Page 1

FORM NO. 3322–108

CLASSIC GARDEN TRACTOR

300 SERIES

S/N 9900001 & Up

Loose

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Hitch Pin

Hairpin Cotter – 1-7/8”

Flat W

Bolt – 1/4–20 x 3/4”

Hex Nut – 1/4–20

Hairpin Cotter – 1-7/8”

Flat W

Operator’

Parts

asher – 1/2 x 1”

asher – 1/2 x 1”

s Manual

1

1

1

2

2

1

1

1

Installing the hitch pin

Attaching the battery cables

Attaching accessory to lift bar

Read before operating tractor

SET UP

INSTRUCTIONS

Set Up Instructions

Riding Mower Safety V

Printed in USA

ideo

1

1

The T

oro Company – 1998

All Rights Reserved

Read before setting up tractor

V

iew before operating tractor

Page 2

Set-Up Instructions

Checking

Check the front and rear tire pressure. The correct

front and rear tire pressure is 12 psi (83 kPa).

Activating

POTENTIAL

the T

ire Pressure

the Battery

HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

WHAT CAN HAPPEN

• If you carelessly drink electrolyte you could

die or if it gets onto your skin you will be

burned.

HOW TO AV

OID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

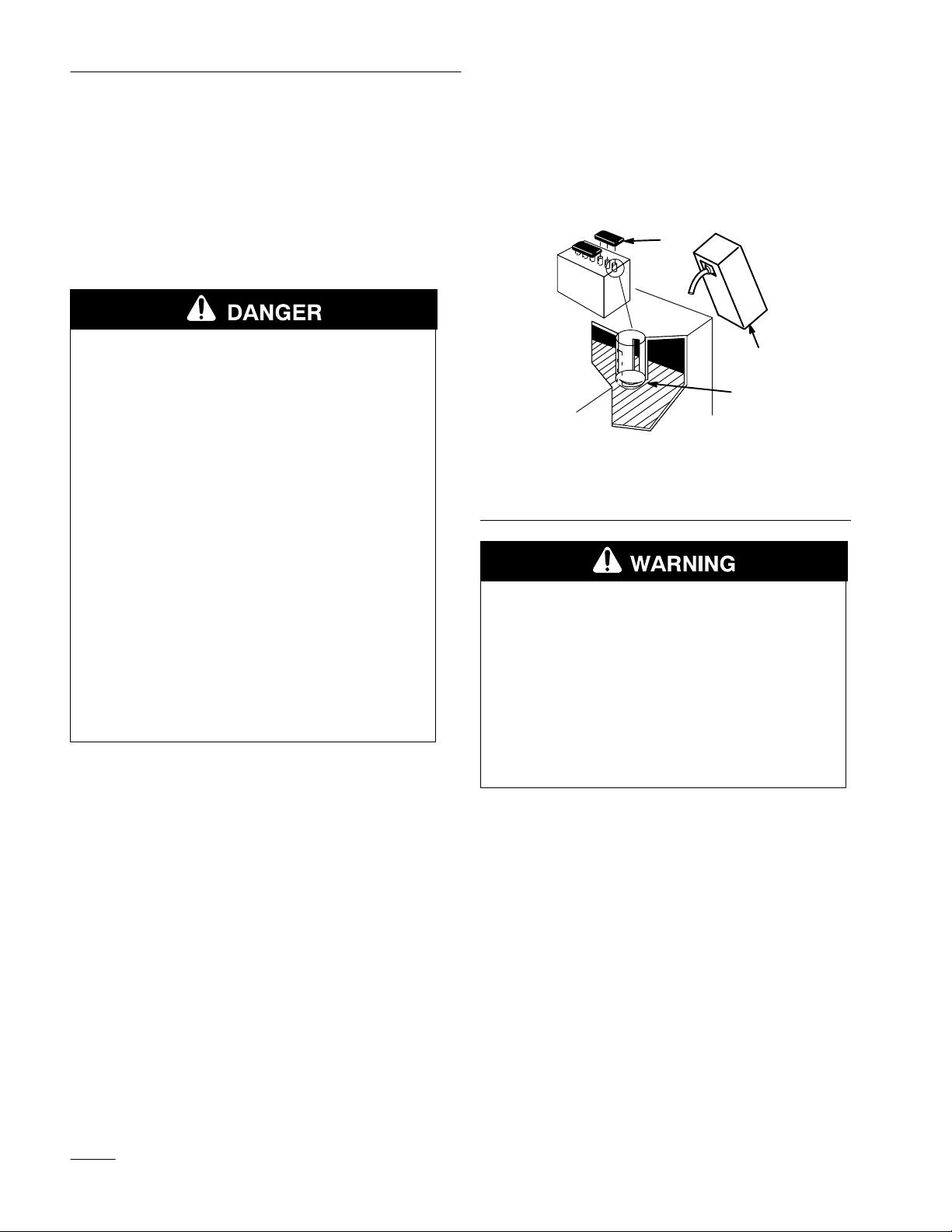

1. Remove the battery from the tractor.

2. Remove the filler caps from the battery. Slowly

pour electrolyte into each cell until the

electrolyte level is up to the lower part of the

tube (Fig. 1). Use an electrolyte with a specific

gravity of 1.265.

1

2

3

1262

Figure 1

1. Filler

2. Electrolyte

Caps

POTENTIAL

HAZARD

• Charging battery pr

WHAT CAN HAPPEN

Lower part of the tube

3.

oduces gasses.

• Battery gasses can explode.

HOW TO AV

OID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

Note: Never fill the battery with electrolyte

with the battery installed in the tractor.

Electrolyte could be spilled on other

parts and cause corrosion.

2

3. Leave the filler caps off and connect a 3–4 amp

battery charger to the battery posts (Fig. 2).

Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

Page 3

Set-Up Instructions

4. When the battery is fully charged, unplug the

charger from the electrical outlet, then

disconnect the charger leads from the battery

posts (Fig. 2).

4

2

3

1

Figure 2

1. Positive

2.

Battery Post

Negative Battery Post

3.

Red (+) Charger Lead

4.

Black (–) Charger Lead

1254

Installing

the Drawbar Hitch

Pin

Insert the drawbar hitch pin into the drawbar hitch

and secure it with a

hairpin cotter (Fig. 3).

1. Drawbar

2.

Drawbar Hitch

Hitch Pin

1/2 x 1”

2

4

Figure 3

flat washer and 1-7/8”

1

3

3.

Flat W

asher 1/2 x 1”

4.

Hairpin Cotter 1-7/8”

m–3396

5. Slowly pour electrolyte into each cell until the

level is once again up to the “UPPER” line on

the battery case (Fig. 1), then install the filler

caps.

6. Install the battery in the tractor and connect the

battery cables. (Refer to the Operator’

s Manual –

Installing the Battery.)

Note: Do not run the tractor with the battery

disconnected, electrical damage may

occur.

Attaching

the W

asher and

Hairpin Cotter onto the Lift Bar

Install a

onto the lift bar (Fig 4).

1. Lift

2.

2

3

Bar

Flat W

1/2 x 1”

asher 1/2 x 1”

flat washer and 1-7/8” hairpin cotter

1

Figure 4

3.

Hairpin Cotter1-7/8”

m–2504

3

Page 4

Set-Up Instructions

Checking

the W

iring and

Fasteners

• Inspect the tractor for any loose electrical

connections and secure as required. Check the

wire routing to make sure no moving parts

interfere with the wires to cause a short.

• Check all fasteners to make sure they are tight.

Test

1. Check the oil level in the crankcase. Refer to the

2. Check the oil level in the transaxle. Refer to the

3. Check to make sure all lubrication points have

Driving the T

Operator’s Manual for oil type, viscosity and

crankcase capacity

Note: When checking the oil level, slide the

dipstick all the way into the filler tube.

Operator’s Manual for oil type, viscosity and

capacity.

been greased as shown in the Maintenance

section of the Operator’s Manual. These points

include the front axle pivot and spindles, foot

pedal(s) and steering gear.

ractor

.

5. As applicable, check and test the operation of the

following:

• Engine, choke and throttle controls

• Gauges

• Headlights (and taillights 314 only)

• Indicator lights (314 only)

• PTO clutch and brake

• Lift system

• Service and parking brakes

• T

ransmission controls

• Steering

• Tractor operation in forward and reverse

6. Test the operation of the safety interlock system.

The engine should not crank if:

• You are out of the seat

• The PTO lever is in the “engaged” position

• The gear shift lever is in the “engaged”

position

4. Fill the tank with unleaded regular gasoline with

an octane rating of at least 85. Open the fuel

shutoff valve and check the fuel hose and fittings

for leaks.

4

Loading...

Loading...