Page 1

Landscape

Dripline

Design

Page 2

Landscape Dripline Design_____________________________________________________________

Table of Contents

■ Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

General Design Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Water Availability and Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Soil Types and Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Plant Material Classification and Planting Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Emitter and Dripline Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Spacing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Dripline Placement From Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Designing for Wind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Designing for Slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Designing for Elevation Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Typical Design Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-17

Designing a Subsurface System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Design Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Typical Design Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-17

Irrigation Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

Application Rate Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Water Application Rate Table (In Inches Per Hour) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Zone Run Time Scheduling Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-34

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Planting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Installation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-34

Routine Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35-36

System Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Routine Inspection Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Component Maintenance Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36-38

Remote Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Dripline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Flush Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Troubleshooting Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Excessively Wet Soil Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Excessively Dry Soils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

System Components and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40-43

Drip Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Blank Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Flushing Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Air Vent/Vacuum Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Compression Fittings and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Micro Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Micro Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Micro Fitting Swivel Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Dual Goof Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Micro Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Irrigation Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Fertilizer Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Water Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Soil Moisture Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

i

Page 3

Introduction

_____________________________________________________________Landscape Dripline Design

Toro provides more than just irrigation products — we provide turf

solutions. For more than forty-five years, we’ve supplied a full line of quality

irrigation equipment to fit any turf need. Customers have grown to trust

Toro because we translate new technology into productive irrigation

products for every turf requirement.

In addition to Drip In® PC Brown Dripline for at-grade installations, Toro

also offers a complete below-grade dripline system, DL2000®, designed

specifically for the residential and commercial turf markets. Toro DL2000®

is the most technologically advanced subsurface irrigation system available.

Through revolutionary ROOTGUARD® technology, DL2000 prevents emitter

clogging while delivering optimal water application directly to the root zone.

DL2000 is perfect for odd-shaped designs, median strips, public recreation

areas and residential property — any place where sprinklers don’t fit the

application.

Whether installing dripline at-grade or below-grade, Toro has the perfect

solution to fit your needs.

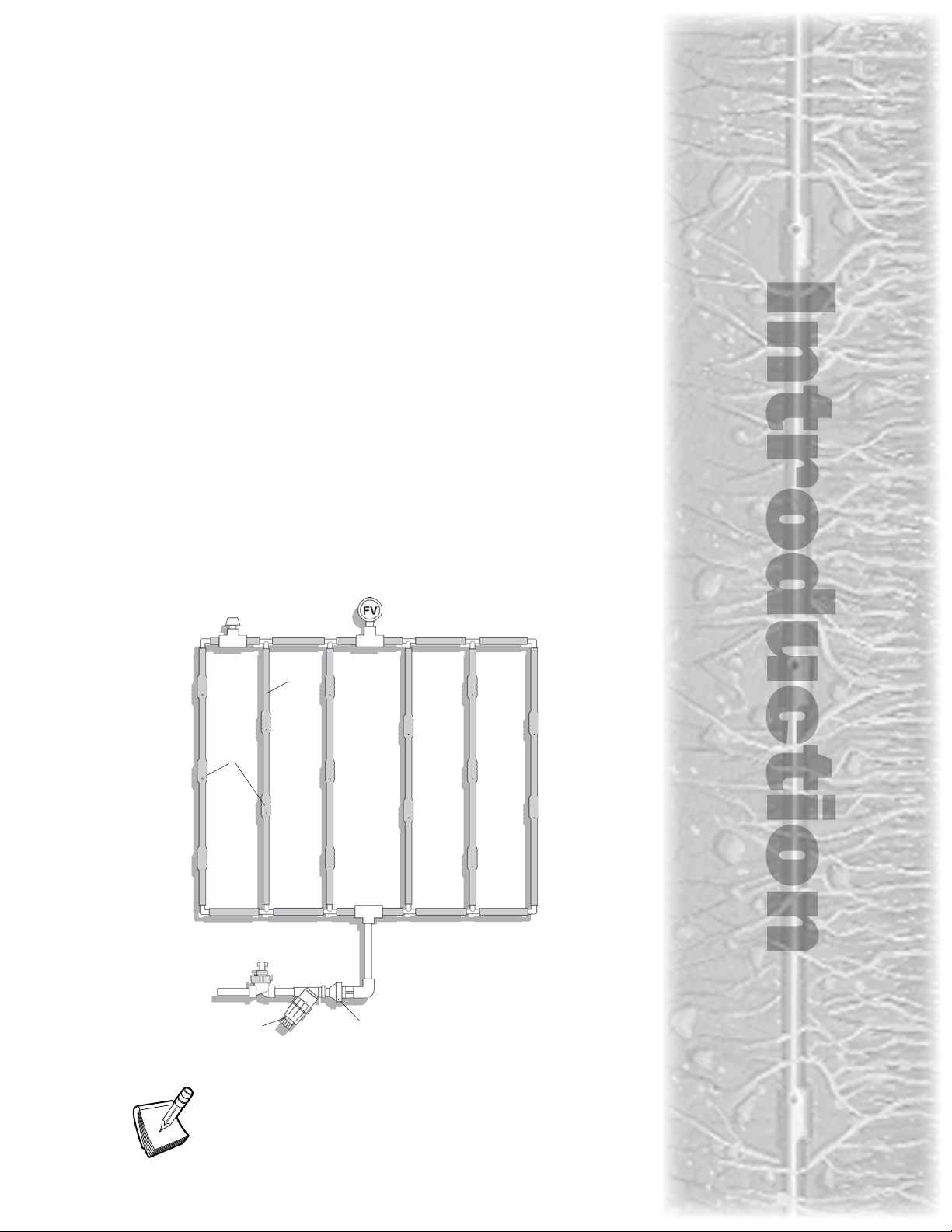

■ Introduction

Water Source

Air/Vacuum

Relief Valve*

Emitter

Control Valve

Typical Dripline Layout

Flush Valve

Dripline

Filter

*Only Required on Subsurface Installations

This manual has been written with the assumption

that users already possess a fundamental understanding

of basic irrigation design.

Pressure Regulator

1

Page 4

Terminology

Landscape Dripline Design _____________________________________________________________

■ Terminology

Application Rate — the rate at which a subsurface grid applies water to a

specific zone, over a given period of time, measured in inches per hour.

Backflow Prevention Device — the device, required by law, on an irrigation

system that prevents water from re-entering the potable water lines once it

flows into the irrigation pipes.

Blackwater — wastewater from toilet, latrine, and agua privy flushing and sinks

used for food preparation or disposal of chemical or chemical-biological

ingredients.

BOD— the abbreviation for “Biochemical Oxygen Demand;” a measure or the

amount of oxygen required to neutralize organic wastes.

Controller — the device that sends timing commands to remote control valves

for actuation.

Design Operating Pressure — the pressure a designer uses to determine spacing

distances and flow for driplines. The design operating pressure is determined

by subtracting estimated friction losses from the static water pressure.

Dynamic Pressure — the pressure reading in a pipeline system with water

flowing.

Effluent Water — any substance, particularly a liquid, that enters the

environment from a point source. Generally refers to wastewater from a

sewage treatment or industrial plant.

Emitter — a device used to control the rate at which water is applied to a

specific area. Emitters are usually injection molded out of chemical-resistant

plastics and come in both inline and online configurations. Toro dripline is

manufactured with factory-installed, inline emitters.

Evapotranspiration — the combined rate at which water evaporates into the

atmosphere and/or is consumed by plants.

Flow — the movement of water through the irrigation piping system.

Flush Cap — a device used to automatically flush sediment and debris from

driplines within a grid. Flushing occurs at the beginning of each irrigation

cycle and ends as soon as the system operation pressure reaches 10 PSI.

Flush Manifold — the end line or pipe in a subsurface grid that connects to all

the driplines. A flush valve and/or cap is installed in the manifold to flush

debris and sediment from the grid during each irrigation cycle.

FPS — the abbreviation for “feet per second;” refers to the velocity of water

in pipes.

Friction Loss — the loss of pressure (force) as water flows through the

piping system.

GPH — the abbreviation for “gallons per hour;” unit of measure for water flow.

GPM — the abbreviation for “gallons per minute;” unit of measure for

water flow.

Greywater —wastewater from washing machines, showers, bathtubs, lavatories

and sinks that are not used for disposal of chemical or chemical-biological

ingredients.

I.D. — the abbreviation for “inside diameter.”

Lateral — the pipe in an irrigation system located downstream from the remote

control valve. Lateral pipes carry water directly to a zone.

Main Line — the pipe in an irrigation system that delivers water from the

backflow prevention device to the remote control valves. This is usually the

largest pipe on the irrigation system, generally under constant pressure and

located upstream from the remote control valves.

2

Page 5

_____________________________________________________________Landscape Dripline Design

■ Terminology

NOTES:

Manifold — a group of control valves located together in the same area.

O.D. — the abbreviation for “outside diameter.”

PSI — the abbreviation for “pounds per square inch;” unit of measure for

water pressure.

PVC Pipe — Poly Vinyl Chloride pipe; the most common pipe used in irrigation

systems.

P.O.C. — abbreviation for “point of connection.” This is the location on the

irrigation system where a tap is made for connection of a backflow prevention

device or water meter.

Potable Water — water used for drinking purposes.

Reclaimed Water — domestic wastewater that has been treated to a quality

suitable for a beneficial use and is under the direct control of a

treatment plant.

Remote Control Valve — the component in the irrigation system that regulates

the on/off of water from the main line to the driplines; activated by the

controller.

Service Line — the pipe supplying water from the city water main to the

water meter.

Spacing — the distance between the emitters or the driplines.

Static Water Pressure — the pressure that exists in a piping system when there is

no flow; measured in pounds per square inch (PSI).

Subsurface Grid — a group of parallel, inline driplines that are connected to

supply manifolds and flush manifolds.

Supply Manifold — the pipe connected to the remote control valves that

supplies water to the driplines within a subsurface grid.

Surge — the build-up of water pressure in a piping system due to certain

characteristics of the pipe, valves and flow.

TDS — the abbreviation for “total dissolved solids.” The sum of all inorganic

and organic particulate material within a given amount of water. TDS is an

indicator test used for wastewater analysis and is also a measure of the mineral

content of bottled water and groundwater.

TSS — the abbreviation for “total suspended solids.” The sum of all non dissolved inorganic and organic material within a given amount of water. The

other component of Total Solids (TS) in water are Total Dissolved Solids, so

generally TSS + TDS = TS.

Velocity — the speed at which water flows through the piping system; measured

in feet per second (FPS).

Wastewater — water containing waste including grey water, black water or

water contaminated by waste contact, including process-generated and

contaminated rainfall runoff.

Water Main — the city water pipe located in the street or right-of-way.

Water Pressure — the force of water that exists in a piping system; measured in

pounds per square inch (PSI).

Working Pressure — the remaining pressure in the irrigation system when all

friction losses are subtracted from the static pressure.

Zone — a subsurface grid or area of dripline that is controlled by the same

remote control valve.

3

Page 6

Design Parameters

Landscape Dripline Design _____________________________________________________________

■ General Design Parameters

Design Parameters

Toro dripline is designed for use in applications using the

grid concept, with supply and flush manifolds at each end to create a

closed-loop system. The result of the grid design is a completely

subsurface-wetted area that is ideal for plant growth and root

development. Toro dripline can also be installed on both sides of tree

and shrub rows when the grid installation is not justified.

Product Selection

Pressure-compensating dripline is available in two nominal

emitter flow rates, 0.5 GPH and1.0 GPH with emitters spaced at 12” and

18” intervals. Please consult performance charts for actual flows. Product

choice is dependent on site conditions and soil types. The choice of

dripper spacing, dripline lateral spacing and depth is dependent on the

types of soil and plants used.

Water Availability and Quality

The allowable water flow (75% of available flow) and pressure are the

determining factors for the maximum allowable zone flow. This is

determined by the capacity at the point of connection and supply

restrictions beyond the point of connection. Available flow and pressure

can be obtained from the following sources:

• Physical pressure and volume tests (most reliable)

• Your local water district ofce

• Engineered calculations based on the size of the point of connection,

meter and static pressure

Always make these determinations during the time of day at which the

water pressure is at its lowest point.

Water quality determines the type of filter used, any necessary treatment

and, in the case of reclaimed or effluent water, which drip emitter product to use. Water quality varies significantly according to the source

which can be classified generally as:

• Potable water

• Irrigation district water

• Greywater or industrial recycled water

• Efuent water

• Recycled water

• Well water

4

Page 7

_____________________________________________________________Landscape Dripline Design

■ General Design Parameters

Potable water, the most common type of water used in landscape

applications, has relatively little debris and chemical contamination.

Therefore, it only needs to be filtered with a screen or disk filter. With

other water sources, it is advisable to obtain a water analysis prior to

designing and installing the system. Some of the important parameters

are:

• Total dissolved solids (tds)

• Iron content

• Calcium, magnesium, sulfates, bicarbonates and hardness

• Chemical compounds present, bod and tss (grey water, industrial

treated water and recycled water)

• The types and amount of sediment present (irrigation district water

and well water)

Soil Types and Preparation

For design purposes, soil classifications of clay (heavy), loam (medium)

and sand (light) are used in conjunction with plant types to determine

the emitter and lateral spacings necessary to provide a uniform subsurface soil moisture regime for the plant material.

As with all types of landscape irrigation systems, properly prepared soil is

necessary to provide a homogenous bed for proper plant establishment,

plant growth and uniform water distribution. Heavily compacted and

layered soils should be ripped and tilled at a uniform eight- to twelveinch depth to improve the consistency and tilth of the soil.

NOTES:

Soil and water analyses are recommended when the soil texture, soil Ph

and water quality are in doubt. This is necessary in order to recommend

soil amendments and water treatment when required. If possible,

pre-irrigate the installation site when the soil is too dry to till and trench.

Plant Material Classification and Planting Layouts

Emitter and lateral spacings are determined by soil and plant material

classifications. For design purposes, two general plant classifications are

used: 1) trees, shrubs and ground cover, and 2) turf. Turf plantings have

a much more intense and compact root structure, thus requiring a closer

emitter and lateral spacing to efficiently irrigate these areas.

Planting layouts determine the size and type of irrigation design

necessary to provide uniform moisture distribution. Individual or isolated

planting areas separated by large expanses of unplanted areas or

hardscapes require individual grids that provide moisture within the

foliage canopy of the landscaped area.

5

Page 8

Landscape Dripline Design _____________________________________________________________

■ General Design Parameters

NOTES:

Narrow, linear tree and shrub plantings require narrow, linear subsurface grids consisting of two to four laterals. More intense plantings that provide a complete foliage canopy at maturity require a

grid design that applies uniform moisture levels within the foliage

canopy (turf, groundcover, and dense shrub and tree plantings).

Use the Spacing Guidelines Table (Table 1.2) to determine the

proper emitter and lateral spacing.

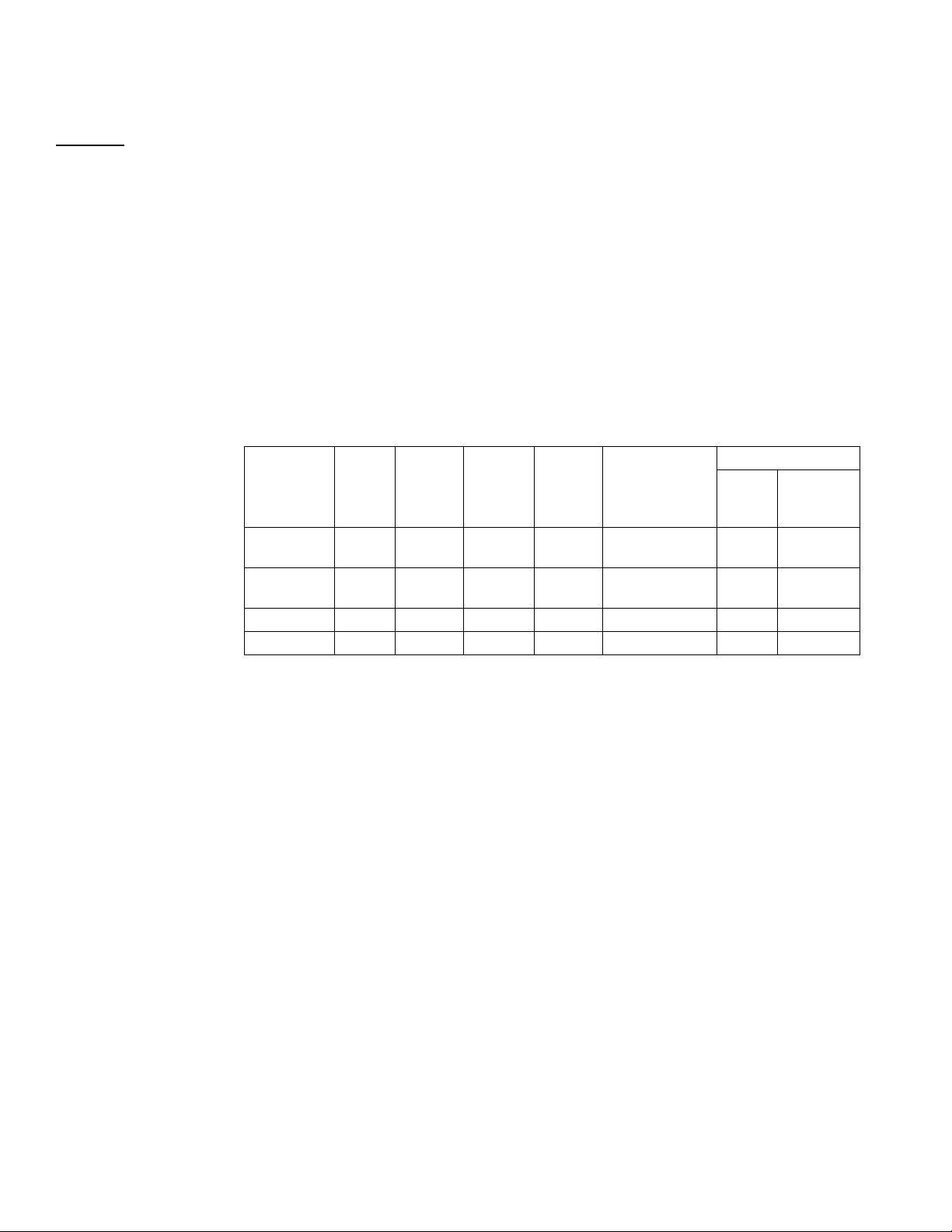

Emitter and Dripline Selection

Toro offers the following types of dripline products:

Installation Type

Dripline

DL2000® 5⁄8”

Drip In® 5⁄8”

Microline 1⁄4” 0.5 GPH No 6”, 12” Yes X X

Soakerline™ 1⁄4” 0.5 GPH No 6”, 12” No X

Tubing

Dia.

Flow

Rate

0.5 &

1.0 GPH

0.5 &

1.0 GPH

Pressure

Comp.

Yes 12”, 18” Yes X X

Yes 12”, 18” No X

Emitter

Spacing

ROOTGUARD®

Protected

Below-

Grade

At-Grade/

Mulched

Over

TABLE 1.1

6

Page 9

_____________________________________________________________Landscape Dripline Design

■ General Design Parameters

NOTES:

Using 1/4” dripline

Toro’s two 1/4” dripline offerings, Microline and Soakerline, are

ideal for small, tight areas because of their flexibility. They can

also be used to loop around trees and bushes. They’re often used

to retrofit sprinkler risers and bubblers to subsurface drip because

they easily attach to a multi-outlet manifold.

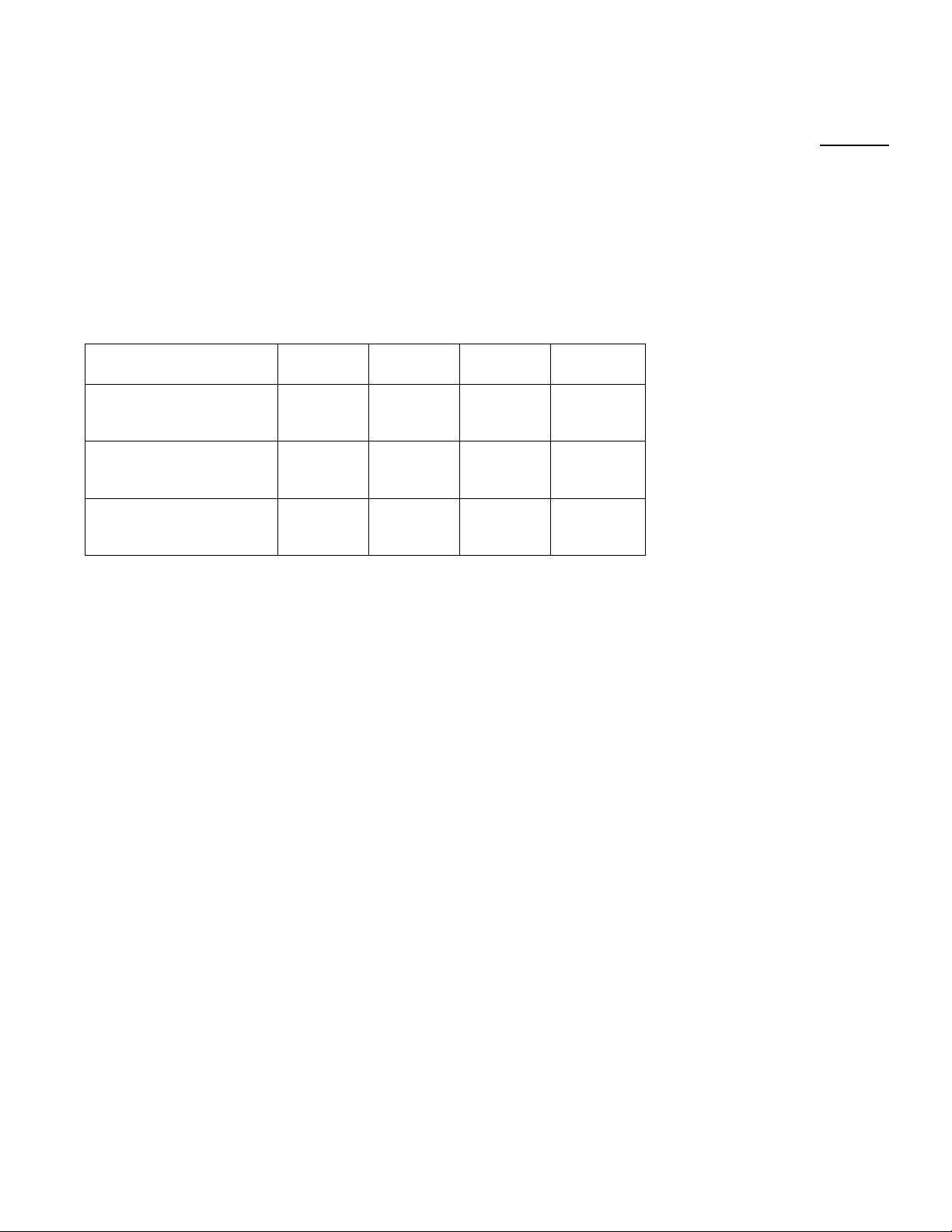

Spacing Guidelines

Soil Type

Medium Sand

• Trees/Shrubs/Groundcover

• Turf*

Loam

• Trees/Shrubs/Groundcover

• Turf*

Clay

• Trees/Shrubs/Groundcover

• Turf*

* For Subsurface Only

TABLE 1.2

Emitter

Spacing

12”

12”

18”

12”

18”

18”

Row

Spacing

18”

12”

18”

18”

24”

18”

Emitter

Flow

1.0 GPH

1.0 GPH

1.0 GPH

1.0 GPH

0.5 GPH

0.5 GPH

Burial

Depth*

4”

4”

6”

4”

6”

4”

Dripline Placement From Edges

Consideration of dripline location is necessary when laying out

zone edges. Hardscape materials act as heat collectors and cause

landscape edges to dry out before the center of the landscape,

making it essential to compensate by placing the first driplines no

more than two to four inches from the landscape edge. In uncontained landscape areas, start the first dripline two to four inches

outside of the planted area. In subsurface applications specifically

watering turf, add dripline over the supply and flush manifolds to

ensure that these edges have adequate moisture coverage.

Wind

As with all total-coverage irrigation systems, attention must be given to windward turf edges in high-wind areas to prevent browning. Place the first dripline no more than two to four inches from

the edge of hardscaped areas or two to four inches outside the

turf edge in uncontained landscape areas. Add an extra dripline six

inches from the first line between the first and second lateral lines

on the windward lateral edge.

7

Page 10

Landscape Dripline Design _____________________________________________________________

■ General Design Parameters

NOTES:

Slopes

Driplines should be located parallel to the contour of slopes

whenever possible. Since dripline runoff occurs on areas with a

slope of greater than 3%, consideration must be given to dripline

density from the top to the bottom of the slope. The dripline on the

top two-thirds of the slope should be placed at the recommended

spacings for the soil type and plant material in use. On the lower

one-third, the driplines should be spaced 25% wider. The last dripline can be eliminated on slopes exceeding 5%. For areas exceeding

ten feet in elevation change, zone the lower one-third of the slope

separately from the upper two-thirds to help control drainage.

Elevation Differences

When utilizing non-pressure-compensating dripline, elevation differences of five feet or more require separate zones or individual

pressure regulators for each six-foot difference on uniform slopes

(see detail number 17, p. 31).

When working with rolling landscapes with elevation differences of

five feet or more within a zone, it is best to use pressure-compensating dripline to equalize pressure differentials created by the elevation differences.

Though vacuum relief valves aren’t necessary when installing Toro

dripline at-grade - even when mulching over - all subsurface irrigation zones must have a vacuum relief valve at the highest point in

order to eliminate the vacuum created by low-line drainage, which

causes soil ingestion. This is especially crucial when the dripline

laterals are placed perpendicular to the contour of the slope as in

street medians. All subsurface dripline laterals within the elevated

area must be connected with an air relief lateral (see detail number

12, p. 28).

In-line spring-check or swing-check valves should be used on slopes

where low-line drainage could cause wet areas in the lowest areas of

an irrigation zone (see detail number 23, p. 34).

8

Page 11

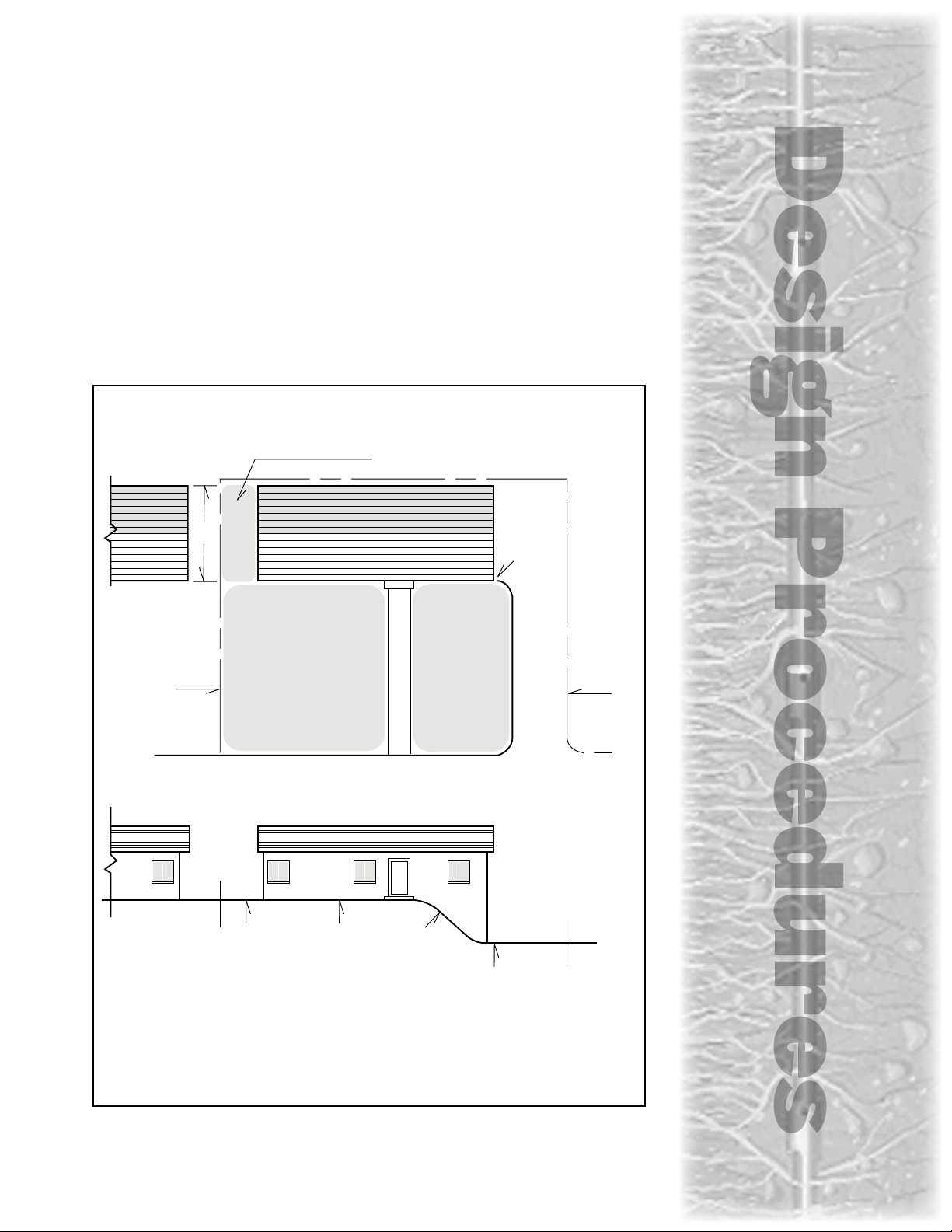

Design Procedures

_____________________________________________________________Landscape Dripline Design

■ Typical Design Procedures

Designing a System

Try designing your own dripline system using the diagram shown

below and the tables and information provided in the remainder of

this section. When you have finished the design worksheet, check

your answers on page 17 at the end of this section.

Design a typical dripline installation for zone #1

where the width is 5’ and the length is 50’.

Flat, Sandy Soil Area

Is In Constant Shade

Property

Line

50’

Sandy Soil,

1

23

Flat, Sandy Soil F35% Slope,

Exposed When

Contractor Cut

Into Hill To

Place The House

Shady,

Sandy

Sunny,

Flat,

Sandy

Sunny,

Clay Soil,

Grass

P. O.C

Clay Soil

Property

Line

Point Of

Connection

Allowable Water Supply = 15 GPM

Dynamic Pressure = 45 PSI

Regulated Dynamic Pressure = 25 PSI

Fig. 1

9

Page 12

Landscape Dripline Design _____________________________________________________________

■ Typical Design Procedures

NOTES:

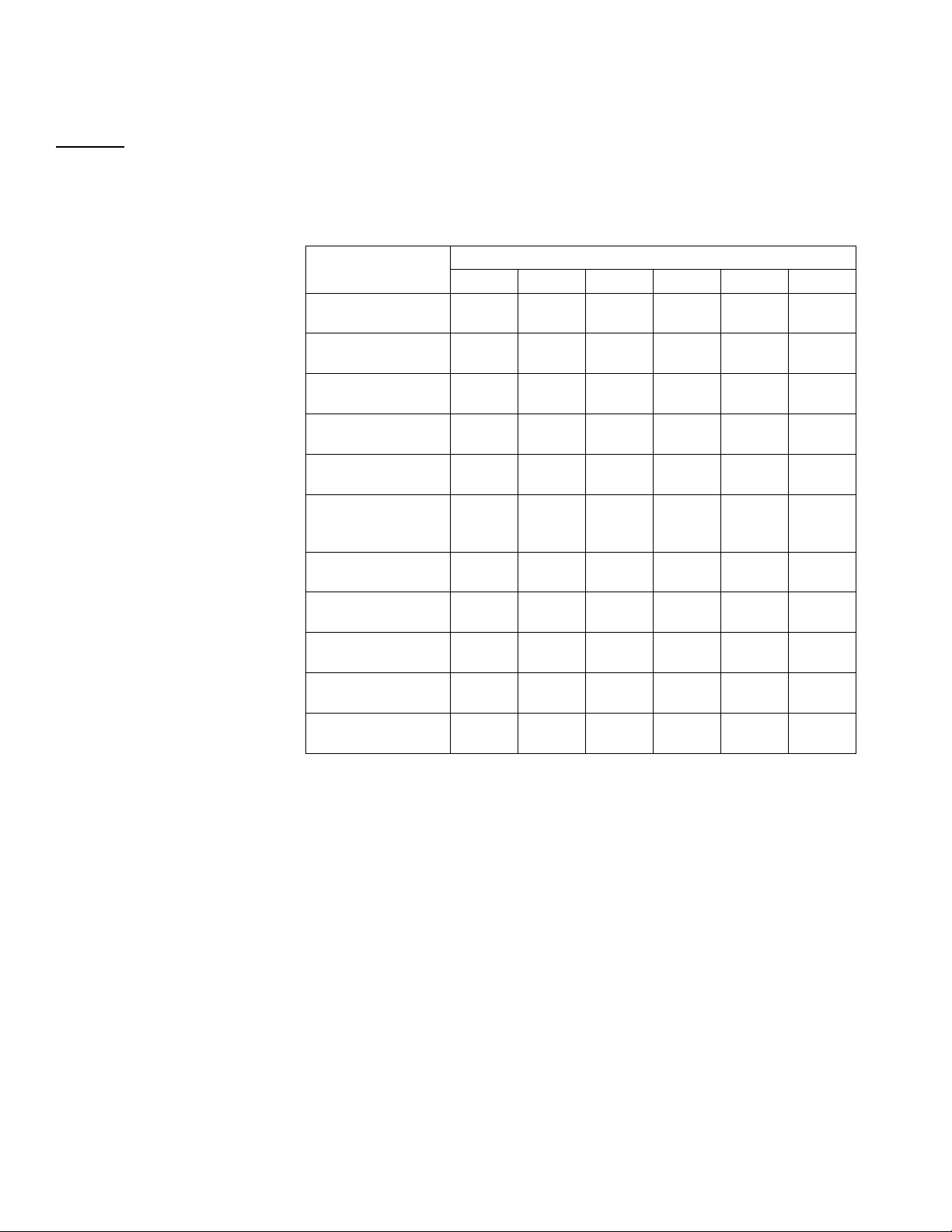

Design Worksheet

Use this worksheet to determine the type and quantity of product

required for the system.

DW1 Allowable Water Supply ____________ GPM

DW2 Dynamic Pressure ____________ PSI

Zones*

1 2 3 4 5 6

DW3

Soil Texture

DW4

Plant Type

DW5

Slope %

DW6

Dripline Product

DW7

Emitter Spacing

DW8

Max. Dripline Lateral

Spacing

DW9

Nominal Flow Rate

DW10

Actual Flow Rate

DW11

Max. Run Length

DW12

Exact Lateral Spacing

DW13

Zone Flow (GPM)

* The number of zones may vary depending on the specic needs of each installation. TABLE 2.1

10

Typical Design Steps

Step 1: Obtain or draw a scaled plan of the area to be irrigated.

Step 2: Locate the point of connection on the scaled plan.

■ Determine the water meter size and/or allowable volume

of the water source: ______ GPM (DW1)

■ Verify the regulated dynamic water pressure: ______ PSI (DW2)

At this point in a typical installation, it would be

necessary to select a pressure regulating device to

establish/control the pressure in the system. Since there’s

a number of factors that can apply to a design (slope, length

of run, dripline type — pressure-compensating vs.

non-pressure-compensating), a regulated dynamic pressure of

25 PSI has been chosen for this example.

Page 13

_____________________________________________________________Landscape Dripline Design

■ Typical Design Procedures

Step 3: Note the site and environmental parameters.

■ Soil texture (clay, loam or sand): ____________ (DW3)

■ Plant material(s) (trees, shrubs, ground cover or turf):

____________ (DW4)

■ Direction and degree of slope: ______________% (DW5)

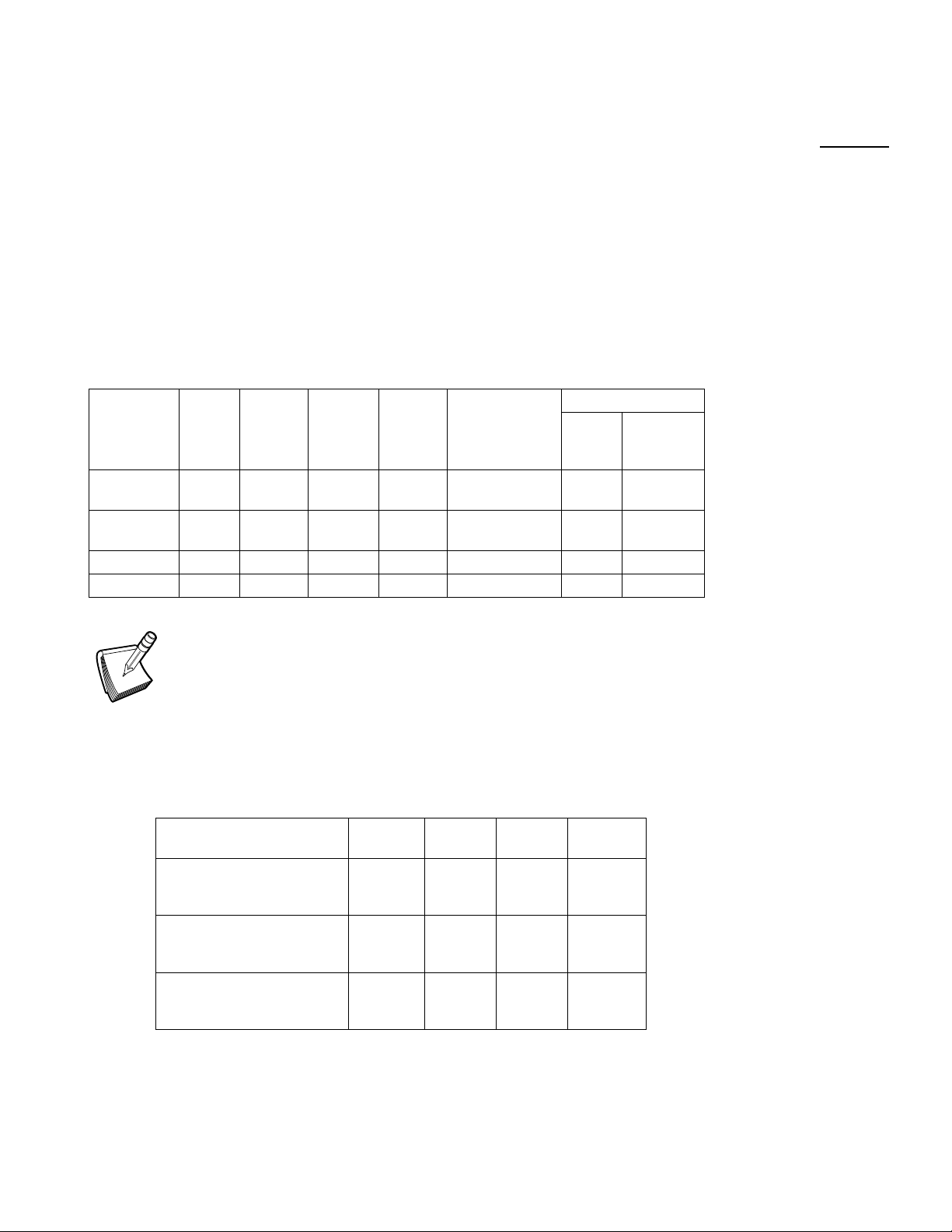

Step 4: Lay out the laterals.

■ Use Table 2.2 below to determine the type of dripline

product necessary to fit the irrigation needs of the site

(i.e., pressure-compensating or non-pressure-compensating;

microline or dripline).

Dripline product: _______________ (DW6)

Installation Type

Dripline

DL2000® 5⁄8”

Drip In® 5⁄8”

Microline 1⁄4” 0.5 GPH No 6”, 12” Yes X X

Soakerline™ 1⁄4” 0.5 GPH No 6”, 12” No X

Tubing

Dia.

Flow

Rate

0.5 &

1.0 GPH

0.5 &

1.0 GPH

Pressure

Comp.

Yes 12”, 18” Yes X X

Yes 12”, 18” No X

Emitter

Spacing

ROOTGUARD®

Protected

Below-

Grade

At-Grade/

Mulched

Use non-pressure-compensating dripline in

applications with less than 20 PSI pressure

in flat areas.

NOTES:

Over

TABLE 2.2

■ Using the Spacing Guidelines Table below, determine the

maximum recommended spacing between drippers and

spacing between driplines based on plant material and

soil types.

Soil Type

Medium Sand

• Trees/Shrubs/Groundcover

• Turf*

Loam

• Trees/Shrubs/Groundcover

• Turf*

Clay

• Trees/Shrubs/Groundcover

• Turf*

* For Subsurface Only

Emitter

Spacing

12”

12”

18”

12”

18”

18”

Row

Spacing

18”

12”

18”

18”

24”

18”

Emitter

Flow

1.0 GPH

1.0 GPH

1.0 GPH

1.0 GPH

0.5 GPH

0.5 GPH

Burial

Depth*

4”

4”

6”

4”

6”

4”

TABLE 2.3

Emitter spacing: ________ inches (DW7)

Maximum dripline lateral spacing: ________ inches (DW8)

11

Page 14

Landscape Dripline Design _____________________________________________________________

■ Typical Design Procedures

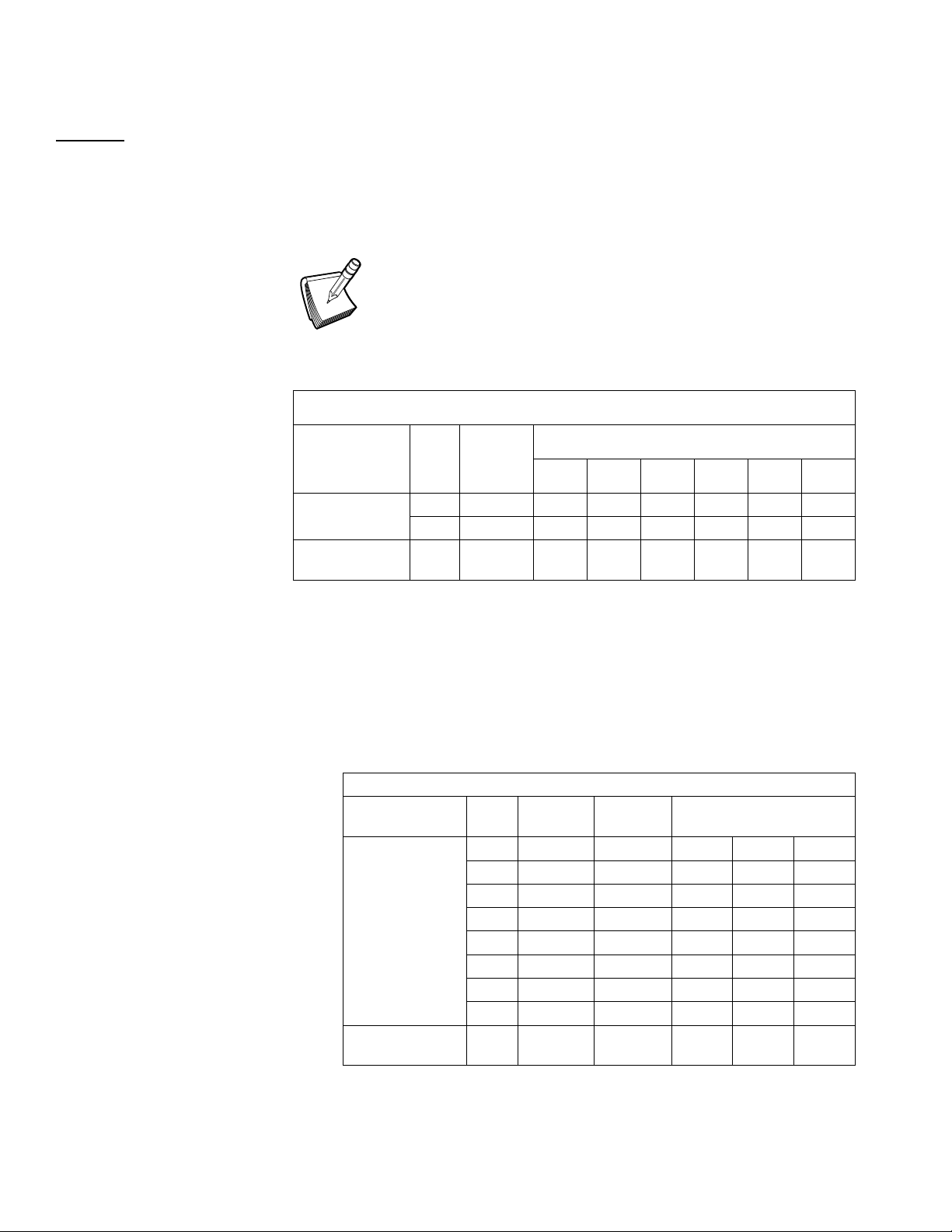

NOTES:

Step 4: Lay out the laterals: (cont.)

■ Using the Spacing Guidelines Table, determine the

nominal emitter flow rate.

Nominal emitter ow rate: __________ GPH (DW9)*

* Actual ow is a function of pressure. Use the Flow

vs. Pressure Table (Table 2.4) to determine actual flow

per emitter: __________ GPH (DW10)

EMITTER FLOW (IN GPH) VS. PRESSURE

Actual Flow

TABLE 2.4

DL2000®

and Drip In®

Microline

and Soakerline™

Tube

Nominal

Dia.

5⁄8” 0.5 GPH 0.53 0.53 0.53 0.53 0.53 0.53

5⁄8” 1.0 GPH 1.02 1.02 1.02 1.02 1.02 1.02

1⁄4” 0.5 GPH 0.50 0.60 0.70 n/a n/a n/a

Flow

15 PSI 20 PSI 25 PSI 30 PSI 35 PSI 40 PSI

■ Determine the maximum recommended run length from

Table 2.5 below for the selected product and pressure.

Maximum length of run: _________ feet (DW11)

MAXIMUM RECOMMENDED LENGTH OF RUN @ 0% SLOPE

DL2000®

and Drip In®

Microline

and Soakerline™

Tube

Dia.

5⁄8” 0.5 GPH 15 PSI n/a 250’ 350’

5⁄8” 1.0 GPH 15 PSI n/a 160’ 240’

5⁄8” 0.5 GPH 25 PSI n/a 360’ 515’

5⁄8” 1.0 GPH 25 PSI n/a 240’ 340’

5⁄8” 0.5 GPH 35 PSI n/a 400’ 565’

5⁄8” 1.0 GPH 35 PSI n/a 260’ 375’

5⁄8” 0.5 GPH 40 PSI n/a 460’ 650’

5⁄8” 1.0 GPH 40 PSI n/a 300’ 430’

1⁄4” 0.5 GPH 20 PSI 19’ 33’ n/a

Nominal

Flow

Initial

Pressure

Spacing Between Emitters

6” 12” 18”

TABLE 2.5

12

Page 15

_____________________________________________________________Landscape Dripline Design

■ Typical Design Procedures

NOTES:

Step 4: Lay out the laterals: (cont.)

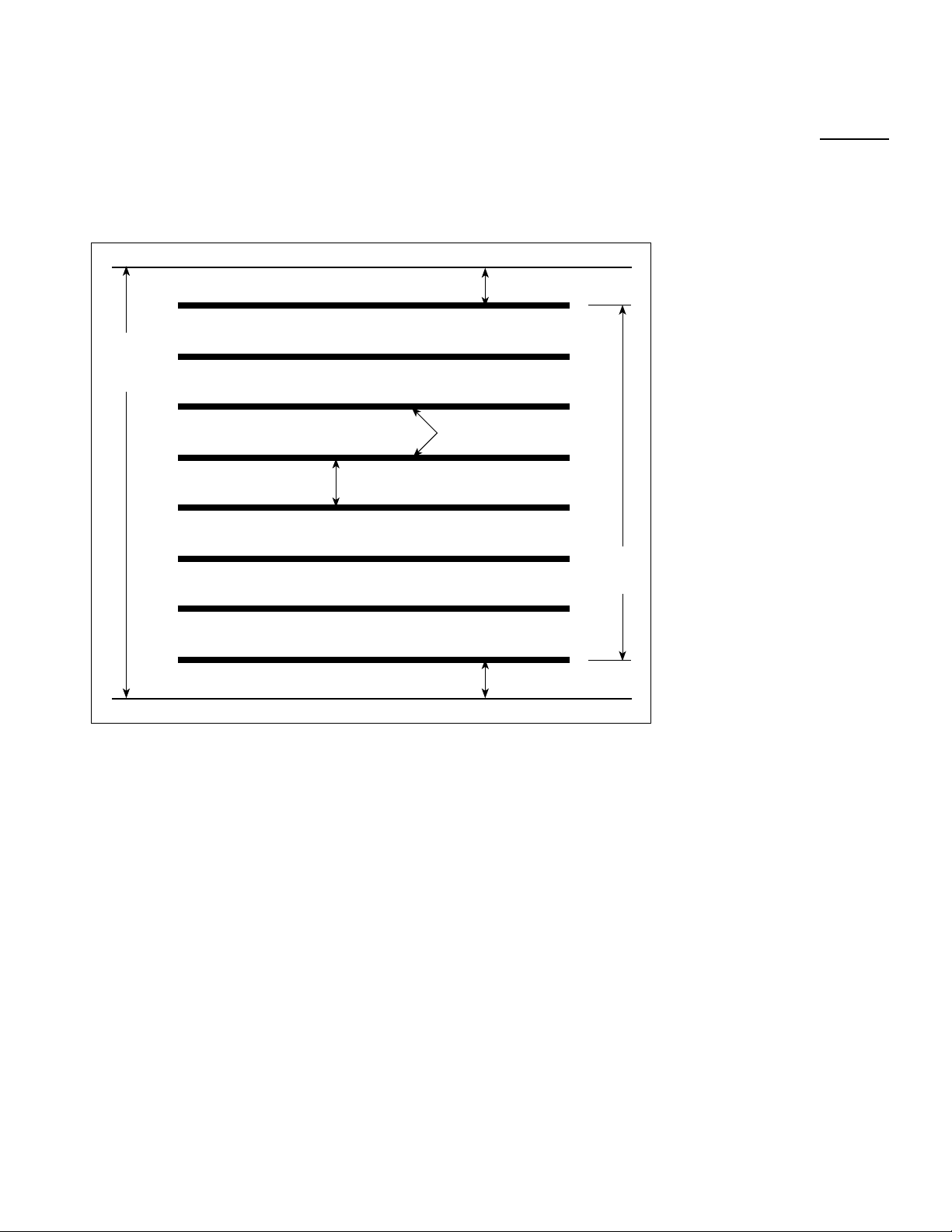

■ Calculate the exact lateral spacing based on the

dimensions of the area to be irrigated with

subsurface drip.

Perimeter

Perimeter Spacing 2”-4”

Widest

Width

Dripline Lateral

Lateral Spacing

Lateral

Area

Perimeter Spacing 2”-4”

Perimeter

TABLE 2.6

A. Measure, in inches, the subsurface drip area at its widest

width.

Width: ________ inches

B. The first and last lateral perimeter spacings can be no

further than two to four inches from the confining

hardscape or two to four inches outside of unconfined

landscapes. For this example we will use 4” spacing.

C. Subtract the sum of the perimeter spacings from the

width to determine the lateral area to be covered by

subsurface driplines.

Width (in inches) – perimeter spacings (in inches)

= Lateral area: ______ inches

13

Page 16

Landscape Dripline Design _____________________________________________________________

■ Typical Design Procedures

NOTES:

■ Step 4: Lay out the laterals: (cont.)

D. Divide the lateral area (as determined in Step C above) by

the recommended lateral spacing (DW8) to obtain the

total number of spaces between laterals. Round off to the

nearest whole number to determine the exact number of

spaces necessary to cover the drip area.

Lateral area

= _______ spaces between driplines

Dripline lateral spacing

E. Add 1 to the number of spaces between driplines (from

Step D above) to determine the total number of driplines

across the widest part of the zone.

1 + Number of spaces between driplines = Total lengths of

dripline: ________

■ Step 5: For applications exceeding a 3% slope, place the laterals parallel

to the slope contour. Increase the calculated lateral spacing by

25% on the lower one-third of the slope to avoid excessive

drainage.

For areas exceeding 10 feet in elevation change, zone the lower

one-third of the slope separately from the upper two-thirds to

help control drainage.

■ Step 6: Determine the total estimated dripline footage required for each

zone. There will always be some waste with each installation.

Therefore, you should plan for additional footage by applying

an appropriate factor for each dripline footage calculation

(10%-25% should suffice).

A. Total dripline footage required: _________ = length of runs x

number of laterals

B. Total dripline footage required x 1.10 (10%) = _________ total

estimated dripline

footage required

(round off to nearest whole number)

14

Page 17

_____________________________________________________________Landscape Dripline Design

■ Typical Design Procedures

NOTES:

■ Step 7: Calculate the total estimated gallons per minute (GPM) per zone

by using one of the two following methods. Be sure to use the

total estimated dripline per zone (see Step 6-A above).

Zone flow: _________ GPM (DW13)

- Determine the total number of drip emitters in each zone,

then calculate the flow per zone based on the total flow rate

of all drippers.

Step A:

Number of drippers =

(within the zone)

Dripline footage required (6A above) x 12”

Dripline emitter spacing (inches)

Step B:

Flow per zone in GPM

Total number of drippers =

x dripper flow rate (GPH)

60 (minutes)

OR

- Calculate zone flow by multiplying the total footage of

dripline in hundreds (footage/100) by the flow per 100 feet

obtained from the following table.

FLOW RATE PER 100 LINEAR FEET (@ 20 PSI)

Product Nominal Flow

DL2000®

and Drip In®

Microline

and Soakerline™

0.5 GPH

0.5 GPH

1.0 GPH

1.0 GPH

0.5 GPH

0.5 GPH

Emitter

Spacing

12”

18”

12”

18”

6”

12”

Actual Flow/100 ft.

GPH GPM

53.00

35.33

102.00

67.99

124.00

62.00

0.88

0.59

1.70

1.13

2.06

1.03

TABLE 2.7

15

Page 18

Landscape Dripline Design _____________________________________________________________

■ Typical Design Procedures

NOTES:

■ Step 8: Locate and size both the supply and flush manifolds in each

zone. Both manifolds should be sized to accommodate the

entire flow of the zone in GPM. (For details, refer to the Toro

Technical Data Book, Form No. 490-1737).

■ Step 9: Determine the number and location of the flush caps for

each zone at a minimum of 10 PSI. One flush cap is required

for each 15 gallons per minute of zone flow. Place the flush

caps at the hydraulic center of the flush manifold(s) (see

details 15 and 16, p. 30).

■ Step 10: (Subsurface installations only) Calculate the total number of

air/vacuum relief valves from the following table.

1⁄2” AIR VACUUM RELIEF VALVE (Item No. T-YD-500-34)

Dripline Nominal Flow 12” Emitter Spacing 18” Emitter Spacing

DL2000 0.5 GPH 750’ 1,125’

DL2000 1.0 GPH 390’ 585’

TABLE 2.8

One air vacuum relief valve is required per footage

length indicated in the chart above. For example, two

air vacuum relief valves are needed for 1,500’ of

dripline with 0.5 GPH flow and 12” emitter spacing.

Place air vacuum relief valve(s) at the highest point(s) of each

zone. Using an air vacuum relief lateral, connect the air

vacuum relief valve to all dripline laterals within the elevated

area (see details 15 and 16, p. 30). If the supply and flush

manifolds are at the same depth as the dripline, and are at

the highest point in the zone, they can be used as the air

relief lateral.

16

Page 19

_____________________________________________________________Landscape Dripline Design

■ Typical Design Procedures

NOTES:

■ Step 11: Size pressure regulators based on the total zone flow using

the table below.

PRESSURE REGULATORS

Product

T-PMR-15 LF 1⁄10 - 8 GPM 15 PSI 3⁄4” FNPT 3⁄4” FNPT

T-PMR-25 LF 1⁄10 - 8 GPM 25 PSI 3⁄4” FNPT 3⁄4” FNPT

T-PMR-25 MF 2 - 20 GPM 25 PSI 3⁄4” FNPT 3⁄4” FNPT

T-PMR-25 HF 10 - 32 GPM 25 PSI 1” FNPT 1” FNPT

T-PMR-40 MF 2 - 20 GPM 40 PSI 3⁄4” FNPT 3⁄4” FNPT

Flow Range

(GPM)

Pre-Set Operating

Pressure (PSI)

Inlet Size

(NPT)

Outlet Size

(NPT)

TABLE 2.9

■ Step 12: Size the zone filter according to the total zone flow

(see DW13) using the Filter Sizing Table below. To

eliminate the chance of debris contamination in the event

of a main or sub-main break, use one filter per zone close

to the dripline

FILTERS

Item Number Size (MIPT) Flow (GPM)

T-ALFS7150-L 3⁄4” 25 GPM 142 PSI

T-ALFS10150-L 1” 35 GPM 142 PSI

Maximum

Pressure

ANSWERS FOR ZONE 1, TABLE 2.1, PAGE 10

DW1: 15 GPM

DW2: 25 PSI

DW3: SAND

DW4: GRASS

DW5: 0%

DW6: PC

DW7: 12”

Element Type Mesh Size

Stainless

Screen

Stainless

Screen

150

150

TABLE 2.10

DW8: 12”

DW9: 1.0

DW10: 1.02

DW11: 234’

DW12: 13”

DW13: 4.25 GPM

17

Page 20

Landscape Dripline Design _____________________________________________________________

Irrigation

Scheduling

■ Irrigation Scheduling

Irrigation scheduling with dripline uses the same methods of

calculation as with sprinklers. The dripline grid system is designed to

wet the irrigated area completely by methods similar to those used

with sprinklers, supplying water in inches per hour. For efficient water

application, it is necessary to apply water rates equal to or less than the

rate at which the plants use water (evapotranspiration rate; ET). The ET

rate is expressed in inches per unit of time, thus our application rates

are expressed in inches per hour. (For regional ET data, refer to the

Toro Rainfall and Evapotranspiration Data Book, Form No. 490-1358.)

The following formula is used to determine application rates for

subsurface drip irrigation.

Application rate (inches per hour) = 231.1 x Emitter flow (GPH)

Dripper spacing x Dripline spacing (in inches)

For example: Dripline row spacing = 12”

Dripline emitter spacing = 12”

Emitter flow rate = .53 GPH

231.1 x .53 GPH = .85 inches per hour

12 (inches) x 12 (inches)

Or, use the Water Application Rate Table below to determine

application rates.

Emitter

Spacing

12” 0.5 GPH 0.85 0.57 0.43

DL2000®

and Drip In®

Microline

and Soakerline™

18” 0.5 GPH 0.57 0.38 0.28

12” 1.0 GPH 1.64 1.09 0.82

18” 1.0 GPH 1.09 0.73 0.55

Emitter

Spacing

6” 0.5 GPH 3.98 1.99 1.33

12” 0.5 GPH 1.99 1.00 0.66

Flow Rate

Flow Rate

Dripline Spacing

12” 18” 24”

Dripline Spacing

6” 12” 18”

TABLE 3.1

18

Page 21

_____________________________________________________________Landscape Dripline Design

■ Irrigation Scheduling

NOTES:

Zone Run Time Scheduling Worksheet

To determine zone run times, obtain the following information:

■ monthly evapotranspiration value for the location

■ irrigation application rate

(For regional ET data, refer to the Toro Rainfall and Evapotranspiration

Data Book, Form No. 490-1358.)

The following formulae can be used to determine run times.

Run time per week =

Weekly evapotranspiration rate

Application rate

Run time per day =

Run time per week

Days per week

MONTH:

ZONES

DAY 1 2 3 4 5 6

Sun.

Mon.

Tues.

Wed.

Thurs.

Fri.

Sat.

* The number of zones may vary depending on the specic needs of each installation. TABLE 3.2

19

Page 22

Installation

Procedures

Landscape Dripline Design _____________________________________________________________

■ Installation Procedures

Special Considerations for Subsurface Installations

1. The typical recommended pipe depth for dripline is 4” below

finished grade.

2. For turf areas where aerification is part of normal maintenance

operations, tubing must be buried below the reach of aerification

equipment.

3. Use 710 Series compression fittings for all dripline connections to

ensure the integrity of the connection. Use ¼-inch barbed

fittings for microline connections.

4. It is imperative that DL2000 dripline is installed at a uniform depth

and width according to specifications.

Dripline can be installed using one of the following methods:

INSERTION METHOD ADVANTAGES DISADVANTAGES

Hand trenching or backfilling – Handles severe slopes and

confined areas

– Uniform depth

Oscillating or vibrating plow

(cable or pipe pulling type)

Trenching machine – Faster than hand trenching

Tractor-mounted 3-point

hitch insertion implement

– Fast in small-to-medium

installations

– Minimal ground

disturbance

– No need to backfill the

trench

– May use 1” blade for most

installations

– Uniform depth

– Fastest method, up to four

plow attachments with reels

– Packer roller compacts soil

over pipe

– Slow

– Labor intensive

– Disrupts existing turf and

ground

– Depth must be monitored

closely

– Cannot use on steeper

slopes (20%)

– Requires practice to set and

operate adequately

– Tends to “stretch” pipe

– Slower, requires labor

– Disrupts surface of existing

turf

– Backfill required

– Only suitable for areas large

enough to maneuver a

small tractor

20

5. When possible, pressure test the system before covering trenches or,

when plowing, pre-test for leaks prior to planting.

Page 23

_____________________________________________________________Landscape Dripline Design

■ Installation Procedures

NOTES:

Planting Guidelines

1. Pre-irrigate to ensure that the soil is hydrated to field capacity

before planting begins. This is especially important when planting

sod or hydroseeding.

2. When planting container plants with pot sizes wider than the

dripline lateral spacing, there are two options:

■ Plant the oversized plants prior to installing the dripline laterals

and plant the smaller plants after installing the dripline laterals.

OR

■ Plant all plants after installing the dripline, taking care to pre-cut

and tape the open ends of the dripline when planting the

oversized plants. Re-connect the severed dripline after planting.

3. As with all types of irrigation, it is critical that the root balls are not

allowed to dry out during the plant-establishment period. Initial

postplanting irrigation is critical, so it is necessary to over-irrigate

to ensure water transfer between the landscape soil medium and

container plant root balls.

4. When planting sod or hydroseeded grasses, establishment can be

accomplished without supplemental overhead watering by:

■ making sure the soil is hydrated to field capacity prior to

planting.

■ thoroughly rolling the sod to ensure optimum contact between

the sod and the soil medium. Use multiple-start run times (up to

10 times per day) until the sod has knit into the soil. Take care

not to let the sod dry out during this period.

■ using multiple start times as described above to establish

seeded or hydroseeded grasses.

21

Page 24

Landscape Dripline Design _____________________________________________________________

■ Installation Procedures

NOTES:

Installation Steps

■ Assemble and install filter, remote control valve and pressure regulating valve assembly(ies) according to detail numbers

1 and 2, p. 23.

■ Assemble and install supply header(s) according to detail numbers

3, 5, 4 and 6, p. 24-25. Tape or plug all open connections to

prevent debris contamination.

■ Assemble and install exhaust header(s) in accordance with detail

numbers 7 and 8, p. 26. Tape or plug all open connections to

prevent debris contamination.

■ Install dripline laterals. Tape or plug all open ends while installing

the dripline to prevent debris contamination.

■ Install air vacuum relief valve(s) at the highest point(s) of the

zone(s) according to detail numbers 9, 10, 11 and 12, p. 27-28.

(only required on subsurface installations)

■ Thoroughly flush supply header(s) and connect dripline laterals

while flushing.

■ Thoroughly flush dripline laterals and connect to exhaust header(s)

or interconnecting laterals while flushing.

■ Thoroughly flush exhaust header(s) and install line flushing valves

according to detail number 13, p. 29.

Thorough flushing of each installation segment is

necessary to ensure that no debris contamination

occurs.

22

Page 25

Installation

_____________________________________________________________Landscape Dripline Design

■ Recommended Installation Instructions

Detail No.1

DZK-EZF-075-LF

1. FINISH GRADE.

2. CONTROL WIRES WITH 36” SERVICE COIL

AND WATERPROOF WIRE CONNECTIONS,

DBY OR EQUAL.

3. RECTANGULAR PLASTIC VALVE BOX. HEAT

BRAND STATION NUMBER ON LID IN 2”

HIGH CHARACTERS.

4. PVC MAINLINE PER SPECIFICATIONS

(LENGTH AS REQUIRED).

5. SCH 40 PVC ELBOW (SxS).

6. NATIVE SOIL PER SPECIFICATIONS.

7. CONTROL WIRES TO CONTROLLER.

8. PVC MAINLINE FITTING.

9. TORO EZF-26-04 INLINE VALVE.(*)

10. TORO 150 MESH Y-FILTER.(*)

11. TORO 25 PSI LOW-FLOW PRESSURE

REGULATOR.(*)

12. SCH 40 PVC MALE ADAPTER.

13. SCH 40 PVC BALL VALVE.(*)

14. SCH 80 PVC CLOSE NIPPLE.(*)

15. PEA GRAVEL SUMP, MINIMUM 6” DEEP.

16. BRICK SUPPORTS (4 COMMON BRICKS

REQUIRED).

17. LATERAL LINE TO DRIP SYSTEM.

*PARTS IN DRIP ZONE KIT

Detail No.2

DZK-EZF-075-MF

1. CONTROL WIRES WITH 12” SERVICE

COIL AND WATER PROOF WIRE

CONNECTIONS, DBY OR EQUAL.

2. TORO EZF-29-03 ANTI-SIPHON VALVE (*).

3. TORO 150 MESH Y-FILTER (*).

4. TORO 25 PSI MEDIUM FLOW PRESSURE

REGULATOR (*).

5. SCH 80 PVC CLOSE NIPPLE (*).

6. SCH 40 PVC BALL VALVE (*).

7. SCH 40 PVC MALE ADAPTER.

8. CONTROL WIRES TO CONTROLLER.

9. PVC MAINLINE PER SPECIFICATIONS.

10. PVC MAINLINE FITTING.

11. NATIVE SOIL PER SPECIFICIATIONS.

12. PVC LATERAL LINE PER SPECIFICATIONS.

13. FINISH GRADE.

14. PVC SCH 40 ELBOW (SxS).

15. LATERAL LINE TO DRIP SYSTEM.

16. HEIGHT ABOVE GRADE PER LOCAL

CODES (8” MINIMUM).

(*) PARTS IN DRIP ZONE KIT.

23

Page 26

Landscape Dripline Design _____________________________________________________________

■ Recommended Installation Instructions

Detail No.3

Center-Feed

Sub-Manifold

1. FINISH GRADE.

2. DEPTH OF TUBING PER SPECIFICATIONS.

3. DEPTH OF PVC SUPPLY MANIFOLD PER

SPECIFICATIONS.

4. PVC CROSS (SxSxSxS).

5. TORO COMPRESSION ADAPTER (T-CA-710).

6. PVC TEE (SxSxS).

7. DRIPLINE LATERAL.

8. PVC SUB-MANIFOLD.

9. PVC TEE (SxSxS).

10. PVC SUPPLY MANIFOLD FROM DRIP ZONE KIT.

Detail No.4

Center-Feed

Supply-Manifold

24

1. FINISH GRADE.

2. DEPTH OF TUBING PER SPECIFICATIONS.

3. DEPTH OF PVC SUPPLY MANIFOLD PER

SPECIFICATIONS.

4. TORO LOC-EZE TEE (T-FTT16).

5. DRIPLINE LATERAL.

6. TORO BLUE STRIPE POLY TUBING

(T-EHD1645-XXX) LENGTH AS NECESSARY.

7. TORO LOC-EZE X 1/2” MTP ADAPTER (T-FAM16).

8. PVC TEE (SxSxS).

9. PVC SUPPLY MANIFOLD FROM DRIP ZONE KIT.

Page 27

_____________________________________________________________Landscape Dripline Design

■ Recommended Installation Instructions

Detail No.5

End-Feed Supply

1. FINISH GRADE.

2. DEPTH OF TUBING PER SPECIFICATIONS.

3. DEPTH OF PVC SUPPLY MANIFOLD PER

SPECIFICATIONS.

4. PVC TEE (SxSxT).

5. TORO LOC-EZE X 1/2” MPT ADAPTER

(T-FAM16).

6. PVC TEE (SxSxS).

7. DRIPLINE LATERAL.

8. PVC SUB-MANIFOLD.

9. PVC TEE (SxSxS).

10. PVC SUPPLY MANIFOLD FROM DRIP ZONE KIT.

Sub-Manifold

1. FINISH GRADE.

2. DEPTH OF TUBING PER SPECIFICATIONS.

3. DEPTH OF PVC SUPPLY MANIFOLD PER

SPECIFICATIONS.

4. TORO LOC-EZE ELBOW (T-FEE16).

5. DRIPLINE LATERAL.

6. TORO BLUE STRIPE POLY TUBING

(T-EHD1645-XXX) LENGTH AS NECESSARY.

7. TORO LOC-EZE X 1/2” MTP ADAPTER (T-FAM16).

8. PVC TEE (SxSxT) WITH 1/2” FPT OUTLET.

9. PVC SUPPLY MANIFOLD FROM DRIP ZONE KIT.

Detail No.6

End-Feed

Supply-Manifold

25

Page 28

Landscape Dripline Design _____________________________________________________________

■ Recommended Installation Instructions

Detail No.7

Center-Feed

Layout

1. TORO AUTOMATIC FLUSH VALVE

(T-FCH-H-FIPT) PLUMBED TO FLUSH

MANIFOLD AT LOW POINT.

2. PVC FLUSH MANIFOLD.

3. TORO MANIFOLD-TO-ELBOW

CONNECTION (TYP).

HIGH POINT

ON SLOPE

Detail No.8

End-Feed

Layout

1. DRIPLINE LATERAL.

2. AREA PERIMETER.

3. DL2000 OPERATION INDICATOR (T-DL-MP9),

OPTIONAL.*

4. TORO AUTOMATIC FLUSH VALVE

(T-FCH-H-FIPT) PLUMBED TO FLUSH

MANIFOLD AT LOW POINT.

*SUBSURFACE INSTALLATIONS ONLY

DIRECTION

OF FLOW

1

2

3

4

26

Page 29

_____________________________________________________________Landscape Dripline Design

■ Recommended Installation Instructions

Detail No.9

1. 1” ABOVE FINISH GRADE.

2. NATIVE SOIL PER SPECIFICATIONS.

3. FINISH GRADE.

4. TORO AIR/VACUUM RELIEF VALVE

(T-YD-500-34).

5. 1/2” PVC COUPLING (TxT).

6. 6” ROUND PLASTIC VALVE BOX. HEAT BRAND

“AR” ON LID IN 1” HIGH CHARACTERS.

7. 1/2” SCH 80 PVC NIPPLE

(LENGTH AS REQUIRED).

8. BRICK SUPPORTS (2 COMMON BRICKS

REQUIRED).

9. PEA GRAVEL SUMP (6” DEEP).

10. PVC TEE (SxSxT) WITH 1/2” THREADED

OUTLET.

11. PVC PIPING.

USE ONE AIR/RELIEF VALVE FOR EVERY 7 GPM PER

ZONE. LOCATE AT HIGH POINTS.

1/2” Air/Vacuum

Relief Valve

(Plumbed to PVC Tee)

1. 1” ABOVE FINISH GRADE.

2. NATIVE SOIL PER SPECIFICATIONS.

3. FINISH GRADE.

4. TORO AIR/VACUUM RELIEF VALVE

(T-YD-500-34).

5. 1/2” PVC COUPLING (TxT).

6. 6” ROUND PLASTIC VALVE BOX. HEAT BRAND

“AR” ON LID IN 1” HIGH CHARACTERS.

7. 1/2” SCH 80 PVC NIPPLE

(LENGTH AS REQUIRED).

8. BRICK SUPPORTS (2 COMMON BRICKS

REQUIRED).

9. PEA GRAVEL SUMP (6” DEEP).

10. PVC ELBOW (SxT) WITH 1/2” THREADED

OUTLET.

11. PVC PIPING.

USE ONE AIR/RELIEF VALVE FOR EVERY 7 GPM PER

ZONE. LOCATE AT HIGH POINTS.

Detail No.10

1/2” Air/Vacuum

Relief Valve

(Plumbed to PVC

elbow)

27

Page 30

Landscape Dripline Design_____________________________________________________________

■ Recommended Installation Instructions

Detail No.11

1/2” Air/Vacuum

Relief Valve

(Plumbed to tubing)

1. 1” ABOVE FINISH GRADE.

2. FINISH GRADE.

3. 6” ROUND PLASTIC VALVE BOX. HEAT BRAND

“AR” ON LID IN 1” HIGH CHARACTERS.

4. TORO AIR/VACUUM RELIEF VALVE

(T-YD-500-34).

5. TORO LOC-EZE X 1/2” FPT TEE (T-FTF16).

6. TORO DRIPLINE OR BLUE STRIPE POLY TUBING

(T-EHD1645-XXX) AIR RELIEF LATERAL.

7. PEA GRAVEL SUMP (6” DEEP).

8. BRICK SUPPORTS (2 COMMON BRICKS

REQUIRED).

9. NATIVE SOIL PER SPECIFICATIONS.

USE ONE AIR/RELIEF VALVE FOR EVERY 7 GPM PER

ZONE. LOCATE AT HIGH POINTS.

Detail No.12

Air/Vacuum Relief

lateral

28

1. FINISH GRADE.

2. DEPTH OF TUBING PER SPECIFICATIONS.

3. PVC CROSS (SxSxSxS).

4. TORO COMPRESSION ADAPTER (T-CA-710).

5. DRIPLINE LATERAL.

6. AIR/VACUUM RELIEF LATERAL, TORO BLUE STRIPE

PLY TUBING (T-EHD1645-XXX) CENTERED ON

MOUND OR BERM.

7. TORO AIR/VACUUM RELIEF VALVE (T-YD-500-34)

AT HIGH POINT. REFER TO AIR/VACUUM RELIEF

VALVE DETAILS.

Page 31

_____________________________________________________________Landscape Dripline Design

■ Recommended Installation Instructions

Detail No.13

1. 1” ABOVE FINISH GRADE.

2. FINISH GRADE.

3. TORO FLUSH VALVE (T-FCH-H-FHT).

4. TORO LOC-EZE X 3/4” MHT ADAPTER

(T-FJA16).

5. TORO BLUE STRIPE POLY TUBING

(T-EHD1645-XXX).

6. TORO DRIPLINE OR BLUE STRIPE POLY

TUBING (T-EHD1645-XXX).

7. 6” ROUND PLASTIC VALVE BOX. HEAT BRAND

“AR” ON LID IN 1” HIGH CHARACTERS.

8. TORO LOC-EZE ELBOW (T-FEE16).

9. BRICK SUPPORTS (2 COMMON BRICKS

REQUIRED).

10. NATIVE SOIL PER SPECIFICATIONS.

11. PEA GRAVEL SUMP (6” DEEP).

USE ONE FLUSH VALVE FOR EVERY 7 GPM PER

ZONE. LOCATE AT LOW POINTS. FLUSH RATE IS

0.8 GPM. FLUSH PRESSURE IS 2 PSI.

Automatic Flush Valve

1. 1” ABOVE FINISH GRADE.

2. NATIVE SOIL PER SPECIFICATIONS.

3. FINISH GRADE.

4. TORO FLUSH VALVE (T-FCH-H-FIPT).

5. 6” ROUND PLASTIC VALVE BOX. HEAT BRAND

“AR” ON LID IN 1” HIGH CHARACTERS.

6. 3/4” SCH 80 PVC NIPPLE

(LENGTH AS REQUIRED).

7. BRICK SUPPORTS (2 COMMON BRICKS

REQUIRED).

8. PEA GRAVEL SUMP (6” DEEP).

9. PVC ELBOW (SxT) WITH 3/4” THREADED

OUTLET.

10. PVC PIPING.

USE ONE FLUSH VALVE FOR EVERY 7 GPM PER

ZONE. LOCATE AT LOW POINTS. FLUSH RATE IS

0.8 GPM. FLUSH PRESSURE IS 2 PSI.

Detail No.14

Automatic Flush Valve

29

Page 32

Landscape Dripline Design _____________________________________________________________

■ Recommended Installation Instructions

1. PVC LATERAL LINE FROM DRIP ZONE KIT.

2. PVC SUPPLY MANIFOLD.

3. MANIFOLD-TO-ELBOW CONNECTION (TYP).

4. DRIPLINE LATERAL.

5. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO TORO BLUE STRIPE POLY

TUBING (T-EHD1645-XXX) AT EACH

HIGH POINT.*

6. AIR/VACUUM RELIEF LATERAL, TORO BLUE

STRIPE POLY TUBING (T-EHD1645-XXX)

CENTERED ON MOUND OR BERM.*

7. PVC FLUSH MANIFOLD.

8. PERIMETER LATERALS 2” TO 4” FROM EDGE.

9. AREA PERIMETER.

10. DL2000 OPERATION INDICATOR

Detail No.15

End-Feed Layout

(T-DL-MP9), OPTIONAL.*

11. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO FLUSH MANIFOLD AT

LOW POINT.

* ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

Detail No.16

Center-Feed Layout

1. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO FLUSH MANIFOLD AT

LOW POINT.

2. PVC FLUSH MANIFOLD.

3. MANIFOLD-TO-ELBOW CONNECTION (TYP).

4. PVC LATERAL LINE FROM DRIP ZONE KIT.

5. PVC SUPPLY MANIFOLD.

6. MANIFOLD-TO-TEE CONNECTION.

7. DRIPLINE LATERAL.

8. AIR/VACUUM RELIEF LATERAL, TORO BLUE

STRIPE POLY TUBING (T-EHD1645-XXX)

CENTERED ON MOUND OR BERM.*

9. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO TORO BLUE STRIPE POLY

TUBING (T-EHD1645-XXX) AT EACH

HIGH POINT.*

10. PERIMETER LATERALS 2” TO 4” FROM EDGE.

11. AREA PERIMETER.

12. DL2000 OPERATION INDICATOR

(T-DL-MP9), OPTIONAL.*

* ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

30

Page 33

_____________________________________________________________Landscape Dripline Design

■ Recommended Installation Instructions

1. PVC LATERAL LINE FROM DRIP ZONE KIT.

2. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO TORO BLUE STRIPE POLY

TUBING (T-EHD1645-XXX) AT EACH

HIGH POINT.*

3. PVC FLUSH MANIFOLD.

4. INLINE SPRING CHECK VALVE (JVO500-S2)

TO HELP CONTROL LOW-HEAD DRAINAGE

(TYP).

5. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO PVC FLUSH MANIFOLD JUST

BELOW EACH CHECK VALVE.*

6. DRIPLINE LATERAL.

7. PVC SUPPLY MANIFOLD

8. MANIFOLD-TO-ELBOW CONNECTION (TYP).

9. PERIMETER LATERALS 2” TO 4” FROM EDGE.

10. AREA PERIMETER.

11. DL2000 OPERATION INDICATOR

(T-DL-MP9), OPTIONAL.*

12. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO FLUSH MANIFOLD AT

LOW POINT.

* ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

Detail No.17

Slope Layout

31

Page 34

Landscape Dripline Design _____________________________________________________________

■ Recommended Installation Instructions

1. PVC LATERAL LINE FROM DRIP ZONE KIT.

2. PVC SUPPLY MANIFOLD.

3. TORO MANIFOLD-TO-ELBOW

CONNECTION (TYP).

4. AIR/VACUUM RELIEF LATERAL, TORO BLUE

STRIPE POLY TUBING (T-EHD1645-XXX)

CENTERD ON MOUND OR BERM.

5. TORO AIR/VACUUM RELIEF VALVE

(T-YD-500-34) PLUMBED TO TORO BLUE

STRIPE POLY TUBING (T-EHD1645-XXX) AT

EACH HIGH POINT.

6. BERM (TYP).

7. EDGE OF PLANTER.

8. PERIMETER LATERALS 2” TO 4” FROM EDGE.

9. TORO LOC-EZE TEE (T-FTT16).

10. TORO DL2000 OPERATION INDICATOR

Detail No.18

Mound Layout Using

Subsurface Dripline

(T-DL-MP9). OPTIONAL.

11. TORO AUTOMATIC FLUSH VALVE

(T-FCH-H-FIPT) PLUMBED TO FLUSH

MANIFOLD AT LOW POINT.

12. PVC FLUSH MANIFOLD.

13. DRIPLINE LATERAL.

14. FINISHED GRADE.

Detail No.19

Irregular Layout

1. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO FLUSH MANIFOLD AT

LOW POINT.

2. DL2000 OPERATION INDICATOR

(T-DL-MP9), OPTIONAL.*

3. PVC FLUSH MANIFOLD

4. MANIFOLD-TO-ELBOW CONNECTION (TYP).

5. TORO LOC-EZE TEE (T-FTT16)

6. PERIMETER LATERALS 2” TO 4” FROM EDGE.

7. DRIPLINE LATERAL

8. AREA PERIMETER.

9. PVC LATERAL LINE FROM DRIP ZONE KIT.

10. PVC SUPPLY MANIFOLD.

11. MANIFOLD-TO-ELBOW CONNECTION.

12. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO TORO BLUE STRIPE POLY

TUBING (T-EHD1645-XXX) AT EACH

HIGH POINT.*

* ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

32

Page 35

_____________________________________________________________Landscape Dripline Design

■ Recommended Installation Instructions

1. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO FLUSH MANIFOLD AT

LOW POINT.

2. PVC FLUSH MANIFOLD.

3. TORO DL2000 OPERATION INDICATOR

(T-DL-MP9), OPTIONAL.*

4.MANIFOLD-TO-ELBOW CONNECTION (TYP).

5. TORO DRIPLINE LATERAL.

6. AREA PERIMETER.

7. PERIMETER LATERALS 2” TO 4” FROM EDGE.

8. PVC LATERAL LINE FROM DRIP ZONE KIT.

9. TORO LOC-EZE TEE (T-FTT16).

10. PVC SUPPLY MANIFOLD.

11. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO SUPPLY MANIFOLD AT

HIGH POINT.*

*ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

Detail No.20

Island Layout

End Feed

1. PVC LATERAL LINE FROM DRIP ZONE KIT.

2. PVC SUPPLY MANIFOLD.

3. PVC TEE (SxSxS).

4. PVC ELBOW (SxS).

5. TORO LOC-EZE ELBOW (T-FEE16).

6. TORO LOC-EZE TEE (T-FTT16).

7. TORO BLUE STRIPE POLY TUBING

(T-EHD1645-XXX) AT SUPPLY AND FLUSH

END OF EACH ISLAND

8. TORO LOC-EZE TEE X 1/2” SLIP ADAPTER

(T-FTV16).

9. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO TORO BLUE STRIPE POLY

TUBING (T-EHD1645-XXX) AT EACH

HIGH POINT.*

10. DRIPLINE LATERAL

11. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO FLUSH MANIFOLD AT

LOW POINT.

12. DL2000 OPERATION INDICATOR

(T-DL-MP9), OPTIONAL.*

13. ISLAND PERIMETER.

14. PERIMETER LATERALS 2” TO 4” FROM EDGE.

* ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

Detail No.21

Island Layout

33

Page 36

Landscape Dripline Design_____________________________________________________________

■ Recommended Installation Instructions

1. PVC LATERAL LINE FROM DRIP ZONE KIT.

2. PVC SUPPLY LINE.

3. MANIFOLD-TO-ELBOW CONNECTION.

4. AIR/VACUUM RELIEF VALVE (T-YD-500-34)

PLUMBED TO TORO BLUE STRIPE POLY

TUBING (T-EHD1645-XXX) AT EACH

HIGH POINT.*

5. AUTOMATIC FLUSH VALVE (T-FCH-H-FIPT)

PLUMBED TO TUBING AT END OF EACH LINE.

6. DL2000 OPERATION INDICATOR (T-DL-MP9),

OPTIONAL.*

7. DRIPLINE LATERAL.

Detail No.22

Tree Layout

8. TREE ROOTBALL.

9. TORO LOC-EZE TEE (T-FTT16).

10. ESTIMATED DRIP LINE OF MATURE TREE.

11. PVC SUPPLY LINE TO OTHER TREES.

* ONLY REQUIRED ON SUBSURFACE

INSTALLATIONS

Detail No.23

Check Valve

1

2

3

1. INLINE CHECK VALVE (JVO500-S2).

2. COMPRESSION ADAPTER (T-CA-710).

3. DRIPLINE

34

Page 37

Preventative

Maintenance

_____________________________________________________________Landscape Dripline Design

■ Routine Preventative Maintenance

System Inspection

Physical inspections are necessary in the following circumstances:

■ At the beginning of each irrigation season

■ After any landscape planting operation or renovation

■ For subsurface dripline installations, after any maintenance

function requiring digging at or below the dripline depth

Physically inspect system components (remote control valves, filters,

automatic flush caps and flush-end pressure checks) on a routine basis

as determined by historical experience.

Base zone-flow readings, supply manifold pressures and flush-end

pressure readings should be recorded with all system components

operating at their optimum capacity. Baseline readings after

installation should be determined during the final system inspection

upon initial startup. However, they can be determined at any time as

long as all system components are operating properly. Record this data

on the System Data Record below as a permanent reference record.

System Data Record

■ Station Number: ______

■ Dripline Model Number: ___________________

■ Emitter Spacing: _______ inches

■ Emitter Flow:_______ GPH

■ Dripline Spacing: ________ inches

■ Initial Supply Manifold Pressure: __________ PSI

■ Initial Flush Valve Pressure: _________ PSI

■ Application Rate: ________ inches per hour

■ Evapotranspiration Rate (inches per week):

Jan. __________ May ____________ Sept. ___________

Feb. __________ June ____________ Oct. ____________

Mar. __________ July_____________ Nov. ___________

Apr. __________ Aug. ____________ Dec.____________

35

Page 38

Landscape Dripline Design _____________________________________________________________

■ Routine Preventative Maintenance

NOTES:

Routine Inspections Checklist

■ Turn on each zone for five to 10 minutes and walk the area, looking

for excessively wet areas that might indicate leaks.

■ Inspect air/vacuum relief valves (subsurface installations only) and

automatic flush caps for proper operation.

■ Check pressures at the supply manifold and flush ends of each zone,

and compare them with the base information on the System Data

Record. For proper flushing, the flush-end pressure should be at least

10 PSI.

■ Check the operational flow of each zone and compare it with the

design flows or the flows on the System Data Record. High flows

could indicate leaks or malfunctioning automatic flush caps. Flows

lower than expected could indicate clogged drippers, drippers with

excessive salt build-up, kinked dripline or a clogged filter. Low flows

might also indicate that the capacity of the installed remote control

valves, filters or pressure regulators are too low, thus restricting the

flow to the zone.

Component Maintenance Checklists

Remote Control Valves

■ Upon initial inspection, check to see if the valve is properly sized for

the zone flow. Refer to the manufacturer’s specification. Oversized

valves may not close properly and undersized valves will restrict flow

and cause excessive pressure loss.

■ Follow the manufacturer’s recommended procedures for repair and

general maintenance.

■ Inspect for proper operation when opening or closing. A weeping

valve can cause excessively wet areas at low points in the zone.

36

Page 39

_____________________________________________________________Landscape Dripline Design

■ Routine Preventative Maintenance

NOTES:

Filters

■ Filters must be inspected and cleaned periodically. The frequency

of inspection is dependent on the water source. Municipal potable

water may require less frequent cleaning than irrigation district

water, pond water or well water. The frequency is determined by

historical experience as new systems are operated.

■ Commercial installations should include pressure gauges, or

facilities to connect pressure gauges, immediately upstream and

downstream of each filter. Filters should be cleaned when the

pressure drop across the filter is 8 PSI or greater, or when the

downstream pressure falls below the designed working pressure

of the system.

■ Filters without pressure gauges should be inspected monthly until

the necessary frequency is determined.

■ Filters should always be inspected when any system break occurs

ahead of the filter.

■ If filters are plugging too frequently, a larger filter (two times the

highest zone flow) may need to be installed upstream of the zone

filters to pre-filter the water supply.

Pressure Regulators

■ Annually check the pressure output just downstream of the

regulators to ensure that the valve is operating at designed

pressures.

Dripline

■ Inspect driplines at the air vent (subsurface installations only)

and/or flush cap locations for salt build-up after the first year of

operation. If necessary, inject commercially available cleansing

solutions through the system at the recommended rates and

continue with annual treatment. Consult with local fertilizer

distributors for recommended materials and rates.

■ Prior to digging in planted areas with subsurface dripline present,

turn on the system long enough to create wet areas on the surface

to locate the driplines.

■ After cultivation or maintenance activities, turn on the system for

five to 10 minutes to inspect for leaks that might have been

caused by these operation

37

Page 40

Landscape Dripline Design _____________________________________________________________

■ Routine Preventative Maintenance

NOTES:

Flush Caps

■ Automatic flush caps operate by automatically flushing a small

amount of water each time the system is activated. Observe the

flush operation annually to ensure that flushing is occurring

properly.

■ The system must be flushed thoroughly after repairs or alterations

are made to the irrigation components. Automatic flush caps do

not allow enough water to pass through excessive debris and,

therefore, must be removed in order to effect a manual flush.

■ Manual flush caps should be flushed three times each irrigation

season for a period of 30 to 60 seconds or until the flush water is

visibly clean. More frequent flushing may be required under

extremely dirty water conditions. Flushing is also necessary any

time the system is repaired.

38

Page 41

_____________________________________________________________Landscape Dripline Design

■ Routine Preventative Maintenance

Troubleshooting Checklists

Excessively Wet Soil Areas

■ Determine if the wet area is caused by damaged dripline. Carefully

dig up the area and expose the dripline. Make a clean cut when

cutting through the damaged area. If the system is a subsurface

grid system, water will flow from both sides of the cut,

automatically flushing any debris that may have worked its way

into the dripline. While the water is running, flush both sides of

the cut and repair it with the appropriate coupling.

■ If the wet area is at the low side of a slope or mound and a leak is

not found, the wet area is probably caused by subsurface runoff.

To remedy the problem, expose the lowest line in the area. Cut

the line and plug it off at both the inlet and flush manifolds.

■ Localized wet areas are sometimes caused by differences in soil

depth or uneven dripline depths. If uneven dripline depth is the

problem, the line must be excavated and re-installed at a uniform

depth. If it is caused by shallow soil conditions, it will be necessary

to correct the shallow condition or wrap some of the dripper

outlets in the area with electrical tape to cut off flow.

NOTES:

■ Localized wet areas also can be caused by leaky fittings. If this is

the case, the fittings are either the incorrect size or not properly

secured.

■ Area-wide wet areas are probably due to improper scheduling. Set

the controller to apply water at rates that correspond to local

evapotranspiration data. Use the Application Rate Table and the

Scheduling Form provided in this manual.

Excessively Dry Soils

■ Check system flows and pressures to determine if the system is

operating at designed pressures. If excessively low pressures are

detected, follow the standard procedures for determining the

cause of a pressure drop (i.e., a clogged filter).

■ Localized dry soil conditions are sometimes caused by kinked or

pinched dripline, or upstream leaks. Dig up the dry area and

correct the situation.

■ Massive dry areas can be caused by improper scheduling. Set the

controller to provide the application rate that corresponds to the

local evapotranspiration data. Use the Application Rate Table and

Scheduling Form provided in this manual.

39

Page 42

System

Components

Landscape Dripline Design _____________________________________________________________

■ System Components Specifications

DL2000® Drip Tubing

Specifications

■ Minimum operating pressure: 15 PSI

■ Maximum operating pressure: 60 PSI

■ Coefficient of variance (Cv):

• pressure compensating: < .05

• non-pressure compensating: .03

■ Emitter outlet: Dual/opposing

■ Emitter flow @ 20 PSI:

• RGP-2XX-XX 0.53 GPH

• RGP-4XX-XX 1.02 GPH

■ Emitter spacing:

• RGX-X12-XX 12”

• RGX-X18-XX 18”

■ Maximum length of run:

• RGP-212-XX 360’ @ 25 PSI

460’ @ 40 PSI

• RGP-412-XX 240’ @ 25 PSI

300’ @ 40 PSI

• RGP-218-XX 515’ @ 25 PSI

650’ @ 40 PSI

• RGP-418-XX 340’ @ 25 PSI

430’ @ 40 PSI

■ Dimensions (L x I.D x O.D.):

• RGP-XXX-01 100’ x .620” x .710”

• RGP-XXX-05 500’ x .620” x .710”

• RGP-XXX-10 1000’ x .620” x .710”

■ Weight:

• RGP-XXX-01 4 lbs.

• RGP-XXX-05 20 lbs.

• RGP-XXX-10 45 lbs.

Drip In® Drip Tubing

Specifications

■ Minimum operating pressure: 15 PSI

■ Maximum operating pressure: 60 PSI

■ Coefficient of variance (Cv):

• pressure compensating: < .05

• non-pressure compensating: .03

■ Emitter outlet: Dual/opposing

■ Emitter flow @ 20 PSI:

• T-PCB1853-XX-XXX 0.53 GPH

• T-PCB1810-XX-XXX 1.02 GPH

■ Emitter spacing:

• T-PCB18XX-12-XXX 12”

• T-PCB18XX-18-XXX 18”

■ Maximum length of run:

• T-PCB1853-12-XXX 3

460’ @ 40 PSI

• T-PCB1810-12-XXX 240’ @ 25 PSI

300’ @ 40 PSI

• T-PCB1853-18-XXX 515’ @ 25 PSI

650’ @ 40 PSI

• T-PCB1810-18-XXX 340’ @ 25 PSI

430’ @ 40 PSI

■ Dimensions (L x I.D x O.D.):

• T-PCB18XX-XX-100

100’ x .620” x .710”

• T-PCB18XX-XX-250

250’ x .620” x .710”

• T-PCB18XX-XX-500

500’ x .620” x .710”

■ Weight:

• T-PCB18XX-XX-100 4 lbs.

• T-PCB18XX-XX-250 9 lbs.

• T-PCB18XX-XX-500 20 lbs.

60’ @ 25 PSI

40

Plastic Y-Filters

Specifications

■ Screen mesh size: 150 mesh

■ Screen material: Stainless steel

■ Maximum pressure: All models 142 PSI

■ Maximum flow rate:

• T-ALFS75150-L 25 GPM

• T-ALFS10150-L 35 GPM

■ Body dimensions (L x W x D):

• T-ALFS75150-L:

9” x 7.32” x 4.29”

• T-ALFS10150-L:

9” x 7.32” x 4.29”

■ Inlet/outlet size:

• T-ALFS75150-L 3⁄4” MIPT

• T-ALFS10150-L 1” MIPT

Page 43

_____________________________________________________________Landscape Dripline Design

■ System Components Specifications

NOTES:

DL2000® Flushing Cap

Specifications

■ Part Number: T-CEFCH-H

■ Sealing pressure: 2 PSI

■ Flush rate: 0.8 GPM

■ Maximum operating pressure: 50 PSI

■ Outlet size: .710” O.D. compression

■ Body dimensions (L x W x D):

3.425” x 1.340” x 1.340

■ Weight: 0.8 oz.

DL2000 Pressure Regulators

Specifications

■ Flow rate:

• T-PMR15-LF 1⁄10 - 8 GPM

(6 - 480 GPH)

• T-PMR25-LF 1⁄10 - 8 GPM

(6 - 480 GPH)

• T-PMR25-MF 2 - 20 GPM

(120 - 1200 GPH)

• T-PR25-HF 10 - 32 GPM

(600 - 1920 GPH)

• T-PMR40-MF 2 - 20 GPM

(120 - 1200 GPH)

■ Pressure regulation:

• T-PMR15-XX 15 PSI +/- 6%

• T-PMR25-XX 25 PSI +/- 6%

• T-PMR40-XX 40 PSI +/- 6%

■ Maximum pressure:

• T-PMRXX-XX 150 PSI

• T-PR25-HF 95 PSI

■ Body dimensions (L x W x D):