Page 1

Residential Products

2014 Power Clear® 418/621

Service Manual

Page 2

Page 3

General Information

1

Safety Information

SAFETY INFORMATION

This symbol means WARNING or

PER SONAL SAFETY INSTRUCTION –

read the instruction because it has to do

with your safety. Failure to comply with

the instruction may result in personal

!

This manual is intended as a service and repair manual

only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Toro Power

Clear® 418 and 621 Snowthrowers.

injury or even death.

Think Safety First

Avoid unexpected starting of engine…

Always turn off the engine and disconnect the spark plug

wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations…

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

The Power Clear operator’s manuals contain safety

informa tion and operating tips for safe operating practices.

Operator’s manuals are available online through your Toro

parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries…

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes and clothing. Battery gases can

explode. Keep cigarettes, sparks and ames away from

the battery.

Avoid injury due to inferior parts…

Use only original equipment parts to ensure that important

safety criteria are met.

Avoid burns…

Do not touch the engine, mufer, or other components,

which may increase in temperature during operation, while

the unit is running or shortly after it has been running.

Avoid res and explosions…

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved, labeled

containers for storing or transporting fuel and lubricants.

Avoid asphyxiation…

Never operate an engine in a conned area without proper

ventilation.

Avoid injury to bystanders…

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles…

Always clear the area of sticks, rocks or any other debris

that could be picked up and thrown by the powered

equipment.

Avoid modications…

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation…

Toro Single Stage Snow Service Manual 1-1

Page 4

SAFETY INFORMATION

NOTES

1-2

Toro Single Stage Snow Service Manual

Page 5

CHAPTER 2 - SPECIFICATIONS & MAINTENANCE

Torque Specications .....................................................2-2

Standard Torque Values (Inch) .......................................2-3

Standard Torque Values (Metric Fasteners) ...................2-3

Other Torque Specications ........................................... 2-4

U.S. to Metric Conversions .............................................2-4

Equivalents & Conversions.............................................2-5

Power Clear® 418 (18 Inch Models) ...............................2-6

Inspecting the Rotor Blades ...........................................2-7

Changing the Engine Oil.................................................2-7

Servicing the Spark Plug ................................................2-9

Replacing the Drive Belt ...............................................2-10

Storage .........................................................................2-12

2

Specications & Maintenance

Power Clear® 621 (21 Inch Models) .............................2-14

Adjusting the Control Cable ..........................................2-15

Inspecting the Rotor Blades .........................................2-17

Changing the Engine Oil...............................................2-17

Servicing the Spark Plug ..............................................2-19

Replacing the Drive Belt ...............................................2-21

Adjusting the Quick Shoot

™

Control .............................2-22

Toro Single Stage Snow Service Manual

2-1

Page 6

SPECIFICATIONS & MAINTENANCE

A

A

B

B

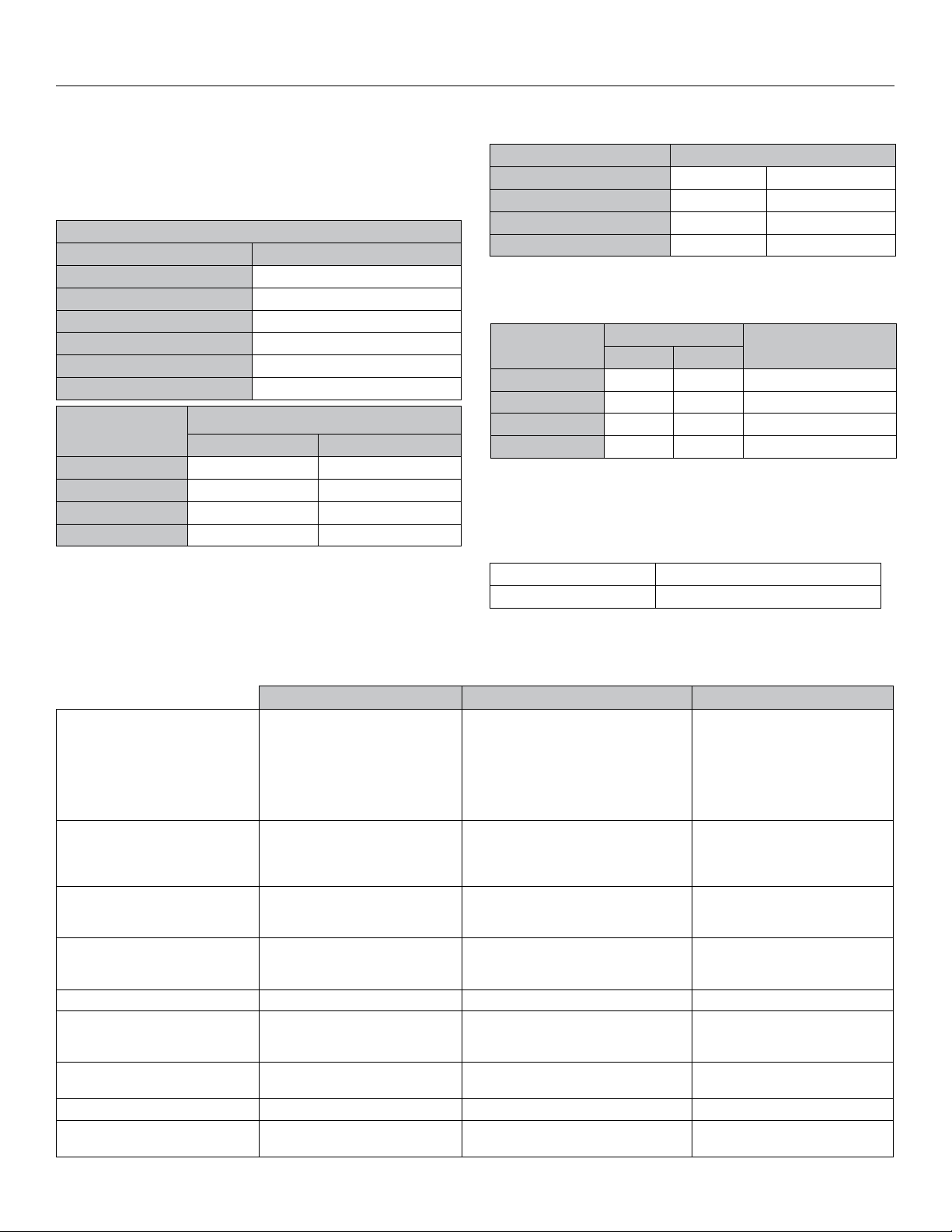

Torque Specications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined by

Toro, either the recommended torque or a torque that is

unique to the application is clearly identied and specied

in the service manual.

These torque specications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specic requirement identied in the service

manual. The following factors shall be consid ered when

applying torque: cleanliness of the fastener, use of a

thread sealant (e.g. Loctite®), degree of lubrication on the

fastener, presence of a prevailing torque feature, hardness

of the surface underneath of the fastener’s head, or similar

condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specic torque value should

be determined based on the aluminum or brass material

strength, fastener size, length of thread

engagement, etc.

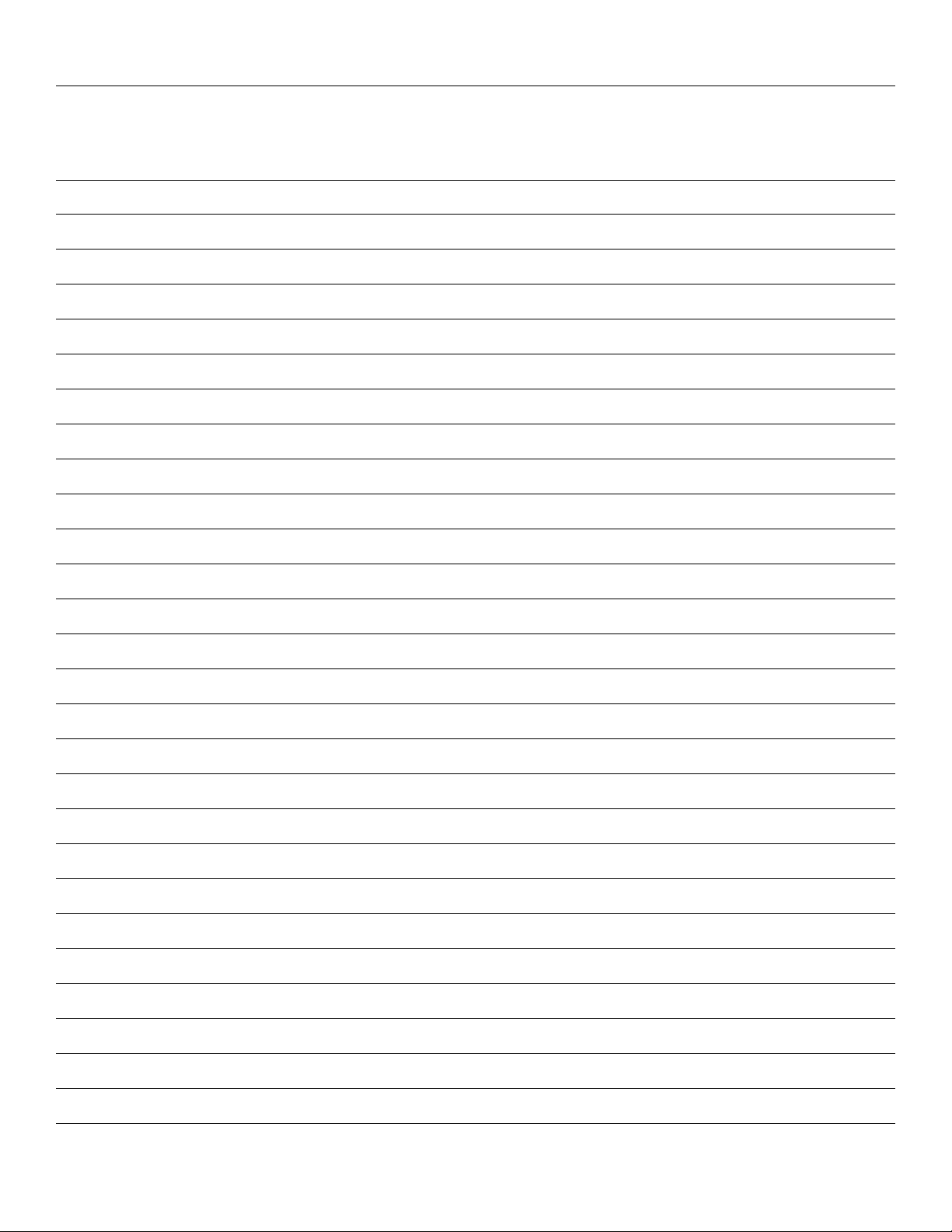

Fastener Identication

C

Inch Series Bolts and Screws

(A) Grade 1 & 2

(B) Grade 5

(C) Grade 8

8.8 10.9

Metric Bolts and Screws

(A) Class 8.8

(B) Class 10.9

The standard method of verifying torque shall be per

formed by marking a line on the fastener (head or nut) and

mating part, then back off fastener 1/4 of a turn. Measure

the torque required to tighten the fastener until the lines

match up.

2-2

Toro Single Stage Snow Service Manual

Page 7

SPECIFICATIONS & MAINTENANCE

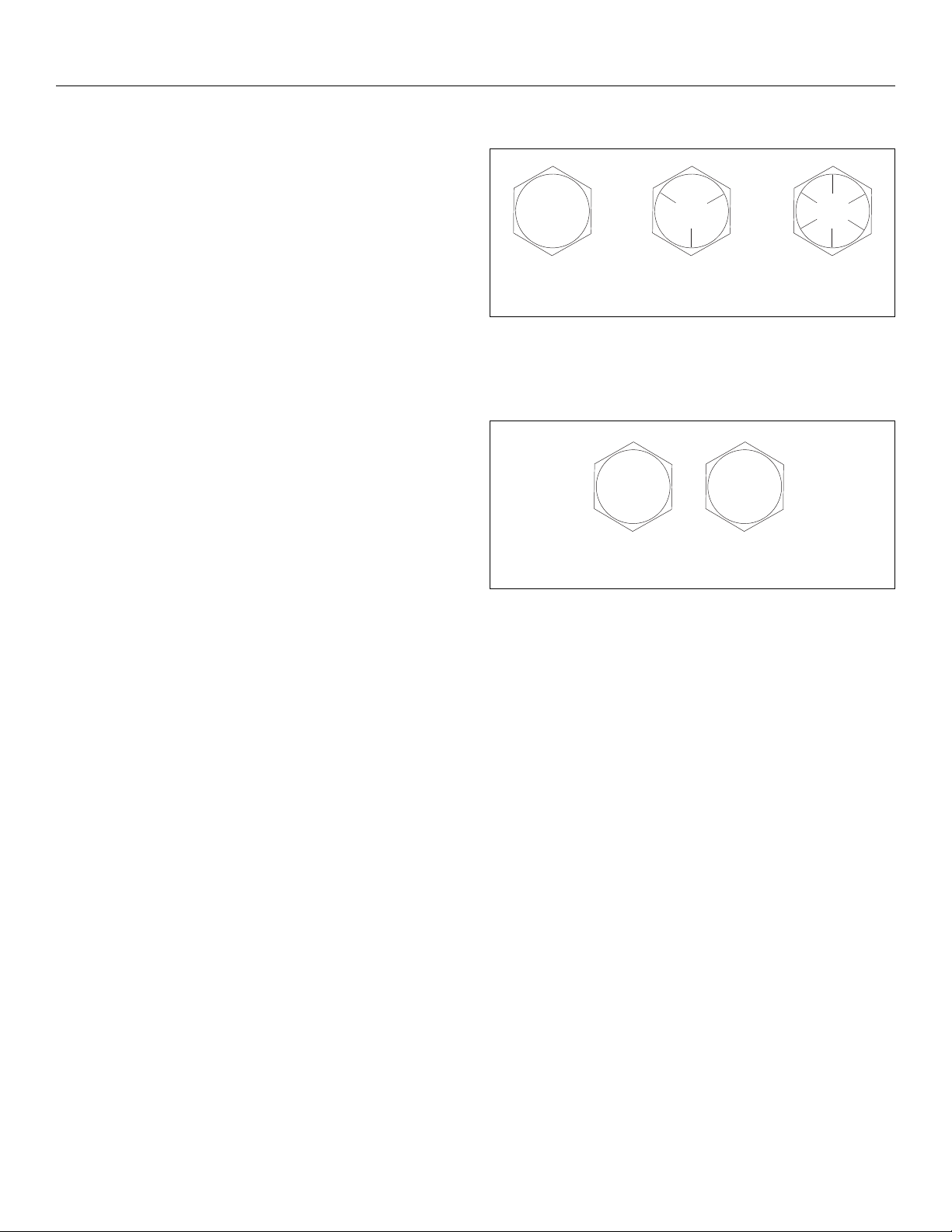

Standard Torque Values (Inch)

Thread Size

1/4-20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4-28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16-18 UNC 115 ± 15 105 ± 15 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16-24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8-16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8-24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16-14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16-20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2-13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2-20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8-11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8-18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4-10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4-16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8-9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8-14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

Grade 1, 5, & 8

with Thin Height

Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts SAE Grade 5 Bolts SAE Grade 8 Bolts

2

Specications & Maintenance

Standard Torque Values (Metric Fasteners)

Thread Size Class 8.8 Bolts Class 10.9 Bolts

M5 X 0.8 57 ± 5 inlb 644 ± 68 Ncm 78 ± 8 inlb 881 ± 90 Ncm

M6 X 1.0 96 ± 10 inlb 1085 ± 113 Ncm 133 ± 14 inlb 1503 ± 158 Ncm

M8 X 1.25 19 ± 2 ftlb 26 ± 3 Nm 28 ± 3 ftlb 38 ± 4 Nm

M10 X 1.5 38 ± 4 ftlb 52 ± 5 Nm 54 ± 6 ftlb 73 ± 8 Nm

M12 X 1.75 66 ± 7 ftlb 90 ± 10 Nm 93 ± 10 ftlb 126 ± 14 Nm

M16 X 2.0 166 ± 15 ftlb 225 ± 23 Nm 229 ± 23 ftlb 310 ± 31 Nm

M20 X 2.5 325 ± 33 ftlb 440 ± 45 Nm 450 ± 36 ftlb 610 ± 62 Nm

INCH/METRIC NOTE: Reduce torque values

listed in the table above by 25% for lubricated

fasteners. Lubricated fasteners are dened

as threads coated with a lubricant such as oil,

graphite, or thread sealant such as Loctite

INCH/METRIC NOTE: Torque values may

have to be reduced when installing fasteners

into threaded aluminum or brass. The

specic torque value should be determined

based on the fastener size, the aluminum

or base material strength, length of thread

engagement, etc.

INCH/METRIC NOTE: The nominal torque

®

.

values listed above for Grade 5 and 8

fasteners are based on 75% of the minimum

proof load specied in SAE J429.

The tolerance is approximately ± 10% of the

nominal torque value. Thin height nuts include

jam nuts.

METRIC NOTE: The nominal torque values

listed above are based on 75% of the

minimum proof load specied in SAE J1199.

The tolerance is approximately ± 10% of the

nominal torque value. Thin height nuts include

jam nuts.

Toro Single Stage Snow Service Manual

2-3

Page 8

SPECIFICATIONS & MAINTENANCE

Other Torque Specications

SAE Grade 8 Steel Set Screws

Thread Cutting Screws (Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 inlb

No. 8 - 32 UNC 30 ± 5 inlb

No. 10 - 24 UNC 38 ± 7 inlb

1/4 - 20 UNC 85 ± 15 inlb

5/16 - 18 UNC 110 ± 20 inlb

3/8 - 16 UNC 200 ± 100 inlb

Thread Size

1/4 - 20 UNC 140 ± 20 inlb 73 ± 12 inlb

5/16 - 18 UNC 215 ± 35 inlb 145 ± 20 inlb

3/8 - 16 UNC 35 ± 10 ftlb 18 ± 3 ftlb

1/2 - 13 UNC 75 ± 15 ftlb 50 ± 10 ftlb

Recommended Torque

Square Head Hex Socket

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF Grade 5 65 ± 10 ftlb 88 ± 14 Nm

1/2 - 20 UNF Grade 5 80 ± 10 ftlb 108 ± 14 Nm

M12 X 1.25 Class 8.8 80 ± 10 ftlb 108 ± 14 Nm

M12 X 1.5Class 8.8 80 ± 10 ftlb 108 ± 14 Nm

** For steel wheels and nonlubricated fasteners.

Thread Cutting Screws (Zinc Plated Steel)

Thread Size

No. 6 18 20 20 ± 5 inlb

No. 8 15 18 30 ± 5 inlb

No. 10 12 16 38 ± 7 inlb

No. 12 11 14 85 ± 15 inlb

* Hole size, material strength, material thickness and nish must be

considered when determining specic torque values. All torque values are

based on nonlubricated fasteners.

Threads per Inch

Type A Type B

Baseline Torque*

Conversion Factors

in-lb x 11.2985 = N-cm Ncm x 0.08851 = inlb 88 ± 14 Nm

ft-lb x 1.3558 = N-m Ncm x 0.73776 = ftlb 108 ± 14 Nm

U.S. to Metric Conversions

To Convert Into Multiply By

Miles

Yards

Linear Measurement

Area

Volume

Weight

Pressure Pounds/Sq. In. Kilopascal 6.895

Work

Liquid Volume

Liquid Flows Gallons/Minute Liters/Minute 3.785

Temperature Fahrenheit Celsius

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces

Footpounds

Footpounds

Inchpounds

Quarts

Gallons

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

NewtonMeters

KilogramMeters

KilogramCentimeters

Liters

Liters

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

1.356

0.1383

1.152144

0.9463

3.785

1. Subtract 32°

2. Multiply by 5/9

2-4

Toro Single Stage Snow Service Manual

Page 9

SPECIFICATIONS & MAINTENANCE

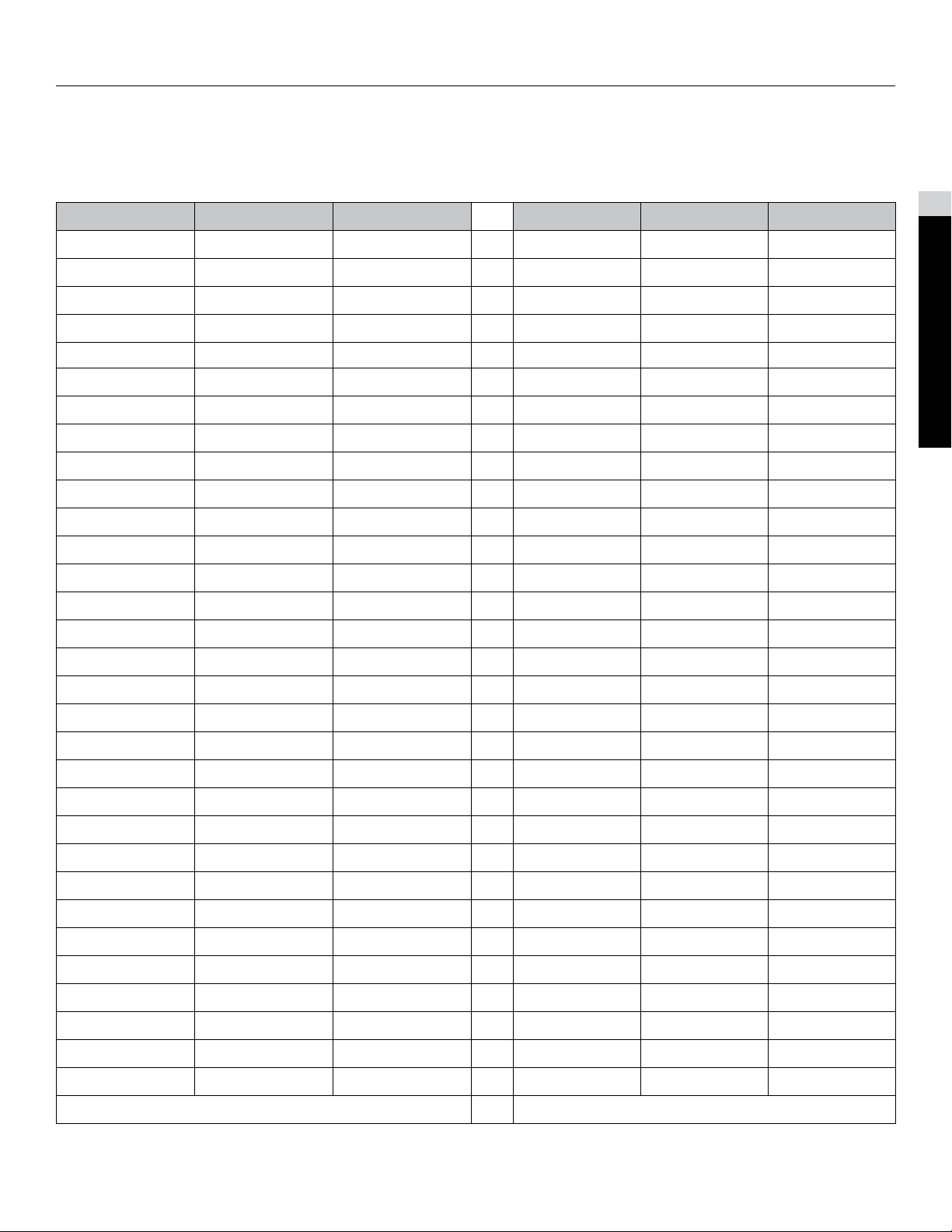

Equivalents & Conversions

Decimal & Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

2

Specications & Maintenance

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254mm

Toro Single Stage Snow Service Manual

2-5

Page 10

SPECIFICATIONS & MAINTENANCE

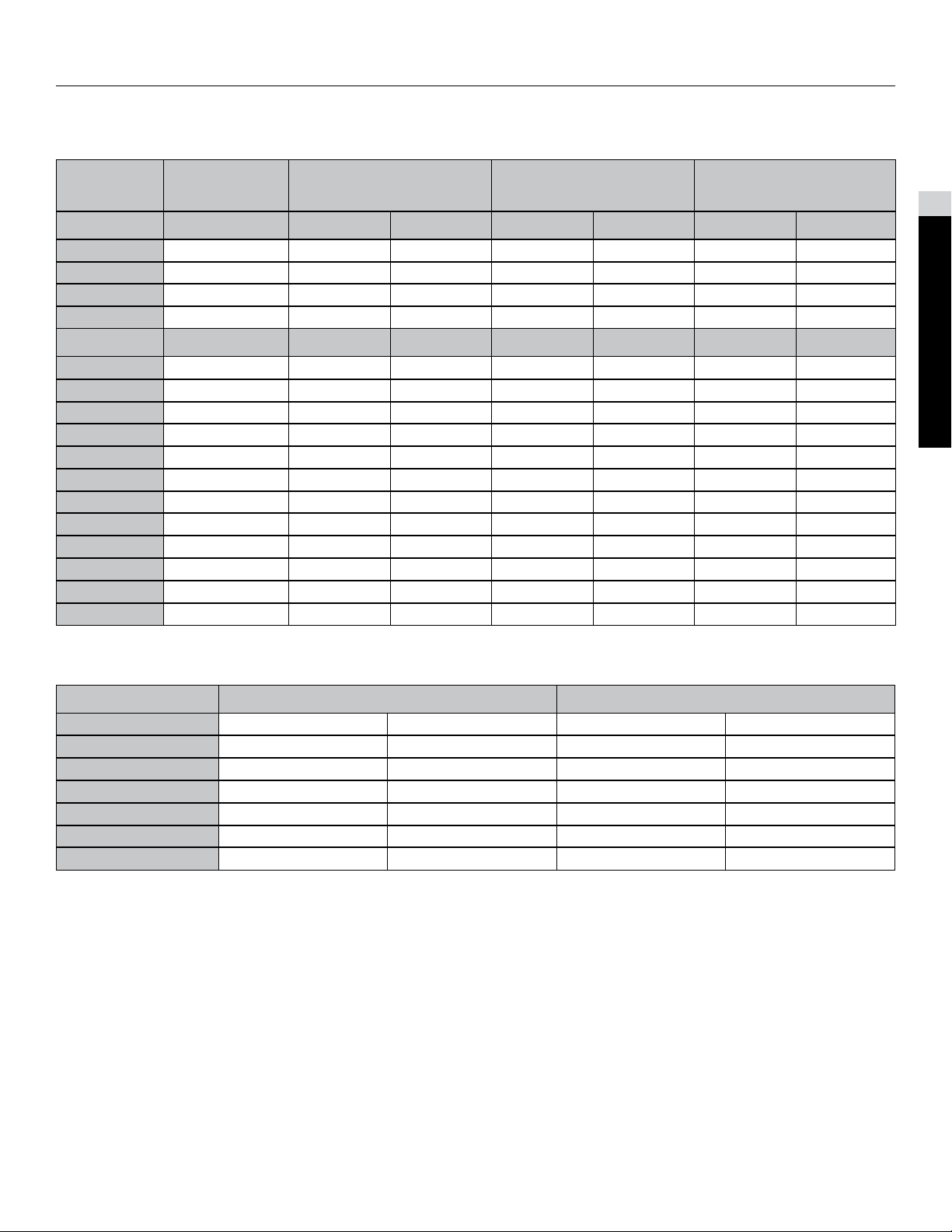

Power Clear® 418 (18 Inch Models)

Maintenance

Recommended Maintenance Schedule(s)

NOTE

Determine the left and right sides of the machine from the normal operating position.

Maintenance Service Interval Maintenance Procedure

After the rst hour

After the rst 2 hours Change the engine oil.

Before each use or daily Check the engine oil level and add oil if necessary.

Yearly

Check the control cable and adjust it if necessary.

Check for loose fasteners and tighten them if necessary.

Check the control cable and adjust it if necessary.

Inspect the rotor blades and replace the rotor blades and

scraper if necessary.

Change the engine oil.

Service the spark plug and replace it if necessary.

Check for loose fasteners and tighten them if necessary.

Inspect the drive belt and replace it if necessary.

Yearly or before storage Prepare the machine for storage.

2-6

Toro Single Stage Snow Service Manual

Page 11

SPECIFICATIONS & MAINTENANCE

A

B

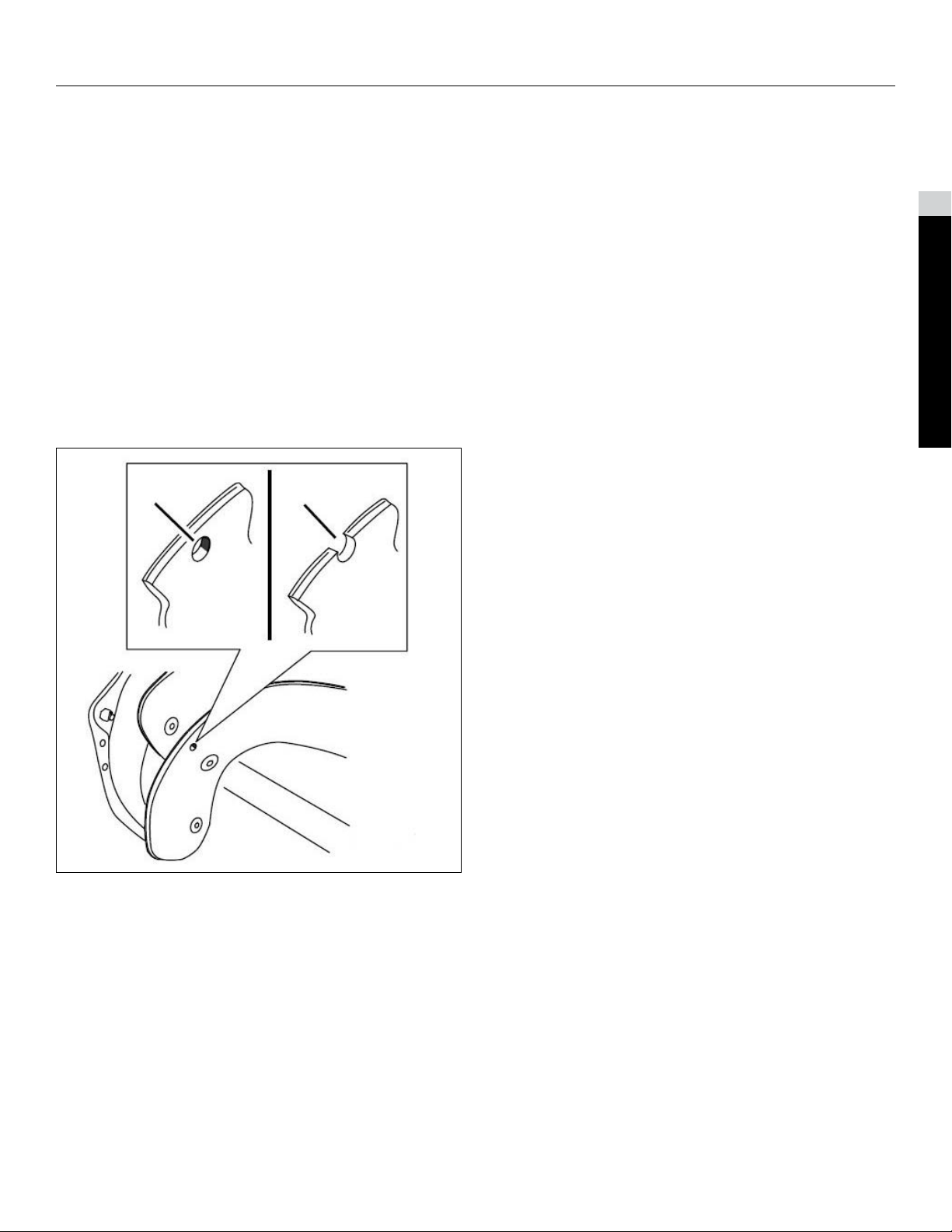

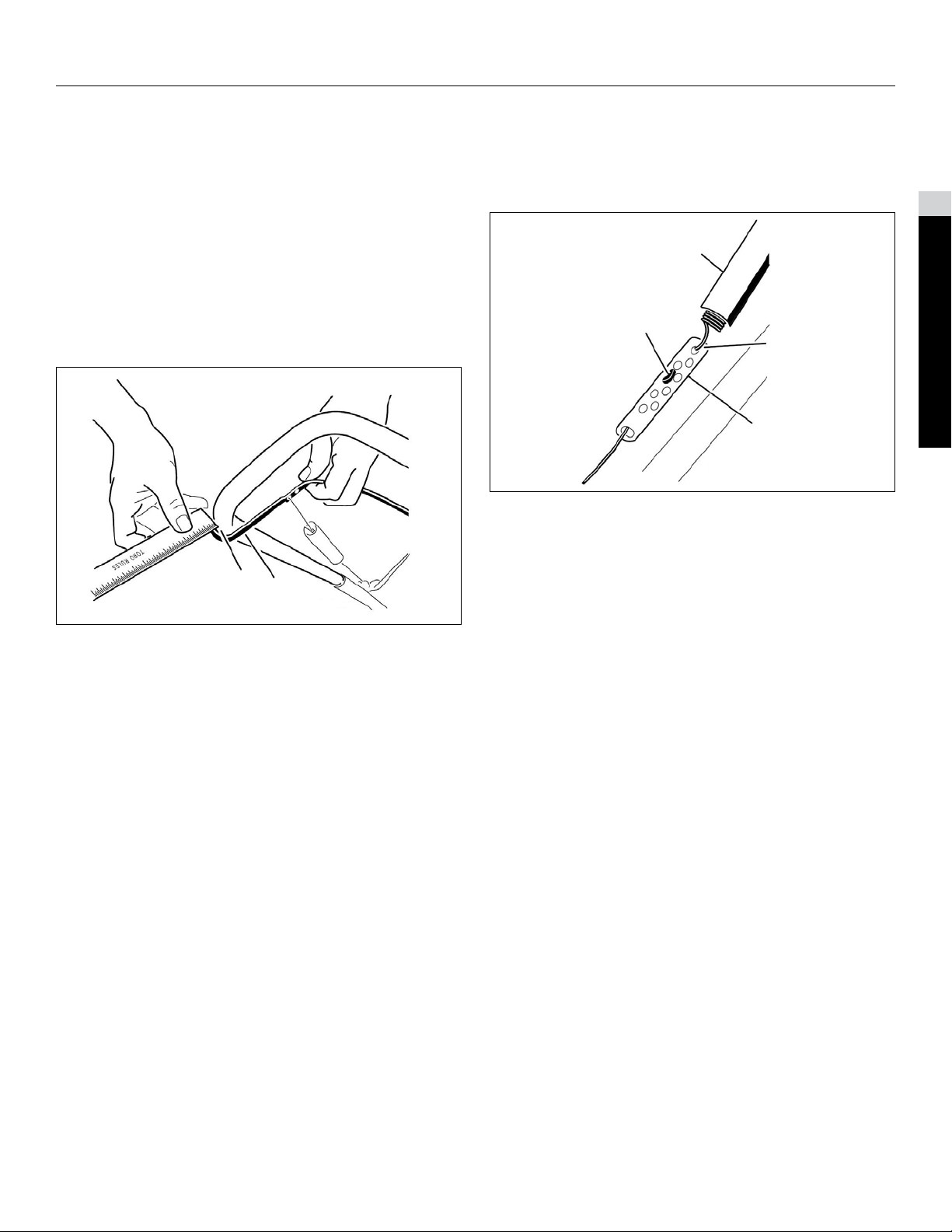

Inspecting the Rotor Blades

Service Interval

Yearly – Inspect the rotor blades and replace the rotor

blades and scraper if necessary.

Before each session, inspect the rotor blades for wear.

When a rotor blade edge has worn down to the wear

indicator hole, replace the rotor blades and the scraper

(Fig. 001).

A. The wear indicator hole is intact; you do not need to

replace the rotor blades.

B. The wear indicator hole is exposed; replace the rotor

blades and scraper.

Changing the Engine Oil

Service Interval

After the rst 2 hours yearly.

Run the engine a few minutes before changing the

oil to warm it. Warm oil ows better and carries more

contaminants.

1. Ensure that the fuel tank is not overlled and that the

fuel cap is securely in place.

2. Move the machine to a level surface.

3. Place an oil drain pan under the oil drain plug

(refer to page 217), remove the oil drain plug, and tip

the machine backward (handle down) halfway to the

ground to drain the used oil into the oil drain pan.

IMPORTANT

Do not tip the machine all the way back to the ground, or

fuel may leak out of the machine.

4. After draining the used oil, return the machine to the

operating position.

2

Specications & Maintenance

Fig. 001

5. Install the oil drain plug and tighten it securely.

6. Clean around the oil ll cap.

7. Unscrew the oil ll cap and remove it.

8. Slowly pour oil into the oil ll hole. Wait 3 minutes,

then check the oil level on the dipstick by wiping the

dipstick clean and then inserting, but not screwing in,

the oil ll cap into the hole.

NOTE

To determine the proper oil level on the dipstick, refer

to Fig. 002.

Toro Single Stage Snow Service Manual

2-7

Page 12

SPECIFICATIONS & MAINTENANCE

A

A

B

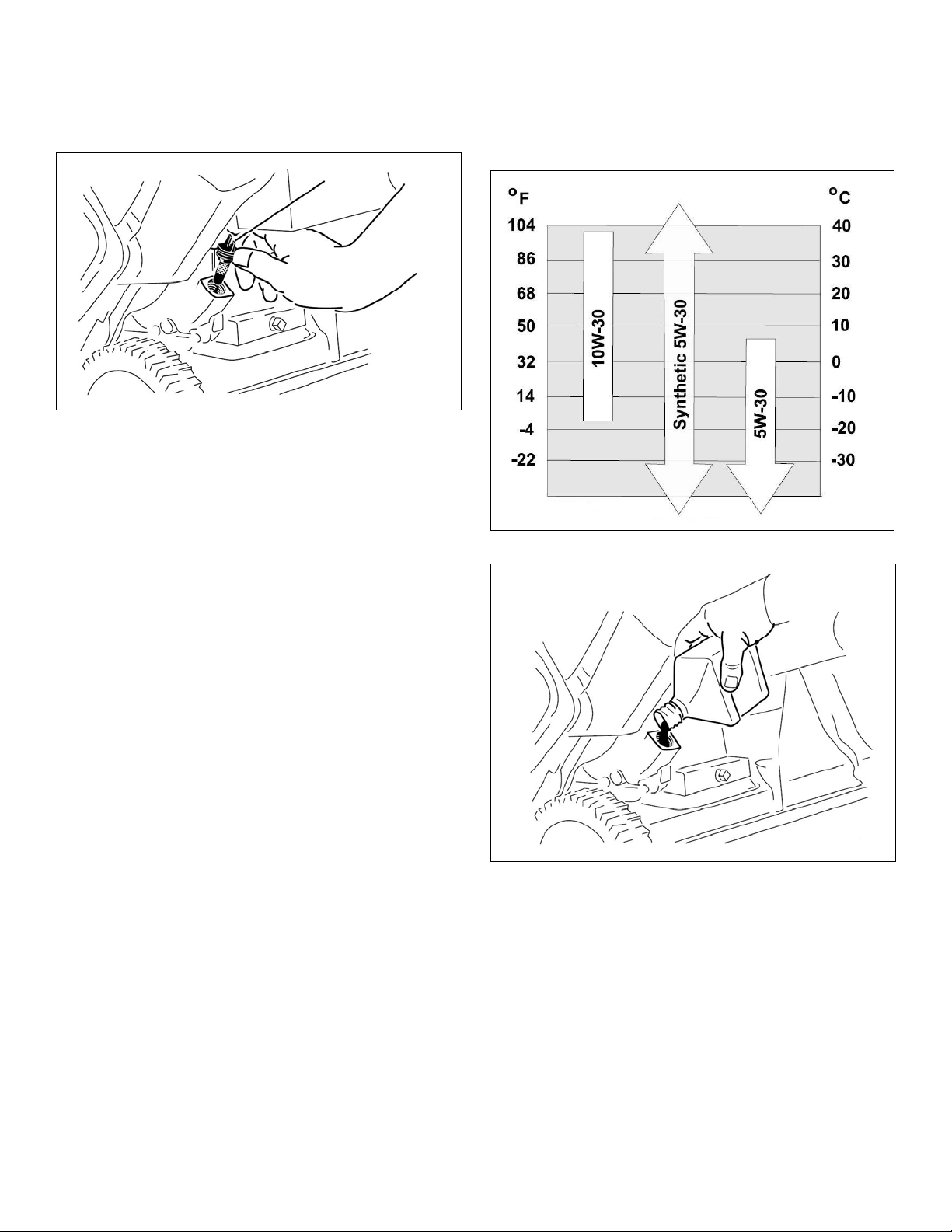

service classication of SJ, SL, or higher.

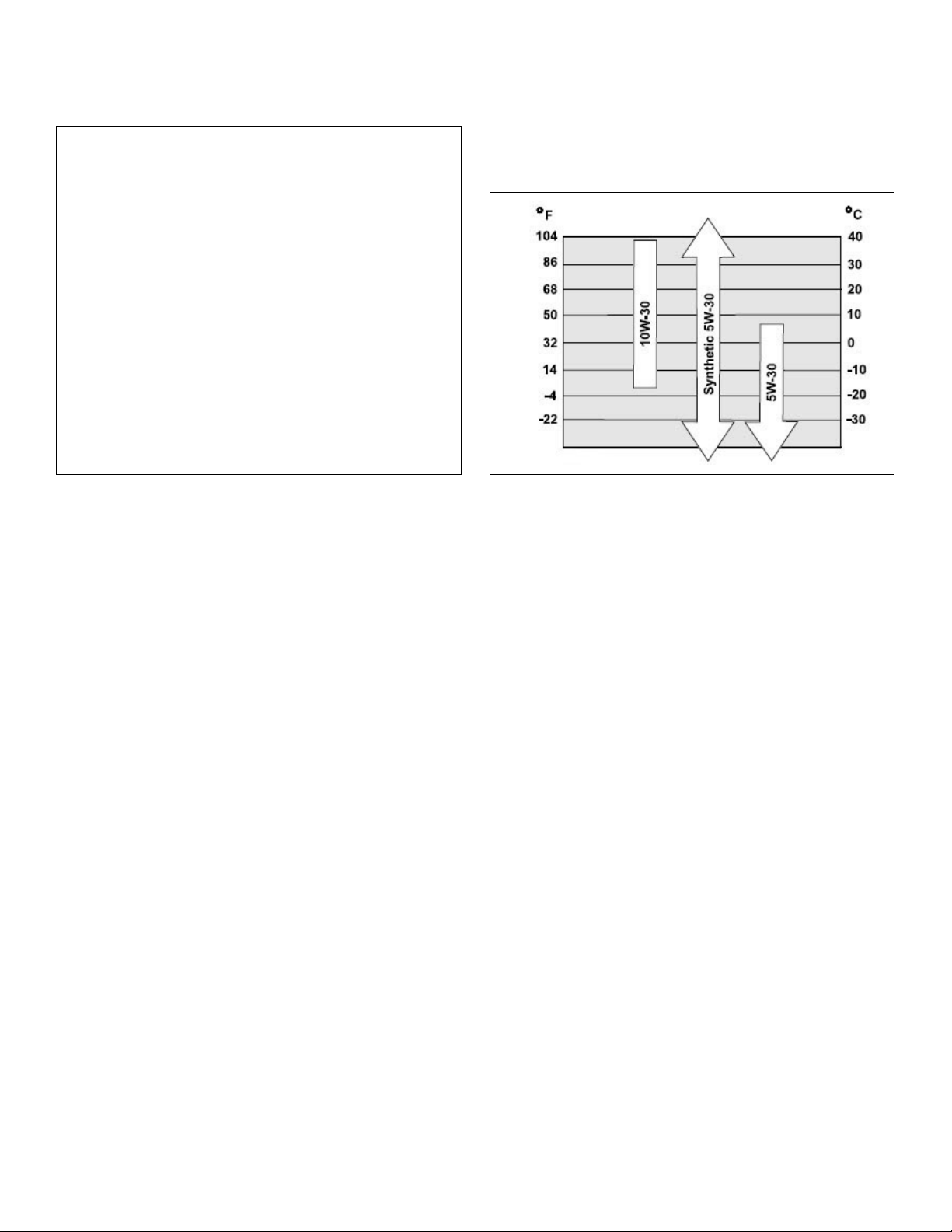

Use Fig. 003 to select the best oil viscosity for the

outdoor temperature range expected.

C

Fig. 002

A. The oil level is at its maximum

B. The oil level is too high, remove oil from the

crank case

C. The oil level is too low, add oil to the crankcase

NOTE

You may tip the machine forward (handle up) a little to

make adding oil easier. Remember to return the machine

to the operating position before checking the oil level.

IMPORTANT

Do not tip the machine all the way forward onto its nose,

or fuel may leak out of the machine.

Max ll

12 oz. (0.35 l), type: automotive detergent oil with an API

Fig. 003

NOTE

Fill the engine crankcase with oil until the dipstick indicates

that the engine oil level is correct as shown in Fig. 002. If

you overll the engine with oil, remove the excess oil from

the drain plug into an oil drain pan.

9. Screw the oil ll cap into the oil ll hole, and hand

tighten it securely.

10. Wipe up any spilled oil.

11. Dispose of the used oil properly at a local

recycling center.

2-8

Toro Single Stage Snow Service Manual

Page 13

SPECIFICATIONS & MAINTENANCE

B

A

Servicing the Spark Plug

Service Interval

Yearly – Service the spark plug and replace it

if necessary.

Use a Toro spark plug (Part No. 1191961).

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug.

3. Clean around the spark plug.

4. Remove the spark plug from the cylinder head.

IMPORTANT

Replace a cracked, fouled, or dirty spark plug. Do not

clean the electrodes because grit entering the cylinder

can damage the engine.

2

Specications & Maintenance

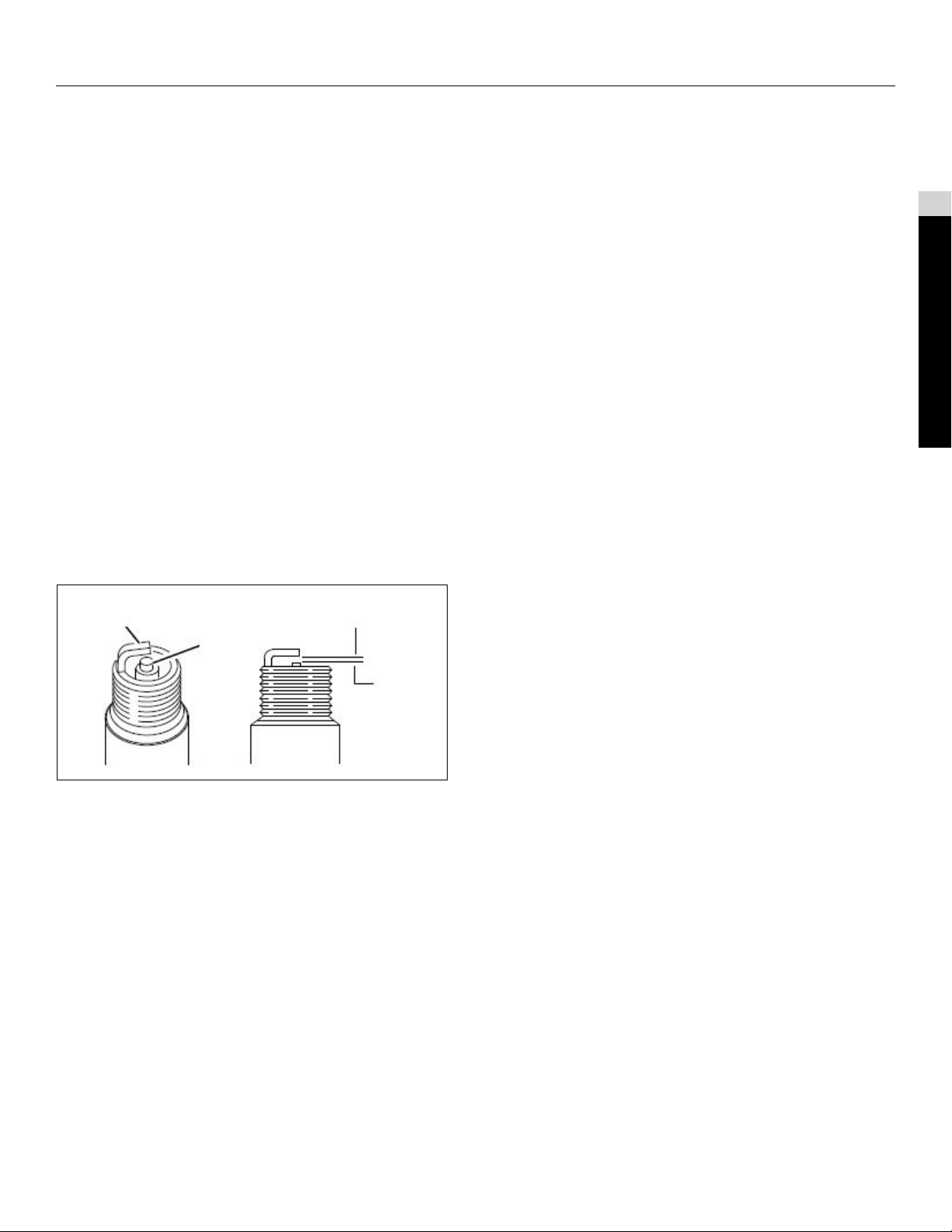

5. Set the gap on the plug to 0.030” (0.76 mm)

(Fig. 004).

C

D

Fig. 004

A. Center Electrode Insulator

B. Side Electrode

C. Air Gap (not to scale)

6. Install the spark plug and torque it to 20–22 ftlb

(27–30 Nm).

7. Connect the wire to the spark plug.

Toro Single Stage Snow Service Manual

2-9

Page 14

SPECIFICATIONS & MAINTENANCE

A

B

A

Replacing the Drive Belt

If drive belt becomes worn, oilsoaked, excessively

cracked, frayed, or otherwise damaged, replace

the belt.

1. Remove the 4 bolts that hold the drive belt cover

(Fig. 005) in place.

2. Remove the belt from the rotor pulley (Fig. 006).

C

D

E

F

G

Fig. 006

A. Rotor Pulley E. Idler Pulley

B. Idler Arm Brake F. Engine Pulley

C. Drive Belt G. Tabs on the Idler Arm

D. Idler Arm

3. Press down on the idler arm and remove the belt from

between the tab on the idler arm brake and the rotor

pulley.

Fig. 005

A. Drive Belt Cover

NOTE

The lower front corner of the drive belt cover is fastened

down with a smaller bolt, a washer, and a locknut.

NOTE

The engine pulley belt guide is very close to the pulley, and

the belt may not t through the gap.

4. Twist the belt out in front of the belt guide so that the

belt is wedged between the belt guide and the

engine pulley.

2-10

Toro Single Stage Snow Service Manual

Page 15

SPECIFICATIONS & MAINTENANCE

A

B

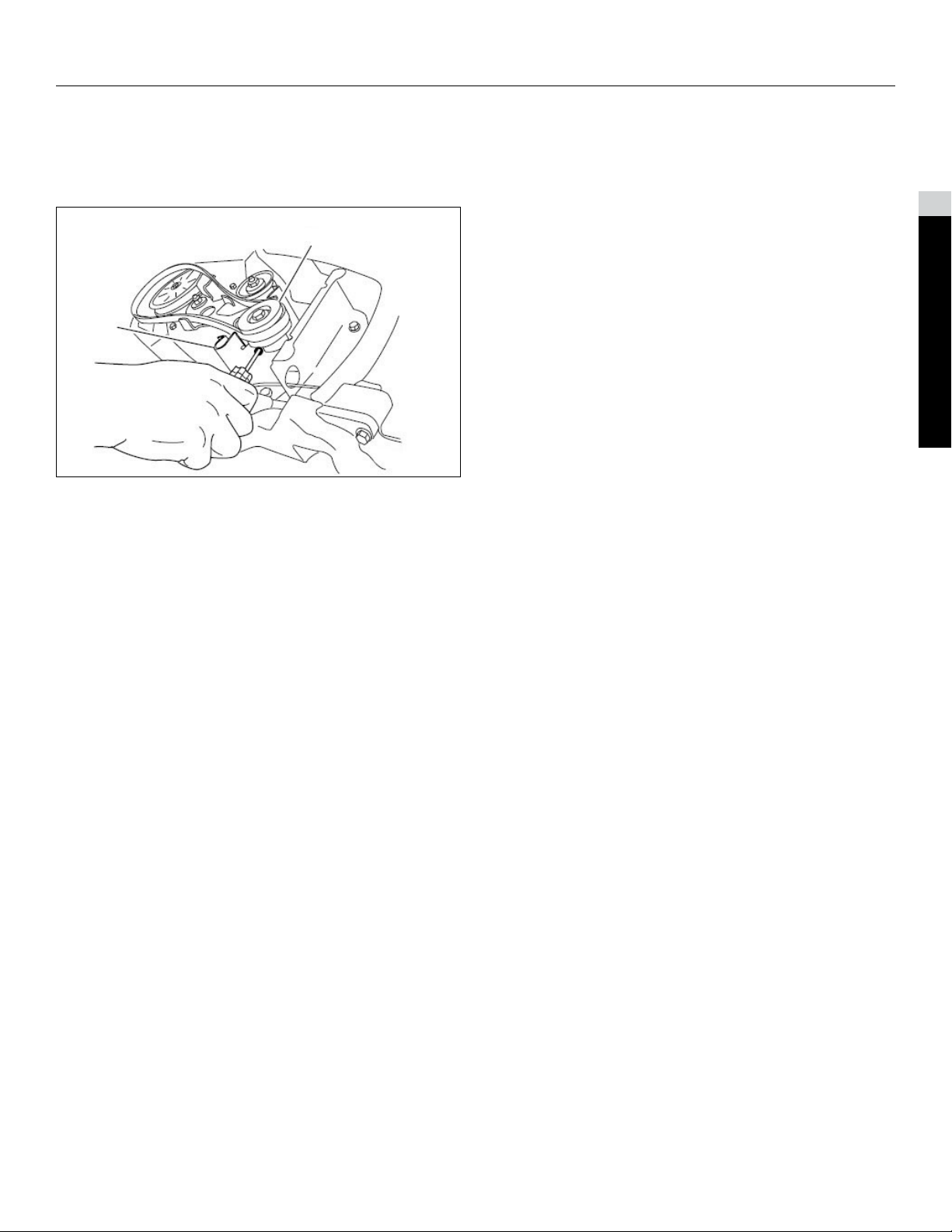

5. Insert a screwdriver into the hole in the belt guide as

shown in Fig. 007 and ex the belt guide toward the

rotor pulley enough to pull the belt through

the gap.

Fig. 007

A. Belt Guide

B. Engine Pulley

2

Specications & Maintenance

NOTE

Take care not to distort or damage the belt guide.

6. To install the new drive belt, reverse the

steps above.

IMPORTANT

Make sure to install the drive belt so that it sits above the

two tabs on the idler arm and below the idler arm brake

(Fig. 006).

7. Install the drive belt cover with the fasteners that you

removed in step 1.

Toro Single Stage Snow Service Manual

2-11

Page 16

SPECIFICATIONS & MAINTENANCE

A

B

Storage

Storing the Machine

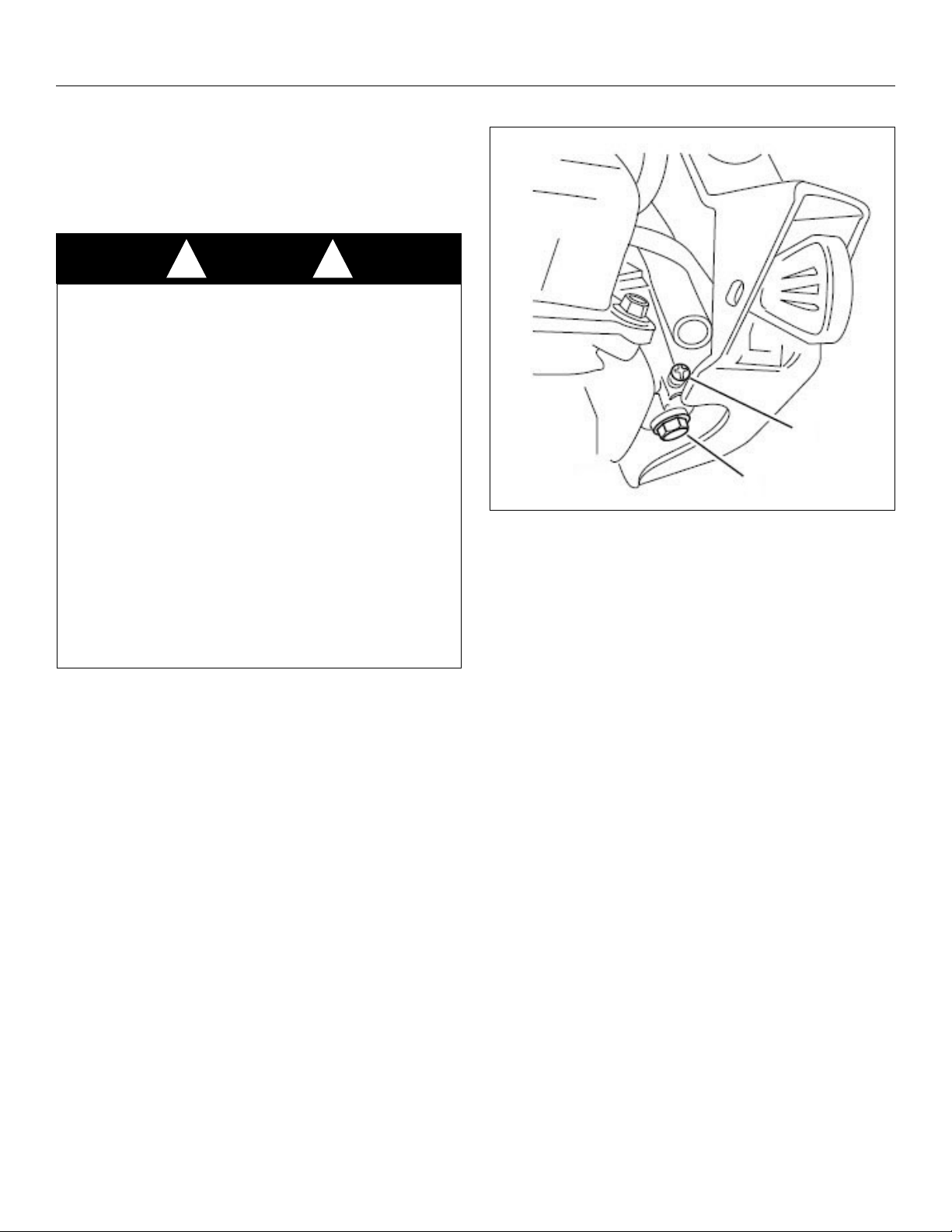

WARNING

! !

• Gasoline fumes are highly ammable, explosive,

and dangerous if inhaled. If you store the product

in an area with an open ame, the gasoline fumes

may ignite and cause an explosion.

• Do not store the machine in a house (living area),

basement, or any other area where ignition sources

may be present, such as hot water and space

heaters, clothes dryers, furnaces, and other

like appliances.

• Do not tip the machine either forward or backward

with fuel in the fuel tank; otherwise, fuel may leak

out of the machine.

• Do not store the machine with its handle tipped

down onto the ground, because oil will leak into the

engine cylinder and onto the ground, and the

machine will not start or run.

1. On the last refueling of the season, add fuel stabilizer

to fresh fuel as directed by the engine manufacturer.

2. Run the engine for 10 minutes to distribute the

conditioned fuel through the fuel system.

3. While the engine is still warm, change the engine oil.

4. Drain the fuel from the tank and carburetor by

performing the following steps:

A. Loosen the fuel tank cap.

B. Unscrew, but do not remove, the small screw on

the side of the carburetor fuel bowl (Fig. 008)

until the fuel begins to drain from the carburetor.

Drain the fuel into an approved fuel container.

Fig. 008

A. Carburetor bowl bolt do not remove

B. Small screw on carburetor

C. Wait for a few minutes until the fuel has drained,

then install the fuel cap and tighten the small

screw on the carburetor.

NOTE

Use a handheld Phillips screwdriver to tighten the

carburetor screw. Overtightening the screw could strip it

and cause leaking.

5. Dispose of unused fuel properly. Recycle it according

to local codes, or use it in your automobile.

6. Remove the spark plug.

7. Squirt 2 teaspoons of oil into the spark plug hole.

8. Install the spark plug by hand and then torque it to

20–22 ftlb (27–30 Nm).

9. With the ignition key in the Off position, pull the recoil

starter slowly to distribute the oil on the inside of

the cylinder.

IMPORTANT

Do not remove the carburetor bowl bolt on the bottom of

the carburetor.

2-12

10. Disconnect the ignition key from the lanyard and store

the ignition key in a safe place.

11. Clean the machine.

Toro Single Stage Snow Service Manual

Page 17

SPECIFICATIONS & MAINTENANCE

12. Touch up chipped surfaces with paint. Sand affected

areas before painting, and use a rust preventative to

prevent the metal parts from rusting.

13. Tighten any loose fasteners. Repair or replace any

damaged parts.

14. Cover the machine and store it in a clean, dry place

out of the reach of children. Allow the engine to cool

before storing it in any enclosure.

2

Specications & Maintenance

Toro Single Stage Snow Service Manual

2-13

Page 18

SPECIFICATIONS & MAINTENANCE

Power Clear® 621 (21 Inch Models)

Maintenance

Recommended Maintenance Schedule(s)

NOTE

Determine the left and right sides of the machine from the normal operating position.

Maintenance Service Interval Maintenance Procedure

After the rst hour

After the rst 2 hours Change the engine oil.

Before each use or daily Check the engine oil level and add oil if necessary.

Yearly

Check the control cable and adjust it if necessary.

Check for loose fasteners and tighten them if necessary.

Check the control cable and adjust it if necessary.

Inspect the rotor blades and replace the rotor blades and scraper

if necessary.

Change the engine oil.

Service the spark plug and replace it if necessary.

Check for loose fasteners and tighten them if necessary.

Inspect the drive belt and replace it if necessary.

Yearly or before storage Prepare the machine for storage.

2-14

Toro Single Stage Snow Service Manual

Page 19

SPECIFICATIONS & MAINTENANCE

B

A

B

A

Adjusting the Control Cable

Checking the Control Cable

Service Interval

After the rst hour – Check the control cable and adjust it

if necessary.

Yearly – Check the control cable and adjust it if necessary.

Move the control bar back toward the handle to remove

the slack in the control cable (Fig. 009).

Adjusting the Control Cable

1. Slide up the spring cover and unhook the spring from

the adjuster link (Fig. 010).

C

D

Fig. 010

A. Adjuster Link B. Spring Cover

C. ZFitting D. Unhook the Spring

2

Specications & Maintenance

A. Control bar (2mm to 3mm) gap

B. 1/16” 1/8”

NOTE

Ensure that a 1/16” 1/8” (2mm to 3mm) gap exists

between the control bar and the handle (Fig. 009).

IMPORTANT

The control cable must contain some slack when you

disengage the control bar for the rotor blades to

stop properly.

Fig. 009

NOTE

You can pull up the adjuster link and cable to make

unhooking the spring easier.

2. Move the Ztting to a higher or lower hole on the

adjuster link as needed to obtain the 1/16” 1/8”

(2 mm to 3 mm) gap between the control bar and

the handle (Fig. 010).

NOTE

Moving the Ztting higher decreases the gap between the

control bar and the handle; moving it lower increases

the gap.

3. Hook the spring to the adjuster link and slide the

spring cover over the adjuster link.

4. Check the adjustment; refer to Checking the

Control Cable.

Toro Single Stage Snow Service Manual

2-15

Page 20

SPECIFICATIONS & MAINTENANCE

B

A

NOTE

After extended use, the drive belt may wear and lose its

proper belt tension. If the drive belt slips (continuously

squeals) under a heavy load,disconnect the spring from

the adjustor link and move the upper end of the spring to

the hole that is further from the pivot point in the control

bar (Fig. 011). Then connect the spring to the adjustor link

and adjust the control cable.

C

D

Fig. 011

A. Remove the upper end of spring from this hole

B. Insert the upper end of spring into this hole

C. Pivot point

D. Upper end of spring

NOTE

The belt may slip (squeal) in wet conditions; to dry out the

drive system, start the rotor and run it without a load for

30 seconds.

2-16

Toro Single Stage Snow Service Manual

Page 21

SPECIFICATIONS & MAINTENANCE

A

B

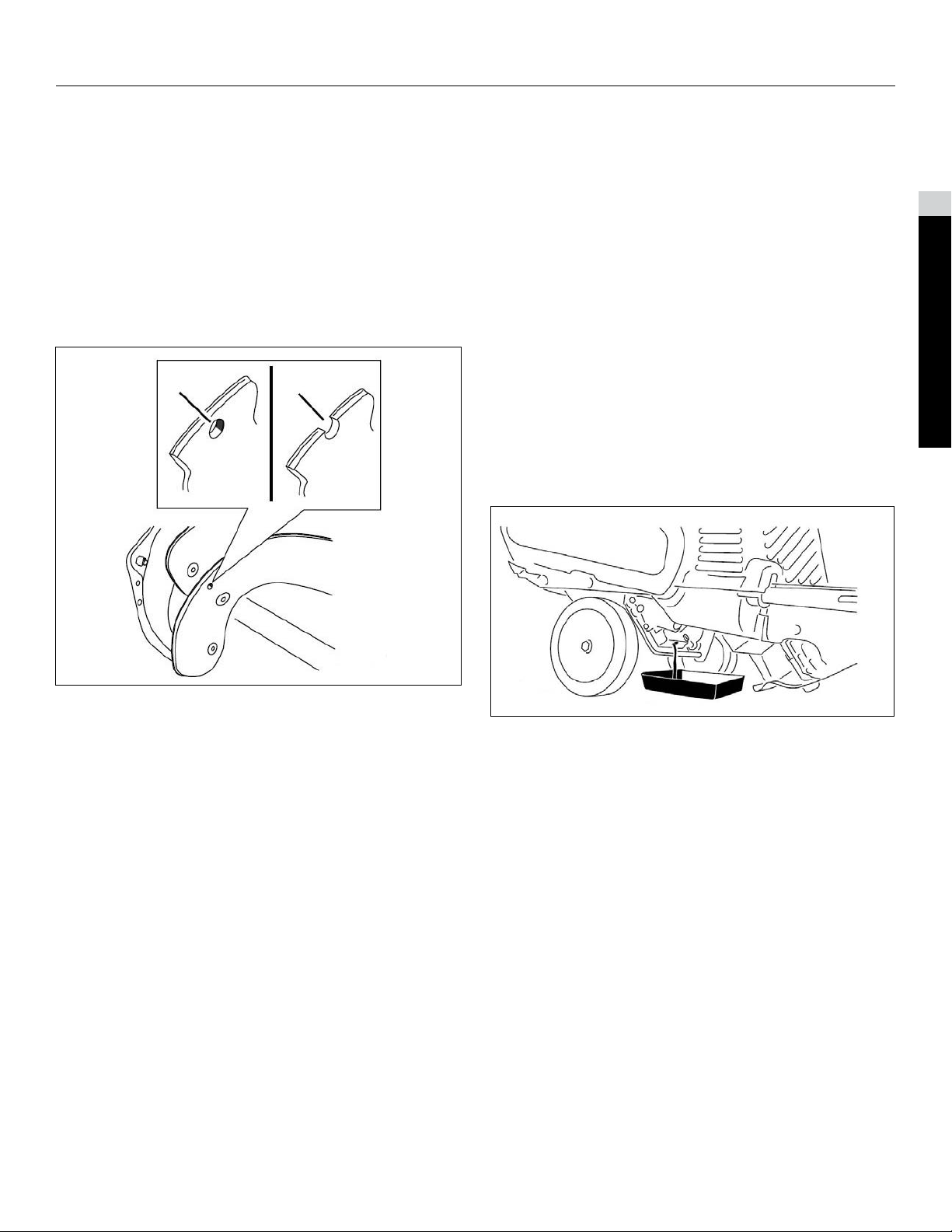

Inspecting the Rotor Blades

Service Interval

Yearly – Inspect the rotor blades and replace the rotor

blades and scraper if necessary.

Before each session, inspect the rotor blades for wear.

When a rotor blade edge has worn down to the wear

indicator hole. Replace the rotor blades and the

scraper (Fig. 012).

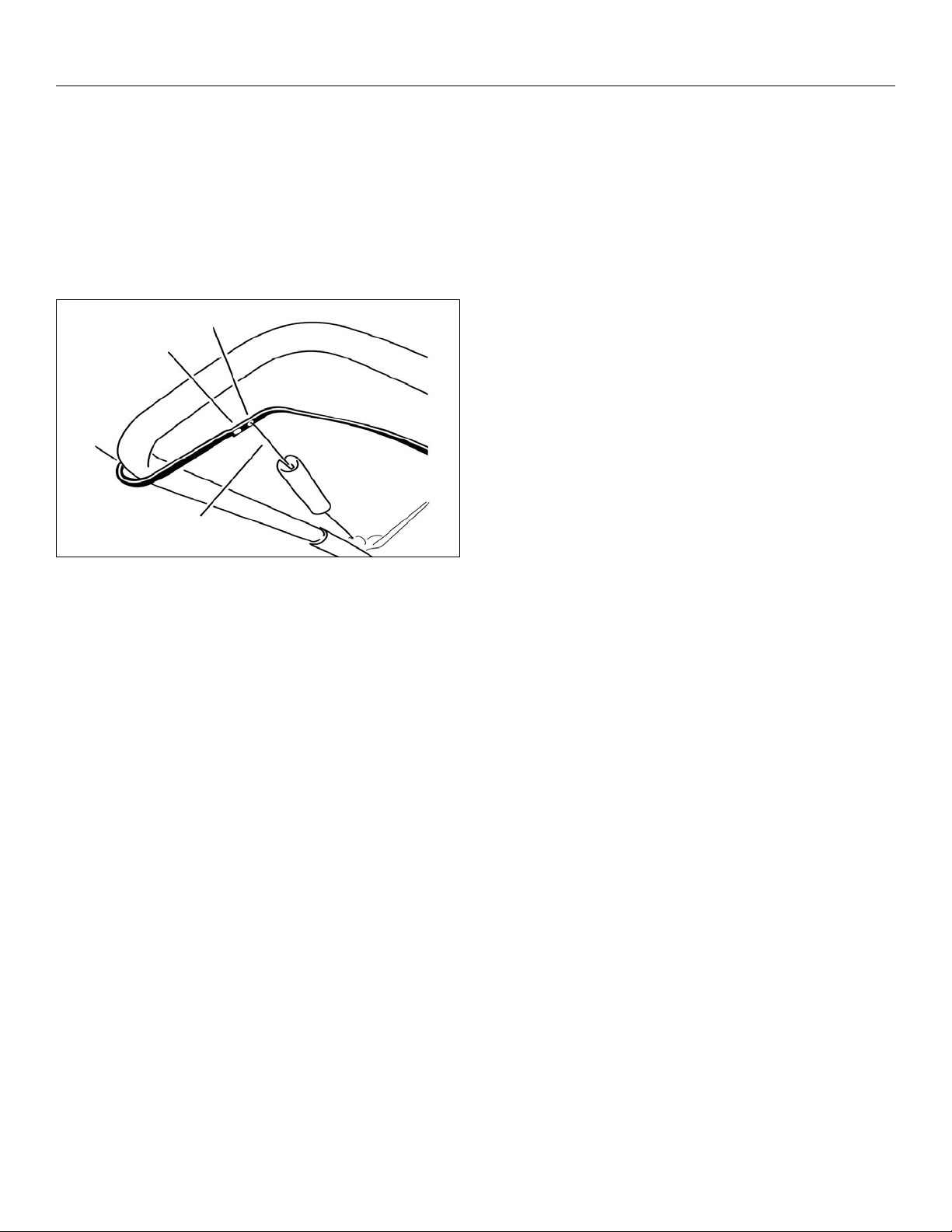

Changing the Engine Oil

Service Interval

• After the rst 2 hours

• Yearly

Run the engine a few minutes before changing the

oil to warm it. Warm oil ows better and carries more

contaminants.

1. Siphon the fuel from the fuel tank into an approved fuel

container, or run the engine until it stops.

2. Move the machine to a level surface.

3. Place an oil drain pan under the oil drain plug, remove

the oil drain plug, and tip the machine backward and

drain the used oil in the oil drain

pan (Fig. 013).

2

Specications & Maintenance

Fig. 012

A. The wear indicator hole is intact; you do not need to

replace the rotor blades.

B. The wear indicator hole is exposed; replace the

rotor blades.

Fig. 013

4. After draining the used oil, return the machine to the

operating position.

5. Install the oil drain plug and tighten it securely.

6. Clean around the oil ll cap (Fig. 014).

Toro Single Stage Snow Service Manual

2-17

Page 22

SPECIFICATIONS & MAINTENANCE

A

7. Unscrew the oil ll cap and remove it (Fig. 014).

Fig. 014

A. Oil ll cap

8. With the machine in the operating position, carefully

pour oil into the oil ll hole. Wait 3 minutes for the

oil to settle and add enough to bring it to the point of

overow (Fig. 016).

9. Screw the oil ll cap into the oil ll hole, and hand

tighten it securely.

Fig. 015

NOTE

You may tip the machine forward (handle up) to make

adding oil easier. Remember to return the machine to the

operating position before checking the oil level.

IMPORTANT

Do not tip the machine all the way forward onto its nose, or

fuel may leak out of the machine.

Max ll: 20 oz. (0.6 l), type: automotive detergent oil with

an API service classication of SJ, SL, or higher.

Use Fig. 015 to select the best oil viscosity for the outdoor

temperature range expected.

Fig. 016

10. Wipe up any spilled oil.

11. Dispose of the used oil properly at a local

recycling center.

2-18

Toro Single Stage Snow Service Manual

Page 23

SPECIFICATIONS & MAINTENANCE

A

B

B

A

Servicing the Spark Plug

Service Interval

Yearly – Check the spark plug and replace it if necessary.

Use a NGK BPR6ES or Champion RN9YC spark plug or

equivalent.

1. Stop the engine and wait for all moving parts to stop.

2. Rotate the discharge chute so that it faces forward.

3. Remove the discharge chute, the discharge chute

handle, and the chute seal by removing the 3 large

screws and one small screw (Fig. 017).

C

D

4. Remove the 4 screws that secure the shroud

(Fig. 018).

C

D

2

Specications & Maintenance

A. Fuel Tank Cap D. Small Screw

B. Large Screws (3) E. Chute Seal

C. Discharge Chute

E

Fig. 017

Fig. 018

A. Screw (4) C. Spark Plug

B. Shroud D. SparkPlug Wire

5. Remove the fuel tank cap.

6. Remove the shroud (Fig. 018).

7. Install the fuel tank cap.

8. Disconnect the wire from the spark plug.

9. Clean around the spark plug.

10. Remove the spark plug from the cylinder head.

IMPORTANT

Replace a cracked, fouled, or dirty spark plug. Do not

clean the electrodes because grit entering the cylinder can

damage the engine.

Toro Single Stage Snow Service Manual

2-19

Page 24

SPECIFICATIONS & MAINTENANCE

B

A

A

B

11. Set the gap on the plug to 0.030” (0.76mm)

(Fig. 019).

C

D

Fig. 019

A. Center Electrode Insulator

B. Side Electrode

C. Air Gap (not to scale)

12. Install the spark plug and torque it to 20–22 ftlb

(27–30 Nm).

13. Connect the wire to the spark plug.

NOTE

Ensure that the breather tube is routed above the spark

plug wire as shown in Fig. 020.

14. Remove the fuel tank cap.

15. Install the shroud with the screws you removed in

step 4.

NOTE

Ensure that the upper and lower shrouds t together in the

side grooves.

16. Install the fuel tank cap.

17. Install the chute seal, the discharge chute, and the

discharge chute handle onto the machine using the

hardware you removed in step 3.

NOTE

The small screw goes through the small hole in the chute

seal at the front of the discharge chute opening.

Fig. 020

A. Breather tube B. Carburetor drain bolt

2-20

Toro Single Stage Snow Service Manual

Page 25

SPECIFICATIONS & MAINTENANCE

B

A

A

B

Replacing the Drive Belt

If drive belt becomes worn, oilsoaked, excessively

cracked, frayed, or otherwise damaged, replace the belt.

1. Remove the drive belt cover by removing the 3 bolts

as shown in Fig. 021.

J

I

H

G

F

E

D

C

Fig. 021

A. Drive Belt Cover G. Rotor Shaft

B. Bolt (3) H. Brake Spring

C. Rotor Pulley Bolt (unhook from idler

D. Curved Washer arm here)

E. Rotor Pulley I. Idler Pulley

F. Drive Belt J. Engine Pulley

2. Unhook the brake spring from the idler arm to release

the belt tension (Fig. 021).

3. Remove the screw and curved washer that holds

the rotor pulley (Fig. 021).

4. Remove the rotor pulley and the drive belt

(Fig. 021).

5. Install the new drive belt, routing it as shown in

(Fig. 022).

2

Specications & Maintenance

C

D

Fig. 022

A. Brake Spring (install on C. Engine Pulley

idler arm here) D. Rotor Pulley

B. Idler Pulley

NOTE

Route the new drive belt rst around the engine pulley,

then the idler pulley, and nally around the loose rotor

pulley positioned just above the rotor shaft (Fig. 022).

6. Install the rotor pulley onto the rotor shaft

(Fig. 022).

7. Install the curved washer and the rotor pulley bolt and

tighten them securely (Fig. 022).

NOTE

The concave side of the curved washer goes against the

outside of the pulley.

8. Install the brake spring onto the idler arm

(Fig. 022).

9. Install the drive belt cover with the bolts you removed

in step 1.

NOTE

Ensure that the drive belt is properly adjusted and

operating; refer to “Checking the Control Cable” and

“Adjusting the Control Cable.”

Toro Single Stage Snow Service Manual

2-21

Page 26

SPECIFICATIONS & MAINTENANCE

A

A

A

Adjusting the Quick

Shoot™ Control

If there is more than 1/2” (13mm) of slack in the

Quick Shoot cable (Fig. 023) or the discharge chute does

not rotate left and right in equal angles, adjust the Quick

Shoot control cables.

Fig. 023

A. 1/2” (13mm) maximum slack

2. Position the Quick Shoot control between the two

arrows located on the right hand side of the upper

handle (Fig. 025).

Fig. 025

A. Arrows

3. Rotate the discharge chute so that it faces straight

ahead and the arrow on the back of the discharge

chute aligns with the arrow on the shroud (Fig. 026).

1. Loosen the two Quick Shoot control cable clamps

(Fig. 024).

A. Cable Clamps

Fig. 024

Fig. 026

2-22

Toro Single Stage Snow Service Manual

Page 27

SPECIFICATIONS & MAINTENANCE

A

A

4. Hold the discharge chute in the straightahead

position, pull the lower cable casing downward until

you remove the slack in the cable, and tighten the

screw on the lower cable clamp securely (Fig. 027).

A. Lower cable casing

2

Specications & Maintenance

Fig. 027

5. Pull the upper cable casing forward until you remove

the slack in the cable, and tighten the screw on the

upper cable clamp securely (Fig. 028).

Fig. 028

A. Upper cable casing

NOTE

Do not overtension the cables. If the cables are

overtensioned, the Quick Shoot will be hard to operate.

Toro Single Stage Snow Service Manual

2-23

Page 28

SPECIFICATIONS & MAINTENANCE

NOTES

2-24

Toro Single Stage Snow Service Manual

Page 29

CHAPTER 3 - CHASSIS

Power Clear® 18 Inch Snowthrower Main Frame – Lower ....................3-2

Power Clear® 18 Inch Snowthrower Main Frame – Housing .................3-3

Power Clear® 18 Inch Snowthrower Main Frame – Shroud ...................3-4

Power Clear® 18 Inch Snowthrower Main Frame – Upper Handle ........3-5

Power Clear® 18 Inch Snowthrower Main Frame – Lower ....................3-6

Power Clear® 21 Inch Snowthrower Main Frame – Housing .................3-7

Power Clear® 21 Inch Snowthrower Main Frame – Chute .......... 3-8 to 3-9

Power Clear® 21 Inch Snowthrower Main Frame – Handles ...............3-10

Power Clear® 21 Inch Snowthrower Main Frame – Power Shoot ........3-11

Power Clear® 21 Inch Snowthrower Main Frame – Shroud .................3-12

Power Clear® 21 Inch Snowthrower Main Frame – Quick Shoot .........3-13

Power Clear® 21 Inch Snowthrower Main Frame – Quick Shoot .........3-14

18 Inch Shroud Removal .....................................................................3-15

21 Inch Shroud Removal .....................................................................3-16

Quick Shoot Contols ............................................................................3-17

3

Chassis

Toro Single Stage Snow Service Manual

3-1

Page 30

CHASSIS

Power Clear® - 18 Inch Snowthrower

Main Frame – Lower

A

B

C

A. Side plate RH

B. Side plate LH

C. Belt Cover

D. Model/Serial Decal

3-2

D

Fig. 001

Toro Single Stage Snow Service Manual

Page 31

Power Clear® - 18 Inch Snowthrower

B

C

Main Frame – Housing

CHASSIS

3

Chassis

A

Fig. 002

A. Lower Handle

B. Scraper

C. Chute Retainer

Toro Single Stage Snow Service Manual

3-3

Page 32

CHASSIS

B

C

Power Clear® - 18 Inch Snowthrower

Main Frame – Shroud

A. Shroud Assembly

B. Lower Shroud LH

C. Lower Shroud RH

A

Fig. 003

3-4

Toro Single Stage Snow Service Manual

Page 33

Power Clear® - 18 Inch Snowthrower

B

Main Frame – Upper Handle

A

G

CHASSIS

F

3

Chassis

E

A. Clutch Bail E. Spring Cover

B. Handle Knob F. Upper Handle Assembly

C. Cable Clutch Adjuster G. Recoil Handle

D. Clutch Spring

Toro Single Stage Snow Service Manual

Fig. 004

3-5

Page 34

CHASSIS

B

C

Power Clear® - 18 Inch Snowthrower

Main Frame – Lower

A

A.ChuteDeectorAssembly

B. Discharge Chute

C. Chute Handle

3-6

Fig. 005

Toro Single Stage Snow Service Manual

Page 35

Power Clear® - 21 Inch Snowthrower

B

C

D

E

Main Frame – Housing

F

CHASSIS

H

3

Chassis

A

A. Scraper Blade E. Extension Spring

B. Auger Housing F. Lower Chute

C. Frame Brace G. Belt Cover

D. Clutch Cable Guide H. Model/Serial Decal

Toro Single Stage Snow Service Manual

G

Fig. 006

3-7

Page 36

CHASSIS

B

Power Clear® - 21 Inch Snowthrower

Main Frame – Chute

D

E

A

F

Fig. 007

A. Chute Ring E. Chute Seal Ring

B. Discharge Chute Assembly F. Chute Ring Gear

C.ChuteDeector

D. Chute Control Handle

3-8

Toro Single Stage Snow Service Manual

Page 37

Power Clear® - 21 Inch Snowthrower

B

C

D

Main Frame – Chute

A

L

F

G

CHASSIS

M

3

Chassis

K

E

J

I

H

A.DeectorTrigger E.Chute I. DetentPaw M.SealRingChute

B.ChuteDeector F. PinionGear J.ChuteSupportRing

C.RatchetDeectorHinge G.PinionBracket K.ChuteRingGear

D.DeectorSeal H.CableRetainer L.ChuteHandle

Toro Single Stage Snow Service Manual

Fig. 008

3-9

Page 38

CHASSIS

B

D

Power Clear® - 21 Inch Snowthrower

Main Frame – Handles

J

A

I

E

F

H

G

A. Upper Handle Assembly E. Clutch Cable Adjuster I. Rope Guide

B.ControlBail F. HandleLock J.RecoilHandle

C. Spring Cover G. Lower Handle

D. Clutch Extension Spring H. Handle Knob

3-10

Fig. 009

Toro Single Stage Snow Service Manual

Page 39

Power Clear® - 21 Inch Snowthrower

Main Frame – Power Shoot

E

A

CHASSIS

F

3

Chassis

J

A. Slider Handle RH E. Slider Pulley I. Trigger

B.ShortChuteCable F. SliderTrack J.CableBracket

C. Long Chute Cable G. Chute Lock Plate

D. Pulley Cover H. Slider Handle LH

G

I

H

Fig. 010

Toro Single Stage Snow Service Manual

3-11

Page 40

CHASSIS

B

Power Clear® - 21 Inch Snowthrower

Main Frame – Shroud

A

I

H

G

F

E

A. Gas Cap E. Lower Shroud H. Primer Bulb

B.ShroudAssembly F. ChokeKnob I. ExhaustBafe

C. Tank Seal G. On/Off Switch

D. Fuel T ank

3-12

Fig. 011

Toro Single Stage Snow Service Manual

Page 41

Power Clear® - 21 Inch Snowthrower

Main Frame – Quick Shoot

Illustration 1

CHASSIS

Illustration 2

3

Chassis

Toro Single Stage Snow Service Manual

Illustration 4

Illustration 3

Fig. 012

3-13

Page 42

CHASSIS

Power Clear® - 21 Inch Snowthrower

Main Frame – Quick Shoot

Illustration 5

Illustration 6

Illustration 7

3-14

Fig. 013

Toro Single Stage Snow Service Manual

Page 43

CHASSIS

B

A

A

A

A

B

B

18 Inch Shroud Removal

1. Remove key from ignition. Remove the screws

securing the lower shrouds (A). Remove the right and

left lower shrouds (B) (Fig. 014).

Fig. 014

2. Remove the belt cover. Disconnect the clutch cable

from the belt guide. Slide the cable through

the housing (Fig. 015).

3. Remove the shroud screws and fuel cap and remove

the shroud. Reinstall fuel cap (Fig. 016).

Fig. 016

3

Chassis

Toro Single Stage Snow Service Manual

Fig. 015

3-15

Page 44

CHASSIS

21 Inch Shroud Removal

1. Remove key from ignition. Remove the bolts that hold

the discharge chute to the chute seal ring

(Fig. 017).

Fig. 017

2. Remove the single screw holding the chute seal ring

Remove the ring (Fig. 018).

3. Remove the two rear screws holding the shroud to

the chassis. Remove the two front screws holding the

shroud to the chassis (Fig. 019).

Fig. 019

4. Remove the shroud (Fig. 020).

3-16

Fig. 020

Fig. 018

Toro Single Stage Snow Service Manual

Page 45

CHASSIS

A

Quick Shoot Contols

1. Remove the bolt holding the quick chute gear

assembly to the chute housing (Fig. 021).

Fig. 021

2. Remove the complete assembly. Remove pinion

spacer sleeve (A) Fig. 022).

3. With a pliers, compress the cable locks and remove

the cables from the pinion bracket (Fig. 023).

Fig. 023

4. Turn the gear assembly over and remove the

cable retainer (Fig. 024).

3

Chassis

Toro Single Stage Snow Service Manual

Fig. 024

Fig. 022

3-17

Page 46

CHASSIS

5. With the cable retainer removed, note the direction

of the cable wrapping (Fig. 025).

Fig. 025

6. To re-wrap the cables, refer to the following steps

and the illustrations on pages 3-13 and 3-14. With

the pinion gear facing up, the black cable is routed

furthest to the bottom of the gear. Insert the barrel

end of the cable into the hole and secure the cable

under the tab in the gear (Fig. 026).

7. Wrap the cable around the bottom of

the spool (Fig. 027).

Fig. 027

8. When the cable is fully wrapped, it should look

like this (Fig. 028).

3-18

Fig. 028

Fig. 026

Toro Single Stage Snow Service Manual

Page 47

CHASSIS

9. Insert the barrel of the grey cable into its slot in the

gear. Secure the cable under the tabs in the gear

(Fig. 029).

Fig. 029

10. Route the cable around the top of the spool (Fig. 030).

12. Slide the gear into the pinion bracket and secure the

cable locks (Fig. 032).

Fig. 032

13. Align the quick chute control and the discharge chute

asoutlinedinthespecicationsandmaintenance

chapter. Insert the pinion spacer sleeve and insert

the pinion and bracket assembly as shown. Tighten

bolt to 8 ft-lbs (11 Nm) (Fig. 033).

3

Chassis

Fig. 030

11. When the cables are routed correctly the cables and

gear should look like this (Fig. 031).

Fig. 031

Toro Single Stage Snow Service Manual

Fig. 033

NOTE

Do not overtighten!

3-19

Page 48

CHASSIS

NOTES

3-20

Toro Single Stage Snow Service Manual

Page 49

CHAPTER 4 - POWER PROPEL SYSTEM

Power Clear® - 18 Inch Snowthrower Rotor Assembly .......4-2

Power Clear® - 18 Inch Snowthrower Drive System ...........4-3

Power Clear® - 21 Inch Snowthrower Rotor Assembly .......4-4

Power Clear® - 21 Inch Snowthrower Drive System ...........4-5

18 Inch Rotor Removal & Replacement .............................4-6

21 Inch Rotor Removal & Replacement .............................4-8

Paddle Replacement (All Models) ....................................4-10

18 Inch Scraper Removal & Replacement .......................4-11

21 Inch Pivoting Scraper Removal & Replacement..........4-12

4

Power Propel System

Toro Single Stage Snow Service Manual

4-1

Page 50

POWER PROPEL SYSTEM

A

B

Power Clear® - 18 Inch Snowthrower

Rotor Assembly

C

D

E

F

A. Side Plate Cap E. Rotor Blade

B. Ball Bearing F. Rotor Assembly

C. Bearing Flange

D. Thrust Washer

4-2

Fig. 001

Toro Single Stage Snow Service Manual

Page 51

POWER PROPEL SYSTEM

A

B

Power Clear® - 18 Inch Snowthrower

Drive System

D

C

F

E

G

4

Power Propel System

A. Engine Pulley E. Idler Arm

B. Ribbed V-Belt F. Rotor Pulley Assembly

C. Belt Guide G. Idler Pulley

D. Clutch Cable

Toro Single Stage Snow Service Manual

Fig. 002

4-3

Page 52

POWER PROPEL SYSTEM

A

B

Power Clear® - 21 Inch Snowthrower

Rotor Assembly

A. Rotor Blade

B. Rotor

4-4

Fig. 003

Toro Single Stage Snow Service Manual

Page 53

Power Clear® - 21 Inch Snowthrower

A

B

Drive System

POWER PROPEL SYSTEM

F

E

D

4

Power Propel System

C

A. Rotor Pulley Assembly E. Idler Arm

B. Drive Belt F. Engine Pulley

C. Idler Pulley G. Pinion Bracket

D. Clutch Cable H. Cable Retainer

Toro Single Stage Snow Service Manual

Fig. 004

4-5

Page 54

POWER PROPEL SYSTEM

A

B

B

A

B

B

A

A

18 Inch Rotor Removal & Replacement

1. Remove the belt cover. Remove the drive belt (A)

and the rotor pulley (B) (Fig. 005).

Fig. 005

2. Remove the three rotor bearing screws on the belt

side of the housing (Fig. 006).

3. Remove the three rotor bearing screws on the

opposite side of the housing (Fig. 007).

Fig. 007

4. Remove three bolts holding the side plate to the

rotor housing (A). Loosen the wheel bracket

bolts (B) (Fig. 008).

4-6

Fig. 006

Fig. 008

Toro Single Stage Snow Service Manual

Page 55

POWER PROPEL SYSTEM

A

5. Pull the side plate out slightly to gain clearance to

get the rotor out (Fig. 009).

Fig. 009

6. Lift rotor assembly out of the housing (Fig. 010).

8. Slide rotor back into the housing. Reinstall the bolts

and torque to 8 ft-lbs (11 Nm) (Fig. 012).

Fig. 012

9. Re-install the rotor pulley and drive belt. Torque rotor

pulley bolt to 8 ft-lbs (11 Nm) (Fig. 013).

7. Replace rotor parts as required (Fig. 011).

4

Power Propel System

Fig. 010

Fig. 013

10. Re-install the belt cover. Torque bolts to 8 ft-lbs

(11 Nm).

Toro Single Stage Snow Service Manual

Fig. 011

4-7

Page 56

POWER PROPEL SYSTEM

B

A

21 Inch Rotor Removal & Replacement

1. Remove the belt cover. Remove the drive belt (A)

and the rotor pulley (B) (Fig. 015).

Fig. 015

2. Remove the three rotor bearing screws on the belt

side of the housing (Fig. 016).

3. Remove the three rotor bearing screws on the

opposite side of the housing (Fig. 017).

Fig. 017

4. Remove the rotor assembly from the housing.

(Fig. 018).

4-8

Fig. 016

Fig. 018

Toro Single Stage Snow Service Manual

Page 57

POWER PROPEL SYSTEM

5. Remove the bearing spacer bolt and bearing spacer.

6. Removebearingsandanges.Replacerotorparts

as required (Fig. 019).

Fig. 019

7. Re-install the bearing spacer and bolt. Torque bolt to

20 ft-lbs (27 Nm) (Fig. 020).

8. Re-install the rotor assembly into the housing.

Re-install the rotor bearing screws. Torque to

8 ft-lbs (11 Nm) (Fig. 021).

Fig. 021

9. Re-install the drive belt and rotor pulley. Torque the

rotor pulley bolt to 8 ft-lbs (11 Nm) (Fig. 022).

4

Fig. 020

Power Propel System

Fig. 022

10. Re-install the belt cover. Torque the bolts to 8 ft-lbs

(11 Nm).

Toro Single Stage Snow Service Manual

4-9

Page 58

POWER PROPEL SYSTEM

Paddle Replacement (All Models)

1. With the rotor assembly removed from the housing,

remove the Torx™ fasteners (Fig. 023).

Fig. 023

2. Remove the two inner bolts holding the paddle to the

rotor (A) (Fig. 024).

3. Remove the paddle. Be sure to remove the rotor

blade spacers (A) and install them in the

new paddles (Fig. 025).

Fig. 025

4. Install new paddles and install rotor assembly back

into the housing.

4-10

Fig. 024

Toro Single Stage Snow Service Manual

Page 59

POWER PROPEL SYSTEM

18 Inch Scraper Removal & Replacement

1. Remove the three bolts attaching the scraper to

the frame.

2. Install a new scraper. Torque bolts to 16 in-lbs

(0.184 kg-m) (Fig. 26).

Fig. 026

4

Power Propel System

Toro Single Stage Snow Service Manual

4-11

Page 60

POWER PROPEL SYSTEM

21 Inch Pivoting Scraper Removal & Replacement

1. Remove the spring from each side of the scraper

(Fig. 027)

Fig. 027

2. Remove the bolts from each side of the scraper

(Fig. 028).

3. Remove the scraper from housing (Fig. 029).

Fig. 029

4. Insert new scraper. Re-install springs and bolts.

Torque bolts to 20 ft-lbs (27 Nm) (Fig. 30).

Toro Single Stage Snow Service Manual

Fig. 030

Fig. 028

4-12

Page 61

CHAPTER 5 - ENGINE MOUNTING

Power Clear® - 18 Inch Snowthrower Engine Mounting ........5-2

Power Clear® - 21 Inch Snowthrower Engine Mounting ........5-3

Engine Removal 18 Inch Models ...........................................5-4

Engine Installation 18 Inch Models ........................................5-5

Engine Removal 21 Inch Models ...........................................5-6

Engine Installation 21 Inch Models ........................................5-8

5

Engine Mounting

Toro Single Stage Snow Service Manual

5-1

Page 62

ENGINE MOUNTING

A

B

Power Clear® - 18 Inch Snowthrower

Engine Mounting

C

D

A. Tank Seal

B. Woodruff Key

C. Choke Lever

5-2

Fig. 001

Toro Single Stage Snow Service Manual

Page 63

Power Clear® - 21 Inch Snowthrower

A

B

Engine Mounting

E

ENGINE MOUNTING

D

A. LC168FS Engine E. Choke Link Knob

B. PTO Engine Plate

C. Side Engine Support

D. Engine Support

C

5

Engine Mounting

Fig. 002

Toro Single Stage Snow Service Manual

5-3

Page 64

ENGINE MOUNTING

AAA

A

A

A

Engine Removal 18 Inch Models

1. Remove the shroud as outlined in Chapter 3.

2. Remove the belt cover and remove belt as outlined

in chapter 2.

3. Remove the engine pulley bolt and remove pulley

(Fig. 003).

Fig. 003

4. From the underside of the chassis, remove the two

engine mounting bolts (A) (Fig. 004).

5. Remove the four engine mounting bolts that connect

the engine to the side plate (A) (Fig. 005).

Fig. 005

6. Remove the engine from the chassis (Fig. 006).

5-4

Fig. 006

Fig. 004

For engine service information,

see Single Stage Snow Engine

Service Manual LC154FS/

LC154FDS (87cc), PN 492-9233

or LC168F/LC168FD (163 cc),

PN 492-9230

Toro Single Stage Snow Service Manual

Page 65

A

A

Engine Installation 18 Inch Models

ENGINE MOUNTING

1. Insert the engine into the chassis. Install the four

engine mounting bolts that connect the engine to the

side plate (A). Torque to 14-18 ft-lbs (19-25 Nm)

(Fig. 007).

Fig. 007

2. From the underside of the chassis, install the two

engine mounting bolts (A). Torque to 14-18 ft-lbs

(19-25 Nm) (Fig. 008).

3. Install the engine pulley. Torque bolt to 19 ft-lbs

(26 Nm) (Fig. 009).

Fig. 009

4. Install the belt as outlined in chapter 2. Install belt

cover. Install shroud as outlined in chapter 2.

Fig. 008

5

Engine Mounting

Toro Single Stage Snow Service Manual

5-5

Page 66

ENGINE MOUNTING

Engine Removal 21 Inch Models

1. Remove the shroud as outlined in chapter 3.

2. Empty the fuel from the fuel tank into a suitable

container. Remove the fuel hose and remove the

fuel tank.

3. Remove the screw from the underside of the choke

knob and remove the choke knob (Fig. 010).

5. Route the recoil rope through the lower shroud and

knot the rope (Fig. 012).

Fig. 012

6. Disconnect the primer hose from the primer bulb and

remove the ignition wires from the ignition switch.

(Fig. 013).

4. Untie the knot on the recoil handle (Fig. 011).

Fig. 010

Fig. 013

Fig. 011

5-6

Toro Single Stage Snow Service Manual

Page 67

ENGINE MOUNTING

A

A

AAA

A

7. From the underside of the chassis, remove the two

engine mounting bolts (A) (Fig. 014).

Fig. 014

8. Remove the belt cover and belt as outlined in

chapter 2 (Fig. 015).

11. Remove the four engine mounting bolts that secure

the engine to the engine plate (A) (Fig. 017).

Fig. 017

12. Remove the engine from the chassis (Fig. 018).

9. Remove the engine pulley.

Fig. 015

10. On some models, the engine pulley has two set

screws. One is an allen head set screw and the

other is a bolt. Be sure to loosen both set screws

before attempting removal (Fig. 016).

Fig. 016

5

Fig. 018

Engine Mounting

Toro Single Stage Snow Service Manual

5-7

Page 68

ENGINE MOUNTING

A

A

A

A

A

A

Engine Installation 21 Inch Models

1. Insert the engine into the chassis. Install the four

engine mounting bolts that secure the engine to the

engine plate (A). Torque to 14-18 ft-lbs (19-25 Nm)

(Fig. 019).

Fig. 019

2. From the underside of the chassis, install the two

engine mounting bolts (A). Torque to 14-18 ft-lbs

(19-25 Nm) (Fig. 020).

3. Install the engine pulley. If the unit has a bolt holding

the engine pulley on, torque the bolt to 19 ft-lbs (26

Nm). If the unit has set screws, slide the pulley onto

the shaft and install the belt. With a straight edge,

align the pulley with the rotor pulley so the belt is

straight.Tighten set screws (Fig. 021).

Fig. 021

4. Connect the primer hose to the primer bulb and plug

the ignition wires into the ignition switch (Fig. 022).

5-8

Fig. 020

Fig. 022

Toro Single Stage Snow Service Manual

Page 69

5. Untie the recoil rope knot and route the rope through the

lower shroud. Install the recoil handle and knot the rope

(Fig. 023).

Fig. 023

6. Slide the choke wire through the lower shroud and

install the choke knob and screw (Fig. 024).

ENGINE MOUNTING

Fig. 024

7. Install the fuel tank and connect the fuel line.

8. Install the belt cover and shroud as outlined in chapter 2.

5

Engine Mounting

Toro Single Stage Snow Service Manual

5-9

Page 70

ENGINE MOUNTING

NOTES

5-10

Toro Single Stage Snow Service Manual

Page 71

Page 72

Residential Products

2014 Power Clear® 418/621

2014 Power Clear® 418/621

Service Manual

Service Manual

Form Number 492-9340

Loading...

Loading...