Page 1

FormNo.3367-329RevA

32inBagger

2011andAfterTimeCutter

®

Z3000Series

RidingMower

ModelNo.79333—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

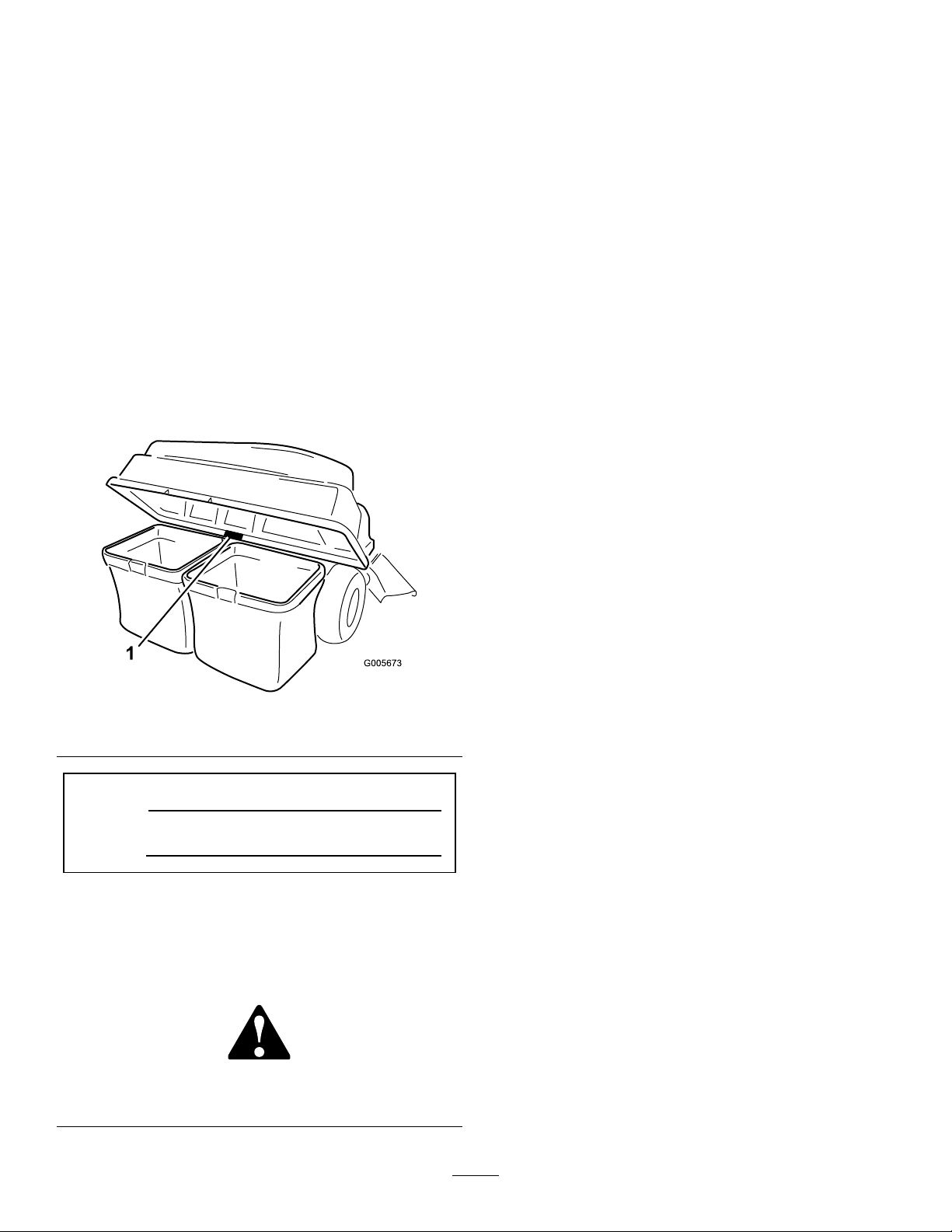

Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

Introduction.................................................................2

Safety...........................................................................3

TowingSafety.......................................................3

SafetyandInstructionalDecals.............................4

Setup............................................................................5

1InstallingtheW eight..........................................6

2InstallingtheRearGuard...................................8

3InstallingtheBaggerFrame................................8

4AssemblingtheBaggerT op..............................10

5InstallingtheBaggerTop.................................10

6InstallingtheChute..........................................11

7ConnectingwiththeDischargeTube................13

8InstallingtheDeckRing...................................13

9InstallingtheBlade..........................................14

Operation...................................................................14

EmptyingtheGrassBags....................................14

ClearingObstructionsfromtheBagger...............15

RemovingtheBagger.........................................15

OperatingTips...................................................15

Maintenance...............................................................17

RecommendedMaintenanceSchedule(s)................17

InspectingtheBaggerAttachment......................17

InspectingtheMowerBlades..............................17

CaringfortheGrassBags...................................18

CleaningtheBaggerAttachment.........................18

Storage.......................................................................18

StoringtheBaggerAttachment...........................18

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

DANGER

Enginescanbecomehotwhentheyareoperating.

Severeburnscanoccurfromcontactinghot

surfaces.

Allowengines,especiallythemufer,tocoolbefore

touching.

DANGER

Debris,suchasleaves,grass,orbrushcancatch

re.Areintheengineareacancausepersonal

injuryandpropertydamage.

TowingSafety

•Donotattachtowedequipmentexceptatthehitch

point.

•Followtheattachmentmanufacturer’s

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftractionandlossofcontrol.Reduce

towedweightandslowdown.

•Stoppingdistanceincreaseswiththeweightofthe

towedload.Travelslowlyandallowextradistance

tostop.

•Keeptheengineandmuferareafreeofdebris

accumulation.

•Takecarewhenopeningthebaggercoverto

keepdebrisfromfallingontotheengineand

muferarea.

•Allowthemachinetocoolbeforestoringit.

•Makewideturnstokeeptheattachmentclearofthe

machine.

•Donottowaloadthatweighsmorethanthetowing

machine.

3

Page 4

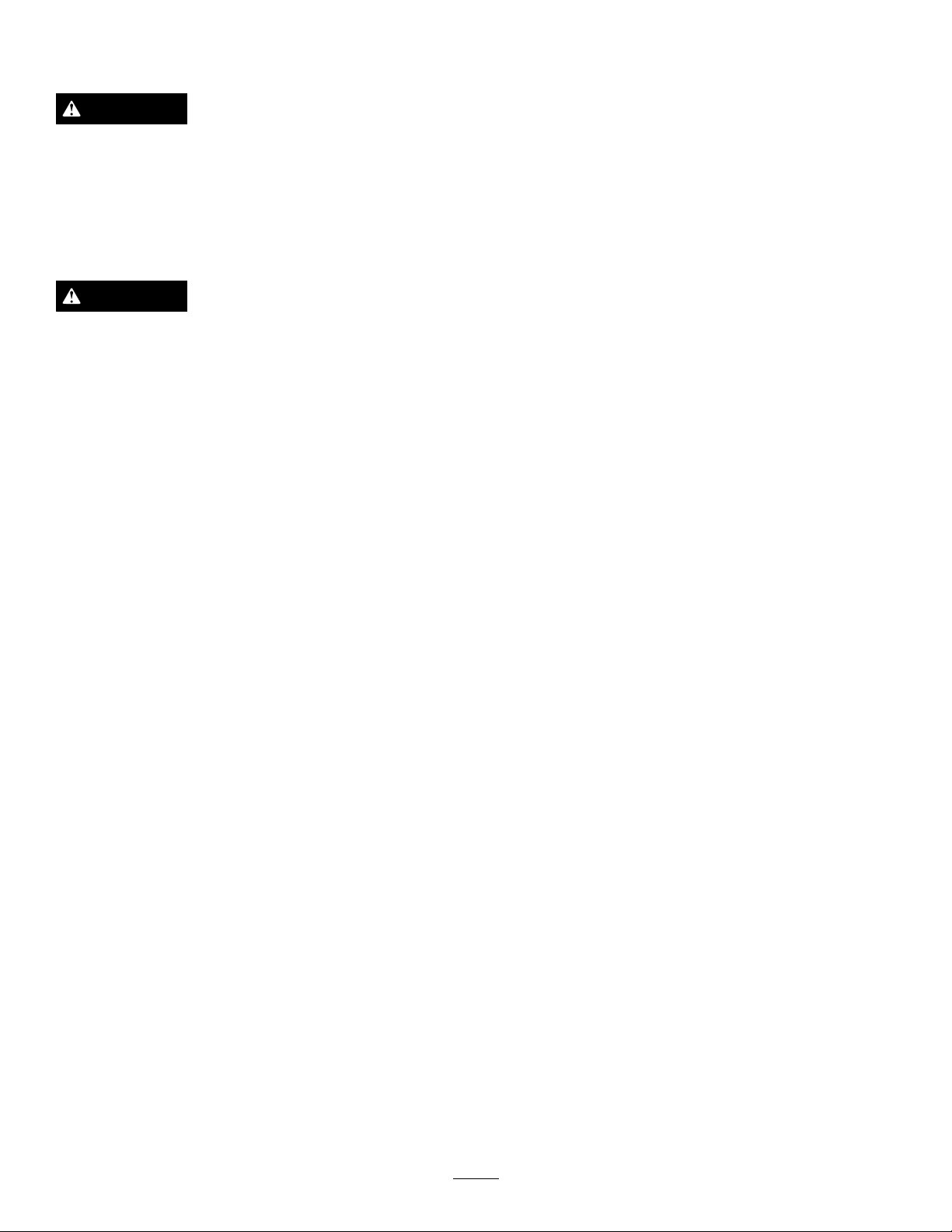

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

109-6809

1.Crushinghazardofhand—donotremovethewholebaggerfromthemachine;openthebaggertopandthenremovethebag(s)

fromthebagger.Donotremovethebaggertopwhenitisclosed;openthebaggertopandthenremoveit.

109-7076

4

Page 5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Bolt(3/8x1-1/4inches)

Locknut(3/8inch)

Weightmountingbracket,left

Weightmountingbracket,right1

Washers4

Weightholdingbracket1

Bolt(3/8x1inch)

Flatweight1

Suitcaseweight

Keyedcrossbar1

Rearguard1

Selftappingscrew(5/16x3/4inch)

Baggerframesupportbracket

Supportspacerplate

Selftappingscrew(5/16x3/4inch)

Bolt(5/16x1inch)

Locknut(5/16inch)

Angledbracket1

Carriagebolt(5/16x3/4inch)

Baggerframe

Clevispin(1/2x2-1/4inch)

Hairpincotter

Rod2

Washer4

Baggertop1

Baggerscreen1

GrassBag

Upperbaggertube1

Cutoffbafe

Chute

Qty.

Use

4

4

1

Installtheweight.

2

1

4

1

1

2

2

4

2

1

1

5

2

1

1

Installtherearguard.

Installthebaggerframe.

Assemblethebaggertop.

Installthebaggertop.

Installthechute.

7

8

9

Nopartsrequired

Deckring4

Bolt(5/16x3/4inch)

Locknut(5/16inch)

Hi-Liftblade

5

–

8

8

1Installtheblade.

Connectwiththedischargetube.

Installthedeckring

Page 6

1

G014875

1

2

3

4

G014877

1

2

3

4

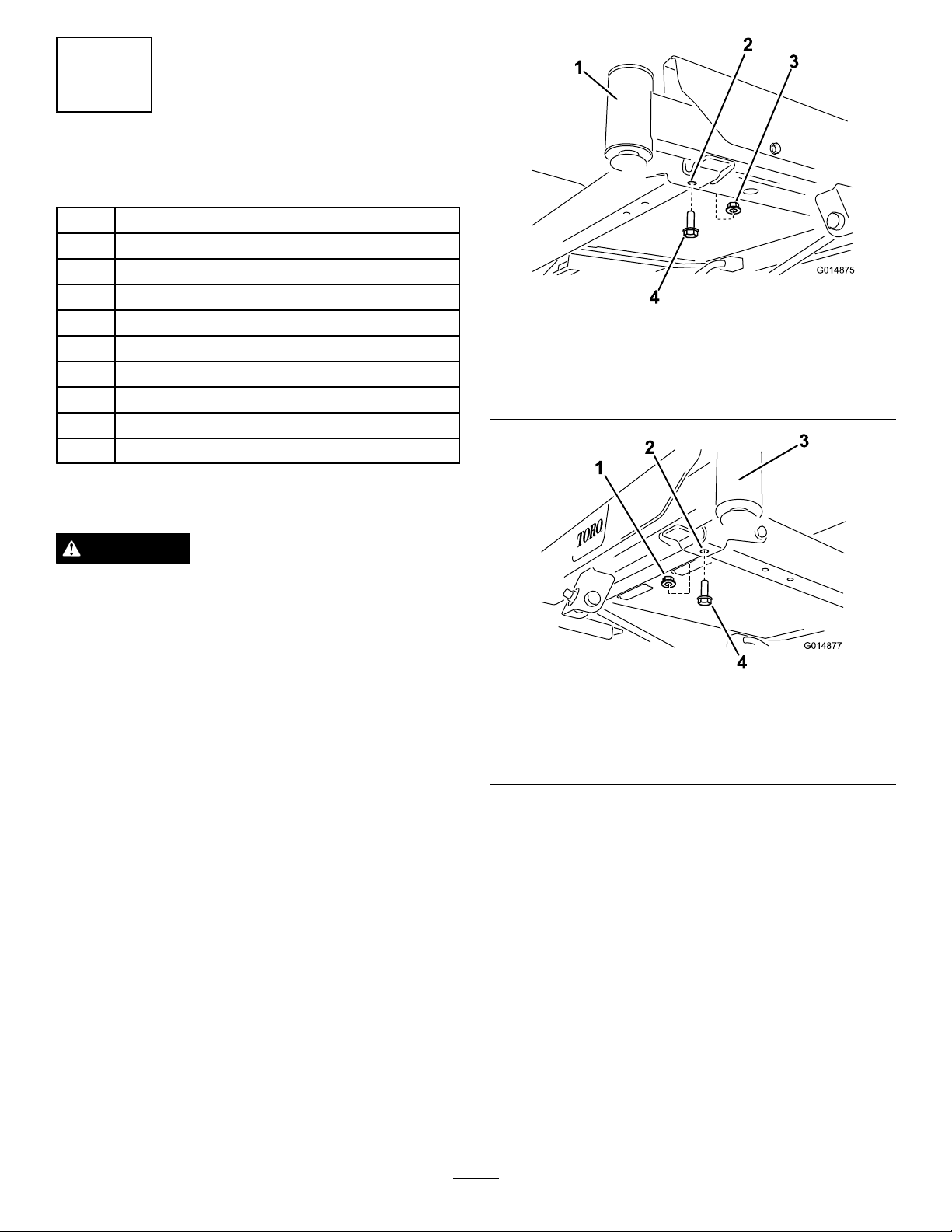

InstallingtheWeight

Partsneededforthisprocedure:

4

Bolt(3/8x1-1/4inches)

4

Locknut(3/8inch)

1

Weightmountingbracket,left

1Weightmountingbracket,right

4Washers

1Weightholdingbracket

2

Bolt(3/8x1inch)

1Flatweight

1

Suitcaseweight

1Keyedcrossbar

Procedure

1.Frontrightcaster(castor

forkandwheelnotshown

forclarity)

2.Forwardhole,rightside

Figure3

3.Bolt(3/8x1inch)

4.Locknut(3/8inch)

CAUTION

Thebaggerchangestheweightdistributionofthe

machine.Operatingthemachinewithoutthefront

weightsmaycauseanunstableconditionwhich

couldresultinalossofcontrol.

Ensurethefrontweightsareproperlyinstalled

beforeoperatingthemachinewiththebagger

attachment.

1.Locatetheforwardboltsontheundersideofthe

frame(Figure3andFigure4).Removethetwobolts

(3/8x1inch)andtwolocknuts(3/8inch).Retain

thelocknuts.

Figure4

1.Locknut(3/8inch)3.Frontleftcaster(castor

2.Forwardhole,leftside4.Bolt(3/8x1inch)

forkandwheelnotshown

forclarity)

2.Locatetheleftandrightweightmountingbrackets

inlooseparts.Startbyinstallingtheleftbracketto

theundersideoftheframe.

3.Securethebrackettotheframeusingtwobolts(3/8

x1-1/4inches),twowashersandtwolocknuts(3/8

Figure5).Onelocknutisfromloosepartsand

inch)(

theotherisreusedfromearlierremoval.

6

Page 7

G014878

1

2

3

4

5

6

7

8

Figure5

G014876

1

2

3

4

5

6

7

8

G014883

1

2

3

4

5

6

7

8

G014879

1

2

3

4

5

1.Locknut(3/8inch),existing5.Hole,existinginframe

2.Forwardhole,leftside

3.Frontleftcaster(castor

forkandwheelnotshown

forclarity)

4.Locknut(3/8inch),loose

parts

6.Washer

7.Bolt(3/8x1-1/4inches)

8.Leftmountingbracket

4.Ontherightsideofthemachineinstalltheright

weightmountingbracket.

•Formachineswithoutafootassistliftpedal:

securethebracketusingtwobolts(3/8x1-1/4

inches),twowashersandtwolocknuts(3/8

Figure6).Onelocknutisfromlooseparts

inch)(

andtheotherisreusedfromearlierremoval.

theforwardfastenersinthefootassistliftpedal

bracket.Securethebracketusingtwoboltsand

twolocknuts(

Figure7).Onelocknutisfrom

loosepartsandtheotherisreusedfromearlier

removal.

Figure7

1.Frontrightcaster(castor

forkandwheelnotshown

forclarity)

2.Forwardhole,rightside

3.Locknut(3/8inch),existing

4.Rightmountingbracket

5.Bolt(3/8x1-1/4inches)

6.Footassistliftpedal

bracket

7.Hole,existinginbracket

8.Locknut(3/8inch),loose

parts

5.Installtheweightholdingbrackettothemounting

brackets(Figure8).Aligntheinboardholesin

thebracketwiththemountingbracketsinstalled

previously.Makesurethebracketiscenteredonthe

frame.Securewithtwobolts(3/8x1inch)andtwo

locknuts(3/8inch).

Figure6

1.Frontrightcaster(castor

2.Forwardhole,rightside6.Washer

3.Locknut(3/8inch),existing7.Hole,existinginframe

4.Rightmountingbracket

forkandwheelnotshown

forclarity)

•Formachineswithafootassistliftpedal:The

washerswillnotbeneeded.Instead,remove

5.Bolt(3/8x1-1/4inches)

8.Locknut(3/8inch),loose

parts

Figure8

1.Locknut(3/8inch)4.Bolt(3/8x1inch)

2.Weightholdingbracket5.Rightmountingbracket

3.Leftmountingbracket

7

Page 8

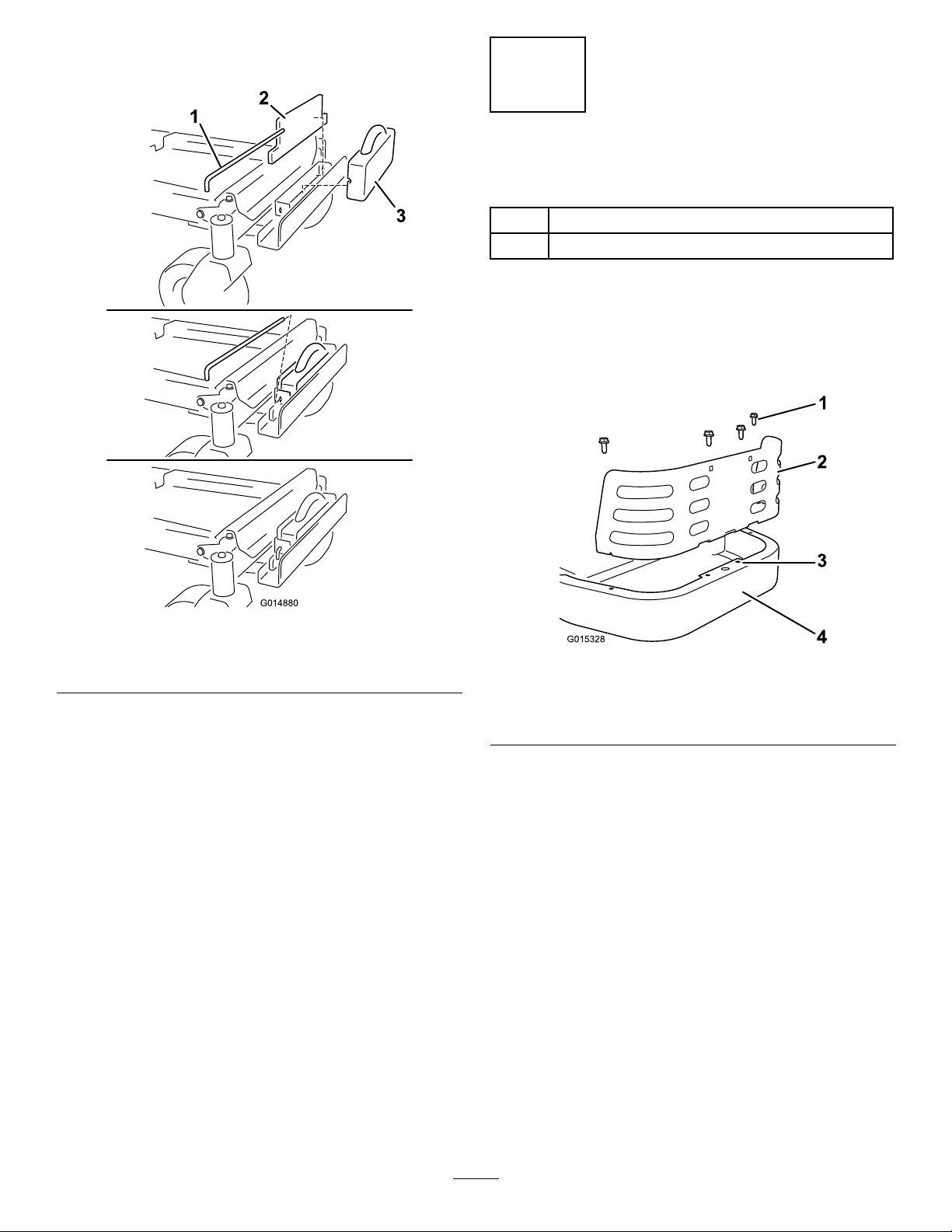

6.Installaatweighttotheholdingbracketandmove

G014880

1

2

3

G015328

1

2

3

4

itrearward,ushwiththebracket(Figure9).

2

InstallingtheRearGuard

Partsneededforthisprocedure:

1Rearguard

4

Selftappingscrew(5/16x3/4inch)

Procedure

1.Installtherearguardtotheframebehindtheengine

Figure10).Aligntheholesinthetabsontheguard

(

withtheexistingholesintherearframe.

Figure9

1.Flatweight3.Keyedcrossbar

2.Suitcaseweight

7.Installasuitcaseweightinfrontoftheatweight

(Figure9).Thegrooveinthesuitcaseweightshould

befacingrearward.

8.Securetheweightstothebracketwithakeyedcross

Figure9).Installthebarandrotateit90degrees

bar(

downwardtolockitinplace.

9.Onceallweightsandbracketshavebeeninstalled,go

backandcheckthatallfastenersaretight.Tighten

asnecessary.

Important:Wheneveryouremovethebagger

attachment,remembertoremovethefrontweights

toreturntheproperstabilitytothemachine.

Figure10

1.Selftappingscrew(5/16x

3/4inch)

2.Rearguard

3.Holeinrearframe,

exisiting

4.Rearframe

2.Securetheguardtotheframewithfourselftapping

screws(5/16x3/4inch)asshowninFigure10.

8

Page 9

3

G014881

1

2

3

4

5

6

1

2

G010578

G014882

1

2

3

4

InstallingtheBaggerFrame

Partsneededforthisprocedure:

1

Baggerframesupportbracket

1

Supportspacerplate

2

Selftappingscrew(5/16x3/4inch)

2

Bolt(5/16x1inch)

4

Locknut(5/16inch)

1Angledbracket

2

Carriagebolt(5/16x3/4inch)

1

Baggerframe

1

Clevispin(1/2x2-1/4inch)

5

Hairpincotter

2Rod

4Washer

Figure12

1.Supportbracket2.Selftappingscrews(5/16

x3/4inch)

3.Installtheangledbaggerbrackettotheengineguard

usingtwocarriagebolts(5/16x3/4inch)andtwo

locknuts(5/16inch).

Procedure

1.Locatethebaggerframesupportspacerplateand

bracketinlooseparts.Installtheplateandbracketto

themachineframeasshowninFigure11.Securethe

plateandbrackettotheframeusingtwobolts(5/16

x1inch)andtwolocknuts(5/16inch).

Figure11

1.Machineframe4.Bolt(5/16x2-1/2inch)

2.Supportspacerplate

3.Supportbracket6.Locknut(5/16inch)

5.Drawbarhole

2.Securethesupportbrackettothebottomofthe

machineframefrombelowusingtwoselftapping

screws(5/16x3/4inch)asshowninFigure12.

Figure13

1.Carriagebolt(5/16x3/4

inch)

2.Angledbracket4.Holeinengineguard,

3.Locknut(5/16inch)

existing

4.Installthebaggerframetothesupportbracket.

Securethebaggerframewithaclevispin(1/2x

2-1/4inch)andhairpincotter(

Figure13).

9

Page 10

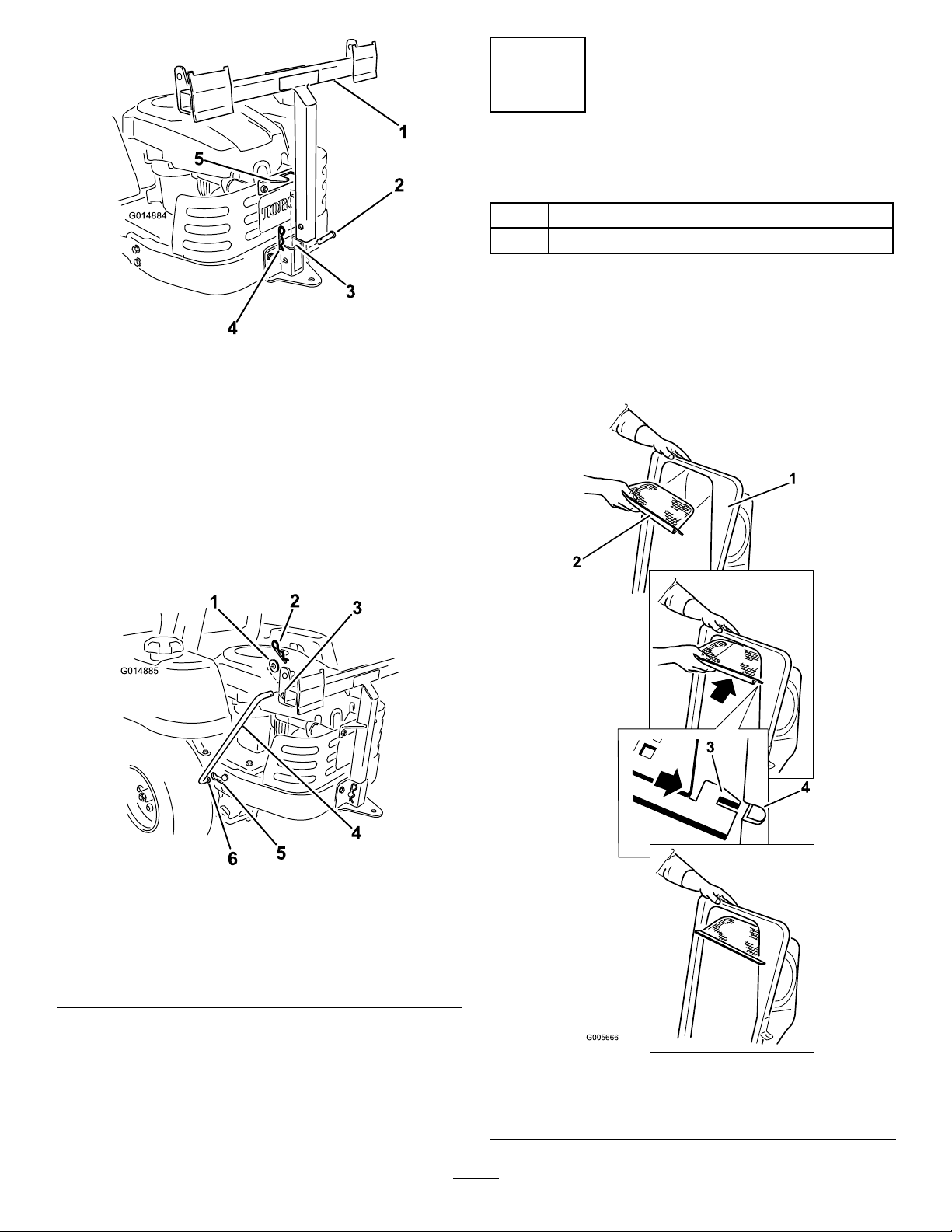

G014884

1

2

3

4

5

Figure14

G014885

1

2

3

4

5

6

G005666

1

2

3

4

1.Baggerframe(60inch

decks)

2.Clevispin(1/2x2-1/4

inch)

3.Supportbracket,receiver

4.Hairpin

5.Anglebracket

5.Installtwosupportrods,onetoeachsideofthe

baggerframe.Locatetheexistingkeyedslotinthe

machineframeandinstallthebent,aredendofthe

rodintothatslot(Figure15).Movetherodrearward

toseatitintheframe.

4

AssemblingtheBaggerTop

Partsneededforthisprocedure:

1Baggertop

1Baggerscreen

Procedure

Turnthebaggertopover.Installthescreenasshown

in

Figure16soitslopesdowntowardthecollection

bags.Makesurethescreenssnapintoplaceandthetabs

engagethebaggertop.

Figure15

Leftsideshown

1.Washer

2.Hairpin5.Keyedslot,existing

3.Bracketframehole6.Bent,aredendofsupport

6.Insertthebentendsoftherodintothebaggerframe

asshowninFigure15.Securetheendoftherod

withawasherandhairpin.

4.Supportrod

rod

Figure16

1.Baggertop

2.Screen4.Slotinbaggertop

3.Screentab

10

Page 11

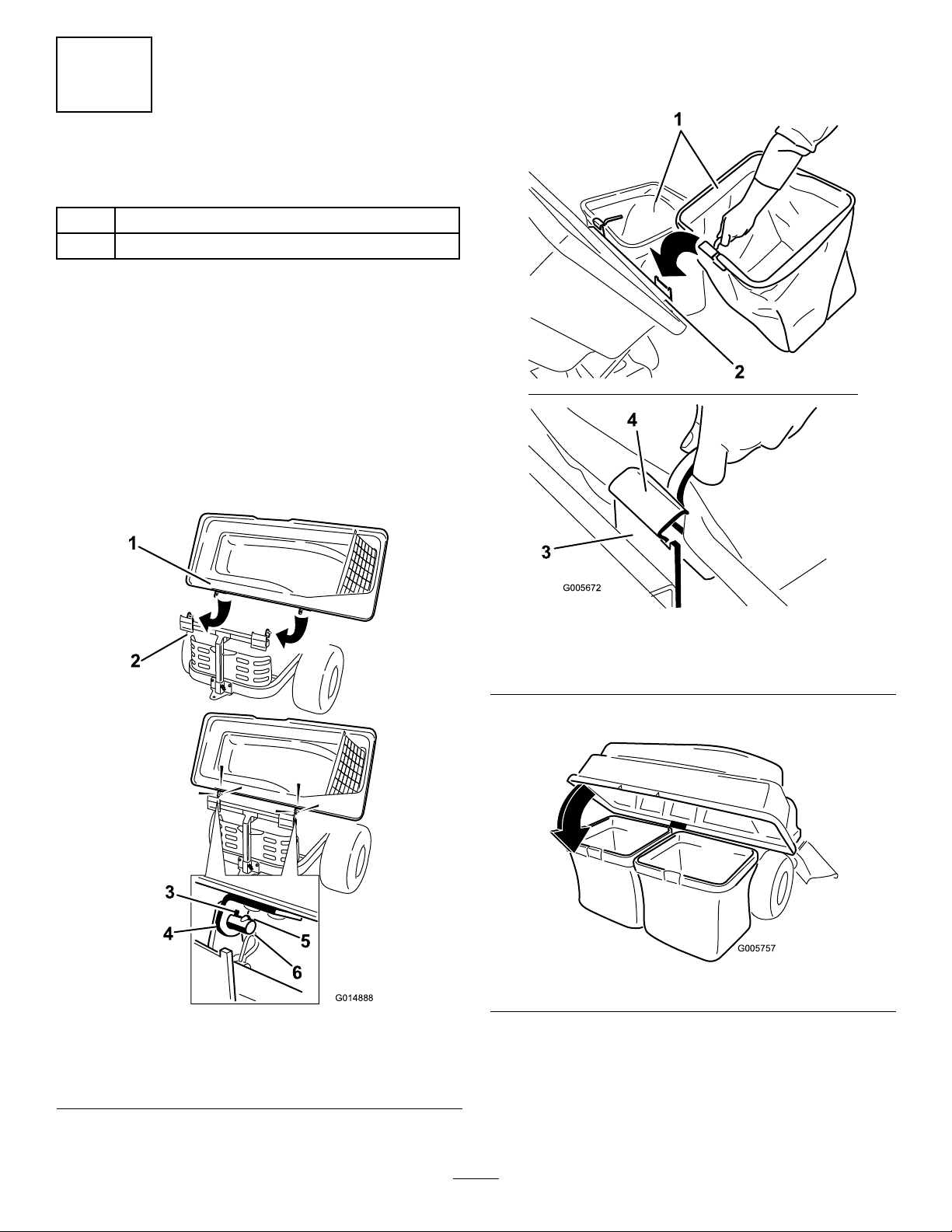

5

G014888

1

2

3

4

5

6

G005672

1

2

3

4

G005757

InstallingtheBaggerTop

Partsneededforthisprocedure:

2

GrassBag

1Upperbaggertube

Procedure

1.Installthebaggertoptothebaggerframe.Rotate

thebaggertoptoalignthekeyholesinthebagger

topbracketswiththekeysinthepostsonthebagger

frame(

androtatethebaggertopdowntotheoperating

position.

Note:Thebaggertopiseasiertoinstalliftwo

peopleworktogether.

Figure17).Slidethebracketsovertheposts

2.Liftthebaggertopandinstallthebagsbysliding

thebagframehooksontotheretainingbrackets

(Figure18).

Figure18

1.Bag3.Retainingbracket

2.Baggerframe4.Bagframehook

3.Lowerthebaggertopontothebag(Figure19).

Figure19

Figure17

1.Baggertop4.Bracket,baggertop

2.Baggerframe

3.Keyhole6.Post

5.Key

4.Installtheupperbaggertube.Insertthecurvedend

intotheopeninginthebaggertop.Makesurethe

aredendwiththeretentionpostispointingdown

andfrowardinpreparationtobematedwiththe

FinishingKit.

11

Page 12

6

G015220

1

2

3

4

5

G015221

1

2

3

4

5

G015222

1

2

3

4

InstallingtheChute

Partsneededforthisprocedure:

1

Cutoffbafe

1

Chute

Procedure

1.Liftupthegrassdeectorandlocatetheexisting

cutoffbafe.

2.Removethelocknutsandboltsecuringthecutoff

bafetotheundersideofthedeck(Figure20).

Retainallfasteners.

Figure21

1.Pivotrod

2.Bolt5.Locknut

3.Cutoffbafe(bagger)

4.Nut(5/16inch)

4.Locatethechuteinlooseparts.Aligntheholesin

thehingeonthechutewiththehingeonthedeck

(Figure22).Securethechutetothedeckusingthe

hairpinonthelanyardconnectedtothechute.

Figure20

1.Pivotrod

2.Bolt5.Locknut

3.Cutoffbafe(existing)

3.Installthenewcutoffbafetotheundersideof

thedeck(Figure21).Secureitwiththefasteners

removedpreviously.

4.Nut(5/16inch)

Figure22

1.Chute

2.Lanyardhairpin4.Hinge,onchute

3.Hinge,ondeck

5.Pivotthechutebackandtowardthedecksochuteis

ushwiththemowerdeck.

Note:Asthechutemateswiththedeck,makesure

theupperlatchisoutofthewayofthepivotrod.

6.Onthetopofthechute,engagetheupperlatch

aroundpivotrodofthedeectorassemblyasshown

12

inFigure23.

Page 13

G015223

1

2

Figure23

G010641

1

2

3

4

5

1.Upperlatch2.Flexiblelatch

7.Securethechutetothedeck.Hooktheexiblelatch

onthechutetotheretainingclaspweldedonthe

mowerdecktotherearoftheopening(Figure23).

7

ConnectingwiththeDischarge

Tube

NoPartsRequired

Figure24

1.Dischargetube,curved

end

2.Openinginbaggertop

3.Dischargetube,aredend

2.Slidethearedendofthedischargetubeoverthe

endofthechute.Movetherubberretainingstrapon

thechutesnapsoverthepegonthedischargetube

tosecureit(Figure24).

4.Peg

5.Rubberstrap

Procedure

1.Slidethecurvedendofthedischargetubeintothe

openinginthebaggertop(Figure24).

8

InstallingtheDeckRing

Partsneededforthisprocedure:

4Deckring

8

Bolt(5/16x3/4inch)

8

Locknut(5/16inch)

Procedure

1.Installtheinterlockingdeckringstothebottomof

themower(Figure25).

13

Page 14

G015226

1

2

3

Operation

G005758

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

WARNING

Toavoidpersonalinjury,followtheseprocedures:

•Becomefamiliarwithalloperatingandsafety

instructionsinthe

mowerbeforeusingthisattachment.

•Neverremovethedischargetube,bags,bagger

top,orthechutewhiletheengineisrunning.

Operator’ s Man ual

forthe

Figure25

1.Locknut(5/16inch)

2.Bolt(5/16x3/4inch)

2.Securetheringstothedeckusing8bolts(5/16x

3/4inch)and8locknuts(5/16inch).

3.Deckring

9

InstallingtheBlade

Partsneededforthisprocedure:

1

Hi-Liftblade

Procedure

1.Removetheexistingmowerbladeinstalledonyour

deck.RefertotheRemovingtheBladessectionin

theOperator’sManualformoreinformation.

•Alwaysshuttheengineoffandwaitforall

movingpartstostopbeforeclearingan

obstructionfromthebaggingsystem.

•Neverdomaintenanceorrepairswhilethe

engineisrunning.

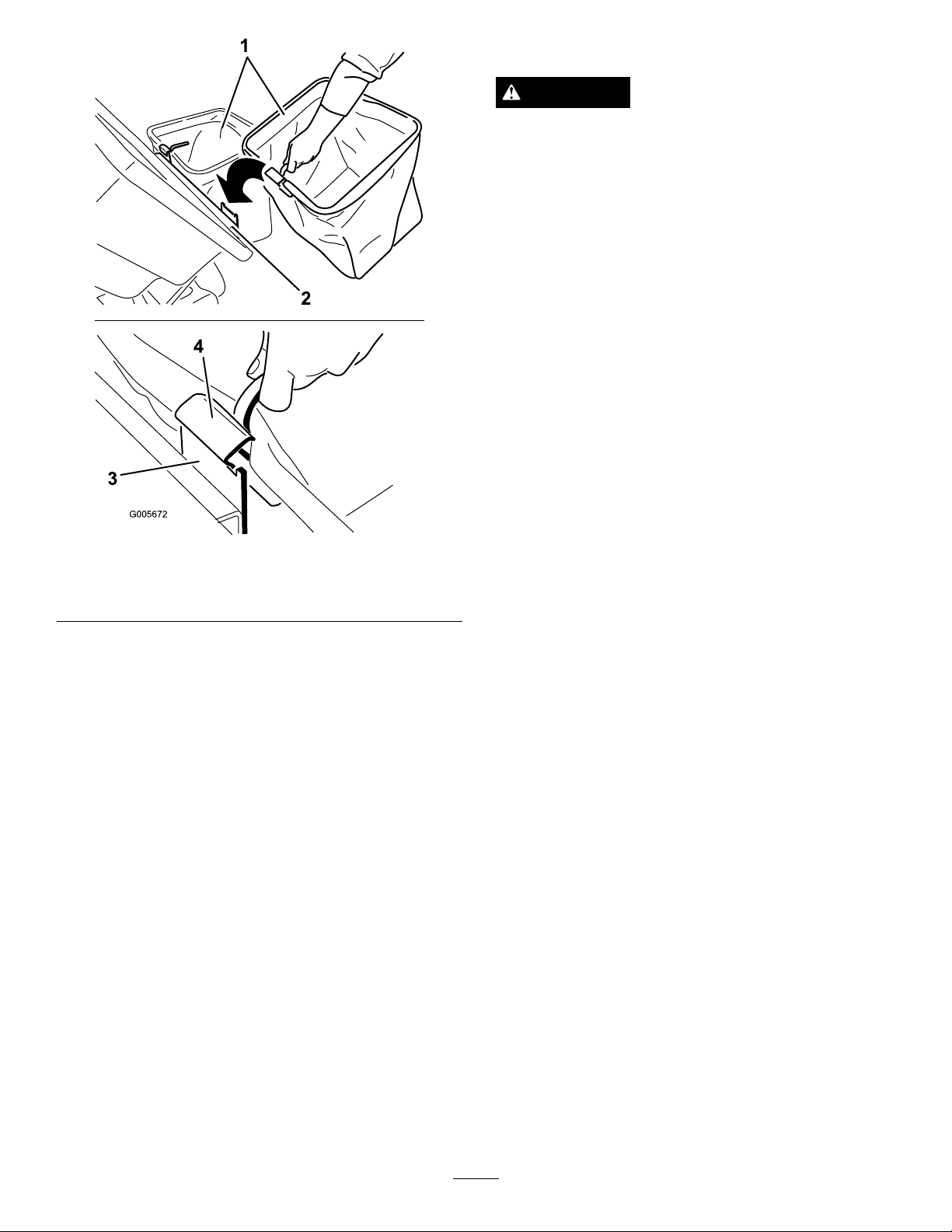

EmptyingtheGrassBags

Becarefulwhenliftingorhandlingagrassbagthatis

full.Toemptythegrassbags:

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,stoptheengine,removethe

key,settheparkingbrakeandwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Open(raise)thebaggertop(

Figure26).

2.InstalltheHi-Liftmowerbladelocatedinloose

parts.RefertotheInstallingtheBladessectioninthe

Operator’sManualformoreinformation.

Figure26

4.Compressdebrisintothebags.Withbothhands,

liftuponthebagandunhookitfromtheretaining

bracket.Emptythebag.Repeattheprocedurefor

theotherbag.

5.Installthebagsbyslidingthebagframehooksonto

theretainingbrackets(Figure27).

14

Page 15

G005672

1

2

3

4

RemovingtheBagger

CAUTION

Failingtoremovethefrontbaggerweights

andoperatingthemachinewithoutthebagger

attachmentmaycauseanunstableconditionwhich

couldresultinalossofcontrol.

•Alwaysremovethefrontweightswhen

removingthebaggerattachment.

•Neveroperatethemachinewithoutthebagger

attachmentandthefrontweightsstillinstalled.

ThebaggercanberemovedbyrepeatingtheSetup

sectionsfromallinstalledbaggerrelatedkitsinreverse

order.Ifweightsareinstalled,alwaysremovethefront

baggerweightswhenremovingthebaggerattachments.

Note:Itisonlynecessarytoremovethecutoffbafe

wheninstallingamulchingkit.

OperatingTips

Figure27

1.Bag3.Retainingbracket

2.Baggerframe4.Bagframehook

6.Lowerthebaggertopontothebags.

ClearingObstructionsfrom

theBagger

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutrallockposition,stoptheengine,removethe

key,settheparkingbrakeandwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Checkthegrassbagsandemptythemiftheyarefull.

4.Removeandseparatethedischargetubeandchute

fromthebaggertopandmower.Usingastick

orsimilarobject,carefullyremoveandclearthe

obstructionfromthemower,dischargetube,chute,

andthebaggertop.

5.Afteryouremovetheobstruction,installthe

completebaggersystemandresumeoperation.

TipsforBagging

Size

Rememberthatthemowerislongerandwiderwiththis

attachmentinstalled.Byturningtoosharplyinconned

placesyoumaydamagetheattachment.

Trimming

Alwaystrimwiththeleftsideofthemower.Donot

trimwiththerightsideofthemowerbecauseyoucould

damagethebagger’schuteanddischargetube.

CuttingHeight

Donotsetthemowercuttingheighttoolowbecause

longgrasssurroundingthemowercanpreventairfrom

gettingunderthemowerandenteringthebagging

system.Ifenoughairdoesn’tgetunderthemower,the

baggingsystemwillplug.

CuttingFrequency

Cutthegrassoften,especiallywhenitgrowsrapidly.

Youwillhavetocutyourgrasstwiceifitgetsexcessively

long.

CuttingTechnique

Forbestlawnappearance,besuretoslightlyoverlap

themowerintothepreviouslycutarea.Thishelps

15

Page 16

reducetheloadontheengineandreducesthechance

ofpluggingthechuteanddischargetube.

BaggingSpeed

Mostoftenyouwillbagwiththemowerthrottlein

theFastpositionanddriveatanormalgroundspeed.

However,inextremelydryanddustygrass,youmay

wanttoslightlyreducethethrottlespeedandincrease

thegroundspeedofthemower.Thebaggingsystem

mayplugifyoudrivetoofastandtheenginespeed

getstooslow.Onhillsitmaybenecessarytoslowthe

mowergroundspeed.Thishelpsmaintaintheengine

speedandbaggingefciency.Mowdownhillwhenever

possible.

CAUTION

Asthebaggerlls,extraweightisaddedtothe

backofthemachine.Ifyoustopandstartsuddenly

onhills,youmaylosesteeringcontrolorthe

machinemaytip.

•Donotstartorstopsuddenlywhengoinguphill

ordownhill.Avoiduphillstarts.

•Ifyoudostopthemachinewhengoinguphill,

disengagethebladecontrol.Thenbackdown

thehillusingaslowspeed.

•Donotchangespeedsorstoponslopes.

•Neveroperatethemachinewithoutthebagger

attachmentandthefrontweightsstillinstalled.

BaggingLongGrass

BaggingLongGrassExcessivelylonggrassisheavyand

maynotbepropelledcompletelyintothegrassbags.If

thishappens,thedischargetubeandchutemayplug.

Toavoidpluggingthebaggingsystem,mowthegrass

atahighheightofcut,thenlowerthemowertoyour

normalcuttingheightandrepeatthebaggingprocess.

BaggingWetGrass

Alwaystrytocutgrasswhenitisdrybecauseyour

lawnwillhaveaneatappearance.Ifyoumustcutwet

grass,usetheconventionalsidedischargefeatureofthe

mower.Severalhourslater,whentheclippingsaredry,

installthecompletebaggerattachmentandvacuumup

thegrassclippings.

SignsofPlugging

Asyouarebagging,asmallamountofgrassclippings

normallyblowoutthefrontofthemower.Anexcessive

amountofclippingsblowingoutindicatesthatthebags

arefullorthesystemisplugged.

16

Page 17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Beforeeachuseordaily

Beforestorage

MaintenanceProcedure

•Inspectthebagger

•Cleanthebagger

•Inspectthebagger

•Cleanthebagger

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

DANGER

Enginescanbecomehotwhentheyareoperating.Severeburnscanoccurfromcontactinghotsurfaces.

Allowengines,especiallythemufer,tocoolbeforetouching.

DANGER

Debris,suchasleaves,grass,orbrushcancatchre.Areintheengineareacancausepersonalinjury

andpropertydamage.

•Keeptheengineandmuferareafreeofdebrisaccumulation.

•Takecarewhenopeningthebaggercovertokeepdebrisfromfallingontotheengineandmuferarea.

•Allowthemachinetocoolbeforestoringit.

InspectingtheBagger

Attachment

ServiceInterval:Aftertherst10hours

Beforestorage

Inspectthebaggerattachmentaftertherst10hoursof

operation,andmonthlythereafter.

1.Checkthechute,dischargetube,andthebaggertop.

Replacethesepartsiftheyarecrackedorbroken.

2.Tightenallnuts,bolts,andscrews.

3.Inspectallfastenersandlatches;replaceanymissing

ordamaged.

4.Inspectthegrassbagsfordeterioration.

InspectingtheMowerBlades

Inspectthemowerbladesregularlyandwhenevera

bladestrikesaforeignobject.

WARNING

Youorbystanderscouldbeseverelyinjuredby

yingdebrisorthrownobjectsthatmaypass

throughtorn,worn,ordeterioratedgrassbags.

•Checkthegrassbagsforholes,rips,wear,

andotherdeterioration.

•Donotwashthegrassbags.

•Ifthebaghasdeteriorated,installnewgrass

bagssuppliedbythemanufacturerofthis

baggerattachment.

17

Page 18

Ifthebladesarebadlywornordamaged,installnew

blades.RefertoyourmowerormowerOperator’ sManual

forcompleteblademaintenance.

Storage

StoringtheBaggerAttachment

CaringfortheGrassBags

Washingthegrassbagsisnotrecommended.

Topreventrapiddeteriorationofthebagmaterial,store

thebagswheretheywilldrycompletelyaftereachuse.

CleaningtheBagger

Attachment

ServiceInterval:Beforeeachuseordaily

Beforestorage

1.Aftereachuse,removeandwashtheinsideand

outsideofthebaggertop,dischargetube,chute,and

theundersideofthemower,usingwatersprayed

fromagardenhose.Useamilddetergenttoremove

stubborndirt.

2.Makesureyouremovemattedgrassfromallparts.

3.Flushthegrassbagswithwaterusinggardenhoseto

removeanydebris.

1.Cleanthebaggerattachment;refertoCleaningthe

BaggerAttachment.

2.Inspectthebaggerattachmentfordamage;referto

InspectingtheBaggerAttachment.

3.Makesurethegrassbagsareemptyandthoroughly

dry.

4.Storethebaggerinaclean,dryplace,outofdirect

sunlight.Thisprotectstheplasticpartsandextends

thelifeofthebagger.Ifyoumuststorethebagger

outside,coveritwithaweatherproofcover.

4.Afterwashing,letallofthepartsdrythoroughly.

18

Page 19

Notes:

19

Page 20

TheToroTotalCoverageGuarantee

AThree-Y earLimitedWarranty

TITANMowers

ConditionsandProductsCovered

TheT oro®Companyanditsafliate,ToroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlypromisetorepairanyT oroProduct,if

defectiveinmaterialsorworkmanshipfortheperiodlistedbelow .

ThisWarrantyappliestoallTITANMowersandtheiraccessories.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

TITANMowers

-Frame

-Engine

Attachments(foraboveunits)3yearsor240hours*

Batteries1year

Warrantymaybedeniedifthehourmeterisdisconnected,altered,or

showssignsofbeingtamperedwith.

3yearsor240hours*

Lifetime(originalowneronly)**

3yearsor240hours*

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorparts,suchaslters,fuel,

lubricants,oilchanges,sparkplugs,airlters,bladesharpening/worn

bladeonmowers,cable/linkageadjustments,orbrakeandclutch

adjustments

•Componentsfailingduetonormalweararenotcoveredbythis

warranty

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetoimproperbatterycare,failuretousefresh

fuel(lessthanonemonthold),orfailuretoproperlypreparetheunit

priortoanyperiodofnon-useoveronemonth

•Pickupanddeliverycharges

•Operationalmisuse,neglect,oraccidents

•RepairsorattemptedrepairsbyanyoneotherthananAuthorized

ToroServiceDealer

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.Tolocateadealerconvenienttoyou,refertotheYellow

Pagesofyourtelephonedirectory(lookunder“LawnMowers”)or

accessourwebsiteatwww.T oro.com.Youmayalsocallthenumbers

listedinitem#3tousethe24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.Thedealerwilldiagnosetheproblemanddetermine

ifitiscoveredunderwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat866-216-6029(U.S.customers)

Tollfreeat866-216-6030(Canadiancustomers)

GeneralConditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingToroapprovedreplacementparts.

RepairbyanAuthorizedToroServiceDealerisyoursoleremedyunder

thiswarranty .

NeitherTheToro®CompanynorToroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Allimpliedwarrantiesofmerchantability(thattheproductistfor

ordinaryuse)andtnessforuse(thattheproductistforaparticular

purpose)arelimitedtothedurationoftheexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

*Whicheveroccursrst.

**LifetimeFrameW arranty-Ifthemainframe,consistingofthepartsweldedtogethertoformthetractorstructurethatothercomponentssuchastheenginearesecuredto,

cracksorbreaksinnormaluse,itwillberepairedorreplacedunderwarrantyatnocostforpartsandlabor.Framefailuresduetomisuseorabuseandfailureorrepair

requiredduetorustorcorrosionarenotcovered.

374-0258RevA

Loading...

Loading...