Page 1

FORM NO. 3322–850

5xi

Wheel

Horse

36” Tiller

for

Lawn and Garden T

Model No. 79375 – 8900001 & Up

ractors

Operator’s Manual

IMPORTANT: Read this manual, and your tractor manual, carefully. They

contain information about your safety and the safety of others. Also

become familiar with the controls and their proper use before you operate

the product.

Page 2

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

plate located in a unique place on the product as

shown below

.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

1

1. Model

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

and Serial Number Plate

m–3497

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

Printed in USA

Page 3

Contents

Page

Safety and Instruction Decals 2.

Installation 3

Loose Parts 3

Assembling the Tiller 4

Tractor Set-Up 5

Installing the Tiller to the Tractor 8

Removing the Tiller 12

Operation 14

Attachment Power Lift 14

Lowering Attachments 15

Tips for Tilling 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Page

Maintenance 16

Service Interval Chart 16

Greasing and Lubrication 17

Checking Tiller Drive Belt Tension 17

Replacing the Tiller Drive Belt 17

Checking PTO Drive Belt Tension 18

Storage 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . .

. . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 4

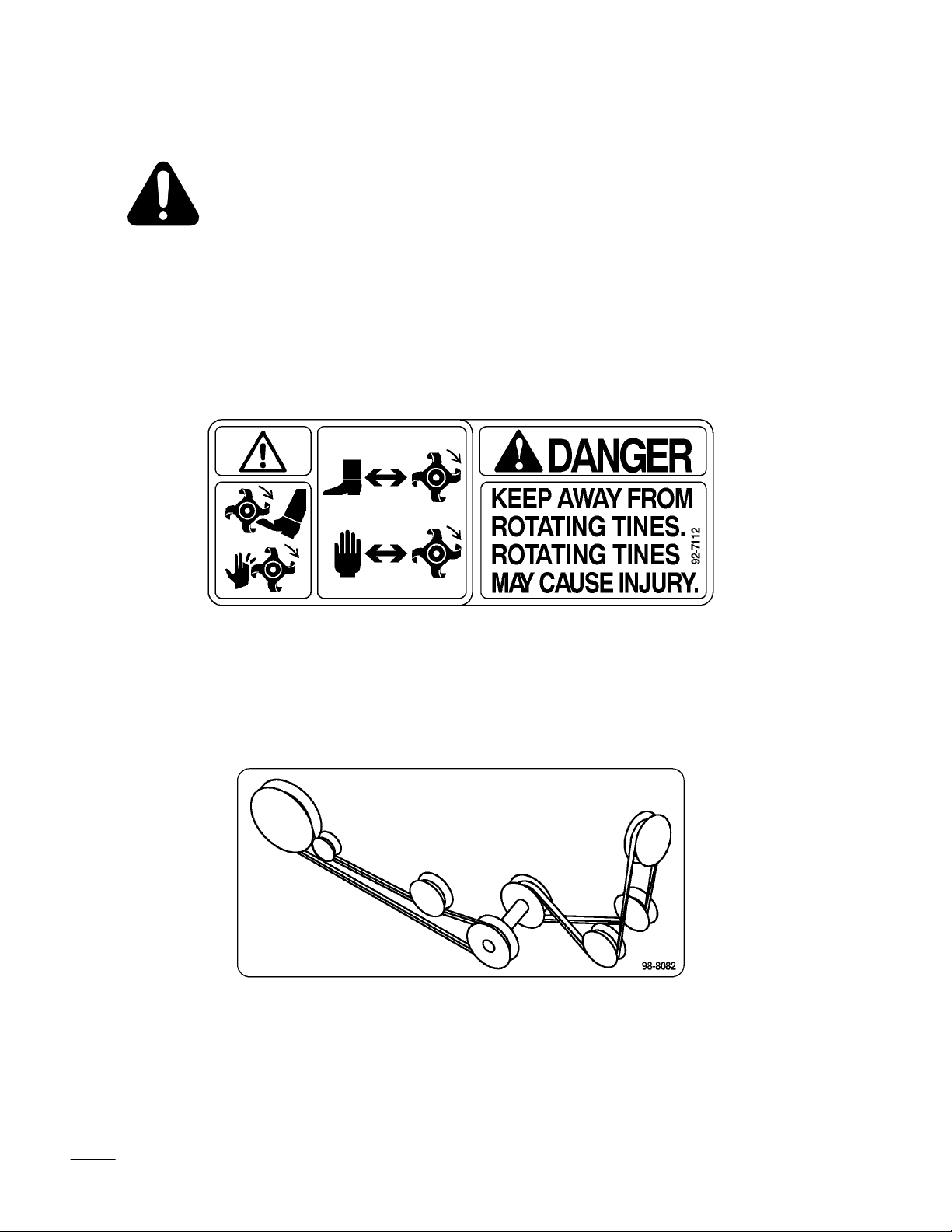

Safety

Safety

and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON TINE SHIELD

LEFT and RIGHT SIDE

(Part No. 92–71

12)

ON PULLEY BOX

(Part No. 98–8082)

2

Page 5

Installation

Loose

Parts

Note: A rear–mount Attach–A–Matic, which must be purchased separately, is required for this tiller. Use

the chart below to identify other parts used for assembly.

DESCRIPTION QTY. USE

T

iller housing

T

iller lift frame

Panel guard

Cotter pin 1/8” x 1” (25 mm)

Pulley

Square key

Set screw

Belt guard

T

iller belt (short belt)

Idler pulley

Bolt, 3/8–16 x 2” (51 mm)

Nut, 3/8”

T

iller pulley box

PT

O drive belt (long belt)

1

1

1

3

1

1

2

1

1

1

1

1

1

1

Assemble the tiller

Assemble tiller pulley

Installing the belt guard

Install pulley box

Clevis pin 3/8” x 1” (25 mm)

Hairpin cotter

Cable guide

Jack shaft assembly

Lift cable

Trunnion

Clevis pin 5/16” x 1” (25 mm)

Locknut

Hairpin cotter

Washer

Operator manual

2

2

1

1

1

1

1

1

2

1

1

Prepare tractor attachment lift

Install the cable guide

Connect drive belts

Install tiller to tractor

Read before operating

3

Page 6

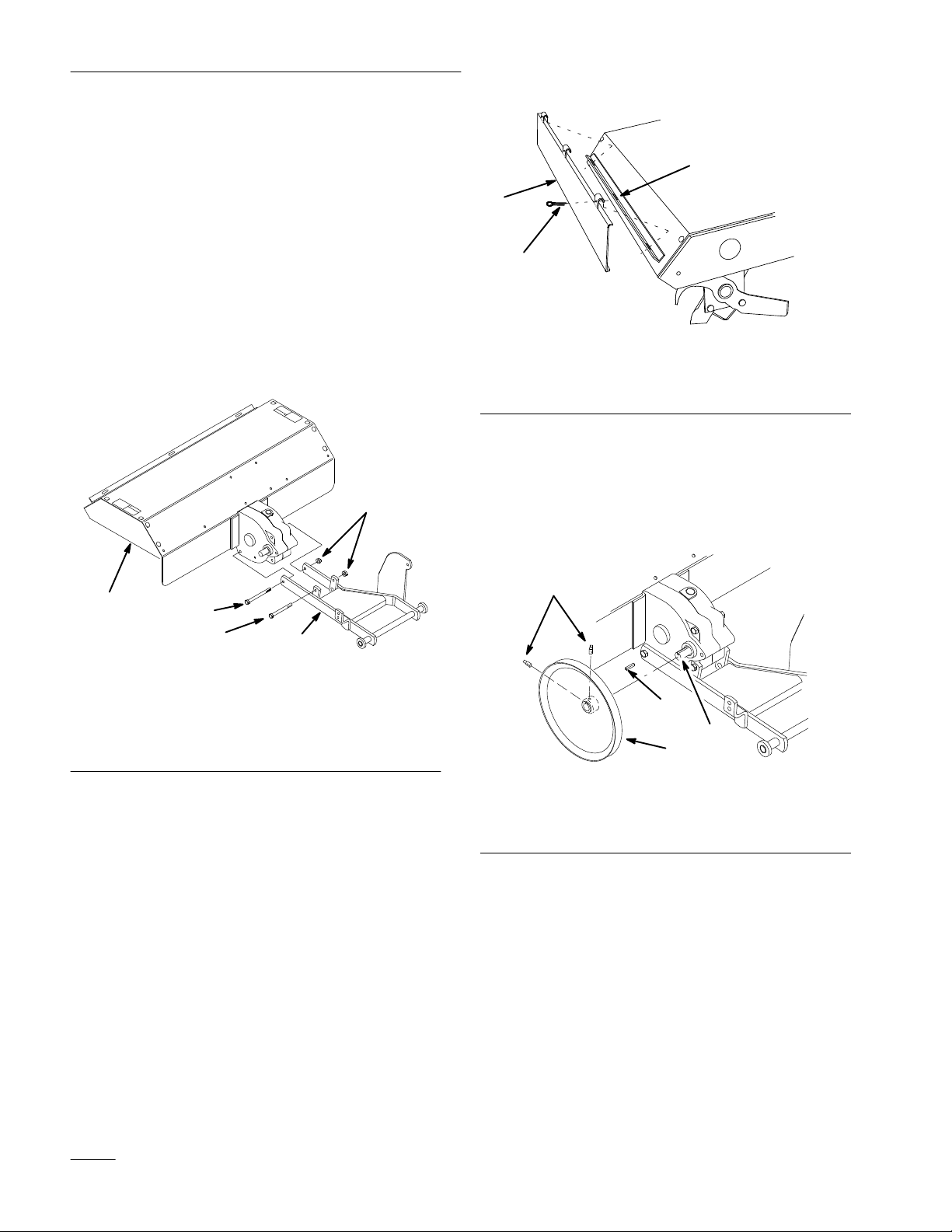

Installation

Assembling

the T

iller

1. Support the tiller housing so it sets in an upright

position. Remove the 3/8 x 5–1/2” (140 mm)

bolt, 3/8 x 4–1/2” (114 mm) bolt, and (2) 3/8”

locknuts; discard the 1/2” nuts (used as spacers

for shipping).

2. Attach the tiller lift frame to the tiller housing

with the previously removed 3/8 x 4–1/2” (114

mm) bolt, 3/8–16 x 5–1/2” bolt (140 mm), and

(2) 3/8” locknuts (Fig. 1). Torque the nuts to

30–32 ft–lbs.

4

3

1

2

m–1282

Figure 2

1. Panel

2.

guard

Cotter pin (3)

3. Slot

4. Install the pulley by inserting the square key into

the input shaft groove. Slip the pulley onto the

shaft (hub toward the gear case) and align it with

the flat idler pulley. Secure it with two

square–head set screws (Fig. 3).

1

3

5

2

m–3506

Figure 1

1. Tiller

2. T

3.

housing

iller lift frame

Bolt 3/8–16 x 5–1/2” (140

mm)

Locknut 3/8”

4.

5.

Bolt 3/8–16 x 4–1/2” (1

mm)

14

3. Hook the panel guard into the slots on the end of

the tiller housing (Fig. 2). Insert (3) cotter pins

and bend the ends of the pins to secure the panel

guard.

3

2

4

1

m–4423

Figure 3

1. Pulley

2. Key

3. Set screw

4.

Input shaft

5. Remove the nut from the gearcase bolt located

just above the input shaft (Fig. 4). The belt

guard mounts to this bolt.

6. Install the tiller belt (short belt) over the input

pulley.

7. Assemble the belt guard to the gearcase bolt

(step 5) and replace the nut loosely.

4

Page 7

Installation

8. Install the ilder pulley on the 3/8–16 x 2” (51

mm) bolt so that the extended hub of the pulley

is toward the tiller lift frame. Route the belt

under the idler pulley, and insert the bolt through

the upper belt guard hole and upper hole in the

tiller lift frame

(Fig. 4). Tighten the nut securely.

3

2

4

4

1

6

8

5

7

m–4422

Figure 4

1. Belt

2.

Gearcase bolt

3.

Input pulley

4.

Locknut, 3/8”

cover

5.

Bolt, 3/8–16 x 2” (51 mm)

6.

Upper hole

7. T

iller Belt (short belt)

8.

Idler pulley

9. Torque the nut on the gearcase (upper end of belt

guard) to 30–32 ft–lbs.

Installing the Front Pulley Box to the

Tractor

1. Attach the pulley box that came with the tiller to

the front Attach–A–Matic.

IMPORTANT: The pulley box for the tiller

and cutter deck are different. Make certain

to always use the tiller pulley box with the

tiller.

2. Make sure the latches on the tractor’s front

Attach–A–Matic are open (Fig. 5). Then slide

the pulley box into the Attach–A–Matic

latches and seat it. Close the latches.

3

1

7

6

1. Attach–A–Matic

2.

Pulley box

3.

Idler pulley

4.

Belt tension release arm

5.

Belt tension adjustment

knob

22

latches

Figure 5

6.

Belt tension indicators

(one on each side)

7. Attach–A–Matic

button (one on each side)

4

m–3642

release

5

Tractor

Set-Up

Installing the Rear Attach–A–Matic to

the Tractor

Follow the installation instructions that come with the

rear Attach–A–Matic

mount.

Remove the drawbar hitch

1. Remove the snap ring from the pin and slide

from the drawbar and spacers. Remove the hitch

from the tractor (Fig. 6).

Note: Save all hardware for use when

re-installing the hitch.

5

Page 8

Installation

1. Snap

2. Pin

ring

Figure 6

4

2

3. Drawbar

4.

Spacer (2)

2314

1

2

3

1

m–3433

Figure 7

1. Clevis

pin 3/8” x 1” (25

mm)

Hairpin cotter

2.

Preparing the Tractor’s Attachment Lift

If you have been using a mower, secure the tractor’s

attachment lift arms in the raised position.

1. Start the tractor.

2. Raise the attachment lift.

3. Set the parking brake and turn the ignition key to

“STOP” to stop the engine. Remove the ignition

key.

4. Install a 3/8” x 1” (25 mm) clevis pin into each

side of the lift assembly in the positions shown

in Figure 7. Secure them with (2) hairpin

cotters.

These pins must be installed when operating with a

blade, snowthrower, or tiller attachment.

Note: The pins are removed to attach a

mower.

6

Page 9

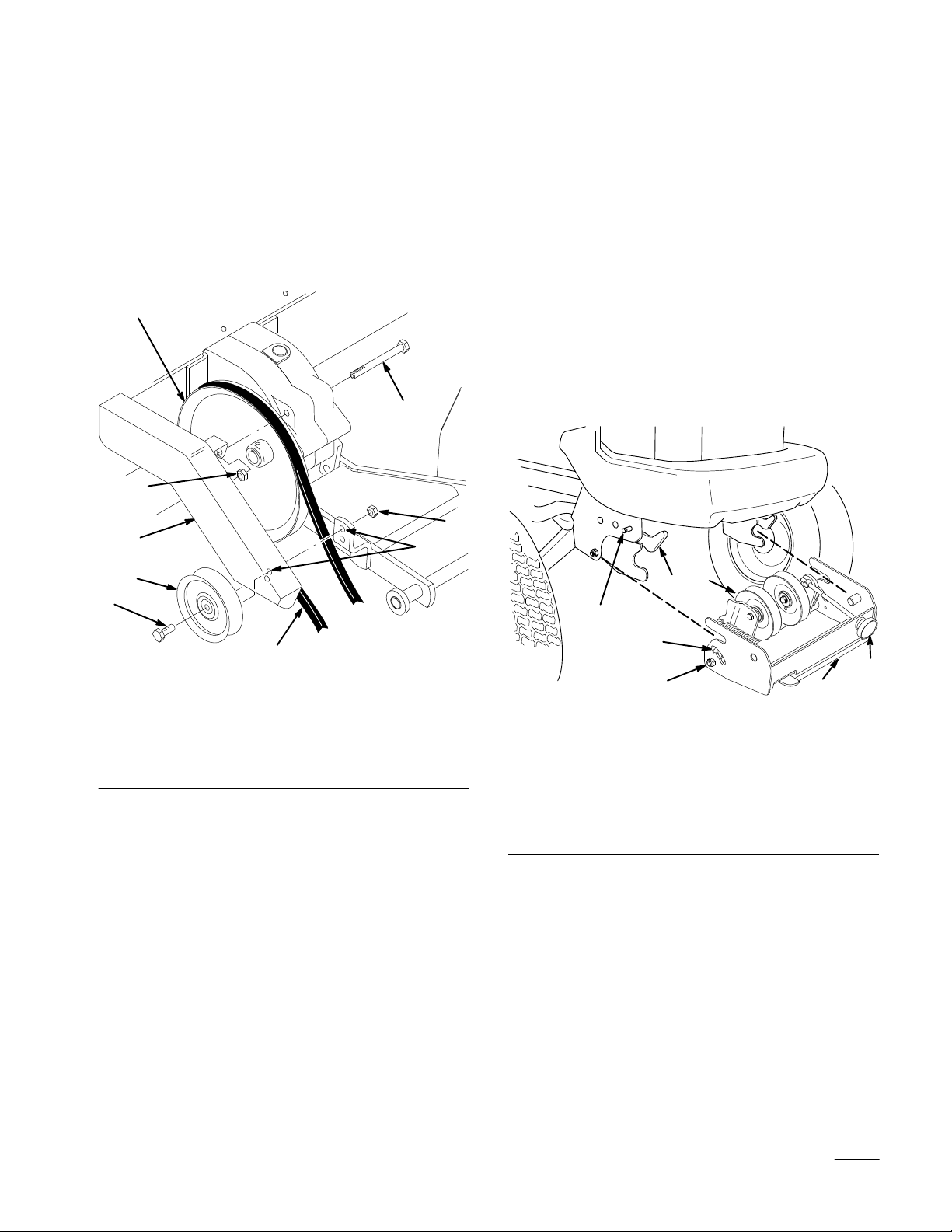

Remove the Rear Transaxle Cover

Remove the transaxle cover from the back of the

tractor (Fig. 8).

1. Remove the two bolts and locknuts securing the

transaxle cover to the tractor frame.

Note: Save all parts and hardware for use

when reinstalling the transaxle cover.

Installation

POTENTIAL HAZARD

• Rotating shaft or cooling fan can cause

injury.

WHAT CAN HAPPEN

• Fingers, hands, feet, hair, etc. can get

caught by shaft or fan.

• Loose clothing can get caught by shaft.

1

m–3436

Figure 8

1. Rear

transaxle cover

Installing the Cable Guide

The cable guide can be installed from the underside

of the tractor. For more visibilty, the drive shaft

maintenance cover can be removed to aid in

installation.

1. Disengage the power take off (PTO), set the

parking brake and turn the ignition key to

“STOP” to stop the engine. Remove the ignition

key.

HOW TO AV

OID THE HAZARD

• Do not operate the tractor without the drive

shaft cover in place.

• Keep hands and arms clear of rotating

shaft or fan.

2. Remove the two bolts in the plastic fan baffle

(Fig. 9) and remove the baffle.

3. Remove the clip nut from the left side of the

plastic fan baffle and install over the hole in the

bent tab of the cable guide (Fig. 9).

4. Remove the nut from the pivot bolt on the left

hand attachment lift arm (Fig. 9). Leave the bolt

in place.

5. Install the rear hole of the cable guide to the left

hand lift arm pivot bolt and replace the nut

loosely (Fig. 9).

6. Reinstall the plastic fan baffle with one of the

previously removed bolts in the right hand side

only (Fig. 9). Leave the bolt loose.

7. Align the front of the cable guide with the hole

in the left hand side of the plastic fan baffle and

reinstall the other bolt previously removed.

Tighten all bolts and nuts securely.

7

Page 10

Installation

8. Replace the drive shaft maintenance cover (if

removed).

1

9

8

7

6

1. Cable

2.

3.

4. Left

5. Plastic

guide

Clip nut

Fan baf

fle bolt

hand lift arm pivot bolt

nut

fan baf

Figure 9

fle

4

5

6.

Right hand attachment lift

arm

7.

Rear of tractor

8.

Pivot bolt

9.

Lift cable

2

3

1

7

3

6

5

8

2

4

9

m–3491

Figure 10

1. Tiller

2. Jack

3.

4. T

5.

shaft assembly

Lift cable

iller belt (short belt)

Idler pulley

6. T

iller hitch bar

7.

Smaller jack shaft bar

8.

Jack shaft/PT

pulley

9.

Larger jack shaft bar

O drive belt

4. Open the latches on the rear Attach–A–Matic.

Place the smaller bar of the jack shaft assembly

into the slots on the front of the rear

Attach–A–Matic (Fig. 11).

2

3

1

Installing

the T

iller to the

Tractor

1. Position the tiller on a level surface with enough

space behind it to accommodate the tractor.

2. Start the tractor and back it into position. Lower

the attachment lift and turn the ignition key to

“STOP” to stop the engine. Remove the ignition

key.

3. Place the jack shaft assembly between the tractor

wheels and oriented with the tiller as shown

(Fig. 10).

8

1. Smaller

2.

jack shaft bar

Rear Attach–A–Matic

Figure 1

m–3505

1

3. Rear

Page 11

5. Open the latches on the mid Attach–A–Matic.

Install the larger bar at the other end of the jack

shaft assembly to the mid Attach–A–Matic.

Then turn the lever of the Attach–A–Matic

counterclockwise to lock the jack shaft assembly

to the tractor (Fig. 12).

Note: The rear Attach–A–Matic may need

to be loosened and realigned with the

mid Attach–A–Matic

jack shaft assembly

Attach–A–Matic bolts

to accept the

. Tighten the rear

securely.

1. Smaller

2. T

iller hitch bar

4

2

jack shaft bar

Figure 13

3.

4. Rear

Installation

3

1

Rear Attach–A–Matic

3

1

2

4

m–3502

Figure 12

1. Attach–A–Matic

2. Attach–A–Matic

button

lever

3. Lock

4.

Larger jack shaft bar

6. Place the tiller hitch bar into the slots in the rear

of the rear Attach–A–Matic. Press on the

latches at the rear until they lock both the tiller

and the jack shaft assembly in place (Fig. 13).

7. Install the tiller belt (short belt) between the

tiller and jack shaft assembly (Fig. 10). Route

the belt under the ilder pulleys and over the jack

shaft pulley.

8. Attach the clevis end of the lift cable to the rear

hole in the tractor’s attachment lift arm located

just in front of the previously installed cable

guide (Fig. 14). Insert a clevis pin and hairpin

cotter.

Note: Attachment lift arm may be different

than shown in Fig. 14. On some

models there may be only a single hole

in which to mount the clevis.

9

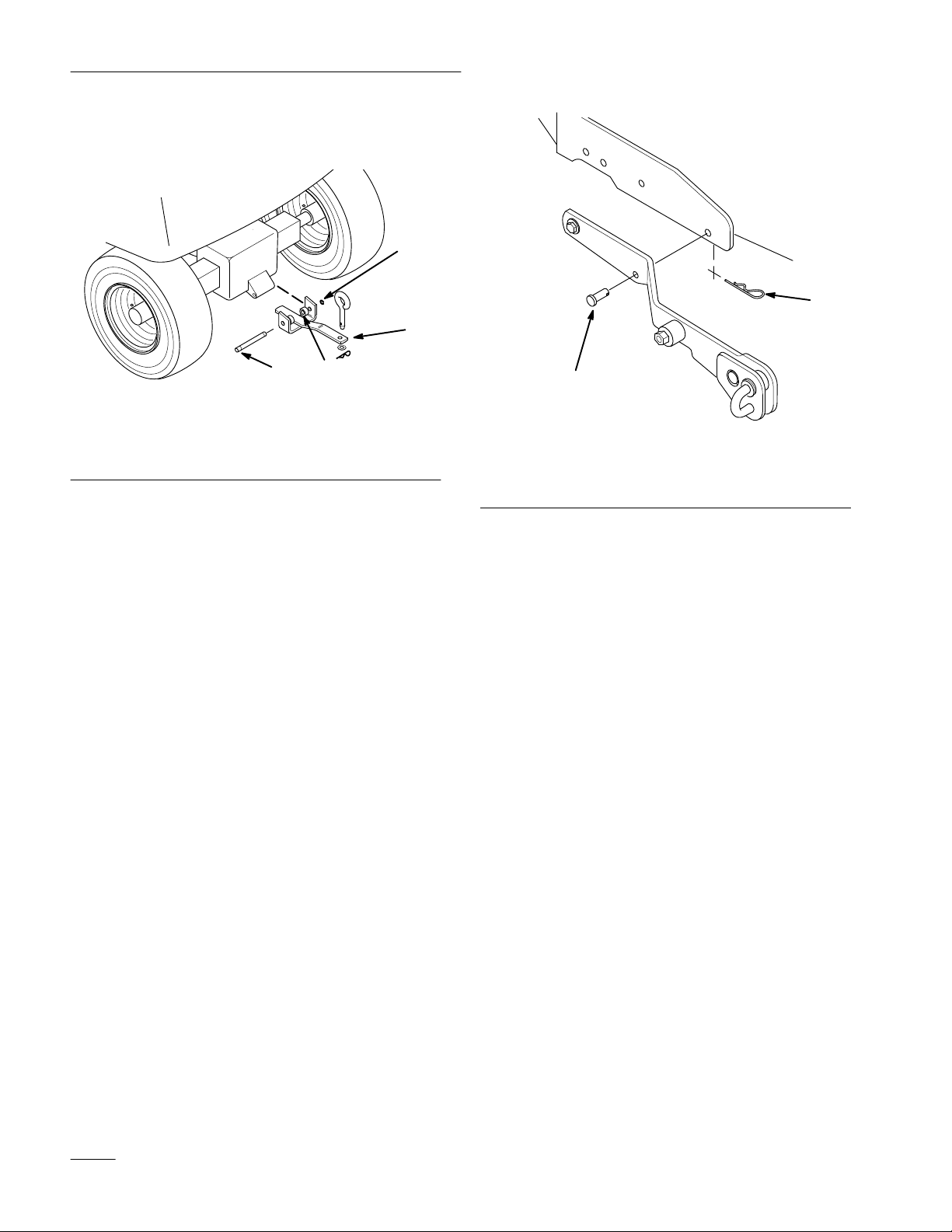

Page 12

Installation

3

4

1

2

5

m–3504

Figure 14

1. Lift

cable

2. Clevis

3.

Attachment lift arm

4.

Clevis pin 5/16” x 1” (25

mm)

5.

Hairpin cotter

9. Route the lift cable under the cable guide and

over the rear axle (Fig. 9).

10. Connect the lift cable to the trunnion by

threading the trunnion onto the lift cable

(Fig. 15).

11. Attach the trunnion to the hole in the tiller lift

cable mount with a washer and hairpin cotter

(Fig. 15).

Note: There should be slack in the cable so

the tiller will drop into the ground.

The amount of cable that is threaded

into the trunnion determines the

maximum depth of tilling and lift

height.

3

4

2

Figure 15

1. Lift

cable

2. Trunnion

3. Locknut

4. Washer

5.

Hairpin cotter

12. Secure the lift cable to the trunnion with a

locknut (Fig. 15).

13. Remove the tractor grille by pulling it out

toward you.

POTENTIAL HAZARD

• Components under the hood will be hot if

the tractor has been running.

WHAT CAN HAPPEN

• Touching hot components can cause burns.

HOW TO AV

OID THE HAZARD

• Allow the tractor to cool before performing

maintenance or touching components

under the hood.

5

1

m–3503

10

14. Route the PTO drive belt around the jack shaft’s

PTO pulley (Fig. 10), then through the center of

the pulley box between the two pulleys.

15. Release the belt tension release arm of the pulley

box housing and swing it out toward you (Fig.

18).

Page 13

Installation

16. Position the end of the PTO belt (long belt) into

the groove of the engine PTO pulley (Fig. 16),

making sure it is also under the pulleys in the

pulley box. The wide, flat surface of the belt

needs to be in contact with the wide, flat surface

of the backside idler pulley (Fig. 17). Additional

belt slack can be obtained (if needed) by turning

the belt tension adjustment knob.

4

3

3.

V–groove idler pulley

4.

Engine PT

5.

Backside idler pulley

m–3561

O pulley

1. Jack

pulley

2. PT

O belt (long belt)

shaft PT

1

2

5

Figure 16

O drive belt

C. If the tension indicators are not in the same

position on both the left and right sides,

release the belt tension, turn the adjustment

knob and repeat steps A and B until the

indicators move to the same position (Fig.

18).

D. Once the indicators are in the same position

on both sides, swing the tension release arm

into the pulley box by moving it into the

position shown in Figure 18.

1

Figure 18

1. Belt

tension indicator (2)

2.

Belt tension adjustment

knob

3.

Seating position for belt

tension release arm

4.

Belt tension released

2

4

m–36433

1

1. V–Groove

Figure

pulley

17

2.

Backside pulley

17. Now adjust the belt tension.

A. Push the belt tension release arm back

toward the pulley box to tension the belt.

B. Check the tension indicators on each side of

the pulley box.

2

18. Replace the front grille of the tractor.

m–3633

11

Page 14

Installation

Removing

the T

iller

Note: Save all hardware, washers and hairpin

cotters for use when installing tiller.

1. Park the tractor on a level surface with enough

space in front of it to disengage from the tiller.

2. Lower the attachment lift, set the parking brake,

and turn the ignition key to “STOP” to stop the

engine. Remove the ignition key.

3. Remove the tractor grille by pulling it out

toward you.

POTENTIAL HAZARD

• Components under the hood will be hot if

the tractor has been running.

WHAT CAN HAPPEN

• Touching hot components can cause burns.

1

4

2

3

5

m–3561

Figure 19

1. Jack

2. PT

shaft PT

pulley

O belt (long belt)

O drive belt

3.

V–groove pulley

4.

Engine PT

5.

Backside idler pulley

O pulley

6. Release the tension on the tiller belt by lifting up

on the idler pulley (Fig. 10). Remove the belt

from the pulleys.

HOW TO AV

OID THE HAZARD

• Allow the tractor to cool before performing

maintenance or touching components

under the hood.

4. Release the belt tension release arm (Fig. 18),

then remove the PTO belt from its position

around the PTO pulley (Fig. 19). Additional belt

slack can be obtained (if needed) by turning the

belt tension adjustment knob.

5. Replace the front grille of the tractor.

7. Disconnect the lift cable by removing the clevis

pin from the clevis and remove the cable from

the attachment lift arm (Fig. 20).

3

4

1

2

5

m–3504

Figure 20

1.

Lift cable

2. Clevis

3.

Attachment lift arm

4.

Clevis pin 5/16” x 1” (25

mm)

5.

Hairpin cotter

12

Page 15

8. Press the release button and open the rear latches

of the rear Attach–A–Matic. Remove the tiller

hitch bar (Fig. 21).

Installation

4

2

Figure 21

1. Smaller

2. T

jack shaft bar

iller hitch bar

3.

Rear Attach–A–Matic

4. Rear

9. Press the release button on the mid

Attach–A–Matic and turn the lever clockwise

to open the latches (Fig. 22). Remove the jack

shaft assembly

.

3

1

m–3501

1

Figure 22

1. Attach–A–Matic

button

2. Attach–A–Matic

10. Replace the rear transaxle cover.

11. Replace the drawbar hitch.

2

m–3502

lever

13

Page 16

Operation

POTENTIAL HAZARD

• Contact with rotating tines may cause

injury.

WHAT CAN HAPPEN

• Rotating tines can cut hands, feet or other

body parts.

1

HOW TO AV

OID THE HAZARD

• Keep away from the rotating tines while

operating the tiller.

• Keep your hands, feet, and any other part

of your body or clothing away from

rotating parts.

• Before adjusting, cleaning, repairing and

inspecting the tiller, shut off the engine and

wait for all moving parts to stop. Move the

power take off (PTO) to “OFF” and rotate

the ignition key to “OFF.” Remove the

ignition key.

Attachment

The attachment power lift (Fig. 23) is used to raise

and lower attachments.

Power Lift

Figure 23

1. Attachment

power lift

Raising Attachments

1. Start the tractor.

2. Pull the lift lever UP to raise the attachment

(Fig. 24). This will lift and hold the attachment

in the raised position.

POTENTIAL HAZARD

• When the engine is off, attachments in the

raised position can gradually lower.

WHAT CAN HAPPEN

• Someone nearby may be pinned or injured

by the attachment as it lowers.

m–3258

14

HOW TO AV

OID THE HAZARD

• Always lower the attachment lift each time

you shut off the tractor.

Page 17

Operation

Lowering

1. Start the tractor.

2. Push the lift lever DOWN to lower the

attachment (Fig. 24).

1. Lift

lever–Up

Attachments

1

Figure 24

2.

Lift lever–Down

2

m–3315

Tips

Clean area of trash, branches and rocks before tilling

to prevent equipment damage.

Always begin tilling with the slowest ground speed

possible. Increase speed if conditions permit.

Always use full throttle (maximum engine speed)

when tilling.

Always engage the power take off (PTO) with tiller in

the raised position.

Till in long, straight passes. Do not make turns while

the tiller is in the ground, as equipment damage may

result.

A small center area will not be tilled due to the gear

case. Overlapping with a second pass will eliminate

this condition.

Avoid excessive tilling of the soil, as finely tilled soil

will not absorb moisture easily and puddles of water

or run-off may occur.

for T

illing

When tilling hard packed, very dry or virgin soil,

raise the tiller so only the very top of the soil is

penetrated. On succeeding passes the depth may be

lowered. This reduces the tiller’s tendency to push the

tractor. If this happens, disengage the power take off

(PTO) and reduce forward speed.

Use low range (on the high–low range lever) for best

performance and smoothest operation.

POTENTIAL HAZARD

• There may be buried power, gas, and/or

telephone lines in the area needing tilling.

WHAT CAN HAPPEN

• Shock or explosion may occur.

HOW TO AV

OID THE HAZARD

• Have the property or area to be tilled

marked for buried lines.

15

Page 18

Maintenance

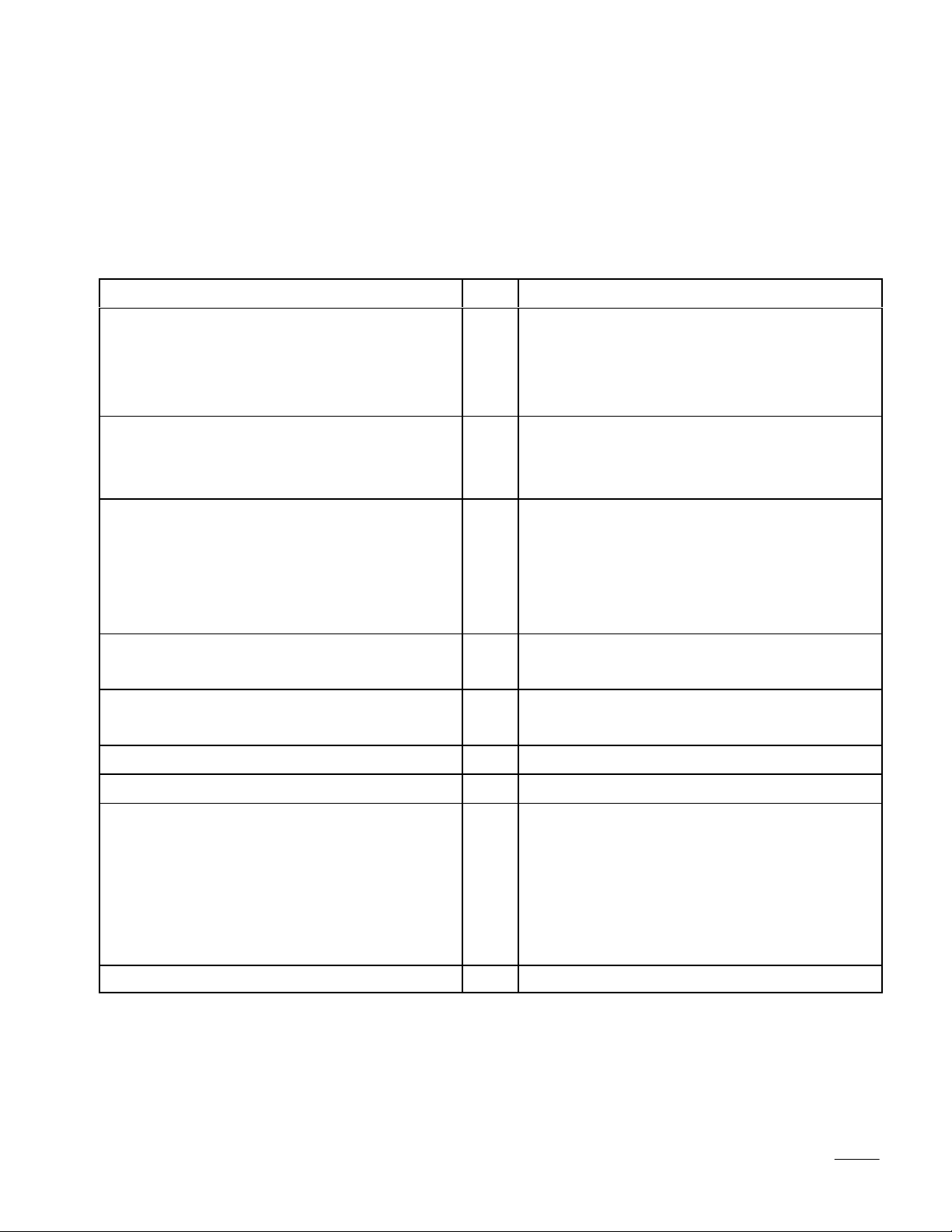

Service

Service

Oil–check level

Belt tension–check

Belt–check for wear/cracks

Chipped surfaces–paint

Interval Chart

Operation

POTENTIAL HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could seriously injure you or other bystanders.

HOW TO AV

• Remove the key from the ignition switch and pull the wire(s) off the spark plug(s)

before you do any maintenance. Also push the wire(s) aside so it does not

accidentally contact the spark plug(s).

OID THE HAZARD

Each

Use5Hours25Hours

X X X

initial X X

Storage

Service

X X

X

Fall

Service

Notes

16

Page 19

Maintenance

Greasing

and Lubrication

Service Interval/Specification

Check the gear lubrication level in the gear case after

every 25 operating hours or once a year, whichever

occurs first. Gear lubrication changes are not

required.

Gear lube type: SAE 90-140 API service GL-4 or

GL-5.

Refill capacity: 1 qt.

Checking Gear Lube

1. Position the tractor and tiller on a level surface

and lower the attachment lift so that the tiller

tines are on the ground. Set the parking brake

and turn the ignition key to “STOP” to stop the

engine. Remove the ignition key.

2. Clean the area around the lower pipe plug

(Fig. 25).

3. Remove the pipe plug carefully because the oil

level may be above the level of the pipe plug.

1

Figure 25

Left side of tiller shown in operating position

1. Pipe

plug (hidden)

Checking Tiller Drive Belt

Tension

1. Disengage the power take off (PTO), set the

parking brake, lower the attachment lift and turn

the ignition key to “STOP” to stop the engine.

Remove the ignition key.

m–3497

4. If gear lube runs from the case when the plug is

removed, the lube in the case is sufficient. Oil

may be added as necessary

5. Apply pipe sealant to the plug and reinstall.

.

2. As the drive belt wears and the tiller is raised

and lowered, the spring–loaded idler arm moves

(Fig. 26).

3. Lower the tiller and observe the spring–loaded

idler arm movement as you push on the belt. The

idler arm spring must be under tension. If it is

not under tension, replace the drive belt.

Replacing

1. Disengage the power take off (PTO), set the

parking brake, lower the attachment lift and turn

the ignition key to “STOP” to stop the engine.

Remove the ignition key.

2. Remove the rear tiller belt (short belt) from the

jack shaft pulley (Fig. 26).

the T

iller Drive Belt

17

Page 20

Maintenance

1

2

3

Figure 26

1. Spring

2. T

loaded idler arm

iller drive belt (short belt)

3.

Jack shaft pulley

3. Remove the belt guard from the gear box and

ilder mounting (Fig. 27).

m–3491

3

2

4

4

1

6

8

5

7

m–4422

4. Remove the belt and replace with a new one.

5. Reinstall the belt guard (Fig. 27) Refer to

“Assembling the Tiller” under Installation. Be

sure to torque the gear case bolt.

Figure 27

1. Belt

cover

2.

Gearcase bolt

3.

Input pulley

4.

Locknut, 3/8”

Checking

PT

O Drive Belt

5.

Bolt, 3/8–16 x 2” (51 mm)

6.

Upper hole

7. T

iller Belt (short belt)

8.

Idler pulley

Tension

1. Check the tension indicators on each side of the

pulley box. If the tension indicators are not in

the same position on both the left and right

sides, release the belt tension and turn the

adjustment knob. Push the belt tension release

arm back toward the pulley box to tension the

belt (Fig. 28).

2. Repeat step 1 until the indicators move to the

same position.

18

3. Once the indicators are in the same position on

both sides, swing the tension release arm into the

pulley box by moving it into the position shown

in Figure 28.

Page 21

Maintenance

2

1

3

m–3643

Figure 28

1. Belt

tension indicator (2)

2.

Belt tension adjustment

knob

3.

Seating position for belt

tension release arm

4.

Belt tension released

Storage

1. Before long term storage wash the machine with

mild detergent and water to remove dirt and

grime from the entire machine.

2. Check the condition of the drive belt.

3. Check gearcase lubrication level; refer to

Greasing and Lubrication, page 17.

4

4. Check and tighten all bolts, nuts, and screws.

Repair or replace any part that is damaged or

defective.

5. Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service

Dealer.

6. Store the tiller in a clean, dry garage or storage

area. Cover the tiller to protect it and keep it

clean.

19

Page 22

Page 23

Page 24

Loading...

Loading...