Page 1

FormNo.3363-985RevA

G132Rear-EngineRidingMower

H132Rear-EngineRidingMower

ModelNo.70185—SerialNo.310000001andUp

ModelNo.70186—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Thisrotary-blade,ridinglawnmowerisintendedto

beusedbyresidentialhomeowners.Itisdesigned

primarilyforcuttinggrassonwell-maintained

lawnsonresidentialproperties.Itisnotdesigned

forcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .

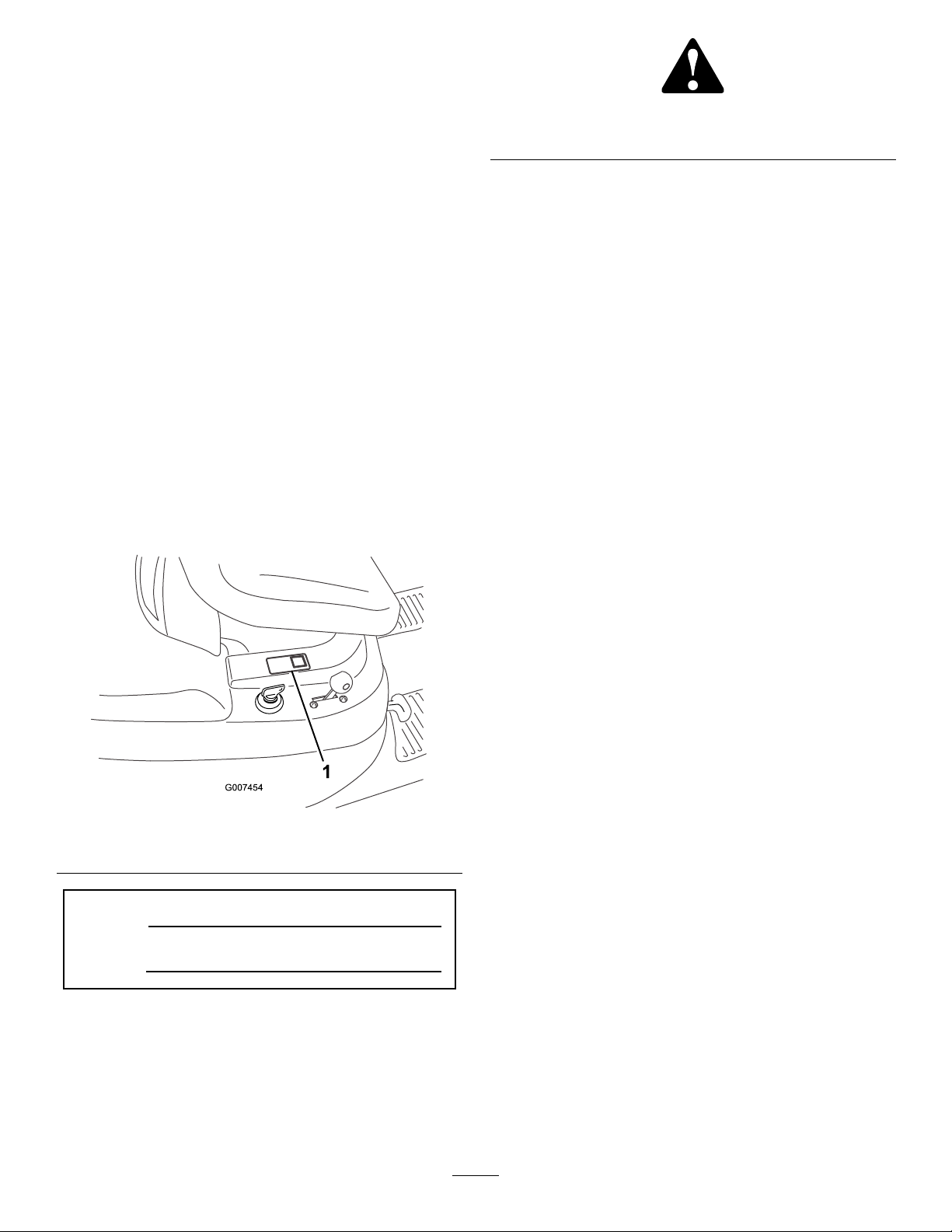

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroRidingMowerSafety....................................5

SoundPressure.....................................................5

SoundPower........................................................5

Vibration..............................................................5

SlopeIndicator.....................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................10

Controls.............................................................10

Specications.....................................................11

Operation...................................................................12

AddingFuel.......................................................12

CheckingtheEngineOilLevel............................13

StartingtheEngine.............................................13

StoppingtheEngine...........................................14

DrivingtheMachineForwardor

Backward.......................................................14

SelectingGroundSpeeds....................................14

DrivingtheMachineForwardor

Backward.......................................................14

StoppingtheMachine.........................................15

PushingtheMachineManually............................15

UsingtheSafetyInterlockSystem.......................15

TestingtheSafetyInterlockSystem.....................17

TestingtheSafetyInterlockSystem.....................17

EmptyingtheGrassCollector.............................18

InstallingtheRecyclerCover...............................18

InstallingtheDischargeChute............................19

OperatingTips...................................................20

Maintenance...............................................................21

RecommendedMaintenanceSchedule(s)................21

Lubrication.............................................................21

GreasingandLubricatingtheMachine................21

EngineMaintenance...............................................21

ServicingtheEngineOil.....................................21

ServicingtheAirCleaner....................................23

ServicingtheSparkPlug.....................................23

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedinItaly

AllRightsReserved

Page 3

FuelSystemMaintenance.......................................25

DrainingtheFuelTank.......................................25

ReplacingtheFuelFilter.....................................25

ElectricalSystemMaintenance................................26

ServicingtheBattery...........................................26

ServicingtheFuses.............................................27

BrakeMaintenance.................................................28

CheckingtheParkingBrake................................28

CheckingtheTirePressure.................................28

BladeMaintenance.................................................28

ServicingtheBlade.............................................28

LevelingtheMower............................................29

Cleaning.................................................................30

WashingundertheMower..................................30

WashingtheMachine..........................................31

Storage.......................................................................31

CleaningandStorage..........................................31

Troubleshooting.........................................................33

Schematics.................................................................35

..........................................................................39

ConditionsandProductsCovered.......................40

LimitedWarrantyforCommercialUse................40

InstructionsforObtainingWarranty

Service...........................................................40

OwnerResponsibilities.......................................40

ItemsandConditionsNotCovered.....................40

GeneralConditions............................................40

Safety

ThismachinemeetsorexceedsEuropeanStandardsin

effectatthetimeofproduction.However,improper

useormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,W ARNING,orDANGER-"personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulations

canrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessional

andpracticalinstruction.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

controllevers.Themainreasonsforlossof

controlare:

◊insufcientwheelgrip,especiallyonwet

grass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

3

Page 4

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning–Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

Operation

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutchesandshiftintoneutral.

•Donotuseonslopesgreaterthan15degrees.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–-donotstoporstartsuddenlywhenonaslope;

–-useslowspeedsonslopesandduringtight

turns;

–-stayalertforhumpsandhollowsandother

hiddenhazards;

•Usecarewhenpullingloadsorusingheavy

equipment.

–-Useonlyapproveddrawbarhitchpoints.

–-Limitloadstothoseyoucansafelycontrol.

–-Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey .

•Disengagedrivetoattachments,stoptheengine,

anddisconnectthesparkplugwire(s)orremovethe

ignitionkey

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthelawn

mower;

–afterstrikingaforeignobject.Inspectthelawn

mowerfordamageandmakerepairsbefore

restartingandoperatingtheequipment;ifthe

machinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

4

Page 5

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumescanreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeof

grass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety .

•Ifthefueltankhastobedrained,thisshouldbe

doneoutdoors.

•Onmulti-bladedmachines,takecareasrotatingone

bladecancauseotherbladestorotate.

•Whenmachineistobeparked,storedorleft

unattended,lowerthecuttingmeansunlessapositive

mechanicallockisused.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichis

anodorless,deadlypoisonthatcankillyou.Donot

runengineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’s

earof86dBA,whichincludesanUncertaintyValue(K)

of1dBA.Thesoundpressurelevelwasdetermined

accordingtotheproceduresoutlinedinEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof100

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

•UseonlyToro-approvedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

Vibration

Hand-Arm

•Measuredvibrationlevelforlefthand=1.9m/s

•Measuredvibrationlevelforrighthand=2.2m/s

•UncertaintyValue(K)=1.1m/s

Themeasuredvaluewasdeterminedaccordingtothe

proceduresoutlinedinEN836.

5

2

2

2

Page 6

WholeBody

•Measuredvibrationlevel=0.75m/s

•UncertaintyValue(K)=0.37m/s

Themeasuredvaluewasdeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

6

Page 7

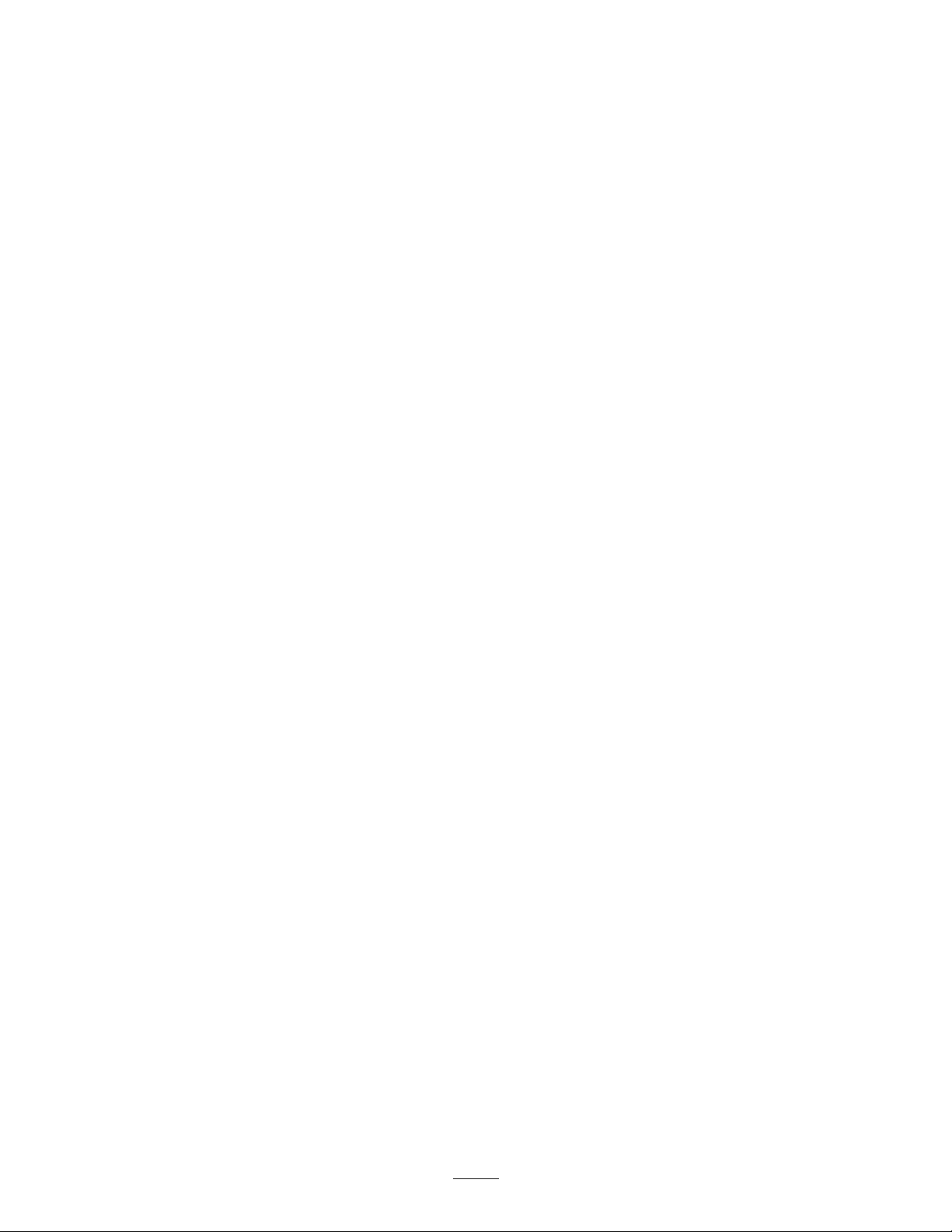

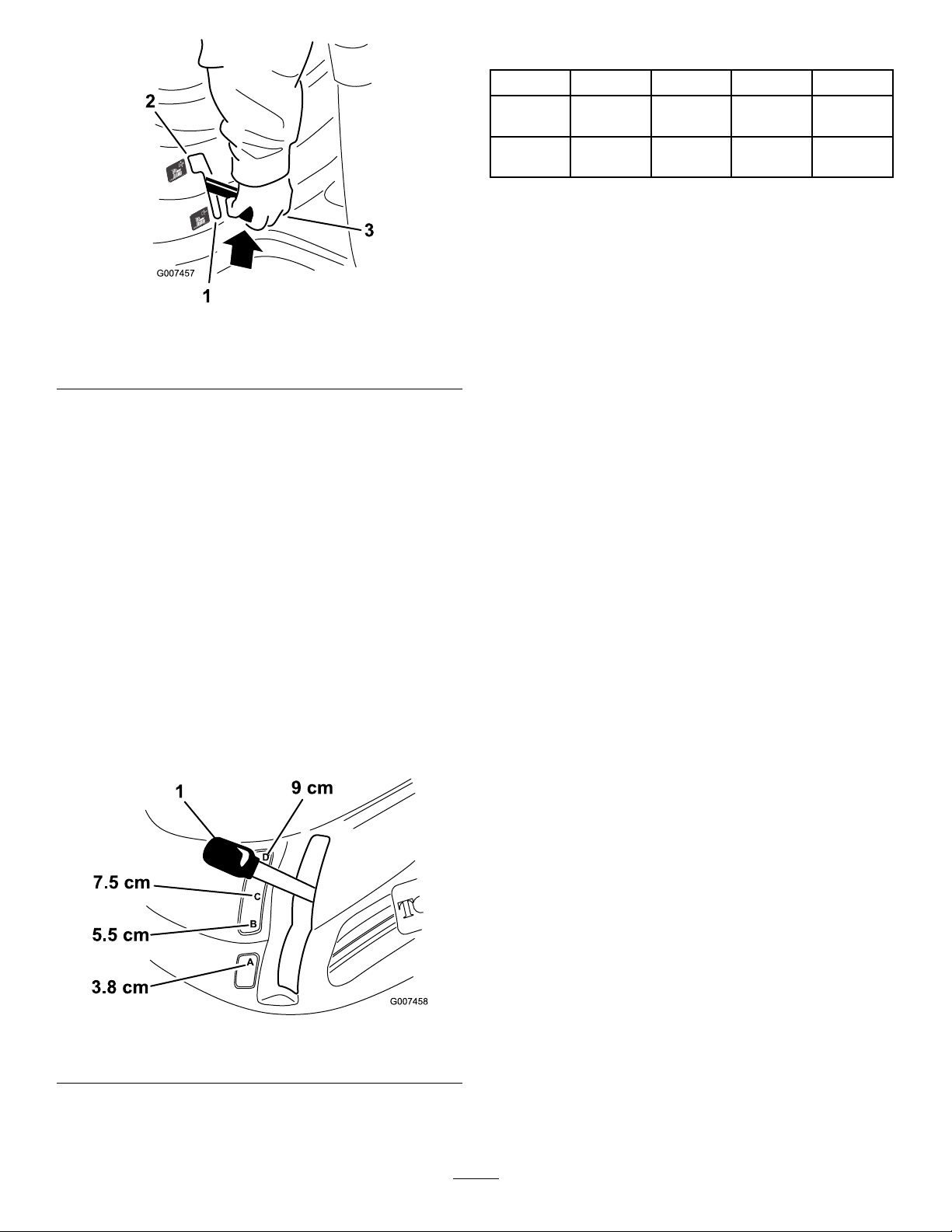

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

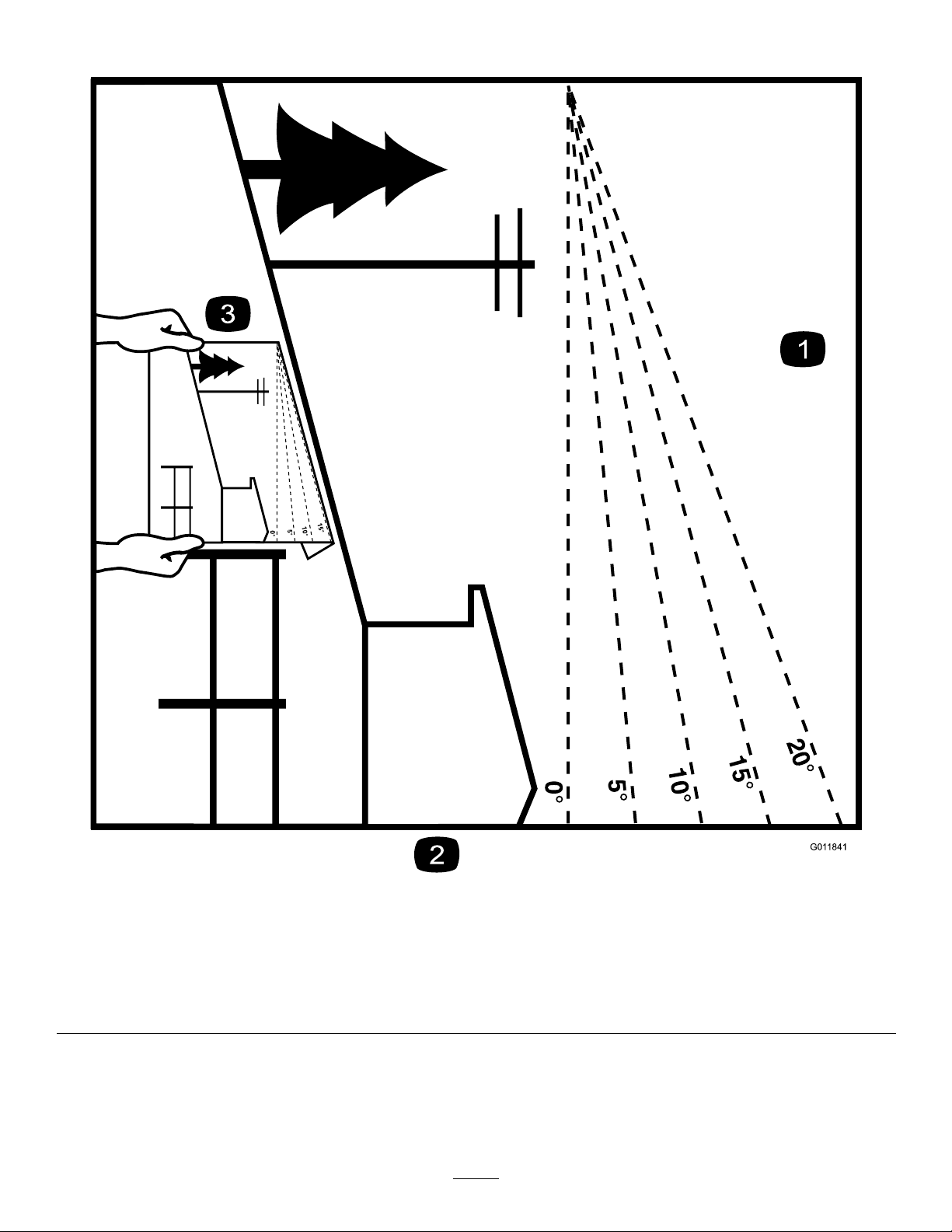

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

99-2986

1.Crushing/dismembermenthazardofbystanders—donot

turnthekeywhilechildrenarepresent;keepchildrenasafe

distancefromthemachine.

105-0529

1.Warning—donottouchthehotsurfaces.

105-0531

1.Disengagethecuttingblade.

105-0532

1.Engagethecuttingblade.

105-0535

1.Grasscollectorfull2.Operatinginreverse

1.Heightofcut

105-0538

1.Transmissionspeeds3.Reverse

2.Neutral

105-0530

8

Page 9

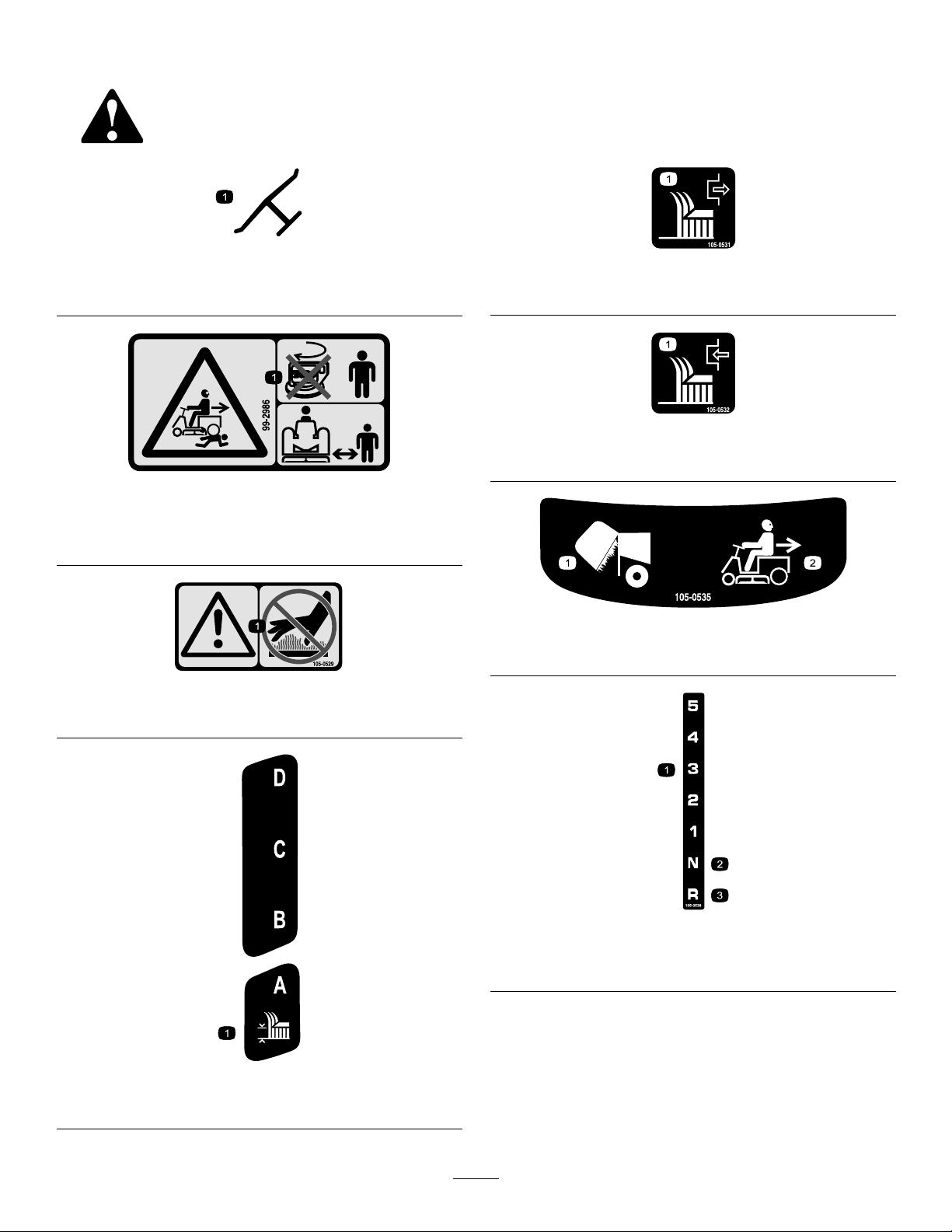

106-1802

1.Warning—readtheOperator’sManual.

2.Cutting/dismembermenthazardofhand—removethe

ignitionkeyandreadtheinstructionsbeforeservicingor

performingmaintenance.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Tippinghazard—donotoperateonslopesgreaterthan10

degrees.

106-2940

1.Warning—donotplaceyouhandsorfeetunderthemower.

106-2943

1.Thrownobjecthazard;cutting/dismembermenthazard—do

notoperatethemachinewiththedischargeopening

uncovered;alwaysoperatethemachinewiththerecycling

cover,reardischargedeector,orgrasscollectorinstalled.

Model70186only

1.Pushtheleverintopushthemachine.

2.Pulltheleverouttodrivethemachine.

1.Turnthekeytomowinreverse.

106-2941

106-2942

9

Page 10

ProductOverview

Note:Thebrakepedalshouldstayinthedepressed

(locked)position.

ReleasingtheParkingBrake

1.Pushdownonthebrakepedal(Figure5)andholdit.

2.Pushtheparkingbrakelever(Figure5)downand

graduallyreleasethebrakepedal.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachineand

aremostcomfortable.

Figure4

1.Throttle

2.Ignitionkey

3.Collectorbin9.Height-of-cutlever

4.Fueltankcap

5.Collectorrod

6.Seat12.Groundspeedpedal

7.KeyChoiceswitch(not

shown)

8.Steeringwheel

10.Bladecontrol(PTO)

11.Brakepedal

Controls

Becomefamiliarwiththecontrolsbeforeyoustartthe

engineandoperatethemachine.

UsingtheParkingBrake

Alwayssettheparkingbrakewheneveryoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

1.Pushthebrakepedaldownandholdit(Figure5).

1.Raisetheseatandloosenthe4bolts(Figure6).

Figure6

1.Bolt(4)

2.Movetheseattothedesiredpositionandtighten

thebolts.

UsingtheBladeControl(PTO)

Thebladecontrol(PTO)leverengagesanddisengages

powertotheblade.

Figure5

1.Brakepedal2.Parkingbrakelever

2.Lifttheparkingbrakelever(Figure5)upand

graduallytakeyourfootoffthebrakepedal.

EngagingtheBlade

1.Depressthebrakepedaltostopthemachine.

2.Slowlyshiftthebladecontrol(PTO)toEngage

Figure7).

(

10

Page 11

Figure7

1.Disengage

2.Engage

3.Bladecontrol(PTO)

DisengagingtheBlade

1.Depressthebrakepedaltostopthemachine.

2.Shiftthebladecontrol(PTO)toDisengage

(Figure7).

Specications

ModelWeightLengthWidthHeight

70185390lb

(177kg)

70186390lb

(177kg)

74in

(188cm)

74in

(188cm)

(86cm)

(86cm)

34in

34in

41in

(104cm)

41in

(104cm)

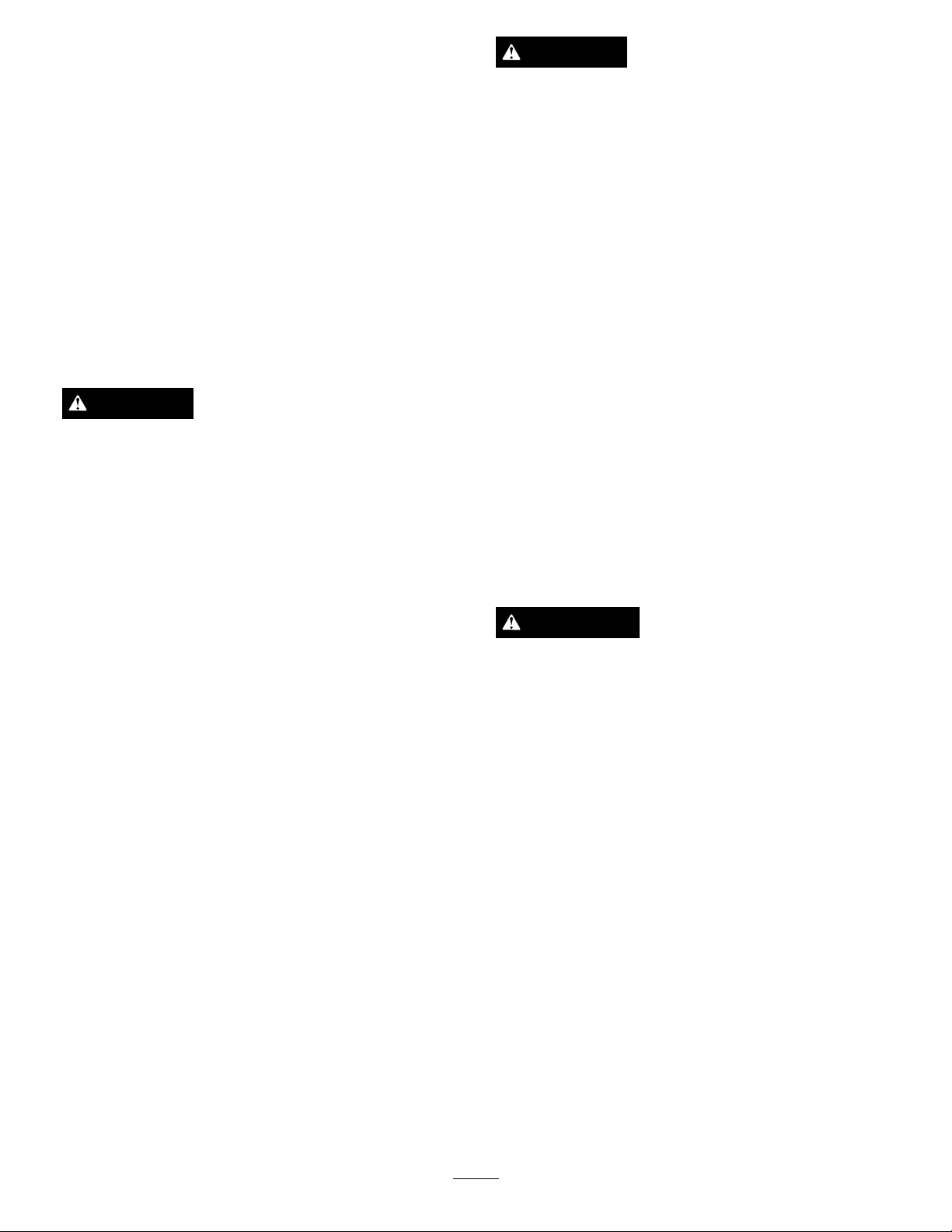

SettingtheHeightofCut

Usetheheight-of-cutlevertoraiseandlowerthemower

tothedesiredcuttingheight.Youcansetthecutting

heightto1of4positionsfromapproximately3.8to9

cm.

1.Disengagethebladecontrol(PTO).

2.Pullontheheight-of-cutlever,moveittothe

desiredposition,andreleaseitslowlyintothenotch

Figure8).

(

1.Height-of-cutlever

Figure8

11

Page 12

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

UseUnleadedRegularGasolinesuitablefor

automotiveuse(85pumpoctaneminimum).Leaded

regulargasolinemaybeusedifunleadedregularisnot

available.

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

12

Page 13

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundeachfueltankcapandremovethecap.

3.Addunleadedregulargasolinetobothfueltanks,

untilthelevelis1/4to1/2inch(6mmto13mm)

belowthebottomofthellerneck.

Thisspaceinthetankallowsgasolinetoexpand.

Donotllthefueltankscompletelyfull.

4.Installfueltankcapssecurely.

5.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

OilLevelinMaintenance.

StartingtheEngine

1.Sitdownontheseat.

2.Settheparkingbrake;refertoSettingtheParking

Brake.

Note:Theenginewillnotstartunlessyouengage

theparkingbrake.

3.ShiftthegroundspeedleverintoNeutral(N)

Figure9).

(

Figure10

1.Disengage

2.Engage

3.Bladecontrol(PTO)

5.ShiftthethrottlelevertoChoke(Figure11).

Figure11

1.Choke3.Slow

2.Fast

Note:Anenginethathasbeenrunningandis

warmmaynotrequirethisstep.

Figure9

1.Groundspeedlever

4.Shiftthebladecontrol(PTO)levertoDisengage

(

Figure10).

6.Turntheignitionkeyclockwiseandholditinthe

Startposition(Figure12).Whentheenginestarts,

releasethekey .

13

Page 14

CAUTION

Suddenlyreleasingtheclutchpedalcould

causeyoutolosecontrolandsuddenlyputthe

machineinmotion.

Alwaysreleasetheclutchpedalslowlywhen

startingthemachineinmotion.

SelectingGroundSpeeds

Figure12

1.Start3.Stop

2.Run

Important:Iftheenginedoesnotstartafter

30secondsofcontinuouscranking,turnthe

ignitionkeytoStopandletthestartermotor

cool;refertoTroubleshooting.

7.Aftertheenginestarts,slowlyshiftthethrottlelever

toFast(

shiftthethrottleleverbacktoChokeforafew

secondsandthenshiftthethrottlelevertoFast.

Repeatthisstepasrequired.

Figure11).Iftheenginestallsorhesitates,

StoppingtheEngine

1.ShiftthethrottlelevertoSlow(Figure11).

2.TurntheignitionkeytoStop(Figure12).

3.Removetheignitionkey.

Model70185only

Important:T oavoidtransmissiondamage,always

depressthebrakepedalbeforeshiftingintoorout

ofReverse.

Alwaysstartthemachineinmotionbydepressingthe

brakepedalandshiftingintothedesiredspeed.Once

themachineisinmotion,youcanshiftintoanyforward

speedwithoutdepressingthebrakepedal.Inmost

conditions,themachineispowerfulenoughtomove

outinanyspeed.Ifitwillnotmoveoutinaselected

speedduetoaheavyload,shifttoalowerspeed.

Important:Donotshiftonslopes.Chooseaslow

speedsothatyouwillnothavetostoporshift

whileontheslope.

DrivingtheMachineForward

orBackward

Model70186only

DrivingtheMachineForward

orBackward

Model70185only

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

2.Depressthebrakepedal.

3.Shiftthegroundspeedlevertothedesiredforward

speedortoReverse.

Note:Asyouslowlyreleasethepedal,themachine

willbegintomove.Steerthemachinewiththe

steeringwheel.

Thethrottlecontrolregulatestheenginespeedas

measuredinRPM(revolutionsperminute).

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake.

2.Placeyourfootonthetractioncontrolpedal.

3.Slowlypressonthetopofthepedaltomovethe

machineforwardoronthebottomofthepedalto

movethemachinebackward.

Note:Thefartheryoumovethetractioncontrol

pedalineitherdirection,thefasterthemachine

movesinthatdirection.Toslowdown,releasethe

pressureonthepedal.Steerthemachinewiththe

steeringwheel.

Important:Toavoidtransmissiondamage,

alwaysreleasetheparkingbrakebeforemoving

thetractioncontrolpedal.

14

Page 15

CAUTION

Suddenlyreleasingthebrakepedalcould

causeyoutolosecontrolandsuddenlyputthe

machineinmotion.

Alwaysreleasethebrakepedalslowlywhen

startingthemachineinmotion.

StoppingtheMachine

1.Depressthebrakepedal(model70185only).

2.ShiftthegroundspeedleverintoNeutral(model

70185only).

3.Releasethetractioncontrolpedal(model70186

only).

4.Disengagethebladecontrol(PTO).

5.TurntheignitionkeytoOfftostoptheengine.

6.Waitforallmovingpartstostop.

7.Settheparkingbrakeifyouleavethemachine

unattended;refertoSettingtheParkingBrake.

8.Removetheignitionkeyfromtheswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

PushingtheMachineManually

Figure13

1.Pushposition

Note:Thisdisengagesthedrivesystemandallows

thewheelstoturnfreely.

6.Lowerthegrasscollector(model70186only).

7.Disengagetheparkingbrake.

Note:Tooperatethemachine:Raisethegrass

collector,slidethedrivecontrolrodtherightand

pullitout,andthenlowerthegrasscollector.

2.Operateposition

UsingtheSafetyInterlock

System

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Important:Alwayspushthemachinemanually.

Nevertowthemachinebecauseyoumaydamage

thetransaxle.

1.ShiftthegroundspeedleverintoNeutral(model

70185only).

2.Disengagetheblade(PTO).

3.Stoptheengineandwaitforallmovingpartsto

stop.

4.Removetheignitionkey.

5.Pushthedrivecontrolrodinandslideittotheleft

tolockitinplace(model70186only)(

Figure13).

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Youaresittingontheseat.

•Thebrakepedalisdepressed.

•Thebladecontrol(PTO)leverisintheDisengage

position.

Thesafetyinterlocksystemisdesignedtostopthe

engineifyoudothefollowing:

•Yourisefromtheseatwhenthebrakepedalis

released.

•Yourisefromtheseatwhenthebladecontrol

(PTO)leverisintheEngageposition.

15

Page 16

•Youshiftintoreversewhilethebladecontrol

(PTO)leverisintheEngagepositionandthe

operating-in-reverseinterlockisnotdeactivated.

•Youremovethegrasscollectororthereardeector

whenthebladecontrol(PTO)leverisintheEngage

position.

DANGER

Youcouldbackoverachildorbystanderwhilethe

mowerbladeorotherattachmentisengagedand

causeseriousinjuryordeath.

•Donotmowinreverseunlessabsolutely

necessary.

SettingtheKeyChoice®Switchto

OperateinReverse

Aninterlockfeatureonthemachinepreventsthepower

take-off(PTO)fromoperatingwhenyoubackupthe

machine.Ifyouputthetractioncontrolpedalinto

ReversewiththePTOengaged(i.e.,withmowerblades

orotherattachmentrunning),theenginewillstop.Do

notmowinreverseunlessitisabsolutelynecessary.

Ifyouneedtousethebladecontrol(PTO)while

backingup,turnofftheinterlockfeatureusingthe

KeyChoiceswitchlocatedneartheseatbracket

Figure14).

(

•DonotinserttheKeyChoicekeyunlessitis

absolutelynecessary.

•Alwayslookbackwardanddownbefore

backingup.

•UsetheKeyChoiceswitchonlyifyouare

certainnochildrenorotherbystanderswill

enterthemowingarea.

•Beveryobservantafterdeactivatingthe

interlockbecausethesoundoftheengine

maypreventyoufromnoticingthatachildor

bystanderhasenteredtheworkarea.

•AlwaysremoveboththeignitionandKeyChoice

keysandputtheminasafeplaceoutofthe

reachofchildrenorunauthorizeduserswhen

leavingtheunitunattended.

1.Engagetheblade(PTO).

2.InserttheKeyChoicekeyintotheswitch(Figure14).

3.TurntheKeyChoicekey .

Note:Aredlightonthefrontconsole(Figure15)

turnson,indicatingthattheinterlockisdisabled.

1.KeyChoiceswitch

Figure14

Figure15

1.Operating-in-reverselight

4.ShiftthegroundspeedleverintoReverseand

completeyourtask(model70185only).

5.PutthetractioncontrolpedalintoReverseand

completeyourtask(model70186only).

16

Page 17

6.Disengagetheblade(PTO)toactivatetheinterlock.

7.RemovetheKeyChoicekeyandputitinasafeplace

outofthereachofchildren.

TestingtheSafetyInterlock

System

Model70185only

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetyinterlocksystem

doesnotoperateasdescribedbelow ,havean

AuthorizedServiceDealerrepairitimmediately.

2.Shiftthebladecontrol(PTO)levertoEngage,sit

ontheseat,androtatetheignitionkeytoStart:

Theengineshouldnotcrank.Ifitdoescrank,the

safetyinterlocksystemismalfunctioningandmust

berepairedbyanAuthorizedServiceDealer.Ifthe

enginedoesnotcrank,gotostep

3.Shiftthebladecontrol(PTO)levertoDisengage,

sitontheseat,depressthebrakeandclutchpedals,

engagetheparkingbrake,shiftthegroundspeed

leverintogear,androtatetheignitionkeytoStart:

Theengineshouldnotcrank.Ifitdoescrank,the

safetyinterlocksystemismalfunctioningandmust

berepairedbyanAuthorizedServiceDealer.Ifthe

enginedoesnotcrank,gotostep

4.Sitontheseat,shiftthegroundspeedleverinto

Neutral,andshiftthebladecontrol(PTO)leverto

Disengage.Ensurethattheparkingbrakeisengaged

androtatetheignitionkeytoStart:Theengine

shouldstartandcontinuetorun.Thenengagethe

bladecontrol(PTO)leverandcarefullyrisefrom

theseat:Theengineshouldstop.Iftheengine

doesnotstoprunning,stoptheengine,waitforall

movingpartstostop,andhavethesafetyinterlock

systemrepairedbyanAuthorizedServiceDealer.If

theenginestopswhenyourisefromtheseat,the

safetyinterlocksystemisfunctioningproperly.

5.Shiftthebladecontrol(PTO)levertoDisengage,

shiftthegroundspeedleverintoNeutral,andstart

theengine.Whiletheengineisrunning,shiftthe

bladecontrol(PTO)levertoEngage,pushinthe

3.

4.

clutch,andshiftthegroundspeedlevertoReverse:

Theengineshouldstop.

6.Shiftthebladecontrol(PTO)levertoDisengage,

shiftthegroundspeedlevertoNeutral,andstart

theengine.Thenshiftthebladecontrol(PTO)lever

toEngageandturntheKeyChoicekeyandrelease

it:TheKeyChoicewarninglightshouldilluminate.

Shiftthebladecontrol(PTO)levertoDisengage:

TheKeyChoicewarninglightshouldturnoff.

TestingtheSafetyInterlock

System

Model70186only

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetyinterlocksystemdoes

notoperateasdescribedbelow ,haveanAuthorized

ServiceDealerrepairitimmediately.

1.Shiftthebladecontrol(PTO)levertoEngage,sit

ontheseat,androtatetheignitionkeytoStart:

Theengineshouldnotcrank.Ifitdoescrank,the

safetyinterlocksystemismalfunctioningandmust

berepairedbyanAuthorizedServiceDealer.Ifthe

enginedoesnotcrank,gotostep

2.Shiftthebladecontrol(PTO)levertoDisengage,

sitontheseat,depressthebrakepedal,engagethe

parkingbrake,androtatetheignitionkeytoStart:

Theengineshouldnotcrank.Ifitdoescrank,the

safetyinterlocksystemismalfunctioningandmust

berepairedbyanAuthorizedServiceDealer.Ifthe

enginedoesnotcrank,gotostep

3.Sitontheseat,putthetractioncontrolpedalinto

Neutral,andshiftthebladecontrol(PTO)leverto

Disengage.Ensurethattheparkingbrakeisengaged

androtatetheignitionkeytoStart:Theengine

shouldstartandcontinuetorun.Thenengagethe

bladecontrol(PTO)leverandcarefullyrisefrom

theseat:Theengineshouldstop.Iftheengine

doesnotstoprunning,stoptheengine,waitforall

movingpartstostop,andhavethesafetyinterlock

systemrepairedbyanAuthorizedServiceDealer.If

2.

3.

17

Page 18

theenginestopswhenyourisefromtheseat,the

safetyinterlocksystemisfunctioningproperly.

4.Shiftthebladecontrol(PTO)levertoDisengage,

putthetractioncontrolpedalintoNeutral,and

starttheengine.Whiletheengineisrunning,shift

thebladecontrol(PTO)levertoEngageandput

thetractioncontrolpedaltoReverse:Theengine

shouldstop.

5.Shiftthebladecontrol(PTO)levertoDisengage,

andstarttheengine.Thenshiftthebladecontrol

(PTO)levertoEngageandturntheKeyChoicekey

andreleaseit:TheKeyChoicewarninglightshould

illuminate.Shiftthebladecontrol(PTO)leverto

Disengage:TheKeyChoicewarninglightshould

turnoff.

EmptyingtheGrassCollector

Whenthecollectorwarninglightonthefrontconsole

comeson,thegrasscollectorisfullandmustbe

emptied.

1.Disengagethebladecontrol(PTO).

2.Pullthecollectorrodforwardtotiltthecollection

Figure16).

bin(

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedinplace,

youandothersareexposedtobladecontactand

throwndebris.Contactwiththerotatingmower

bladeandthrowndebriswillcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoudisengagethepowertake-off

(PTO)andturntheignitionkeytoOff.Also

removethekeyanddisconnectthewirefrom

thesparkplug.

1.Parkthemachineonalevelsurface.

2.Disengagetheblade(PTO).

3.ShiftthegroundspeedleverintoNeutral(model

70185only).

4.Settheparkingbrake.

Figure16

1.Collectorrod2.Collectionbin

3.Shakethecollectionbinuntilitiscompletelyempty.

4.Slowlyreturnthecollectionrodtotheoperating

position.

InstallingtheRecyclerCover

ARecyclercoverisincludedwiththemachine.Youcan

useitwhenyoudonotwanttobagthegrassclippings.

5.Stoptheengineandwaitforallmovingpartsto

stop.

6.Removetheignitionkey.

7.Raisethegrasscollectorandremovethehairpin,

2washers,andclevispinthatsecurethedischarge

tubetotherearplate(

1.Rearplate4.Hairpin

2.Dischargetube5.Washers

3.Clevispin

Figure17).

Figure17

8.Removethenutandouterwasherthatsecurethe

dischargechutetothedischargetube(Figure18).

18

Page 19

Figure18

1.Dischargetube3.Dischargechute

2.Nutandouterwasher

9.Movetheheight-of-cutlevertothelowestposition.

12.Removethedischargechutefromthemower

housing.

Note:Attachthenutandouterwasherthatyou

removedtothedischargechutetopreventlosing

them.

13.InstalltheRecyclercoverontothemower.

14.Jointhe2strapendsaroundtheRecyclercoveras

shown(

Figure19).

15.Aligntheholesinthestrapendsandfastenthem

togethersnuglywiththebolt,washer,andnutyou

previouslyremoved.

16.Raisethegrasscollectorandinstalltheclevispin,2

washers,andhairpintosecurethedischargetubeto

therearplate(

Figure20).

10.Removethebolt,washer,andnutthatsecurethe2

strapendstogether(

1.Straps

2.Nut4.Bolt

Figure19).

Figure19

3.Washer

11.Movethestrapsawayfromthedischargechute.

Note:Donotremovethestrapsfromthemower

housing.Ifastrapcomesoffthehousing,insertit

asshownin(Figure20).

Figure20

1.Insertingthestrapintothe

slot

2.Thestrapisinsertedinto

theslot

InstallingtheDischargeChute

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedinplace,

youandothersareexposedtobladecontactand

throwndebris.Contactwiththerotatingmower

bladeandthrowndebriswillcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoudisengagethepowertake-off

(PTO)andturntheignitionkeytoOff.Also

removethekeyanddisconnectthewirefrom

thesparkplug.

1.Parkthemachineonalevelsurface.

2.Disengagetheblade(PTO).

3.ShiftthegroundspeedleverintoNeutral(model

70185only).

4.Settheparkingbrake.

5.Stoptheengineandwaitforallmovingpartsto

stop.

6.Removetheignitionkey.

7.Raisethegrasscollectorandremovethehairpin

andclevispinthatsecurethedischargetubetothe

rearplate(

8.Movetheheightofcutlevertothelowestposition.

9.Removethebolt,washer,andnutthatsecurethe2

strapendstogether(

Figure17).

Figure19).

19

Page 20

10.Movethestrapsawayfromthethedischargechute.

Note:Donotremovethestrapsfromthemower

housing.

11.RemovetheRecyclercoverfromthemower

housing.

12.Installthedischargechuteontothemower.

13.Raisethegrasscollectorandinstalltheclevispin

andhairpintosecurethedischargetubetotherear

Figure17).

plate(

14.Installthenutandouterwasherthatsecurethe

dischargechutetothedischargetube(

15.Jointhe2strapendsaroundthedischargechuteas

showninFigure19.

16.Aligntheholesinthestrapendsandfastenthem

togethersnuglywiththebolt,washer,andnutyou

previouslyremoved(

Figure19).

Figure18).

OperatingTips

•Forthebestperformance,operatetheengineat

themaximumspeed.Themowerrequiresairto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cuttooloworcompletelysurroundthe

mowerinuncutgrass.Alwaysleaveonesideofthe

mowerfreefromuncutgrasstoallowtheairtobe

drawnintothemower.

–Engagethebladeandmovetoapreviouslycut

area.

–Dispersetheclippingsevenlybyraisingthe

mower1or2height-of-cutsettingswhiledriving

forwardwiththebladeengaged.

•Usethewashoutporttocleanclippingsanddirt

fromtheundersideofthemoweraftereachuse.If

grassanddirtbuildupinsidethemower,thecutting

qualitywilleventuallybecomeunsatisfactory.

•Maintainasharpbladethroughouttheseason.A

sharpbladecutsgrasscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

thegrassturnsitbrownattheedges,whichslows

itsgrowthandincreasesthechanceofdisease.

Every30days,checkthebladeforsharpnessand

ledownanynicks.

•Cutthegrassslightlylongerthannormaltoensure

thatthecuttingheightofthemowerdoesnotscalp

anyunevenground.Whencuttinggrasslonger

than15cmtall,cutthelawntwicetoensurean

acceptableappearance.

•Itisbesttocutonlyabout1/3ofthegrassblade.

Donotcutmorethanthatunlessthegrassissparse

oritislatefallwhengrassgrowsmoreslowly .

•Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

andenhancesdecompositionandfertilization.

•Grassgrowsatdifferentratesatdifferenttimesof

theseason.T omaintainthesamecuttingheight,

whichisagoodpractice,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmid

summer,mowlessfrequently.

•Ifthegrassislongerthannormal,orifitcontains

ahighdegreeofmoisture,raisethecuttingheight

higherthanusual,cutthegrassatthatsetting,and

thencutthegrassagainatthelower,normalsetting.

•Ifyoumuststopthemachinewhilemowing,you

mayleaveaclumpofgrassclippingsonyourlawn.

Toavoidthis,dothefollowing:

20

Page 21

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Beforestorage

MaintenanceProcedure

•Changetheoil.

•Checktheoillevel.

•Greasethemachinewithageneral-purposegrease.

•Cleanthefoamelement.

•Checkthesparkplug.

•Changetheoil.

•Replacethepaperelement.

•Replacethesparkplug.

•Replacethefuellter.

•Chargethebattery .

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Lubrication

GreasingandLubricatingthe

Machine

ServiceInterval:Every25hours

1.Disengagetheblade(PTO).

2.ShiftthegroundspeedleverintoNeutral(model

70185only).

3.Settheparkingbrake.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Removetheignitionkey.

6.Lubricatethefrontwheels.

7.Wipeupanyexcessgrease.

EngineMaintenance

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,or

higher)

CrankcaseCapacity:1400cc/1.4l

Viscosity:Seethetablebelow .

Figure21

21

Page 22

CheckingtheOilLevel

ChangingtheOil

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface.

2.Disengagetheblade(PTO).

3.ShiftthegroundspeedleverintoNeutral(model

70185only).

4.Settheparkingbrake.

5.Stoptheengineandwaitforallmovingpartstostop.

6.Removetheignitionkey.

7.Raisetheseat.

8.Cleanaroundtheoildipstick(

Figure22)sothatdirt

cannotfallintothelltubeanddamagetheengine.

ServiceInterval:Aftertherst5hours

Every50hours

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitdrainsbetter.

2.Parkthemachinesothattherightfrontsideis

slightlylowerthantheleftsidetoensurethattheoil

drainscompletely .

3.Disengagetheblade(PTO).

4.ShiftthegroundspeedleverintoNeutral.(model

70185only).

5.Settheparkingbrake.

6.Stoptheengineandwaitforallmovingpartstostop.

7.Removetheignitionkey.

8.Raisetheseat.

9.Insertthedrainingtubeontotheoildrainvalve

Figure23).

(

Figure22

1.Oildipstick/lltube

2.Metalend

9.Unscrewtheoildipstickandwipethemetalend

clean(Figure22).

10.Screwtheoildipstickfullyontothelltube

(

Figure22).Unscrewthedipstickagainandlookat

themetalend.Iftheoillevelislow ,slowlypouronly

enoughoilintothelltubetoraisetheleveltothe

Fullmarkonthedipstick.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagemay

result.

Figure23

1.Oildrainvalve

2.Oildipstick/lltube

3.Drainingtube

10.Placeapanbelowthedrainingtube.

11.Opentheoildrainvalve(

Figure23).

12.Whentheoilhasdrainedcompletely,removethe

drainingtubeandclosetheoildrainvalve.

Note:Disposeoftheusedoilatacertiedrecycling

center.

13.Slowlypourapproximately80%ofthespecied

amountofoilintothelltube(Figure22).Check

theoillevel;refertosteps9and10ofCheckingthe

OilLevel.

22

Page 23

ServicingtheAirCleaner

ServiceInterval:Every25hours

Every100hours

RemovingtheFoamandPaper

Elements

1.Settheparkingbrake,stoptheengine,andremove

theignitionkey .

2.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

Figure24).

(

CleaningtheFoamandPaperElements

FoamElement:

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.Do

notoiltheelement.

Important:Replacethefoamelementifitis

tornorworn.

PaperElement:

1.Lightlytaptheelementonaatsurfacetoremove

dustanddirt.

2.Carefullycleantherubbersealonthepaperelement

topreventdebrisfromenteringtheengine.

3.Inspecttheelementfortears,anoilylm,and

damagetotherubberseal.

Important:Nevercleanthepaperelement

withpressurizedairorliquids,suchassolvent,

gasoline,orkerosene.Replacethepaper

elementifitisdamagedorcannotbecleaned

thoroughly.

Figure24

1.Aircleanercover2.Aircleanercoverhandle

3.Pullupontheaircleanercoverhandleandrotateit

towardtheengine(Figure24).

4.Removetheaircleanercover.

5.Carefullyslidethepaperelementandfoamelement

fromtheblowerhousing(

Figure25

1.Paperelement4.Tab

2.Foamelement

3.Aircleanercover

Figure25).

5.Slot

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Placethefoamelementandpaperelementintothe

blowerhousing.

Note:Ensurethattherubbersealisatagainstthe

aircleanerbase.

2.Alignthetabsontheaircleanercoverwiththeslots

oftheblowerhousing(

3.Hookthehandleontothecoverandpressdownon

thehandletolockthecoverinplace.

Figure25).

ServicingtheSparkPlug

ServiceInterval:Every25hours

Every100hours

InstallanewChampionRJ-19LMorequivalentspark

plug.Ensurethattheairgapbetweenthecenterandside

electrodesis0.76mmbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugandagappingtoolorfeelergaugetocheck

andadjusttheairgap.

RemovingtheSparkPlug

1.Disengagetheblade(PTO).

23

Page 24

2.ShiftthegroundspeedintoNeutral(model70185

only).

3.Settheparkingbrake.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Removetheignitionkey.

6.Reachunderthebodyofthemachineabovetheleft

rearwheelanddisconnectthewirefromthespark

Figure26).

plug(

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

Figure27)andbendthesideelectrodeifthegap

(

isnotcorrect.

InstallingtheSparkPlug

1.Installthesparkplugandmetalwasher.

Note:Ensurethattheairgapissetcorrectly.

2.Tightenthesparkplugto20N-m.

Figure26

1.Spark-plugwire2.Sparkplug

7.Cleanaroundthesparkplugtopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

8.Removethesparkplugandmetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure27).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

3.Connectthewiretothesparkplug(

Figure26).

Figure27

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

24

Page 25

FuelSystem

Maintenance

DrainingtheFuelTank

10.Installthefuellineontothelter.

11.Slidethehoseclampclosetotheltertosecurethe

fuellineandlter.

12.Installtheenginecover.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachinesothattheleftfrontsideisslightly

lowerthantherightsidetoensurethatthefueltank

drainscompletely .

2.Disengagetheblade(PTO).

3.ShiftthegroundspeedleverintoNeutral(model

70185only).

4.Settheparkingbrake.

5.Stoptheengine.

6.Removetheignitionkey.

ReplacingtheFuelFilter

ServiceInterval:Every100hours

Note:Thebesttimetoreplacethefuellter(Figure28)

iswhenthefueltankisempty .Neverinstalladirtylter

ifitisremovedfromthefuelline.

1.Disengagetheblade(PTO).

2.ShiftthegroundspeedleverintoNeutral(model

70185only).

3.Settheparkingbrake.

4.Stoptheengine.

5.Removetheignitionkey.

6.Removetheenginecover.

7.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(

8.Removethelterfromthefuellines.

9.Installanewlterandmovethehoseclampsclose

tothelter.

10.Installtheenginecover.

Figure28).

7.Removetheenginecover.

8.Squeezetheendsofthehoseclamptogether

andslideitupthefuellinetowardthefueltank

(Figure28).

Figure28

1.Hoseclamp3.Filter

2.Fuelline

9.Pullthefuellineoffthelter(Figure28)andallow

thegasolinetodrainintoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuel

lterbecausethefueltankisempty.

25

Page 26

ElectricalSystem

Maintenance

9.Disconnectthepositive(red)cablefromthebattery

post.

10.Removethebatteryfromthebatterybox.

ServicingtheBattery

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatteryandbatterybox.If

thebatteryterminalsarecorroded,cleanthemwitha

solutionof4partswaterand1partbakingsoda.Apply

alightcoatingofgreasetothebatteryterminalsto

preventcorrosion.

Batteryvoltageandamperage:12volts,155

cold-crankingamps

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponents,causingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Disengagetheblade(PTO).

2.ShiftthegroundspeedleverintoNeutral.

3.Settheparkingbrake.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Removetheignitionkey.

6.Removetheenginecover.

7.Disconnectthenegative(black)groundcablefrom

thebatterypost.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

8.Slidetherubbercoverupthepositive(red)cable.

InstallingtheBattery

1.Putthebatteryintothebatteryboxinthechassis.

2.Usingthebolt,washers,andnut,connectthepositive

(red)cabletothepositive(+)batterypost.

3.Slidetherubbercoveroverthebatterypost.

4.Usingthebolt,washers,andnut,connectthe

negative(black)cabletothenegative(–)batterypost.

5.Installtheenginecover.

CheckingtheElectrolyteLevel

1.Removetheenginecover.

2.Lookatthesideofthebattery.Theelectrolytemust

beuptotheupperline(Figure29).

Figure29

1.Ventcaps3.Lowerline

2.Upperline

Note:Donotallowtheelectrolytetofallbelowthe

lowerline(Figure29).

3.Iftheelectrolyteislow,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery.

DANGER

Batteryelectrolytecontainssulfuricacid,a

deadlypoisonthatcanseverelyburnyouand

others.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethemachine.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

26

Page 27

1.Removethebatteryfromthemachine;referto

RemovingtheBattery.

2.Cleanthetopofthebatterywithapapertowel.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthe

machine.Electrolytecouldbespilledonother

partsandcausecorrosion.

3.Removetheventcapsfromthebattery(

Figure29).

4.Slowlypourdistilledwaterintoeachbatterycelluntil

theelectrolytelevelisuptotheUpperline(Fig.19)

onthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

5.Wait5to10minutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(

Figure29)onthe

batterycase.

6.Installthebatteryventcaps.

ChargingtheBattery

ServiceInterval:Beforestorage

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Figure30

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(–)chargerlead

6.Installthebatteryinthemachineandconnectthe

batterycables;refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

ServicingtheFuses

Theelectricalsystemisprotectedby7.5amp,blade-type

fuses.Nomaintenanceisrequired,however,ifafuse

blows,checkthecircuitwiringforashort.

1.Pulloutthefuse(Figure31)toremoveitfromthe

socket.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.260specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel.

3.Ensurethattheventcapsareinstalledinthebattery.

Chargethebatteryfor1hourat25to30ampsor6

hoursat4to6amps.Donotoverchargethebattery.

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet.

5.Disconnectthechargerleadsfromthebatteryposts

Figure30).

(

Figure31

1.Fuses(undertheseat)

2.Pushdownonthefusetoinsertit.

27

Page 28

BrakeMaintenance

BladeMaintenance

CheckingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Checktheparkingbrakedailyto

ensurethatitholdssecurely .

1.Parkthemachineonalevelsurface.

2.Disengagetheblade(PTO).

3.Settheparkingbrake.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Removetheignitionkey.

6.Iftherearwheelslockandskidwhenyoutrytopush

themachineforward,youdonotneedtoadjustthe

parkingbrake.Butiftherearwheelsturnanddonot

lock,youneedtohaveanAuthorizedServiceDealer

adjusttheparkingbrake.

CheckingtheTirePressure

Maintaintheairpressureinthetiresat80kPa.Check

thetirepressureaftereachuse.Checkthetireswhen

theyarecoldtogetthemostaccuratepressurereading.

ServicingtheBlade

Toensureasuperiorqualityofcut,keepthebladesharp.

Forconvenientsharpeningandreplacement,youmay

wanttohaveanextrablade.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

InspectingtheBlade

1.Inspectthecuttingedges(Figure32).Iftheedges

arenotsharporhavenicks,removethebladeand

sharpenthem;refertoSharpeningtheBlade.

Figure32

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

2.Inspecttheblade,especiallythecurvedarea

Figure32).Ifyounoticeanydamage,wear,oraslot

(

forminginthisarea,immediatelyinstallanewblade.

RemovingtheBlade

1.Stoptheengineandwaitforallmovingpartstostop.

2.Removetheignitionkey.

3.Disconnectthewirefromthesparkplug.

4.Shiftthetransaxleintorstgear.

5.Settheparkingbrake.

6.Grasptheendofthebladeusingaragorthickly

paddedglove.Thenremovethebladebolt,curved

washer,bladestiffener,andblade(

blockofwoodmaybewedgedbetweentheblade

Figure33).A

28

Page 29

andthemowertolockthebladewhenyouare

removingthebolt.

Figure33

1.Blade3.Bladeboltandcurved

washer

2.Bladestiffener

SharpeningtheBlade

1.Usealetosharpenthecuttingedgeatbothends

oftheblade(Figure34).Maintaintheoriginalangle.

Thebladeretainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

InstallingtheBlade

1.Installtheblade,bladestiffener,curvedwasher,and

bladebolt(Figure33).

Important:Thecurvedpartoftheblademust

bepointingtowardtheinsideofthemowerto

ensurepropercutting.

2.Tightenthebladeboltto61to82N-m.

Important:Ensurethatthecuttingedgeofthe

bladeisawayfromthemowerhousing.

LevelingtheMower

1.Ifthemowercutsunevenlyandthecuttingbladeis

notbent,youmustlevelthemower.

2.Settheparkingbrake.

3.Stoptheengineandwaitforallmovingpartstostop.

4.Removetheignitionkey.

5.Disconnectthewirefromthesparkplug.

6.Settheairpressureinthetirestotherecommended

level;refertoCheckingtheTirePressure.

7.Removethecotterpinatthefrontoftheadjusting

Figure36).

rod(

Figure34

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure35).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetal

offofthebacksideoftheblade.Repeatthisstep

untilthebladeisbalanced.

Figure35

1.Blade2.Balancer

Figure36

1.Adjustingrod3.Nut

2.Cotterpin

8.Loosenthenutattherearoftheadjustingrod

(Figure36).

Important:Ensurethatthecuttingedgeofthe

bladeisawayfromthemowerhousing.

9.Turntheadjustingrodtothedesiredlevel.

29

Page 30

10.Tightenthenut.

11.Installthecotterpin.

Cleaning

WashingundertheMower

1.Parkthemachineonahardlevelsurface.

2.Disengagetheblade(PTO).

3.Stoptheengineandwaitforallmovingpartstostop.

4.Removetheignitionkey.

5.Attachthehosecouplingtotheendofthe

mowerwashoutttingandturnthewateronhigh

Figure37).

(

Figure37

1.Washoutport3.Hose

2.Coupling

Note:Spreadpetroleumjellyonthewashouttting

o-ringtomakethecouplingslideoneasierandto

protecttheo-ring.

6.Setthemowertothesecondheight-of-cut(B)level.

7.Sitontheseatandstarttheengine.

8.Engagetheblade(PTO)andletthemowerrunfor

1to3minutes.

9.Disengagetheblade(PTO).

10.Stoptheengineandwaitforallmovingpartstostop.

11.Removetheignitionkey .

12.Shutoffthewaterandremovethecouplingfrom

thewashouttting.

Note:Ifthemowerisnotcleanafteronewashing,

soakitandletitstandfor30minutes.Thenrepeat

theprocess.

13.Runthemoweragainfor1to3minutestoremove

theexcesswater.

30

Page 31

WARNING

Abrokenormissingwashoutttingcould

exposeyouandotherstothrownobjectsorblade

contact.Contactwiththebladeorthrowndebris

contactmaycauseinjuryordeath.

•Replacebrokenormissingwashouttting

immediately,beforeusingmoweragain.

•Pluganyholesinmowerwithboltsand

locknuts.

•Neverputyourhandsorfeetunderthe

mowerorthroughopeningsinthemower.

WashingtheMachine

1.Stoptheengineandwaitforallmovingpartstostop.

2.Removetheignitionkey.

3.Wait10to15minutesfortheenginetocooldown.

4.Washthemachinewithmilddetergentandwater.

Important:Donotuseapressurewasher

towashthemachine.Pressurewashingmay

damagetheelectricalsystemorwashaway

necessarygreaseatfrictionpoints.Avoid

excessiveuseofwater,especiallynearthe

controlpanel,lights,engine,andbattery .

5.Starttheenginetodryitoff.

Storage

CleaningandStorage

1.Disengagetheblade(PTO).

2.Settheparkingbrake.

3.Stoptheengineandwaitforallmovingpartstostop.

4.Removetheignitionkey.

5.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleanthedirtandchafffromtheoutsideof

theenginecylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotuseapressure

washertowashthemachine.Pressurewashing

maydamagetheelectricalsystemorwash

awaynecessarygreaseatfrictionpoints.Avoid

excessiveuseofwater,especiallynearthe

controlpanel,lights,engine,andbattery .

6.Checktheparkingbrake;refertoCheckingthe

ParkingBrake.

7.Servicetheaircleaner;refertoServicingtheAir

Cleaner.

8.Changetheengineoil;refertoServicingtheEngine

Oil.

9.Checkthetirepressure;refertoCheckingtheTire

Pressure.

10.Whenstoringthemachineforover30days,prepare

itasfollows:

A.Addapetroleumbasedstabilizer/conditionerto

thefuelinthetankaccordingtotheinstructions

fromthestabilizermanufacturer.Donot

useanalcoholbasedstabilizer(ethanolor

methanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineand

usedatalltimes.

B.Runtheenginefor5minutestodistribute

conditionedfuelthroughthefuelsystem.

C.Stoptheengine,allowittocool,anddrainthe

fueltank;refertoDrainingtheFuelTank.

D.Starttheengineandrunituntilitstops.

E.Chokeorprimetheengine.

F.Startandruntheengineuntilitwillnotstart

again.

G.Recycletheoldfuelaccordingtolocalcodes.

Important:Donotstore

stabilizer/conditionedgasolineover90

days.

31

Page 32

11.Removeandinspectthesparkplug;refertoServicing

theSparkPlug.Withthesparkplugremovedfrom

theengine,pour2tablespoonsofengineoilintothe

sparkplughole.Usetheelectricstartertocrank

theengineanddistributetheoilinsidethecylinder.

Installthesparkplug,butdonotconnectthewireto

thesparkplug.

12.Disconnectthenegativebatterycable.Cleanthe

batteryandbatteryterminals.Checktheelectrolyte

levelandchargeitfully;refertoServicingtheBattery.

Leavethenegativebatterycabledisconnectedfrom

thebatteryduringstorage.

Important:Thebatterymustbefullycharged

topreventitfromfreezingandbeingdamaged

attemperaturesbelow32°F(0°C).Youcanstore

afullychargedbatteryduringthewinterwithout

recharging.

13.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatiswornordamaged.

14.Paintallscratchedorbaremetalsurfaceswithpaint

availablefromanAuthorizedServiceDealer.

15.Storethemachineinaclean,drygarageorstorage

area.RemovetheignitionandKeyChoicekeysfrom

themowerandkeeptheminamemorableplace.

Coverthemachinetoprotectitandkeepitclean.

32

Page 33

Troubleshooting

Problem

Thestarterdoesnotcrank.

Theenginewillnotstart,startshard,or

failstokeeprunning.

PossibleCauseCorrectiveAction

1.Thebladecontrol(PTO)isengaged.1.Disengagetheblade(PTO).

2.Theparkingbrakeisnotengaged.

3.Thebatteryisdead.

4.Theelectricalconnectionsarecorroded

orloose.

5.Afuseisblown.5.Replacethefuse.

6.Arelayorswitchisdamaged.

1.Theoperatorisnotseated.

2.Thefueltankisempty.2.Fillthefueltankwithgasoline.

3.Theaircleanerisdirty.

4.Thesparkplugwireislooseor

disconnected.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Thechokeisnotclosing.6.Adjustthethrottlecable.

7.Thereisdirtinthefuellter.7.Replacethefuellter.

8.Theidlespeedistooloworthemixture

isincorrect.

9.Dirt,water,orstalefuelisinthefuel

system.

10.Theengineisooded.

11.Thebatteryisdead.

2.Settheparkingbrake.

3.Chargethebattery .

4.Checktheelectricalconnectionsfor

goodcontact.

6.ContactanAuthorizedServiceDealer.

1.Sitontheseat.

3.Cleanorreplacetheaircleaner

element.

4.Connectthewiretothesparkplug.

5.Installanew ,correctly-gappedspark

plug.

8.ContactanAuthorizedServiceDealer.

9.ContactanAuthorizedServiceDealer.

10.Removethesparkpluganddryitout.

11.Chargethebattery .

Theenginelosespower .

Theengineoverheats.

Thereisanabnormalvibration.

1.Theengineloadisexcessive.

2.Theaircleanerelementisdirty.

3.Theoillevelinthecrankcaseislow.3.Addoiltothecrankcase.

4.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Thereisdirtinthefuellter.6.Replacethefuellter.

7.Dirt,water,orstalefuelisinthefuel

system.

1.Theengineloadisexcessive.

2.Theoillevelinthecrankcaseislow.2.Addoiltothecrankcase.

3.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

1.Thebladeisbentorunbalanced.1.Installanewblade.

2.Theblademountingboltisloose.2.Tightentheblademountingbolt.

3.Theenginemountingboltsareloose.3.Tightentheenginemountingbolts.

4.Thereisalooseenginepulley ,idler

pulley,orbladepulley.

5.Theenginepulleyisdamaged.

1.Shiftintoalowergeartoreducethe

groundspeed.

2.Cleantheaircleanerelement.

4.Removetheobstructionfromthe

coolingnsandairpassages.

5.Installanew ,correctly-gappedspark

plug.

7.ContactanAuthorizedServiceDealer.

1.Shiftintoalowergeartoreducethe

groundspeed.

3.Removetheobstructionfromthe

coolingnsandairpassages.

4.Tightentheappropriatepulley.

5.ContactanAuthorizedServiceDealer.

Thebladedoesnotrotate.

1.Thebladedrivebeltisworn,loose,or

broken.

2.Thebladedrivebeltisoffofthepulley.2.ContactanAuthorizedServiceDealer.

1.ContactanAuthorizedServiceDealer.

33

Page 34

Problem

PossibleCauseCorrectiveAction

Themachinedoesnotdrive.

Thecuttingheightisuneven.

Thecuttingqualityispoor.

Thegrasscollectorfailstoll.

1.Thetractionbeltisworn,loose,or

broken.

2.Thetractionbeltisoffthepulley.2.ContactanAuthorizedServiceDealer.

3.Thetransmissiondoesnotshift.3.ContactanAuthorizedServiceDealer.

1.Thetirepressureisincorrect.

2.Themowerisnotlevel.2.Levelthemower .

3.Theundersideofthemowerisdirty.3.Cleanunderthemower.

1.Thecuttingbladeisworn.

2.Thecuttingheightisincorrect.2.Adjustthecuttingheight.

1.Thecuttingheightistoolow.1.Raisethecuttingheight.

2.Thegrassistooheavyordamp.2.Waituntilthegrasshasdried.

3.Thecuttingbladeisworn.

4.Thegrassistoohigh.4.Raisethecuttingheight.

5.Thedischargeareaisblocked.

1.ContactanAuthorizedServiceDealer.

1.Setthetirepressure.

1.Sharpenorreplacethecuttingblade.

3.Sharpenorreplacetheblade.

5.Removetheobstructionfromthe

dischargearea.

34

Page 35

Schematics

Model70185(Rev.A)

35

Page 36

Model70186(Rev.A)

36

Page 37

Notes:

37

Page 38

Notes:

38

Page 39

InternationalDistributorList

Distributor:

AtlantisSuveSulamaSisstemleriLt

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

EquiverMexico525553995444

FemcoS.A.Guatemala

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IbeaS.P .A.

IrriamcPortugal351212388260

IrrigationProductsInt’lPvtLtd.India862283960789

JeanHeybroekb.v .Netherlands31306394611

Lely(U.K.)Limited

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

MetraKft

Mountelda.s.CzechRepublic

MunditolS.A.

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

ParklandProductsLtd.NewZealand6433493760

Prochaska&Cie

RTCohen2004Ltd.

Riversa

RothMotorgerateGmBh&Co.Germany

ScSvendCarlsenA/S

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

T-MarktLogisticsLtd.Hungary3626525500

ToroAustraliaAustralia61395807355

ToroEuropeBVBABelgium3214562960

Country:

Turkey902163448674

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Japan81726325861

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479

Egypt2025194308

Italy390331853611

UnitedKingdom441480226800

Japan81332522285

Hungary3613263880

Argentina541148219999

Ecuador59342396970

Finland35898700733

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France33130817700

India911292299901

PhoneNumber:

5062391 138

94112746100

5024423277

30109350054

862087651338

4635100000

5712364079

420255704220

34952837500

4971442050

35722434131

374-0269RevA

Page 40

TheT oroWarranty

ConditionsandProductsCovered

TheToro®Companyanditsafliate,T oroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheToroProduct

listedbelowifusedforresidentialpurposes*ifdefectiveinmaterialsor

workmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

WalkPowerMowers2yearlimitedwarranty

RearEngineRiders2yearlimitedwarranty

Lawn&GardenTractors

ElectricHandHeldProducts2yearlimitedwarranty

Snowthrowers

ConsumerZeroTurn

*OriginalPurchasermeansthepersonwhooriginallypurchasedtheT oro

Product

*Residentialpurposesmeansuseoftheproductonthesamelotasyour

home.Useatmorethanonelocation,orinstitutionalorrentaluse,is

consideredcommercialuse,andthecommercialusewarrantywould

apply.

2yearlimitedwarranty

2yearlimitedwarranty

2yearlimitedwarranty

LimitedWarrantyforCommercialUse

ToroConsumerProductsandattachmentsusedforcommercial,

institutional,orrentaluse,arewarrantedagainstdefectsinmaterials

orworkmanshipforthefollowingtimeperiodsfromthedateoforiginal

purchase:

ProductsWarrantyPeriod

WalkPowerMowers90daywarranty

RearEngineRiders90daywarranty

Lawn&GardenTractors

ElectricHandHeldProducts90daywarranty

Snowthrowers

ConsumerZeroTurn

90daywarranty

90daywarranty

45daywarranty

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.Contactyoursellertoarrangeserviceoftheproduct.Ifforanyreason

itisimpossibleforyoutocontactyourseller,youmaycontactany

ToroAuthorizedDistributortoarrangeservice.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.IfforanyreasonyouaredissatisedwiththeService

Dealer’sanalysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Manager:T echnicalProductSupport:001–952–887–8248

SeeattachedDistributorList

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thisexpresswarrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorwearparts,suchasrotor

blades(paddles),scraperblades,belts,fuel,lubricants,oilchanges,

sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Engineandtransmission.Thesearecoveredbytheappropriate

manufacturer’sguaranteeswithseparatetermsandconditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingToroapprovedreplacementparts.

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry.Therights

towhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythiswarranty.

374-0268RevA

Loading...

Loading...