Page 1

FormNo.3375-659RevC

ZMaster

®

Commercial3000

SeriesRidingMower

with60inTURBOFORCE

Mower

ModelNo.74956—SerialNo.313000001andUp

®

SideDischarge

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3375-659*C

Page 2

WARNING

1

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedToroDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Note:ItisaviolationofCaliforniaPublicResource

CodeSection4442touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandwithout

asparkarrestermufermaintainedinworkingorder,or

theengineconstricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmayhave

similarlaws.

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

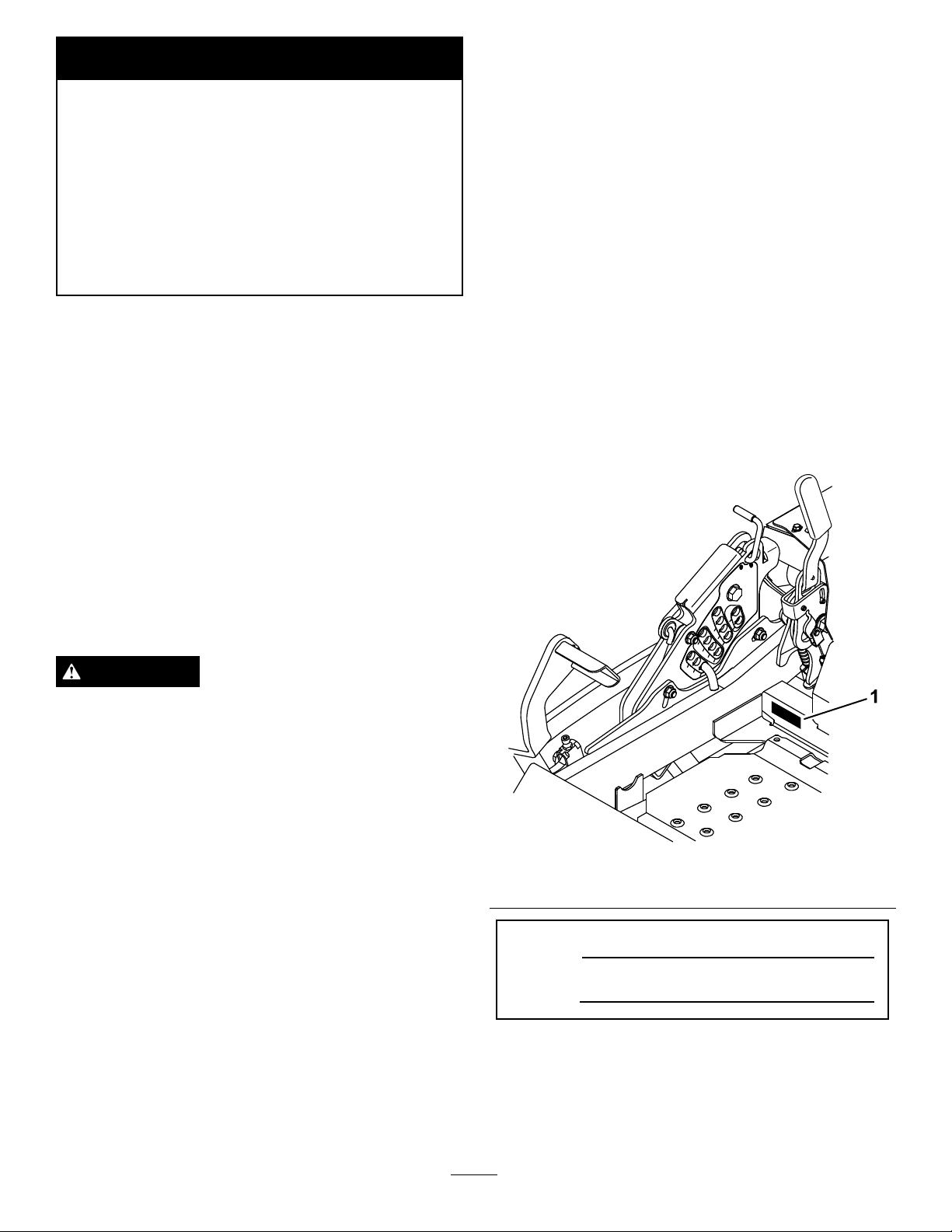

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalT oroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................11

Controls...............................................................11

Specications........................................................12

Operation....................................................................13

AddingFuel...........................................................13

CheckingtheEngineOilLevel.................................14

BreakingInaNewMachine.....................................14

UsingtheRolloverProtectionSystem(ROPS)............14

ThinkSafetyFirst...................................................15

OperatingtheParkingBrake....................................16

OperatingtheMowerBladeControlSwitch

(PTO)...............................................................16

OperatingtheThrottle............................................17

OperatingtheIgnitionSwitch..................................17

UsingtheFuelShut-OffValve..................................17

StartingandStoppingtheEngine..............................17

TheSafetyInterlockSystem.....................................19

DrivingForwardorBackward..................................19

StoppingtheMachine.............................................21

AdjustingtheHeightofCut.....................................21

AdjustingtheAnti-ScalpRollers...............................22

AdjustingtheFlowBafeCamLocks........................23

PositioningtheFlowBafe......................................23

PositioningtheSeat................................................24

UsingtheDriveWheelReleaseValves.......................24

UsingtheSideDischarge.........................................25

LoadingMachines..................................................25

TransportingMachines............................................26

OperatingTips......................................................27

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

Lubrication...............................................................29

GreasingandLubrication........................................29

WheretoGreasetheMower.....................................29

LubricatetheCasterWheelHubs..............................30

EngineMaintenance..................................................31

ServicingtheAirCleaner.........................................31

ServicingtheEngineOil..........................................32

ServicingtheSparkPlug..........................................35

CheckSparkArrester(ifequipped)............................36

FuelSystemMaintenance...........................................37

ServicingtheElectronicFuelInjection

System..............................................................37

ReplacingtheLowPressureFuelFilter......................37

ServicingtheHighPressureFuelFilter......................37

ServicingtheFuelTank...........................................37

ElectricalSystemMaintenance....................................38

ServicingtheBattery...............................................38

ServicingtheFuses.................................................40

DriveSystemMaintenance.........................................40

CheckingtheSeatBelt.............................................40

CheckingtheRolloverProtectionSystem(ROPS)

Knobs...............................................................40

AdjustingtheTracking............................................41

CheckingtheTirePressure......................................41

CheckingtheWheelLugNuts..................................42

CheckingtheWheelHubSlottedNut........................42

AdjustingtheCasterPivotBearing............................42

UsingtheClutchShim............................................43

CoolingSystemMaintenance......................................44

CleaningtheEngineScreenandEngineOil

Cooler...............................................................44

CleaningtheEngineCoolingFinsand

Shrouds.............................................................44

CheckandCleantheHydraulicUnits.........................45

BrakeMaintenance....................................................46

AdjustingtheParkingBrake.....................................46

BeltMaintenance......................................................47

InspectingtheBelts................................................47

ReplacingtheMowerBelt........................................47

ReplacingtheHydraulicPumpDriveBelt...................48

ControlsSystemMaintenance.....................................49

AdjustingtheControlHandlePosition......................49

AdjustingtheMotionControlLinkage......................49

AdjustingtheMotionControlDamper......................50

AdjustingtheMotionControlNeutralLock

Pivot.................................................................50

HydraulicSystemMaintenance....................................51

ServicingtheHydraulicSystem.................................51

MowerDeckMaintenance...........................................53

LevelingtheMowerDeck........................................53

ServicingtheCuttingBlades.....................................55

RemovingtheMowerDeck.....................................57

ReplacingtheGrassDeector..................................58

Cleaning...................................................................58

CleaningUndertheMower......................................58

WasteDisposal.......................................................58

Storage........................................................................59

CleaningandStorage..............................................59

Troubleshooting...........................................................60

Schematics...................................................................63

3

Page 4

Safety

Improperuseormaintenancecanresultininjury.T oreduce

thepotentialforinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalertsymbol,which

meansCAUTION,WARNING,orDANGER-“personal

safetyinstruction."Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

touserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Iftheoperator(s)ormechanic(s)cannotreadEnglishitis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.

•Slowdownanduseextracareonhillsides,whenmaking

turns,whencrossingroadsandsidewalks,andwhen

changingdirectionsonslopes.Besuretotravelsideto

sideonhillsides.Turfconditionscanaffectthemachine's

stability.Usecautionwhileoperatingneardrop-offs.Stop

bladesifnotmowing.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engageparking

brake(ifprovided),shutoffenginebeforeleavingthe

operator'spositionforanyreasonincludingemptyingthe

catchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Safehandlingoffuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

4

Page 5

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Maintenanceandstorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.W aitforall

movementtostopbeforeadjusting,cleaningorrepairing.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.Never

allowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminalrst

andthepositivelast.Reconnectthepositiverstand

negativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

5

Page 6

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

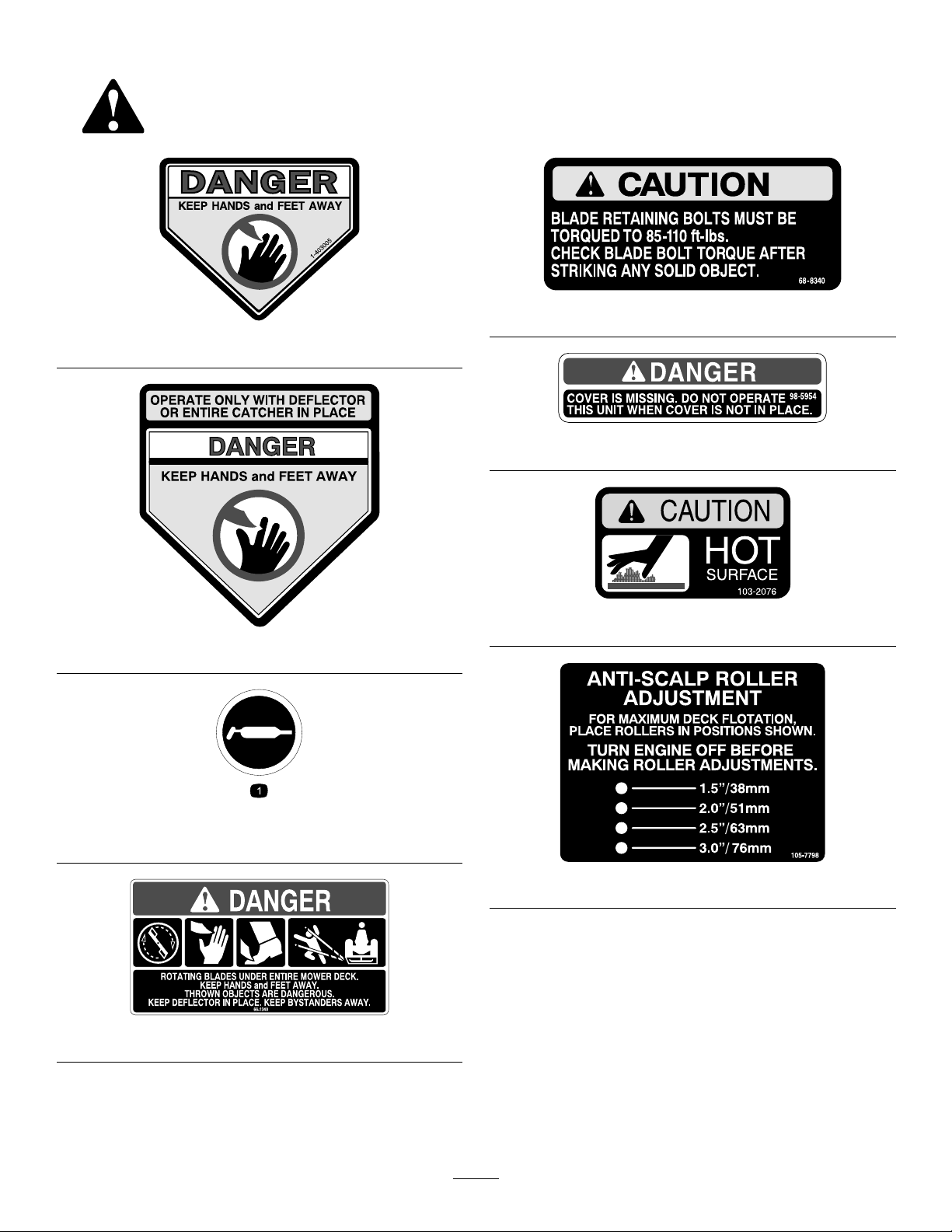

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1-403005

68-8340

98-5954

103-2076

54-9220

58-6520

1.Grease

105-7798

66-1340

7

Page 8

110-2067

110-2068

1.ReadtheOperator'sManual.

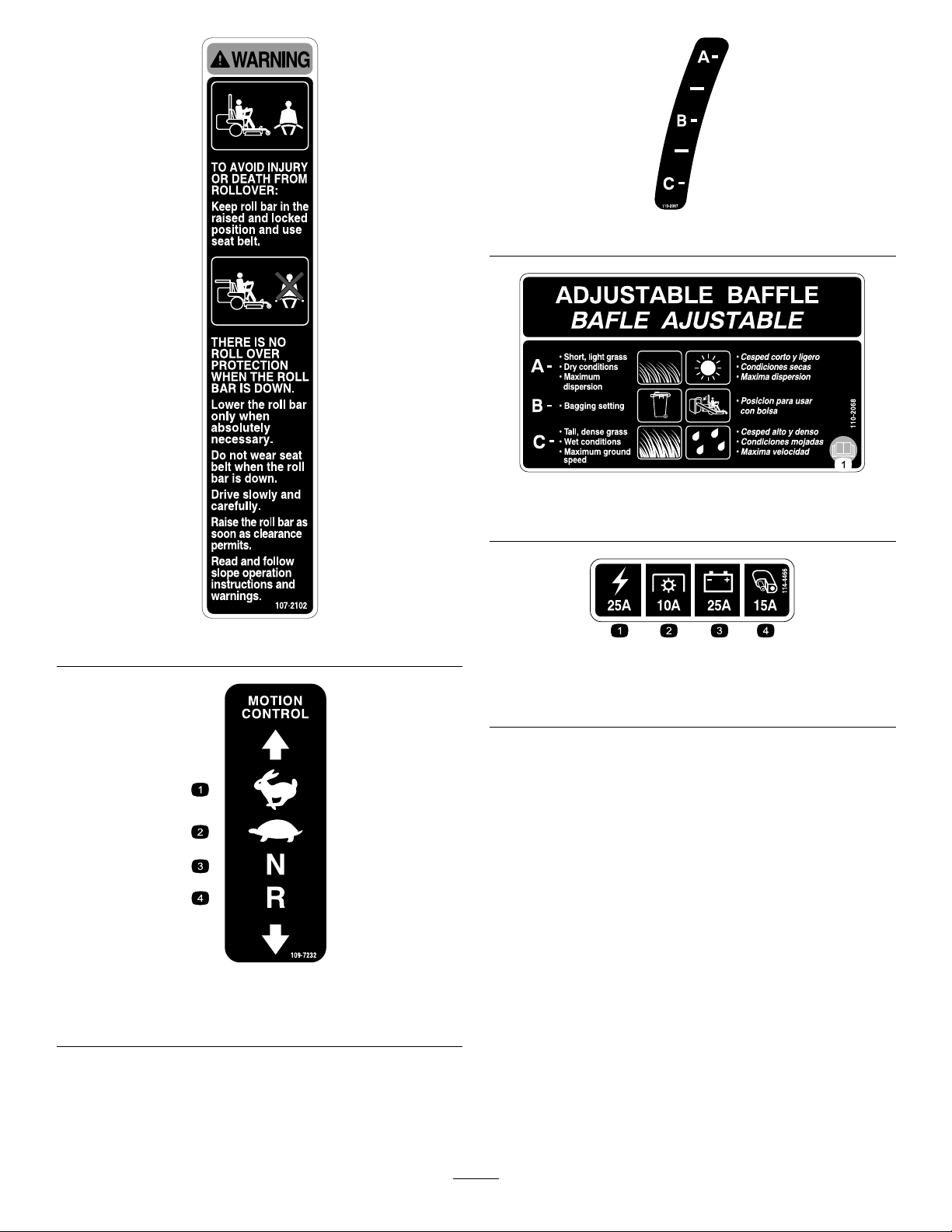

107-2102

114-4466

109-7232

1.Fast3.Neutral

2.Slow

1.Main,25A

2.PTO,10A

4.Reverse

3.Charge,25A

4.Auxiliary,15A

8

Page 9

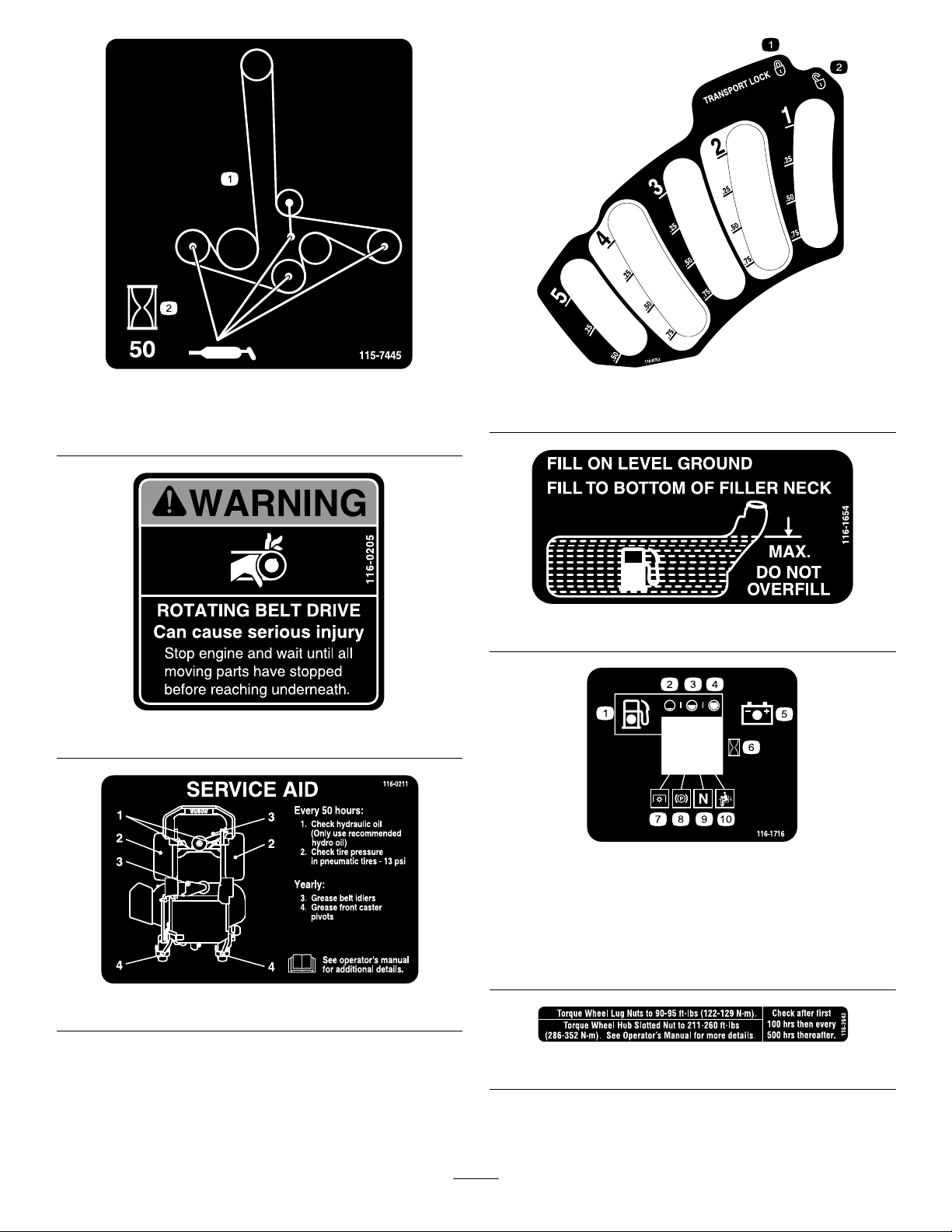

115-7445

116-0752

1.Greasepulleysandspindles

2.Maintenanceinterval—50hours

1.Latch2.Unlatch

116-1654

116-0205

116-1716

116-0211

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

116-2643

9

7.PTO

8.Parkingbrake

10.Operatorpresenceswitch

Page 10

121–7586

1.Fast

116-3303

2.Variablespeedcontrol

3.Slow

4.Powertake-off(PTO)

BatterySymbols

Someorallofthesesymbolsareonyourbattery

116-4858

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

116-5944

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

109-7069

10

Page 11

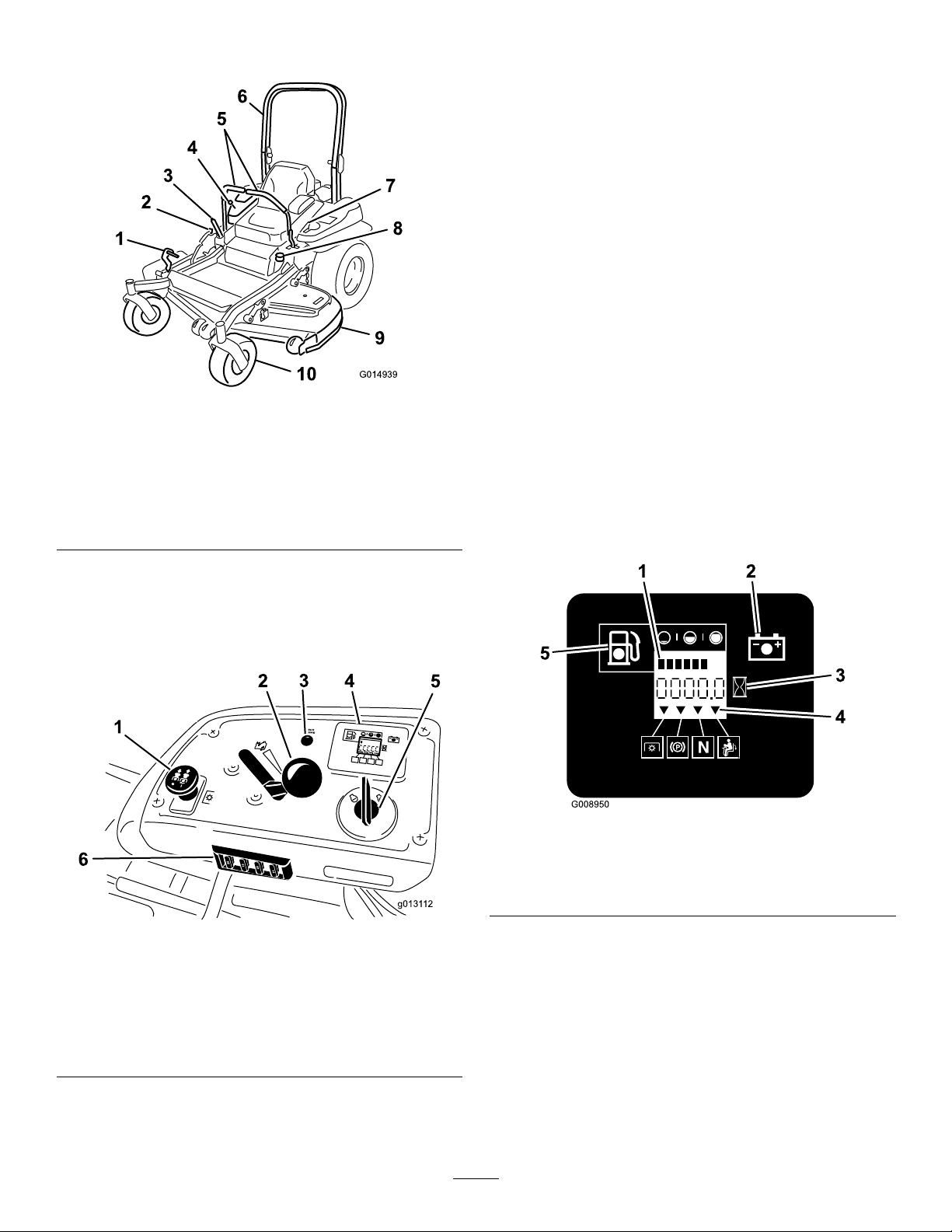

ProductOverview

G014939

g0131 12

1

2

3

4

5

6

25

25

10

15

C

H

ECK

ENG

IN

E

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure6).

FuelGauge

Thefuelgaugeislocatedwiththehourmeterandthebars

lightupwhentheignitionswitchison(Figure6).

Theindicatorlightappearswhenthefuellevelislow

(approximatelyonegallonremaininginthefueltank).

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandtheindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

position(Figure6).

Figure4

1.Height-of-cutdecklift

pedal

2.Transportlock

3.Parkingbrakelever8.Fuelcap

4.Controls

5.Motioncontrollevers

6.Rollbar

7.Seatbelt

9.Mowerdeck

10.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

BatteryIndicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

6).

Figure6

1.Fuelgauge(bars)4.Safetyinterlocksymbols

2.Batterylight

3.Hourmeter

5.Lowfuelindicatorlight

Figure5

1.PTOSwitch4.Hourmeter/Safety

2.Throttlecontrol5.Ignitionswitch

3.Malfunctionindicatorlight

(MIL)

interlockdisplay/Fuel

gauge

6.Fuses

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengagetheelectric

clutchanddrivethemowerblades.Pulltheswitchupto

engagethebladesandrelease.Todisengagetheblades,push

thebladecontrolswitch(PTO)downormoveamotion

controlleverintotheneutrallockposition.

11

Page 12

IgnitionSwitch

Length:

Thisswitchisusedtostartthemowerengineandhas3

positions:Start,RunandOff.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemtoengageandtodetermineneutralposition.

FuelShut-offValve

Closethefuelshut-offvalve(undertheseat)when

transportingorstoringthemower.

ElectronicControlUnitMalfunction

IndicatorLight

Theelectroniccontrolunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

60inchDeck

RollBar-Up

RollBar-Down

211.1cm(83.1inches)

215.4cm(84.8inches)

Height:

RollBar-UpRollBar-Down

179.1cm(70.5inches)118.9cm(46.8inches)

Weight:

ModelWeight

74956

532kg(1172lbs)

Ifaproblemorfaultwithinthesystemisdetected,the

malfunctionindicatorlight(MIL)isilluminated.

TheMIListheredlightlocatedintherightconsolepanel.

OncetheMILilluminates,initialtroubleshooting

checksshouldbemade.RefertotheMILsectionunder

Toubleshooting.

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width:

60inchDeck

WithoutDeck

DeectorUp156.8cm(61.7inches)

DeectorDown192.2cm(75.7inches)

134.6cm(53.0inches)

12

Page 13

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoorsonlevelground,in

anopenarea,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Fill

thefueltanktothebottomofthellerneck.

Theemptyspaceinthetankallowsgasolineto

expand.Overllingmayresultinfuelleakage

ordamagetotheengineoremissionsystem(if

equipped).

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

13

Page 14

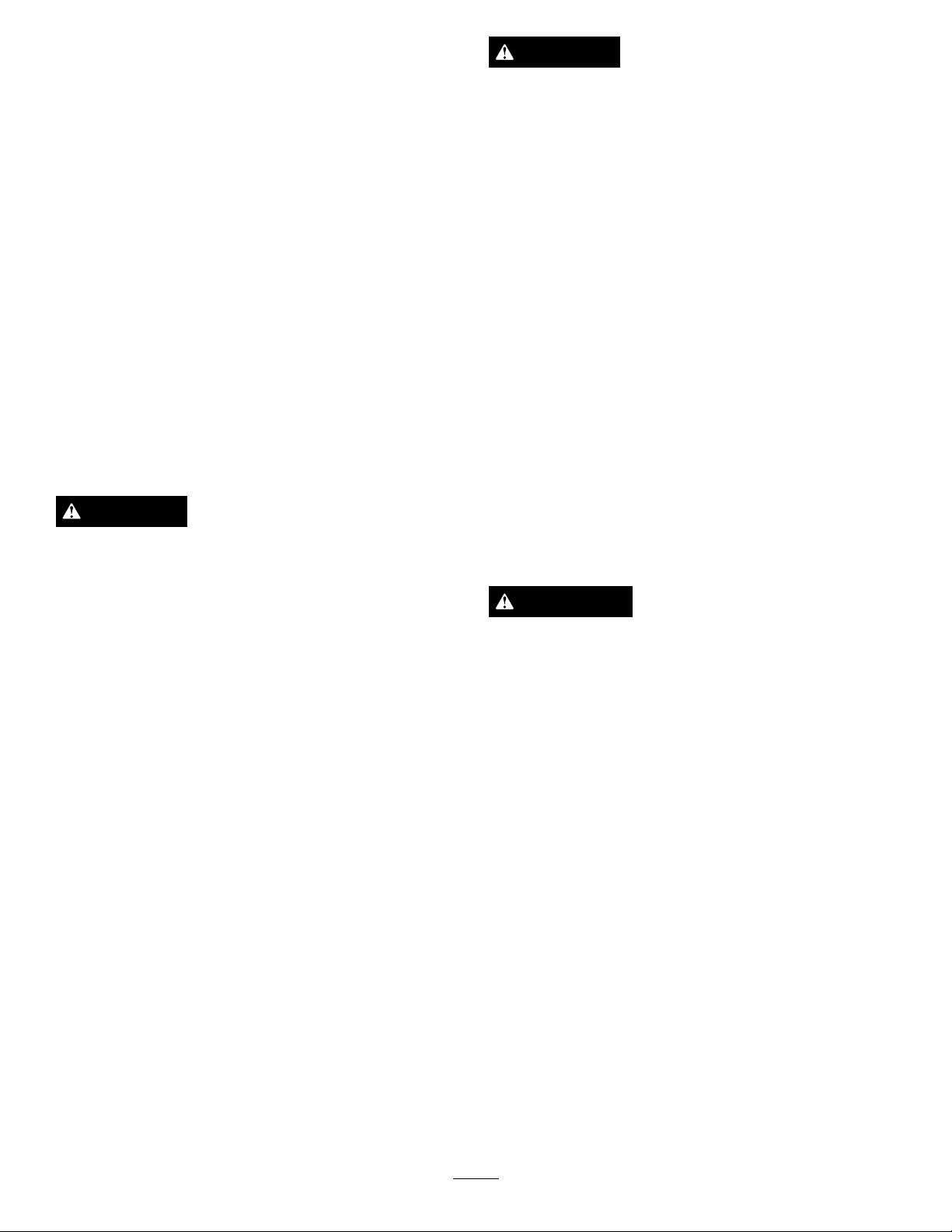

FillingtheFuelTank

G009189

G012429

1

2

4

3

5

Note:Donotllthefueltankcompletelyfull.Fillthefuel

tanktothebottomofthellerneck.Theemptyspaceinthe

tankallowsthegasolinetoexpand.

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefueltankcap.

4.Fillthefueltanktothebottomofthellerneck.

Ensurethereisemptyspaceinthetanktoallowthe

gasolinetoexpand(

Figure7).

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

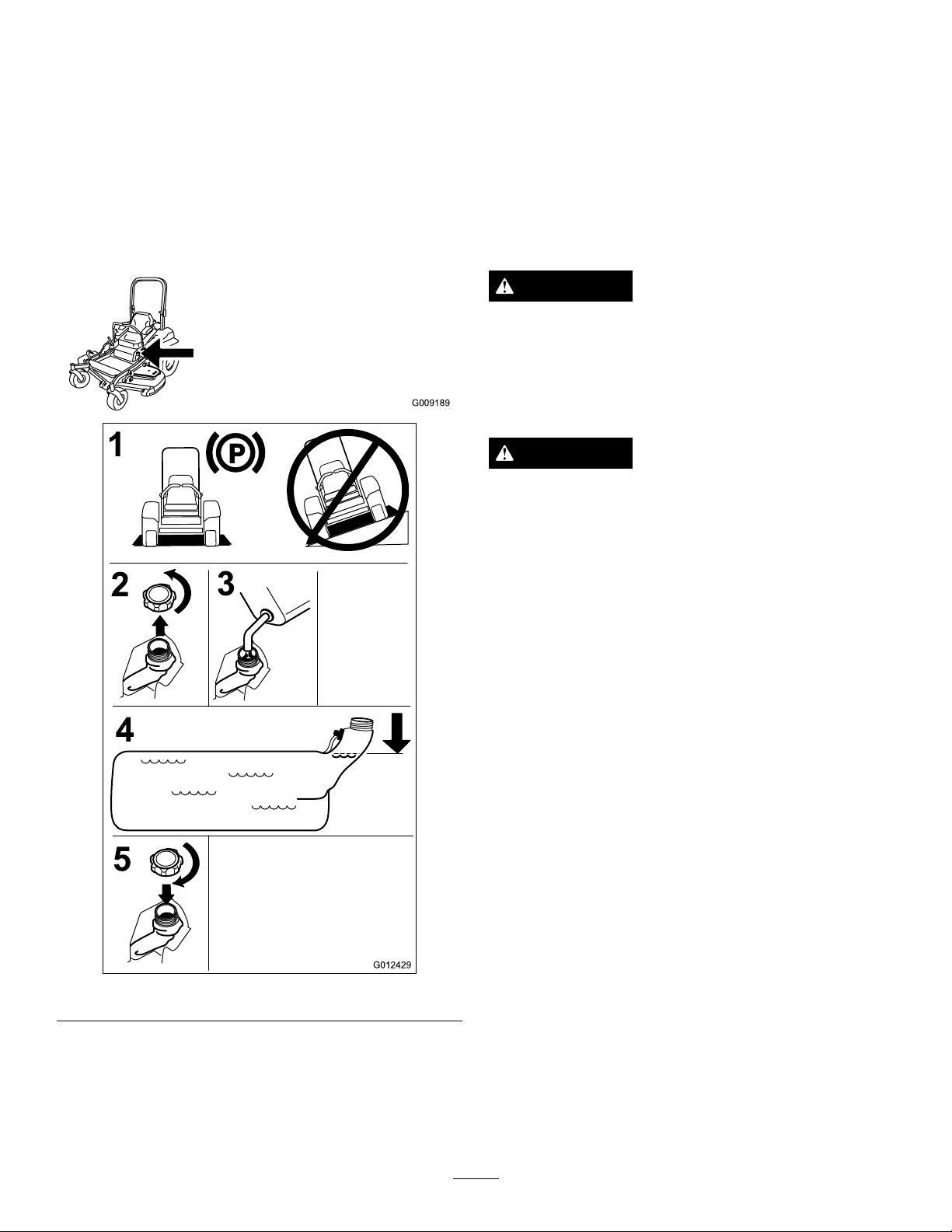

UsingtheRolloverProtection System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensuretheseatissecuredtothemachine.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

Important:Ensuretheseatissecuredtothemachine.

1.Tolowertherollbar,applyforwardpressuretothe

upperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sotheyare

notengaged(Figure8).

3.Lowertherollbartothedownposition(Figure8).

Figure7

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine

OilLevel.

14

Page 15

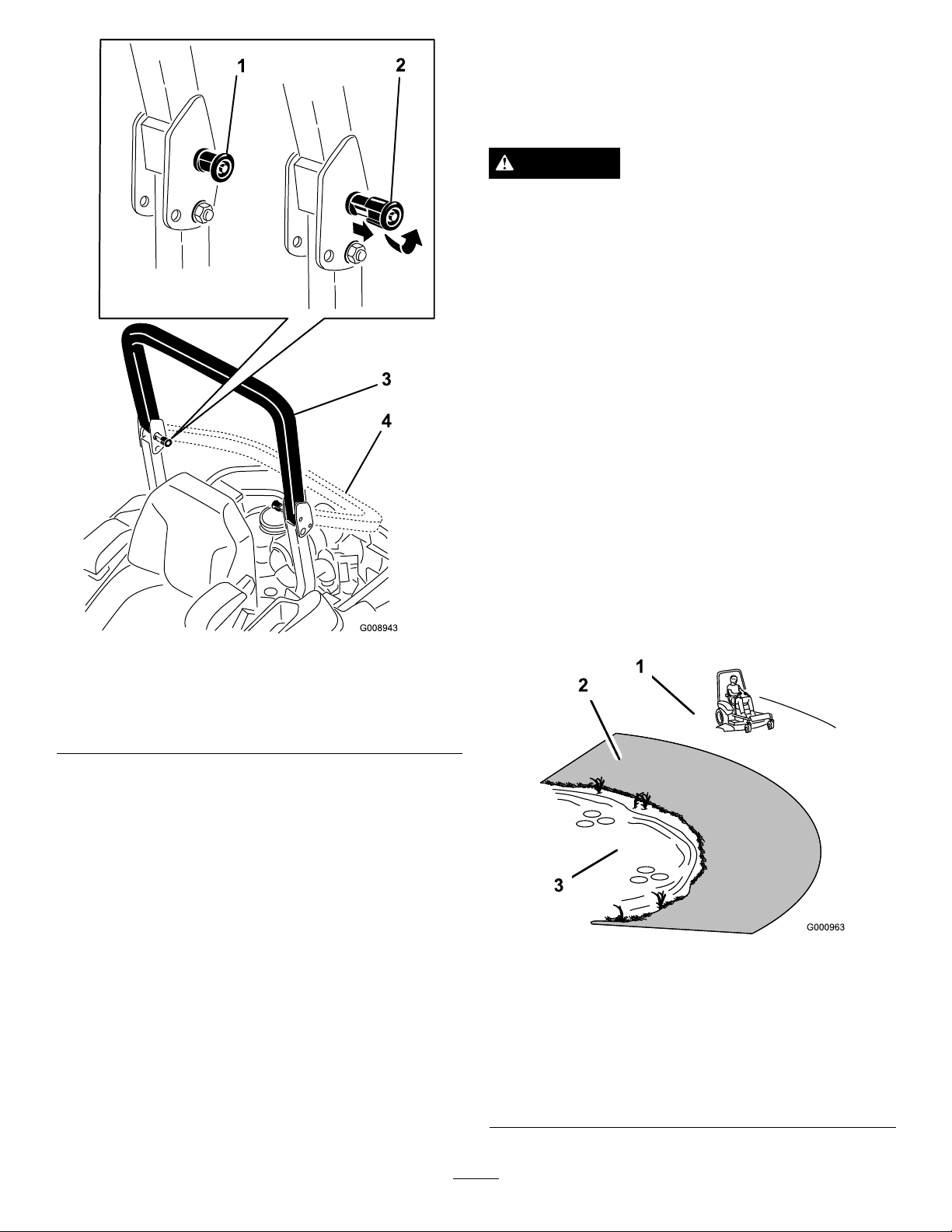

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

Figure8

1.ROPSknob

2.PullROPSknoboutand

rotate90degrees

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

4.Toraisetherollbar,raisetherollbartotheoperate

position,rotatetheknobssotheymovepartiallyinto

thegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswillsnap

intopositionwhentheholesalignwiththepins(Figure

8).Pushontherollbarandensurethatbothpinsare

engaged.

Important:Alwaysusetheseatbeltwiththeroll

barinthefullyraisedposition.

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure9

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.DangerZone-useawalk

behindmowerand/ora

handtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

15

Page 16

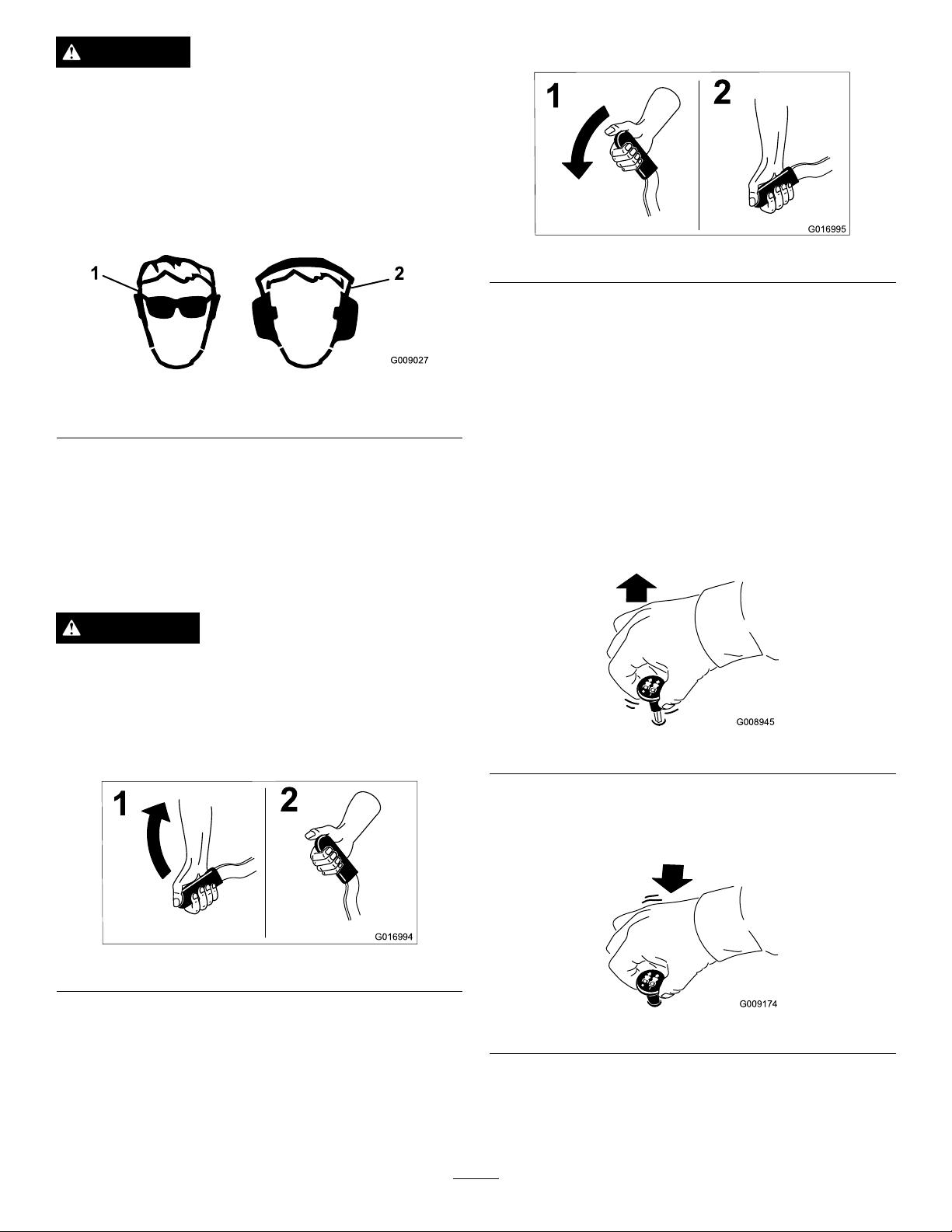

CAUTION

G009027

1

2

G016994

1

2

G016995

1

2

G008945

G009174

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feetandhead

isrecommended.

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

OperatingtheParkingBrake

ReleasingtheParkingBrake

Figure12

OperatingtheMowerBlade ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

WARNING

Parkingbrakemaynotholdmachineparkedona

slopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlesswheelsarechocked

orblocked

Figure11

Note:Engagingthebladecontrolswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

Figure13

DisengagingtheBladeControlSwitch

(PTO)

Figure14

16

Page 17

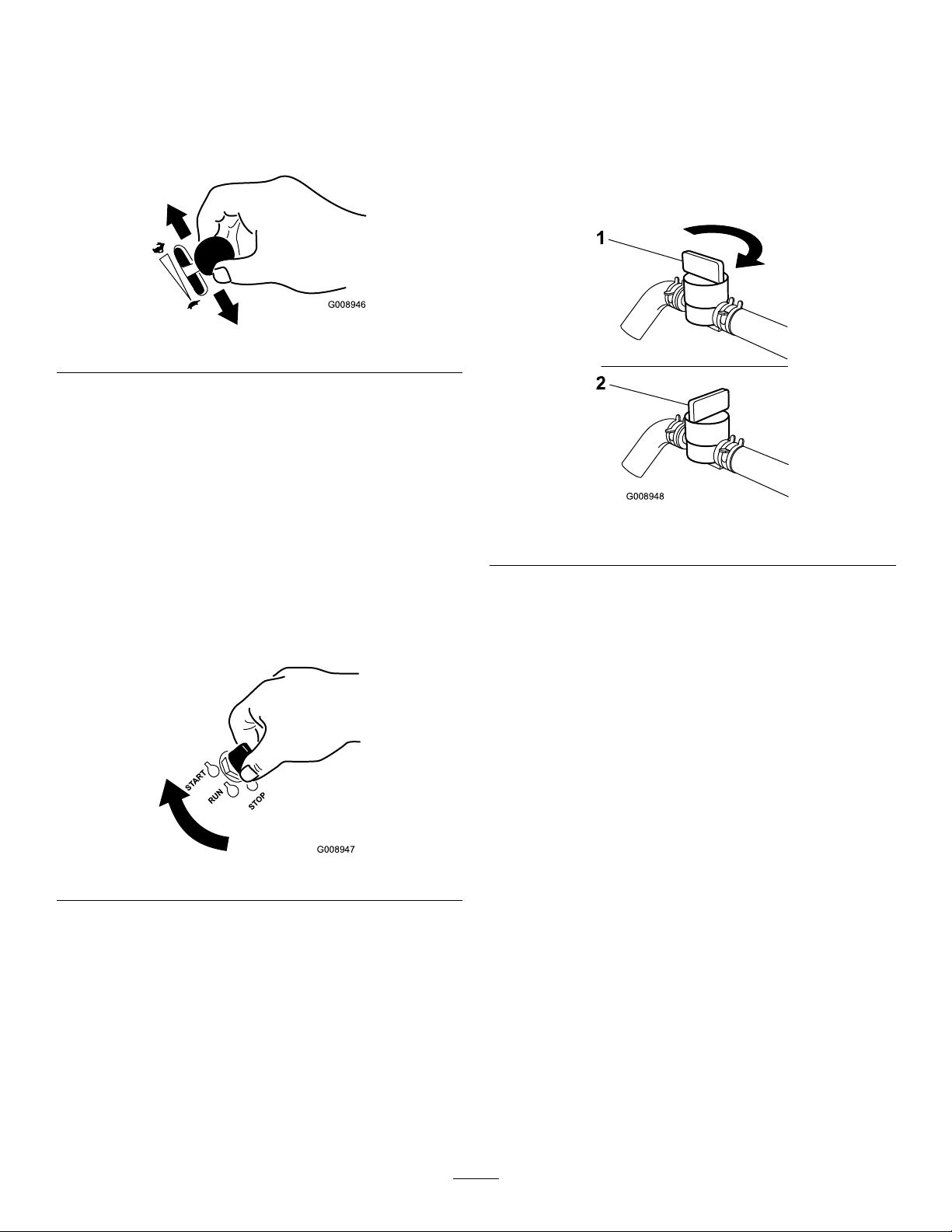

OperatingtheThrottle

G008946

START

RUN

STOP

G008947

G008948

1

2

UsingtheFuelShut-OffValve

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure15).

Alwaysusethefastpositionwhenturningonthemowerdeck

withthebladecontrolswitch(PTO).

Figure15

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition(Figure16).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Thefuelshut-offvalveislocatedundertheseat.Movethe

seatforwardtoaccessit.

Closethefuelshut-offvalvefortransport,maintenance,and

storage.

Ensurethefuelshut-offvalveisopenwhenstartingthe

engine.

Figure17

1.On2.Off

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

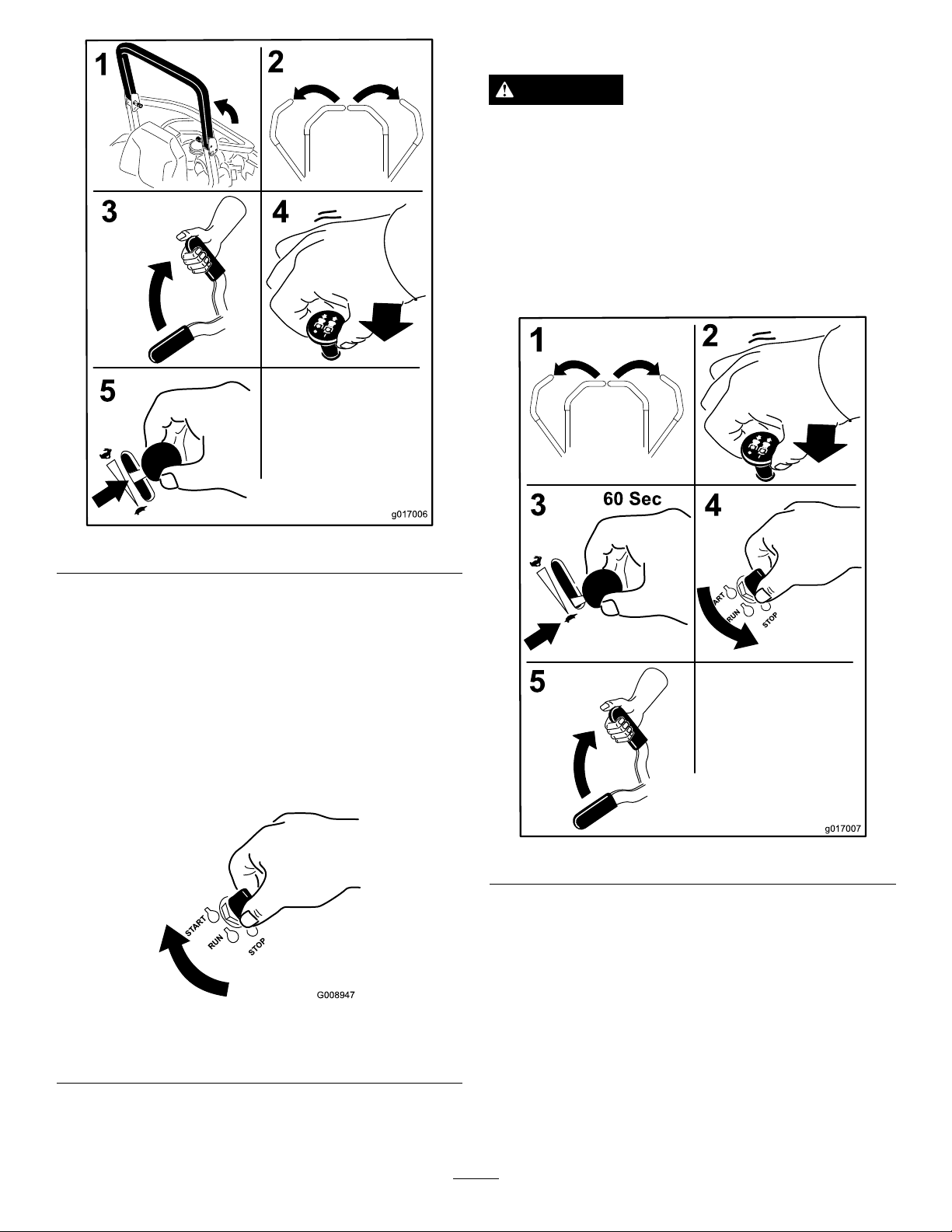

StartingandStoppingthe Engine

StartingtheEngine

1.RaisetheROPSupandlockintoplace,sitontheseat

andfastentheseatbelt.

2.Movethemotioncontrolstoneutrallockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.Movethebladecontrolswitch(PTO)totheOff

Figure16

2.Turntheignitionkeytostoptostoptheengine.

position(Figure18).

5.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

17

Page 18

g017006

START

RUN

STOP

G008947

StoppingtheEngine

g017007

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

Figure18

6.TurntheignitionkeytotheStartposition(Figure16).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure19

Figure20

Important:Makesurethatthefuelshutoffvalveis

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesuretoremovethekeyasthefuel

pumpmayrunandcausethebatterytolosecharge.

1.Off3.Start

2.Run

18

Page 19

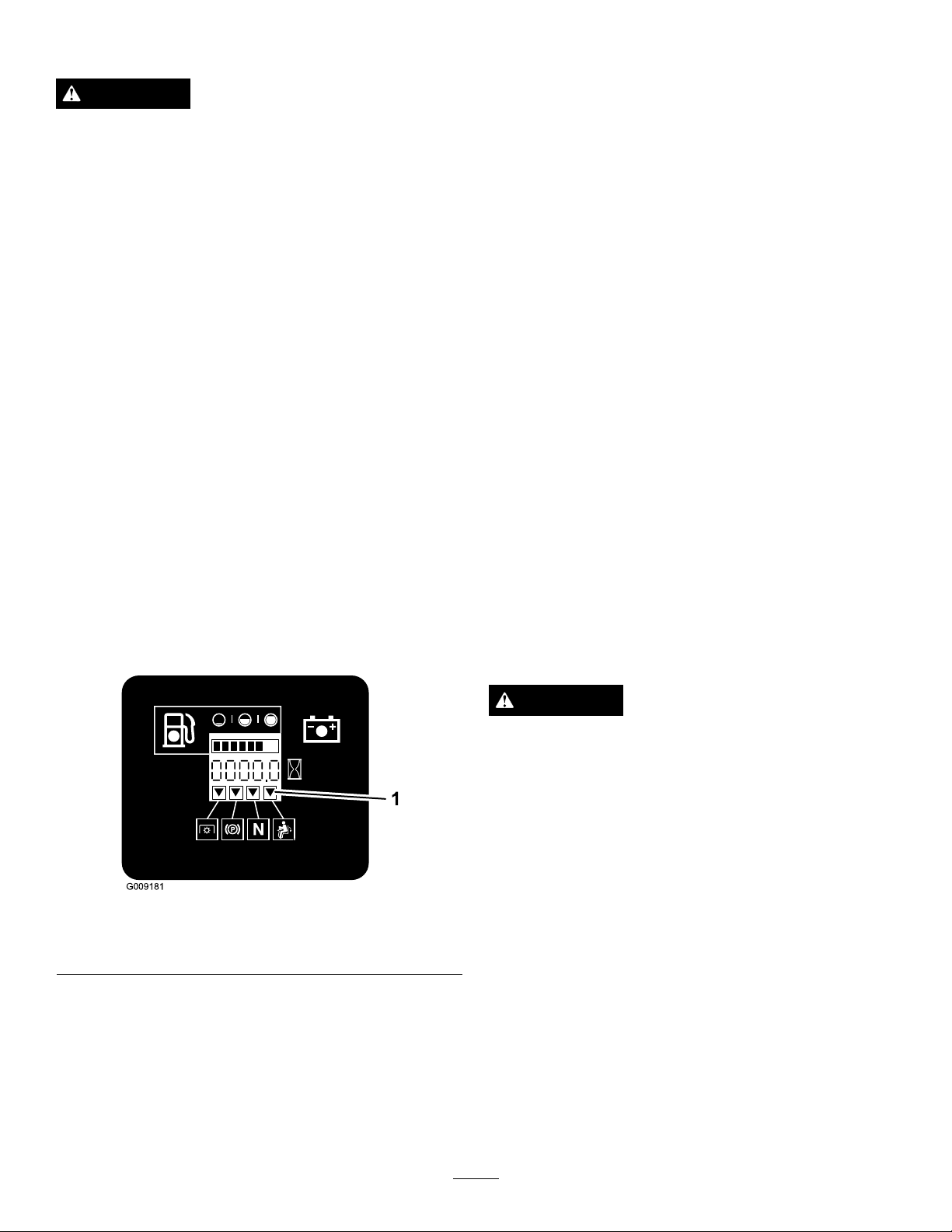

TheSafetyInterlockSystem

G009181

1

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Thebladecontrolswitch(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthelocked

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllightup

inthecorrespondingsquare.

1.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)toon.Trystartingthe

engine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)tooff.Moveeither

motioncontrollever(outofneutrallockedposition).

Trystartingtheengine;theengineshouldnotcrank.

Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,releasetheparking

brake,engagethebladecontrolswitch(PTO)andrise

slightlyfromtheseat;theengineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,centereither

motioncontrolandmove(forwardorreverse);the

engineshouldstop.Repeatforothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,move

thebladecontrolswitch(PTO)tooffandmovethe

motioncontrolleverstoneutrallockposition.Try

startingtheengine;theengineshouldnotcrank.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

Figure21

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

19

Page 20

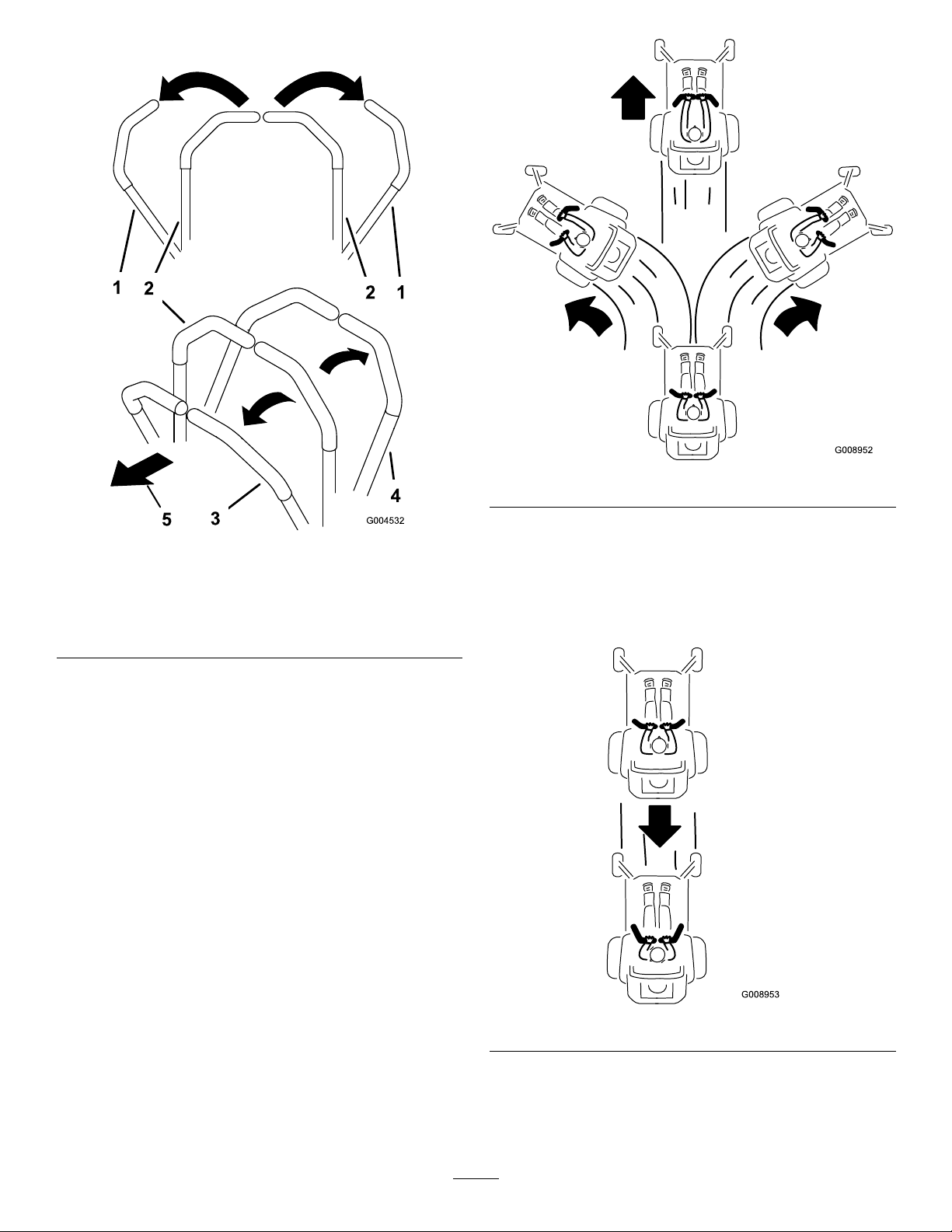

UsingtheMotionControlLevers

G008952

G008953

Figure23

Figure22

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForward

Note:Theenginewillkillifthetractioncontrolleversare

movedwiththeparkingbrakeengaged.

Tostop,pullthemotioncontrolleverstotheneutralposition.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrollevers

forward(Figure23).

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrollevers

rearward(

Figure24).

Figure24

20

Page 21

StoppingtheMachine

Tostopthemachine,movethetractioncontrolleversto

neutralandmovetolockedposition,disengagethepower

takeoff(bladecontrolswitch(PTO),andturntheignition

keytooff.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrakeinOperation.Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhastwopositionsandisusedwiththe

deckliftpedal.Thereisalockpositionandaunlockposition

forthetransportposition.Thetransportlockisusedwiththe

deckliftpedal.RefertoFigure25.

Figure25

TransportLockPositions

1.Transportlock3.Unlockposition—doesnot

2.Lockposition—mower

deckwilllockintotransport

position

21

lockthemowerdeckinto

transportposition

Page 22

AdjustingtheHeight-of-CutPin

1

3

2

G017027

Theheight-of-cutisadjustedfrom1to5-1/2inches(25to

140mm)in1/4inch(6mm)incrementsbyrelocatingthe

clevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeckliftpedalwithyourfootandraisethe

mowerdecktothetransportposition(alsothe5-1/2

inch(140mm)cuttingheightposition)(

3.Toadjust,rotatethepin90degreesandremovethepin

fromtheheight-of-cutbracket(Figure26).

Figure26).

4.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesiredand,insertthepin(Figure

26).

5.Pushonthedecklift,pullbackonthetransportlock,

andslowlylowerthemowerdeck.

Figure27

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

1.Anti-scalproller3.FlangeNut

2.Bushing4.Bolt

5.Bolt

Figure28

Figure26

1.Deckliftpedal

2.Cutofheightpin

AdjustingtheAnti-Scalp Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Transportlock

Figure29

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

22

5.Bolt

Page 23

AdjustingtheFlowBafeCam

G008961

1

2

3

4

PositioningtheFlowBafe

Locks

Thisprocedureisapplicableonlytomachineswiththeow

bafelocks.Certainmodelswillhavenutsandboltsin-place

oftheowbafelocksandcanbeadjustedthesame.

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlocksandbafeto

givethebestqualityofcut.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthecamlocks,swingtheleveruptoloosen

thecamlock(Figure30).

4.Adjustthebafeandcamlocksintheslotstothe

desireddischargeow .

5.Swingtheleverbackovertotightenthebafeandcam

Figure30).

locks(

6.Ifthecamlocksdonotlockthebafeintoplaceorit

istootight,loosentheleverandthenrotatethecam

lock.Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition.Thesuggesteduseforthis

positionisafollows.

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthemower.

1.Unlocklever

2.Rotatethecamlockto

increaseordecrease

lockingpressure

Figure31

PositionB

Usethispositionwhenbagging.Alwaysalignitwiththe

bloweropening.

Figure30

3.Positionthebafe

4.Locklever

Figure32

23

Page 24

PositionC

G008962

g015123

UsingtheDriveWheelRelease

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows.

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

•ThispositionissimilartothebenetsoftheToroSFS

mower.

Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey,andallowall

movingpartstostopbeforeaccessingthedrive

wheelreleasevalves.

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.Touchingahotengineorhydraulicdrive

unitscancausesevereburns.

Allowtheengineandhydraulicdriveunitstocool

completelybeforeaccessingthedrivewheelrelease

valves.

Thedrivewheelreleasevalvesarelocatedinthebackofeach

hydraulicdriveunit,undertheseat.

Figure33

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlockseat(Figure34).

Figure34

Note:Makesurethereleasevalvesareinthefullyhorizontal

positionwhenoperatingthemachineorseveredamagetothe

hydraulicsystemcanoccur.

1.DisengagethePTO(bladecontrolswitch)andturnthe

ignitionkeytooff.Movetheleverstoneutrallocked

positionandapplyparkingbrake.Removethekey.

2.Rotatethereleasevalveleversverticallytopushthe

machine.Thisallowshydraulicoiltoby-passthepump

enablingthewheelstoturn(Figure35).

3.Disengageparkingbrakebeforepushing.

1.Verticaltopushthe

machine

24

Figure35

2.Horizontaltorunthe

machine

Page 25

4.Rotatethereleasevalvelevershorizontallytorunthe

machine(Figure35).

UsingtheSideDischarge

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff(blade

controlswitch(PTO)totheoffposition,rotate

theignitionkeytooffandremovethekey.

•Makesurethegrassdeectorisinthedown

position.

•Useextremecautionwhenoperatingauniton

aramp.

•EnsuretheROPSisintheuppositionwhile

usingtheseatbeltwhenloadingthemachine.

EnsuretheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtrailerortruck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefullwidthrampthatiswideenoughtoextendbeyond

thereartiresisrecommendedinsteadofindividualrampsfor

eachsideoftheunit(Figure36).Thelowerrearsectionof

themachineframeextendsbackbetweentherearwheelsand

servesasastopfortippingbackward.Havingafullwidth

rampprovidesasurfacefortheframememberstocontactif

theunitstartstotipbackward.Ifitisnotpossibletouseone

fullwidthramp,useenoughindividualrampstosimulatea

fullwidthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(

mowercomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Important:DoNotattempttoturntheunitwhileon

theramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

Figure36).Asteeperanglemaycause

Figure36

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

25

Page 26

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw.Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,petsorbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway .

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(

Figure37

1.Tractionunittiedownloops

Figure37).

26

Page 27

OperatingTips

FastThrottleSetting

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethecutting

heightofthemowerdoesnotscalpanyunevenground.

However,thecuttingheightusedinthepastisgenerallythe

bestonetouse.Whencuttinggrasslongerthansixinchestall,

youmaywanttocutthelawntwicetoensureanacceptable

qualityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently .Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

27

Page 28

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

MaintenanceProcedure

•Checkthewheellugnuttorque.

•Checkthewheelhubslottednuttorque.

•Checktheparkbrakeadjustment.

•Changethehydraulicltersandhydraulicoilwhenusinganytypeofoil.

•Checkthesafetysystem.

•Checktheengineoillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Cleantheenginescreenandtheoilcooler.

•Checkandcleanthehydraulicunits.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethemowerdeckspindlesandidlerarm.

•Checksparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicoillevel.

•Lubricatethemowerdeckliftpivots.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Checkandcleanenginecoolingnsandshrouds.

•Inspecttheprimarylterandairinletscreen.

Every200hours

Every250hours

Every300hours

Every500hours

Every600hours

Yearlyorbeforestorage

•Changetheengineoillter.

•Cleantheengineoilcooler.

•Check,cleanandregapthesparkplug.

•Replacethefuellter.(moreoftenindirtyordustyconditions).

•ChangethehydraulicltersandhydraulicoilwhenusingMobil®1oil(moreoftenin

dirtyordustyconditions).

•Replacetheprimaryairlter.(moreoftenindustyorsandyconditions)

•Checktheinnerairlter.

•Checkthewheellugnuttorque.

•Checkthewheelhubslottednuttorque.

•Adjustthecasterpivotbearing.

•Checktheparkbrakeadjustment.

•ChangethehydraulicltersandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil(moreoftenindirtyordustyconditions).

•Replacetheinnerairlter.

Monthly

Yearly

•Checkthebattery .

•Greasethepumpbeltidlerarm.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Repackthefrontcasterwheelbearings(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

28

Page 29

CAUTION

G017028

G009029

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

GreasingandLubrication

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy .

GreaseType:No.2generalpurposelithiumbaseor

molybdenumbasegrease

HowtoGrease

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

WheretoGreasetheMower

ServiceInterval:Every50hours—Greasethemowerdeck

spindlesandidlerarm.

Yearly—Greasethepumpbeltidlerarm.

Yearly—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Yearly—Repackthefrontcasterwheelbearings(more

oftenindirtyordustyconditions).

Important:Makesurecuttingunitspindlesarefullof

greaseweekly .

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Greasethemowerdeckidlerpulleypivotuntilgrease

comeoutthebottom(

4.Greasethethreespindlebearingsuntilgreasecomes

outthelowerseals(Figure39).

Figure39).

WheretoAddLightOilorSpray

Lubrication

ServiceInterval:Every100hours

Lubricatethedeckliftpivots.

Figure38

Figure39

5.Greasethedrivebeltidlerarm(Figure40).

29

Page 30

Figure40

g014942

LubricatetheCasterWheel Hubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey .Engagetheparkingbrake.

Figure42

6.Removethedustcapandadjustthecasterpivots.

Keepthedustcapoffuntilgreasingisdone.Referto

AdjustingtheCasterPivotBearinginMaintenance.

7.Removethehexplug.Threadagreasezerkintothe

hole.

8.Pumpgreaseintothezerkuntilitoozesoutaround

thetopbearing.

9.Removethegreasezerkinthehole.Installthehexplug

anddustcap(

Figure41).

Figure41

1.Sealguard2.Spacernutwithwrench

ats

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Remove1ofthespacernutsfromtheaxleassemblyin

thecasterwheel.Notethatthreadlockingadhesive

hasbeenappliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly .

5.Pryouttheseals,andinspectthebearingsforwearor

damageandreplaceifnecessary.

6.Packthebearingswithageneral-purposegrease.

7.Insert1bearingand1newsealintothewheel.

Note:Thesealsmustbereplaced.

8.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathreadlockingadhesiveto1

spacernutandthreaditontotheaxlewiththewrench

atsfacingoutward.Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leaveapproximately

3mm(1/8inch)fromtheoutersurfaceofthespacer

nuttotheendoftheaxleinsidethenut.

9.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

10.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

11.Insertthesecondbearingandnewsealintothewheel.

12.Applyathreadlockingadhesivetothesecondspacer

nutandthreaditontotheaxlewiththewrenchats

facingoutward.

13.Torquethenutto8-9N-m(75-80in-lb),loosen,then

re-torqueto2-3N-m(20-25in-lb).Makesurethatthe

axledoesnotextendbeyondeithernut.

30

Page 31

14.Installthesealguardsoverthewheelhubandinsert

g012996

3

4

1

2

thewheelintothecasterfork.Installthecasterbolt

andtightenthenutfully.

Important:T opreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecastertire.The

tireshouldnotspinfreely(morethan1or2revolutions)

orhaveanysideplay.Ifthewheelspinsfreely,adjustthe

torqueonthespacernutuntilthereisaslightamountof

drag.Applythreadlockingadhesive.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every300hours/Yearly(whichevercomes

rst)—Replacetheprimaryairlter.(moreoftenin

dustyorsandyconditions)

Every300hours—Checktheinnerairlter.

Every600hours—Replacetheinnerairlter.

Note:Checktheltersmorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Releasethelatchesontheaircleanerandpulltheair

inletcoverofftheaircleanerbody(Figure43).

4.Cleantheairinletscreenandcover.

5.Installtheairinletcoverandsecureitwiththelatches

(Figure43).

Figure43

1.Airinletcover3.Aircleanerbody

2.Airinletscreen4.Latch

6.Releasethelatchesontheaircleanerandpulltheair

cleanercoverofftheaircleanerbody(Figure44).

7.Cleantheinsideoftheaircleanercoverwith

31

compressedair.

8.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure44).

Note:Avoidknockingthelterintothesideofthe

body.

9.Removetheinnerlteronlyifyouintendtoreplaceit.

Page 32

Important:Neverattempttocleantheinnerlter.

g012997

1

2

3

4

5

Ifthesafetylterisdirty,thentheprimarylteris

damaged.Replacebothlters.

Figure44

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheaircleanercoverandsecurethelatches

(Figure44).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceclassSJorhigher)

OilCapacity:withalterchange,58ounces(1.7L);withno

lterchange,48ounces(1.4L)

Viscosity:Seethetablebelow .

1.Innerlter

2.Primarylter

3.Aircleanercover

10.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Ifthelterisdamaged,discardit.

4.Latch

5.Aircleanerbody

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,replaceit.

•Donotcleantheprimarylter.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Neverattempttocleanthesafetylter.

Ifthesafetylterisdirty,thentheprimarylteris

damaged.Replacebothlters.

InstallingtheFilters

Important:T opreventenginedamage,alwaysoperate

theenginewithbothairltersandcoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Iftheinnerlterisbeingreplaced,carefullyslideitinto

thelterbody(

3.Carefullyslidetheprimarylterovertheinnerlter

(Figure44).

Note:Ensurethattheprimarylterisfullyseatedby

pushingonitsouterrimwhileinstallingit.

Figure44).

Figure45

Note:Useofsyntheticoilhaving5W-20or5W -30ratingis

acceptable,upto4degreesC(40degreesF).

Note:Syntheticoilswillprovidebetterstartinginextreme

coldbelow-23degreesC(-10degreesF).

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure46).

32

Page 33

G008804

G008792

1

2

5

6

7

3

9

10

4

8

ChangingtheEngineOil

G008804

G008793

1

2

3

4

4

5

ServiceInterval:Every100hours(moreoftenindirtyor

dustyconditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylowerthan

thefronttoensuretheoildrainscompletely .

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure47).

Figure46

Figure47

33

Page 34

4.Slowlypourapproximately80%ofthespeciedoil

G008796

2

3

4

5

6

1

G008804

G008748

3/4

1

2

3

4

5

6

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure48).

ChangingtheEngineOilFilter

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

Figure48

5.Starttheengineanddrivetoaatarea.Checktheoil

levelagain.

2.Changetheengineoillter(

Figure49).

Figure49

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

ServicingtheEngineOilCooler

ServiceInterval:Every200hours

1.Keeptheoilcoolerfreeofdebris.bycleaningthens

withabrush.

34

Page 35

2.Removetheboltsholdingtheoilcoolertotheengine

G008804

g01301 1

1 2

2

G008803

housing.

3.Cleantheinsideoftheoilcoolerwithabrush.

4.Installtheoilcoolertotheenginehousing.

Figure50

1.Engineoilcooler2.Bolts

ServicingtheSparkPlug

ServiceInterval:Every200hours—Check,cleanandregap

thesparkplug.

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:Champion

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Removethelefthandhydraulicunitshroudintheorder

listedwith

sparkplug.

®

XC12YC,orequivalent

Figure51.Thisgivesyouaccesstothefront

Figure51

1.Pullthistabouttothe

sideinthedirectionofthe

arrow

2.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

3.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

4.Shroud

4.Removethesparkplug.

Figure52

5.Installthelefthandhydraulicunitshroud(Figure51).

35

Page 36

CheckingtheSparkPlug

G008794

1

2

Important:Replacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,cracksor

reuseisquestionable.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.030inches(0.76mm).

Figure53

InstallingtheSparkPlug

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakelooseparticlesoutofthearrester

andcleanscreenwithawirebrush(soakinsolventif

necessary).Reinstallarresteronexhaustoutlet.

Tightenthesparkplug(s)to18-22ft.-lb(24.4–29.8N-m).

Figure54

CheckSparkArrester(if equipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

36

Page 37

FuelSystem

G008963

12

3

Maintenance

WARNING

Fuelsystemcomponentsareunderhighpressure.

Theuseofimpropercomponentscanresultin

systemfailure,gasolineleakageandpossible

explosion.

Useonlyapprovedfuellinesandfuellters.

ServicingtheElectronicFuel InjectionSystem

Thismachinecontainsanelectronicfuelinjectionsystem.It

controlsthefuelowunderdifferentoperatingconditions.

Theelectroniccontrolunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunctionindicatorlight(MIL)isilluminated.TheMILis

theredlightlocatedintherightconsolepanel.

OncetheMILilluminates,initialtroubleshooting

checksshouldbemade.RefertotheMILsectionunder

Toubleshooting.

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

ReplacingtheLowPressure FuelFilter

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

5.Closethefuelshutoffvalveundertheseat(

Figure55).

Figure55

1.Fuellter

2.Hoseclamp

6.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure55).

7.Removethelterfromthefuellines.

8.Installanewlterandmovethehoseclampscloseto

thelter(Figure55).

9.Openthefuelshutoffvalve.

Note:Itisimportanttoreinstallthefuellinehosesand

securewithplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineawayfrom

componentsthatcouldcausefuellinedamage.

3.Fuelline

ServicingtheHighPressure FuelFilter

Donotattempttoservicethehighpressurefuellter.The

highpressurelterisintegratedwithinthefuelpumpmodule.

Thefuellterandothercomponentsinsidethefuelpump

modulearenotservicable.DoNotattempttoopenthefuel

pumpmodule.

EnsurethatanAuthorizedServiceDealerreplacesthefuel

pumpmodulewiththehighpressurefuellter.

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankandservices

anycomponentsofthefuelsystem.

37

Page 38

ElectricalSystem

g014731

+

-

+

-

+

-

1

2

3

4

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(

4.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure56).

Figure56).

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

5.Removethewingnutsecuringthebatteryclamp

(Figure56).

6.Removetheclamp(Figure56).

7.Removethebattery.

Figure56

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

3.Removethepositive

batterycable

4.Removebattery

38

Page 39

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure56).

2.First,installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Theninstallthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

Figure56).

(

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut(Figure

56).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure57).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

1.PositiveBatteryPost

2.NegativeBatteryPost

Figure57

3.Red(+)ChargerLead

4.Black(-)ChargerLead

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

39

Page 40

ServicingtheFuses

g020464

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

1.Thefusesarelocatedonrighthandconsolenextto

theseat(

2.Toreplacethefuses,pulloutonthefusetoremoveit.

3.Installanewfuse(Figure58).

Figure58).

Maintenance

CheckingtheSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproperoperation

ofretractorandbuckle.Replacebeforeoperatingifdamaged.

CheckingtheRollover ProtectionSystem(ROPS) Knobs

ServiceInterval:Beforeeachuseordaily

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensuretheseatissecuredtothemachine.

Figure58

1.Optionalaccesory-15amp

2.Charge-25amp5.Console

3.PTO-10amp

Checkthatboththemountinghardwareandtheknobsare

4.Main-25amp

ingoodworkingcondition.Makesuretheknobsarefully

engagedwiththeROPSintheraisedposition.Theupper

hoopoftherollbarmayneedtobepushedforwardorpulled

rearwardtogetbothknobsfullyengaged.

40

Page 41

8.Tightenthestopplate(Figure60).

Figure59

1.ROPSknob(locked

position)

2.PullROPSknoboutand

rotate90degreesto

changerollbarposition

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

AdjustingtheTracking

1.Disengagethebladecontrolswitch(PTO).

2.Drivetoanopenatarea,movethemotioncontrol

leverstotheneutrallockedposition.

3.Movethethrottlemidwaybetweenfastandslow.

4.Movebothmotioncontrolleversallthewayforward

untiltheybothhitthestopsintheT-slot.

Figure60

Leftcontrollevershown

1.Controllever3.Stopplate

2.Bolt

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthefrontandreartiresat13psi

(90kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccuratepressure

reading.

5.Checkwhichwaythemachinetracks.

6.Ifittrackstotheright,loosentheboltsandadjust

theleftstopplaterearwardontheleftT-slotuntilthe

machinetracksstraight(

Figure60).

7.Ifittrackstotheleft,loosentheboltsandadjustthe

rightstopplaterearwardontherightT-slotuntilthe

machinetracksstraight(

Figure60).

Figure61

41

Page 42

CheckingtheWheelLugNuts

Checkandtorquethewheellugnutsto90-95ft-lb(122-129

N-m).

CheckingtheWheelHub

5.Torquetheslottednutto200ft-lb(271N-m).

6.Thentightennutuntilthenextsetofslotslineup

withthecrossholeinshaft.Donotloosennutto

aligntheslot.Ifrequired,tightentothenextset

ofslots.

7.Installanewcotterpin.

SlottedNut

ServiceInterval:Aftertherst100hours

Every500hours

SeeFigure62todeterminewhichslottednuthasbeen

installedontheunit.

Figure62

1.StyleA(blacknish)3.StyleB(yellowzinc)

2..03inch(.76mm)4..24inch(6mm)

•StyleA(blacknish):

Torquetheslottednutto211-260ft-lb(286-352N-m).

Note:DoNotuseanti-seizeonwheelhub.

•StyleB(yellowzinc):

Note:DoNotuseanti-seizeonwheelhub.

AdjustingtheCasterPivot Bearing

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethedustcapfromcasterandtightenlocknut

Figure64).

(

4.Tightenthelocknutuntilthespringwashersareatand

thenbackoffa1/4turntoproperlysetthepre-loadon

thebearings(Figure64).

Important:Makesurethespringwashersare

installedcorrectlyasshowninFigure64.

5.Installthedustcap(Figure64).

1.Removeanddiscardthecotterpin.

2.Torquetheslottednutto200ft-lb(271N-m).

3.Checkdistancefrombottomofslotinnuttoinside

edgeofhole.Twothreads(0.1inch)orlessshould

beshowing.

Figure63

1.0.1inchmax2.Nomorethantwothreads

(0.1inchmax)shouldbe

showinghere.

4.Ifmorethantwothreads(0.1inch)areshowing

removenutandinstallwasherbetweenhuband

nut.

Figure64

1.SpringWashers3.DustCap

2.LockNut

42

Page 43

UsingtheClutchShim

Somelatermodelyearunitshavebeenbuiltwithclutchesthat

containabrakeshim.Whentheclutchbrakehasworntothe

pointwheretheclutchnolongerengagesconsistently ,the

shimcanberemovedtoextendtheclutchlife.

A.Loosenbothbrakemountingboltsone-halfto

onefullturnasshownbelow .

Note:DoNotremovethebrakepolefromthe

eldshell/armature.Thebrakepolehasworn