Page 1

FORM NO. 3319–230 A

523Dxi GARDEN TRACTOR

MODEL NO. 73551–8900001 & UP

Loose Parts

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Rear Wheel

Wheel Bolt

R.H. Wheel Spindle

L.H. Wheel Spindle

Unplated Thrust Washer – 1.56” O.D x .06”

Thick

Plated Wheel Washer –1.50” O.D x .05” Thick

Bolt – 5/16”-18 x 2.25” Long

Hex Nut – 5/16”-18

Spindle Cap

2

10

1

1

2

4

2

2

2

Installing the rear wheels

Installing the front wheels

SET UP

INSTRUCTIONS

Front Wheel

Hubcap Washer – 2.50” O.D x .05” Thick

Cotter Pin –.156” x 1.50” Long

Shim Washer – 1.50” O.D x .015” Thick

Hubcap

Steering Wheel

Boot Washer

Nut

Lock Washer

Trim Cover

Seat Assembly

Shoulder Bolt – 5/16”

Locknut – 5/16”

Printed in USA

2

2

2

2

2

1

1

1

1

1

1

2

2

Installing the steering wheel

Installing the seat

The Toro Company – 1997

All Rights Reserved

Page 2

Set-Up Instructions

DESCRIPTION USEQTY.

Bolt – 1/4”-20 x .75” Long

Wing Nut – 1/4”-20

Grill Screw – #8 x .50” Long

Grill Washer – .75” O.D.

Hitch Pin

Hairpin Cotter

Flat Washer – .50” I.D.

Key 1 Use in ignition switch

Operator’s Manual 1 Read before operating the tractor

Engine Operator’s Manual 1 Read before operating the tractor

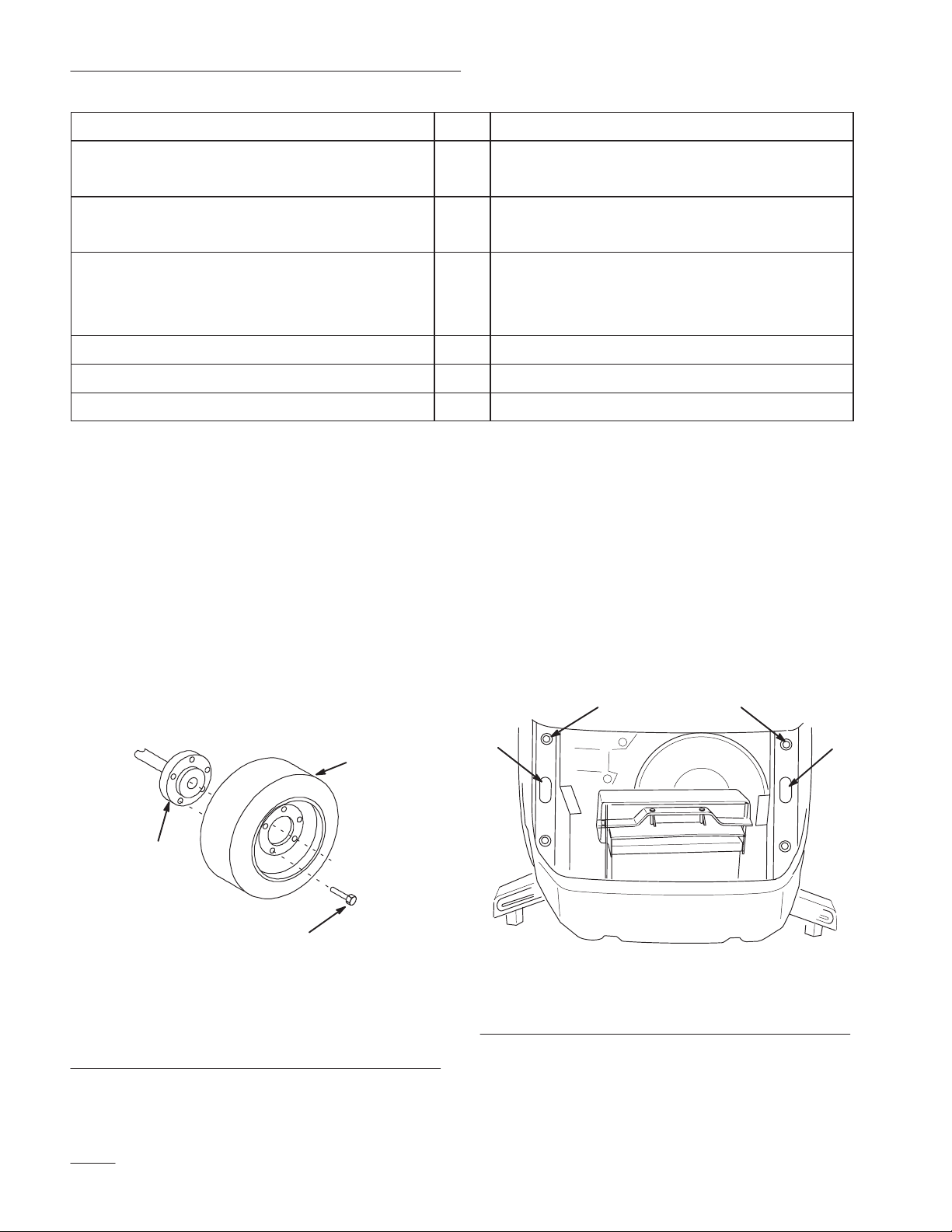

Installing the Rear Wheels

1. Remove the four wheel bolts holding the rear

shipping brackets to the rear hubs.

2

2

2

2

1

1

2

Attaching the battery cables

Securing the grill

Installing the drawbar hitch pin

Installing the Front Wheels

IMPORTANT: Never raise the front of the

tractor by placing a jack under the bumper

or front axle because the tractor may be

2. Using a jack or suitable hoist, raise the rear of

damaged.

the tractor only high enough to install the rear

wheels.

1. The front hood support braces have two slots

(Fig. 2) that may be used to lift the tractor to

3. Install the wheels onto the hubs with the valve

stems facing inward (Fig. 1).

install the front wheel spindles. To access these

slots, remove the front grill and raise the hood.

4. Tighten the wheel bolts to 75–80 ft-lb

(105–112 Nm).

1

3

Figure 1

1. Hub

2. Rear wheel

3. Wheel bolt (5)

2 2

11

2

m–3454

m–1278

1. Slots 2. Grill Grommets

Figure 2

Note: Remove, or be careful not to damage,

the two upper grill grommets (Fig. 2).

2

Page 3

Set-Up Instructions

2. Using a suitable hoist, raise the front of the

tractor only high enough to install the front

wheel spindles.

IMPORTANT: Do not pivot the weight of the

tractor onto the rear drawbar hitch because

the hitch will be damaged.

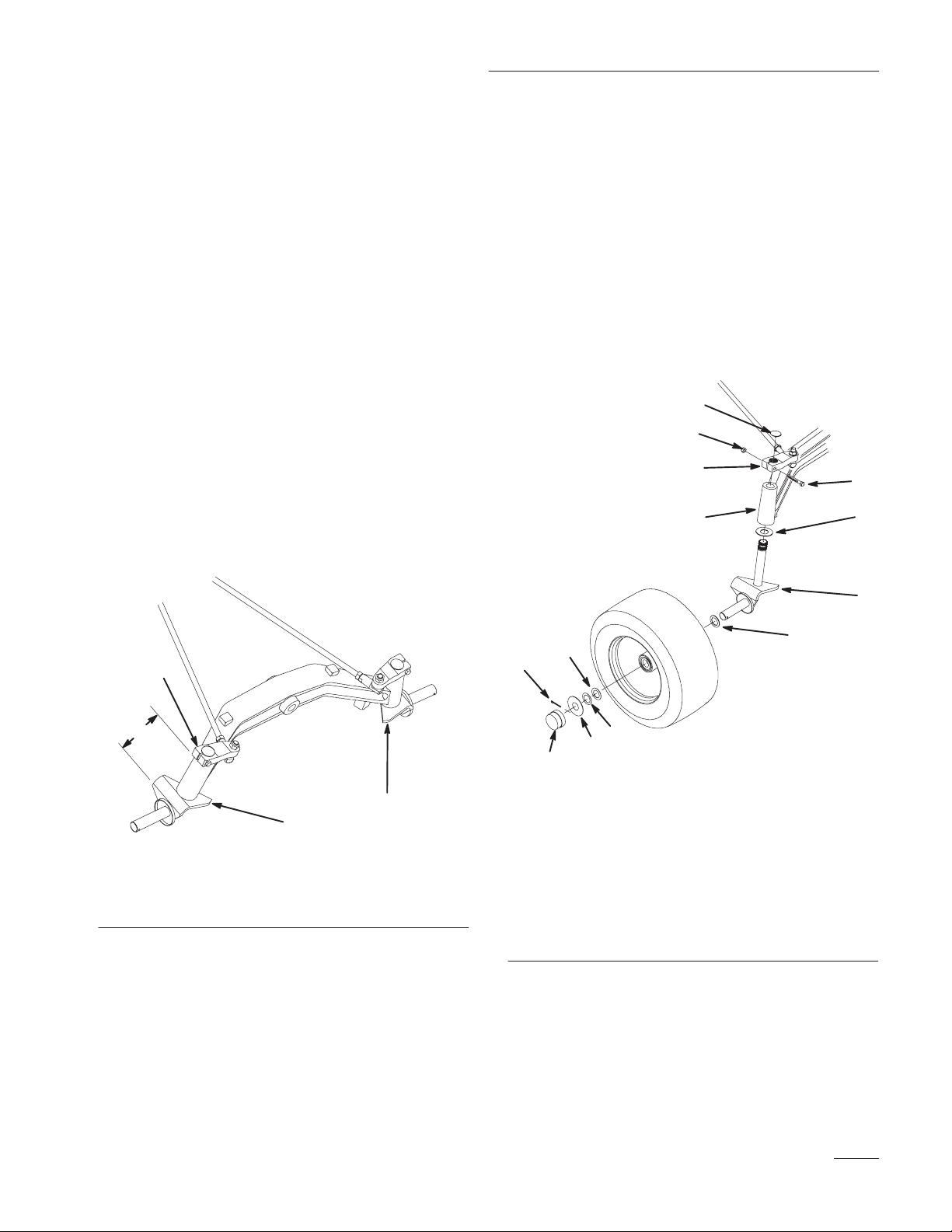

3. Install a 1.56” O.D. x .06” thick unplated thrust

washer onto the splined shaft of the R.H. wheel

spindle (Fig. 4).

4. Install the splined end of the R.H. spindle

through the R.H. end of the front axle and into

the steering arm (Fig. 4).

Note: The L.H. and R.H. spindles are

different. Assemble the spindles as

shown in figure 3.

Note: The outside edge of the spindle must

be parallel to the end of the steering

arm (Fig. 3).

7. Install a front wheel onto the R.H. spindle with

the valve stem facing inward (Fig 4).

8. Insert another 1.50” O.D x .05” thick plated

wheel washer onto the R.H. spindle (Fig. 4).

9. Install a 2.50” O.D x .05” thick hub cap washer

onto the spindle. Now insert a .156 x 1.50” long

cotter pin into the hole in the spindle (Fig. 4).

10. Check the front wheel end play. Install shim

washers inside the hubcap washer as necessary

so there is minimum end play.

7

6

4

3

5

2

3

4

2

1

m–3610

Figure 3

1. R.H. Spindle

2. L.H. Spindle

3. Steering arm

4. Parallel relationship

5. Secure the spindle shaft to the steering arm with

a 5/16”–18 x 2.25” bolt and 5/16” nut (Fig. 4).

Torque the nut to 230 25 in–lbs.

6. Insert a 1.50” O.D x .05” thick plated wheel

washer onto the R.H. spindle (Fig. 4).

1

8

8

11

10

12

9

m–3452

Figure 4

1. Wheel s p indle

2. Unplated thrust washer

1.56” x .06” thick

3. Front axle

4. Steering arm

5. Bolt 5/16”–18 x 2.25”

6. Nut 5/16”

7. Spindle cap

8. Plated wheel washer 1.50”

O.D. x .05” thick

9. Hub cap washer 2.50”

O.D. x .05” thick

10. Shim washer 1.50” O.D. x

.015” thick

11. Cotter pin .056” x 1.50”

12. Hubcap

11. Secure the wheel to the spindle with a cotter pin.

Bend the ends of the cotter pin completely

around the spindle.

12. Install a hubcap onto the hubcap washer until it

snaps in place (Fig. 4).

3

Page 4

Set-Up Instructions

13. Look at the end of the steering arm and the

inside edge of the tire. The end of the steering

arm and the inside edge of the tire must be

parallel (Fig. 5). Adjust the steering arm if

required.

2

1

m–3451

Figure 5

1. Wheel

2. Steering a r m

3. Parallel relationship

14. Insert a spindle cap into the steering arm

(Fig. 4).

15. Repeat the procedure on the opposite end of the

front axle.

16. After servicing the battery, replace the front grill

of the tractor and secure the grill with two #8 x

.50” long grill screws and .75” O.D. grill

washers in the upper two grill mounting holes

(Fig. 6).

2

3

1

m–3558

Figure 6

1. Grill screw (1 of 2) 2. Grill washer (1 of 2)

17. Lubricate the spindles and front axle pivot until

grease begins to come out of the bearings.

18. With the tractor on a level surface, check to

make sure the front wheel toe-in is between 1/8”

and 1/4”. For instructions on adjusting toe-in,

refer to the Maintenance section in Operator’s

Manual.

Checking Tire Pressure

Check front and rear tire pressure. The correct front

and rear tire pressure is 12 psi (82.7 kPa).

4

Page 5

Set-Up Instructions

Installing the Seat

1. Mount the seat to the seat base using two 5/16”

shoulder bolts and lock nuts (Fig. 7).

2. Insert the seat switch wire through the center

opening in the seat base (Fig 7).

3. Push the seat switch wire connector into the wire

harness connector.

1

3

Installing the Steering Wheel

1. Install the boot washer onto the steering shaft

(Fig. 8).

2. Remove the plastic trim cover from the steering

wheel (Fig. 8)

3. Install the steering wheel onto the shaft,

carefully aligning the splines (Fig. 8).

Note: There is no fixed straight ahead

position on power steering models.

4. Secure the steering wheel to the shaft with a lock

washer and nut

to 45–50 ft–lbs.

5. Install the trim cover on the steering wheel.

6

3

(Fig. 8). Tighten the retaining nut

5

4

2

6

1. Seat

2. Seat base

3. 5/16” shoulder bolt (2)

4. 5/16” Locknut (4)

Figure 7

5

4

m–3453

5. Seat switch wire

connector

6. Opening for seat switch

wire

1. Boot washer

2. Steering shaft

3. Steering wheel

1

2

m–2482

Figure 8

4. Lock washer

5. Nut

6. Trim cover

5

Page 6

Set-Up Instructions

Activating the Battery

POTENTIAL HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

2

WHAT CAN HAPPEN

• If you carelessly drink electrolyte you could

die or if it gets onto your skin you will be

burned.

HOW TO AVOID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

1. Remove the battery from the tractor (refer to

Removing the Battery in your tractor Operator’s

Manual).

Note: Never fill the battery electrolyte with

the battery installed in the tractor.

2. Remove the cell cover from the battery. Slowly

pour electrolyte into each cell until the

electrolyte level is up to the lower part of the

tube (Fig. 9). Use an electrolyte with a specific

gravity of 1.265.

1

3

m–3799

Figure 9

1. Cell cover

2. Electrolyte

3. Lower part of tube

POTENTIAL HAZARD

• Charging battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

3. Leave the cell cover off and connect a 3–4 amp

battery charger to the battery posts (Fig. 10).

Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

6

Page 7

Set-Up Instructions

4. When the battery is fully charged, unplug the

charger from electrical outlet, then disconnect

the charger leads from the battery posts

(Fig. 10).

4

2

3

1. Positive battery post

2. Negative battery post

1

Figure 10

3. Red (+) charger lead

4. Black (–) charger lead

m–3798

Installing the Drawbar Hitch

Pin

Insert the drawbar hitch pin into the drawbar hitch

and secure it with a .50” I.D. flat washer and hairpin

cotter (Fig. 11).

1

1. Drawbar hitch pin

2. Drawbar hitch

2

4

Figure 11

3. .50” Flat washer

4. Hairpin cotter

3

m–2481

5. Slowly pour electrolyte into each cell until the

level is once again up to the lower part of the

tube (Fig. 9), then install the cell cover.

6. Install the battery in the tractor and connect the

battery cables (refer to Installing the Battery in

your tractor Operator’s Manual).

Note: Do not run the tractor with the battery

disconnected.

7

Page 8

Set-Up Instructions

Checking the Wiring and

Fasteners

• Inspect the tractor for any loose electrical

connections and secure them as required. Check

the wire routing to make sure moving parts do

not interfere with wires and cause a short.

• Assure all fasteners are tight.

Burnishing the Clutch

The following break–in procedure must be performed

as part of predelivery service or when a new clutch is

installed.

Note: There must be a PTO driven

attachment installed to provide a load

in order to burnish the clutch facings

properly.

1. Run the engine at full throttle and engage the

clutch bringing the load to full speed. Then

disengage the clutch.

2. Let the load come to a full stop, then engage

again.

4. Make sure all water is drained from the fuel filter

(refer to Draining Water From The Fuel

Filter/Water Separator in your tractor Operator’s

Manual).

5. Check to make sure all lubrication points have

been greased as shown in the Maintenance

section of tractor Operator’s Manual.

6. Fill the tank with fresh diesel fuel with a

minimum cetane rating of 40 and the proper

grade for the ambient temperature conditions

(refer to Adding Fuel in your tractor Operator’s

Manual) Open the fuel shutoff valve and check

the fuel hose and fittings for leaks.

7. As applicable, check and test the operation of the

following:

• Engine and throttle controls

• Gauges

• Headlights and taillights

• Indicator lights

• PTO clutch and brake

• Lift system

3. Repeat these procedures (1 and 2) 5 times.

Test Driving the Tractor

1. Check the oil level in the crankcase (refer to

Engine Oil in your tractor Operator’s Manual for

oil type, viscosity and crankcase capacity).

2. Check the oil level in the transaxle (refer to

Transaxle Fluid in your tractor Operator’s

Manual for oil type, viscosity and capacity).

3. Check that the coolant level is between the two

lines on the coolant recovery tank when the

engine is cold (refer to Check the Cooling

System in your tractor Operator’s Manual).

• Service and parking brakes

• Transmission controls

• Steering

• Tractor operation in forward and reverse

8. Test the operation of the safety interlock system

(refer to the tractor Operator’s Manual for the

correct procedure).

8

Loading...

Loading...