Page 1

DH200,DH210,andDH220LawnTractors

SerialNo.280000001andUp

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3360-473RevB

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

SteeringWheel

LockWasher1

Nut1

Seat

Bolts2

FlatWashers2

SpringWashers

TrailerHitch1

Bolts2

Nuts2

CollectorCover

GrassCollector—PartiallyAssembled

GrassBag

FastenerPackage1

ArrowDecal1

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

1

Installingthesteeringwheel

1

Installingtheseat

2

Attachingthetrailerhitch

1

1

1

–

–

–

Assemblingthegrasscollector

Checkingtheoillevel

Activatingthebattery

Fillingthefueltank

8

9

10

11

12

13

©2009—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Nopartsrequired

Keys2

Nopartsrequired

Operator’sManual

EngineOperator’sManual

CerticateofConformance

Registeratwww.Toro.com.

–

–

–

1

1

1

Checkingthetirepressure

Lubricatingthemachine

UsingintheignitionandKeyChoice™

switch

Checkthesafetysystem

Readingbeforeoperatingthemachine

CEconformance

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

1

2

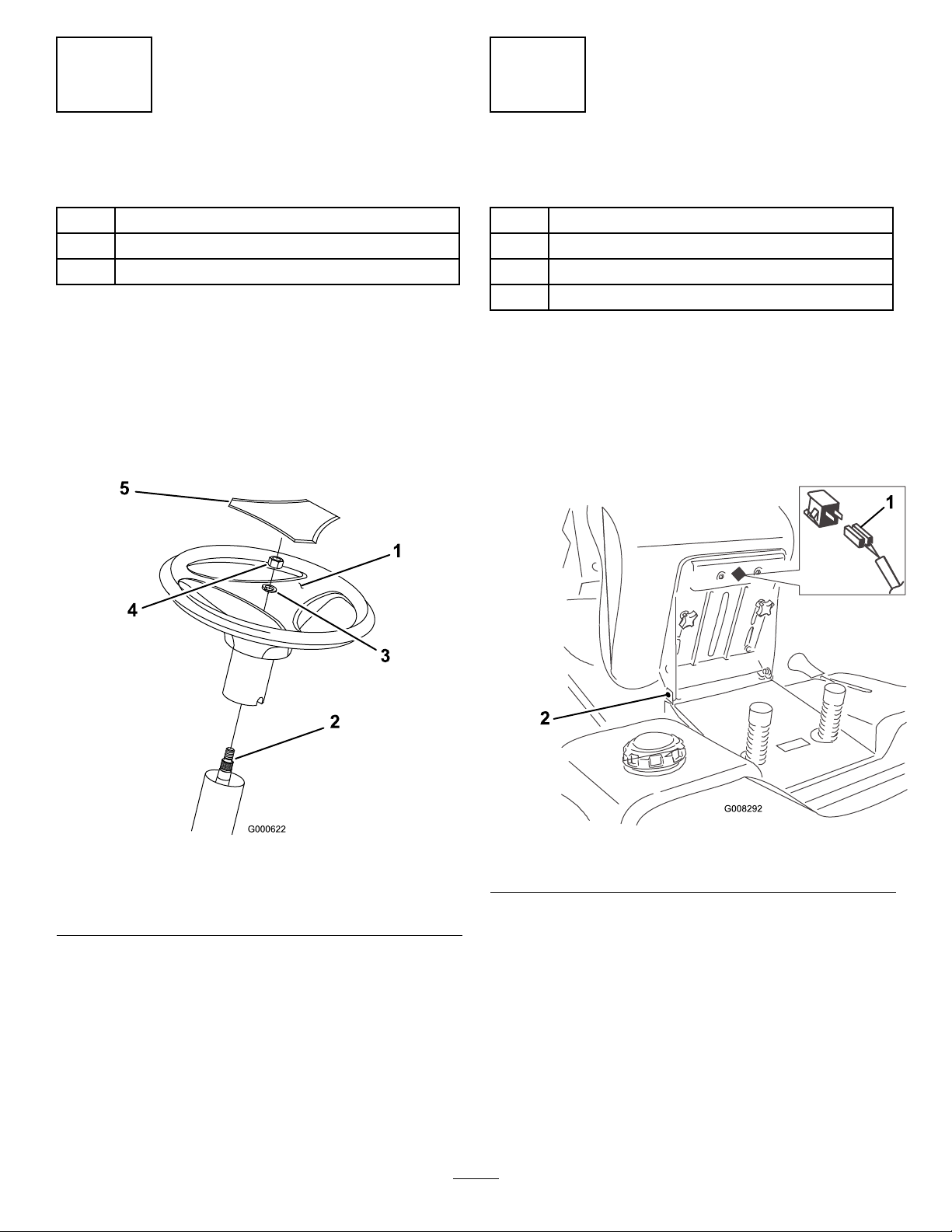

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

SteeringWheel

1LockWasher

1Nut

Procedure

1.Positionthefrontwheelsstraightahead.

2.Removethelogocoverbyreleasingthe3latches

fromthebacksidewithascrewdriver.

3.Lineupthecenterspoketowardtheseatandposition

thesteeringwheelontotheshaftspline(Figure1).

InstallingtheSeat

Partsneededforthisprocedure:

1

Seat

2Bolts

2FlatWashers

2

SpringWashers

Procedure

1.Removetheplasticcoverfromtheseatanddiscardit.

2.Loosenthetwoboltsontheseathinges.

3.Settheseatinplaceandsecureitwiththetwobolts,

springwashers,andatwashers(Figure2).

Figure1

1.Centerspoke

2.Shaftspline

3.Lockwasher

4.Securethesteeringwheelwithalockwasherandnut

(Figure1).

5.Torquethesteeringwheelnutto50ft-lb(37N-m).

6.Snapthelogocoverintoplace(Figure1).

4.Nut

5.Logocover

Figure2

1.Safetyswitch

4.Ensurethatthesafetyswitchisconnectedtotheseat

(Figure2).

2

2.Boltandwashers

Page 3

3

4

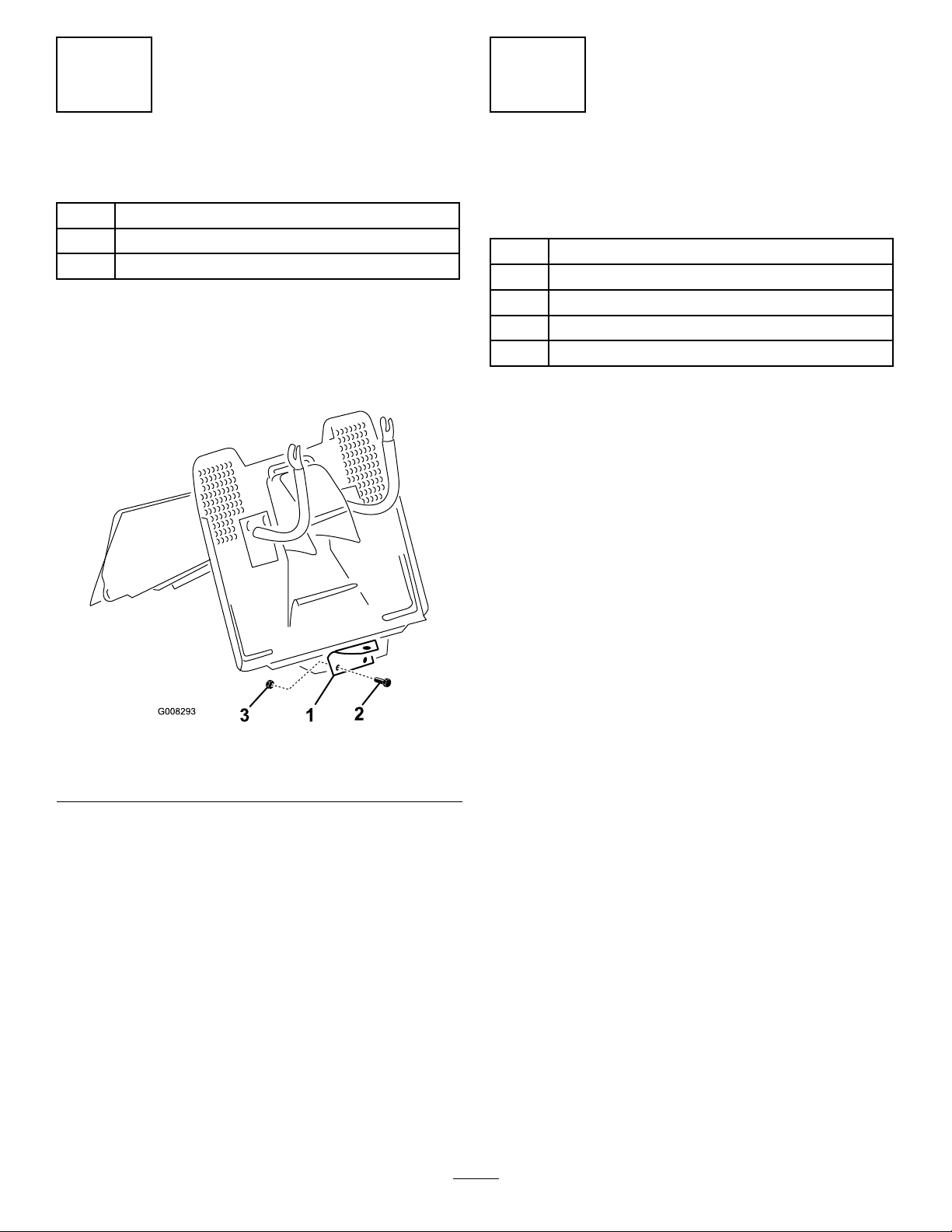

AttachingtheTrailerHitch

Partsneededforthisprocedure:

1TrailerHitch

2Bolts

2Nuts

Procedure

1.Lineuptheholesinthetrailerhitchwiththeholesin

themachineframe.

2.Attachthehitchwithtwoboltsandnuts(Figure3).

AssemblingtheGrass

Collector

Partsneededforthisprocedure:

1

CollectorCover

1

GrassCollector—PartiallyAssembled

1

GrassBag

1FastenerPackage

1ArrowDecal

Procedure

1.Tiltthefronttubeofthepartiallyassembled

collector.

2.Aligntheupperholeswiththeholesontheupper

tube.Looselyfastenthetubestogetherwiththe

upperbolts(Figure4).

Figure3

1.Trailerhitch3.Nut

2.Bolt

3

Page 4

12.Placethecoveronthegrasscollector.

13.Alignthecoverwiththerearfenderbyadjustingthe

rearmachinesupportsuntilthereisaproperseal

betweenthecoverandthecollector.

14.Tightentherearmachinesupportbolts.

15.Removethegrasscollectorfromthemachine.

16.Tightenallscrewssecurely.

17.Usetheplasticextrusionsonthebagedgestox

thebagtotheframetube.

18.Insertthedumpingleverthroughtheholeofthe

coverandsecureitwiththeM5x12screwandM5

nut(insidethetube)(Figure4).

19.Installthegrasscollectortothemachine(referto

theOperator’sManual).

20.Whenthegrasscollectorisproperlypositioned,

placethearrowdecaldirectlyoppositethearrow

symbolontherearofthemachine.

Figure4

1.Cover

2.Upperbolts

3.Fronttube9.Bottomtube

4.M5boltsandnuts10.Bag

5.Leftandrightsupports

6.Screws

3.Placethecollectorontherearmachinesupports

(refertotheOperator’sManual)andalignthecollector

framewiththemachinefenders.

4.Tightentheupperbolts(Figure4).

5.Stretchthebagandputitovertherearhandle

(Figure4).

6.Insertthebottomtubeintothebag(Figure4).

7.Insertthecornersupportsunderthetoptube.

8.Fastenthecornersupportstothetopandbottom

tubesusingtheM5boltsandnutsfromunderthe

collectorcover(Figure4).

7.Lowerbrace

8.Cornerupports

11.Dumpinglever

12.Rearhandle

5

CheckingtheOilLevel

NoPartsRequired

Procedure

Themachinecomesfromthefactorywithoilinthe

enginecrankcase;however,itmaybenecessarytoadd

oil.RefertotheOperator’sManualforoiltype,viscosity,

andcrankcasecapacity.Addonlyenoughoiltoraisethe

leveltotheFullmarkonthedipstick.

6

ActivatingtheBattery

NoPartsRequired

9.FastenthebottomtubetothefronttubewithM5

boltsandnuts(Figure4).

10.Tilttheleftandrightsupportsrearward.

11.Placethelowerbraceontheoutsideofthebag

andsecureittotheleftandrightsupportswiththe

screws(Figure4).

Procedure

1.Removethebatteryfromthemachine;refertothe

Operator’sManual.

2.Removethellercapsfromthetopofthebattery.

4

Page 5

Batteryelectrolytecontainssulfuricacidthat

ispoisonous(ifconsumed)andcanseverely

burnyou.

8

CheckingtheTirePressure

•Donotdrinkelectrolyte.

•Avoidcontactwithskin,eyesorclothing.

•Wearsafetyglassestoshieldyoureyesand

rubberglovestoprotectyourhands.

•Fillthebatterywherecleanwaterisavailable

forushingtheskin.

•Followallinstructionsandcomplywithall

safetymessagesontheelectrolytecontainer.

3.Slowlypourelectrolyteintoeachcelluntilthelevelis

uptothelowerpartofthetube.

4.Leavethellercapsoffandconnecta3-to4-amp

batterychargertothebatteryposts.

5.Chargethebatteryatarateof2amperesorlessfor

4hours(12volts).Donotoverchargethebattery.

Installthellercapsafterthebatteryisfullycharged.

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfromthebattery.

6.Installthebatteryinthechassis;refertotheOperator’ s

Manual.

NoPartsRequired

Procedure

Checkfrontandreartiresforproperination;referto

theOperator’sManualfortherecommendedination

pressure.

9

Lubricatingthemachine

NoPartsRequired

Procedure

Ensurethatallofthenecessarypointsonthemachine

arelubricated;refertotheOperator’sManual.

10

InsertingtheKeysintothe

Switches

Partsneededforthisprocedure:

7

FillingtheFuelTank

NoPartsRequired

Procedure

Addfueltothefueltank;refertotheOperator’ sManual.

2Keys

Procedure

TheKeyChoiceswitchislocatedontherightsideof

seatbracketbelowtheseat.

11

CheckingtheSafetySystem

NoPartsRequired

Procedure

RefertotheOperator’sManual.

5

Page 6

12

TestDrivingtheMachine

Partsneededforthisprocedure:

1

Operator’sManual

1

EngineOperator’sManual

Procedure

Ensurethatallelectricalandmechanicalsystemsare

operatingproperly.RefertotheOperator’ sManualfor

howtoproperlyoperatethecontrols.

13

CEConformance

Partsneededforthisprocedure:

1

CerticateofConformance

6

Page 7

Notes:

7

Page 8

Loading...

Loading...