Page 1

5XI SERIES TRACTOR SERVICE MANUAL

Table of Contents – Page 1 of 2

SAFETY INFORMATION

SPECIFICATIONS

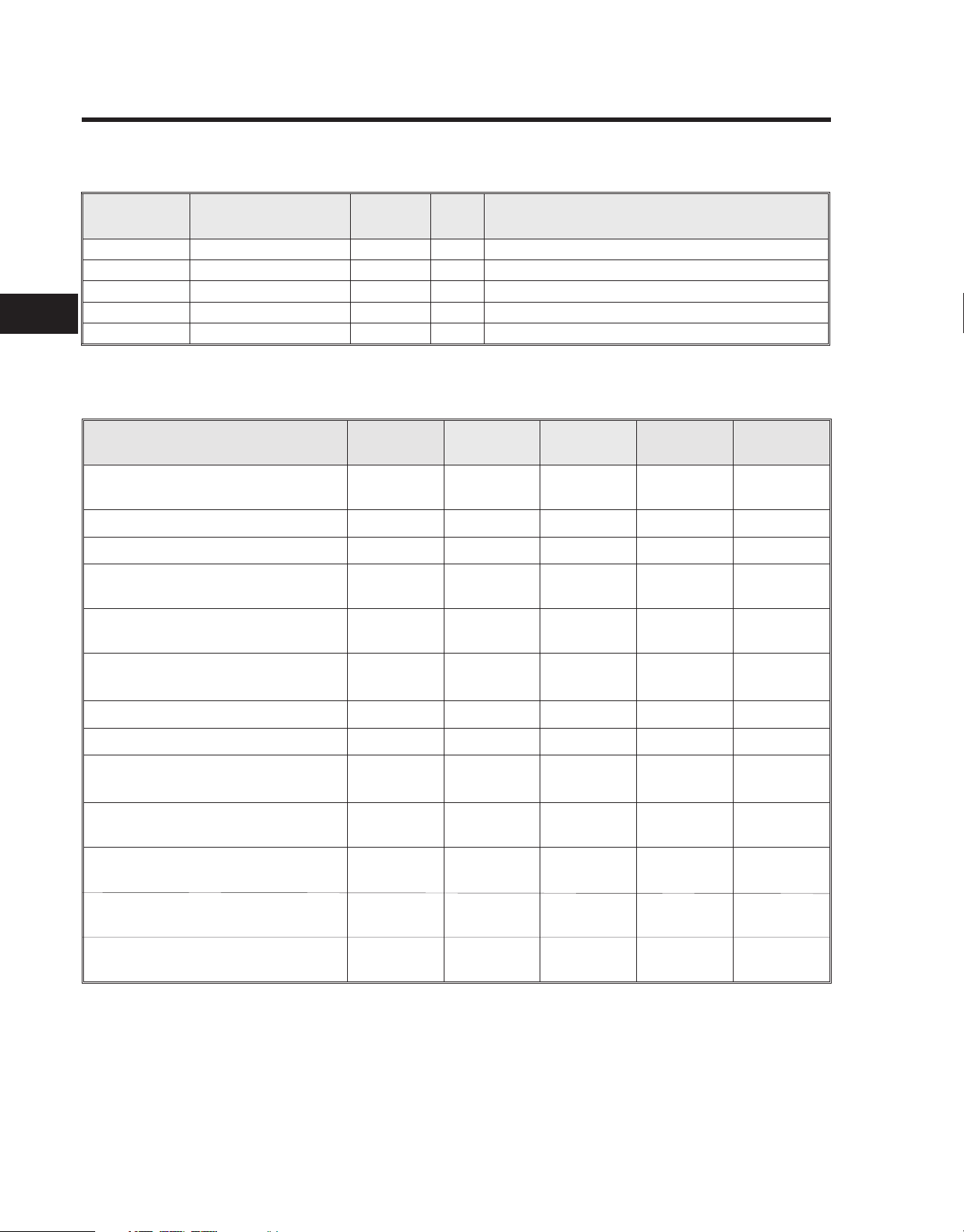

PRODUCT LINEUP

TRACTOR SPECIFICATIONS

ATTACHMENTS AND ACCESSORIES (PARTIAL LISTING)

ENGINE SPECIFICAT IONS (AIR- CO O LED)

ENGINE SPECIFICATIO NS (LIQUI D- COO LED)

MAINTENANCE TABLE

SERVICE SCHEDULE

CHASSIS

MODEL/SERIAL NUMBER LOCATION

GREASING AND LUBRICATION

REAR FENDERS, FOOTRESTS, & TUNNEL

FRONT WHEEL TOE-IN

STEERING WHEEL

POWER STEERING

SMART TURNÉ STEERING

MOTION CONTROL PEDAL

TIRE PRESSURE

FUEL TANK SHUT-OFF VALVE

ELECTRIC PTO CLUTCH

DRIVE SHAFT

HYDROSTATIC DRIVE

TROUBLESHOOTING

TRANSAXLE FLUID

BRAKE

NEUTRAL ADJUSTMENT

GASOLINE ENGINE

TROUBLESHOOTING

ENGINE CRANKS BUT WILL NOT START.

STARTER DOES NOT CRANK.

ENGINE STARTS BUT DOES NOT KEEP RUNNING.

ENGINE IS DIFFICULT TO START.

ENGINE RUNS BUT KNOCKS OR MISSES.

ENGINE WILL NOT IDLE.

ENGINE OVERHEATS.

ENGINE LOSES POWER.

ENGINE KNOCKS.

AIR CLEANER

ENGINE OIL

OIL FILTER

SPARK PLUG

FUEL FILTER

Page 2

5XI SERIES TRACTOR SERVICE MANUAL

Table of Contents – Page 2 of 2

GASOLINE ENGINE - continued

COOLING SYSTEM, AIR

COOLING SYSTEM, LIQUID

DIESEL ENGINE

TROUBLESHOOTING

ENGINE CRANKS BUT WILL NOT START.

STARTER DOES NOT CRANK.

ENGINE STARTS BUT DOES NOT KEEP RUNNING.

ENGINE IS DIFFICULT TO START.

ENGINE RUNS BUT KNOCKS OR MISSES.

ENGINE WILL NOT IDLE.

ENGINE OVERHEATS.

ENGINE LOSES POWER.

ENGINE KNOCKS.

EXCESSIVE BLACK SMOKE FROM EXHAUST.

EXCESSIVE W H IT E SMOKE FRO M EX HAU ST.

AIR CLEANER

ENGINE OIL

OIL FILTER

COOLING SYSTEM

ENGINE MOUNTS

FUEL SYSTEM

GLOW PLUGS

ELECTRICAL

BATTERY

FUSE

HEADLIGHTS

INSTRUMENT PANEL LIGHTS

TAILLIGHTS

ELECTRIC CLUTCH TROUBLESHOOTING

SAFETY INTERLOCK SYSTEM

CRUISE CONTROL

FUEL GAUGE

CHARGING SYSTEM

SCHEMATICS

Page 3

TORO

5xi Series

Tractor

Service Manual

Page 4

ABOUT THIS MANUAL

This service manual was written expressly for Toro Wheel Horse 5xi series garden tractors. The Toro Company

has made every effort to make the information in this manual complete and correct.

This manual was written for the service technician; basic mechanical/electrical skills are assumed. The Table of

Contents lists the systems and the related topics covered in this manual.

For information on the electrical system, please refer to the Toro Electrical Demystification Guide (492-4404). For

information specific to the engines used on these garden tractors, refer to the appropriate engine manufacturer’s

service and repair instructions.

We are hopeful that you will find this manual a valuable addition to your service shop. If you have any questions

or comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specifications or this manual without notice.

Copyright© All Rights Reserved

©1997 The Toro Company

Page 5

QUICK REFERENCE SECTION

TABLE OF CONTENTS

Safety Information..............................................

Specifications .................................................

Maintenance Table .............................................

SERVICE SECTION

Chassis.........................................................

Hydrostatic Drive .................................................

Gasoline Engine..................................................

1a

1b

1c

2

3

4

Diesel Engine ....................................................

Electrical........................................................

5

6

5xi Series Tractor Service Manual 1-1

Page 6

QUICK REFERENCE

SAFETY INFORMATION

General Information ..................................... 1-3

Think Safety First ....................................... 1-3

SPECIFICATIONS

Product Lineup......................................... 1-4

Tractor Specifications ................................... 1-4

Attachments and Accessories ............................. 1-5

Engine Specifications ................................... 1-6

Table of Contents

MAINTENANCE TABLE ..................................... 1-7

1-2 5xi Series Tractor Service Manual

Page 7

SAFETY INFORMATION

This symbol means WARNING or

PERSONAL SAFETY

INSTRUCTION - read the

instruction because it has to do

with your safety. Failure to comply

with the instruction may result in

personal injury or even death.

This manual is intended as a service and repair

manual only. The safety instructions provided herein

THINK SAFETY FIRST

Avoid unexpected starting of engine...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

Avoid lacerations and amputations...

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as if they

were moving whenever the engine is running or has

the potential to start.

are for troubleshooting, service, and repair of the

5xi series garden tractor. The tractor and attachment

operator’s manuals contain safety information and

operating tips for safe operating practices. Operator’s

manuals are available through your local Toro

distributor or:

The Toro Company

Publications Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Avoid injury from batteries...

Battery acid is poisonous and can cause burns. Avoid

contact with skin, eyes, and clothing. Battery gases

can explode. Keep cigarettes, sparks, and flames

away from the battery.

Avoid injury due to inferior parts...

Use only original equipment parts to ensure that

important safety criteria are met.

1a

Avoid burns...

Do not touch the engine, muffler, or other

components which may increase in temperature

during operation, while the unit is running or shortly

after it has been running.

Avoid fires and explosions...

Avoid spilling fuel and never smoke while working

with any type of fuel or lubricant. Wipe up any spilled

fuel or oil immediately. Never remove the fuel cap or

add fuel when the engine is running. Always use

approved, labeled containers for storing or

transporting fuel and lubricants.

Avoid asphyxiation...

Never operate an engine in a confined area without

proper ventilation.

Avoid injury to bystanders...

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due to projectiles...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid modifications...

Never alter or modify any part unless it is a factory

approved procedure.

Avoid unsafe operation...

Always test the safety interlock system after making

adjustments or repairs on the machine. Refer to the

Electrical chapter later in this manual for more

information.

5xi Series Tractor Service Manual 1-3

Page 8

SPECIFICATIONS

Product Lineup

1b

Model

(International)

73470 518xi Kohler 18 Eaton 11 Hydro, 2 speed Uni-Drive® transaxle

73540 (73541) 520xi Kohler 20 Eaton 11 Hydro, 2 speed Uni-Drive® transaxle

73560 522xi Kohler 22 Eaton 11 Hydro, 2 speed Uni-Drive® transaxle

73545 (73546) 520Lxi Kawasaki 20 Eaton 11 Hydro, 2 speed Uni-Drive® transaxle

73550 (73551) 523Dxi Daihatsu 23 Eaton 11 Hydro, 2 speed Uni-Drive® transaxle

Name Engine HP Drive Type

Tractor Specifications

Item 73470 73540

(73541)

Fuel Tank Capacity 4.25 gal

(16.1l)

Hydraulic System Capacity 6 Qts (5.7l) 6 Qts (6.6 l) 7 Qts (6.6 l) 7 Qts (6.6 l) 7 Qts (6.6 l)

Battery Size (Cold Cranking Amps) 12V 380CCA 12V 380CCA 12V 380CCA 12V 380CCA 12V 495CCA

Ground Speed Forward (High Range) 0-7.4 mph

(11.9 km/hr)

Ground Speed Forward (Low Range) 0-4.4 mph

(7.1 km/hr)

4.25 gal

(16.1l)

0-7.4 mph

(11.9 km/hr)

0-4.4 mph

(7.1 km/hr)

73560 73545

(73546)

4.25 gal

(16.1l)

0-7.4 mph

(11.9 km/hr)

0-4.4 mph

(7.1 km/hr)

4.25 gal

(16.1l)

0-7.4 mph

(11.9 km/hr)

0-4.4 mph

(7.1 km/hr)

73550

(73551)

4.25 gal

(16.1l)

0-7.4 mph

(11.9 km/hr)

0-4.4 mph

(7.1 km/hr)

Ground Speed Reverse (High Range)

Tire Size - Front 16 x 7.5-8 16 x 7.5-8 16 x 7.5-8 16 x 7.5-8 16 x 7.5-8

Tire Size - Rear 23 x 10.5-12 23 x 10.5-12 23 x 10.5-12 23 x 10.5-12 23 x 10.5-12

Tire Pressure 12 psi

Wheel Base 52 in

Turning Radius 20 in

Total Width 40.5 in

Length 76.5 in

0-3.4 mph

(5.48 km/hr)

(82.7 kPa)

(132.1 cm)

(50.8 cm)

(102.8 cm)

(196.9 mm)

0-3.4 mph

(5.48 km/hr)

12 psi

(82.7 kPa)

52 in

(132.1 cm)

20 in

(50.8 cm)

40.5 in

(102.8 cm)

76.5 in

(196.9 mm)

0-3.4 mph

(5.48 km/hr)

12 psi

(82.7 kPa)

52 in

(132.1 cm)

20 in

(50.8 cm)

40.5 in

(102.8 cm)

76.5 in

(196.9 mm)

0-3.4 mph

(5.48 km/hr)

12 psi

(82.7 kPa)

52 in

(132.1 cm)

20 in

(50.8 cm)

40.5 in

(102.8 cm)

76.5 in

(196.9 mm)

0-3.4 mph

(5.48 km/hr)

12 psi

(82.7 kPa)

52 in

(132.1 cm)

20 in

(50.8 cm)

40.5 in

(102.8 cm)

76.5 in

(196.9 mm)

Note: Specifications shown are for 1998 models. Subsequent production may vary. As part of

a continuous improvement process, the Toro Company reserves the right to change

specifications without notice.

1-4 5xi Series Tractor Service Manual

Page 9

SPECIFICATIONS

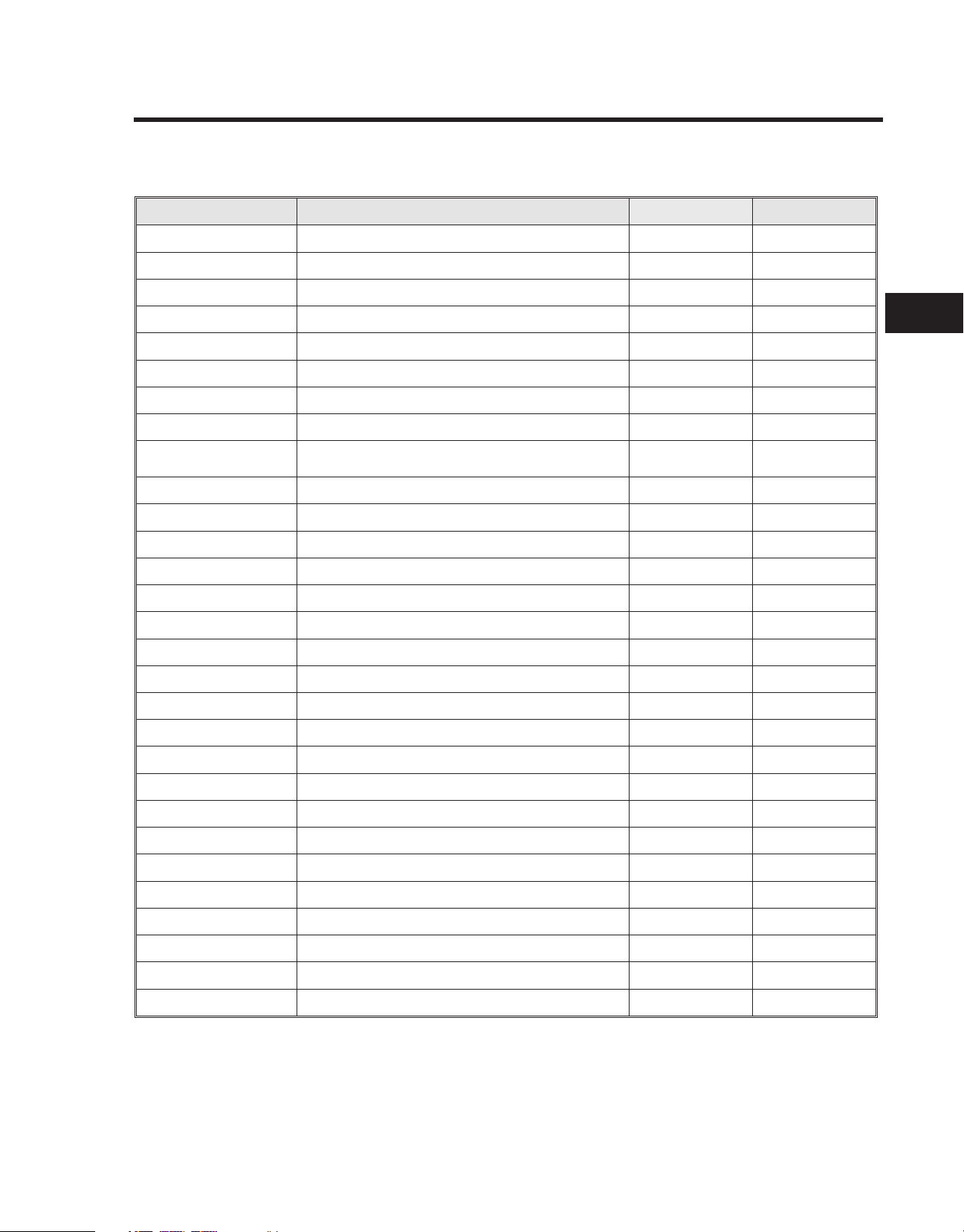

Attachments and Accessories (partial listing)

Part # (International) Description Drive Belt Spindle Belt

78353 (78442) 42" Rear Discharge Mower

78357 (78444) 44" Side Discharge Mower

78358 44" Recycler® Mower

78363 (78448) 48" Side Discharge Mower

78364 48" Recycler® Mower

78370 (78452) 52" Side Discharge Mower

78375 52" Recycler® Mower

78395 (78469) 60" Side Discharge Mower

79375* 36" Tiller

79355* 48" Snow/Dozer Blade

79356* 50" Mid-Mount Grader Blade

79305 (79444) 44" Vac/Bagger

79310 (79448) 48" Vac/Bagger

95-4093

95-4094

95-4094

95-4095

95-4095

95-4094

95-4094

95-4093

Front

94-7877

93-8007

79-7490

95-4230

95-4228

95-4228

95-3878

95-3878

94-2501

94-2501

95-4229

Rear

94-7878

1b

79977 Front Mount Dethatcher

79365 42" Single Stage Snowthrower

79366 *** 44" Two Stage Snowthrower

79919 Snow Cab

79210 Roll-Over-Protection System (ROPS)

95-4220 Rear Attach-A-Matic® (from Parts)

79947** Bucket Loader

94-2050 Dual Wheel Adapter Kit (From Parts)

94-7800 Clevis Hitch (From Parts)

94-4090 48" Blade Retrofit Kit (From Parts)

95-4091 Diesel Block Heater (From Parts)

95-7858 Sidelight Kit (From Parts)

86041 44" Recycler® Kit

79195 48" Recycler® Kit

79185 52" Recycler® Kit

79948 Weight Box

95-3918

95-3917

* Requires 95-4220 Rear Attach-A-Matic®

** Requires 79948 weight Box

***Requires rear wheel weights, 95-4220 Rear Attach-A-Matic®

5xi Series Tractor Service Manual 1-5

Page 10

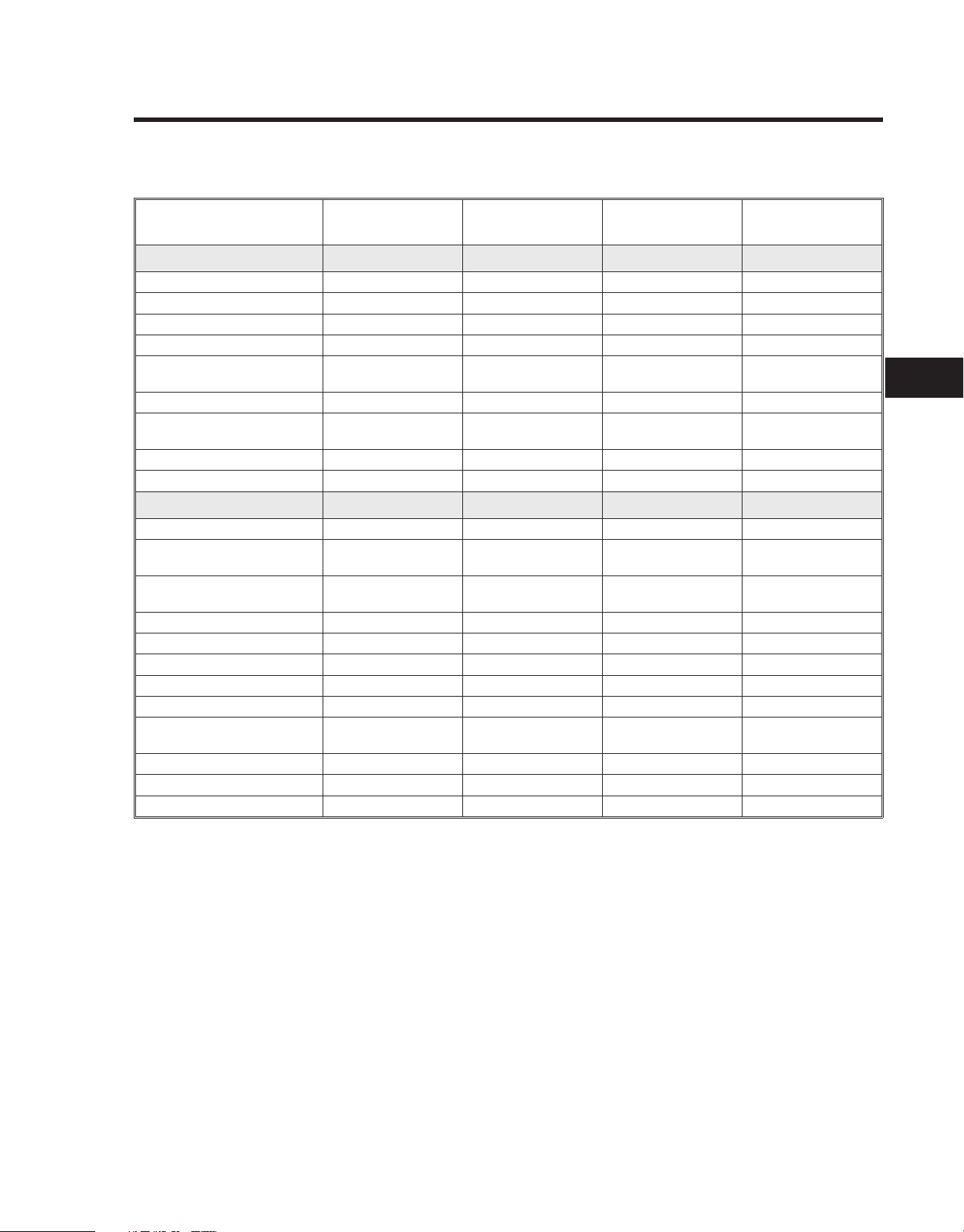

1b

SPECIFICATIONS

Engine Specifications (air-cooled)

Item 73470 73540 (73541) 73560

Manufacturer/Model Kohler/CH18S Kohler/CH20S Kohler/CH22S

Horsepower (kW) 18 HP (13.4 kW) 20 HP (14.9 kW) 22 HP (16.4 kW)

Oil Viscosity Over 0° F (-18° C)

Below 32°F (0° C)

Oil Capacity (With Filter) 2.1 Qts. (2 l) U.S. Qts. U.S. Qts. U.S. Qts.

Spark Plug (Champion # Shown) RC12YC RC12YC RC12YC

Spark Plug Gap .030 in (.76 mm) .030 in (.76 mm) .030 in (.76 mm)

10W-30

5W-20 or 5W-30

10W-30

5W-20 or 5W-30

10W-30

5W-20 or 5W-30

Recommended Engine Speed

(No Load) (International Unit)

Idle Speed 1400 RPM 1400 RPM 1400 RPM

Charging System Output 15 amps 15 amps 15 amps

Head Bolt Torque

Connecting Rod Torque 130 in·lb (17.3 N·m) 130 in·lb (17.3 N·m) 130 in·lb (17.3 N·m)

Flywheel Torque 49 ft·lb (66.4 N·m) 49 ft·lb (66.4 N·m) 49 ft·lb (66.4 N·m)

3400 RPM

2300 RPM

30 ft·lb (40.7 N·m)

3400 RPM

2300 RPM

30 ft·lb (40.7 N·m) 30 ft·lb (40.7 N·m)

3400 RPM

2300 RPM

Engine Specifications (liquid-cooled)

Item 73545 (73546) 73550 (73551)

Manufacturer/Model Kawasaki/FD620D Daihatsu/582447 Diesel

Horsepower (kW) 20 HP (14.9 kW) 23 HP (17.1)

Oil Viscosity Over 40° F (5°C)

Below 40° F (5°C)

Oil Capacity (With Filter) 1.9 U.S. Qts. (1.8l) 3.5 U.S. Qts. (3.3 l )

Coolant Capacity 4.1 Qts. 5 Qts.

10W-30 or 10W-40 Above 0°F (-18°C)

5W-20 or 5W-30 Below 32° F (0° C)

10W-30 or 10W-40 Above 0°F (-18°C)

5W-30 Below 50° F (10°C)

Spark Plug (NGK # Shown) BMR4A N/A

Spark Plug Gap .024 -.028 in (0.6 - 0.7 mm) N/A

Recommended Engine Speed

(International Units)

Idle Speed 1550 1850

Charging System Output 20 amps 40 amps

Head Bolt Torque 15 ft·lb (21 N·m) 25 ft·lb (34 N·m)

Connecting Rod Torque 15 ft·lb (21 N·m) 27 ft·lb (36 N·m)

Flywheel Torque 80 ft·lb (110 N·m) 35 ft·lb (47 N·m)

1-6 5xi Series Tractor Service Manual

3400 RPM

2300 RPM

3400 RPM

2200 RPM

Page 11

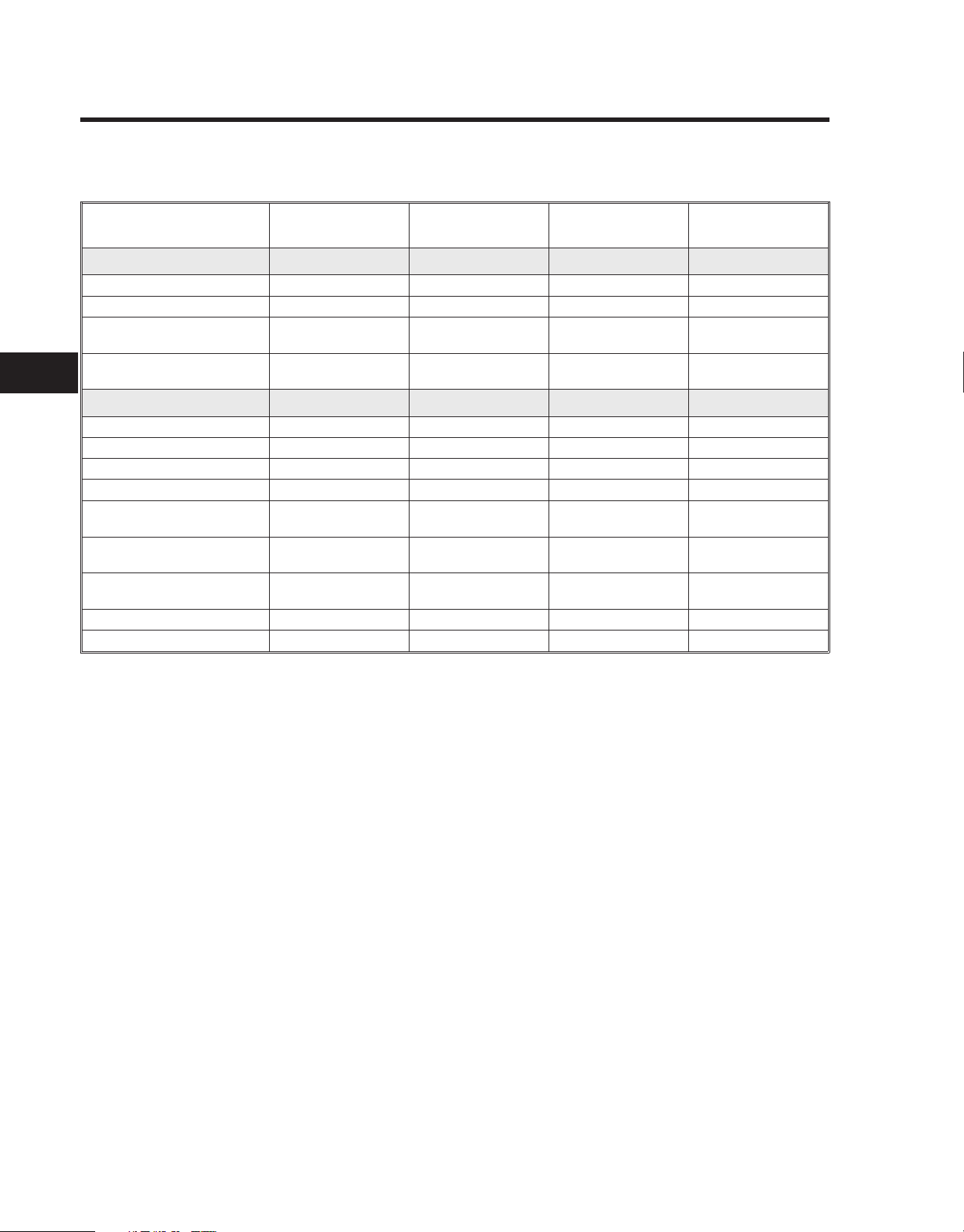

MAINTENANCE TABLE

Service Schedule

Item Kohler, Manual

Steering

Grease Zerks

Front wheel spindles (2) Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

Front axle pivot (1) Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

Maintenance panel (3) Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

Pulley box (2) Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

Deck spindles (3) until

resistance is felt

Deck idler & wheels (3) 60" Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

60" deck gage wheels

grease

Foot pedal shaft (1) Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

Steering (1) one pump Every 50 hrs. N/A N/A N/A

Engine

Check oil level Every use Every use Every use Every use

Oil change @ 5 hrs.

Oil filter change Every 200 hrs. Every 200 hrs. Every 200 hrs. @ 50 hrs.

Air filter Every 100 hrs. Every 100 hrs. Every 100 hrs. Every 100 hrs.

Precleaner clean & oil Every 25 hrs. Every 25 hrs. Every 25 hrs. N/A

Fuel filter Every 100 hrs. Every 100 hrs. Every 100 hrs. Every 400 hrs.

Radiator level check N/A N/A Every use Every use

Radiator screen clean N/A N/A Every use Every use

Radiator flush N/A N/A Every 400 hrs. or

Change spark plugs Every 200 hrs. Every 200 hrs. Every 100 hrs. N/A

Drain water from fuel filter N/A N/A N/A Every use

Check fan belt N/A N/A Every 100 hrs. Every 100 hrs.

Every 25 hrs. Every 25 hrs. Every 25 hrs. Every 25 hrs.

Every 25 hrs. Every 25 hrs. Every 25 hrs. Every 25 hrs.

Every 100 hrs.

Kohler, Power

Steering

@ 5 hrs.

Every 100 hrs.

Kawasaki Daihatsu

@ 5 hrs.

Every 100 hrs.

2 yrs.

@ 5 hrs.

Every 100 hrs.

Every 200 hrs.

Every 400 hrs. or

2 yrs.

1c

@ = initial service

NOTE: Service more frequently under dry/dirty/dusty conditions

5xi Series Tractor Service Manual 1-7

Page 12

MAINTENANCE TABLE

Service Schedule (cont’d)

1c

Item Kohler, Manual

Steering

Transaxle & Hydraulics

Oil level check 25 hrs. 25 hrs. 25 hrs. 25 hrs.

Oil change Every 200 hrs. Every 200 hrs. Every 200 hrs. Every 200 hrs.

Oil filter change @ 50 hrs.;

Every 200 hrs.

Clean power steering

screen

Miscellaneous

Check PTO belt tension Every 50 hrs. Every 50 hrs. Every 50 hrs. Every 50 hrs.

Check battery electrolyte Every 25 hrs. Every 25 hrs. Every 25 hrs. Every 25 hrs.

Tire pressure Every 25 hrs. Every 25 hrs. Every 25 hrs. Every 25 hrs.

Safety interlock Every use Every use Every use Every use

Clean clippings from

deck

Check under hood for

grass build up

Check service brake

function

Clean 3 air intake screens Every use Every use Every use Every use

Clean rear transaxle cover Every use Every use Every use Every use

N/A @ 50 hrs.;

Every use Every use Every use Every use

Every use Every use Every use Every use

Every use Every use Every use Every use

Kohler, Power

Steering

@ 50 hrs.;

Every 200 hrs.

Every 200 hrs.

Kawasaki Daihatsu

@ 50 hrs.;

Every 200 hrs.

@ 50 hrs.;

Every 200 hrs.

@ 50 hrs.;

Every 200 hrs.

@ 50 hrs.;

Every 200 hrs.

@ = initial service

1-8 5xi Series Tractor Service Manual

Page 13

QUICK REFERENCE SECTION

CHASSIS

Safety Information ................................................

Specifications....................................................

Maintenance Table................................................

SERVICE SECTION

Chassis ......................................................

Hydrostatic Drive .................................................

Gasoline Engine..................................................

1a

1b

1c

2

3

4

Diesel Engine ....................................................

Electrical........................................................

5

6

5xi Series Tractor Service Manual 2-1

Page 14

22

CHASSIS

Table of Contents

MODEL/SERIAL NUMBER LOCATION ......................... 2-4

GREASING AND LUBRICATION

Service Interval/Specification.............................. 2-4

Lubrication Points ...................................... 2-4

REAR FENDERS, FOOTREST, & TUNNEL

General Information ..................................... 2-7

Removal .............................................. 2-7

Reassembly ........................................... 2-9

FRONT WHEEL TOE-IN

Specification/Service Interval............................. 2-10

Measurement ......................................... 2-10

Adjustment ........................................... 2-11

Spindle Adjustment .................................... 2-11

STEERING WHEEL

Remove Steering Wheel ................................ 2-12

Reassembly .......................................... 2-12

POWER STEERING

General Information .................................... 2-13

Maintenance.......................................... 2-13

SMART TURN STEERING

General Information .................................... 2-15

Theory of Operation .................................... 2-15

Inspection ............................................ 2-16

Adjustments .......................................... 2-16

2-2 5xi Series Tractor Service Manual

Page 15

CHASSIS

MOTION CONTROL PEDAL

Adjustment ...........................................2-20

TIRE PRESSURE .........................................2-20

FUEL TANK SHUT-OFF VALVE ..............................

ELECTRIC PTO CLUTCH

General Information ....................................2-21

Break-In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

DRIVE SHAFT

General Information ....................................2-22

Inspection ............................................2-22

Assembly.............................................2-22

2-20

2

5xi Series Tractor Service Manual 2-3

Page 16

CHASSIS

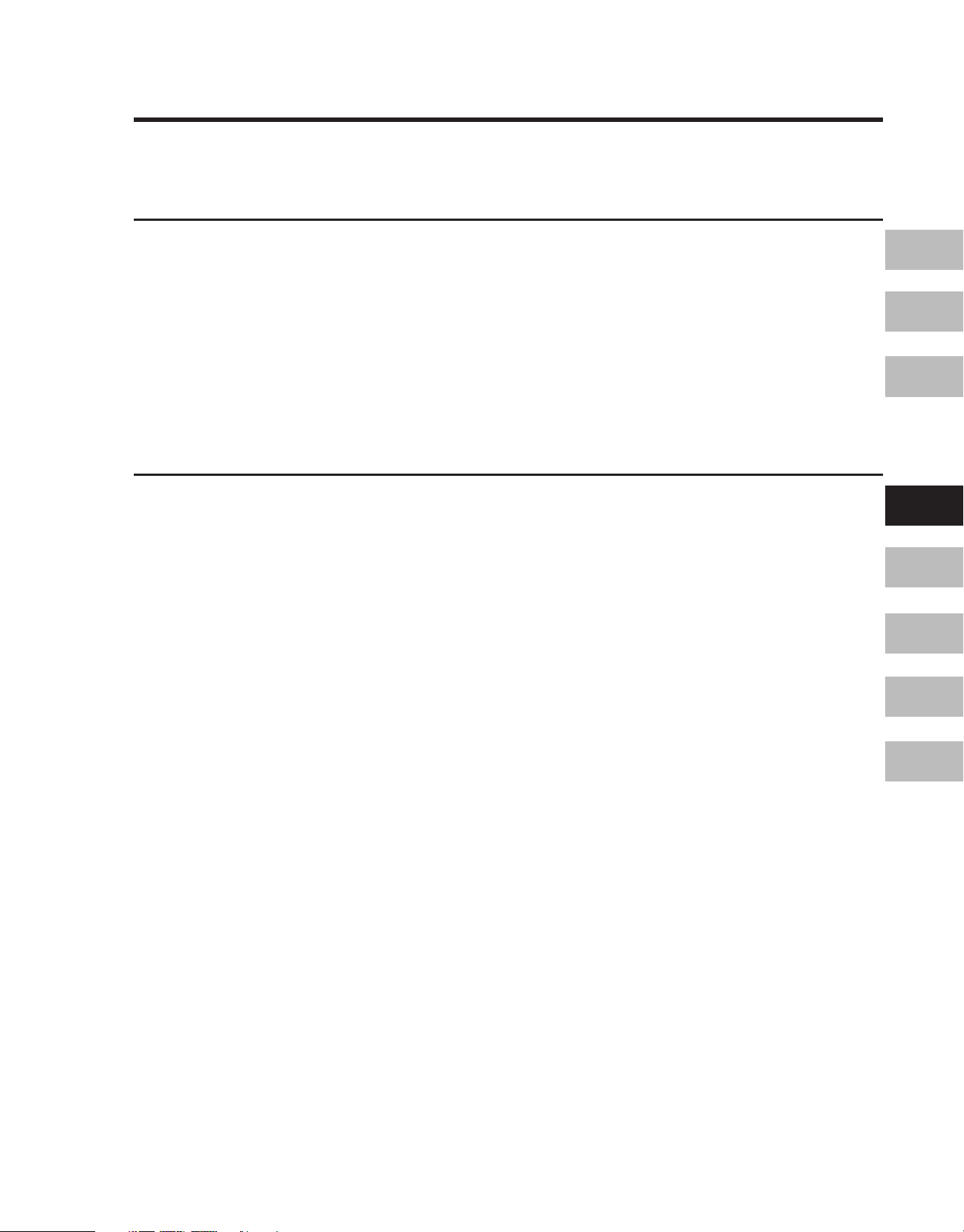

MODEL/SERIAL NUMBER LOCATION

The tractor model and serial number plate

location is shown in the illustration.

The engine has its own model and serial

number identification. Consult the appropriate

engine manufacturer’s service literature for the

location and translation of the engine model

and serial number information.

GREASING AND LUBRICATION

2.0757.015

22

Service Interval/Specification

The machine should be greased every 50 hours

or yearly, whichever occurs first. You should

grease more frequently when operating

conditions are extremely dusty or sandy. See

the maintenance table in section 1c.

Grease Type: General-purpose lithium base

grease

2.0109.033

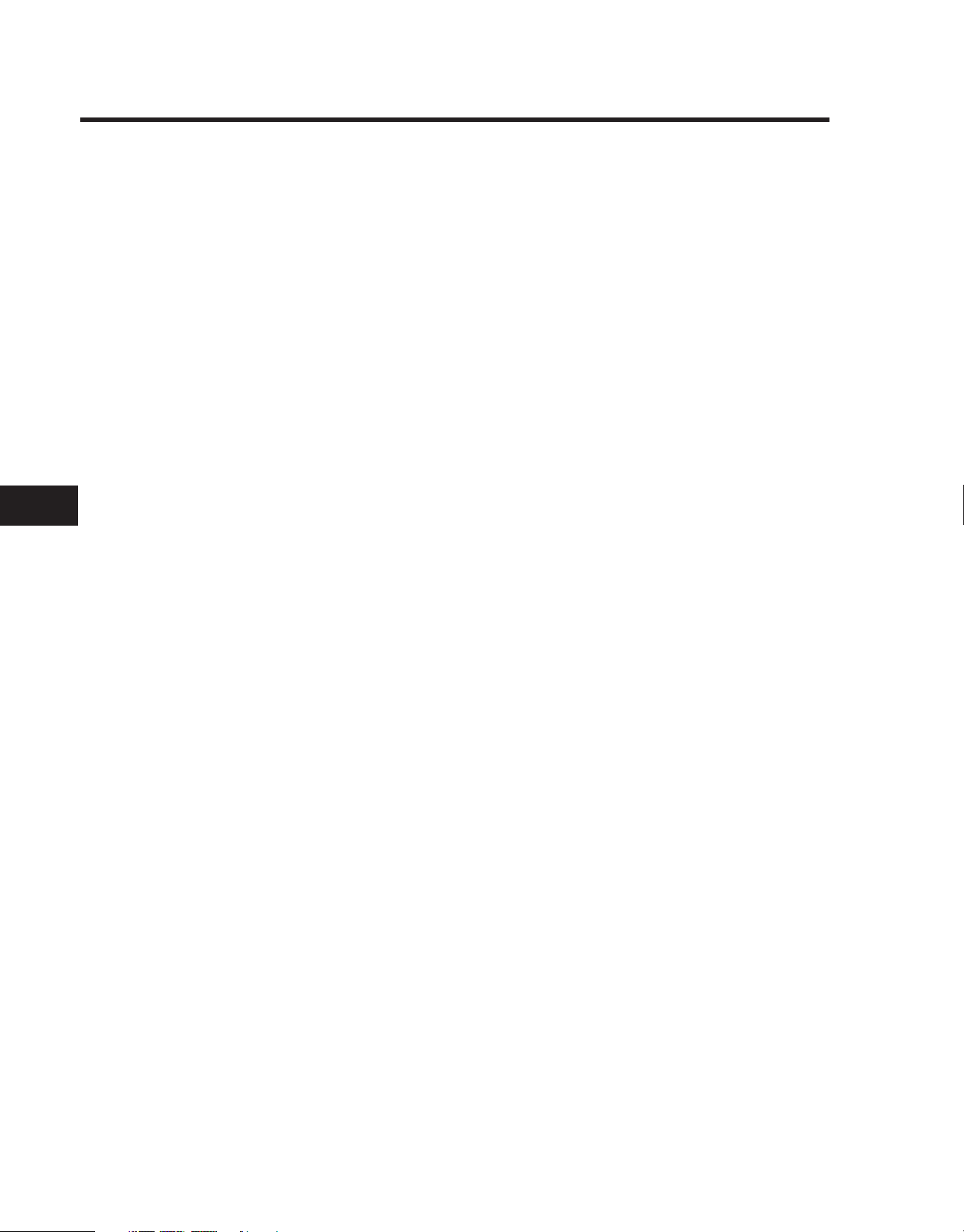

Lubrication Points

There are 3 grease zerks on the front axle; one

on at each spindle and one at the center pivot.

2.0109.043

2-4 5xi Series Tractor Service Manual

Page 17

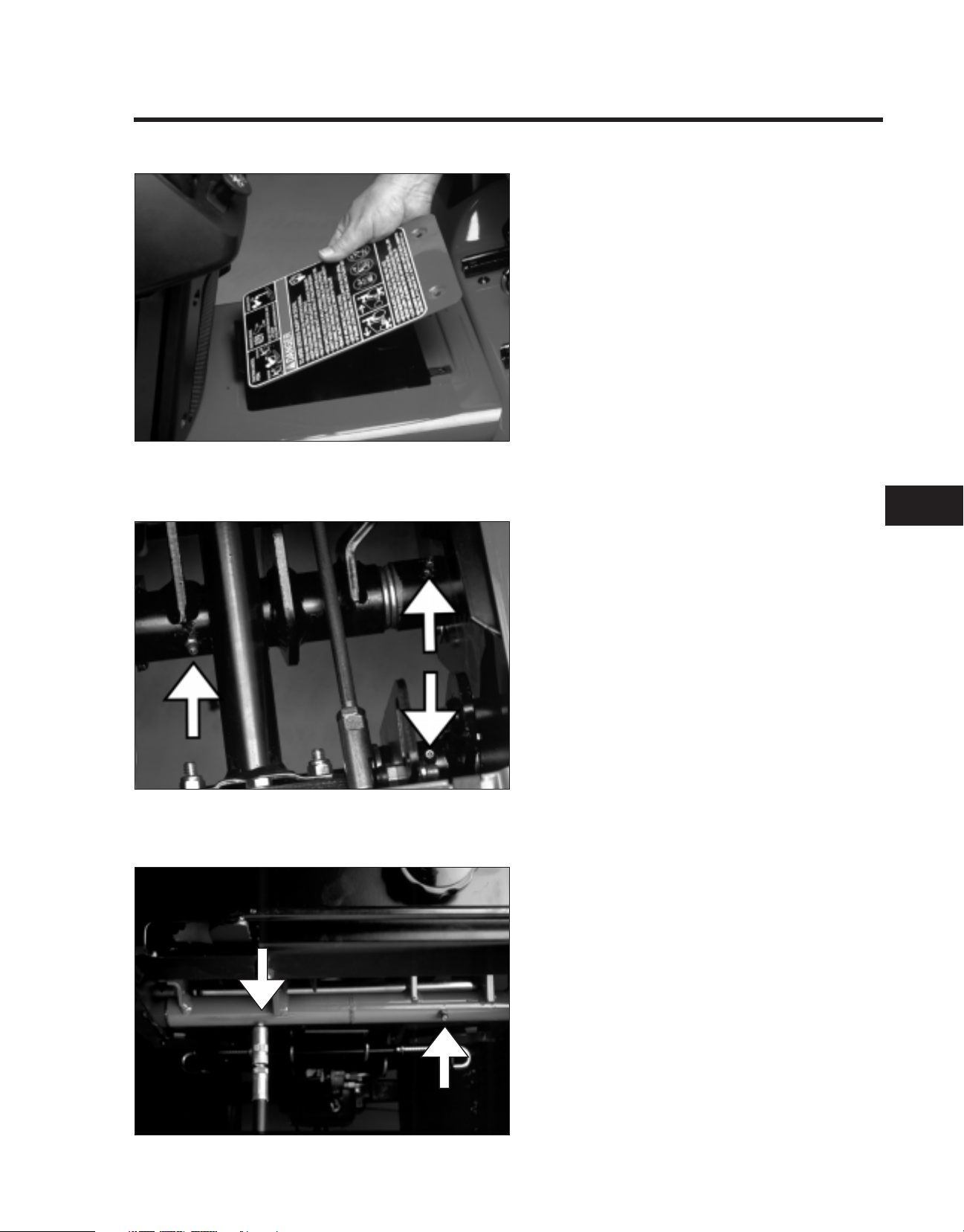

2.0109.026

CHASSIS

Remove the maintenance panel located in the

tunnel in front of the seat.

2.0109.024

This will allow access to the 3 zerk fittings below.

The pulley box for the mower deck contains 2

zerk fittings; one at each pulley pivot.

2

2.0144.023

5xi Series Tractor Service Manual 2-5

Page 18

CHASSIS

GREASING AND LUBRICATION (cont’d)

There are 3 zerk fittings located on the mower

deck spindles. Apply grease until resistance is

felt from the grease gun handle (2-3 pumps).

Also lubricate the mower deck idler arm on

decks so equipped.

The 60" deck has zerk fittings on the gage

wheels, grease every 25 hours of operation.

2.0415.001

22

There is 1 zerk fitting located on the foot pedal

shaft which requires greasing.

2.0415.012

Models with manual steering have a lubrication

point on the steering gear. Do not force

excessive amounts of grease into this fitting

(one pump of the grease gun handle only).

2.0144.069

2-6 5xi Series Tractor Service Manual

Page 19

2.0109.039

CHASSIS

REAR FENDERS, FOOTRESTS, & TUNNEL

General Information

The seat, rear fenders, footrests, and tunnel can

be removed as a unit providing easy access to

chassis components.

2.0109.021

Removal

1. Disconnect the electrical connections for the

seat switch, cruise control, and taillights (as

applicable) from the wiring harness.

NOTE: The cruise control and taillights

share the same connector, which is located

under the right fender.

2. Remove the brake and motion control

pedals.

2

2.0109.003

5xi Series Tractor Service Manual 2-7

2.0109.020

Page 20

CHASSIS

REAR FENDERS, FOOTRESTS, & TUNNEL (cont’d)

3. Remove the four bolts securing the fenders

to the frame (two on each side of the seat).

2.0109.004

22

4. Remove the nuts from the front footrest

supports and the clamps from the rear

supports.

2.0109.019

5. Remove the three air intake screens.

2.0109.015

2-8 5xi Series Tractor Service Manual

Page 21

2.0109.017

CHASSIS

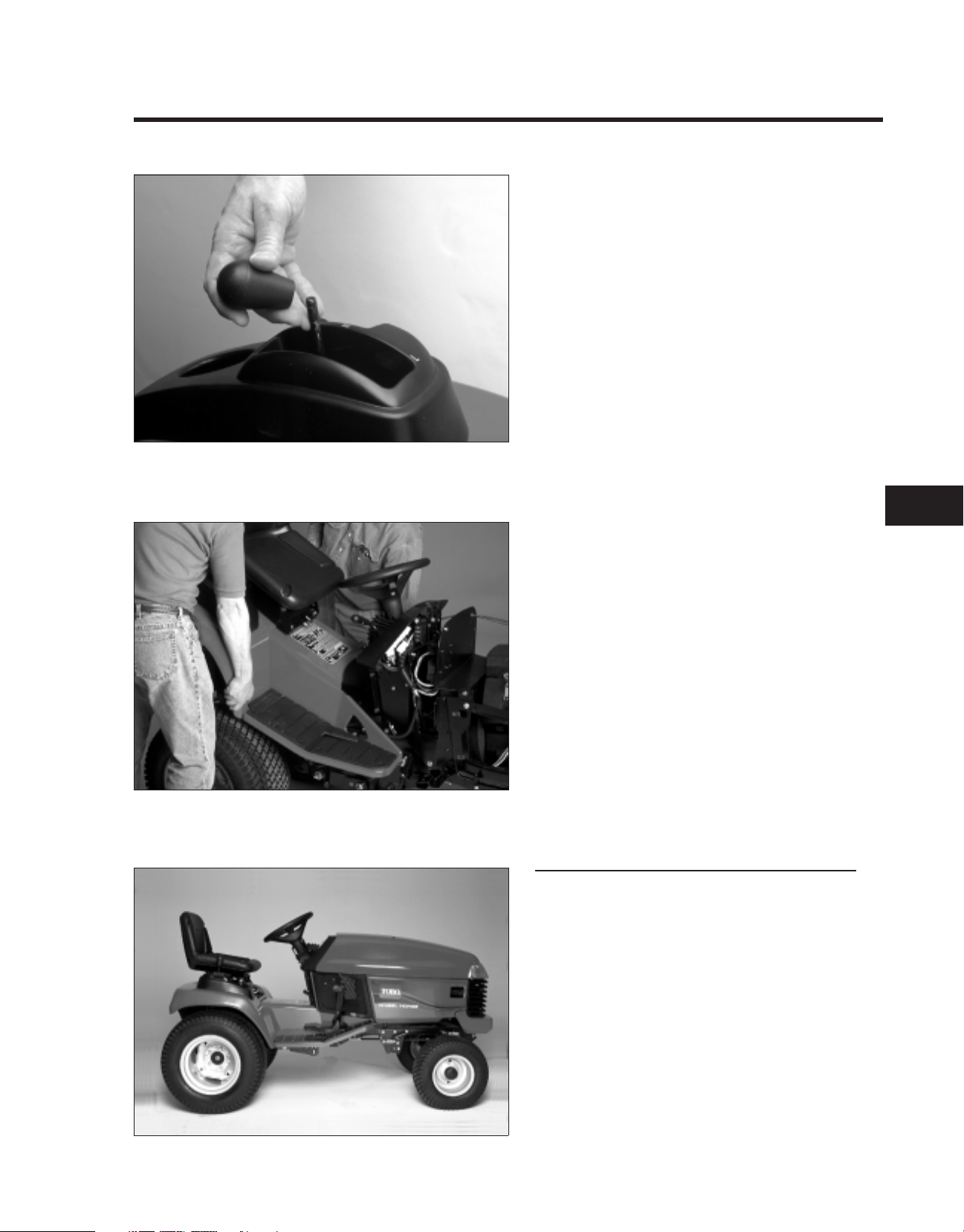

6. Remove the knob for the transaxle range

selector.

2.0109.014

7. With the help of an assistant, lift the rear of

the fender assembly until it clears the

transaxle shift lever. Then remove the

assembly to the rear of the tractor.

Reassembly

Reverse steps 1-7 to reassemble the seat, rear

fenders, footrests, and tunnel.

NOTE: Failure to keep all hoses in place on the

top of the fuel tank could result in improper

operation of the fuel vent or supply system.

2

NOTE: Do not pinch any wiring between the

fender assembly and the top edges of the frame.

2.0109.039

5xi Series Tractor Service Manual 2-9

Page 22

CHASSIS

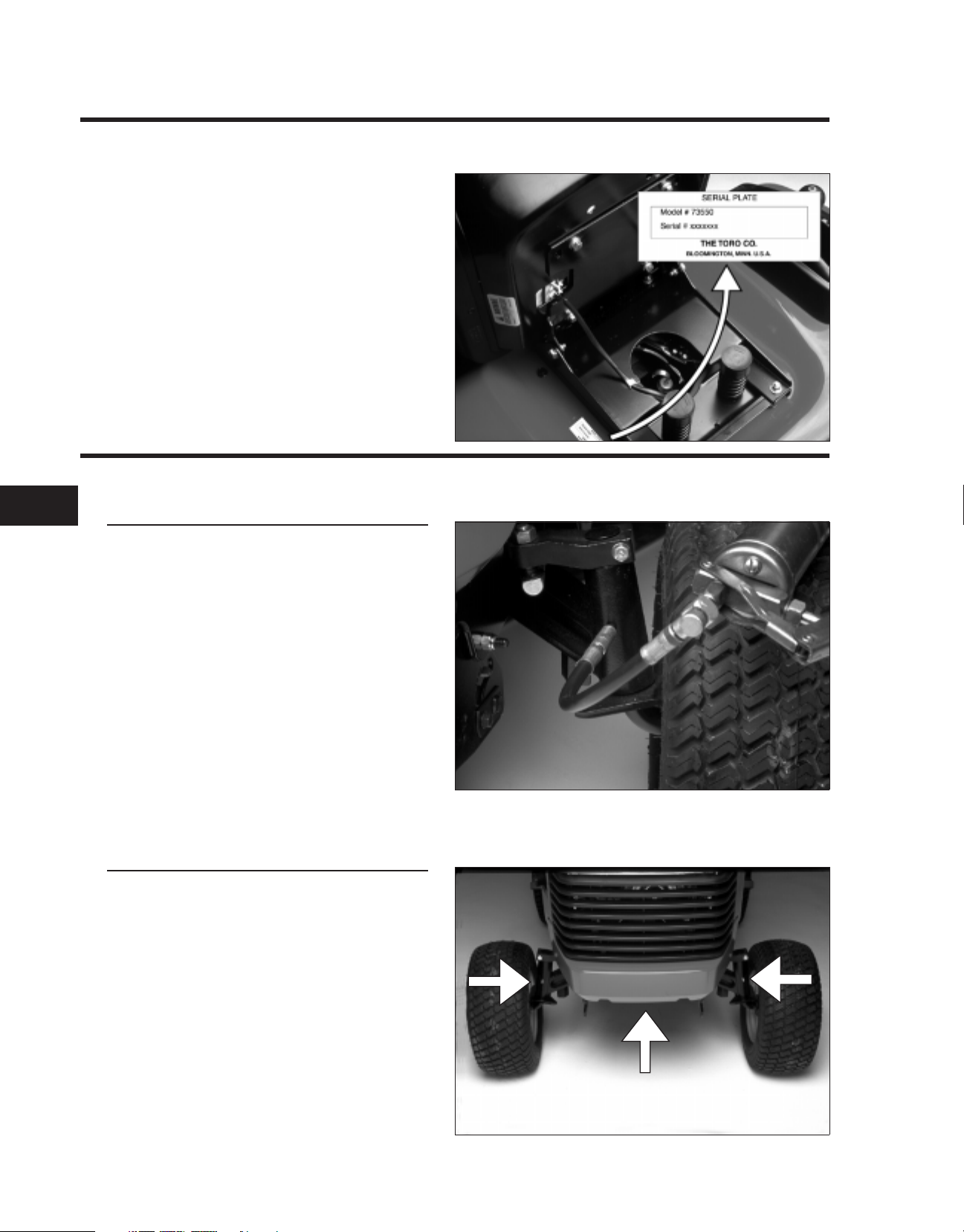

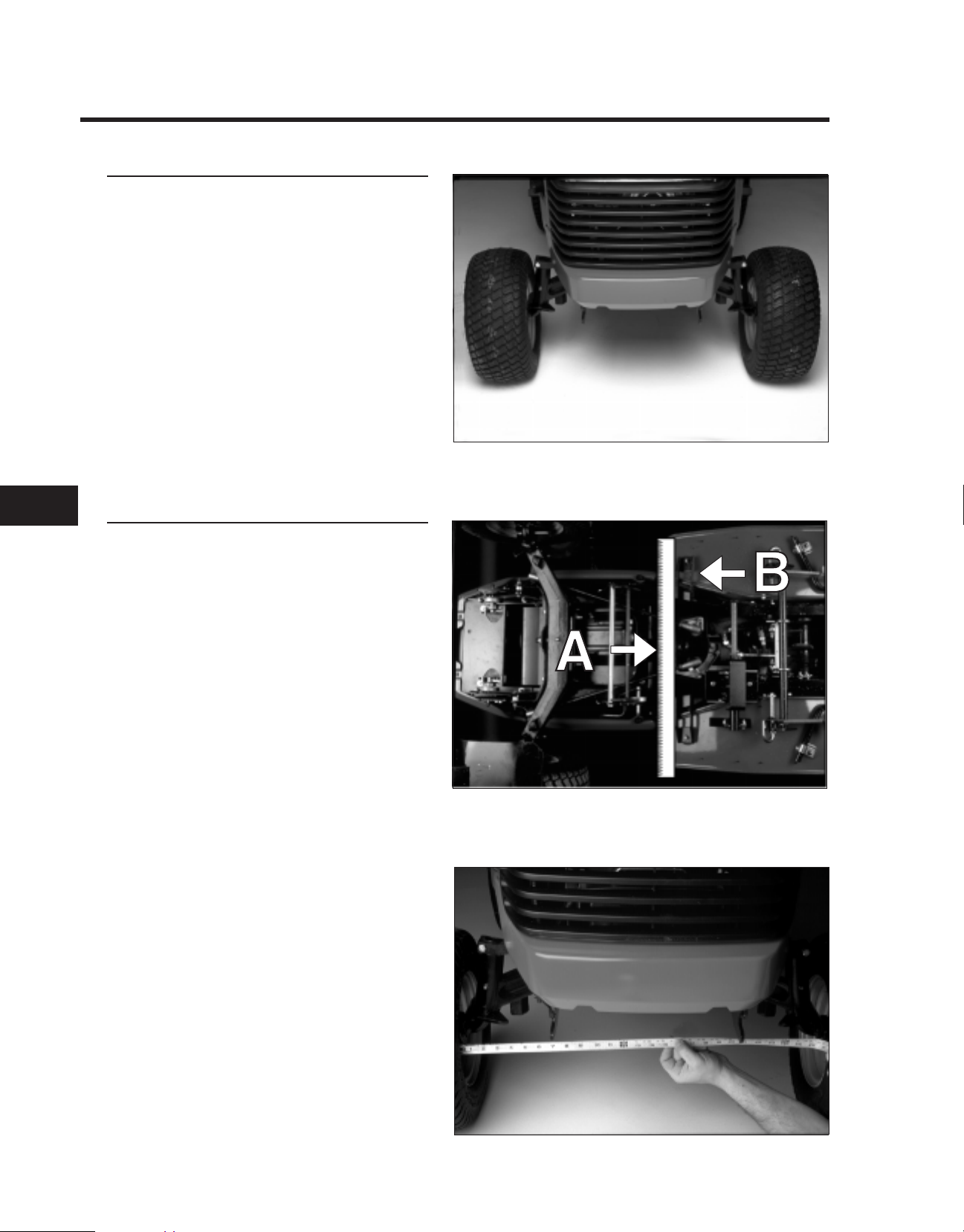

FRONT WHEEL TOE-IN

Specification/Service Interval

If there is uneven tire wear, lawn scuffing, or

hard steering, toe-in may need to be adjusted.

Toe-in should be 1/8" - 1/4" (3 to 6 mm) on the

front wheels. This should be checked every

100 hours or once a year, whichever occurs first.

2.0109.043

22

Measurement

1. Disengage the PTO, set the parking brake,

and turn the ignition key to OFF to stop the

engine. Remove the key.

2. Turn wheels straight ahead. Square the

lower steering plate to the center line of the

frame rails by aligning a straight edge (A)

with the footrest support (B) as shown.

3. Push the front of the tires out to remove

normal looseness in the linkage.

2.0144.050

4. Measure the distance between both front

tires at spindle level (at the front and rear of

the wheels).

5. The front measurement should be 1/8" to

1/4" (3 to 6 mm) less than the rear

measurement.

If adjustment is needed, follow the steps

outlined on the next page.

Note: The black steering tie rod end goes to the

front and has right hand threads.

2.0109.035

2-10 5xi Series Tractor Service Manual

Page 23

2.0109.047

CHASSIS

Adjustment

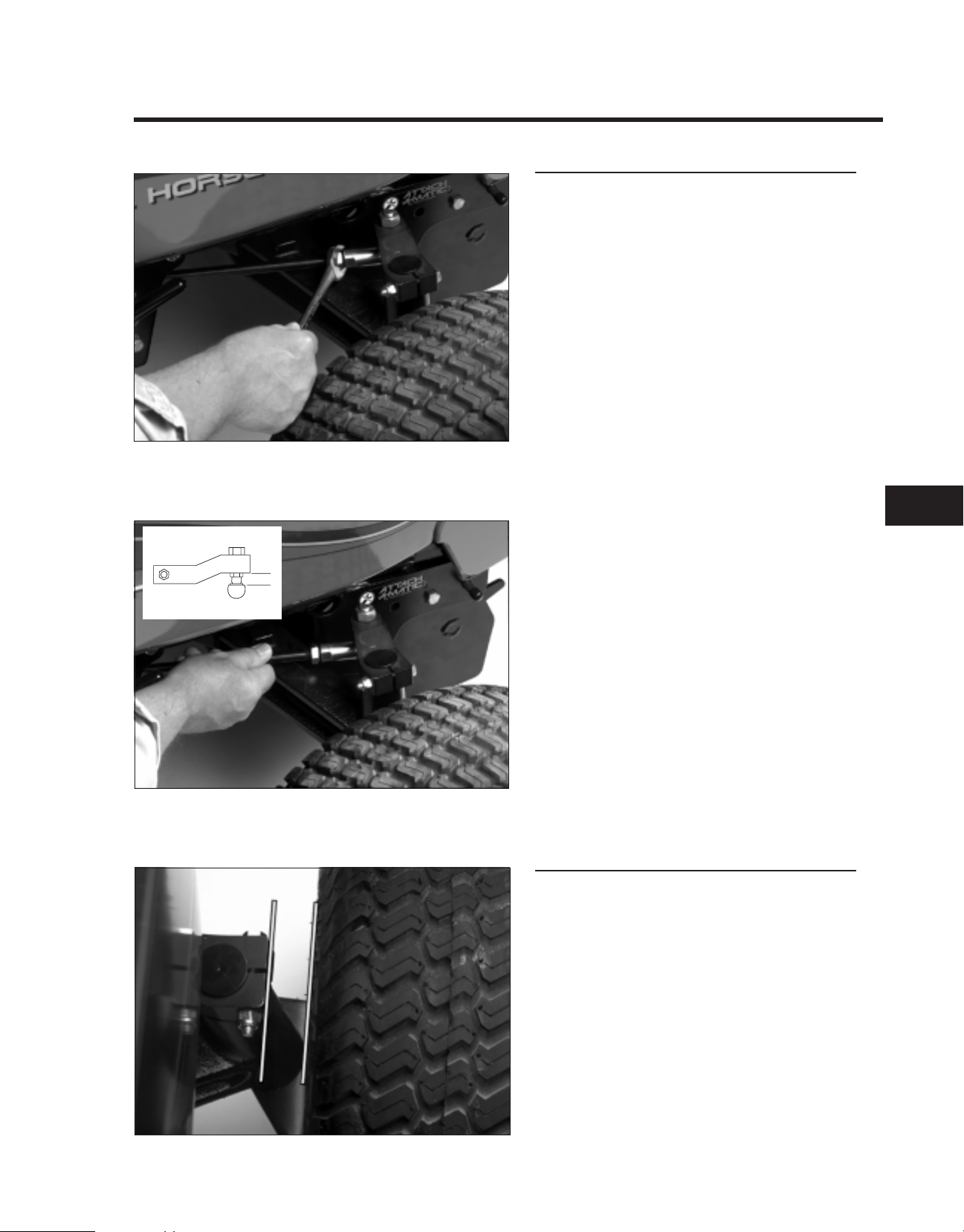

1. Loosen the jam nuts at the ends of the

steering rods.

2.0109.048

2. Rotate both steering rods equal amounts to

adjust the toe-in to 1/8" to 1/4" (3 to 6 mm) .

3. Recheck the toe-in as described earlier.

IMPORTANT: Make sure that the flat surface

on the top of the front tie rod ends are

parallel to the bottom of the steering arms

(inset).

Spindle Alignment

When installing the spindle to the steering arm,

you must align the wheel so that it is parallel to

the steering arm as shown.

2

2.0109.046

5xi Series Tractor Service Manual 2-11

Page 24

CHASSIS

STEERING WHEEL

Remove Steering Wheel

1. Remove plastic trim cover.

2. Loosen the nut securing the wheel.

2.0144.051

22

3. Install puller as shown. Tighten forcing

screw to remove steering wheel.

NOTE: Install large flat washers on puller

bolts to protect steering wheel.

Reassembly

1. Place the steering wheel on the shaft,

carefully aligning the splines.

NOTE: On manual steering models, be sure to

align steering wheel in the “straight ahead”

position. There is

position on power steering models.

no fixed “straight ahead”

2.0144.053

2. Torque the retaining nut to 45 - 50 ft·lbs.

3. Replace the trim cover.

2.0144.052

2-12 5xi Series Tractor Service Manual

Page 25

3.7195.029

CHASSIS

POWER STEERING

General Information

The 22 HP, 20 HP liquid-cooled and 23 HP

diesel tractors are equipped with power

steering.

This system routes pressurized hydraulic fluid

supplied by the hydrostatic transmission to a

directional valve located at the base of the

steering column. When the steering wheel is

turned, this valve directs pressure to a double

acting hydraulic cylinder, causing the steering

plate to pivot as the cylinder extends or

contracts. Tie rods attached to the steering

plate turn the front spindles.

2.0109.044

When the tractor is not running, some oil will

drain from the power steering system. When

this happens, it will be necessary to purge the

air from the system. This is done by turning the

steering wheel with the engine running until the

wheels turn fully and smoothly in both

directions.

Maintenance

The power steering system is equipped with an

in-line filter screen. It should be cleaned after

initial 50 hours, then every 200 hours, or if the

power steering gets noisy.

2

To clean the power steering screen:

1. Remove the left and center air intake

screens.

2. Remove the screen housing from the clamp

securing it to the left-hand side of steering

tower.

.3. Remove the top hose first to prevent oil from

back-flushing the screen.

4. Remove the hydraulic lines, and seal the

2.0144.16

5xi Series Tractor Service Manual 2-13

ends to keep out dirt.

Page 26

CHASSIS

POWER STEERING (cont’d)

3. Disassemble the housing, and clean the

screen with solvent.

2.0144.076

22

4. Inspect the “O” rings that seal the lines and

housing. Replace them if there are any

signs of cuts or deterioration, (i.e. hardening

or swelling of the rubber).

Lubricate the “O” rings before reassembly.

2.0144.086

5. Reassemble the housing, replace the lines,

and secure to steering tower.

6. Bleed air from the system by turning the

steering wheel from stop to stop several

times.

7. Check the hydrostatic transmission

fluid level.

2.0144.16

2-14 5xi Series Tractor Service Manual

Page 27

2.3653.005

CHASSIS

SMART TURN™ STEERING

General Information

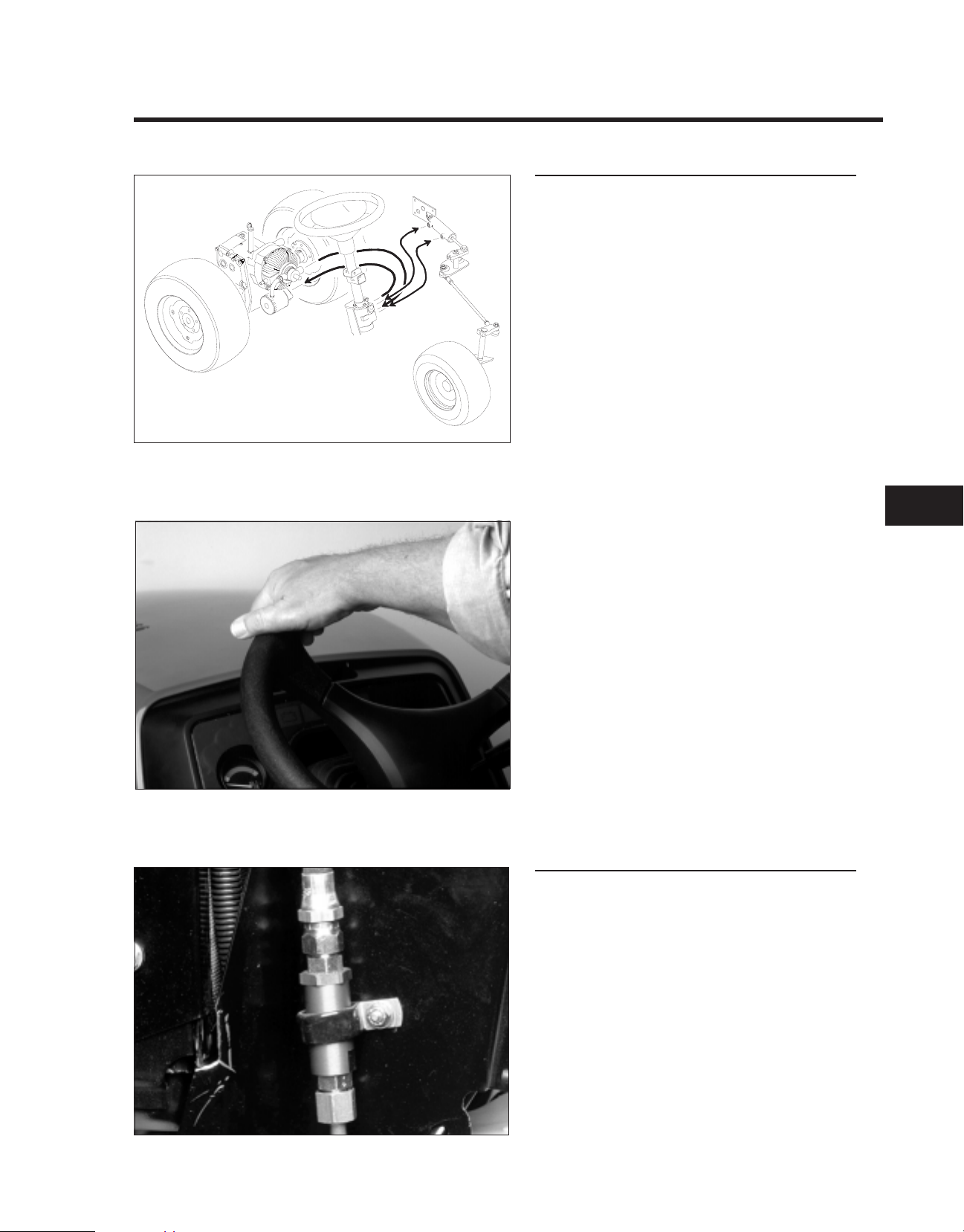

The Smart Turn Steering™ feature automatically

lowers the speed of the tractor in tight turns.

The decrease in speed is directly proportional

to the sharpness of the turn, up to a maximum

speed reduction of approximately 40% .

The Smart Turn Steering feature permits sharp

turns to be made without always having to

change speed control position. The original

speed is restored as the turn is completed.

2.0144.059

Theory of Operation

The steering plate (A) is attached to the speed

control lever (B) on the hydrostatic transmission

through a system of linkage and levers.

When the steering wheel is turned, the linkage

pushes the speed control lever (A) on the

hydrostatic transmission towards the neutral

position and slows the tractor.

2

2.0144.63

5xi Series Tractor Service Manual 2-15

Page 28

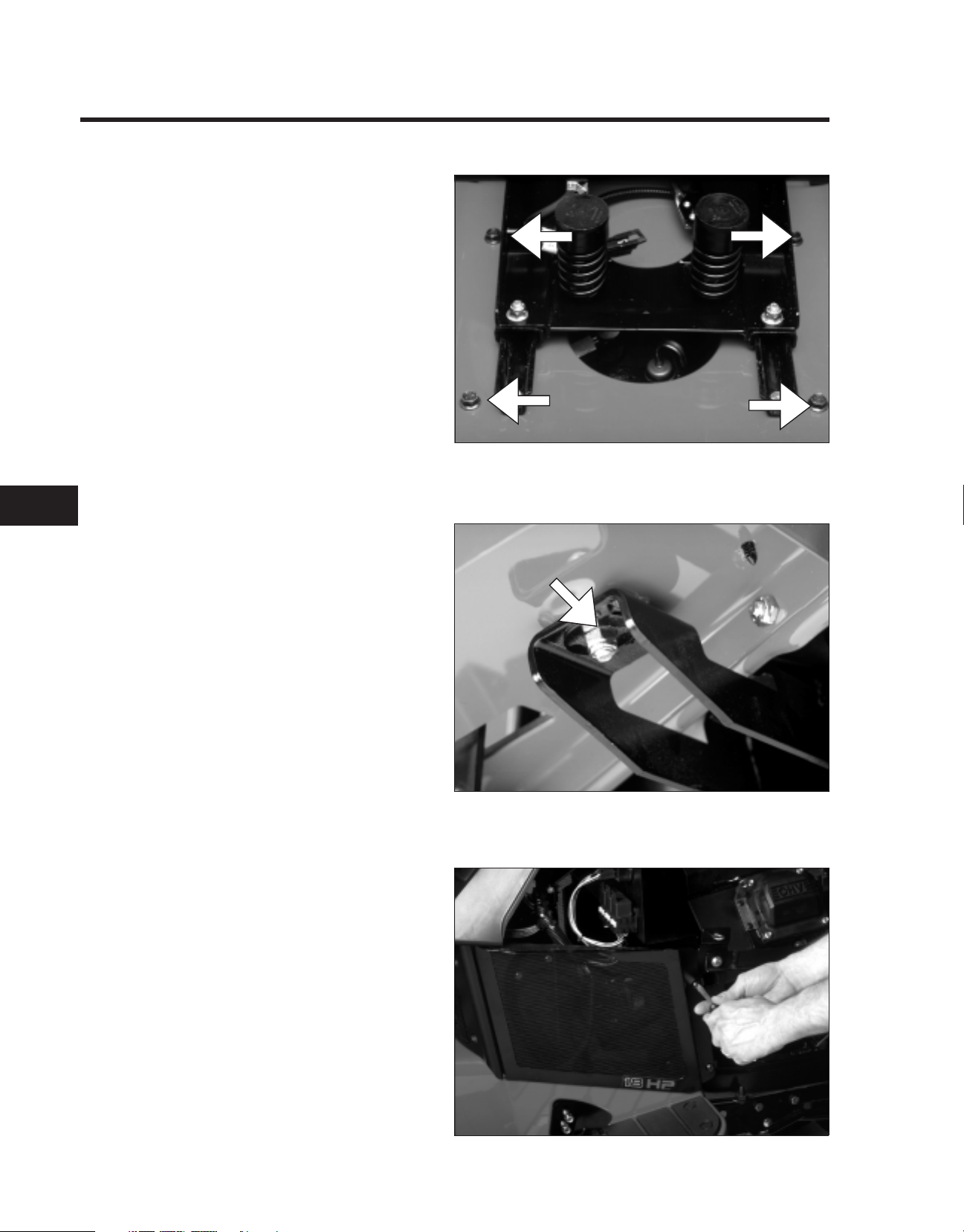

CHASSIS

SMART TURN™ STEERING (cont’d)

Inspection

The Smart Turn Steering system was set-up at

the factory and should not need any

adjustment. Adjustment must be verified if the

transaxle is removed and reinstalled.

2.0144.059

22

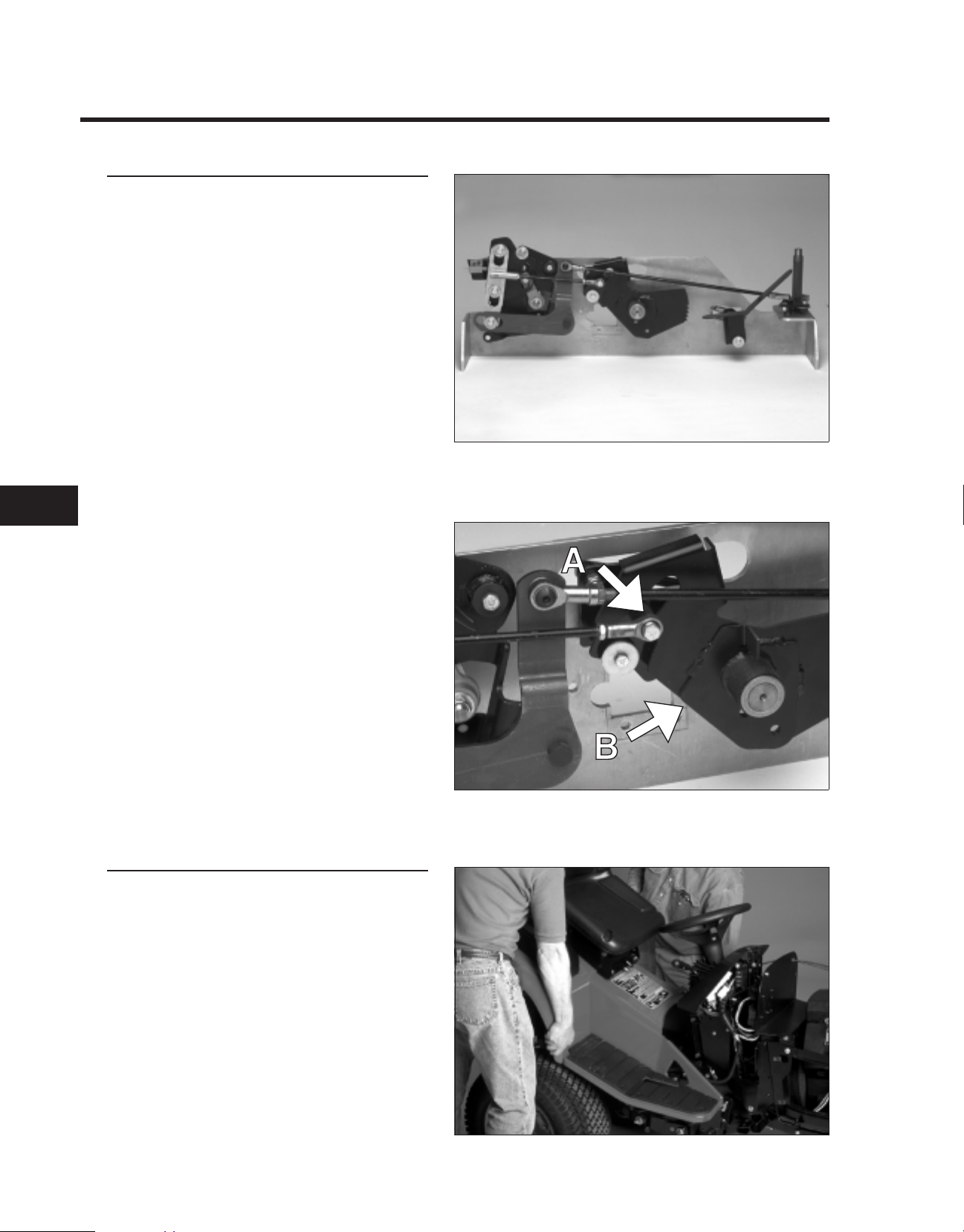

Correct adjustment can be verified by checking

the position of the bushing (A) in the slot of the

brake pivot plate (B). The bushing should not

contact either side of the slot.

Correct adjustment can be verified by removing

the maintenance panel and visually checking

the position of bushing (A). It should be

centered in the slot in the brake pivot (B). The

bushing should not contact either side of the

slot when the brake is applied.

2.0144.066

Adjustments

IMPORTANT: The adjustment procedure must

be performed in the sequence given.

If adjustment of the system is necessary:

1. Remove the rear fenders and tunnel from the

tractor as outlined on page 2-7.

NOTE: It is important that the toe-in is properly

adjusted before adjusting the Smart Turn

Steering linkage. Verify setting by following the

procedure starting on page 2-10.

2.0109.014

2-16 5xi Series Tractor Service Manual

Page 29

2.0144.059

CHASSIS

2. Check the adjustment of link (A) which

connects the lower steering plate (B) to the

bell crank (C). To do this:

2.0109.043

A. Align the front wheels straight ahead so that the

front of the lower steering plate is square to the

frame rails of the tractor. Verify the alignment by

placing a straight edge across the front edge of

the lower steering plate (A), aligning it with the

foot rest support (B) as described on page 2-10.

Note: Keep wheels aligned straight ahead

except where noted.

B. Check the slider (D) making sure it is all the way

down, flush with top of spacer (E).

IMPORTANT: There must be a slight vertical

looseness (F) in the slider or there may be

binding in the pedal linkages. Lift up on the

slider to check.

2

2.0144.087

5xi Series Tractor Service Manual 2-17

Page 30

CHASSIS

SMART TURN™ STEERING (cont’d)

If the slider is not adjusted correctly,

loosen jam nuts (E), and turn the link to

adjust the length. Then tighten the jam

nuts securely.

NOTE: The front jam nut is left hand

thread, and the rear jam nut is right hand

thread.

NOTE: Jam nuts “E” are marked with

paint at the factory to discourage

unnecessary tampering.

2.0144.085

22

3. Test the adjustment of link (F) (see page

2-16). If adjustment is necessary:

A. Depress the brake. Push forward lightly

on link (F) to remove slack from the

system.

G - Rear Jam Nut (Right Hand Thread)

H - Front Jam Nut (Left Hand Thread)

I - Front Rod End Fitting

2.0144.059

Check the bushing (A) making sure it is

centered in the slot in the brake pivot plate

(B). If the bushing contacts the sides of the

slot, loosen jam nuts (G and H), and turn the

link until the bushing is centered in the slot.

2.0144.089

2-18 5xi Series Tractor Service Manual

Page 31

2.7233.073

CHASSIS

Tighten the rear jam nut first. Hold the front

rod end fitting while tightening the front jam

nut.

IMPORTANT: There must be axial

looseness in the rod (A) or there may be

binding in the pedal linkages.

2.0144.089

Test the adjustment by cycling the brake.

The slot should travel over bushing (A)

without touching.

4. Check the neutral adjustment. If the tractor

creeps in neutral, adjust the motion control

lever following the procedure on page 3-8,

Neutral Adjustment in the Hydrostatic Drive

section of this manual.

2

2.0144.072

5xi Series Tractor Service Manual 2-19

Page 32

CHASSIS

MOTION CONTROL PEDAL

Adjustment

1. Push the motion control pedal to the full

reverse position.

2. Check the clearance between the pedal

support and the reverse stop.

3. Adjust the rod as necessary to obtain the

correct clearance.

Clearance: 1/16" (1.7 mm)

TIRE PRESSURE

2.0144.034

22

Pressure: 12 psi (82.7 kPa) front and rear.

Check the tire pressure after every 25 operating

hours or monthly, whichever occurs first. Check

the tires when they are cold to get the most

accurate pressure reading.

Since tire pressure affects the position of the

mower deck, it is important to check the tire

pressure before leveling the mower and to

maintain the the correct tire pressure to

preserve the level adjustment.

2.0109.045

FUEL TANK SHUT-OFF VALVE

The fuel shut-off valve is located on the bottom

of the fuel tank.

Normally the shut-off valve is kept in the ON

position. However, if transporting the tractor on

a trailer or truck, it is good practice to place the

valve in the OFF position. Although unlikely with

this tractor’s fuel system design, closing the fuel

valve will prevent the possibility of the

carburetor flooding over while going over

bumps and filling the crankcase with gasoline.

2.0109.29

2-20 5xi Series Tractor Service Manual

Page 33

2.0109.042

CHASSIS

ELECTRIC PTO CLUTCH

General Information

The 5xi series garden tractor is equipped with a

heavy-duty electric clutch.

This clutch is maintenance free and, therefore,

requires no air gap adjustment.

Note: Troubleshooting procedures, for the

electric PTO system, are located in the

Electrical section of this manual.

If the clutch is replaced, apply high temperature

Never Seize to the crankshaft threads, use a

new thread locking patch bolt torque to

50 - 60 ft·lb (70 - 84 N·m).

2.0757.021

Break-In

The following break-in procedure must be

performed as part of predelivery service or

when a new clutch is installed.

NOTE: There must be a PTO driven attachment

installed to provide a load in order to burnish

the clutch facings properly.

NOTE: After burnish procedure is complete to

maximize deck drive life, always engage clutch

at full throttle.

1. Run the engine at full throttle and engage

the clutch bringing the load to full speed.

Then disengage the clutch.

2. Let the load come to a full stop, then engage

again.

2

3. Repeat these procedures (1 and 2) 5 times.

2.0109.022

5xi Series Tractor Service Manual 2-21

Page 34

CHASSIS

DRIVE SHAFT

General Information

Power is transmitted from the engine to the

transmission by a drive shaft running between

the frame rails.

The drive shaft is supported by two flexible

couplings located at each end.

The drive shaft assembly requires no periodic

maintenance or adjustments.

2.0144.005

22

Inspection

Visually inspect the flexible couplings for tears,

fraying, or deterioration.

2.0144.077

Assembly

1. Insert the two drive shaft retaining screws

(B) through the rear flange with the bolt

heads toward the transmission. Place the

rear flange over the woodruff key on the

transmission input shaft. Torque the

retaining bolt (A) to 90 - 120 in·lbs (122 - 163

N·m).

2. Torque the two set screws (C) to

120 - 160 in·lbs (163 - 217 N·m).

IMPORTANT: Assembly procedure must be

performed in the correct sequence.

2.3653.013

2-22 5xi Series Tractor Service Manual

Page 35

2.7162.005

CHASSIS

3. On the engine end of the driveshaft, slide

the front flange over the square key on the

engine crankshaft (A).

2.3653.011

Note: On diesel powered tractors, the key is

fitted to the flange (B). Then the flange is slid

into a hub (C) mounted to the crankshaft’s

pulley.

4. Install the four spacers through the rubber

couplings making sure they are properly

seated and squared to the coupling.

Note: The spacers with the tall heads (A)

attach the coupling to the flange on the

transmission.

2

2.3653.014

5xi Series Tractor Service Manual 2-23

Page 36

CHASSIS

DRIVE SHAFT (cont’d)

5. Install the drive shaft to the rear flange by

sliding the long head spacers over the bolts.

Torque the nuts to 170 - 220 in·lbs

(231 - 299 N·m).

2.0144.094

22

6. Align the bolt holes in the tall headed

spacers (C) in the front flexible coupling with

the bolt holes in the flange and slide flange

on shaft up to the spacers. Install the nuts,

bolts, and washers. Washer and bolt head

are against flexible coupling; nut is on back

side of flange. Then torque the bolts to

170 - 220 in·lbs (231 - 299 N·m).

7. Torque the two set screws(A) and (B) to

120 - 160 in·lbs (163 - 217 N·m).

The flex coupling should be deformed no

more than 1/8" out of flat.

2.0144.077

Rotate the drive shaft, and check for excessive

run out which can cause vibration.

2.0144.094

2-24 5xi Series Tractor Service Manual

Page 37

QUICK REFERENCE SECTION

HYDROSTATIC DRIVE

Safety Information ................................................

Specifications....................................................

Maintenance Table................................................

SERVICE SECTION

Chassis.........................................................

Hydrostatic Drive ................................................

Gasoline Engine..................................................

1a

1b

1c

2

3

4

Diesel Engine ....................................................

Electrical........................................................

5

6

5xi Series Tractor Service Manual 3-1

Page 38

HYDROSTATIC DRIVE

Table of Contents

TROUBLESHOOTING

Tractor will not operate in either direction because the

engine bogs down or stalls ............................... 3-3

Tractor goes forward only at partial speed and is slow or

does not operate in reverse............................... 3-3

Tractor will not operate in either direction. ................... 3-3

Tractor operates erratically ............................... 3-4

Tractor operates in both directions but with loss of power.

Condition becomes worse as transmission becomes hot........ 3-4

3

Transmission overheating ................................ 3-4

Abnormal vibration or noise............................... 3-4

TRANSAXLE FLUID

General Information ..................................... 3-5

Checking Fluid Level .................................... 3-5

Fluid Change .......................................... 3-6

Filter Change .......................................... 3-6

BRAKE

General Information ..................................... 3-7

Adjustment ............................................ 3-7

NEUTRAL ADJUSTMENT

General Information ..................................... 3-8

Adjustment Procedure ................................... 3-8

3-2 5xi Series Tractor Service Manual

Page 39

HYDROSTATIC DRIVE

TROUBLESHOOTING

Whenever a problem occurs with the hydrostatic drive system, you should always check

these items first:

1. Transmission oil is at proper level and air is bled from system.

2. Make sure the high-low speed lever is not in neutral.

3. Speed control linkage is functioning properly.

4. Cruise control is turned off.

Tractor will not operate in either direction because the engine bogs down

or stalls.

Possible Cause Corrective Action

Low transmission oil level Fill to full “F” mark on dipstick (when trans. is cold)

Motion control linkage Adjust, repair, or replace

The brake is sticking Repair linkage; replace brake assembly

Brake adjustment it too tight Adjust the brake

Tractor goes forward only at partial speed and is slow or does not operate

in reverse.

Possible Cause Corrective Action

The cruise control was engaged when the High-Low

range lever was in “N.”

The engine is running at partial speed Move the throttle to “FAST.”

The Linkage is out of adjustment Verify full motion is obtain on motion control shaft.

There is Internal hydro wear Repair/replace transmission

Turn the cruise control off

Adjust if necessary.

Tractor will not operation in either direction.

Possible Cause Corrective Action

The transmission oil is low Fill to full “F” mark on transmission oil dipstick when

transmission is cold

The control linkage needs adjustment or replacement Adjust, repair, or replace

The parking brake was not released or the parking

brake is not releasing

The drive shaft or wheel hub key has been damaged Replace

Faulty transmission/transaxle Repair/replace transmission/transaxle

The power steering filter is dirty Clean power steering filter

Release the parking brake or check the linkage

3

5xi Series Tractor Service Manual 3-3

Page 40

HYDROSTATIC DRIVE

TROUBLESHOOTING (cont’d)

Tractor operates erratically.

Possible Cause Corrective Action

The transmission control linkage needs adjustment or

replacement

The transmission oil level is low Fill to the full “F” mark on the transmission oil dipstick

The transmission is faulty Repair/replace

Tractor operates in both directions but with loss of power.

Condition becomes worse as transmission becomes hot.

Possible Cause Corrective Action

The transmission oil level is low Fill to the full “F” mark on the transmission dipstick

The transmission shows signs of overheating or water

contamination

The cooling fan and/or transmission cooling fins are

faulty or dirty

3

The engine is not operating at full throttle Increase the engine speed to full throttle

The power steering filter is dirty Clean the power steering filter

Adjust, repair, or replace

when transmission is cold

when transmission is cold

Replace the transmission oil and filter

Clean the transmission and/or replace the fan.

Transmission overheating.

Possible Cause Corrective Action

Not operating engine at full throttle Increase engine speed to full throttle

Low oil level Fill full “F” mark on dipstick (when trans. is cold)

Accumulation of dirt and debris on hydrostatic trans. Clean

Loose fan or broken blades Repair or replace

Abnormal vibration or noise.

Possible Cause Corrective Action

The engine mounting bolts are loose Tighten the engine mounting bolts

The idler pulley or cutter deck blade is loose Tighten the appropriate pulley

The transaxle cooling fan is loose Repair or replace as necessary

There is a problem with the electric clutch Repair or replace as necessary

3-4 5xi Series Tractor Service Manual

Page 41

2.0144.029

HYDROSTATIC DRIVE

TRANSAXLE FLUID

General Information

All models of the 5xi series tractor are equipped

with the Toro Wheel Horse transaxle with the

Eaton model 11 hydrostatic transmission. The

transmission is equipped with a charge pump

which supplies hydraulic pressure to operate

the attachment lift and power steering on units

so equipped . The charge pump also provides

pressurized fluid to the transmission pump to

make up for normal internal leakage.

FLUID TYPE: SAE 10W-30 detergent oil

(API service SH or higher).

Checking Fluid Level

2.0757.015

1. The transaxle fluid level must be checked

when the machine is

level surface.

2. Tilt the seat forward.

3. Clean around the dipstick to prevent dirt

from falling into the system when the

dipstick is removed.

NOTE: Allowing dirt in the reservoir may

result in severe damage to the transmission.

4. Remove the dipstick. If necessary, add oil to

the Full line on the dipstick.

IMPORTANT: Do not fill the reservoir above

the FULL line as the reservoir may overflow

during use.

cold and parked on a

3

2.0109.007

5xi Series Tractor Service Manual 3-5

Page 42

HYDROSTATIC DRIVE

TRANSAXLE FLUID (cont’d)

Fluid Change

The hydrostatic fluid should be changed every

200 hours of operation.

Remove the drain plug and drain the transaxle

fluid into a suitable container.

Replace the drain plug, and fill the transaxle to

the FULL mark with 10W-30 detergent oil with

an API service rating of SH or higher.

System Capacity (refill capacity is 4.5 quarts):

With power steering: 7 qts. (6.6 l)

Without power steering: 6 qts. (5.6 l)

Filter change

2.0415.004

3

The transaxle is equipped with a 10 micron

spin-on oil filter. This filter should be changed

after the first 50 hours of operation and then

every 200 hours thereafter.

2.0144.031

When replacing the filter, coat the gasket with

transaxle fluid. Tighten until the gasket contacts

the base, then an additional 1/2 turn.

2.0144.014

3-6 5xi Series Tractor Service Manual

Page 43

3.7197.067

HYDROSTATIC DRIVE

BRAKE

General Information

The 5xi series series tractor is equipped with an

external band parking brake which is located on

the right side of the transaxle.

When the brake pedal is pressed, the linkage

returns the transmission to neutral, then applies

the brake.

The primary function of the brake is to keep the

tractor from rolling after it has been stopped. It

can also be locked in the applied position and

serves as the parking brake.

Adjustment

2.0109.005

1. Place the transmission in neutral.

2. Depress the brake pedal. There should be 2"

(51 mm) of free travel.

4. Turn the adjustment nut until the above

condition is met.

CAUTION: Do not overtighten the

adjustment nut.

3

2.0109.010

5xi Series Tractor Service Manual 3-7

Page 44

HYDROSTATIC DRIVE

NEUTRAL ADJUSTMENT

General Information

The hydrostatic transmission linkage is

designed to be self-centering or “return to

neutral”. If the wheels continue to drive with no

pressure on the control pedal (tractor creeps),

neutral adjustment is required.

CAUTION: The hydrostatic cooling fan

will be spinning. Use extreme caution to

avoid making contact with the fan while

performing this adjustment.

Adjustment Procedure

2.0144.001

3

1. Bring the hydrostatic transmission up to

operating temperature.

2. Place the rear axle on jack stands, and

remove the rear wheels.

NOTE: Do not set the parking brake.

2.3653.006

3. To gain access to the adjustment eccentric,

turn the front wheels in either direction to the

steering stop.

2.0144.072

3-8 5xi Series Tractor Service Manual

Page 45

2.0144.072

HYDROSTATIC DRIVE

4. Loosen the through bolt just enough to allow

rotation of the eccentric (A).

2.0144.071

5. With the engine running, rotate the eccentric

until the right rear wheel hub begins to turn.

Note the position of the eccentric. Rotate the

eccentric in the opposite direction until the

wheel hub again begins to turn.

6. Center the eccentric between these points,

and tighten the through bolt while holding

the eccentric.

NOTE: Do not turn the eccentric more than

90° in either direction. Notch in eccentric

must be away from pivot point of control arm.

3

2.144.72

5xi Series Tractor Service Manual 3-9

Page 46

QUICK REFERENCE SECTION

GASOLINE ENGINE

Safety Information ................................................

Specifications....................................................

Maintenance Table................................................

SERVICE SECTION

Chassis.........................................................

Hydrostatic Drive .................................................

Gasoline Engine .................................................

1a

1b

1c

2

3

4

Diesel Engine ....................................................

Electrical........................................................

5

6

5xi Series Tractor Service Manual 4-1

Page 47

GASOLINE ENGINE

TROUBLESHOOTING

Engine cranks but will not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Starter does not crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Engine starts but does not keep running. . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Engine is difficult to start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Engine runs but knocks or misses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Engine will not idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Engineoverheats..........................................4-4

Engine loses power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Table of Contents

4

Engineknocks ............................................4-4

AIR CLEANER

Service Interval/Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

ENGINE OIL

Service Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Changing/Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

OIL FILTER

Service Interval/Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Changing ................................................4-7

SPARK PLUG

Specification/Service Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

FUEL FILTER

Service Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

COOLING SYSTEM, AIR

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

COOLING SYSTEM, LIQUID

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

4-2 5xi Series Tractor Service Manual

Page 48

GASOLINE ENGINE

TROUBLESHOOTING

Engine cranks but will not start.

Possible Cause Corrective Action

Incorrect starting procedure Ensure throttle is at full, and choke is on

The fuel tank is empty Fill with fresh fuel

The fuel shut-off valve is closed Open fuel shut-off valve

Dirt or water is in the fuel system Drain and flush fuel system; add fresh fuel

Clogged fuel line Clean or replace

The spark plug lead is disconnected Reconnect spark plug

The kill relay not energized Inspect safety switches and wiring

A spark plug is faulty Replace spark plug

Faulty ignition module Replace ignition module

Starter does not crank.

Possible Cause Corrective Action

Blown or loose fuse Determine cause, correct and replace fuse

Battery is discharged Charge battery or replace if necessary

Safety interlock system malfunctioning Inspect safety switches and wiring harness

Faulty starter or starter solenoid Replace

Seized internal engine components Replace

Poor ground; loose connections Clean and tighten

Engine starts but does not keep running.

4

Possible Cause Corrective Action

Misadjusted or faulty choke or throttle control cable Adjust or replace

The fuel tank vent is restricted Vent system hoses kinked or plugged, clean or repair

Dirt or water in the fuel system Drain and flush fuel system; add fresh fuel

The fuel filter is clogged Replace the fuel filter

The fuel pump is faulty Repair or replace

The carburetor is faulty Clean or rebuild

Loose wires or poor connections Check and tighten wire connections

The cylinder head gasket is faulty Replace

Engine is difficult to start.

Possible Cause Corrective Action

Improper starting procedure Ensure throttle is at full, and choke is on

Dirt or water in the fuel system Drain and flush fuel system, add fresh fuel

Clogged fuel filter Replace

Loose wires or poor connections Troubleshoot and repair

Misadjusted or faulty choke or throttle control cable Adjust or replace

Faulty spark plug Replace

Low compression Test compression, correct as needed

5xi Series Tractor Service Manual 4-3

Page 49

GASOLINE ENGINE

TROUBLESHOOTING (cont’d)

Engine runs but knocks or misses.

Possible Cause Corrective Action

Dirt, water, or stale fuel is in the fuel system Drain and flush the fuel system; add fresh fuel

A spark plug lead is loose Reconnect the spark plug lead

A spark plug is faulty Replace the spark plug

Loose wires or poor connections Check and tighten wire connections

Engine overheating See ENGINE OVERHEATS

Engine will not idle.

Possible Cause Corrective Action

The fuel tank is restricted Check hoses, clean or replace

Dirt or water is in the fuel system Drain and flush fuel system; add fresh fuel

A spark plug is faulty Replace the spark plug

Carburetor idle passages are plugged Clean or replace carburetor

The Idle speed adjusting screw is incorrectly set Reset to factory specifications

The fuel pump is faulty Repair or replace

Low compression Test compression, correct as needed

Engine overheats.

Possible Cause Corrective Action

4

(3) air intake screens are dirty Clean with every use

Restricted air flow into the engine or radiator

The crankcase oil level is incorrect Fill or drain to the full mark

The fuel mixture is lean Clean carburetor, check float level, and inspect main jet

Excessive loading Reduce load; use lower ground speed

Defective thermostat Replace the thermostat

More coolant is needed Check and add coolant

Inspect & clean the (3) air intake screens & radiator screen

Engine loses power.

Possible Cause Corrective Action

The crankcase oil level is incorrect Fill or drain to the full mark

The air cleaner element is dirty Clean or replace

Dirt, water, or stale fuel is in the fuel system Drain and flush fuel system; add fresh fuel

The engine is overheated See ENGINE OVERHEATS

A spark plug is faulty Replace the spark plug

Low compression Test compression, correct as needed

Engine knocks.

Possible Cause Corrective Action

Old or improper fuel Drain system and add fresh fuel

Internal wear or damage Inspection required

4-4 5xi Series Tractor Service Manual

Page 50

2.7146.035

GASOLINE ENGINE

AIR CLEANER

Service Interval/Specification

Foam Element (A): Clean and re-oil after every

25 operating hours, or yearly, whichever occurs

first.

Paper Element (B): Replace after every 100

operating hours or yearly, whichever comes first.

NOTE: Service the air cleaner more frequently

(every few hours) if operating conditions are

extremely dusty or sandy.

Cleaning

2.0144.019

FOAM ELEMENT

1. Wash the foam element in liquid soap and

warm water. When the element is clean,

rinse it thoroughly.

2. Dry the element by squeezing it in a clean

cloth.

3. Put one or two ounces of oil in the element.

Squeeze the element to distribute the oil.

IMPORTANT: Replace the foam element if it

is torn or worn.

PAPER ELEMENT

1. Lightly tap the element on a flat surface to

remove dust and dirt.

2. Inspect the element for tears, an oily film, or

damage to the rubber seal.

4

IMPORTANT: Never clean the paper

element with pressurized air or liquids, such

as solvent, gasoline, or kerosene. Replace

the paper element if it is damaged or

defective.

2.0144.099

5xi Series Tractor Service Manual 4-5

Page 51

GASOLINE ENGINE

ENGINE OIL

Service Interval

Oil Type: Detergent oil (API service SH or

higher).

Crankcase capacity (with filter): 3.8 pt. (1.8 l).

Viscosity: See table.

Change oil:

• After first 5 operating hours.

4

• After every 100 operating hours.

Changing/Draining

1. Run the engine for five minutes.

2. Park the machine so the drain side is slightly

lower than the opposite side. Set the parking

brake and turn the engine off.

3. Slide a piece of 1/2" (12 mm) hose over the

oil drain.

4. Open the drain by turning it clockwise 1/8

turn and pull it out.

5. Let oil drain completely. Close drain.

6. Refill with recommended oil.

-20 0 2032406080100

F

-30 -20 -10 0 10 20 30 40

C

3.7197.079

2.0144.054

OIL FILTER

Service Interval/Specification

Replace the oil filter every 200 hours or every

other oil change.

NOTE: Change the oil filter more frequently

when operating conditions are extremely dusty.

2.0144.092

4-6 5xi Series Tractor Service Manual

Page 52

3.0144.014

GASOLINE ENGINE

Changing

1. Drain the oil from the engine.

2. Remove the old filter and wipe the filter

adapter gasket surface.

3. Apply a thin coat of new oil to the rubber

gasket on the replacement filter.

4. Install the new filter to the filter adapter.

Turn the filter clockwise until the gasket

contacts the filter adapter, then tighten the

filter an additional 1/2 turn.

5. Fill the crankcase with the proper oil.

SPARK PLUG

Service Interval/Specification

2.0144.040

Kohler Engines

Type: Champion RC12YC (or equivalent)

Air Gap: 0.030 in (.76 mm)

Kawasaki Engines

Type: NGK BMR4A

Air Gap: .024 - .028 in (0.6 - 0.7 mm)

Install new spark plugs after every 100

operating hours/Kawasaki, 200 hours/Kohler.

Check the spark plugs after every 25 operating

hours. Make sure the air gap is correct before

installing the the spark plug.

If the insulator on the spark plug is light brown

or gray, the engine is running properly. A black

coating on the insulator indicates the air cleaner

may be dirty.

IMPORTANT: Never clean the spark plugs.

Always replace the spark plugs when it has a

black coating, worn electrodes, an oily film, or

cracks.

4

2.0144.011

5xi Series Tractor Service Manual 4-7

Page 53

GASOLINE ENGINE

SPARK PLUG (cont’d)

Installation

Install the spark plugs and metal washer. Make

sure the air gap (.028) is set correctly. Torque

the spark plugs to specifications.

Spark plug torque:

Kohler engines 18-22 ft·lbs (24-30 N·m)

Kawasaki engines 18 ft·lbs (25 N·m)

FUEL FILTER

Service Interval

2.0144.048

Replace the fuel filter after every 100 operating

hours or yearly, whichever occurs first.

4

COOLING SYSTEM, AIR

General Information

Models 518xi, 520xi, and 522xi are equipped

with air-cooled engines.

The engine is cooled by air drawn through the

air intake screen by a fan attached to the

flywheel. Engine heat is carried away when

shrouds attached to the engine direct the air

flow through fins located on the cylinders and

cylinder heads.

2.0144.092

2.0109.40

4-8 5xi Series Tractor Service Manual

Page 54

2.0415.008

GASOLINE ENGINE

Maintenance

Inspect air intake screens often. Keep cooling

and combustion air paths free of debris at all

times.

Consult the engine manufacturer’s service

manual for specific instructions and service

intervals.

NOTE: Operating the engine with a blocked air

intake screen, dirty or plugged cooling fins,

and/or cooling shrouds removed, will cause

engine damage due to overheating.

It is preferable to blow dirt out, rather than

washing it out. If water is used, keep it away

from electrical items.

COOLING SYSTEM, LIQUID

General Information

2.7163.09

Models 520Lxi are equipped with a

liquid-cooled engine.

This engine uses a gear driven water pump to

circulate coolant through passages in the

engine block and cylinder heads. The coolant

carries engine heat to a radiator which transfers

the heat stored in the coolant to the

surrounding air by drawing the cooler ambient

air through fins in the radiator with a belt driven

fan.

Engine temperature is maintained by a

thermostat which opens at approximately 150°

F (66° C). When the thermostat is open, it

allows coolant to flow through the radiator.

When the coolant temperature falls below 150°

F (66° C) the thermostat closes, bypassing the

radiator allowing faster warm-up and consistent

operating temperature.

4

The cooling system is pressurized at operating

temperature to prevent evaporation and raise

the boiling point of the coolant .

2.7163.013

5xi Series Tractor Service Manual 4-9

Page 55

GASOLINE ENGINE

COOLING SYSTEM, LIQUID (cont’d)

Maintenance

Inspect the cooling system often. Carefully

clean grass clippings and other debris from air

intake screens and radiator fins.

2.0144.012

4

Maintain coolant level in the coolant recovery

tank between two lines on reservoir bottle with a

50/50 mix of antifreeze and water.

Caution: Do not remove the radiator cap

when the engine is hot. Discharge of hot

coolant can cause severe burns.

2.0144.049

Inspect coolant hoses and fan belt for

deterioration every 100 hours of operation.

Replace when deterioration is noted.

Watch for signs of leaks such as rust streaks or

puddles of coolant under the tractor.

Change engine coolant according to the service

interval and instructions in the engine

manufacturer’s service manual.

2.0144.039

4-10 5xi Series Tractor Service Manual

Page 56

QUICK REFERENCE SECTION

DIESEL ENGINE

Safety Information ................................................

Specifications....................................................

Maintenance Table................................................

SERVICE SECTION

Chassis.........................................................

Hydro Drive .....................................................

Gasoline Engine ................................................

1a

1b

1c

2

3

4

Diesel Engine .................................................

Electrical........................................................

55

6

5xi Series Tractor Service Manual 5-1

Page 57

DIESEL ENGINE

TROUBLESHOOTING

Engine cranks but will not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Starter does not crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Engine starts but does not keep running. . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Engine is difficult to start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Engine runs but knocks and misses . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Engine will not idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Engineoverheats..........................................5-4

Engine loses power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Table of Contents

5

Engineknocks ............................................5-5

Excessive black smoke from exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Excessive white smoke from exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

AIR CLEANER

Service Interval/Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

ENGINE OIL

Service Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Changing/Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

OIL FILTER

Service Interval/Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

Changing ................................................5-7

COOLING SYSTEM

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8

ENGINE MOUNTS

EngineMounting ..........................................5-9

FUEL SYSTEM

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

GLOW PLUGS

Cold Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10

5-2 5xi Series Tractor Service Manual

Page 58

DIESEL ENGINE

TROUBLESHOOTING

Warning: Diesel fuel under high pressure. Cover fittings before loosening. High pressure fuel can

penetrate skin causing blood poisoning or infection.

Engine cranks but will not start.

Possible Cause Corrective Action

Contaminated fuel Clean fuel system

Incorrect starting procedure Activate glow plugs before attempting to start

The fuel tank is empty Fill with fresh fuel

The fuel shut-off valve is closed Open the fuel shut- off valve

Dirt or water is in the fuel system Drain and flush fuel system; add fresh fuel

Clogged fuel line Clean or replace

Air in fuel Bleed nozzles, check for leaks on suction side of

system

Inoperative glow plugs Check fuse, glow plugs, and wiring

Inoperative fuel solenoid Check wiring, start switch, and fuel solenoid

Slow cranking speed Check battery, oil viscosity,and starter motor

Insufficient combustion air supply Check air filter and combustion air path

Low compression Perform cylinder leak down test. Adjust, repair, or

replace affected parts.

Starter does not crank.

Possible Cause Corrective Action

The fuse is blown or loose Correct or replace the fuse

The battery is discharged Charge the battery or replace it

The safety interlock system is malfunctioning Inspect safety switches and wiring harness

A faulty starter, starter solenoid, relay, or ignition switch Replace

Seized internal engine components Replace

Engine starts but does not keep running.

Possible Cause Corrective Action

Contaminated fuel Clean fuel system

Air in fuel Bleed nozzles, check for leaks on suction side of

system

Waxing fuel below 32° F (0° C) Use a winter blend fuel when the ambient temperature

is below freezing

The fuel filter is clogged Replace the fuel filter

Dirt or water in the fuel system Drain fuel filter. Flush fuel system if necessary

The fuel tank vent is restricted Vent system hoses kinked or plugged, clean or replace

Loose wires or poor connectors Check and tighten wire connections

5

5xi Series Tractor Service Manual 5-3

Page 59

DIESEL ENGINE

TROUBLESHOOTING (cont’d)

Engine is difficult to start.

Possible Cause Corrective Action

Improper starting procedure Activate glow plugs before attempting to start

Air in fuel Bleed nozzles, check for leaks on suction side of

system

Inoperative glow plugs Check fuse, glow plugs, and wiring

Insufficient combustion air supply Check air filter and combustion air path

Faulty injection nozzles Test nozzles, clean or replace as necessary

Clogged fuel filter Replace

Incorrect injection pump timing Perform complete timing procedure

Low ambient temperature Activate block heater, check oil viscosity

Worn injection pump (hard starting warm) Check fuel supply from nozzles

Low compression Perform cylinder leakage test

Engine runs but knocks or misses.

Possible Cause Corrective Action

Air in fuel Bleed nozzles, check for leaks on suction side of

system

Dirt, water, or stale fuel in fuel system Drain and flush fuel filter; add fresh fuel

Faulty injection nozzle(s) Test nozzles, clean or replace as necessary

Low compression Perform cylinder leakage test

Engine will not idle.

5

Possible Cause Corrective Action

Air in fuel Bleed nozzles, check for leaks on suction side of

Idle speed too low Adjust idle speed

The fuel injection pump is faulty Repair or replace as necessary

The fuel tank vent is restricted Check hoses, clean, or replace

Dirt or water is in the fuel system Drain and flush fuel system; add fresh fuel

Engine overheats.

Possible Cause

(3) air intake screens are dirty Clean with every use

More coolant is needed Check and add coolant

Restricted air flow through radiator Clean debris from radiator and cooling air path

Defective thermostat Replace the thermostat

The crankcase oil level is incorrect Fill or drain to the full mark

Faulty thermostat Replace

Excessive loading Reduce load; use lower ground speed

system

Corrective Action

5-4 5xi Series Tractor Service Manual

Page 60

DIESEL ENGINE

Engine loses power.

Possible Cause Corrective Action

Insufficient combustion air supply Check air filter and combustion air path

Air in fuel Bleed nozzles, check for leaks on suction side of

system

Dirt, water, or stale fuel is in the fuel system Drain and flush fuel system; add fresh fuel

Faulty injection nozzle(s) Test nozzles, clean or replace as necessary

Incorrect injection pump timing Perform complete timing procedure

Faulty injection pump Repair or replace as necessary

Low compression Perform cylinder leakage test

The vent hole in the fuel tank vent fitting is plugged Repair or replace vent system

The engine load is excessive Reduce ground speed

The crankcase oil level is incorrect Fill or drain to the full mark

Engine knocks.

Possible Cause Corrective Action

Sticking injection nozzles Clean or replace nozzles

Incorrect injection pump timing Perform complete timing procedure

Excessive carbon build-up Clean carbon from cylinder head and piston

Internal wear or damage Inspection required

Excessive black smoke from exhaust.

Possible Cause Corrective Action

Insufficient combustion air supply Check air filter and combustion air path

Incorrect injection pump timing Perform complete timing procedure

Improper fuel Drain fuel system and refill with specified fuel

Faulty injection nozzles Clean or replace nozzles

Excessive white smoke from exhaust.

Possible Cause Corrective Action

Low engine temperature Check thermostat

Inoperative glow plugs Check fuse, glow plugs, and wiring

Faulty injection nozzles Clean or replace nozzles

Incorrect injection pump timing Perform complete timing procedure

Low compression Perform cylinder leakage test

5

5

5xi Series Tractor Service Manual 5-5

Page 61

DIESEL ENGINE

AIR CLEANER

Service Interval/Specification

Paper Element: Replace after every 100

operating hours or yearly, whichever comes first.

NOTE: Service the air cleaner more frequently

(every few hours) if operating conditions are

extremely dusty or sandy.

3.7230.079

5

ENGINE OIL

Cleaning

1. Lightly tap the element on a flat surface to

remove dust and dirt.

2. Inspect the element for tears, an oily film, or

damage to the rubber seal.

IMPORTANT: Never clean the paper

element with pressurized air or liquids, such

as solvent, gasoline, or kerosene. Replace

the paper element if it is damaged,

defective, or cannot be cleaned thoroughly.

2.3653.007

Service Interval

Oil Type: Detergent oil (API service CD or

higher).

Crankcase capacity (with filter): 3.5 Qts (3.3 l).

Viscosity: See table.

Change oil:

After first 50 operating hours.

•

After every 100 operating hours

•

-20 0 20 32 40 60 80 100

F

-30 -20 -10 0 10 20 30 40

C

3.7197.079

5-6 5xi Series Tractor Service Manual

Page 62

2.0757.008

DIESEL ENGINE

Changing/Draining