Page 1

User’s Guide

CUSTOM COMMAND

TM

CONTROLLER SERIES

Español - P. 31

Français – P. 65

Page 2

i

Thank you for purchasing a Custom Command controller. Listed

below are some important features you should be aware of before you

begin programming. Details on how to implement these features are

described on the following pages.

• Four fully independent programs that can run concurrently

• Watering programmable for days of the week, odd days, even days

or intervals from 1 to 30 days. Selective removal of days from the

Odd/Even schedule

• 365-day calendar, with automatic compensation for leap year

• Sixteen total start times to use in any program

• Start time stacking overlap protection within each program

• Station watering time from 0 minutes to 10 hours in 1-minute

increments

• Program erase independent for each program

• Non-volatile memory that retains programmed information for up

to 30 years in the event of a power failure

• Accurate time and date retention during power failures for up to 90

days continuous via a 9-volt alkaline battery (included)

• % Season Adjust from 0 to 200% in 10% increments

• Rain delay programmable to 7 days

• Self-diagnostic electronic circuit breaker that identifies and over-

rides faulty stations

• Master valve/pump start operation selectable per program

• Complete manual operations available by station and program

• Sensor switch-ready for operation with any normally-closed rain

switch device

• Slide switch control provided for rain switch sensor override

• Unique modular design for ease of installation and service

To take full advantage of all Custom Command features, please review

the User’s Guide completely before installing or programming your

new controller.

FEATURES

Features

Page 3

1

Features....................................................................................................i

Controller Components.....................................................................2–3

General Information..........................................................................4–6

How the Backup System Works.......................................................4

How the Electronic Circuit Breaker Works.....................................5

How the Sensor Feature Works.......................................................6

Programming the Controller...........................................................7–15

Getting Started.............................................................................7–9

Setting the Current Time and Date...............................................10

Erasing Any Prior Programs...........................................................11

Setting the Station Run Time........................................................11

Master Valve/Pump Start On/Off ..................................................12

Setting Program Start Times....................................................12–13

Selecting the Days to Water....................................................13–15

Operating the Controller ...............................................................15–18

% Season Adjust ............................................................................15

Manual Operations...................................................................16–17

Off and Rain Delay ..................................................................17–18

Installation Procedures ..................................................................19–24

Selecting an Installation Site.........................................................19

Mounting the Controller...............................................................20

Installing Electrical Conduit ..........................................................20

Connecting Valve Wiring..............................................................21

Connecting an Optional Pump Start Relay..................................22

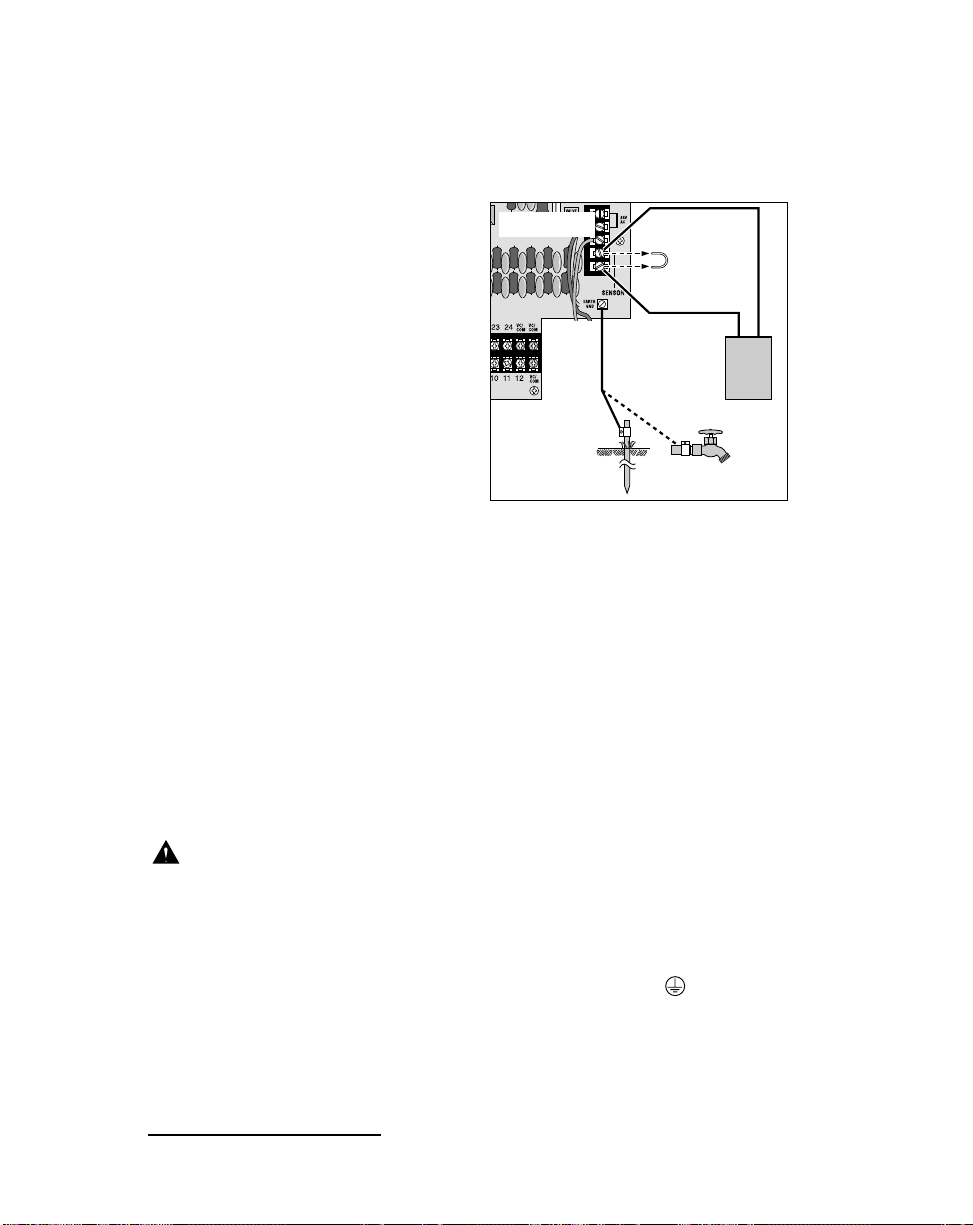

Connecting an Optional Rain Switch Sensor...............................23

Connecting an Earth Ground........................................................23

Connecting the Power Wires.........................................................24

Appendix A - Troubleshooting......................................................25-26

Appendix B - Fuse Replacement ........................................................27

Appendix C - Specifications................................................................28

Warranty...............................................................................................29

TABLE OF CONTENTS

Table of Contents

Page 4

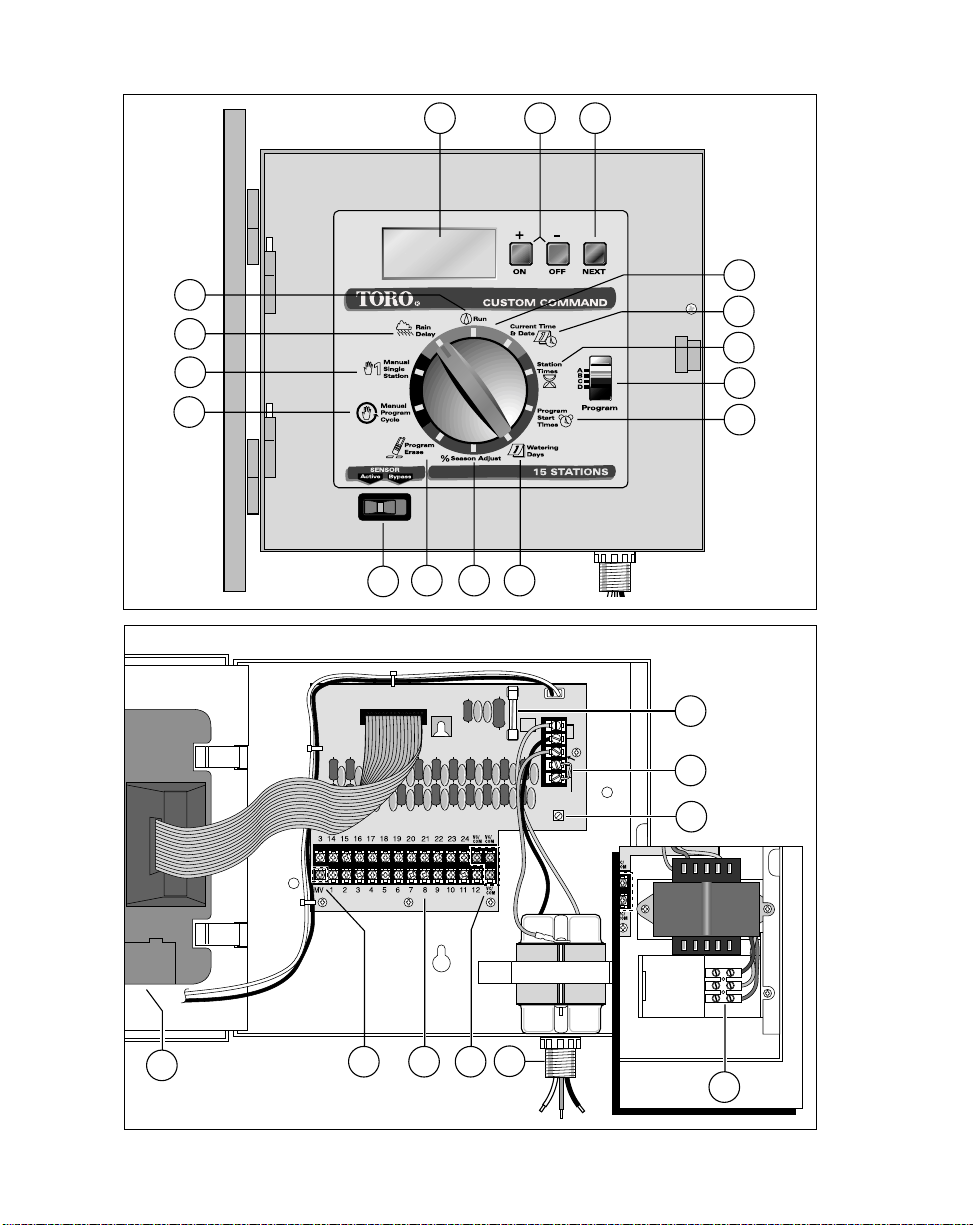

2

Controller Components

▲ FIGURE 1

1 LCD Display: For viewing time, program and status information.

2

+ /On & – /Off Buttons: For entry of program information.

3

Next Button: For selection of information to be programmed or

reviewed.

4

Function Dial: For selecting the programming and operating

functions.

5

Current Time & Date: For setting the current time and date.

6

Station Times: For setting individual watering time for each station.

7

Program Select Switch: For selection of programs A, B, C or D.

8

Program Start Times: For setting the time each program cycle

will start.

9

Watering Days: For setting a watering day schedule for each

program.

10

% Season Adjust: For the increase or decrease of station times for

all stations within a program without changing program memory.

11

Program Erase: For erasing information within a selected program.

12

Sensor Control Switch: To override rain switch sensor input.

13

Manual Program Cycle: For manual operation start of a selected

program watering cycle.

14

Manual Single Station: For timed or untimed operation of a

single station.

15

Off / Rain Delay: For immediate shut down of all controller

output. Programmable output delay for 1–7 days (Rain Delay).

16

Run: For automatic operation.

▲ FIGURE 2

17 Safety Fuse: Replaceable 2.0A slow-blow fuse provides

protection from an internal short-circuit condition.

18

Sensor Connection Terminals: For the connection an optional

(normally-closed) rain switch device.

19

Earth Ground Lug: For connection of a 12–16 (2.0–1.0mm2)

gauge copper ground wire.

20

1/2" NPT Conduit Nipple: For the connection of an electrical

conduit access body for 120 V a.c. power wiring.

21

(Inset) Terminal Strip: For the connection of 220/240 V a.c.

power wiring. (Export models only.)

22

Valve Common Terminals: For the connection of up to three

field (24V) common wires.

23

Valve Wire Terminals: For the connection of valve control wires.

24

Master Valve Terminal: For the connection of a master valve or

pump start relay control wire.

25

Battery Compartment: 9-volt alkaline battery access compartment.

CONTROLLER COMPONENTS

Page 5

3

Off /

24V

EARTH

GND

AC

G

N

D

SENSOR

SENSOR

VALVE

TEST

123

4

5

6

7

8

9

10

12

11

13

14

15

16

17

18

19

20

22

23

24

25

Figure 1

Figure 2

Controller Components

21

Page 6

4

This section contains general information on:

• How the backup system works

• How the electronic circuit breaker works

• How the sensor feature works

HOW THE BACKUP SYSTEM WORKS

The Custom Command uses non-volatile memory to store watering

programs. This type of memory prevents the watering program

information from becoming lost in the event of a power failure. An

additional benefit of non-volatile memory is that a factory-installed

backup program is not necessary, thereby avoiding the potential for

dead-heading a pump.

Because the current time and date are always changing, only the most

recent date can be saved in non-volatile memory. Therefore, a battery

is required to maintain the correct time and date in the event of a

power failure. A 9-volt alkaline battery (provided) will maintain the

correct time and date during power failures up to 90 days. In a typical

installation, the battery should last from two to four years before

replacement is necessary. Once the battery or AC power is connected,

the controller can be fully programmed for operation.

Note: For operation of the valves, AC power must be applied.

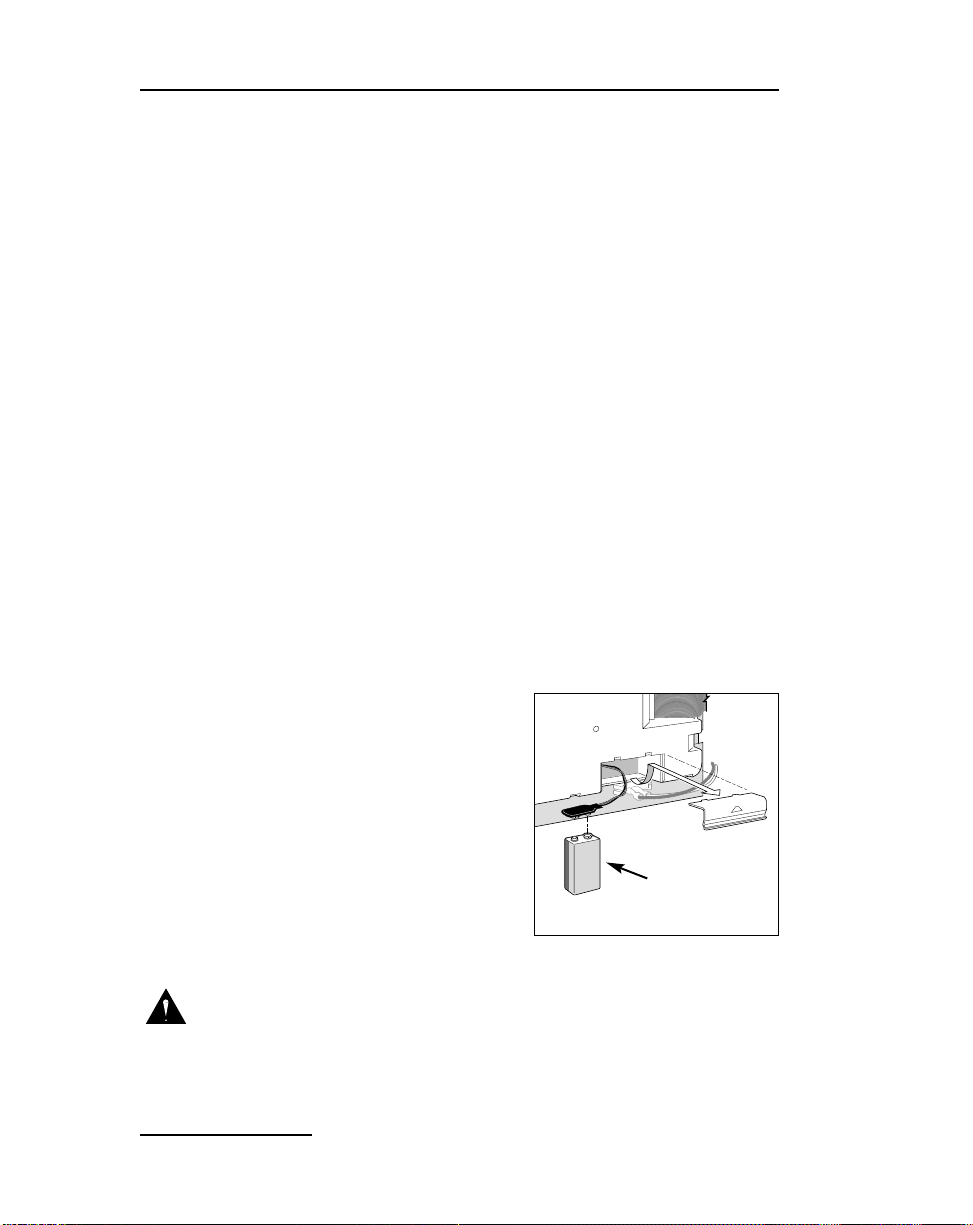

To install the battery:

1. Remove the screw from the hinged

control module assembly and carefully

swing it outward to open.

2. Locate and remove the battery

compartment cover from the lower

back side of the module.

3. Connect the 9-volt alkaline battery

supplied to the battery clip terminals.

4. Insert the battery into the

compartment and reinstall the battery compartment cover.

Caution: Batteries contain hazardous material. Always handle

and discard batteries properly in accordance with the battery

manufacturer’s recommendations.

GENERAL INFORMATION

General Information

Figure 3

9-Volt Alkaline

Battery

Page 7

5

General Information

HOW THE ELECTRONIC CIRCUIT

BREAKER WORKS

The controller is equipped with an electronic circuit breaker. If the

controller detects a short circuit, the shorted station (valve) will be

turned off automatically. The display will then flash “

SHORT” and the

shorted station number or “

MASTER VALVE.” The controller continues

to automatically water the other stations and the following watering

programs until the shorted station is repaired. The program will be

cancelled if the master valve circuit is shorted. Each automatic start

will attempt another cycle and retest the short-circuited valve.

Listed below are the most common conditions which will activate the

electronic circuit breaker. After correcting the problem, return the

controller to normal operation as follows:

1. Set the dial to one of the following positions:

Run,

Manual-Single Station

or

Manual-Program Cycle

.

2. Press the

OFF

button to return the controller to the normal

operating mode.

Condition: The word “SHORT ” displays with one or more station

numbers.

Diagnosis: One or more stations are shorted.

Solution: Check the wiring of the displayed stations for the cause

of the shorted condition. Repair valve(s) and/or wiring

as needed.

Diagnosis: Too many valves operating at the same time causing an

overload condition.

Solution: Check watering programs for concurrent station

operation. Include master valve/pump start relay if used.

Maximum total output is 24 V a.c. at 1.25 amps.

Reduce the number of stations running at the same

time.

Condition: The word “SHORT” displays without any station

numbers.

Diagnosis: A short circuit has occurred with a time duration too

short for the controller to determine the station.

Solution: Check all valve wiring for breaks in the insulation

which may cause a station output to short to common.

Diagnosis: A transient power surge spike has occurred.

Solution: Reset the controller.

Diagnosis: A short or overload occurred on one watering cycle but

was no longer there on a subsequent cycle.

Solution: Check for loose and/or exposed valve wiring.

Page 8

6

HOW THE SENSOR FEATURE WORKS

The Custom Command is equipped to operate with an optional rain

sensing device, commonly called a “Rain Switch,” to prevent

automatic watering during rain.

The rain switch is a simple device, typically installed on a roof

overhang or stationary structure exposed to rainfall and full sun, and

shielded from irrigation spray.

When rain occurs, the normally closed rain switch senses the moisture

and opens the valve common circuit, effectively preventing all output

to the field. The electronic programming portion of the controller is

isolated from the rain sensor switch, and continues to operate as

programmed. When rain stops and the rain switch returns to its

normally closed state, the valve common circuit is restored, enabling

watering to resume as scheduled.

A two-position Sensor switch (see item 19 on page 3) is provided to

enable you to easily bypass operation of the rain switch at any time. If

you choose to disregard rain switch input, place the

SENSOR

switch in

the

Bypass

position. To enable rain switch operation, place the Sensor

switch in the

Active

position.

Note: A jumper wire is installed across the sensor terminals. The

jumper must be removed when the rain switch wires are connected.

General Information

Page 9

7

This section covers the following topics:

•

Getting started

• Setting the current time and date

• Erasing any prior programs

• Setting the station run time

• Selecting Master Valve/Pump Start on/off

• Setting the program start times

• Selecting the days to water

GETTING STARTED

The unique modular design of the Custom Command enables you to easily

remove the control module from the cabinet and take it anywhere for

handy programming– even to your favorite easy chair! Just swing the

module out, unplug the cables, then lift the module from its hinges. Now,

by installing a 9-volt alkaline battery you can program and review your

watering schedules and have it ready to operate upon completion of the

installation. (See battery installation instructions on page 4.)

Note: To extend battery life, the display will automatically dim after two

minutes of inactivity. To restore the display, simply turn the function dial

to any position.

WHAT IS A WATERING PROGRAM?

In basic terms, a watering program is a small set of instructions which tells

the controller when to start a watering cycle, which stations will operate

during the cycle, which days the cycle will be active and how long each

station will operate during the cycle. The Custom Command has four

independent watering programs for your use. Separate programs are usually

used to group stations with similar watering requirements. For example,

you might use one program to water lawns in full sun every day. Another

program could be used to water lawns in partial shade only on Monday,

Wednesday and Friday. Trees and shrubs using drip irrigation could run on

a separate program once every two weeks. The garden area requirements

might include watering every other day. As you can see, the availability of

four programs allows you to have unique watering programs for your varied

landscape needs.

PROGRAMMING THE

CONTROLLER

Programming the Controller

Page 10

8

WHAT IS A PROGRAM WATERING CYCLE?

When a watering start time is selected, that time becomes the beginning

of an automatic watering cycle. A watering cycle operates each station

assigned to the program, one by one, in numerical order. When setting

up watering schedules, it is important to remember that start times are

assigned to programs, not individual stations.

In the following example, (also shown on the sample watering plan on

page 9) we have set up Program A to start at 2: 00 a.m. and again at

3:00 a.m. on a 1-day interval (every day). Stations 1, 2, 4 and 5 are front

and back yard lawn areas which get full sun throughout the day. These

stations will run for 10 minutes each for a total of 20 minutes run time

per day. Stations 3, 6 and 7 are lawn areas which are shaded during the

afternoon hours. These areas require less water, so we have assigned them

to Program B and set them to run for 20 minutes on a 2-day interval

(every other day).

At 2:00 a.m., Program A watering cycle starts. Station 1 turns on, runs

for 10 minutes, and shuts off. Station 2 turns on, runs for 10 minutes, and

shuts off. Stations 4 and 5 operate sequentially in the same manner, each

running for their set run time. When Station 5 shuts off, the watering

cycle is completed for the first start time. At 3:00 a.m., the watering

cycle starts again and repeats the same station-by-station watering

sequence.

Note that we have 40 minutes total watering time per cycle in

Program A. If we had set the next start time at 2:30 a.m., the start time

would have been delayed until 2:40 a.m., enabling the first cycle to finish

as programmed. This function is called “start time stacking”, and can

occur within each program.

Watering programs, however, operate independently, which means that

two or more programs can run simultaneously. In our example,

Program B will also start at 2:00 a.m. Therefore, Stations 1 and 3 will

turn on at the same time, and Station 2 will turn on while Station 3 is

running. This feature enables more watering to be completed within the

prime “watering window”, which is generally between Midnight and

6:00 a.m.

Note: When scheduling watering programs to run simultaneously, it is

important to ensure the water supply has sufficient pressure and volume

to maintain optimum sprinkler performance.

Programming the Controller

Page 11

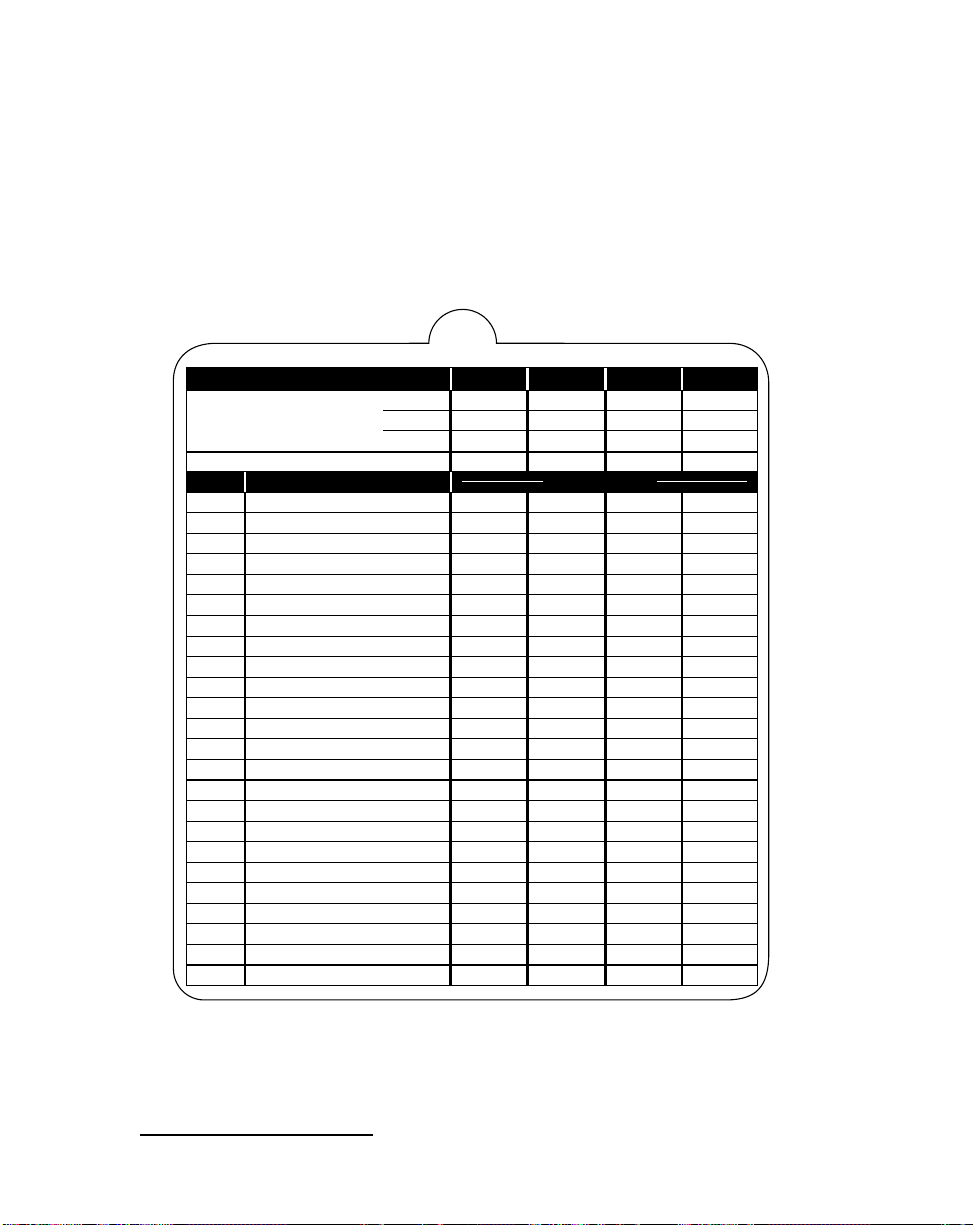

WATERING SCHEDULE FORM (SAMPLE)

For your convenience, a Watering Schedule Form/Quick Reference Card

is provided. Use the form to plan and record your automatic watering

activities. Use the quick reference instructions when minor programming

changes are required. Keep the card with the controller by attaching it to

the inside front cover

9

Programming the Controller

Station

Watering Day Schedule

Station Description

Week Days

Odd/Even

Interval

1

Watering CycleStart Times

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

22

20

24

23

Program A Program B Program C Program D

Watering Schedule Form

Station Run Time

FFrroonntt LLaawwnn ((ssuunn)) 1100 mmiinn

FFrroonntt LLaawwnn ((ssuunn)) 1100 mmiinn

SSiiddee LLaawwnn ((sshhaaddee)) 2200 mmiinn

BBaacckk LLaawwnn ((ssuunn)) 1100 mmiinn

BBaacckk LLaawwnn ((ssuunn)) 1100 mmiinn

BBaacckk LLaawwnn ((sshhaaddee)) 2200 mmiinn

BBaacckk LLaawwnn ((sshhaaddee)) 2200 mmiinn

11

22

22 aamm,, 33 aamm

22 aamm

(Example)

Page 12

10

SETTING THE CURRENT TIME AND DATE

Before you can program the controller for automatic watering, you must

set the controller clock to the current time and date. This controller

features a 365-day calendar with automatic

leap year compensation. Once

the date is set, the controller keeps track of the

date and enables troublefree, odd-even day of the month watering required in some locations.

The time and date apply to all programs. To set the time and date, follow

the steps below.

1. Turn the Function Dial to the

Current Time & Date

position.

The Hour digits and

AM/PM

will flash.

2. Press the + button to increase or – button to decrease the hour

digit.

Note: Continuous pressure on the + or – buttons, causes the

display to change rapidly.

3. Press the

NEXT

button to select the minutes digits.

Use the

+ and/or – buttons to set the current minute.

4. Press the

NEXT

button to select the year digits.

Use the

+ and/or – buttons to set the current year.

5. Press the

NEXT

button to select the month.

Use the

+ and/or – buttons to set the current month.

6. Press the

NEXT

button to select the day digit(s).

Use the

+ and/or – buttons to set the current calendar day.

7. Return the Function Dial to the

Run

position when the current

time and date have been set.

Programming the Controller

Page 13

11

ERASING ANY PRIOR PROGRAMS

This process enables you to easily clear the controller memory of all

user-defined watering program information within an individual

program. This is an optional procedure and can be skipped if you wish

to retain previous program operating information or the controller has

not yet been programmed.

Erasing a program resets the memory to factory conditions: No station

run time, program start time or active watering days. Season Adjust is

set to 100% and Master Valve/Pump Start is set to be “On”.

Note: This process is program independent and resets only the

information for the selected program.

To erase program information for a selected program:

1. Select Program A, B, Cor Dwith the Program switch.

2. Turn the function dial to the

Program Erase

position. The

display will show “

ERASE”.

3. Press and hold the

OFF

button until “DONE” is displayed.

4. Repeat this procedure for each program you wish to erase.

SETTING THE STATION RUN TIME

A station is assigned to a program when it is given a station run time

(from 1 minute to 10 hours) in that program. The station can have only

one run time per program. Additionally, the station can be assigned to

any number of programs and have a different run time assigned in each.

To set the run time for each station:

1. Turn the function dial to the

Station Times

position. The

controller displays

STATION NUMBER 1 and OFF (or the current

station run time).

2. Select Program

A, B, C

or Dwith the Program switch.

3. Press the

NEXT

button to select the station number you wish to set

(if other than the one displayed).

4. Use the

+ and/or – buttons to display the desired station run time.

Note: OFF is the factory setting for each station. If the station has a

run time and you wish to remove it from this program, use the

+

and/or – buttons to select OFF, (displayed between 10:00 [ten hours]

and

00:01 [one minute]). (CONTINUED)

Programming the Controller

Page 14

12

5. Repeat steps 3 and 4 to set a run time for each station you wish to

assign to the selected program.

6. Repeat steps 2 through 5 for each program as necessary.

MASTER VALVE/PUMP START ON/OFF

The Custom Command enables automatic operation of the Master

Valve/Pump Start output circuit to be controlled independently for

each watering program. For example, if a program is used for drip

irrigation and the system pump is not required, the Master

Valve/Pump Start output circuit can be shut off whenever that

program begins operation.

The factory setting is

ON for each program. Use the steps below to

select the operation of this feature for each program as necessary.

1. Turn the function dial to the

Station Times

position.

2. Select Program

A, B, C

or Dwith the

Program

switch.

3. Press the

NEXT

button repeatedly until MASTER VALVE is displayed.

4. Press the

OFF

or

ON

button to display the operation of the master

valve/pump start output for the selected program.

5. Repeat steps 2 through 4 for each program as necessary.

SETTING PROGRAM START TIME(S)

This procedure is used to set the watering cycle start time(s) for each

program. A maximum of 16 start times can be allocated to the four

programs in any manner. Each start time will initiate a sequential

watering cycle of all stations with an assigned run time in the program.

Note: When 16 start times have been allocated, the display will show

NONE REMAINING when attempting to assign additional start times.

To set program cycle start time(s):

1. Turn the function dial to the

Program Start Times

position.

2. Select Program

A, B, C

or Dwith the

Program

switch.

3. Use the

+ and/or – buttons to display the start time.

Note: To remove a start time, adjust the time to display OFF

(located between 11:59 p.m. and 12:00 a.m.).

4. Press the

NEXT

button to assign another start time to the program.

5. Repeat steps 2 through 4 for each program as necessary.

Programming the Controller

Page 15

13

Note: The Custom Command will operate one watering cycle in a

program at a time. If a start time occurs while a watering cycle is in

progress, the start time will be delayed until the previous cycle is

finished (this is called “start time stacking”). If the watering cycle

extends past midnight into the next day, the cycle will continue

operating until finished. However, if a watering cycle has been delayed

until after midnight into a non-watering day, the watering cycle will

not occur.

SELECTING THE DAYS TO WATER

Several watering day scheduling options are available. Each watering

program can utilize any ONE of the following schedules:

•

Days of the week

Use this type of schedule to water on specific days of the week. The

days are displayed as three-letter abbreviations. For example, Sunday is

SUN, Monday is MON, etc. Only the days you select to water will

remain on the display.

• Odd Days or Even Days

To select every o dd or even number calendar day, use this option.

Because the 31st and the 1st are both odd number days, the 31st is

automatically removed from the schedule. This watering day option

also enables selected days of the week to be removed from the

schedule.

• Day Interval

Selecting watering days by Day Interval enables a specific number of

days between watering to be selected. For example, selecting a 1-day

Interval schedules watering for every day. A 2-day interval schedules

watering for every other day. A 30-day interval is the maximum

interval frequency, which provides watering once every 30 days.

Another setting within the Day Interval is the current day of the

schedule. The current day (displayed as

TODAY) can be set for any day

within the interval. This number automatically increases by one every

day. When the

TODAY number equals the Day Interval number, a

watering day will occur. For example, to water every third day starting

today, a 3-day interval would be set with

TODAY as day 3. Or, to water

every 5 days starting tomorrow, a 5-day interval would be selected with

TODAY as day 4.

Programming the Controller

Page 16

14

To set a watering day schedule for each program:

1. Turn the function dial to the

Watering Days

position. The

display will show the current watering day schedule for the

selected program.

2. Select Program

A, B, C

or Dwith the

Program

switch.

3. Set the watering day(s) for the program using one of the three

following procedures: Days of the Week, Odd Days/Even Days or

Day Interval scheduling procedure.

4. Repeat steps 2 and 3 as necessary to set a watering day schedule

for each program.

Days of the Week

A. Press the

NEXT

button until the weekday abbreviations are

shown at the top of the display.

B. Press the

ON

button. SUN (Sunday) will begin flashing.

C. To select the day, press the

ON

button. To remove the day

from the schedule, press the

OFF

button.

D. Press the

NEXT

button to select the next day.

E. Repeat steps C and D to set the remaining days of the week.

Odd Days or Even Days

A. Press the

NEXT

button until ODD DAYS or EVEN DAYS is

displayed.

B. Press the

ON

button to select the schedule.

Optional: To remove selected days of the week from the

Odd/Even watering schedule:

1. Press the

NEXT

button until the selected day begins

flashing.

2. Press the

OFF

button to exclude the day from the schedule.

(Press the

ON

button to restore the day to the schedule.)

Day Interval

A. Press the

NEXT

button until the DAY INTERVAL option is

displayed.

B. Press the

ON

button to select this option.

C. Press the

NEXT

button. The display shows the current Day

Interval number (1–30).

Programming the Controller

Page 17

15

D. Use the + or – button to select the Day Interval (1–30 days).

E. Press the

NEXT

button. The controller displays TODAY and its

current setting.

F. Use the + or – button to select the desired setting for to day.

This section includes instructions for the following controller operations:

• % Season Adjust

• Manual Operations

• Off and Rain Delay Modes

% SEASON ADJUST

The % Season Adjust feature enables you to easily increase or decrease

the station run time (by percentage) of all

stations assigned to a

selected program. This is handy for making temporary, overall station

run time adjustments without changing the original run time settings.

% Season Adjust values range from 0 to 200% in 10% increments,

with 100% being the normal setting.

For example, as the fall season approaches and the temperature

decreases, you may want to reduce the station time for the stations in

program A by 30%. Later you can return station times to their original

values by setting the % Season Adjust value back to 100%.

Note: It is possible to inadvertently cause start time stacking when

increasing station run time. Careful planning and use of % Season

Adjust will prevent this from happening.

To change the % Season Adjust percentage value of a selected

program:

1. Turn the function dial to the

% Season Adjust

position.

2. Select Program

A, B, C

or Dwith the

Program

switch.

3. Use the

+ and/or – buttons to increase or decrease the percentage

value (0–200%).

4. Turn the function dial to the

Run

position.

Note: The controller displays the % symbol in the

Run

position when % Season Adjust is in use for any

program. During operation, the adjusted run time will be

displayed.

OPERATING THE CONTROLLER

Operating the Controller

Page 18

16

MANUAL OPERATIONS

Manual operation allows you to run individual stations or start automatic

watering programs as needed. The Custom Command provides separate

dial positions for each type of operation: Single Station and Program

Cycle.

SINGLE STATION

This option enables individual stations to be operated for an untimed

duration (turned On/Off) or operated for a selectable duration from

one minute to 10 hours.

1. Turn the function dial to the

Manual Single Station

position.

2. Select Program

A, B, C

or Dwith the

Program

switch.

Note: The programmed status of the master valve/pump start in

the selected program determines whether the master valve/pump

start will be activated with the manual operation.

3. Use one of the following options to operate the station.

For untimed operation:

A. Press the

NEXT

button as necessary to display the station you

wish to operate.

B. Press the

ON

button. The station will turn on and remain on

until one of the following occurs:

•The

OFF

button is pressed

•The controller clock passes midnight

•The function dial is moved to another position

For timed operation:

A. Press the

NEXT

button as necessary to display a station you wish

to operate.

B. Use the + and/or – buttons to set the desired amount of station

run time (for this operation only), from one minute to 10 hours.

C. To select additional stations to operate in sequence, repeat steps

A and B as desired. Each station will operate one-by-one in the

order they were selected.

D. Leave the function dial in the Manual

Single Station

position until the manual operation is complete,

then return the dial to the

Run

position.

Operating the Controller

Page 19

17

PROGRAM CYCLE

Use this feature to manually operate watering programs. You can run

the entire program or start anywhere within the station sequence of

the program.

Note: Only the stations with an assigned run time in the program will

operate during the program watering cycle.

1. Turn the function dial to the

Manual

Program Cycle

position.

2. Select Program

A, B, C

or Dwith the

Program

switch.

3. Press the

NEXT

button to select the first station of the watering

sequence (if other than the station number displayed).

4. Press the

ON

button to start the watering cycle. Watering will start

with the selected station and will be followed by all subsequent

stations. The display will show the run time remaining for the

operating station.

Note: You may advance through the stations by pressing the

NEXT

key for the next station. To terminate operation at any time, press

the

OFF

button.

5. Leave the function dial in the

Manual

Program Cycle

position until the manual operation is complete, then

return the dial to the

Run

position.

OFF AND RAIN DELAY

Use this feature to turn off controller operation for indefinite periods of

time (Off mode) or for a selected number of days (Rain Delay mode).

Turning Off the Controller

Turning the function dial to the

Off / Rain Delay

position places

the controller in the Off mode. After a 2-second delay, any current

watering activity will shut off and all subsequent watering program

activity will be suspended. As long as the function dial is in the

Off / Rain Delay

position, the controller will remain in the Off

mode. The controller clock continues to update current time and date,

and all watering program information is retained while in the Off

mode. Normal controller operation is resumed by simply placing the

function dial in any other position.

Using the Rain Delay Mode

The Rain Delay mode enables automatic watering to be delayed from

1 to 7 days. At the end of the selected delay period, the controller

resumes automatic operation. (

CONTINUED)

Operating the Controller

Page 20

18

To set a Rain Delay period

1. Turn the function dial to the

Off / Rain Delay

position.

2. Use the

+ and/or – buttons to select the number of days (1–7) to

delay operation.

3. Turn the function dial to the

Run

position.

The display will show the number of days remaining in the delay

period. The day number will automatically decrease by one digit

each time the clock passes midnight. Automatic operation resumes

when the display shows no delay days remaining.

Note: The controller can be operated manually while in the Rain

Delay mode.

To cancel the Rain Delay mode:

1. Turn the function dial to the

Off / Rain Delay

position.

2. Press the

– button until the display shows no delay days

remaining.

3. Turn the function dial to the

Run

position.

Operating the Controller

Page 21

19

Installation Procedures

This section includes instructions for mounting the controller cabinet

and making the necessary wiring connections. To ensure safe

operation, it is important to follow the instructions carefully. The

following procedures include:

• Selecting an Installation Site

• Mounting the Controller

• Installing Electrical Conduit

• Connecting the Valve Wiring

• Connecting an Optional Pump Start Relay

• Connecting an Optional Rain Switch Sensor

• Connecting an Earth Ground

• Connecting the Power Wires

SELECTING AN INSTALLATION SITE

Selecting the proper installation site for the controller is essential to

safe and reliable operation. The Custom Command features a weather

resistant cabinet designed for indoor or outdoor installation.

For easy operation and better view of the display, install the controller

so that the display is at, or slightly below eye level.

The controller should be installed on a vertical wall or other sturdy

structure near a grounded power source. Select a location that shades

the controller during the hottest hours of the day and provides as

much protection from direct sunlight, rain, wind and snow as possible.

DO NOT mount the controller where it will be exposed to direct

spray from the irrigation system.

INSTALLATION PROCEDURES

Page 22

20

MOUNTING THE CONTROLLER

1. Place the mounting template (provided) on the wall, positioning

the controller display area at or slightly below eye level. Using a

small punch or nail, mark the locations of the top and bottom

centerline mounting holes and the additional lower holes if extra

cabinet support is desired. (Only two mounting screws are

provided.)

2. Drill pilot holes at least 1-1/4" (32mm) deep into the wall using a

3/32" (2.5mm) drill for wall stud, or 1/4" (6.5mm) drill for

masonry.

3. For the masonry wall installation only, insert the plastic screw

anchors (provided) into the pilot holes.

Optional: The door and control module can be easily removed

from the cabinet to simplify installation. To do this, unplug the

ribbon cable connector from the control module and the two

push-on wire connectors from the bypass switch. Lift the cover

and control module up and off the hinge pins.

4. Place a small plastic washer and a rubber washer on each screw.

Install the #10 screws into the top and bottom locations leaving

the screw head about 1/2" (13mm) from the wall.

Note: If installing additional lower mounting screws, remove

plastic hole plugs at this time.

5. Hang the cabinet on the screws using the keyhole slots. Ensure the

screws engage the slotted portion of the keyhole with the plastic

washer positioned between the screw head and the inner cabinet

wall. Tighten the screws securely. Install additional screws in the

lower left and/or right mounting holes as required.

INSTALLING ELECTRICAL CONDUIT

Note: Electrical conduit and adapters are not supplied with the

controller but may be required for installation in your area. Check

local electrical codes and install conduit according to requirements.

1. For power wires, install a 1/2" NPT threaded conduit access body to

the transformer assembly threaded nipple. From the access body,

install conduit to the source point of connection. (Domestic and

international models only.)

2. For field (low voltage) wiring, install a 2" (52mm) conduit adapter

and conduit.

Installation Procedures

Page 23

21

CONNECTING THE VALVE WIRING

1. To provide a field common wire, attach one wire to either solenoid

lead of all sprinkler valves and master valve (optional).

2. Attach a separate control wire to the remaining solenoid lead of

each valve. Label the control wires with the intended station

number for identification at the controller.

Caution: All wiring splices must be waterproofed to prevent

short circuits and corrosion.

A maximum load of 12 VA (0.5 amps) may be connected to

each station. A maximum load (including master valve) of

30 VA (1.25 amps) may be programmed to operate

simultaneously. Exceeding these limits can damage the

controller.

3. Route the control and common wires into the controller cabinet

through the 2" (52mm) access opening. Remove approximately

1/2" (13mm) insulation from the ends of each wire.

4. Attach the field common wire to one of the three valve common

terminals labeled

VC/COM.

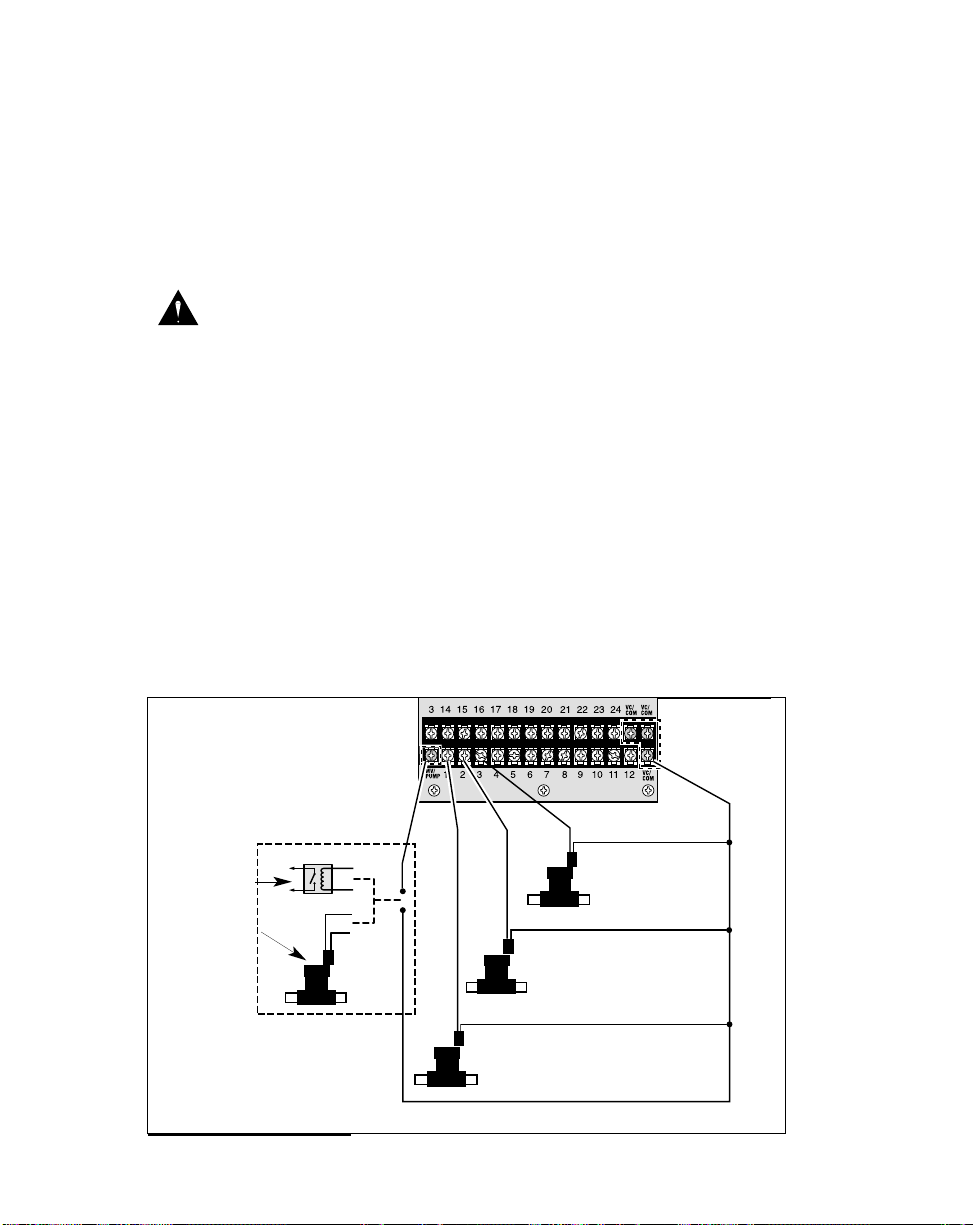

5. Referring to

Figure 4, connect each valve control wire to the

appropriate station number terminal. If an optional master valve

is installed, connect its control wire to the terminal labeled

MV/PUMP. Tighten all terminal screws securely.

Installation Procedures

Pump Start

Relay

or

Master Valve

Valve Common

Figure 4

Valve Station 1

Valve Station 2

Valve Station 3

Page 24

22

CONNECTING A PUMP START RELAY

When a pump is to be operated by the controller, a compatible relay

must be used. The relay coil will be connected to the master valve

(MV) terminal and must be rated for 24 V a.c. at 0.5A maximum. The

relay contacts will be connected to the pump start terminals and must

be rated for use with the particular pump.

Note: Transient suppressors may be needed across the relay contacts

in installations using large pumps.

Caution: Do not connect the master valve output terminal directly

to the pump start terminals. This will damage the controller.

To connect the pump start relay:

1. Connect the master valve output terminal (MV) to one side of

the relay coil.

2. Connect the other side of the relay coil to the valve common

(VC) terminal. See

Figures 4 and 5.

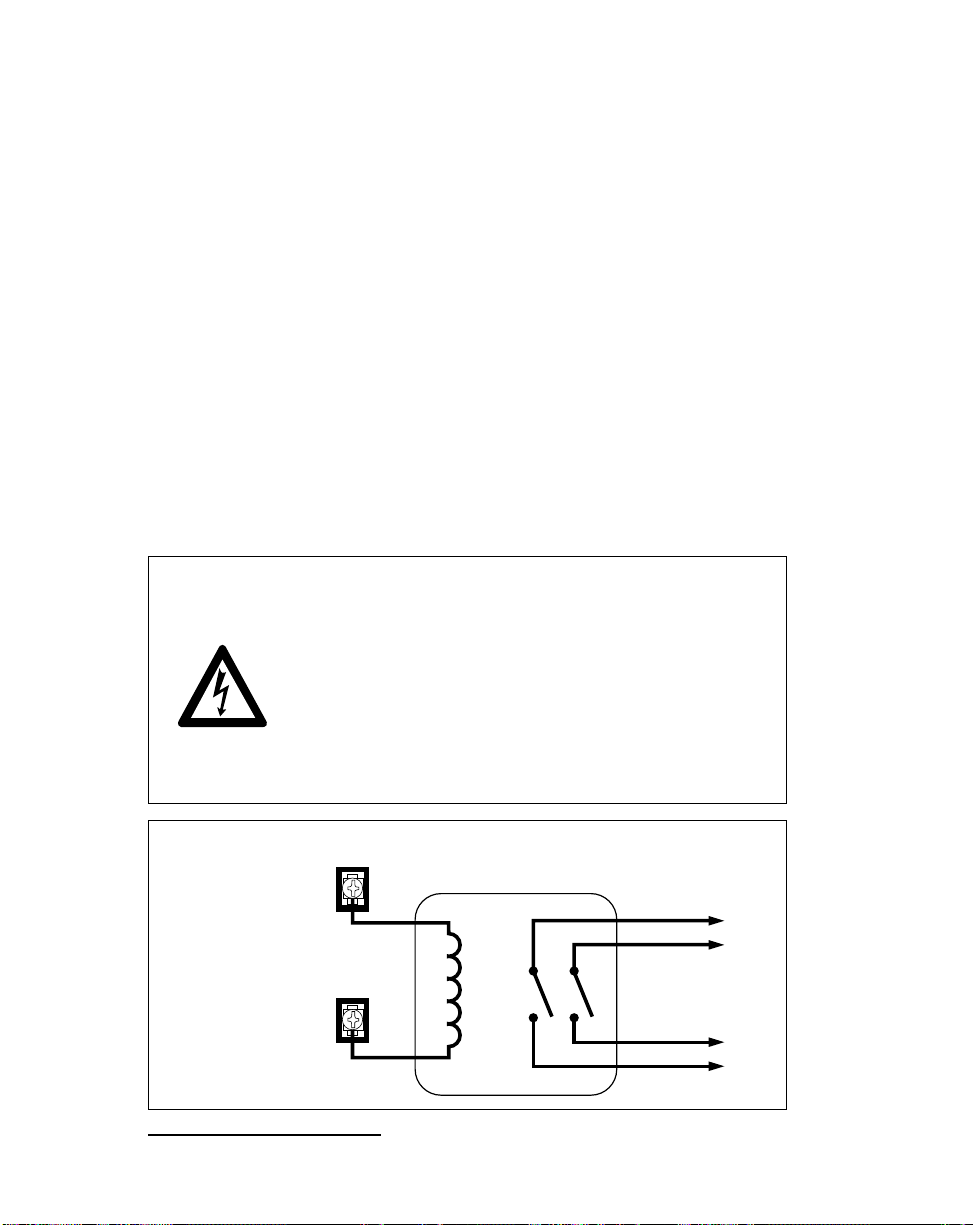

WARNING

Proper connection of the pump and relay contacts

depends on the pump configuration and may involve

HIGH VOLTAGE. This connection should be performed by a licensed electrical contractor in

accordance with all requirements of the National

Electrical Code, applicable state and local codes and

the pump manufacturer’s recommendations.

Master Valve

(MV) Terminal

To Pump

Starter

Valve Common

(VC) Terminal

Figure 5

Installation Procedures

Page 25

23

CONNECTING A RAIN SWITCH SENSOR

The Custom Command is designed for use with a normally closed rain

sensor or “Rain Switch.” (Refer to page 6 for additional important rain

switch information.)

To connect the rain switch sensor:

1. Route the two wires from the

sensor into the cabinet through

the field wire access opening.

2. Connect the wires to the

“

SENSOR” terminals in either

order. See

Figure 6.

Note: Refer to the installation

instructions provided with the

sensor for additional

information.

CONNECTING AN EARTH GROUND

A power surge is a sudden rise in voltage on the power main line. It is

then often followed by a drop in voltage as the power line equipment

tries to protect area users. A lightning strike on the power grid is the

most common cause of power surges and can be damaging to the

controller.

*Surge protection is built into the Custom Command PC

board to reduce the potential for surge damage by shunting the voltage

to earth ground. Therefore, an important step in the installation

process is to properly connect the controller to an earth ground

source, especially if the controller is located in a lightning-prone area.

*Note: The Custom Command international units are manufactured

without output surge protection. If output surge protection is required,

contact your local Toro dealer for assistance.

Caution: The built in surge protection components cannot

effectively protect the controller circuitry from power surge unless

properly connected to an earth ground source.

To connect an earth ground:

1. Route a 12–16 gauge (2.0–1.0mm2) solid copper wire in the

shortest and most direct path from the “

EARTH GND” lug,

located on the controller’s terminal board (see page 3,item 19) to

an earth ground source such as metal (not plastic) water pipe or

copper-clad ground rod. See

Figure 6.

2. Clamp the bare wire securely to the pipe or ground rod. Make sure

the wire contact area is free of dirt and corrosion.

Figure 6

Normally

Closed

Rain Switch

Earth Ground

Jumper

Wire

Installation Procedures

Page 26

24

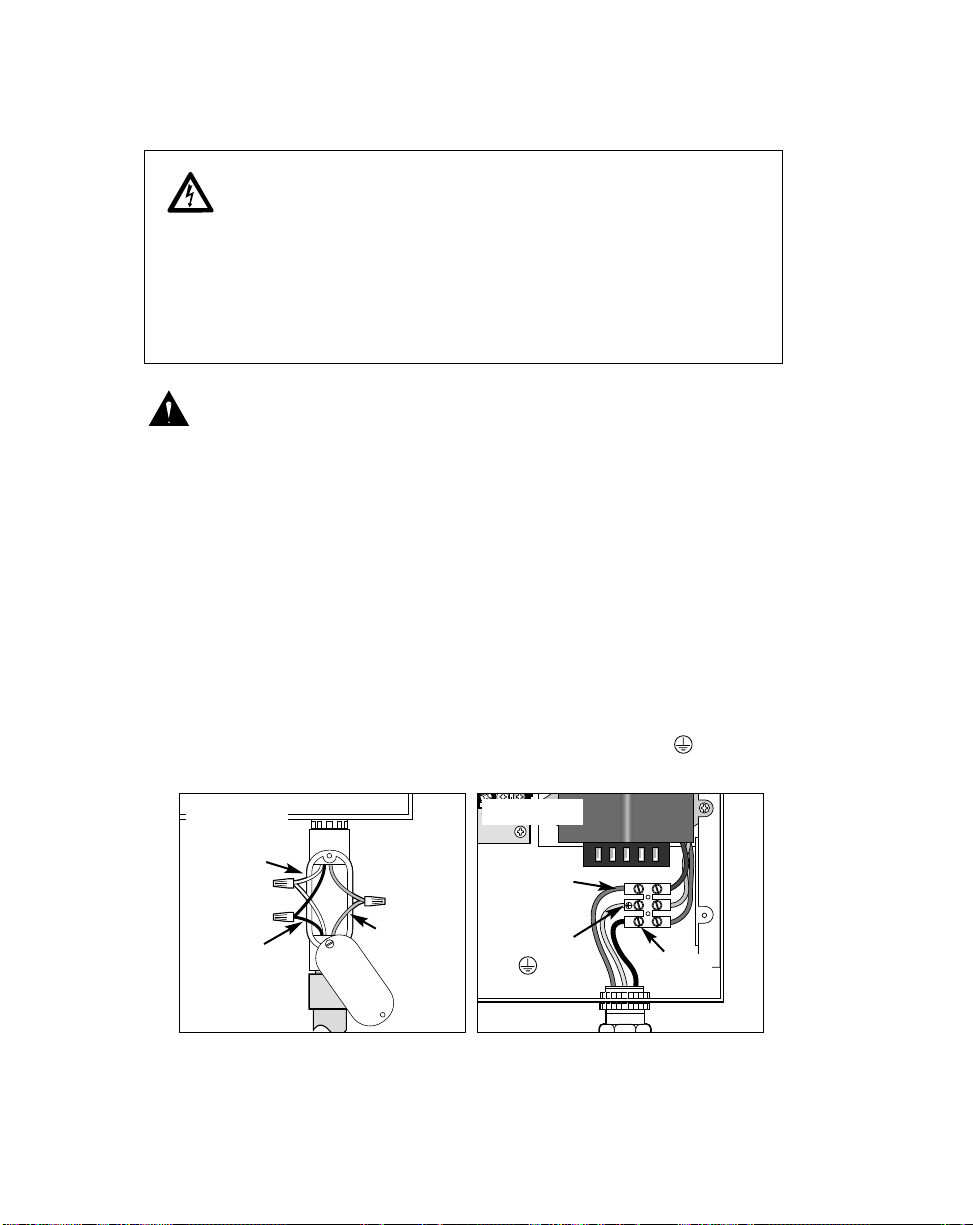

CONNECTING THE POWER WIRES

Caution: Do not connect the controller to one phase of a threephase power supply used by a pump or other electrical

equipment.

1. Ensure the power is disconnected at the source.

2. Route the AC power and equipment ground wires through electrical

conduit to the controller.

3. For 120 V a.c. models: Attach the Hot to the Black wire, Neutral to

the White wire and Equipment Ground to the Green or wire.

Properly insulate all wire connections. See Figure 7A. Close and

secure the conduit body cover.

. For 220/230 V a.c models: Remove the cover plate installed

directly below the transformer. Using a small flat blade

screwdriver, secure AC mains to the terminal block as follows:

Line 1 to “L”, Line 2 to“N” and Equipment Ground to . See

Figure 7B. Reinstall the cover plate.

4. Apply power to the controller.

WARNING:

All electrical components must meet applicable

national and local electrical codes including installation by

qualified personnel. These codes may require an external

junction box mounted on the transformer nipple (domestic model)

and a means in the fixed wiring of disconnecting AC power having a

contact separation of at least 0.120" (3mm) in the line and neutral

poles. Ensure the AC power source is OFF prior to connecting to

the controller. The wire used for connection to the controller must

have insulation rated at 105°C minimum.

Installation Procedures

Figure 7A

Figure 7B

Line 2

to “N”

Hot to

Black

Neutral to

White

Line 1

to “L”

Equipment

Ground to

Green

Equipment

Ground

to

LN

Page 27

25

❖ Error Solution

❖ All valves 1. Verify program: station time, watering start

will not times, watering days schedule, current time,

turn on current day, water budget and rain delay.

automatically

2. Check valve common wire for proper

connection.

3. Check for a shorted station; refer to

“How the electronic circuit breaker works”

on page 5.

5. Ensure rain sensor (if installed) is properly

connected and functioning properly.

If rain

sensor is not installed, ensure the

SENSOR SWITCH is in BYPASS position.

6. Check fuse, replace if necessary. See p. 27.

❖ Cannot 1. Disconnect power to controller for

program 1 minute. Reconnect power and reprogram.

2. Install fresh 9-volt alkaline battery.

3. Verify that all 16 start times are not in

use by other programs.

❖ Controller 1. Verify watering start times, current time

skips a cycle and watering days schedule.

❖ No display 1. Check power source for tripped circuit

breaker.

2. If control module has been removed, this

is a normal battery-saving feature. Turn dial

to any position to reactivate display.

3. Disconnect power to controller for

1 minute. Reconnect power and reprogram.

4. Replace battery

5. Check fuse, replace if necessary. See p. 27.

Appendix A

TROUBLESHOOTING

Troubleshooting

Page 28

26

❖ Error Solution

❖ Valve 1. Check station times and water budget.

stays on

2. C

heck for Manual mode; place dial in

the

Run position.

3. Disconnect valve wire. If still on, valve

malfunction is indicated.

4. Check for manual bleed closure at valve.

❖ Valve will 1. Ensure dial is not in Off / Rain Delay

not turn on

position or Rain Delay mode active.

2. Verify program: station time, watering start

times, watering days schedule, current time,

current day and water budget.

3. Make sure common wire and valve wire are

correctly connected.

4. Check for a shorted station, refer to page 5.

5. If using sensor, check sensor.

6. Check for blown fuse. Replace if necessary.

See page 27 for fuse replacement information.

❖ “Short” or 1. See “How the Electronic Circuit Breaker

“Master Valve” Works” on page 5 for troubleshooting

is displayed information.

❖ Waters too 1. Too many program start times set. Check

often each program to determine the number of

start times assigned and remove as necessary.

Troubleshooting

Page 29

27

1. Disconnect power to the controller.

2. Locate fuse (see page 3, item 17) and carefully remove it from the

retaining clips.

3. Locate the replacement fuse supplied in the mounting hardware

accessory bag. Install the new 2.0A slow-blow fuse, ensuring it is

securely seated in the retaining clips.

4. Restore power to the controller.

Fuse Replacement

Appendix B

FUSE REPLACEMENT

WARNING

If fuse replacement is required, replace only with the same type

and rating. Installing a higher amperage fuse can result in serious

injury and or equipment damage due to fire hazard. Ensure power

to controller is off prior to removing or installing fuse.

Page 30

28

Cabinet:

Metal, weather-resistant, indoor/outdoor, wall mount with key-actuated

locking cover

Dimensions:

10.75" W x 9.5" H x 5.75" D

(27.3cm W x 24.1cm H x 14.6cm D)

Wiring/Conduit Provision:

Power Wiring - 1/2" NPT end bell nipple

Field Wiring - 2" (52mm) diameter conduit access

Power Specifications, Domestic Model:

Input –

120 V a.c., 60 Hz, 0.5A

Output – 24 V a.c., 60 Hz, 30 VA (max. total), 0.5A (max. per station)

Power Specifications, International Model:

Input –

230 V a.c., 50 Hz, 0.5A

Output – 24 V a.c., 50 Hz, 30 VA (max. total), 0.5A (max. per station)

Power Specifications, Australian Model:

Input –

240 V a.c., 50 Hz, 0.5A

Output – 24 V a.c., 50 Hz, 30 VA (max. total), 0.5A (max. per station)

Sensor Input: Normally-closed rain switch (override switch provided)

Master Valve/Pump Start Relay Output: 24 V a.c., 0.5A (maximum)

Battery: 9-volt, Alkaline

Fuse: 250V, 2.0A, Slow-Blow (extra fuse provided)

Temperature Limit Specifications:

Operating –

32°F to 140°F (0°C to 60°C)

Storage – -22°F to 149°F (-30°C to 65°C)

Appendix C

SPECIFICATIONS

Specifications

Page 31

29

Warranty

The Toro Promise — Limited Five-Year Warranty

The Toro Company and its affiliate, Toro Warranty Company, pursuant to

an agreement between them, jointly warrants, to the owner, each new piece

of equipment (featured in the current catalog at date of installation) against

defects in material and workmanship for for a period described below,

provided they are used for irrigation purposes under manufacturer's

recommended specifications. Product failures due to acts of God

(i.e., lightning, flooding, etc.) are not covered by this warranty.

Neither Toro nor Toro Warranty Company is liable for failure of products

not manufactured by them even though such products may be sold or used in

conjunction with Toro products.

During such warranty period, we will repair or replace, at our option, any

part found to be defective. Your remedy is limited solely to the replacement

or repair of defective parts.

Return the defective part to your local Toro distributor, who may be listed

in your telephone directory Yellow Pages under "Irrigation Supplies" or

"Sprinkler Systems," or contact The Toro Warranty Company P.O. Box 489,

Riverside, California, 92502. Phone (800) 664-4740 for the location of your

nearest Toro distributor or outside the U.S., call (909) 688-9221.

This warranty does not apply where equipment is used, or installation is

performed, in any manner contrary to Toro’s specifications and instructions,

nor where equipment is altered or modified.

Neither Toro nor Toro Warranty Company is liable for indirect,

incidental or consequential damages in connection with the use of

equipment, including but not limited to: vegetation loss, the cost of

substitute equipment or services required during periods of malfunction or

resulting non-use, property damage or personal injury resulting from

installer’s actions, whether negligent or otherwise.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply

to you.

All implied warranties, including those of merchantability and fitness

for use, are limited to the duration of this express warranty.

Some states do not allow limitations of how long an implied warranty

lasts, so the above limitation may not apply to you.

This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

The Custom Command series controllers are covered by this warranty for

a period of five years from the date of installation.

Page 32

Electromagnetic Compatibility

Domestic:

This equipment generates and uses radio frequency energy and if not

installed and used properly, that is, in strict accordance with the manufacturer's

instructions, may cause interference to radio and television reception. It has

been type tested and found to comply with the limits for a FCC Class B

computing device in accordance with the specifications in Subpart J of Part 15

of FCC Rules, which are designed to provide reasonable protection against such

interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does

cause interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

•Reorient the receiving antenna.

•Relocate the irrigation controller with respect to the receiver.

•Move the irrigation controller away from the receiver.

•Plug the irrigation controller into a different outlet so that the irrigation

controller and receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet

prepared by the Federal Communications Commission helpful:

"How to Identify and Resolve Radio-TV Interference Problems". This booklet is

available from the U.S. Government Printing Office, Washington, DC 20402.

Stock No. 004-000-00345-4.

International: This is a CISPR 22 Class B product.

The Toro Company

Irrigation Division

An ISO 9001 Certified Facility

P.O. Box 489

Riverside, California 92502

1-800 664-4740 (in USA) • 1-909-688-9221 (outside USA)

© 2001 The Toro Company Form Number 373-0005 Rev. C

30

Page 33

Guía del Usuario

PROGRAMADOR DE LA SERIE

CUSTOM COMMAND

™

31

Español

Page 34

32

Le damos las gracias por haber adquirido un programador Custom Command.

Se enumeran a continuación algunas de las características importantes que

usted debería conocer antes de comenzar la programación de esta unidad. Los

detalles sobre cómo implementar estas características se describen en las

páginas que siguen.

• Cuatro programas totalmente independientes que pueden operar

simultáneamente.

• Riego programable para los días de la semana, días impares, días pares o

intervalos de 1 a 30 días. Eliminación selectiva de días del plan de días

impares/pares.

• Un calendario de 365 días con compensación automática para los años

bisiestos.

• Un total de dieciséis horas de arranque para usarse en cualquier programa.

• Protección para evitar solapes en la puesta en espera de las horas de

arranque dentro de cada programa.

• Tiempos de riego de las estaciones desde 2 minutos hasta 10 horas en

incrementos de 1 minuto.

• Función de borrado de un programa independiente para cada programa.

• Memoria no volátil que retiene la información programada hasta un

máximo de 30 años en el caso de interrumpirse la energía eléctrica.

• Retención exacta de las horas y fechas hasta un máximo de 90 días

continuos con ayuda de una pila alcalina de 9 voltios incluida en el caso

de producirse interrupciones de la energía eléctrica.

• El porcentaje del agua de riego puede ajustarse desde 0 a 200% en

incrementos de 10%.

• Suspensión temporal por lluvia programable hasta 7 días.

• Disyuntor de circuito electrónico auto diagnosticador que identifica y

anula las estaciones defectuosas.

• Operación de arranque de la válvula maestra/bomba seleccionable por

programa.

• Operaciones manuales completas disponibles por estación y por programa.

• Conexión del interruptor del sensor para su operación con cualquier

dispositivo de interrupción por lluvia normalmente cerrado.

• Control de interruptor deslizante provisto para la anulación del rain

switch®(sensor de lluvia).

• Un singular diseño mo dular para facilitar la instalación y el servicio de

mantenimiento.

Para beneficiarse al máximo de todas las características del programador

Custom Command, tenga la bondad de leer detenidamente la Guía del

Usuario antes de proceder a la programación o instalación de su nuevo

programador.

CARACTERISTICAS

Características

Page 35

33

Características..................................................................................................32

Componentes del programador..................................................................34-35

Información general ........................................................................................36

Cómo funciona el programa de seguridad ................................................36

Cómo funciona el disyuntor de circuito electrónico................................37

Cómo funcionan los sensores ...................................................................38

Programación del programador .................................................................39-47

Cómo empezar......................................................................................39-41

Establecimiento de la hora y fecha actuales.............................................42

Borrado de cualquier programa anterior...................................................43

Establecimiento de los tiempos de riego de las estaciones ......................43

Activación/Desactivación de la Válvula Maestra/Bomba...............................

44

Establecimiento de las horas de arranque de los programas................44-45

Selección de los días de riego..............................................................45-47

Operación del programador ......................................................................47-50

Ajuste porcentual de los tiempos de riego por temporada ......................47

Operaciones manuales ........................................................................48-49

Desactivación por lluvia y Suspensión temporal por lluvia ................49-50

Procedimientos de instalación...................................................................51-56

Selección del lugar de instalación ..........................................................51

Montaje del programador ..........................................................................52

Instalación de los conductos de cables .....................................................52

Conexión del cableado de campo (cables de bajo voltaje) ......................53

Conexión de un relé de arranque de la bomba.........................................54

Conexión de un rain switch®(sensor del interruptor por lluvia) ............55

Toma a tierra.............................................................................................55

Conexión de los cables de alimentación eléctrica ...................................56

Apéndice A - Localización de averías.......................................................57-58

Apéndice B - Cambio del fusible....................................................................59

Apéndice C - Especificaciones........................................................................60

Garantía............................................................................................................61

TABLA DE MATERIAS

Tabla de Materias

Page 36

34

Componentes del Programador

▲FIGURA 1

11 LCD Display (Pantalla LCD): Para visualizar la información sobre el tiempo, programas y

estado.

12 +/On & –/Off Buttons (Botones +/Activar y –/Desactivar): Para ingresar la

información de los programas.

13 Next Button (Botón Siguiente): Para seleccionar la información que ha de

programarse o revisarse.

14 Function Dial (Dial de funciones): Para seleccionar las funciones de programación y

operación.

15 Current T ime & Date (Hora y Fecha actuales):Para establecer la hora y fecha actuales.

16

Station T imes (Tiempos de riego de las estaciones): Para establecer el tiempo de riego

individual de cada estación.

17 Program Select Switch (Botones selectores de programas): Para seleccionar los programas A,

B, C o D.

18 Start T imes (Horas de arranque):Para establecer la hora de arranque de cada ciclo del

programa.

19 Water Days (Días de riego): Para establecer un plan de días de riego para cada programa.

10

%Season Adjust (Ajuste porcentual de los tiempos de riego por temporada): Para aumentar

o reducir los tiempos de riego de todas las estaciones dentro de u n programa sin necesidad de

cambiar la memoria del programa.

11

Program Erase (Borrado de programas): Para borrar la información dentro de un programa

seleccionado.

12 Sensor Control Switch (Interruptor de control del sensor): Para anular la entrada del rain

switch

®

(sensor del interruptor por lluvia).

13

Manual Program Cycle (Ciclo del programa-Manual): Para el arranque manual del ciclo de

riego de un programa seleccionado.

14 Manual Single Station (Estación individual-Manual): Para la operación de una estación

individual durante un tiempo determinado o indeterminado.

15 Off / Rain Delay (Desactivación por lluvia y Suspensión temporl por lluvia): Para detener

inmediatamente todas las actividades del programador. Las demoras de las actividades son

programables desde 1 a 7 días (Suspensión temporal por lluvia).

16

Run (Operar): Para la operación automática.

▲FIGURA 2

17 Fusible de seguridad: Un fusible de fusión lenta de 2.0 A proporciona protección contra

posibles cortocircuitos internos.

18

T erminales de conexión del sensor: Para la conexión de un dispositivo opcional de

interrupción por lluvia (normalmente cerrado).

19

Orejeta de toma a tierra: Para la conexión de un cable de cobre de 2,0 a 1,0 mm2de espesor a

una buena tierra.

20

Niple de conducto de cables con una rosca de 1/2" NPT : Para la conexión de una caja de

acceso de un conducto para los cables de alimentación eléctrica de 120 V c.a. (Modelos

nacionales solamente).

21

Regleta de terminales: Para la conexión de los cables de alimentación de corriente alterna de

230/240 V. (Modelos de exportación solamente).

22

T erminales comunes de las válvulas: Para la conexión de hasta tres cables de campo (24 V))

comunes.

23

T erminales de los cables de válvulas: Para la conexión de los cables de control de las válvulas.

24

T erminal de la válvula maestra: Para la conexión del cable de control del relé de arranque de

una válvula maestra o bomba.

25 Compartimiento de la pila: Compartimiento de acceso a la pila alcalina de 9 voltios.

COMPONENTES DEL PROGRAMADOR

Page 37

35

Off /

123

4

5

6

7

8

9

10

12

11

13

14

15

16

Figura 1

Figura 2

Componentes del Programador

24V

EARTH

GND

AC

G

N

D

SENSOR

SENSOR

VALVE

TEST

17

18

19

20

22

23

24

25

21

Page 38

36

Esta sección contiene información general para:

• Cómo funciona el sistema de seguridad

• Cómo funciona el disyuntor de circuito electrónico

• Cómo funcionan los sensores

COMO FUNCIONA EL SISTEMA DE SEGURIDAD

El programador “Custom Command” usa una memoria no volátil para

almacenar los programas de riego. Este tipo de memoria evita que la

información de los programas de riego se pierda en caso de producirse un

corte de la alimentación eléctrica. Una ventaja adicional de la memoria no

volátil es que el programa de seguridad instalado en fábrica no es necesario,

por lo que se evita la posibilidad de activar la bomba sin carga.

Debido a que las horas y las fechas actuales cambian continuamente,

solamente la fecha más reciente puede almacenarse en una memoria no

volátil. Por lo tanto, es necesario disponer de una pila para mantener la hora

y la fecha actuales en el caso de interrumpirse la alimentación eléctrica. Se

usa una pila alcalina de 9 voltios (incluida) para mantener la hora y fecha

correctas durante las interrupciones de corriente eléctrica hasta un máximo

de 90 días. En una instalación típica, la pila dura de dos a cuatro años antes

de que sea necesario cambiarla. Una vez conectada la pila o la alimentación

de corriente alterna, el programador podrá programarse completamente para

su operación.

Nota: Para la operación de las válvulas, será necesario aplicar corriente

alterna a las mismas.

Cómo instalar la pila:

1. Extraiga el tornillo del conjunto del módulo de

control abisagrado y gírelo con cuidado hacia

afuera para abrirlo.

2. Localice y retire la tapa del compartimiento de

la pila en la parte inferior del lado trasero del

módulo.

3. Conecte la pila alcalina de 9 voltios, incluida

con el programador, a los terminales del clip

para la pila.

4. Introduzca la pila en el compartimiento y reinstale la tapa del compartimiento de

la pila.

Precaución: Las pilas contienen materiales dañinos. Manipule y

deseche siempre las pilas de acuerdo con las recomendaciones del

fabricante.

INFORMACION GENERAL

Información General

Figura 3

Pila alcalina de

9 voltios

Page 39

37

Información General

COMO FUNCIONA EL DISYUNTOR DE CIRCUITO

ELECTRONICO

El programador está equipado de un disyuntor de circuito electrónico. Si el

programador detecta un cortocircuito, la estación (o válvula) cortocircuitada

será desactivada inmediatamente. Entonces aparecerá destellando en la pantalla

la palabra “SHORT” (Cortocircuito) y el número de la estación o la VALVULA

MAESTRA

que tengan un cortocircuito. El programador continuará regando

automáticamente las demás estaciones y los siguientes programas de riego hasta

que se haya reparado la estación cortocircuitada. El programa será cancelado si el

circuito de la válvula maestra está cortocircuitado. Cada arranque automático

tratará de iniciar otro ciclo y verificará de nuevo la válvula cortocircuitada. Se

enumeran a continuación las condiciones más comunes que activarán el

disyuntor de circuito electrónico. Después de corregir el problema, haga lo

siguiente para que el programador reanude su operación normal:

1. Gire el dial a una de las posiciones siguientes: Run (Operar), Manual-Single

Station (Estación individual- Manual)

o Manual-Program Cycle (Ciclo del

programa-Manual)

.

2. Oprima el botón OFF para que el programador vuelva a la modalidad de

operación normal.

Condición: Aparece en pantalla la palabra “SHORT” con uno o más

números de estación.

Diagnóstico: Una o más estaciones están cortocircuitadas.

Solución: Compruebe el cableado de las estaciones indicadas en

pantalla para determinar la causa del cortocircuito. Repare

la válvula o válvulas y/o el cableado según sea necesario.

Diagnóstico: Demasiadas válvulas operan al mismo tiempo, lo que

causa una condición de sobrecarga.

Solución: Compruebe los programas de riego para ver si hay estaciones

que funcionan simultáneamente. Incluya el relé de arranque

de la válvula maestra/bomba en caso de usarse. La máxima

salida total es de 24 V c.a. a 1,25 amperios. Reduzca el

número de estaciones que funcionan al mismo tiempo.

Condición: Aparece en pantalla la palabra “SHORT” sin ningún

número de estación.

Diagnóstico: Se ha producido un cortocircuito con un tiempo de

duración demasiado corto para que el programador haya

podido determinar la estación.

Solución: Inspeccione el cableado de todas las válvulas para ver si hay

grietas en el aislamiento, lo cual podría hacer que la salida

de una estación se cortocircuitara con un cable común.

Diagnóstico: Se ha producido una punta transitoria de exceso de

corriente o voltaje.

Solución: Reposicione el programador.

Diagnóstico: Se produjo un cortocircuito o una sobrecarga en un ciclo

de riego pero ya no se produjo en un ciclo posterior.

Solución: Inspeccione si el cableado de alguna válvula se ha aflojado

y/o está expuesto.

Page 40

38

COMO FUNCIONAN LOS SENSORES

El programador “Custom Command” está equipado para funcionar con un

dispositivo sensor de lluvia opcional “Rain Switch®” (interruptor por lluvia)

para evitar la operación automática del programador en caso de lluvia.

El “Rain Switch®” (interruptor por lluvia) es un dispositivo sencillo que

generalmente está instalado en el voladizo del techo o sobre una estructura

estacionaria expuesta a la lluvia y a los rayos solares, y protegido del alcance

del riego.

Cuando llueve, el interruptor por lluvia normalmente cerrado detecta la

humedad, por lo que abre el circuito común de las válvulas y evita

eficazmente toda salida eléctrica hacia el campo. La porción de programación

electrónica del programador está aislada del interruptor del sensor de lluvia y

continúa funcionando tal como ha sido programada. Cuando cesa de llover y

el interruptor por lluvia regresa a su estado normalmente cerrado, se restaura

el circuito común de las válvulas, permitiendo que el riego se reanude tal

como había sido programado.

Se provee un interruptor del sensor de dos posiciones (vea el dispositivo 12

en la página 34) para que usted pueda anular la operación del interruptor por

lluvia en cualquier momento. Si usted elige pasar por alto la entrada del

interruptor por lluvia, coloque el interruptor del SENSOR en la posición de

Bypass (Anulación). Para habilitar la operación del interruptor por lluvia,

coloque el interruptor del sensor en la posición Active (Activo).

Nota: Hay un cable puente instalado a través de los terminales del sensor.

Deberá retirarse este cable puente cuando se conecten los cables del

interruptor por lluvia.

Información General

Page 41

39

Esta sección abarca los siguientes temas:

• Cómo empezar

• Establecimiento de la hora y fecha actuales

• Borrado de cualquier programa anterior

• Establecimiento de los tiempos de riego de las estaciones

• Selección de activación/desactivación de la válvula maestra/bomba

• Establecimiento de las horas de arranque de los programas

• Selección de los días de riego

COMO EMPEZAR

El singular diseño del programador Custom Command permite que el módulo

de programación se separe fácilmente de su armario para que usted se lo lleve

a otro lugar y pueda programarlo con toda comodidad - ¡incluso sentado en su

sillón favorito! Todo lo que tiene que hacer es girar el módulo hacia afuera,

desconectar los cables y levantar el módulo de sus bisagras. Seguidamente,

proceda a la instalación de la pila alcalina de 9 voltios para poder programar

y revisar sus planes de riego y tener el programador listo para operar

inmediatamente después de completar la instalación (Vea las instrucciones de

instalación de la pila en la página 36).

Nota: Para prolongar la vida útil de la pila, la pantalla se oscurecerá

automáticamente después de dos minutos de inactividad. Para restaurar la

visualización, gire simplemente el dial de funciones a cualquier posición.

¿QUE ES UN CICLO DE RIEGO?

En términos básicos, un programa de riego es un pequeño conjunto de

instrucciones que indica al programador la hora en que ha de arrancar un

ciclo de riego, las estaciones que han de operar durante el ciclo, los días en

los que el ciclo estará activado y cuánto tiempo operará cada estación durante

el ciclo. El programador Custom Command tiene cuatro programas de riego

independientes disponibles para su uso. Se usan normalmente programas

separados para agrupar las estaciones que tienen requisitos de riego similares.

Por ejemplo, usted puede usar un programa para regar los céspedes a pleno sol

cada día. Otro programa puede usarse para regar los céspedes en penumbra

solamente los lunes, miércoles y viernes. Los árboles y arbustos que usan riego

por goteo podrían ser regados por un programa separado una vez cada dos

semanas. Las necesidadey de la zona de jardín pueden ser de un riego cada dos

días. Como puede ver, la disponibilidad de cuatro programas le permitirá

utilizar programas de riego que se adapten especialmente a las distintas

necesidadey de riego de sus zonas verdes.

PROGRAMACION DEL

PROGRAMADOR

Programación del Programador

Page 42

Programación del Programador

40

¿QUE ES EL CICLO DE RIEGO DE UN PROGRAMA?

Cuando se selecciona una hora de arranque de riego, esa hora representa el

principio de un ciclo de riego automático. Un ciclo de riego opera todas las

estaciones asignadas al programa de una en una en orden numérico. Al establecer

los programas de riego, es importante recordar que las horas de arranque se asignan

a los programas, no a las estaciones individuales.

En el ejemplo siguiente (que también puede verse en el plan de riego de muestra

de la página 41), hemos configurado el Programa A para que arranque a las 2:00

a.m. y de nuevo a las 3:00 a.m. con un intervalo de 1 día (es decir, cada día). Las

estaciones 1, 2, 4 y 5 son áreas de césped de las zonas delantera y trasera que

reciben pleno sol durante todo el día. Estas estaciones funcionarán durante 10

minutos cada una hasta que completen un tiempo de riego total de 20 minutos por

día. Las estaciones 3, 6 y 7 son áreas de césped sombreadas por la tarde. Estas áreas

necesitan menos agua, de manera que las hemos asignado al Programa B y las

hemos programado para que sean regadas durante 20 minutos a intervalos de 2 días

(es decir, un día sí y otro no).

A las 2:00 a.m, arranca el ciclo de riego del Programa A. La estación 1 se activa,