Page 1

Form No. 3326–603

48 inch Snow/Dozer Blade

Wheel Horse 300 Series Classic Garden

Tractor Attachment

Model No. 79364—220000001 and Up

Operator’s Manual

Domestic English (EN)

Page 2

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembling the Blade 3. . . . . . . . . . . . . . . . . . . . .

Mounting the Rear Hitch on the Tractor 4. . . . . . .

Installing Blade to Tractor 5. . . . . . . . . . . . . . . . . .

Removing the Blade 6. . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Raising and Lowering the Blade 7. . . . . . . . . . . . .

Adjusting Dial-A-Height 8. . . . . . . . . . . . . . . . . . .

Adjusting the Blade Angle 8. . . . . . . . . . . . . . . . . .

Adjusting the Blade Trip Springs 8. . . . . . . . . . . .

Tips for Using the Blade 8. . . . . . . . . . . . . . . . . . .

Maintenance 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 9. . . . . . . .

Greasing and Lubrication 9. . . . . . . . . . . . . . . . . . .

Reversing the Scraper Blade 10. . . . . . . . . . . . . . . .

Storage 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied with

your new product, so feel free to contact your local

Authorized Service Dealer for help with service, genuine

replacement parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. You will find the model and serial

number plate at the location shown in Figure 1.

For your convenience, write the product model and serial

numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate and

maintain your product correctly. Reading this manual will

help you and others avoid personal injury and damage to

the product. Although we design, produce and market

safe, state-of-the-art products, you are responsible for

using the product properly and safely. You are also

responsible for training persons, who you allow to use the

product, about safe operation.

The warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury, even death. Danger,

Warning, and Caution are signal words used to identify

the level of hazard. However, regardless of the hazard, be

extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if the recommended precautions are not

followed.

Warning signals a hazard that may cause serious injury or

death if the recommended precautions are not followed.

Caution signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed.

Two other words are also used to highlight information.

Important calls attention to special mechanical

information, and Note emphasizes general information

worthy of special attention.

Determine the left and right side of the machine from the

normal operating position.

Figure 1

1. Model and serial number plate

2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

m–1237

1

All Rights Reserved

2

Printed in the USA

Page 3

Setup

Loose Parts

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Blade assembly

Rod

Control rod

Cotter pin, 1/8 x 1 in.

Frame assembly

Bolt, 3/4-16 x 3-3/4 in.

Locknut, 3/4-16 in.

Hairpin cotter, large

Bolt, 1/2-13 x 1 in

Jam nut, 1/2-13 in.

Cable

Bolt, 1/4 x 1 in.

Locknut, 1/4-20 in.

Cable clip

Cable bracket

Cotter pin, 1-1/4 in.

Rear hitch assembly

Strap

Angle bracket (if required)

Carriage bolt, 3/8-16 x 3-1/2 in.

Locknut, 3/8-16 in.

1

1

1

3

1

1

1

1

1

1

1

3

3

3

1

1

1

2

2

4

4

Assembling the blade

Mounting the rear hitch to the tractor

Lift link

Clevis pin, 3/8 x 7/8 in.

Hairpin cotter, medium

Assembling the Blade

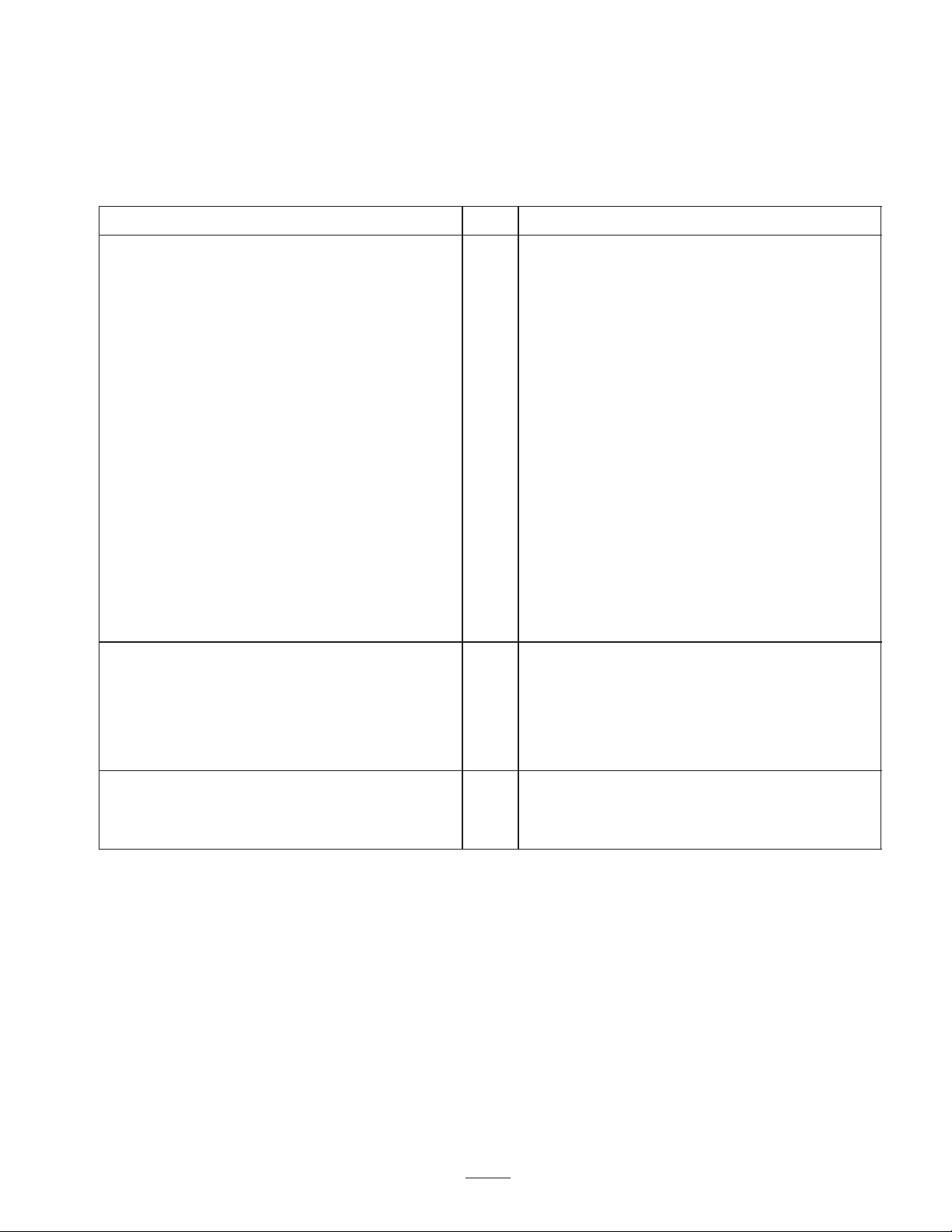

1. Lift and rotate the channel and trip spring assembly so

that the holes align with the lower blade mounts.

2. Slide the rod through the holes and secure with two 1

in. cotter pins (Fig. 2).

Note: If you have difficulty sliding the rod through the

holes, partially remove the upper rod and use a hammer to

drive the rod through. Then, install the upper rod.

3. Bend the ends of the cotter pins to secure the rod.

1

2

2

3

Assembling the lift link to the tractor lift

Page 4

4

3

2

3

1

m–3269

Figure 2

1. Channel

2. Rod

3. Cotter pin, 1/8 x 1 in.

4. Upper rod

4. Insert the end of the control rod through the 1/2 in.

(13 mm) hole in the bottom plate of the channel

(Fig. 3).

1. Channel

2. Grease here

4

1

2

m–1469

3

Figure 4

3. Bolt, 3/4–16 x 3-3/4 in.

4. Locknut, 3/4 in.

3

1

2

m–3271

Figure 3

1. Control r o d

2. 1/2 in. (13 mm) hole

3. Cotter pin, 1/8 x 1 in.

5. Insert a cotter pin (1/8 x 1 in.) through the hole in the

rod and bend the ends of the pin (Fig. 3).

6. Apply general purpose grease to the pivot area of the

frame and channel.

7. Slide the channel between the frame mount and secure

it with a bolt (3/4–16 x 3-3/4 in.) and a locknut

(3/4 in.) (Fig. 4).

Note: Insert the bolt up from the underside of the frame

(Fig. 4).

Important Do not tighten the nut and bolt excessively,

thereby causing binding on the channel as it pivots from

side to side.

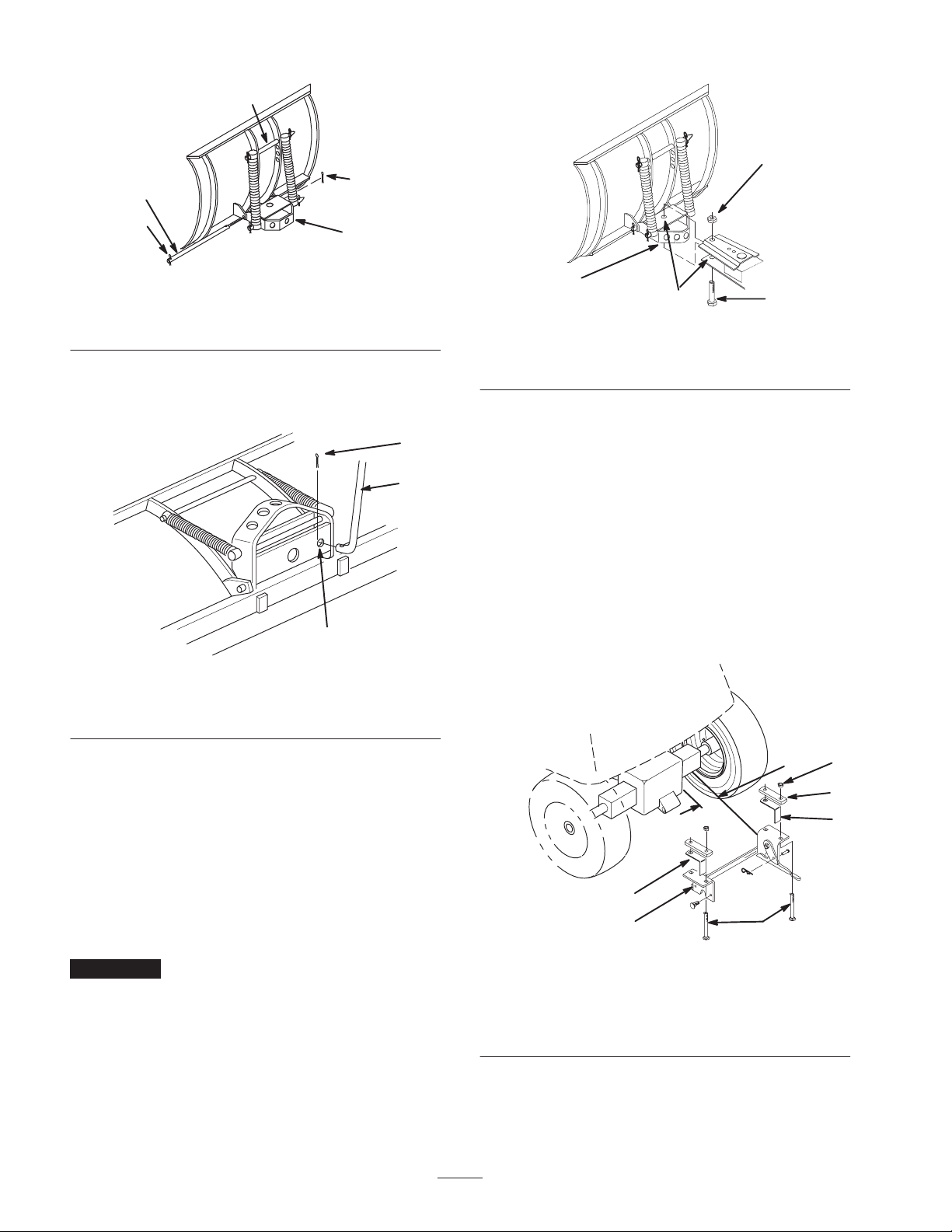

Mounting the Rear Hitch on the

Tractor

Center the hitch on the axle housing and secure it using 4

carriage bolts (3/8 x 3-1/2 in.) , 2 straps, and 4 locknuts

(3/8 in.) as illustrated in Figure 5.

Note: On hydrostatic models with the oil filter facing the

rear, install the hitch 3-1/4 in. (8.3 cm) from the right side

of the center housing.

Note: On 8-speed gear drive models, install angle spacers,

positioned along top and rear of axle (Fig. 5).

6

5

1. Rear hitch

2. Carriage bolt, 3/8 x

3-1/2 in.

3. Strap

1

Figure 5

2

4. Locknut, 3/8 in.

5. Angle spacer (if required)

6. 3-1/4 in. (8.3 cm) location

m–3357

4

3

5

4

Page 5

Installing Blade to Tractor

1. Remove PTO cover from the side of tractor, if so

equipped, and store it in a safe location so you can

install it when you remove the blade.

2. Install the PTO cover knobs back on the studs on the

tractor.

3. Position the blade on a level surface with space behind

it for the tractor.

11. Rotate the control handle to align the hole at the

bottom of the handle with the control rod.

1

5

6

7

4

4. Park the tractor over the blade, with the frame between

the wheels.

5. Set the parking brake, stop the engine, and remove the

key.

6. Continue sliding the frame to the rear hitch.

7. Open the latch levers and lift the frame into the rear

hitch.

8. Close the latch levers and secure them with clevis pins

(1/4 x 3/4 in.) clevis pins and small hairpin cotters

(Fig. 6).

2

1

3

4

m–2945

Figure 6

1. Frame mount

2. Latch lever

3. Clevis pin, 1/4 x 3/4 in.

4. Hairpin cotter-small

8

6

7

8

3

10

9

2

Figure 7

1. Control handle

2. Control rod

3. Large hairpin cotter

4. Release lever

5. Z-fitting

6. Bolt, 1/4 x 1 in.

7. Cable clip

8. Locknut, 1/4-20 in.

9. Bolt, 1/2-13 x 1 in.

10. Jam nut, 1/2-13 in.

12.Insert the control rod through the handle end and

secure it with a large hairpin cotter (Fig. 7).

m–5576

9. Attach the control handle to the pivot support using the

pivot bolt (1/2-13 x 1 in.). Screw the bolt into the pivot

support until the handle is snug and then back it off

slightly to let the handle pivot freely (Fig. 7).

10.Secure the bolt with a jam nut (1/2 in.) (Fig. 7).

13.Thread the balled end of the cable through the keyhole

slot in the frame up to the fitting on the cable jacket.

14.Slide the fitting through the slot and push it to the

right, ensuring there is a jam nut (1/2 in.) on each side

of the frame (Fig. 8).

5

Page 6

15.Connect the Z-fitting on the end of the cable to the

release lever (Fig. 7).

19.Pull down on the cable jacket to remove slack and

secure the cable to the handle using 3 cable clips, 3

bolts (1/4 x 1 in.), and 3 locknuts (1/4-20 in.) (Fig. 7).

1

5

7

6

2

4

Figure 8

1. Rear view

2. Front view

3. Cable jacket

4. Cable

16.Tighten the jam nuts (Fig. 8).

3

6

7

5. Fitting

6. Keyhole slot

7. Jam nuts

m05040 & 5041

20.Set the Dial-a-Height to the Mounting Position (lowest

setting), and lower the attachment lift all the way.

21.Attach the lift link between blade and tractor

attachment lift hole, using 2 clevis pins (3/8 x 7/8 in.)

and medium hairpin cotters (Fig. 10).

1

3

2

4

m–2946

Figure 10

1. Attachment lift

2. Lift link

3. Clevis pin, 3/8 x 7/8 in.

4. Hairpin cotter, mediu m

Note: To use the blade with down pressure, purchase a

long lift link kit and install it between tractor lift and

blade.

17.Insert the balled end of the cable into the cable bracket

(Fig. 9).

3

4

1

1

2

4

m–5043

Figure 9

1. Cable bracket

2. Cable

3. Angle pin

4. Cotter pin, 1-1/4 in.

(32 mm)

18.Attach the cable bracket to the angle pin at the blade

assembly (Fig. 9) with a cotter pin (1-1/4 in.).

Note: Put the cotter pin through the hole that removes the

most slack from the cable.

Removing the Blade

Note: Save all hardware, rods, washers, and hairpin

cotters for reuse when installing blade.

1. Park the machine on a level surface.

2. Raise attachment lift to the transport position.

3. Turn the Dial-a-Height knob counterclockwise, all the

way, and lower the attachment lift lever to the

mounting position.

4. Set the parking brake, stop the engine, and remove the

key.

5. Remove the two clevis pins and hairpin cotters

securing the lift link between the blade and the tractor

attachment lift (Fig. 10).

6. Open the latch levers and lower the frame from the

rear hitch.

7. Close the latch levers and secure them closed with the

clevis pins and hairpin cotters (Fig. 11).

Note: Save all hardware, rods, washers and hairpin cotters

for use when installing blade.

6

Page 7

2

1

1

2

1

3

Figure 11

1. Frame mount

2. Latch lever

8. Remove the hairpin cotter and control rod from the

control handle (Fig. 7).

9. Begin sliding the blade forward and toward the right

side of the tractor.

10.After the frame clears the right rear tire, rotate the

control handle, next to the frame.

11. Roll the tractor away from the frame.

4

3. Clevis pin

4. Hairpin cotter

m–2945

Operation

Caution

If you hit fixed objects with the blade, the tractor

could stop abruptly, causing you to lose control,

personal injury, and equipment damage.

• Travel at a safe, slow speed.

• Check the area to be plowed and mark all fixed

objects so you can avoid them.

2

Figure 12

1. Up 2. Down

2

1

Figure 13

1. Lift lever

2. Button

3. Dial-A-Height

m–2317

3

m–2514

Raising and Lowering the

Blade

Depending on your tractor model, it will have either a

power or a manual lift lever (Fig. 12 and 13) to raise and

lower attachments.

Raising the Blade Using a Power Lift

Lever

1. Turn key to the On or Run position.

2. Push the lift lever up to raise the attachment lift

(Fig. 12).

Lowering the Blade Using a Power Lift

Lever

1. Turn key to the On or Run position.

2. Push the lift lever down to lower the attachment lift

(Fig. 12).

7

Page 8

Raising the Blade Using a Manual Lift

Lever

1. Stop the machine.

2. Pull the attachment lift lever rearward until the blade

raises and the latch locks (Fig. 13).

Lowering the Blade Using a Manual Lift

Lever

1. Stop the machine.

2. Pull attachment lift lever rearward, to release lift

pressure and push the button on top to release the latch

(Fig. 13).

3. Move the lift lever forward to lower the blade (Fig.13).

Adjusting Dial-A-Height

The Dial-A-Height control (Fig. 13) is used to adjust the

downward travel of the attachment.

2. Push or pull the handle to change the angle.

3. Release the lever and pull or push the handle until the

locking pin on the blade snaps into place.

Adjusting the Blade Trip

Springs

You can mount the blade trip springs in four positions.

The top hole provides the greatest scraping pressure and

the bottom hole provides the least scraping pressure

(Fig. 15). Toro recommends using the second hole from

the top for removing snow.

1. Remove the hairpin cotter and slide the rod from the

blade and springs (Fig. 15).

2. Slide the rod through the springs and the new hole

position in the blade (Fig. 15).

1

4

1. Raise the attachment lift.

2. Rotate the Dial-a-Height knob to change the stop

location.

Turn the knob clockwise to raise and counterclockwise

to lower the height of the attachment.

Adjusting the Blade Angle

You can turn the blade from side to side, in 5 positions.

You control the angle using the control handle (Fig. 14).

1. Squeeze the release lever toward the handle (Fig. 14).

2

Figure 14

1. Handle 2. Release lever

1

m–5577

2

1. Hairpin cotter

2. Rod

Figure 15

3. Spring

4. T op hole

3

m–3395

Tips for Using the Blade

The following lists contains information that will help you

obtain the best possible results with your blade:

• Remove snow as soon as possible after it falls.

• Remove snow from a driveway by making one pass

down the center and then plowing snow to either side

on successive passes.

• If the tractor looses traction when using the snow

blade, install wheel weights and/or tire chains, which

are available from your Authorized Service Dealer.

• Install the optional skid shoe kit is to control the height

of blade from the ground for even scraping if desired.

8

Page 9

Maintenance

Recommended Maintenance Schedule

Maintenance Service

Interval

25 hours

Yearly/Storage Service

Maintenance Procedure

• Grease the channel pivot

• Oil the linkages

• Grease the channel pivot

• Oil the linkages

• Examine the scraper for wear and replace if damaged or worn

• Paint chipped surfaces (Paint is available from your Authorized Service Dealer.)

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug before you do

any maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

Greasing and Lubrication

Grease and oil the machine after every 25 operating hours

or once a year, whichever occurs first.

Grease Type: General-purpose grease.

Oil Type: SAE 10W or l0W30.

Grease the Channel Pivot

1. Lower the attachment.

2. Set the parking brake, stop the engine, and remove the

ignition key.

3. Clean the area around the channel pivot with a rag.

Apply grease to the pivot bolt, frame and sector

(Fig. 16).

m–1473

Figure 16

4. Wipe off excess grease.

Oil Linkages

1. Set the parking brake, stop the engine, and remove the

ignition key.

2. Place a few drops of oil on all movable linkages

(Fig. 16).

3. Wipe off excess oil.

9

Page 10

Reversing the Scraper Blade

The scraper blade contacts the ground, preventing damage

to the snow blade. Periodically inspect the scraper blade

for wear. When the scraper becomes worn, before the

working surface contacts the housing, reverse the scraper

blade.

1. Start the tractor, raise the blade, and support the

housing off the ground.

2. Set the parking brake, stop the engine, and remove the

ignition key.

3. Remove the locknuts and carriage bolts securing the

scraper (Fig. 17).

4. Reverse the scraper blade to replace a worn edge and

install it with the previously removed hardware

(Fig. 17).

3

2

7. Cover the machine to protect it and keep it clean.

1

m–1468

Figure 17

1. Lock nut

2. Carriage bolt

3. Scraper blade

Storage

1. Before long-term storage, wash the machine with mild

detergent and water to remove dirt and grime from the

entire machine.

2. Check the condition of the scraper blade; refer to

Reversing the Scraper Blade, page 10.

3. Grease and oil the blade; refer to Greasing and

Lubrication, page 9.

4. Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is damaged.

5. Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Toro Dealer.

6. Store the machine in a clean, dry garage or storage

area.

10

Page 11

11

Page 12

Loading...

Loading...