Toro 75951 Operator's Manual

FormNo.3414-606RevC

ZMaster

®

Professional5000

SeriesRidingMower

with60inTURBOFORCE

Mower

ModelNo.75951—SerialNo.400000000andUp

®

SideDischarge

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3414-606*C

ThissparkignitionsystemcomplieswithCanadian

ICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalToropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

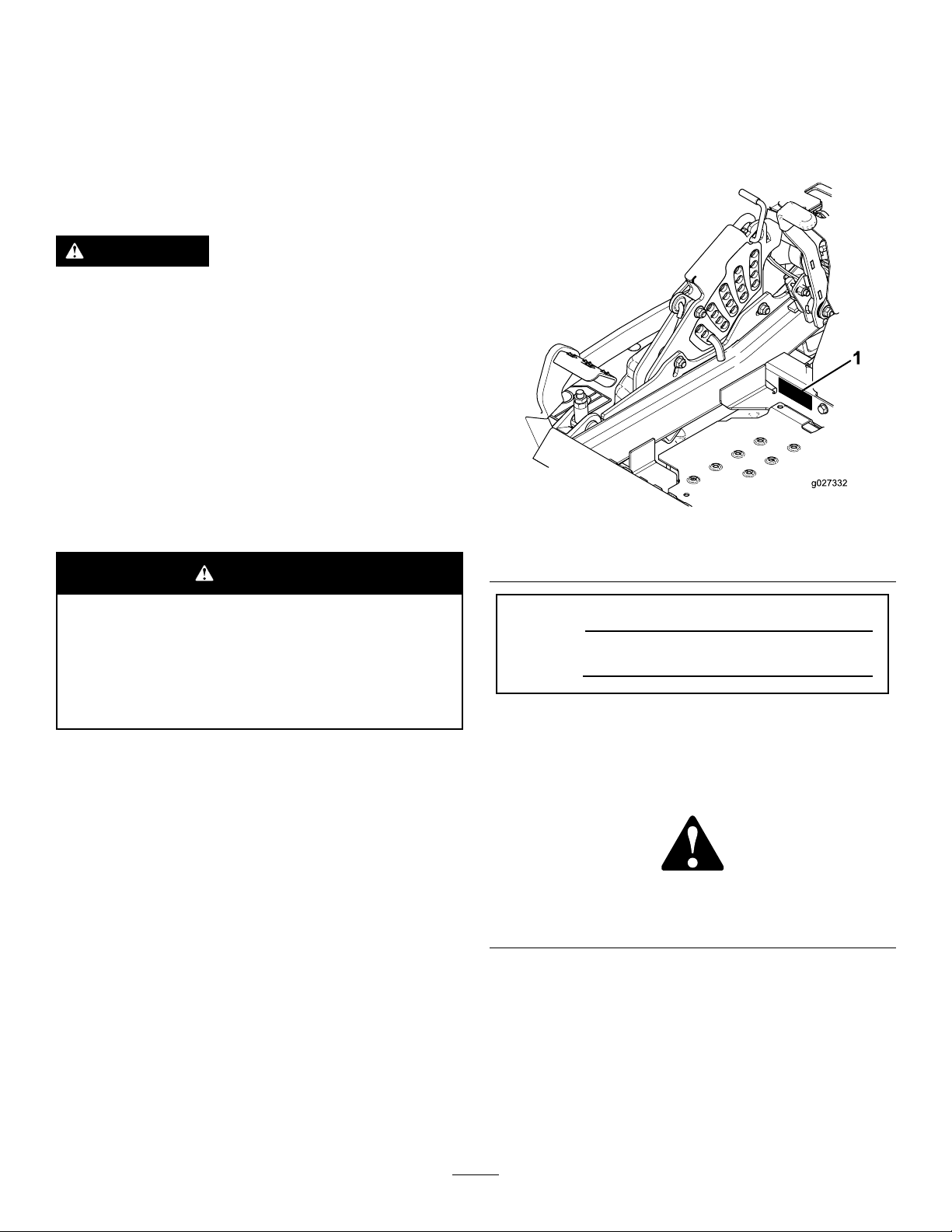

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely .

g027332

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................13

Controls...........................................................13

Specications..................................................14

BeforeOperation.................................................15

BeforeOperationSafety...................................15

RecommendedFuel.........................................15

UsingStabilizer/Conditioner.............................16

FillingtheFuelTank..........................................16

CheckingtheEngine-OilLevel..........................17

BreakinginaNewMachine..............................17

UsingtheRolloverProtectionSystem

(ROPS).........................................................17

ThinkSafetyFirst..............................................18

UsingtheSafety-InterlockSystem....................18

UnlatchingtheSeat..........................................19

AdjustingtheMyRide™Suspension

System..........................................................20

DuringOperation.................................................21

DuringOperationSafety...................................21

OperatingtheParkingBrake.............................22

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................23

OperatingtheThrottle.......................................23

OperatingtheIgnitionSwitch............................23

StartingtheEngine...........................................23

ShuttingOfftheEngine.....................................24

UsingtheMotion-ControlLevers.......................25

DrivingtheMachine..........................................25

StoppingtheMachine.......................................26

UsingtheSideDischarge.................................26

AdjustingtheHeightofCut...............................27

AdjustingtheAnti-ScalpRollers........................28

AdjustingtheFlowBafeCamLocks................28

PositioningtheFlowBafe................................29

OperatingTips.................................................30

AfterOperation....................................................31

AfterOperationSafety......................................31

UsingtheFuel-ShutoffValve.............................31

UsingtheDrive-Wheel-ReleaseValves............31

TransportingtheMachine.................................32

LoadingtheMachine........................................33

Maintenance...........................................................34

RecommendedMaintenanceSchedule(s)...........34

Pre-MaintenanceProcedures..............................35

MaintenanceandStorageSafety......................35

Lubrication..........................................................36

AddingLightOilorSprayLubrication................36

GreasingtheMowerDeck................................36

GreasingthePump-Belt-IdlerArm....................36

GreasingtheCaster-WheelBearings...............37

LubricatingtheCaster-WheelHubs..................37

EngineMaintenance...........................................38

EngineSafety...................................................38

ServicingtheAirCleaner..................................38

ServicingtheEngineOil....................................40

ServicingtheSparkPlug...................................43

CheckingtheSparkArrester.............................44

FuelSystemMaintenance...................................45

ServicingtheElectronicFuel-Injection

System..........................................................45

ReplacingtheLow-PressureFuel

Filter..............................................................45

ServicingtheHigh-PressureFuelFilter.............45

ServicingtheFuelT ank.....................................45

ElectricalSystemMaintenance...........................46

ElectricalSystemSafety...................................46

ServicingtheBattery.........................................46

ServicingtheFuses..........................................47

Jump-StartingtheMachine...............................48

DriveSystemMaintenance..................................49

CheckingtheSeatBelt.....................................49

CheckingtheRolloverProtectionSystem

(ROPS)Knobs..............................................49

AdjustingtheTracking......................................50

CheckingtheTirePressure...............................50

CheckingtheWheel-LugNuts..........................51

CheckingtheWheel-HubSlottedNut................51

AdjustingtheCaster-PivotBearing...................51

UsingtheClutchShim......................................51

CoolingSystemMaintenance..............................53

CleaningtheEngineScreenandEngine-Oil

Cooler...........................................................53

CleaningtheEngine-CoolingFinsand

Shrouds........................................................54

CheckingandCleaningtheHydraulic-Unit

Shrouds........................................................54

BrakeMaintenance.............................................55

AdjustingtheParkingBrake..............................55

BeltMaintenance................................................56

InspectingtheBelts..........................................56

ReplacingtheMowerBelt.................................56

ReplacingtheHydraulicPump-Drive

Belt................................................................57

ControlsSystemMaintenance.............................58

AdjustingtheControl-HandlePosition..............58

AdjustingtheMotion-ControlLinkage...............58

AdjustingtheMotion-ControlDamper...............59

AdjustingtheMotion-ControlNeutral-Lock

Pivot..............................................................60

HydraulicSystemMaintenance...........................60

HydraulicSystemSafety...................................60

ServicingtheHydraulicSystem........................60

MowerDeckMaintenance....................................63

LevelingtheMowerDeck..................................63

ServicingtheCuttingBlades.............................65

RemovingtheMowerDeck...............................68

ReplacingtheGrassDeector..........................69

Cleaning..............................................................70

CleaningundertheMower................................70

CleaningtheSuspensionSystem.....................70

3

DisposingofWaste...........................................70

Storage...................................................................71

CleaningandStorage.......................................71

Troubleshooting......................................................72

Schematics.............................................................75

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

4

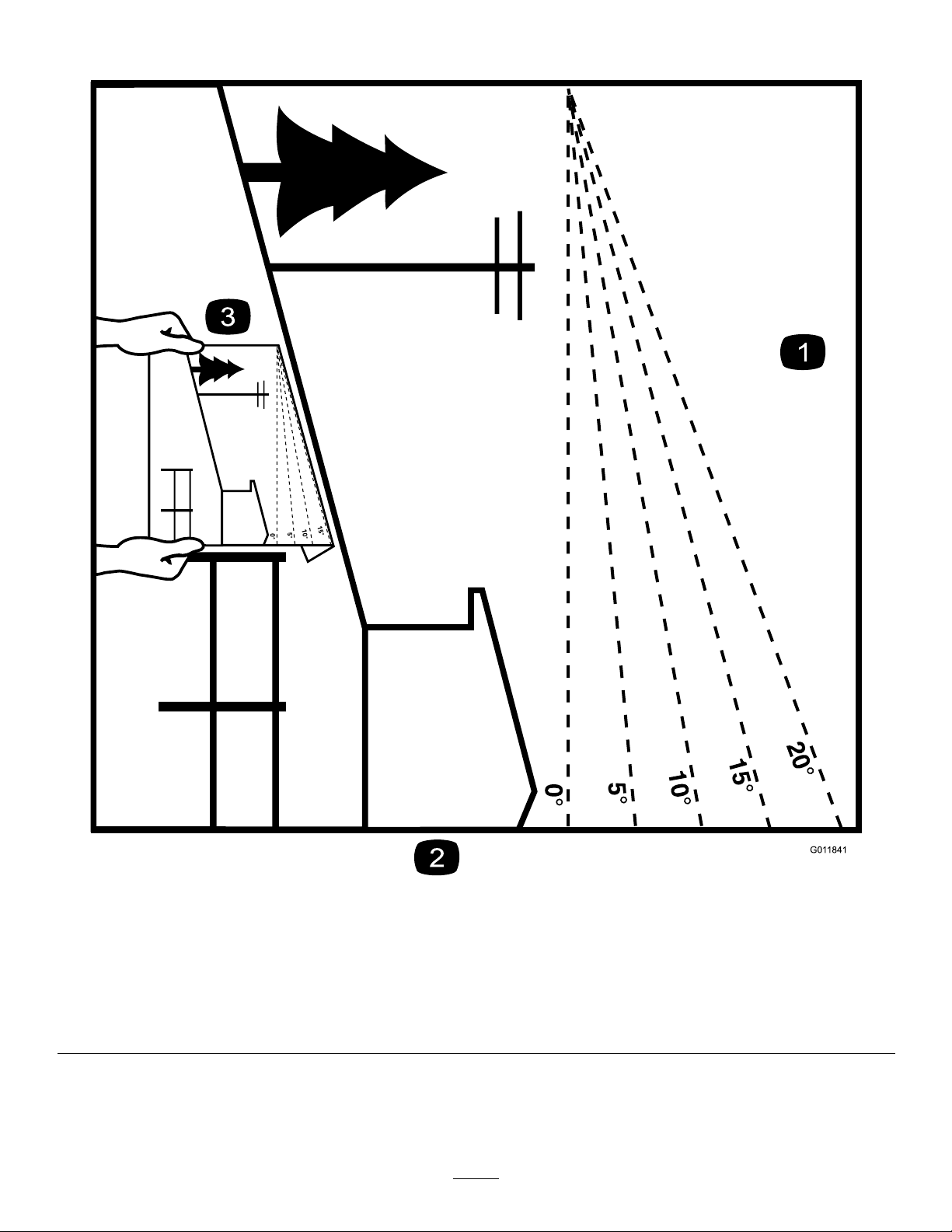

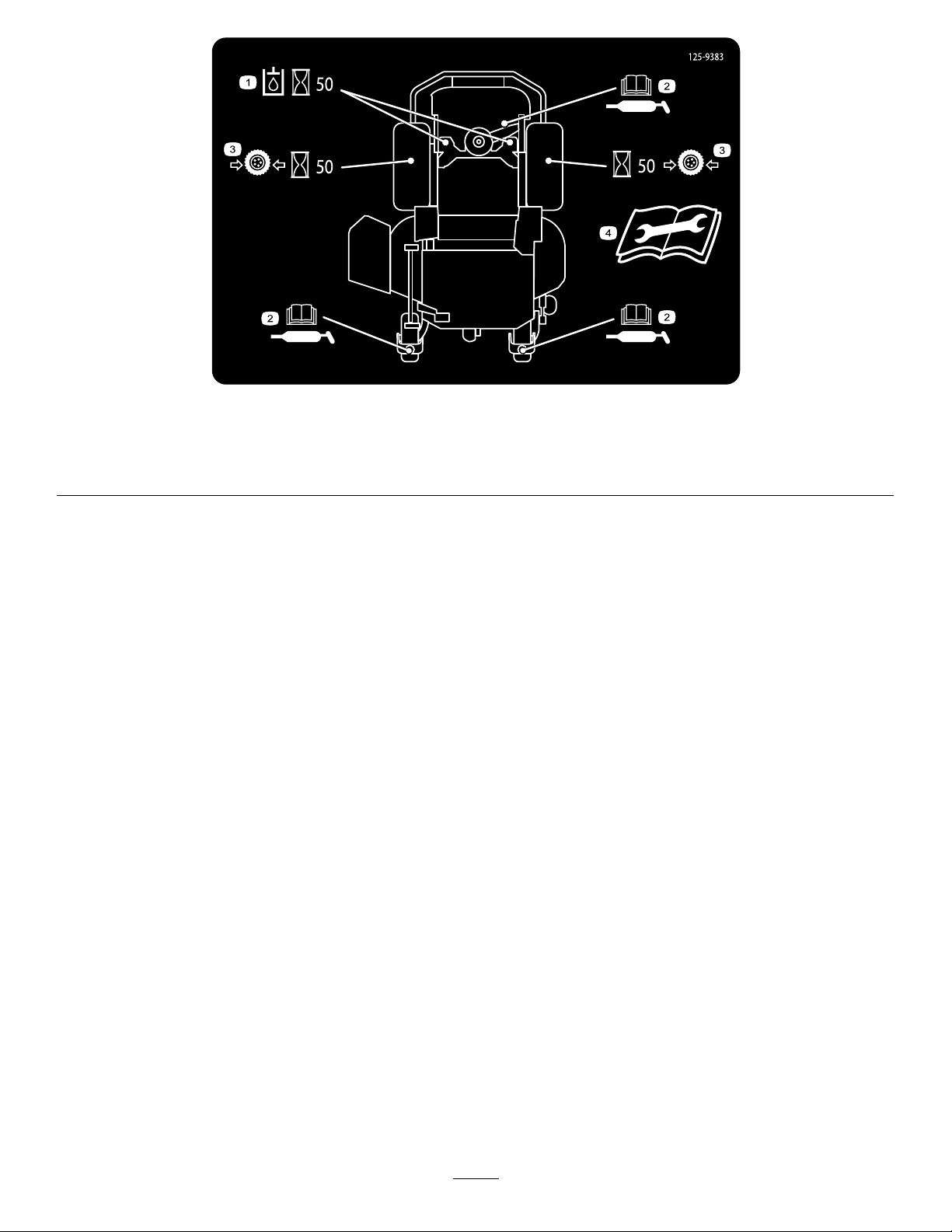

SlopeIndicator

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

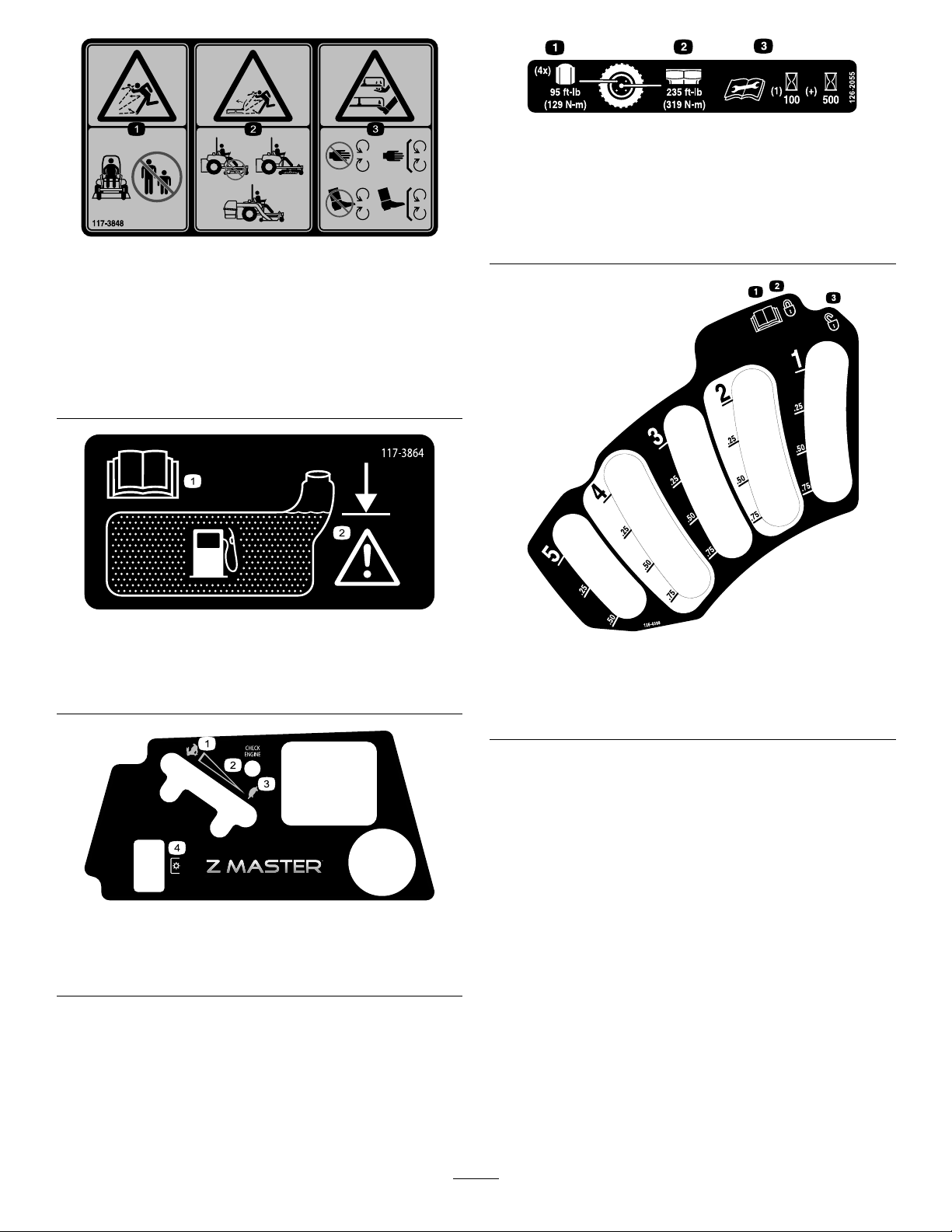

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

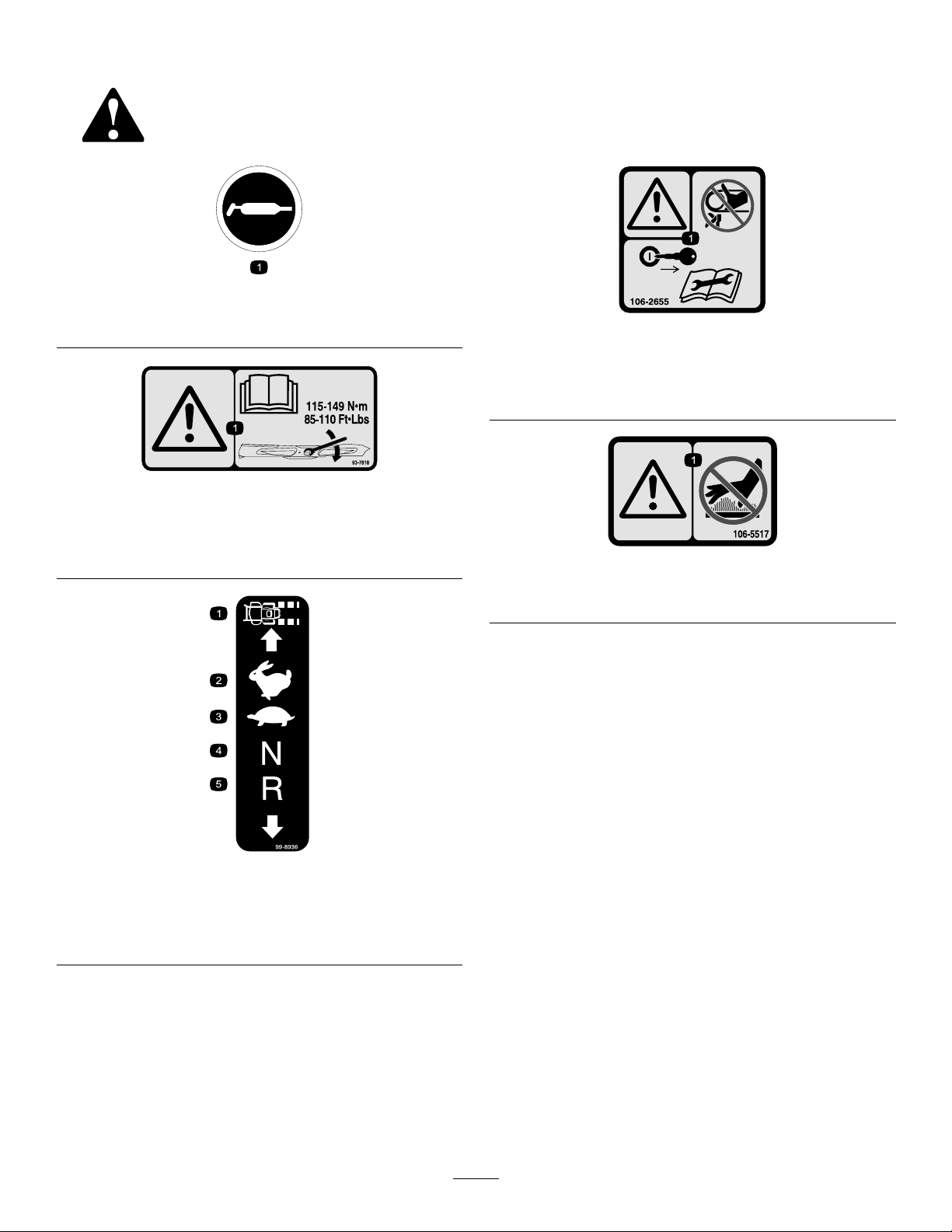

58-6520

1.Grease

93-7818

decal58-6520

decal106-2655

106-2655

1.Warning—donottouchorapproachmovingbelts;remove

theignitionkeyandreadtheinstructionsbeforeservicing

orperformingmaintenance.

decal93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to110

ft-lb).

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

decal106-5517

106-5517

1.Warning—donottouchthehotsurface.

decal99-8936

6

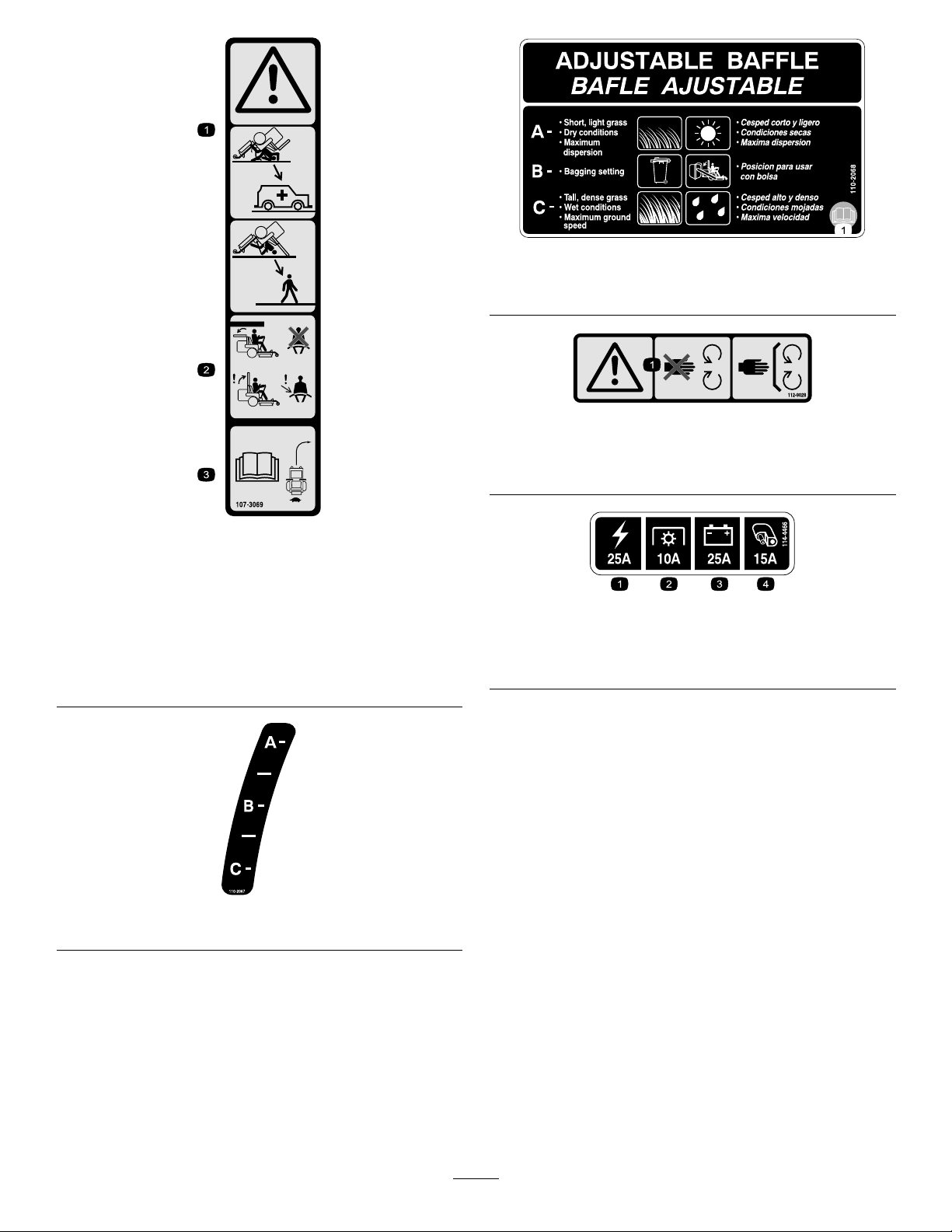

decal107-3069

107-3069

1.Warning—thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotwearthetheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

decal110-2068

110-2068

1.ReadtheOperator'sManual.

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

decal114-4466

114-4466

1.Main(25A)3.Charge(25A)

2.PTO(10A)4.Auxiliary(15A)

decal110-2067

110-2067

7

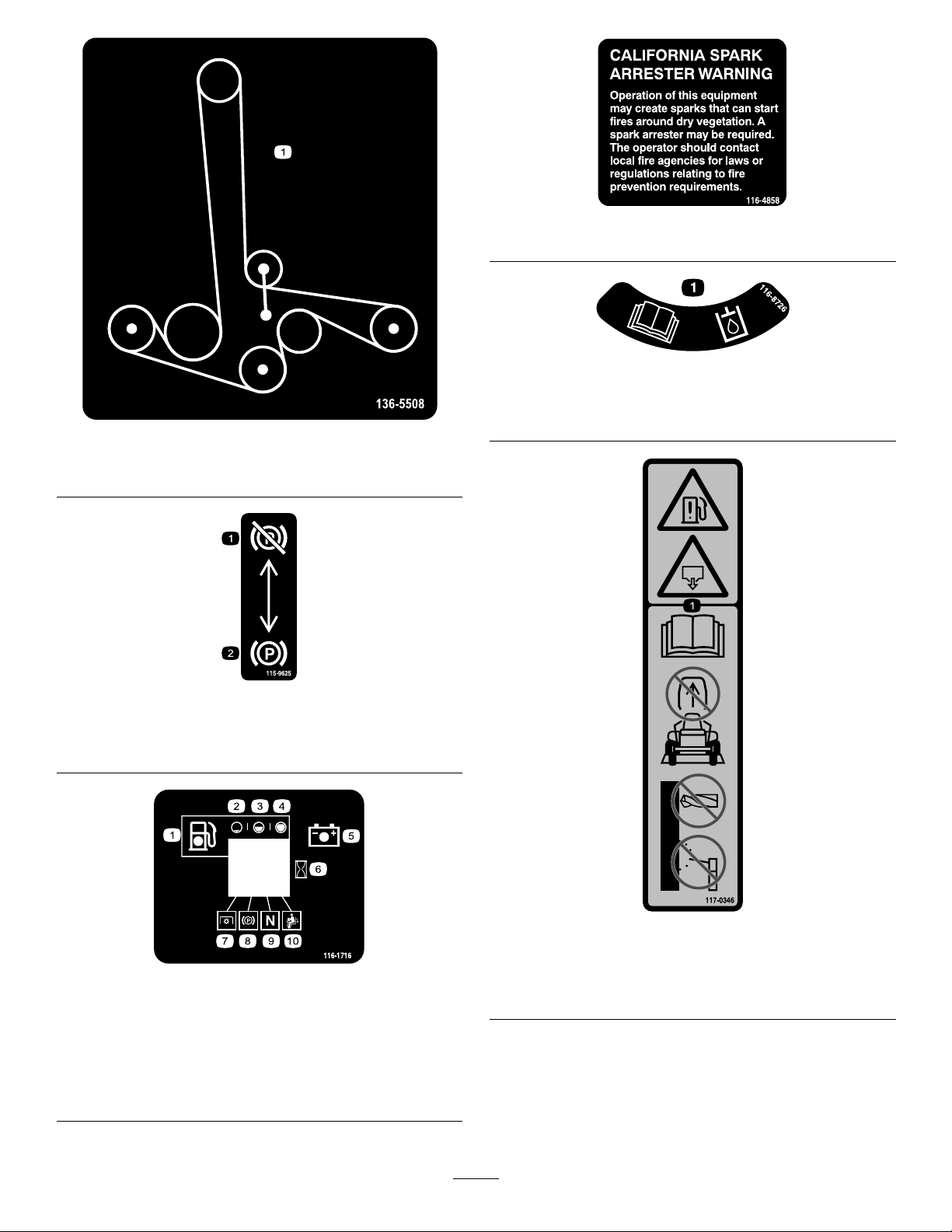

decal116-4858

116-4858

decal116-8726

116-8726

1.ReadtheOperator’sManualforrecommendedhydraulic

decal136-5508

uid.

136-5508

1.Beltrouting

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

116-1716

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operator-presenceswitch

decal115-9625

decal117-0346

117-0346

decal116-1716

1.Fuelleakhazard—readtheOperator'sManual;donot

attempttoremovetherollbar;donotweld,drill,ormodify

therollbarinanyway.

8

117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

2.Thrownobjecthazard,mower—donotoperatethemachine

withoutdeector,dischargecover,orgrasscollection

systeminplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

decal126-2055

126-2055

1.Wheellug-nuttorque129N∙m(95ft-lb)(4x)

2.Wheelhub-nuttorque319N∙m(235ft-lb)

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance,checktorqueaftertherst

decal117-3848

100hoursthenevery500hoursthereafter.

1.ReadtheOperator’s

Manual.

1.Fast

2.Variablespeedcontrol

117-3864

2.Filltobottomofllerneck;

121–7586

3.Slow

4.Powertakeoff(PTO)

warning—donotoverll

thetank.

decal117-3864

decal126-4398

126-4398

1.ReadtheOperator’s

manual

2.Lock

decal121-7586

3.Unlock

9

decal127-0326

127-0326

1.ReadtheOperator's

Manual.

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

performingmaintenance

orservicingthemachine.

2.Heightofcut

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

decal132-5063

132-5063

1.Camlock2.Camunlock

decal132-5067

132–5067

decaloemmarkt

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decalbatterysymbols

1.Explosionhazard

2.Nore,opename,or

6.Keepbystandersasafe

7.Weareyeprotection;

smoking

3.Causticliquid/chemical

8.Batteryacidcancause

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

10.Containslead;donot

Manual.

distanceawayfromthe

battery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard

10

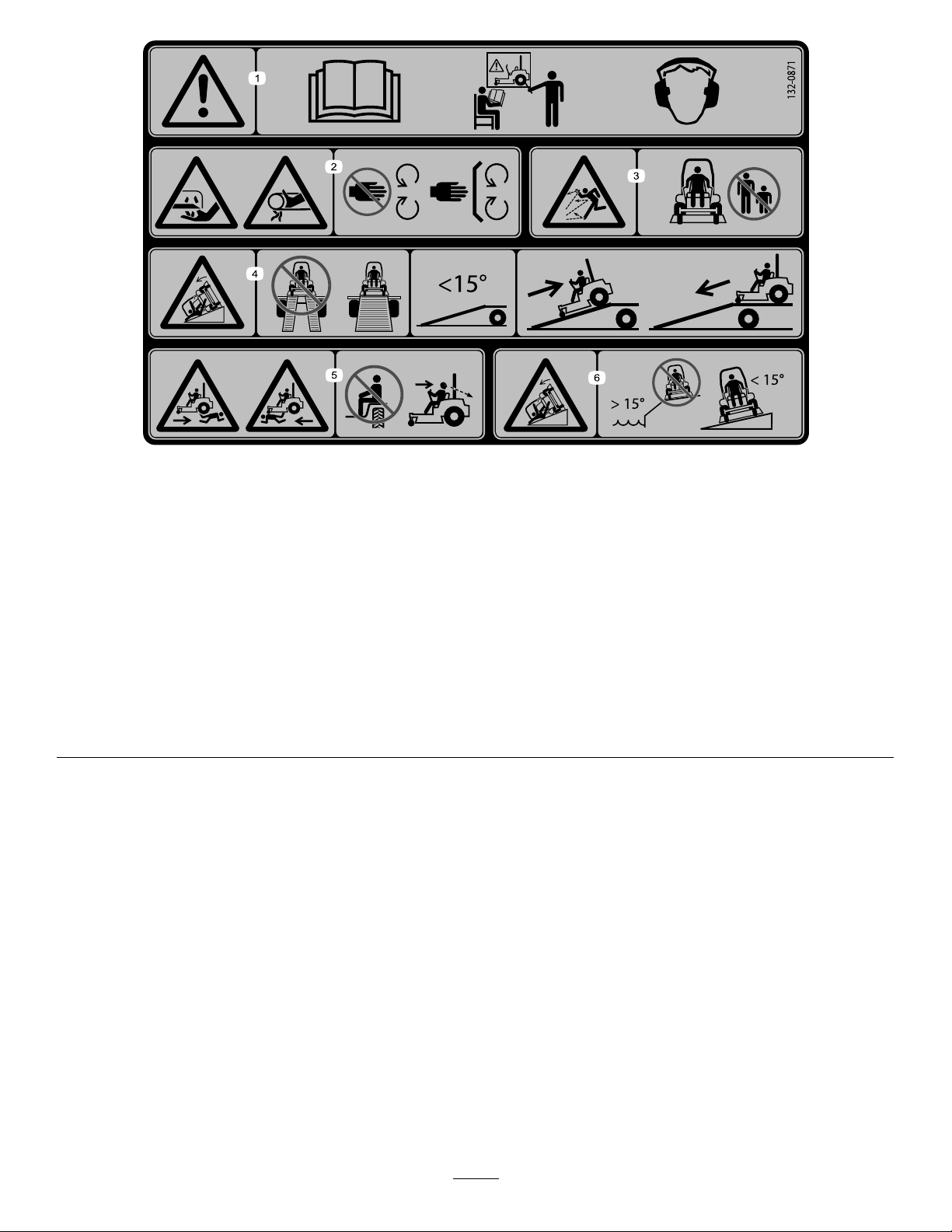

125–9383

1.Checkhydraulicuidevery50operatinghours.3.Checkthetirepressureevery50operatinghours.

2.ReadtheOperator’sManualforinformationonlubricating

themachine.

4.ReadtheOperator’sManualbeforeservicingorperforming

maintenance.

decal125-9383

11

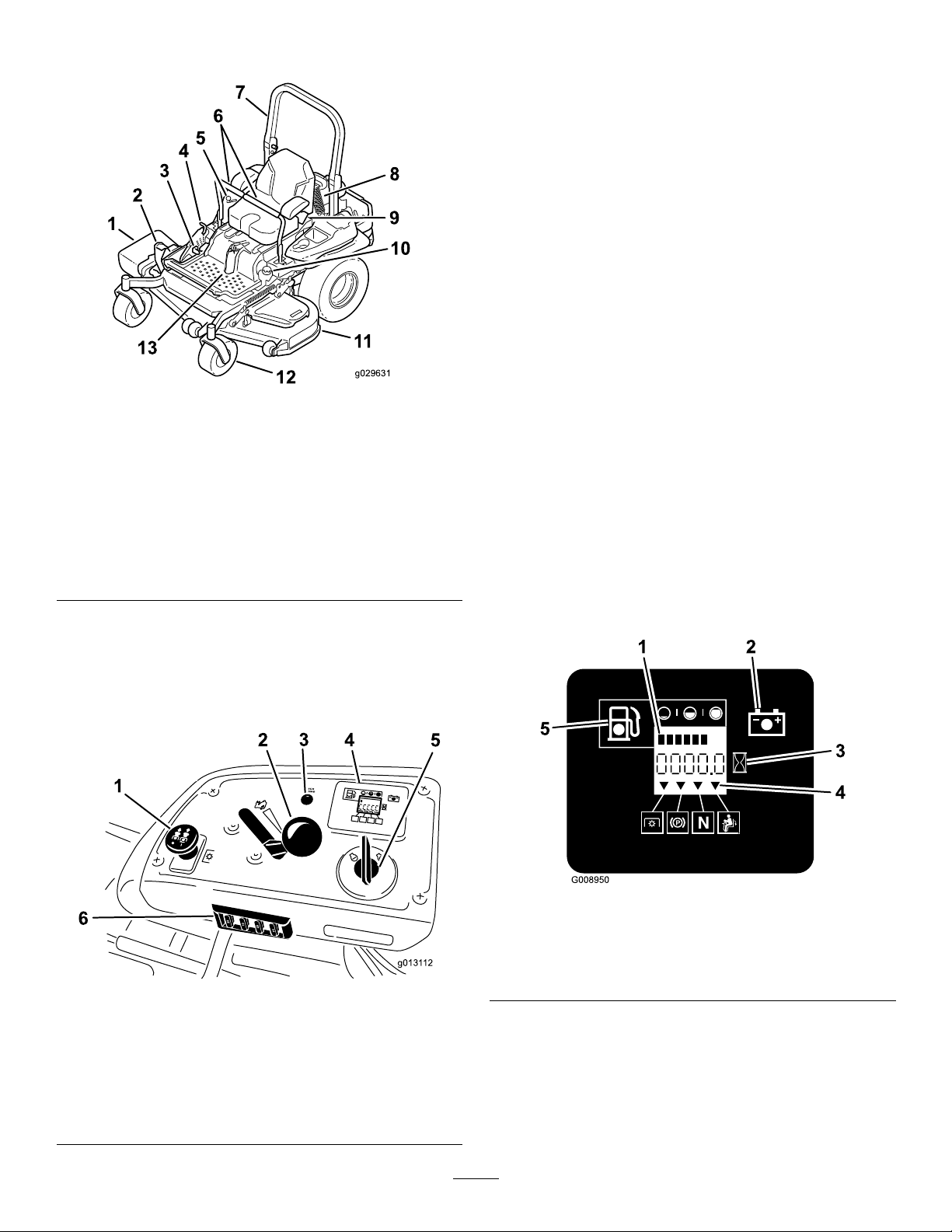

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0871

1.Warning—readtheOperator’sManual;donotoperatethis

machineunlessyouaretrained;wearhearingprotection.

2.Cutting,dismembering,andentanglementhazard—keep

handsawayfrommovingparts;keepallguardsandshieldsin

place.

3.Thrownobjecthazard—keepbystandersaway.6.Tippinghazardonslopes—donotuseonslopesnearopen

4.Ramphazard—whenloadingontoatrailer ,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15°;backuptheramp(in

reverse)anddriveforwardofftheramp.

5.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

water;donotuseonslopesgreaterthan15°.

12

ProductOverview

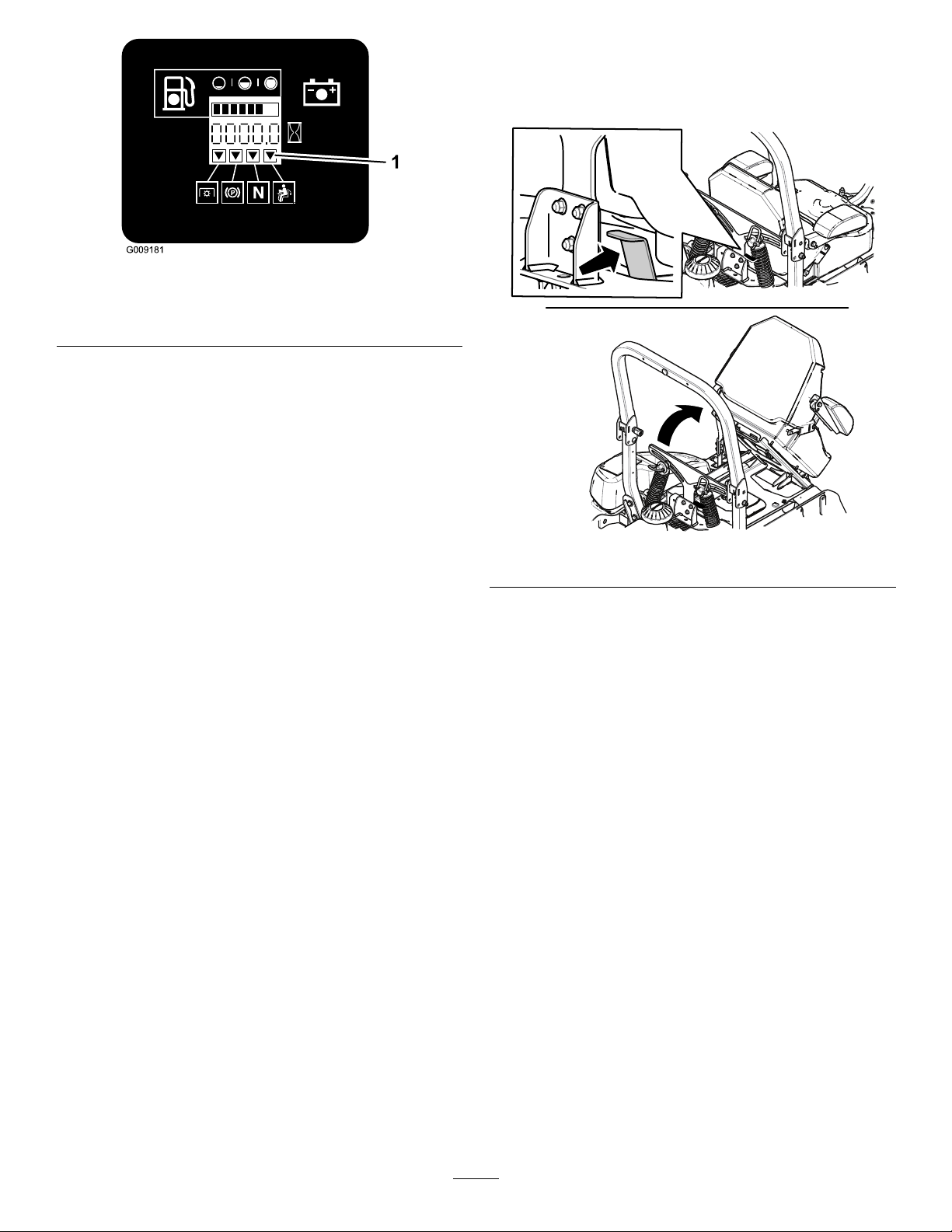

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

FuelGauge

Thefuelgaugeislocatedwiththehourmeter,and

thebarslightupwhentheignitionswitchisintheON

position(Figure6).

Theindicatorlightappearswhenthefuellevelislow

(approximately1gallonremaininginthefueltank).

Safety-InterlockIndicators

Figure4

1.Side-dischargedeector

2.Height-of-cutdeck-lift

pedal

3.Parking-brakelever10.Fuelcap

4.Transportlock11.Mowerdeck

5.Controls12.Casterwheel

6.Motion-controllevers13.Front-shockassembly

7.Rollbar

8.Rear-shockassembly

9.Seatbelt

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure4and

Figure5).

g029631

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure6).

Battery-IndicatorLight

IfyouturntheignitionkeytotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure6).

Figure5

1.PTOswitch

2.Throttlecontrol5.Ignitionswitch

3.Malfunctionindicatorlight

(MIL)

4.Hour

6.Fuses

meter/Safety-interlock

display/Fuelgauge

g008950

Figure6

1.Fuelgauge(bars)4.Safety-interlocksymbols

2.Batterylight

g013112

3.Hourmeter

5.Lowfuel-indicatorlight

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure5).

13

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch(PTO)engagesand

disengagespowertothemowerblades(Figure5).

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

IgnitionSwitch

Usethisswitchtostartthemowerengine.Ithas3

positions:START,RUN,andOFF.

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection.

Neutral-LockPosition

UsetheNEUTRAL-LOCKpositionwiththe

safety-interlocksystemtoengageandtodetermine

theNEUTRALposition.

Fuel-ShutoffValve

Closethefuel-shutoffvalve(undertheseat)when

transportingorstoringthemower.

Electronic-ControlUnit

WithoutDeck

DeectorUp157cm(62inches)

DeectorDown192cm(76inches)

135cm(53inches)

Length

RollBarUp

RollBarDown

211cm(83inches)

215cm(85inches)

Height

RollBarUpRollBarDown

179cm(71inches)127.8cm(50.3inches)

Weight

Weight

587kg(1,295lb)

Malfunction-IndicatorLight

Theelectronic-controlunit(ECU)continuously

monitorstheoperationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunction-indicatorlight(MIL)illuminates.

TheMIListheredlightlocatedintherightconsole

panel.

OncetheMILilluminates,makeinitialtroubleshooting

checks;refertotheMILsectionunderTroubleshooting

(page72).

Ifthesechecksdonotcorrecttheproblem,further

diagnosisandservicingbyanAuthorizedService

Dealerisnecessary.

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

14

Operation

containersontheground,awayfromyourvehicle

beforelling.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

15

Using Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless

(drainthefueltankwhenstoringthemachinefor

morethan90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.Tominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

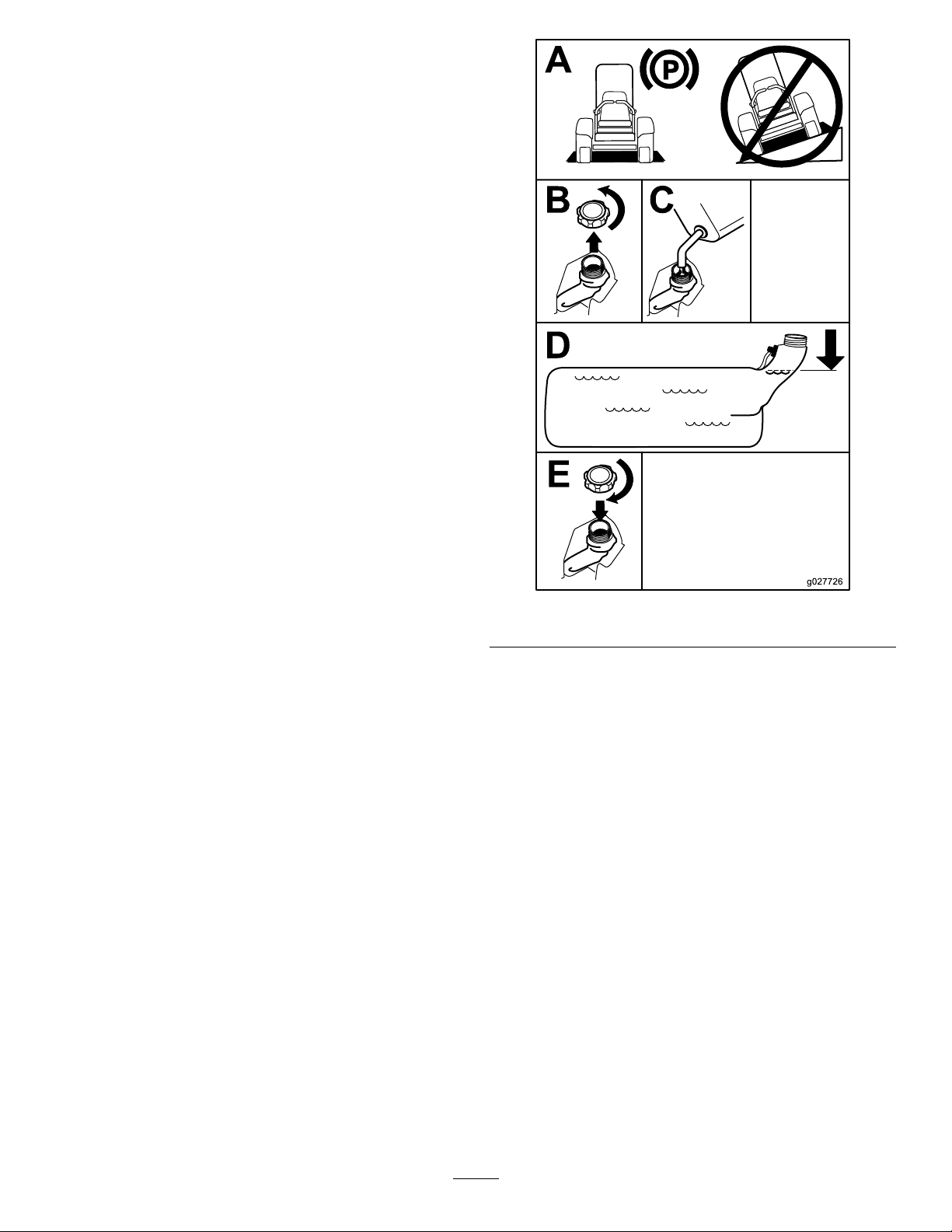

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shutofftheengineandengagetheparking

brake.

3.Cleanaroundthefuel-tankcap.

4.Fillthefueltanktothebottomofthellerneck

(Figure7).

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

g027726

Figure7

16

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page40).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

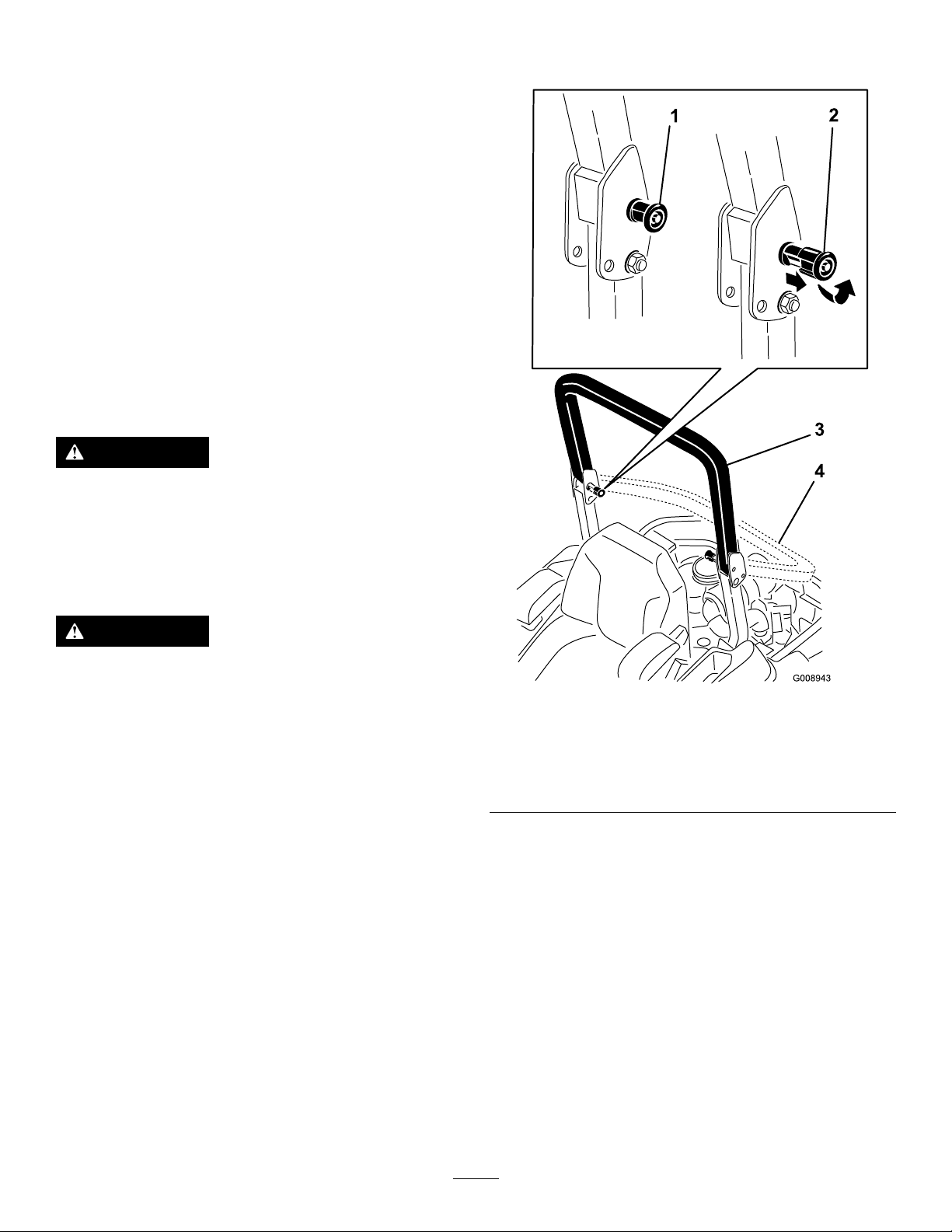

UsingtheRollover ProtectionSystem(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarinthefullyraisedlockedposition

andusetheseatbelt.

3.Lowertherollbartothedownposition(Figure

8).

Ensurethattheseatissecuredtothe

machine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

Important:Lowertherollbaronlywhen

absolutelynecessary.

Important:Ensurethattheseatissecuredto

themachine.

1.Tolowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sothey

arenotengaged(Figure8).

Figure8

1.ROPSknob

2.PulltheROPSknobout

androtate90degrees

4.Toraisetherollbar,raisetherollbartothe

operateposition,rotatetheknobssothatthey

movepartiallyintothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinssnap

intopositionwhentheholesalignwiththepins

(Figure8).

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

Important:Alwaysusetheseatbeltwiththe

rollbarintheraisedposition.

6.Pushontherollbarandensurethatbothpins

areengaged.

g008943

17

ThinkSafetyFirst

CAUTION

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteep

slopescancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Donotoperatethemachineneardrop-offs.

DANGER

Operatingthemachinewhiletherollbaris

downmayleadtoseriousinjuryordeathin

theeventofarollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,

feet,andhead.

g009027

Figure10

1.Weareyeprotection.2.Wearhearingprotection.

UsingtheSafety-Interlock System

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedlycausingpersonalinjury.

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

Figure9

3.Water

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

g000963

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

Thesafety-interlocksystemalsoisdesignedtoshutoff

theenginewhenthetractioncontrolsaremovedfrom

thelockedpositionwiththeparkingbrakeengagedor

ifyourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhen

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,a

trianglelightsupinthecorrespondingsquare.

18

Figure11

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)tothe

ONposition.Trystartingtheengine;theengine

shouldnotstart.

2.Sittingontheseat,engagetheparkingbrake

andmovetheblade-controlswitch(PTO)tothe

OFFposition.Moveeithermotion-controllever

(outoftheNEUTRAL-LOCKposition).Trystarting

theengine;theengineshouldnotstart.Repeat

fortheothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,disengage

theparkingbrake,engagetheblade-control

switch(PTO),andriseslightlyfromtheseat;the

engineshouldshutoff.

4.Sittingontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,center

eithermotioncontrolandmove(forwardor

reverse);theengineshouldshutoff.Repeatfor

othermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.

UnlatchingtheSeat

Tounlatchtheseat,pushtheseatlatchforward

(Figure12).

g009181

g204507

Figure12

19

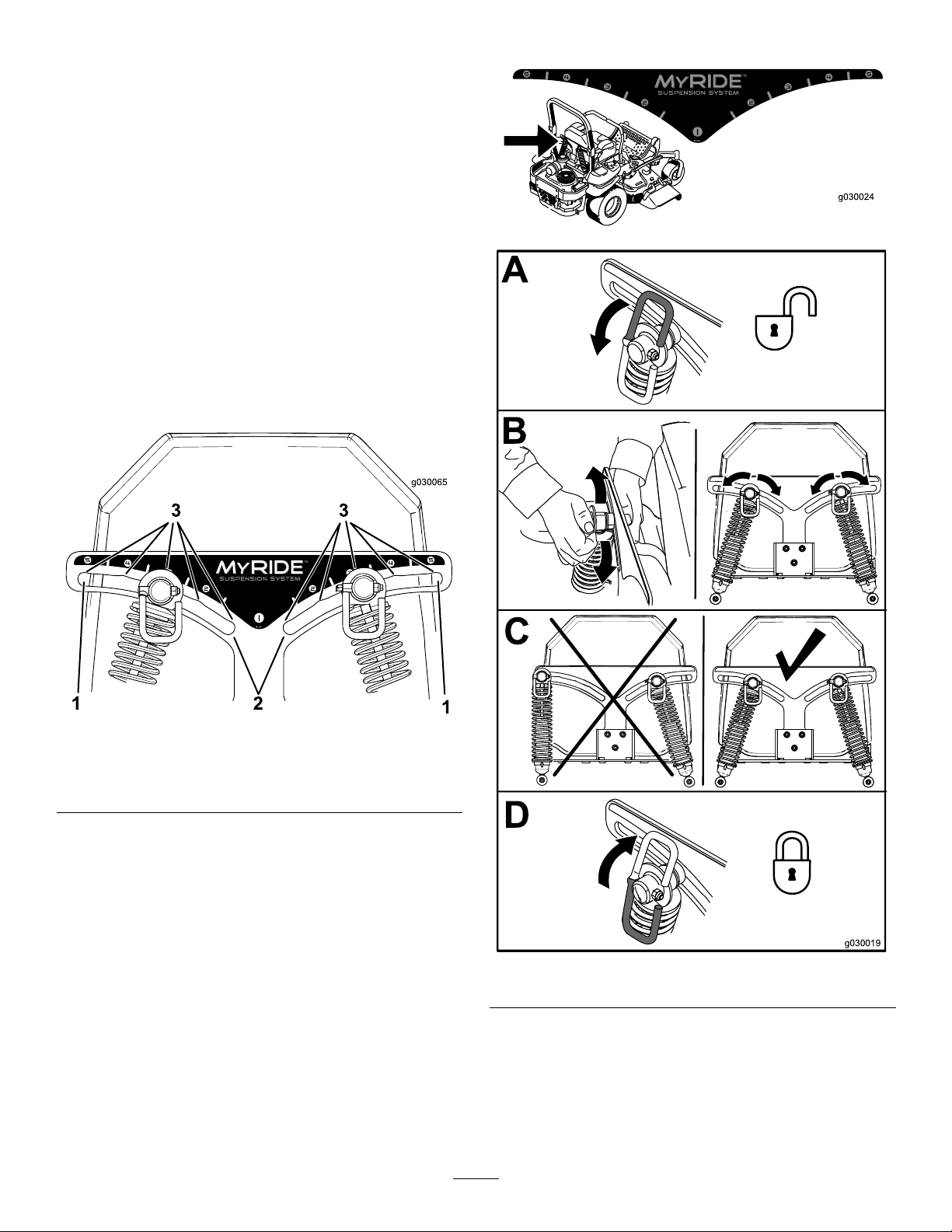

AdjustingtheMyRide™ SuspensionSystem

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Youcanadjustthe

rear2-shockassembliestoquicklyandeasilychange

thesuspensionsystem.Positionthesuspension

systemwhereyouaremostcomfortable.

AdjustingtheRear-Shock Assemblies

Theslotsfortherear-shockassemblieshave

detentpositionsforreference.Y oucanpositionthe

rear-shockassembliesanywhereintheslot,notjust

inthedetentpositions.

Thefollowinggraphicshowsthepositionforasoftor

rmrideandthedifferentdetentpositions(Figure13).

Adjusttherear-shockassemblies(Figure14).

g030024

Figure13

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

g030065

g030019

Figure14

20

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;and

hearingprotection.Tiebacklonghairanddonot

wearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useaccessoriesandattachmentsapprovedby

Toroonly.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

RolloverProtectionSystem (ROPS)Safety

•Donotremovetherollbarfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Alwayswearyourseatbeltwhentherollbarisup.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•Keeptherollbarinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•Replaceadamagedrollbar.Donotrepairoralter

it.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

21

SlopeSafety

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

sloperequiresextracaution.

•Operatethemachineatalowerspeedwhenyou

areonaslope.

OperatingtheParking Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

WARNING

Theparkingbrakemaynotholdthemachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.T allgrasscanhideobstacles.

•Choosealowgroundspeedsoyouwillnothave

tostoporshiftwhileonaslope.

•Arollovercanoccurbeforethetireslosetraction.

•Avoidoperatingthemachineonwetgrass.Tires

maylosetraction;regardlessifthebrakesare

availableandfunctioning.

•Avoidstarting,stopping,orturningthemachine

onaslope.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

•Donooperatethemachineneardrop-offs,ditches,

embankments,orbodiesofwater.Themachine

couldsuddenlyrolloverifawheelgoesoverthe

edgeortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard(2machine

widths).

Donotparkonslopesunlessthewheelsare

chockedorblocked.

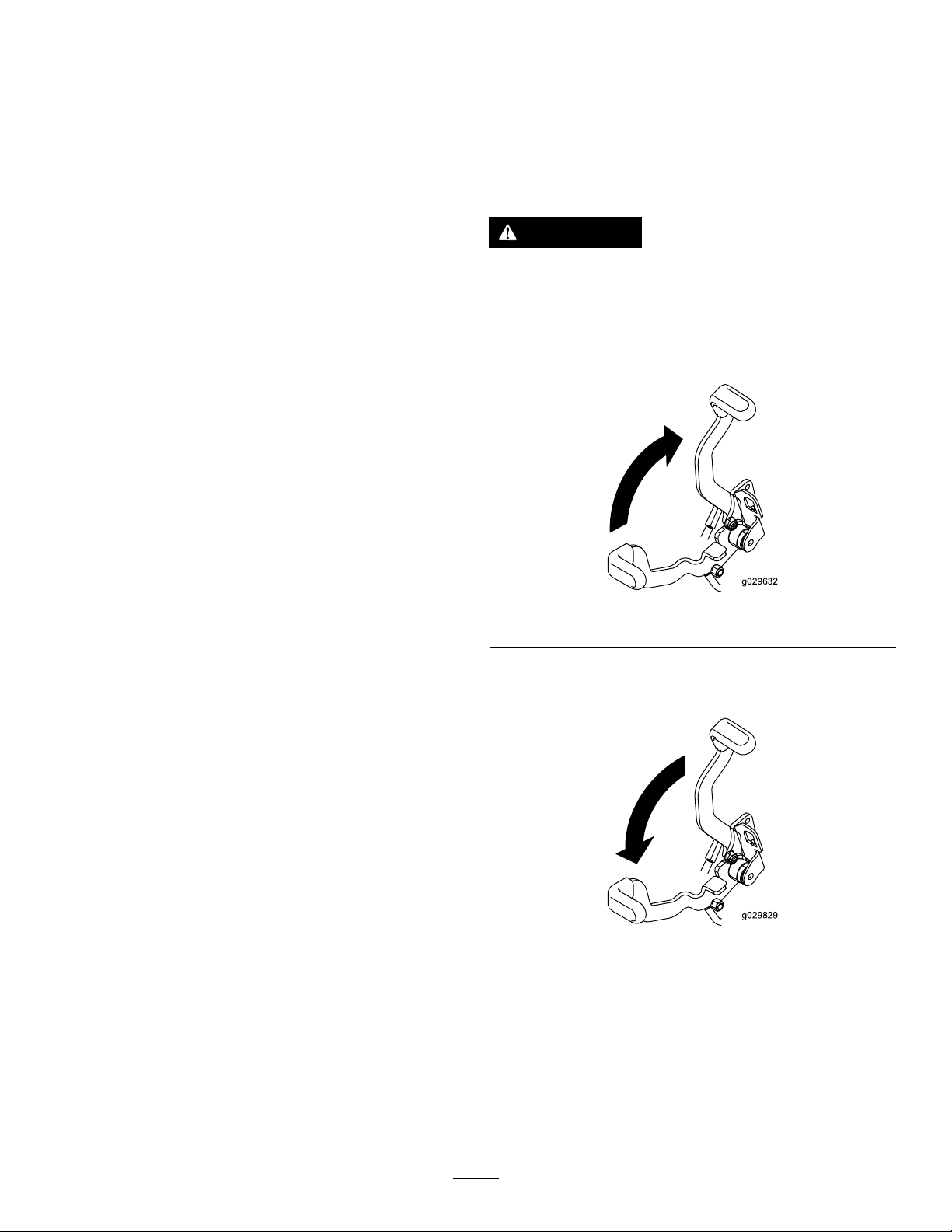

g029632

Figure15

DisengagingtheParkingBrake

g029829

Figure16

22

OperatingtheMower Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

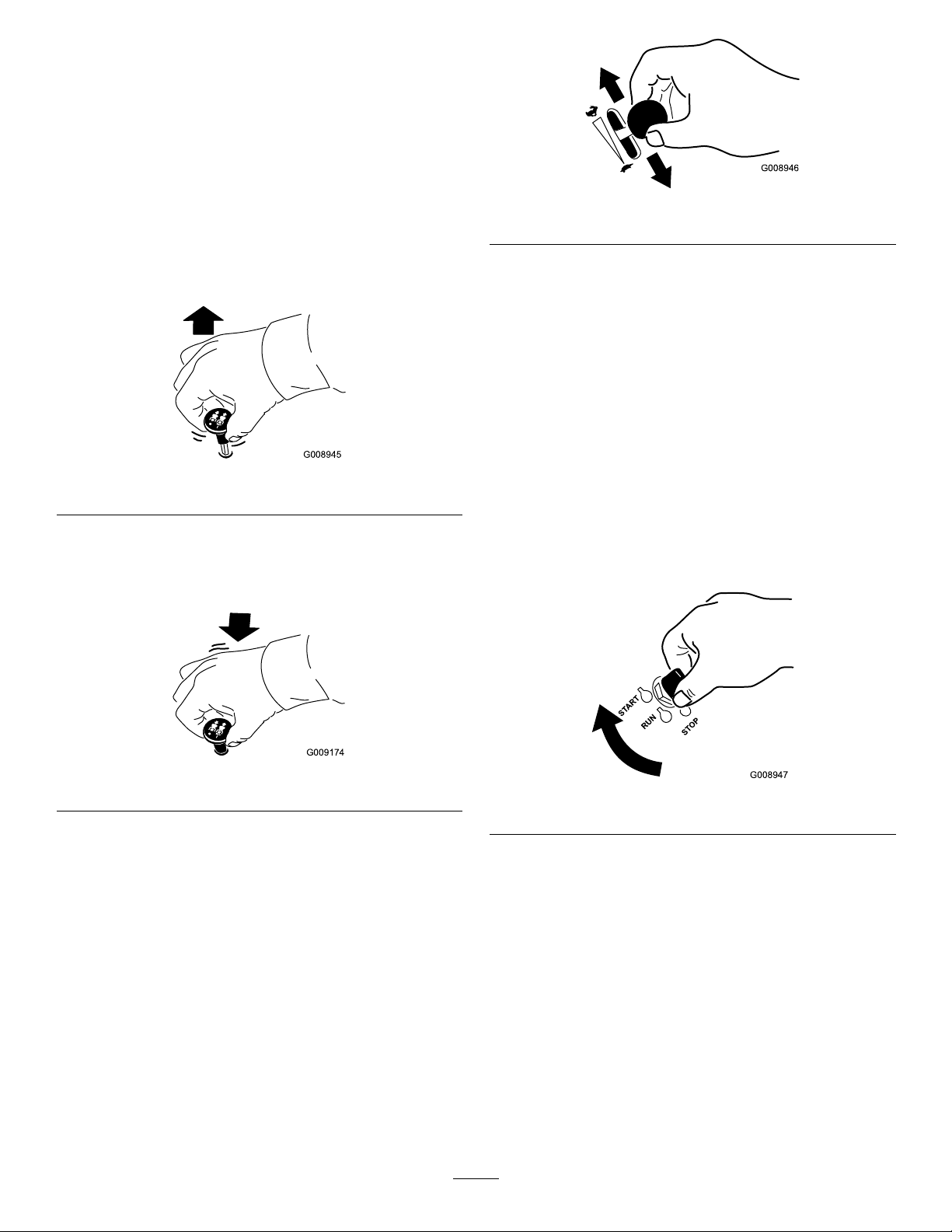

Figure17

DisengagingtheBlade-Control Switch(PTO)

g008946

Figure19

OperatingtheIgnition Switch

1.TurntheignitionkeytotheSTARTposition

(Figure20).

Note:Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformore

g008945

than5secondsatatime.Iftheenginefails

tostart,allowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Youmayneedmultipleattemptstostart

theenginewhenyoustartitthersttimeafter

thefuelsystemhasbeenwithoutfuelcompletely.

Figure18

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweentheFAST

andSLOWpositions(Figure19).

AlwaysusetheFASTpositionwhenturningonthe

mowerdeckwiththeblade-controlswitch(PTO).

g009174

g008947

Figure20

2.Turntheignitionkeytoshutofftheengine.

StartingtheEngine

1.Raisetherollbarupandlockitintoplace,siton

theseat,andfastentheseatbelt.

2.MovethemotioncontrolstotheNEUTRAL-LOCK

position.

3.Engagetheparkingbrake;refertoEngagingthe

ParkingBrake(page22).

4.Movetheblade-controlswitch(PTO)totheOFF

position(Figure21).

5.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions.

23

Loading...

Loading...