Page 1

© 2014 Toro Australia Pty Ltd

Micro-Master Touch User Guide

Micro-Master

®

Series

Page 2

Page 3

Micro-Master Series by Toro

Micro-Master Touch User Guide

by Toro Australia Pty Ltd

Congratulations on purchasing a Micro-Master Touch Irrigation Controller.

The Micro-Master Touch Controller represents a significant change in the

capabilities of irrigation controllers.

Some of the Micro-Master Touch features include

Touch Screen Control

Modular Construction for ease of expansion and repair

Life Support

Powerful Rules capability

Multiple Pump Sets

Multiple Filter Banks

In-field upgrades

Extensive connectivity options

Direct communications

USB, RS232, RS485

Modems

Analog,

GSM

Internet

GPRS Modem

Ethernet,

Wireless LAN

Toro Australia Pty Ltd

53 Howards Road

Beverley SA 5009

A.B.N. 47 001 310 443

Customer Service Phone: 1300 130 898

Fax: 08 8234 2940

Page 4

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic,

electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval

systems - without the written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of the

respective owners. The publisher and the author make no claim to these trademarks.

While every precaution has been taken in the preparation of this document, the publisher and the author

assume no responsibility for errors or omissions, or for damages resulting from the use of information

contained in this document or from the use of programs and source code that may accompany it. In no

event shall the publisher and the author be liable for any loss of profit or any other commercial damage

caused or alleged to have been caused directly or indirectly by this document.

Digital copies of this manual in various formats are available for download from

http://www.tdssoftware.com.au/manuals/

Printed: June 2014 in Australia.

Technical support for the Micro-Master Touch Controller can be obtained from:

Toro Technical Services

53 Howards Road

Beverley SA 5009

A.B.N. 47 001 310 443

Customer Service Phone: 1300 130 898

Fax: 08 8234 2940

For service or repair, contact:

TDS Software Solutions Pty Ltd

Unit 11 / 78 Morrow Rd,

Lonsdale

South Australia, 5160

Phone: +61 8 8383 6851

Mobile: 0414 645 171

Email: david@tdssoftware.com.au

Web: www.tdssoftware.com.au

Micro-Master Forum: forum.tdssoftware.com.au

Micro-Master Touch User Guide

© 2014 Toro Australia Pty Ltd

Page 5

Micro-Master Touch User Guide

i

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Table of Contents

Foreword

0

1 Introduction

1

................................................................................................................................... 1

1.1

Controller Capabilites

................................................................................................................................... 2

1.2

Do's & Dont's

2 About This Manual

3

3 Controller Part Numbers

4

4 Installation Instructions

7

................................................................................................................................... 7

4.1

Wall Mount Installation

................................................................................................................................... 7

4.2

Module Installation

................................................................................................................................... 9

4.3

Master/Remote selection

................................................................................................................................... 10

4.4

Connecting Valve Wire

................................................................................................................................... 11

4.5

Earth Stake

................................................................................................................................... 11

4.6

Standby Battery

................................................................................................................................... 11

4.7

12 Volt DC Operation

5 Controller Setup and Configuration

13

................................................................................................................................... 13

5.1

Overview

................................................................................................................................... 15

5.2

Setup Selection

................................................................................................................................... 17

5.3

System Setup and Upgrade

................................................................................................................................... 18

5.4

Unit Configuration

................................................................................................................................... 19

5.5

Expansion Module Configuration

................................................................................................................................... 21

5.6

Radio-Master for Touch Field Modules

................................................................................................................................... 26

5.7

Communication Module Options

................................................................................................................................... 28

5.8

PIN Number Setup

................................................................................................................................... 28

5.9

Commissioning Table

................................................................................................................................... 30

5.10

Global Setup

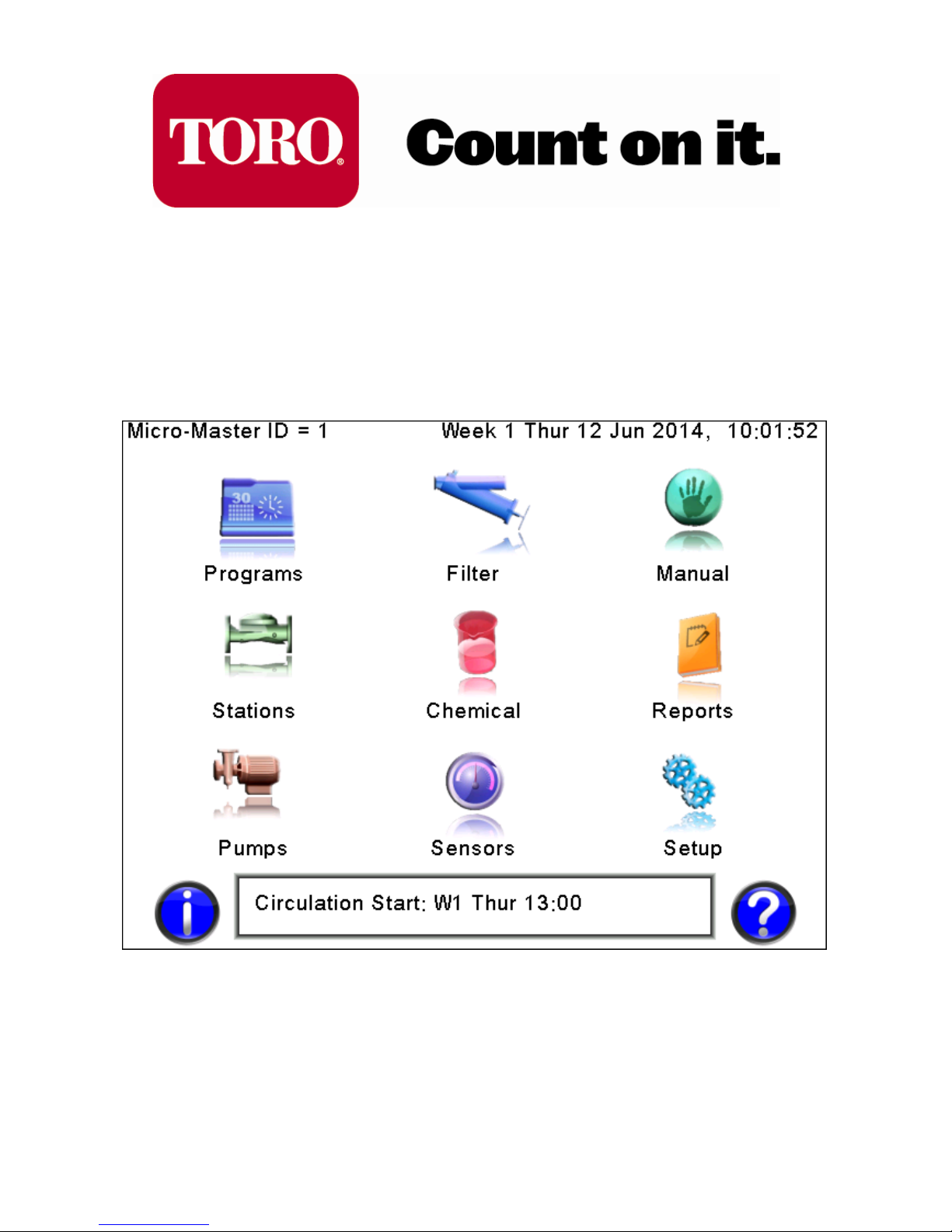

6 Micro-Master Touch Screen Introduction

32

7 Home Screen

35

8 Status Screen

37

9 Multi Station Programs

38

................................................................................................................................... 38

9.1

Overview and Operation

................................................................................................................................... 43

9.2

Program Edit Screens

.......................................................................................................................................................... 43

Program List 9.2.1

.......................................................................................................................................................... 44

Program Edit - Sequential 9.2.2

.......................................................................................................................................................... 46

Program Edit - Grouping 9.2.3

Page 6

Micro-Master Touch User Guide

ii

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

.......................................................................................................................................................... 47

Chemical Edit 9.2.4

.......................................................................................................................................................... 48

Irrigation, Cycles and Start Times 9.2.5

.......................................................................................................................................................... 49

Program Mode and Units 9.2.6

.......................................................................................................................................................... 50

Program Delays 9.2.7

.......................................................................................................................................................... 51

Control Inputs 9.2.8

.......................................................................................................................................................... 52

Pumps, Filters and Flow Meters 9.2.9

.......................................................................................................................................................... 53

Program Status and Totals 9.2.10

10 Single Station Programs

54

................................................................................................................................... 54

10.1

Overview and Operation

................................................................................................................................... 56

10.2

Station List

................................................................................................................................... 58

10.3

Station Edit

................................................................................................................................... 59

10.4

Station Advanced Parameters

11 Pump Sets

64

................................................................................................................................... 64

11.1

Overview and Operation

................................................................................................................................... 66

11.2

Pump Set List

................................................................................................................................... 67

11.3

Pump Set Edit

................................................................................................................................... 68

11.4

Pump Set Advanced Parameters

12 Filter Banks

71

................................................................................................................................... 71

12.1

Overview and Operation

................................................................................................................................... 73

12.2

Filter Bank List

................................................................................................................................... 74

12.3

Filter Bank Edit

................................................................................................................................... 75

12.4

Filter Bank Advanced Parameters

13 Chemicals

77

................................................................................................................................... 77

13.1

Overview and Operation

................................................................................................................................... 79

13.2

Chemical List

................................................................................................................................... 80

13.3

Chemical Edit

................................................................................................................................... 81

13.4

Chemical Advanced Parameters

14 Control Sensors

82

................................................................................................................................... 82

14.1

Overview and Operation

................................................................................................................................... 83

14.2

Sensor Selection

................................................................................................................................... 84

14.3

Rules

.......................................................................................................................................................... 84

Overview and Operation 14.3.1

.......................................................................................................................................................... 86

Rules List 14.3.2

.......................................................................................................................................................... 87

Rules Edit 14.3.3

.......................................................................................................................................................... 88

Rule Status and Totals 14.3.4

................................................................................................................................... 88

14.4

Flow Meters

.......................................................................................................................................................... 88

Overview and Operation 14.4.1

.......................................................................................................................................................... 91

Flow Meter List 14.4.2

.......................................................................................................................................................... 92

Flow Meter Edit 14.4.3

.......................................................................................................................................................... 94

Flow Meter Status and Totals 14.4.4

................................................................................................................................... 94

14.5

Aggregate Flow Meters

.......................................................................................................................................................... 94

Overview and Operation 14.5.1

Page 7

Micro-Master Touch User Guide

iii

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

.......................................................................................................................................................... 96

Aggregate Flow Meter List 14.5.2

.......................................................................................................................................................... 97

Aggregate Flow Meter Edit 14.5.3

.......................................................................................................................................................... 98

Aggregate Status and Totals 14.5.4

................................................................................................................................... 99

14.6

Digital Sensors

.......................................................................................................................................................... 99

Overview and Operation 14.6.1

.......................................................................................................................................................... 100

Digital List 14.6.2

.......................................................................................................................................................... 101

Digital Edit 14.6.3

.......................................................................................................................................................... 102

Digital Status and Totals 14.6.4

................................................................................................................................... 102

14.7

Rain Bucket

.......................................................................................................................................................... 102

Overview and Operation 14.7.1

.......................................................................................................................................................... 104

Rain Bucket Edit 14.7.2

................................................................................................................................... 105

14.8

Analogue Sensors

.......................................................................................................................................................... 105

Overview and Operation 14.8.1

.......................................................................................................................................................... 107

Analogue List 14.8.2

.......................................................................................................................................................... 108

Analogue Edit 14.8.3

.......................................................................................................................................................... 110

Analogue Status and Totals 14.8.4

................................................................................................................................... 110

14.9

Switch Sensors

.......................................................................................................................................................... 110

Overview and Operation 14.9.1

.......................................................................................................................................................... 112

Switch Sensor List 14.9.2

.......................................................................................................................................................... 113

Switch Sensor Edit 14.9.3

.......................................................................................................................................................... 114

Switch Input Status and Totals 14.9.4

15 Manual Spot Watering

115

................................................................................................................................... 115

15.1

Overview and Operation

................................................................................................................................... 115

15.2

Manual Operation

16 Reports

118

................................................................................................................................... 118

16.1

Overview

................................................................................................................................... 118

16.2

Report Selection

................................................................................................................................... 119

16.3

Report List

................................................................................................................................... 120

16.4

Report Edit

................................................................................................................................... 121

16.5

Report Settings

17 Life Support

123

................................................................................................................................... 123

17.1

Overview

................................................................................................................................... 124

17.2

Life Support Screen

18 Generic Edit Screens

126

................................................................................................................................... 126

18.1

Text Edit

................................................................................................................................... 126

18.2

Number Edit

................................................................................................................................... 127

18.3

Time Edit

................................................................................................................................... 128

18.4

Group Edit

................................................................................................................................... 128

18.5

Allocated Station Edit

................................................................................................................................... 129

18.6

Control / Sensor Selection

................................................................................................................................... 130

18.7

Log View

19 TMR1 Series Remote

131

Page 8

Micro-Master Touch User Guide

iv

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

20 Technical Specifications

132

21 Fault Finding

135

................................................................................................................................... 135

21.1

Overview

................................................................................................................................... 136

21.2

Fault Finding Flow Chart

................................................................................................................................... 136

21.3

Fault Finding - Possible Cause

................................................................................................................................... 137

21.4

Diagnostics

................................................................................................................................... 138

21.5

Checking Field Wiring and Valve Currents

................................................................................................................................... 139

21.6

Voltage On Unused Pins

22 Copyright Notice

141

23 Glossary of Terms

142

Page 9

Micro-Master Touch User Guide

1

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

1 Introduction

The Micro-Master Touch Irrigation Controller is the latest in a long line of reliable Australian designed

and built controllers brought to you by Toro. It uses the latest in microprocessor technology, including

a full colour, touch screen LCD display.

Each controller consists of a Master Unit, and up to 4 Remote Units.

The Master Unit is supplied with one 8 Station Module, and can be expanded with 8 Station Modules

up to a total of 32 Stations.

Remote Units are supplied with one 8 Station Module, and can be expanded with 8 Station Modules

up to a total of 32 Stations.

It is not necessary to expand each unit before another Remote Unit is added to the controller. Since

each Remote Unit has it's own power supply and is physically separate from the Master Unit, Remote

Units can be placed in different locations to the Master Unit. For example, the Master Unit could be

located in the main office, and an Expansion Unit could be located in the pump shed, and used to

control the pumps, filters and chemical injection system.

1.1

Controller Capabilites

The Micro-Master Touch controller supports various expansion and communication cards.

Expansion Modules include 8 station modules, digital input modules, and analogue input modules.

Communication cards include RS232 modules, Analogue/GSM/GPRS Modem interface modules,

RS485 modules, USB modules, and Ethernet interface cards.

Each Micro-Master Touch controller can be expanded out to 160 stations using additional Remote

controller units (up to 4 units). Communication between units is achieved by RS485 communication

modules or through the addition of the Radio-Master for Touch range of wireless modules.

The Touch Controller supports 32 individual irrigation programs. Each program operates

independently and can be in sequential or grouping mode. Irrigation Programs can be independently

Enabled, (Rain Switched). There are two levels of globally enabling irrigation programs. A global

enable and rain switch stops all idle programs from starting but allows currently active programs to

complete. Individual programs can be set to ignore the rain switch control.

Programs have the following capabilities:

· Irrigation Units can be seconds, minutes or volumetric,

· Chemical Injection Units can be set independently of the main program. Each chemical has it's

own units and may be seconds, minutes, or volumetric.

· 14 day daytable. Each day can have different number of cycles, and include or exclude chemical

injection,

· Up to 8 start times,

· 4 chemicals per group or station,

· Up to 48 groups with up to 40 Stations per group,

· Water budget percentage, 0 to 250%,

· Individual external inputs for starting, stopping, holding and skipping groups/stations,

· Individual Flow Meters for each program, pump, and chemical,

· Staggered programs, where the completion of one program can start another,

· Filter bank support,

· Pump set support.

The chemical system supports up to eight chemicals.

Each chemical has individual prewet/mixing times and can be assigned to any station outputs in the

Page 10

Micro-Master Touch User Guide

2

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

controller.

Any four of the eight chemicals can be associated with each program.

The Filter Bank system supports up to eight separate banks of filters.

Each filter bank may contain up to eight filters, and each filter can be assigned to any station output

in the controller.

The Pump Set system supports up to eight separate sets of pumps.

Each pump set may contain up to four pumps, and each pump can be assigned to any station output

in the controller.

Each pump set supports runtime levelling, priority, and can support a VFD as pump 1.

1.2

Do's & Dont's

The Micro-Master Touch controller will give you many years of faithful service, as do all Micro-Master

products, but there are certain requirements that should be observed when using the controller, as

with all electrical equipment.

· Don't leave the door open when you have finished with the controller. Water entering into the

controller via an open door is not covered by your warranty. A burst pipe in a pump shed, for

example, can do a lot of damage.

· Do ensure that all wiring holes in the case are sealed. Ants, mice and slugs can also destroy the

unit if they are allowed entry and will not be covered by your warranty.

· Don't use metal objects to select icons on the LCD screen. You can destroy the touch pad. A

finger, eraser tipped pencil or wand is all that is needed.

· Don't mount the unit where it is exposed to full sun during the day. Temperatures within the unit

may become excessive causing it to fail. Always supply some shade from the elements.

· Do install a backup battery. This will support the unit during any minor power outages.

· Don't use any chemical products to clean the LCD display. A slightly moist clean cloth is all that is

required to lightly wipe away any marks.

· Do use an earthed power source as this will supply greater protection for the unit.

· Don't open up the 240v AC side of the controller. These voltages can be lethal, particularly

if water has entered the case. Always use a licensed support person or return the unit for repair.

· In areas with known voltage fluctuations, or frequent 'brownouts', we recommend that the controller

be connected to a UPS and surge protection device.

Page 11

Micro-Master Touch User Guide

3

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

2 About This Manual

Digital interactive copies of this manual in various formats are available for download from http://

www.tdssoftware.com.au/manuals/

This manual (in digital form) has been designed to be context sensitive, and includes many topic links

and image hotspots.

Clicking a button in an image will, where possible, cause a jump to the same screen as if the button

were clicked on the physical Touch controller.

Where not possible or appropriate, the hotspot links to a paragraph explaining the purpose of the

button.

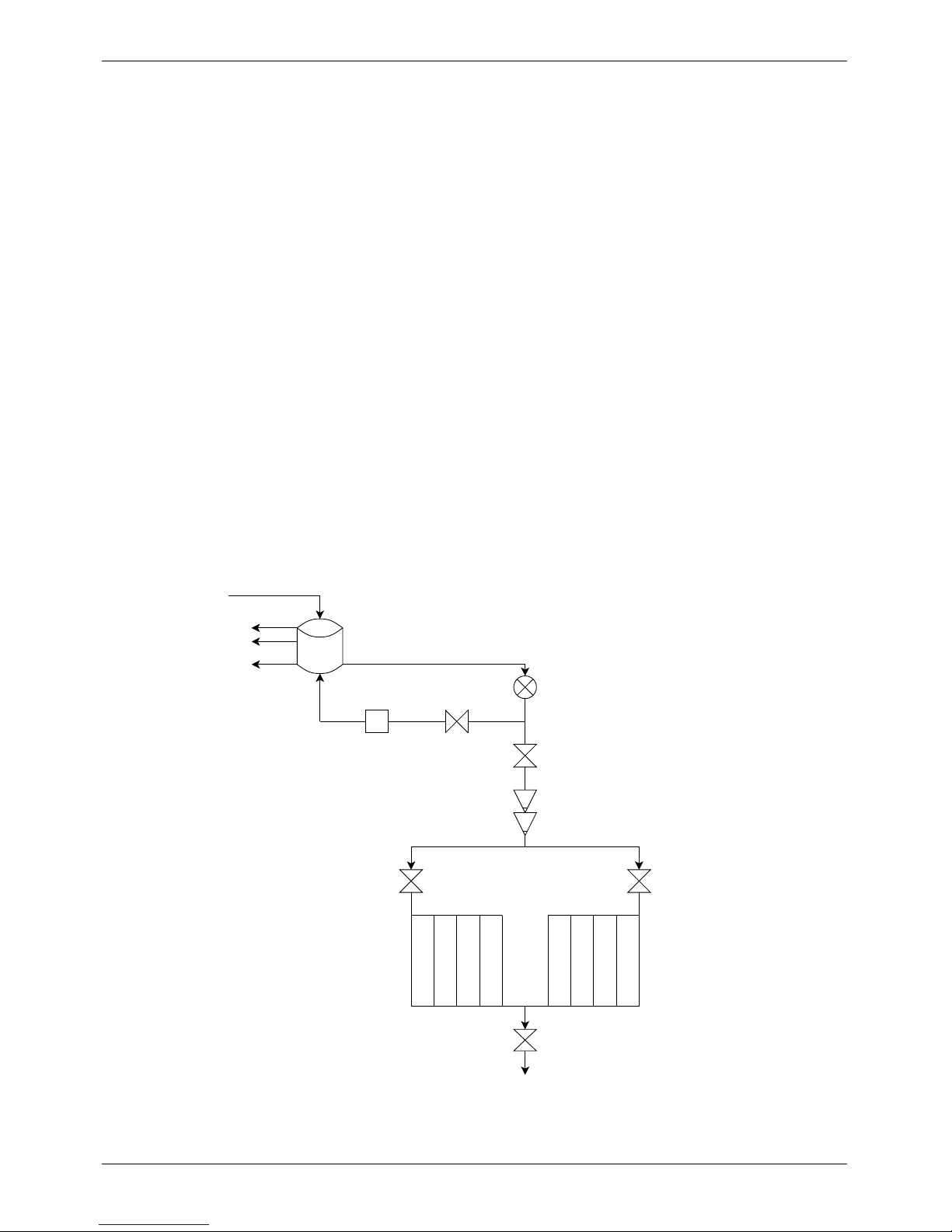

Where appropriate, examples in this manual have been drawn from a real world example.

In this example, a treelot is irrigated using recycled water from a storage tank. There are two zones

in the treelot, allocated to Stations 1 and 2, and a flushing valve (station 4) is connected to both

zones to drain solids from the line after irrigation. The treelot irrigation program operates in grouping

mode. The storage tank is circulated with a five minute on, five minute off cycle repeating 6 times

each shift, running four times every day. Two master valves are connected to the irrigation (station

5) and circulation (station 6) mainlines A pump is connected to station 7, an ozone generator is

connected to station 11, and two filters in a single bank are connected to stations 9 and 10. Chemical

injection is performed each treelot irrigation. Three level sensors detect when the tank is empty,

almost full, and full. The empty and full sensors control the treelot irrigation, and the almost full

sensor stops the ozone generator, and stops the circulation program.

A diagram of the real world example is shown below.

1 2

5

6

7

9

10

11

4

Tank Full

Tank Empty

Almost Full

(Circulation Stop)

Treelot

Zone 1

Treelot

Zone 2

Figure 1 - Real World Example Schematic

Page 12

Micro-Master Touch User Guide

4

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

3 Controller Part Numbers

The Micro-Master Touch controller is a modular design.

The Master Unit is supplied as a minimum, with one 8 Station Module, and can be expanded with 8

Station Modules up to a total of 32 Stations.

Remote Units are supplied as a minimum, with one 8 Station Module, and can be expanded with 8

Station Modules up to a total of 32 Stations.

It is not necessary to expand each unit before another Remote Unit is added to the controller. Since

each Remote Unit has it's own power supply and is physically separate from the Master Unit, Remote

Units can be placed in different locations to the Master Unit. For example, the Master Unit could be

located in the main office with one 8 Station Module, and an Expansion Unit could be located in the

pump shed, and used to control the pumps, filters and chemical injection system with multiple 8

Station Modules.

Product Description

MMTOUCH-MST8 / 16 / 24 / 32 Micro-Master Touch Master Unit, 8, 16, 24, 32 station variants

MMTOUCH-REM8 / 16 / 24 / 32 Micro-Master Touch Remote Unit, 8, 16, 24, 32 station

variants

MMTOUCH-STN Micro-Master Touch 8 Station Relay Module

MMTOUCH-DIG Micro-Master Touch 8 Input Digital Input Module

MMTOUCH-ANL Micro-Master Touch 8 Input Analogue Input Module

MMTOUCH-485E Micro-Master Touch RS485 Remote Communication Module

MMTOUCH-485C Micro-Master Touch RS485 Master Communication Module

MMTOUCH-USB Micro-Master Touch USB Communication Module

MMTOUCH-ETH Micro-Master Touch Ethernet Communication Module

MMTOUCH-232 Micro-Master Touch RS232 Communication Module

MMTOUCH-MDM Micro-Master Touch Modem Communication Module

MMTOUCH-WIF Micro-Master Touch WiFi Communication Module

RMT200 Radio-Master for Touch Radio Expansion Module

RMT100 Radio-Master for Touch PC Radio

RMT800 Radio-Master for Touch 8 Station Field Module

RMT440A Radio-Master for Touch 4 Station, 4 Analog Input Field

Module

RMT440D Radio-Master for Touch 4 Station, 4 Digital Input Field Module

RMT-ANT Radio-Master for Touch Antenna

Spare Parts Description

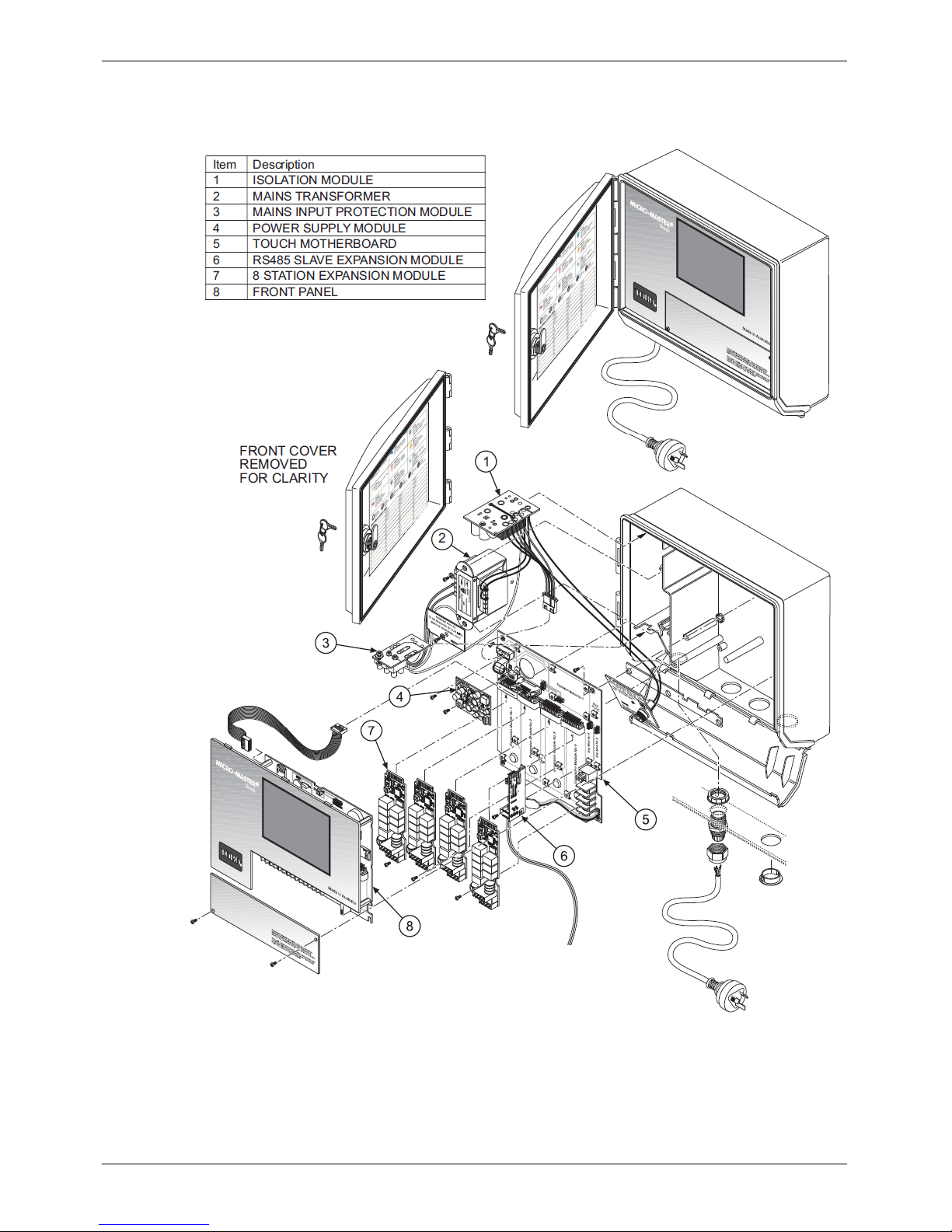

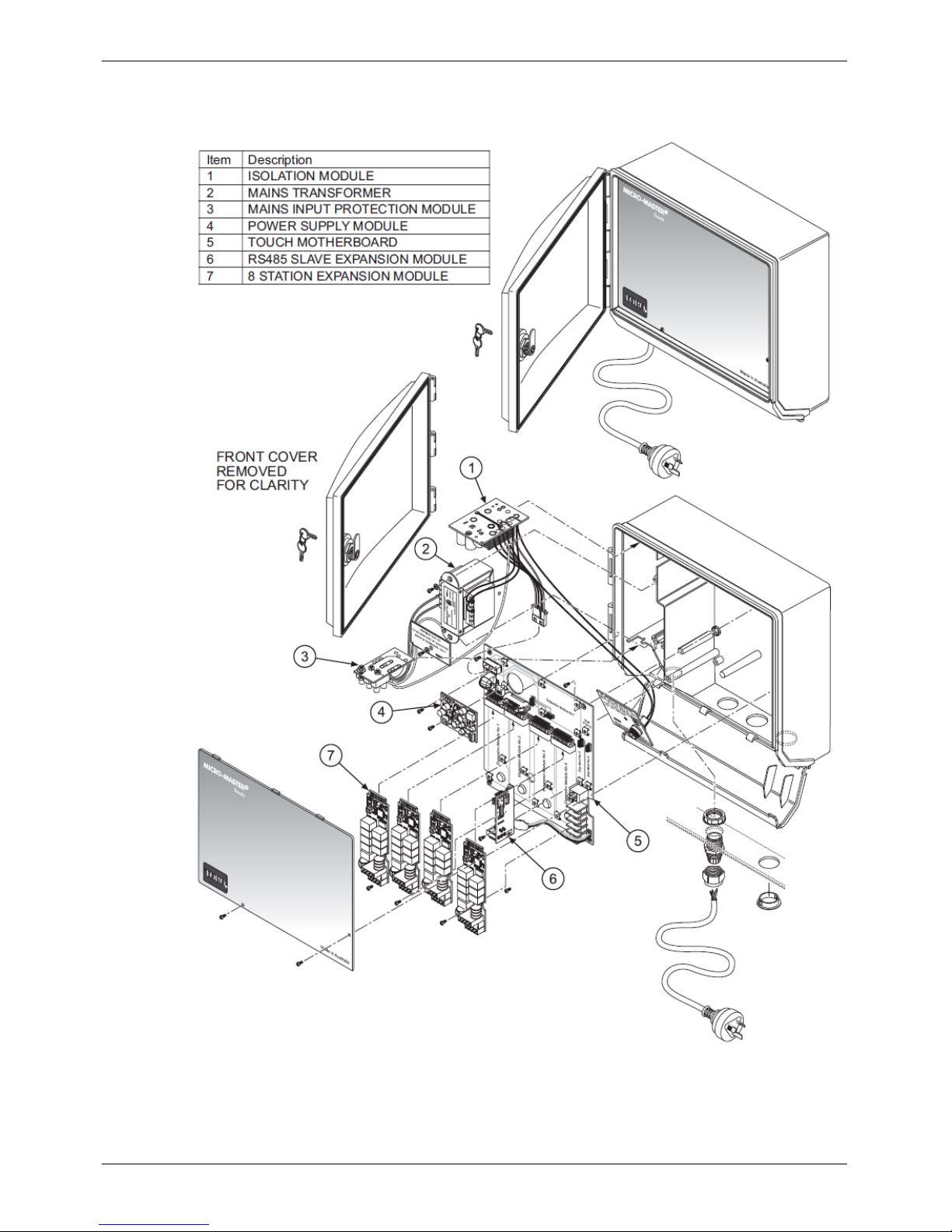

(refer Exploded Diagrams Figs 2 & 3)

MMTOUCH-FP Micro-Master Touch Front Panel

MMTOUCH-MTH Micro-Master Touch Motherboard

MMTOUCH-POW Micro-Master Touch Power Supply

MMTOUCH-TRN Micro-Master Touch Mains Transformer

MMTOUCH-MIP Micro-Master Touch Mains Input Protection Module

MMTOUCH-ISO Micro-Master Touch Isolation Module

Page 13

Micro-Master Touch User Guide

5

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

The diagram below shows the breakdown of a Micro-Master Touch Master Unit.

Figure 2 - Micro-Master Touch Master Unit - Exploded Diagram

Page 14

Micro-Master Touch User Guide

6

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

The diagram below shows the breakdown of a Micro-Master Touch Remote Unit.

Figure 3 - Micro-Master Touch Remote Unit - Exploded Diagram

Page 15

Micro-Master Touch User Guide

7

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

4 Installation Instructions

4.1 Wall Mount Installation

On the back of the controller is a “keyhole” shaped mounting slot as well as 2 mounting holes along

the bottom edge. These mounting holes are shown circled red in the next picture. Access to the 2

mounting holes is from the front behind the bottom cover plate.

Figure 4 - Back of Micro-Master Touch Controller

When attaching to wall studs use a No. 10 self tapping screw and leave approx. 6mm of the head

exposed to slip into the “keyhole” slot. To secure and stabilise the controller, drive additional screws

through the bottom mounting holes.

NOTE: When mounting the controller to a sheet metal wall, it is essential to mount timber mounts to

the wall first and then mount the controller to the timber. This prevents high temperatures being

conducted to the controller.

4.2

Module Installation

The Touch controller uses various modules installed into "slots" on both the motherboard and

processor boards to increase its versatility or capacity.

A wide range of modules are available for both the communication slots on the processor board and

expansion slots on the motherboard. Both employ a similar method of mounting and are easy to

install or remove.

Page 16

Micro-Master Touch User Guide

8

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

NOTE:

Before any installation or removal of a module occurs,

all power to the unit MUST

be removed

, including the backup battery. Never install or remove a module with power

applied. Damage to the module may occur and this is NOT covered by your warranty.

NOTE:

Two screws are used to provide power and to secure the Expansion Modules.

All

screws must be installed

for the Expansion Module to operate correctly.

The motherboard, which is at the bottom of the case, holds all of the field wiring modules, along with

a power supply module and Radio-Master for Touch RMT200 module, if fitted.

The Power module (already fitted) and Expansion Slots number 5, 6 & 7 use screws to hold the

module in place and are connected to the controller via 8 pins.

Expansion slots 1 to 4 are for the Station(Valve) relay modules, Analogue Input and Digital Input

modules. Each of these modules is connected to the controller by a 20 way edge connector and held

in place by 2 screws. The screw connection points supply 24V AC and GND to the modules, for the

field wiring. Installing a module in slots 1 to 4 is achieved by inserting the tongue of the expansion

module into the edge connector until the 2 screw holes align and then fitting the screws.

The tongue of the module is the slightly smaller end that has stripes down the edge, on both the top

and bottom sides.

Expansion modules 5 & 6 are fitted on edge. Ensure that all the gold pins enter the header connector

on the module and the screw mount aligns with the bracket, then insert the screw. Typically, this is

where the RS485 modules would reside, when other remote units are connected using wire.

Expansion module 7 requires the pins to come through the board into the header and 4 screws to

hold the module in place.

Remember, no power should be present when installing or removing modules. You may also find a

magnetic screw driver of help when trying to install or remove screws.

The processor (or logic) board is the top board in the controller with the LCD screen attached. This

board has 2 slots on the right hand side for various types of communication modules to be installed.

These modules are shorter than the motherboard expansion modules and should never be

interchanged. The connection of the module is achieved by an edge connector and a single screw to

hold the module in place. Once again, slide the tongue of the module into the edge connector until

the screw hole aligns and then insert the screw.

When you restart the controller, navigate to the Expansion Module Configuration page and initiate a

scan by clicking the scan button.

The controller will perform a scan to determine what modules are fitted to the unit and update its

configuration.

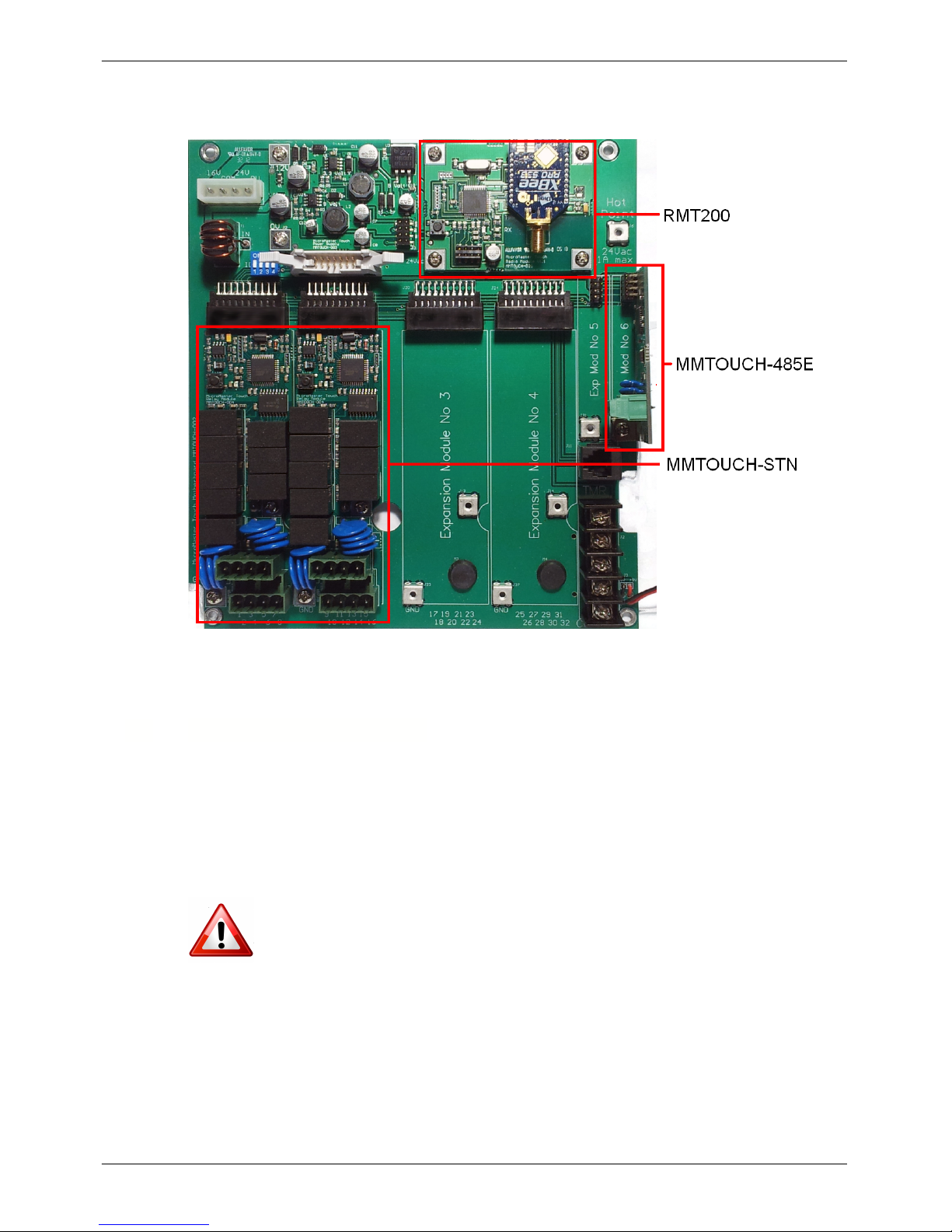

An example of a motherboard is shown in Figure 5. This motherboard has been populated with 2 8

Station Relay Modules (MMTOUCH-STN) in Expansion Module numbers 1 and 2, an RS485 Remote

Expansion Module (MMTOUCH-485E) in Expansion Module number 6 and a Radio-Master for Touch

Page 17

Micro-Master Touch User Guide

9

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Radio Expansion Module (RMT200) in Expansion Module number 7.

Figure 5 - Touch Motherboard with 2 MMTOUCH-STN,

RMT200 and MMTOUCH-485E modules

4.3

Master/Remote selection

The Micro-Master Touch controller can support up to a total of 160 station outputs. This is dependant

on the number of remote units connected and the expansion modules fitted. One Micro-Master

Touch Master Unit can support up to four Touch Remote Units, each fitted with a variety of expansion

modules.

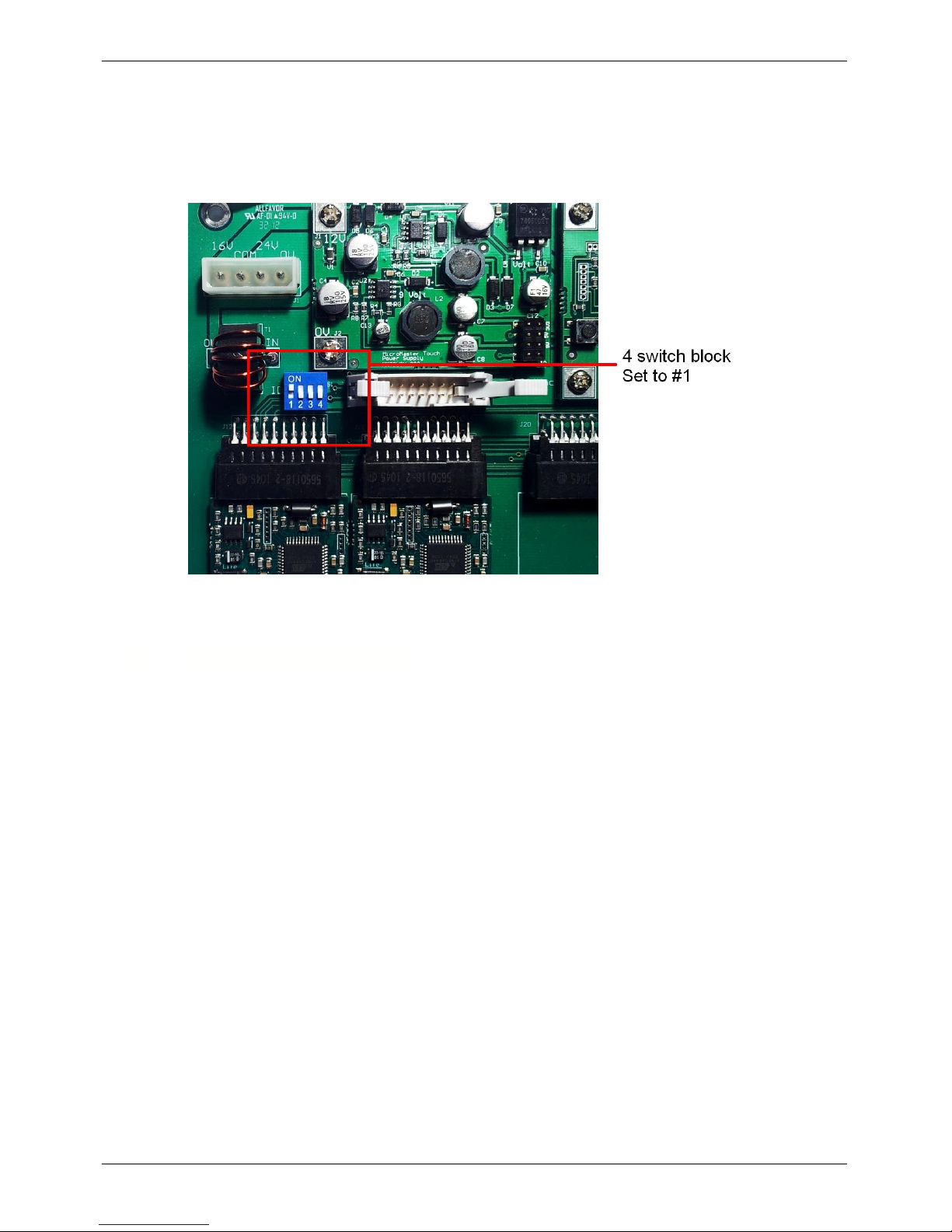

Configuration of a Touch Unit as either a Master Unit or Remote Unit is performed via a four switch

block, numbered 1 to 4, on the motherboard, next to the ribbon cable connector and above

Expansion Module number 1.

When configuring units, all power to the unit MUST be removed, including the backup

battery.

To designate a unit as the Master, all switches on the block should be in the OFF position.

For Remote Unit number 1, the number 1 switch should be ON, all others OFF.

For Remote Unit number 2, the number 2 switch should be ON, all others OFF.

For Remote Unit number 3, the number 3 switch should be ON, all others OFF.

Page 18

Micro-Master Touch User Guide

10

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

For Remote Unit number 4, the number 4 switch should be ON, all others OFF.

There can only be one Master controller and one of each of the remotes connected as a group.

In the example below, a unit has been configured as Remote Unit number 1.

Figure 6 - Master / Remote Selection Switch

4.4

Connecting Valve Wire

1. Remove bottom cover.

2. Route 1 wire from each valve though one of the three holes in the bottom of the

controller case. Insert each lead into the appropriate terminal on the connector.

For ease of wiring the connector heads can be removed if required.

3. The common wire for each valve should be attached to a single “Common” wire.

Connect this Common wire to one of the terminals labeled COMMON.

4. When all valve wires have been connected, ensure that all holes and spaces

between valve wires are sealed with a silicone sealant or similar. This ensures

that insects, ants and vermin cannot enter the controller.

Page 19

Micro-Master Touch User Guide

11

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

An example of correctly terminated valve wiring is shown below.

Figure 7 - Wiring Terminal Blocks

4.5

Earth Stake

The Micro-Master Touch controllers have a high level of field surge protection (4500 amp 20usec).

For this to work effectively, a good low resistance earth path must be provided to shunt the surges. A

resistance value <10 ohms is acceptable. A resistance value between 10-30 ohms is marginal. A

resistancevalue higher than 30 ohms is not acceptable. In severe lightning areas a 2 metre earth

stake connected to one of the GND terminals can be used ( Use multi-strand 4-6mm wire ).

Ensure soil around the earth stake is kept moist to create a good earth.

4.6

Standby Battery

The Standby Battery is a 9V alkaline MN1604 miniature Battery. This will give several hours of

standby time. The alkaline battery is essential in high temperature conditions as they have a shelf

life of approximately 5 years at 40 degrees Celsius. In the long term, an alkaline battery will be more

reliable and cheaper than an equivalent NiCad battery. They are replaced every 1 to 2 years

depending on the number of power failures in the area.

Note: For extreme conditions with many power failures, a battery holder with (6 AA alkaline cells) will

give an increased Standby time.

NI-Cad (Nickel Cadmium ) batteries should not be used for 2 reasons.

1. For a Ni-cad to be efficient, the operating cycle should be fully charged, then fully discharged.

This is not the case for a Standby battery in an irrigation controller.

2. Poor operation in a high temperature environment. The capacity is only 20% of an alkaline cell

and this is further reduced in high temperature environment.

The 216 standard carbon zinc battery should not be used because of very poor high temperature

performance and low capacity.

4.7

12 Volt DC Operation

The Touch Series controllers can be easily changed to operate on 12VDC. It should only be used

with caution as valves must be fitted locally as wires carrying DC current should not be installed

under ground because of electrolysis. Ideal installation when hydraulic valves are used.

Page 20

Micro-Master Touch User Guide

12

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

1. Remove the 4 way connector from the motherboard.

2. Plug in the 12VDC adaptor plug supplied with the controller.

3. Connect the RED lead to +12VDC.

4. Connect the BLACK lead 0VDC.

5. Connect Earth stake as described in the Earth Stake installation instructions.

Page 21

Micro-Master Touch User Guide

13

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

5 Controller Setup and Configuration

5.1 Overview

The Micro-Master Touch contains a large number of setup and configuration options.

The various options are described below.

System Setup

The controller setup supports multiple controller ID's within the one installation. To prevent confusion

each controller must be assigned a unique controller identification number. Numbers do not need to

be sequential.

A system wide date/time subsystem keeps track of day and time. The day and time is used to tag

events within the controller.

The controller serial number is a unique factory assigned number.

The controller version displays the current revision of the firmware. The firmware number is in the

form xx,yy,zz. Major revisions ( denoted by xx ) may not be compatible with earlier versions of the

software or hardware. Minor revision numbers ( denoted by yy ) and indicate updated or added

functionality in the firmware. All minor revisions are compatible within a major revision. For

example, minor revision 1.4.z is compatible with revisions 1.0.z through 1.3.z. Minor changes to

controller firmware are denoted by zz.

Changing the firmware is possible by loading a compatible firmware on to a USB flash storage device

and installing the USB device in the front panel USB connector. Selecting the revision in the System

Setup window and clicking the Edit icon will request confirmation. If approved, the controller will

reboot and attempt to update the firmware from the file on the USB device. If a compatible file is not

found, the controller will abort the firmware upgrade and restart.

Global Setup

The controller supports several functions for upgrading, or controller maintenance. The Global Setup

screen supports backup of all controller configuration and totals to a connected USB storage device.

This file can be used to restore the controller to a known state in the event that the front panel needs

to be replaced, or the controller is inadvertently reset.

Options exist to clear the controller totals and logs only, or clear the entire controller configuration to

the factory defaults.

For maintenance purposes the controller has two levels of program control. A Global Enable

prevents all programs from starting. A rain switch enable prevents programs from starting, unless the

program has the Ignore Rain Switch option ticked. By default, all programs obey the rain switch.

It is recommended that after the controller has been installed and configured, a backup of the

controller be performed and the USB backup file stored in a safe location.

Unit Configuration

Each Unit can be assigned a name and individually be enabled or disabled. Each Remote Unit can

be accessed using RS485 or RMT200 expansion modules. Selecting the Comms item and selecting

edit will display a list of available Radio-Master for Touch radio addresses or RS485 addresses.

Selecting the scan option on the radio address screen will search the controller network for all

Radio-Master for Touch or RS485 based modules.

Page 22

Micro-Master Touch User Guide

14

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Expansion Module Configuration

Each expansion module in the Master Unit (except expansion module 1) or a Remote Unit can be

replaced in the field by a Radio-Master for Touch Field Module. The Expansion Module configuration

screen allows selection of the expansion module. Selecting edit will display a list of available

Radio-Master for Touch addresses. Selecting the scan option on the address screen will search the

controller network for all Radio-Master for Touch Field Modules.

Selecting a radio designates the selected field module as a replacement for the expansion module. If

an expansion module has been replaced by a field module, the expansion module in the master or

remote unit becomes inoperable. If an Expansion Module in position 1 is replaced by a field module,

no communication with a Remote Unit will be possible. Hence it is possible to have up to four radio

expansion modules forming a virtual remote unit, without the need for a physical Remote Unit. When

Radio-Master for Touch Field Modules are added to a controller, it is recommended that field

modules remain separate from Remote Units. For example, if an installation has a Master Unit and 1

Remote Unit (Unit 1), then Field Modules should be added as Unit 2/Module 1 etc.

Access PIN Numbers

The controller supports two options for restricting access to levels of functionality in the controller.

Once entered, a valid PIN is active for a user configurable time period. The default time period is 60

minutes. If a PIN is required, the user is directed to the PIN Entry screen.

Limited access allows users to view the status of the various subsystems in the controller, and to

control single station and programs.

Full access allows users access to all areas of the controller. Only users with full access can change

the PIN numbers.

If a PIN number is forgotten, please contact Toro Technical Services for assistance.

Communication Options

The controller supports a number of communication options for connection to outside computing

resources. These options are USB, RS232, RS485, Ethernet, WiFi, and GPRS/GSM/Analogue

Modems.

Depending on the communication module option installed will determine the parameters available for

configuration.

The Ethernet and WiFi communication modules support DHCP address resolution. The WiFi module

supports WPA, WEP, and WPA2 encryption.

Diagnostics

The Micro-Master Touch controller contains a variety of diagnostic tools, for isolating faults in the

front panel. The ability to produce a log file on an attached USB flash storage device can provide

important information regarding the current operation of the controller.

Page 23

Micro-Master Touch User Guide

15

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

5.2

Setup Selection

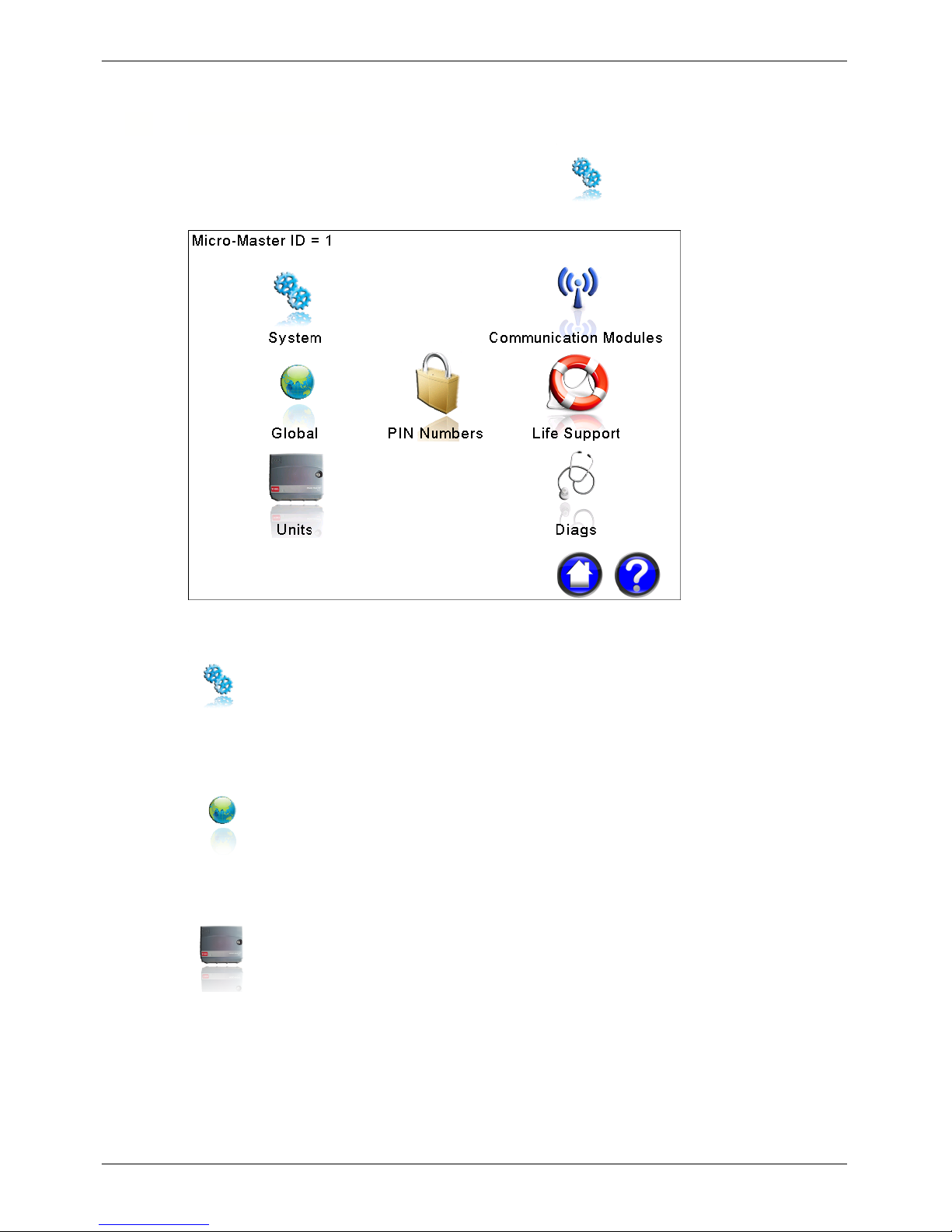

The Setup Selection screen is displayed by pressing the icon on the Home Screen.

Figure 8 - Setup Selection Screen

System Setup and Configuration

Pressing this icon displays the System Setup screen to allow edit and control of the Controller ID,

System Date and Time and allow in-field upgrade of the controller firmware.

Global Setup and Configuration

Pressing this icon displays the Global Setup screen to allow reset of the controller memories, and for

setting controller global enable/disable control.

Unit Setup and Configuration

Pressing this icon displays the Unit Setup screen to allow configuration of Units and Expansion

Modules.

Page 24

Micro-Master Touch User Guide

16

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

PIN number lock

Pressing this icon displays the PIN Number Setup screen to allow configuration of the controller PIN

security.

Communication Modules

Pressing this icon displays the Communication Module Status screen to show the communication

status and allow modification of available controller communication module options.

Life Support Setup and Configuration

Pressing this icon displays the Life Support Setup screen to allow edit and control of the Life Support

features of the Controller. Life Support provides two levels of limited controller functionality in the

event that the main control panel is inoperable.

Diagnostic Setup and Configuration

Pressing this icon displays the Diagnostics screen to allow diagnostic testing of the controller front

panel.

Help

Pressing this icon displays a help screen explaining the options available.

Page 25

Micro-Master Touch User Guide

17

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

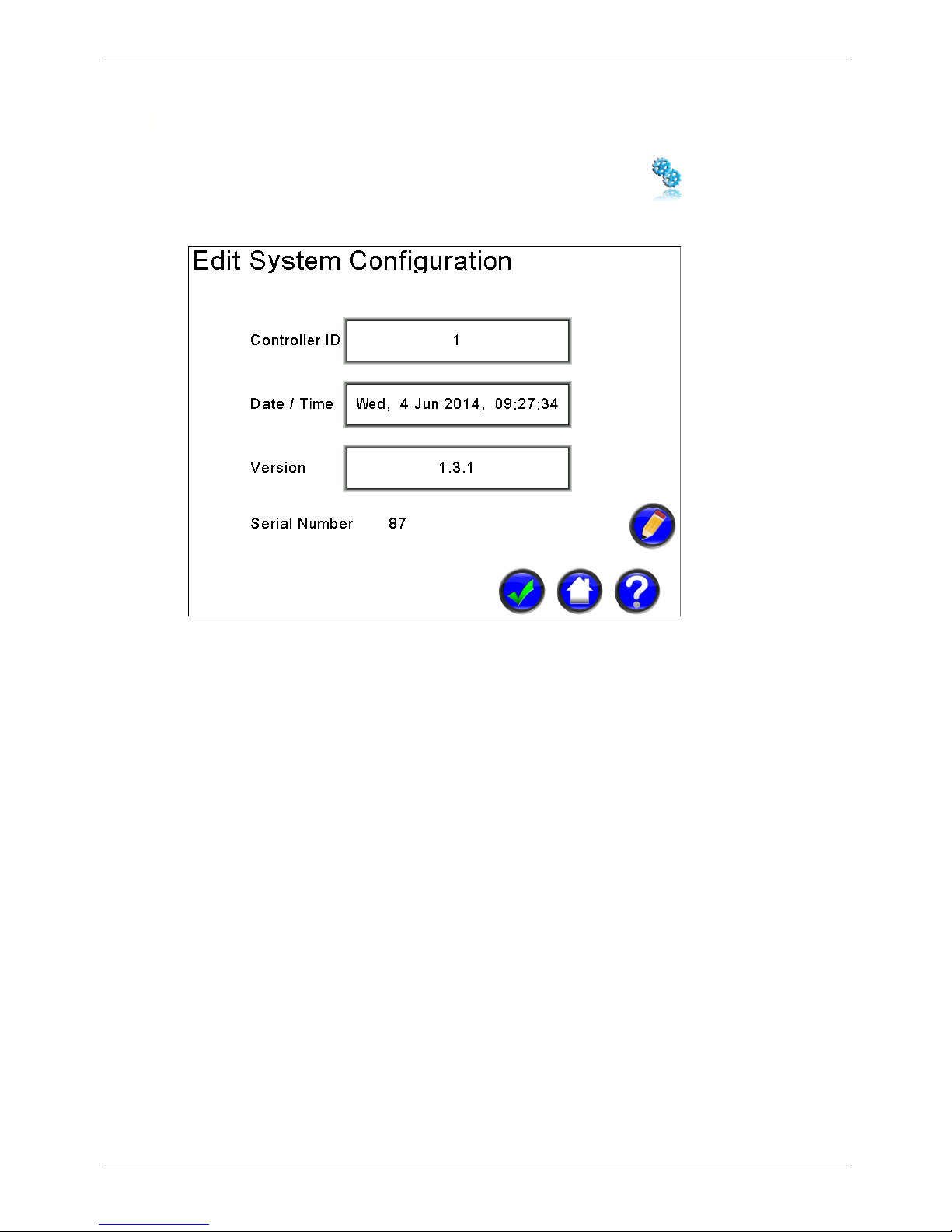

5.3

System Setup and Upgrade

The System Configuration Setup screen is displayed by pressing the icon on the Setup

Selection screen.

Figure 9 - System Configuration

Controller Identification Number

Clicking on the Controller ID will select the item, changing the background to light blue. Selecting the

Controller ID then clicking Edit will display the Number Edit screen, allowing the controller ID to be

changed.

Date Time

Clicking on the Date and Time will select the item, changing the background to light blue. Selecting

the Date/Time then clicking Edit will display the Time Edit screen, allowing the controller date and

time to be changed.

Version

This item displays the current version number of the controller firmware. Clicking on the version item

will select the item, changing the background to light blue. Selecting version and then clicking Edit

will display a confirmation screen. If confirmed, the controller will reset and update the controller

from an upgrade file on the USB flash storage device if one is present.

The firmware update process does not perform any checks for operating programs or input

conditions. The user must ensure that all controller programs are stopped before attempting a

firmware upgrade.

Page 26

Micro-Master Touch User Guide

18

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Controller Serial Number

The Controller Serial Number is a unique factory assigned number and is not configurable.

5.4

Unit Configuration

The Unit Configuration Setup screen is displayed by pressing the icon on the Setup

Selection screen.

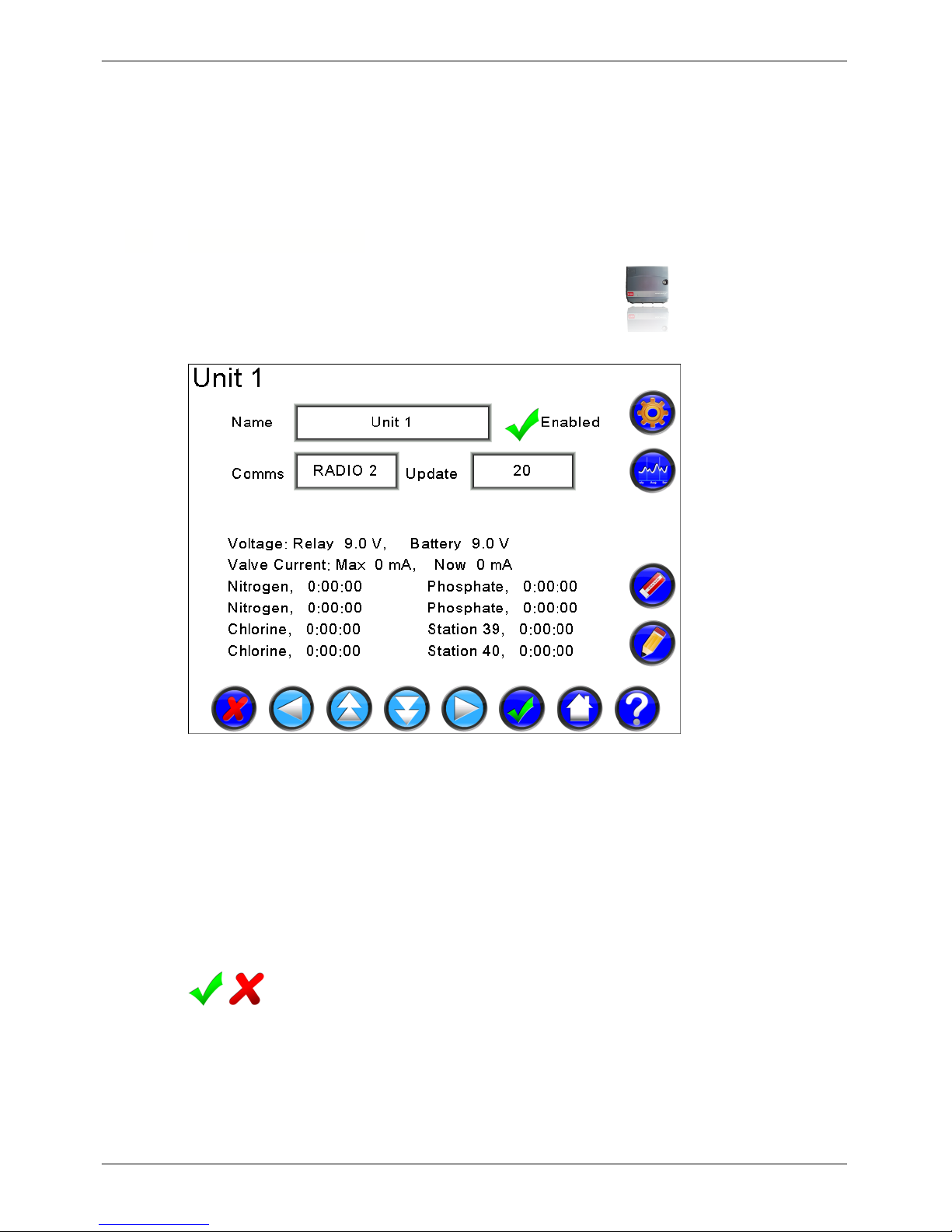

Figure 10 - Controller Unit Configuration

In the example screen shown in Figure 10, Remote Unit 1 has the default name of Unit 1, and is

connected to the network using Radio Module number 2. The status for the unit is updated every 20

seconds, and the current runtime status is shown. The status shown is dependant on the type of

modules in the remote unit. For analogue sensors, the current value of the sensor is shown, and for

digital modules, the open/closed status is shown.

Unit Name

Each Unit can be assigned a name. Names are limited to 20 characters. Selecting the name button

and clicking Edit will display the Text Edit screen.

Unit Enabled

Remote Units can be enabled or disabled. Disabling an Remote Unit prevents stations on that

Remote Unit from being operated for example, to allow maintenance to occur. Clicking on the tick

(cross) will change the Unit to disabled (enabled).

Page 27

Micro-Master Touch User Guide

19

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Unit Update Rate

Clicking on the update item will select the item, changing the background of the selected item to light

blue. Selecting the update item and clicking Edit will display the Number Edit screen.

The Unit Update Rate is the number of seconds between updates and defines how often the Master

Unit communicates with Remote Units to gather status information. Changing the Unit Update Rate

to a shorter time means the status of units is checked more often. Care should be taken to not set

this rate too low, as it could delay the operation of stations being turned on or off. A value of 10

seconds is considered an absolute minimum without severely impacting station operations.

Unit Module Status

This area displays the current status of the unit expansion modules.

Unit Communication Method

Clicking on the Comms item will select the item, changing the background of the selected item to

light blue. Selecting an item and then clicking Edit will display the Control Select screen to allow

selection of available communication devices.

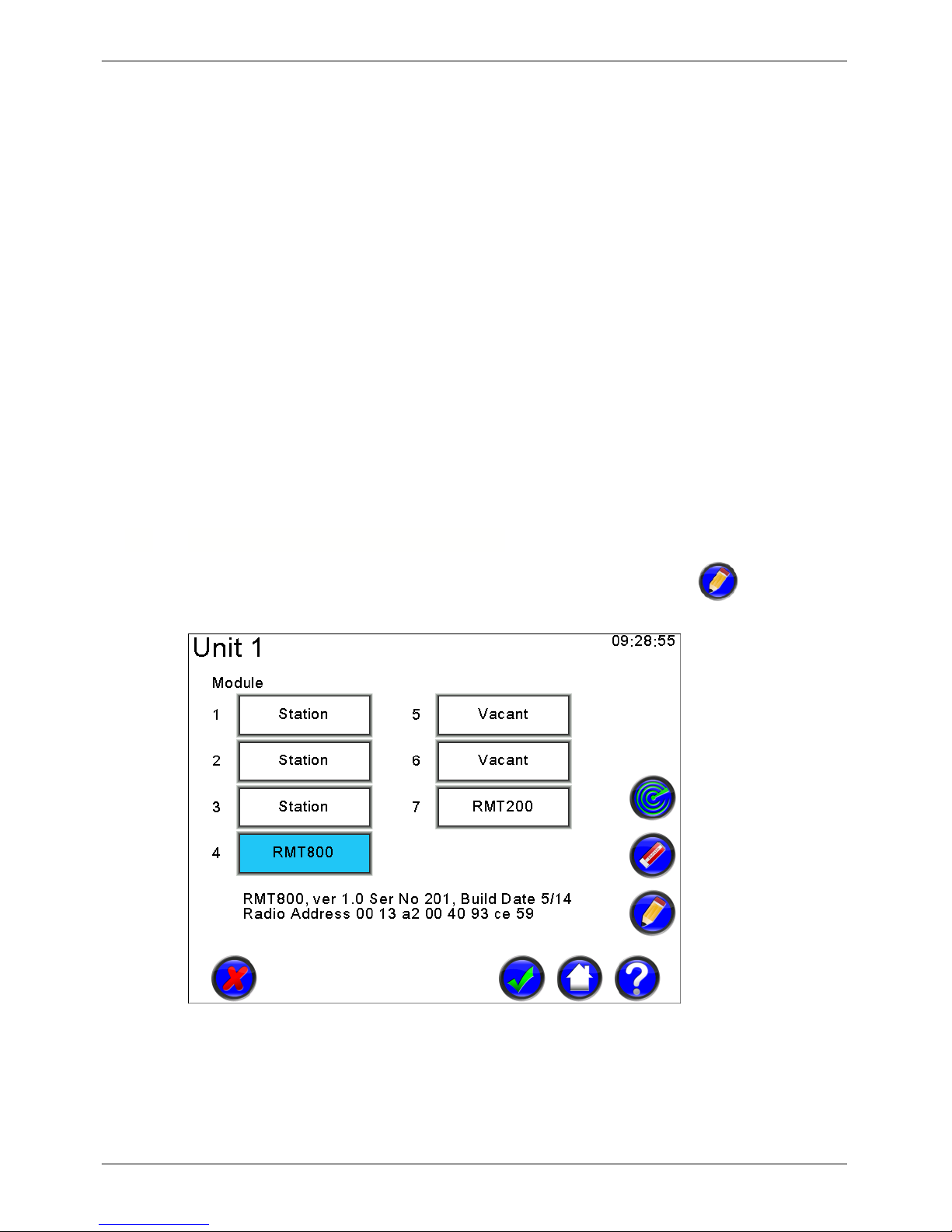

5.5 Expansion Module Configuration

The Unit Expansion Module Configuration screen is displayed by pressing the icon on the Unit

Configuration screen.

Figure 11 - Controller Expansion Module Configuration

In the example screen shown above, Expansion Module 4 in the Remote Unit 1 has been replaced by

a Radio-Master for Touch RMT800 Field Module with radio address 00 13 a2 00 40 93 ce 59. The

module is version 1.0, serial number 201 and was manufactured in May 2014.

Page 28

Micro-Master Touch User Guide

20

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Module Identification and Version

Clicking on the Expansion Module will select the item, changing the background to light blue. It will

also show the build date, serial number and communication method for the selected expansion

module.

Scan Expansion Modules

This icon will cause a scan of the selected Remote Unit to determine the current configuration of

each expansion module in the Remote Unit.

Page 29

Micro-Master Touch User Guide

21

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

5.6

Radio-Master for Touch Field Modules

RMT Field Module Installation

Figure 12 - RMT800 Panel with connector positions

Aerial Installation

Figure 13 - Aerial mounted on Solar Panel

Note: Depending on the particular installation environment it may be easier to install the antenna

prior to mounting the Solar Panel assembly onto the mast. Remember, the higher the antenna, the

better the coverage.

Loosen the nut on the base of the antenna and slide the antenna into the slot located on the top edge

of the Solar Panel Mounting Plate.

Retighten the nut on the base of the antenna.

Solar Panel Mounting Bracket Installation

The Solar Panel Mounting Plate has been designed to maximise the average available solar power

whilst reducing wind resistance and providing ease of assembly. The angle of the Solar Panel has

Page 30

Micro-Master Touch User Guide

22

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

been optimised for locations near the latitude of Sydney, Adelaide, and Perth, but will provide good

operation over most of Australia.

The Solar Panel Mounting Plate kit is supplied with 4 saddle clamps. Both 2” (50mm) and 1” (25mm)

water pipe saddle clamps are supplied to allow several mounting options. Only two saddle clamps

are required to mount the Solar Panel Mounting Plate.

Attach the Solar Panel Mounting plate to the mast using two saddle clamps and 3/16” bolts and nuts.

Orientate the Solar Panel Mounting Plate so that the dark face of the Solar Panel is facing the

direction of the midday sun. This is approximately North and maximises the Solar Panel output.

Tighten the 3/16” nuts.

Route the Solar Panel power cable and antenna cable to the RMT Field Module. Secure the cables

using cable ties or other appropriate means.

RMT Field Module Installation

NOTE: It is important for the correct and continued reliable operation of the RMT Field Modules that

cables and wires are not subjected to deformation or damage during installation or normal use.

During installation, ensure that cables and wires are not positioned or routed such that deformation of

cables or wires could occur. Routing of the antenna cable should not result in a bend radius of less

than 75mm.

Using appropriate fasteners, attach the RM106 Module Mounting Plate in the desired position using

the two ¼” holes located at the top and bottom of the Module Mounting Plate. Using the 3/16” bolts

and nuts attach the RMT Field Module to the Module Mounting Plate and tighten.

Remove the front cover of the Radio-Master for Touch Field Module.

Connect the antenna cable by passing the gold coloured cable connector through the left hand cable

gland on the bottom of the RMT Field Module. Route the antenna cable such that a Rain drip loop is

formed. The apex of the loop should hang below the bottom edge of the RMT Field Module case.

Take the antenna cable connector and gently screw it onto the gold antenna connection protruding

from under the keyboard panel. Ensuring that the cable is not under stress tighten the gland to

exclude water and pests. Damage caused by water and pests (ants, slugs, mice, etc.) is not covered

under your warranty.

Connecting the Solar Panel Cable

Loosen the right hand cable gland nut and insert the Solar Panel power wires.

Strip 5mm of insulation from the Solar Panel wires.

Connect the red Solar Panel wire to the Connector Block Pwr position labelled”+” and connect the

blue or black Solar Panel wire to the Connector Block Pwr position labelled “-“.

Tighten the cable gland nut.

Connecting the Battery Cable

The battery connector which was unplugged for shipment should now be connected to the Batt

position on the right hand side of the RMT Field Module board, next to the Pwr connector. This must

be done in order for the unit to function correctly.

Powering the RMT Field Module from a RM101 Plug Pack

Ensure the RM101 Plug Pack is not plugged into the 240V mains wall socket. Remove the connector

from the cable by cutting the 2.1mm plug from the RM101 Plug Pack cable.

Page 31

Micro-Master Touch User Guide

23

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Loosen the right hand cable gland nut and insert the plug pack wires.

Separate the plug pack wire into the two conductors and strip 5mm of insulation from each wire.

Connect the wire with the white stripe to the Connector Block Pwr position labelled ”+” and connect

the other wire to the Connector Block Pwr position labelled “-“.

Plug the RM01 Plug Pack into a 240V mains wall socket and switch on. Using a voltmeter on at least

a 20V DC range, confirm that a nominal 12Vdc is present across the Connector Block Pwr position.

Tighten the cable gland nut.

Connecting Valve Wire, All Radio-Master for Touch Modules

The RMT Field Module is designed for 2 wire solenoid operation; 12V is momentarily applied across

the connector block positions labelled “L” and “U” for each valve when commanded on or off by a

Micro-Master Touch controller.

Loosen an appropriate cable gland nut and insert the solenoid wires.

Strip 5mm of insulation from the solenoid wires.

Connect the solenoid latch wire to the Connector Block positions marked “L” for the appropriate valve

number. For a Bermad S985 solenoid the Latch Wire is White. For a Baccara 2 wire latching solenoid

the Latch wire is Green.

Connect the solenoid unlatch wire to the Connector Block positions marked “U” for the appropriate

valve number as shown in the previous picture. For a Bermad S985 solenoid the Unlatch Wire is

Red. The Black wire is unused. For a Baccara 2 wire latching solenoid the Unlatch wire is Black.

Tighten the cable gland nut.

To prevent insect infestation, any gaps should be eliminated, by tightening the cable glands securely,

or filling the gaps with a suitable all weather sealant.

Connecting Digital Sensors, RMT440D Field Modules

The RMT440D is designed to accept four digital pulse sensors. The RMT440D inputs accept voltage

free contact closures. The sensor wiring positions are on the left hand side connectors and marked 1

to 4 with + and – positions. The – position goes to ground, and the + position to the sensor output as

shown in Figure 14.

RMT440D Inputs

1 2 3 4

+ - + - + - + -

Figure 14 - RMT440D Connection Schematic

Page 32

Micro-Master Touch User Guide

24

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Connecting Analogue Sensors, RMT440A Field Modules

The RMT440A is designed to accept four 4-20mA Analogue sensors. The sensor wiring positions are

on the left hand side connectors and marked 1 to 4 with + and – positions. The RMT440A supplies

24VDC to the + terminal to power sensors. A typical sensor connection is shown in Figure 15. Refer

to the sensor manufacturers manual for correct connection of the sensor.

GND

+

O/P

GND

+

O/P

GND

+

O/P

GND

+

O/P

RMT440A Inputs

1 2 3 4

+ - + - + - + -

Figure 15 - RMT440A Connection Schematic

Interfacing the RMT Field Module module with a Micro-Master Touch

Master

The Valve outputs of each RMT Field Module are numbered 1 to 8. Each RMT Field Module module

will replace 1 Expansion Module from slot 2 to 4 in the Master unit, or, any or all Expansion Modules

in a Remote Unit. This means that you can have a mix of a Master, Remotes and RMT Field Module’

s, or a Master and all RMT Field Module’s. This allows maximum flexibility when designing and using

the system. The only condition is that slot 1 in the Master must always be a Station Module.

The radio system in the Touch controllers allows use on up to 8 separate channels. By default, the

radio channel is set to channel 1. If multiple Touch systems have been installed in the surrounding

area it may be necessary to select another channel. The channel of the Master Unit dictates the

channel to be used in the RMT Field Modules. If the channel is set to 2 in the Master, then the

channel must be set to 2 in all Remote Units and RMT Field Modules that you wish to use with that

Master Unit. This only needs to be done if you are not going to use the default settings.

Once setup and turned on, the RMT Field Module will automatically announce and configure itself in

to the Touch Master Unit.

Resetting the Module back to Factory settings

Resetting the module back to the factory settings can be achieved easily. Ensure that the unit is

turned off. Press and hold the SET key then turn the unit on. This will reset the module to Channel =

1, PosiSense = off, Unit = 0, Module = 0. All LEDs will flash 3 times.

Setting the Channel Number

By default, the channel number is set to 1. Figure 12 shows the front panel of the RMT Field Module.

It can be seen that many of the keys have multiple functions.

To set a new channel number, ensure that the unit is turned on, then, in order, one button at a time,

press SET, CHANNEL and the number of the new channel to use (1 to 8). You will have 5 seconds

Page 33

Micro-Master Touch User Guide

25

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

between each key press. If you take longer than 5 seconds between each key the command

sequence will abort and no change will be effected. Once entered correctly the module will flash the

ON LED 3 times.

Setting the Unit Number and Expansion Module Slot Number

The RMT Field Module is capable of being a member of the Master Unit (Expansion Modules 2-4) or

any Remote Unit ( Expansion Modules 1 to 4). Use the guide below to set the relevant unit and

module ID.

To join the Master Unit press, SET, UNIT, SET. ie. press SET followed by UNIT(1) followed by SET.

The ON LED will flash 3 times.

To be part of Remote Unit 1 press, SET, UNIT, 1.

To be part of Remote Unit 2 press, SET, UNIT, 2.

To be part of Remote Unit 3 press, SET, UNIT, 3.

To be part of Remote Unit 4 press, SET, UNIT, 4.

Then select the Expansion Module position this module is to occupy by pressing, SET, MODULE,

followed by 1, 2, 3, or 4. The ON LED will flash 3 times.

Remember only 2 to 4 is valid for the Master Unit and ensure the module position is vacant, as a

RMT Field Module will take priority over an installed expansion module.

Setting PosiSense

The RMT Field Module is capable of supporting non-PosiSense and PosiSense solenoids in any mix

across the valve positions. Setting PosiSense is achieved in a similar manner as described above.

The ON LED will flash 3 times on a successful command.

For example, pressing SET, PosiSense, BERMAD, 2 will set output 2 as a Bermad solenoid.

Pressing SET, PosiSense, BACCARA, 7 will set output 7 as a Baccara solenoid.

Pressing SET, PosiSense, OFF, 1 will turn off PosiSense on output 1. PosiSense should be turned

off if an RM401 Pump Start Relay is connected to the output.

Any option selected without an output number at the end will have the effect of a blanket change on

all outputs.

For example, pressing SET, PosiSense, BERMAD (with no number keyed for 5 seconds), will set all

outputs for a Bermad solenoid.

Pressing SET, PosiSense, OFF (with no number keyed for 5 seconds) wil turn PosiSense OFF for all

outputs.

LED Indicators

The RMT Field Module has 5 LED lights across the right hand top of the keyboard panel. These are

marked as ON, OFF, PWR, RX & TX and behave as follows:

ON – flashes when a valve is turned on by pressing a valve key on the keyboard.

It is also used to show the valid entry of a setup command via the keyboard.

OFF – flashes when a valve is turned off by pressing a valve key on the keyboard.

PWR – Shows power to the module and the state of the radio connection. A solid ON or OFF

indicates a power issue, or a radio issue with the radio being unable to join the radio network. A

Page 34

Micro-Master Touch User Guide

26

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

double flash approximately every 5 seconds indicates a successful network connection.

RX – flashes when data is received by the module.

TX – flashes when data is transmitted by the module.

Turning Valves On & OFF manually

To turn a valve ON & OFF press the relevant button numbered 1 to 8 on the keyboard. When the key

is pressed the ON LED will flash to show the valve is turning on, or, the OFF LED will flash is the

valve is being turned off. Repeated pressing of the selected valve will turn the valve on and off.

5.7

Communication Module Options

The Communication Option screens are displayed by pressing the icon on the Setup

Selection screen.

Figure 16 - Communication Module Parameters

Page 35

Micro-Master Touch User Guide

27

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Figure 17 - Communication Module Configuration Parameters

In the example screen shown above, an ethernet communication module has been installed in

position 2, and has been assigned an IP address of 192.168.1.10 by a DHCP server on address

192.168.1.1

Communication Module Selection

Clicking on a Communication Module item will select the item, changing the background of the item

to light blue. Selecting the button and then clicking Edit will display an appropriate screen to allow

modification of available communication parameters for the selected communication module.

Communication Module Status

This area displays the current status for the communication modules.

Communication Module Parameters

This area displays available communication module parameters. The type of parameters available

depends on the selected communication module. Clicking on an item will select the item, changing

the background of the item to light blue. Selecting the button and then clicking Edit will display an

appropriate screen to allow modification of the selected communication parameter.

Page 36

Micro-Master Touch User Guide

28

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

5.8

PIN Number Setup

The PIN Number Setup screen is displayed by pressing the icon on the Setup Selection

screen.

Figure 18 - PIN Number Setup

Limited Access PIN

Clicking on the Limited Access PIN item will select the item, changing the background of the item to

light blue. Selecting the button and then clicking Edit will display the Number Edit screen.

Full Access PIN

Clicking on the Full Access item will select the item, changing the background of the item to light

blue. Selecting the button and then clicking Edit will display the Number Edit screen.

PIN Timeout

Clicking on the PIN Timeout item will select the item, changing the background of the item to light

blue. Selecting the button and then clicking Edit will display the Number Edit screen.

Lost PIN

If a Full Access PIN number is forgotten, no access to any function is possible. Please contact Toro

Technical Services for assistance.

5.9

Commissioning Table

Use the Commissioning Sheet (Table 1) on the next page to fill in commissioning data for later

reference.

Print 1 sheet for each Unit.

Page 37

Micro-Master Touch User Guide

29

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Micro-Master Touch Controller Output Commissioning Sheet

Unit No.

Station

Number

Valve Location

Valve

Current

Wire Colour /

Radio

Address

Comments

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Table 1 - Output Commissioning Sheet

Page 38

Micro-Master Touch User Guide

30

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

5.10

Global Setup

The Global Setup screen is displayed by pressing the icon on the Setup Selection screen.

Figure 19 - Global System Configuration

Reset Controller

Clicking on Reset Controller will select the item, changing the background to light blue. Selecting

Reset Controller and then clicking Edit will display a confirmation screen. If confirmed, the controller

will reset the controller to the factory default condition.

Reset Totals / Logs

Clicking on Reset Total / Logs will select the item, changing the background to light blue. Selecting

Reset Totals / Logs and then clicking Edit will display a confirmation screen. If confirmed, the

controller will reset the controller totals and logs to zero. This option does not erase the configuration

of programs, sensors etc.

Backup Controller

Clicking on Backup Controller will select the item, changing the background to light blue. Selecting

Backup Controller and then clicking Edit will display a confirmation screen. If confirmed, and a USB

flash storage device is connected, the controller will backup the controller configuration and totals to

the USB flash storage device.

Restore Controller

Clicking on Restore Controller will select the item, changing the background to light blue. Selecting

Restore Controller and then clicking Edit will display a confirmation screen. If confirmed, and a USB

flash storage device with a valid backup file is connected, the controller will restore the controller to a

previously saved controller configuration.

Page 39

Micro-Master Touch User Guide

31

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

Global Program Enable

A tick indicates that all controller programs are able to start. A cross indicates that all controller

programs will not start. Clicking the tick (cross) will disable (enable) the programs.

Rain Switch

A tick indicates that the controller is in a rain switch condition. Only programs that have been

configured to Ignore Rain Switch will start. Clicking the tick (cross) will disable (enable) the

programs.

Page 40

Micro-Master Touch User Guide

32

© 2014 Toro Australia Pty Ltd Ver 1.2, June 2014

6 Micro-Master Touch Screen Introduction

Each screen in the Micro-Master Touch controller has been designed to follow a common layout

whenever possible. This serves to simplify the familiarity process and greatly ease the operation of

the controller.

Generally, from the Home Screen, each major function area shows a list of eight function entries, eg

a list of programs, list of pumps etc. If there are more than eight entries in the function area, a row of

four navigation buttons along the bottom of the screen allows access to the next list of eight entries.

When necessary, the labels of the four buttons changes to allow access to further entries.

The right hand side of the screen contains action buttons. Depending on the function area, these

buttons will initiate commands on the selected entry, or allow access to the editing functions for the

selected entry.

On the edit screens, buttons in the navigation area allow the user to accept, or cancel any changes to

the function parameters, or navigate to the next entry in the function. A home button returns the user

directly to the main menu, without saving any changes to the function. A help button shows

information relating to the function.

On the right hand of the edit screen, a number of action buttons allow further modification of the

functions parameters. As far as possible, these buttons will have similar affects on each screen they

are displayed.

For example, consider the Pump Set Edit Screen as shown in Figure 20, where the Action,

Navigation, and Function Parameter areas are shown.

Figure 20 - Touch Screen Layout

In the Action Area, icons represent various actions that will be applicable for the currently displayed

function. Not all icons will be displayed for all functions.

The advanced parameter edit button will display more advanced parameters, including

parameters that are unlikely to change frequently, and status and totaliser data for the function.

The log button displays a graphical log of parameters appropriate to the function. In most

cases, this will be a graph of the associated flow meter.

Page 41