Page 1

FormNo.3393-327RevA

ZMaster

®

Professional6000

SeriesRidingMower

with60inor72inTURBOFORCE

DischargeMower

ModelNo.74963—SerialNo.315000001andUp

ModelNo.74964—SerialNo.315000001andUp

®

Side

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3393-327*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

CustomerServiceandhavethemodelandserialnumbersof

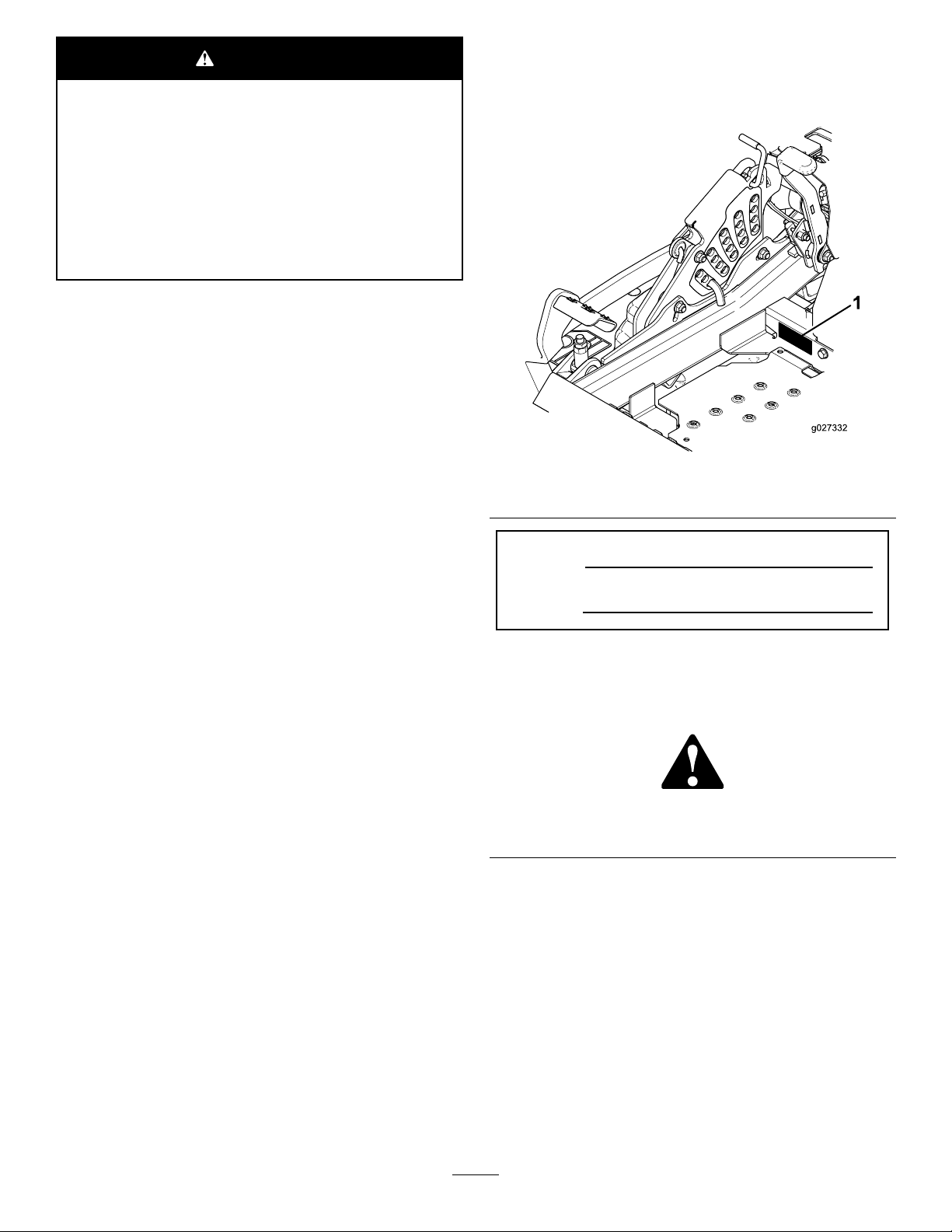

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................14

Operation....................................................................15

AddingFuel...........................................................15

CheckingtheEngine-OilLevel.................................16

BreakinginaNewMachine......................................17

UsingtheRolloverProtectionSystem(ROPS)............17

ThinkSafetyFirst...................................................18

OperatingtheParkingBrake....................................18

OperatingtheMowerBlade-ControlSwitch

(PTO)...............................................................19

OperatingtheThrottlewithHorizon™

Technology........................................................19

OperatingtheIgnitionSwitch..................................19

UsingtheFuel-ShutoffValve...................................20

StartingandStoppingtheEngine..............................20

UsingtheSafety-InterlockSystem.............................21

DrivingForwardorBackward..................................22

StoppingtheMachine.............................................23

AdjustingtheHeight-of-Cut....................................23

AdjustingtheAnti-ScalpRollers...............................24

AdjustingtheFlowBafeCamLocks........................25

PositioningtheFlowBafe......................................25

PositioningtheSeat................................................26

UnlatchingtheSeat.................................................26

ChangingtheSeatSuspension..................................27

UsingtheDrive-Wheel-ReleaseValves.......................27

UsingtheSideDischarge.........................................27

TransportingtheMachine........................................28

LoadingtheMachine..............................................28

OperatingTips......................................................30

Maintenance.................................................................31

RecommendedMaintenanceSchedule(s)......................31

Lubrication...............................................................32

LubricatingtheMachine..........................................32

GreasingtheMower...............................................32

LubricatetheCasterWheelHubs..............................34

EngineMaintenance..................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOil..........................................36

ServicingtheSparkPlugs.........................................39

CheckSparkArrester(ifequipped)............................40

FuelSystemMaintenance...........................................41

ServicingtheElectronicFuelInjection

System..............................................................41

ReplacingtheLow-PressureFuelFilter......................41

ServicingtheHigh-PressureFuelFilter......................41

ServicingtheFuelTank...........................................42

ElectricalSystemMaintenance....................................42

ServicingtheBattery...............................................42

ServicingtheMachineFuses....................................44

ServicingtheEngineFuses......................................44

Jump-StartingtheMachine......................................44

DriveSystemMaintenance.........................................45

CheckingtheSeatBelt.............................................45

CheckingtheKnobsontheRolloverProtection

System(ROPS)..................................................45

AdjustingtheTracking............................................46

CheckingtheTirePressure......................................46

CheckingtheWheelLugNuts..................................47

CheckingtheWheelHubSlottedNut........................47

AdjustingtheCasterPivotBearing............................47

UsingtheClutchShim............................................47

CoolingSystemMaintenance......................................49

CleaningtheEngineCoolingFinsand

Shrouds.............................................................49

CheckandCleantheHydraulic-UnitShrouds.............49

BrakeMaintenance....................................................50

AdjustingtheParkingBrake.....................................50

BeltMaintenance......................................................51

InspectingtheBelts................................................51

ReplacingtheMowerBelt........................................51

ReplacingtheHydraulicPumpDriveBelt...................52

ControlsSystemMaintenance.....................................53

AdjustingtheControlHandlePosition......................53

AdjustingtheMotion-ControlLinkage......................54

AdjustingtheMotion-ControlDamper.....................55

AdjustingtheMotion-ControlNeutralLock

Pivot.................................................................55

HydraulicSystemMaintenance....................................56

ServicingtheHydraulicSystem.................................56

MowerDeckMaintenance...........................................58

LevelingtheMowerDeck........................................58

ServicingtheCuttingBlades.....................................60

RemovingtheMowerDeck.....................................62

ReplacingtheGrassDeector..................................64

Cleaning...................................................................64

CleaningundertheMower.......................................64

DisposingofWaste.................................................64

Storage........................................................................65

CleaningandStorage..............................................65

Troubleshooting...........................................................66

Schematics...................................................................69

3

Page 4

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

—personalsafetyinstruction.Failuretocomply

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformationitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Caution, W ar ning ,

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

or

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk;donotrun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshieldorotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly ,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),andshutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersonthemachine.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

4

Page 5

RolloverProtectionSystem

(ROPS)—UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine

andremovethekeyordisconnectthespark-plugwire.

Waitforallmovementtostopbeforeadjusting,cleaning

orrepairingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Cleangrassanddebrisfromthecuttingunit,thedrives,

themufers,andtheenginetohelppreventres.Clean

upoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorthespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Connectthepositiverstand

negativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)

orwearthickly-paddedgloves,andusecautionwhen

servicingthem.Onlyreplaceblades.Neverstraighten

orweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingthemachineintoatrailer

ortruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

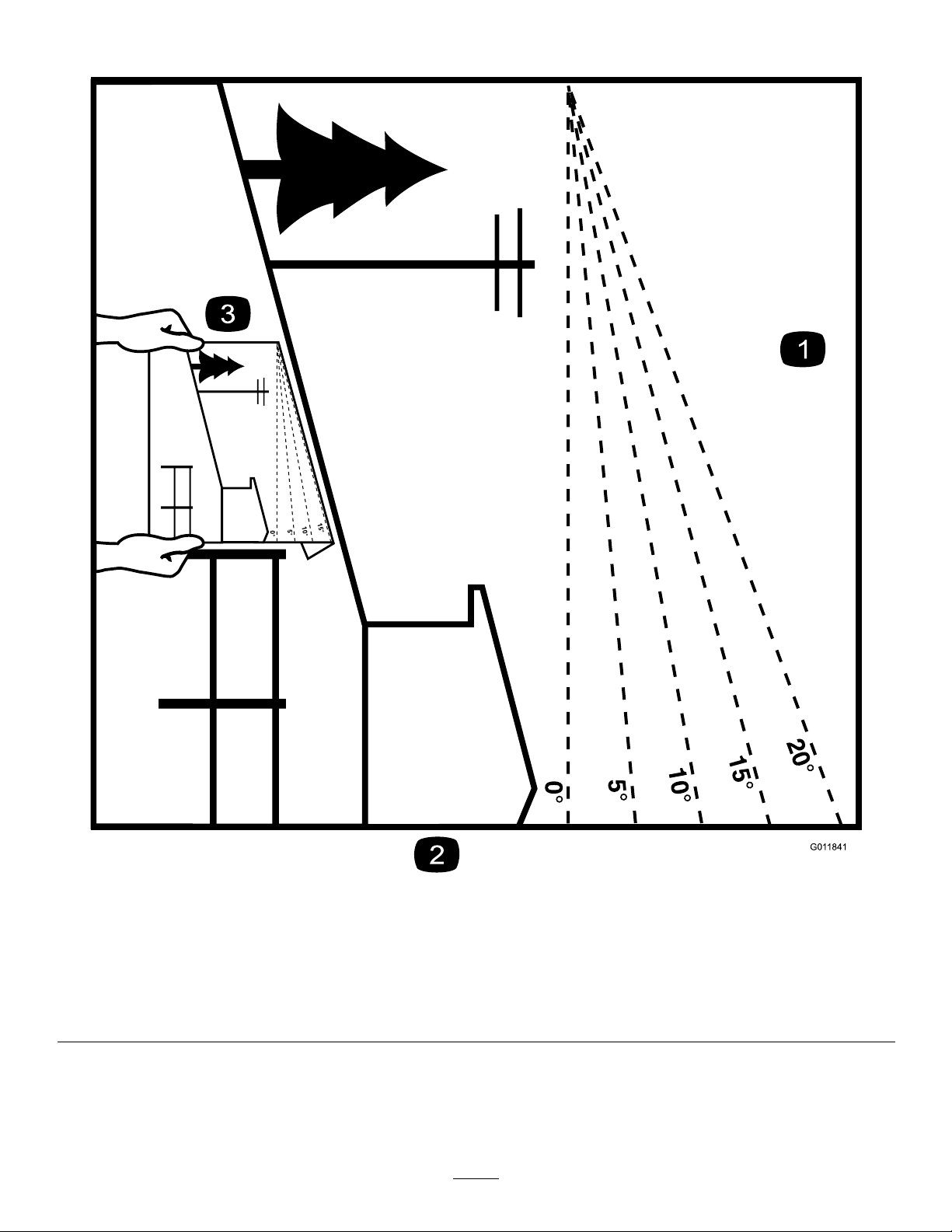

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

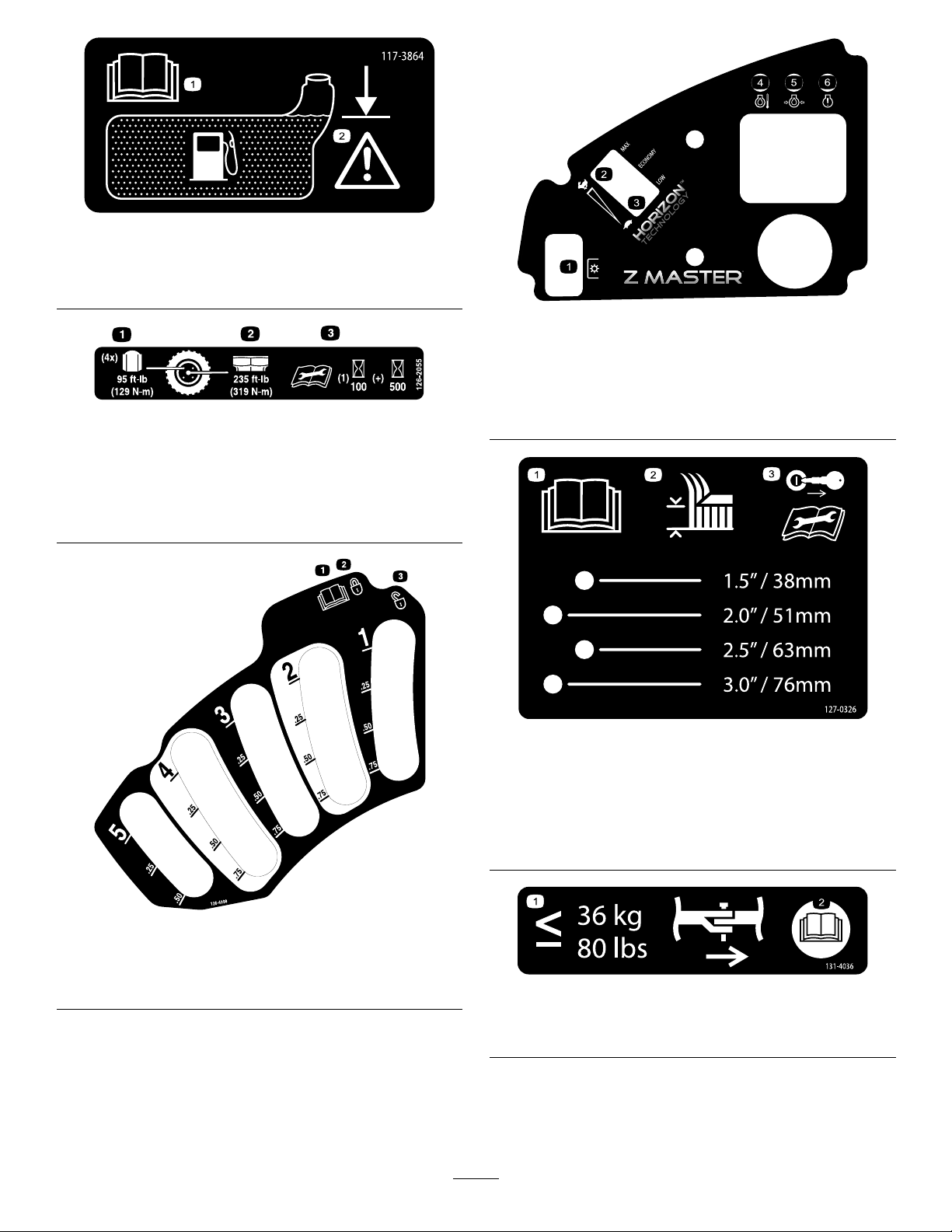

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

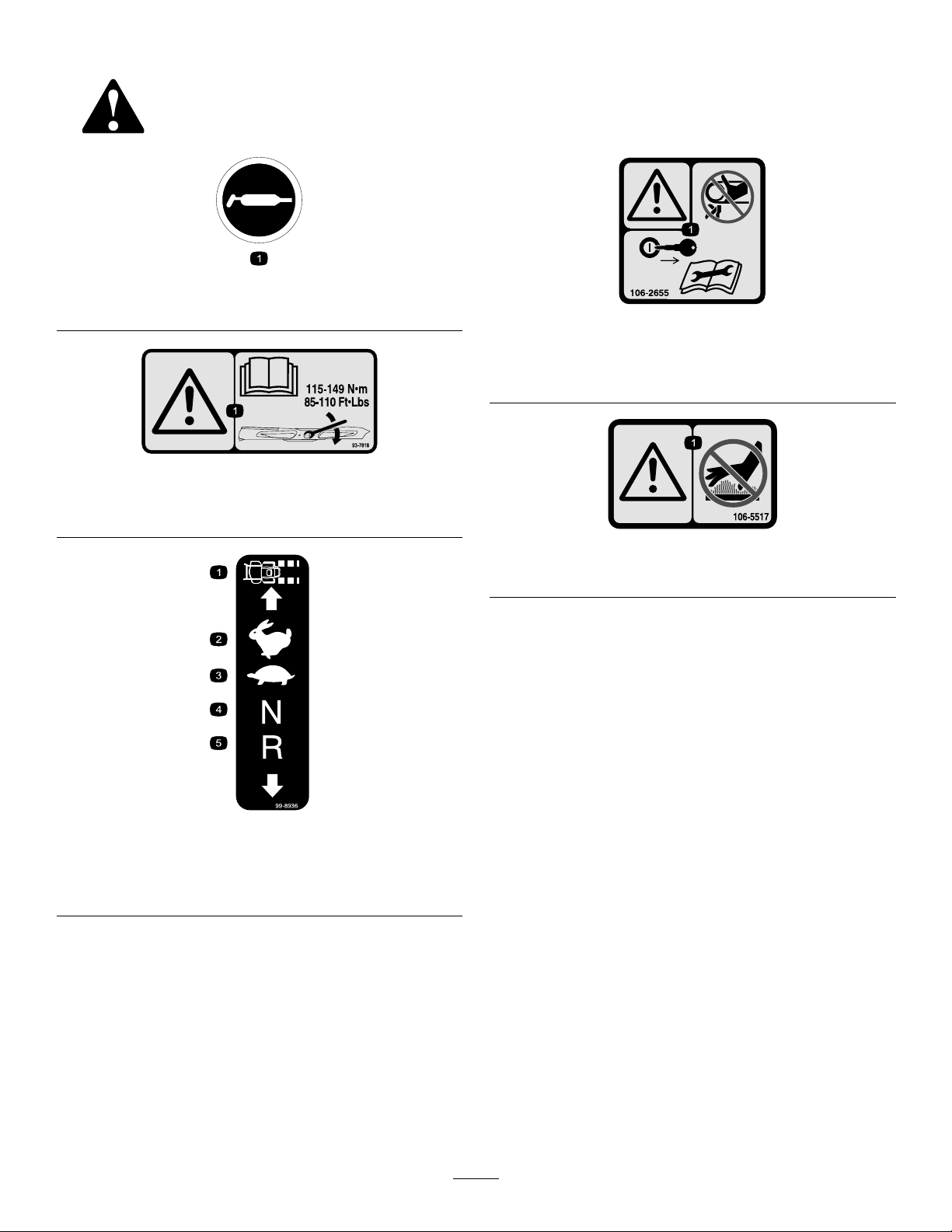

58-6520

1.Grease

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

106-2655

1.Warning-donottouchorapproachmovingbelts;remove

theignitionkeyandreadtheinstructionsbeforeservicing

orperformingmaintenance.

106-5517

1.Warning—donottouchthehotsurface.

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

7

Page 8

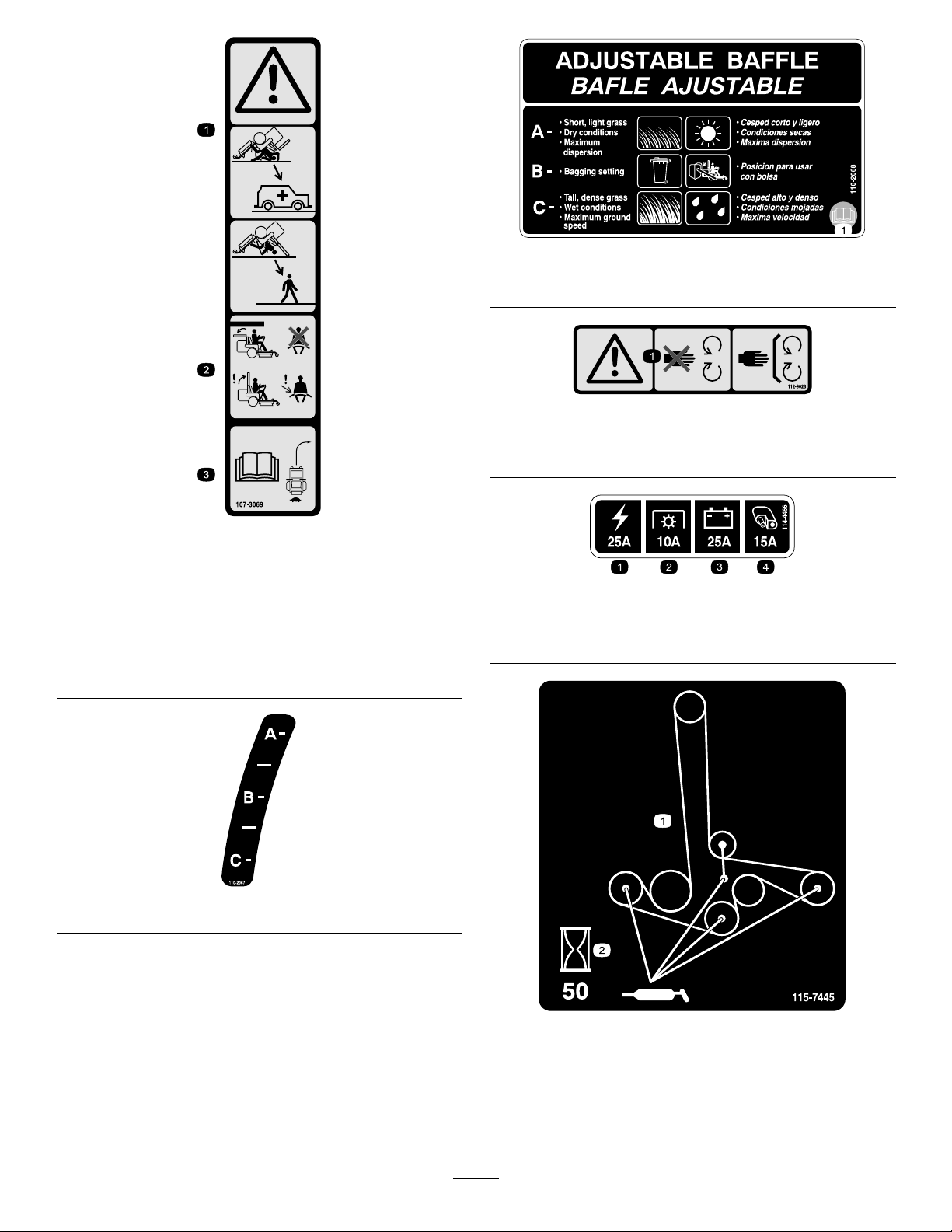

107-3069

1.Warning-thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotweartheseatbeltwhentherollbaris

down.

3.ReadtheOperator’smanual;driveslowlyandcarefully.

110-2068

1.ReadtheOperator'sManual.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

114-4466

1.Main,25A

2.PTO,10A

3.Charge,25A

4.Auxiliary,15A

110-2067

115-7445

1.Greasepulleysandspindles

2.Maintenanceinterval—50hours

8

Page 9

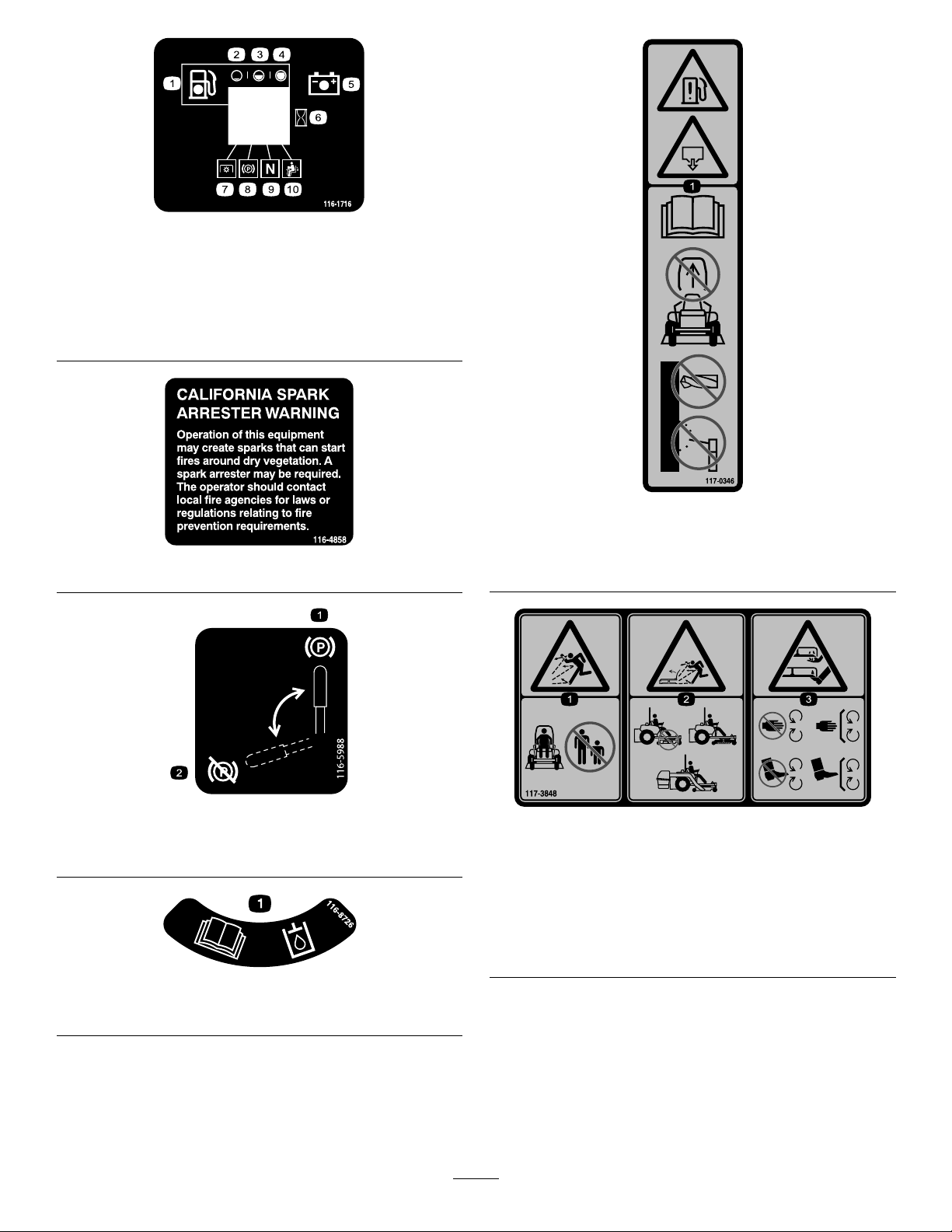

116-1716

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operatorpresenceswitch

116-4858

117-0346

1.Fuelleakhazard—readtheOperator'sManual;donot

attempttoremovetherollbar;donotweld,drillormodify

therollbarinanyway.

116-5988

1.Parkingbrake—engaged2.Parking

brake—disengaged

116-8726

1.ReadtheOperator’sManualforrecommendedhydrooil.

117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine

2.Thrownobjecthazard,mower-donotoperatewithoutthe

deector,dischargecoverorgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

9

Page 10

117-3864

1.ReadtheOperator’s

Manual.

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

126-2055

1.Wheellugnuttorque95ft-lb(129N-m)(4x)

2.Wheelhubnuttorque235ft-lb(319N-m)

3.ReadandunderstandtheOperator’smanualbefore

performinganymaintenance,checktorqueafterrst100

hoursthenevery500hoursthereafter.

127-0314

1.PTOswitch

2.Maximumspeed5.Lowoil-pressureindicator

3.Lowspeed

4.Highoil-temperature

indicator

6.Malfunction-indicatorlight

(MIL)

1.ReadtheOperator’s

manual

2.Lock

127-0326

1.ReadtheOperator's

Manual.

2.Height-of-cut

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

performingmaintenance

orservicingthemachine.

126-4398

3.Unlock

131-4036

1.Maximumdrawbarpull36

kg(80lb)

2.ReadtheOperator's

Manual.

10

Page 11

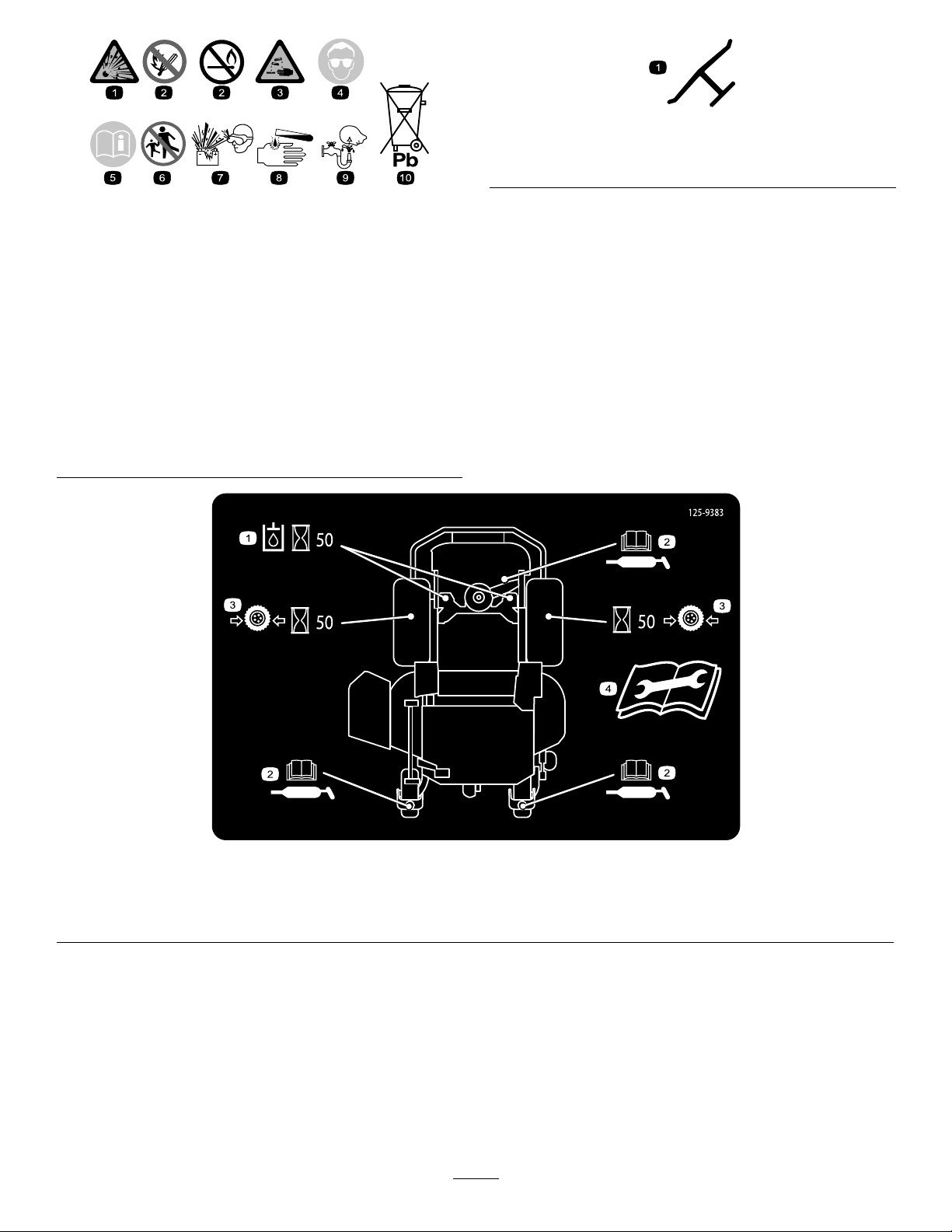

BatterySymbols

Someorallofthesesymbolsareonyourbattery

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

125–9383

1.Checkhydraulicoilevery50operatinghours.3.Checkthetirepressureevery50operatinghours.

2.ReadtheOperator’sManualforinformationonlubricating

themachine.

4.ReadtheOperator’sManualbeforeservicingorperforming

maintenance.

11

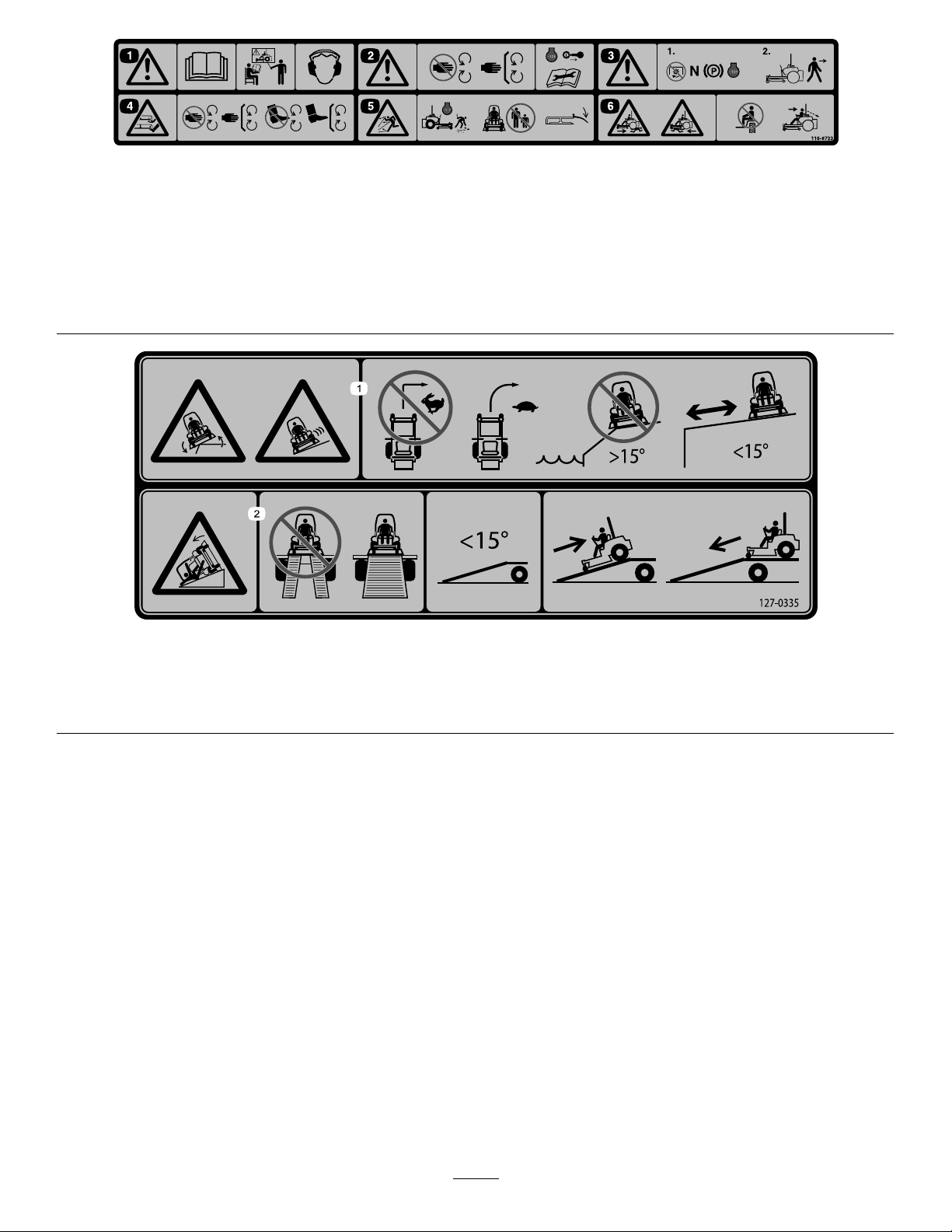

Page 12

116-8722

1.Warning-ReadtheOperator’sManual.DoNotoperatethis

machineunlessyouaretrained.Wearhearingprotection.

2.Warning-Stayawayfrommovingparts;keepallguards

inplace.Stopengineandremovekeybeforeadjusting,

servicing,orcleaning.

3.Warning-DisengagePTO,movedriveleversouttoneutral

lockposition,engageparkingbrake,andstopenginebefore

leavingtheoperator’sposition.

4.Cutting/dismembermentofhandorfoot-stayawayfrom

movingparts;keepallguardsandshieldsinplace.

5.Thrownobjecthazard-Pickupobjectsthatcouldbethrown

bymower.Donotoperatewhenpeopleandpetsareinthe

area.Keepdeectorinplace.

6.Crushing/dismembermenthazardofbystanders-donotcarry

passengers,lookforwardanddownwhenoperatingthe

machine,lookbehindanddownwhenreversing.

127–0335

1.Tippinghazardonslopes—donotmakesudden,tightturns;

makeslow,wideturns;donotuseonslopesnearopenwater;

donotusethismachineonslopesgreaterthan15degrees.

2.Ramphazard—whenloadingontoatrailer ,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15degrees;backupthe

ramp(inreverse)anddriveforwardofftheramp.

12

Page 13

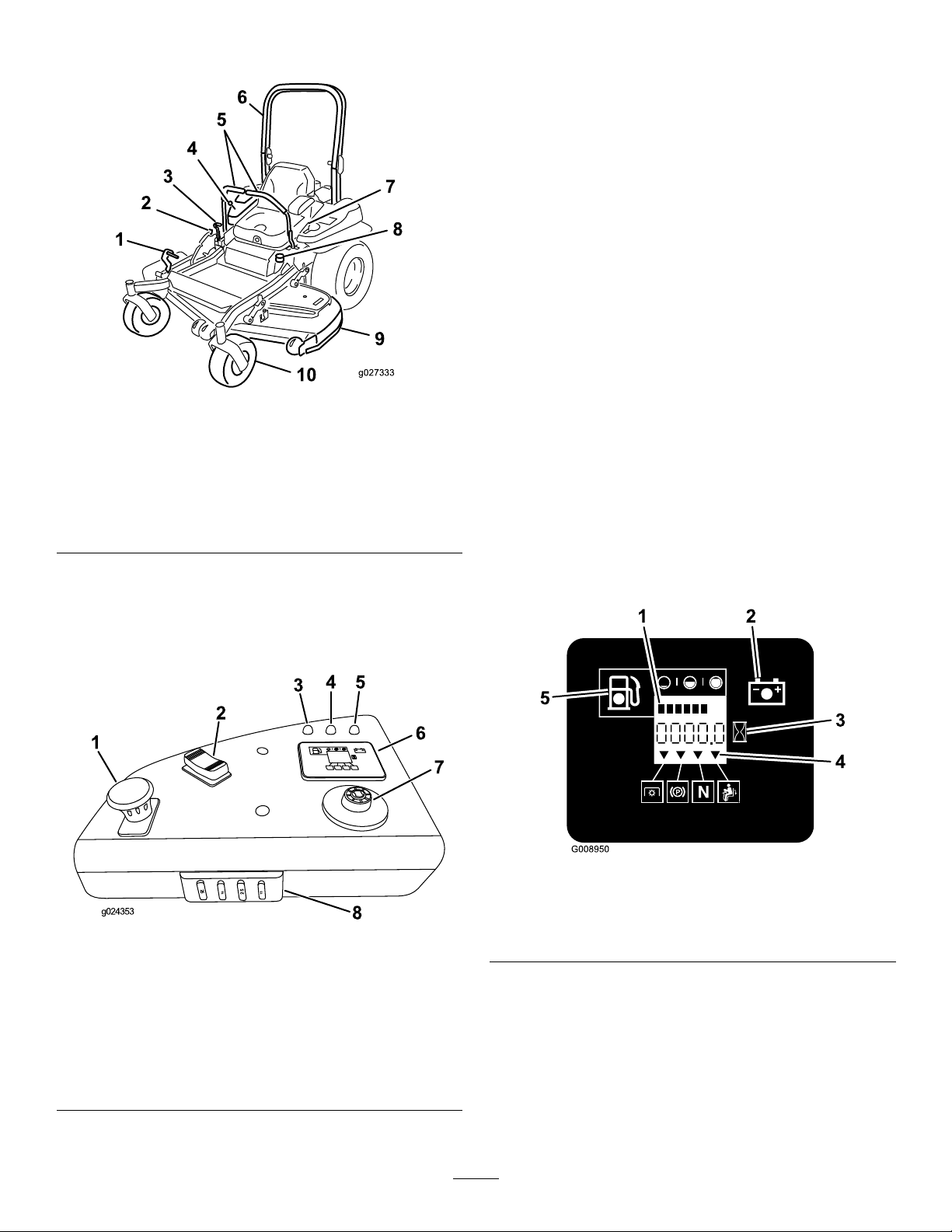

ProductOverview

g027333

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure6).

FuelGauge

Thefuelgaugeislocatedwiththehourmeter,andthebars

lightupwhentheignitionswitchisintheOnposition(Figure

6).

Theindicatorlightappearswhenthefuellevelislow

(approximatelyonegallonremaininginthefueltank).

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

Figure4

position(Figure6).

1.Height-of-cutdecklift

pedal

2.Transportlock

3.Parkingbrakelever8.Fuelcap

4.Controls

5.Motion-controllevers

6.Rollbar

7.Seatbelt

9.Mowerdeck

10.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

Battery-IndicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

6).

Figure6

Figure5

1.PTOswitch5.Malfunction-indicatorlight

2.Throttleswitch6.Hour

3.Highoil-temperature

indicator

4.Lowoil-pressureindicator8.Fuses

(MIL)

meter/Safety-interlock

display/Fuelgauge

7.Ignitionswitch

1.Fuelgauge(bars)4.Safety-interlocksymbols

2.Batterylight

3.Hourmeter

5.Lowfuel-indicatorlight

ThrottleControl

Thereare3speedpositions:maximumspeed,economy

speed,andlowspeed.

13

Page 14

Blade-ControlSwitch(PTO)

Low-OilPressureIndicatorLight

Theblade-controlswitch(PTO)isusedtoengagetheelectric

clutchanddrivethemowerblades.Pulltheswitchupto

engagethebladesandrelease.Todisengagetheblades,

pushtheblade-controlswitch(PTO)downormovea

motion-controlleverintotheneutral-lockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas3

positions:Start,Run,andOff.

Motion-ControlLevers

Themotion-controlleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

Neutral-LockPosition

Theneutral-lockpositionisusedwiththesafety-interlock

systemtoengageandtodetermineneutralposition.

Fuel-ShutoffValve

Closethefuel-shutoffvalve(undertheseat)when

transportingorstoringthemower.

Thisisthemiddlemalfunction-indicatorlight(Figure5).

Iftheengine-oilpressuredropsbelowasafelevel,thislight

illuminates,theengineautomaticallyreducestherpm,andthe

machinewillremaininasafemodeuntilthecorrectiveaction

istaken;refertoTroubleshooting(page66).

Electronic-ControlUnit

Malfunction-IndicatorLight

Theelectronic-controlunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunctionindicatorlight(MIL)isilluminated.

TheMILisfoundontherightsideofthecontrolpanel

(Figure5).

OncetheMILilluminates,initialtroubleshooting

checksshouldbemade.RefertotheMILsectionunder

Troubleshooting(page66).

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

Attachments/Accessories

High-OilTemperatureIndicatorLight

Thisisthemalfunction-indicatorlightfoundontheleftside

(Figure5).

Iftheengine-oiltemperaturerisesabovethesafelevel,

thelightilluminates,theengineautomaticallyreducesthe

rpm,andthemachinewillremaininasafemodeuntilthe

correctiveactionistaken;refertoTroubleshooting(page66).

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width:

60-inchDeck72-inchDeck

WithoutDeck

DeectorUp156.8cm(61.7

DeectorDown192.2cm(75.7

Length:

RollBar—Up

RollBar—Down

134.6cm(53.0

inches)

inches)

inches)

60-inchDeck72-inchDeck

211.1cm(83.1

inches)

215.4cm(84.8

inches)

150.1cm(59.1

inches)

187cm(73.6

inches)

222.4cm(87.6

inches)

218.7cm(86.1

inches)

223.0cm(87.8

inches)

Height:

14

Page 15

RollBar—UpRollBar—Down

179.1cm(70.5inches)118.9cm(46.8inches)

Weight:

ModelWeight

74963

74964

569kg(1255lb)

612kg(1350lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

15

Page 16

DANGER

G009189

Incertainconditionsduringfueling,static

electricitycancauseasparkwhichcanignitethe

gasolinevapors.Areorexplosionfromgasoline

canburnyouandothersandcandamageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandfueltheequipment

withthewheelsontheground.

Ifthisisnotpossible,thenfuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromagasoline-dispensernozzle.

•Ifagasolinedispensermustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

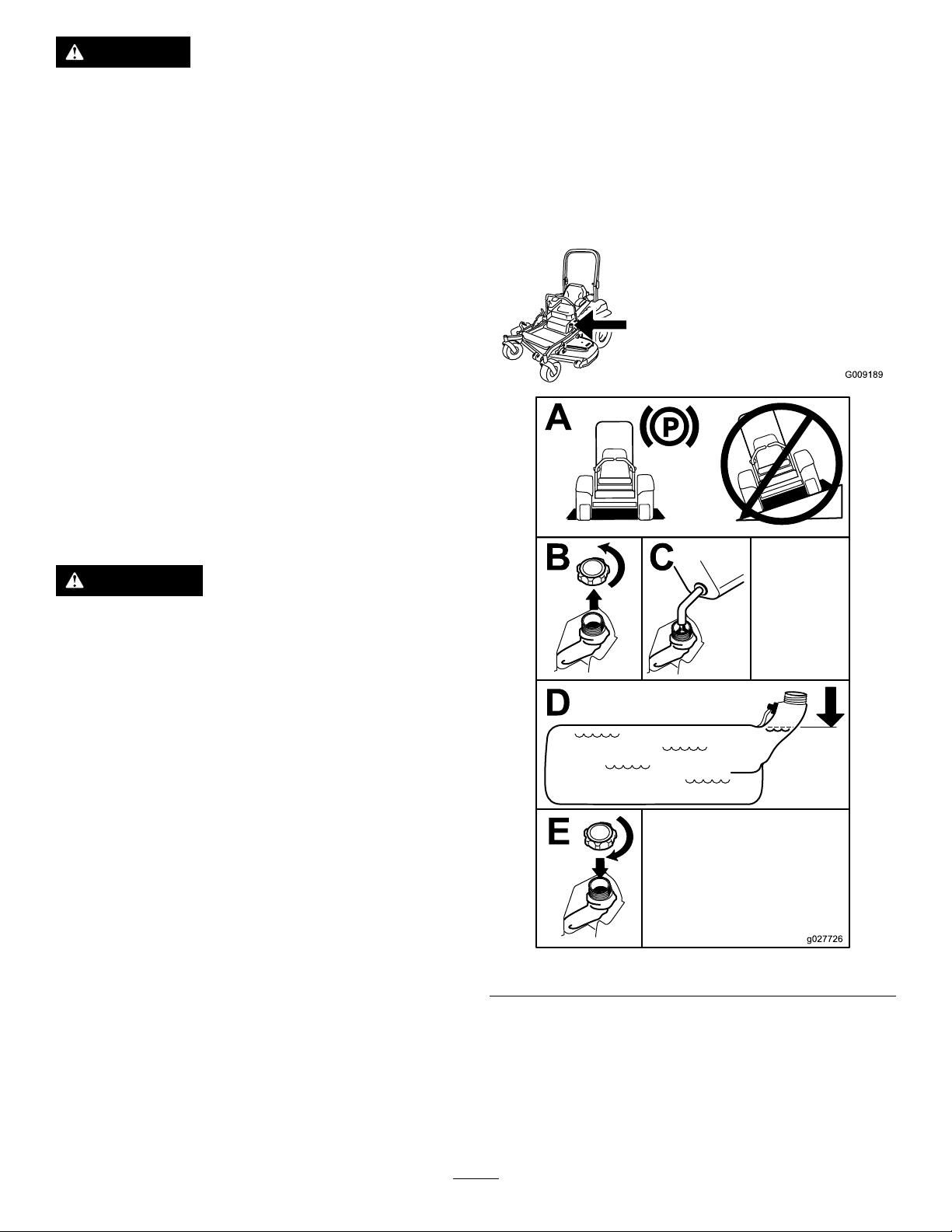

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcapandremoveit.Add

regularunleadedgasolinetothefueltankuntilthelevel

is6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsthe

gasolinetoexpand.Donotllthefueltankcompletely

full;referto(Figure7).

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorageof90daysorless.Ifyouarestoring

themachineforlonger,drainthefueltank;refertoServicing

theFuelTank(page42).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Figure7

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page36).

16

Page 17

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

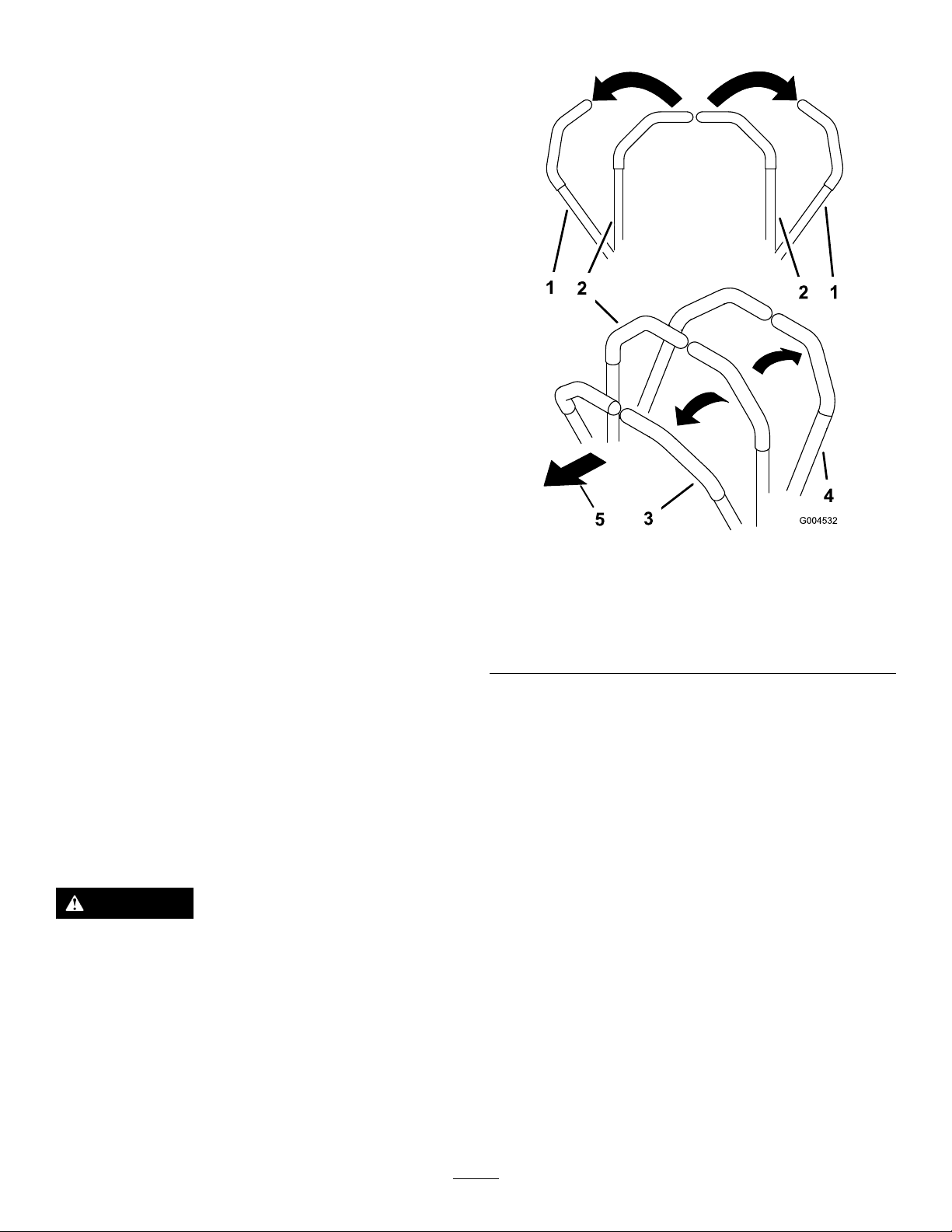

UsingtheRolloverProtection System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

1.Tolowertherollbar,applyforwardpressuretothe

upperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sothatthey

arenotengaged(Figure8).

3.Lowertherollbartothedownposition(Figure8).

Figure8

1.ROPSknob

2.PullROPSknoboutand

rotate90degrees

4.Toraisetherollbar,raisetherollbartotheoperate

position,rotatetheknobssothattheymovepartially

intothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswillsnap

intopositionwhentheholesalignwiththepins(Figure

8).Pushontherollbarandensurethatbothpinsare

engaged.

Important:Alwaysusetheseatbeltwiththeroll

barinthefullyraisedposition.

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

17

Page 18

ThinkSafetyFirst

G009027

1

2

g027334

CAUTION

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan15degrees.

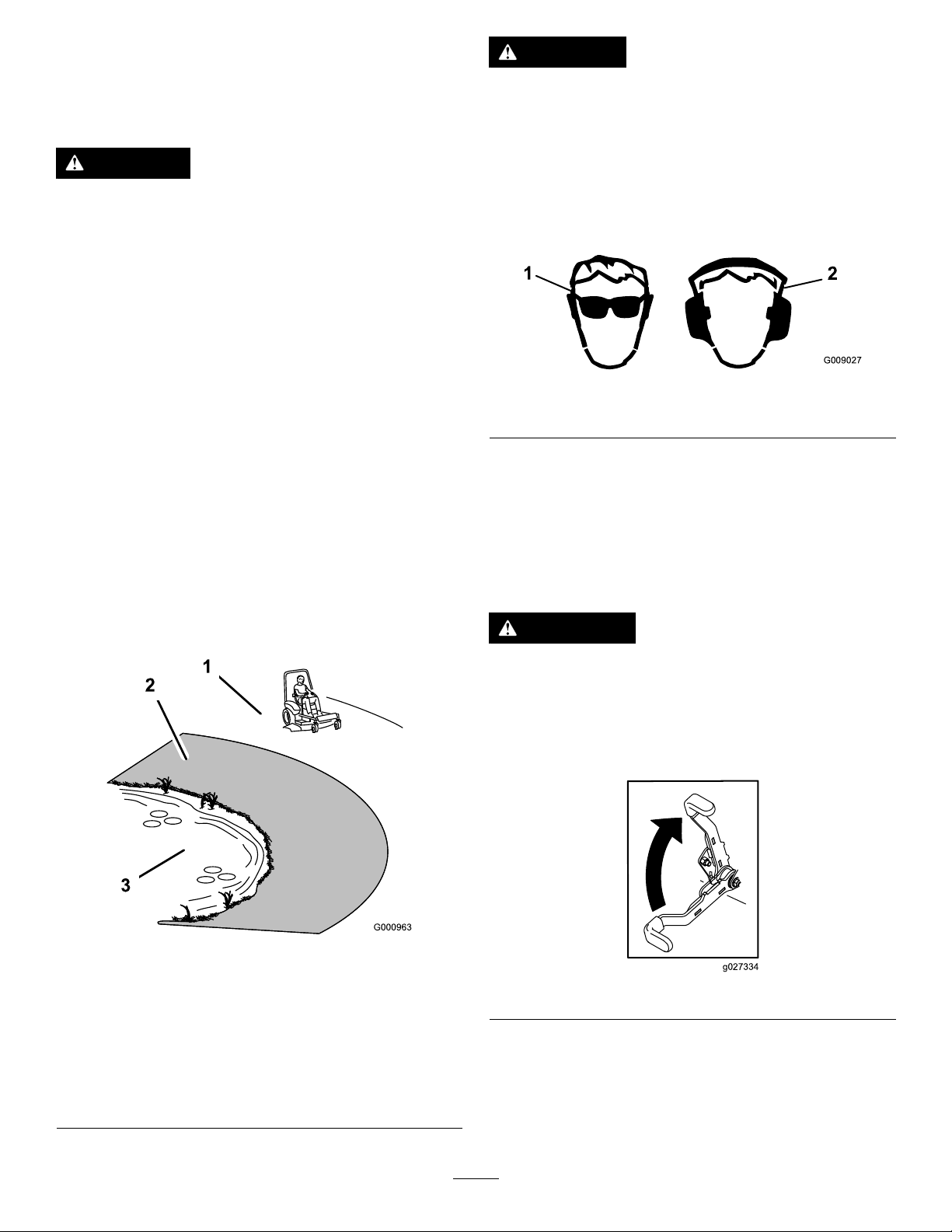

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure9

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.DangerZone-useawalk

behindmowerand/ora

handtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

SettingtheParkingBrake

WARNING

Theparkingbrakemaynotholdmachineparkedon

aslopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlessthewheelsare

chockedorblocked.

Figure11

18

Page 19

ReleasingtheParkingBrake

g027335

G008945

G009174

OperatingtheMower

Fromtheeconomyspeed(middle)position,pushdown

onthefrontoftheswitchtoplacethethrottleintothe

maximum-speedposition(Figure15).

Fromtheeconomyspeed(middle)position,pushdownon

thebackoftheswitchtoplacethethrottleintothelow-speed

position(Figure15).

Figure12

Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-ControlSwitch

(PTO)

Figure13

DisengagingtheBlade-ControlSwitch

(PTO)

Figure14

Figure15

1.Frontposition/Maximum

speed

2.Middleposition/Economy

speed

3.Rearposition/Lowspeed

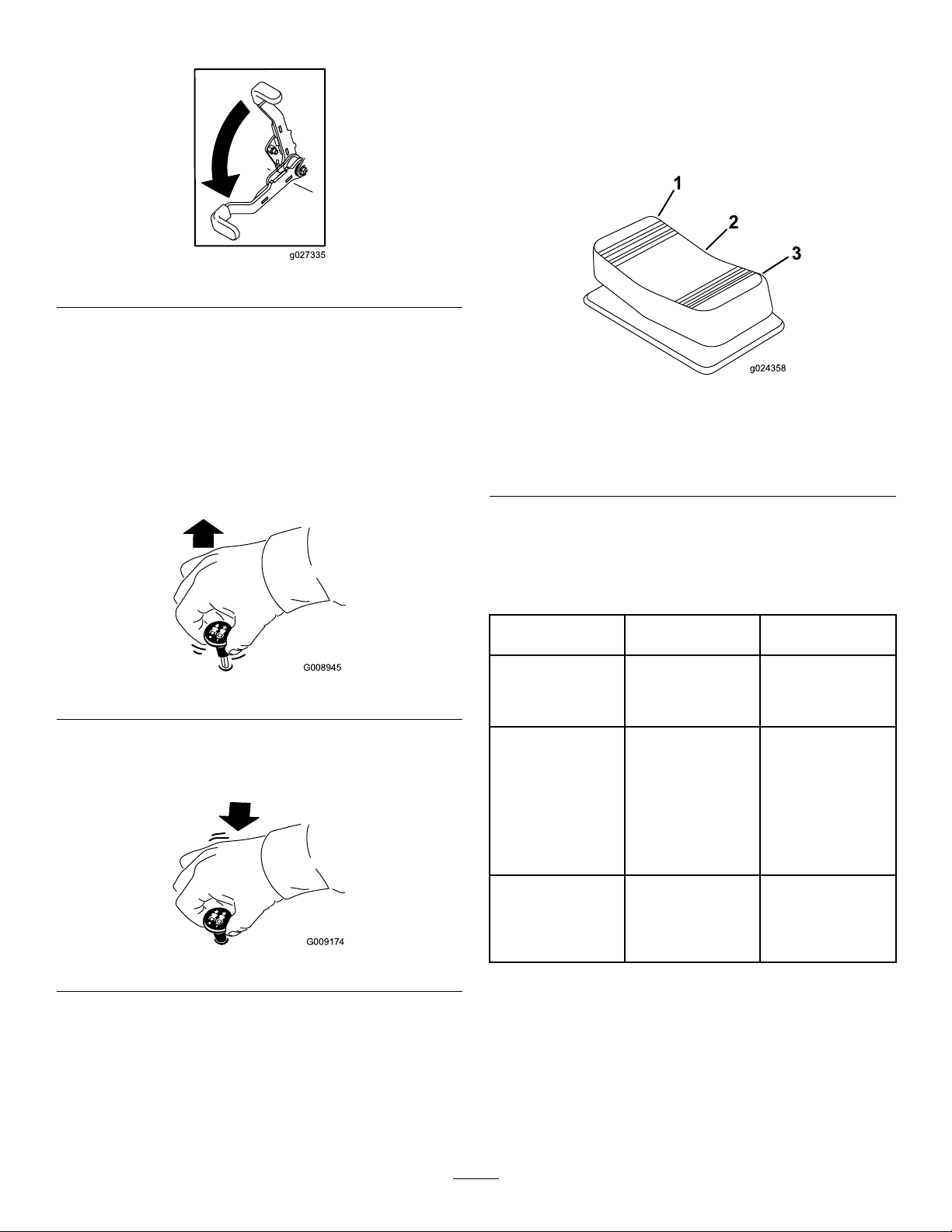

Positioningthethrottleswitchtomaximum,economy,or

lowallowsfor6differentoperationalmodes—3modeswith

thePTOdisengaged(transport)and3modeswiththePTO

engaged(mow).Seethefollowingtabletodeterminethe

appropriateenginespeed.

Throttle-Switch

Position

FrontpositionMaximumtransport

MiddlepositionMediumtransport

RearpositonLowtransport

PTODisengaged

(TransportMode)

speed/Highidle

speed/Clutch

engagement

speed/Lowidle

PTOEngaged

(MowMode)

Maximumthrottle

setting—maximum

powerforextreme

mowingconditions

Economythrottle

setting—standard

powerfornormal

mowingconditions.

Thisisthelowered

enginerpmand

isthemost

fuel-efcientmode

formowing.

Lowthrottle

setting—reduces

thedeckpacking

inwetmowing

conditions.

OperatingtheThrottlewith Horizon™Technology

Thereare3positionsthatthethrottleswitchcanoperate

at—maximumspeed,economyspeed,andlowspeed

(Figure15).

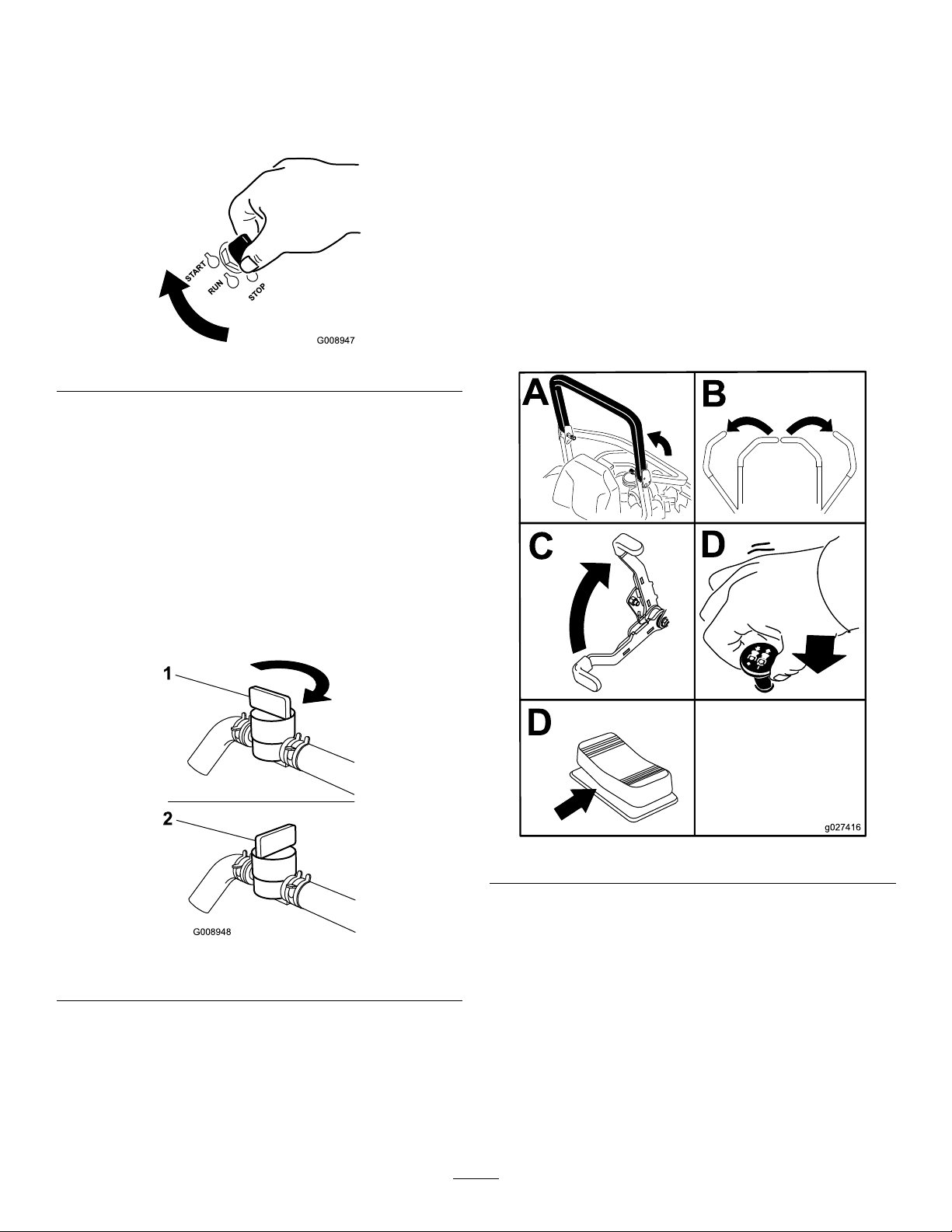

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition(Figure16).

Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

19

Page 20

attempts.Failuretofollowtheseinstructionscan

START

RUN

STOP

G008947

G008948

1

2

A

B

C

D

D

g027416

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelywithoutfuel.

Figure16

2.Tostoptheengine,turntheignitionkeytothestop

position.

UsingtheFuel-ShutoffValve

StartingandStoppingthe Engine

StartingtheEngine

1.RaisetheROPSupandlockintoplace,sitontheseat,

andfastentheseatbelt.

2.Movethemotioncontrolstoneutral-lockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake(page18).

4.Movetheblade-controlswitch(PTO)totheOff

position(Figure18).

5.Movethethrottleswitchtothemiddleposition

betweenthefrontandrearpositions.

Thefuel-shutoffvalveislocatedundertheseat.Movethe

seatforwardtoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,and

storage.

Ensurethatthefuel-shutoffvalveisopenwhenstartingthe

engine.

1.On2.Off

Figure17

Figure18

6.TurntheignitionkeytotheStartposition(Figure19).

Note:Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15-secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

20

Page 21

START

RUN

STOP

G008947

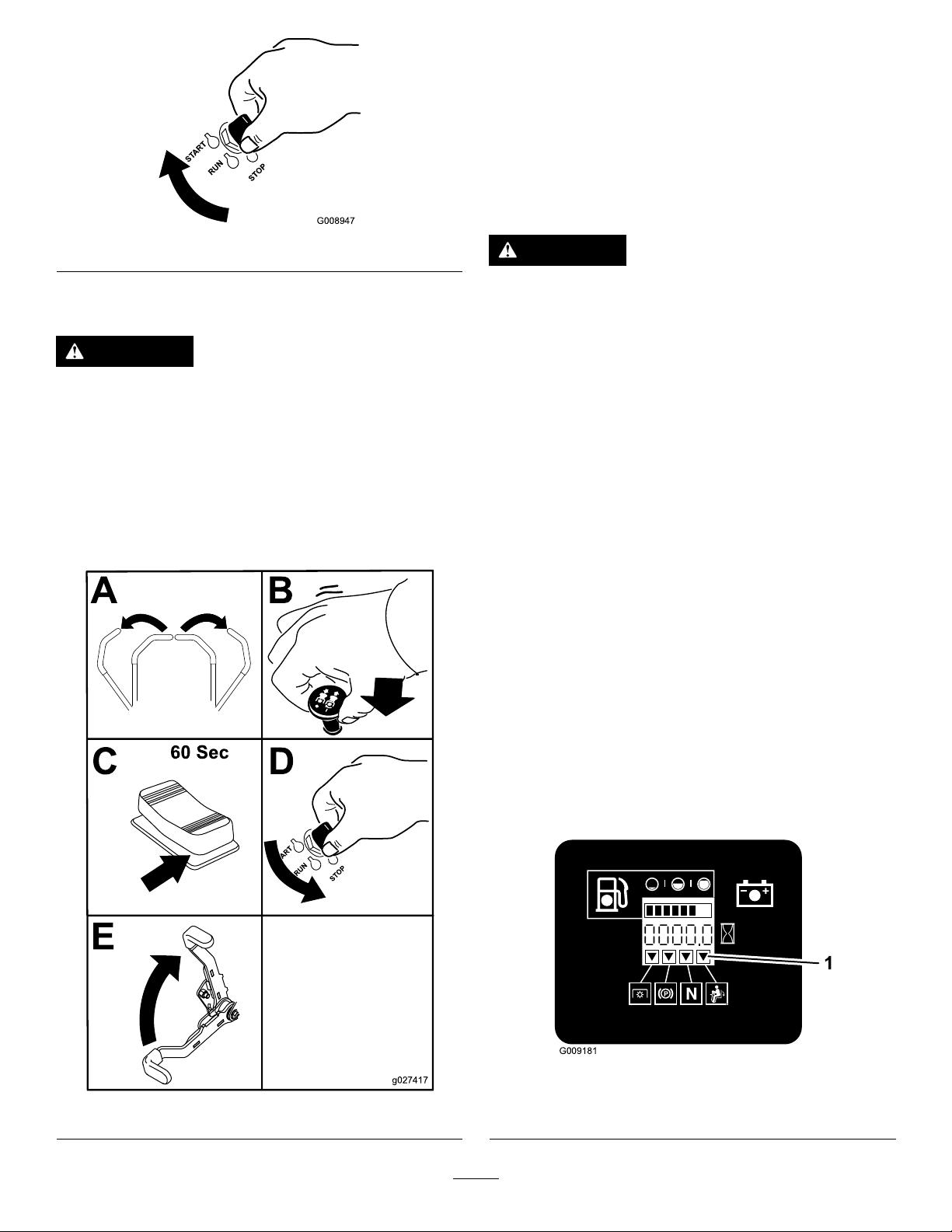

StoppingtheEngine

g027417

A B

C D

E

G009181

1

Important:Makesurethatthefuelshut-offvalveis

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesuretoremovethekeyasthefuel

pumpmayrunandcausethebatterytolosecharge.

UsingtheSafety-Interlock System

Figure19

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(intherearposition)for

60secondsbeforeturningtheignitionswitchoff.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheneutral-locked

position.

Thesafety-interlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthelocked

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllightup

inthecorrespondingsquare.

Figure20

Figure21

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

21

Page 22

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrakeandmove

theblade-controlswitch(PTO)totheOnposition.

Trystartingtheengine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

theblade-controlswitch(PTO)totheOffposition.

Moveeithermotion-controllever(outofneutrallocked

position).Trystartingtheengine;theengineshould

notcrank.Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,move

theblade-controlswitch(PTO)totheOffposition,

andmovethemotion-controlleverstoneutral-lock

position.Nowstarttheengine.Whiletheengine

isrunning,releasetheparkingbrake,engagethe

blade-controlswitch(PTO)andriseslightlyfromthe

seat;theengineshouldstop.

UsingtheMotion-ControlLevers

4.Sittingontheseat,engagetheparkingbrake,move

theblade-controlswitch(PTO)totheOffposition,

andmovethemotion-controlleverstoneutral-lock

position.Nowstarttheengine.Whiletheengine

isrunning,centereithermotioncontrolandmove

(forwardorreverse);theengineshouldstop.Repeat

forothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,move

theblade-controlswitch(PTO)totheOffposition,

andmovethemotion-controlleverstoneutral-lock

position.Trystartingtheengine;theengineshould

notcrank.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

Figure22

1.Motion-control

lever—neutral-lock

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForward

Note:Theenginewillkillifthetraction-controlleversare

movedwiththeparkingbrakeengaged.

Tostop,pullthemotion-controlleverstotheneutralposition.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page19).

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotion-controllevers

forward(Figure23).

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

22

Page 23

G008952

Figure23

G008953

thepowertakeoff(blade-controlswitch(PTO),andturnthe

ignitionkeytotheOffposition.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrake(page18).Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeight-of-Cut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwiththe

deck-liftpedal.Thereisalockpositionandaunlockposition

forthetransportposition.Thetransportlockisusedwith

thedeck-liftpedal(Figure25).

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(Figure24).

Figure24

StoppingtheMachine

Tostopthemachine,movethetraction-controlleversto

neutral,andthenmovethemtothelockedposition,disengage

23

Page 24

AdjustingtheHeight-of-CutPin

Theheight-of-cutisadjustedfrom25to140mm(1to

5-1/2inches)in6mm(1/4inch)incrementsbyrelocating

theclevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeck-liftpedalwithyourfoot,andraisethe

mowerdecktothetransportposition(alsothe140mm

(5-1/2inches)cuttingheightposition)asshownin

Figure26.

3.Toadjust,rotatethepin90degreesandremovethepin

fromtheheight-of-cutbracket(Figure26).

4.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesired,andinsertthepin(Figure

26).

5.Pushonthedecklift,pullbackonthetransportlock,

andslowlylowerthemowerdeck.

Figure25

Transport-LockPositions

1.Transportlock3.Unlockposition—doesnot

lockthemowerdeckinto

transportposition

2.Lockposition—mower

deckwilllockintotransport

position

Figure26

1.Deck-liftpedal

2.Cut-of-heightpin

3.Transportlock

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheightofcut,itisrecommendedto

adjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

24

Page 25

Figure27

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

AdjustingtheFlowBafeCam

Locks

Thisprocedureisapplicableonlytomachineswiththeow

bafelocks.Certainmodelswillhavenutsandboltsin-place

oftheowbafelocksandcanbeadjustedthesame.

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlocksandbafeto

givethebestqualityofcut.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthecamlocks,swingtheleveruptoloosen

thecamlock(Figure30).

4.Adjustthebafeandcamlocksintheslotstothe

desireddischargeow.

5.Swingtheleverbackovertotightenthebafeandcam

locks(Figure30).

6.Ifthecamlocksdonotlockthebafeintoplaceorit

istootight,loosentheleverandthenrotatethecam

lock.Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

Figure28

1.Anti-scalproller3.Flangenut

2.Bushing4.Bolt

Figure29

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

Figure30

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition.Thesuggesteduseforthis

positionisasfollows.

•Useforshort,lightgrass-mowingconditions.

•Useindryconditions.

25

Page 26

•Forsmallergrassclippings.

g019754

g019755

•Propelsgrassclippingsfartherawayfromthemower.

Figure31

PositionB

Usethispositionwhenbagging.Alwaysalignitwiththe

bloweropening.

Figure33

PositioningtheSeat

Theseatmovesforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Figure32

PositionC

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows.

•Useintall,densegrass-mowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

Toadjust,movetheleversidewaystounlocktheseat(Figure

34).

Figure34

UnlatchingtheSeat

•ThispositionissimilartothebenetsoftheToroSFS

mower.

Figure35

1.Seatlatch2.Seat

26

Page 27

ChangingtheSeatSuspension

g019768

1

g029142

Theseatisadjustabletoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Toadjustit,turntheknobinfronteitherdirectiontoprovide

thebestcomfort(Figure36).

Figure36

2.Rotatetherelease-valveleversverticallytopushthe

machine(Figure37).

Note:Thisallowshydraulicoiltobypassthepump

enablingthewheelstoturn.

3.Disengagetheparkingbrakebeforepushingthe

machine.

1.Seatsuspensionknob

UsingtheDrive-Wheel-Release Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheel-releasevalves.

WARNING

Theengineandhydraulic-driveunitscanbecome

veryhot.Touchingahotengineorhydraulic-drive

unitscancausesevereburns.

Allowtheengineandhydraulic-driveunitstocool

completelybeforeaccessingthedrive-wheel-release

valves.

Figure37

1.Verticaltopushthe

machine

4.Rotatetherelease-valvelevershorizontallytorunthe

machine(Figure37).

2.Horizontaltorunthe

machine

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

Thedrive-wheel-releasevalvesarelocatedinthebackofeach

hydraulic-driveunit,undertheseat.

Note:Makesurethereleasevalvesareinthefullyhorizontal

positionwhenoperatingthemachineorseveredamagetothe

hydraulicsystemcanoccur.

1.DisengagethePTO(blade-controlswitch)andturn

theignitionkeytotheOffposition,movetheleversto

neutral-lockedposition,applytheparkingbrake,and

removethekey.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(blade-controlswitch(PTO)totheoffposition,

rotatetheignitionkeytooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

27

Page 28

TransportingtheMachine

g029141

g028043

LoadingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow-moving

vehicleemblemisdangerousandcanleadto

accidentscausingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure38).

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backuprampsand

driveforwarddownramps(Figure39).

Figure39

1.Backupramps

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure40).Onat

ground,thisrequiresaramptobeatleastfourtimes(4X)as

longastheheightofthetrailerortruckbedtotheground.A

steeperanglemaycausemowercomponentstogetcaughtas

theunitmovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

loadingonornearaslope,positionthetrailerortrucksothat

itisonthedownsideoftheslopeandtherampextendsup

theslope.Thiswillminimizetherampangle.

2.Driveforwarddownramps

1.Tie-downloops

Figure38

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•EnsurethattheROPSisintheuppositionand

usetheseatbeltwhenloadingorunloadingthe

machine.EnsurethattheROPSwillclearthe

topofanenclosedtrailer.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethelengthoframpisatleastfourtimes

(4X)aslongastheheightofthetrailerortruck

bedtotheground.Thiswillensurethatramp

angledoesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

28

Page 29

g027996

5

1

2

6

Figure40

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleastfourtimes

(4X)aslongastheheight

ofthetrailerortruckbed

totheground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

29

Page 30

OperatingTips

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

sixinchestall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cutting1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

StoppingtheMachine

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeepingtheUndersideoftheMower

Clean

AlternatingtheMowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

AdjustingtheCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

30

Page 31

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

MaintenanceProcedure

•Checkthewheellugnuttorque.

•Checkthewheelhubslotted-nuttorque.

•Checktheparkingbrakeadjustment.

•Changethehydraulicltersandhydraulicoilwhenusinganytypeofoil.

•Checkthesafetysystem.

•Checktheengineoillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Checkandcleanthehydraulicunitshrouds.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethemowerdeckspindlesandidlerarm.

•Checksparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicoillevel.

•Lubricatethemowerdeckliftpivots.

•Changetheengineoil.(Itisrecommendedtochangetheoillterwhentheengine

oilischanged.)

•Checkandcleanenginecoolingnsandshrouds.

•Inspecttheprimarylterandair-inletscreen.

•Replacethefuellter(moreoftenindirtyordustyconditions).

Every200hours

Every250hours

Every300hours

Every500hours

Every600hours

Monthly

Yearly

Yearlyorbeforestorage

•Changetheengineoillter.

•ChangethehydraulicltersandhydraulicoilwhenusingMobil®1oil(moreoftenin

dirtyordustyconditions).

•Replacetheprimaryairlter(moreoftenindustyorsandyconditions).

•Checktheinner-airlter.

•Replaceandgapthesparkplugs.

•Checkthewheellugnuttorque.

•Checkthewheelhubslotted-nuttorque.

•Adjustthecasterpivotbearing.

•Checktheparkingbrakeadjustment.

•ChangethehydraulicltersandhydraulicoilwhenusingToro®HYPR-OIL™500

hydraulicoil(moreoftenindirtyordustyconditions).

•Replacetheinner-airlter.

•Checkthebattery .

•Greasethepumpbeltidlerarm.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Repackthefrontcasterwheelbearings(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

31

Page 32

CAUTION

G017028

G017050

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

LubricatingtheMachine

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy.

GreaseType:No.2general-purposelithium-basedor

molybdenum-basedgrease

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Figure42

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

AddingLightOilorSprayLubrication

ServiceInterval:Every100hours

Lubricatethedeckliftpivots.

GreasingtheMower

ServiceInterval:Every50hours—Greasethemowerdeck

spindlesandidlerarm.

Yearly—Greasethepumpbeltidlerarm.

Yearly—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Yearly—Repackthefrontcasterwheelbearings(more

oftenindirtyordustyconditions).

Important:Makesurethatthecuttingunitspindlesare

fullofgreaseweekly.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Greasethemowerdeckidlerpulleypivotuntilgrease

comeoutthebottom(Figure43).

4.Greasethe3spindlebearingsuntilgreasecomesout

thelowerseals(Figure43).

Figure41

32

Page 33

G009029

Figure43

g027339

5.Greasethedrivebeltidlerarm(Figure43).

Figure44

Figure45

6.Removethedustcapandadjustthecasterpivots.

Note:Keepthedustcapoffuntilgreasingiscomplete.

RefertoAdjustingtheCasterPivotBearing(page47).

7.Removethehexplugandthreadagreasettinginto

thehole.

8.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

9.Removethegreasettingfromthehole.

10.Installthehexpluganddustcap(Figure45).

33

Page 34

LubricatetheCasterWheel Hubs

13.Applyathreadlockingadhesivetothesecondspacer

nutandthreaditontotheaxlewiththewrenchats

facingoutward.

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey.Engagetheparkingbrake.

Figure46

1.Sealguard2.Spacernutwithwrench

ats

2.Raisethefrontofthemachineupandsupportitwith

jackstands.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub.

14.Torquethenutto8-9N-m(75-80in-lb),loosen,then

re-torqueto2-3N-m(20-25in-lb).

Note:Makesurethattheaxledoesnotextendbeyond

eithernut.

15.Installthesealguardsoverthewheelhubandinsert

thewheelintothecasterfork.Installthecasterbolt

andtightenthenutfully.

Important:T opreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecastertire.The

tireshouldnotspinfreely(morethan1or2revolutions)

orhaveanysideplay .Ifthewheelspinsfreely,adjustthe

torqueonthespacernutuntilthereisaslightamountof

drag.Applythreadlockingadhesive.

5.Remove1ofthespacernutsfromtheaxleassembly

inthecasterwheel.

Note:Notethatthreadlockingadhesivehasbeen

appliedtolockthespacernutstotheaxle.Remove

theaxle(withtheotherspacernutstillassembledtoit)

fromthewheelassembly.

6.Pryouttheseals,andinspectthebearingsforwearor

damageandreplaceifnecessary.

7.Packthebearingswithageneral-purposegrease.

8.Insert1bearingand1newsealintothewheel.

Note:Thesealsmustbereplaced.

9.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathreadlockingadhesiveto1

spacernutandthreaditontotheaxlewiththewrench

atsfacingoutward.

Note:Donotthreadthespacernutalloftheway

ontotheendoftheaxle.Leaveapproximately3mm

(1/8inch)fromtheoutersurfaceofthespacernutto

theendoftheaxleinsidethenut.

10.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

11.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

12.Insertthesecondbearingandnewsealintothewheel.

34

Page 35

EngineMaintenance

g029143

3

4

1

2

g029784

2

3

4

5

1

8.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure48).

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every300hours/Yearly(whichevercomes

rst)—Replacetheprimaryairlter(moreoftenin

dustyorsandyconditions).

Every300hours

Every600hours

Note:Checktheltersmorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Releasethelatchesontheaircleanerandpullthe

air-inletcoverofftheair-cleanerbody(Figure47).

4.Cleantheair-inletscreenandcover.

5.Installtheair-inletcoverandsecureitwiththelatches

(Figure47).

Note:Avoidknockingthelterintothesideofthe

body.

Figure48

1.Innerlter

2.Primarylter

3.Air-cleanercover

9.Removetheinnerlteronlyifyouintendtoreplaceit.

Note:Neverattempttocleantheinnerlter.Ifthe

innerlterisdirty,thentheprimarylterisdamaged;

replacebothlters.

10.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

Note:Anyholesinthelterwillappearasbright

spots.Ifthelterisdamaged,discardit.

4.Latch

5.Air-cleanerbody

Figure47

1.Air-inletcover3.Air-cleanerbody

2.Air-inletscreen4.Latch

6.Releasethelatchesontheaircleanerandpullthe

air-cleanercoverofftheair-cleanerbody(Figure48).

7.Cleantheinsideoftheair-cleanercoverwith

compressedair.

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,replaceit.

•Donotcleantheprimarylter.

ServicingtheInnerFilter

Replacetheinnerlter,nevercleanit.

Important:Neverattempttocleantheinnerlter.Ifthe

innerlterisdirty,thentheprimarylterisdamaged;

replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,alwaysoperate

theenginewithbothairltersandcoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Iftheinnerlterisbeingreplaced,carefullyslideitinto

thelterbody(Figure48).

35

Page 36

3.Carefullyinstalltheprimarylterovertheinnerlter

g029316

0

0

50

SAE 30

75

20W -50

(Figure48).

Note:Ensurethattheprimarylterisfullyseatedby

pushingonitsouterrimwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheaircleanercoverandsecurethelatches

(Figure48).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceclassSL,SM,SN,or

higher)

OilCapacity:withalterchange,2.56L(2.7USqt);withno

lterchange,2.37L(2.5USqt)

Viscosity:Seethetablebelow.

Figure49

Note:Changetheengineoilandoilltermorefrequently

whenoperatingconditionsareextremelydustyorsandy.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure50).

36

Page 37

g029145

B

A

C

D

E

g029321

F

G

H

ChangingtheEngineOil

g029145

ServiceInterval:Every100hours(Itisrecommendedto

changetheoillterwhentheengineoil

ischanged.)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylowerthan

thefronttoensurethattheoildrainscompletely.

2.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(Figure51).

Figure50

Figure51

37

Page 38

4.Ifdesired,replacetheoillter.

B

A

C

D

E

g029322

g029145

B

A

C D

E

F

3/4

g027477

5.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure52).

6.Starttheengineanddrivetoaatarea.Checktheoil

levelagain.

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page37).

2.Changetheengineoillter(Figure53).

Figure52

Figure53

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheEngineOil(page37).

38

Page 39

ServicingtheSparkPlugs

g029146

g029147

B

A

g027478

B

A

g027479

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)—Replaceandgapthesparkplugs.

Makesurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplugs.Usea

spark-plugwrenchforremovingandinstallingthesparkplugs

andagappingtool/feelergaugetocheckandadjusttheair

gap.Installnewsparkplugsifnecessary.

Type:Champion

AirGap:0.76mm(0.030inch)

RemovingtheSparkPlugs

1.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

2.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedpositionandsettheparkingbrake.

3.Removetheleft-handhydraulicunitshroudinthe

orderlistedwithFigure54.

®

RA8HCorequivalent

4.Removethesparkplugs.

Figure55

5.Installthelefthandhydraulicunitshroud(Figure54).

Note:Thisgivesyouaccesstothefrontsparkplug.

CheckingtheSparkPlugs

Important:Replacethesparkplugswhentheyhave:a

blackcoating,wornelectrodes,anoilylm,cracksor

reuseisquestionable.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meansthattheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

Figure56

InstallingtheSparkPlugs

1.Pullthistabouttothe

sideinthedirectionofthe

arrow.

2.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow.

Tightenthesparkplugsto24.4to29.8N-m(18to22ft.-lb).

Figure54

3.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow.

4.Shroud

39

Page 40

CheckSparkArrester(if equipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotfuelorruntheengineunlesssparkarrester

isinstalled.

Figure57

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakelooseparticlesoutofthearrester

andcleanscreenwithawirebrush(soakinsolventif

necessary).Reinstallarresteronexhaustoutlet.

40

Page 41

FuelSystem

B

A

C

D

g027753

Maintenance

WARNING

Fuelsystemcomponentsareunderhighpressure.

Theuseofimpropercomponentscanresultin

systemfailure,gasolineleakage,andpossible

explosion.

Useonlyapprovedfuellinesandfuellters.

ServicingtheElectronicFuel InjectionSystem

Thismachinecontainsanelectronicfuelinjectionsystem.It

controlsthefuelowunderdifferentoperatingconditions.

Theelectroniccontrolunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunctionindicatorlight(MIL)isilluminated.TheMILis

theredlightlocatedintherightconsolepanel.

OncetheMILilluminates,initialtroubleshooting

checksshouldbemade.RefertotheMILsectionunder

Troubleshooting.

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

ReplacingtheLow-Pressure FuelFilter

ServiceInterval:Every150hours(moreoftenindirtyor

dustyconditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

1.DisengagethePTO ,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Closethefuel-shutoffvalveundertheseat(Figure58).

Figure58

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure58).

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampscloseto

thelter(Figure58).

8.Openthefuel-shutoffvalve.

Note:Itisimportanttoinstallthefuellinehosesandsecure

themwithplastictiesthesameastheywereoriginallyinstalled

atthefactory,tokeepthefuellineawayfromcomponents

thatcouldcausefuellinedamage.

ServicingtheHigh-Pressure FuelFilter

Donotattempttoservicethehigh-pressurefuellter.The

high-pressurelterisintegratedwithinthefuelpumpmodule.

Thefuellterandothercomponentsinsidethefuelpump

modulearenotserviceable.Donotattempttoopenthefuel

pumpmodule.

EnsurethatanAuthorizedServiceDealerreplacesthefuel

pumpmodulewiththehigh-pressurefuellter.

41

Page 42

ServicingtheFuelTank

ElectricalSystem

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltank.

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygasestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygasestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

42

Page 43

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Firstdisconnectthenegativebatterycable(black)from