Page 1

FormNo.3417-433RevA

TimeCutter

®

HDZX4800and

ZX5400RidingMower

ModelNo.75201—SerialNo.401500000andUp

ModelNo.75202—SerialNo.401500000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3417-433*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

GrossorNetTorque

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourT oroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachine

hasbeenconvertedforhigh-altitudeuse,lookfor

thefollowinglabel.

decal127-9363

Thegrossornettorqueofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewith

theSocietyofAutomotiveEngineers(SAE)J1940or

J2723.Asconguredtomeetsafety,emission,and

operatingrequirements,theactualenginetorqueon

thisclassofmowerwillbesignicantlylower.

Gotowww.Toro.comtoviewspecicationsonyour

mowermodel.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalT oropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

Important:IfyouareusingamachinewithaToro

engineabove1500m(5,000ft)foracontinuous

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EP A

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyhomeownersinresidentialapplications.Itis

designedprimarilyforcuttinggrassonwell-maintained

lawns.Itisnotdesignedforcuttingbrush,mowing

grassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

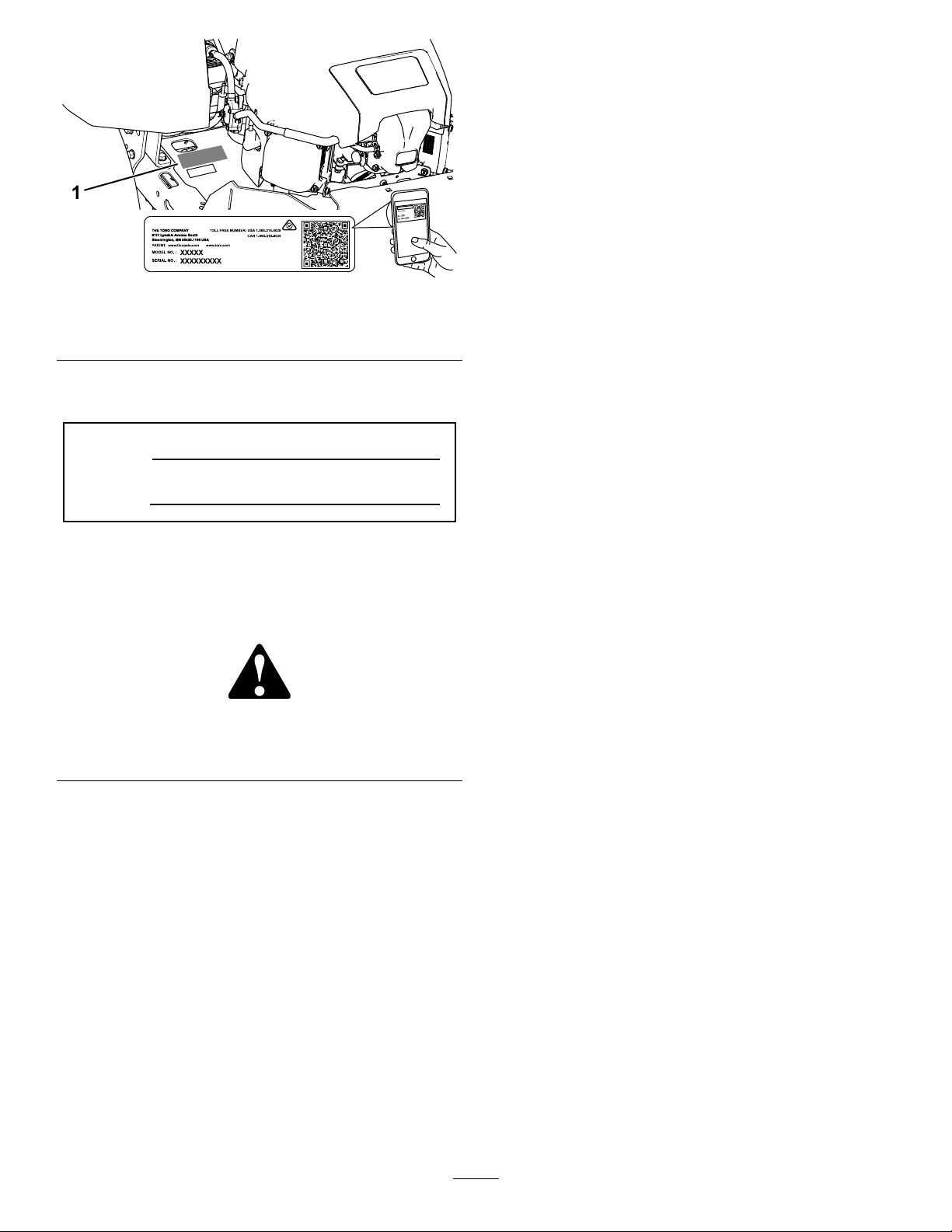

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthe

spacebelow:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-AlertSymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................10

Controls...........................................................10

BeforeOperation.................................................12

BeforeOperationSafety...................................12

AddingFuel......................................................12

PerformingDailyMaintenance..........................13

g234368

g000502

BreakinginaNewMachine..............................13

UsingtheSafety-InterlockSystem....................14

PositioningtheSeat..........................................14

AdjustingtheMotion-ControlLevers.................15

DuringOperation.................................................15

DuringOperationSafety...................................15

OperatingtheParkingBrake.............................17

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................18

OperatingtheThrottle.......................................18

OperatingtheChoke.........................................18

StartingtheEngine...........................................19

ShuttingOfftheEngine.....................................19

UsingtheMotion-ControlLevers.......................19

DrivingtheMachine..........................................20

UsingtheSmartSpeed

TM

Control

System..........................................................21

UsingtheSideDischarge.................................21

AdjustingtheHeightofCut...............................22

AdjustingtheAnti-ScalpRollers........................22

UsingAttachmentsandAccessories.................23

OperatingTips.................................................23

AfterOperation....................................................24

AfterOperationSafety......................................24

PushingtheMachinebyHand..........................24

TransportingtheMachine.................................25

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

MaintenanceSafety..........................................28

EngineMaintenance...........................................28

EngineSafety...................................................28

ServicingtheAirCleaner..................................28

ServicingtheEngineOil....................................30

ServicingtheSparkPlug...................................32

CleaningtheCoolingSystem............................33

FuelSystemMaintenance...................................34

ReplacingtheIn-LineFuelFilter.......................34

ElectricalSystemMaintenance...........................35

ElectricalSystemSafety...................................35

ServicingtheBattery.........................................35

ServicingtheFuses..........................................36

DriveSystemMaintenance..................................37

CheckingtheTirePressure...............................37

MowerMaintenance.............................................37

ServicingtheCuttingBlades.............................37

3

Page 4

LevelingtheMowerDeck..................................40

RemovingtheMowerDeck...............................42

InstallingtheMowerDeck.................................43

ReplacingtheGrassDeector..........................43

MowerBeltMaintenance......................................44

InspectingtheBelts..........................................44

ReplacingtheMowerBelt.................................44

Cleaning..............................................................45

WashingtheUndersideoftheMower................45

DisposingofWaste...........................................46

Storage...................................................................46

StorageSafety..................................................46

CleaningandStorage.......................................46

StoringtheBattery............................................47

Troubleshooting......................................................48

Schematics.............................................................50

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.1-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15degrees.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepchildrenandbystandersoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

Page 5

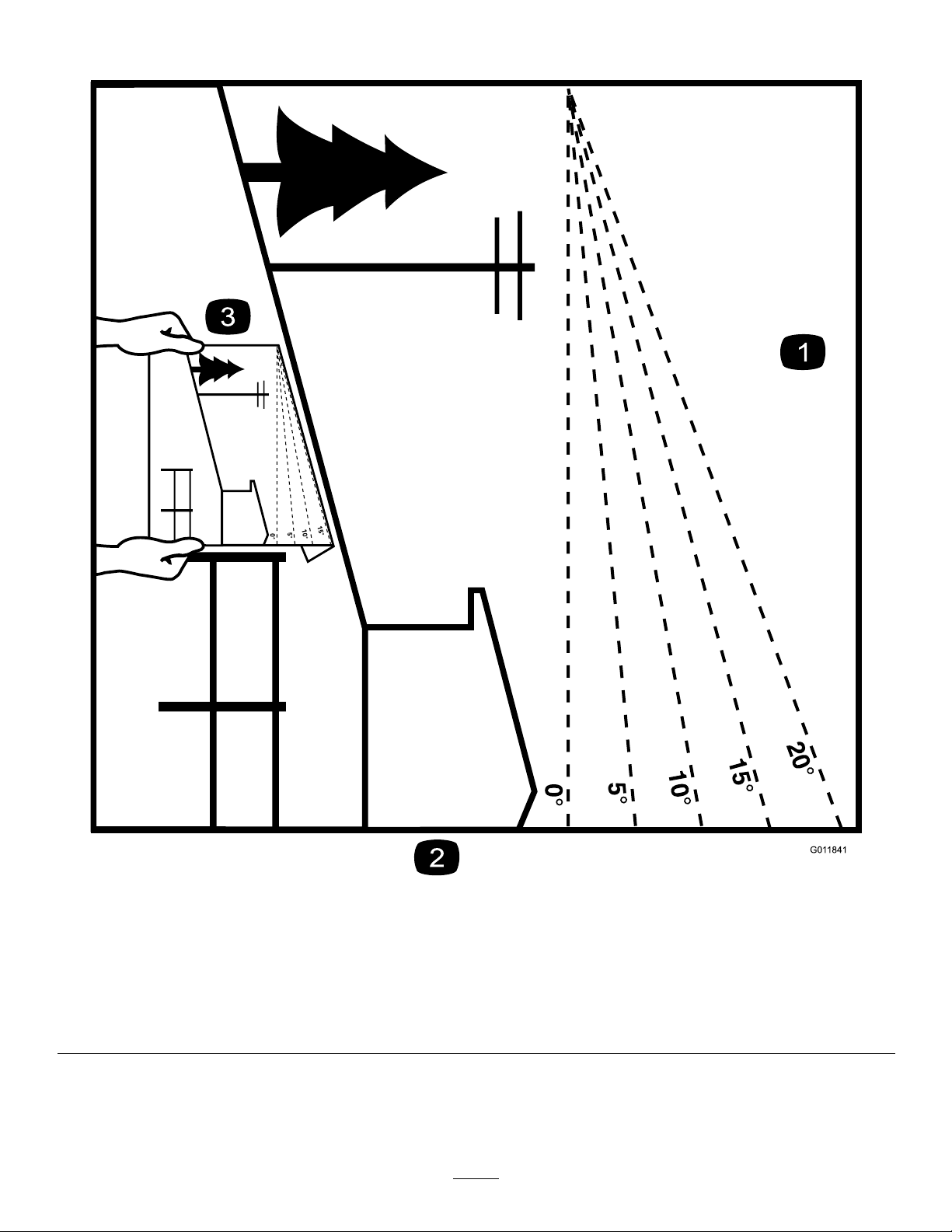

SlopeIndicator

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

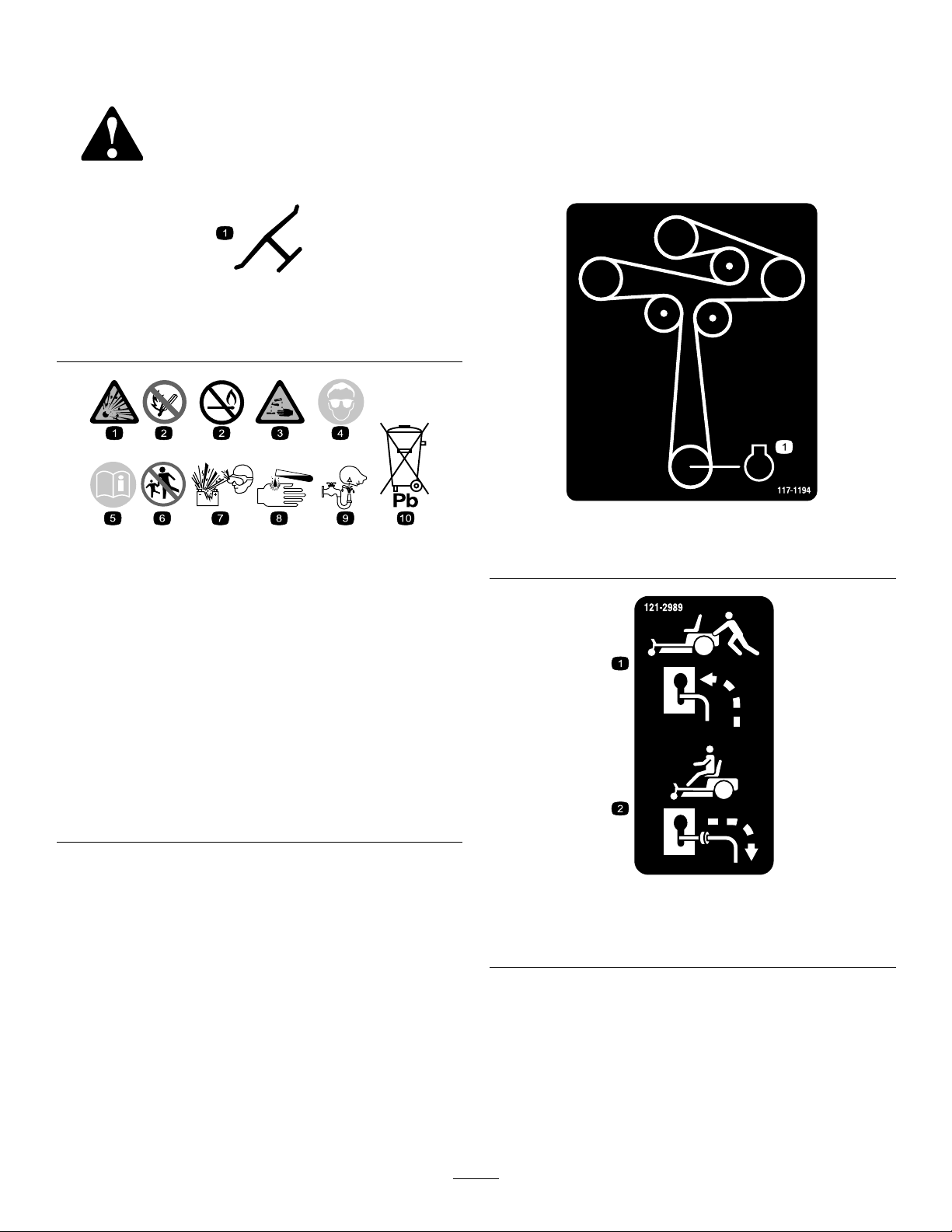

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

decaloemmarkt

decal117-1 194

decalbatterysymbols

1.Engine

117-1194

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distanceawayfromthe

battery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard

1.Bypassleverpositionfor

pushingthemachine

decal121-2989b

121-2989

2.Bypassleverpositionfor

operatingthemachine

6

Page 7

decal131-1097

131-1097

1.Oildrain

decal130-0654

130-0654

1.Transport—lock

2.Transport—unlock

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

3.Heightofcut

130-0731

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

decal132-0872

decal130-0731

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

132-0872

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

130-0765

3.Removethekeyfromthe

keyswitchandreadthe

Operator'sManualbefore

performingmaintenance.

decal130-0765

136-4243

decal136-4243

1.Fast4.Reverse

2.Slow

5.Parkingbrakedisengaged

3.Neutral6.Parkingbrakeengaged

7

Page 8

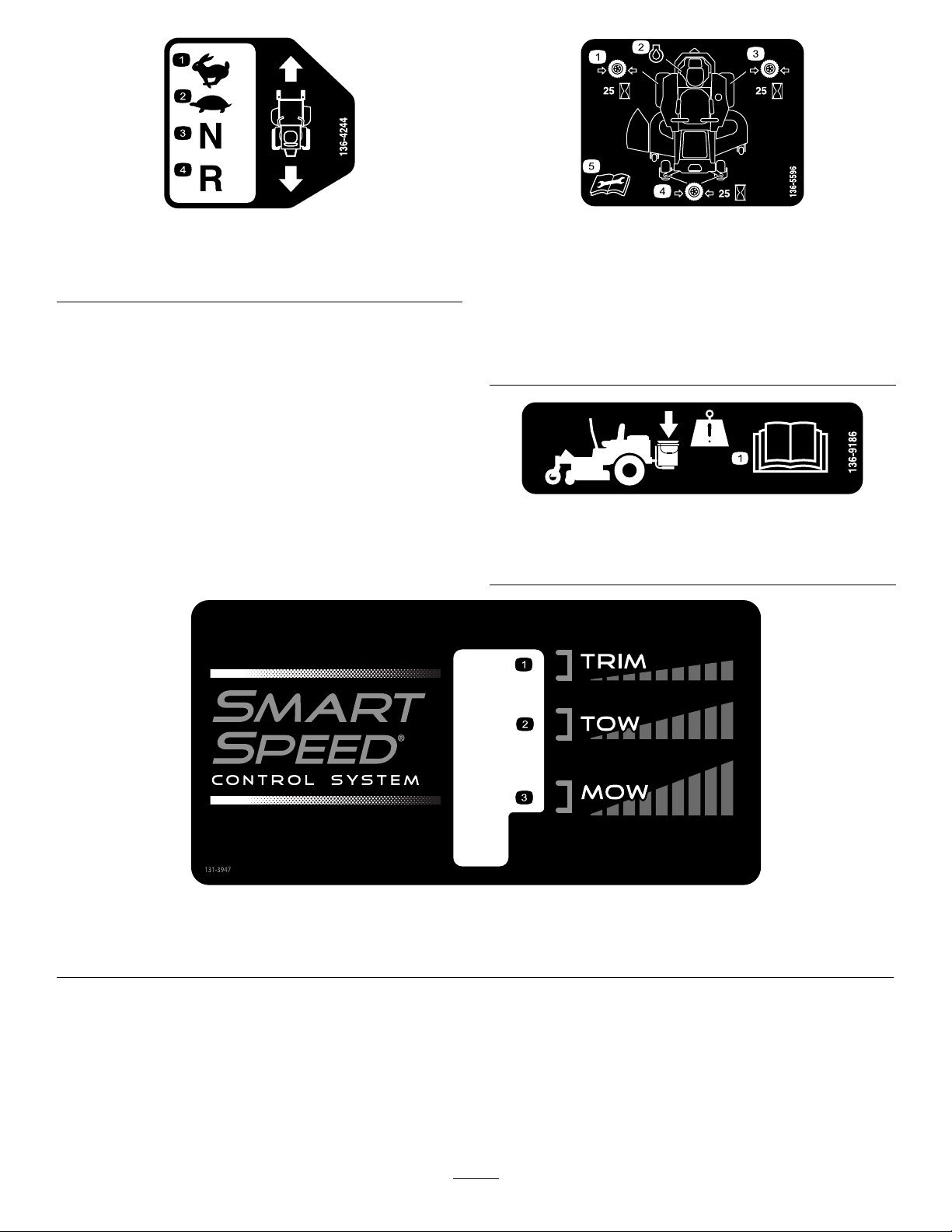

136-4244

1.Fast3.Neutral

2.Slow

decal136-4244

decal136-5596

136-5596

1.Checkthetirepressure

4.Reverse

every25operatinghours.

2.Engineoil

3.Checkthetirepressure

every25operatinghours.

4.Checkthetirepressure

every25operatinghours.

5.ReadtheOperator's

Manualbeforeperforming

maintenance.

decal136-9186

136-9186

1.ReadtheOperator'sManualbeforeaddingweighttothe

bucket.

decal131-3947

131-3947

1.Trim—slow

2.Tow—medium

3.Mow—fast

8

Page 9

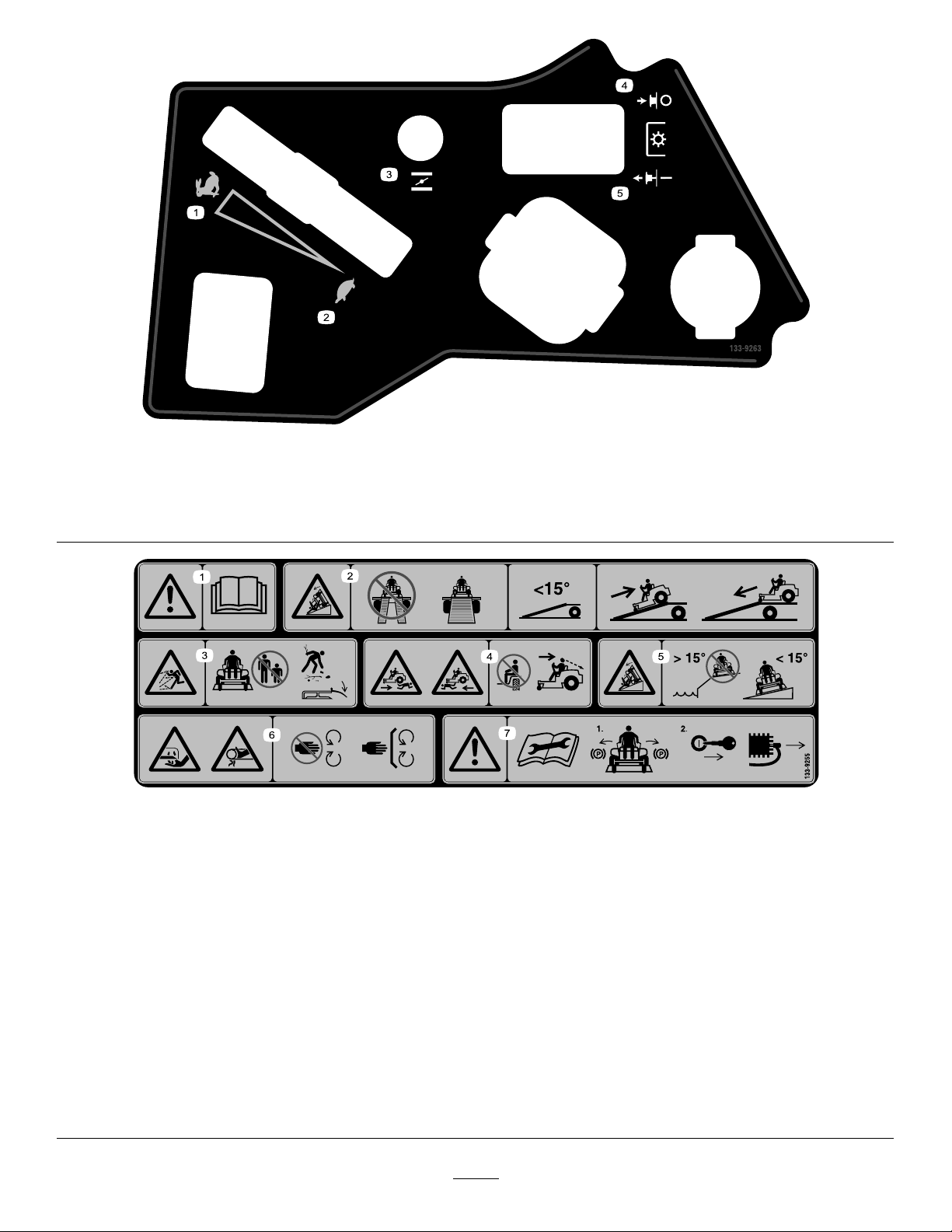

decal133-9263

133-9263

1.Fast

4.PTOdisengage

2.Slow5.PTOengage

3.Choke

133-9255

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal133-9255

1.Warning—readtheOperator'sManual.

2.Ramphazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptherampwhenloadingthe

machineanddriveforwardofftherampwhenunloading.

3.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine,pickupdebrisbeforeoperating,andkeepthe

deectorshielddown.

4.Bodilyharmhazard—donotcarrypassengers;lookbehind

youwhenmowinginreverse.

5.Tippinghazard—donotuseonslopesnearopenwater;do

notuseonslopesgreaterthan15°.

6.Cuttingandpinchhazard—keepawayfrommovingparts;

keepallguardsandshieldsinplace.

7.Warning—beforeperformingmaintenance,readthe

Operator'sManual;engagetheparkingbrake,removethe

key,anddisconnectthesparkplug.

9

Page 10

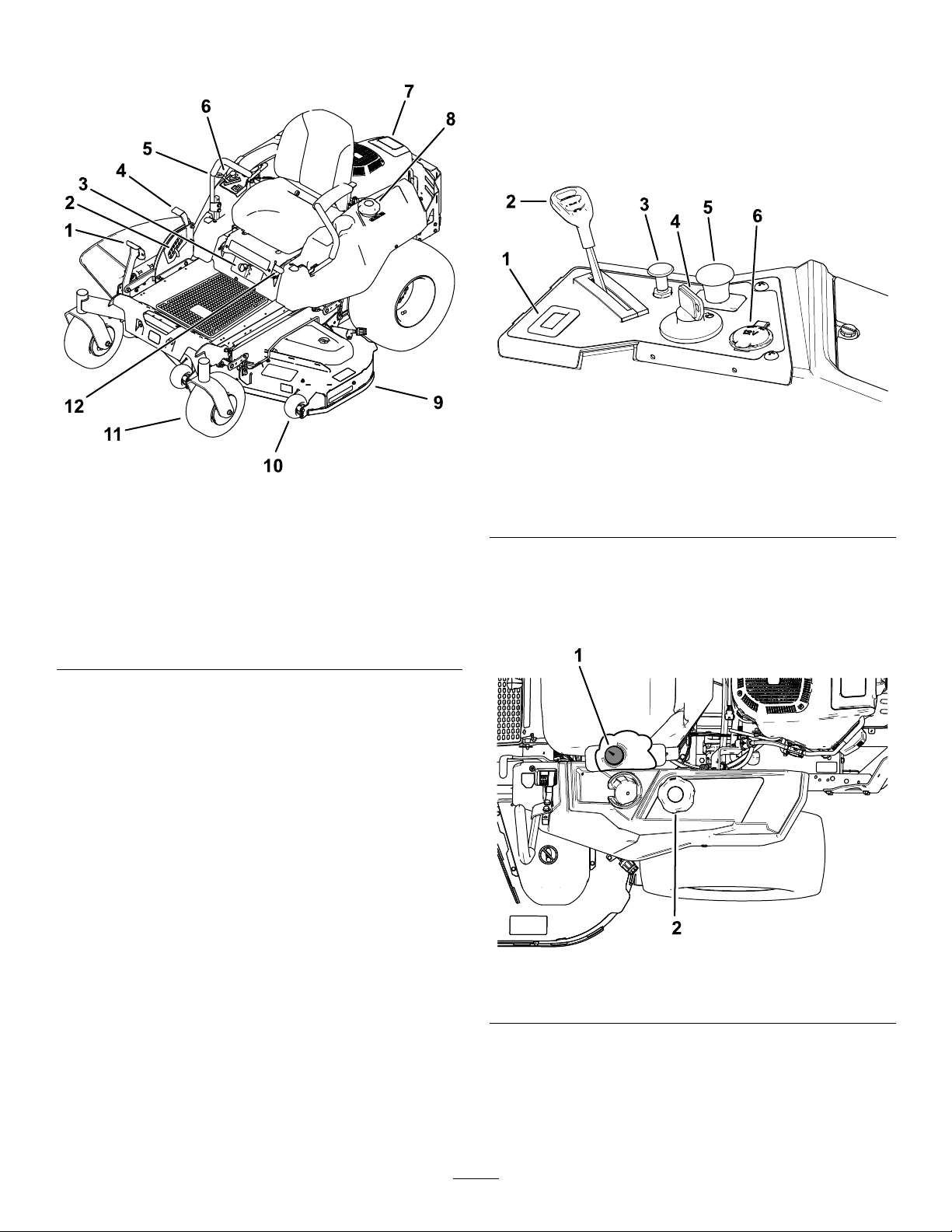

ProductOverview

1.Deck-liftpedal

2.Height-of-cutpin

3.Height-of-cut

lever/transportlock

4.SmartSpeed™lever

5.Motion-controllever

6.Controls

Figure5

7.Engine

8.Fuelcap

9.Mowerdeck

10.Anti-scalproller

11.Casterwheel

12.Parking-brakelever

Controls

BecomefamiliarwithallcontrolsinFigure6and

Figure7beforeyoustarttheengineandoperatethe

machine.

ControlPanel

g188738

Figure6

1.Hourmeter4.Keyswitch

g188739

2.Throttlecontrol5.Blade-controlswitch

3.Chokecontrol

(powertakeoff)

6.12Vpowerpoint

FuelGauge

Thefuelgaugedisplaystheamountoffuelinthetank

(Figure7).

Figure7

1.Fuelgauge2.Fuel-tankcap

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure6).

10

g238298

Page 11

ChokeControl

12VPowerPoint

Usethechokecontroltostartacoldengine.

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure5).

Neutral-LockPosition

Movethemotion-controlleversoutwardfromthe

centertotheNEUTRAL-LOCKpositionwhenexiting

themachine(Figure21).Alwayspositionthe

motion-controlleversintotheNEUTRAL-LOCKposition

whenyoustopthemachineorleaveitunattended.

Parking-BrakeLever

Theparking-brakeleverislocatedontheleftsideof

theconsole(Figure5).Thebrakeleverengagesa

parkingbrakeonthedrivewheels.

Usethepowerpointtopower12Vaccessories

(Figure6).

Important:Whennotusingthe12Vpowerpoint,

inserttherubberplugtopreventdamagetothe

powerpoint.

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.Referto

StartingtheEngine(page19).

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

disengagespowertothemowerblades(Figure6).

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedalto

lockthedeckinaspeciccuttingheight.Adjustthe

heightofcutonlywhenthemachineisnotmoving

(Figure5).

Toengagetheparkingbrake,pulluptheleveruntilit

latchesintothedetentslot.

Todisengagetheparkingbrake,pulltheleveroutof

thedetentslotandtowardyou,thenpushitdown.

FootPedalDeck-LiftSystem

Thefootpedaldeck-liftsystemallowsyoutolower

andraisethedeckfromtheseatedposition.Y ou

canusethefootpedaltoliftthedeckbrieytoavoid

obstaclesorlockthedeckinthehighestheightofcut

ortransportposition(Figure5).

SmartSpeed™ControlSystem

Lever

TheSmartSpeed™Control-Systemlever,located

belowtheoperatingposition,givesyouachoiceto

drivethemachineat3speedranges—trim,tow,and

mow(Figure24).

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

11

Page 12

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

12

Page 13

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless

(drainthefueltankwhenstoringthemachinefor

morethan90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

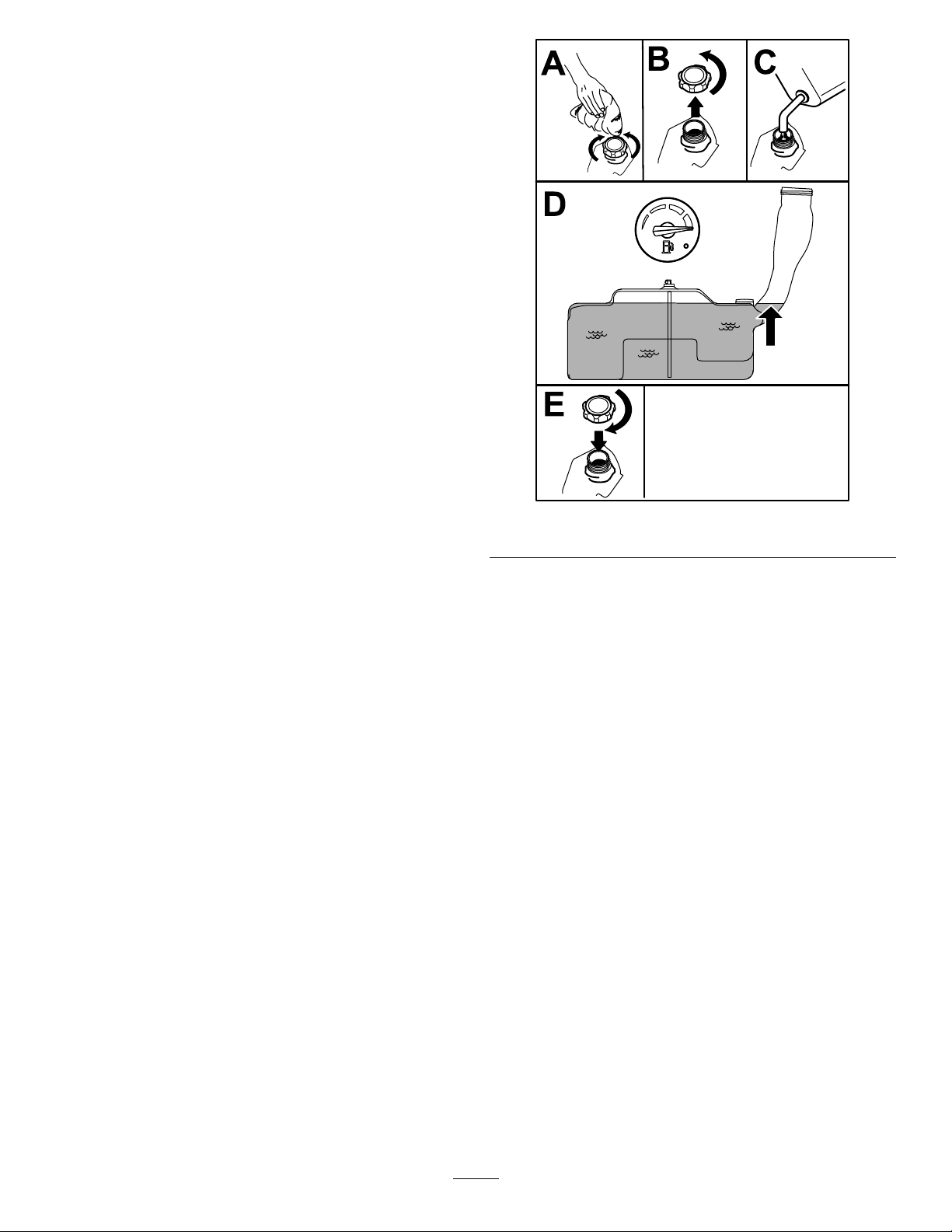

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltankuntilthefuelgaugereadsatthe

fullmark(Figure8).

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

g197123

Figure8

PerformingDaily Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page27).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

13

Page 14

UsingtheSafety-Interlock System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theblade-controlswitch(PTO)isdisengaged.

andriseslightlyfromtheseat;theengineshould

shutoff.

4.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

toNEUTRAL-LOCKposition.Starttheengine.

Whiletheengineisrunning,centereither

motion-controlleverandmoveitforwardor

reverse;theengineshouldshutoff.Repeatfor

othermotion-controllever.

5.Sitontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controlleversto

NEUTRAL-LOCKposition.Trystartingtheengine;

theengineshouldnotcrank.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure9).

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

•Theparkingbrakeisengaged.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewheneverthecontrolleversareoutof

theNEUTRAL-LOCKpositionandyourisefromtheseat.

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheON

position.Trystartingtheengine;theengine

shouldnotcrank.

2.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheOFF

position.Moveeithermotion-controllever(out

oftheNEUTRAL-LOCKposition).Trystartingthe

engine;theengineshouldnotcrank.Repeatfor

othercontrollever.

g027632

Figure9

3.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controlleversto

theNEUTRAL-LOCKposition.Starttheengine.

Whiletheengineisrunning,releasetheparking

brake,engagetheblade-controlswitch(PTO),

14

Page 15

Adjustingthe Motion-ControlLevers

AdjustingtheHeight

Youcanadjustthemotion-controllevershigheror

lowerformaximumcomfort(Figure10).

Figure10

AdjustingtheTilt

Youcanadjustthemotion-controlleversforwardor

rearwardforyourcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrol-armshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforwardorrearward(Figure10).

3.Tightenbothboltstosecurethecontrolleverin

thenewposition.

4.Repeattheadjustmentfortheothercontrollever.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;slip-resistant,substantial

footwear;andhearingprotection.Tiebacklong

hairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

g027252

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

15

Page 16

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicleunless

ithasahitchinstalled.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useonlyaccessoriesandattachmentsapproved

byToro.

•Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardropoffs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandtrimmertomowthegrassin

theseareas.

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

Figure11

1.Wearhearingprotection.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15

degrees.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweights.

g229846

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

operatingonslopescancausethemachineto

becomeunstable.

•A2-postROPS(RolloverProtectionSystem)is

availableforthemachineasanaccessory.A

ROPSisrecommendedifyouwillbemowingnext

todrop-offs,nearwater,oronsteepbanks,which

couldresultinarollover.ContactanAuthorized

ServiceDealerformoredetails.TheCalifornia

CodeofRegulationsrequiresROPS(ifavailable)

onallmowersusedcommercially ,effectiveMarch

1,201 1.

16

Page 17

Figure12

OperatingtheParking Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

Parkthemachineonalevelsurface.

g22911 1

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

3.Water

4.W=widthofthemachine

5.Keepasafedistance

(twicethewidthofthe

machine)betweenthe

machineandanyhazard.

TowingSafety

•Donotattachtowedequipmentexceptatthehitch

point.

•Followtheattachmentmanufacturer's

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.Thetowed

weightmustnotexceedtheweightofthemachine,

operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,or

inthetowingmachineOperator’sManual.

•Neverallowchildrenorothersnearthetowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftraction,increasedriskofrollover,

andlossofcontrol.Reducethetowedweightand

slowdown.

Figure13

DisengagingtheParkingBrake

Todisengagetheparkingbrake,pulltheleveroutof

thedetentslotandtowardyou,thenpushitdown

(Figure14).

Figure14

1.Pushtheparkingbrake

outofthedetentslotand

towardyou.

2.Pushtheparkingbrake

down.

g188778

g188777

•Thestoppingdistanceincreaseswiththeweight

ofatowedload.Travelslowlyandallowextra

distancetostop.

•Makewideturnstokeeptheattachmentclearof

themachine.

17

Page 18

OperatingtheMower

OperatingtheThrottle

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBlade-Control Switch(PTO)

Figure15

Note:Alwaysengagethebladeswiththethrottlein

theFASTposition(Figure16).

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure18).

AlwaysusetheFASTpositionwhenengagingthePTO.

g187517

Figure18

g008945

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure19).

DisengagingtheBlade-Control Switch(PTO)

Note:Ensurethatyoufullyengagethechoke.

Youmayneedtoholdtheknobupwhenyou

usethekeyswitch.

2.Pushdownthechoketodisengagethechoke

aftertheenginehasstarted(Figure19).

g187516

Figure16

Figure17

g009174

Figure19

1.ONposition2.OFFposition

18

g008959

Page 19

StartingtheEngine

ShuttingOfftheEngine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformore

than5secondsatatime.Engagingthestarter

motorformorethan5secondscandamagethe

startermotor.Iftheenginefailstostart,wait10

secondsbeforeoperatingtheenginestarteragain.

1.Disengagethebladesbymovingthe

blade-controlswitchtotheOFFposition(Figure

17).

2.Engagetheparkingbrake;refertoEngagingthe

ParkingBrake(page17).

3.MovethethrottlecontroltotheFASTposition.

4.TurnthekeytotheOFFpositionandremove

thekey.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

UsingtheMotion-Control Levers

Figure20

g189354

g004532

Figure21

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

19

4.Backward

Page 20

DrivingtheMachine

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

WARNING

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingForward

Note:Theengineshutsoffwhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostopthemachine,pullthemotion-controllevers

totheNEUTRALposition.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page17).

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotion-control

leversforward(Figure22).

g008952

Figure22

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-control

leversrearward(Figure23).

g008953

Figure23

20

Page 21

UsingtheSmartSpeed

ControlSystem

TheSmartSpeed

belowtheoperatingposition(Figure24),givesthe

operatorachoicetodrivethemachineat3ground

speedranges—trim,tow,andmow.

TM

Control-Systemlever,located

Figure24

TM

Tow

Thisisthemediumspeed.Thesuggestedusesfor

thisspeedareasfollows:

•Bagging

•Mulching

Mow

Thisisthefastestspeed.Thesuggestedusesforthis

speedareasfollows:

•Normalmowing

•Movingthemachine

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

g027625

turf.

1.Smart-speedlever

Tochangespeeds,dothefollowing:

1.Movethemotion-controlleverstoneutraland

outwardtothePARKposition.

2.Disengagetheblade-controlswitch.

3.Adjustthelevertothedesiredposition.

Thefollowingareonlyrecommendationsforuse.

Adjustmentsvarybygrasstype,moisturecontent,

andtheheightofthegrass.

Suggested

uses:

ParkingX

Heavy,wet

grass

TrainingX

BaggingX

MulchingX

Normal

mowing

Movingthe

machine

TrimTowMow

X

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatethekeyswitchtotheOFF

position,andremovethekeyfromthekey

switch.

X

X

•Makesurethatthegrassdeectorisinthe

downposition.

Trim

Thisisthelowestspeed.Thesuggestedusesforthis

speedareasfollows:

•Parking

•Heavy,wetgrassmowingconditions

•Training

21

Page 22

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldeck-lift

system.Youcanusethefootpedaltoliftthedeck

brieytoavoidobstaclesorlockthedeckinthe

highestheightofcutortransportposition.Youcan

usetheheight-of-cutleverwiththefootpedaltolock

thedeckinaspeciccuttingheight.

UsingtheFootPedalDeck-Lift System

•Pressthedeck-liftpedaldowntoraisethedeck;

continuetopressthepedaluntilthedecklocksin

thetransportposition(Figure25).

•Pushonthedeck-liftpedalwithyourfootandpull

thetransportlockhandlerearwardtodisengage

thetransportlock(Figure25).

3.Selectaholeintheheight-of-cutsystem

correspondingtothedesiredheightofcutand

insertthepin(Figure26).

4.Pushonthedeck-liftpedalwithyourfootand

pullthehandlerearwardtodisengagethe

transportlock(Figure25).

5.Lowerthedeckslowlyuntilthelevermakes

contactwiththepin.

Figure25

TransportLockPosition

AdjustingtheHeightofCut

Youcanadjusttheheightofcutfrom38to114mm

(1-1/2to4-1/2inches)in6mm(1/4inch)increments

bymovingtheheight-of-cutpinintodifferenthole

locations.

g188850

Figure26

1.Deck-liftpedal

2.Handle

3.Pin

4.Height-of-cutpositions

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheightofcut,adjustthe

heightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollers

g024409

donottouchthegroundinnormal,atmowingareas.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitchandengagetheparking

brake;refertoEngagingtheParkingBrake

(page17).

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

27.

1.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktothetransport-lock

position(alsothe114mm(4-1/2inch)cutting

heightposition)asshowninFigure26.

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure26).

22

Page 23

Figure27

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

UsingAttachmentsand

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

deckinuncutgrass.Alwaystrytohave1sideofthe

mowerdeckfreefromuncutgrass,whichallowsair

tobedrawnintothemowerdeck.

g029955

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdeckdoesnotscalp

anyunevenground.However,thecuttingheight

usedinthepastisgenerallythebestonetouse.

Whencuttinggrasslongerthan15cm(6inches)tall,

youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

Accessories

UseonlyToroapprovedattachmentsandaccessories.

Ifyouattachabuckettotheengineguard,useanylon

straptosecureit.

Important:Ifyouarecarryingmorethan4.5

kg(10lb)inabucketattachedtotheengine

guard,youshouldequipyourmachinewiththe

Bucket-SupportKit.

ContactyourauthorizedToroservicedealer.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

23

Page 24

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

AfterOperation

AfterOperationSafety

MowerDeckClean

Cleanclippingsanddirtfromtheundersideofthe

mowerdeckaftereachuse.Ifgrassanddirtbuildup

insidethemowerdeck,cuttingqualitywilleventually

becomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

PushingtheMachineby Hand

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausetowingmay

damageit.

Thismachinehasanelectric-brakemechanism,

andtopushthemachine,thekeymustbeinthe

RUNposition.Thebatteryneedstobechargedand

functioningtodisengagetheelectricbrake.

PushingtheMachine

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

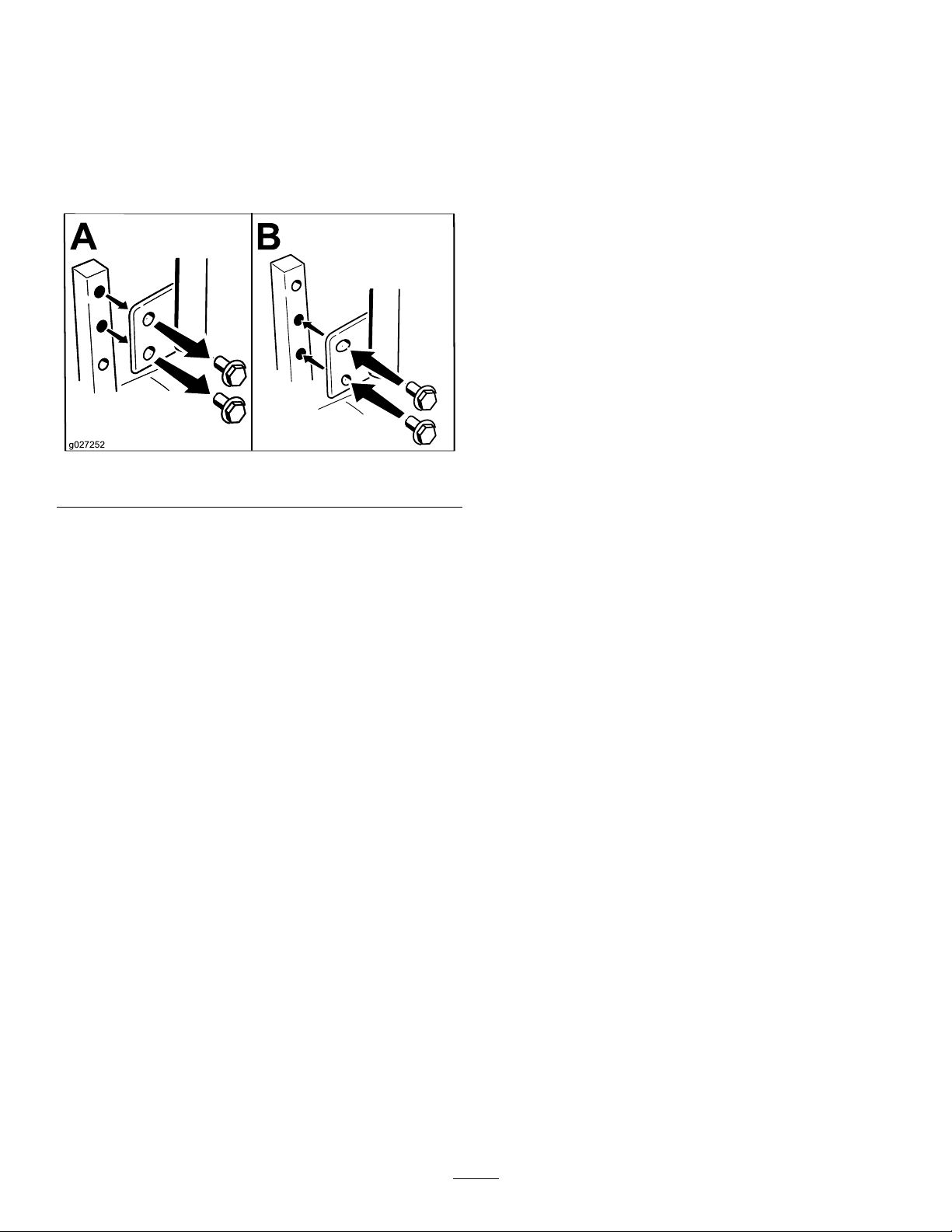

3.Locatethebypassleversontheframeonboth

sidesoftheengine.

4.Movethebypassleversforwardthroughthekey

holeanddowntolocktheminplace(Figure28).

Note:Dothisforeachlever.

5.Turntheignitionkeyonanddisengagethe

parkingbrake.

Note:Donotstartthemachine.

24

Page 25

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

g207190

Figure28

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethatthekeyhasbeen

returnedtotheSTOPpositiontoavoiddraining

thebatterycharge.

3.Leverpositionforpushing

themachine

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure28.

Note:Dothisforeachlever.

Donotdrivethemachineonapublicstreet

orroadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure29).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoftherampisat

least4timesaslongastheheightofthe

trailerortruckbedtotheground.This

ensuresthattherampangledoesnot

exceed15degreesonatground.

25

Page 26

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure29).

4.Backthemachineuptheramp(Figure30).

Figure30

g027995

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

LoadingtheMachine

Figure29

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

5.Shutofftheengine,removethekey,andengage

theparkingbrake.

6.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure31).Refertolocal

regulationsfortie-downrequirements.

g027996

g027708

Figure31

1.Tie-downloops

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Backthemachineuptherampanddriveit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

UnloadingtheMachine

1.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure29).

2.Drivethemachineforwarddowntheramp

(Figure30).

26

Page 27

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,loose,ordamagedparts.

•Checktheengine-oillevel.

•Cleantheairintakescreen.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemower-deckhousing.

•Cleantheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Checktirepressure.

•Checkthebeltsforwearorcracks.

•Replacetheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Cleanthepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Changetheengineoilandoillter(moreoftenindirtyordustyconditions).

•Checkthesparkplug(s).

•Checkthein-linefuellter.

•Replacethepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Replacethesparkplug(s).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

27

Page 28

Pre-Maintenance

EngineMaintenance

Procedures

EngineSafety

MaintenanceSafety

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy.

RemovingtheFoamandPaper Elements

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundtheair-cleanercovertoprevent

dirtfromgettingintotheengineandcausing

damage.

4.Liftthecoverandrotatetheair-cleanerassembly

outoftheengine(Figure32).

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingcondition

andallhardwaretightened,especiallythe

blade-attachmentbolts.Replaceallwornor

damageddecals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

28

Page 29

ServicingtheFoamAir-Cleaner Element

ServiceInterval:Every25hours/Monthly(whichever

comesrst)—Cleantheair-cleaner

foamelement(moreoftenindusty,

dirtyconditions).

Every100hours/Y early(whichevercomes

rst)—Replacetheair-cleanerfoamelement

(moreoftenindusty,dirtyconditions).

g027800

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-Cleaner Element

ServiceInterval:Every100hours—Cleanthepaper

air-cleanerelement(moreoftenin

dirtyordustyconditions).

Figure32

5.Separatethefoamandpaperelements(Figure

33).

Figure33

Every200hours—Replacethepaperair-cleaner

g027801

element(moreoftenindirtyordustyconditions).

1.Cleanthepaperelementbytappingitgentlyto

removedust.

Note:Ifitisverydirty,replacethepaper

elementwithanewone.

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

Important:Donotcleanthepaperlter.

g027802

29

Page 30

InstallingtheAirCleaner

CheckingtheEngine-OilLevel

1.Installthefoamelementoverthepaperelement.

Note:Ensurethatyoudonotdamagethe

elements.

2.Aligntheholesofthelterintothemanifold

ports.

3.Rotatethelterdownintothechamberandfully

seatitagainstthemanifold(Figure34).

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmay

damagetheengine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Note:Ensurethattheengineiscoolsothatthe

oilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure36).

Figure34

4.Closethecover.

ServicingtheEngineOil

Engine-OilSpecications

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

CrankcaseCapacity:2.4L(81oz)withoillter

Viscosity:Seethetablebelow.

g228022

Figure35

g235263

Figure36

g029683

30

Page 31

ChangingtheEngineOilandOil Filter

ServiceInterval:Aftertherst5hours/Afterthe

rstmonth(whichevercomes

rst)—Changetheengineoiland

lter.

Every100hours/Y early(whichevercomes

rst)—Changetheengineoilandoillter(more

oftenindirtyordustyconditions).

1.Parkthemachineonalevelsurfacetoensure

thattheoildrainscompletely.

2.Disengagetheblade-controlswitch(PTO)and

engagetheparkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Draintheoilfromtheengine.

g027799

g029570

Figure37

31

Page 32

5.Changetheengine-oillter(Figure38).

Note:Ensurethattheoil-ltergaskettouches

theengineandthenturnthelteranextra3/4

turn.

g235264

Figure39

Figure38

6.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

39).

7.Disposeoftheusedoilatarecyclingcenter.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Yearly(whichever

g027477

Every200hours/Every2years(whichever

comesrst)—Replacethesparkplug(s).

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplugandagappingtoolorfeelergaugeto

checkandadjusttheairgap.Installanewsparkplug

ifnecessary.

Type:Champion

Airgap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

comesrst)—Checkthespark

plug(s).

®

RN9YCorNGK

®

BPR6ES

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleantheareaaroundthebaseoftheplugto

keepdirtanddebrisoutoftheengine.

4.Removethesparkplug(Figure40).

32

Page 33

CleaningtheCooling System

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

Figure40

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

g027478

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheairlterfromtheengine.

4.Removetheengineshroud.

5.Topreventdebrisenteringtheairintake,install

theairltertothelterbase.

6.Cleandebrisandgrassfromtheparts.

7.Removetheairlterandinstalltheengine

shroud.

8.Installtheairlter.

Figure41

InstallingtheSparkPlug

Figure42

g027479

g027960

33

Page 34

FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyou,others,and

candamageproperty.

•Performanyfuel-relatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanyfuelthat

spills.

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

ReplacingtheIn-LineFuel Filter

g027939

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthein-linefuel

lter.

Every200hours/Every2years(whichever

comesrst)—Replacethein-linefuellter.

Neverinstalladirtylterafterremovingitfromthe

fuelline.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Replacethelter(Figure43).

Note:Note:Ensurethatthemarkingsonthe

lterfollowthefuelowdirection.

g033082

Figure43

34

Page 35

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

g190587

Figure44

1.Batterycover2.Fasteners

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

ServicingtheBattery

RemovingtheBattery

WARNING

Incorrectlyremovingthecablesfrombattery

coulddamagethemachineandcables,

causingsparks.Sparkscancausethebattery

gassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

4.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure45).

Note:Retainallfasteners.

5.Slidetherubbercoverupthepositive(red)

cable.

6.Disconnectthepositive(red)cablefromthe

batterypost(Figure45).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure45),and

liftthebatteryfromthebatterytray.

g188903

Figure45

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthe2fastenersonthebatterycover

counterclockwise1/4turn,andremovethe

batterycover(Figure44).

1.Battery

2.Negative(–)batterypost

3.Bolt,washer,andnutfor

thenegative(–)battery

post

4.Bolt,washer,andnutfor

thepositive(+)battery

post

35

5.Positive(+)batterypost

6.Terminalboot

7.Batteryhold-down

Page 36

ChargingtheBattery

ServicingtheFuses

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectthebatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page35).

2.Chargethebatteryforaminimumof1hourat

6to10A.

Note:Donotoverchargethebattery .

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure46).

Figure46

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

InstallingtheBattery

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(15A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

ToreplacetheMain(15A)fuse,reachintothe

openinginthesideoftheconsole,pulloutthefuse,

andinstallanew15Afuse(Figure47).

g000538

1.Main(15A)2.Consoleopening

Figure47

ToreplacetheChargeCircuit(25A)fuse,locatethe

fusetotheleftofbattery,pulloutthefuse,andinstall

anew25Afuse(Figure48).

g190588

1.Positionthebatteryinthetray(Figure45).

2.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Usingthefastenerspreviouslyremoved,install

thenegativebatterycabletothenegative(-)

batteryterminal.

4.Slidetheredterminalbootontothepositive

(red)batterypost.

5.Securethebatterywiththehold-down(Figure

45).

6.Installthebatterycoverbypushingdownand

tighteningthe2fastenersclockwise(Figure44).

g190589

Figure48

1.Chargecircuit(25A)

36

Page 37

DriveSystem

MowerMaintenance

Maintenance

ServicingtheCutting

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseuneven

cut.Checkthepressureatthevalvestem(Figure49).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethefrontcasterwheeltiresto103kPa(15psi).

Inatethereardrivewheeltiresto90kPa(13psi).

Figure49

1.Valvestem

Blades

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,

keepextrabladesonhand.

BladeSafety

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.Tryingto

repairadamagedblademayresultindiscontinued

safetycerticationoftheproduct.

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

g000554

BeforeInspectingorServicingthe Blades

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure50).

2.Iftheedgesarenotsharporhavenicks,remove

andsharpentheblade;refertoSharpeningthe

Blades(page39).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforming

inthisarea,immediatelyinstallanewblade

(Figure50).

37

Page 38

Figure50

g006530

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfacefor

thefollowingprocedure.

1.Raisethemowerdecktothehighest

height-of-cutposition.

2.Whilewearingthicklypaddedgloves,orother

adequatehandprotection,slowlyrotatethe

bladeintoapositionthatallowsyoutomeasure

thedistancebetweenthecuttingedgeandthe

levelsurfacethemachineison(Figure51).

Figure51

1.Deck3.Blade

2.Spindlehousing

3.Measurefromthetipofthebladetotheat

surface(Figure52).

g014973

Figure52

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothat

theopposingcuttingedgeisnowinthesame

position(Figure53).

g014974

Figure53

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

g014972

position

5.Measurefromthetipofthebladetotheat

surface(Figure54).

Note:Thevarianceshouldbenomorethan

3mm(1/8inch).

38

Page 39

Figure54

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch),replacethebladewith

anewblade;refertoRemovingtheBlades

(page39)andInstallingtheBlades(page

40).

RemovingtheBlades

Replacethebladesiftheyhitasolidobject,orifthe

bladeisoutofbalanceorbent.

1.Holdthebladeendusingaragorthicklypadded

glove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure55).

g014973

Note:Ifabentbladeisreplacedwitha

newblade,andthedimensionobtained

continuestoexceed3mm(1/8inch),the

bladespindlecouldbebent.Contactan

AuthorizedServiceDealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

6.Repeatthisprocedureoneachblade.

g010341

Figure55

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure56).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

g000552

Figure56

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure57).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesome

metalofftheendofthesailareaonly(Figure56).

39

Page 40

Figure57

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeis

balanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

55).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

2.Installthecurvedwasher(cuppedsidetoward

theblade)andthebladebolt(Figure55).

3.Torquethebladeboltto135to150N∙m(100

to110ft-lb).

LevelingtheMowerDeck

Checktoensurethatthemowerdeckislevelanytime

g000553

youinstallthemowerorwhenyouseeanunevencut

onyourlawn.

Checkthemowerdeckforbentbladespriorto

leveling,andremoveandreplaceanybentblades;

refertoServicingtheCuttingBlades(page37)before

continuing.

Levelthemowerdeckside-to-siderst;thenyoucan

adjustthefront-to-rearslope.

Requirements:

•Themachinemustbeonalevelsurface.

•Alltiresmustbeproperlyinated;refertoChecking

theTirePressure(page37).

CheckingtheSide-to-SideLevel

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Figure58

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

3.Carefullyrotatethebladessidetoside.

4.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure59).

Note:Ifbothmeasurementsarenotwithin5

mm(3/16inch),anadjustmentisrequired;refer

toLevelingtheMowerDeck(page41).

g004536

g229303

Figure59

1.Bladessidetoside

2.Outsidecuttingedges

3.Measurefromthetipofthe

bladetotheatsurface

here.

40

Page 41

CheckingtheFront-to-RearBlade

LevelingtheMowerDeck

Slope

Checkthefront-to-rearbladelevelanytimeyouinstall

themower.Ifthefrontofthemowerismorethan

7.9mm(5/16inch)lowerthantherearofthemower,

adjustthebladelevel.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Carefullyrotatethebladessotheyarefacing

fronttorear(Figure60).

4.Measurefromthetipofthefrontbladetothe

atsurfaceandthetipoftherearbladetothe

atsurface(Figure60).

Note:Ifthefrontbladetipisnot1.6to7.9mm

(1/16to5/16inch)lowerthantherearbladetip,

continuetotheLevelingtheMowerDeck(page

41)procedure.

1.Settheanti-scalprollerstothetopholesor

removethemcompletelyforthisprocedure;refer

toAdjustingtheAnti-ScalpRollers(page22).

2.Settheheight-of-cutlevertothe76mm(3inch)

position;refertoAdjustingtheHeightofCut

(page22).

3.Place2blocks,eachhavingathicknessof6.6

cm(2-5/8inches),undereachsideofthefront

edgeofthedeckbutnotundertheanti-scalp

rollerbrackets(Figure61).

4.Place2blocks,eachhavingathicknessof7.3

cm(2-7/8inches),undertherearedgeofthe

cuttingdeckskirt,1oneachsideofthecutting

deck(Figure61).

Figure60

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here.

2.Outsidecuttingedges

g024428

Figure61

1.Woodblock—6.6cm

(2-5/8inches)thick

2.Woodblock—7.3cm

(2-7/8inches)thick

g229304

3.Frontedge

5.Loosentheadjustmentboltsonall4cornersso

thatthedeckissittingsecurelyonall4blocks

(Figure62).

41

Page 42

Figure62

1.Deck-liftarm

2.Chain

3.Hook

4.Adjustmentbolt

6.Ensurethatthereistensiononall4chains

(Figure62).

7.Tightenthe4adjustmentbolts(Figure62).

8.Ensurethattheblockstsnuglyunderthedeck

skirtandthatallboltsaretight.

9.Verifythatthedeckislevelbycheckingthe

side-to-sidelevelandfront-to-rearbladeslope;

repeatthedecklevelingprocedureifnecessary.

g028276

Figure63

1.Linkpin3.Hairpincotter

2.Washer

6.Liftupthemowerdecktorelievetensionfrom

themowerdeck.

g024313

7.Removethechainsfromthehooksonthe

deck-liftarms(Figure64).

RemovingtheMowerDeck

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

3.Lowerthemowertothe76mm(3inches)

height-of-cutposition.

4.Removethemowerbeltfromtheenginepulley;

refertoReplacingtheMowerBelt(page44).

5.Removethehairpincotterandwashersecuring

thelinkpintotheframeanddeck,andremove

thelinkbar(Figure63).

Figure64

1.Deck-liftarm

2.Chain

3.Hook

4.Adjustmentbolt

8.Raisetheheightofcuttothetransportposition.

9.Removethebeltfromtheclutchpulleyonthe

engine.

10.Slidethemoweroutfromunderneaththe

machine.

Note:Retainallpartsforfutureinstallation.

g024313

42

Page 43

InstallingtheMowerDeck

ReplacingtheGrass

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

3.Slidethemowerunderthemachine.

4.Lowertheheight-of-cutlevertothelowest

position.

5.Placetheheight-of-cutpininthelockposition

forlowestheightofcut.

6.Lifttherearofthemowerdeckandattachthe

chainstotherearliftarms(Figure64).

7.Attachthefrontchainstothefrontliftarms

(Figure64).

8.Installthelonglinkbarthroughtheframehanger

anddeck.

9.Securethelinkpinwiththehairpincottersand

washersremovedpreviously(Figure63).

10.Installthemowerbeltontotheenginepulley;

refertoReplacingtheMowerBelt(page44).

Deector

ServiceInterval:Beforeeachuseordaily—Inspect

thegrassdeectorfordamage.

WARNING

Anuncovereddischargeopeningcouldallow

thelawnmowertothrowobjectstowardyou

orbystanders,resultinginseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethemachinewithoutthe

grassdeector,thedischargecover,orthe

grass-collectionsysteminplace.

Neveroperatethemachinewithoutthe

grassdeector,thedischargecover,orthe

grass-collectionsysteminplace.

1.Disengagethespringfromthenotchinthe

deectorbracketandslidetherodoutofthe

weldeddeckbrackets,spring,anddischarge

deector(Figure65).

Figure65

1.Rod4.Deckbrackets

2.Spring5.Springinstalledoverthe

rod

3.Deector

2.Removethedamagedorworndischarge

deector.

3.Positionthenewdischargedeectorwiththe

bracketendsbetweentheweldedbracketson

thedeckasshowninFigure66.

43

g197127

Page 44

4.Installthespringontothestraightendoftherod.

5.PositionthespringontherodasshowninFigure

66sothattheshorterspringendcomesfrom

undertherodbeforethebendandgoingover

therodasitreturnsfromthebend.

6.Lifttheloopendofthespringandplaceitinto

thenotchonthedeectorbracket(Figure66).

MowerBeltMaintenance

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebelts

forwearorcracks.

Replacethebeltifitisworn.Thesignsofawornbelt