Page 1

Part No. 13200SL

Service Manual

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Workman MDX--D.

REFER TO THE OPERA T OR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

Workman

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give im portant instructionswhich must be followed to prevent damage to systems or components on the

machine.

MDX--D

R

E The Toro Company -- 2013

Page 2

This page is intentionally blank.

Workman MDX--D

Page 3

Table Of Contents

Chapter 1 -- Safety

Safety Instructions 1 -- 2..........................

Jacking and Other Instructions 1 -- 4...............

Safety and Instruction Decals 1 -- 6................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Diesel Engine

Specifications 3 -- 2..............................

General Information 3 -- 3........................

Adjustments 3 -- 5...............................

Service and Repairs 3 -- 6........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

SM--E3B SERIES

Chapter 4 -- Drive Train

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Drive Train Operation 4 -- 4.......................

Special Tools 4 -- 7..............................

Troubleshooting 4 -- 8............................

Adjustments 4 -- 9...............................

Service and Repairs 4 -- 10.......................

Chapter 5 -- Electrical System

General Information 5 -- 2........................

Special Tools 5 -- 3..............................

Troubleshooting 5 -- 5............................

Electrical System Quick Checks 5 -- 7..............

Component Testing 5 -- 8.........................

Service and Repairs 5 -- 23.......................

Chapter 6 -- Chassis

Specifications 6 -- 2..............................

General Information 6 -- 3........................

Special Tools 6 -- 4..............................

Troubleshooting 6 -- 5............................

Adjustments 6 -- 8...............................

Service and Repairs 6 -- 11.......................

Chapter 7 -- Electrical Drawings

Electrical Schematic 7 -- 3........................

Circuit Diagrams 7 -- 4...........................

Electrical Harness Drawings 7 -- 8.................

SafetyProduct Records

Diesel

Drive TrainElectrical

and Maintenance

Engine

System

Workman MDX--D

Chassis

Electrical

Drawings

Page 4

This page is intentionally blank.

Workman MDX--D

Page 5

Table of Contents

SAFETY INSTRUCTIONS 2......................

Supervisor’s Responsibilities 2.................

Before Operating 2............................

While Operating 3............................

Maintenance and Service 3....................

JACKING AND OTHER INSTRUCTIONS 4........

Jack Vehicle 4................................

Transport Vehicle 4...........................

Tow Vehicle 4................................

Transaxle Neutral Position 5...................

SAFETY AND INSTRUCTION DECALS 6..........

Chapter 1

Safety

Safety

Workman MDX--D Page 1 -- 1 Safety

Page 6

Safety Instructions

Workman MDX--D vehicles are designed and tested to

offer safe service when operated and maintained properly. Although hazard control and accident prevention

partially are dependent upon the design and configuration of the machine, these factors are also dependent

upon the awareness, concern and proper training of the

personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or

maintenance of the machine can result in injury or

death.

Read and understand the contents of the Operator’s

Manual before starting and operating the machine. Become familiar with all controls and know how to stop it

quickly. Additional copies of the Operator ’s Manual are

available on the internet at www.Toro.com.

Supervisor’s Responsibilities

The safety alert symbol means

CAUTION, WARNING or DANGER —

“personal safety instruction”. Read

and understand the instruction because it has to

do with safety. Failure to comply with the instruction may result in personal injury.

WARNING

To reduce the potential for injury or death, comply with the following safety instructions.

WARNING

The Workman is an off--h ighway vehicle only. It is

not designed, equipped or manufactured for use

on public streets, roads or highways.

1. Make sure operators are thoroughly trained and familiar with the Operator’s Manual and all labels on the

vehicle.

Before Operating

1. Read and understand the contents of the Operator’s

Manual and Operator’s DVD before starting and operating the vehicle. Become familiar with the controls and

know how to stop the vehicle and engine quickly. Additional copies of the Operator’s Manual are available on

the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the vehicle. Also, tighten any loose nuts, bolts or screws to ensure vehicle is in safe operating condition.

2. Be sure to establish your own special procedures

and work rules for unusual operating conditions (e.g.

slopes too steep for vehicle operation).

3. Since diesel fuel used in your Workman MDX--D

vehicle is flammable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not r emove vehicle fuel tank cap while engine

is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill

the fuel tank.

E. Cleanupanyspilledfuel.

Workman MDX--DPage 1 -- 2Safety

Page 7

While Operating

1. Sit on the operator seat when starting and operating

the vehicle.

2. Before starting the engine:

A. Sit on o perator’sseat and depress the brake pedal. Make sure that the parking brake is released.

B. Turn ignition switch to the ON position. When the

glow plug indicator goes off, the engine is ready to

start.

C. Turn ignition switch to the START position. Release switch to the ON position once the engine

starts.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

Maintenance and Service

1. Before servicing or making adjustments, turn all accessories off, stop the engine, set parking brake and remove key from the ignition switch.

4. Do not touch engine, radiator, exhaust system or

transaxle while engine is running or soon after it is

stopped. These areas could be hot enough to cause

burns.

5. Before getting off the seat:

A. Stop movement of the vehicle.

B. Turn ignition switch to OFF and wait for all movement to stop.

C. Apply parking brake.

D. Remove key from ignition switch.

E. Do not park on slopes unless wheels are chocked

or blocked.

10.Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

Safety

2. Make sure vehicle is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never work under a raised bed without placing the

bed on the fully extended prop rod.

4. Never store the vehicle or fuel container inside

where there is an open flame, such as near a water heater or furnace.

5. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt.

6. If engine must be running to perform maintenance or

an adjustment, keep clothing, hands, feet and other

parts of the body away from moving parts. Keep bystanders away.

7. Do not overspeed the engine by changing governor

setting. To assure safety and accuracy, check maximum

engine speed. Maximum engine speed is 3470 RPM.

8. Shut engine off before checking or adding oil to the

engine crankcase.

9. Disconnect battery before servicing the vehicle. Disconnect negative (--) battery cable first and positive (+)

cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the battery.

Attach positive (+) cable first and negative (--) cable last.

11.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

12.If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

13.To assure optimum performance and continued

safety of the vehicle, use genuine Toro replacement

parts and accessories. Replacement parts and accessories made by other manufacturers may result in nonconformance with safety standards, and the warranty

may be voided.

14.When raising the vehicle to change tires or to perform other service, use correct blocks, hoists and jacks.

Make sure vehicle is parked on a solid level surface such

as a concrete floor. Prior to raising the vehicle, remove

any attachments that may interfere with the safe and

proper raising of the vehicle. Always chock or block

wheels. Use appropriate jack stands to support the

raised vehicle. If the vehicle is not properly supported by

jack stands, the vehicle may move or fall, which may result in personal injury (see Jack Vehicle in this section).

15.Make sure to dispose of potentially harmful waste

(e.g. fuel, oil, engine coolant, filters, battery) in an environmentally safe manner. Follow a ll local codes and regulations when recycling or disposing of waste.

Workman MDX--D Page 1 -- 3 Safety

Page 8

Jacking and Other Instructions

Jack Vehicle

DANGER

POTENTIAL HAZARD

A vehicle that is not properly supported

may become unstable.

WHAT CAN HAPPEN

The vehicle may move or fall. Personal

injury or damage to the machine may result.

HOW TO AVOID THE HAZARD

Make sure vehicle is parked on a solid level

surface, such as a concrete floor.

Make sure engine is off and key is removed

from the ignition switch before getting off

the vehicle.

Before raising the vehicle, remove any

attachments that may interfere with the safe

and proper raising of the vehicle.

Always chock or block wheels to prevent

the vehicle from rolling.

Do not start vehicle while it is on jack

stands without placing transaxle in neutral.

Make sure proper hoists, jacks and jack

stands are used to raise and support the

vehicle.

1

Figure 1

1. Front frame 2. Towing tongue

2

2

1

Jacking Locations

1. Jack front of the vehicle on the front of the frame and

behind the towing tongue (Fig. 1).

2. Jack rear of the vehicle under each rear axle tube. Do

not jack vehicle below the transaxle case (Fig. 2).

Transport Vehicle

When moving the vehicle long distances, use a trailer or

flatbed truck. Make sure vehicle is secured to the trailer

properly. Refer to Operator’s Manual for transport information.

Tow Vehicle

IMPORTANT: Frequent or long distance towing of

the Workman MDX--D is not recommended.

In case of emergency, the vehicle can be towed for a

short distance. Refer to Operator’s Manual for towing

information.

Figure 2

1. Transaxle case 2. Axle tube

IMPORTANT: If vehicle is towed, make sure that

ignition switch is in the OFF position and key is removed from switch.

Workman MDX--DPage 1 -- 4Safety

Page 9

Transaxle Neutral Position

When performing routine maintenance and/or engine

testing, the transaxle must be shifted into the neutral

position.

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

2

Safety

2. Move shift lever to the neutral position (Fig. 3).

3. Make sure transaxle is in the neutral position by rotating the driven clutch. The tires should not rotate when

the transaxle is in the neutral position. If tire rotation

does occur, see Adjust Shift Cables in the Adjustments

section of Chapter 4 -- Drive Train.

3

1. Shift lever (in neutral)

2. Forward position

1

Figure 3

3. Reverse position

Workman MDX--D Page 1 -- 5 Safety

Page 10

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

your Workman. If any decal becomes illegible or damaged, install a new decal. Part numbers are listed in the

Parts Catalog. Order replacement decals from your Authorized Toro Distributor.

Workman MDX--DPage 1 -- 6Safety

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series). 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners). 5..........

Other Torque Specifications 6..................

Conversion Factors 6.........................

Product Records

Chapter 2

and Maintenance

Product Records

Insert Operator’s Manual and Parts Catalog for your

Workman at the end of this chapter. Additionally, if any

optional equipment or accessories have been installed

to your machine, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for those options

at the end of this chapter.

Maintenance

Maintenance procedures and recommended service intervals for your Workman are covered in the Operator’s

Manual. Refer to that publication when performing regular equipment maintenance.

Workman MDX--D Page 2 -- 1 Product Records and Maintenance

Page 12

Equivalents and Conversions

0.09375

Workman MDX--DPage 2 -- 2Product Records and Maintenance

Page 13

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature,

hardness of the surface underneath the fastener’s head

or similar condition which affects the installation.

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

thelinesmatchup.

and Maintenance

Product Records

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

Workman MDX--D Page 2 -- 3 Product Records and Maintenance

Page 14

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

#6--32UNC

#6--40UNF 17 + 2 192 + 23 25 + 3 282 + 34

#8--32UNC

#8--36UNF 31 + 4 350 + 45 43 + 5 486 + 56

#10--24UNC

#10--32UNF 48 + 5 542 + 56 68 + 7 768 + 79

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 11 3 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in-- lb in--lb N--cm in-- lb N--cm in --lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft-- lb ft-- lb N--m ft-- lb N--m ft-- lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

29 + 3 328 + 34 41 + 5 463 + 56

42 + 5 475 + 56 60 + 6 678 + 68

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Workman MDX--DPage 2 -- 4Product Records and Maintenance

Page 15

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N --cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N - -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft-- lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft-- lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10% of the

and Maintenance

Product Records

Workman MDX--D Page 2 -- 5 Product Records and Maintenance

Page 16

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Typ e A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque*

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 11 0 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft-- lb X 1.3558 = N--m N-- m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

* Hole size, material strength, material thickness and fin-

ish must be considered when determining specific

torque values. All torque values are based on non--lubri-

cated fasteners.

Workman MDX--DPage 2 -- 6Product Records and Maintenance

Page 17

Table of Contents

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

ADJUSTMENTS 5..............................

Adjust Throttle Cable 5........................

SERVICE AND REPAIRS 6......................

Air Cleaner 6.................................

Exhaust System 8............................

Fuel Tank 10.................................

Radiator 12..................................

Engine 14....................................

Engine Removal 15..........................

Engine Installation 16........................

Engine Clutch Adapter 18......................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

SM--E3B SERIES

Chapter 3

Diesel Engine

Diesel

Engine

Workman MDX--D Page 3 -- 1 Diesel Engine

Page 18

Specifications

Item Description

Make / Designation Kubota water--cooled, Diesel,

Number of Cylinders 2

Bore x Stroke 2.83” x 2.9” (72mm x 73.6mm)

Total Displacement 36.55 in3(599 c c)

Compression Ratio 24.0:1

Firing Order 1 (closest to gear case end) -- 2 (closest to flywheel end)

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel Fuel with Low or

Fuel Injector Pump Bosch MD Type Mini

Fuel Injection Nozzle Bosch Throttle Type

Fuel Capacity 6.5 U.S. gallons (24.6 liters)

Governor Mechanical

Model Z602--E3B

Ultra Low Sulfur Content

Low Idle (no load) 1300 + 70 RPM

High Idle (no load) 3470 + 50 RPM

Engine Oil API CH--4, CI--4, CJ--4 or higher

Engine Oil Viscosity See Operator’s Manual

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 2.6 U.S. quarts (2.5 liters) with filter

Cooling System Capacity (including reserve tank) 3.0 U.S. quarts (2.8 liters)

Starter 12 VDC 0.95 KW

Alternator/Regulator 12 VDC 40 AMP

Dry Weight (approximate) 132 lbs (60 kg)

Workman MDX--DPage 3 -- 2Diesel Engine

Page 19

General Information

This Chapter gives information about specifications,

maintenance, troubleshooting, testing and repair of the

dieselengineusedintheWorkmanMDX--D.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

tools a re described in the Kubota Workshop Manual,

Diesel Engine, SM--E3B Series. The use of some specialized test equipment is explained. However, the cost

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Workman MDX--D vehicle. Refer to the

Operator’s Manual for additional information when servicing the machine.

of the test equipment and the specialized nature of

some repairs may dictate that the work be done at an engine repair facility.

Service and repair parts for the Kubota engine in your

Workman are supplied through your local Toro distributor. If no parts list is available, be sure to provide your

distributor with the Toro model and serial number.

Diesel

Engine

Workman MDX--D Page 3 -- 3 Diesel Engine

Page 20

This page is intentionally blank.

Workman MDX--DPage 3 -- 4Diesel Engine

Page 21

Adjustments

Adjust Throttle Cable

Proper throttle operation is dependent upon proper adjustment of throttle control. Make sure throttle control is

operating properly.

NOTE: The shoulder bolt that secures the throttle cable

to the engine speed control lever should be positioned

inthelowestholeinthelever.

1. Fully depress throttle pedal to position engine speed

control lever in the high speed position.

2. Check position of the engine speed control lever on

the fuel injection pump (Fig. 1). The speed control lever

should contact the high speed screw when the throttle

pedal is fully depressed.

3. If necessary, throttle control can be adjusted by loosening cable jam nuts and repositioning throttle cable until speed control lever contacts high speed screw when

the throttle pedal is fully depressed (Fig. 2). Tighten

cable jam nuts after adjustment has been completed.

3

1

1. High speed screw

2. Speed control lever

2

Figure 1

3. Engine run solenoid

Diesel

Engine

4. Release throttle pedal and make sure that cable is

loose enough to allow engine speed control lever to return to the idle position.

2

5

1. Diesel engine

2. Throttle cable

3. Shoulder bolt

1

3

4

Figure 2

4. Flange nut

5. Throttle cable mount

Workman MDX--D Page 3 -- 5 Diesel Engine

Page 22

Service and Repairs

Air Cleaner

8

10

5

3

1

7

2

4

9

11

6

1. Air cleaner assembly

2. Carriage screw (2 used)

3. Air intake hose

4. Air cleaner mounting bracket

Figure 3

5. Air inlet hood

6. Flange nut (2 used)

7. Hose clamp (2 used)

8. Throttle cable

FRONT

RIGHT

9. Shoulder bolt

10. Throttle cable mount

11. Fla nge nut

Workman MDX--DPage 3 -- 6Diesel Engine

Page 23

Air Cleaner Removal (Fig. 3)

1. Park machine on a level surface, stop the engine, engage parking brake and remove the key from the ignition

switch.

1

5

2

2. Raise and support cargo bed to access air cleaner.

3. Remove air cleaner components as needed using

Figure 3 as a guide.

4. Check air cleaner hose (item 3 in Fig. 3) for damage

or wear. Replace hose if damage is found.

5. Disassemble air cleaner as necessary (Fig. 4).

6. Check air cleaner housing and cover for damage that

could cause possible air leaks.

Air Cleaner Installation (Fig. 3)

IMPORTANT: Any leaks in the air cleaner system

will allow dirt into engine and will cause serious engine damage. Make sure that all air cleaner components are in good condition and are properly

secured during assembly.

1. Assemble air cleaner system using Figures 3 and 4

as guides.

A. If plug (item 5 in Fig. 4) was removed from air

cleaner housing, apply sealant to threads of plug beforeassembly.Torqueplugto30 in-- lb (3.4 N--m).

B. Make sure that vacuator valve on air cleaner assembly is pointed down after assembly.

30 in--lb

(3.4 N--m)

1. Housing

2. Filter element

3. Cover

2

Figure 4

4. Vacuator valve

5. Plug

6. Gasket

0.180” (4.6 mm)

3

1

4

Maximum

6

3

Diesel

Engine

C. Make sure that clearance between air intake

hose and air inlet hood is less than 0.180” (4.6 mm)

(Fig. 5). If this clearance is excessive, the intake

hose may contact secondary clutch during suspension movement. Rotate intake hose to modify clearance as needed.

2. Lower and secure cargo bed.

1. Air cleaner assembly

2. Air inlet hood

Figure 5

3. Air intake hose

Workman MDX--D Page 3 -- 7 Diesel Engine

Page 24

Exhaust System

RIGHT

FRONT

1

7

9

6

1. Engine

2. Exhaust header

3. Coupler spring (2 used)

3

2

4. Flange nut (4 used)

5. Muffler

6. Hex nut (4 used)

4

Figure 6

5

4

3

8

7. Exhaust gasket

8. Flange head screw (4 used)

9. Lock washer (4 used)

Workman MDX--DPage 3 -- 8Diesel Engine

Page 25

Exhaust System Removal (Fig. 6)

Exhaust System Installation (Fig. 6)

1. Park machine on a level surface, stop the engine, engage parking brake and remove the key from the ignition

switch.

2. Raise and support cargo bed to access exhaust system.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the muffler.

3. Remove exhaust system components as needed using Figure 6 as a guide.

1. Make sure the engine is off.

IMPORTANT: If exhaust studs were removed from

engine cylinder head, thoroughly clean threads in

head and apply Loctite #277 (or equivalent) to stud

threads before installing studs into head.

NOTE: Make sure exhaust header flange and engine

exhaust manifold sealing surfaces are free of debris or

damage that may prevent a tight seal.

2. If exhaust gasket (item 7) was removed, place new

exhaust gasket on the engine exhaust manifold.

NOTE: To ensure proper exhaust system sealing,

mount all exhaust system components loosely before

fully tightening any fastener.

3. Assemble all removed exhaust system components

usingFigure6asaguide.

4. After all exhaust components have been assembled,

make sure that all fasteners are properly tightened.

Also, make sure that all electrical wires and control

cables are not contacted by exhaust components.

Diesel

Engine

5. Lower and secure cargo bed.

Workman MDX--D Page 3 -- 9 Diesel Engine

Page 26

Fuel Tank

RIGHT

FRONT

1

9

10

5

3

4

2

6

8

7

1. Seat

2. Fuel tank

3. Fuel hose (to fuel separator)

4. Fuel hose (return from engine)

Figure 7

5. Seat base

6. Web strapping

7. Hex head flange screw (8 used)

8. Flat washer (8 used)

9. Parking brake support

10. Shift bracket

Workman MDX--DPage 3 -- 10Diesel Engine

Page 27

Fuel Tank Removal (Fig. 7)

17

CAUTION

Read safety precautions for handling fuel before

working on the fuel system (see Safety Instructions in Chapter 1 -- Safety).

1. Remove seat base from the frame (see Seat Base in

the Service and Repairs section of Chapter 6 -- Chassis).

2. Use f uel transfer pump to remove fuel from fuel tank.

3. Loosen hose clamp and disconnect fuel return hose

(item 13 in Figure 8) from elbow fitting in fuel tank.

4. Loosen hose clamp and disconnect fuel supply hose

(item 17 in Figure 8) from the fuel pump.

5. Disconnect fuel pump electrical connector from

vehiclewireharness.

6. Release tank strap that secures fuel tank to frame.

Do not remove strap from floor plate and frame cross

member. Lift fuel tank assembly from frame.

7. Remove fuel tank components as needed using Figure 8 as a guide.

12

15

12

1. Fuel tank

2. Fuel cap

3. Rollover valve

4. Bushing

5. Grommet

6. Stand pipe

7. Elbow fitting

8. Fuel gauge

9. Grommet

14

13

1

16

12

11

4

Figure 8

10. Vent hose

11. Hose clam p

12. Hose clamp

13. Fuel return hose

14. Fuel pump

15. Fuel pump holder

16. Fuel supply hose

17. Fuel supply hose

10

8

11

3

6

7

5

9

2

Diesel

Engine

8. Clean fuel tank before installing it back on vehicle.

Fuel Tank Installation (Fig. 7)

1. Install all removed fuel tank components using Figure 8 as a guide.

2. Position fuel tank to frame. Secure tank to frame and

cross member with tank strap.

3. Connect fuel supply hose (item 17 in Figure 8) to the

fuel pump and fuel return hose (item 13 in Figure 8) to

the elbow fitting. Secure hoses with hose clamps.

4. Connect fuel pump electrical connector to vehicle

wire harness.

5. Install seat base to the frame (see Seat Base in the

Service and Repairs section of Chapter 6 -- Chassis).

6. Fill fuel tank.

Workman MDX--D Page 3 -- 11 Diesel Engine

Page 28

Radiator

13

3

13

RIGHT

2

16

15

23

21

23

4

18

14

14

20

5

22

1

12

7

20

10

12

19

17

19

12

5

12

9

6

23

8

12

11

FRONT

1. Surge tank

2. Tank cap

3. Radiator

4. Washer head screw (2 used)

5. Flange nut (3 used)

6. Cap

7. Cap decal

8. Filler neck

9. Lower radiator hose

10. Upper radiator hose

11. Straight hose

12. Hose clamp (6 used)

13. Carriage screw (3 used)

14. Flange nut (3 used)

15. Cap

16. Hose clamp

CAUTION

DO NOT open radiator cap or drain coolant if the

engine or radiator is hot. Pressurized hot coolant

can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of it properly or store it in a properly labeled

container away from children and pets.

Figure 9

17. Lower radiator shroud

18. Upper radiator shroud

19. Speed nut (4 used)

20. Washer head screw (4 used)

21. Coolant hose

22. Coolant hose

23. Hose clamp (4 used)

Radiator Removal (Fig. 9)

1. Park machine on a level surface, stop the engine, en-

gage parking brake and remove the key from the ignition

switch.

2. Raise and support cargo bed to access radiator.

3. Remove knob that secures radiator screen to right

side of rear frame (Fig. 10). Lift screen to separate tabs

on screen from slots in frame and then remove screen

from vehicle.

Workman MDX--DPage 3 -- 12Diesel Engine

Page 29

4. Remove caps (items 2 and 6) from surge tank and radiator filler neck to allow complete draining of cooling

system.

5. Drain radiator into a suitable container by disconnecting lower radiator hose from the radiator.

6. Disconnect upper radiator hose from the radiator.

7. Disconnect the coolant hose (item 22) from the fitting

located on the lower r adiator tube.

8. Remove four (4) washer head screws (item 20) and

three (3) flange nuts (item 14) that secure the radiator

shrouds. Also, disconnect wire harness clips from upper

radiator shroud. Carefully remove upper r adiator shroud

from vehicle.

9. Position lower radiator shroud away from the radiator.

IMPORTANT: Use a 50/50 mix of ethylene--glycol

and water when filling cooling system.

7. Fill cooling system with coolant as follows (Fig. 11):

A. Make sure that surge tank cap is installed on

surge tank.

B. Remove cap on radiator filler neck and fill cooling

system with coolant.

C. Install cap into radiator filler neck and tighten.

D. Remove surge tank cap and fill surge tank to the

bottom of the filler neck. Install surge tank cap.

8. Check radiator, surge tank, hoses and all connections for leaks.

9. Lower and secure cargo bed.

10.Remove three (3) carriage head screws (item 13)

and flange nuts (item 14) that secure the radiator to the

rear frame.

11. Carefully remove radiator from vehicle.

Radiator Installation (Fig. 9)

1. Make sure that lower radiator shroud is positioned

under the engine fan.

2. Carefully position radiator to the rear frame. Secure

radiator to frame with three (3) carriage head screws

(item 13) and flange nuts (item 14).

3. Position upper and lower radiator shrouds around

the fan and to the radiator. Secure shrouds together with

four (4) washer head screws (item 20). Then, secure

shrouds to frame with three (3) flange nuts (item 14).

Make sure that equal clearance exists between shrouds

and fan at all points.

4. Connect upper and lower radiator hoses to radiator

and secure with hose clamps.

5. Connect coolant hose (item 22) to the fitting located

on the lower radiator tube and s ecure with hose clamp.

Make sure that hose is not kinked at any point after installation.

1. Rear frame

2. Radiator screen

1

4

Figure 10

3. Knob

4. Slot

Diesel

Engine

1

4

2

3

2

6. Install radiator screen to rear frame and secure with

knob (Fig. 10).

Figure 11

1. Filler neck cap 2. Surge tank cap

Workman MDX--D Page 3 -- 13 Diesel Engine

Page 30

Engine

17

1

11

2

9

10

8

7

4

3

6

16

15

5

7

RIGHT

14

FRONT

13

12

1. Engine

2. Engine wire harness connector

3. Hex nut

4. Negative battery cable

5. Engine wire harness connector

6. Lock washer

Figure 12

7. Flange head screw (8 used)

8. Hex nut (4 used)

9. Lock washer (4 used)

10. Exhaust header

11. Flange nut (4 used)

12. Cap screw (4 used)

13. Snubbing washer (4 used)

14. Spacer (4 used)

15. Engine mount (4 used)

16. Engine bracket (front shown)

17. Drive belt

Workman MDX--DPage 3 -- 14Diesel Engine

Page 31

Engine Removal (Fig. 12)

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch.

CAUTION

The engine, radiator and exhaust system may be

hot. To avoid possible injury, allow machine to

cool before working on the engine.

2

3

5

1

2. Disconnect negative (black) cable from the battery.

Then, disconnect positive (red) cable from the battery.

3. Remove cargo b ox to gain access to the engine (see

Cargo Box in the Service and Repairs s ection of Chapter

6--Chassis).

4. Carefully remove drive belt from drive clutch.

5. Depending on needed engine repairs, it may be easier to drain oil from engine before engine removal.

IMPORTANT: To prevent contaminants from enter ing the engine and fuel system, make sure all hoses

and engine openings are c overed or plugged after

disconnecting.

6. Drain radiator into a suitable container by disconnecting lower radiator hose from the radiator. Then, remove upper radiator hose from the radiator.

7. Remove air intake hose from the air cleaner and engine intake (see Air Cleaner in this section).

8. Remove muffler and exhaust header from the

vehicle (see Exhaust System in this section).

9. Remove shoulder bolt and flange nut that secure the

throttle cable end to injector pump speed control lever

(Fig. 13). Loosen nuts that secure throttle cable to cable

mount. Position throttle cable away from e ngine.

1. Diesel engine

2. Throttle cable

3. Shoulder bolt

2

1

1. Alternator

2. Temperature switch

2

Figure 13

Figure 14

2

4

4. Flange nut

5. Throttle cable mount

4

3

3. Glow plug bus

4. Engine run solenoid

Diesel

Engine

3

CAUTION

Read safety precautions for handling fuel before

working on the fuel system (see Safety Instructions in Chapter 1 -- Safety).

10.Disconnect fuel supply hose from the injector pump

and fuel return hose from the #2 injector. Drain any fuel

trapped in the hoses into a suitable container. Plug

hoses and position them away from engine assembly.

1. Flange nut (8 used)

2. Flange screw (8 used)

1

Figure 15

3. Engine mount (4 used)

Workman MDX--D Page 3 -- 15 Diesel Engine

1

Page 32

11. Disconnect electrical connections from the following

engine components:

A. Disconnect main wire harness connections to

glow plug bus, temperature sender and engine run

solenoid (Fig. 14).

B. Disconnect main wire harness connection to fusible link harness.

C. Disconnect engine wire harness connector from

themainwireharness.Theenginewireharnessincludes connectors for the alternator, oil pressure

switch, starter solenoid and engine ground.

D. Remove flange head screw from front engine

mount that secures negative battery cable and engine ground connector. Make sure to note location of

lock washer when removing screw. Position negative battery cable away from engine.

12.Remove four (4) flange nuts, spacers, snubbing

washers and cap screws that secure the engine to the

engine mounts.

1

4

Figure 16

1. Front engine bracket

2. Rubber bumper

Engine Installation (Fig. 12)

1. Install all removed mounts, components and attach-

ments to the engine.

3. Lock nut (3 used)

4. Carriage screw (3 used)

2

3

CAUTION

Make sure that hoist or lift used t o remove engine

can properly support engine. Engine assembly

weighs approximately 170 pounds (77 kg). Also,

one person should operate the hoist while a

second person guides the engine out of the

vehicle.

13.Remove engine from the vehicle.

A. Attach a short section of chain between both engine lift tabs.

B. Connect hoist to center of chain.

IMPORTANT: Make sure to not damage the engine, fuel hoses, electrical harness or other parts

while removing the engine.

C. Carefully move the engine assembly away from

the r adiator and when the engine has cleared the radiator shrouds, carefully raise the engine from the

vehicle.

14.Remove engine brackets, components and attachments a s necessary to repair the engine.

15.Inspect engine mounts (Fig. 15) and bumper assembly (Fig. 16) for wear or damage and replace components if necessary.

CAUTION

Make sure that hoist or lift u sed to install engine

can properly support engine. Engine assembly

weighs approximately 170 pounds (77 kg). Also,

one person should operate the hoist while a

second person guides the engine into the

vehicle.

2. Install engine to the vehicle.

A. Attach a short section of chain between both engine lift tabs.

B. Connect a hoist at the center of the short section

of chain.

IMPORTANT: Make sure to not damage engine,

fuel lines, electrical harness or other parts while

installing the engine.

C. Carefully lower engine assembly into the engine

area of the vehicle. Align holes in engine brackets

with engine mounts attached to frame.

3. Secure engine to engine mounts with four (4) cap

screws, snubbing washers, spacers and flange nuts.

Workman MDX--DPage 3 -- 16Diesel Engine

Page 33

4. Connect the following electrical components:

A. Connect main wire harness connections to glow

plug bus, temperature sender and engine run solenoid (Fig. 14).

8. Install exhaust header and muffler to the vehicle (see

Exhaust System in this section).

9. Install air intake hose to the air cleaner and engine

intake (see Air Cleaner in this section).

B. Connect main wire harness connection to fusible

link harness.

C. Connect engine wire harness connector to the

main wire harness.

D. Secure negative battery cable and engine ground

connector to front engine mount with flange head

screw. The order of assembly should be lock washer,

negative battery cable, engine ground connector

and then flange head screw. Coat connectors with

skin over grease or terminal protector (see Special

Tools in Chapter 5 -- Electrical System) after assembly.

5. Install drive belt to drive clutch.

IMPORTANT: Make sure to remove all plugs and

covers that were placed on hose and engine openings during engine removal.

6. Connect fuel supply hose to the injector pump and

fuel return hose to the #2 injector.

7. Position throttle cable to engine. Secure the throttle

cable end to injector pump speed control lever with

shoulder bolt and flange nut. Tighten cable nuts to secure cable to cable mount (Fig. 13). Check throttle cable

adjustment (see Adjust Throttle Cable in the Adjustments section of this chapter).

10.Connecting lower and upper radiator hoses to t he radiator. Fill cooling system with coolant (see Radiator in

this section). Check radiator and hoses for leaks.

11.Make sure that alternator belt tension is properly adjusted.

12.Check that the gap between the rubber bumper and

front engine bracket is 0.090” (2.2 mm) (Fig.16).Ifgap

is incorrect, loosen three (3) lock nuts and adjust bumper to provide correct gap. Tighten lock nuts to secure

bumper after adjustment.

13.Make sure engine oil level is correct.

14.Install cargo box to the frame (see Cargo Box in the

Service and Repairs section of Chapter 6 -- Chassis).

15.Connect positive (red) cable to the battery. Then,

connect negative (black) cable to the battery.

Diesel

Engine

Workman MDX--D Page 3 -- 17 Diesel Engine

Page 34

Engine Clutch Adapter

7

17 to 22 ft--lb

6

1

Loctite #242

3

(23to29N--m)

5

RIGHT

FRONT

1. Drive belt

2. Cap screw

3. Flange washer

4. Drive clutch

5. Cap screw (5 used)

Removal (Fig. 17)

1. Park machine on a level surface, stop the engine, engage parking brake and remove the key from the ignition

switch.

2. Raise and support cargo bed to access engine.

3. Carefully remove drive belt from drive clutch.

4. Remove drive clutch from clutch adapter on engine

(see Drive Clutch in the Service and Repairs section of

Chapter 4 -- Drive Train).

2

4

Figure 17

6. Clutch adapter

7. Engine assembly

Installation (Fig. 17)

1. Position clutch adapter to engine flywheel and se-

cure with five (5) cap screws.

2. Secure drive clutch to clutch adapter on engine (see

Drive Clutch in the Service and Repairs section of

Chapter 4 -- Drive Train).

3. Install drive belt to drive clutch.

4. Lower and secure cargo bed.

5. Remove five (5) cap screws that secure clutch

adapter to engine flywheel. Remove clutch adapter from

engine.

Workman MDX--DPage 3 -- 18Diesel Engine

Page 35

Table of Contents

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

DRIVE TRAIN OPERATION 4....................

Clutch System Operation 4.....................

Drive Clutch Operation 5.......................

Driven Clutch Operation 6.....................

SPECIAL TOOLS 7.............................

TROUBLESHOOTING 8.........................

Clutch 8.....................................

ADJUSTMENTS 9..............................

Adjust Shift Cables 9..........................

SERVICE AND REPAIRS 10.....................

Drive Clutch 10...............................

Drive Clutch Service 12........................

Driven Clutch 14..............................

Driven Clutch Service 15.......................

Transaxle 16.................................

Removal 17................................

Installation 18...............................

Transaxle Service 20..........................

Transaxle Disassembly and Inspection 21......

Transaxle Assembly 32......................

Chapter 4

Drive Train

Drive Train

Workman MDX--D Drive TrainPage 4 -- 1

Page 36

Specifications

Item Description

Transaxle

Transaxle Fluid Capacity 1.5 quarts (1.4 liters)

Transaxle Fluid SAE 10W--30 Motor Oil

Transaxle Dry Weight 73 pounds (33 kilograms)

Clutch System Continuously variable transmission type, torque convertor

Drive Clutch Speed sensing with mechanical fly weights

Driven Clutch Torque sensing with spring loaded cam

Workman MDX--DPage 4 -- 2Drive Train

Page 37

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Workman MDX--D vehicle. Refer to the

Operator’s Manual for additional information when servicing the machine.

Drive Train

Workman MDX--D Drive TrainPage 4 -- 3

Page 38

Drive Train Operation

v

Clutch System Operation

LOW ENGINE SPEED

LIGHT LOAD

3

FULL ENGINE SPEED

DECREASING LOAD

4

1

FULL ENGINE SPEED

INCREASING LOAD

6

7

1. Drive clutch

2. Driven clutch

3. Moveable sheave (drive clutch)

8

5

4. Fixed sheave (drive clutch)

5. Moveable sheave (driven clutch)

6. Spring

Power is transferred from t he engine to the transaxle by

a variable clutch system that consists of two (2) clutches

connected by a drive belt. The drive clutch responds to

engine speed and is mounted to the engine crankshaft.

The driven clutch responds to changes in load to the rear

axle and is mounted to the transaxle input shaft.

2

Figure 1

7. Fixed sheave (driven clutch)

8. CVT drive belt

The two (2) clutches work together to automatically up-shift and back--shift as changes in load and speed occur.

This shifting changes the turning ratio between the drive

and driven clutches and allows the engine to operate at

optimum efficiency.

Workman MDX--DPage 4 -- 4Drive Train

Page 39

Drive Clutch Operation

The operation of the drive clutch is affected by engine

shaft speed. With the engine not turning, the CVT drive

belt rests low within the drive clutch sheaves as the pressure of the spring holds the sheaves apart. As the engine increases in speed, the clutch weights attached to

the moveable sheave move outward as they spin about

the engine driveshaft. The outward movement of the

clutch weights presses against the rollers and overcomes spring pressure through the spider assembly, which

forces the moveable sheave closer to the fixed sheave.

This inward movement of the sheave engages the drive

belttodrivethedrivenclutch.

With increasing engine speed, the moveable sheave

continues to move inward, which forces the drive belt to

ride towards the outer diameter of the clutch sheaves.

When engine speed is decreased, the clutch weights

exert less force on the rollers and thus the spring. The

spring pressure overcomes the force of the clutch

weights and shifts the moveable sheave away from the

fixed sheave. The drive belt disengages from the clutch

sheaves at a point where the force of the spring is greater than that of the clutch weights.

1

1. Fixed sheave

2. Moveable sheave

3. Spider assembly

4. Cover

2

5

Figure 2

3

5. Clutch weight (3 used)

6. Roller (3 used)

7. Spring

4

7

6

Drive Train

Workman MDX--D Drive TrainPage 4 -- 5

Page 40

Driven Clutch Operation

Theoperationofthedrivenclutchisaffectedbytransaxle load. When the vehicle is stopped, the drive belt is

held at the outer diameter of the driven clutch sheaves

from the pressure of the spring pushing the moveable

sheave against the fixed sheave and away from the

fixed cam.

Once the drive belt starts rotating, the driven clutch also

starts to rotate. With increasing speed of the drive clutch

on the engine, the drive belt begins to climb to the outer

diameter of the drive clutch sheaves. This increases the

tension on the drive belt and forces the moveable

sheave of the driven clutch to move away from the fixed

sheave against the pressure of the driven clutch spring.

As the belt tightens and the driven clutch sheaves open

up, the drive belt rides lower in the driven clutch

sheaves.

With increased load to the transaxle, the driven clutch

fixed cam resists forward movement relative to the

moveable sheave and drive belt. Torque from the drive

belt along with spring pressure moves the moveable

sheave up the ramp of the fixed cam. The drive belt becomes positioned closer to the outer diameter of the

driven clutch sheaves.

2

1. Moveable sheave

2. Fixed sheave

3

1

Figure 3

3. Spring

The fixed cam on the driven clutch moveable sheave rotates on a pair of rollers in the fixed sheave base to allow

low friction movement of the moveable sheave (Fig. 3).

Workman MDX--DPage 4 -- 6Drive Train

Page 41

Special Tools

Order special tools from your Toro Distributor.

Drive Clutch Removal Tool

This tool is required to remove the drive clutch from the

tapered drive shaft of the engine. It is placed in the

threaded hole of the fixed clutch sheave after the clutch

retaining screw is removed.

Toro Part Number: TOR6014

Figure 4

Drive Train

Workman MDX--D Drive TrainPage 4 -- 7

Page 42

Troubleshooting

Clutch

Problem Possible Cause

Poor upshifting. Governed engine speed is adjusted too low.

Driveand/ordrivenclutchassemblieshaveaccumulationofdirtor

debris.

Drive belt is worn.

Clutch sheaves are worn or damaged.

Poor downshifting. Driveand/ordrivenclutchassembly has accumulation of dirt or

debris.

Drive belt is worn.

Clutch sheaves are worn or damaged.

Vehicle creeps at idle. Engine idle speed is too high.

Drive clutch has accumulation of dirt or debris preventing full backshifting.

Drive and driven clutches are not aligned.

Rough clutch engagement. Engine idle speed is too low.

Drive clutch assembly has accumulation of dirt or debris.

Drive belt is worn.

Drive clutch sheaves are worn or damaged.

Noisy clutch operation. Engine idle speed is too low causing excess shaking.

Worn drive clutch roller or weight bushings.

Worn drive clutch spider slides (drive clutch replacement necessary

if found).

Workman MDX--DPage 4 -- 8Drive Train

Page 43

Adjustments

Adjust Shift Cables

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

Raise and support cargo box.

2. Set the shift lever into the Neutral position. Rotate

driven clutch to insure transmission is in neutral.

3. The transaxle select lever assembly should be in a

level position and parallel to the cable mounting bracket.

4. While holding the cable below the lever, tighten the

lock nut on one of the shift cables to allow 0.030” to

0.060” (0.8 to 1.5 mm) freeplay in the cable (Fig. 6).

5. Repeat process for other shift cable.

6. Pull up on each shift cable to make sure that freeplay

is correct. If necessary, readjust nut (Fig. 6).

7. Start engine and verify transaxle engagement in forward, reverse and neutral as the shift lever is moved.

8. Finally, check vehicle operation in forward, reverse

and neutral. Readjust shift cables if needed for correct

operation.

2

1

3

1. Select lever assembly

2. Lock nut location

Figure 5

3. Shift cable

2

3

Drive Train

9. Lower and secure cargo box.

2

3

1. Select lever

2. Cable pull direction

0.030” to 0.060”

(0.8 to 1.5 mm)

1

Figure 6

3. Cable boot

Workman MDX--D Drive TrainPage 4 -- 9

Page 44

Service and Repairs

v

Drive Clutch

1

4

RIGHT

FRONT

1. Engine

2. Clutch adapter

3. Cap screw (5 used)

2

4. Drive belt

5. Drive clutch

5

Loctite #242

3

6

17 to 22 ft--lb

(23 to 29 N--m)

7

Figure 7

6. Flange washer

7. Cap screw

Workman MDX--DPage 4 -- 10Drive Train

Page 45

Drive Clutch Removal (Fig. 7 )

Drive Clutch Installation (Fig. 7)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

Raise and support cargo box.

2. Carefully remove drive belt from the drive clutch.

3. Remove cap screw (item 7) and flange washer (item

6) securing the drive clutch to the clutch adapter.

IMPORTANT: Lightly grease end of clutch removal

tool to prevent wear or damage to removal tool and

clutch adapter. Prevent damage to clutch threads;

thread tool into clutch only enough to remove the

clutch.

4. Use drive clutch removal tool (see Special Tools in

this chapter) to remove drive clutch from the tapered

clutch adapter.

5. Inspect the tapered ends of the clutch adapter and

fixed sheave of drive clutch. If e ither is severely damaged, replace component as damage to the taper will allow loosening of the clutch during operation.

1. Thoroughly clean the tapered surfaces of the clutch

adapter and drive clutch.

2. Slide drive clutch onto the clutch adapter.

3. Apply Loctite #242 (or equivalent) to the threads of

the cap screw (item 7).

4. Secure clutch to clutch adapter with cap screw (item

7) and flange washer (item 6). Torque cap screw from 17

to 22 ft--lb (23 to 29 N--m).

5. Install drive belt to the drive clutch.

6. Lower and secure cargo box.

Drive Train

Workman MDX--D Drive TrainPage 4 -- 11

Page 46

Drive Clutch Service

v

11

6

10

40 to 50 in--lb

(4.6 to 5.6 N-- m)

1. Flange head screw (6 used)

2. Cover

3. Compression spring

4. Limiter shim

Disassembly (Fig. 8)

7

9

8

5

3

105 to 120 in--lb

(12to13.5N--m)

4

2

1

Figure 8

5. Shoulder screw (3 used)

6. Lock nut (3 used)

7. Clutch weight (3 used)

8. Spider

9. Shim

10. Moveable sheave

11. Fixed sheave

IMPORTANT: Make note of the “X” mark cast into

the cover and spider before clutch disassembly.

These marks must be aligned during assembly for

proper clutch operation.

1. Make note of the “X” mark cast into the cover and spider before clutch disassembly (Fig. 9). These marks

must be aligned during assembly for proper clutch operation.

CAUTION

Loosen the flange head screws that secure cover

slowly. The cover is under pressure from the

compression spring.

2. Using a crossing pattern, loosen and remove six (6)

flange head screws (item 1) that secure the cover to the

movable sheave.

3. Carefully remove cover, compression spring and limiter shim from clutch.

2

1

Figure 9

1. Spider 2. Cover

4. Remove lock nut (item 6) from each of the shoulder

screws (item 5). Discard lock nuts after removal.

Workman MDX--DPage 4 -- 12Drive Train

Page 47

5. Slide shoulder screw from each of the clutch weights

(item 7) and then remove weights from clutch.

6. Clean all dust and debris from clutch components

with a soft bristle brush. If necessary, use water to remove dirt and dry immediately with compressed air to

remove all dirt and water. Remove any remaining debris

with a fast drying contact or brake parts cleaner. Focus

debris removal on and around moving clutch components.

Inspection

NOTE: Ifdriveclutchwearordamageoccurs,clutchre-

placement may be necessary. Refer to your parts catalog to identify individual drive clutch components that

are available.

3. Position limiter shim, compression spring and cover

to clutch. Make sure that the “X” mark cast into the cover

and spider are aligned.

4. Secure cover to the movable sheave with six (6)

flange head screws in a crossing pattern and in three (3)

steps. Final torque on screws should be from 105 to 120

in--lb (12 to 13.5 N--m).

2

1

1. Inspect the tapered ends of the engine crankshaft

and fixed sheave of drive clutch. If either is severely

damaged, replace component as damage to the taper

will allow loosening of the clutch during operation.

2. Inspect the compression spring (item 3) and replace

if damaged or fatigued.

3. Clean and inspect shoulder screws (item 5). If the

shoulder area of the screws is worn or if the threads are

damaged, replace the screws.

4. Check the contact surface of the clutch weights (Fig.

10). If surface is worn or damaged, replace all three (3)

clutch weights as a set.

5. Check the rollers in the spider assembly for binding

or wear (Fig. 11). If binding or uneven wear is found, replace clutch assembly.

6. Check the belt contact surfaces of the movable and

fixed sheaves. Remove any belt material from sheave

faces with a fine abrasive pad or fine steel wool. If

sheave surfaces are worn, replace clutch assembly.

Assembly (Fig. 8)

Figure 10

1. Clutch weight 2. Contact surface

2

3

1

Figure 11

1. Roller

2. Weight contact surface

2

3. Roller uneven wear

1

Drive Train

2

IMPORTANT: For proper drive clutch operation, DO

NOT lubricate drive clutch components.

IMPORTANT: To maintain the balance of the clutch,

all shoulder screws must be installed with their

threads pointing in a clockwise direction (Fig. 12).

1. Position clutch weights to moveable sheave and

slide shoulder screw into sheave and weight. Make sure

that shoulder screw threads are pointing in a clockwise

direction.

2. Install new lock nuts on the shoulder screws. DO

NOT reuse removed lock nuts. Tighten nuts until they

contact screw shoulder and then torque nuts from 40 to

50 in--lb (4.6 to 5.6 N--m).

Workman MDX--D Drive TrainPage 4 -- 13

1

2

Figure 12

1. Shoulder screw head 2. Lock nut

1

Page 48

Driven Clutch

Driven Clutch Removal (Fig. 13)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

Raise and support cargo box.

2. Remove muffler from the vehicle (see Exhaust System in the Service and Repairs section of Chapter 3 -Diesel Engine).

3. Carefully remove drive belt from the driven clutch.

4. Remove cap screw and stepped washer securing

the driven clutch to the input shaft of the transaxle.

5. Slide driven clutch from the transaxle input shaft.

Driven Clutch Installation (Fig. 13)

3

4

2

1

1. Coat transaxle input shaft with antiseize lubricant.

2. Position driven clutch to the input shaft. Make sure

pulley side of the clutch is next to the transaxle case.

3. Secure driven clutch to the transaxle input shaft with

cap screw and stepped washer. Torque cap screw from

39 to 47 ft--lb (53 to 63 N--m).

4. Install drive belt to the driven clutch.

5. Install muffler to the vehicle (see Exhaust System in

the Service and Repairs section of Chapter 3 -- Diesel

Engine).

6. Lower and secure cargo box.

Antiseize

Lubricant

1. Cap screw

2. Stepped washer

39 to 47 ft--lb

(53 to 63 N--m)

Figure 13

3. Driven clutch

4. Input shaft (transaxle)

Workman MDX--DPage 4 -- 14Drive Train

Page 49

Driven Clutch Service

1. Use a suitable press to compress the clutch spring

enough t o allow removal of the retaining ring.

2. Remove retaining ring.

2

3

3. Carefully, allow the spring to extend fully.

4. Remove outer spring retainer, spring and inner

spring retainer from clutch.

5. Make note of the “X” mark cast into the fixed sheave

and moveable sheave before removing the moveable

sheave. These marks must be aligned during assembly

for proper clutch operation.

6. Separate the clutch sheaves. Locate and retrieve

thrust washer.

7. Clean and inspect driven clutch components:

A. Clean all dust and debris from clutch components. If necessary, use contact or brake cleaner to

remove any oil or other lubricants from clutch components.

B. Inspect the spring and replace if damaged or fatigued.

C. Check the rollers in the fixed sheave for binding or

wear. If binding or uneven wear is found, replace

driven clutch assembly.

1

1. Fixed sheave

2. Thrust washer

3. Moveable sheave

4. Inner spring retainer

4

6

7

5

Figure 14

5. Spring

6. Outer spring retainer

7. Retaining ring

Drive Train

D. Check the contact surface of the sheaves for

wear and/or fraying. If wear or damage is found, replacedrivenclutchassembly.

8. Assemble the driven clutch in the reverse order of

disassembly. Make sure that the “X” mark cast into the

fixed and moveable sheaves are aligned. Also, make

sure that the retaining ring is fully seated in groove after

installation.

Workman MDX--D Drive TrainPage 4 -- 15

Page 50

Transaxle

v

13

Loctite #242

18

Antiseize

Lubricant

15

4

23

10

Antiseize

Lubricant

39 to 47 ft--lb

(53to63N--m)

2

12

14

7

17

1

27

6

8

120 ft--lb

(162 N--m)

5

24

7

3

20

9

28

26

25

19

Antiseize

21

Lubricant

16

RIGHT

FRONT

1. Transaxle assembly

2. Driven clutch

3. Parking brake cable (2 used)

4. Shift cable (2 used)

5. Hardened washer (4 used)

6. Stepped washer

7. Flange nut (4 used)

8. Cap screw

9. Brake drum (2 used)

10. Cap screw (4 used)

11

80 to 90 ft-- lb

(109 to 122 N--m)

Figure 15

11. Cap screw (4 used)

12. Flat washer (2 used)

13. Swing arm

14. Lock nut (2 used)

15. Flat washer

16. Skid plate

17. R--clamp

18. Lock nut

19. Washer (2 used)

20. Spring washer (2 used)

29

22

21. Slotted hex nut (2 used)

22. Cotter pin (2 used)

23. Select lever

24. Wheel hub (2 used)

25. Wheel stud (5 used per hub)

26. Brake assembly (LH shown)

27. Rear brake line

28. Rear wheel assembly (2 used)

29. Lug nut (5 used per wheel)

Workman MDX--DPage 4 -- 16Drive Train

Page 51

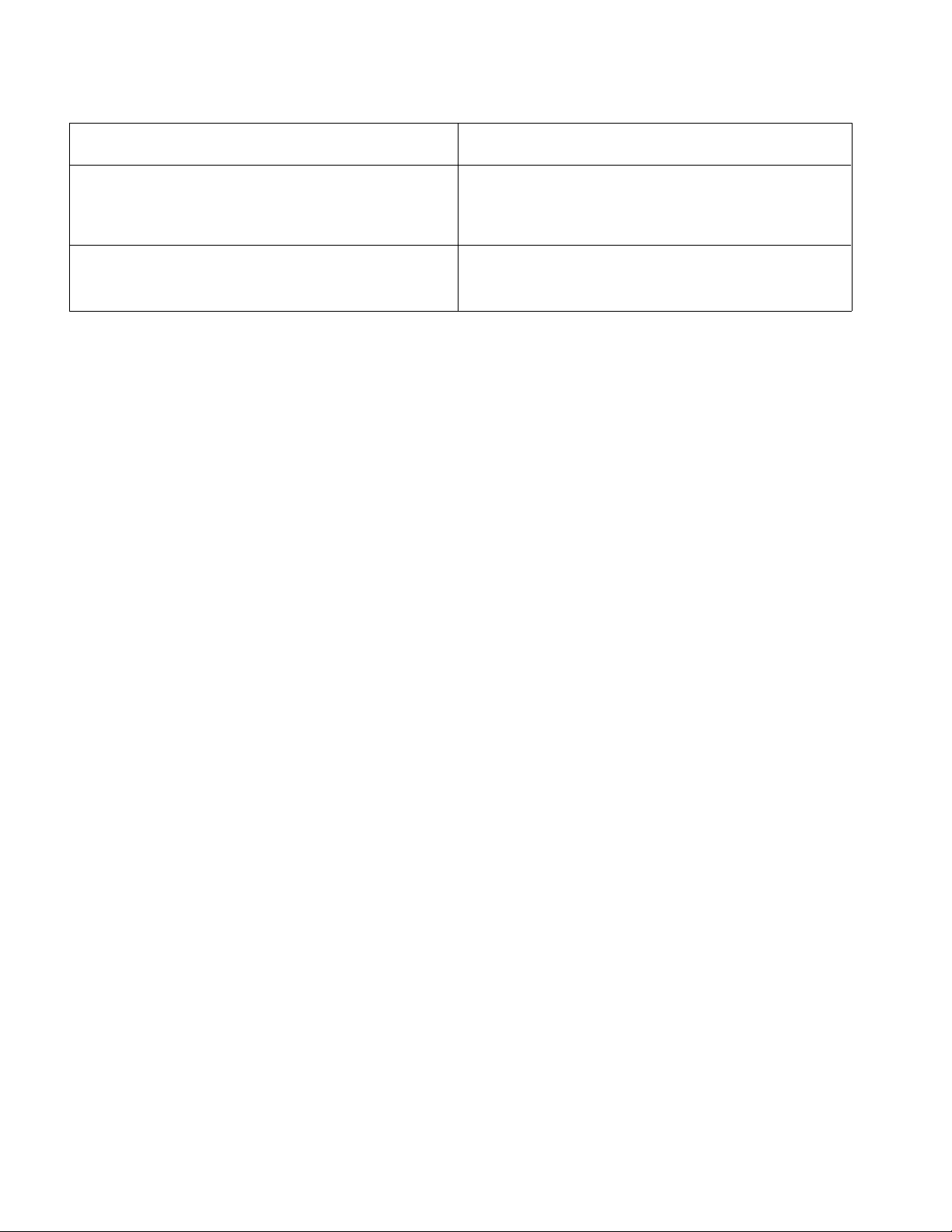

Removal ( Fig. 15)

7. Support the transaxle to prevent it from shifting.

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

2. Raise and support cargo box.

3. Carefully remove drive belt from the driven clutch on

transaxle.

4. Separate shift cables from transaxle:

A. Loosen jam nuts securing both shift cables to the

cable bracket on the transaxle (Fig. 16).

B. Remove lock nut and flat washer that secures the

select lever to the transaxle selector shaft (Fig. 17).

C. Separate select lever and shift cable assembly

from the transaxle.

D. Remove cap screw (item 11 in Fig. 15) and flange

nut (item 7 in Fig. 15) that secure r--clamp (item 17 in

Fig. 15) to skid plate.

E. Note routing of shift cables for assembly purposes. Position select lever with attached shift

cables away from transaxle assembly.

8. Remove four (4) cap screws (item 10) and flat washers (item 5) that secure the transaxle to the swing arm.

IMPORTANT: Take care to not damage the

transaxle, brake hoses, electrical harness, cables or

other parts while lowering the transaxle assembly

from the vehicle.

9. Carefully lower transaxle assembly and remove it

from the rear of the vehicle.

1

4

2

2

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 -- Safety.

5. Jack up both sides of the frame enough to remove

rear wheels.

A. Chock the front and rear of both front tires to prevent the vehicle from moving.

B. Support both sides of the frame with appropriate

jack stands positioned just in front of the transaxle

tubes.

6. Remove both rear wheels and brake assemblies

from the transaxle (see Rear Wheels and Brakes in the

Service and Repairs section of Chapter 6 -- Chassis).

CAUTION

To prevent personal injury, make sure that

transaxle is properly supported as it is removed

from the machine. Transaxle weighs approxi mately 73 pounds (33 kg).

3

1. Select lever assembly

2. Cable jam nut location

5

4

Loctite #242

1. Transaxle assembly

2. Selector shaft

3. Select lever

Figure 16

3. Shift cable

4. Cable bracket

2

3

Figure 17

3

4. Flat washer

5. Lock nut

Drive Train

1

Workman MDX--D Drive TrainPage 4 -- 17

Page 52

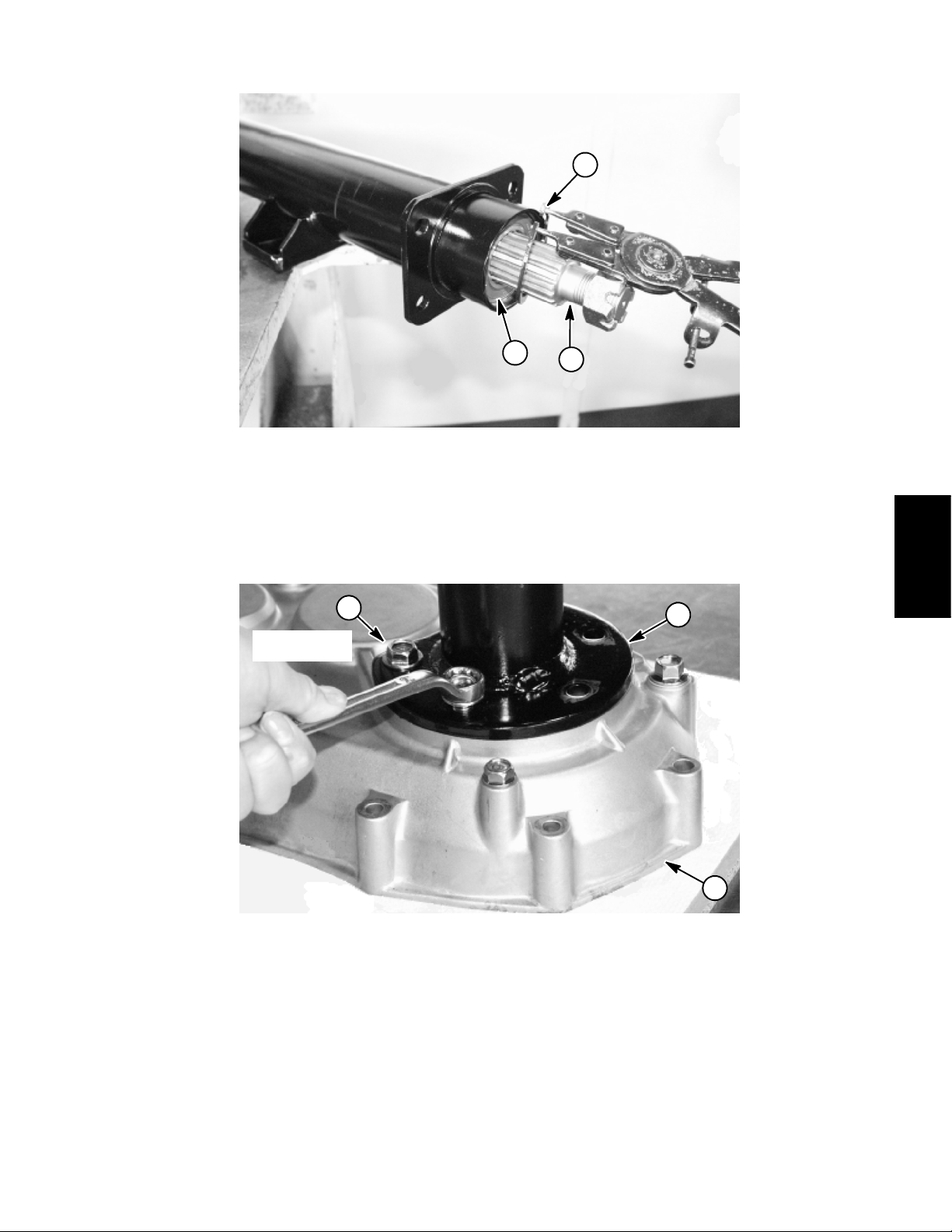

Installation (Fig. 15)

1. Position transaxle assembly under the vehicle swing

arm.

CAUTION

To prevent personal injury, make sure that

transaxle is properly supported as it is installed

into the machine. Transaxle weighs approximately 73 pounds (33 kg).

IMPORTANT: Take care to not damage the

transaxle, brake hoses, electrical harness, cables or

other parts while raising the transaxle assembly

into the vehicle.

B. Slide select lever with attached shift cables onto

transaxle selector shaft.

C. Apply Loctite #242 (or equivalent) to threads of

lock nut (item 18). Secure select lever assembly to

the selector shaft with flat washer (item 15) and lock

nut (item 18).

D. Secure both shift cables to the cable bracket with

jam nuts.

E. Secure r--clamp (item 17) with shift cables to skid

plate with cap screw (item 11) and flange nut (item 7).

F. Check shift cable adjustment and make necessary cable adjustments (see Shift Cable Adjustment

in the Adjustments section of this chapter).

5. Install drive belt to the driven clutch.

2. Carefully raise transaxle assembly and align it with

swing arm mounting points.

3. Secure the transaxle to the swing arm with four (4)

cap screws (item 10) and flat washers (item 5).

4. Secure shift cables to transaxle:

A. Position select lever with attached shift cables to

transaxle assembly. Use notes taken before removal

to properly route cables around transaxle.

6. Install both brake assemblies and wheels to the

transaxle (see Rear Wheels and Brakes in the Service

and Repairs section of Chapter 6 -- Chassis). Make sure

that brakes are bled and parking brake is adjusted.

7. Lower vehicle to the ground.

8. Make sure transaxle oil level is correct.

9. Lower and secure cargo box.

10.Check brakes for proper operation.

Workman MDX--DPage 4 -- 18Drive Train

Page 53

This page is intentionally blank.

Drive Train

Workman MDX--D Drive TrainPage 4 -- 19

Page 54

Transaxle Service

16

55

52

55

57

25 to 31 ft --lb

(34 to 42 N -- m)

18

50

35

29

17

53

8

15

56

13

3

4

5

58

6

2

24

20

11

10

12

26

9

26

27

38

39

47

1

38

40

28

41

40 to 45 ft --lb

7

46

43

42

48

(54 to 61 N-- m)

49

45

44

42

43

36

30

59

31

32

25

23

33

34

33

37

21

22

7

51

19

59

12

11

17

35

25 to 31 ft --lb

(34to42N--m)

14

56

57

10

16

55

9

15

54

8

55

Figure 18

52

Workman MDX--DPage 4 -- 20Drive Train

Page 55

1. Case (LH)

2. Oil seal

3. Oil seal

4. Snap ring

5. Spacer

6. Selector shaft

7. Oil seal (2 used)

8. Flange bolt (4 used)

9. Oil check plug (2 used)

10. Gasket (2 used)

11. Oil drain plug (2 used)

12. Gasket (2 used)

13. Oil filler plug

14. Case (RH)

15. Axle bracket (2 used)

16. Collar (2 used)

17. Flange bolt (4 used)

18. Flange bolt (6 used)

19. Gasket

20. Input shaft

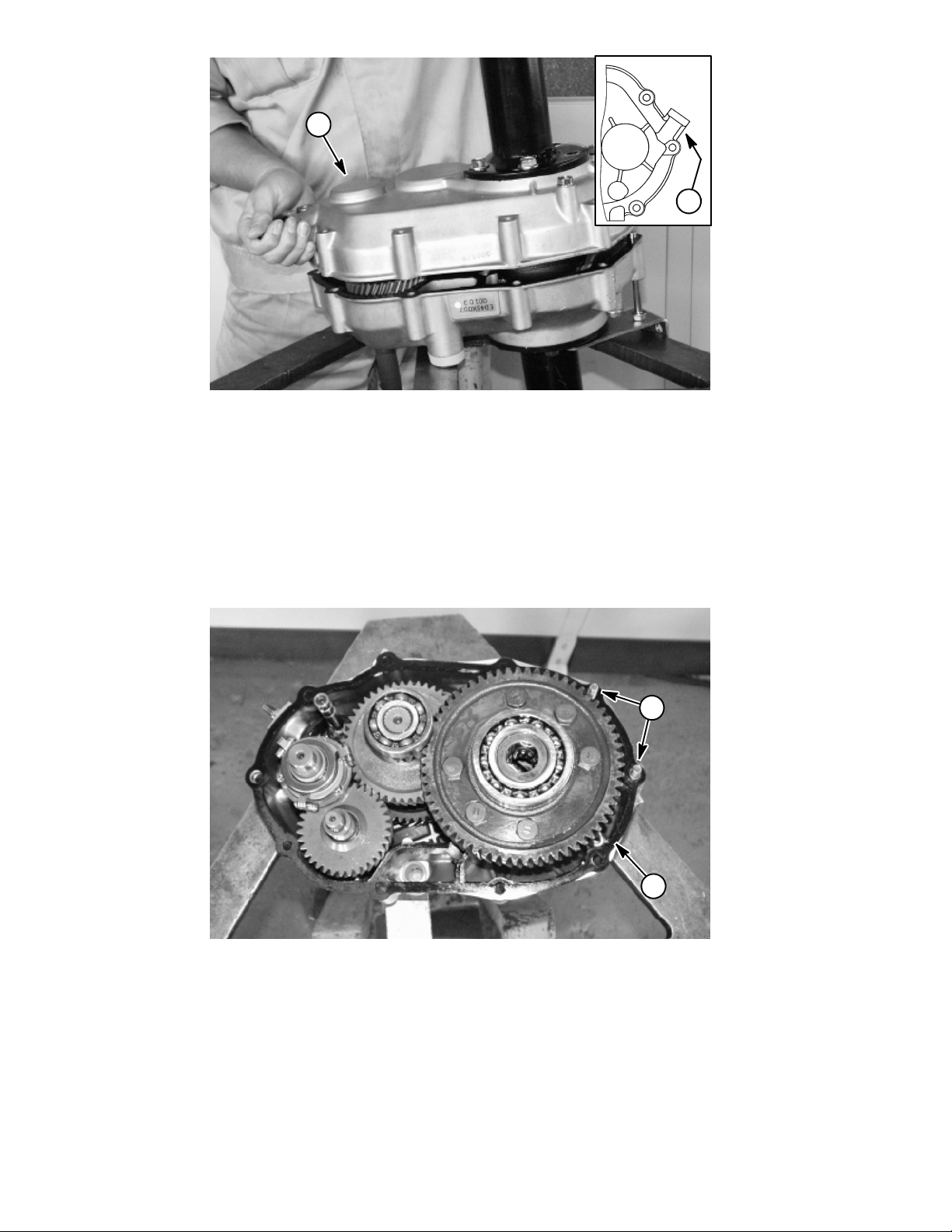

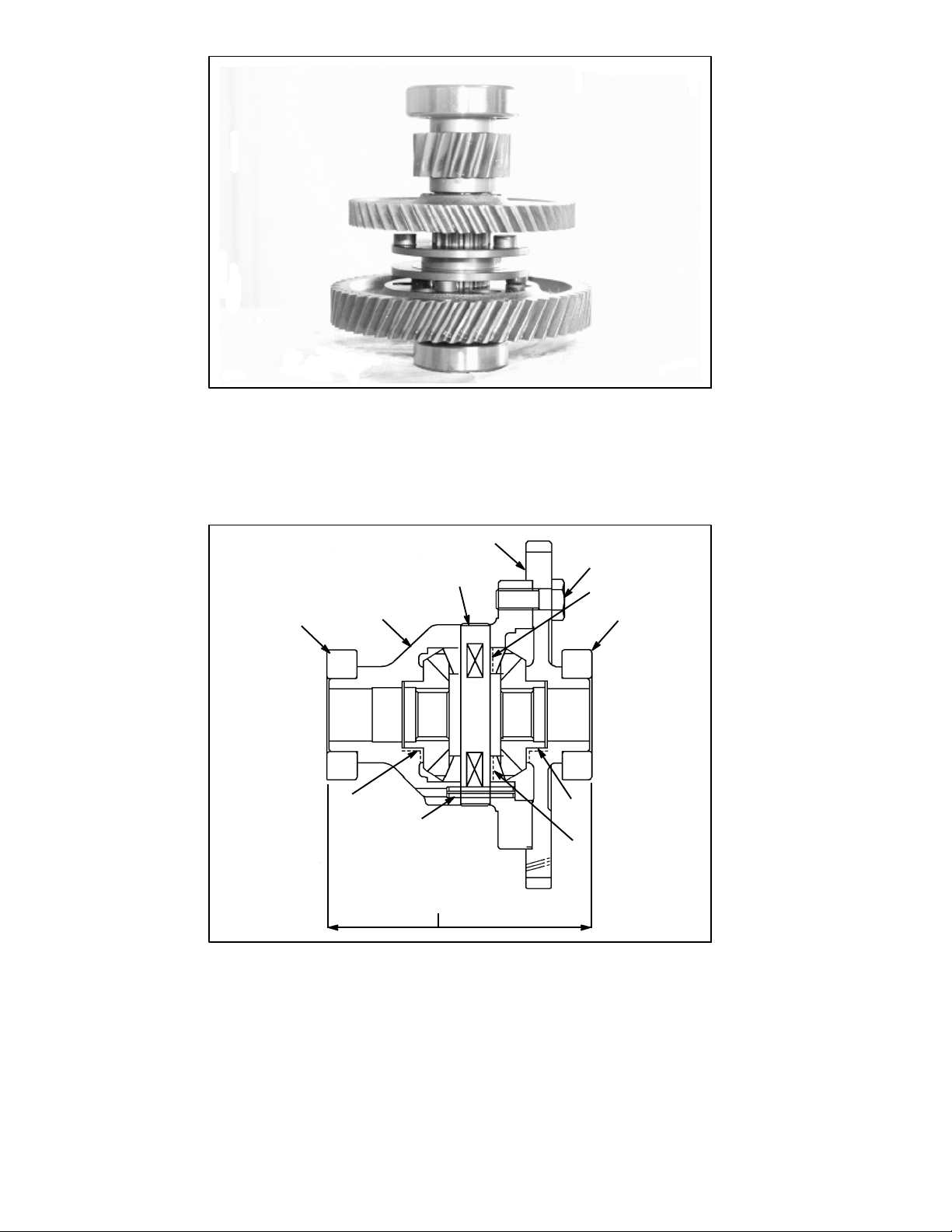

Transaxle Disassembly and Inspection

1. Disassemble case (LH and RH)

Figure 18 (Continued)

21. Bolt

22. Gasket

23. Spring