Page 1

Micro-Irrigation

Drip

Drip In® PC

Pressure Compensating Dripline

A technologically superior

and cost effective

way to irrigate

• Difficult topographical conditions

• Low and varying water pressures

• Installations requiring longer lateral runss

Features & Benefits:

Highly clog resistant

Due to wide, deep turbulent passageways

and raised inlets.

Extremely accurate flow rate

Due to high quality control standards.

Reduced labor and installation cost

No hole punching, lost emitters or handling

damage. Emitters are factory spaced.

Can’t separate

Because there are no clip-ons or connections.

Lower friction loss

Due to jointless design, allows longer runs and

fewer mainlines.

Versatility

Flow rates available in three hose sizes:

(0.550" (16mm), 0.620" (18mm) and 0.710"

(20mm)

In

®

Page 2

Drip In® PC

Design Advantages:

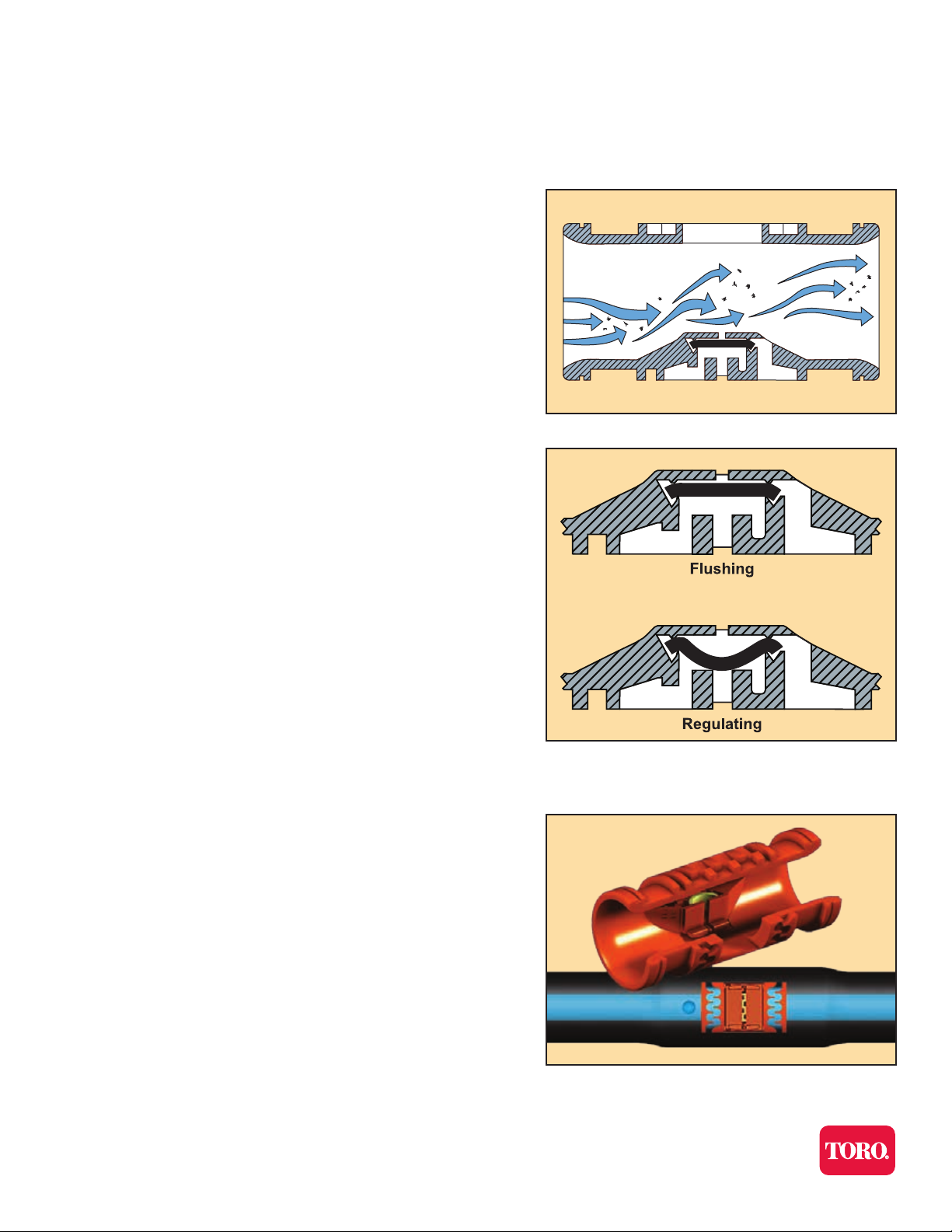

High Resistance to Plugging

Water enters the emitter through a raised filtration

system. Debris is deflected upward and away from the

inlet because of the unique construction of the emitter.

This feature significantly reduces the amount of debris

entering the emitter when the system is operating. The

positioning of the raised inlet also prevents sediment from

collecting near the inlet while the system is not operating,

and being ingested into the emitter at start-up. The

emitters filter ensures that only particles smaller than the

emitters cross sectional dimensions will enter.

Three flushing cycles to ensure continued

reliability and performance.

1.Pre-regulating Flush:

The automatic flushing feature is activated at low

pressures during system startup. The diaphragm is

relaxed allowing particles to be freely flushed out.

2.Irrigation Flush:

During the irrigation cycle the diaphragm is depressed

across the compensating chamber. If the emitter begins

to clog, there is a reduction of flow, and pressure

on both sides of the diaphragm begins to equalize.

The diaphragm returns to its relaxed position and

particles are flushed out. The dripper returns to normal

performance.

3.Shut-down Flush:

As pressure is reduced, the diaphragm returns to its

relaxed position allowing accumulated particles to be

flushed out.

Wide Compensating Range

At low pressures, 10 - 15 psi, the emitter behaves like a

turbulent-flow emitter. From 15 - 60 psi, the emitter is

fully pressure compensating.

Flat discharge curve over a wide range of pressures (10-60 PSI)

Chemical Resistance

Drip In PC is manufactured from the highest quality

materials. The emitter body is made from injection

molded polyethylene resins. The diaphragm is made

from silicon. This combination will withstand acids down

to pH2 as well as most commonly used ag chemicals,

fertilizers and chlorine.

Uniformity

Drip In PC’s state of the art manufacturing process and

high quality control standards assures dependable,

uniform and precise emitter discharge. Drip In emitters

have Cv values less than .05, one of the highest rankings

of all manufacturers.

Page 3

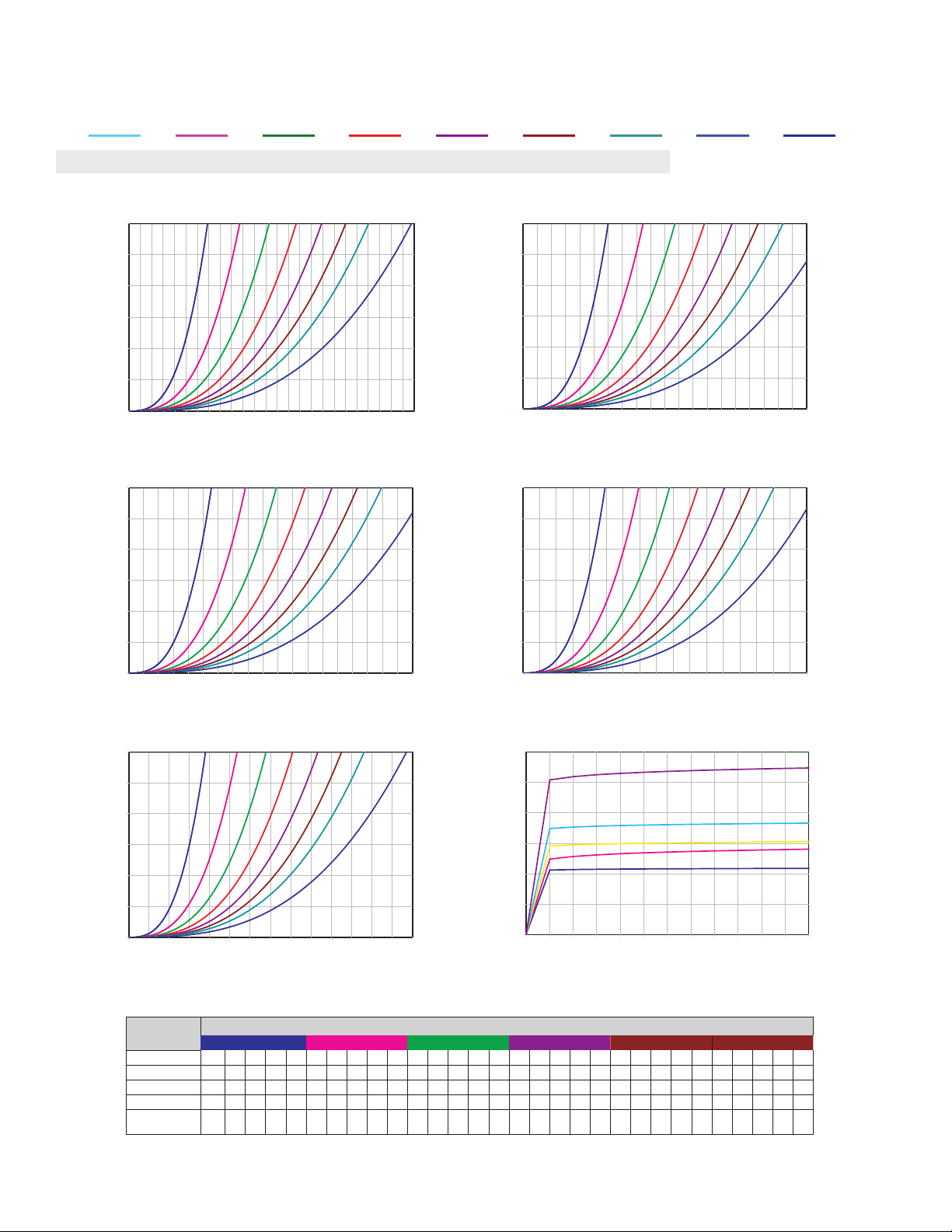

Drip In® PC

1500

Dripline Length (feet)

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

1400

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

Head Loss v. Dripline Length and Emitter Spacing

900

Dripline Length (feet)

Head Loss (psi)

1200

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

Spacings:

12"

0.550" (16MM) DRIP IN® PC DRIPLINE

18"

24"

30"

36"

42"

48"

54"

60"

30

25

20

15

10

5

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400

30

25

20

15

10

5

Drip In 16mm .42 GPH PC Emitter 0% Slope.

Drip In 16mm .63 GPH PC Emitter 0% Slope.

30

25

20

15

10

5

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

30

25

20

15

10

5

Drip In 16mm .53 GPH PC Emitter 0% Slope.

Drip In 16mm 1.02 GPH PC Emitter 0% Slope.

0

0 100 200 300 400 500 600 700 800 900 1000 1100

16mm Drip In PC – Maximum Recommended Dripline Length (Feet) (0.550" I.D./0.640" O.D./0.045" Wall)

Inlet

Pressure

15 psi

25 psi

35 psi

45 psi

Dripper Flow

Rate (gph)

12” 18” 24” 36” 42” 48”

199 174 156 115 286 250 224 165 366 321 287 211 513 449 402 296 581 509 456 335 649 566 507 373

297 260 233 171 426 373 334 246 546 478 428 315 766 670 600 442 867 759 680 500 964 844 756 556

358 313 280 206 513 449 402 296 658 576 516 379 922 807 723 532 1044 914 819 602 1161 1016 910 670

404 354 317 233 585 508 455 335 743 651 583 429 1042 912 817 601 1180 1033 925 681 1312 1149 1029 757

0.42 0.53 0.63 1.02 0.42 0.53 0.63 1.02 0.42 0.53 0.63 1.02 0.42 0.53 0.63 1.02 0.42 0.53 0.63 1.02 0.42 0.53 0.63 1.02

Barb Loss Factor (kd) 2.07 Coef ficient of variation ≤5%

Maxiumum length of run based on EU and minimum pressures – please contact Toro for

length of run based on other criteria such as flushing velocity.

Dripper Spacing

0

0 100 200 300 400 500 600 700 800

1.20

1.00

0.80

0.60

Flow rate (gph)

0.40

0.20

0.00

0 5 10 15 20 25 30 35 40 45 50 55 60

16mm Emitter discharge rate v. pressure

1.06

1.05

1.05

1.04

1.02

0.62

0.62

0.61

0.60

0.58

0.49

0.40

0.00

0.00

0.00

0.000.00

0.52

0.51

0.41

0.41

0.53

0.42

0.54

0.42

Pressure in psi

1.07

1.06

1.06

0.64

0.63

0.63

0.54

0.43

0.55

0.54

0.43

0.43

1.07

0.65

0.55

0.44

1.07

0.65

0.56

0.44

Page 4

Drip In® PC

1800

Dripline Length (feet)

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

1300

Dripline Length (feet)

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

1500

Dripline Length (feet)

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

1100

Dripline Length (feet)

Head Loss (psi)

Head Loss v. Dripline Length and Emitter Spacing

Spacings:

12"

0.620" (18MM) DRIP IN® PC DRIPLINE

18"

24"

30"

36"

42"

48"

54"

60"

30

25

20

15

10

5

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700

30

25

20

15

10

Drip In 18mm .42 GPH PC Emitter 0% Slope.

Drip In 18mm .75 GPH PC Emitter 0% Slope.

30

25

20

15

10

5

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400

30

25

20

15

10

Drip In 18mm .53 GPH PC Emitter 0% Slope.

Drip In 18mm 1.02 GPH PC Emitter 0% Slope.

5

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

5

0

0 100 200 300 400 500 600 700 800 900 1000

1.20

1.00

0.80

0.60

Flow rate (gph)

0.40

0.20

0.00

0 5 10 15 20 25 30 35 40 45 50 55 60

18mm Emitter discharge rate v. pressure

1.04

1.03

1.01

0.99

0.96

0.78

0.78

0.77

0.76

0.74

0.55

0.54

0.54

0.53

0.52

0.41

0.00

0.00

0.000.00

0.00

0.43

0.43

0.44

0.45

Pressure in psi

18mm Drip In PC™ – Ma ximum Recommended Dripline Length (Feet) (0.620" I.D./0.710" O.D./0.045" Wall)

Inlet

Pressure

15 psi

25 psi

35 psi

45 psi 551

Dripper Flow

Rate (gph)

12” 18” 24” 36” 42” 48”

271 238 190 157 384 336 270 222 488 427 342 281 673 589 473 388 758 664 532 438 839 735 589 484

405 354 284 234 573 502 102 331 727 637 510 420 1004 879 705 579 1131 990 794 653 1252 1096 878 722

488 427 4342 281 690 604 484 398 876 767 615 505 1210 1059 849 698 1362 1193 956 786 1508 1320 1058 870

482 387 318 780 683 548 450 990 867 695 571 1367 1197 959 789 1540 1348 1088 888 1704 1492 1196 983

0.42 0.53 0.75 1.02 0.42 0.53 0.75 1.02 0.42 0.53 0.75 1.02 0.42 0.53 0.75 1.02 0.42 0.53 0.75 1.02 0.42 0.53 0.75 1.02

Dripper Spacing

Barb Loss Factor (kd) 0.98 Coefficient of variation ≤5%

Maxiumum length of run based on EU and minimum pressures – please contact Toro for

length of run based on other criteria such as flushing velocity.

1.07

1.06

1.05

0.80

0.79

0.79

0.55

0.55

0.55

0.45

0.46

0.45

1.08

0.81

0.56

0.46

1.09

0.81

0.56

0.47

Page 5

Drip In® PC

0.710" (20mm) Drip In®PC Dripline

18" 24" 12" 30" 36" 42" 48" 60"

Head Loss v. Dripline Length and Emitter Spacing

Head Loss v. Dripline Length and Emitter Spacing

Head Loss v. Dripline Length and Emitter Spacing

Head Loss v. Dripline Length and Emitter Spacing

Head Loss v. Dripline Length and Emitter Spacing

Spacings:

12"

0.710" (20MM) DRIP IN® PC DRIPLINE

18"

24"

30"

36"

42"

48"

54"

60"

30

25

20

15

Head Loss (psi)

10

5

0

30

25

20

15

Head Loss (psi)

10

5

Drip In 20mm .42 GPH PC Emitter 0% Slope.

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

Drip In 20mm .63 GPH PC Emitter 0% Slope.

Dripline Length (feet)

30

25

20

15

Head Loss (psi)

10

5

0

30

25

20

15

Head Loss (psi)

10

5

Drip In 20mm .53 GPH PC Emitter 0% Slope.

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

Dripline Length (feet)

Drip In 20mm .75 GPH PC Emitter 0% Slope.

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900

30

25

20

15

Head Loss (psi)

10

5

0

Drip In 20mm 1.02 GPH PC Emitter 0% Slope.

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400

20mm Drip In PC™ – Maximum Recommended Dripline Length (Feet) (0.710" I.D./0.805" O.D./0.047" Wall)

Dripline Length (feet)

Dripline Length (feet)

Inlet

Pressure

15 psi

25 psi

35 psi

45 psi 725

Dripper Flow

Rate (gph)

12” 18” 24” 36” 42” 48”

357 312 280 251 206 502 440 394 353 290 635 556 498 445 366 871 762 683 611 502 979 857 767 687 565 1081 947 848 759 624

532 466 418 374 307 749 656 588 526 432 947 829 742 664 546 1299 1137 1019 9122 749 1460 1278 1145 1024 842 1613 1412 1265 1132 930

614 561 503 450 370 903 790 708 633 521 1140 998 894 800 658 1588 1369 1227 1098 903 1758 1539 1379 1234 1014 1942 1700 1523 1363 1121

634 568 509 418 1020 893 800 716 589 1288 1128 1010 904 743 1795 1548 1387 1241 1020 1987 1740 1558 1394 1146 2195 1922 1721 1540 1267

0.42 0.53 0.63 0.75 1.02 0.42 0.53 0.63 0.75 1.02 0.42 0.53 0.63 0.75 1.02 0.42 0.53 0.63 0.75 1.02 0.42 0.53 0.63 0.75 1.02 0.42 0.53 0.63 0.75 1.02

Maxiumum length of run based on EU and minimum pressures – please contact Toro for length of run based on

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700

1.20

1.00

0.80

0.60

Flow rate (gph)

0.40

0.20

0.00

0 5 10 15 20 25 30 35 40 45 50 55 60

20mm Emitter discharge rate v. pressure

1.05

1.04

1.01

0.71

0.70

0.69

0.59

0.59

0.58

0.49

0.42

0.00

0.00

0.00

0.00

0.00

0.52

0.51

0.43

0.43

Dripper Spacing

Barb Loss Factor (kd) 0.75 Coefficient of variation ≤5%

other criteria such as flushing velocity.

Dripline Length (feet)

1.07

1.06

1.06

0.72

0.72

0.71

0.60

0.60

0.60

0.53

0.43

0.54

0.54

0.43

0.43

Pressure in psi

1.08

1.07

0.72

0.72

0.60

0.60

0.55

0.54

0.43

0.43

1.09

0.73

0.61

0.55

0.43

1.09

0.73

0.61

0.56

0.43

Page 6

The growers most economical choice

for vineyards, orchards, and row crops.

Advantages:

• Highly clog-resistant due to wide, deep

turbulent passageways and raised inlets.

• Extremely accurate flow rate due to

high quality control standards.

• Reduced labor and installation cost. No

hole punching, lost emitters or handling

damage.

• Can’t separate because there are no

clip-ons or connections.

• Lower friction loss due to jointless

design, allows longer runs and fewer

mainlines.

• For above and below ground

applications.

• Emitters are factory spaced, thus

requiring no field installation

(hole punching, clip-ons, etc.).

The In-line Emitter is enclosed and

inseparably welded to the inside wall

of the tubing as it is extruded in the

manufacturing process. This emitter

has enjoyed over 20 years of reliable

performance in a variety of applications.

Pressure Compensating Dripline is a

one piece, jointless emitter enclosed tube.

It is rugged, lightweight and very flexible.

It can be laid out and re-rolled easily

with no damage to the in-line emitters.

Only the highest quality resins are used.

®

Drip In

economical choice for permanent or row

crops. PC dripline now comes with the

Toro Ag Irrigation Blue Stripe of quality.

High Speed Installation and Removal

In addition to high speed layout and

recovery, tractor-mount spindle reels

provide convenient storage between

seasons, plus easy shipment and handling.

Built-in emitters make

Drip In® the ideal dripline for quick,

damage-free re-rolling through dense

crops like tomatoes or cotton.

dripline is the most effective and

Other Drip In® Products

Drip In

Drip In dripline comes factory-installed

with clip rings.

• Dramatically reduces labor and

installation time in the field.

• Unique engineering plastics provide

unparalleled strength on the wire.

• Superior control of water placement by

directing water droplet to the plant.

• Low profile for mechanical harvesting.

• Works with 14 gauge wire.

• Patent Pending

®

Clipperline

Drip In® Rootguard

ROOTGUARD protection technology

combines Treflan® with the drip emitter

to inhibit root growth. This is a patented

technology where the herbicide is

released at a uniform rate over a long

period of time. It maintains a sufficient

concentration in the soil immediately

surrounding the drip emitter, to prevent

root growth into the emitter.

®

®

©2014 The Toro Company

Micro-Irrigation Business

1588 N. Marshall Avenue, El Cajon, CA 82020-1523, USA

Tel: +1 (800) 333-8125 or +1 (619) 562-2950

Fax: +1 (800) 892-1822 or +1 (619) 258-9973

toro.com

DLT002 06/14

Loading...

Loading...