Page 1

Introduction

Built on proven technologies and components, the Toro P-220 Series plastic valves are

tough, have excellent performance and are extremely reliable.

A self-cleaning metering system and 220 PSI rating assures years of trouble-free

performance.

In commercial installations, it is advantageous to install the valves in a valve box. This

enables the valve to be easily located, accessed and maintained. The use of clean

aggregate in the the bottom of the box, and locating the valve box away from structures,

potential hardscaping features (such as sidewalks) and large planting locations is

recommended. Additionally, valve box locations generally should be in shrub beds and

at right angles to structure locations. If the valves are installed below grade without a

valve box, access to the top of the valve should be provided by using a section of

4" PVC pipe and a Toro Valve Cover (P/N 850-00) installed directly over each valve.

Features:

220 PSI maximum pressure rating

Removable, self-cleaning metering system

Precise pressure control with compact EZReg dial design (pressure regulating models)

Pressure regulated in electric and manual modes, serviceable under pressure

Schrader-type valve for pressure gauge attachment

Manual flow control: adjustable to zero flow

Internal manual bleed screw: bleeds internally downstream

External manual bleed screw: bleeds to atmosphere, allows cleaning of metering rod and provides maximum flushing

Specifications:

Models:

P-220 Series electric, and electric pressure regulating -

1", 1

1

⁄2", 2" and 3"

Body Style:

Globe/Angle with Female Threads (all models)

BSP Threads Available

Dimensions:

1" – 6

1

⁄4" H x 33⁄4" W

1

1

⁄2" — 61⁄2" H x 35⁄8" W

2" — 9

1

⁄2" H x 61⁄8" W

3" — 101⁄4" H x 61⁄8" W

Flow range:

1" — 5-50 GPM

1

1

⁄2" — 30-110 GPM

2" — 80-180 GPM

3" — 150-300 GPM

Burst pressure safety rating: 750 PSI

P-220 Series Plastic Valves

Installation Instructions

Operating pressure:

Electric models: 10-220 PSI maximum

Pressure regulating models:

EZR-30 (5-30 PSI, ± 3 PSI)

EZR-100 (5-100 PSI, ± 3 PSI)

Minimum pressure differential (between inlet and outlet): 10 PSI

Solenoid (standard): 24 V a.c.

Inrush: 0.40 amps, 11.50 VA

Holding: 0.20 amps, 5.75 VA

Voltage Requirement (based on inlet pressure):

22.5 V a.c. @ 220 PSI

21.1 V a.c. @ 200 PSI

20.2 V a.c. @ 175 PSI

19.1 V a.c. @ 150 PSI

18.2 V a.c. @ 125 PSI

16.1 V a.c. @ 75 PSI

16.0 V a.c. @ 50 PSI

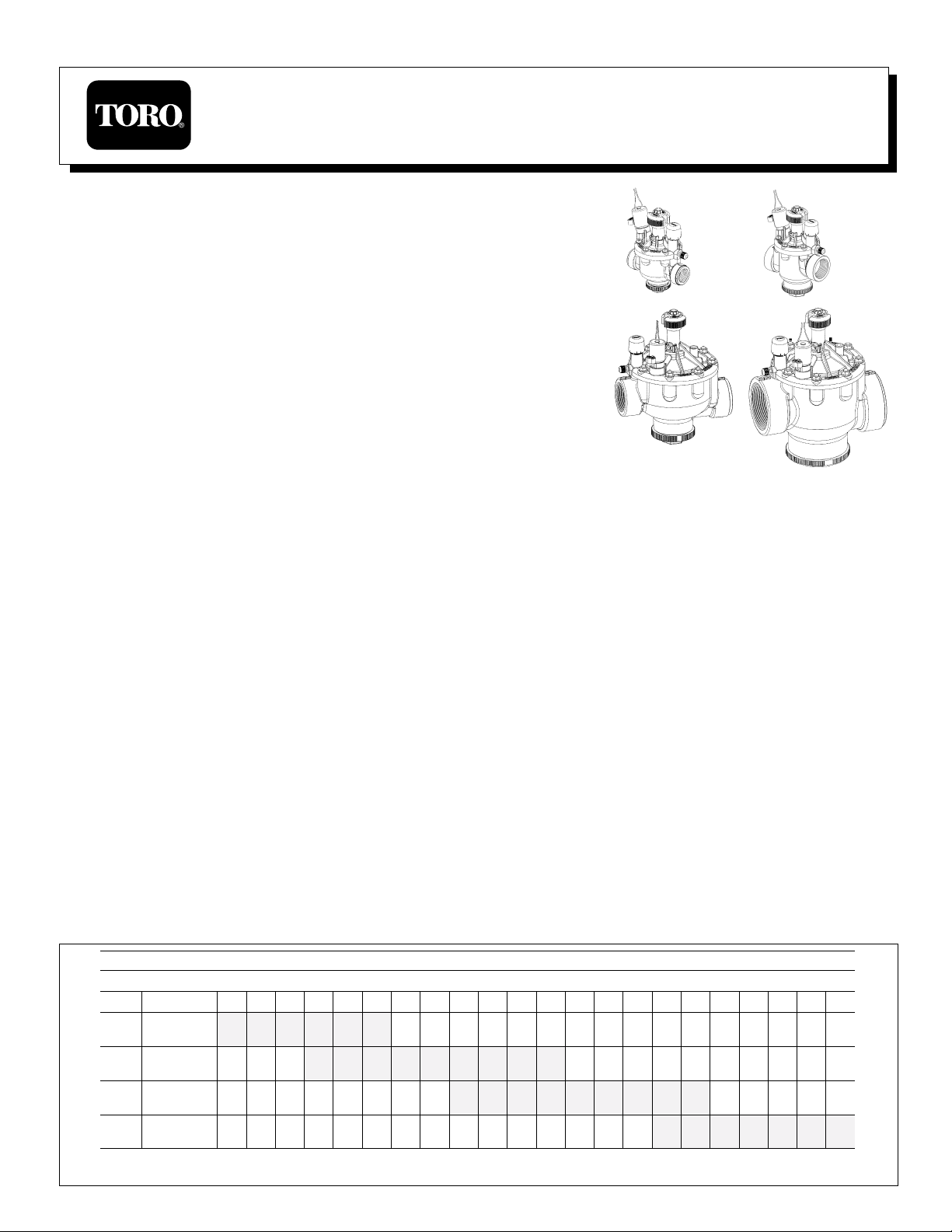

P-220, 1"

P-220, 1

1

⁄2"

P-220, 2"

P-220, 3

"

Size Configuration 5 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 180 200 225 250 275 300

1"

11⁄2"

2"

3"

Notes: For optimum performance when designing a system, be sure to calculate total friction loss to ensure sufficient downstream pressure.

Globe 4.00 4.20 3.20 4.10 7.20 10.90

Angle 4.00 4.20 3.10 2.70 4.80 7.90

Globe 1.60 2.30 3.60 5.20 7.00 9.20 11.70 14.40 17.50

Angle 1.30 1.60 2.80 4.00 5.50 7.10 9.00 11.00 13.30

Globe 2.10 2.70 3.30 4.00 4.80 5.60 6.50 7.50 8.05

Angle 1.20 1.60 2.00 2.40 2.80 3.30 3.90 4.40 5.10

Globe 2.50 3.00 4.10 5.30 6.70 8.30 10.10

Angle 1.90 2.40 3.30 4.30 5.50 6.90 8.50

For optimum regulation performance, size regulating valves toward the higher flow ranges.

Friction Loss — U.S. (PSI)

GPM Flow

Page 2

Installation Guidelines

• Note the flow direction arrows on the bonnet or body and install accordingly

CAUTION: Using pipe dope on valve connections can cause thread damage and failure of the valve body.

Use only teflon tape or pipe thread sealant.

• The valve can be installed at any angle without af

fecting operation.

• The valve body plug and o-ring must be properly installed in the unused inlet.

•

•Waterproof wire splice connectors are absolutely essential for proper electric control system operation. Follow the installation

instructions provided with the connectors for optimum waterproof splice protection.

• Leaving a wire expansion loop at each valve location on long-run wire lengths is recommended.

Valve Operation and Adjustment

Flow Control

The flow control is used to reduce the flow and pressure to valve outlet. By turning the control handle clockwise, the flow will be

gradually reduced to zero.

• For valve models without EZReg, adjust the flow control as necessary for optimum sprinkler performance.

• For valve models with EZReg, the flow control should remain in the fully open position. Use only for emergency shut off or

for valve zone fine tuning.

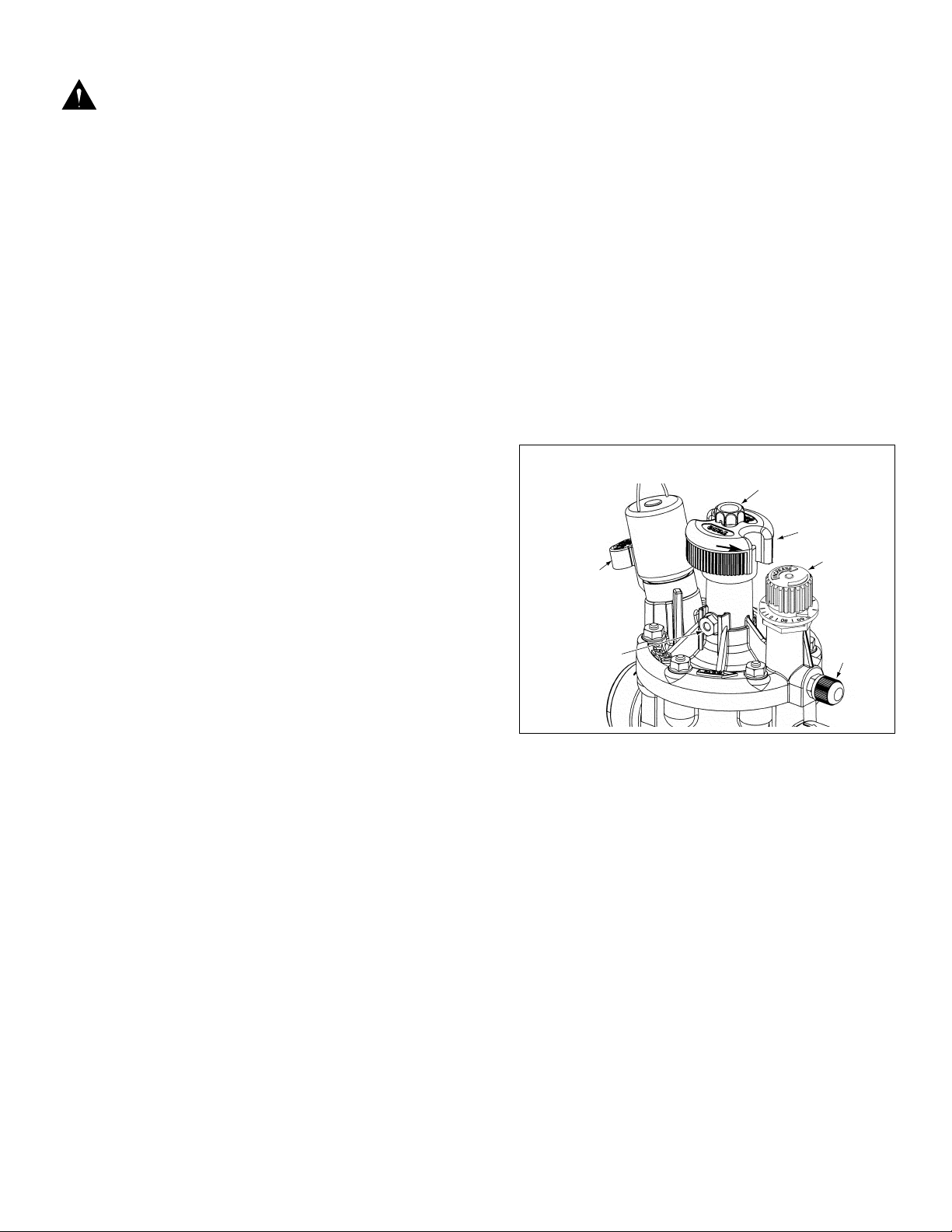

Internal Manual Bleed Knob

The internal manual bleed system is used to manually operate the

valve. Turning the internal bleed knob (located beneath the solenoid)

counterclockwise allows water to bleed downstream from the

diaphragm chamber. Internal pressure is relieved from the top of the

diaphragm, allowing the valve to open. Turning the bleed knob

clockwise until tight shuts off the discharge enabling pressure to

build within the diaphragm chamber, causing the valve to close.

External Manual Bleed Knob (flush mode)

The external manual bleed knob, located on top of the flow control

handle, is used for system flushing. Turning this knob

counterclockwise allows water in the diaphragm chamber to vent to

atmosphere, creating maximum opening power and debris flushing

action. This operation bypasses the regulator (if installed) and opens

the valve fully, regardless of regulator setting. In addition, the

metering rod (attached to the external bleed knob) can be easily

removed for cleaning as necessary.

EZReg Adjustment (pressure regulating models only)

An accurate, adjustable dial, coupled with a forward-flow valve design, allows the P-220 series valve with EZReg to regulate

downstream water pressure with precision. It’s easy and simple to use and requires only 10 PSI differential pressure to

operate. The EZReg will operate during powered and manual valve operation using internal manual bleed.

To adjust the downstream pressure, remove the cover from the regulator dial, then turn the dial until the pointer is on the

desired pressure of 5-30 PSI (EZR-30) or 5-100 PSI (EZR-100).

Note: Due to the micro-adjustment feature of the EZReg, the dial requires 10 revolutions for complete regulation range.

Operate the valve (electrically or manually). Check the flow control to confirm that it is in the fully open position. Adjust the

regulator dial if necessary for optimum sprinkler operation.

To confirm the downstream pressure using a pressure gauge, remove the cap from the Schrader-type valve located directly

below the EZReg. Attach a Toro pressure gauge (Model 995-51) to the Schrader-type valve for a direct reading. Adjust the

EZReg dial as necessary for the desired pressure.

Note: The valve will remain watertight in the closed position if removal of the EZReg assembly is required.

© 2004 The Toro Company, Irrigation Division Form Number 373-0102 Rev. B

External Manual

Bleed Knob

Flow Control

Knob

Internal Manual

Bleed Knob

Spare Bonnet

Nut

EZReg

Schrader

V

alve

Figure 1

Use direct-burial wire, utilizing different color codes for each station control wire and one color for the common wire to all valves.

Loading...

Loading...