Page 1

FormNo.3426-322RevA

SandPro

ModelNo.08706—SerialNo.403300001andUp

®

2040ZTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3426-322*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedToroServiceDealer.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

Introduction

Thismachineisaride-onpieceofutilityequipment

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forconditioningsandtrapsonwell-maintainedgolf

coursesandcommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Exmark.comforproductsafetyand

operationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

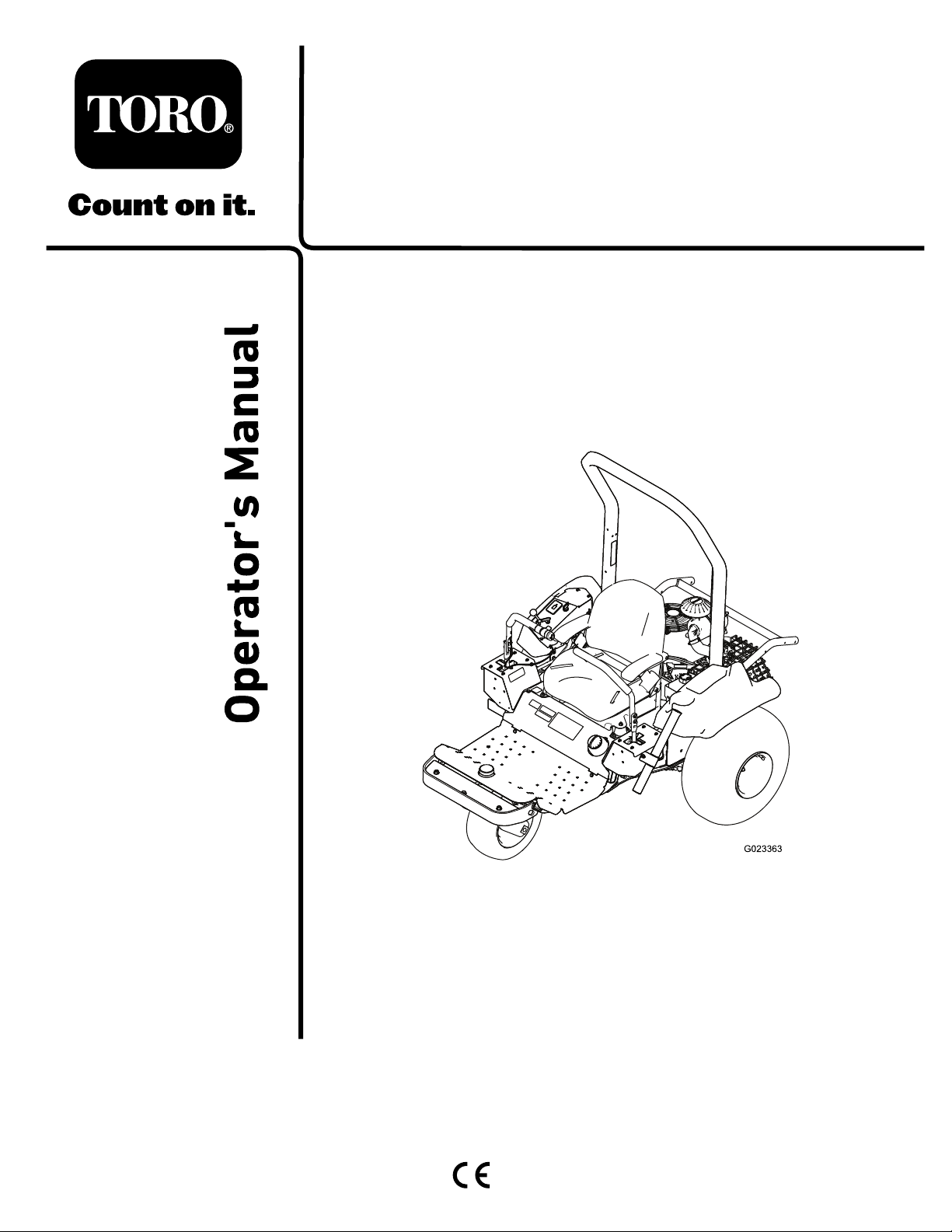

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberplatetoaccesswarranty ,parts,andother

productinformation.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

1.Modelandserialnumberlocation

2

g234875

Figure1

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Page 3

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup......................................................................10

1RemovingtheShippingBoard.........................11

2InstallinganAttachment..................................11

3InstallingtheFrontWeights.............................11

4ConnectingtheBattery..................................12

5ApplyingtheCEServiceDecal(CE

Only).............................................................12

6InstallingtheRollBar.....................................13

g000502

ProductOverview...................................................14

Controls...........................................................14

Specications..................................................16

Attachments/Accessories.................................16

BeforeOperation.................................................16

BeforeOperationSafety...................................16

BreakingintheMachine...................................17

InstallingandRemovingtheWeights................17

CheckingtheLeveloftheEngineOil.................17

FillingtheFuelTank..........................................19

CheckingtheLeveloftheHydraulic

Fluid..............................................................19

CheckingtheTirePressure...............................20

TorquingtheWheelLugNuts............................20

DuringOperation.................................................21

DuringOperationSafety...................................21

StartingandShuttingOfftheEngine.................22

UsingtheParkingBrake...................................22

UsingtheSafetyInterlockSystem....................23

DrivingtheMachine..........................................24

RakingaSandTrap..........................................25

AfterOperation....................................................26

AfterOperationSafety......................................26

PushingorT owingtheMachine........................26

TransportingtheMachine.................................28

LoadingtheMachine........................................28

InstallingaWirelessHourMeter.......................29

Maintenance...........................................................30

MaintenanceSafety..........................................30

RecommendedMaintenanceSchedule(s)...........30

DailyMaintenanceChecklist.............................31

Pre-MaintenanceProcedures..............................32

LiftingtheMachine...........................................32

Lubrication..........................................................32

GreasingtheMachine.......................................32

EngineMaintenance...........................................33

EngineSafety...................................................33

ServicingtheEngineOilandFilter....................33

ServicingtheAirCleaner..................................35

ServicingtheSparkPlugs.................................36

CheckingandAdjustingtheValve

Clearance.....................................................36

CleaningandLappingtheV alve-Seating

Surface.........................................................36

FuelSystemMaintenance...................................37

3

Page 4

ReplacingtheCarbon-CanisterFilter................37

ReplacingtheFuelFilter...................................37

ElectricalSystemMaintenance...........................38

ElectricalSystemSafety...................................38

Jump-StartingtheMachine..............................38

ReplacingtheFuses.........................................39

ServicingtheBattery.........................................39

DriveSystemMaintenance..................................42

CheckingtheTracking......................................42

AdjustingtheTracking......................................42

ReplacingtheDriveBeltandtheT ensioner

Pulley............................................................42

ControlsSystemMaintenance.............................43

AdjustingtheControl-HandlePosition..............43

AdjustingtheControl-HandleLinkage...............44

AdjustingtheControl-HandleDampers.............45

AdjustingtheNeutral-LockResistance.............45

AdjustingtheEngineControls...........................46

HydraulicSystemMaintenance...........................48

HydraulicSystemSafety...................................48

CheckingtheHydraulicSystem........................48

ChangingtheHydraulicFluidand

Filters............................................................48

CheckingtheHydraulicLinesand

Hoses............................................................50

Cleaning..............................................................50

InspectingandCleaningtheMachine...............50

Storage...................................................................51

StoringtheMachine..........................................51

Troubleshooting......................................................52

Safety

Thismachinehasbeendesignedinaccordance

withDirective2006/42/ECandANSIB71.4-2017.

However,whenyouinstallattachmentsonthe

machine,youmustaddadditionalweighttothe

machine,asspecied,tocomplytothestandards.

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineasafedistanceawayfrom

bystanderswhileitismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicingorfuelingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

,which

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

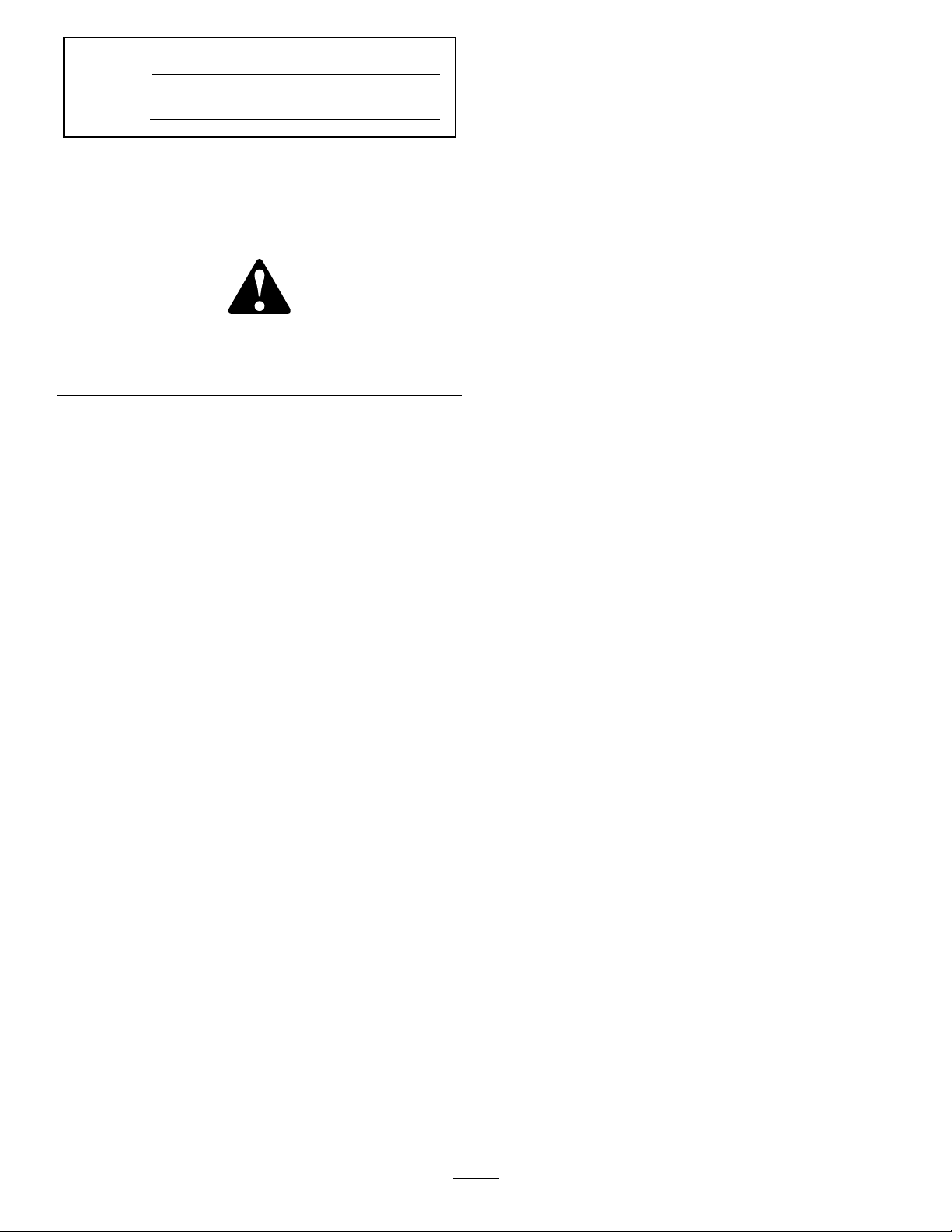

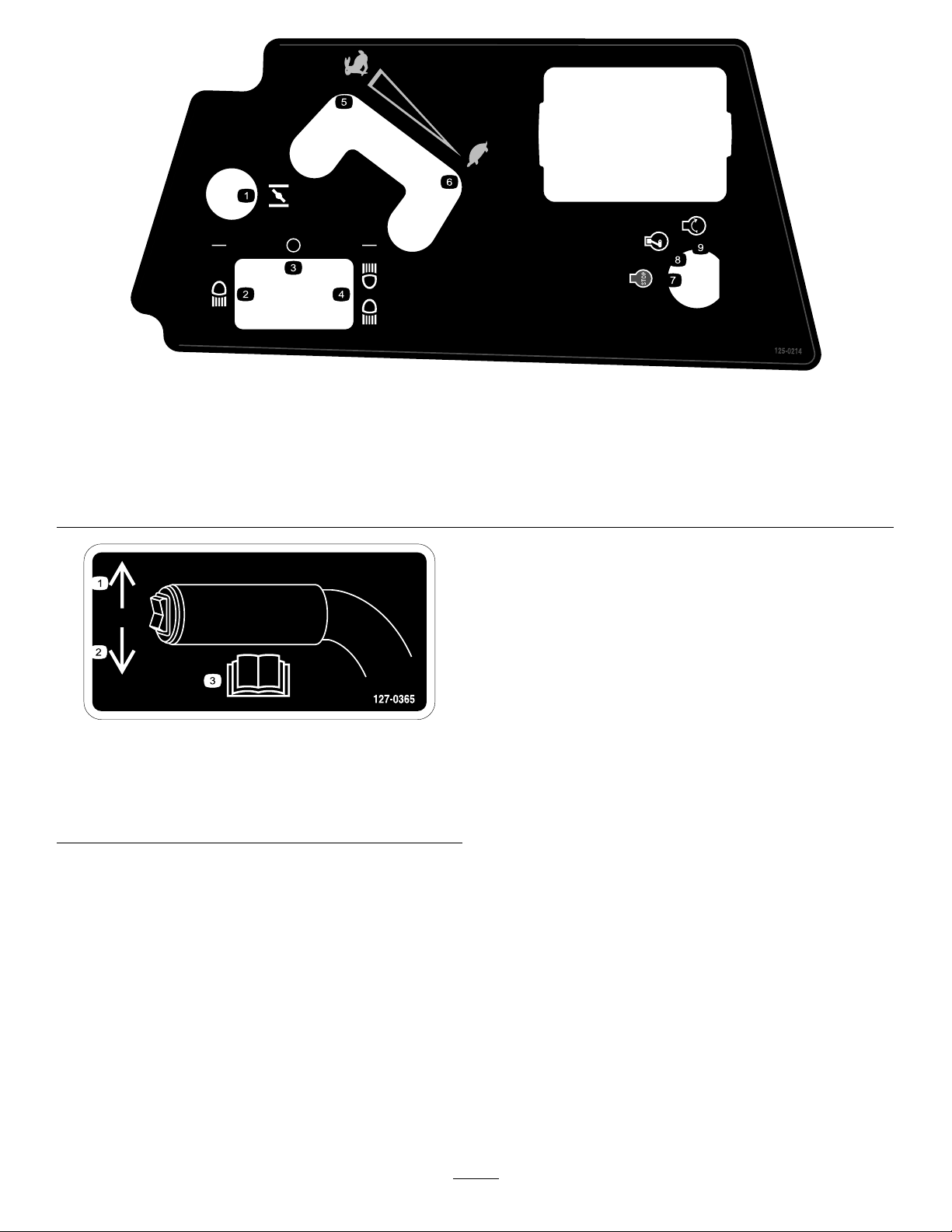

decal116-5610

116–5610

109-7232

1.Fast3.Neutral

2.Slow

decal109-7232

4.Reverse

1.Hourmeter4.Neutral

2.Powertake-off(PTO)5.Operator-presenceswitch

3.Parkingbrake6.Battery

decal116-5944

116-5944

decal133-8062

133-8062

115-8226

1.Tippinghazard—readtheOperator'smanual;alwayswear

aseatbeltwhenoperating;donotremovetherollover

protectionsystem(ROPS).

decal115-8226

5

Page 6

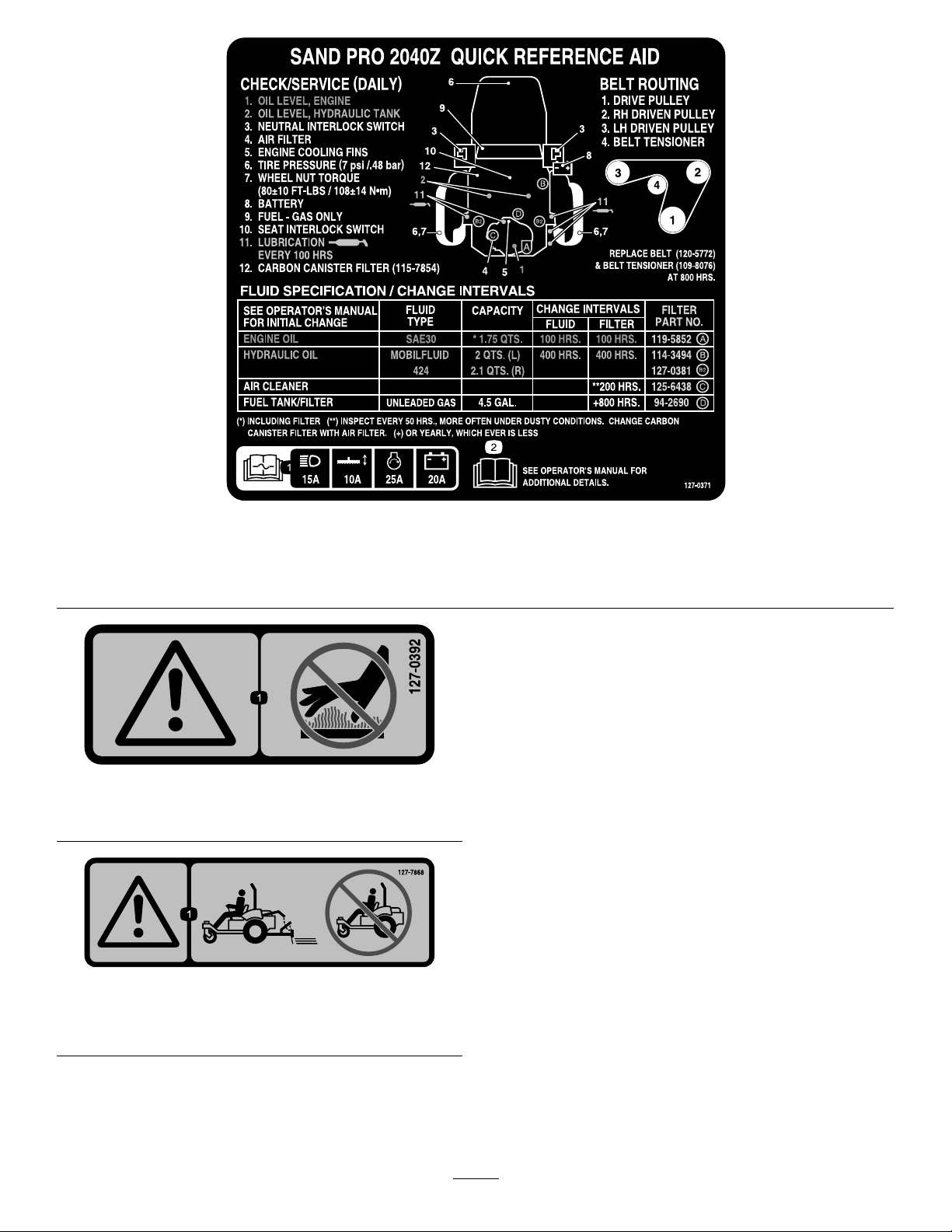

125–0214

1.Choke6.Slow

2.Headlight7.Engine—stop

3.Off

4.Headlightandtaillight9.Engine—start

5.Fast

decal127-0365

127–0365

decal125-0214

8.Engine—run

1.Pressuptoraisethe

attachment.

2.Pressdowntolowerthe

attachment.

3.ReadtheOperator’s

Manual.

6

Page 7

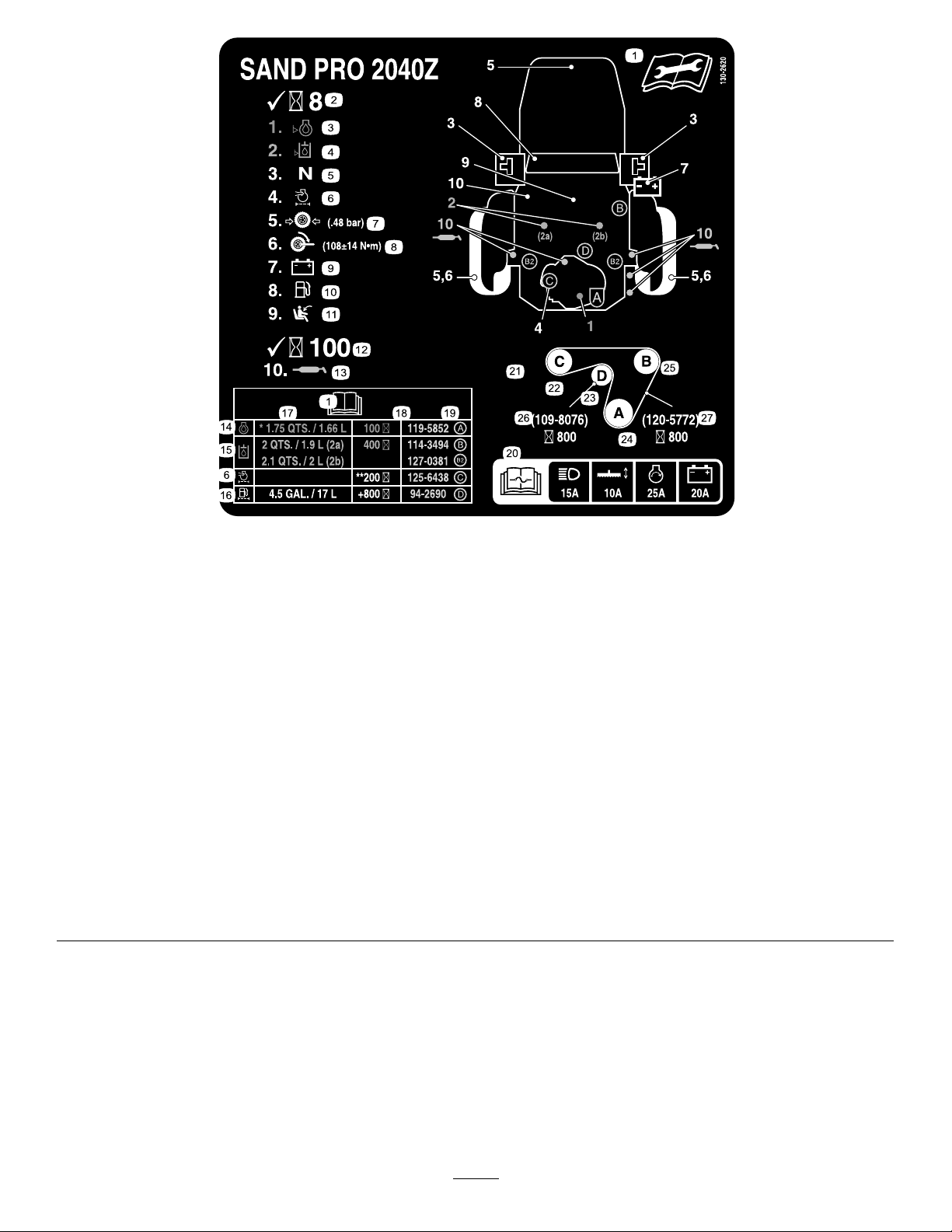

decal127-0371

127–0371

1.ReadtheOperator’sManualforinformationon

fuses—Headlights15A;Attachment10A;Enginestart25A;

Battery20A.

127–0392

1.Warning—keepawayformhotsurfaces.

127–7868

2.ReadtheOperator’sManual.

decal127-0392

decal127-7868

1.Warning—donotoperatethemachinewithoutthe

attachmentinstalled.

7

Page 8

decal130-2620

130–2620

CEonly

1.ReadtheOperator’sManualforinformationonmaintenance.

15.Hydraulicoil

2.Checkevery8operatinghours.16.Fueltank/lter

3.Oillevel—engine17.Capacity

4.Oillevel—hydraulictank18.Serviceinterval

5.Neutralinterlockswitch19.Filterpartnumber

6.Airlter20.ReadtheOperator’sManualforinformationon

fuses—Headlights15A;Attachment10A;Enginestart25A;

Battery20A.

7.Tirepressure(0.48bar)

21.Beltrouting

8.Wheelnuttorque(61to75N∙m)22.Leftdrivenpulley

9.Battery

23.Belttensioner

10.Fuel—gasolineonly24.Drivepulley

11.Seatinterlockswitch

25.Rightdrivenpulley

12.Checkevery100operatinghours.26.Belttensioner—partnumber(replaceevery800operating

hours)

13.Lubrication

27.Belt—partnumber(replaceevery800hours)

14.Engineoil

8

Page 9

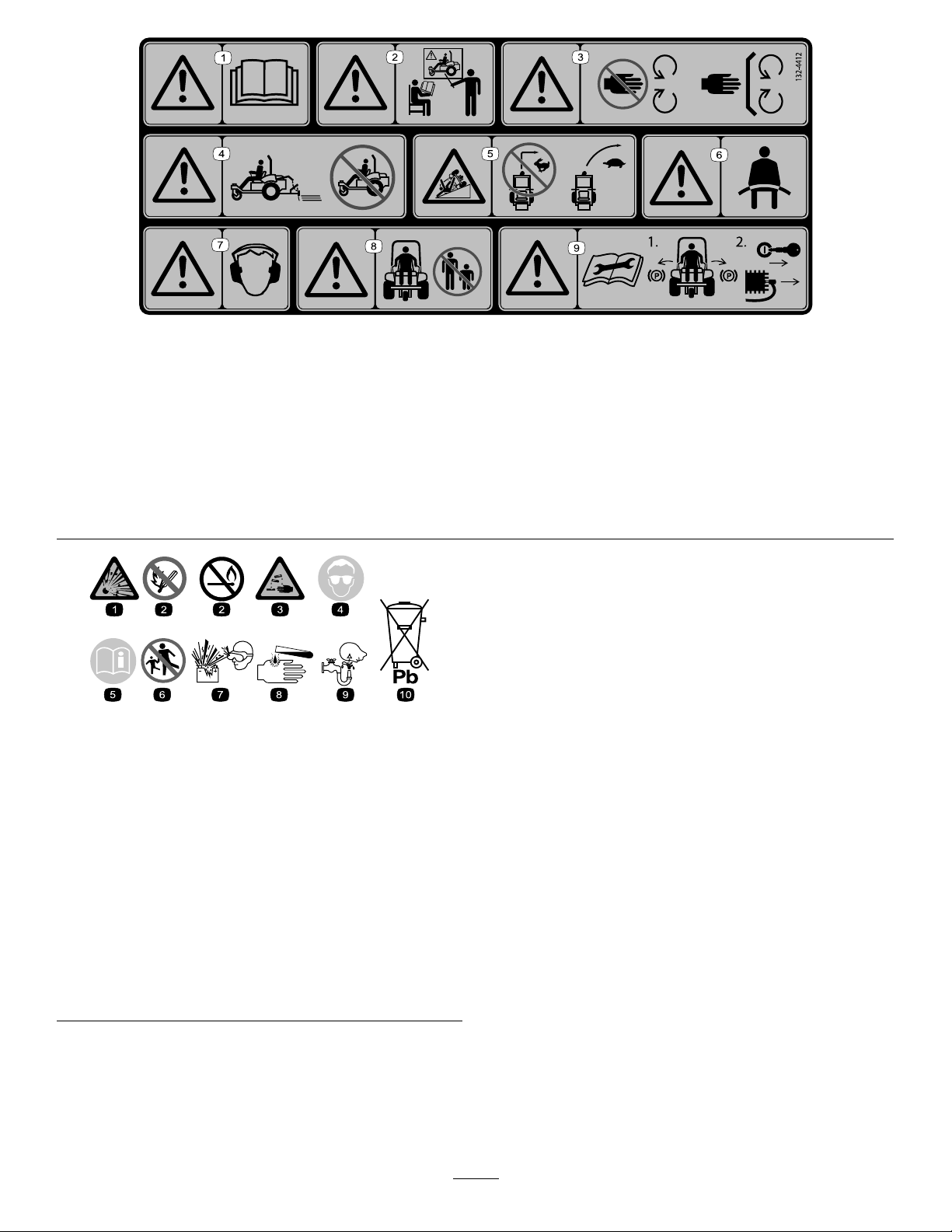

decal132-4412

132-4412

1.Warning—readtheOperator’sManual.

6.Warning—wearaseatbelt.

2.Warning—donotoperatethemachineunlessyouaretrained.7.Warning—wearhearingprotection.

3.Warning—keepawayfrommovingparts;keepallguardsand

8.Warning—keepbystandersaway.

shieldsinplace.

4.Warning—donotoperatethemachinewithouttheattachment

installed.

9.Warning—readtheOperator’sManualbeforeperforming

maintenance;1)Engagetheparkingbrakes;2)Removethe

keyfromtheignitionandremovethewirefromthesparkplug.

5.Tippinghazard,slopes—donotturnathighspeed;slowdown

andturngradually.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distanceawayfromthe

battery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard;recycle

9

Page 10

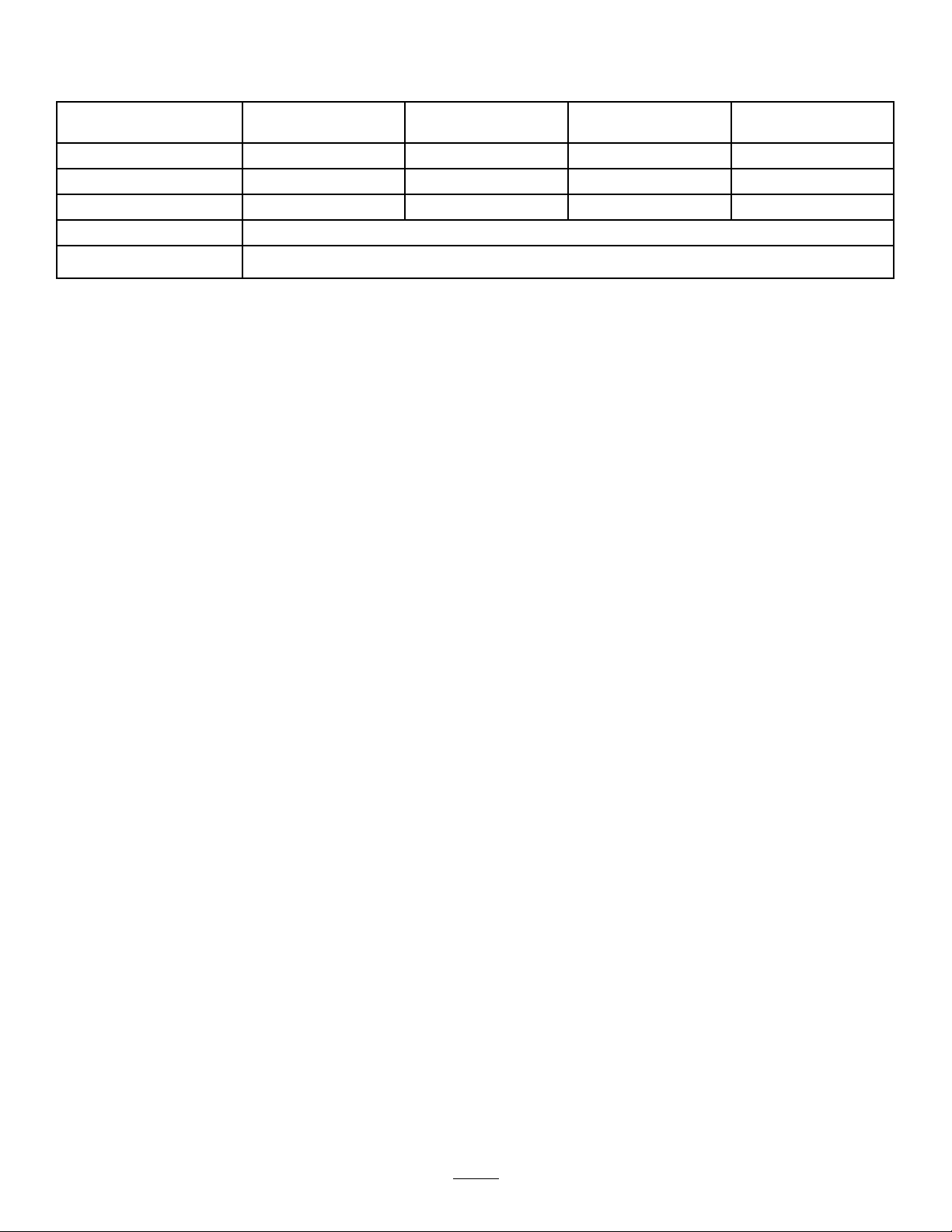

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Attachmentandrelatedparts(sold

separately)

Frontweights(asneededper

attachment)

Bolt(5/16x3/4inch)

Nut(5/16inch)

Servicedecal(130-2620)

Rollbar1

Bolt4

Flangelocknut4

Springwasher

Bracket2

MediaandAdditionalParts

Description

Operator'sManual

Engineowner’smanual1

Pre-deliveryinspectionsheet1

CerticateofCompliance

Qty.

Qty.

–

–

–

1

2

1

4

1

Readthesheetbeforeoperating.

1

ThecerticateindicatesCEcompliance.

Removetheshippingboard.

Installanattachment.

Installthefrontweights.

Connectthebattery.

ApplytheCEservicedecal,ifrequired

(CEonly).

Installtherollbar.

Use

Use

Key2

Starttheengine.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Removeanddiscardalltheshippingbracketsandfasteners.

10

Page 11

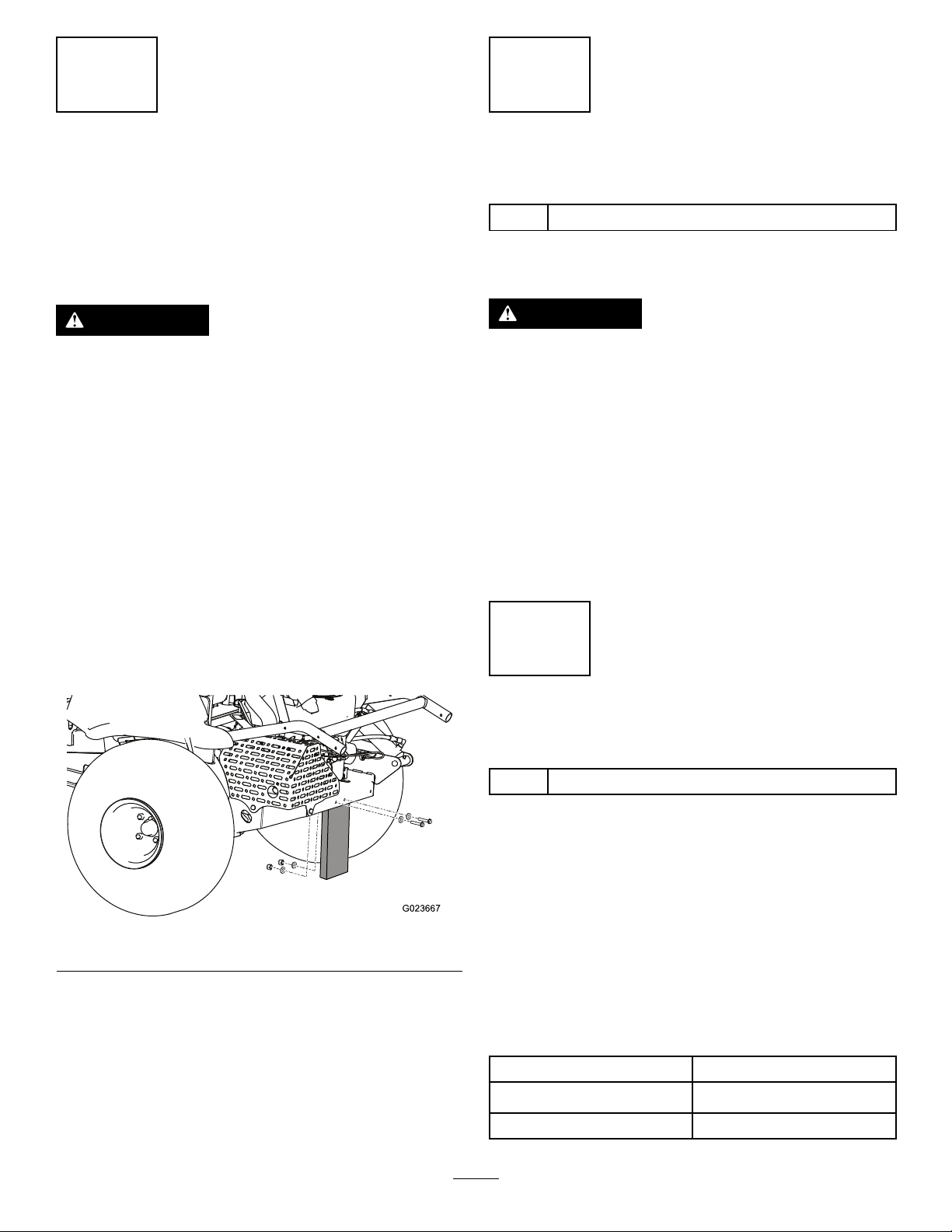

1

2

RemovingtheShipping Board

NoPartsRequired

Procedure

WARNING

Ifyoudrivethemachinewithouttheshipping

boardoranattachmentinstalled,themachine

cantipoverandinjuresomeoneordamage

property.

Drivethemachineonlyiftheshippingboard

oranapprovedattachmentisinstalled.

Beforeyoucaninstallanattachmentonthemachine,

youmustremovetheshippingboard.

1.Parkthemachineonalevelsurface,movethe

controlhandlestotheneutral-lockedposition,

engagetheparkingbrake,shutofftheengine,

andremovethekey.

InstallinganAttachment

Partsneededforthisprocedure:

–

Attachmentandrelatedparts(soldseparately)

Procedure

WARNING

Ifyoudrivethemachinewithoutanattachment

installed,itcantipoverandinjuresomeone

ordamageproperty.

Drivethemachineonlyifthereisanapproved

attachmentinstalled.

Parkthemachineonalevelsurface,movethecontrol

handlestotheneutral-lockedposition,engagethe

parkingbrake,shutofftheengine,andremovethe

key.

RefertotheattachmentInstallationInstructionsfor

informationoninstallingtheattachment.

2.Removethenuts,bolts,andwasherssecuring

theshippingboardtotherearofthemachine

(Figure3).

Figure3

3.Discardthefastenersandtheshippingboard.

3

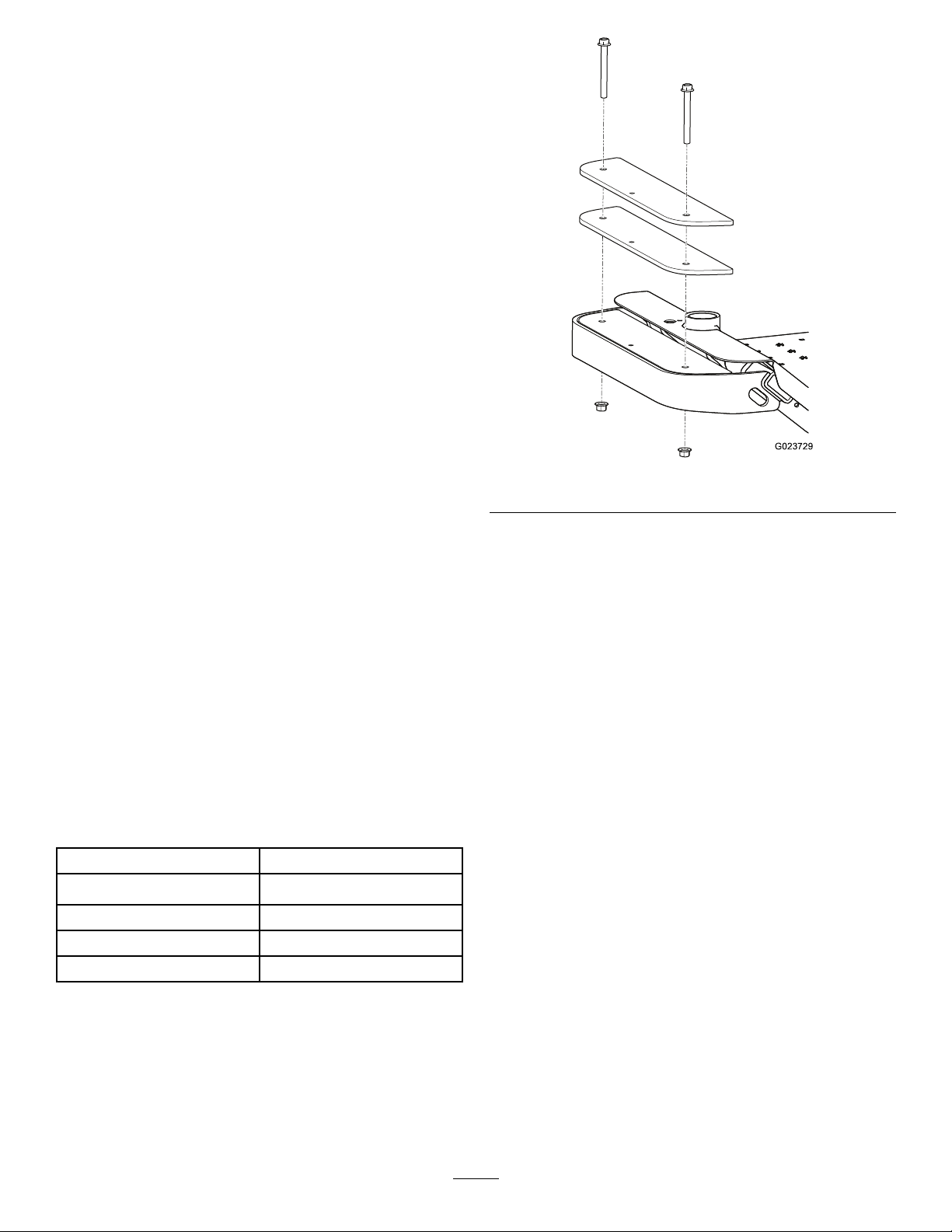

InstallingtheFrontWeights

Partsneededforthisprocedure:

–

Frontweights(asneededperattachment)

Procedure

Thismachinehasbeendesignedinaccordancewith

2006/42/ECandANSIB71.4-2012.

g023667

However,whenyouinstallattachmentsonthe

machine,youmustaddadditionalweighttothe

machine,asspecied,tocomplytothestandards.

Usethechartbelowtodeterminetheadditionalweight

required.Themachinecomeswith4weights.Each

attachmentcomeswiththenecessaryadditional

weights,ifrequired.

Attachment

Flextoothrake4

Numberofweightsrequired

Flextoothrakewithnishbrush

11

6

Page 12

Attachment

Naildrag6

Naildragwithnishdragmat

RefertoInstallingandRemovingtheWeights(page

17).

Numberofweightsrequired

8

4

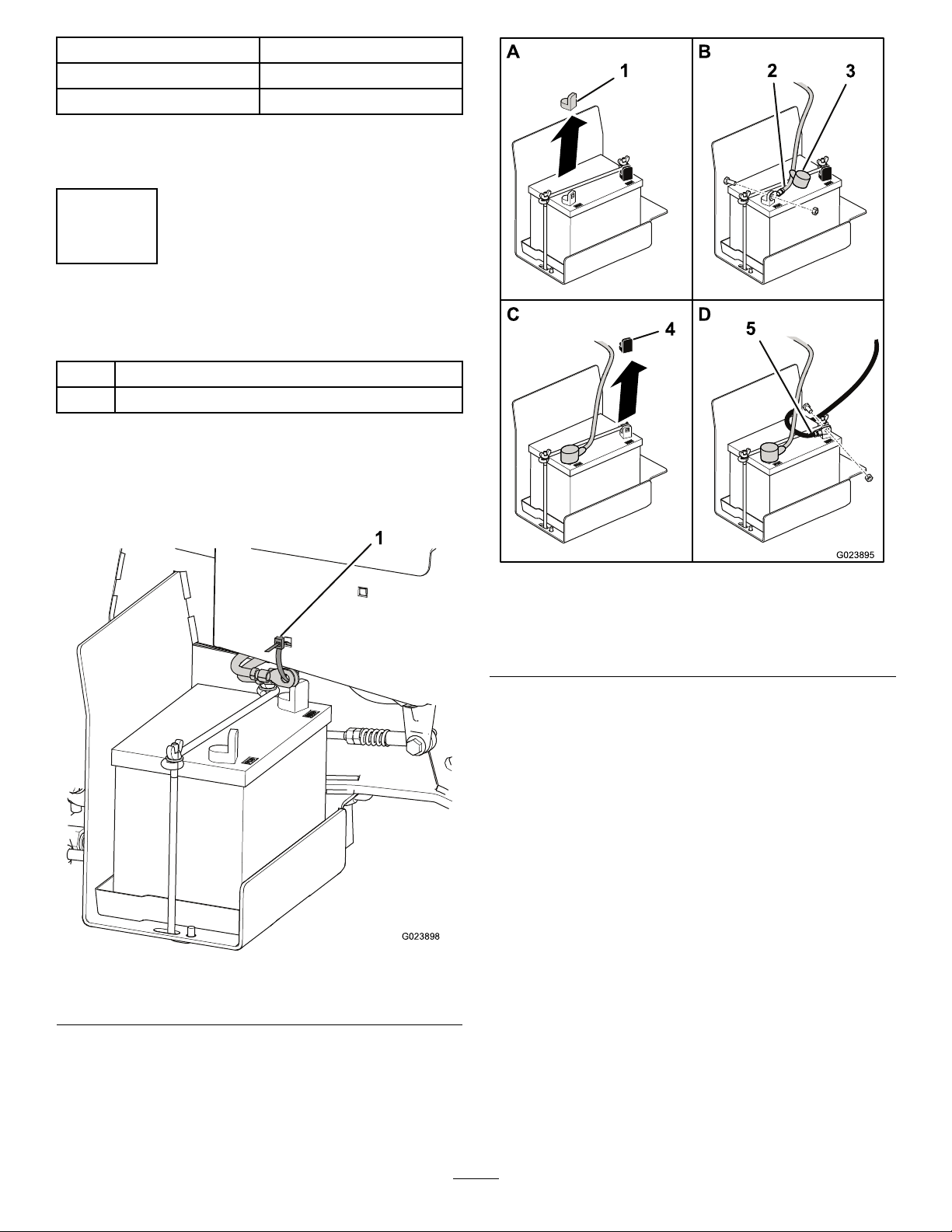

ConnectingtheBattery

Partsneededforthisprocedure:

1

Bolt(5/16x3/4inch)

2

Nut(5/16inch)

Procedure

1.Cutthecabletiesecuringthebatterycablesto

theframe,anddiscardthecabletie(Figure4).

1.Cabletie

g023895

Figure5

1.Redcover4.Blackcover

2.Positivecable5.Negativecable

3.Boot

3.Slidetheredbootawayfromtheendofthe

positivebatterycable,anduseabolt(5/16x3/4

inch)andanut(5/16inch)tomountthepositive

cabletothepositivebatteryterminal.

4.Slidetheredbootovertheterminalandthe

fasteners.

5.Removetheblackplasticcoverfromthe

negativebatteryterminal.

6.Useabolt(5/16x3/4inch)andanut(5/16inch)

tomountthenegativecabletothenegative

batteryterminal.

g023898

Figure4

2.Removetheredplasticcoverfromthepositive

batteryterminal(Figure5).

12

Page 13

5

ApplyingtheCEService

Decal(CEOnly)

Partsneededforthisprocedure:

1

Servicedecal(130-2620)

Procedure

IfthismachinemustbeCEcompliant(Europe),apply

theCEservicedecal(130-2620)overtheexisting

servicedecal(127–0371).

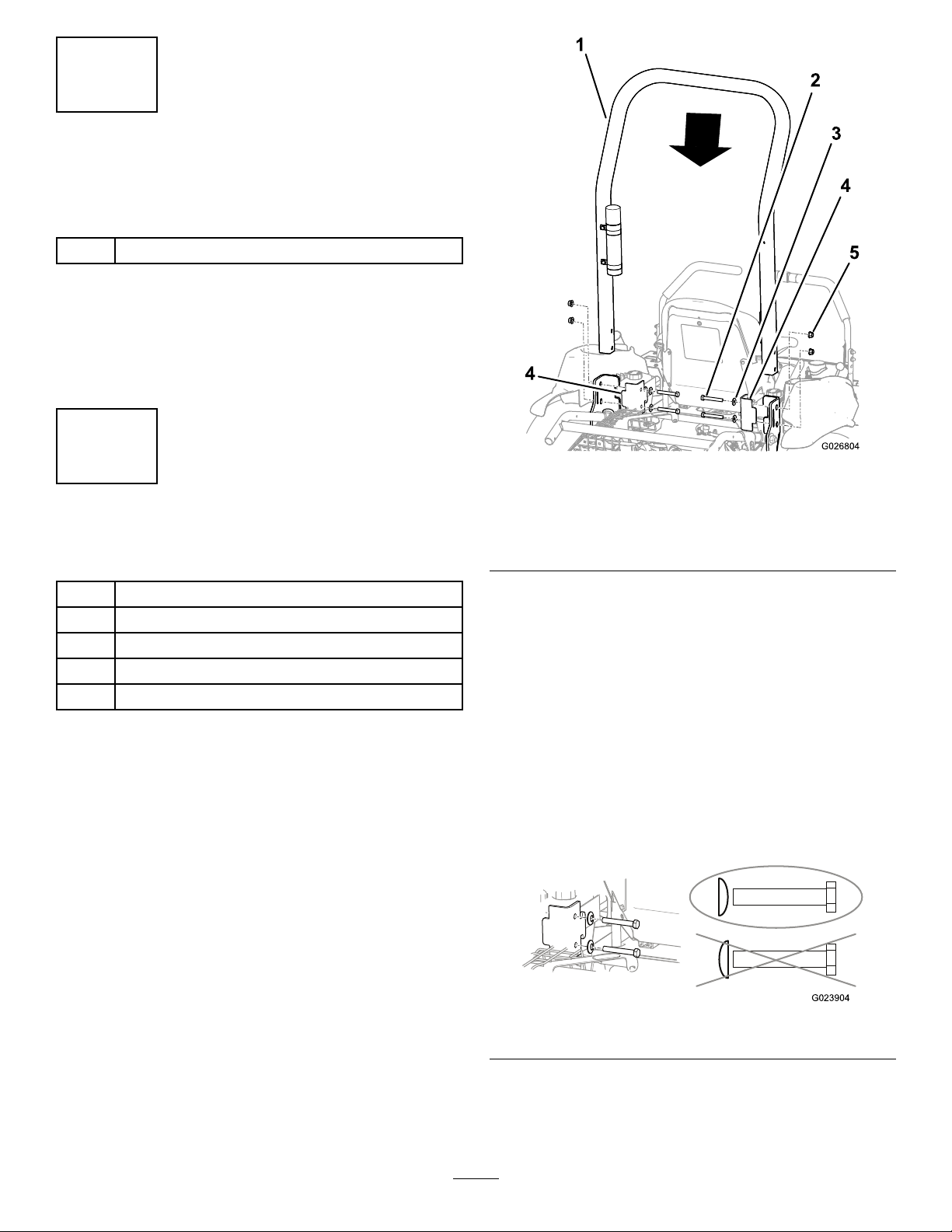

6

g026804

Figure6

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbar

4Bolt

4Flangelocknut

4

Springwasher

2Bracket

Procedure

1.Removetherollbarfromthecrate.

2.Placetherollbaronthemachineasshownin

Figure6.

1.Rollbar

2.Bolt(4)5.Flangelocknut(4)

3.Springwasher(4)

3.Installthebracketsontheframeofthemachine.

Important:Ensurethatthethrottlecable

andthechokecableareoutoftheway,so

thattheydonotgetpinchedbytherollbar

orabracket.

4.Aligntheholesinthebrackets,therollbar,and

theframe.

5.Installabolt,withaspringwasher,througheach

hole.

Important:Ensurethateachspringwasher

ispositionedsothattheconvexsidefaces

theboltheadasshowninFigure7.

4.Bracket(2)

Figure7

6.Installaangelocknutoneachbolt,andtorque

eachofthemto102N∙m(75ft-lb).

13

g023904

Page 14

ProductOverview

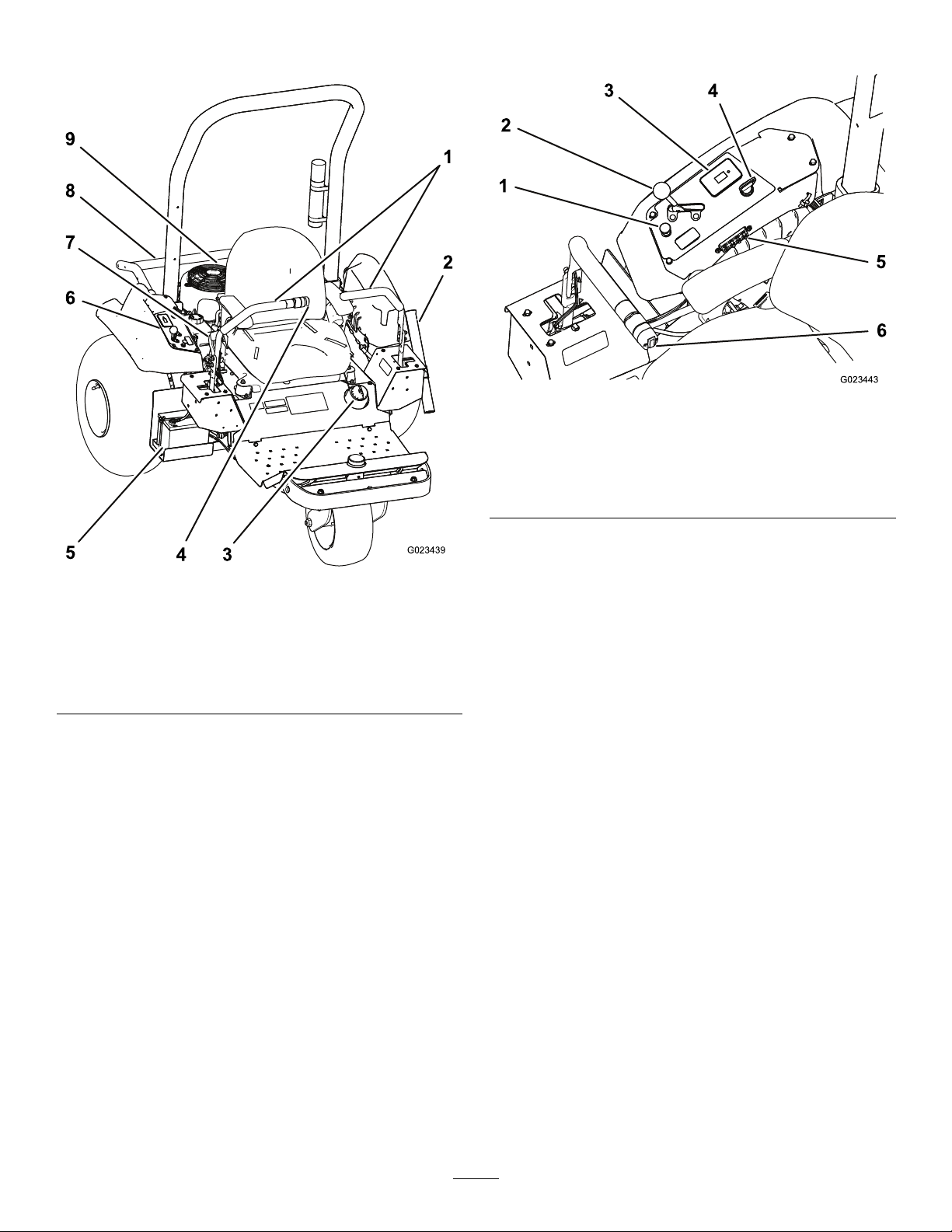

Controls

g023443

Figure9

1.Control

handles

2.Raketube5.Battery

3.Fuel-tankcap

Figure8

4.Attachment

switch

6.Controlpanel

7.Parkingbrake

8.Attachmentlift

9.Engine

1.Chokecontrol

2.Throttlelever5.Fuses

3.Hourmeter;

safety-interlockdisplay

4.Ignitionswitch

6.Attachmentswitch

ControlHandles

g023439

Usethecontrolhandles(Figure8)todrivethe

machineforwardandbackward,andtoturnineither

direction.

IgnitionSwitch

Theignitionswitch(Figure9),usedtostartandshut

offtheengine,has3positions:OFF,RUN,andST ART.

RotatethekeyclockwisetotheSTARTpositiontostart

theengine.Releasethekeywhentheenginestarts.

ThekeywillmoveautomaticallytotheRUNposition.

Toshutofftheengine,rotatethekeycounterclockwise

totheOFFposition.

ChokeControl

Tostartacoldengine,closethecarburetorchokeby

pullingthechokecontrol(Figure9)uptotheCLOSED

position.Aftertheenginestarts,regulatethechoke

tokeeptheenginerunningsmoothly.Assoonas

possible,openthechokebypushingthecontroldown

totheOPENposition.

Note:Awarmenginerequireslittleornochoking.

14

Page 15

ThrottleLever

HourMeter

Thethrottlelever(Figure9)controlsthespeedofthe

engine.Movingthethrottleleverforwardtowardthe

FASTpositionincreasestheenginespeed.Movingit

backwardtowardtheSLOWpositiondecreasesthe

enginespeed.

Note:Thethrottlelevercannotshutofftheengine.

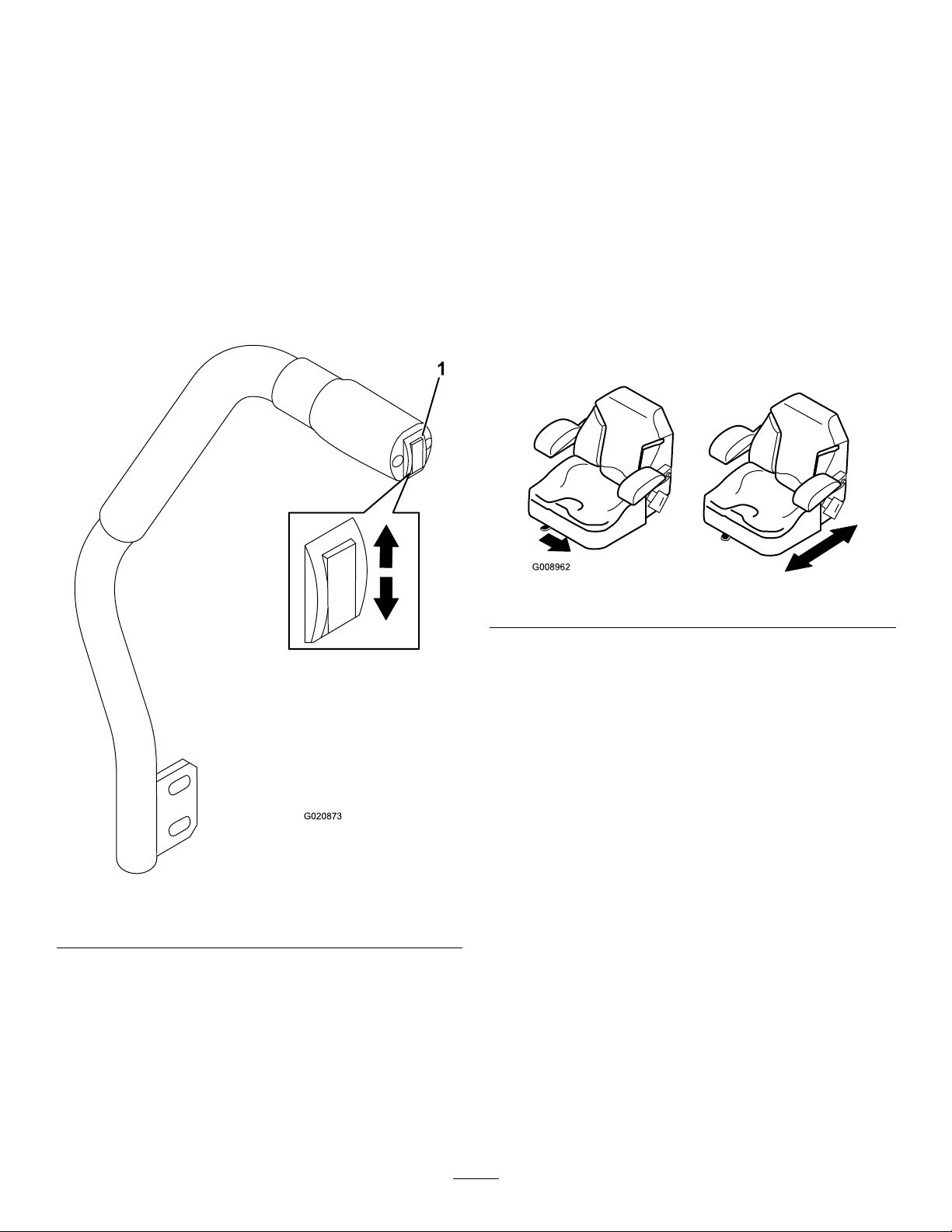

AttachmentSwitch

Toraisetheattachment,presstheupperpartof

theattachmentswitch(Figure10);tolowerthe

attachment,pressthelowerpartoftheattachment

switch.

Thehourmeter(Figure9)indicatesthetotalhoursof

machineoperation.Thehourmeterrunswhenever

theignitionswitchisintheONposition,aslongasthe

batteryisfullycharged(13.8Vormore)oryouare

sittingintheseat,therebyactivatingtheseatswitch.

Anoptionalwirelesshourmeterisavailablethrough

yourAuthorizedT oroDistributor.Toinstallit,referto

InstallingaWirelessHourMeter(page29).

Seat-AdjustmentLever

Whilesittingontheseat,movetheleverinfrontofthe

seat(Figure11)totheleft,andslidetheseattothe

desiredposition.Releasethelevertolocktheseat

intoposition.

Figure10

1.Attachmentswitch

Note:Themachinehasadouble-actingliftcylinder.

Youcanapplydownpressuretotheattachmentfor

certainoperatingconditions.

g008962

Figure11

g020873

ParkingBrake

Toengagetheparkingbrake(Figure8),pullbackon

theleveroftheparkingbrake.T odisengageit,push

theleverforward.

15

Page 16

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Machineonly

Weight

Width

Length

Height

Wheelbase

*with4weights,emptyfueltank,andnooperator

**withtheattachmentandweights,emptyfueltank,andnooperator

399kg(880lb)*417kg(920lb)**439kg(970lb)**445kg(980lb)**

147cm(58inches)213cm(84inches)182cm(71.5inches)198cm(78inches)

186cm(73.3inches)226cm(89.0inches)215cm(84.8inches)297cm(1 17inches)

Withextoothrake

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorDistributoror

gotowww.Exmark.comforalistofallapproved

attachmentsandaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,Toro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

WithnaildragWithnaildragand

nishmat

185cm(73inches)

147cm(58inches)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Parkthemachineonalevelsurface;engagethe

parkingbrake,shutofftheengine,removethekey,

andwaitforallmovementtostopbeforeleaving

themachine.

•Knowhowtostopthemachineandenginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforeoperating,alwaysinspectthemachine

toensurethatthecomponentsandfasteners

areingoodworkingcondition.Replacewornor

damagedcomponentsandfasteners.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

16

Page 17

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainthefuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

BreakingintheMachine

Newenginestaketimetodevelopfullpower.Drive

systemshavemorefrictionwhentheyarenew,

placingadditionalloadontheengine.

Allowtherst8hoursofoperatingtimeforthe

break-inperiod.

Sincethersthoursofoperationarecriticaltofuture

dependabilityofthemachine,monitorthefunctions

andperformancecloselysothatyoucannoticeand

correctminordifculties,whichcouldleadtomajor

problems.Inspectthemachinefrequentlyduring

thebreak-inperiod,forsignsofoilleakage,loose

fasteners,oranyothermalfunction.

InstallingandRemoving theWeights

ThemachinecomplieswiththeANSIB71.4-2012

standardsatthetimeofproduction.However,

whenthefollowingattachmentsareinstalledonthe

machine,additionalweightisrequiredtocomplyto

thestandards.Usethechartbelowtodeterminethe

additionalweightrequired.Themachinecomeswith4

weights.Eachattachmentcomeswiththenecessary

additionalweights,ifrequired.

Attachment

Flextoothrake4

Flextoothrakewithnishbrush

Naildrag6

Naildragwithnishdragmat

1.Removethe2boltsand2nutssecuringthe

existingweightsonthefrontofthemachine

(Figure12).

Note:Ifthemachineisequippedwiththelight

kit,removethenutandtheboltsecuringthe

frontlighttothemachine.Retainalloftheparts;

refertotheLightKitInstallationInstructions.

Numberofweightsrequired

6

8

g023729

Figure12

2.Addorremoveweightsasnecessary.

3.Securetheweightswiththe2boltsandthe2

nuts.

•Formostoftheattachments,usetheexisting

bolts.

•Thenishdragmatincludes2longerbolts

toaccommodatetheadditionalweightsthat

itrequires.

Note:Ifthemachineisequippedwiththelight

kit,installthefrontlightbyinsertingthebolt

throughtheweightsandsecuringitwiththenut;

refertotheLightKitInstallationInstructions.

CheckingtheLevelofthe EngineOil

ServiceInterval:Beforeeachuseordaily—Check

theleveloftheengineoil.

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDistributor.

CrankcaseCapacity:1.8L(1.7USqt)withlter

change

Use4-cycleengineoilthatmeetsorexceedsthe

followingrequirements:

•APIservicecategory:SJ,SL,SM,orhigher

•Viscosity:SAE30;refertothefollowingchartfor

otherviscosities(Figure13):

17

Page 18

Important:Usingmulti-viscosityoils,suchas

10W-30,increasesoilconsumption.Checkthe

oillevelmorefrequentlywhenusingthem.

Figure13

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Removethedipstick(Figure14)andwipeitwith

acleancloth(Figure15).

g023445

g008792

Figure15

3.Insertthedipstickintothelltubewithout

threadingitintotheport.

4.Removethedipstickfromthetubeandcheck

g023517

Figure14

theoillevel.Iftheoillevelislow,slowlypour

onlyenoughoilintothelltubetoraisetheoil

leveltotheupper-limitmarkonthedipstick

1.Dipstick

Important:Keeptheengineoillevel

betweentheupperandlowerlimitsonthe

dipstick.Enginefailuremayoccurasaresult

ofrunningtheenginewithtoomuchortoo

littleengineoil.

5.Installthedipstickrmlyinplace.

Important:Thedipstickmustbefullyseated

inthetubetoprovidepropersealingof

theenginecrankcase.Failuretosealthe

crankcasemayresultinenginedamage.

18

Page 19

FillingtheFuelTank

CheckingtheLevelofthe

Fueltankcapacity:17L(4.5USgallons)

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.EthanolandMTBE

arenotthesame.Gasolinewith15%ethanol

(E15)byvolumeisnotapprovedforuse.Never

usegasolinethatcontainsmorethan10%ethanol

byvolume,suchasE15(contains15%ethanol),

E20(contains20%ethanol),orE85(contains85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Cleantheareaaroundthefuel-tankcap(Figure

16).

HydraulicFluid

ServiceInterval:Beforeeachuseordaily—Check

thelevelofthehydraulicuid.

Important:Foraccuracy,checkthelevelofthe

hydraulicuidonlywhentheengineandthe

hydraulicsystemarecold.

Thereservoirsofthemachinearelledatthefactory

withhigh-qualityhydraulicuid.Thebesttimeto

checkthehydraulicuidiswhentheuidiscold.The

machineshouldbeinthetransportconguration.If

theuidlevelisbelowthetopofthehorizontalpartof

thecut-outsightwindowontherearofthehydraulic

reservoirs(Figure17),adduidtobringtheuidto

theacceptablelevel.Donotoverllthereservoirs.

Iftheuidlevelisatthetopofthehorizontalpartof

thesightwindow,nouidadditionisrequired.The

recommendedreplacementuidis:

FluidType:T oroPremiumTransmission/Hydraulic

TractorFluidorMobiluid

Capacity:

•Leftside—1.9L(2.0USqt)

•Rightside—2.0L(2.1USqt)

Alternativeuids:Ifthespecieduidisnotavailable,

otheruniversaltractorhydraulicuids(UTHF)may

beused,buttheymustbeonlyconventional,

petroleum-basedproducts,notsyntheticsor

biodegradableuids.Thespecicationsmustfall

withinthelistedrangeforallofthefollowingmaterial

propertiesandtheuidshouldmeetlistedindustry

standards.Checkwithyouruidsuppliertoseeifthe

uidmeetsthesespecications.

®

424

Figure16

1.Fuel-tankcap

3.Removethefuel-tankcap.

4.Fillthetanktoabout25mm(1inch)belowthe

topofthetank(bottomofthellerneck).Donot

overll.

5.Installthecap.

6.Wipeupanyfuelthatmayhavespilled,to

preventarehazard.

Note:T orowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

g023449

19

Page 20

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)55to62

ViscosityIndexASTMD2270

PourPoint,ASTMD97-37°Cto-43°C(-35°Fto-46°F)

IndustrySpecications:

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25,andVolvoWB-101/BM

140to152

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicuidisavailablein20ml(2/3oz)

bottles.Onebottleissufcientfor15to22L(4to

6USgallons)ofhydraulicuid.Orderpartnumber

44-2500fromyourAuthorizedT oroDistributor.

A.Cleantheareaaroundtheuid-reservoir

capstopreventdebrisfromenteringthe

system(Figure17).

B.Removethecapsfromthereservoirs.

C.Slowlyllthereservoirwiththeappropriate

hydraulicuiduntilthelevelreachesthe

bottomoftheopeningsinthebrackets.

Important:Topreventsystem

contamination,cleanthetopoftheuid

containerbeforeopeningit.Ensurethat

thepourspoutandthefunnelareclean.

Important:Donotoverllthereservoirs.

D.Installthereservoircaps.

1.Parkthemachineonalevelsurface,lowerthe

attachment,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Lookattheopeningineachoftheuid-reservoir

brackets,andcheckthelevelofthehydraulic

uid.

Note:Theuidlevelshouldbeatthebottomof

eachoftheopenings,asshowninFigure17.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Parkthemachineonalevelsurface,lowerthe

attachment,engagetheparkingbrake,shutoffthe

engine,andremovethekey .

Checkthetirepressurebeforeoperatingthemachine

(Figure18).

Pressure:48kPa(7psi)

Figure17

1.Hydraulic-uidreservoirs

2.Fluid-reservoircap4.Fluidlevel

3.Bracket

3.Iftheuidlevelislowineitherofthereservoirs,

adduidasfollows:

g002706

Figure18

1.Valvestem2.Lugnut

TorquingtheWheelLug

g023450

Nuts

ServiceInterval:Aftertherst8hours

Every100hours

Parkthemachineonalevelsurface,lowerthe

attachment,engagetheparkingbrake,shutoffthe

engine,andremovethekey .

20

Page 21

Torquethelugsnuts(Figure18)to61to75N∙m(45

to55ft-lb).

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthemachineandinspecttheattachment

afterstrikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonlevelground.

–Lowertheattachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Whennecessary ,wetsurfacespriortoconditioning

tominimizedustcreation.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

RolloverProtectionSystem (ROPS)Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairoralter

it.

•TheROPSisanintegralsafetydevice.

•Alwayswearyourseatbelt.

SlopeSafety

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

sloperequiresextracaution.

•Operatethemachineatalowerspeedwhenyou

areonaslope.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.T allgrasscanhideobstacles.

•Choosealowgroundspeedsoyouwillnothave

tostoporshiftwhileonaslope.

•Arollovercanoccurbeforethetireslosetraction.

21

Page 22

•Avoidoperatingthemachineonwetgrass.Tires

maylosetraction;regardlessifthebrakesare

availableandfunctioning.

3.PullthechokecontrolupwardtotheONposition

(whenstartingacoldengine),andmovethe

throttlelevertotheSLOWposition.

•Avoidstarting,stopping,orturningthemachine

onaslope.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,orbodiesofwater.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecavesin.Establisha

safetyareabetweenthemachineandanyhazard

(2machinewidths).

StartingandShuttingOff theEngine

1.Movethecontrolhandlestotheneutral-locked

position(Figure19).

Important:Whenoperatingthemachine

intemperatureslessthan0°C(32°F)allow

themachinetimetowarmupbeforeusing

it.Thispreventsdamagetothehydraulic

system.

4.Insertthekeyintotheignitionswitchandrotate

itclockwisetostarttheengine.Releasethekey

whentheenginestarts.Regulatethechoketo

keeptheenginerunningsmoothly.

Important:Topreventoverheatingofthe

startermotor,donotkeeptheignitionkey

intheST ARTpositionforlongerthan10

seconds.After10secondsofcontinuous

cranking,wait60secondsbeforeusingthe

startermotoragain.

5.Toshutofftheengine,movethethrottlecontrol

totheSLOWposition,andturnthekeytothe

OFFposition.Removethekeyfromtheswitch

topreventaccidentalstarting.

Note:Inanemergency,simplyturnthekeyto

theOFFposition.

Figure19

1.Controlhandle

(neutral-lockedposition)

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

UsingtheParkingBrake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

Toengagetheparkingbrake,pullupwardonthe

handle(Figure20).

g004532

2.Engagetheparkingbrake;refertoEngagingthe

ParkingBrake(page22).

g016994

Figure20

22

Page 23

DisengagingtheParkingBrake

Todisengagetheparkingbrake,pushdownwardon

thehandle(Figure21).

Figure21

UsingtheSafetyInterlock System

CAUTION

Ifthesafetyinterlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Thecontrolhandlesareintheneutral-locked

position

Thesafetyinterlocksystemalsostopstheengine

whenyoumovethecontrolhandlesoutofthe

neutral-lockedpositionwhileyouareoutoftheseator

whiletheparkingbrakeisset.

Thehourmeterhassymbolstonotifyyouwhenthe

interlockcomponentisinthecorrectposition.When

thecomponentisinthecorrectposition,atriangle

appearsinthecorrespondinglocation(Figure22).

g016995

1.Trianglesappearwhentheinterlockcomponentsareinthe

correctposition.

Figure22

g023660

Note:ThePTO(powertake-off)interlockisnotused

onthismachine.

TestingtheSafetyInterlock System

ServiceInterval:Beforeeachuseordaily

Ifthesafetyinterlocksystemdoesnotoperateas

describedbelow,haveanAuthorizedToroDistributor

repairitimmediately.

1.Sitontheseat,movethecontrolhandlestothe

neutralposition,andengagetheparkingbrake.

2.Starttheengine.

3.Getofftheseatandslowlymoveeachcontrol

handleforwardandbackward.

Theengineshouldshutoffin1to3secondsafter

movingeithercontrolhandleineitherdirection.

Ifitdoesnot,correcttheproblem.Repeatsteps

2and3fortheothercontrolhandle.

4.Sittingontheseat,engagetheparking

brake.Moveeithercontrolhandleoutofthe

neutral-lockedposition.Trystartingtheengine;

theengineshouldnotcrank.Repeatthisstep

fortheothercontrolhandle.

23

Page 24

DrivingtheMachine

CAUTION

Operatingthemachinedemandsattentionto

preventtippingorlossofcontrol.

•Usecarewhenenteringandleavingsand

traps.

•Useextremecautionaroundditches,

creeks,orotherhazards.

•Usecautionwhenoperatingthemachine

onasteepslope.

•Reduceyourspeedwhenmakingsharp

turnsorwhenturningonhillsides.

•Avoidsuddenstopsandstarts.

•Donotgofromreversetofullforward

withoutrstcomingtoacompletestop.

CAUTION

UsingtheControlHandles

Themachinecanspinveryrapidly.Ifyou

misusethecontrolhandles,youmaylose

controlofthemachineandinjuresomeoneor

damagethemachineorotherproperty.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Figure23

1.Controlhandle

(neutral-lockedposition)

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

DrivingtheMachineForward

Note:Theengineshutsoffifyoumovethecontrol

handleswhiletheparkingbrakeisengaged.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page23).

2.Movethecontrolhandlestothecenter,unlocked

position.

3.Togoforward,slowlypushthecontrolhandles

forward(Figure24).

Tostopthemachine,movethecontrolhandles

totheneutralposition.

g004532

24

Page 25

Figure24

DrivingtheMachineBackward

1.Ensurethattheattachmentisinthedesired

position.

2.Movethecontrolhandlestothecenter,unlocked

position.

3.Togobackward,lookbehindandslowlypullthe

controlhandlesbackward(Figure25).

g023442

Figure25

g023441

RakingaSandTrap

Readthisentiresectiononrakingbeforerakinga

sandtrap.Therearemanyconditionsthatdetermine

theadjustmentsnecessary.Thetextureanddepthof

thesand,moisturecontent,weeds,andtheamountof

compactionareallfactorsthatcanvaryfromcourseto

course,orevenfromtraptotraponthesamecourse.

Maketheadjustmentsontherakeforoptimumresults

inyourparticulararea.

LearningHowtoRake

Practicerakinginalargeandleveltraponthecourse.

Practicestartingandstopping,turning,raisingand

loweringtherake,enteringandleavingthetrap,etc.

Practiceatamoderateenginespeedandaslow

groundspeed.Thistraininghelpstheoperatortogain

condenceintheperformanceofthemachine.

Therecommendedpatternforrakingatrapisshown

inFigure26.Thispatternavoidsunnecessary

overlap,keepscompactiontoaminimum,andleaves

aneat,attractivepatternonthesand.Thisisthemost

efcientrakingmethod,however,itisimportantto

varytherakingpatternregularlytoreducethechance

ofcreatingawashboardeffect.

25

Page 26

Throughexperienceandpractice,theoperatorwill

soonunderstandtherequiredtimingforenteringand

leavingthetrapproperly.

AfterOperation

AfterOperationSafety

•Cleangrassanddebrisfromthemuferand

enginecompartmenttohelppreventres.Clean

upoilorfuelspills.

•Parkthemachineonalevelsurface;engagethe

parkingbrake;shutofftheengine;removethekey;

andwaitforallmovementtostopbeforeleaving

themachine.

Figure26

1.Enteratrapstraightinto

thelongdimensionina

levelarea.

Enterthetrapstraightintothelongdimension,where

thebankistheleaststeep.Drivethroughthecenter

ofthetrapalmosttotheend,turntoeitherdirection

assharpasyoucan,andcomebackrightnexttothe

rstpass.SpiraloutwardasshowninFigure26,and

leavethetrapatarightangleinalevelarea.

Leavesteep,shortbanksandsmallpocketsfor

touch-upwithahandrake.

RakingTips

2.Exitatrapatarightangle

inalevelarea.

•Ifthesandisdeepenough,youcanrakerightup

totheedgeofthetrapinlevelareas.

•Ifthesandfeathersouttotheturf,stayfarenough

awayfromtheedgetoavoiddisturbingthe

underlyingsoil.

•Donotraketooclosetoashort,steepbank.The

sandwillmerelyowdownintothebottomofthe

trap.

•Sometouch-upwithahandrakemaybenecessary

onsteepbanks,smallpockets,etc.

EnteringandLeavingtheTrap

Whenenteringthetrap,donotlowertherakeuntilitis

overthesand.Thisavoidscuttingtheturfordragging

grassclippingsorotherdebrisintothetrap.Lowerthe

rakewhilethemachineismoving.

g003409

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Maintainandcleantheseatbelt(s)asnecessary.

•Replaceallwornordamageddecals.

PushingorTowingthe Machine

WARNING

Theengineandhydrostatictransmissions

canbecomeveryhotandcausesevereburns.

Allowtheengineandhydrostatic

transmissionstocoolcompletelybefore

accessingthebypass-valvelevers.

Important:Donottowthemachineforlong

distancesorathighspeeds.Doingsocould

damagethemachine.Y oucantowthemachine

slowlyfromthegroomingsurfacetotheon-site

trailer.

Thebypass-valveleversarelocatedonthetopof

eachhydrostatictransmission.

Whenleavingthetrap,startraisingtherakewhenthe

frontwheelleavesthetrap.Asthemachinemoves

out,therakewillbeliftingandwillnotdragsandout

ontothegrass.

Important:Ensurethatthebypass-valvelevers

areinthefullyforwardpositionwhenoperating

themachine,orseveredamagetothehydraulic

systemcanoccur.

26

Page 27

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Fromunderneaththemachine,rotatethe

bypass-valvelevers(Figure27andFigure28)

sothattheypointinward,towardthecenterof

themachine(Figure29),anddisengagethe

parkingbrake;refertoUsingtheParkingBrake

(page22).

Note:Thisallowsthehydraulicuidtobypass

thepumps,enablingthewheelstoturnfreely.

g023555

Figure29

Figure27

Leftbypass-valvelever

Figure28

Rightbypass-valvelever

1.Inwardtopushortowthe

machine

2.Forwardtodrivethe

machine

3.Whenyouarenishedpushingortowingthe

machine,rotatethebypass-valveleverssothat

g023553

theypointtowardthefrontofthemachine,to

allowthemachinetodrive(Figure29).

g023554

27

Page 28

TransportingtheMachine

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

LoadingtheMachine

Useextremecautionwhenloadingorunloadingthe

machineontoatraileroratruck.Useafull-widthramp

thatiswiderthanthemachineforthisprocedure.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Thetrailerortruckandrampshouldbeaslevelas

possiblewhenloadingthemachinetoavoidgetting

theattachmentcaughtasthemachinemovesfrom

thegroundtotheramp.

Ifyouareloadingthemachineonornearaslope,

positionthetrailerortrucksothatitisonthedown

sideoftheslopeandtherampextendsuptheslope;

thisminimizestherampangle.

3.Loadthemachineontothetrailerortruck.

4.Movethecontrolhandlestotheneutral-locked

position,engagetheparkingbrake,shutoffthe

engine,andremovethekey.

5.Usethetie-downpointsonthemachine(Figure

30)tosecurelyfastenthemachinetothe

transportvehiclewithstraps,chains,cable,or

ropes.

Figure30

1.Tie-downpoints

WARNING

Loadingthemachineontoatransportvehicle

increasesthepossibilityoftippingoverand

couldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatingthe

machineonaramp.

•EnsurethattheROPSisinstalledand

secureandusetheseatbeltwhenloading

orunloadingthemachine.Ensurethatthe

ROPSclearsthetopofanenclosedtrailer.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonaramp,as

thiscouldcausealossofcontrolora

tip-over.

g023892

•Ensurethatanattachmentisinstalledand

intheraisedpositionwhenloadingthe

machineontoatransportvehicle.

28

Page 29

Figure31

g268630

1.Trailer3.Full-widthramp—side

view

2.Full-widthramp

InstallingaWirelessHour Meter

Anoptionalwirelesshourmeterisavailablethrough

yourAuthorizedT oroDistributor.

RefertotheWirelessHourmeterSystemguide.

1.Parkthemachineonalevelsurface,lowerthe

attachment,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Removethecontrolpanel(Figure32).

g023736

Figure32

1.Controlpanel2.Screw(4)

3.Locatethewirelesshour-meterjumper.

Note:Thejumperislabeled.

4.Attachthewirelesshourmeter.

5.Tiethewirelesshourmetertotheexisting

harnesstopreventexcessivemotioninthe

console.

6.Installthecontrolpanel.

29

Page 30

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyoudoanymaintenance.

MaintenanceSafety

•Beforeadjusting,cleaning,repairing,orleaving

themachine,dothefollowing:

–Parkthemachineonalevelsurface.

–Movethethrottleswitchtothelow-idleposition.

–Lowertheattachment.

–Ensurethatthetractionisinneutral.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

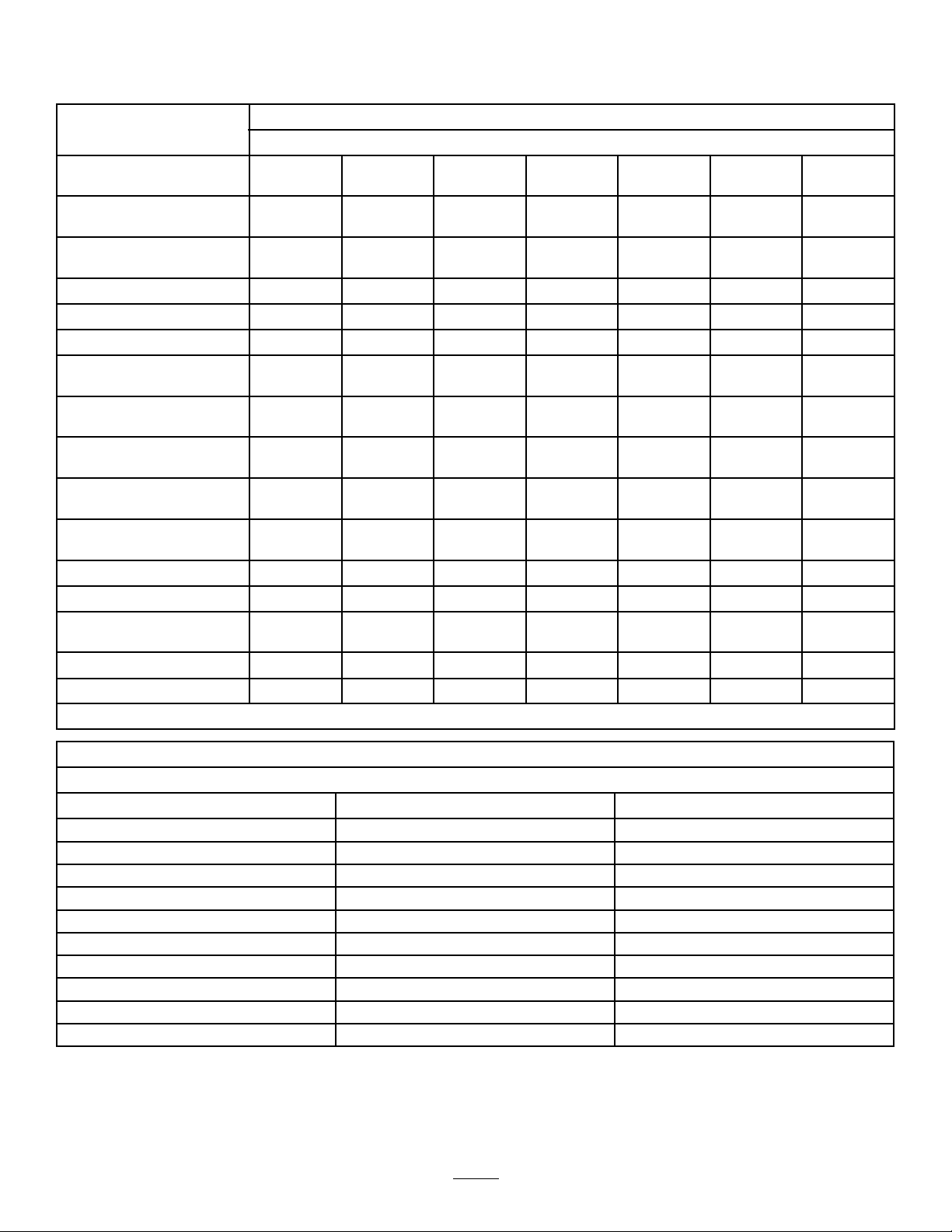

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

MaintenanceProcedure

•T orquethewheellugnuts.

•Changetheengineoil.

•Changetheengineoillter.

•Changethehydraulicuidandlters.

•Checktheleveloftheengineoil.

•Checkthelevelofthehydraulicuid.

•Checkthetirepressure.

•Checkthesafetyinterlocksystem.

•Checktheconditionofthehydrauliclinesandhoses.

•Inspectandcleanthemachine.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•T orquethewheellugnuts.

•Greasethemachine.

•Changetheengineoil(moreofteninextremelydustyordirtyoperatingconditions).

Every100hours

Every200hours

Every300hours

Every400hours

Every800hours

•Changetheengineoillter(moreofteninextremelydustyordirtyoperating

conditions).

•Servicethesparkplugs.

•Checkthebatterycableconnections.

•Replacetheairlter(moreoftenindustyconditions).

•Replacethecarbon-canisterlter.

•Checkandadjustthevalveclearance.

•Cleanandlapthevalve-seatingsurface.

•Changethehydraulicuidandlters.

•Replacethefuellter.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

30

Page 31

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlock

operation.

Checktheparkingbrake

operation.

Checktheoperationofthe

controlhandles.

Checkthefuellevel.

Checktheengineoillevel.

Checktheairltercondition.

Cleantheenginecooling

ns.

Checkunusualengine

noises.

Checkunusualoperating

noises.

Checkthelevelofthe

hydraulicuid.

Checkhydraulichosesfor

damage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrument

operation.

Lubricateallgreasettings.

Touch-updamagedpaint.

1.Immediatelyaftereverywashing,regardlessoftheintervallisted.

1

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

31

Page 32

Pre-Maintenance

Lubrication

Procedures

GreasingtheMachine

LiftingtheMachine

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury.

Usejackstandswhensupportingthe

machine.

RefertoFigure33forthesupportpoints.

ServiceInterval:Every100hours

GreaseType:No.2lithiumgrease

Greaseeachgreasettinglocatedonthefrontwheel

hub,thebelttensioner,andtheattachmentliftas

follows:

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Wipethegreasettingcleansothatforeign

mattercannotbeforcedintothebearingor

bushing.

3.Attachagreaseguntothetting,andpump

greaseintothetting.

4.Wipeupanyexcessgrease.

•Frontwheelbearing(1)—Figure34

Figure33

1.Supportpoints(rear)2.Supportpoints(front)

g023550

g023436

Figure34

•Belttensioner(1)—Figure35

32

Page 33

Figure35

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

ServicingtheEngineOil andFilter

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

g023437

Every100hours—Changetheengineoil(more

ofteninextremelydustyordirtyoperating

conditions).

•Attachmentlift(4)—Figure36

Figure36

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDistributor.

CrankcaseCapacity:1.66L(1.75USqt)withlter

change

Use4-cycleengineoilthatmeetsorexceedsthe

followingrequirements:

•APIservicecategory:SJ,SL,SM,orhigher

•Viscosity:SAE30;refertothefollowingchartfor

otherviscosities(Figure37):

Important:Usingmulti-viscosityoils,suchas

10W-30,increasesoilconsumption.Checkthe

g023438

oillevelmorefrequentlywhenusingthem.

Figure37

1.Runtheengineforafewminutestowarmtheoil.

2.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

33

g023445

Page 34

3.Removethedrainplug(Figure39)andletthe

oildrainintoasuitablecontainer.Whentheoil

stopsdraining,installthedrainplug.

Note:Insertapieceofpaperorlightcardboard

intothedrainholetochanneltheoilawayfrom

theenginemountingplate(Figure38).

4.Removethedipstickandwipeitwithaclean

cloth(Figure40).

Figure38

1.Cardboard

2.Drainplug

Figure39

1.Drainplug3.Dipstick

2.Oillter

3.Drainhole

g008796

Figure40

g026690

5.Pourfreshoilintothelltube.

6.Starttheengineandletitrunforabout3

minutes,andensurethattherearenoleaks.

7.Stoptheengine.

8.Checktheoillevel,andaddoilifnecessary.

9.Installthedipstick.

10.Disposeoftheusedoilaccordingtolocalcodes.

ChangingtheEngineOilFilter

ServiceInterval:Aftertherst8hours—Changethe

engineoillter.

Every100hours—Changetheengineoillter

(moreofteninextremelydustyordirtyoperating

conditions).

1.Runtheengineforafewminutestowarmtheoil.

2.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

g023444

brake,shutofftheengine,andremovethekey.

3.Draintheengineoil;refertoServicingthe

EngineOilandFilter(page33).

4.Placeadrainpanundertheoillter,andturnthe

ltercounterclockwisetoremoveit(Figure41).

34

Page 35

ServicingtheAirCleaner

ReplacingtheAirFilter

ServiceInterval:Every200hours(moreoftenin

dustyconditions).

Note:Changingtheairlterbeforeitisnecessary

onlyincreasesthechanceofdirtenteringtheengine

whenthelterisremoved.

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Releasethelatchessecuringtheair-cleaner

covertotheair-cleanerbody(Figure42).

Figure41

5.Applyalightcoatofcleanoiltothegasketof

thenewlter.

6.Installthenewlter,turningitbyhanduntilthe

gasketcontactsthelteradapter;thentightenit

3/4turnmore.

Important:Donotovertightenthelter.

7.Checktheoillevel;refertoCheckingtheLevel

oftheEngineOil(page17).

8.Ifnecessary,addoilintothelltube.

9.Starttheengineandletitrunforabout3

minutes,andensurethattherearenoleaks.

10.Shutofftheengine.

11.Checktheoillevel,andaddoilifnecessary.

Note:Thelterholdssomeoil,sotheoillevel

maydecreasewheninstallinganewlter.

12.Installthedipstick.

13.Disposeoftheusedoilaccordingtolocalcodes.

g008748

g023446

Figure42

1.Latch(2)3.Cover

2.Airlter

4.Dirt-ejectionport

3.Removethecoverfromtheair-cleanerbody .

4.Removetheoldlter,andinstallthenewlter.

Note:Inspectthenewlterforshipping

damage,checkingthesealingendofthelter

andthebody .Donotuseadamagedelement.

Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister.

Donotapplypressuretotheexiblecenterof

thelter.

Note:Donotcleantheusedelement,because

itcandamagetheltermedia.

35

Page 36

5.Cleanthedirt-ejectionportlocatedinthe

removablecover.

6.Installthecoversothatthedirt-ejectionport

pointsdownward.

7.Securethelatches.

8.Checkthewholeintakesystemforleaks,

damage,orloosehoseclamps.

ServicingtheSparkPlugs

ServiceInterval:Every100hours

Type:NGKBPR4ES(orequivalent)

5.Foreachsparkplug,setthegapbetweenthe

centerelectrodeandthesideelectrodeto0.76

mm(0.030inch);refertoFigure44.Installeach

ofthecorrectlygappedsparkplugswithagasket

seal,andtightentheplugsto22N∙m(16ft-lb).

Gap:0.76mm(0.030inch)

Note:Thesparkplugsusuallylastalongtime;

however,youshouldcheckthemwhenevertheengine

malfunctions.

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Cleantheareaaroundeachofthespark

plugssothatforeignmattercannotfallintothe

cylinderswhenyouremovethesparkplugs.

Figure44

1.Sideelectrode

2.Centerelectrode4.0.76mm(0.030inch)gap

3.Insulator

CheckingandAdjustingthe ValveClearance

ServiceInterval:Every300hours

Thisproceduremustbeperformedwiththeproper

tools.SeeyourauthorizedKawasakienginedealer

forservice,unlessyouhavetheproperequipment

andadequatemechanicalprociency.

CleaningandLappingthe Valve-SeatingSurface

ServiceInterval:Every300hours

g019300

Figure43

1.Spark-plugwires

3.Disconnectthespark-plugwiresfromthespark

plugs,andremovetheplugsfromthecylinder

heads.

4.Checktheconditionofthesideelectrode,the

centerelectrode,andtheinsulatortoensure

thatthereisnodamage.

Important:Replacethesparkplugsif

theyarecracked,fouled,dirty,orotherwise

malfunctioning.Donotcleantheelectrodes,

becausegritenteringthecylindermay

damagetheengine.

Thisproceduremustbeperformedwiththeproper

tools.SeeyourauthorizedKawasakienginedealer

g023447

forservice,unlessyouhavetheproperequipment

andadequatemechanicalprociency.

36

Page 37

FuelSystem

5.Installtheseatsupportplateandtheseat.

Maintenance

Replacingthe Carbon-CanisterFilter

ServiceInterval:Every200hours

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Removethefastenerssecuringtheseat

assemblytothemachine.

ReplacingtheFuelFilter

ServiceInterval:Every800hours

Thefuellinehasanin-linelter.Replaceitasfollows:

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Loosenthehoseclamponthecarburetorsideof

thelter,andremovethefuellinefromthelter

(Figure47andFigure48).

Figure45

1.Seatassembly3.Washer(4)

2.Bolt(4)

3.Disconnectthelterfromthecarboncanister

(Figure46).

Figure46

1.Carbon-canisterlter

4.Connectthenewltertothecarboncanister.

g023448

Figure47

1.Fuellter

g023891

g023990

Figure48

1.Fuellter

2.Hoseclamp(2)

3.Fuelline

g008963

37

Page 38

3.Placeadrainpanunderthelter,loosenthe

remaininghoseclamp,andremovethelter.

ElectricalSystem

4.Slidethehoseclampsontotheendsofthefuel

lines.

5.Pushthefuellinesontothenewfuellter,and

securethemwiththehoseclamps.

Note:Installthenewlterwiththearrowon

thelterbodypointingawayfromthefueltank

(towardthecarburetor).

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.

•Wearprotectiveclothinganduseinsulatedtools.

Jump-StartingtheMachine

1.Removeanycorrosionfromthebattery

terminals,andensurethattheconnectionsare

tightbeforejump-startingthemachine.

Important:Corrosionorlooseconnections

cancauseunwantedelectricalvoltage

spikesatanytimeduringthejump-starting

procedure,whichcoulddamagetheengine.

Donotattempttojump-startthemachineif

thebatteryterminalsarelooseorcorroded.

DANGER

Jump-startingaweakbatterythatis

crackedorfrozen,orhasalowelectrolyte

leveloranopen/shortedbatterycell,can

causeanexplosionresultinginserious

personalinjury.

Donotjump-startaweakbatteryifthese

conditionsexist.

2.Ensurethattheboosterbatteryisagood,fully

chargedlead-acidbatterywithatleast12.6V .

Useproperlysizedjumpercableswithshort

lengthstoreducethevoltagedropbetweenthe

systems.Makesurethatthecablesarecolor

codedorlabeledforthecorrectpolarity.

Note:Besurethattheventcapsaretightand

level.Placeadampcloth,ifavailable,overthe

ventcapsoneachbattery .Besurethatthe

machinesdonottouchandthatbothelectrical

systemsareturnedoffandhavethesamerated

systemvoltage.Theseinstructionsarefor

negative-groundsystemsonly.

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswired

tothestarterorsolenoidasshowninFigure49.

38

Page 39

Figure49

ReplacingtheFuses

Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparkingbrake,

shutofftheengine,andremovethekey.

Thefuseblock(Figure51)islocatednearthecontrol

panel.

g012785

1.Positive(+)cableon

dischargedbattery

2.Positive(+)cableon

boosterbattery

3.Negative(–)cableonthe

boosterbattery

4.Negative(–)cableonthe

engineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

4.Connecttheotherendofthepositivecableto

thepositiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.Makethenalconnectionontheengineblock

(notonthenegativebatterypost)ofthemachine

withthedischargedbattery,awayfromthe

battery,andstandback(Figure50).

g023451

Figure51

1.Lights(soldseparately)

2.Attachment—10A

3.Enginestart—25A

4.Battery—20A

Toreplaceafuse,removeitbysimplypullingitout

fromthefuseblock,andinstallanewfuse

Important:Alwaysuseafuseofthesametype

andamperageastheoneyouarereplacing;

otherwise,youcoulddamagetheelectrical

system.Refertothedecalonthebackoftheseat

forthefunctionandamperageofeachfuse.

Figure50

1.Engineblock

2.Negative(–)cable

7.Starttheengine,andremovethecablesinthe

reverseorderofconnection.

Note:Disconnectthecableconnectedtothe

engineblock(blackcable)rst.

ServicingtheBattery

ChargingtheBattery

g013117

WARNING

Chargingthebatteryproducesgasesthatcan

explode,seriouslyinjuringyouorbystanders.

Neversmokenearthebattery,andkeep

sparksandamesawayfromthebattery.

Important:Alwayskeepthebatteryfullycharged.

Thisisespeciallyimportanttopreventbattery

damagewhenthetemperatureisbelow0°C(32°F).

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

39

Page 40

2.Chargethebatteryfor10to15minutesat25to

30A,or30minutesat10A.

3.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

52).

4.Installthebatteryinthemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page41).

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemay

occur.

g023653

Figure53

Figure52

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

Ifthebatterynolongerholdsacharge,replaceit;

refertoRemovingtheBattery(page40)andInstalling

theBattery(page41).

RemovingtheBattery

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Removethewingnutsandwasherssecuring

thebatteryhold-down(Figure53).

3.Disconnectthenegative(black)groundcable

fromthebatterypost.

g000960

WARNING

Incorrectbatterycableroutingcould

damagethemachineandcables,causing

sparks.Sparkscancausethebattery

gasestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

40

Page 41

WARNING

Batteryterminalsormetaltools

couldshortagainstmetalmachine

components,causingsparks.Sparks

cancausethebatterygasestoexplode,

resultinginpersonalinjury .

•Whenremovingorinstallingthe

battery,donotallowthebattery

terminalstotouchanymetalpartsof

themachine.

•Donotallowmetaltoolstoshort

betweenthebatteryterminalsand

metalpartsofthemachine.

4.Slidetheredterminalbootoffthepositive(+)

batteryterminal,andremovethepositive(red)

batterycable.

5.Removethebattery.

3.Installthenegative(black)groundcabletothe

negative(-)batteryterminal,andtightenthenut

ontothebolt.

4.Slidetheredterminalbootontothepositive(+)

batterypost.

5.Installthehold-down,andsecureitwiththewing

nutsandwashers.

CheckingandCleaningtheBattery

ServiceInterval:Every100hours—Checkthe

batterycableconnections.

Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparkingbrake,

shutofftheengine,andremovethekey.

Keepthetopofthebatteryclean.Ifthemachineis

storedinalocationwheretemperaturesareextremely

high,thebatterywilldischargemorerapidlythanifthe

machineisstoredinacoolerlocation.

InstallingtheBattery

1.Placethebatteryinthetray.

Keepthetopofthebatterycleanbywashingitwith

abrushdippedinammoniaorasolutionofsodium

bicarbonate.Flushthetopsurfacewithwaterafter

cleaning.Donotremovethellcapwhilecleaning

thebattery.

Thebatterycablesmustbetightontheterminalsto

providegoodelectricalcontact.

Ifcorrosionoccursatthebatteryterminals,disconnect

thecables,negative(-)cablerst,andscrapethe

clampsandterminalsseparately.Connectthecables,

positive(+)cablerst,andcoattheterminalswith

petroleumjelly.

Figure54

2.Installthepositive(red)batterycabletothe

positive(+)batteryterminal,andtightenthenut

ontothebolt.

Important:Theredcablemaybecovered

byawireloom.Thepositivecableistheone

withtheredboot.

g023659

41

Page 42

DriveSystem

Maintenance

Important:Ensurethateachcontrolhandle

stopsagainstthestopplateandnotagainstthe

transmissioninternalstop.

CheckingtheTracking

1.Drivetoaat,openarea,andmovethecontrol

handlestotheneutral-lockedposition.

2.MovethethrottlemidwaybetweentheFASTand

SLOWpositions.

3.Movebothcontrolhandlesallthewayforward

untiltheybothhitthestopsintheT-slot.

4.Checkwhichwaythemachinetracks.

AdjustingtheTracking

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Dependingonwhichwaythemachinetracks,

dothefollowing:

•Ifittrackstotheright,loosentheboltsand

adjusttheleftstopplaterearwarduntilthe

machinetracksstraight(Figure55).

•Ifittrackstotheleft,loosentheboltsand

adjusttherightstopplaterearwarduntilthe

machinetracksstraight(Figure55).

ReplacingtheDriveBelt andtheTensionerPulley

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Raisetherearofthemachineandsupportitwith

jackstands;refertoLiftingtheMachine(page

32).

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

3.Usearatchetinthesquareholeinthetensioner

armtocounteractagainstthetensionerspring

(Figure56),andremovethebeltfromthe

tensionerpulley.

Figure55

Leftcontrolhandleshown

1.Bolt(4)2.Stopplate

3.Tightentheboltstosecurethestopplate(Figure

55).

g023453

Figure56

1.Lefttransmissionpulley

2.Tensionerspring5.Enginepulley

g023556

3.Tensionerarm6.Righttransmissionpulley

4.Unhookthetensionerspringfromthetensioner

armandtheframe(Figure56).

5.Removethenutthatsecuresthetensioner

assemblytotheframe(Figure57).

42

4.Tensionerpulley

Page 43

ControlsSystem

Maintenance

Adjustingthe Control-HandlePosition

Thereare2heightpositionsforthecontrolhandles;

highandlow.

Figure57

1.Tensionerassembly2.Nut

6.Removetheboltsecuringtheoldtensioner

pulleytothetensionerarm,andinstallanew

pulley(Figure58).

g023551

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Loosentheboltsandangenutsthatattachthe

handlestothelevers(Figure59).

Figure59

1.Bolt3.Lever

2.Controlhandle

4.Flangenut

g009040

Figure58

1.Bolt4.Pulley

2.Spacer

3.Seal

7.Removethebeltfromthetransmissionpulleys

andtheenginepulley.

8.Installthenewbeltaroundtheenginepulleyand

the2transmissionpulleys.

9.Installthespringonthetensionerarmandthe

frame(Figure56).

10.Usearatchetinthesquareholeinthetensioner

armtotemporarilystretchthetensionerspring,

andalignthebelttothetensionerpulley .

5.Tensionerarm

3.Alignthefront-to-rearpositionofthehandlesby

g023552

43

bringingthemtogethertotheneutralposition,

andslidingthemuntiltheyarealigned(Figure

60).

Page 44

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

3.Pressdownontheseat,orplaceaweighton

theseat,topresstheinterlockswitchdown.

4.Starttheengineandmovethethrottleleverto

theFastposition.

5.Removethepressure(orweight)fromtheseat.

6.Disengagetheparkingbrake.

7.On1sideofthemachine,slowlyturnthedouble

nutsonthelinkage(Figure61)untilthewheel

onthatsidestartstorotate,thenturnthedouble

nutsintheoppositedirectionuntilthewheel

rotatesintheotherdirection.

Figure60

4.Tightentheboltsandangenutstosecurethe

handlestothelevers.

Adjustingthe Control-HandleLinkage

Turningthedoublenutsonthecontrol-handlelinkage

allowsyoutone-tunetheadjustmentsothatthe

machinedoesnotmoveinneutral.Makeadjustments

forneutralpositioningonly.

WARNING

Toadjustthecontrol-handlelinkage,the

enginemustberunningandthedrivewheels

mustbeabletoturn.Contactwithmoving

partsorhotsurfacesmaycausepersonal

injury.

Keephands,feet,otherbodyparts,and

clothingawayfromrotatingpartsandhot

surfaces.

g009195

Note:Thecontrolhandlesneedtobeinthe

neutralpositionwhilemakinganynecessary

adjustments.

g023650

Figure61

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Raiseall3wheelsofthemachineupoffthe

oor,andsupportthemachinewithjackstands

justhighenoughtoallowthedrivewheelstoturn

freely;refertoLiftingtheMachine(page32).

1.Doublenuts

8.Turnthedoublenutsbacktheotherway

untiltheyareatthemidpointbetweenthe2

positions.

9.Repeatsteps7and8fortheotherside.

10.Shutofftheengine.

44

Page 45

11.Removethejackstands,andcarefullylowerthe

machinetotheground.

12.Starttheengineagain,andensurethatthe

machinedoesnotcreepinneutralwiththe

parkingbrakedisengaged.

Adjustingthe Control-HandleDampers

Youcanadjustthetopdamper-mountingboltto

changethecontrol-handleresistance.

1.Parkthemachineonalevelsurface,lowerthe

attachment,movethecontrolhandlestothe

neutral-lockedposition,engagetheparking

brake,shutofftheengine,andremovethekey.

2.Toaccessthedamper-mountingbolts,remove

theboltsthatsecurethestopplatestotheframe

(Figure62).

Figure62

Leftsideshown

1.Bolt(4)2.Stopplate

g008620

Figure63

Rightsideshown

1.Locknut