Page 1

FormNo.3414-701RevC

ZMaster

®

Commercial3000

SeriesRidingMower

with60inTURBOFORCE

Mower

ModelNo.75990—SerialNo.400000000andUp

®

SideDischarge

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3414-701*C

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

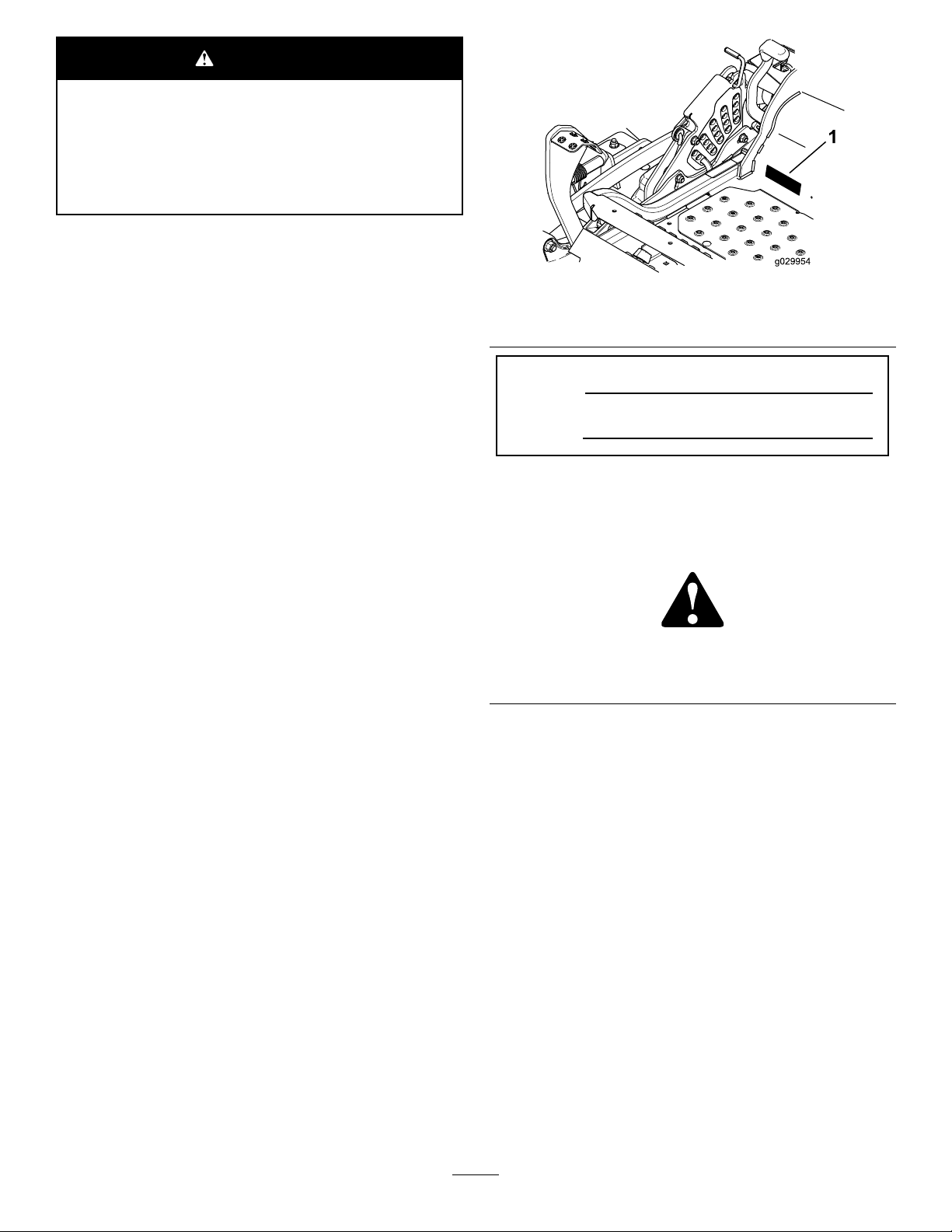

g029954

Figure1

1.Modelandserialnumberlocation

ModelNo.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ToroMowerSafety..............................................5

SlopeIndicator...................................................7

SafetyandInstructionalDecals..........................8

ProductOverview...................................................15

Controls...........................................................15

Specications..................................................16

Operation................................................................17

AddingFuel......................................................17

CheckingtheEngine-OilLevel..........................19

BreakinginaNewMachine..............................19

UsingtheRolloverProtectionSystem

(ROPS).........................................................19

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

EnteringtheUserPosition................................20

ThinkSafetyFirst..............................................20

OperatingtheParkingBrake.............................21

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................21

OperatingtheThrottle.......................................22

OperatingtheChoke.........................................22

OperatingtheIgnitionSwitch............................22

UsingtheFuel-ShutoffValve.............................23

StartingtheEngine...........................................23

StoppingtheEngine.........................................24

TheSafety-InterlockSystem.............................24

DrivingForwardorBackward............................25

StoppingtheMachine.......................................26

AdjustingtheHeightofCut...............................26

AdjustingtheAnti-ScalpRollers........................27

AdjustingtheFlowBafeCamLocks................28

PositioningtheFlowBafe................................29

PositioningtheSeat..........................................29

UnlatchingtheSeat..........................................30

AdjustingtheMyRide™Suspension

System..........................................................30

UsingtheDriveWheelReleaseV alves.............31

UsingtheSideDischarge.................................32

TransportingtheMachine.................................32

LoadingtheMachine........................................33

OperatingTips.................................................34

Maintenance...........................................................35

RecommendedMaintenanceSchedule(s)...........35

Lubrication..........................................................36

GreasingandLubrication..................................36

GreasingtheMowerDeck................................36

GreasingthePump-Belt-IdlerArm....................37

GreasingtheCaster-WheelBearings...............37

LubricatingtheCaster-WheelHubs..................38

EngineMaintenance...........................................39

ServicingtheAirCleaner..................................39

ServicingtheEngineOil....................................40

ServicingtheSparkPlugs.................................42

CheckingtheSparkArrester.............................44

FuelSystemMaintenance...................................44

ReplacingtheFuelFilter...................................44

ServicingtheFuelT ank.....................................45

ElectricalSystemMaintenance...........................45

ServicingtheBattery.........................................45

ServicingtheFuses..........................................47

DriveSystemMaintenance..................................48

CheckingtheSeatBelt.....................................48

CheckingtheRolloverProtectionSystem

(ROPS)Knobs..............................................48

AdjustingtheTracking......................................48

CheckingtheTirePressure...............................49

CheckingtheWheelLugNuts...........................49

CheckingtheWheelHubSlottedNut................49

AdjustingtheCaster-PivotBearing...................49

UsingtheClutchShim......................................50

CoolingSystemMaintenance..............................52

CleaningtheEngineScreenandEngine-Oil

Cooler...........................................................52

CleaningtheEngineCoolingFinsand

Shrouds........................................................52

CheckingandCleaningtheHydraulic

Units..............................................................53

BrakeMaintenance.............................................53

AdjustingtheParkingBrake..............................53

BeltMaintenance................................................54

InspectingtheBelts..........................................54

ReplacingtheMowerBelt.................................54

ReplacingtheHydraulicPump-Drive

Belt................................................................56

ControlsSystemMaintenance.............................56

AdjustingtheControlHandlePosition...............56

AdjustingtheMotion-ControlLinkage...............57

AdjustingtheMotion-ControlDamper...............58

AdjustingtheMotion-ControlNeutral-Lock

Pivot..............................................................58

HydraulicSystemMaintenance...........................59

ServicingtheHydraulicSystem........................59

MowerDeckMaintenance....................................61

LevelingtheMowerDeck..................................61

ServicingtheCuttingBlades.............................63

RemovingtheMowerDeck...............................65

ReplacingtheGrassDeector..........................67

Cleaning..............................................................67

CleaningundertheMower................................67

CleaningtheSuspensionSystem.....................67

DisposingofWaste...........................................67

Storage...................................................................68

CleaningandStorage.......................................68

Troubleshooting......................................................69

Schematics.............................................................71

3

Page 4

Safety

Improperuseormaintenanceofthemachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecycling

grassor,whenequippedwithagrassbagger,for

catchingcutgrass.Anyuseforpurposesother

thanthesecouldprovedangeroustotheuserand

bystanders.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

standardB71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.

•Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Inspecttheareawheretheequipmentisused,

andremoveallobjectsthatcanbethrownbythe

machine.

•Checkthatoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Operateonlyinwell-litareas,keepingawayfrom

holesandhiddenhazards.

•Ensurethatalldrivesareinneutralandthatthe

parkingbrakeisengagedbeforestartingengine.

Starttheengineonlyfromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhile

usingthismachine,especiallywhenbackingup.

Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

•Donotraisethemowerdeckwiththeblades

running.

•DonotoperatethemachinewithoutthePTO

shieldorotherguardssecurelyinplace.Besure

thatallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeople,or

damagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincluding:substantial

slip-resistantfootwear,safetyglasses,andhearing

protection.Tiebacklonghairanddonotwear

jewelry.

•Donotoperatewiththedischargedeectorraised,

removed,oraltered,unlessyouareusingagrass

catcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkthemachineonalevelsurface,disengagethe

drives,engagetheparkingbrake(ifprovided),and

shutofftheenginebeforeleavingtheoperator's

positionforanyreason,includingemptyingthe

catchersoruncloggingthechute.

•Stopthemachineandinspectthebladesafter

strikingobjectsorifanabnormalvibrationoccurs.

Makethenecessaryrepairsbeforeresuming

operation.

•Keepyourhandsandfeetawayfromthecutting

unit.

4

Page 5

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopthe

bladesifyouarenotmowing.

•Beawareofthemower-dischargedirectionand

donotpointitatanyone.

•Donotoperatethemowerwhileill,tired,orunder

theinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineis

extremelyammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,

oronatrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,

thenaddfuelwithsuchequipmentasaportable

containerratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.

•Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

•Donotoverllthefueltank.Afterllingthetank,

replacethefuelcapandtightenitsecurelytothe

tank.

stopbeforeadjusting,cleaning,orrepairingthe

machine.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorefuelnearamesordrainfuelindoors.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Useafull-widthrampforloadingmachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsandothersafetyinformationthatyou

mustknow.

Thisproductiscapableofamputatinghandsand

feet,andofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

MaintenanceandStorage

•Disengagedrives,engagetheparkingbrake,shut

offtheengine,andremovethekey,disconnect

thespark-plugwire,andwaitforallmovementto

Thisproductisdesignedforcuttingandrecycling

grass,or,whenequippedwithagrassbagger,for

catchingcutgrass.Anyuseforpurposesother

thanthesecouldprovedangeroustotheuserand

bystanders.

5

Page 6

UsingtheRollover-Protection System(ROPS)

•TheROPSisanintegralsafetydevice.Keepthe

ROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowertheROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenthe

ROPSisfoldeddown.

•Beawarethereisnorolloverprotectionwhenthe

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleased

quicklyintheeventofanemergency.

•Checktheareatobemowedandneverfold

downtheROPSinareaswherethereareslopes,

drop-offs,orwater.

•Checkcarefullyforoverheadclearances(e.g.,

branches,doorways,orelectricalwires)before

drivingunderanyobjectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairor

revise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedby

themanufacturer.

•Donotmowslopesgreaterthan15degrees.

Service

•Donotstorethemachineorafuelcontainerinside

wherethereisanopename,suchasneara

waterheaterorfurnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Tobestprotectyourinvestmentandmaintain

optimalperformanceofyourToroequipment,count

onT orogenuineparts.Whenitcomestoreliability,

Torodeliversreplacementpartsdesignedtothe

exactengineeringspecicationsofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

•Checkbrakeoperationfrequently .Adjustand

serviceasrequired.

6

Page 7

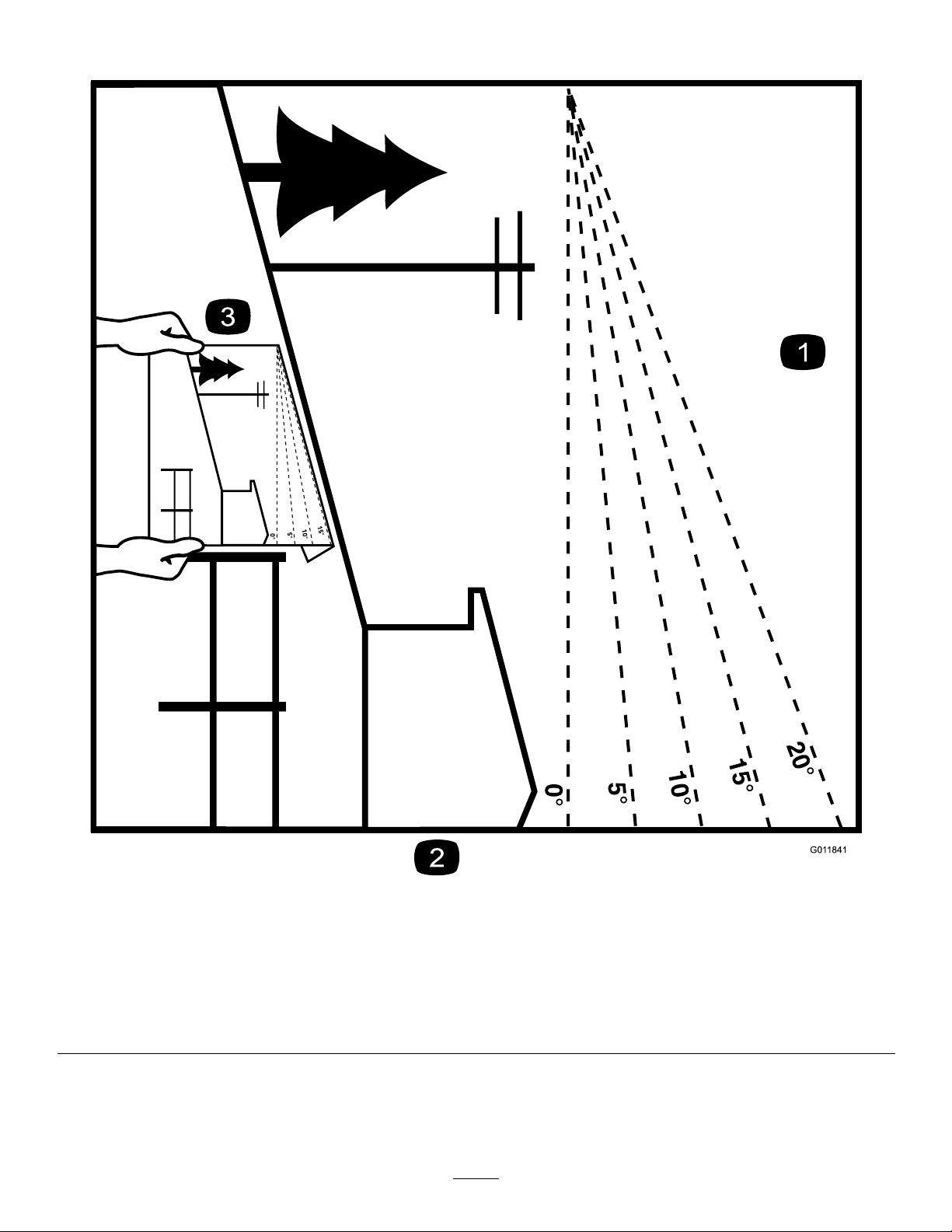

SlopeIndicator

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

g011841

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

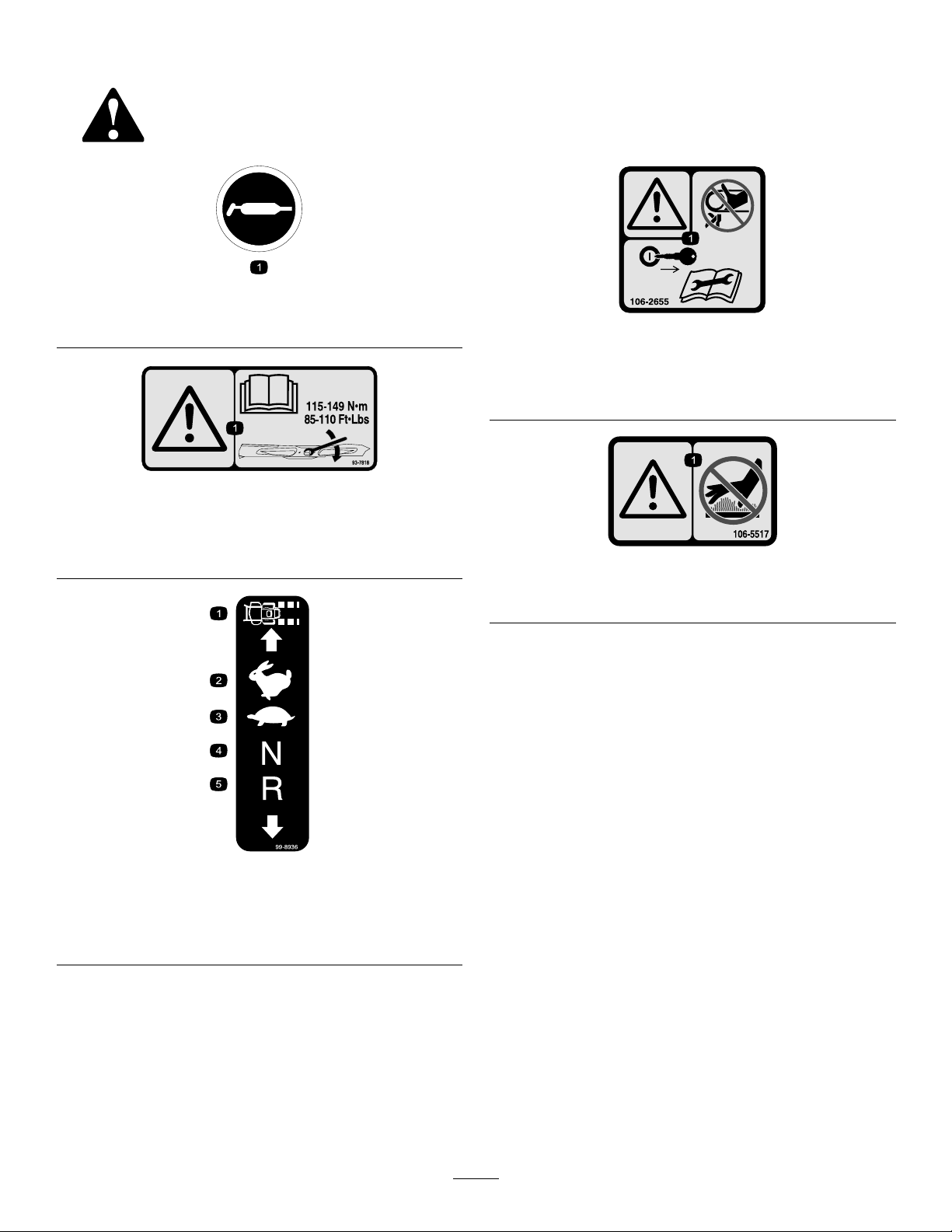

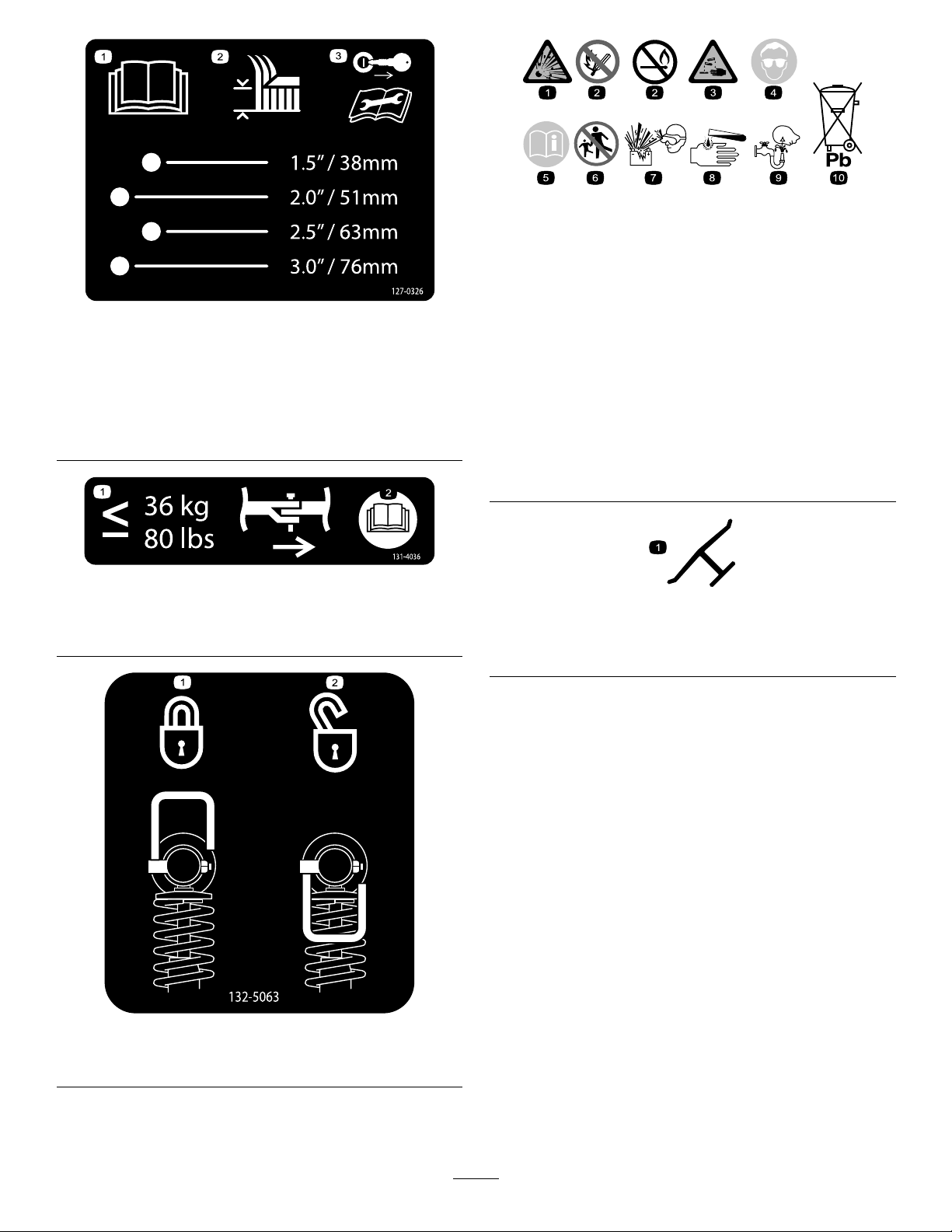

58-6520

1.Grease

93-7818

decal58-6520

decal106-2655

106-2655

1.Warning—donottouchorapproachmovingbelts;remove

theignitionkeyandreadtheinstructionsbeforeservicing

orperformingmaintenance.

decal93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

decal106-5517

106-5517

1.Warning—donottouchthehotsurface.

decal99-8936

8

Page 9

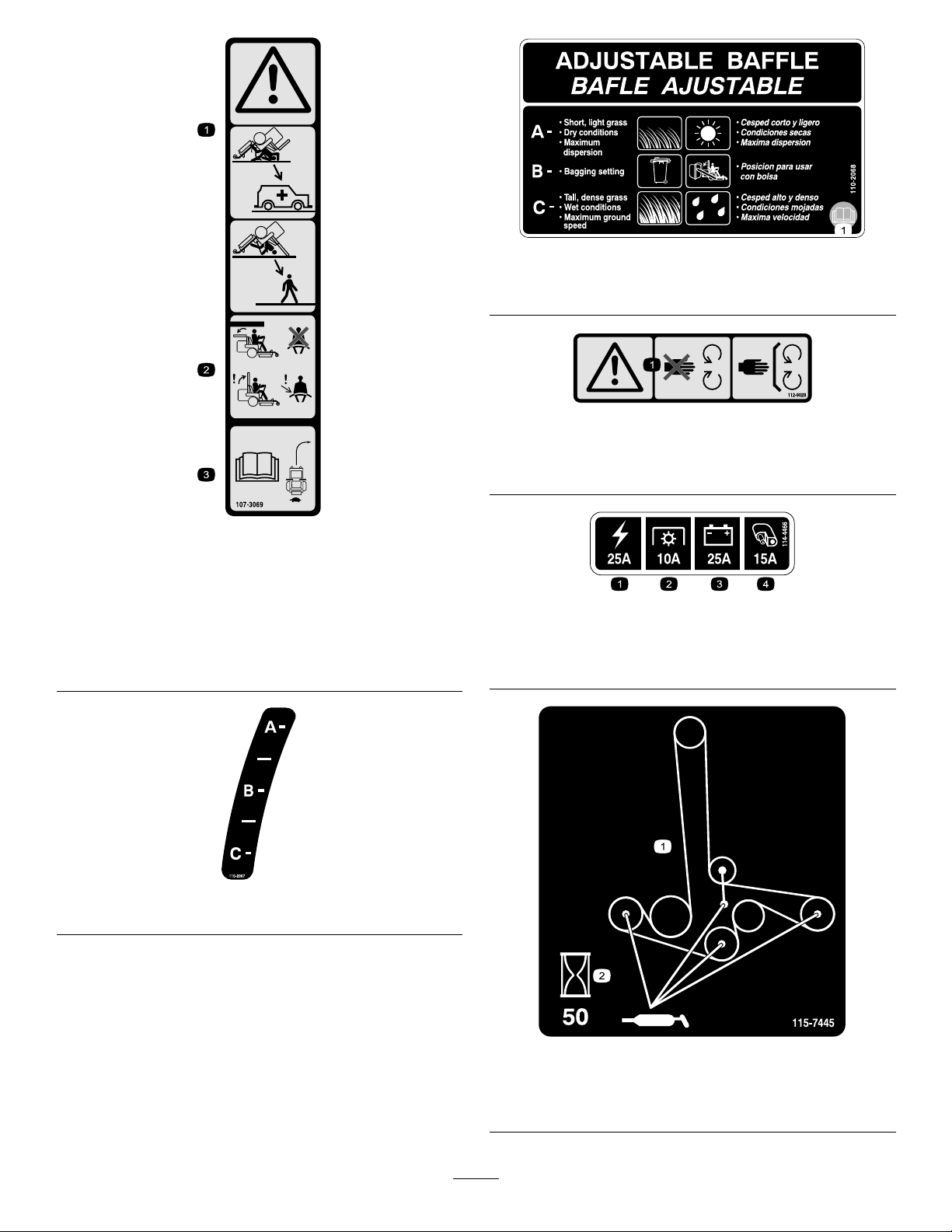

decal107-3069

107-3069

1.Warning—thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

decal110-2068

110-2068

1.ReadtheOperator'sManual.

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

decal114-4466

114-4466

1.Main,25A

2.PTO,10A

3.Charge,25A

4.Auxiliary,15A

decal110-2067

110-2067

decal115-7445

115-7445

1.Greasepulleysandspindles

2.Maintenanceinterval—50hours

9

Page 10

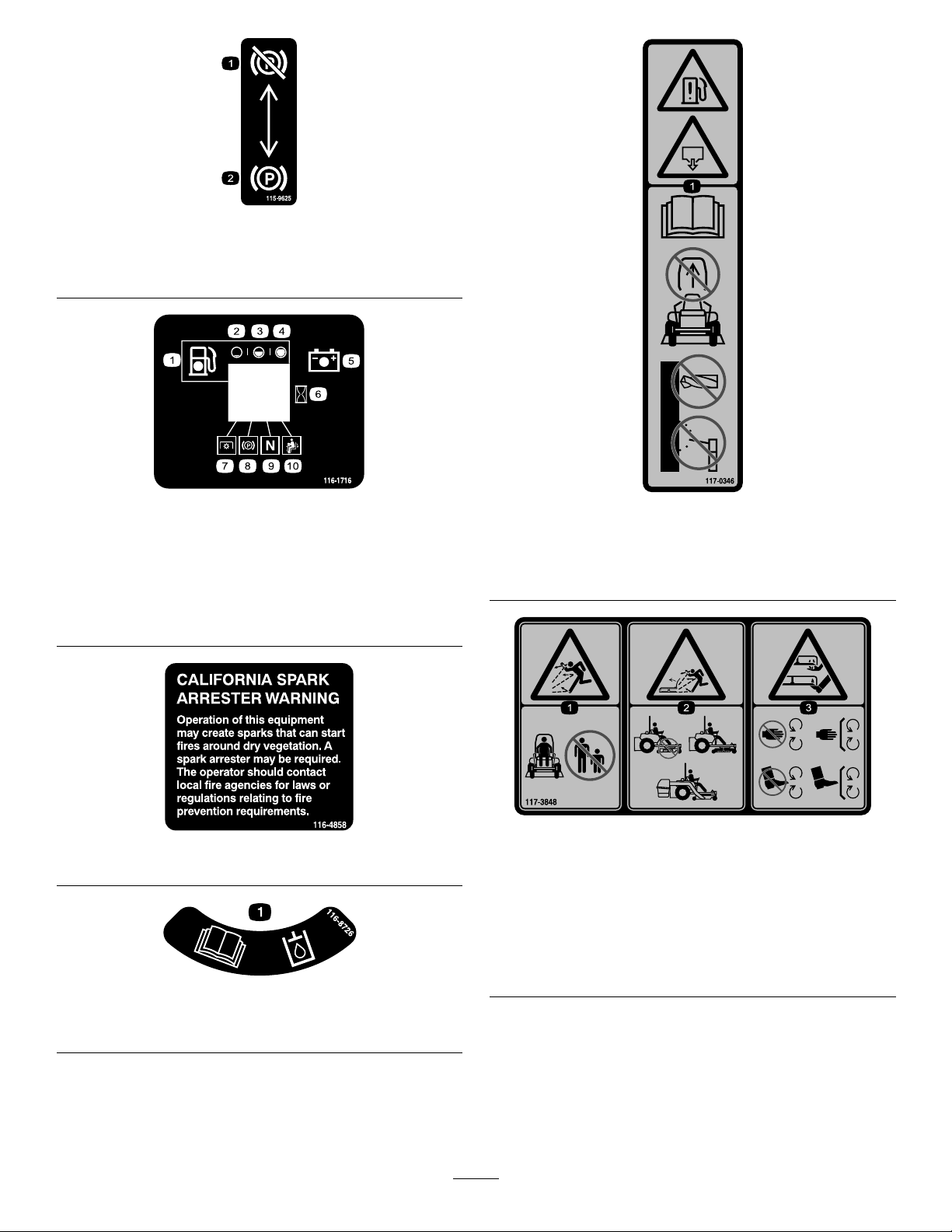

decal115-9625

115-9625

1.Parking

2.Parkingbrake—engaged

brake—disengaged

116-1716

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operatorpresenceswitch

decal116-1716

decal117-0346

117-0346

1.Fuelleakhazard—readtheOperator'sManual;donot

attempttoremovetherollbar;donotweld,drillormodify

therollbarinanyway.

116-4858

116-8726

1.ReadtheOperator’sManualforrecommendedhydraulicoil.

decal116-4858

117-3848

decal117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecoverorgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

decal116-8726

movingparts;keepallguardsandshieldsinplace.

10

Page 11

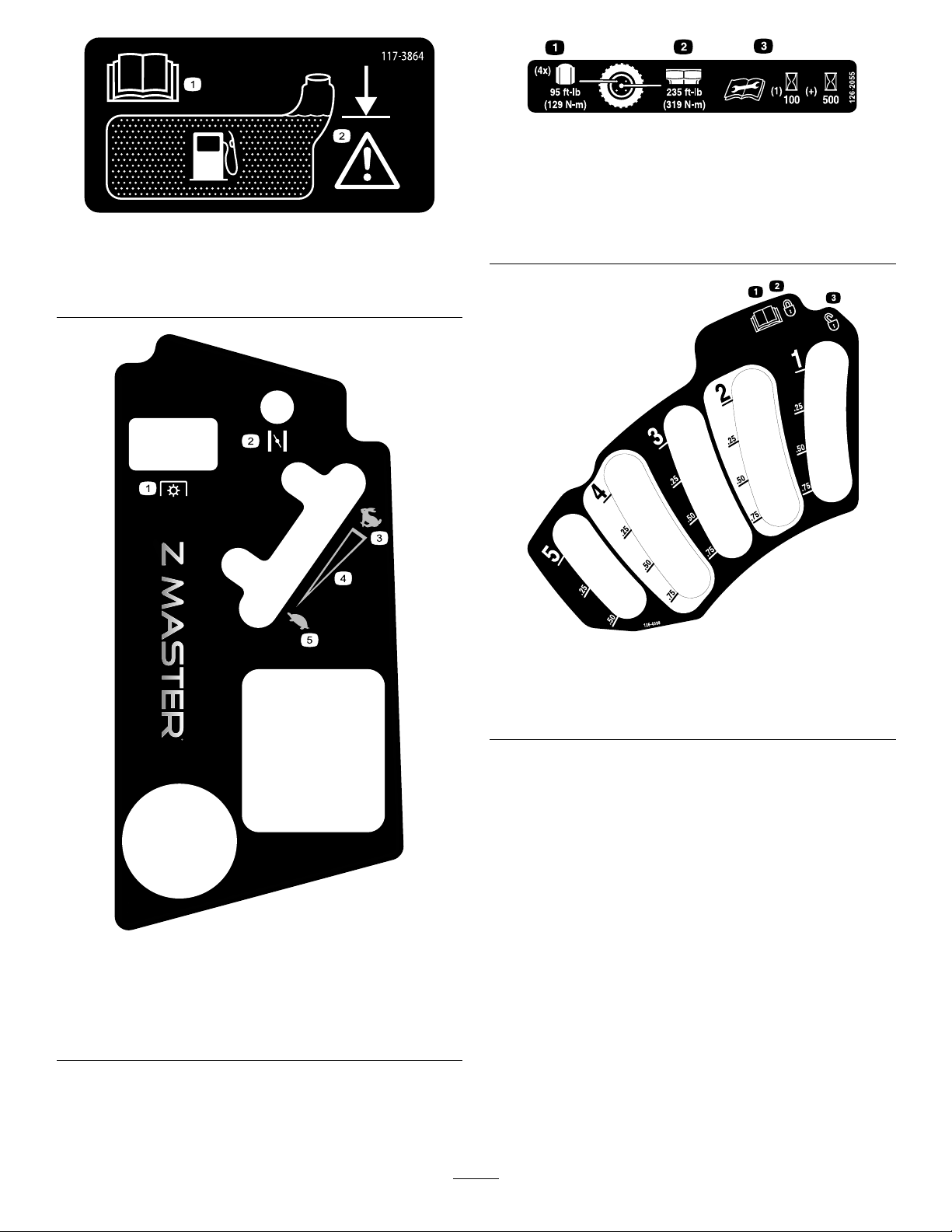

1.ReadtheOperator’s

Manual.

117-3864

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

decal126-2055

126-2055

1.Wheellugnuttorque95ft-lb(129N-m)(4x)

2.Wheelhubnuttorque235ft-lb(319N-m)

decal117-3864

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance,checktorqueaftertherst

100hoursthenevery500hoursthereafter.

121-7551

1.Powertakeoff(PTO)4.Continuousvariable

setting

2.Choke5.Slow

3.Fast

decal126-4398

126-4398

1.ReadtheOperator’s

manual

2.Lock

decal121-7551

3.Unlock

11

Page 12

BatterySymbols

Someorallofthesesymbolsareonyourbattery

decalbatterysymbols

1.ReadtheOperator's

Manual.

2.Heightofcut

1.Maximumdrawbarpull36

kg(80lb)

127-0326

3.Removethekeyfrom

131-4036

2.ReadtheOperator's

theignitionandreadthe

Operator'sManualbefore

performingmaintenance

orservicingthemachine.

Manual.

1.Explosionhazard

6.Keepbystandersasafe

distanceawayfromthe

battery.

decal127-0326

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

decal131-4036

10.Containslead;donot

discard

decaloemmarkt

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

132-5063

1.Camlock2.Camunlock

decal132-5063

12

Page 13

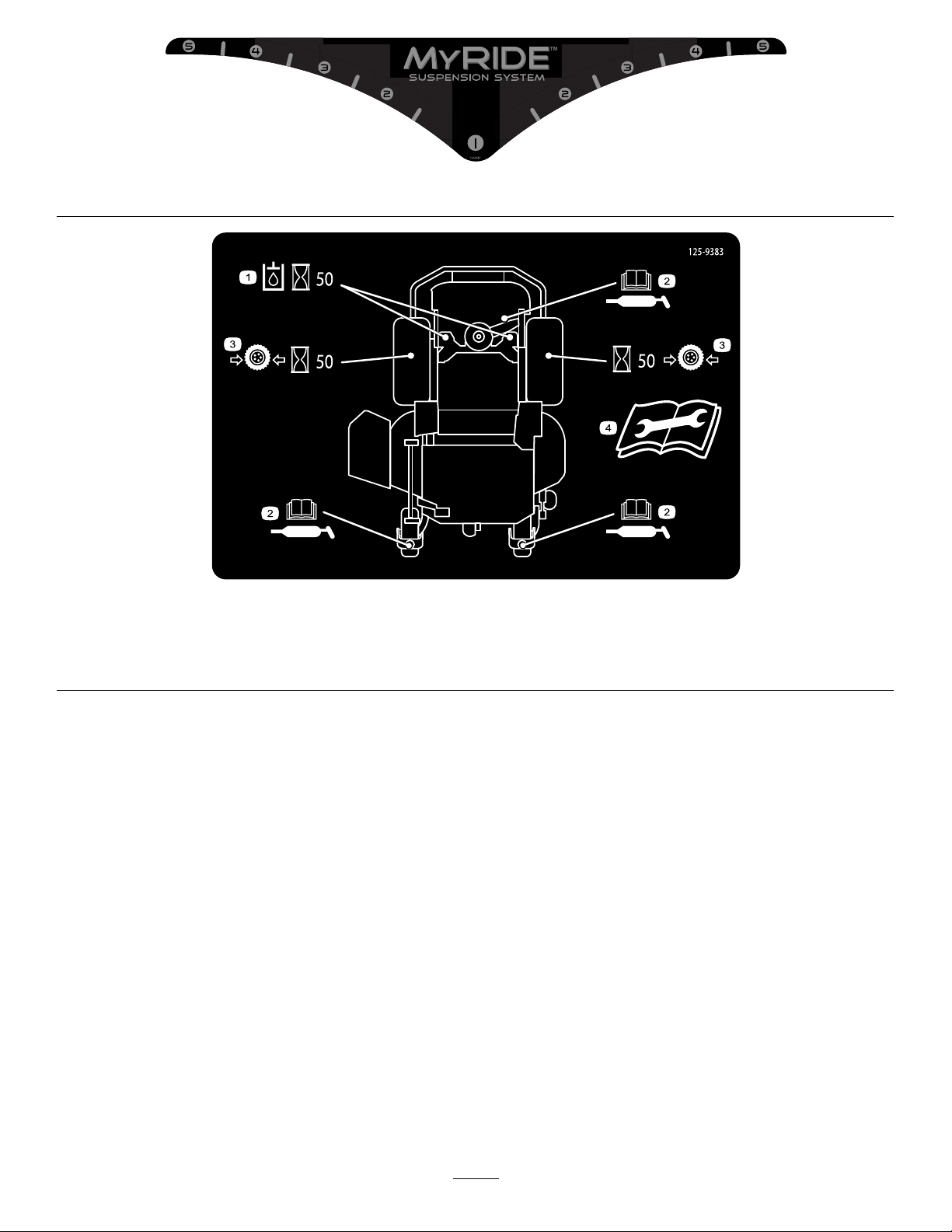

decal132-5067

132–5067

decal125-9383

125–9383

1.Checkhydraulicoilevery50operatinghours.3.Checkthetirepressureevery50operatinghours.

2.ReadtheOperator’sManualforinformationonlubricating

themachine.

4.ReadtheOperator’sManualbeforeservicingorperforming

maintenance.

13

Page 14

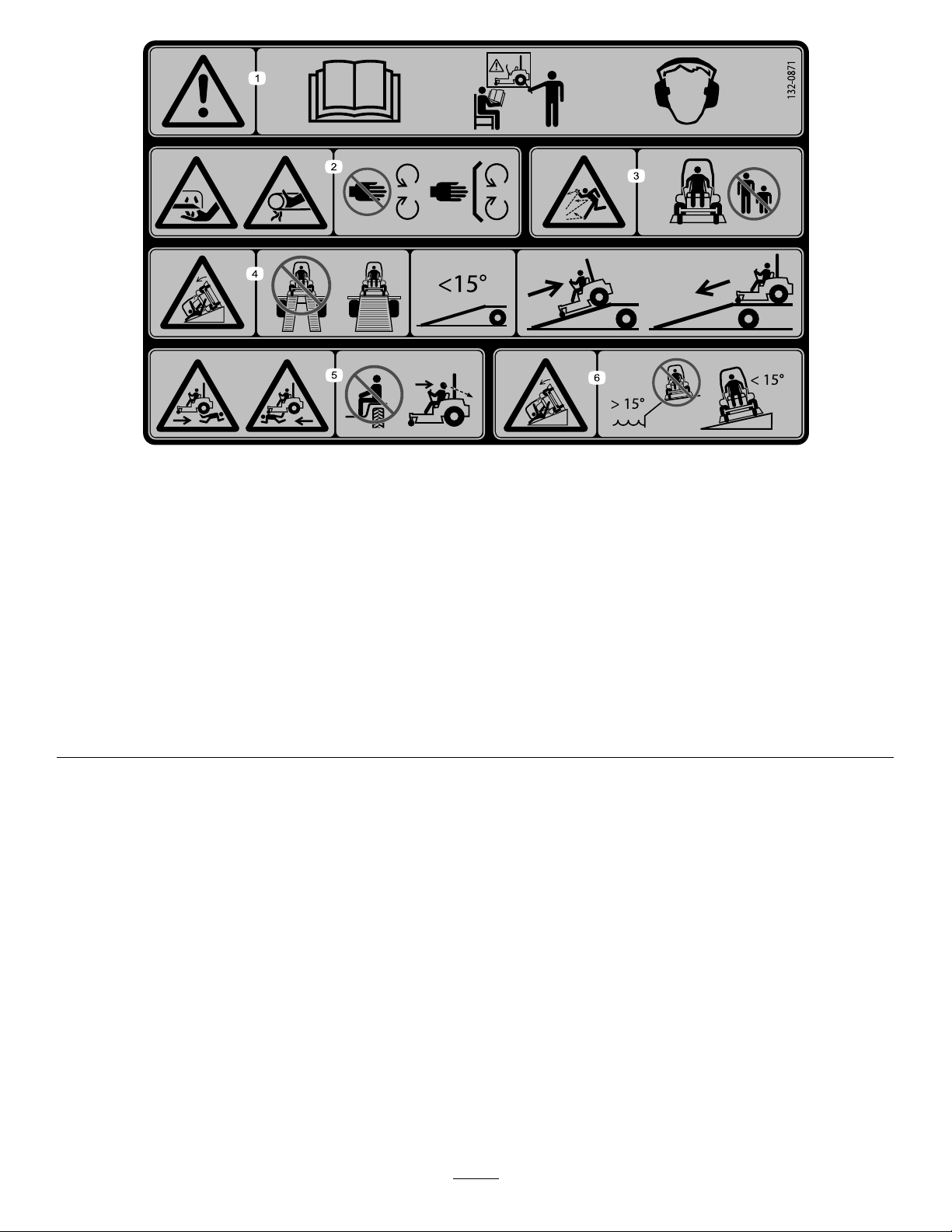

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0871

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

2.Cutting,dismembering,andentanglementhazard—keep

handsawayfrommovingparts;keepallguardsandshieldsin

place.

3.Thrownobjecthazard—keepbystandersaway.6.Tippinghazardonslopes—donotuseonslopesnearopen

4.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15°;backuptheramp(in

reverse)anddriveforwardofftheramp.

5.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

water;donotuseonslopesgreaterthan15°.

14

Page 15

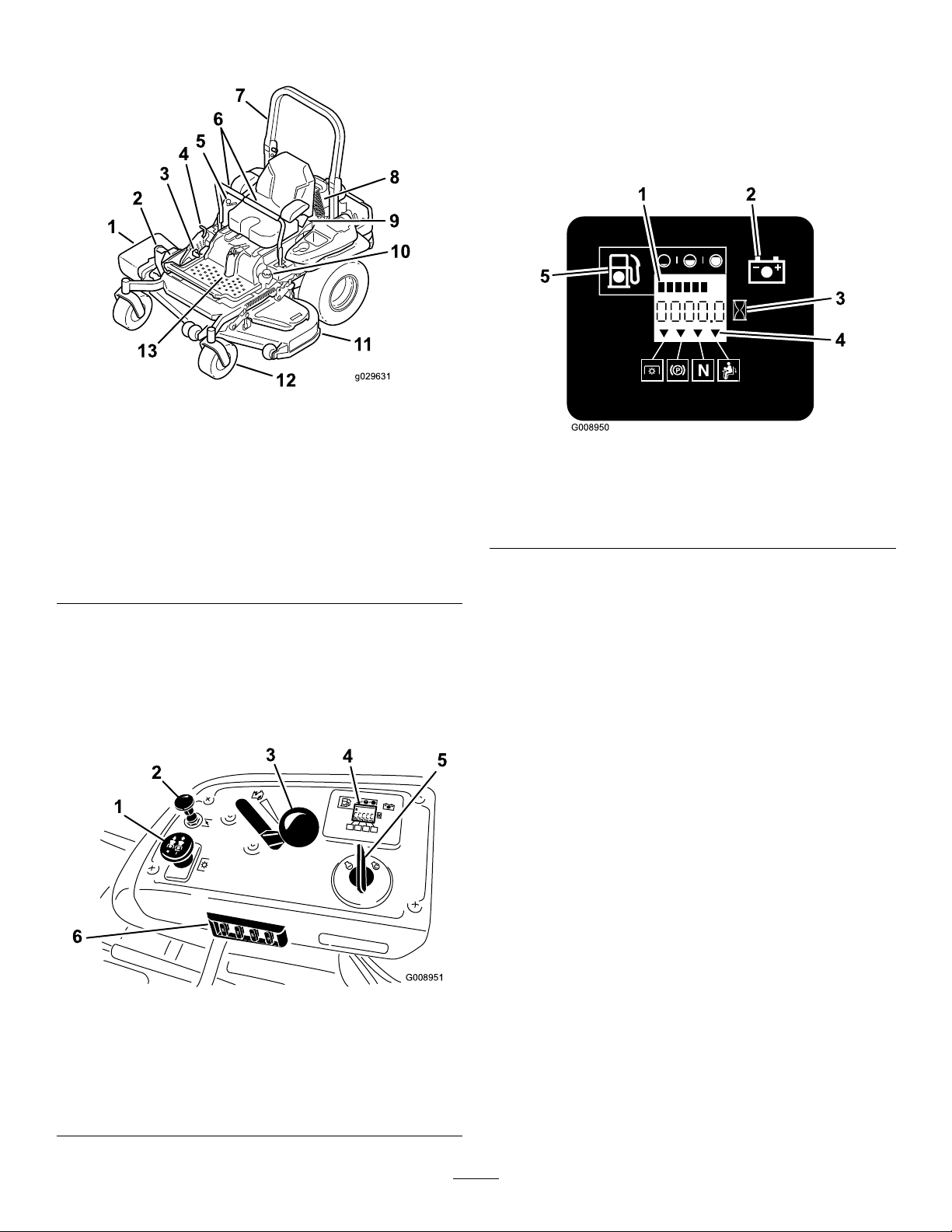

ProductOverview

Figure4

1.Side-dischargedeector

2.Height-of-cutdecklift

pedal

3.Parking-brakelever10.Fuelcap

4.Transportlock11.Mowerdeck

5.Controls12.Casterwheel

6.Motion-controllevers13.Frontshockassembly

7.Rollbar

8.Rearshockassembly

9.Seatbelt

FuelGauge

Thefuelgaugeislocatedwiththehourmeter,andthe

barslightupwhentheignitionswitchison(Figure6).

Theindicatorlightappearswhenthefuellevelis

low—approximately3.8L(1USgallon)remainingin

thefueltank.

g029631

g008950

Figure6

1.Fuelgauge(bars)4.Safety-interlocksymbols

2.Batterylight

3.Hourmeter

5.Low-fuelindicatorlight

HourMeter

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure4and

Figure5).

Figure5

1.PTOswitch

2.Choke

3.Throttlecontrol6.Fuses

4.Hour

meter/Safety-interlock

display/Fuelgauge

5.Ignitionswitch

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

Safety-InterlockIndicators

Therearesymbolsonthehourmeterandtheindicate

withablacktrianglethattheinterlockcomponentisin

thecorrectposition(Figure6).

Battery-IndicatorLight

WhentheignitionkeyisinitiallyturnedtotheRUN

positionforafewseconds,thebatteryvoltage

appearswherethehoursnormallyappear.

Thebatterylightturnsonwhenyouturnontheignition

andwhenthechargeisbelowthecorrectoperating

g008951

level(Figure6).

ThrottleControl

ThethrottlecontrolisvariablebetweenFASTand

SLOW.

15

Page 16

Choke

Specications

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)isusedtoengage

theelectricclutchanddrivethemowerblades.Pull

theswitchuptoengagethebladesandrelease.T o

disengagetheblades,pushtheblade-controlswitch

(PTO)downormoveamotion-controlleverintothe

neutral-lockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:ST ART,RUNandOFF.

Motion-ControlLevers

Themotion-controlleversareusedtodrivethe

machineforward,reverse,andturneitherdirection.

Neutral-LockPosition

Theneutral-lockpositionisusedwiththe

safety-interlocksystemtoengageandtodetermine

neutralposition.

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width:

60inchDeck

Withoutdeck

Deectorup156.8cm(61.7inches)

Deectordown192.2cm(75.7inches)

Length:

Rollbarup

Rollbardown

Height:

RollbarupRollbar—down

179.1cm(70.5inches)118.9cm(46.8inches)

Weight:

ModelWeight

75990

134.6cm(53.0inches)

60inchDeck

211.1cm(83.1inches)

215.4cm(84.8inches)

585kg(1,290lb)

Fuel-ShutoffValve

Closethefuel-shutoffvalve(undertheseat)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

16

Page 17

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycancauseasparkwhichcanignite

thegasolinevapors.Areorexplosionfrom

gasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbed,because

interiorcarpetsorplastictruck-bedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

fueltheequipmentwiththewheelsonthe

ground.

Ifthisisnotpossible,thenfuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasoline-dispensernozzle.

•Ifagasolinedispensermustbeused,keep

thenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimes

untilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastank

orconditionerbottleopening.

•Avoidcontactwithskin;washoffspillage

withsoapandwater.

17

Page 18

UsingFuelStabilizer/Conditioner

FillingtheFuelTank

Useafuelstabilizer/conditionerinthemachineto

keepthefuelfreshduringstorageof90daysorless.

Ifyouarestoringthemachineforlonger,drainthefuel

tank;refertoServicingtheFuelT ank(page45).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionerto

thefuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcapandremoveit.

Addregularunleadedgasolinetothefueltank

untilthelevelis6to13mm(1/4to1/2inch)

belowthebottomofthellerneck.Thisspacein

thetankallowsthegasolinetoexpand.Donot

llthefueltankcompletelyfull;referto(Figure

7).

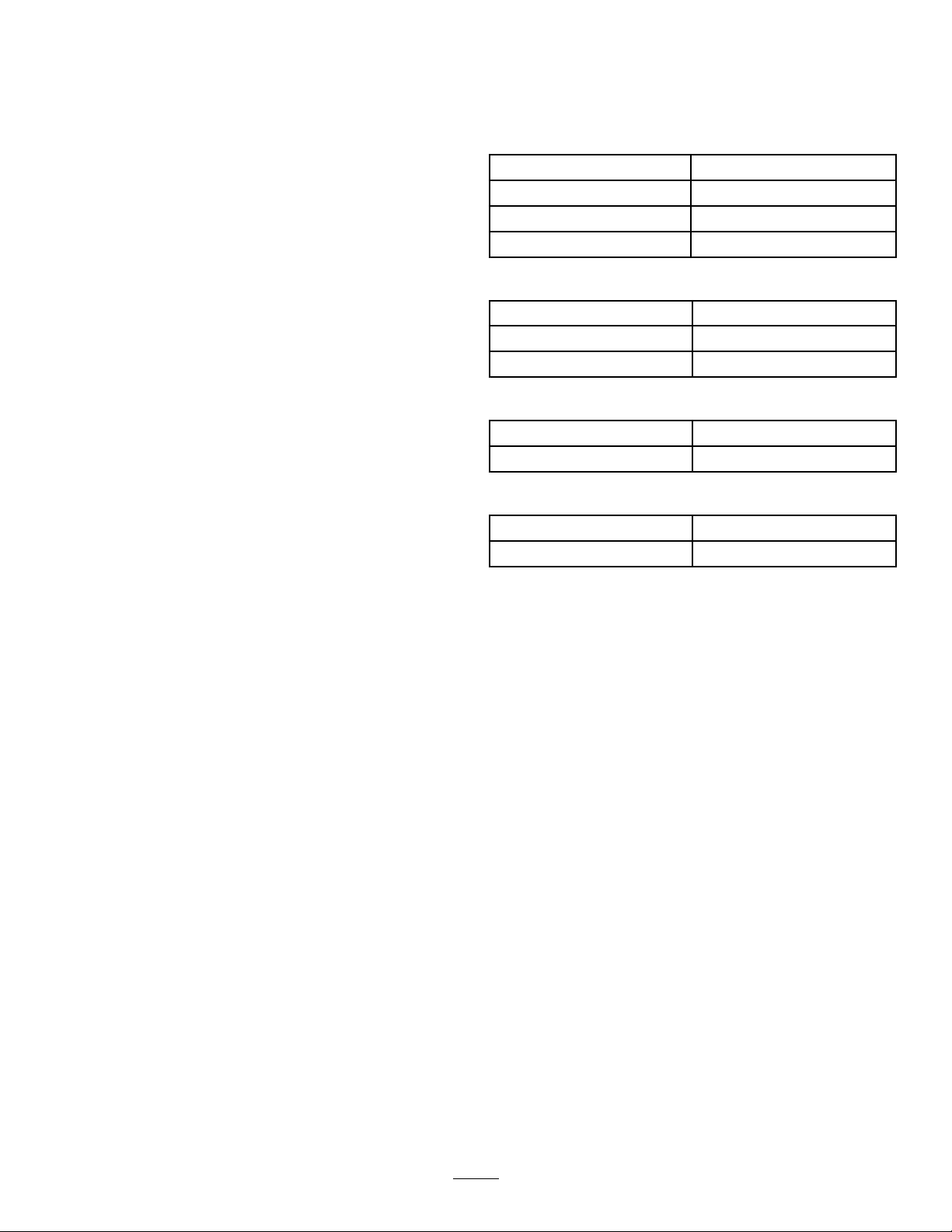

g029938

g027726

Figure7

18

Page 19

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page40).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

UsingtheRollover ProtectionSystem(ROPS)

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarinthefullyraisedlockedposition

andusetheseatbelt.

Ensurethattherearpartoftheseatissecured

withtheseatlatch.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(e.g.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

Important:Lowertherollbaronlywhen

absolutelynecessary.

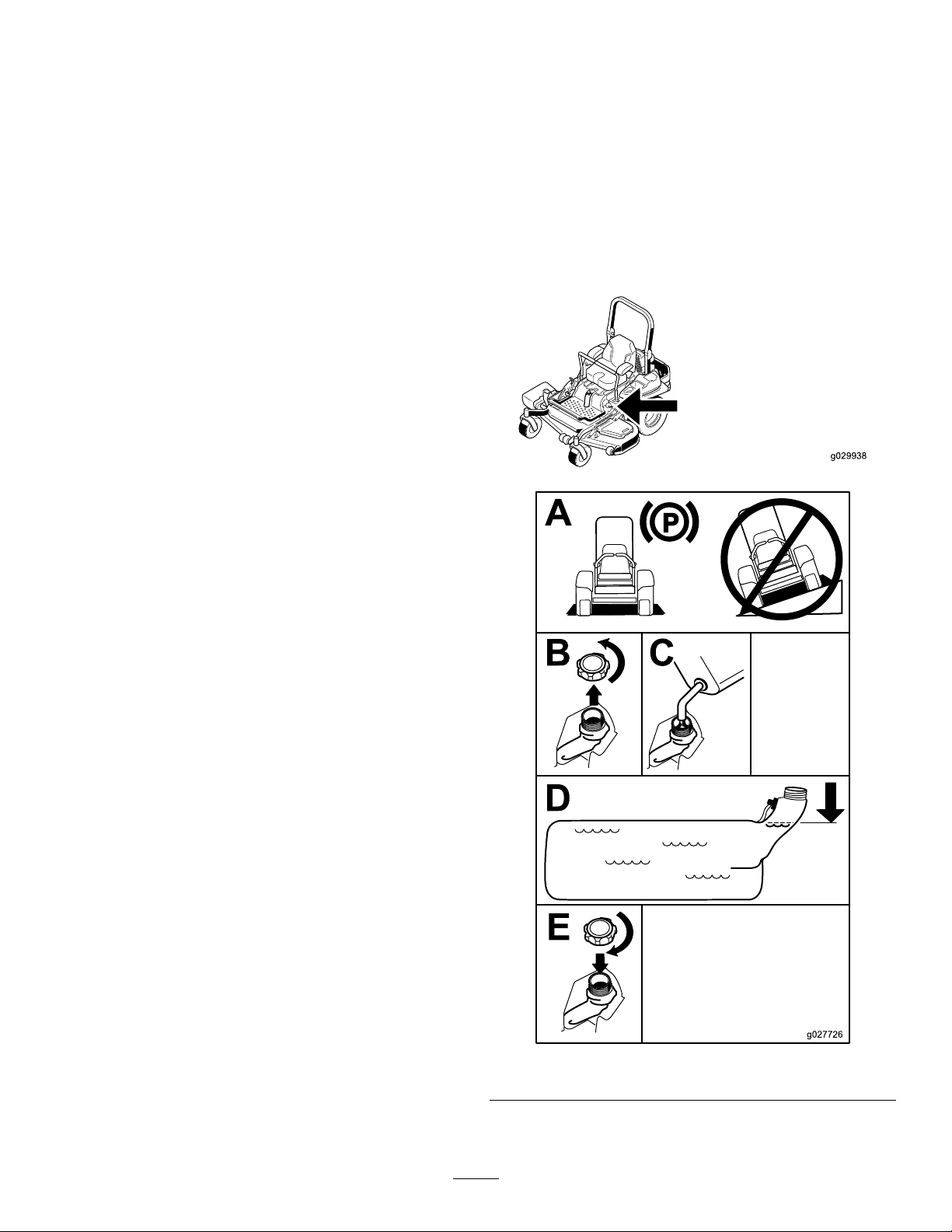

Figure8

1.ROPSknob

2.PullROPSknoboutand

rotate90degrees

4.Toraisetherollbar,raisetherollbartowards

theuprightpositionandrotatetheknobssothat

theymovepartiallyintothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswill

snapintopositionwhentheholesalignwiththe

pins(Figure8).Pushontherollbarandensure

thatbothpinsareengaged.

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

Important:Alwaysusetheseatbeltwiththe

rollbarinthefullyraisedposition.

g008943

1.Tolowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sothat

theyarenotengaged(Figure8).

3.Lowertherollbartothefoldedposition(Figure

8).

19

Page 20

EnteringtheUserPosition

Usethemowerdeckasasteptogetintotheuser

position(Figure9).

g000963

Figure10

Figure9

1.Mowerdeck

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescan

causeslidingandlossofcontrol.

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

Thereisnorolloverprotectionwhentheroll

barisdown.

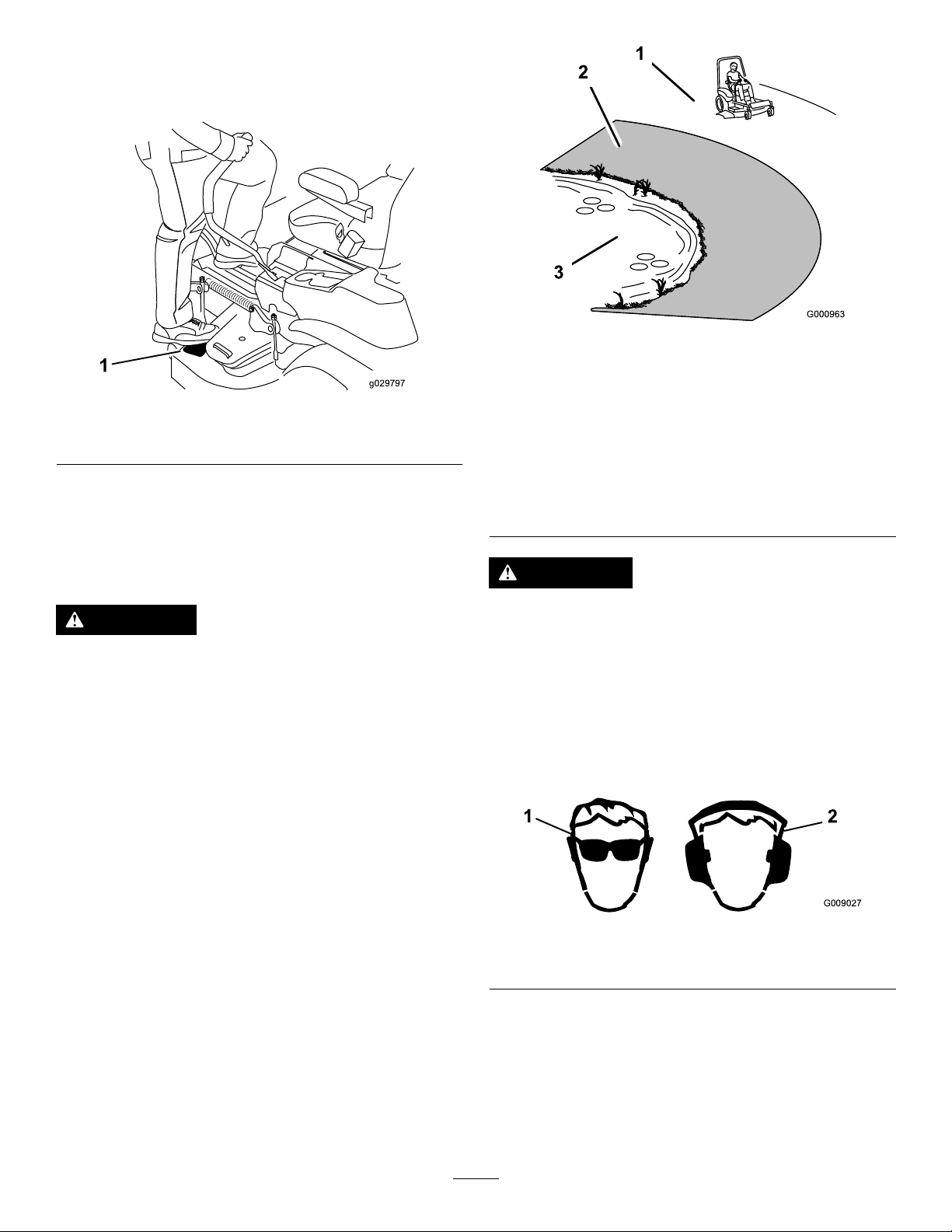

1.SafeZone—usethe

g029797

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsand

water.

3.Water

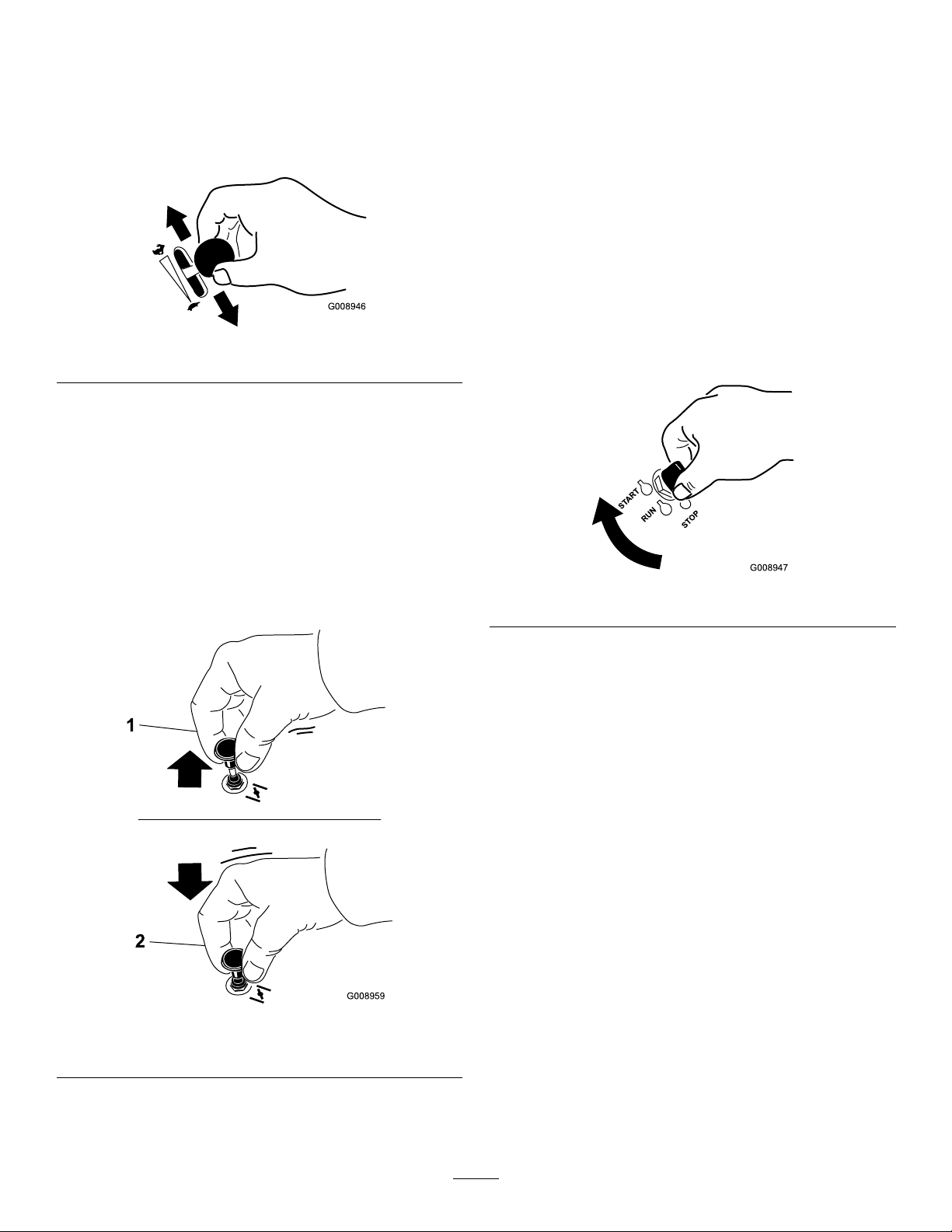

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useofprotectiveequipmentforyoureyes,ears,

hands,feet,andhead.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Readandfollowtherolloverprotection

instructionsandwarnings.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotoperateneardrop-offsornear

water.

•Donotoperateonslopesgreaterthan

15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeed

changes.

g009027

Figure11

1.Weareyeprotection.2.Wearhearingprotection.

20

Page 21

OperatingtheParking

OperatingtheMower

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

WARNING

Theparkingbrakemaynotholdamachine

thatisparkedonaslopeandcouldcause

personalinjuryorpropertydamage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

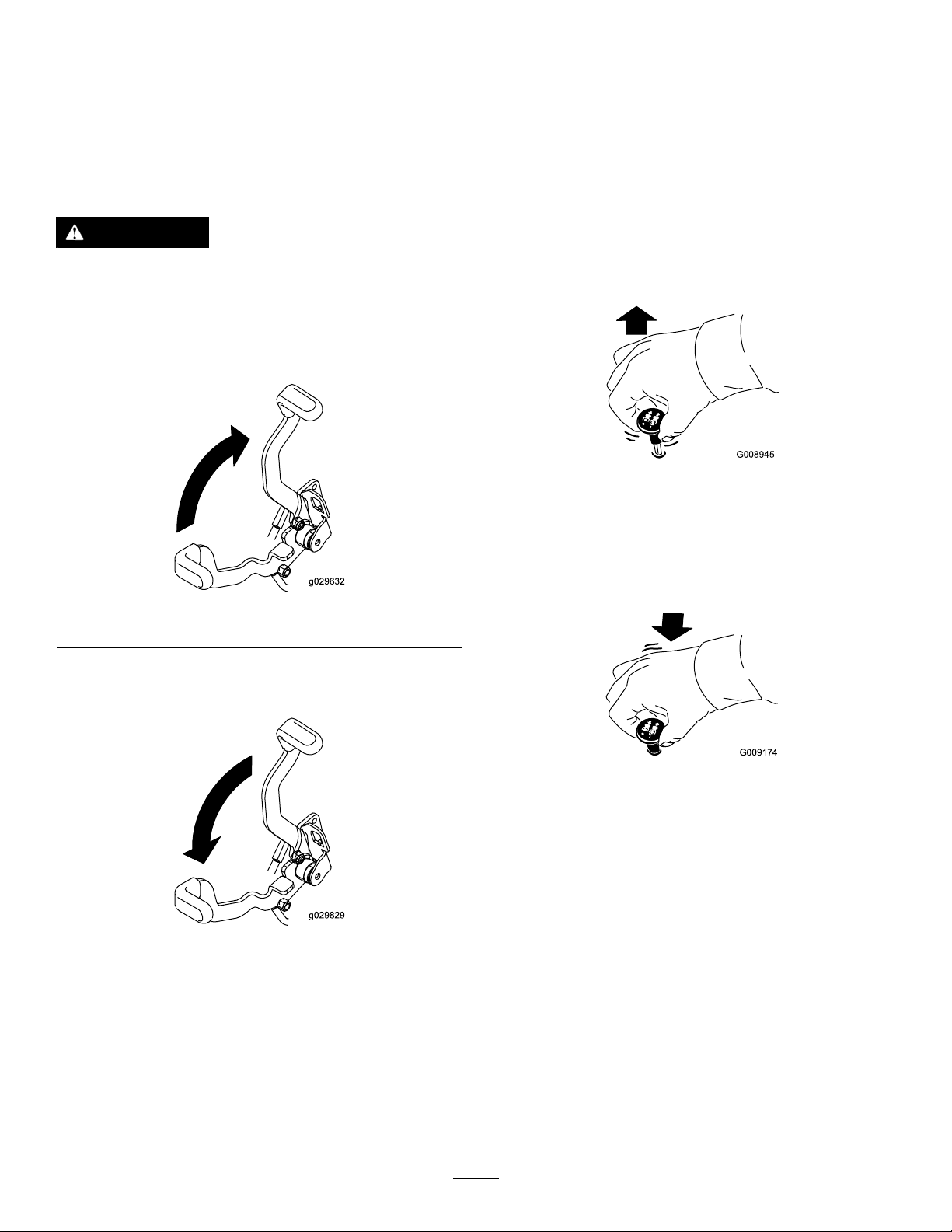

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control Switch(PTO)

Important:Engagingtheblade-controlswitch

(PTO)withthethrottlepositionathalforlesswill

causeexcessiveweartothedrivebelts.

g008945

Figure14

Figure12

ReleasingtheParkingBrake

Figure13

DisengagingtheBlade-Control

g029632

g029829

Switch(PTO)

g009174

Figure15

21

Page 22

OperatingtheThrottle

OperatingtheIgnition

ThethrottlecontrolcanbemovedbetweentheFAST

andSLOWpositions(Figure16).

AlwaysusetheFASTpositionwhenengagingthe

mowerdeckwiththeblade-controlswitch(PTO).

Figure16

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

Switch

1.TurntheignitionkeytotheSTARTposition

(Figure18).Whentheenginestarts,release

thekey.

Important:Donotengagethestarterfor

morethan5secondsatatime.Iftheengine

failstostart,allowa15secondcool-down

periodbetweenattempts.Failuretofollow

theseinstructionscanburnoutthestarter

motor.

Note:Additionalstartingcyclesmaybe

g008946

requiredwhenstartingtheenginefortherst

timeafterthefuelsystemhasbeencompletely

withoutfuel.

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure17).

3.Pushdownonthechoketodisengagethechoke

aftertheenginehasstarted(Figure17).

g008947

Figure18

2.Toshutofftheengine,turntheignitionkeyto

theSTOPposition.

Figure17

1.On2.Off

g008959

22

Page 23

UsingtheFuel-Shutoff

StartingtheEngine

Valve

Thefuel-shutoffvalveislocatedundertheseat.Move

theseatforwardtoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage.

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

1.Raiseandlocktherollbarintoplace,sitonthe

seat,andfastentheseatbelt.

2.Movethemotioncontrolstoneutral-locked

position.

3.Engagetheparkingbrake;refertoEngagingthe

ParkingBrake(page21).

4.Movetheblade-controlswitch(PTO)totheOFF

position(Figure20).

5.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions.

Figure19

1.ON2.OFF

g008948

g029634

Figure20

6.TurntheignitionkeytotheSTARTposition

(Figure18).Whentheenginesstarts,release

thekey.

23

Page 24

StoppingtheEngine

CAUTION

TheSafety-Interlock System

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

LettheengineidleattheSLOWpositionfor60seconds

beforeturningtheignitionswitchoff.

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamagedthemachinecould

operateunexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheneutral-locked

position

Thesafety-interlocksystemalsoisdesignedtoshutoff

theenginewhenthetractioncontrolsaremovedfrom

thelockedpositionwiththeparkingbrakeengaged,or

ifyourisefromtheseatwhenthePTOisengaged.

Figure21

Important:Ensurethatthefuelshut-offvalveis

closedbeforetransportingorstoringthemachine,

asfuelleakagemayoccur.Engagetheparking

brakebeforetransporting.Makesuretoremove

thekeyfromtheignition,asthefuelpumpmay

runandcausethebatterytolosecharge.

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglewilllightupinthecorrespondingsquare.

g029635

g009181

Figure22

1.Triangleindicatorlight

24

Page 25

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)toon.

Trystartingtheengine;theengineshouldnot

crank.

2.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)to

off.Moveeithermotion-controllever(outof

neutral-lockedposition).Trystartingtheengine;

theengineshouldnotcrank.Repeatforother

controllever.

3.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)tooffand

movethemotion-controlleverstoneutral-lock

position.Nowstarttheengine.Whiletheengine

isrunning,releasetheparkingbrake,engage

theblade-controlswitch(PTO)andriseslightly

fromtheseat;theengineshouldstop.

CAUTION

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowdownthemachinebeforemaking

sharpturns.

UsingtheMotion-ControlLevers

4.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)tooffand

movethemotion-controlleverstoneutral-lock

position.Nowstarttheengine.Whiletheengine

isrunning,centereithermotioncontroland

move(forwardorreverse);theengineshould

stop.Repeatforothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)tooffand

movethemotion-controlleverstoneutral-lock

position.Trystartingtheengine;theengine

shouldnotcrank.

DrivingForwardor Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

Figure23

1.Motion-control

lever—neutral-lock

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForward

Note:Ifyoumovethetraction-controlleverswiththe

parkingbrakeengaged,theenginewillshutoff.

Tostop,pullthemotion-controlleverstotheneutral

position.

g004532

1.Releasetheparkingbrake;refertoReleasing

theParkingBrake(page21).

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotion-control

leversforward(Figure24).

25

Page 26

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

toneutralandmovetolockedposition,disengagethe

powertakeoff(blade-controlswitch(PTO),andturn

theignitionkeytooff.

Engagetheparkingbrakewhenyouleavethe

machine;refertoEngagingtheParkingBrake(page

21).Removethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandengage

theparkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

Figure24

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-control

leversrearward(Figure25).

g008952

AdjustingtheHeightofCut

UsingtheTransportLock

ThetransportlockhasaLOCKpositionandanUNLOCK

positionandisusedwiththedeck-liftpedal.Refer

toFigure26.

Figure25

g008953

26

Page 27

AdjustingtheHeight-of-CutPin

Theheightofcutisadjustedfrom25to140mm(1to

5-1/2inches)in6mm(1/4inch)incrementsbymoving

theclevispinintodifferentholelocations.

1.MovethetransportlocktotheLOCKposition.

2.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktothetransportposition

(alsothe140mm(5-1/2inch)cutting-height

position);refertoFigure27.

3.Toadjust,rotatethepin90degreesandremove

thepinfromtheheight-of-cutbracket(Figure

27).

4.Insertthepinintoaholethatcorrespondstothe

desiredheightofcut(Figure27).

5.Pushonthedeck-liftpedal,pullbackonthe

transportlock,andslowlylowerthemowerdeck.

Figure26

TransportLockPositions

1.Transportlock3.UNLOCKposition—the

2.LOCKposition—the

mowerdecklocksinto

thetransportposition.

mowerdeckisnotlocked

intothetransportposition

g029840

Figure27

1.Deck-liftpedal

2.Height-of-cutpin

g032377

3.Transportlock

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheneutral-locked

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

28,Figure29,andFigure30.

27

Page 28

Figure28

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

AdjustingtheFlowBafe

CamLocks

Thisprocedureisapplicableonlytomachineswith

theowbafelocks.Certainmodelswillhavenuts

andboltsin-placeoftheowbafelocksandcanbe

adjustedthesame.

Themowerdischargeowcanbeadjustedfor

differenttypesofmowingconditions.Positionthecam

g029955

locksandbafetogivethebestqualityofcut.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheneutral-locked

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Toadjustthecamlocks,swingtheleverupto

loosenthecamlock(Figure31).

4.Adjustthebafeandcamlocksintheslotsto

thedesireddischargeow.

5.Swingtheleverbackovertotightenthebafe

andcamlocks(Figure31).

Figure29

1.Anti-scalproller3.Flangenut

2.Bushing4.Bolt

Figure30

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

6.Ifthecamlocksdonotlockthebafeintoplace

oritistootight,loosentheleverandthenrotate

thecamlock.Adjustthecamlockuntilyou

g029956

g029957

achievethedesiredlockingpressure.

g027727

Figure31

28

Page 29

PositioningtheFlowBafe

PositionC

Thefollowingguresareonlyrecommendationsfor

use.Adjustmentswillvarybygrasstype,moisture

content,andheightofgrass.

Note:Iftheenginepowerdrawsdownandthe

mowergroundspeedisthesame,openupthebafe.

PositionA

Thisisthefull-rearposition.Thesuggestedusefor

thispositionisasfollows:

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Useforsmallergrassclippings.

•Usetopropelgrassclippingsfartherawayfrom

themower.

Thisisthefull-openposition.Thesuggestedusefor

thispositionisasfollows:

•Useintall,densegrass-mowingconditions.

•Useinwetconditions.

•Usetolowertheenginepowerconsumption.

•Usetoallowincreasedgroundspeedinheavy

conditions.

•Thispositionoffersbenetssimilartothoseofthe

ToroSFSmower.

Figure32

PositionB

Usethispositionwhenbagging.Alwaysalignitwith

thebloweropening.

Figure33

g005834

g005832

Figure34

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

Toadjusttheseat,movetheleversidewaystounlock

(Figure35).

g008962

Figure35

g005833

29

Page 30

UnlatchingtheSeat

AdjustingtheMyRide™ SuspensionSystem

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Youcanadjustthe

rear2-shockassembliestoquicklyandeasilychange

thesuspensionsystem.Positionthesuspension

systemwhereyouaremostcomfortable.

AdjustingtheRear-Shock Assemblies

Theslotsfortherear-shockassemblieshave

detentpositionsforreference.Y oucanpositionthe

rear-shockassembliesanywhereintheslot,notjust

inthedetentpositions.

Thefollowinggraphicshowsthepositionforasoftor

rmrideandthedifferentdetentpositions(Figure37).

g204507

Figure36

Figure37

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

g029988

30

Page 31

Adjusttherear-shockassemblies(Figure38).

UsingtheDriveWheel ReleaseValves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,

whichcouldresultinseriousinjury.

g030024

Stoptheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drivewheelreleasevalves.

WARNING

Theengineandhydraulicdriveunitscan

becomeveryhot.Touchingahotengineor

hydraulicdriveunitscancausesevereburns.

Allowtheengineandhydraulicdriveunitsto

coolcompletelybeforeaccessingthedrive

wheelreleasevalves.

Thedrivewheelreleasevalvesarelocatedintheback

ofeachhydraulicdriveunit,undertheseat.

Note:Ensurethatthereleasevalvesareinthefully

horizontalpositionwhenoperatingthemachine;

otherwise,severedamagetothehydraulicsystem

canoccur.

1.DisengagethePTO(blade-controlswitch)and

turntheignitionkeytoOFF.Movethelevers

totheNEUTRAL-LOCKEDposition,engagethe

parkingbrake,andremovethekey.

Figure38

2.Rotatethereleasevalveleversverticallytopush

themachine.Thisallowsthehydraulicuidto

bypassthepump,enablingthewheelstoturn

(Figure39).

3.Disengageparkingbrakebeforepushingthe

machine.

g030019

31

Page 32

Figure39

1.Verticaltopushthe

machine

4.Rotatethereleasevalvelevershorizontallyto

runthemachine(Figure39).

2.Horizontaltorunthe

machine

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

g029831

slow-movingvehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

UsingtheSideDischarge

Thismachinehasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrass-catcherassemblymountedin

place,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfrom

themachine,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

machine.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoumovethepower

takeoff(blade-controlswitch/PTO)tothe

OFFposition,shutofftheengine,and

removethekey .

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Engagetheparkingbrake,shutofftheengine,

removethekey,andclosethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure40).

g029641

Figure40

1.Tie-downloops

•Makesurethatthegrassdeectorisinthe

downposition.

32

Page 33

LoadingtheMachine

Useextremecautionwhenloadingorunloading

machinesontoatraileroratruck.Useafull-width

rampthatiswiderthanthemachineforthisprocedure.

Backuptherampanddriveforwarddowntheramp

(Figure41).

Figure41

g027995

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Ensurethattherollbarisintheupposition

andusetheseatbeltwhenloadingor

unloadingthemachine.Ensurethattheroll

barwillclearthetopofanenclosedtrailer.

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure42

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.Heightofthetraileror

truckbedtotheground

6.Trailer

•Ensurethatthelengthoframpisatleast

4timesaslongastheheightofthetrailer

ortruckbedtotheground.Thisensures

thattherampangledoesnotexceed15

degreesonatground.

•Backthemachineuptherampanddriveit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

33

Page 34

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepast

isgenerallythebestonetouse.Whencuttinggrass

longerthan15.2cm(6inches)tall,youmaywantto

cutthelawntwicetoensureanacceptablequalityof

cut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,

raisethecuttingheighthigherthanusualandcutthe

grassatthissetting.Thencutthegrassagainusing

thelower,normalsetting.

WhenStopping

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmaydrop

ontoyourlawn.T oavoidthis,moveontoapreviously

cutareawiththebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.T earingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

cutterbladesdailyforsharpness,andforanywearor

damage.Filedownanynicksandsharpentheblades

asnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthe

grassgrowthrateslowsinmidsummer,mowless

frequently.Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight;thenmowagaintwo

dayslateratalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

34

Page 35

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheellugnuttorque.

•Checkthewheelhubslotted-nuttorque.

•Checktheparkingbrakeadjustment.

•Changethehydraulicltersandhydraulicuidwhenusinganytypeofuid.

•Checkthesafetysystem.

•Checktheengineoillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Cleantheenginescreenandtheoilcooler.

•Checkandcleanthehydraulicunits.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethemowerdeckspindlesandidlerarm(ifequipped).

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicuidlevel.

•Lubricatethemowerdeckliftpivots.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Checkandgapthesparkplugs.

•Checkandcleanenginecoolingnsandshrouds.

Every200hours

Every250hours

Every500hours

Monthly

Yearly

Yearlyorbeforestorage

•Changetheengineoillter.

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

•ChangethehydraulicltersandhydraulicuidwhenusingMobil®1oil(moreoften

indirtyordustyconditions).

•Replacethesecondaryairlter.

•Replacethefuellter.(moreoftenindirtyordustyconditions).

•Checkthewheellugnuttorque.

•Checkthewheelhubslotted-nuttorque.

•Adjustthecasterpivotbearing.

•Checktheparkingbrakeadjustment.

•ChangethehydraulicltersandhydraulicuidwhenusingToro®HYPR-OIL™500

hydraulicoil(moreoftenindirtyordustyconditions).

•Checkthebattery.

•Greasethepump-belt-idlerarm.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Repackthefrontcaster-wheelbearings(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

35

Page 36

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

GreasingandLubrication

Greasemorefrequentlywhenoperatingconditions

areextremelydustyorsandy.

GreaseType:No.2lithiumormolybdenumgrease

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheneutral-locked

positionandengagetheparkingbrake.

2.Stoptheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.Scrapeany

paintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pump

greaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

GreasingtheMowerDeck

ServiceInterval:Every50hours—Greasethemower

deckspindlesandidlerarm(if

equipped).

Important:Makesurethatthecuttingunit

spindlesarefullofgreaseweekly.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Greasethemower-deckidlerpulleypivotuntil

greasecomesoutthebottom(Figure44).

4.Ifequipped,greasethe3spindlebearingsuntil

greasecomesoutthelowerseals(Figure44).

UsingLightOilorSpray Lubrication

ServiceInterval:Every100hours

Deckliftpivots.

g009029

Figure44

g029642

Figure43

36

Page 37

Greasingthe

GreasingtheCaster-Wheel

Pump-Belt-IdlerArm

ServiceInterval:Yearly—Greasethepump-belt-idler

arm.

Greasethepump-belt-idlerarm(Figure45).

Figure45

Bearings

ServiceInterval:Yearly—Greasethefrontcaster

pivots(moreoftenindirtyordusty

conditions).

Yearly—Repackthefrontcaster-wheelbearings

(moreoftenindirtyordustyconditions).

1.Removethedustcapandadjustthecaster

pivots.

Note:Keepthedustcapoffuntilgreasingis

done.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

5.Removethegreasettinginthehole.

6.Installthehexpluganddustcap(Figure46).

g009030

Figure46

7.Greasethecaster-wheelbearings(Figure46).

37

g009187

Page 38

Lubricatingthe Caster-WheelHubs

ServiceInterval:Yearly

1.Engagetheparkingbrake,shutofftheengine,

waitforallmovingpartstostop,andremove

thekey.

11.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

12.Insertthesecondbearingandanewsealinto

thewheel.

13.Applyathread-lockingadhesivetothesecond

spacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

14.T orquethenutto8to9N∙m(75to80in-lb),

loosenit,thentorqueitto2to3N∙m(20to25

in-lb).Makesurethattheaxledoesnotextend

beyondeithernut.

15.Installthesealguardsoverthewheelhuband

insertthewheelintothecasterfork.Installthe

casterboltandtightenthenutfully.

16.Removethejackstands.

g006115

Figure47

1.Sealguard2.Spacernutwithwrench

ats

2.Raisethefrontofthemachineup,andsupportit

withjackstands(orequivalentsupport)justhigh

enoughtoallowthefrontwheelstoturnfreely.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub.

5.Remove1ofthespacernutsfromtheaxle

assemblyinthecasterwheel.Notethat

thread-lockingadhesivehasbeenappliedto

lockthespacernutstotheaxle.Removethe

axle(withtheotherspacernutstillassembledto

it)fromthewheelassembly.

6.Pryoutseals,andinspectthebearingsforwear

ordamageandreplacethemifnecessary.

7.Packthebearingswithageneral-purpose

grease.

8.Insertonebearing,onenewsealintothewheel.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

casterwheel.Thewheelshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

play.Ifthewheelspinsfreely,adjustthetorqueon

spacernutuntilthereisaslightamountofdrag.

Applythread-lockingadhesive.

Note:Thesealsmustbereplaced.

9.Iftheaxleassemblyhashadbothspacer

nutsremoved(orbrokenloose),applya

thread-lockingadhesivetoonespacernutand

threaditontotheaxlewiththewrenchats

facingoutward.Donotthreadthespacernut

allthewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

10.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

38

Page 39

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawaythemuferandother

hotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacethe

primaryairlter.

Every250hours—Checkthesecondaryair

lter.

Every500hours—Replacethesecondaryair

lter.

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy .

Figure48

1.Air-cleanerclamps

2.Air-cleanercover

3.Primaryairlter

4.Secondaryairlter

ServicingthePrimaryFilter

1.Donotcleanthepaperlter,replaceit(Figure

48).

g009031

RemovingtheFilters

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKEDposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Pushdowntoreleasetheretainingclampson

theaircleanerandpulltheair-cleanercoveroff

oftheair-cleanerbody(Figure48).

4.Cleantheinsideoftheaircleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheair

cleanerbody(Figure48).Avoidknockingthe

lterintothesideofthebody.

6.Removethesecondarylteronlyifyouintend

toreplaceit.

Important:Neverattempttocleanthe

secondarylter.Ifthesecondarylteris

dirty,thentheprimarylterisdamagedand

youshouldreplacebothlters.

7.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.Holesinthelterwillappear

asbrightspots.Ifthelterisdamageddiscardit.

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty ,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

1.Ifinstallingnewlters,checkeachlterfor

shippingdamage.Donotuseadamagedlter.

2.Ifthesecondarylterisbeingreplaced,carefully

slideitintothelterbody(Figure48).

3.Carefullyslidetheprimarylteroverthe

secondarylter(Figure48).Ensurethatitis

fullyseatedbypushingontheouterrimofthe

lterwhileinstallingit.

Important:Donotpressonthesoftinside

areaofthelter.

4.Installtheair-cleanercoverwiththebreather

capdownandrotatesotheretainingclamps

lockthecoverinplace(Figure48).

39

Page 40

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,or

SL)

CrankcaseCapacity:withalterchange,2.1L(2.2

USqt);withoutalterchange,1.8L(1.9USqt)

Viscosity:Seethetablebelow.

Figure49

g029644

g004216

Note:Useofmulti-gradeoils(5W-20,10W-30,or

10W-40)willincreaseoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawayfromthemuferand

otherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runtheenginewithoilbelowthelowmark;the

enginemaybedamaged.

1.DisengagethePTO,movethemotion-control

leverstotheneutral-lockedpositionandengage

theparkingbrake.

g027659

Figure50

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure50).

40

Page 41

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirtyordusty

conditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylower

thanthefronttoensuretheoildrainscompletely.

2.DisengagethePTO,movethemotion-control

leverstotheneutral-lockedposition,andengage

theparkingbrake.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure51).

4.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

52).

g029644

Figure52

5.Starttheengineanddrivetoaatarea.Check

theoillevelagain.

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page41).

2.Changetheengineoillter(Figure53).

g027660

Figure51

g027734

41

Page 42

ServicingtheSparkPlugs

ServiceInterval:Every100hours

Makesurethattheairgapbetweenthecenter

electrodeandthesideelectrodeiscorrectbefore

installingeachsparkplug.Useaspark-plugwrench

g029644

forremovingandinstallingthesparkplugsanda

gappingtool/feelergaugetocheckandadjusttheair

gap.Installnewsparkplugsifnecessary .

Type:NGK

®

BPR4ESorequivalent

AirGap:0.76mm(0.030inch)

RemovingtheSparkPlug

1.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

2.DisengagethePTO,movethemotion-control

leverstotheneutral-lockedposition,andengage

theparkingbrake.

3.Removethelefthydraulic-unitshroudinthe

orderlistedinFigure54.

Note:Thisgivesyouaccesstothefrontspark

plug.

Figure53

Note:Ensuretheoilltergaskettouchesthe

engineandthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoChangingtheEngineOil(page41).

g027477

42

Page 43

CheckingtheSparkPlugs

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablack

coating,wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,the

g029645

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

g027479

Figure56

1.Pullthistabouttothe

sideinthedirectionofthe

arrow

2.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

4.Removethesparkplug.

g009919

Figure54

3.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

4.Shroud

g029646

Figure55

5.Installthelefthydraulic-unitshroud(Figure54).

g027478

43

Page 44

InstallingtheSparkPlugs

Tightenthesparkplugsto24.4to29.8N∙m(18to22

ft-lb).

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Y early(whichever

comesrst)(moreoftenindirtyor

dustyconditions).

Thefuellterislocatedneartheengineonthefront

orrearsideoftheengine.

1.DisengagethePTO,movethemotion-control

leverstotheneutral-lockedposition,andengage

theparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Figure57

CheckingtheSpark Arrester

IfEquipped

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

fuelvaporsevenafteryoushutofftheengine.

Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotfuelorruntheengineunlessthespark

arresterisinstalled.

g027735

3.Allowthemachinetocooldown.

4.Closethefuel-shutoffvalveundertheseat

(Figure58).

Figure58

1.Fuellter

2.Hoseclamp

3.Fuelline

g008963

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsare

observed,replacethearrester.

4.Ifpluggingofthescreenisobserved,remove

thearresterandshakeanylooseparticlesoutof

thearrester,andcleanthescreenwithawire

brush(soakitinsolventifnecessary).Installthe

sparkarresterontheexhaustoutlet.

5.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure58).

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclamps

closetothelter(Figure58).

8.Openthefuel-shutoffvalve.

Important:Installthefuellinehosesandsecure

withplastictiesthesameastheywereoriginally

installedatthefactory,tokeepthefuellineaway

fromcomponentsthatcoulddamagethefuelline.

44

Page 45

ServicingtheFuelTank

ElectricalSystem

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankand

servicesanycomponentsofthefuelsystem.

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichislethalifconsumedandcauses

severeburns.

Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygases

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

45

Page 46

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausing,sparks.

Sparkscancausethebatterygasesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheneutral-locked

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthenegativebatterycable(black)

fromthenegative(-)batteryterminal(Figure59).

4.Slidetheredterminalbootoffthepositive(red)

batteryterminalandremovethepositive(+)

batterycable(Figure59).

5.Removethewingnutsecuringthebatteryclamp

(Figure59).

6.Removetheclamp(Figure59).

7.Removethebattery.

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminal

postsoppositefromthehydraulictank(Figure

59).

2.Installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Installthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(Figure59).

5.Slidetheredterminalbootontothepositive

(red)batterypost.

6.Installtheclampandsecureitwiththewingnut

(Figure59).

Figure59

g029644

g027728

46

Page 47

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgasesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Chargebatteryfor10to15minutesat25to30

A,or30minutesat10A.

2.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet;then

disconnectthechargerleadsfromthebattery

posts(Figure60).

3.Installthebatteryinthemachineandconnect

thebatterycables,refertoInstallingtheBattery

(page46).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Theelectricalsystemisprotectedbyfuses.Itrequires