Page 1

FORM NO. 3321–112

Z – Master

Collection System

for

OUT FRONT Z – 48” MOWER

Model No. 79434– 890001 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Page 2

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

plate located in a unique place on the product as

shown below.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

1

1. Model and Serial Number Plate

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

Printed in USA

The Toro Company – 1997

Page 3

Contents

Safety and Instruction Decals 2. . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 3. . . . . . . . . . . . . . . . . . . . . . . . .

Mower Preparation 5. . . . . . . . . . . . . . . . . . .

Install Blower 6. . . . . . . . . . . . . . . . . . . . . . .

Install Hopper 9. . . . . . . . . . . . . . . . . . . . . . .

Install Wire Harness 10. . . . . . . . . . . . . . . . . .

Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Power Take Off (PTO) 12. . . .

Dumping the Hopper 13. . . . . . . . . . . . . . . . .

Tilting the Mower 13. . . . . . . . . . . . . . . . . . .

Page

Page

Recycler Operation 15. . . . . . . . . . . . . . . . .

Bagging Tips 16. . . . . . . . . . . . . . . . . . . . . . .

Maintenance 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 17. . . . . . . . . . . . . . . .

Cleaning Hopper Screens 17. . . . . . . . . . . . . .

Replacing the Blower Belt 18. . . . . . . . . . . . .

Cleaning the Hopper Full Sensor 18. . . . . . . .

Greasing and Lubrication 19. . . . . . . . . . . . . .

Storage 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 20. . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 4

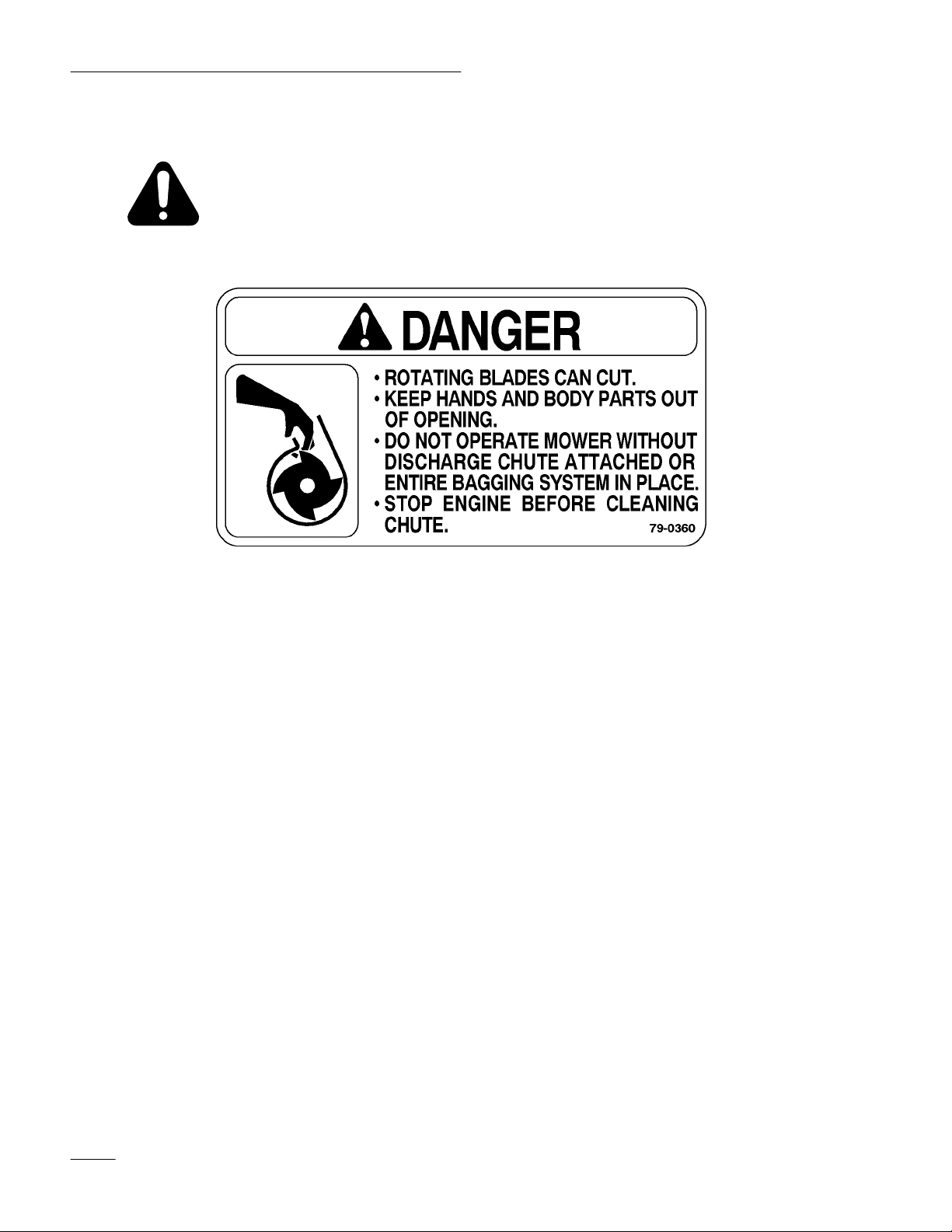

Safety

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

2

Page 5

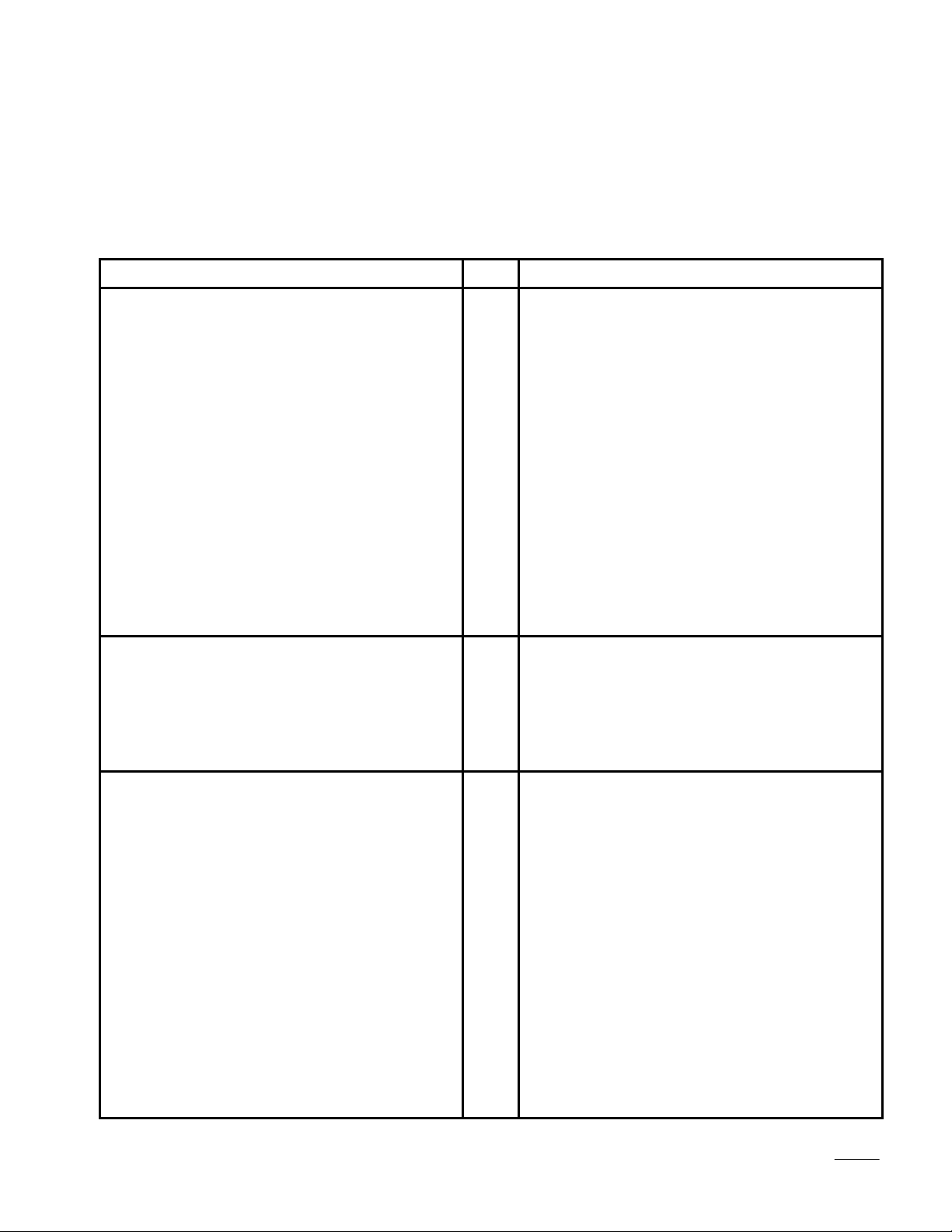

Installation

Loose Parts

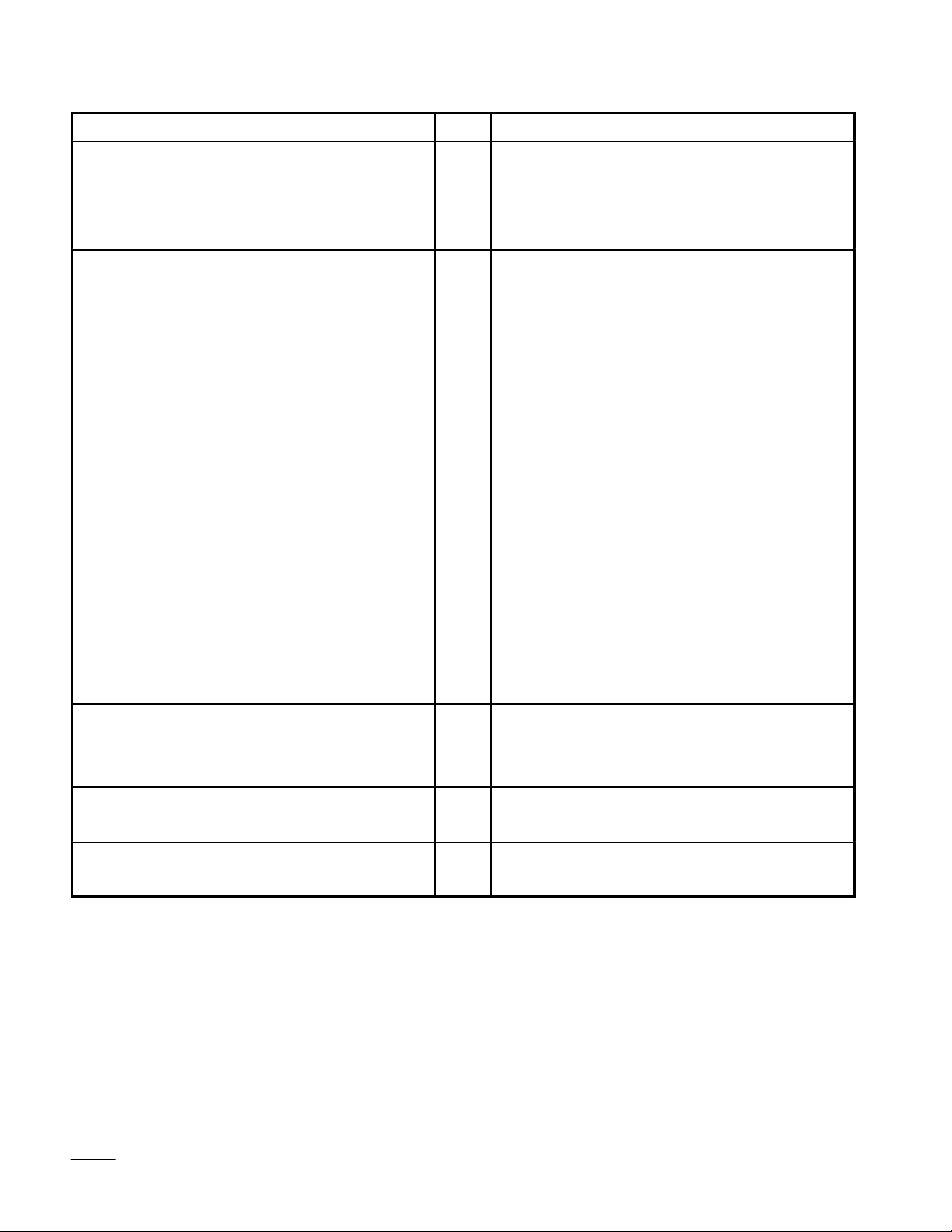

Note: Use the chart below to identify parts used for assembly when unit is to be installed on traction unit.

DESCRIPTION QTY. USE

Bagger baffle–left

Bagger baffle–right

Discharge baffle–left

Discharge baffle–right

Carriage bolt 5/16”–18 x 3/4” (19 mm)

Locknut 5/16”–18

Chute latch

Screw 10–24 x 1/2” (13 mm)

Locknut 10–24

Clevis pin

Hairpin cotter

Spring

Spring bracket

PTO Pulley

Key

Square head set-screw 5/16–18 x 1/2” (13 mm)

Blower belt

1

1

1

1

10

10

1

2

2

1

1

1

1

1

1

2

1

Install baffles and latch to mower

Install PTO drive pulley to PTO gearbox

Thread lock

Blower assembly

Bolt 3/8–16 x 1” (26 mm)

Bolt 3/8–16 x 2-3/4” (70 mm)

Idler assembly

Spacer

Washer 3/8” x 7/8” (9 x 22 mm)

Flange locknut 3/8–16

Spring

Bolt 5/16–18 x 1-1/4” (32 mm)

Nut 5/16–18

Flange locknut 5/16–18

Interlock switch bracket assembly

Bolt 3/8–16 x 3/4” (19 mm)

1

1

1

1

1

1

1

2

1

1

1

1

1

1

Install blower, idler and switch assemblies to

traction unit

3

Page 6

Installation

DESCRIPTION USEQTY.

Blower

Blower outlet chute

Bolt 5/16–18 x 5” (127 mm)

Flange locknut 5/16–18

Bumper

Tilt brackets

Bolt 3/8–16 x 1” (26 mm)

Flange locknut 3/8–16

Bolt 1/2–13 x 2-3/4” (70 mm)

Bolt 1/2–13 x 1-1/4” (32 mm)

Locknut 1/2–13

Gas spring

Safety clip

Ball stud

Locknut 5/16–18

Draw latch

Washer 1/2” (13 mm)

1

1

2

2

1

2

4

4

2

2

5

1

2

2

2

1

1

Assemble blower and outlet chute

Install bumper and gas spring to traction unit

Bolt 1/2–13 x 1” (26 mm)

Hopper assembly

Clevis pin 3/8 x 1” (26 mm)

Hairpin cotter–small

Wire harness

Cable ties

Buzzer

Clevis pin 3/8 x 1” (26 mm)

Hairpin cotter–small

Operator’s Manual

Parts Catalog

1

1

2

2

1

4

1

1

1

1

1

Install wire harness and buzzer

Lockout for blower belt when Recycler is

installed

Read before operating

Ordering parts

4

Page 7

Installation

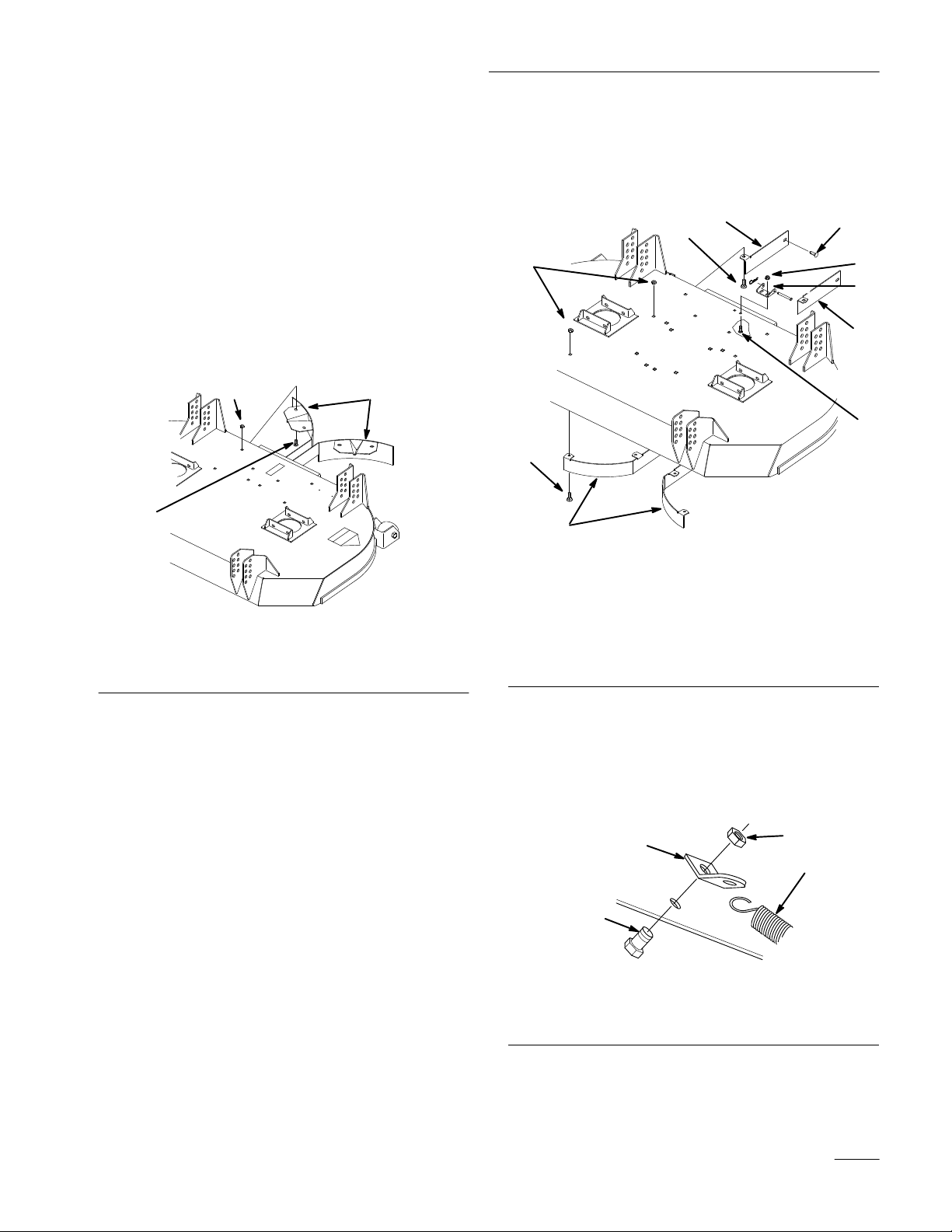

Mower Preparation

Remove Recycler Baffles

1. Tilt mower into the vertical position, refer to;

Tilting the Mower, page 13.

2. Remove locknuts, carriage bolts and the

Recycler

Note: Save all hardware for use when

2

1. Recycler baffle

2. Carriage bolt

baffles from the mower (Fig. 1).

installing Recycler

3

baffles.

1

Figure 1

3. Locknut

m-3562

4. Locate the latch on top of the mower and secure

with (2) 10–24 x 1/2” (13 mm) screws, through

from the bottom of mower, and (2) 10–24

locknut (Fig. 2).

2

3

1

1. Bagger baffle

2. Locknut 3/8”

3. Carriage bolt

5/16–18 x 3/4” (19 mm)

4. Discharge baffle

3

Figure 2

4

5. Latch

6. Screw 10–24 x 1/2”

(13 mm)

7. Locknut 10–24

2

m-3544

7

5

4

6

Install Bagger and Discharge Baffles,

Chute Latch and Spring

1. Locate the left and right bagger baffles inside the

mower and secure with (6) 5/16–18 x 3/4”

(19 mm) carriage bolts, through from the bottom

of mower, and (6) 5/16” locknuts (Fig. 2).

2. Locate the left and right discharge baffles inside

the mower and secure with (4) 5/16–18 x 3/4”

(19 mm) carriage bolts, through from the bottom

and inside of mower, and (4) 5/16”

locknut.(Fig. 2).

3. Mount latch on chute and hold against rear of

mower. If holes are not drilled, mark, center

punch and drill two 17/64” (7mm) holes in

mower for latch.

5. Attach spring bracket below traction unit control

plate with existing rear center bolt, down from

the top, and locknut (Fig. 3). Hook chute spring

into bracket

3

4

m-3563

2

1. Spring bracket

2. Existing bolt

1

Figure 3

3. Existing locknut

4. Spring

5

Page 8

Installation

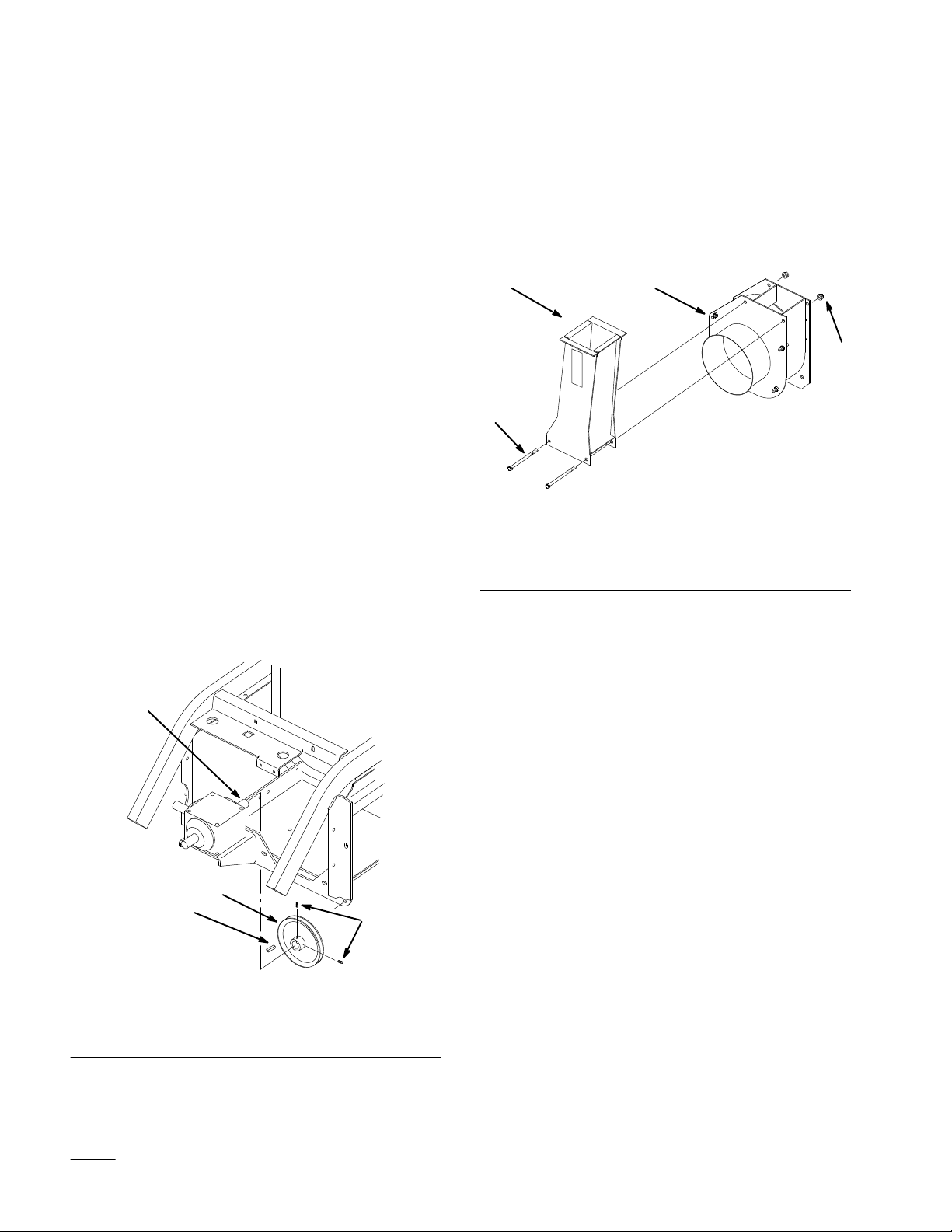

Install Blower

For ease in performing the following steps, block the

right drive wheel, raise the rear of the traction unit,

minimum 16” (406 mm) under rear of engine carrier

frame, and block with jack stands, and remove the

left drive wheel.

Install PTO (Power Take Off) Pulley

Note: On 25 hp models only, remove the oil

filter for clearance.

1. Apply thread lock to (2) pulley setscrews

(Fig. 4).

Note: Before installing drive pulley, bend

R–clamp holding fuel line on engine

up, to provide pulley clearance.

2. Slide key and pulley, with setscrews toward

gearbox, onto PTO gearbox rear output shaft

(Fig. 4). Do not tighten (2) setscrews at this

time.

Assemble Blower

4. Place impeller chute above blower opening with

flanges outside blower housing. Secure to

blower with (2) 5/16–18 x 5” (127 mm) bolts

and 5/16–18 flange locknuts (not shown)

(Fig. 5).

1

3

1. Chute

2. Blower housing

2

m–3540

Figure 5

3. Bolt 5/16–18 x 5”

(127 mm)

4. Flange locknut 5/16–18

4

3. Place blower drive belt around PTO pulley.

3

1

1. Pulley

2. Key

2

Figure 4

3. Gearbox rear shaft

4. Setscrew

4

m-3538

6

Page 9

Installation

Mount Blower and Idler Assemblies

Note: It may be convenient to loosen, not

remove, parking brake switch and

hydraulic oil filter brackets to ease

installation.

5. Slide blower\chute assembly up from bottom of

the machine and place against traction unit frame

(Fig. 6).

6. Place blower drive belt around PTO and blower

pulleys before bolting blower assembly to

traction unit frame (Fig. 7).

7. Install 3/8–16 x 1” (25 mm) carriage bolt in

lower right hole of rear blower flange. Secure

with a 3/8–16 flange locknut (Fig. 6).

8. Install 3/8–16 x 2-3/4” (70 mm) bolt through

lower left hole of blower rear flange (Fig. 6).

9. Slide spacer, idler assembly and 3/8” (9.5 mm)

washer onto bolt and secure with 3/8–16 flange

locknut (Fig. 6).

10. Thread 5/16–18 nut onto 5/16–18 x 1-1/4”

(32 mm) spring mount bolt and place into lower

frame hole. Secure with 5/16–18 locknut

(Fig. 6).

1

13

3

1. Blower assembly

2. Carriage bolt 3/8–16 x 1”

(25 mm)

3. Flange locknut 3/8–16

4. Bolt 3/8–16 x 2-3/4”

(70 mm)

5. Spacer

6. Idler assembly

4

2

Figure 6

12

3

7

6

5

11

10

7. Washer3/8” (9.5 mm)

8. Bolt 5/16–18 x 1-1/4”

(32 mm)

9. Nut 5/16–18

10. Locknut 5/16–18

11. Spring

12. Switch assembly

13. Bolt 3/8–16 x 3/4” (19 mm)

9

m-3539

3

8

11. Hook spring over bolt and stretch to hook on

arm of idler assembly (Fig. 6).

12. Hold switch bracket assembly to back side of

frame cross member. Insert 3/8–16 x 3/4”

(19 mm) bolt, from inside impeller chute,

through chute, frame and switch bracket. Secure

with 3/8–16 locknut (Fig. 6).

13. Tighten all mounting hardware securely.

7

Page 10

Installation

14. Using blower belt as a guide slide the PTO

pulley, in or out on gearbox shaft, to align with

blower pulley.

15. Torque setscrews to 15–18 ft.-lbs. (20–24 N

16. Pull down on idler assembly, place belt above

idler pulley and release tension Use a straight

edge to check for belt alignment.

3

2

1. PTO pulley

2. Blower pulley

Figure 7

3. Belt

4. Setscrew

4

m-3550

m)

Install Chute

19. Raise mower and slide chute into blower inlet

(Fig. 9).

20. Lower mower and slide chute forward against

rear of mower. Secure chute to rear of mower

latch with clevis and hairpin cotter pin (Fig. 9).

1

2

1. Chute

2. Hairpin cotter

1

4

3

m-3564

Figure 9

3. clevis pin

4. Blower inlet

17. Push up and hold the spring loaded idler arm,

behind blower, to relax pressure on blower belt

(Fig. 8).

18. If holes do not align, mark the idler arm hole

location onto the frame member. Center punch

and drill a 13/32” (11 mm) hole for the clevis pin

(Fig. 8).

1

2

Figure 8

1. Idler arm

2. Frame

3

m–3807

3. Mark and drill hole 13/32”

(11 mm)

8

Page 11

Installation

Install Hopper

1. Place hopper tilt brackets inside bumper with

tube weld away from the opening. Secure to

bumper with (4) 3/8–16 x 1” (26 mm) bolts and

(4) 3/8–16 flange locknuts (Fig. 10).

1

4

5

Figure 10

1. Bumper

2. Tilt bracket weld

3. Bolt 3/8–16 x 1” (26 mm)

4. Flange locknut 3/8–16

5. Adjustment slot

2. Position bumper around top rear of frame and

secure in the center with (2) 1/2–13 x 1-1/4”

(32 mm) bolts and 1/2–13 locknuts (Fig. 11).

Secure to outer holes with (2) 1/2–13 x 2-3/4”

(57 mm) bolts and 1/2–13 locknuts.

3. Install ball stud to hopper frame and traction unit

frame tab with 5/16–18 locknut (Fig. 11).

2

3

m–3803

4. Secure hopper latch to the frame with 1/2”–13 x

1” (25 mm) bolts and 1/2”–13 locknut (Fig. 12).

1

4

1. Hopper latch

2. Bolt 1/2”–13 x 1” (25 MM)

3. Washer 1/2” (13 mm)

Figure 12

4. Locknut 1/2”–13

5. Front of unit

2

5

3

m-3554

5. Place hopper assembly onto frame and align

with holes in bumper mounts. Insert (2) clevis

pins and secure with hairpin cotters (Fig. 13).

6. Adjust tilt brackets in slots (Fig. 10) so chute

opening and hopper opening align at the front.

7. Snap gas spring rod ends over ball stud at frame

and hopper. Secure with safety clips (Fig. 11).

Note: Rod end of gas spring must face the

rear and attach to the traction unit

frame.

6

1. Bumper

2. Bolt 1/2–13 x 1-1/4”

(32 mm)

3. Bolt 1/2–13 x 2-3/4”

(57 mm)

8

Figure 11

3

5

7

4. Locknut 1/2–13

5. Ball stud

6. Locknut 5/16–18

7. Gas spring

8. Safety clip

2

6

m-3513

2

1

1

3

m-3565

Figure 13

1. Hopper frame assembly

2. Clevis pin

3. Hairpin cotter

9

Page 12

Installation

Install Wire Harness

8. Unplug clutch connector from existing main

wire harness (Fig. 14). Located below and

behind muffler.

9. Insert new jumper connectors of new wire

harness between clutch connector and main wire

harness. Align connectors and push together

firmly so latches lock (Fig. 14).

1

2

4

3 m-3566

3

11. Route new wire harness along left horizontal

frame member and secure to existing wire

harness with wire ties to keep harness away from

engine.

12. Loosen left console clamp and two lower front

mounting bolts. Pull console away from left

frame member to gain access to holes in frame

and console. Route new wire harness through

holes in frame and into bottom of console

(Fig. 16).

13. Remove instrument panel and remove plug in

opening or drill a 1-1/8” (29 mm) hole for

buzzer 1-1/2” (39 mm) below hour meter.

14. Insert buzzer, from the rear, and secure with

retaining ring (Fig. 16).

15. Connect new wire harness pink lead to +

terminal and green lead to – terminal (Fig. 16).

16. Coil excess wire harness behind panel

Figure 14

1. Clutch connector

2. Main wire connector

3. New jumper connector

4. Latch

10. Route remainder of new wire harness around

back of engine to the left vertical frame member,

following main wire harness. Attach wire ties to

keep harness out of castor wheel (Fig. 15).

1

2

m-3567

1. New wire harness

2. Existing wire harness

3

Figure 15

3. Castor wheel

7

6

5

3

1

2

Figure 16

1. Console clamp

2. Front bolt

3. Hole in console

4. 1-1/8” (29 mm) Hole 1-1/2”

(39 mm) below hourmeter

8

4

9

m-3568

5. Buzzer

6. Retaining ring

7. Pink +

8. Green –

9. Wire harness

10

Page 13

Installation

2

17. Route hopper full sensor wire harness below

bumper and frame. Connect hopper full sensor

wire harness terminals to (3) round terminal of

main wire harness (Fig. 17).

IMPORTANT: Color codes may not match at

all (3) terminals and must be as follows or

diode will be damaged.

Green – Green or Grey (on some models)

Pink – Pink

Black – Black

18. Push terminals together firmly so latches lock

(Fig. 17).

19. Install wire tie around bumper to hold sensor

wire harness (Fig. 17).

3

1

4

2

20. Remove jumper wire from main wire harness

terminal and install interlock switch connector.

Align connector tab and push together firmly so

latch locks (Fig. 18).

Note: After assembly, adjustment of

magnetic switch may be required.

Bend mounting bracket, as required, to

place switch close to magnet on

bottom of hopper.

5

4

1. Jumper wire connector

2. Main wire harness

terminal

3

Figure 18

3. Switch connector

4. Tab and latch

5. Bend bracket

m-3553

1

1. Sensor wire harness

2. Round terminals

m-3570

Figure 17

3. Latch

4. Wire tie

11

Page 14

Operation

Operating the Power Take Off

(PTO)

The power take off (PTO) switch engages and

disengages power to the electric clutch.

Engaging the PTO

1. Release pressure on the traction control levers

and place in neutral (Fig. 19).

2. Release the parking brake (Fig. 19).

1

2

3

3. To engage lift cover and move the PTO switch to

the “ON” position (Fig. 20).

Disengaging the PTO

1. Closing the cover moves the PTO switch to the

“OFF”position (Fig. 20).

2

1

m-2721

Figure 20

1. PTO-Off 2. PTO-On

1. Traction control lever

2. Parking brake

m-3180

Figure 19

3. PTO-Switch

12

Page 15

Operation

Dumping the Hopper

The hopper is equipped with a hopper full sensor that

checks for a full condition. When the alarm buzzer

sounds the hopper needs to be emptied.

1. Locate the traction unit so the hopper door is

where you want to dump the clippings.

2. Move the power take off (PTO) switch to off,

move the traction controls to neutral and set the

parking brake.

IMPORTANT: The hopper is interlocked

with the engine ignition and the engine will

stop if these steps are not followed before

dumping the hopper or getting out of the seat.

3. Unhook the door latches on the rear sides and

the hopper latch on the front left side of the

hopper (Fig. 21).

4. Open the door and lift up on the hopper at the

lower front and dump the clippings (Fig. 21).

Tilting the Mower

The mower can be tilted up for ease of service or to

shorten unit length for transport and storage.

To Raise Mower

1. Turn engine off, set the parking brake and check

that PTO cover is down against footrest

(Fig. 23).

2. Remove the hairpin cotter and clevis pin from

the latch, at the rear of the mower. Slide the

chute rearward into blower inlet (Fig. 22).

Spring holds chute in place.

3

1

2

2

1. Door latch

2. Hopper latch

3

Figure 21

3. Lift here

m-3571

5. Lower the hopper and secure the door latches on

the rear sides and the hopper latch on the front

left side of the hopper (Fig. 21).

IMPORTANT: Front left latch must be

secured to prevent hopper from accidently

tilting during transport.

m-3564

1

1. Hairpin cotter

2. Clevis pin

Figure 22

3. Chute

13

Page 16

Operation

3. Lift on side of the mower to release weight on

latch pin and pull out on latch pin to release

(Fig. 23). Lower rear of mower onto anti-scalp

rollers. Repeat on the other side.

4

1

3

m-3374

1. Parking brake

2. PTO cover

2

Figure 23

3. Latch pin

4. Notch–open

To Lower Mower

1. Pull out latch pins and rotate into notch, holding

in the open position (Fig. 23). Standing in front

of the mower, pull forward on the front and

lower mower (Fig. 24).

2. Rotate latch pins into released position and lift

up on side of the mower until latch pin engages

(Fig. 23). Repeat on the other side.

3. With rear of chute inside blower housing slide

forward against rear of the mower and secure

with clevis pin and hairpin cotter (Fig. 22).

4. Standing in front of the mower, lift up and push

rearward on front to raise mower (Fig. 24). Raise

mower until it contacts stops and latch pins snap

into locked position.

1

m–3375

Figure 24

1. Mower up

14

Page 17

Operation

Recycler Operation

When operating the mower with Recycler baffles

installed you must disengage the blower drive belt.

1. Stop the engine, remove the key and disconnect

the spark plug wire(s) from the spark plug(s).

2. Remove hairpin cotter and clevis pin from outer

hole in idler arm (Fig. 25).

3. Push up on the spring loaded idler arm, behind

PTO (power take off) gearbox, to relax pressure

on blower belt (Fig. 25).

4. Align inner hole in idler arm with slot in frame

and insert clevis pin. Secure with hairpin cotter

to hold in position.

2

4

3

5. Remove the bagger and discharge baffles from

the mower and install the Recycler baffles

(Fig. 26).

1

m-3562

Figure 26

1. Recycler baffle

1. Idler arm

2. Frame slot

1

m-3548

Figure 25

3. Clevis pin

4. Hairpin cotter

15

Page 18

Operation

Bagging Tips

For best performance, regulate traction speed to keep

engine rpm high and somewhat constant. A good rule

to follow is: decrease ground speed as the load on the

cutting blade increases; and increase ground speed as

load on the blade decreases. This allows the engine,

working with the transmission, to sense the proper

ground speed while maintaining high blade tip speed,

necessary for good quality-of-cut, vacuuming action

and to throw grass into the hopper. If blower speed

drops too low, plugging may result. Refer to Cutting

Unit and Traction Unit Operator’s Manual for

operation of each.

1. Stop engine when emptying hopper to prevent

engine air intake from being clogged with

clippings.

2. Do not collect extremely long grass as the bag

will fill too quickly.

3. The grass collector hopper is designed to exhaust

air through the rear cover. This allows the hopper

to fill completely. Grass will fall through the

chute when the hopper is full. When the hopper

full buzzer sounds immediately disengage the

power take off (PTO) and empty the hopper.

Failure to empty the hopper will plug the chute

and cause clumping on the lawn. After emptying

hopper, check that grass clippings have not fallen

into chute.

4. When bagging wet, heavy grass, some clippings

may not be thrown completely through the

chute. When this happens, reduce ground speed.

5. While operating, check frequently for excessive

clippings left on turf or uncut grass. If those

conditions occur, the blower or cutting unit may

be plugged. Stop unit, disengage PTO, set

parking brake and shut of ignition. Check for

obstructions in the chute, blower or cutting unit.

Clear any obstructions using a stick or similar

tool. Check that screen in hopper is clear of

obstructions. Check blower belt for slipping.

6. Cut grass often, especially when growth is rapid.

If shorter grass is desired, cut the grass again.

Overlap swaths to produce an even cutting

pattern.

16

Page 19

Maintenance

Service Interval Chart

Each

Service Operation

Belts – check for wear/cracks X

Hopper – clean X X

Screens – clean (as required) X

Chipped Surfaces – paint X

Cleaning Hopper Screens

For best clipping collection, maximum air flow

through the hopper is required. To provide maximum

air flow, the hopper screens must be kept clean.

1. To clean the hopper screens dump the hopper to

remove grass clippings.

2. With the door open, remove the knobs at the

upper front of the hopper and slide the screens

out the rear of the hopper (Fig. 27).

Use50Hours

3. Clean the screen by brushing off with your hand,

4. Replace the screens and secure with knobs

Storage

Service

blowing with compressed air or spraying with a

stream of water.

(Fig. 27). Close and latch the hopper door.

1

Notes

2

Figure 27

1. Knob 2. Screen

m–3546

17

Page 20

Maintenance

Replacing the Blower Belt

Squealing when the belt is rotating, blower slipping

causing frequent clogging of chute and blower, frayed

belt edges, burn marks and cracks are all signs of a

worn blower belt. Replace the blower belt if any of

these conditions are evident.

1. Stop the engine, remove the key and disconnect

the spark plug wire(s) from the spark plug(s).

2. Push up on the spring loaded idler pulley behind

PTO (power take off) gearbox to relax pressure

on blower belt (Fig. 28). Lock into frame slot,

refer to (Fig. 25).

3. Remove worn blower belt.

Note: On 25hp traction units: loosen, but do

not remove, blower mounting bolts for

clearance between engine oil cooler

and blower shaft bolt so belt clears.

4. Install new blower belt around PTO gearbox and

blower pulleys. Then push up on the idler and

place belt above idler pulley (Fig. 28).

5. Check that belt aligns with PTO, blower and

idler pulleys (Fig. 28).

Cleaning the Hopper Full

Sensor

The hopper full sensor, inside the top right side of the

hopper, detects a beam of light from the transmitter to

the receiver. If the light beam is blocked the sensor

buzzer sounds. If the lenses are covered with

clippings or debris it may give false hopper full

signals and needs to be cleaned.

1. To clean the hopper full sensor dump the hopper

to remove grass clippings.

2. With the door open, wipe off the lenses of both

the transmitter and receiver with a soft cloth or

paper towel (Fig. 29).

3. To test the hopper full sensor for proper

operation turn the ignition key and PTO switch

to “ON”, but do not start the engine. Place a

piece of heavy cardboard in front of the

transmitter to block the light beam (Fig. 29). The

alarm buzzer should sound.

Note: Do not use your hand to test for proper

sensor operation as the light beam may

pass through or around your hand and

not properly activate the sensor.

1

3

1. Blower belt

2. PTO Gearbox pulley

Figure 28

3. Blower pulley

4. Idler pulley

4

m-3550

2

1

Figure 29

1. Transmitter 2. Receiver

2

m-3549

18

Page 21

Maintenance

Greasing and Lubrication

All bearings of the blower drive system are

permanently lubricated and do not need to be greased.

Storage

1. Clean any dirt and chaff from the chute, blower

and hopper.

2. Scrape any heavy buildup of grass and dirt from

the chute, blower and hopper, then wash with a

garden hose.

3. Check the condition of the blower belt.

4. Check and tighten all bolts, nuts and screws.

Repair or replace any part that is damaged or

defective.

5. Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service

Dealer.

6. Store the machine in a clean, dry garage or

storage area. Cover the machine to protect it and

keep it clean.

19

Page 22

Troubleshooting

PTO

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTION

Blower does not rotate. 1. PTO drive disengaged.

2. PTO drive belt is broken.

3. Blower drive belt is off pulley. 3. Install blower drive belt and

4. Blower drive belt is broken. 4. Install new blower drive belt.

Abnormal vibration.

Clippings not being collected.

1. Blower is plugged with

clippings.

2. Loose gearbox pulley, idler

pulley, or blade pulley.

3. Gearbox pulley is damaged. 3. Replace gearbox pulley.

1. Chute plugged. 1. Stop and clean out chute.

2. Blower plugged. 2. Stop and clean out blower .

3. Hopper screens covered. 3. Stop and clean off screens.

4. Underside of mower is dirty. 4. Clean the underside of the

1. Remove pin and engage

.

2. Install new PTO drive belt.

check the idler pulley, idler

arm and spring for correct

position and function.

1. Stop and clean out blower

and chute.

2. Tighten the appropriate

pulley.

mower.

20

Page 23

Page 24

Loading...

Loading...