Page 1

Sand/Infield Pro) 2020

Model No. 08884—Serial No. 270000001 and Up

Form No. 3357–598 Rev. C

Operator’s Manual

Domestic English (EN)

Page 2

Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

The enclosed Engine Owner’s Manual is supplied for

information regarding The U.S. Environmental

Protection Agency (EPA) and the California Emission

Control Regulation of emission systems, maintenance

and warranty.

Keep this engine Owner’s Manual with your unit.

Should this engine Owner’s Manual become damaged

or illegible, replace immediately. Replacements may be

ordered through the engine manufacturer.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Before Operating 3. . . . . . . . . . . . . . . . . . . . . . . . . .

While Operating 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure Level 4. . . . . . . . . . . . . . . . . . . . . . .

Sound Power Level 5. . . . . . . . . . . . . . . . . . . . . . . .

Vibration Level 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . . .

Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 7. . . . . . . . . . . . . . . . . . . . .

Measurements 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Steering Wheel 9. . . . . . . . . . . . . . . . .

Activating and Charging the Battery 9. . . . . . . . . . .

Installing the Battery 9. . . . . . . . . . . . . . . . . . . . . . .

Installing the Refuse Container 10. . . . . . . . . . . . . . .

Installing the Decals 10. . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Crankcase Oil 11. . . . . . . . . . . . . . . . . .

Filling the Fuel Tank 12. . . . . . . . . . . . . . . . . . . . . . .

Checking the Hydraulic System 13. . . . . . . . . . . . . . .

Checking the Tire Pressure 13. . . . . . . . . . . . . . . . . .

Operation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Controls 14. . . . . . . . . . . . . . . . . . . . . . . . .

Operation 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping the Engine 16. . . . . . . . . . . . . .

Checking the Interlock System Operation 16. . . . . . .

Towing the Machine 16. . . . . . . . . . . . . . . . . . . . . . . .

Break-In Period 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Characteristics 17. . . . . . . . . . . . . . . . . . . .

Inspecting and Cleaning the Machine 17. . . . . . . . . .

Maintenance 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 18. . . . . . . . .

Daily Maintenance Checklist 19. . . . . . . . . . . . . . . . .

Lubricating the Machine 20. . . . . . . . . . . . . . . . . . . .

Changing the Engine Oil and Filter 21. . . . . . . . . . . .

Servicing the Engine Air Cleaner 21. . . . . . . . . . . . .

General Air Cleaner Maintenance 21. . . . . . . . . . . . .

Servicing the Remote Air Cleaner 21. . . . . . . . . . . . .

Adjusting the Throttle Control 22. . . . . . . . . . . . . . . .

Adjusting the Choke Control 22. . . . . . . . . . . . . . . . .

Adjust the Engine Governor Speed Control 23. . . . .

Replacing the Spark Plugs 23. . . . . . . . . . . . . . . . . . .

Cleaning the Cylinder Head Fins 24. . . . . . . . . . . . . .

Changing the Hydraulic System Oil and Filter 24. . .

Checking the Hydraulic Lines and Hoses 24. . . . . . .

Charging the Hydraulic System 24. . . . . . . . . . . . . . .

Adjusting the Steering Chain 25. . . . . . . . . . . . . . . . .

Replacing the Fuel Filter 25. . . . . . . . . . . . . . . . . . . .

Adjusting the Traction Drive for Neutral 26. . . . . . . .

Adjusting the Traction Interlock Switch 26. . . . . . . .

Adjusting the Pedal for Forward 26. . . . . . . . . . . . . .

Adjusting the Brake Interlock Switch 27. . . . . . . . . .

Adjusting the Brake Linkage 27. . . . . . . . . . . . . . . . .

Adjusting the Lift Lever 28. . . . . . . . . . . . . . . . . . . . .

Storing the Battery 28. . . . . . . . . . . . . . . . . . . . . . . . .

Caring for the Battery 28. . . . . . . . . . . . . . . . . . . . . .

Storage 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Schematic 30. . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Schematic 31. . . . . . . . . . . . . . . . . . . . . . .

Evaporative Emission Control Warranty Statement . . 35

The Toro General Commercial Products Warranty 36. . .

W 2008 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. These numbers are

stamped into a plate located on the left fender.

Before Operating

• Read and understand the contents of this Operator’s

Manual before operating the machine. Become familiar

with all of the controls and know how to stop quickly. A

free replacement manual is available by sending the

complete Model and Serial Number to The Toro

Company, 8111 Lyndale Avenue South, Bloomington,

Minnesota 55420-1196.

• Operate the machine only after reading and

understanding the contents of this manual.

• Never allow children to operate the machine or adults to

operate it without proper instructions.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

• Become familiar with the controls and know how to

stop the engine quickly.

• Keep all shields, safety devices, and decals in place. If a

shield, safety device, or decal is malfunctioning,

illegible, or damaged, repair or replace it before

operating the machine.

• Always wear substantial shoes. Do not operate machine

while wearing sandals, tennis shoes, or sneakers. Do not

wear loose fitting clothing which could get caught in

moving parts and cause personal injury.

• Wearing safety glasses, safety shoes, long pants, and a

hard hat is advisable and required by some local safety

and insurance regulations.

• Ensure that the traction interlock switch is adjusted

correctly so that the engine cannot be started unless the

traction pedal is released and in the neutral position.

• Keep everyone, especially children and pets, away from

the areas of operation.

• Since gasoline is highly flammable, handle it carefully.

– Use an approved gasoline container.

– Do not remove the cap from the fuel tank when

engine is hot or running.

– Do not smoke while handling gasoline.

Safety

This machine meets or exceeds ANSI B71.4–2004

specifications in effect at the time of production.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

Caution,Warning or Danger–“personal safety

instruction”. Failure to comply with the instruction may

result in personal injury or death.

– Fill the fuel tank outdoors and to about 1 in.

(25 mm) below top of tank (bottom of the filler

neck). Do not overfill.

– Wipe up any spilled gasoline.

• Check the safety interlock system daily for proper

operation. If the switch should malfunction, replace the

switch before operating machine.

While Operating

• Exhaust fumes are hazardous and could be deadly, so do

not run the engine in a confined area without adequate

ventilation.

3

Page 4

• Sit on seat when operating the machine. Never carry

passengers.

• When starting the engine:

– Make sure that the traction pedal is released.

Maintenance

• Before servicing or making adjustments to the machine,

stop the engine and pull the spark plug wire off of the

spark plug to prevent accidental starting of the engine.

– After the engine is started, keep your foot off of the

traction pedal. The machine must not move. If

movement is evident, the neutral return bracket is

adjusted incorrectly; therefore, shut the engine off

and adjust the bracket so that the machine does not

move when in the neutral position. If the engine

does not start, check the interlock switch for proper

adjustment.

• Using the machine demands attention. To prevent

tipping or loss of control:

– Use care when entering and leaving sand traps. Use

extreme caution around ditches, creeks, or other

hazards.

– Watch for holes or other hidden hazards.

– Use caution when operating the machine on a steep

slope. Reduce your speed when making sharp turns

or when turning on hillsides.

– Avoid sudden stops and starts. Do not go from

reverse to full forward without first coming to a

complete stop.

– Before backing up, look to the rear and ensure that

no one is behind the machine.

– Watch out for traffic when near of crossing roads.

Always yield the right of way.

• If the optional Draw Bar, Part No. 92-2330, is installed

on the machine, the vertical load on the hitch should not

exceed 200 lb. (91 kg).

• Do not touch the engine, muffler, or exhaust pipe while

the engine is running or soon after it has stopped

because these areas are hot enough to cause burns.

• If the machine ever vibrates abnormally, stop

immediately, turn the engine off, wait for all motion to

stop, and inspect for damage. Repair all damage before

commencing operation.

• Before getting off of the seat:

– Engage the parking brake and lower the attachment.

Take precautions to prevent accidental starts, rolling

away, etc.

– Shut the engine off and wait for all movement to

stop.

• Whenever the machine is left unattended, be sure that

the engine is stopped, the parking brake is engaged, the

implement is lowered, and the key is removed from the

ignition.

• Make sure that all hydraulic line connectors are tight,

and all hydraulic hoses and lines are in good condition

before applying pressure to the system.

• Keep your body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not your hands, to search for

leaks. Hydraulic fluid escaping under pressure can have

sufficient force to penetrate skin and do serious damage.

If fluid is injected into the skin it must be surgically

removed within a few hours by a doctor familiar with

this form of injury or gangrene may result.

• Before disconnecting or performing any work on the

hydraulic system, all pressure in the system must be

relieved by stopping the engine, engaging the parking

brake, and lowering the attachments to the ground.

• To make sure that the entire machine is in good

condition, keep all nuts, bolts, and screws properly

tightened.

• If major repairs are ever needed or assistance is

required, contact an Authorized Toro Distributor.

• To reduce potential fire hazard, keep the engine area

free of excessive grease, grass, leaves, and

accumulation of dirt.

• If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and any parts of

the body away from the engine and any moving parts.

Keep everyone away.

• Do not overspeed engine by changing governor settings.

Maximum engine speed is 3200 RPM. To ensure safety

and accuracy, have an Authorized Toro Distributor

check the maximum engine speed with a tachometer.

• The engine must be shut off before checking the oil or

adding oil to the crankcase.

• To be sure of optimum performance and safety, always

purchase genuine Toro replacement parts and

accessories. Replacement parts and accessories made by

other manufacturers could be dangerous. Such use

could void the product warranty.

Sound Pressure Level

This unit has an equivalent continuous A-weighted sound

pressure at the operator ear of: 82 dB(A), based on

measurements of identical machines per ISO 11201.

4

Page 5

Sound Power Level

This unit has a guaranteed sound power level of:

96 dBA/1 pW, based on measurements of identical

machines per EN ISO 3744.

Vibration Level

Hand-Arm

This unit does not exceed a vibration level of 2.5 m/s@, at

the hands based on measurements of identical machines per

EN 1033.

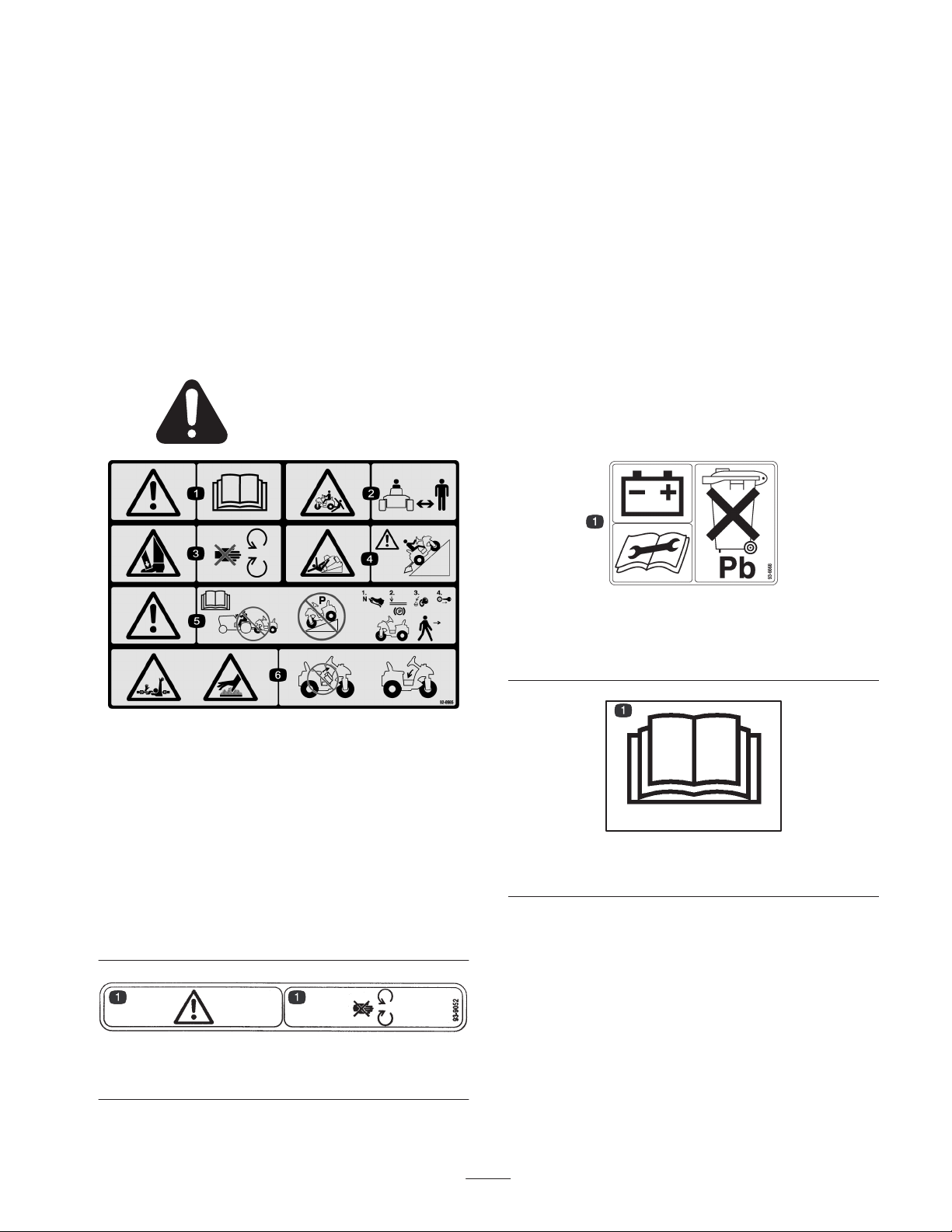

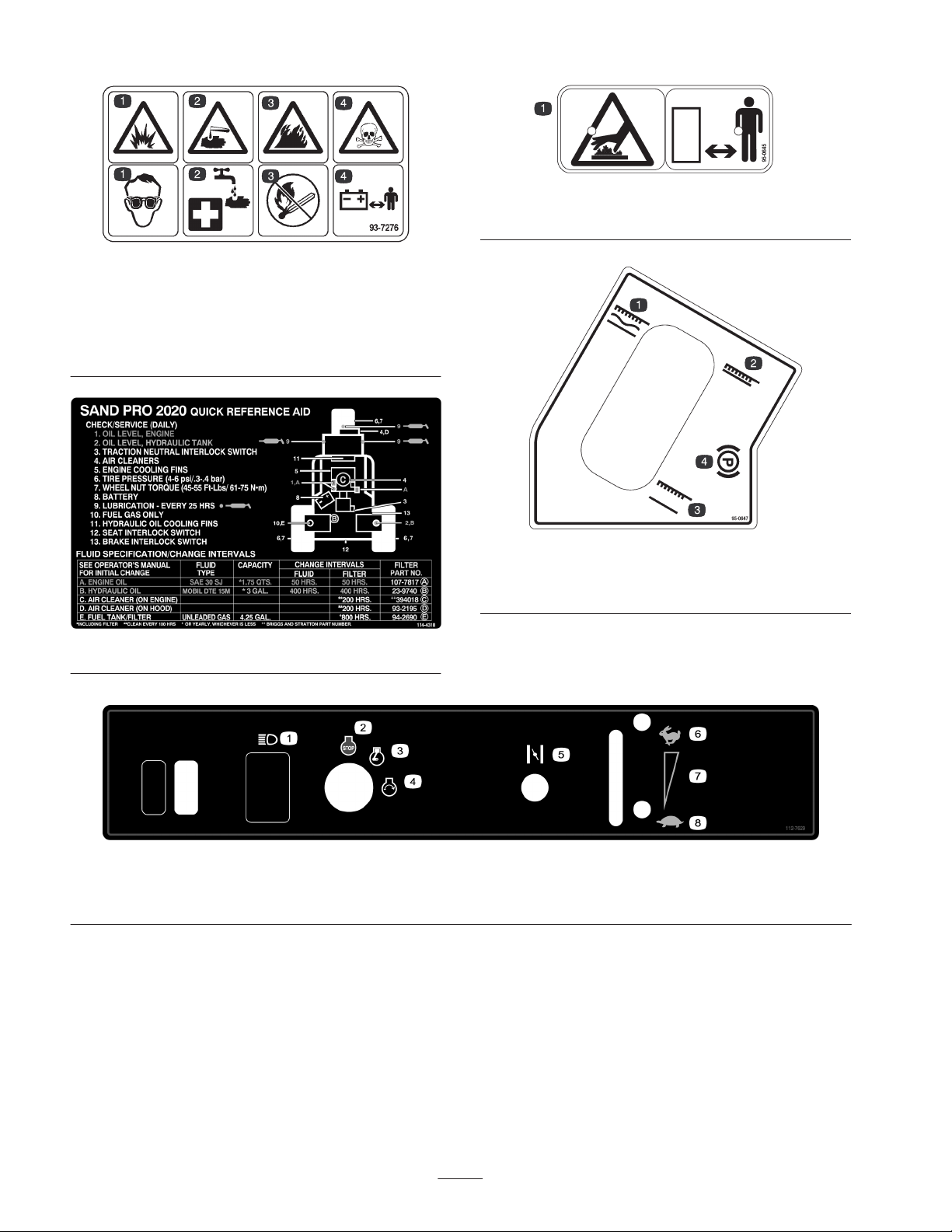

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

Whole Body

This unit does not exceed a vibration level of 0.5 m/s@ at

the posterior based on measurements of identical machines

per EN 1032.

92-8985

1. Warning—read the Operator’s Manual.

2. Crushing/dismemberment hazard, bystanders—keep

bystanders a safe distance from the machine.

3. Crushing hazard of foot—keep guards in place, stay away from

moving parts.

4. Tipping hazards—Use caution when operating on slopes.

5. Warning—read the Operator’s Manual, do not tow the

machine; do not park the machine on a slope; before leaving

the machine, put the traction control pedal in neutral, lower the

implement, turn the engine off, and remove the ignition key.

6. Entanglement hazard, shaft; burn hazard—do not operate the

machine without the center shroud in place and the seat

latched.

93-9052

1. Warning—stay away from moving parts.

93-6668

1. The battery contains lead. Do not throw the battery in the

garbage. Read the operator’s manual before performing

maintenance.

93-9051

93-9051

1. Read the operator’s manual.

5

Page 6

93-7276

1. Explosion hazard—wear eye protection.

2. Chemical burns to hands—flush with water and seek medical

attention.

3. Fire hazard—no sparks, flame, or smoking.

4. Poison—keep children away from the battery.

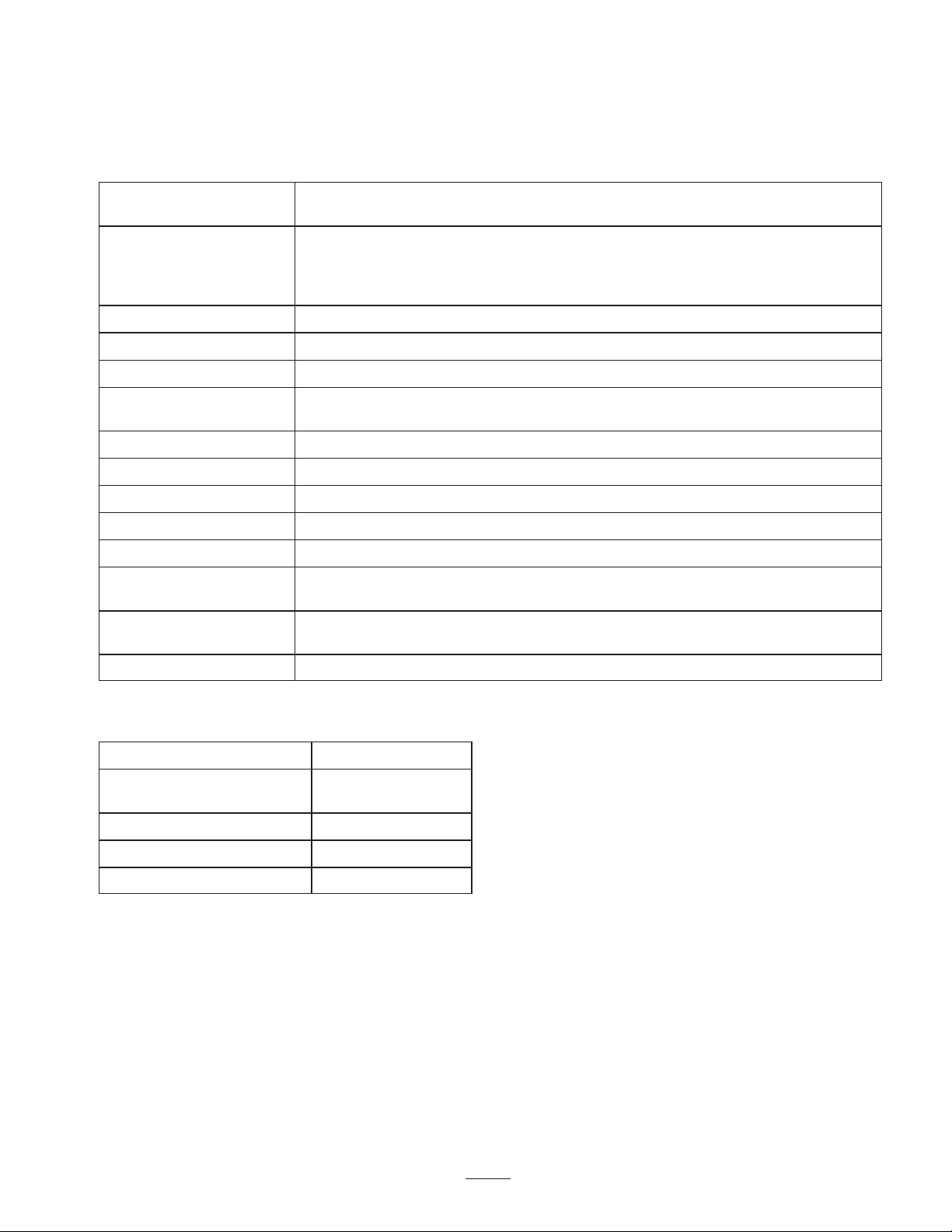

95-0645

1. Hot surface—keep bystanders away.

95-0647

1. Implement float position

2. Implement lower position

3. Implement raise position

4. Parking brake

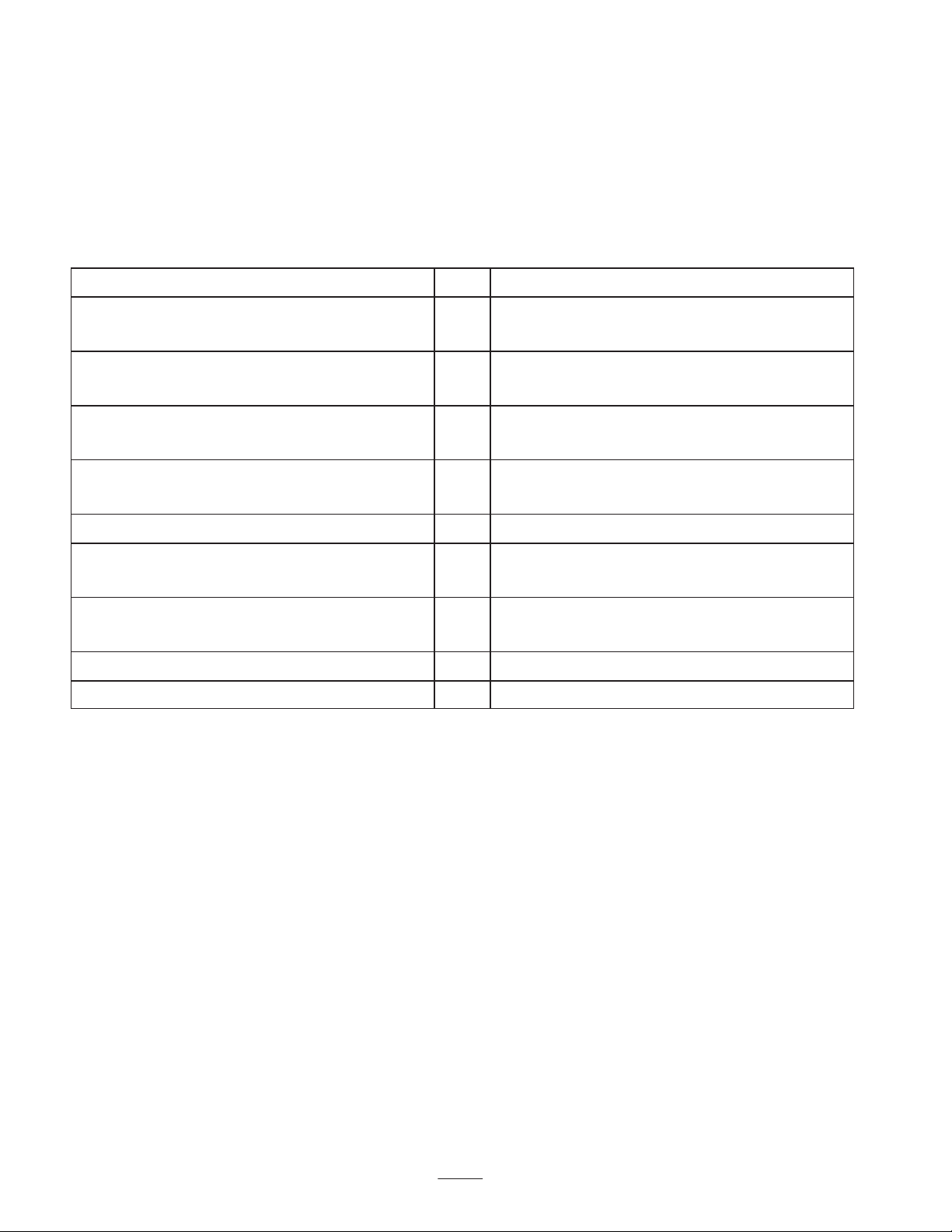

1. Headlights

2. Engine—stop

114-4318

3. Engine—run

4. Engine—start

112-7629

5. Choke

6. Fast

7. Continuous variable setting

8. Slow

6

Page 7

Specifications

General Specifications

Configuration

Engine

Instrumentation Hour meter

Gas Tank 4-1/4 gallon (16.1 l) capacity

Battery 12 volt, lead acid, 32 amp. hour

Drive

Hydraulic Oil Filter 25 micron, spin-on type

Hydraulic Oil Reservoir 3 gallon (11.4 l) capacity

Valve Single section for raising and lowering of implement with float and holding checks.

Cylinder Double acting

Wheel Bearings Tapered roller bearing in each wheel motor. Roller bearings on front spindle.

Tires

Speeds (at 3200 RPM)

Seat Adjustment 4 inches (10.2 cm) fore and aft. Secondary position adds 2.5 inches (6.4 cm) fore.

Short wheel base tricycle vehicle with mid engine placement. Rear wheels

powered. Front wheel steering. Operator positioned centrally.

Briggs & Stratton, V-twin cylinder, 4 cycle, OHV, air cooled, gas engine with cast

iron sleeves. 16 hp @ 3600 RPM, 29.3 cu. in. (480 cc) displacement, 1-3/4 US qt.

(1.66 l) oil capacity. Electronic ignition. Full pressure lubrication, oil filter. Engine

and remote mounted air cleaners.

Hydraulic. Coupling driven variable displacement piston pump with integral auxiliary

charge pump to geroller motors which directly drive wheels.

22 x 11.00-8 two-ply pneumatic tubeless. De-mountable and interchangeable.

Recommended tire pressure is 4–6 psi (28–41 kPa).

Variable between 0 and 9 MPH (0 and 14 km/h) forward and 0 and 4 MPH (0 and

6 km/h) reverse.

Measurements

Width without implement 57-1/2 in. (146 cm)

Width with rake Model No.

08812

Height 45 in. (114 cm)

Length without rake 76 in. (193 cm)

Net weight (wet) 650 lb.( 295 kg)

75 in. (191 cm)

7

Page 8

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

Note: Use this chart as a checklist to ensure that all parts necessary for assembly have been shipped. If any of these parts are

missing, total setup cannot be completed.

Description

Steering wheel

Roll pin, 1/4 x 2 in.

Capscrew, 5/16 x 5/8 in.

Locknut, 5/16 in.

Capscrew, 1/2 x 1-1/4 in.

Washer, 1/2 in.

Cylinder pin

Cotter pin

Decal 2 Affix on machine, if desired.

Key

Parts catalog

Operator’s Manual

Engine Operator’s Manual

Operator Training Material

Registration card 1 Fill out and return to Toro.

Qty. Use

1

Mounting the steering wheel

1

2

Securing the battery cables to the battery

2

4

Attaching the implements to the frame

4

1

Attaching the cylinder to the implement

2

2

1

1

Read before operating the machine.

1

Note: Specifications and design subject to change without notice.

8

Page 9

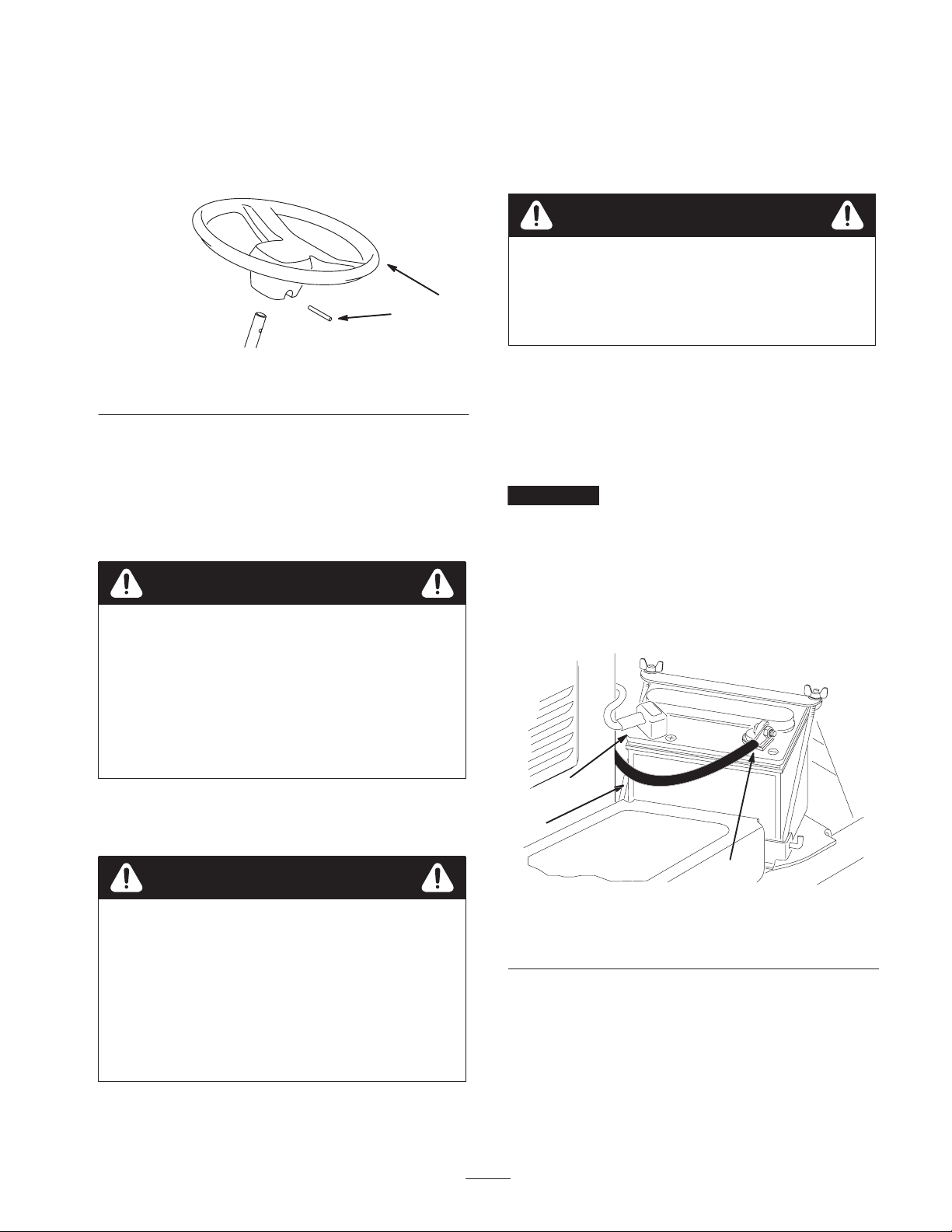

Installing the Steering Wheel

1. Move the front wheel so that it points straight ahead.

2. Slide the steering wheel onto the steering shaft, aligning

the mounting holes(Fig. 1).

1

2

1. Remove the filler caps from the battery and slowly fill

each cell until electrolyte is up to the fill line.

2. Replace the filler caps and connect a 3 to 4 amp. battery

charger to the battery posts. Charge the battery at a rate

of 3 to 4 amperes for 4 to 8 hours.

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

Figure 1

1. Steering wheel 2. Roll pin

3. Secure the steering wheel in place with the roll pin

(Fig. 1).

Activating and Charging the

Battery

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

If the battery is not filled with electrolyte or activated, bulk

electrolyte with 1.260 specific gravity must be purchased

from a local battery supply outlet and added to the battery.

3. When the battery is charged, disconnect the charger

from the electrical outlet and battery posts. Allow the

battery to sit for 5–10 minutes.

4. Remove the filler caps. Slowly add electrolyte to each

cell until the level is up to the fill line. Install the filler

caps.

Important Do not overfill the battery. Electrolyte will

overflow onto other parts of the machine and severe

corrosion and deterioration will result.

Installing the Battery

1. Set the battery in place, with the negative (–) terminal

to the outside (Fig. 2).

2

1

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

3

Figure 2

1. Battery

2. Positive (+) terminal

2. Secure the positive cable (red), which is the wire

attached to the solenoid under the front shroud, to the

positive (+) terminal with a capscrew and locknut.

9

3. Negative (–) terminal

Page 10

Warning

Incorrect battery cable routing could damage the

machine and cables causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

Warning

Battery terminals or metal tools could short

against metal machine components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the machine.

• Do not allow metal tools to short between the

battery terminals and metal parts of the

machine.

3. Secure the negative cable (black) to the negative (–)

terminal of the battery with a capscrew and locknut

(Fig. 2).

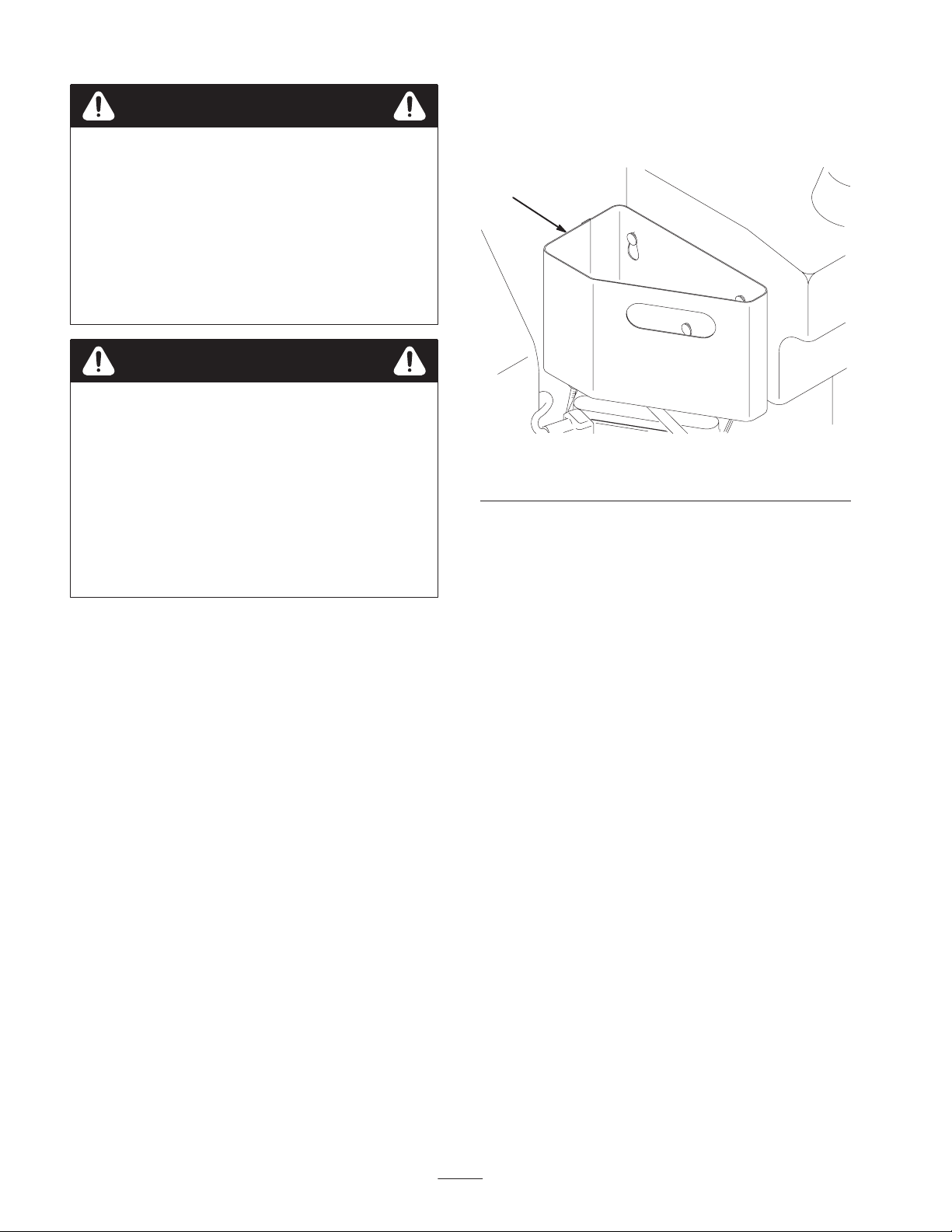

Installing the Refuse Container

Slide the refuse container onto the mounting studs on the

front of the fuel tank (Fig. 3).

1

Figure 3

1. Refuse container

Installing the Decals

Affix an Infield Pro® decal over each Sand Pro decal, if

desired.

4. Coat the terminals and mounting fasteners with

petroleum jelly to prevent corrosion. Slide the rubber

boot over the positive (+) terminal to prevent a possible

short from occurring.

5. Install the battery clamp and secure the battery with the

rods and wing nuts.

10

Page 11

Before Operating

Caution

If you leave the key in the ignition switch, someone

could accidently start the engine and seriously

injure you or other bystanders.

Remove the key from the ignition and disconnect

the wire from the spark plug before you do any

maintenance. Set the wire aside so that it does not

accidentally contact the spark plug.

Checking the Crankcase Oil

The engine is shipped with oil in the crankcase; however,

the oil level must be checked before and after the engine is

first started.

Crankcase capacity is approximately 1–3/4 US quarts

(1.66 l) with the filter.

Use high-quality engine oil that meets the following

specifications:

API Classification Level Required: SJ, SK, SL or

higher.

Preferred oil: SAE 30 (above 40 degrees F)

1. Position the machine on a level surface.

2. Pivot the seat rearward.

3. Pull out the dipstick (Fig. 4) and wipe it with a clean

rag. Insert the dipstick into the tube and make sure that

it is seated fully. Remove the dipstick from the tube and

check the oil level. If the oil level is low, remove the

filler cap from the valve cover and add enough oil to

raise the level to the FULL mark on the dipstick.

1

2

Figure 4

1. Dipstick 2. Filler cap

4. Install the dipstick firmly in place.

Important The dipstick must be fully seated in the tube

to provide proper sealing of the engine crankcase. Failure

to seal the crankcase may result in engine damage.

5. Install the engine cover.

Important Check the oil level every 8 operating hours

or daily. Initially, change the oil and filter after the first 8

hours of operation; thereafter, under normal conditions,

change the oil and filter every 50 hours. However, change

the oil more frequently when the engine is operated in

extremely dusty or dirty conditions.

Important Be sure to keep the engine oil level between

the upper and lower limits on the oil gauge. Engine failure

may occur as a result of over filling or under filling the

engine oil.

11

Page 12

Filling the Fuel Tank

Use UNLEADED Regular Gasoline suitable for automotive

use (87 pump octane minimum). Leaded regular gasoline

may be used if unleaded regular is not available.

Important Never use methanol, gasoline containing

methanol, or gasohol containing more than 10% ethanol

because the fuel system could be damaged. Do not mix oil

with gasoline.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1 in.

(25 mm) below the bottom of the filler neck.

This empty space in the tank allows gasoline to

expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

Warning

Gasoline is harmful or fatal if swallowed.

Long-term exposure to vapors can cause serious

injury and illness.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank or

conditioner opening.

• Keep gas away from eyes and skin.

Fuel tank capacity is approximately 4-1/4 gallons (16.1 l).

1. Clean the area around the fuel tank cap (Fig. 5).

2. Remove the fuel tank cap.

3. Fill the tank to about 1 in. (25 mm) below the top of the

tank (bottom of the filler neck). Do not overfill. Install

the cap.

4. Wipe up any fuel that may have spilled to prevent a fire

hazard.

1

Figure 5

1. Fuel tank cap

12

Page 13

Checking the Hydraulic System

The machines reservoir is filled at the factory with

approximately 3 U.S. gallons (11.4 l) of high quality

hydraulic fluid. Check the level of the hydraulic fluid

before the engine is first started and daily thereafter.

The recommended replacement fluid is:

Toro Premium All Season Hydraulic Fluid

(Available in 5 gallon pails or 55 gallon drums. See

parts catalog or Toro distributor for part numbers.)

Alternate fluids: If the Toro fluid is not available, other

fluids may be used provided they meet all the following

material properties and industry specifications. We do not

recommend the use of synthetic fluid. Consult with your

lubricant distributor to identify a satisfactory product

Note: Toro will not assume responsibility for damage

caused by improper substitutions, so use only products

from reputable manufacturers who will stand behind their

recommendation.

High Viscosity Index/Low Pour Point Antiwear

Hydraulic Fluid, ISO VG 46

Material Properties:

Viscosity, ASTM D445 cSt @ 40_C 44 to 48

cSt @ 100_C 9.1 to 9.8

Viscosity Index ASTM D2270 140 to 160

Pour Point, ASTM D97 –34_F to –49_F

2. Remove the cap from the hydraulic oil reservoir

(Fig. 6).

1

Figure 6

1. Oil reservoir cap

3. Check the oil level in the reservoir. The oil level should

be up to the top of the cone point on the tank screen.

4. If the fluid level is low, slowly fill the reservoir with the

appropriate hydraulic fluid until the level reaches the

bottom of the screen. Do not overfill.

5. Install the reservoir cap.

Important To prevent system contamination, clean the

top of the hydraulic oil containers before puncturing.

Ensure that the pour spout and funnel are clean.

Industry Specifications:

Vickers I–286–S (Quality Level), Vickers M–2950–S

(Quality Level), Denison HF–0

Note: Many hydraulic fluids are almost colorless, making it

difficult to spot leaks. A red dye additive for the hydraulic

system oil is available in 2/3 oz. (20 ml) bottles. One bottle

is sufficient for 4–6 gal (15–22 1) of hydraulic oil. Order

part no. 44–2500 from your authorized Toro distributor.

Biodegradable Hydraulic Fluid – Mobil 224H

Toro Biodegradable Hydraulic Fluid

(Available in 5 gallon pails or 55 gallon drums. See

parts catalog or Toro distributor for part numbers.)

Alternate fluid: Mobil EAL 224H

This is vegetable–oil based biodegradable oil tested and

approved by Toro for this model. This fluid is not as

resistant to high temperatures as standard fluid, so install an

oil cooler if required by the operator manual and follow

recommended fluid change intervals with this fluid.

Contamination by mineral–based hydraulic fluids will

change the biodegradability and toxicity of this oil. When

changing from standard fluid to the biodegradable type, be

certain to follow the approved flushing procedure. Contact

your local Toro Distributor for details.

Checking the Tire Pressure

Check the tire pressure before operating the machine. The

correct air pressure in the front and rear tires is 4–6 psi

(28–41 kPa).

1. Clean the area around the hydraulic oil reservoir cap to

prevent debris from entering the tank (Fig. 6).

13

Page 14

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Important For maximum pulling power, the throttle

should be in the Fast position and the traction pedal just

barely depressed.

Caution

Using the Controls

Traction and Stopping Pedal

The traction pedal (Fig. 7) has 3 functions: to make the

machine move forward, to move it backward, and to stop

the machine. Using the heel and toe of the right foot,

depress the top of the pedal to move forward and the

bottom of pedal to move backward or to assist in stopping

when moving forward (Fig. 8). Also, allow the pedal to

move or move it to the neutral position to stop the machine.

For operator comfort, do not the rest heel of the foot on

reverse when operating forward (Fig. 10).

1

Figure 7

1. Traction and stopping pedal

Use the maximum ground speed only when driving

from one area to another.

Maximum speed is not recommended when using

an attached or towed implement.

Important Do not operate in reverse with the

implement in the down (operating) position, or the

implement could be severely damaged.

Ignition Switch

The ignition switch (Fig. 9), used to start and stop the

engine, has three positions: Off, Run, and Start. Rotate the

key clockwise to the Start position to engage the starter

motor. Release the key when the engine starts. The key will

move automatically to the On position. To shut the engine

off, rotate the key counterclockwise to the Off position.

Choke Control

To start a cold engine, close the carburetor choke by pulling

the choke control (Fig. 9) out to the On position. After the

engine starts, regulate the choke to keep the engine running

smoothly. As soon as possible, open the choke by pushing

it downward to the Off position. A warm engine requires

little or no choking.

4

Figure 8

Ground speed is proportionate to how far the traction pedal

is depressed. For maximum ground speed, the pedal must

be fully depressed while the throttle is in the Fast position.

To get maximum power or when ascending a hill, have the

throttle in the Fast position while depressing the pedal

slightly to keep the engine RPM high. When the engine

RPM begins to decrease, release the pedal slightly to allow

the RPM to increase.

5

7

1. Ignition switch

2. Choke control

3. Throttle control

4. Hour meter

14

6

1

2

3

Figure 9

5. Fuse (option lights)

6. Lights (optional)

7. Fuse (main)

Page 15

Throttle Control

Fuel Shutoff Valve

The throttle control lever (Fig. 9) connects to and operates

the throttle linkage to the carburetor. The control has 2

positions: Slow and Fast. The engine speed can be varied

between the 2 settings.

Note: The engine cannot be stopped by the throttle control.

Hour Meter

The hour meter (Fig. 9) indicates the total hours of machine

operation. The hour meter starts to function whenever the

key switch is rotated to the On position.

Lift Lever

To raise the implement, pull the lift lever (Fig. 10) back; to

lower the implement, push the lever forward. For the float

position, move the lever into the detent position. When the

desired position is attained, release the lever and it will

return to neutral.

Note: The machine has a double-acting lift cylinder. Down

pressure can be applied to the implement for certain

operating conditions.

Parking Brake

To engage the parking brake (Fig. 10), pull back on the

lever. To disengage it, push the lever forward.

Close the fuel shutoff valve (Fig. 11) when storing the

machine.

1

Figure 11

1. Fuel shutoff valve

Seat Adjustment

Move the lever on the side of the seat outward, slide the

seat to the desired position, and release the lever to lock the

seat into position.

An additional 2–1/2 inches of forward adjustment may be

attained by , proceed as follows:

2

Figure 10

1. Lift lever 2. Parking brake

1. Remove the (4) locknuts securing the seat slides to the

1

seat plate.

2. Move the seat/slides to the forward set of mounting

holes in the seat plate.

3. Secure the seat slides to the seat plate with the locknuts

previously removed.

15

Page 16

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Checking the Interlock System

Operation

Caution

Starting and Stopping the

Engine

1. Remove your foot from the traction pedal, make sure

that the pedal is in the neutral position, and engage the

parking brake.

2. Pull the choke lever out to the On position (when

starting a cold engine) and the throttle lever to the Slow

position.

3. Insert the key into the ignition switch and rotate it

clockwise to start the engine. Release the key when the

engine starts. Regulate the choke to keep the engine

running smoothly.

Important To prevent overheating of the starter motor,

do not engage the starter longer than 10 seconds. After 10

seconds of continuous cranking, wait 60 seconds before

engaging the starter motor again.

4. When the engine is started for the first time, or after an

overhaul of the engine, operate the machine in forward

and reverse for 1 to 2 minutes. Also operate the lift

lever to be sure of proper operation of all parts.

5. To stop the engine, move the throttle control to the Slow

position and rotate the ignition key to Off. Remove the

key from the switch to prevent accidental starting.

6. Close the fuel shutoff valve before storing the machine.

Caution

Shut the engine off and wait for all moving parts to

stop before checking for oil leaks, loose parts, and

other malfunctions.

If safety interlock switches are disconnected or

damaged the machine could operate unexpectedly

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

The purpose of the interlock system is to prevent the engine

from cranking or starting unless the traction pedal is in the

neutral position.

1. Check the interlock operation in a wide open area free

of debris and bystanders. Stop the engine.

2. Sit on the seat. Depress the traction pedal in forward

and reverse while trying to start the engine. If the

engine cranks, there may be a malfunction in the

interlock system. Repair it immediately. If the engine

does not crank, the system is operating correctly.

3. With the operator on the seat and the engine running,

raise off the seat while depressing the traction pedal.

The engine should stop within 2 seconds. If the engine

does not stop, there may be a malfunction in the

interlock system. Repair it immediately. If the engine

does stop, the system is operating correctly.

4. With the operator on the seat, the parking brake

engaged and the engine running, Depress the traction

pedal in forward and reverse. The engine should stop

within 2 seconds. If the engine does not stop, there may

be a malfunction in the interlock system. Repair it

immediately. If the engine does stop, the system is

operating correctly.

Towing the Machine

In case of emergency, the machine can be towed for a short

distance. However, we do not recommend this as a standard

procedure.

Important Do not tow the machine faster than

2–3 MPH (3–5 km/h) because the drive system may be

damaged. If the machine must be moved a considerable

distance, transport it on a truck or trailer. The tires may

lock up if the machine is towed too fast. If this occurs, stop

towing the machine and wait for the traction circuit

pressure to stabilize before resuming towing at a slower

speed.

16

Page 17

Break-In Period

Inspecting and Cleaning the

Only 8 hours of operating time is required for the break-in

period.

Since the first hours of operation are critical to future

dependability of the machine, monitor its functions and

performance closely so that minor difficulties, which could

lead to major problems, are noted and can be corrected.

Inspect the machine frequently during break-in for signs of

oil leakage, loose fasteners, or any other malfunction.

Operating Characteristics

Practice driving the machine because its operating

characteristics are different than some utility vehicles. Two

points to consider when operating the vehicle are

transmission and engine speed.

To maintain somewhat constant engine RPM, depress the

traction pedal slowly. This allows the engine to keep up

with the ground speed of the vehicle. By contrast, pushing

down quickly on the traction pedal will reduce engine RPM

and, as a result, there will not be enough torque-power to

move the vehicle. Therefore, to transfer maximum power to

the rear wheels, move the throttle to Fast and slightly

depress the traction pedal. By comparison, maximum

ground speed with no load results when the throttle is in the

Fast position and the traction pedal is slowly but fully

depressed. In summary, always keep the engine RPM high

enough to deliver maximum torque-power to the rear

wheels.

Machine

At the completion of operation, thoroughly wash the

machine with a garden hose—without a nozzle—so that

excessive water pressure will not cause contamination and

damage to the seals and bearings.

Make sure that the cooling fins and area around the engine

cooling air intake are kept free of debris. After cleaning,

inspect the machine for possible hydraulic fluid leaks,

damage, or wear to hydraulic and mechanical components.

Caution

Operating the machine demands attention to

prevent tipping or loss of control.

• Use care when entering and leaving sand traps.

• Use extreme caution around ditches, creeks, or

other hazards.

• Use caution when operating the machine on a

steep slope.

• Reduce your speed when making sharp turns or

when turning on hillsides.

• Avoid sudden stops and starts.

• Do not go from reverse to full forward without

first coming to a complete stop.

17

Page 18

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule

Maintenance Service

Interval

After first 8 hours

Before each use or

daily

Every 25 hours

Every 50 hours • Change the engine oil and filter.

Every 100 hours

Maintenance Procedure

• Change the engine oil and filter.

• Torque the wheel lug nuts.

• Change the hydraulic oil filter.

• Check the operation of the interlock switches.

• Check the engine oil level.

• Check the hydraulic fluid level.

• Check the tire pressure.

• Check the condition of the hydraulic .

• Inspect and clean the machine.

• Check the battery fluid level.

• Check the battery cable connections.

• Lubricate the front wheel bearing.

• Lubricate the traction control linkage.

• Inspect the remote air filter element.

• Inspect the engine air filter element.

• Lubricate the steering shaft grease fitting.

• Check the steering chain adjustment.

• Torque the wheel lug nuts.

Every 200 hours

Every 400 hours or

annually, whichever

occurs first

Every 800 hours

Every 1500 hours or 2

years, whichever occurs

first

Important Refer to your engine operator’s manual for additional maintenance procedures.

• Replace the remote air filter element.

• Replace the engine air filter element.

• Change the hydraulic oil.

• Replace the hydraulic oil filter.

• Replace the spark plugs.

• Replace the fuel filter.

• Decarbon the combustion chamber.

• Adjust the valves and torque head.

• Check the engine RPM (at idle and full throttle).

• Drain and clean the fuel tank.

• Replace moving hoses.

18

Page 19

Daily Maintenance Checklist

Duplicate this page for routine use.

For the week of:

Maintenance Check Item

Check safety interlock operation.

Check steering operation.

Check the engine oil level.

Check the air filter/pre-cleaner condition.

Clean the engine cooling fins.

Check unusual engine noises.

Check unusual operating noises.

Check the hydraulic system oil level.

Check the hydraulic hoses for damage.

Check for fluid leaks.

Check the fuel level.

Check the tire pressure.

Check instrument operation.

Touch up damaged paint.

Notation for Areas of Concern

Inspection performed by:

Mon. Tues. Wed. Thurs. Fri. Sat. Sun.

Item Date Information

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

19

Page 20

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug before you do any

maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

Lubricating the Machine

The machine has 3 grease fittings that must be lubricated

regularly with No. 2 General Purpose Lithium Base Grease.

Lubricate the front wheel bearings after every 25 hours of

operation. Lubricate the steering shaft every 100 hours.

Lubricate the following bearings and bushings:

• Front wheel bearings (Qty. 2) (Fig. 12)

• Steering shaft and sprocket (Fig. 13)

1. Wipe the grease fitting clean so that foreign matter

cannot be forced into the bearing or bushing.

2. Pump grease into the bearing or bushing.

3. Wipe up excess grease.

Figure 13

Figure 12

Note: Do not lubricate the steering chain unless it becomes

stiff because of rust. If the chain rusts, it may be lubricated

lightly with a dry-type lubricant.

20

Page 21

Changing the Engine Oil and

Filter

4. Remove the filter and cover plate. Inspect the filter for

cleanliness, ruptures, holes, and tears. Replace a

damaged filter element.

Change the oil and filter initially after the first 8 hours of

operation; thereafter change the oil and the filter every 50

hours.

1. Park the machine on a level surface and turn the engine

off.

2. Remove the drain plug (Fig. 14) and let oil flow into a

drain pan. When the oil stops, install the drain plug.

3. Remove the oil filter (Fig. 14). Apply a light coat of

clean oil to the new filter gasket.

1

2

Figure 14

1. Drain plug 2. Oil filter

Important With the air cleaner disassembled, check the

air cleaner components for damage. Replace them if

necessary. Make sure that the rubber breather tube in the

base plate is securely in place or severe engine damage may

occur.

1

2

Figure 15

1. Air cleaner cover 2. Paper element

5. Install the air cleaner element and cover plate.

4. Screw the filter on by hand until the gasket contacts the

filter adapter; then tighten 1/2 to 3/4 turn further. Do

not overtighten.

5. Add oil to the crankcase; refer to Checking the

Crankcase Oil.

6. Dispose of used oil properly.

Servicing the Engine Air

Cleaner

Inspect the paper element every 100 hours of operation and

replace it every 200 hours or when it becomes dirty or

damaged. Do not wash the paper element or do not clean it

with compressed air as damage will occur.

1. Park the machine on a level surface and turn the engine

off.

2. Pivot the seat upward.

3. Remove the knobs and air cleaner cover (Fig. 15).

6. Install the air cleaner cover and secure it with the knobs.

General Air Cleaner

Maintenance

Check the air cleaner body for damage which could

possibly cause an air leak. Replace a damaged air cleaner

body.

Replace the air cleaner filter every 200 hours (more

frequently in extremely dusty or dirty conditions). Do not

over-service the air filter.

Be sure that the cover is sealing around the air cleaner

body.

Servicing the Remote Air

Cleaner

1. Release the latches securing the air cleaner cover to the

air cleaner body (Fig. 16). Separate the cover from the

body. Clean the inside of the air cleaner cover.

21

Page 22

Adjusting the Throttle Control

1

3

Figure 16

1. Air cleaner latches

2. Dust cap

3. Filter

2. Washing Method

A. Prepare a solution of filter cleaner and water and

soak the filter element about 15 minutes. Refer to

the directions on the filter cleaner carton for

complete information.

B. After soaking the filter for 15 minutes, rinse it with

clear water. Maximum water pressure must not

exceed 40 psi (276 kPa) to prevent damage to the

filter element. Rinse the filter from the clean side to

the dirty side.

C. Dry the filter element using warm, flowing air

(160°F [71°C] max), or allow the element to air-dry.

Do not use a light bulb to dry the filter element

because damage could result.

3. Compressed Air Method

A. Blow compressed air from the inside to the outside

of a dry filter element. Do not exceed 100 psi

(689 kPa) to prevent damage to the element.

B. Keep the air hose nozzle at least 2 in. (5 cm) from

the filter and move the nozzle up and down while

rotating the filter element. Inspect the filter for holes

and tears by looking through the filter toward a

bright light.

4. Inspect the new filter for shipping damage. Check the

sealing end of the filter. Do not install a damaged filter.

5. Insert the new filter properly into the air cleaner body.

Make sure that the filter is sealed properly by applying

pressure to the outer rim of the filter when installing it.

Do not press on the flexible center of the filter.

Proper throttle operation is dependent upon proper

2

adjustment of the throttle control. Before adjusting the

carburetor, ensure that the throttle control is operating

properly.

1. Pivot the seat upward and remove the engine shield.

2. Loosen the cable clamp screw securing the cable to the

engine (Fig. 17).

3. Move the remote throttle control lever forward to the

Fast position.

5

6

4

3

1

2

Figure 17

1. Throttle casing clamp

screw

2. Throttle cable

3. Swivel

4. Stop

5. Choke casing clamp

screw

6. Choke cable

4. Pull firmly on the throttle cable until the back of the

swivel contacts the stop (Fig. 17).

5. Tighten the cable clamp screw and check the engine

RPM setting:

High Idle: 3150±50

Low Idle: 1750±50

Adjusting the Choke Control

1. Pivot the seat upward and remove the engine shield.

2. Loosen the cable clamp screw securing the cable to the

engine (Fig. 17).

3. Move the remote choke control lever forward to the

Closed position.

6. Install the cover and secure the latches. Make sure that

the cover is positioned with the TOP side up.

4. Pull firmly on the choke cable (Fig. 17) until the choke

butterfly is completely closed; then tighten the cable

clamp screw.

22

Page 23

Adjust the Engine Governor

Speed Control

4. Adjust the idle stop screw until the idle speed is

increased 25 to 50 RPM over the idle speed set in step

3. Final idle speed must be 1750$100 RPM.

Important Before the engine governor speed control is

adjusted, the throttle and choke controls must be adjusted

properly.

Warning

The engine must be running during the adjustment

of the engine governor speed control. Contact with

moving parts or hot surfaces may cause personal

injury.

• Ensure traction pedal is in neutral and engage

the parking brake before performing

this procedure.

• Keep hands, feet, face, and other body parts

away from rotating parts, the muffler, and other

hot surfaces.

Note: To adjust the low idle, use all the following steps. If

only the high idle is to be adjusted, proceed directly to

step 5.

1. Start the engine and let it run at half throttle for

approximately five minutes to warm up.

2. Move the throttle control to the Slow setting. Adjust the

idle stop screw counterclockwise until it no longer

contacts the throttle lever.

3. Bend the governed idle spring anchor tang (Fig. 18) to

attain an idle speed of 1750$50 RPM. Check the speed

with a tachometer.

5. Move the throttle control to the Fast position. Bend the

high speed spring anchor tang (Fig. 18) to attain a high

speed of 3150$50 RPM.

Replacing the Spark Plugs

Replace the spark plugs after every 800 operating hours or

yearly, whichever occurs first.

Type: Champion RC12YC (or equivalent)

Air Gap: 0.030 in. (0.76 mm)

Note: The spark plug usually lasts a long time; however,

the plug should be removed and checked whenever the

engine malfunctions.

1. Clean the area around the spark plugs so that foreign

matter cannot fall into the cylinder when the spark plug

is removed.

2. Pull the spark plug wires off of the spark plugs and

remove the plugs from the cylinder head.

3. Check the condition of the side electrode, center

electrode, and center electrode insulator to ensure that

there is no damage.

Important A cracked, fouled, dirty, or otherwise

malfunctioning spark plug must be replaced. Do not

sand-blast, scrape, or clean the electrodes by using a wire

brush because grit may eventually release from the plug

and fall into the cylinder. The result is usually a damaged

engine.

1

Shown with Carb Adapter Removed

1. Governed idle spring

anchor tag

4. Set the air gap between the center and side of the

electrodes at 0.030 in. (0.76 mm) (Fig. 19). Install the

correctly gapped spark plug with gasket seal, and

tighten the plug to 200 in.-lb. (23 N⋅m). If a torque

wrench is not used, tighten the plug firmly.

2

0.030 in.

(0.76 mm)

Figure 19

Figure 18

2. High speed spring anchor

tag

23

Page 24

Cleaning the Cylinder Head

Fins

8. Run the engine until the lift cylinder extends and

retracts and forward and reverse wheel motion is

achieved.

To avoid overheating and possible engine damage, the

cooling fins on the cylinder head must be kept clean.

Changing the Hydraulic

System Oil and Filter

The hydraulic system filter must be changed initially, after

the first 8 hours of operation, and thereafter every 400

hours of operation or yearly, whichever occurs first. Use a

genuine Toro oil filter for replacement. The hydraulic oil

must be changed every 400 hours of operation or yearly,

whichever occurs first.

1. Park the machine on a level surface and turn the engine

off.

2. Pivot the seat upward.

3. Disconnect the tube from the bottom fitting of the

reservoir and let the oil flow into a drain pan. Install and

tighten the tube when the oil stops draining.

4. Clean the area around the hydraulic oil filter (Fig. 20).

Remove the filter from the bottom of the filter housing

and allow the oil to flow into a drain pan. Use a

bottom-type filter wrench. Dispose of the oil filter

properly.

9. Stop the engine and check the oil level in the reservoir.

Add oil if necessary.

10. Check all connections for leaks.

11. Lower the seat.

12. Dispose of used oil properly.

Checking the Hydraulic Lines

and Hoses

Check the hydraulic lines and hoses daily for leaks, kinked

lines, loose mounting supports, wear, loose fittings, weather

deterioration, and chemical deterioration. Make all

necessary repairs before operating.

Warning

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

• Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic leaks.

• Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

• Seek immediate medical attention if fluid is

injected into skin.

1

Figure 20

1. Hydraulic filter

5. Apply a film of oil on the filter gasket. Install the filter

by hand until the gasket contacts the mounting head;

then tighten the filter an additional 3/4 turn.

6. Fill the reservoir to the proper level; refer to Checking

the Hydraulic System.

7. Place all of the controls in the neutral or disengaged

position and start the engine. Run the engine at the

lowest possible RPM to purge the system of air.

Charging the Hydraulic System

Whenever a hydraulic component is repaired or replaced,

the hydraulic oil filter should be changed and the hydraulic

system charged.

Important Make sure that the hydraulic reservoir and

filter are filled with oil at all times when charging the

hydraulic system.

1. Park the machine on a level surface and turn the engine

off.

2. Pivot the seat upward and remove the engine shield.

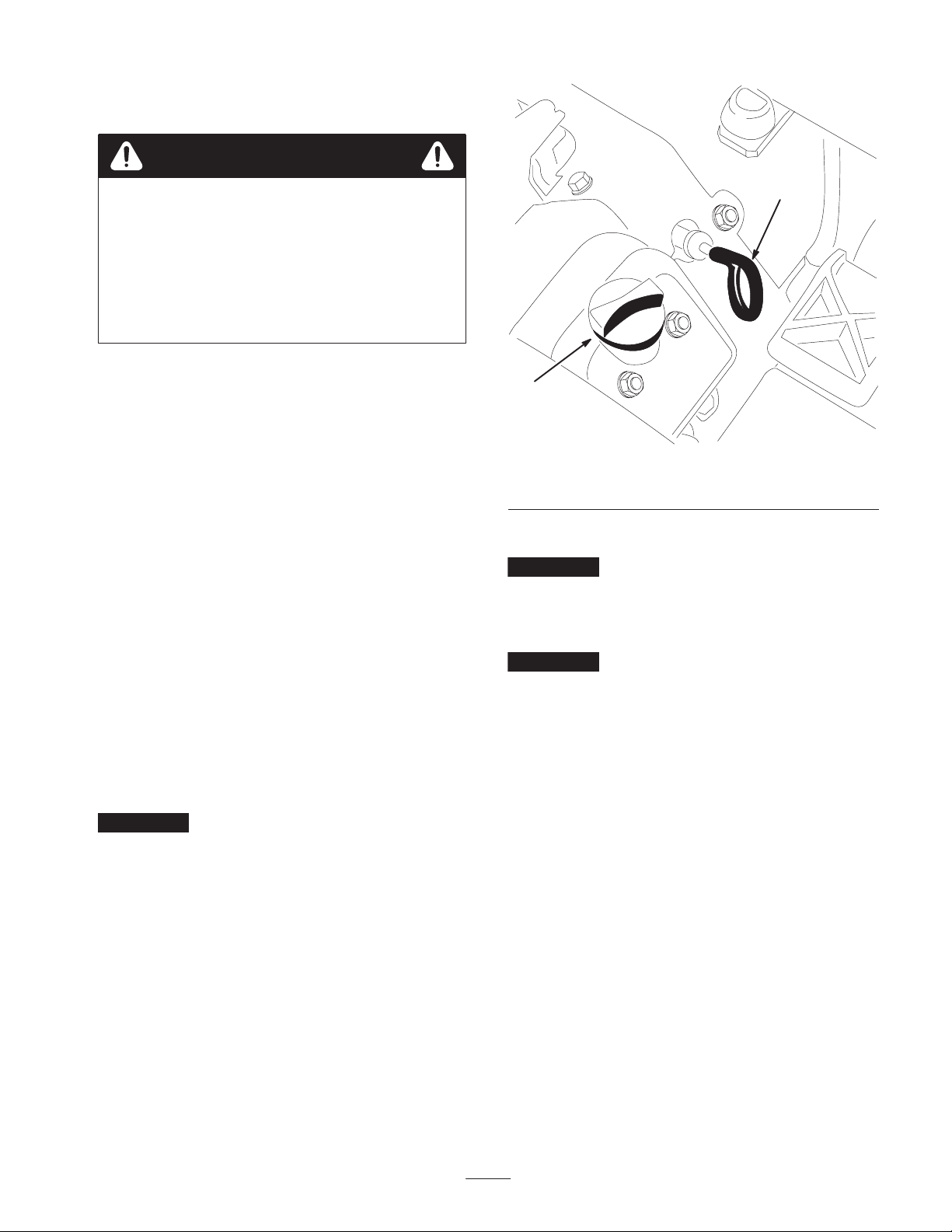

3. Loosen the locknut on the spring adjusting pin until the

bearing moves freely from the cam on the lever

(Fig. 21), allowing the pump shaft freedom to rotate

during start-up.

24

Page 25

3

2

pump and reverse the locations. If the wheel rotates in

the proper direction, stop the engine and adjust the

spring adjusting pin locknut. Adjust the traction neutral

position; refer to Adjusting the Traction Drive for

Neutral.

8. Check the adjustment of the traction interlock switch;

refer to Adjusting the Traction Interlock Switch.

9. Install the engine shield and lower the seat.

Adjusting the Steering Chain

Since the chain and sprocket are subjected to sand thrown

up by the front tire, inspect them frequently for wear. If

either the chain or sprocket is worn beyond acceptable

limits, both should be replaced.

1

Figure 21

1. Spring adjusting pin

2. Bearing

4. Raise one rear wheel off of the floor and place support

blocks under the frame.

5. Start the engine and set the throttle to allow the engine

to run at approximately 1800 RPM.

6. Actuate the lift valve lever until the lift cylinder rod

moves in and out several times. If the cylinder rod does

not move after 10–15 seconds or the pump emits

abnormal sounds, shut the engine off immediately and

determine the cause or problem. Inspect for the

following:

• Loose filter or suction lines

• Loose or faulty coupler on the pump

• Blocked suction line

• Faulty charge relief valve

• Faulty charge pump

3. Cam

1. Place the front wheel in the straight ahead position.

2. Adjust the locknuts until the chain is snug on both sides

of the sprocket (Fig. 22).

3. Turn the steering wheel full left and full right to be sure

that the chain does not bind or hang up in either

direction. Adjust as required.

1

Figure 22

1. Adjusting nuts

If the cylinder moves in 10–15 seconds, proceed to

step 7.

Note: A hydrostatic transmission service manual (Bulletin

No. 9646) and a repair manual (Bulletin No. 9659) can be

obtained from:

Sundstrand Corporation

2800 East 13th Street

Ames, Iowa 50010

7. Operate the traction pedal in forward and reverse. The

wheel that is off of the floor should rotate in the proper

direction. If the wheel rotates in the wrong direction,

stop the engine, remove the lines from the rear of the

Replacing the Fuel Filter

An inline filter is incorporated into the fuel line. Change

the filter every 800 hours. Use the following procedures

when replacement becomes necessary:

1. Close the fuel shutoff valve.

2. Clamp both fuel lines that connect to the fuel filter

(Fig. 23) so that gasoline cannot drain when the lines

are removed.

3. Loosen the hose clamps at both ends of the filter and

pull the fuel lines off of the filter.

25

Page 26

2

1

Figure 23

1. Fuel filter 2. Hose clamps

4. Slide the hose clamps onto the ends of the fuel lines.

Push the fuel lines onto the fuel filter and secure them

with the hose clamps. Be sure that the arrow on the side

of the filter points toward the carburetor.

Adjusting the Traction Drive for

Neutral

If the machine moves when the traction pedal is in the

neutral position, the traction cam must be adjusted.

1. Park the machine on a level surface and turn the engine

off.

Warning

The engine must be running so that the final

adjustment of the traction adjustment cam can be

performed. Contact with moving parts or hot

surfaces may cause personal injury.

Keep hands, feet, face, and other body parts away

from rotating parts, the muffler, and other hot

surfaces.

5. Start the engine and rotate the cam hex (Fig. 24) in both

directions to determine the mid position of the neutral

span.

6. Tighten the locknut securing the adjustment.

7. Stop the engine.

8. Install the engine shield and lower the seat.

9. Remove the jack stands and lower the machine to the

shop floor. Test drive the machine to make sure that it

does not move when the traction pedal is in neutral.

Adjusting the Traction Interlock

Switch

2. Pivot the seat upward and remove the engine shield.

3. Raise one rear wheel off of the floor and place support

blocks under the frame.

4. Loosen the locknut on the traction adjustment cam

(Fig. 24).

1

2

3

4

Figure 24

1. Traction adjustment cam

2. Locknut

3. Screw

4. Gap

1. Adjust the transmission for neutral; refer to Adjusting

the Traction Drive for Neutral.

2. Activate the pump lever to ensure that all parts are

operating freely and seated properly.

3. Adjust the screw until the air gap is .060 inches $ .030

(Fig. 24).

4. Check for proper operation.

Adjusting the Pedal for

Forward

The pedal must be adjusted for forward if the jam nuts on

the control rod are loosened or if the pedal is removed.

1. Park the machine on a level surface, turn the engine off,

and engage the parking brake.

2. Make sure that the pump is in neutral.

3. Loosen the jam nuts on the control rod (Fig. 25).

4. Press down on the rear of the pedal until the pedal

contacts the footrest.

5. Adjust the jam nuts to allow full stroke of the pump,

slightly deflecting the control rod when the pedal is at

full stroke.

26

Page 27

1. Pedal

2. Jam nuts

1

Figure 25

3. Control rod

3

2

1

2

Figure 27

1. Brake switch mounting

nut

2. Parking brake lift lever

link

Adjusting the Brake Interlock

Switch

1. Park the machine on a level surface and turn the engine

off.

2. Disengage the parking brake.

3. Remove the knob from the lift lever (Fig. 26).

1

2

2

7. Engage and disengage the parking brake to make sure it

does not interfere with the switch.

8. Test for proper operation.

9. Install the valve shroud.

10. Adjust the lift lever guide. Refer to Adjusting the Lift

Lever, Page 27.

Adjusting the Brake Linkage

The brakes have been set at the factory for optimum

performance, but after use and wear an adjustment may be

required.

1. Park the machine on a level surface, turn the engine off,

and block the wheels.

2. Loosen the jam nut on the actuator rod (Fig. 28).

Remove the cotter pin retaining the actuator rod.

Increase or decrease the actuator rod length by rotating

the rod. Install the actuator rod using a new cotter pin

and secure the jam nut.

13 4

Figure 26

1. Lift lever knob 2. Valve shroud mounting

screws

4. Remove the (3) mounting screws and remove the valve

shroud (Fig. 26).

5. Loosen the (2) nuts securing brake interlock switch to

brake sensor bracket (Fig. 27).

6. Adjust the brake switch until the air gap between the

switch and the parking brake lever link is .060 inches $

.030. (Fig. 27). Tighten the switch mounting nuts.

1. Actuator rod

2. Adjustment rod (2)

27

4

2

3

Figure 28

3. Jam nut (3)

4. Cotter pin (3)

Page 28

3. If modifying the actuator rod length does not improve

brake performance, adjust both the left and right

adjustment rods equally using the same procedure

described in step 2.

Adjusting the Lift Lever

If the implement fails to float when the lift lever is in the

detent position, an adjustment to the lever guide is required.

Caring for the Battery

The battery electrolyte level must be properly maintained

and the top of the battery kept clean. lf the machine is

stored in a location where temperatures are extremely high,

the battery will run down more rapidly than if the machine

is stored in a location where temperatures are cool.

Danger

1. Park the machine on a level surface, turn the engine off,

and engage the parking brake.

2. Disconnect the implement from the lift cylinder and

extend the cylinder part way.

3. Loosen the capscrews and locknuts securing the lever

guide (Fig. 29) to the valve shroud.

4. Move the lever guide until the cylinder moves freely

when the lift lever is in the detent position.

5. Tighten the capscrews and locknuts locking the

adjustment.

1

2

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

Keep the top of the battery clean by washing it periodically

with a brush dipped in ammonia or bicarbonate of soda

solution. Flush the top surface with water after cleaning.

Do not remove the fill cap while cleaning.

The battery cables must be tight on the terminals to provide

good electrical contact.

Warning

Incorrect battery cable routing could damage the

machine and cables causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

Figure 29

1. Lift lever 2. Lever guide

Storing the Battery

If the machine will be stored for more than 30 days, remove

the battery and charge it fully. Either store it on the shelf or

on the machine. Leave the cables disconnected if it is stored

on the machine. Store the battery in a cool atmosphere to

avoid quick deterioration of the charge in the battery. To

prevent the battery from freezing, make sure that it is fully

charged. The specific gravity of a fully charged battery is

1.250.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

If corrosion occurs at the battery terminals, disconnect the

cables, negative (–) cable first, and scrape the clamps and

terminals separately. Reconnect the cables, positive (+)

cable first, and coat the terminals with petroleum jelly.

Check the electrolyte level every 25 operating hours or, if

the machine is in storage, every 30 days.

Maintain the cell level with distilled or demineralized

water. Do not fill the cells above the fill line.

28

Page 29

Storage

Traction Unit

1. Thoroughly clean the traction unit, attachments and the

engine.

2. Check the tire pressure. Inflate all traction unit tires to

4–6 psi.

3. Check all fasteners for looseness; tighten as necessary.

4. Grease or oil all grease fittings and pivot points. Wipe

off any excess lubricant.

5. Lightly sand and use touch up paint on painted areas

that are scratched, chipped or rusted.

A. Remove the battery terminals from the battery posts.

B. Clean the battery, terminals and posts with a wire

brush and baking soda solution.

C. Coat the cable terminals and battery posts with

Grafo 112X skin–over grease (Toro Part No.

505–47), or petroleum jelly to prevent corrosion.

D. Slowly recharge the battery for 24 hours every 60

days to prevent lead sulfation of the battery.

Note: The specific gravity of a fully charged battery is

1.250.

Note: Store the battery in a cool atmosphere to avoid quick

deterioration of the charge in the battery. To prevent the

battery from freezing, make sure that it is fully charged.

Engine

1. Change the engine oil and filter. Refer to Changing the

Engine Oil and Filter.

2. Start the engine and run it at idle speed for two minutes.

3. Thoroughly clean and service the air cleaner assembly.

Refer to Servicing the Air Cleaner.

4. Seal the air cleaner inlet and the exhaust outlet with

weather proof masking tape.

5. Check the oil filler cap and fuel tank cap to ensure they

are securely in place.

29

Page 30

Electrical Schematic

30

Page 31

Hydraulic Schematic

RH WHEEL MOTOR

WITH BLEED OFF

FOR OIL COOLING

IN FORWARD

A

47.2

12.48

GPM LPM

*FLOW RATE

BARS

----62.05

2

lbs/in

----900

3

15

3

.915

DISPLACEMENT PRESSURE

in /rev cm /rev

17

4.5

5.41

.33

---

---

127.84

7.8 127.84

7.8

-

-

6.2

90

--

--

M2

LEFT

M1

RIGHT

DISPLACEMENT, FLOW RATE. AND PRESSURE CHART

P1

COMPONENT

**

P2M1M2R1R2

FLOW RATE CALCULATED AT 3150 RPM AND 100% EFFICENCY

*

B

LIFT VALVE

A

B

FORWARD

LIFT CYLINDER

R1

XX

R2

XX

FILTER

HYDROSTAT

P2

P1

OIL COOLER

31

Page 32

NOTES

32

Page 33

NOTES

33

Page 34

NOTES

34

Page 35

Evaporative Emission Control Warranty Statement

California Evaporative Emission Control Warranty Statement

Your Warranty Rights and Obligations

Introduction

The California Air Resources Board and The Toro® Company are pleased to explain the evaporative emission control system’s warranty on

your 2007 model year equipment. In California, new equipment that use small off–road engines must be designed, built, and equipped to

meet the State’s stringent anti–smog standards. The Toro) Company must warrant the evaporative emission control system on your

equipment for two years provided there has been no abuse, neglect or improper maintenance of your equipment.

Your evaporative emission control system may include parts such as: fuel lines, fuel line fittings, and clamps.

Manufacturer’s Warranty Coverage:

This evaporative emission control system is warranted for two years. If any evaporative emission–related part on your equipment is

defective, the part will be repaired or replaced by The Toro

®

Company.

Owner’s Warranty Responsibilities:

• As the equipment owner, you are responsible for performance of the required maintenance listed in your Operator’s Manual. The Toro

Company recommends that you retain all receipts covering maintenance on your equipment, but The Toro® Company cannot deny

warranty solely for the lack of receipts.

• As the equipment owner, you should however be aware that The Toro

®

Company may deny you warranty coverage if your emission

warranty parts have failed due to abuse, neglect, or improper maintenance or unapproved modifications.

• You are responsible for presenting your equipment to an Authorized Service Dealer as soon as the problem exists. The warranty repairs

should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding your warranty coverage,

you should contact The Toro

®

Company at 1–952–948–4027 or call us toll free at the number listed in your Toro Warranty statement.

Defects Warranty Requirements:

6. The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

7. General Evaporative Emissions Warranty Coverage. The emission warranty parts must be warranted to the ultimate purchaser and any

subsequent owner that the evaporative emission control system when installed was

A. Designed, built, and equipped so as to conform with all applicable regulations; and

B. Free from defects in materials and workmanship that causes the failure of a warranted part for a period of two years.

8. The warranty on evaporative emissions–related parts will be interpreted as follows:

A. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions must be warranted for

the warranty period of two years. If any such part fails during the period of warranty coverage, it must be repaired or replaced by The

®

Toro

Company. Any such part repaired or replaced under the warranty must be warranted for a time not less than the remaining

warranty period.

B. Any warranted part that is scheduled only for regular inspection in the written instructions must be warranted for the warranty period

of two years. A statement in such written instructions to the effect of ”repair or replace as necessary” will not reduce the period of

warranty coverage. Any such part repaired or replaced under warranty must be warranted for a time not less than the remaining

warranty period.

C. Any warranted part that is scheduled for replacement as required maintenance in the written instructions must be warranted for the