Page 1

FormNo.3407-540RevB

MBTX2500TrackedMudBuggy

ModelNo.68138—SerialNo.400000000andUp

ModelNo.68138G—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3407-540*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g185889

Figure1

1.Modelandserialnumberlocation

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

ThissparkignitionsystemcomplieswithCanadianICES-002

Theenclosedengineowner'smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thismachineisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Thismachineisa

stable,reliable,andproductivemachineforcarryingand

movingmaterialsforanyjobsite.Itisprimarilydesignedto

moveconcrete,mortar,gravel,dirt,ordebrisaroundjobsites.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SafetyandInstructionalDecals.................................6

ProductOverview..........................................................9

Controls................................................................9

Specications.........................................................9

Operation....................................................................10

ThinkSafetyFirst...................................................10

AddingFuel...........................................................10

PerformingDailyMaintenance.................................11

OperatingtheParkingBrake....................................12

OperatingtheThrottle............................................12

OperatingtheChoke..............................................12

StartingtheEngine.................................................13

ShuttingOfftheEngine..........................................13

OperatingtheHopper.............................................13

RemovingDebrisfromtheMachine..........................14

LoweringtheHopperwithoutPower.........................14

TransportingtheMachine........................................14

LiftingtheMachine................................................15

Maintenance.................................................................16

RecommendedMaintenanceSchedule(s)......................16

Pre-MaintenanceProcedures......................................17

ReleasingtheCushionforRearAccess.......................17

UsingtheCylinderLock..........................................17

Lubrication...............................................................18

GreasingtheMachine.............................................18

EngineMaintenance..................................................18

ServicingtheAirCleaner.........................................18

CheckingtheEngine-OilLevel.................................19

ChangingtheEngineOilandFilter...........................20

ServicingtheSparkPlugs.........................................21

CleaningtheBlowerHousing...................................22

FuelSystemMaintenance...........................................22

ReplacingtheFuelFilter..........................................22

DrainingtheFuelTank...........................................23

RemovingtheFuelTank..........................................23

ElectricalSystemMaintenance....................................24

ServicingtheBattery...............................................24

ServicingtheFuses.................................................25

DriveSystemMaintenance.........................................26

ServicingtheTracks................................................26

ServicingtheDriveBelt...........................................27

ControlsSystemMaintenance.....................................28

AdjustingtheMotion-ControlLevers........................28

BrakeMaintenance.................................................29

HydraulicSystemMaintenance....................................30

ServicingtheHydraulicDriveSystem........................30

ServicingtheHydraulicLiftSystem...........................32

CheckingtheHydraulicLines...................................34

Cleaning...................................................................35

RemovingDebrisfromtheMachine..........................35

Storage........................................................................35

3

Page 4

Safety

Improperuseormaintenanceofthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeans

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Wearappropriateclothingincludinghardhat,eye

protection,longpants,substantial,slip-resistantfootwear,

andhearingprotection.Tiebacklonghair.Donotwear

jewelry.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromthemachine

beforeuse.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhilethe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverfuelordrainthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

Caution

,

W ar ning

–Keepcontainernozzleincontactwiththetankduring

lling.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

,

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingtheengine.

Onlystarttheenginefromtheoperator'sposition.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stopthemachineonlevelground,lowerthehopper,and

shutofftheenginebeforeleavingtheoperator'sposition

foranyreason.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Shutoffthemachineifanyone

entersthearea.

•Neverleavearunningmachineunattended.

•Donotexceedtheratedoperatingcapacity ,asthe

machinemaybecomeunstablewhichmayresultinloss

ofcontrol.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.,branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

4

Page 5

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Locatethepinchpointareasmarkedonthemachineand

keephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotoverloadthehopperandalwayskeeptheload

levelwhenoperatingthemachine.

SlopeOperation

MaintenanceandStorage

•Lettheenginecoolbeforestoringanddonotstorethe

machinenearanopename.

•Engagetheparkingbrake,shutofftheengine,andwait

forallmovementtostopbeforeadjusting,cleaning,or

repairingthemachine.

•Cleandebrisfromdrives,mufers,andtheenginetohelp

preventres.Cleanupoilorfuelspills.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Operateupanddownslopeswiththeheavyendof

themachineuphill.Weightdistributionchanges.An

emptyhoppermakestherearofthemachinetheheavy

end,andafullhoppermakesthefrontofthemachine

theheavyend.

•Raisingthehopperonaslopewillaffectthestabilityof

themachine.Keepthehopperintheloweredposition

whenonslopes.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthemachineuphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifatrackgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Usecautionwhenoperatingonwetsurfaces.Reduced

tractioncouldcausesliding.

•Donotparkthemachineonahillsideorslopewithout

loweringtheattachmenttothegroundandengagingthe

parkingbrake.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebattery,negativeterminalrstandpositive

terminallast,beforemakinganyrepairs.Connectthe

batterypositiveterminalrstandnegativeterminallast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,well-ventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.W ear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Usethecylinderlocktosecurethehopperintheraised

position.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•UseonlygenuineT ororeplacementpartstoensurethat

originalstandardsaremaintained.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverfuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

5

Page 6

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthigh-pressurehydraulicuid.Use

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

115-4212

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

1.Hydraulic-uidlevel

2.ReadtheOperator's

Manual.

3.Warning—donottouchthe

hotsurface.

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

116-8775

1.ReadtheOperator’s

Manual.

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

132-8961

1.Batterychargingcondition4.Hopperislowering.

2.Hourmeter5.Hopperisdown.

3.Hopperisraising.6.Hopperislowering

automatically.

decal132-9051

132-9051

1.Tie-downpoint

decal132-9052

132-9052

1.Main(15A)3.Logic(7.5A)

decal117-2718

2.Auxiliary(15A)

117-2718

6

Page 7

decal137-0575

137-0575

1.ReadtheOperator’s

Manual.

2.Transmissionuid

3.Cold-llline

7

Page 8

decal136-4615

136-4615

1.Parking-brakerelease

7.Explosionhazard—shutofftheengine

beforeaddingfuel;nore,open

ames,orsmokingwhenaddingfuel.

2.Parkingbrake8.Machinetippinghazard—donotdrive

forwardwiththehopperraised;do

notdrivedownslopeswiththehopper

raised;donotdriveacrossslopeswith

thehopperraised;driveslowlywiththe

hopperdown.

3.Warning—readtheOperator’sManual;

hearingprotectionmustbeworn.

9.Warning—keepbystandersasafe

distancefromthemachine;watch

behindyouwhenmovinginreverse.

4.Warning—alloperatorsshouldbe

trainedbeforeoperatingthemachine.

10.Warning—engagetheparkingbrake,

shutofftheengine,andremovethekey

beforeleavingtheoperatorposition.

5.Warning-keepawayfrommovingparts;

11.Lefttractioncontrols

keepallguardsandcoversinplace.

6.Poisonousfumesortoxicgases,

12.Raisehopper

asphyxiationhazard—donotrunthe

engineinanenclosedspace.

13.Lowerhopper

14.Movethehandlesintooperate.

15.Righttractioncontrols

16.Engine-speedcontrol

8

Page 9

ProductOverview

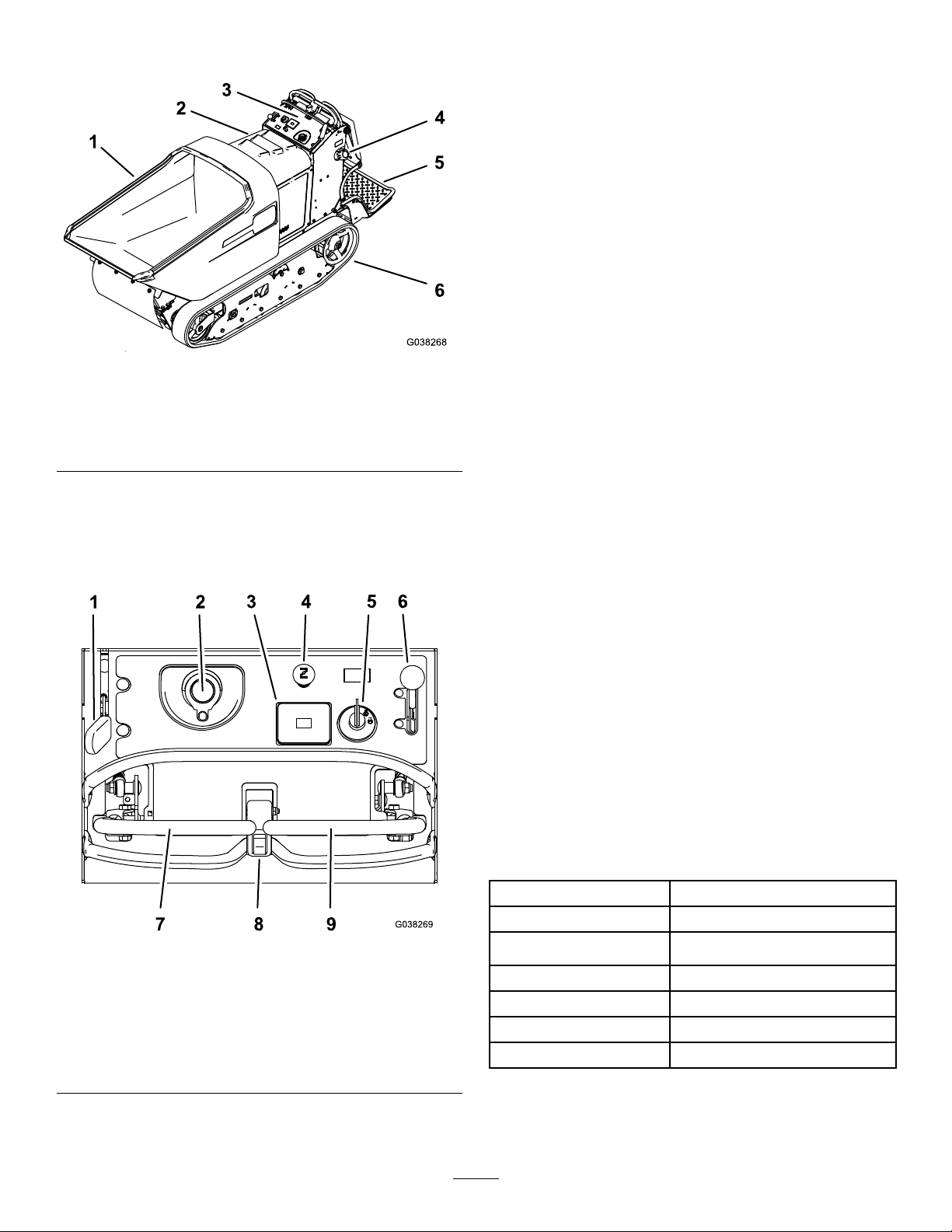

Figure3

1.Hopper4.Fuel-tankcap

2.Hood

3.Controlpanel

5.Operatorplatform

6.Track

ParkingBrakeLever

Toengagetheparkingbrake,pullbackthelever.(Figure4).

Toreleasetheparkingbrake,pushtheleverforward.

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure4).

ChokeControl

Usethechoketostartacoldengine.Pullthechokeknob

uptoengageit.Pushthechokeknobdowntodisengage

g038268

it(Figure4).

KeySwitch

Usethekeyswitchtostarttheengine(Figure4).Theswitch

has3positions:OFF,RUN,andSTART.

ThrottleLever

Controls

Becomefamiliarwithallthecontrols(Figure4)beforeyou

starttheengineandoperatethemachine.

Figure4

ThethrottleleverisvariablebetweentheFASTandSLOW

positions(Figure4).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachineforward

andreverseandtoturneitherdirection(Figure4).

DumpSwitch

Usethedumpswitchtodumpandlowerthehopper.Ifyou

holdtheswitchdown0.2to1.3seconds,thehopperfully

lowersautomatically .

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

g038269

Length

Height

90.2cm(35-1/2inches)

268.0cm(105-1/2inches)

121.2cm(47.7inches)

1.Parking-brakelever6.Throttlelever

2.Hydraulic-tankcap

3.Hourmeter8.Dumpswitch

4.Chokecontrol

5.Keyswitch

7.Leftmotion-controllever

9.Rightmotion-controllever

Weight

Hoppercapacity

Maximumload

DischargeHeight

9

734kg(1619lb)

0.45m

1134kg(2,500lb)

38.1cm(15inches)

3

(16ft3)

Page 10

Operation

G009027

1

2

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Youshould

alsoknowandhavemarkedthelocationsofallutility

lines.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsfuel

toexpand.

•Neversmokewhenhandlingfuelandstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark,which

canignitethefuelvapors.Areorexplosionfrom

g009027

Figure5

1.Weareyeprotection.2.Wearhearingprotection.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•ETHANOL:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

10

Page 11

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromnozzleandfueltank

orconditioneropening.

•Keepfuelawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.For

longerstorage,drainthefueltank.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

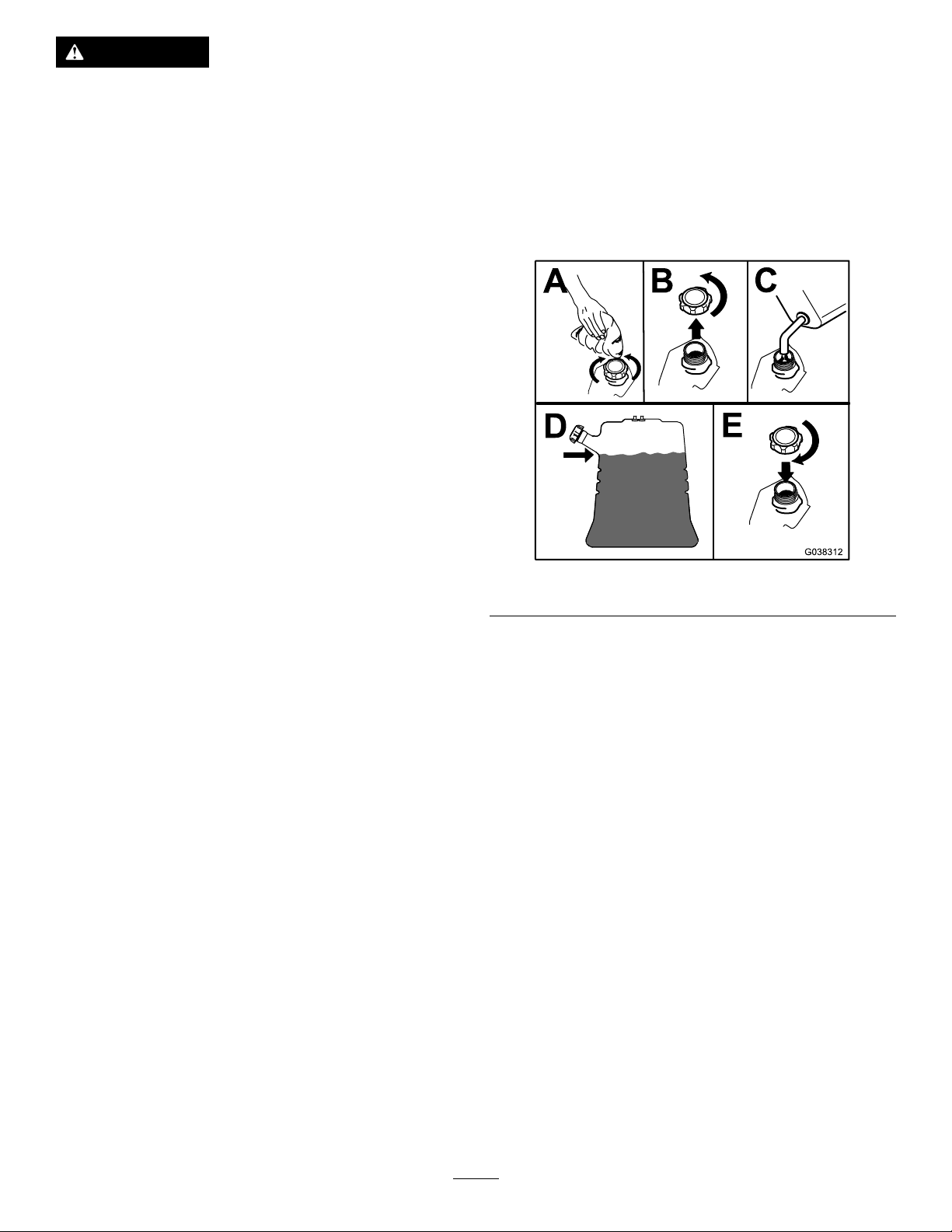

FillingtheFuelTank

Fuel-tankcapacity:40.1L(10.6USgallons)

1.Cleantheareaaroundthefuel-tankcap.

2.Removethecap.

3.Addfueluntilitisatthebottomofthellerneck.

Note:Donotllthefueltankcompletelyfull.The

emptyspaceinthetankallowsthefueltoexpand.

4.Installthecap.

Addthecorrectamountofstabilizer/conditionertothe

fuel.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.Tominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizerat

alltimes.

g038312

Figure6

PerformingDailyMaintenance

Beforestartingtheengineeachday,performthefollowing

procedures:

•Checktheengine-oillevel—refertoCheckingthe

Engine-OilLevel(page19).

•Checkthehydraulic-uidlevelforthedrivesystem—refer

toCheckingtheHydraulic-FluidLevelfortheDrive

System(page30)

•Checkthehydraulic-uidlevelfortheliftsystem—refer

toCheckingtheHydraulic-FluidLevelfortheLiftSystem

(page32).

11

Page 12

OperatingtheParkingBrake

G008946

G008959

1

2

OperatingtheChoke

Alwaysengagetheparkingbrakewhenyoustopthemachine

orleaveitunattended.Beforeeachuse,checktheparking

brakeforproperoperation.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended.

EngagingtheParkingBrake

Pulltheparking-brakeleverrearwardintotheENGAGED

position(Figure7).

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure9).

2.Pushdownthechokeknobtodisengagethechoke

aftertheenginehasstarted(Figure9).

g008959

Figure9

Figure7

1.Parkingbrake—engaged2.Parkingbrake—released

g009465

1.Onposition2.Offposition

ReleasingtheParkingBrake

Pushtheparking-brakeleverforward(Figure7).

OperatingtheThrottle

ThethrottlecontrolmovesbetweenFASTandSLOWpositions

(Figure8).

AlwaysusetheFASTpositionwhenmovingthemachine.

g008946

Figure8

12

Page 13

StartingtheEngine

ShuttingOfftheEngine

1.Engagetheparkingbrake.

2.Engagethechoke.

Note:Awarmorhotenginemaynotrequirechoking.

Youmayneedtorepeatthestartingcyclewhenyou

starttheengineforthersttimeafteryouhavelleda

completelyemptyfuelsystemwithfuel.

3.MovethethrottlebetweentheFASTandSLOW

positions.

4.TurnthekeyswitchtotheSTARTposition.

5.Whentheenginestarts,disengagethechoke.

Important:Donotengagethestarterformorethan5

secondsatatime.Iftheenginefailstostart,allowa

15-secondcool-downperiodbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthestarter.

1.MovethethrottlebetweentheFASTandSLOW

positions.

2.Engagetheparkingbrake.

3.TurnthekeyswitchtotheOFFpositionandremove

thekey.

g038314

Figure11

Figure10

OperatingtheHopper

Hoppercapacity:1134kg(2,500lb)

Knowtheloadcapacityofthemachineandneverexceedit.

Thismachinenormallyoperatesonuneven,unpaved,bumpy,

and/orinclinedsurfaces—adjusttheloadaccordingly.

1.Positionthemachinewhereyouintendtodumpthe

load.

2.Dumpthehopperbypushingthetopofthedump

switch(Figure12).

3.Lowerthehopperbypushingthebottomofthedump

switch(Figure12).

g038313

Note:Ifyouholdthebottomoftheswitch0.2to1.3

seconds,thehopperfullylowersautomatically.

Figure12

1.Dumpthehopper.2.Lowerthehopper.

13

g038270

Page 14

RemovingDebrisfromthe

TransportingtheMachine

Machine

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Cleantheinsideofthehopperusingahose.

4.Cleananydebrisfromunderthehopper.

5.Wipeawaydebrisfromtheaircleaner.

6.Cleananydebrisbuildupontheengineandinthe

transmissionwithabrushorblower.

Important:Itispreferabletoblowdirtout,rather

thanwashingitout.Ifyouusewater,keepitaway

fromelectricalpartsandhydraulicvalves.Do

notuseahigh-pressurewasher.High-pressure

washingcandamagetheelectricalsystemand

hydraulicvalvesordepletegrease.

LoweringtheHopperwithout

Useaheavy-dutytrailerortruckwithfull-widthrampsto

transportthemachine.Ensurethatthetrailerortruckhasall

thenecessarybrakes,lighting,andmarkingasrequiredbylaw .

Pleasecarefullyreadallthesafetyinstructions.Knowingthis

informationcouldhelpyou,yourfamily,petsorbystanders

avoidinjury.Refertoyourlocalordinancesfortrailerand

tie-downrequirements.

Important:Donotoperateordrivethemachineon

roadways.

1.Lowerthehopper.

2.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Carefullyloadthemachineontothetrailerortruck.

5.Shutofftheengine,removethekey ,andsetthebrake.

6.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure14).

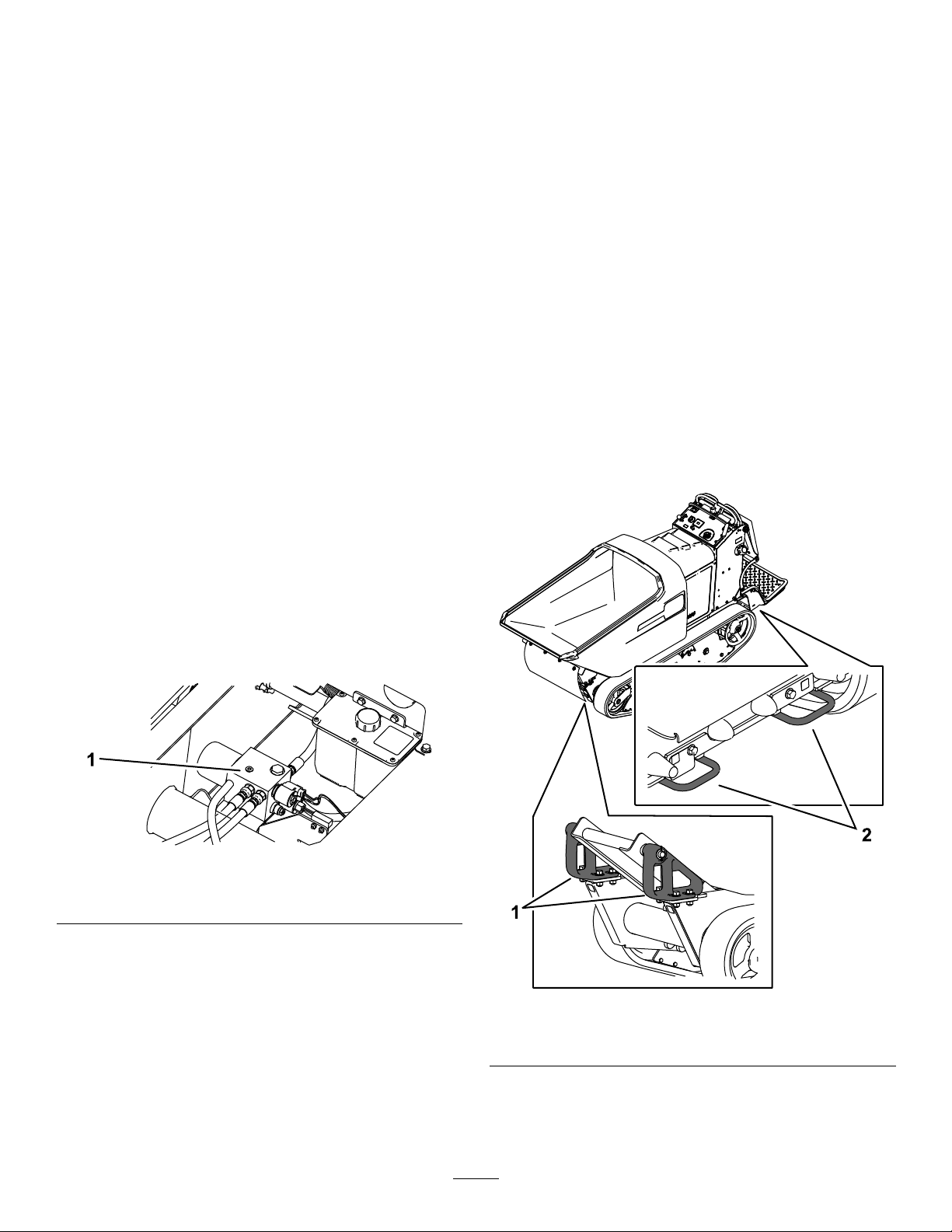

Power

1.Installthecylinderlock;refertoInstallingtheCylinder

Lock(page17).

2.Ensurethatthetubisempty.

3.Placealargedrainpanunderthehydraulic-manifold

block(Figure13).

Figure13

1.Hydraulic-manifoldblock

4.Disconnectthehosettingsinthemanifoldblockand

allowtheuidtodrainintothepain.

g186548

Note:Disposeoftheuseduidatacertiedrecycling

center.

5.Connectthehosettings.

6.Useahoistorhave2peopleholdupthehopperand

removethecylinderlock.

7.Carefullylowerthehoppertothemachineframe.

g185890

Figure14

1.Fronttie-downloops2.Reartie-downloops

14

Page 15

LiftingtheMachine

Hoistthemachineusing2liftpointsunderthehopperand

2reartie-downloops.Tiltthehopperforwardtolocatethe

2liftloopsandattachachainorstrapsateachoftheloops

asshowninFigure15.

Note:Takeuptheslackinthechainorstrapstoproperly

balancetheunit.

1.Liftpointsunderhopper

g194436

Figure15

2.Reartie-downloops

15

Page 16

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Beforeeachuseordaily

Every25hours

Every40hours

Every50hours

Every100hours

MaintenanceProcedure

•Checkandadjustthetracktension(every10hoursuntil50hours).

•Checktheengine-oillevel.

•Cleantheblowerhousing(moreoftenunderextremelydusty ,dirtyconditions).

•Checktheconditionofthetrack.

•Checktheparkingbrakeoperation.

•Checkthehydraulic-uidlevelforthedrivesystem.

•Checkthehydraulic-uidlevelfortheliftsystem.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Serviceorreplacetheair-cleanerfoamelement(moreoftenunderextremelydusty ,

dirtyconditions).

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,anddeterioration.

•Greasethemachine(greaseimmediatelyaftereverywashing).

•Checkthebattery.

•Checkandadjustthetracktension.

•Replacetheair-cleanerpaperelement(moreoftenunderextremelydusty,dirty

conditions).

•Changetheengineoilandtheengine-oillter.

•Checkthesparkplug.

•Removethecoolingshroudsandcleanthecoolingareas(moreoftenunder

extremelydusty,dirtyconditions).

•Replacethefuellter(moreoftenunderdusty ,dirtyconditions).

•Inspectthedrivebelt.

•Cleandirtbuildupinthechassis.

•Replacethesparkplug.

•Checktheroadwheels.

Every300hours

•Replacethedrivebelt.

•Changethehydraulicuidandlterforthedrivesystem.

•Changethehydraulicuidfortheliftsystem.

•Replacethehydrauliclterfortheliftsystem.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

16

Page 17

Pre-Maintenance

Procedures

ReleasingtheCushionfor RearAccess

Youcanreleasethecushionforrearaccesstothemachinefor

maintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthemachine

(Figure16).

Figure16

1.Twistknob

2.Cushion

g185887

Figure17

1.Cylinderlock2.Lift-cylinderrod

4.Slowlylowerthehopperuntilthecylinderlockcontacts

thecylinderbodyandrodend.

g032556

RemovingandStoringtheCylinder

Lock

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinsonboth

sidesofthemachine.

6.Tightenthetwistknobs.

UsingtheCylinderLock

InstallingtheCylinderLock

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andfullyraisethehopper.

2.Removethe2cotterlesspinssecuringthecylinderlock

tothemachine.

3.Slidethecylinderlockoverthelift-cylinderrodand

securewiththecotterlesspins(Figure17).

Important:Removethecylinderlockfromthe

lift-cylinderrodandfullysecureitinthestorageposition

beforeoperatingthemachine.

1.Startthemachine.

2.Fullyraisethehopper.

3.Shutofftheengine.

4.Removethecotterlesspinssecuringthecylinderlock.

5.Placethecylinderlockonthepostsinsidethemachine

frameandsecurewiththecotterlesspins.

6.Lowerthehopper.

17

Page 18

Lubrication

g019608

EngineMaintenance

GreasingtheMachine

ServiceInterval:Every50hours

Whenoperatingthemachineundernormalconditions,

lubricateallgreasettingsforthebearingsandbushingswith

No.2lithiumgrease.Lubricatethebearingsandbushings

immediatelyaftereverywashing,regardlessoftheinterval

listed.Applyalightcoatingofoilontothecontrolcables.

Cylinderpivots(2)—Figure18

ServicingtheAirCleaner

ServiceInterval:Every25hours—Serviceorreplacethe

air-cleanerfoamelement(moreoften

underextremelydusty,dirtyconditions).

Every100hours—Replacetheair-cleanerpaper

element(moreoftenunderextremelydusty,dirty

conditions).

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairintothe

engine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunderextremely

dusty,dirtyconditions.

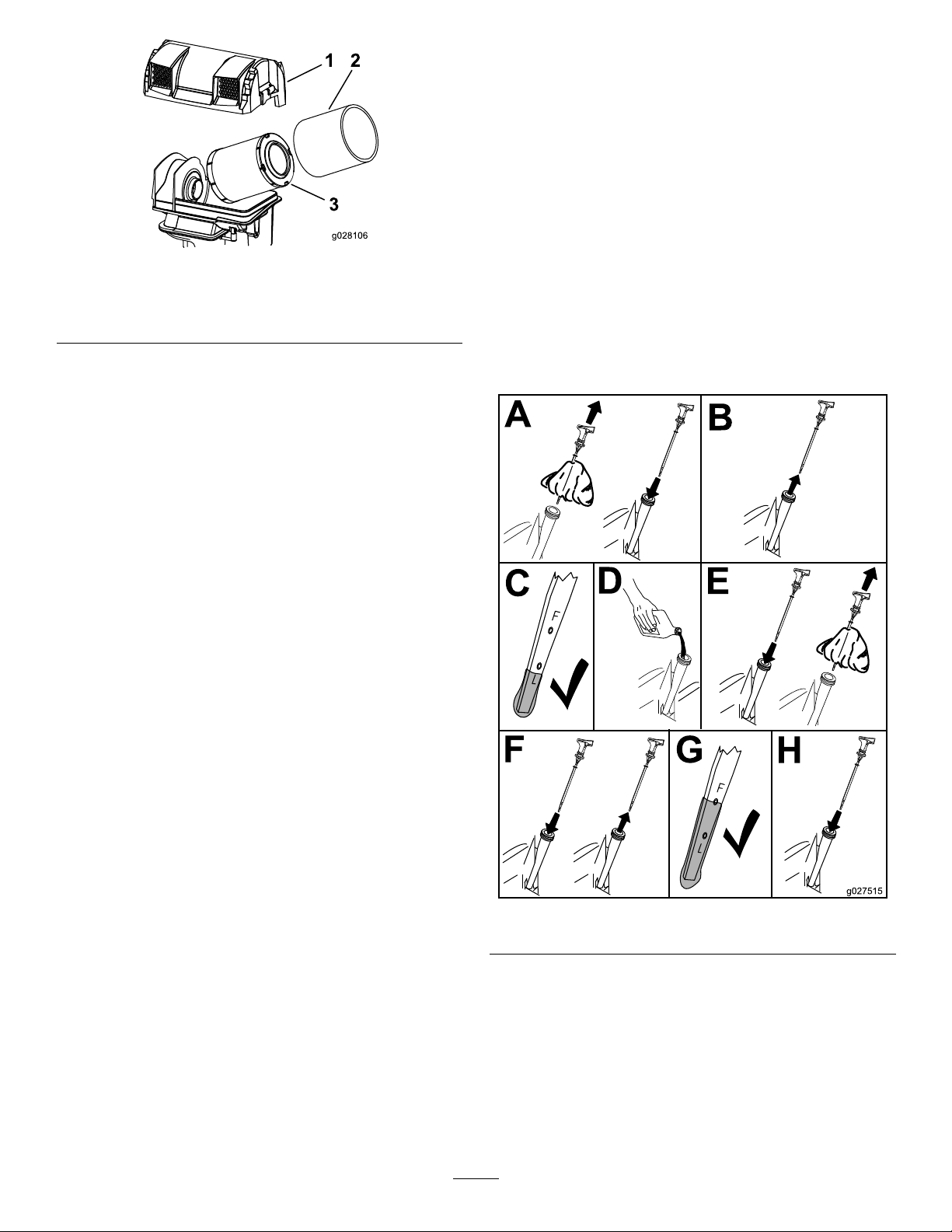

RemovingtheElements

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleanerelements

(Figure19).

Figure18

g019608

g028105

Figure19

1.Air-cleanercover2.Air-cleanerlatch

3.Removethefoamandpaperelements(Figure20).

4.Removethefoamelementfromthepaperelement

(Figure20).

18

Page 19

Figure20

B

A

C

D

E

g027515

F

G

H

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Important:Remembertoadd80%oftheoil,andthen

graduallyllittotheFullmarkonthedipstick.

Important:Donotruntheenginewiththeoillevel

abovetheFullmarkorbelowthelowmark.Otherwise,

doingsomaydamagetheengine.

1.Parkthemachineonalevelsurface,movethe

g028106

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

1.Air-cleanercover3.Paperelement

2.Foamelement

ServicingtheFoamElement

1.Washthefoamelementinwarmwateranddetergent.

2.Rinseandallowittoairdry.

3.Lightlyoilthefoamelementwithnewoilandsqueeze

outexcessoil.

ServicingthePaperElement

1.Gentlytapthepaperelementtodislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthisdamagestheelement.

Note:Replaceadirty,bent,ordamagedelement.

Handlethenewelementcarefully;donotuseifthe

sealingsurfacesarebentordamaged.

2.Cleantheair-cleanerbaseasrequired,andcheckthe

condition.

InstallingtheElements

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Openthecowl.

4.Checktheengine-oillevelasshowninFigure21.

1.Installthefoamelementontothepaperelement.

2.Installtheelementsontotheair-cleanerbase(Figure

20).

3.Installthecover,andsecureitwiththelatches(Figure

19).

g027515

Figure21

19

Page 20

ChangingtheEngineOiland

g017552

0

0

50

SAE 30

B

A

C D

E

F

3/4

g027477

Filter

ServiceInterval:Every100hours

OilType::Detergentoil(APIserviceSJorhigher)

EngineOilCapacity:1.9L(2.0USquarts)

Viscosity:Refertothetablebelow .

Figure22

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,raisethehopper,andinstall

thecylinderlock.

g185888

g031623

Figure23

g017552

5.Torquetheplugto13.6N∙m(10ft-lb).

6.Changetheengine-oillterasshowninFigure24.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Startandrunengineforafewminutestowarmthe

engineoil,thenshutofftheengine.

4.ChangetheengineoilasshowninFigure23.

g027477

Figure24

20

Page 21

7.Slowlypourapproximately80%ofthespeciedoil

B

A

C

D

E

g027517

B

A

g027478

B

A

g027479

intothellertube(Figure25).

ServicingtheSparkPlugs

ServiceInterval:Every100hours—Checkthesparkplug.

Every300hours—Replacethesparkplug.

ThesparkplugsareRFIcompliant.Equivalentalternate

brandplugscanalsobeused.

Type:ChampionXC12YC

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Beforeremovingthesparkplug(s),cleanthearea

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

4.Removethesparkplug(Figure26).

g027517

Figure25

g027478

Figure26

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.03inch).

g027479

Figure27

21

Page 22

InstallingtheSparkPlug

B

A

20 ft-lb

27 N-m

g028109

C

D

B

A

C

D

g027753

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Y early(whichevercomes

rst)(moreoftenunderdusty ,dirty

conditions).

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.ReplacethefuellterasshowninFigure29.

g028109

Figure28

CleaningtheBlowerHousing

Every100hours/Y early(whichevercomesrst)

Toensurepropercooling,ensurethatthegrassscreen,

coolingns,andotherexternalsurfacesoftheengineare

keptcleanatalltimes.

Makesurethecoolingshroudsareinstalled.

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremovedcausesenginedamagedue

tooverheating.

g185888

g027753

Figure29

22

Page 23

DrainingtheFuelTank

RemovingtheFuelTank

Youcandrainthefueltankbyremovingitandpouringthe

fueloutofthellneck;refertoRemovingtheFuelTank

(page23).Youcanalsodrainthefueltankbyusingasiphon

inthefollowingprocedure.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfrom

gasolinecanburnyouandothersandcandamage

property.

•Drainfuelfromthefueltankwhentheengineis

cold.Dothisoutdoorsinanopenarea.Wipe

upanyfuelthatspills.

•Neversmokewhendrainingfuelandstayaway

fromanopename,orwhereasparkmayignite

thefuelfumes.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure30).

4.Removethefuelcap.

1.Lowertheplatform.

2.Releasethecushion;refertoReleasingtheCushionfor

RearAccess(page17).

3.Removethecrossbracket(Figure31).

Figure31

1.Fueltank

4.Removethefueltankandsetitontheoperator

platform.

Note:Ifyouwanttomovethefueltankfurtherfrom

themachine,removethefuelandventlinesfromthe

topofthetank.

2.Crossbracket

g186223

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoacleangas

can(Figure30).

7.Wipeupanyspilledfuel.

Figure30

1.Fuelcap

g186224

23

Page 24

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Every50hours

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Removethenegativebatterycablefromthebattery

(Figure32).

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponents,causingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Figure32

1.Positivebatterycable

2.Securingrod

4.Removethepositivebatterycablefromthebattery

(Figure32).

5.Removethe2wingnuts,securingrod,andthebattery

(Figure32).

3.Wingnut(2)

4.Negativebatterycable

InstallingtheBattery

1.Placethebatteryontheplatformandsecureitusing

the2wingnutsandthesecuringrod(Figure32).

2.Installthepositivebatterycabletothebattery(Figure

32).

3.Installthenegativebatterycabletothebattery(Figure

32).

g185906

WARNING

Incorrectbattery-cableroutingcoulddamagethe

machineandcables,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforeconnectingthenegative(black)cable.

24

Page 25

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamagewhen

thetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page24).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthebattery.

4.Chargethebatteryfor1hourat25to30Aor6hours

at4to6A.

5.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(Figure33).

6.Installthebatteryontothemachineandconnectthe

batterycables;refertoInstallingtheBattery(page24).

Theelectricalsystemisprotectedbyfusesandrequiresno

maintenance.Ifafuseblows,checkthecomponentorcircuit

foramalfunctionorshort.

1.Releasethecushionfromtherearofthemachine.

2.Pulloutthefusetoremoveorreplaceit(Figure34).

3.Installthecushiontotherearofthemachine.

Note:Ensurethatthecorrect-sizefuseisinstalled

Figure34.

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure33

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

g189366

Figure34

1.Mainpowerfuse(15A)3.Logicfuse(7.5A)

2.Auxiliarypowerfuse(15

A)

g000538

25

Page 26

DriveSystem

Maintenance

ServicingtheTracks

AdjustingtheTrackTension

Ifyouplacethetabofthetensioningtoolalongtherearedge

ofthetensionnut,theotherendofthetensioningtoolshould

alignwiththeedgeofthetensionarmasshowninFigure36.

Ifthedistanceisnotcorrect,adjustthetracktensionusing

thefollowingprocedure:

ServiceInterval:Beforeeachuseordaily—Checkthe

conditionofthetrack.

Aftertherst10hours—Checkandadjustthetrack

tension(every10hoursuntil50hours).

Every50hours—Checkandadjustthetracktension.

Every300hours—Checktheroadwheels.

CleaningtheTracks

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Lift/supportthesideofthemachinetobeworkedon

sothatthetrackis3to4inches(7.6to10cm)off

theground.

4.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressurewaterto

washonlythetrackarea.Donotuseahigh-pressure

washertocleantherestofthemachine.Donotuse

highpressurewaterbetweenthedrivesprocketand

themachineoryoumaydamagethemotorseals.

High-pressurewashingcandamagetheelectrical

systemandhydraulicvalvesordepletegrease.

Important:Ensurethatyoufullycleantheroadwheels,

thefrontwheel,andthedrivesprocket(Figure35).The

roadwheelsshouldrotatefreelywhenclean.

Note:Ifthetensioningtoolisnotavailable,thedistance

betweenthenutandedgeofthetensionarmshouldbe7.1

cm(2-13/16inch).

Figure36

LeftTrackShown

1.Tensionnut

2.Tensioningtool(equalto

7.1cmor2-13/16inch)

3.Tensioningbolt7.Tab

4.Bolt(1/4x1-5/8inch)

5.Spacer

6.Nut

8.Tensionarm

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Cleanthetrackswithhigh-pressurewater.

g202806

Figure35

1.Frontwheel3.Roadwheel

2.Track4.Drivesprocket

Important:Ensurethatyouusehigh-pressure

g186007

watertowashonlythetrackarea.Donotuse

ahigh-pressurewashertocleantherestofthe

machine.Donotusehighpressurewaterbetween

thedrivesprocketandthemachineoryoumay

damagethemotorseals.High-pressurewashing

candamagetheelectricalsystemandhydraulic

valvesordepletegrease.

4.Cleanthedrivesprocket,thefrontwheel,andtheroad

wheels.Theroadwheelsshouldspinfreelywhenclean.

5.Removethebolt(1/4x1-5/8inch),spacer,andnut

(Figure36).

26

Page 27

6.Turnthetensioningbolttoadjustthedistancebetween

thetensionnutandtheendtangentofthetensiontube

untilthedistanceiscorrect,asshowninFigure36)

7.Aligntheclosestnotchinthetensioningbolttothe

boltholeandsecurethetensioningboltwiththebolt

(1/4x1-5/8inch),spacer,andnut(Figure36).

ReplacingtheTracks

ServicingtheDriveBelt

InspectingtheDriveBelt

ServiceInterval:Every100hours

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

Replacethetrackswhentheyarebadlyworn.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Lift/supportthesideofthemachinetobeworkedon

sothatthetrackis3to4inches(7.6to10cm)off

theground.

4.Removetheretainingboltforthetensioningscrew .

5.Releasethedrivetensionbyturningthetensioning

screwclockwise(Figure36andFigure37).

Figure37

1.Frontwheel4.Roadwheel

2.Track5.Drivesprocket

3.Tensioningscrewand

retainingbolt

6.Removethetrackatthetopofthefrontwheel,peeling

itoffthewheelwhilerotatingthetrackforwards.

7.Whenthetrackisoffthefrontwheel,removeitfrom

thedrivesprocketandroadwheels(Figure37).

8.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugsonthetrack

tbetweenthespacersonthesprocket(Figure37).

9.Pushthetrackunderthelugsandbetweentheroad

wheels(Figure37).

10.Startingatthebottomofthefrontwheel,installthe

trackaroundthewheelbyrotatingthetrackrearward

whilepushingthelugsintothewheel.

11.Tensionthetrack;refertoAdjustingtheTrackTension

(page26).

12.Lowerthemachinetotheground.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Releasethecushionandremovethefueltank;referto

RemovingtheFuelTank(page23).

4.Inspectthebelt(Figure38).Replacethebeltifitis

worn;refertoReplacingtheDriveBelt(page27).

Note:Thesignsofawornbeltincludesquealing

whilethebeltisrotating,frayededges,burnmarks,and

cracksonthebelt.

g189546

Figure38

1.Extensionspring2.Belt

ReplacingtheDriveBelt

ServiceInterval:Every300hours

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Releasethecushionandremovethefueltank;referto

RemovingtheFuelTank(page23).

4.Raisetherearofthemachineandsupportthemachine

onjackstands.

5.Removetheextensionspring(Figure38).

6.Removethe2bolts,2nuts,andgearpumpfromthe

pumpmount(Figure39).

Note:Youdonotneedtoremovethettingsfrom

thepump.

13.Repeatsteps3through12toreplacetheothertrack.

27

Page 28

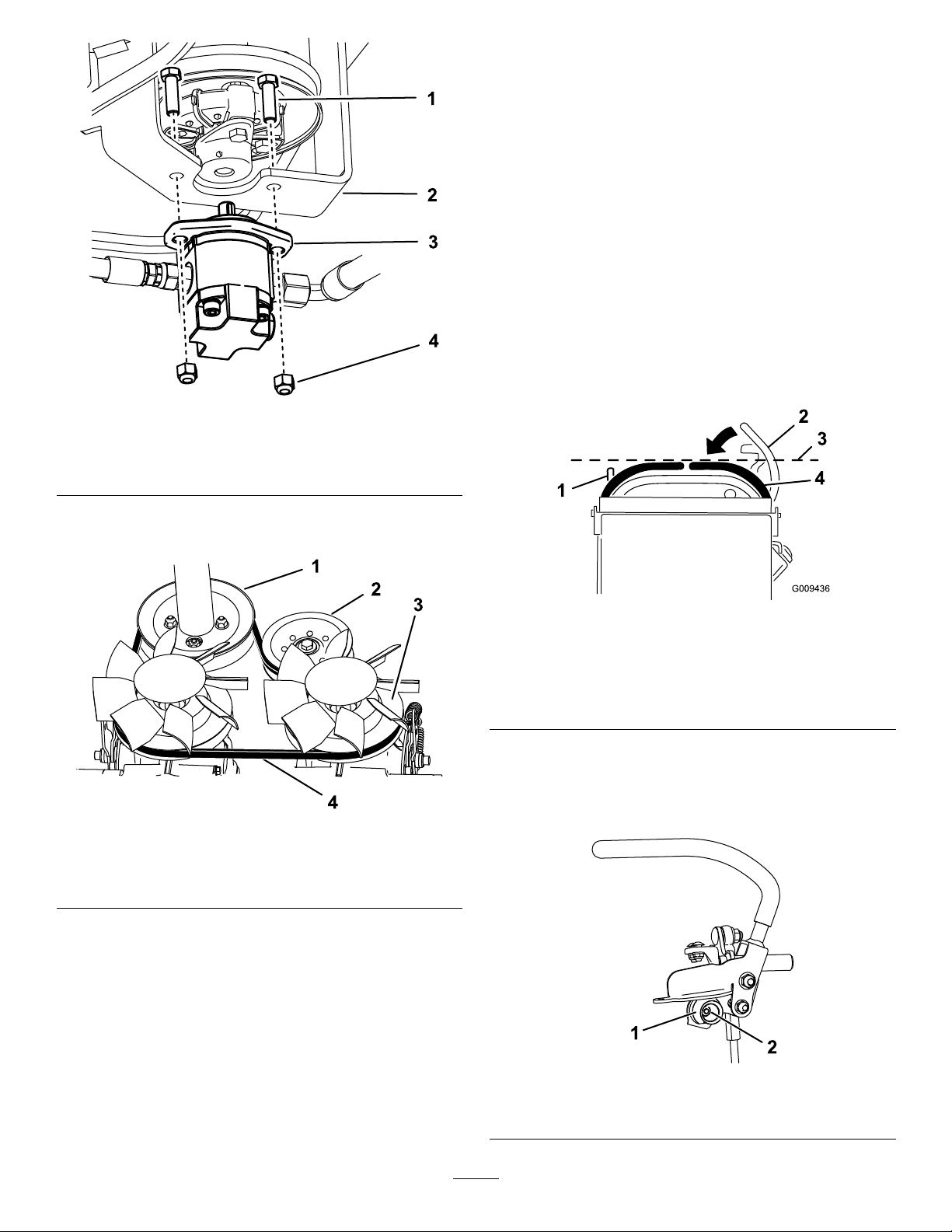

Figure39

1.Bolt(2)3.Gearpump

2.Pumpmount

4.Nut(2)

ControlsSystem

Maintenance

AdjustingtheMotion-Control Levers

Ifthemotion-controlleversdonotalignhorizontally,adjust

therightsidemotion-controllever.

1.Parkthemachineonalevelsurface,lowerthehopper,

engagetheparkingbrake,shutofftheengine,and

removethekey .

2.Pushthemotion-controlleversdownoutofthe

NEUTRAL-LOCKposition(Figure41).

3.Checkiftherightmotion-controlleveraligns

horizontallywiththeleftmotion-controllever(Figure

g189559

41).

7.Removethedrivebeltfromtheenginepulleyand2

transmissionpulleys

Figure40

1.Enginepulley

2.Idlerpulley4.Belt

3.Transmissionpulley(2)

8.Routethenewbeltaroundtheenginepulleyand2

transmissionpulleys(Figure40).

g009436

Figure41

1.Leftmotion-controllever3.Checkthehorizontal

2.Rightmotion-controllever

intheNeutral-lockposition

alignmenthere

4.Rightmotion-controllever

4.Toadjustthemotion-controllevershorizontally,you

mustadjustthecam.

5.Releasethecushionfromtherearofthemachine.

g189571

6.Loosenthenutholdingthecam(Figure42).

9.Installthegearpump(Figure39).

10.Installtheextensionspring(Figure38).

11.Installthefueltank;refertoRemovingtheFuelTank

(page23).

12.Raisethecushion.

g189389

Figure42

1.Cam

28

2.Nut

Page 29

7.Adjustthecamuntilitalignswiththeleft

motion-controlleverandtightenthenutforthecam.

Note:Movingthecamclockwise(inthevertical

position)lowersthehandle;movingthecam

counterclockwise(intheverticalposition)raisesthe

handle.

Important:Ensurethattheatportionofthe

camdoesnotgoaboveaverticalposition(rightor

left);otherwiseyoumaydamagetheswitch.

8.Repeatsteps2through7fortheleftmotion-control

lever.

BrakeMaintenance

WARNING

Ifthebrakesarenotproperlyadjusted,serious

injury,ordeath,mayoccur.

Checkyourbrakesdaily.Ifyouencounterany

problemswiththebrakeswhileoperatingthe

machine,stopthemachineimmediatelyandbring

ittoanAuthorizedToroServiceDealerforrepair.

AdjustingtheParkingBrake

1.Removethefueltank;refertoRemovingtheFuelTank

(page23).

2.Insidetheleftsideofthecontroltower,adjustthenuts

untilthecablesaretaught(Figure43).

Figure43

1.Cable

2.Nuts

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,lowerthehopper,

andengagetheparkingbrake.

2.Starttheengineandmovethethrottlelevertothe

FASTposition.

3.Movethemotion-controlleversforward.

Note:Themachineshouldnotmoveforward.

Note:Ifthemachinemovesforward,referto

AdjustingtheParkingBrake(page29).

4.Releasetheparkingbrake.

5.Movethemotion-controlleversforward.

Note:Themachineshouldmoveforward.

Note:Ifthemachinedoesnotmoveforward,referto

AdjustingtheParkingBrake(page29).

6.Engagetheparkingbrakeandshutoffthemachine.

3.Installthefueltank,crossbracket,andcushion.

29

Page 30

HydraulicSystem

Maintenance

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

ServicingtheHydraulicDrive System

Expansion-tankcapacity:1.4L(1.5USquarts)

Figure44

1.Expansion-tankcap

2.Sightwindow

5.Iftheoillevelislow ,removethecaplockandcap

fromthetopoftheexpansiontank(Figure45),and

addenoughofthespeciedhydraulicuidtoraiseit

totheproperlevel.

3.Fluidatllline

g203616

Hydraulic-uidtype:Toro®HYPR-OIL™500

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein2/3oz.(20ml)bottles.Onebottle

issufcientfor4-6gal(15-221)ofhydraulicoil.Orderpart

number44-2500fromyourauthorizedT orodistributor.

CheckingtheHydraulic-FluidLevelfor

theDriveSystem

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Openthecowl.

4.Usethesightwindowtochecktheuidlevelinthe

expansiontank(Figure44).

Note:Theuidlevelshouldbeatthelllineonthe

decal.

Figure45

1.Bolt

2.Caplock

6.Installthecapandcaplock.Wipeupanyspilled

hydraulicuid.

3.Cap

ChangingtheHydraulicFluidandFilter

fortheDriveSystem

ServiceInterval:Every300hours

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Lowerthecushionandremovethefueltank;referto

RemovingtheFuelTank(page23).

4.Removethe6bolts(2rear,4side)fromtheskidplate

andremovetheskidplate(Figure46).

30

Page 31

Figure46

1.Rearbolt(2)3.Sidebolt(4)

2.Skidplate

5.Locatethedrainpluginthebottomofeach

transmission,thenplaceadrainpanundertheplugs

(Figure47).

g203662

g203517

Figure48

1.Ventplug

11.Slowlyaddapproximately6.2L(208oz)uidtothe

expansiontankuntilitstartstocomeoutofthevent

plugs.

Important:UsetheuidspeciedinServicingthe

HydraulicDriveSystem(page30)orequivalent.

Otheruidscouldcausesystemdamage.

Important:Monitorthelevelofuidinthe

expansiontanksothatyoudonotoverllit.

12.Tightentheventplugs.

13.Addhydraulicuidtotheexpansiontankuntilit

reachestheuidline(Figure44).

Important:Donotoverll.

14.Installtheexpansion-tankcap.

Figure47

1.Hydrauliclter

2.Drainplug

6.Removethedrainplugsandallowthehydraulicuidto

fullydrainfromthemachine.

7.Removethehydraulic-ltercapandhydrauliclter

fromeachtransmission(Figure47).

8.Installanewhydrauliclterwiththespringsidefacing

outandthehydraulic-ltercapforeachtransmission.

Torqueto13to15N∙m(115to135in-lb).

9.Installthedrainplugs.

10.Loosentheventplugineachtransmissionuntilloose

(Figure48).

Note:Thisallowsairtoescapethehydraulicsystem

asyouaddhydraulicuid.

g203515

15.Installtheskidplate(Figure46).

16.Installthefueltank;refertoRemovingtheFuelTank

(page23).

17.Starttheengineandletitrunforabout2minutesto

purgeairfromthesystem.

18.Shutofftheengineandcheckforleaks.

31

Page 32

BleedingtheHydraulicDriveSystem

ServicingtheHydraulicLift

Bleedthetractionhydraulicsystemwheneveryouperform

maintenanceonthehydrostatictransmissionoraddhydraulic

uidtotheexpansiontank.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Checkthehydraulicuidlevelandaddhydraulicuid

asnecessary;refertoCheckingtheHydraulic-Fluid

LevelfortheDriveSystem(page30).

4.Supportthemachineonjackstands,highenoughto

raisethetracksofftheground.

5.Startthemachine.Slowlymovethemotion-control

leversforwardandreverse5to6times.

6.Checkthehydraulicuidlevelandaddhydraulicuid

asnecessary.

7.Repeatsteps5and6asnecessaryuntilalltheairis

completelypurgedfromthesystem.

Note:Purgingiscompletewhenyouobtainnormal

forwardandreversespeed.

8.Lowerthemachineandrepeattheprocedurewiththe

tracksontheground.

System

CheckingtheHydraulic-FluidLevelfor

theLiftSystem

ServiceInterval:Beforeeachuseordaily

Reservoir-tankcapacity:1.4L(1.5USquarts)

Hydraulic-uidtype:ToroPremiumAllSeasonHydraulic

FluidorMobil®424HydraulicFluid

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein2/3oz.(20ml)bottles.Onebottle

issufcientfor4-6gal(15-221)ofhydraulicoil.Orderpart

number44-2500fromyourauthorizedT orodistributor.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,raisethehopper,andinstall

thecylinderlock.

2.Shutoffthemachineandremovethekey.Allowthe

machinetocoolcompletely.

3.Removethellercapfromthereservoirtank(Figure

49).

CAUTION

Thehydraulicbreather/llercapisdesigned

topressurizethereservoirto34kPa(5psi).

Loosenthecapslowlytoavoidinjurywhenever

addingoilorworkingonthehydraulicsystem.

Useawrenchonthehexdirectlyunderthe

cap.

32

Page 33

g019614

1

2

Figure49

1.Hex2.Fillercap

4.Lookinsidethetanktochecktheuidlevel.

Note:Ifthemachineiscool,theuidshouldbeat

theCOLDlevel;ifthemachineishot,theuidshould

beattheHOTlevel.

ChangingtheHydraulicFluidforthe

LiftSystem

ServiceInterval:Every300hours

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,raisethehopper,andinstall

g185888

thecylinderlock.

2.Shutoffthemachineandremovethekey.Allowthe

machinetocoolcompletely.

3.Removethellercapfromthereservoirtank(Figure

49).

CAUTION

Thehydraulicbreather/llercapisdesigned

topressurizethereservoirto34kPa(5psi).

Loosenthecapslowlytoavoidinjurywhenever

g019614

addingoilorworkingonthehydraulicsystem.

Useawrenchonthehexdirectlyunderthe

cap.

4.Placealargedrainpanunderthettingsatthebottom

ofthereservoirtank.

5.Disconnectahosettingandallowtheuidtodrain

intothepan.

6.Whennished,installandtightenthetting.

Note:Disposeoftheuseduidatacertiedrecycling

center.

7.Fillthereservoirtankwithapproximately2.2L(2.3US

quarts)andinstallthellercap.

8.Removethecylinderlock.

9.Starttheengine.Raiseandlowerthehopper3timesto

llthecylinderandhoseswithuid.

10.Raisethehopperandinstallthecylinderlock.

11.Shutofftheengine.

12.Add0.60L(20oz)ofhydraulicuidandinstallthe

llercap.

Figure50

1.HOTlevel2.COLDlevel

5.FillthetankwithhydraulicuidonlyuptotheCOLD

level.

6.Installthellcap.Wipeupanyspilledhydraulicuid.

7.Removethecylinderlockandlowerthehopper.

Note:TheuidlevelshouldbeattheColdllline.

Donotllpastthisline.

13.Removethecylinderlock.

14.Starttheengine.Raiseandlowerthehopperseveral

g189403

timestoremoveairfromthesystem.

ReplacingtheHydraulicFilterforthe

LiftSystem

ServiceInterval:Every300hours

Important:Donotsubstituteanautomotiveoillteror

severehydraulicsystemdamagemayresult.

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

33

Page 34

engagetheparkingbrake,raisethehopper,andinstall

B

A

C D

E

F

3/4

g027477

thecylinderlock.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.ReplacethelterasshowninFigure51.

CheckingtheHydraulicLines

ServiceInterval:Every40hours—Checkthehydrauliclines

forleaks,loosettings,kinkedlines,

loosemountingsupports,wear,and

deterioration.(Makenecessaryrepairs

beforeoperating.)

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

g186042

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

4.Starttheengineandletitrunforabout2minutesto

purgeairfromthesystem.

5.Shutofftheengineandcheckforleaks.

6.Checktheuidlevelinthereservoirtank,referto

CheckingtheHydraulic-FluidLevelfortheLiftSystem

7.Removethecylinderlockandlowerthehopper.

(page32).

Note:Donotoverllthereservoirtank.

Figure51

g027477

34

Page 35

Cleaning

RemovingDebrisfromthe Machine

ServiceInterval:Beforeeachuseordaily

Every100hours

1.Parkthemachineonalevelsurface,movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

engagetheparkingbrake,andlowerthehopper.

2.Shutofftheengine,andremovethekey .Allowthe

enginetocool.

3.Cleantheinsideofthehopperusingahose.

4.Cleananydebrisfromunderthehopper.

5.Wipeawaydebrisfromtheaircleaner.

6.Cleananydebrisbuildupontheengineandinthe

transmissionwithabrushorblower.

Important:Itispreferabletoblowdirtout,rather

thanwashingitout.Ifyouusewater,keepitaway

fromelectricalpartsandhydraulicvalves.Do

notuseahigh-pressurewasher.High-pressure

washingcandamagetheelectricalsystemand

hydraulicvalvesordepletegrease.

Storage

1.Shutofftheengineandengagetheparkingbrake.

2.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

chafffromtheoutsideoftheenginecylinderheadns

andblowerhousing.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page18).

4.Greasethemachine;refertoGreasingtheMachine

(page18).

5.Changetheenginecrankcaseoil;refertoChangingthe

EngineOilandFilter(page20).

6.Forstorageover30days,preparethemachineas

follows:

A.Addapetroleumbasedstabilizer/conditioner

tofuelinthetank.Followmixinginstructions

fromstabilizermanufacturer.Donotuse

analcohol-basedstabilizer(ethanolor

methanol).

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandusedat

alltimes.

B.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

C.Shutofftheengine,allowittocool,anddrainthe

fueltankusingapump-typesyphon.

D.Starttheengineandrunituntilitstops.

E.Choketheengine.

F.Startandruntheengineuntilitdoesnotstart

again.

G.Disposeoffuelproperly .Recycleasperlocal

codes.

Important:Donotstorestabilizer/conditioned

fuelover90days.

7.Removethesparkplugsandchecktheconditionof

them;refertoServicingtheSparkPlugs(page21).

8.Preparetheengineasfollows:

A.Withthesparkplugsremovedfromtheengine,

pour2tablespoonsofengineoilintothespark

plugholes.

B.Placearagoverthesparkplugholestocatchany

oilspray ,thenpullthestarterropetocrankthe

engineanddistributetheoilinsidethecylinder.

C.Installthesparkplugs.

Note:Donotinstallthewireonthesparkplugs.

9.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

10.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

35

Page 36

11.Storethemachineinaclean,drygarageorstoragearea.

12.Coverthemachinetoprotectitandkeepitclean.

36

Page 37

Notes:

Page 38

Notes:

Page 39

Notes:

Page 40

TheToroWarranty

Alimitedwarranty(seewarrantyperiodsbelow)

Concrete,Masonry ,

andCompaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuanttoanagreement

betweenthem,jointlywarrantyourT oroConcrete,Masonry,andCompaction

EquipmentProductslistedbelowtobefreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor ,butyoumustpaytransportationcosts.

Thefollowingtimeperiodsapplyfromtheoriginaldateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*

1

•Engine

MortarMixers1year

•DrumBearingsandSealsLifetime*

1

•Engine

ForwardPlateCompactors

2

•Engine

ReversiblePlates1year

1

•Engine

RammerCompactors

1

•Engine

MudBuggy1year

1

•Engine

PowerT rowels1year

1

•Engine

Whereawarrantableconditionexists,wewillrepairtheProductatnocosttoyouincludingdiagnosis,

labor,andparts.

*

LifetimeWarranty-OriginalOwnerOnly-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbe

replacedunderwarranty ,atnocostforpartsorlabor.

1

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer.

1year

2years

2years

2years

2years

2years

2years

2years

2years

2years

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsorworkmanship,

followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheirdealership.

Tolocateoneconvenienttoyou,accessourwebsiteatwww.Toro.com.Select

“WheretoBuy”andselect“Contractor”underproducttype.Y oumayalsocall

ourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysisorwith

theassistanceprovided,contactusat:

ToroWarrantyCompany

SWSCustomerCareDepartment

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromToroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenanceprocedures

describedintheOperator’sManual.Suchroutinemaintenance,whetherperformedby

adealerorbyyou,isatyourexpense.Partsscheduledforreplacementasrequired

maintenance(“MaintenanceParts”),arewarrantedfortheperiodoftimeuptothe

scheduledreplacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiodare

defectsinmaterialsorworkmanship.Thisexpresswarrantydoesnotcoverthe

following:

•Productfailureswhichresultfromtheuseofnon-T ororeplacementparts,orfrom

installationanduseofadd-on,modied,orunapprovedaccessories

•Productfailureswhichresultfromfailuretoperformrequiredmaintenanceand/or

adjustments

•Productfailureswhichresultfromoperatingtheproductinanabusive,negligent,

orrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormalproduct

operationinclude,butarenotlimitedto:belts,wipers,sparkplugs,tires,lters,

gaskets,wearplates,seals,O-rings,drivechains,orclutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutsideinuence

include,butarenotlimitedto,weather,storagepractices,contamination,useof

unapprovedcoolants,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butisnotlimited

to,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuelprocedure(consult

Operator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontainsmorethan

10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-useoverone

month

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorizedRental

Customerisyoursoleremedyunderthewarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliableforindirect,

incidentalorconsequentialdamagesinconnectionwiththeuseoftheToro

Productscoveredbythiswarranty,includinganycostorexpenseofproviding

substituteequipmentorserviceduringreasonableperiodsofmalfunction

ornon-usependingcompletionofrepairsunderthiswarranty .Allimplied

warrantiesofmerchantabilityandtnessforusearelimitedtothedurationof

thisexpresswarranty .Somestatesdonotallowexclusionsofincidentalor

consequentialdamages,orlimitationsonhowlonganimpliedwarrantylasts,

sotheaboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveotherrights

whichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarrantyreferenced

below,ifapplicable,thereisnootherexpresswarranty .TheEmissionsControlSystem

onyourProductmaybecoveredbyaseparatewarrantymeetingrequirements

establishedbytheU.S.EnvironmentalProtectionAgency(EPA)ortheCalifornia

AirResourcesBoard(CARB).RefertotheCaliforniaEmissionControlWarranty

StatementsuppliedwithyourProductorcontainedintheenginemanufacturer’s

documentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry ,

province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheToroimporter.Ifallother

remediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer .

374-0288RevD

Loading...

Loading...