator of expected

flow based on current stations operating

and their expected flows.

Actual > Expected (Overflow)

Actual < Expected (Underflow)

Actual = Expected (Flow is happy)

Flow Alarm Exists

Alarm Exists – Blank Otherwise

7

Page 8

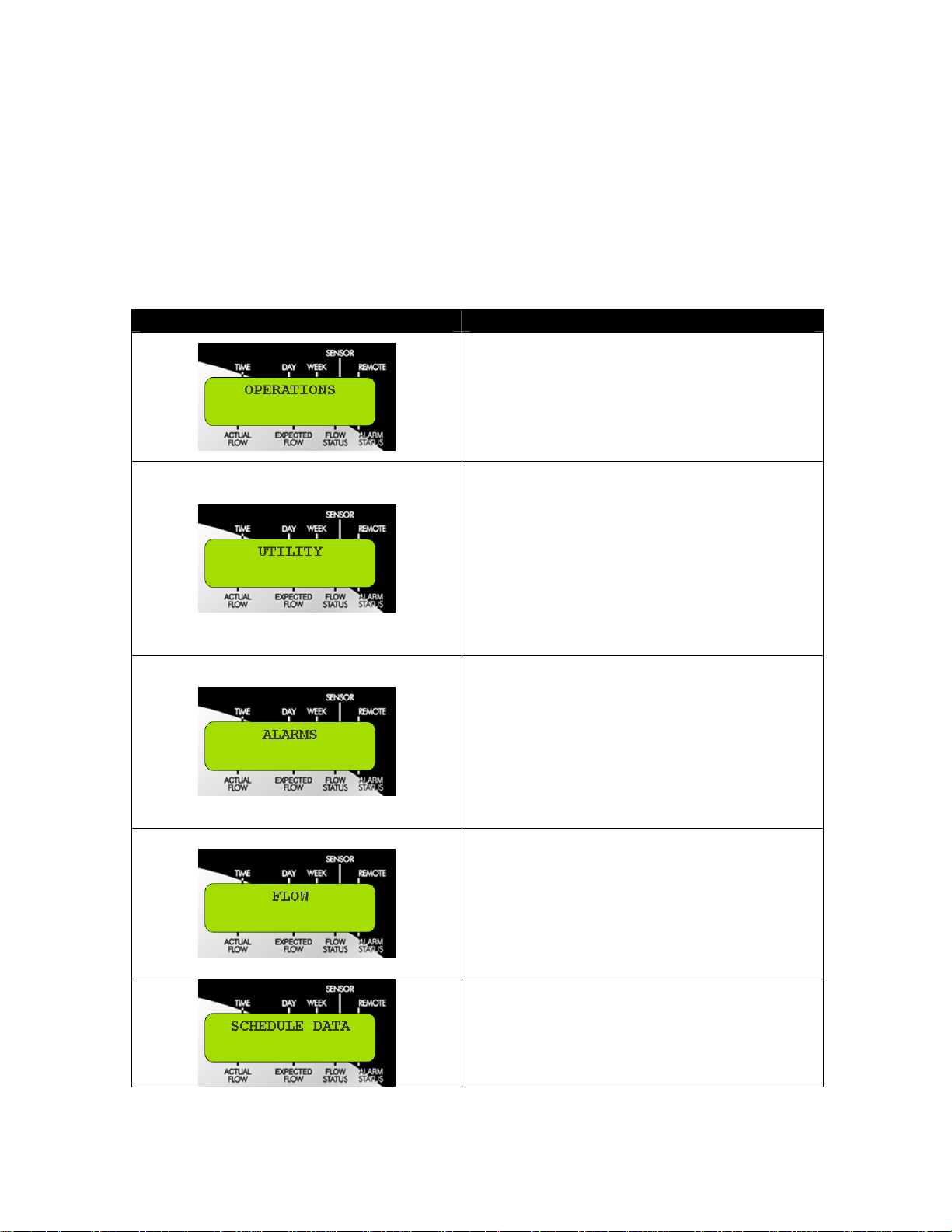

III. PROGRAMMING OVERVIEW & NAVIGATION

The Sentinel Controller is programmed by navigating through a Main Menu which

includes seven options: Operations, Utility, Alarms, Flow, Schedule Data, Program

Data, and Zone/ET Data. Each of these Main Menu options has a Submenu for entering

and changing data. This structure is detailed below as well as being shown on the

Program Instructions Card on the control module itself.

MENU SUBMENU

• Manual

• Auto Slot / Station

• Rain Off Days

• All Manuals Off

• All Autos Off

• Station Days Off

• Time & Day

• Day Change Hour

• Unit Code

• Station Count

• Program Clear

• N/O Master

• Wireless Group

• Map Unit Precode

• Two-Wire / Irritrol Mode

• Master Minimum

• Unexpected Flow

• Over Flows

• Over Currents

• Clear Flow Alarms

• Clear Fuse Alarms

• Clear Map Alarms

• Clear Power Fail

• K Factor

• Offset Factor

• Current Flow

• Expected Flows

• Maximum Flows

• Flow Processing

• Read Flow Totals

• Run Days

8

Page 9

• Start Times

• Slot-Station-Time

• Percent Scale

• Repeats

• Repeat Delay time

• Continuous Run

• Water Window

• Assigned Schedule

• Plant Factor

• Application Rate

• Default ET

• Maximum ET

• Program ET Toggle

• Station Type

• Map Stations

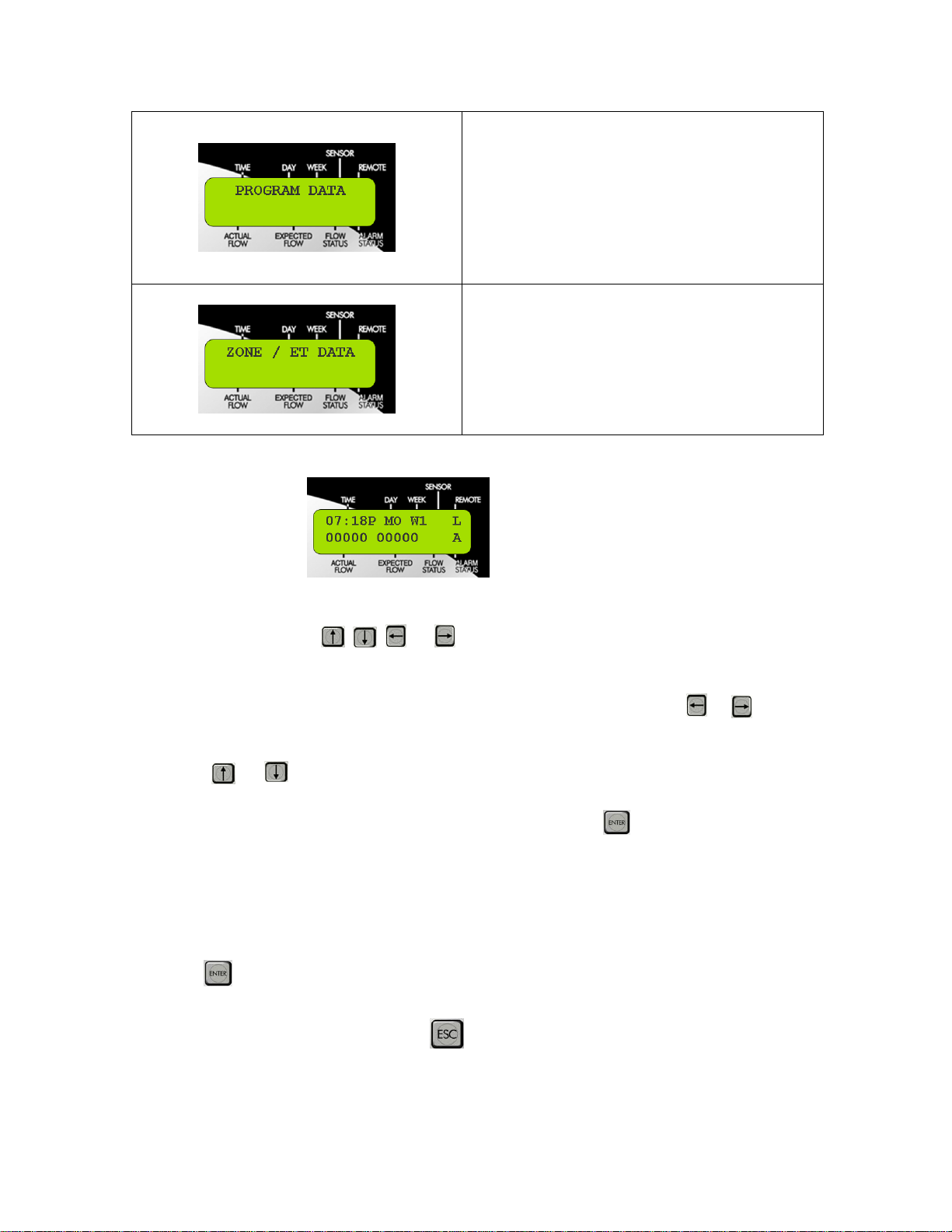

The controller normal mode (default) screen looks like:

• To enter the Main Menu from this default screen, you need to hit any of the arrow

keys on the keypad: , , or This will bring up the OPERATIONS op

, . tion

of the Main menu.

• To navigate through the Main Menu, use the right or left arrow keys: or .

• To enter a submenu for any of the Main menu options, use the up or down arrow

keys: or .

• When the desired submenu is reached, press the enter key to view or change data

in the submenu.

IMPORTANT: When entering data into one of the submenus, the controller is in the

Edit Mode. The controller will not begin any scheduled operation until you have exited

the Edit Mode. Programs that are running prior to entering the Edit Mode will

continue running. Any time you enter or change any data, you must press the

ENTER key to save the data. Otherwise, the newly entered data will not be saved.

To exit the Edit Mode, press the ESC Escape) key once or twice as necessary

to return to normal mode (default) screen. If you forget to press the ESC key, the

controller will automatically revert to normal mode after two minutes.

9

Page 10

CHAPTER 2: BASIC CONTROLLER PROGRAMMING

This section will provide the information on how to program the basic elements for

automatic irrigation to occur. The following Menus and Submenu items will be used in

this programming:

Menu

Submenu

• Time & Day

• Day Change Hour

• Unit Code

• Station Count

• Master Valve

I. CONTROLLER SETUP

• Time & Day

• Day Change Hour

• Unit Code

• Station Count

• Master Valve

UTILITY SCHEDULE DATA PROGRAM DATA

• Run Days • Start Times

• Slot-Station-Time

• Percent Scale

• Repeats

• Repeat Delay Time

• Continuous Run

• Water Window

• Assigned Schedule

UTILITY → Time & Day → Edit Mode

The controller setup functions are accessed through the Utility Menu. When starting from

the normal mode (default screen) as shown below:

Hit any of the Arrow Keys ( , , or , once. This should bring up the Main

Menu on OPERATIONS:

Hit the Right Arrow Key ( ), once to bring up the UTILITY menu:

, )

10

Page 11

Hit the Down Arrow ( ), once to access the Utility Submenu and the first submenu

option of Time & Day:

Hit Enter ( ) to access the Time & Day Edit Mode:

You are now in the Edit Mode and can change the Time, Day, and Schedule Week in the

controller. As in the example display above, the first digit of the hour should be have the

cursor under it, indicating you can change this value. Use the Numeric keys to change the

Time. The cursor will automatically advance to the next digit, or you can use the Right

and Left Arrow keys ( , or ), to move the cursor.

Use the Up or Down Arrow keys ( , ) to change from AM (A) to PM (P) as

necessary, when the cursor is on the A/P.

Use the Up or Down Arrow keys ( , ) to change the Day of the week when the

cursor is on the day.

Use the Up or Down Arrow keys ( , eek (schedule week) when the

cursor is on the week position. When initially programming the controller, set it to Week

1 (W1).

) to change the W

When all changes are made, hit the ENTER key ( ) to save changes.

it the Escape key to exit to the Utility Submenu, Time & Day option:

H

11

Page 12

Hit the Down Arrow ( ), once to access the submenu option of Day Change Hour:

IMPORTANT: From this point forward in the User’s Guide, we will not show step-by

step the navigation through the Main Menu and the Submenus and into the Edit Mode

for each submenu. Navigation, editing, cursor movement, etc, works the same for all

functions in controller programming.

Note: You must remember to hit ENTER () after changes have been made, or your

changes will not be saved.

UTILITY → Day Change Hour → Edit Mode

Sentinel allows you to choose the hour you want the controller to advance to the next

day. As an example, the day would change from Monday to Tuesday at midnight. You

can command the controller to wait until 8 AM Tuesday before it changes to Tuesday.

This way, the controller will have until 8 AM Tuesday to finish all watering cycles on the

Monday schedule.

To set the Day Change Hour, position the cursor under the item to be changed and edit as

desired using the numeric keys on the keypad. Use the Up and Down Arrow keys ( ,

) for the AM/PM toggle field. Press the ENTER key ( ) to save after editing.

UTILITY → Unit Code → Edit Mode

Every controller must have a three digit code assigned to it. This is known as the

controller’s address. You may select any three digit code from 000 to 999. This is the

identifier that is used when selecting an individual field controller with the hand held

radio or from the central controller.

12

Page 13

Position the cursor using the Right and Left Arrow keys ( , or ) under the digit being

dited. Use the numeric keys on the keypad to ) to save after

e edit. Press ENTER key (

editing.

IMPORT

f the satellite programming will be from the central software, you need to set the Unit

o

Code.

TILITY → Station Count → Edit Mode

U

Use this menu to inform the controller the number of stations it has. The Sentinel

controllers typically have station counts in 12-stati

ANT: The unit code is required for Central Control operations. Even if most

on increments (12, 24, 36, or 48).

Use the Up and Down Arrow keys ( , ) to scroll through the station count options

nd specify the number of stations in the controller. Press the ENTER key ( ) to save

a

after editing.

TILITY → N/O Master U

This menu item allows you to configure the master valve/pump start output for either

normally open or normally closed operation.

Use the Up and Down Arrow keys ( , ) to toggle between Normally: CLOSED and

ormally: OPEN options. Press the ENTER key ( ) to save after editing.

N

→ Edit Mode

13

Page 14

II. SCHEDULE SETUP

• Run Days

Schedule refers to the days of the week you want a program to run. Up to 16 unique

watering day schedules can be d

schedule has a number assignm

e ill be indicated by “S” and then the two-digit schedule Number (01, 02,…

th schedules w

16). For example, Schedule 12 would be shown as “S12.”

Each schedule is six weeks long with any combination of watering days and may be

assigned to any of the sixteen programs (covered in Program Setup). You must assign a

schedule to a program to activate it. The current Schedule Week was set in Time & Day

s part of controller setup (example was set to W1). When a

of Week 6 (w6) it loops back and starts again with Week 1 (W1).

SCHEDULE DATA → Run Days → Edit Mode

Use this Submenu Edit Mode to configure the sixteen independent schedules (water

ays): d

efined in the Sentinel Controller. For identification, each

ent ranging from 1–16. In the Display of the controller,

the controller reaches the end

The second line of the display indicates as follows:

S01 = Schedule 1

WK 1 = Week 1 of Schedule

U = Sunday

S

ON = On (active watering day)

Use the CLUSTER/SCHEDUL

(S01…S16). Position the cursor usin

ig rrow keys ( , ) to select the week desired.

K d it and use the Up or Down AW

Position the cursor under the day of the week and use the Up or Down Arrow keys (

) to select the weekday (SU, MO, TU, WE, TH, FR, SA) desired.

Position the cursor under the ON (or OFF) indica n d use the OFF/NO or ON/YEtio an

keys ( , ) or the Up or Down Arrow keys ( , ) keys to designate the day as a

watering day (ON) or a non-watering day (OFF).

E SELECT key to select the schedule desired

g the Right and Left Arrow keys ( , ) under the

S

,

Press ENTER (

entire schedule or to view the status of the other days.

) to save the status of the day. Continue this process to set up the

14

Page 15

As example, a Visual Representation of an every other day schedule follows:

WK1

WK2

WK3

WK4

WK5

WK6

SU MO TU WE TH FR SA

ON OFF ON OFF ON OFF ON

OFF ON OFF ON OFF ON OFF

ON OFF ON OFF ON OFF ON

OFF ON OFF ON OFF ON OFF

ON OFF ON OFF ON OFF ON

OFF ON OFF ON OFF ON OFF

Summary:

16 Schedules: S01, S02,….S16

6 per S le: W K2, WK4 5, WK

Weeks chedu K1, W WK3, , WK 6

7 er W U, M , WE FR, S

Days p eek: S O, TU , TH, A

If you did not set current in Tim y – go and d

week e/Da back o it.

I. PROGRAM SETUP

II

• Start Times

• Slot-Station-Time

• Percent Scale

• Repeats

• Repeat Delay Time

Continuous Run

•

• Water Window

• Assigned Schedule

n e sixteen independent Programs. They are divided into four

Se tinel controllers hav

u h D) with four Programs (1 through 4) within each Cluster. For

Cl sters (A throug

example, Clu

a entering or changing data, always make sure the desired Cluster

is nother. When you are

d ted on the display. When needed in the Edit Mode, the desired

an Program are selec

cluster and program can be selected by

ster A Program 3 (CAP3) is one program and Cluster C Program 3 (CCP3)

using the CLUSTER / SCHEDULE SELECT key

and the PROGRAM SELECT key

.

PROGRAM DATA → Start Times → Edit Mode

A Start Time initiates the automatic watering cycle. Each program can be assigned to

start up eight times within a 24-hour period.

Note: All start times must occur within the defined Water Window time frame.

When multiple start times are used, they must be spaced far enough apart to enable the

rogram irrigation cycle to be completed.

p

The controller offers eight start times per program. If more t

needed, see Repeats and Continuous Run below. Use this submenu item to display/edi

any one of the eight start times.

han eight start times are

15

t

Page 16

Use the CLUSTER/SCHEDULE SELECT ( ) and the PROGRAM SELECT ( )

keys to select the desired cluster & program, respectively. Use the Left and Right Arrow

keys ( , ) to position the cursor under the field being edited and edit as desired.

Use the Up and Down Arrow keys ( , ) to select the Start Time to edit (ST 1, ST2,…

ST 8).

Use the Numeric Keys to set the time.

Use the Up and Down Arrow keys ( , ) to toggle to the A (AM) or P (PM).

o eliminate a start time, press the OFF / NO key ( ).

T

Press ENTER (

ROGRAM DATA → Slot-Stn-Time → Edit Mode

P

One of the most unique and powerful programming features of the Sentinel Contro

e method used to organize and control satellite station outputs within each irrigation

th

program. This method is referred to as “Program Sl .” Pots

quential matrix from Slot 1 to Slot 48, for a total of 48 slot positions.

se

he program ope ting sequence begins at SlT

ssigned to a slot and given a run time duration ranging from 0 to 4 Hour and 15 Minutes.

a

Station numbers range from 0 (inactive) to 48. Stations can be

order and as many times as preferred (that is, one station can appear multiple times in the

48 Slots of one program, if desired.

.

When an irrigation program is running, any slot with 0 (or blank) run time is ignored. A

slot with an assigned run time duration ≥1 minute, but without a station a

create a pause in the watering cycle for the assigned duration.

Sentinel programming allows you to reconfigure the operating order of the stations by

enabling any station to be assigned to any slot.

Visually, the Slots can be represented

) to save the Start Time.

ller is

rogram Slots are organized in a

ra ot 1 and ends at Slot 48. Stations are

assigned to slots in any

ssignment, will

in a matrix as follows:

16

Page 17

Slot-Stn-Time Submenu Edit Mode:

The second line of the display indicates

CAP1 = Cluster A, Program 1

01-01-0:10 = Slot 1 - Station 1 – 10 Minutes

From the factory, the Slot and Station numbers are set to be the same; i.e., Station 1 is

assigned to Slot 1 and will run first. Station 2 will run next in Slot 2, etc. Use the

LUSTER/SCHEDULE SELECT key and the PROGRAM SELECT key to

C

select the desired cluster program.

Use the Right and Left Arrow keys ( , ) to p

se the Up and Down Arrow keys ( , ) to select the slot desired.

U

Use the Right Arrow key ( ) to position the cursor under the Station field. Use th

and Down Arrow keys ( , ) to select the desired Station to run

in the slot shown.

Press the Right Arrow key ( ), again, to position the cursor under the time field. Enter

the desired run time using the Numeri ke from 0:00 to 4:15 (4 Hours and 15 Minutes)

as follows:

osition the cursor under the slot field.

e Up

c ys

Press ENTER ( ) to save the Slot details. Continue this process to set up all the Slots

or to view the status of the other Slots.

Note: This feature (The Slots in a Program) allows the user to run an

order desired and e

at the controller will run the slots sequentially. Stations can be assigned to slots

th

allowing any order of programming.

ven repeat the desired station within the same program. Keep in mind

y station in any

17

Page 18

ROGRAM DATA → Percent Scale → Edit Mode P

Percent Scale Adjusts the run time of all stations assigned to the program by percentage

ranging from 0 to 255% (100% = no change).

Use the CLUSTER SELECT and the PROGRAM SELECT keys to select the desired

cluster program. Position the cursor under the field being edited and edit as desired. Press

NTER to save.

E

PROGRAM DATA → Repeats → Edit Mode

Repeats enables the watering cycle to be repeated from 1 to 250 times per start time.

Use the CLUSTER SELECT and the PROGRAM SELECT keys to select the desired

cluster program. Position the cursor under the Repeat field and edit as desired. Press

NTER to save. E

PROGRAM DATA → Repeat Dly Time → Edit Mode

Repeat Delay Time places a delay period, ranging from 0 to 255 minutes, between

program repeats. Use this menu item to display/edit the repeat delay time for any one of

the 16 program

Use the CLUSTER SELECT and the PROGRAM SELECT to select the desired cluster

program. Position the cursor under the field to be edited and edit as desired. This is used

n conjunction withi

s.

Repeats above. Press ENTER to save.

18

Page 19

PROGRAM DATA → Continuous Run → Edit Mode

Selecting Continuous Run will automatically repeat the program cycle continuously for

the defined Water Window duration.

The controller is capable of running any one or combination of programs continuously.

To manually start the desired cluster program, use the same procedure as in Auto

Slot/Stn. Use the CLUSTER SELECT and the PROGRAM SELECT keys to select the

esired cluster program. Use the ON ad

ress ENTER to save. Use Water Windows below to set up continuous run start and stops

P

automatically.

nd OFF keys to turn continuous run on and off.

PROGRAM DATA → Water Window → Edit Mode

The Water Window is the period of time in a 24-hour day that automatic watering can

ccur. Selecting a From and To time defines the Water Window start time, duration and

o

end time. A program that is running at the end of the Water Window is automatically

terminated.

Use the CLUSTER SELECT and the PROGRAM SELECT keys to select the desired

cluster program. Position the cursor under FROM or TO and toggle using the Up and

Down arrow keys. Use the Right and Left arrow keys to position the cursor under the

ime digit to t

u

nder the A (AM) or P (PM) field. Press ENTER to save. Pressing the OFF key will clear

the water window entry. Press ENTER after any change to save.

be edited and edit as desired. Use the Right arrow key to place the cursor

PROGRAM DATA → Selected Schedule → Edit Mode

Up to 16 unique watering day schedules can be defined in the controller. For

entification, each schedule has a number assignment ranging from 1–16. each program id

must be assigned a schedule in order to run.

19

Page 20

Use the CLUSTER SELECT and the PROGRAM SELECT keys to select the desired

cluster program. Use the Right and Left arrow keys to position the cursor under the field

to be edited and edit as desired. Use the Up and Down arrow keys to select from schedule

1– 4. Press ENTER after any change to save.

isually, the information and data input into a program includes the following: V

20

Page 21

IMPORTANT! At this point, you have completed the required steps for

Automatic Irrigation to occur. The remaining instructions in this user

guide deal with advanced operations and functionality not yet covered.

21

Page 22

CHAPTER 3: ADVANCED PROGRAMMING

This section covers Menus and Submenus not covered as part of Basic Programming.

I. OPERATIONS MENU

• Manual

• Auto Slot / Station

• Rain Off Days

• All manuals Off

• All Autos Off

• Station Days Off

Manual (Manual Station)

To manually operate stations, select Manual and press ENTER. Use the Up or Down

arrow key to select the desired station number. Use the ON/YES key to turn the station

On and the OFF/NO key to turn the station Off. A 30 minute run time is automatically set

for the selected station. To change the run time, position the cursor using the Left or

Right arrow key under the digit you wish to change, use the number keys to select the

desired time (1 minute to 4 hours and 15 minutes), then press ENTER. You can repeat

this procedure to run up to six stations at one time. When finished, press the ESC key

twice.

Note: Exceeding the maximum allowable output current when turning on multiple

stations will cause the controller to automatically turn off the station that caused the

condition and flag the station so that it will not run again. This is a safety feature that

prevents an over-current condition from exceeding the output capacity of the satellite. If

the station is checked and found to be electrically safe, remove the disable flag through

the Over Currents (Alarms) menu item.

Auto Slot/Stn (Manual Program Start)

Auto Slot/Station - To manually start or stop any program, open the Auto Slot/Stn menu.

Use the CLUSTER SELECT and the PROGRAM SELECT keys to choose the desired

cluster program you want to run. You may start the program from any slot. It will start

with Slot #1 unless you choose otherwise. Use the Right and Left arrow keys to

maneuver to the slot field in the display. Use the Up and Down arrow keys to select the

desired slot. Use the Left arrow key to place the cursor under the ON/OFF status. Use the

Up or Down arrow keys to toggle the program status. When the ON/OFF

status of the program(s) have been changed as desired, press the ENTER key to confirm.

Press the ESC key twice to exit the Edit mode and allow the internal computer to change

the program status. Allow up to 60 seconds for the changes to take effect.

Note: To stop the manually started Program, use the “All Autos Off” function under the

OPERATIONS Menu. The “All Manuals Off” function stops only stations individually

manually started, not stations started as part of a program.

22

Page 23

Rain Off Days

This menu item allows you to disable any program for a specific number of days. Select

the Rain Off Days menu using the Right and Left arrow key. Use the CLUSTER

SELECT and the PROGRAM SELECT keys to select the desired cluster program. Use

the Right and Left arrow keys to place the cursor under the digit being changed (the

number of days you want to activate rain shut down). Use the number keys on the keypad

to edit the digit as desired. Press the ENTER key to save the new rain day value.

All Manuals Off (Manual Stations Off)

Selecting this from the menu system provides a quick way to turn off any stations that

have been turned on manually without having to select each station individually. If more

than one manual station is on, the controller will turn off one station at a time every five

seconds to prevent the possibility of water hammer. Select All

Manuals Off from the main menu using the Right and Left arrow key. Press ENTER to

activate.

All Autos Off (Manual / Auto Programs Off)

Selecting this menu item will provide an automatic method to turn off any automatic

programs (or manually started programs) that may be running. To activate, select this

item from the main menu and press ENTER. One program will be shut down every five

seconds. The display will show DONE when the process is complete.

Stn Days Off

Station Days Off - Selecting this menu item allows you to disable individual stations for

the number of days desired. Choose Stn Days Off from the main menu. Select the station

number by placing the cursor under the station number.

Specify the amount of days off by entering it under the three digit rain days. Press the

ENTER key to save the new value. The rain days will automatically decrease by one each

day until the days off is zero. The station will then resume normal operation.

II. UTILITY MENU

• Program Clear

• Wireless Group

• Map Unit Precode

• Two-Wire / Irritrol Mode

Program Clear

This menu allows you to set all of the slot/station times within a selected program to zero.

Select the cluster program to be cleared using the CLUSTER SELECT and the

PROGRAM SELECT keys. Clear the selected program by toggling to ON and pressing

the ENTER key. This function is helpful when clearing all 16 programs.

23

Page 24

Manually clearing the station times in all 16 programs can be time consuming without

this option.

Wireless Group

Function Not Used – Removed in Firmware Version 1.42

Map Unit Precode

Function Not Used – Removed in Firmware Version 1.42

Two-Wire / Irritrol Mode

The default/standard setting for this option is OFF. Set this option to ON if the Sentinel is

connected to an Irritrol MC via RetroLink Card or if connected to a Two-Wire system.

Press ENTER to save your selection.

III. FLOW MENU

• K factor

• Offset Factor

• Current Flow

• Expected Flows

• Maximum Flows

• Flow Processing

• Read Flow Totals

Note: If a flow meter is connected to the satellite sensor terminals, the controller will

read and react to flow.

K Factor

This menu allows you to enter/edit the K factor associated with the flow metering device

being used. The K factor may be found in the specification sheet for the flow meter. Edit

the K factor by positioning the cursor under the desired digit and using the number keys

of the keypad. Press ENTER when editing is complete.

Offset Factor

This menu allows you to enter/edit the Offset Factor associated with the flow metering

device. The offset factor may be found in the specification sheet for the flow meter. Edit

the offset factor by positioning the cursor under the desired digit and using the number

keys of the keypad. Press ENTER when editing is complete.

24

Page 25

Current Flow

Selecting this menu item will display the current flow meter reading in gallons per

minute. Press ENTER to update the display as often as desired.

Expected Flows

This menu allows you to enter/edit the Expected Flow values (in gallons per minute) for

individual stations. Use the Up and Down arrow keys to select stations and the Right and

Left arrow keys to position the cursor under the digit being edited. Edit as desired and

press ENTER to save the flow value. The controller will use expected flow values to

calculate and provide a display of expected flow next to the actual flow in the controller

display.

Expected flow values will be displayed even if there is no flow meter to collect and read

actual flow values.

Maximum Flows

This menu allows you to specify/enter the maximum flow values in gallons per minute

for each individual station. Use the Up and Down arrow keys to select the station and the

Right and Left arrow keys to position the cursor under the digit being edited. Edit as

desired and press ENTER to save the flow value. The maximum flow may be obtained

(as a suggestion) by adding a percentage to the expected flow value. The percentage

added will vary with system design, size and personal preferences. This maximum flow

value will be used by the controller to check for flow-violating stations and to prevent

their operation if an unacceptable flow condition occurs.

Flow Processing

This menu allows you to turn the flow processing functions off or on. After choosing this

menu, toggle the Up or Down arrows to off or on and press ENTER.

Note: Do not turn on flow processing if it is not properly set up.

Read Flow Totals

To look at the current month’s water usage, previous month’s water usage or the previous

year’s water usage. Select Read Flow Totals from the menu and toggle the Up and Down

arrows and the Left and Right arrows to view the desired information.

25

Page 26

IV. ALARMS MENU

• Master Minimum

• Unexpected Flow

• Over Flows

• Over Currents

• Clear Flow Alarms

• Clear Fuse Alarms

• Clear Map Alarms

• Clear Power Fail

Note: The controller is capable of posting alarms when it detects excessive water flow or

excessive current.

Master Minimum

Selecting this menu item will display the status of the minimum flow alarm. The normal

status of this flag is off. It may be toggled on or off by using the Up and Down arrow

keys. If this flag displays ON, there has been a minimum flow alarm. Correct the problem

and set the flag to OFF. The minimum flow is necessary when the pump station requires

a minimum flow for cooling purposes. This alarm will turn off the master output to save

the pump from damage. The programs will continue to run. This alarm is operated by the

central system.

Unexpected Flow

Selecting this menu item will display the status of the unexpected flow alarm. The normal

status of this flag is off. It may be toggled to on or off by using the Up and Down arrow

keys. If this flag displays ON, there has been an unexpected flow condition. Correct the

problem if necessary and set the flag to OFF. This flag is set when the controller detects

flow while no station is running in the field controller.

Over Flows

Selecting this menu item will display the flow alarm status of the individual stations.

There must be a flow meter installed at the data retrieval port on the controller for this

feature function. If flow values have been properly set, the controller will watch the flow

as programs run. If there is a problem with a station such as broken line, broken heads,

etc., the controller will set the alarm for that station. If there are numerous stations

running at any one time and there is a flow problem with one station, the controller will

shut down the stations one at a time and check flow. This process will continue until the

malfunctioning station or stations are detected and disabled. Other stations that were

running will return to normal operation one at a time.

Use the Up and Down arrow keys to step through the stations and view or edit the ON or

OFF status of the flow alarms. The normal status is OFF. If the alarm status of a station is

ON, the station will not run in automatic mode.

26

Page 27

Clear the alarm by selecting the desired station and pressing the OFF key. A station may

be disabled or eliminated from auto operation by manually turning the alarm status to

ON. This is useful if the station is in need of repair or if disabling is desired for a single

station.

Note: Disabling a station by setting its alarm status to ON does not change the length of

time a program runs. The program will still reserve a time slot during operation, but will

not energize the station.

Over Currents

Selecting this menu item will display the over current status of individual stations. Over

current alarms are set to ON if a station has an electrical problem that can cause a fuse to

blow if allowed to continue running. The status of the over current alarms may be

changed by selecting the desired stations and pressing the ON/OFF keys.

Even when a station has been electrically disabled, the time management is left in the

control of the operator.

Note: Over current protection does not operate while in the Edit mode.

Clear Flow Alarms

Clear Flow Alarms - Selecting this menu allows global clearing of all flow alarms on all

stations. Pressing ENTER will execute the command and display WAIT. When the

alarms are cleared, DONE will be displayed. Normal program operation will then

resume.

Clear Fuse Alarms

Clear Fuse Alarms - Selecting this menu item allows global clearing of all fuse alarms on

all stations. Pressing ENTER will execute the command and display WAIT. When the

alarms are cleared, DONE will be displayed. Normal program operation will then

resume.

Clear Map Alarms

Select this option to clear all remote output alarms. This includes all mapped output

communication alarms. They may be MapTo Universal, Two-Wire, or wireless outputs.

Pressing ENTER will execute the command and display WAIT. When the alarms are

cleared, DONE will be displayed. Normal program operation will then resume.

Clear Power Fail

Clear Power Failure - Selecting this menu item allows clearing of the power failure

alarm. Whenever power is lost, the power failure alarm is activated. Select Clr Power Fail

from the menu and press ENTER to clear the alarm.

27

Page 28

V. ZONE / ET DATA MENU

• Plant Factor

• Application Rate

• Default ET

• Maximum ET

• Program ET Toggle

• Station Type

• Map Station

Note: The controller is capable of running irrigation programs based on ET

(evapotranspiration). When the ET functions are activated, the controller automatically

adjusts program run times according to the ET data. A weather station or ET gauge

needs to be connected to the sensor input terminals of the controller or at the central to

provide ET data.

Plant Factor:

This menu item enables you to assign a percentage factor to any zone for the type of plant

material that the zone is irrigating. For instance, you may assign a bluegrass turf zone a

factor of 100% and a ground cover zone that needs less water a 50% factor. Use the Up

and Down arrow keys to get to the station desired. Use the Right arrow to place the

cursor under the percentage field and edit as desired. Press ENTER to save.

Application Rate:

This is the amount of water a zone applies in inches per hour. For example, a zone of

fixed spray heads may apply the water at the rate of 2" per hour while a rotary sprinkler

zone may apply water at the rate of 0.50" per hour.

You can determine a zone's application rate by multiplying its gallons per minute by 96.3

and dividing that figure by the square feet covered by the zone. To enter the application

rate, use the Up and Down arrow keys to get to the station desired.

Use the Right arrow key to move the cursor under the application rate field and edit the

data. Press ENTER to save.

Default ET

This is the minimum ET figure (in inches) that is used as the default ET regardless of the

weather conditions or if data is missing from the ET gauge or weather station. ET can

vary depending on the time of the season and weather. Generally, daily ET can be from

0.00" to 0.50". Use the Up or Down arrows to toggle the value up or down. Press ENTER

to save.

Maximum ET

Set this to the maximum ET value that can be accumulated between watering days. This

value is the maximum value that a program will ever replace in a single day. Typically

choose a value that is your maximum daily ET multiplied by the number of days between

watering.

28

Page 29

Program ET Toggle

Set to ON for any programs you wish to run based on ET values, for time-based watering

set to OFF.

Station Type

The following station types are available:

UNIVRSAL – Use this option to turn on outputs locally and on a universal map to (when

mapped) (this is the default option)

LOCAL – Use this option to turn outputs on locally (out the front of the satellite).

BL-FL/PR – Not currently utilized. Baseline Flow & Pressure.

BL-SENS2 – Not currently utilized. Baseline Sensor.

BASELINE – Use this option to turn output on locally and on Baseline two-wire system.

TORO-2WD – Use this option to turn output on locally and on Toro two-wire system.

WIRELESS – Choose this option to run outputs on a wireless output board.

Map Stations

Each station can be mapped, or associated with hardware other than the Sentinel

controller output board. This setting relates to “Station Type” as set above.

Version 1.41 Firmware:

MAP 01 to 000:00

MAP SS to CCC:NN

LOCAL output:

No mapping necessary, any values entered are ignored.

UNIVERSAL output:

Setting for MapTo Universal,

Set PPP = 000

Set CCC = unit code of map to universal field unit

Set NN = map to universal output number

Version 1.42 Firmware:

01 -> 000/000:00

SS -> PPP/CCC:NN

Each station can be mapped, or associated with other hardware by way of the 8 numbers

to the right of the arrow. The fields labeled SS are the Sentinel station to be mapped (01-

96). The rest of the fields depend on the station type selected:

LOCAL output:

No mapping necessary, any values entered are ignored.

UNIVERSAL output:

Setting for MapTo Universal,

29

Page 30

Set PPP = 000

Set CCC = unit code of map to universal field unit

Set NN = map to universal output number

BASELINE:

SS corresponds to the Baseline decoder address, mapped in the Baseline setup software

to a physical decoder

Set PPP = 000

Set CCC = 001 (address of Baseline gateway connected to Sentinel serial port)

Set NN = Baseline decoder output number 01-04

TORO-2WD:

Set PPP/CCC = 0 + 5 digit decoder address

Set NN = decoder output number 01-04

WIRELESS Output:

Set PPP/CC to 000/00

The last C digit is the board number.

NN is the output number (01-12)

30

Loading...

Loading...