Page 1

FormNo.3362-225RevA

Reelmaster

®

5210/5410/5510/5610

Two-WheelDriveTractionUnits

ModelNo.03660—SerialNo.290000001andUp

ModelNo.03670—SerialNo.290000001andUp

ModelNo.03680—SerialNo.290000001andUp

ModelNo.03690—SerialNo.290000001andUp

ModelNo.03691—SerialNo.290000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareonaplatemountedontheleft

sideoftheframeunderthefootrest.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroRidingMowerSafety....................................5

SoundPressureLevel...........................................6

SoundPowerLevel...............................................6

VibrationLevel.....................................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................12

1AdjustingtheTirePressure..............................12

2AdjustingtheStepHeight................................12

3AdjustingtheControlArmPosition.................13

4InstallingtheCuttingUnits..............................13

5AdjustingtheTurfCompensation

Spring............................................................16

6InstallingRearWeights.....................................17

7InstallingtheCEHoodLatch...........................21

8UsingtheCuttingUnitKickstand.....................21

9UsingtheGaugeBar........................................22

10ReadingtheManualandViewingtheSafety

Video.............................................................22

ProductOverview......................................................23

Controls.............................................................23

Specications.....................................................26

Attachments/Accessories...................................26

Operation...................................................................27

CheckingtheEngineOilLevel............................27

CheckingtheCoolingSystem..............................28

AddingFuel.......................................................28

CheckingtheHydraulicFluid..............................30

CheckingtheReeltoBedknifeContact................31

ChecktheTorqueoftheWheelNuts...................31

BleedingtheFuelSystem....................................31

StartingandStoppingtheEngine........................32

SettingtheReelSpeed.........................................32

AdjustingtheLiftArmCounterbalance...............33

AdjustingtheLiftArmTurnAround

Position..........................................................34

PushingorTowingtheMachine..........................34

JackingPoints.....................................................35

TieDowns.........................................................35

UnderstandingtheDiagnosticLight....................35

DiagnosticAceDisplay.......................................36

CheckingtheInterlockSwitches.........................36

HydraulicValveSolenoidFunctions....................38

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

OperatingTips...................................................38

Maintenance...............................................................39

RecommendedMaintenanceSchedule(s)................39

DailyMaintenanceChecklist...............................40

ServiceIntervalChart.........................................41

Lubrication.............................................................41

GreasingtheBearingsandBushings....................41

EngineMaintenance...............................................43

ServicingtheAirCleaner....................................43

ServicingtheEngineOilandFilter......................43

AdjustingtheThrottle........................................44

FuelSystemMaintenance.......................................45

DrainingtheFuelTank.......................................45

CheckingtheFuelLinesandConnections...........45

ServicingtheWaterSeparator.............................45

FuelPick-upTubeScreen...................................45

BleedingAirfromtheFuelInjectors...................45

ElectricalSystemMaintenance................................46

ServicingtheBattery...........................................46

Fuses..................................................................47

DriveSystemMaintenance.....................................47

AdjustingtheTractionDriveforNeutral.............47

AdjustingtheRearWheelToe-in.........................48

CoolingSystemMaintenance..................................49

RemovingDebrisfromtheCooling

System............................................................49

BrakeMaintenance.................................................50

AdjustingtheServiceBrakes...............................50

AdjustingtheParkingBrake................................50

BeltMaintenance....................................................51

TensioningtheAlternatorBelt............................51

HydraulicSystemMaintenance...............................51

ChangingtheHydraulicFluid.............................51

ReplacingtheHydraulicFilters...........................52

CheckingtheHydraulicLinesandHoses.............52

HydraulicSystemTestPorts...............................53

CuttingUnitSystemMaintenance...........................54

BacklappingtheCuttingUnits............................54

Storage.......................................................................55

PreparingtheTractionUnit................................55

PreparingtheEngine..........................................55

Schematics.................................................................56

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectattimeof

production,whenequippedwithrearweight.Refer

tothesectioninthismanualonInstallingRear

Weight.

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•Readtheoperator’smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

3

Page 4

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthattheoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator’smanual.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingsor

over-speedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’ sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

4

Page 5

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reels

ifnotmowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingthecylinders/reels.Wear

glovesandusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecare

asrotatingonecylinder/reelcancauseother

cylinders/reelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO ,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usejackstandstosupportcomponentswhen

required.

•Usingthemachinedemandsattention.T oprevent

lossofcontrol:

5

Page 6

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

withatachometer.Maximumgovernedenginespeed

shouldbe3200RPM.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly ,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

SoundPressureLevel

TheseunitshaveanequivalentcontinuousA-weighted

soundpressureattheoperatorearof:85dB(A),based

onmeasurementsofidenticalmachinesperISO11201.

SoundPowerLevel

Theseunitshaveaguaranteedsoundpowerlevelof:

105dBA/1pW ,basedonmeasurementsofidentical

machinesperISO11094.

VibrationLevel

Thisunitdoesnotexceedavibrationlevelof2.5m/s

thehandsbasedonmeasurementsofidenticalmachines

perEN1033andEN836.

2

at

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

Thisunitdoesnotexceedavibrationlevelof0.5m/s

attheposteriorbasedonmeasurementsofidentical

machinesperEN1032andEN836.

2

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

6

Page 7

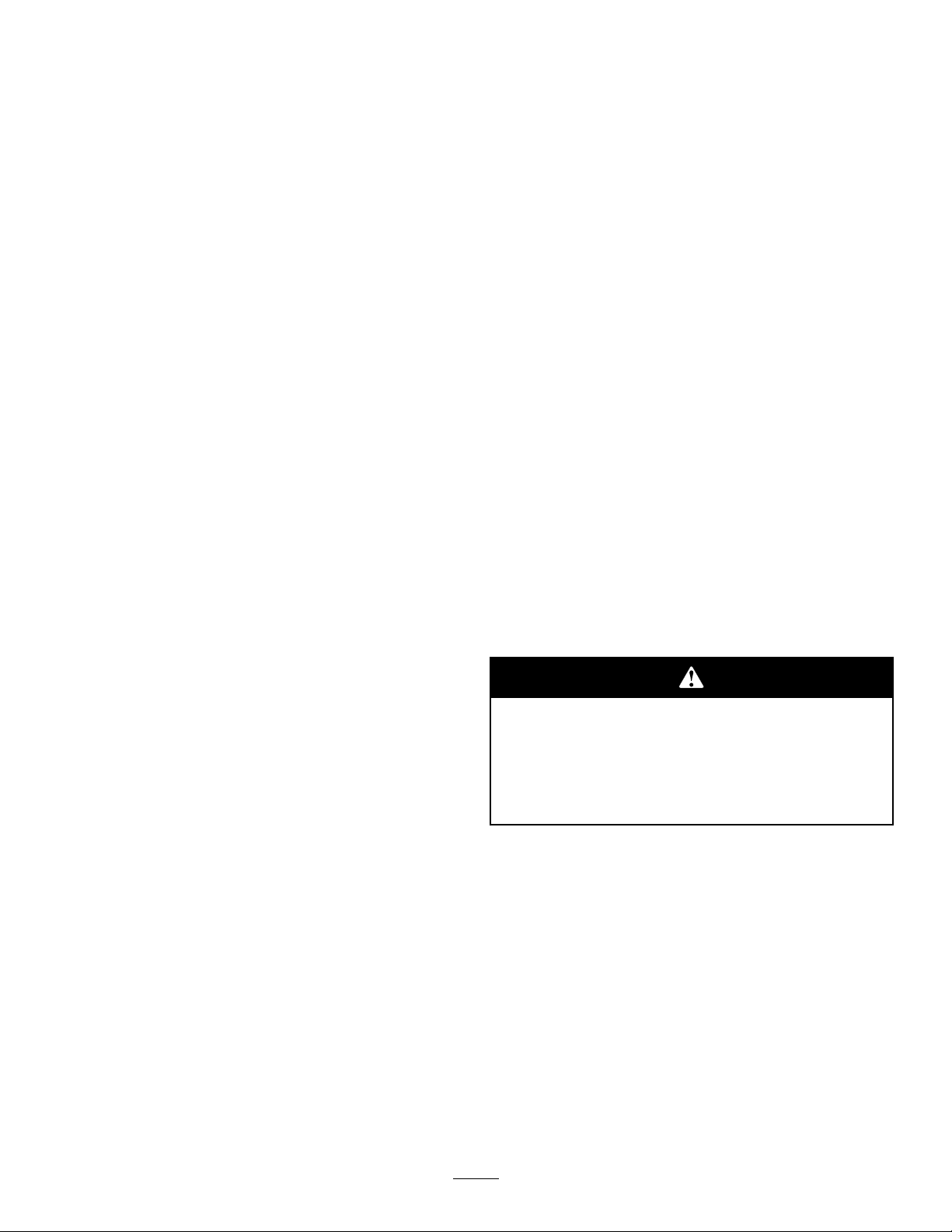

SafetyandInstructionalDecals

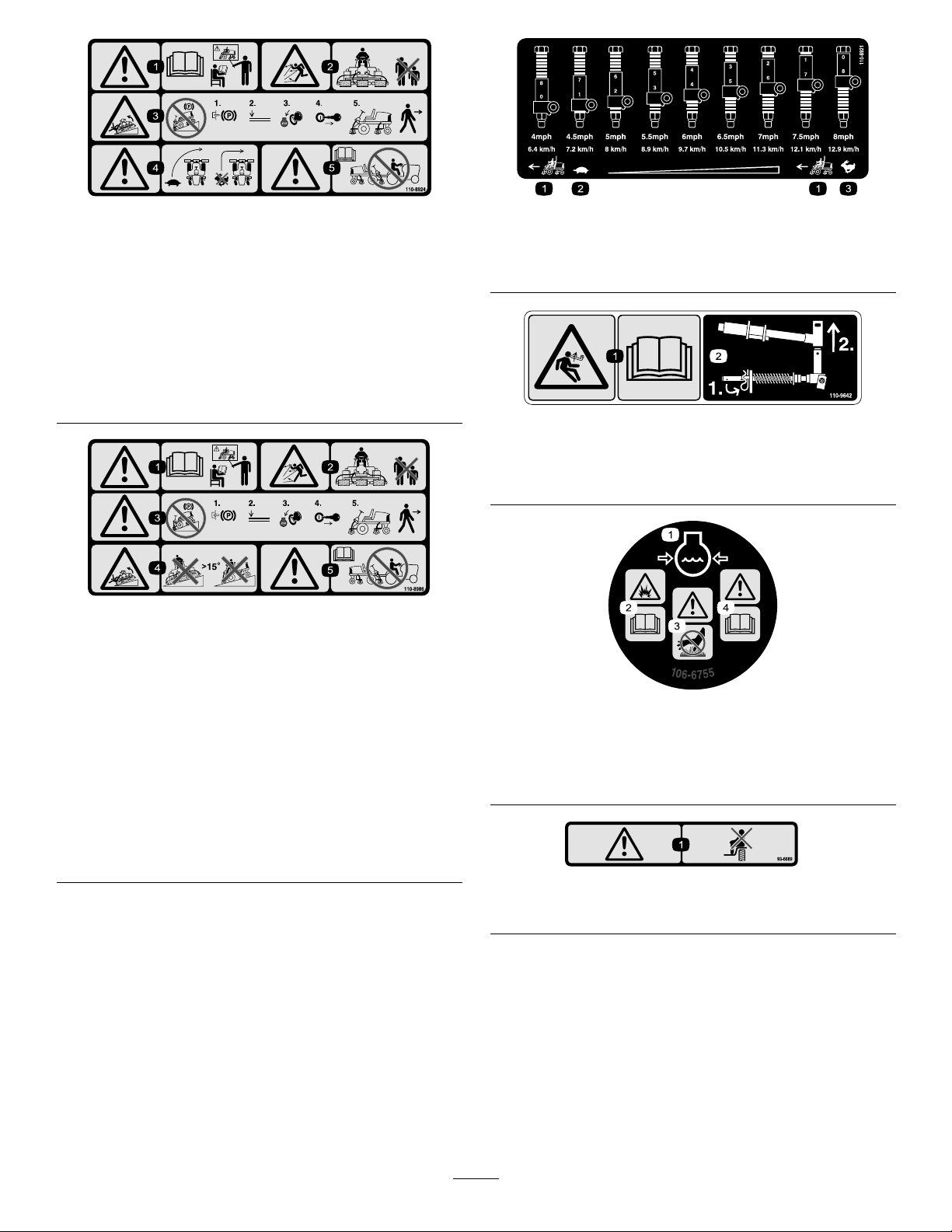

93- 6696

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

108-5278

1.ReadtheOperator’sManual.

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfromoving

parts.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

93-6696

1.Storedenergyhazard—readtheOperator’sManual.

110-0984

1.ReadtheOperator’sManual.

2.Engine—Start

3.Engine—Preheat

4.Engine—Stop

110-0986

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

110-0989

1.ReadtheOperator’sManual.

7

Page 8

110-8924

1.Warning—readtheOperator’sManualandreceivetraining.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

4.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes.

5.Warning—readtheOperator’sManual,donottowthe

machine.

110-8986

(Afxoverpartno.110–8924forCE*)

*Thissafetydecalincludesaslopewarningrequiredonthemachine

forcompliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.The

conservativemaximumslopeanglesindicatedforoperationofthismachineare

prescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator’sManualandreceivetraining.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

4.Tippinghazard—donotoperateonslopesgreaterthan15°.

5.Warning—readtheOperator’sManual,donottowthe

machine.

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

110-9642

1.Storedenergyhazard—readtheOperator’sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator’sManual.

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

93-6689

1.Warning—donotcarrypassengers.

8

Page 9

1.Headlights

2.Reels—enabled

3.Reelsdisabled—liftonly

4.Reelsloweredandon

whenenabled—forward

andbacklap

110-0998

5.Reelsraisedandoff

6.Throttle—fast

7.Throttle—slow

8.ReadtheOperator’s

Manual.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

9

Page 10

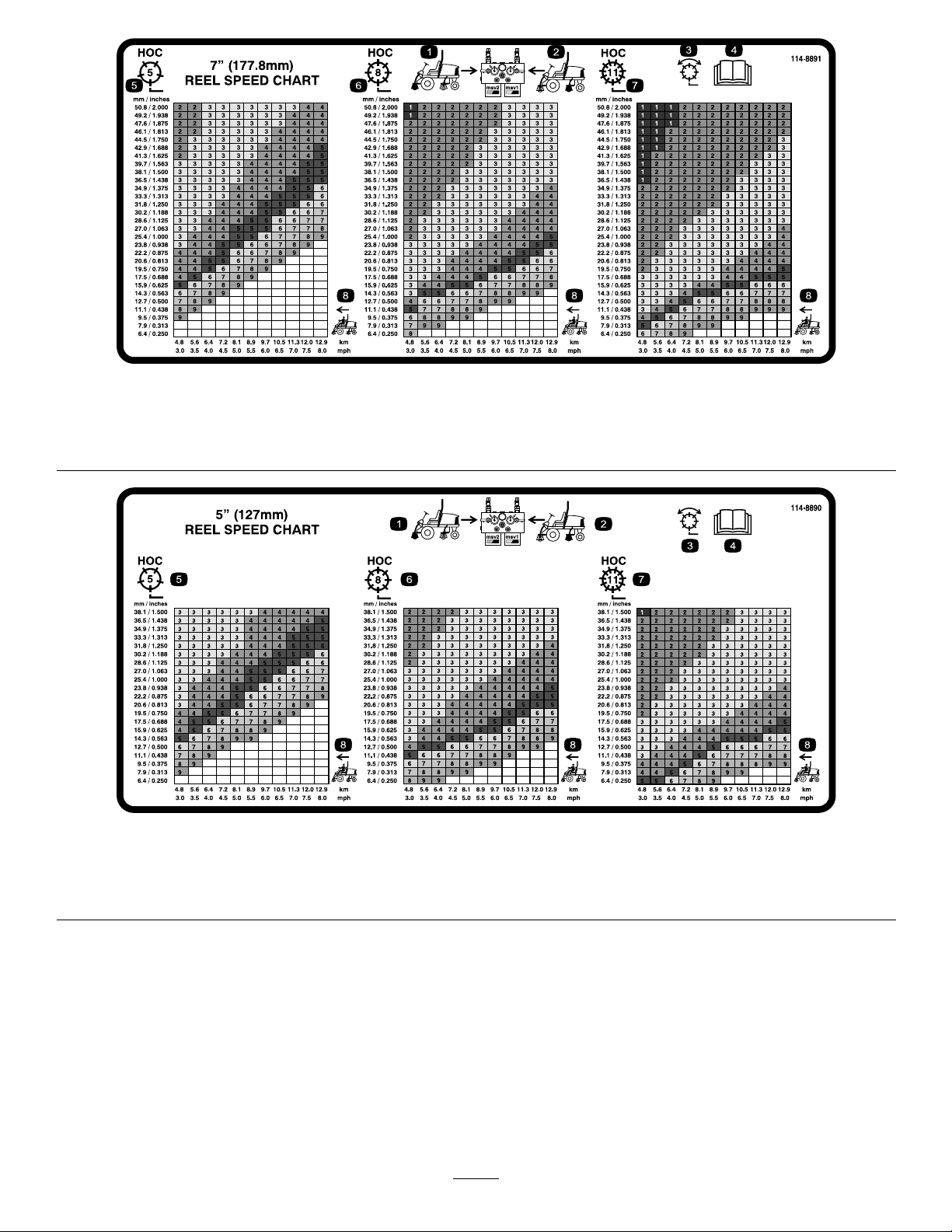

(UseforModels5510&5610with7inchreelcuttingunits)

1.Frontreelscircuitcontrols3.Mowandbacklap

2.Rearreelscircuitcontrols

4.ReadtheOperator’sManual.

(UseforModels5210&5410with5inchreelcuttingunits)

1.Frontreelscircuitcontrols3.Mowandbacklap

2.Rearreelscircuitcontrols

4.ReadtheOperator’sManual.

114–8891

5.Height-of-cut

6.Tractionunitspeed

114–8890

5.Height-of-cut

6.Tractionunitspeed

10

Page 11

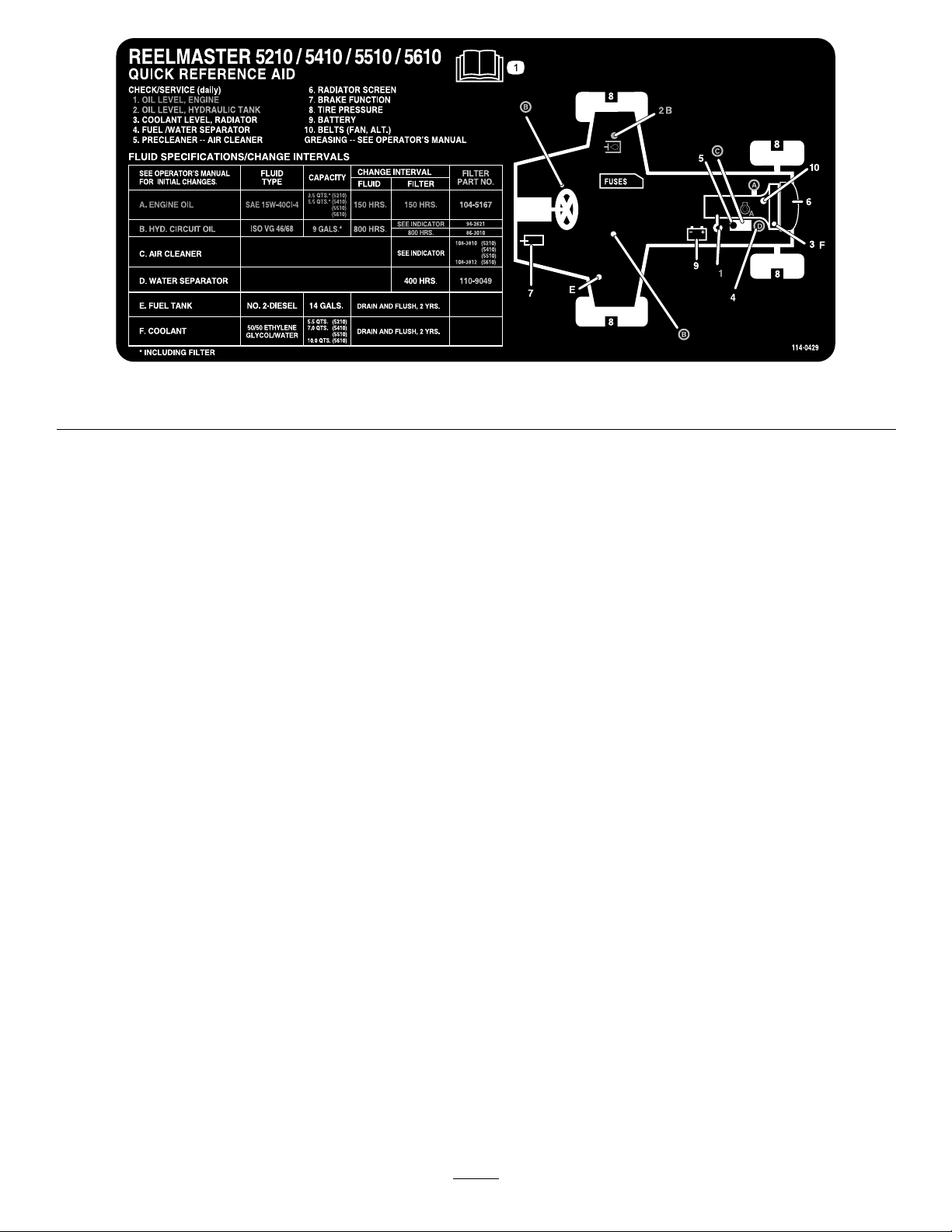

1.ReadtheOperator’sManual.

114-0429

11

Page 12

Setup

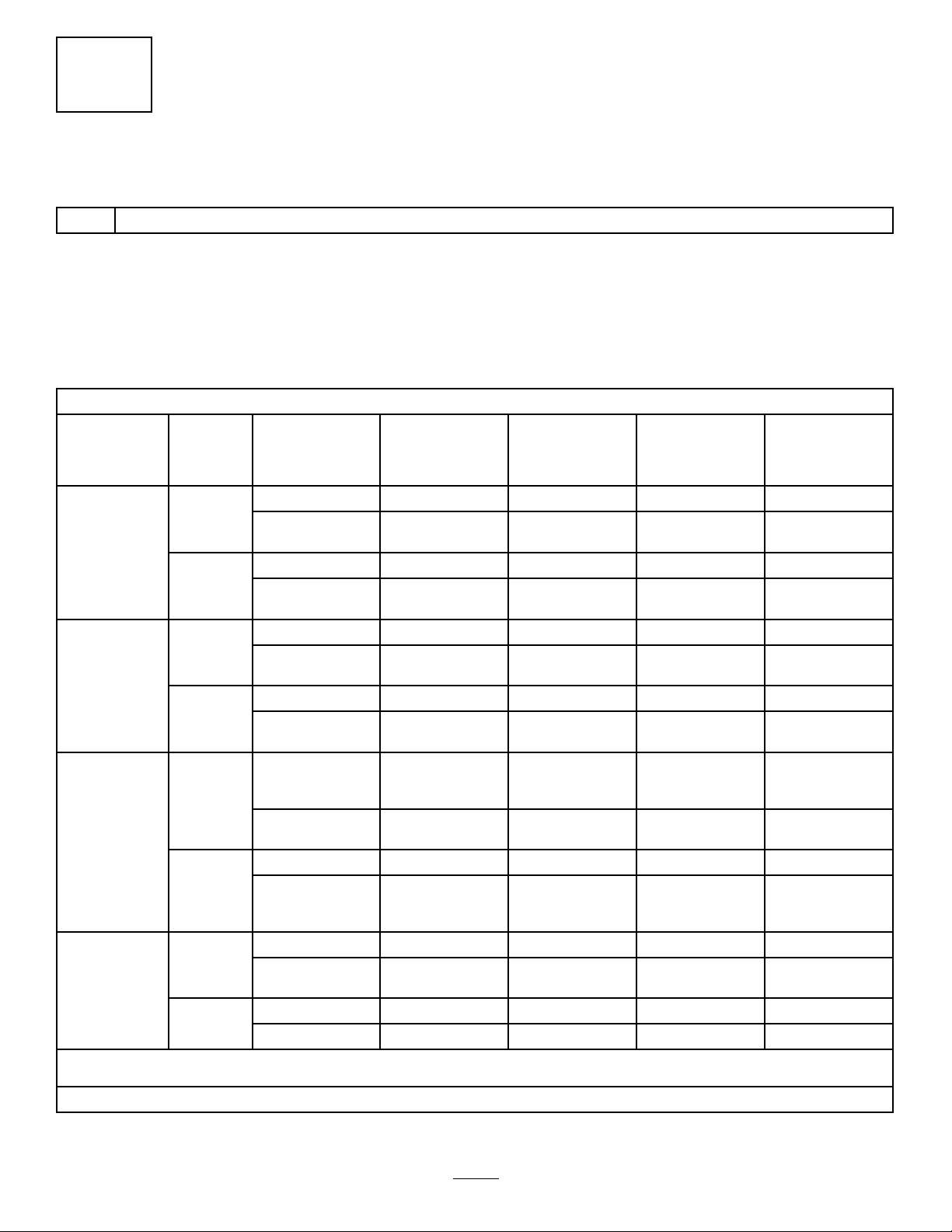

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

Nopartsrequired

Nopartsrequired

Nopartsrequired

Fronthoseguide-R.H.1

Fronthoseguide-L.H.1

Nopartsrequired

Rearweights(sizevarieswith

conguration).

Hoodlatchassembly1

Washer1

Cuttingunitkickstand

Gaugebar

Operator’sManual

EngineOperator’sManual

PartsCatalog

CEcerticate

OperatorTrainingMaterial

Varies

Qty.

Use

–

–

–

–

1

1

1

1

1

1

1

Adjustthetirepressure.

Adjustthestepheight.

Adjustthecontrolarmposition.

Installthecuttingunits

Adjusttheturfcompensationspring.

Installrearweights(orderfromyour

ToroDistributor).

InstalltheCEHoodLatch

InstalltheCuttingUnitKickstand.

Usethegaugebartoadjustthecutting

unit.

ReadtheOperator’sManualandwatch

thevideobeforeoperatingthemachine.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.Correct

airpressureinthefrontandreartiresis12to15psi(83

to103kPa).

Important:Maintainevenpressureinalltiresto

ensureuniformcontactwiththeturf.

2

AdjustingtheStepHeight

NoPartsRequired

Procedure

Theheightofthestepscanbeadjustedfortheoperators

comfort.

1.Removethe2boltsandnutssecuringthestep

bracketstothetractionunitframe(Figure2)

12

Page 13

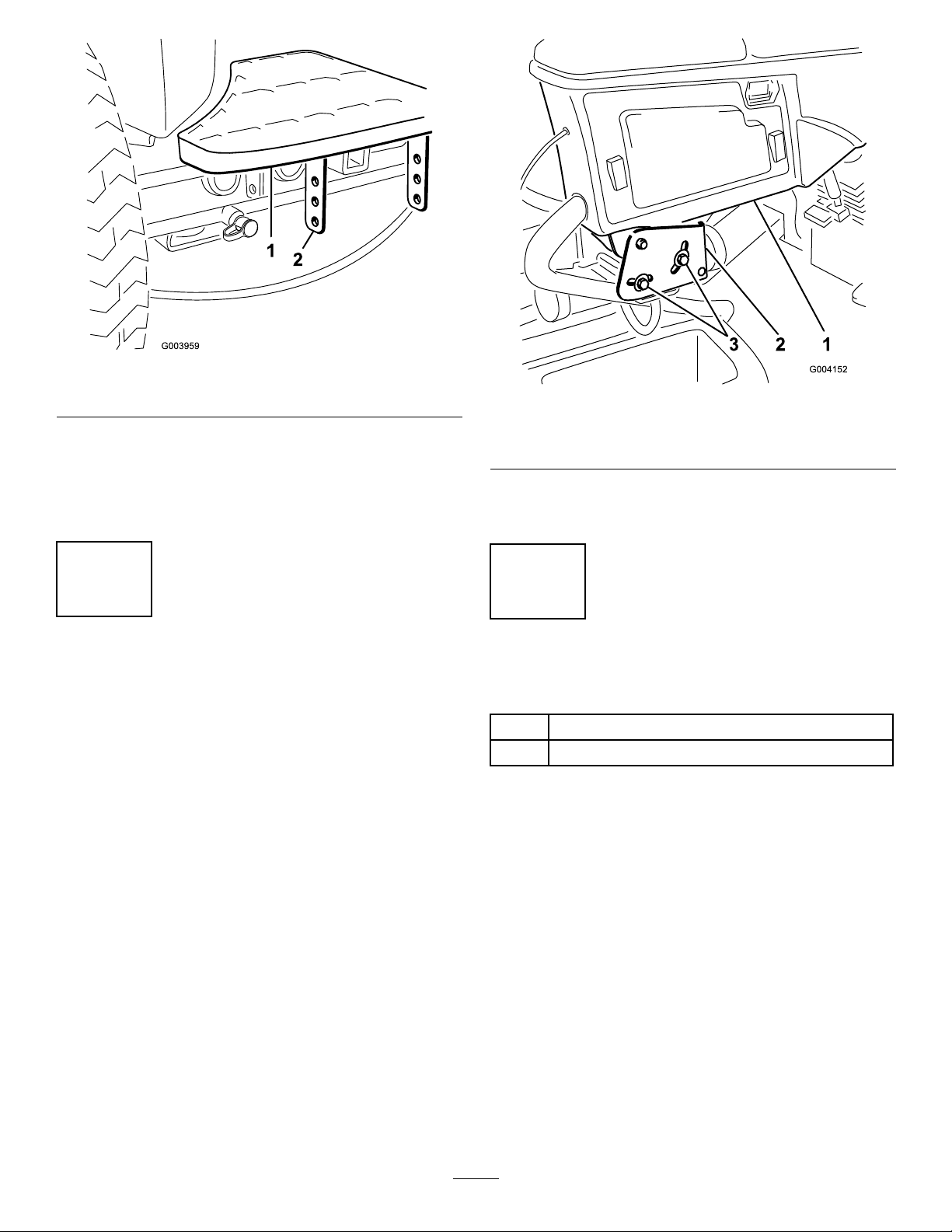

Figure2

1.Step2.Stepbrackets

2.Raiseorlowerthesteptothedesiredheightand

re-securethebracketstotheframewiththe2bolts

andnuts.

3.Repeattheprocedureontheotherstep.

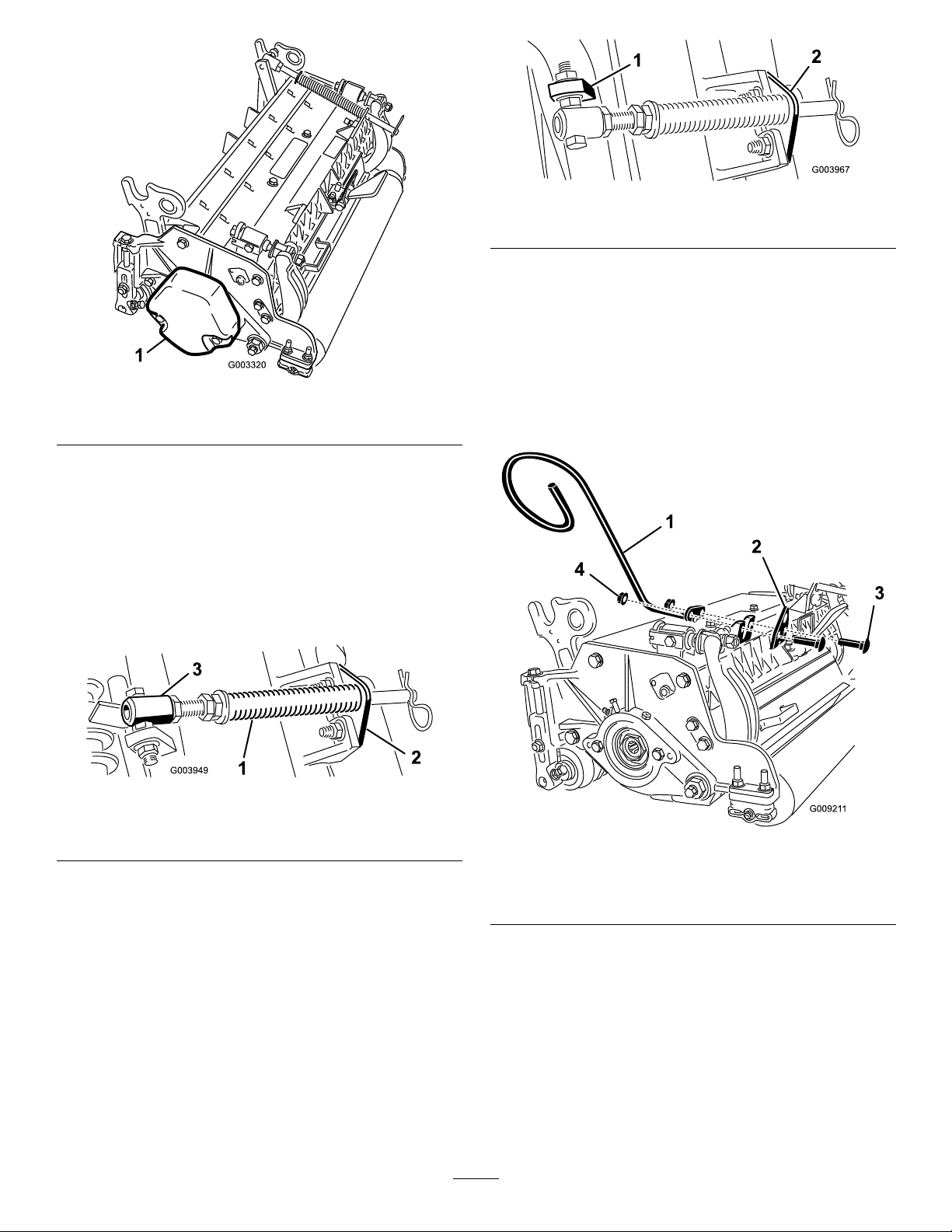

Figure3

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredpositionand

tightenthe2bolts.

3

AdjustingtheControlArm

Position

NoPartsRequired

Procedure

Thecontrolarmpositioncanbeadjustedforthe

operatorscomfort.

1.Loosenthe2boltssecuringthecontrolarmtothe

retainingbracket(Figure3).

4

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1Fronthoseguide-R.H.

1Fronthoseguide-L.H.

Procedure

1.Removethereelmotorsfromtheshippingbrackets.

2.Removetheshippingbracketsanddiscard.

3.Removethecuttingunitsfromthecartons.Assemble

andadjustasdescribedinthecuttingunitOperator’s

Manual.

4.Makesurethecounterweight(Figure4)isinstalled

totheproperendofthecuttingunitasdescribedin

thecuttingunitOperator’sManual.

13

Page 14

Figure6

1.Oppositecarrierframetab

2.Rodbracket

D.Mounttherodbrackettothecuttingunittabs

withthecarriageboltsandnuts(Figure6).Also,

onthe#4cuttingunit,mountthelefthandhose

guidetothefrontofthecuttingunittabswhen

reinstallingtherodbracket(Figure7).

Figure4

1.Counterweight

5.Allthecuttingunitsareshippedwiththeturf

compensationspringmountedtotherightsideof

thecuttingunit.Theturfcompensationspring

mustbemountedtothesamesideofthecutting

unitasthereeldrivemotor.Repositiontheturf

compensationasfollows:

A.Removethe2carriageboltsandnutssecuring

therodbrackettothecuttingunittabs(Figure5).

Figure5

1.Turfcompensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthespringtube

capscrewtothecarrierframetab(Figure5)

Removetheassembly .

C.Mountthespringtubecapscrewtotheopposite

tabonthecarrierframeandsecurewiththe

angenut.Thecapscrewheadistobepositioned

totheoutersideofthetabasshowninFigure6.

Note:Onthe#5cuttingunit,usetherod

bracketmountingnutstoinstalltherighthand

hoseguidetothefrontofthecuttingunittabs.

Figure7

1.Hoseguide(Lefthand

shown)

2.Rodbracket4.Nuts

3.Carriagebolts

Note:Wheninstallingorremovingthecutting

units,makesurethehairpincotterisinstalled

inthespringrodholenexttotherodbracket.

Otherwise,thehairpincottermustbeinstalledin

theholeintheendoftherod.

6.Loweralltheliftarmscompletely.

7.Removethesnapperpinandthecapfromthelift

armpivotyoke(Figure8).

14

Page 15

Figure8

1.Snapperpin2.Cap

8.Forthefrontcuttingunits,slideacuttingunitunder

theliftarmwhileinsertingthecarrierframeshaftup

intotheliftarmpivotyoke(Figure9).

B.Inserttheliftarmyokeontothecarrierframe

shaft(Figure9).

C.Inserttheliftarmshaftintotheliftarm

andsecureitwiththewasherandlynchpin

(Figure10).

10.Insertthecapoverthecarrierframeshaftandlift

armyoke.

11.Securethecapandthecarrierframeshafttothe

liftarmyokewiththesnapperpin.Usetheslotifa

steeringcuttingunitisdesiredorusetheholeifthe

cuttingunitistobelockedinposition(Figure8).

12.Securetheliftarmchaintothechainbracketwith

thesnapperpin(Figure11).Usethenumberofchain

linksdescribedinthecuttingunitOperator’ sManual.

Figure9

1.Liftarm3.Liftarmpivotyoke

2.Carrierframeshaft

9.Usethefollowingprocedureontherearcuttingunits

whentheheightofcutisabove3/4inch.

A.Removethelynchpinandwashersecuringthe

liftarmpivotshafttotheliftarmandslidethe

liftarmpivotshaftoutoftheliftarm(Figure10).

Figure11

1.Liftarmchain2.Chainbracket

13.Coatthesplineshaftofthereelmotorwithclean

grease.

14.OilthereelmotorO-ringandinstallitontothe

motorange.

15.Installthemotorbyrotatingitclockwisesothat

themotorangesclearthecapscrews(Figure12).

Rotatethemotorcounterclockwiseuntiltheanges

encirclethecapscrewsthentightenthecapscrews.

Important:Makesurethereelmotorhoses

arenottwisted,kinkedorintheriskofbeing

pinched.

Figure10

1.Liftarmpivotshaftlynchpinandwasher

15

Page 16

Figure12

1.Reeldrivemotor2.Mountingcapscrews

Figure13

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespring

roduntilthecompressedlengthofthespringis5

inches(12.7cm)onReelmaster5210&5410,5inch

cuttingunitsor6.25inches(15.9cm)onReelmaster

5510&5610,7inchcuttingunits(Figure13).

5

AdjustingtheTurf

CompensationSpring

NoPartsRequired

Procedure

Theturfcompensationspring(Figure13)transfers

weightfromthefronttotherearroller.(Thishelps

toreduceawavepatternintheturf,alsoknownas

marcellingorbobbing.)

Important:Makespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightaheadandloweredtotheshopoor.

1.Makesurethehairpincotterisinstalledintherear

holeinthespringrod(Figure13).

Note:Whenoperatingonroughterraindecrease

thespringlengthby1/2inch.Groundfollowingwill

beslightlydecreased.

16

Page 17

6

InstallingRearWeights

Partsneededforthisprocedure:

Varies

Rearweights(sizevarieswithconguration).

Procedure

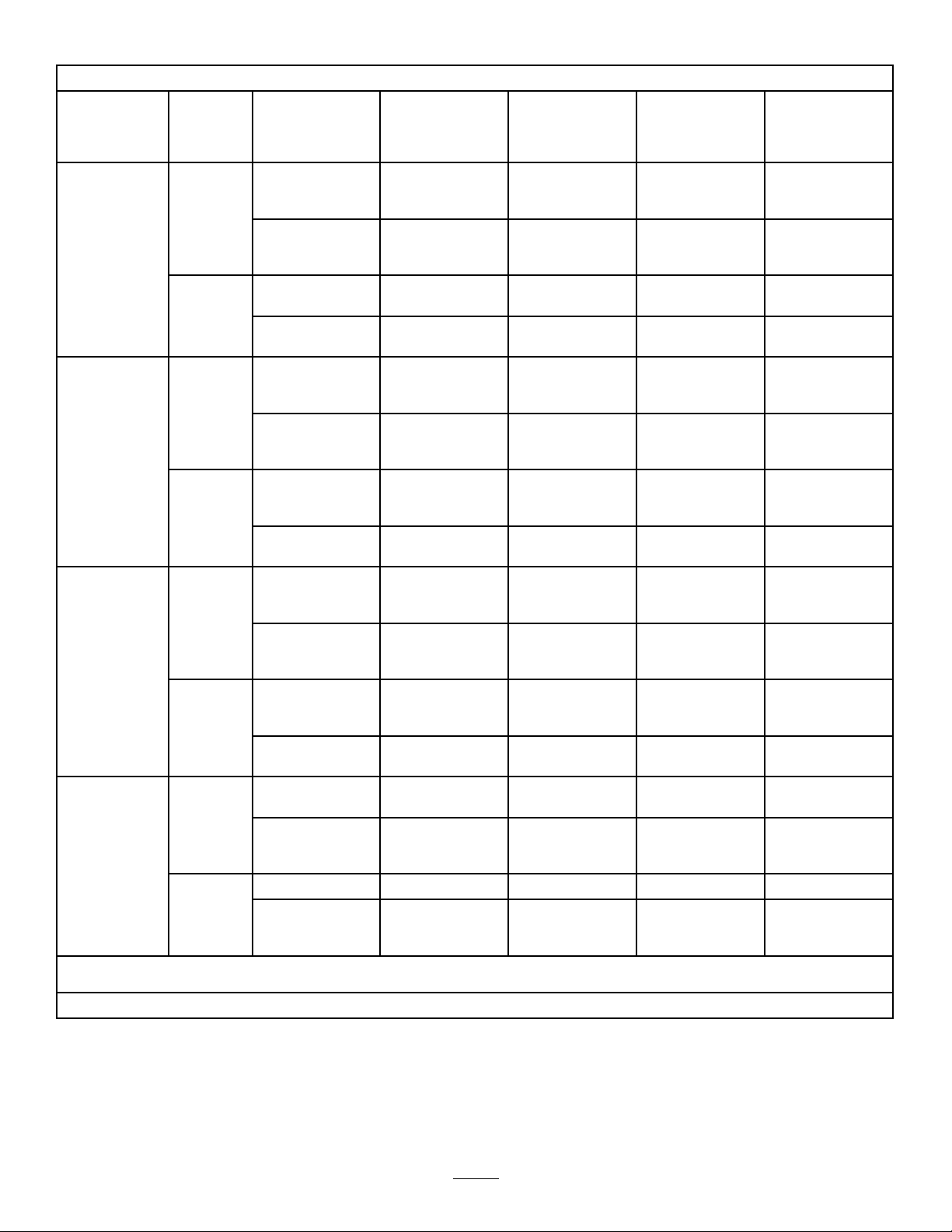

TheReelmaster5210/5410/5510and5610TractionUnitscomplywithCENstandardEN836:1997,ISOstandard

5395:1990,andANSIB71.4-2004Standardswhenequippedwithrearweightsand/or90lbofcalciumchloride

ballastisaddedtorearwheels.Usethefollowingchartstodeterminethecombinationsofweightsrequiredforyour

conguration.OrderpartsfromyourlocalAuthorizedToroDistributor.

WeightP/N110-8985-03

Tractor

RM5210

RM5410

RM5510

RM5610

2*or4

Wheel

Drive

2*

4

2*

4

2*

4

2*

4

Groomers,roller

brushes,and/or

baskets

No00

Yes

No00

Yes20

No00

Yes

No00

Yes20

No40

Yes

No00

Yes44

No00

Yes94

No00

Yes00

Numberof

weightsto

meetANSI(US)

standards

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**

Numberof

weightstomeet

CE(European)

standards

90lbcalcium

chloride**

Fasteners(2

eachrequired)

forweights

N/AN/A

7

9

3231-11Carriage

Bolt,104-8301Nut

N/AN/A

3231-6Carriage

Bolt,104-8301Nut

N/AN/A

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

3231-6Carriage

Bolt,104-8301Nut

3231-7Carriage

Bolt,104-8301Nut

N/AN/A

N/AN/A

3231-7Carriage

Bolt,104-8301Nut

N/AN/A

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

N/AN/A

WeightLocation

Underbumper

Underbumper

Underbumper

Underbumper

1ontopofbumper

and3under

bumper

1ontopofbumper

and3under

bumper

Underbumper

*Includes2WDunitswiththeROPSoption.

**Installtubesinsidethereartiresbeforeaddingcalciumchloride.

17

Page 18

Usethefollowingcharttodeterminetherearweightrequirementswhena4PostROPSConversionKitisadded.

WeightP/N110-8985-03

Tractor

RM5210

RM5410

RM5510

RM5610

2*or4

Wheel

Drive

2*

4

2*

4

2*

4

2*

4

Groomers,roller

brushes,and/or

baskets

No99

Yes

No

Yes

No99

Yes

No44

Yes

No

Yes

No44

Yes

No44

Yes

No00

Yes44

Numberof

weightsto

meetANSI(US)

standards

90lbcalcium

chloride**plus

5weights

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**plus

5weights

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**plus

9weights

90lbcalcium

chloride**

90lbcalcium

chloride**plus

2weights

Numberof

weightstomeet

CE(European)

standards

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**plus

5weights

90lbcalcium

chloride**

Fasteners(2

eachrequired)

forweights

3231-34Carriage

Bolt,104-8301Nut

3231-11Carriage

Bolt,104-8301Nut

N/AN/A

N/AN/A

3231-34Carriage

Bolt,104-8301Nut

9

9

9

3231-34Carriage

Bolt,104-8301Nut

3231-7Carriage

Bolt,104-8301Nut

N/AN/A

3231-34Carriage

Bolt,104-8301Nut

3231-34Carriage

Bolt,104-8301Nut

3231-7Carriage

Bolt,104-8301Nut

N/AN/A

3231-7Carriage

Bolt,104-8301Nut

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

3231-7Carriage

Bolt,104-8301Nut

WeightLocation

2ontopofbumper

and7under

bumper

Underbumper

2ontopofbumper

and7under

bumper

2ontopofbumper

andtheremaining

underbumper

1ontopofbumper

and3under

bumper

2ontopofbumper

and7under

bumper

2ontopofbumper

andtheremaining

underbumper

1ontopofbumper

and3under

bumper

Underbumper

2ontopofbumper

andtheremaining

underbumper

1ontopofbumper

and3under

bumper

*Includes2WDunitswiththeROPSoption.

**Installtubesinsidethereartiresbeforeaddingcalciumchloride.

18

Page 19

Usethefollowingcharttodeterminetherearweightrequirementswhenthetractionunitisalsoequippedwitha

SunshadeCanopyona2PostROPS.

WeightP/N110-8985-03

Tractor

RM5210

RM5410

RM5510

RM5610

2*or4

Wheel

Drive

2*

4

2*

4

2*

4

2*

4

Groomers,roller

brushes,and/or

baskets

No20

Yes

No00

Yes42

No22

Yes

No00

Yes42

No62

Yes

No00

Yes66

No00

Yes

No00

Yes00

Numberof

weightsto

meetANSI(US)

standards

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**

90lbcalcium

chloride**

Numberof

weightstomeet

CE(European)

standards

90lbcalcium

chloride**

Fasteners(2

eachrequired)

forweights

3231-6Carriage

Bolt,104-8301Nut

9

9

6

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

3231-7Carriage

Bolt,104-8301Nut

3231-6Carriage

Bolt,104-8301Nut

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

3231-7Carriage

Bolt,104-8301Nut

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

N/AN/A

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

3231-34Carriage

Bolt,104-8301Nut

N/AN/A

N/AN/A

WeightLocation

Underbumper

Underbumper

1ontopofbumper

andtheremaining

underbumper

Underbumper

2ontopofbumper

and7under

bumper

Underbumper

Underbumper

3ontopofbumper

and3under

bumper

2ontopofbumper

and4under

bumper

*Includes2WDunitswiththeROPSoption.

**Installtubesinsidethereartiresbeforeaddingcalciumchloride.

Important:Alwaysinstalltubesinsidethereartiresbeforecalciumchlorideisinstalled.Ifapuncture

occursinatirewithcalciumchloride,removethemachinefromtheturfareaasquicklyaspossible.To

preventpossibledamagetotheturf,immediatelysoaktheaffectedareawithwater.

Ontwowheeldrivemodels,mounttheappropriateamountofweight(seeweightcharts)tothetoporbottomof

therearbumperasshowninFigure14.

19

Page 20

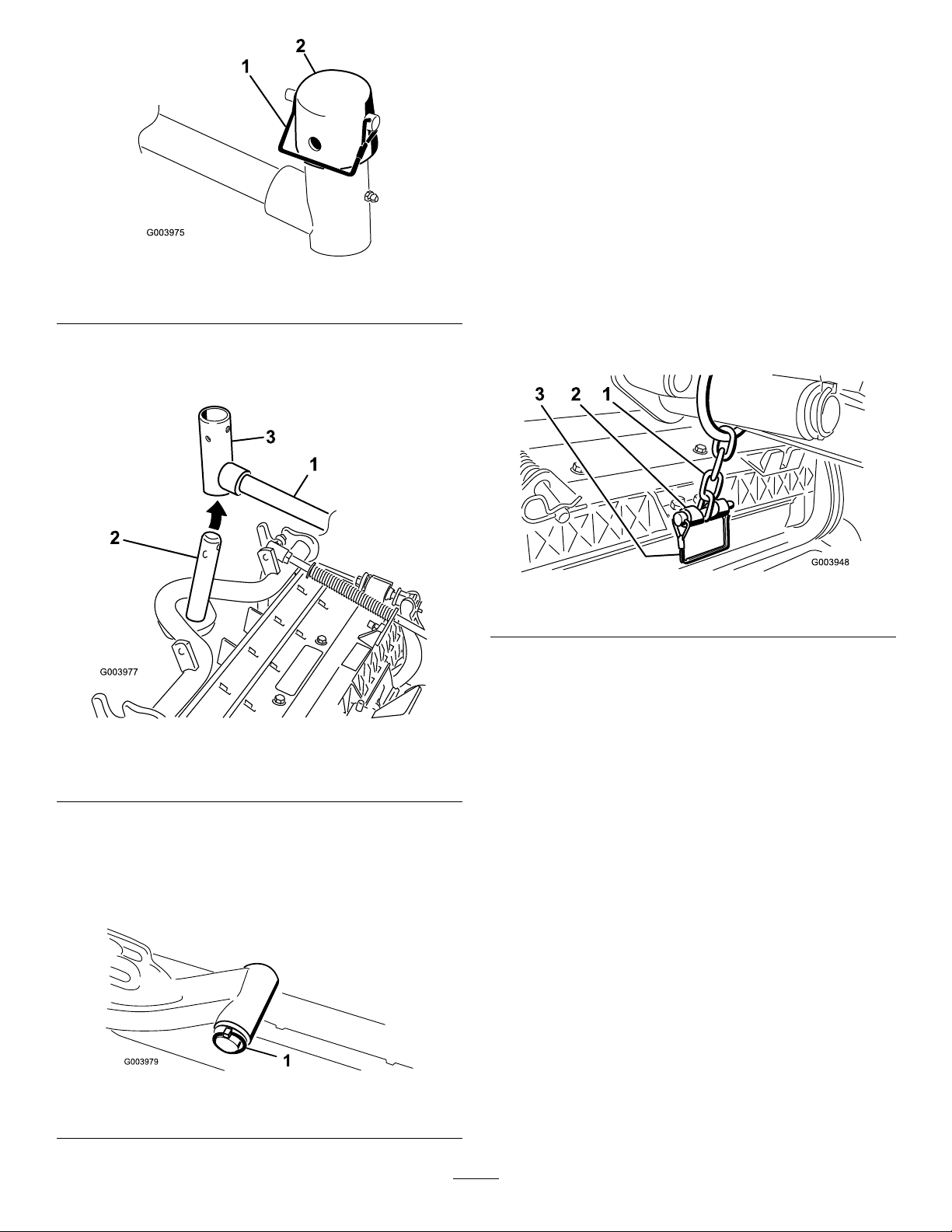

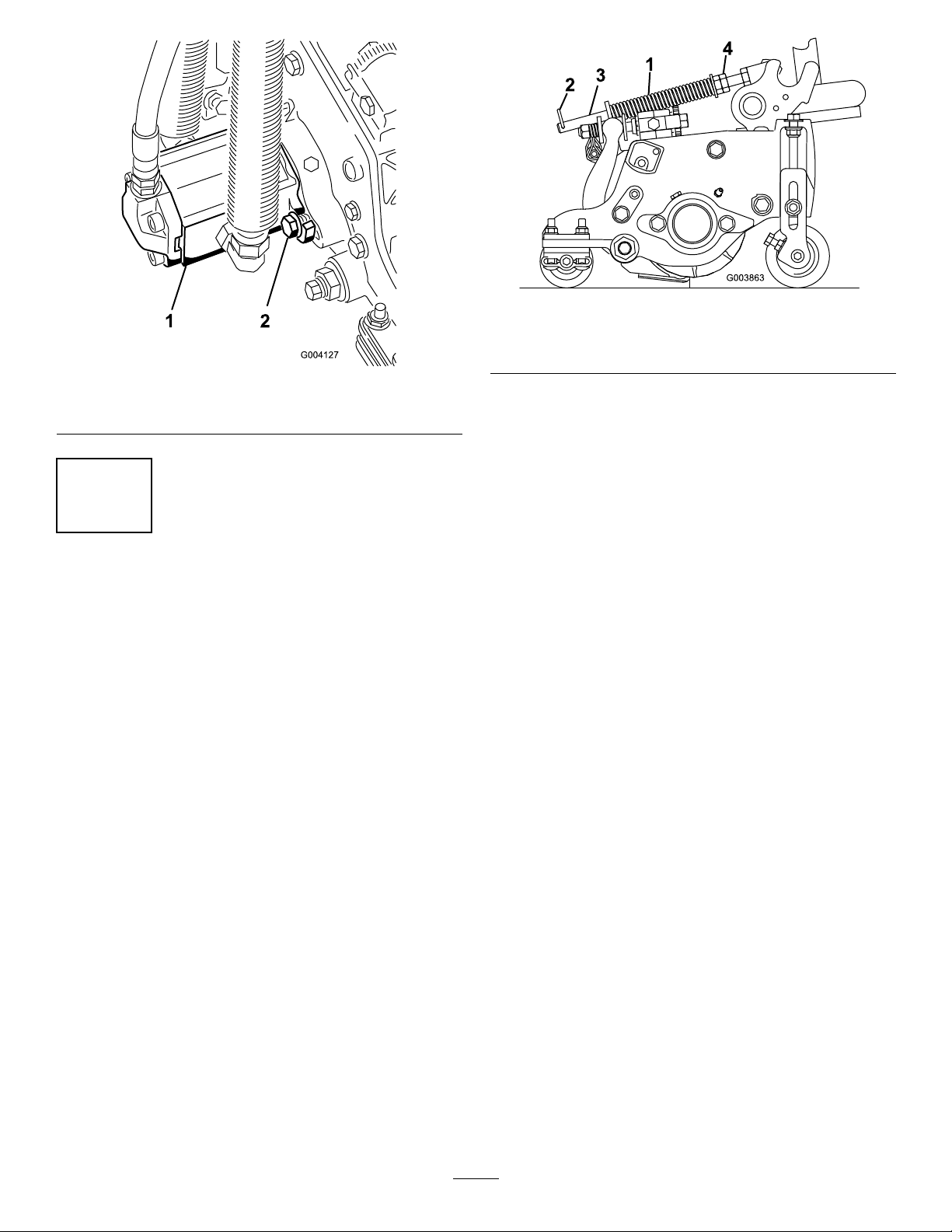

Figure14

1.Weight3.Nut

2.Carriagebolt

Onfourwheeldrivemodels,usethefollowingproceduretomounttheappropriateamountofweight(seeweight

charts)tothetoporbottomoftherearbumperasshowninFigure15.

Figure15

1.Tractionmanifold5.Weight(s)

2.Spacers6.Carriagebolt

3.Bolts7.Nut

4.Washers

•Removethe3bolts,washers,andspacerssecuringthetractionmanifoldtothebottomoftherearbumper

(Figure15a).

•Positiontheappropriateamountofweightonthetopand/orbottomoftherearbumper.

•Mounttheweight(s)andthetractionmanifoldtothebumperwiththe3bolts,washersandspacerspreviously

removed(Figure15b).

Note:Donotusethespacerswheninstallingmorethantwoweightsunderthebumper(Figure15c).

•Securetheouteredgesoftheweight(s)tothebumperwith2carriageboltsandnuts(Figure15c).

20

Page 21

7

InstallingtheCEHoodLatch

Partsneededforthisprocedure:

1Hoodlatchassembly

1Washer

4.Outsidethehood,insertthehookendofthelatch

throughtheholeinthehood.Makesuretherubber

sealingwasherremainstotheoutersideofthehood.

5.Insidethehood,insertthemetalwasherontothe

latchandsecurewiththenut.Makesurethelatch

engagestheframecatchwhenitislocked.Usethe

enclosedhoodlatchkeytooperatethehoodlatch.

8

Procedure

1.Unlatchandraisethehood.

2.Removetherubbergrommetfromtheholeinthe

leftsideofthehood(Figure16).

Figure16

1.Rubbergrommet

UsingtheCuttingUnit

Kickstand

Partsneededforthisprocedure:

1

Cuttingunitkickstand

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwith

thekickstandtomakesurethenutsonthebackendof

thebedbaradjustingscrewsarenotrestingonthework

surface(Figure18).

3.Removethenutfromthehoodlatchassembly

(Figure17).

Figure17

1.Hoodlatch3.Rubberwasher

2.Nut4.Metalwasher

Figure18

1.Cuttingunitkickstand

Securethekickstandtothechainbracketwiththe

snapperpin(Figure19).

21

Page 22

Figure19

1.Chainbracket3.Cuttingunitkickstand

2.Snapperpin

9

UsingtheGaugeBar

Figure20

1.Gaugebar4.Holesusedforsetting

GroomerHOG

2.Heightadjustingscrew5.Holenotused

3.Nut

10

ReadingtheManualand

ViewingtheSafetyVideo

Partsneededforthisprocedure:

1

Gaugebar

Procedure

Usethegaugebartoadjustthecuttingunit.Referto

theCuttingUnitOperator’ sManualfortheadjustment

procedures(Figure20).

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

CEcerticate

1

OperatorTrainingMaterial

Procedure

•ReadtheOperator’ sManual.

•ViewtheOperatorTrainingMaterial.

•Storealldocumentationinasafeplaceforfutureuse.

•Fillouttheregistrationcard.

•UsethediagnosticACEdisplayoverlaywhen

troubleshootingproblemswiththemachine(storeit

intheserviceshopuntilneeded).

22

Page 23

ProductOverview

1.Enginehood

2.Operator’sseat

3.Controlarm

4.Steeringwheel

Controls

SeatAdjustingKnobs

Figure21

5.Seat

6.Frontcuttingunits

7.Rearcuttingunits

speeddependsonhowfaryoupressthepedal.Forno

load,maximumgroundspeed,fullypressthepedalwhile

thethrottleisintheFastposition.

Tostop,reducefootpressureonthetractionpedaland

allowittoreturntothecenterposition.

Figure23

1.Tractionpedal4.Brakepedal

2.Mowspeedlimiter5.Parkingbrake

3.Spacers

6.Tiltsteeringpedal

Theseatadjustinglever(Figure22)allowsyoutoadjust

theseatforeandaft.Theweightadjustingknobadjusts

theseatfortheoperator’ sweight.Theweightgauge

indicateswhentheseatisadjustedtotheweightofthe

operator.Theheightadjustingknobadjuststheseatfor

theoperator’ sheight.

Figure22

1.Weightgauge3.Heightadjustingknob

2.Weightadjustingknob

4.Adjustinglever(foreand

aft)

TractionPedal

Thetractionpedal(Figure23)controlstheforwardand

reverseoperation.Pressthetopofthepedaltomove

forwardandthebottomtomoverearward.Ground

MowSpeedLimiter

Whenthemowspeedlimiter(Figure23)isippedupit

willcontrolthemowspeedandallowthecuttingunits

tobeengaged.Eachspaceradjuststhemowingspeed

by½mileperhour.Themorespacersyouhave,onthe

topoftheboltthesloweryouwillgo.Fortransport,ip

backthemowspeedlimiterandyouwillhavemaximum

transportspeed.

BrakePedal

Pressthebrakepedal(Figure23)tostopthemachine.

ParkingBrake

Toengagetheparkingbrake,(Figure23)pushdownon

thebrakepedalandpressthetopforwardtolatch.T o

releasetheparkingbrake,pressthebrakepedaluntilthe

parkingbrakelatchretracts.

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefoot

pedal(Figure23)down,andpullthesteeringtower

towardyoutothemostcomfortablepositionandthen

releasethepedal.

23

Page 24

ThrottleControl

LowerMow/RaiseControlLever

Movethethrottlecontrol(Figure24)forwardtoincrease

theenginespeedandrearwardtodecreasespeed.

Figure24

1.Throttlecontrol6.Enginecoolant

2.Enable/disableswitch

3.Glowplugindicatorlight8.Chargeindicator

4.Enginecoolant

temperaturewarning

light

5.Diagnosticlight

temperaturegauge

7.Engineoilpressure

warninglight

9.Keyswitch

10.Lowermow/raisecontrol

lever

KeySwitch

Thekeyswitch(Figure24)hasthreepositions:Off,

On/Preheat,andStart.

EngineCoolantTemperatureWarning

Light

Thislever(Figure24)raisesandlowersthecuttingunits

andalsostartsandstopsthereelswhenthereelsare

enabledinthemowmode.

GlowPlugIndicatorLight

Thislight(Figure24)illuminateswhentheglowplugs

arepreheating.

EngineOilPressureWarningLight

Thislight(Figure24)indicatesdangerouslylowengine

oilpressure.

ChargeIndicator

Thechargeindicator(Figure24)illuminateswhenthe

systemchargingcircuitmalfunctions.

Enable/DisableSwitch

Usetheenable/disableswitch(Figure24)inconjunction

withthelowermow/raisecontrollevertooperate

thereels.Thereelscannotbeloweredwhenthe

mow/transportleverisinthetransportposition.

BacklapLevers

Usethebacklapleversinconjunctionwiththelower

mow/raisecontrolleverforbacklappingthereels

(Figure25).

ReelSpeedControls

Thereelspeedcontrolscontrolthespeedofthefront

andrearcuttingunits(Figure25).Thereelspeed

increasesastheknobsareturnedcounterclockwise.

Thislight(Figure24)illuminatesandthereelsshutdown

whentheenginecoolantreachesahightemperature.

Iftheenginetemperaturecontinuestorise,theengine

willshutdown.

EngineCoolantTemperatureGauge

Duringnormaloperatingconditionsthegauge

(Figure24)shouldbeinthegreenrange.Checkthe

coolingsystemifthegaugegoestotheyelloworred

range.

DiagnosticLight

Itwillilluminateshouldasystemfaultberecognized.

Figure25

1.Backlaplevers

2.Reelspeedcontrols

24

Page 25

HourMeter

FuelGauge

Thehourmeter(Figure26)showsthetotalhoursthat

themachinehasbeenoperated.

Figure26

1.Hourmeter

HydraulicFilterRestrictionIndicator

Thefuelgauge(Figure28)showstheamountoffuel

inthetank.

Figure28

1.Fueltankcap

2.Fuelgauge

Withtheenginerunningatnormaloperating

temperature,viewtheindicator(Figure27),itshouldbe

intheGreenzone.WhentheindicatorisintheRed

zone,changethehydrauliclters.

Figure27

1.Hydrauliclterrestrictionindicator

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights

(Figure29).

25

Figure29

1.Headlightswitch

Page 26

PowerPoint

Thepowerpointisa12voltpowersupplyforelectronic

devices(Figure30).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Figure30

1.Powerpoint

SpecicationReelMaster®5210ReelMaster®5410ReelMaster®5510ReelMaster®5610

TransportWidth

Widthofcut100inches(254cm)100inches(254cm)100inches(254cm)100inches(254cm)

Length

Height

Weight

EngineKubota28hpKubota35.5hpKubota35.5hp

Fueltankcapacity

Transportspeed

Mowingspeed

90inches(228cm)90inches(228cm)92inches(233cm)92inches(233cm)

11 1inches(282cm)11 1inches(282cm)11 1inches(282cm)11 1inches(282cm)

62inches(157cm)63inches(160cm)63inches(160cm)63inches(160cm)

2,396lb(1,087kg)2,505lb(1,136kg)2,693lb(1,222kg)2,813lb(1,276kg)

Kubota44.2hp(Turbo)

13.5USgallons(51l)13.5USgallons(51l)13.5USgallons(51l)13.5USgallons(51l)

0–10mph(0–16kph)0–10mph(0–16kph)0–10mph(0–16kph)0–10mph(0–16kph)

0–8mph(0–13kph)0–8mph(0–13kph)0–8mph(0–13kph)0–8mph(0–13kph)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

26

Page 27

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Lowerthecuttingunitstotheground,setthe

parkingbrakeandremovethekeyfromthe

ignitionswitchbeforeservicingormaking

adjustmentstothemachine.

CheckingtheEngineOilLevel

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityformodel5210isapproximately

3.5qt.(3.3l)withthelter.Crankcasecapacityfor

models5410,5510and5610isapproximately5.5qt.

(5.2l)withthelter.

Figure31

1.Dipstick

4.Removedipstickandcheckoillevelondipstick.

TheoillevelshouldbeuptotheFullmark.

5.IftheoillevelisbelowtheFullmark,removethe

llcap(Figure32)andaddoiluntillevelreaches

theFullmarkondipstick.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher

•Preferredoil:SAE15W-40(above0degreesF)

•Alternateoil:SAE10W-30or5W -30(all

temperatures)

ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W -30viscosity .

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrakeandremovethekeyfromthe

ignitionswitch.

2.Openthehood.

3.Removethedipstick,wipeitclean,andinstallit

(Figure31).

Figure32

1.Oilllcap

Donotoverll.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

27

Page 28

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

2.Ifthecoolantlevelislow ,removetheexpansion

tankcapandreplenishthesystem.Donotoverll.

6.Installtheoilllcapandclosethehood.

CheckingtheCoolingSystem

Cleandebrisoffofthescreen,oilcooler,andfront

oftheradiatordailyandmoreoftenifconditionsare

extremelydustyanddirty.Refertothesectionon

RemovingDebrisfromtheCoolingSystemin,page.

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolantifreeze.

Checkthelevelofcoolantintheexpansiontankatthe

beginningofeachdaybeforestartingtheengine.The

capacityofthecoolingsystemforthemodel5210is5.5

quarts(5.2l).Thecapacityformodel5410is7.0quarts

(6.6l)andmodels55105610is10.0quarts(9.5l).

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

1.Checkthelevelofcoolantintheexpansiontank

(Figure33).

3.Installtheexpansiontankcap.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:13.5gallons(51l)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

Thecoolantlevelshouldbebetweenthemarkson

thesideofthetank.

Figure33

1.Expansiontank

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

28

Page 29

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure34).

Figure34

1.Fueltankcap2.Fuelgauge

29

Page 30

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.

Thiswillminimizepossiblebuildupofcondensation

insidethefueltank.

bymineral-basedhydraulicuidswillchangethe

biodegradabilityandtoxicityofthisoil.Whenchanging

fromstandarduidtothebiodegradabletype,be

certaintofollowtheapprovedushingprocedure.

ContactyourlocalToroDistributorfordetails.

1.Positionmachineonalevelsurface,lowerthe

cuttingunitsandstoptheengine.

CheckingtheHydraulicFluid

Themachinesreservoirislledatthefactorywith

approximately8U .S.gallons(30l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

productNote:T orowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

2.Ontherightsideofthemachine,raisethehydraulic

tankcover(Figure35).

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein2/3oz.(20

ml)bottles.Onebottleissufcientfor4-6gal(15-22

1)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

BiodegradableHydraulicFluid-Mobil224H

ToroBiodegradableHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorToro

distributorforpartnumbers.)

Alternateuid:MobilEAL224H

Note:Thisisvegetable-oilbasedbiodegradable

oiltestedandapprovedbyT oroforthismodel.

Thisuidisnotasresistanttohightemperaturesas

standarduid,sobesuretofollowtherecommended

uidchangeintervalswiththisuid.Contamination

Figure35

1.Hydraulictankcover

3.Cleanareaaroundllerneckandcapofhydraulic

tank(Figure36).Removecapfromllerneck.

30

Page 31

Figure36

1.Hydraulictankcap

4.Removedipstickfromllerneckandwipeitwith

acleanrag.Insertdipstickintollerneck;then

removeitandchecklevelofuid.Fluidlevelshould

be1/4inchofmarkondipstick.Donotoverll.

5.Iflevelislow,addappropriateuidtoraiselevel

tofullmark.

6.Installdipstickandcapontollerneck.

CheckingtheReeltoBedknife

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components;i.e.,lterreplaced,separatorserviced,

etc.

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2in.(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

Contact

Eachdaybeforeoperating,checkreeltobedknife

contact,regardlessifthequalityofcuthadpreviously

beenacceptable.Theremustbelightcontactacross

thefulllengthofthereelandthebedknife(referto

AdjustingtheReeltoBedknifeinthecuttingunit

Operator’sManual).

ChecktheTorqueoftheWheel

Nuts

Torquethewheelnutsto70to90ft-lb(94to122

N⋅m).after1-4hoursofoperationandagainafter10

hoursofoperation.Torqueevery250hoursthereafter.

Failuretomaintainpropertorqueofthewheel

nutscouldresultinpersonalinjury.

1.Parkthemachineonalevelsurfaceandensurethat

thefueltankisatleasthalffull.

2.Openthehood.

3.Opentheairbleedscrewonthefuelinjectionpump

(Figure37)witha12mmwrench.

Figure37

1.Bleedscrew

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingthe

engineifanyofthefollowingsituationshaveoccurred:

4.TurnthekeyintheignitionswitchtotheOn

position.Theelectricfuelpumpwillbegin

operation,therebyforcingairoutaroundtheair

31

Page 32

bleedscrew .LeavethekeyintheOnpositionuntil

asolidstreamoffuelowsoutaroundthescrew .

5.TightenthescrewandturnthekeytotheOff

position.

Note:Normally,theengineshouldstartafterthe

abovebleedingproceduresarefollowed.However,

ifenginedoesnotstart,airmaybetrappedbetween

injectionpumpandinjectors;refertoBleedingAir

fromtheInjectorsin,page.

SettingtheReelSpeed

Toachieveaconsistent,highquality-of-cutanda

uniformaftercutappearance,itisimportantthatyou

setthereelspeedcontrols(locatedundertheseat)

correctly.Adjustthereelspeedcontrolsasfollows:

1.Selecttheheight-of-cutatwhichthecuttingunits

areset.

2.Choosethedesiredgroundspeedbestsuitedfor

conditions.

StartingandStoppingthe

Engine

Important:Youmustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengine

forthersttime,theenginehasstoppeddueto

lackoffuel,oryouhaveperformedmaintenanceon

thefuelsystem;refertoBleedingtheFuelSystem.

StartingtheEngine

1.Sitontheseat,keepyourfootoffofthetraction

pedalsothatitisinNeutral,engagetheparking

brake,setthethrottletotheFastposition,and

ensurethattheEnable/Disableswitchisinthe

Disableposition.

2.TurntheignitionswitchtotheOn/Preheatposition.

Anautomatictimerwillcontroltheglowplug

preheatfor6seconds.

3.Afterpreheatingtheglowplugs,turnkeytothe

Startposition.

3.Usingtheappropriategraphondecal110–0996

(Figure39)forReelmaster5510&5610,7inch

reelcuttingunitsordecal110–8923(Figure40)for

Reelmaster5210&5410,5inchreelcuttingunits

determinetheproperreelspeedsetting.

Tosetthereelspeed,rotateknobs(Figure38)until

theindicatorarrowsareinlinewiththenumber

designatingthedesiredsetting.

Figure38

1.Reelspeedcontrolknobs

Cranktheenginefornolongerthan15seconds.

Releasethekeywhentheenginestarts.Ifadditional

preheatingisrequired,turnkeytotheOffposition

andthentotheOn/Preheatposition.Repeatthis

processasrequired.

4.Runtheengineatlowidlespeeduntilitwarmsup.

StoppingtheEngine

1.MoveallcontrolstoNeutral,settheparkingbrake,

movethethrottletothelowidlepositionandallow

theenginetoreachlowidlespeed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafullload

operation.Failuretodosomayleadtotrouble

onaturbo-chargedengine.

2.TurnthekeytotheOffpositionandremoveit

fromtheswitch.

Note:Thereelspeedcanbeincreasedordecreased

tocompensateforturfconditions.

32

Page 33

1.Frontreelscircuitcontrols3.Reel—mowandbacklap

2.Rearreelscircuitcontrols

1.Frontreelscircuitcontrols3.Reel—mowandbacklap

2.Rearreelscircuitcontrols

4.ReadtheOperator’sManual.

4.ReadtheOperator’sManual.

Figure39

5.Reel—heightofcut

6.Machinespeed

Figure40

5.Reel—heightofcut

6.Machinespeed

AdjustingtheLiftArm

Counterbalance

Youcanadjustthecounterbalanceontherear

cuttingunitliftarmstocompensatefordifferentturf

conditionsandtomaintainauniformheight-of-cutin

theroughconditionsorinareasofthatchbuildup.

Youcanadjusteachcounterbalancespringtooneof

foursettings.Eachincrementincreasesordecreases

counterbalanceonthecuttingunitby5lb(2.3kg).The

springscanbepositionedonthebacksideofthespring

actuatortoremoveallcounterbalance(forthposition).

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

2.Insertatubeorsimilarobjectontothelong

springendtorelievethespringtensionduringthe

adjustment(Figure41).

33

Page 34

Thespringsareundertension.

Usecautionwhenadjustingthem.

3.Whilerelievingthespringtension,removethebolt

andlocknutsecuringthespringactuatortothe

bracket(Figure41).

Figure41

1.Spring

2.Springactuator

4.Movethespringactuatortothedesiredhole

locationandsecurewithlocknut.

5.Repeattheprocedureontheremainingspring.

3.Holelocations

Figure42

1.Switch2.Liftarmsensingdevice

PushingorTowingthe

Machine

Inanemergency,themachinecanbemovedby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

Important:Donotpushortowthemachine

fasterthan2-3mph(3-4.8km/h)becauseinternal

transmissiondamagemayoccur.Thebypassvalve

mustbeopenwheneverthemachineispushedor

towed.

1.Thebypassvalveislocatedontheleftsideofthe

hydrostat(Figure43).Rotatethebolt1–1/2turns

toopenandallowoiltobypassinternally.Because

uidisbypassed,themachinecanbemovedslowly

withoutdamagingthetransmission.

AdjustingtheLiftArmTurn

AroundPosition

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

2.Theliftarmswitchislocatedunderneaththe

hydraulictankbehindthefrontrightliftarm

(Figure42).

3.Loosentheswitchmountingscrews(Figure42)and

movetheswitchdowntoincreasetheliftarmturn

aroundheightormovetheswitchuptodecreasethe

liftarmturnaroundheight.Tightenthemounting

screws.

Figure43

1.Bypassvalve

2.Closethebypassvalvebeforestartingtheengine.

However,donotexceed5-8ft.-lb.(7-11N·m)

torquetoclosethevalve.

34

Page 35

Important:Runningtheenginewiththe

bypassvalveopenwillcausethetransmission

tooverheat.

JackingPoints

Note:Usejackstandstosupportthemachinewhen

required.

•Front—rectangularpad,undertheaxletube,inside

eachfronttire(Figure44).

Figure45

1.Fronttiedown

•Rear—eachsideofthemachineontherearframe

(Figure46).

Figure44

1.Frontjackingpoint

•Rear—rectangularaxletubeontherearaxle.

TieDowns

•Front—theholeintherectangularpad,underthe

axletube,insideeachfronttire(Figure45).

Figure46

1.Reartiedown

UnderstandingtheDiagnostic

Light

Themachineisequippedwithadiagnosticlightwhich

indicatesiftheelectroniccontrollersensesanelectronic

malfunction.Thediagnosticlightislocatedonthe

controlarm(Figure47).Whentheelectroniccontroller

isfunctioningcorrectlyandthekeyswitchismovedto

theOnposition,thecontrollerdiagnosticlightwillturn

ONfor3secondsandturnOFFtoindicatethelight

isworkingproperly .Ifthemachinekillsthelightwill

35

Page 36

turnonsteadyuntilthekeypositionischanged.The

lightwillblinkifthecontrollerdetectsamalfunctionin

theelectricalsystem.Thelightwillstopblinkingand

automaticallyresetwhenthekeyswitchisturnedtothe

Offpositiononcethefaulthasbeenresolved.

Figure47

1.Diagnosticlight

Whenthecontrollerdiagnosticlightblinks,oneofthe

followingproblemshasbeendetectedbythecontroller:

DiagnosticAceDisplay

Themachineisequippedwithanelectroniccontroller

whichcontrolsmostmachinefunctions.Thecontroller

determineswhatfunctionisrequiredforvariousinput

switches(i.e.seatswitch,keyswitch,etc.)andturns

ontheoutputstoactuatesolenoidsorrelaysforthe

requestedmachinefunction.

Fortheelectroniccontrollertocontrolthemachineas

desired,eachoftheinputswitches,outputsolenoids,

andrelaysmustbeconnectedandfunctioningproperly.

UsetheDiagnosticACEdisplaytohelpverifyand

correctelectricalfunctionsofthemachine.

CheckingtheInterlock

Switches

Thepurposeoftheinterlockswitchesistopreventthe

enginefromcrankingorstartingunlessthetraction

pedalisintheNeutralposition,theEnable/Disable

switchisintheDisableposition,andtheLower

Mow/RaisecontrolisintheNeutralposition.In

addition,theengineshouldstopwhenthetraction

pedalispressedwithoperatoroffoftheseatorifthe

parkingbrakeisleftengaged.

•Oneoftheoutputshasbeenshorted.

•Oneoftheoutputsisopencircuited.

Usingthediagnosticdisplay ,determinewhichoutput

ismalfunctioning;refertoCheckingtheInterlock

Switches.

Ifthediagnosticlightisnotilluminatedwhenthekey

switchisintheOnposition,thisindicatesthatthe

electroniccontrollerisnotoperating.Possiblecauses

areasfollows:

•Loop-backisnotconnected.

•Thelightisburnedout.

•Fusesareblown.

•Itisnotfunctioningcorrectly.

Checktheelectricalconnections,inputfuses,and

diagnosticlightbulbtodeterminethemalfunction.

Ensurethattheloop-backconnectorissecuredtothe

wireharnessconnector.

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

VerifyingtheInterlockSwitchFunction

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andengagethe

parkingbrake.

2.Removetheaccesspanelfromthesideofthe

controlarm.

3.Locatethewireharnessandconnectorsnearthe

controller(Figure48).

36

Page 37

8.Individually,changeeachoftheswitchesfrom

opentoclosed(i.e.,sitonseat,engagetraction

pedal,etc.),andnotethattheappropriateLED

onDiagnosticACEwillblinkonandoffwhen

correspondingswitchisclosed.Repeatthisforall

switchesthatyoucanchangebyhand.

9.IfaswitchisclosedandtheappropriateLEDdoes

notturnon,checkallwiringandconnectionsto

theswitchand/orchecktheswitcheswithanohm

meter.Replaceanydefectiveswitchesandrepair

anydefectivewiring.

Figure48

1.Wireharnessandconnectors

4.Carefullyunplugloopbackconnectorfromharness

connector.

5.ConnecttheDiagnosticACEdisplayconnectorto

theharnessconnector(Figure49).

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACEdisplay.

Note:TheDiagnosticACEalsohastheabilityto

detectwhichoutputsolenoidsorrelaysareturned

on.Thisisaquickwaytodetermineifamachine

malfunctioniselectricalorhydraulic.

VerifyingOutputFunction

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andengagethe

parkingbrake.

2.Removetheaccesspanelfromthesideofthe

controlarm.

3.Locatewireharnessandconnectorsnearcontroller.

4.Carefullyunplugloopbackconnectorfromharness

connector.

5.ConnecttheDiagnosticACEconnectortothe

harnessconnector.

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACE.

6.TurnthekeyswitchtotheONposition,butdonot

startmachine.

Figure49

1.DiagnosticACE

6.TurnthekeyswitchtotheOnposition,butdonot

startthemachine.

Note:Theredtextontheoverlaydecalrefersto

inputswitchesandthegreentextreferstooutputs.

7.The“inputsdisplayed”LED ,onthelower

rightcolumnoftheDiagnosticACE,shouldbe

illuminated.Ifthe“outputsdisplayed”LEDis

illuminated,pressthetogglebutton,onDiagnostic

ACE,tochangeLEDto“inputsdisplayed”.

TheDiagnosticACEwillilluminatetheLED

associatedwitheachoftheinputswhenthatinput

switchisclosed.

Note:Theredtextontheoverlaydecalrefersto

inputswitchesandthegreentextreferstooutputs.

7.The“outputsdisplayed”LED,onlowerright

columnofDiagnosticACE,shouldbeilluminated.

Ifthe“inputsdisplayed”LEDisilluminated,press

thetogglebutton,ontheDiagnosticACE,to

changetheLEDto“outputsdisplayed”.

Note:Itmaybenecessarytotogglebetween

“inputsdisplayed”and“outputsdisplayed”several

timestodothefollowingstep.T otogglebackand

forth,pressthetogglebuttononce.Thismaybe

doneasoftenasrequired.Donotholdthebutton.

8.Sitontheseatandattempttooperatethedesired

functionofthemachine.Theappropriateoutput

LEDsshouldilluminatetoindicatethattheECMis

turningonthatfunction.

37

Page 38

Note:IfthecorrectoutputLEDsdonotilluminate,

verifythattherequiredinputswitchesareinthe

necessarypositionstoallowthatfunctiontooccur.

Verifycorrectswitchfunction.

IftheoutputLEDsareonasspecied,butthe

machinedoesnotfunctionproperly,thisindicatesa

non-electricalproblem.Repairasnecessary.

Note:Ifeachoutputswitchisinthecorrectposition

andfunctioningcorrectly,buttheoutputLEDsarenot

correctlyilluminated,thisindicatesanECMproblem.

Ifthisoccurs,contactyourT oroDistributorfor

assistance.

Important:TheDiagnosticACEdisplaymust

notbeleftconnectedtothemachine.Itisnot

designedtowithstandtheenvironmentofthe

machine’severydayuse.Whendoneusingthe

DiagnosticACE,disconnectitfromthemachine

andconnectloop-backconnectortoharness

connector.Themachinewillnotoperatewithout

loopbackconnectorinstalledontheharness.Store

theDiagnosticACEindry,securelocationinthe

shop,notonthemachine.

HydraulicValveSolenoid

Functions

Usethelistbelowtoidentifyanddescribethedifferent

functionsofthesolenoidsinthehydraulicmanifold.

Eachsolenoidmustbeenergizedtoallowfunctionto

occur.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

youoperatethemachinewithamalfunction.

Mowing

StarttheengineandmovethethrottletotheFast

position.MovetheEnable/Disableswitchtothe

EnablepositionandusetheLowerMow/Raiselever

tocontrolthecuttingunits(thefrontcuttingunitsare

timedtolowerbeforetherearcuttingunits).Tomove

forwardandcutgrass,pressthetractionpedalforward.

Note:Allowtheenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Failuretodo

somayleadtoturbo-chargertrouble.

Transport

MovetheEnable/DisableswitchtotheDisable

positionandraisethecuttingunitstothetransport

position.MovetheMow/Transportlevertothe

transportposition.Becarefulwhendrivingbetween

objectssoyoudonotaccidentallydamagethemachine

orcuttingunits.Useextracarewhenoperatingthe

machineonslopes.Driveslowlyandavoidsharpturns

onslopestopreventrollovers.Lowerthecuttingunits

whengoingdownhillforsteeringcontrol.

Solenoid

MSV2

MSV1

SVRVLift/lowercuttingunits

SV1Lift/lowerfrontcuttingunit

SV3Lift/lowerrearcuttingunit

SV2

Frontreelcircuit

Rearreelcircuit

Raiseanycuttingunits

Function

OperatingTips

Familiarization

Beforemowinggrass,practiceoperatingthemachine

inanopenarea.Startandstoptheengine.Operatein

forwardandreverse.Lowerandraisethecuttingunits

andengageanddisengagethereels.Whenyoufeel

familiarwiththemachine,practiceoperatingupand

downslopesatdifferentspeeds.

38

Page 39

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•T orquethewheellugnutsto70to90ft-lb(94to122N⋅m).

•Checktheconditionandtensionofthealternatorbelt.

•T orquethewheellugnutsto70to90ft-lb(94to122N⋅m).

•Checkandadjustthebrakecablestoequalizetheengagement.

•Changetheengineoilandlter.

•ChecktheengineRPM(idleandfullthrottle).

•Checktheengineoillevel.

•Checkthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthereeltobedknifecontact.

•Checktheoperationoftheinterlockswitches.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.(Greasethemimmediatelyaftereverywashing

regardlessoftheintervallisted.)

•Checktheconditionofandcleanthebattery.

•Checkthebatterycableconnections.

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

Every150hours

Every200hours

Every250hours

Every400hours

Every800hours

Beforestorage

Every2years

•Changetheengineoilandlter.

•Drainmoisturefromthefuelandhydraulicuidtanks.

•Checkthereelbearingpreload.

•T orquethewheellugnutsto70to90ft-lb(94to122N⋅m).

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanister.

•ChecktheengineRPM(idleandfullthrottle).

•Drainandcleanthefueltank

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters(sooneriftheserviceintervalindicatorisintheRed

zone).

•Packtherearwheelbearings

•Adjusttheenginevalves(refertotheengineOperator’sManual)

•Drainandcleanthefueltank

•Flushandreplacethecoolingsystemuid.

•Drainandushthehydraulictank.

•Replaceallmovinghoses.

39

Page 40

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Drainthewater/fuelseparator.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkthehydrauliclterindicator.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrumentoperation.

Checkthereel-to-bedknifeadjustment.

Checktheheight-of-cutadjustment.

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

3

Sat.Sun.

2.Checkwiththeenginerunningandtheoilatoperatingtemperature

3.Immediatelyaftereverywashing,regardlessoftheintervallisted