Toro Power Clear 418 38272, Power Clear 418 38282, Power Clear 418 ZR, Power Clear 418 ZE Operator's Manual

Page 1

FormNo.3369-487RevB

PowerClear418ZR/ZESnowthrower

ModelNo.38272—SerialNo.312000001andUp

ModelNo.38282—SerialNo.312000001andUp

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdriveways

andsidewalks,andothersurfacesfortrafcon

residentialorcommercialproperties.Itisnot

designedforremovingmaterialsotherthansnow,

norisitdesignedforclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

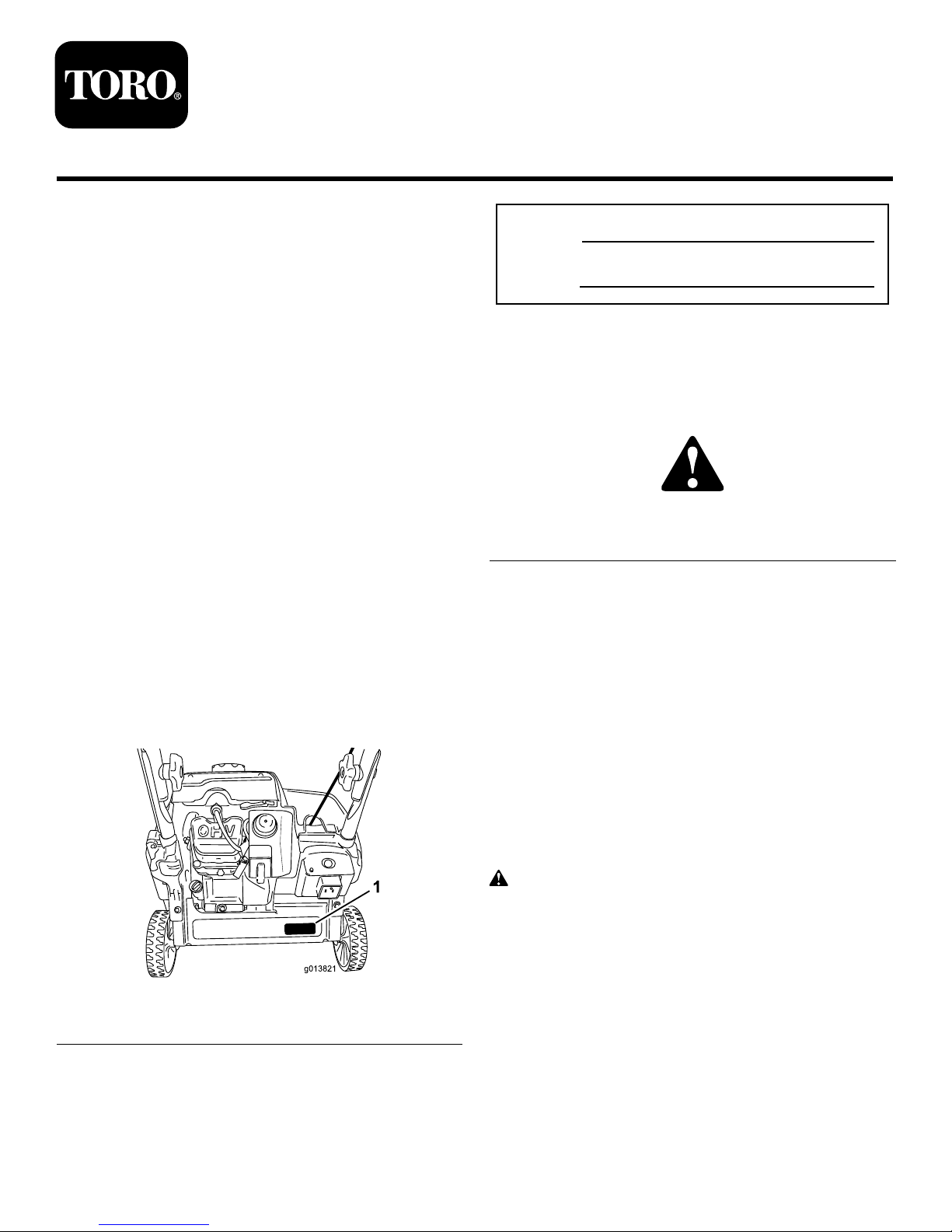

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Safety

ThismachinemeetsorexceedstheB71.3

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Readandunderstandthecontentsofthismanual

beforeyoustarttheengine.

Thisisthesafetyalertsymbol.Itisusedtoalert

youtopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoid

possibleinjuryordeath.

Improperlyusingormaintainingthismachine

couldresultininjuryordeath.Toreducethis

potential,complywiththefollowingsafety

instructions.

Thismachineiscapableofinjuringhandsandfeet

andofthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injury.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

Training

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrols

andtheproperuseofthemachine.Knowhowto

stopthemachineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperatethemachinewithoutproper

instruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren.

•Exercisecautiontoavoidslippingorfalling.

Preparation

•Thoroughlyinspecttheareawherethemachineis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Donotoperatethemachinewithoutwearing

adequatewintergarments.Avoidloosetting

clothingthatcangetcaughtinmovingparts.Wear

footwearthatwillimprovefootingonslippery

surfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

llfueltankindoors.

–Neverllcontainersinsideavehicleorona

truckortrailerbedwithaplasticliner.Always

placecontainersontheground,awayfromyour

vehicle,beforelling.

–Whenpractical,removegas-poweredmachinery

fromthetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuelsuch

machineryonatrailerwithaportablecontainer,

ratherthanfromagasolinedispensernozzle.

–Keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimes,until

refuelingiscomplete.Donotuseanozzle

lock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilled

fuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Useextensioncordsandreceptaclesasspecied

bythemanufacturerforallmachineswithelectric

startingmotors.

•Donotattempttoclearsnowfromagravelor

crushedrocksurface.Thisproductisintendedfor

useonlyonpavedsurfaces.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwhenspecically

recommendedbymanufacturer).

•Alwayswearsafetyglassesoreyeshieldsduring

operationorwhileperforminganadjustmentor

repairtoprotecteyesfromforeignobjectsthatmay

bethrownfromthemachine.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removetheignitionkey,thoroughlyinspectthe

machineforanydamage,andrepairthedamage

beforerestartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtherotorbladehousing

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairing,orinspectingthemachine,

stoptheengineandmakecertainthattherotor

bladesandallmovingpartshavestopped.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards

andothersafetyprotectivedevicesinplaceand

working.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.Keepchildren

andothersaway.

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

•Lookbehindandusecarewhenbackingupwiththe

machine.

2

Page 3

•Disengagepowertotherotorbladeswhenmachine

istransportedornotinuse.

•Neveroperatethemachinewithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

rmholdonthehandles.Walk;neverrun.

•Nevertouchahotengineormufer.

ClearingaCloggedDischarge

Chute

Handcontactwiththerotatingrotorbladesinsidethe

dischargechuteisthemostcommoncauseofinjury

associatedwithsnowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltank

insideabuildingwhereignitionsourcesarepresent,

suchashotwaterheaters,spaceheaters,orclothes

dryers.Allowtheenginetocoolbeforestoringin

anyenclosure.

•AlwaysrefertotheOperator’sManualforimportant

detailsifthemachineistobestoredforanextended

period.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnow

topreventfreeze-upoftherotorblades.

ToroSnowthrowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknow.

•Rotatingrotorbladescaninjurengersor

hands.Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Beforeadjusting,cleaning,repairing,andinspecting

themachine,andbeforeuncloggingthedischarge

chute,stoptheengine,removethekey,andwait

forallmovingpartstostop.

•Beforeleavingtheoperatingposition,stopthe

engine,removetheignitionkey,andwaitforall

movingpartstostop.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,orlost,repairorreplaceitbeforebeginning

operation.Also,tightenanyloosefasteners.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoon

afterithasstoppedbecausetheenginemaybehot

enoughtocauseaburn.

•Performonlythosemaintenanceinstructions

describedinthismanual.Beforeperformingany

maintenance,service,oradjustment,stoptheengine

andremovethekey.Ifmajorrepairsareeverneeded,

contactanAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,

drainthefuelfromthefueltanktopreventa

potentialhazard.Storefuelinanapprovedfuel

container.Removethekeyfromtheignitionswitch

beforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

3

Page 4

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

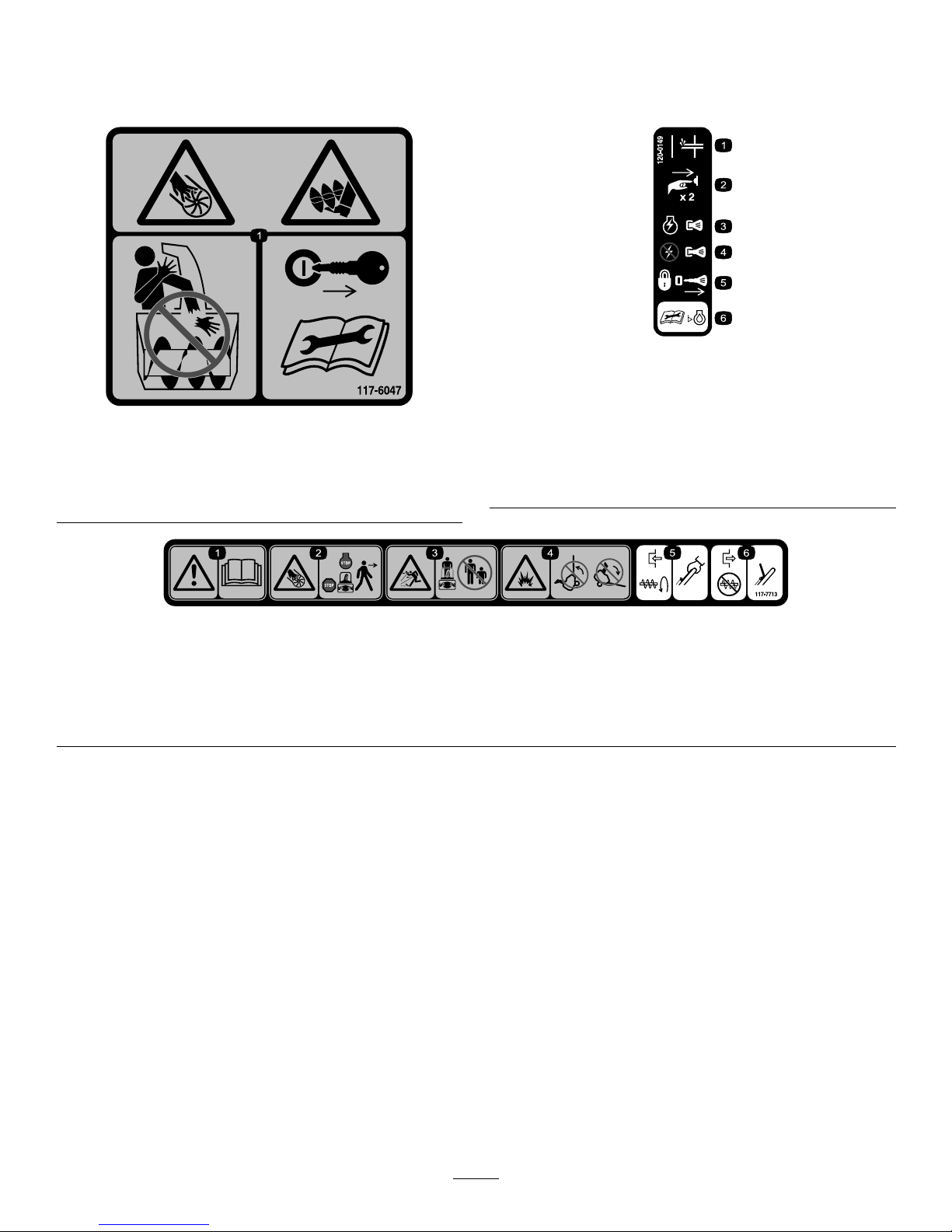

117-6047

1.Cuttingdismemberment,impellerandcutting

dismemberment,augerhazards—donotplaceyourhandin

thechute;removetheignitionkeyandreadtheinstructions

beforeservicingorperformingmaintenance.

120-0149

1.Primer4.Pullkeytoswitchengine

switchOff.

2.Pushtheprimertwotimes

toprimetheengine.

5.Removekeytolock

machine.

3.Pushkeyintoswitch

engineOn.

6.ReadtheOperator’s

Manualbeforechecking

engineoillevel.

117-7713

1.Warning—readtheOperator'sManual.4.Fuelspillhazard—donottipmachineforwardorbackward.

2.Cutting/dismembermenthazard,impeller—stoptheengine

beforeleavingthemachine.

5.Toengagetheauger,squeezethecontrolbar.

3.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

6.Releasethecontrolbartodisengagetheauger.

4

Page 5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

Oval-headbolts

2

Curvedwashers

2

1

Handleknobs2

Installthehandle.

2

Nopartsrequired

–

Installtherecoilstarterhandle.

Dischargechuteassembly1

Screws

2

Washers2

Locknuts2

3

Knob1

Installthedischargechuteassembly.

4

Bottleofengineoil

1Filltheenginewithoil.

5

Nopartsrequired

–

Adjustthecontrolcable.

1

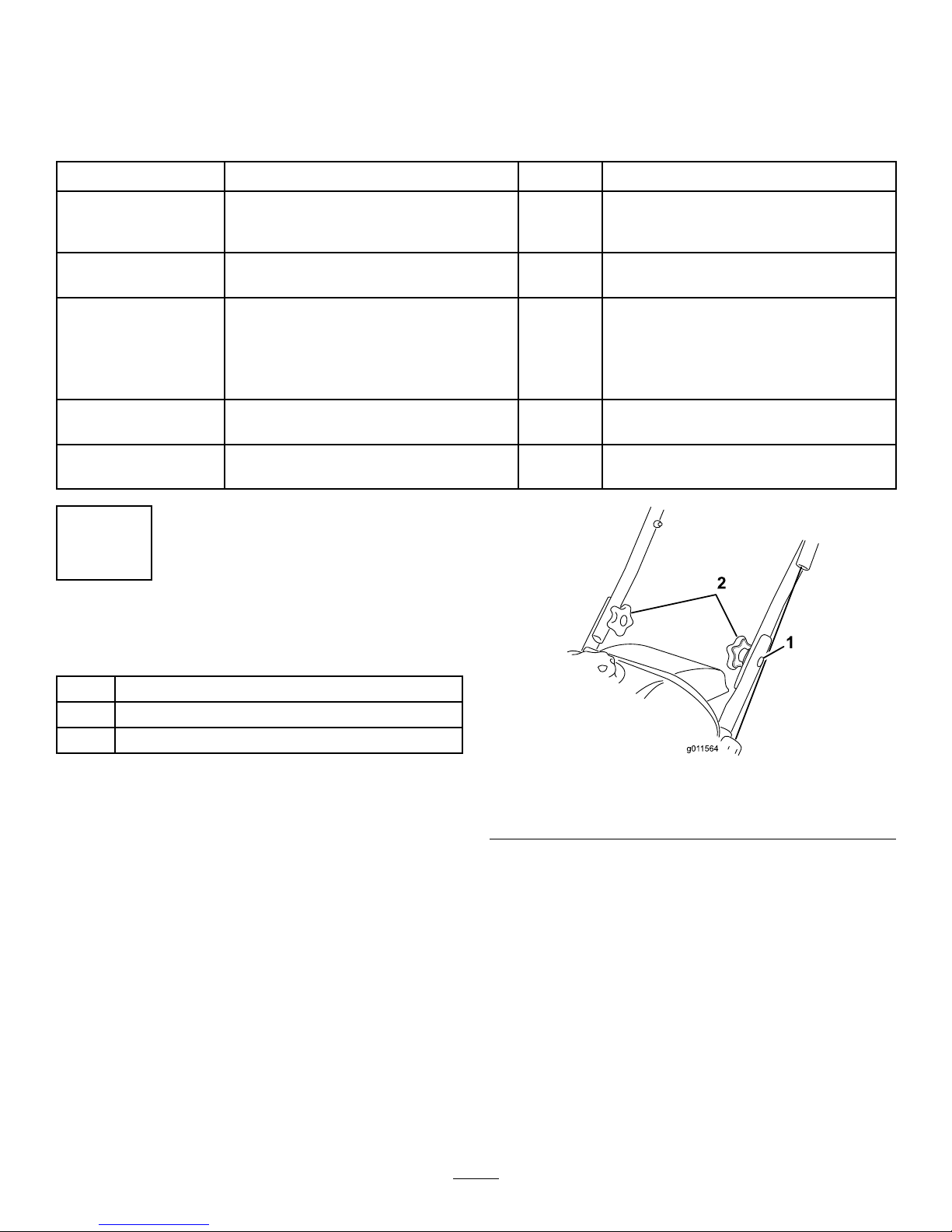

InstallingtheHandle

Partsneededforthisprocedure:

2

Oval-headbolts

2

Curvedwashers

2Handleknobs

Procedure

1.Positiontheendsoftheupperhandleontheinside

ofthelowerhandleandaligntheholes.

2.Inserttheoval-headboltsintothealignedholes,with

theboltheadsontheoutsideofthehandle(

Figure3).

Figure3

1.Oval-headbolt(2)2.Curvedwashersand

handleknobs

3.Installthecurvedwashersandthehandleknobs

ontheoval-headboltsontheinsideofthehandle

(

Figure3)andtightentheknobssecurely.

Important:Ensurethatthecableisroutedto

theoutsideofthehandle.

5

Page 6

2

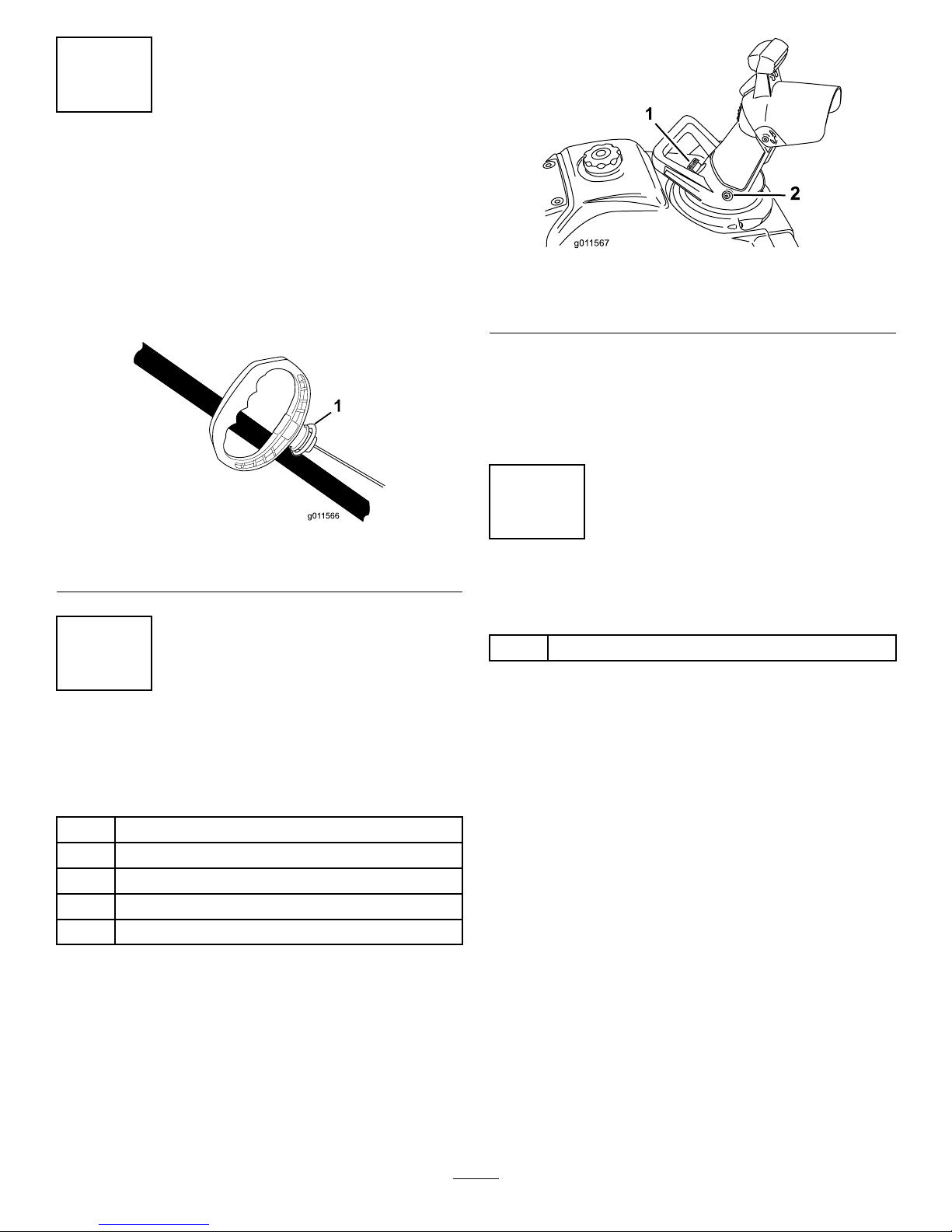

InstallingtheRecoilStarter

Handle

NoPartsRequired

Procedure

Installtherecoilstarterhandleintheropeguideas

showninFigure4.

Figure4

1.Ropeguide

3

InstallingtheDischargeChute

Assembly

Partsneededforthisprocedure:

1Dischargechuteassembly

2

Screws

2Washers

2Locknuts

1Knob

Procedure

InstallthedischargechuteassemblyasshowninFigure5.

Figure5

1.Knob

2.Bolt(2),washer(2),and

locknut(2)

Note:Installtheboltsfromtheinsideofdischarge

chuteassemblysothatthewashersandlocknutsareon

theoutsideofthechute.

Important:Donotovertightenthelocknuts.

4

FillingtheEnginewithOil

Partsneededforthisprocedure:

1

Bottleofengineoil

Procedure

Yourmachinedoesnotcomewithoilintheengine,but

itdoescomewithabottleofoil.

Important:Beforestartingtheengine,llthe

enginewithoil.

Maxll:12oz.(0.35l),type:automotivedetergentoil

withanAPIserviceclassicationofSJ,SL,orhigher.

Use

Figure6toselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

6

Page 7

Figure6

1.Movethemachinetoalevelsurface.

2.Cleanaroundtheoilllcap(Figure11).

3.Unscrewtheoilllcapandremoveit.

4.Slowlypouroilintotheoilllhole.W ait3minutes,

thenchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewing

in,theoilllcapintothehole.

Note:Todeterminetheproperoillevelonthe

dipstick,referto

Figure7.

Figure7

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshowninFigure7.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChanging

theEngineOil.

Note:Youmaytipthemachineforward(handle

up)alittletomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingpositionbefore

checkingtheoillevel.

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutof

themachine.

5.Screwtheoilllcapintotheoilllholeandhand

tightenitsecurely.

5

AdjustingtheControlCable

NoPartsRequired

CheckingtheControlCable

ServiceInterval:Afterthersthour—Check

thecontrolcableandadjustitif

necessary.

Yearly—Checkthecontrolcableand

adjustitifnecessary.

Important:Youmustcheckandmayneedto

adjustthecontrolcablebeforeyouoperatethe

machineforthersttime.

Movethecontrolbarbacktowardthehandletoremove

theslackinthecontrolcable(

Figure8).

Figure8

1.Controlbar2.1/16to1/8inch(2to3

mm)

7

Page 8

Note:Ensurethatagapof1/16to1/8inch(2to

3mm)existsbetweenthecontrolbarandthehandle

(Figure8).

Important:Thecontrolcablemustcontainsome

slackwhenyoudisengagethecontrolbarforthe

rotorbladestostopproperly.

AdjustingtheControlCable

1.Slideupthespringcoverandunhookthespring

fromtheadjusterlink(

Figure9).

Figure9

1.Adjusterlink

3.Springcover

2.Z-tting

4.Unhookthespringhere.

Note:Youcanpulluptheadjusterlinkandcableto

makeunhookingthespringeasier.

2.MovetheZ-ttingtoahigherorlowerholeonthe

adjusterlinkasneededtoobtainthe1/16-inchto

1/8-inch(2mmto3mm)gapbetweenthecontrol

barandthehandle(

Figure9).

Note:MovingtheZ-ttinghigherdecreasesthe

gapbetweenthecontrolbarandthehandle;moving

itlowerincreasesthegap.

3.Hookthespringtotheadjusterlinkandslidethe

springcoverovertheadjusterlink.

4.Checktheadjustment;refertoCheckingtheControl

Cable.

Note:Thebeltmayslip(squeal)inwetconditions;

todryoutthedrivesystem,starttherotorandrun

itwithoutaloadfor30seconds.

ProductOverview

Figure10

1.Controlbar6.Chutedeectortrigger

2.Recoilstarthandle

7.Chutedeector

3.Springcover

8.Dischargechute

4.Fueltankcap9.Rotorblades

5.Chutehandle

Figure11

1.Sparkplug

5.Primer

2.Oilllcap

6.Ignitionkey

3.Oildrainplug

7.Electric-startbutton

(model38282only)

4.Chokelever8.Plug-inforelectricstart

(model38282only)

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

•Donottipthemachineeitherforwardor

backwardwithfuelinthefueltank;otherwise,

fuelmayleakoutofthemachine.

FillingtheFuelTank

Fillthefueltankwithfreshunleadedgasolinehavingan

octaneratingatornear87fromamajorname-brand

servicestation(Figure12).

Figure12

1.1/2inch(13mm)

Important:Donotaddoiltothegasoline.

Important:DonotuseE85orE20fuel.Alternative

fuelswithhighalcoholcontentcancausehard

starting,poorengineperformance,andmaycause

internalenginedamage.

Note:Forbestresults,purchaseonlythequantityof

gasolinethatyouexpecttousein30days.Otherwise,

youmayaddfuelstabilizertonewlypurchasedgasoline

tokeepitfreshforupto6months.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengineoillevelandaddoilif

necessary.

1.Ensurethatthefueltankisnotoverlled(referto

Figure12)andthatthefuelcapissecurelyinplace.

2.Movethemachinetoalevelsurface.

3.Cleanaroundtheoilllcap(

Figure11).

4.Unscrewtheoilllcapandremoveit.

5.Wipethedipstickontheoilllcapwithacleancloth.

6.Insert,butdonotscrewin,theoilllcapintothe

oilllhole.

7.Removetheoilllcapandcheckthedipstick.

8.Todeterminetheproperoillevelonthedipstick,

referto

Figure13.

Figure13

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

9.Iftheoillevelislow ,slowlypouroilintotheoilll

hole.Wait3minutes,thenchecktheoillevelon

thedipstickbywipingthedipstickcleanandthen

inserting,butnotscrewingin,theoilllcapinto

thehole.

Note:Youmaytipthemachineforward(handle

up)alittletomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingpositionbefore

checkingtheoillevel.

9

Page 10

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutof

themachine.

Maxll:12oz.(0.35l),type:automotivedetergent

oilwithanAPIserviceclassicationofSJ,SL,or

higher.

Use

Figure14toselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

Figure14

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshownin

Figure13.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChanging

theEngineOil.

10.Screwtheoilllcapintotheoilllholeandhand

tightenitsecurely.

StartingtheEngine

1.PushtheignitionkeyfullyinwardtotheOnposition

(Figure15).

Figure15

1.Ignitionkey

2.Movethechokeleverfullytotheright(Figure16).

Figure16

1.Chokelever

3.Firmlypushintheprimer2timeswithyourthumb,

holdingtheprimerinforasecondbeforereleasing

iteachtime(

Figure17).

10

Page 11

Figure17

Note:Removeyourglovewhenyoupushinthe

primersothataircannotescapefromtheprimer

hole.

Important:Donotusetheprimerorthechoke

iftheenginehasbeenrunningandishot.

Excessiveprimingmayoodtheengineand

preventitfromstarting.

4.Connectanextensioncordtoapowersourceand

themachine,andpushtheelectric-startbutton

(model38282only)(

Figure18),orpulltherecoil

starthandle(Figure19).

Figure18

1.Electric-startbutton

Note:UseonlyaUL-listed,16-gaugeextension

cordrecommendedforoutdoorusethatisnot

longerthan50feet(15m).

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcordbefore

pluggingitintoapowersource.Ifthe

cordisdamaged,donotuseittostartthe

machine.Replaceorrepairthedamagedcord

immediately.ContactanAuthorizedService

Dealerforassistance.

Figure19

Important:Runtheelectricstarternomore

than10timesatintervalsof5secondson,then

5secondsoff.Runningtheelectricstarter

extensivelycanoverheatanddamageit.Ifthe

enginedoesnotstartafterthisseriesofattempts,

waitatleast40minutestoallowthestarterto

coolbeforeattemptingtostartitagain.Ifthe

enginedoesnotstartafterthesecondseriesof

attempts,takethemachinetoanAuthorized

ServiceDealerforservice(model38282only).

Note:Iftherecoilstarterdoesnotoperateproperly,

itmaybefrozen.Thawoutthestarterbefore

attemptingtostartthemachine.

5.Whiletheengineisrunning,movethechokelever

graduallytotheleft.

6.Unplugtheextensioncordfromthepowersource

andthemachine(model38282only).

CAUTION

Ifyouleavethemachinepluggedintoapower

source,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty

(model38282only).

Unplugthepowercordwheneveryouarenot

startingthemachine.

11

Page 12

EngagingtheRotorBlades

Toengagetherotorblades,holdthecontrolbaragainst

thehandle(Figure20).

Figure20

1.Controlbar

DisengagingtheRotorBlades

Todisengagetherotorblades,releasethecontrolbar

(Figure21).

Figure21

StoppingtheEngine

Tostoptheengine,pulltheignitionkeyoutwarduntil

itclicksintotheOffposition(Figure22)ormovethe

chokeleverfullytotheright(Figure16).

Figure22

1.Ignitionkey

AdjustingtheDischargeChute

andChuteDeector

Toadjustthedischargechute,movethechutehandleas

showninFigure23.

Figure23

1.Chutehandle

Toraiseorlowertheangleofthechutedeector,press

thetriggeronthechutedeectorandmovethechute

deectorupordown(Figure24).Releasethetriggerto

lockthechutedeectorinplace.

12

Page 13

Figure24

1.Trigger

2.Chutedeector

ClearingaCloggedDischarge

Chute

Important:Handcontactwiththerotatingrotor

bladesinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwithmachine.

Neveruseyourhandtocleanoutthedischarge

chute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands.

Self-propellingthe

Snowthrower

Liftthemachinehandleuntilthewheelsarejustoff

thegroundandthescraperandrotorbladestouchthe

ground,Themachinewillpropelforward(

Figure25).

Figure25

1.Wheelsofftheground2.Scraperandrotorblades

incontractwiththeground

Note:Byslightlyvaryingliftingforceonthehandle,you

cancontroltheforwardspeedofthemachine.Inheavy

snow,pushforwardonthehandle,ifnecessary,butlet

themachineworkatitsownpace.Donotliftthehandle

anymorethannecessary,becausethescraperwillliftoff

thegroundandsnowwillescapebehindthemachine.

PreventingFreeze-upafterUse

•Lettheenginerunforafewminutestoprevent

movingpartsfromfreezing.Stoptheengine,wait

forallmovingpartstostop,andremoveiceand

snowfromthemachine.

•Cleanoffanysnowandicefromthebaseofthe

chute.

•Rotatethedischargechuteleftandrighttofreeit

fromanyicebuildup.

•WiththeignitionkeyintheOffposition,pullthe

recoilstarterhandleseveraltimesorconnectthe

electricalcordtoapowersourceandthemachine

andpushtheelectricstartbuttononce(model38282

only)topreventtherecoilstarterand/ortheelectric

starterfromfreezingup.

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessiveforce

whentryingtooperatefrozencontrols.Ifyouhave

difcultyoperatinganycontrolorpart,startthe

engineandletitrunforafewminutes.

OperatingTips

WARNING

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

•Removethesnowassoonaspossibleafteritfalls.

•Overlapeachswathtoensurecompletesnow

removal.

•Dischargethesnowdownwindwheneverpossible.

13

Page 14

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Checkthecontrolcableandadjustitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

Aftertherst2hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengineoillevelandaddoilifnecessary.

Yearly

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

•Servicethesparkplugandreplaceitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary.

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary .

Yearlyorbeforestorage

•Preparethemachineforstorage.

AdjustingtheControlCable

RefertoAdjustingtheControlCableinSetup.

InspectingtheRotorBlades

ServiceInterval:Yearly—Inspecttherotorbladesand

haveanAuthorizedServiceDealer

replacetherotorbladesandscraperif

necessary.

Beforeeachsession,inspecttherotorbladesforwear.

Whenarotorbladeedgehasworndowntothewear

indicatorhole,haveanAuthorizedServiceDealer

replacetherotorbladesandthescraper(

Figure26).

Figure26

1.Thewearindicatorholeis

intact;youdonotneedto

replacetherotorblades.

3.Scraper

2.Thewearindicatorholeis

exposed;replacetherotor

bladesandscraper.

ChangingtheEngineOil

ServiceInterval:Aftertherst2hours

Yearly

Runtheengineafewminutesbeforechangingtheoil

towarmit.Warmoilowsbetterandcarriesmore

contaminants.

1.Ensurethatthefueltankisnotoverlled(referto

Figure12)andthatthefuelcapissecurelyinplace.

2.Movethemachinetoalevelsurface.

14

Page 15

3.Placeanoildrainpanundertheoildrainplug

(Figure11),removetheoildrainplug,andtipthe

machinebackward(handledown)halfwaytothe

groundtodraintheusedoilintotheoildrainpan.

Important:Donottipthemachinealltheway

backtotheground,orfuelmayleakoutofthe

machine.

4.Afterdrainingtheusedoil,returnthemachinetothe

operatingposition.

5.Installtheoildrainplugandtightenitsecurely.

6.Cleanaroundtheoilllcap(

Figure11).

7.Unscrewtheoilllcapandremoveit.

8.Slowlypouroilintotheoilllhole.W ait3minutes,

thenchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewing

in,theoilllcapintothehole.

Note:Todeterminetheproperoillevelonthe

dipstick,referto

Figure27.

Figure27

1.Theoillevelisatits

maximum.

3.Theoillevelistoo

low—addoiltothe

crankcase.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

Note:Youmaytipthemachineforward(handle

up)alittletomakeaddingoileasier.Rememberto

returnthemachinetotheoperatingpositionbefore

checkingtheoillevel.

Important:Donottipthemachinealltheway

forwardontoitsnose,orfuelmayleakoutof

themachine.

Maxll:12oz.(0.35l),type:automotivedetergent

oilwithanAPIserviceclassicationofSJ,SL,or

higher.

Use

Figure28toselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

Figure28

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshowninFigure27.Ifyouoverlltheengine

withoil,removetheexcessoilfromthedrainplug

intoanoildrainpan.

9.Screwtheoilllcapintotheoilllhole,andhand

tightenitsecurely.

10.Wipeupanyspilledoil.

11.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Yearly—Servicethesparkplugand

replaceitifnecessary.

UseaTorosparkplug(PartNo.119-1961).

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(

Figure11).

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

5.Setthegapontheplugto0.030inch(0.76mm)

(

Figure29).

15

Page 16

Figure29

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

6.Installthesparkplugandtorqueitto20–22ft-lb

(27–30N-m).

7.Connectthewiretothesparkplug.

ReplacingtheDriveBelt

Ifdrivebeltbecomesworn,oil-soaked,excessively

cracked,frayed,orotherwisedamaged,replacethebelt.

1.Removethe4boltsthatholdthedrivebeltcover

(Figure30)inplace.

Figure30

1.Drivebeltcover

Note:Thelowerfrontcornerofthedrivebelt

coverisfasteneddownwithasmallerbolt,awasher,

andalocknut.

2.Removethebeltfromtherotorpulley.

Figure31

1.Rotorpulley5.Idlerpulley

2.Idlerarmbrake6.Enginepulley

3.Drivebelt7.Tabsontheidlerarm

4.Idlerarm

3.Pressdownontheidlerarmandremovethebelt

frombetweenthetabontheidlerarmbrakeandthe

rotorpulley.

Note:Theenginepulleybeltguideisverycloseto

thepulley,andthebeltmaynottthroughthegap.

4.Twistthebeltoutinfrontofthebeltguidesothat

thebeltiswedgedbetweenthebeltguideandthe

enginepulley.

5.Insertascrewdriverintotheholeinthebeltguideas

shownin

Figure32,andexthebeltguidetoward

therotorpulleyenoughtopullthebeltthroughthe

gap.

Figure32

1.Beltguide2.Enginepulley

Note:Takecarenottodistortordamagethebelt

guide.

6.Toinstallthenewdrivebelt,reversethestepsabove.

16

Page 17

Important:Ensurethatyouinstallthedrivebelt

sothatitsitsabovethetwotabsontheidlerarm

andbelowtheidlerarmbrake(Figure31).

7.Installthedrivebeltcoverwiththefastenersthatyou

removedinstep

1.

Storage

StoringtheMachine

WARNING

•Gasolinefumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyoustorethe

productinanareawithanopename,the

gasolinefumesmayigniteandcausean

explosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,and

otherlikeappliances.

•Donottipthemachineeitherforwardor

backwardwithfuelinthefueltank;otherwise,

fuelmayleakoutofthemachine.

•Donotstorethemachinewithitshandletipped

downontotheground,becauseoilwillleakinto

theenginecylinderandontotheground,and

themachinewillnotstartorrun.

1.Onthelastrefuelingoftheseason,addfuelstabilizer

tofreshfuelasdirectedbytheenginemanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Whiletheengineisstillwarm,changetheengineoil.

RefertoChangingtheEngineOil.

4.Drainthefuelfromthetankandcarburetorby

performingthefollowingsteps:

A.Loosenthefueltankcap.

B.Unscrew,butdonotremove,thesmallscrewon

thesideofthecarburetorfuelbowl(

Figure33)

untilthefuelbeginstodrainfromthecarburetor.

Drainthefuelintoanapprovedfuelcontainer.

Important:Donotremovethecarburetor

bowlboltonthebottomofthecarburetor.

Figure33

1.Carburetorbowlbolt—do

notremove

2.Smallscrewoncarburetor

C.Waitforafewminutesuntilthefuelhasdrained,

theninstallthefuelcapandtightenthesmall

screwonthecarburetor.

5.Disposeofunusedfuelproperly.Recycleitaccording

tolocalcodes,oruseitinyourautomobile.

6.Removethesparkplug.

7.Squirt2teaspoonsofoilintothesparkplughole.

8.Installthesparkplugbyhandandthentorqueitto

20–22ft-lb(27–30N-m).

9.WiththeignitionkeyintheOffposition,pullthe

recoilstarterslowlytodistributetheoilontheinside

ofthecylinder.

10.Disconnecttheignitionkeyfromthelanyardand

storetheignitionkeyinasafeplace.

11.Cleanthemachine.

12.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sandaffected

areasbeforepainting,andusearustpreventativeto

preventthemetalpartsfromrusting.

13.Tightenanyloosefasteners.Repairorreplaceany

damagedparts.

14.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheengineto

coolbeforestoringitinanyenclosure.

17

Page 18

Notes:

18

Page 19

FederalEmissionControlWarrantyStatement

ATwo-YearLimitedWarranty

YourWarrantyRightsandObligations

TheU.S.EnvironmentalProtectionAgency(EP A),TheT oroCompany ,and

itsafliate,ToroWarrantyCompany ,arepleasedtoexplaintheemission

controlsystemwarrantyonyour2009andlaterutility/lawn/garden

equipmentengine.2009andlatermodelyearutility/lawn/garden

equipmentenginesmustbedesigned,builtandequipped,atthetime

ofsale,tomeettheU.S.EPAregulationsforsmallnon-roadengines.

Theequipmentenginemustbefreefromdefectsinmaterialsand

workmanship,whichcauseittofailtoconformwithU.S.EPAstandards,

forthersttwoyearsofengineusefromthedateofsaletotheultimate

purchaser.TheToroCompanyanditsafliate,ToroWarrantyCompany ,

warranttheemissioncontrolsystemonyourutility/lawn/gardenequipment

enginefortheperiodoftimelistedabove,providedtherehasbeenno

abuse,neglect,orimpropermaintenanceofyourutility/lawn/garden

equipmentengine.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor

orfuelinjectionsystem,theignitionsystem,andcatalyticconverter.Also

includedmaybefuellines,fuellinefasteners,connectors,andother

emission-relatedassemblies.

Whereawarrantableconditionexists,TheT oroCompanyanditsafliate,

ToroWarrantyCompany ,promisetorepairyourengineatnocosttoyou,

includingdiagnosis,parts,andlabor.

Manufacturer’sWarrantyCoverage

TheT oroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantthe2009andlater

utility/lawn/gardenequipmentenginesfortwoyearsfromthedateof

delivery.Ifanyemission-relatedpartonyourengineisdefectivein

materialsorworkmanship,wewillrepairorreplacethepart,freeofcharge.

OwnerResponsibilities

Astheengineowner,youareresponsiblefortheperformanceofthe

requiredmaintenancelistedinyourOperator'sManual.Werecommend

thatyouretainallreceiptscoveringmaintenanceonyourequipment,but

wecannotdenywarrantysolelyforthelackofreceiptsorforyourfailureto

ensuretheperformanceofallscheduledmaintenance.

Anyreplacementpartorservicethatisequivalentinperformanceand

durabilitymaybeusedinnon-warrantymaintenanceorrepairs,andshall

notreduceourwarrantyobligation.

Astheengineowner,youshouldbeawarethatwemaydenyyouwarranty

coverageifyourengineoraparthasfailedduetoabuse,neglect,

impropermaintenance,orunapprovedmodicationsorparts.

YouareresponsibleforpresentingyourequipmentenginetoanAuthorized

ServiceDealerassoonasaproblemexists.Thewarrantyrepairsshould

becompletedinareasonableamountoftime,nottoexceedthirty(30)

days.

Ifyouhaveanyquestionsregardingyourwarrantyrightsand

responsibilities,contactusat:

CustomerCareDepartment,ConsumerDivision

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat800–348–2424(U.S.customers)

Tollfreeat800–544–5364(Canadiancustomers)

WarrantedParts

Thewarrantyperiodbeginsonthedatetheengineorequipmentis

deliveredtoaretailpurchaser.TheToroCompanyanditsafliate,

ToroWarrantyCompany,jointlywarranttotheinitialownerandeach

subsequentpurchaserthattheengineisfreefromdefectsinmaterialsand

workmanship,whichcausetheenginetofailtoconformwithapplicable

regulations,foraperiodoftwoyears.

Failurescausedbyabuse,neglect,orimpropermaintenancearenot

covered.Theuseofadd-onormodiedpartscanbegroundsfor

disallowingawarrantyclaim.Wearenotliabletocoverfailuresof

warrantedpartscausedbytheuseofadd-onormodiedparts.Weare

liablefordamagestootherenginecomponentscausedbythefailureof

awarrantedpartstillunderwarranty.Theownerisresponsibleforthe

performanceoftherequiredmaintenance,asdenedintheOperator's

Manual.

Anywarrantedpartwhichisnotscheduledforreplacementasrequired

maintenance,orwhichisscheduledonlyforregularinspectiontotheeffect

of“repairorreplaceasnecessary”shallbewarrantedforthewarranty

period.Anywarrantedpartwhichisscheduledforreplacementasrequired

maintenanceshallbewarrantedfortheperiodoftimeuptotherst

scheduledreplacementpointforthatpart.Coverageunderthiswarranty

extendsonlytothepartslistedbelow(theemissionssystemparts)tothe

extentthatthesepartswerepresentontheenginewhenpurchased.

•FuelMeteringSystem

—Coldstartenrichmentsystemincludingthechokemechanismor

primingsystem

—Fuelpump

—Carburetorandinternalparts

•AirInductionSystem

—Aircleaner

—Intakemanifold

—Controlledhotairintakesystem

•IgnitionSystem

—Sparkplug(s)

—Ignitioncoilsandelectronics

—Advance/retardmechanisms

•Mufer

•MiscellaneousItemsUsedintheAboveSystems

—Vacuum,temperature,andtime-sensitivevalvesandswitches

—Hoses,connectors,andassembliesofsame

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceat

theirdealership.T olocateadealerconvenienttoyou,refertothe

YellowPagesofyourtelephonedirectory(lookunder“LawnMowers”)

oraccessourwebsiteatwww .Toro.com.Youmayalsocallthe

numberslistedabovetousethe24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

Theownershallnotbechargedfordiagnosticlaborwhichleadstothe

determinationthatawarrantedpartisdefective,ifthediagnosticwork

isperformedatawarrantystation.

GeneralConditions

NeitherTheT oroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Allimpliedwarrantiesofmerchantability(thattheproductistforordinary

use)andtnessforuse(thattheproductistforaparticularpurpose)are

limitedtothedurationoftheexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,sotheaboveexclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

374-0267RevA

Page 20

PowerClear180

Single-StageSnowthrowers

TheToroTotalCoverageGuarantee

AT wo-YearFullWarranty(45DayLimitedWarrantyforCommercialUse)

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheT oroProduct

listedbelowifusedforresidentialpurposes*,ifdefectiveinmaterialsor

workmanshiporifitstopsfunctioningduetothefailureofacomponent

fortheperiodlistedbelow.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Powerclear180SnowthrowersandAttachments

2years

LimitedWarrantyforCommercialUse

Gas-poweredT oroProductsusedforcommercial,institutional,or

rentaluse,arewarrantedfor45daysagainstdefectsinmaterialsor

workmanship.Componentsfailingduetonormalweararenotcovered

bythiswarranty.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.Tolocateadealerconvenienttoyou,refertotheYellow

Pagesofyourtelephonedirectory(lookunder“LawnMowers”)or

accessourwebsiteatwww .Toro.com.Youmayalsocallthenumbers

listedinitem#3tousethe24-hourToroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.Thedealerwilldiagnosetheproblemanddetermine

ifitiscoveredunderwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat866-336-5205(U.S.customers)

Tollfreeat866-854–9033(Canadiancustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceorwearparts,suchasrotorblades

(paddles),scraperblades,belts,fuel,lubricants,oilchanges,spark

plugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Pickupanddeliverycharges

•Operationalmisuse,neglect,oraccidents

•RepairsorattemptedrepairsbyanyoneotherthananAuthorized

ToroServiceDealer

•Repairsoradjustmentstocorrectstartingdifcultiesduetothe

following:

–failuretofollowpropermaintenanceprocedures

–snowthrowerauger/paddlesstrikinganobject

–contaminantsinthefuelsystem

–improperfuelorfuel/oilmixture(consultyourOperator'sManual

ifindoubt)

–failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

Ifyouarehavingdifcultystartingyourunit,pleasechecktheOperator's

Manualtoensurethatyouareusingthecorrectstartingprocedures.This

cansaveanunnecessaryvisittoaServiceDealer.

GeneralConditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingToroapprovedreplacementparts.

RepairbyanAuthorizedT oroServiceDealerisyoursoleremedyunder

thiswarranty .

NeitherTheT oroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,sotheaboveexclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedToroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

*Residentialpurposesmeansuseoftheproductonthesamelotasyourhome.Useatmorethanonelocation,orinstitutionalorrentaluse,isconsidered

commercialuse,andthecommercialusewarrantywouldapply.

374-0263RevB

Loading...

Loading...