Page 1

KAWASAKI FD620D 4-STROKE LIQUID COOLED ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 2

GENERAL INFORMATION

BEFORE SERVICING

MODEL IDENTIFICATION

GENERAL SPECIFICATIONS

PERIODIC MAINTENANCE CHART EXCEPT U.S.

PERIODIC MAINTENANCE CHART FOR U.S.

TORQUE AND LOCKING AGENT

FUEL SYSTEM

EXPLODED VIEW

SPECIFICATIONS

GOVERNOR LINK MECHANISM

CARBURETOR

INTAKE MANIFOLD

FUEL PUMP

AIR CLEANER

COOLING SYSTEM

EXPLODED VIEW

SPECIFICATIONS

COOLING SYSTEM

COOLANT

DISASSEMBLY AND ASSEMBLY PRECAUTIONS

WATER PUMP

RADIATOR

COOLING FAN, FAN BELT

THERMOSTAT

THERMO SWITCH

ENGINE TOP END

EXPLODED VIEW

SPECIFICATIONS

SPECIAL TOOLS

CYLINDER HEAD

VALVES

CYLINDER, PISTON

MUFFLER

LUBRICATION SYSTEM

EXPLODED VIEW

ENGINE OIL FLOW CHART

SPECIFICATIONS

ENGINE OIL AND OIL FILTER

PRESSURIZED LUBRICATION SYSTEM

OIL PUMP AND RELIEF VALVE

OIL SCREEN FILTER

Page 2

KAWASAKI FD620D 4-STROKE LIQUID COOLED ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 2

CAMSHAFT / CRANKSHAFT

EXPLODED VIEW

SPECIFICATIONS

CRANKCASE

BREATHER

CAMSHAFT TAPPET

CRANKSHAFT, CONNECTING ROD

ELECTRICAL SYSTEM

EXPLODED VIEW

SPECIFICATIONS

SPECIAL TOOLS

WIRING DIAGRAM

WIRE HARNESS

PRECAUTIONS

CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER SYSTEM

TROUBLESHOOTING

ENGINE TROUBLESHOOTING GUIDE

STARTER MOTOR TROUBLESHOOTING GUIDE

Page 3

*y

4-stroke liquid-cooled v-twin gasoline engine

Service Manual

Page 4

O-l

Kawasaki

FD62QD

4-stroke liquid cooled v-twin gasoline engine

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior

written permission of Quality Assurance Department/Consumer Products Group/Kawasaki Heavy Industries,

Ltd., Japan. .’

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care

has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to

make such changes to products manufactured previously.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication are intended for reference use only and may not

depict actual model component parts.

0 Kawasaki Heavy Industries. Ltd. 1996

Second Edition(l) : Jan. 20,1996(T)

-

Page 5

o-2

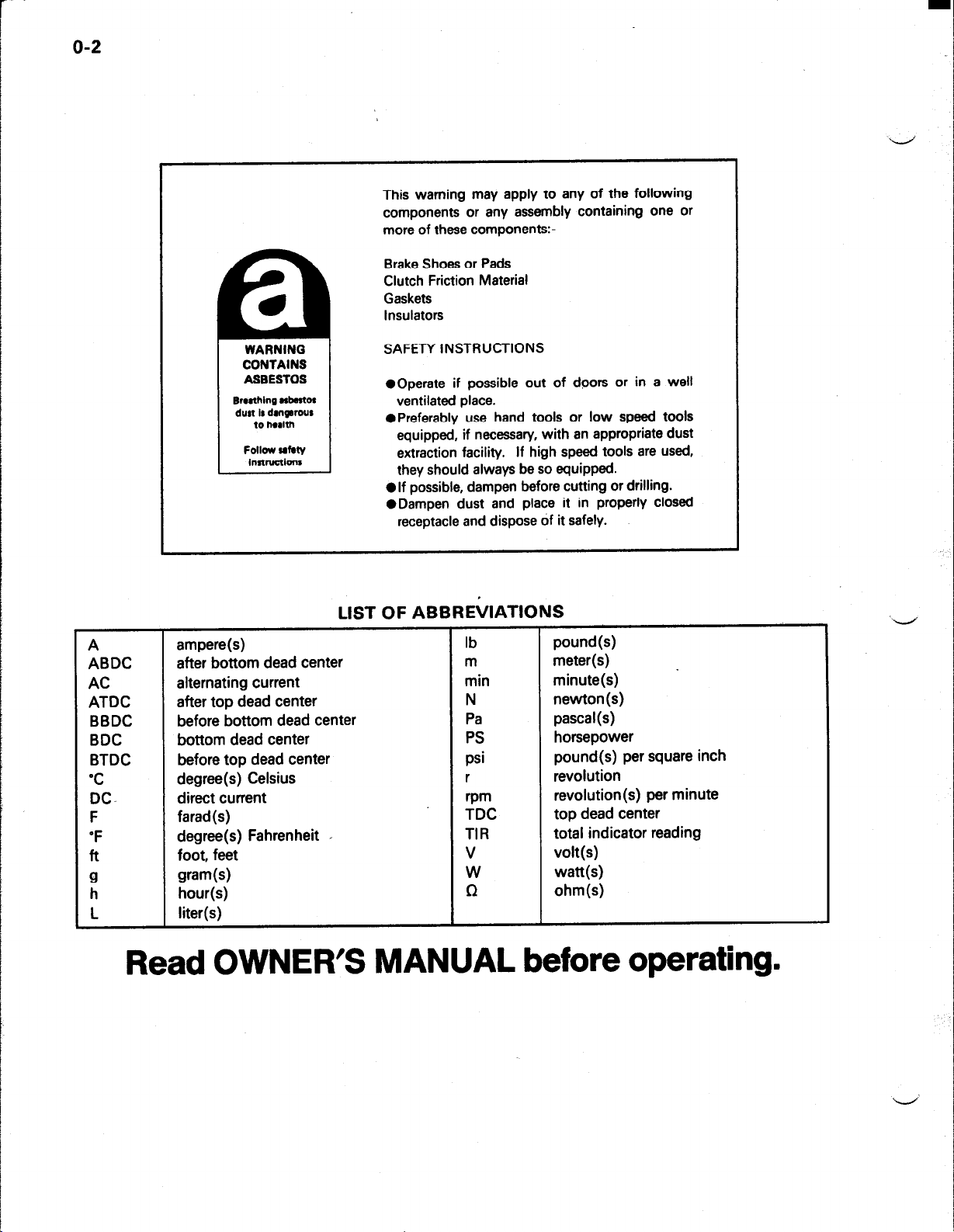

This warning may apply to any of the following

components or any assembly containing one or

more of these components:-

Brake Shoes or Pads

Clutch Friction Material

Gaskets

Insulators

Emthing rbmto~

dust is dm~rous

instructionr

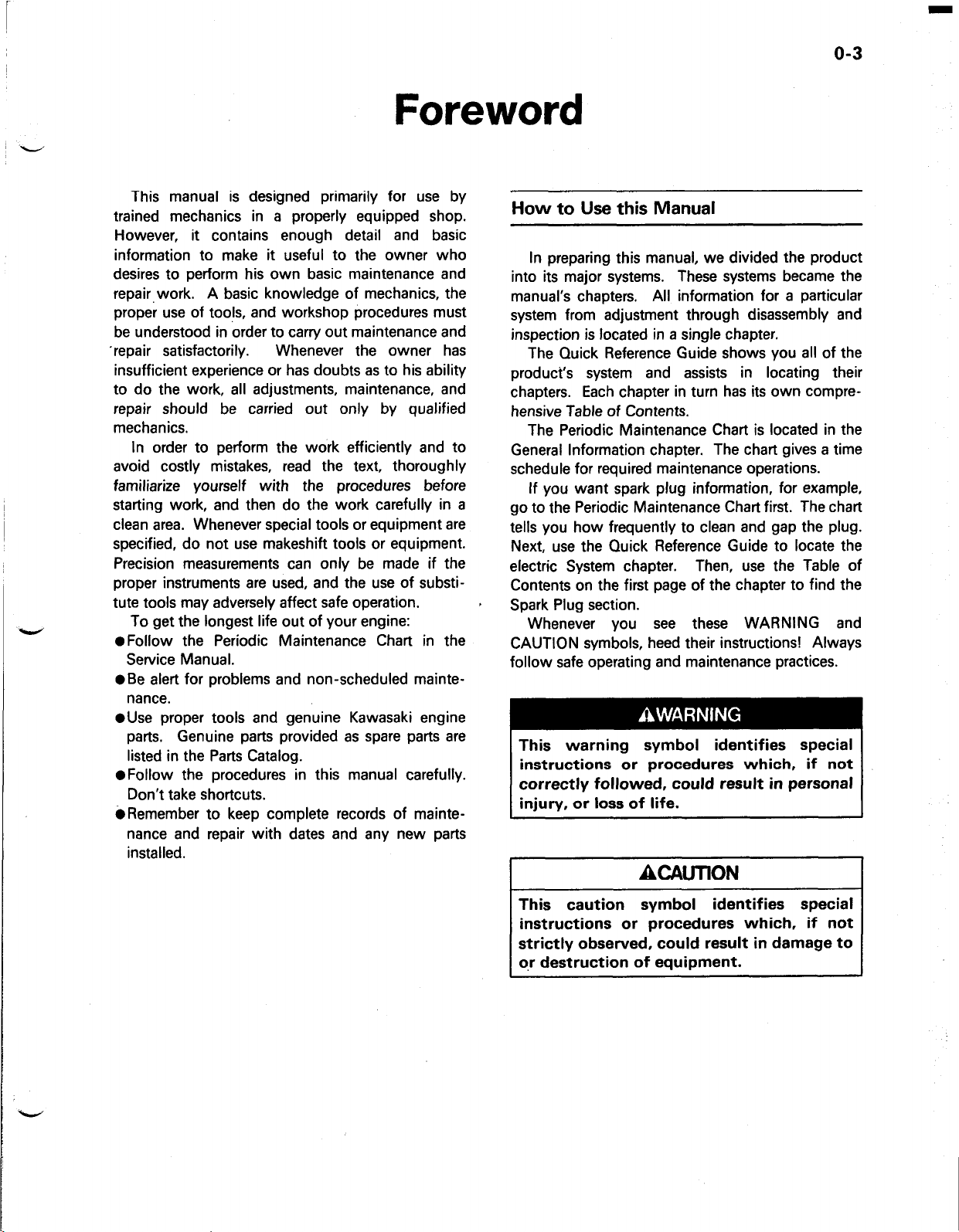

A ampere(s)

ABDC

AC

ATDC

BBDC

BDC

BTDC

‘C

DCF

after bottom dead center

alternating current

after top

dead center

before bottom dead center

bottom dead center

before top dead center

degree(s) Celsius

direct current

farad(s)

‘F degree(s) Fahrenheit ,

ft

9 gram(s)

h

L

foot, feet

hour(s)

liter(s)

1

SAFETY INSTRUCTIONS

l

Operate if possible out of doors or in a well

ventilated place.

l

Preferably use hand tools or low speed tools

equipped, if necessary, with an appropriate dust

extraction facility. If high speed tools are used,

they should always be so equipped.

l

lf possible, dampen before cutting or drilling.

@Dampen dust and place it in properly closed

receptacle and dispose of it safely.

LIST OF ABBRE(/IATIONS

lb

m

min

N

Pa

PS

psi

r

rpm

TDC

TIR

v

W

n

pound(s)

meter(s)

minute(s)

newton(s)

Pascal(s)

horsepower

pound(s) per square inch

revolution

revolution(s) per minute

top dead center

total indicator reading

volt(s)

watt(s)

ohm(s)

Read OWNER’S MANUAL before operating.

Page 6

Foreword

m

o-3

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic

information to make it useful to the owner who

desires to perform his own basic maintenance and

repair,work. A basic knowledge of mechanics, the

proper use of toofs, and workshop procedures must

be understood in order to carry out maintenance and

‘repair satisfactorily.

insufficient experience or has doubts as to his ability

to do the work, all adjustments, maintenance, and

repair should be carried out only by qualified

mechanics.

In order to perform the work efficiently and to

avoid costly mistakes, read the text, thoroughly

familiarize yourself with the procedures before

starting work, and then do the work carefully in a

clean area. Whenever special tools or equipment are

specified, do not use makeshift tools or equipment.

Precision measurements can only be made if the

proper instruments are used, and the use of substitute tools may adversely affect safe operation.

To get the longest life out of your engine:

l

Follow the Periodic Maintenance Chart in the

Service Manual.

l

Be alert for problems and non-scheduled mainte-

nance.

l

Use proper tools and genuine Kawasaki engine

parts. Genuine parts provided as spare parts are

listed in the Parts Catalog.

l

FOIIOW the procedures in this manual carefully.

Don’t take shortcuts.

*Remember to keep complete records of mainte-

nance and repair with dates and any new parts

installed.

Whenever the owner has

How to Use this Manual

In preparing this manual, we divided the product

into its major systems. These systems became the

manual’s chapters. All information for a particular

system from adjustment through disassembly and

inspection is located in a single chapter.

The Quick Reference Guide shows you all of the

product’s system and assists in locating their

chapters. Each chapter in turn has its own comprehensive Table of Contents.

The Periodic Maintenance Chart is located in the

General Information chapter. The chart gives a time

schedule for required maintenance operations.

If you want spark plug information, for example,

go to the Periodic Maintenance Chart first. The chart

tells you how frequently to clean and gap the plug.

Next, use the Quick Reference Guide to locate the

electric System chapter. Then, use the Table of

Contents on the first page of the chapter to find the

Spark Plug section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions! Always

follow safe operating and maintenance practices.

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in personal

injury, or loss of life.

ACAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in damage to

or destruction of equipment.

Page 7

This manual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

I

NOTE

o This note symbol indicates points of partic-

ular interest for more efficient and convenient

operation.

l

Indicates a procedural step or work to be done.

olndicates a procedural sub-step or how to do the

work of the procedural step it follows. It also

precedes the text of a WARNING, CAUTION, or

NOTE.

*Indicates a conditional step or what action to take

based on the results of the test or inspection in the

procedural step or sub-step it follows.

In most chapters an exploded view illustration of

the system components follows the Table of

Contents.

instructions indicating which parts require specified

tightening torque, oil, grease or a locking agent

during assembly.

In these illustrations you will find the

Page 8

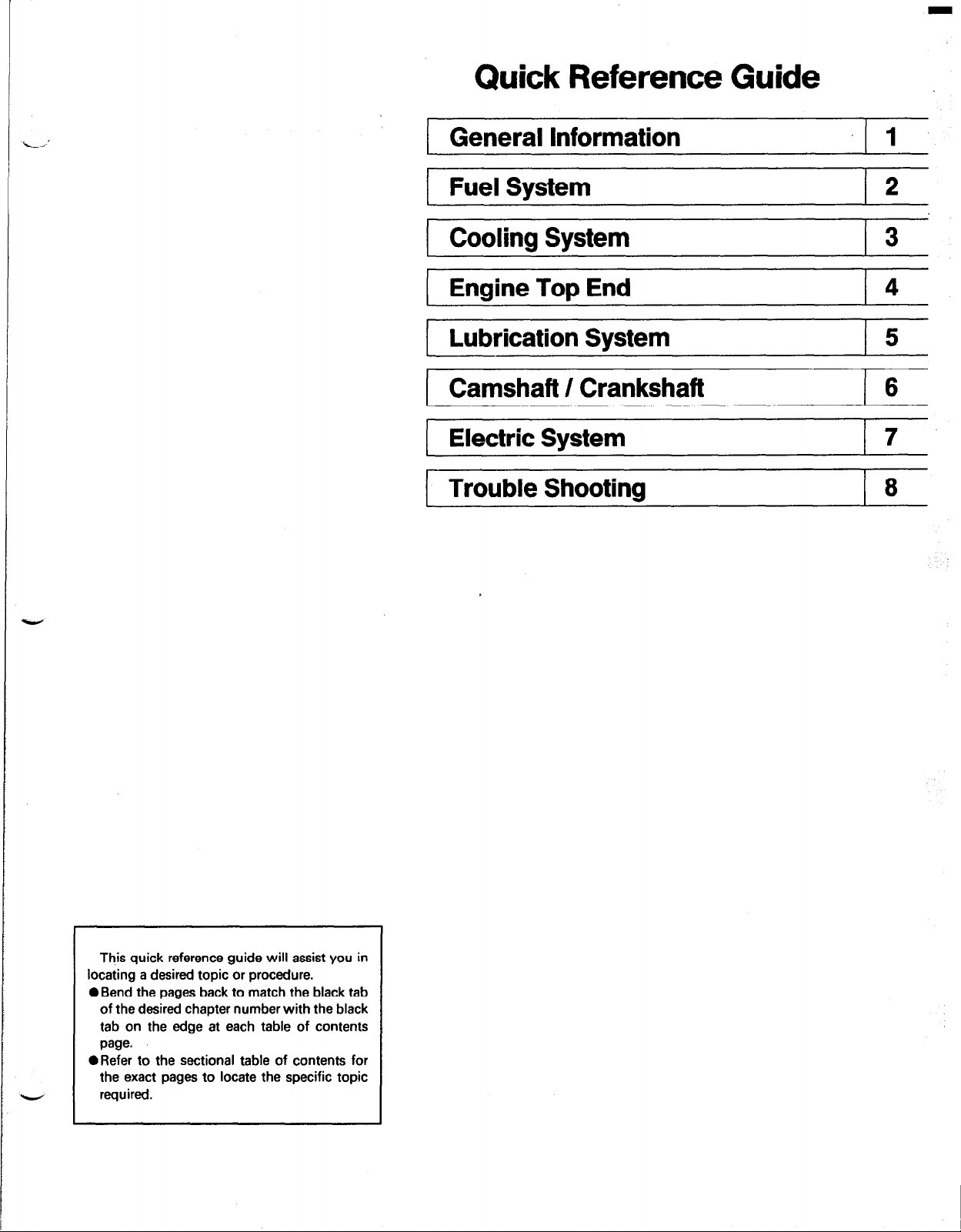

Quick Reference Guide

1 General Information I 1

1 Fuel System

( Cooling System

1 Engine Top End

Lubrication System ( 5

I

( Camshaft / Crankshaft

1 Electric System

I Trouble Shooting

I 2

I 3

This quick reference guide will assist you in

locating a desired topic or procedure.

0 Bend the pages back to match the black tab

of the desired chapter number with the black

tab on the edge at each table of contents

page.

l

Refer to the sectional table of contents for

the exact pages to locate the specific topic

-

required.

Page 9

GENERAL INFORMATION l-l

General Information

Table of Contents

1

II

Before Servicing .........................................................................................................

Model Identification ....................................................................................................

General Specifications

Periodic Maintenance Chart except U.S

Periodic Maintenance Chart for

Torque and Locking Agent.. ......................................................................................

............................................

......................................................................

U.S. ......................................................................... .1-B

. ................................................... l-6

.I -2

l-5

1-7

.l -9

Page 10

1-2 GENERAL INFORMATION

Before Servicing

Before starting to service the engine, carefully read the applicable section to eliminate unnecessary work.

Photographs, diagrams, notes, cautions, warnings, and detailed descriptions have been included wherever

necessary. Nevertheless, even a detailed account has limitations, a certain amount of basic knowledge is required

for successful work.

Especially note the following:

(1) Dirt

Before removal and disassembly, clean the engine. Any dirt entering the engine, carburetor, or other

parts, will work as an abrasive and shorten the life of engine.

part, clean off any dust or metal filings.

:) Battery Ground

(2

Remove the ground (-) lead from the battery before performing any disassembly operations on the

equipment. This prevents:

(a) the possibility of accidentally turning the engine over while partially disassembled.

(b) sparks at electrical connections which will occur when they are disconnected.

(c) damage to electrical parts.

(3) Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes and

tighten them to a snug fit. Then tighten them evenly, in a staggered sequence. This is to avoid distortion

of the part and/or causing gas or oil leakage. Conversely, when loosening the bolts, nuts, or screws, first

loosen all of them by about a quarter of a turn and then remove them. Where there is a tightening sequence

indication in this Service Manual, the bolts, nuts, or screws must be tightened in the order and method

indicated.

(4) Torque

When torque values are given in this Service Manual, use them. Either too little or too much torque may

lead to serious damage. Use a good quality, reliable torque wrench.

(5) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If a part seems

especially difficult to remove or install, stop and examine what may be causing the problem. Whenever

tapping is necessary, tap lightly using a wooden or plastic-faced mallet. Use an impact driver for screws

(particularly for the removal of screws held by a locking agent) in order to avoid damaging the heads.

(6) Edges

Watch for sharp edges, especially during major engine disassembly and assembly. Protect your hands

with gloves or a piece of thick cloth when lifting the engine or turning it over.

(7) High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent commonly

available in North America is Stoddard solvent (generic name). Always follow manufacturer and container

directions regarding the use of any solvent.

(8) Gasket, O-Ring

Do not reuse a gasket or O-ring once it has been in service.

should be free of foreign matter and perfectly smooth to avoid oil or compression leaks.

(9) Liquid Gasket, Non-Permanent Locking Agent

Follow manufacturer’s directions for cleaning and preparing surfaces where these compounds will be

used. Apply sparingly. Excessive amounts may block engine oil passages and cause serious damage. An

example of a non-permanent locking agent commonly available in North America is Loctite Lock’n Seal

(Blue).

(10) Press

A part installed using a press or driver, such as a journal, should first be coated with oil on its outer or

inner circumference so that it will go into place smoothly.

(11) Ball Bearing

When installing a ball bearing , the bearing race which is affected by friction should be pushed by a

suitable driver. This prevents severe stress on the balls and races, and prevents races and balls from being

dented. Press a ball bearing until it stops at the stop in the hole or on the shaft.

For the same reason, before installing a new

The mating surfaces around the gasket

.-~

Page 11

GENERAL INFORMATION 1-3

(12) Oil Seal, Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals.

When pressing in a seal which has manufacturer’s marks, press it in with the marks facing out. Seals

should be pressed into place using a suitable driver, which contacts evenly with the side of seal, until the

face of the seal is even with the end of the hole.

(13) Seal Guide

A seal guide is required for certain oil or grease seals during installation to avoid damage to the seal lips.

Before a shaft passes through a seal, apply a little oil, preferably high temperature grease on the lips to

reduce rubber to metal friction.

(14) Circlip, Retaining Ring

Replace any circlips and retaining rings that were removed with new ones, as removal weakens and

deforms them. When installing circlips and retaining rings, take care to compress or expand them only

enough to install them and no more.

(15) Cotter Pin

Replace any cotter pins that were removed with new ones, as removal deforms and breaks them.

(16) Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the rubbing

surfaces have an adequate lubricative film. During assembly, oil or grease (whichever is more suitable)

should be applied to any rubbing surface which has lost its lubricative film. Old grease and dirty oil should

be cleaned off. Deteriorated grease has lost its lubricative quality and may contain abrasive foreign particles.

Don’t use just any oil or grease. Some oils and greases in particular should be used only in certain

applications and may be harmful if used in an application for which they are not intended. This manual

makes reference to molybdenum disulfide grease (MO& ) in the assembly of certain engine parts. Always

check manufacturer recommendations before using such special lubricants.

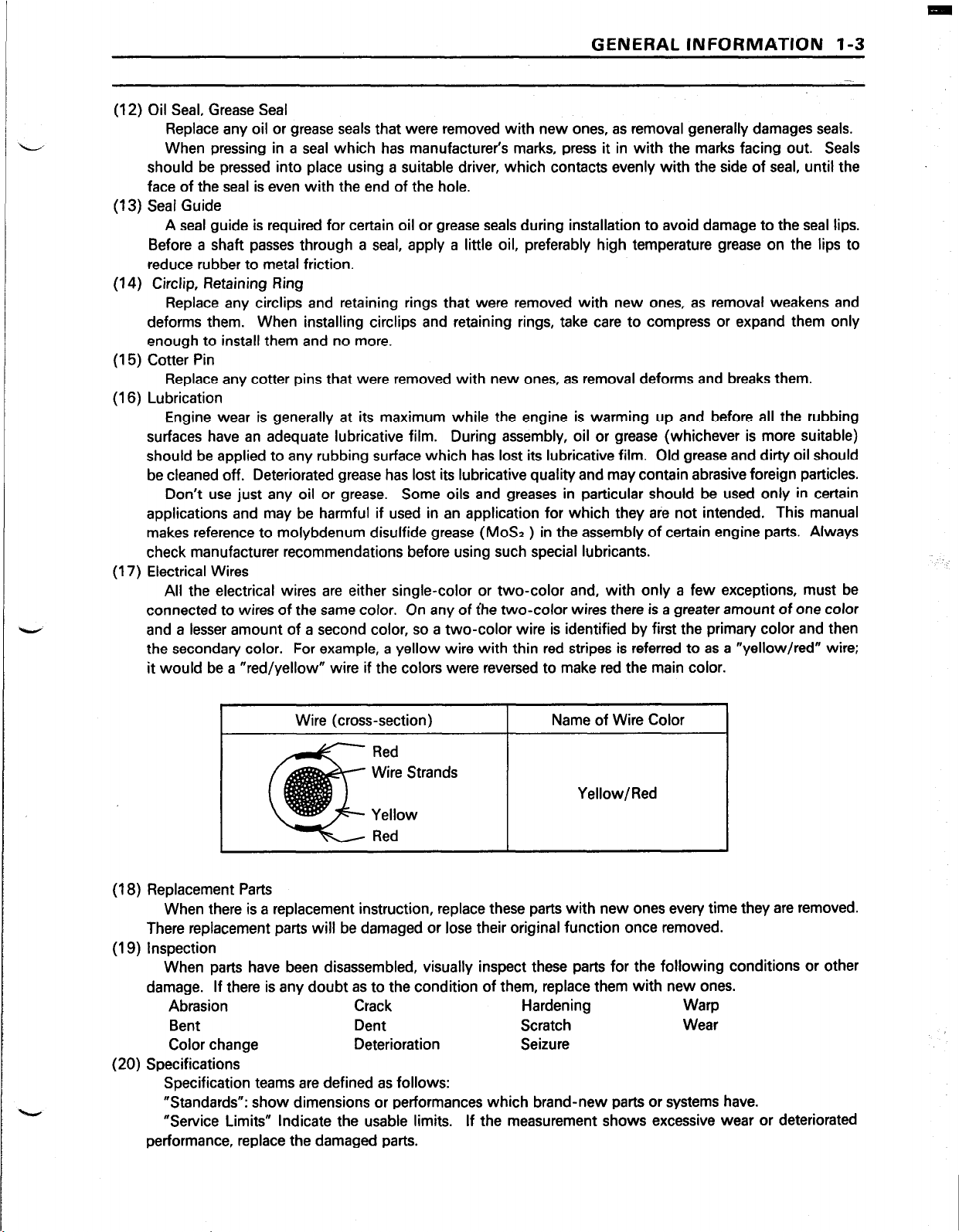

(17) Electrical Wires

All the electrical wires are either single-color or two-color and, with only a few exceptions, must be

connected to wires of the same color. On any of the two-color wires there is a greater amount of one color

and a lesser amount of a second color, so a two-color wire is identified by first the primary color and then

the secondary color. For example, a yellow wire with thin red stripes is referred to as a “yellow/red” wire;

it would be a “red/yellow” wire if the colors were reversed to make red the main color.

-

Wire (cross-section)

Red

Wire Strands

Yellow

Red

(18) Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are removed.

There replacement parts will be damaged or lose their original function once removed.

(19) Inspection

When parts have been disassembled, visually inspect these parts for the following conditions or other

damage. If there is any doubt as to the condition of them, replace them with new ones.

Abrasion Crack

Bent Dent Scratch

Color change Deterioration Seizure

(20) Specifications

Specification teams are defined as follows:

“Standards”: show dimensions or performances which brand-new parts or systems have.

“Service Limits” Indicate the usable limits. If the measurement shows excessive wear or deteriorated

performance, replace the damaged parts.

Name of Wire Color

I

Yellow/Red

Hardening Warp

I

Wear

Page 12

l-4 GENERAL INFORMATION

KAWASAKI Multimeter:

KAWASAKI Multimeter (P/N 3951 OO-9803A) is recommended for the electrical system check because a

meter of other type may indicate different value.

Page 13

Model Identification

GENERAL INFORMATION 1-5

Cylinder Number Designation:

No.1 Cyl. is the right-hand cylinder viewed from the flywheel.

No.2 Cyl. is the left-hand cylinder viewed from the flywheel.

Page 14

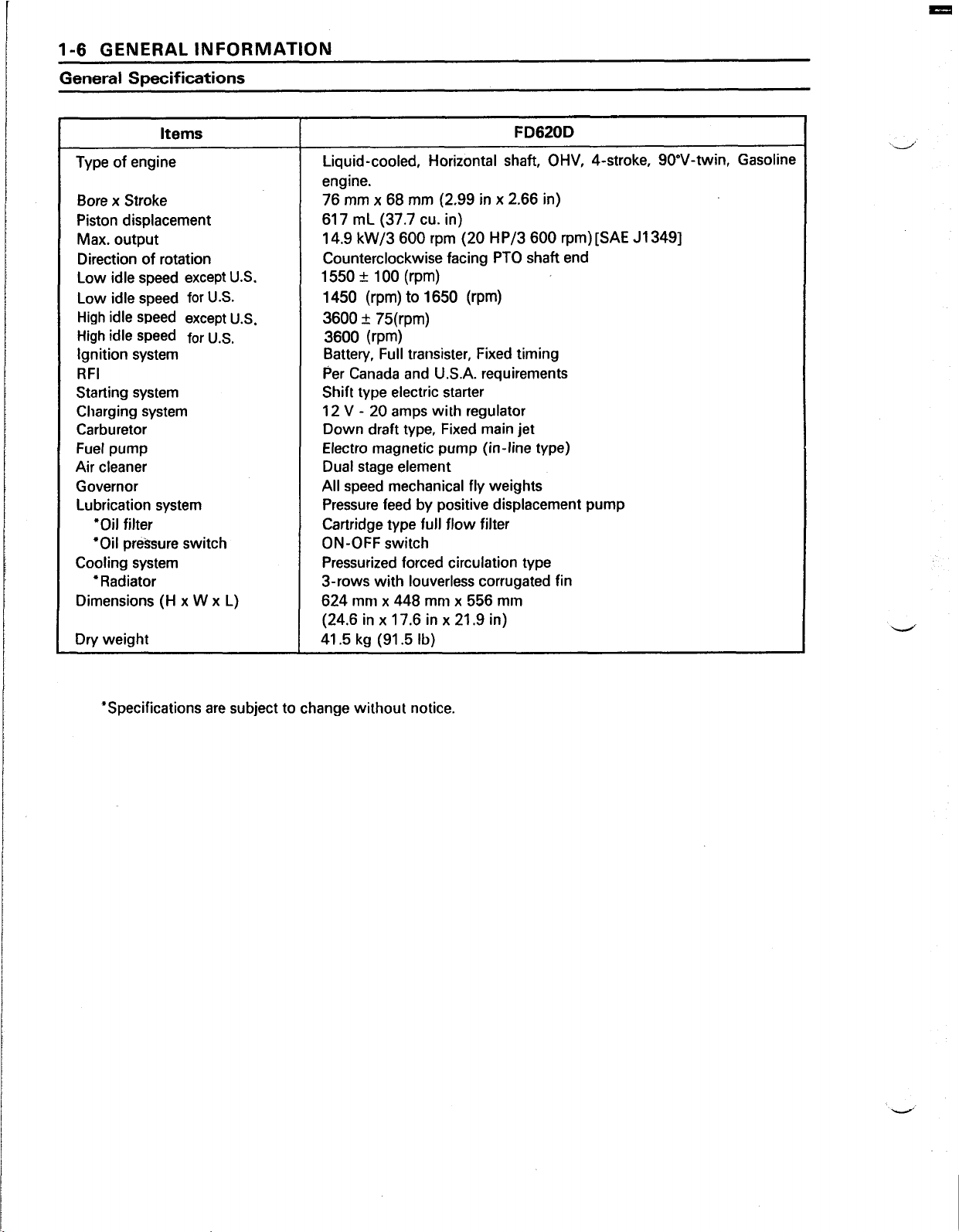

1-6 GENERAL INFORMATION

General Specifications

Items

Type of engine

Bore x Stroke

Piston displacement

Max. output

Direction of rotation

Low idle speed except U.S.

Low idle speed for U.S.

High idle speed except U.S.

High idle speed for U.S.

Ignition system

RFI

Starting system

Charging system

Carburetor

Fuet pump

Air cleaner

Governor

Lubrication system

“Oil filter

‘Oil pressure switch

Cooling system

l

Radiator

Dimensions (H x W x L)

Dry weight 41.5 kg (91.5 lb)

Liquid-cooled, Horizontal shaft, OHV, 4-stroke, 9O”V-twin, Gasoline

engine.

76 mm x 68 mm (2.99 in x 2.66 in)

617 mL (37.7 cu. in)

14.9 kW/3 600 rpm (20 HP/3 600 rpm)[SAE J1349]

Counterclockwise facing PTO shaft end

1550 -?r 100 (rpm)

1450 (rpm) to 1650 (rpm)

3600 + 75(rpm)

3600 (rpm)

Battery, Full transister, Fixed timing

Per Canada and U.S.A. requirements

Shift type electric starter

12 V - 20 amps with regulator

Down draft type, Fixed main jet

Electra magnetic pump (in-line type)

Dual stage element

All speed mechanical fly weights

Pressure feed by positive displacement pump

Cartridge type full flow filter

ON-OFF switch

Pressurized forced circulation type

3-rows with louverless corrugated fin

624 mm x 448 mm x 556 mm

(24.6 in x 17.6 in x 21.9 in)

FD620D

‘Specifications are subject to change without notice.

Page 15

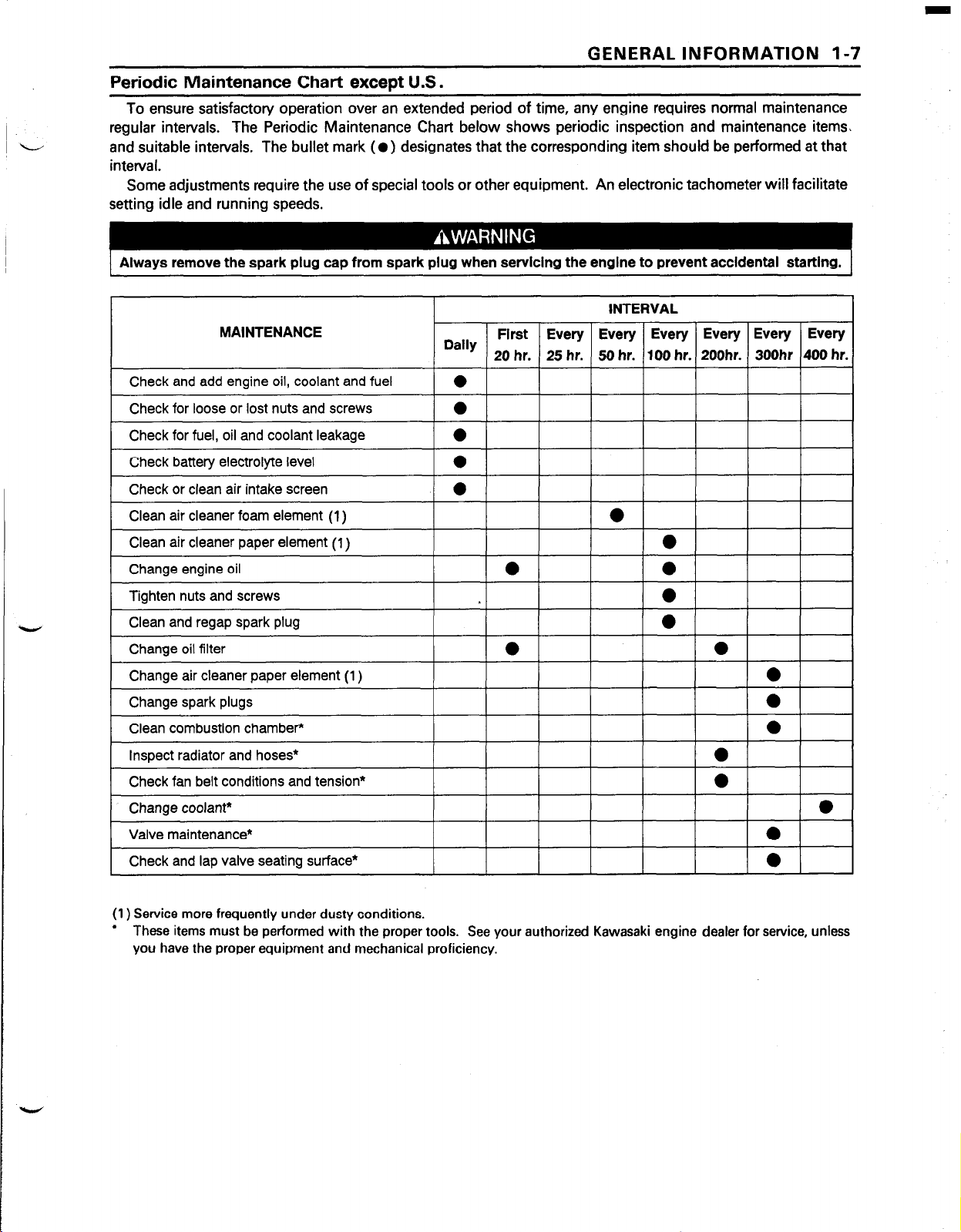

GENERAL INFORMATION l-7

Periodic Maintenance Chart except U.S.

To ensure satisfactory operation over an extended period of time, any engine requires normal maintenance

regular intervals. The Periodic Maintenance Chart below shows periodic inspection and maintenance items\

and suitable intervals. The bullet mark (0) designates that the corresponding item should be performed at that

interval.

Some adjustments require the use of special tools or other equipment. An electronic tachometer will facilitate

setting idle and running speeds.

Always remove the spark plug cap from spark plug when servicing the engine to prevent accldental starting.

INTERVAL

MAINTENANCE

Check and add engine oil, coolant and fuel

Check for loose or lost nuts and screws

Check for fuel, oil and coolant leakage

Check battery electrolyte level

Check or clean air intake screen

Clean air cleaner foam element (1)

Clean air cleaner paper element (I )

Change engine oil

Tighten nuts and screws

Clean and regap spark plug

Change oil filter

Change air cleaner paper element (1)

Change spark plugs

Clean combustion chamber*

Inspect radiator and hoses*

Check fan belt conditions and tension*

Change coolant*

Valve maintenance*

I

Check and lap valve seating surface*

Dally

I I I

I I I I I I

First Every Every Every Every Every Every

20 hr. 25 hr. 50 hr. 100 hr. 200hr. 3OOhr 400 hr.

l

a

0

0

l

l

0

I 0 I I 0 I

( 0 1

0

0 0

0

0

l

l

l

l

I.1 I

( 0 )

I

(1) Service more frequently under dusty conditions.

l

These items must be performed with the proper tools. See your authorized Kawasaki engine dealer for service, unless

you have the proper equipment and mechanical proficiency.

Page 16

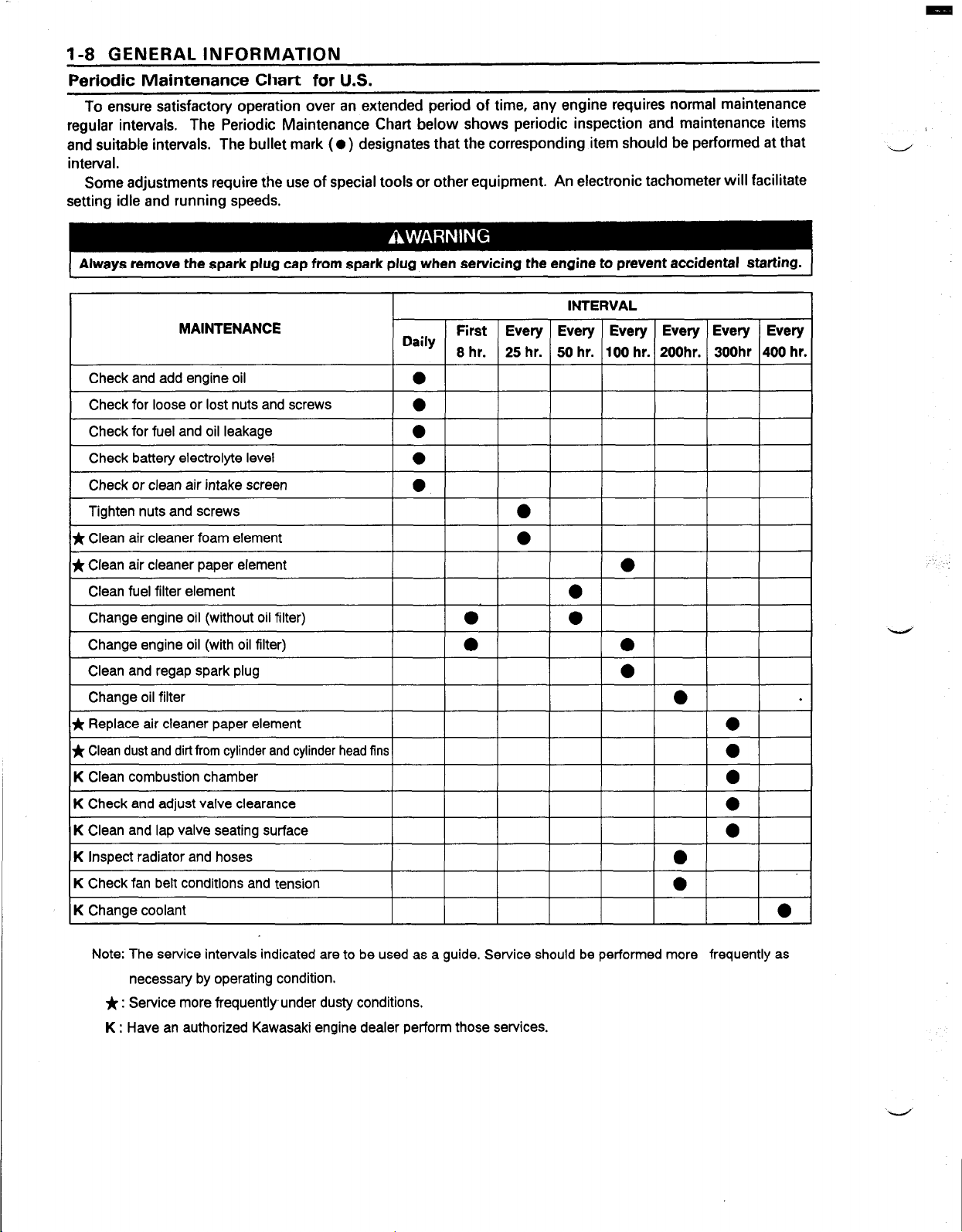

1-8 GENERAL INFORMATION

Periodic Maintenance Chart

To ensure satisfactory operation over an extended period of time, any engine requires normal maintenance

regular intervals. The Periodic Maintenance Chart below shows periodic inspection and maintenance items

and suitable intervals. The bullet mark (0) designates that the corresponding item should be performed at that

interval.

Some adjustments require the use of special tools or other equipment. An electronic tachometer will facilitate

setting idle and running speeds.

Always remove the spark plug cap from spark plug when servicing the engine to prevent accidental starting.

MAINTENANCE

for

U.S.

K Clean and lap valve seating surface

K Inspect radiator and hoses

K Check fan belt conditions and tension

K Change coolant

Note: The service intervals indicated are to be used as a guide. Service should be performed more frequently as

necessary by operating condition.

* : Service more frequently.under dusty conditions.

K : Have an authorized Kawasaki engine dealer perform those services.

0

0

0

0

Page 17

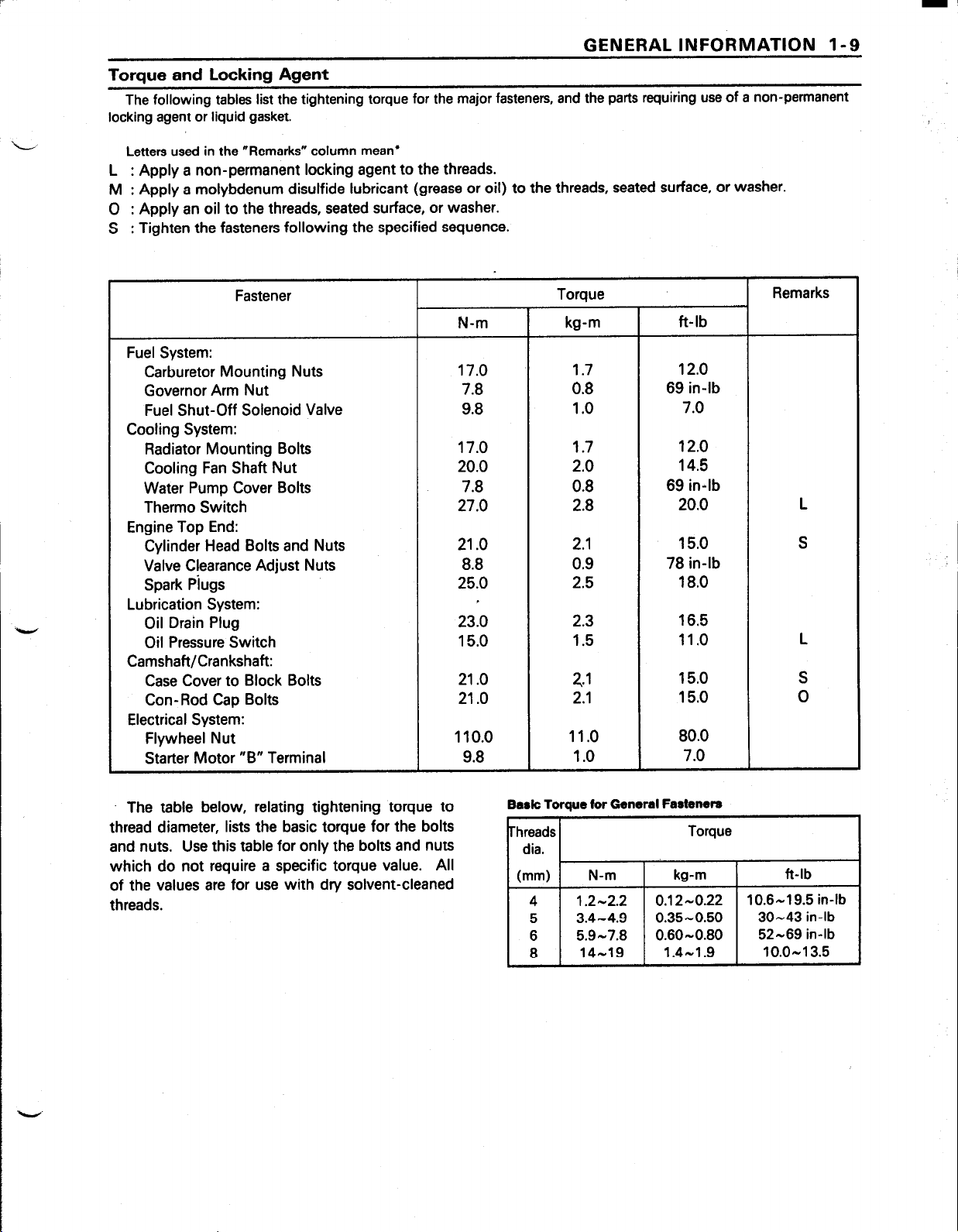

GENERAL INFORMATION l-9

Torque and Locking Agent

The following tables list the tightening torque for the major fasteners, and the parts requiring use of a non-permanent

locking agent or liquid gasket.

L,

Letters used in the “Remarks” column mean*

L : Apply a non-permanent locking agent to the threads.

M : Apply a molybdenum disulfide lubricant (grease or oil) to the threads, seated surface, or washer.

0 : Apply an oil to the threads, seated surface, or washer.

S : Tighten the fasteners following the specified sequence.

Fastener

N-m

Torque Remarks

kg-m ft-lb

Fuel System:

Carburetor Mounting Nuts

Governor Arm Nut

Fuel Shut-Off Solenoid Valve

17.0

7.8

9.8

1.7

0.8

12.0

69 in-lb

1 .o 7.0

Cooling System:

Radiator Mounting Bolts

Cooling Fan Shaft Nut

Water Pump Cover Bolts

Therm0 Switch

17.0

20.0

7.8

27.0

1.7 12.0

2.0 14.5

0.8 69 in-lb

2.8 20.0

Engine Top End:

Cylinder Head Bolts and Nuts

Valve Clearance Adjust Nuts

Spark Piugs

21 .o

8.8

25.0

2.1 15.0

0.9 78 in-lb

2.5 18.0

Lubrication System:

Oil Drain Plug

Oil Pressure Switch

23.0

15.0

2.3

16.5

1.5 11 .o L

Camshaft/Crankshaft:

Case Cover to Block Bolts

Con-Rod Cap Bolts

21 .o

21 .o

2.1

15.0 S

2.1 15.0 0

Electrical System:

Flywheel Nut

Starter Motor “B” Terminal

110.0

9.8

11 .o 80.0

1 .o 7.0

L

S

The table below, relating tightening torque to

thread diameter, lists the basic torque for the bolts

and nuts. Use this table for only the bolts and nuts

which do not require a specific torque value. All

of the values are for use with dry solvent-cleaned

threads.

Bark Toraue for General Fasteners

hreads

dia.

(mm)

4 1.2-2.2

5 3.4-4.9

6 5.9-7.8

8 14-19

N-m

Torque

Page 18

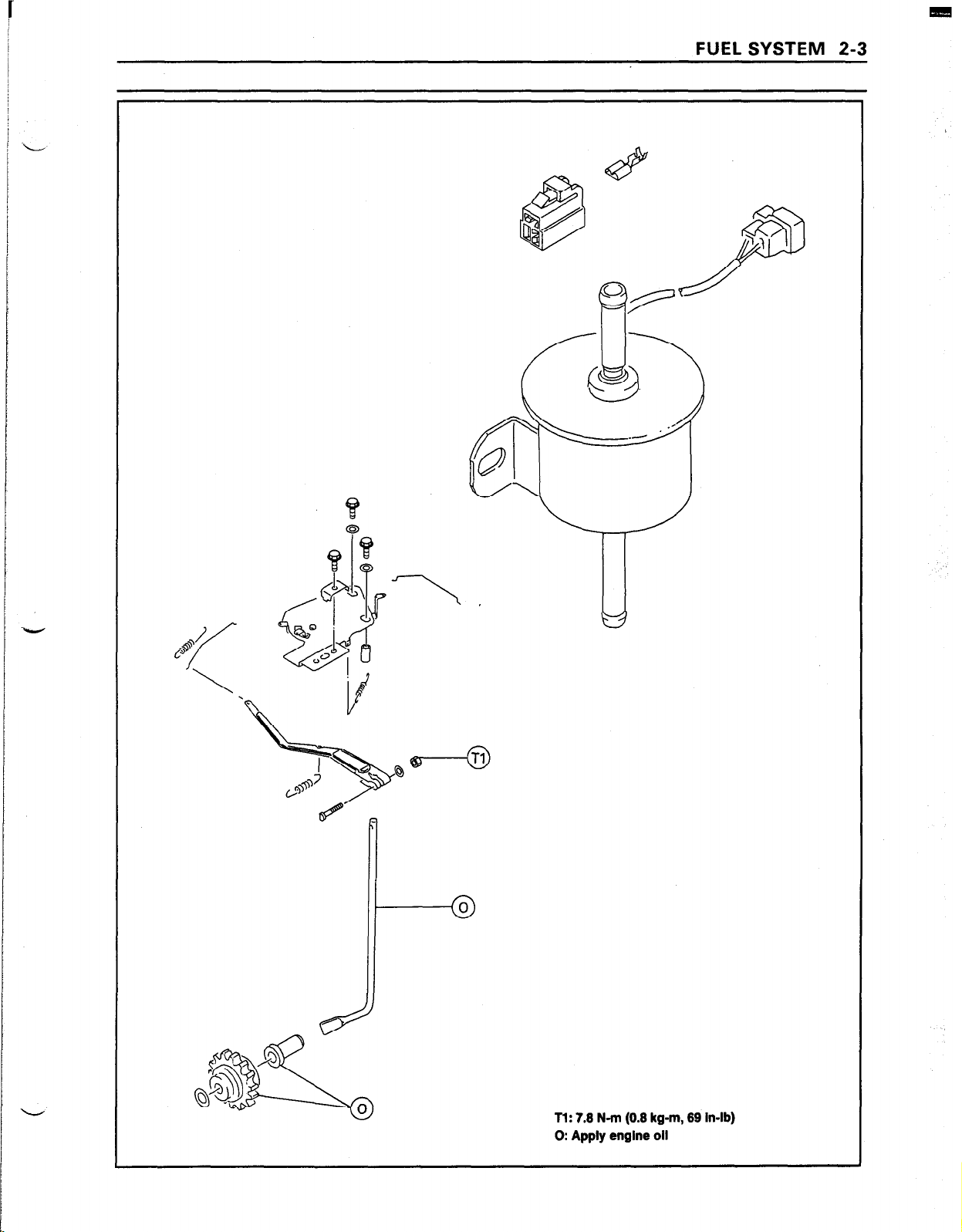

Fuel System

Table of Contents

FUEL SYSTEM 2-l

2

L

Exploded View

Specifications..

Governor Link Mechanism

Control Panel Assembly/Removal

Control Panel Assembly Installation Notes

Governor Am, Removal

Governor Arm Installation

Governor Assembly Removal

Governor Assembly Installation Notes

Governor Assembly Inspection

Governor Shaft Removal

Governor Shaft Installation Notes

Carburetor

Fuel and Air Flow

Fuel Shut Off Solenoid Valve ..............................................................................................

Idle Mixture Screw (Pilot Screw) and Idle Speed Adjustment

Fast Idle Speed Adjustment..

High Altitude Operation

Main Jet Replacement..

Fuel System Cleanliness

Carburetor Removal

Installation Notes

Disassembly Assembly Notes ............................................................................................

Cleaning

Inspection..

Fuel Shut-Off Solenoid Valve Test

Intake Manifold..

Removal. ..............................................................................................................................

Installation Notes

inspection

Fuel Pump..

Fuel Pump Test ..................................................................................................................

Air Cleaner.. .......................................................................................................................... ...2-17

Element Removal.. ............................................................................................................. .2-l 7

Element Installation Notes..

Element Cleaning and Inspection

Cleaner Body and Bracket Removal

Cleaner Body and Bracket Installation Notes

Housing (Case and Body) Inspection

.......................................................................................................................... 2-2

.......................................................................................................................... 2-4

.......................................................................................................

.......................................................................................

........................................................................................................

....................................................................................................

...............................................................................................

............................................................................................

.....................................................................................................

......................................................................................

.................................................................................................................................. 2-8

.......................................... 0 ......................................................................

............................................................................................... 2-9

..................................................................................................... 2-10

..................................................................................................... 2-10

Inspection

........................................................................................................... 2-l 1

............................................................................................................... 2-l 1

............................................................................................................................. 2-12

......................................................................................................................... 2-l 3

....................................................................................

..................................................................................................................... 2-l 5

............................................................................................................... 2-l 5

.........................................................................................................................

.......................................................................................................................... ...2-16

...............................................................................................

......................................................................................

........................................................................

................................................................................

..........................................

.................................................................................. 2-l 1

................................................................................ ..2-18

.................................................................... 2-18

...............................................................................

2-5

2-5

.2-5

2-5

2-5

2-6

2-6

2-6

.2-6

.2-7

2-8

2-8

2-9

2-l 2

2-14

2-l 5

..2-15

2-16

2-17

2-17

2-18

Page 19

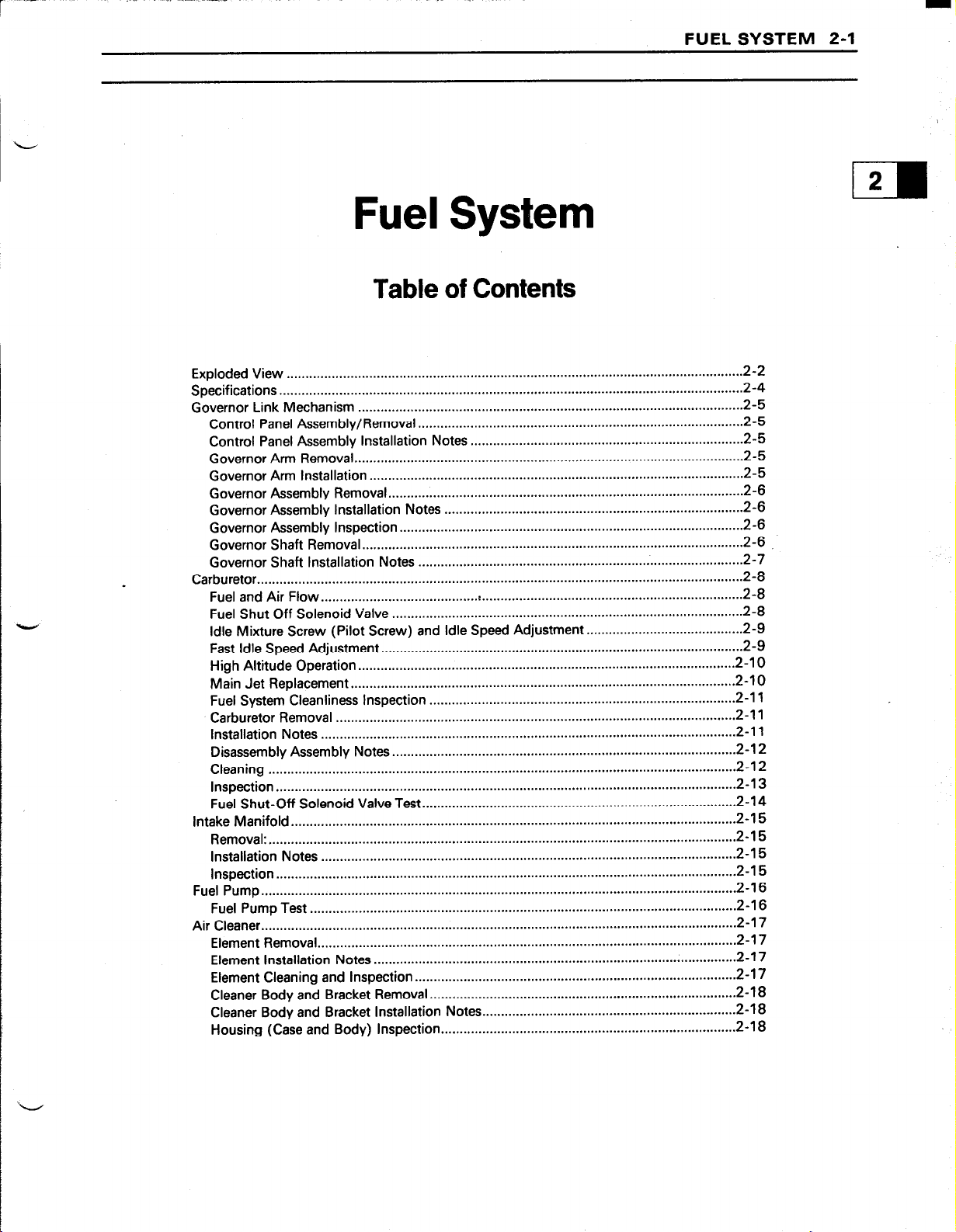

2-2 FUEL SYSTEM

Exploded View

Tl: 2.00 N-m (0.20kg-m,17.0 in-lb)

(Stopper Screw)

T2: 1.16 N-m (0.13 kg-m, 10.3 in-lb)

(Drain Screw)

T3: 0.66 N-m (0.90 kg-m, 7.6 in-lb)

(Throttle Valve Screws)

T4: 9.80 N-m (1 .OO kg-m, 87.0 In-lb)

(Solenoid Valve)

T5: 1.00 N-m (0.10 kg-m, 8.9 in-lb)

(Main Jet)

T6: 2.94 N-m (0.30 Kg-m, 26.0 In-lb)

(Air Hone Mounting Screws)

T7: 1.00 N-m (0.10 kg-m, 8.9 in-lb)

(Pilot Ah Jet)

T8: 0.88 N-m (0.90 kg-m, 7.8 in-lb)

(Choke Valve Screw)

l8: 1.00 N-m (0.10 kg-m, 8.9 in-lb)

(Main Air Jet)

TlO: 17.00 N-m (1.7 kg-m, 12.0 Mb)

(Carb. Mounting Nuts)

Page 20

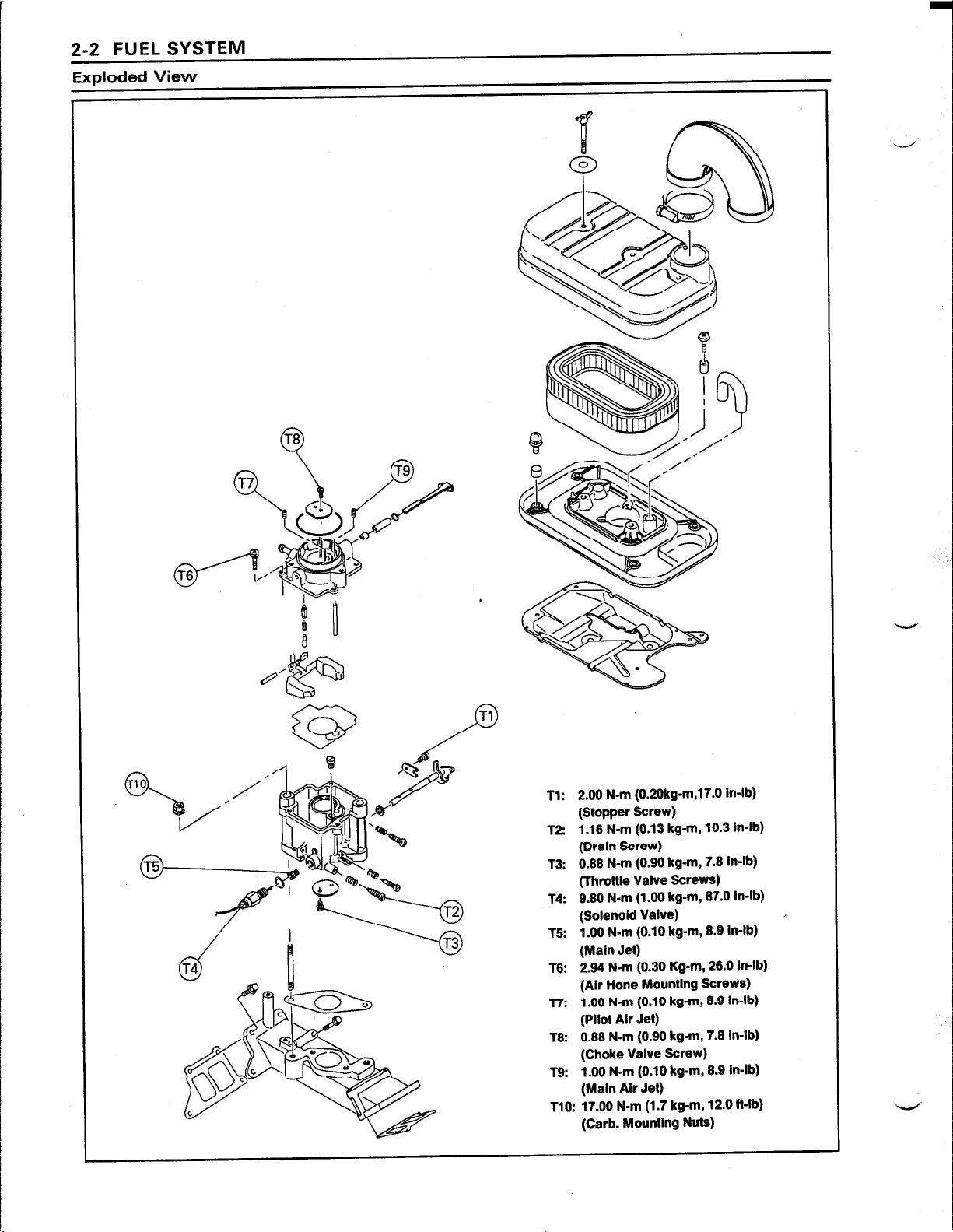

FUEL SYSTEM 2-3

.

4

Tl: 7.6 N-m (0.8 kg-m, 89 in-lb)

0: Apply engine oil

Page 21

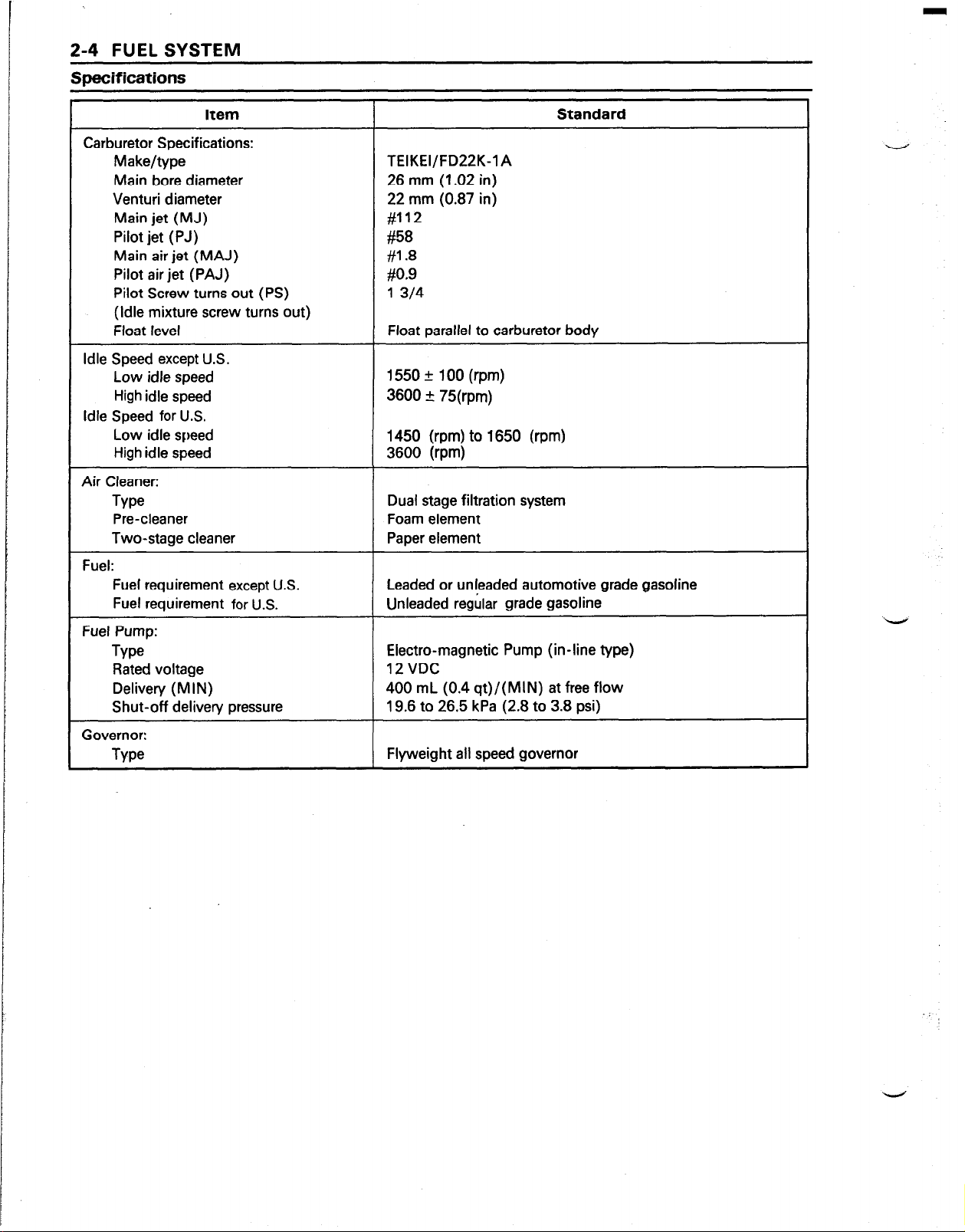

2-4 FUEL SYSTEM

Specifications

Item

Carburetor Specifications:

Make/type

Main bore diameter

Venturi diameter

Main jet (MJ)

Pilot jet (PJ)

Main air jet (MAJ)

Pilot air jet (PAJ)

Pilot Screw turns out (PS)

(Idle mixture screw turns out)

Float level

Idle Speed except U.S.

Low idle speed

High idle speed

Idle Speed for U.S.

Low idle speed

High idle speed

Air Cleaner:

Type

Pre-cleaner

Two-stage cleaner

Standard

TEIKEI/FD22K-1 A

26 mm (1.02 in)

22 mm (0.87 in)

#112

#58

#1.8

#0.9

1 314

Float parallel to carburetor body

1550 _+ 100 (rpm)

3600 a 75(rpm)

1450 (rpm) to 1650 (rpm)

3600 (rpm)

Dual stage filtration system

Foam element

Paper element

Fuel:

Fuel requirement except U.S.

Fuel requirement

Fuel Pump:

Type

Rated voltage

Delivery (MIN)

Shut-off delivery pressure

Governor:

Type

for U.S.

Leaded or unleaded automotive grade gasoline

Unleaded regular grade gasoline

Electra-magnetic Pump (in-line type)

12VDC

400 mL (0.4 qt)/(MIN) at free flow

19.6 to 26.5 kPa (2.8 to 3.8 psi)

Flyweight all speed governor

Page 22

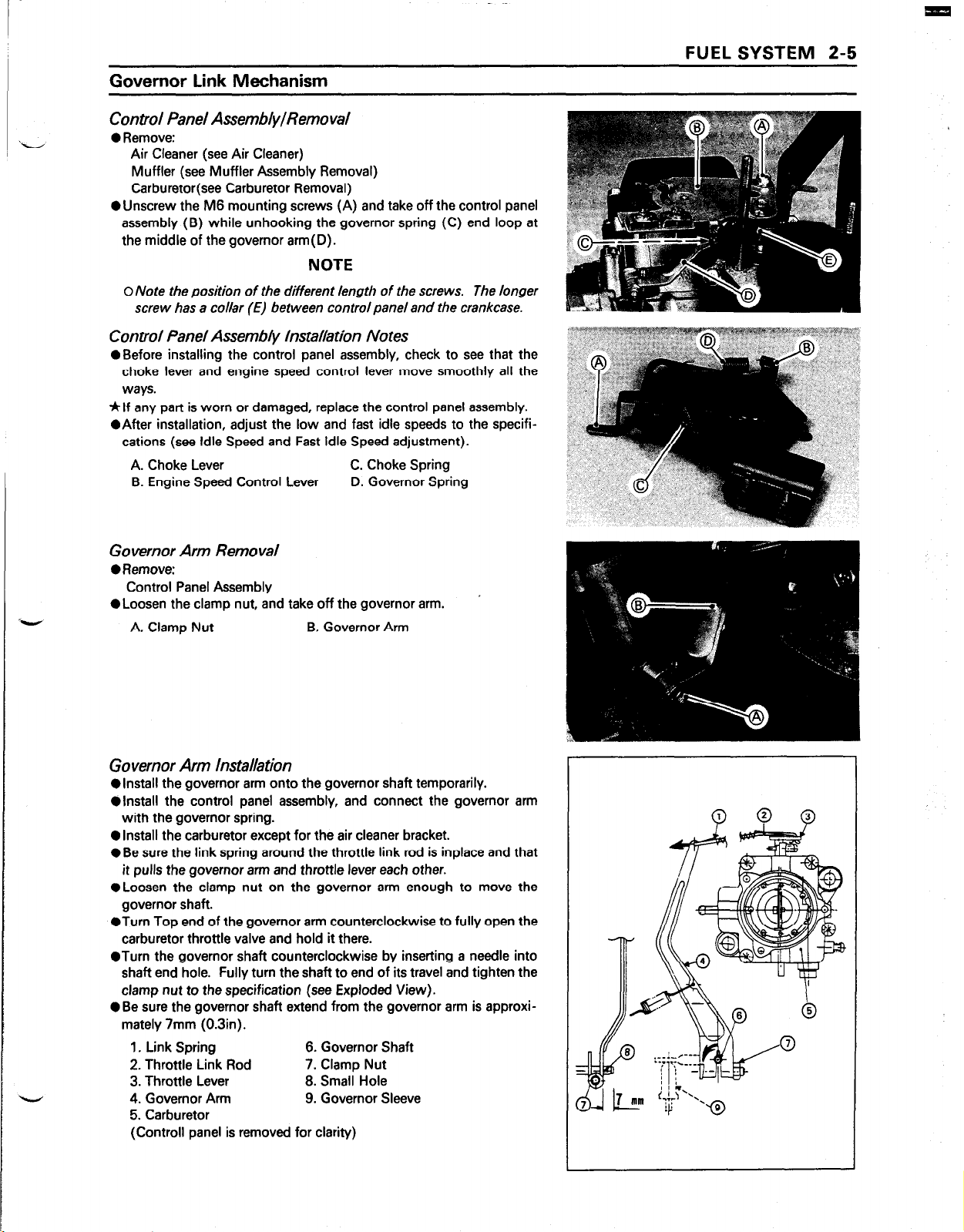

Governor Link Mechanism

Control Panel Assembly/Removal

0 Remove:

Air Cleaner (see Air Cleaner)

Muffler (see Muffler Assembly Removal)

Carburetor(see Carburetor Removal)

OUnscrew the M6 mounting screws (A) and take off the control panel

assembly (B) while unhooking the governor spring (C) end loop at

the middle of the governor arm(D).

NOTE

0 Note the position of the different length of the screws. The longer

screw has a collar (E) between control panel and the crankcase.

Control Panel Assembly Installation Notes

l

Before installing the control panel assembly, check to see that the

choke lever and engine speed control lever move smoothly all the

ways.

*If any part is worn or damaged, replace the control panel assembly.

l

After installation, adjust the low and fast idle speeds to the specifications (see Idle Speed and Fast Idle Speed adjustment).

A. Choke Lever C. Choke Spring

B. Engine Speed Control Lever D. Governor Spring

FUEL SYSTEM 2-5

Governor Arm Removal

0 Remove:

Control Panel Assembly

l

Loosen the clamp nut, and take off the governor arm.

A. Clamp Nut B. Governor Arm

Governor Arm Installation

l

install the governor arm onto the governor shaft temporarily.

l

install the control panel assembly, and connect the governor arm

with the governor spring.

0 Install the carburetor except for the air cleaner bracket.

l

Be sure the link spring around the throttle link rod is inplace and that

it pulls the governor arm and throttle lever each other.

l

Loosen the clamp nut on the governor arm enough to move the

governor shaft.

l

Turn Top end of the governor arm counterclockwise to fully open the

carburetor throttle valve and hold it there.

@Turn the governor shaft counterclockwise by inserting a needle into

shaft end hole. Fully turn the shaft to end of its travel and tighten the

clamp nut to the specification (see Exploded View).

l

Be sure the governor shaft extend from the governor arm is approximately 7mm (0.3in).

1. Link Spring 6. Governor Shaft

2. Throttle Link Rod 7. Clamp Nut

3. Throttle Lever 6. Small Hole

4. Governor Arm 9. Governor Sleeve

5. Carburetor

(Controll panel is removed for clarity)

Page 23

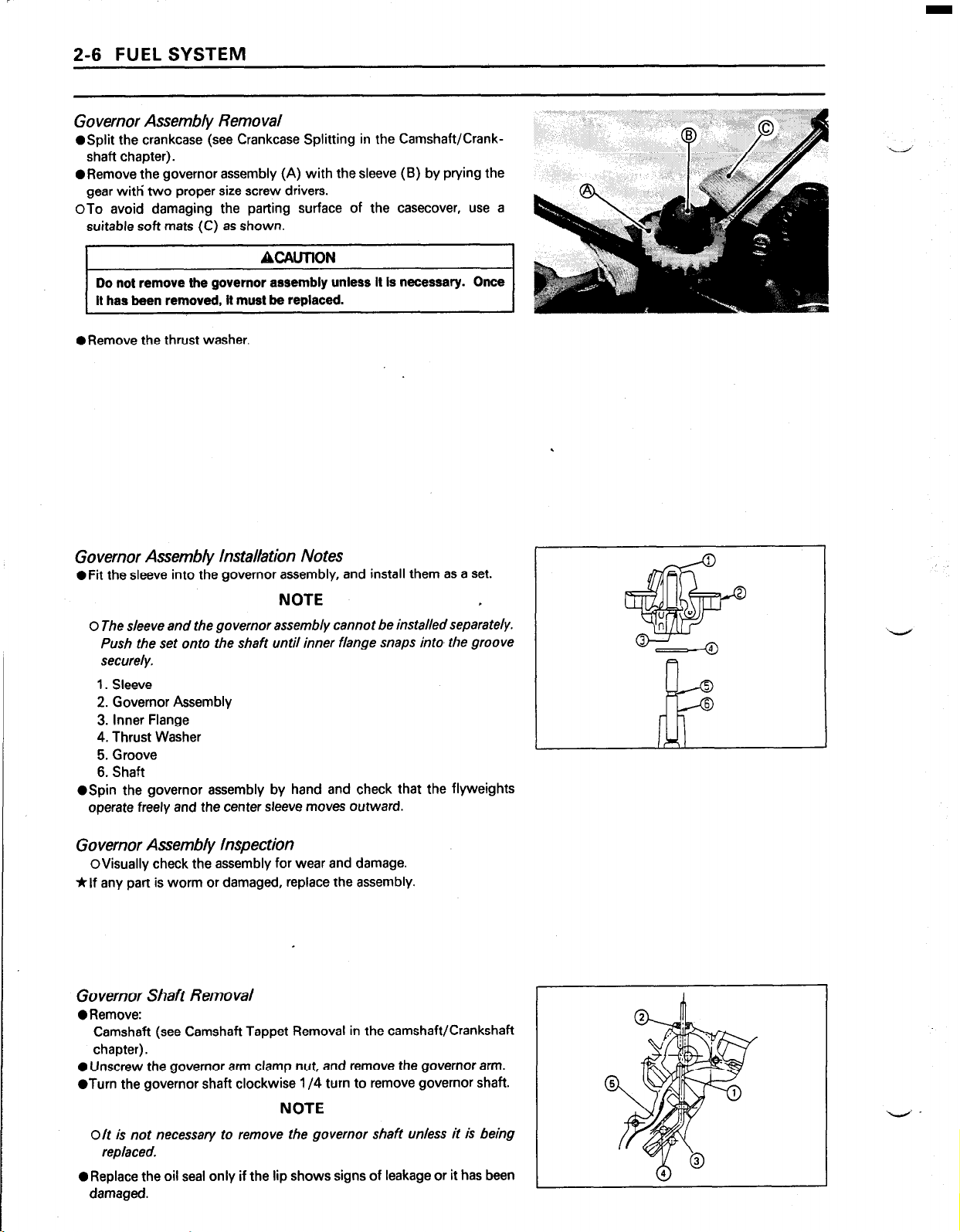

2-6 FUEL SYSTEM

Governor Assembly Removal

@Split the crankcase (see Crankcase Splitting in the Camshaft/Crank-

shaft chapter).

@Remove the governor assembly (A) with the sleeve (B) by prying the

gear with’ two proper size screw drivers.

OTo avoid damaging the parting surface of the casecover, use a

suitable soft mats (C) as shown.

ACAUTION

Do not remove the governor assembly unless it is necessary. Once

It has been removed, it must be replaced.

oRemove the thrust washer.

Governor Assembly Installation Notes

OFit the sleeve into the governor assembly, and install them as a set.

NOTE ,

0 The sleeve and the governor assembly cannot be installed separately.

Push the set onto the shaft until inner flange snaps into the groove

securely.

1. Sleeve

2. Governor Assembly

3. Inner Flange

4. Thrust Washer

5. Groove

6. Shaft

@Spin the governor assembly by hand and check that the flyweights

operate freely and the center sleeve moves outward.

Governor Assembly Inspection

OVisually check the assembly for wear and damage.

*If any part is worm or damaged, replace the assembly.

Governor Shaft Removal

0 Remove:

Camshaft (see Camshaft Tappet Removal in the camshaft/Crankshaft

chapter).

0 Unscrew the governor arm clamp nut, and remove the governor arm.

ofurn the governor shaft clockwise l/4 turn to remove governor shaft.

NOTE

O/t is not necessary to remove the governor shaft unless it is being

replaced.

0 Replace the oil seal only if the lip shows signs of leakage or it has been

damaged.

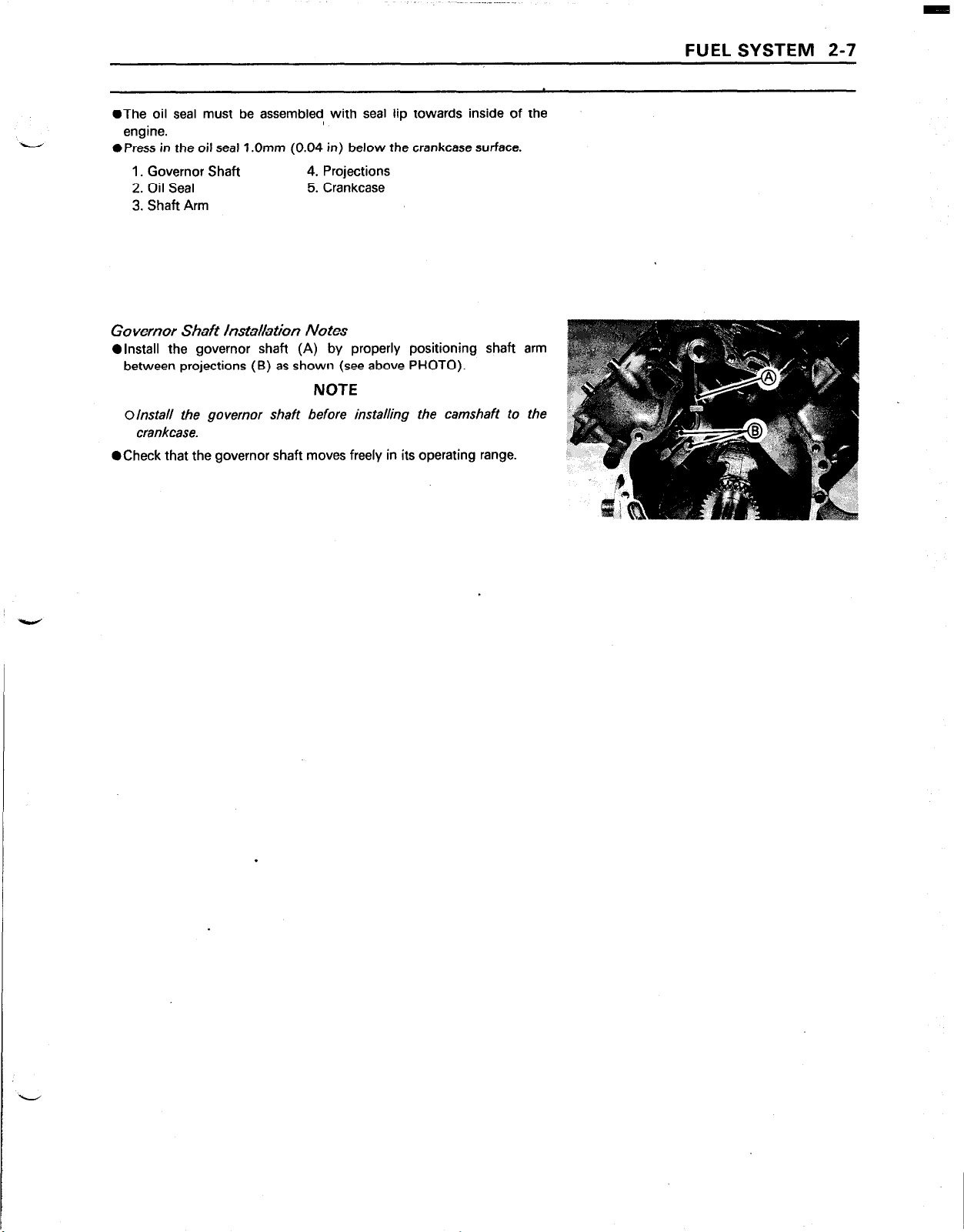

Page 24

l

The oil seal must be assembled, with seal lip towards inside of the

engine.

l

Press in the oil seal 1 .Omm (0.04 in) below the crankcase surface.

1. Governor Shaft

2. Oil Seal 5. Crankcase

3. Shaft Arm

4. Projections

Governor Shaft Installation Notes

l

install the governor shaft (A) by properly positioning shaft arm

between projections (B) as shown (see above PHOTO).

NOTE

olnstall the governor shaft before installing the camshaft to the ‘>

crankcase.

l

Check that the governor shaft moves freely in its operating range.

FUEL SYSTEM 2-7

-

.

Page 25

2-8 FUEL SYSTEM

Carburetor

Fuel and Air Flow

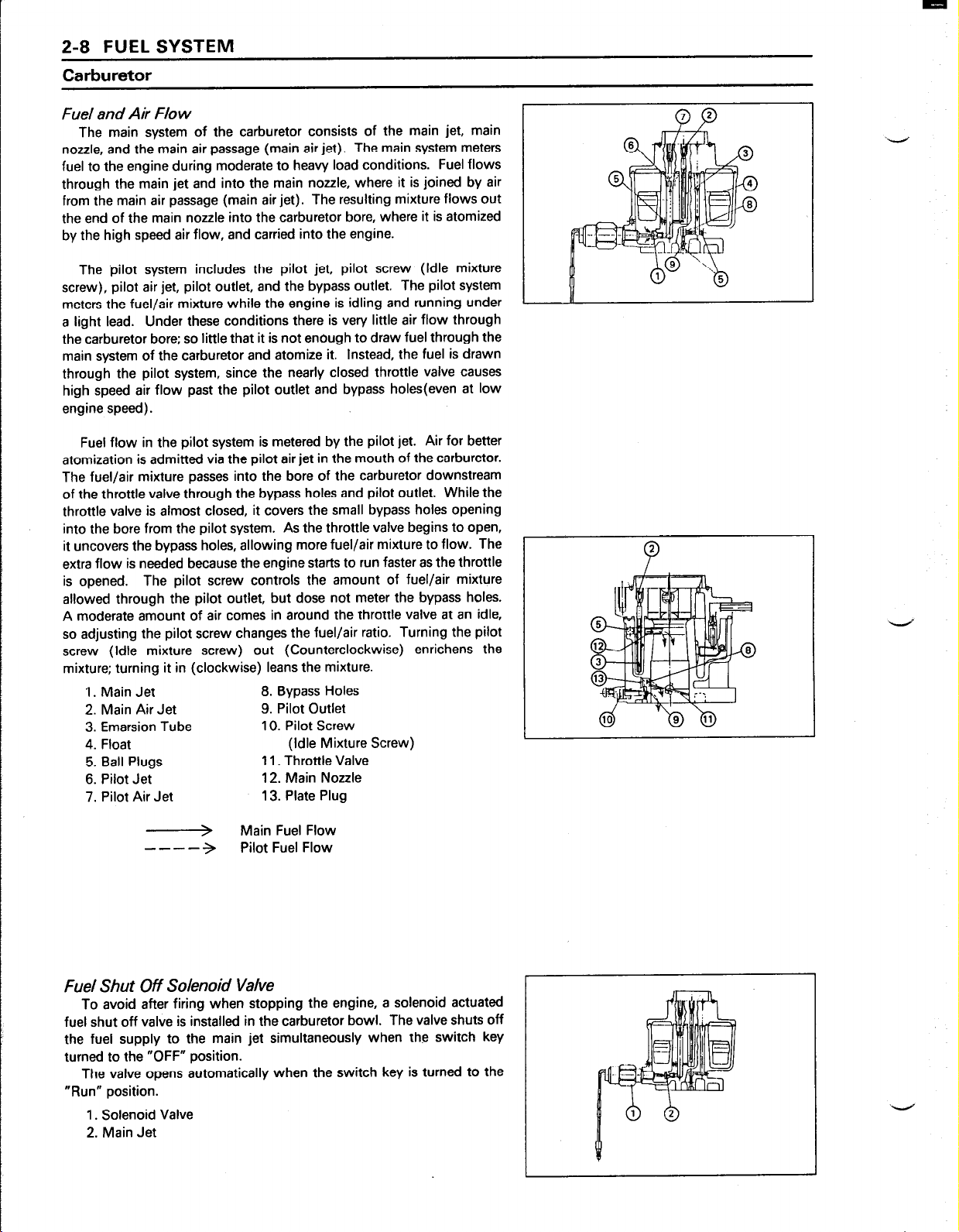

The main system of the carburetor consists of the main jet, main

nozzle, and the main air passage (main air jet). The main system meters

fuel to the engine during moderate to heavy load conditions. Fuel flows

through the main jet and into the main nozzle, where it is joined by air

from the main air passage (main air jet). The resulting mixture flows out

the end of the main nozzle into the carburetor bore, where it is atomized

by the high speed air flow, and carried into the engine.

The pilot system includes the pilot jet, pilot screw (Idle mixture

screw), pilot air jet, pilot outlet, and the bypass outlet. The pilot system

meters the fuel/air mixture while the engine is idling and running under

a light lead. Under these conditions there is very little air flow through

the carburetor bore; so little that it is not enough to draw fuel through the

main system of the carburetor and atomize it. Instead, the fuel is drawn

through the pilot system, since the nearly closed throttle valve causes

high speed air flow past the pilot outlet and bypass holes(even at low

engine speed).

Fuel flow in the pilot system is metered by the pilot jet. Air for better

atomization is admitted via the pilot air jet in the mouth of the carburetor.

The fuel/air mixture passes into the bore of the carburetor downstream

of the throttle valve through the bypass holes and pilot outlet. While the

throttle valve is almost closed, it covers the small bypass holes opening

into the bore from the pilot system. As the throttle valve begins to open,

it uncovers the bypass holes, allowing more fuel/air mixture to flow. The

extra flow is needed because the engine starts to run faster as the throttle

is opened. The pilot screw controls the amount of fuel/air mixture

allowed through the pilot outlet, but dose not meter the bypass holes.

A moderate amount of air comes in around the throttle valve at an idle,

so adjusting the pilot screw changes the fuel/air ratio. Turning the pilot

screw (Idle mixture screw) out (Counterclockwise) enrichens the

mixture; turning it in (clockwise) leans the mixture.

1. Main Jet 8. Bypass Holes

2. Main Air Jet 9. Pilot Outlet

3. Emarsion Tube 10. Pilot Screw

4. Float (Idle Mixture Screw)

5. Ball Plugs 11. Throttle Valve

6. Pilot Jet

7. Pilot Air Jet 13. Plate Plug

12. Main Nozzle

Main Fuel Flow

----

>

Pilot Fuel Flow

3

Fuel Shut Off Solenoid Valve

To avoid after firing when stopping the engine, a solenoid actuated

fuel shut off valve is installed in the carburetor bowl. The valve shuts off

the fuel supply to the main jet simultaneously when the switch key

turned to the “OFF” position.

The valve opens automatically when the switch key is turned to the

“Run” position.

1. Solenoid Valve

2. Main Jet

Page 26

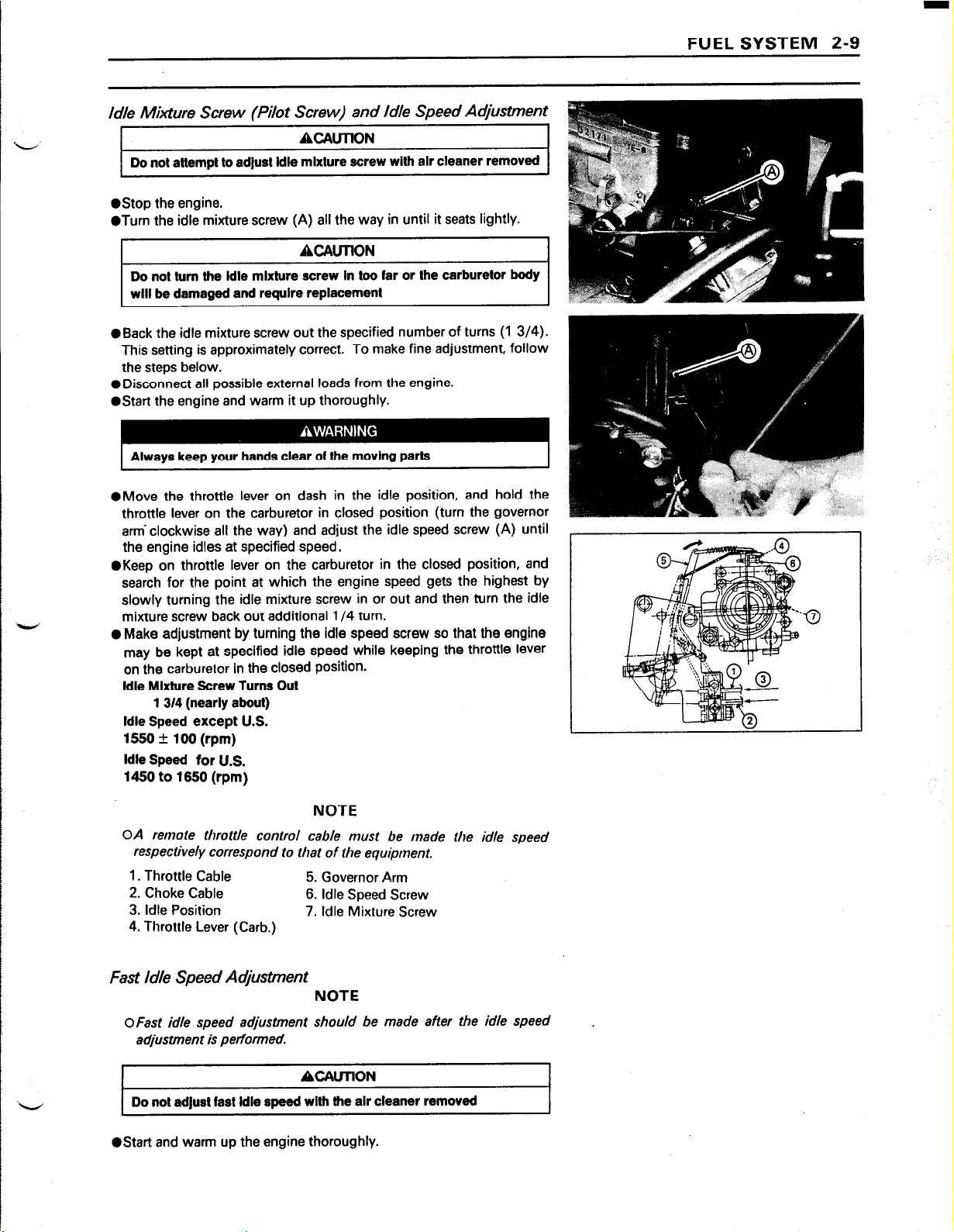

Idle Mixture Screw (Pilot Screw) and Idle Speed AcQustment

ACAlJTtON

Do not attempt to adjust idle mixture screw with air cleaner removed

l

Stop the engine.

@Turn the idle mixture screw (A) all the way in until it seats lightly.

ACAlJTfON

Do not turn tfte idle mixture screw in too far or the carburetor body

will be damaged and require replacement

@Back the idle mixture screw out the specified number of turns (1 3/4).

This setting is approximately correct. To make fine adjustment, follow

the steps below.

l

Disconnect all possible external loads from the engine.

l

Start the engine and warm it up thoroughly.

FUEL SYSTEM 2-9

Always keep your hands clear of the moving

@Move the throttle lever on dash in the idle position, and hold the

throttle lever on the carburetor in closed position (turn the governor

arm clockwise all the way) and adjust the idle speed screw (A) until

the engine idles at specified speed.

l

Keep on throttle lever on the carburetor in the closed position, and

search for the point at which the engine speed gets the highest by

slowly turning the idle mixture screw in or out and then turn the idle

mixture screw back out additional l/4 turn.

0 Make adjustment by turning the idle speed screw so that the engine

may be kept at specified idle speed while keeping the

on the carburetor in the closed position.

idle Mixture Screw Turns Out

1 3/4 (nearly about)

idle Speed except U.S.

1550 + 100 (rpm)

idle Speed for U.S.

1450 to 1650 (rpm)

parts

throttle lever

NOTE

OA remote throttle control cable nlust be made the idle

respectively

1. Throttle Cable

2. Choke Cable

3. Idle Position

4. Throttle Lever (Carb.)

correspond to that of the equipment.

5. Governor Arm

6. Idle Speed Screw

7. Idle Mixture Screw

speed

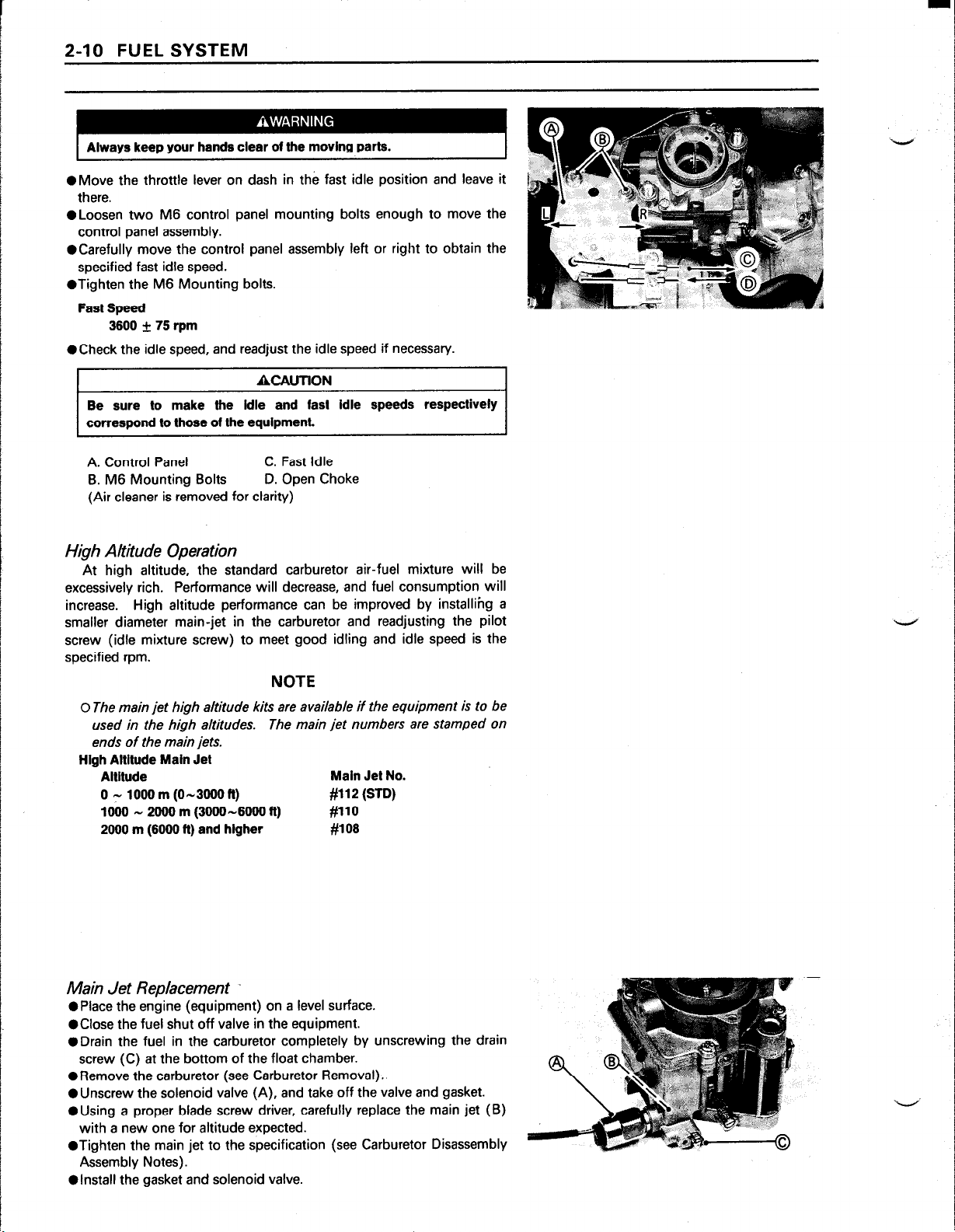

Fast Idle Speed Ac#ustment

NOTE

OFast idle speed adjustment should be made after the idle speed

adjustment is performed.

ACAUllON

Do not adjust fast idle speed with the air cleaner removed

l

Start and warm up the engine thoroughly.

Page 27

2-10 FUEL SYSTEM

Always keep your hands clear of the moving parts.

l

Move the throttle lever on dash in the fast idle position and leave it

there.

@Loosen two M6 control panel mounting bolts enough to move the

control panel assembly.

l

Carefully move the control panel assembly left or right to obtain the

specified fast idle speed.

*Tighten the M6 Mounting bolts.

Fast Speed

3600 f 75 rpm

l

Check the idle speed, and readjust the idle speed if necessary.

ACAlJTlON

Be sure to make the idle and fast idle speeds respectively

correspond to those of the equipment.

A. Control Panel C. Fast Idle

B. M6 Mounting Bolts

(Air cleaner is removed for clarity)

D. Open Choke

High Altitude Operation

At high altitude, the standard carburetor air-fuel mixture will be

excessively rich. Performance will decrease, and fuel consumption will

increase. High altitude performance can be improved by installihg a

smaller diameter main-jet in the carburetor and readjusting the pilot

screw (idle mixture screw) to meet good idling and idle speed is the

specified rpm.

NOTE

0 The main jet high altitude kits are available if the equipment is to be

used in the high altitudes.

ends of the main jets.

High Altitude Main Jet

Altitude

0 y 1000 m (o-3000 ft)

1000 - 2000 m (3000 -6000 ft) #llO

2000 m (6000 ft) and higher #lOS

The main jet numbers are stamped on

Main Jet No.

#112 (STD)

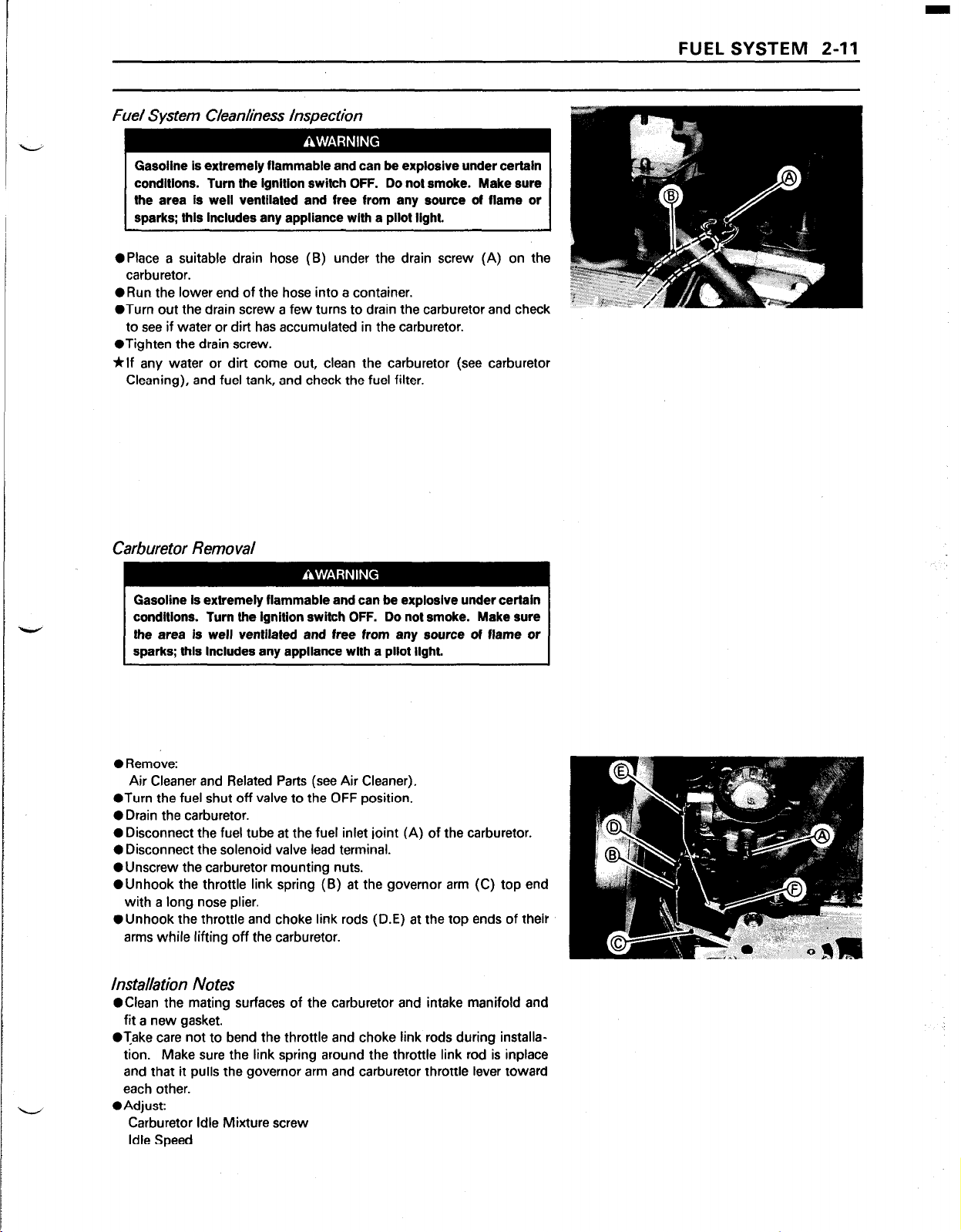

Main Jet Replacement

l

Place the engine (equipment) on a level surface.

l

Close the fuel shut off valve in the equipment.

l

Drain the fuel in the carburetor completely by unscrewing the drain

screw (C) at the bottom of the float chamber.

ORemove the carburetor (see Carburetor Removal).

l

Unscrew the solenoid valve (A), and take off the valve and gasket.

@Using a proper blade screw driver, carefully replace the main jet (B)

with a new one for altitude expected.

@Tighten the main jet to the specification (see Carburetor Disassembly

Assembly Notes).

l

install the gasket and solenoid valve.

Page 28

f uef System Cleanliness inspection

Gasoline is extremely flammable and can be explosive under certain

conditions. Turn the ignition switch OFF. Do not smoke. Make sure

the area is well ventilated and free from any source of flame or

sparks; this includes any appliance with a pilot light.

l

Place a suitable drain hose (B) under the drain screw (A) on the

carburetor.

l

Run the lower end of the hose into a container.

l

Turn out the drain screw a few turns to drain the carburetor and check

to see if water or dirt has accumulated in the carburetor.

l

Tighten the drain screw.

*If any water or dirt come out, clean the carburetor (see carburetor

Cleaning), and fuel tank, and check the fuel filter.

FUEL SYSTEM 2-11

Carburetor Removal

Gasoline is extremely flammable and can be explosive under certain

conditions. Turn the ignition switch OFF. Do not smoke. Make sure

the area is well ventilated and free from any source of flame or

sparks; this includes any appliance with a pilot light.

0 Remove:

Air Cleaner and Related Parts (see Air Cleaner).

@Turn the fuel shut off valve to the OFF position.

0 Drain the carburetor.

0 Disconnect the fuel tube at the fuel inlet joint (A) of the carburetor.

0 Disconnect the solenoid valve lead terminal.

l

Unscrew the carburetor mounting nuts.

l

Unhook the throttle link spring (B) at the governor arm (C) top end

with a long nose plier.

l

Unhook the throttle and choke link rods (D.E) at the top ends of their

arms while lifting off the carburetor.

Installation Notes

l

Clean the mating surfaces of the carburetor and intake manifold and

fit a new gasket.

l

Take care not to bend the throttle and choke link rods during installation. Make sure the link spring around the throttle link rod is inplace

and that it pulls the governor arm and carburetor throttle lever toward

each other.

l

Adjust:

Carburetor Idle Mixture screw

Idle Speed

Page 29

2-12 FUEL SYSTEM

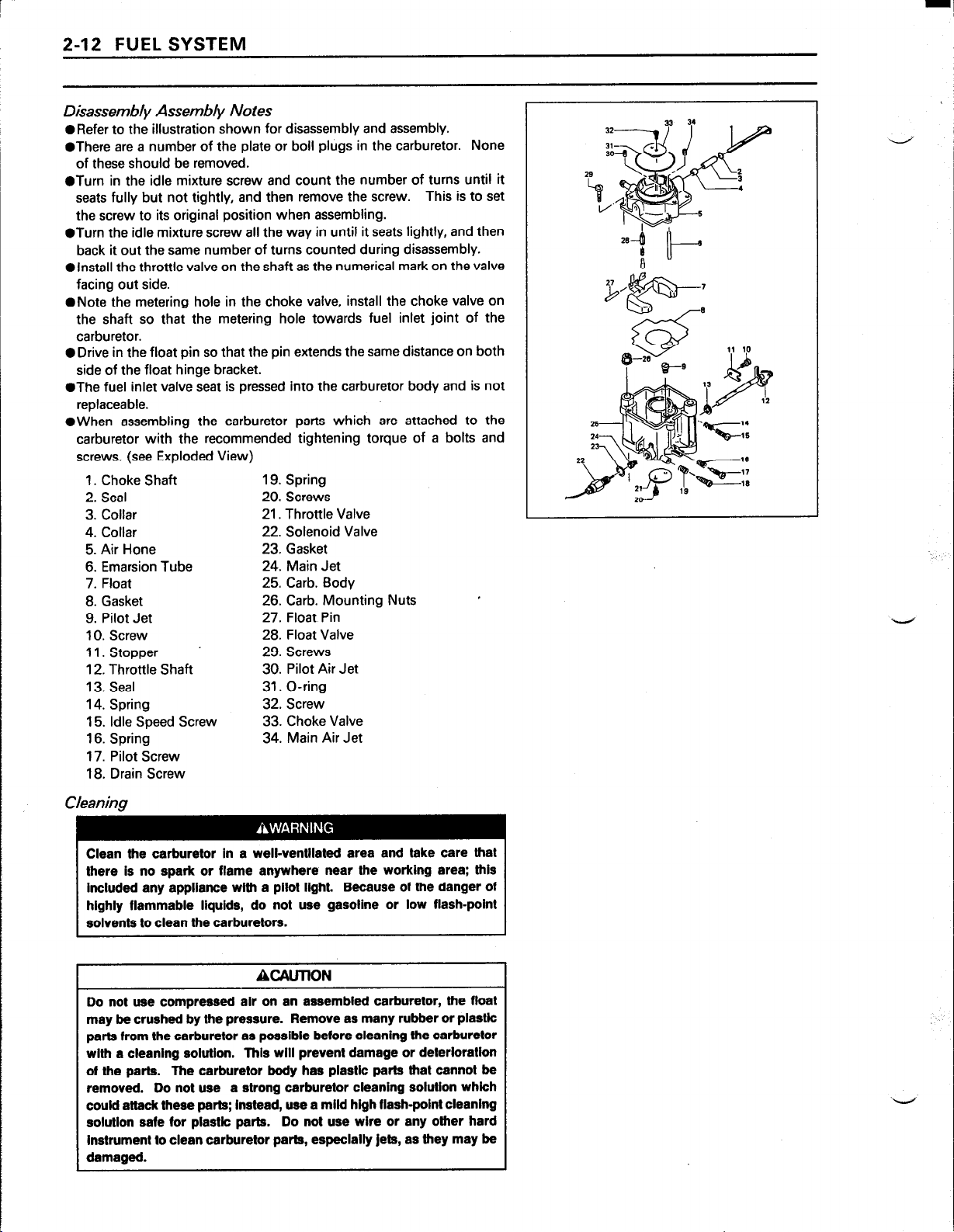

Disassembly Assembly Notes

@Refer to the illustration shown for disassembly and assembly.

@There are a number of the plate or boll plugs in the carburetor. None

of these should be removed.

@Turn in the idle mixture screw and count the number of turns until it

seats fully but not tightly, and then remove the screw. This is to set

the screw to its original position when assembling.

l

Turn the idle mixture screw all the way in until it seats lightly, and then

back it out the same number of turns counted during disassembly.

l

install the throttle valve on the shaft as the numerical mark on the valve

facing out side.

l

Note the metering hole in the choke valve, install the choke valve on

the shaft so that the metering hole towards fuel inlet joint of the

carburetor.

l

Drive in the float pin so that the pin extends the same distance on both

side of the float hinge bracket.

l

The fuel inlet valve seat is pressed into the carburetor body and is not

replaceable.

l

When assembling the carburetor parts which are attached to the

carburetor with the recommended tightening torque of a bolts and

screws. (see Exploded View)

1. Choke Shaft 19. Spring

2. Seal 20. Screws

3. Collar

4. Collar 22. Solenoid Valve

5. Air Hone 23. Gasket

6. Emarsion Tube

7. Float 25. Carb. Body

8. Gasket 26. Carb. Mounting Nuts

9. Pilot Jet 27. Float Pin

10. Screw 28. Float Valve

11. Stopper 29. Screws

12. Throttle Shaft 30. Pilot Air Jet

13. Seal 31. O-ring

14. Spring

15. Idle Speed Screw 33. Choke Valve

16. Spring 34. Main Air Jet

17. Pilot Screw

18. Drain Screw

21. Throttle Valve

24. Main Jet

32. Screw

Cleaning

Clean the carburetor in a well-ventilated area and take care that

there is no spark or flame anywhere near the working area: this

Included any appliance wlth a pilot light. Because of the danger of

highly flammable liquids, do not use gasoline or low flash-point

solvents to clean the carburetors.

ACAUTION

Do not use compressed air on an assembled carburetor, the float

may be crushed by the pressure. Remove as many rubber or plastk

parts from the carburetor as possible before cleaning the carburetor

wltft a cleaning solution. This will prevent damage or deterloratkn

of the parts. The carburetor body has plastic parts that cannot be

removed. Do not use a strong carburetor cleaning solution which

could attack these parts; instead, use a mild high flash-point cleaning

solution safe for plastic parts. Do not use wire or any other hard

Instrument to clean carburetor parts, especially jets, as they may be

damaged.

Page 30

0 Disassemble the carburetor.

l

immerse all the carburetor metal parts in a carburetor cleaning solution

and clean them.

l

Rinse the carburetor parts in water and dry them with compressed air.

l

Do not use a rags or paper to dry parts. Lint may plug the holes or

passages.

0 Blow air through the holes and fuel passages with the compressed air.

All holes must be open.

l

Assemble the carburetor.

Inspection

Gasoline is extremely flammable and can be explosive under certain

Turn the lgnilion switch OFF. Do not smoke. Make sure the area Is

well ventilated and free from any source of flame or sparks; this

includes any appliance with a pilot light.

*Inspect the carburetor body for damage. Flange sealing surfaces

should be smooth and free of burrs and nicks. Replace the gasket if

necessary.

l

Turn the throttle and choke shafts to check that the throttle and choke

butterfly valves move smoothly.

*If the valves do not more smoothly, replace the carburetor body and/or

throttle shaft and choke shaft assembly.

l

Check that the gasket on the carburetor body.

*if the gasket is not in good condition, replace it.

l

Check the other parts of the carburetor for wear or damage. Replace

the part if necessary.

l

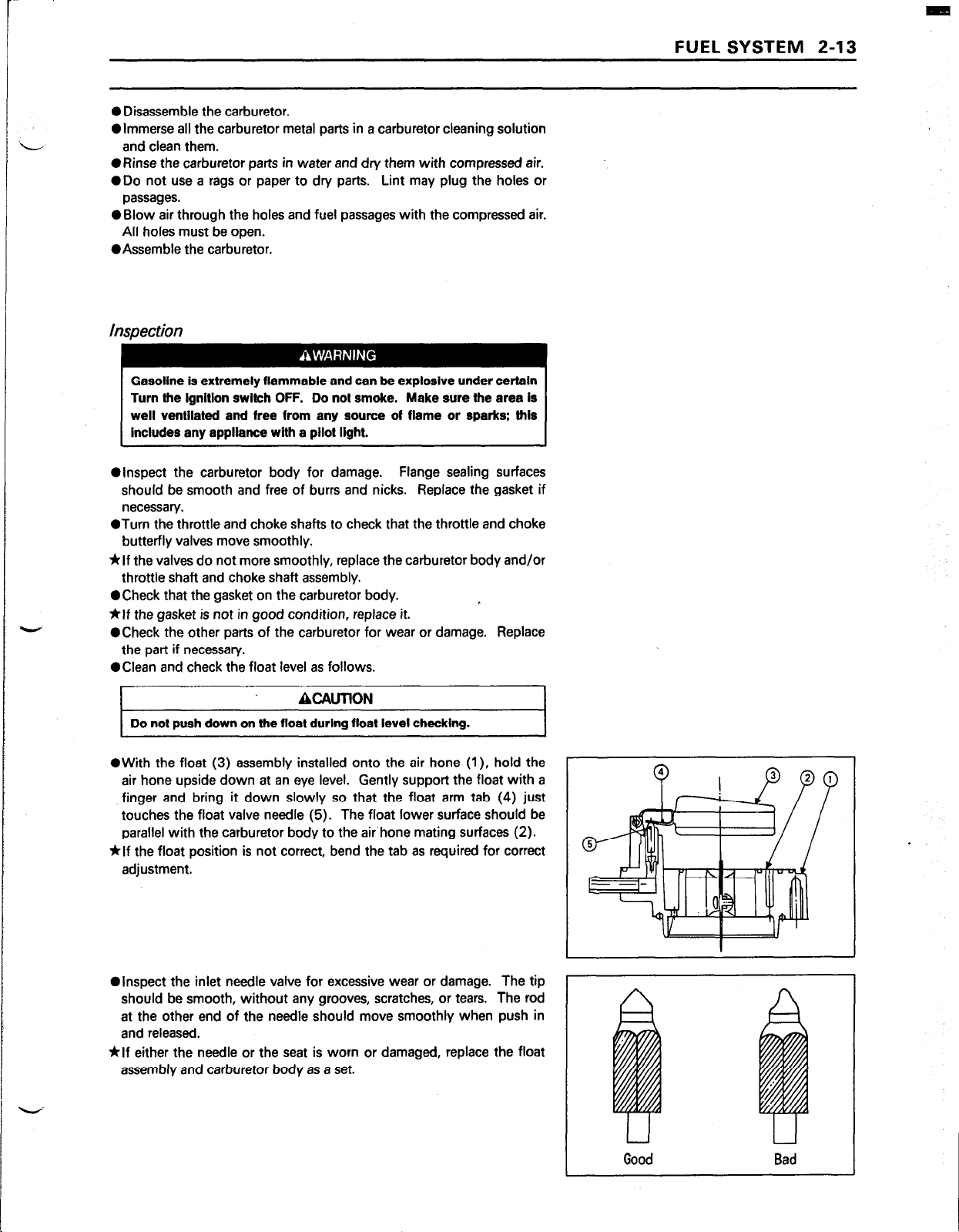

Clean and check the float level as follows.

FUEL SYSTEM 2-13

ACAUTlON

Do not push down on the float durlng float level checking.

r

l

With the float (3) assembly installed onto the air hone (I), hold the

air hone upside down at an eye level. Gently support the float with a

finger and bring it down slowly so that the float arm tab (4) just

touches the float valve needle (5). The float lower surface should be

parallel with the carburetor body to the air’hone mating surfaces (2).

*If the float position is not correct, bend the tab as required for correct

adjustment.

@Inspect the inlet needle valve for excessive wear or damage. The tip

should be smooth, without any grooves, scratches, or tears. The rod

at the other end of the needle should move smoothly when push in

and released.

*If either the needle or the seat is worn or damaged, replace the float

assembly and carburetor body as a set.

I

I

Bad

I

Page 31

2-14 FUEL SYSTEM

@Inspect the tapered portion (B) of the screw for wear or damage. @Inspect the tapered portion (B) of the screw for wear or damage.

*If the pilot screw (A) is worn or damaged, on the taper portion, replace *If the pilot screw (A) is worn or damaged, on the taper portion, replace

it. it.

l

Check the spring for weakened condition, replace it, if necessary.

l

Check the spring for weakened condition, replace it, if necessary.

Fuel Shut- Off Solenoid Valve Test

@Unscrew the fuel shut off valve and remove the valve.

@Connect a 12 VDC source to the solenoid as shown.

*If the actuate solenoid plunger (Needle Valve) does not pop in when

the Test Voltage is applied, replace it.

NOTE

Olf

may be necessary to push the plunger slightly for the plunger to

withdraw.

-

-

Page 32

Intake Manifold

Removal:

0 Remove:

Air Cleaner

Carburetor

Control Panel Assembly

@Drain the coolant in the engine (see coolant Draining)

l

Unscrew the manifold mounting bolts in numerical sequence, l/4 turn

at a time, until all bolts are loose.

*If the mounting bolts removal sequence is not followed, manifold

mating surfaces may be warped.

0 Remove the manifold and gaskets.

A. No.1 C.yi. Head

B. No. 2 Cyl. Head D. Intake Manifold

C. Gaskets

FUEL SYSTEM 2-15

Installation Notes

@Before assembling the manifold, install the cylinder heads on each

cylinder and tighten the head bolts in the specified sequence

temporarily (see Cylinder Head Installation Notes).

l

Place a new gaskets on each mating surface, and install the manifold.

l

Follow the sequence shown, tighten the mounting bolts to 4 N-m (35

in-lb).

l

Tighten the bolts in sequence 3 N-m (26 in-lb) at a time until the

torque on each bolt is 6.0 N-m (52 in-lb).

l

Note the position of the different length of bolts.

l

Then tighten the cylinder head bolts to the specified torque.

Head Assembly Installation Note).

Cylinder

Inspection

l

Visually inspect the coolant passage in the manifold for deposits or

corrosion in layers inside the passage, clean the passage if necessary.

@An improperly installed gaskets can cause coolant leakage and air

drawn into the induction passage. Check the gaskets for correct

installation.

NOTE

OSmall coolant leaks appear only as a rust, corrosion or stain.

l

inspect the intake manifold for cracks or porous casting.

l

Cracks not visible to the eye may be detected by coating the suspected

area with mixture of 25 % kelosene and 75 % light engine oil.

l

Wipe the area dry and immediately apply a coating of zinc oxide

dissolved in wood alcohol.

become discolored at the defective area.

*If a cracks is present in the intake manifold, replace it.

l

inspect the gasket surfaces for burrs and nicks.

If a cracks is present, the coating will

Page 33

2-16 FUEL SYSTEM

Fuel Pump

The optional location fuel pump (A) is not installed in the engine

when shipped. The fuel pump must be installed onto an equipment as

inlet

and

outlet pipes are horizontal or vertical (Outlet is up side).

l

The fuel pump cannot be disassembled ,if any damage for the pump

is appeared replace it with a new one.

Fuel Pump Test

Before this test, be sure the battery is fully charged.

explosive. Do not expose to spark or flame. Personal

lniurv could result.

0 Disconnect and plug the fuel pump outlet pipe.

@Connect proper pressure gauge to the fuel pump outlet pipe.

l

Turn the engine switch to the “RUN” position, the fuel pump will

operates. Record the pressure reading. Stop the fuel pump.

ORemove the pressure gauge and connect the outlet fuel tube.

l

Disconnect the fuel pump outlet tube from the carburetor inlet.

l

Put the tube end in a graduated container.

l

Run the fuel pump for 30 seconds. Stop the fuel pump.

container measurement.

l

Compare the readings to the specifications.

*If low, check for clogged or damaged tubes, fuel filter, or fuel tank.

Replace fauln/ fuel pump.

Minimum Specifications

Fuel Pressure

Fuel Flow 160mU30 seconds

19kPa (2.76 psi)

Record the

l_,l “”

I

I

Page 34

Air Cleaner

Element Removal

ORemove the wing bolts, washers and air cleaner case.

l

Take off the air cleaner elements from the body.

A. Wing Bolts D. Elements

B. Washers E. Body

C. Case

Element Installation Notes

l

install the elements correctly on the air cleaner body.

l

The elements can be installed either way on the air cleaner body.

sure the elements is inplace on the air cleaner body.

FUEL SYSTEM 2-17

Be

Element Cleaning and Inspection

NOTE

0 In dusty areas, the elements should be cleaned more frequently than

the recommended intervals.

Clean the element In a well-ventilated area, and take ample care that

there are no sparks or flame anywhere near the worklng area.

Because of the danger of highly flammable Ilqulds, do not use

gasoline or a low flash-point solvent to clean Ihe element.

ORemove the air cleaner element, and separate the foam element (A)

from the paper element (B).

l

Clean the foam element in a bath of detergent and water, and then dry

it with compressed air or by shaking it.

l

After cleaning, saturate the foam element with clean engine oil,

squeeze out the excess, then wrap it in a clean rag and squeeze it as

dry as possible. Be careful not to tear the foam element.

l

Clean the paper element by tapping it gently on a flat surface to remove

dust. If the element is very dirty, replace it with a new one or wash the

element in a detergent and water.

l

Rinse the element until a water is clear. Let the element air-dry

thoroughly before install it.

ACAUTION

Do not use compressed alr to clean the paper element.

paper element.

Do not oil the

Page 35

2-18 FUEL SYSTEM

Cleaner Body and Bracket Removal

*Remove the cleaner body mounting screws, spring washers and plain

washers.

NOTE

0 Do not let the screws, spring washers and plain washers fall into the

carburetor bore.

*Pull the breather hose off the pipe at the back of the body, and remove

the cleaner body.

@Unscrew the carburetor mounting nuts, then take off the bracket.

A. Screws

B. Spring Washers F. Breather Hose

C. Plain Washers G. Pipe

D. Body

E. Bracket

H. U-bend Hose

LMountinag Nuts

Cleaner Body and Bracket Installation Notes

I

When assemljling the cleaner body onto the bracket, do not let *the

screws, spring washers and plain washers fall Into the carburetor

bore.

l

Note the positions of different length of screws and different diameter

of the plain washers.

@Install the U-bend breather hose so that the end of the hose positions

just above the carburetor bore.

l

Connect the breather hose from the

of the cleaner body.

ACAUTION

crankcase

to the pipe at the back

Housing (Case and Body) inspection

l

Clean the housing with detergent and water and dry thoroughly.

@Check the housing for deformation or other damage. The housing

must seal well and permit only filtered air to reach the carburetor.

*If the housing is damaged, it must be replaced.

l

Check that no foreign material is otistructing the air passage.

1

-

Page 36

COOLING SYSTEM 3-1

Cooling System

Table of Contents

Exploded View

Specifications ..............................................................................................................

Cooling System

Coolant..

Coolant Deterioration

Coolant Level Inspection ........................................................................................

Coolant Draining .....................................................................................................

Coolant Filling.. ......................................................................................................

Air Bleeding ........................................................................................................... .3-8

Visual Leak inspection

Cooling System Pressure Testing.. ........................................................................

Flushing

Disassembly and Assembly Precautions

Water Pump

Water Pump Removal

Installation Notes

Disassembly

Pump Parts Inspection .........................................................................................

Assembly Notes ....................................................................................................

Radiator

Removal ................................................................................................................

Radiator Inspection..

Radiator Cap Inspection

Radiator Hose Inspection

Radiator Hose Installation Notes ..........................................................................

Cooling Fan, Fan Belt

Belt Tension Check

Belt Replacement Notes

Removal ................................................................................................................

Installation Notes

Inspection ................................................................ +. .......................................... .3-l 6

Fan Bearing Removal ...........................................................................................

Fan Bearing Installation Notes..

Thermostat..

Thermostat Removal

Thermostat Inspection ......................................................................................... .3-l 8

Therm0 Switch

Therm0 Switch Removal and Installation Notes

therm0 Switch Inspection

............................................................................................................

........................................................................................................... 3-5

...................................................................................................................... 3-6

..............................................................................................

............................................................................................ 3-8

....................................................................................................................

...................................................................

..............................................................................................................

...........................................................................................

..................................................................................................

.......................................................................................................... 3-l 0

.....................................................................................................................

............................................................................................

.......................................................................................

.....................................................................................

...............................................................................................

............................................................................................. ..3-15

..................................................................................... ..3-15

..................................................................................................

..........................................................................

............................................................................................................... 3-18

.............................................................................................

........................................................................................................ ..3-19

.................................................

.................................................................................. ..3-19

3-2

3-4

3-6

3-6

3-6

.3-7

.3-8

3-9

.3-9

3-10

3-10

3-10

3-I I

3-l 1

3-l 2

3-12

.3-l 2

3-13

3-l 4

3-14

3-l 5

3-16

3-16

3-17

.3-l 7

3-18

3-19

3

i

Page 37

3-2 COOLING SYSTEM

ExDloded View

T3

D: Apply engine oil

G: Apply grease

2 Apply a non-permanent locking

agent to the threads

b

Tl: 27 N-m (2.8 kg-m, 20 Mb)

(Therm0 Switch)

T2: 20 N-m (2.0 kg-m, 14.5 &lb)

(Fan Shafl Nut)

T3: 21 N-m (2.1 kg-m, 15.0 A-lb)

(Pump Cover Bolt M8)

-

Page 38

COOLING SYSTEM 3-3

Tl: 2.0 N-m (0.2 kg-m, 17 in-lb) Tl: 2.0 N-m (0.2 kg-m, 17 In-lb)

(Finger Tight) (Finger Tight)

T2: 14 N-m (1.4 kg-m, 10 Mb) T2: 14 N-m (1.4 kg-m, 10 Mb)

(Drain Screws [Black Head]) (Drain Screws [Black Head])

Page 39

3-4 COOLING SYSTEM

Specifications

item Standard

‘Coolant:

Type

Color Green

Mixed ratio 50% solution of ethylene glycol

Freezing point -35°C (-31 “F)

Total amount

Radiator Cap Relief Pressure:

Pressure valve (positive) 73.3 to 102.7 kPa (10.6 to 14.9 psi)

Vacuum Valve (negative) 4.90 kPa (0.71 psi)

Thermostat:

Valve openning temperature 63 to 66°C (145 to 150°F)

Valve full openning lift not less than 7mm (0.28 in) at 80°C (176°F)

Therm0 Switch:

Detect Temperature 108 to 114°C (226 to 237°F)

“A permanent type of antifreeze is not installed in the cooling system when shipped.

Permanent type of antifreeze for aluminum engine and radiator

2.7 L (0.7 us gallon)

Page 40

Cooling System

This engine is equipped with a highly efficient pressurized cooling

system using a thermostat to maintain an optimum operating temperature. Coolant bypasses the closed thermostat when cold until operating

temperature is attained, causing the engine to warm up more quickly. If

the coolant temperature becomes too high, a therm0 switch on the

engine activates the coolant warning lamp to alert the operator or cooling

problem.

1. Water Pump

2. Cylinder Jackets

3. Cylinder Heads

4. Intake Manifold

5. Thermostat

6. Bypass Tube

7. Therm0 Switch

8. Radiator

9. Radiator Cap

10. Cooling Fan

11. Cylinder Block

COOLING SYSTEM 3-5

Page 41

3-6 COOLING SYSTEM

Coolant

Coolant Deterioration

@Visually inspect the coolant in the radiator.

Olf

whitish cotton-like wafts are observed, aluminum parts in the

cooling system are corroded. If the coolant is brown, iron or steel parts

are rusting. In either case, flush the cooling system.

0 If the coolant gives off an abnormal smell when changing, check for a

cooling system leak. It may be caused by exhaust gas leaking in to the

cooling system.

Coolant Level Inspection

@Put the engine on a level surface.

ORemove the radiator cap turning it counterclockwise and check the

coolant level in the radiator.

Always allow the engine to tool before removing the radiator cap.

Then remove the cap slowly and carefully to avoid a possible fast

’ discharge of hot coolant which could cause severe burns.

l

Coolant level must be maintained a level of the filler neck bottom (A).

*If the amount of the coolant is insufficient, fill the radiator up to the

bottom of the radiator filler neck (A) with the coolant, and install the

cap turning it clockwise.

ACAUTION

For refilling, add the specified mixture of coolant and soft water.

Adding water alone dilutes the coolant and degrades its anticorrosion properties. The diluted coolant can attack the aluminum engine

parts. In an emergency, soft water can be added. But the diluted

coolant must be returned to Vie correct mixture ratio within a few

days.

H coolant must be added often, there is probably leakage in the

cooling system. Check the system for leaks (see Visual Leak

Inspection, and pressure Testing).

Coolant Draining

The coolant should be changed periodically to ensure long engine life.

ACAUTION

Use coolant containing corrosion inhibitors made specifically for

aluminum engines and radiators in accordance with the instructions

of the manufactures (see Coolant Filling Section).

Page 42

To avoid burns do not remove the radiator cap or try to change the

coolant when the engine is still hot. Wait until it cools down.

Since coolant is harmful to the human body, do not use for drinking.

ORemove the radiator cap (A) as follows.

0 First turn the cap counterclockwise to the first stop and wait there for

a few seconds.

OPush down the cap, then turn the cap counterclockwise to the next

stop.

0 Lift off the cap.

l Place a suitable container under the radiator. Turn the drain screw (B)

few turns counterclockwise to drain the coolant in the radiator.

COOLING SYSTEM 3-7

ORemove the muffler (see Muffler Removal).

@Remove one of the casecover mounting bolts (A) which attachs the

dipstick tube bracket (B) and casecover to the block together, and

then take off the dipstick assembly.

@To drain the coolant in the engine, place a suitable chute under the

drain screws (black head) (C) located at the lowest water jacket of the

each cylinder to avoid a possible contamination of the starting motor

(D) and igniter.

l

inspect the old coolant for color and smell (see Coolant Deterioration).

Coolant Filling

l

install the drain plugs. Always replace the gaskets with a new ones,

if they are damaged.

@Tighten the drain screws to the specification (see Exploded Views).

@Fill the radiator up to bottom of the radiator filler neck (A) with

coolant, and install the cap turning it clockwise.

NOTE

0 Pour in the coolant slowly so that it can expel the air from the engine

and radiator.

0 To install the radiator cap, push down it and then turn the cap

clockwise to the rest of the way.

Soft or distilled water must be used with the antifreeze in the cooling

If hard water is used in the system, it causes scales accumulation in

the water passages, and considerably reduces the efficiency of tie

II..

NOTE

OChoose a suitable mixture ratio by referring to the coolant

manufacture/s instructions.

Page 43

3-8 COOLING SYSTEM

Original Coolant

Type:

Color:

Mixed ratio:

Freezing Point:

Total amount:

Permanent type antifreeze for aluminum engine

and radiator

Green

50% solution of ethylene giycoi

-35°C (-31°F)

2.7L (0.7 U.S. gallon)

Air Bleeding

Before putting the engine into operation, any air trapped in the

cooling system must be removed as follows.

0 Remove the radiator cap.

@Fill the radiator up to the radiator filler neck with coolant.

l

Check the cooling system for leaks.

l

install the radiator cap.

l

Start the engine, warm it up thoroughly, and then stop it.

l

Check the coolant level in the radiator after the engine cools down.

*If the coolant level is low, add coolant up to the filler neck bottom (A).

Install the cap.

Visual Leak Inspection

Any time the system slowly loses water, inspect for leaks. Small leaks

may appear only a rust, corrosion or stain due to evaporation. Watch for

these trouble spots.

l

Check the water pump housing drainage outlet passage (1) for

coolant leaks.

*If the mechanical seal is damaged, the coolant leaks through the seal

and drain through the passage. Replace the mechanical seal (2).

*If there are no apparent leaks, pressure test the system.

Cooling System Pressure Testing

Air pressure leakage tester can help locate external leaks but they

cannot depended upon to locate small combustion leaks.

ACAUTION

During pressure testing, do not exceed the pressure for which the

system is designed. The maximum pressure is 102.7 kPa (14.9 psi).

ORemove the radiator cap, and install a cooling system pressure tester

(A) on the radiator filler neck.

l

Wet the cap sealing surfaces with water or coolant to prevent pressure

leaks.

@Build up pressure in the system carefully until the pressure reaches 60

kPa (8.7 psi).

l

Watch the pressure gauge for at least 6 seconds. If the pressure holds

steady, the system is all right.

ORemove the pressure tester, replenish the coolant, and install the cap.

*If the pressure drops and no external source is found, check for internal

leaks. Droplets in the engine oil indicate internal leakage. Check the

cylinder head gaskets.

Page 44

Flushing

Over a period of time, the cooling system accumulates rust, scale, and

lime in the water jacket and radiator. When this accumulation is

suspected or observed, flush the cooling system. If this accumulations

is not removed, it will clog up the water passage and considerably reduce

the efficiency of the cooling system.

0 Drain the cooling system.

OFill the cooling system with fresh water mixed with a flushing

compound.

ACZAUTION

Avofd the use of a flushing compound which is harmful to Ule

aluminum englne and radiator. Carefully follow the instructions

supplied by the manufacturer of the cleaning product.

l

Warm up the engine, and run it at normal operating temperature for

about ten minutes.

l

Stop the engine, and drain the cooling system.

0 Fill the system with fresh water.

l

Warm up the engine and drain the system.

0 Repeat the previous two steps once more.

@Fill the system with a permanent type coolant, and bleed the air from

the system.

COOLING SYSTEM 3-9

Disassembly and Assembly Precautions .

l

Prior to disassembly of cooling system parts (radiator, pump, sensor,

etc), wait until the coolant cools down, and then drain the coolant.

@After assembling and filling the system with a coolant, purge any air

from the system.

Page 45

3-10 COOLING SYSTEM

Water Pump

Water Pump Removal

0 Remove:

Muffler (see Muffler Assembly Removal)

0 Loosen the hose clamp (A) and disconnect the radiator hose (B) at

the coolant inlet port of of the water pump (C).

l

Loosen the tube clamp (D), and pull off the coolant by-pass tube (E).

@Unscrew the water pump mounting bolts, and remove the water pump

assembly.

NOTE

0

Note the position of different length of bolts so they can be installed

in their original positions.

Installation Notes

@Chip the old gasket off the mating surfaces of the casecover and pump

housing.

l

Put a new gasket on the pump housing.

l

Be sure to suitable set the pump gear to be meshed with the cam gear

when installing the pump assembly.

position.

@Install the mounting bolts and tighten them to the specification (see

Torque Table).

0 Note the p.osition of different length of bolts.

Do not force the pump into

Boll Dimensions

A. Bolt M6 I = 75 mm (2.95 in)