Page 1

Wheel

Horse

38” Mower

for

FORM NO. 3319–558

Lawn and Garden T

Model No. 78216 – 8900001 & Up

Model No. 78226 – 8900001 & Up

ractors

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Page 2

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

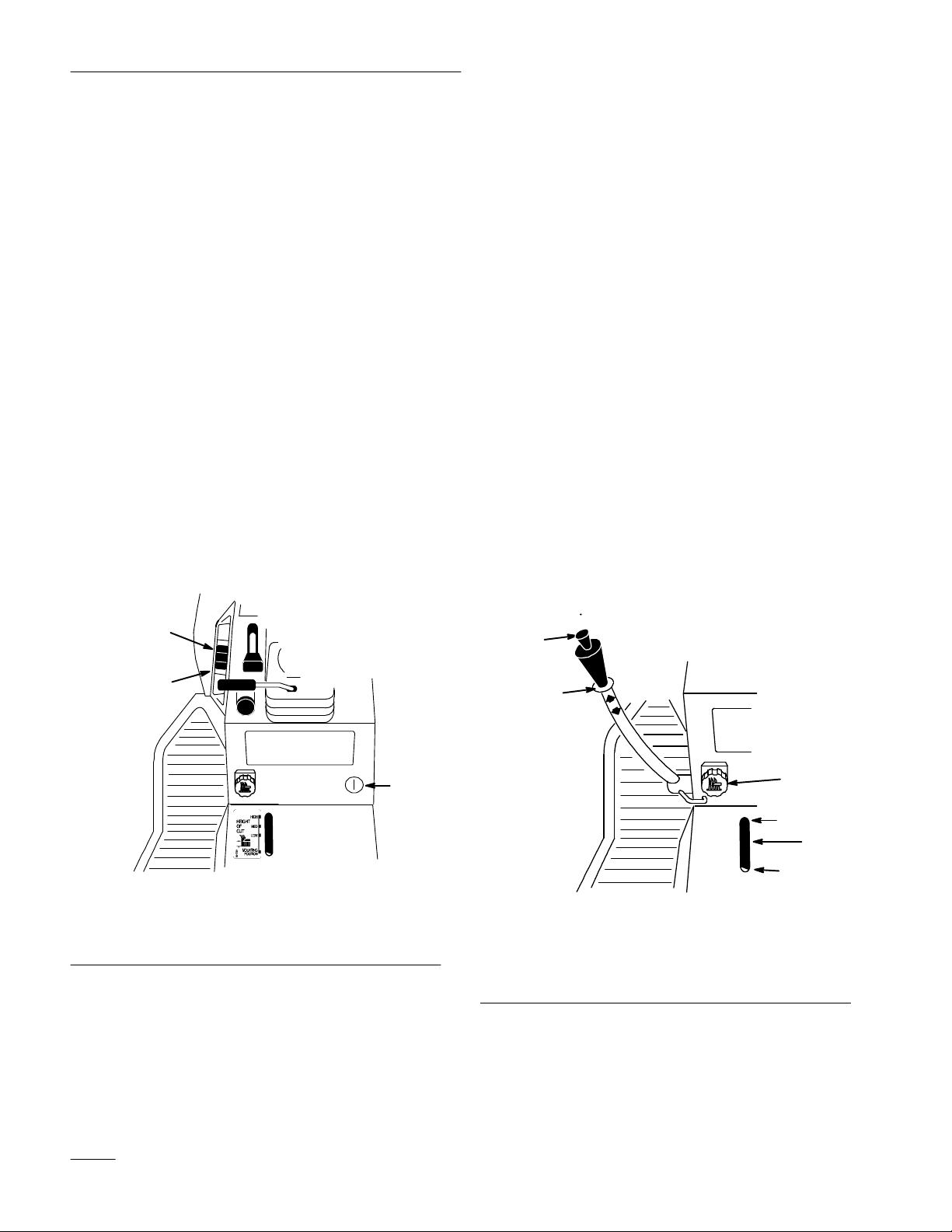

product. You will find the model and serial number

plate located in a unique place on the product as

shown below

.

1

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

1222

1.

Model

and Serial Number Plate

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

Printed in USA

The T

oro Company – 1997

All Rights Reserved

Page 3

Contents

Page

Safety and Instruction Decals 2.

Assembly 3

Operation 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 3

Installing Discharge Chute and

Tension Spring 4

Installing Discharge Cover

(Mulching Model(s) Only) 5

Installing the Mower 5

Transport Height Adjustment 7

Side-to-Side Mower Leveling 7

Front-to-Rear Blade Slope 9

Removing the Mower 10

Side Discharge or Mulching Grass 11

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . .

Page

Operating the Power Take Off (PTO) 11

Attachment Power Lift 12

Attachment Lift Lever 12

Adjusting Dial-A-Height 13

Adjusting Anti-Scalp Rollers 13

Tips for Mowing and Recycling Grass 14

Maintenance 15

Service Interval Chart 15

Cutting Blade16. . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication 18

Blade Drive Belt 18

Washing Underside of Mower 19

Storage 20

Troubleshooting 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . .

. . .

1

Page 4

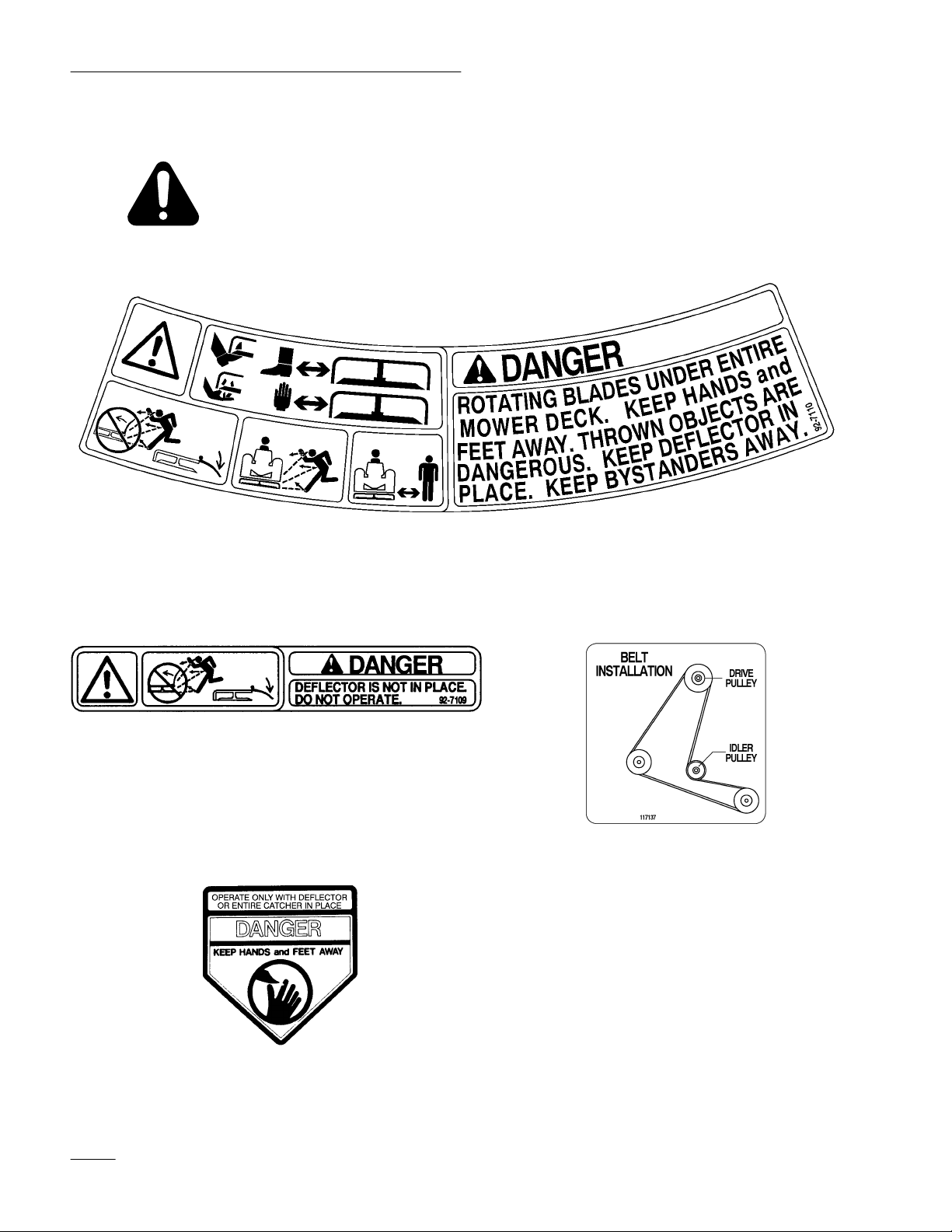

Safety

Safety

and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON MOWER LEFT SIDE

(Part No. 92–71

10)

UNDER GRASS DEFLECT

(Part No. 92–7109)

ON GRASS DEFLECT

AND ON

MOWER RIGHT SIDE

(Part No. 93–1

122)

OR

OR

ON MOWER CENTER

(Part No. 1

17137)

2

Page 5

Assembly

Loose

Parts

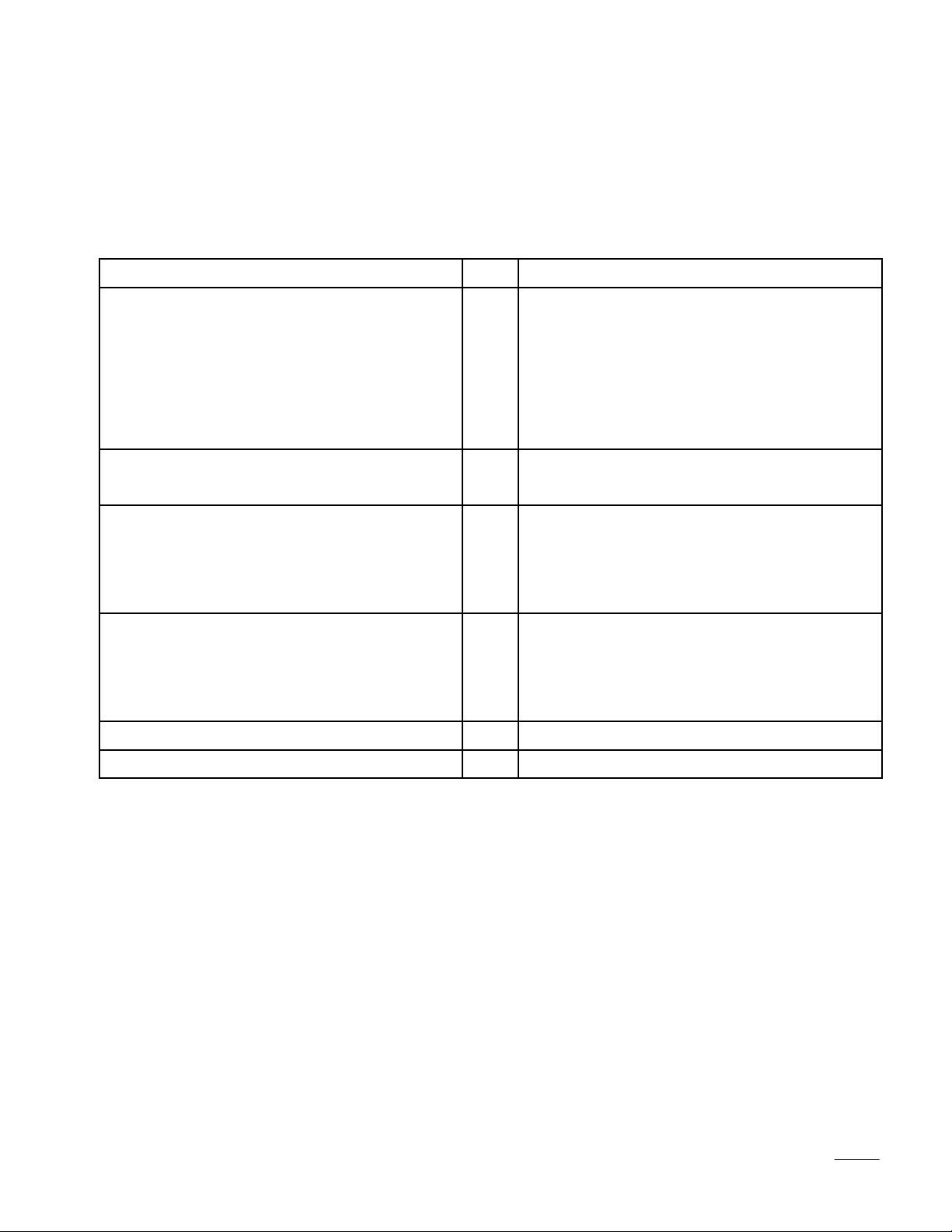

Note: Use the chart below to identify parts used for assembly.

DESCRIPTION QTY. USE

Grass deflector

T

orsion spring

Rod

Stand-off–long

Nut (3/8”)

T

ension spring

Hairpin cotter (3–3/8”)

Washer (3/4” )

Rear link

Washer (3/8”)

Cotter pin (1”)

Hairpin cotter (2–9/16”)

Adjustable link

1

1

1

Install grass deflector and tension spring

1

1

1

2

Install mower to tractor

2

1

3

Install rear link

1

2

1

Washer (3/8”)

Hairpin cotter (2–9/16”)

Cotter pin (1”)

V–belt 1

Operator’

s Manual

2

1

1

1

Install adjustable link

Install mower drive belt

Read before operating

3

Page 6

Assembly

Installing

T

ension Spring

Grass Deflector and

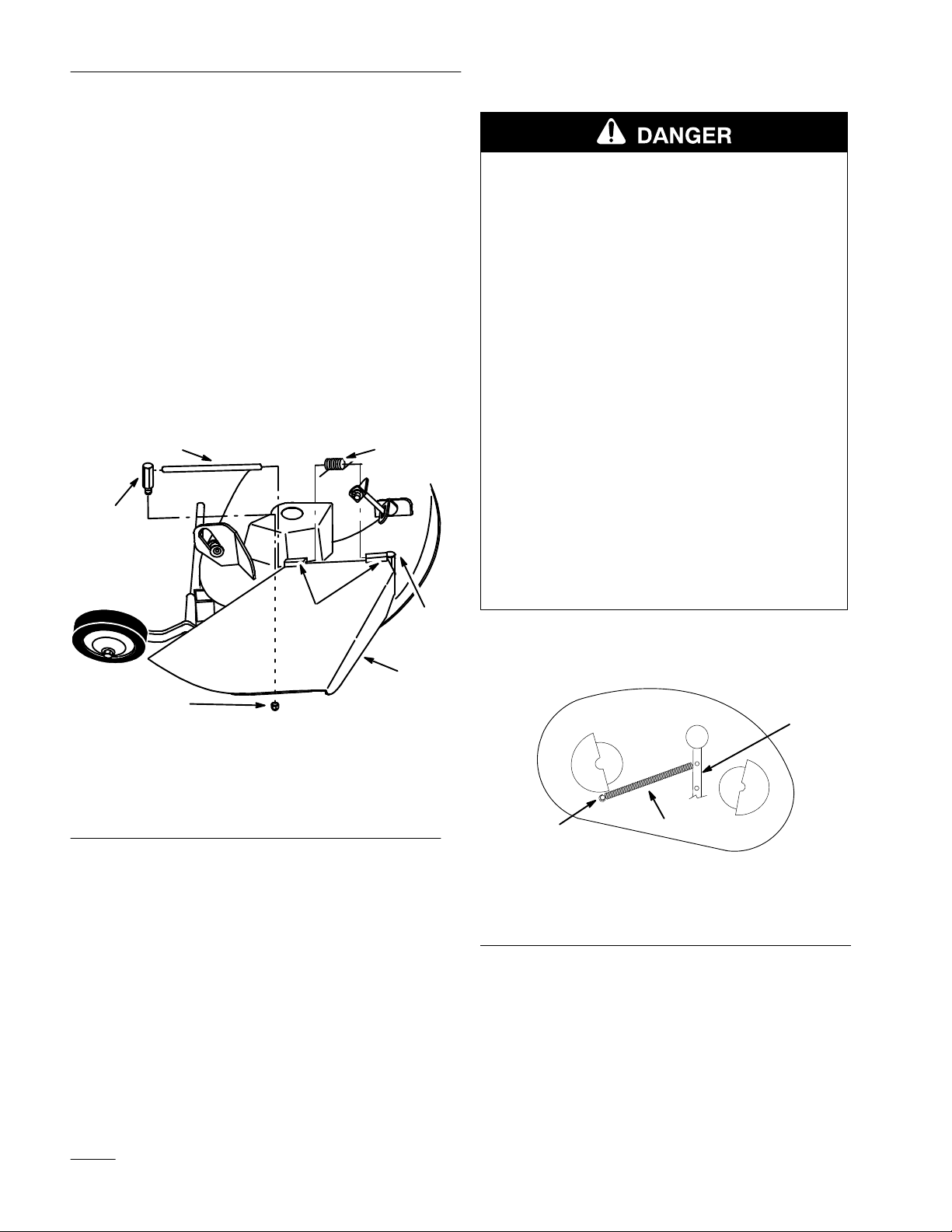

1. Locate items shown in Fig. 1.

2. Slide rod, non-rib end, through rear grass

deflector bracket.

3. Place spring on rod, with end wires down,

between grass deflector brackets, and slide rod

through second grass deflector bracket.

4. Insert rod at front of grass deflector into short

stand-off on deck. Secure rear end of rod to deck

with long stand-off and nut (Fig. 1).

4

6

3

POTENTIAL HAZARD

• Without the grass deflector mounted in

place, you and others are exposed to blade

contact and thrown debris.

WHAT CAN HAPPEN

• Contact with rotating mower blade(s) and

thrown debris will cause injury or death.

HOW TO AV

•

NEVER r

OID THE HAZARD

emove the grass deflector from

the mower because the grass deflector

routes material down toward the turf. If the

grass deflector is ever damaged, replace it

immediately.

• Never put your hands or feet under the

mower.

• Never try to clear discharge area or mower

blades unless you move the power take off

(PTO) to “OFF” and rotate the ignition key

to “OFF.” Also remove the key and pull the

wire off the spark plug(s).

2

7

Figure 1

1.

Grass

2.

3.

4.

deflector

Bracket

Spring

Rod

5.

Short stand-of

6.

Long stand-of

7.

Nut (3/8”)

IMPORTANT: Grass deflector must be

spring loaded in the down position. Lift

deflector up to test that it snaps to the full

down position.

5

5. Hook the tension spring onto the idler arm and

the bolt by the belt cover (Fig. 2).

1

1228

2

f

f

1

Figure 2

1645

3.

Bolt

1.

2.

Tension

Idler

3

spring

4

Page 7

Assembly

Installing

Discharge Cover

(Recycling Model(s) Only)

To convert from side discharge to recycling, install

the discharge cover into the opening at the side of the

mower.

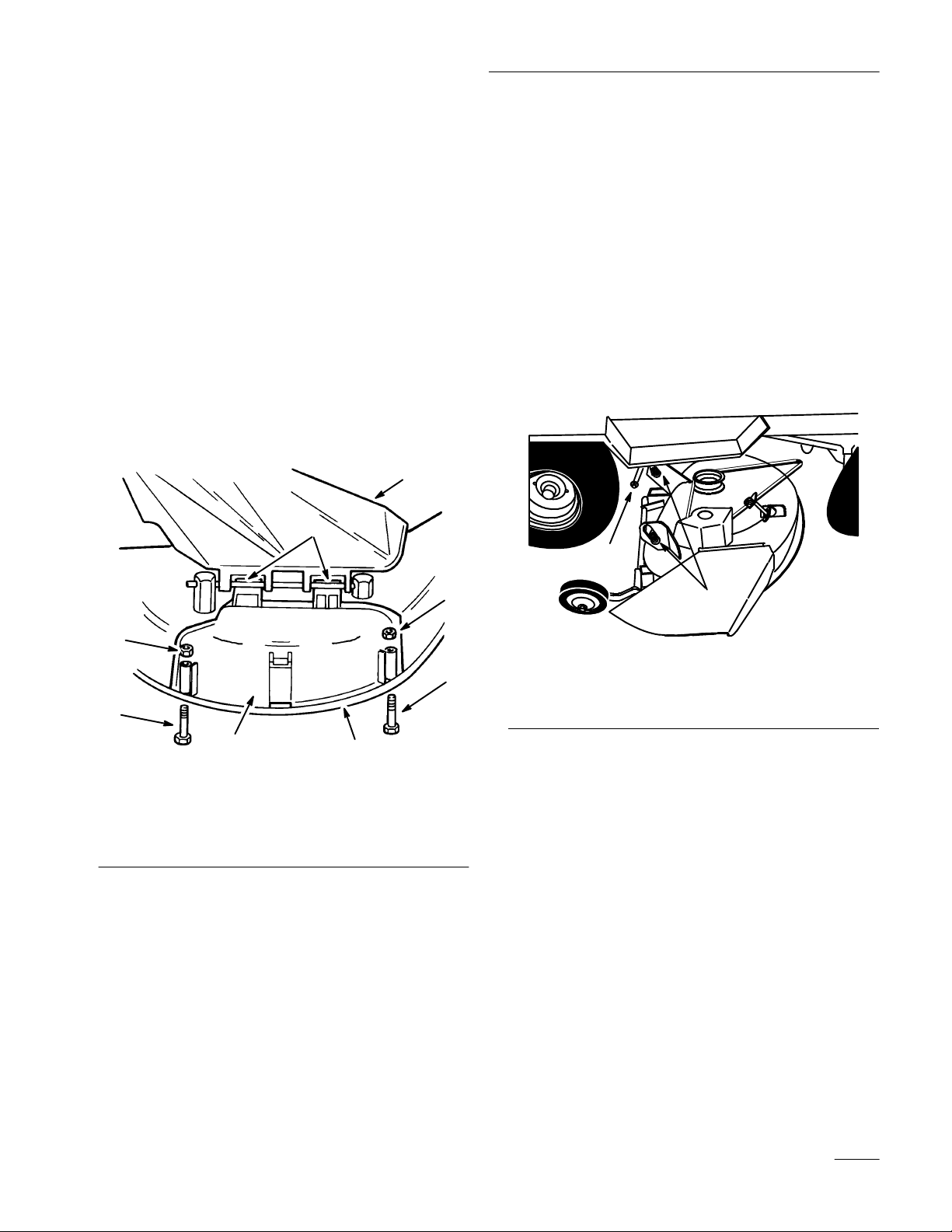

1. Lift the grass deflector and slide the tabs on top

of the discharge cover under the grass deflector

retaining rod. Rotate the discharge cover down

over the opening, and onto the lower lip of the

mower (Fig. 3).

2. Secure the discharge cover to the lower lip of the

mower with (2) 1/4”–20 x 2–1/2” bolts and (2)

1/4” nuts (Fig. 3).

1

2

Installing

the Mower

1. Park the tractor on a flat surface, disengage the

power take off (PTO), set the parking brake, and

turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Turn the front wheels fully to the left and raise

attachment lift lever all the way to the latched

position; refer to tractor Operator’

s Manual.

3. Slide the mower under the chassis from the right

side (Fig. 4) and align rear mounting bushings

with ends of lift arms.

1

6

5

1.

Grass

2.

T

abs under rod

3.

Discharge cover

deflector

3

Figure 3

4.

5.

6.

4

Lower lip

Bolt (1/4”–20 x 2–1/2”)

Nut (1/4”)

3. To convert back to a side discharge mower,

remove the discharge cover and lower the grass

deflector over the discharge opening.

6

Figure 4

5

1.

Lift

arms

2.

Mounting bushing

2

1232

4. Straighten the front wheels, turn Dial-A-Height

knob counterclockwise, all the way, and lower

the attachment lift lever to the mounting

position; refer to tractor Operator’

s Manual.

5

Page 8

Assembly

5. Place rear guide bushings, first left side then

right, onto lift arms then slide deck left into

position (Fig. 5).

6. Secure deck to rear lift arms with washers and

(2) 3–3/8” hairpin cotters (Fig. 5).

1

2

3

1234

Figure 5

1.

Lift

2.

arm

W

asher (3/4”)

3.

Hair pin cotter (3–3/8”)

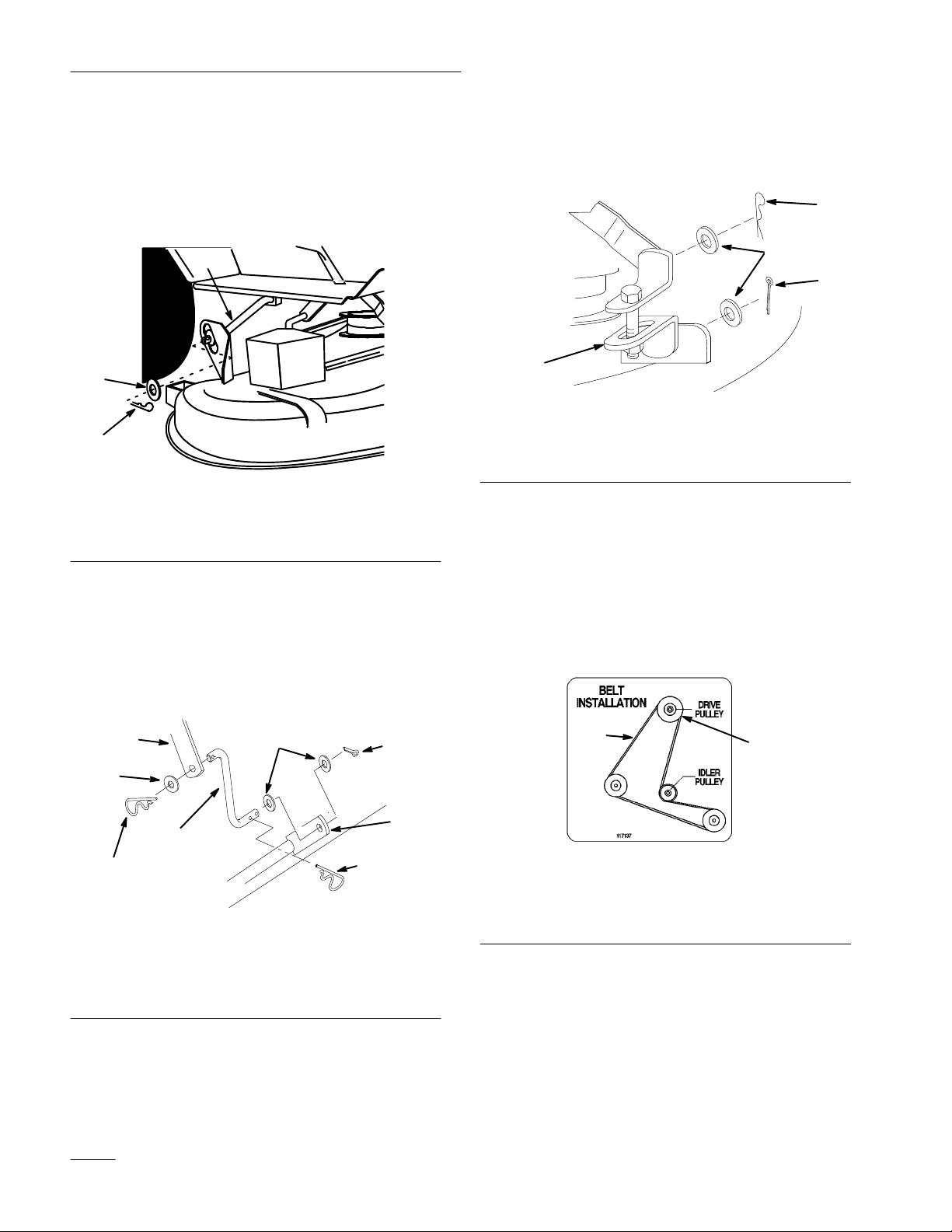

7. Install link to mower lift arm with 1” cotter pin,

(2) 3/8” washers and a 2–9/16” hairpin cotter

(Fig. 6). Attach rear link to tractor rear

attachment lift arm with a 3/8” washer and a

2–9/16” hairpin cotter (Fig. 6).

8. Install adjustable link between front bracket and

lift arm with (2) 3/8” washers, a 2–9/16” hairpin

cotter, and a 1” cotter pin (Fig. 7).

3

2

4

1

m–3165

Figure 7

1.

Adjustable

2.

W

link

asher (3/8”)

3.

Hairpin cotter (2–9/16”)

4.

Cotter pin (1”)

9. Pull on idler pulley to relax belt tension and

install mower drive belt to the engine pulley

(Fig. 8). Place belt in upper pulley groove if

engine has a double groove pulley.

Note: Ensure belt is properly located in

engine, deck, and idler pulleys.

1.

2.

3.

6

5

3

6

Mower

lift arm

Rear link

W

asher (3/8”)

3

4

1

2

1

2

6

m–3531

1.

Mower

belt

Figure 8

T

op V

iew

2.

Engine pulley

Figure 6

4.

Cotter pin (1”)

5.

Rear lift arm

6.

Hair pin cotter (2–9/16”)

10. Check mower level; refer to Side-to-Side Mower

Leveling, page 7, and Front-to-Rear Blade

Slope, page 9.

11. Raise attachment lift lever all the way to the

latched position and adjust mower height-of-cut;

refer to Transport Height Adjustment, page 7.

Page 9

Assembly

Transport

Height Adjustment

Transport height is set at the factory and should not

need adjustment; however if the belt covers contact

the footrest in the raised position, adjustment is

required.

1. Adjust by turning transport height nut, (Fig. 9)

on lift mechanism, clockwise to raise or

counterclockwise to lower mower.

2. Adjust nut until there is 1/16–1/8 inch clearance

between belt cover and left footrest.

1

Side-to-Side

Mower Leveling

The mower blades must be level from side to side.

Check the side-to-side level any time you install the

mower or when you see an uneven cut on your lawn.

Before you level the mower, set the air pressure in the

front and rear tires to 12 psi (.85 kPa).

3” to 4” Height-of-Cut Range

When the mower height-of-cut is set to the 3” to 4”

range the mower is suspended from the tractor. The

side-to-side adjustment for this height range is made

as follows;

1. Park the tractor on a flat surface, disengage the

power take off (PTO), set the parking brake, and

turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Raise attachment lift lever all the way to the

latched position.

1223

Figure 9

1.

Nut

3. Carefully rotate blade(s) side to side (Fig. 10).

Measure between the outside cutting edges and

the flat surface (Fig. 10). If both measurements

are not within 3/16” (4.762mm), an adjustment

is required; refer to steps 4 through 6.

2

3

1.

Blades

side to side

2.

Outside cutting edges

Figure 10

3.

1

2

3

Measure here

7

Page 10

Assembly

4. Loosen adjustment bolt on one side of tractor

and rotate hanger bracket to raise or lower

mower (Fig. 11).

5. After adjusting, tighten bolt and check

side-to-side level.

IMPORTANT: If hanger is rotated to the end

of adjustment on one side and mower is not

level, adjust the opposite side.

1

2

Figure 1

1.

Bolt

2.

1

Hanger

bracket

1224

3. Carefully rotate blade(s) side to side (Fig. 10).

Measure between the outside cutting edges and

the flat surface (Fig. 10). If both measurements

are not within 3/16” (4.762mm), an adjustment

is required.

4. Raise attachment lift lever to release pressure on

the gage wheels. Remove 1–7/16” hairpin cotter

from trunnion (Fig. 12).

5. Rotate trunnion to adjust side-to-side level

adjustment (Fig. 12).

2

1

m–3541

Figure 12

1.

Trunnion

2.

Hairpin

cotter 1–7/16”

6. Now check the front-to-rear blade slope; refer to

Front-to-Rear Blade Slope, page 9.

3/4” to 3” Height-of-Cut Range

When the mower height-of-cut is set to the 3/4” to 3”

range the gage wheels contact the ground. The

side-to-side adjustment for this height range is made

as follows:

1. Park the tractor on a flat surface, disengage the

power take off (PTO), set the parking brake, and

turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Set Dial-a-Height to the middle of the

height-of-cut range or until gage wheels are on

the ground; refer to Adjusting Dial-a-Height,

page 13.

6. After adjusting, secure trunnion with 1–7/16”

hairpin cotter, lower attachment lift, and check

side-to-side level.

8

Page 11

Assembly

Front-to-Rear

Blade Slope

Check the front-to-rear blade slope any time you

install the mower. Before checking the slope, set air

pressure in the front and rear tires to 12 psi (.85 kPa).

If the front blade tip is not 0–1/8” (0–3.2 mm) lower

than the rear blade tip, adjust the blade slope using

the following instructions:

1. Park the tractor on a flat surface, disengage the

power take off (PTO), set the parking brake, and

turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Check and adjust side-to-side blade level if you

have not checked the setting; refer to

Side-to-Side Mower Leveling, page 7.

3. Adjust the Dial-A-Height knob so the

height-of-cut is in the middle of the range and

lower attachment lift.

4. Carefully rotate blades so they are facing front

and rear (Fig. 13).

6. To adjust front-to rear blade level loosen jam nut

on front adjustable link. (Fig. 14).

7. Rotate the bolt on front adjustable link to change

front-to rear blade level (Fig. 14).

Note: To raise the front of the mower,

shorten the adjustable link by turning

bolt clockwise.

3

1

2

m–3534

Figure 14

1.

Adjustable

2.

Jam nut

link

3.

Bolt

5. Measure between the tip of the front blade

(Fig. 13). and the tip of the rear blade to the flat

surface. If the front blade tip is not 0–1/8”

(0–3.2 mm) lower than the rear blade tip adjust

front adjustment link.

2

1

3

Figure 13

1.

Blade

front to rear

2.

Measure front blade tip

3.

Measure rear blade tip

8. When front-to-rear slope is correct, tighten jam

nut. Recheck side-to-side mower level; refer to

Side-to-Side Mower Leveling, page 7.

1

9

Page 12

Assembly

Removing

the Mower

1. Park the tractor on a flat surface, disengage the

power take off (PTO), set the parking brake, and

turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Raise attachment lift, turn Dial-a-Height knob

counterclockwise, all the way, and lower the

attachment lift lever to the mounting position;

refer to tractor Operator’

s Manual.

3. Pull on idler pulley to relax belt tension and

remove mower drive belt from engine drive

pulley.

4. Remove 1–7/16” hairpin cotter and 3/8” washer

from front adjustable link and remove from front

lift arm (Fig. 15).

1

3

2

4

Figure 16

1.

Lift

2.

Rear lift link

arm

3.

Hair pin cotter (3–3/8”)

4. W

asher (3/4”)

8. Turn the front wheels fully to the left and raise

attachment lift lever all the way to the latched

position; refer to tractor Operator’

s Manual.

Slide the mower out from under the chassis to

the the right side (Fig. 17)

1234

2

1

3

m–3536

Figure 15

1.

Adjustable

2.

Hairpin cotter (1–7/16”)

link

3. W

asher (3/8”)

5. Remove 2–9/16” hairpin cotter and 3/8” washer

from rear lift link and remove from attachment

lift (Fig. 16).

6. Remove (2) 3–3/8” hairpin cotters and (2) 3/4”

washers from rear lift arms (Fig. 16).

7. Slide deck right, off rear lift arms (Fig. 16).

Note: Save all hardware, washers and hairpin

cotters for use when installing deck.

1232

Figure 17

10

Page 13

Operation

Side

Discharge

or Recycling Grass

POTENTIAL

• Without the grass deflector, discharge

cover, or bagger attachment mounted in

place, you and others are exposed to blade

contact and thrown debris.

WHAT CAN HAPPEN

• Contact with rotating mower blade(s) and

thrown debris will cause injury or death.

HOW TO AV

•

NEVER r

the mower because the grass deflector

routes material down toward the turf. If the

grass deflector is ever damaged, replace it

immediately.

• Never put your hands or feet under the

mower.

• Never try to clear discharge area or mower

blades unless you move the power take off

(PTO) to “OFF” and rotate the ignition key

to “OFF.” Also remove the key and pull the

wire off the spark plug(s).

HAZARD

OID THE HAZARD

emove the grass deflector from

Operating

Power T

The power take off (PT

power to the electric clutch.

While the ignition key is in the “RUN” or “LIGHTS”

positions and the power take off (PTO) is engaged

“ON“, the PTO light, in the Indicator Module, will be

“ON“. When this light is “ON” it is a reminder; the

starter will not crank and to turn off the PTO before

getting off.

the

ake Off (PT

O) engages and disengages

O)

Engaging the Power Take Off (PTO)

1. Depress the brake and/or clutch pedal(s) to stop

the machine.

2. Pull the power take off (PTO) to “ON” (Fig. 18).

1

2

1. The mower has a hinged grass deflector that

disperses clippings to the side and down toward

the turf.

2. To recycle grass clippings you must install the

discharge cover (optional on some models) into

the opening in the side of the mower; refer to

Installing the Discharge Cover, page 5.

1206

Figure 18

1.

Off-Disengaged

2.

On-Engaged

Disengaging the Power Take Off (PTO)

1. Depress the brake and/or clutch pedal(s) to stop

the machine.

2. Push the power take off (PTO) to “OFF”

(Fig.18).

11

Page 14

Operation

Attachment

Power Lift

The attachment power lift (on some models) (Fig. 19)

is used to raise and lower attachments.

Raising Attachments

1. Turn key to the “ON” or “RUN” position

(Fig. 19).

2. Push the lift switch in the “UP” direction to raise

the attachment lift (Fig. 19). This will lift and

hold the attachment in the up, or raised position.

Lowering Attachments

1. Turn key to the “ON” or “RUN” position

(Fig. 19).

2. Push the lift switch in the “DOWN” direction to

lower the attachment lift (Fig. 19). This will

lower the attachment lift.

Attachment

Lift Lever

The attachment lift lever (on some models) (Fig. 20)

is used to raise and lower attachments.

Raising Attachments

1. Depress the clutch and/or brake pedal(s) to stop

the machine.

2. Pull attachment lift lever rearward until latch

locks. In this position the lift will hold the

attachment in the up, or raised position.

Lowering Attachments

1. Depress the clutch and/or brake pedal(s) to stop

the machine.

2. Pull attachment lift lever rearward, to release lift

pressure, and push the button on top to release

the latch. Move lift lever foreword to lower

attachment.

1.

2.

Key

Lift

switch UP

2

3

1

2266

Figure 19

3.

Lift switch DOWN

1.

2.

3.

2

1

Lift

lever

Button

Dial-A-Height

Figure 20

4.

5.

6.

3

5

6

Indicator

High

Mounting position

4

1205

12

Page 15

Operation

Adjusting

Dial-A-Height

The Dial-A-Height control (Fig. 20) is used to limit

the downward travel of the attachment. The

Dial-A-Height knob is rotated to change the location

of this stop, up or down.

1. Raise the attachment lift lever: Refer to Raising

Attachments. In the raised, position the

Dial-A-Height knob (Fig. 20) can be rotated to

change the stop location. Turn clockwise to raise

and counterclockwise to lower the height of the

attachment.

2. The Dial-A-Height indicator (Fig. 20) will show

the change, high to low, in attachment lift height

as adjustment is made.

Adjusting

Anti-Scalp Rollers

The anti-scalp rollers guide the mower over uneven

turf without scalping the lawn. For most cutting

conditions they should be located in the lower hole.

When cutting in 1-1/2” height-of-cut, or lower, move

the anti-scalp rollers to the upper hole position.

1. Raise the attachment lift lever: Refer to Raising

Attachments.

2. Remove cotter pin, bolt and shaft to change hole

location (Fig. 21).

3. Select the hole position for the height-of-cut to

be used and insert rod (Fig. 21).

4. Secure rod with bolt and cotter pin.

3

4

1

Figure 21

1.

Roller

2.

Cotter

pin

3.

Bolt

4.

Rod

5.

Upper hole

6.

Lower hole

5

6

2

1220

13

Page 16

Operation

Tips

for Mowing and Recycling

Grass

Fast Throttle Setting

For best mowing and maximum air circulation,

operate the engine at “FAST.” Air is required to

thoroughly cut grass clippings, so do not set the

height-of-cut so low, as to totally surround the mower

by uncut grass. Always try to have one side of the

mower free from uncut grass, which allows air to be

drawn into the mower.

Cutting a Lawn for the First Time

Cut grass slightly longer than normal to ensure the

cutting height of the mower does not scalp any

uneven ground. However, the cutting height used in

the past is generally the best one to use. When cutting

grass longer than six inches tall, you may want to cut

the lawn twice to ensure an acceptable quality-of-cut.

Avoid Cutting Too Low

If the cutting width of the mower is wider than the

mower you previously used, raise the cutting height

to ensure that uneven turf is not cut too short.

Long Grass

If the grass is allowed to grow longer than normal, or

if it contains a high degree of moisture, raise the

cutting height higher than usual and cut the grass at

this setting. Then cut the grass again using the lower,

normal setting.

When Stopping

If the machine’s forward motion must be stopped

while mowing, a clump of grass clippings may drop

onto your lawn. To avoid this:

1. With the blade(s) “ENGAGED,” move onto a

previously cut area.

Cut 1/3 of the Grass Blade

It is best to cut only about 1/3 of the grass blade.

Cutting more than that is not recommended, unless

grass is sparse or it is late fall when grass grows more

slowly.

Mowing Direction

Alternate mowing direction to keep the grass standing

straight. This also helps disperse clippings which

enhances decomposition and fertilization.

Mow at Correct Intervals

Normally, mow every 4 days, but remember that

grass grows at different rates at different times. To

maintain the same cutting height, which is a good

practice, mow more often in early spring. As the

grass growth rate slows in mid summer, mow less

frequently. If you cannot mow for an extended period,

first mow at a high cutting height; then mow again 2

days later at a lower setting.

2. To disperse the clippings evenly, raise the mower

one or two height-of-cut settings while driving

forward with the blade(s) “ENGAGED.”

Keep the Underside of the Mower Clean

Clean clippings and dirt from the underside of the

mower after each use. If grass and dirt build up inside

the mower, cutting quality will eventually become

unsatisfactory.

Blade Maintenance

Maintain a sharp blade throughout the cutting season

because a sharp blade cuts cleanly without tearing or

shredding the grass blades. Tearing and shredding

turns grass brown at the edges, which slows growth

and increases the chance of disease. Every 30 days,

check the cutter blade(s) for sharpness and file down

any nicks.

14

Page 17

Maintenance

Service

Service

Cutter Blade—check

Grease–Mower deck

Belts—check for wear/cracks

Mower Housing—clean

Chipped Surfaces—paint

T

ires—check pressure

Interval Chart

Operation

POTENTIAL HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could seriously injure you or other bystanders.

Each

Use5Hours25Hours50Hours

X X X

X X

X X X

X X

Storage

Service

X

X

Notes

HOW TO AV

OID THE HAZARD

• Remove the key from the ignition switch and pull the wire off the spark plug before

you do any maintenance. Also push the wire aside so it does not accidentally contact

the spark plug.

15

Page 18

Maintenance

Cutting

Blade

To ensure a superior quality of cut, keep the blade(s)

sharp. For convenient sharpening and replacement,

you may want to have an extra blade(s).

POTENTIAL HAZARD

• A blade that is worn or damaged could

break apart and pieces could be thrown at

bystanders or at you as you use the mower.

WHAT CAN HAPPEN

• Pieces of blade that may be thrown could

seriously injure or kill you or bystanders.

HOW TO AV

OID THE HAZARD

• Periodically inspect the blade for wear and

damage. Immediately install a new blade if

it is worn or damaged.

1

1.

Cutting

2.

Curved area

edge

Figure 22

3.

2

W

ear/slot forming

Removing the Blade

1. Remove the mower; refer to Removing the

Mower, page 10.

3

151

Inspecting the Blade(s)

1. Remove the mower; refer to Removing the

Mower, page 10.

2. Inspect the cutting edges (Fig. 22). If the edges

are not sharp or have nicks, remove the blade(s)

and sharpen them; refer to Sharpening the

Blade(s), page 17.

3. Inspect the blade(s), especially the curved area

(Fig. 22). If you notice any damage, wear, or a

slot forming in this area (Fig. 22), immediately

install a new blade.

2. Carefully tip the mower over.

3. Remove the bolt (5/8” wrench), washer, retainer

and blade (Fig. 23). A block of wood may be

wedged between the blade and the mower to

lock the blade when you are removing the bolt.

4. Inspect all parts. If a defect or damage is noticed,

install new parts.

4

3

2

5

1

Figure 23

1.

2.

3.

Bolt

Retainer

Blade

(recycling only)

4.

5.

Spindle

Washer

16

Page 19

Maintenance

Sharpening the Blade(s)

1. Use a file to sharpen the cutting edge at both

ends of the blade (Fig. 24). Maintain the original

angle. The blade retains its balance if the same

amount of material is removed from both cutting

edges.

1

Figure 24

1.

Sharpen

at original angle

2. Check the balance of the blade by putting it on a

blade balancer (Fig. 25). If the blade stays in a

horizontal position, the blade is balanced and can

be used. If the blade is not balanced, file some

metal off the back side of the blade. Repeat this

procedure until the blade is balanced.

Installing the Blade(s)

1. Install the blade, blade retainer, washer, and the

blade bolt (Fig. 26).

IMPORTANT: The curved part of the blade

must be pointing up to ensure proper cutting.

2. Tighten the blade bolt to 45–60 ft–lb

(61–81 Nm).

4

3

2

5

1

Figure 26

1.

2.

3.

Bolt

Retainer

Blade

(recycling only)

4.

5.

Spindle

Washer

2

1

Figure 25

1.

Blade

2.

Balancer

17

Page 20

Maintenance

Greasing

and Lubrication

Service Interval/Specification

Grease the machine after every 50 operating hours or

once a year, whichever occurs first. Grease more

frequently when operating conditions are extremely

dusty or sandy.

Grease Type: General-purpose grease.

How to Grease

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key

2. Clean the grease fittings with a rag. Make sure to

scrape any paint off the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease

into the fittings.

Blade

Drive Belt

Removing the Blade Drive Belt

1. Remove the mower; refer to Removing the

Mower, page 10.

2. Remove the pulley cover mounting screws and

pulley covers from both blade pulleys (Fig. 28).

3. Remove the belt from the pulleys (Fig. 28).

Installing the Blade Drive Belt

1. Install the new belt around the blade pulleys and

the idler pulley.

2. Install the left and right pulley covers with the

mounting screws (Fig. 28).

3. Install the mower; refer to Installing the Mower,

page 5.

4. Wipe up any excess grease.

Where to Add Grease

1. Lubricate the blade spindles, idler pulley arm

and gage wheel bearings (Fig. 27).

1225

Figure 27

1

1.

Pulley

2.

Idler pulley

cover

3

Figure 28

T

op V

iew

3.

2

1

Mower belt

18

Page 21

Maintenance

Washing

Underside of Mower

After each use, wash the underside of the mower to

prevent grass build-up for improved recycling and

clipping dispersal.

1. Park the machine on a hard, level surface,

disengage the power take off (PTO) and turn the

ignition key to “OFF” to stop the engine.

2. Screw coupling to the end of a garden hose,

attach coupling to mower washout fitting and

turn water on high (Fig. 29).

Note: Spread petroleum jelly on washout

fitting o-ring to make coupling slide on

easier and protect o-ring.

3. Lower the mower to the lowest height-of-cut.

4. Sit on the seat and start the engine. Engage

power take off (PTO) and let mower run for one

to three minutes.

5. Disengage the power take off (PTO) and turn the

ignition key to “OFF” to stop the engine.

6. Turn the water off, remove coupling from the

washout fitting and hose.

Note: If the mower is not clean after one

washing, soak and let stand for 30

minutes. Then repeat process again.

7. Run mower again for one to three minutes to

remove excess water

.

3

2

1

Figure 29

1.

Washout

2.

Coupling

POTENTIAL

fitting

HAZARD

3.

Hose

• A broken or missing washout fitting could

expose you and others to thrown objects or

blade contact.

WHAT CAN HAPPEN

• Contact with thrown debris or blade

contact will cause injury or death.

HOW TO AV

OID THE HAZARD

• Replace broken or missing washout fitting

immediately, before using mower again.

• Plug any hole(s) in mower with bolts and

locknuts.

• Never put your hands or feet under the

mower or through openings in the mower.

m–2755

19

Page 22

Maintenance

Storage

1. Clean dirt and chaff from the outside of the

engine’s cylinder head fins and blower housing.

Also remove grass clippings, dirt, and grime

from the external parts of the entire machine,

especially the engine, shrouding, and the top of

the mower.

IMPORTANT: You can wash the machine

with mild detergent and water. Do not

pressure wash the machine. A

use of water, especially near the control panel,

lights, engine, and the battery.

2. Scrape heavy buildup of grass and dirt from the

underside of the mower. Then wash the mower

with a garden hose.

3. Check the condition of the blade(s); refer to

Cutting Blade, page 16.

void excessive

4. Check the condition of the blade drive belt.

5. Grease the mower deck; refer to Greasing and

Lubrication, page 18.

6. Check and tighten all bolts, nuts, and screws.

Repair or replace any part that is damaged or

defective.

7. Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service

Dealer.

8. Store the machine in a clean, dry garage or

storage area. Remove the key from the ignition

switch and keep it in a memorable place. Cover

the machine to protect it and keep it clean.

20

Page 23

Troubleshooting

gg

PROBLEM

Abnormal vibration.

Blade(s) does not rotate.

Uneven cutting height.

POSSIBLE CAUSES

1.

Cutting blade(s) is bent or

unbalanced.

2.

Blade mounting bolt is loose.

3.

Engine mounting bolts are

loose.

4.

Loose engine pulley

pulley

, or blade pulley

5.

Engine pulley is damaged.

6.

Blade drive belt of

1.

Blade drive belt is worn, loose

or broken.

2.

Blade drive belt is off pulley

1. T

ire pressure is incorrect.

2.

Mower is not level.

f pulley

, idler

.

.

. 2.

CORRECTIVE ACTION

1.

Install new cutting blade(s).

2. T

ighten blade mounting bolt.

3. T

ighten engine mounting

bolts.

4. T

ighten the appropriate

pulley.

5.

Contact Authorized Service

Dealer.

6.

Install blade drive belt and

check idler pulley and belt

guides for correct position.

1.

Install new blade drive belt.

Install blade drive belt and

check idler pulley and belt

guides for correct position.

1.

Set tire pressure.

2.

Level mower from

side-to-side and front-to-rear.

3.

Underside of mower is dirty

. 3.

Clean the underside of the

mower.

21

Page 24

Loading...

Loading...