Page 1

FormNo.3403-166RevA

Dingo

ModelNo.22317—SerialNo.314000001andUp

®

220CompactToolCarrier

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3403-166*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisacompacttoolcarrierintendedforusein

variousearthandmaterialsmovingactivitiesforlandscaping

andconstructionwork.Itisdesignedtooperateawidevariety

ofattachmentseachofwhichperformaspecializedfunction.

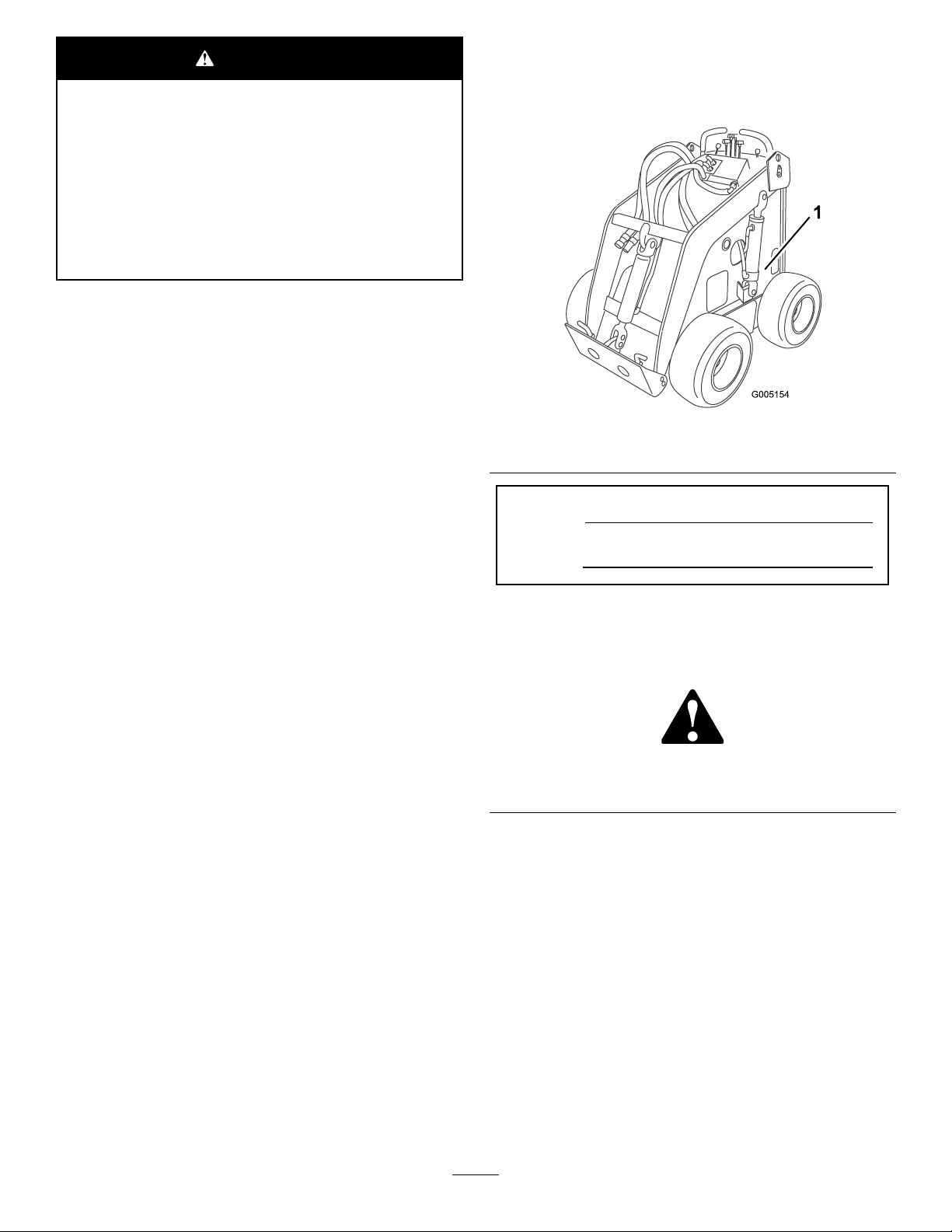

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

Setup............................................................................9

1InstallingtheValveLever.......................................9

2CheckingFluidLevelsandDriveChain

Tension..............................................................9

3ChargingtheBattery..............................................9

ProductOverview.........................................................11

Controls...............................................................11

Specications........................................................13

Attachments/Accessories........................................13

StabilityData.........................................................14

Operation....................................................................15

AddingFuel...........................................................15

CheckingtheEngineOilLevel.................................16

RemovingDebrisfromtheTractionUnit...................16

CheckingtheHydraulicFluidLevel...........................17

CheckingtheTirePressure......................................17

StartingandStoppingtheEngine..............................17

DrivingtheTractionUnit........................................18

StoppingtheTractionUnit......................................18

MovingaNon-functioningTractionUnit...................18

UsingtheCylinderLocks.........................................18

UsingAttachments.................................................19

SecuringtheTractionUnitforTransport....................20

AdjustingtheThighSupport....................................20

Maintenance.................................................................22

RecommendedMaintenanceSchedule(s)......................22

Lubrication...............................................................23

GreasingtheTractionUnit......................................23

EngineMaintenance..................................................23

ServicingtheAirCleaner.........................................23

ServicingtheCarbonCanister..................................24

ServicingtheEngineOil..........................................25

ServicingtheSparkPlugs.........................................26

FuelSystemMaintenance...........................................27

ChangingtheFuelFilter..........................................27

DrainingtheFuelTank...........................................27

ElectricalSystemMaintenance....................................28

ReplacingtheBattery..............................................28

ServicingtheBattery...............................................29

DriveSystemMaintenance.........................................30

ServicingtheTractionDriveChains..........................30

HydraulicSystemMaintenance....................................32

ReplacingtheHydraulicFilter..................................32

ChangingtheHydraulicFluid...................................32

CheckingtheHydraulicLines...................................33

Storage........................................................................33

Troubleshooting...........................................................35

Schematics...................................................................36

Improperuseormaintenancebytheoperatororowner

canresultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

,which

—personalsafety

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingeyeprotection,

slip-resistantsubstantialfootwear,andhearingprotection.

Tiebacklonghair.Donotwearjewelry.

•Beforedigging,havetheareamarkedforunderground

utilities,anddonotdiginmarkedareas.

•Beforeoperatinginanareawithhigh-voltagelinesor

cables,contacta“One-CallSystemDirectory”service.In

theUSA,call811oryourlocalutilitycompany.Ifyou

donotknowyourlocalutilitycompany’sphonenumber,

callthenationalnumber(USAandCanadaonly)at

1-888-258-0808.Also,contactanyutilitycompaniesthat

arenotparticipantsofthe“One-CallSystemDirectory”

service.

3

Page 4

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingtheengine.

Onlystarttheenginefromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.

•Slowdownandusecautionwhenmakingturns,crossing

roadsandsidewalks,andwhenchangingdirectionson

slopes.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly ,and

functioningproperty.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerimplements,disengagethe

auxiliaryhydraulics,andshutofftheenginebeforeleaving

theoperator'spositionforanyreason.

•Keephandsandfeetawayfrommovingattachments.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Donotoperatethemachinewhiletired,ill,orunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Readallattachmentmanuals.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthetractionunit.Stopthetractionunitif

anyoneentersthearea.

•Neverleavearunningtractionunitunattended.Always

lowertheloaderarms,stoptheengine,andremovethe

keybeforeleaving.

•Donotexceedtheratedoperatingcapacity,asthetraction

unitmaybecomeunstablewhichmayresultinlossof

control.

•Donotcarryaloadwiththearmsraised.Alwayscarry

loadsclosetotheground.

•Donotover-loadtheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Logs,boards,and

otheritemscouldrolldowntheloaderarms,injuringyou.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethetractionunitinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthetractionunit

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Locatethepinchpointareasmarkedonthetractionunit

andattachmentsandkeephandsandfeetawayfrom

theseareas.

•Beforeoperatingthetractionunitwithanattachment,

ensurethattheattachmentisproperlyinstalled.

•Donotplaceyourfeetundertheplatform.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotoperatethetractionunitonhillsidesorslopes

exceedingtheanglesrecommendedinStabilityData

(page14),andthoseintheattachmentOperator'sManual.

SeealsotheSlopeIndicator(page6).

•Operateupanddownslopeswiththeheavyendof

thetractionunituphill.W eightdistributionchanges.

Anemptybucketwillmaketherearofthetractionunit

theheavyend,andafullbucketwillmakethefrontofthe

tractionunittheheavyend.Mostotherattachmentswill

makethefrontoftractionunittheheavyend.

•Raisingtheloaderarmsonaslopewillaffectthestability

ofthemachine.Wheneverpossible,keeptheloaderarms

intheloweredpositionwhenonslopes.

•Removinganattachmentonaslopewillmaketherear

ofthetractionunitheavy.RefertoStabilityData(page

4

Page 5

14),todeterminewhethertheattachmentcanbesafely

removedontheslope.

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthetractionunit.Tallgrasscan

hideobstacles.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristicsof

thetractionunit.Warrantymaybevoidedifusedwith

unapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthetractionunit

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthetractionunituphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Thetractionunitcouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthetractionunitonahillsideorslope

withoutloweringtheattachmenttothegroundand

chockingthewheels.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheloaderarmsto

beintheraisedposition,securethearmsintheraised

positionwiththehydrauliccylinderlock.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthetractionunitfreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthetraction

unittocoolbeforestoring.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthetractionunitindoors.

–Neverstorethetractionunitorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Donottrytostabilizethetractionunitbyputtingyour

footontheground.

MaintenanceandStorage

•Disengagetheauxiliaryhydraulics,lowertheattachment,

stoptheengine,andremovethekey.Waitforall

movementtostopbeforeadjusting,cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethesparkplugwires

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectpositive

rstandnegativelast.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

5

Page 6

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachineon,refertotheStabilityDatasection.Usetheslope

indicatortodeterminethedegreeofslopeofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthanthat

speciedintheStabilityDatasection.Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

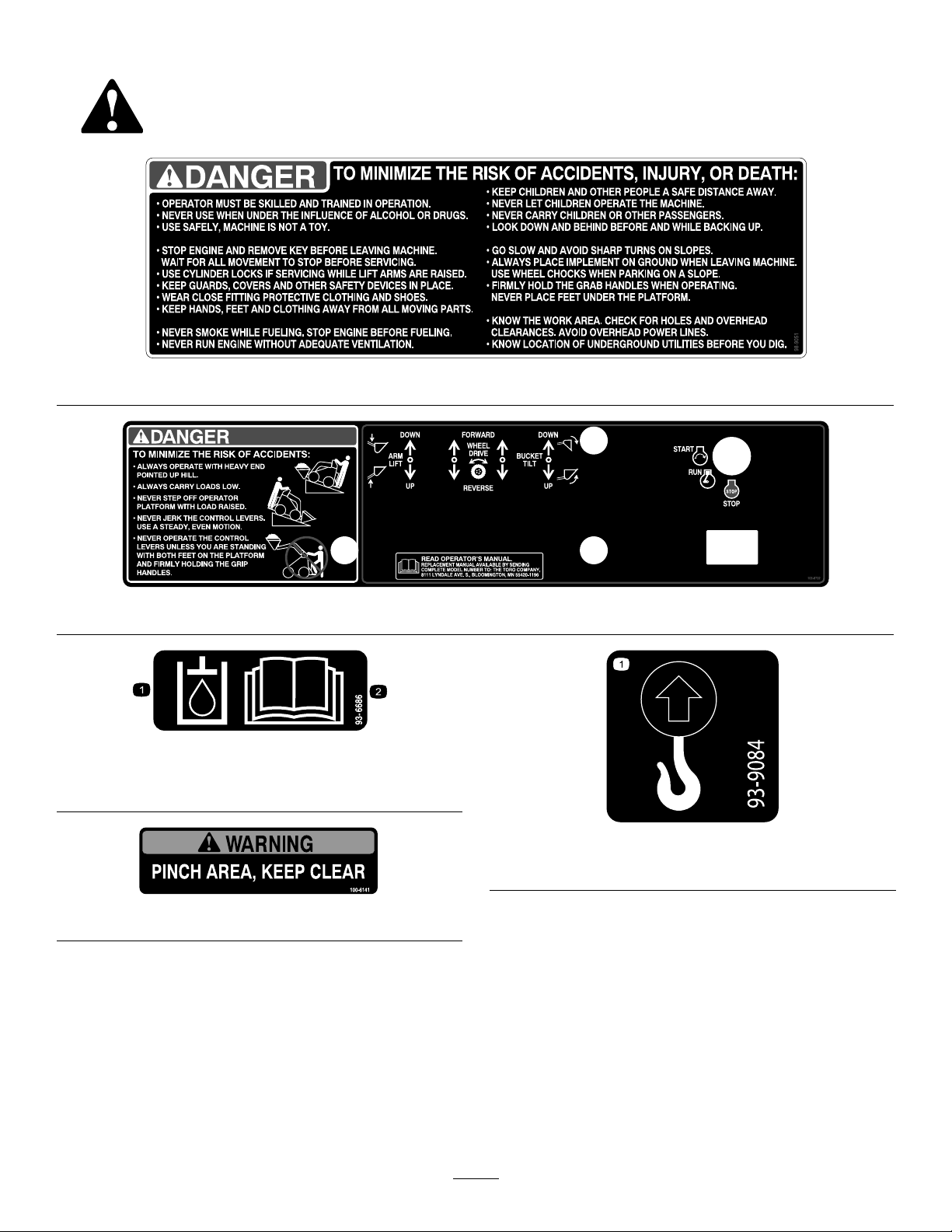

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

98-9051

1.Hydraulicoil

108-9732

93–6686

2.ReadtheOperator's

Manual.

93-9084

1.Liftpoint

100-6141

7

Page 8

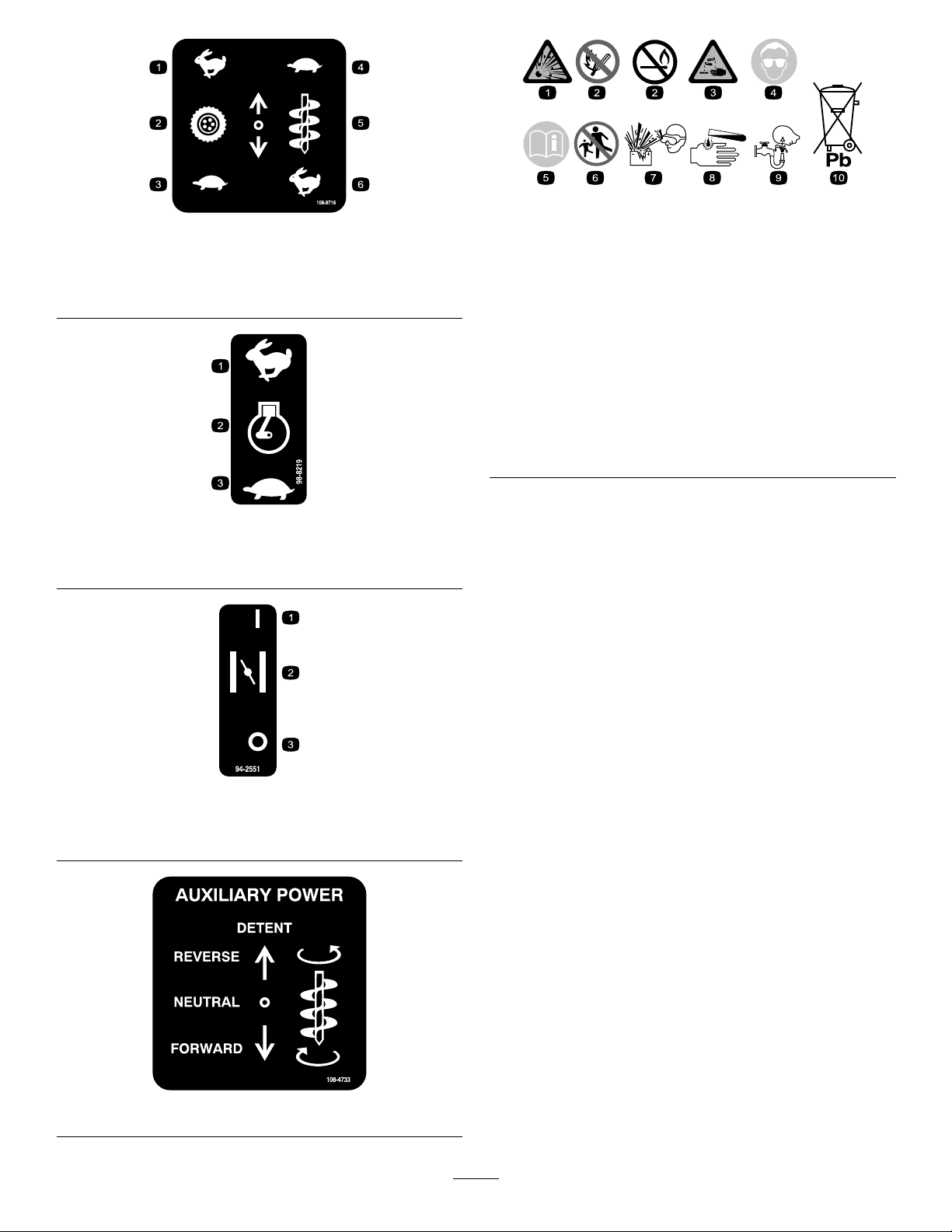

108-9716

1.Fast

2.Tractiondrive5.Attachmentspeed

3.Slow

4.Slow

6.Fast

98-8219

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.Fast

2.Throttle

3.Slow

94-2551

1.On3.Off

2.Choke

108-4733

8

Page 9

Setup

•CheckingtheEngineOilLevel(page16)

•CheckingtheHydraulicFluidLevel(page17)

•ServicingtheTractionDriveChains(page30)

1

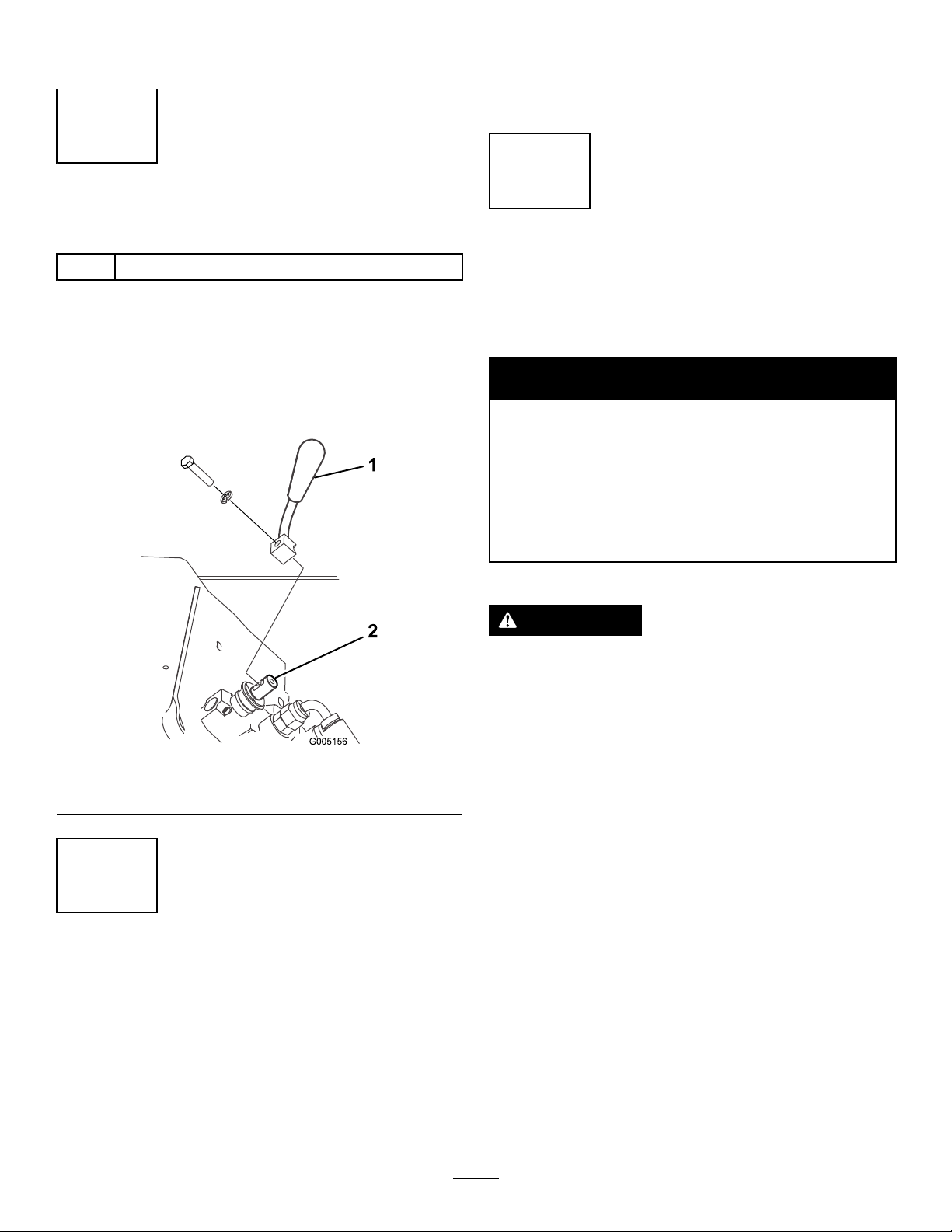

InstallingtheValveLever

Partsneededforthisprocedure:

1

Speedselectorvalvelever

Procedure

1.Removeanddiscardthenutsecuringtheboltandlock

washertothespeedselectorlever.

2.Securethelevertothespeedselectorvalveusingthe

boltandlockwasherasillustratedinFigure4.

3

ChargingtheBattery

NoPartsRequired

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

WARNING

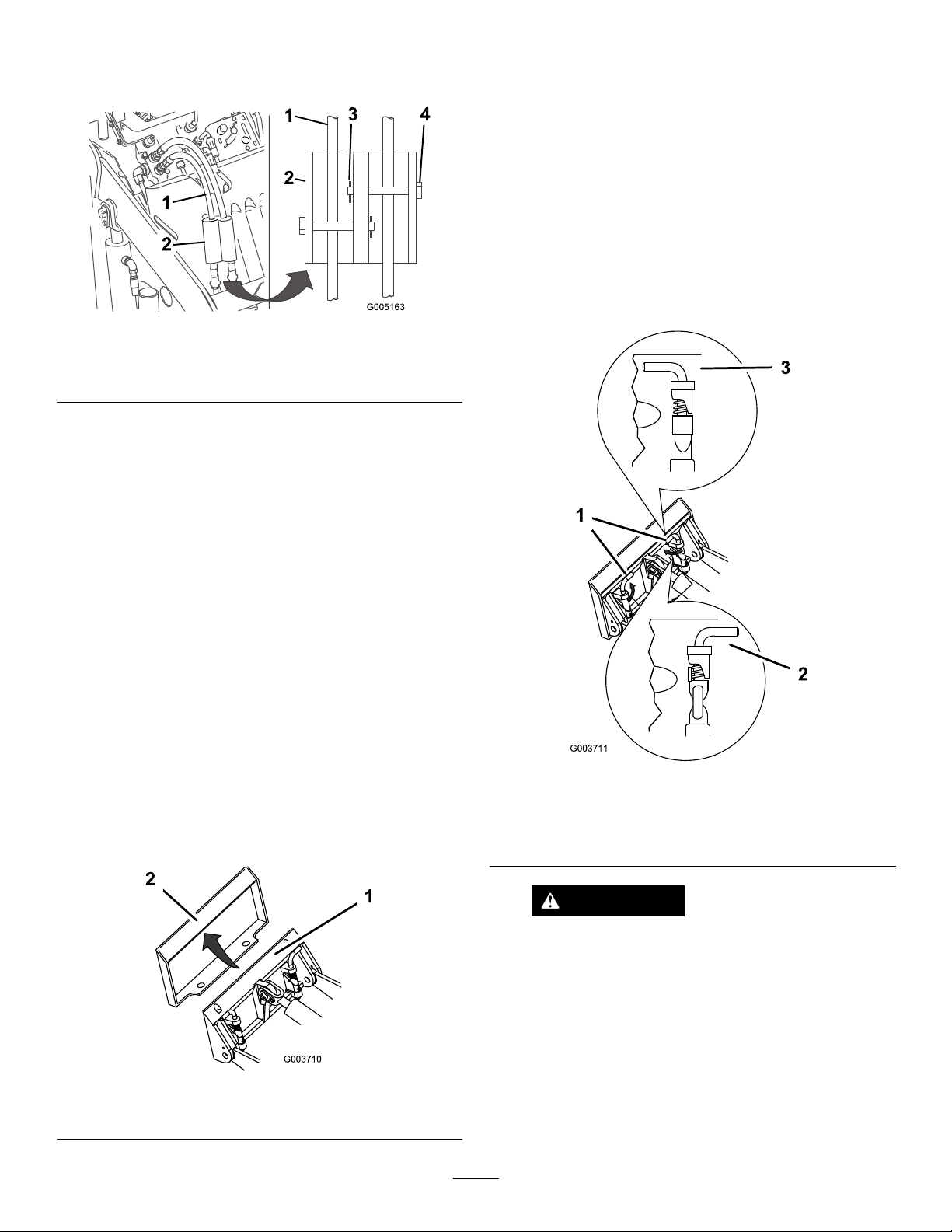

Figure4

1.Speedselectorvalvelever2.Speedselectorvalve

2

CheckingFluidLevelsand DriveChainTension

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checktheengine

oilandhydraulicuidlevelsandthetractiondrivechain

tension.Refertothefollowingsectionsformoreinformation:

Batteryterminalsormetaltoolscouldshortagainst

metalcomponents,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthetractionunit.

•Donotallowmetaltoolstoshortbetweenthe

batteryterminalsandmetalpartsofthetraction

unit.

1.Parkthetractionunitonalevelsurface,raisetheloader

arms,andinstallthecylinderlocks.

2.Stoptheengineandremovethekey.

3.Connectachargertothebattery(Figure5)andcharge

itforaminimumof1hourat6to10amps.Donot

overchargethebattery.

9

Page 10

1

2

3

4

G003792

Figure5

1.Positivepost

2.Negativepost

3.Chargerred(+)wire

4.Chargerblack(—)wire

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure5).

10

Page 11

ProductOverview

4

5

16

G019355

G005160

631524

789

Figure6

1.Mountplate5.Handles

2.Tiltcylinder

3.Auxiliaryhydrauliccouplers7.Wheel11.Aircleaner15.Fueltank

4.Loaderarms

6.Liftcylinder

8.Counterweight

Controls

9.Operatorplatform13.Controlpanel

10.Engine

12.Thighsupport

14.Liftpoints

Tostoptheengine,rotatethekeytotheoffposition.

Becomefamiliarwithallthecontrols(Figure7)beforeyou

starttheengineandoperatethetractionunit.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed.

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Figure7

1.Tractioncontrollevers6.Throttlelever

2.Attachmenttiltlever

3.Loaderarmlever8.Keyswitch

4.Auxiliaryhydraulicslever9.Hourmeter

5.Speedselectorlever

7.Chokelever

Note:Awarmenginerequireslittleornochoking.

TractionControlLevers

Tomoveforward,movethetractioncontrolleversforward.

Tomoverearward,movethetractioncontrolleversrearward.

Togostraight,movebothtractioncontrolleversequally.

KeySwitch

Thekeyswitch,usedtostartandstoptheengine,hasthree

positions:off,run,andstart.

Tostarttheengine,rotatethekeytothestartposition.Release

thekeywhenenginestartsanditwillmoveautomaticallyto

therunposition.

Toturn,movetheleverlocatedonthesideyouwanttoturn

backtowardtheneutralpositionwhilekeepingtheother

leverengaged.

Thefartheryoumovethetractioncontrolleversineither

direction,thefasterthetractionunitwillmoveinthat

direction.

Tosloworstop,movethetractioncontrolleverstoneutral.

11

Page 12

AttachmentTiltLever

Totilttheattachmentforward,slowlypushtheattachment

tiltleverforward.

Totilttheattachmentrearward,slowlypulltheattachment

tiltleverrearward.

LoaderArmLever

Tolowertheloaderarms,slowlypushtheloaderarmlever

forward.

Toraisetheloaderarms,slowlypulltheloaderarmlever

rearward.

AuxiliaryHydraulicsLever

Tooperateahydraulicattachmentinforwarddirection,slowly

pulltheauxiliaryhydraulicsleverupwardandthenrearward.

Tooperateahydraulicattachmentinreversedirection,slowly

pulltheauxiliaryhydraulicsleverupwardandthenpushit

forward.Thisisalsocalledthedetentpositionbecauseitdoes

notrequireoperatorpresence.

youtochangetheoil.Afterevery100hours,thescreen

displaysSVCtoremindyoutoperformtheothermaintenance

proceduresbasedona100,200,or400hourschedule.These

reminderscomeonstartingthreehourspriortotheservice

intervaltimeandashatregularintervalsforsixhours.

SpeedSelectorLever

Movethespeedselectorlevertotheforwardpositiontoset

thetractiondrive,loaderarms,andattachmenttilttohigh

speedandtheauxiliaryhydraulicstolowspeed.

Movethespeedselectorlevertotherearwardpositiontoset

theauxiliaryhydraulicstohighspeedandthetractiondrive,

loaderarms,andattachmenttilttolowspeed.

WARNING

Ifyoumovethespeedselectorleverwhilethe

tractionunitisinmotion,thetractionunitwill

eitherstopsuddenlyoracceleratequickly.Ifyou

operatethetractionunitwiththespeedselector

leverinanintermediateposition,thetractionunit

willoperateerraticallyandmaybedamaged.You

couldlosecontrolofthetractionunitandinjure

bystandersoryourself.

•Donotmovethespeedselectorleverwhenthe

tractionunitisinmotion.

•Donotoperatethetractionunitwhenthespeed

selectorisinanyintermediateposition(i.e.,

anypositionotherthanfullyforwardorfully

rearward).

HourMeter

Thehourmeterdisplaysthenumberofhoursofoperation

thathavebeenloggedonthetractionunit.

After50hoursandthenevery100hoursthereafter(thatisat

150,250,350,etc.)thescreendisplaysCHGOILtoremind

12

Page 13

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width

Length

Height

Weight(withoutattachmentorcounterweight)1430lb(649Kg)

Weightofthecounterweight165lb(75Kg)

Operatingcapacity(with200lboperator,thestandardbucket,andwithoutthecounterweight)515lb(234Kg)

Tippingcapacity(with200lboperator,thestandardbucket,andwithoutthecounterweight)1030lb(467Kg)

Wheelbase

Dumpheight(withstandardbucket)47inches(120cm)

Reach—fullyraised(withstandardbucket)26inches(66cm)

Heighttohingepin(narrowbucketinstandardposition)66inches(168cm)

40.5inches(103cm)

60inches(152cm)

49inches(125cm)

28inches(71cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

Important:UseonlyT oroapprovedattachments.Otherattachmentsmaycreateanunsafeoperatingenvironment

ordamagethetractionunit.

13

Page 14

StabilityData

Thefollowingtableslistthemaximumsloperecommendedforthetractionunitinthepositionslistedinthetables.Slopesover

thelisteddegreemaycausethetractionunittobecomeunstable.Thedatainthetablesassumethattheloaderarmsarefully

lowered;raisedarmsmayaffectthestability.

Ineachattachmentmanualisasetofthreestabilityratings,oneforeachhillposition.Todeterminethemaximumslopeyou

cantraversewiththeattachmentinstalled,ndthedegreeofslopethatcorrespondstothestabilityratingsoftheattachment.

Example:IftheattachmenthasaFrontUphillratingofB,aRearUphillratingofD ,andaSideUphillratingofC,thenyou

coulddriveforwardupan18°slope,rearwardupa10°slope,orsidewaysona14°slope,aslistedinthefollowingtable.

MaximumRecommendedSlopewhen

FrontUphillRearUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithcounterweight,withoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C15°16°14°

D

E

8°20°17°

5°21°17°

25°25°20°

18°19°17°

10°10°9°

5°5°5°

Operatingwith:

SideUphill

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoillevel,removedebrisfromthetractionunit,andcheckthe

tirepressure.Also,ensurethattheareaisclearofpeopleanddebris.Y oushouldalsoknowandhavemarked

thelocationsofallutilitylines.

CAUTION

Youcouldfalloffoftheplatformandbeseriouslyinjuredduringoperation.

Donotmovethecontrolleversunlessyouarestandingwithbothfeetontheplatformandyourhands

areholdingthehandles.

AddingFuel

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Important:T oreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithgasoline

lessthan30daysold;runthemachinedrybeforestoring

itformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,or

isopropanol.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltanksoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltanksinsideanenclosed

trailer.

•Donotllthefueltankscompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

15

Page 16

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling .

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

FillingtheFuelTank

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit.

Note:Thecapistetheredtothefueltank.

4.Addunleadedgasolinetothefueltank,untilthelevel

is1/4to1/2inch(6to13mm)belowthebottomof

thellerneck.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely,turningituntilitclicks.

6.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Figure8

1.Oildipstick

2.Fillercap4.Metalend

4.Pulloutthedipstickandwipethemetalendclean

(Figure8).

5.Slidethedipstickfullyintothedipsticktube(Figure8).

6.Pullthedipstickoutandlookatthemetalend.

7.Iftheoillevelislow ,cleanaroundtheoilllercapand

removethecap(Figure8).

8.Slowlypouronlyenoughoilintothevalvecoverto

raisetheleveltotheF(full)mark.

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

9.Replacethellercapanddipstick.

3.Valvecover

RemovingDebrisfromthe TractionUnit

ServiceInterval:Beforeeachuseordaily

Important:Operatingtheenginewithablockedgrass

screen,dirtyorpluggedcoolingns,and/orcooling

shroudsremoved,willresultinenginedamagefrom

overheating.

1.Parkthetractionunitonalevelsurface,raisetheloader

arms,andinstallthecylinderlocks.

2.Stoptheengineandremovethekey.

3.Cleananydebrisfromthegrillbeforeeachuseand/or

duringuse,ifrequired.

4.Wipeawaydebrisfromtheaircleanerbeforeeachuse

and/orduringuse,ifrequired.

5.Cleananydebrisbuild-upontheenginewithabrush

orblowerbeforeeachuse.

ServiceInterval:Beforeeachuseordaily

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundtheoildipstick(Figure8).

Important:Itispreferabletoblowdirtout,rather

thanwashingitout.Ifwaterisused,keepitaway

fromelectricalitemsandhydraulicvalves.Do

notuseahigh-pressurewasher.High-pressure

washingcandamagetheelectricalsystemand

hydraulicvalvesordepletegrease.

6.Removeandstorethecylinderlocksandlowerthe

loaderarms.

16

Page 17

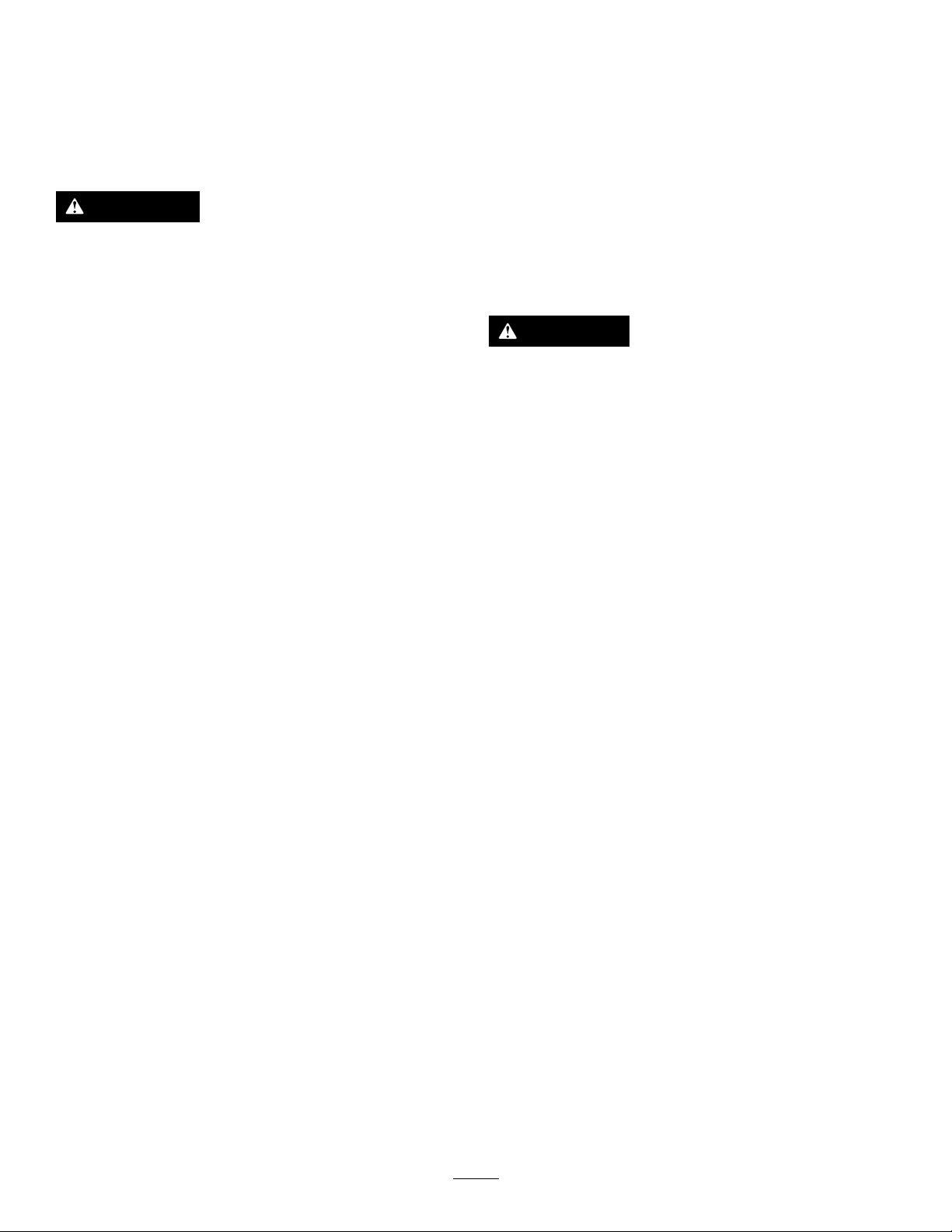

CheckingtheHydraulicFluid

1

G003793

Level

ServiceInterval:Every25hours

Checkthehydraulicuidlevelbeforetheengineisrst

startedandafterevery25operatinghours.

HydraulicTankCapacity:16.25USgallons(62l)

RefertoChangingtheHydraulicFluid(page32)forhydraulic

uidspecications.

Figure10

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

1.Removetheattachment,ifoneisinstalled.

2.Parkthetractionunitonalevelsurface,raisetheloader

arms,andinstallthecylinderlocks.

3.Stoptheengine,removethekey ,andallowtheengine

tocool.

4.Cleantheareaaroundthellerneckofthehydraulic

tank(Figure9).

5.Removethecapfromthellerneckandchecktheuid

levelonthedipstick(Figure9).

Theuidlevelshouldbebetweenthemarksonthe

dipstick.

Figure9

1.Fillerneckcap2.Dipstick

6.Ifthelevelislow,addenoughuidtoraiseittothe

properlevel.

7.Installthecaponthellerneck.

8.Removeandstorethecylinderlocksandlowerthe

loaderarms.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetiresasspecied.Checkthe

tireswhentheyarecoldtogetthemostaccuratereading.

Pressure:15-20psi

Note:Usealowertirepressure(15psi)whenoperatingin

sandysoilconditionstoprovidebettertractionintheloose

soil.

1.Valvestem

StartingandStoppingthe Engine

StartingtheEngine

1.Standontheplatform.

2.Ensurethattheauxiliaryhydraulicsleverisinneutral.

3.Movethechokeleverfullyforwardifyouarestartinga

coldengine.

Note:Awarmorhotenginemaynotrequirechoking.

4.Movethethrottlelevermidwaybetweenslow(turtle)

andfast(rabbit)positions.

5.Turntheignitionkeytothestartposition.Whenthe

enginesstarts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa30secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

6.Aftertheenginestarts,graduallymovethechoke

rearward.Iftheenginestallsorhesitates,movethe

chokeforwardagainuntiltheenginewarmsup.

7.Movethethrottlelevertodesiredsetting.

Important:Ifyouruntheengineathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

ambientairtemperatureisnearfreezingorlower),

hydraulicsystemdamagecouldoccur.When

startingtheengineincoldconditions,allowthe

enginetoruninthemiddlethrottlepositionfor

2to5minutesbeforemovingthethrottletofast

(rabbit).

Note:Ifoutdoortemperatureisbelowfreezing,store

thetractionunitinagaragetokeepitwarmerandaid

instarting.

StoppingtheEngine

1.Movethethrottleleverto3/4ofthewaytotheFast

position.

17

Page 18

2.Lowertheloaderarmstotheground.

3.Turntheignitionkeyoff.

Note:Iftheenginehasbeenworkinghardorishot,

letitrunforaminutebeforeturningtheignitionkey

off.Thishelpscooltheenginebeforeitisstopped.In

anemergency,theenginemaybestoppedimmediately.

Figure11

DrivingtheTractionUnit

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottleleverinthe

fast(rabbit)positionforbestperformance.

Note:Thethrottlepositioncanbeutilizedtooperateat

slowerspeeds.

Todrivethetractionunit,completethefollowingactionsas

necessary:

•Tomoveforward,movethetractioncontrollevers

forward.

•Tomoverearward,movethetractioncontrollevers

rearward.

•Togostraight,movebothtractioncontrolleversequally.

•Toturn,movetheleverlocatedonthesideyouwantto

turntowardtheneutralpositionwhilekeepingtheother

leverengaged.

•Tosloworstop,movethetractioncontrolleversto

neutral.

Note:Thefartheryoumovethetractioncontrolleversin

eitherdirection,thefasterthetractionunitwillmoveinthat

direction.

1.Liftpoints

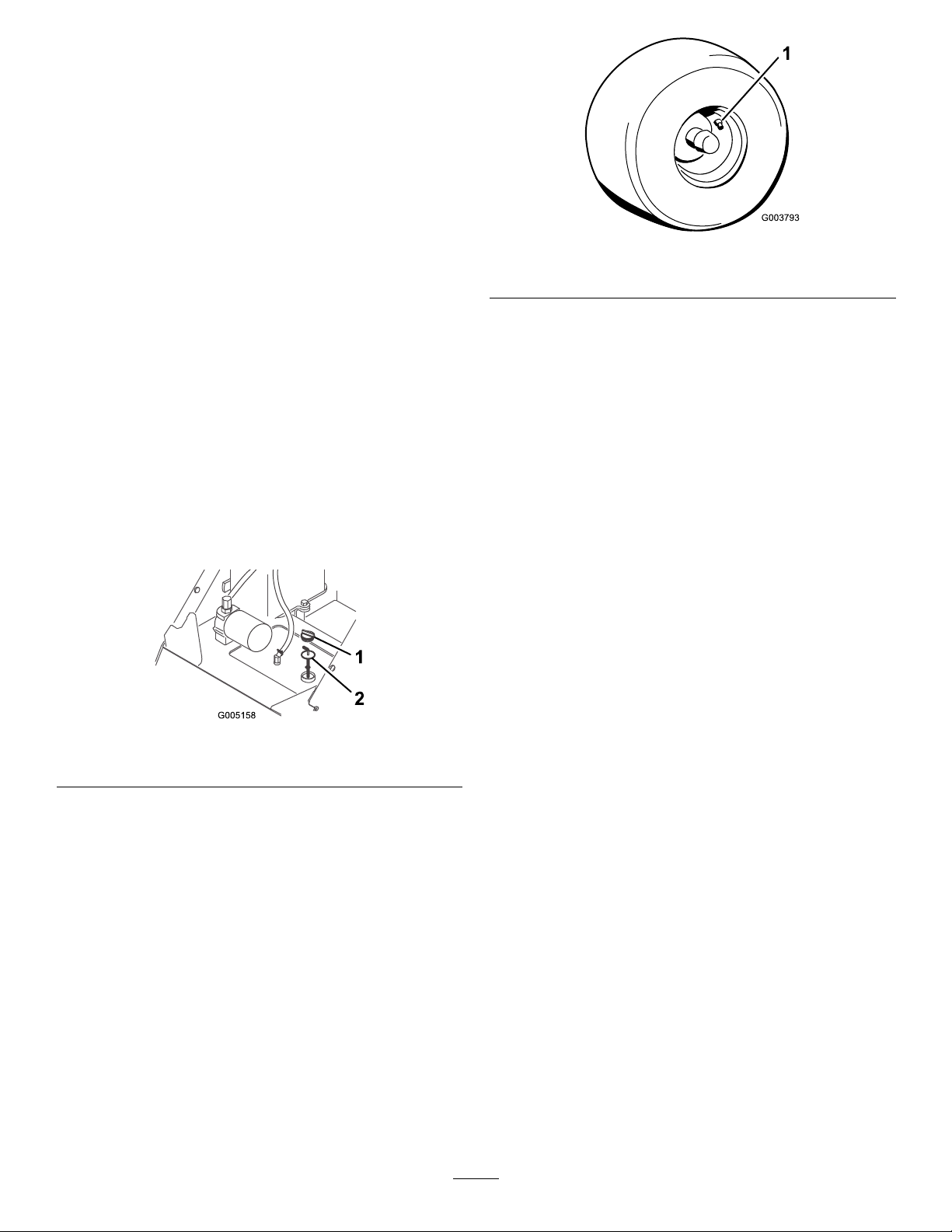

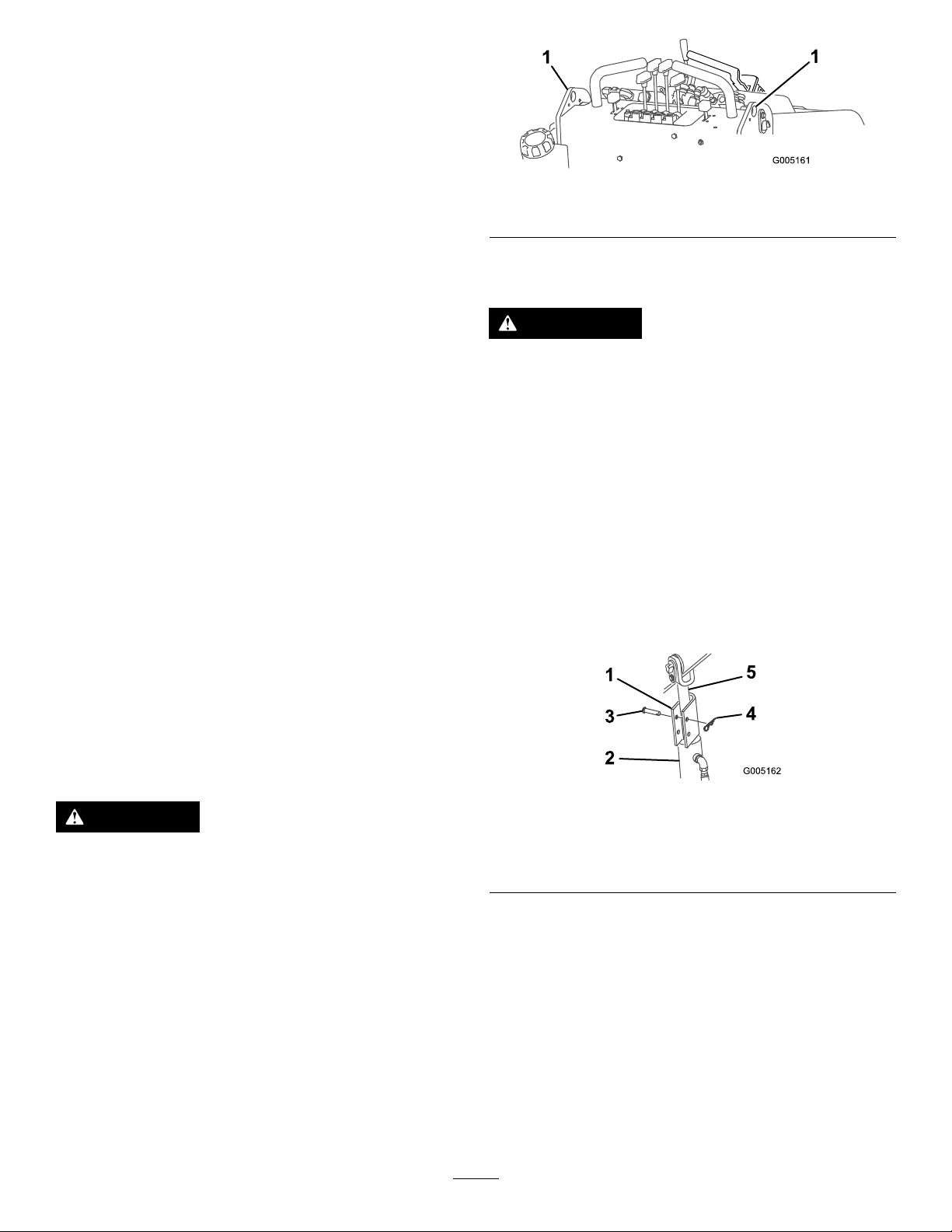

UsingtheCylinderLocks

WARNING

Theloaderarmsmaylowerwhenintheraised

positioncrushinganyoneunderthem.

Installthecylinderlocksbeforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLocks

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Stoptheengine.

4.Positionaloaderarmcylinderlockovereachlift

cylinderrod(Figure12).

5.Secureeachloaderarmcylinderlockwithaclevispin

andcotterpin(Figure12).

StoppingtheTractionUnit

Tostopthetractionunit,movethetractioncontrolleversto

neutral,movethethrottlelevertoslow(turtle),lowerloader

armstotheground,andstoptheengine.Removethekey.

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethetractionunitandbeinjured.

Removethekeyfromtheswitchwhenleavingthe

tractionunit,evenifjustforafewseconds.

MovingaNon-functioning TractionUnit

Important:Nevertoworpullthetractionunit.Rotating

thewheelsmanuallywillcausedamagetothehydraulic

wheelmotors.

1.Stoptheengine.

2.Liftthetractionunitofftheground,usingthetwolift

points(Figure11)andmoveitontoatrailer.

Figure12

1.Cylinderlock4.Clevispin

2.Liftcylinder5.Liftcylinderrod

3.Hairpincotter

6.Withtheengineoff,lowertheloaderarms.

Removing/StoringtheCylinderLock

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Stoptheengine.

4.Removetheclevispinandcotterpinsecuringeach

cylinderlock.

5.Removethecylinderlocks.

6.Lowertheloaderarms.

18

Page 19

7.Installthecylinderlocksoverthehydraulichosesand

securethemwiththeclevispinsandcotterpins(Figure

13).

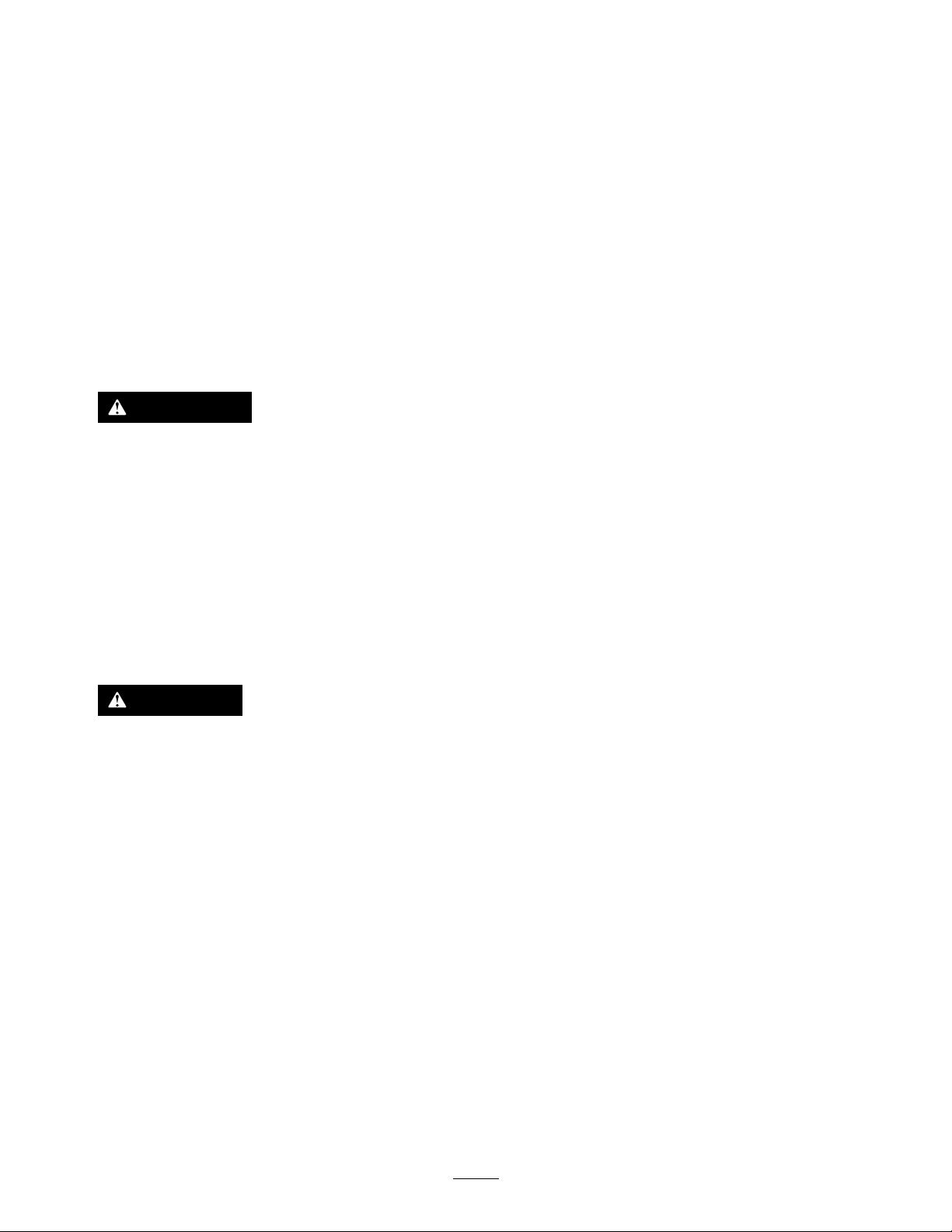

Figure13

1.Hydraulichoses3.Hairpincotter

2.Cylinderlocks4.Clevispin

UsingAttachments

5.Raisetheloaderarmswhiletiltingbackthemountplate

atthesametime.

Important:Theattachmentshouldberaised

enoughtocleartheground,andthemountplate

shouldbetiltedallthewayback.

6.Stoptheengine.

7.Engagethequickattachpins,ensuringthattheyare

fullyseatedinthemountplate(Figure15).

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnotfully

alignedwiththeholesintheattachmentreceiver

plate.Checkthereceiverplateandcleanitif

necessary.

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandtheoperating

characteristicsofthetractionunit.Thewarrantyofthe

tractionunitmaybevoidedifusedwithunapproved

attachments.

Important:Beforeinstallingtheattachment,ensure

thatthemountplatesarefreeofanydirtordebrisand

thatthepinsrotatefreely.Ifthepinsdonotrotatefreely,

greasethem.

1.Positiontheattachmentonalevelsurfacewithenough

spacebehindittoaccommodatethetractionunit.

2.Starttheengine.

3.Tilttheattachmentmountplateforward.

4.Positionmountplateintotheupperlipofthe

attachmentreceiverplate(Figure14).

Figure15

1.Quickattachpins(shown

inengagedposition)

2.Disengagedposition

3.Engagedposition

WARNING

Ifyoudonotfullyseatthequickattachpins

throughtheattachmentmountplate,the

attachmentcouldfalloffofthetractionunit,

crushingyouorbystanders.

Figure14

1.Mountplate2.Receiverplate

Ensurethatyourquickattachpinsarefully

seatedintheattachmentmountplate.

ConnectingtheHydraulicHoses

Iftheattachmentrequireshydraulicsforoperation,connect

thehydraulichosesasfollows:

19

Page 20

1.Stoptheengine.

2.Movetheauxiliaryhydraulicsleverforward,backward,

andbacktoneutraltorelievepressureatthehydraulic

couplers.

3.Movetheauxiliaryhydraulicsleverforwardintothe

detentposition.

4.Removetheprotectivecoversfromthehydraulic

couplersonthetractionunit.

5.Ensurethatallforeignmatteriscleanedfromthe

hydraulicconnectors.

6.Pushtheattachmentmaleconnectorintothefemale

connectoronthetractionunit.

Note:Whenyouconnecttheattachmentmale

connectorrst,youwillrelieveanypressurebuiltupin

theattachment.

3.Disengagethequickattachpinsbyturningthemto

theoutside.

4.Iftheattachmentuseshydraulics,movetheauxiliary

hydraulicsleverforward,backward,andbacktoneutral

torelievepressureatthehydrauliccouplers.

5.Iftheattachmentuseshydraulics,slidethecollarback

onthehydrauliccouplersanddisconnectthem.

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystemcontamination

duringstorage.

6.Installtheprotectivecoversontothehydrauliccouplers

onthetractionunit.

7.Starttheengine,tiltthemountplateforward,andback

thetractionunitawayfromtheattachment.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponentsyoumaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbefore

touchinghydrauliccomponents.

SecuringtheTractionUnitfor Transport

Whentransportingthetractionunitonatrailer,alwaysuse

thefollowingprocedure:

Important:Donotoperateordrivethetractionunit

onroadways.

1.Lowertheloaderarms.

2.Stoptheengine.

3.Securethetractionunittothetrailerwithchainsor

strapsusingthetie-down/liftloops(Figure6)tosecure

therearofthetractionunitandtheloaderarms/mount

platetosecurethefrontofthetractionunit.

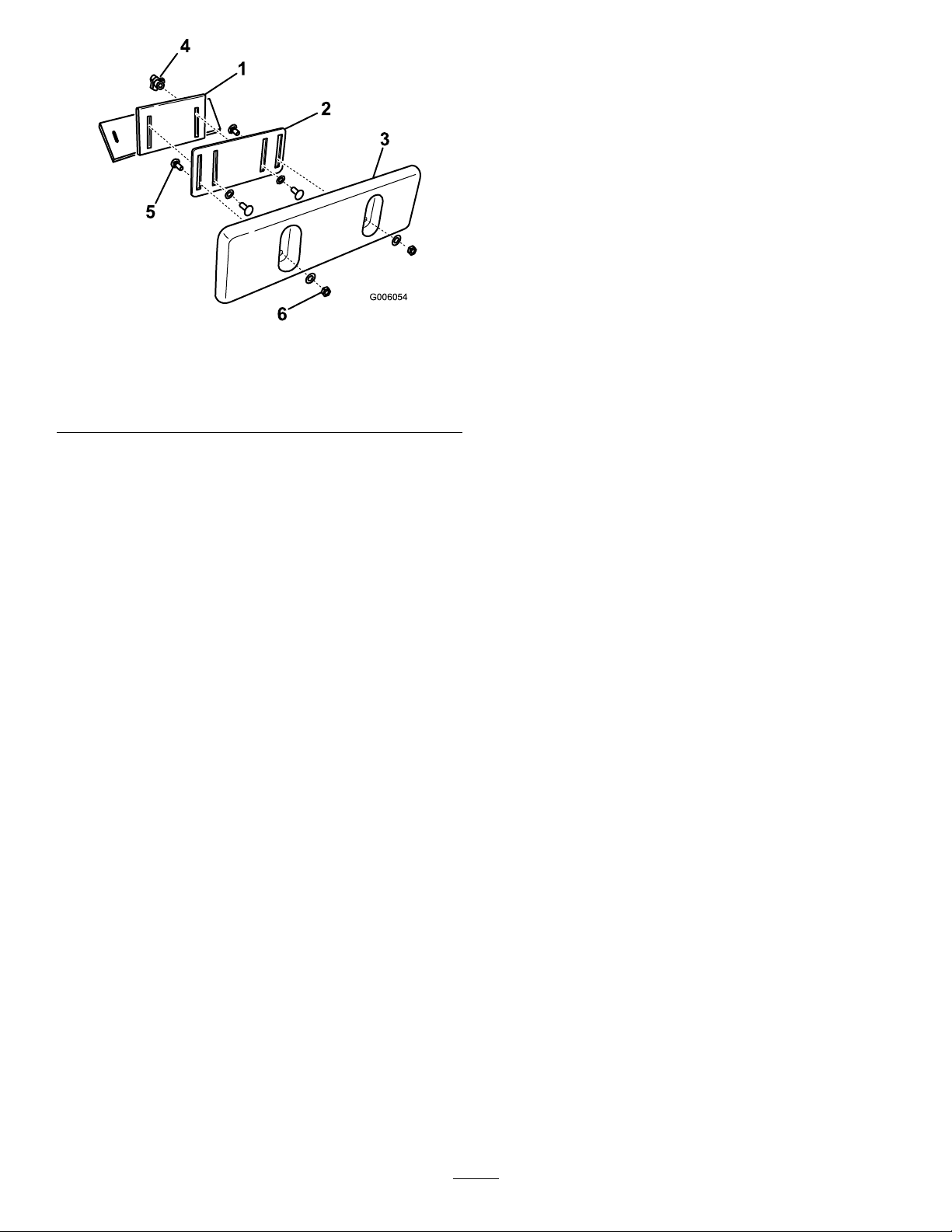

AdjustingtheThighSupport

Toadjustthethighsupport(Figure16),loosentheknobs

andraiseorlowerthesupportpadtothedesiredheight.You

canalsoobtainadditionaladjustmentbylooseningthenut

securingthepadtotheadjustmentplate,movingtheplate

upordownasneeded.Tightenallfastenerssecurelywhen

nished.

•Donottouchhydraulicuidspills.

7.Pushtheattachmentfemaleconnectorintothemale

connectoronthetractionunit.

8.Conrmthattheconnectionissecurebypullingon

thehoses.

9.Movetheauxiliaryhydraulicslevertoneutral.

RemovinganAttachment

1.Lowertheattachmenttotheground.

2.Stoptheengine.

20

Page 21

G006054

3

2

1

4

5

6

Figure16

1.Thighsupportbracket

2.Adjustmentplate

3.Thighsupportpad

4.Knobandatwasher

5.Carriagebolt

6.Locknutandatwasher

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Ifyouwillbetiltingthemachinemorethan

25degrees,clampofftheventhoseonthetopofthefuel

tanktopreventfuelfromfoulingthecarboncanister.

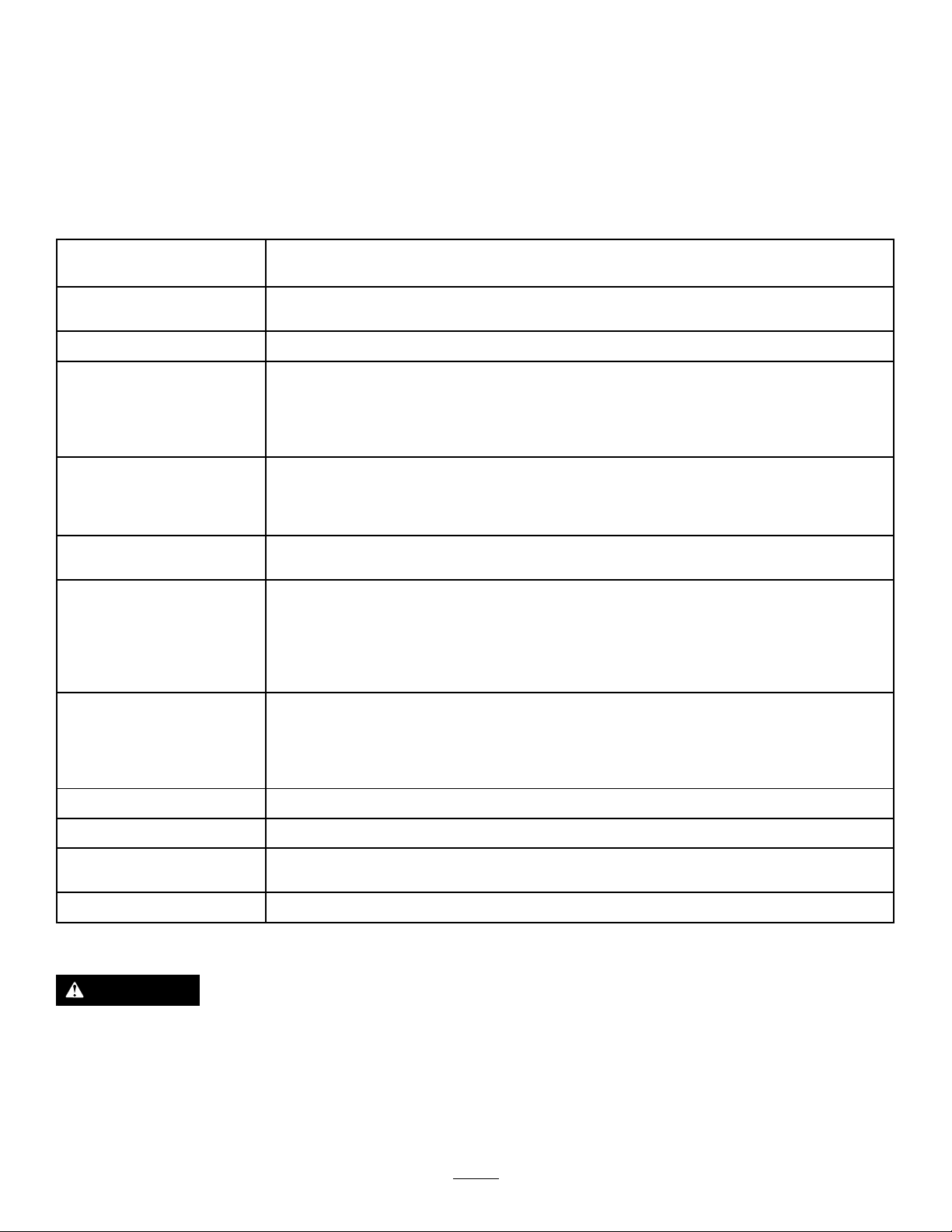

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Replacethehydrauliclter.

•T orquethewheellugnutsto50ft-lb(68N⋅m).

•Changetheengineoilandlter.

•Checktheengineoillevel.

•Removedebrisfromthetractionunit.

•Checkthetirepressure.

•Greasethetractionunit.

•Checkforloosefasteners.

•Checkthehydraulicuidlevel.

•Cleanthefoamairlterandcheckthepaperlterfordirtordamage.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Lubricatethetractiondrivechains.

•Checkthedrivechaintension.

•Replacethepaperairlter.

•Changetheengineoilandlter(morefrequentlywhenoperatingconditionsare

extremelydustyorsandy).

•Checkthebatteryelectrolytelevel(replacementbatteryonly).

•Checkthebatterycableconnections.

•T orquethewheellugnutsto50ft-lb(68N⋅m).

•Replacethecarboncanisterairlter.(Servicemorefrequentlyifconditionsare

extremelydustyorsandy.)

Every200hours

Every400hours

Every1,500hours

Yearly

Yearlyorbeforestorage

Important:Refertoyour

•Replacethecarboncanisterpurge-linelter.(Servicemorefrequentlywhenusing

thevibratoryplowattachment.)

•Checkthesparkplugs.

•Replacethehydrauliclter.

•Replaceallmovinghydraulichoses.

•Changethefuellter.

•Changethehydraulicuid.

•T ouchupchippedpaint

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewiresfromthesparkplugsbeforeyoudoany

maintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

22

Page 23

Lubrication

EngineMaintenance

GreasingtheTractionUnit

ServiceInterval:Beforeeachuseordaily

Greaseallpivotjointsevery8operatinghoursand

immediatelyaftereverywashing.

GreaseType:General-purposegrease.

1.Lowertheloaderarmsandstoptheengine.Remove

thekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure17and

Figure18).

ServicingtheAirCleaner

FoamPre-lter:Cleanevery25operatinghours.

PaperFilter:Checkevery25operatinghours.Replaceafter

every100operatinghours.

Note:Servicetheaircleanermorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

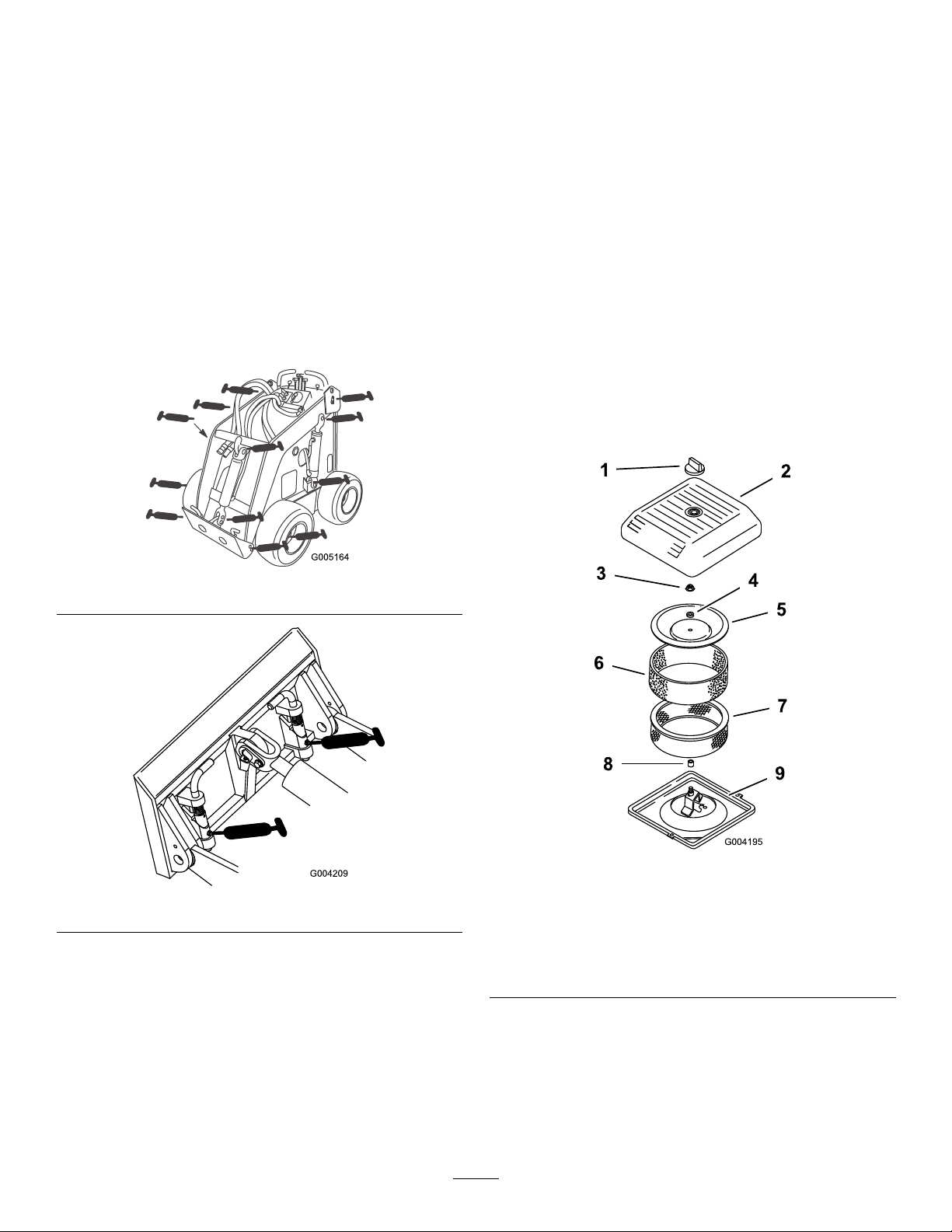

3.Unscrewtheknobandremovetheaircleanercover

(Figure19).

Figure17

Figure18

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

Note:Atthecenterofeachfrontwheelhubisa

greasettingcoveredbyarubbercap.Fillthesettings

withgreaseuntiltheblueringaroundthettingmoves

allofthewayouttowardyou,thenreplacethecap.

5.Wipeupanyexcessgrease.

Figure19

1.Knob

2.Aircleanercover

3.Covernut

4.Spacer

5.Cover

4.Carefullyslidethefoampre-lteroffofthepaper

element(Figure19).

5.Unscrewthecovernutandremovethecover,spacer

andpaperlter(Figure19).

6.Foampre-lter

7.Paperlter

8.Rubberseal

9.Aircleanerbase

23

Page 24

Cleaning/ReplacingtheFilters

G018290

1

2

2

4

3

5

ServiceInterval:Every25hours

Every100hours

Important:Replacethefoamelementifitistornor

worn.

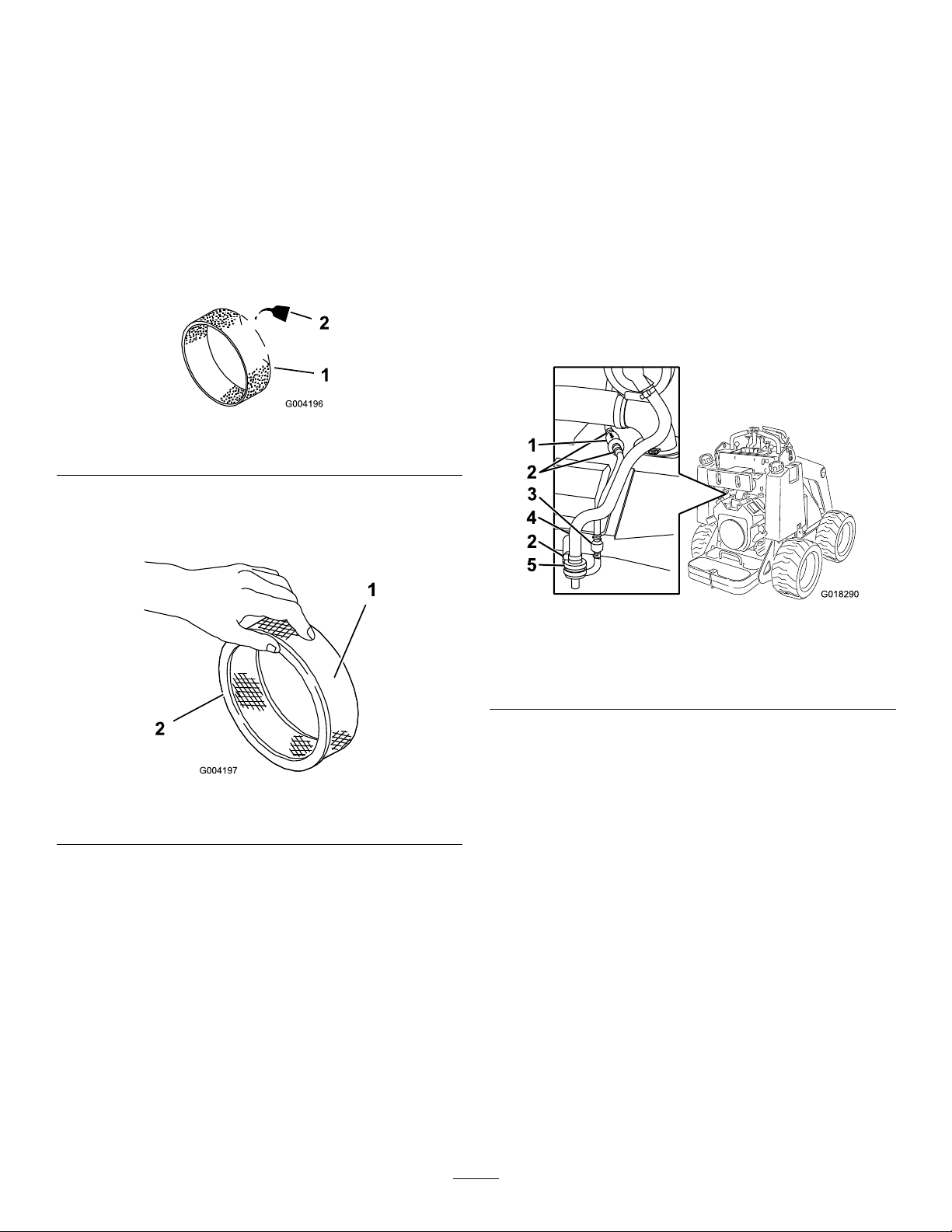

1.Washthefoampre-lterinliquidsoapandwarmwater.

Whenclean,rinseitthoroughly.

2.Drythepre-lterbysqueezingitinacleancloth(do

notwring).

3.Putoneortwoouncesofoilonthepre-lter(Figure

20).

Figure20

3.Installthecover,spacerandsecureitwiththecovernut

(Figure19).Torquethenutto95inch-lb(11N⋅m).

4.Installtheaircleanercoverandsecureitwiththeknob

(Figure19).

ServicingtheCarbonCanister

ReplacingtheCarbonCanisterAirFilter

ServiceInterval:Every200hours(Servicemorefrequentlyif

conditionsareextremelydustyorsandy.)

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Loosenthehoseclampabovethecarboncanisterair

lter(Figure22).

1.Foamelement

4.Squeezethepre-ltertodistributetheoil.

5.Lightlytapthepaperlteronaatsurfacetoremove

dustanddirt(Figure21).

1.Paperelement2.Rubberseal

6.Inspectthepaperlterfordirt,tears,anoilylm,and

damagetotherubberseal.

Important:Nevercleanthepaperelement.

Replacethepaperelementifitisdirtyordamaged.

2.Oil

Figure21

InstallingtheFilters

Figure22

1.Purge-linelter

2.Hoseclamp

3.Checkvalve

3.Removeanddiscardtheairlter(Figure22).

Important:Ifasmalltubesectioncomesoutof

thelargerhoseonthebarbofthelter,removeit

fromthelterandinsertitbackintothehose.

4.Installanewlterintothehoseandsecureitwiththe

hoseclamp(Figure22).

4.Hosetocarboncanister

5.Airlter

ReplacingtheCarbonCanister

Purge-lineFilter

ServiceInterval:Every200hours(Servicemorefrequently

whenusingthevibratoryplow

attachment.)

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Carefullyslidethefoampre-lterontothepaperlter

(Figure21).

2.Placetheaircleanerassemblyontotheaircleanerbase

(Figure19).

Note:Checkthepurge-linelteroccasionallyfordirt.Ifthe

lterappearstobedirty,replaceit.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Movethespring-typehoseclampsonbothsidesofthe

carboncanisterpurge-linelterawayfromthelter

(Figure22).

24

Page 25

3.Removeanddiscardthecarbonlter(Figure22).

4.Installanewlterintothehosewiththearrowonthe

lterpointingtowardsthecheckvalveandsecureit

withthehoseclamps(Figure22).

ServicingtheEngineOil

Changeoilandlteraftertherst50operatinghoursand

thenevery100operatinghoursthereafter.

Note:Changeoilmorefrequentlywhenoperatingconditions

areextremelydustyorsandy.

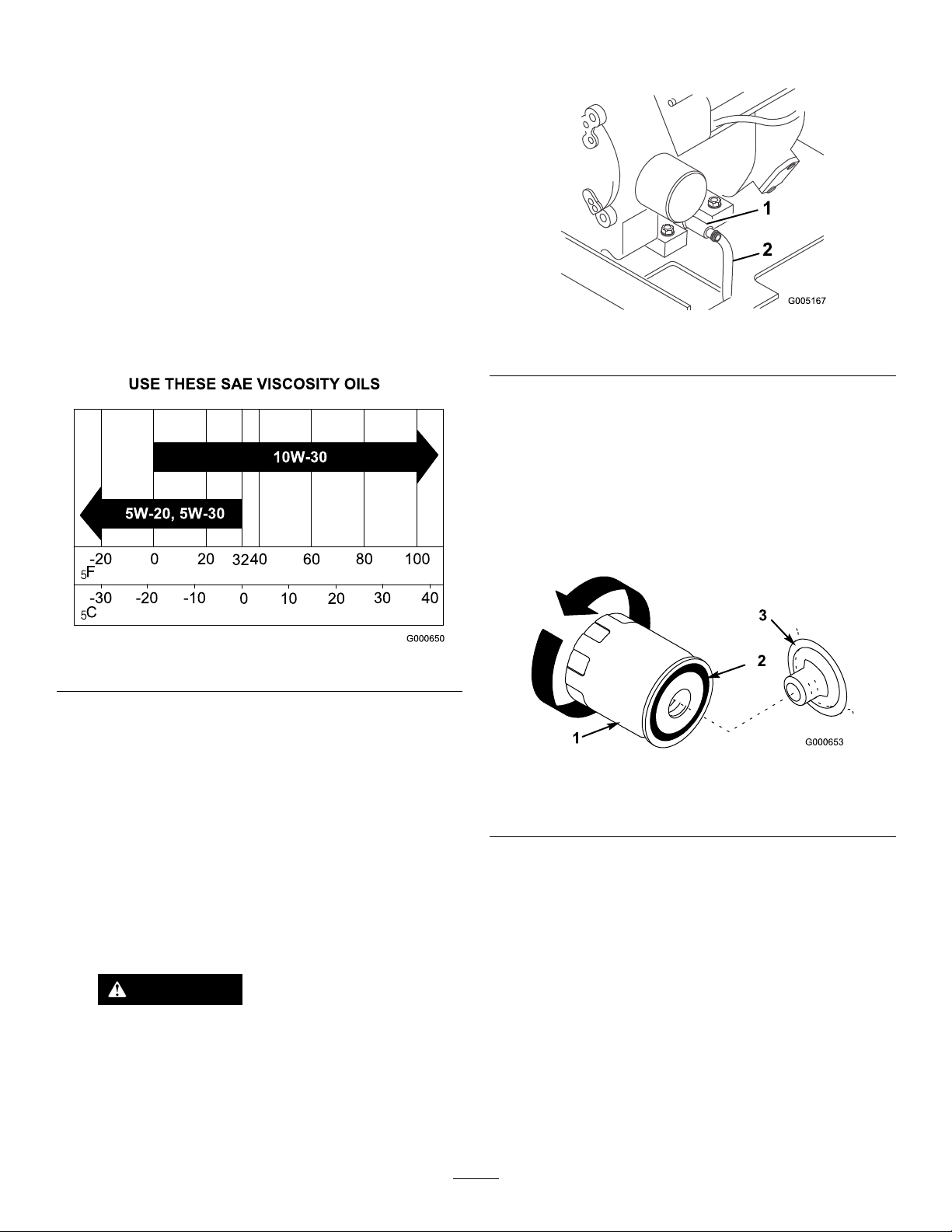

OilType:Detergentoil(APIserviceSG,SH,SJ,orhigher)

CrankcaseCapacity:w/lter,67oz(2l)

Viscosity:Seetablebelow

4.Placeoneendofahoseonthedrainvalveandthe

otherendinapan(Figure24).

Figure24

1.Oildrainvalve

5.Openthedrainvalvebyturningitcounterclockwise,

pullingoutasyouturnit(Figure24).

6.Whentheoilhasdrainedcompletely,closethedrain

valveandremovethehose.

Note:Disposeoftheusedoilatacertiedrecycling

center.

Figure23

ChangingtheOilandFilter

ServiceInterval:Aftertherst50hours

Every100hours

1.Starttheengineandletitrunforveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthetractionunitsothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely.

3.Lowertheloaderarms,chockthewheels,stopthe

engine,andremovethekey.

CAUTION

Componentswillbehotifthetractionunithas

beenrunning.Ifyoutouchhotcomponents

youmaybeburned.

Allowthetractionunittocoolbefore

performingmaintenanceortouching

componentsunderthehood.

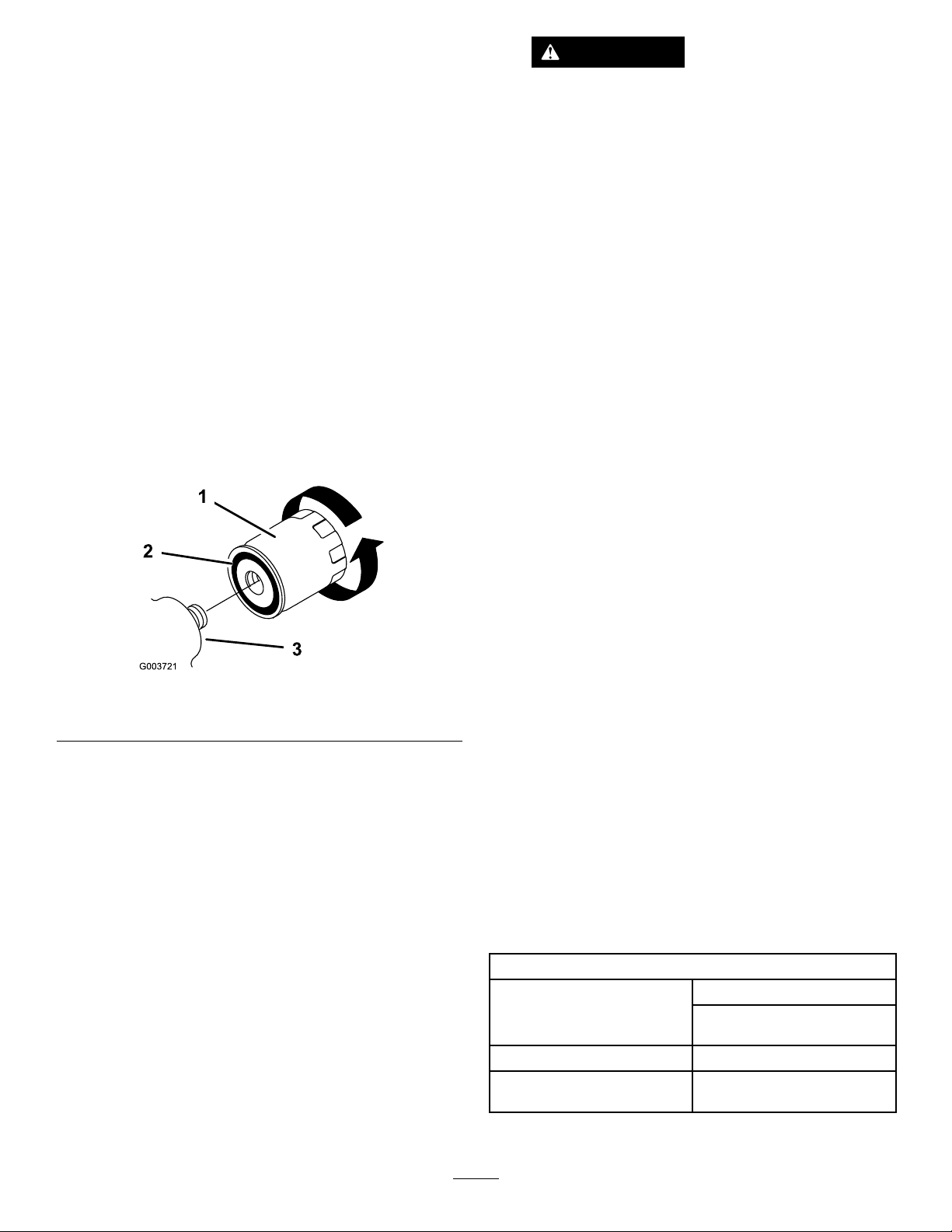

7.Removetheoldlterandwipethelteradapter(Figure

25)gasketsurface.

Figure25

1.Oillter

2.Gasket

8.Pournewoilofthepropertypeinthroughthecenter

holeofthelter.Stoppouringwhentheoilreaches

thebottomofthethreads.

9.Allowaminuteortwofortheoiltobeabsorbedby

ltermaterial,thenpourofftheexcessoil.

10.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure25).

11.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn(Figure25).

12.Removetheoilllcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthe

valvecover.

3.Adapter

25

Page 26

13.Checktheoillevel;refertoCheckingtheEngineOil

Level(page16).

14.SlowlyaddadditionaloiltobringtheleveltotheF

(full)markonthedipstick.

15.Replacethellcap.

ServicingtheSparkPlugs

Checkthesparkplugsafterevery200operatinghours.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingeachsparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplugsanda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installnewsparkplugsifnecessary.

Type:ChampionPremiumGold2071,RC12YC,or

equivalent.AirGap:0.030inch(0.76mm)

RemovingtheSparkPlugs

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Pullthewiresoffofthesparkplugs(Figure26).

Figure27

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure27).

3.Bendthesideelectrode(Figure27)ifthegapisnot

correct.

InstallingtheSparkPlugs

1.Threadthesparkplugsintothesparkplugholes.

2.Tightenthesparkplugsto20ft-lb(27N⋅m).

3.Pushthewiresontothesparkplugs(Figure26).

Figure26

1.Sparkplugwire2.Sparkplug

3.Cleanaroundthesparkplugs.

4.Removebothsparkplugsandmetalwashers.

CheckingtheSparkPlugs

ServiceInterval:Every200hours

1.Lookatthecenterofbothsparkplugs(Figure27).If

youseelightbrownorgrayontheinsulator,theengine

isoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Important:Nevercleanthesparkplugs.Always

replacethesparkplugswhentheyhaveablack

coating,wornelectrodes,anoilylm,orcracks.

26

Page 27

FuelSystem

2.Lowertheloaderarms,stoptheengine,andremove

thekey.

Maintenance

ChangingtheFuelFilter

ServiceInterval:Yearly

Replacethefuellteryearly.

Important:Neverinstalladirtylter.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Shutoffthefuelvalveonthebottomofthefueltank

(Figure29).

3.Clampthefuellinebetweenthefueltankandthefuel

ltertoblockthefuelow .

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure28).

Figure28

1.Filter2.Hoseclamp

3.Shutoffthefuelvalveinthehosenearthebottomof

thefueltank(Figure29).

Figure29

1.Fuelvalve,open2.Fuelvalve,closed

4.Loosenthehoseclampatthefuellterandslideitup

thefuellineawayfromthelter.

5.Pullthefuellineoffofthefuellter,openthefuel

valve,loosenthefueltankcap,andallowthegasoline

todrainintoagascanordrainpan.

6.Installthefuellineontothefuellter.

7.Slidethehoseclampclosetothefuelltertosecure

thefuelline.

8.Openthefuelvalveinthehosenearthebottomofthe

fueltankasillustratedinFigure29.

5.Placeadrainpanunderthefuellinestocatchanyleaks,

thenremovethelterfromthefuellines(Figure28).

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Removetheclampblockingfuelowandopenthefuel

valve.

DrainingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

Note:Nowisthebesttimetoinstallanewfuellterbecause

thefueltankisempty .

1.Parkthetractionunitonalevelsurface,toensurethat

thefueltankdrainscompletely.

27

Page 28

ElectricalSystem

Maintenance

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalcomponents,causingsparks.

Sparkscancausethebatterygassesto

WARNING

explode,resultinginpersonalinjury.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ReplacingtheBattery

Whenthebatterynolongerholdsacharge,replaceit.

Important:UseonlyagenuineTororeplacement

battery.

1.Parkthetractionunitonalevelsurface,raisetheloader

arms,andinstallthecylinderlocks.

2.Stoptheengineandremovethekey.

3.Removethewingnutandboltsecuringthebattery

clampandstrip(undertheclamp)andremovethe

clampandstrip(Figure30).

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthetractionunit.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thetractionunit.

4.Disconnectthenegative(black)batterycablefromthe

battery,savingtheboltandnut.

5.Disconnectthepositive(red)batterycablefromthe

battery,savingtheboltandnut.

6.Gentlypushthehydraulichosesasideandliftthe

batteryoutofthechassis.

7.Activatethenewbatteryasdirectedonthebattery

labeling.

8.Installthebatteryintothechassis(Figure30).

9.Securethebatteryinthechassis(Figure30).

10.Usingtheboltandwingnutsuppliedwiththebattery,

connectthepositive(red)cabletothepositive(+)

batterypost(Figure30).Slidetherubbercoverover

thebatterypost.

Figure30

1.Battery4.Rubbercover

2.Batteryclamp5.Negativecable

3.Positivecable

WARNING

Incorrectbatterycableroutingcoulddamage

thetractionunitandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Always

batterycablebeforedisconnectingthe

positive(red)cable.

•Always

cablebeforeconnectingthenegative

(black)cable.

11.Usingtheboltandwingnutsuppliedwiththebattery,

connectthenegative(black)cabletothenegative(-)

batterypost(Figure30).

Note:Ensurethatthebatterycablesdonotcontact

anysharpedgesoreachother.

disconnect

connect

thenegative(black)

thepositive(red)battery

28

Page 29

ServicingtheBattery

2

3

1

G003794

DANGER

Important:Thefollowingproceduresapplywhen

servicinga(dry)batterythathasreplacedtheoriginal

battery.Theoriginal(wet)batterydoesnotrequire

service.

Checktheelectrolytelevelinthebatteryevery100hours.

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionoffourpartswaterand

onepartbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstoreducecorrosion.

Voltage:12v,450ColdCrankingAmps

CheckingtheElectrolyteLevel

ServiceInterval:Every100hours

Every100hours

1.Stoptheengineandremovethekey.

2.Removethe4boltssecuringthebatterycoverand

removeitfromoverthebattery.

3.Lookatthesideofthebattery.Theelectrolytemust

beuptotheUpperline(Figure31).Donotallowthe

electrolytetofallbelowtheLowerline(Figure31).

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Removethebatteryfromthetractionunit.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthetraction

unit.Electrolytecouldbespilledonotherparts

andcausecorrosion.

2.Cleanthetopofthebatterywithapapertowel.

3.Removethellercapsfromthebattery(Figure31).

4.Slowlypourdistilledwaterintoeachbatterycelluntil

theelectrolytelevelisuptotheUpperline(Figure31)

onthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

5.Waitvetotenminutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(Figure31)onthebattery

case.

6.Installthebatteryllercaps.

ChargingtheBattery

WARNING

Figure31

1.Fillercaps3.Lowerline

2.Upperline

4.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery

(page29).

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethetractionunit.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow325F

(05C).

1.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel(page29).

2.Makesurethellercapsareinstalledinthebattery.

3.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat4to6amps(Figure32).Do

notoverchargethebattery.

29

Page 30

1

2

3

4

G003792

DriveSystem

Maintenance

ServicingtheTractionDrive Chains

LubricatingtheDriveChains

ServiceInterval:Every50hours

Figure32

1.Positivebatterypost

2.Negativebatterypost

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure32).

5.Replacethebatterycover.

3.Red(+)chargerlead

4.Black(-)chargerlead

Lubricatethedrivechainevery50operatinghours.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Applyageneralpurposeoil(10W30)ontoupperand

lowerchainspans.

3.Startthetractionunitandslowlymoveitforwardto

exposeunlubedupperandlowerchainspans.

4.Stoptheengineandremovethekey.

5.Applyoiltonewlyexposedunlubedchainspans.

CheckingtheDriveChainTension

ServiceInterval:Every50hours

Checkthedrivechaintensionbeforeusingthetractionunit

forthersttimeandevery50hoursofusethereafter.

Thedrivechainsshouldhaveabout1-1/2to2-1/2inches(3.8

to6.35cm)ofslackbetweenthebottomofthechainguard

andthebottomchainspanwhenthetopchainspanispulled

tight.Usethefollowingproceduretocheckthetension:

1.Withthebucketinstalled,loweritintothegrounduntil

thefronttiresareoffoftheground.

2.Stoptheengineandremovethekey.

3.Turnthefrontwheelforwardononesideofthe

tractionunituntilthetopspanofthedrivechainis

tight.

4.Measurethedistancebetweenthebottomofthechain

guardandthelowerchainspan(Figure33).Iftheslack

inthechainisnotwithin1-1/2to2-1/2inches(3.8

to6.35cm),adjustthetension(refertoAdjustingthe

DriveChainTension(page31)).

30

Page 31

Figure33

1.Chainguard3.1-1/2to2-1/2inches

2.Bottomspanofthechain

5.Repeatsteps3and4fortheotherdrivechain.

6.Starttheengineandraisethebuckettoreturnthefront

wheelstotheground.

AdjustingtheDriveChainTension

tosecureitinplace(Figure34)andtorquethenutto

30ft-lb(40.7N⋅m).

8.Tightenthenutssecuringtheaxleretainingbracketand

torquethemto75ft-lb(102N⋅m).

9.Repeatsteps3through8fortheotherdrivechain.

10.Starttheengineandraisethebuckettoreturnthefront

wheelstotheground.

1.Withthebucketinstalled,loweritintothegrounduntil

thefronttiresareoffoftheground.

2.Stoptheengineandremovethekey.

3.Loosenthenutssecuringtheaxleretainingbracket

(Figure34).

4.Loosenthenutonthechaintensioningboltandloosen

thebolt(Figure34).

Figure34

1.Axleretainingbracket

2.Nut4.Nut

3.Chaintensioningbolt

5.Turnthefrontwheelononesideofthetractionunit

untiltheupperspanofthedrivechainistight.

6.Adjustthechaintensioningboltuntilthedistance

betweenthebottomofthechainguardandthelower

chainspaniswithin1-1/2to2-1/2inches(3.8to6.35

cm)(Figure33).

7.Positiontheaxleretainingbrackettightagainstthe

axleandtheframe,thentightenthenutonthebolt

31

Page 32

HydraulicSystem

Maintenance

ReplacingtheHydraulicFilter

ServiceInterval:Aftertherst8hours

Every400hours

Important:Donotsubstituteanautomotiveoillteror

severehydraulicsystemdamagemayresult.

Changethehydrauliclteraftertherst8operatinghours

andthenevery400operatinghoursthereafter.

1.Positiontractionunitonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinderlocks,

stoptheengine,andremovethekey.

3.Placeadrainpanunderthelter.

4.Removetheoldlter(Figure35)andwipethesurface

ofthelteradaptergasketclean.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

10.Checktheuidlevelinthehydraulictank(referto

CheckingtheHydraulicFluidLevel(page17))andadd

uidtoraisetheleveltomarkondipstick.Donotover

llthetank.

11.Removeandstorethecylinderlocksandlowerthe

loaderarms.

ChangingtheHydraulicFluid

Figure35

1.Hydrauliclter

5.Applyathincoathydraulicuidtotherubbergasket

onthereplacementlter(Figure35).

6.Installthereplacementhydrauliclterontothelter

adapter(Figure35).Tightenitclockwiseuntilthe

rubbergasketcontactsthelteradapter,thentighten

thelteranadditional1/2turn.

7.Cleanupanyspilleduid.

8.Starttheengineandletitrunforabouttwominutesto

purgeairfromthesystem.

9.Stoptheengineandcheckforleaks.

ServiceInterval:Yearly

HydraulicFluidSpecication:

Useonlyoneofthefollowinguidsinthehydraulicsystem:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedT oroDealerformore

information)

•ToroPremiumAllSeasonHydraulicFluid(referto

yourAuthorizedToroDealerformoreinformation)

•IfneitheroftheaboveTorouidsareavailable,

youmayuseanotherUniversalTractorHydraulic

Fluid(UTHF),buttheymustbeonlyconventional,

petrolium-basedproducts.Thespecicationsmustfall

withinthelistedrangeforallofthefollowingmaterial

propertiesandtheuidshouldmeetthelistedindustry

standards.Checkwithyouroilsuppliertodetermineif

theoilmeetsthesespecications.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendations.

MaterialProperties

cStat40degreesC:55to62 Viscosity,ASTMD445

cStat100degreesC:9.1to

9.8

Viscosityindex,ASTMD2270

PourPoint,ASTMD97-35to-46degreesF(-37to

140to152

-43degreesC)

32

Page 33

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM.

Storage

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

Note:Manyhydraulicuidsarealmostcolorless,making

itdifculttospotleaks.Areddyeadditiveforthe

hydraulicsystemoilisavailablein2/3oz(20ml)bottles.

Onebottleissufcientfor4-6gal(15-22l)ofhydraulic

oil.Orderpartno.44-2500fromyourAuthorizedToro

Dealer.

1.Positionthetractionunitonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinderlocks.

3.Stoptheengineandremovethekey.

4.Placealargedrainpanunderthetractionunitthatcan

holdatleast17USgallons(67l).

5.Removethedrainplugfromthebottomofthe

hydraulictankandallowtheuidtocompletelydrain

out.

6.Installthedrainplug.

7.Fillthehydraulictankwithapproximately15US

gallons(57L)ofhydraulicuidasspeciedabove;

refertoCheckingtheHydraulicFluidLevel(page17).

Note:Disposeofusedoilatacertiedrecycling

center.

8.Removeandstorethecylinderlocksandlowerthe

loaderarms.

2.Removedirtandgrimefromtheexternalpartsofthe

entiretractionunit,especiallytheengine.Cleandirt

andchafffromtheoutsideoftheengine'scylinder

headnsandblowerhousing.

Important:Youcanwashthetractionunitwith

milddetergentandwater.Donotpressurewash

thetractionunit.Avoidexcessiveuseofwater,

especiallynearthecontrolpanel,engine,hydraulic

pumps,andmotors.

3.Servicetheaircleaner;referto(page).

4.Greasethetractionunit;refertoGreasingtheTraction

Unit(page23).

5.Changetheengineoil;refertoChangingtheOiland

Filter(page25).

6.Removethesparkplugsandchecktheconditionof

each;refertoServicingtheSparkPlugs(page26).

7.Withthesparkplugsremovedfromtheengine,pour

twotablespoonsofengineoilintoeachsparkplughole.

8.Placeragsoverthesparkplugholestocatchanyoil

spray,thenusethestartertocranktheengineand

distributetheoilinsidethecylinder.

9.Installthesparkplugs,butdonotinstallthewireson

thesparkplugs.

CheckingtheHydraulicLines

ServiceInterval:Every25hours

Every1,500hours

Afterevery25operatinghours,checkthehydrauliclinesand

hosesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.Replace

allmovinghydraulichosesevery1500hoursor2years,which

evercomesrst.Makenecessaryrepairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks,

neveruseyourhands.

10.Checkthetirepressure;refertoCheckingtheTire

Pressure(page17).

11.Chargethebattery;referto3ChargingtheBattery

(page9).

12.Forstorageover30days,preparethetractionunitas

follows:

A.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer(1oz.pergallon).Do

notuseanalcoholbasedstabilizer(ethanol

ormethanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshgasolineandused

atalltimes.

B.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

C.Stoptheengine,allowittocool,anddrainthefuel

tanks;refertoDrainingtheFuelTank.

D.Starttheengineandrunituntilitstops.

E.Choketheengine.

F.Startandruntheengineuntilitwillnotstartagain.

33

Page 34

G.Disposeoffuelproperly.Recycleasperlocal

codes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

13.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedordefective.

14.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

15.Storethetractionunitinaclean,drygarageorstorage

area.Removethekeyfromtheignitionswitchand

keepitinamemorableplace.

16.Coverthetractionunittoprotectitandkeepitclean.

Important:Whenremovingthetractionunitfrom

storage,chargethebattery;referto3Chargingthe

Battery(page9).

34

Page 35

Troubleshooting

Problem

Thestarterdoesnotcrank

Theenginewillnotstart,startshard,or

failstokeeprunning.

Theenginelosespower.

PossibleCauseCorrectiveAction

1.Theauxiliaryhydraulicsleverisnotin

theneutralposition.

2.Thebatteryisdischarged.

3.Theelectricalconnectionsare

corrodedorloose.

4.Therelayorswitchisdamaged.

1.Thefueltankisempty.1.Fillthefueltankwithgasoline.

2.Thechokeisnoton.

3.Theaircleanerisdirty.

4.Thesparkplugwiresarelooseor

disconnected.

5.Thesparkplugsarepitted,fouled,or

thegapisincorrect.

6.Thereisdirtinthefuellter.6.Replacethefuellter.

7.Dirt,water,orstalefuelisinfuel

system.

1.Theengineloadisexcessive.1.Reducegroundspeed.

2.Theaircleanerisdirty.

3.Theoillevelincrankcaseislow.

4.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

5.Thesparkplugsarepitted,fouled,or

thegapisincorrect.

6.Thereisdirtinthefuellter.6.Replacethefuellter.

7.Dirt,water,orstalefuelisinfuel

system.

1.Movethelevertotheneutralposition.

2.Chargethebatteryorreplaceit.

3.Checktheelectricalconnectionsfor

goodcontact.

4.ContactyourAuthorizedService

Dealer.

2.Movethechokeleverfullyforward.

3.Cleanorreplacetheaircleaner

elements.

4.Installthewiresonthesparkplugs.

5.Installnew,correctlygappedspark

plugs.

7.ContactyourAuthorizedService

Dealer.

2.Cleanorreplacetheaircleaner

elements.

3.Checkandaddoiltothecrankcase.

4.Removeanyobstructionsfromthe

coolingnsandairpassages.

5.Installnew,correctlygappedspark

plugs.

7.ContactyourAuthorizedService

Dealer.

Theengineoverheats.

Abnormalvibration.1.Theenginemountingboltsareloose.1.Tightentheenginemountingbolts.

Thetractionunitdoesnotdrive.

Whenatrest,theloaderarmscreep

downwardmorethan3inchesperhour

(lessthan3inchesanhourisnormalfor

thistractionunit).

Whenatrest,loaderarmssettledownward

2inchesquicklyandthenstop.

1.Theengineloadisexcessive.1.Reducegroundspeed.

2.Theoillevelinthecrankcaseislow.

3.Thecoolingnsandairpassages

undertheengineblowerhousingare

plugged.

1.Thehydraulicuidlevellow.1.Checkandaddhydraulicuid.

2.Thehydraulicsystemisdamaged.

1.Thevalvespoolisleaking

1.Thecylindersealsareleaking1.Replacetheseals.

2.Checkandaddoiltothecrankcase.

3.Removeanyobstructionsfromthe

coolingnsandairpassages.

2.ContactyourAuthorizedService

Dealer.

1.ContactyourAuthorizedService

Dealer.

35

Page 36

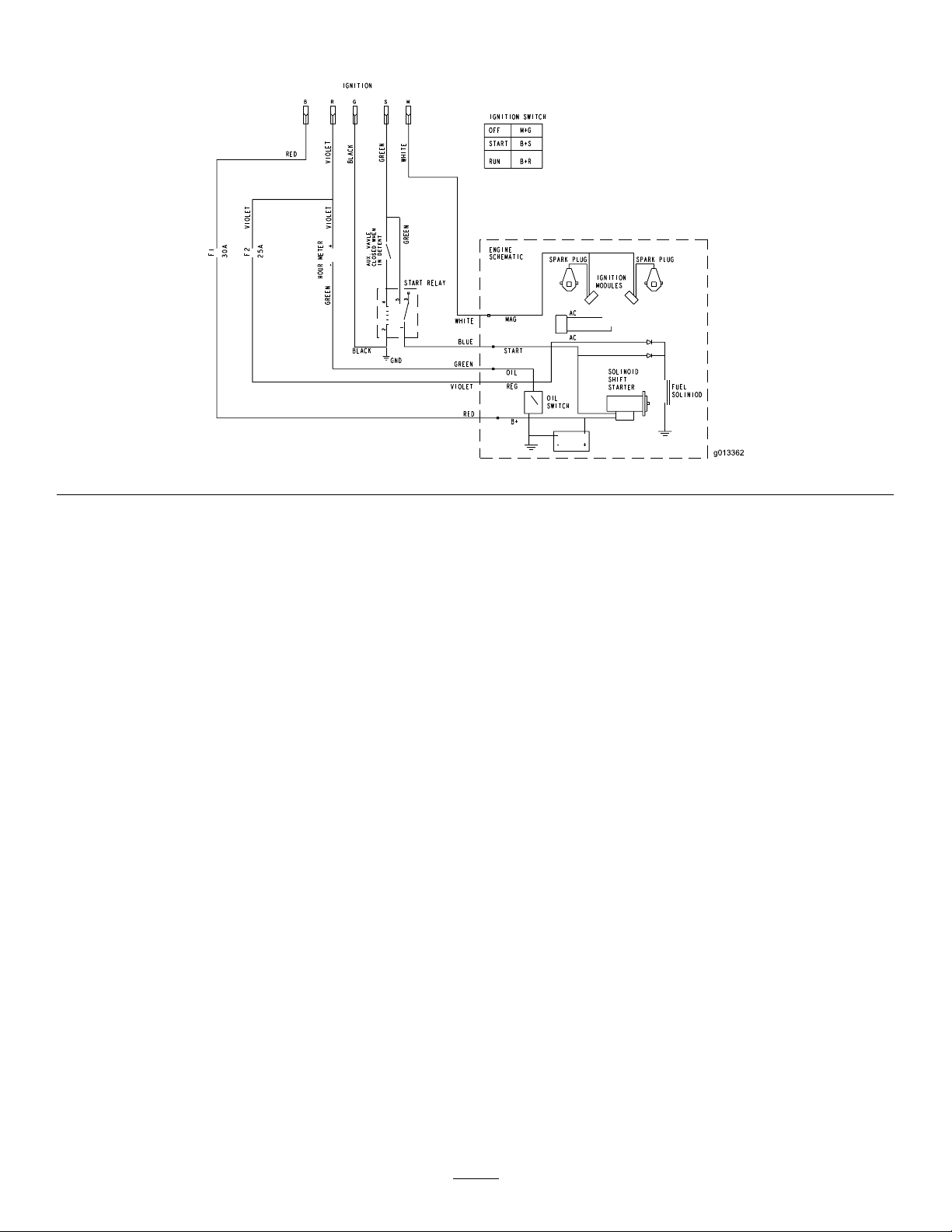

Schematics

ElectricalSchematic(Rev .A)

36

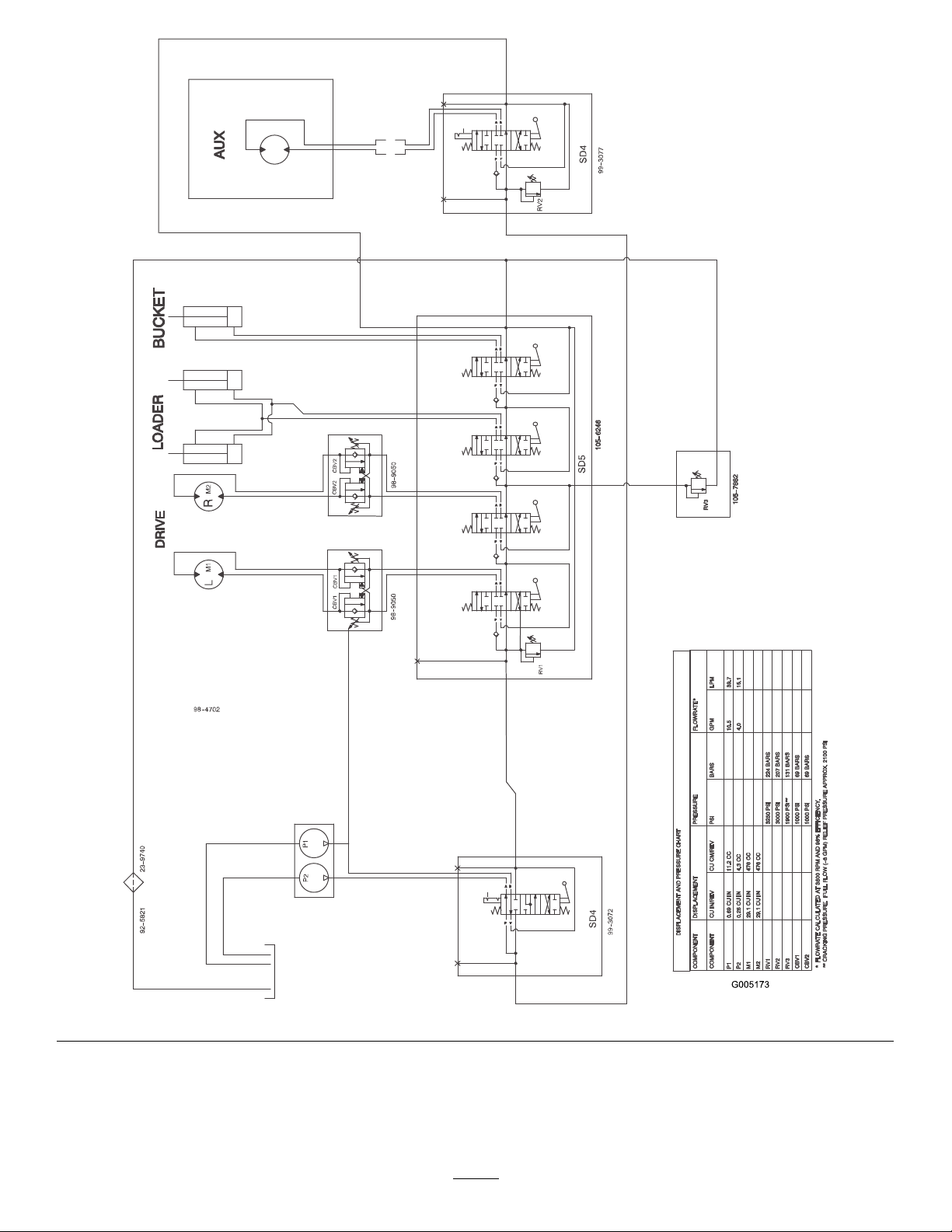

Page 37

HydraulicSchematic(Rev .A)

37

Page 38

Notes:

38

Page 39

Notes:

39

Page 40

TheToroWarranty

AOne-Y earLimitedWarranty

CompactUtilityEquipment

(CUE)Products

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,ToroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlywarrantyourToroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ProSneak

CompactToolCarriers,

Trenchers,StumpGrinders,

andAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer .

1yearor1000operatinghours,

whicheveroccursrst

*

*

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.T olocatea

dealerconvenienttoyou,accessourwebsiteatwww .T oro.com.You

mayalsocallourToroCustomerCareDepartmenttollfreeatthe

numberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts