FormNo.3418-252RevA

4-in-1Electric/HydraulicBucket

TX1000CompactToolCarrier

ModelNo.BU-003895

ModelNo.BU-003915

ModelNo.BU-004001

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3418-252*A

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Gotowww.Toro.comtoaccesswarranty,parts,and

otherproductinformation.

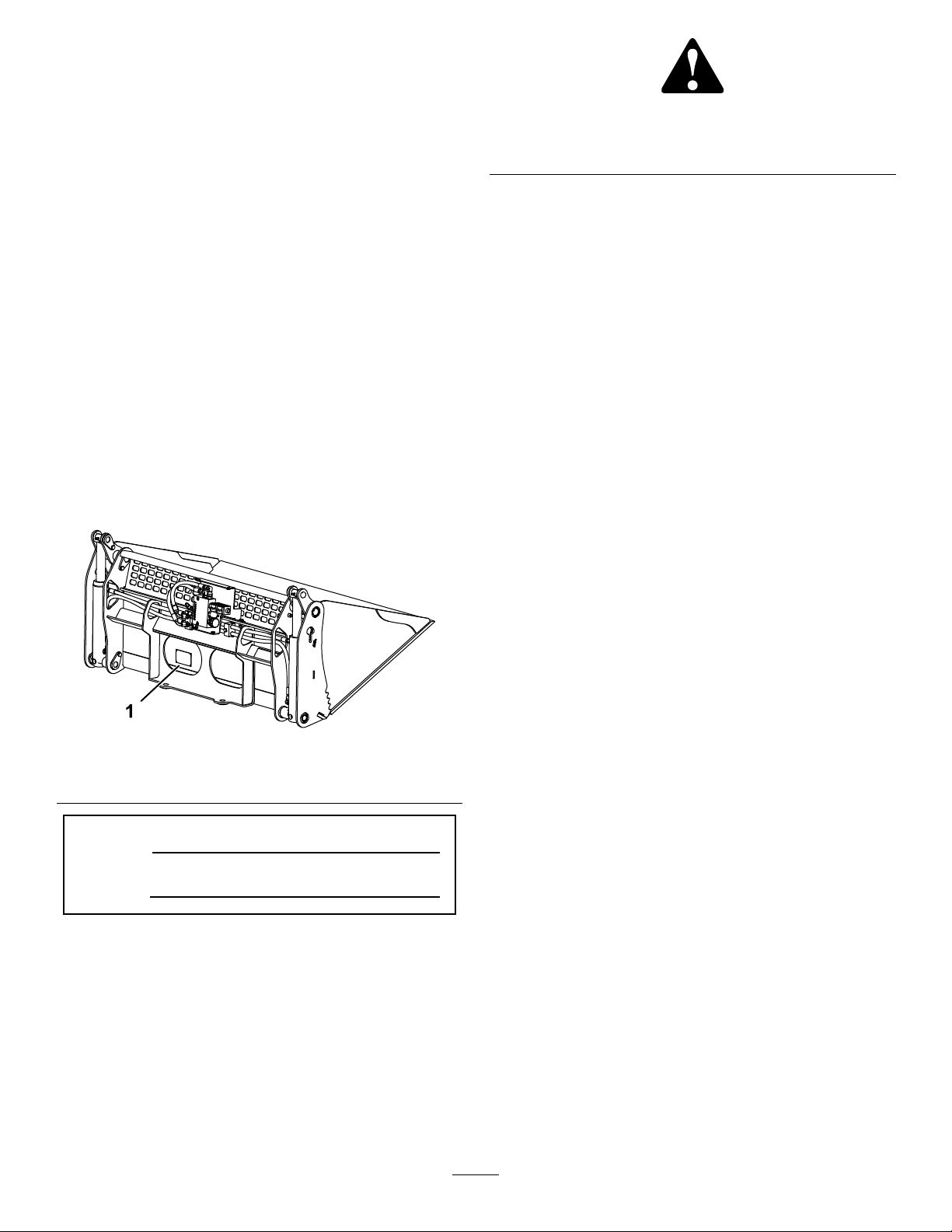

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g243011

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................3

AttachmentSafety..............................................4

MaintenanceandStorageSafety........................4

BeforeDigging....................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................6

1PreparingtheMachine.....................................6

2InstalltheConnectorandConnectorMount

Bracket............................................................7

3ConnectingtheLoaderArmBranch.................8

4ConnectingtheRelayandPowerLead

Connectors....................................................11

5RemovingtheExistingLever..........................13

6Installingthe4-in-1BucketLever...................14

7InstallingtheValveManifoldSolenoid

Harness........................................................15

8T estingtheInstallation...................................16

9CompletingtheInstallation.............................17

ProductOverview...................................................17

Controls...........................................................17

Specications..................................................18

MaximumMaterialDensityatCapacity.............19

Operation................................................................20

InstallingandRemovingtheAttachment...........20

4-in-1OperationandControl............................20

TransportPosition............................................20

BucketOperation..............................................21

BladeOperation...............................................21

LevellerOperation............................................21

GrappleBucketOperation................................21

Maintenance...........................................................22

RecommendedMaintenanceSchedule(s)...........22

LubricatingtheBucket......................................22

Adjustingthe4-in-1BucketOperation...............22

Storage...................................................................23

Troubleshooting......................................................24

Schematics.............................................................25

©2018—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedinAustralia

AllRightsReserved

Safety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(Call

1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donotcarryaloadwiththearmsraised;always

carryloadsclosetotheground.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

bucketmakestherearofthemachinetheheavy

end,andafullbucketmakesthefrontofthe

machinetheheavyend.Mostotherattachments

makethefrontofmachinetheheavyend.

•Raisingtheloaderarmsonaslopeaffectsthe

stabilityofthemachine.Keeptheloaderarmsin

theloweredpositionwhenonslopes.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,orbodiesofwater.The

machinecouldsuddenlyrolloverifawheelor

trackgoesovertheedgeortheedgecavesin.

Maintainasafedistancebetweenthemachine

andanyhazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

3

AttachmentSafety

BeforeDigging

•Weargloves,eyeprotection,longpants,

substantialslip-resistantfootwear,andhearing

protectionduringoperationorwhileadjustingor

repairingthemachine.Tiebackhairanddonot

wearloosejewelry.

•Afterstrikingaforeignobject,shutofftheengine,

removethekey,thoroughlyinspecttheattachment

foranydamage,andrepairthedamagebefore

startingandoperatingtheattachment.

•Alwayslowertheattachmenteachtimeyoushut

offthemachineorleavetheoperatingposition.

•Cleananydirtordebristhatmayhinderconnecting

theattachmenttothemachine.Ensurethatthe

attachment-lockingpinsarefullyseatedinthe

holesoftheattachment-mountplate.Refertothe

Operator’sManualforthemachinefordetailed

informationonsafelyconnectinganattachmentto

yourmachine.

•Whenliftingtheattachmentkeepitleveland

preventtheloadfromspillingbackward.

Topreventdamageanddisruptiontounderground

pipeandcablenetworksinyourproposedexcavation

site,contacttheDialBeforeYouDigservice.Y ou

candial1100toaccessplansforunderground

networksanywhereinAustralia.Y oumayalsolog

ontowww.dialbeforeyoudig.com.auforadditional

information.

Remember,everyonehasaDutyofCaretolocate

undergroundpipesandcablesbeforediggingor

excavating.

Diggingorexcavatingwithoutrstdialing1100could

leadtoinjuryordeathtoyouandbystanders.Itcould

alsoleadtocostlydisruptionofessentialservicesand

nancialpenalties.

MaintenanceandStorage Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertotheOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime

•Maintainorreplaceanysafetyandinstruction

labelsthataredamagedormissing.

g244146

Figure3

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

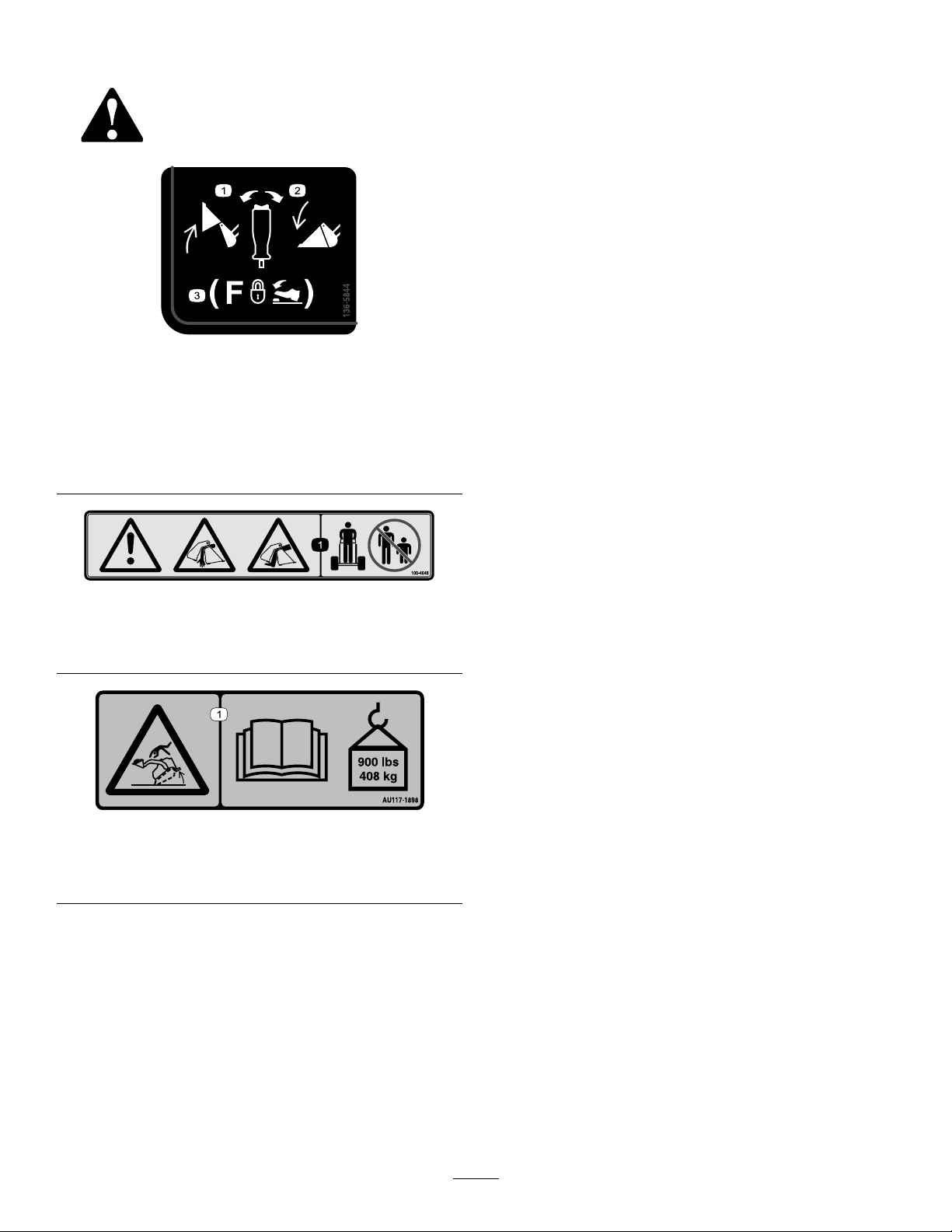

136-5844

decal136-5844

1.Pressthejoystickswitch

lefttoopenthebucket

jaws.

2.Pressthejoystickswitch

righttoclosethebucket

jaws.

3.Locktheaccessoryinto

Forward.

100-4648

1.Warning;crushingofarmhazard;crushingofleg

hazard—keepbystandersawayfromthemachine.

AU117-1898

decal100-4648

decalau117-1898

1.Tippinghazard—readtheOperator’sManual;themaximum

loadis408kg(900lb).

5

Setup

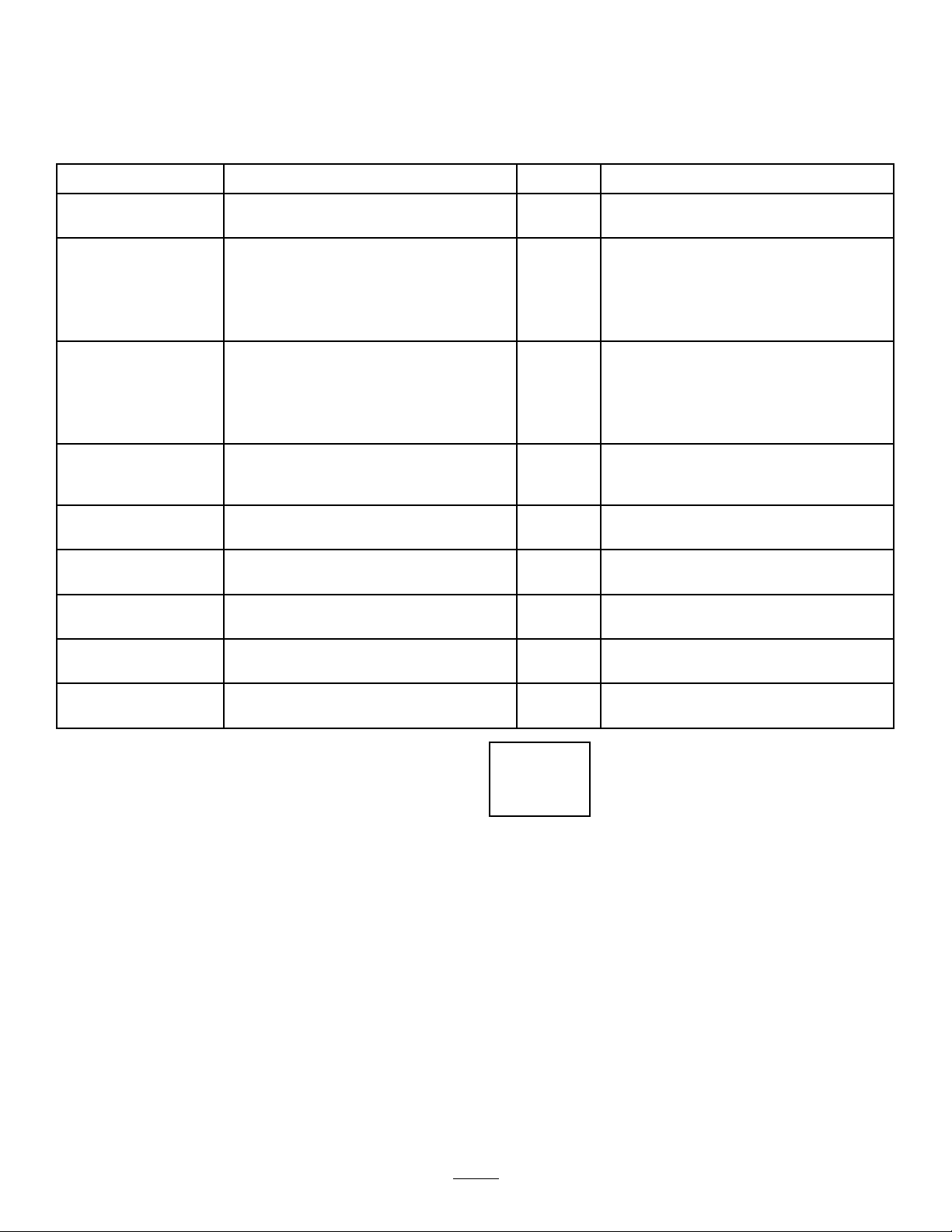

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Connectormountbracket

7-pinconnector1

Bolt(5/32inches)

Spacer

Nut(5/32inches)

Relayandloaderarmharness1

Plugnut1

Grommet

Wireharnessretainer1

Screw

Self-tappingscrew

Relay2

Fuse(5A)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

–

1

2

2

2

2

2

1

–

–

–

Preparethemachine.

Installtheconnectorandconnector

mountbracket.

Connecttheloaderarmbranch.

Connecttherelayandpowerlead

connectors.

Removetheexistinglever.

Installthe4-in-1bucketlever.

Installthevalvesolenoidharness.

8

9

Note:Retainallremovedpartsforlaterinstallation

unlessotherwisedirected.

Important:Youmustacquire2screws(5/16–18

TPI1.75inches)tocompletethisinstallation.

Important:Caporpluganydisconnected

hydraulichoses,tubes,orcomponentportsto

preventcontaminationenteringthesystem.

Nopartsrequired

Nopartsrequired

–

–

Testtheinstallation.

Completetheinstallation.

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Installthebucket;refertoyourmachine

Operator’sManualforinformationoninstalling

andremovingthebucket.

Important:Alwaysusethetractionunitto

liftandmovetheattachment.

Important:Beforeinstallingthebucket,

ensurethatthemountplatesarefreeofany

dirtordebrisandthatthepinsrotatefreely.

Ifthepinsdonotrotatefreely,greasethem.

6

2.Parkthemachineonalevelsurface,engagethe

parkingbrakeandlowerthearms.

3.Shutofftheengine,removethekeyandallow

theenginetocool.

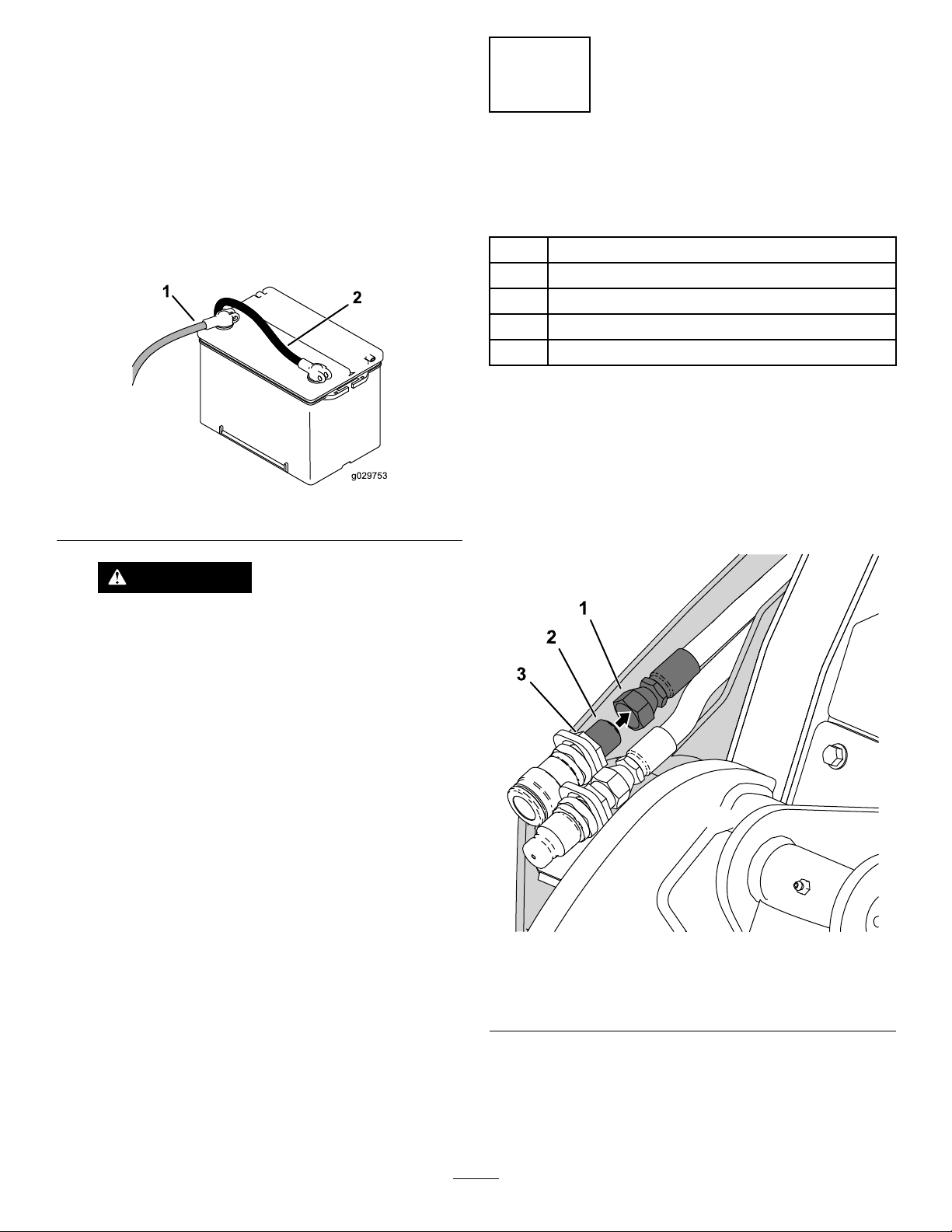

4.Turnthebattery-disconnectswitchtotheoff

position;refertoyourmachineOperator’s

Manual.

5.Ifyourmachinedoesnothavea

battery-disconnectswitch,disconnectthe

negative(black)cablefromthebattery,then

disconnectthepositive(red)cable(Figure4).

Figure4

2

InstalltheConnectorand ConnectorMountBracket

Partsneededforthisprocedure:

1

Connectormountbracket

17-pinconnector

2

Bolt(5/32inches)

2

Spacer

2

Nut(5/32inches)

Procedure

1.Releaseanybuiltuphydraulicpressureby

movingtheauxiliaryhydraulicsleverforward

andbackwardafewtimes.

g029753

2.Disconnecttherightsideouterhosetting

(1–1/8inches)fromthebulkheadcouplerand

plugthehoseend.

WARNING

Incorrectbatterycableroutingcould

damagethemachineandcables,causing

sparks.Sparkscancausethebattery

gassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

1.Hosetting

2.Bulkheadcouplerthreads

g242258

Figure5

3.Bulkheadcouplerlocknut

3.Removethebulkheadcouplerlocknut(1–5/16

inches).

4.Aligntheconnectormountbracketoverthe

threadedendofthebulkheadcouplerand

secureitwiththebulkheadcouplerlocknut.

7

Figure6

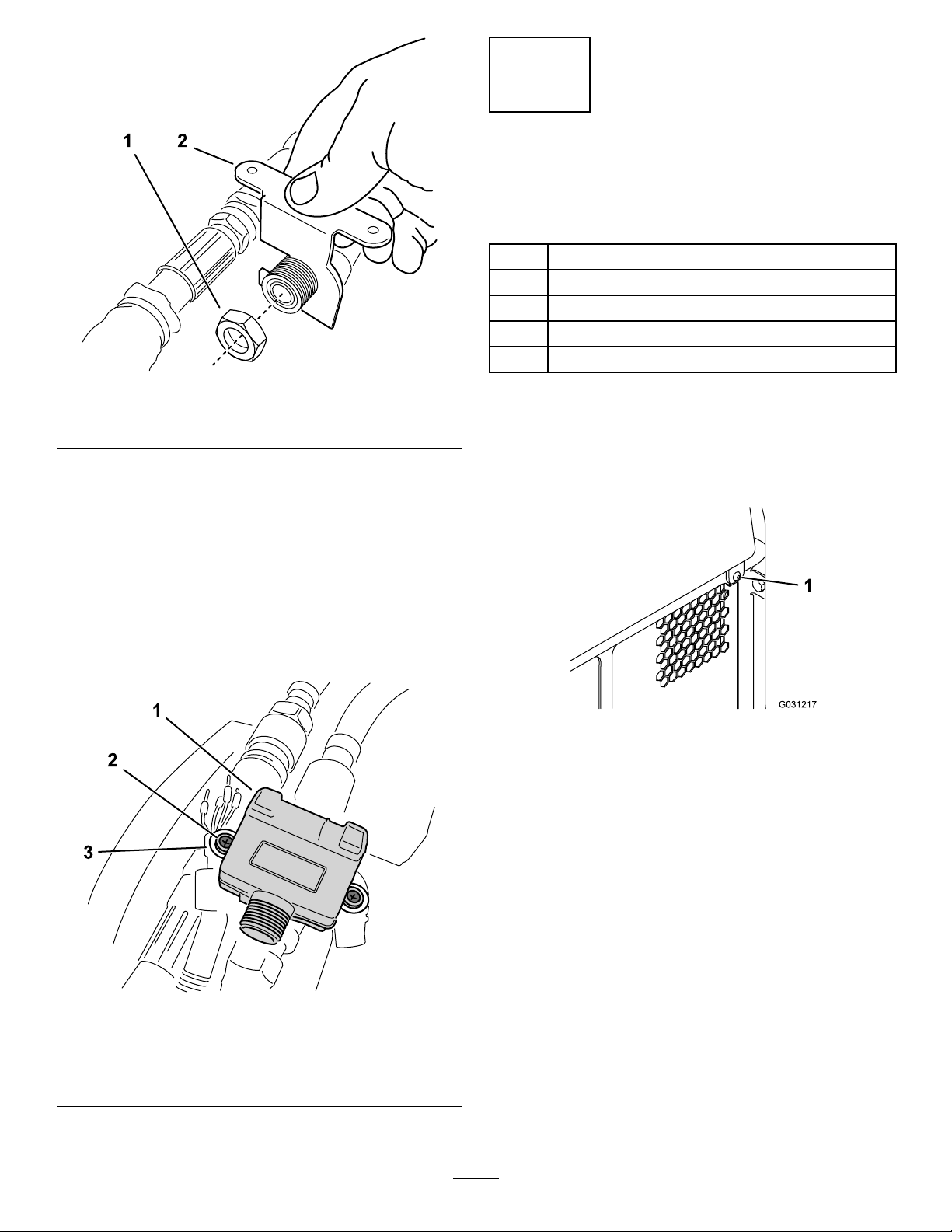

3

ConnectingtheLoaderArm Branch

Partsneededforthisprocedure:

1Relayandloaderarmharness

1Plugnut

Grommet

1Wireharnessretainer

2

Screw

g242236

1.Bulkheadcouplerlocknut

5.Removetheplugandconnectthehosetting

removedinstep2.T orquethettingto60to74

ft-lb(81to100N·m).

6.Removethegrommetandplugnutfromtherear

ofthe7-pinconnector,aswellasthepartsbag

insidetheconnector.

7.Installthe7-pinconnectortothetopofthe

connectormountbracketwith2bolts(5/32

inches),washers,andnuts(Figure7).Tighten

thenutssecurely.

2.Connectormountbracket

Procedure

1.Loosenthecaptivescrew(7/16inch)onthe

bottomrightoftherear-accesscoverandopen

it(Figure8).

g031217

Figure8

1.Captivescrew

2.Alongthetoprailoftherightloaderarm,remove

the2screws,hosehold-downplates,and

spacertubes(Figure9).

1.7-pinconnector

2.Bolt(washerandnuton

undersideofbracket)

g242253

Figure7

3.Connectormountbracket

8

Figure9

g242240

1.Screw3.Spacertube

2.Hosehold-downplate4.Loaderarm

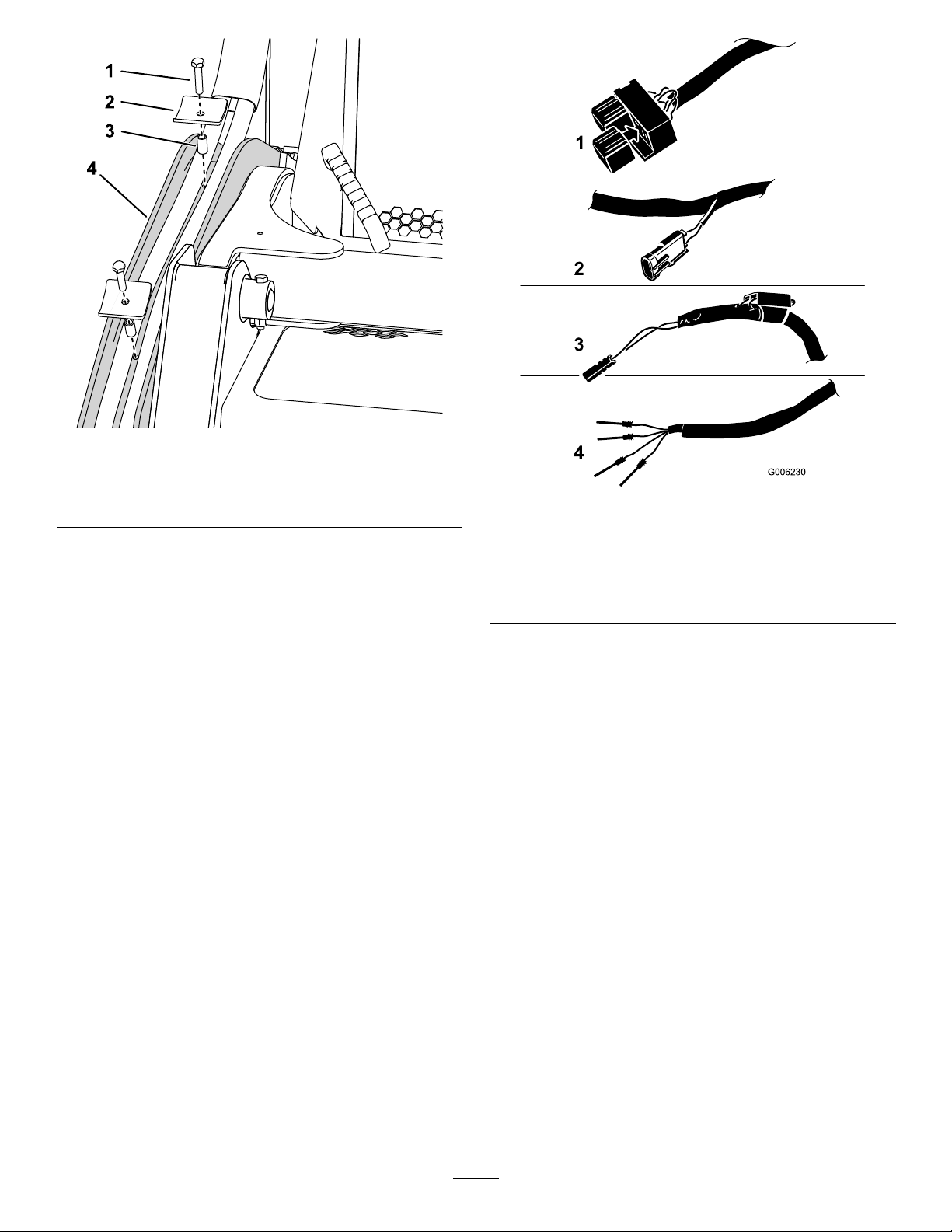

3.Findtheloaderendbranchoftherelayand

loaderarmharness(Figure10).

Figure10

Relayandloaderarmharnessconnections

1.Relaybranch3.Powerleadbranch

2.Loaderarm/attachment

leverconnector

4.Loaderendbranch

g006230

9

4.Routetheloaderendbranchintotherearofthe

machinealongthelowerfrontendoftheloader

armvalveassembly(Figure11)andoutthrough

therighthoseaccess(Figure12).

5.Routetheloaderendbranchupintotheouter

protectivesleeve,thenrouteitalongthebottom

oftheinnerhydraulichosesothatthewires

reachthe7-pinconnector.

6.Installtheplugnut(large)andthenthegrommet

(small,narrowendfacingthe7-pinconnector)

overthewires.

Figure11

1.Loaderendbranch2.Righthoseaccess

g242387

g242237

Figure13

1.Plugnut

2.Grommet

7.Removethetophalfofthe7-pinconnectorand

installthe4loaderendwiresintothecorrect

connectorterminalsinsideasshowninFigure

14.

1.Righthoseaccess

2.Loaderendbranch

g242409

Figure12

3.Outerprotectivesleeve

g242270

Figure14

1.Wireharnessretainer4.Yellow-T erminal2

2.White-T erminal65.Black-T erminal7

3.Black-T erminal5

10

8.Tightentheterminalscrewsandpullonthewires

toensurethattheyaresecurelyconnected.

9.Installthewireharnessretainerand2screws

(Figure14).

10.Installtheconnectortophalfandscrewonthe

plugnutsecurely ,atthesametimeseatingthe

grommet(Figure15).

Figure15

1.Threadtheplugnutonto

the7-pinconnector

2.Connectortophalf

4

ConnectingtheRelayand PowerLeadConnectors

Partsneededforthisprocedure:

2

Self-tappingscrew

2Relay

1

Fuse(5A)

AssemblingtheRelayConnectors

totheMachine

ForModel22327withserialnumbersprior

to316000467andModel22328withserial

g242272

numberspriorto316999999

1.Fromtherearofthemachine,positionthe

relayconnectorsonthelowerrearfaceofthe

auxiliaryvalvebracketandmarkthelocationof

themountingholesonthebracket.

11.Installthehosehold-downplatesandspacer

tubesremovedinstep2.

Important:Ensurethatthewireharnessis

nottootautatthe7-pinconnector;givethe

harnesssufcientslackbeforetightening

thehold-downplates.

12.Replacethepreviouslyremovedscrewswith2

longerscrews(5/16–18TPIx1.75inches).

Note:Thesescrewsarenotsuppliedwiththe

attachment.

g242413

Figure16

1.Auxiliaryvalvebracket3.Relayconnectors

2.Drillahole(4mm)here.4.Self-tappingscrews

2.Drillholes(2)usinga4mmdrillbitatthemarks

madeinstep1.

3.Usingthe2self-tappingscrews,installtherelay

connectorstotheauxiliaryvalvebracket(Figure

16).

11

4.Installthe2relaystothebucketrelayconnectors

andcontinuetoConnectingthePowerLead

Branch(page12).

AssemblingtheRelayConnectors

totheMachine

ForModel22327withserialnumbersafter

316000467andModel22328withserial

numbersafter316999999

1.Fromtherearofthemachine,removeboth

existingrelaysfromtheignitionrelayconnectors

(Figure17).

ConnectingthePowerLead

Branch

1.Withacabletie,securetheharnesstothehose

ttingintheT1portontheleftsideoftheloader

armvalveassembly.

Important:Routethewireharnessaway

fromanyhotormovingparts,securewith

cabletiesasneeded.

2.Openthehood,propitup,andremovetheheat

shield(Figure18).

Figure17

1.Bucketrelayconnectors3.Ignitionrelayconnectors

2.Matingtangs4.Ignitionrelays

2.Loosentheignitionrelayconnectormounting

boltsandnuts.

3.Slidethematingtangsofthebucketrelay

connectorsontothetangsoftheleftignition

relayconnector(Figure17).

4.Tightentheignitionrelayconnectormounting

hardwareandinstalltherelaysremovedinstep

1.

5.Installthe2relaystothebucketrelayconnectors

andcontinuetoConnectingthePowerLead

Branch(page12).

g038212

Figure18

1.Screw(3)

2.Heatshield

3.Feedthepowerleadbranchforwardandaround

thefrontoftheauxiliaryvalve.

g242426

4.Removethecapfromtheplug-and-socket

connectorontheauxiliarylowowharnessand

connectthepowerleadbranchtotheopen

connector(Figure19).

g038242

Figure19

1.Powerleadconnector

2.Auxiliarylowow

connector

5.Installthecapintotheshort,taped-back

connectoronthepowerleadbranch.

Note:Securethewireharnesssothatitdoes

notcontacttheheatshield.

12

6.Installthe5Afuseintotheinlinefuseblockon

thepowerleadbranch.

5

RemovingtheExisting Lever

NoPartsRequired

Procedure

1.Removetheretainingringfromtheloader

arm/attachmenttiltlevershaftandmovethe

washerup(Figure20).

Figure20

2.Pushuptheairdeectorfrombelowthecontrol

panelandslideitupthelever(Figure20).

Note:Y oumayneedtoadjustthepositionof

thelevertoremovetheairdeector.

3.Loosenthelocknut(3/4inch)atthebaseofthe

lever(Figure21).

g242427

Figure22

1.Drilla5mmdiameterhole

fortheleverconnector

wire

2.Cuta30mmslotfromthe

centreofthedrilledhole

3.10mmfromtheedgeof

theexistingholetothe

centreofthenewhole

g242495

4.Existinghole

5.Slotsfacetowardlower

rightsideofcontrolpanel

Figure21

Somepartsnotshownforclarity

4.Unscrewandremovetheleverandairdeector

(Figure21).

5.ModifytheairdeectorasshowninFigure22.

g242496

13

6

Installingthe4-in-1Bucket Lever

NoPartsRequired

Procedure

1.Ensurethattherockerswitchesatthetopof

the4-in-1bucketleverareatrightanglestothe

shaftopeningasshowninFigure23andtighten

thehandlelocknut.

8.Attachthehandleinstructionaldecalontothe

bottomleftcornerofthecontrolpaneldecalas

showninFigure24.

Note:Cleanandpreparethecontrolpanel

decalbeforeinstallingthehandledecal.

2.Removetheinsertlocknut(Figure23)and

puttheleverthroughtheairdeectorwiththe

openingfacingforwardandthelevershaftlead

andconnectorfedthroughthesmalldrilledhole.

3.Installthelocknuttothebottomoftheleverand

threadtheleverintotheloadervalveassembly.

Note:Rotatetheairdeector,lever,andlever

connectorwirealtogethertomaintainthecorrect

orientation.

Figure23

1.Rockerswitch4.Insertlocknut

2.Handlelocknut

3.Shaftopening

5.Levershaftlead

g242493

Figure24

g242494

4.Withtheshaftopeningfacingforward,secure

theleverfromrotationandtightentheinsert

locknut(18mm)securelytotheloadervalve

assembly.

5.Loopthelevershaftleadclockwisearoundthe

topoftheloadervalveassembly.

6.Connecttheleverconnectortotheloader

arm/attachmentleverconnectorbeneaththe

controlpanel(Figure10).

7.Pushtheairdeectorbelowthecontrolpanel

andmovetheleverinalldirectionstoensure

thatitslidesfreely.

14

7

InstallingtheValveManifold SolenoidHarness

NoPartsRequired

Procedure

1.Removethe4boltsandwasherssecuringthe

manifoldcoverfromthe4-in-1bucket(Figure

25).

g242609

Figure26

Figure25

1.Manifoldcover2.Boltandwasher(4)

2.Feedthesolenoidconnectorendofthevalve

manifoldsolenoidharnessdowntheouter

protectivesleeveofthe4-in-1buckethoses.

3.Removetheplugsfromthevalvemanifold

terminalsandinstallthesolenoidconnectorsas

showninFigure26.

1.Valvemanifold3.Valvemanifoldsolenoid

harness

2.Leftandrightsolenoid

connectors

4.Tightenthecentrescrewsonthesolenoid

connectorssecurely.

g242611

15

5.Liftupthespring-loadedcoveronthe7-pin

connectorandinsertthevalvemanifoldsolenoid

harnessconnector(Figure26).

4.Turnthelowowswitchontoactivatethe

auxiliaryhydraulicslowowsystem.

5.Setthethrottletofastandlocktheauxiliary

hydraulicsleverintheforwardowposition;

refertoyourmachineOperator’sManual.

Important:Operatethebucketjawsonly

withtheauxiliaryhydraulicsleverinthe

forwardowposition.

6.Operatetheleftandrightsidesoftherocker

switchontopofthe4-in-1bucketlever;the

bucketshouldopenandcloseandagreen

LEDwithineachofthevalvemanifoldsolenoid

harnessconnectorsshouldilluminate.

Note:Whentheleftsideoftherockerswitchis

depressedthejawsshouldopen,whentheright

sideispressedthejawsshouldclose.Ifthejaws

open/closeinreverse,loosenthehandlelocknut

(Figure23)andscrewthehandledown180°.

Securethehandleandtightenthelocknut.

Figure27

1.7-pinconnector3.Lockingtang

2.Spring-loadedcover4.Valvemanifoldsolenoid

harnessconnector

Note:Ensurethatthecoverisfullyclosedover

thelockingtangsonthevalvemanifoldsolenoid

harnessconnector.

8

TestingtheInstallation

NoPartsRequired

Procedure

1.Turnthebattery-disconnectswitchtotheON

position;refertoyourmachineOperator’s

Manual.

g242610

7.Movetheauxiliaryhydraulicslevertotheneutral

position.

8.Raisetheloaderarmtothehalfwayposition

andfullytiltthebucketforward.

9.Ensurethatthereisnotensiononthevalve

manifoldsolenoidharnessattheconnectionto

theloaderarmharness.

10.Fullydumpandcurlthebucket;atthemidpoint

ofthismotionensurethatthehosesdonotbend

excessivelyattheirconnectionstothemanifold

assembly.

Important:Ifthereisexcessivebendingin

thehoses,youmustloosenandadjustthe

portttingstocorrecttheangle;excessive

bendingofthehosescausesstressand

damagetothehosesandttings.

2.Ifyourmachinedoesnothavea

battery-disconnectswitch,connectthe

positive(red)cabletothepositive(+)terminal

andthenegative(black)cabletothenegative(-)

terminalofthebattery(Figure4).

Note:Securethecablesusingthecable

mountinghardwareusedpreviously.

3.Starttheengineandraisetheloaderarmsothe

bucketisofftheground.

16

9

CompletingtheInstallation

NoPartsRequired

Procedure

1.Tiltthe4-in-1bucketbackandlowertheloader

arm.

2.Shutofftheengineandremovethekey.

3.Checkallhydraulicconnectionsforleaksand

correctasnecessary.

4.Checkthehydraulicuidlevelandcorrectas

necessary;refertoyourmachineOperator’s

Manual.

5.InstalltheheatshieldasshowninFigure18.

6.Closeandsecuretheenginehood.

7.Installthevalvemanifoldcovertothe4-in-1

bucketandsecureitwiththe4boltsand

washersasshowninFigure24.

ProductOverview

g242329

Figure28

1.4-in-1bucket3.Hydraulicandelectrical

connections

2.Manifoldcover4.Loaderarm/attachmenttilt

lever

Important:The4-in-1bucketmustnot

beusedwithoutthevalvemanifoldcover

installed.Thewarrantyonthevalvemanifold

assemblywillbevoidedifthecoverisnot

installedorinstalledincorrectly.

Controls

Becomefamiliarwithallthecontrols(Figure29and

Figure30)beforeyoustarttheengineandoperate

thetractionunit.

AuxiliaryHydraulicsLowFlow

Switch

Pressonthefrontoftheauxiliaryhydraulicslowow

switchtoturniton.

17

g239507

Figure29

1.Lowowswitch

LoaderArm/AttachmentTiltLever

Specications

Usetheloaderarm/attachmenttiltlevertooperatethe

4-in-1bucket(Figure30).

Important:Forthebucketjawstooperate,you

musthavetheauxiliaryhydraulicsleverinthe

forwarddetentposition.

Figure30

1.Lowertheloaderarms

2.Raisetheloaderarms

3.Tiltthebucketrearward

4.Tiltthebucketforward

5.Open/closethebucket

jaws

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

4-in-1ExtraHighVolumeBucket

ModelBU003915

1346mm Width

(53inches)

804mm Length

(31.7inches)

Height

Weight

Capacity(SAEstruck

capacity)

Maximumdensity ,heaped

Maximumdensity ,struck

g242271

4-in-1WideBucket

ModelBU003895

Length

Height

Weight

Capacity(SAEstruck

capacity)

Maximumdensity ,heaped

Maximumdensity ,struck

558mm(22inches)

212kg(467.4lbs)

3

0.22m

(7.8ft

2151kg/m

(134.3lb/ft

2558kg/m

(159.7lb/ft

1067mm Width

(42inches)

685mm(27inches)

558mm(22inches)

166kg(365lbs)

3

0.15m

(5.3ft3)

1796kg/m

(112.1lb/ft

2156kg/m

(134.6lb/ft

3

)

3

3

)

3

3

)

3

3

)

3

3

)

4-in-1NarrowBucket

ModelBU004001

Width

Length

Height

Weight

Capacity(SAEstruck

capacity)

Maximumdensity ,heaped

Maximumdensity ,struck

18

863mm(34inches)

685mm(27inches)

558mm(22inches)

145kg(319.7lbs)

3

0.12m

(4.3ft3)

1004kg/m

(66.7lb/ft

1221kg/m

(76.2lb/ft

3

3

)

3

3

)

MaximumMaterialDensityat Capacity

Thedensityofthematerialsmovedbythebucket

variesand,therefore,sodoestheamountofmaterial

thatthebucketcancarrybeforereachingthe

maximumloadrating.ThetablesinSpecications

(page18)listthedensityofmaterialthatcanbe

carried,bothheapedandstruck(i.e.,leveledoff),in

thebucket.Thetablebelowlistscommonmaterials

andtheirdensities.

Tomovethematerialswithdensitiesgreaterthanthe

maximumallowedforthebucket,reducethevolume

ofthematerialplacedinthebucket.

MaterialDensity

Material

Caliche1250kg/m

Clay:

Naturalbed

Dry

Wet

Withgravel,dry

Withgravel,wet

Coal:

Anthracite,broken

Bituminous,broken

Earth:

Dry,packed

Wet,packed

Loam

Granite,brokenorlarge

crushed

Gravel:

Dry

Pitrun(graveledsand)

Dry,13to51

mm(1/2to2inch)

Wet,13to51mm(1/2

to2inch)

Limestone,brokenorcrushed

Sand:

Dry

Wet

Withgravel,dry

Withgravel,wet

Sandstone,broken1510kg/m

Shale1250kg/m

Slag,broken1750kg/m

Stone,crushed1600kg/m

Topsoil

Density(Approximate)

3

(78lb/ft

1600kg/m

1480kg/m

1660kg/m

1420kg/m

1540kg/m

1100kg/m

830kg/m

1510kg/m

1600kg/m

1250kg/m

1660kg/m

1510kg/m

1930kg/m

1690kg/m

2020kg/m

1540kg/m

1420kg/m

1840kg/m

1720kg/m

2020kg/m

950kg/m

3

3

3

3

3

(96lb/ft

3

3

(52lb/ft

3

3

3

(78lb/ft

3

(104lb/ft

3

3

3

3

(126lb/ft

3

(96lb/ft

3

3

3

3

(126lb/ft

3

(94lb/ft

3

(78lb/ft

3

(109lb/ft

3

(100lb/ft

3

(59lb/ft

3

)

(104lb/ft

(93lb/ft

(104lb/ft

(89lb/ft

(69lb/ft

(94lb/ft

(100lb/ft

(94lb/ft

(120lb/ft

(106lb/ft

(89lb/ft

(115lb/ft

(107lb/ft

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

19

Operation

The4-in-1bucketcanbeusedin4differentoperating

modes:

•Bucket

•Blade

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Leveller

•Grapplebucket

InstallingandRemoving theAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationandremovalprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely .Ifthepins

donotrotatefreely,greasethem.

Note:Alwaysusethetractionunittoliftandmove

theattachment.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

4-in-1Operationand Control

Afteryouattachthe4-in-1buckettothemountplate

ofthetractionunit,ensurethatthehydrauliccouplers

areconnected,andthattheauxiliaryhydraulicslow

owsystemisturnedon.Startandrunthemachineat

fullthrottle.

Whenloadingmaterial,alwayshavethebucketlevel

tothegroundandmoveforwardintothematerialto

belifted.Whenthebucketisfull,tiltitrearwardto

decreasetheliftingresistancewhenyoulifttheload.

TransportPosition

Whentransportingaload,keeptheattachmentas

closetothegroundaspossible,nomorethan6

inchesabovethelowestposition.Tiltitrearwardto

keeptheloadlevel.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

1.Nomorethan6inches

20

g240205

Figure31

2.Tilttheloadrearward

abovethelowestposition

BucketOperation

Youcandrawthejawstogethertousethisattachment

asastandardbucket.Youcanalsoopenthe4-in-1

bucketjawstodumpthecontentsintoahigherarea

thanastandardbucketcanreach.

Whenloadingmaterial,alwayshavethebucketlevel

tothegroundandmoveforwardintothematerialto

belifted.Whenthebucketisfull,tiltitrearwardto

decreasetheliftingresistancewhenyoulifttheload.

Whentransportingaload,keepthebucketasclose

tothegroundaspossible.

BladeOperation

Withthejawscompletelyopen,youcanusetheback

ofthebucketasabladetopushmaterial.Y oucan

alsopartiallyclosethejawsandusingthebottomof

thefrontbuckettoknockthetopofclumpsandgrade

withtherearblade.

Whenscraping,levellingandsurfacestripping,lower

thebladetotheground,ensuringthatthecuttingedge

makescontact.Thebladewillbiteintothesoilasyou

moveforward.

g235997

Figure32

Correctoperation

Important:Donotusetheoortopickorpull

objects.Thiswillcausedamagetotheoor/

bucketandwillvoidthebucketwarranty(Figure

33).

LevellerOperation

Withthejawsfullyopenandthebuckettippedslightly

forwardsothatthebackcuttingedgeoftheoorison

theground,andthefrontedgeisofftheground.The

angleofthebackcuttingedgeyoucanusethebucket

asalevellerbymovingthecuttingedgebackacross

thesurfaceoftheground.

GrappleBucketOperation

Thesidejawscanalsobeusedforpickingupmaterial

byclosingthemoverobjectsormaterialstobe

transported(Figure32).

Note:T akecarewhenusingthismethodthatyou

don’tcrushanobjectthatyouarepickingupbetween

thesidejaws.

g235998

Figure33

Incorrectoperation

21

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every200hours

Beforestorage

MaintenanceProcedure

•Lubricatethebucket

•Ensurethatallfastenersaresecurelytightened.

•Inspectthehydraulicsystemforleaksandloosettings.

•Cleantheareasaroundthebucketcylinderandmountplatepivot.

•Checkforwearofpins,linkages,andcuttingedges.

•Greasethebucketpivotpoints.

•Ensurethattherelayandloader-endharnessandvalvemanifoldsolenoidharness

aresecure.

•Lubricatethebucket

•Inspectthehydraulicsystemforleaksandloosettings.

•Inspectthehydraulicsystemforleaksandloosettings.

LubricatingtheBucket

ServiceInterval:Beforeeachuseordaily

Every200hours

Usingagreasegun,pumpgeneralpurposegrease

intothesixgreasettingsonthe4-in-1bucketuntil

thegreasebeginstoooze(Figure34).Wipeaway

anyexcessgreasewithashopcloth.

Adjustingthe4-in-1Bucket Operation

Thespeedcontrolonthevalvemanifoldcanbeused

toadjusttheopeningandclosingspeedofthe4-in-1

bucketjaws.

1.Starttheengineandraisetheloaderarmsothat

the4-in-1bucketisclearoftheground.

1.Greasettings

2.Removethe4boltsandwasherssecuringthe

valvemanifoldcovertothe4-in-1bucketand

removethecover(Figure25).

3.Movetheauxiliaryhydraulicsleverfromthe

neutraltoforwardowdirectionacoupleof

timestorelieveanyhydraulicsystempressure

inthevalvemanifold.

Note:Ifthereishydraulicpressureactingin

thevalvemanifoldthecontrolknobcannotbe

moved.

4.Loosenthespeedcontrollockingnut(turning

itcounterclockwise)toallowtheadjustmentof

speedcontrolknob(Figure35).

g006224

Figure34

22

Figure35

Somepartsnotshownforclarity

1.Valvemanifold3.Speedcontrolknob

2.Speedcontrollockingnut

5.Adjustthespeedcontrolknob:

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Checkandtightenallbolts,nutsandscrews.

Repairorreplaceanypartthatisdamagedor

worn.

3.Ensurethatallthehydraulichosecouplersare

connectedtogethertopreventcontamination

enteringthehydraulicsystem.

4.Paintallscratchedorbaremetalsurfaces.

Note:PaintisavailablefromyourAuthorized

ServiceDealer.

g242385

5.Greasethepivotpoints;refertoLubricatingthe

Bucket(page22).

6.Storetheattachmentinaclean,drygarageor

storagearea.

7.Coverthebuckettoprotectitandkeepitclean.

•Toincreasetheopening/closingspeedofthe

bucket,turntheknobclockwise.

•Todecreasetheopening/closingspeedof

thebucket,turntheknobcounterclockwise.

6.Movetheauxiliaryhydraulicsleverfromthe

neutraltoforwarddirectionacoupleoftimes

torelieveanyhydraulicsystempressureinthe

valvemanifold.

7.Turnthespeedcontrollockingnutclockwiseto

securethesetting.

8.Installthevalvemanifoldcovertothe4-in-1

bucketandsecureitwiththe4boltsandwashers

removedinstep2.Tightentheboltssecurely.

Important:The4-in-1Bucketmustnot

beusedwithoutthevalvemanifoldcover

installedandsecuredinplace.Thewarranty

onthevalvemanifoldassemblywillbe

voidedifthecoverisnotinstalled,or

incorrectlyinstalled.

23

Troubleshooting

Problem

Bucketdoesnotopenorclose.

PossibleCauseCorrectiveAction

1.Electricalcircuitissue.1.Inspectthewireharnessandelectrical

2.Thefuse(s)areblown.2.Replaceanyblownfuses.

3.Thereareloosepowerorearth

connection(s).

4.Therearedisconnectedwire(s)at

systemterminal(s).

5.Thereareopenorshortcircuit(s)inthe

wire(s).

6.Thewireharnessrelay(s)arenot

functioningcorrectly.

7.Theloaderarm/attachmenttiltlever

contactsarenotfunctioningcorrectly .

8.Thevalvemanifoldsolenoid(s)are

notfunctioningcorrectly(Resistance

acrosssolenoidterminalsshouldbe

approximately6.5ohms).

9.Thehydrauliccoupler(s)arenot

completelyconnected.

10.Thereismoisturebetweenthevalve

solenoidcoilsandthevalvesolenoid

shaft.

11.Thevalvemanifoldand/oraninternal

valveisnotoperatingcorrectly.

12.Thereisanobstructioninahydraulic

hose.

13.Theauxiliaryvalveonthetractionunit

isnotoperatingcorrectly .

14.The4-in-1buckethydrauliccylinder(s)

arenotoperatingcorrectly.

connections.Refertothewiring

diagram.

3.Ensurethatallwireconnectionsare

correctlyconnectedandsecure.

4.Ensurethatallwireconnectionsare

correctlyconnectedandsecure.

5.Replaceanynon-operationalwire

harness(es).

6.Replaceanynon-operationalrelay(s).

7.Repairorreplacetheloader

arm/attachmenttiltlever.

8.Replaceanynon-operationalvalve

manifoldsolenoids.

9.Ensurethatthecouplersarecorrectly

connectedandsecured.

10.Removethenutsecuringthevalve

solenoidcoilstothesolenoidshaft.

Pullthecoilsfromtheshaftandclean

them;ensurethatthereisnomoisture

betweenthecomponents.Install

thecomponentsandtightenthenut

securely.

11.Repairorreplacethenon-operational

component.

12.Findandremovetheobstruction.

13.Repairorreplacethevalve.

14.Repairorreplaceanynon-operational

hydrauliccylinder(s).

24

Schematics

(Rev.A)

g239505

25

Notes:

Notes:

TheToroWarranty

4in1bucket

Conditions

TheT oro®Companyanditsafliate,T oroWarrantyCompany ,pursuanttoanagreementbetweenthem,jointlywarrantyourT oroProduct(“Product”)

tobefreefromdefectsinmaterialsorworkmanship.

ThewarrantyappliesfromthedateoftheProductisdeliveredtotheoriginalretailpurchaser:

Whereawarrantableconditionexists,wewillrepairtheProductatnocosttoyouincludingdiagnosis,labourandparts.

ProductsWarrantyPeriod

Bucket12months

Wireharnessandvalvemanifold

6months

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsorworkmanship,followthisprocedure:

1.ContactanyAuthorisedT oroServiceDealertoarrangeserviceattheirdealership.T olocateaConstructiondealerconvenienttoyou,accessour

websiteatwww.T oro.com.au.

2.Bringtheproductandyourproofofpurchase(salesreceipt)andanexplanationofthefaulttotheServiceDealer .Allcostsassociatedwiththe

returnoftheproductarethepurchaser’sresponsibility.

3.If,foranyreason,youaredissatisedwiththeServiceDealer’sanalysisorwiththeassistanceprovided,contactusat:

CustomerServiceDepartment

ToroAustraliaPtyLtd

Unit1,13DownardStreet

Braeside,Victoria3195

Ph:(03)95807355

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenanceproceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Partsscheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),are

warrantedfortheperiodoftimeuptothescheduledreplacementtimeforthatpart.Failuretoperformrequiredmaintenanceandadjustmentscanbe

groundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiodaredefectsinmaterialsorworkmanship.Thisexpresswarrantydoes

notcoverthefollowing:

•Productfailureswhichresultintheuseofnon-Tororeplacementparts,orfrominstallationanduseofadd-on,modied,orunapprovedaccessories

•Productfailureswhichresultfromfailuretoperformrequiredmaintenanceand/oradjustments

•Productfailureswhichresultfromoperatingtheproductinanabusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.Examplesofpartswhichareconsumed,orusedup,duringnormalProduct

operationinclude,butarenotlimitedto,diggingteeth,tines,sparkplugs(petrolmodels),tracks,lters,chains,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutsideinuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butisnotlimitedto,wornpaintedsurfaces,scratcheddecalsorwindows,etc.

•Anycomponentcoveredbyaseparatedmanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry .Therightstowhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythewarrantyandthebenetsprovidedunderthiswarrantyareinadditiontoanyrightsandremediesunderanyapplicablelaws..

AllrepairscoveredbythesewarrantiesmustbeperformedbyanAuthorizedT oroServiceDealerusingT oroapprovedreplacementparts.Repairbyan

AuthorizedT oroServiceDealerisyoursoleremedyunderthiswarranty.

Totheextentpermittedbylaw,neitherTheT oroCompanynorToroWarrantyCompanyisliableforindirect,incidental,orconsequential

damagesinconnectionwiththeuseoftheToroProductscoveredbythesewarranties,includinganycostorexpenseofprovidingsubstitute

equipmentorserviceduringreasonableperiodsofmalfunctionornon-usependingcompletionofrepairsunderthesewarranties.

AustralianConsumerLaw:

Australiancustomerswhoareconsidered”consumers”forthepurposesoftheAustralianConsumerLaw:Ourgoodscomewithguaranteesthat

cannotbeexcludedundertheAustralianConsumerLaw.Y ouareentitledtoareplacementorrefundforamajorfailureandcompensationforany

otherreasonablyforeseeablelossordamage.Y ouarealsoentitledtohavethegoodsrepairedorreplacedifthegoodsfailtobeofacceptable

qualityandthefailuredoesnotamounttoamajorfailure.

374-0327RevA

Loading...

Loading...