Page 1

Introduction ______________________________________________________________________

The DT34 and DT54 series full-circle rotary sprinklers are designed

specifically for golf course applications.

Manufactured from durable, high-strength engineering plastic and

stainless-steel components, these sprinklers incorporate many innovative

and time-proven features for lasting, maintenance-free operation.

Prior to installing the sprinkler, read through the recommended installation

and start-up procedures. Please observe all WARNINGS and CAUTIONS

when installing and operating this equipment.

Features _______________________________________________________________________________

Specifications and Performance/Application Data _______________________________________

DT34 Series

■ Radius: 52'–92' (15,9–28,0 m)

■ Flow Rate: 15–50 GPM (56,7–189,3 LPM)

■ Trajectory: Selectable 15° or 25°

■ Arc: Full Circle

■ Recommended Operating Pressure: 65–100 PSI

(4,5–6,9 Bar)

■ Minimum Pressure: 40 PSI (2,8 Bar)

■ Maximum Pressure: 150 PSI (10,3 Bar)

■ Precipitation Rate:

■

Minimum: 0.46"/hr (11,7 mm/hr)

■ Maximum: 0.63"/hr (16 mm/hr)

■ Body Height: 10" (25.4 cm)

■ Pop-Up Height: 4.1875" (10.6 cm)

■ Inlet Size: 1" NPT, BSP or ACME

■ Electric Valve-in-head Solenoid:

■ Inrush current: 0.30A @ 24 VAC, 50/60 Hz

■ Holding current: 0.20A @ 24 VAC, 50/60 Hz

■ Manual Control (Electric VIH only): On-Off-Auto

■ Check-O-Matic model checks up to 37' (11,2 m) of elevation.

■ Seven Nozzle Variations: See chart on page 2.

DT54 Series

■ Radius: 52'–100' (15,9 m–30,5 m)

■ Flow Rate: 15–62 GPM (56,8–234,7 LPM)

■ Trajectory: Selectable 15° or 25°

■ Arc: Full Circle

■ Recommended Operating Pressure: 65–100 PSI (4,5–6,9 Bar)

■ Minimum Pressure: 40 PSI (2,8 Bar)

■ Maximum Pressure: 150 PSI (10,3 Bar)

■ Precipitation Rate:

■ Minimum: 0.50"/hr (12,7 mm/hr)

■ Maximum: 0.72"/hr (18,3 mm/hr)

■ Body Height: 11" (27.9 cm)

■ Pop-Up Height: 4.1875" (10.6 cm)

■ Inlet Size: 1.5" NPT, BSP or ACME

■ Solenoid:

■ Inrush current: 0.30A @ 24 VAC, 50/60 Hz

■ Holding current: 0.20A @ 24 VAC, 50/60 Hz

■ Manual Control (Electric VIH only): On-Off-Auto

■ Check-O-Matic model checks up to 37' (11,2 m) of elevation.

■ Nine Nozzle Variations: See chart on page 2.

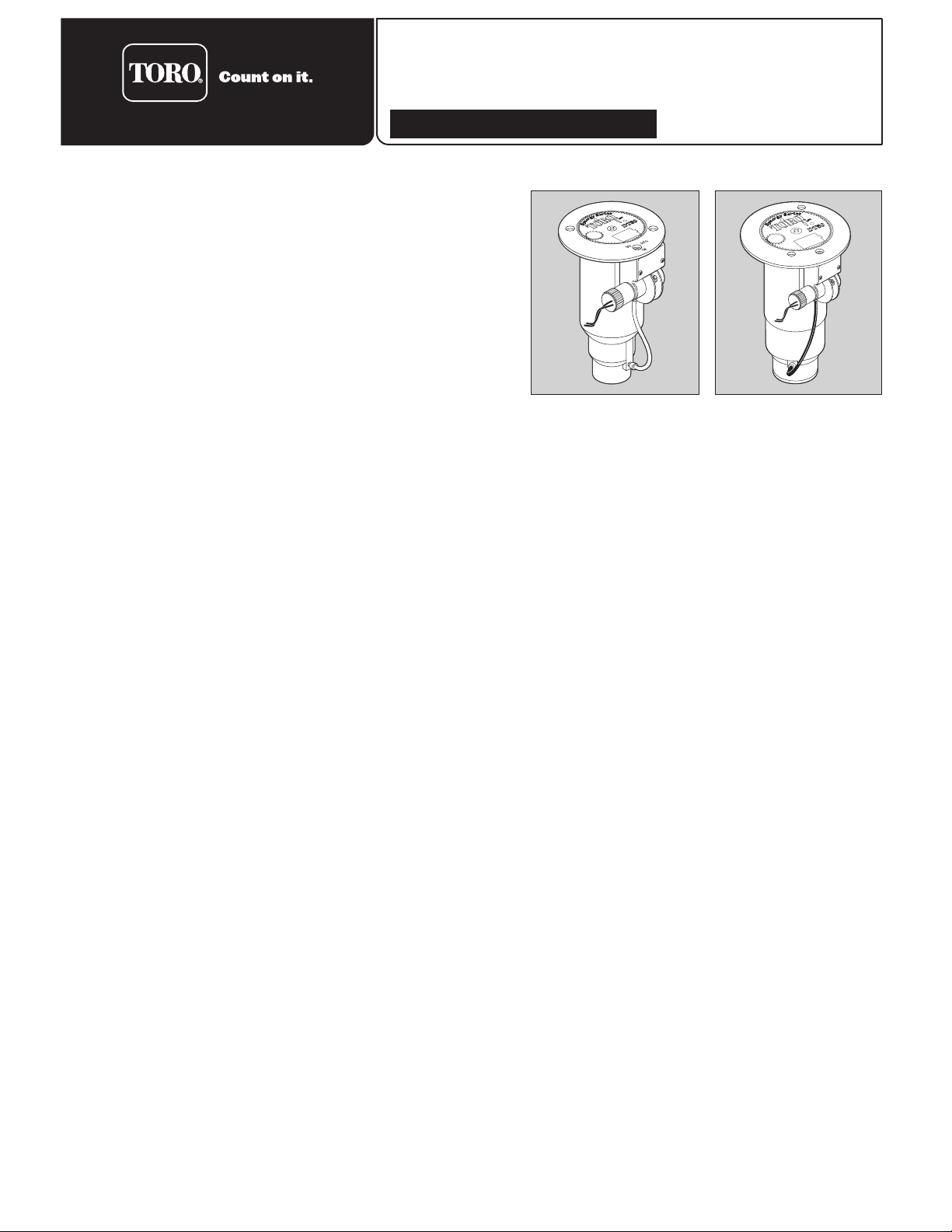

DT34 Electric Valve-In-Head DT54 Electric Valve-In-Head

■ Main nozzle trajectory allows for 25 and 15 degree selections

■ Full 4" (10,1 cm) pop-up clears tall grasses

■ Nozzles color-coded by radius and gallonage

■ Cap serves as an effluent water indicator

■ Variable stators

■ Selectable pressure regulation settings of 50 psi (3.4 bar),

65 psi (4.5 bar), 80 psi (5.5 bar) or 100 PSI (6.9 bar) to

ensure consistently accurate nozzle performance

regardless of elevation (electric models only)

■ Three body activation types available: Electric VIH,

Normally Open Hydraulic VIH, and Check-O-Matic

■ Three body thread types available: NPT, BSP and ACME

■ Manual sprinkler control, On-Off-Auto (electric models only)

■ Bowl-vented discharge (atmospheric) minimizes the

differential pressure required for regulation and ensures

positive valve closure (electric models only)

■ All internal components serviceable from the top of the

sprinkler

■ Large selection of color-coded nozzles available

■ Durable plastic and stainless-steel construction

■ Optional radius reduction screw

DT34 and DT54 Series Rotary Sprinklers

Installation & Service Instructions

Note: For preliminary use only.

A U T O

O F F

O N

Page 2

2

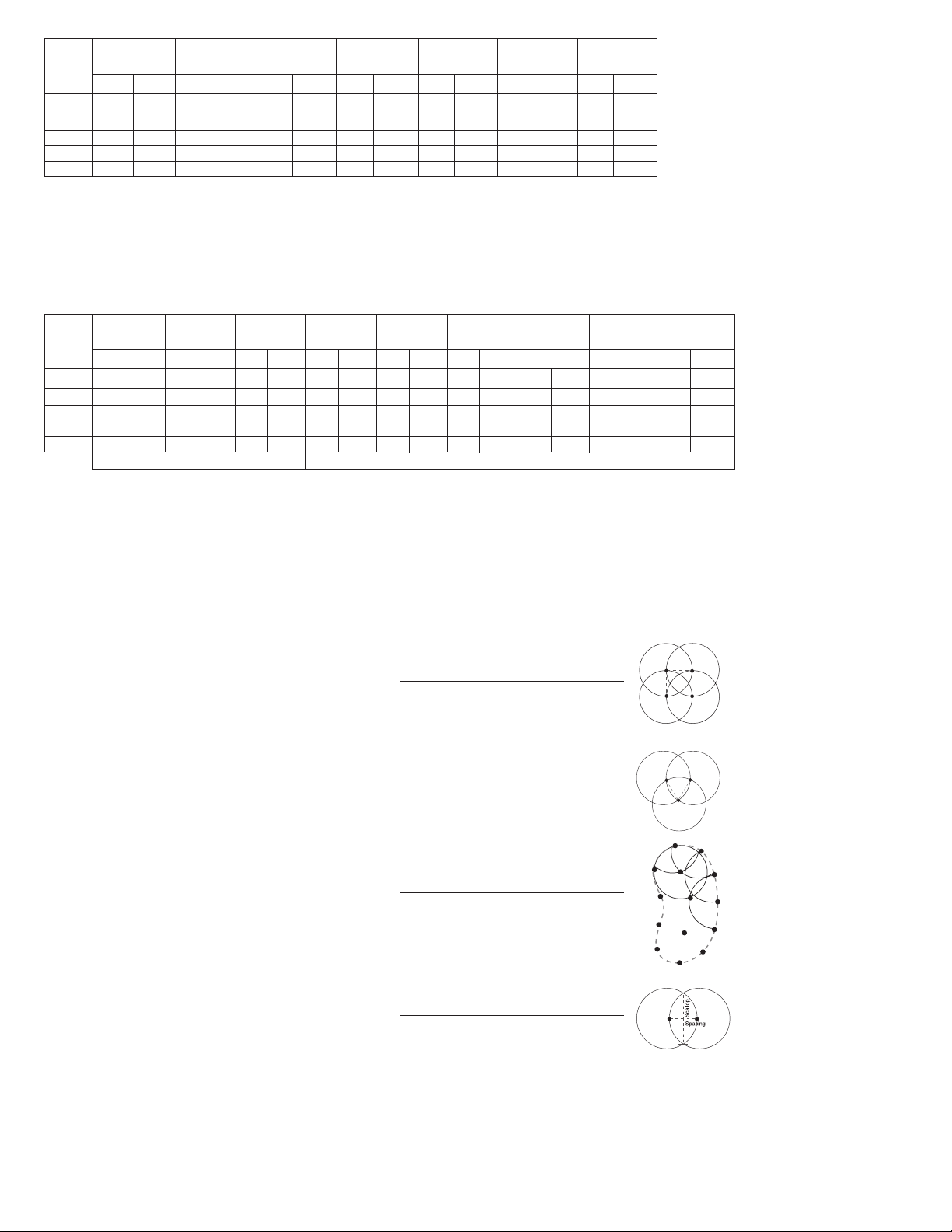

Precipitation Rate Formulas

❚ Square-spaced sprinklers in pattern:

GPM of full circle x 96.3

(Spacing)

2

❚ Triangular-spaced sprinklers in pattern:

GPM of full circle x 96.3

(Spacing)2(0.866)

❚ Area and flow:

Total GPM of zone x 96.3

Total irrigated

square feet of zone

❚ Single row:

GPM of full circle x 96.3

(Spacing) (Scallop)

Sprinkler Spacing Guidelines

❚ Square Spacing

No wind - 55% of diameter

4 mph wind - 50% of diameter

8 mph wind - 45% of diameter

❚ Triangular Spacing

No wind - 60% of diameter

4 mph wind - 55% of diameter

8 mph wind - 50% of diameter

❚ Single-Row Spacing

No wind - 50% of diameter

4 mph wind - 50% of diameter

8 mph wind - 45% of diameter

Note: Designing for zero (0) mph

wind conditions is not recommended.

Design for worst wind conditions.

For additional information, refer to

Toro Technical Data Manual,

form number 490-1737.

DT54 Series Sprinkler Performance Data

DT34 Series Sprinkler Performance Data

Base

Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set

Pressure

31 ● (Yellow) 32 ● (Blue) 33 ● (Brown) 34 ● (Orange) 35 ● (Green) 36 ● (Gray) 37 ● (Black)

★ BLUE ■ YELLOW ★ RED ■ YELLOW ★ RED ■ YELLOW ★ BEIGE ■ YELLOW ★ BIEGE ■ YELLOW ✪ RED ■ YELLOW ✪ GRAY ■ YELLOW

psi Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM

50 56 13.2 60 16.6 64 22.3 65 27.4

65 58 15.0 62 20.0 66 25.0 70 30.0 75 35.0

80 61 16.5 66 22.1 70 27.4 73 33.2 78 38.4 84 41.0 87 45.0

100 63 18.4 71 24.7 74 30.3 76 37.0 81 42.5 87 46.0 90 49.5

Radius shown in feet.

Toro recommends the use of a 11⁄4" (30mm) swing joint at flows over 25 GPM (95 LPM). Sprinkler radius of throw per ASAE standard S398.1

●

= Main Nozzle★= Intermediate Nozzle✪= Intermediate Nozzle w/ Straightener■= Inner Nozzle (Yellow w/ Yellow Restrictor)

All sprinklers are equipped with the selectable pilot valve that allows settings at 50, 65, 80 and 100 psi.

Base

Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set Nozzle Set

Pressure

51 ● (Yellow) 52 ● (Blue) 53 ● (Brown) 54 ● (Orng) 55 ● (Green) 56 ● (Gray) 57 ● (Black) 58 ● (Red) 59 ● (Beige)

★

BLUE

■YELLOW ★

RED

■YELLOW ★

RED

■YELLOW ★

BEIGE

■YELLOW ★

BEIGE

■YELLOW ✪

RED

■YELLOW ★

BRN✪GRY

■YLW ★

BRN✪GRY

■YLW ✪

GRAY

■YELLOW

psi

Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM Radius GPM

50 56 13.2 60 16.6 64 22.3 65 27.4

65 58 15.0 62 20.0 66 25.0 70 30.0 75 35.0

80 61 16.5 66 22.1 70 27.4 73 33.2 78 38.4 84 41.0 87 45.0 90 52.0 94 57.5

100 63 18.4 71 24.7 74 30.3 76 37.0 81 42.5 87 46.0 90 49.5 95 56.5 100 62.0

Low-flow Stator Medium-flow Stator High-flow

Radius shown in feet.

Toro recommends the use of a 11⁄4" (30mm) swing joint at flows over 25 GPM (95 LPM). Sprinkler radius of throw per ASAE standard S398.1

●

= Main Nozzle★= Intermediate Nozzle✪= Intermediate Nozzle w/ Straightener■= Inner Nozzle (Yellow w/ Yellow Restrictor)

All sprinklers are equipped with the selectable pilot valve that allows settings at 50, 65, 80 and 100 psi.

Page 3

Installation Procedure ___________________________________________________

To assure maximum performance from your 800S series sprinklers, read these instructions

completely prior to installation or service.

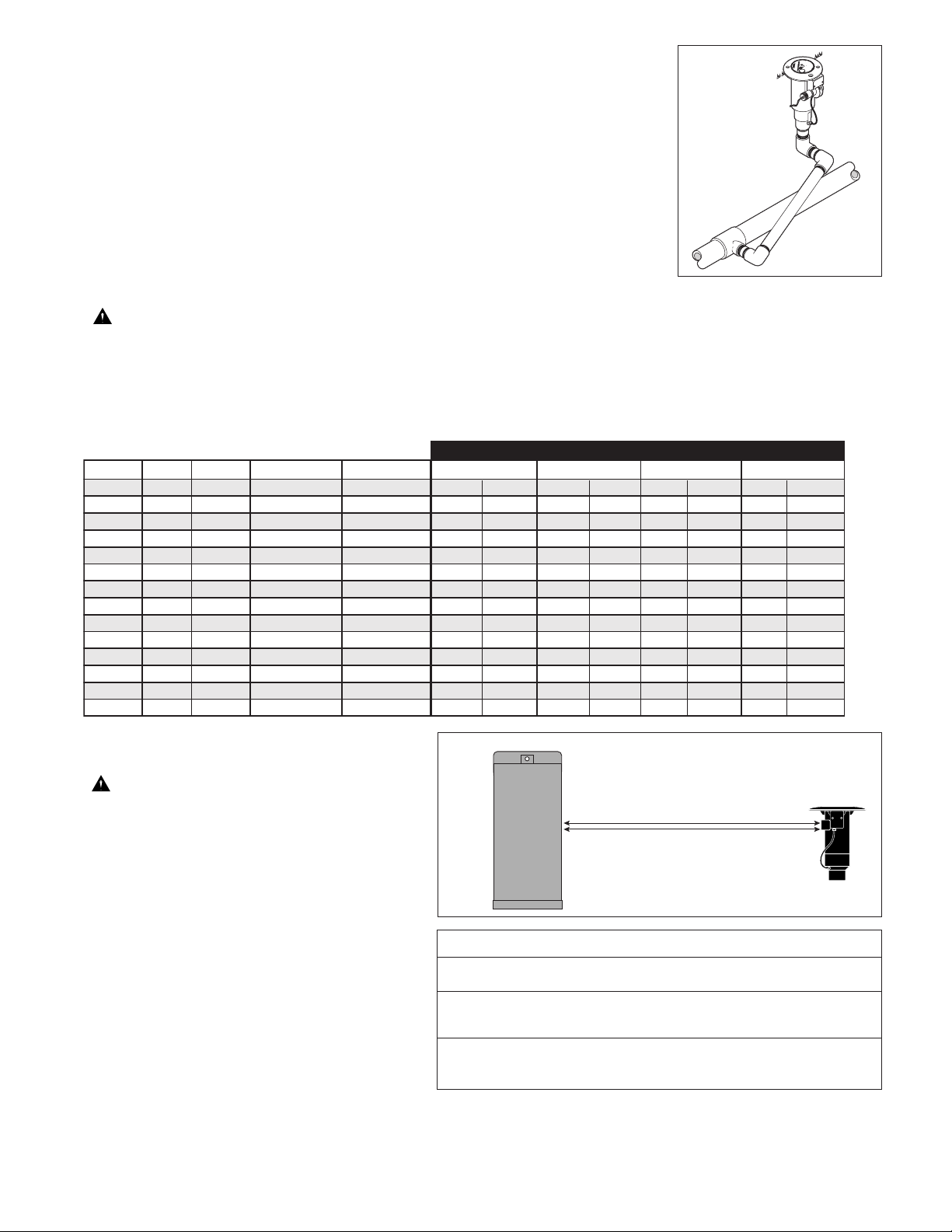

Constructing Swing Joints

1. Construct or provide triple swing joints for each sprinkler as shown in Figure 1. Use PVC or

ABS pipe nipple for the sprinkler connection.

Note: On sites where the possibility of heavy equipment rolling over a sprinkler exists, the

swing joint will flex preventing damage to the lateral or main lines. On a new installation in

raw ground where the sprinklers are to be initially installed above the finished grade and

lowered when new turf is established, the swing joint allows sprinkler repositioning without

changing risers. This is a common and practical procedure which eliminates the problem of

dirt being accidentally introduced into the lateral lines when a riser is changed.

2. Flush lines thoroughly prior to installing sprinkler.

3. Apply PTFE tape on riser threads (not required on ACME threads). Install sprinkler to riser and tighten.

CAUTION: Use only PTFE tape on riser threads. Use of pipe dope or other types of sealing compounds can cause

deterioration of sprinkler body threads.

Connecting Control Wires (Electric Models Only)

1. Route control wires to sprinklers. Provide extra wire at sprinkler to allow for height adjustment. One common wire and station

wire is required for each sprinkler. See Wire Sizing Chart, Table 1 for proper application.

Note: Wire length data provided in Table 1 is the sum of the station and common wire legs. See example in Figure 2.

2. Attach control wires to solenoid leads using an

approved waterproof splicing method.

CAUTION: All wire splices and field

connections must be waterproofed to prevent

short circuit to ground and subsequent controller

damage.

Connecting Hydraulic Control Tubing

1. Route control tubing from the controller to the

sprinkler location(s).

Note: Leave an 18" (45.7 cm) service loop of tubing

at each sprinkler to facilitate movement of sprinkler

and service operations. Refer to Table 2 for tubing

run length and sprinkler elevation information.

2. Flush tubing thoroughly to remove all air and debris.

3. Remove the tube retainer and poly cap from the

tubing adapter at the base of the sprinkler.

4. Slide the tube retainer over the end of the control

tubing and attach tubing to adapter.

5. Slide tube retainer over adapter area to secure tubing.

3

Table 2: Hydraulic Control Systems

Maximum Distance

Type of System* From Controller Elevation Restrictions

Normally Open (01) Valve elevation should not exceed

with 3/16" Control Tubing 500' 25' ABOVE controller elevation or

70' BELOW controller elevation.

Normally Open (01) Valve elevation should not exceed

with 1/4" Control Tubing 1000' 25' ABOVE controller elevation or

70' BELOW controller elevation

Table 1: Wire Sizing Chart

*

- All hydraulic connections on Toro valves are 1⁄4" insert type.

- Control line pressure must be equal to or greater than mainline pressure.

- Control line pressure range is 40 to 150 PSI.

Figure 1

Figure 2

Station Wire = 1095' (334m)

Common Wire = 1095' (334m)

Total Wire Length = 2190' (668m)

T O

A U

F F

O

N

O

Voltage AWG mm

23

23

23

23

23

23

23

14/14

14/12

14/10

12/12

12/10

12/8

10/10

24 14/14 5 4100 4106' 2053' 1369' 1026'

24 14/12 5 5315

24 14/10 5 7250 7261' 3631'

24

24

24

24

12/12

12/10

12/8

10/10 10/10

2.5/2.5

2.5/4.0

2.5/5.5

4.0/4.0

4.0/5.5

4.0/7.0

5.5/5.5

2.5/2.5

2.5/4.0

2.5/5.5

4.0/4.0

4.0/5.5

4.0/5.5

2

Voltage Drop

Circular Mils 1 Sprinkler

4 4100 3285' 1001 m

45315

4 7250

46530

4 8465

4 11515

4 10400

56530 6540' 3270' 2180' 1635'

5 8465 8478' 4239' 2826'

5 11515 11533'

5 10400 10416' 5208' 3472' 2604'

Total Wire Length Between Controller and Sprinkler

2 Sprinklers3 Sprinklers 4 Sprinklers

1642' 1095' 821'

4259' 2129' 1419' 1064'

5809' 2904' 1936' 1452'

5232' 2616' 1744' 1308'

6783' 3391' 2261' 1695'

9227' 4613' 3075'

8333' 4166' 2778'

1298 m

1770 m

1595 m

2067 m

2812 m

2540 m

1251 m

5323'

1622 m

2662' 1774'

2213 m

1993 m

2584 m

3515 m

5766'

3175 m

500 m

649 m

885 m

797 m

1033 m

1406 m

1270 m

626 m

811 m

1106 m

996 m

1292 m

1757 m

158

7 m

2420'

3844'

334 m

432 m

590 m

531 m

689 m

937 m

846 m

417 m

541 m

738 m

664 m

861 m

1172 m

1058 m

2306'

2083'

1331'

1815'

2119'

2883'

250 m

324 m

443 m

399 m

517 m

703 m

635 m

313 m

406 m

553 m

498 m

646 m

879 m

790 m

Page 4

System Start Up _________________________________________________________

The following is a recommended procedure that will protect system components during system start-up. The procedure is based on a

velocity fill rate of less than 2' (.61 m) per second. See Table 3 below.

Table 3: Recommended System Fill Rate

1. Use a jockey pump only to fill the system at a velocity fill rate of less than 2' (0.61 m) per second.

CAUTION: Failure to comply with recommended fill rate will increase line pressure resulting in a water hammer

effect that could damage sprinklers and piping components. See Warning above.

2. At all tees and greens use quick coupler keys with quick coupler valves to bleed air from the system lines during the filling

process. For best results, do not compress air and then relieve it – bleed the air constantly while filling the system.

3. After water has filled all lines and all air is removed, remove the quick coupler keys.

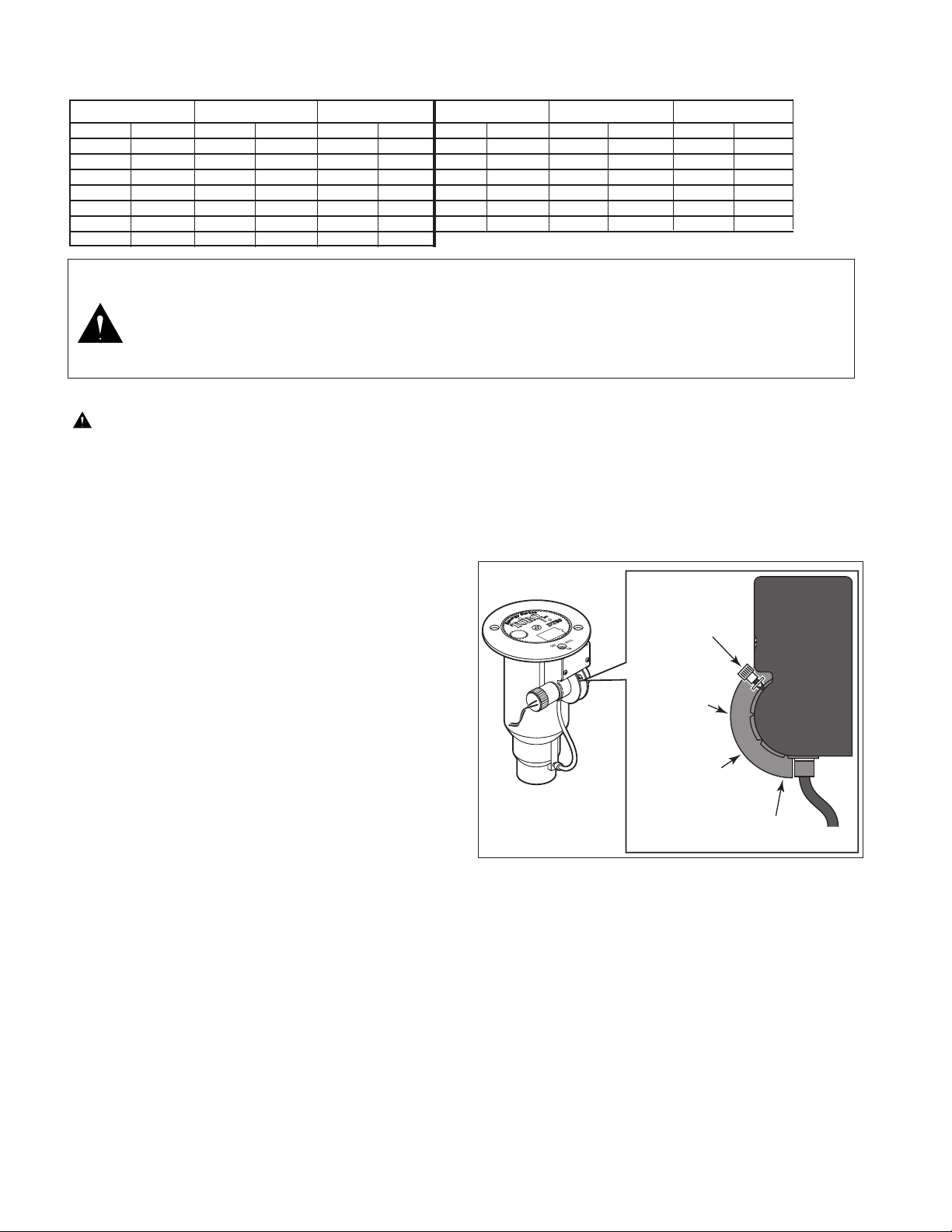

Pilot Valve Operation (Electric Models Only) ________________________________________

The pilot valve controls the operation of the main valve located in the

base of the sprinkler body. The main valve is operated by the release

of water metered through the pilot valve when it is activated either

manually at the sprinkler or by the irrigation system controller.

The sprinkler operation mode is set using a Toro Selector Tool

(P/N 995-15) inserted through the body flange onto the pilot valve

D-shaped selector cam. The "AUTO" mode permits automatic

operation from the system controller. The "ON" mode opens the main

valve for manual operation and "OFF" mode prevents the main valve

from opening.

The pilot valve regulates the water pressure to the sprinkler nozzle.

Pressure regulation compensates for large variations within the

system and maintains a constant pressure for optimum sprinkler

operation. The pilot valve is factory set to regulate one of four

pressure levels: 50 psi (3.4 bar), 65 psi (4.5 bar), 80 psi (5.5 bar) or

100 PSI (6.9 bar).

Change the pilot valve operating pressure by loosening the thumb

screw that secures the selector lever. Position the selector lever to

the desired operating pressure and hand-tighten the nut. See Figure 3.

4

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED,

DURING MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE

PROCEDURES. DIRECT CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED

SPRINKLER CONNECTION OR SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER

PRESSURE CAN CAUSE SERIOUS INJURY.

Pipe Size Flow Velocity Pipe Size Flow Velocity

in. cm GPM LPM ft/sec m/sec in. cm GPM LPM ft/sec m/sec

1/2 1.3 2 7.6 1.60 0.49 3 7.6 45 170.3 1.86 0.57

3/4 1.9 3 11.4 1.92 0.59 4 10.1 75 283.9 1.87 0.57

1 2.5 5 18.9 1.50 0.46 6 15.2 150 567.8 1.73 0.53

1-1/4 3.1 10 37.9 1.86 0.57 8 20.2 250 946.3 1.70 0.52

1-1/2 3.8 10 37.9 1.41 0.43 10 25.4 450 1703.0 1.97 0.60

2 5.0 20 75.7 1.80 0.55 12 30.5 500 1893.0 1.55 0.47

2-1/2 6.4 30 113.6 1.84 0.56

Figure 3

100 PSI

(7.0 kg/cm

2

)

80 PSI

(5.6 kg/cm

2

)

65 PSI

(4.6 kg/cm

2

)

50 PSI (3.5 kg/cm

2

)

Page 5

Nozzle Trajectory Adjustment Procedure _______________________________________

Note: The nozzle trajectory is factory pre-set at 25 degrees.

1. Insert the multi-purpose tool (P/N 995-83) into the slot provided in the top of the cap. Pull the riser assembly up, then grasp the

assembly to hold it in the popped-up position.

2. Remove the cap retaining screw and cap.

3. Using a 5/8" nut driver (P/N 995-99), turn the nozzle/housing assembly left to select 15° trajectory as shown in Figure 4. Turn the

nozzle/housing assembly right to select 25° trajectory as shown in Figure 5.

4. Install the cap making sure the top the nozzle housing is correctly nested in the cap.

5. Install the cap retaining screw.

6 Activate the sprinkler to check the spray trajectory.

5

Figure 5

Figure 5

Page 6

Troubleshooting _________________________________________________________

■

Pilot Valve

Possible equipment failures with causes and corrective action are listed below.

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

SPRINKLER WILL (a) No 24 VAC to coil assembly. (Electric Models)

NOT TURN ON – Measure voltage with a Digital Volt Meter (DVM). Check wiring and controller program.

– Refer to Controller Operating Instructions.

(b) Selector cam in "OFF" position.

– Set to "AUTO" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 11.)

(d) Insufficient pressure in controller supply line and/or sprinkler control tube. (N.C. Models)

– Check pressure.

SPRINKLER WILL (a) Constant 24 VAC from controller. (Electric Models)

NOT SHUT OFF – Check for voltage using a DVM. If voltage is present, disconnect wire.

If sprinkler closes, service controller. Refer to Controller Service Manual.

(b) Selector cam in manual "ON" position.

– Set to "AUTO" or "OFF" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 11.)

(d) Constant pressure from controller. (N.C. Models)

– Check pilot valve at controller for constant flow.

– Check elevation differential. Valve elevation should not exceed 0' above

controller elevation or 70' (21.3 m) below controller elevation.

■

Sprinkler Assembly

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

SPRINKLER WON'T ROTATE (a) Debris wedged between stator and turbine.

– Remove obstruction.

(b) Drive assembly defective.

– Replace drive assembly.

(c) Nozzle base assembly defective.

– Replace nozzle base assembly.

HEAD STICKS UP (a) Dirt in riser assembly.

– Flush out. (See Flushing Procedure on page 11.)

(b) Damaged or missing return spring.

– Replace.

(c) Damaged riser.

– Replace.

POOR DISTRIBUTION PATTERN (a) Nozzle plugged with debris.

– Clean or replace nozzle.

(b) Nozzle orifice damaged.

– Replace nozzle.

(c) Low operating pressure.

– Determine why system overloaded and correct.

■

Main Valve

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

VALVE WON'T CLOSE (a) Continuous 24 VAC to sprinkler.

(Electric ) – Check controller for voltage source.

(b) Leak in pilot valve assembly.

– Replace pilot valve assembly.

(c) Plugged supply screen on piston.

– Clean or replace screen.

(d) Manual control selector on pilot valve assembly turned to "ON" position.

– Turn to "AUTO" position.

(e) Plunger movement restricted.

– Inspect and clean or replace.

(f) Valve cylinder misaligned with sprinkler body communication tube.

– Remove valve assembly and install correctly.

(g) Foreign object keeping valve from seating.

– Remove, clean and check valve for damage. Replace if necessary.

(h) Damaged piston seal or piston assembly.

– Replace valve assembly.

6

Page 7

VALVE WON'T CLOSE (a) Leak in control tubing.

(Hydraulic) – Isolate and repair.

(b) Pilot valve leak in controller.

– Confirm by observing constant dripping from discharge line of controller.

Refer to Controller Service Manual.

(c) Valve cylinder misaligned with sprinkler body communication tube.

– Remove valve assembly and install correctly.

(d) Foreign object keeping valve from seating.

– Remove, clean and check valve for damage. Replace if necessary.

(e) Damaged piston seal or piston assembly.

– Replace valve assembly.

VALVE WON'T OPEN (a) Control (field) wires severed.

(Electric) – Isolate and repair.

(b) No power to controller.

– Establish controller power.

(c) No power from controller to solenoid.

– Check for blown fuse and replace.

(d) Manual control selector on pilot valve assembly turned to "OFF" position.

– Turn to "AUTO" position.

(e) Pilot valve solenoid inoperative.

– Remove and replace.

(f) Pilot valve plunger movement restricted.

– Inspect, clean and/or replace.

(g) No supply from main valve.

– Debris in control tube, main valve assembly and/or communication passages in

body. Flush thoroughly.

VALVE WON'T OPEN (a) Plugged controller discharge line or discharge port in pilot valve.

(Hydraulic) – Verify by checking for discharge at discharge line when station is

activated. If no discharge, refer to Controller Service Manual.

SPRINKLER WEEPING (a) Damaged or blocked valve seat.

(Slow leak in valve) – Remove blockage and, if necessary, replace valve assembly.

(b) Damaged piston seal or piston assembly.

– Replace valve assembly.

(c) Low pressure on supply line .

– Check for low pressure reason and correct.

(d) Elevation of normally closed sprinkler exceeds 75' (22.9 m) differential.

SEVERAL VALVES ON DIFFERENT (a) Control tubing leak which lowers supply pressure to other stations.

STATIONS FAIL TO CLOSE – Turn controller from station to station until a station is reached where

(Hydraulic) only valves on that station stay open. The leak would be in the tubing

on that station. Isolate and repair.

(b) Leak in supply line to controller.

– Verify by checking pressure in all control lines.

(c) Leak in controller pilot valve.

– Verify by constant discharge from controller.

(d) Plugged supply line filter.

– Replace filter if more than 3 psi (0.21 bar) differential exists.

7

Page 8

Servicing Procedures ____________________________________________________

The DT series sprinklers are designed to provide the user trouble-free operation for many years without scheduled maintenance. If it

becomes necessary to disassemble the sprinkler to correct a malfunction or replace a component, all internal parts of the sprinkler

can be accessed from the top. Refer to the Troubleshooting Procedure in this manual in the event of a malfunction. Some special

tools are required for disassembly and/or maintenance of the sprinkler and are available from your Toro dealer.

Servicing Sprinkler Mechanism

Note: Refer to Figure 6 for the following procedure:

1. Insert hooked end of multi-purpose tool (P/N 995-83)

into slot provided in top of cap (3). Pull assembly

upward, grasp and hold in position.

2. Insert hooked end of multi-purpose tool into slot in

snap ring (11). Pull snap ring inward toward the

sprinkler assembly, then upward to remove from the

snap ring groove in sprinkler body. Pull riser assembly

out of sprinkler body.

3. Use a 5/8" nut driver (P/N 995-99) to unscrew main

nozzle (10).

4. Remove cap screw (1) and cap (3).

5. Grasp return spring (14) and riser (16) firmly and hold

in place while removing nozzle base (4). Turn nozzle

base assembly counterclockwise to remove.

6. Carefully release tension from return spring (14).

7. Remove spring and seal retainer/o-ring assembly

(12 and 13).

8. Remove o-ring (13).

9. Remove rock screen (19) turning it counterclockwise

with edge of multi-purpose tool or tips of snap ring

pliers (P/N 995-100).

10. Remove drive assembly (17) and stator (18) from

riser assembly by carefully pressing on end of

threaded shaft.

11. Using a 5/16" nut driver (P/N 995-105), unscrew

intermediate nozzle (5 & 6) and inner nozzle (5) and

plugs (7) from the nozzle base assembly.

12. Thoroughly clean and inspect all parts and replace

as necessary. Reassemble in the reverse order.

Note: During reassembly, ensure snap ring is

correctly installed and fully seated in snap ring groove

before operating sprinkler. See WARNING above..

Figure 6

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED,

DURING MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE

PROCEDURES. DIRECT CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED

SPRINKLER CONNECTION OR SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER

PRESSURE CAN CAUSE SERIOUS INJURY.

8

Page 9

Servicing Main Valve

1. See WARNING above. To remove valve assembly, squeeze

snap ring ears together with snap ring pliers (P/N 995-100) and

remove snap ring from sprinkler body. See Figure 7.

2. Use valve removal tool P/N 995-08 for DT34 or 995-09 for DT54

to remove valve assembly from base of sprinkler body. Valve

removal tool is inserted into sprinkler body and pushed through

valve ribs. A slight twist will catch tool under ribs enabling valve

removal by pulling straight up and out. See Figure 8.

Note: If valve removal tool is not available, use snap ring pliers

to grasp rib of valve cylinder assembly and pull up and out of

sprinkler body.

3. Reinstall valve assembly using valve insertion tool P/N 995-76

for DT34 or 995-101 for DT54 as follows:

• Load snap ring on insertion tool carrier with stepped side

against carrier as shown in Figure 9. While holding snap ring in

compressed position, slide retainer clip in to hold snap ring ears

• Load valve assembly on carrier as shown.

• Locate position of communication tube in bottom of sprinkler body and orient insertion tool accordingly.

• Insert tool straight down into sprinkler body aligning bosses on t-handle with holes on sprinkler body flange. When valve

assembly clears vertical side wall ribs inside body, pull up on snap ring release mechanism (DT54 models only) and press valve

assembly into position. Snap ring will lock into groove when properly installed. Remove insertion tool and check snap ring to

confirm that it is fully seated in groove.

9

Figure 9

Snap Ring

Released

Valve Assembly

Pressed Into Position

Valve Assembly

Orientation In Carrier

Snap Ring In

Retainer Clip

Stepped Side

of Snap Ring

Figure 8Figure 7

Snap Ring Release

Mechanism

WARNING

IF THE VALVE SNAP RING IS DIFFICULT TO REMOVE, RESIDUAL WATER PRESSURE MAY BE

REMAINING IN THE SYSTEM. TO PREVENT POSSIBLE SERIOUS INJURY DUE TO VALVE BEING

EJECTED UPWARD UNDER PRESSURE, CONFIRM THE FOLLOWING CONDITIONS EXIST PRIOR TO

REMOVING THE SNAP RING AND VALVE:

A. WATER SUPPLY TO SPRINKLER IS SHUT OFF AT SOURCE.

B. All PRESSURE IS BLED FROM SYSTEM, INCLUDING CONTROL TUBES.

C. AC POWER IS DISCONNECTED AT SOURCE.

Page 10

Servicing Pilot Valve

Note: Refer to Figure 10 for the following procedure.

1. Make sure that the water supply to sprinkler

is positively shut off and any residual

pressure has been bled off. If the sprinkler is

pressurized, main valve will open when the

pilot valve is disconnected from control tube.

2. Carefully remove turf and soil from the side

of the sprinkler to expose pilot valve and

control tubing.

3. Remove the two retaining screws from the

pilot valve housing.

4. Pull the pilot valve assembly away from the

sprinkler body and cut the control tubing just

below tube retainer. Unless pilot valve has

been previously removed, control tubing

length will be sufficient for re-connection.

5. Remove tube retainer and remaining piece

of control tubing from valve body fitting.

6. Remove the solenoid (1, 2 or 3) by turning it

counterclockwise.

7. Remove the retaining nut (18) and washer

(17) from the pressure adjuster (11) and pull

the pilot valve body assembly out of housing

(16).

8. Remove diaphragm assembly (15), piston

(14), spring (13), traveling adjuster (12),

pressure adjuster (11) and o-ring (7).

9. Remove selector shaft assembly (9) and plunger assembly (5). (The selector shaft retains the plunger in the valve body.)

10. Thoroughly clean and inspect all parts. Replace damaged parts as necessary and reassemble in reverse order.

Note: Refer to Illustrated Parts Breakout Book, form number 368-0044 for service part numbers.

Flushing Sprinkler _______________________________________________________________

1. With sprinkler operating, carefully step down on center of cap several times. Water will flow around riser and flush out debris.

2. Cycle sprinkler on and off several times to check for proper retraction. Cap should be even with top of body flange when fully

retracted. If riser sticks in up position, check for debris lodged between riser and body. Flush out all debris. Remove sprinkler

mechanism if necessary.

10

Figure 10

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED, DURING

MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE PROCEDURES. DIRECT

CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED SPRINKLER CONNECTION OR

SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER PRESSURE CAN CAUSE SERIOUS INJURY.

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED, DURING

MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE PROCEDURES. DIRECT

CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED SPRINKLER CONNECTION OR

SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER PRESSURE CAN CAUSE SERIOUS INJURY.

9

10

8

1

2

7

5

3

4

12

11

6

14

13

15

16

17

18

Page 11

Notes:

11

Page 12

Notes:

© 2007 The Toro Company • Irrigation Division • www.toro.com Form Number 373-0423 Rev. 2

Loading...

Loading...