Page 1

P220G Series Plastic Valve

P220G Series Plastic Valve

Installation and Operating Instructions

Installation and Operating Instructions

Introduction

e P220G Series valves are available in two operation and

two activation types.

Operation

• P220G is intended for golf and commercial applications with

normal water conditions.

• P220GS “Scrubber Valve” models are intended for applications with dirty

water conditions. ese models include Toro’s patented “ACT” system

with a rotating turbine that continuously cleans the stainless steel screen

during operation.

P220 (G,S)

1”

P220 (G,S)

1½”

Activation

AC powered - For satellite systems, the 24 VAC Spike Guard solenoid

P220 (G,S)

2”

provides 20,000 volt lightning protection to minimize down time and service

costs. Moreover, it draws less than half the wattage of traditional solenoids for

a lower long-term cost of ownership.

DC powered - For GDC 2-wire systems, a DC-latching solenoid reduces the

system wire load to lower initial system cost. It is activated by a momentary

pulse “on” and “o”, meaning there is no continuous power draw, providing a

lower long-term cost of ownership.

e P220G EZReg pressure regulator adjusts easily with the micro-adjust dial

and indicator to provided constant downstream pressure between 5-100 psi (,34-6,9 bar).

Note: e P220G valve should be installed below grade in a valve box or vault (see page 2) to provide service access and vandal

resistance. e valve installation site should be readily accessible by grounds maintenance personnel and well clear of hardscape

features, cart paths, and foot trac areas.

Specifications

Conguration

• globe and angle forward ow

• plastic and stainless steel construction

• 1” (25 mm), 1 ½” (40 mm),

2” (50 mm)

NPT and BSP models

• electric actuation

• pressure regulating

Dimensions

1” 6¾” H x 3⅝” W

25 mm 171 mm H x 92 mm W

1½” 7¼” H x 3⅝” W

40 mm 184 mm H x 92 mm W

2” 7½” H x 6⅛” W

50 mm 241 mm H x 156 mm W

Operating Pressure Range

• Inlet - 1” and 1½” models:

10-220 psi (,69-15,2 bar)

• Inlet - 2” models:

20-220 psi (1,39 - 15,2 bar)

• Outlet: 5-100 +/- 3 psi

(,34-6,89 bar +/- ,2 bar)

• minimum inlet / outlet dierential:

10 psi (,69 bar)

• burst pressure safety rating:

750 psi (51,7 bar)

SpikeGuard solenoid

(for satellite control systems)

24 VAC, 50/60 Hz

Inrush - 0.12 amps

Holding - 0.10 amps

Diaphragm

EPDM diaphragm for improved

chlorine resistance

Manual Flow Control

adjustable to zero ow

Manual Bleed

enables manual valve operation

bleeds o water internally downstream

EZReg Pressure Regulator

• compact, precision-dial design

• regulates during automatic and

manual operation

• serviceable while valve is pressurized

• poppet valve (Schrader-type) for

downstream pressure verication

Flow Range

1” (25 mm) 5-40 gpm

19-151 lpm

1½” (40 mm) 30-100 gpm

114-379 lpm

2” (50 mm) 80-180 gpm

303-681 lpm

DC-latching solenoid

(for GDC 2-Wire control systems)

momentary low-voltage pulse

1

Page 2

Installation

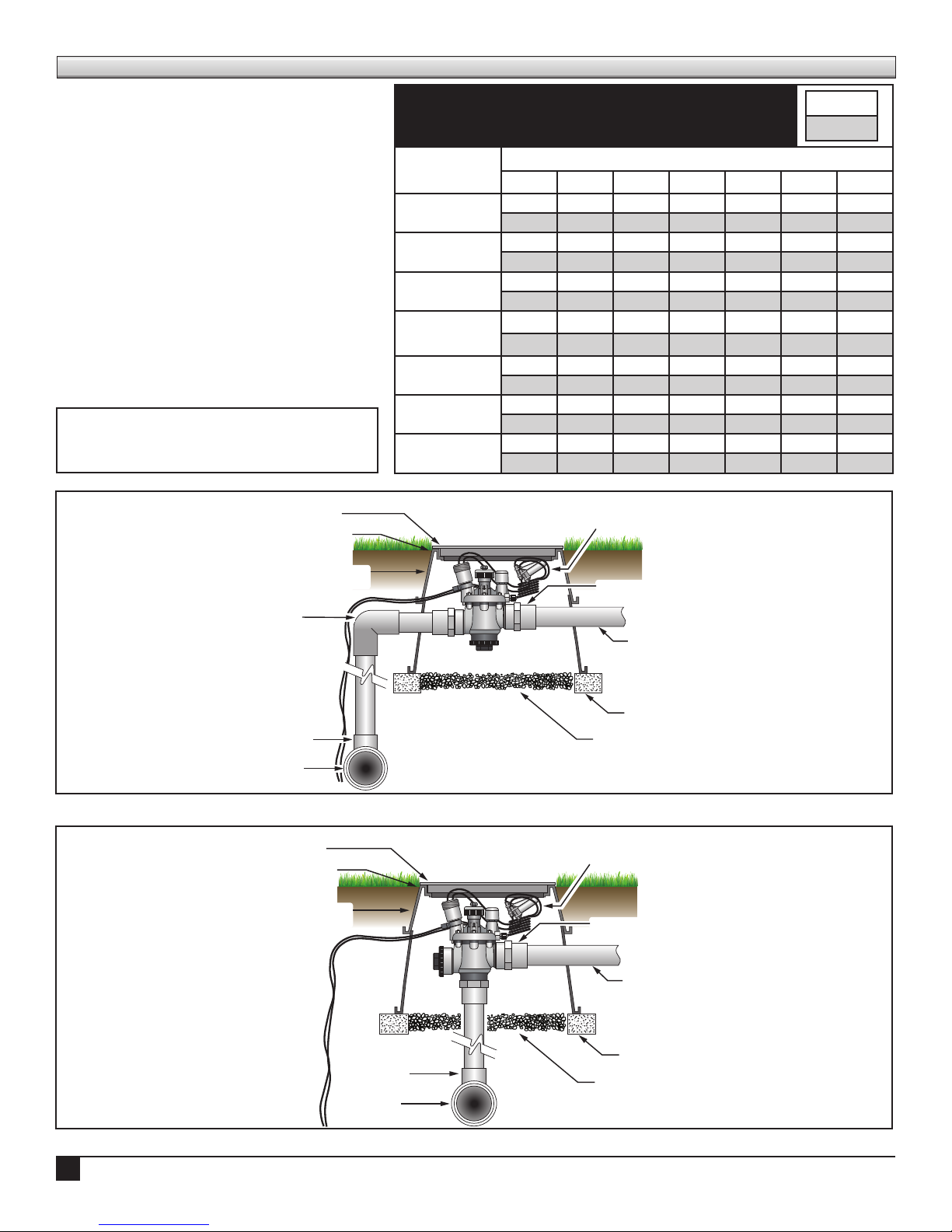

• Note the ow direction arrow in the side of the

valve body and install accordingly.

• e valve can be installed at any angle without

aecting operation.

• Use direct-burial irrigation control wire for

connection from the controller to valves.

• Leave a 12” (305 mm) wire expansion loop at

each valve location on long-run wire lengths.

• Waterproof wire splice connectors are

absolutely essential for proper electric control

system operation. Follow the installation

instructions provided by the connector

manufacturer for optimum performance.

* Distances specied under the following

conditions: minimum voltage: 20 VAC, amperage:

0.12A, operating pressure: 150 psi (10,3 bar).

Chart showing the maximum one-way wire distance

between controller and valve solenoid *

Common Wire

Gauge Size

18

16

14

18 16 14 12 10 8 6

2040 2520 2940 3280 3540 3720 3860

622 768 896 1000 1079 1134 1177

2520 3260 4000 4660 5220 5620 5920

768 994 1219 1420 1591 1713 1804

2940 4000 5180 6360 7420 8300 8960

896 1219 1579 1939 2262 2530 2731

Control Wire Gauge Size

3280 4660 6360 8240 10100 11800 13180

12

10

8

6

1000 1420 1939 2512 3078 3597 4017

3540 5220 7420 10100 13180 16060 18770

1079 1591 2262 3078 4017 4895 5721

3720 5260 8300 11800 16060 20800 25540

1131 1603 2530 3597 4895 6340 7785

3860 5960 8960 13180 18700 25540 33080

1177 1817 2731 4017 5700 7785 10083

feet

meters

TORO TVB MODEL

VALVE BOX & COVER

FINISHED GRADE

TORO TVB MODEL

VALVE BOX EXTENSION

(if required)

ELBOW

MAIN LINE

TEE

OR ELBOW

TORO TVB MODEL

VALVE BOX & COVER

FINISHED GRADE

TORO TVB MODEL

VALVE BOX EXTENSION

(if required)

CONTROL WIRES WITH 12”

SERVICE COIL AND WATERPROOF

WIRE SPLICE CONNECTORS

MALE ADAPTER (TYP.)

LATERAL LINE

CONTINUOUS BRICK SUPPORT

CLEAN AGGREGATE

(305 mm)

side inlet installation

CONTROL WIRES WITH 12”

SERVICE COIL AND WATERPROOF

WIRE SPLICE CONNECTORS

MALE ADAPTER (TYP.)

(305 mm)

2

MAIN LINE

TEE

OR ELBOW

LATERAL LINE

CONTINUOUS BRICK SUPPORT

CLEAN AGGREGATE

bottom inlet installation

Page 3

Valve Adjustment

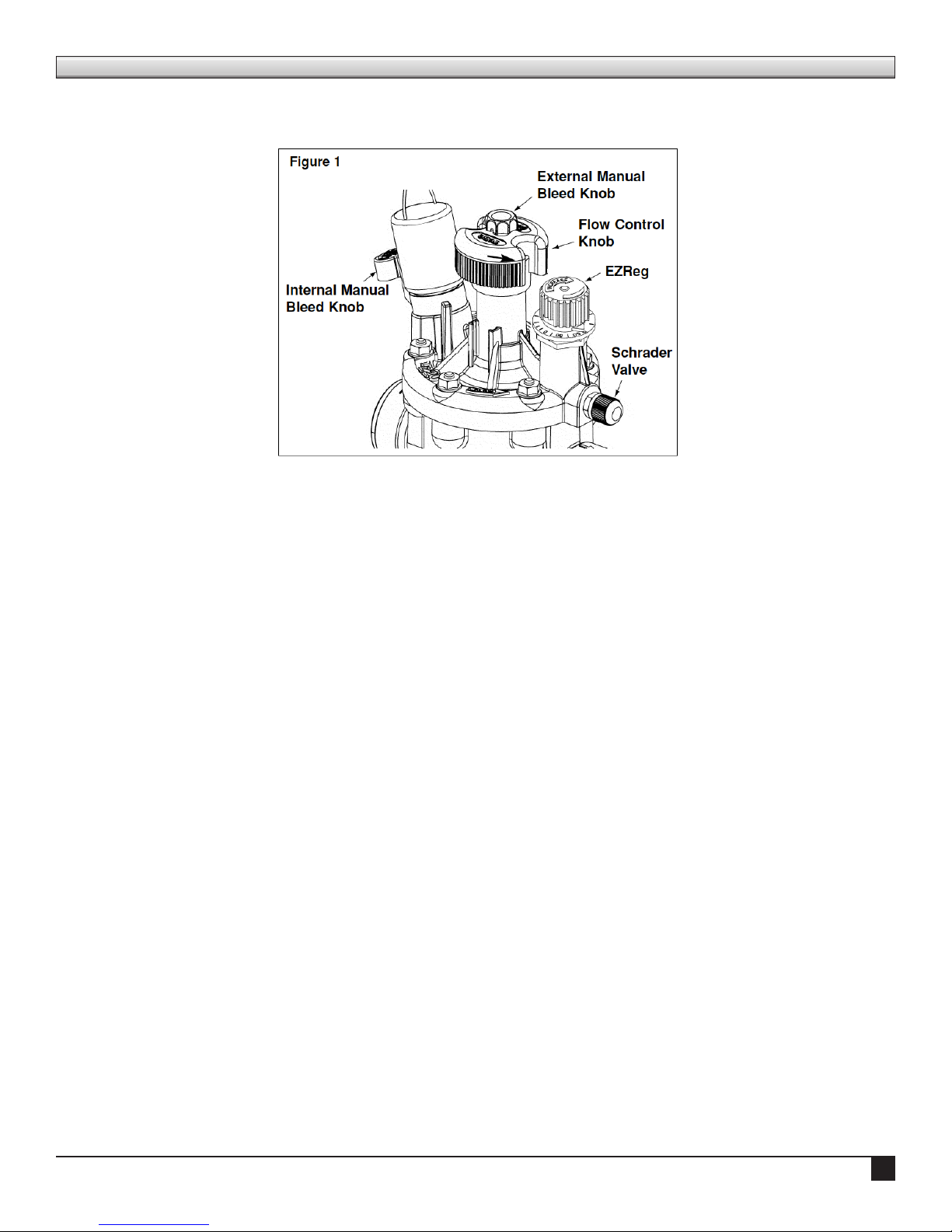

Flow Control

e ow control is used to reduce the ow and pressure to

valve outlet. By turning the

ow control handle clockwise,

the ow will be gradually

reduced to zero.

Note: e ow control

should remain in the fully

open position. Use only for

emergency shut o or for valve

zone ne-tuning.

Internal Bleed Knob Downstream pressure

regulation maintained

e internal manual bleed

system is used to manually

operate the valve. Turning

the internal bleed knob

(located beneath the solenoid)

counterclockwise allows water

to bleed downstream from the diaphragm chamber. Internal

pressure is relieved from the top of the diaphragm, allowing

the valve to open. Turning the bleed knob clockwise until

tight shuts o the discharge enabling pressure to build within

the diaphragm chamber, causing the valve to close.

External Manual Bleed Knob (ush mode)

e external manual bleed knob, located on top of the ow

control handle, is used for system ushing. Turning this knob

counterclockwise allows water in the diaphragm chamber to

vent to atmosphere, creating maximum opening power and

debris ushing action. is operation bypasses the regulator

and opens the valve fully, regardless of regulator setting. In

addition, the metering rod (attached to the external bleed

knob) can be easily removed for cleaning as necessary.

EZReg Adjustment

An accurate, adjustable dial, coupled with a forward-ow

valve design, allows the P220

series valve with EZReg to

regulate downstream water

pressure with precision.

It’s easy and simple to use

and requires only 10 PSI

dierential pressure to operate.

e EZReg will operate

during powered and manual

valve operation using internal

manual bleed.

To adjust the downstream

pressure, remove the cover

from the regulator dial, then

turn the dial until the pointer

is on the desired pressure of

5-100 PSI (EZR-100).

Note: Due to the microadjustment feature of the EZReg, the dial requires 10

revolutions for complete regulation range.

Operate the valve (electrically or manually). Check the

ow control to conrm that it is in the fully open position.

Adjust the regulator dial if necessary for optimum sprinkler

operation.

To conrm the downstream pressure using a pressure gauge,

remove the cap from the Schrader-type valve located directly

below the EZReg. Attach a Toro pressure gauge (Model 995-

51) to the Schrader-type valve for a direct reading. Adjust the

EZReg dial as necessary for the desired pressure.

Note: e valve will remain watertight in the closed position

if removal of the EZReg assembly is required.

3

Page 4

Friction Loss Charts

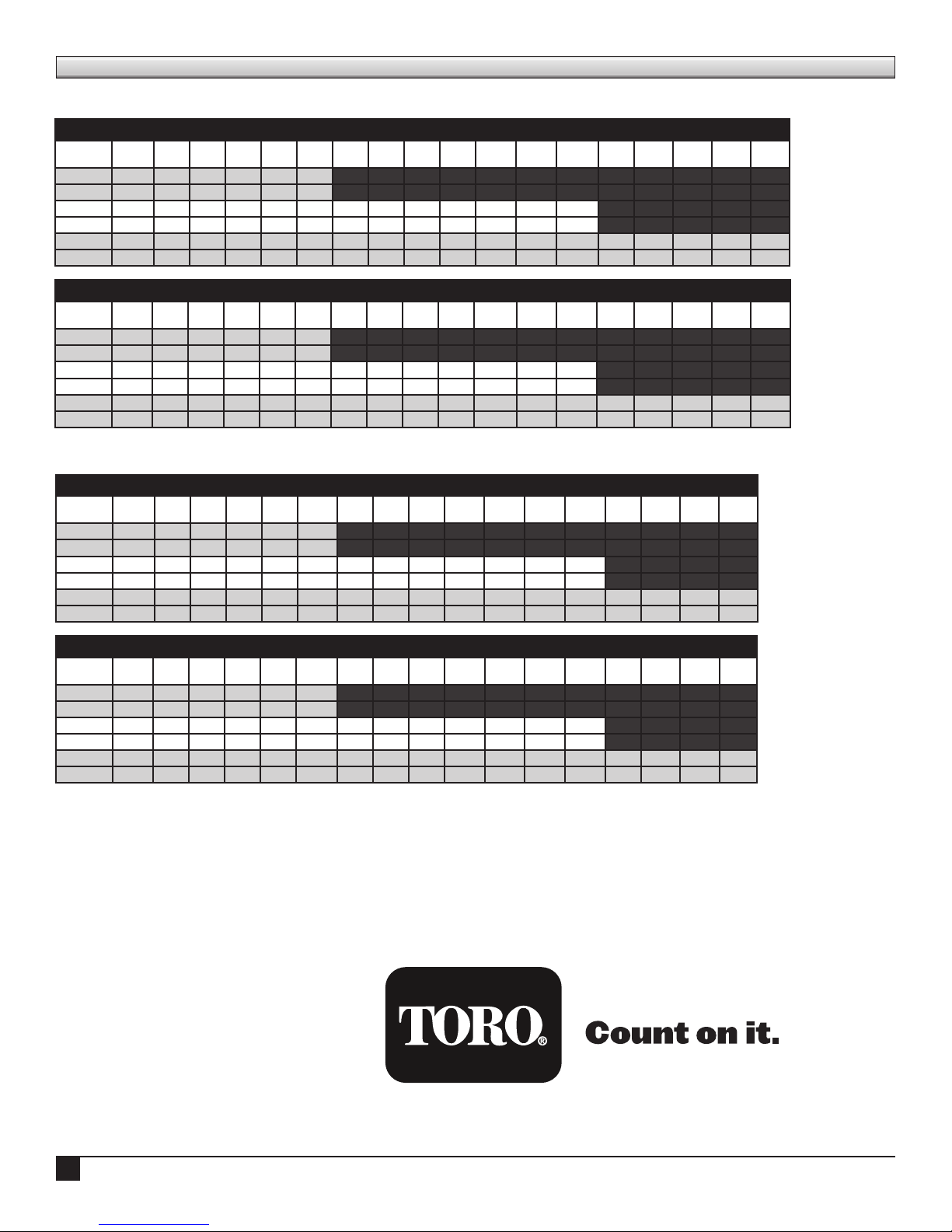

P220G Standard Valves

Friction Loss in PSI

GPM

Type 5 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 180

1”

1 1/2”

2”

Friction Loss in BAR

LPM

25 mm

40 mm

50 mm

globe 4.00 4.20 3.20 4.10 7.20

angle 4.00 4.20 3.10 2.70 4.80

globe 1.60 2.30 3.60 5.20 7.00 9.20 11.20 13.60 16.40

angle 1.30 1.60 2.80 4.00 5.50 7.10 8.90 10.90 13.50

globe 2.10 2.70 3.30 4.00 4.80 5.60 6.50 7.50 8.70

angle 1.20 1.60 2.00 2.40 2.80 3.30 3.90 4.40 5.20

Type 19 38 76 114 152 190 227 265 303 341 379 417 455 493 531 569 682

globe 2.76 2.89 2.20 2.82 4.96

angle 2.76 2.89 2.14 1.86 3.31

globe 1.10 1.58 2.48 3.58 4.82 6.34 7.72 9.37 11.30

angle 0.90 1.10 1.93 2.76 3.79 4.89 6.13 7.51 9.30

globe 1.45 1.86 2.27 2.76 3.31 3.86 4.48 5.17 5.99

angle 0.83 1.10 1.38 1.65 1.93 2.27 2.69 3.03 3.58

P220G Scrubber Valves

Friction Loss in PSI

GPM

1”

1 1/2”

2”

Type 5 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

globe 4.63 4.74 3.10 6.05 10.75

angle 4.14 4.64 2.54 5.53 9.46

globe 1.14 1.56 2.85 4.36 6.28 8.57 11.20 14.03 17.20 20.46

angle 0.95 1.51 2.28 3.69 5.29 6.97 9.26 11.80 14.60 17.40

globe 3.57 4.62 5.33 6.80 8.20 9.02 10.46 11.61

angle 2.79 3.50 4.41 5.62 6.39 7.35 8.81 9.37

Friction Loss in BAR

LPM

25 mm

40 mm

50 mm

Type 19 38 76 114 152 190 227 265 303 341 379 417 455 493 531 569

globe 3.19 3.27 2.14 4.17 7.41

angle 2.85 3.20 1.75 3.81 6.52

globe 0.79 1.07 1.96 3.00 4.33 5.90 7.72 9.67 11.85 14.10

angle 0.65 1.04 1.57 2.54 3.64 4.80 6.38 8.13 10.06 11.99

globe 2.46 3.18 3.67 4.69 5.65 6.21 7.21 8.00

angle 1.92 2.41 3.04 3.87 4.40 5.06 6.07 6.46

© 2016 The Toro Company • Irrigation Division • 1-877-345-8676 Form Number 373-0883 Rev. A

4

Loading...

Loading...