Toro 79361 Operator's Manual

FORM NO. 3318–826

Wheel Horse

44” Snowthrower

for

Garden Tractors

Model No. 79361 – 6900001 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

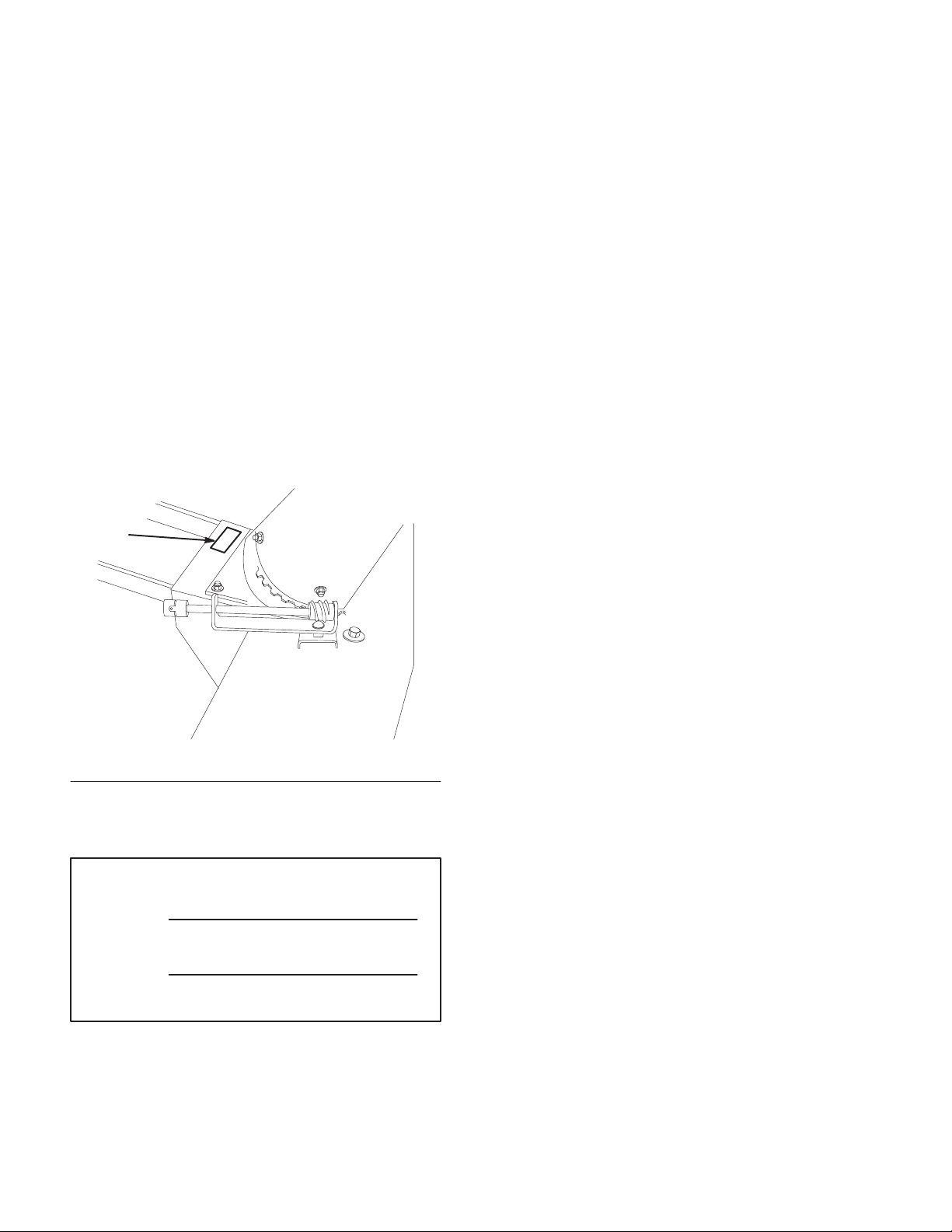

product. You will find the model and serial number

plate located in a unique place on the product as

shown below.

1

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

1280

1. Model and Serial Number Plate

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

Printed in USA

The TORO Company – 1996

Contents

Safety and Instruction Decals 2. . . . . . . . . . . . . .

Assembly 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 3. . . . . . . . . . . . . . . . . . . . . . . . .

Assemble Snowthrower 5. . . . . . . . . . . . . . .

Install Snowthrower to Tractor 7. . . . . . . . .

Removing the Snowthrower 11. . . . . . . . . . .

Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Power Take Off (PTO) 15. . . .

Attachment Lift Lever 16. . . . . . . . . . . . . . . .

Attachment Power Lift 16. . . . . . . . . . . . . . . .

Adjusting Dial-A-Height 17. . . . . . . . . . . . . .

Page

Page

Adjusting Discharge Chute 17. . . . . . . . . . . .

Tips for Throwing Snow 18. . . . . . . . . . . . . .

Maintenance 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 19. . . . . . . . . . . . . . . .

Greasing and Lubrication 20. . . . . . . . . . . . . .

Adjusting Skids 21. . . . . . . . . . . . . . . . . . . . .

Replacing Scraper Blade 21. . . . . . . . . . . . . .

Adjusting Drive Chain Tension 22. . . . . . . . .

Replace Drive Belt 22. . . . . . . . . . . . . . . . . . .

Storage 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 24. . . . . . . . . . . . . . . . . . . . . . . . .

1

Safety

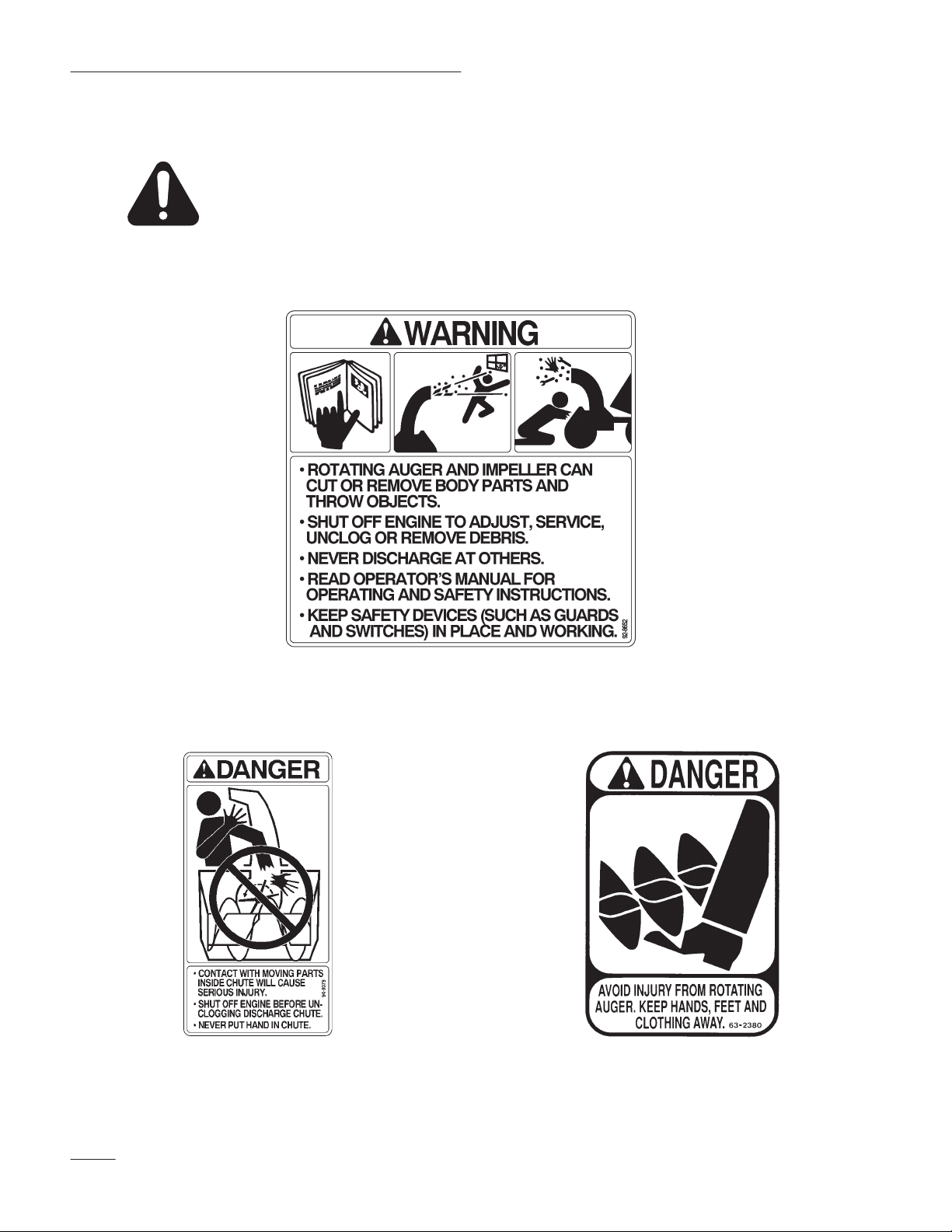

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON BACK OF HOUSING

(Part No. 92–8652)

RIGHT SIDE

ON BACK OF CHUTE

LEFT AND RIGHT SIDE (2)

(Part No. 94–8079)

ON BACK OF HOUSING

LEFT AND RIGHT SIDE (2)

(Part No. 63–2380)

2

Assembly

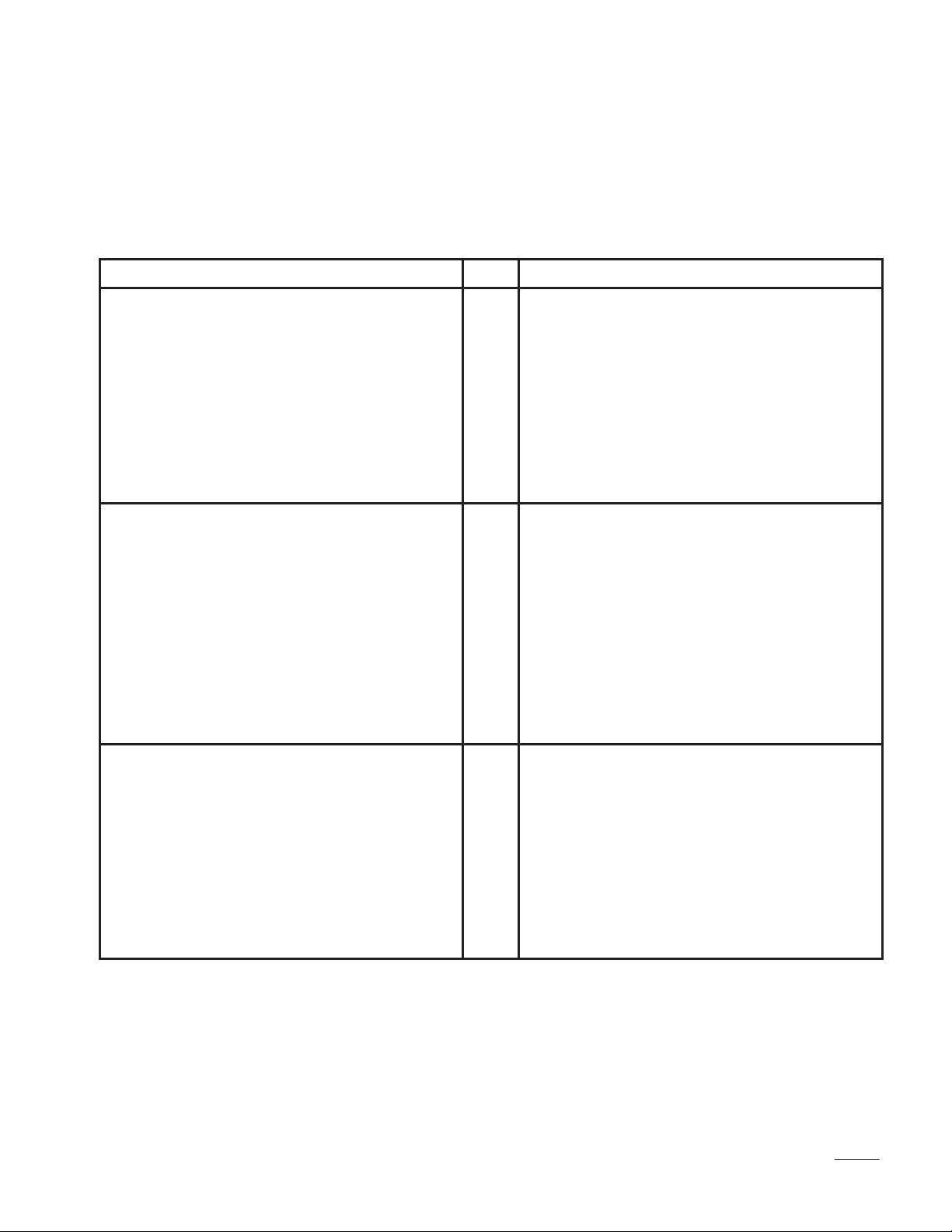

Loose Parts

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Housing

Frame

Bolt 3/8–16 x 1”

Locknut 3/8”

Spring

Drive chain

Chain cover

Bolt 1/4–20 x 1/2”

Rotor assembly

Carriage bolt 5/16–18 x 1”

Discharge chute-upper section

Discharge chute-lower section

Discharge cover

Carriage bolt 5/16–18 x 5/8”

Carriage bolt 5/16–18 x 3/4”

Washer 5/16”

Locknut 5/16”

1

1

6

6

1

1

1

2

1

1

1

1

1

2

3

5

6

Install frame and pulley

Install rotator and discharge chute assembly

Belt guard bracket

Bolt 3/8–16 x 2”

Locknut 3/8”

Anti-sway bracket

Clevis pin

Belt cover

Washer 3/8”

Hairpin cotter

1

2

2

1

Install belt guard and anti-sway brackets

1

1

2

3

3

Assembly

DESCRIPTION QTY. USE

Snowthrower assembly

Lift link

Lift rod

Lift assist spring

Adjustable link

Clevis pin

Washer 9/32”

Hairpin cotter

Lift spring

Retainers

Belt

Crank handle

Handle support

Clevis pin-locking

1

1

1

1

1

1

4

Mount snowthrower to tractor

8

1

2

1

1

1

1

4

Assembly

Assemble Snowthrower

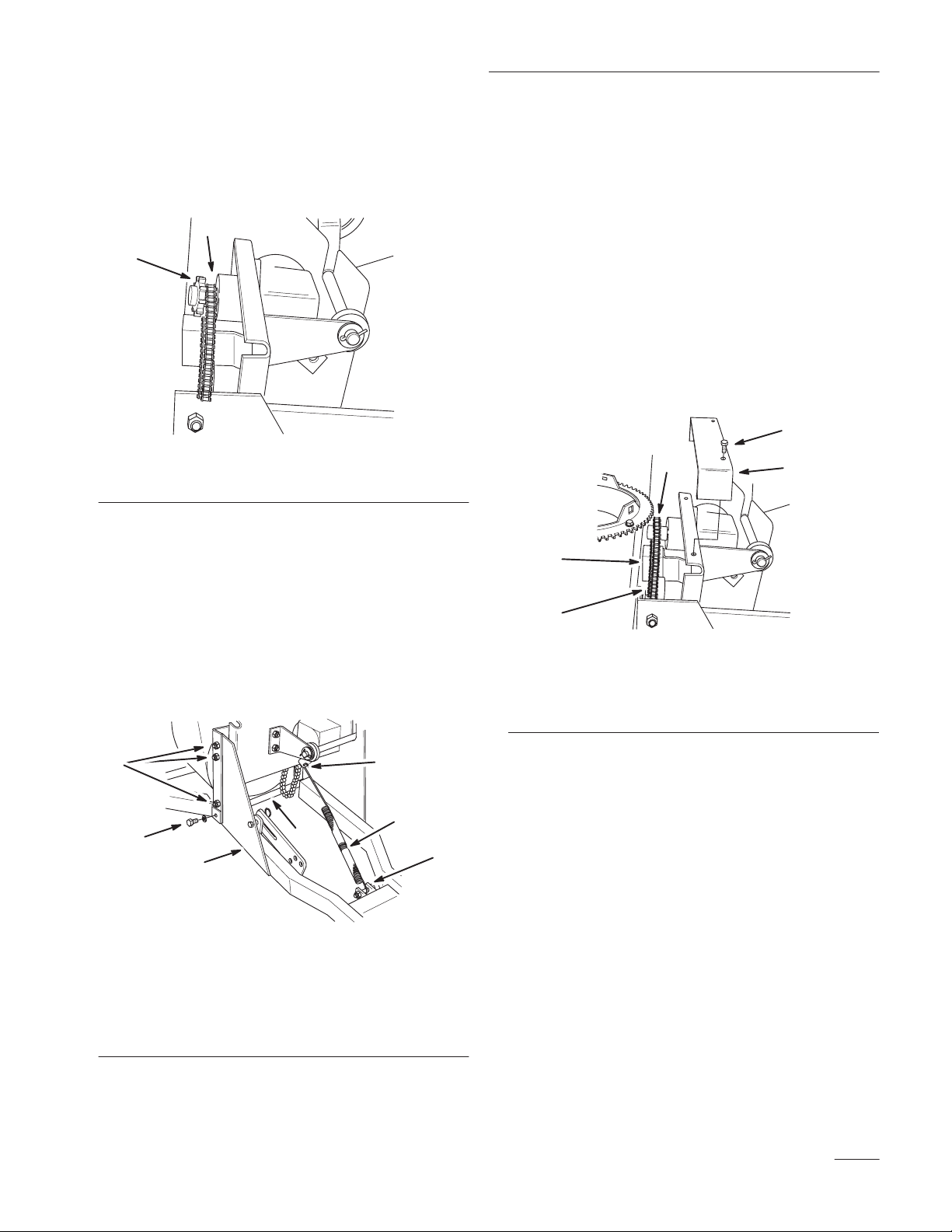

1. Place drive chain behind, not on, gearbox drive

sprocket (Fig. 1).

2

1

7

m–2581

Figure 1

1. Drive sprocket 2. Drive chain

2. Remove cross bar from frame, secured by (2)

bolts and lock washers (Fig. 2). Slide frame into

housing and secure with cross bar, bolts and lock

washers, previously removed and

(6) 3/8 x 1” bolts (heads to the inside) and (4)

3/8” locknuts (Fig. 2).

3. Hook long end of spring between frame bolt and

idler pulley bellcrank (Fig. 2).

4. Place drive chain on gearbox and large sprockets

(Fig. 3).

IMPORTANT: Check that sprockets are in

line with each other. If not, loosen set screws

and align.

5. Adjust chain tension block so chain deflects

3/8”to 5/8” between sprockets (Fig. 3).

IMPORTANT: Do not overtighten chain or

excessive wear will occur.

6. Install chain cover with (2) 1/4 x 1/2” bolts

(Fig. 3).

5

3

2

1. Chain

2. Large sprocket

3. Tension block

1

Figure 3

4. Chain cover

5. Bolt 1/4 x 1/2”

4

m–2583

4

1

1. Frame

2. Cross bar

3. Bolt and lock washer

4. Bolt 3/8 x 1” and Locknut

3/8”

7

5

23

6

m–2582

Figure 2

5. Spring

6. Frame bolt

7. Bellcrank

5

Assembly

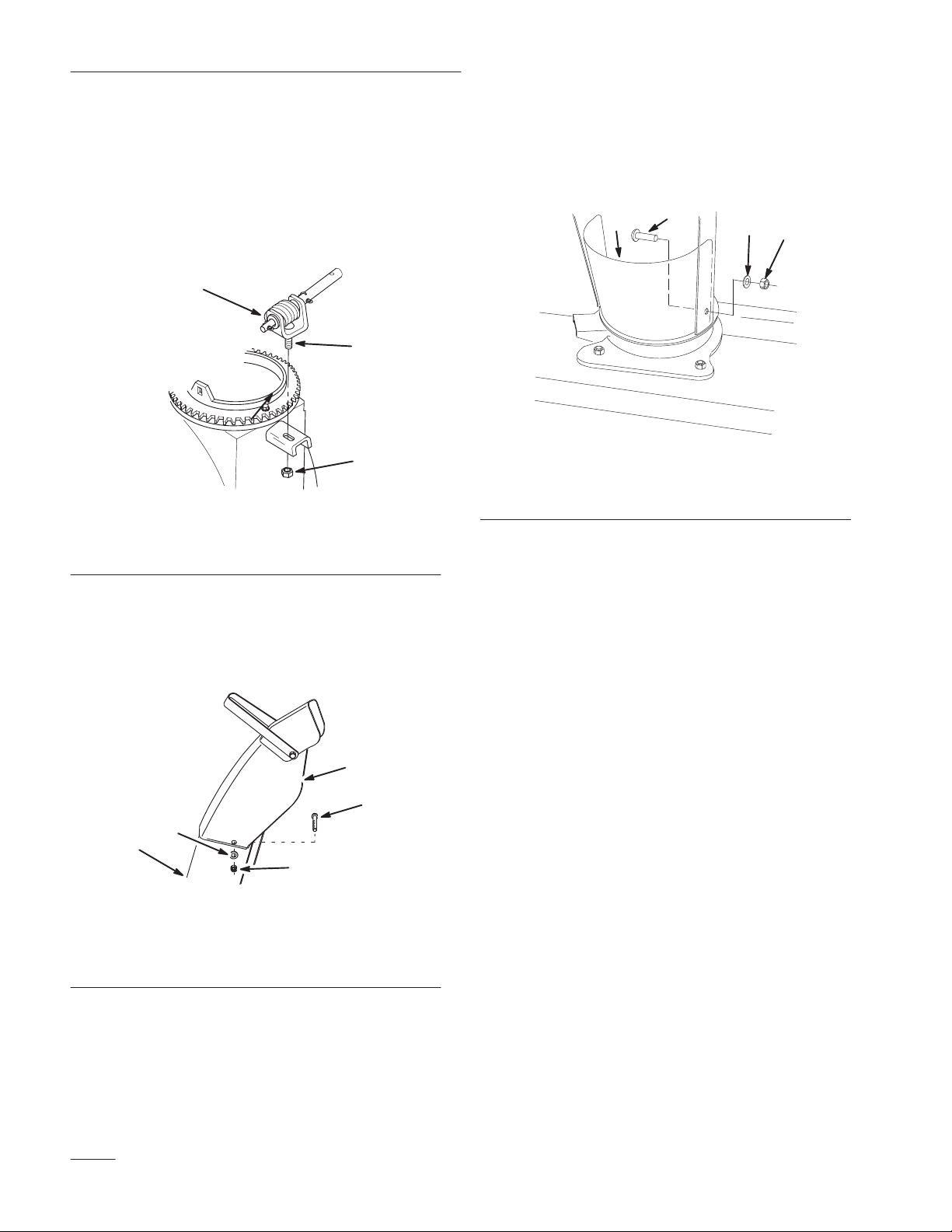

7. Install discharge chute rotator assembly into slot

in housing with 5/16 x 1” carriage bolt (head to

top) and 5/16” locknut (Fig. 4).

8. Adjust rotator assembly so that worm gear is at

right angle with chute, the teeth mesh fully and

the chute turns freely, tighten locknut securely.

1

2

1

3

m–2584

Figure 4

1. Rotator assembly

2. Carriage bolt 5/16 x 1”

3. Locknut 5/16”

10. Install discharge chute assembly and cover onto

housing with (3) 5/16 x 3/4” carriage bolts

(heads to inside), (3) 5/16” washers and (3)

5/16” locknuts (Fig. 6).

12

1. Discharge chute cover

2. Carriage bolt 5/16 x 3/4”

Figure 6

3. Washer 5/16”

4. Locknut 5/16”

3

4

2241

9. Assemble upper discharge chute section outside

and on top of lower section with (2) 5/16 x 5/8”

carriage bolts (heads on inside), (2) 5/16”

washers and (2) 5/16” locknuts (Fig. 5).

1

3

4

2

1. Upper section

2. Lower section

3. Carriage bolt 5/16 x 5/8”

5

Figure 5

4. Washer 5/16”

5. Locknut 5/16”

1290

6

Assembly

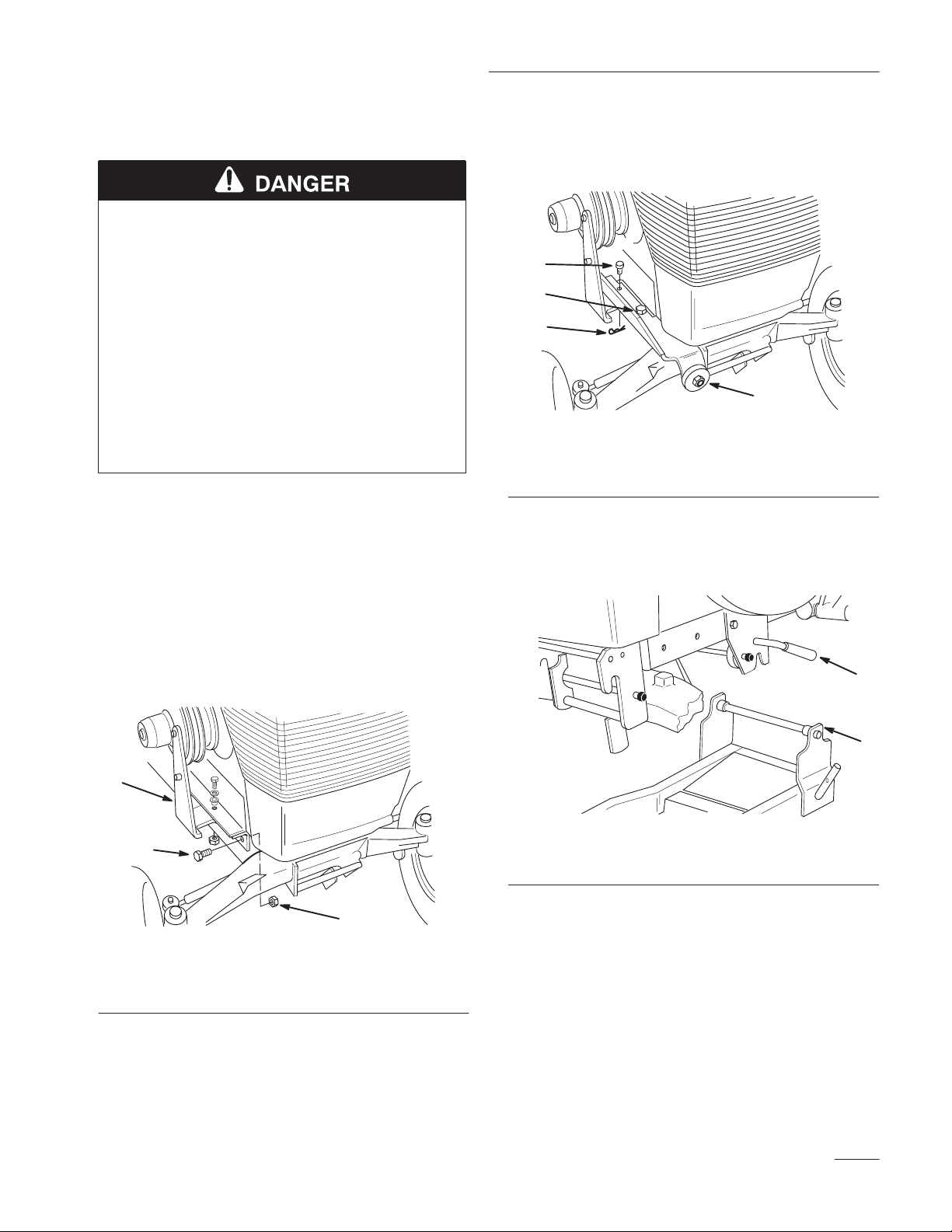

Install Snowthrower to Tractor

POTENTIAL HAZARD

• When snowthrower is attached to the

tractor, without additional weight, the

tractor may become unstable.

WHAT CAN HAPPEN

• Loss of traction and stability may cause

loss of tractor control.

HOW TO AVOID THE HAZARD

• NEVER operate tractor, equipped with

snowthrower, unless 100lb rear wheel

weights are installed.

1. Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

4. Slide anti-sway bracket into guide slot in the

front of the belt guard bracket and secure to

frame with clevis pin and hairpin cotter (Fig.

3

2

4

1. Anti-sway bracket

2. Guide

1

Figure 8

3. Clevis pin

4. Hairpin cotter

m–2588

5. Position tractor over rear of snowthrower frame.

Open mid-mount hitch and lift frame rod into

hitch. Close and lock hitch (Fig. 9).

2. Remove the belt cover; refer to tractor

Operator’s Manual.

3. Install belt guard bracket to tractor frame with

(2) 3/8 x 2” bolts and 3/8” locknuts (Fig. 7).

1

2

m–2587

1. Belt guard bracket

2. Bolt 3/8 x 2”

3

Figure 7

3. Locknut 3/8”

1

2

m–2585

Figure 9

1. Mid–mount hitch 2. Frame rod

7