FORM NO. 3318–329 Rev. A

Wheel

Horse

36” Tiller

for

Classic

Model No. 79370 – 6900001 & Up

Garden T

ractors

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

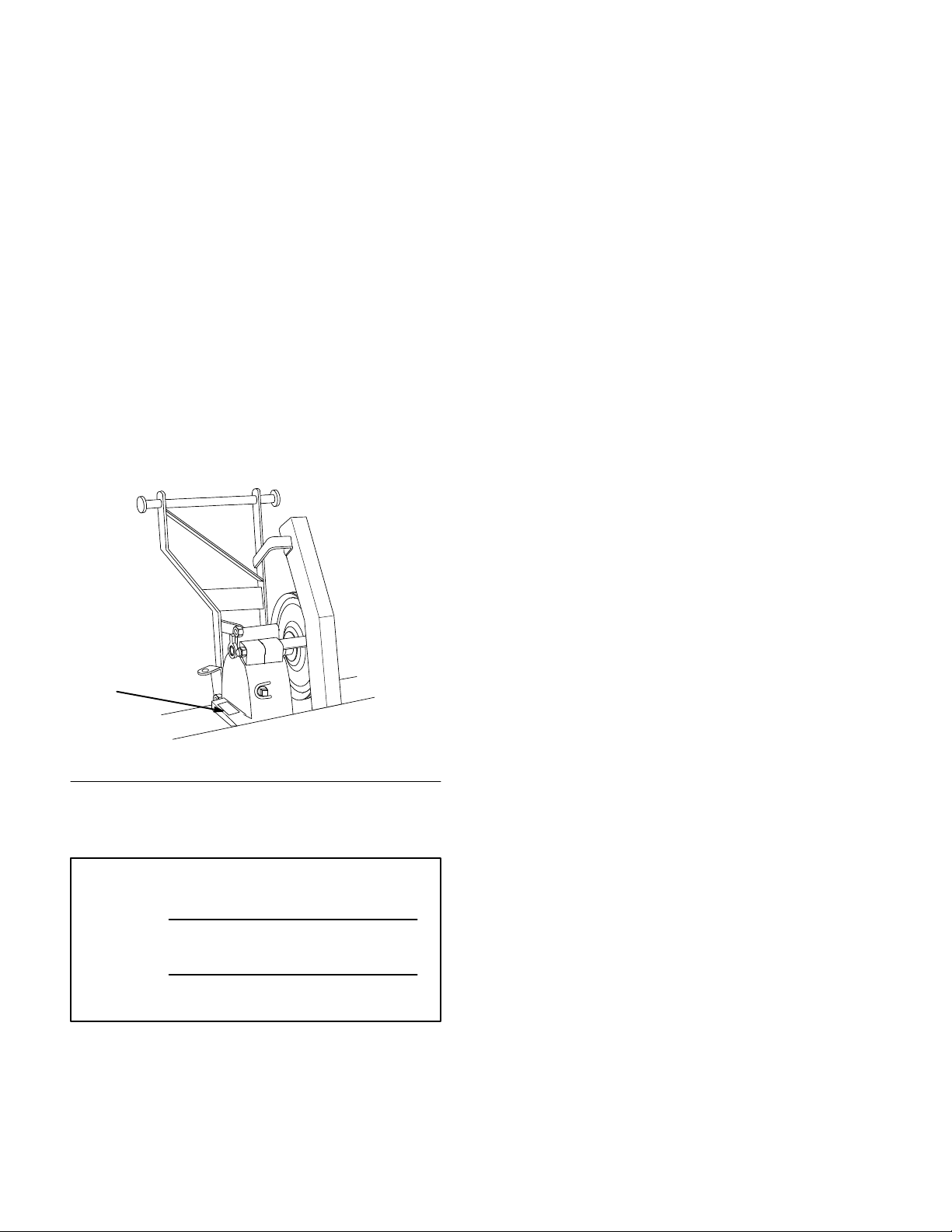

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

plate located in a unique place on the product as

shown below

.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

1

2276

1. Model

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

and Serial Number Plate

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

Printed in USA

Contents

Page

Safety and Instruction Decals 2.

Installation 3

Loose Parts 3

Assemble T

Tractor Set-Up 6

Installing Tiller to Tractor 9

Removing the Tiller 12

Operation 14

Operating the Power Take Off (PTO) 14

Attachment Lift Lever 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

iller 5

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . .

Page

Attachment Power Lift 15

Adjusting Dial-A-Height 16

Adjusting Lift Chain 16

Tips for Tilling 17

Maintenance 18

Service Interval Chart 18

Greasing and Lubrication 19

Adjusting Drive Belt Tension 19

Storage 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . .

1

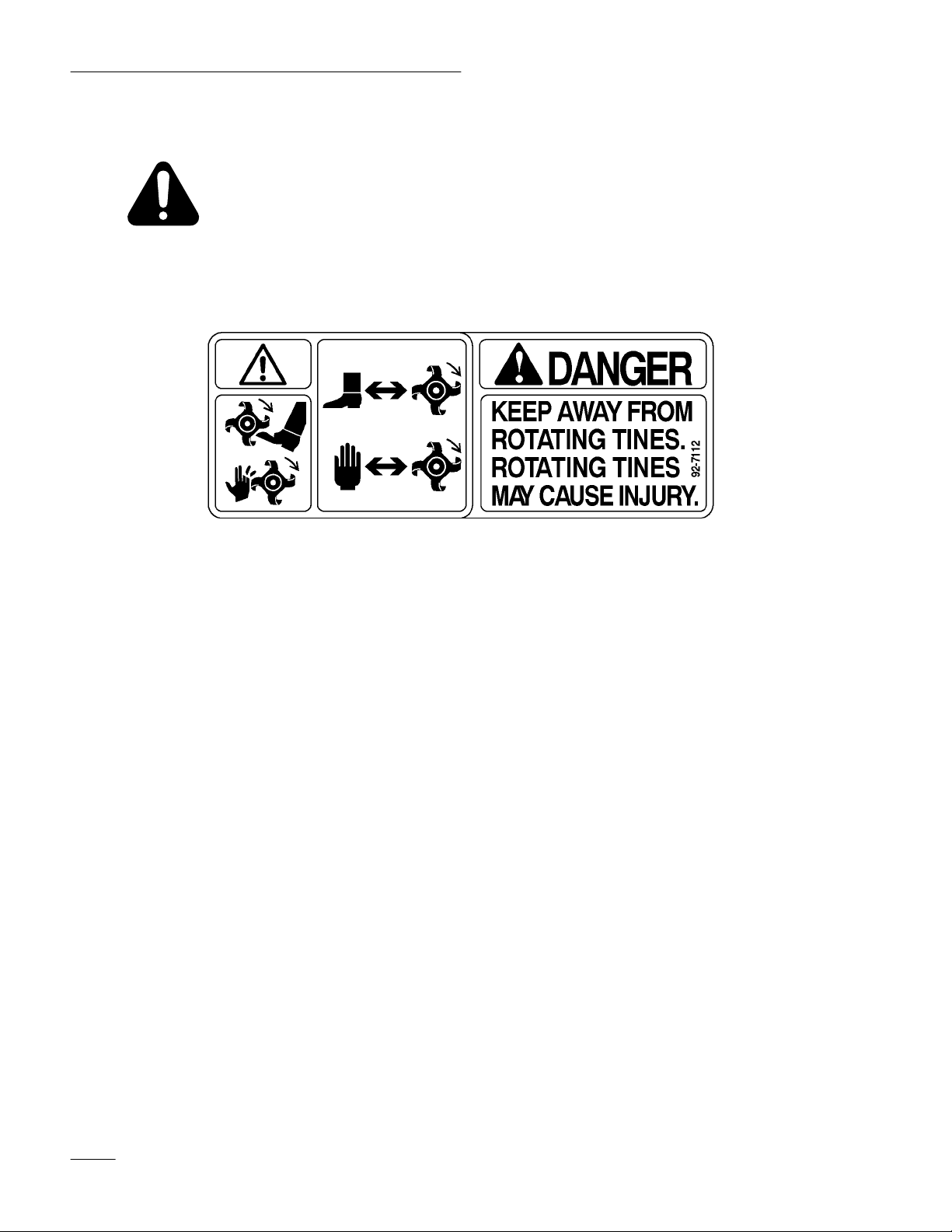

Safety

Safety

and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON TINE SHIELD

LEFT and RIGHT SIDE

(Part No. 92–71

12)

2

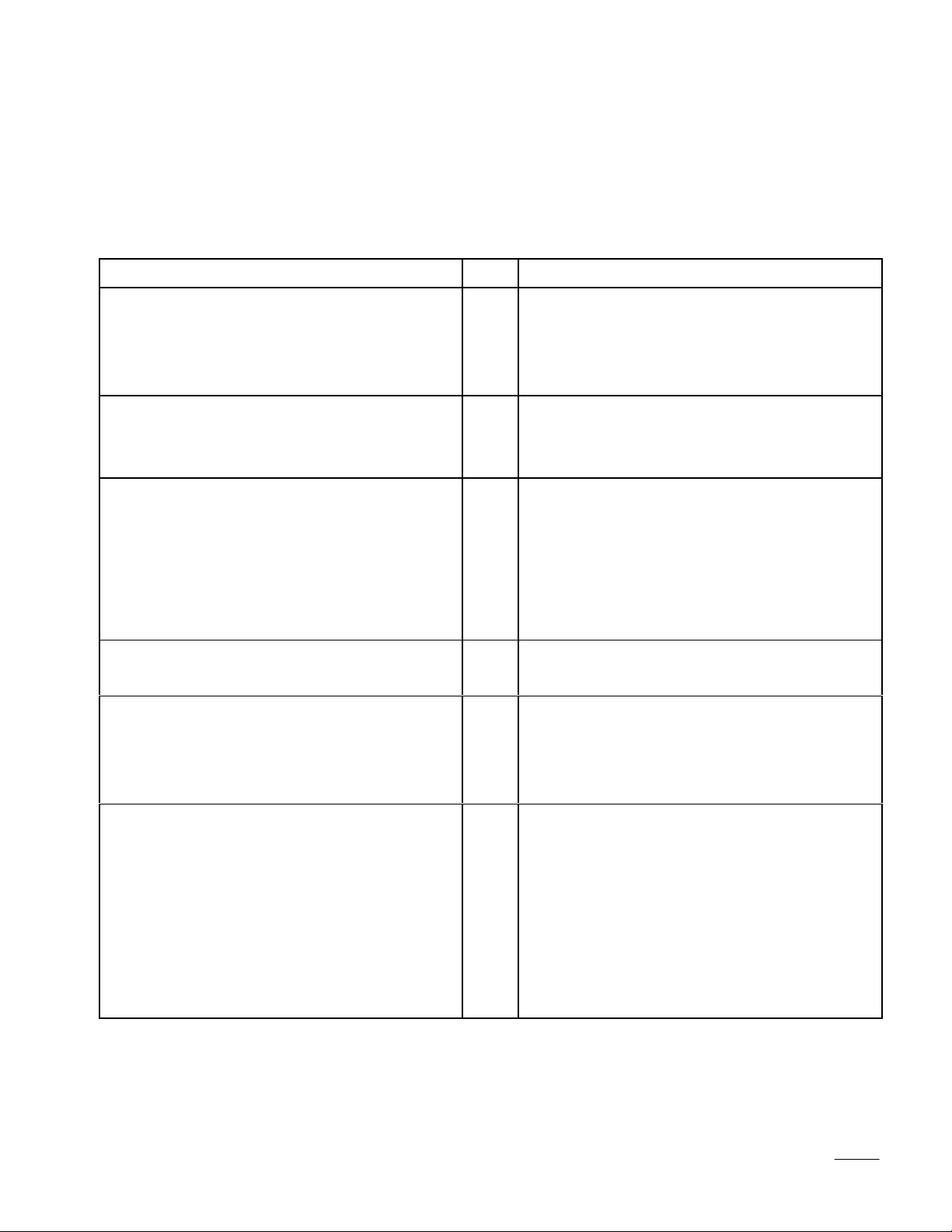

Installation

Loose

Parts

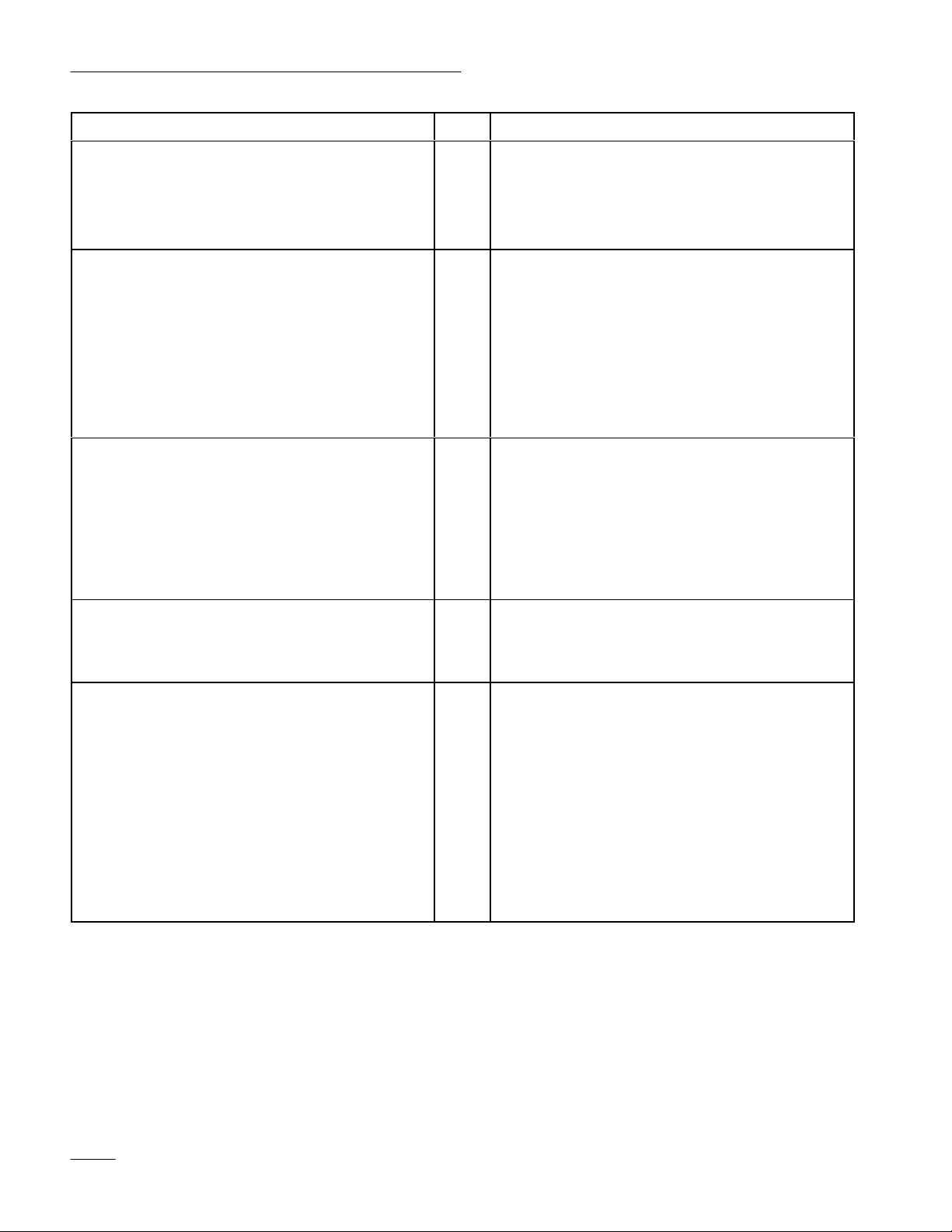

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Hitch

Spring bracket

Bolt (installed in case for shipping) 3/8 x 5-1/2”

Nut (installed in case for shipping) 3/8”

Pulley

Key

Set screw 15/16”

Idler pulley

Spacer

Belt guide

Belt guard

Bolt 3/8–16 x 2-1/4”

Lock nut 3/8”

1

1

2

2

1

1

1

1

1

1

1

1

1

Install tiller hitch to tiller gear case.

Install drive pulley to tiller gear case.

Install idler pulley and belt guard.

Rear shield

Cotter pin 1”

Lift chain

Clevis

Clevis pin

Cotter pin 3/4”

Tube-Hydro\Gear

Clamp

Cable

Clevis-Short\Long

Clevis pin

Cotter pin 1”

Trunnion

W

asher 5/8”

1

3

1

1

1

1

2

1

1

2

1

2

1

1

Install rear shield to tiller

Install lift chain to tiller

Install lift cable to tractor

.

.

.

3

Installation

DESCRIPTION USEQTY.

Lift lever

Bushing

Shim washer

E-ring

Latching plate

Latch lever

Carriage bolt 3/8–16 x 1”

W

asher 3/8”

Lock nut 3/8”

Clevis pin

Cotter pin 3/4”

Latch plate assembly

Link bracket-right

Link bracket-left

Angle spacer (if required)

Carriage bolt 3/8–16 x 3-1/2”

Lock nut 3/8”

1

2

4

2

1

2

2

2

2

2

2

1

1

1

1

4

4

Install lift lever to tractor

Assemble mounting plate.

Install mounting plate to tractor

.

.

Spring-large

Eye bolt

Lock nut 3/8”

Mid-mount bracket assembly

Belt

Bolt 3/8–16 x 2-3/4”

Bolt 3/8–16 x 1-3/4”

W

asher 38”

Lock nut 3/8”

Spring-small

Belt guard

Bolt-self tapping 1/4 x 1/2”

1

1

1

1

1

1

1

1

3

1

1

2

Install lift assist spring to tiller

Install idler pulley assembly to tractor

.

.

4

Installation

Assemble Tiller

1. Tip tiller onto back and support in an upright

position. Remove 3/8 x 5-1/2” and 3/8 x 4-1/2”

bolts. (Fig. 1). Discard extra nuts used as spacers

for shipping.

2. Fasten hitch and spring bracket with bolts and

nuts as shown in (Fig. 1). Tighten bolts securely.

3. Install pulley with hub 1/4” in from the end of

drive shaft (Fig. 1). Secure with square key and

(2) 5/16” square head set screws.

IMPORTANT: Key must be located under a

set scr

ew to be retained.

4. Assemble idler and belt guide into lower hole of

belt guard and install onto hitch through upper

hole with 3/8 x 2-1/4” bolt and 3/8” lock nut

(Fig. 1).

10

1

8

11

9

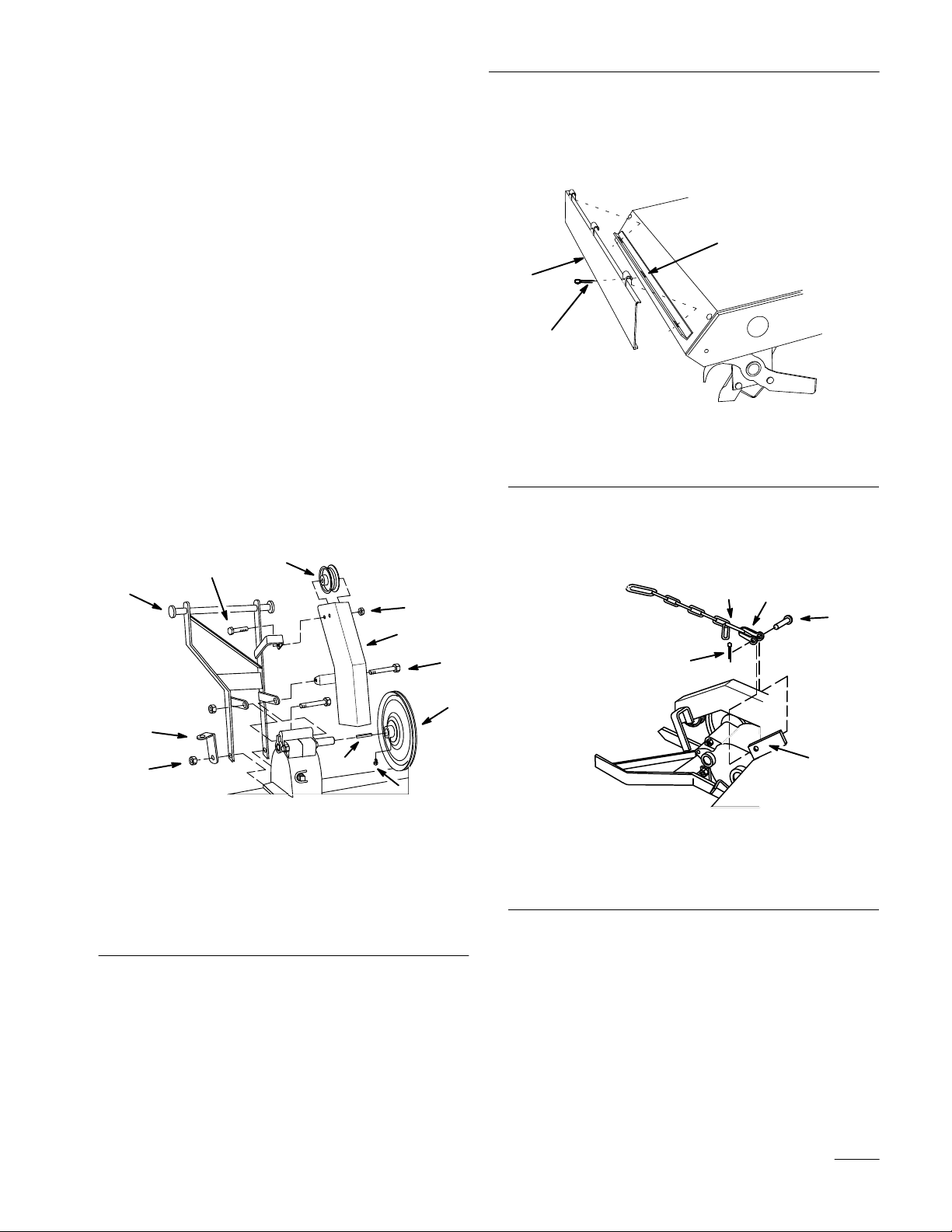

5. Rotate tiller down and hook rear shield into slots

at rear of tine shield. Secure with (3) 1” cotter

pins (Fig. 2).

3

1

2

1282

Figure 2

1. Rear

2.

shield

Cotter pin 1”

3. Slot

6. Attach lift chain, short link end, one link short,

to lift bracket with clevis, clevis pin and secure

with 3/4” cotter pin (Fig. 3).

1

2

3

2

4

1. Hitch

2. Spring

3.

4.

5. Pulley

6. Key

bracket

Bolt (in tiller case)

Nut (on tiller bolt)

Figure 1

6

7.

Set screw 5/16”

8. Idler

9.

Belt cover

10.

Bolt 3/8–16 x 2-1/4”

11.

Lock nut 3/8”

3

5

5

4

2292

7

2294

Figure 3

1. Short

2. Clevis

3.

link

Clevis pin

4. Bracket

5.

Cotter pin 3/4”

5

Installation

Tractor

Set-Up

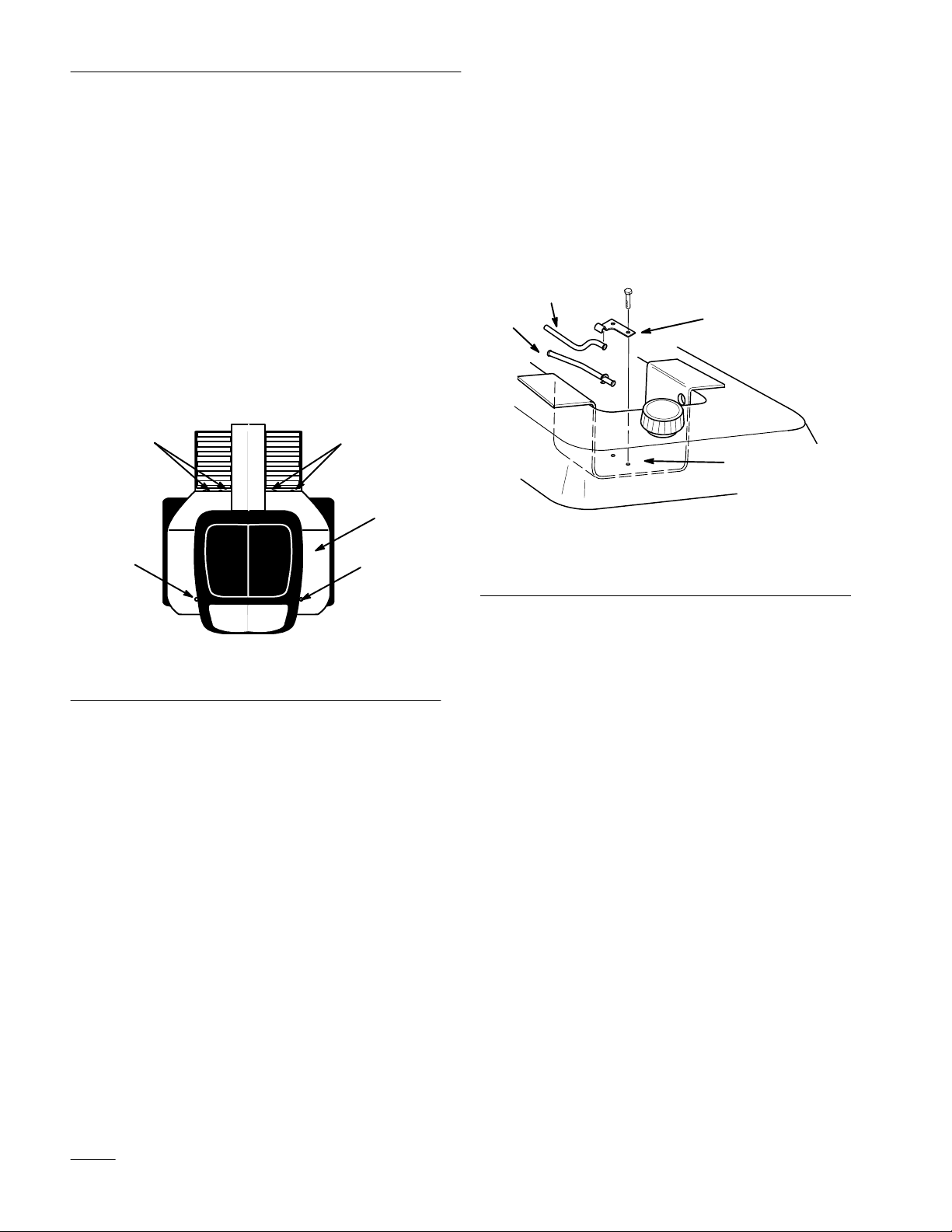

1. Remove and save carriage bolts at fender mount

under the seat and attaching footrests. (Fig. 4).

2. Unplug seat wiring harness connector and

remove wire harness from wire clip.

Note: If tractor has a 25 amp fuse clipped

inside console, remove the fuse.

3. Remove the fender\seat pan from the tractor.

Note: Save all hardware for use when

re-installing fenders.

2

2

2

1

2

4. Remove bolts and lock washers securing fuel

tank bracket to the top of transmission.

5. Select proper cable tube (straight for gear drive,

bent for hydrostatic) and install on the top of fuel

tank bracket. Secure to fuel tank bracket with

clamp and previously removed lock washers and

bolts.

2

1

1. Cable

2.

tube-gear drive

Cable tube-hydrostatic

Figure 5

3

4

2293

3. Clamp

4. Bracket

1. Fender\seat

pan

Figure 4

2.

Carriage bolt

1229a

6

Installation

6. Slide a shim washer and bushing onto ends of

lift lever rod (Fig. 6).

IMPORTANT: Check that bushings slide

easily onto rod ends and into frame. Remove

paint if necessary.

7. Position lift lever into frame and slide bushings

and shim washers outward into frame holes.

Secure in position with E-rings (Fig. 6).

IMPORTANT: Lift lever must not have

excessive end play (more than .015 inch). Use

extra shim washers (.015 and .020 thick) to

reduce end play.

1

2

5

3

8. Slide ball end of attachment lift cable through

cable tube from the rear.

9. Select correct clevis as follows:

2” long clevis: for 8-speed gear drive and

hydrostatic models with oil filter on right side.

3-1/8” long clevis: for hydrostatic models with

oil filter facing rear.

10. Lower attachment lift and place cable, ball end,

into slot in clevis (Fig. 7). Attach clevis to hole

in attachment lift and secure with clevis pin and

and 1” cotter pin. (Fig. 7).

3

2

Figure 6

1. Bushing

2. Shim

W

required)

asher (as

3.

Lift lever

4.

Frame hole

5. E-ring

Note: If tractor has a 25 amp fuse clipped

inside console, install the fuse.

5

4

2291

1. Lift

cable knob

2.

Clevis (select proper size)

3.

Attachment lift

4

Figure 7

4.

5.

1

2315

Clevis pin

Cotter pin 1”

7

Installation

11. Thread trunnion 1” into end of lift cable threaded

end and insert into lower hole of lift lever.

Secure with 5/8” washer and hairpin cotter

(Fig. 8).

4

Figure 8

3

4. W

asher 5/8”

5.

Hairpin cotter

5

2309

1. Trunnion

2. Lift

cable threaded end

3.

Lower hole in lift lever

1

2

12. Install fenders and seat with previously removed

hardware.

15. Center hitch on axle housing and install with (4)

3/8 x 3-3/4” carriage bolts, left side angle plate

(with hole rearward), right side strap and 3/8”

lock nut as shown (Fig. 10).

Note: On hydrostatic models with oil filter

facing rear locate hitch 3-1/4” (8.3 cm)

from right side of center housing.

Note: To tighten hitch mounting, install

angle spacers, positioned along top and

rear of axle, on 8-speed gear drive and

hydrostatic models with oil filter on

right side.

6

5

4

7

13. Plug seat wiring harness connector and insert

wire harness into wire clip.

14. Install latch levers to mounting plate with

3/8 x 1” carriage bolts, 3/8” washers and 3/8”

lock nuts (Fig. 9).

Note: Tighten nuts so latch levers move, but

hold in position for ease of tiller

mounting to tractor.

3

5

1

Figure 9

1. Mounting

2.

Carriage bolt 3/8 x 1”

3. W

plate

asher 3/8”

4.

Latch lever

5.

Lock tut 3/8”

4

2308

3

7

1

2

2295

Figure 10

1. Mounting

2.

Carriage bolt 3/8 x 3-3/4”

3.

Angle plate-left side

4.

Strap-right side

plate

5.

Lock nut 3/8”

6.

3-1/4” (8.3 cm) location

7.

Angle spacer-if required

2

8

Installation

16. Check mounting location of idler arm in hole of

idler bracket (Fig. 11). Correct location is as

follows:

Front hole for 400 & 500 Series Twin cylinder

tractors and all Single cylinder tractors.

Rear hole for C & GT Series Twin cylinder

tractors.

17. If necessary, remove 3/8” lock nut (Fig. 11) and

change idler arm hole location. Secure with same

lock nut.

5

3

2

1. Front

2.

Rear hole

3.

Lock nut 3/8”

hole

Figure 1

1

1

4.

Idler arm assembly

5.

Idler bracket

4

2310

Installing Tiller to T

ractor

1. Remove snap ring from pin and slide from

drawbar and spacers. Remove hitch from tractor

(Fig. ).

Note: Save all hardware for use when

re-installing hitch.

1

3

2

2314

Figure 12

1. Snap

2. Pin

ring

3. Drawbar

4. Spacer

1. Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Position tiller behind and under rear tractor hitch

with idler pulley bracket above right latch lever.

Lift latch levers and install frame mounting rod.

Center tiller between hitch latches (Fig. 13).

3. Secure latch levers closed with clevis pins and

hairpin cotters (Fig. 13).

4

1

2296

1. Latch

2.

Mounting rod

3

Figure 13

lever

3.

Clevis pin

4.

Hairpin cotter

2

9

Installation

4. Set Dial-a-Height to the Mounting Position, and

lower attachment lift all the way; refer to Setting

Height-of-Cut.

5. Remove trunnion and slide long link of lift chain

under attachment lift arm and hook into lower

notch (Fig. 14). Install trunnion into bottom hole

of lift lever.

6. Raise attachment lift lever to the transport

position and place a block under tiller gear case.

7. Hook lift assist spring through left hitch angle

mounting plate and eye bolt. Secure eye bolt

through bracket with 3/8” lock nut (Fig. 14).

Adjust lock nut so there is light spring tension in

the fully raised position.

1

2

2

4

5

1

3

6

2311

Figure 15

1. Mid-mount

2.

idler bracket

3. Spring

hitch

4.

Bolt 3/8 x 1-3/4”

5.

Lock nut 3/8”

6.

Idler arm assembly

11. Remove hairpin cotter and trunion from PTO

engagement plate (Fig. 16).

12. Unlatch and remove clevis pin that secures yoke

assembly to clutch shaft and pivot forward to

remove from engagement plate (Fig. 16).

3

4

5

6

7

2297

Figure 14

1. Long

2. Notch

3. Trunnion

4.

link

Lift assist spring

5.

Eye bolt

6. Bracket

7.

Lock nut 3/8”

8. Open mid-mount hitch and insert rod of idler

bracket(Fig. 15).

9. Slide spring onto 3/8 x 1-3/4” bolt and thread on

first 3/8’ lock nut (Fig. ). Place bolt through hole

in frame, just in front of mid-mount hitch, and

secure with a second 3/8” lock nut (Fig. 15).

10. Hook spring into hole in idler arm assembly.

4

1. Hairpin

2. Trunnion

3.

cotter

Engagement plate

5

2

3

1

6

1

2300

Figure 16

4.

Clevis pin

5. Yoke

6.

Clutch shaft

10

Installation

13. Loop belt between clutch yoke and engagement

plate and place on inner groove of PTO, power

take off clutch (Fig. 16).

14. Assemble yoke and engagement plate and attach

clevis pin, trunnion and hairpin cotter to secure

(Fig. 16).

15. Route belt around and mid-mount idler pulleys,

below frame and behind right rear tire (Fig. 17).

16. Pull on idler arm spring to relieve tension and

route belt around tiller drive pulley, under tiller

idler and inside belt guide (Fig. 17).

17. Check that belt is properly routed around all

pulleys and belt guide (Fig. 17).

IMPORTANT: Belt must be properly routed

behind belt guide to prevent jumping off and

premature failure.

3 1

18. Install belt guard to mid-mount bracket with (2)

1/4 x 1/2” self tapping bolts (Fig. 18).

1

2

1. Belt

guard

2.

Mid-mount bracket

3

Figure 18

3.

Bolt 1/4 x 1/2”

2312

1. Inner

2.

groove of (PT

power take of

Mid-mount idler pulleys

f, clutch

Figure 17

O)

4

2313

2

3. T

iller pulley

4. T

iller idler

11

Installation

Removing

the T

iller

Note: Save all hardware, washers and hairpin

cotters for re-use when installing tiller.

1. Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Turn the Dial-a-Height knob counterclockwise,

all the way and lower the attachment lift lever to

the mounting position; refer to Lowering

Attachment.

3. Remove the belt guard (Fig. 18).

4. Pull on idler arm spring to relieve belt tension

and remove tiller drive belt from tiller pulley and

slide belt out of groove (Fig. 19).

5. Remove hairpin cotter and trunion from power

take off PTO engagement plate (Fig. 19).

2

5

4

3

1

7

6

1

8

2300

Figure 19

1. Hairpin

2. Trunnion

3.

4.

cotter

Engagement plate

Clevis pin

5. Yoke

6.

Clutch shaft

7.

Belt groove

8.

Idler arm

9. Open mid-mount hitch and remove idler bracket

assembly (Fig. 20). Unhook spring from idler

arm (Fig. 20).

6. Unlatch and remove clevis pin that secures yoke

assembly to clutch shaft and pivot forward to

remove from engagement plate (Fig. 19).

7. Remove belt from between clutch yoke and

engagement plate (Fig. 19).

8. Assemble yoke and engagement plate and attach

clevis pin, trunnion and hairpin cotter to secure

(Fig. 19).

10. Remove second lock nut from spring mounting

bolt and remove (Fig. 20).

1

4

2

1. Mid-mount

2.

Idler bracket assembly

hitch

Figure 20

3. Spring

4.

3

Lock nut

2311

12

Installation

11. Raise attachment lift to the transport position

and place a block under tiller gear case.

12. Loosen lock nut on eye bolt and unhook lift

assist spring from tractor (Fig. 21).

13. Turn the Dial-a-Height knob counterclockwise,

all the way, remove block and lower the

attachment lift lever to the mounting position;

refer to Lowering Attachment.

14. Remove hairpin cotter and trunnion from lift arm

and unhook long link of lift chain from lift arm

(Fig. 21). Install trunnion and hairpin cotter

(Fig. 21).

5

3

4

15. Remove hairpin cotters and clevis pins from

latch levers (Fig. 22). Open latch levers and

remove mounting rod.

2

1

3

2296

4

Figure 22

1. Hairpin

2.

cotter

Clevis pin

3.

Latch lever

4.

Mounting rod

Note: Save all hardware, washers and hairpin

cotters for reuse when installing tiller.

1. Lock

2.

3.

nut

Lift assist spring

Hairpin cotter

2

Figure 21

4. Trunnion

5.

1

Long link

2297

13

Operation

POTENTIAL HAZARD

• Rotating tines can cut hands, feet or other

body parts.

WHAT CAN HAPPEN

• Contact with rotating tines may cause

injury.

HOW TO AV

• Keep away from the rotating tines while

operating the tiller.

• Keep your hands, feet, and any other part

of your body or clothing away from

rotating parts.

• Before adjusting, cleaning, repairing and

inspecting the tiller, shut off the engine and

wait for all moving parts to stop. Move the

power take off (PTO) to “OFF” and rotate

the ignition key to “OFF.” Remove the key.

OID THE HAZARD

Operating

Power T

The power take off (PT

power to the clutch.

Engaging the Power Take Off (PTO)

1. Depress the brake and/or clutch pedal(s) to stop

the machine.

2. Move the power take off (PTO) to “ON”

(Fig. 23).

the

ake Off (PT

O) engages and disengages

O)

2

1

2318

Figure 23

1. Off-Disengaged 2. On-Engaged

Disengaging the Power Take Off (PTO)

1. Depress the brake and/or clutch pedal(s) to stop

the machine.

2. Move the power take off (PTO) to “OFF”

(Fig.23).

14

Operation

Attachment

Lift Lever

The attachment lift lever (Fig. 24) is used to raise and

lower various attachments.

Raising Attachments

1. Depress the clutch and/or brake pedal(s) to stop

the machine.

2. Pull attachment lift lever rearward until latch

locks. In this position the lift will hold the

attachment in the up, or raised position.

Lowering Attachments

1. Depress the clutch and/or brake pedal(s) to stop

the machine.

2. Pull attachment lift lever rearward, to release lift

pressure, and push the button on top to release

the latch. Move lift lever forward to lower

attachment.

Attachment

Power Lift

The attachment power lift (optional on some models)

(Fig. 25) is used to raise and lower attachments.

Raising Attachments

1. Start the engine.

2. Move the lift lever in the “UP” direction to raise

the attachment lift (Fig. 25). This will lift and

hold the attachment in the up, or raised position.

Lowering Attachments

1. Start the engine.

2. Move the lift lever in the “DOWN” direction to

lower the attachment lift (Fig. 25). This will

lower the attachment lift.

2

3

5

4

6

1. Lift

lever

2. Button

3. Dial-A-Height

Figure 24

4. Indicator

5. High

6.

2

1

Mounting position

2321

1. Lift

1

lever UP

Figure 25

2.

2317

Lift lever DOWN

15

Operation

Adjusting

Dial-A-Height

The Dial-A-Height control (Figs. 24) is used to limit

the downward travel of the attachment, on gear drive

tractors only. The Dial-A-Height knob is rotated to

change the location of this stop, up or down.

1. Raise the attachment lift lever: Refer to Raising

Attachments. In the raised position the

Dial-A-Height knob (Fig. 24) can be rotated to

change the stop location. Turn clockwise to raise

and counterclockwise to lower the height of the

attachment.

2. The Dial-A-Height indicator (Fig. 24) will show

the change, high to low, in attachment lift height

as adjustment is made.

Adjusting

Lift Chain

1. For maximum tilling depth and transport lift

height locate link of lift chain in the lowest

notch of lift lever (Fig. 26). This position will

have the greatest lift effort.

2. For minimum tilling depth and reduced lift

height, locate the link of lift chain in the upper

clevis notch of lift lever (Fig. 26). This position

will have lowest lift effort.

3. For variations of less than the three notches in

the lift lever, disconnect the lift cable from the

lift arm and rotate the trunnion (Fig. 26) Turning

clockwise increases lift height and reduces tilling

depth and counter clockwise reduces lift height

and increases tilling depth.

2

3

1

POTENTIAL

HAZARD

• Rotating tines can cut hands, feet or other

body parts.

WHAT CAN HAPPEN

• Contact with rotating tines may cause

injury.

HOW TO AV

OID THE HAZARD

• Keep away from the rotating tines while

operating the tiller.

• Keep your hands, feet, and any other part

of your body or clothing away from

rotating parts.

• Before adjusting, cleaning, repairing and

inspecting the tiller, shut off the engine and

wait for all moving parts to stop. Move the

power take off (PTO) to “OFF” and rotate

the ignition key to “OFF.” Remove the key.

Changing the lift chain link location at the lift arm

notch, affects maximum tilling depth, transport lift

height and lift effort. The location can be changed at

the lever (Fig. 26).

1. Lowest

2.

Highest notch

notch

4

Figure 26

3.

Lift cable

4. Trunnion

2309

16

Operation

Tips

Clean area of trash, branches and rocks before tilling

to prevent equipment damage.

Always begin tilling with the slowest ground speed

possible. Increase speed if conditions permit.

Always use full throttle (maximum engine speed)

when tilling.

Always engage the power take off (PTO) with tiller in

the raised position.

Till in long straight passes. Do not make turns while

tiller is in the ground, as equipment damage may

result.

A small center area will not be tilled due to the gear

case. Overlapping with a second pass will eliminate

this condition.

Avoid excessive tilling of the soil, as finely tilled soil

will not absorb moisture easily and puddles of water

or run-off may occur.

for T

illing

When tilling hard packed, very dry or virgin soil,

raise tiller so only the very top of the soil is

penetrated. On succeeding passes the depth may be

lowered. This reduces the tendency of the tiller to

push the tractor. If this happens, disengage power

take off (PTO) and reduce forward speed.

17

Maintenance

Service

Service

Oil–check level

Belt–check for wear/cracks

Chipped Surfaces–paint

Interval Chart

Operation

POTENTIAL HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could seriously injure you or other bystanders.

HOW TO AV

• Remove the key from the ignition switch and pull the wire off the spark plug before

you do any maintenance. Also push the wire aside so it does not accidentally contact

the spark plug.

OID THE HAZARD

Each

Use5Hours25Hours

X X X

Storage

Service

X X

X

Fall

Service

Notes

18

Maintenance

Greasing

and Lubrication

Service Interval/Specification

Check the gear lube level in the gear case after every

25 operating hours or once a year, whichever occurs

first. Gear lube changes are not required.

Gear lube type: SAE 90-140 API service GL-4 or

GL-5.

Refill capacity: 1 qt.

Checking Gear Lube

1. Position the tractor and tiller on a level surface

and lower the attachment lift so that the tiller

tines are on the ground. Set the parking brake

and turn the ignition key to “STOP” to stop the

engine. Remove the key.

2. Clean the area around the lower pipe plug

(Fig. 27).

Adjusting

Drive Belt T

ension

The drive belt is spring loaded and needs only

periodic adjustment, to maintain proper spring

tension.

Checking Drive Belt Tension

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. As the drive belt wears, and the tiller is raised

and lowered, the spring loaded idler arm moves

(Fig. 28).

3. Lower the tiller and observe the spring loaded

idler arm movement as you push on the belt. The

idler arm spring must be under tension. If it is

not under tension, replace the drive belt.

3. Remove the pipe plug carefully because the oil

level may be above the level of the pipe plug.

4. If gear lube runs from the case when the plug is

removed, the lube in the case is sufficient. Oil

may be added as necessary

Figure 27

Left side of tiller shown in operating position

1. Pipe

plug (hidden)

.

1

m–3497

1. Spring

loaded idler arm

Figure 28

2. Spring

2

1

2319

19

Maintenance

Storage

1. Before long term storage wash the machine with

mild detergent and water to remove dirt and

grime from the entire machine.

2. Check the condition of the drive belt.

3. Check gearcase lubrication level; refer to

Greasing and Lubrication, page 19.

4. Check and tighten all bolts, nuts, and screws.

Repair or replace any part that is damaged or

defective.

5. Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service

Dealer.

6. Store the machine in a clean, dry garage or

storage area. Cover the machine to protect it and

keep it clean.

20

Loading...

Loading...