Page 1

Consumer Products

LX Lawn

Tractor

Service Manual

Page 2

Page 3

TABLE OF CONTENTS

SAFETY INFORMATION

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series) . . . . . . . . . . . . . .

Standard Torque for Dry, Zinc and Steel Fasteners (Metric Fasteners) . . . . . . . . . . . . . .

Other Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equivalents and Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS

Front Pivot Axle Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Assembly Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Shaft Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Clutch Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fender Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tower Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower Transmission Drive Belt Replacement - Gear Drive Models

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper Transmission Drive Belt Replacement - Gear Drive Models

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Drive Belt (Hydro) Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variable Speed Pulley Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-1

2-1

2-2

2-3

2-4

2-5

2-6

3-1

3-7

3-14

3-17

3-19

3-20

3-21

3-24

3-27

3-28

3-29

3-30

3-31

3-32

3-33

3-39

3-45

3-53

3-62

3-64

3-67

3-69

3-71

3-74

3-77

3-79

iLX Lawn Tractor Service Manual

Page 4

TABLE OF CONTENTS

CHASSIS cont.

Variable Speed Pulley Service

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging the System - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Change - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Neutral Adjustment - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Toe-in Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Toe-in Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autodrive Pedal Adjustment - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment - Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle/Choke Cable Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE

Engine Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR DRIVE SYSTEM

CVT Transmission Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Puck Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-81

3-82

3-82

3-83

3-84

3-85

3-86

3-87

3-91

3-93

3-96

4-1

4-7

5-1

5-4

5-9

5-11

5-14

HYDROSTATIC DRIVE SYSTEM

Hydro Transmission Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOWER DECK

42” Mower Deck - Brake Idler Assembly Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck - Idler Assembly Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - RH Idler Bracket Assembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Brake Assembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - LH Idler Assembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-7

7-1

7-3

7-6

7-8

7-11

7-13

7-14

7-16

7-19

7-20

7-21

7-23

ii LX Lawn Tractor Service Manual

Page 5

TABLE OF CONTENTS

MOWER DECK cont.

46” Mower Deck - Lower Idler Bracket

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Lower Mower Deck Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Upper Mower Deck Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck - Belt Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck - Idler Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck - Spindle Replacement

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck - Spindle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Double Pulley Spindle Service . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck - Single Pulley Spindle Service . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck - Spindle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42” Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46” Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50” Mower Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-25

7-26

7-27

7-30

7-34

7-35

7-36

7-38

7-39

7-41

7-43

7-45

7-47

7-51

7-56

7-60

7-64

7-67

7-69

7-72

7-74

7-76

ELECTRICAL

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1

iiiLX Lawn Tractor Service Manual

Page 6

TABLE OF CONTENTS

THIS PAGE INTENTIONALLY LEFT BLANK.

iv LX Lawn Tractor Service Manual

Page 7

SAFETY INFORMATION

General Information

This symbol means WARNING or

PERSONAL SAFETY INSTRUCTION

- read the instruction because it has to

do with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

This manual is intended as a service and repair

manual only. The safety instructions provided herein

are for troubleshooting, service, and repair of the

LX Series Riding Lawn Tractor.

Think Safety First

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they were

moving whenever the engine is running or has the

potential to start.

The riding mower and attachment operator's manual

contain safety information and operating tips for safe

operating practices. Operator's manuals are available

through your Toro parts source or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases

can explode. Keep cigarettes, sparks, and flames away

from the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

1

Avoid burns...

Do not touch the engine, muffler, or other components

which may increase in temperature during operation,

while the unit is running or shortly after it has been

running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working with

any type of fuel or lubricant. Wipe up any spilled fuel or

oil immediately. Never remove the fuel cap or add fuel

when the engine is running. Always use approved,

labeled containers for storing or transporting fuel and

lubricants.

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical section in this manual for more information.

1-iLX Lawn Tractor Service Manual

Page 8

1

SAFETY INFORMATION

THIS PAGE INTENTIONALLY LEFT BLANK.

1-ii LX Lawn Tractor Service Manual

Page 9

SPECIFICATIONS

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

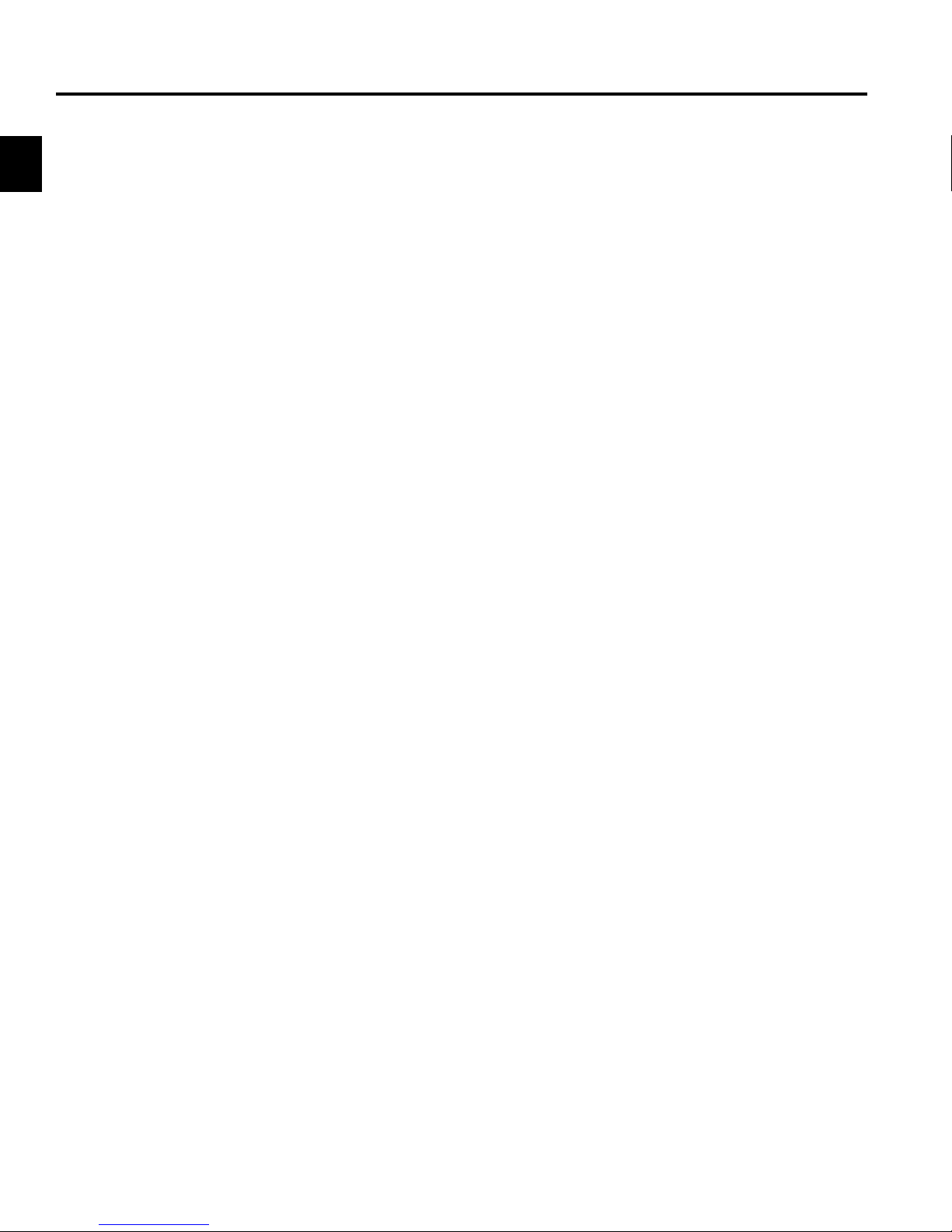

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

2

Figure 1

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure 2

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

2-1LX Lawn Tractor Service Manual

Page 10

SPECIFICATIONS

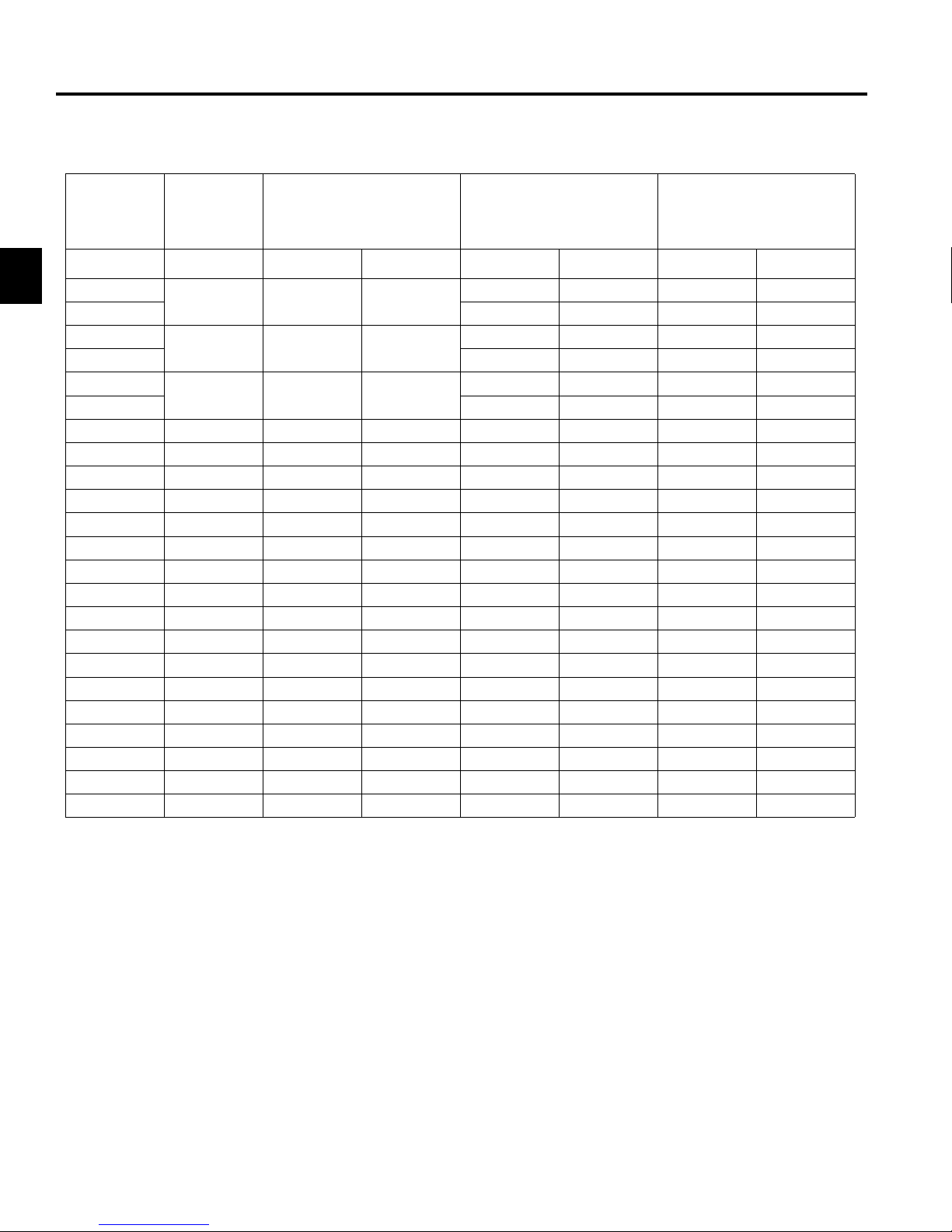

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

2

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

2-2 LX Lawn Tractor Service Manual

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Page 11

SPECIFICATIONS

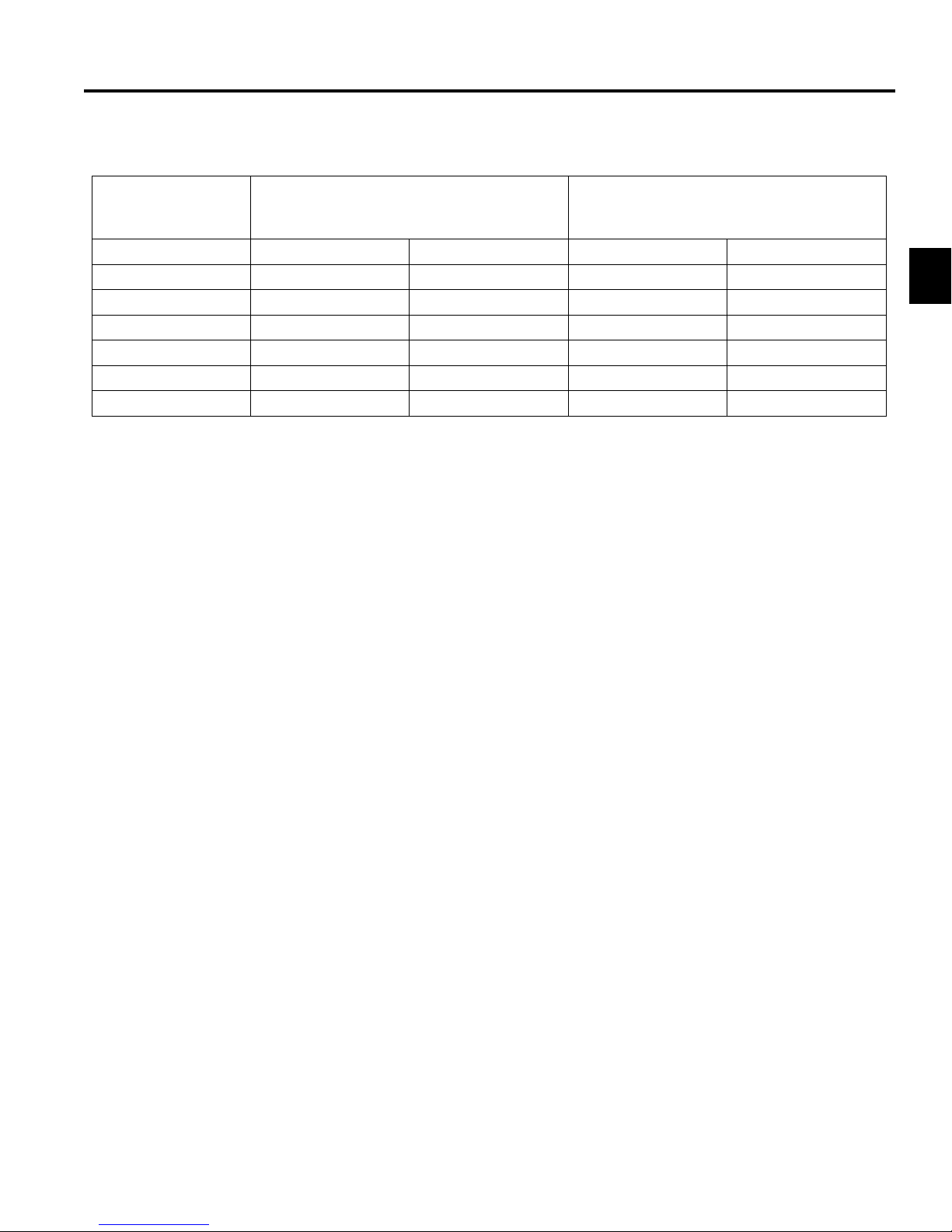

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

2

± 10% of

2-3LX Lawn Tractor Service Manual

Page 12

SPECIFICATIONS

Other Torque Specifications

2

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

Thread Cutting Screws

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

2-4 LX Lawn Tractor Service Manual

Page 13

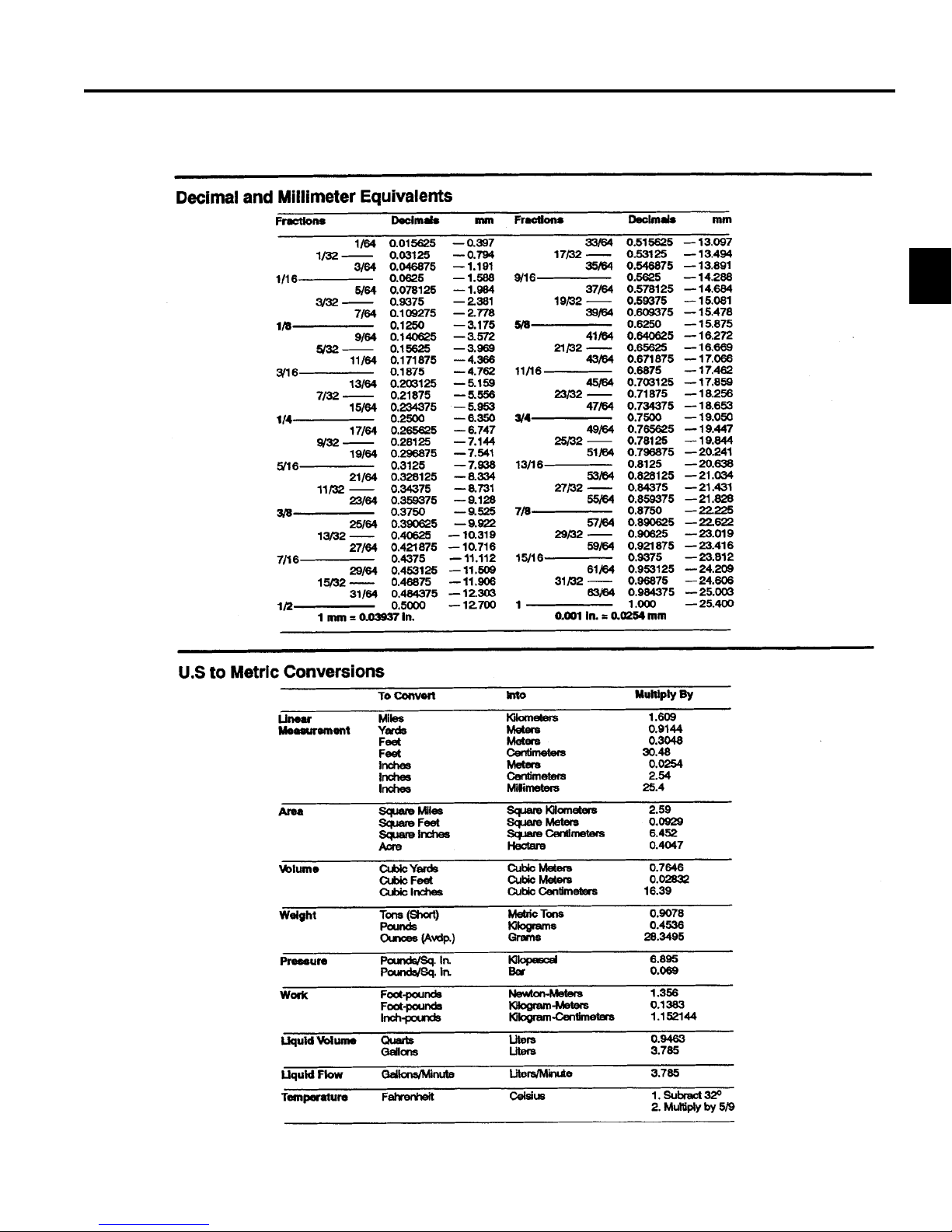

Equivalents and Conversions

SPECIFICATIONS

2

2-5LX Lawn Tractor Service Manual

Page 14

2

SPECIFICATIONS

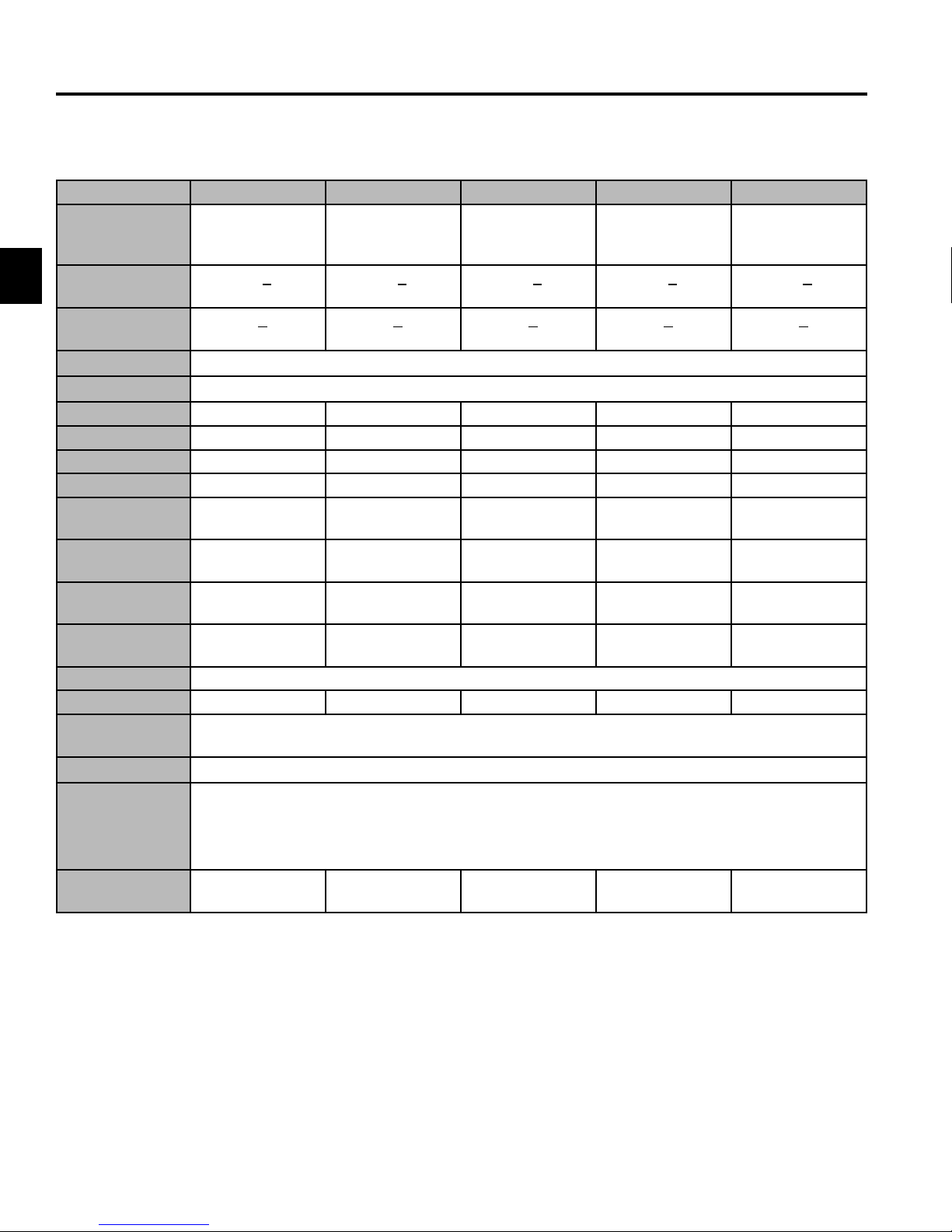

Product Specifi cations

Name LX420 LX425 LX460 LX465 LX500

Engine 18 HP

Single Cylinder

Kohler Courage

RPM Setting -

High

RPM Setting –

Low

Construction

Fuel Capacity

Wheel Base 46” (116.8cm) 46” (116.8cm) 46” (116.8cm) 46” (116.8cm) 46” (116.8cm)

Overall Length 68” (172.7cm) 68” (172.7cm) 68” (172.7cm) 68” (172.7cm) 68” (172.7cm)

Overall Width 42” (114.3cm) 42” (114.3cm) 48” (127.9cm) 49” (124.4cm) 54” (137.2cm)

Overall Height 43” (109.2cm) 43” (109.2cm) 43” (109.2cm) 43” (109.2cm) 43” (109.2cm)

Weight

(approximate)

Traction System CVT* Transaxle CVT* Transaxle CVT* Transaxle Hydro-Gear

Ground Speed –

Forward

Ground Speed –

Reverse

Front Tires

Rear Tires 20 x 8 20 x 8 20 x 8 20 x 8 20 x 10

Tire Pressure

(Front/Rear)

Turning Radius

Electrical

System

3450 + 75 3450 + 75 3450 + 75 3450 + 75 3300 + 75

1700 + 150 1700 + 150 1700 + 150 1700 + 150 1750 + 150

498 lbs.

(225.9kg)

0 – 5.5 mph 0 – 5.5 mph 0 – 5.5 mph 0 – 6.4 mph 0 – 5.5 mph

0 – 2.3 mph 0 – 2.3 mph 0 – 2.3 mph 0 – 2.5 mph 0 – 2.3 mph

20 HP

Single Cylinder

Kohler Courage

498 lbs.

(225.9kg)

Alternator: 15 Amp Regulated

20 HP

Single Cylinder

Kohler Courage

12 Gauge Steel Frame

3.0 Gallon (11.4 Liters)

501 lbs.

(227.25kg)

15 x 6

14psi / 10psi

18” (46cm)

Voltage: 12-volt Negative

Ground Battery: 190 CCA

Fuse: 20 Amp

20 HP

Single Cylinder

Kohler Courage

498 lbs.

(225.9kg)

LT-0510

22 HP

Twin Cylinder

Kohler Courage

525 lbs.

(238kg)

CVT* Transaxle

42”, Two Blade,

Mower Deck

CVT = Constant Velocity Transaxle

2-6 LX Lawn Tractor Service Manual

13 Gauge Steel

42”, Two Blade,

13 Gauge Steel

46”, Three Blade,

12 Gauge Steel

46”, Three Blade,

12 Gauge Steel

50”, Three Blade,

12 Gauge Steel

Page 15

CHASSIS

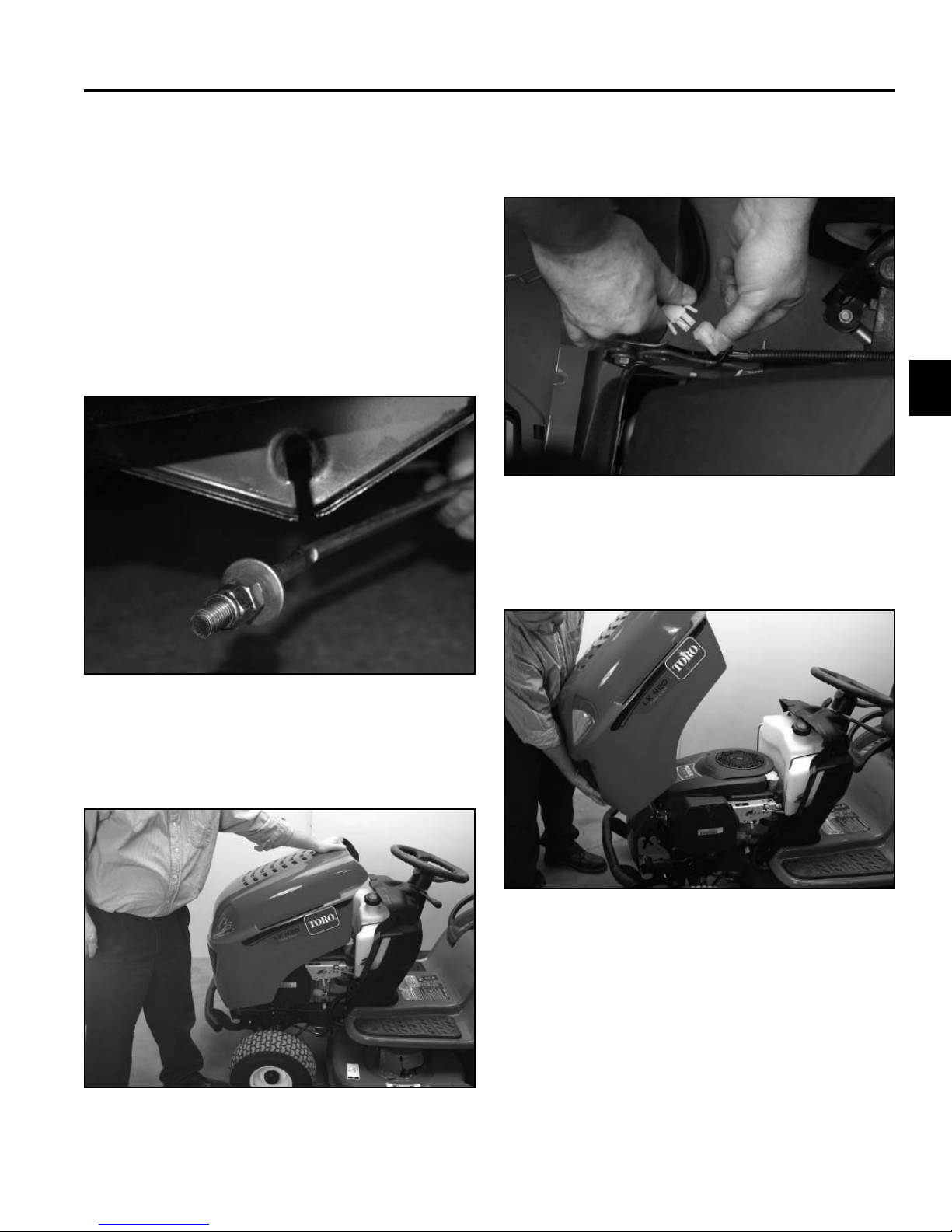

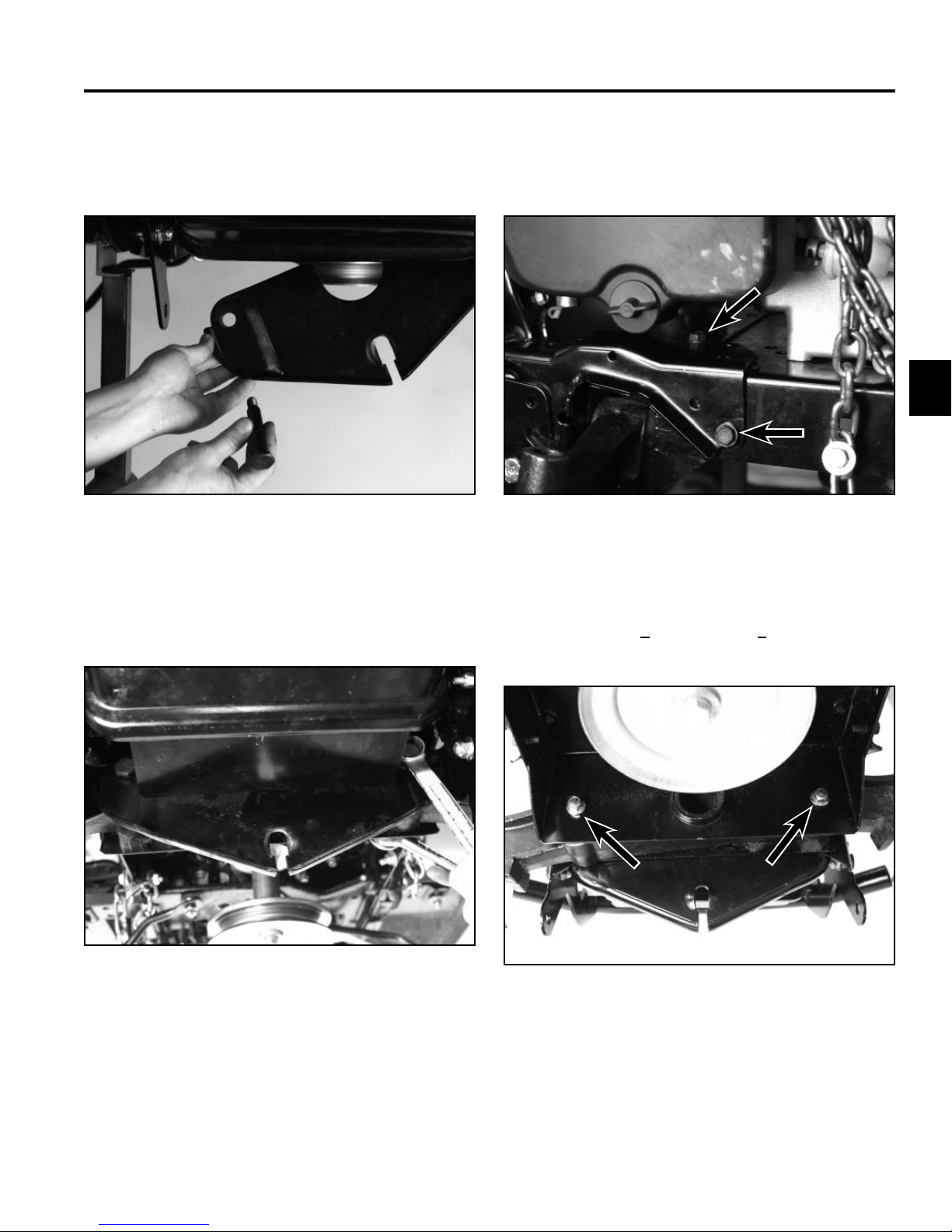

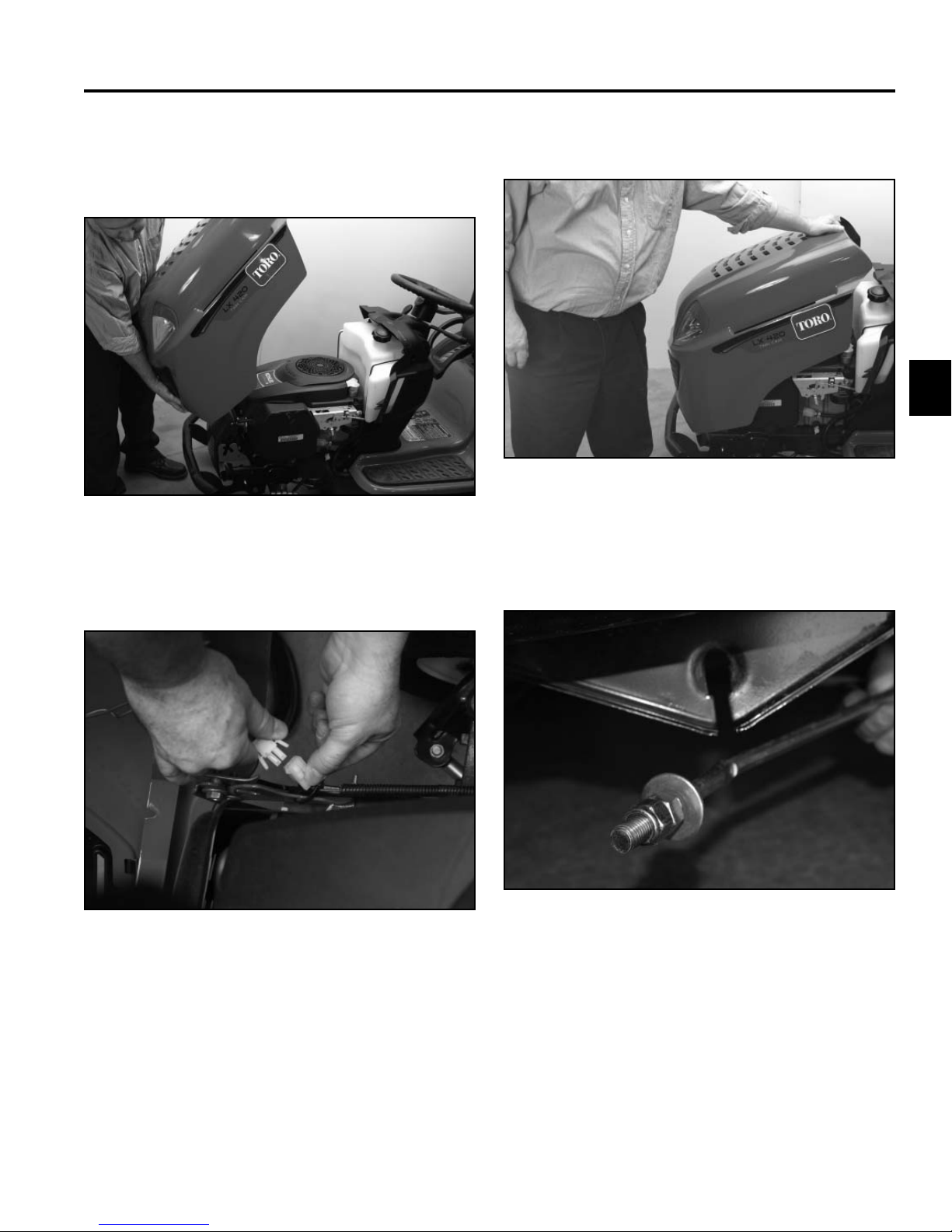

Front Pivot Axle Replacement

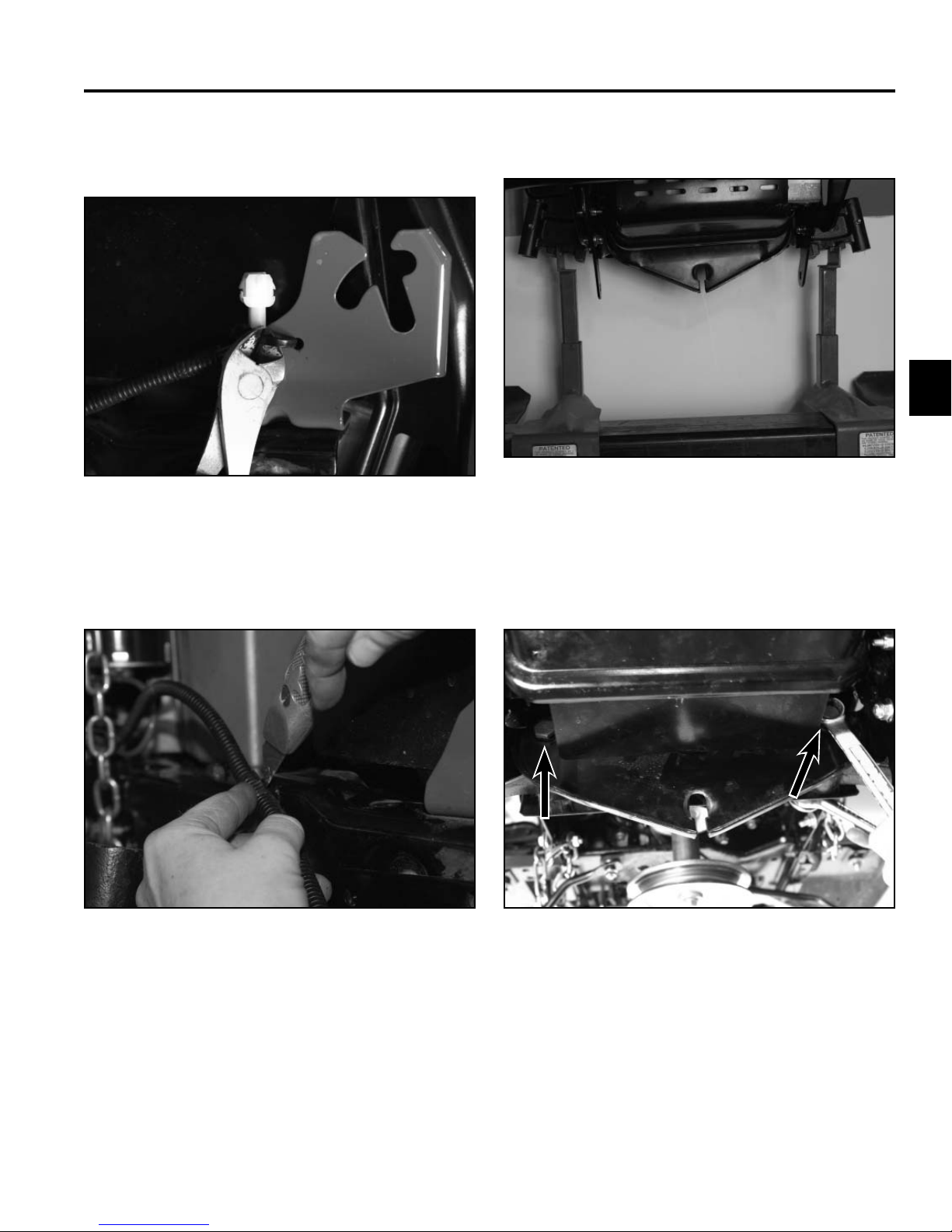

Removal

1. Disconnect the negative and then the positive

battery cable.

2. Remove the mower deck: 42” deck on page 7-64;

46” deck on page 7-69; 50” deck on page 7-74.

3. Remove the deck rod from the deck hanger bracket

(Fig. 001).

5. Unplug the headlights from the wire harness (Fig.

003).

3

Fig 003 PICT-7064

6. Remove the hood from the frame (Fig. 004).

Fig 001 PICT-7399a

4. Raise the hood (Fig. 002).

Fig 002 PICT-7063

Fig 004 PICT-7066

3-1LX Lawn Tractor Service Manual

Page 16

3

CHASSIS

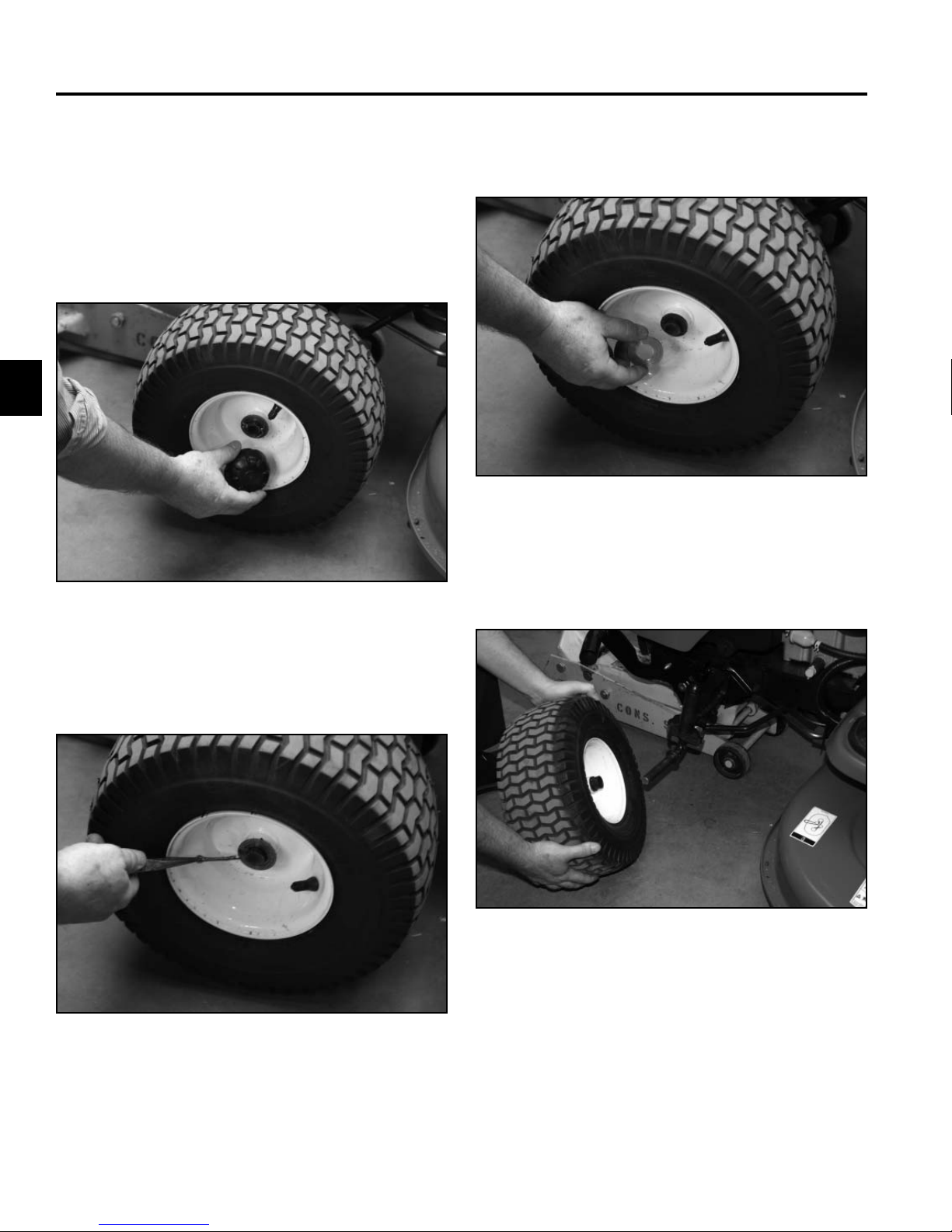

10. Remove the washer from the two axles (Fig. 007).7. Elevate and secure the front end of the machine so

the front axle can be accessed.

8. Remove the hub caps from the two front tires (Fig.

005).

Fig 007 PICT-7402

Fig 005 PICT-7400

9. Remove and discard the cotter pins from the two

axles (Fig. 006).

Fig 006 PICT-7401

11. Remove the wheel and tire assembly from the two

axle assemblies (Fig. 008).

Fig 008 PICT-7403

3-2 LX Lawn Tractor Service Manual

Page 17

CHASSIS

Note: There are inner and outer bushings included

with the rim assembly. When the wheel is

removed, the inner bushing may come off

with the wheel or stay on the axle.

Bushing stays in rim of tire (Fig. 009):

Fig 009 PICT-7410a

12. Remove the bushing from each of the axle assem-

blies if it stayed in place at tire assembly removal

(Fig. 011).

3

Fig 011 PICT-7415a

13. Remove the nut securing the ball joint to the axle

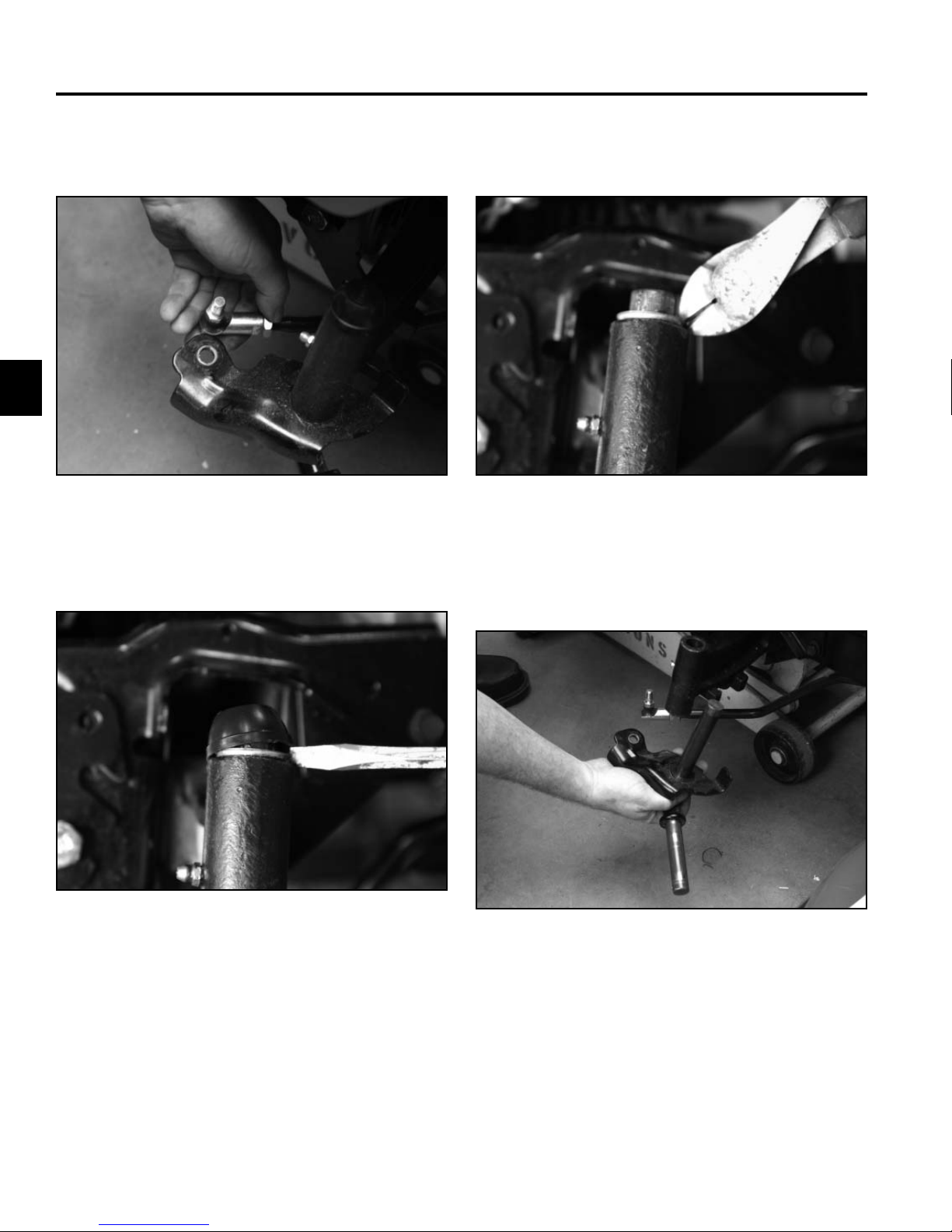

assemblies (Fig. 012).

Bushing stays on axle (Fig. 010):

Fig 010 PICT-7413

Fig 012 PICT-7421

3-3LX Lawn Tractor Service Manual

Page 18

CHASSIS

3

14. Remove the ball joint from the axle assembly (Fig.

013).

Fig 013 PICT-7423

15. Remove the cap from the axle assembly (Fig. 014). 17. Remove the axle assembly from the front pivot axle

16. Remove the push nut from the axle assembly (Fig.

015).

Fig 015 PICT-7425

(Fig. 016).

Fig 014 PICT-7424

3-4 LX Lawn Tractor Service Manual

Fig 016 PICT-7431a

18. Repeat steps 13-17 to remove the second axle.

Page 19

right hand hood pivot bracket (Fig. 017).

Fig 017 PICT-7434

CHASSIS

21. Support the front pivot axle (Fig. 019).19. Cut the cable tie securing the wire harness to the

3

Fig 019 PICT-7439a

20. Cut the electrical tape securing the wire harness to

the plastic harness guide (Fig. 018).

Fig 018 PICT-7462a

22. Remove the nuts from the 2 bolts securing the pivot

axle and deck hanger bracket to the frame (Fig.

020).

Fig 020 PICT-7442

3-5LX Lawn Tractor Service Manual

Page 20

CHASSIS

3

23. Remove the 4 bolts (2 on the right, 2 on the left)

securing the left and right pivot supports to the frame

(Fig. 021).

Fig 021 PICT-7436

24. Remove one of the bolts securing the deck hanger

plate and pivot axle to the frame (Fig. 022).

25. Remove the second bolt and deck hanger plate from

the pivot axle (Fig. 023).

Fig 023 PICT-7447

26. Remove the muffl er, heat shield and bracket assem-

bly (Fig. 024).

Fig 022 PICT-7444

3-6 LX Lawn Tractor Service Manual

Fig 024 PICT-7449

Page 21

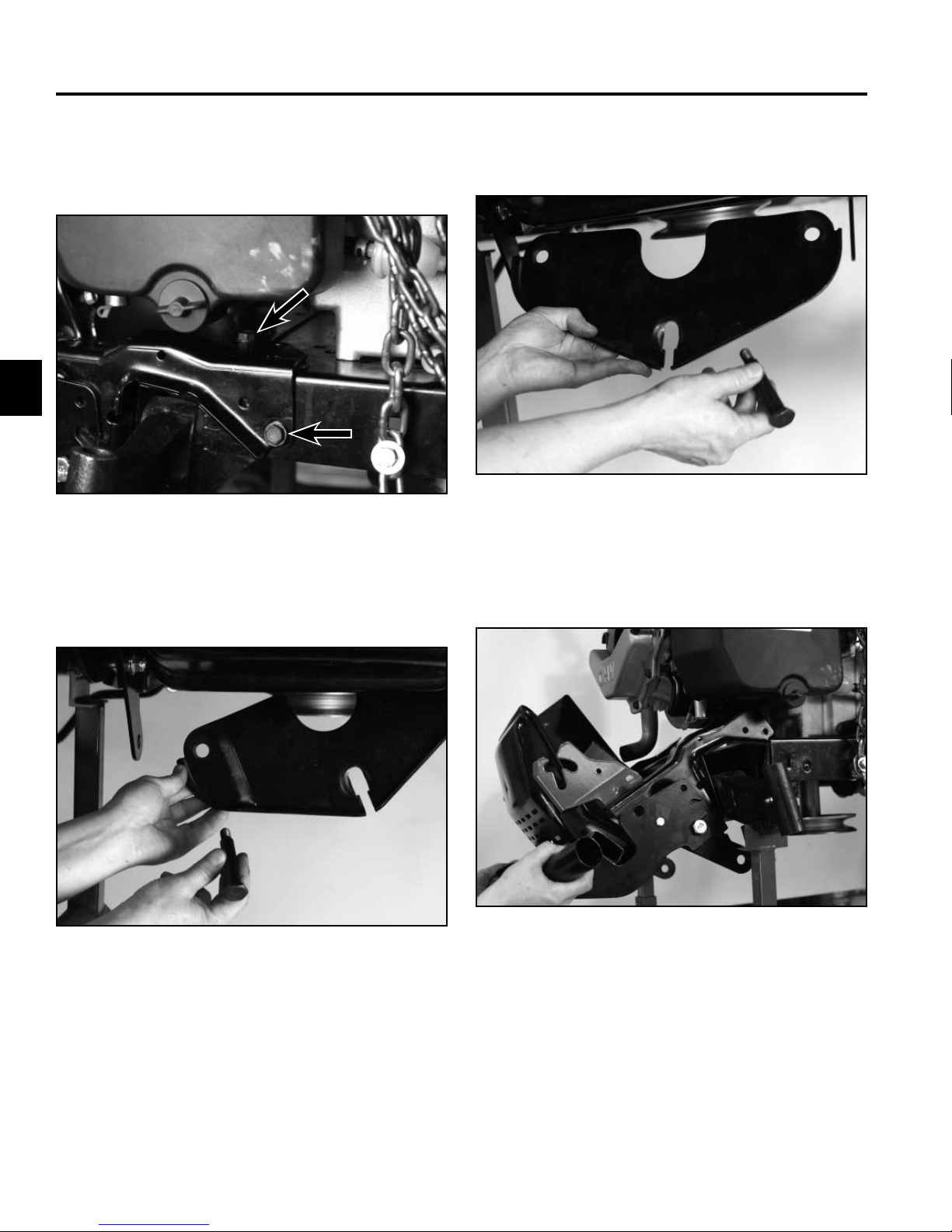

CHASSIS

27. Remove the pivot bar bracket (Fig. 025).

Fig 025 PICT-7450

28. Remove the front pivot axle (Fig. 026).

Installation

1. Position the front pivot axle to the front of the frame

(Fig. 027).

3

Fig 027 PICT-7451

Fig 026 PICT-7451

2. Position the pivot bar bracket to the front pivot axle

(Fig. 028).

Fig 028 PICT-7450

3-7LX Lawn Tractor Service Manual

Page 22

CHASSIS

3

3. Position the muffl er, heat shield and bracket assem-

bly to the frame (Fig. 029).

Fig 029 PICT-7449

Note: The tailpipe needs to be aligned and inserted

into the muffl er upon assembly (Fig. 030).

4. Loosely install 4 bolts securing the left and right pivot

supports to the frame (2 bolts on the left side bracket

and 2 bolts on the right side bracket) (Fig. 031).

Fig 031 PICT-7436

5. Position the deck hanger plate to the pivot axle and

install a shoulder bolt (Fig. 032).

Fig 030 PICT-7457

3-8 LX Lawn Tractor Service Manual

Fig 032 PICT-7447

Page 23

CHASSIS

6. Align the second hole in the deck hanger bracket

with the pivot axle and install a second shoulder bolt

(Fig. 033).

Fig 033 PICT-7444

8. Tighten the 4 bolts securing the left and right pivot

supports to the frame (2 bolts on the left side bracket

and 2 bolts on the right side bracket) (Fig. 035).

3

Fig 035 PICT-7436

7. Loosely install a nut onto the 2 shoulder bolts securing the pivot axle and deck hanger bracket to the

frame (Fig. 034).

Fig 034 PICT-7442

9. Torque the 2 nuts installed on the shoulder bolts

securing the pivot axle and deck hanger bracket to

the frame to 30 + 3 ft-lbs. (40.67 + 4.06 Nm) (Fig.

036).

Fig 036 PICT-7460

3-9LX Lawn Tractor Service Manual

Page 24

CHASSIS

3

10. Apply electrical tape to secure the wire harness to

the plastic harness guide (Fig. 037).

Fig 037 PICT-7464

11. Secure the wire harness to the right hand hood pivot

bracket with a cable tie (Fig. 038).

Note: The following steps, 12 thru 21, should be

done on both the right and left sides of the

axle.

12. Insert the axle assembly into the pivot axle (Fig.

039).

Fig 039 PICT-7468a

Fig 038 PICT-7466

13. Position the ball joint into the axle assembly (Fig.

040).

Fig 040 PICT-7469a

3-10 LX Lawn Tractor Service Manual

Page 25

29 ft-lbs. (16.94 to 39.54 Nm) (Fig. 041).

Fig 041 PICT-7470a

CHASSIS

16. Apply grease to the axle assembly (Fig. 043).14. Install a nut onto the ball joint and torque to 12.5 to

3

Fig 043 PICT-7472

15. Install a cap/push nut onto the axle assembly (Fig.

042).

Fig 042 PICT-7471

17. Slide the wheel and tire assembly onto the axle

assembly (Fig. 044).

Note: The wheel bearing is installed in the rim.

Fig 044 PICT-7473

3-11LX Lawn Tractor Service Manual

Page 26

3

CHASSIS

20. Apply grease to the wheel bearing (Fig. 047).18. Install a washer onto the axle assembly (Fig. 045).

Fig 045 PICT-7474a

19. Install a cotter pin into the axle assembly (Fig. 046). 21. Install the hub cap (Fig. 048).

Fig 046 PICT-7475a

Fig 047 PICT-7477a

Fig 048 PICT-7478

3-12 LX Lawn Tractor Service Manual

Page 27

23. Position the hood on the chassis (Fig. 049).

Fig 049 PICT-7066

CHASSIS

25. Lower the hood (Fig. 051).22. Lower the machine.

3

Fig 051 PICT-7063

24. Plug the headlights into the wire harness (Fig. 050).

Fig 050 PICT-7064

26. Install the deck rod into the deck hanger bracket

(Fig. 052).

Fig 052 PICT-7399a

27. Install the mower deck: 42” deck on page 7-67; 46”

deck on page 7-72; 50” deck on page 7-76.

28. Connect the positive and then the negative battery

cable.

29. Check the toe-in measurement and adjust as needed. Refer to “Front Wheel Toe-In Measurement” on

page 3-85.

3-13LX Lawn Tractor Service Manual

Page 28

CHASSIS

3

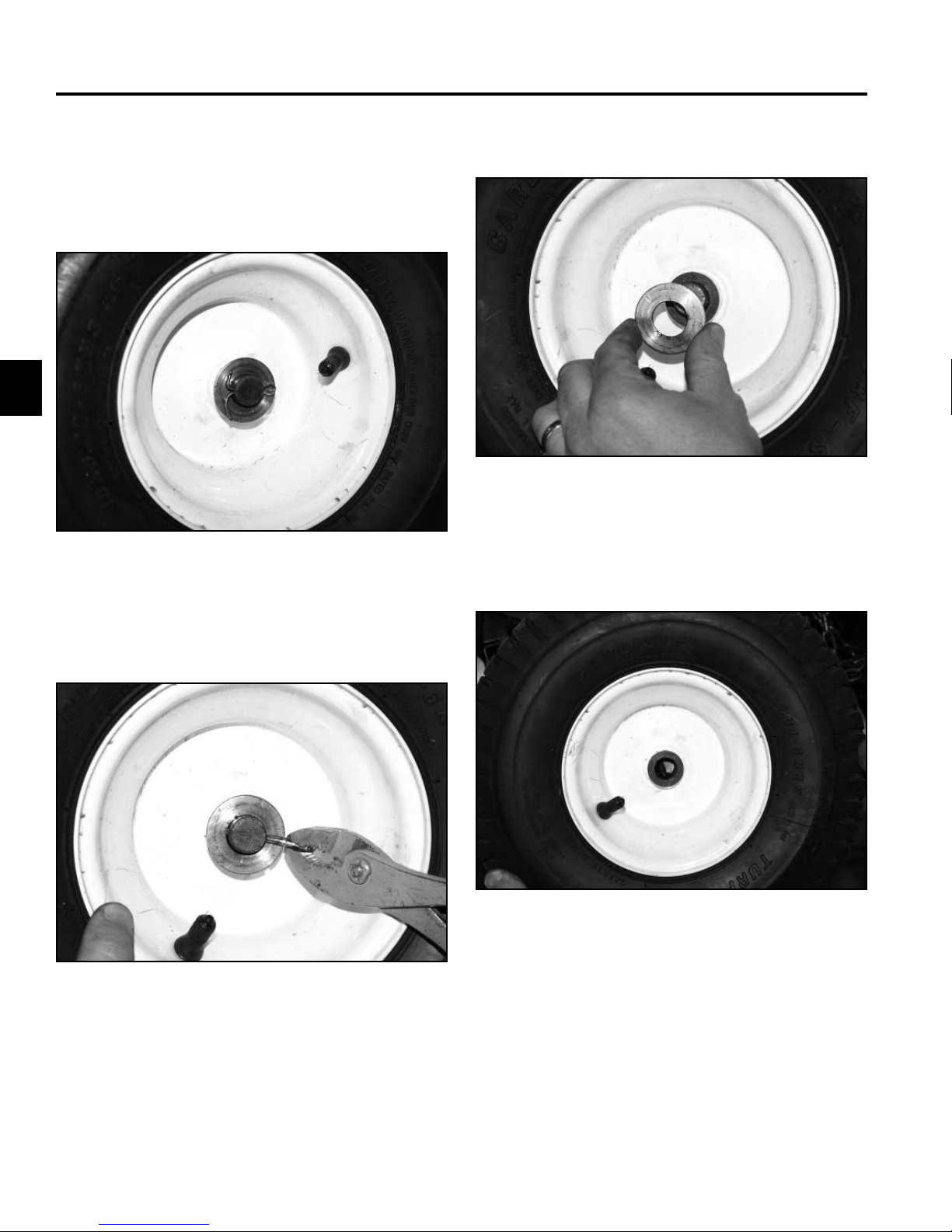

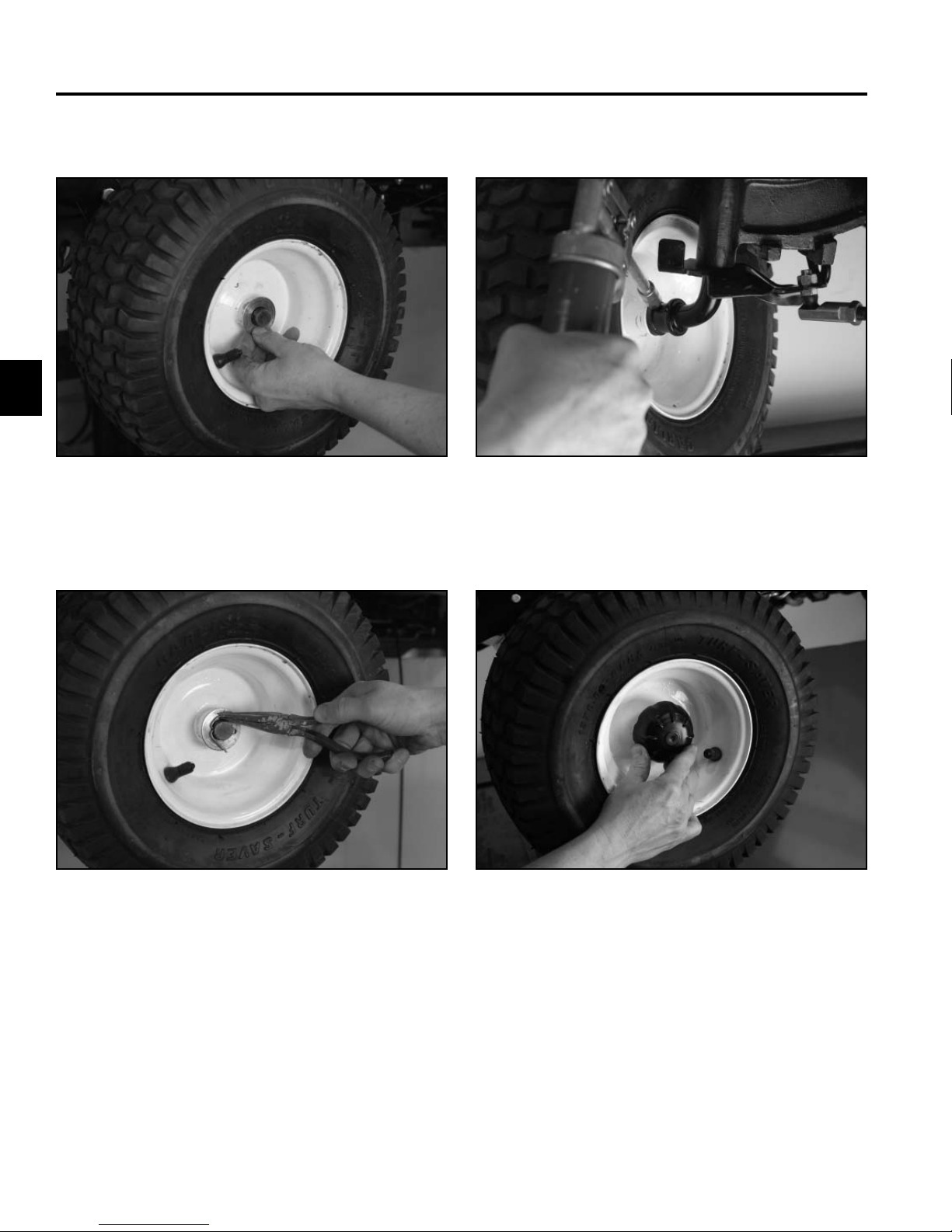

Axle Assembly Replacement

Removal

1. Raise the front of the machine.

2. Remove the hub cap (Fig. 053).

Fig 053 PICT-7067

4. Remove the washer from the axle assembly (Fig.

055).

Fig 055 PICT-7070

5. Remove the wheel and tire assembly from the axle

assembly (Fig. 056).

3. Remove the cotter pin from the axle assembly (Fig.

054).

Fig 054 PICT-7069

Fig 056 PICT-7072

3-14 LX Lawn Tractor Service Manual

Page 29

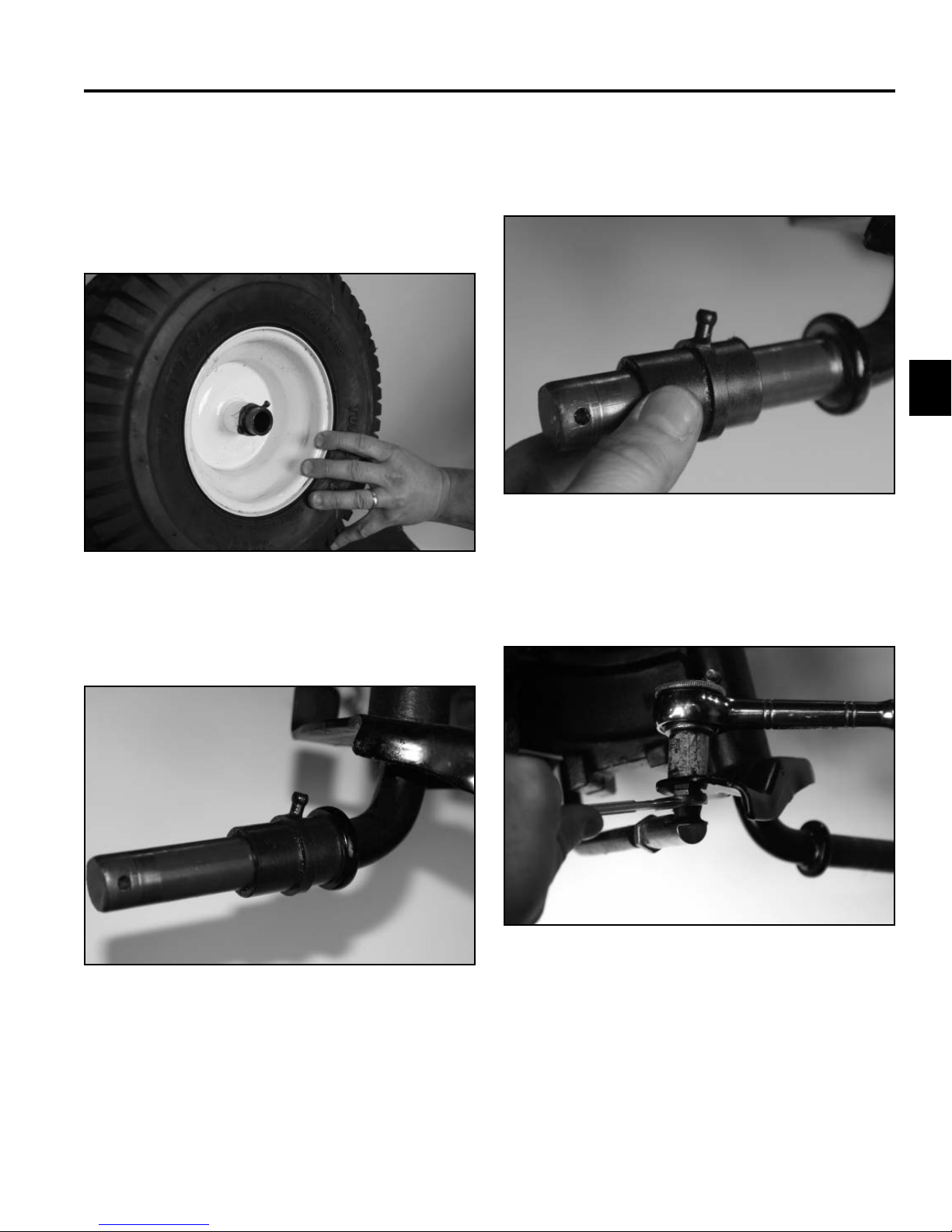

CHASSIS

Note: There are inner and outer bushings included

with the rim assembly. When the wheel is

removed, the inner bushing may come off

with the wheel or stay on the axle assembly.

Bushing stays in rim of tire (Fig. 057):

Fig 057 PICT-7410a

6. Remove the bushing from each of the axle assem-

blies if it stayed in place at tire assembly removal

(Fig. 059).

3

Fig 059 PICT-7415a

7. Remove the nut securing the ball joint to the axle

assembly (Fig. 060).

Bushing stays on axle assembly (Fig. 058):

Fig 058 PICT-7413

Fig 060 PICT-7077a

3-15LX Lawn Tractor Service Manual

Page 30

CHASSIS

3

8. Remove the ball joint from the axle assembly (Fig.

061).

Fig 061 PICT-7078

9. Remove the cap from the axle assembly (Fig. 062).

10. Remove the push nut from the axle assembly (Fig.

063).

Fig 063 PICT-7425

11. Remove the axle assembly from the axle pivot (Fig.

064).

Fig 062 PICT-7424

3-16 LX Lawn Tractor Service Manual

Fig 064 PICT-7087

Page 31

CHASSIS

Installation

1. Position the axle assembly into the axle pivot (Fig.

065).

Fig 065 PICT-7087

2. Install a cap/push nut onto the axle assembly (Fig.

066).

3. Position the ball joint into the axle assembly (Fig.

067).

4. Install a nut onto the ball joint and torque to 12.5 to

29 ft-lbs. (16.94 to 39.54 Nm) (Fig. 068).

Fig 067 PICT-7078

3

Fig 066 PICT-7471

Fig 068 PICT-7077a

3-17LX Lawn Tractor Service Manual

Page 32

CHASSIS

3

5. Apply grease to lubricate the front axle pivot (Fig.

069).

Fig 069 PICT-7091a

6. Slide the wheel and tire assembly onto the axle

assembly (Fig. 070).

7. Install a washer onto the axle assembly (Fig. 071).

Fig 071 PICT-7070

8. Install a cotter pin into the axle pivot (Fig. 072).

Note: The wheel bearing is installed in the rim.

Fig 070 PICT-7072

Fig 072 PICT-7093

3-18 LX Lawn Tractor Service Manual

Page 33

CHASSIS

9. Apply grease to the wheel bearing (Fig. 073).

Fig 073 PICT-7092

10. Install the hub cap (Fig. 074).

Steering Wheel Replacement

Removal

1. Remove the steering wheel cap (Fig. 075).

3

Fig 075 PICT-7103

Fig 074 PICT-7067

11. Lower the machine.

2. Remove the bolt and washer securing the steering

wheel to the steering shaft (Fig. 076).

Fig 076 PICT-7104

3-19LX Lawn Tractor Service Manual

Page 34

CHASSIS

3

3. Remove the steering wheel (Fig. 077).

Fig 077 PICT-7105

Installation

1. Position the front tires so that they are pointing

straight forward. Slide the steering wheel onto the

steering shaft (Fig. 078).

2. Install the washer and bolt to secure the steering

wheel to the steering shaft (Fig. 079).

3. Install the steering wheel cap (Fig. 080).

Fig 079 PICT-7104

Fig 078 PICT-7105

3-20 LX Lawn Tractor Service Manual

Fig 080 PICT-7106

Page 35

CHASSIS

Steering Shaft Replacement

Removal

1. Remove the steering wheel cap (Fig. 081).

Fig 081 PICT-7103

3. Remove the steering wheel (Fig. 083).

3

Fig 083 PICT-7105

4. Raise the hood (Fig. 084).

2. Remove the bolt and washer securing the steering

wheel to the steering shaft (Fig. 082).

Fig 082 PICT-7104

Fig 084 PICT-7063a

3-21LX Lawn Tractor Service Manual

Page 36

3

CHASSIS

8. Lift the fuel tank out of the tower (Fig. 087).5. Remove the mower deck: 42” deck on page 7-64;

46” deck on page 7-69; 50” deck on page 7-74.

6. Disconnect the fuel line from the fuel fi lter and drain

all the fuel from the fuel tank. Reconnect the fuel line

to the fuel fi lter (Fig. 085).

Fig 087 PICT-7655a

Fig 085 PICT-7094

7. Remove the two screws securing the fuel tank

support rods to the dash supports (Fig. 086).

Fig 086 PICT-7099a

9. Raise the machine to access the steering gear

assembly.

10. Secure the steering gear in place with a Phillips

screwdriver and remove the nut from the end of the

steering shaft (Fig. 088).

Fig 088 PICT-7656a

3-22 LX Lawn Tractor Service Manual

Page 37

11. Remove the pinion from the steering shaft (Fig. 089). 13. Lower the machine.

14. Pull the steering shaft up out of the hex fl ange bear-

ing, angle the steering shaft in between the pedal

levers and lower it out of the tower (Fig. 091).

Fig 089 PICT-7659a

CHASSIS

3

12. Push up on the steering shaft and remove the

washer (Fig. 090).

Fig 090 PICT-7661a

Fig 091 PICT-7663

15. Remove the hex fl ange bushing (Fig. 092).

Note: Inspect the hex fl ange bushing and replace if

worn or damaged.

Fig 092 PICT-7666a

3-23LX Lawn Tractor Service Manual

Page 38

CHASSIS

3

Installation

1. Install the hex fl ange bushing into the steering

support bracket ensuring the hex is seated in the

bracket (Fig. 093).

Fig 093 PICT-7668a

3. Raise the tractor.

4. Push up on the steering shaft to install a washer

onto the steering shaft (Fig. 095).

Fig 095 PICT-7661a

2. Slide the steering shaft up into the tower from below,

insert the lower end of the steering shaft into the hex

fl ange bushing (Fig. 094).

Fig 094 PICT-7663

5. Slide the pinion onto the steering shaft (Fig. 096).

Fig 096 PICT-7659a

3-24 LX Lawn Tractor Service Manual

Page 39

CHASSIS

6. Loosely install a nut on the steering shaft. Secure

the steering gear in place with a Phillips screwdriver

and tighten the nut (Fig. 097).

Fig 097 PICT-7656a

7. Grease the pinion gear with #2 general purpose

grease (Fig. 098).

8. Lower the tractor.

9. Position the fuel tank into the tower (Fig. 099).

3

Fig 099 PICT-7655a

10. Position the fuel tank support rods and install two

screws securing the fuel tank support rods to the

dash supports (Fig. 100).

Fig 098 PICT-7676

Fig 100 PICT-7099a

3-25LX Lawn Tractor Service Manual

Page 40

3

CHASSIS

11. Lower the hood (Fig. 101). 13. Install the washer and bolt to secure the steering

wheel to the steering shaft (Fig. 103).

Fig 101 PICT-7063a

Fig 103 PICT-7104

12. With the tractor’s wheels straight ahead, position the

steering wheel onto the steering shaft (Fig. 102).

Fig 102 PICT-7105

14. Install the steering wheel cap (Fig. 104).

Fig 104 PICT-7106

15. Install the mower deck: 42” deck on page 7-67; 46”

deck on page 7-72; 50” deck on page 7-76.

3-26 LX Lawn Tractor Service Manual

Page 41

CHASSIS

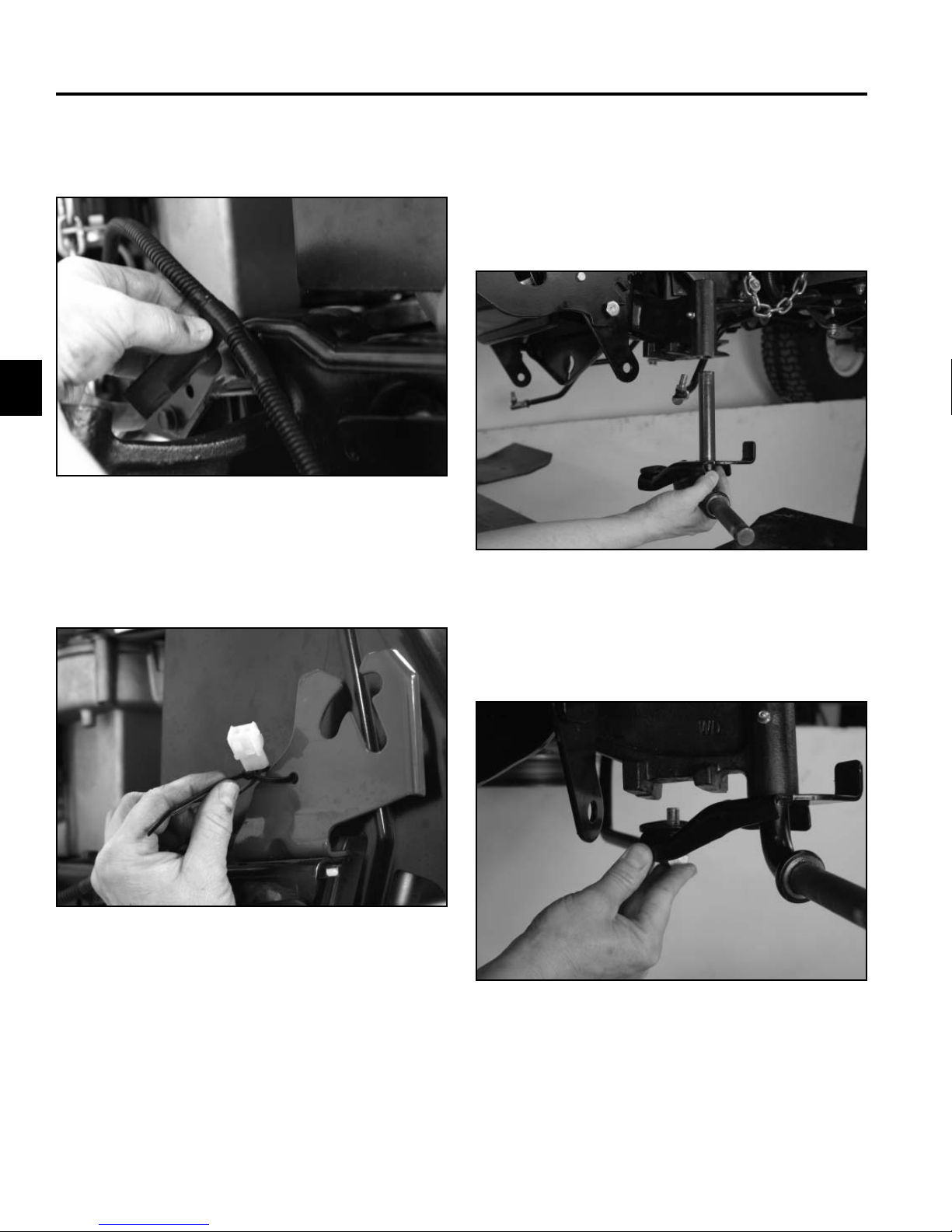

Electric PTO Clutch Replacement

Removal

1. Remove the mower deck from the tractor. Refer to

“50” Mower Deck Removal” on page 7-74.

2. Raise the tractor so the clutch can be accessed.

3. Unplug the clutch from the wire harness (Fig. 105).

4. Route the clutch connector out through the slot in

the frame.

5. Remove the bolt and lock washer securing the clutch

to the crankshaft (Fig. 106).

3

Fig 106 PICT-7982

Fig 105 PICT-7977a

6. Remove the clutch and washer(s) from the crankshaft (Fig. 107).

Fig 107 PICT-7988

3-27LX Lawn Tractor Service Manual

Page 42

CHASSIS

3

Installation

1. Apply anti-seize compound to the crankshaft (Fig.

108).

Fig 108 PICT-7984

3. Align the keyway in the clutch with the key on the

crankshaft and slide the clutch and washer assembly

onto the crankshaft. (Fig. 110).

Fig 110 PICT-7988

2. Lay the washer(s) on top of the clutch (Fig. 109).

Fig 109 PICT-7985

4. Install the bolt and lock washer securing the clutch

to the crankshaft. Torque the bolt to 37.5–50 ft-lbs.

(50.84–67.79 Nm) (Fig. 111).

Fig 111 PICT-7986

3-28 LX Lawn Tractor Service Manual

Page 43

CHASSIS

5. Route the clutch plug through the slot in the frame.

6. Plug the clutch into the wire harness (Fig. 112).

Fig 112 PICT-7977a

7. Lower the tractor to the ground.

Fuel Tank Replacement

Removal

1. Raise the hood (Fig. 113).

3

Fig 113 PICT-7063

8. Install the mower deck onto the tractor. Refer to “50”

Mower Deck Installation” on page 7-76.

2. Disconnect the fuel line from the fuel fi lter and drain

all the fuel from the fuel tank into an approved

container (Fig. 114).

Fig 114 PICT-7094

3-29LX Lawn Tractor Service Manual

Page 44

CHASSIS

3

3. Remove the two screws securing the fuel tank

support rods to the dash supports (Fig. 115).

Fig 115 PICT-7099a

4. Remove the fuel tank from the engine compartment

(Fig. 116).

Installation

1. Position the fuel tank into the engine compartment

(Fig. 117).

Fig 117 PICT-7100a

2. Position the fuel tank support rods and install screws

to secure the fuel tank (Fig. 118).

Fig 116 PICT-7100a

3-30 LX Lawn Tractor Service Manual

Fig 118 PICT-7099a

Page 45

CHASSIS

3. Connect the fuel line to the fuel fi lter and secure with

a hose clamp (Fig. 119).

Fig 119 PICT-7094

4. Lower the hood (Fig. 120).

Hood Replacement

Removal

1. Raise the hood (Fig. 121).

3

Fig 121 PICT-7063

Fig 120 PICT-7063

2. Unplug the headlights from the wire harness (Fig.

122).

Fig 122 PICT-7064

3-31LX Lawn Tractor Service Manual

Page 46

3

CHASSIS

2. Plug the headlights to the wire harness (Fig. 125).3. Remove the hood from the chassis (Fig. 123).

Fig 123 PICT-7066

Installation

1. Position the hood on the chassis (Fig. 124).

Fig 125 PICT-7064

3. Lower the hood (Fig. 126).

Fig 126 PICT-7063

Fig 124 PICT-7066

3-32 LX Lawn Tractor Service Manual

Page 47

CHASSIS

Fender Replacement

Removal

1. Lift the seat to access the battery compartment.

2. Disconnect the negative battery cable from the

battery terminal (Fig. 127).

4. Remove the battery hold down rod (Fig. 129).

3

Fig 129 PICT-7109a

5. Remove the battery from the battery tray (Fig. 130).

Fig 127 PICT-7107

3. Disconnect the positive battery cable from the

battery terminal (Fig. 128).

Fig 128 PICT-7108

Fig 130 PICT-7110

3-33LX Lawn Tractor Service Manual

Page 48

CHASSIS

3

6. Remove the battery tray (Fig. 131).

Fig 131 PICT-7111

7. Disconnect the two seat switch wires (Fig. 132).

8. Loosen the bolt and nut securing the left seat mount

bracket to the seat bracket (Fig. 133).

Fig 133 PICT-7115

9. Release the extension spring from the seat mount

bracket (Fig. 134).

Fig 132 PICT-7113

3-34 LX Lawn Tractor Service Manual

Fig 134 PICT-7117

Page 49

CHASSIS

10. Remove the 4 bolts securing the seat mount brackets to the fender (Fig. 135).

Fig 135 PICT-7119

11. Remove the seat (Fig. 136).

12. Remove the shifter knob from the shift lever (Fig.

137).

3

Fig 137 PICT-7122

13. Remove the height-of-cut grip from the height-of-cut

lever (Fig. 138).

Fig 136 PICT-7121

Fig 138 PICT-7123

3-35LX Lawn Tractor Service Manual

Page 50

CHASSIS

3

14. Pry up the front portion of the left hand foot pad (Fig.

139).

Fig 139 PICT-7124

15. Remove the bolt, nut and washer securing the fender to the frame (Fig. 140).

16. Pry up the front portion of the right hand foot pad

(Fig. 141).

Fig 141 PICT-7213

17. Remove the bolt nut and washer securing the fender

to the frame (Fig. 142).

Fig 140 PICT-7125

3-36 LX Lawn Tractor Service Manual

Fig 142 PICT-7127a

Page 51

CHASSIS

A

B

18. Locate the 2 screws under the danger decal on the

fender. Cut the decal to expose the bolt heads (Fig.

143).

Fig 143 PICT-7129

19. Remove the 2 screws (Fig. 144).

20. Raise the fender and prop it slightly to access the

fasteners securing the brake pedal to the brake

control assembly (Fig. 145).

3

Fig 145 PICT-7131a

Remove the two sets of fasteners securing the brake

pedal lever to the brake control assembly (Fig. 146):

Fig 144 PICT-7130

A

B

Fig 146 PICT-7132

A. Torx screw and washer

B. Hex head bolt, lock washer and nut

3-37LX Lawn Tractor Service Manual

Page 52

3

CHASSIS

23. Remove the speed control pedal (Fig. 149).21. Remove the brake pedal (Fig. 147).

Fig 147 PICT-7134

22. Remove the two bolts securing the speed control

pedal to the speed control assembly (Fig. 148).

Fig 148 PICT-7135

Fig 149 PICT-7136

24. Remove the fender (Fig. 150).

Fig 150 PICT-7138

3-38 LX Lawn Tractor Service Manual

Page 53

CHASSIS

Installation

1. Position the fender onto the frame (Fig. 151).

Fig 151 PICT-7138

2. Position the speed control pedal to the speed control

assembly (Fig. 152).

3. Install 2 bolts to secure the speed control pedal to

the speed control assembly (Fig. 153).

3

Fig 153 PICT-7211

4. Position the brake pedal to the brake control

assembly (Fig. 154).

Fig 152 PICT-7136

Fig 154 PICT-7212

3-39LX Lawn Tractor Service Manual

Page 54

CHASSIS

A

B

3

5. Raise the fender and prop it slightly to access the

fasteners securing the brake pedal to the brake

control assembly (Fig. 155).

Fig 155 PICT-7131a

7. Begin securing the fender to the frame by installing

2 screws located under the danger decal (Fig. 157).

Glue the cut decal pieces into place or replace the

decal.

Fig 157 PICT-7130

6. Install the two sets of fasteners securing the brake

pedal lever to the brake control assembly (Fig. 156):

A

B

Fig 156 PICT-7132

A. Torx screw and washer

B. Hex head bolt, washer and nut

8. Install the bolt, nut and washer securing the right

side of the fender to the frame and tighten (Fig. 158).

Fig 158 PICT-7127a

3-40 LX Lawn Tractor Service Manual

Page 55

CHASSIS

9. Push the foot pad down to the foot rest by applying

pressure down on the ratchet clip (Fig. 159).

Fig 159 PICT-7216

10. Install the bolt, nut and washer securing the left side

of the fender to the frame and tighten (Fig. 160).

11. Push the left side foot pad down to the foot rest by

applying pressure down on the ratchet clip (Fig.

161).

3

Fig 161 PICT-7217

12. Install the height-of-cut grip onto the height-of-cut

lever (Fig. 162).

Fig 160 PICT-7125

Fig 162 PICT-7123

3-41LX Lawn Tractor Service Manual

Page 56

CHASSIS

3

13. Install the shifter knob onto the shift lever (Fig. 163).

Fig 163 PICT-7122

14. Position the seat onto the fender, aligning the seat

mount bracket holes with the holes in the fender

(Fig. 164).

15. Install the 4 bolts securing the seat mount brackets

to the fender (Fig. 165).

Fig 165 PICT-7119

16. Loosen the bolt and nut securing the left seat mount

bracket to the seat (Fig. 166).

Fig 164 PICT-7121

3-42 LX Lawn Tractor Service Manual

Fig 166 PICT-7115

Page 57

CHASSIS

17. Install the extension spring from the seat mount

bracket to the seat pivot bracket (Fig. 167).

Fig 167 PICT-7117

18. Tighten the bolt and nut to secure the left seat mount

bracket to the seat mount (Fig. 168).

19. Connect the two seat switch connectors to the

switch springs (Fig. 169).

3

Fig 169 PICT-7113

20. Install the battery tray (Fig. 170).

Fig 168 PICT-7115

Fig 170 PICT-7111

3-43LX Lawn Tractor Service Manual

Page 58

CHASSIS

3

21. Install the battery in the battery tray (Fig. 171).

Fig 171 PICT-7110

22. Install the battery hold down rod (Fig. 172).

23. Connect the positive battery cable to the battery

terminal (Fig. 173).

Fig 173 PICT-7108

24. Connect the negative battery cable to the battery

terminal (Fig. 174).

Fig 172 PICT-7109a

3-44 LX Lawn Tractor Service Manual

Fig 174 PICT-7107

25. Test operate tractor to ensure all controls and the

seat switch are operating properly.

Page 59

CHASSIS

Tower Replacement

Removal

1. Remove the steering wheel cap (Fig. 175).

Fig 175 PICT-7141

3. Remove the steering wheel (Fig. 177).

3

Fig 177 PICT-7143

4. Disconnect the fuel line from the fuel fi lter and drain

all the fuel from the fuel tank into an approved container (Fig. 178).

2. Remove the bolt and washer securing the steering

wheel to the steering shaft (Fig. 176).

Fig 176 PICT-7142

Fig 178 PICT-7094

3-45LX Lawn Tractor Service Manual

Page 60

CHASSIS

3

5. Remove the rear fender. See “Fender Replacement Removal” on page 3-33.

6. Remove the two screws securing the fuel tank

support rods to the tower supports (Fig. 179).

Fig 179 PICT-7144a

8. Unplug the hour meter from the wire harness (Fig.

181).

Fig 181 PICT-7148

9. Electric PTO models: Unplug the electric PTO

switch plug (Fig. 182).

7. Remove the fuel tank from the engine compartment

(Fig. 180).

Fig 180 PICT-7146a

Fig 182 PICT-9826

3-46 LX Lawn Tractor Service Manual

Page 61

CHASSIS

10. Disconnect the ignition module from the wire

harness (Fig. 183).

Fig 183 PICT-7149

11. Unplug the ignition switch from the wire harness

(Fig. 184).

12. Remove the fuse holder from the tower support by

depressing the tabs (Fig. 185).

3

Fig 185 PICT-7210

13. Remove the throttle decal from the tower (Fig. 186).

Fig 184 PICT-7150

Fig 186 PICT-7153

3-47LX Lawn Tractor Service Manual

Page 62

CHASSIS

3

14. Remove the bolt and nut securing the control knob

to the throttle/choke assembly (Fig. 187).

Fig 187 PICT-7154

15. Remove the control knob (Fig. 188).

16. Remove the 2 screws securing the throttle/choke

assembly to the tower (Fig. 189).

Fig 189 PICT-7156

17. Pull the throttle/choke assembly out from the rear of

the tower (Fig. 190).

Fig 188 PICT-7155

3-48 LX Lawn Tractor Service Manual

Fig 190 PICT-7158

Page 63

CHASSIS

18. Remove the 2 nuts securing the deck engage handle

to the PTO engage lever and stop bracket (manual

PTO models) (Fig. 191).

Fig 191 PICT-7159

20. Separate the deck engage handle/bolt assembly

from the PTO engage lever (manual PTO models)

(Fig. 193).

3

Fig 193 PICT-7165

19. Remove the stop bracket (manual PTO models)

(Fig. 192).

Fig 192 PICT-7164

21. Remove the cotter pin from the park brake linkage

rod (Fig. 194).

Fig 194 PICT-7166

3-49LX Lawn Tractor Service Manual

Page 64

CHASSIS

3

22. Remove the linkage rod from the park brake lever

(Fig. 195).

Fig 195 PICT-7168

23. Remove the cotter pin from the cruise control linkage

rod (Fig. 196).

24. Remove the linkage rod from the cruise control lever

(Fig. 197).

Fig 197 PICT-7170

25. Remove the screws securing the top of the tower to

the top of the tower support brackets (Fig. 198).

Fig 196 PICT-7169

3-50 LX Lawn Tractor Service Manual

Fig 198 PICT-7172

Page 65

CHASSIS

26. Remove the 2 screws securing the lower front left

and right corners of the tower to the frame (Fig.

199).

Fig 199 PICT-7198

27. Loosen the 2 bolts securing the lower rear corners of

the tower to the frame (Fig. 200).

28. Lift the tower assembly off the frame (Fig. 201).

3

Fig 201 PICT-7175

29. Remove the PTO knob from the deck engage handle

in the tower (Fig. 202).

Fig 200 PICT-7174

Fig 202 PICT-7179a

3-51LX Lawn Tractor Service Manual

Page 66

CHASSIS

3

30. Remove the deck engage handle from the tower by

routing it out the back side of the tower (Fig. 203).

Fig 203 PICT-7182

31. Remove the hour meter from the tower by squeezing

the tabs (Fig. 204).

32. Remove the ignition switch module by depressing

the 4 tabs (Fig. 205).

Fig 205 PICT-7186

33. Remove the screw securing the bent lever rod to

the back of the tower and then remove the rod/lever

assembly from the tower (Fig. 206).

Fig 204 PICT-7184

3-52 LX Lawn Tractor Service Manual

Fig 206 PICT-7188a

Page 67

CHASSIS

34. Remove the 2 screws securing the left tower support

to the frame (Fig. 207).

Fig 207 PICT-7191

35. Remove the left tower support from the frame (Fig.

208).

Installation

1. Position the left tower support onto the frame (Fig.

209).

3

Fig 209 PICT-7194

2. Install 2 screws to secure the support onto the frame

(Fig. 210).

Fig 208 PICT-7192

36. Repeat steps 34 and 35 on the right tower support.

Fig 210 PICT-7191

3-53LX Lawn Tractor Service Manual

Page 68

CHASSIS

3

3. Repeat steps 1 and 2 to install the right tower

support.

4. Position the bent lever rod into the tower and secure

with a screw (Fig. 211).

Fig 211 PICT-7188a

6. Install the hour meter into the tower (Fig. 213).

Fig 213 PICT-7184

7. Position the deck engage handle into the tower by

routing it in through the back side of the tower (Fig.

214).

5. Install the ignition switch module into the tower (Fig.

212).

Fig 212 PICT-7186

Fig 214 PICT-7195

3-54 LX Lawn Tractor Service Manual

Page 69

CHASSIS

8. Install the PTO knob onto the deck engage handle

(Fig. 215).

Fig 215 PICT-7179a

9. Position the tower assembly so that the 2 tabs on

the lower rear corners of the tower are slid under the

2 loose bolts on the frame (Fig. 216).

10. Tighten the 2 bolts to secure the lower rear corners

of the tower to the frame (Fig. 217).

3

Fig 217 PICT-7174

11. Install 2 screws to secure the lower front corners of

the tower to the frame (Fig. 218).

Fig 216 PICT-7197

Fig 218 PICT-7173

3-55LX Lawn Tractor Service Manual

Page 70

CHASSIS

3

12. Install the screws securing the top of the tower to the

top of the tower support brackets (Fig. 219).

Fig 219 PICT-7172

13. Position the cruise control rod into the cruise control

lever (Fig. 220).

14. Install a cotter pin to secure the rod to the cruise

control lever (Fig. 221).

Fig 221 PICT-7169

15. Position the park brake rod into the park brake lever

(Fig. 222).

Fig 220 PICT-7170

3-56 LX Lawn Tractor Service Manual

Fig 222 PICT-7168

Page 71

CHASSIS

16. Install a cotter pin to secure the park brake rod to the

park brake lever (Fig. 223).

Fig 223 PICT-7166

17. Insert the two bolts on the deck engagement handle

assembly into the PTO engage lever (manual PTO

models) (Fig. 224).

18. Assemble the stop bracket onto the deck engagement handle bolts (manual PTO models) (Fig. 225).

3

Fig 225 PICT-7164a

19. Install 2 nuts securing the deck engagement handle

assembly and stop bracket to the PTO engage lever

(manual PTO models) (Fig. 226).

Fig 224 PICT-7201

Fig 226 PICT-7200

3-57LX Lawn Tractor Service Manual

Page 72

CHASSIS

3

20. Position the throttle/choke assembly into the slot in

the tower (Fig. 227).

Fig 227 PICT-7206

21. Install 2 screws to secure the throttle/choke assembly to the tower (Fig. 228).

22. Slide the control knob onto the throttle/choke

assembly (Fig. 229).

Fig 229 PICT-7208

23. Install the bolt and nut securing the control knob to

the throttle/choke assembly (Fig. 230).

Fig 228 PICT-7156

3-58 LX Lawn Tractor Service Manual

Fig 230 PICT-7154

Page 73

CHASSIS

24. Install the throttle decal onto the tower (Fig. 231).

Fig 231 PICT-7153

25. Install the fuse holder into the dash support (Fig.

232).

26. Plug the ignition switch into the wire harness (Fig.

233).

3

Fig 233 PICT-7150

27. Connect the ignition module to the wire harness (Fig.

234).

Fig 232 PICT-7210

Fig 234 PICT-7149

3-59LX Lawn Tractor Service Manual

Page 74

CHASSIS

3

28. Electric PTO models: Plug the electric PTO switch

plug into the switch (Fig. 235).

Fig 235 PICT-9826

29. Plug the hour meter into the wire harness (Fig. 236).

30. Position the fuel tank into the engine compartment

(Fig. 237).

Fig 237 PICT-7146a

31. Install two screws securing the fuel tank support

rods to the dash supports (Fig. 238).

Fig 236 PICT-7148

3-60 LX Lawn Tractor Service Manual

Fig 238 PICT-7144

Page 75

CHASSIS

32. Install the fender. Refer to “Fender Replacement Installation” on page 3-39.

33. Connect the fuel line to the fuel fi lter and secure in

place with a hose clamp (Fig. 239).

Fig 239 PICT-7094

35. Install the washer and secure the steering wheel to

the steering shaft with a bolt (Fig. 241).

3

Fig 241 PICT-7142

36. Install the steering wheel cap (Fig. 242).

34. With the front wheels pointing straight ahead, position the steering wheel onto the steering shaft (Fig.

240).

Fig 240 PICT-7143

Fig 242 PICT-7106

37. Start the machine.

38. Operate all controls and test the interlock system to

ensure proper operation.

3-61LX Lawn Tractor Service Manual

Page 76

CHASSIS

3

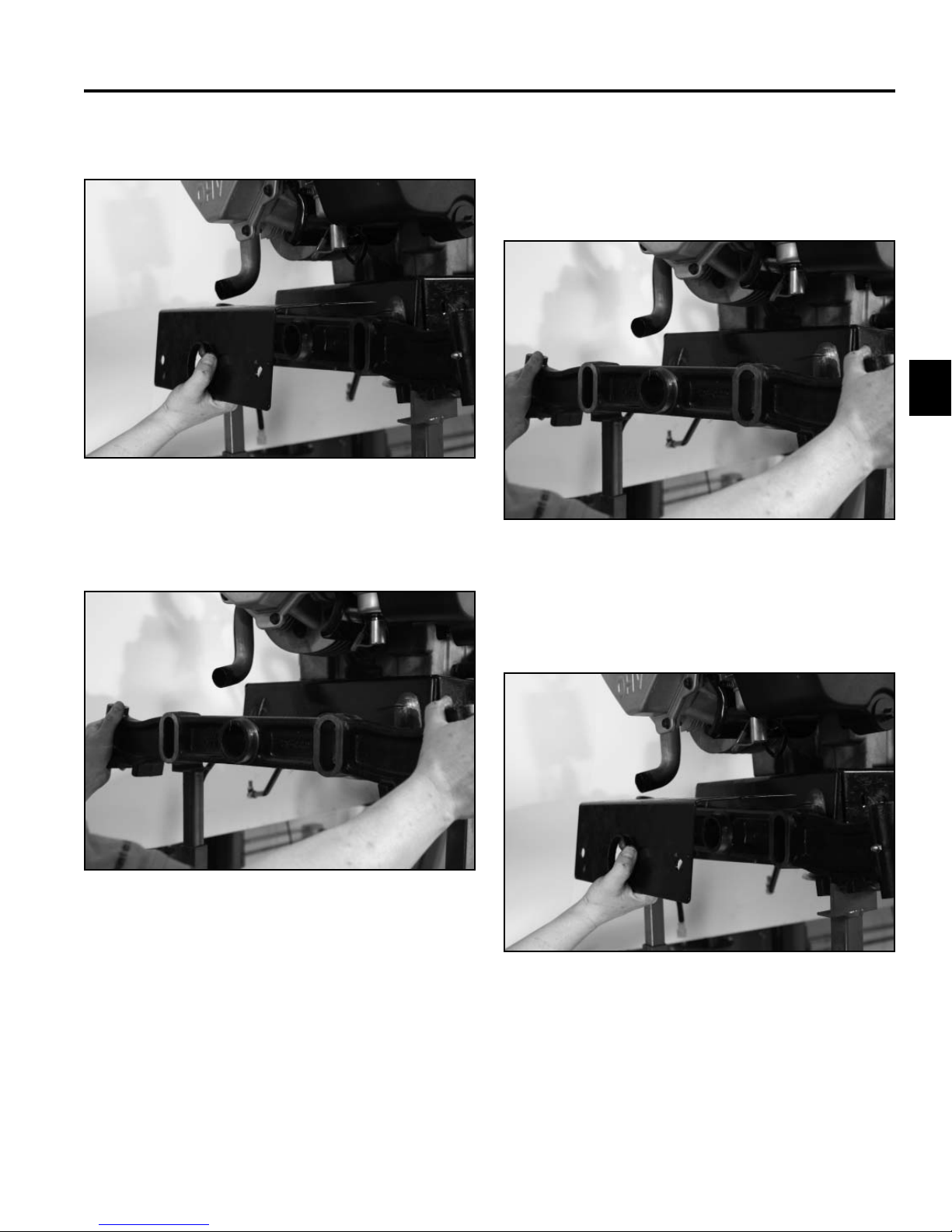

Lower Transmission Drive Belt

Replacement - Gear Drive Models

Removal

1. Remove the mower deck: 42” deck on page 7-64;

46” deck on page 7-69; 50” deck on page 7-74.

2. Remove the upper transmission drive belt. See

“Upper Transmission Drive Belt Replacement Removal” on page 3-67.

3. Electric PTO models: Remove the electric PTO

clutch. Refer to “Electric PTO Clutch Replacement Removal” on page 3-27.

4. Raise the machine to access the belt.

5. Remove the bolt securing the belt keeper rod to the

chassis (Fig. 243).

6. Remove the belt keeper rod (Fig. 244).

Fig 244 PICT-7301

7. Secure the engine pulley and remove the crankshaft

bolt and washer (Fig. 245).

Fig 243 PICT-7296

3-62 LX Lawn Tractor Service Manual

Fig 245 PICT-7302

Page 77

CHASSIS

8. While sliding the pulley off the crankshaft, slip the

lower transmission drive belt off the pulley (Fig. 246).

Fig 246 PICT-7305

9. Remove the pulley from the crankshaft (Fig. 247).

10. Electric PTO models: Slide the engine pulley off

the crankshaft. While sliding the pulley off the crankshaft remove the belt from the pulley. (Fig. 248).

3

Fig 248 PICT-7305

11. Remove the belt guide (bolt and spacer) from the

frame. It must be accessed through the steering

support bracket (Fig. 249).

Fig 247 PICT-7306

Fig 249 PICT-7308

3-63LX Lawn Tractor Service Manual

Page 78

CHASSIS

3

12. Remove the belt from around the crankshaft and

feed it back toward the rear of the machine, removing it from the double idler pulleys (Fig. 250).

Fig 250 PICT-7309

13. Remove the lower transmission drive belt from the

variable speed pulley and pull it out of the machine

(Fig. 251).

Installation

1. Route the lower transmission drive belt into the

variable speed pulley by lifting up on the middle

section of the pulley and placing the belt into the

lower groove of the pulley (Fig. 252).

Fig 252 PICT-7312

2. Continue routing the belt forward above the steering

support bracket and then up around the crankshaft

(Fig. 253).

Fig 251 PICT-7311

3-64 LX Lawn Tractor Service Manual

Fig 253 PICT-7314

Page 79

CHASSIS

3. Apply anti-seize compound to the crankshaft (Fig.

254).

Fig 254 PICT-7315

4. Electric PTO models: Slide the engine pulley onto

the crankshaft. While sliding the pulley up, route the

belt around the pulley (Fig. 255).

5. While sliding the engine pulley onto the crankshaft,

slip the lower transmission drive belt onto the engine

pulley (Fig. 256).

3

Fig 256 PICT-7317

6. Install the crankshaft bolt and washer securing the

engine pulley to the crankshaft. Torque the bolt to

37.5 to 50 ft-lbs. (50.84 to 67.79 Nm) (Fig. 257).

Fig 255 PICT-9828

Fig 257 PICT-7328

3-65LX Lawn Tractor Service Manual

Page 80

CHASSIS

3

7. Install the rod end of the keeper rod into the frame.

Secure the keeper rod by installing a bolt through

the loop end and into the frame (Fig. 258).

Fig 258 PICT-7318

8. Install the belt guide (bolt and spacer) to the frame

through the steering support bracket. Ensure the belt

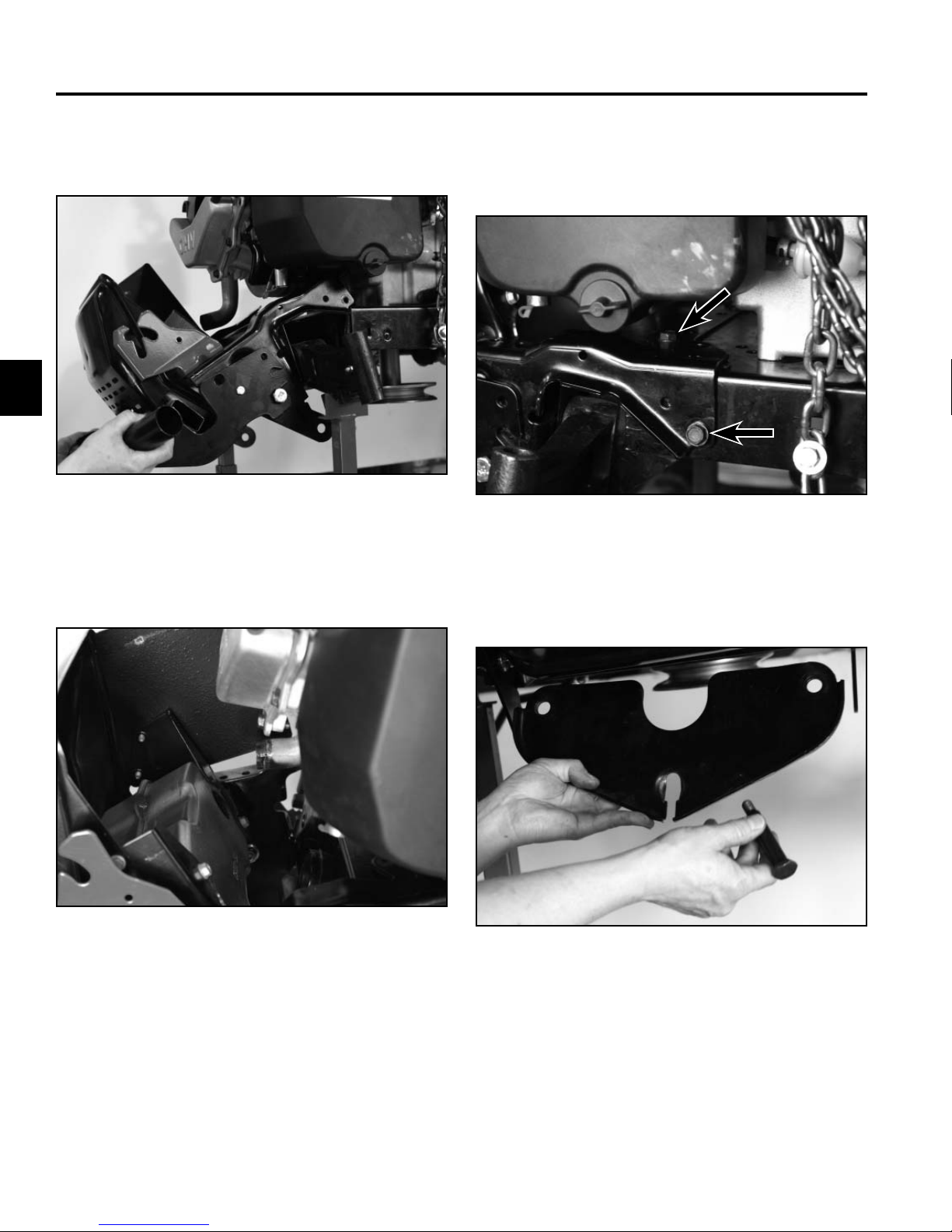

is routed to the right of the belt guide (Fig. 259).

9. Route the belt around the double idler pulleys (Fig.

260).

Fig 260 PICT-7332

10. Electric PTO models: Install the electric PTO

clutch onto the crankshaft. Refer to “Electric PTO

Clutch Replacement - Installation” on page 3-28.

11. Lower the machine.

Fig 259 PICT-7331

12. Install the upper transmission drive belt. See “Upper

Transmission Drive Belt Replacement - Installation”

on page 3-69.

13. Install the mower deck: 42” deck on page 7-67; 46”

deck on page 7-72; 50” deck on page 7-76.

3-66 LX Lawn Tractor Service Manual

Page 81

CHASSIS

Upper Transmission Drive Belt

Replacement - Gear Drive Models

The mower deck has been removed for photo purposes.

Removal

1. Disconnect the negative battery cable and then the

positive battery cable.

2. Remove the battery hold down strap (Fig. 261).

3. Remove the battery from battery compartment (Fig.

262).

3

Fig 262 PICT-7276

4. Remove the battery tray (Fig. 263).

Fig 261 PICT-7109a

Fig 263 PICT-7277

3-67LX Lawn Tractor Service Manual

Page 82

CHASSIS

A

A

3

5. Place a strap around the idler arm. Pull on the strap

and secure it so that tension is released from the

belt (Fig. 264).

A

Fig 264 PICT-7280

A. Strapped idler arm

7. Remove the transmission pulley from the transmission (Fig. 266).

Fig 266 PICT-7283

8. Remove the belt from the top groove of the variable

speed pulley (Fig. 267).

6. Using a screwdriver, secure the transmission pulley

through the vent hole. Remove the nut that secures

the transmission pulley to the transmission (Fig.

265).

A

Fig 265 PICT-7282

A. Screwdriver

Fig 267 PICT-7287a

3-68 LX Lawn Tractor Service Manual

Page 83

CHASSIS

9. Remove the upper transmission drive belt from the

idler pulley and remove it from the machine (Fig.

268).

Fig 268 PICT-7284

Installation

1. Secure the idler arm with a strap so the belt will not

be under tension during installation. Install the upper

transmission drive belt onto the idler pulley (Fig.

269).

2. Route the belt into the top groove of the variable

speed pulley (Fig. 270).

3

Fig 270 PICT-7287a

3. Position the transmission pulley above the transmission and rout the upper transmission belt around

it. Engage the grooves in the pulley with the splines

of the transmission pulley hub (Fig. 271).

Fig 269 PICT-7286a

Fig 271 PICT-7289a

3-69LX Lawn Tractor Service Manual

Page 84

CHASSIS

A

3

4. With a screwdriver inserted through the pulley vent

hole, secure the transmission pulley to the transmission with a nut. Torque the nut to 35-33 ft-lbs.

(33.9-44.7 Nm) (Fig. 272).

A

Fig 272 PICT-7282

A. Screwdriver

7. Place the battery into the battery compartment (Fig.

274).

Fig 274 PICT-7276

8. Install the battery hold down strap (Fig. 275).

5. Remove the strap securing the idler pulley.

6. Install the battery tray (Fig. 273).

Fig 273 PICT-7277

Fig 275 PICT-7497

9. Connect the positive battery cable and then the

negative battery cable.

3-70 LX Lawn Tractor Service Manual

Page 85

CHASSIS

Transmission Drive Belt (Hydro)

Replacement

Removal

1. Remove the mower deck. Refer to “46” Mower Deck

Removal” on page 7-69.

2. Disconnect the negative battery cable (Fig. 276).

4. Remove the battery hold down strap (Fig. 278).

3

Fig 278 PICT-7109a

5. Lift the battery out of the battery tray (Fig. 279).

Fig 276 PICT-7494

3. Disconnect the positive battery cable (Fig. 277).

Fig 277 PICT-7495

Fig 279 PICT-7499

3-71LX Lawn Tractor Service Manual

Page 86

CHASSIS

A

3

6. Remove the battery tray (Fig. 280).

Fig 280 PICT-7500

7. Remove tension from the center double idler bracket

and remove the transmission drive belt from the idler

pulley (Fig. 281).

8. Remove the transmission drive belt from the fi xed V

idler (Fig. 282).

Fig 282 PICT-7508

9. Secure the engine pulley and remove the bolt and

washer retaining it to the crankshaft (Fig. 283).

A

Fig 281 PICT-7505

A. Spring removal tool

3-72 LX Lawn Tractor Service Manual

Fig 283 PICT-7507

Page 87

CHASSIS

10. Begin sliding the engine pulley down the crankshaft

and remove the transmission drive belt from the

pulley (Fig. 284).

Fig 284 PICT-7510

11. Remove the transmission drive belt from around the

crankshaft (Fig. 285).

12. Remove the transmission drive belt from above the

steering support bracket (Fig. 286).

3

Fig 286 PICT-7515

13. Remove the transmission drive belt from around the

transmission pulley and fan and remove it from the

machine (Fig. 287).

Fig 285 PICT-7514

Fig 287 PICT-7518

3-73LX Lawn Tractor Service Manual

Page 88

CHASSIS

3

Installation

1. Position the transmission belt around the transmission fan pulley (Fig. 288).

Fig 288 PICT-7583

2. Route the belt between the frame and the steering

support bracket (Fig. 289).

3. Continue routing the belt forward and position it

around the crankshaft (Fig. 290).

Fig 290 PICT-7314

4. Apply anti-seize compound to the crankshaft (Fig.

291).

Fig 289 PICT-7587

3-74 LX Lawn Tractor Service Manual

Fig 291 PICT-7589

Page 89

CHASSIS

5. Align the key of the engine pulley with the keyway

on the crankshaft. Slide the engine pulley onto the

crankshaft and install the transmission belt onto the

pulley (Fig. 292).

Fig 292 PICT-7590

6. Install a bolt and washer to secure the engine pulley

to the crankshaft and torque to 37.5 to 50 ft-lbs.

(50.84 to 67.79 Nm) (Fig. 293).

7. Route the transmission drive belt around the fi xed

V-idler pulley (Fig. 294).

3

Fig 294 PICT-7594

8. Remove tension from the center double idler bracket

and install the transmission drive belt around the

idlers (Fig. 295).

Fig 293 PICT-7328

Fig 295 PICT-7595

3-75LX Lawn Tractor Service Manual

Page 90

CHASSIS

3

9. Install the mower deck. Refer to “46” Mower Deck

Installation” on page 7-72.

10. Install the battery tray (Fig. 296).

Fig 296 PICT-7500

12. Install the battery hold down strap (Fig. 298).

Fig 298 PICT-7497

13. Connect the positive battery cable (Fig. 299).

11. Position the battery into the battery tray (Fig. 297).

Fig 297 PICT-7499

Fig 299 PICT-7495

3-76 LX Lawn Tractor Service Manual

Page 91

CHASSIS

14. Connect the negative battery cable (Fig. 300).

Fig 300 PICT-7494

15. Purge the system. Refer to “Purging the System” on

page 3-82.

Removal

1. Disconnect the negative battery cable and then the

positive battery cable.

2. Remove the battery hold down strap (Fig. 301).

3

Fig 301 PICT-7109a

16. Check the neutral adjustment. Refer to “Neutral

Adjustment” on page 3-84.

17. Check the brake adjustment. Refer to “Brake Adjustment” on page 3-91.

Variable Speed Pulley Replacement

The mower deck has been removed for photo purposes.

3. Remove the battery from battery compartment (Fig.

302).

Fig 302 PICT-7276

3-77LX Lawn Tractor Service Manual

Page 92

CHASSIS

A

3

4. Remove the battery tray (Fig. 303).

Fig 303 PICT-7277

5. Place a strap around the idler arm. Pull on the strap

and secure it so that tension is released from the

belt (Fig. 304).

6. Slip both the lower and upper belts off the variable

speed pulley (Fig. 305).

Fig 305 PICT-7346

7. Remove the 2 screws securing the variable speed

pulley to the frame (Fig. 306).

A

Fig 304 PICT-7280

A. Strapped idler arm

Fig 306 PICT-7333a

3-78 LX Lawn Tractor Service Manual

Page 93

CHASSIS

8. Slide the variable speed pulley off the transmission

shaft (Fig. 307).

Fig 307 PICT-7339

Installation

1. Place the variable speed pulley onto the transmission shaft and install the upper and lower belts onto

the pulley (Fig. 308).

2. Position the variable speed pulley with the bracket

up against the frame and install the 2 bolts (Fig.

309).

3

Fig 309 PICT-7333a

3. Release the strapped idler arm making sure the belt

is in the idler pulley groove (Fig. 310).

Fig 308 PICT-7346

Fig 310 PICT-7280

3-79LX Lawn Tractor Service Manual

Page 94

CHASSIS

3

4. Install the battery tray (Fig. 311).

Fig 311 PICT-7277

5. Place the battery into the battery compartment (Fig.

312).

6. Install the battery hold down strap (Fig. 313).

Fig 313 PICT-7497

7. Connect the positive battery cable (Fig. 314).

Fig 312 PICT-7276

3-80 LX Lawn Tractor Service Manual

Fig 314 PICT-7495

Page 95

CHASSIS

8. Connect the negative battery cable (Fig. 315).

Fig 315 PICT-7494

Variable Speed Pulley Service

2. Remove the 3 bolts securing the bearing cup to the

pulley bracket (Fig. 317).

3

Fig 317 PICT-7342

3. Remove the bearing cup (Fig. 318).

Disassembly

1. Remove the center bolt and washer securing the

bearings to the pulley shaft (Fig. 316).

Fig 316 PICT-7340

Fig 318 PICT-7343

3-81LX Lawn Tractor Service Manual

Page 96

CHASSIS

3

4. Remove the 2 ball bearings (Fig. 319).

Fig 319 PICT-7344

5. Remove the pulley bracket (Fig. 320).

Assembly

Assemble the variable speed pulley assembly in reverse

order of disassembly.

Purging the System - Hydrostatic

Models

Due to the effect air has on effi ciency in hydrostatic

drive applications, it is critical that it be purged from the

system.

These purge procedures should be implemented any

time a hydrostatic system has been opened to facilitate

maintenance or any additional oil has been added to the

system.

Air creates ineffi ciency because its compression and

expansion rate is higher than the oil in hydrostatic drive

systems.

The resulting symptoms in hydrostatic systems may be:

Fig 320 PICT-7345

6. Inspect the bearings for wear and damage. Replace

if necessary.

1. Noisy operation

2. Lack of power or drive after short term operation

3. High operation temperature and excessive expansion of oil

3-82 LX Lawn Tractor Service Manual

Page 97

CHASSIS

Before starting, make sure the transaxle is at the specifi ed oil level (Fig. 321).

A

BC

Fig 321 fi g. 4 310-0510 IHTa

A. Fill port C. 1-1/4” (31.75mm) max.

B. Oil level depth at 50º-100º F

(10º-38º C)

Fluid Change - Hydrostatic Models

The Hydro-Gear transaxle is factory fi lled, sealed and

does not require oil maintenance. However, in the event

of oil contamination or degradation, oil replacement

may correct certain performance problems. Remove the

transaxle from the vehicle and completely drain the oil

from the top fl uid fi ll port. Refi ll unit as near the top of fi ll

port as is practical. Tipping the unit forward, backward

and from side to side will allow air to escape. The tipping

and fi lling activity may need to be repeated several

times. Refer to the oil fi ll range (Fig. 322).

3

A

BC

The following procedures should be performed with the

vehicle drive wheels off the ground, then repeated under

normal operating conditions.

1. With the bypass valve open and the engine running,

slowly move the directional control (foot control) in

both forward and reverse directions 5 to 6 times; as

air is purged from the unit, the oil level will drop.

2. With the bypass valve in the closed position and the

engine running, slowly move the directional control

valve (foot control) in both forward and reverse

directions 5 to 6 times. After stopping the engine,

check the oil level and add oil as required.

3. It may be necessary to repeat Steps 1 and 2 until all

the air is completely purged from the system. When

the transaxle moves forward and reverse at normal

speed purging is complete.

A. Fill port C. 1-1/4” (31.75mm) max.

B. Oil level depth at 50º-100º F

(10º-38º C)

Reinstall transaxle and perform purging procedures.

If the oil drained from the transaxle is severely

contaminated or overheated, the transaxle should be

disassembled for inspection, cleaning, and repair, as

needed.

Fluid Description Volume

20W-50 engine oil 79 fl . oz. (2336ml)

Fig 322 fi g. 4 310-0510 IHTa

3-83LX Lawn Tractor Service Manual

Page 98

CHASSIS

A

3

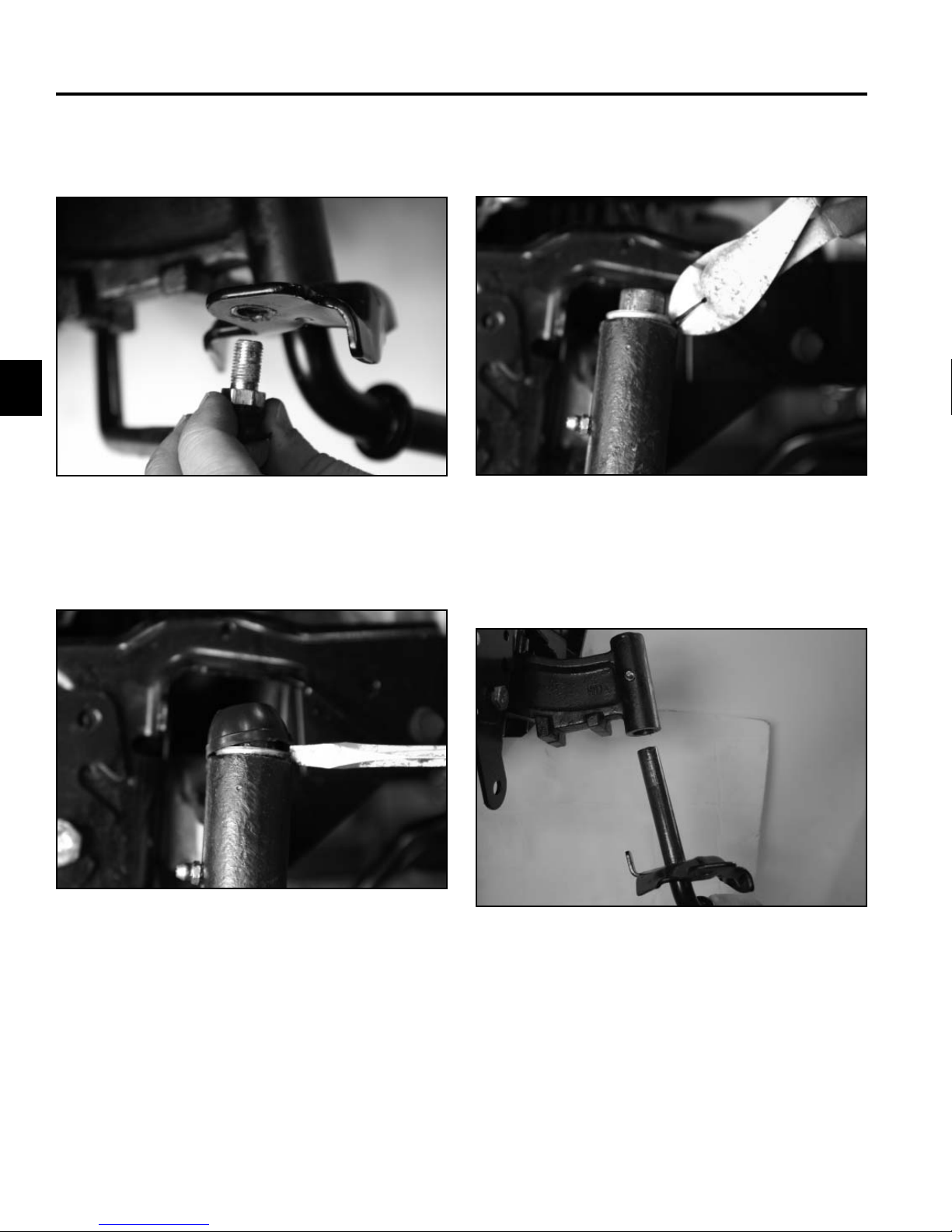

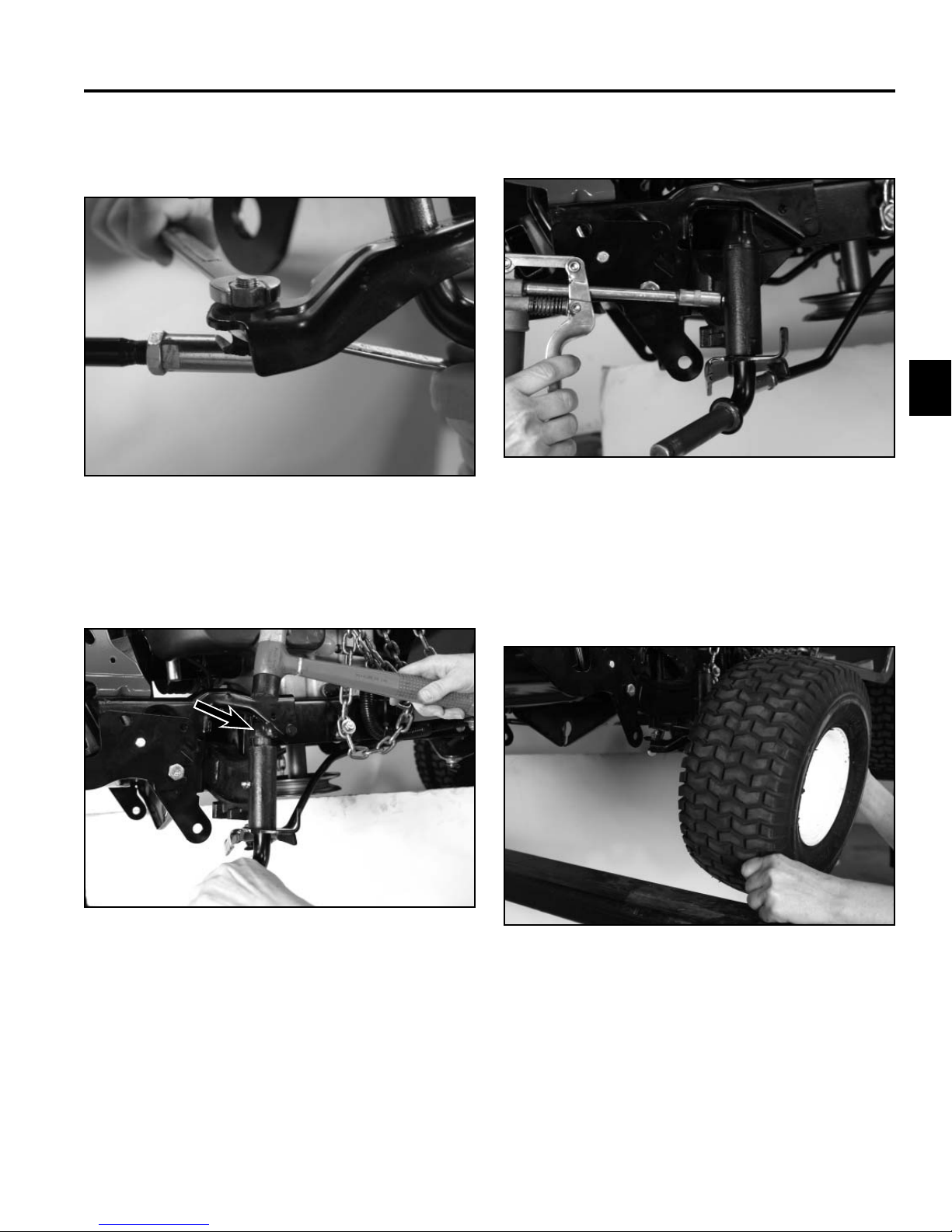

Neutral Adjustment - Hydrostatic

Models

Before making a neutral adjustment, the transmission

must be warmed up for at least 10 minutes.

1. Loosen the bolt and washer retaining the right side

wheel to the right side axle (Fig. 323).

Fig 323 PICT-7221

3. Remove the bolt, washer and wheel assembly from

the right axle (Fig. 324).

Fig 324 PICT-7597

4. Locate the neutral adjusting puck and loosen the

Allen head bolt. If it’s diffi cult to loosen, heat the

aluminum housing near the bolt with a propane torch

(Fig. 325).

2. Raise and support the right rear end of the tractor to

permit removing the right rear tire. Make sure the left

rear tire stays on the ground.

A

Fig 325 PICT-7599

A. Adjusting puck

3-84 LX Lawn Tractor Service Manual

Page 99

CHASSIS

5. Start the engine and run it at full throttle.

6. Rotate the adjusting puck in both directions and

watch the axle direction. Adjust the puck so it is set

at the midpoint between forward and reverse axle

rotation. Make sure the axle is not moving.

7. Once in neutral, hold the puck with an adjustable

wrench so it won’t move. Tighten the Allen head bolt

(Fig. 326).

Front Wheel Toe-in Measurement

If there is uneven tire wear, lawn scuffi ng, or hard steer-

ing, toe-in may need to be adjusted. The front toe-in